Aluminosilicate glass having high thermal stability and low processing temperature

A technology of aluminosilicate glass and processing temperature, applied in the field of aluminosilicate glass, can solve problems such as insufficient anti-devitrification performance, loss of glass characteristics, and influence on glass forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0163] A glass composition according to the invention is selected and a glass is produced therefrom. For the melting, a 4 liter platinum pot was used, in which the raw material was placed at a melting temperature of 1580° C. for more than 8 hours and kept there at this temperature for 14 hours. The glass melt was then cooled to 1400° C. within 8 hours with stirring and then poured into a graphite mold preheated to 500° C. After pouring, the casting mold was placed in a cooling furnace preheated to 650° C., which was cooled to room temperature at 5° C. / hour.

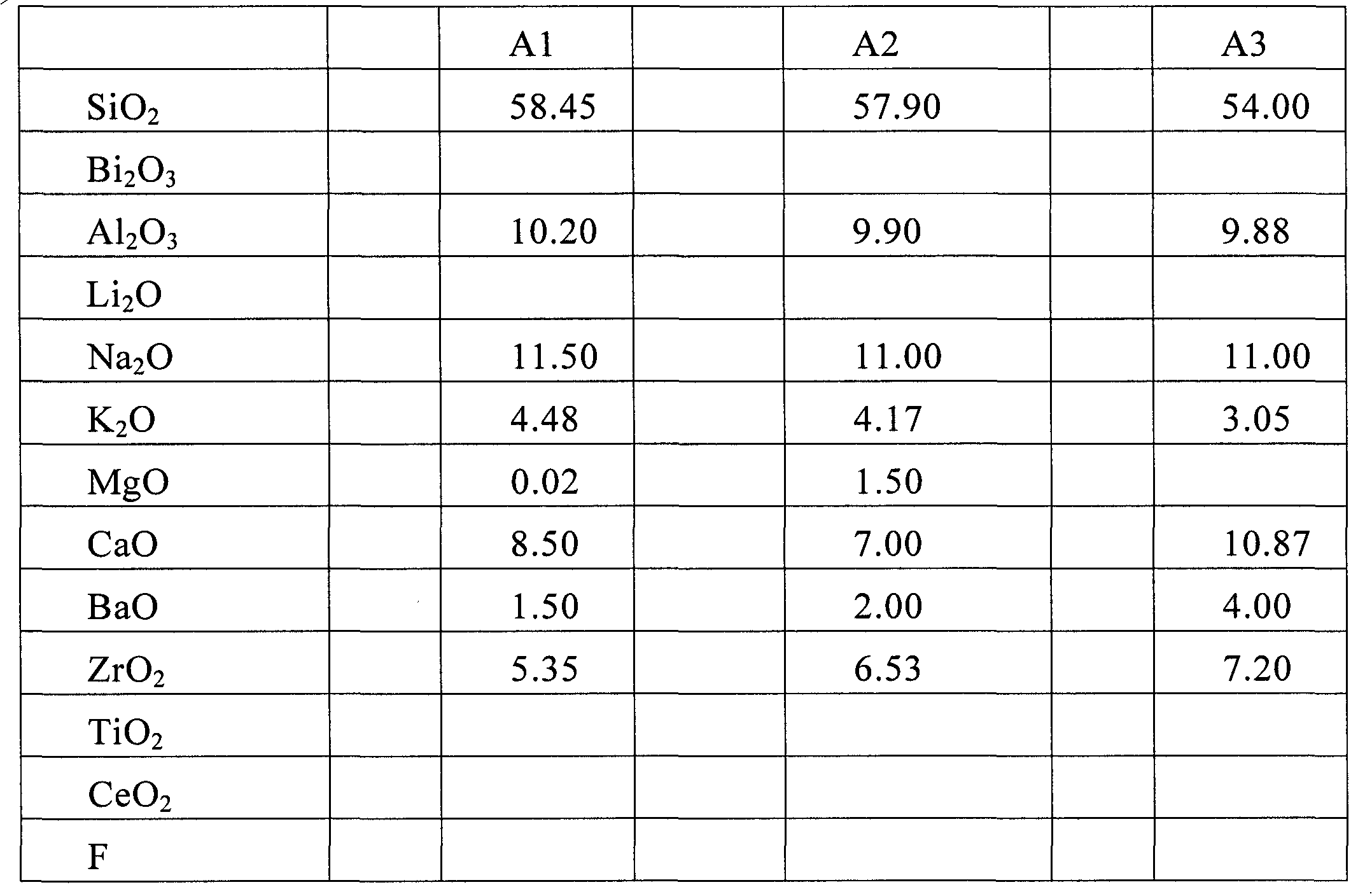

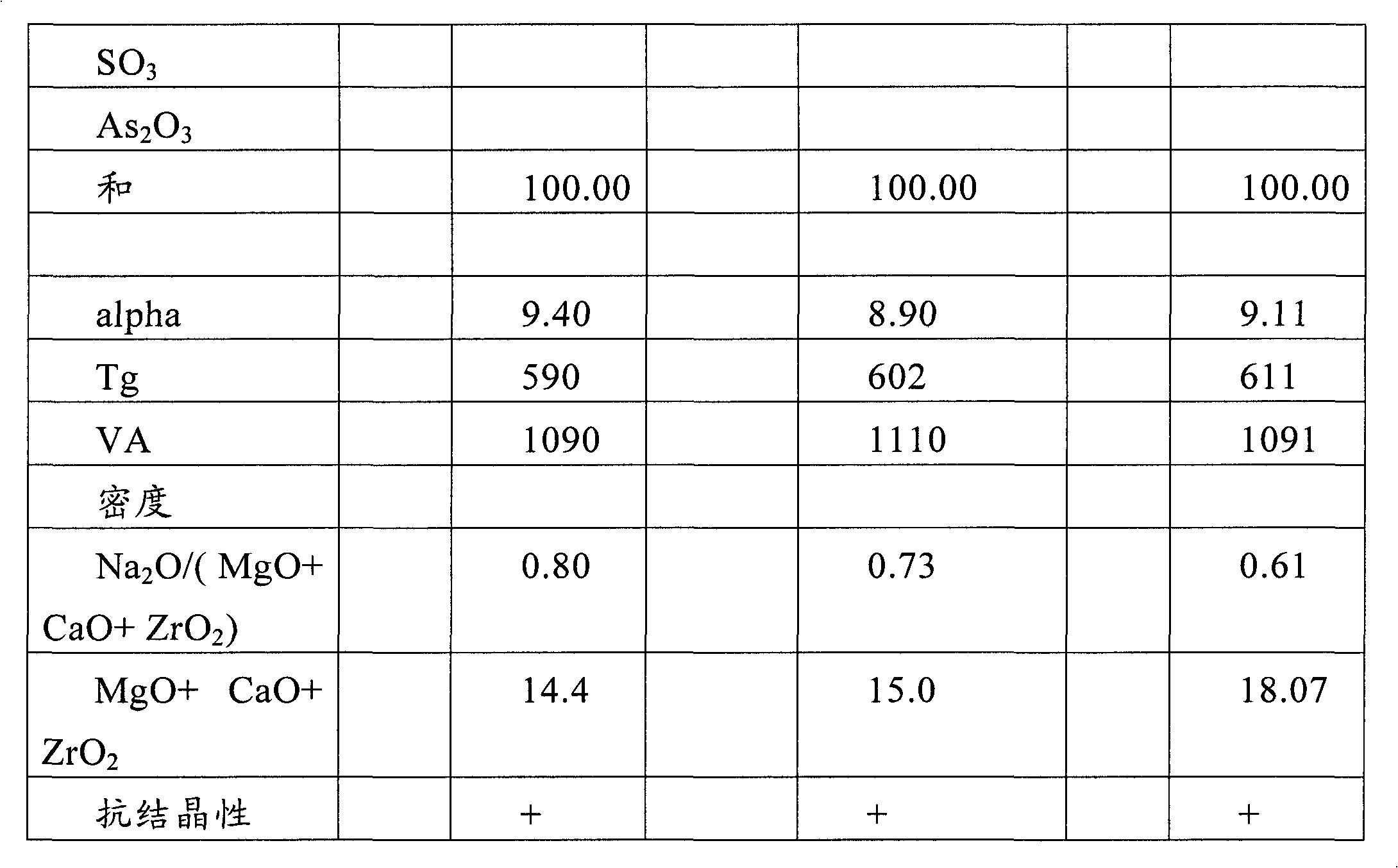

