Patents

Literature

176results about How to "Raise the processing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

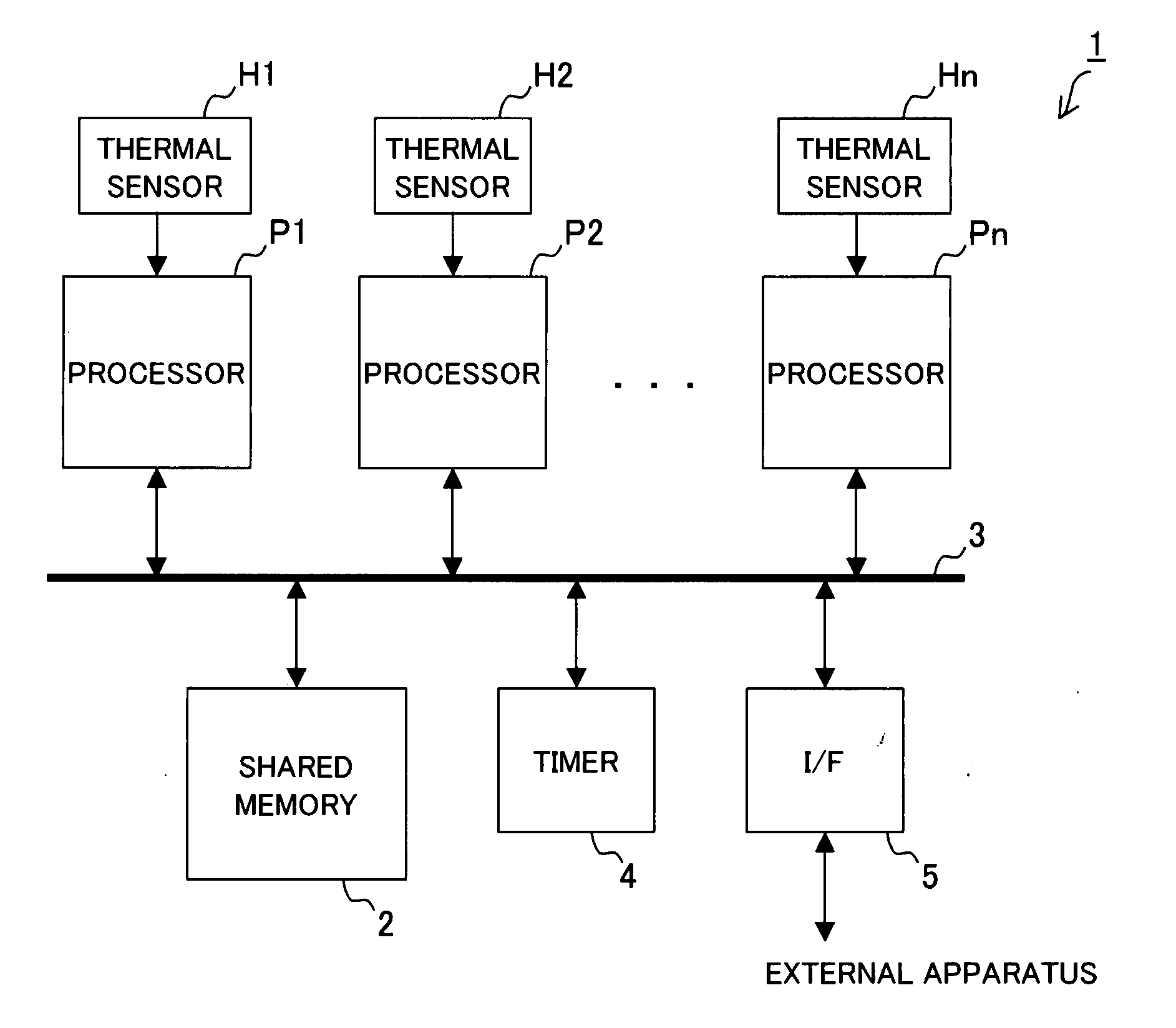

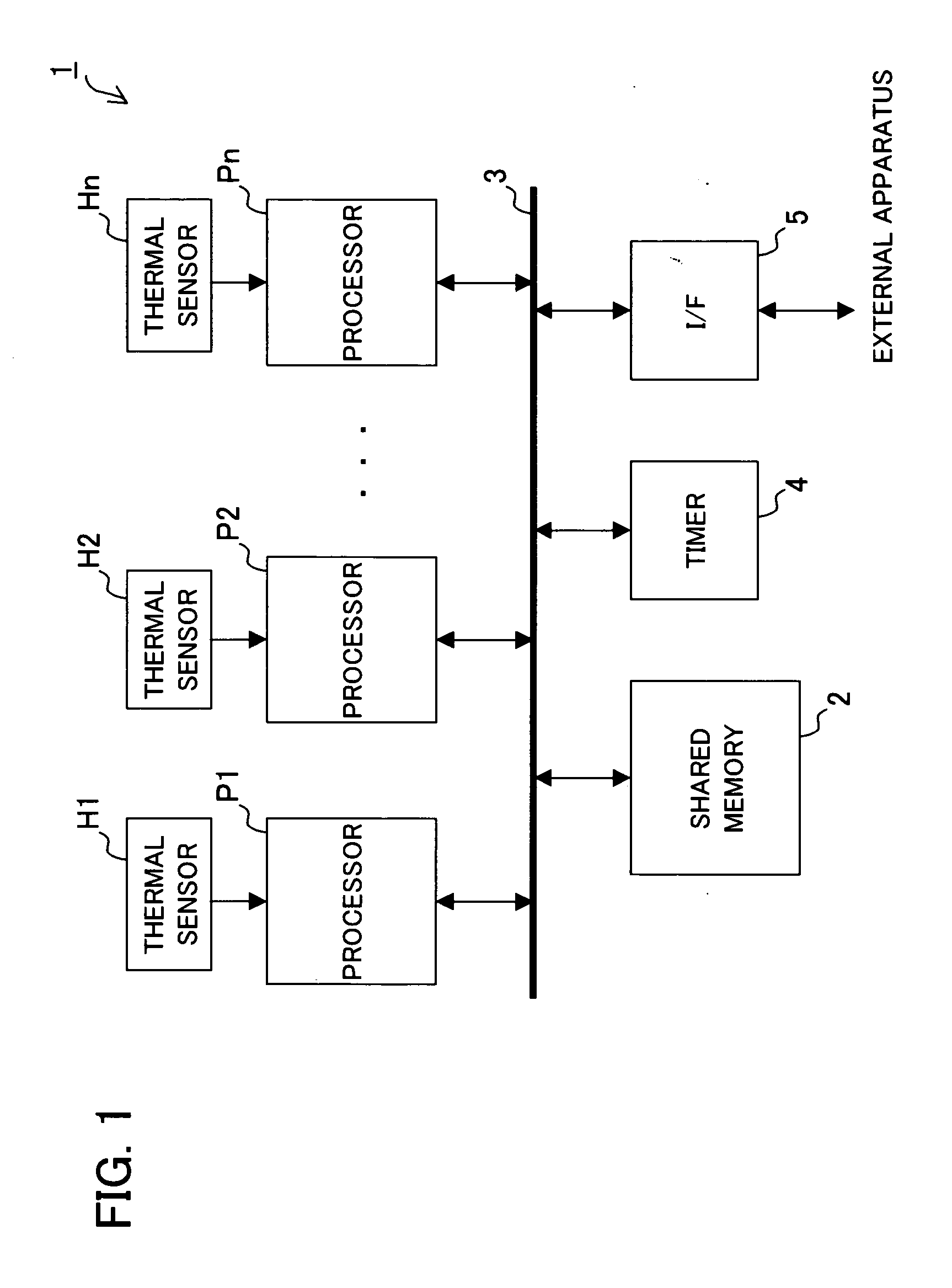

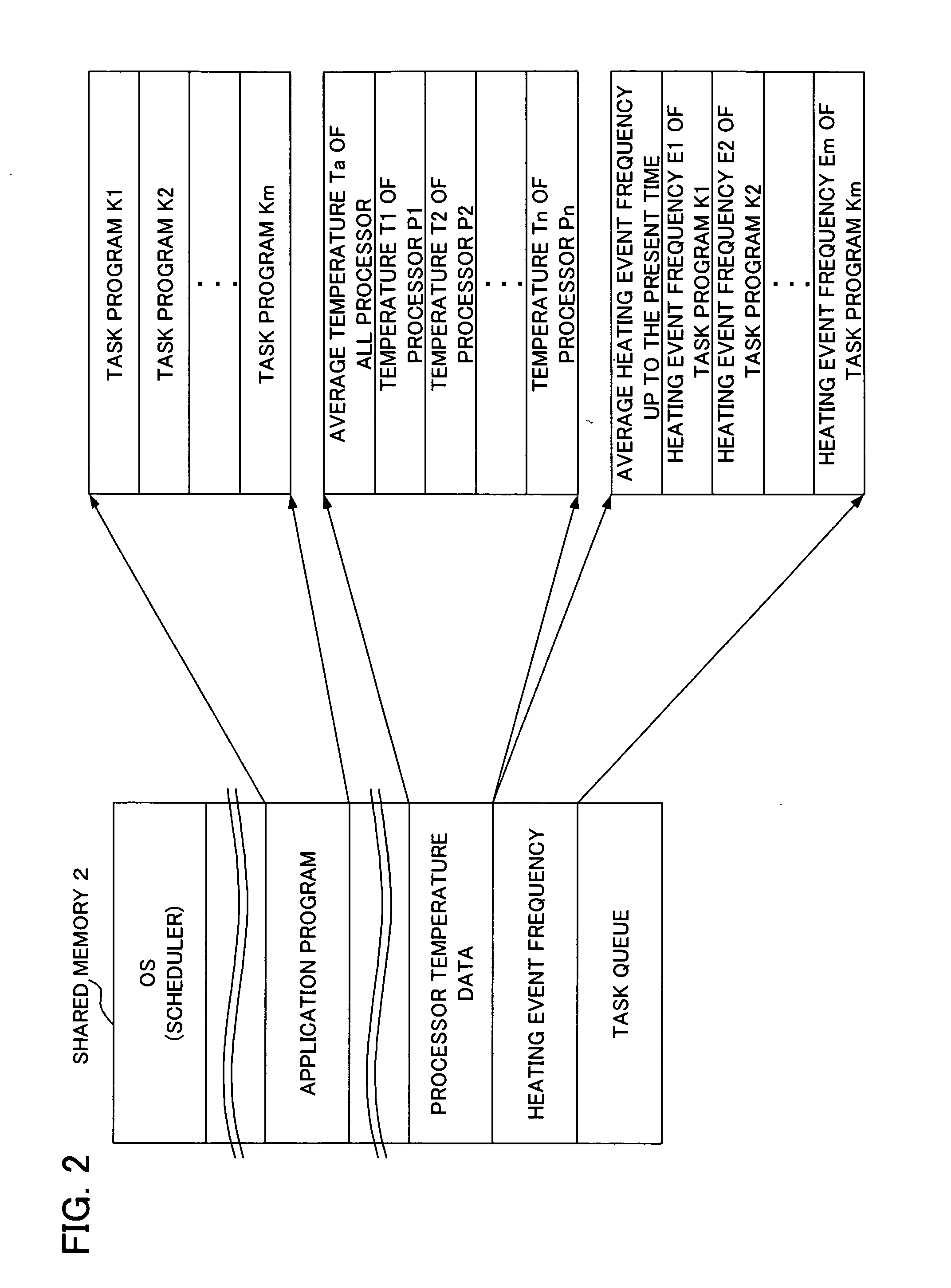

Task scheduling apparatus in distributed processing system

InactiveUS20050278520A1Raise the processing temperatureReduce heatEnergy efficient ICTProgram initiation/switchingProcessing elementHandling system

A task scheduling apparatus of a distributed processing system having a plurality of processing units for processing a plurality of distributed tasks is provided. As a first task scheduling method, the task scheduling apparatus allocates a task to a processing unit having the lowest temperature. As a second task scheduling method, the task scheduling apparatus selects a task based on both temperature of each processing unit and characteristic values of tasks related to degree of temperature rise or consumption power increase caused by execution, and allocates the selected task to the object processing unit. For example, as the second task scheduling method, a task producing a large degree of temperature rise (for example, a task having a number of instructions to be processed per unit time) is allocated to a processing unit having a low temperature. With such a scheduling method, uniform temperature of each processing unit can be obtained.

