Patents

Literature

832 results about "Plastic waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

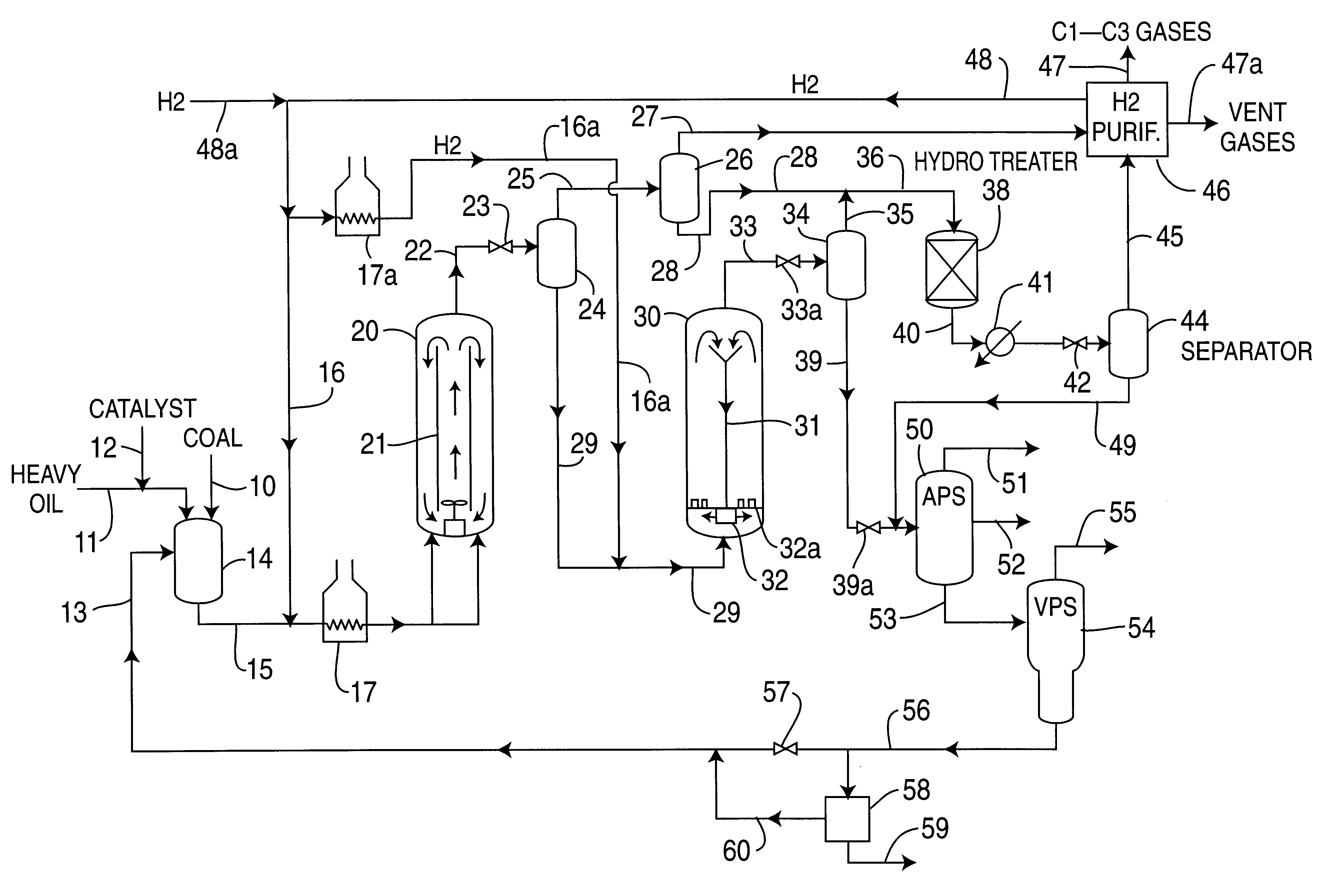

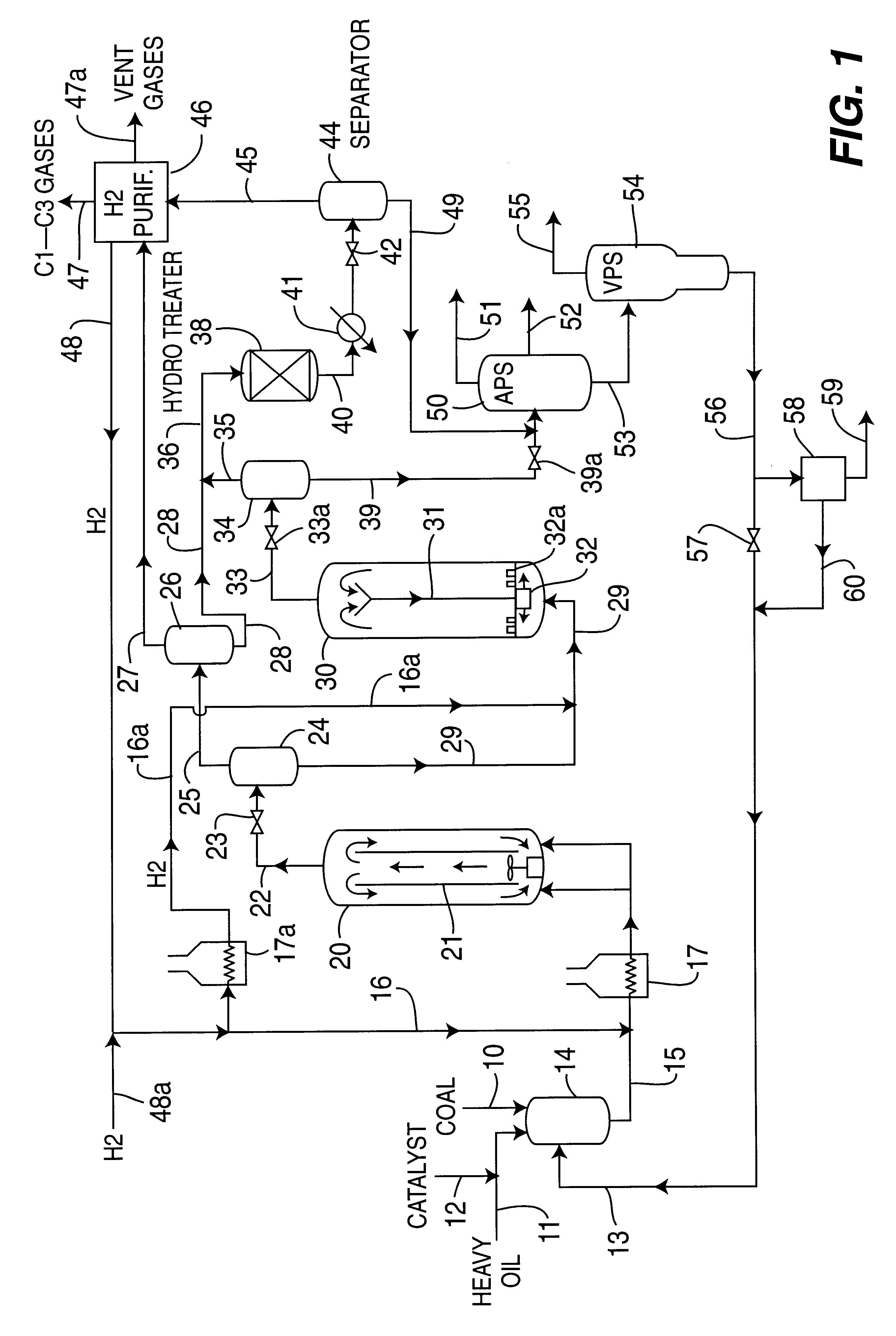

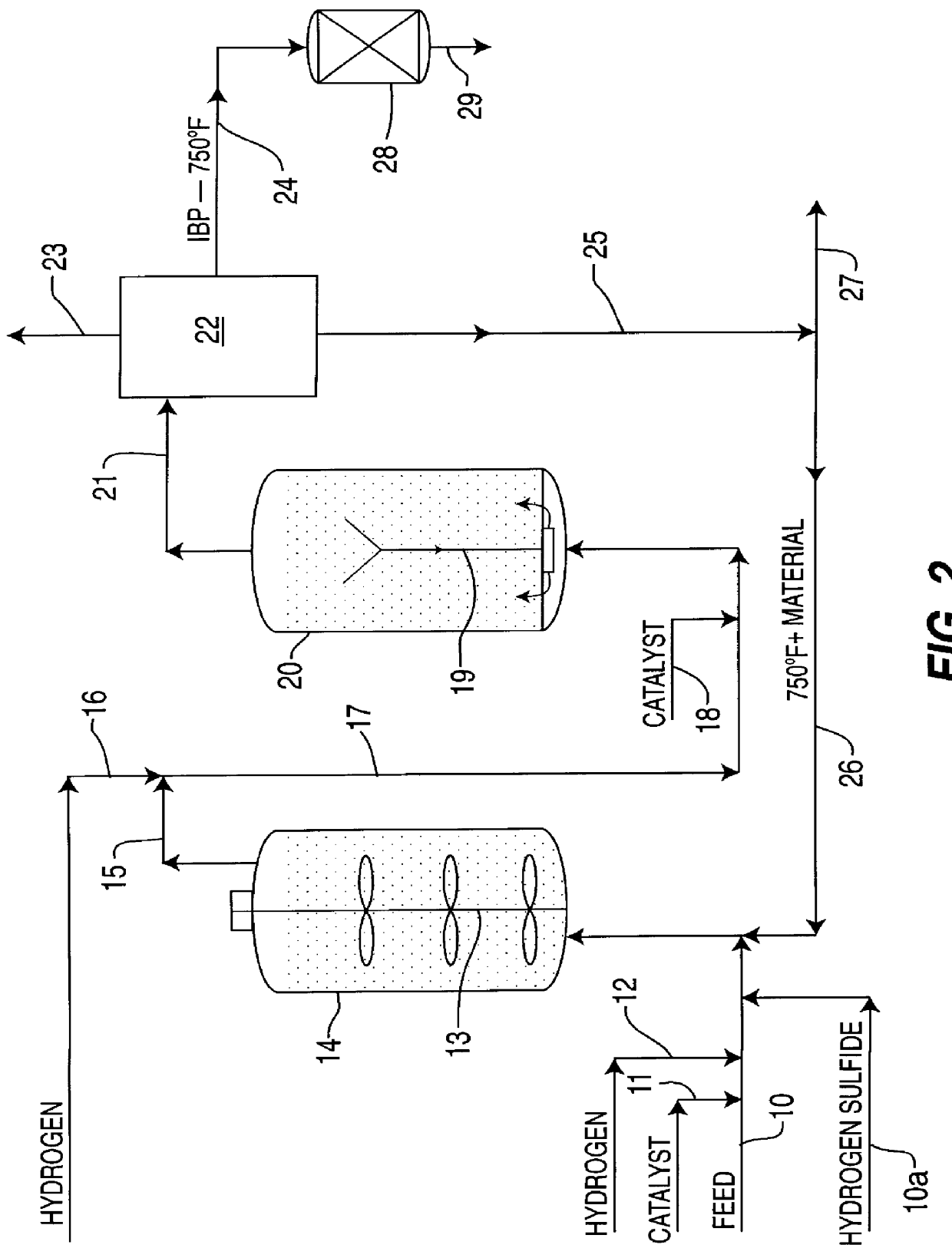

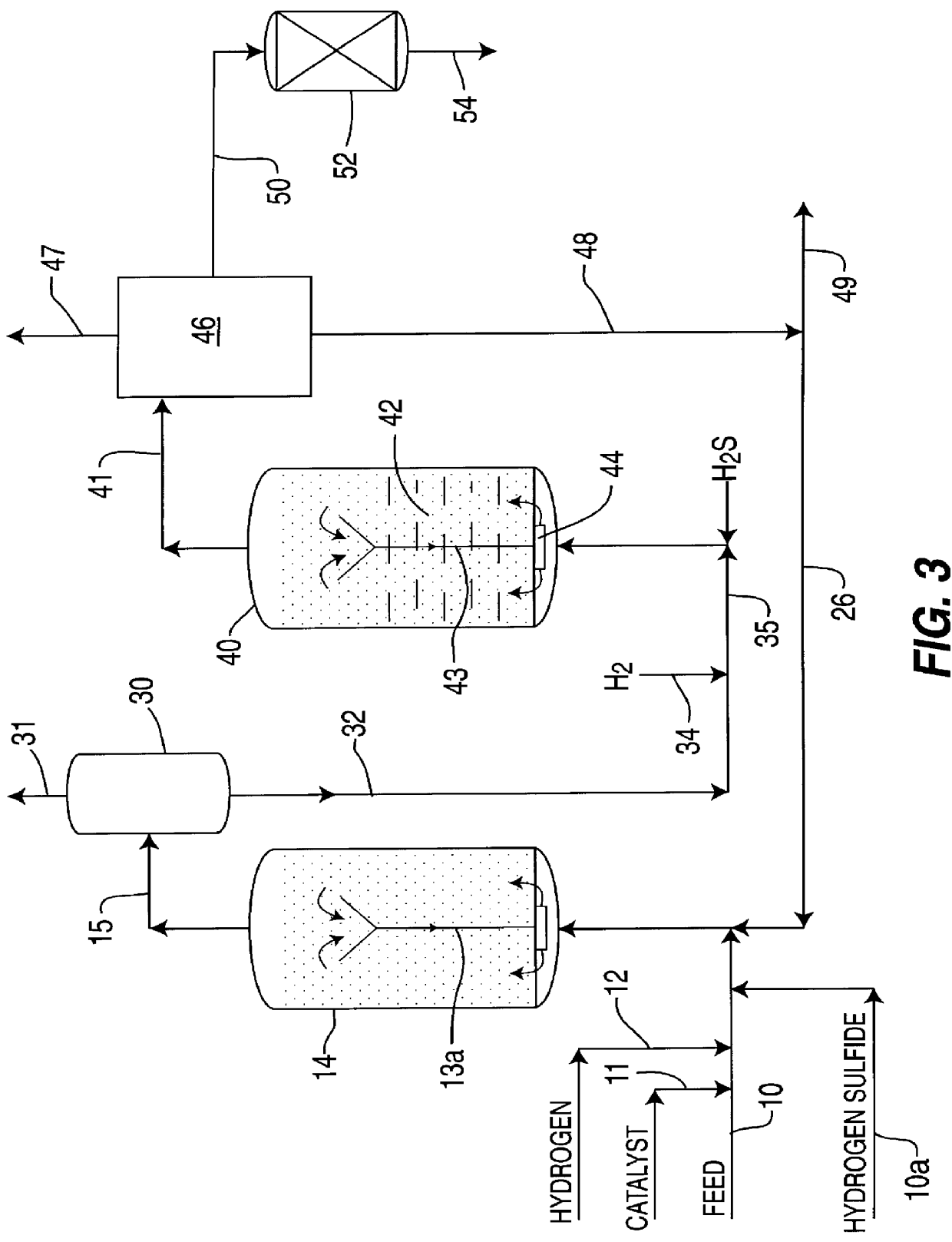

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