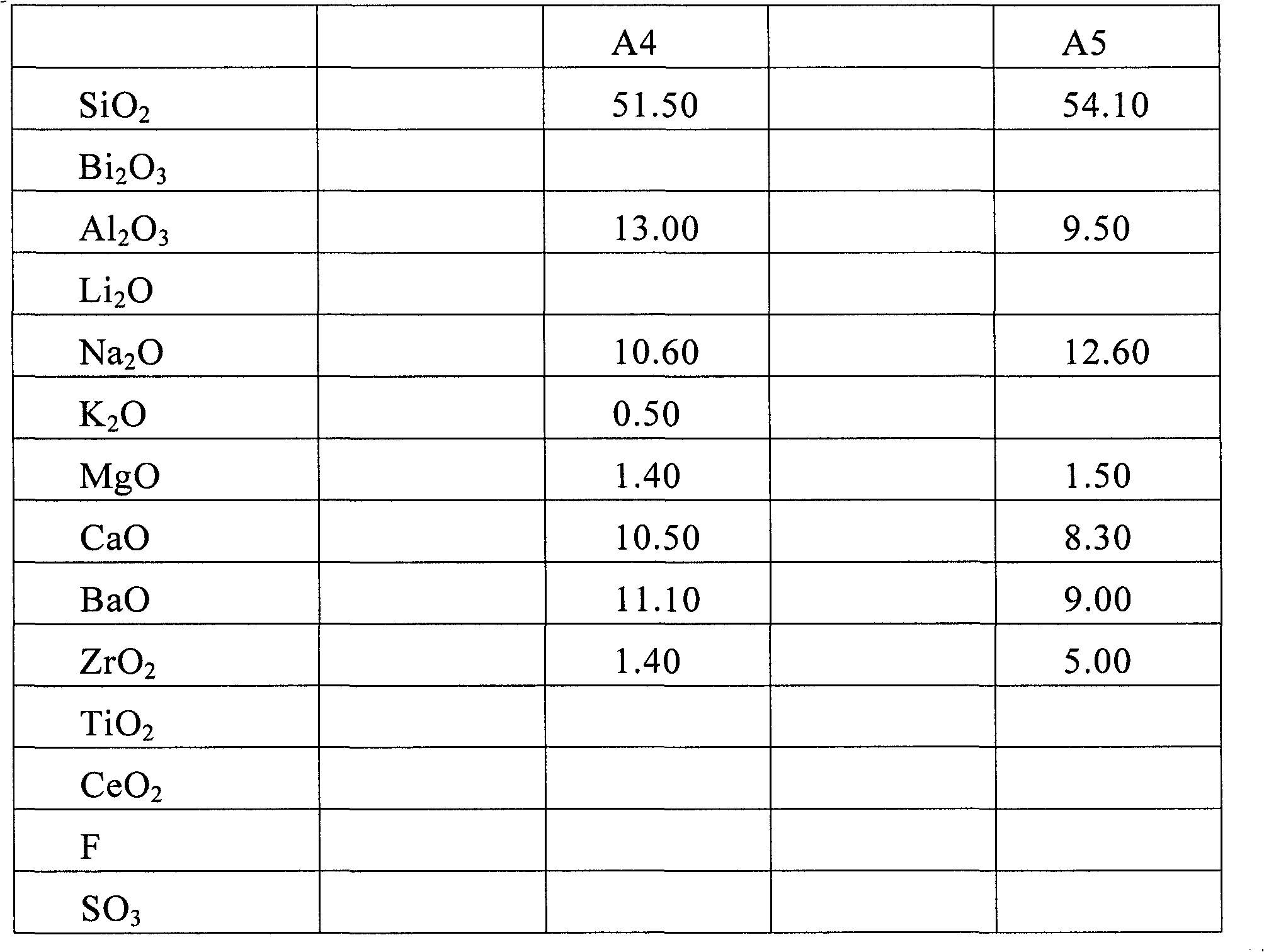

[0164] The compositions and properties of the glasses according to the invention are summarized in Tables 1 and 2 below.

[0165] Table 1

[0166]

[0167]

[0168] Table 2

[0169]

[0170]

[0171]

[0172] Anti-crystallization:

[0173] + good

[0174] O Moderate

[0175] - Difference

[0176] It is thus described for the first time by the present invention to provide an alternative glass compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com