Patents

Literature

271 results about "Soda-lime glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soda–lime glass, also called soda–lime–silica glass, is the most prevalent type of glass, used for windowpanes and glass containers (bottles and jars) for beverages, food, and some commodity items. Glass bakeware is often made of borosilicate glass. Soda–lime glass accounts for about 90% of manufactured glass.

Cis Compound Semiconductor Thin-Film Solar Cell and Method of Forming Light Absorption Layer of the Solar Cell

InactiveUS20070289624A1Improve conversion efficiencyImprove productivityFinal product manufacturePhotovoltaic energy generationProduction rateAbsorption layer

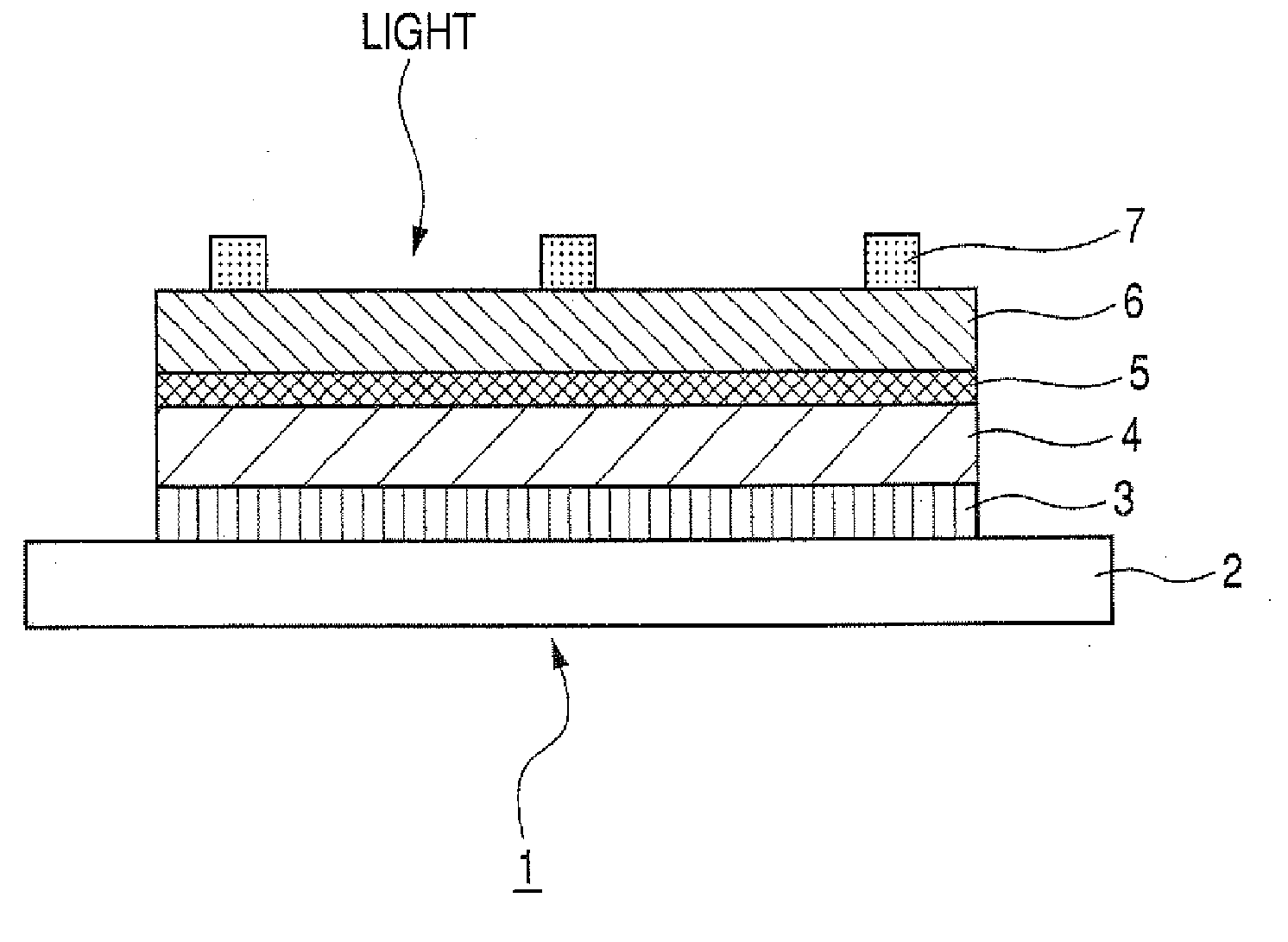

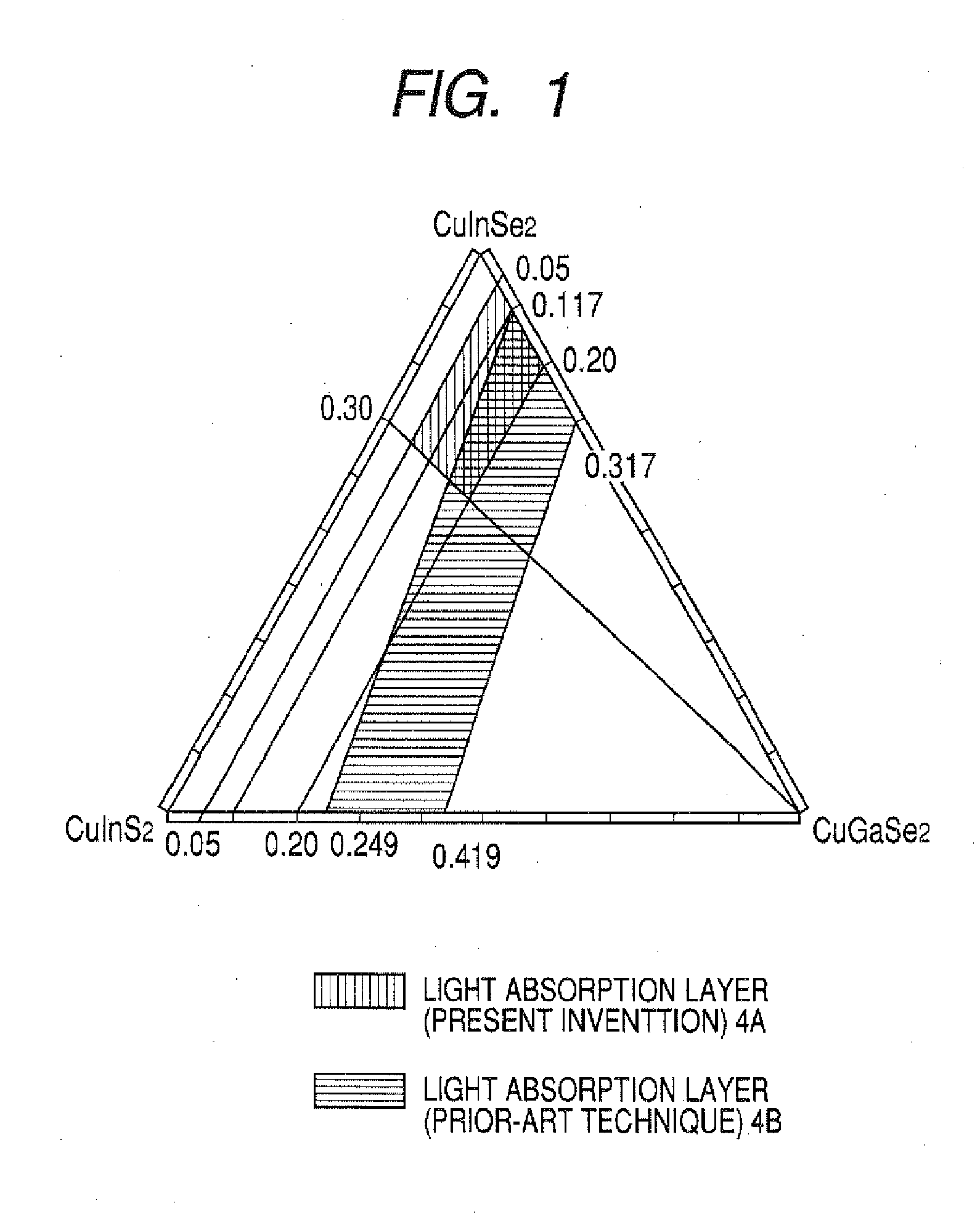

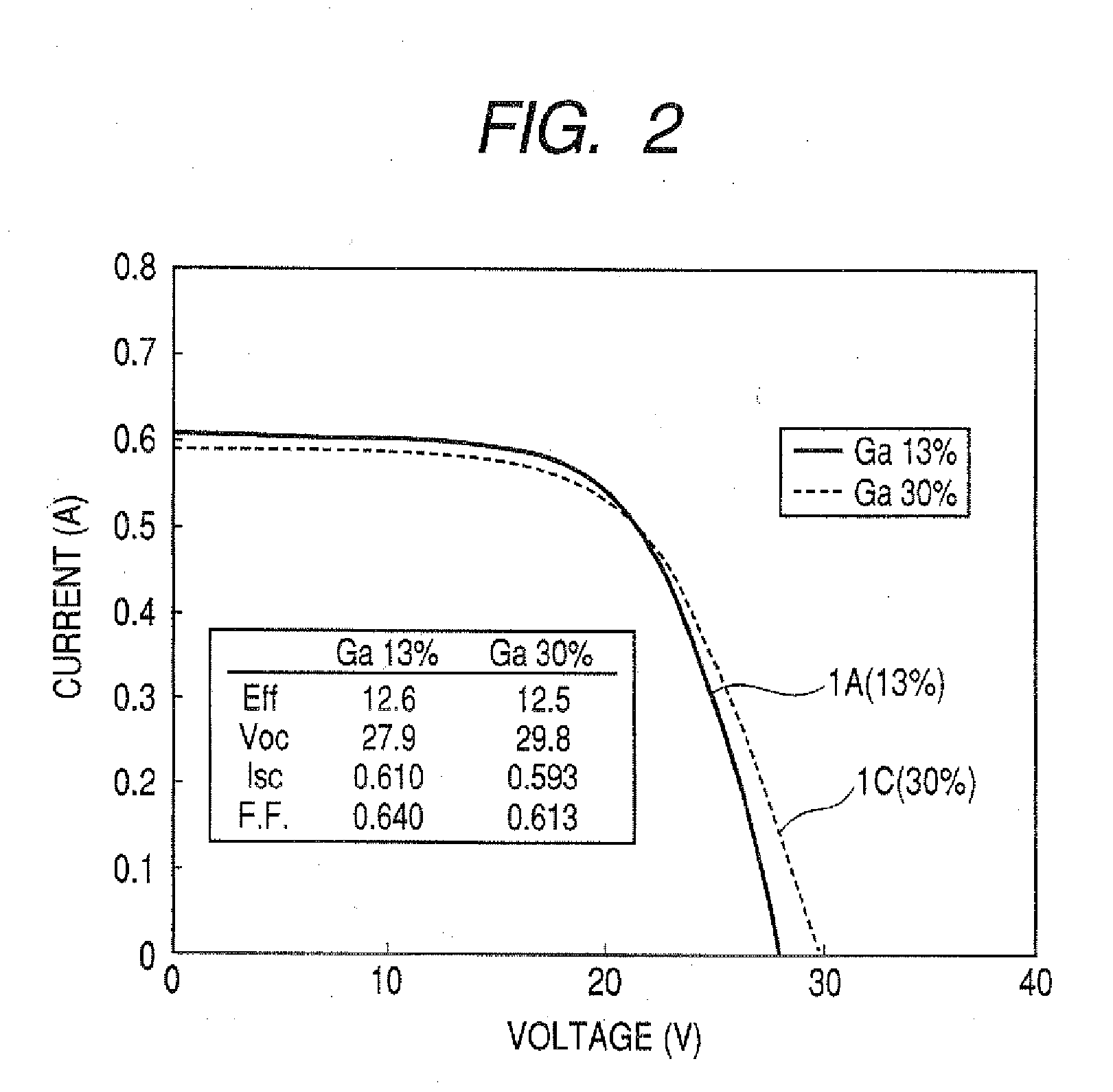

Film formation is conducted at a low temperature to improve conversion efficiency and productivity and to enable a wider choice of substrate materials to be used. The invention relates to the light absorption layer of a CIS compound semiconductor thin-film solar cell and to a method of forming the layer. The light absorption layer comprises a compound represented by Cux(In1-yGay)(Se1-zSz)2 and having a chalcopyrite type structure, the proportions of the components satisfying 0.86≦x≦0.98, 0.05≦y≦0.25, 0≦z≦0.3, x=αT+β, α=0.015y−0.00025, and β=−7.9y+1.105, provided that T (° C.) is anneal temperature and the allowable range for x is ±0.02. The layer is formed by the selenization method at a low temperature (about 500≦T≦550). As the substrate is used a soda-lime glass having a low melting point.

Owner:SHOWA SHELL SEKIYU KK

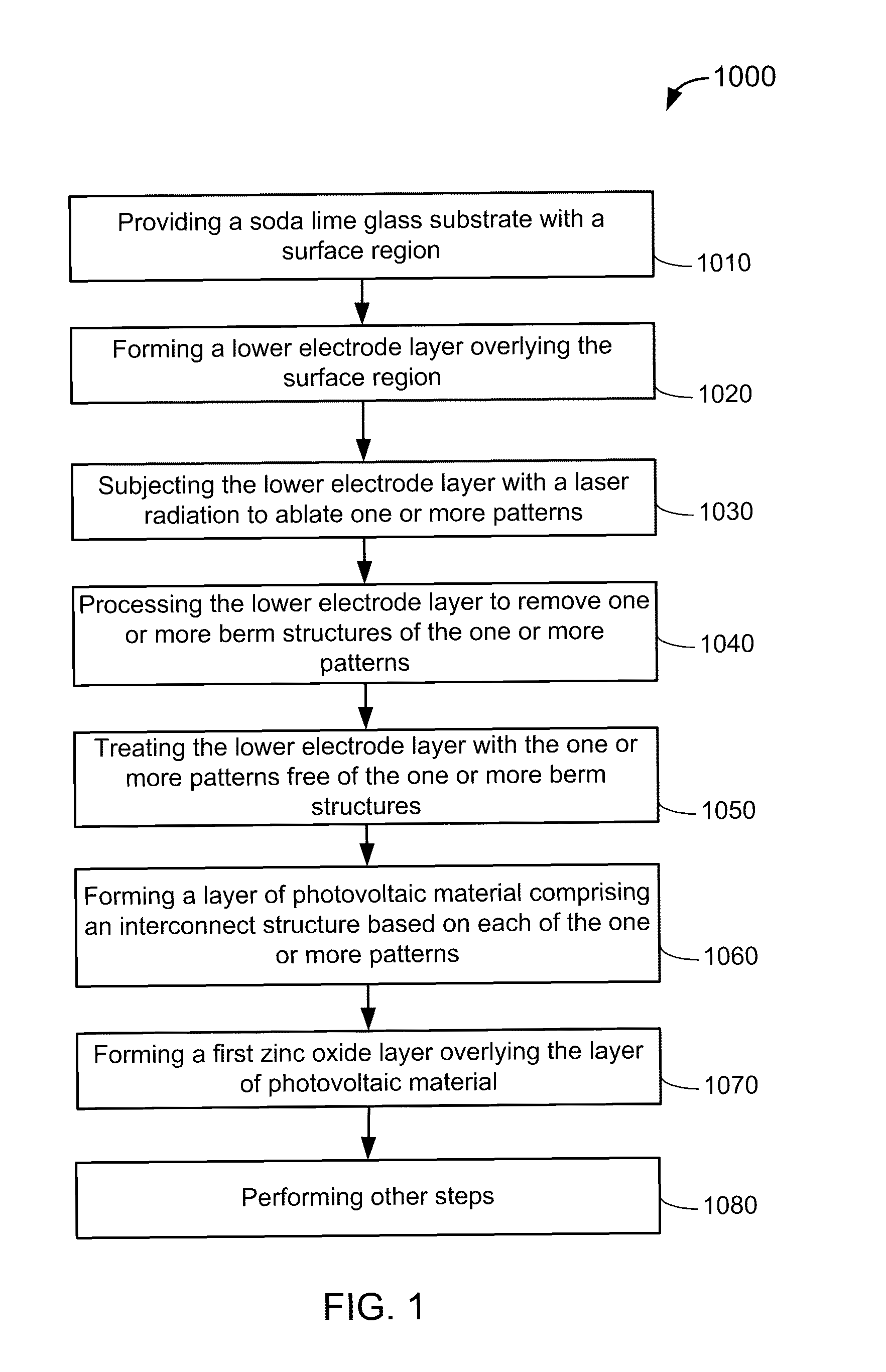

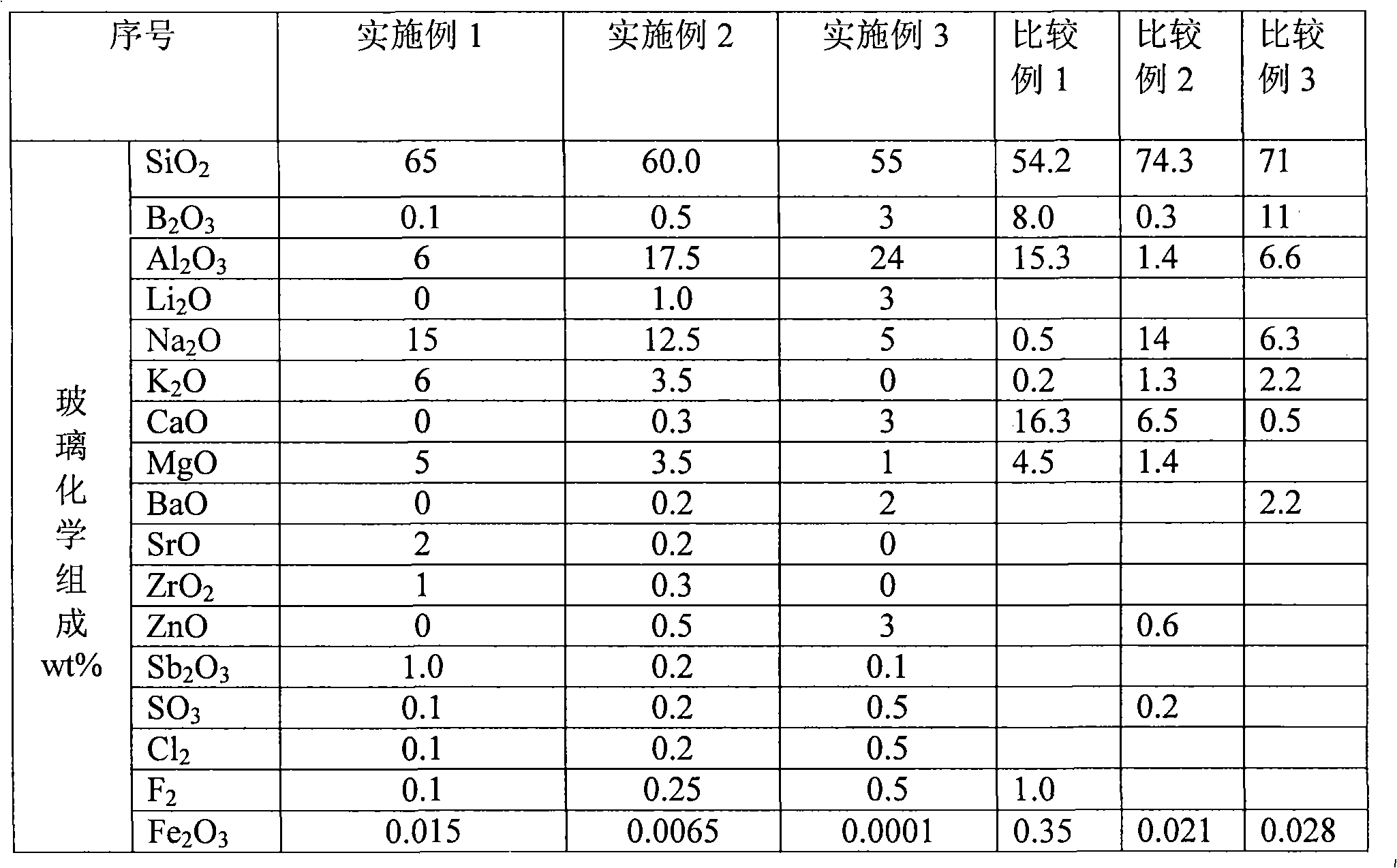

Patterning electrode materials free from berm structures for thin film photovoltaic cells

InactiveUS7863074B2Solid-state devicesSemiconductor/solid-state device manufacturingBrush deviceOptoelectronics

A method for forming a thin film photovoltaic device having patterned electrode films includes providing a soda lime glass substrate with an overlying lower electrode layer comprising a molybdenum material. The method further includes subjecting the lower electrode layer with one or more pulses of electromagnetic radiation from a laser source to ablate one or more patterns associated with one or more berm structures from the lower electrode layer. Furthermore, the method includes processing the lower electrode layer comprising the one or more patterns using a mechanical brush device to remove the one or more berm structures followed by treating the lower electrode layer comprising the one or more patterns free from the one or more berm structures. The method further includes forming a layer of photovoltaic material overlying the lower electrode layer and forming a first zinc oxide layer overlying the layer of photovoltaic material.

Owner:CM MFG

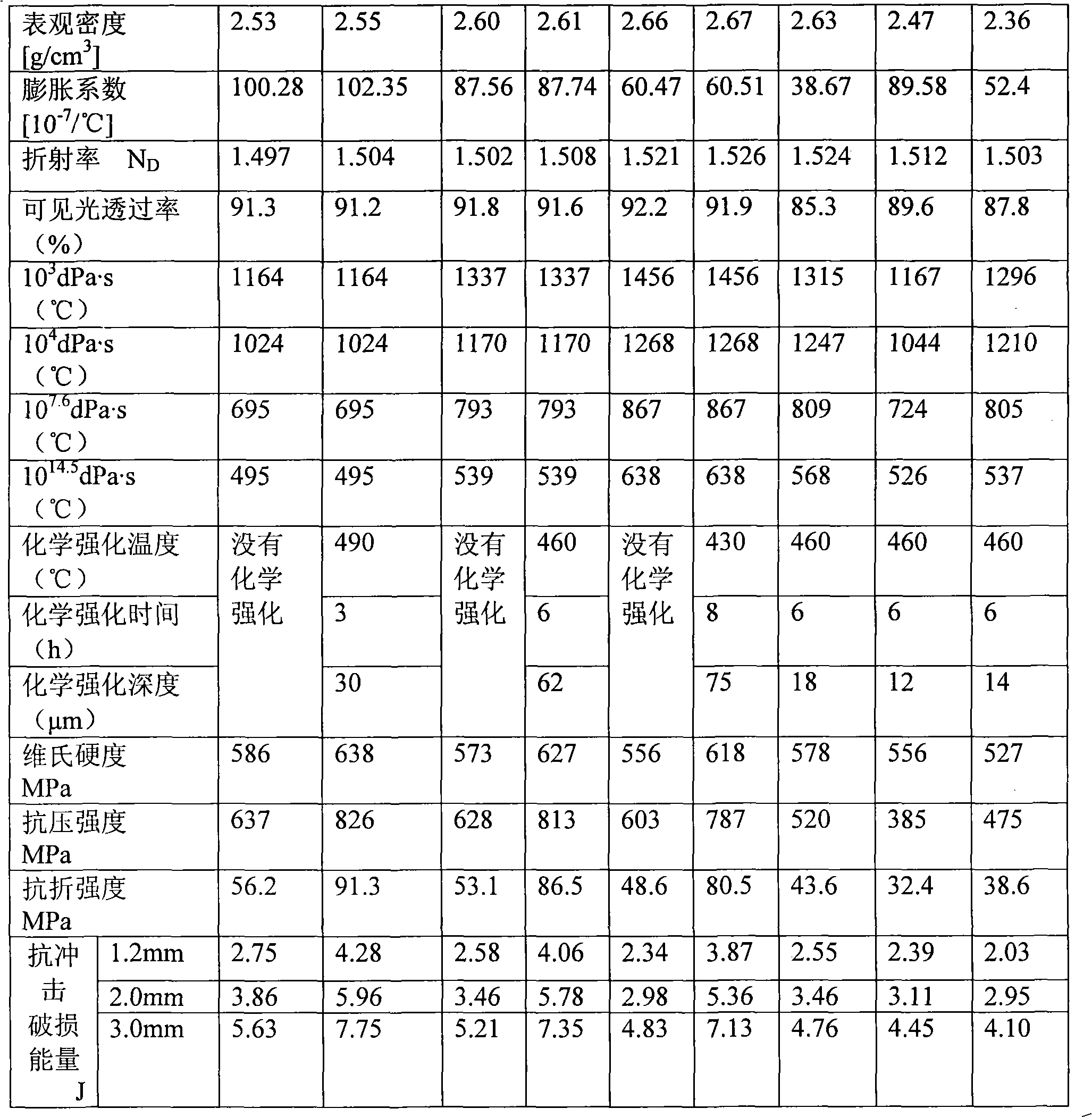

High strength aluminosilicate glass and chemically toughening process thereof

ActiveCN101337770AMeet the screen saver functionProtective functionGlass tempering apparatusAlkali freeShock resistance

The invention relates to a high-strength aluminate silicate glass and a chemical toughening method thereof, and belongs to the silicate glass field. The glass comprises the following chemical components (weight percent): 55 to 65 weight percent of SiO2, 0.1 to 3 weight percent of B2O3, 6 to 24 weight percent of Al2O3, 3 to 9 weight percent of MgO plus CaO plus BaO plus SrO, 0 to 1 weight percent of ZrO2, 0 to 2 weight percent of ZnO, 0.1 to 0.5 weight percent of Cl2, 0.1 to 1.0 weight percent of Sb2O3, 0.1 to 0.5 weight percent of SO3 and 0.1 to 0.5 weight percent of F2, and belongs to a aluminate silicate glass system. The high-strength aluminate silicate glass is prepared through a known plate glass production method, and then is subjected to the strengthening treatment by adopting the chemical toughening method. The glass has high permeability of visible light, and relatively common soda lime glass, neutral medicine glass and alkali-free high-aluminum glass have good shock resistance property, high scratch resistance property and high durability. The high-strength aluminate silicate glass is applied to the screen surface protection of plasma display products and liquid crystal display products, the protection of touch screens, the screen protection of automated teller machines, and the screen protection of other electronic products (Mobile phones, PDAs and media machines, etc.), thereby effectively preventing the impact and the scratch damage to the glass surface of display products. The high-strength aluminate silicate glass contains no harmful elements.

Owner:SUZHOU SHINWU OPTRONICS TECH

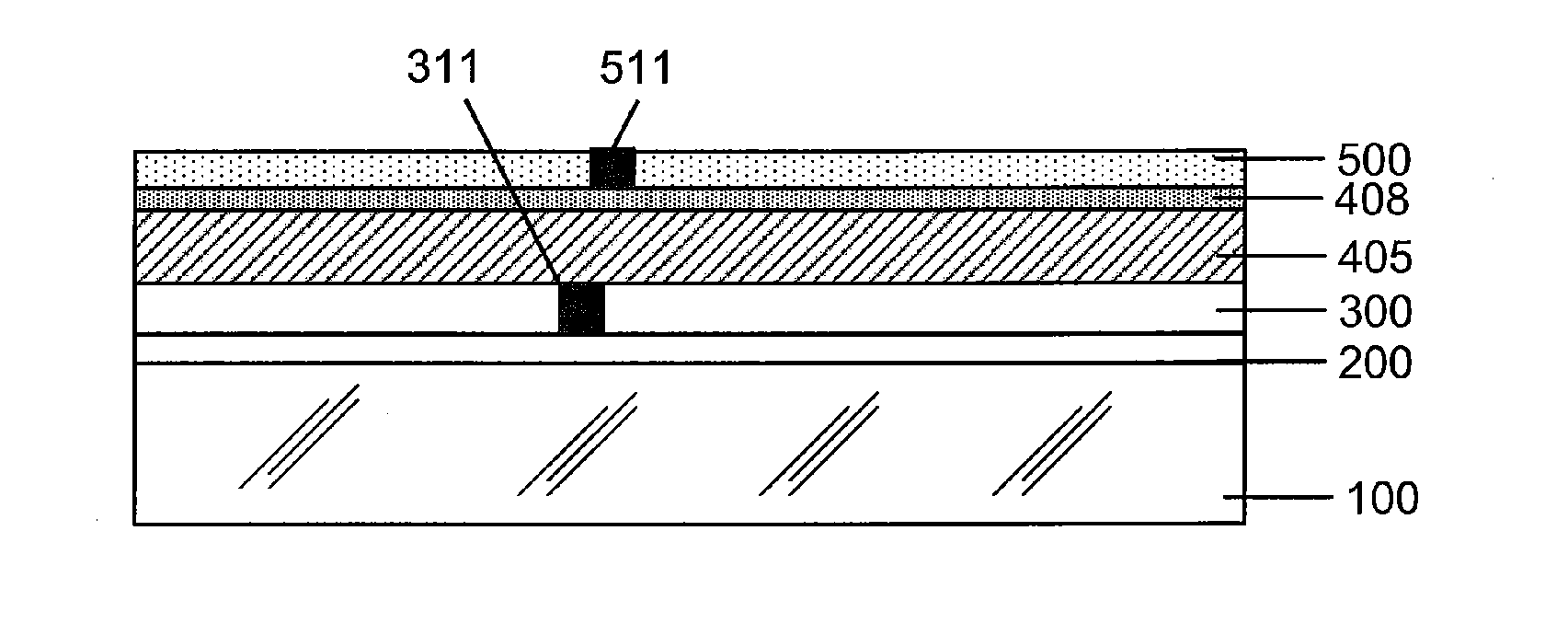

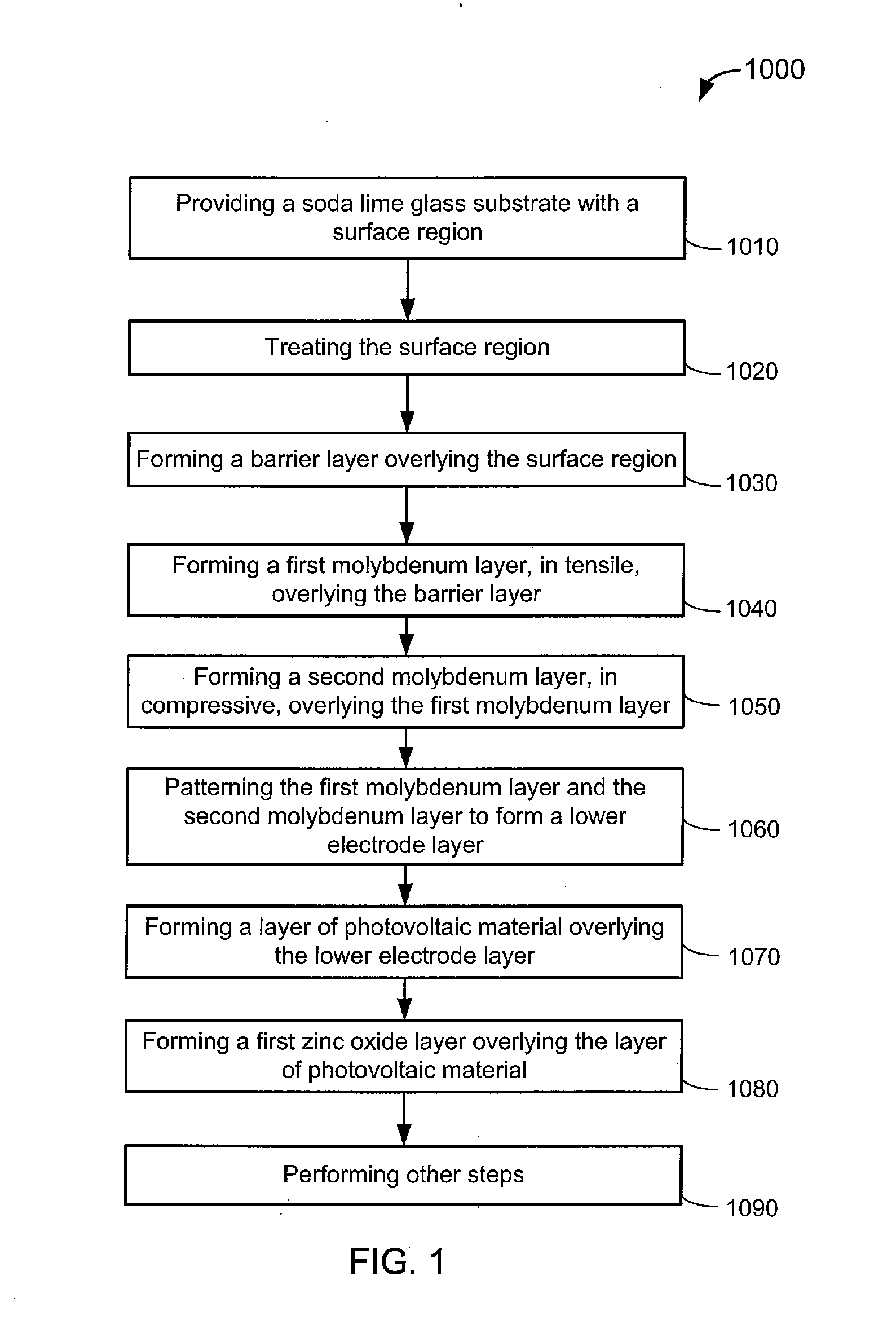

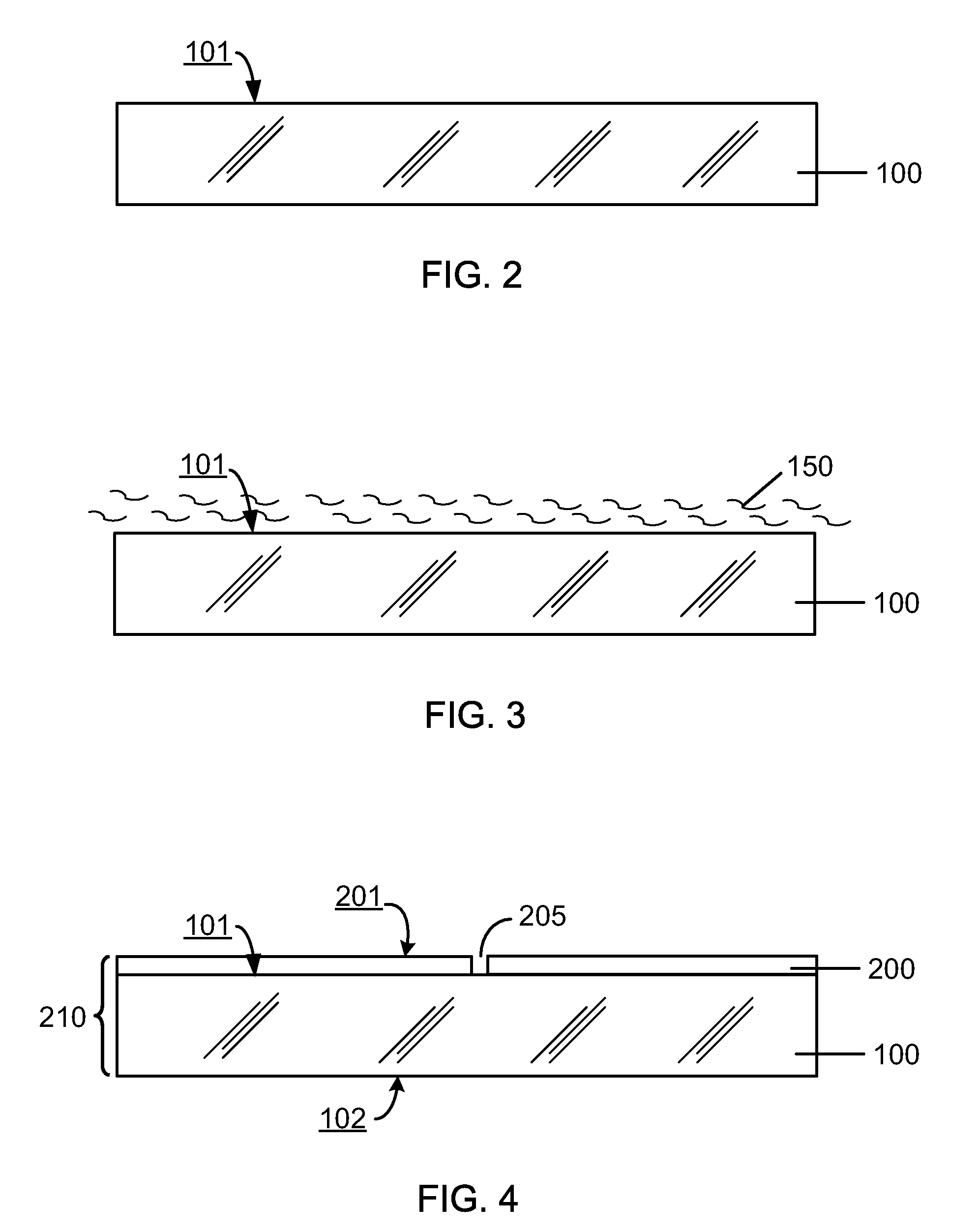

Thin film sodium species barrier method and structure for cigs based thin film photovoltaic cell

