Patents

Literature

622results about How to "Shorten molding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

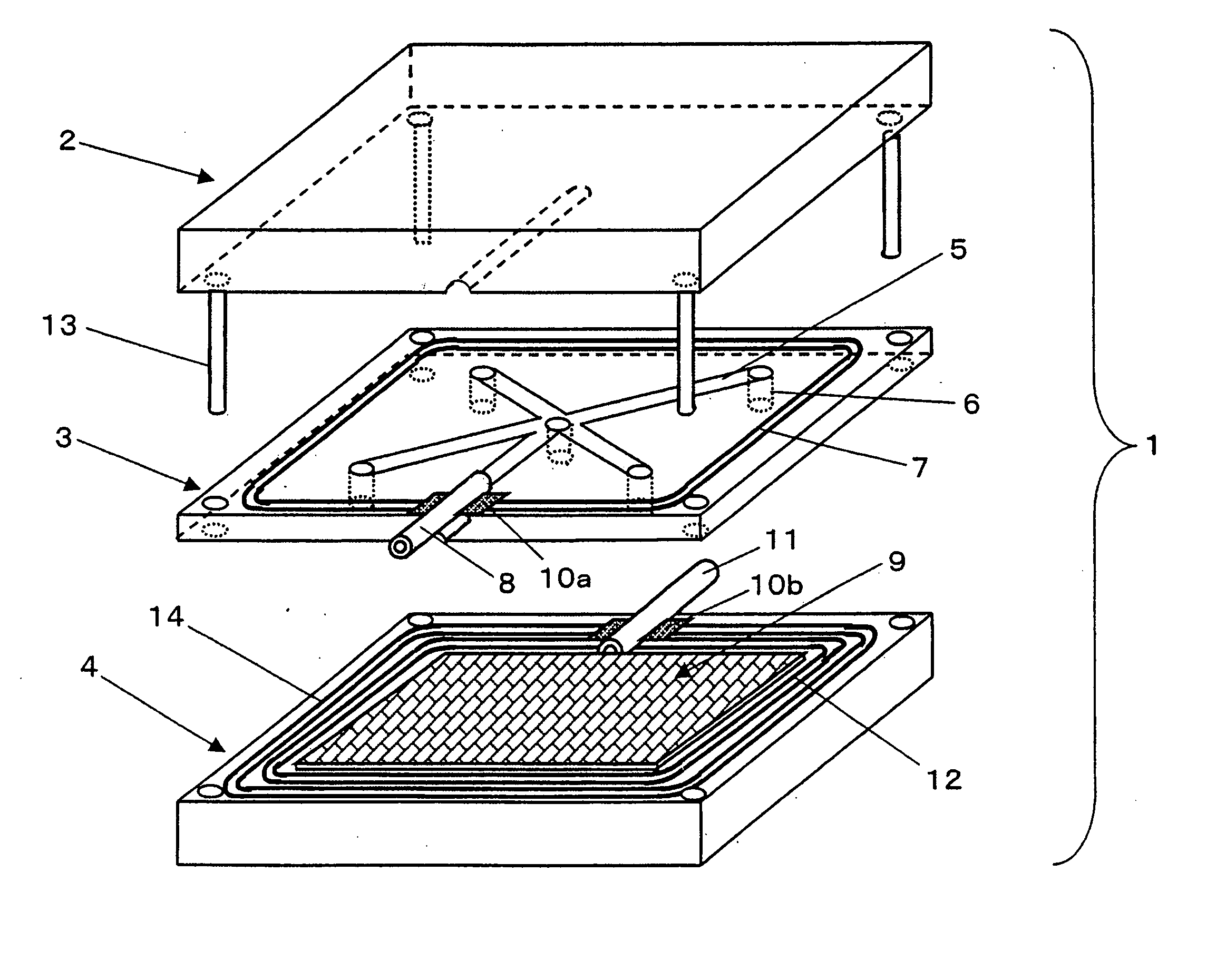

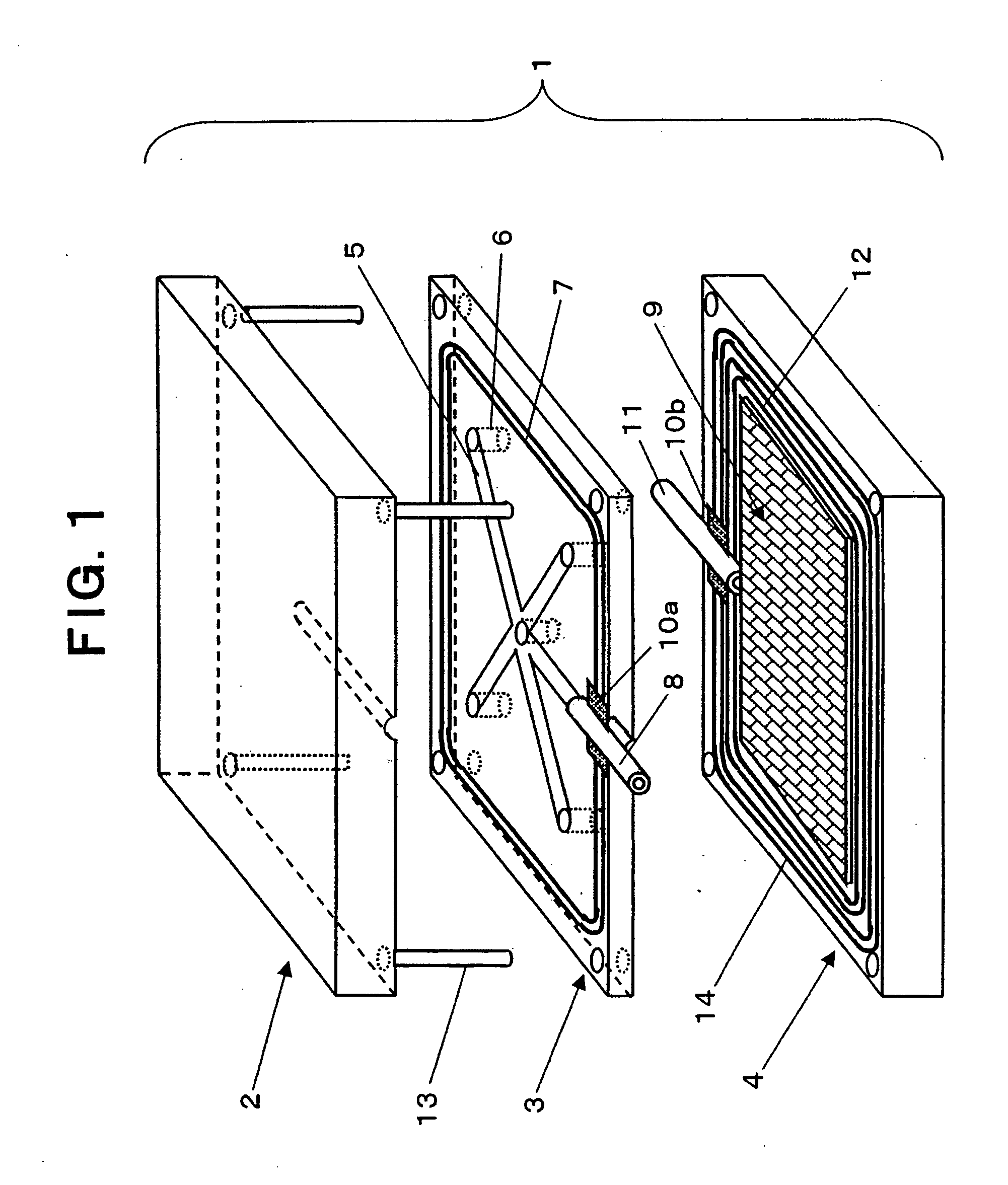

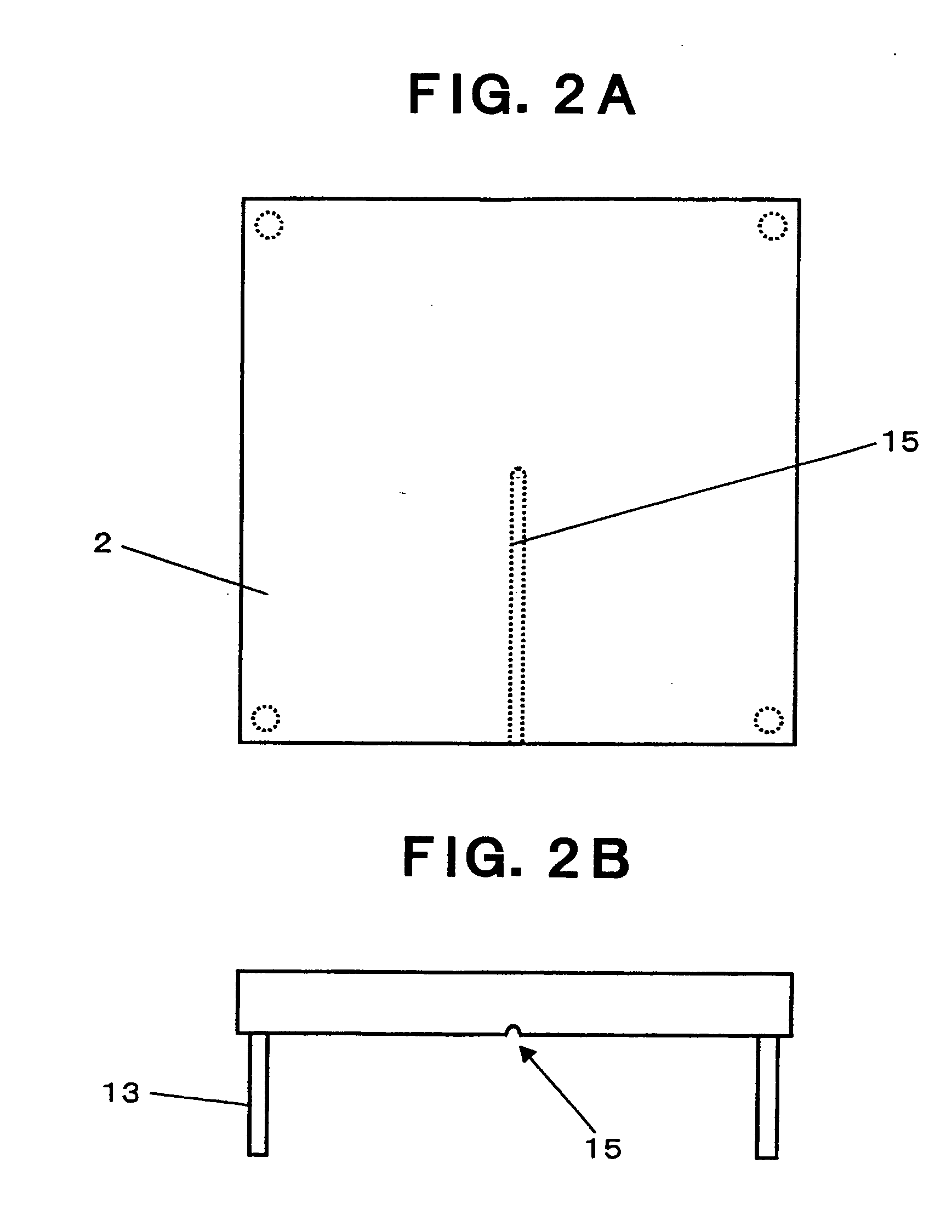

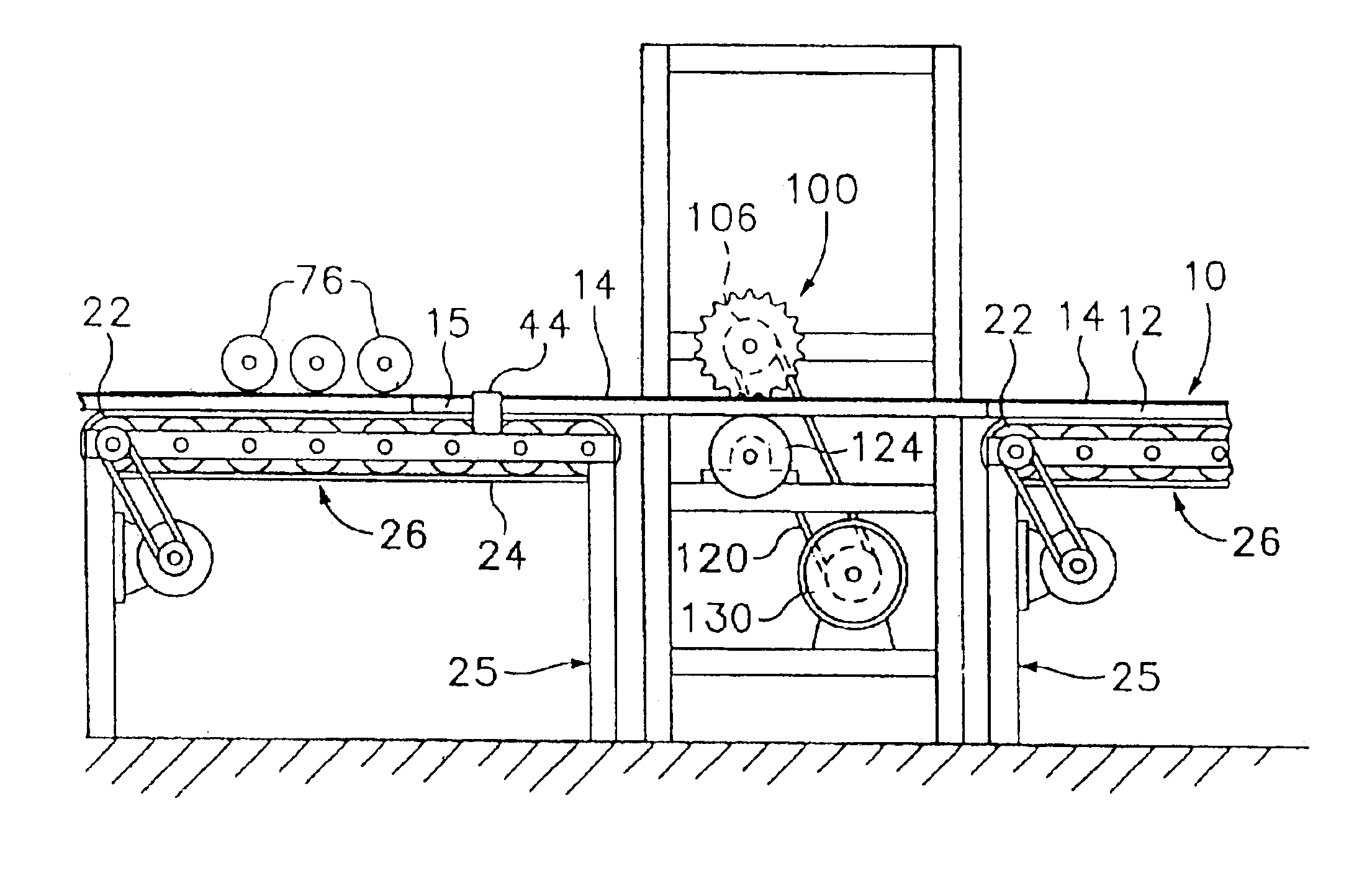

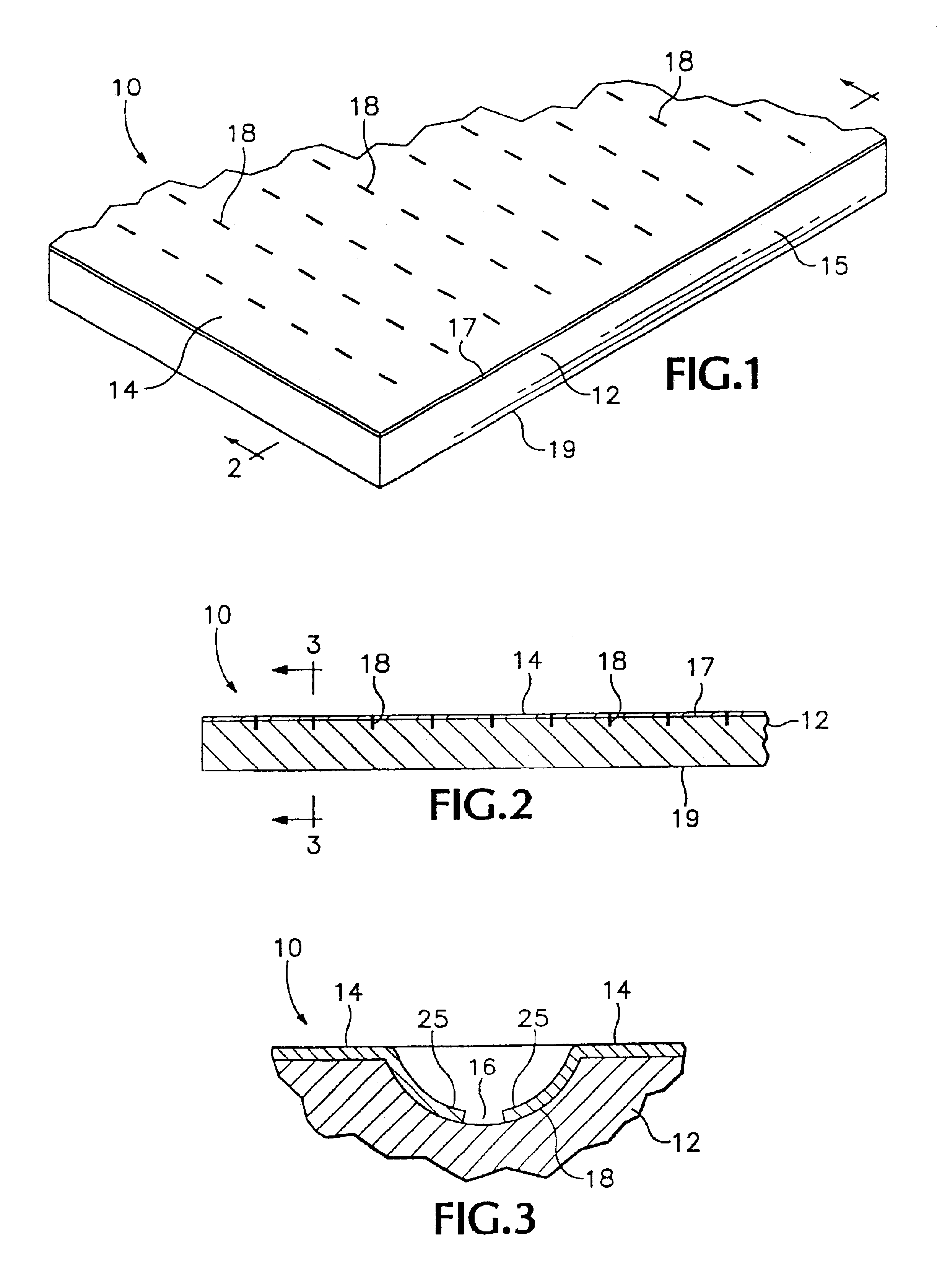

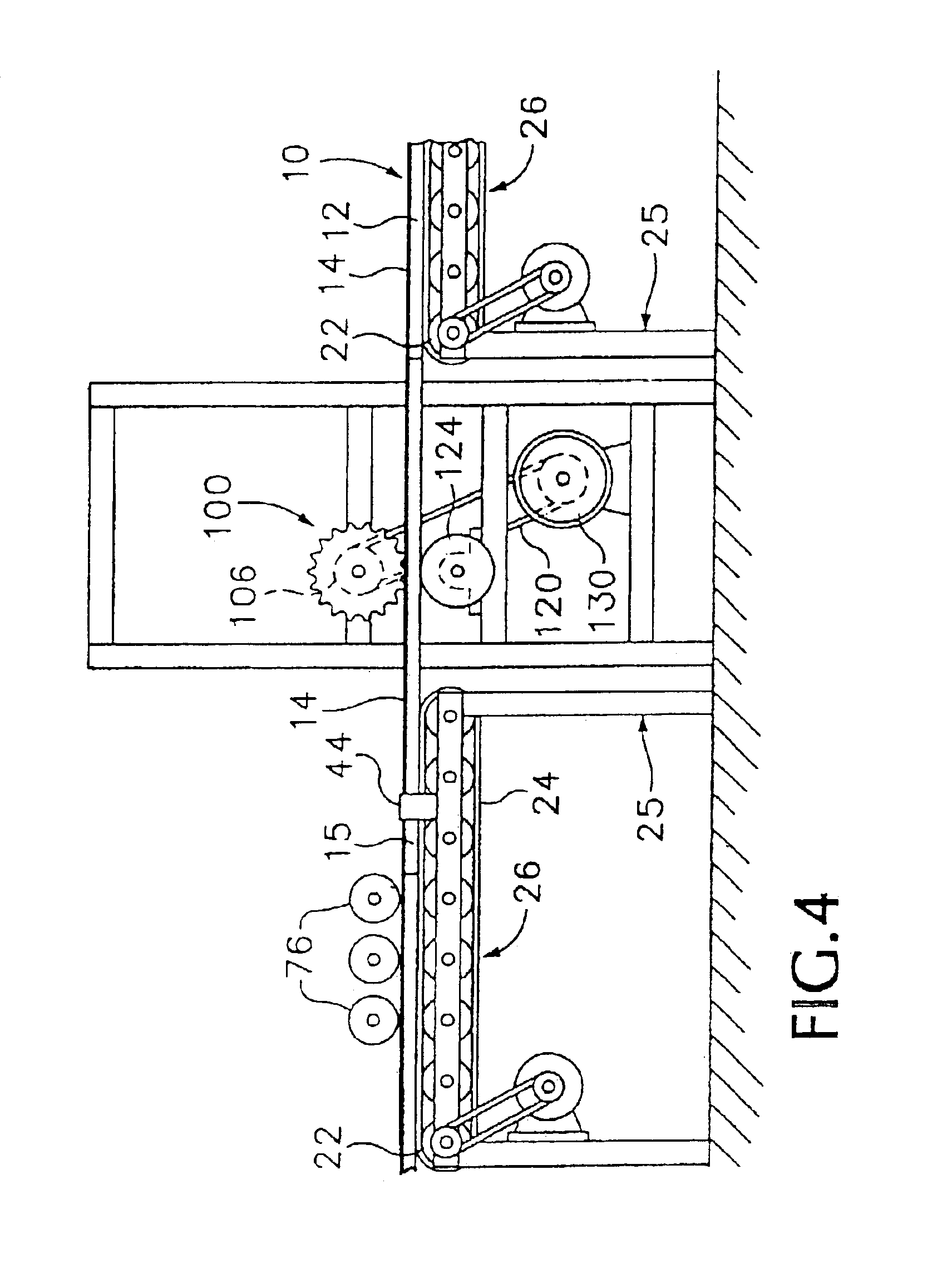

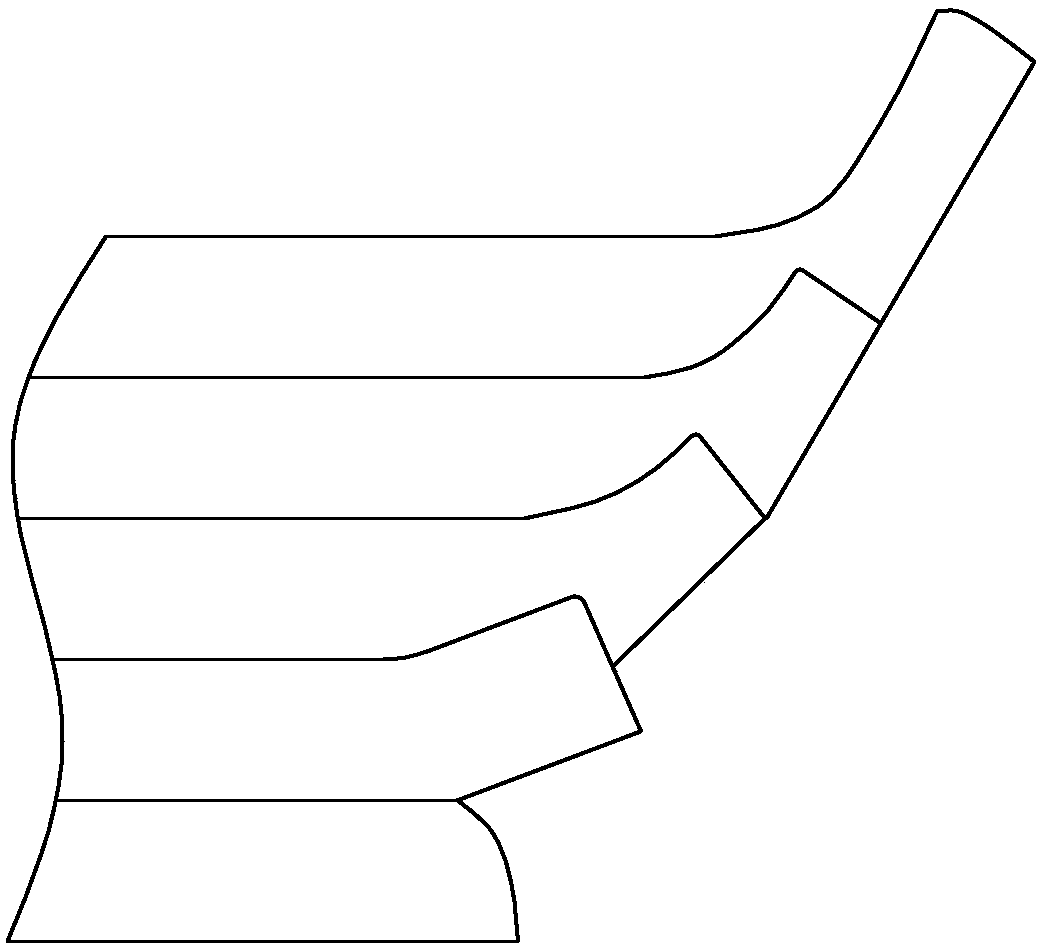

Rtm molding method and device

InactiveUS20070182071A1Shorten molding timeReduce the amount of solutionConfectioneryWood working apparatusFiber

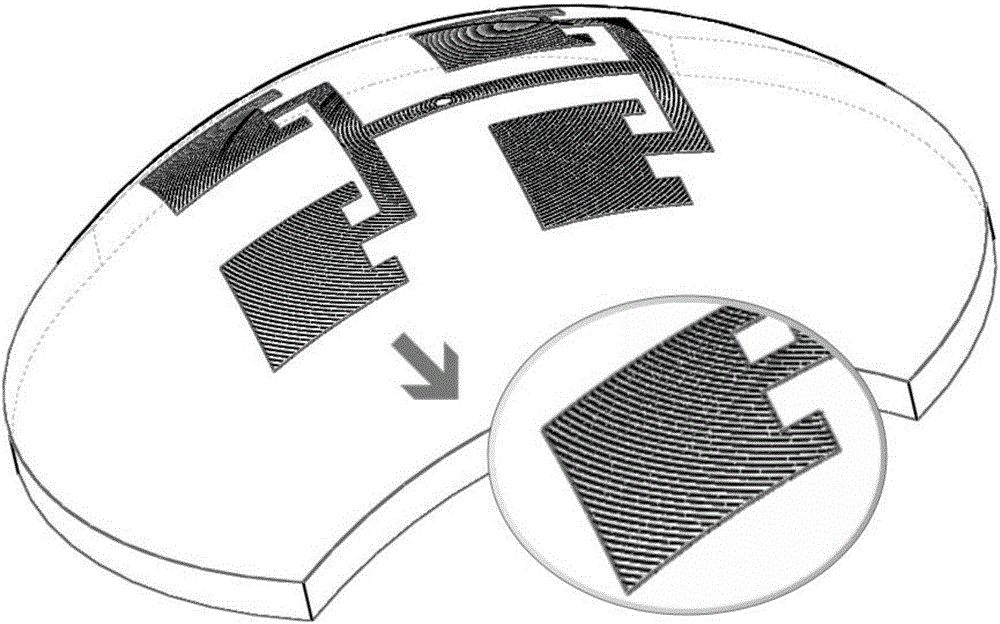

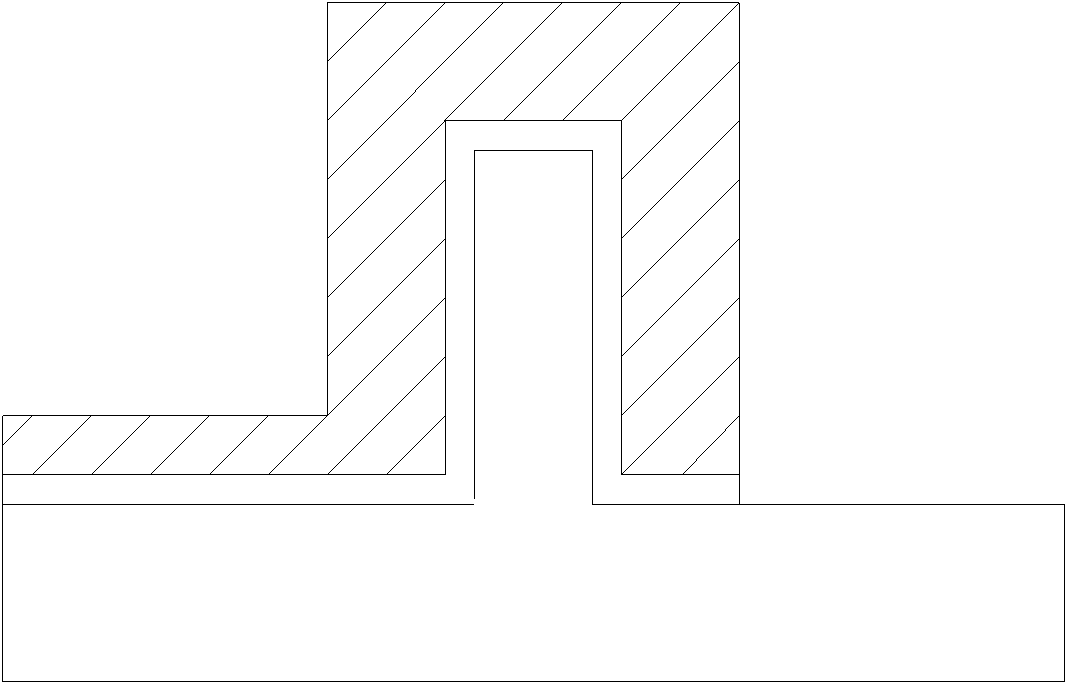

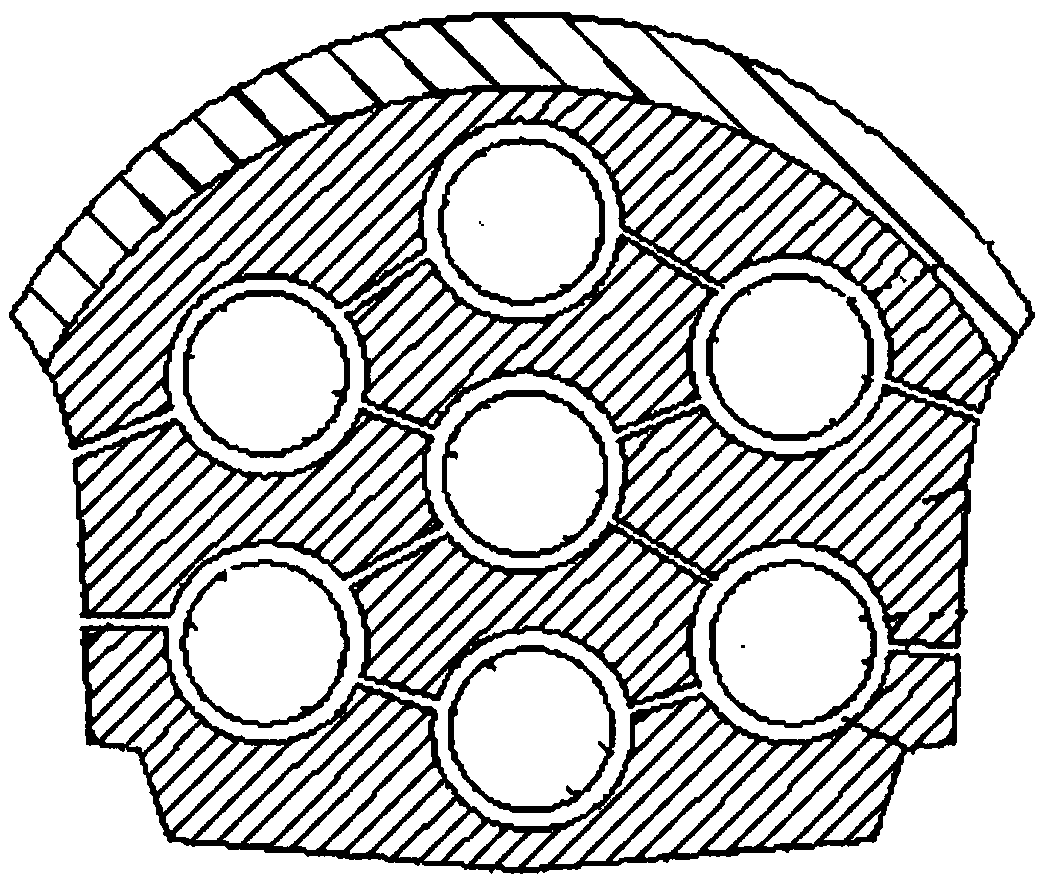

An RTM molding method comprising disposing a reinforcing fiber substrate in a cavity of a mold consisting of a plurality of dies, clamping the mold, and thereafter injecting resin to complete molding, characterized in that divided areas with respect to the surface direction of the reinforcing fiber substrate are assumed, each divided area is one in which injected resin expands over the entire surface in the area and can be substantially uniformly impregnated in the thickness direction of the substrate, and resin introducing paths are formed for respective assumed divided areas for introducing the injected resin into the respective divided areas; and an RTM molding device. When a relatively large molded product is to be molded, a molding step from resin injection to impregnating / curing can be implemented at high speed without generating a non-resin-flowing area, thereby enabling a high-quality molded product to be produced free from voids, etc., with a molding time shortened and production speed and volume increased.