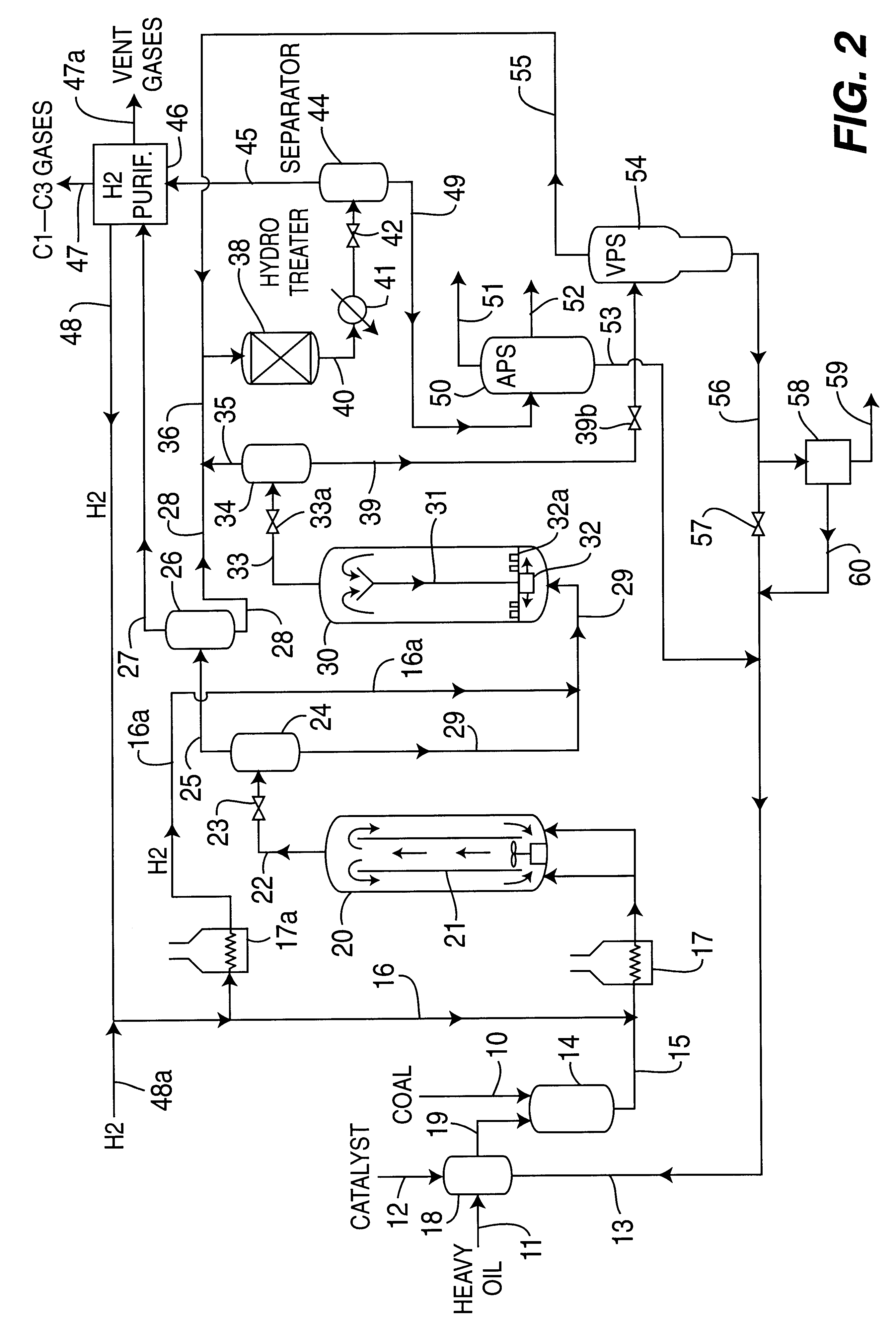

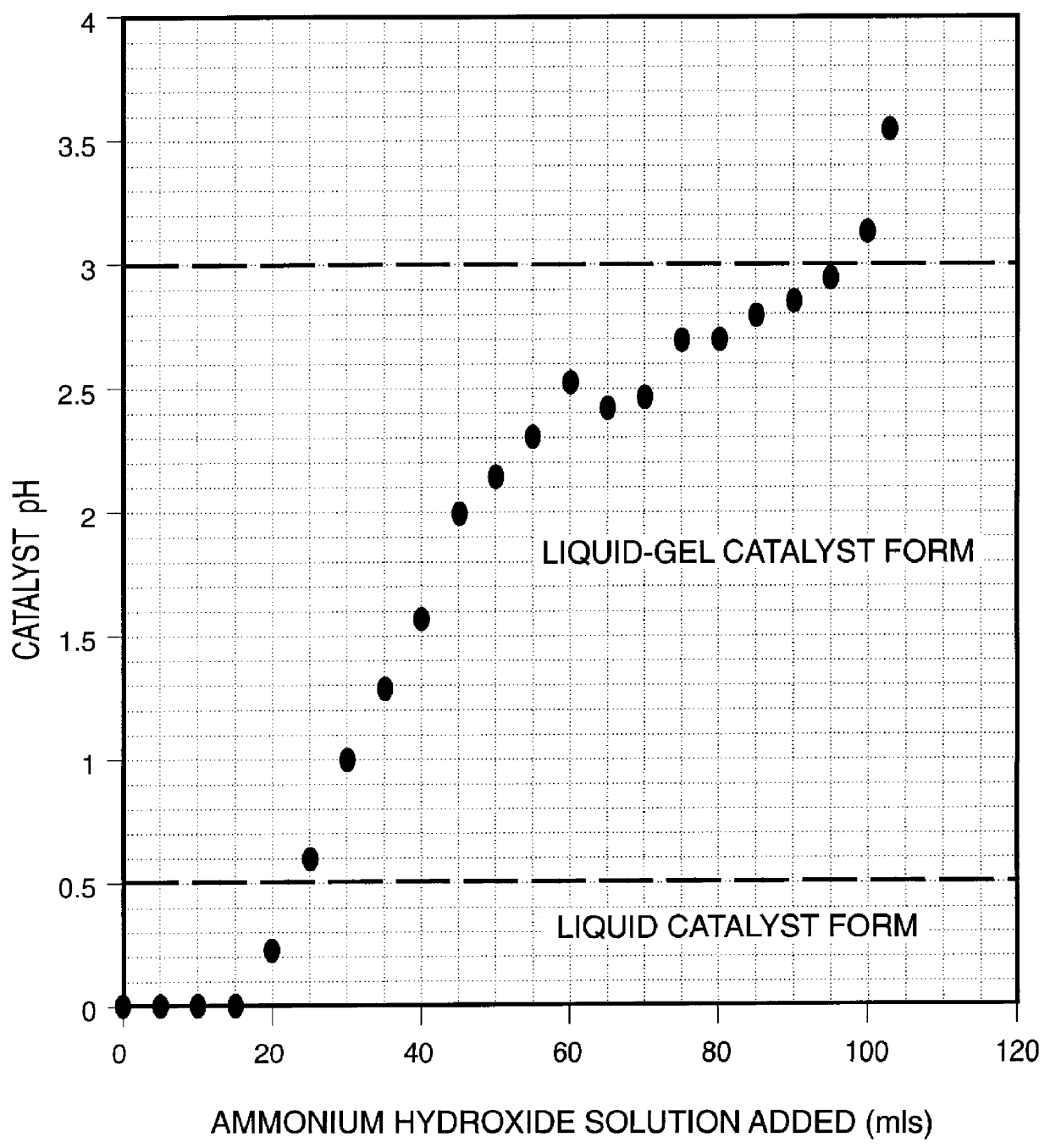

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

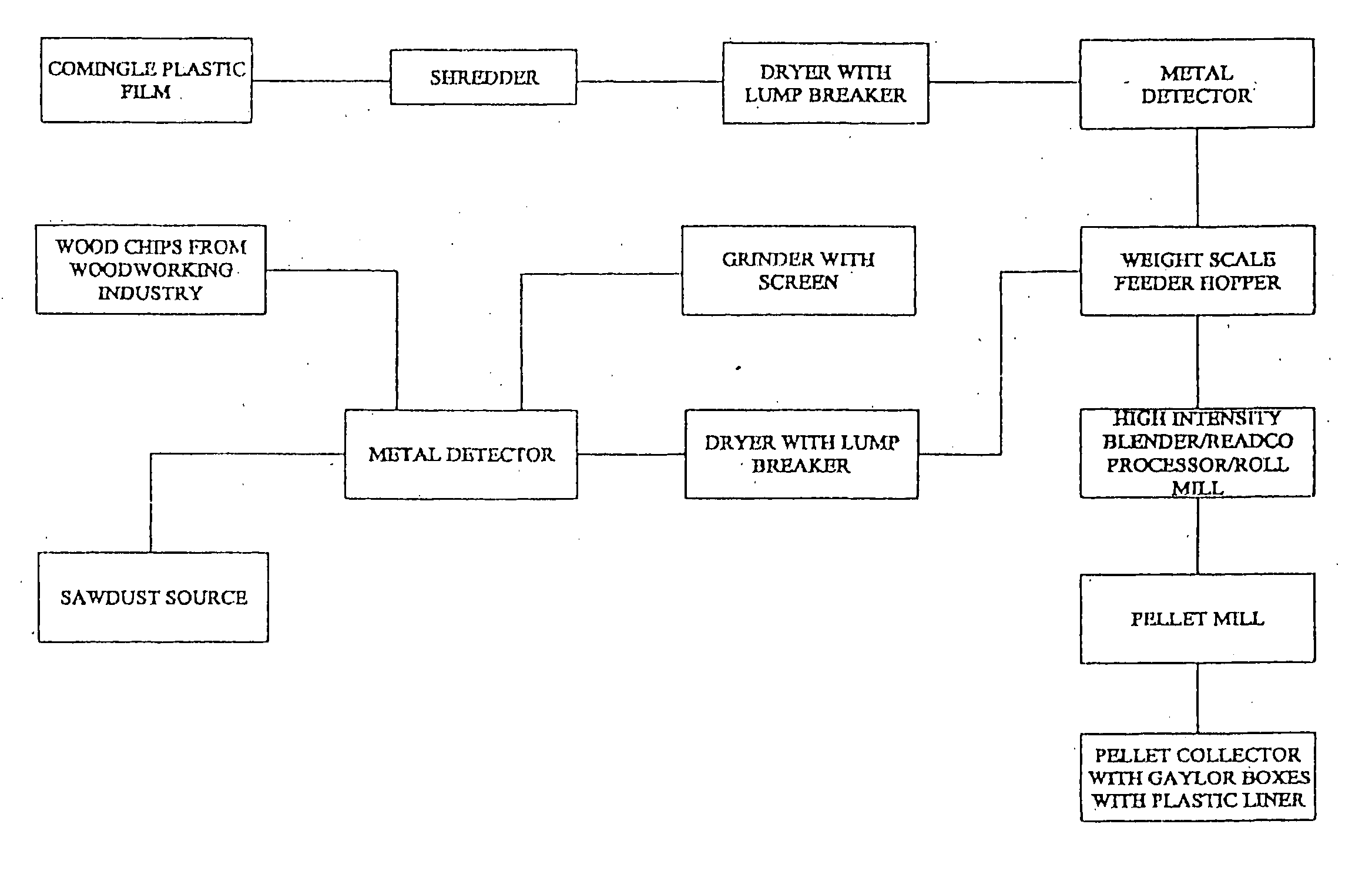

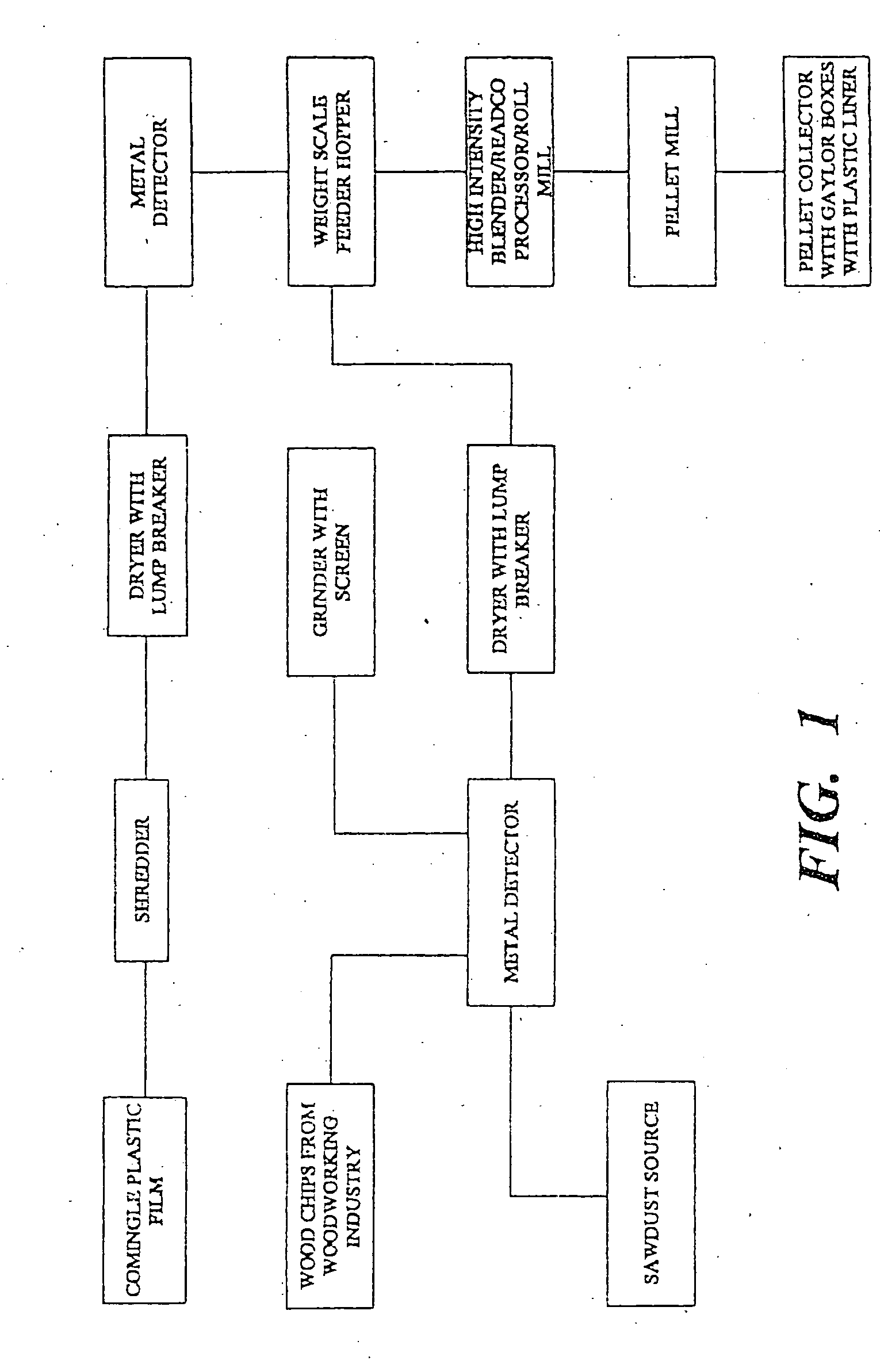

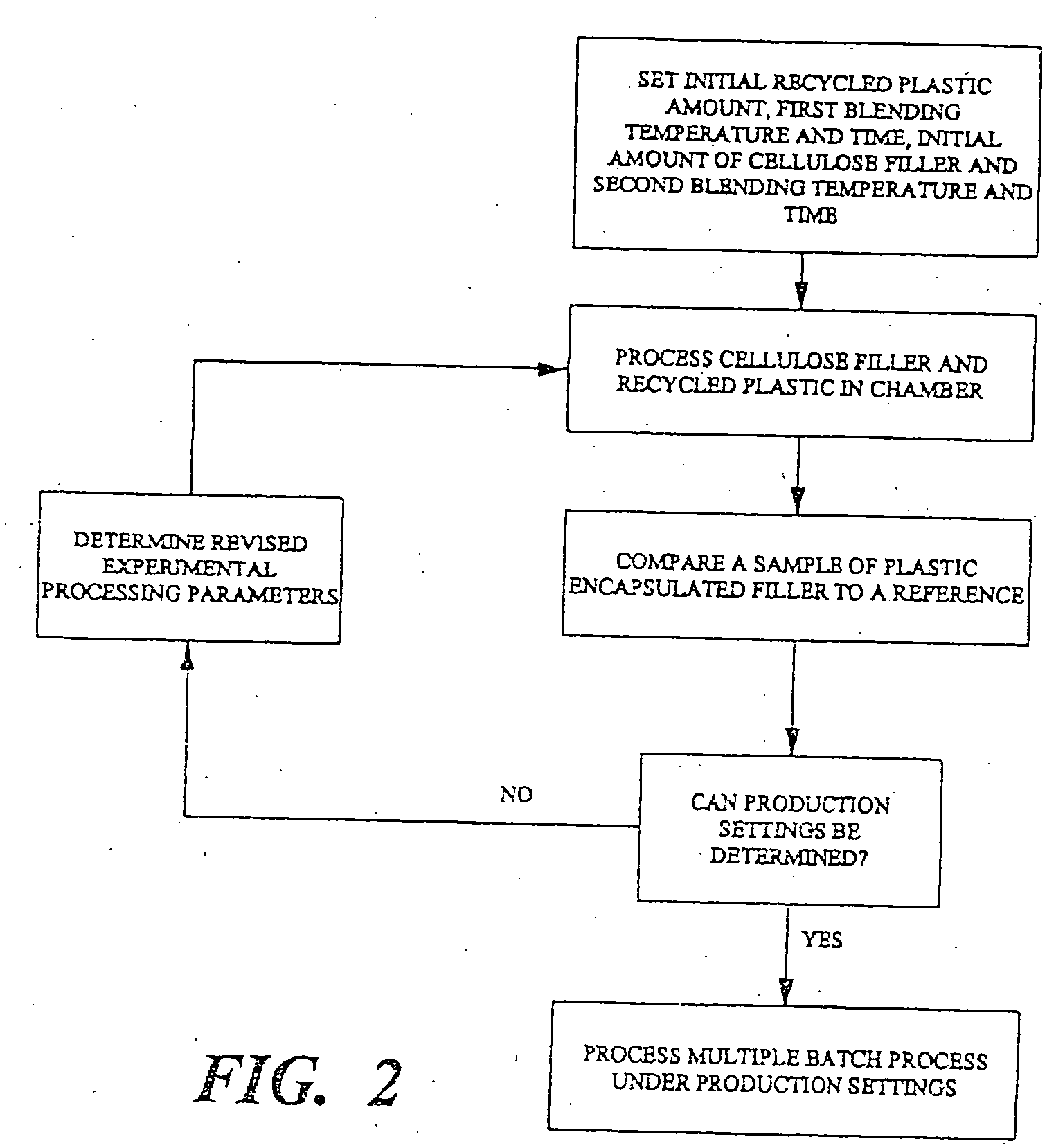

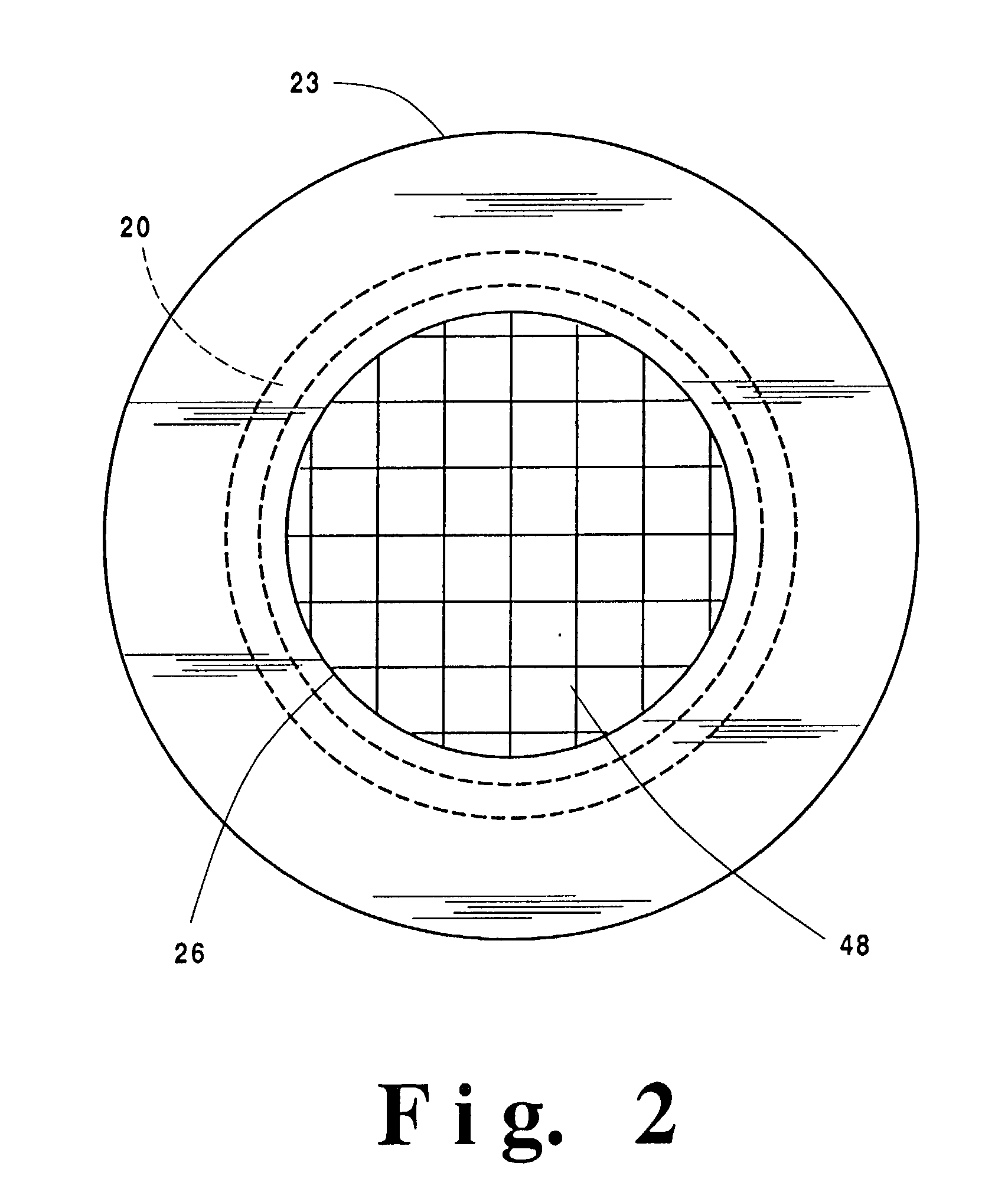