InactiveUS20100258179A1Large grainImprove efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationOptoelectronicsSpecies barrier

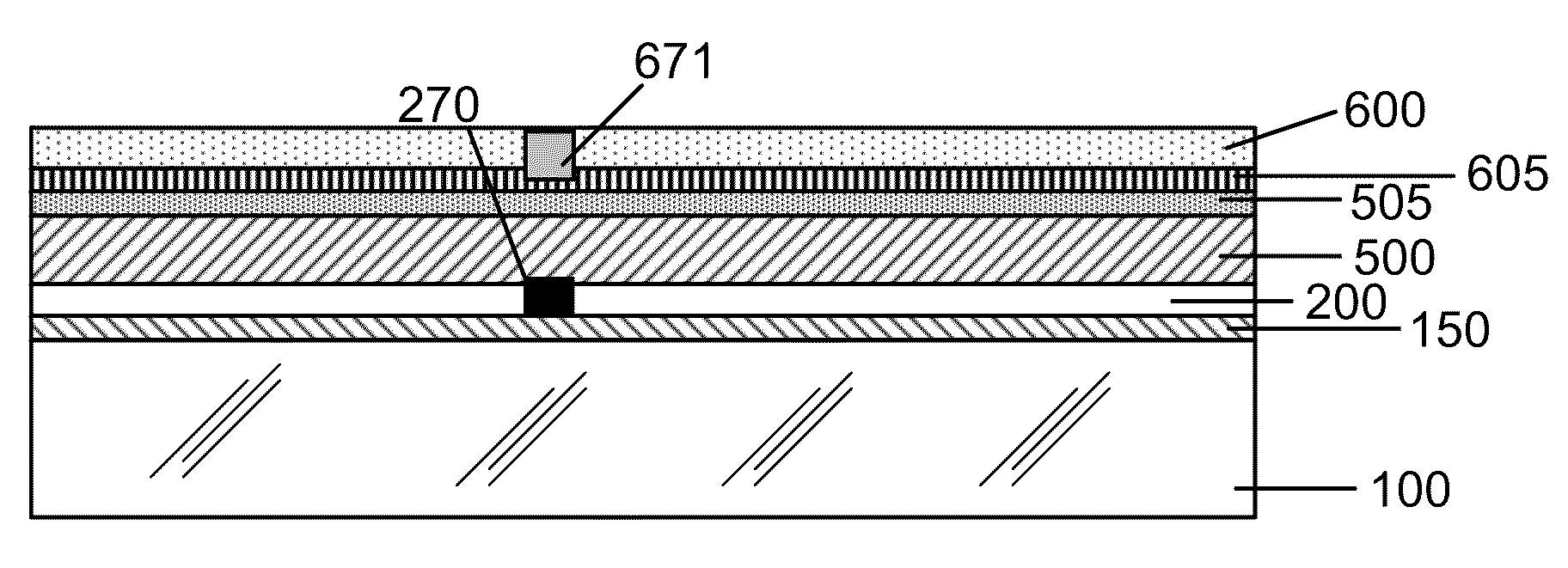

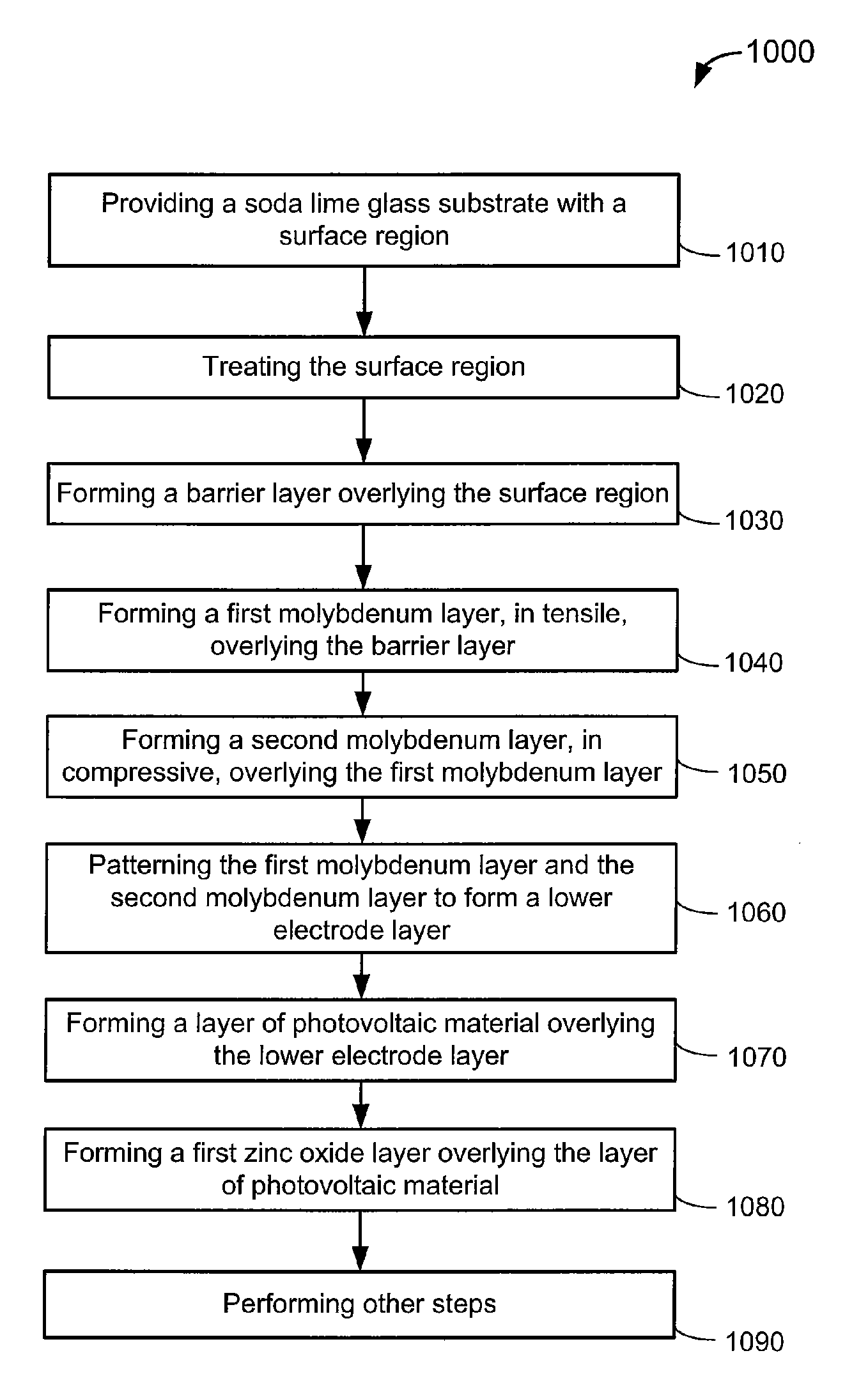

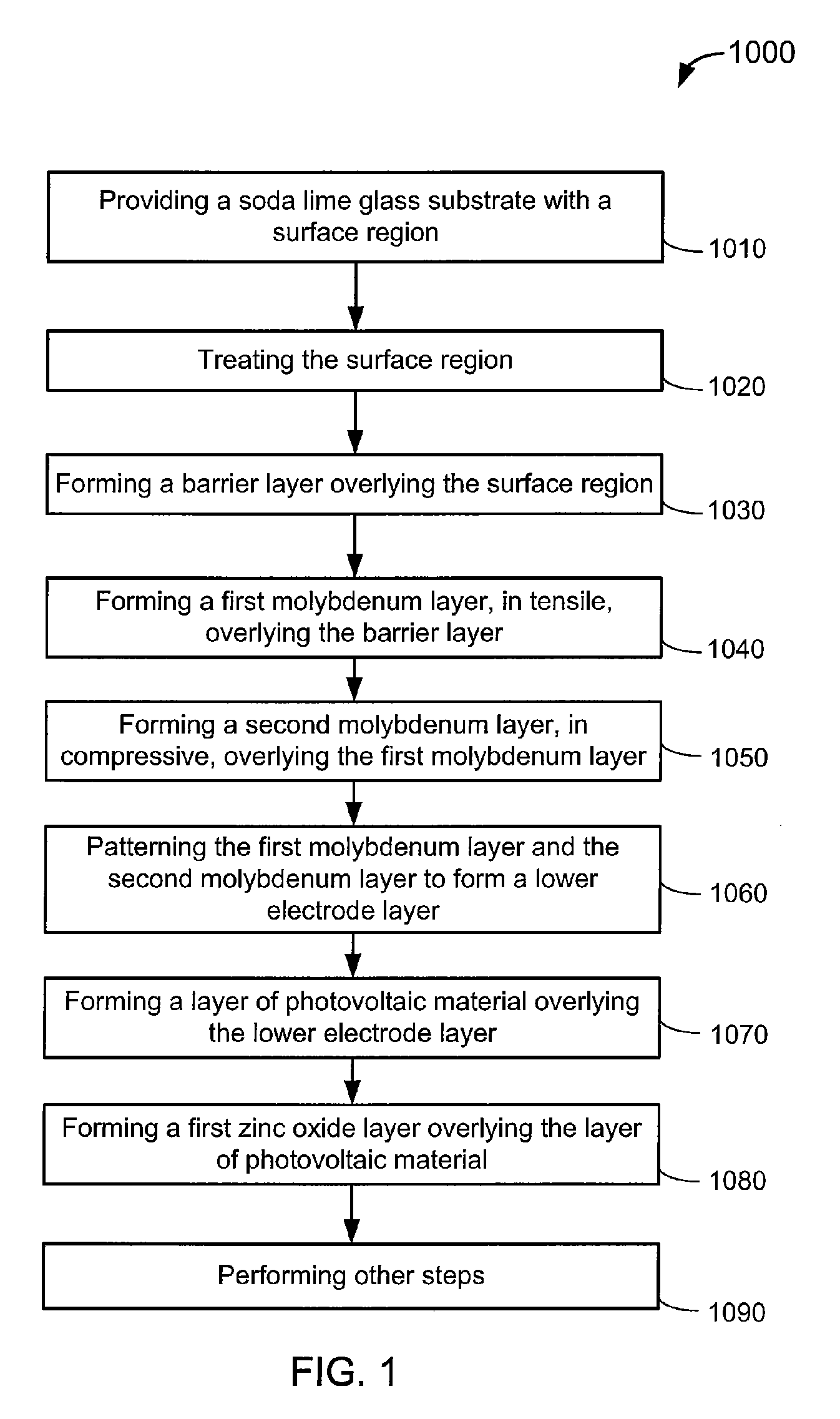

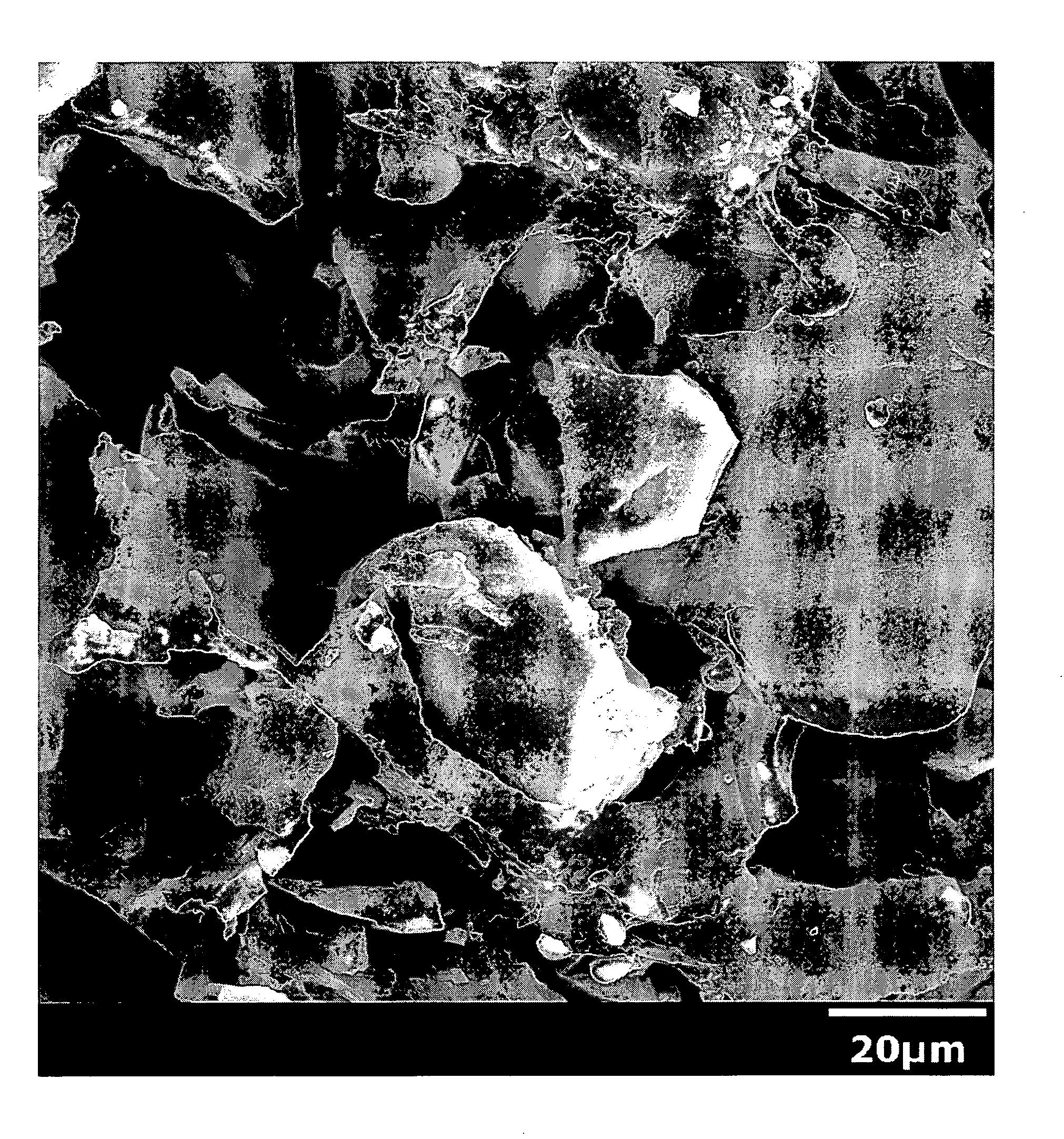

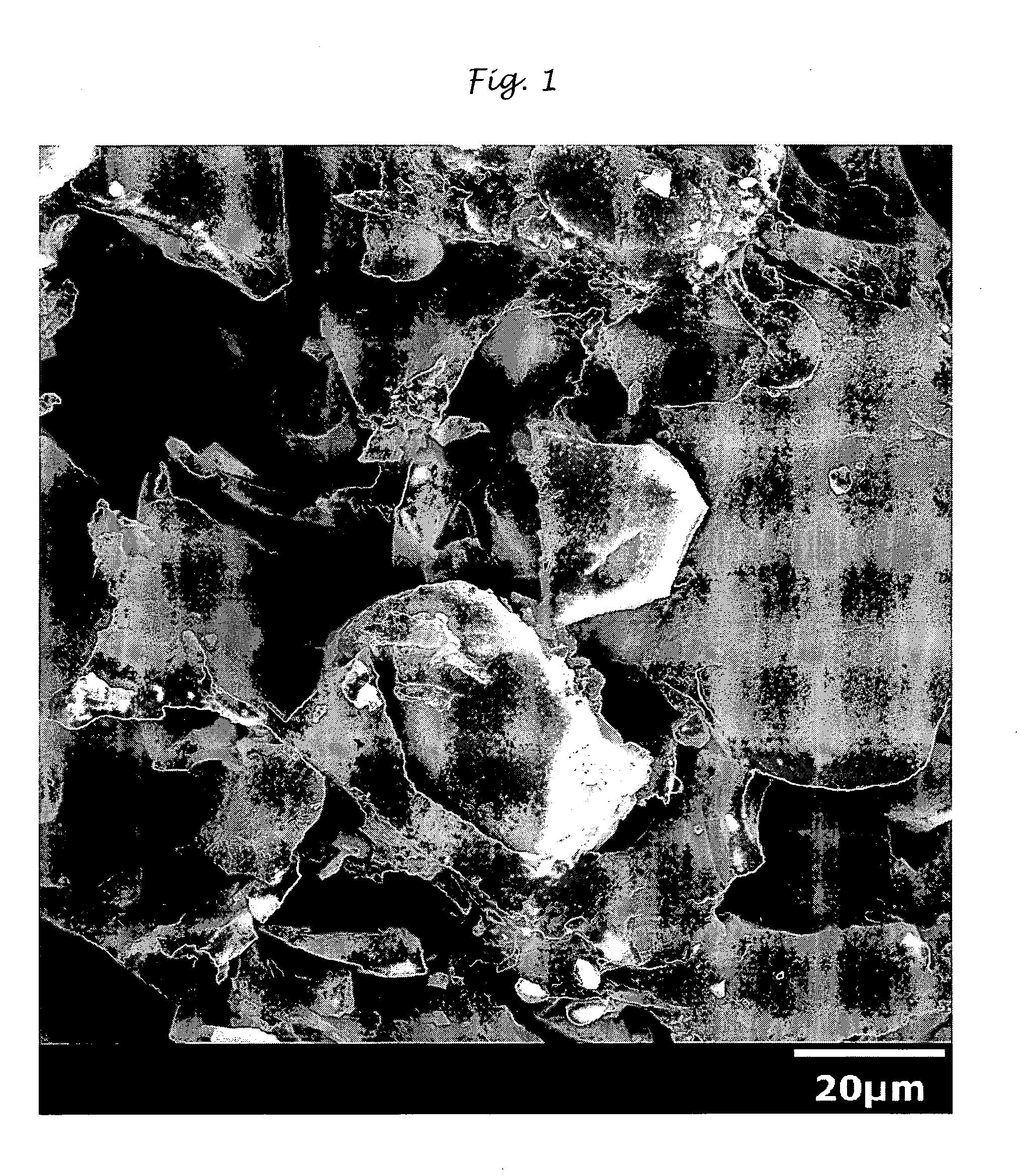

A method for fabricating a thin film solar cell includes providing a soda lime glass substrate comprising a surface region and a concentration of sodium oxide of greater than about 10 wt % and treating the surface region with one or more cleaning process, using a deionized water rinse, to remove surface contaminants having a particles size of greater than three microns. The method also includes forming a barrier layer overlying the surface region, forming a first molybdenum layer in tensile configuration overlying the barrier layer, and forming a second molybdenum layer in compressive configuration using a second process overlying the first molybdenum layer. Additionally, the method includes patterning the first molybdenum layer and the second molybdenum layer to form a lower electrode layer and forming a layer of photovoltaic material overlying the lower electrode layer. Moreover, the method includes forming a first zinc oxide layer overlying the layer of photovoltaic materials.

Owner:CM MFG

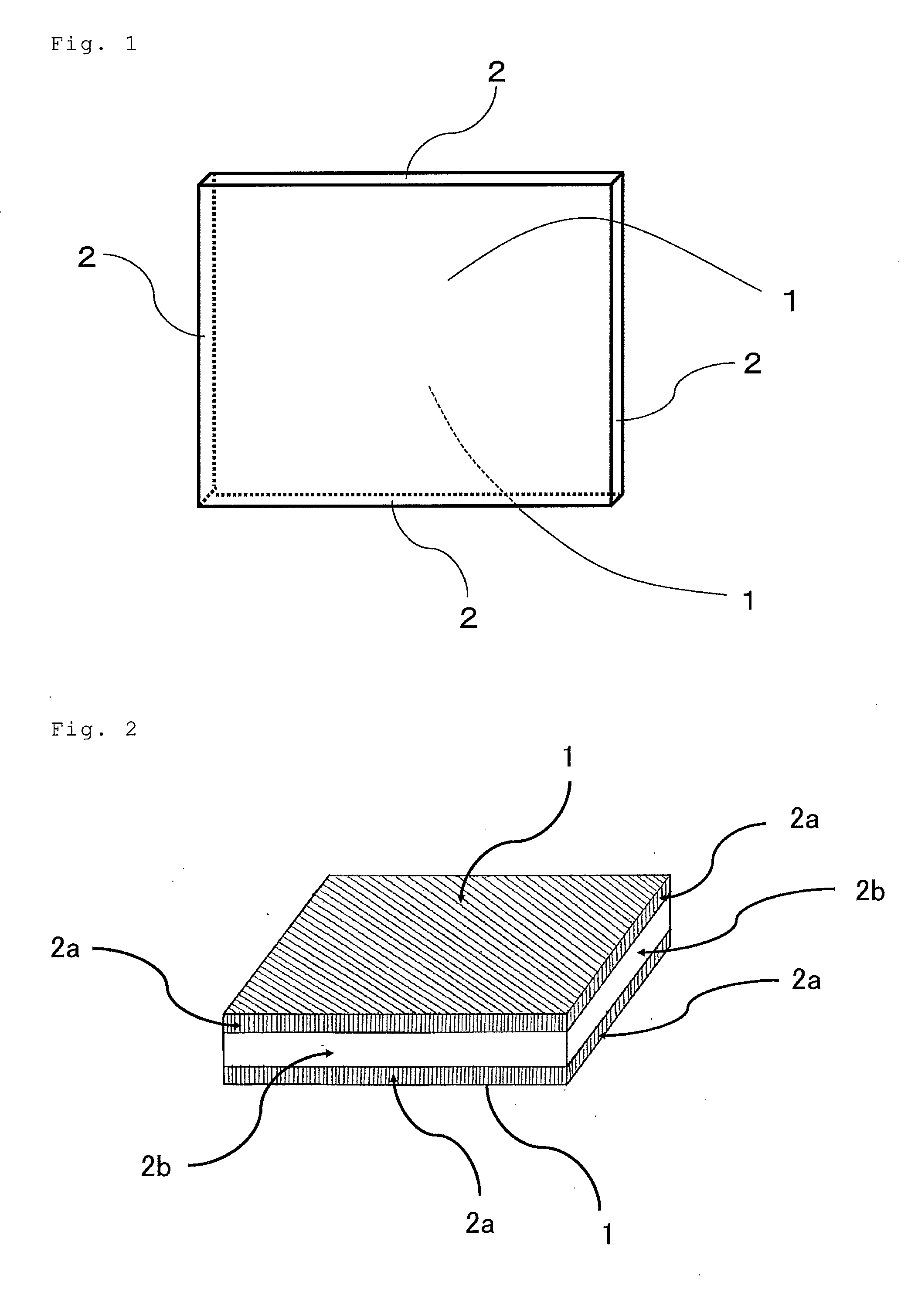

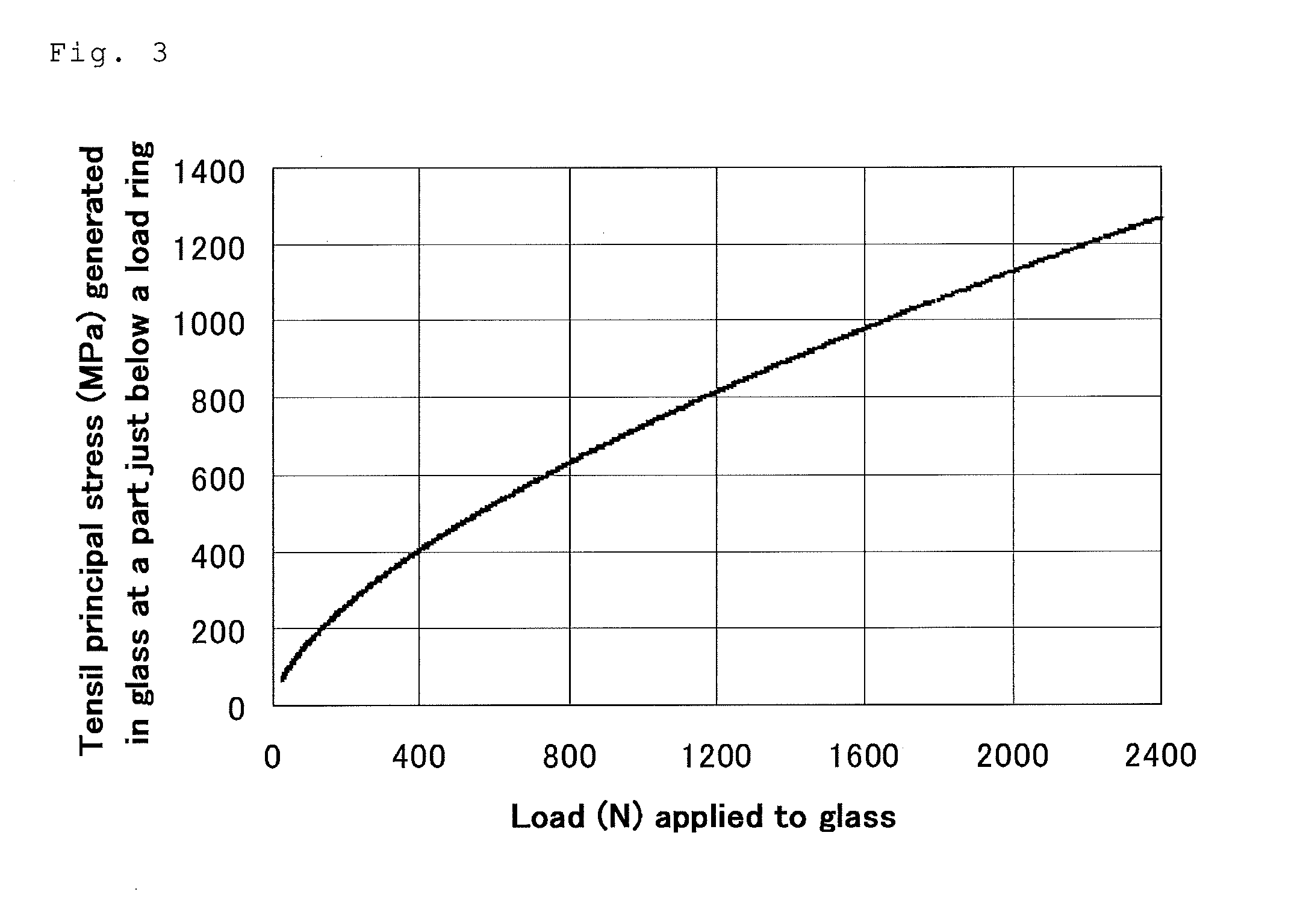

Cover glass for display device, and manufacturing method for same

InactiveUS20140227525A1High mechanical strengthHigh strengthGlass/slag layered productsDisplay deviceIon exchange

The present invention aims to provide a cover glass for display devices, made of soda-lime glass, excellent in cutting easiness and reliability of surface strength. The cover glass for display devices of the present invention includes a chemically strengthened glass, and has a compressive stress layer having a depth of 6 to 15 μm.In the cover glass, a shape parameter determined in accordance with JIS R 1625 (1996) based on analysis of a facture stress of the cover glass measured by a coaxial double ring test is not less than 7, and strength of the cover glass when a cumulative fracture probability is 1% is not less than 450 MPa.The glass plate before the ion exchange is made of soda-lime glass.