Owner:TORAY IND INC

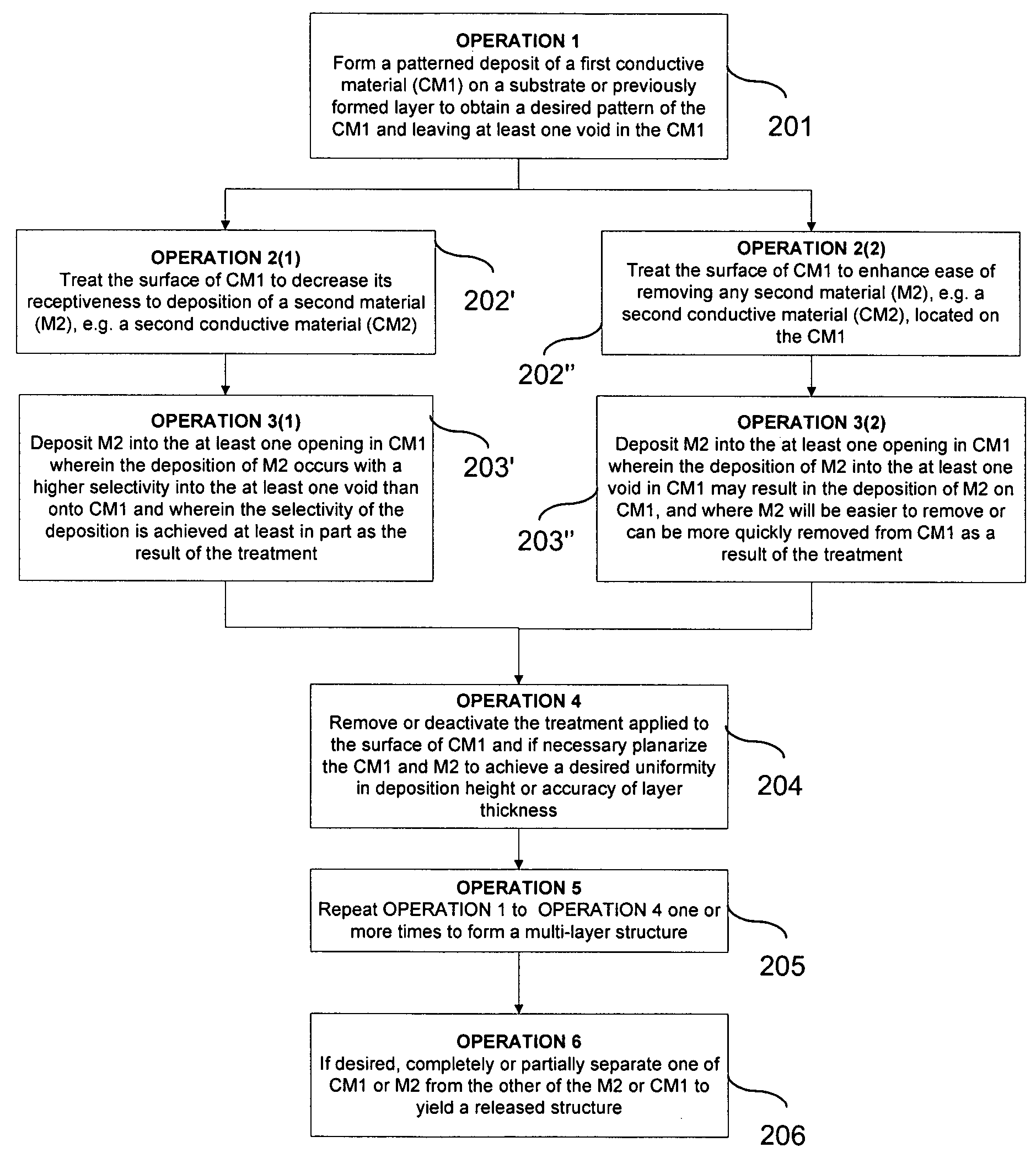

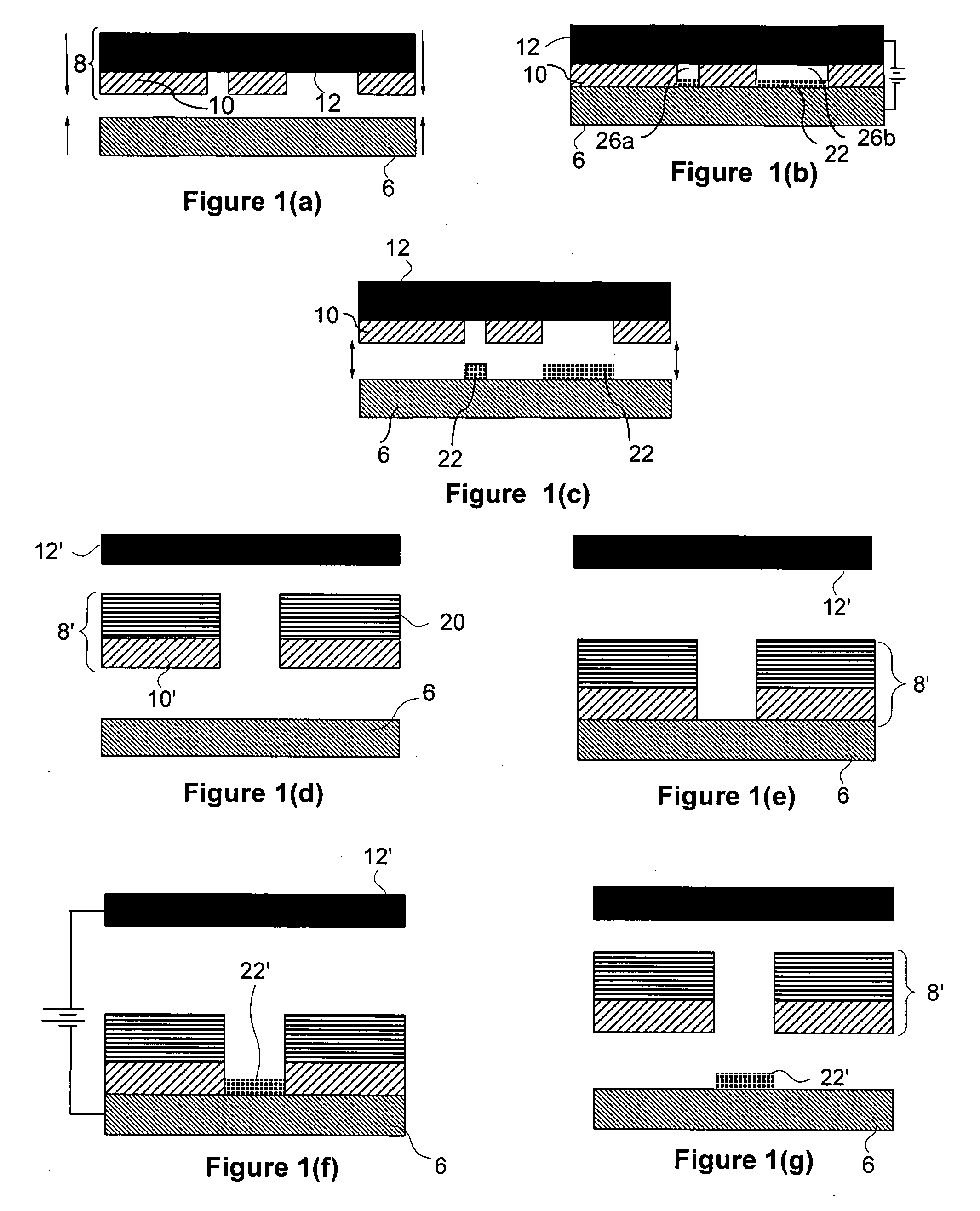

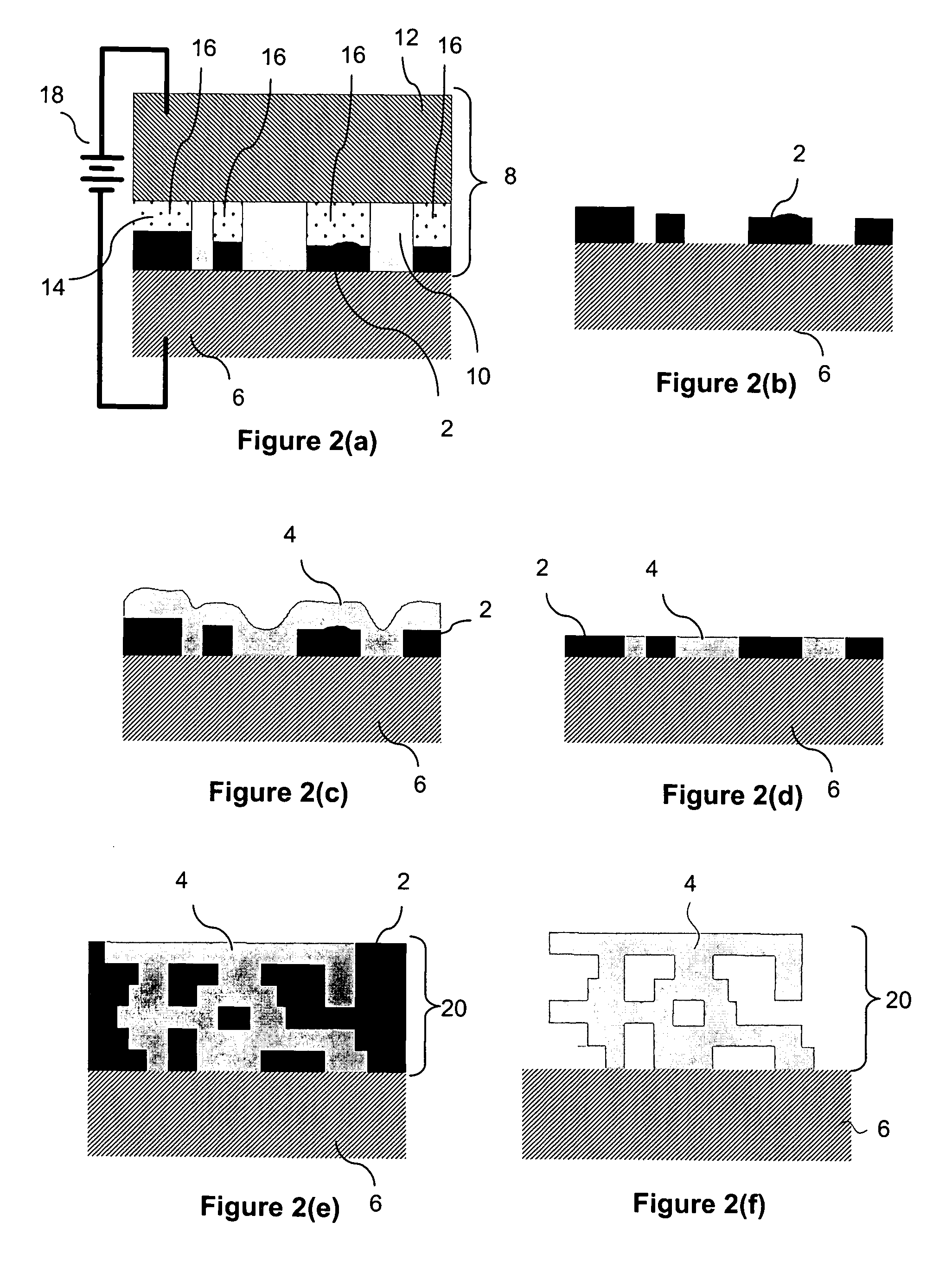

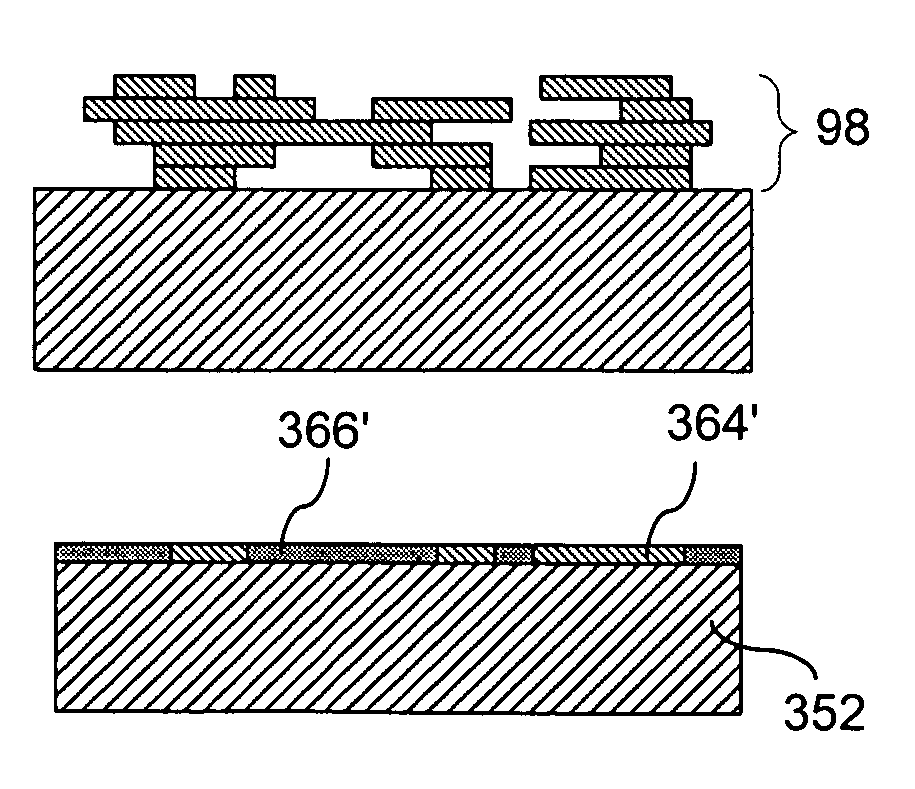

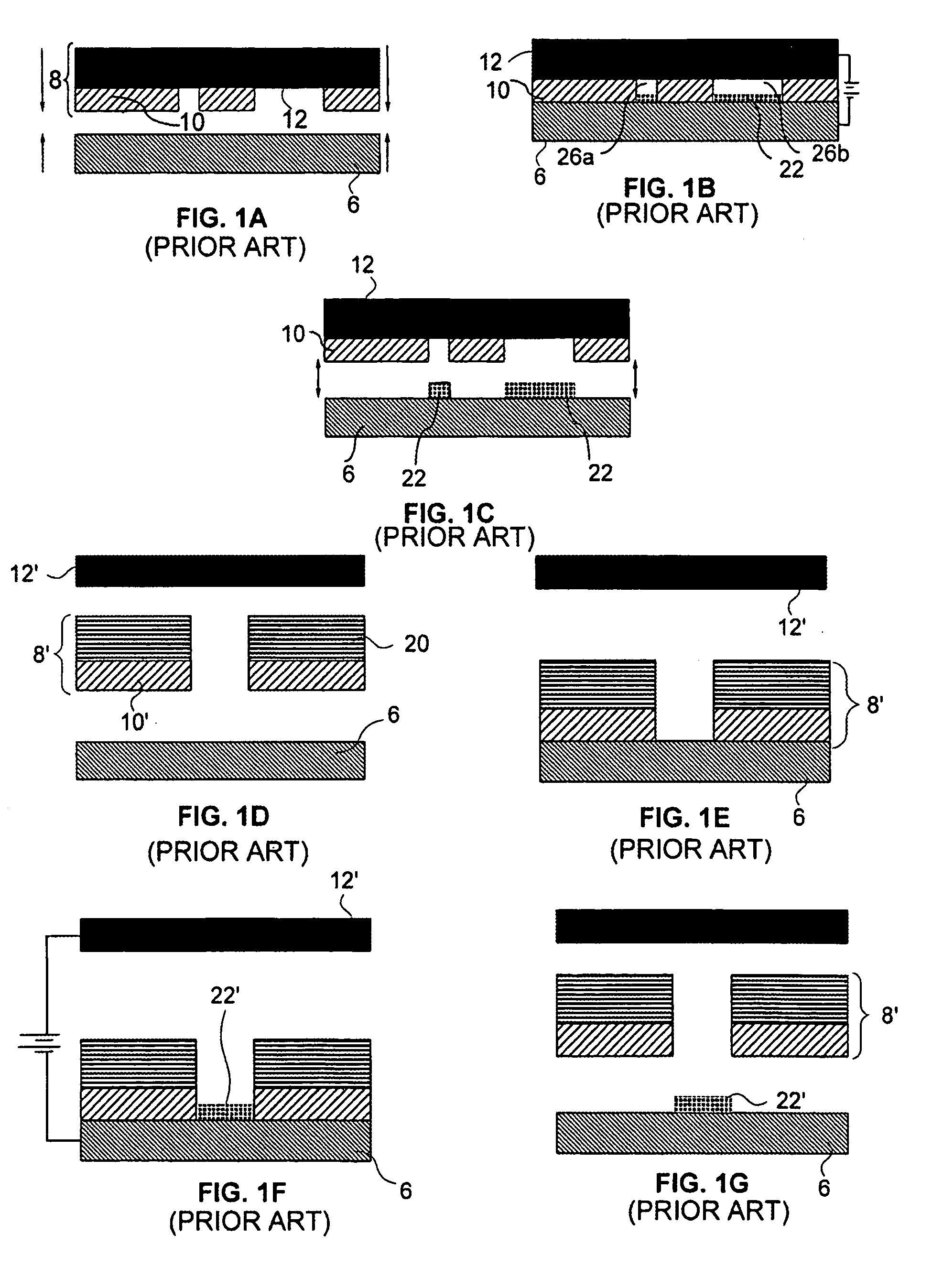

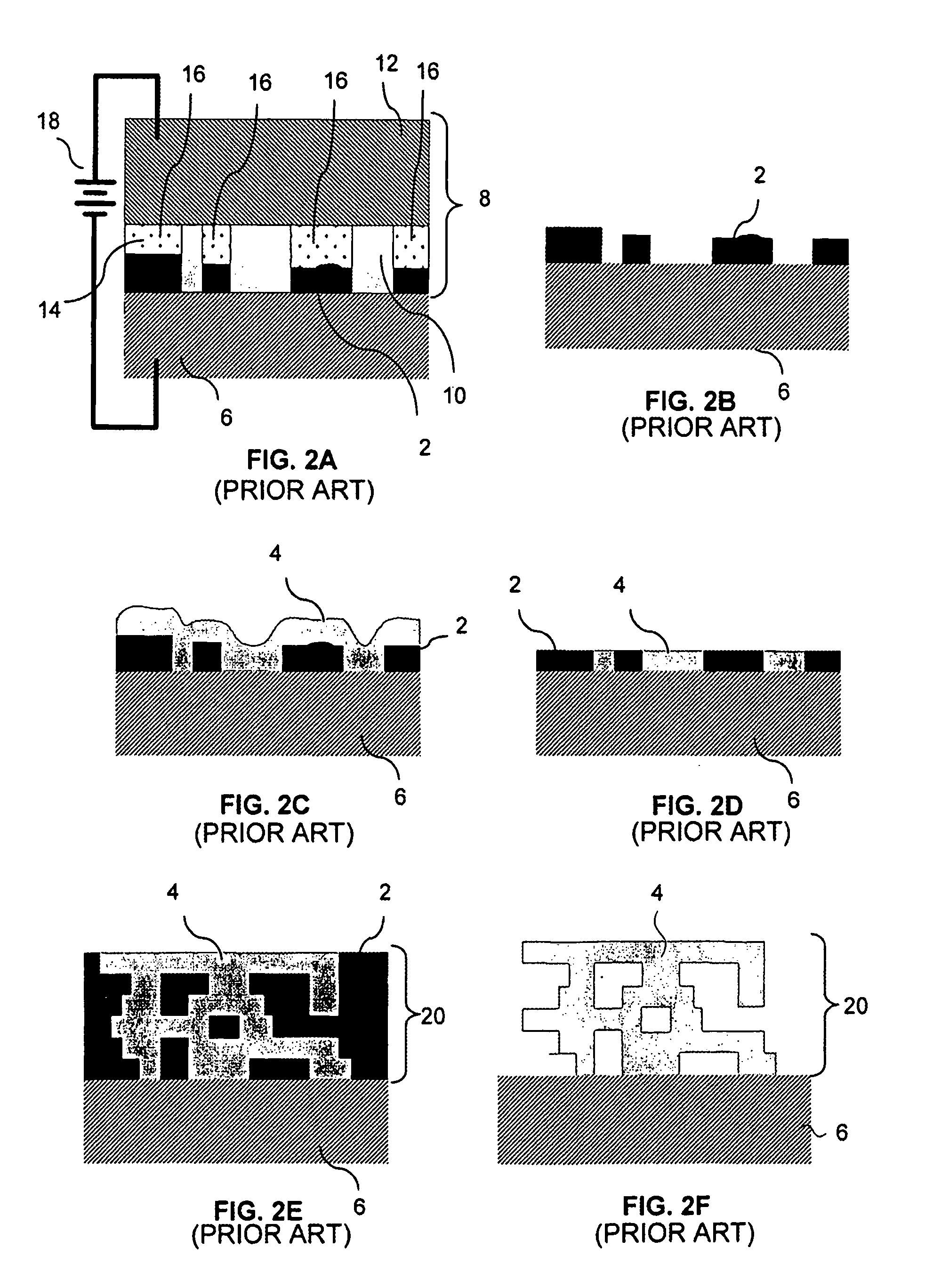

Electrochemical fabrication methods including use of surface treatments to reduce overplating and/or planarization during formation of multi-layer three-dimensional structures

InactiveUS20050032362A1Reduced layer formation timeShorten molding timeAdditive manufacturing apparatusSemiconductor/solid-state device manufacturingConductive materialsElectrochemistry

A method of fabricating three-dimensional structures from a plurality of adhered layers of at least a first and a second material wherein the first material is a conductive material and wherein each of a plurality of layers includes treating a surface of a first material prior to deposition of the second material. The treatment of the surface of the first material either (1) decreases the susceptibility of deposition of the second material onto the surface of the first material or (2) eases or quickens the removal of any second material deposited on the treated surface of the first material. In some embodiments the treatment of the first surface includes forming a dielectric coating over the surface and the second material is electrodeposited (e.g. using an electroplating or electrophoretic process). In other embodiments the first material is coated with a conductive material that doesn't readily accept deposits of electroplated or electroless deposited materials.