Owner:FUJITSU LTD

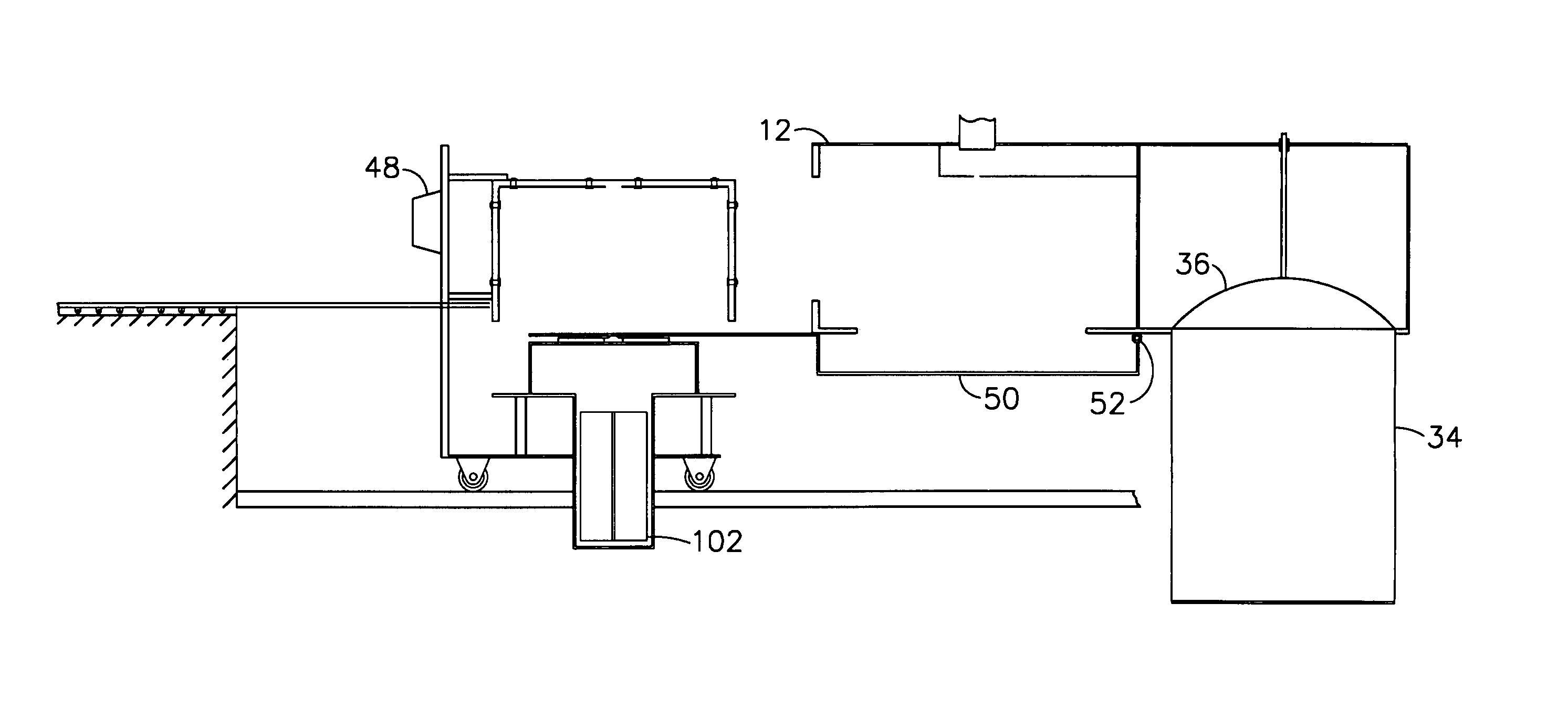

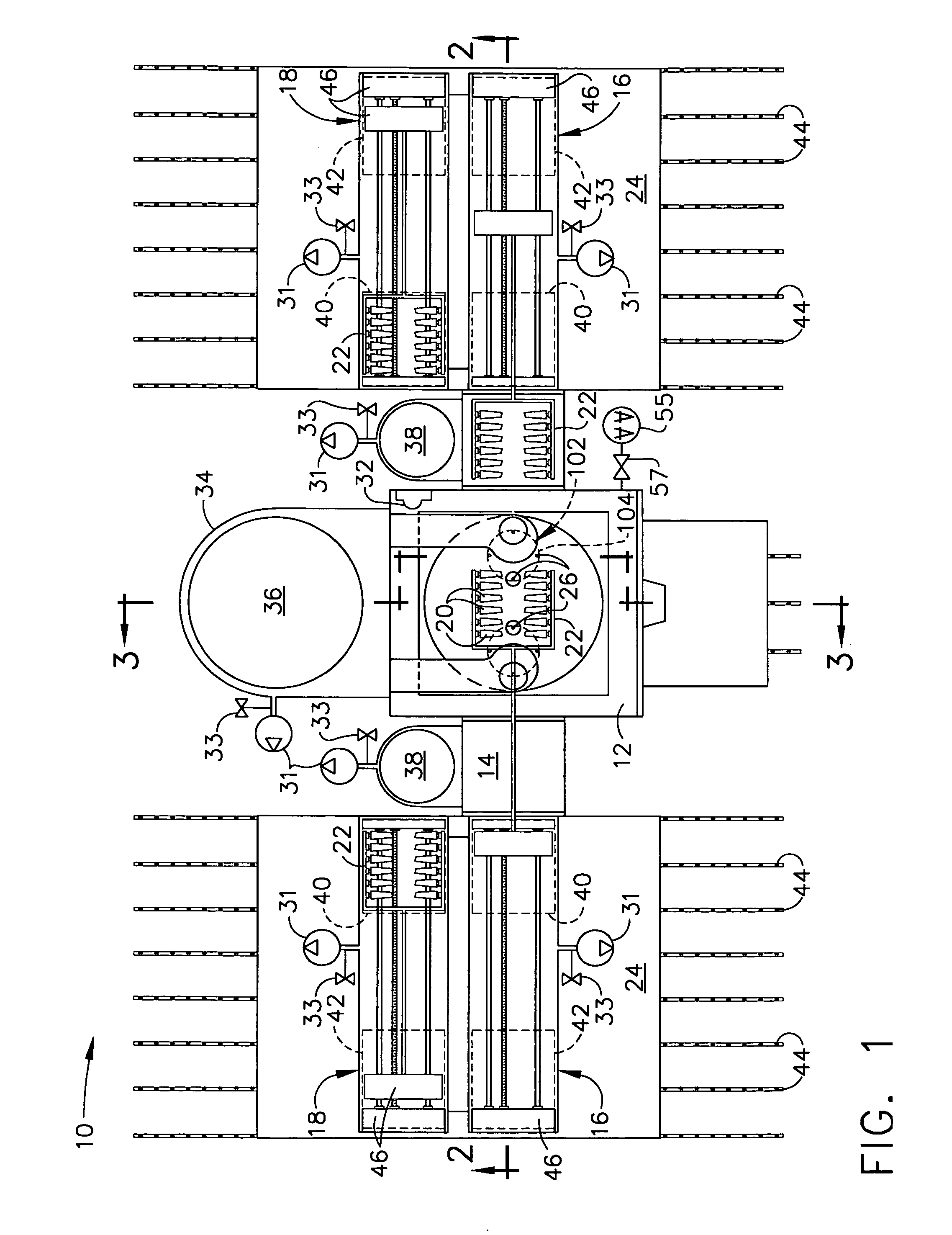

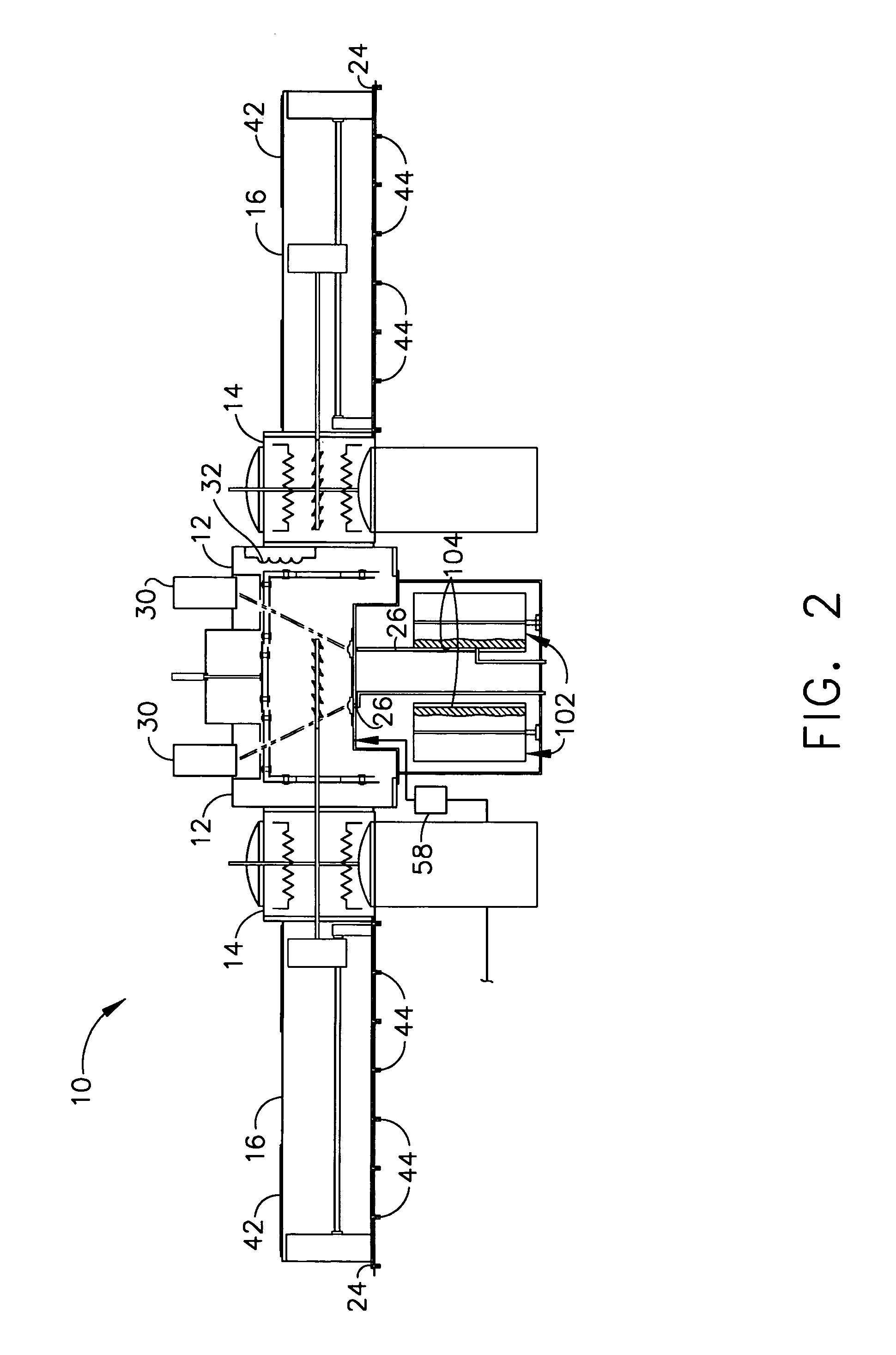

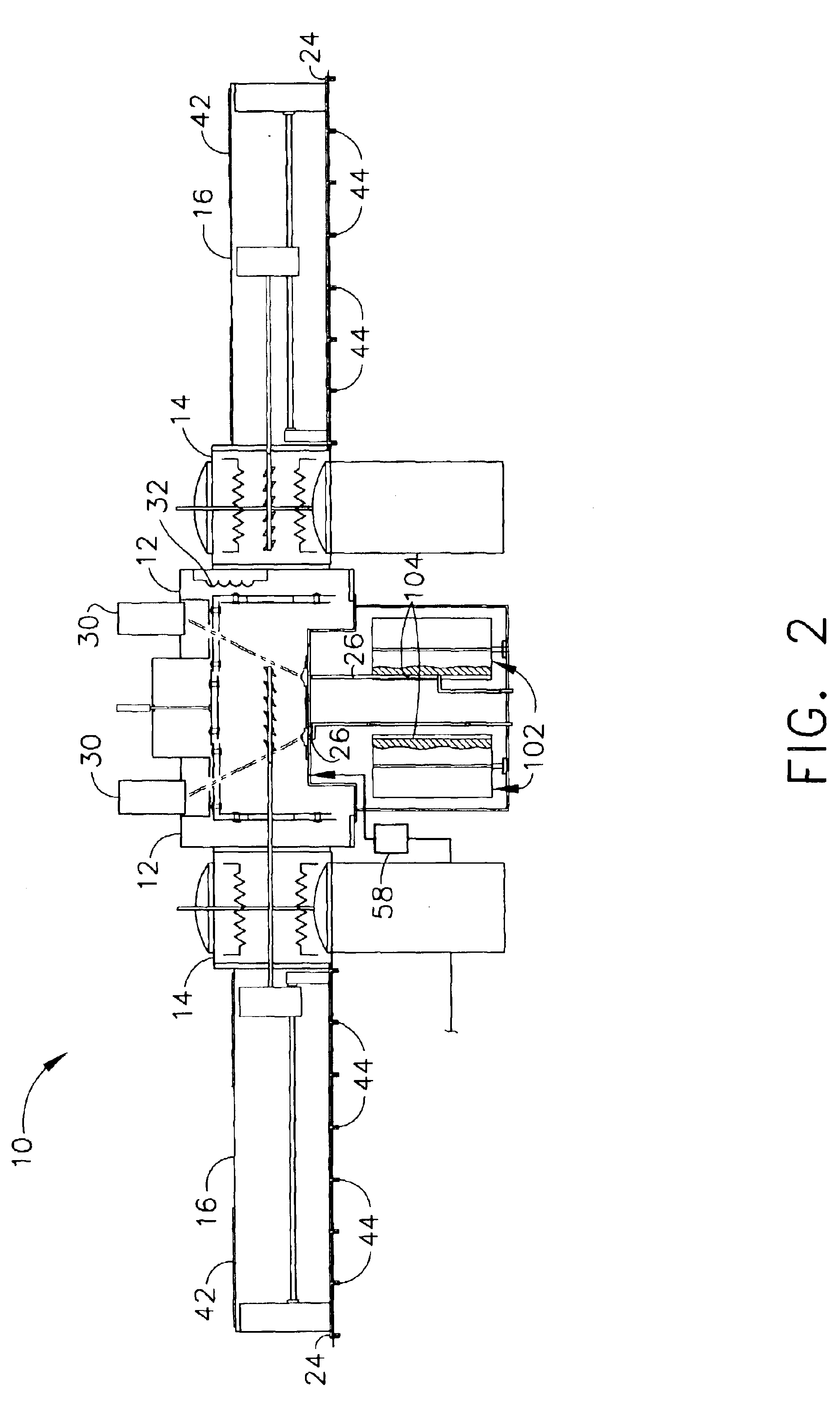

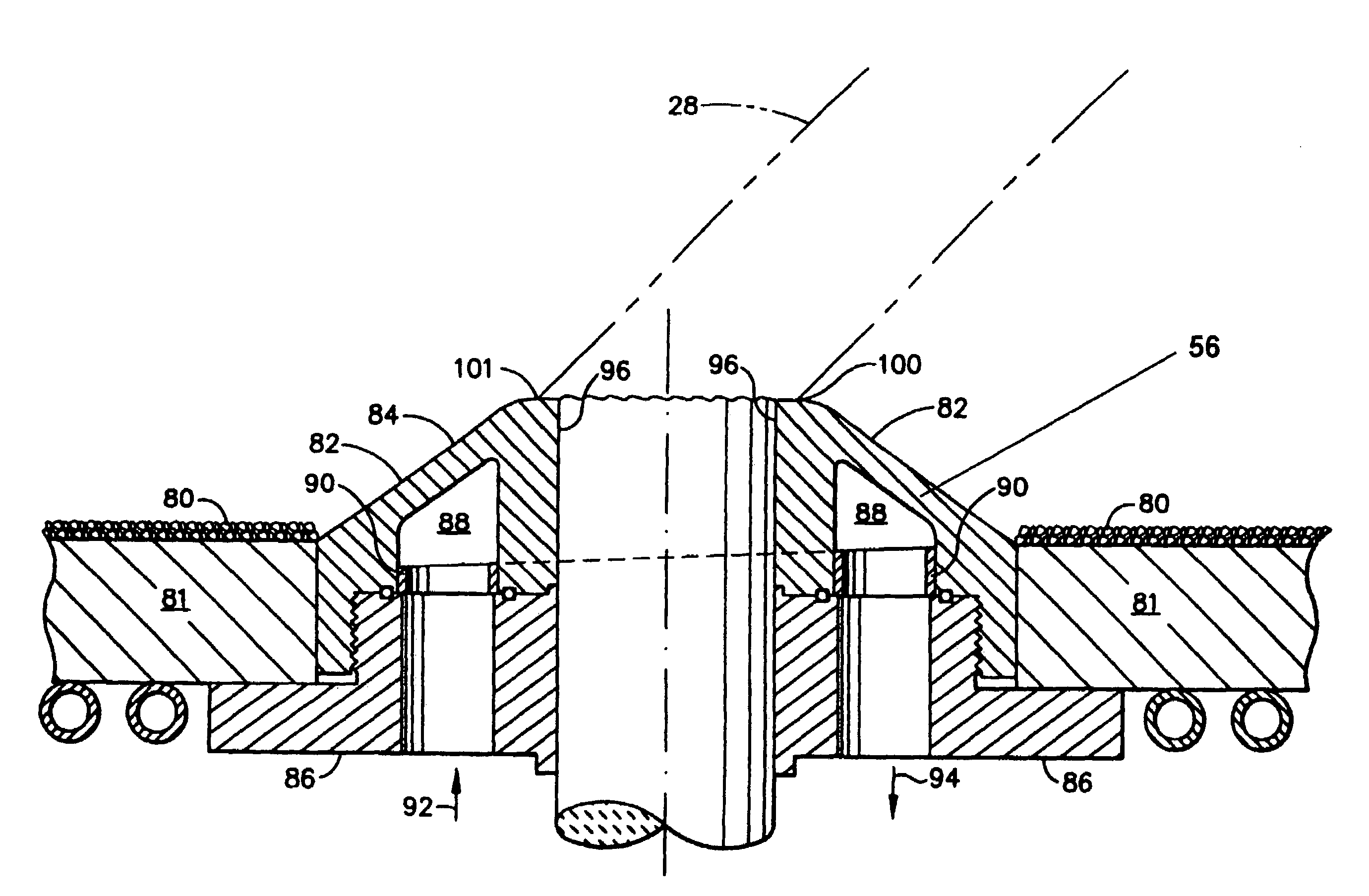

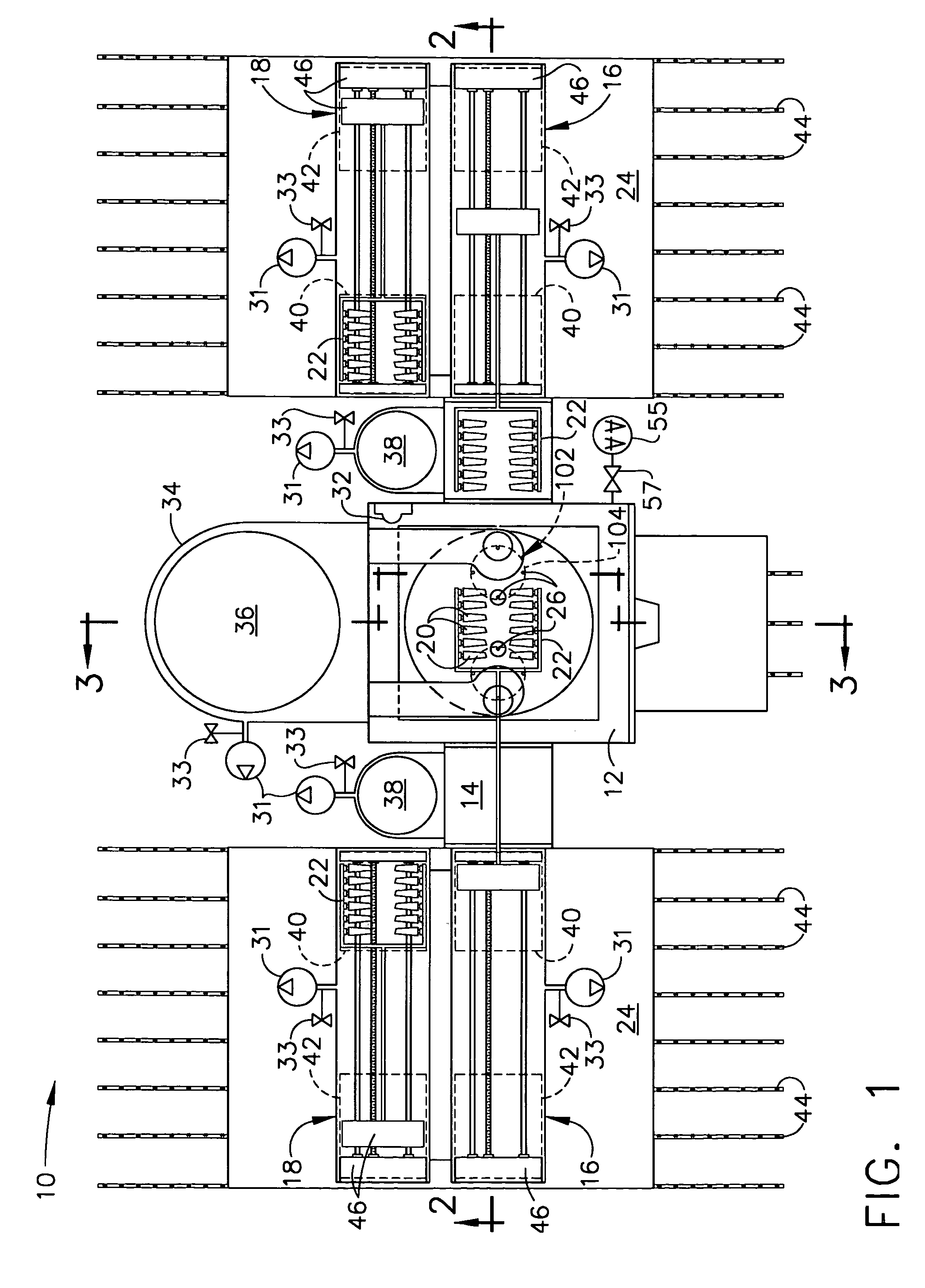

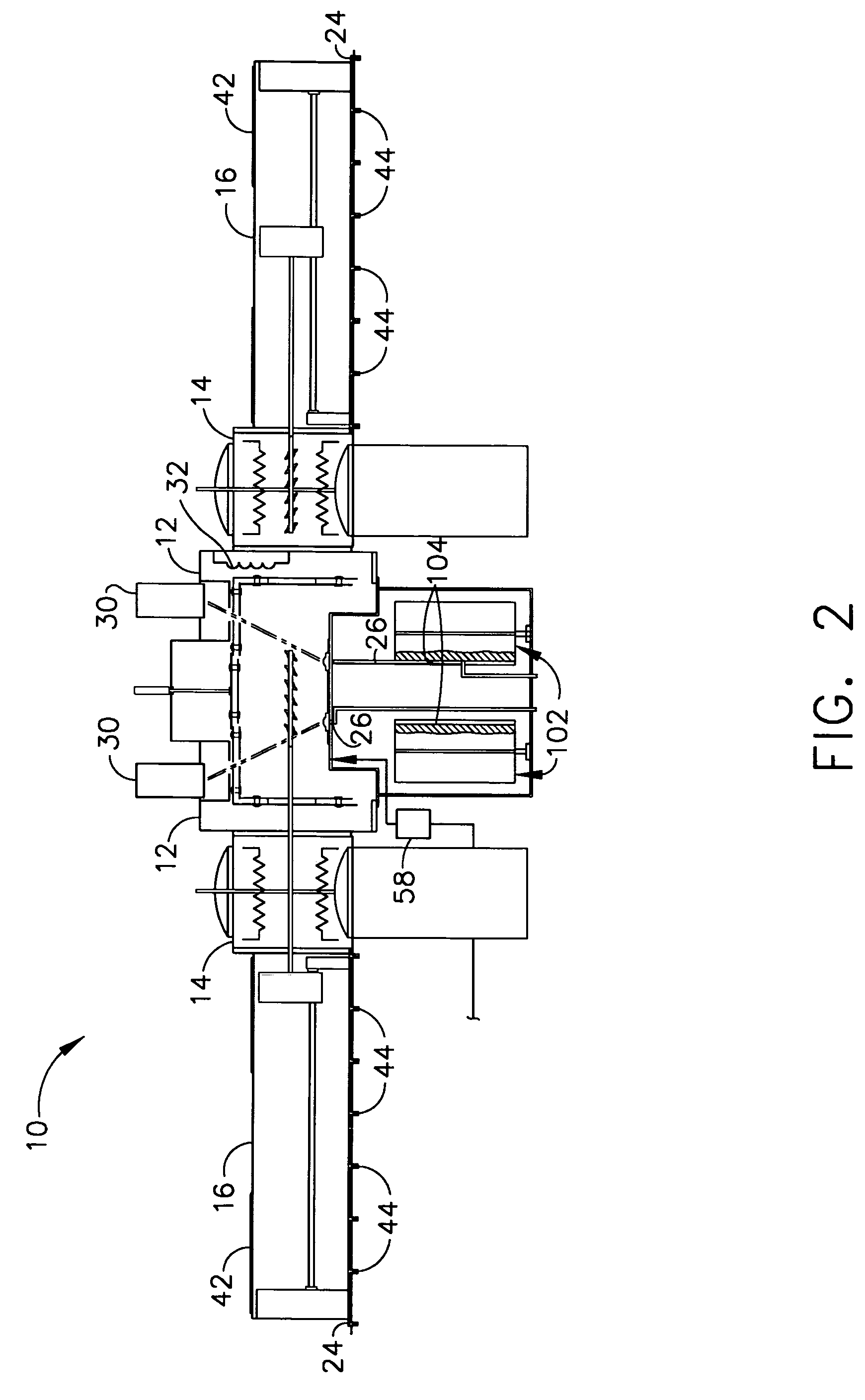

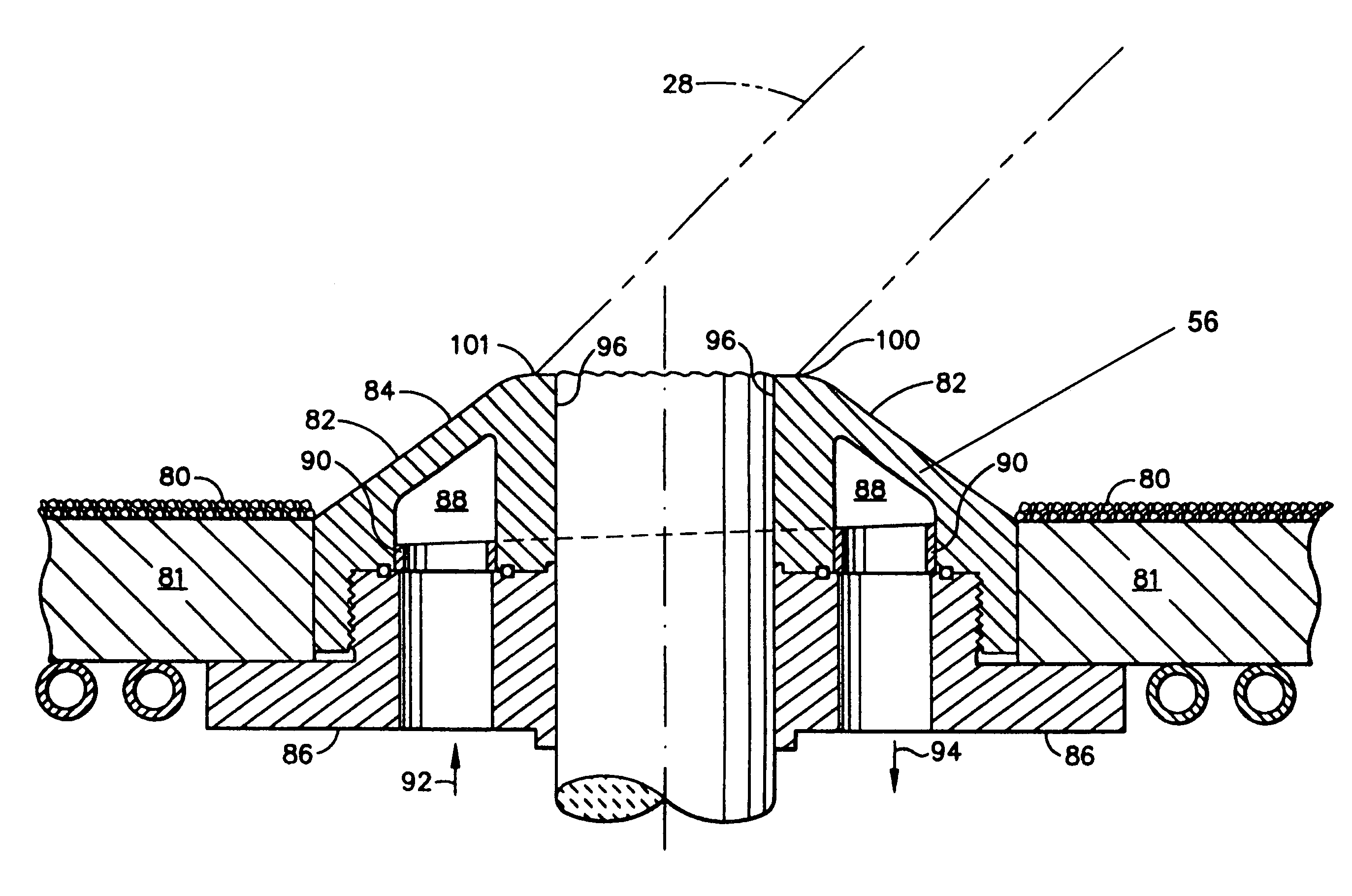

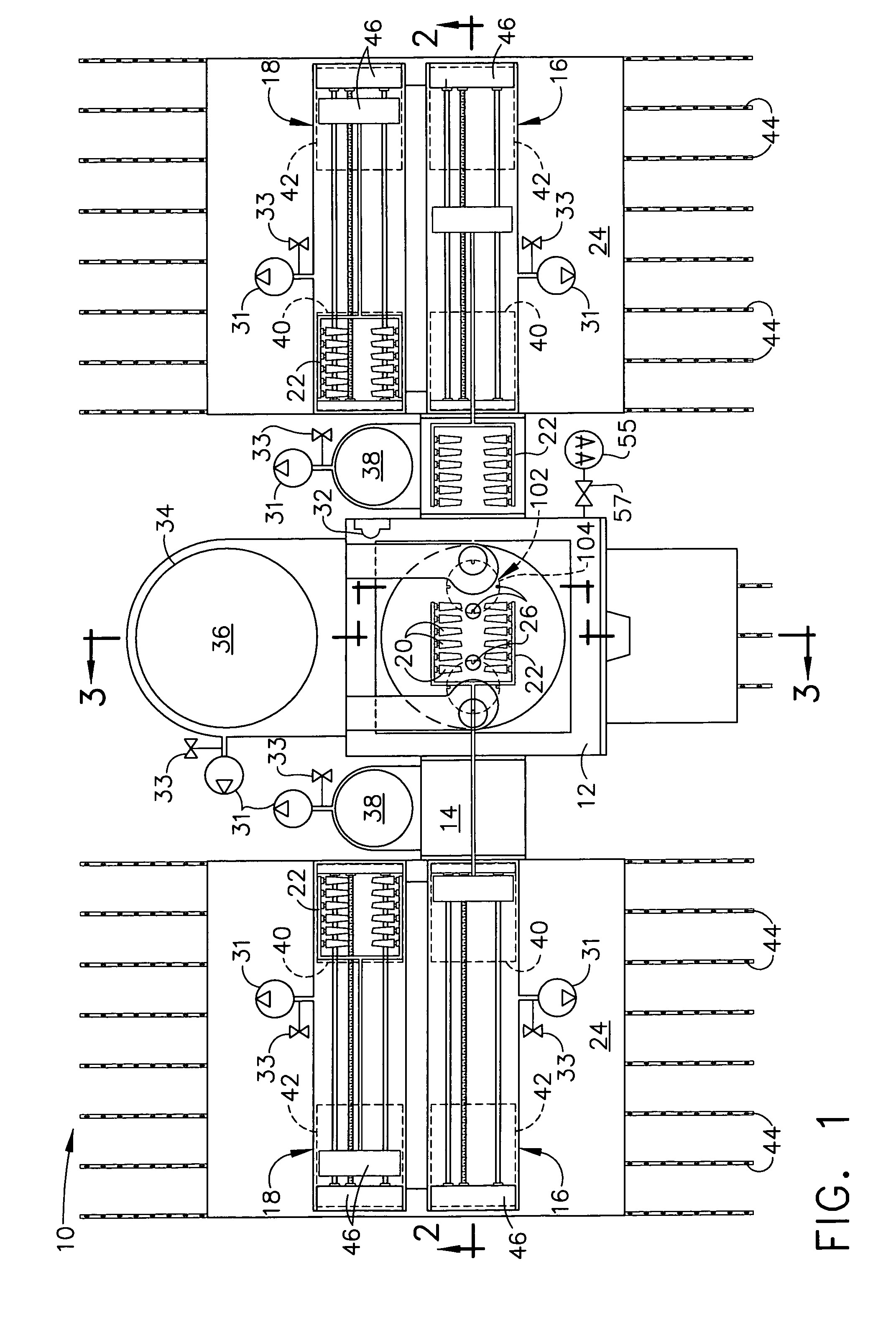

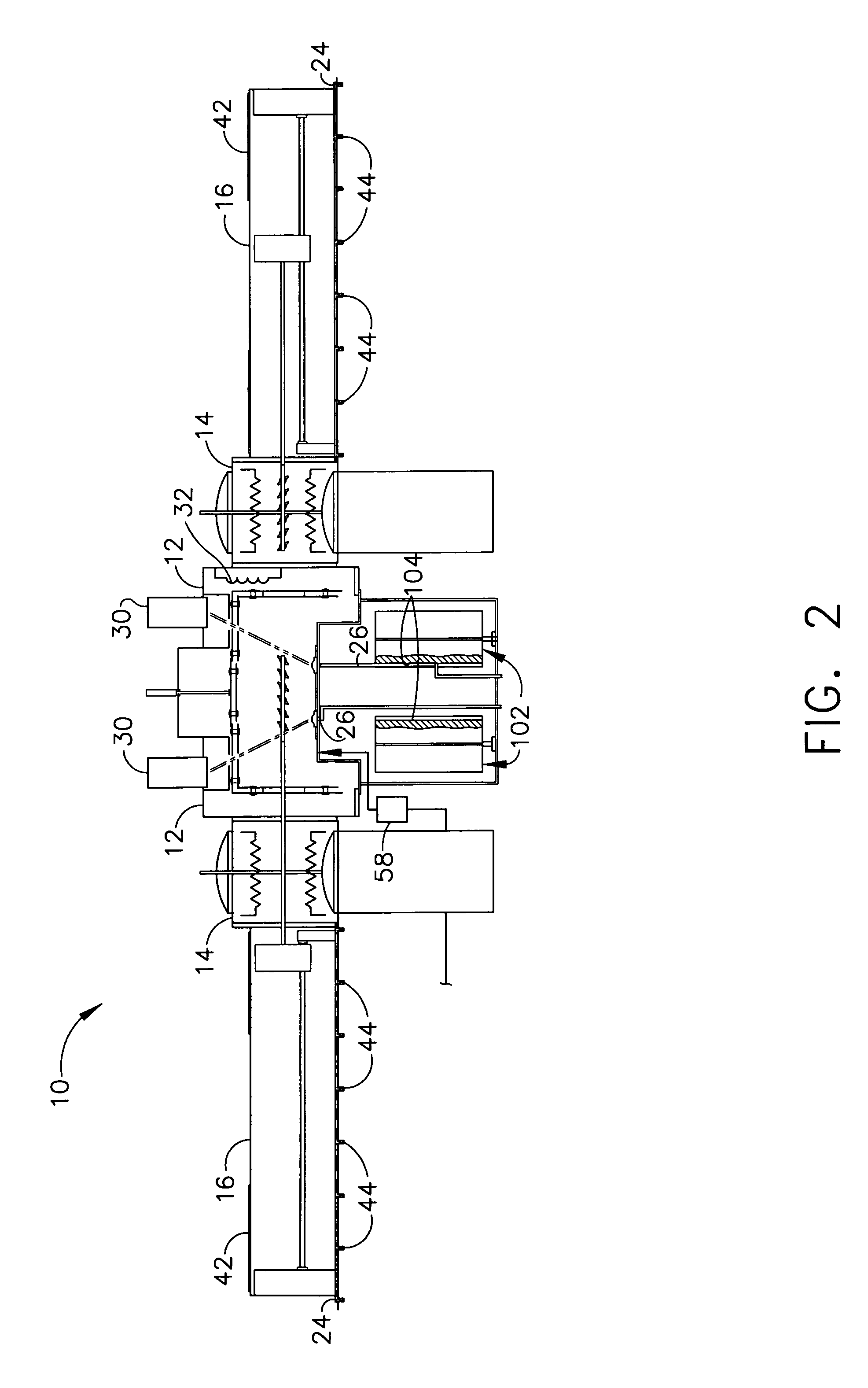

Electron beam physical vapor deposition apparatus

InactiveUS6946034B1Increase or decreaseEasy to operateElectric discharge tubesVacuum evaporation coatingElectron beam physical vapor depositionThermal barrier coating

An electron beam physical vapor deposition (EBPVD) apparatus for producing a coating material (e.g., a ceramic thermal barrier coating) on an article. The EBPVD apparatus generally includes a coating chamber that is operable at elevated temperatures and subatmospheric pressures. An electron beam gun projects an electron beam into the coating chamber through an aperture in a wall of the chamber and onto a coating material within a coating region defined within the chamber, causing the coating material to melt and evaporate. An article is supported within the coating chamber so that vapors of the coating material deposit on the article. The operation of the EBPVD apparatus is enhanced by the inclusion within the coating chamber of a second chamber that encloses the aperture so as to separate the aperture from the coating region. The second chamber is maintained at a pressure lower than the coating region.