Owner:CENT GLASS CO LTD

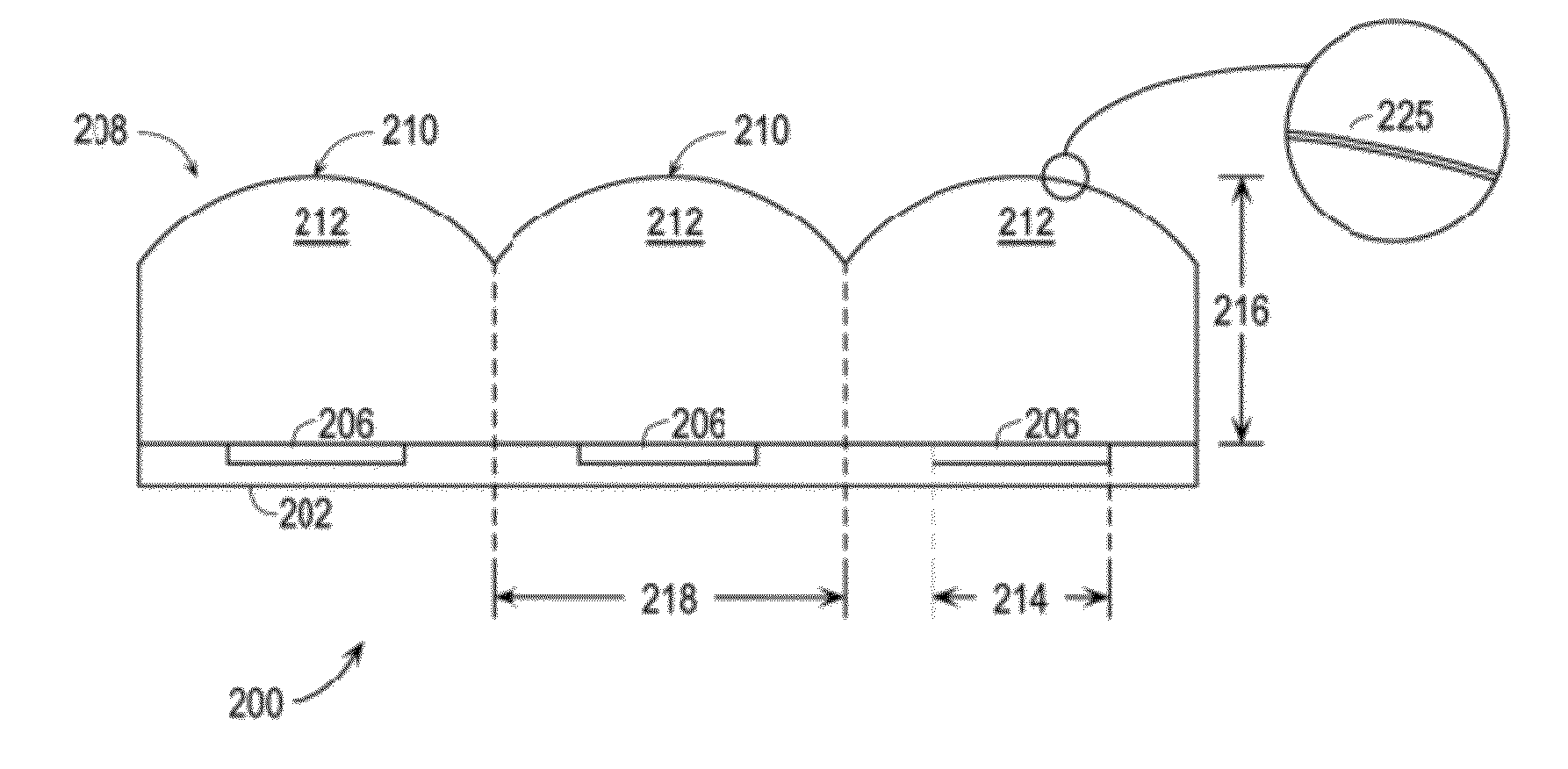

High impact and load bearing solar glass for a concentrated large area solar module and method

InactiveUS20120167946A1Simple structureReduce the amount requiredPV power plantsPhotovoltaic energy generationEngineeringSoda-lime glass

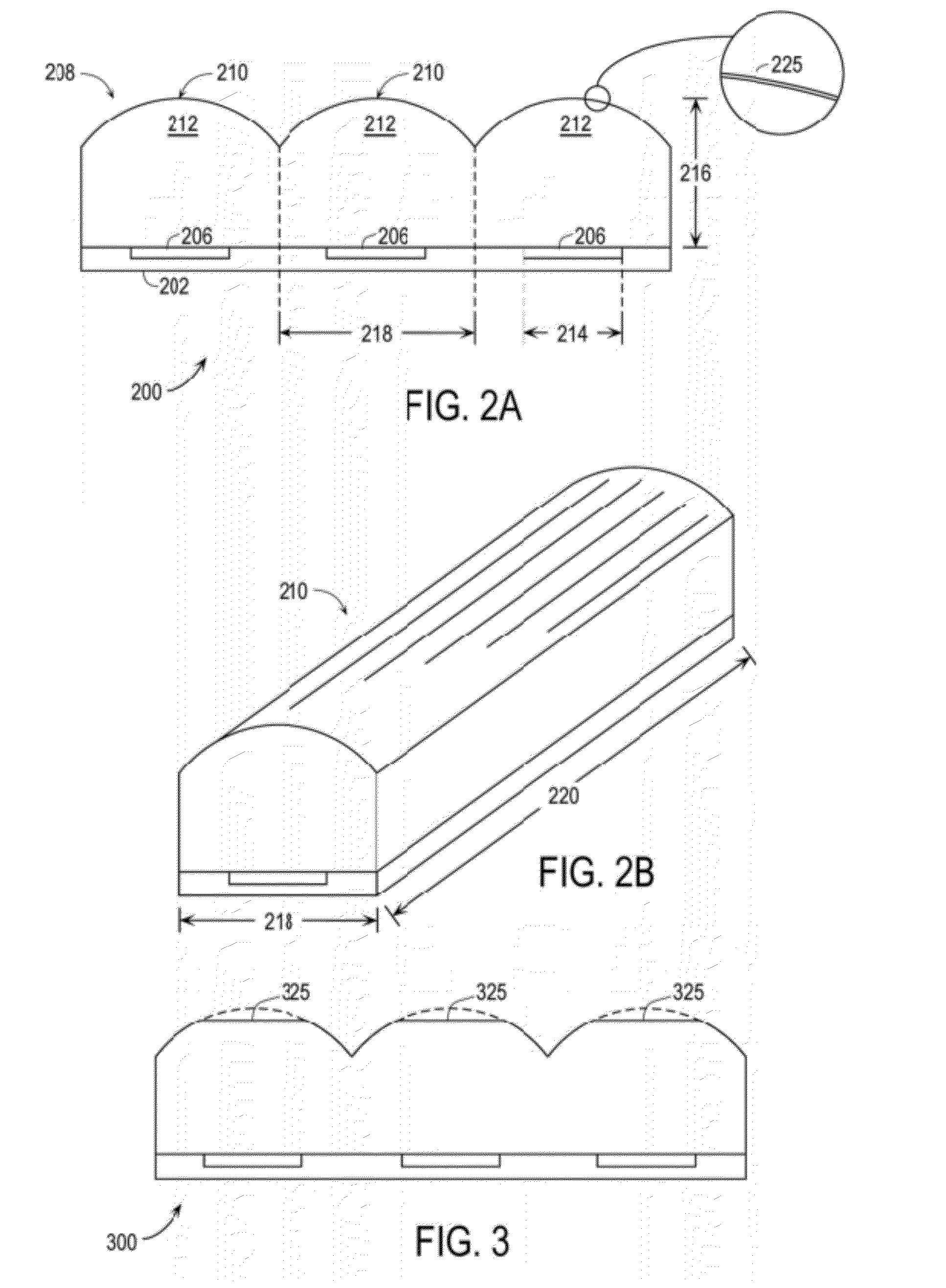

A solar module device. The device has a substrate having a surface region. The device has one or more photovoltaic regions overlying the surface region of the substrate. In a preferred embodiment, each of the photovoltaic strips is derived from dicing a solar cell in to each of the strips. Each of the strips is a functional solar cell. The device also has an impact resistant glass member having a plurality of elongated concentrating elements spatially arranged in parallel configuration and operably coupled respectively to the plurality of elongated concentrating elements. Preferably, the impact resistant glass has a strength of at least 3× greater than a soda lime glass, e.g., conventional soda lime glass for conventional solar cells, e.g., a low iron soda lime glass. In a preferred embodiment, the impact resistant glass member comprises a planar region and a concentrator region comprising the plurality of elongated concentrating element spatially arranged in parallel configuration.

Owner:SOLARIA CORP

Thin film sodium species barrier method and structure for cigs based thin film photovoltaic cell

InactiveUS8217261B2Large grainImprove efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationBarrier methodWater rinsing

Owner:CM MFG

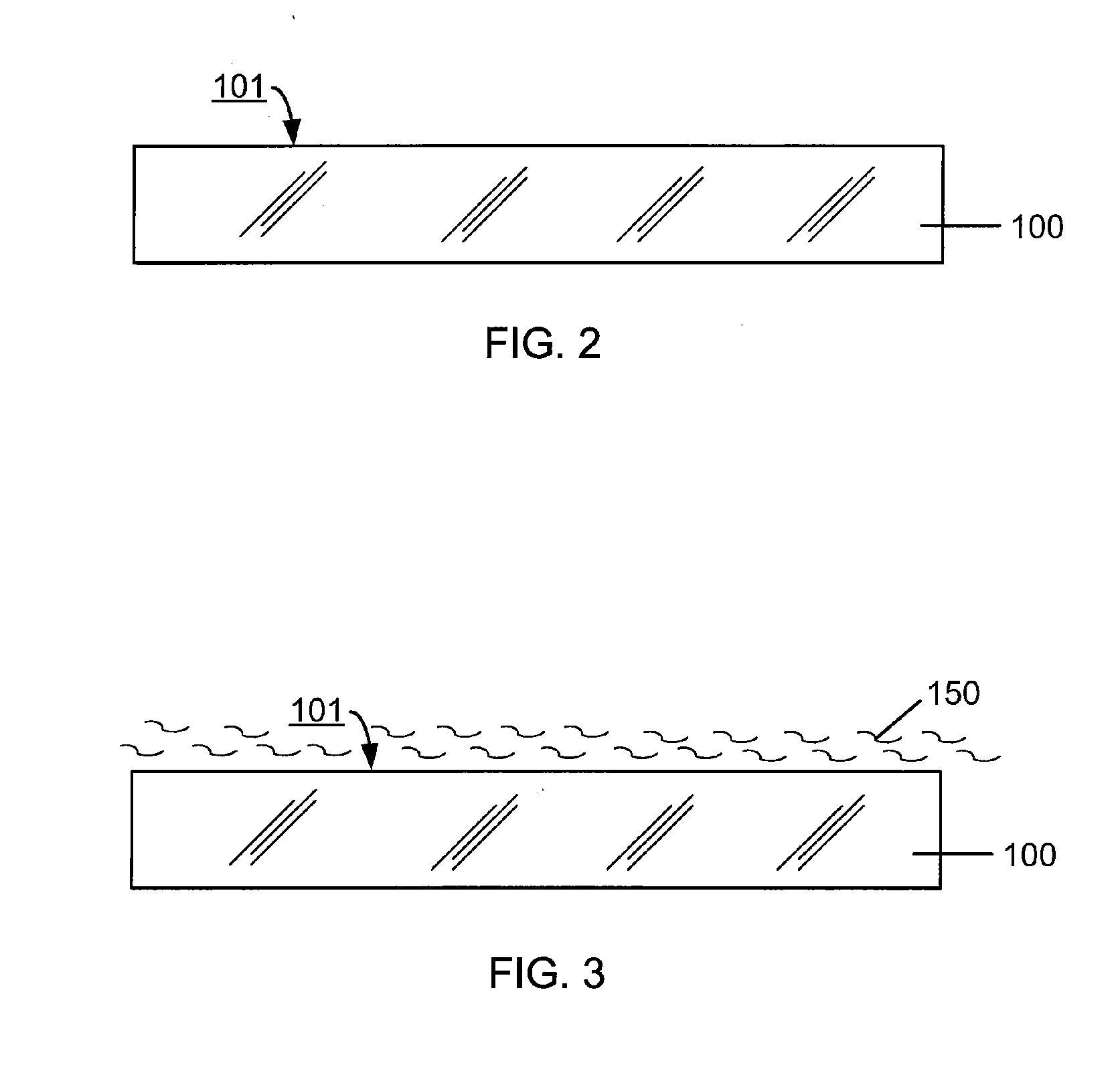

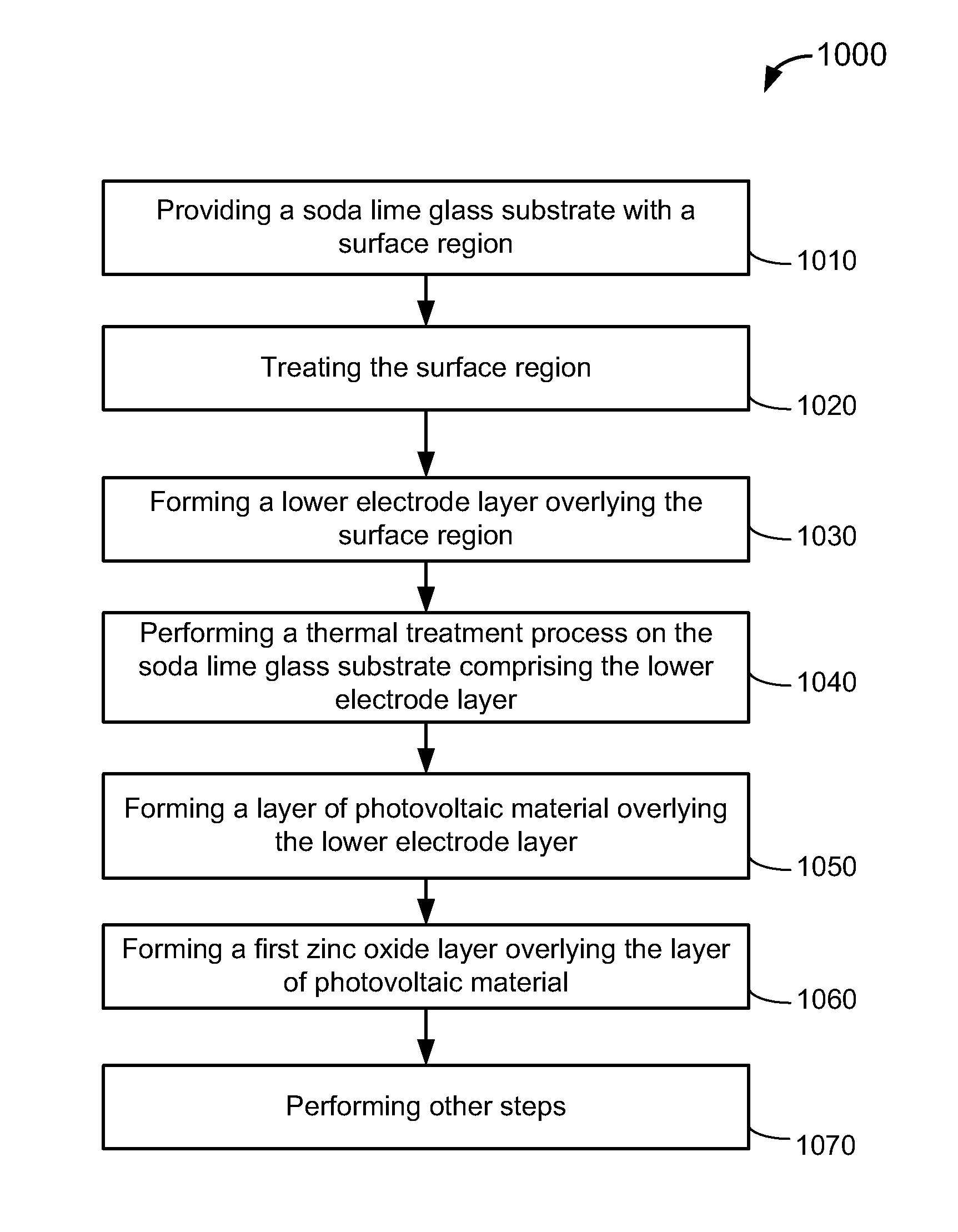

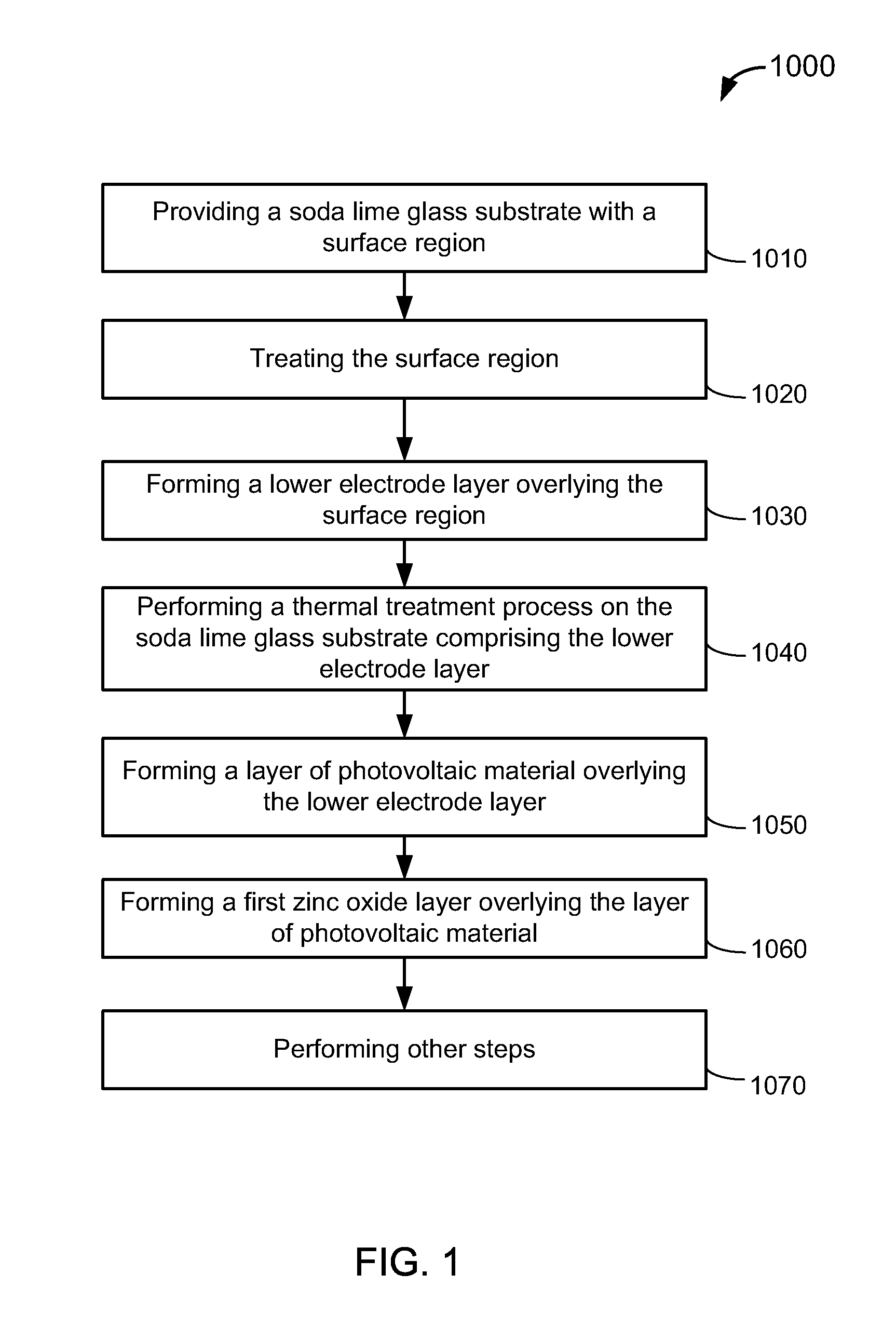

Thermal pre-treatment process for soda lime glass substrate for thin film photovoltaic materials

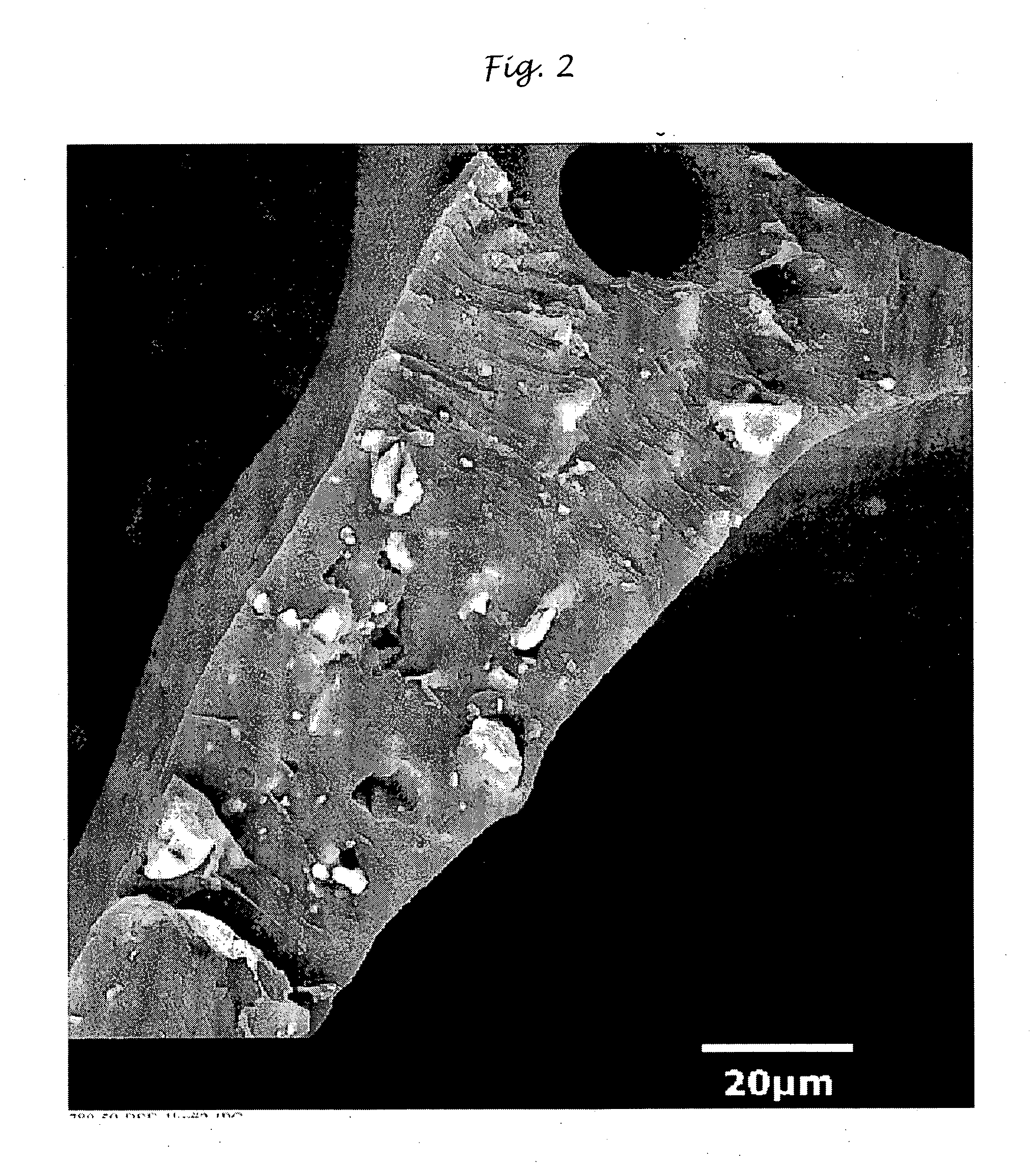

InactiveUS20110020980A1Easy to implementHigh efficiency photovoltaic absorber layerFinal product manufactureSemiconductor/solid-state device manufacturingMaterials scienceSoda-lime glass

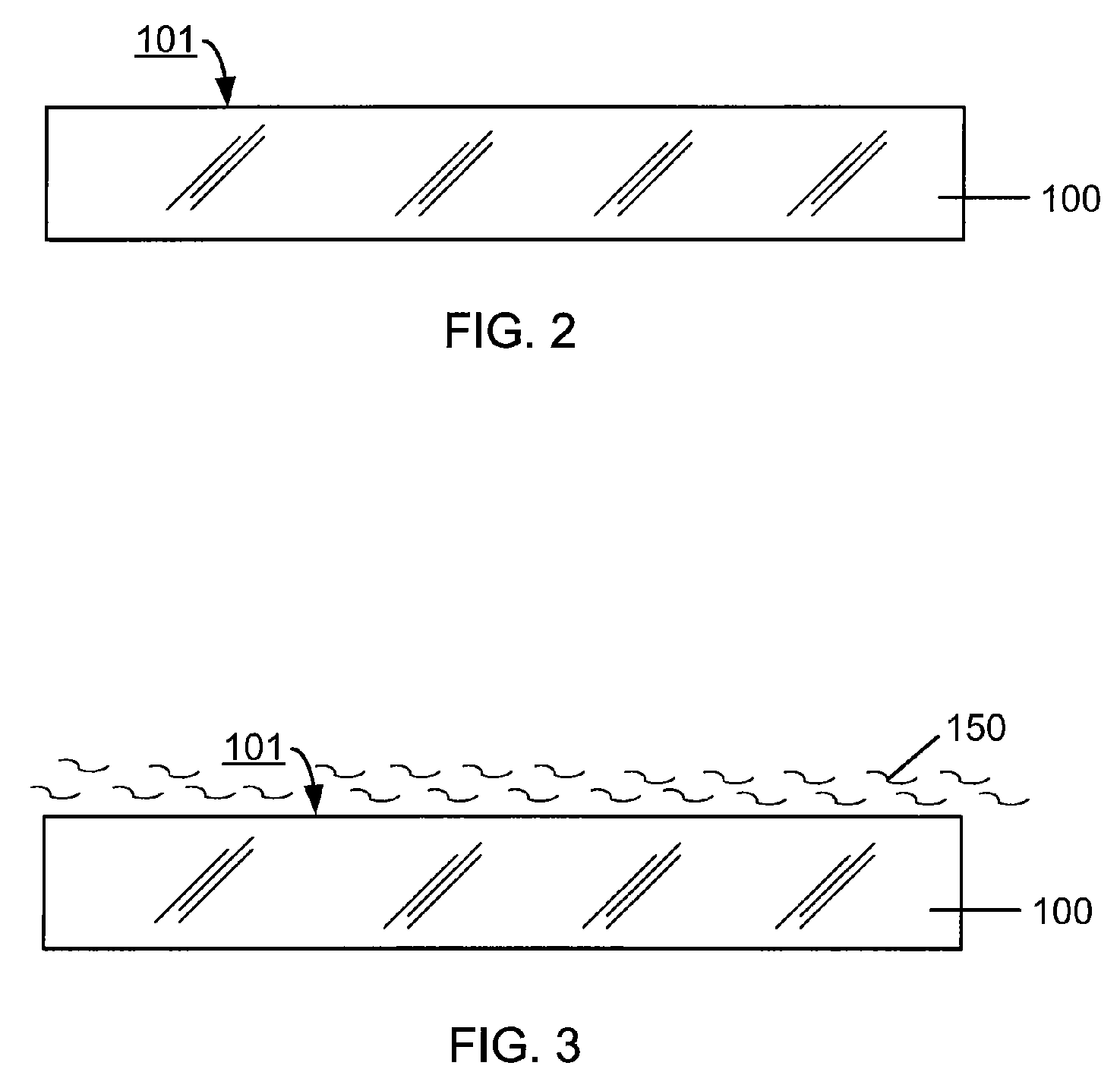

A method for fabricating a thin film solar cell includes providing a soda lime glass substrate comprising a surface region, treating the surface region with one or more cleaning process including an aqueous solution to remove one or more contaminants and / or particulates, and forming a lower electrode layer overlying the surface region. The method also includes performing a thermal treatment process to remove any residual water species to substantially less than a monolayer of water species from the lower electrode layer and soda lime glass substrate. The thermal treatment process changes a temperature of the soda lime glass substrate from a first temperature to a second temperature to pre-heat the soda lime glass substrate. Additionally, the method includes transferring the soda lime glass substrate, which has been preheated, to a deposition chamber and forming a layer of photovoltaic material overlying the lower electrode layer within the deposition chamber.

Owner:CM MFG

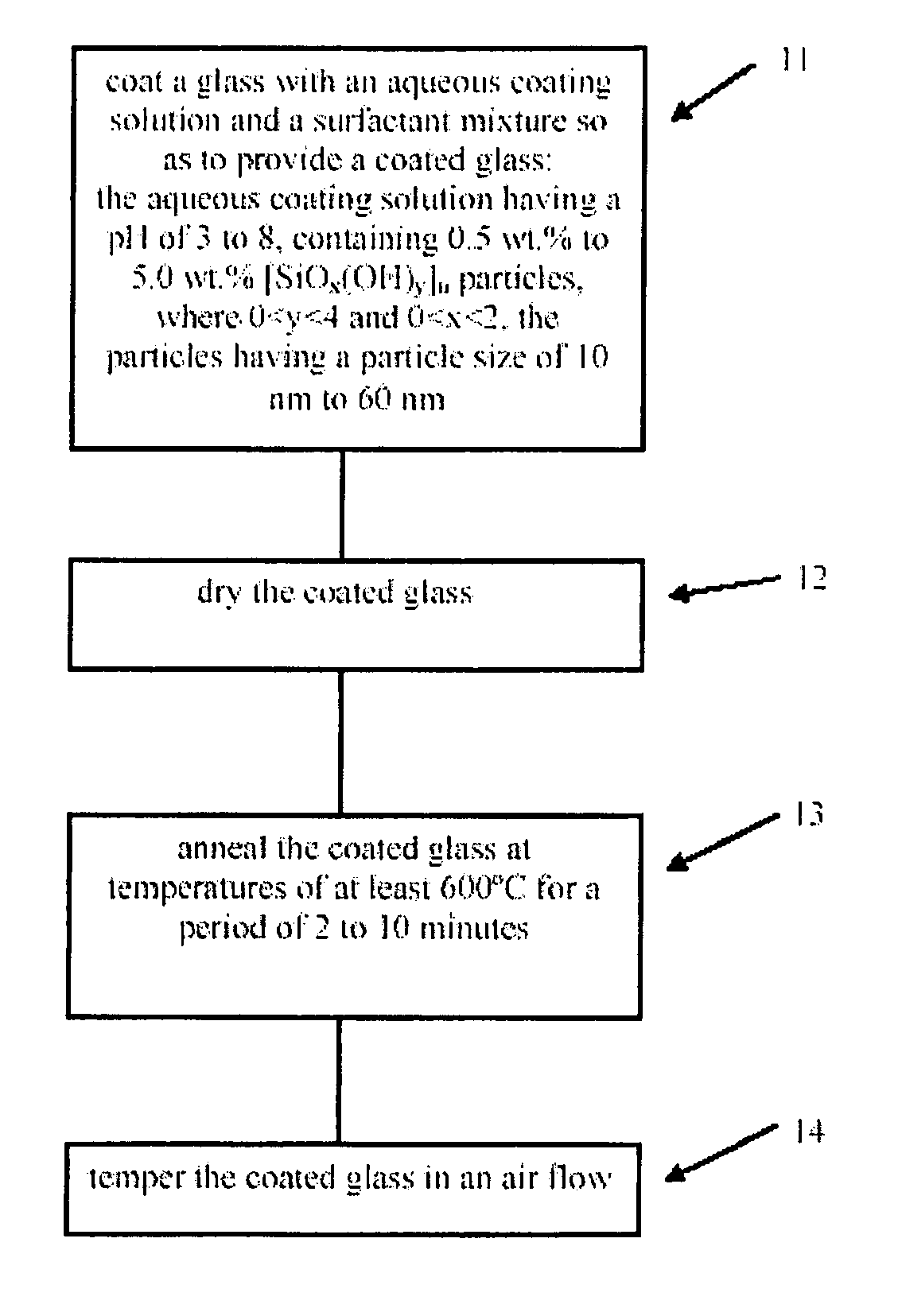

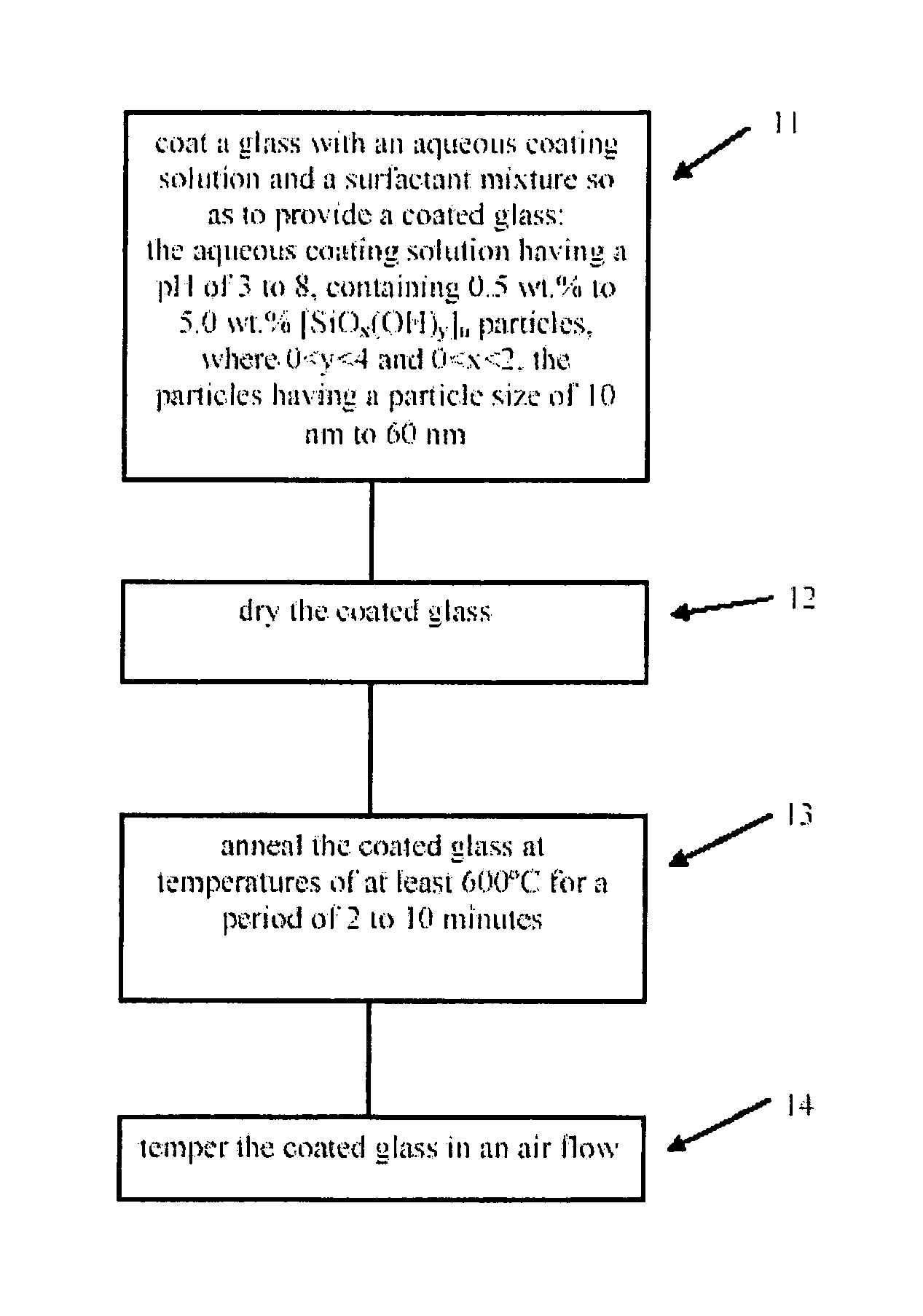

Method for making thermally tempered glass comprising a non-abrasive, porous, SiO2 antireflection layer

InactiveUS7128944B2Easy to operateSpread the wordLayered productsPretreated surfacesRefractive indexPolymer chemistry

The invention relates to thermally tempered safety glass comprising an non-abrasive and porous SiO2 layer which is stable during sintering and has a refractive index of between 1.25 and 1.40. The inventive safety glass can be obtained by coating standard soda-lime glass with an aqueous coating solution having a pH value of between 3 and 8 and containing between 0.5 and 5.0 wt. % of [SiOx(OH)y]n particles (0<y<4 and 0<x<2) having a particle size of between 10 and 60 nm, and a surfactant mixture. The coated glass is then dried, thermally hardened at temperatures of at least 600° C. for several minutes, and thermally tempered by a flow of air.