Owner:MICROFAB

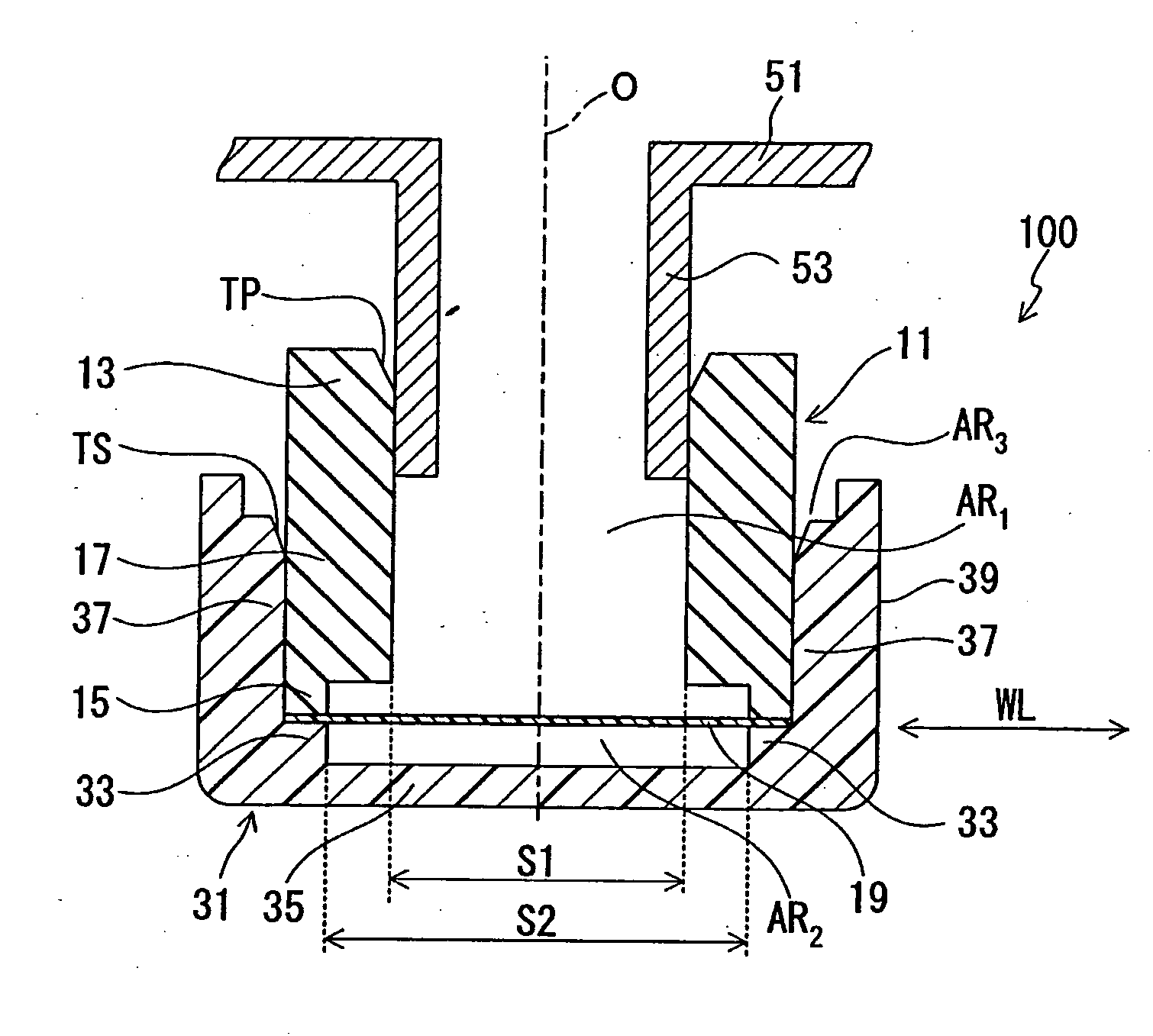

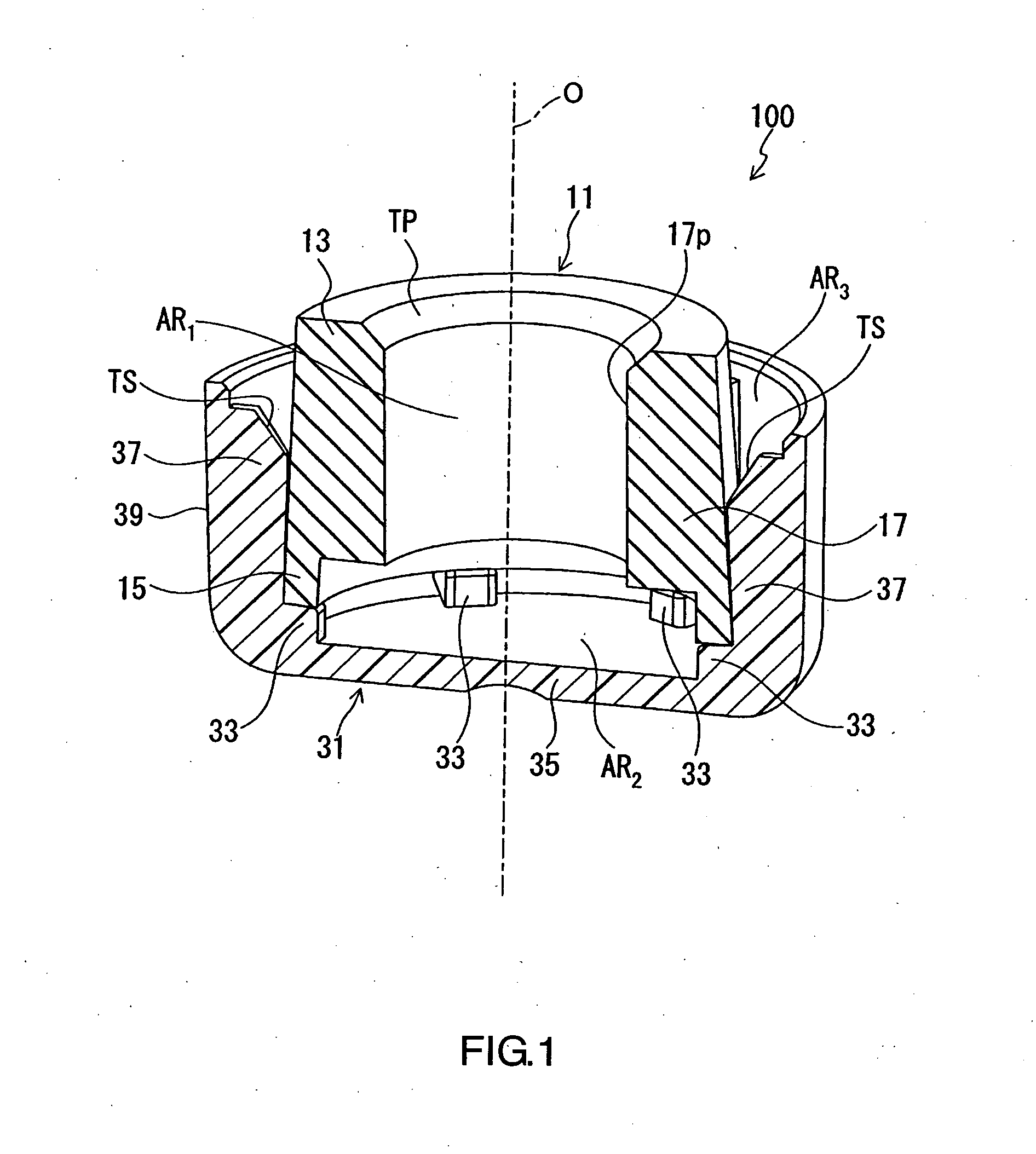

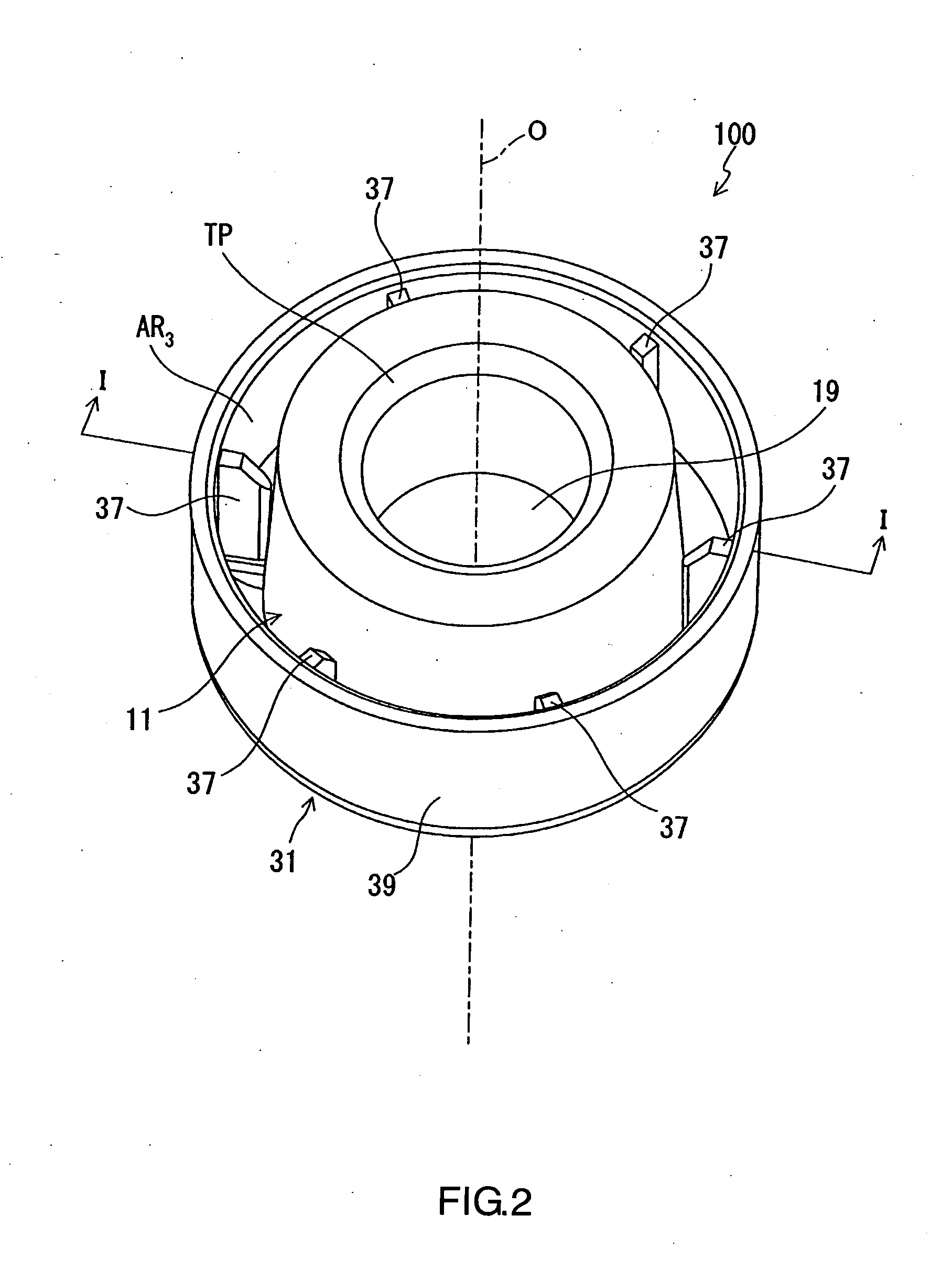

Ventilation member

Owner:NITTO DENKO CORP

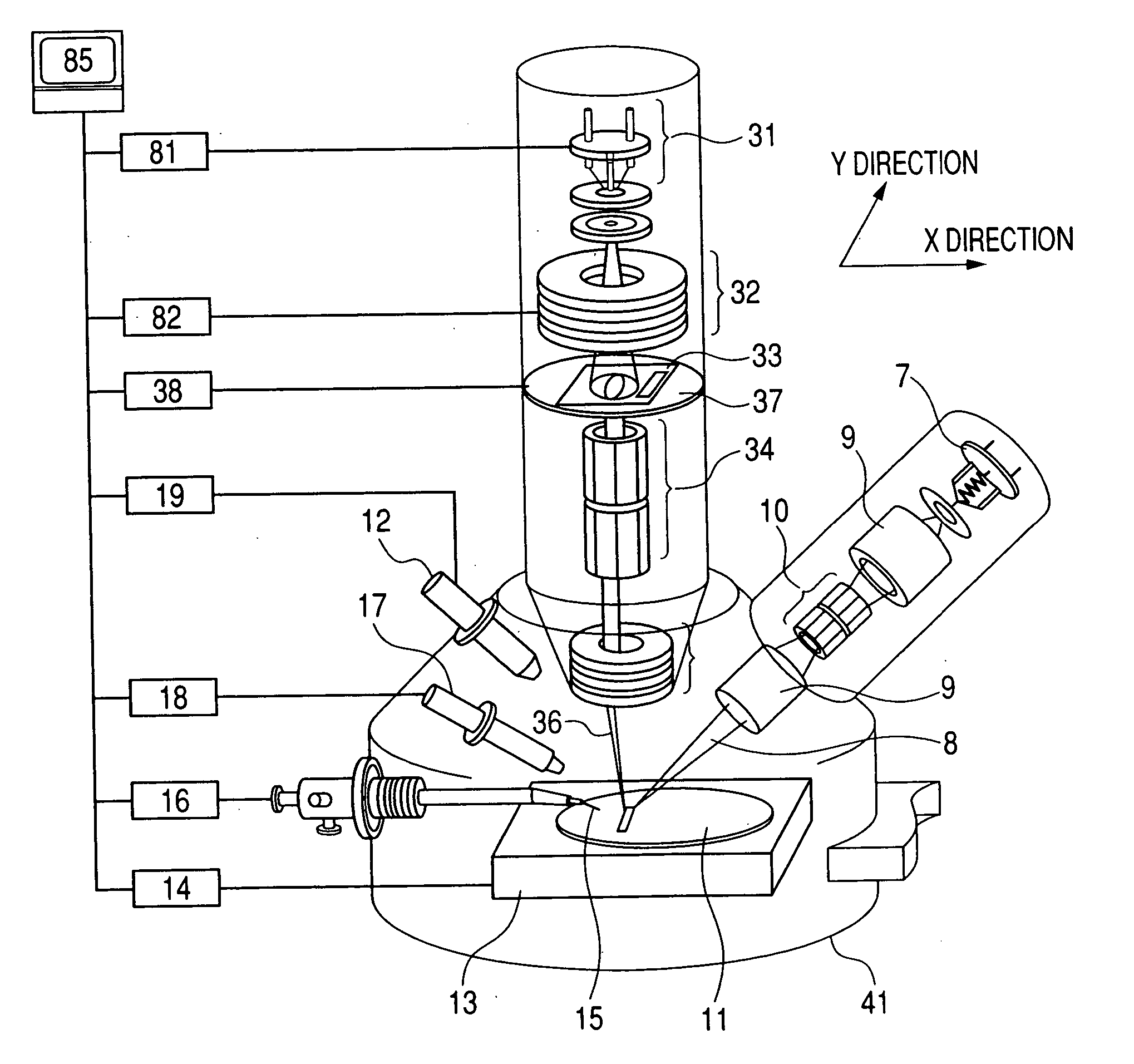

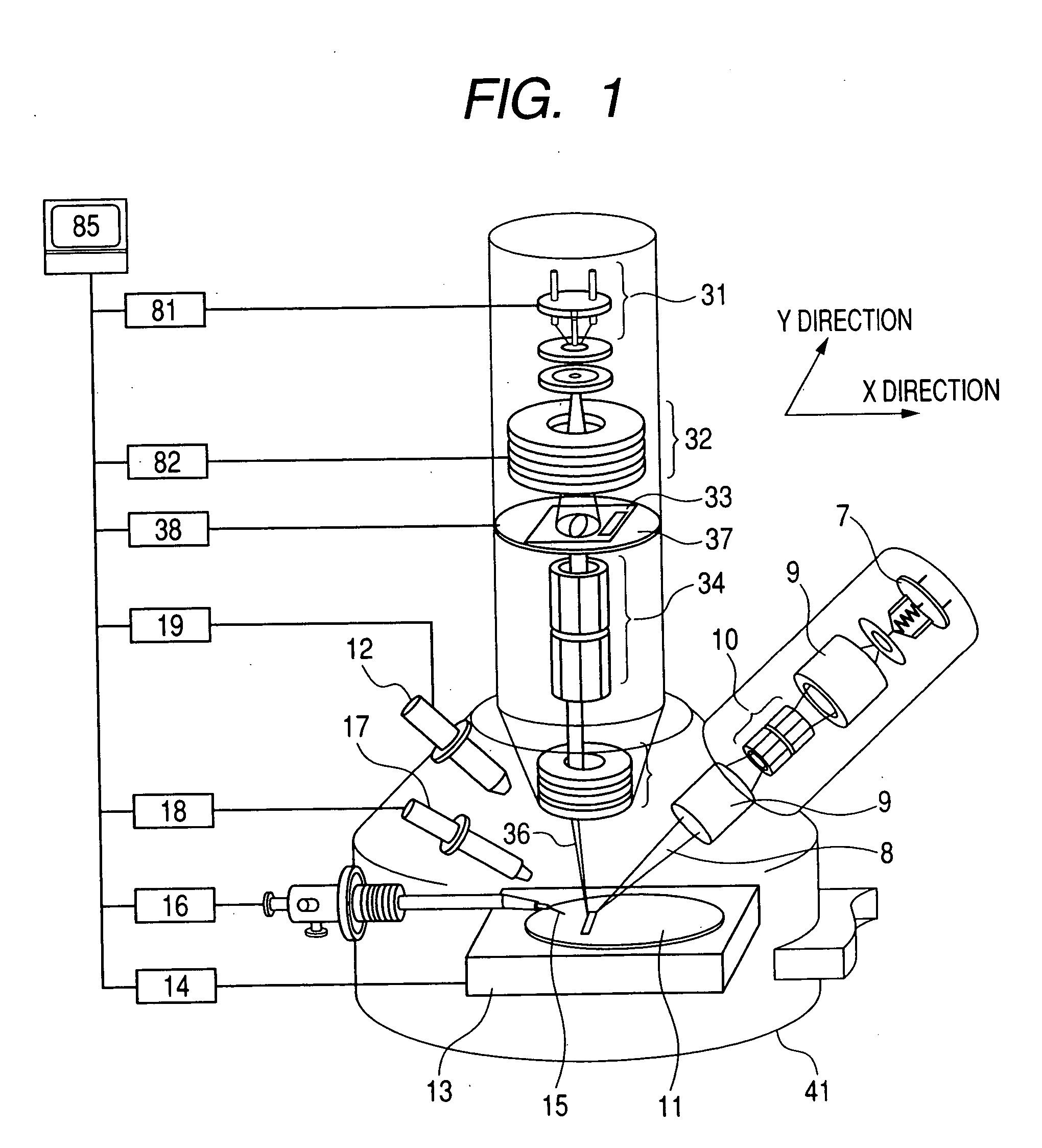

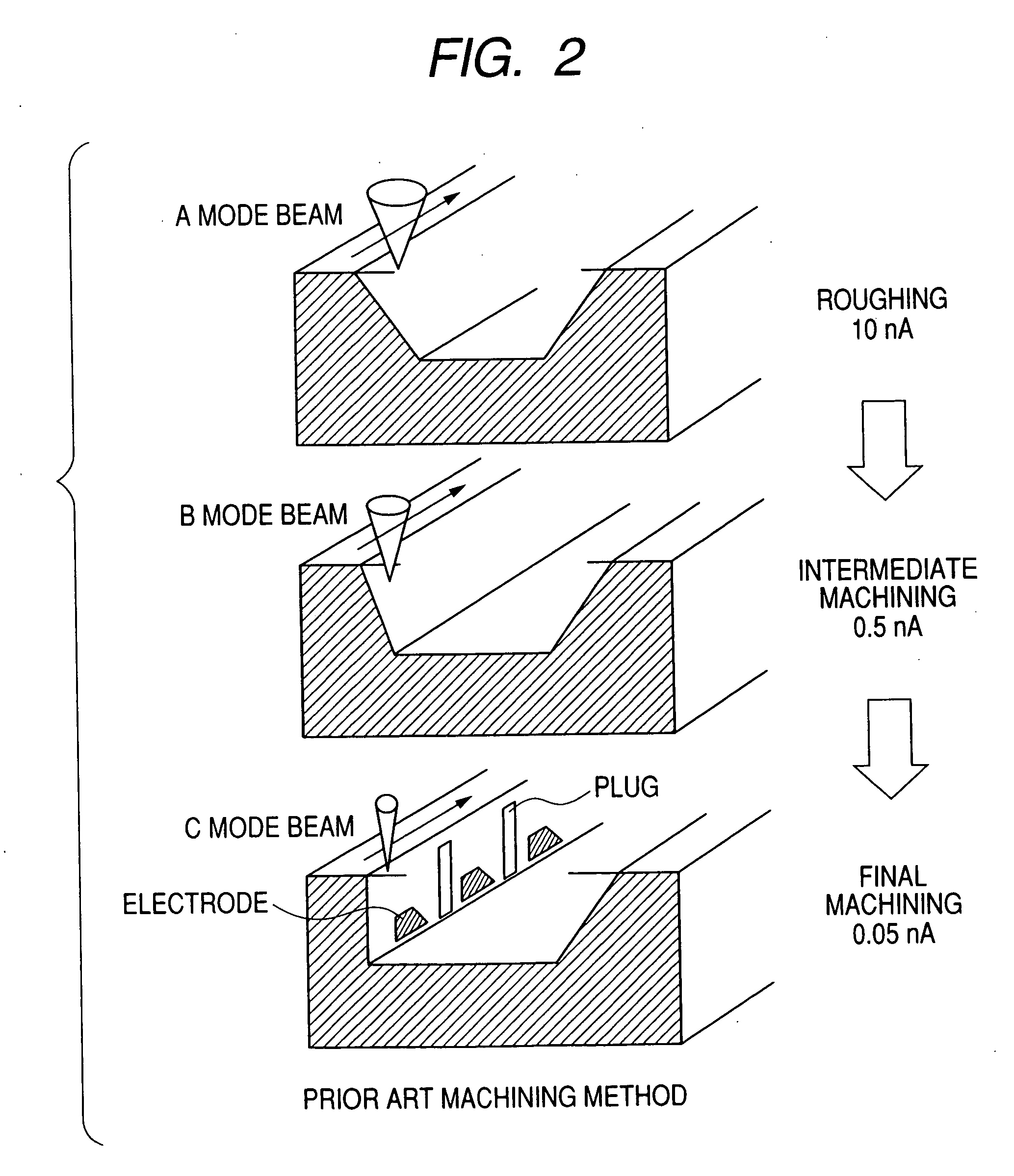

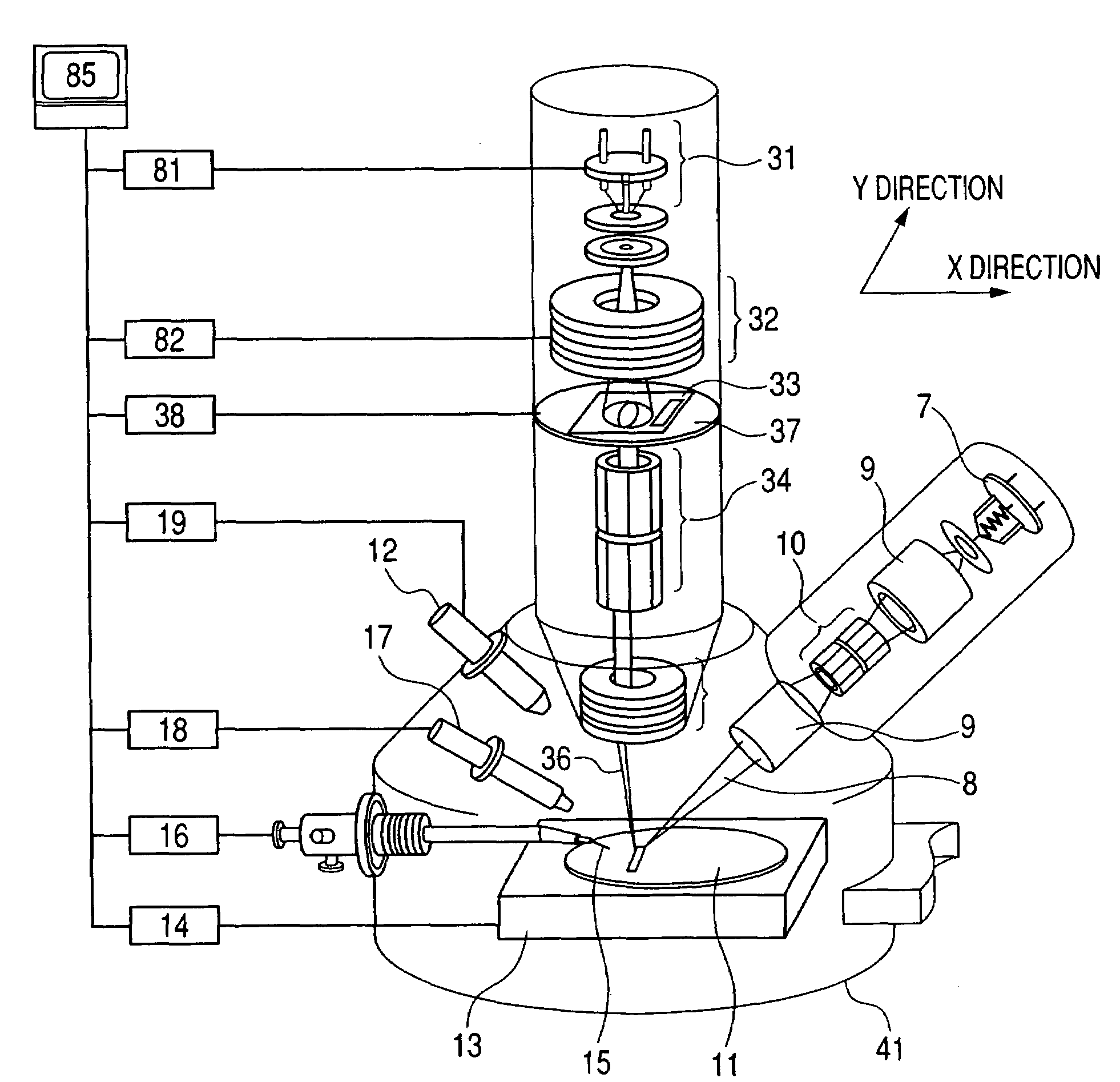

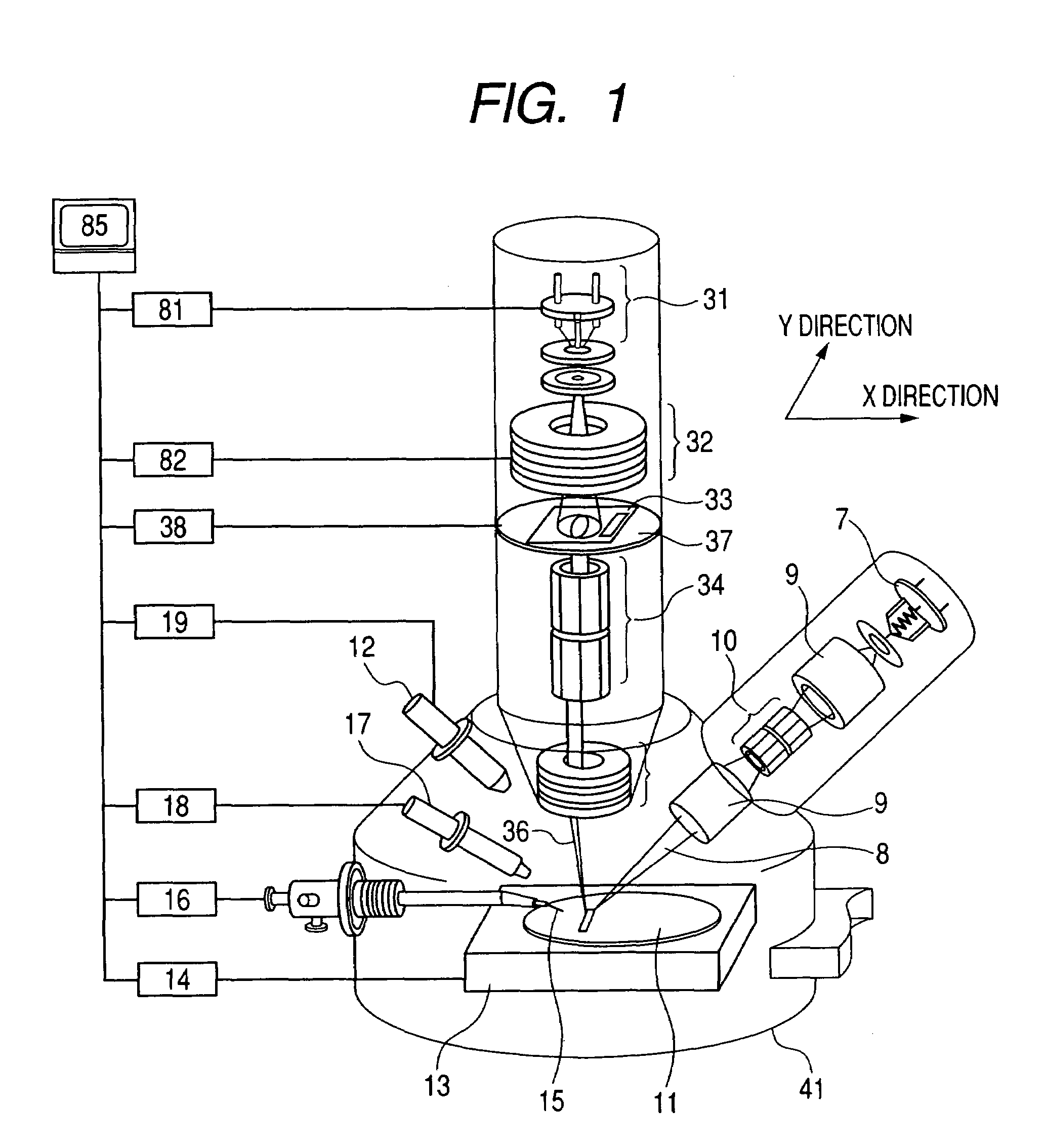

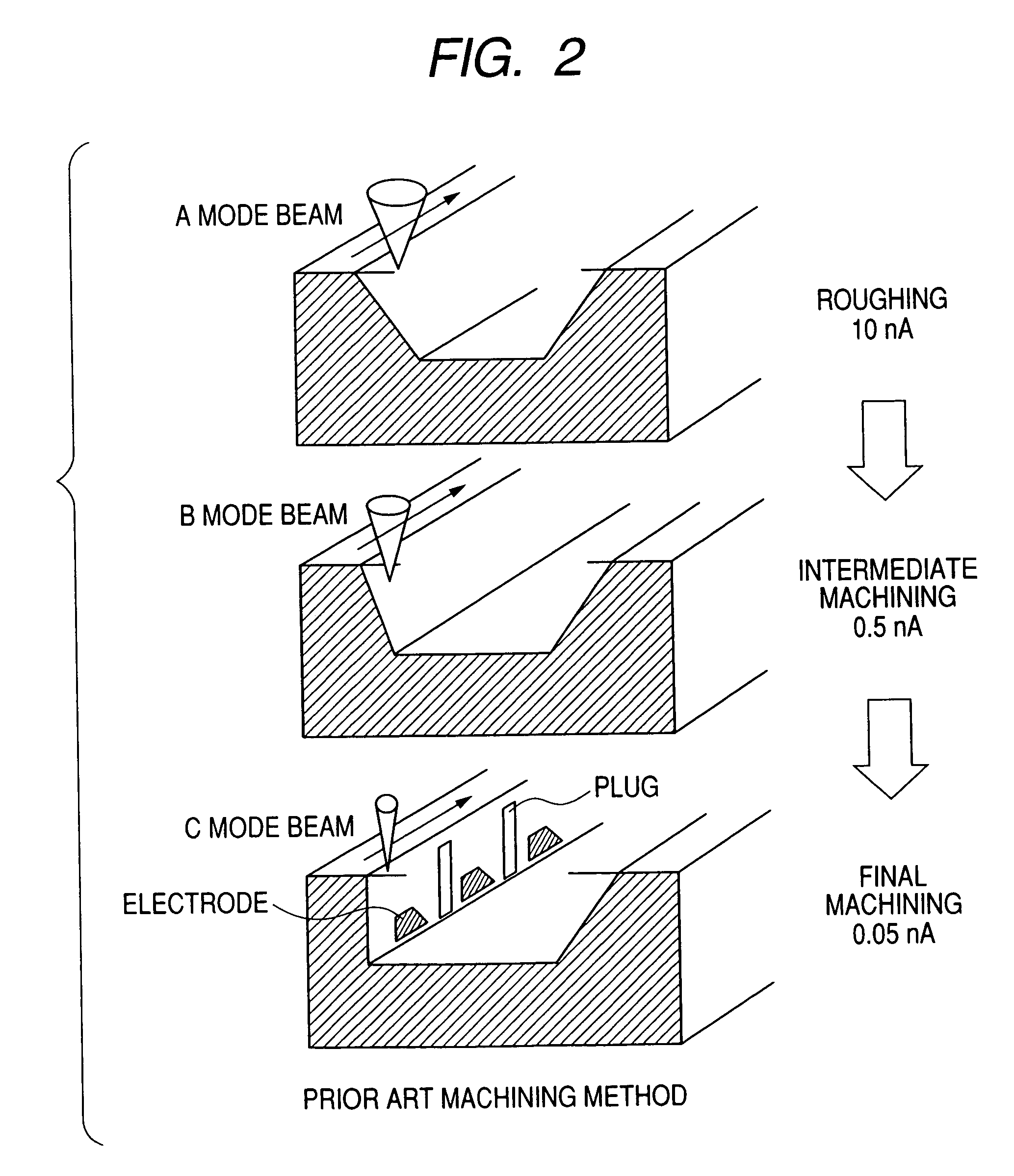

Ion beam system and machining method

InactiveUS20060065854A1Short timeReduce manufacturing costPreparing sample for investigationIon beam tubesMachining systemAnalysis method

There is a machining method which shortens a cross-section forming time by an ion beam, a machining method which shortens a machining time for separating a micro sample from a wafer, and an ion beam machining system. The ion beam machining system has a vacuum container containing a duoplasmatron, non-axially symmetric ion beam lens and stencil mask, wherein a micro sample is removed from a sample by an argon ion beam having a steep beam profile in a direction perpendicular to the cross-section. The cross-section observations for wafer inspection / defect analysis used in device manufacture can be obtained in a short time. Further, there is a inspection / analysis method which does not cause defects even if a sample is removed and a wafer is returned to the process.

Owner:HITACHI HIGH-TECH CORP

Electrochemical fabrication methods including use of surface treatments to reduce overplating and/or planarization during formation of multi-layer three-dimensional structures

InactiveUS7109118B2Shorten molding timeReduce the amount requiredAdditive manufacturing apparatusSemiconductor/solid-state device manufacturingConductive materialsElectrochemistry

A method of fabricating three-dimensional structures from a plurality of adhered layers of at least a first and a second material wherein the first material is a conductive material and wherein each of a plurality of layers includes treating a surface of a first material prior to deposition of the second material. The treatment of the surface of the first material either (1) decreases the susceptibility of deposition of the second material onto the surface of the first material or (2) eases or quickens the removal of any second material deposited on the treated surface of the first material. In some embodiments the treatment of the first surface includes forming a dielectric coating over the surface and the second material is electrodeposited (e.g. using an electroplating or electrophoretic process). In other embodiments the first material is coated with a conductive material that doesn't readily accept deposits of electroplated or electroless deposited materials.