Owner:GENERAL ELECTRIC CO

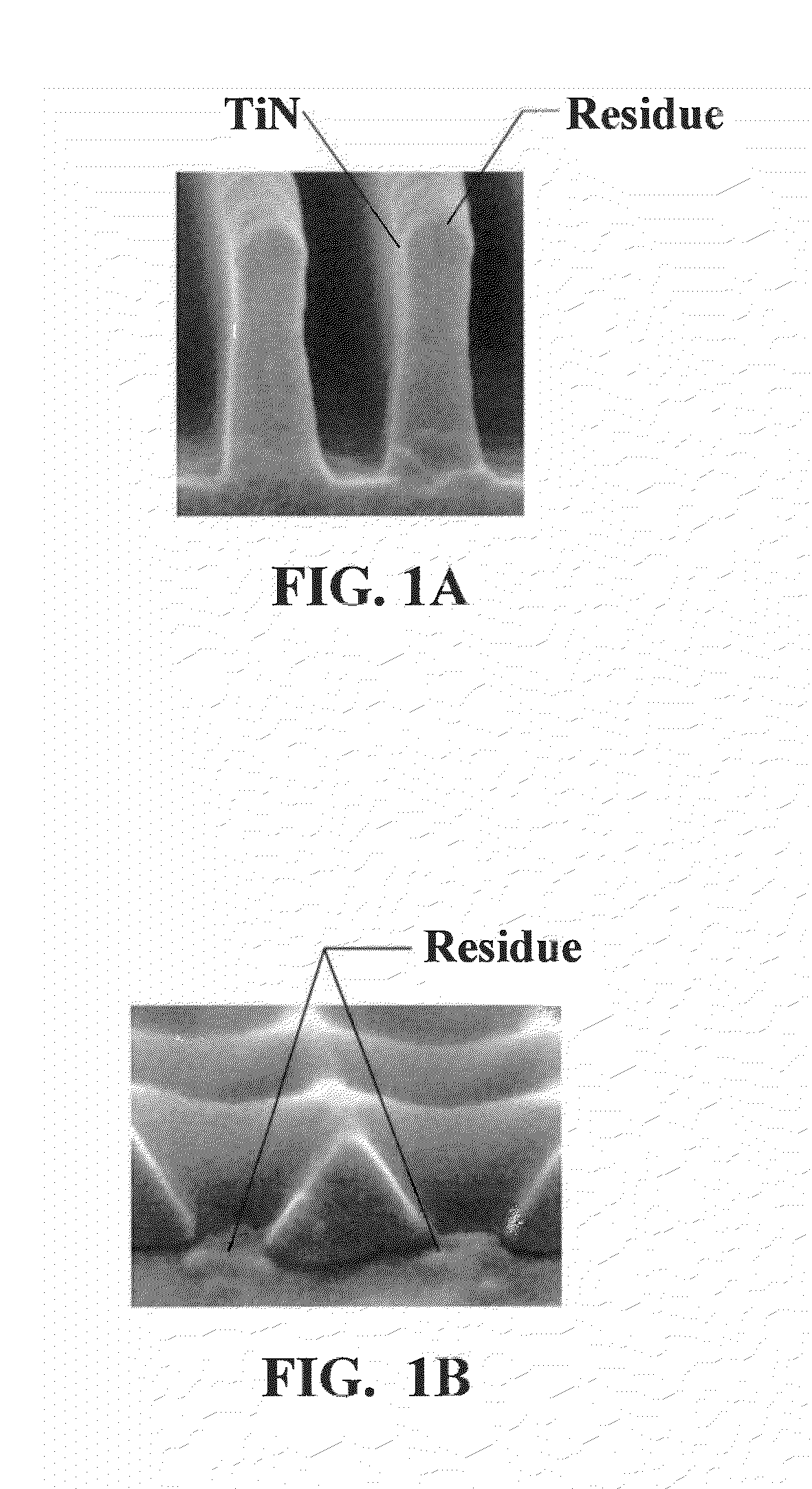

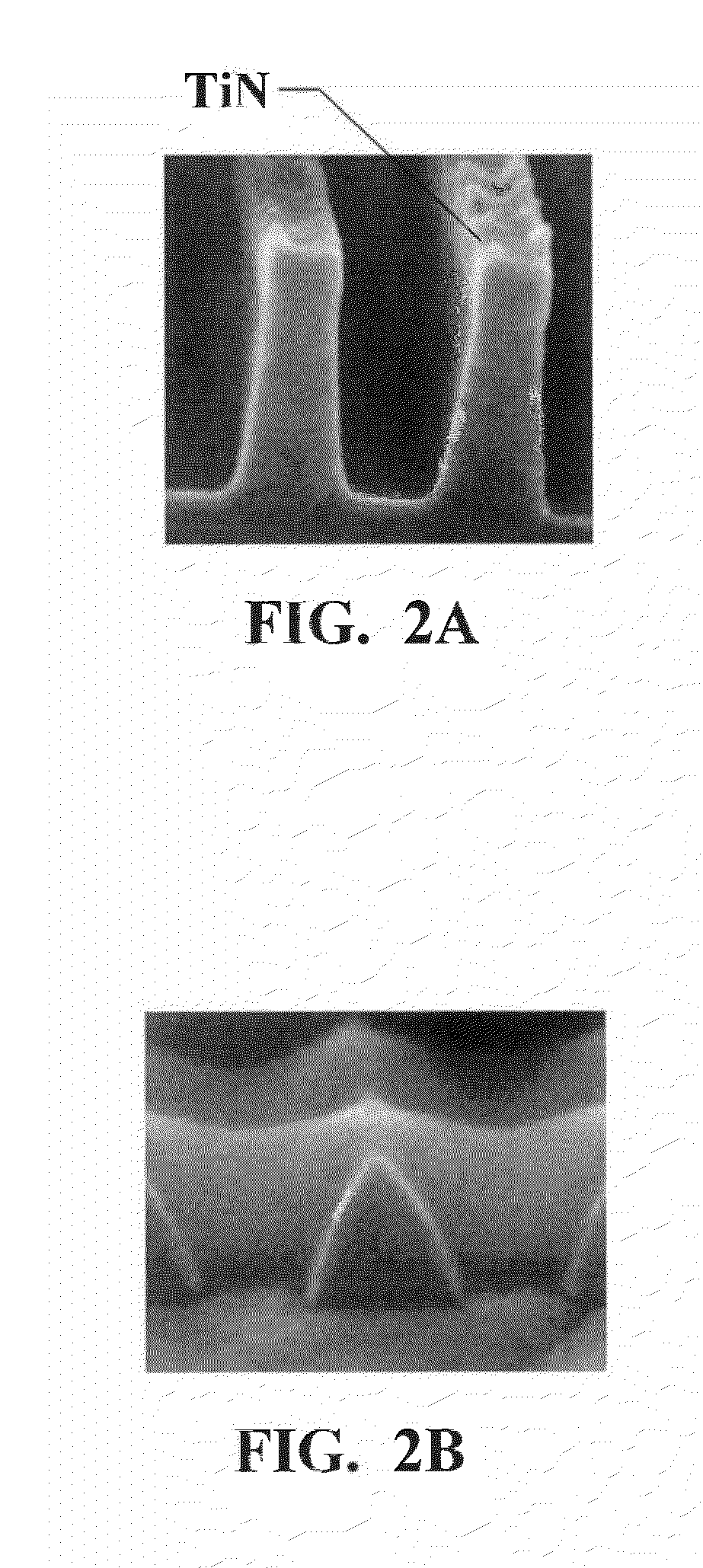

Method and composition for selectively removing metal hardmask and other residues from semiconductor device substrates comprising low-k dielectric material and copper

InactiveUS20150104952A1Increase etch rateReduced oxidizer decomposition rateDetergent mixture composition preparationSemiconductor/solid-state device manufacturingCarboxylic acidAlloy

An aqueous removal composition having a pH in the range of from 2 to 14 and method for selectively removing an etching mask consisting essentially of TiN, TaN, TiNxOy, TiW, W, or alloy of Ti or W relative to low-k materials from a semiconductor substrate comprising said low-k materials having a TiN, TaN, TiNxOy, TiW, W, or alloy of Ti or W etching mask thereon wherein the removal composition comprises at least one oxidizing agent and a carboxylate compound.

Owner:EKC TECH

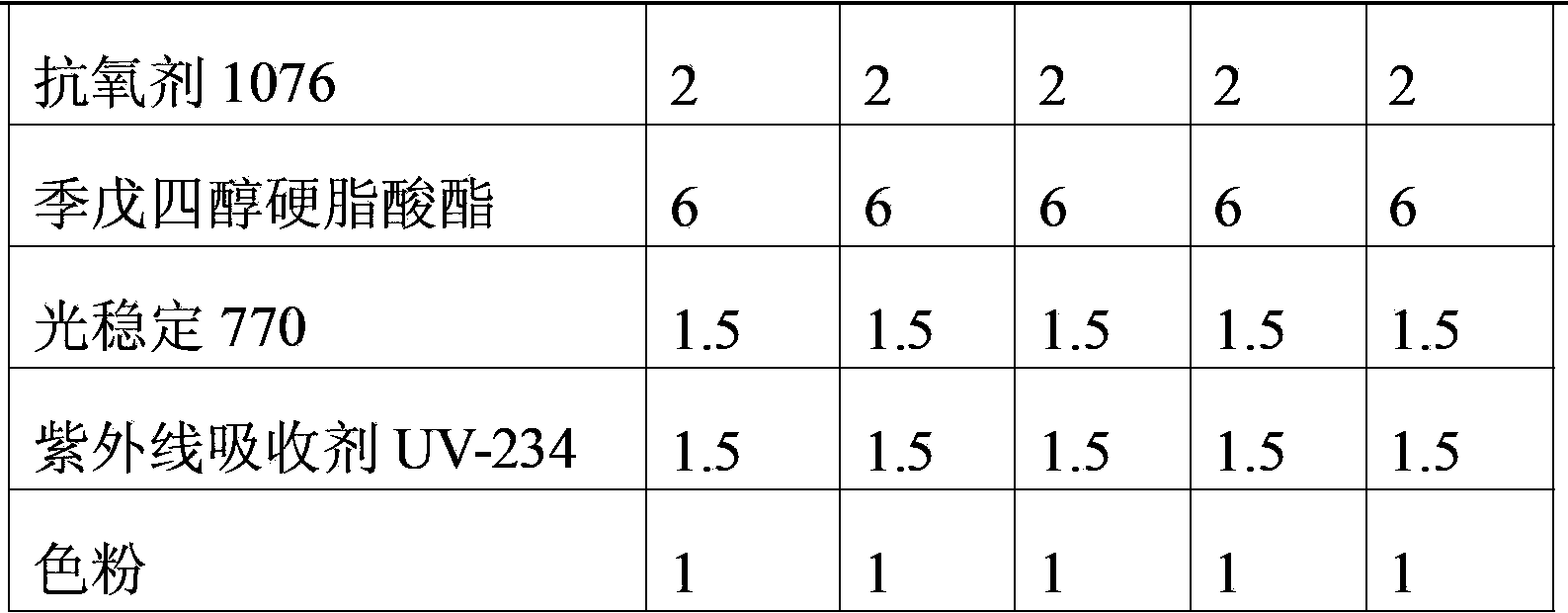

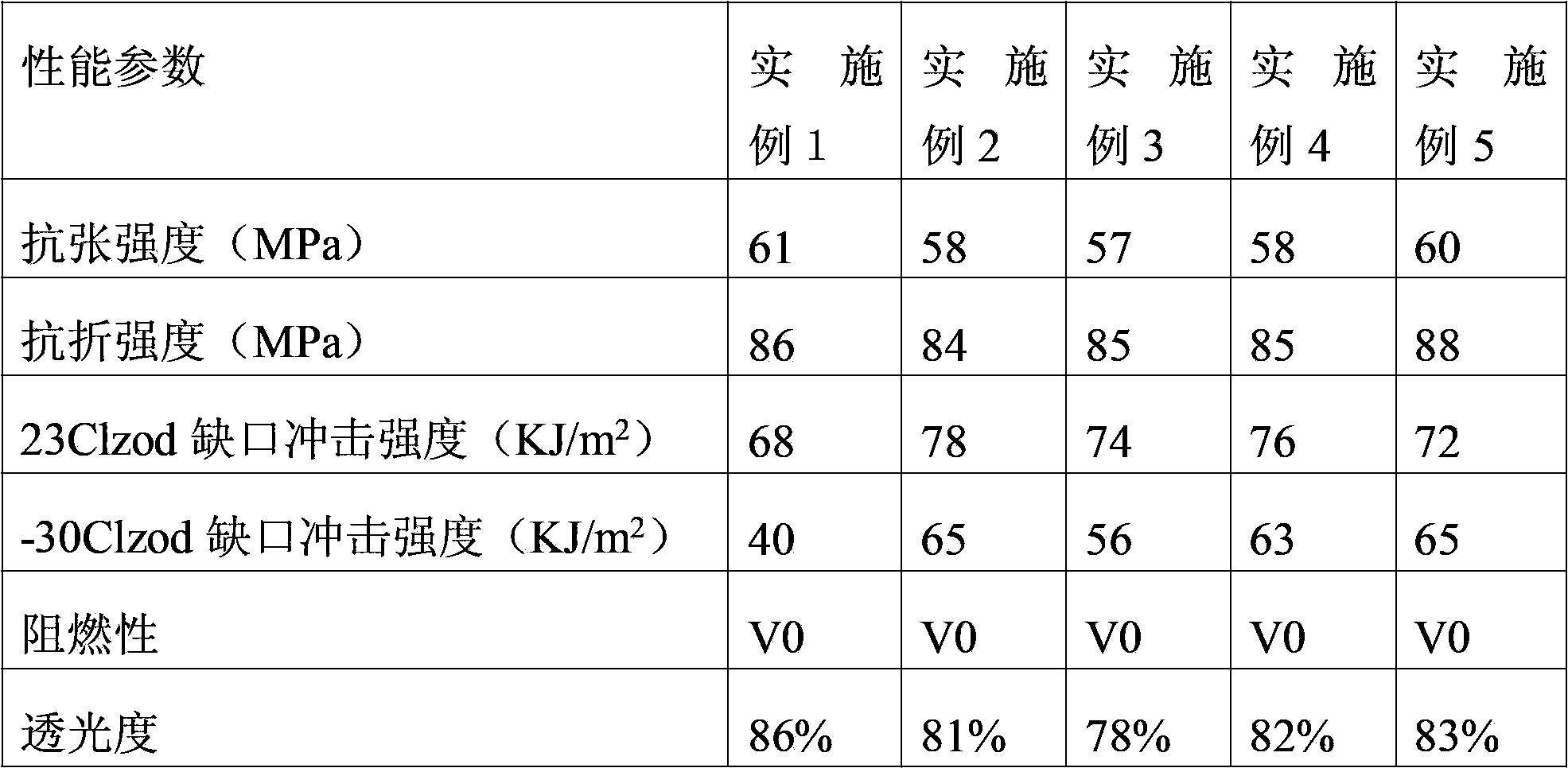

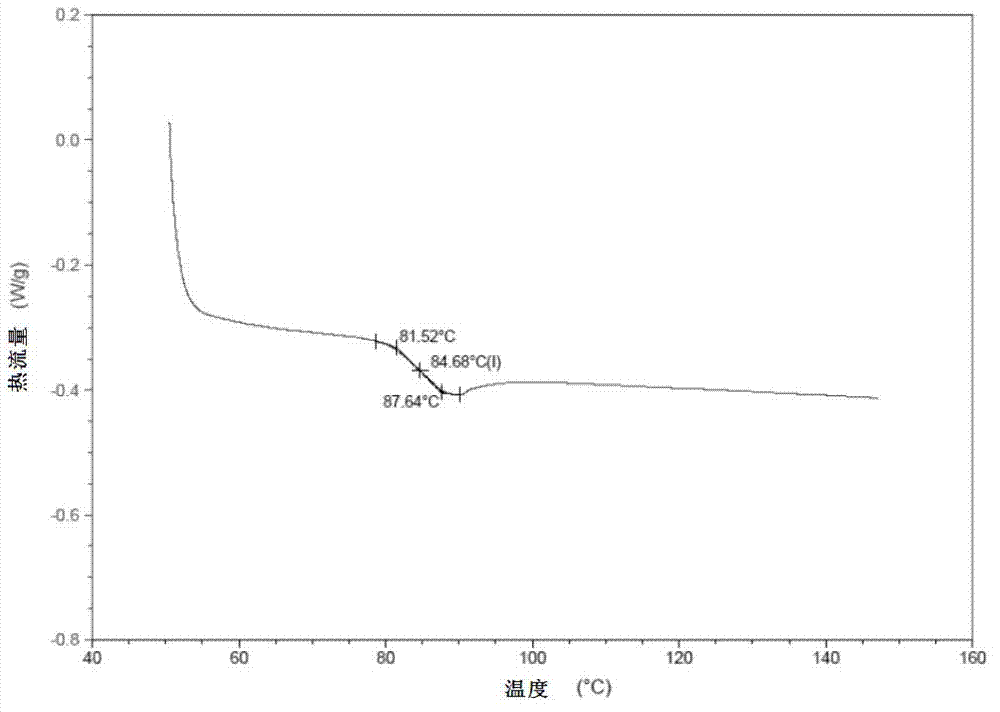

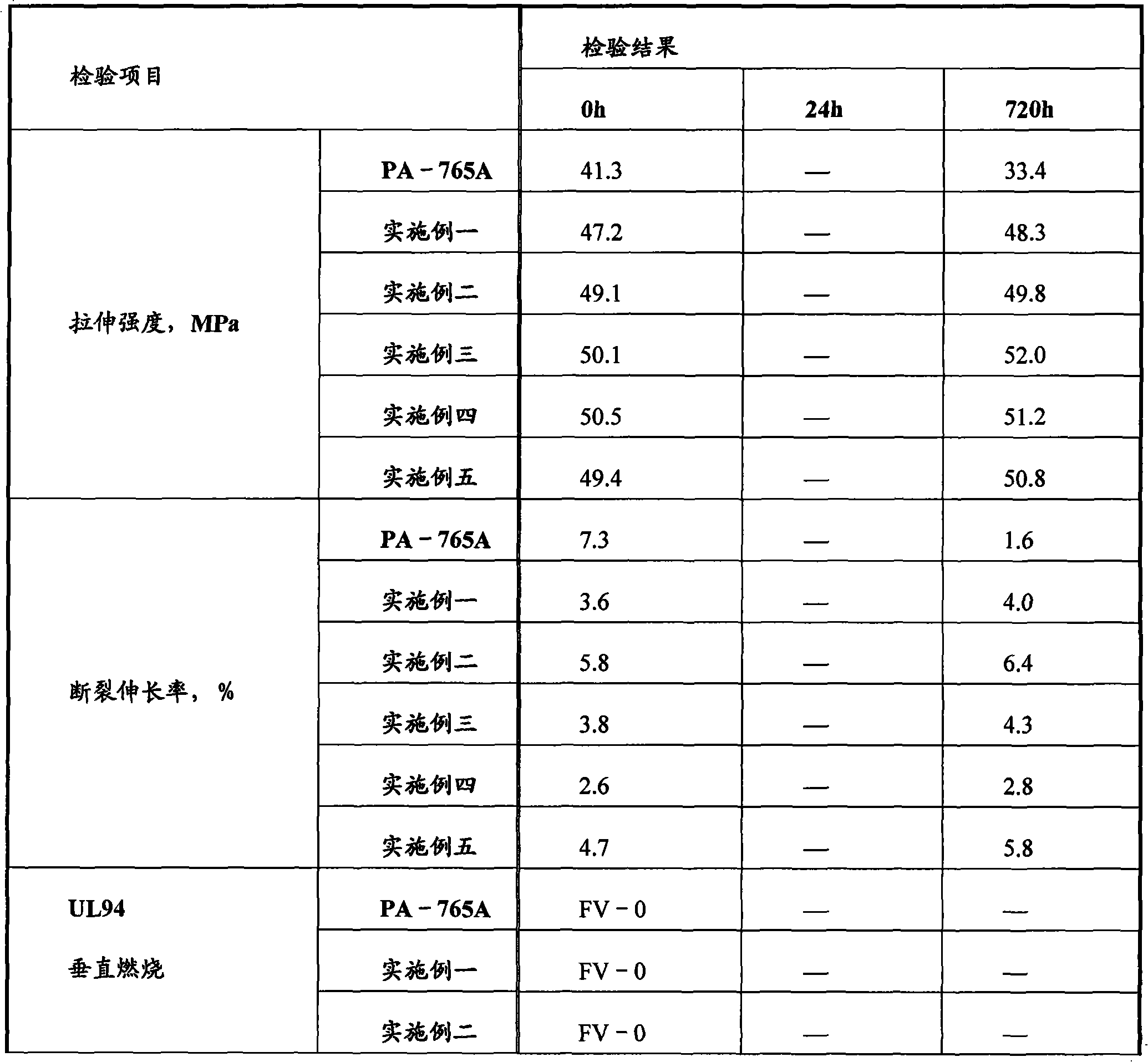

High-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and preparation method thereof

ActiveCN103788610AImprove low temperature impact resistanceEnhance and improve low temperature impact resistanceMold fillingPotassium