Owner:DUCATT NV

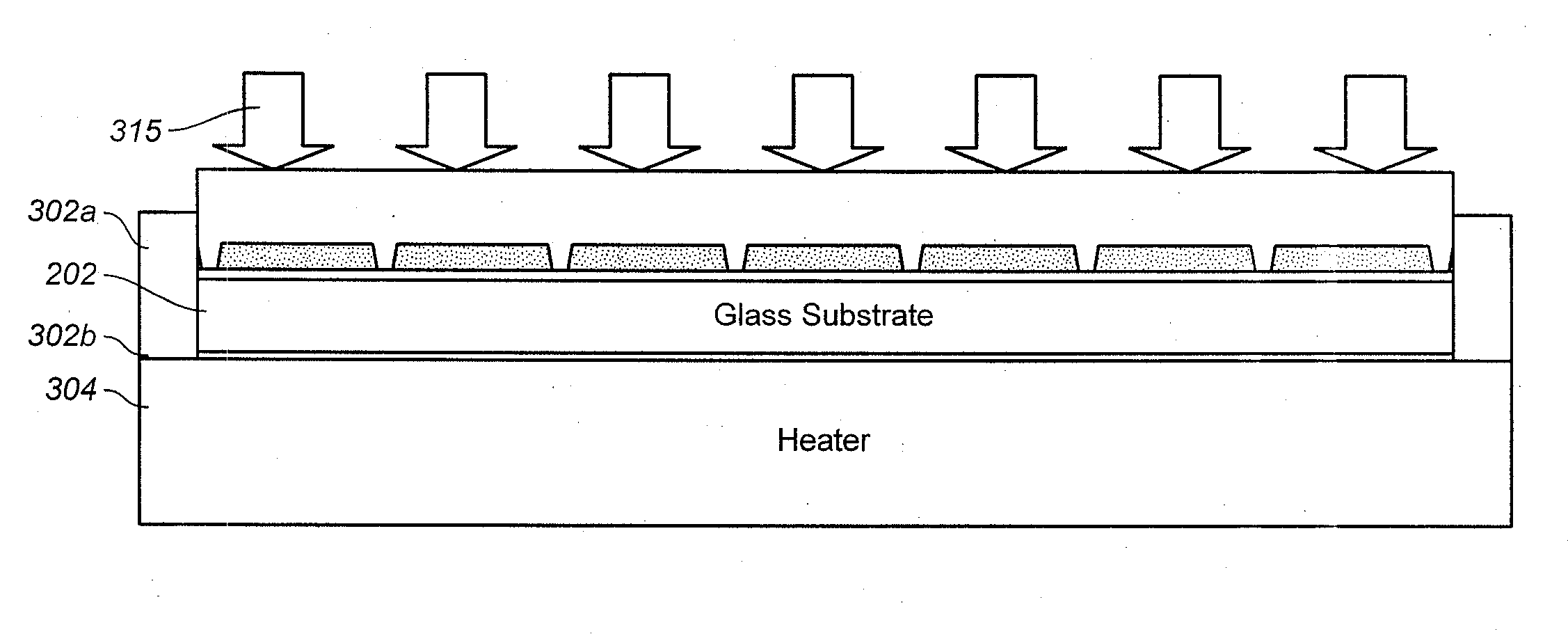

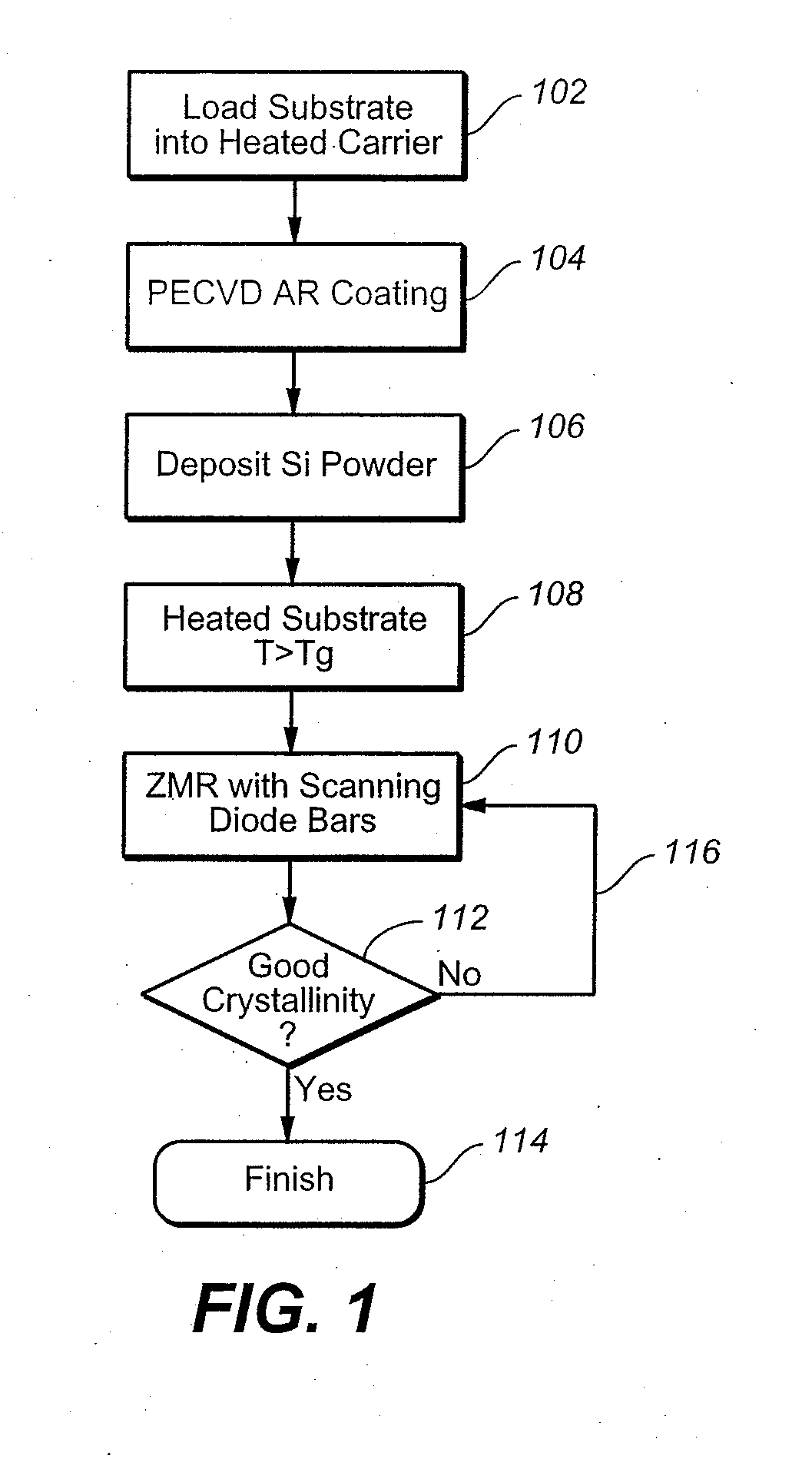

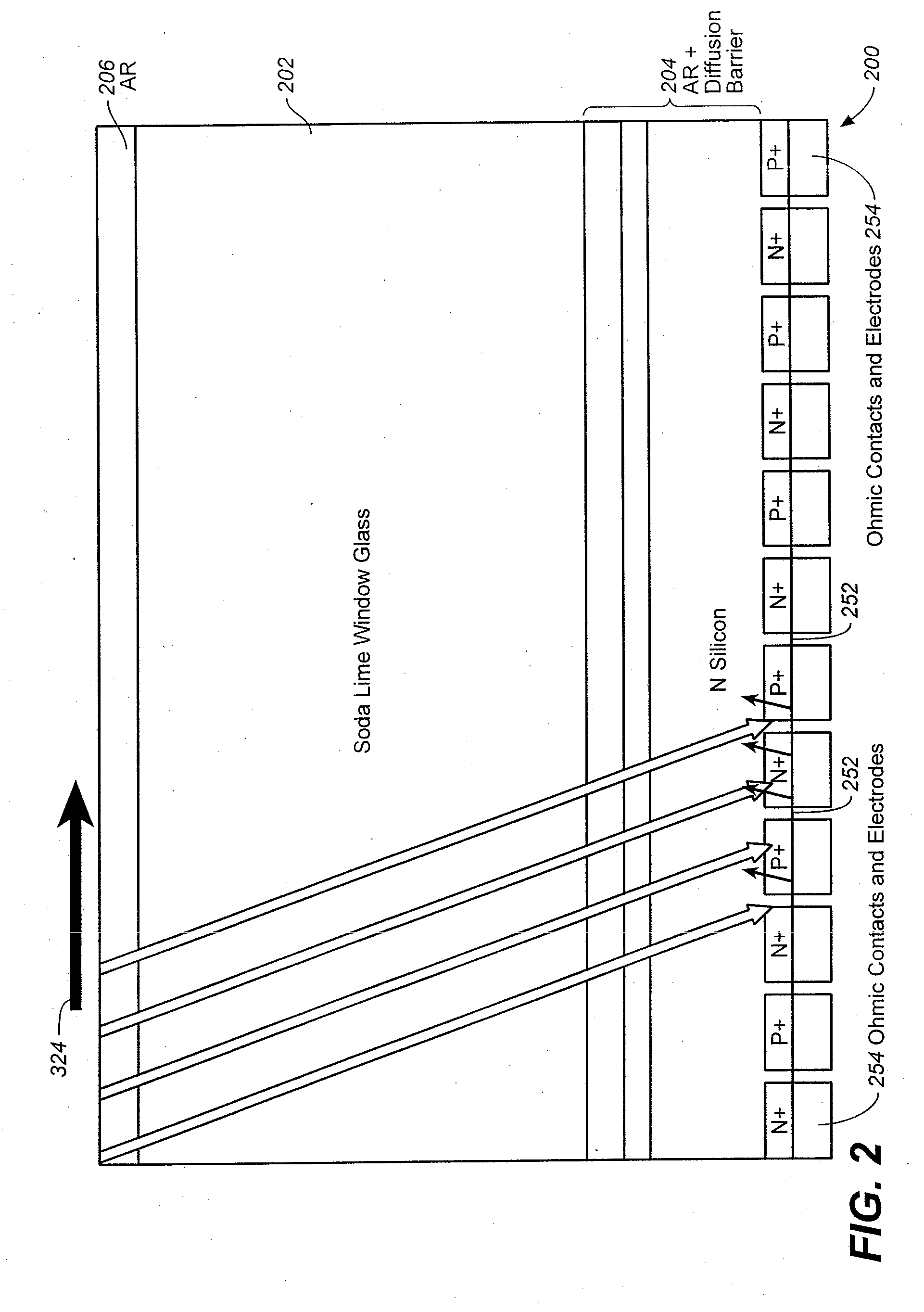

Thick Crystalline Silicon Film On Large Substrates for Solar Applications

InactiveUS20080295885A1Polycrystalline material growthFinal product manufactureElectricityCrystalline silicon

An apparatus for converting sunlight to electricity comprises a sheet of soda lime glass having a softening point not exceeding 600° C. and a layer of crystalline silicon over said sheet of soda lime glass. The layer has a thickness not less than about 5 microns and grains with grain size not less than about 100 microns. A method for making a device for converting sunlight to electricity comprises forming a film on a soda lime glass substrate, dispersing silicon powder onto the film and pressing a surface onto the silicon powder to form a layer of silicon powder on said film. The substrate and film are heated from below to a temperature so that the soda lime glass substrate softens. While the substrate is in a softened state, the silicon powder layer is heated by scanning a line focus laser beam or an elongated heater strip over a spatial sequence of adjacent elongated zones of the silicon powder consecutively so that the silicon powder in each of the zones melts and recrystallizes consecutively to form a layer of crystalline silicon with a thickness in the range of 5 to 100 micron over said film. Preferably the laser beam or heater strip scans and heats a triangular area of the layer of silicon powder, where the area has an apex leading said scan area during scanning.

Owner:SOLAR NOTION

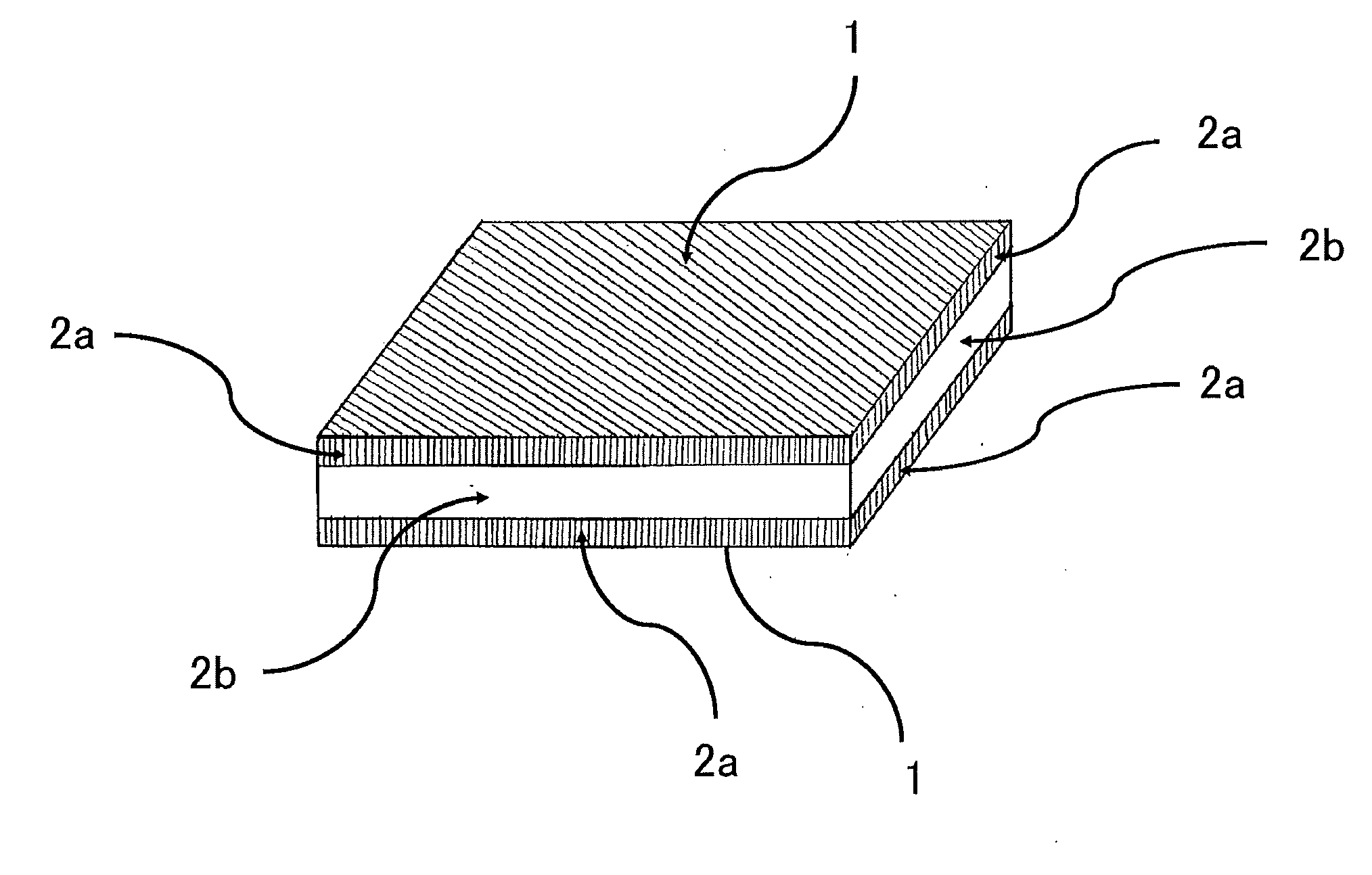

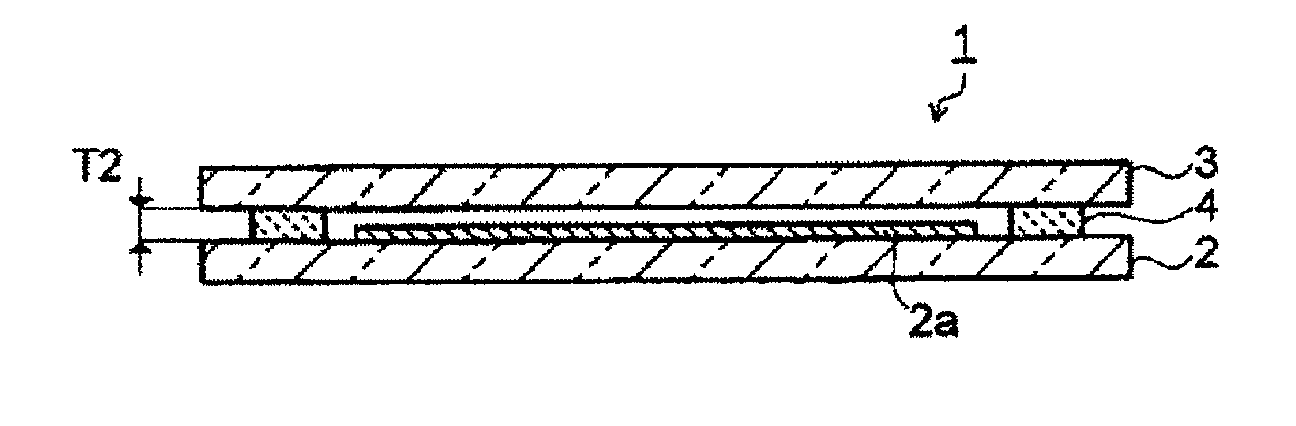

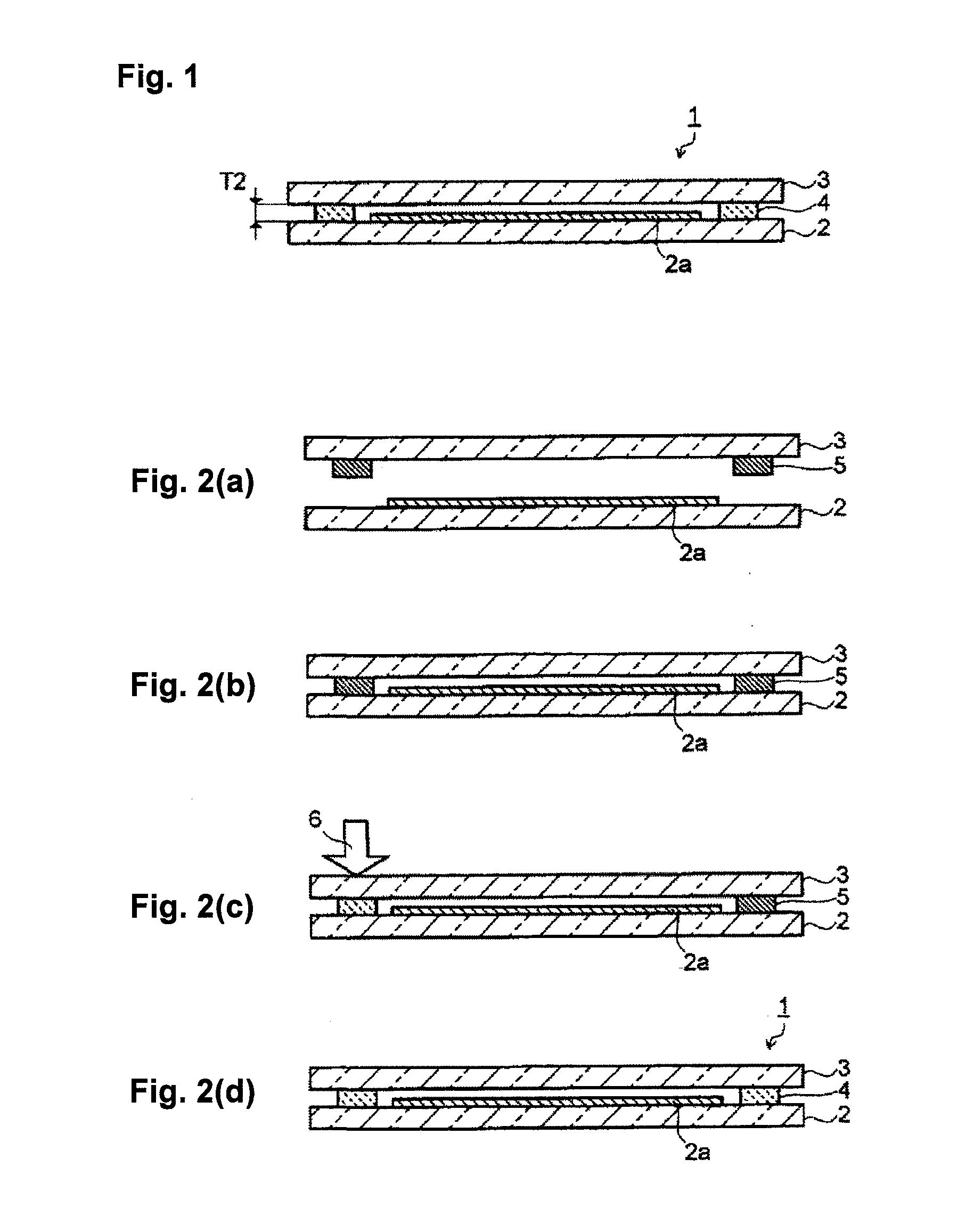

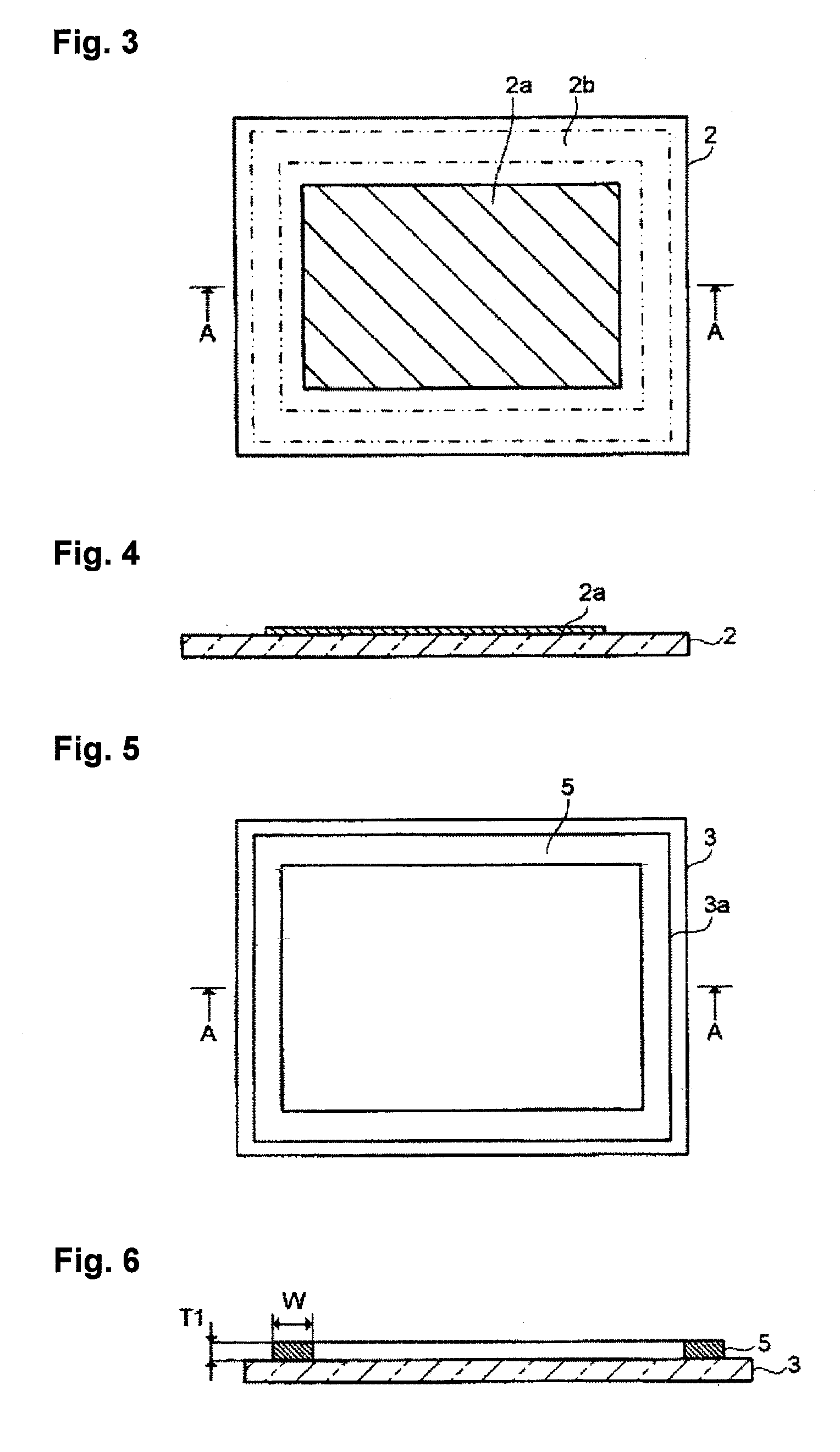

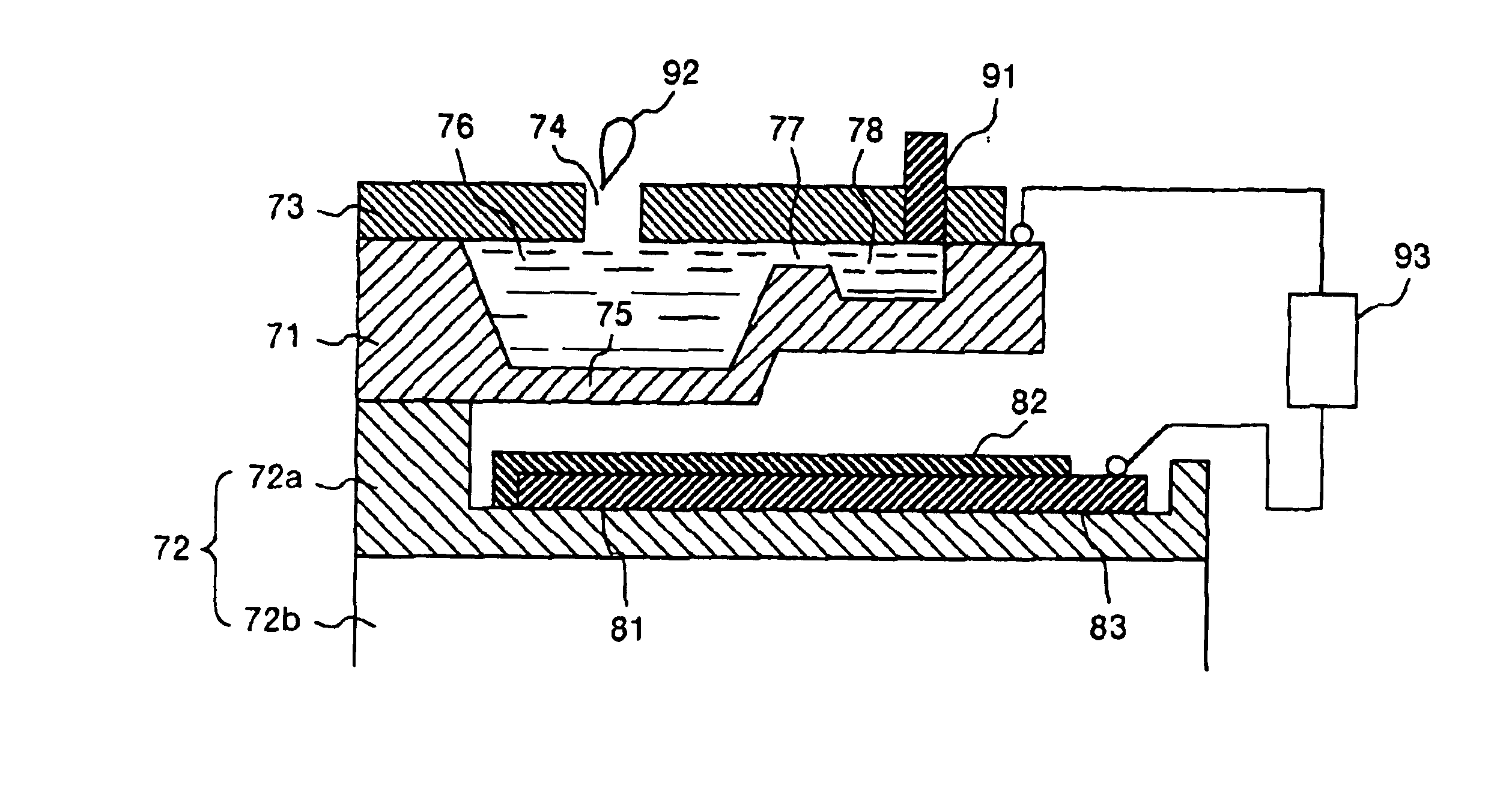

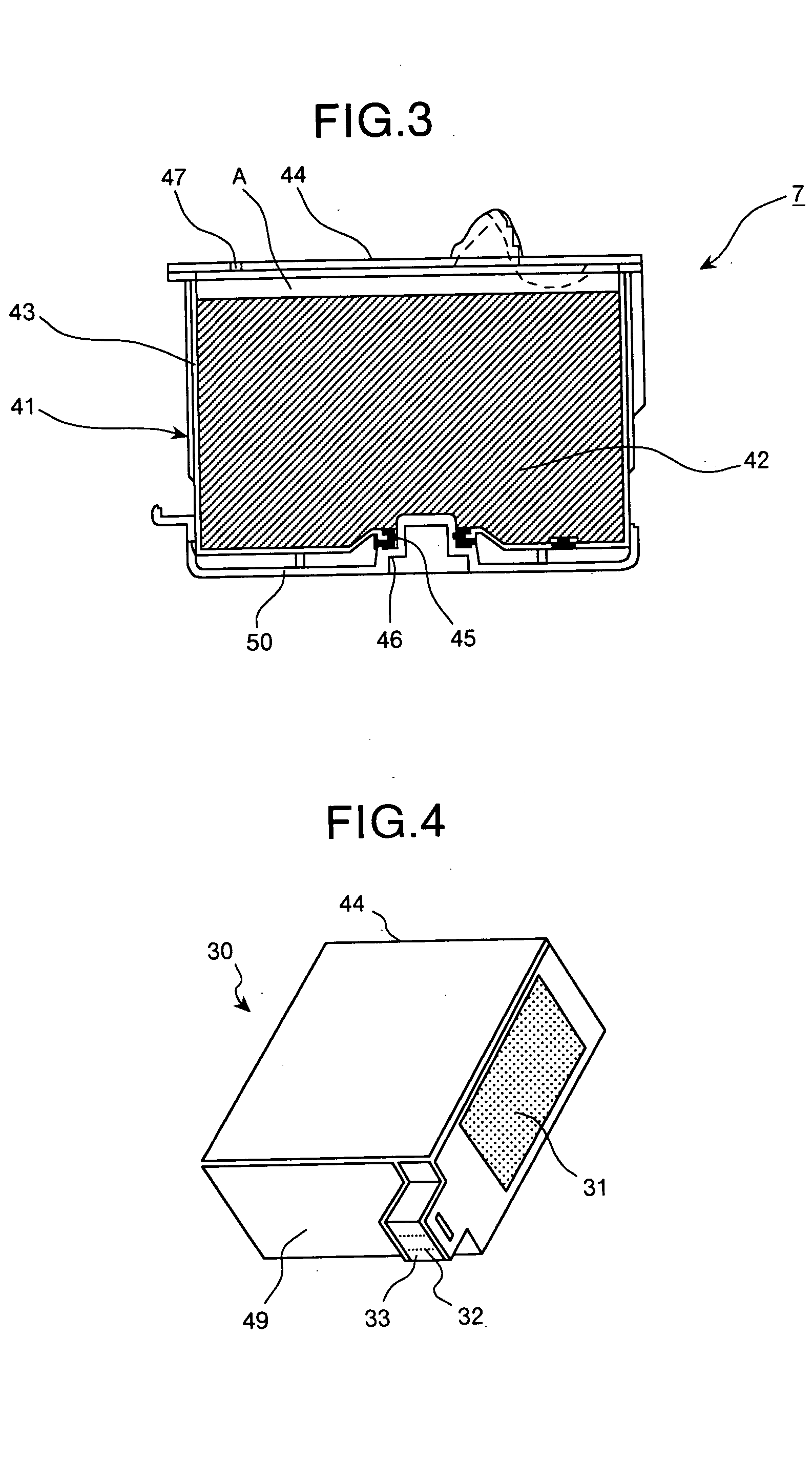

Sealing glass, glass member provided with sealing material layer, electronic device and process for producing it

InactiveUS20110223371A1High bonding strengthGood reproducibilityElectrolytic capacitorsFinal product manufactureLaser lightBonding strength

The bonding strength to a glass substrate comprising soda lime glass is increased with good reproducibility at a time of laser sealing, to improve the sealing ability and the reliability of an electronic device.A glass substrate 3 has a sealing region. On the sealing region, a sealing material layer 5 is provided, which is a fired layer of a glass material for sealing containing a sealing glass, a low-expansion filler and a laser absorbent. The sealing glass contains, as represented by mass percentage, from 70 to 90% of Bi2O3, from 1 to 20% of ZnO, from 2 to 12% of B2O3 and from 10 to 380 ppm of Na2O. Such a glass substrate 3 and a glass substrate 2 having an element-formed region provided with an electronic element, are laminated, the sealing material layer 5 is irradiated with a laser light 6 to be melted to bond the glass substrates 2 and 3.