Owner:MICROFAB

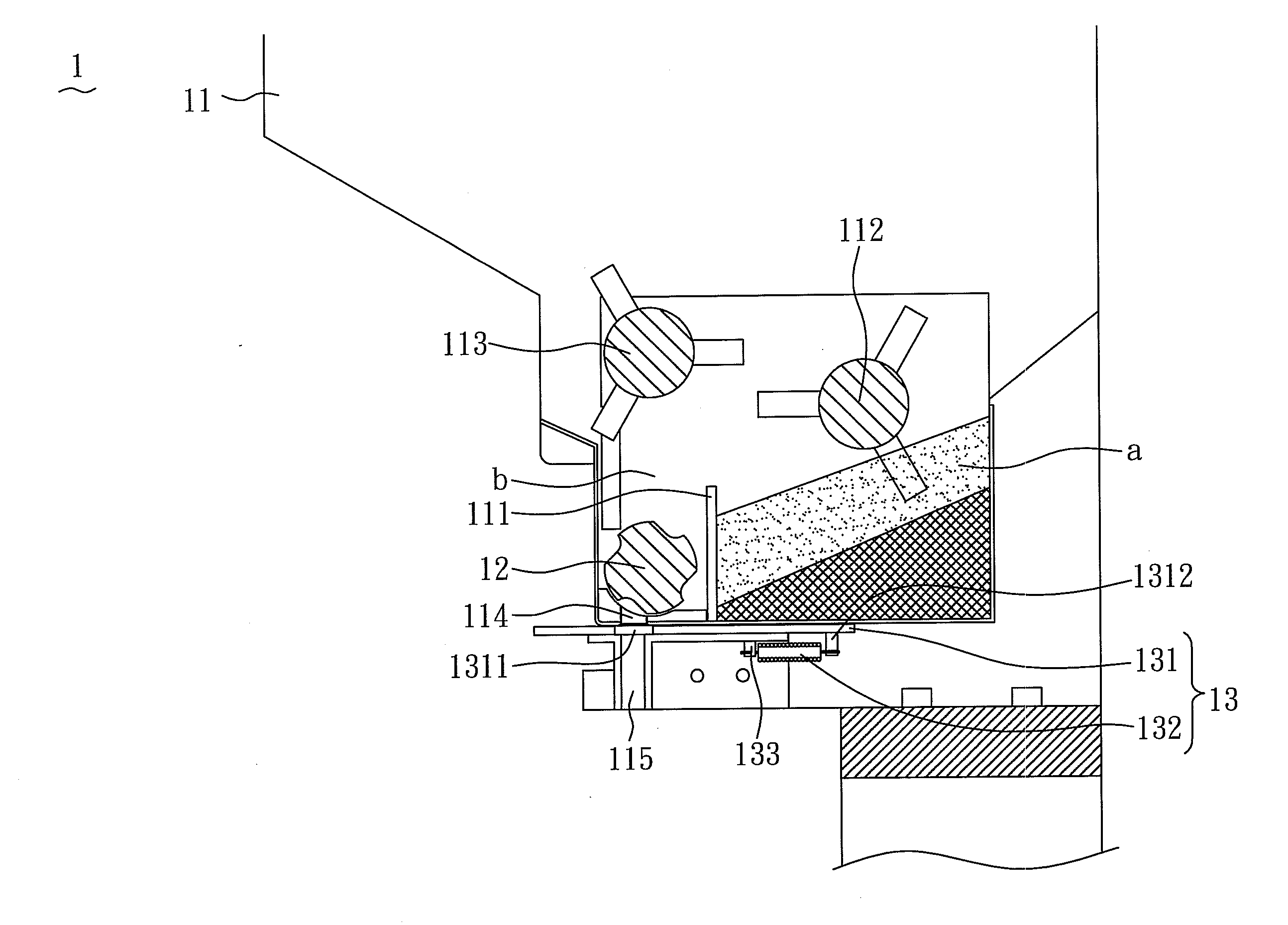

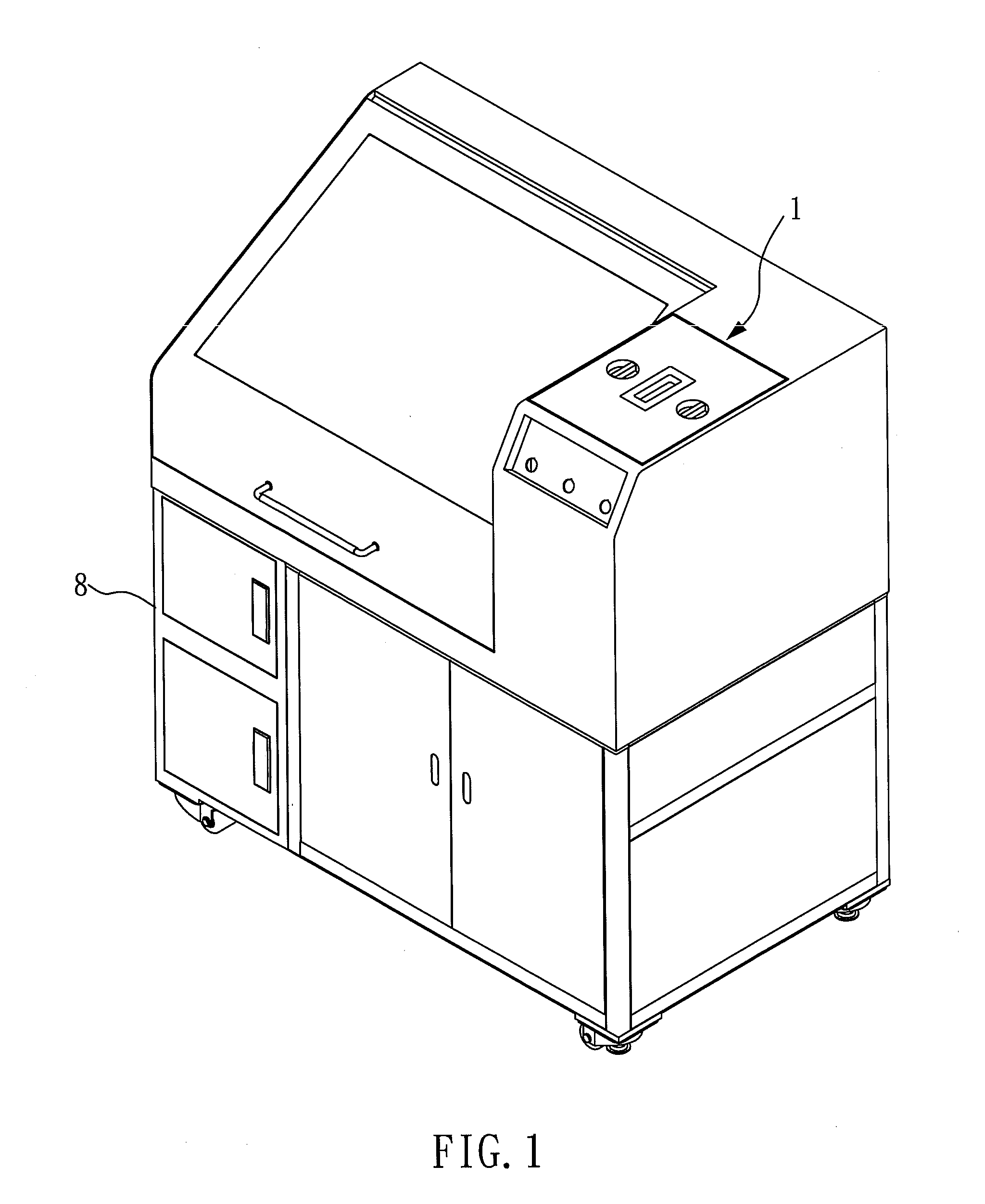

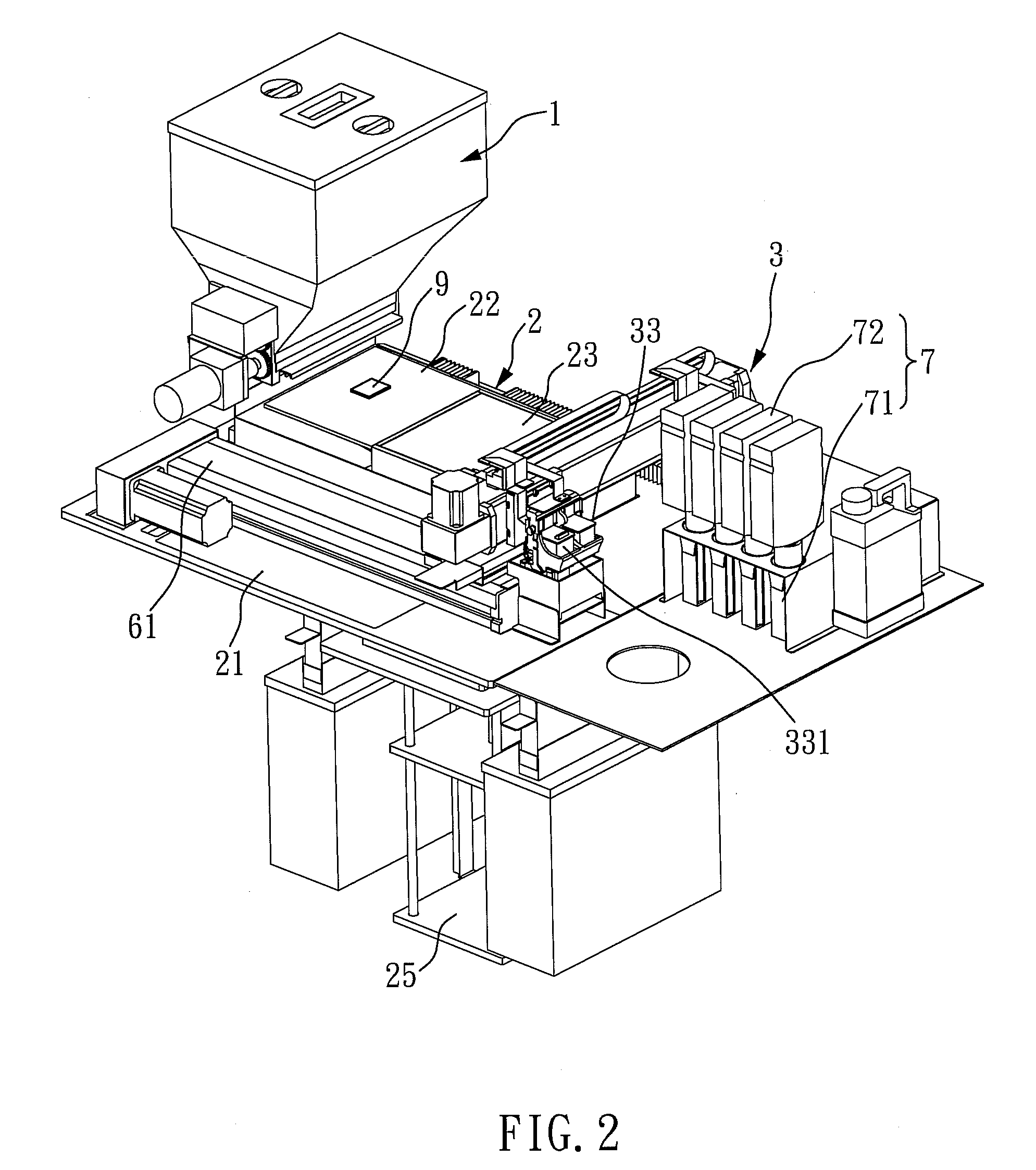

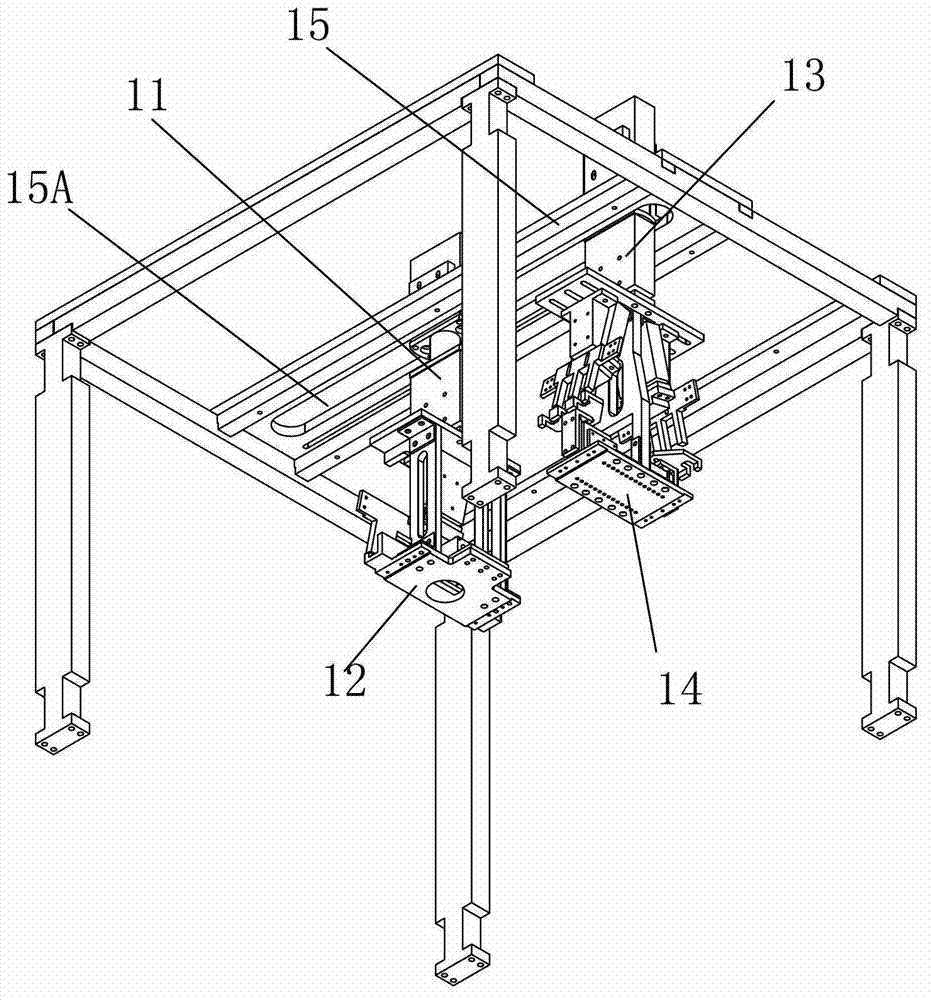

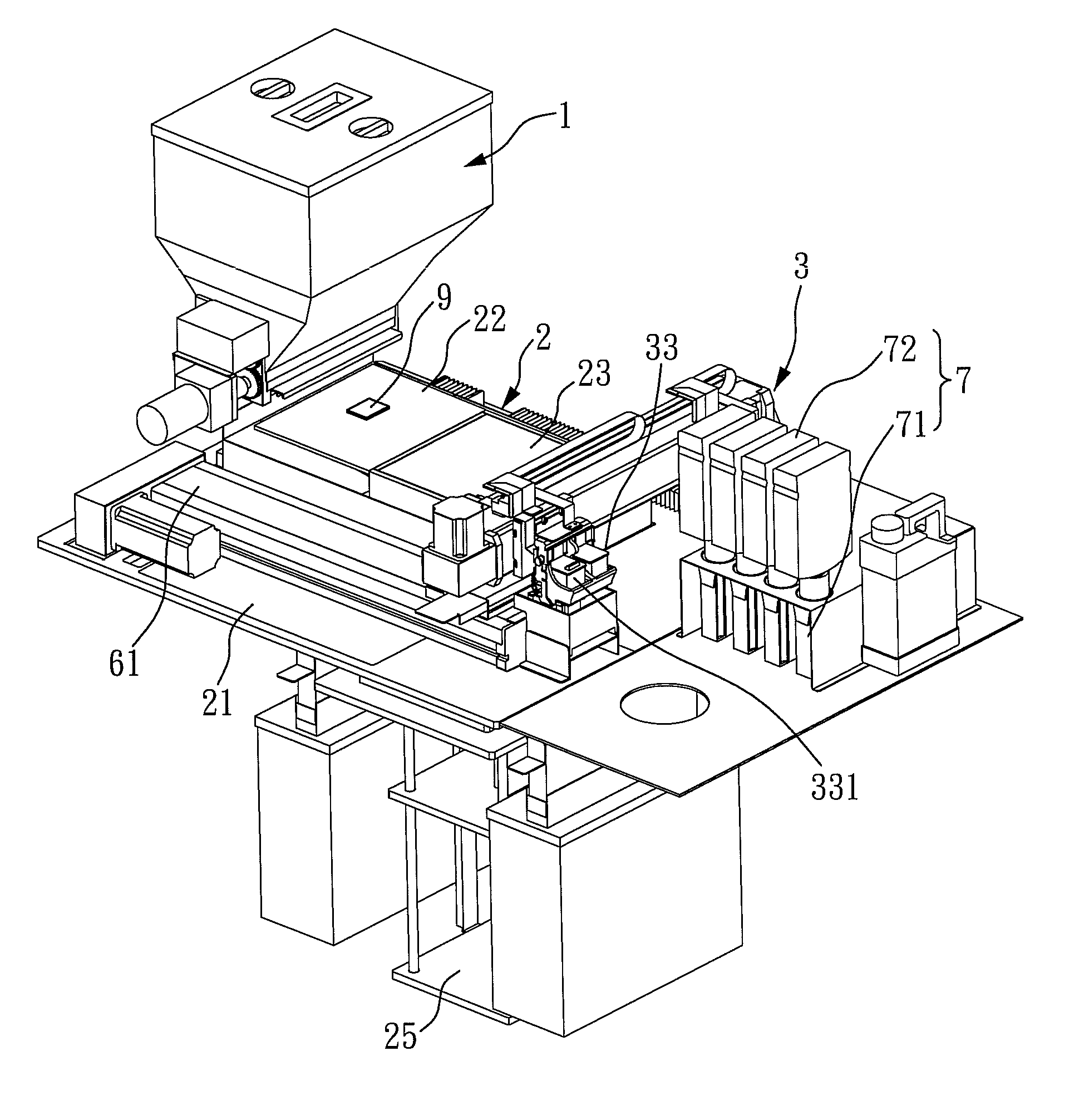

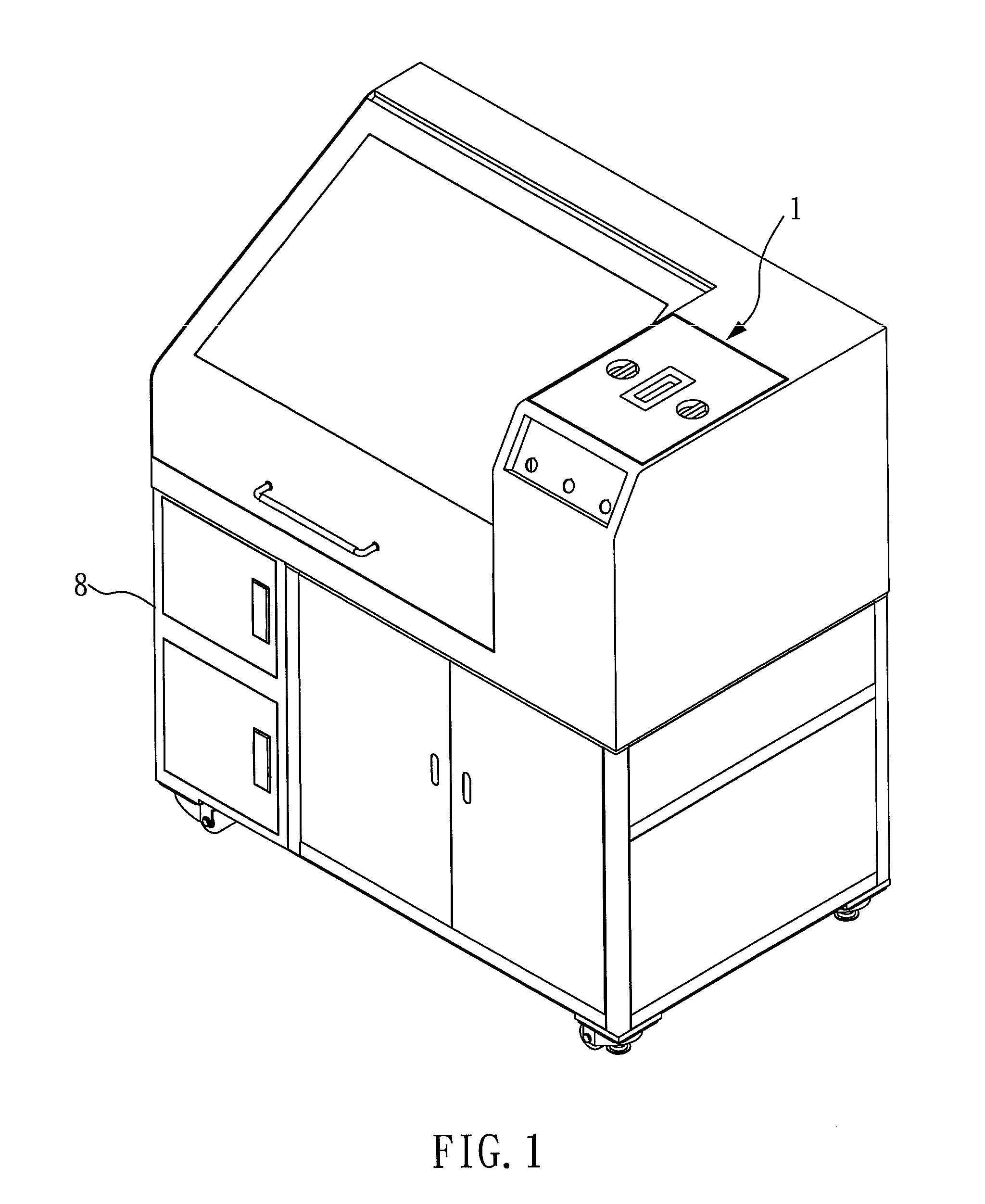

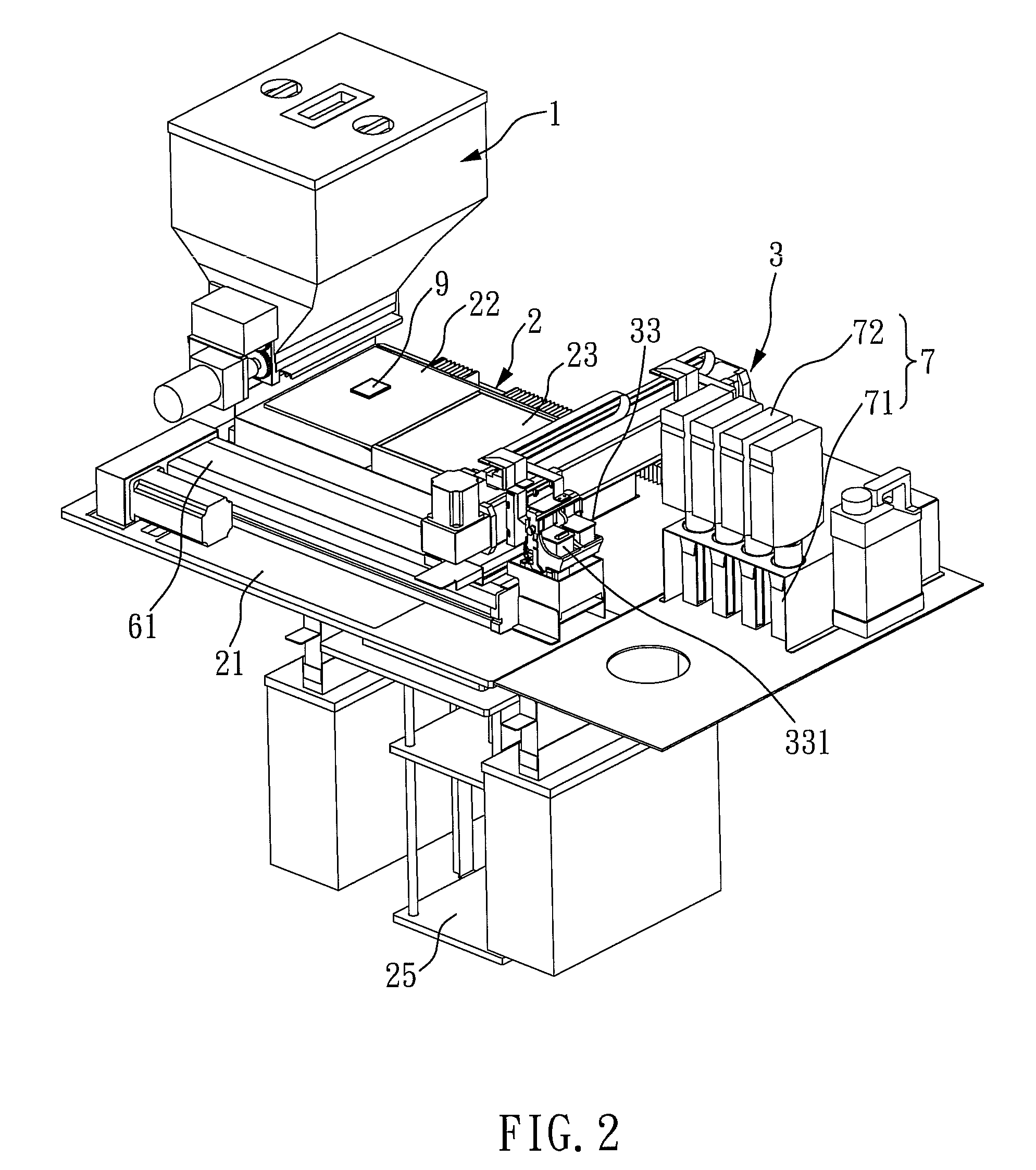

Three-dimensional object-forming apparatus

ActiveUS20110300248A1Avoid wastingLow production costManufacturing enclosuresConfectioneryEngineeringHeating system

A three-dimensional object-forming apparatus is disclosed, which includes an in-batches powder-rationing tank system, a construction tank system, a printing powder-applying system, a rapid drying heating system, a printing maintenance device, a dust-proof device, a successive liquid-supplying device, a powder auto-filtrating and recycling device, and a print quality detection device.

Owner:MICROJET TECH

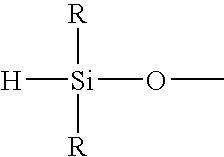

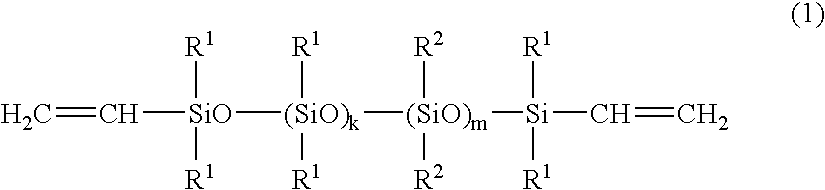

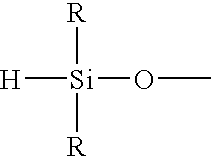

Lens-forming silicone resin composition and silicone lens

Silicone resin compositions comprising (A) an organopolysiloxane containing at least two aliphatic unsaturated bonds and having a viscosity of 100-1,000,000 mPa·s at 25° C., (B) an organohydrogenpolysiloxane having at least three silicon-bonded hydrogen atoms (SiH groups) in the form of HR62SiO-, and (C) a platinum group metal base catalyst cure into colorless transparent parts which are useful lenses.

Owner:SHIN ETSU CHEM IND CO LTD

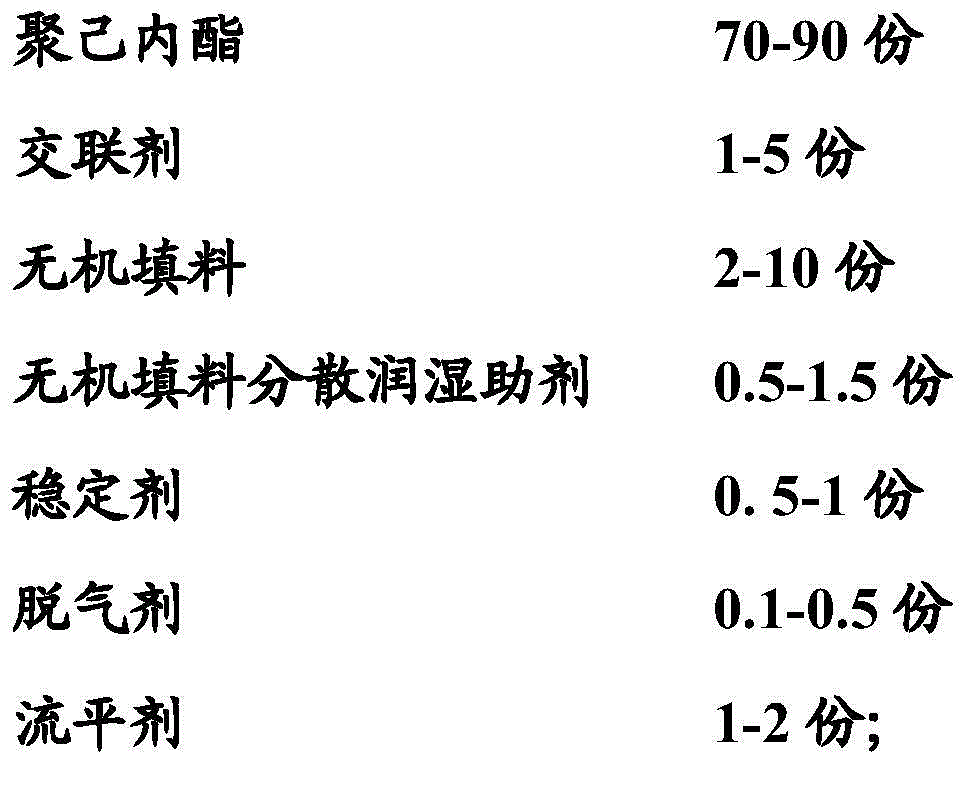

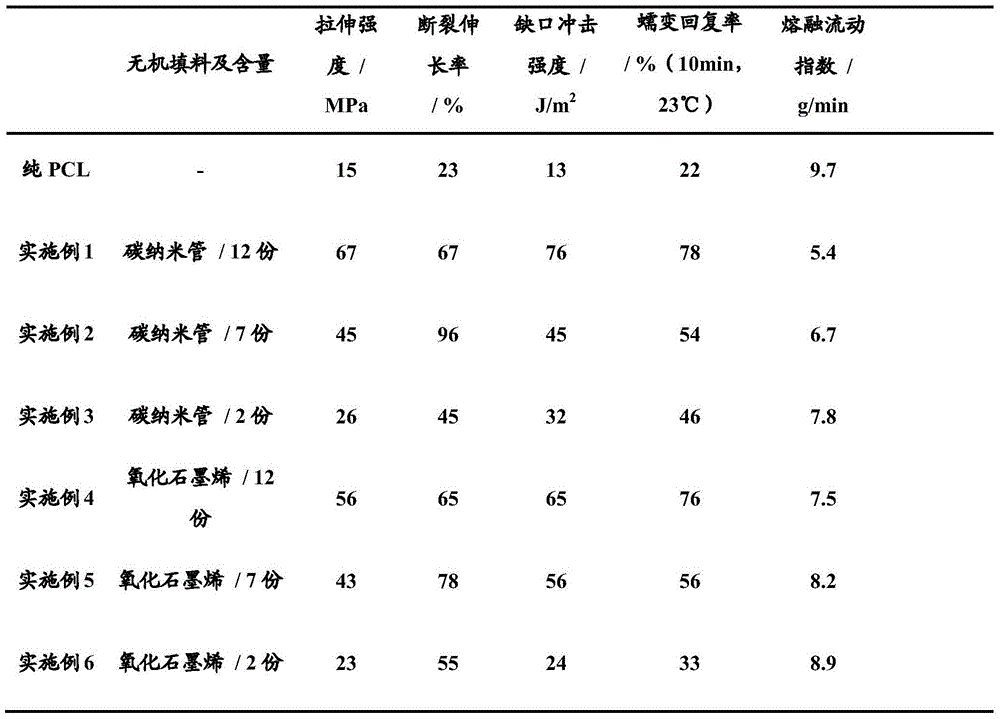

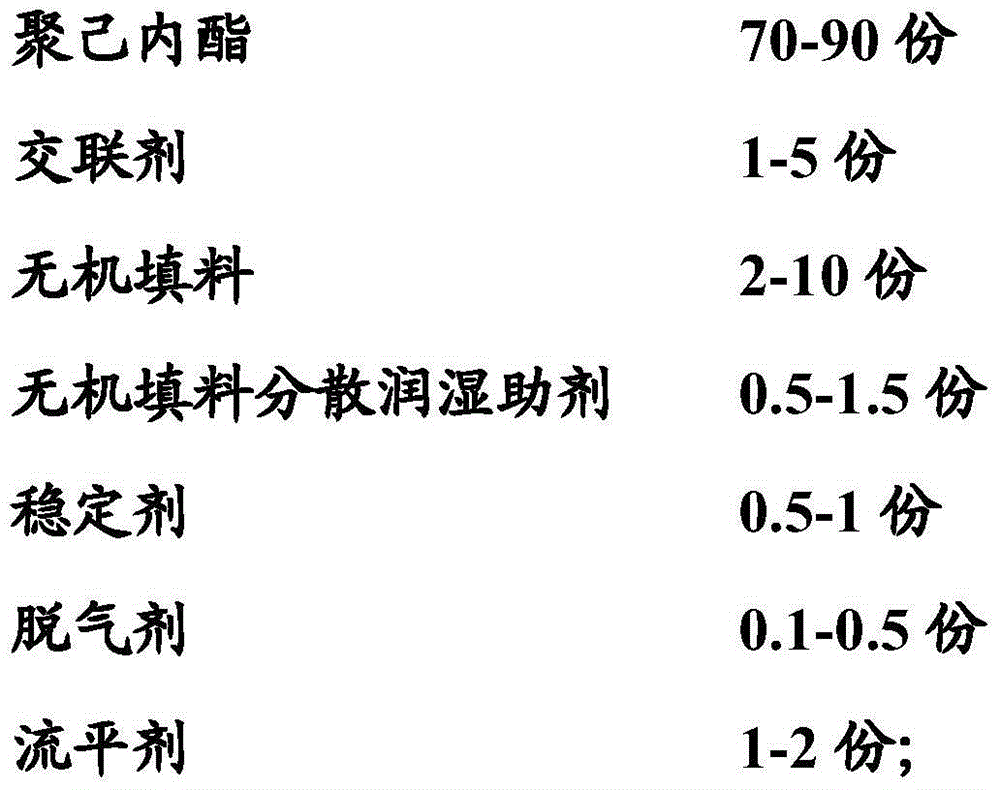

3D printing polycaprolactone material and preparation method thereof

The invention discloses a high-strength biodegradable polycaprolactone 3D printing material which comprises the following components in parts by weight: 70-90 parts of polycaprolactone, 1-5 parts of a crosslinking agent, 2-10 parts of an inorganic filler, 0.5-1.5 parts of an inorganic filler dispersing wetting auxiliary agent, 0.5-1 part of a stabilizer, 0.1-0.5 part of a degassing agent, and 1-2 parts of a leveling agent. With targeted selection of the inorganic components for modification treatment on polycaprolactone, the polycaprolactone modified material exerts excellent impact-resistance strength and creeping resistance. The material allows the degradable 3D printing material to exert better mechanical properties while broadening the 3D printing material type.