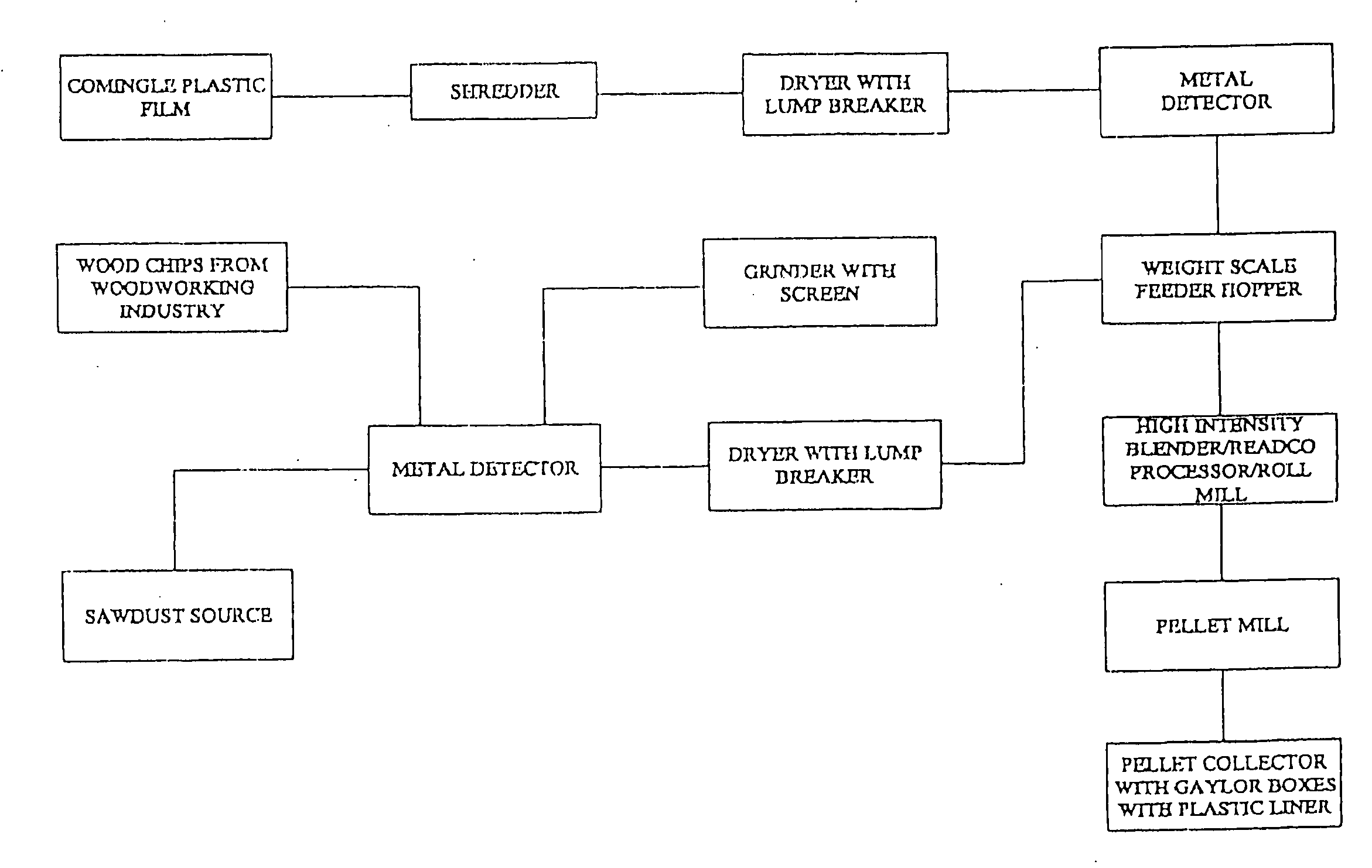

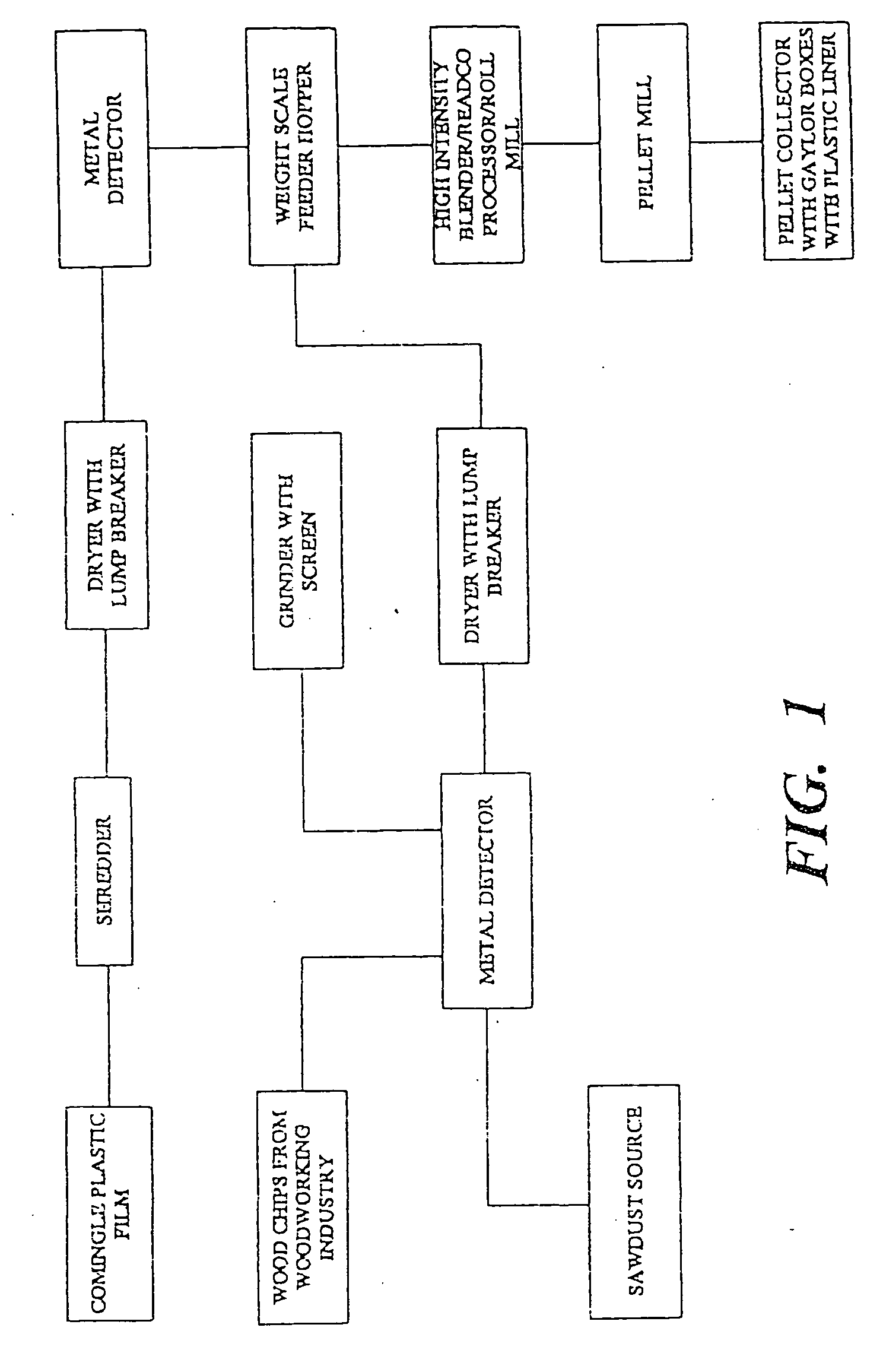

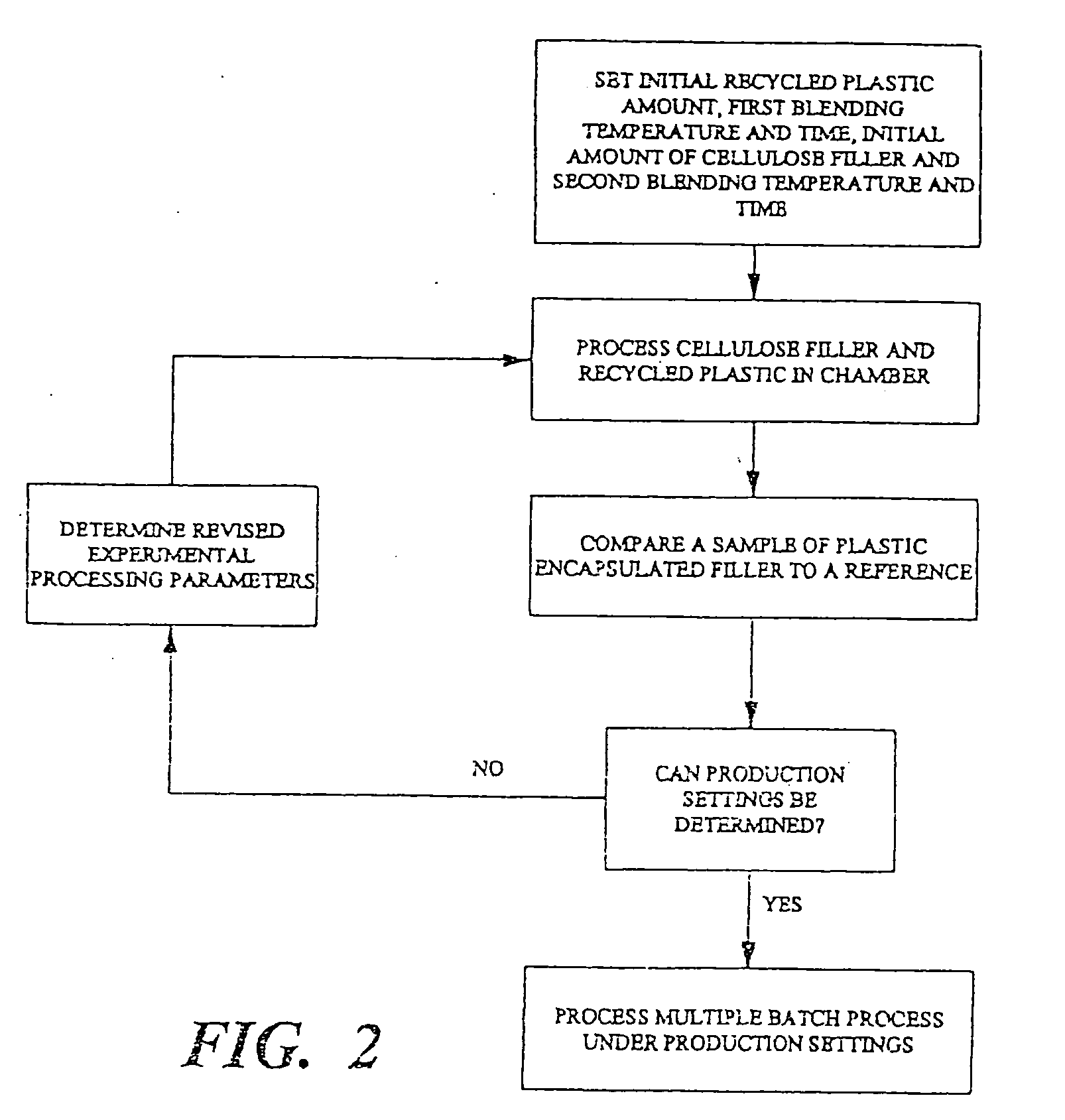

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20060006564A1Reduce the possibilityLower melting and softening temperaturePlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