Owner:ASAHI GLASS CO LTD

Composition of materials for production of acid resistant cement and concrete and methods thereof

InactiveUS6749679B2High strengthImprove moisture and high-temperature curing propertySolid waste managementAlkali metal silicate coatingsSlagPortland cement

A cement composition for use in acidic environment containing liquid alkali silicate, vitreous silicate setting agent, lime containing material and inert filler and building materials made therefrom as well as the method of making such building materials. The liquid alkali silicate may include sodium silicate or potassium silicate. The vitreous silicate setting agent may include soda-lime glass powder or coal fly ash. The lime containing material refers to the materials containing more than 20% lime and may include quicklime, hydrated lime, Portland cement, blast furnace slag or steel slag. The inert fillers include ground quartz, ground ceramic, and / or clay.

Owner:ADVANCED MATERIALS TECHNOLOGIES

Chemically strengthened glass and method for producing same

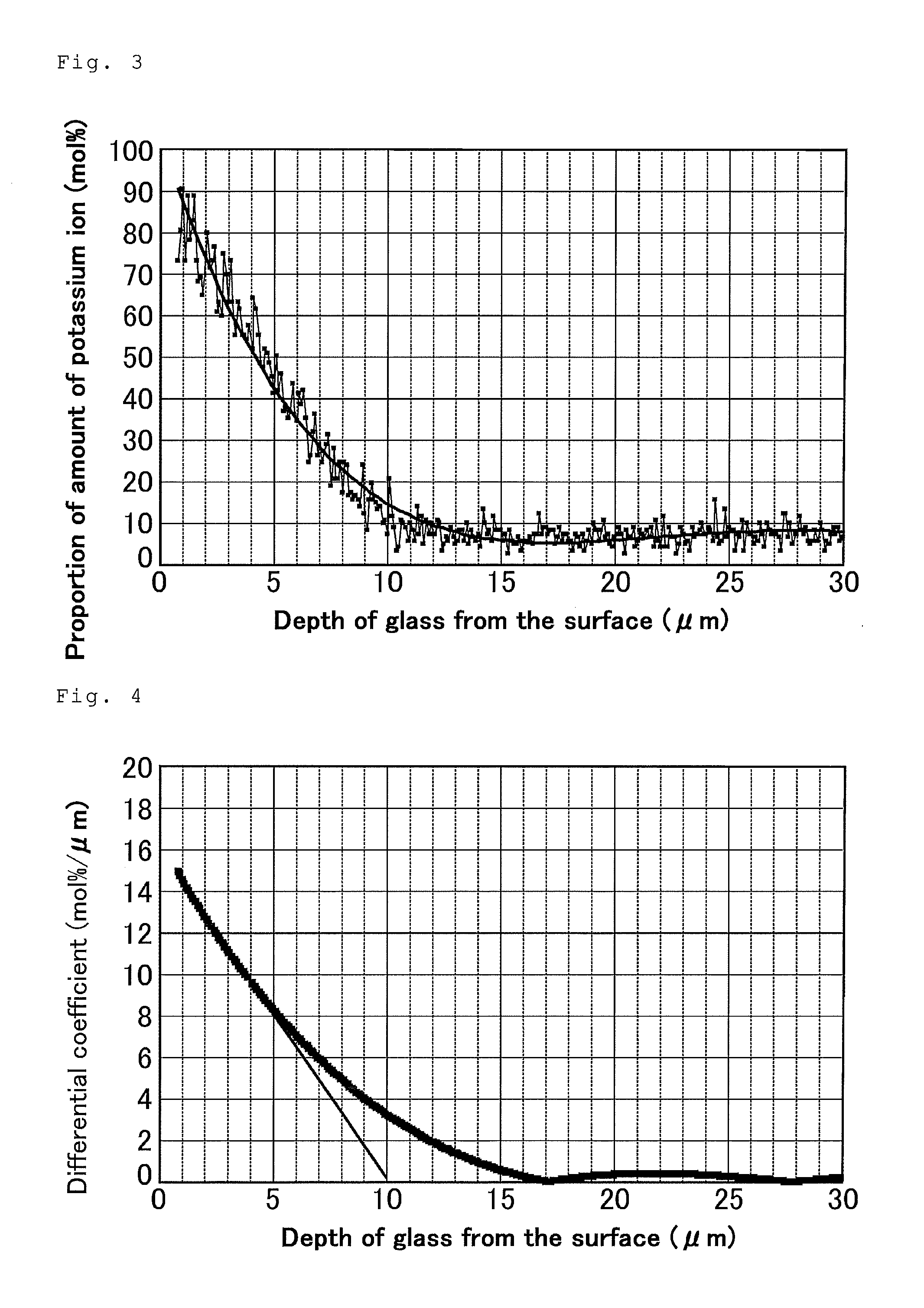

InactiveUS20140248495A1Easy to cutHigher compressive residual stressGlass/slag layered productsThin material handlingIon exchangeSoda-lime glass

The present invention aims to provide a chemically strengthened glass with cutting easiness and a higher compressive residual stress than the conventional one, made of soda-lime glass.The chemically strengthened glass of the present invention is a chemically strengthened glass manufactured by ion exchange of a surface layer of a glass article to replace alkali metal ions A which are the largest in amount among all the alkali metal ion components of the glass article with alkali metal ions B having a larger ionic radius than the alkali metal ions A,wherein the glass article before the ion exchange is made of soda-lime glass substantially composed of SiO2: 65 to 75%, Na2O+K2O: 5 to 20%, CaO: 2 to 15%, MgO: 0 to 10%, and Al2O3: 0 to 5% on a mass basis,the chemically strengthened glass after the ion exchange has a surface compressive stress of 600 to 900 MPa, and has a compressive stress layer with a depth of 5 to 20 μm at a surface of the glass.

Owner:CENT GLASS CO LTD

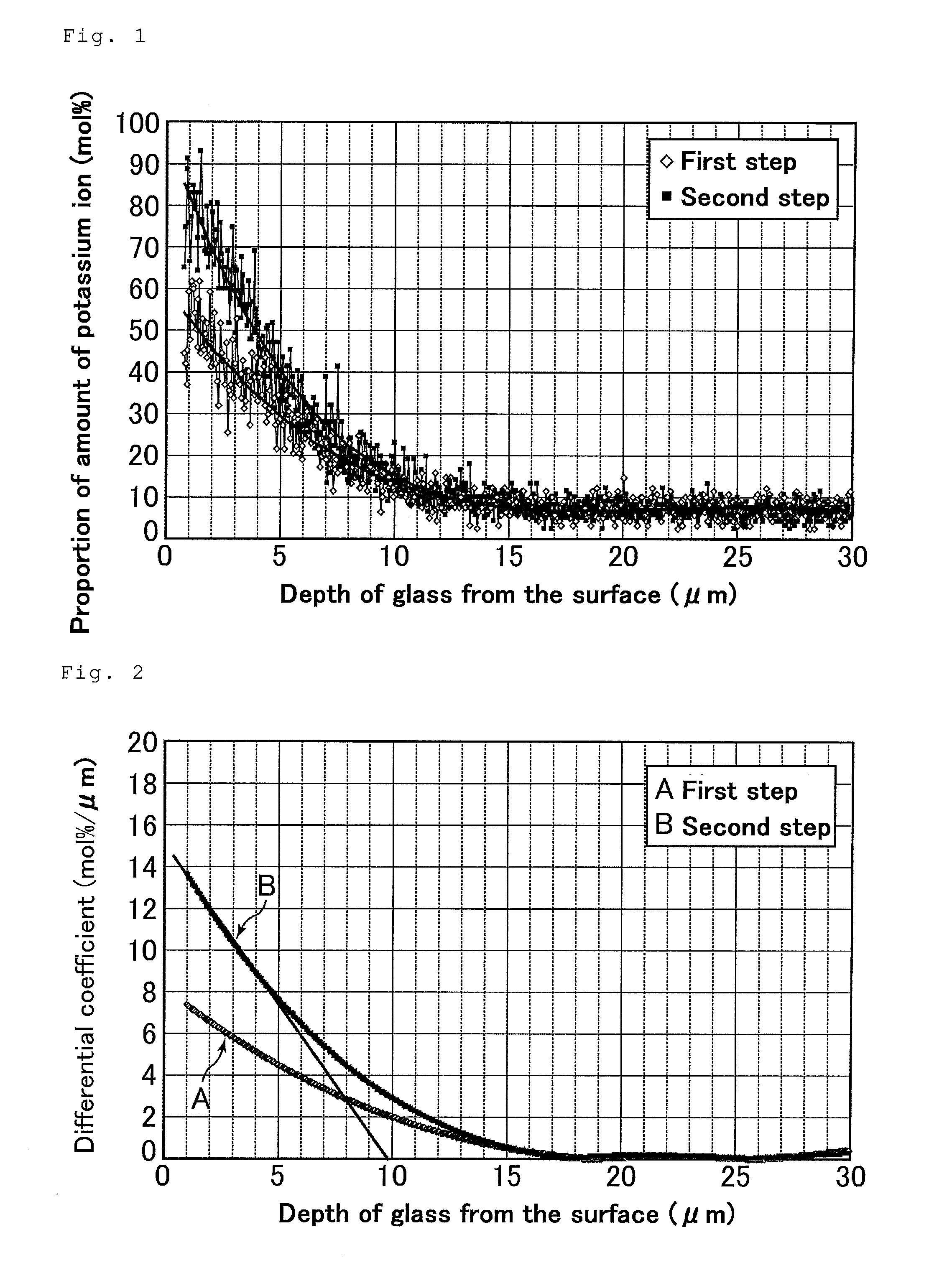

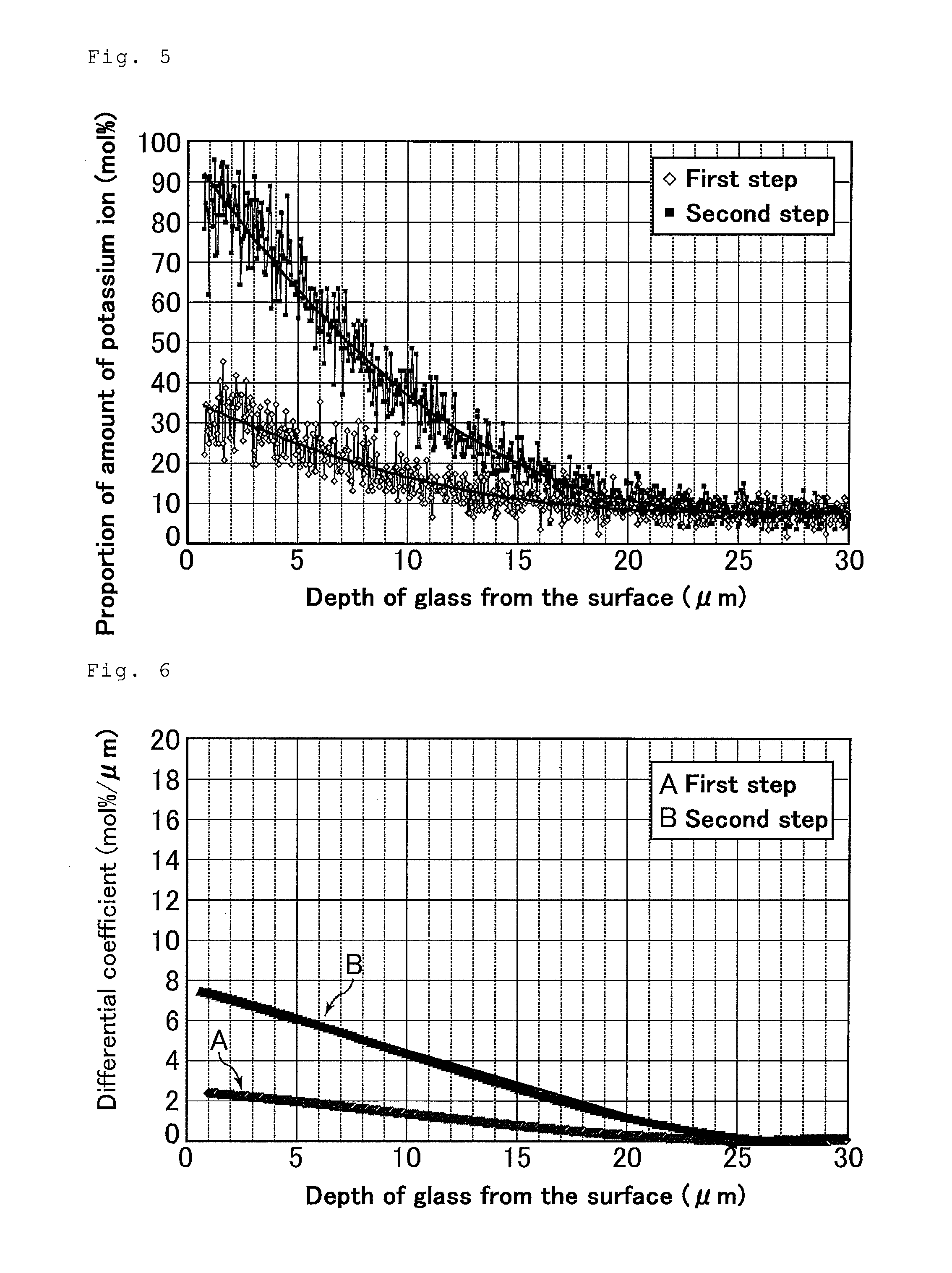

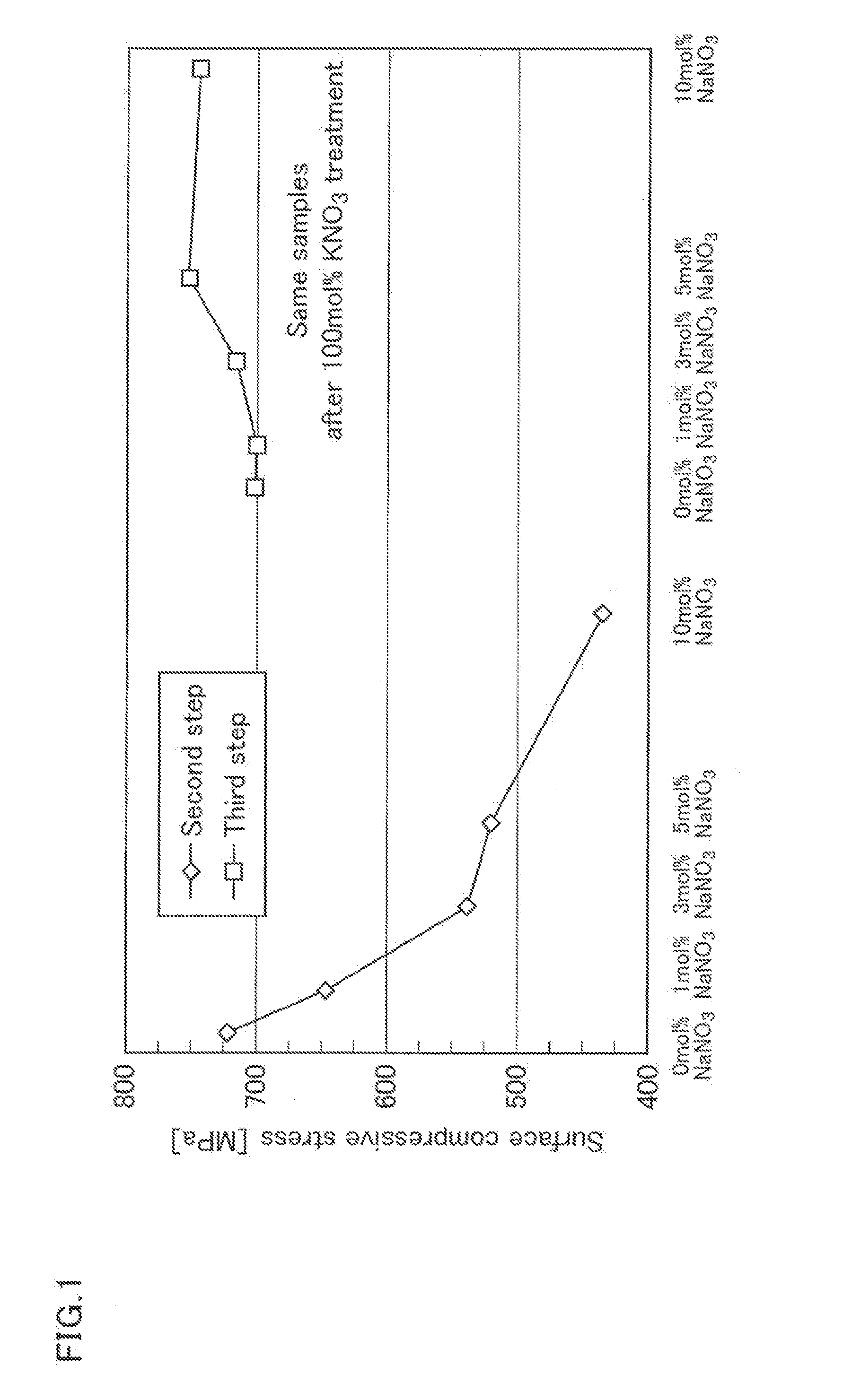

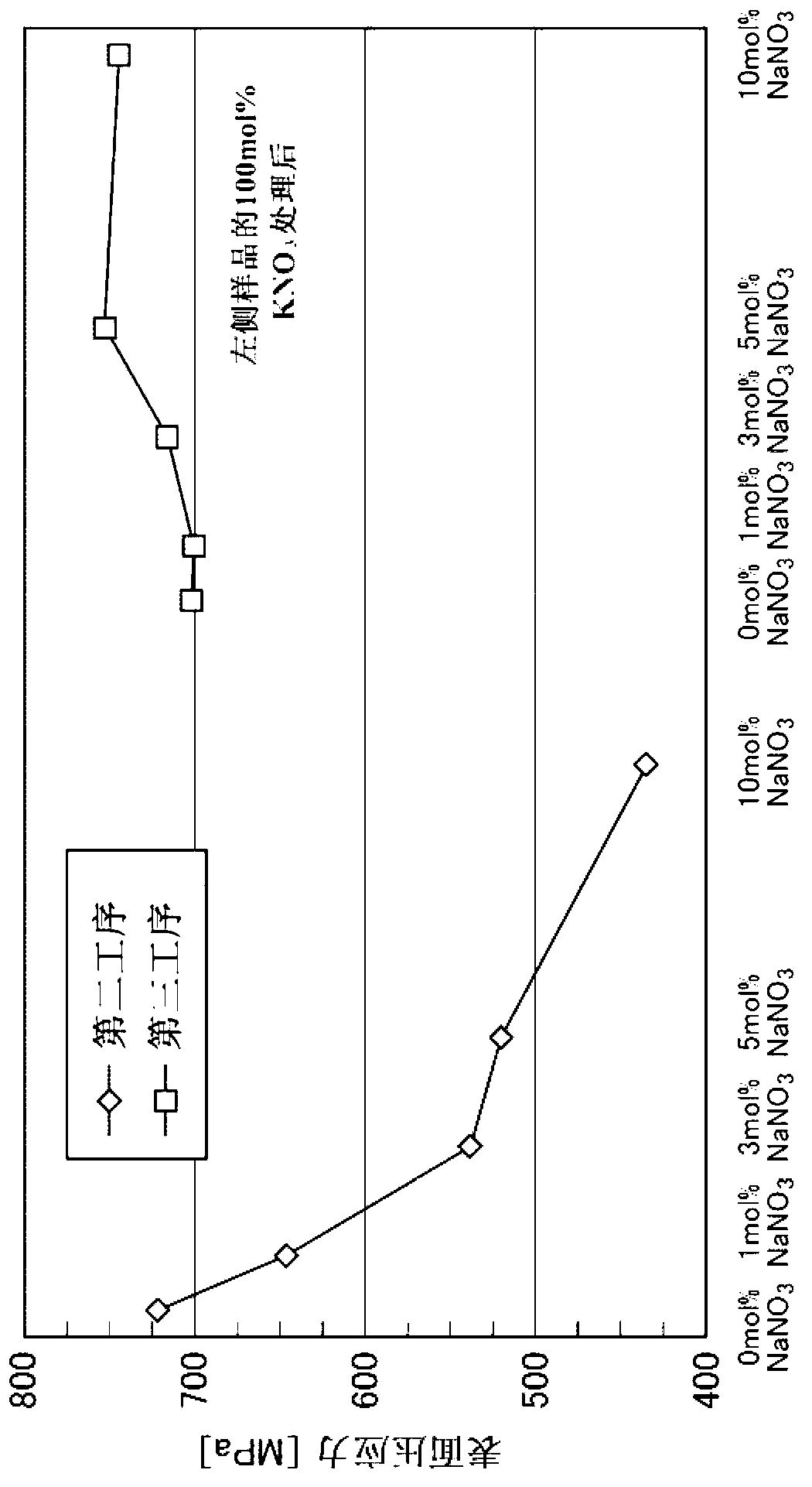

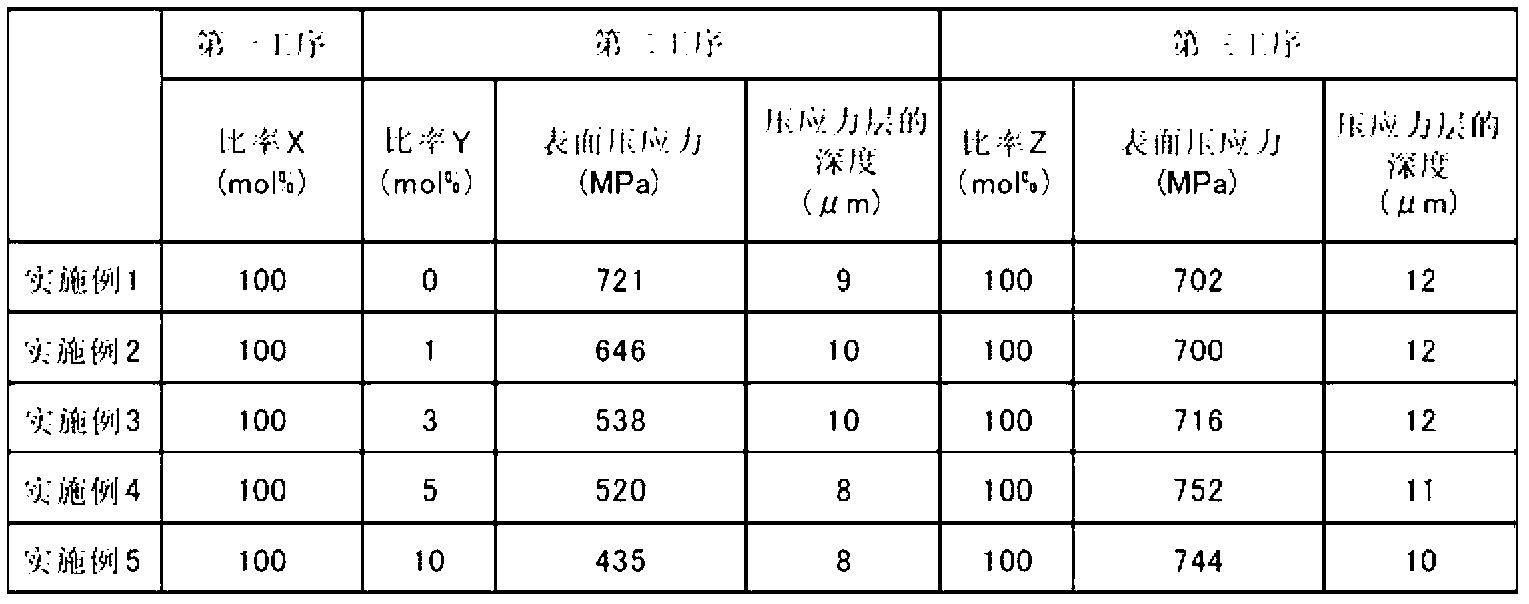

Method of manufacturing chemically strengthened glass plate

InactiveUS20130219966A1Increase the surface compressive stressEfficient productionIon exchangeGlass sheet

[Subject]An object of the present invention is to provide a method for manufacturing a chemically strengthened glass plate having a high surface compressive stress with high efficiency using a soda-lime glass, the composition of which is not particularly suited for chemical strengthening.[Solution]The present invention provides a method of manufacturing a chemically strengthened glass plate by ion-exchanging a glass base plate to replace alkali metal ions A that are the main alkali metal ion component of the glass base plate with alkali metal ions B having a larger ionic radius than the alkali metal ions A at a surface of the glass base plate,the unexchanged glass base plate made of a soda-lime glass,the method including:a first step of contacting the glass base plate with a first salt containing the alkali metal ions A, the first salt containing the alkali metal ions A at a ratio X, as expressed as a molar percentage of total alkali metal ions, of 90 to 100 mol %;a second step of contacting the glass plate with a second salt containing the alkali metal ions B after the first step, the second salt containing the alkali metal ions A at a ratio Y, as expressed as a molar percentage of the total alkali metal ions, of 0 to 10 mol %; anda third step of contacting the glass plate with a third salt containing the alkali metal ions B after the second step, the third salt containing the alkali metal ions B at a ratio Z, as expressed as a molar percentage of the total alkali metal ions, of 98 to 100 mol %.

Owner:CENT GLASS CO LTD

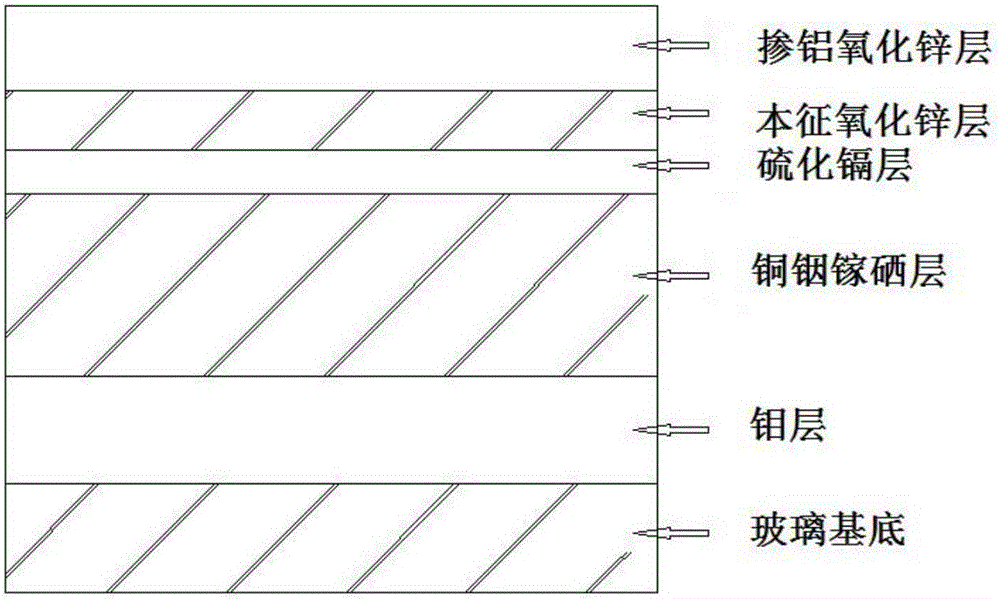

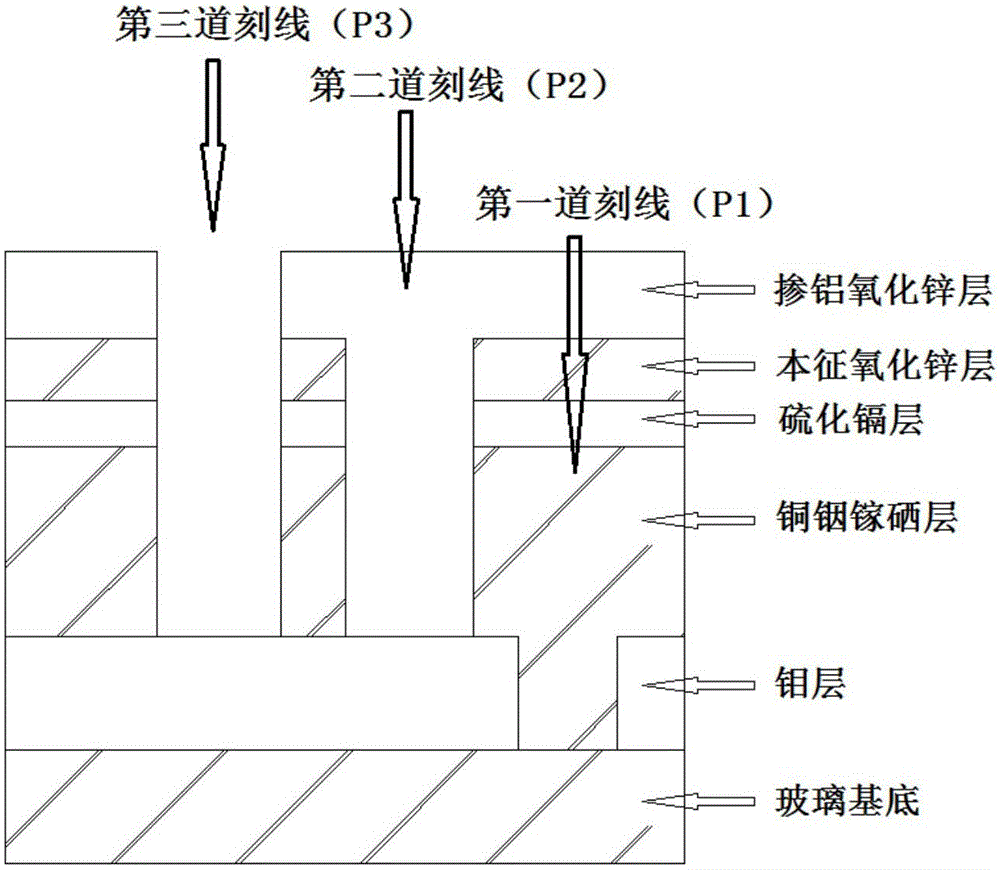

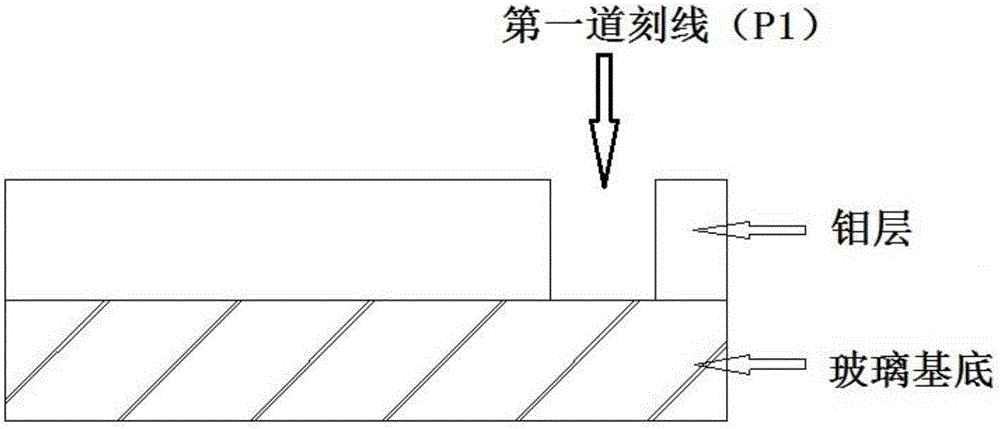

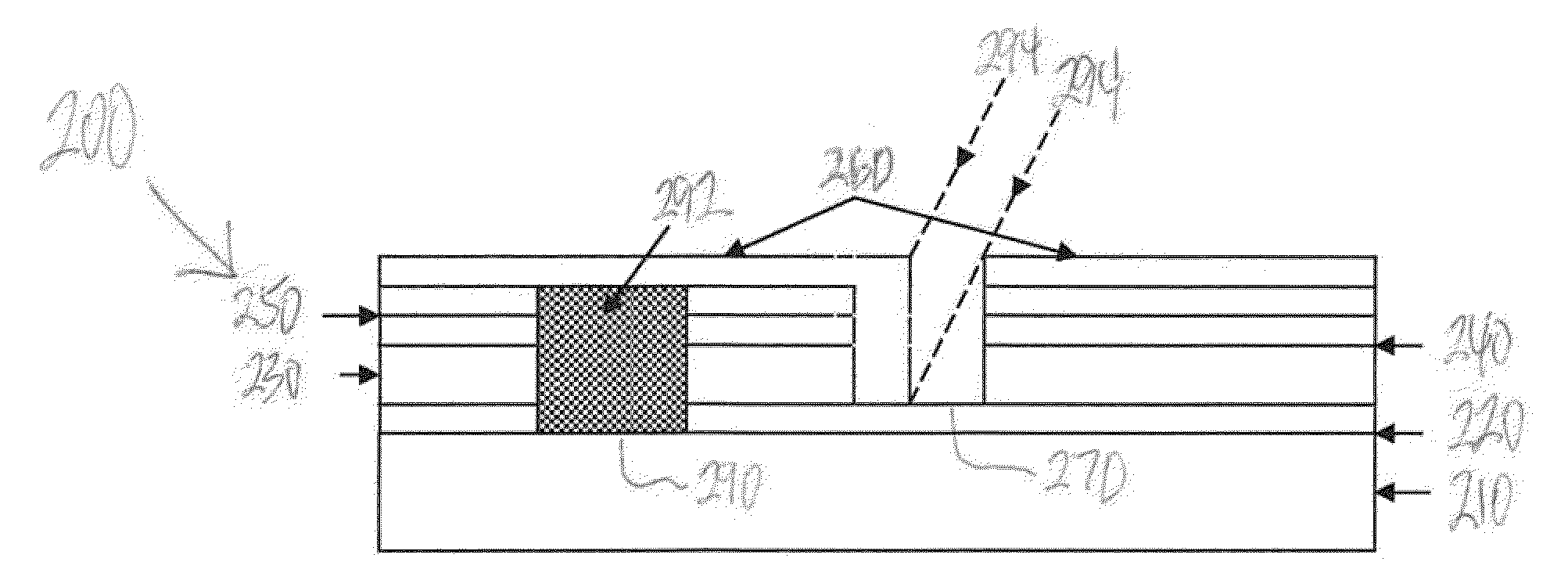

Full-laser grooving and scribing method of large-area copper indium gallium selenide (CIGS) thin-film solar cell assembly

ActiveCN104993013AIncrease component powerReduce dead areaFinal product manufactureSemiconductor/solid-state device manufacturingIndiumAluminum doped zinc oxide

The invention provides a full-laser grooving and scribing method of a large-area copper indium gallium selenide (CIGS) thin-film solar cell assembly. The method comprises steps of using a laser to groove and scribe a molybdenum thin film prepared on soda-lime glass so as to form a first scribed line (P1); successively preparing a CIGS layer, a cadmium sulfide layer and an intrinsic zinc oxide layer on the molybdenum layer where the P1 has been grooved and scribed; after finishing the above film layer preparation, using a laser to perform grooving and scribing so as to form a second scribed line (P2) which is parallel to the P1; and after preparing an aluminum-doped zinc oxide layer on the intrinsic zinc oxide layer where the P2 has been grooved and scribed, using a laser to perform grooving and scribing so as to form a third scribed line (P3) which is parallel to the P1. According to the invention, inner join is performed for the CIGS thin-film solar cell assembly by the laser grooving and scribing method, so defects of large area of dead zones and frequency change of machinery needles in traditional machinery grooving and scribing technology can be overcome, thereby increasing efficiency of the assembly, improving stability of the grooving and scribing device and achieving objectives to reduce production cost and improve production efficiency.

