Composite heat-insulating wallboard and preparation method thereof

A composite thermal insulation and wallboard technology, applied in the field of thermal insulation wallboards, can solve the problems of interface defects, poor compatibility between organic EPS aggregates and inorganic cementitious materials, and unsatisfactory physical and mechanical properties of wallboards. The effect of optimizing gradation, improving interfacial compatibility, and improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Weigh 100 parts of 42.5 ordinary Portland cement, 10 parts of class II fly ash, 5 parts of gypsum, 0.5 parts of latex powder, 0.8 parts of naphthalene superplasticizer, and 0.1 part of anhydrous calcium chloride and add them to the mortar mixer In the process, first dry mix evenly, then add water to the mortar mixer at a water-cement ratio of 0.5, and continue stirring.

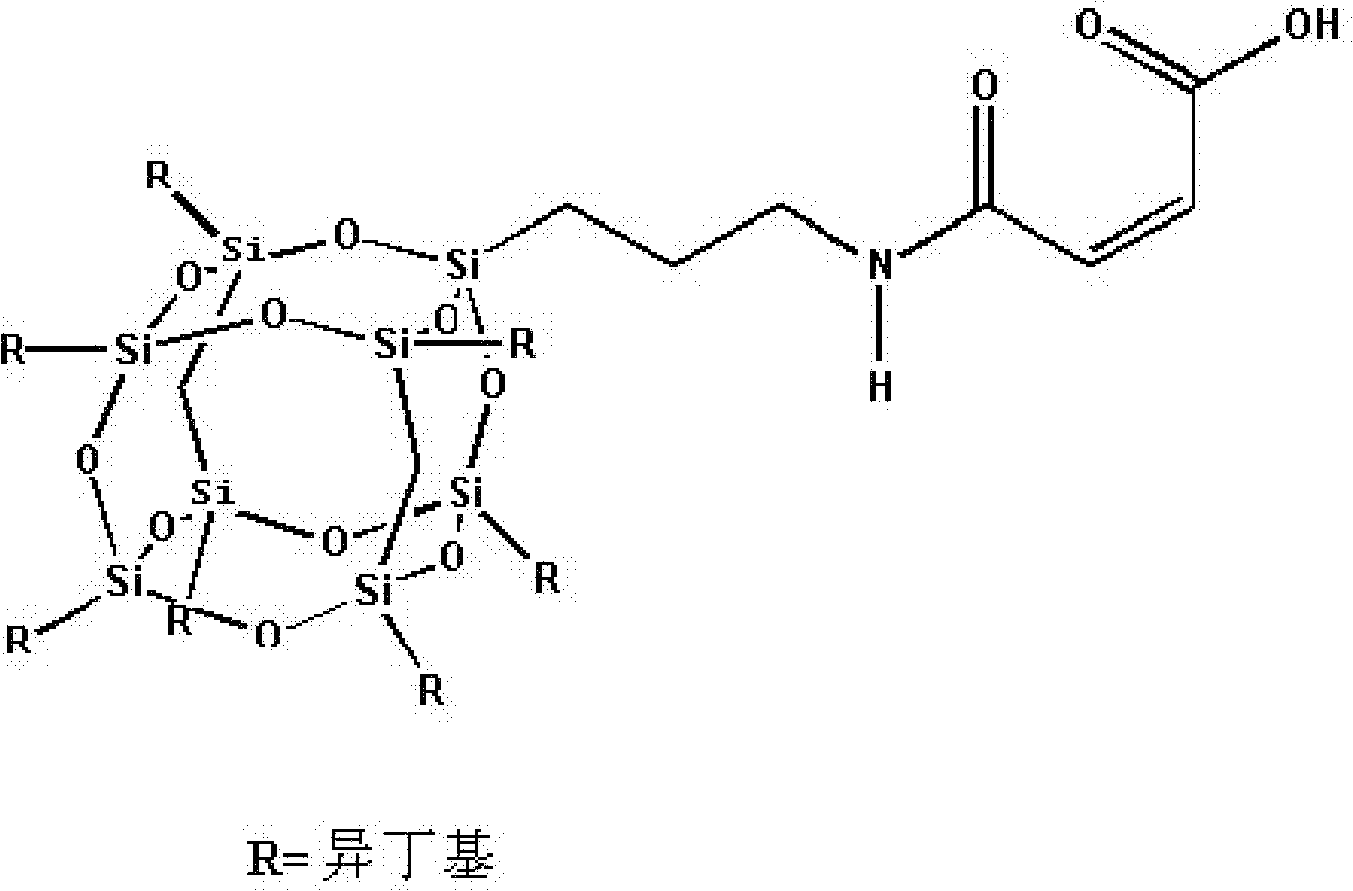

[0030] 2) Weigh 0.1 part of Maleamic Acid-Isobutyl POSS (manufactured by American hybrid plastics company), 1.5 parts of EPS (3:1 for particle size 4mm and 2mm), and dissolve Maleamic Acid-Isobutyl POSS in n-hexane at a ratio of 1:10 In the process, the dissolved solution is sprayed on the EPS, and the EPS whose surface is wetted by the POSS solution is added to the mixer for continuous stirring.