The invention discloses a high-transparency low-temperature-impact-resistant flame-retardant polycarbonate composite material and a preparation method thereof. The composite material comprises following components by weight: 700-850 parts of polycarbonate resin, 100-250 parts of organosilicone co-polymer PC, 0-30 parts of a low-temperature-impact modifying agent and 10-14 parts of a flame retardant. The low-temperature-impact modifying agent is one of an organosilicone type flexibilizer and an acrylate type flexibilizer or a mixture of the organosilicone type flexibilizer and the acrylate type flexibilizer. The flame retardant is one of or a mixture of several compounds selected from decabromodiphenylethane, poly(bromocarbonate), potassium perfluorobutane sulfonate or diphenylsulfonesulfonate. The organosilicone co-polymer PC is polycarbonate resin obtained by copolymerization of bisphenol A and organosilicone and has a relative molecular weight of 20000-30000. The preparation method of the composite material is also provided. According to the composite material and the preparation method, the low-temperature-impact-resistant performance of the PC resin is largely enhanced, and the composite material has excellent flame retardance and can preserve the high transparency of the material itself. In addition, the material has advantages of easy mold filling, low processing temperature, short processing and forming period, and the like.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

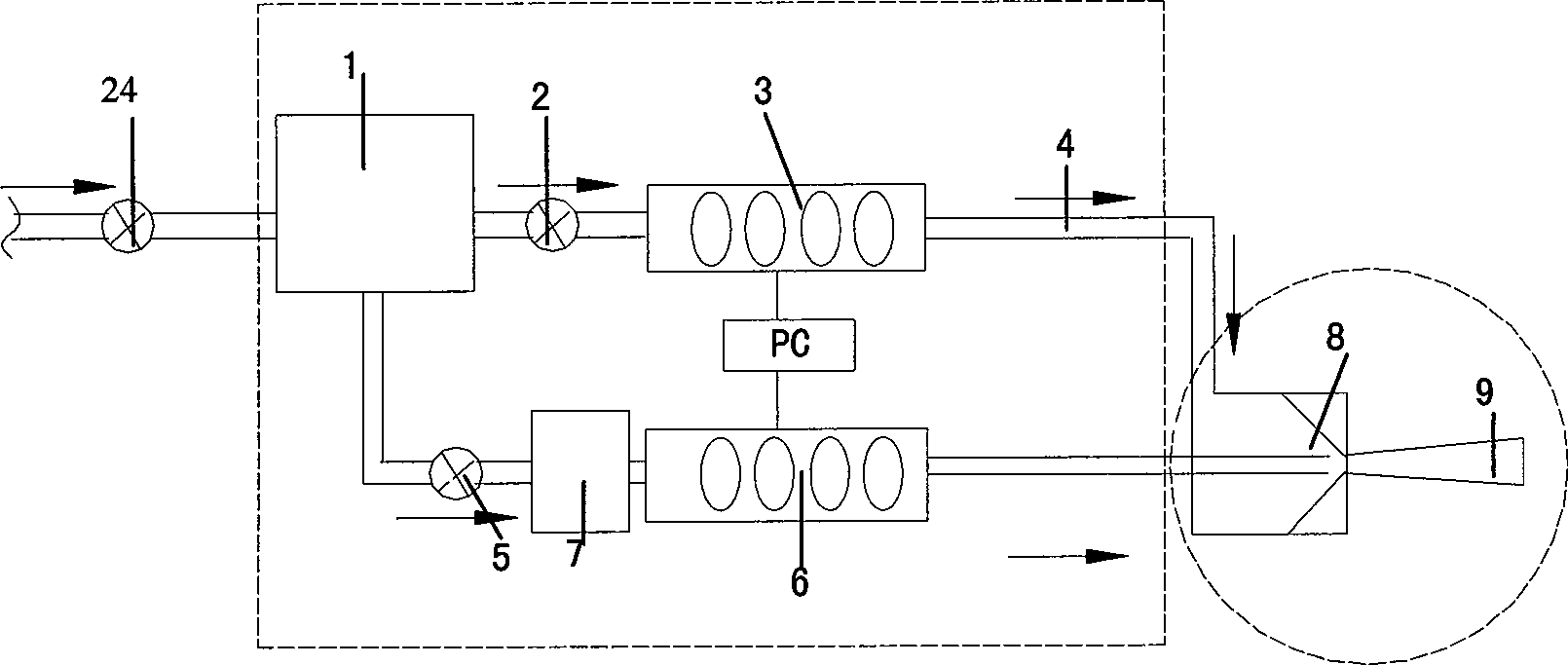

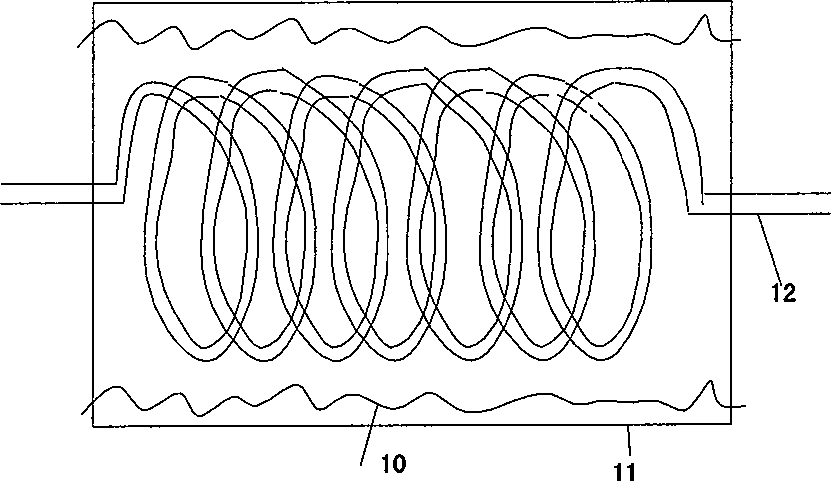

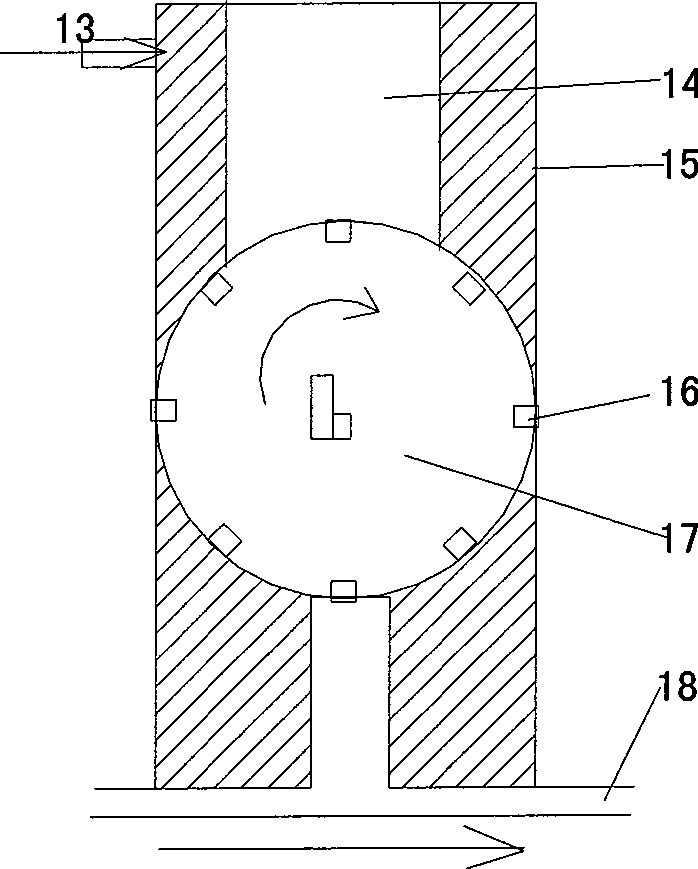

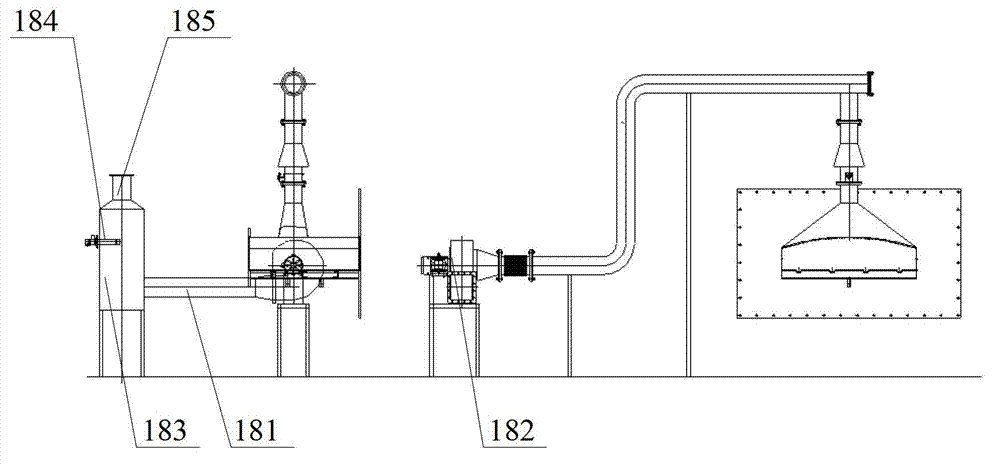

Portable cold-air dynamic spraying device

InactiveCN101422769AIncrease process temperatureReduce carrier gas pressureLiquid surface applicatorsHeat inorganic powder coatingCold airMixing chamber

The invention relates to a device for carrying out antiseptic treatment to a material surface, in particular to a portable cold-gas-powered spraying device which adopts cold gas power to spray metal antiseptic coating. A plant gas source is connected by an adjusting valve and divided into two paths by a gas controlling and dividing unit in a tee manner; one path of the gas enters a gas heater through a main gas flow and pressure control valve, and the gas enters a gas-powder mixing chamber through a flexible metal pipe after being preheated; and the other path of the gas enters a scraper type powder supplier through the main gas flow and pressure control valve to control the amount of powder supplied in a powder heater, and then enters a nozzle through the flexible metal pipe. The surface coating deposition is realized after the speed-up of the gas and the powder. The device has compact structure and reliable principle and is easy to be carried and used, the deposition efficiency is high, the utilization rate of the gas and the powder is good, and the coating cost is low.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

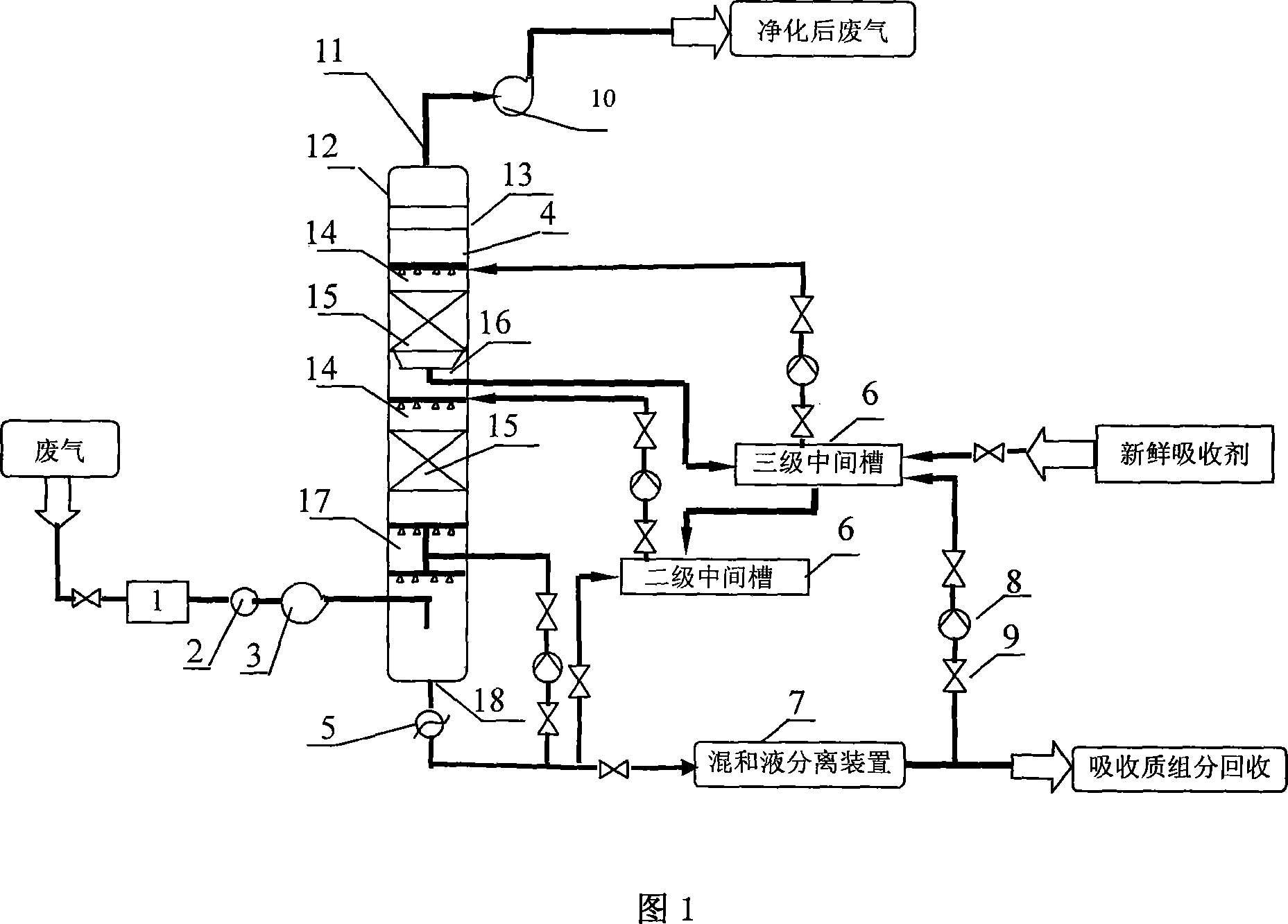

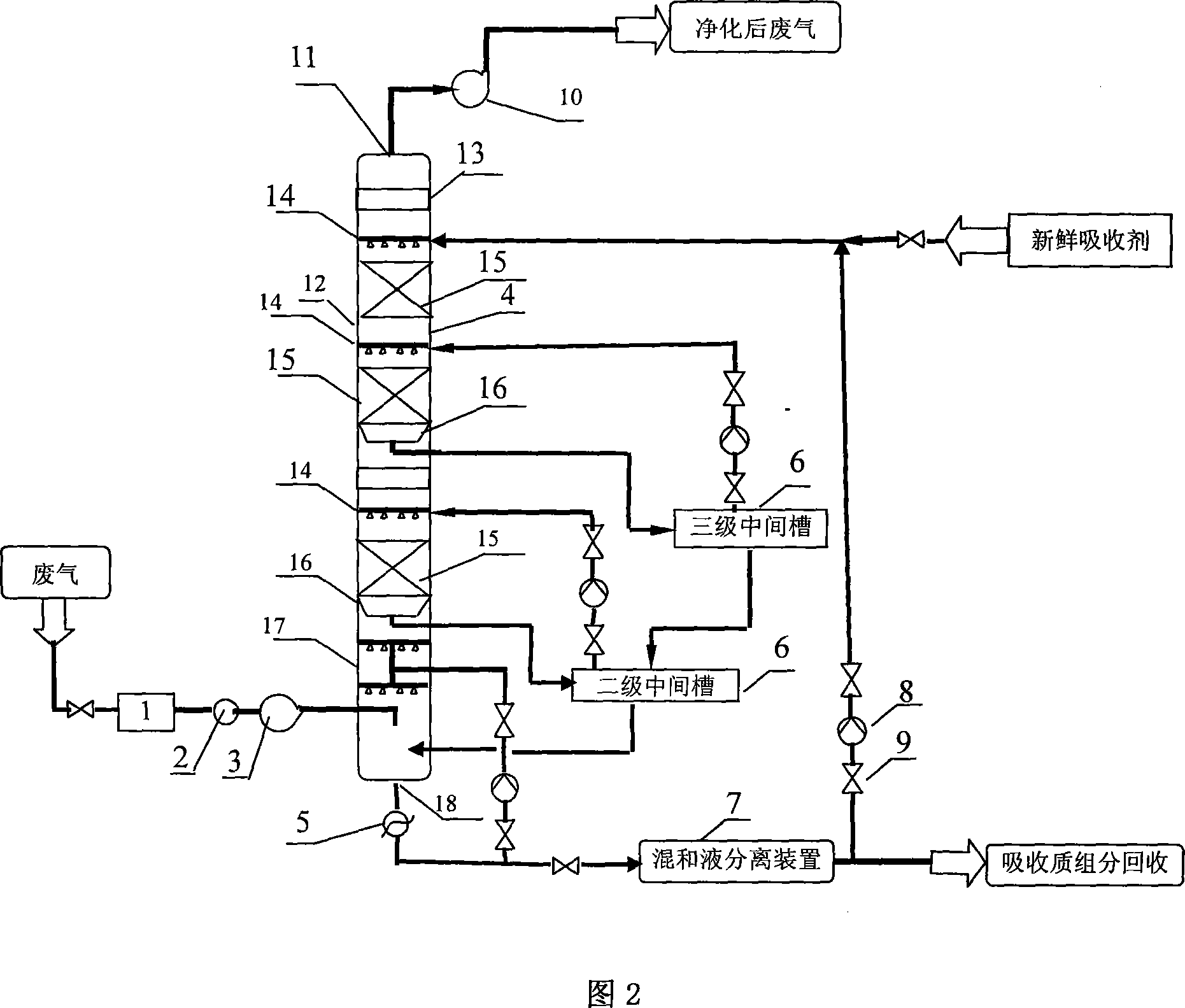

Process method of purifying and recycling mixed organic waste gas

InactiveCN101108296APromote absorptionHigh flash pointDispersed particle separationChemical industryOrganic solvent

The invention belongs to chemical industry and waste gas process field, in particular providing a process method which mixes organic waste gas purifying and resource recovery. The specific procedure is that: make the mixed waste gas pass through a filter to be filtered, and then enters into a single-seat multilevel absorption tower and contacts with a packing layer and a liquid distribution device; when the series of the single-seat tower is 3, the second-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising the mixing liquid which is pumped in after cooled by a heat interchanger at the bottom of the adsorption tower and the mixing liquid which generates in the middle groove of the third-grade; the third-grade liquid distribution device adopts a kind of absorbent which is a mixing liquid comprising fresh absorbent, the regenerating liquid recycled by a mixing liquid separation device and the collecting liquid collected by a collecting hopper of third-grade; when the series of the single-seat tower is N and is larger than 3, all grades of absorbent from the second grade to the N minus 2 is a mixing liquid comprising a mixing liquid generated in the middle groove of the next grade and a collecting liquid collected by the collecting hopper on the same grade, the absorbent of the N minus grade is the colleting liquid collected by the collecting hopper of the N minus 1 grade, the absorbent of the N grade is a mixing liquid comprising of pumped fresh absorbent and the regenerating liquid recycled by the mixing liquid separation device. The fresh absorbent is an environment-protected organic solvent with high boiling point, strong lipophilicity and low volatility. The invention can recycle a plurality of organic infectant in waste gas, the technics procedure is simple, practical, and the operation cost is low.

Owner:上海同济华康环境科技有限公司

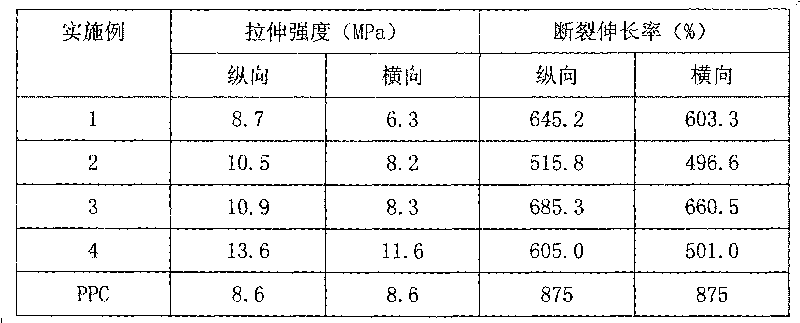

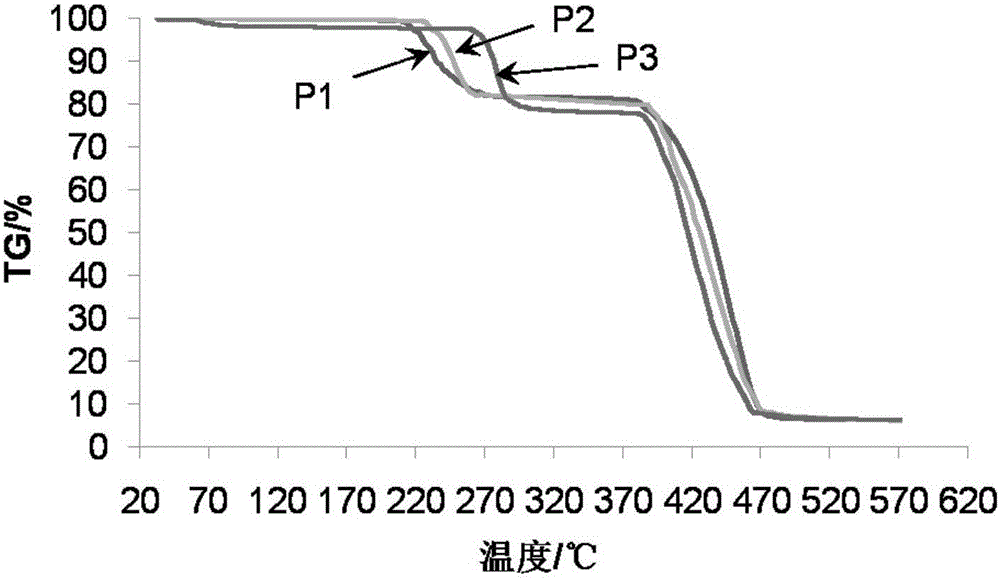

Method for preparing flexible biodegradable polytrimethylene carbonate composite film

ActiveCN101717567AImprove brittlenessImprove low temperature viscous flow problemComposite filmPolymer science

The invention discloses a flexible biodegradable polytrimethylene carbonate composite film and a preparation method thereof. The composite film is formed by blowing a film after melting and mixing polytrimethylene carbonate, thermoplastic polyurethane elastomers, a bulking agent, antioxygen, a heat resistant stabilizing agent, a slipping agent, an antiblocking agent, a filling agent, a biodegradation accelerating agent and a light decomposition agent. In the invention, PPC and elastomers TPU are effectively compounded, thereby solving the problems of brittleness and low-temperature viscous flow of materials; the processing temperature of unsealed PPC is expanded to 170 DEG C, and the thermal degradation temperature is improved to 210 DEG C. Meanwhile, the composite film has good mechanical property and film blowing stability, can be applied to the fields of soft film materials, such as disposable shopping bags, land films, preservative films, and the like, and opens a new approach for the popularization and the application of PPC.

Owner:CHINA NAT OFFSHORE OIL CORP +3

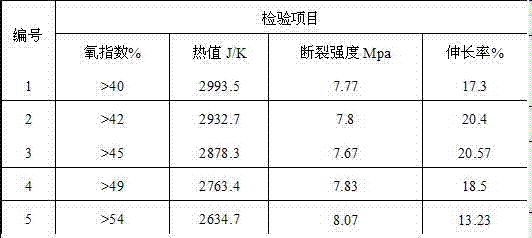

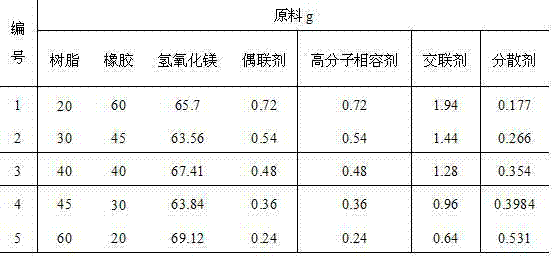

Material special for level-A fire-proof aluminum-plastic board core and preparation method thereof

The invention relates to an aluminum-plastic compound board sandwich layer material, in particular to a material special for a level-A fire-proof aluminum-plastic board core and a preparation method thereof. An inorganic flame retardant, i.e., magnesium hydroxide is taken as a flame retardant, and a high filling technology is adopted. Aids such as a coupling agent, a dispersing agent, a high-molecular compatilizer and the like are used for performing modification pretreatment on magnesium hydrate, so that the magnesium hydrate flame retardant has superior performance, the filling amount of the flame retardant in a substrate is up to 80-90 percent by weight, which is much higher than the adding amount of a flame retardant of the same type of products, the oxygen index of the product is remarkably increased in comparison to that of the same type of products, and the flame-retarding environmental protection performance is improved remarkably. An aluminum-plastic board core material prepared by adopting the method has the characteristics of freeness from halogen, low thermal value, low smoke, flame retardance, drop resistance, nontoxicity and freeness from pollution.