Owner:BEIJING SIFANG JIBAO AUTOMATION

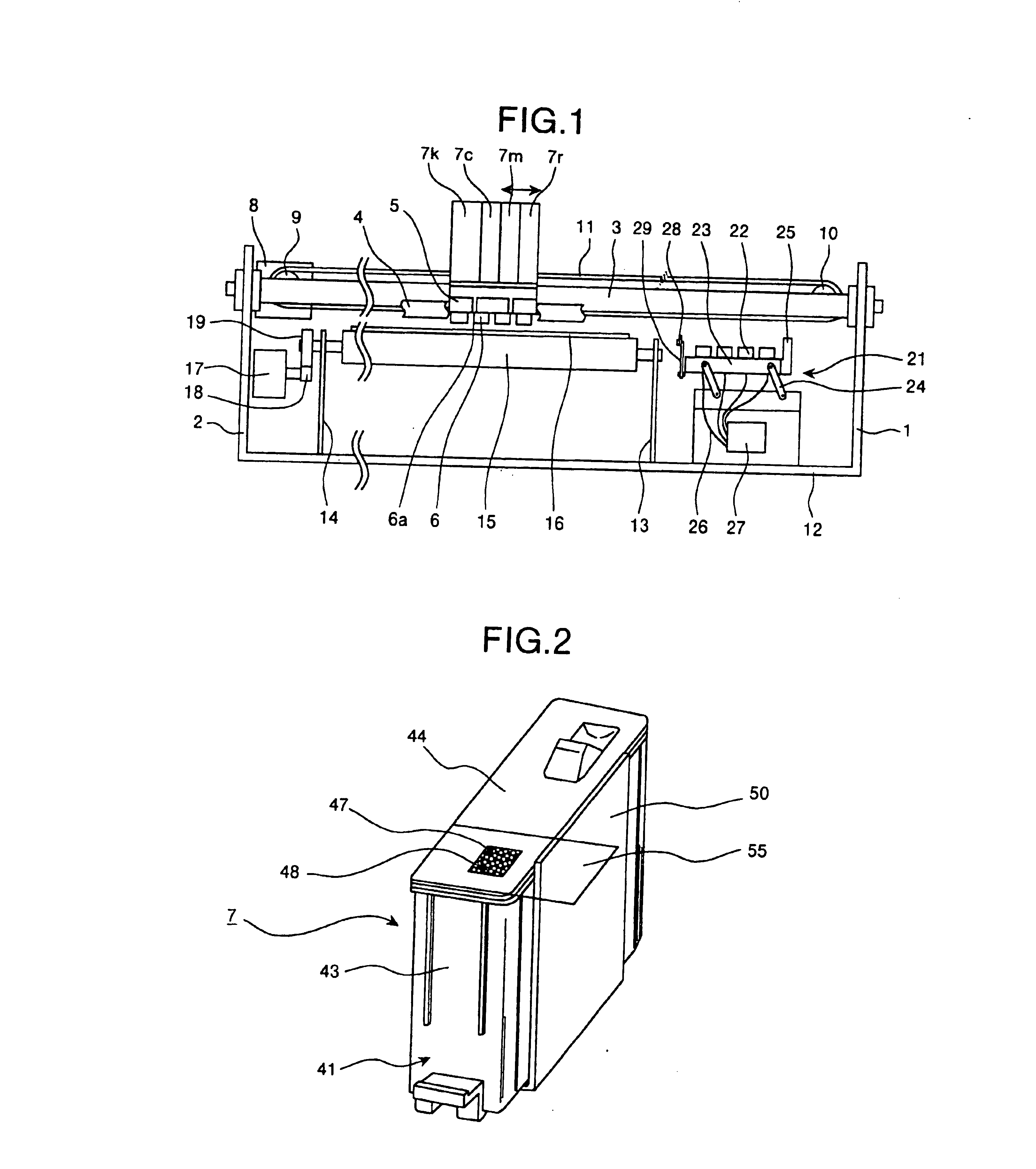

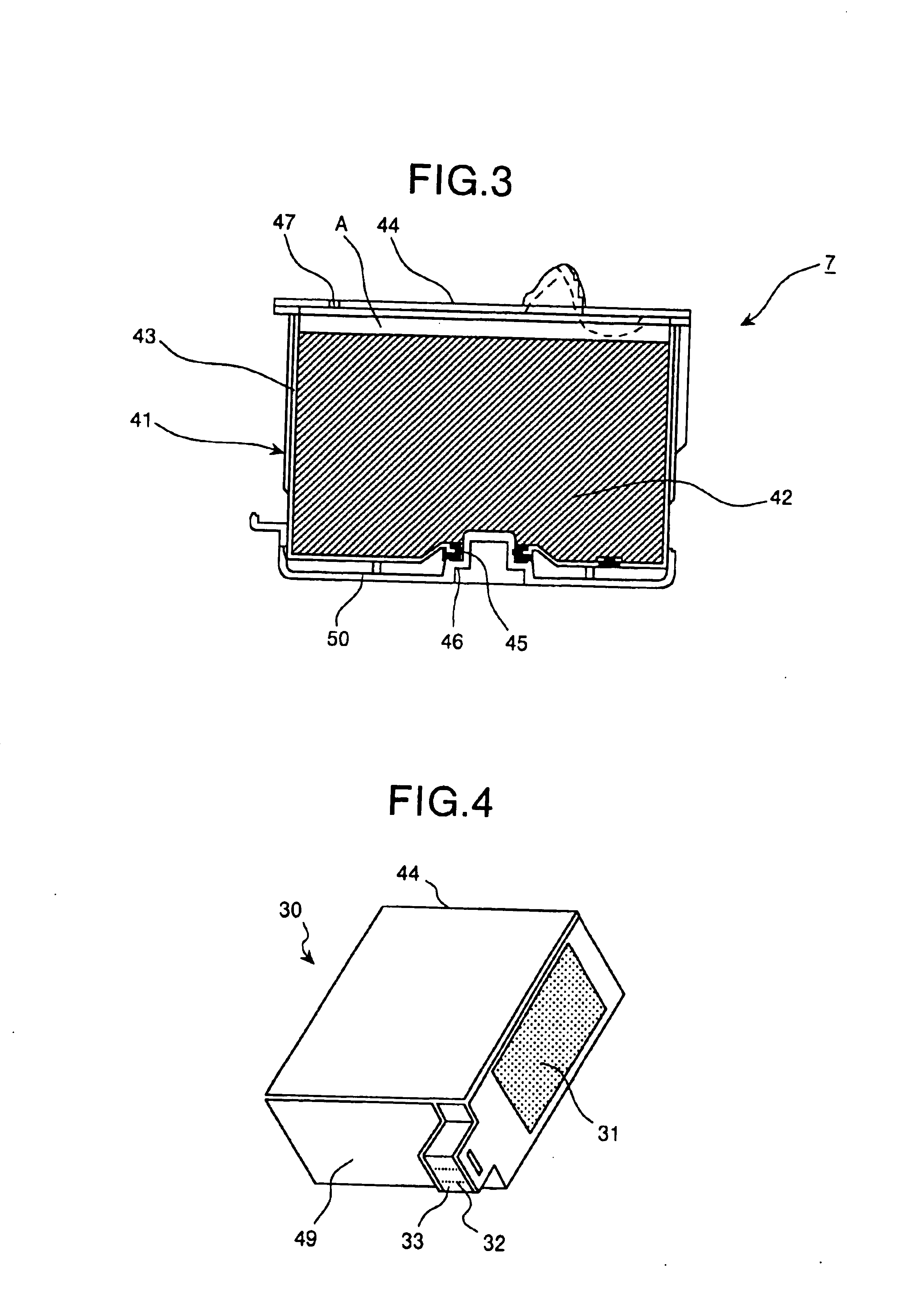

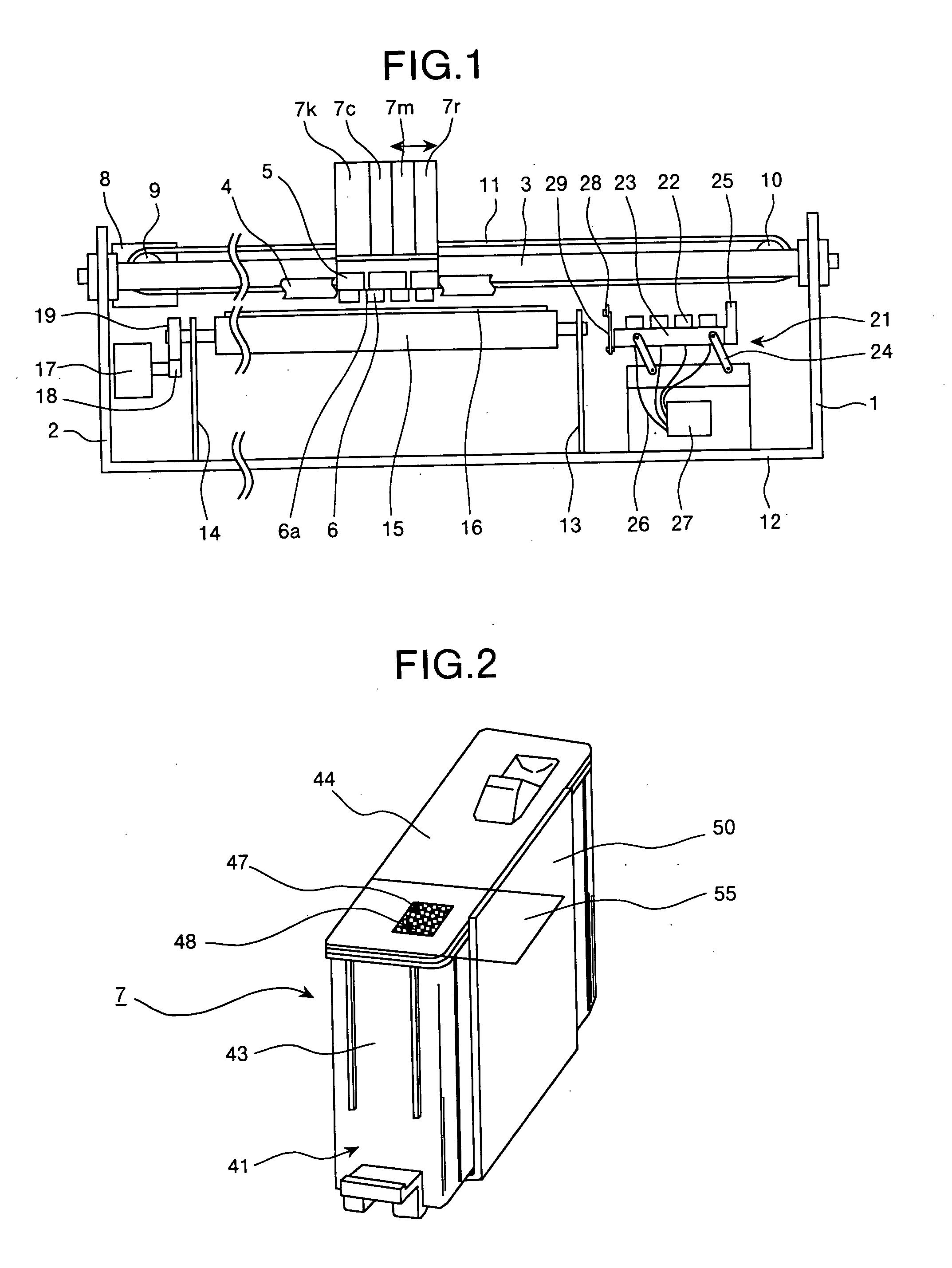

Ink for ink jet recording, ink jet recording method, ink cartridge and ink jet recording apparatus

InactiveUS6899751B2Good dispersibilityImprove stabilityMeasurement apparatus componentsInksPhosphoniumTitanium nitride

An ink for ink jet recording which is used for an ink jet printer in which at least a portion of a member being in contact with the ink is formed by any one of a borosilicate glass, a soda lime glass, a photosensitive glass, single crystal silicon, polysilicon, a silicon oxide film, a titanium nitride film, a zirconium film, a titanium oxide film, and a silicon nitride film, wherein a corrosion inhibitor is contained, and a phosphonium ion represented by the general formula (Formula 1) described below is contained: (wherein in Formula 1, Ra, Rb, Rc and Rd represent a linear, branched, or cyclic alkyl group having 1 to 4 carbon atoms, a hydroxyalkyl group, a halogenated alkyl group and a substituted or non substituted phenyl group, and X− represents a counter ion) is provided.

Owner:RICOH KK

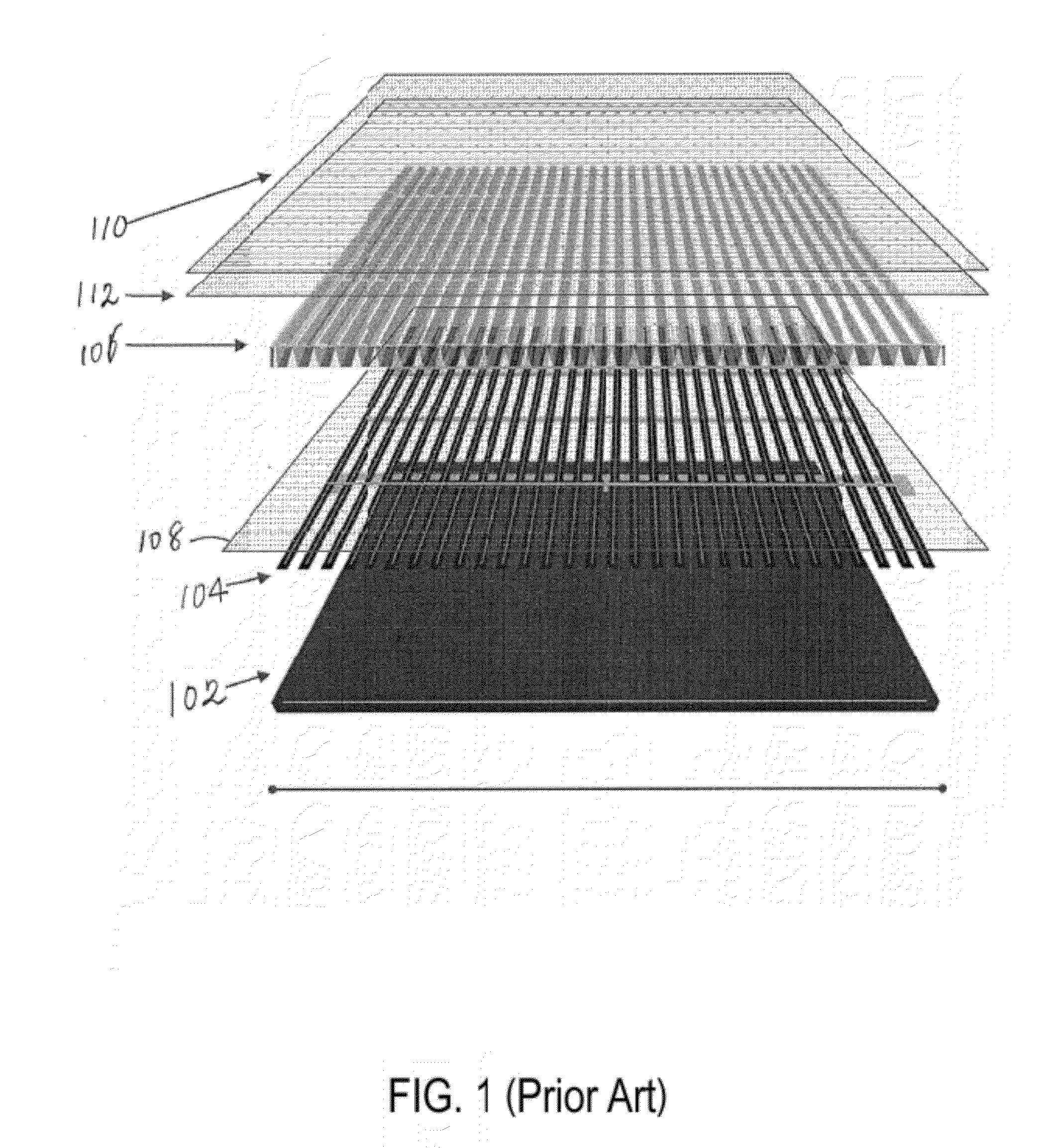

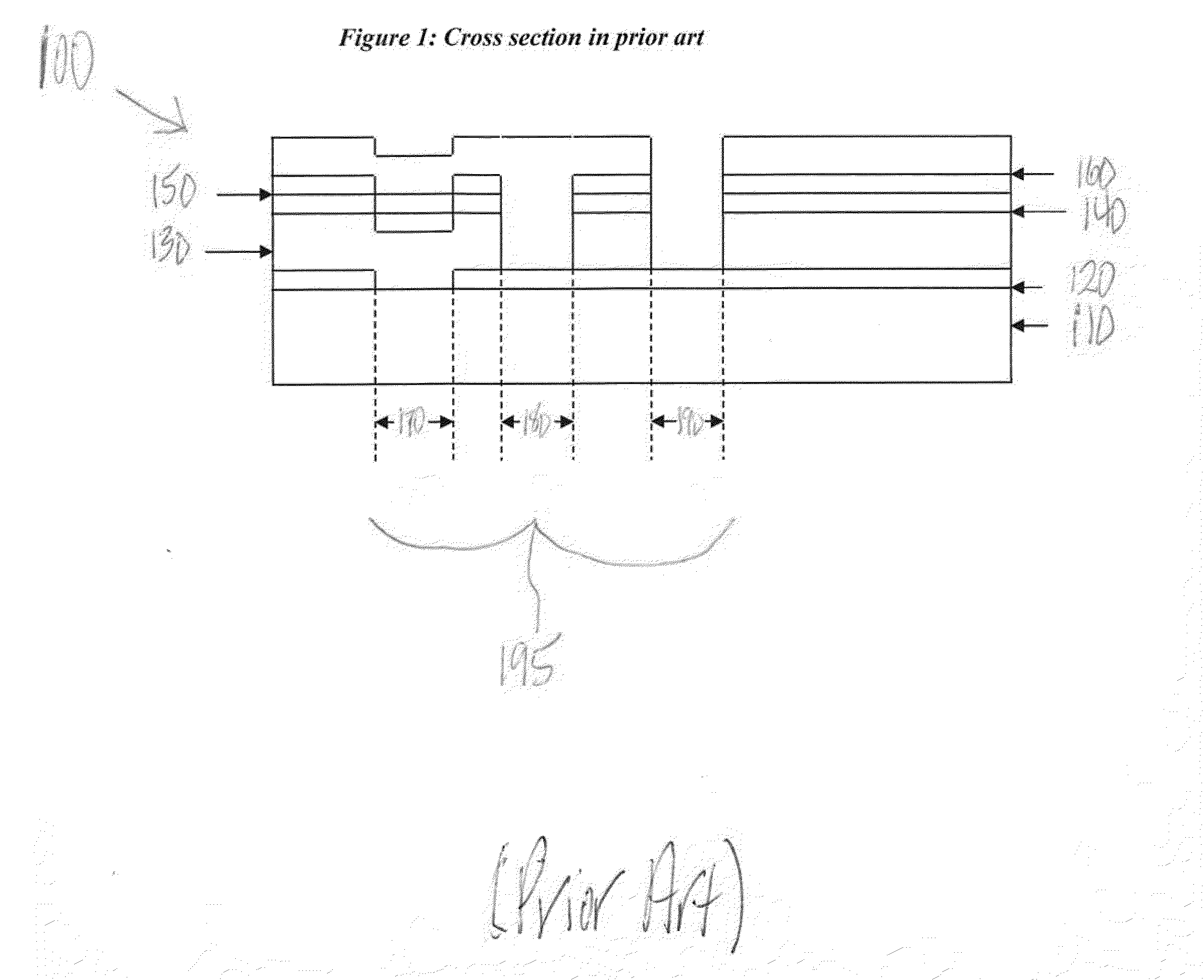

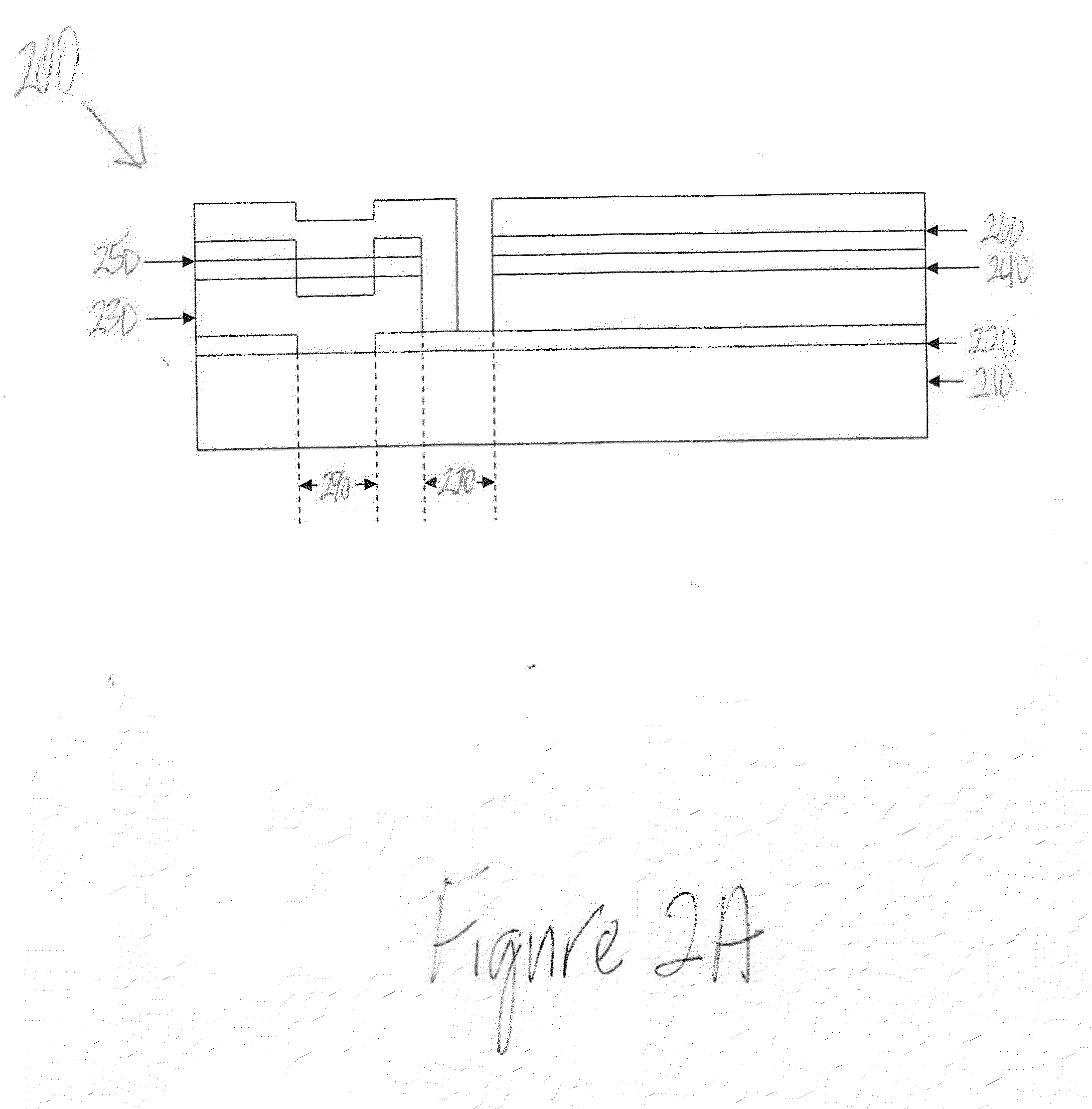

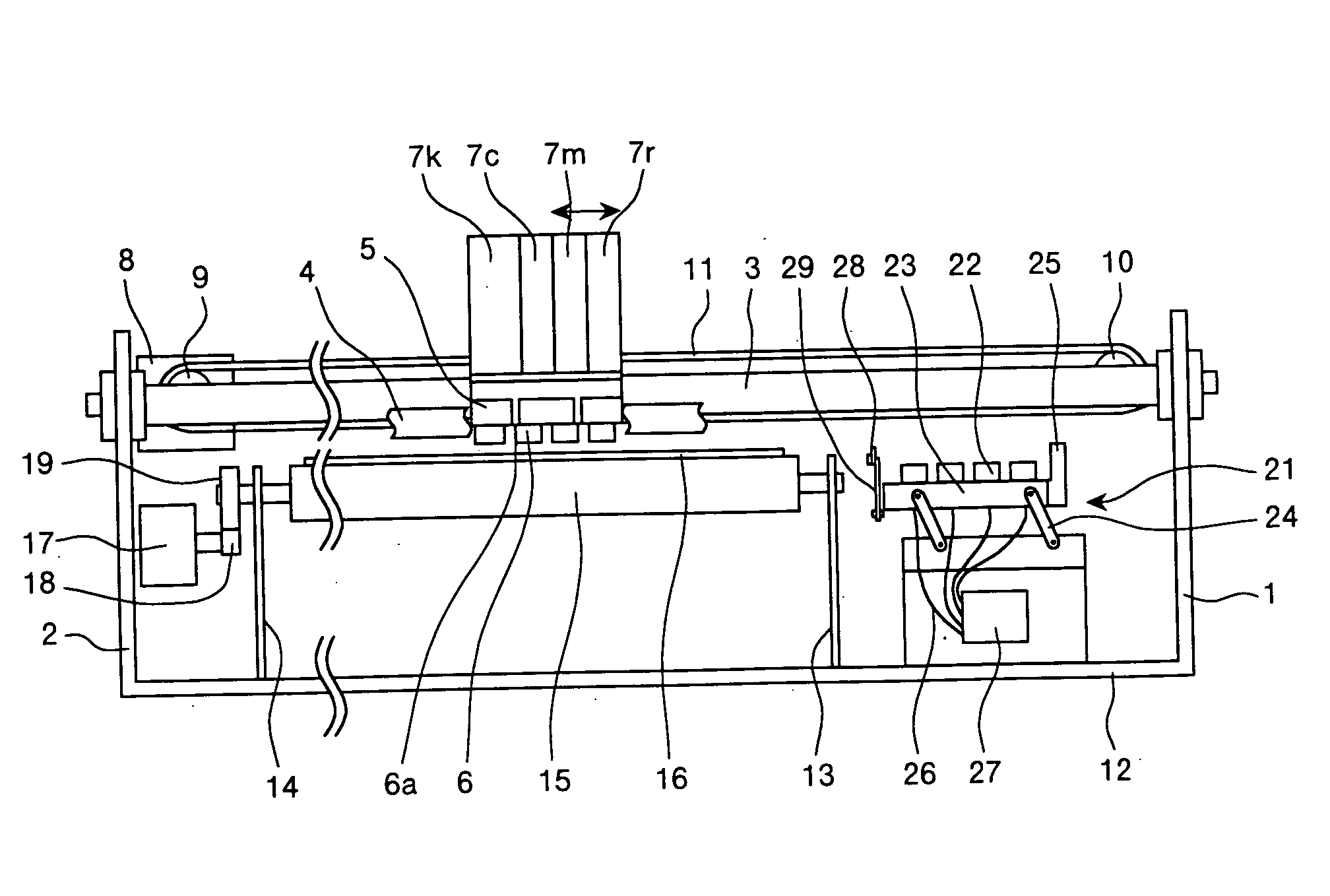

Method and device for scribing a thin film photovoltaic cell

InactiveUS20110240118A1Increase productionIncrease powerVacuum evaporation coatingSputtering coatingIndiumAluminum doped zinc oxide

The present invention is a method for scribing a thin film solar cell that includes a soda lime glass substrate, a film of molybdenum (Mo), a film of copper indium gallium diselenide (GIGS), a buffering layer, a layer of zinc oxide (i-ZnO), a layer of aluminum doped zinc oxide (n-ZnO:Al or AZO), a first scribe, a conductive link and a second scribe. The method steps include producing the first scribe on the Mo film, depositing the CICS film, the buffering layer and the zinc oxide layer onto the Mo film, producing the second scribe on the CICS film, the zinc oxide layer and the buffering layer above the Mo film, depositing and filling a first insulating material into the first scribe. and depositing a second insulating material that covers the solar cell while filling the first scribe forming a conduction layer.

Owner:BEATTY PAUL HANLON JAMES

Polyurethane compositions with glass filler and method of making same

InactiveUS20050282001A1Without adversely affecting the polyurethane articleImprove uniformityAnimal housingCeramic layered productsSoda-lime glassChemistry

The method forms a polyurethane article and involves dispersing polyurethane particles in a substantially aqueous liquid, mixing in a fine glass filler such as a post-consumer ground soda-lime glass, casting the filled dispersion and coalescing the particles by removing the liquid such that a polyurethane article having fused particles are formed. The polyurethane articles are useful as carpet backings.