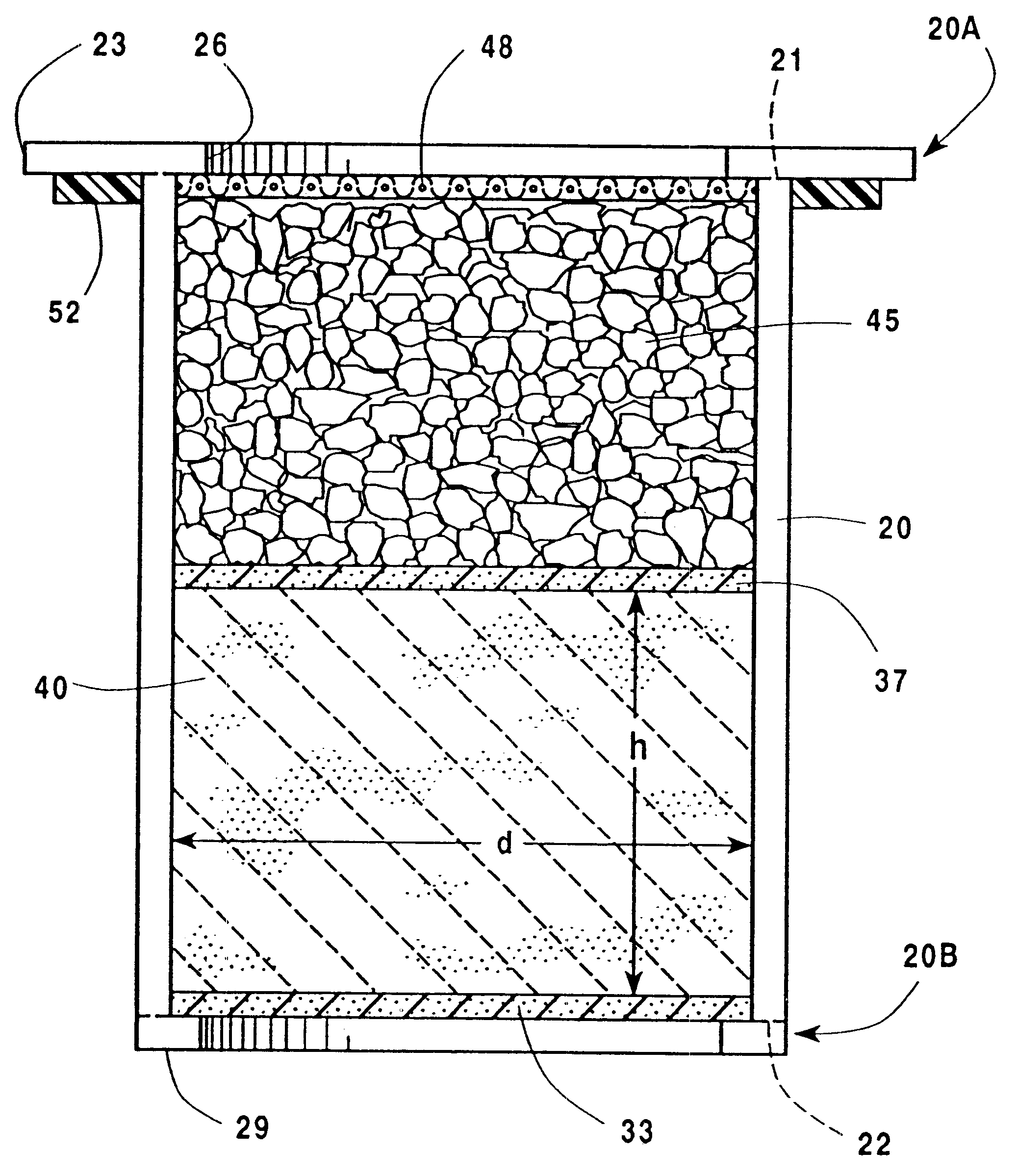

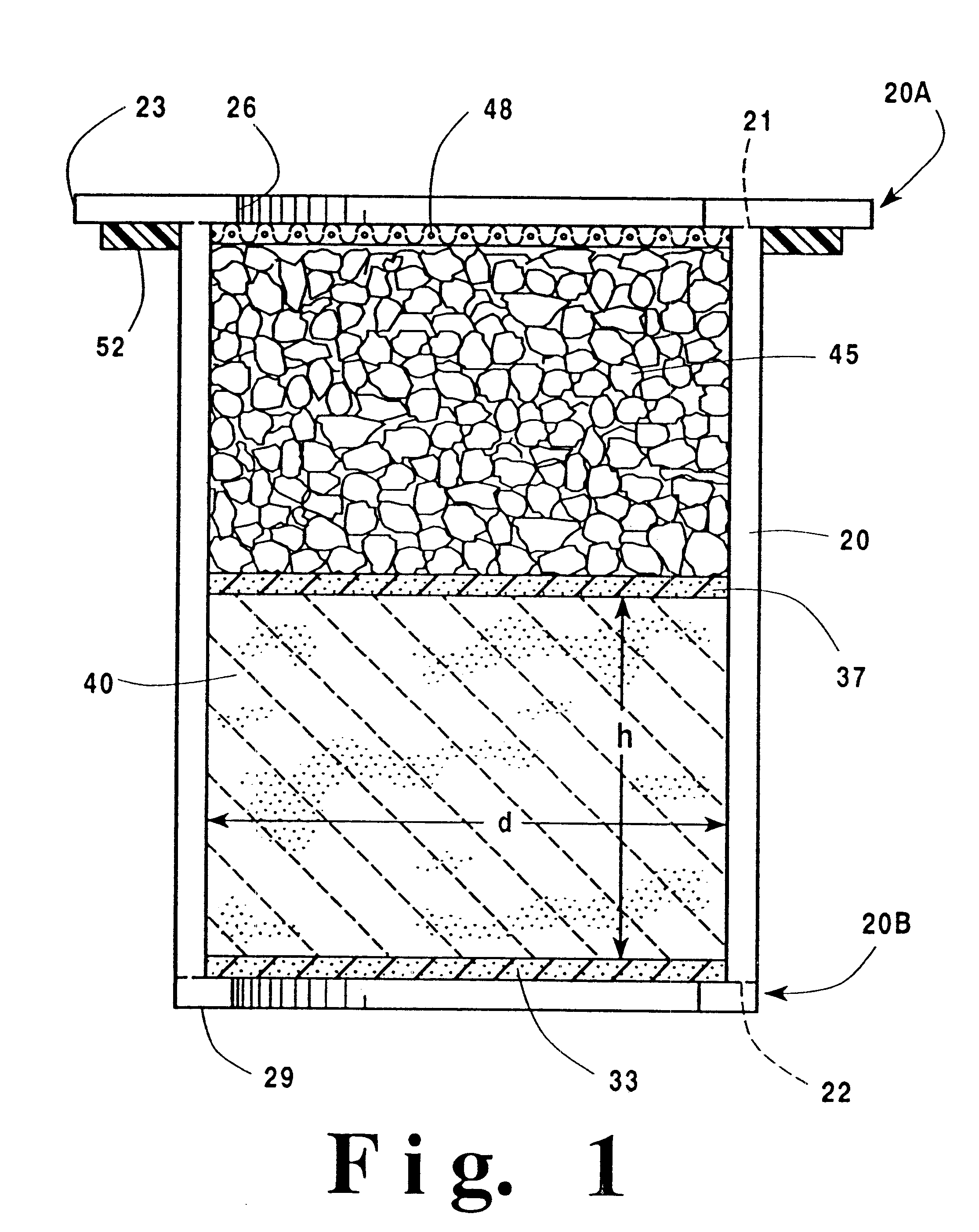

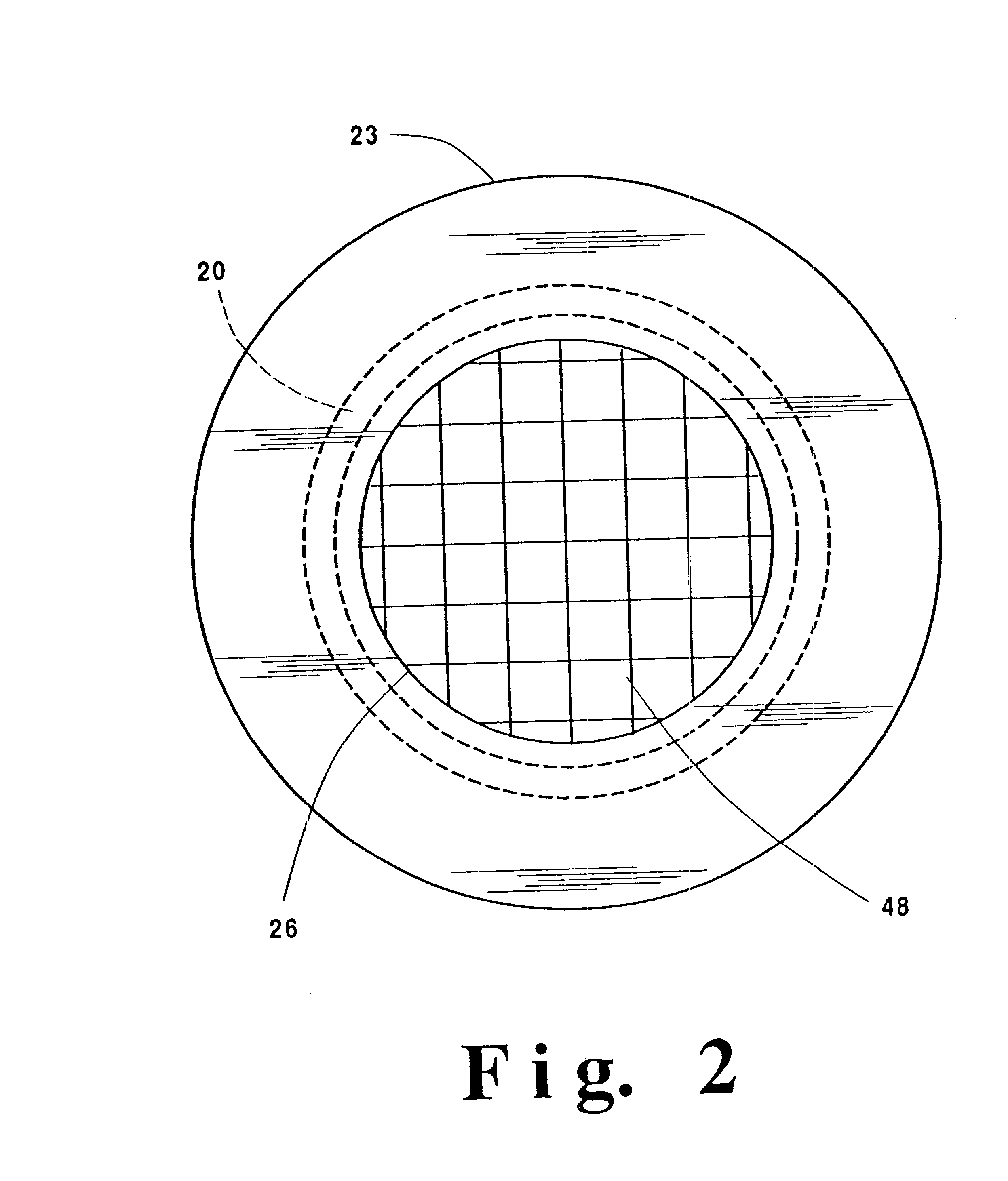

Separation of hydrocarbons from hydrocarbon containing liquid

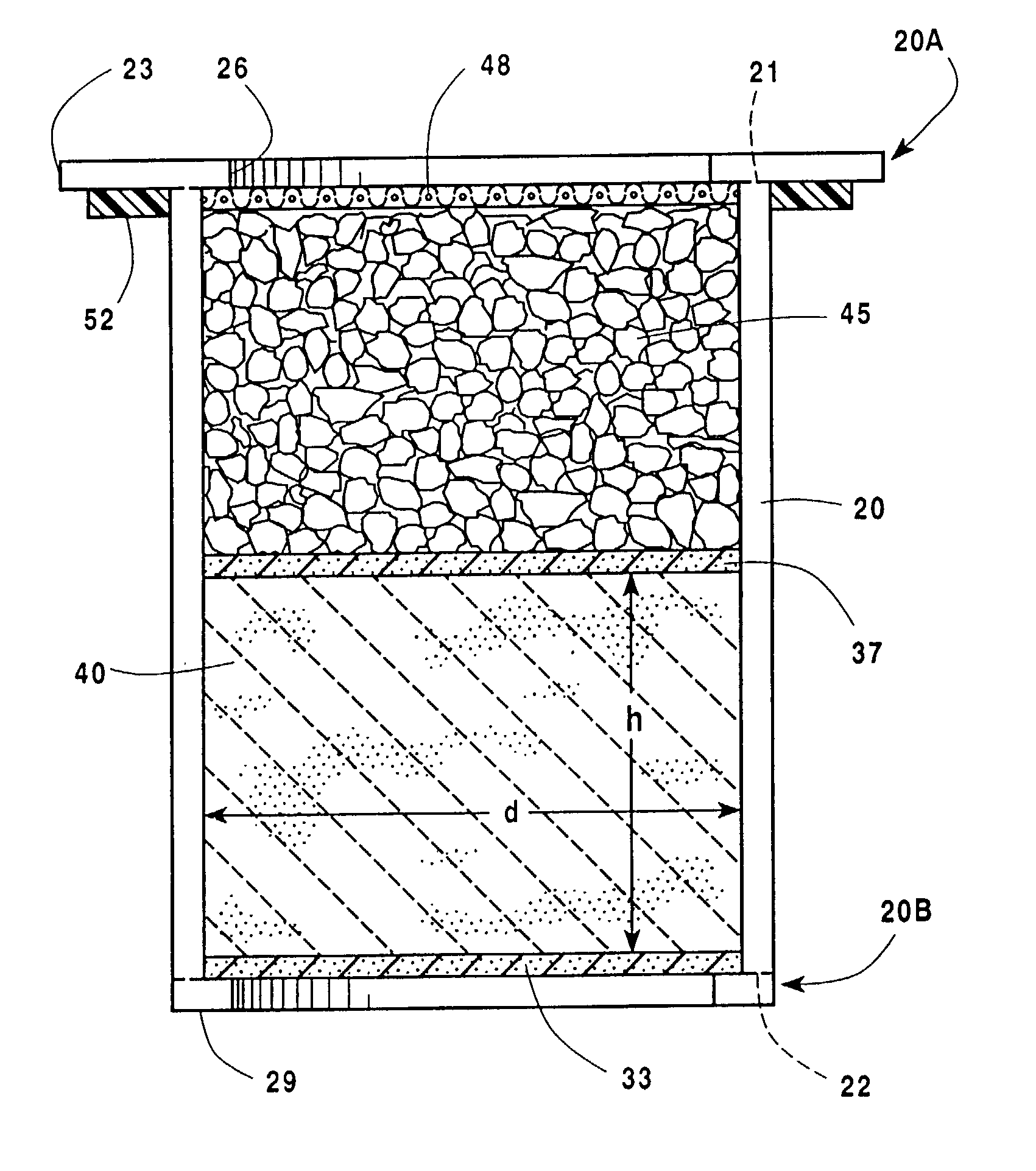

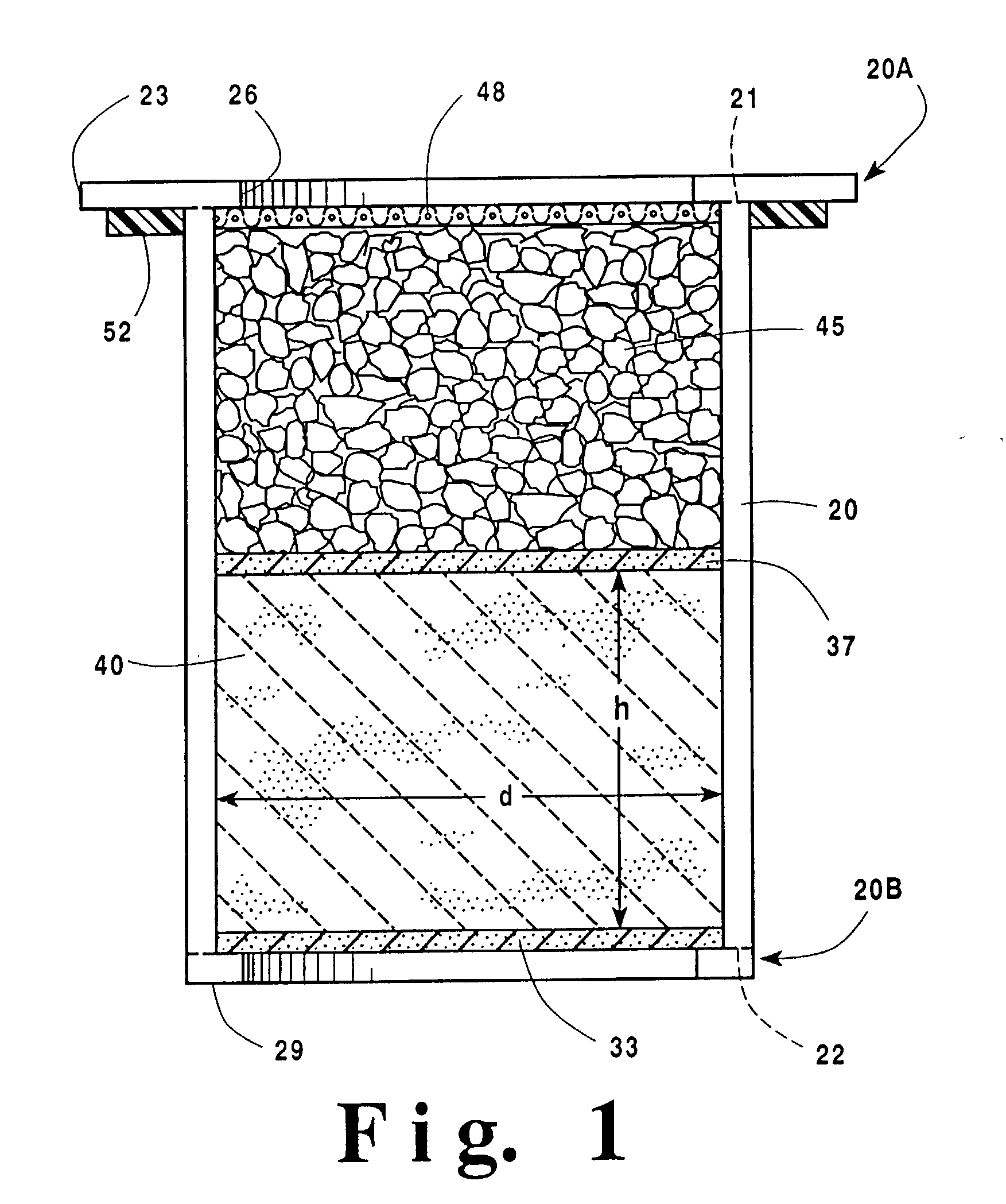

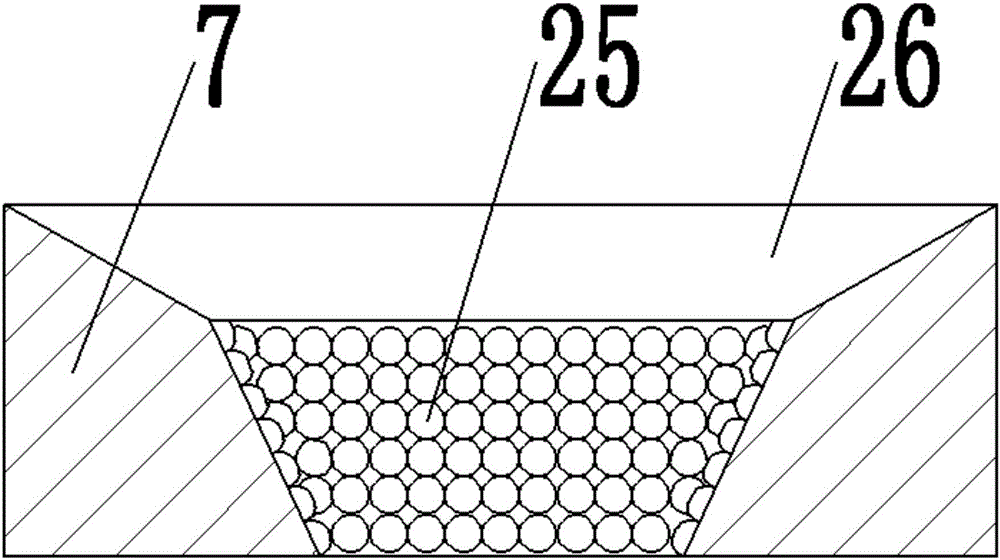

InactiveUS6485639B1Avoid dischargePreventing discharge of hydrocarbonLiquid suspension thickening by filtrationPaving gutters/kerbsPolyolefinFiltration

A novel filtration media employing polymeric absorbents comprising a material selected from the group consisting of styrene, pentadiene, cyclopentadiene, butylene, ethylene, isoprene, butadiene, propylene and mixtures thereof; and a filtration enabler intimately mixed with the polymeric absorbent. Preferably, the filtration enabler comprises clay, ground glass, talc, mica, recycled rubber, sand, gravel, vermiculite, recycled plastic chips, an inert, non-absorbent material, or mixtures thereof. Preferably, the polymeric absorbent may be further compounded to incorporate about 10 to 50% recycled or waste plastic scrap, scrap polyolefins, inorganic fillers, or other inexpensive, relatively inert solids. Other compounding materials may include clay, talc, mica, ground glass, silica, and mixtures thereof. Upon contact with a hydrocarbon containing liquid, the liquid partially dissolves the polymeric absorbent forming a partial filtration barrier prior to the filtration media substantially absorbing the hydrocarbons, and allowing hydrocarbon-free liquid to flow through the filtration media. In situations of a leak or spill wherein an excess of hydrocarbons are present, the filtration media forms a plug to seal and prevent further discharge of the hydrocarbons. The filtration media may be placed inside a portable container for insertion into an existing drain such that hydrocarbon containing liquid is filtered through the device allowing hydrocarbon-free liquid to flow from the device. The filtration media has a thickness within the container adapted to substantially filter out hydrocarbons while capable of forming a plug in an excess of hydrocarbons. The filtration media of the present invention may be employed in pits, pipes, and self-contained cartridges of various sizes to remove and contain hydrocarbons from a hydrocarbon containing liquid or a hydrocarbon spill or leak, and that the absorbent will form a plug in an excess of hydrocarbons entering the pit, pipe or cartridge. Also described are methods of filtering and preventing discharge of a hydrocarbon containing liquid.