[0031] 3) Add 0.2 parts of wd-11 cement foaming agent into the foaming machine and foam for 4-5 minutes to obtain a large amount of foam into the mixer and stir evenly to obtain the insulation core materi...

Embodiment 2~6

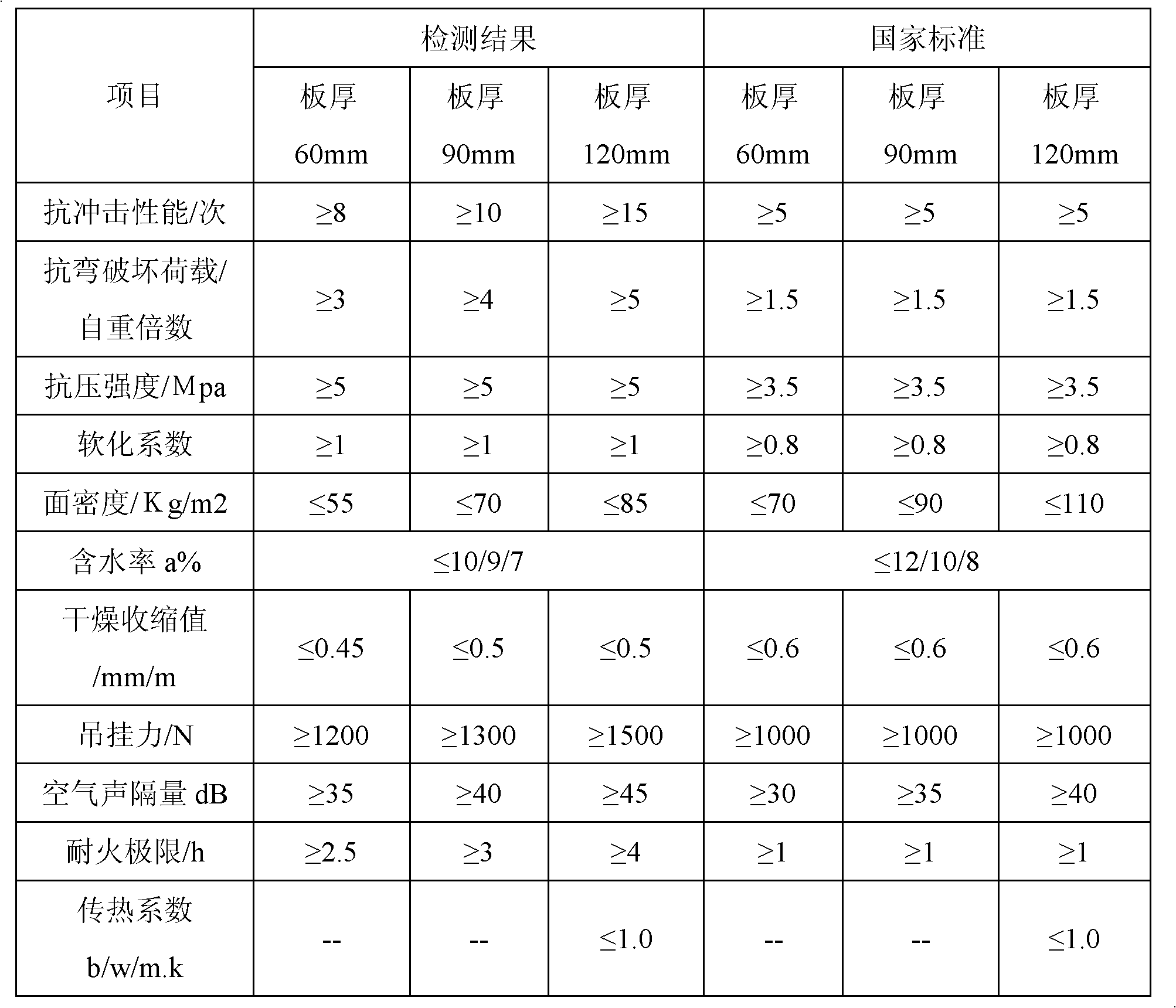

[0037] The preparation method is the same as in Example 1, and the dosage of each component is changed as shown in Table 2. The physical performance test results of the light-weight, energy-saving and heat-preserving composite wallboard obtained are the same as in Example 1.