Owner:INST OF CHEM CHINESE ACAD OF SCI

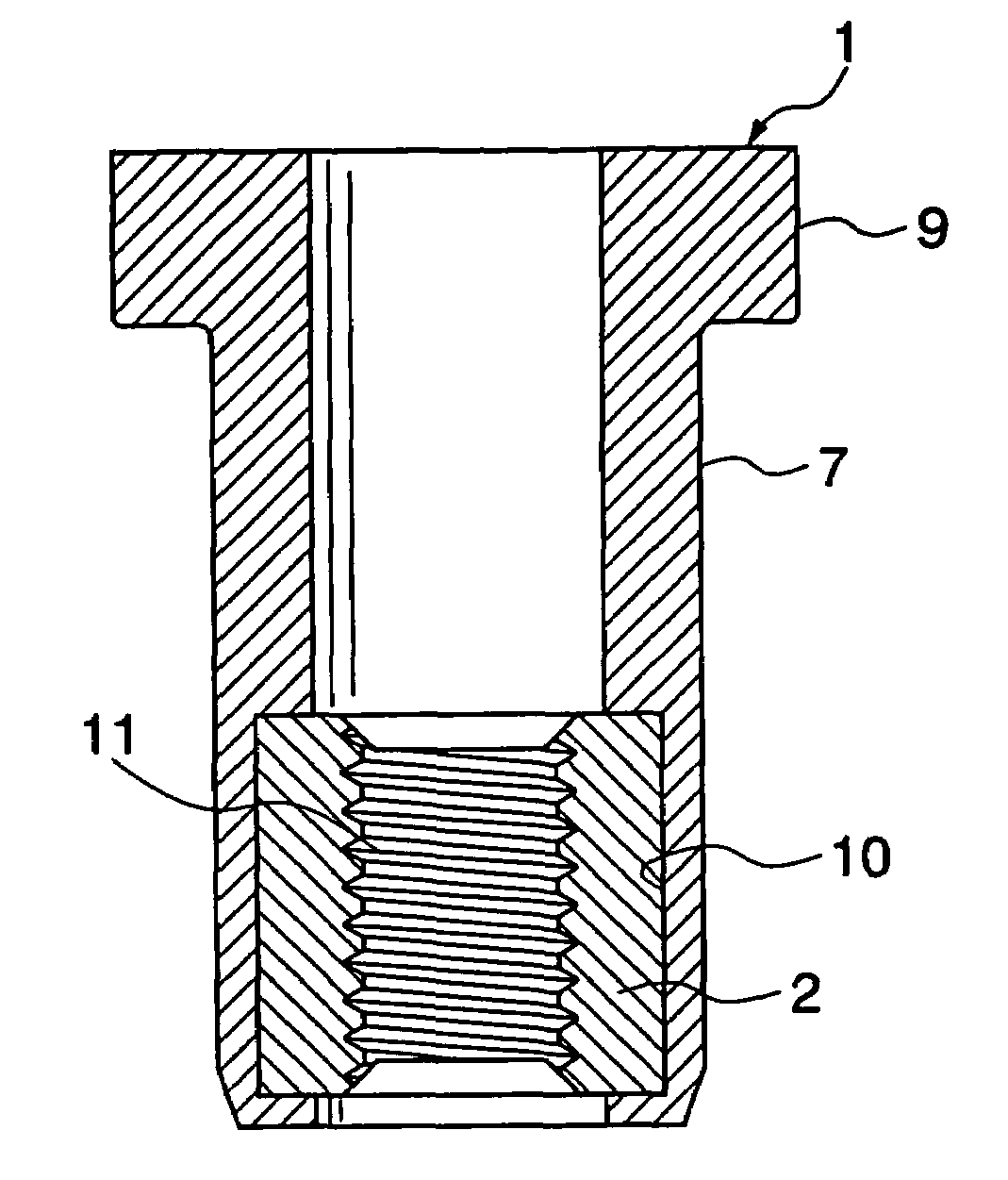

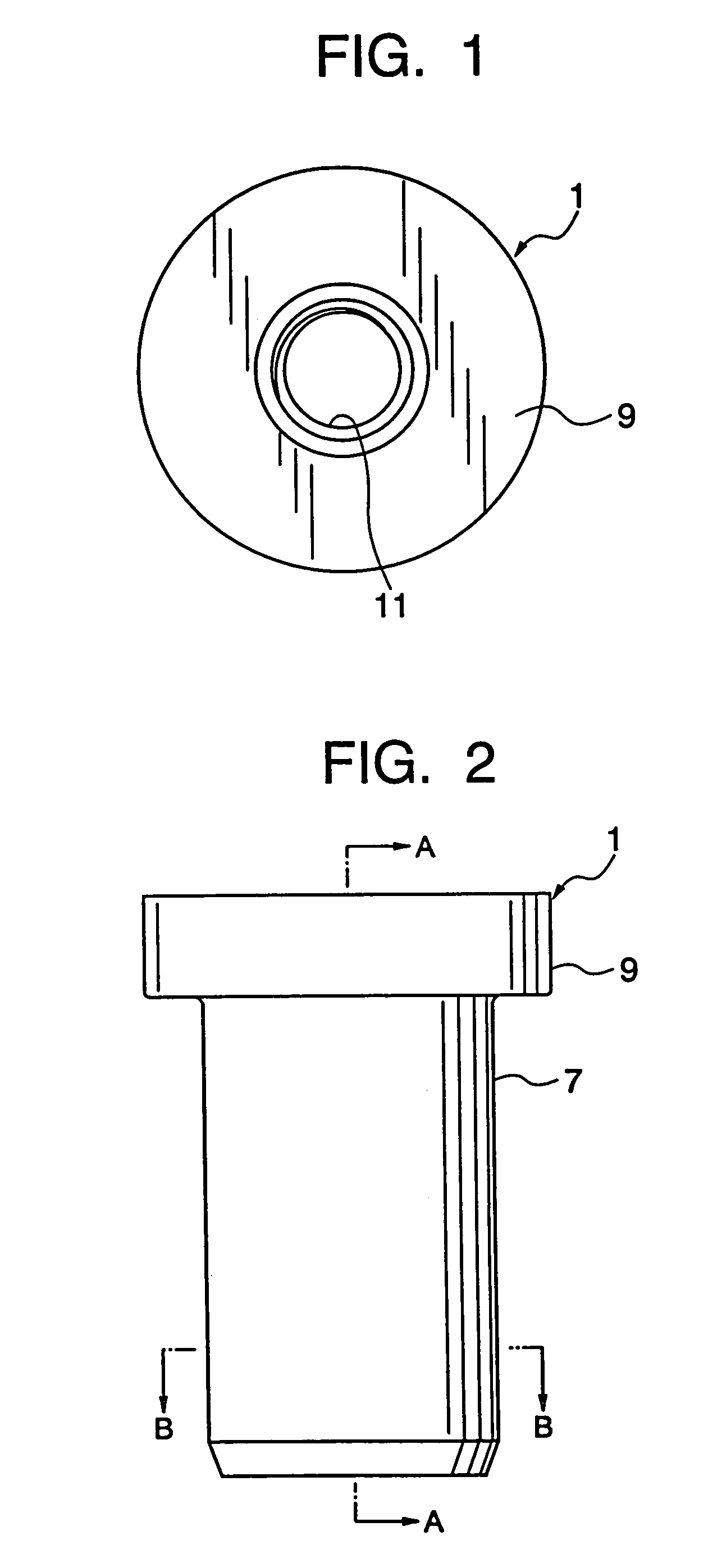

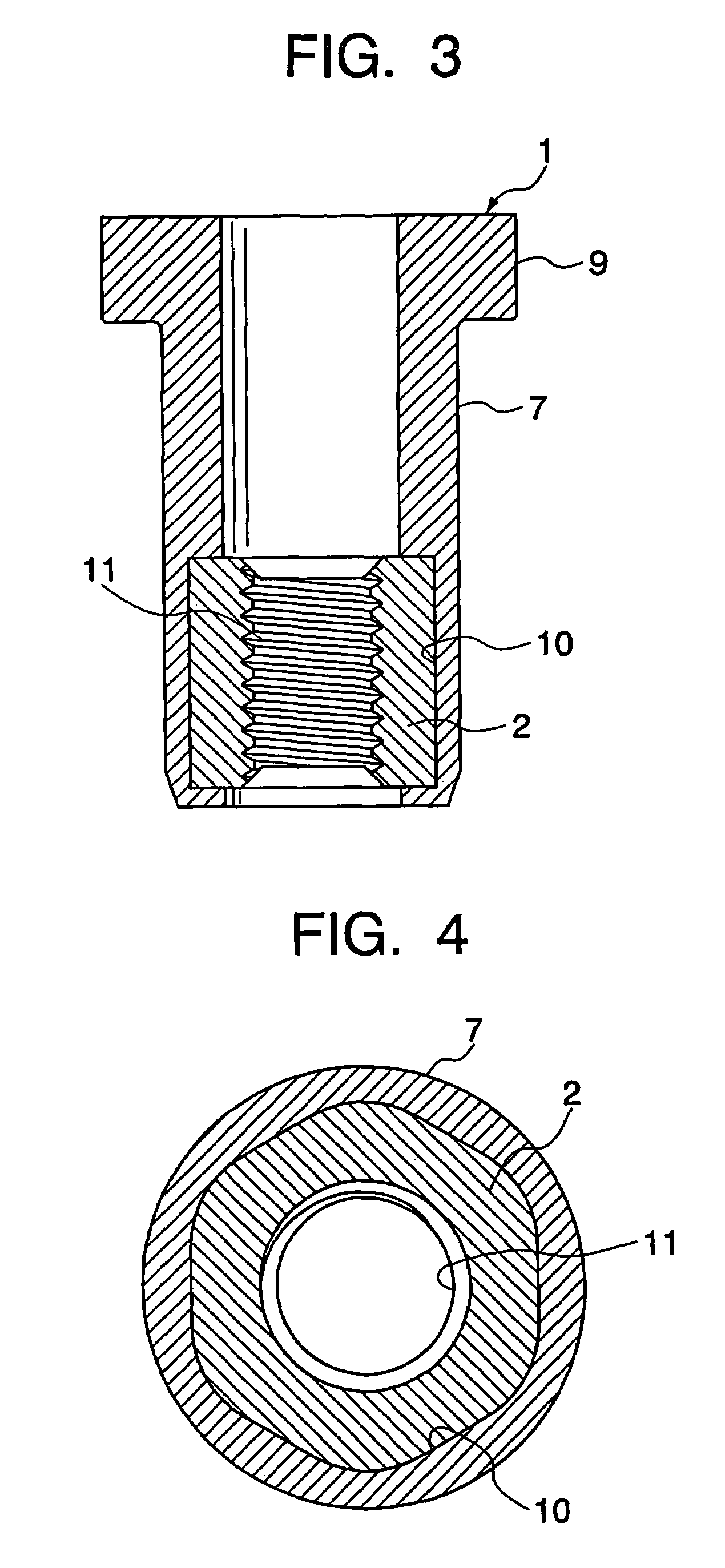

Elastic fastener

An elastic fastener 1 comprises a hollow tubular portion 7, an internally threaded portion 2 provided at one of the ends of the tubular portion 7, and a flange 9 formed at the other end of the tubular portion 7. The tubular portion 7 and the flange 9 are integrally formed of an elastomeric material, such as a styrene-based elastomer, a polyamide-based elastomer and a polyester-based elastomer. The internally threaded portion 2 is formed of a rigid resin material such as a polycarbonate resin. The internally threaded portion 2 is integrally fixed to the tubular portion 7 in a hole of the tubular portion.

Owner:NEWFREY

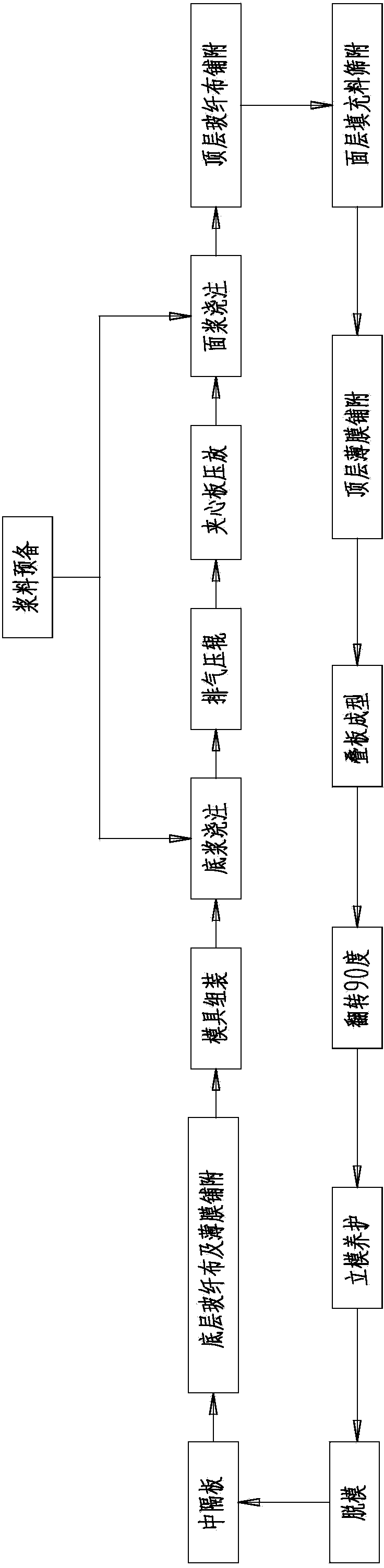

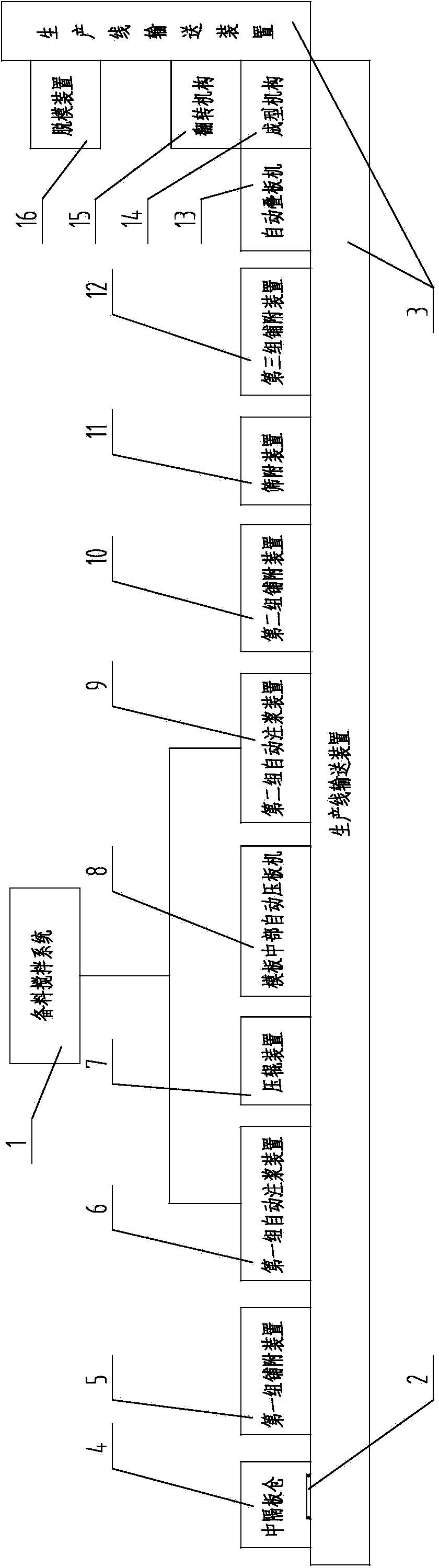

Composite heat insulation light wall board production process and production device

ActiveCN104070600AEasy to produceShorten molding timeDischarging arrangementCeramic shaping plantsMaterials preparationProduction line

The invention relates to a composite heat insulation light wall board production process and a production device for achieving the process. The process includes the procedures of paste preparation, flat mould grouting, vertical mould curing and demoulding which are conducted sequentially. The production device comprises a material preparation stirring system, a production line conveying device and a middle partition plate bin, a first group of paving devices, a first group of automatic grouting devices, a compression roller device, a mould plate middle automatic plate pressing machine, a second group of automatic grouting devices, a second group of paving devices, a screening device, a third group of paving devices, an automatic plate stacking machine, a molding mechanism, an overturning mechanism and a demoulding device which are sequentially arranged in the conveying direction of the production line conveying device. Flat mould grouting and vertical mould curing are adopted by the process, double-layer or multi-layer structure arrangement can be achieved, and diversified products can be produced conveniently. The production device adopts a flat mould automatic production line. By means of the production device, the molding time of a composite heat insulation light wall board is greatly reduced, the labor intensity is reduced, and the quality of the produced products is stable.

Owner:QUANZHOU S L MACHINERY MFG

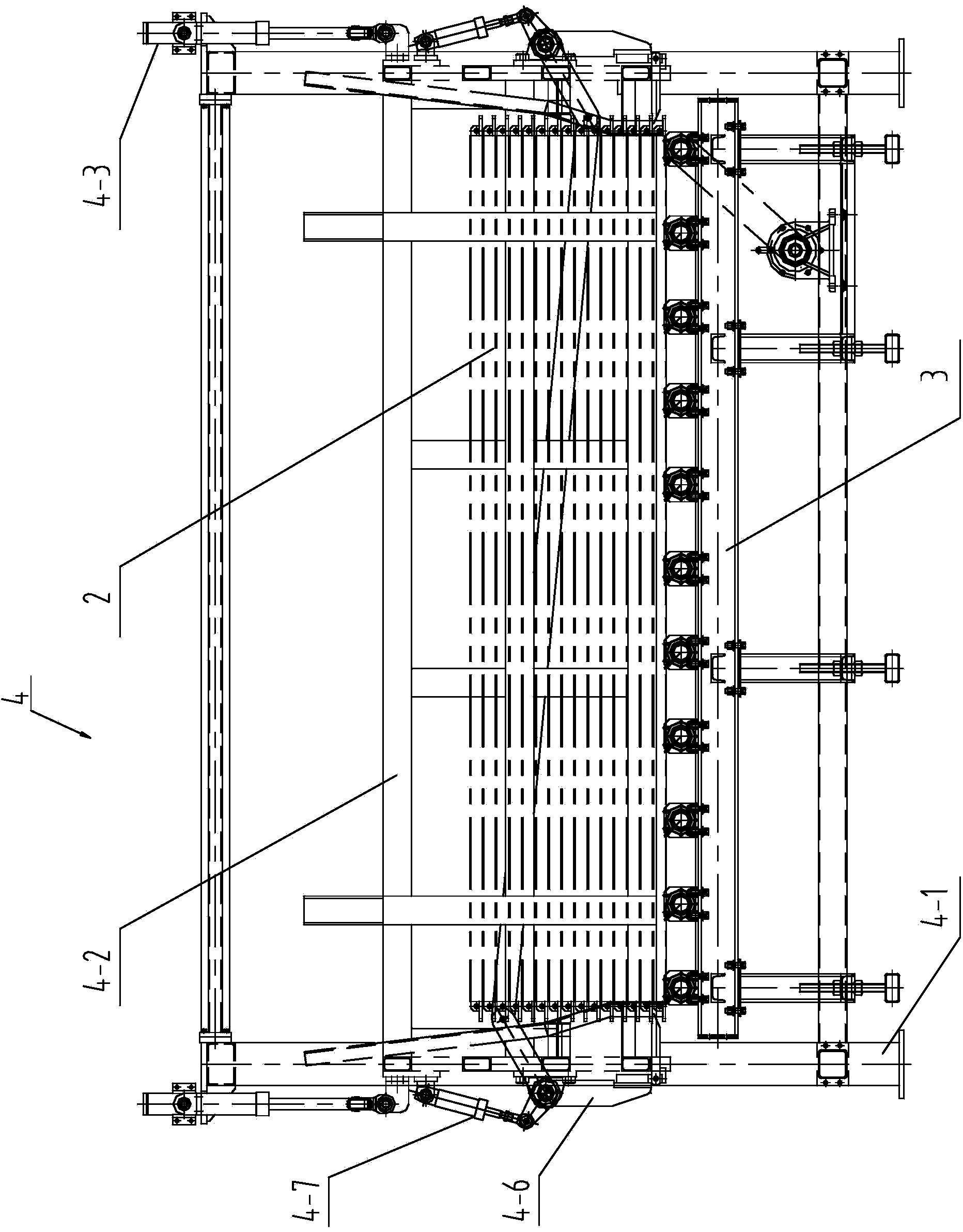

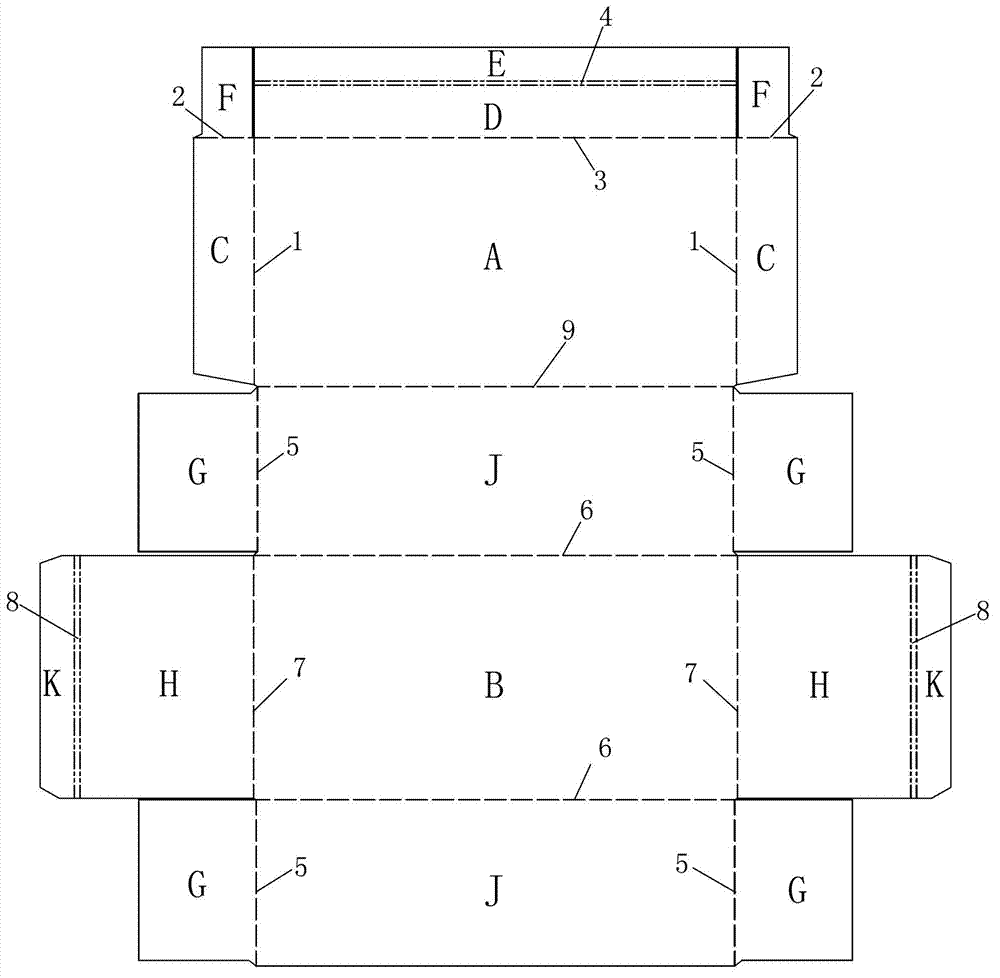

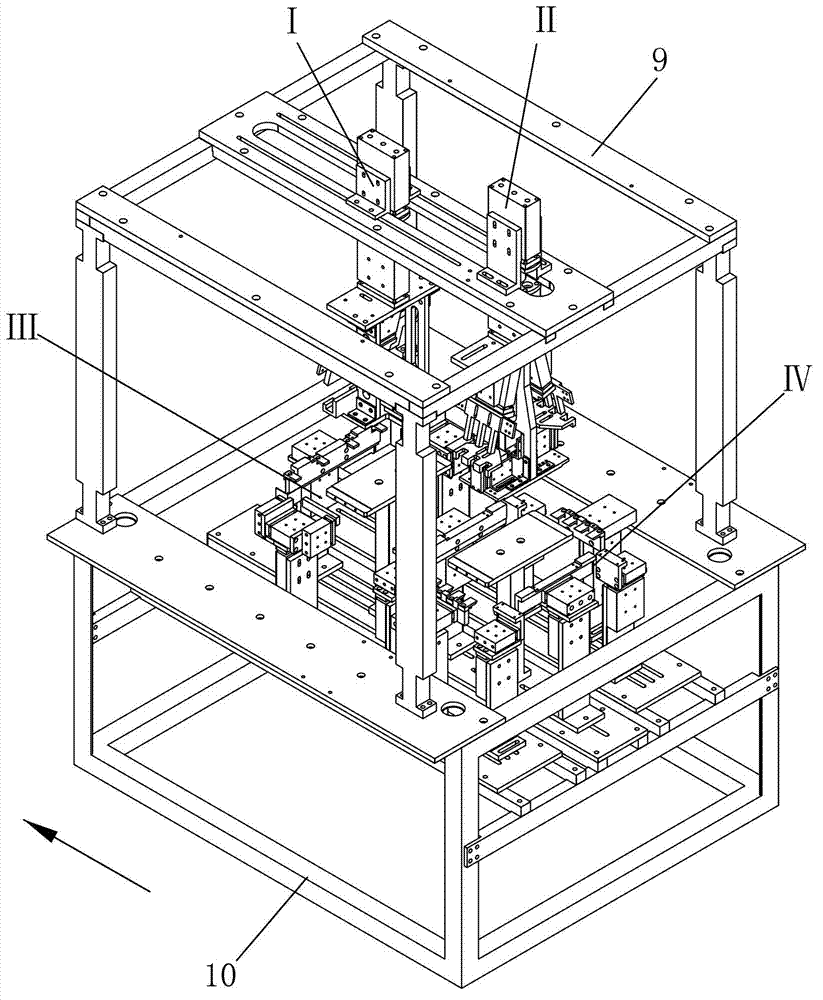

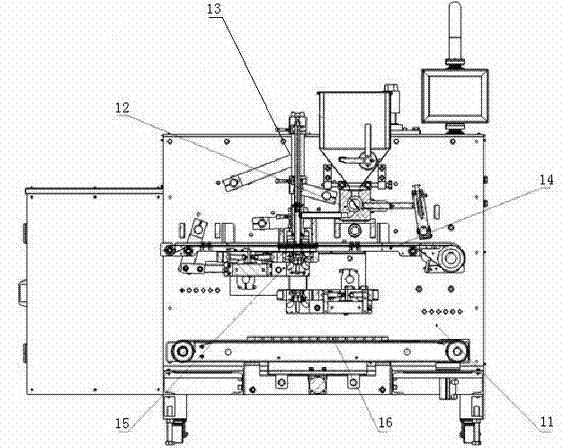

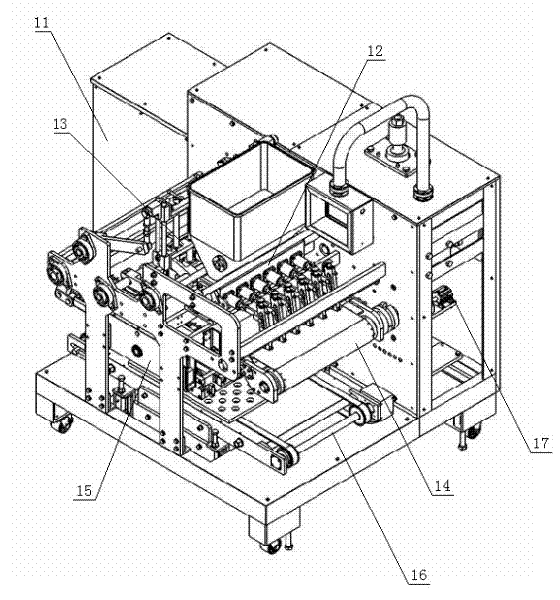

Connected paper box forming machine

ActiveCN103240920AHigh degree of automationImprove work efficiencyBoxes/cartons making machineryEngineeringAutomation

The invention relates to a connected paper box forming machine and aims to allow the forming machine to automatically complete paper box forming, shorten forming time, and lower labor intensity. The forming machine is high in automation level and work efficiency and convenient to use. According to the technical scheme, the connected paper box forming machine is characterized by comprising a first station for folding box covers and a second station for folding box bodies. Each station comprises a main cylinder device mounted on an upper frame and a edge folding device mounted on a lower frame.

Owner:余才

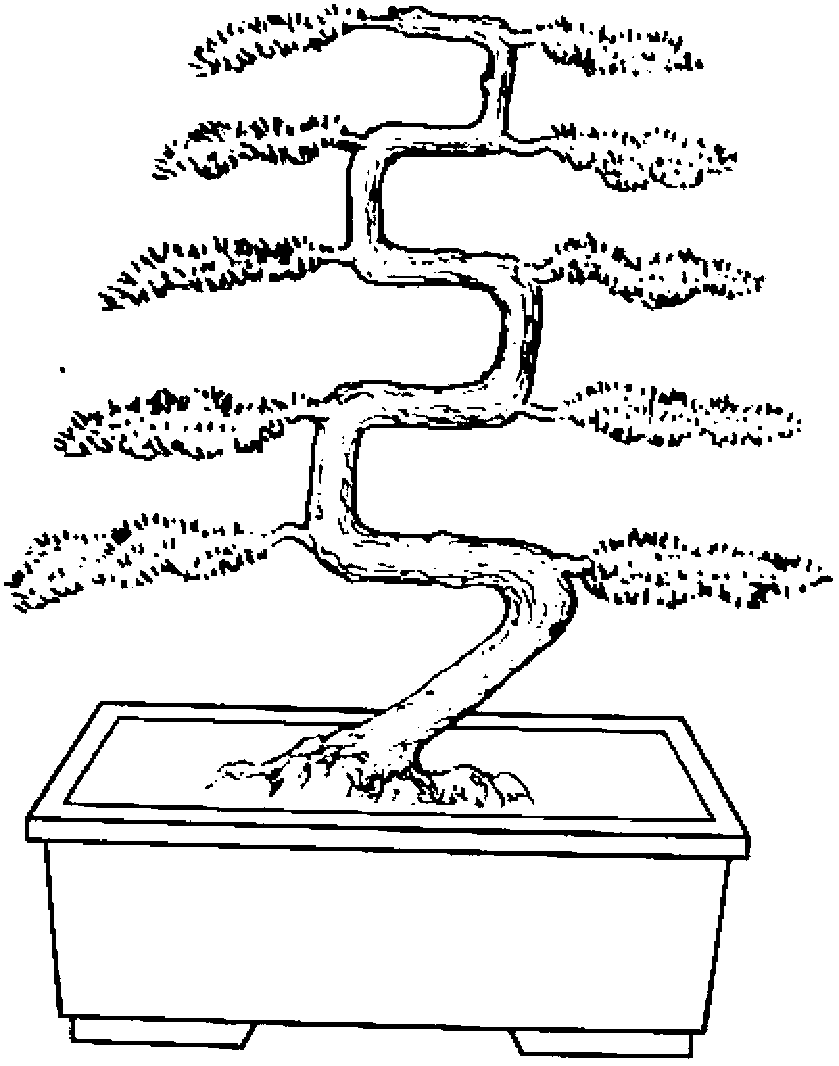

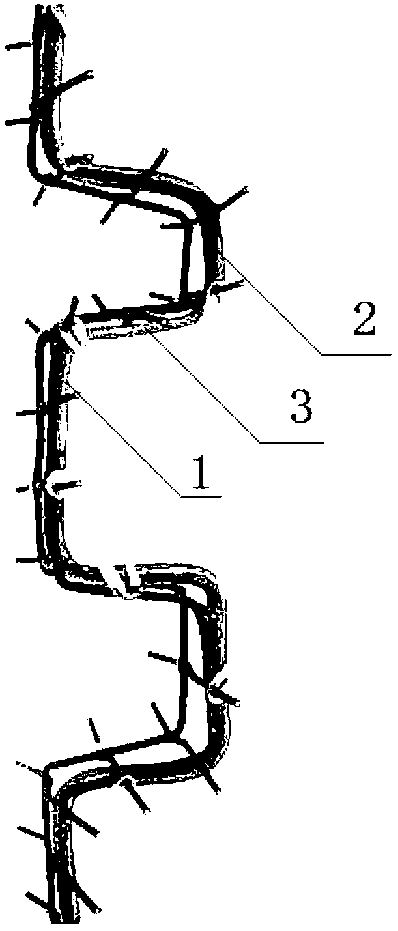

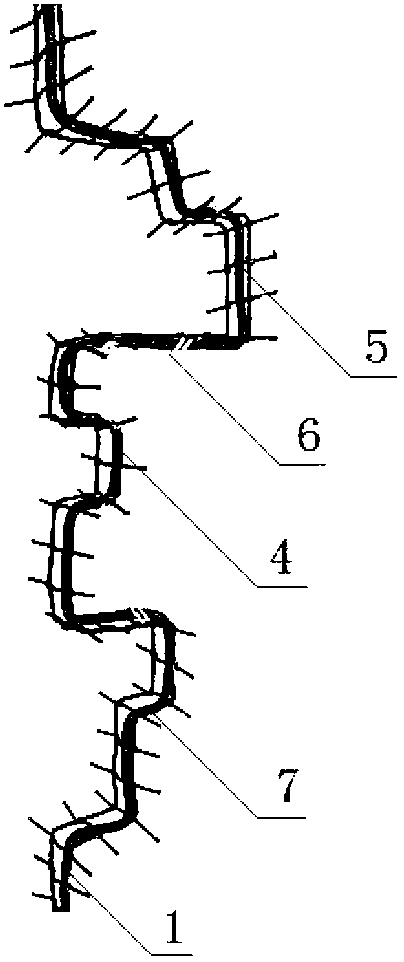

Bow-type cultivation trunk molding method of lythraceae lagerstroemia trunks

The invention discloses a bow-type cultivation trunk molding method of lythraceae lagerstroemia trunks. The method mainly includes the following steps: (1) designing trunk molds, deconstructing the molds into single-plant technical atlases, and selecting a planting bed for cultivating nursery-grown plants; (2) manufacturing and installing a supporting net frame in the planting bed; (3) manufacturing and installing a bow-shaped cultivation trunk molding ladder frame on the supporting frame; (4) carrying out bud fixing and bud picking on the nursery-grown plants; (5) binding and fixing twigs on the bow-shaped cultivation trunk molding ladder frame; (6) unbinding and exchanging binding objects which are not beneficial for trunk growth; (7) carrying out multi-point nurse grafts on the bow-shaped trunks according to molding design; and (8) cultivating in a healing mode, constructing crowns, the trunks and branches, and forming the target molds. The bow-type cultivation trunk molding method of the lythraceae lagerstroemia trunks is creative. Moreover, the nurse grafts can be carried out on single plants of the certain number to obtain the molded trunks, molding time is shortened, and characters, patterns or three-dimensional bodies can also be molded on planes or curved surfaces of the trunks.