Owner:SPI FILTRATION

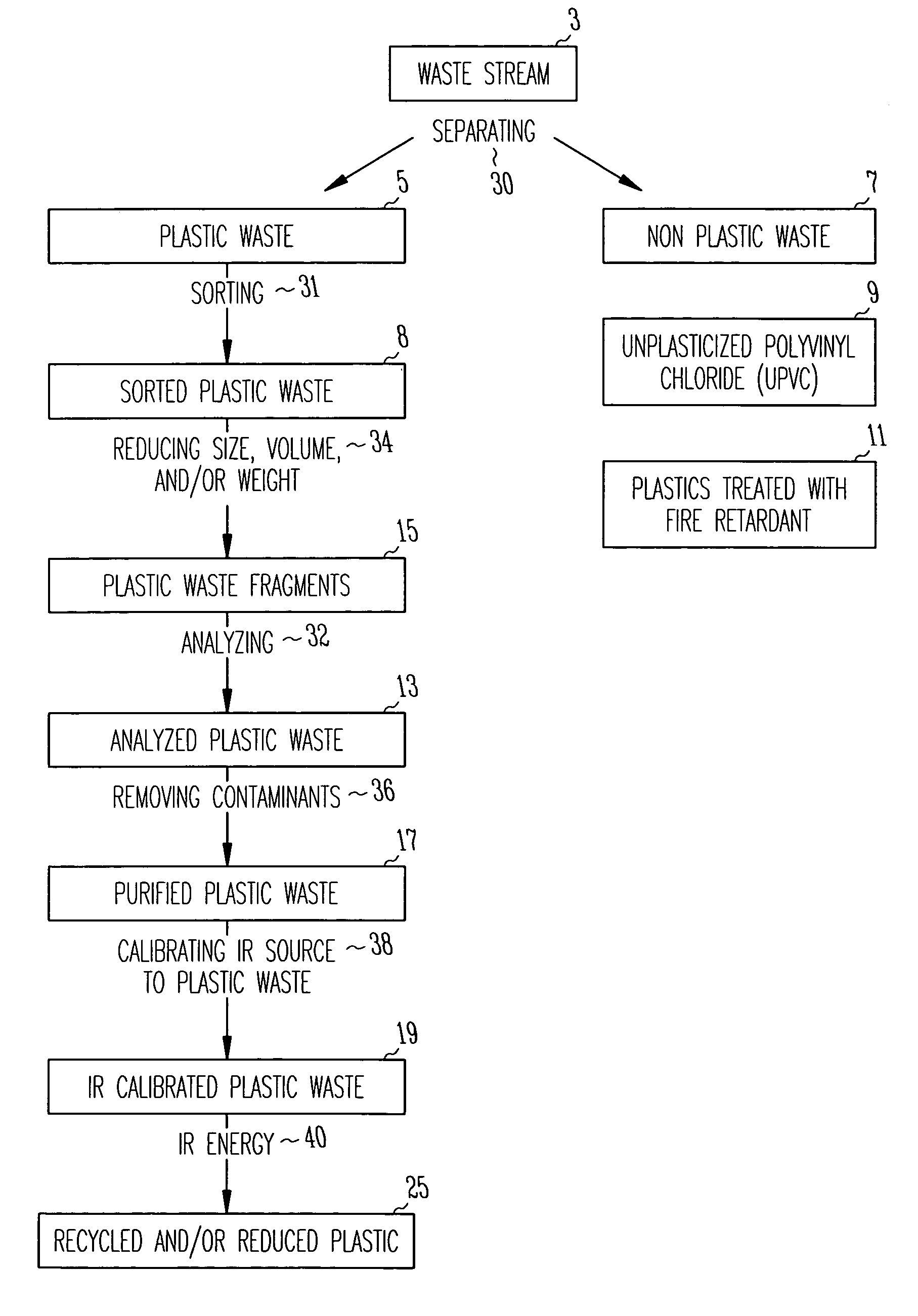

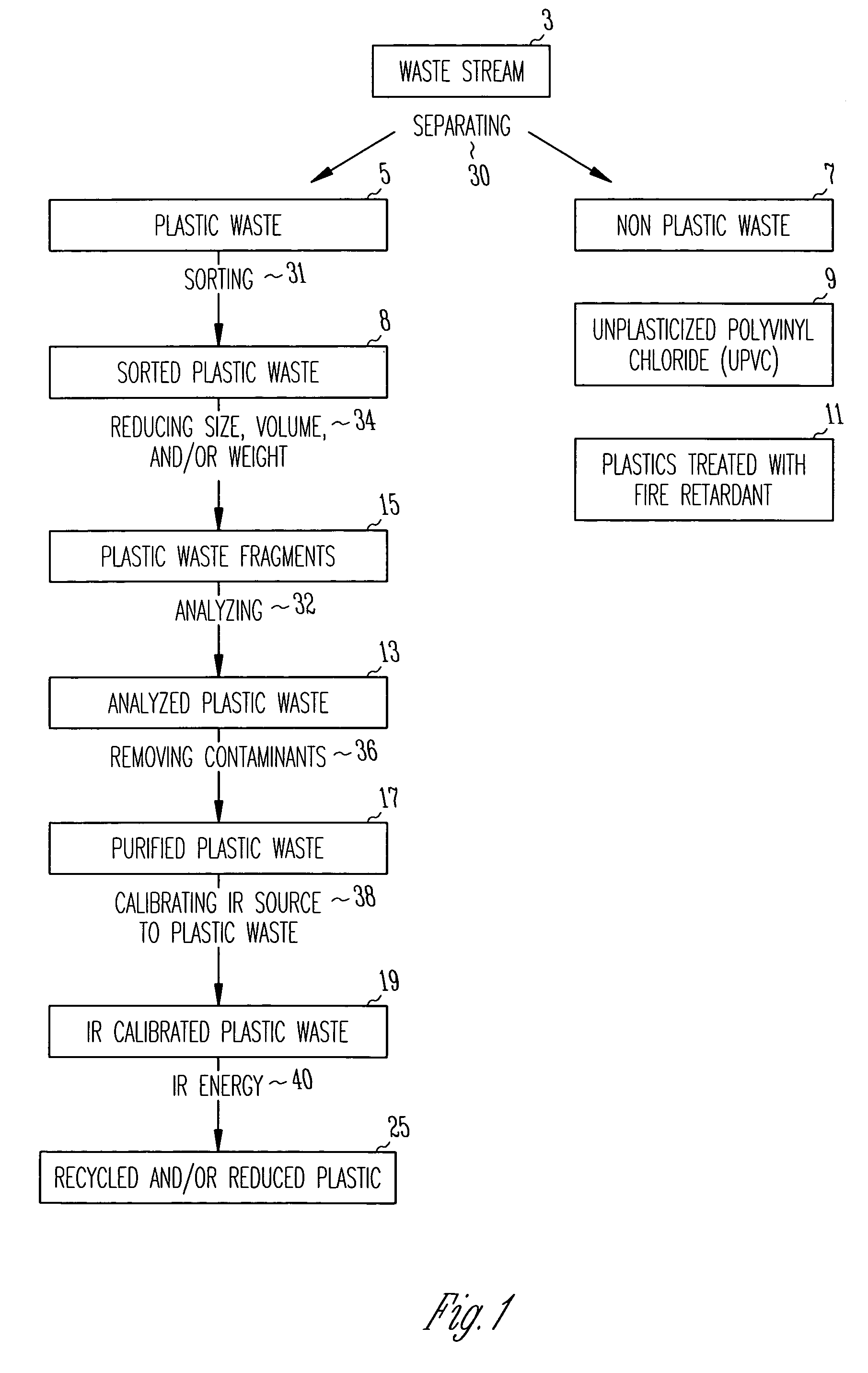

Recycling and reduction of plastics and non-plastics material

InactiveUS7799835B2Small sizeChange volumeRadiation pyrometryMangetographic processInfraredWaste stream

The present invention provides, e.g., methods to recycle and / or reduce plastic, non-plastic, or a combination thereof, from a waste stream. The methods of the present invention include contacting the plastic waste with infrared (IR) energy at one or more frequencies and at one or more intensities, over a period of time effective to heat plastic present in the plastic waste.

Owner:NEXTTEC

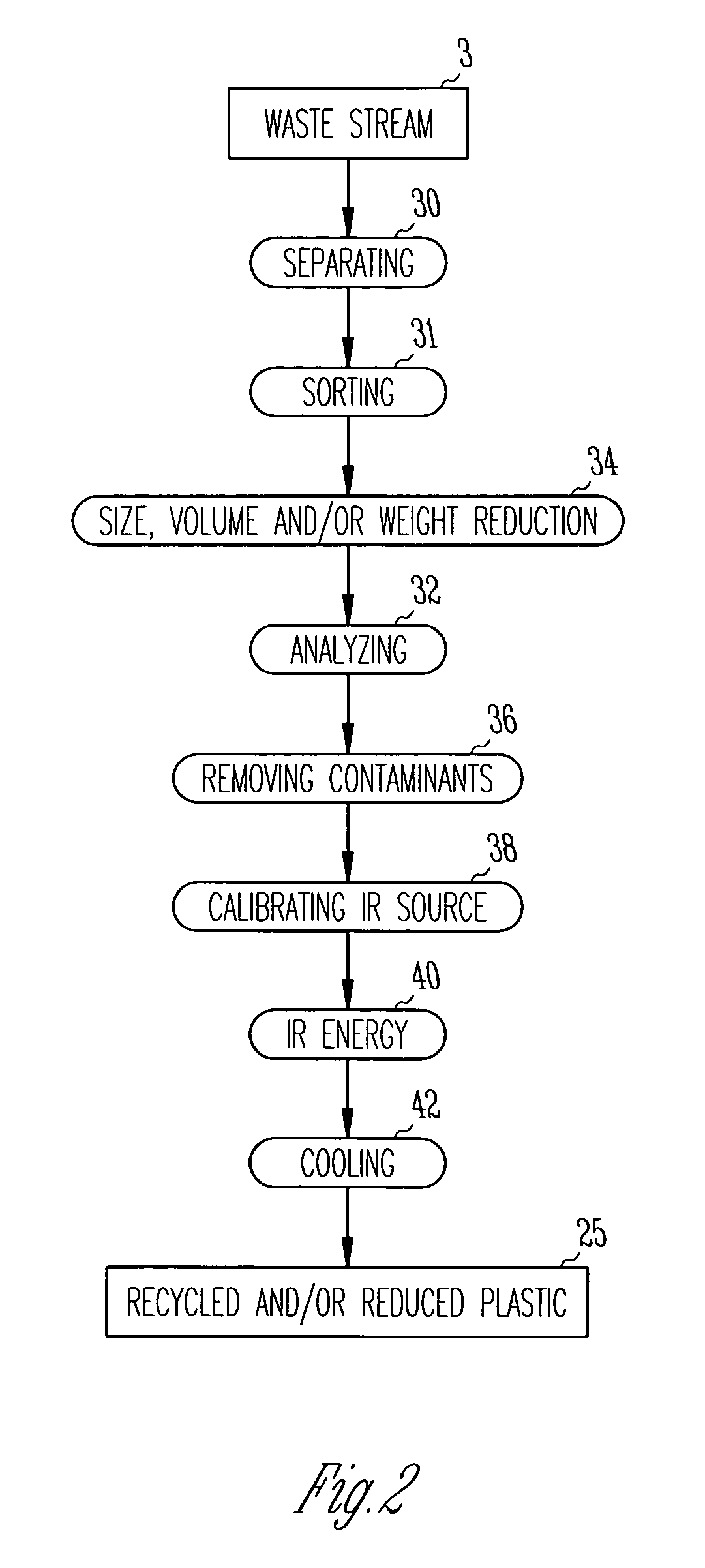

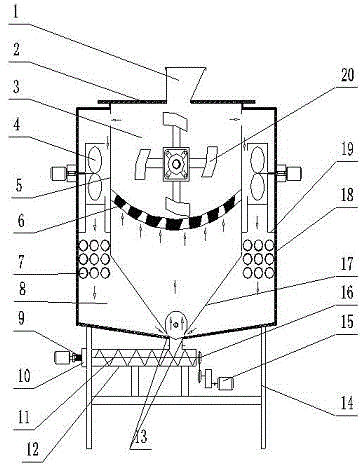

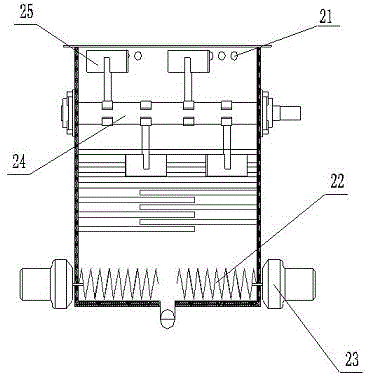

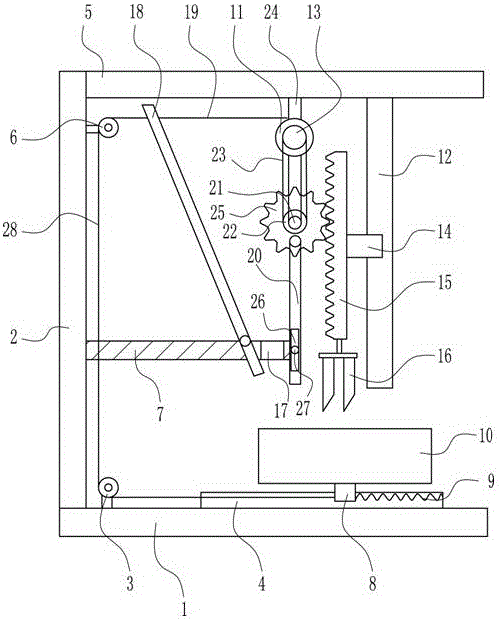

Continuous integral plastic waste recovery and processing device

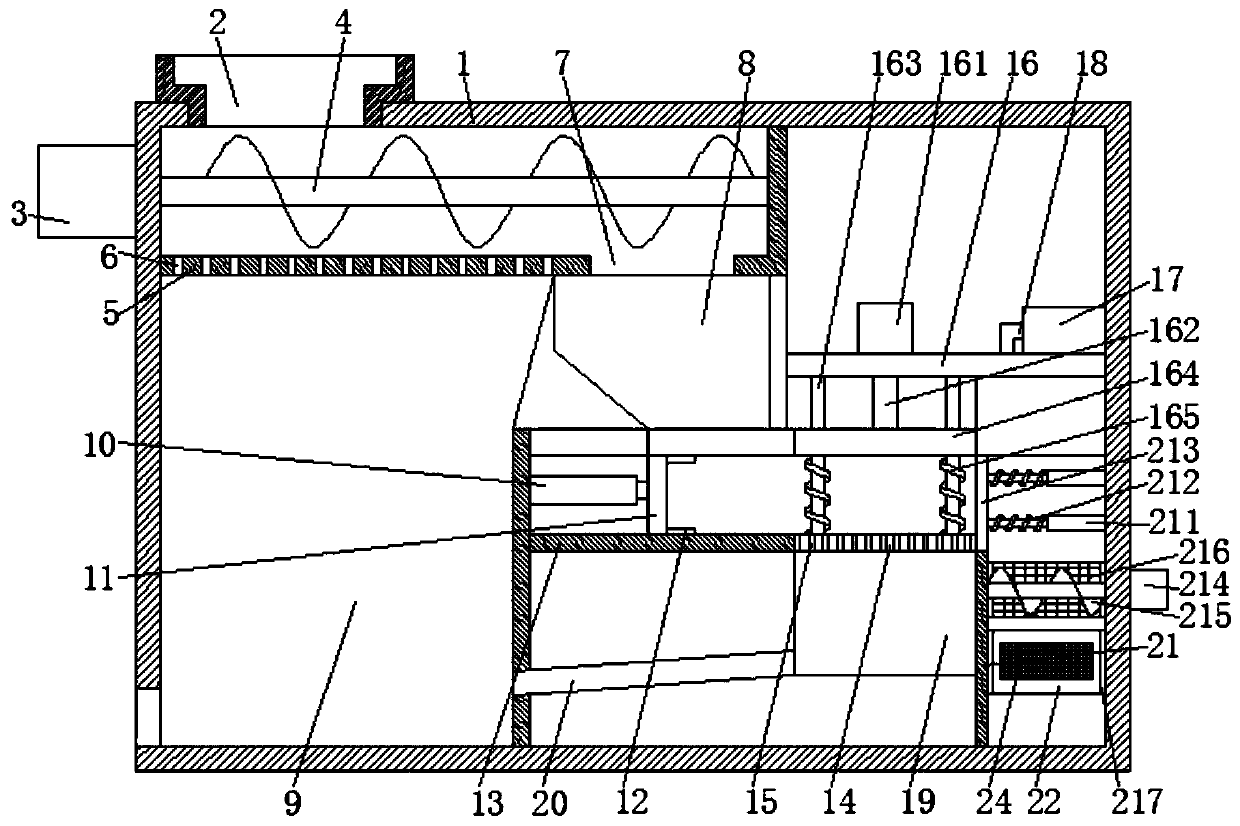

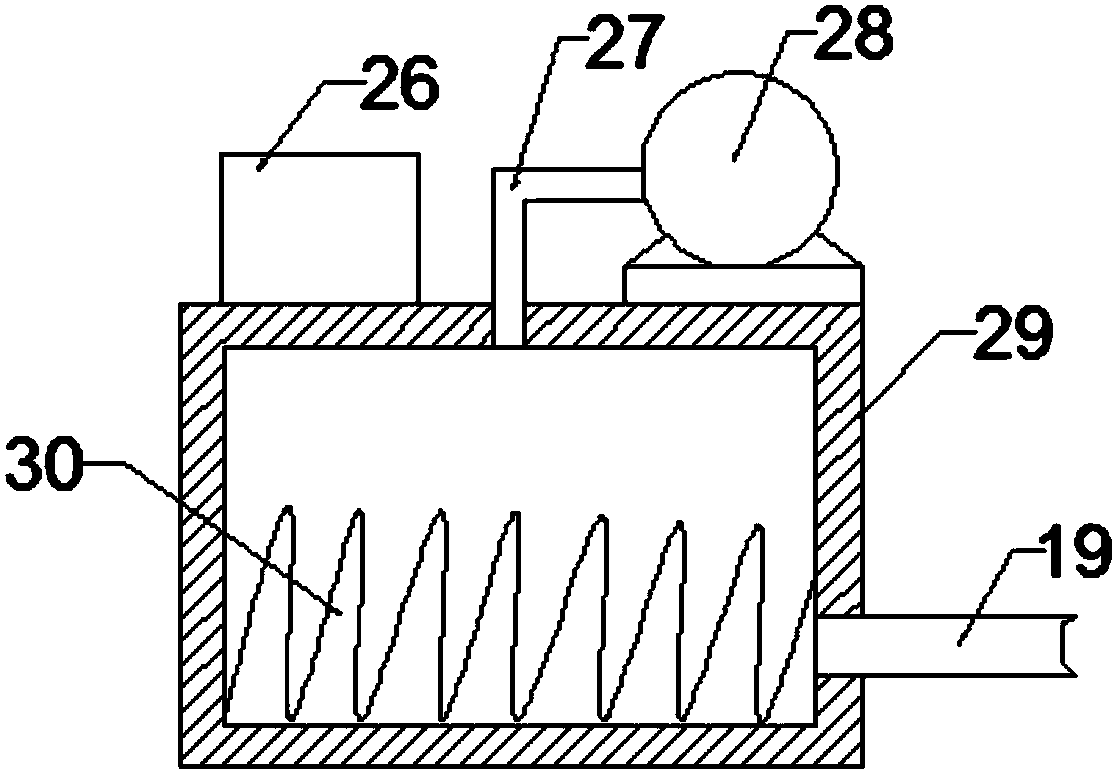

InactiveCN107901283AAdequate cleaningAchieve cleanupPlastic recyclingDrying gas arrangementsPlastic wasteCam

The invention discloses a continuous integral plastic waste recovery and processing device, and belongs to the field of plastic recovery equipment. The continuous integral plastic waste recovery and processing device comprises a crushing chamber, a cleaning chamber and a drying chamber. The crushing chamber is arranged on the upper portion of the cleaning chamber. A feeding hopper is arranged at the top end of the crushing chamber and arranged on the center line of the top end of the crushing chamber. A crushing roller device is arranged in the part, below the feeding hopper, of the crushing chamber. A first motor is fixedly arranged on the lower left portion of the cleaning chamber. An output shaft of the first motor is connected with a spiral conveying paddle. The drying chamber is arranged on the right side of the cleaning chamber. The drying chamber communicates with the cleaning chamber through a discharging outlet. A vibration cam is arranged on the inner side of the conveying belt. The continuous integral plastic waste recovery and processing device is reasonable in structure design and convenient to use, plastic waste can be crushed, cleaned and dried continuously by arranging the crushing chamber, the cleaning chamber and the drying chamber, time and effort are saved, and the plastic waste can be recycled advantageously.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