Owner:JENKINES RANDALL C +2

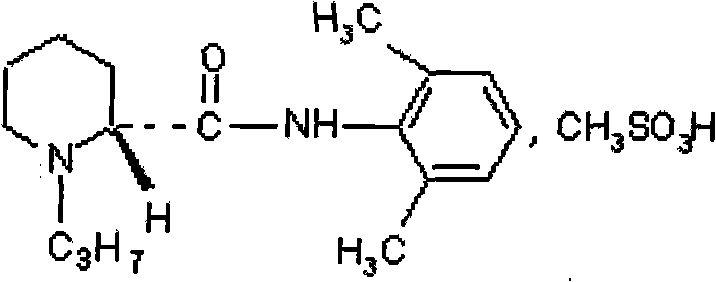

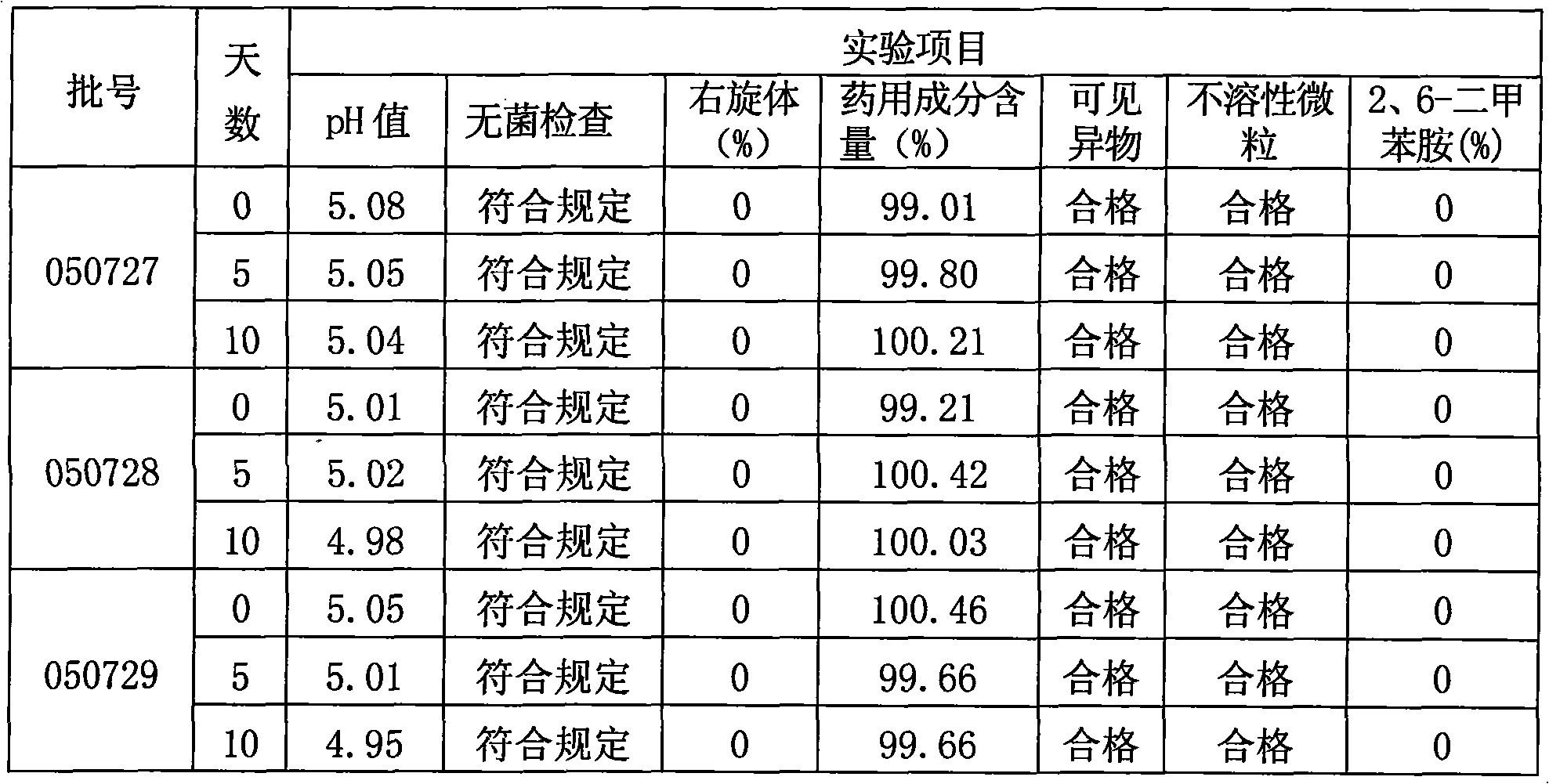

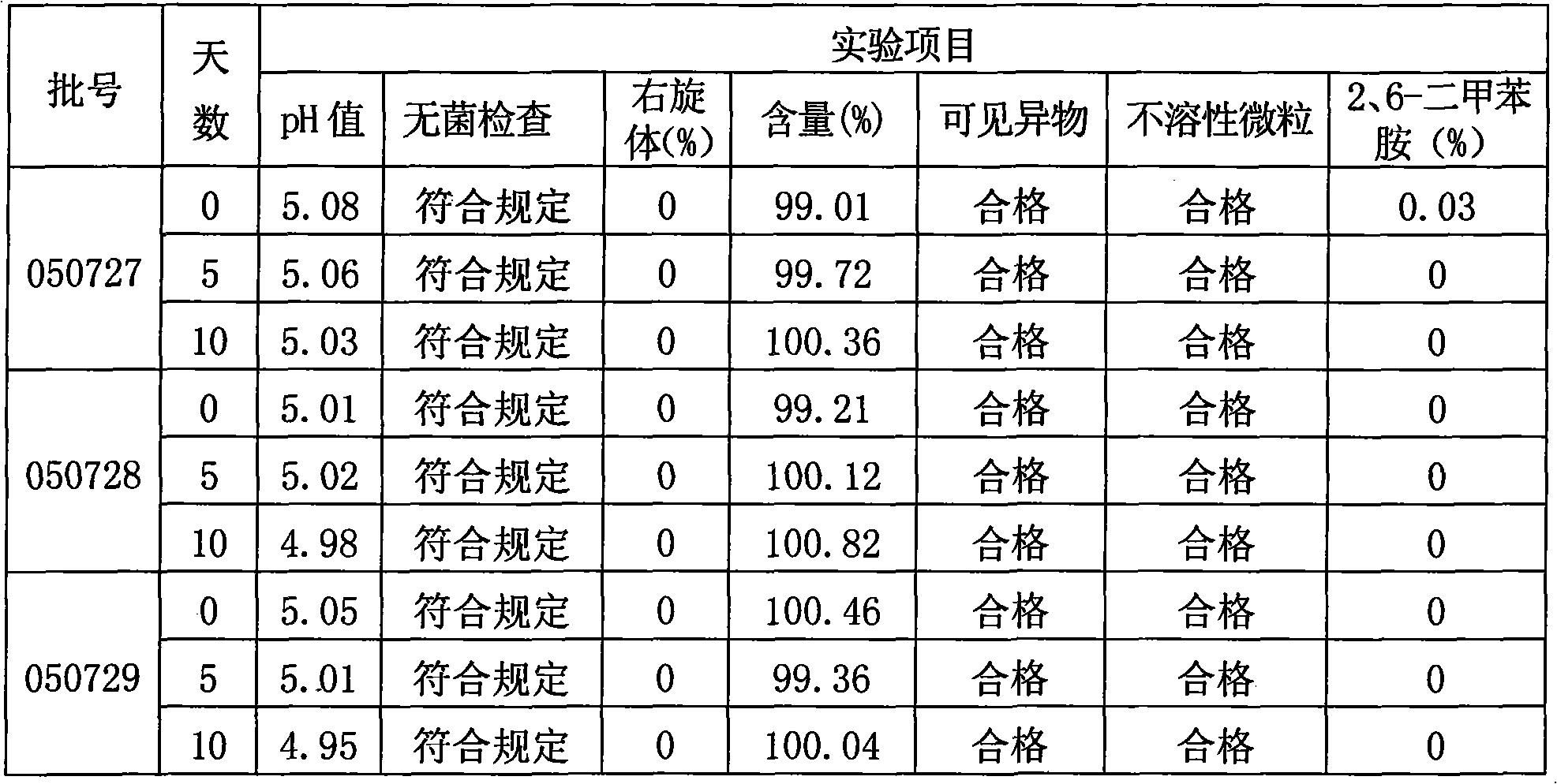

Preparation method of ropivacaine mesylate injection packed by soda-lime glass bottle

InactiveCN101658490AGuaranteed stabilityGood acid and alkali resistanceAmpoule syringesPharmaceutical delivery mechanismFiltrationAdditive ingredient

The invention relates to a preparation method of ropivacaine mesylate injection packed by a soda-lime glass bottle, which comprises the following processing steps of ingredient preparation, liquor preparation, soda-lime glass bottle and rubber plug cleaning, filling, capping, sterilization, lamp test, labeling, packing and finished product inspection. The injection is subject to a filtration sterilization processing step once and a flowing steam sterilization processing step once, wherein microorganisms larger than 0.22 microns in liquid medicine are removed by a filter method, microorganismssmaller than 0.22 microns are killed by flowing steam sterilization, and insoluble particles in the liquid medicine are removed during filtration sterilization simultaneously, thereby greatly reducingthe occurrence of phlebitis; and the invention is packed by the soda-lime glass bottle which has the advantages of heat resistance, acid and alkali resistance, large strength, and the like, thereby ensuring the stability of the medicine. Clinic comparison tests show that the ropivacaine mesylate injection packed by a soda-lime glass bottle has the advantages of quicker effect, long action time, reliable anesthetic effect, small toxicity to heart, separate blocking pf sensory and motor nerves, and the like, thereby being suitable for anesthesia in surgeries and postoperative analgesia.

Owner:陕西吉尾斯美业有限公司

Composition of materials for production of acid resistant cement and concrete and methods thereof

InactiveUS20030136305A1Reduce amountImprove acid resistanceSolid waste managementAlkali metal silicate coatingsSlagPortland cement

A cement composition for use in acidic environment containing liquid alkali silicate, vitreous silicate setting agent, lime containing material and inert filler and building materials made therefrom as well as the method of making such building materials. The liquid alkali silicate may include sodium silicate or potassium silicate. The vitreous silicate setting agent may include soda-lime glass powder or coal fly ash. The lime containing material refers to the materials containing more than 20% lime and may include quicklime, hydrated lime, Portland cement, blast furnace slag or steel slag. The inert fillers include ground quartz, ground ceramic, and / or clay.

Owner:ADVANCED MATERIALS TECHNOLOGIES

Ink for ink jet recording, ink jet recording method, ink cartridge and ink jet recording apparatus

InactiveUS20050168552A1Good dispersibilityImprove stabilityMeasurement apparatus componentsInksPhosphoniumTitanium nitride

An ink for ink jet recording which is used for an ink jet printer in which at least a portion of a member being in contact with the ink is formed by any one of a borosilicate glass, a soda lime glass, a photosensitive glass, single crystal silicon, polysilicon, a silicon oxide film, a titanium nitride film, a zirconium film, a titanium oxide film, and a silicon nitride film, wherein a corrosion inhibitor is contained, and a phosphonium ion represented by the general formula (Formula 1) described below is contained: (wherein in Formula 1, Ra, Rb, Rc and Rd represent a linear, branched, or cyclic alkyl group having 1 to 4 carbon atoms, a hydroxyalkyl group, a halogenated alkyl group and a substituted or non substituted phenyl group, and X− represents a counter ion) is provided.

Owner:RICOH KK

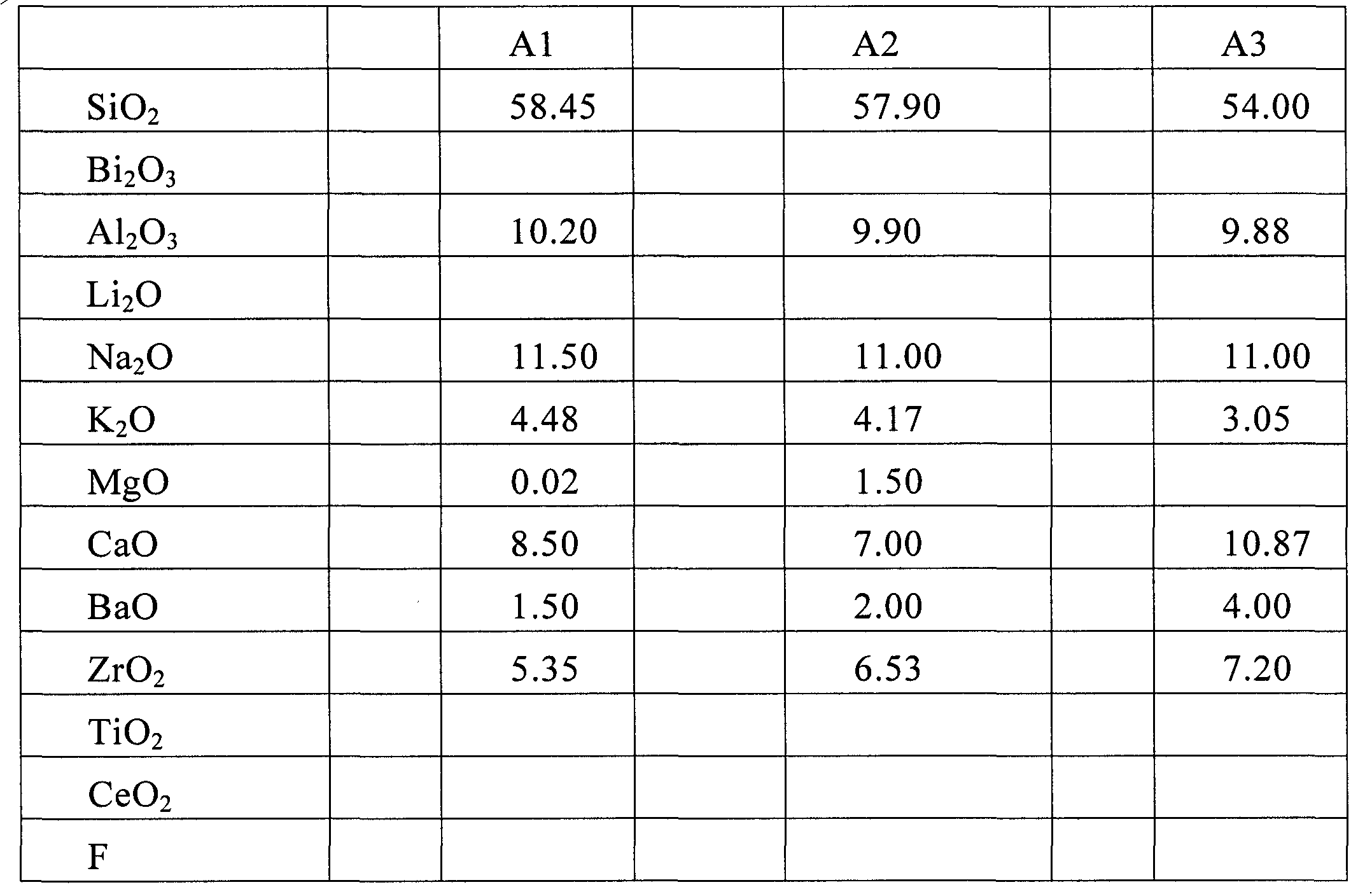

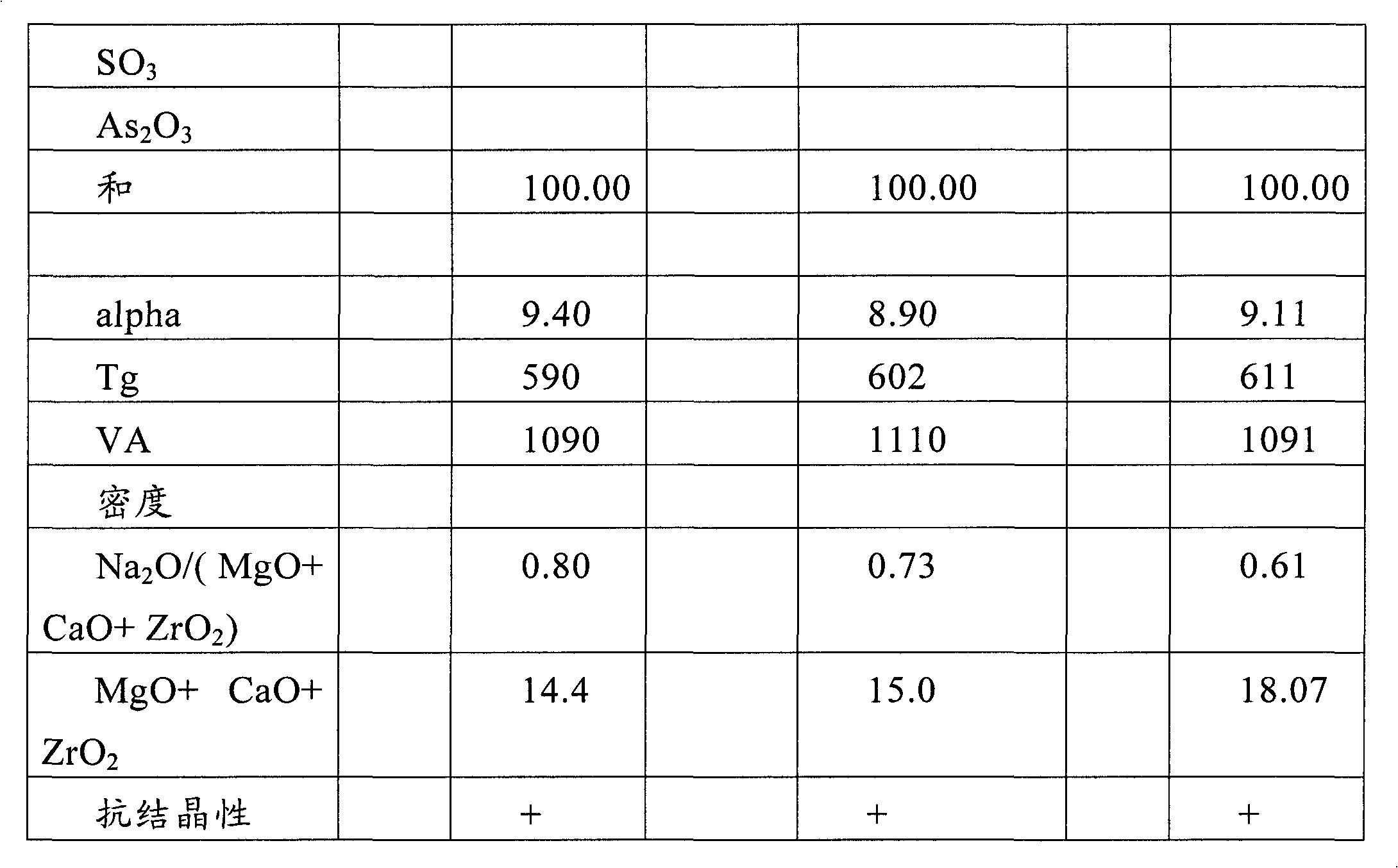

Aluminosilicate glass having high thermal stability and low processing temperature

ActiveCN102548919AImprove efficiencyRaise the processing temperatureThermal dilatationSoda-lime glass

The invention relates to an aluminosilicate glass having a thermal expansion coefficient ranging from 8 to 10 x 10-6 / K in a temperature range of 20 to 300 DEG C, a transformation temperature Tg ranging from 580DEG C; C to 640DEG C; C, and a processing temperature VA ranging from 1065DEG C; C to 1140DEG C; C, and thus can be used as an alternative to soda lime glass. The invention further relates to the use of the glass according to the invention in applications where high thermal resistance of the glass is advantageous, in particular as substrate glass, superstrate glass and / or cover glass in the field of semiconductor technology, preferably for Cd-Te or for CIS and / or CIGS photovoltaic applications, and for other applications in solar technology.

Owner:SCHOTT AG

Alumino-silicate glass having high thermal stability and low processing temperature

The invention relates to an alumino-silicate glass which has a thermal expansion coefficient in the range of 8 to 10×10−6 / K in a temperature range of 20 to 300° C., a transformation temperature Tg in a range of 580° C. to 640° C., and a processing temperature VA in a range of 1065° C. to 1140° C. and which can therefore be used as an alternative for soda lime glasses. An object of the invention is also the use of the inventive glasses in applications where a high temperature stability of the glasses is advantageous, in particular as substrate glass, superstrate glass and / or cover glass in the field of semiconductor technology, preferably for Cd—Te or for CIS or CIGS photovoltaic applications and for other applications in solar technology.

Owner:SCHOTT AG

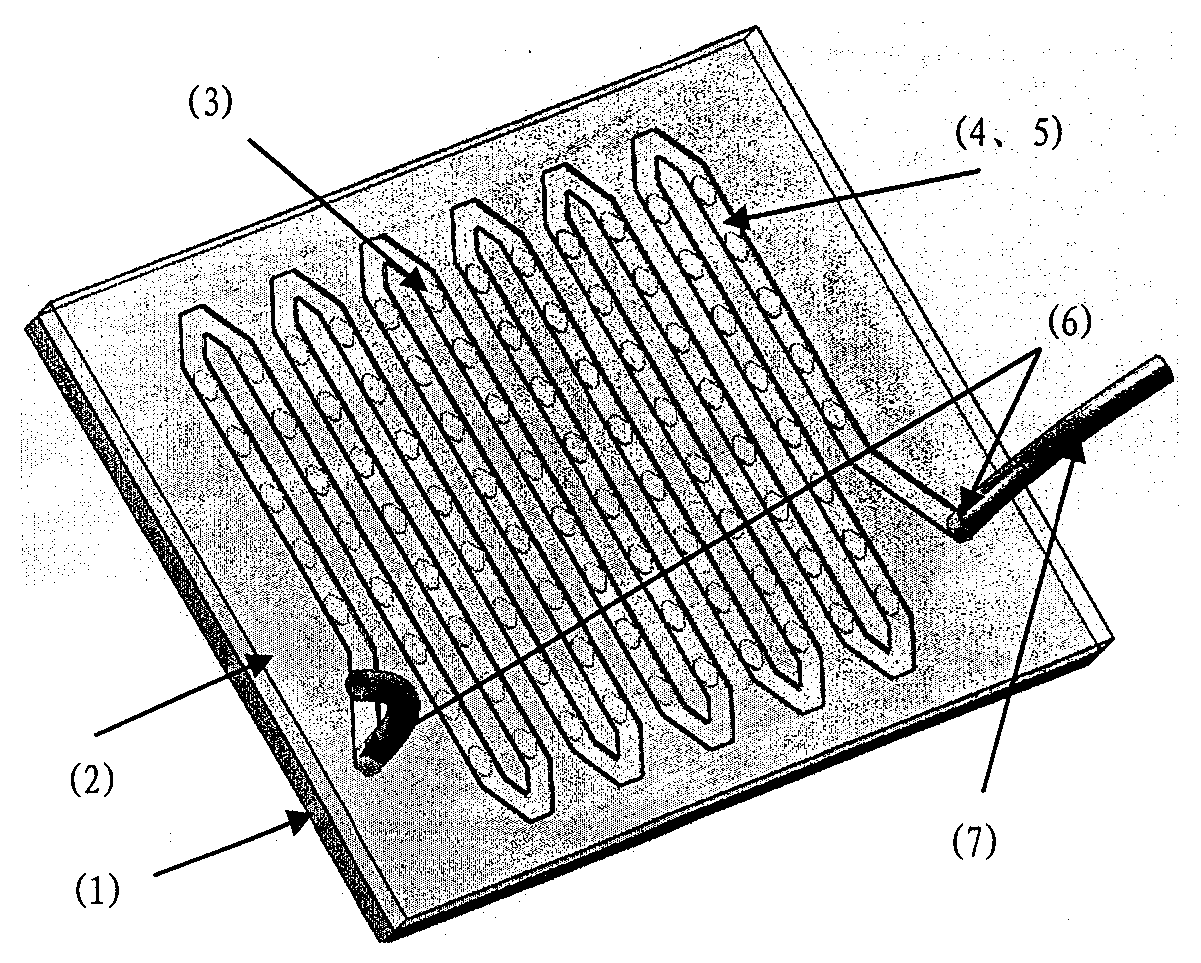

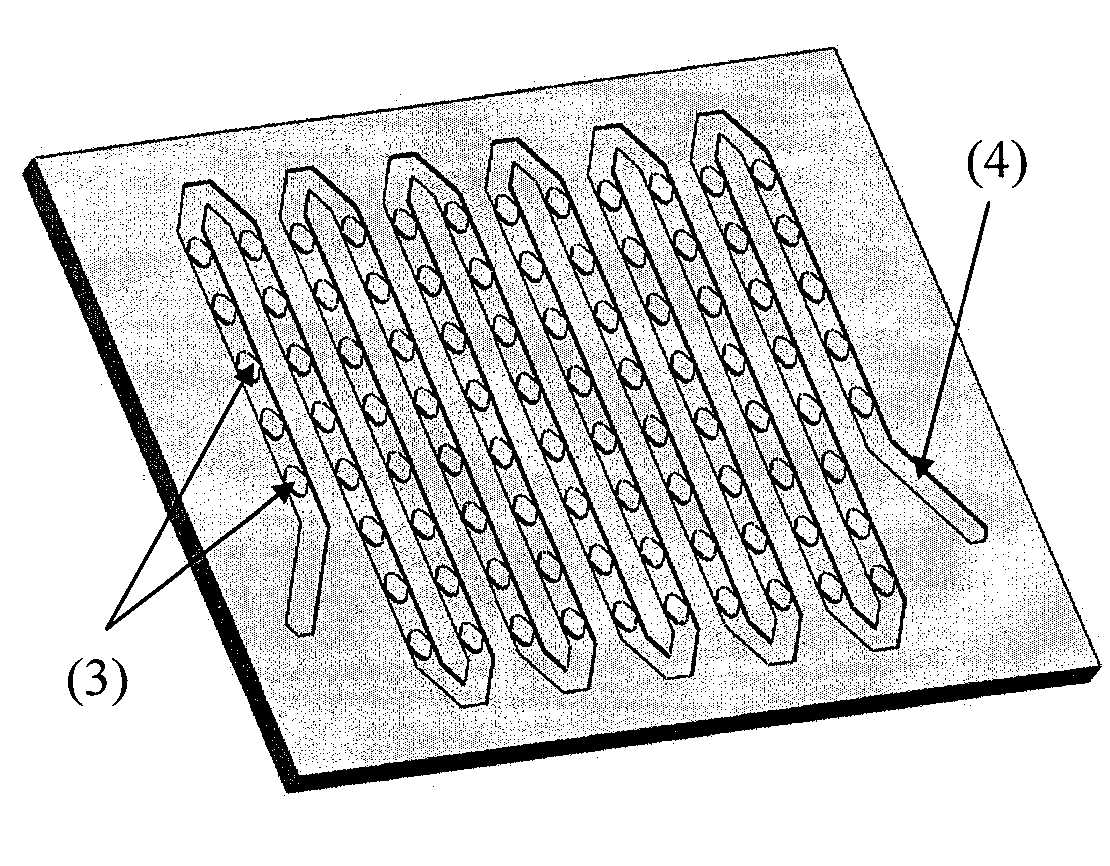

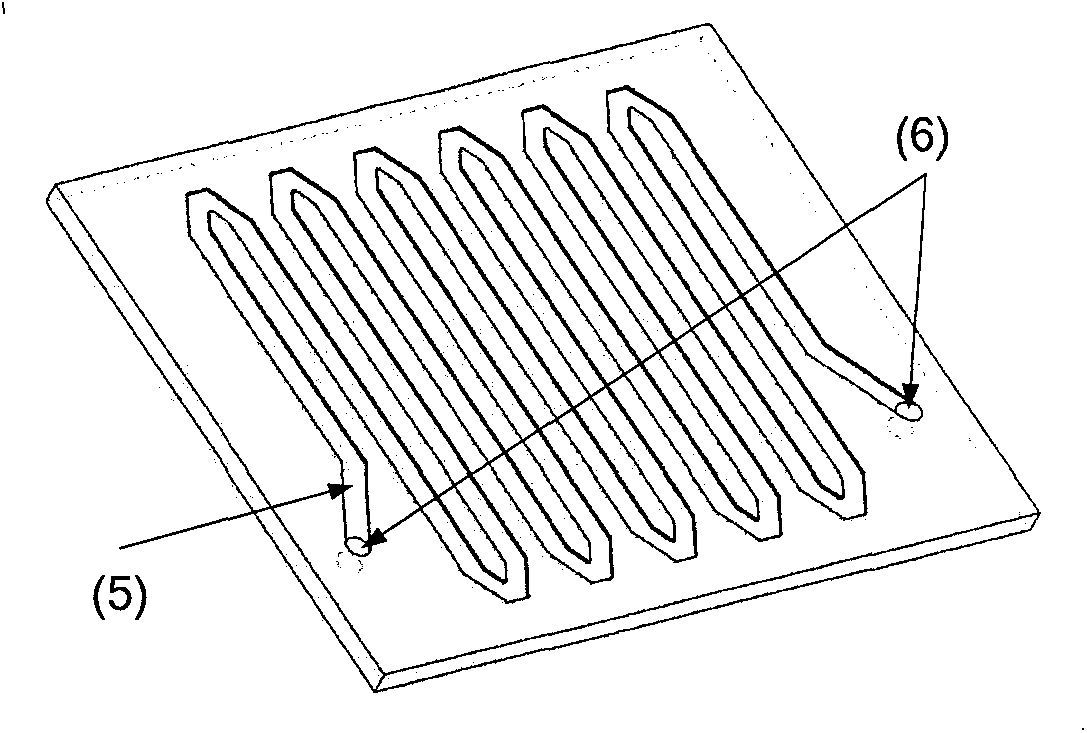

Microfluidic array chip for cell capture

InactiveCN103387935AWith micro volumeFlexible and customizable structureBioreactor/fermenter combinationsBiological substance pretreatmentsMicro structureCancer cell

The invention relates to a microarray-type structure chip adopting micro-flow pipes and taking advantage of diameter difference of different types of cells, and micro column arrays with different intervals and different sizes are etched in the micro-flow pipes. The chip structure is formed by up-down bonding of a silicon Si material negative-film substrate and a soda-lime glass upper cover. According to the different intervals of the column micro structure, the microarray-type structure chip can be divided into two series: variable interval and fixed interval; and according to the different sizes of the column micro structure, the microarray-type structure chip can be divided into a plurality of types: ranging from 2-30 [mu] m. The microarray-type structure chip is characterized in that: when a liquid fluid containing the different types of cells flows through the chip micro structure, and passes through the column microarrays with different intervals and diameters, different types (different sizes) of cells can be captured by different micro column array structures, and retained on the different micro column arrays with different micro structures in the pipes, and the captured results can be observed and analyzed by used of a microscope. The microarray-type structure chip has the characteristics of micro volume, flexible and customizable structure, no moving parts and the like, and can be widely applied to capture and analysis and other fields of various cancer cells in the blood, and comprehensive analysis and measuring and calculating determine of the cell type and quantity in the blood of patients can be conducted through use of different kinds of chips.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

Method of manufacturing chemically strengthened glass plate

InactiveCN103214172AEfficient preparationIncrease the surface compressive stressGlass tempering apparatusIon exchangeGlass sheet

The present invention provides a method of manufacturing a chemically strengthened glass plate by ion-exchanging a glass base plate to replace alkali metal ions A that are the main alkali metal ion component of the glass base plate with alkali metal ions B having a larger ionic radius than the alkali metal ions A at a surface of the glass base plate, the unexchanged glass base plate made of a soda-lime glass, the method including: a first step of contacting the glass base plate with a first salt containing the alkali metal ions A, the first salt containing the alkali metal ions A at a ratio X, as expressed as a molar percentage of total alkali metal ions, of 90 to 100 mol %; a second step of contacting the glass plate with a second salt containing the alkali metal ions B after the first step, the second salt containing the alkali metal ions A at a ratio Y, as expressed as a molar percentage of the total alkali metal ions, of 0 to 10 mol %; and a third step of contacting the glass plate with a third salt containing the alkali metal ions B after the second step, the third salt containing the alkali metal ions B at a ratio Z, as expressed as a molar percentage of the total alkali metal ions, of 98 to 100 mol %.