Owner:大连亚泰科技新材料股份有限公司

Biodegradable film containing aliphatic polycarbonate and preparation method thereof

InactiveCN101857718ABiodegradableRaise the processing temperatureFlat articlesPolymer scienceButanedioic acid

The invention, which belongs to the technical field of biodegradable films, relates to a biodegradable film containing aliphatic polycarbonate. The biodegradable film is characterized in that the biodegradable film consists of the following components in part by weight: 30 to 60 parts of polycarbonate1, 2-malonic ester; 40 to 70 parts of one or the mixture of poly(butanediol succinate) and poly(butanediol succinate / adipate) copolyester; 5 to 15 parts of toughening agent; 0.5 to 5 parts of plasticizer; 0.5 to 3 parts of heat stabilizer; and 1 to 40 parts of inorganic filler. The prepared film is biodegradable, and can be directly contacted with food. By adding the heat stabilizer, the thermolysis of bend is inhibited, so that the processing temperature of the film can be increased to 190 DEG C; by adding the toughening agent and the plasticizer, the impact resistance of the finished film product is enhanced, the maximum dart drop impact on the film with the thickness of 20Mum can be up to 130g, the tensile strength is higher than 50MPa, the elongation at break is higher than 600 percent, and therefore the film can fully meet the requirements of ordinary packaging materials.

Owner:NANTONG HUASHENG PLASTIC PRODS +1

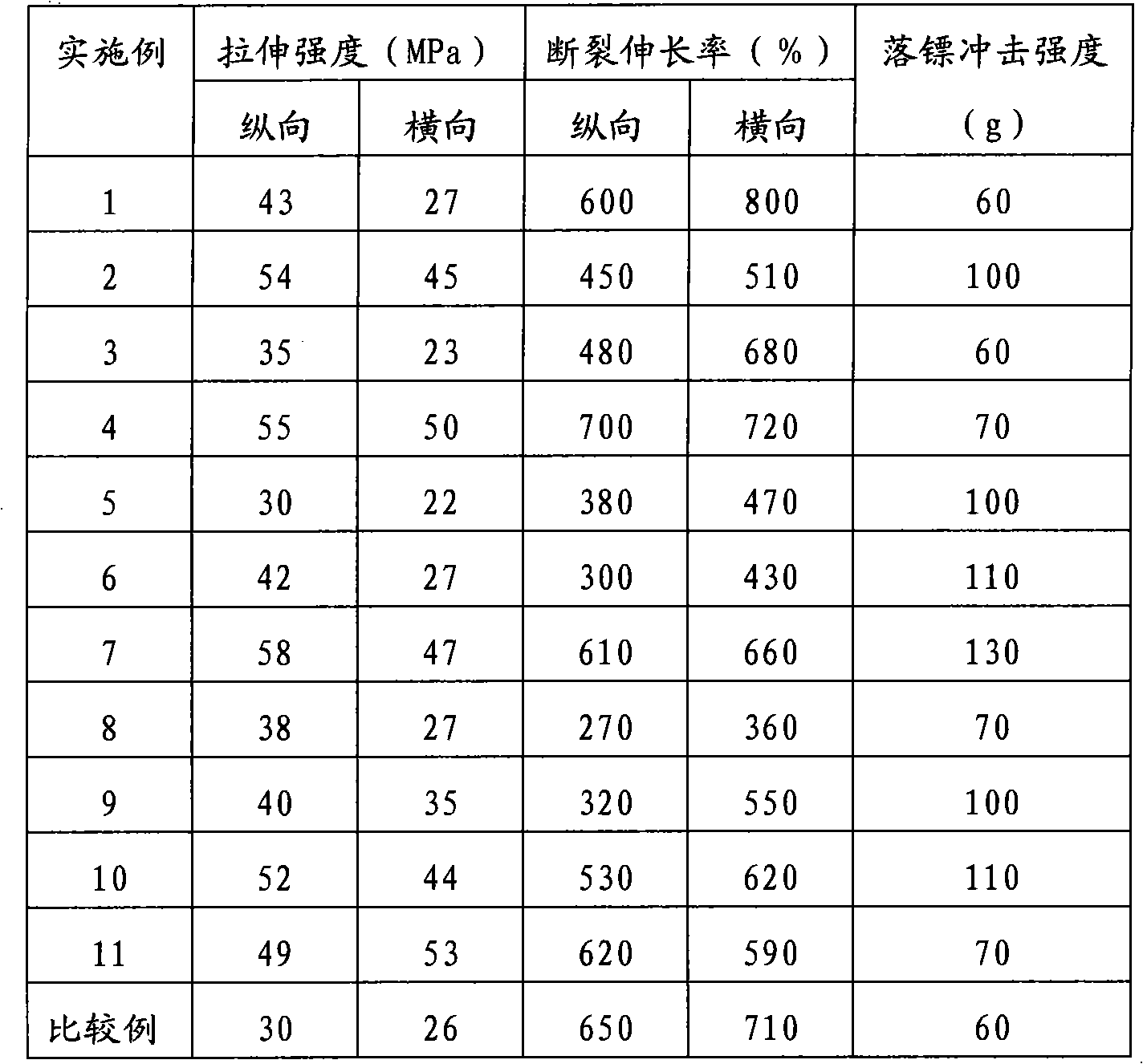

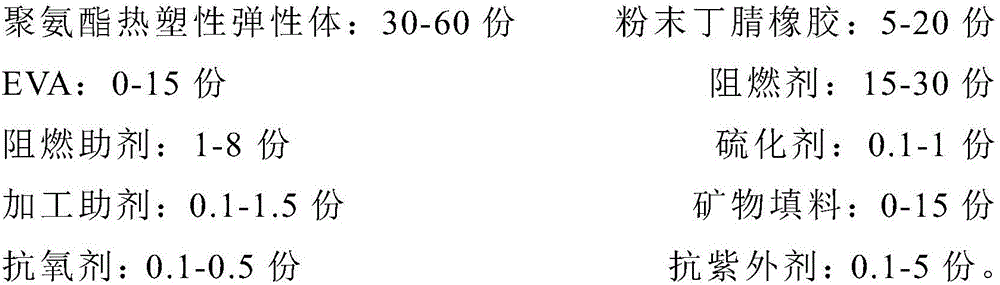

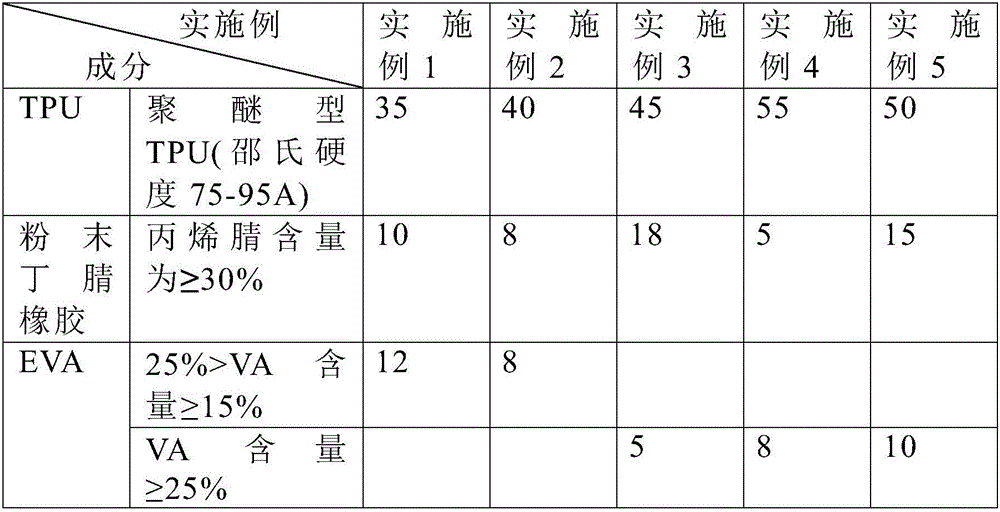

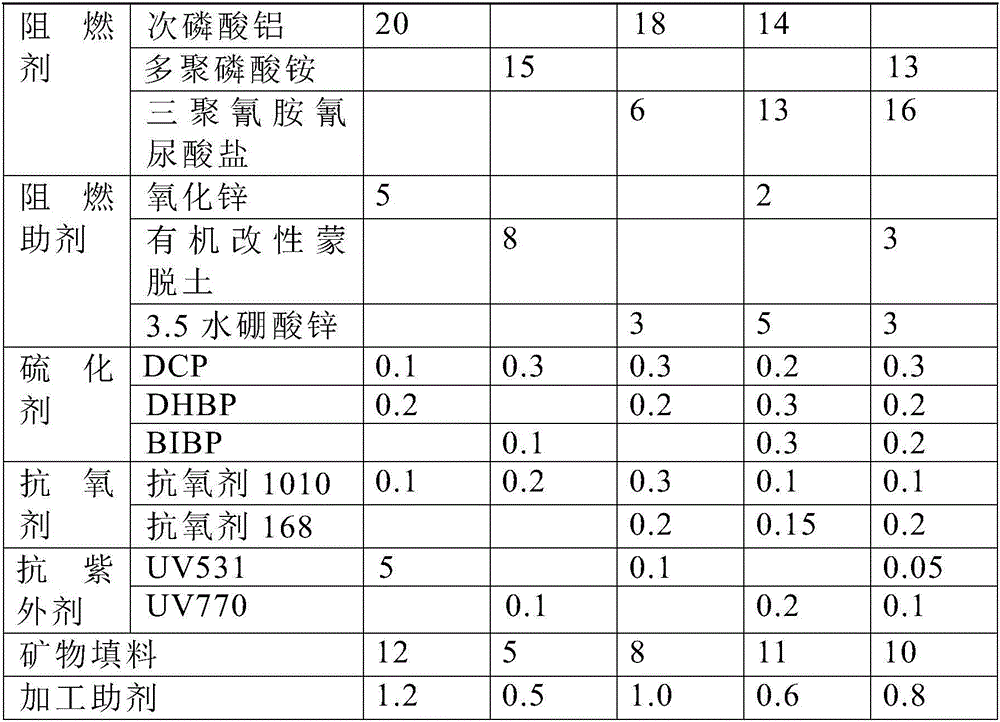

High-oil-resistance charging-pile halogen-free flame-retardant TPU (thermal receiver unit) cable material and preparation method thereof

InactiveCN106349685AGood oil resistanceRaise the processing temperaturePlastic/resin/waxes insulatorsClimate change adaptationProcedure AgentsPolymer science

The invention relates to a high-oil-resistance charging-pile halogen-free flame-retardant (thermal receiver unit) cable material and preparation method thereof and belongs to the technical field high polymer materials. The high-oil-resistance charging-pile halogen-free flame-retardant cable material comprises raw materials including, by weight, 30-60 parts of thermoplastic polyurethane elastomers, 5-20 parts of powdered acrylonitrile-butadiene rubber, 0-15 parts of EVA (ethyleno vinyl acetale copolymetr), 15-30 parts of flame retardant, 1-8 parts of a flame retardant agent, 0.1-1 part of a vulcanizing agent, 0.1-1.5 parts of a processing agent, 0-15 parts of mineral fillers, 0.1-0.5 part of antioxygen and 0.1-5 of parts an ultraviolet screening agent. The invention further discloses the preparation method of the TPU cable material. The rational compatibility of components of the thermoplastic polyurethane elastomers, powdered acrylonitrile-butadiene rubber, the fire retardant and the like is achieved for the TPU cable material, oil resistance, processing performance and flame retardant property are effectively improved, and the material is good in hydrolysis resistance and ageing resistance and conforms to operation requirements of charging-pile cables.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

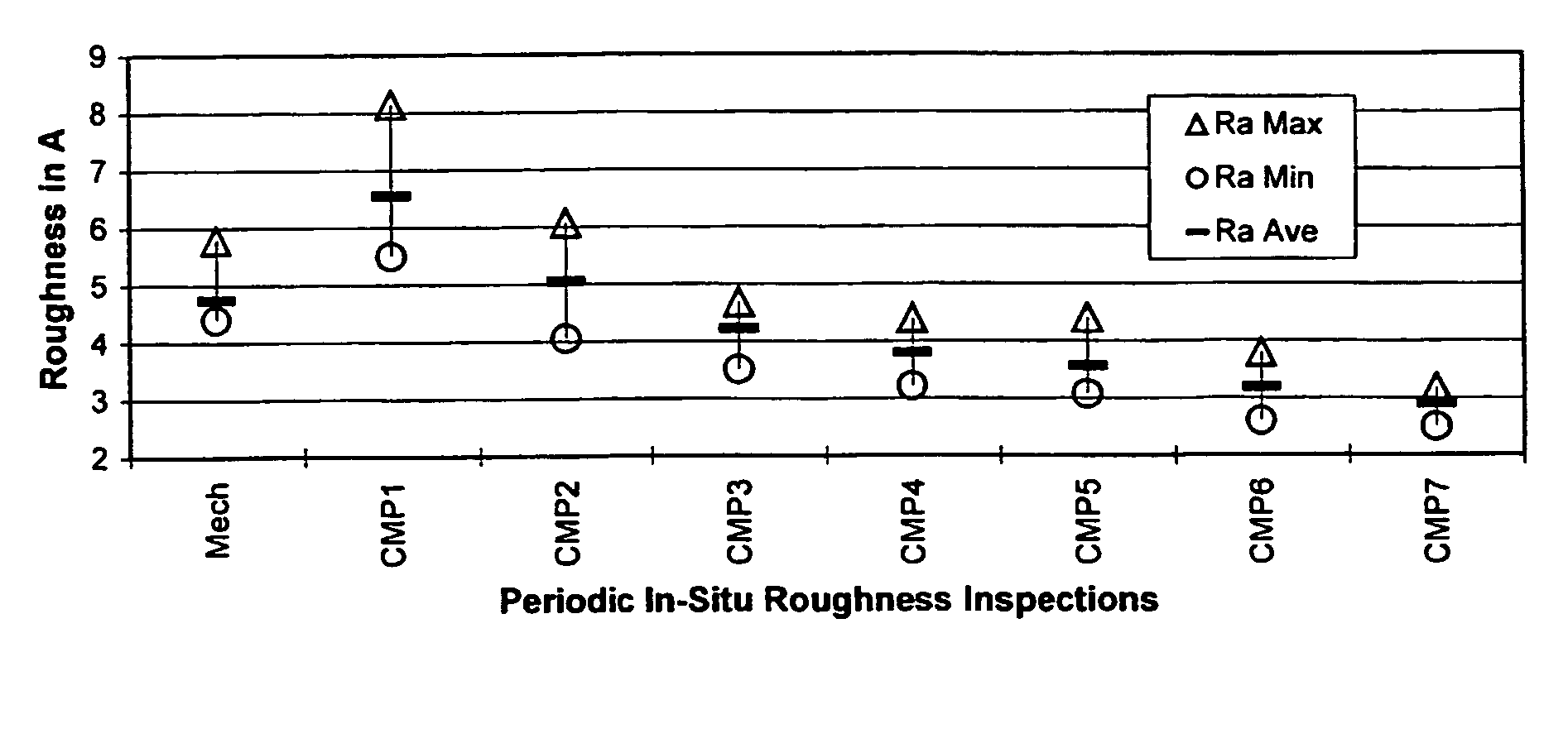

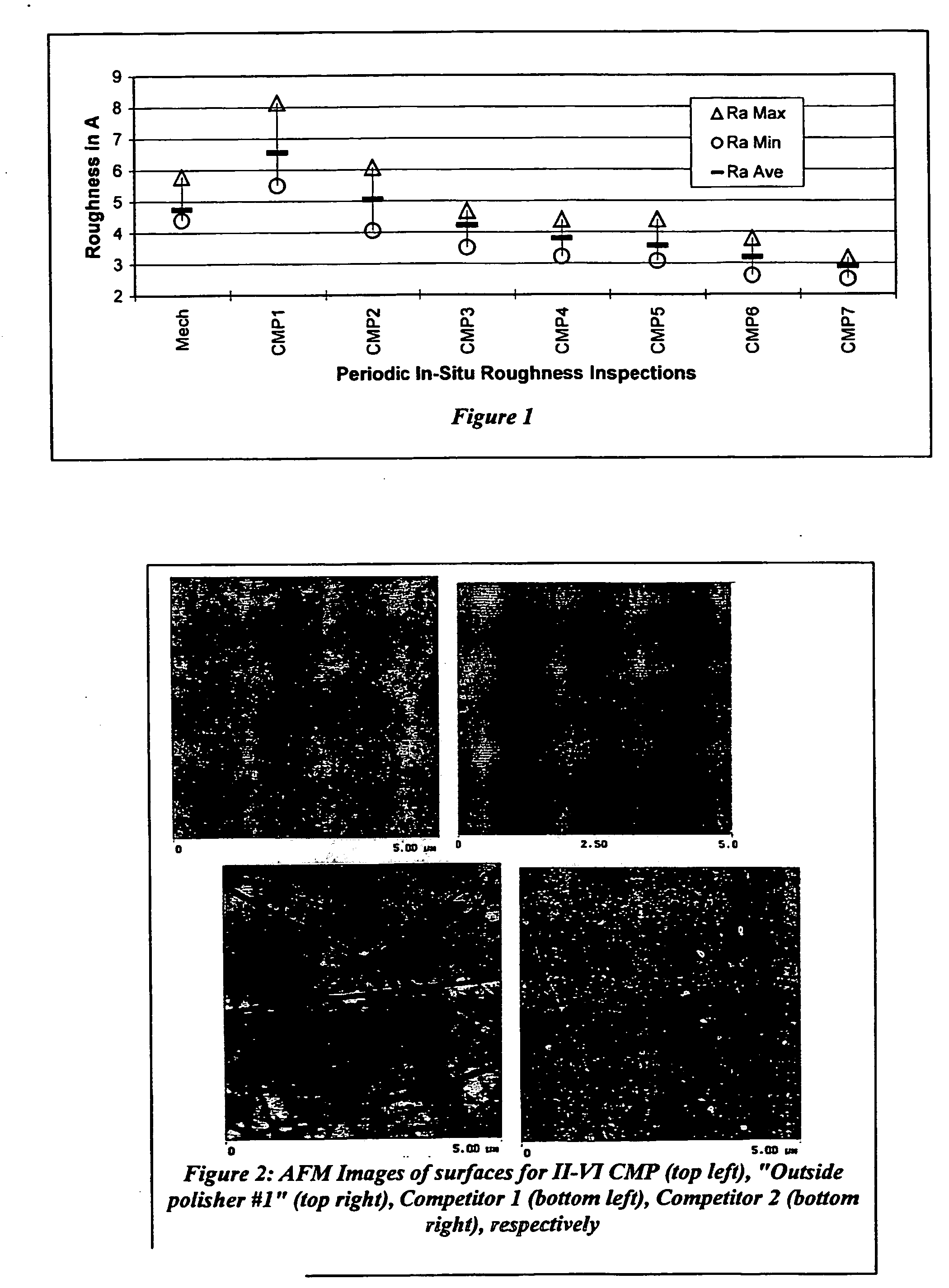

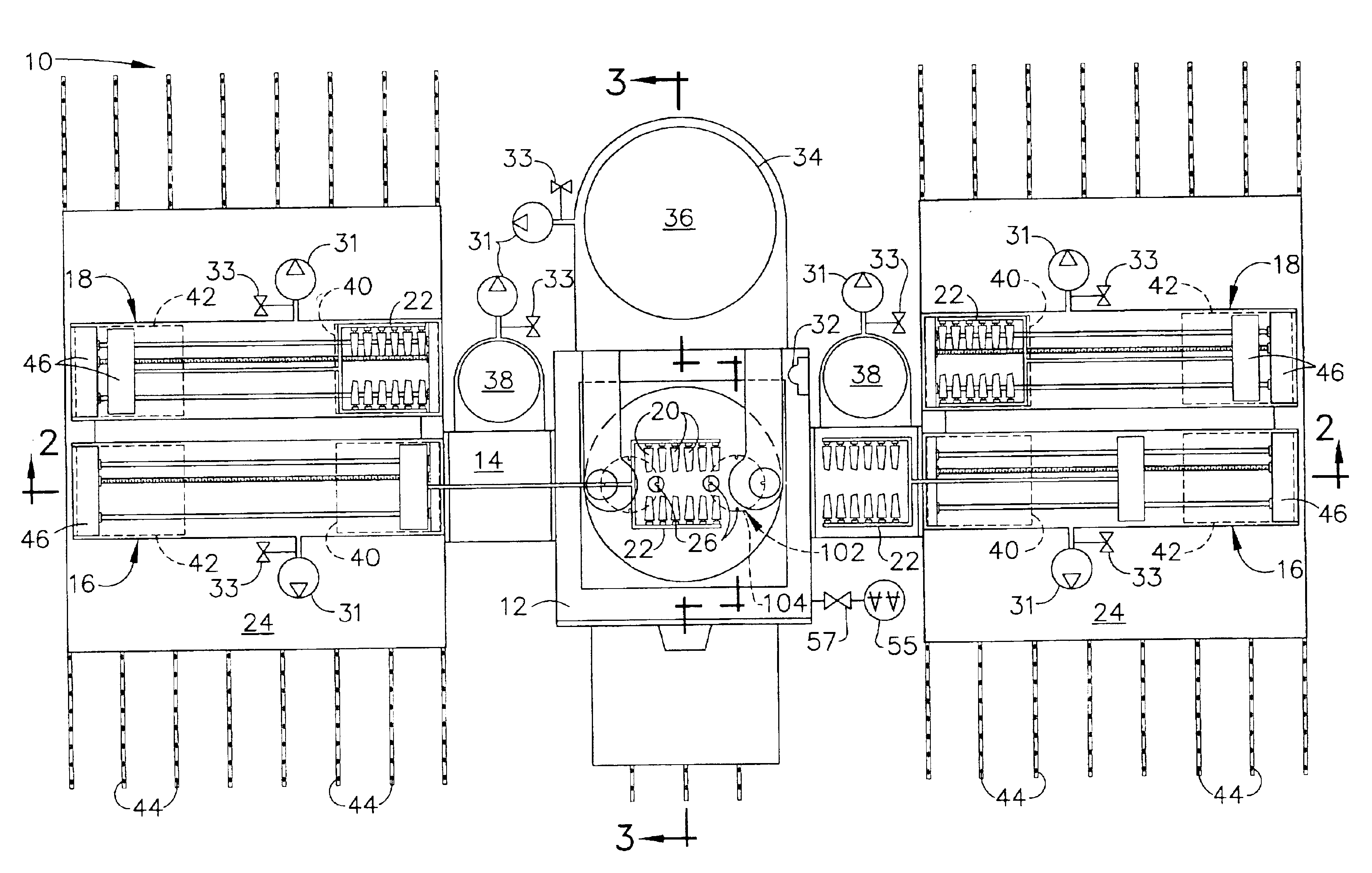

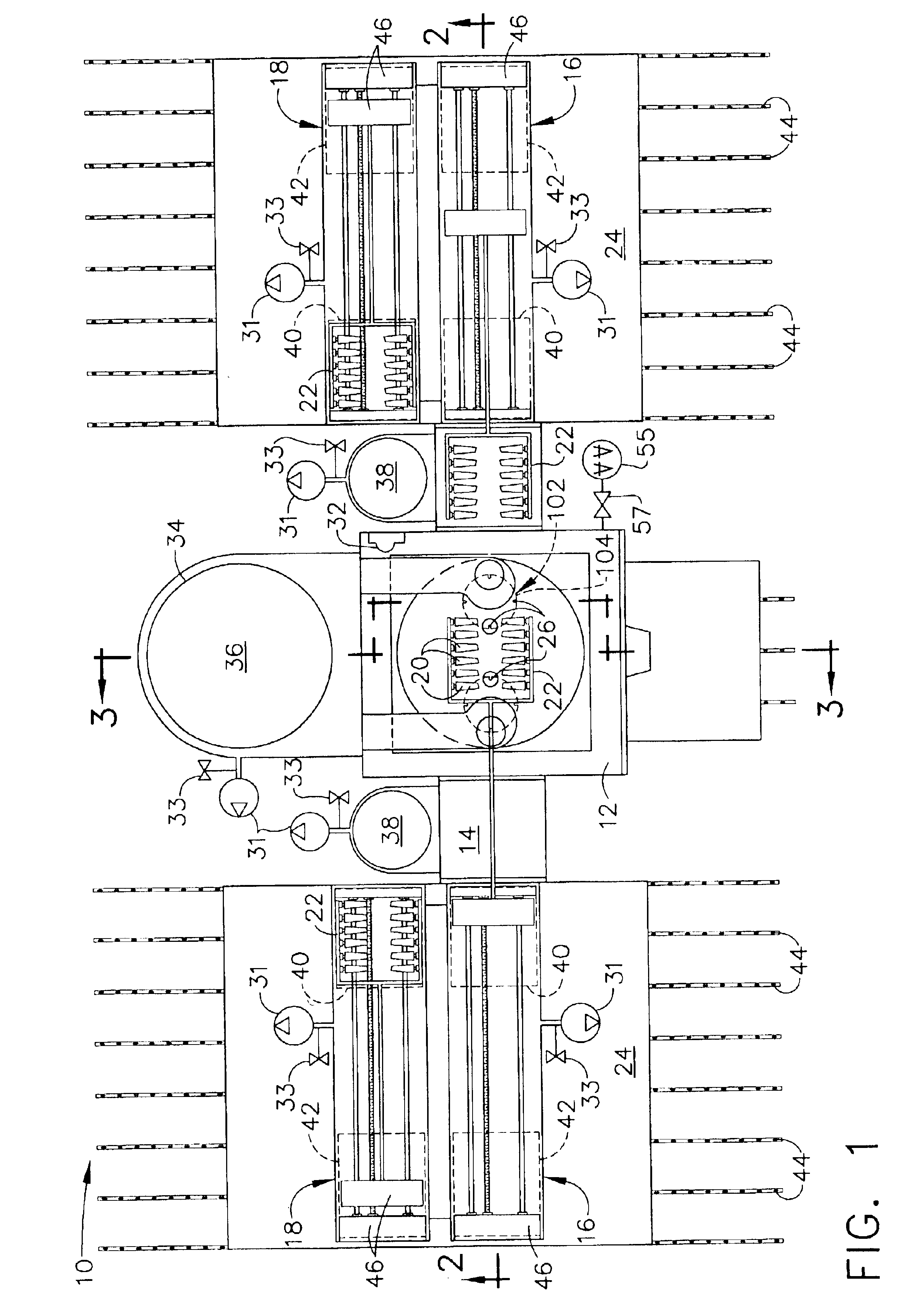

Chemical-Mechanical Polishing of Sic Surfaces Using Hydrogen Peroxide or Ozonated Water Solutions in Combination with Colloidal Abrasive