Owner:TONGREN MANTANGHONG AGRI TECH

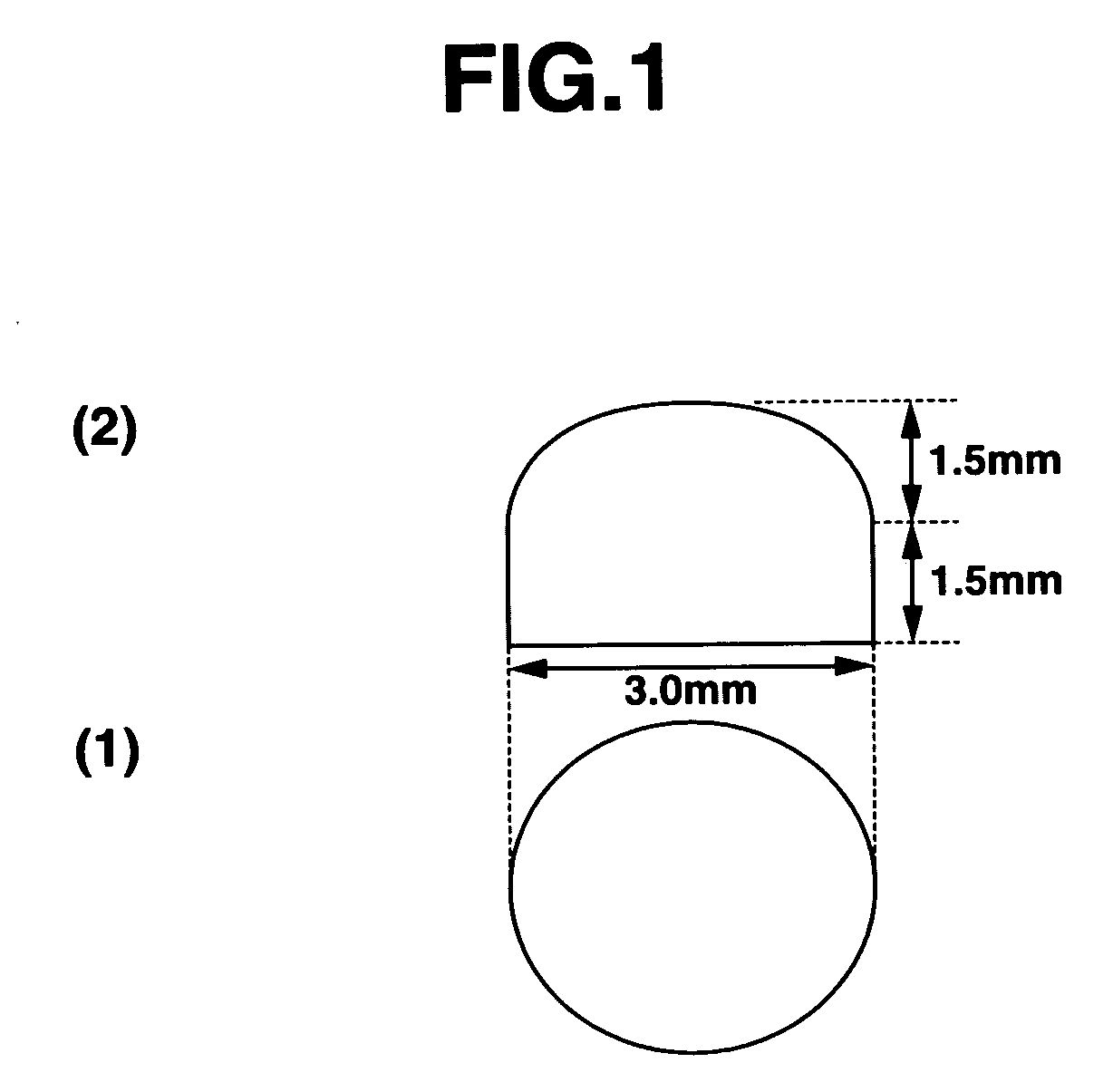

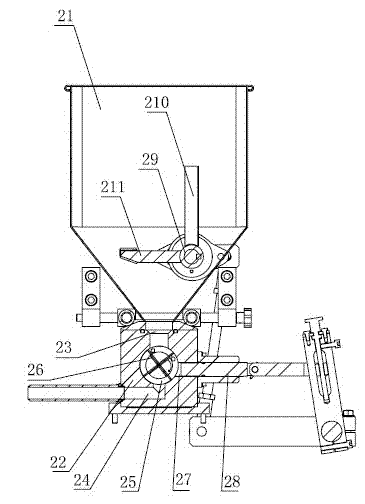

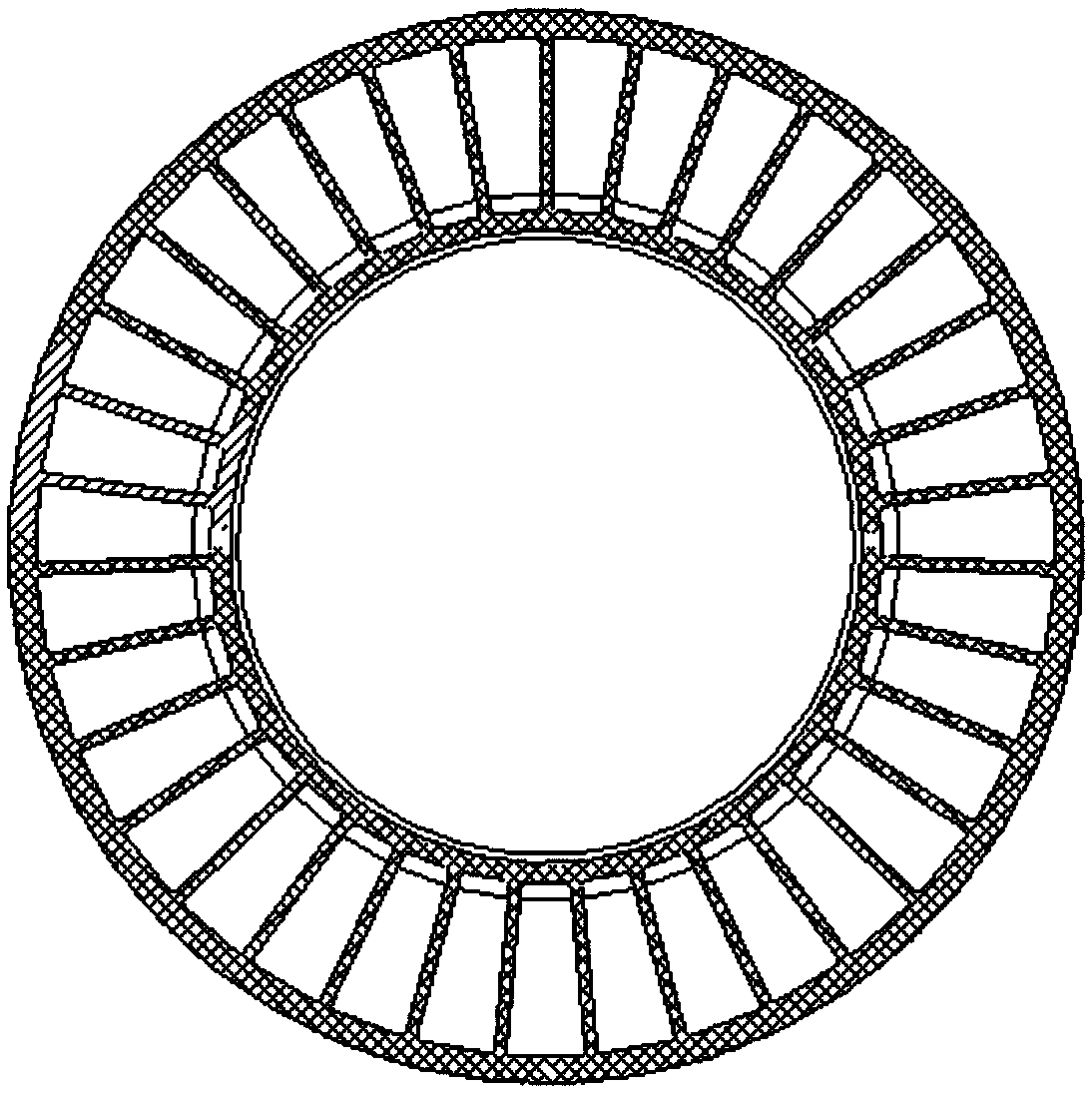

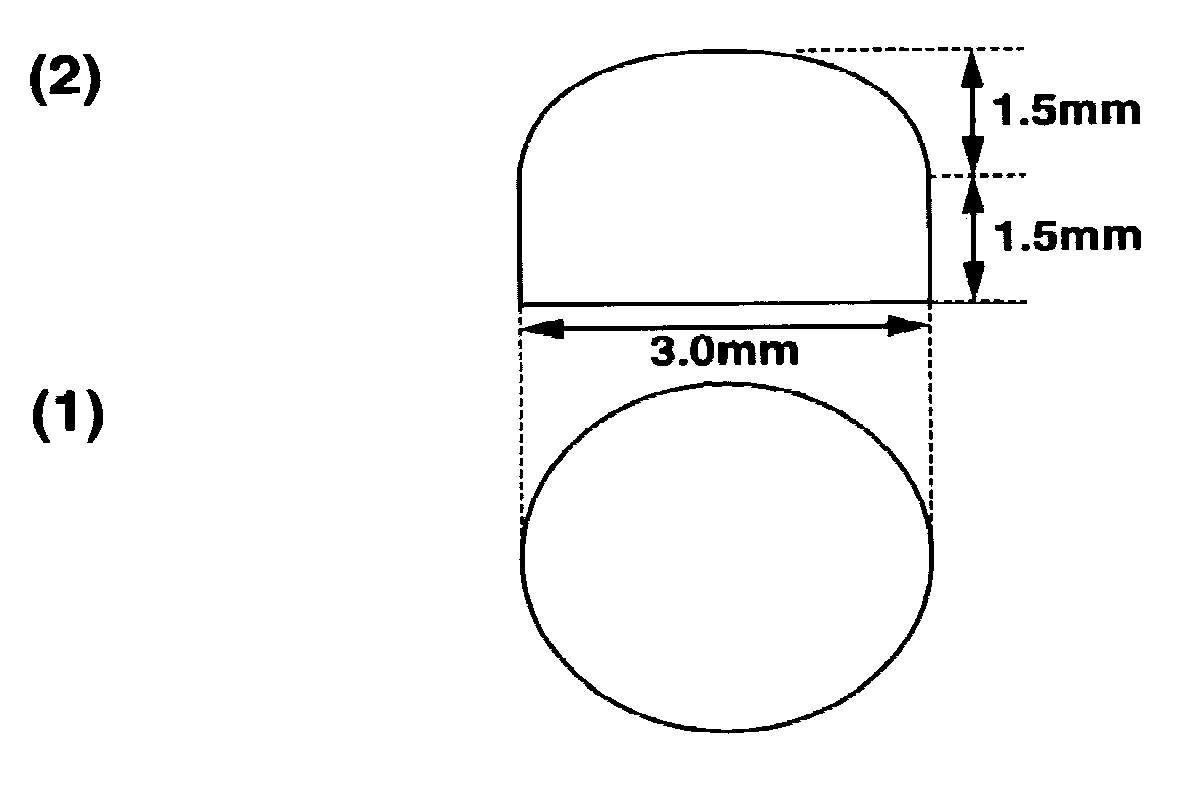

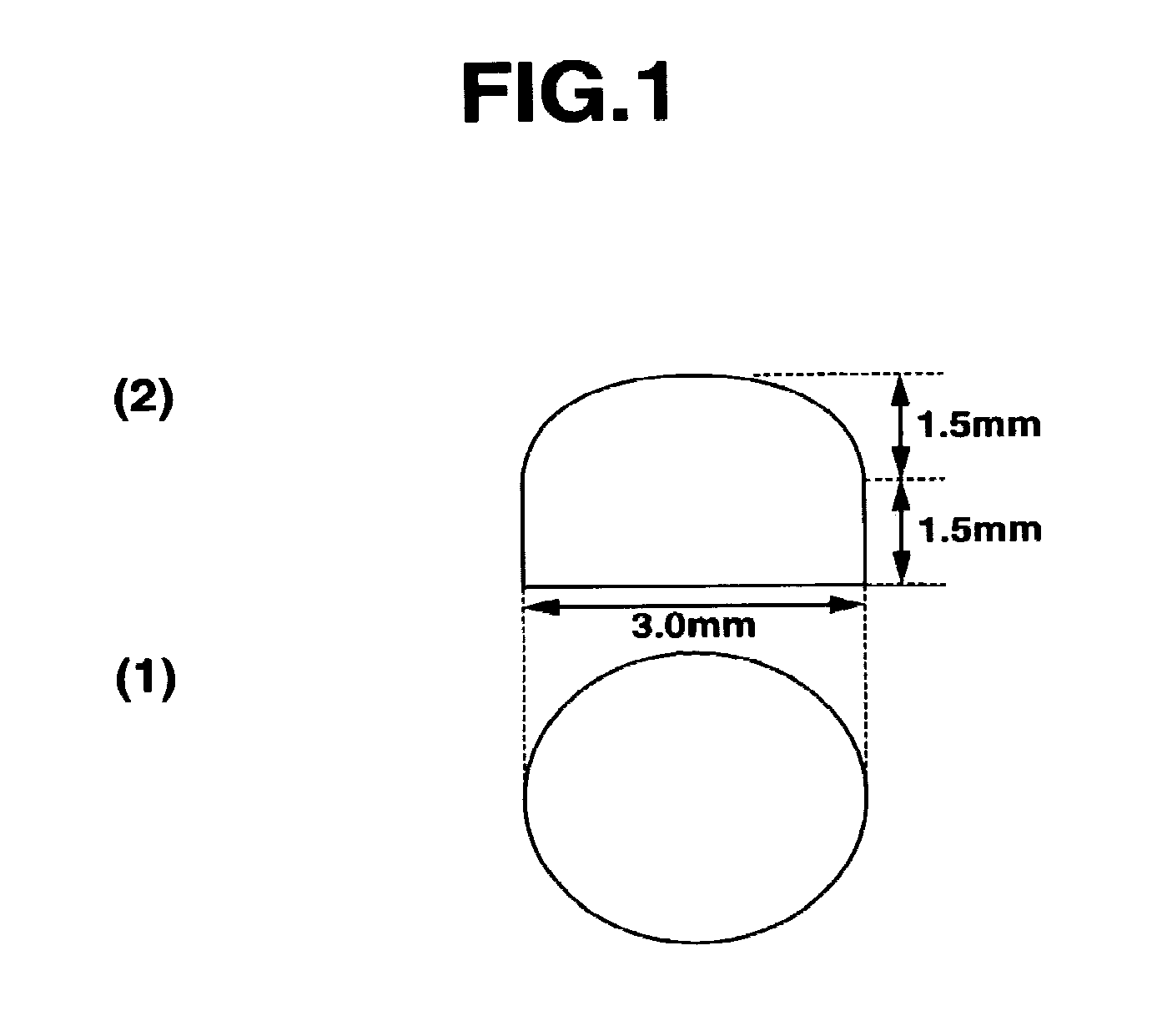

Food encrusting device

ActiveCN102177928AIncrease the number ofDoes not affect normal operationDough shaping and cutting apparatusDough dividingBiomedical engineeringFood products

The invention relates to the technical field of food machines, in particular to a food encrusting device, which comprises a food encrusting device machine frame, a food encrusting device stuffing injection component, food encrusting, stuffing pushing and wrapper cutting devices, a wrapper delivering component, a food encrusting device wrapper forming device, a food encrusting device conveying mechanism and a food encrusting device driving mechanism, wherein the food encrusting device stuffing injection component has a plurality of independent discharging channels and a plurality of food encrusting, stuffing pushing and wrapper cutting devices which are arranged in a way of corresponding to the discharging channels and complete stuffing pushing and wrapper cutting at the same station. The food encrusting device has the advantages that: the stuffing injection and wrapper cutting device are arranged in a linear mode, so a plurality of the stuffing injection and wrapper cutting devices can operate without interference, and even if one stuffing injection and wrapper cutting device has a fault, other stuffing injection and wrapper cutting devices can still work normally; and due to the linear arrangement mode, in a range matched with a driving mechanism, the stuffing injection and wrapper cutting devices can be increased randomly, so large-scale production can be realized, and the working efficiency is improved.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

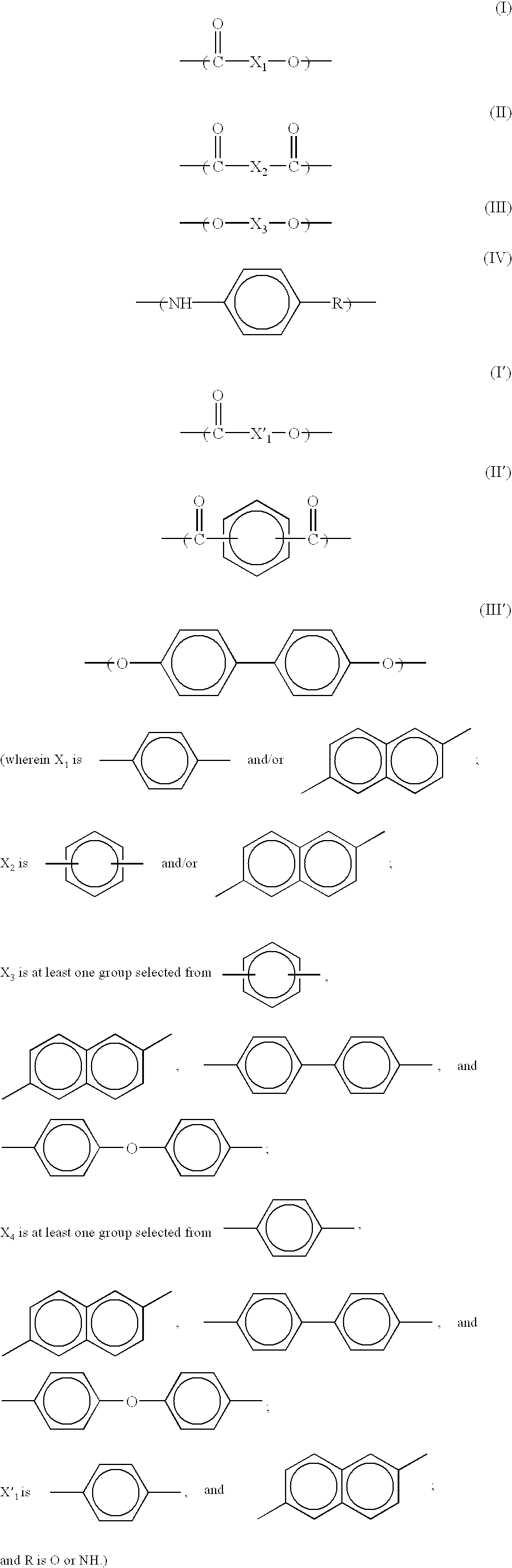

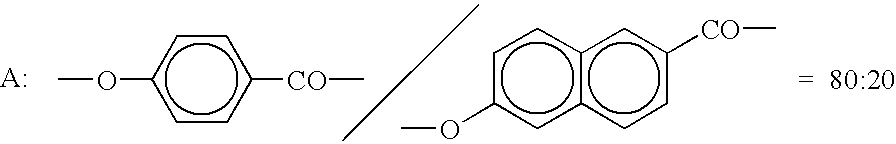

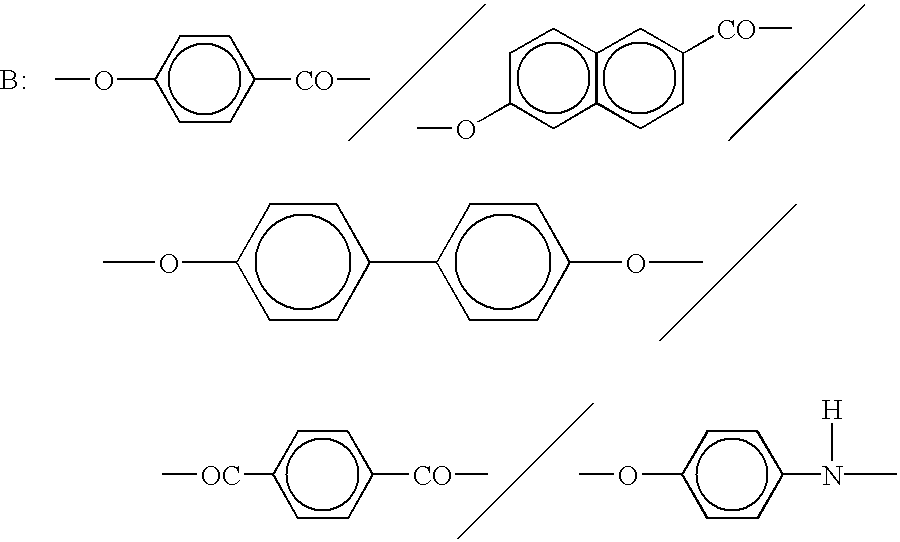

Liquid-crystalline polymer composition and molding method

InactiveUS20020190432A1Shorten molding timeImprove rigidityLiquid crystal compositionsPolyesterPolymer science

To provide liquid crystal polymer materials superior in shortening the molding time, which are suitable for connectors, electronic appliances, etc. That is, a liquid crystal polymer composition including (A) from 90 to 50% by weight of a liquid crystal polymer made of a specified aromatic polyester and (B) from 10 to 50% by weight of a liquid crystal polymer made of a specified aromatic polyester amide.

Owner:POLYPLASTICS CO LTD

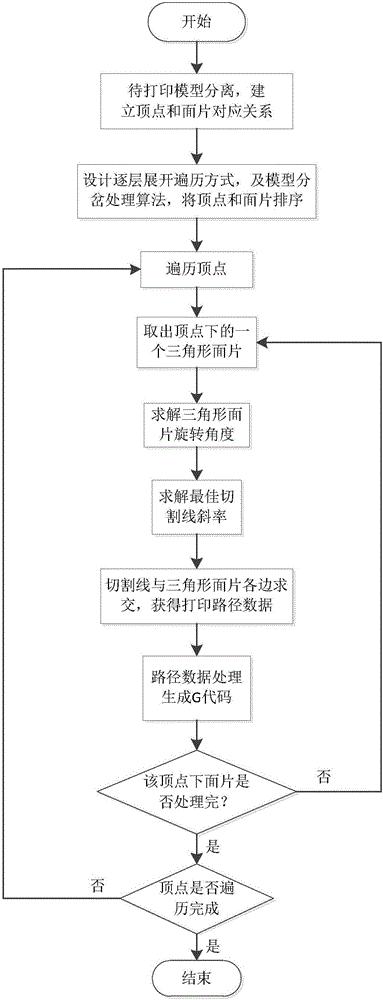

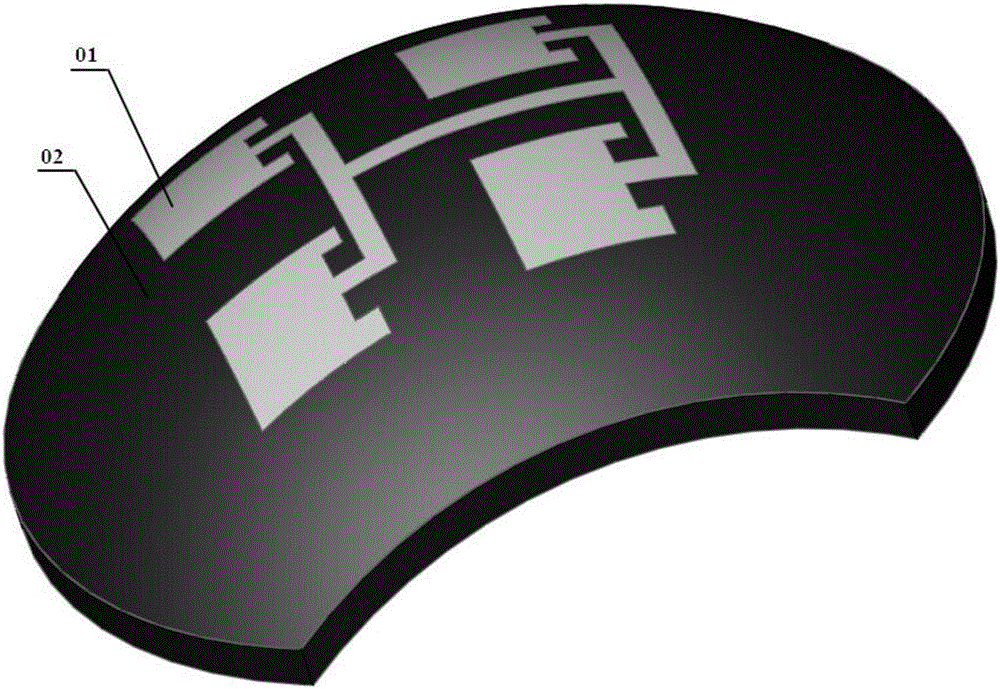

Slicing treatment method for surface model surface ink jet printing

ActiveCN106738864AImprove connectivityImprove qualityAdditive manufacturing apparatus3D object support structuresSurface modeData treatment

The invention discloses a slicing treatment method for surface model surface ink jet printing. The method comprises the following steps: a surface model to be printed is separated from a computer, and is preserved as a STL format for data processing to remove redundant data; a corresponding relation between a peak and a facet is built; a layer-by-layer unfolding traversal mode of the peak of the STL model and a fork processing algorithm are designed; the peak and the facet are arranged by a certain sequence; the peak is traversed; the facet included under the peak is read; an angle of rotating the facet to be printed to the horizontal position and an optimal cutting line slope are calculated; a printing error is reduced; a layering tangent line and each edge of the triangular facet are intersected to obtain printing path data; and all peaks and facets are traversed to obtain a complete G code of the model to be printed. The slicing treatment method can prevent the step effect of the forming surface of the surface model and the precision problem caused by ink flowing, and can improve the surface overall connectivity and the printing precision.

Owner:XIDIAN UNIV

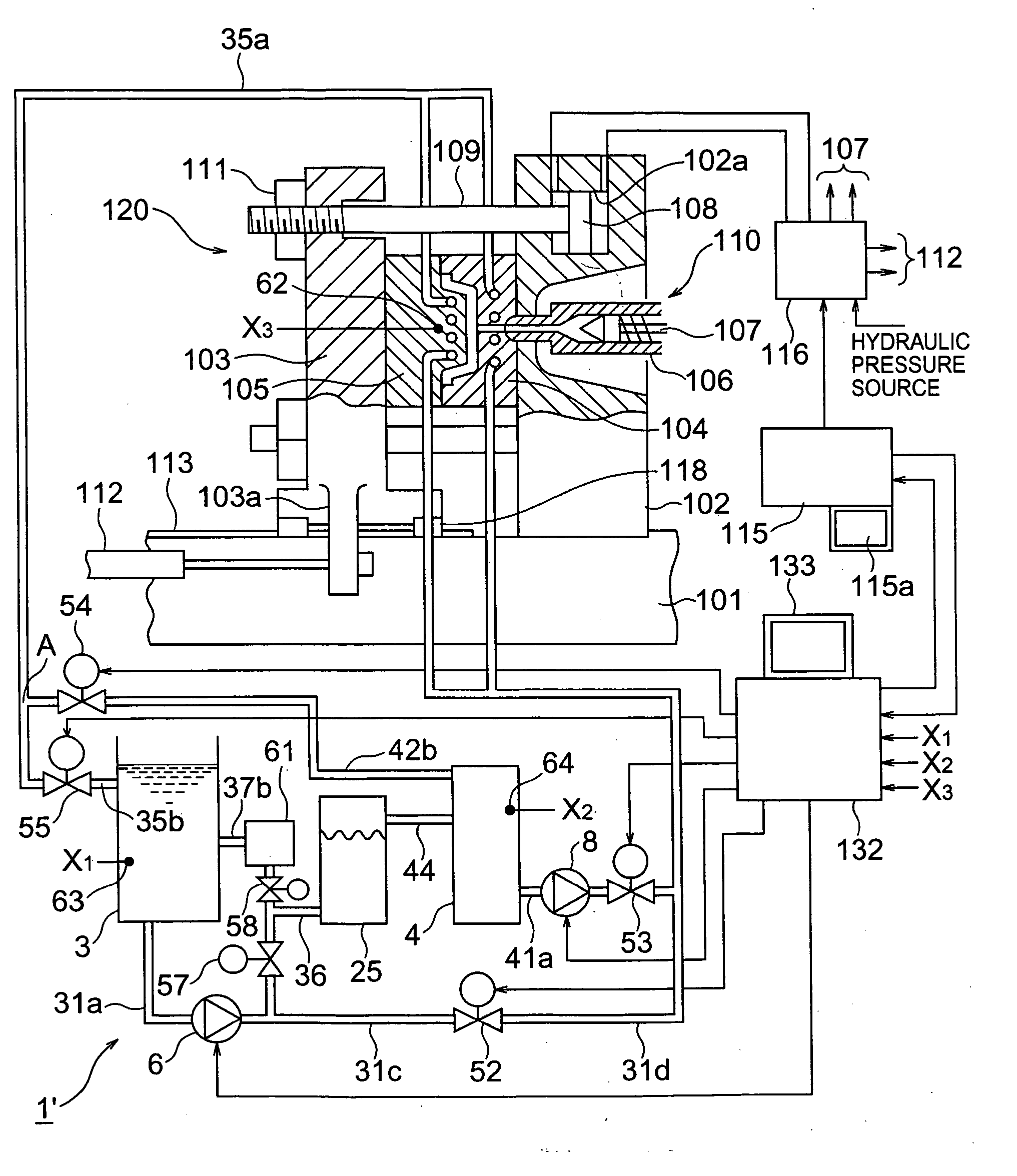

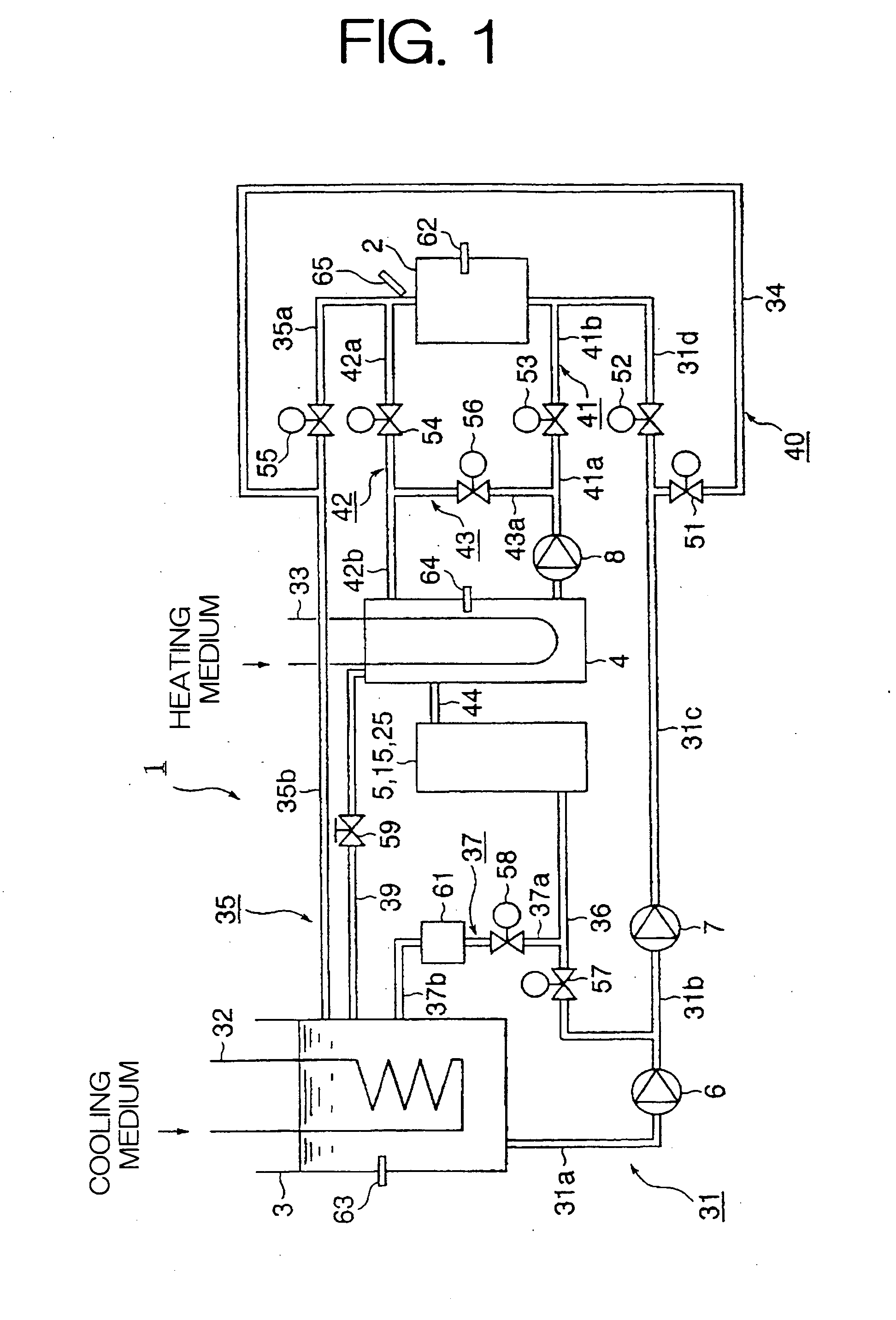

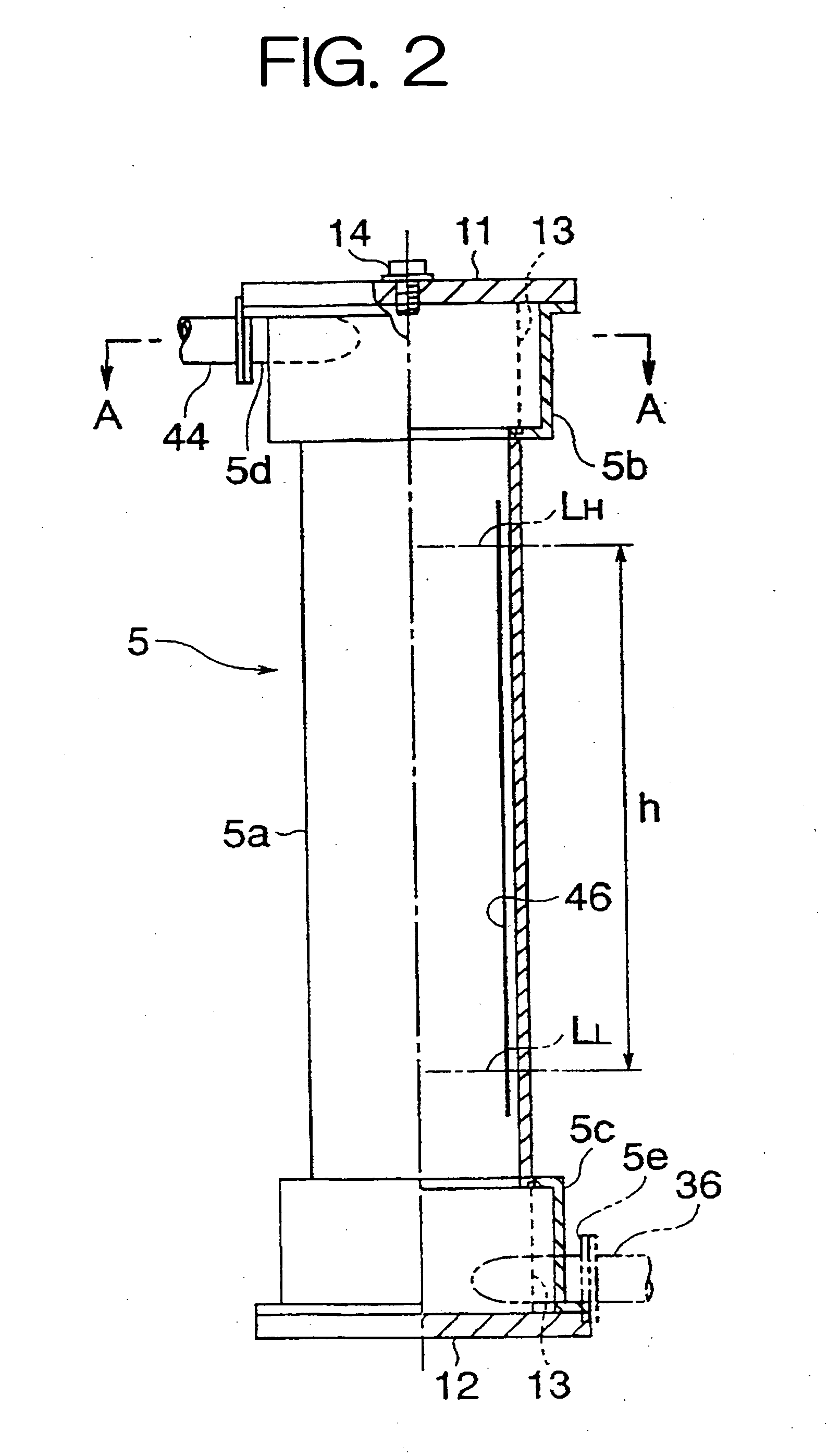

Mold temperature adjusting apparatus/method and mold temperature control unit

InactiveUS20050179157A1Mixing of fluid can be reducedReduce mixTemperature control without auxillary powerAuxillary shaping apparatusTemperature controlHeat transmission

