Ferrous disulfide semiconductor film preparation method

A kind of ferrous disulfide, semiconductor technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

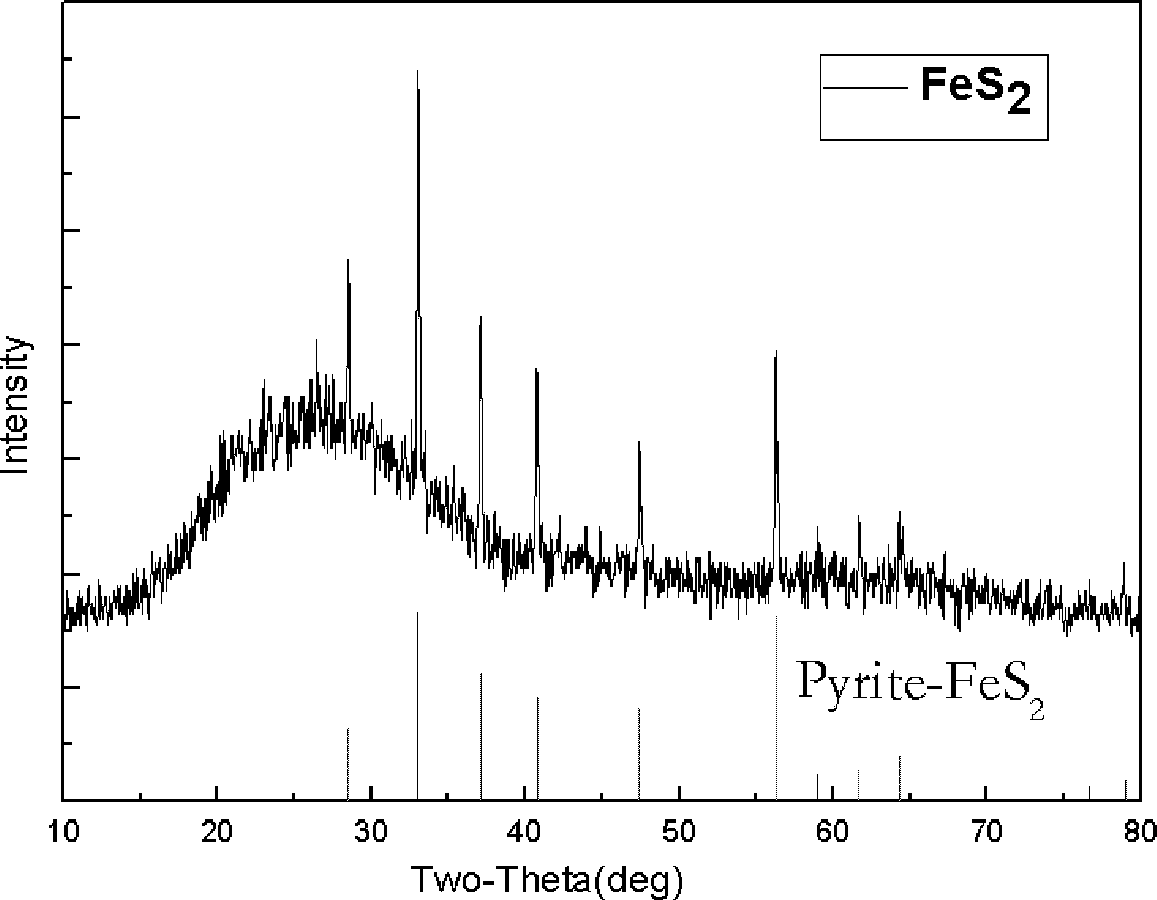

[0034] This embodiment illustrates a kind of ferrous disulfide provided by the invention (chemical formula is FeS 2 ) Preparation method of semiconductor thin film.

[0035] Step 1: Deposition Substrate Surface Preparation

[0036] Choose ordinary soda-lime glass of 35×25×5mm as the deposition substrate: a. Degreasing agent cleaning of the substrate: use detergent as the degreasing agent, place the glass substrate in the aqueous solution of detergent, and oscillate ultrasonically at 30°C Wash for 60 minutes. b. Alkaline cleaning of the substrate: Add 100ml of ammonia water and 100ml of deionized water into a 500ml beaker, place the glass substrate in the above solution, and clean it with ultrasonic vibration at 50°C for 30 minutes. c. Ultrasonic vibration ethanol cleaning of the substrate: Take 200ml of absolute ethanol and add it to a 500ml beaker, place the glass substrate in ethanol, and clean it by ultrasonic vibration at 40°C for 60 minutes. d. Ultrasonic vibration was...

Embodiment 2

[0046] This embodiment illustrates a kind of ferrous disulfide provided by the invention (chemical formula is FeS 2 ) Preparation method of semiconductor thin film.

[0047] Step 1: Deposition Substrate Surface Preparation

[0048] Select a molybdenum sheet of 25×25×0.2mm as the deposition substrate: a. Degreasing agent cleaning of the substrate: use acetone as the degreasing agent, add 100ml of acetone to a 200ml beaker, place the molybdenum sheet in acetone, at 50 Ultrasonic vibration cleaning at ℃ for 90 minutes. b. Alkaline cleaning of the substrate: Add 20g of sodium hydroxide and 200ml of deionized water into a 500ml beaker, place the molybdenum sheet in the above solution, and clean it with ultrasonic vibration at 60°C for 30 minutes. c. Ultrasonic vibration ethanol cleaning of the substrate: Take 200ml of absolute ethanol and add it to a 500ml beaker, place the molybdenum sheet in ethanol, and clean it by ultrasonic vibration at 50°C for 90 minutes. d. Ultrasonic vi...

Embodiment 3

[0059] This embodiment illustrates a kind of ferrous disulfide provided by the invention (chemical formula is FeS 2 ) Preparation method of semiconductor thin film.

[0060] Step 1: Deposition Substrate Surface Preparation

[0061] Select 25×25×2mm ITO conductive glass as the deposition substrate: a. Base degreasing agent cleaning: use degreasing agent as degreasing agent, add 100ml degreasing agent into a 200ml beaker, place stainless steel sheet in degreasing agent , ultrasonic cleaning at 80°C for 15 minutes. b. Alkaline cleaning of the substrate: Add 20g of sodium carbonate and 200ml of deionized water into a 500ml beaker, place the stainless steel sheet in the above solution, and clean it with ultrasonic vibration at 40°C for 25 minutes. c. Ultrasonic vibration ethanol cleaning of the substrate: Take 200ml of absolute ethanol and add it to a 500ml beaker, place the stainless steel sheet in the ethanol, and clean it by ultrasonic vibration at 70°C for 45 minutes. d. Ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com