[0038] Table 2 The amount of each component in each embodiment (mass parts)

[0039]

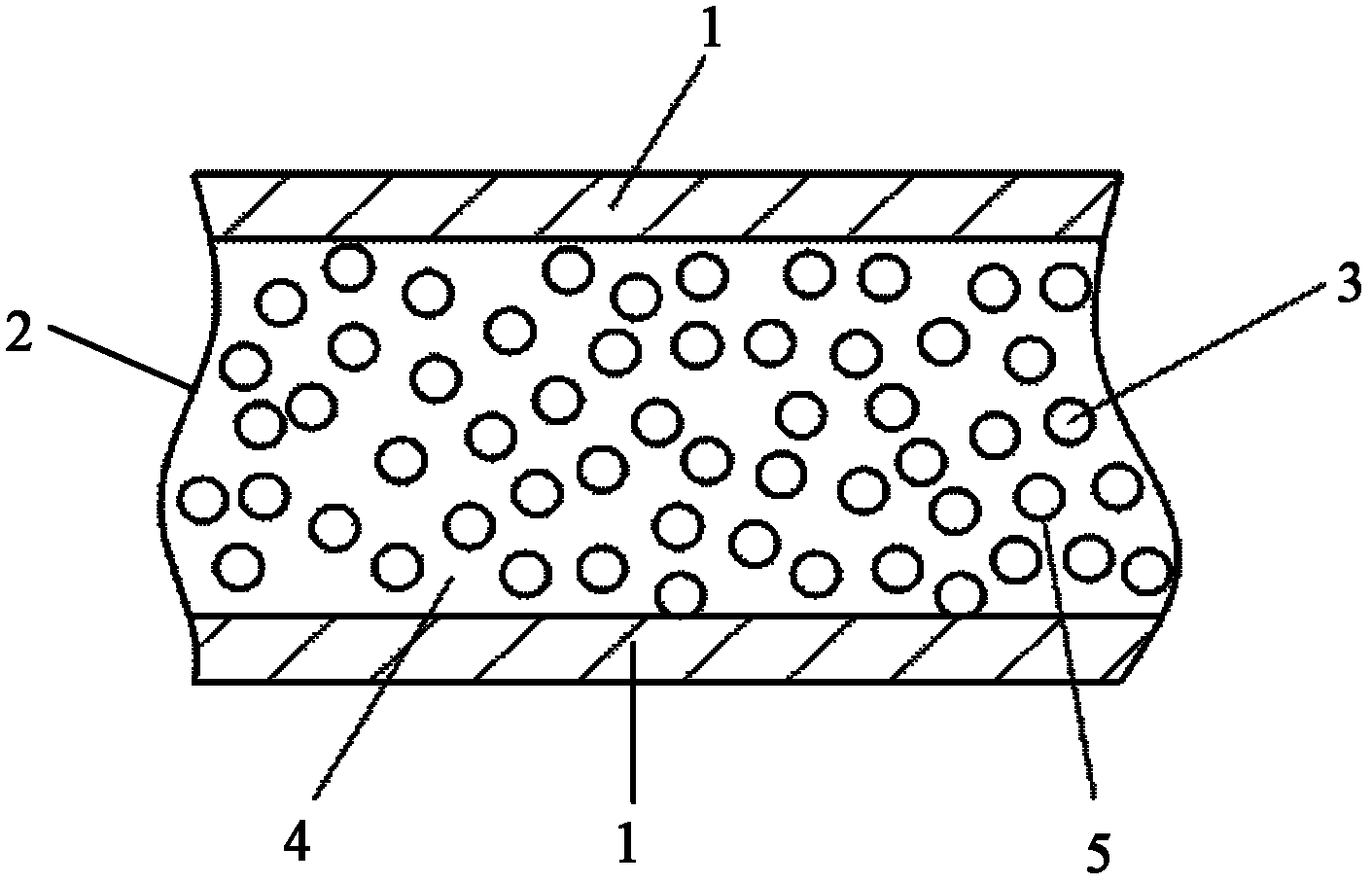

[0040] figure 1 A schematic diagram of the structural composition of the lightweight composite thermal insulation wallboard of the present invention is given, in figure 1 In the middle, the upper and lower panels 1 are made of calcium silicate board, and the insulation core material 2 sandwiched between the upper and lower panels 1 is composed of EPS as aggregate 3 and aerated concrete (including various additives) 4 , EPS surface coated with Maleamic Acid-Isobuty POSS layer 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com