A mold temperature adjusting apparatus is provided in which change-over timing of high temperature medium and low temperature medium is adjusted by a heat transmission delay in heating and cooling of a mold being taken into consideration, so that a cycle time of molding steps is shortened, a temperature deflection from a set temperature of the high temperature and low temperature medium is reduced, an energy loss is reduced and an optimal mold temperature for an injection step can be obtained. The mold temperature adjusting apparatus comprises a high temperature fluid tank and a low temperature fluid tank, a high temperature fluid supply system and a high temperature fluid return system between the mold and the high temperature fluid tank, a low temperature fluid supply system and a low temperature fluid return system between the mold and the low temperature fluid tank, a high temperature fluid by-pass system and a low temperature fluid by-pass system, a heat recovery tank connected to the high temperature fluid tank and a pressure adjusting means.

Owner:MITSUBISHI HEAVY IND LTD

Low emissivity products and methods for making same

The method of this invention adheres a low emissivity radiant barrier material to an underlying lignocellulosic substrate within the primary manufacturing operation of the underlying lignocellulosic substrate. Thus, a radiant barrier covered substrate is formed by integrally joining the radiant barrier covering to a mat of lignocellulosic material during consolidation thereof with a first adhesive bonding material to form an underlying substrate. The integral joining operation can, for example, be accomplished by bonding the radiant barrier covering to a lignocellulosic mat in a product formation press. This is typically accomplished using a second adhesive bonding material for adhesion of the radiant barrier material to the lignocellulosic mat, and a first adhesive bonding material for consolidating the lignocellulosic mat to form a lignocellulosic substrate. More specifically, this invention is directed to a method whereby a low emissivity radiant barrier material is joined in situ to a mat of lignocellulosic particles using a second adhesive material, during the consolidation of the lignocellulosic particles and a first adhesive bonding material to form an underlying substrate, an integral laminated radiant barrier covered lignocellulosic product being produced.

Owner:GANG NAIL SYST

Ion beam system and machining method

InactiveUS7326942B2Short timeReduce manufacturing costPreparing sample for investigationIon beam tubesLight beamMachining system

Owner:HITACHI HIGH-TECH CORP

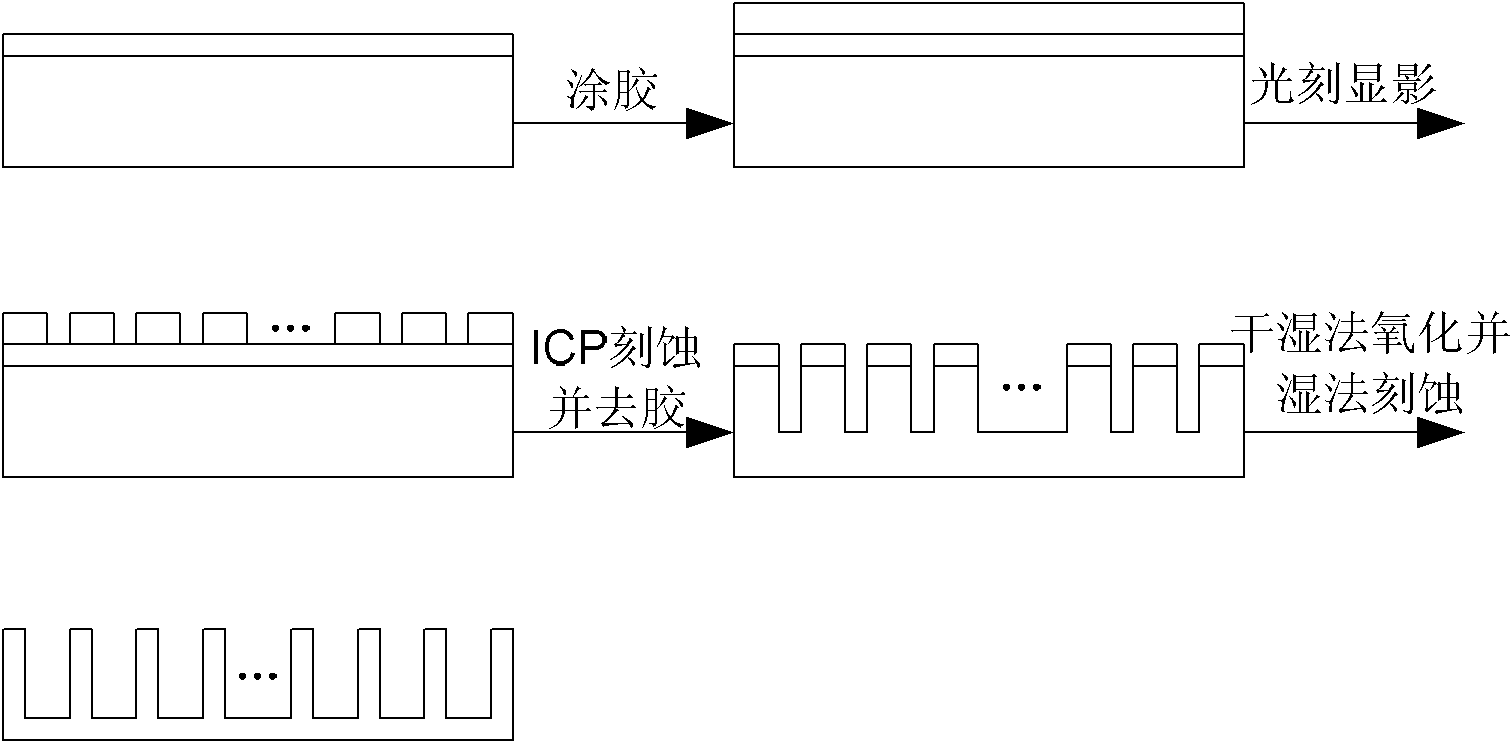

Preparation method of silicon nano-wire field-effect transistor

InactiveCN102214586AEasy to controlSmooth and steep etch effectSemiconductor/solid-state device manufacturingNanotechnologySilicon nanowiresField effect

The invention relates to the field of microelectronic apparatus manufacture, and discloses a top-down preparation method of a vertical silicon nano-wire gate field-effect transistor. The vertical silicon nano-wire gate field-effect transistor includes a semiconductor substrate, a nano-wire channel region vertically arranged on the semiconductor substrate and an annular grid conductive layer arranged out of the channel. The nano-wire channel region is provided with an active conductive layer; the upper part is doped with n impurity to serve as a source end n area; the semiconductor substrate contacting with the bottom of the drain conductive layer is doped with n impurity to serve as a drain end n area; and a non-symmetrical Halo-doped structure p+ region is added between the source end and the channel. The method for preparing the vertical silicon nano-wire gate field-effect transistor can well control the consistency of the position and size of the nano-wire, thus simplifying the manufacture process and reducing the manufacture cost.

Owner:XI AN JIAOTONG UNIV

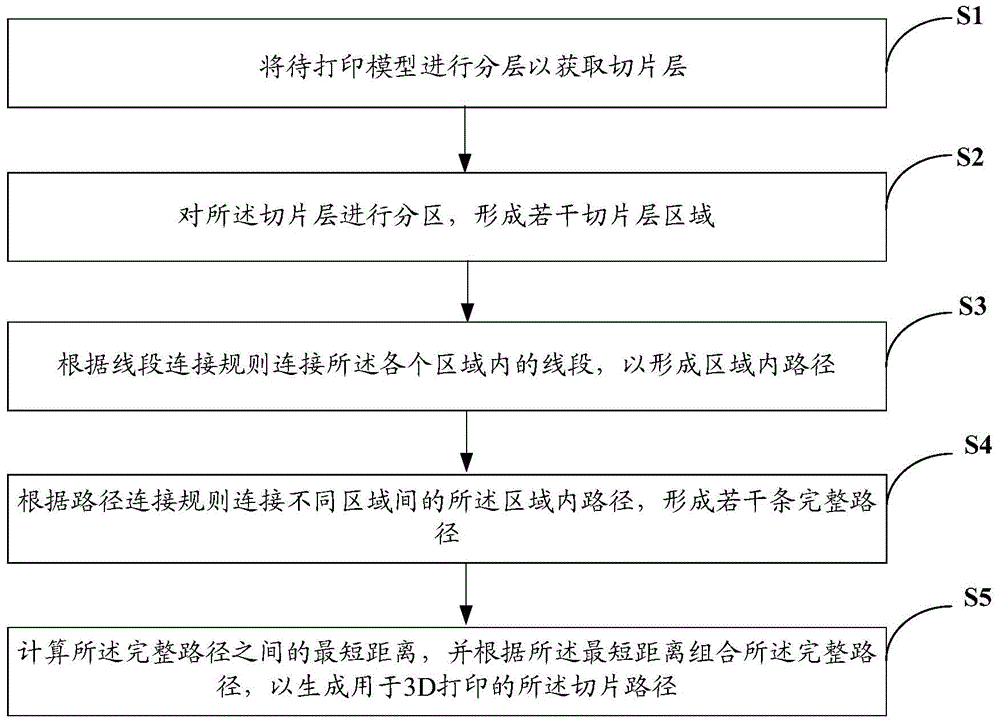

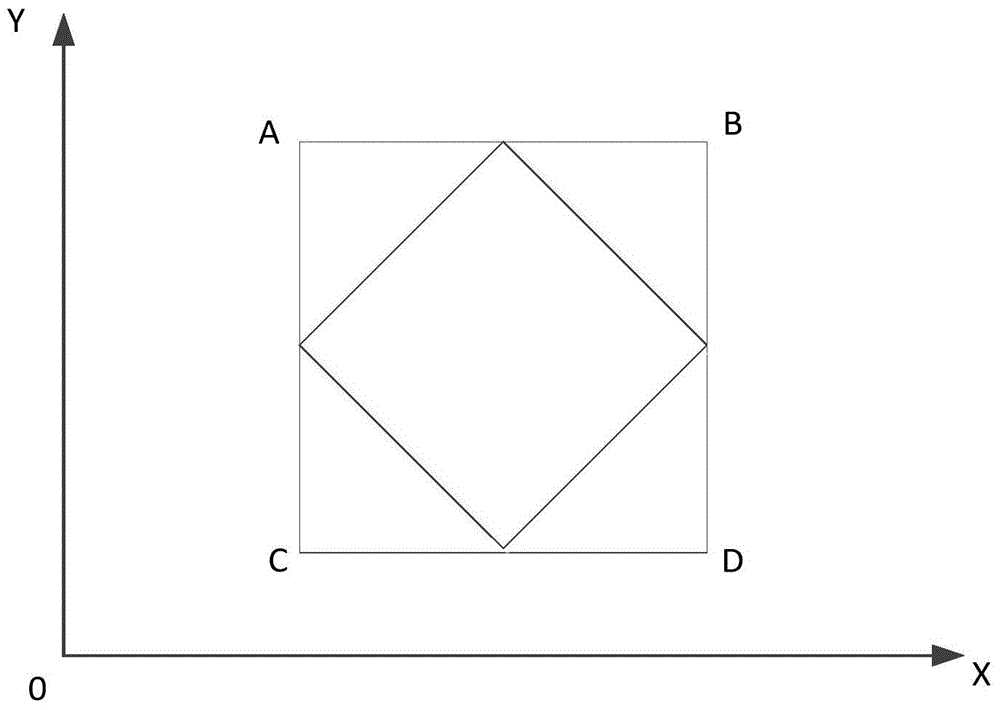

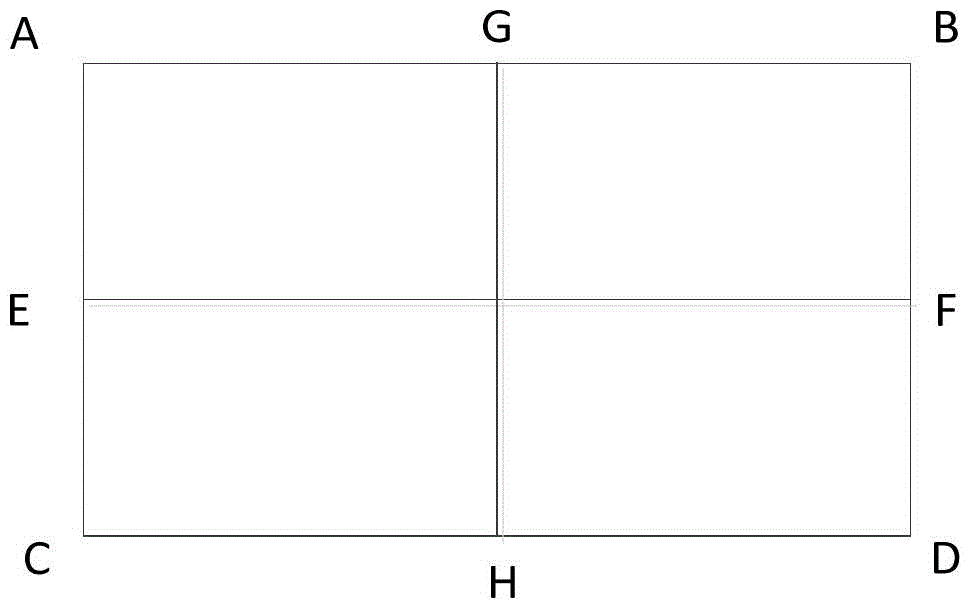

Generating method and system for slice path used for 3D printing

InactiveCN106273446AReduce the number of scansShorten molding timeAdditive manufacturing apparatusAlgorithmShortest distance

The invention discloses a generating method and system for a slice path used for 3D printing. The generating method comprises the following steps that S1, a to-be-printed model is layered so that slice layers can be obtained; S2, the slice layers are partitioned, and a plurality of slice layer areas are formed; S3, line segments in all the areas are connected according to the line segment connecting rule so that intra-area paths can be formed; S4, the intra-area paths in the different areas are connected according to the path connecting rule, and a plurality of complete paths are formed; and S5, the shortest distance among the complete paths is calculated, and the complete paths are combined according to the shortest distance so that the slice path used for 3D printing can be generated. According to the provided generating method and system for the slice path used for 3D printing, a slice path scanning mode that subarea scanning is conducted based on the model characteristics is put forward, thus, the number of times of empty scanning during machining is greatly decreased, the forming time is shortened, and in addition, the forming effect is improved.

Owner:SHENZHEN WEISTEK TECH

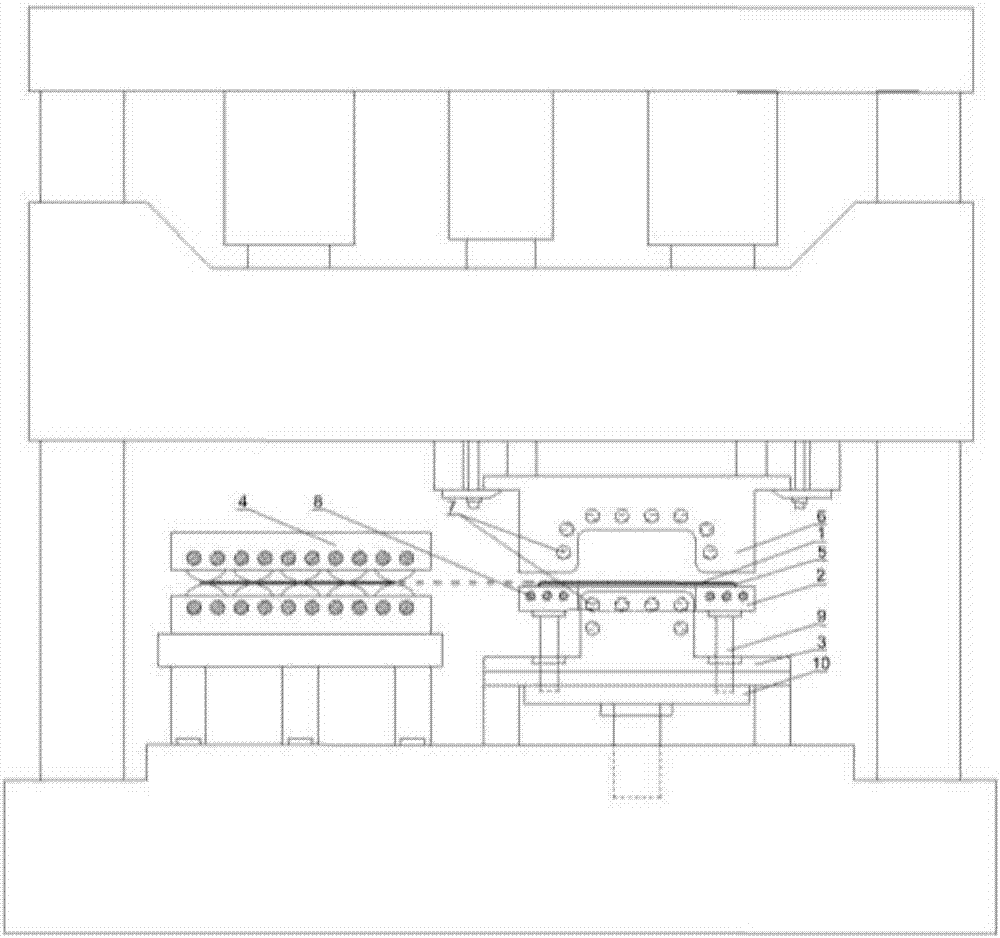

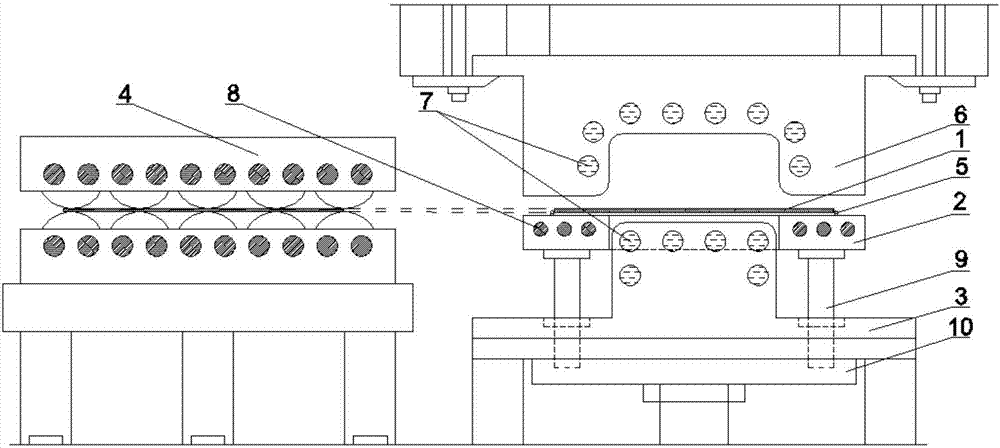

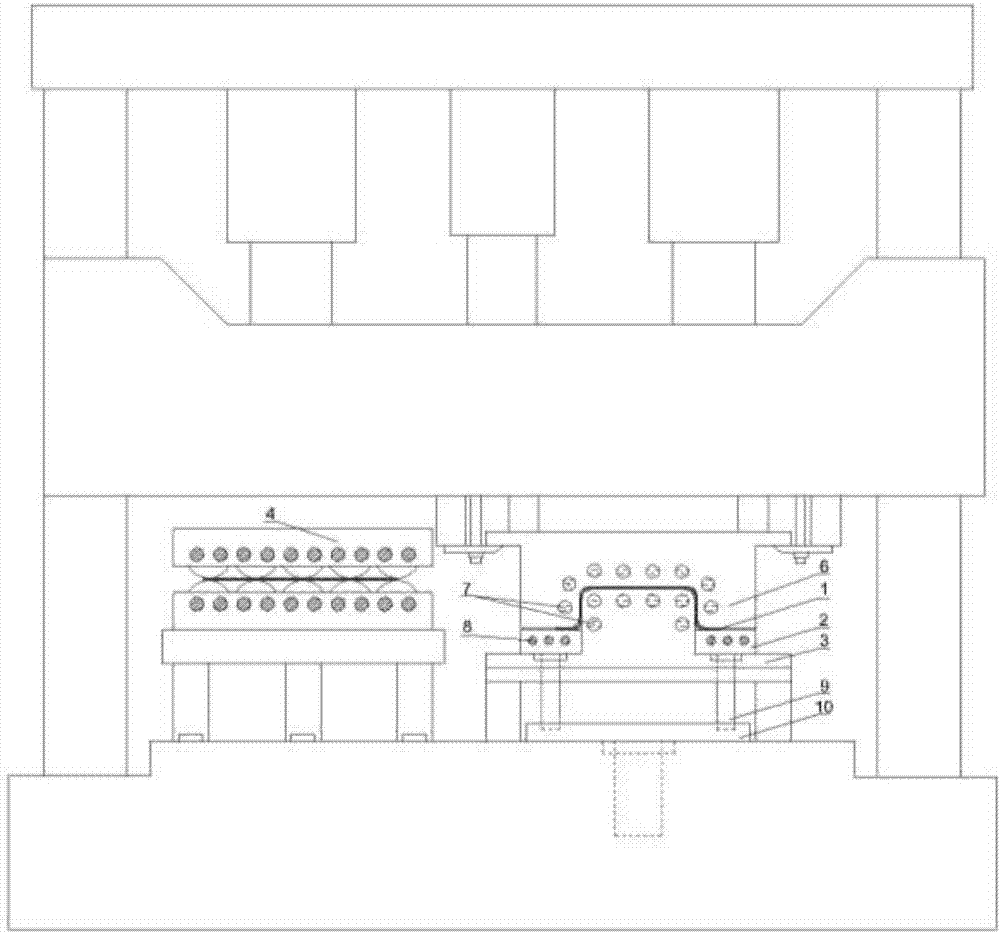

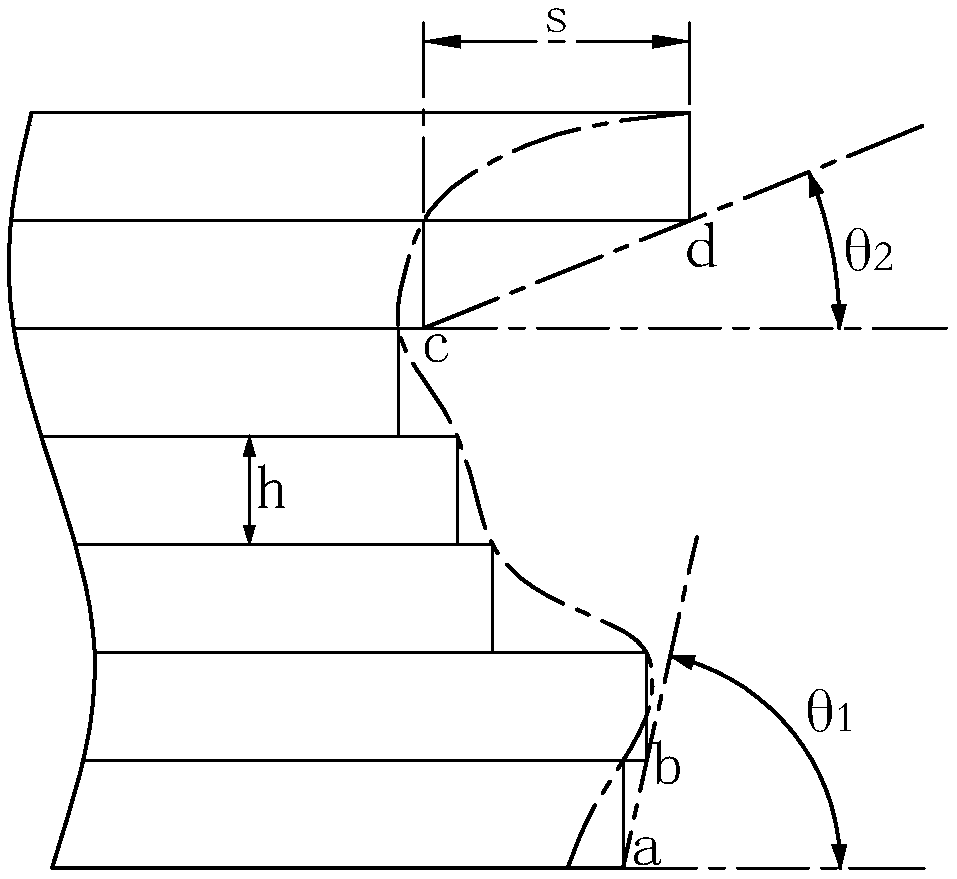

Aluminium alloy sheet mould pressing quenching composite molding method and integrated device thereof

ActiveCN107297407AAvoid timeShorten molding timeShaping toolsQuenching devicesQuenchingHeating furnace

The invention discloses an aluminium alloy sheet mould pressing quenching composite molding method and an integrated device thereof. The method comprises the steps of heating a slab type blank holder, and cooling a female die and a male die; conducting solution heat treatment on an aluminium alloy sheet in a heating furnace; then conveying the aluminium alloy sheet subjected to solid solution and heat preservation from the heating furnace to the blank holder to be place in a centring mode, and ensuring that the sheet is still in a high-temperature state before molding; then conducting die assembly, completing the cooling and quenching process when aluminium alloy parts are in a die assembly state, and ensuring that the shapes of the parts do not change during quenching; conducting die sinking, wherein the aluminium alloy parts and the blank holder demould from the male die synchronously, taking out molding parts, fast moving the molding parts to the aluminium alloy sheet subjected to solid solution and heat preservation according to beats, and finally performing enhanced treatment on the aluminium alloy parts to obtain the final aluminium alloy parts. According to the aluminium alloy sheet mould pressing quenching composite molding method and the integrated device thereof, inverted female and male dies and a composite die are adopted, and the method is applicable to the preparation of aluminium alloy sheet parts capable of being subjected to heat treatment.