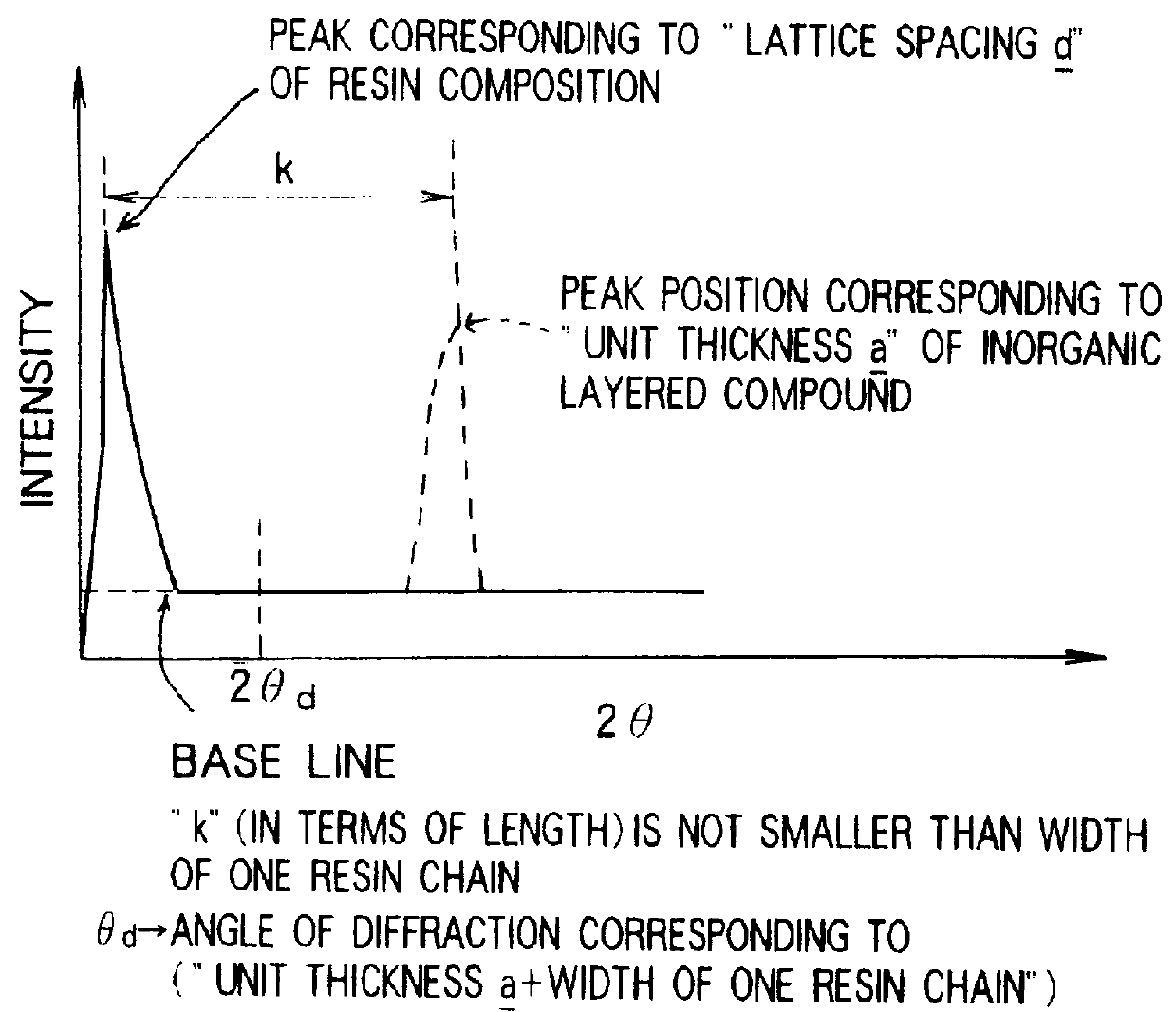

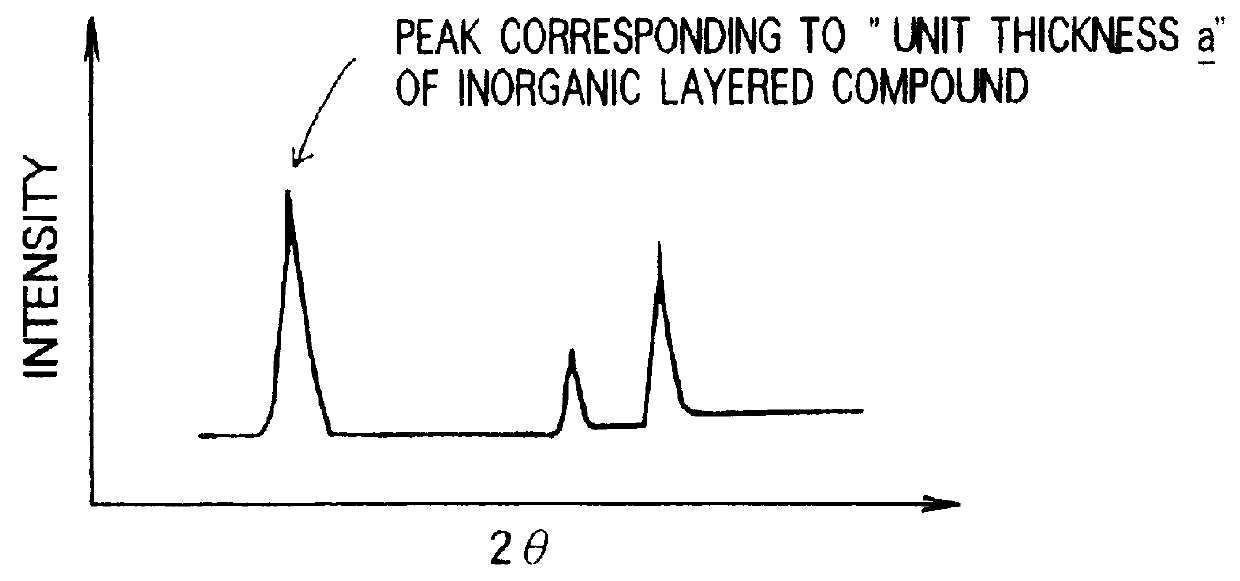

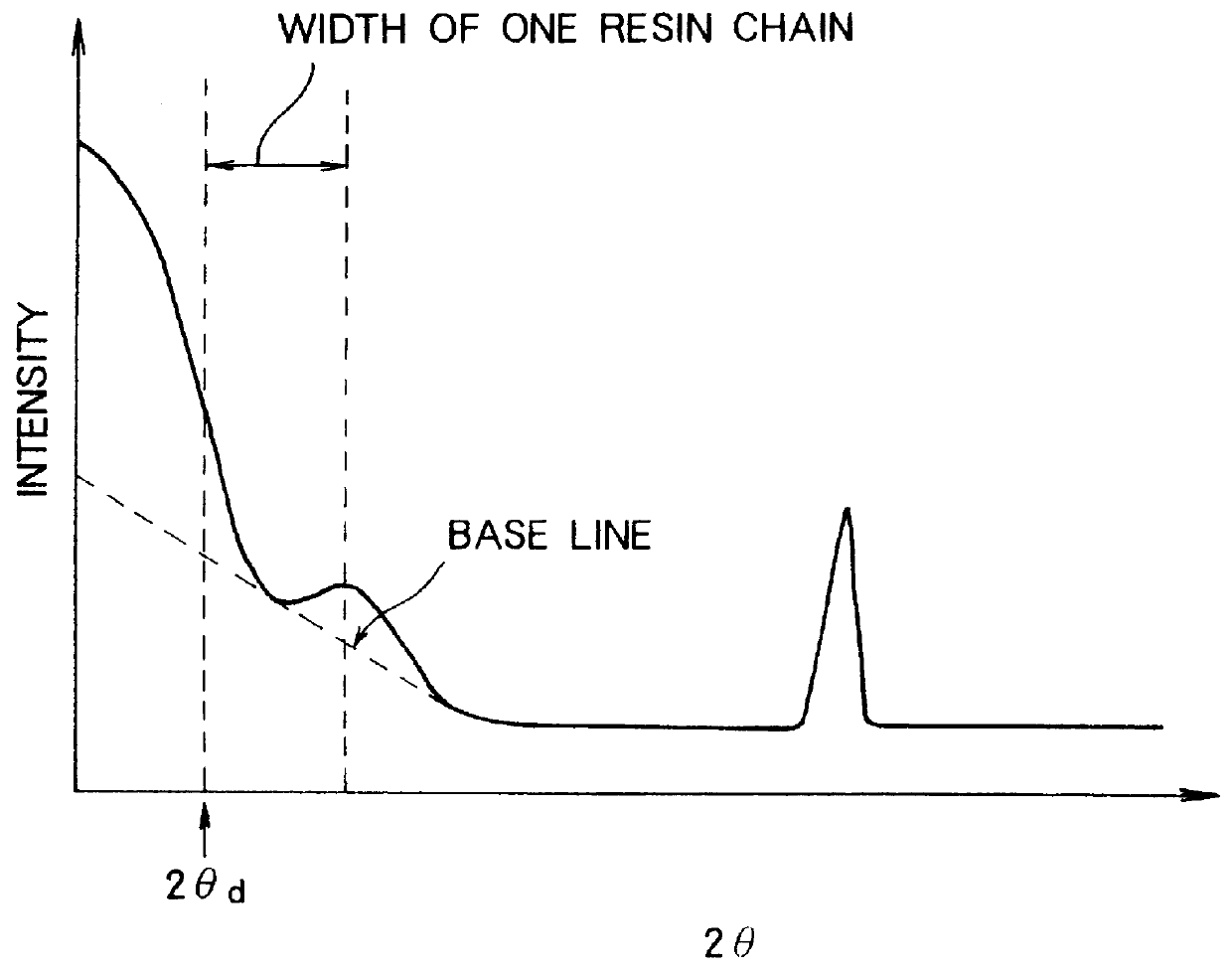

Bio-degradable resin composition, film and shaped article

InactiveUS6146750AImprove water resistanceIncrease flexibilitySynthetic resin layered productsCellulosic plastic layered productsPlastic wastePolymer chemistry

PCT No. PCT / JP95 / 00071 Sec. 371 Date Sep. 22, 1995 Sec. 102(e) Date Sep. 22, 1995 PCT Filed Jan. 24, 1995 PCT Pub. No. WO95 / 20013 PCT Pub. Date Jul. 27, 1995The disclosed composition contains a biodegradable resin, and an inorganic laminar compound having an aspect ratio of not less than 50 and not more than 5000. A biodegradable film or shaped article includes, as at least a portion thereof, a layer (1) found from this biodegradable resin composition. The biodegradable resin composition, film or shaped article can exhibit a good gas barrier property while substantially retaining the desired biodegradability. Therefore, it can considerably contribute to the maintenance or protection of a terrestrial environment such as the disposal of trash or rubbish, or plastic wastes; and the reduction in the amount of wastes in landfills.

Owner:SUMITOMO CHEM CO LTD

Composite board produced with waste and old plastic and coal ash, and producing method thereof

The invention discloses a composite board made from waste plastics and fly ashes and a method for producing the same. The composite board is prepared from the waste plastics and the fly ashes according to certain weight ratio. The main raw materials for producing the composite board comprise the waste plastics and the fly ashes, wherein the waste plastics are discarded in industrial production and in human life and comprise waste polypropylene plastic, waste polyethylene plastic, waste polystyrene plastic and waste polyvinyl chloride plastic and the like, and the fly ashes are discharged by coal-fired power plants and the chemical industry; the main raw materials are manufactured into the composite board through crushing and hot pressing; the manufactured composite board meets the national standards for construction templates, not only reduces the environmental pollution caused by industrial fly ashes and plastic wastes, but also can be applied to replacing wooden construction templates or steel construction templates widely used in the prior building operations, and not only has the advantages of low production cost, light weight, high strength, impact resistance, and easy demoulding, but also 'turns harmful into beneficial and changes waste into valuable', and significantly speeds up the process of recycling wastes in China.