Owner:CENT GLASS CO LTD

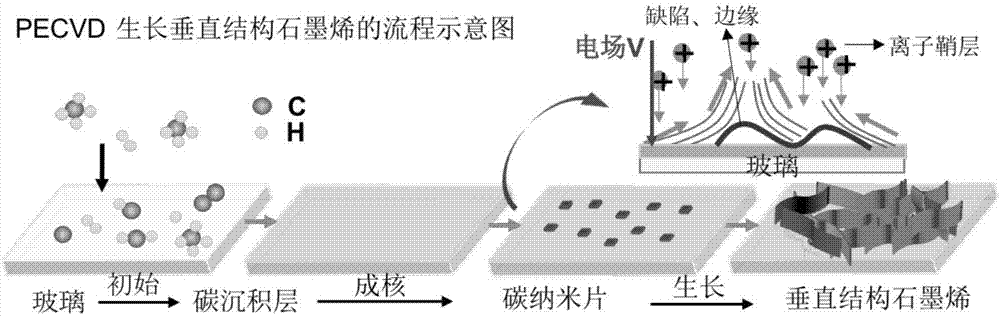

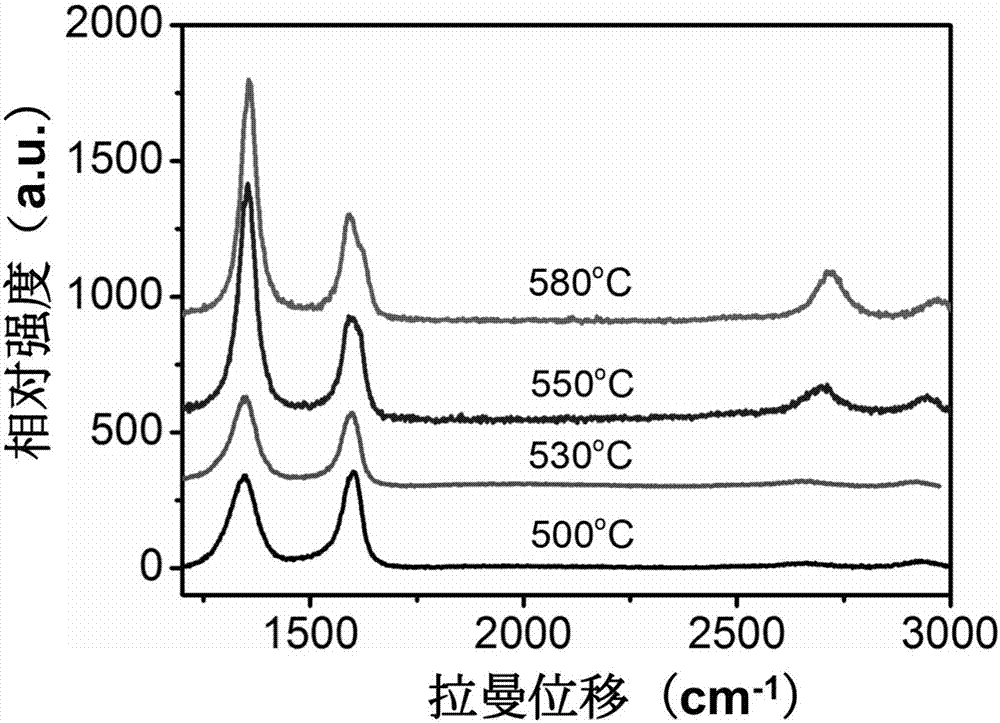

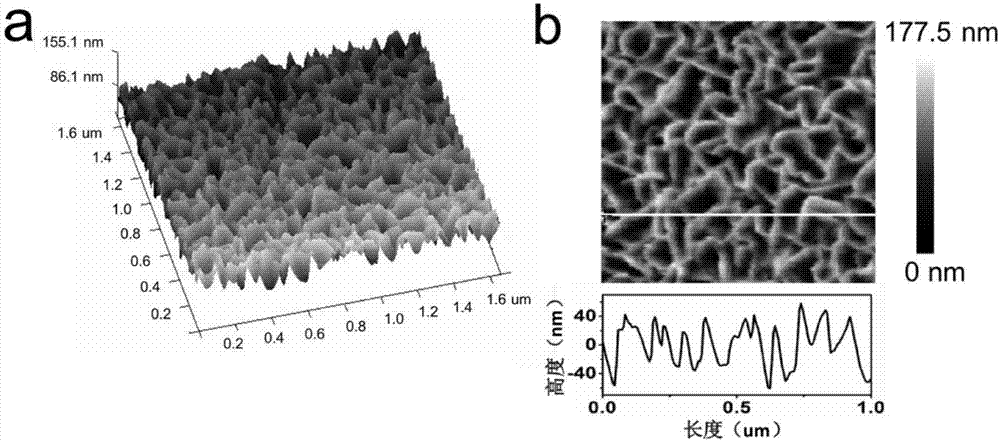

Method of preparing three-dimensional graphene glass composite

The invention discloses a method of preparing a three-dimensional graphene glass composite, which comprises the steps of providing a glass substrate, and directly growing graphene on the surface of the glass substrate by a plasma-enhanced chemical vapor deposition method. Compared with graphene glass prepared by the traditional transfer and oxidation reduction method, the preparation method is simple; cohesion with the glass substrate is high; vertical height control of a graphene nanosheet is precise; and the repeatability is high. In addition, the preparation method adopts the most common soda lime glass in daily life of people, so that compared with quartz glass and sapphire glass used in other experiments, the cost is greatly lowered. The method can realize uniform, controllable and quick preparation of graphene glass below the glass softening point temperature (600 DEG C), requires no catalyst, greatly simplifies a preparation growth technology of the graphene glass, and provides a premise for a subsequent industrial application.

Owner:PEKING UNIV

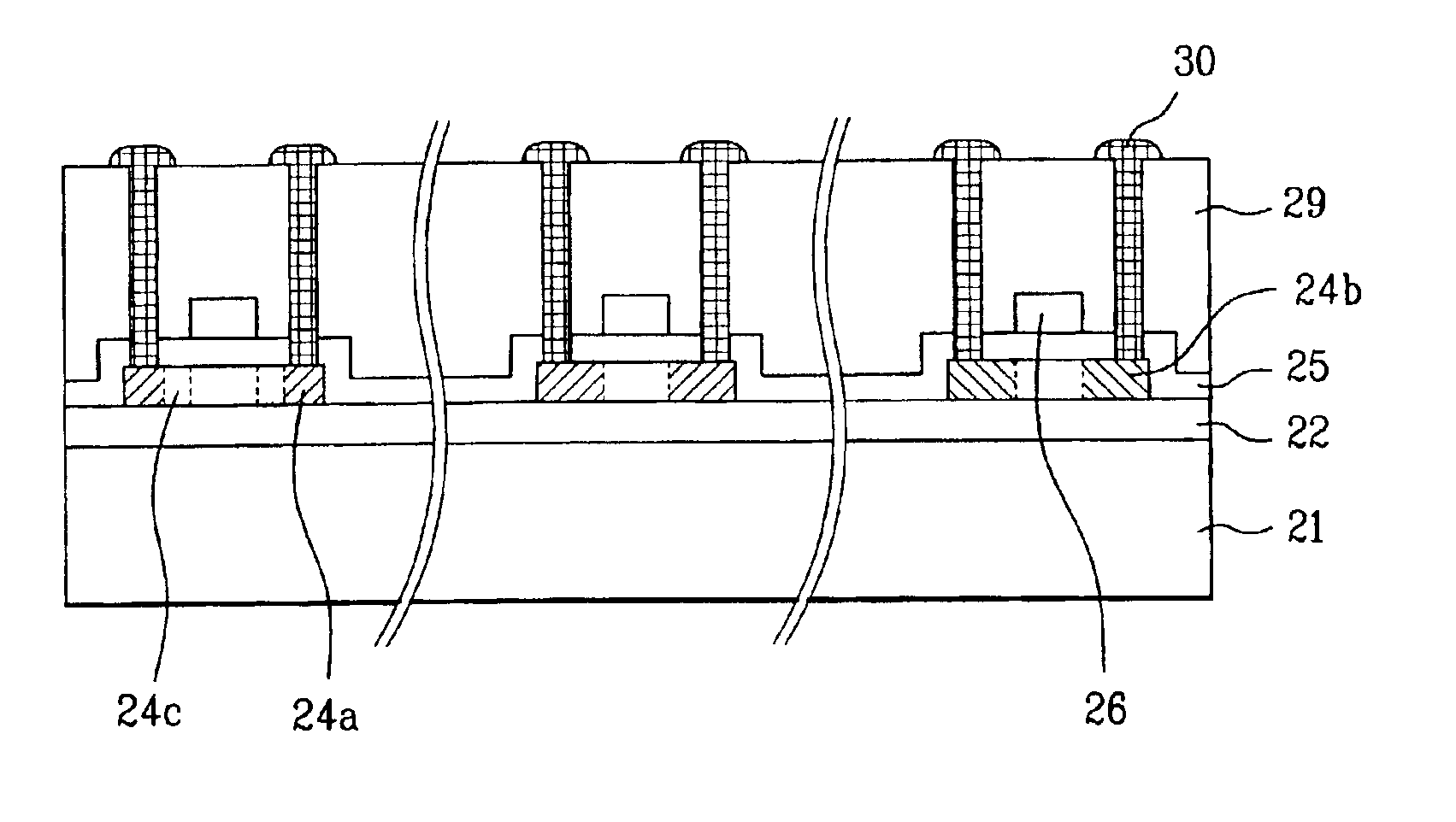

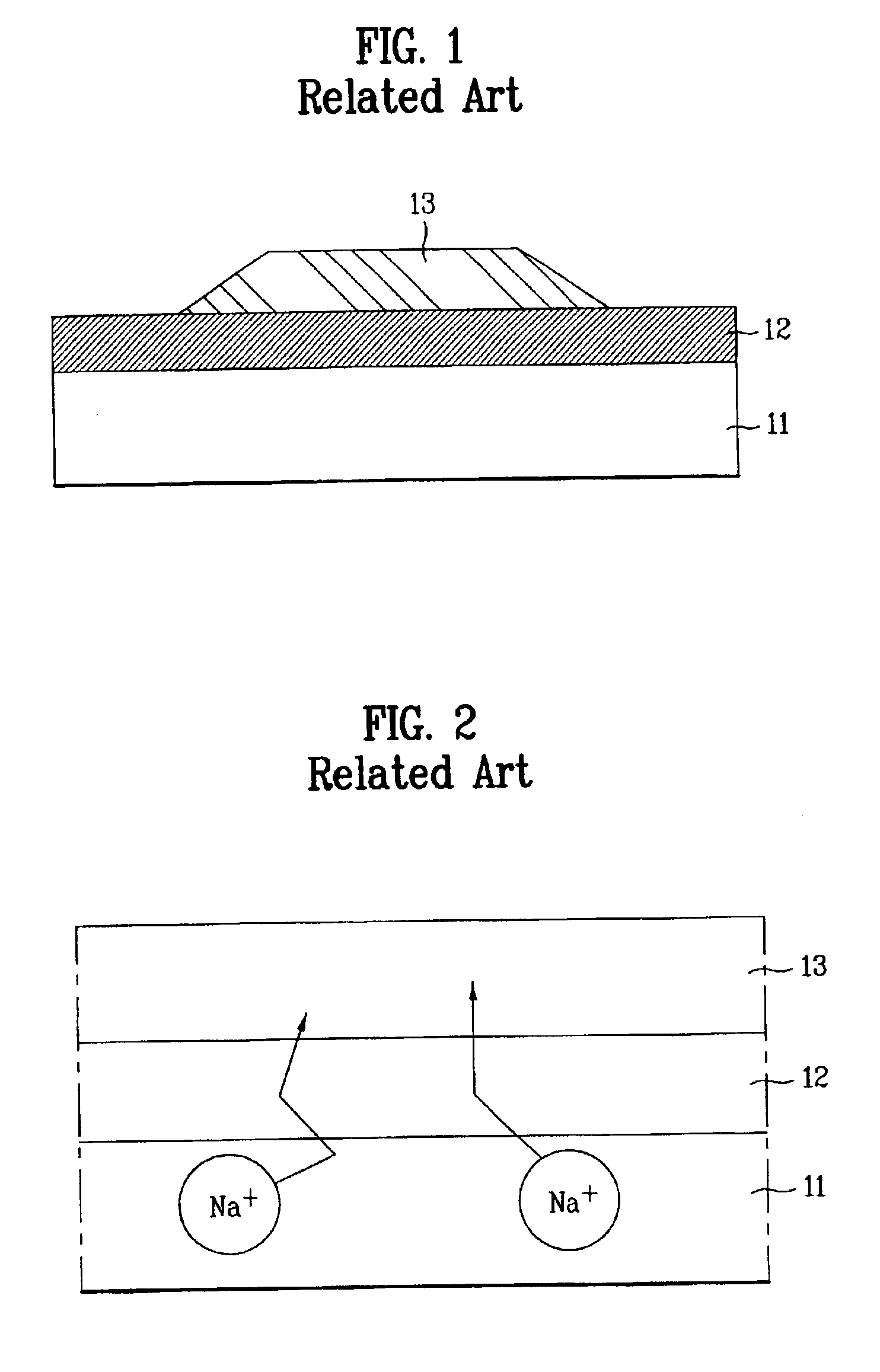

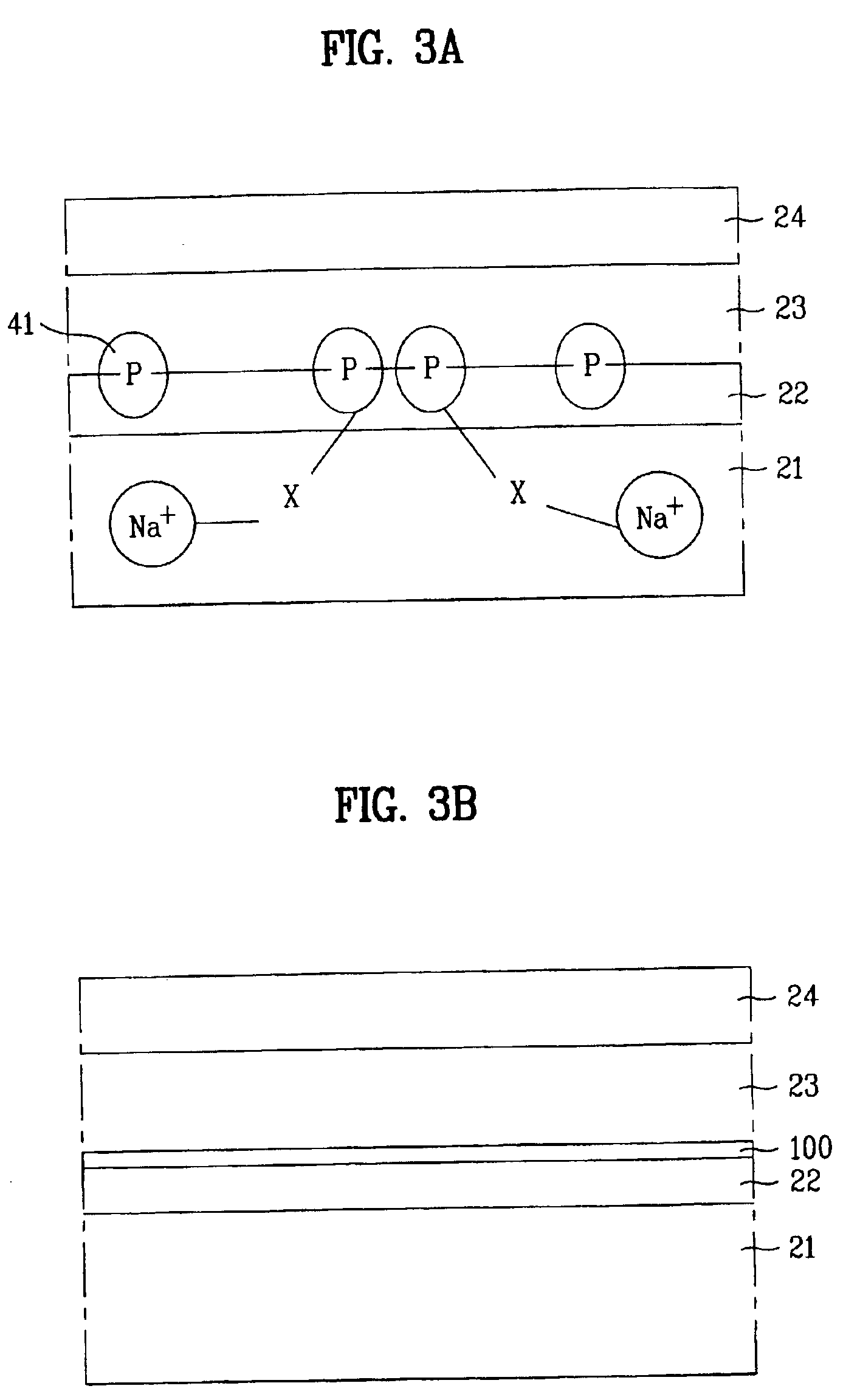

Thin film transistor array substrate and method for manufacturing the same

A thin film transistor array substrate and a method for manufacturing the same is disclosed, in which it is possible to prevent mobile ions contained in a substrate from penetrating into a semiconductor layer by the gettering effect or neutralization in case soda lime glass is used for the substrate. The method includes forming a buffer layer on a substrate; doping impurity ions in the buffer layer; and forming a pixel electrode and a thin film transistor including a semiconductor layer on the buffer layer.

Owner:LG DISPLAY CO LTD

Laminated toughened glass insulator and preparation method thereof

InactiveCN101409119APrevent self-explosionGuaranteed uptimeQuartz/glass/vitreous enamelsSuspension/strain insulatorsTemperature differenceToughened glass

The invention discloses a laminated toughened glass insulator and a preparation method thereof. The insulator is formed with soda-lime glass or ceramic white porcelain glass as the center and externally coated with aluminosilicate glass or low borosilicate glass. The section structure comprises a first and a third layer of aluminosilicate glass or low borosilicate glass; a middle layer of soda-lime glass or ceramic white porcelain glass. A double layer melting furnace is adopted to melt glass raw materials and form glass material base and then a laminated toughened glass insulator is obtained which has a transparent external layer and a blue middle after forming and annealing. The insulator is characterized by more resistance to external impact, no easy occurrence of unfilled corner, fracture and other phenomenon, no generation of cracking, resistance to temperature difference of over 150 DEG C, hard and fine surface without pores, easy self-cleaning, high strength, is bright (like a new one) after long time of outdoor use and has important significance for ensuring the normal operation of electrical power systems.

Owner:迷你仓(上海)储物设备有限公司

Coated substrate with a very low solar factor

InactiveUS8017244B2High selectivityReduce reflectivityRecord information storageMagnetic recordingSolar factorOptoelectronics

A transparent soda-lime glass substrate coated with a stack of layers including at least two infrared reflecting layers, each being directly adjacent to two light absorbent layers is provided. The coated substrate has a light absorption value between 35 and 67% and colorimetric indices of reflected color of a* between 0 and −10 and b* between 0 and −20. Glazing units containing the coated transparent soda-lime glass substrate are also provided.

Owner:AGC FLAT GLASS EUROPE SA

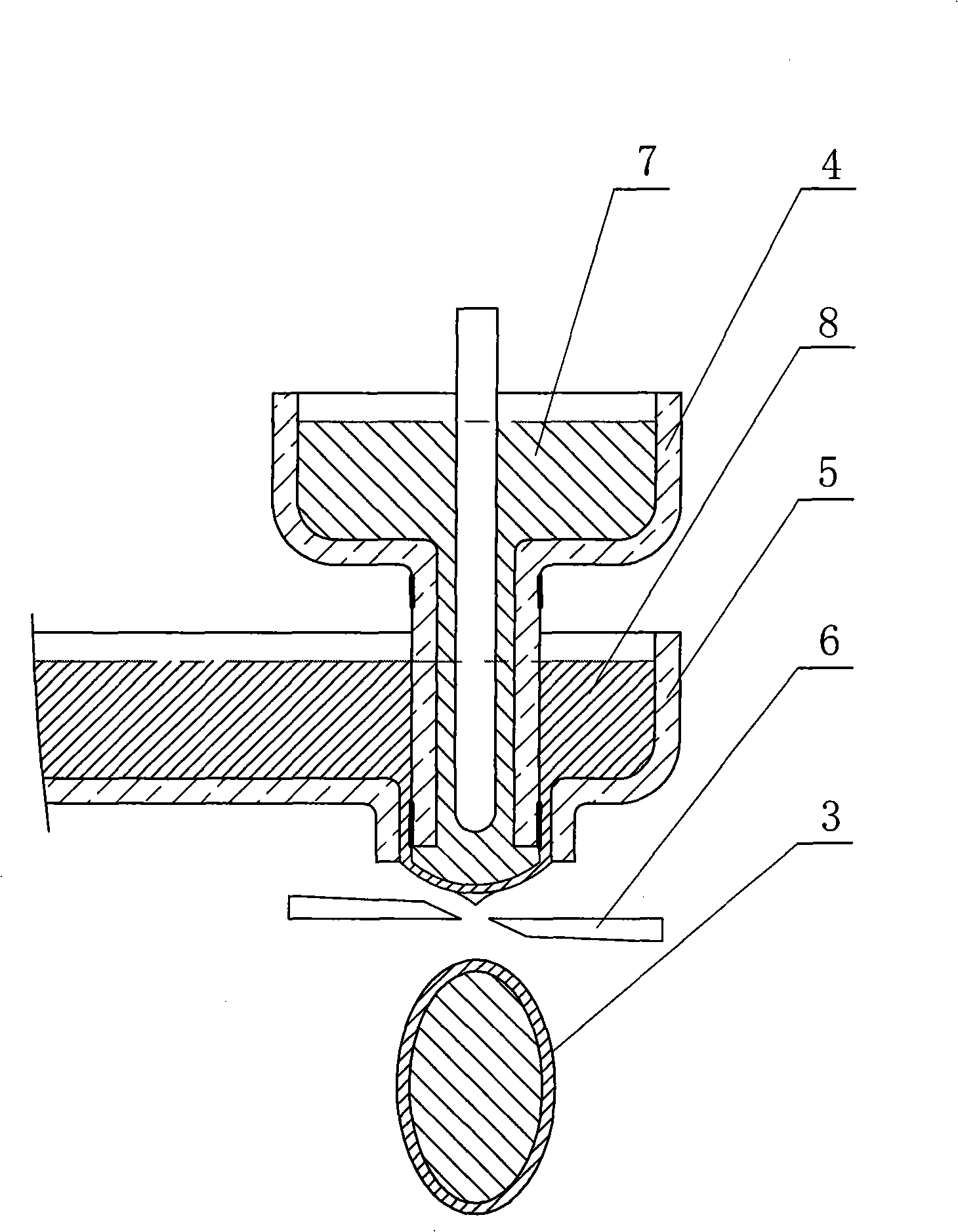

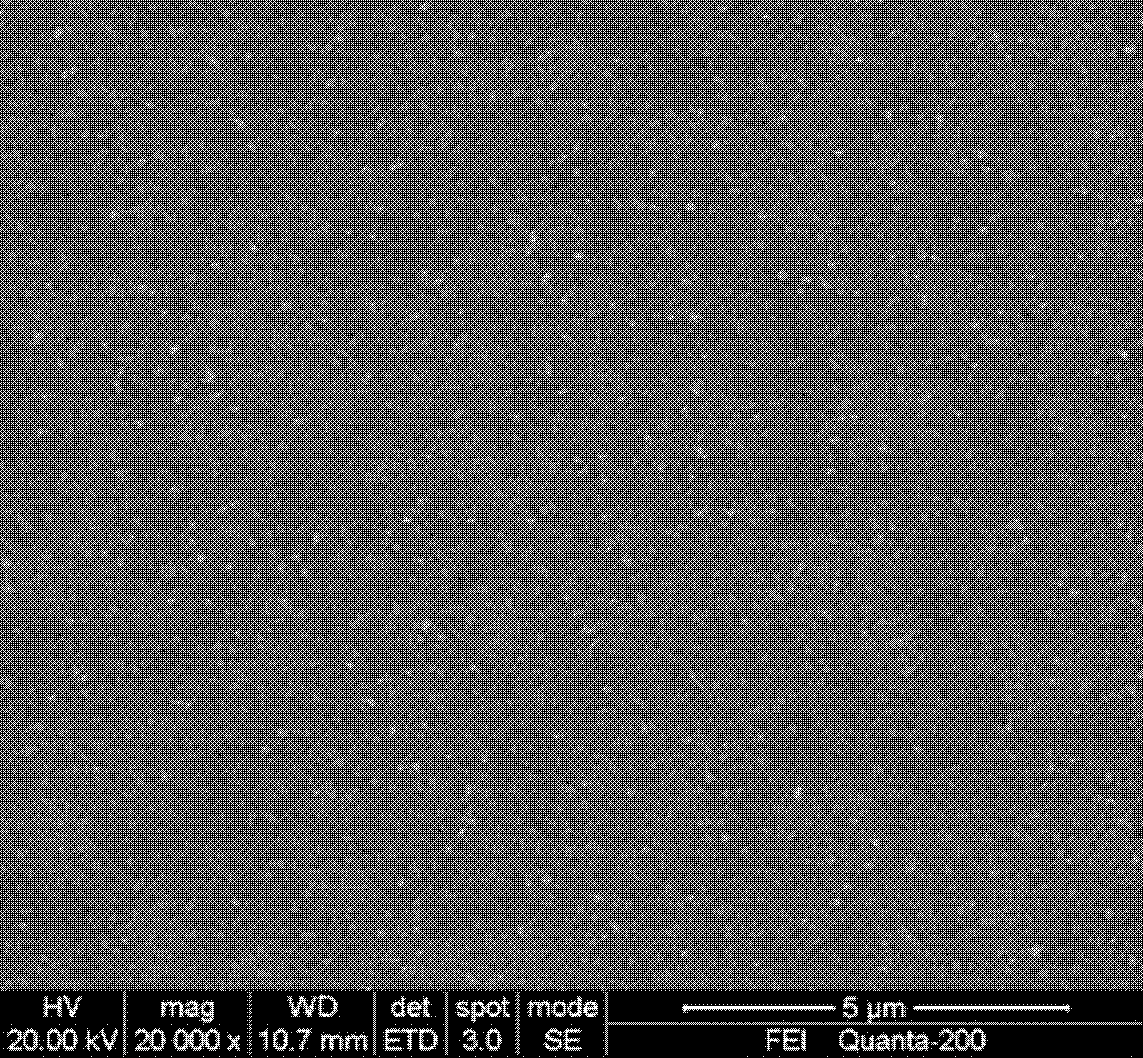

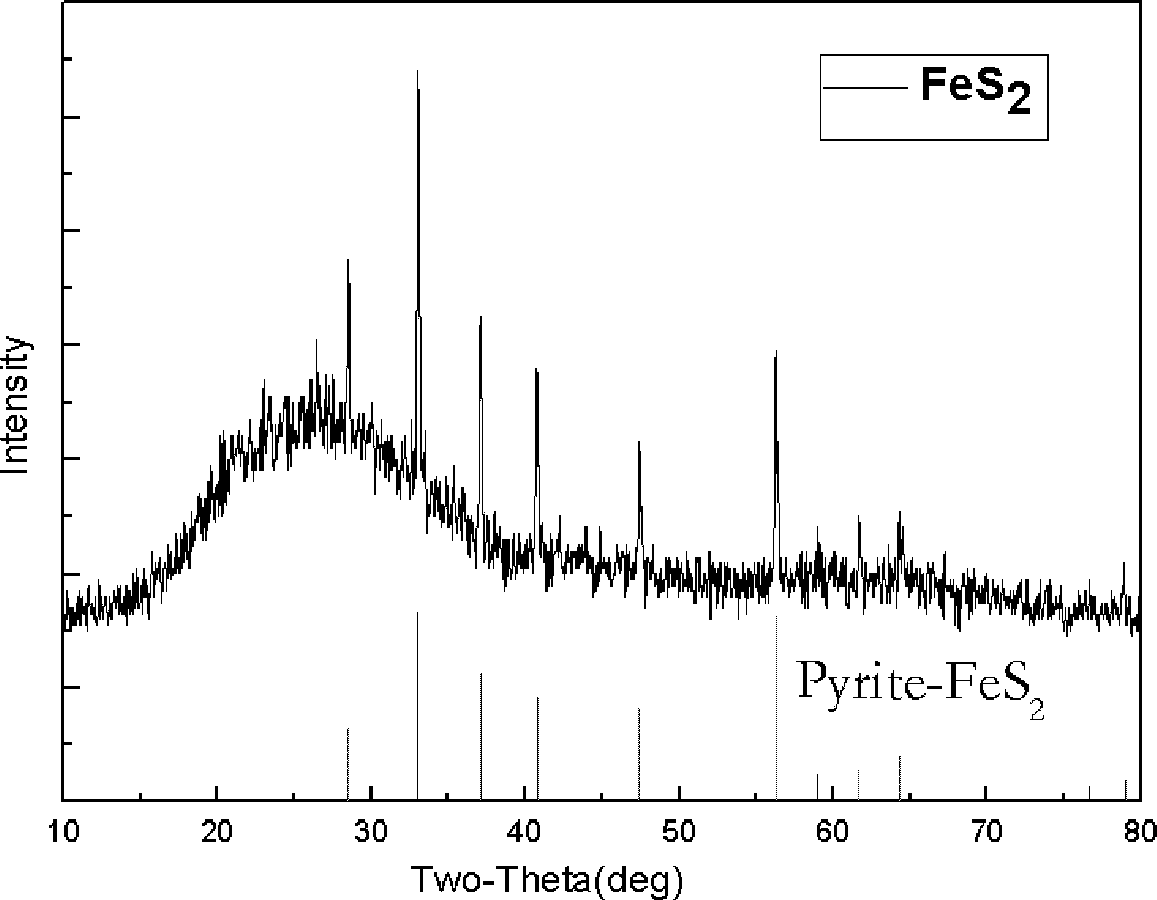

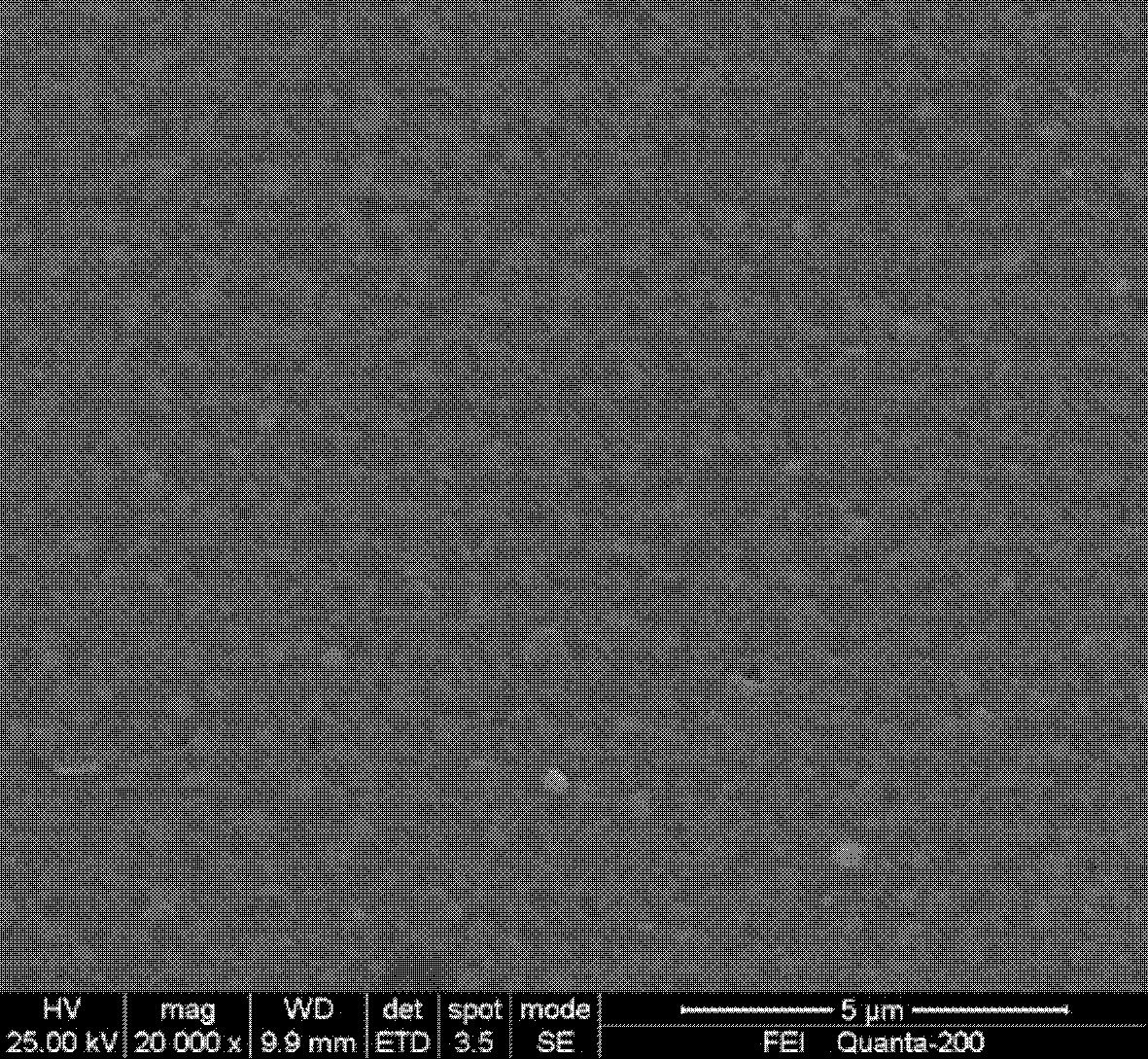

Ferrous disulfide semiconductor film preparation method

ActiveCN102642874AThickness is easy to controlEasy for large-scale continuous productionIron sulfidesVulcanizationIron(II) chloride

The invention discloses a ferrous disulfide semiconductor film preparation method, which relates to the field of preparation of compound semiconductor films for solar cells and the like. The method includes: by an aqueous solution deposition method, using ferrous sulfate or ferrous chloride aqueous solution as cation precursor solution, and using sodium polysulfide aqueous solution as anion precursor solution; controlling immersion time of a substrate in the precursor solution and circulation times to deposit a ferrous disulfide film premade layer; and subjecting the premade layer to vulcanization heat treatment at the high temperature to obtain a ferrous disulfide film. The ferrous disulfide semiconductor film preparation method is short in procedure, low in cost, high in reproducibilityand easy in massive continuous production, and the film is controllable in component and suitable for large-area growth. The deposition substrate can be normal soda lime glass, conductive glass, flexible stainless steel plates, titanium plates, molybdenum plates or plastic plates. The film prepared by the method is controllable in thickness and component, compact and uniform in appearance, high in crystallizing performance and photoelectric property and applicable to thin film solar cells.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com