Bamboo fiber reinforced degradable PLA material and preparation method thereof

A bamboo fiber and raw material technology, applied in the field of bamboo fiber-reinforced degradable PLA material and its preparation, can solve the problems of difficult self-degradation of plastic waste, low weight utilization rate, ecological environment pollution, etc., and achieve good environmental benefits and economical Benefits, high production efficiency, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

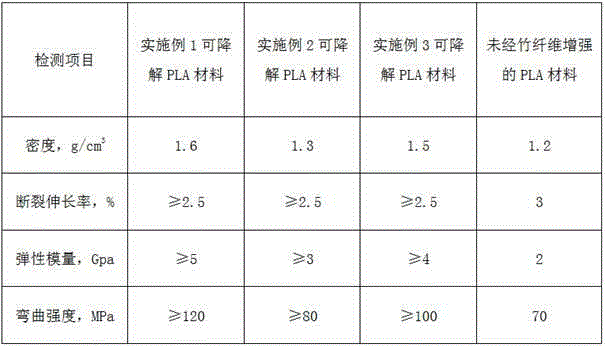

Examples

Embodiment 1

[0028] (1) Weigh 30 parts of polylactic acid resin by weight; 15 parts of bamboo fiber; 0.5 parts of hexamethyldisilazane coupling agent; 100 parts of calcium carbonate; maleic anhydride grafted polypropylene (PP-g-MA ) 0.5 parts; antioxidant 0.1 parts; stearic acid 0.5 parts; polyethylene wax 3 parts;

[0029] (2) Crush the bamboo fiber into bamboo powder that can pass through a 60-mesh sieve, and then vacuum-dry it at 110°C for 12 hours to make the moisture content 1%; Modified treatment to obtain active bamboo powder;

[0030] (3) Add the obtained active bamboo powder, polylactic acid resin, inorganic powder, compatibilizer, antioxidant, dispersant, and lubricant into the high-speed mixer in proportion, and mix at 1000r / min for 20min to make a premix;

[0031] (4) Inject the obtained premixed material into a single-screw extruder with an extrusion die temperature of 150°C, melt blend and granulate at a screw speed of 200r / min to obtain the bamboo fiber-reinforced degradabl...

Embodiment 2

[0033] (1) Weigh 40 parts by weight of polylactic acid resin; 27 parts of bamboo fiber; 1 part of aluminate coupling agent; 18 parts of talcum powder; maleic anhydride grafted EPDM rubber (EPDM-g-MA) 3.5 parts; 0.4 parts of antioxidant; 1.8 parts of magnesium stearate; 4 parts of polypropylene wax;

[0034] (2) Crush the bamboo fiber into bamboo powder that can pass through a 120-mesh sieve, and then vacuum-dry it at 110°C for 12 hours to make the moisture content 2%; Modified treatment to obtain active bamboo powder;

[0035] (3) Add the obtained active bamboo powder, polylactic acid resin, inorganic powder, compatibilizer, antioxidant, dispersant, and lubricant into the high-speed mixer in proportion, and mix at 1000r / min for 20min to make a premix;

[0036] (4) Inject the obtained premixed material into a single-screw extruder with an extrusion die temperature of 150°C, melt blend and granulate at a screw speed of 200r / min to obtain the bamboo fiber-reinforced degradable P...

Embodiment 3

[0038] (1) Weigh 70 parts by weight of polylactic acid resin; 40 parts of bamboo fiber; 0.5 parts of titanate coupling agent, 1.5 parts of polymerized isocyanate; 20 parts of kaolin, 10 parts of wollastonite powder; 5 parts of ethylene propylene rubber (EPDM-g-MA); 0.5 parts of antioxidant; 3 parts of magnesium stearate; 2 parts of strontium stearate, 3 parts of paraffin;

[0039] (2) Crush the bamboo fiber into bamboo powder that can pass through a 325-mesh sieve, and then vacuum-dry it at 110°C for 12 hours to make the moisture content 10%; Modified treatment to obtain active bamboo powder;

[0040] (3) Add the obtained active bamboo powder, polylactic acid resin, inorganic powder, compatibilizer, antioxidant, dispersant, and lubricant into the high-speed mixer in proportion, and mix at 1000r / min for 20min to make a premix;

[0041] (4) Inject the obtained premix into a multi-screw extruder with an extrusion die temperature of 150°C, melt blend and pelletize at a screw spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com