InactiveUS20080261401A1Raise the processing temperatureAid removalPolishing machinesSemiconductor/solid-state device manufacturingColloidal silicaControl manner

A process is taught for producing a smooth, damage-free surface on a SiC wafer, suitable for subsequent epitaxial film growth or ion implantation and semiconductor device fabrication. The process uses certain oxygenated solutions in combination with a colloidal abrasive in order to remove material from the wafer surface in a controlled manner. Hydrogen peroxide with or without ozonated water, in combination with colloidal silica or alumina (or alternatively, in combination with HF to affect the oxide removal) is the preferred embodiment of the invention. The invention also provides a means to monitor the sub-surface damage depth and extent since it initially reveals this damage though the higher oxidation rate and the associated higher removal rate.

Owner:II VI

Method of operating an electron beam physical vapor deposition apparatus

InactiveUS6863937B2Increase or decreaseEasy to operateElectric discharge heatingElectric discharge tubesElectron beam physical vapor depositionThermal barrier coating

An electron beam physical vapor deposition (EBPVD) apparatus and a method for using the apparatus to produce a coating material (e.g., a ceramic thermal barrier coating) on an article. The EBPVD apparatus generally includes a coating chamber that is operable at elevated temperatures and subatmospheric pressures. An electron beam gun projects an electron beam into the coating chamber and onto a coating material within the chamber, causing the coating material to melt and evaporate. An article is supported within the coating chamber so that vapors of the coating material deposit on the article. The operation of the EBPVD apparatus is enhanced by the inclusion or adaptation of one or more mechanical and / or process modifications, including those necessary or beneficial when operating the apparatus at coating pressures above 0.010 mbar.

Owner:GENERAL ELECTRIC CO

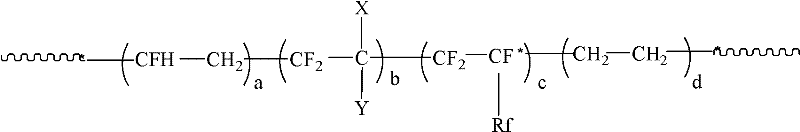

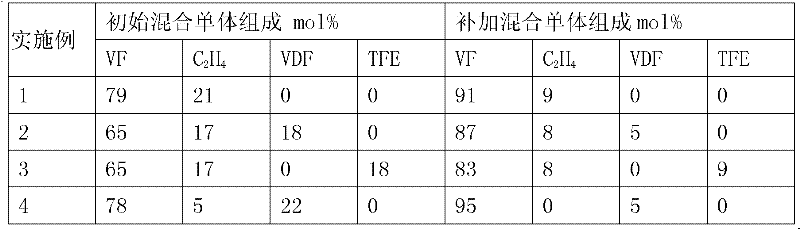

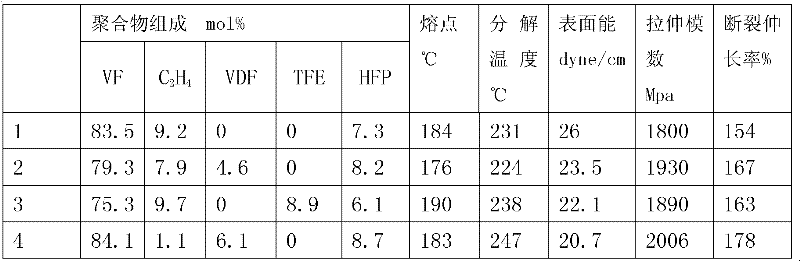

Melt-processable modified polyvinyl fluoride resin and preparation method thereof

The invention relates to a melt-processable modified polyvinyl fluoride (PVF) resin which is polymerized by vinyl fluoride, ethylene, one or more of CF2=CXY and one or more of CF2=CFRf. Reaction monomers are subjected to a copolymerization reaction under the action of an initiating agent in an aqueous phase or an emulsion, reaction temperature ranges from 40 DEG C to 100 DEG C, and reaction pressure ranges from 1 MPa to 10 MPa. According to the melt-processable modified polyvinyl fluoride resin, high-temperature performance of the PVF resin is kept, treatment temperature of the resin is reduced simultaneously, conventional melt processing can be used for processing the resin, and obtained thin-film materials have good combination properties.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

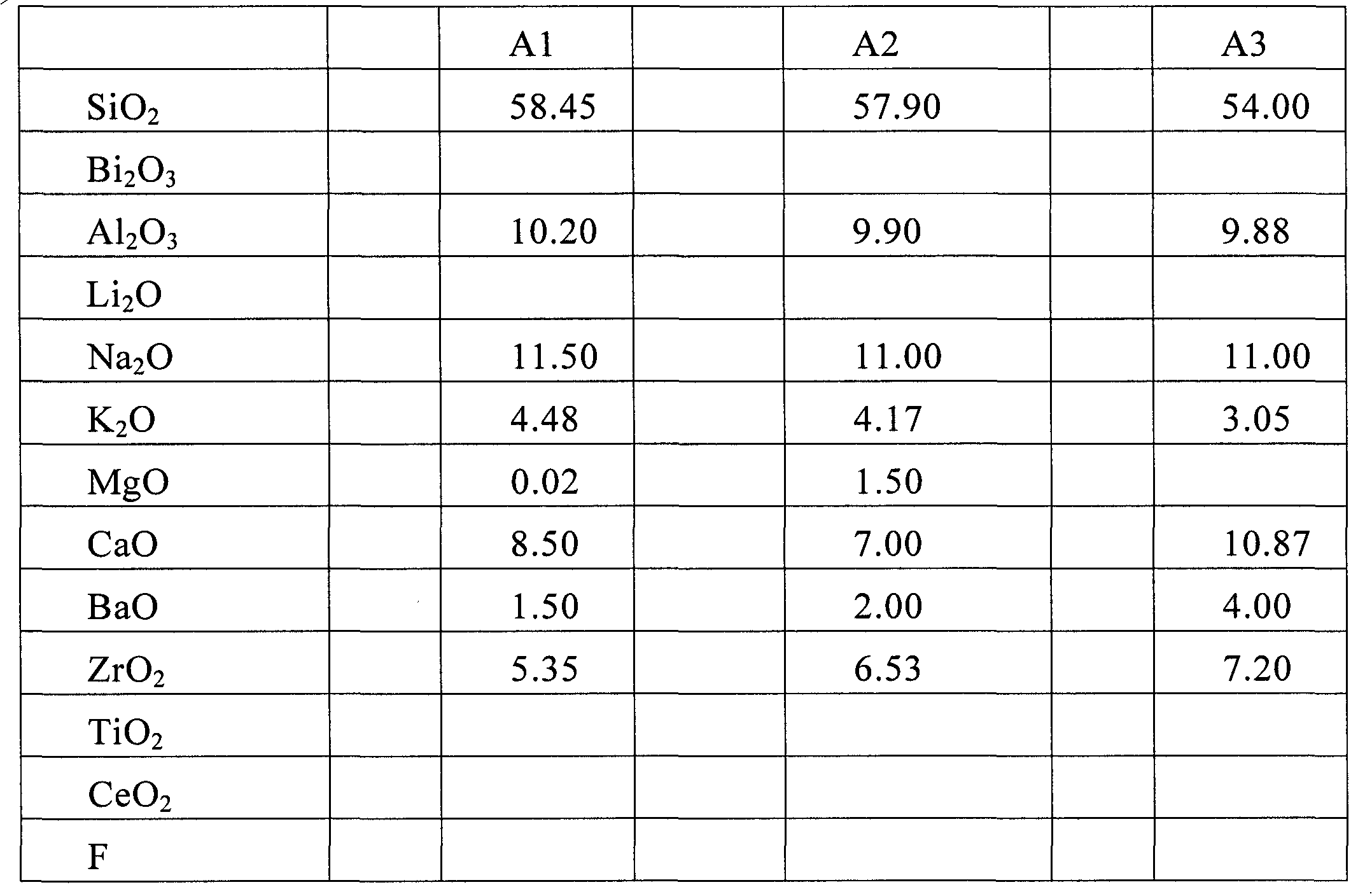

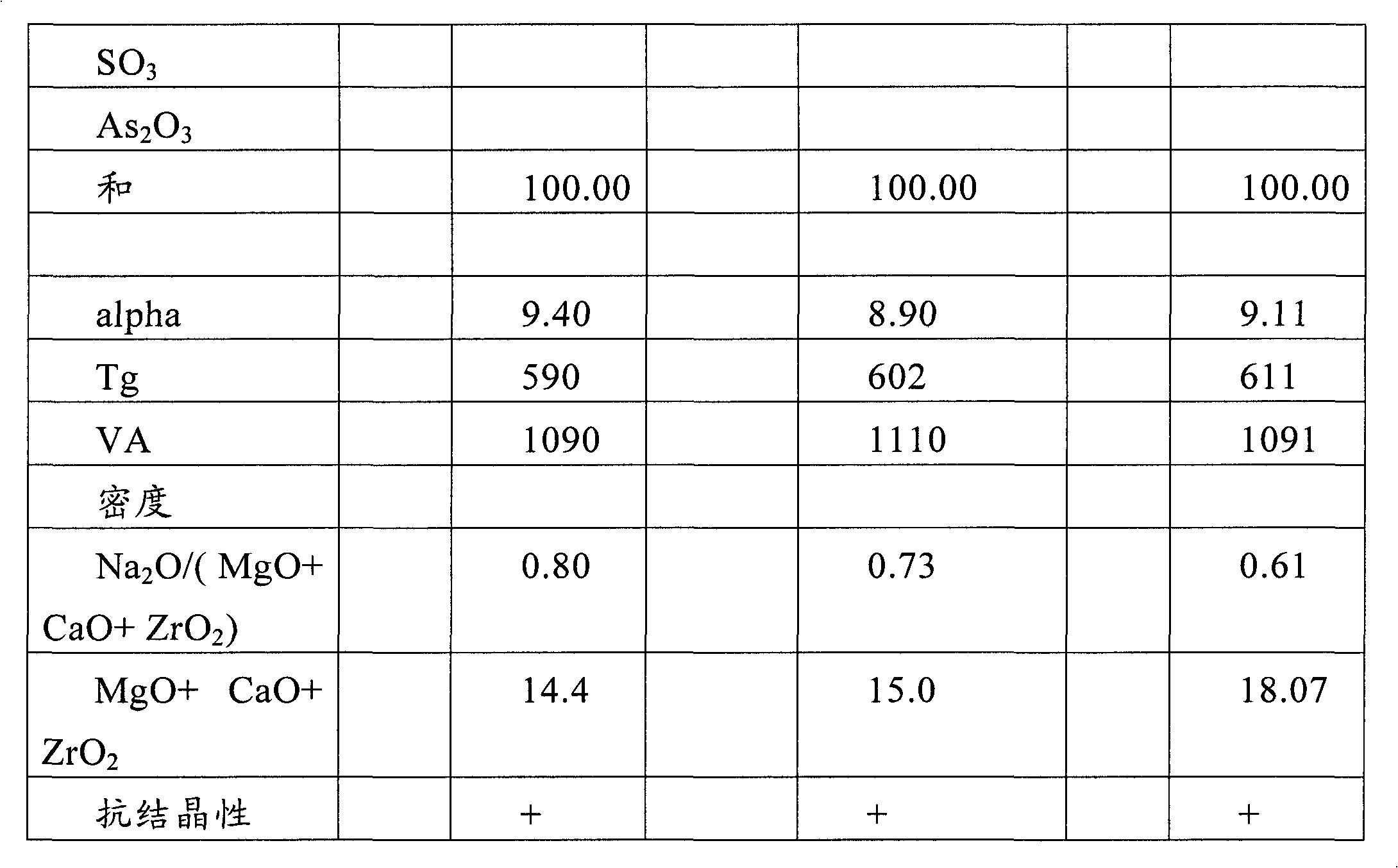

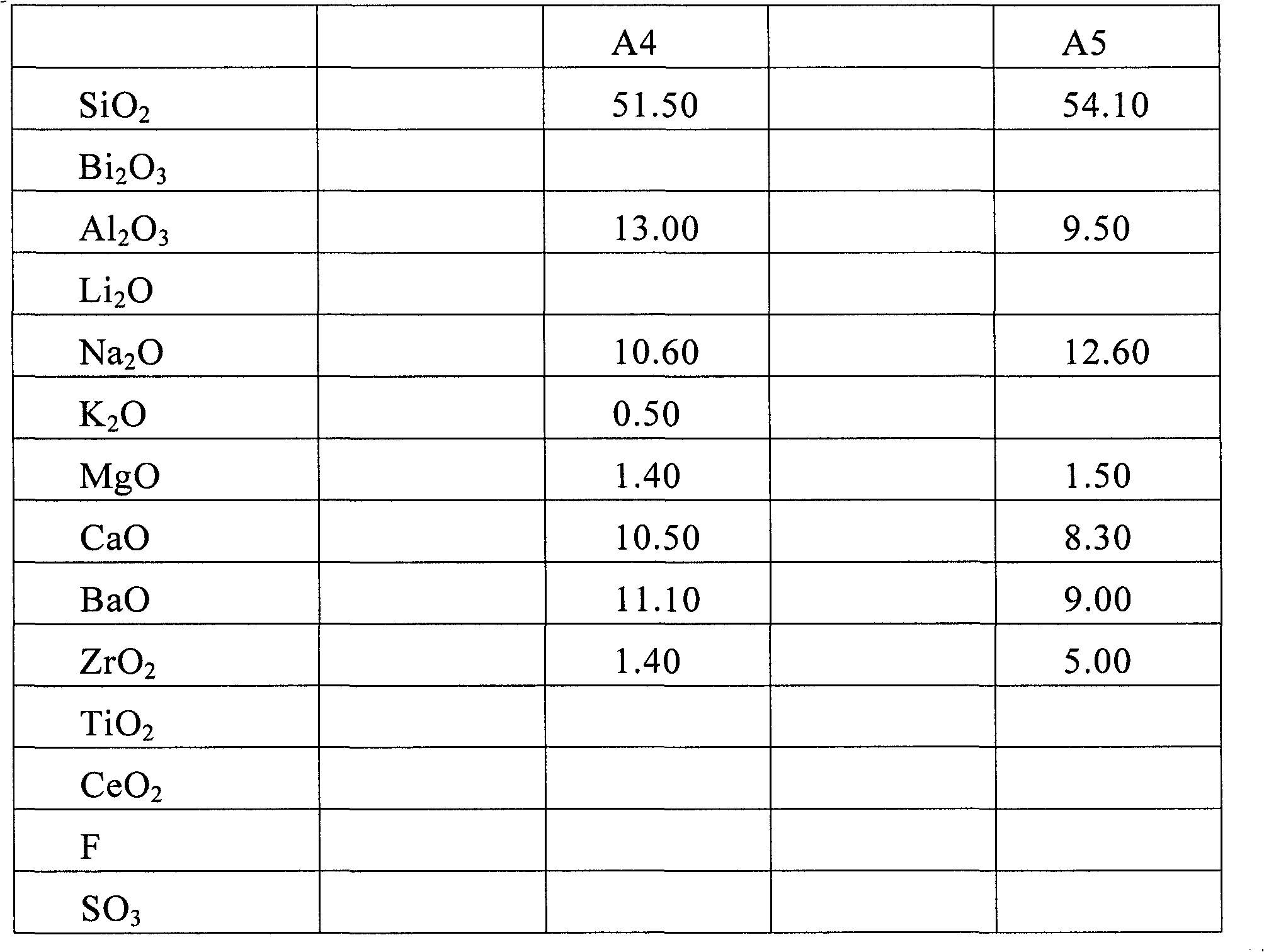

Aluminosilicate glass having high thermal stability and low processing temperature

ActiveCN102548919AImprove efficiencyRaise the processing temperatureThermal dilatationSoda-lime glass

The invention relates to an aluminosilicate glass having a thermal expansion coefficient ranging from 8 to 10 x 10-6 / K in a temperature range of 20 to 300 DEG C, a transformation temperature Tg ranging from 580DEG C; C to 640DEG C; C, and a processing temperature VA ranging from 1065DEG C; C to 1140DEG C; C, and thus can be used as an alternative to soda lime glass. The invention further relates to the use of the glass according to the invention in applications where high thermal resistance of the glass is advantageous, in particular as substrate glass, superstrate glass and / or cover glass in the field of semiconductor technology, preferably for Cd-Te or for CIS and / or CIGS photovoltaic applications, and for other applications in solar technology.

Owner:SCHOTT AG

Polycarbonate/ABS polymer and its prepn process

The present invention relates to organic chemical technology, and is one kind of polycarbonate / ABS polymer material and its preparation process. The polycarbonate / ABS polymer material is prepared with polycarbonate 40-70 wt%, ABS polymer 15-40 wt%, acrylonitrile-styrene copolymer 5-15 wt%, roughening compatibilizing agent 3-15 wt%, PTFE 1-3 wt%, lubricant 0.2-1 wt% and antioxidant 0.4-1 wt%, and through drying, mixing, extruding and cutting into grain. The polycarbonate / ABS polymer material has high rigidity and very high impact resistance.

Owner:威海联桥新材料科技股份有限公司

Method for preparing silicone oil surface modified aluminium hydroxide flame retardant

InactiveCN102031025AImprove thermal stabilityHigh decomposition temperaturePigment treatment with organosilicon compoundsChemical LinkageDecomposition

The invention discloses a method for preparing a silicone oil surface modified aluminium hydroxide flame retardant, which is characterized by taking silicone oil as a surface modifier, uniformly wrapping the surface of aluminium hydroxide powder with the silicone oil through physical adsorption under action of stirring and then adding a catalyst to impel the functional groups on the molecules of the modified silicon oil to react with the hydroxyl groups on the surface of aluminium hydroxide powder so that the silicone oil is tightly wrapped on the surface of aluminium hydroxide powder throughchemical bonding, thus obtaining the modified aluminium hydroxide powder. The modified aluminium hydroxide prepared by the method has good thermal stability and high decomposition temperature, can improve the mechanical property and flame retardant property of the composite materials and has simple process.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

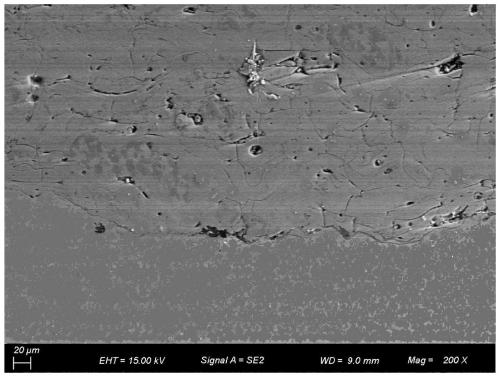

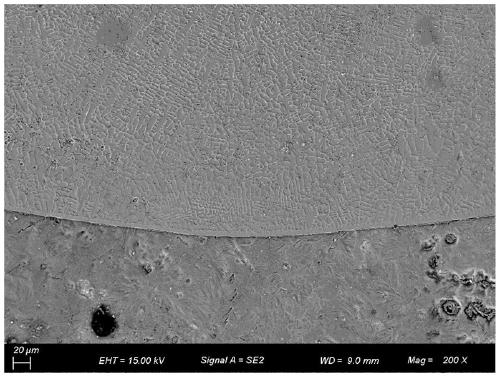

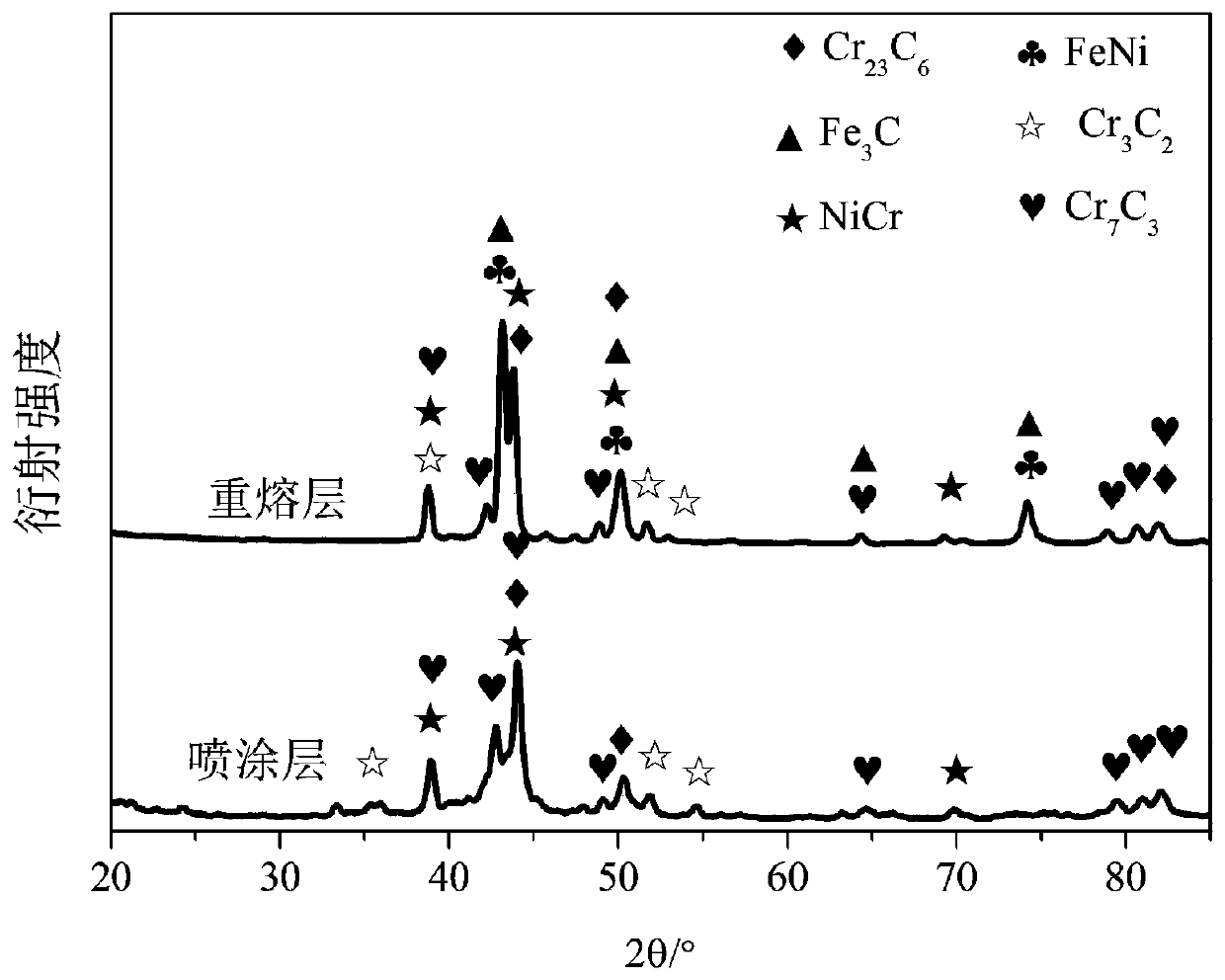

Preparation method of nickel-chromium chromium carbide wear-resistant coating

InactiveCN110079756AUniform and dense phase distributionPrevent oxidationMolten spray coatingChromium carbideWear resistant

The invention provides a preparation method of a nickel-chromium chromium carbide wear-resistant coating. The preparation method includes the following steps that 1, powder of NiCr and Cr3C2 is mixedto be uniform in proportion, and after the mixture is sintered, nickel-chromium chromium carbide powder is obtained; and 2, a nickel-chromium chromium carbide (NiCr-Cr3C2) remelted coating is prepared, wherein 1), the surface of a matrix is subjected to sand blasting pretreatment; 2), the matrix obtained after sand blasting treatment is subjected to plasma spraying; 3), a coating sample obtained after plasma spraying is subjected to preheating treatment before remelting, then a tungsten electrode argon arc welding machine is adopted for TIG remelting treatment, then heat insulation treatment after remelting is carried out, and finally the nickel-chromium chromium carbide wear-resistant remelted coating is obtained; argon is adopted as shielding gas in the TIG remelting process, wherein theTIG remelting current is 85-100 A, the argon arc length is 2 mm, the argon flow is 10 L / min, the remelting speed is 200 mm / min, and the step length is 1.5 mm. The preheating temperature and the heatinsulation temperature are both 300 DEG C, and the time is 2 hours. By means of the method, mechanical bonding between the coating and the matrix is converted into metallurgical bonding, and the mechanical performance and the wear-resistant performance of the coating are improved.