Owner:SHANGHAI UNIV

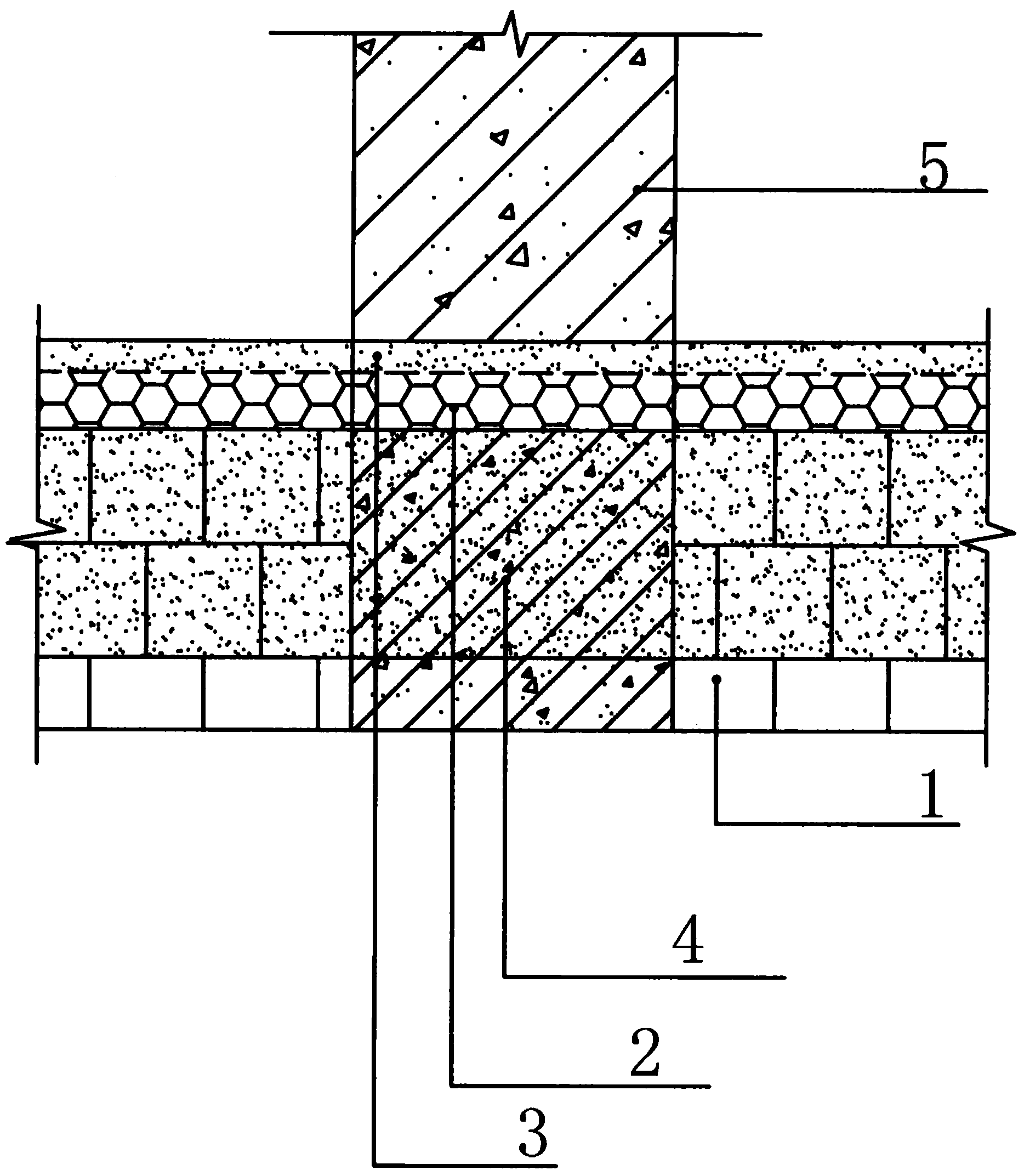

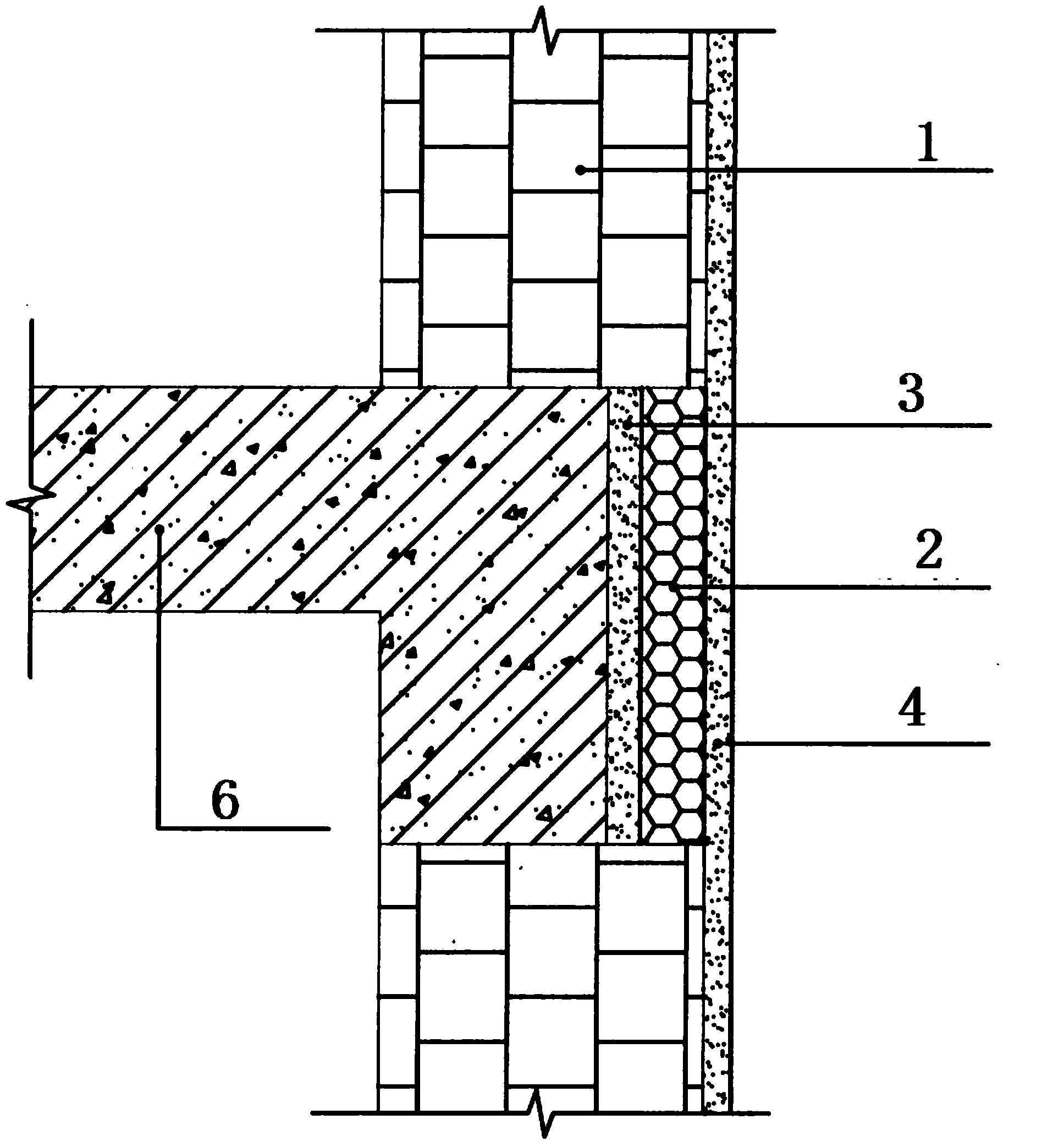

Grade-A fireproof self-heat-insulation wall body and manufacturing method thereof

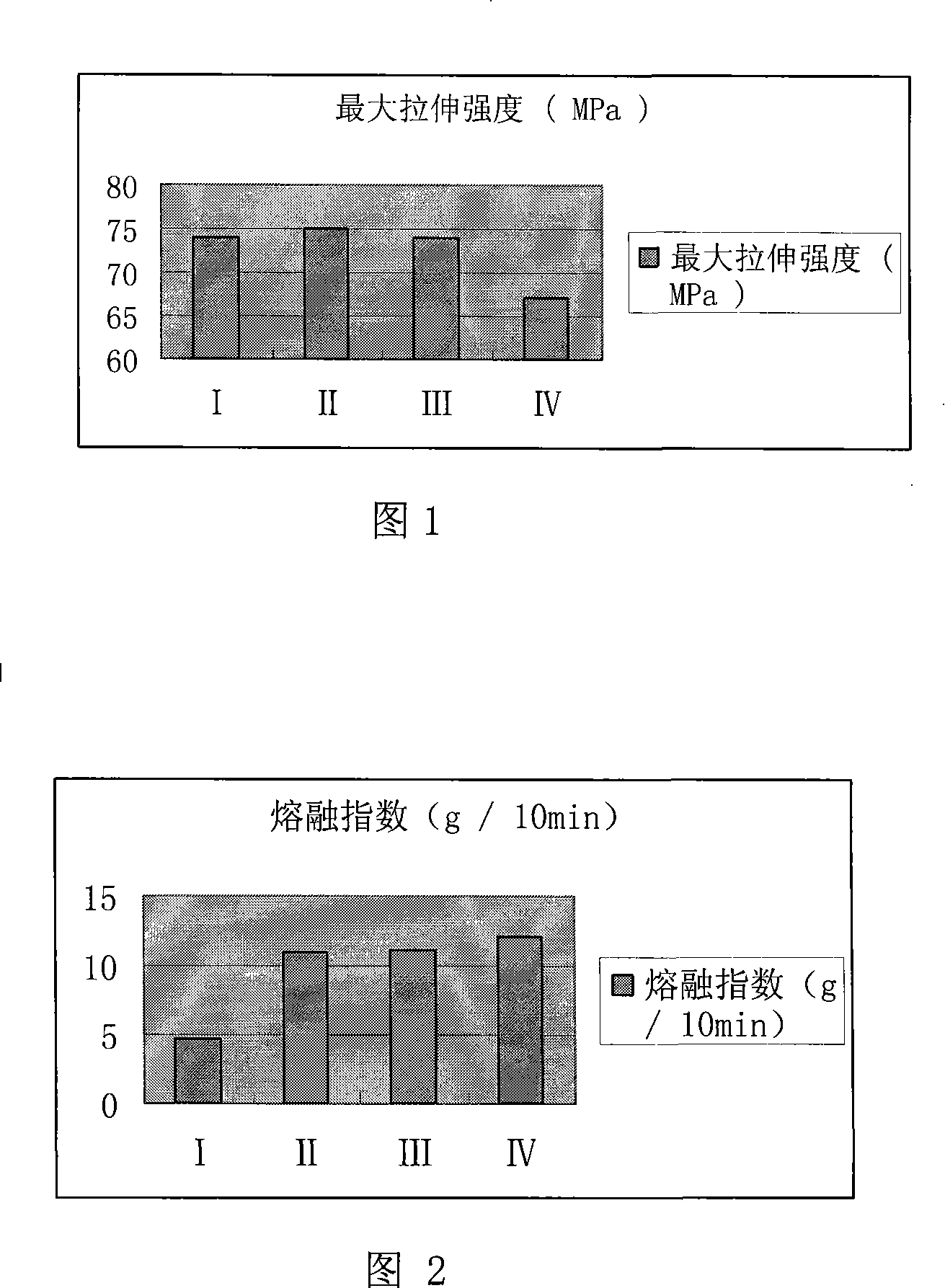

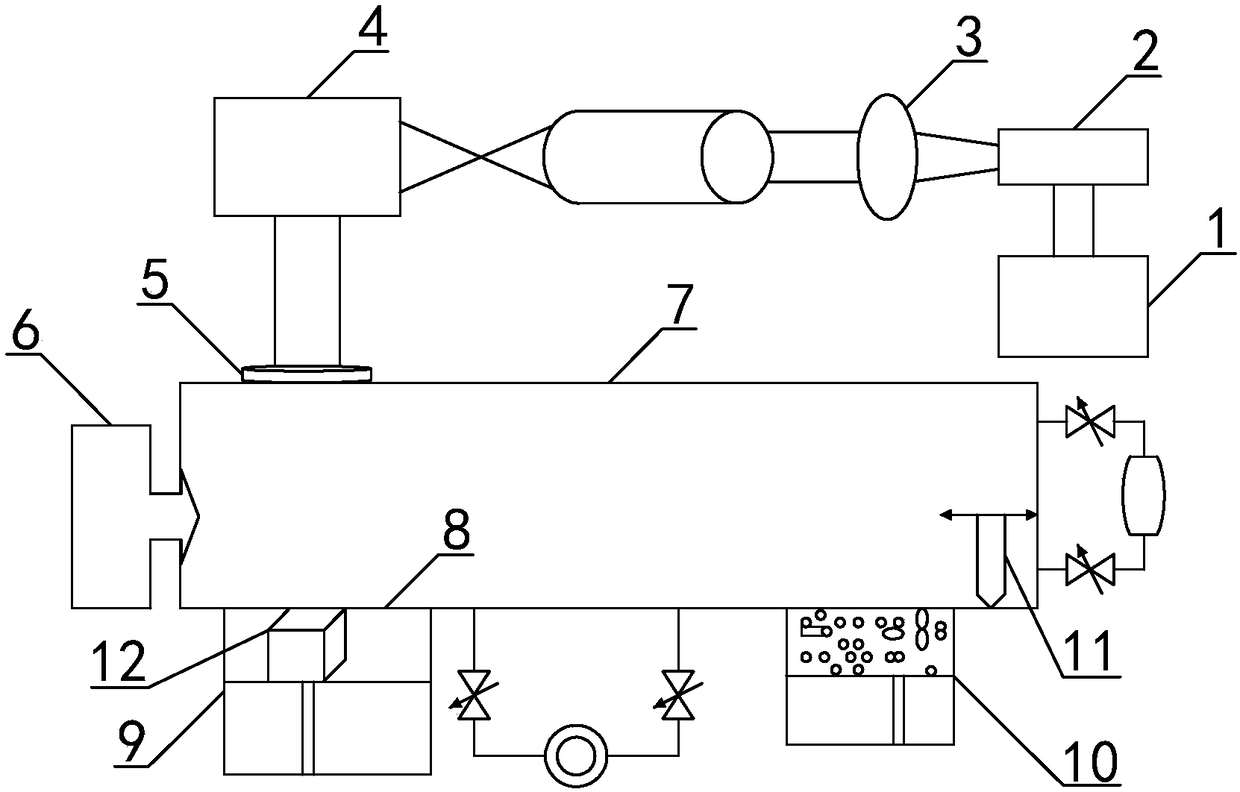

ActiveCN103755287AEasy to solidifyShorten molding timeSolid waste managementUltimate tensile strengthMaterials science

The invention discloses a grade-A fireproof self-heat-insulation wall body and a manufacturing method thereof. The wall body comprises a grade-A fireproof self-heat-insulation wall body building block, a heat-insulation plate, a plastic rivet bolt, a masonry mortar layer and a heat-insulation anti-crack mortar layer, wherein the heat-insulation plate is adhered to a beam column of a frame structure through the masonry mortar layer; heat-insulation anti-crack mortar wraps each surface of the combination of the heat-insulation plate and the masonry mortar layer; the grade-A fireproof self-heat-insulation wall body building block, the heat-insulation plate, the plastic rivet bolt, the masonry mortar layer and the heat-insulation anti-crack mortar layer adopt an integrated structure; moreover, manufacturing methods for each part are introduced in detail. According to the grade-A fireproof self-heat-insulation wall body and the manufacturing method thereof, the product strength is greatly improved, the volume-weight is reduced on the basis that the product strength meets requirements, and the labor intensity is further reduced; the load of a building is reduced, the weight is light, the strength is high, and the fireproof, waterproof and heat-insulation effects are good; one-time construction is performed, the masonry of a main wall body is completed, the requirement for saving 65 percent of energy is also met, heat-insulation construction is not required to be performed, and the service life of the wall body is the same as that of the building.

Owner:环秀(青岛)建材科技有限公司

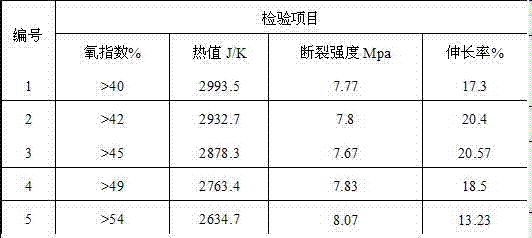

Material special for level-A fire-proof aluminum-plastic board core and preparation method thereof

The invention relates to an aluminum-plastic compound board sandwich layer material, in particular to a material special for a level-A fire-proof aluminum-plastic board core and a preparation method thereof. An inorganic flame retardant, i.e., magnesium hydroxide is taken as a flame retardant, and a high filling technology is adopted. Aids such as a coupling agent, a dispersing agent, a high-molecular compatilizer and the like are used for performing modification pretreatment on magnesium hydrate, so that the magnesium hydrate flame retardant has superior performance, the filling amount of the flame retardant in a substrate is up to 80-90 percent by weight, which is much higher than the adding amount of a flame retardant of the same type of products, the oxygen index of the product is remarkably increased in comparison to that of the same type of products, and the flame-retarding environmental protection performance is improved remarkably. An aluminum-plastic board core material prepared by adopting the method has the characteristics of freeness from halogen, low thermal value, low smoke, flame retardance, drop resistance, nontoxicity and freeness from pollution.

Owner:大连亚泰科技新材料股份有限公司

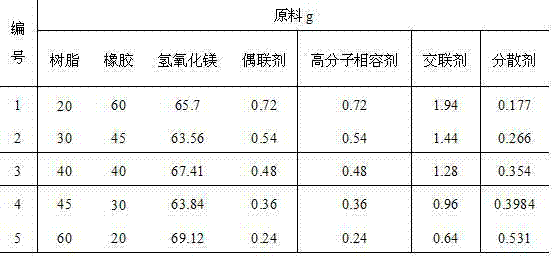

Rubber product one-step injection, hollowing and vulcanization forming production method

The invention discloses a rubber product one-step injection, hollowing and vulcanization forming production method, which belongs to the technical field of rubber product processes. By adopting the rubber product one-step injection, hollow and vulcanization forming production method, the injection, hollowing and vulcanization procedures can be completed in a same mold cavity, the mold cavity comprises an upper half mold, a lower half mold and a mold core, the mold core sets a foundation for the hollowing of the mold cavity, after the hollowing, the condition for introducing the high-temperature high-pressure gas for the vulcanization can be satisfied, the injection molding, hollowing and vulcanization apparatus can be integrated, the heat loss caused by the procedure circulation and the procedure circulation cost in the prior art can be avoided, and the traditional defects of the traditional rubber product production process such as re-pressurizing, heating, energy consumption, time consumption and high cost can be solved.

Owner:东营睿港招商服务有限责任公司

Three-dimensional object-forming apparatus

ActiveUS8523554B2Avoid wastingAdditional drawbackManufacturing enclosuresConfectioneryEngineeringHeating system

A three-dimensional object-forming apparatus is disclosed, which includes an in-batches powder-rationing tank system, a construction tank system, a printing powder-applying system, a rapid drying heating system, a printing maintenance device, a dust-proof device, a successive liquid-supplying device, a powder auto-filtrating and recycling device, and a print quality detection device.

Owner:MICROJET TECH

Processing techniques of carbon fiber products and glass fiber products

The invention discloses a processing techniques of carbon fiber products and glass fiber products, which comprises the steps of pretreating, molding, contouring and the like, wherein a quick cooling / heating conversion machine is used in the molding process to quickly heat and cool a mold, thereby shortening the molding time and greatly improving the production efficiency; in the molding process, the surfaces of piled carbon fiber prepregs or glass fiber prepregs are coated with release films, so that resin on the carbon fiber prepregs or the glass fiber prepregs can be transversely and uniformly leveled at high temperature and high pressure so as to obtain carbon fiber semi-finished products or glass fiber semi-finished products the surfaces of which are smooth and have no pits and pinholes, thereby reducing subsequent surface treatment difficulty, and saving the subsequent procedures and working time; and the surface of the mold used in the molding process is subject to mirror polish and electroplating treatments, so that the surface of the product produced by the mold has the highlight effect, the paint baking or other post-treatment technic of the product is omitted, the working time can be reduced, and the cost can be lowered.

Owner:KUSN TONG YIN INDAL ELECTRONICS MAKING

Lens-forming silicone resin composition and silicone lens

Silicone resin compositions comprising (A) an organopolysiloxane containing at least two aliphatic unsaturated bonds and having a viscosity of 100-1,000,000 mPa·s at 25° C., (B) an organohydrogenpolysiloxane having at least three silicon-bonded hydrogen atoms (SiH groups) in the form of HR62SiO—, and (C) a platinum group metal base catalyst cure into colorless transparent parts which are useful lenses.

Owner:SHIN ETSU CHEM IND CO LTD

Synthesis process for ultra-branching nylon 6

The process of producing super branched nylon-6 includes the following steps: the first compounding salt solution of dendritic polymer; the subsequent displacement and ring opening hydrolysis reaction first at 0.3-1.0 MPa and 200-220 deg.c for one period of time, then at 245-250 deg.c and 0.3-1.5 MPa for one other period of time and finally at normal pressure and 260-280 deg.c; and discharging to obtain the super branched nylon-6 product. The super branched nylon-6 melt has flowability 2-3 times that of common nylon-6 in similar mechanical performance and improved extrusion, spraying and forming performance for making nylon devices.

Owner:HUNAN UNIV

Method for optimizing metal parts of SLM formed overhanging structure

ActiveCN108161007AReduce in quantityAdd lessAdditive manufacturing apparatusIncreasing energy efficiencySlagThin walled

The invention discloses a method for optimizing metal parts of a SLM formed overhanging structure. The method comprises the following steps of 1, optimization of a spatial position; 2, optimization ofa support structure; and 3, optimization of local energy. According to the method, by optimizing the placing positions of the metal parts, the number of the overhanging structures can be reduced, theforming angle of key parts of the overhanging structure is increased so as to improve the forming quality, and the adding amount of supports can be effectively reduced; then the support structure isoptimized, the multiple cross supports with hollow thin walls provided with saw teeth are adopted to form a net-shaped structure, the supporting strength requirement is met, meanwhile, the powder using amount and the forming time required by supporting forming can be reduced, and the machining efficiency is improved; and then when the overhanging structure is formed, the scanning speed is improvedproperly or the laser frequency is reduced according to the size of the inclination angle of the overhanging structure so as to reduce input of local energy, lower the warping deformation trend and reduce slag hanging amount, and finally, a metal part overhanging structure meeting the requirements of high forming precision, small deformation and low surface roughness is obtained.

Owner:广州瑞通增材科技有限公司

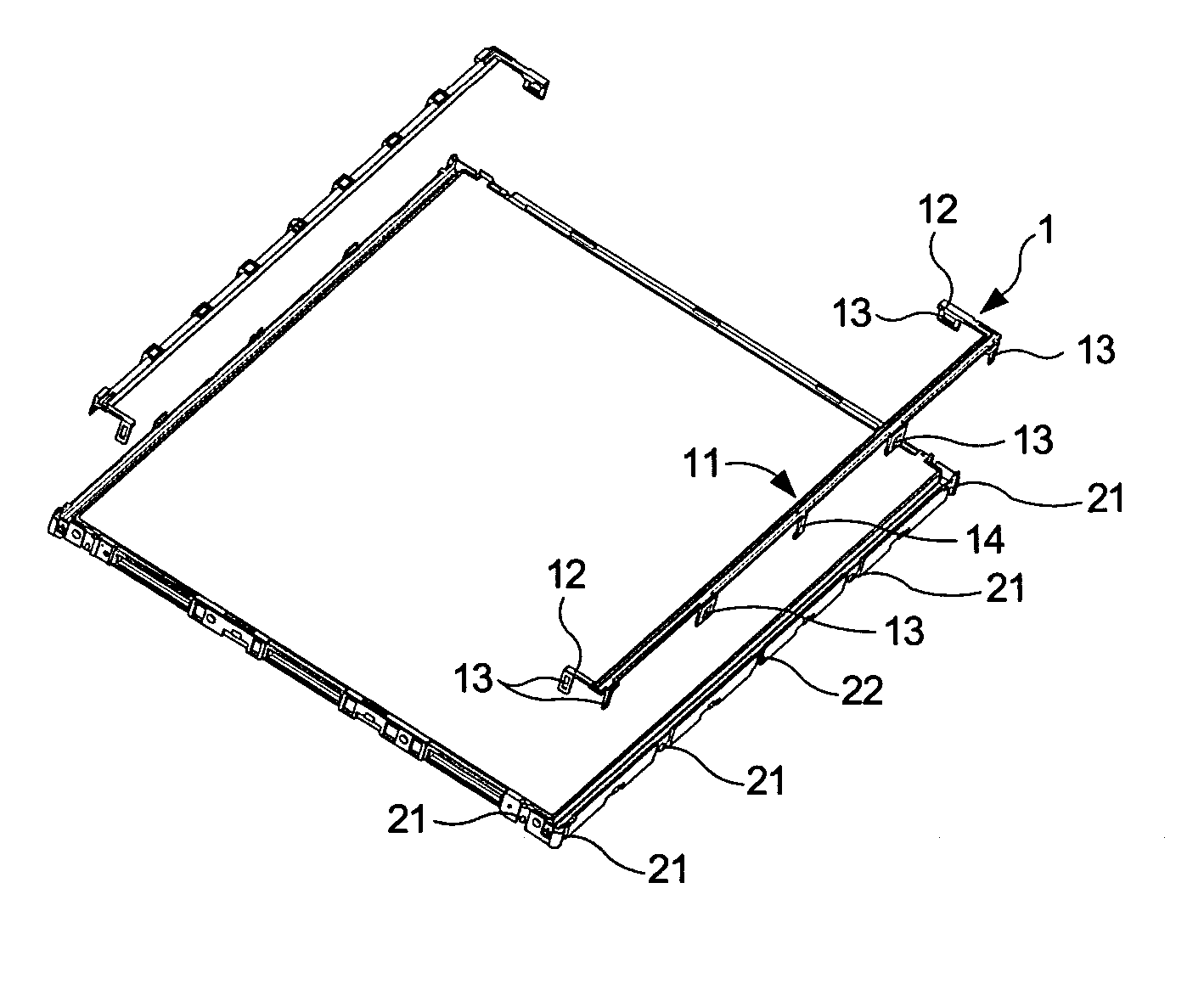

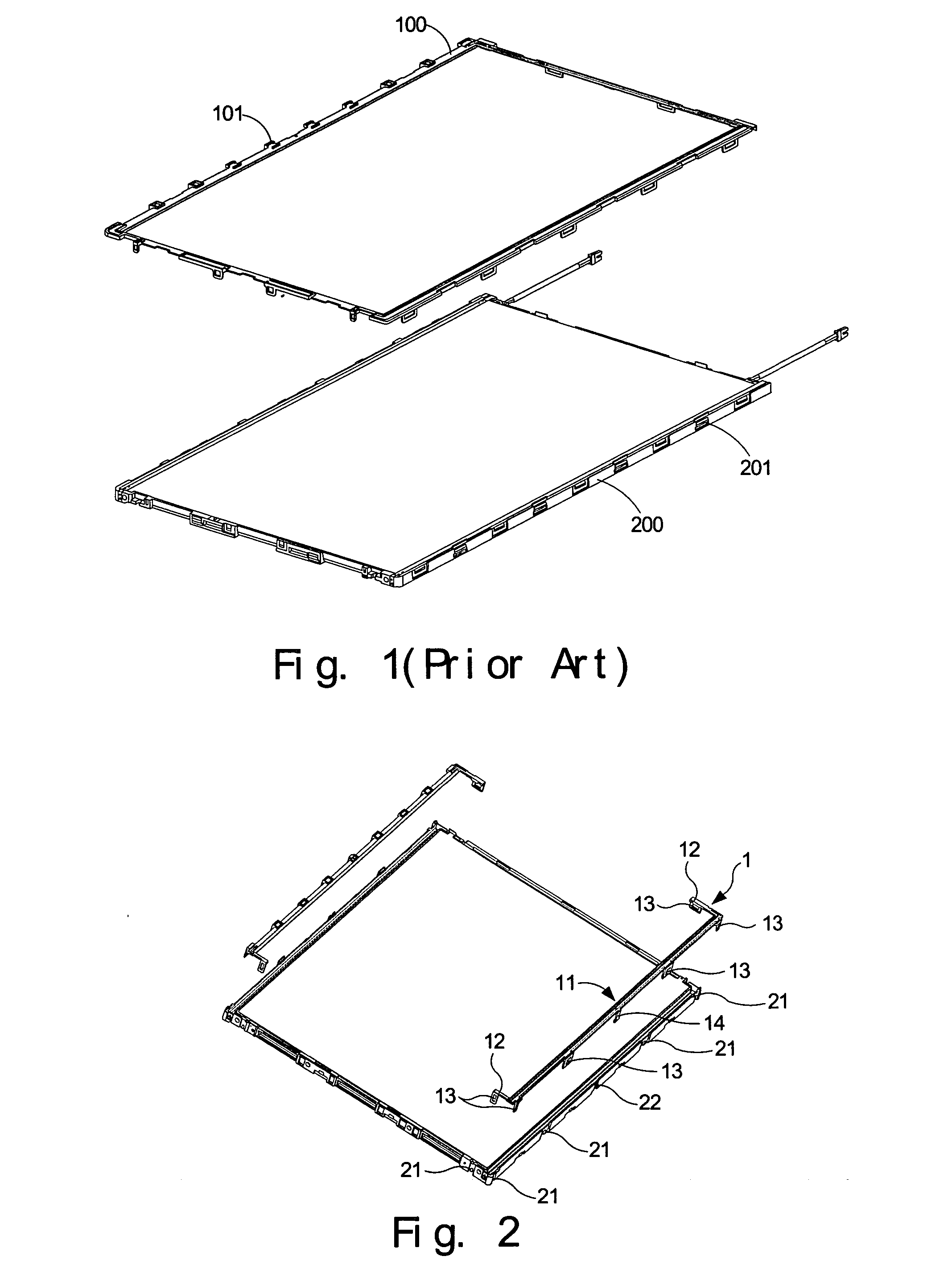

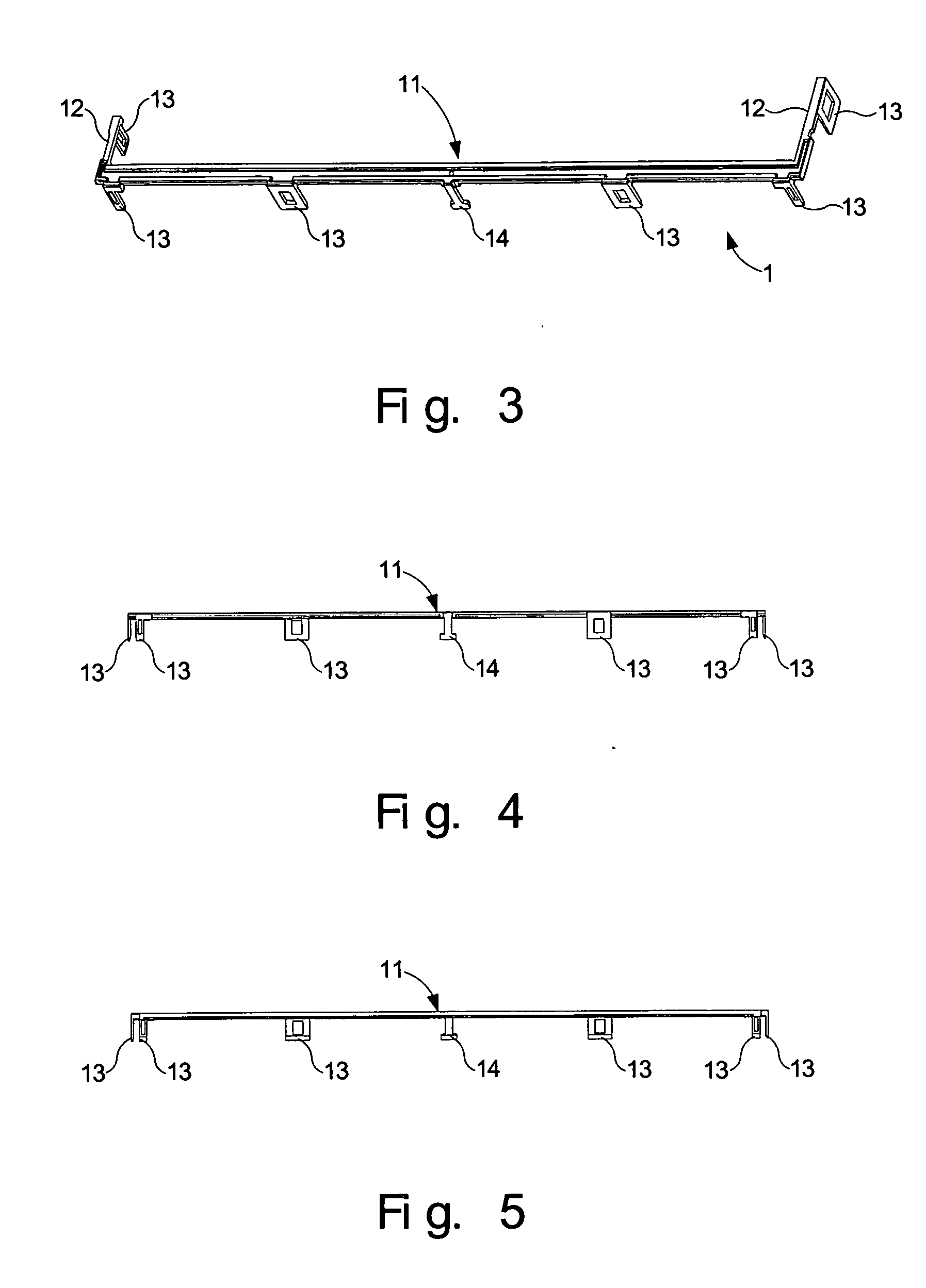

Side fixing frame for a liquid crystal display device

ActiveUS20050206799A1Expand field of viewShorten molding timeNon-linear opticsLiquid-crystal displayFixed frame

A side fixing frame for a liquid crystal display device is provided. The side fixing frame has a U-shaped configuration and is provided with multiple engaging elements. The engaging elements of the side fixing frame couple with corresponding counterparts of a supporting frame used in a liquid crystal display device so as to fasten the side fixing frame with the supporting frame. Because of the U-shaped configuration design of the side fixing frame, the frame can attain the desired securing strength and reduce the materials needed for producing the side fixing frame and the production cost.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com