Owner:GUIZHOU UNIV

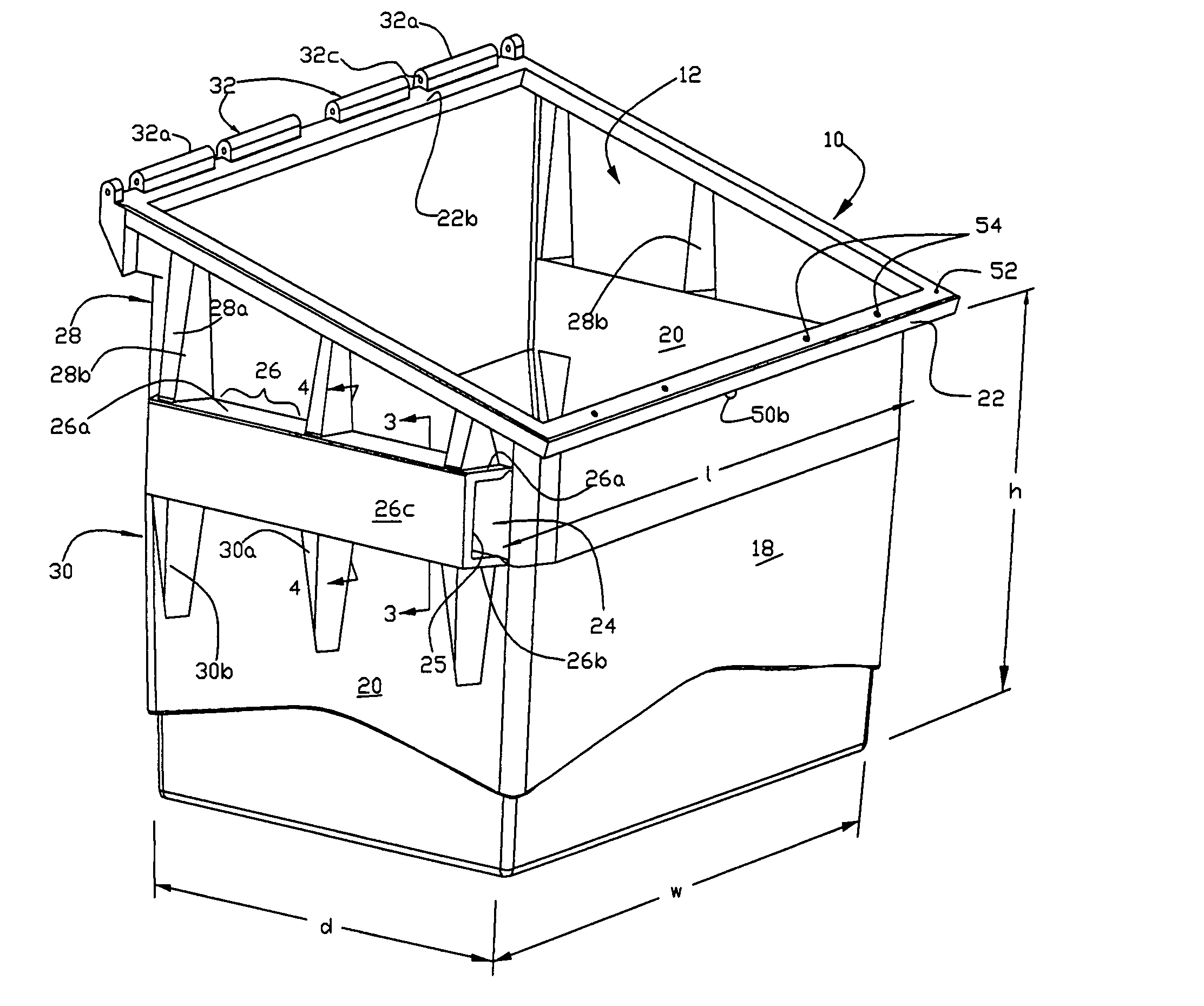

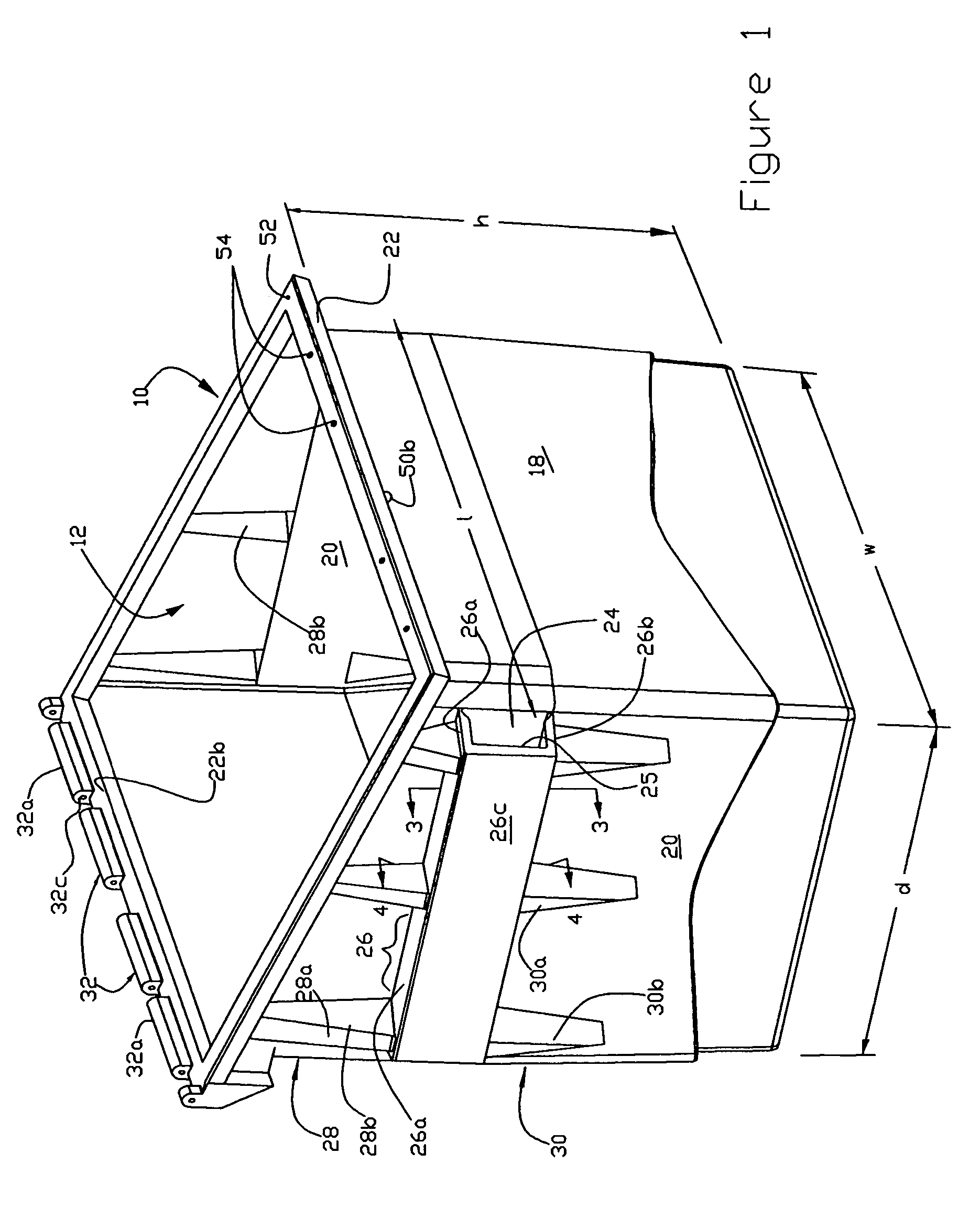

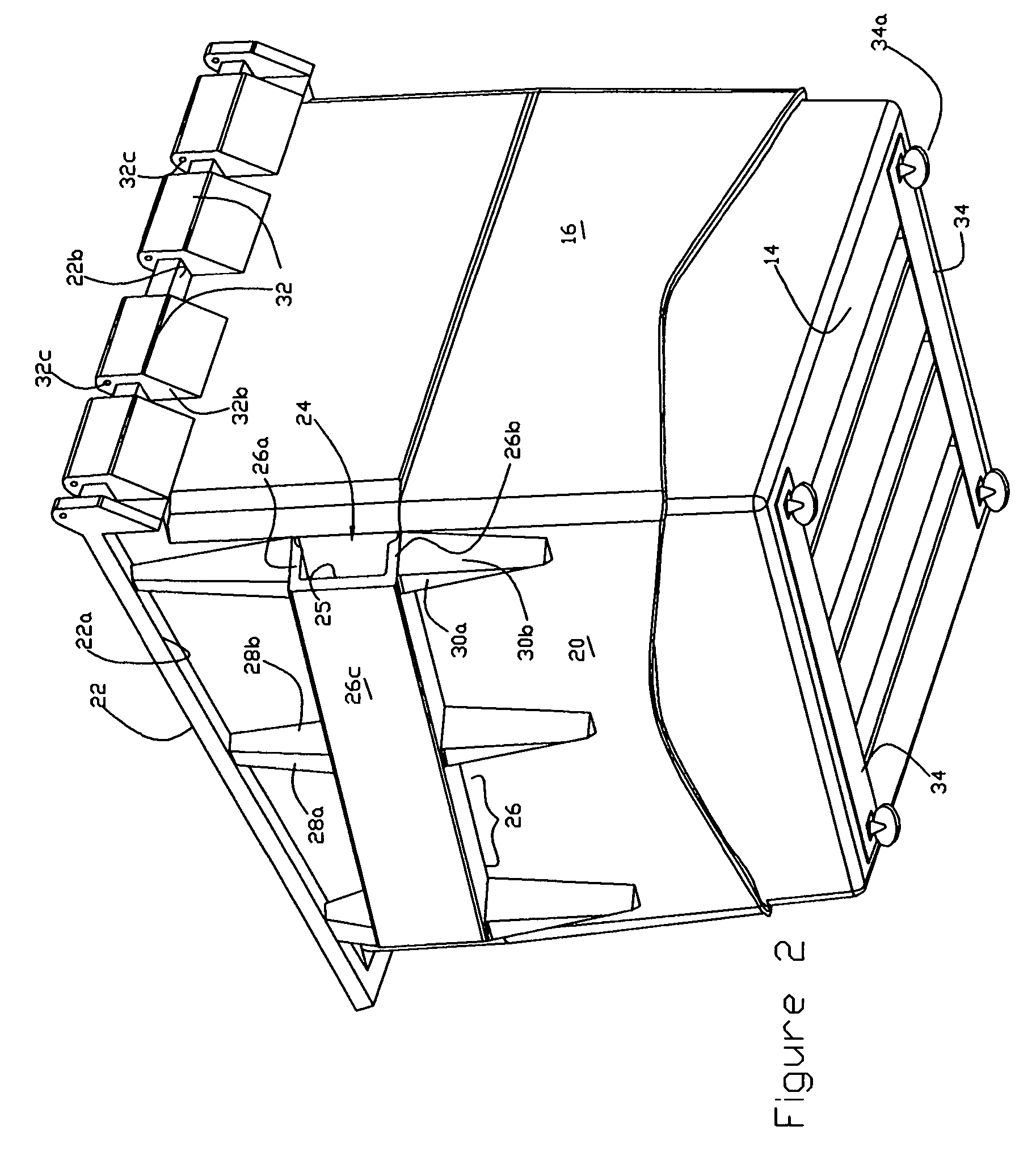

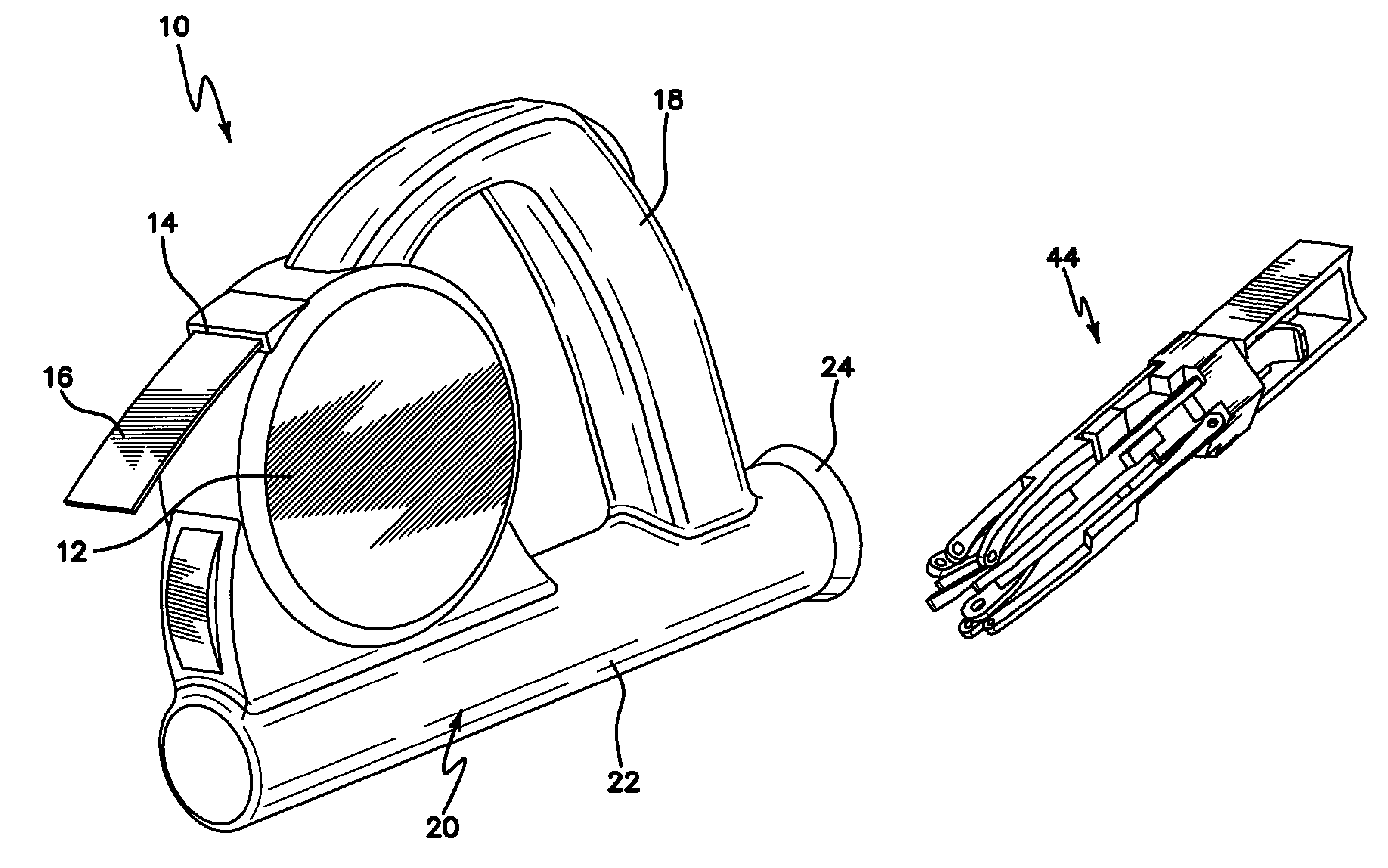

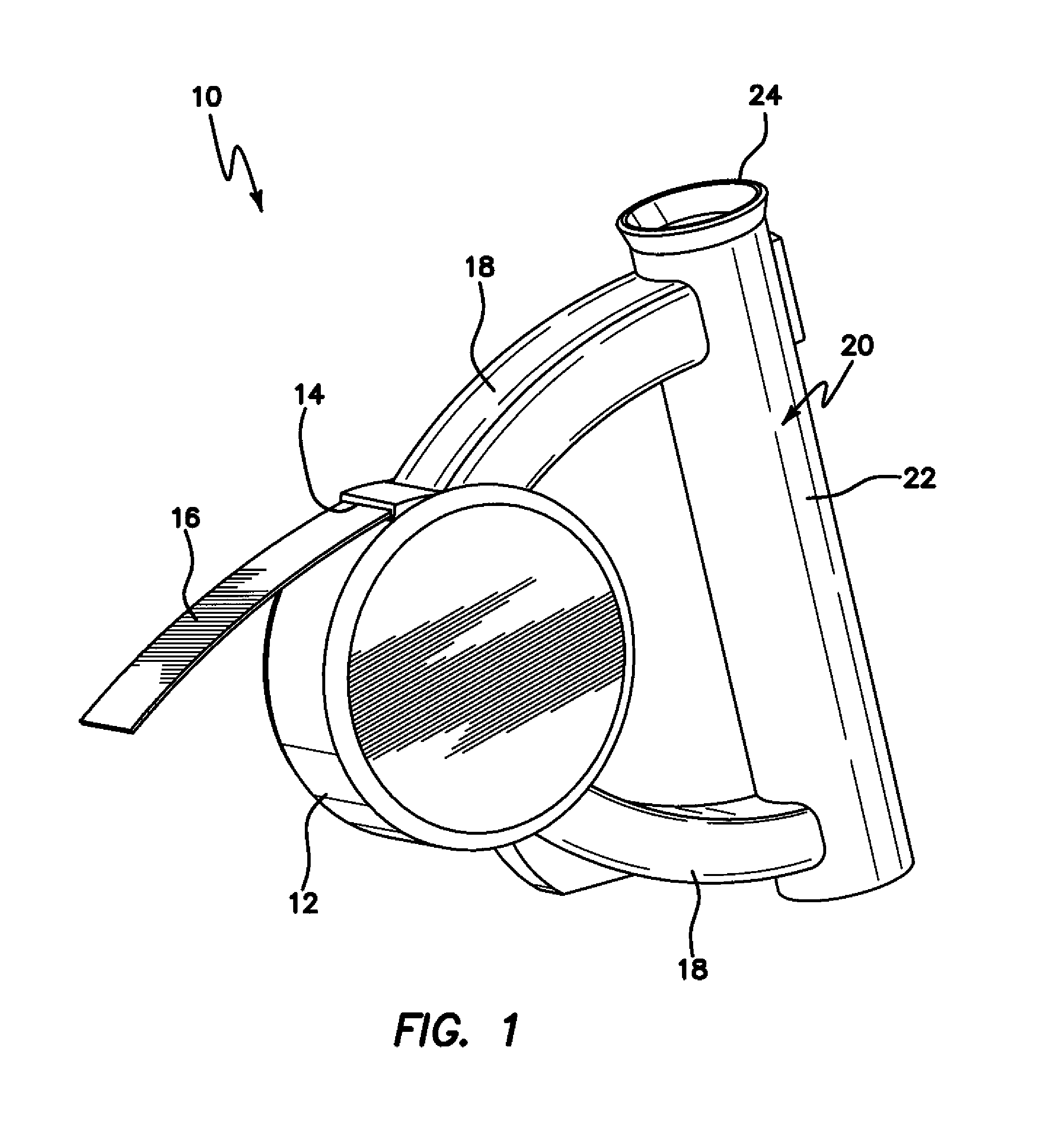

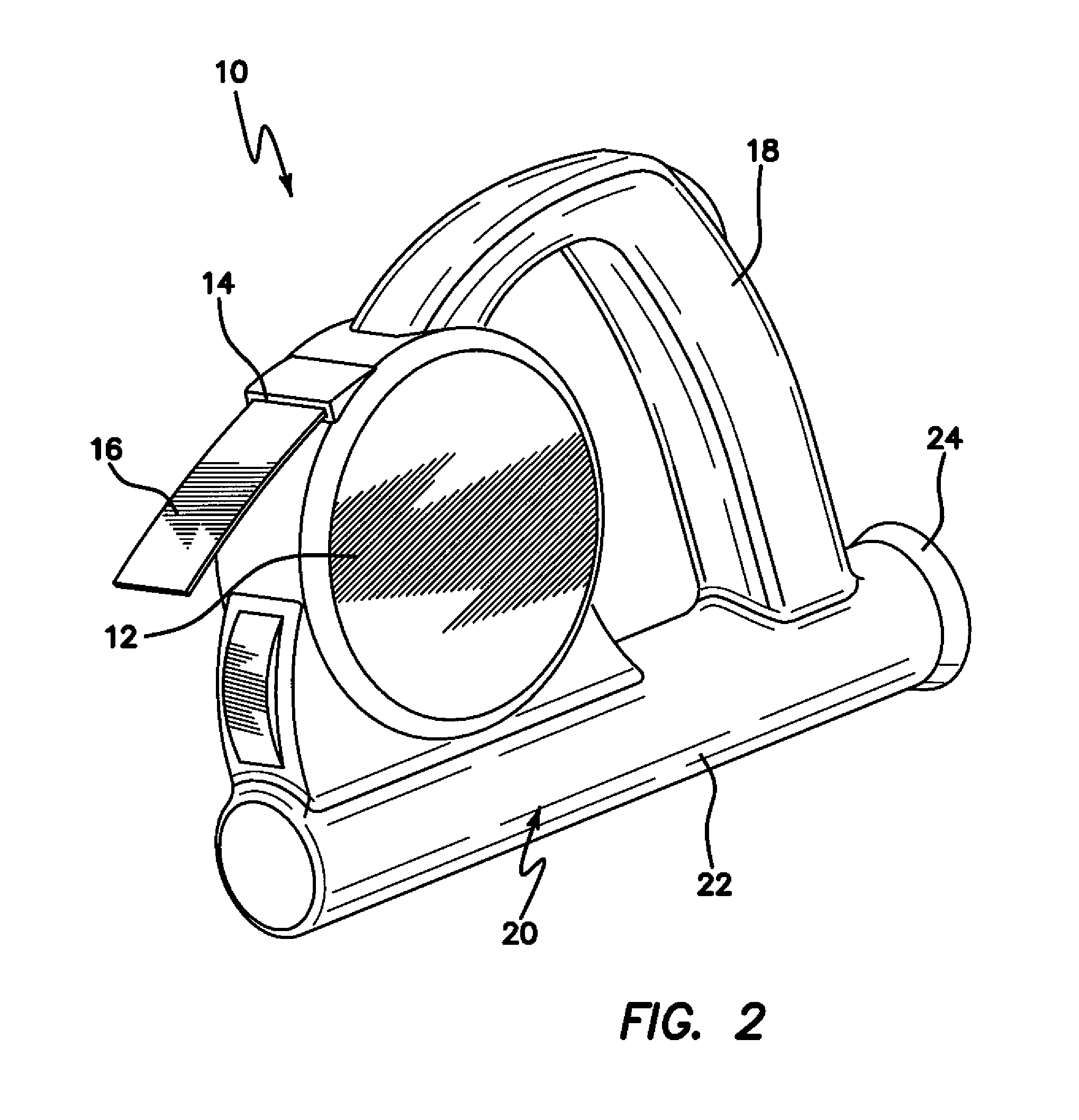

Molded plastic waste container with integral side channels for receiving lifting prongs and method

A plastic waste container is rotationally molded with a hollow material carrying or holding compartment having a bottom, rear, front and opposed side walls. A plastic pocket defining a prong receiving channel, located on each side wall, is integrally formed with the compartment, i.e., molded therewith or premolded and subsequently bonded thereto. Preferably a skirt, extending around each of the pockets, is integrally molded with the compartment and includes struts extending along the side walls of the compartment, above and below the pockets.