Owner:HEBEI UNIV OF TECH

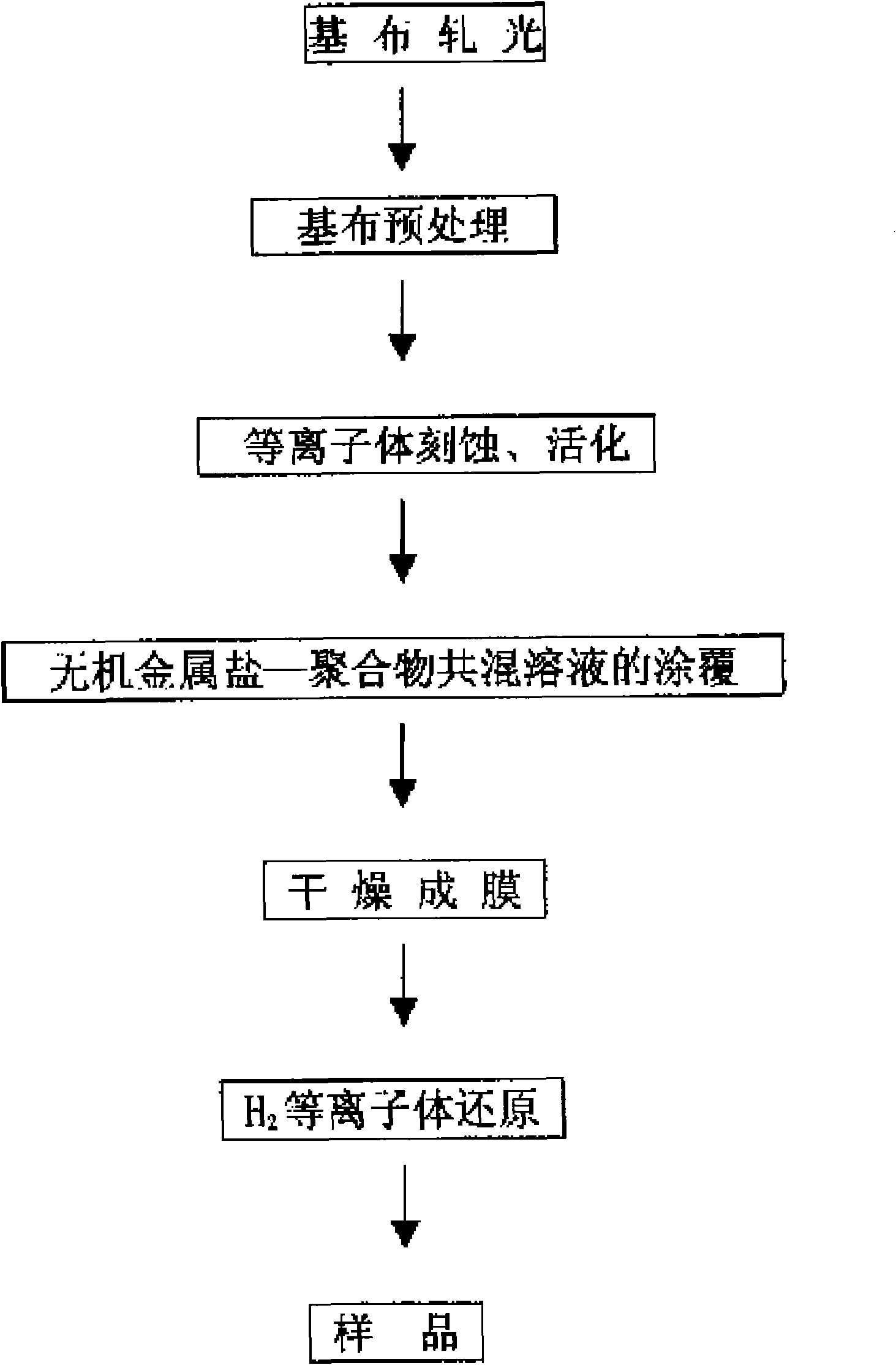

Fabric surface metallization processing method

InactiveCN102758352AImprove bindingImprove bonding fastnessPhysical treatmentPlasma technologySurface cleaning

The invention belongs to the technical field of textile material functional finishing, and especially relates to a method for carrying out metallization processing upon fabric surface with a plasma technology. According to the invention, with low-temperature plasma processing, fabric surface cleaning, etching and activating are realized. An inorganic metal salt-polymer complex is used for coating; and hydrogen plasma is used for reducing, such that a surface metallized fabric is obtained, wherein a coating and a substrate are bonded with chemical bonds. The method is simple and effective. With the method provided by the invention, a defect of poor bonding force between a metal layer and substrate cloth in prior arts is overcome, and chemical waste liquid treatment is avoided. The product can be used in microwave and electromagnetic shielding materials, reflective and insulation materials, and decorative and fire preventing materials.

Owner:SUZHOU OPS PLASMA TECH

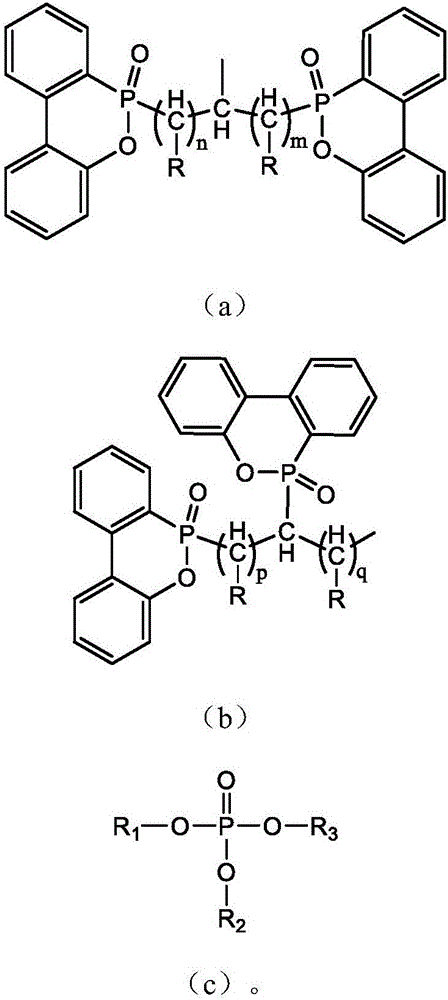

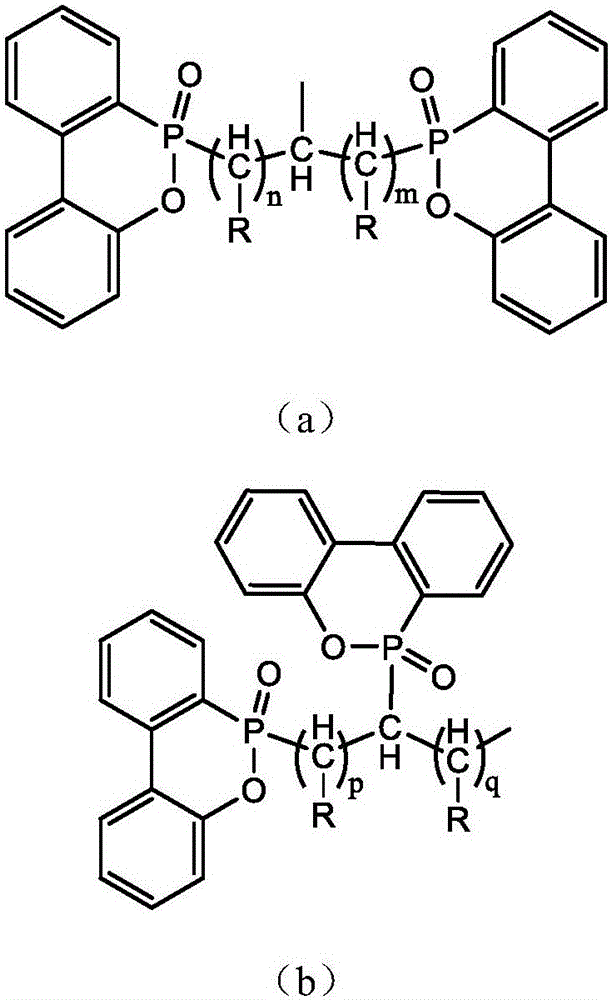

Composite structural phosphorus fire retardant containing poly-DOPO cyclic phosphate and preparation method thereof

ActiveCN106432340AHigh flame retardant efficiencyEasy to synthesizeGroup 5/15 element organic compoundsChemistryAlkane

The invention discloses a composite structural phosphorus fire retardant containing poly-DOPO cyclic phosphate and preparation method thereof; the structural formula of the composite structural phosphorus fire retardant includes not less than 1 organophosphorus ester and not less than 2 DOPO cyclic phosphates. The DOPO is mixed with polyhydroxy alkane or substituted chain hydrocarbon, wherein there are not less than 3 hydroxide radicals of polyhydroxy alkane, and not less than 3 hydroxy carbons in the substituted chain hydrocarbon; heating a mixture to 195-210 DEG C under the protection gas and reacting for 14-17 hours, cooling to room temperature; and then adding halogenated oxygen phosphor or incomplete esterified halogenated oxygen phosphor; then raising temperature to 55-65 DEG C and reacting for 1.5-3 hours; cooling to room temperature and obtaining the composite structural phosphorus fire retardant. The invention provides fire retarding effect at two decomposing temperatures, wherein the one is appeared within 230 and 310 DEG C and the other one is appeared after 345 DEG C; the composite structural phosphorus fire retardant is simple in compound, convenient to use, high in phosphorus content, and better in fire retarding effect.

Owner:淮安丹文化工科技有限公司

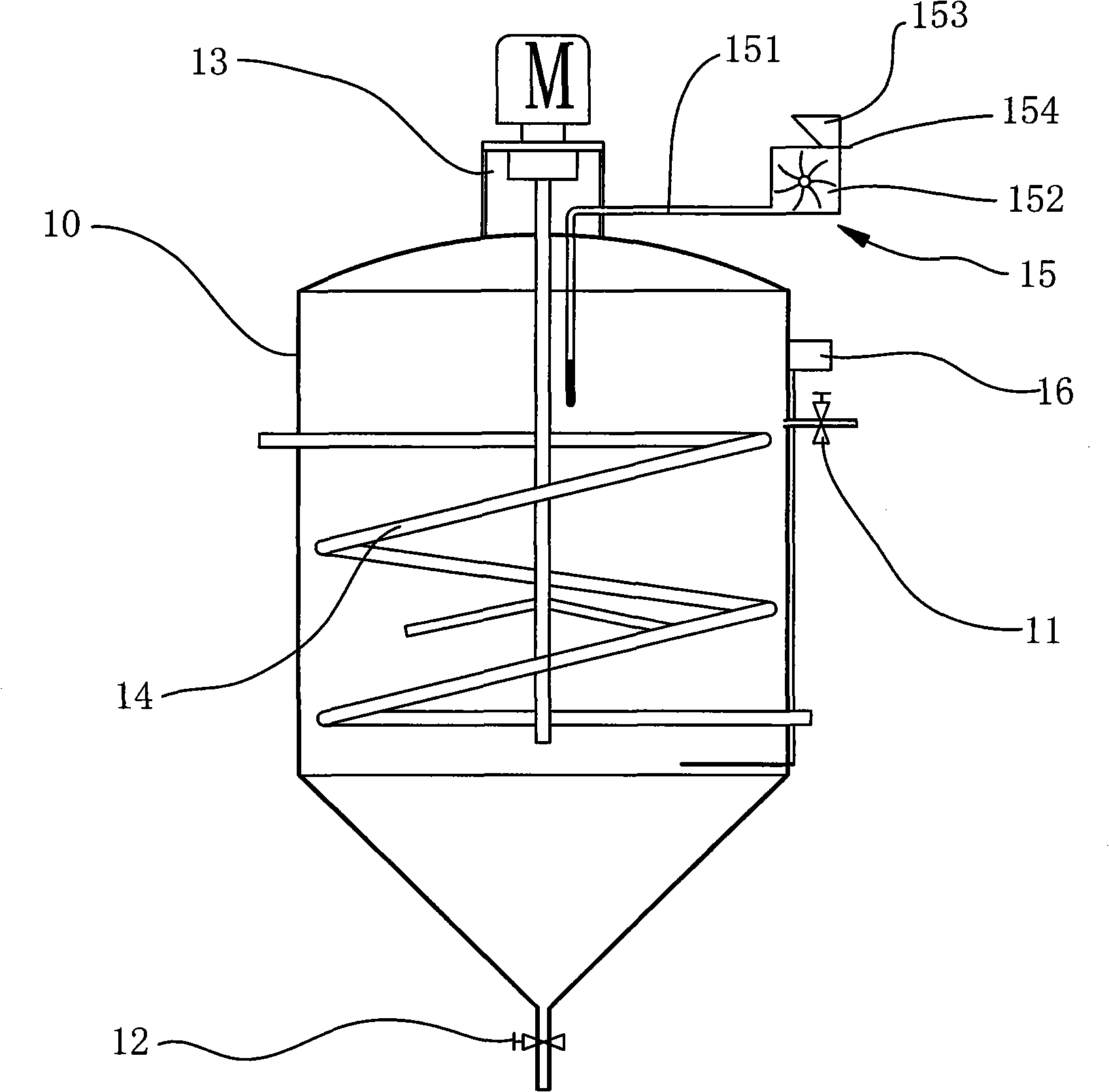

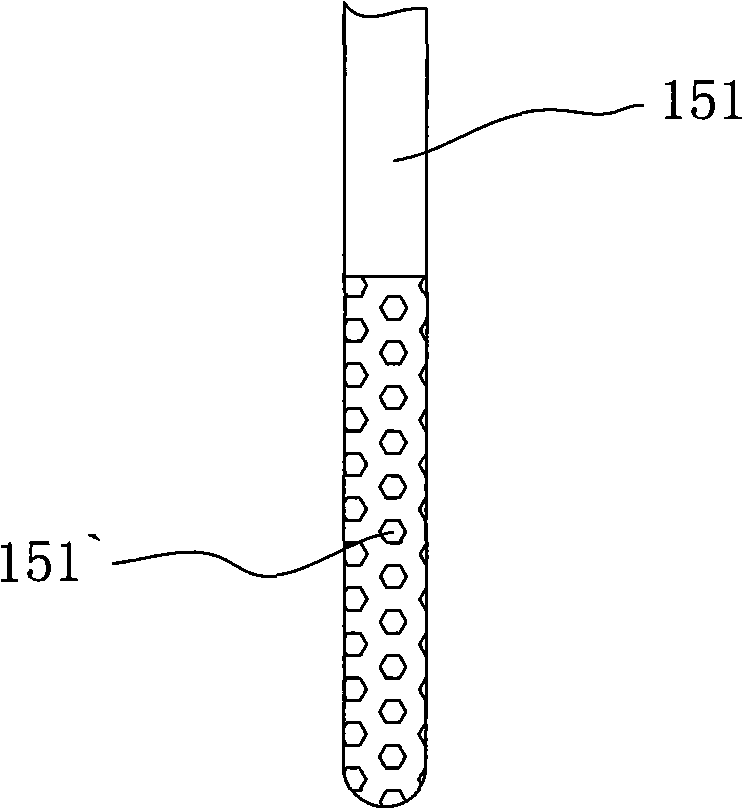

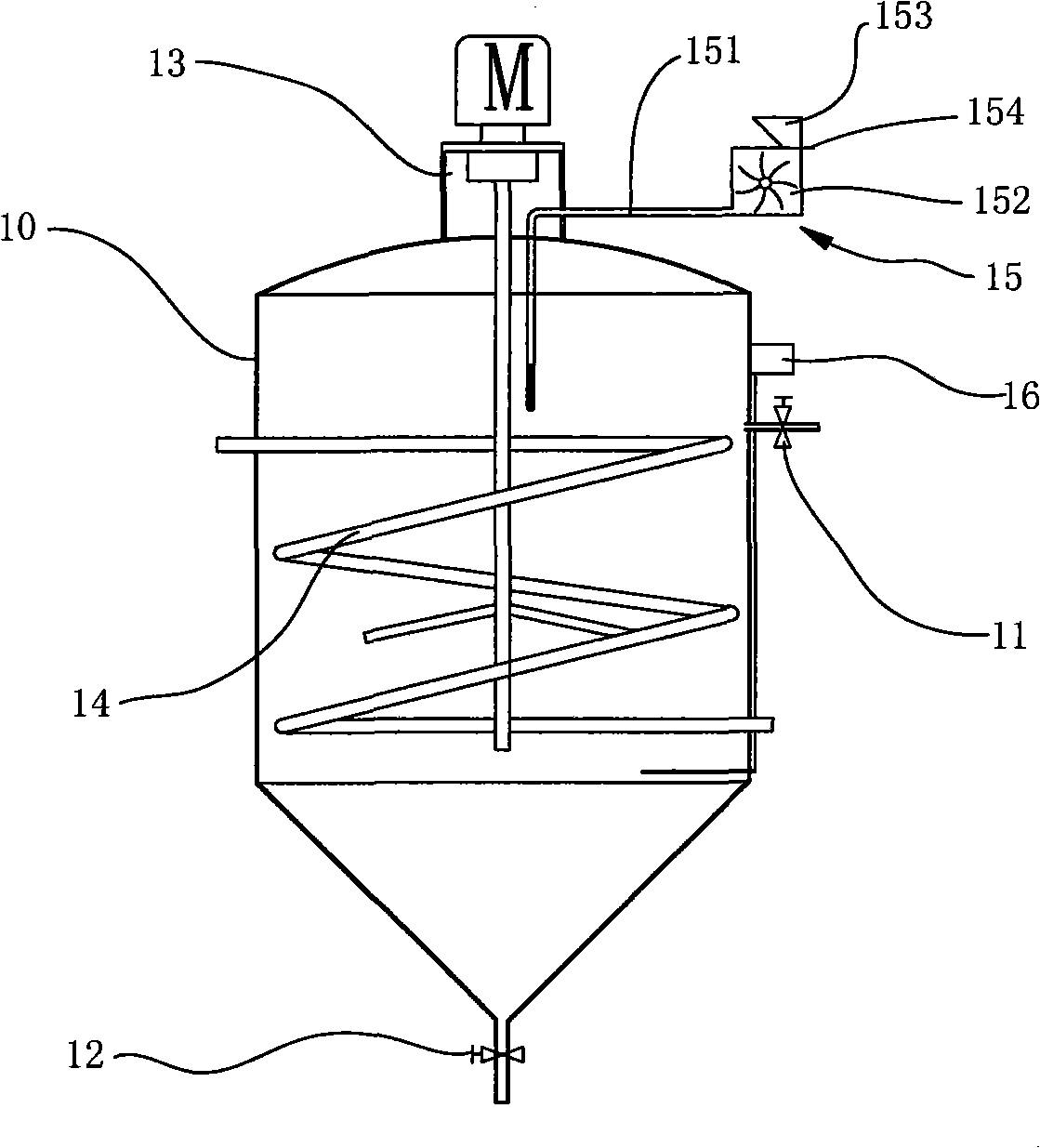

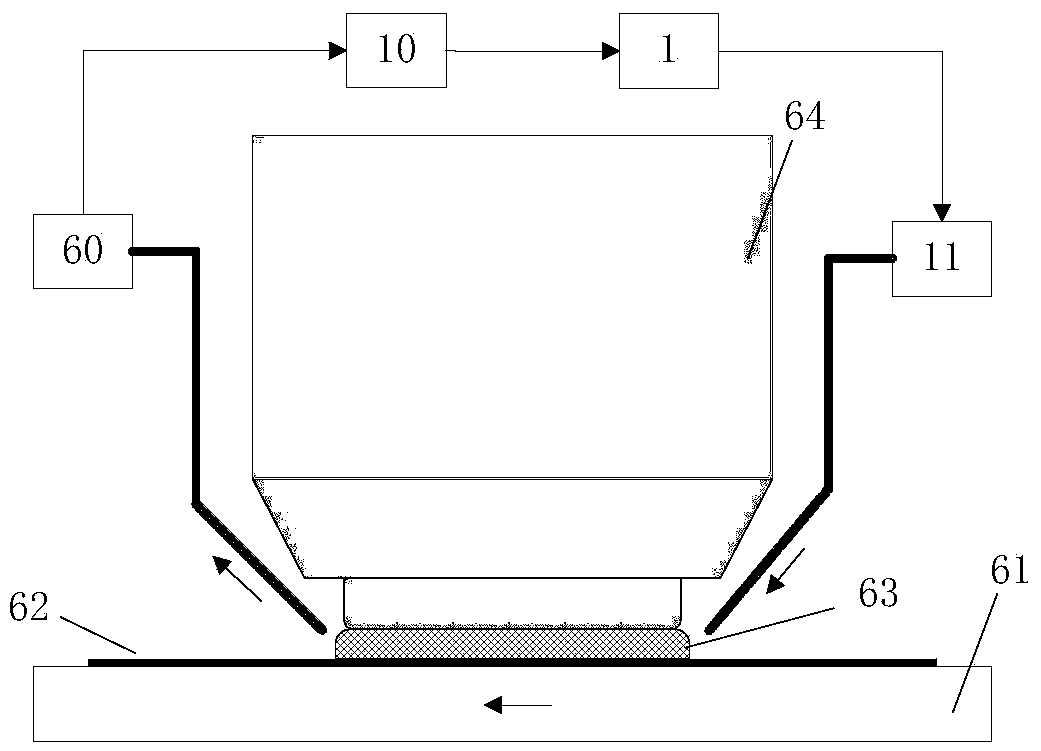

Efficient winterization device and winterization method of tea oil

InactiveCN101892125AFast crystallizationFast filteringFatty-oils/fats refiningSeed crystalWinterization

The invention aims to provide an efficient winterization device and an operation method of tea oil. The device is composed of a tank body, a condenser and a stirrer, wherein the tank body is provided with an oil inlet valve and an oil outlet valve; the condenser is used for condensing materials in the tank; and the stirrer is used for stirring the materials in the tank. The device is characterized by also comprising a seed crystal thrower for adding seed crystals. The winterization method has the following steps: injecting the materials into the tank body, cooling the materials at the temperature of 9 DEG C under a stirring condition, adopting the seed crystal thrower to throw a proper amount of seed crystals in the materials, and continuing to stir and cool; and preserving the temperature for above 24h when the temperature of the materials are cooled to 0 DEG C, heating the materials to 5 DEG C, discharging the materials from the oil outlet valve, and filtering to obtain filtrate as the product in the invention, wherein the seed crystals are solid powders difficultly soluble in the materials and difficult to produce chemical reactions with the materials. Due to trigger action, the seed crystals can accelerate freezing and crystallizing of saturated acid ester in the tea oil, and crystals are filtered out to realize tea oil purification, thus improving winterization processing efficiency of the tea oil.

Owner:黄山裕籽贵茶油有限公司

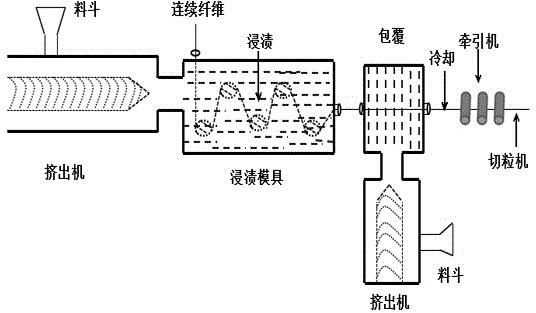

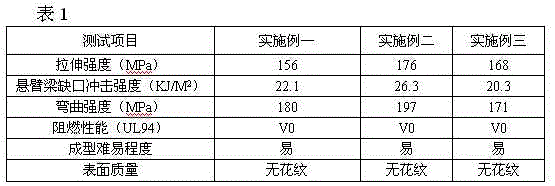

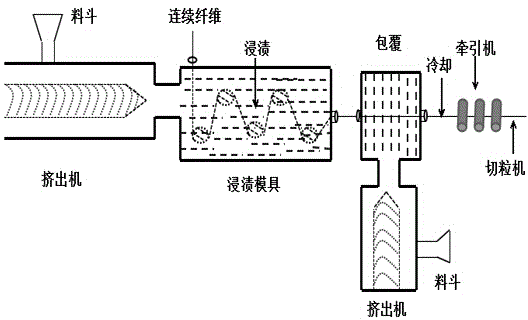

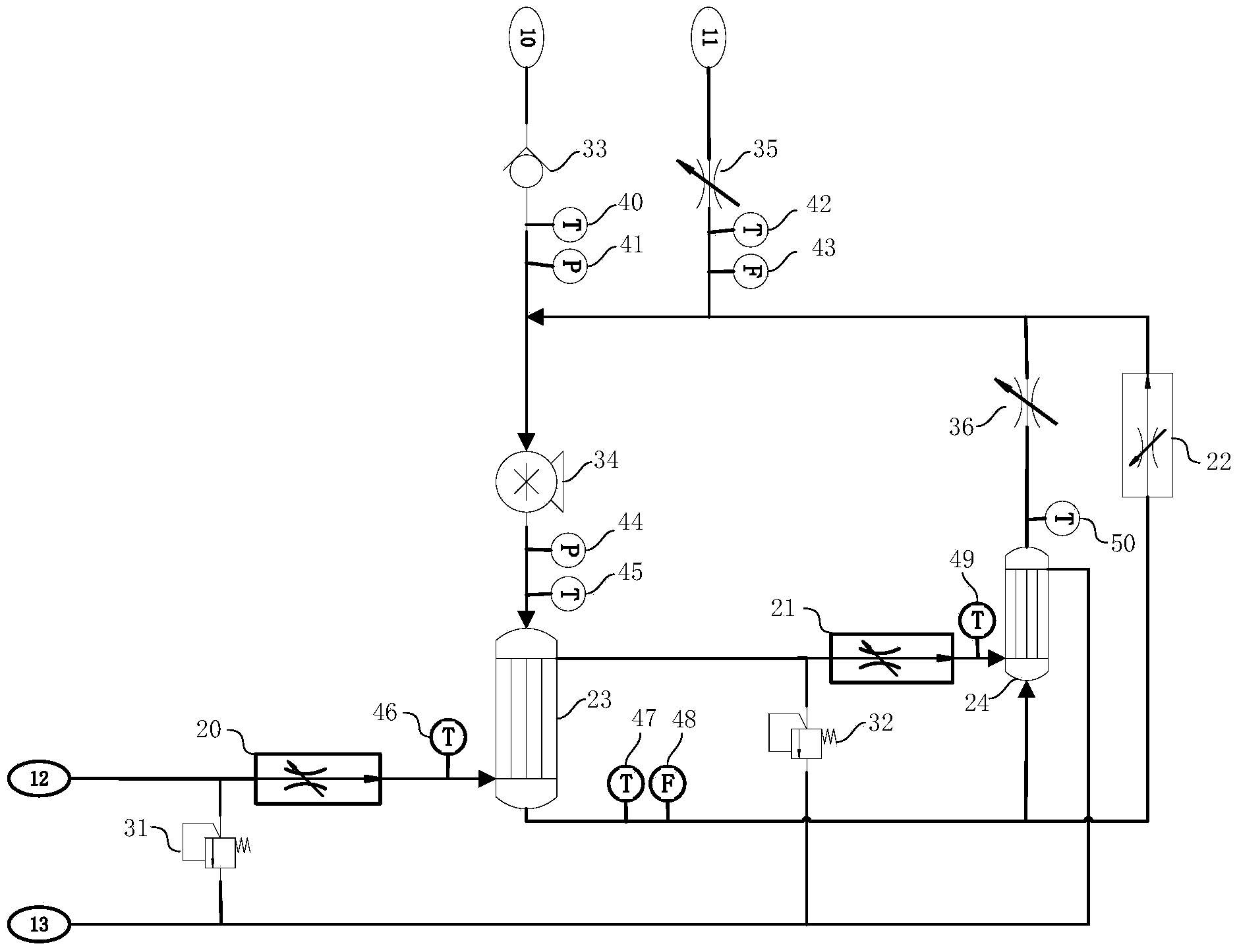

High-performance halogen-free flame-retardant long fiber reinforced polylactic acid composite material and preparation method thereof

ActiveCN104371291ARaise the processing temperatureImprove bindingGlycidyl methacrylatePolymer science

The invention discloses a high-performance halogen-free flame-retardant long fiber reinforced polylactic acid composite material and a preparation method thereof. The preparation method includes that polylactic acid is adopted as matrix resin, processing temperature of the polylactic acid is increased by adding chain extender, a ternary random copolymer of styrene-acrylonitrile-glycidyl methacrylate is taken as a compatilizer, the compatilizer can improve bonding force between the matrix resin and fibers, and compatibility between the matrix resin and flexibilizer is improved; a one-step method is adopted to prepare the high-performance halogen-free flame-retardant long fiber reinforced (PLC) polylactic acid composite material, in other words, soaking of continuous fibers by the matrix resin is completed through a soaking die, coating of matrix fused mass with halogen-containing flame retardant on a soaking material strip is completed in a coating die, cooling and traction are performed, and the soaking material strip is cut into needed length through a granulator. Compared with an existing two-step method, the preparation method is simple in process, and the high-performance halogen-free flame-retardant long fiber reinforced polylactic acid composite material is excellent in mechanical performance and good in flame retardant effect.

Owner:贵州凯科特材料有限公司

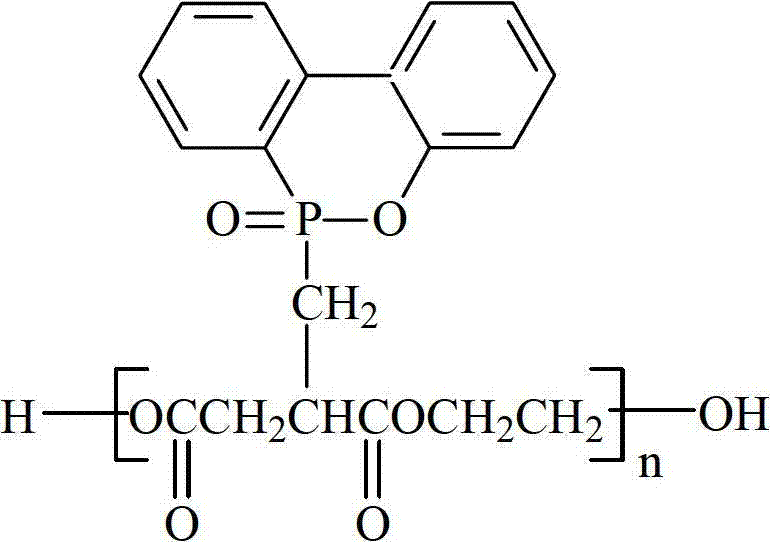

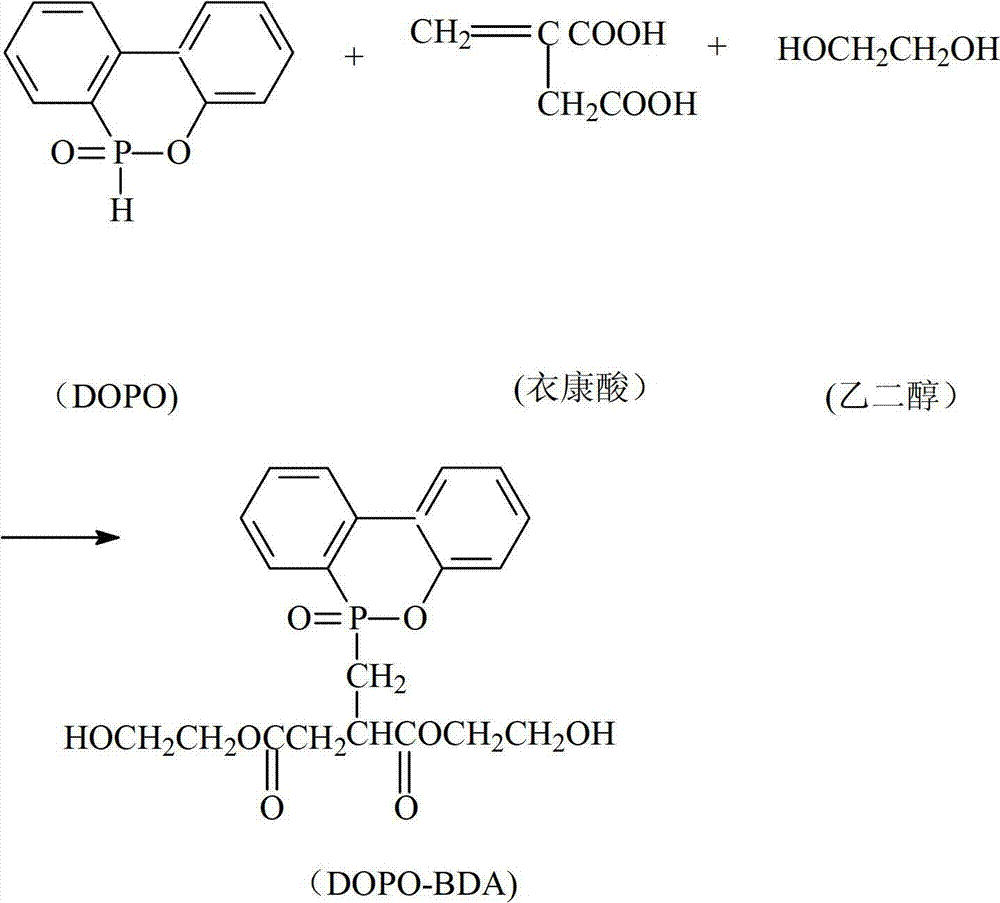

Additive type phosphorus phenanthrene oxa-flame retardant and preparation method thereof

InactiveCN102888085ARaise the processing temperatureImprove flame retardant performanceGroup 5/15 element organic compoundsFiberPolyester

The invention discloses an additive type phosphorus phenanthrene oxa-flame retardant and a preparation method thereof. The chemical name of the additive type phosphorus phenanthrene oxa-flame retardant is poly-(10-taconic acid gylcol ester-9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide). The preparation method comprises the following steps of: firstly carrying out a reaction on DOPO, itaconic acid and ethylene glycol to generate a monomer midbody 10-taconic acid gylcol ester-9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide; and polymerizing the reacting midbody at high temperature under the function of catalyst to obtain a target product. The additive type phosphorus phenanthrene oxa-flame retardant provided by the invention is applicable to various high molecular materials with higher processing temperature such as linear polyester, fiber, polyamide, polyurethane and the like; and the preparation method is free from halogen, environment-friendly, simple in operation process, easy to control, high in yield, good in product repeatability, and less in impurity, wherein the product yield can be 98.5%-99.9%, and the production cost can be reduced.

Owner:SHOUGUANG WEIDONG CHEM

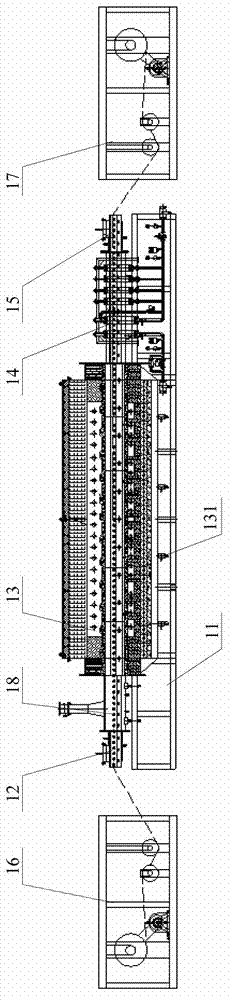

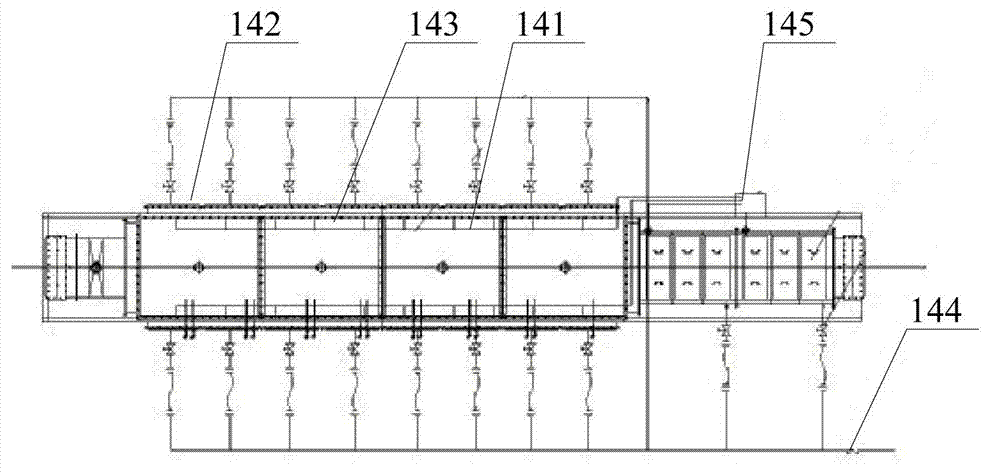

Ultra-high-temperature carbonization device

ActiveCN103031688AImprove processing qualityEasy dischargeHeating/cooling textile fabricsInlet valveCarbonization

The invention discloses an ultra-high-temperature carbonization device. The ultra-high-temperature carbonization device comprises a main workbench, wherein a feeding and sealing device, a carbonizing device, a cooling device and a discharging and sealing device, which are mutually matched, are sequentially arranged on the main workbench in the material conveying direction, an uncoiling device is arranged at the upper stream of the main workbench, a coiling device is arranged at the lower stream of the main workbench, and a traction device matched with material is arranged on the coiling device; and the cooling device comprises an inner housing and an outer housing, which are sheathed and matched, a cooling cavity for accommodating cooling water is arranged between the inner housing and the outer housing, a water inlet valve which communicates the cooling cavity with an external water supply device is arranged on the outer housing, and a water return tank communicated with the cooling cavity is further arranged on the outer housing. The processing process does not need to perform shutdown frequently to cool, take and place the material, the continuity of the whole process is greatly improved, the whole carbonization processing process is more continuous and more reliable, the product specification is strong in applicability, the follow-up splicing and other operations are not required, and the utilization rate and the applicability of a product are greatly improved.

Owner:湖南顶立科技股份有限公司

Modified polystyrene material

The invention discloses a modified polystyrene material which comprises the following raw materials in percentage by weight: 65-90% of polystyrene resin, 8-30% of styrene-butadiene copolymer and 1-5% of liquid paraffin. The raw materials according to the formula are proportionally added, and a mixer is started to mix the raw materials for 5 minutes; and the mixture can be directly put into a common injection molding machine for production without drying the raw materials. The transparency of the modified GPPS (general purpose polystyrene) material disclosed by the invention remains the transparency of the original GPPS material, the elongation at break is enhanced from 2% to 5%, and the impact strength can be enhanced from 3KJ / m<2> to 15KJ / m<2>.

Owner:CHANGHONG MEILING CO LTD

Electron beam physical vapor deposition process

InactiveUS7128950B2Increase or decreaseEasy to operateElectric discharge heatingElectric discharge tubesElectron beam physical vapor depositionGas phase

An electron beam physical vapor deposition (EBPVD) process performed with a coating apparatus to produce a coating material (e.g., a ceramic thermal barrier coating) on an article. The EBPVD apparatus generally includes a coating chamber operated at an elevated temperature and a subatmospheric pressure. The coating chamber contains a crucible and a coating material surrounded by and contained within the crucible, and the coating material has a surface exposed by the crucible. The process entails projecting an electron beam onto the surface of the coating material, wherein the electron beam defines a beam pattern having a higher intensity at an interface of the surface of the coating material with the crucible than at a central region of the surface of the coating material.

Owner:GENERAL ELECTRIC CO

High-performance antibacterial long fiber-enhanced polylactic acid composite material and preparation method thereof

ActiveCN104387734ARaise the processing temperatureImprove bindingCoatingsGlycidyl methacrylateAcrylonitrile

Owner:贵州凯科特材料有限公司

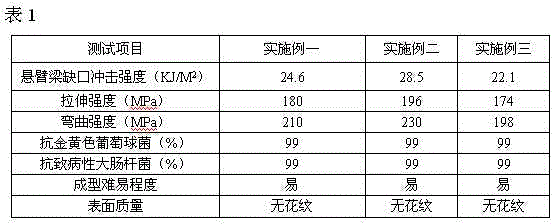

Device for precisely controlling temperature of immersing liquid of immersed photoetching machine and temperature control method thereof

InactiveCN103969965ARealize two-level regulationImmersion is stable and preciseAuxillary controllers with auxillary heating devicesPhotomechanical exposure apparatusTemperature controlEngineering

The invention discloses a device for precisely controlling temperature of immersing liquid of an immersed photoetching machine. The device comprises a pressurization pump, a primary heat exchanger, a secondary heat exchanger and a flow servo valve, wherein an immersing liquid inlet of the primary heat exchanger is communicated with an outlet of the pressurization pump, and the immersing liquid is subjected to heat exchange in the primary heat exchanger so as to realize primary control on the temperature of the immersing liquid; an immersing liquid inlet of the secondary heat exchanger is communicated with an immersing liquid outlet of the primary heat exchanger, and the immersing liquid is subjected to heat exchange in the secondary heat exchanger so as to realize secondary control on the temperature of the immersing liquid; an inlet of the flow servo valve is communicated with the immersing liquid outlet of the primary heat exchanger; the flow servo valve is connected in parallel with the secondary heat exchanger and is used for adjusting the flow of the immersing liquid entering the secondary heat exchanger. The flow of coolants entering the primary heat exchanger and the secondary heat exchanger are cooperatively controlled, and the flow servo valve is used for adjusting the flow of the immersing liquid entering the secondary heat exchanger, so that two-stage control on the temperature of the immersing liquid can be realized, and the immersing liquid with stable and precise temperature is obtained and used for an immersed type photoetching technology.

Owner:HUAZHONG UNIV OF SCI & TECH

Flame-retardant anti-aging ABS and preparation thereof

InactiveCN101328300ALong-term anti-aging and no discolorationImprove performanceAcrylonitrileTitanium

The invention relates to a composition of an arcylonitrile-butadiene-styrene and a preparation method thereof in particular to a fire-retardant antiaging ABS. The fire-retardant antiaging ABS comprises the following components in mass percentage: 60 to 80 percent of ABS, 12 to 25 percent of microencapsulation environment-friendly fire retardant, 0 to 0.5 percent of antioxidant 1076, 0 to 0.5 percent of antioxidant 168, 0.1 to 1.0 percent of light stabilizer 770, 0.1 to 1.0 percent of light stabilizer 327, 0.1 to 1.0 percent of coupling agent KH550, 4 to 10 percent of diantimony trioxide, 1.0 to 3.0 percent of calcium stearate and 1.0 to 3.0 percent of titanium pigment. The heat-resistant environment-friendly fire-retardant antiaging ABS mainly resolves the conflict between the fire retardant and the light stabilizer.

Owner:珠海市远康企业有限公司

Electron beam physical vapor deposition apparatus

InactiveUS6983718B1Increase or decreaseEasy to operateElectric discharge tubesVacuum evaporation coatingElectron beam physical vapor depositionCrucible

An electron beam physical vapor deposition (EBPVD) apparatus and a method for using the apparatus to produce a coating material (e.g., a ceramic thermal barrier coating) on an article. The EBPVD apparatus generally includes a coating chamber that is operable at elevated temperatures and subatmospheric pressures. An electron beam gun projects an electron beam into the coating chamber and onto a coating material within the chamber, causing the coating material to melt and evaporate. An article is supported within the coating chamber so that vapors of the coating material deposit on the article. The operation of the EBPVD apparatus is enhanced by the shape and intensity of the electron beam pattern on the coating material and on a crucible containing the molten coating material.

Owner:GENERAL ELECTRIC CO

High-temperature processed wood-plastic composite and preparation method thereof

InactiveCN106752011AImprove interface strengthHigh mechanical strength and modulusThermoplasticHot pressing

The invention provides a high-temperature molded wood-plastic composite and a preparation method thereof and belongs to the technical field of wood-plastic composites and preparation methods thereof. The invention aims at solving a problem that the wood-plastic composite is hard to prepare at high temperature. The high-temperature molded wood-plastic composite contains a modified plant material, a general-purpose plastic, a coupling agent or an interface compatibilizer, a lubricating agent, a heat stabilizer and a mineral filler; and the modified plant material is a plant material modified by a modifying agent. The preparation method for the high-temperature molded wood-plastic composite comprises the steps: 1, modifying the plant material with the modifying agent; 2, mixing the modified plant material together with the thermoplastic plastic, the coupling agent, the lubricating agent, the heat stabilizer and the mineral filler; 3, melting and blending a mixture obtained in the step 2 by using a double screw; and 4, adding a blend to an extruder for extrusion molding; and carrying out injection molding by using an injection molding machine or carrying out hot press molding by using a hot press; or directly carrying out operations of the steps 2, 3 and 4 on the modifying agent solid and other solids.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com