Owner:BALL BOUNCE & SPORT

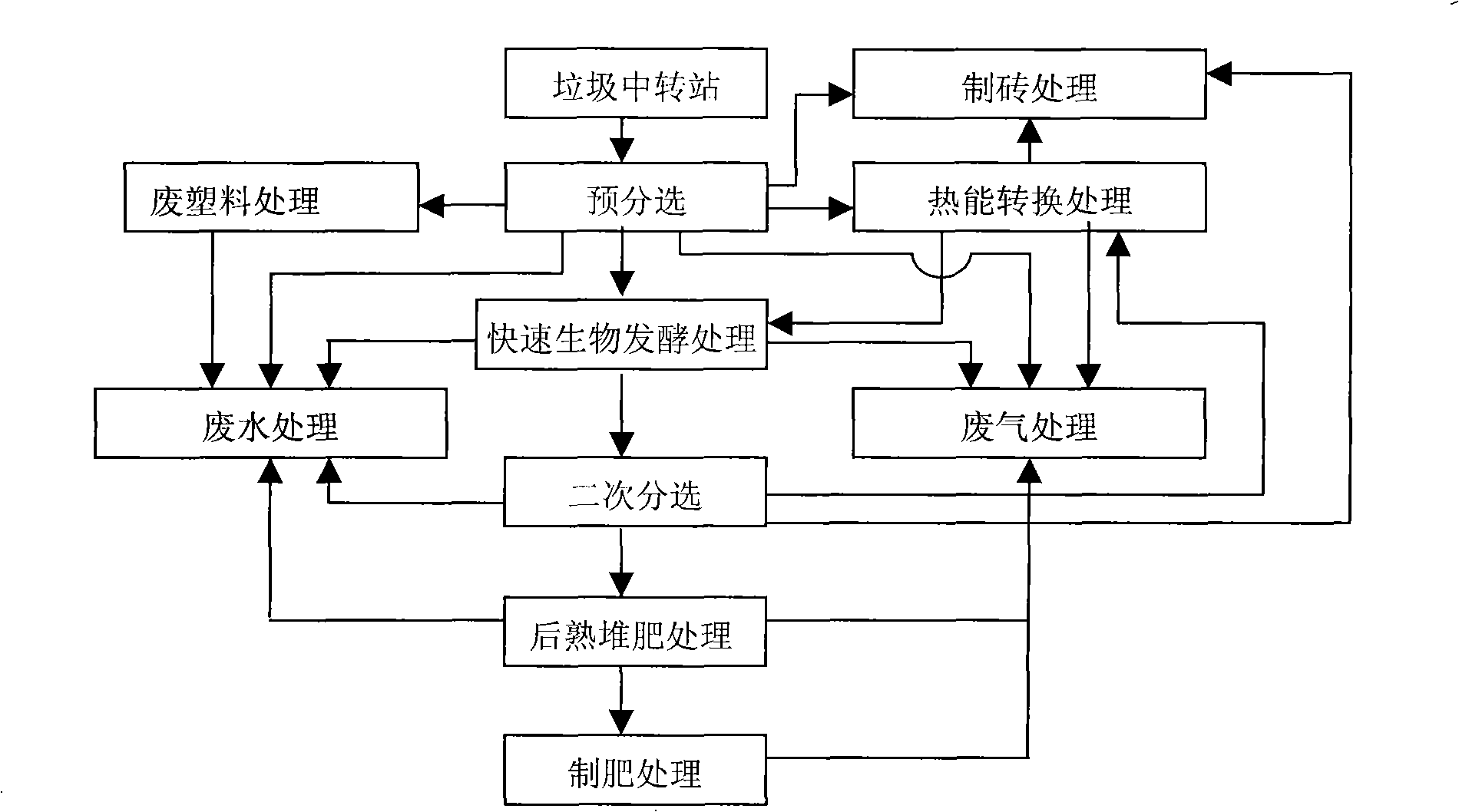

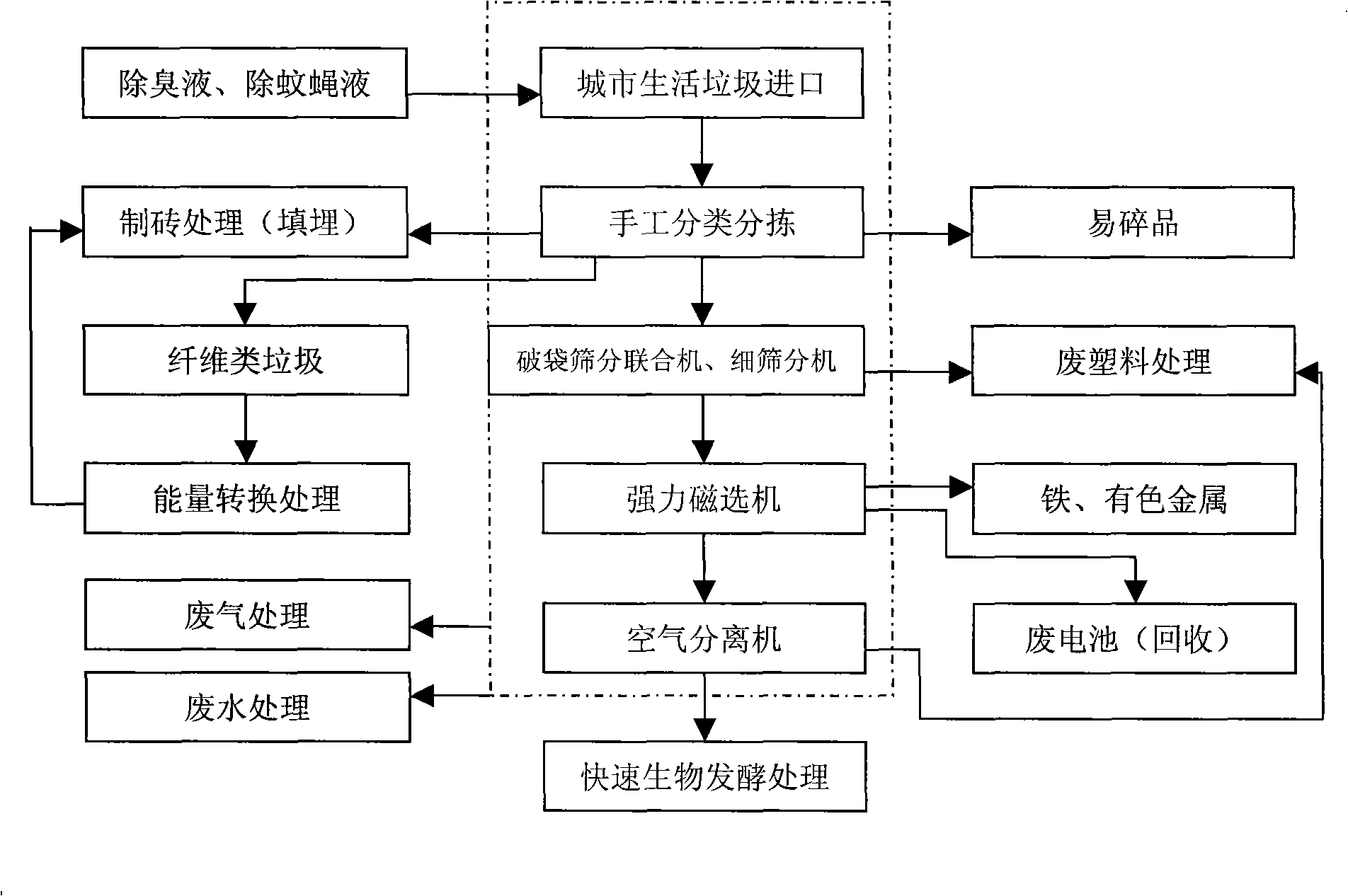

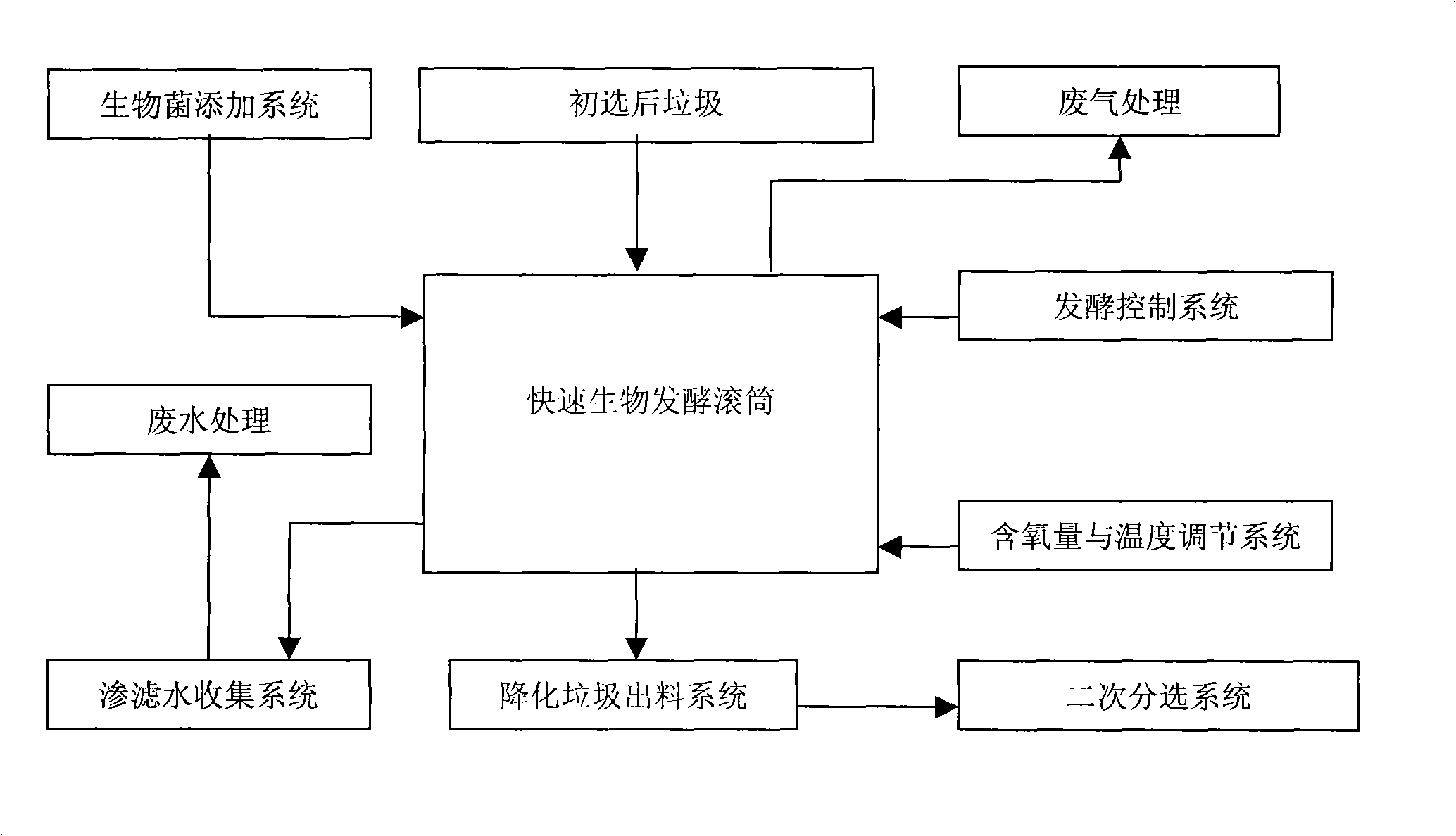

Integral treatment method for city household refuse

InactiveCN101289336ANo secondary pollutionHigh degree of harmlessnessSolid waste disposalClimate change adaptationFiberBrick

Owner:ZHEJIANG UNIV

Treatment process for kitchen waste

InactiveCN102731172AEfficient use ofResolve homologyClimate change adaptationOrganic fertilisersHouseflyPlastic waste

The invention discloses a treatment process for kitchen waste. The process comprises the following steps: step one, mechanical pretreatment of kitchen waste; step two, separation of plastic waste, glass bottles, cans and iron in the kitchen waste; step three, stewing and pressing of kitchen waste solids; step four, utilization and treatment of the kitchen waste; step five, breeding of housefly larvae; and step six, drying and utilization of fresh housefly larvae. The process provided in the invention enables the kitchen waste to be used effectively, overcomes the problem of feed homology, produces no environmental pollution and saves energy.

Owner:浙江省长三角循环经济技术研究院

Process for producing fuel from plastic waste material by using dolomite catalyst

A process for producing fuel by cracking a plastics-derived liquid, which is obtained from a pyrolysis process, using a dolomite catalyst. The plastics-derived liquid is produced by the pyrolysis of plastic waste, such as of one or more of polyethylene, polystyrene or polypropylene. The plastic-derived liquid is first subjected to a semi-batch catalytic cracking reaction over a very low cost dolomite catalyst to obtain high quality oil for fuel, which comprises mainly light and heavy naphtha. Moreover, the catalytic cracking reaction is conducted at operating temperatures lower than 320° C.

Owner:SRINAKRUANG JUMLUCK

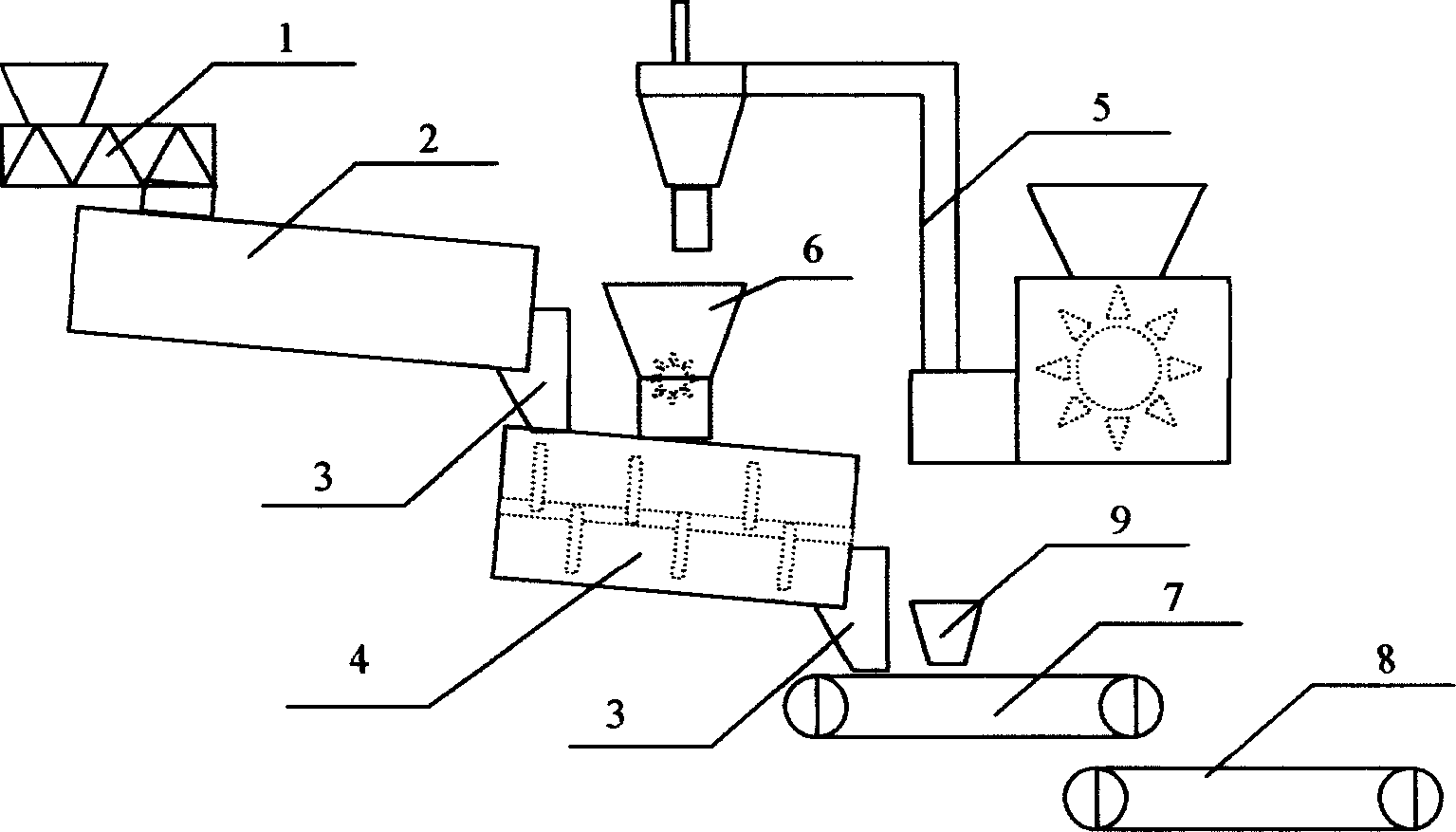

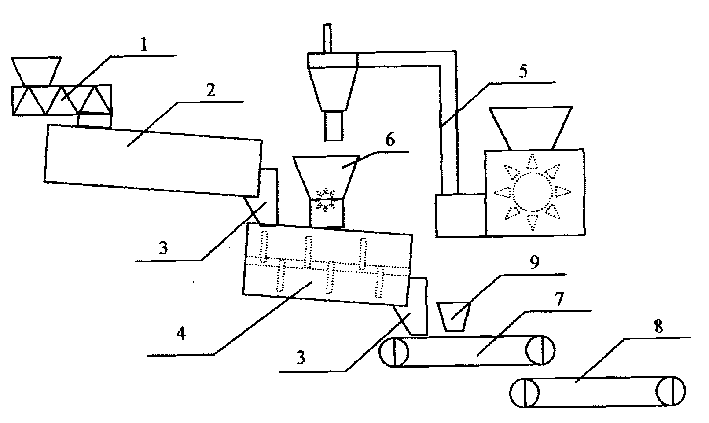

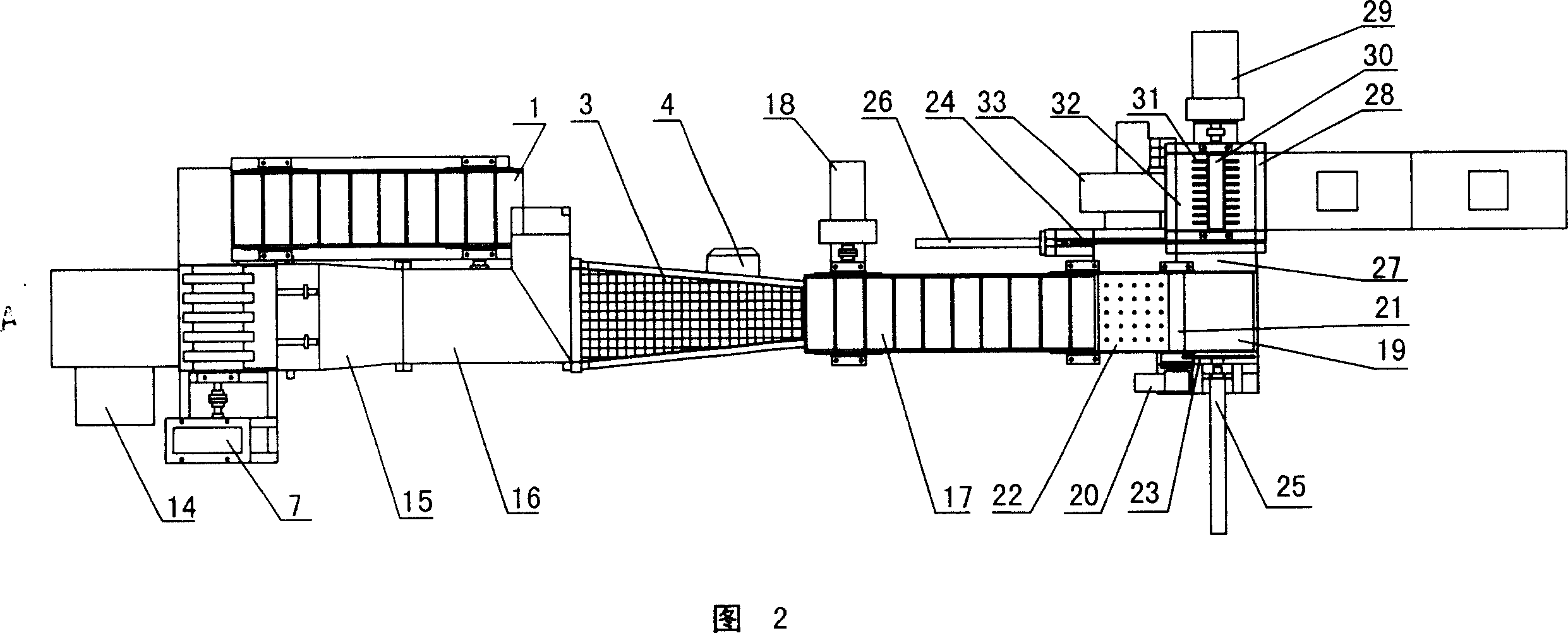

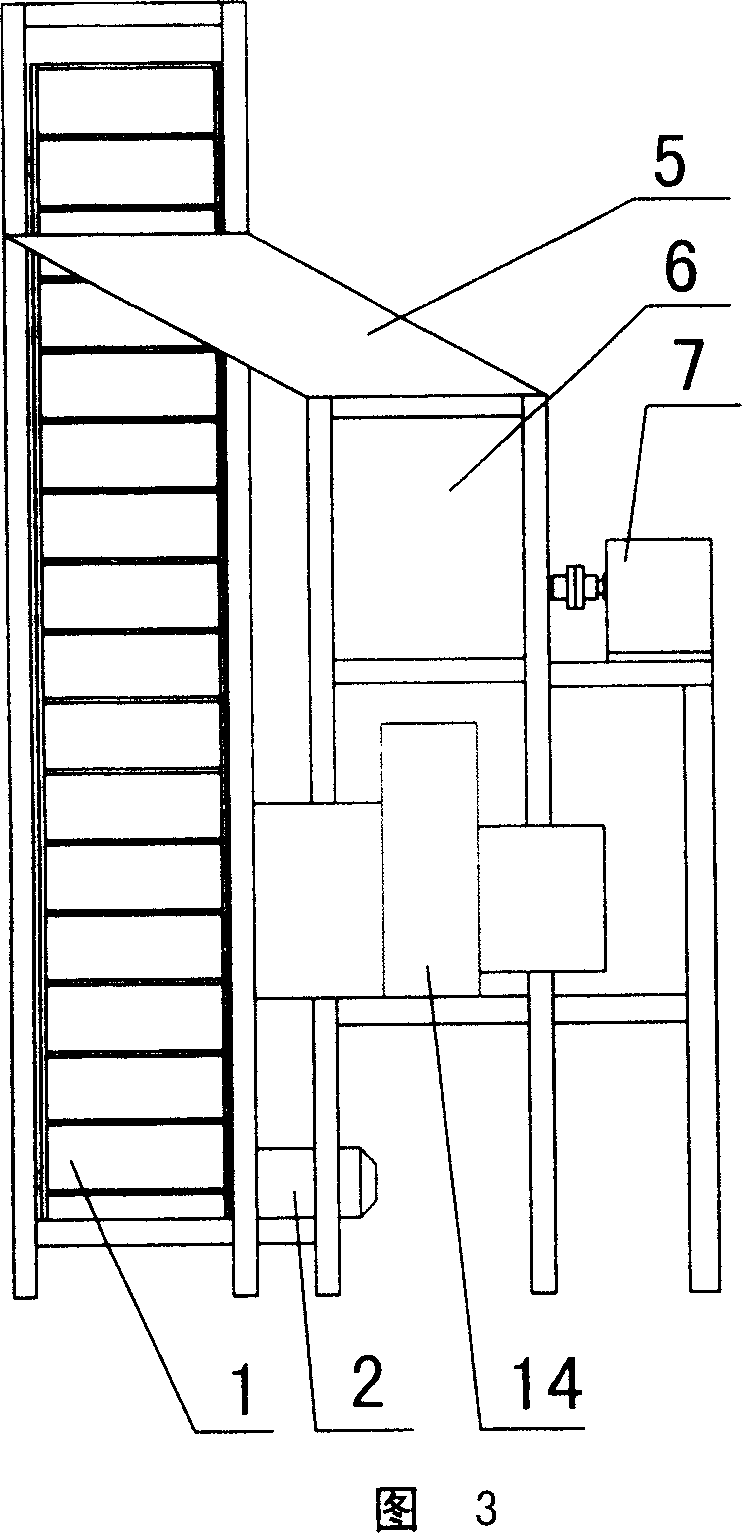

Waste plastic processing method for increasing coke strength and its apparatus system

The invention publishes a kind of process method of plastic waste to improve coke's intensity and the setting system. It relates to technique and setting of plastic waste. The characteristic of process method of the plastic waste follows this. teat the plastic waste by hot-melt method and then carbonize it with coal blending by special ratio to improve the quality of coke. The setting system is composed by feedway, breaking plant, heat flux plant, hot-melt plant, carrying vehicle and coking and coal blending mixing device. The invention's advantage rest with that many complicated working processes are not needed such as air sizing and graining because of hot-melt process. It can solve the problem that mixture of plastic and coal liquating is not odds and can reduce or eliminate the use of additives. So the quality of coke can be improved by plastic waste or additives and the the working cost and operating cost can be reduced by far.

Owner:SHOUGANG CORPORATION

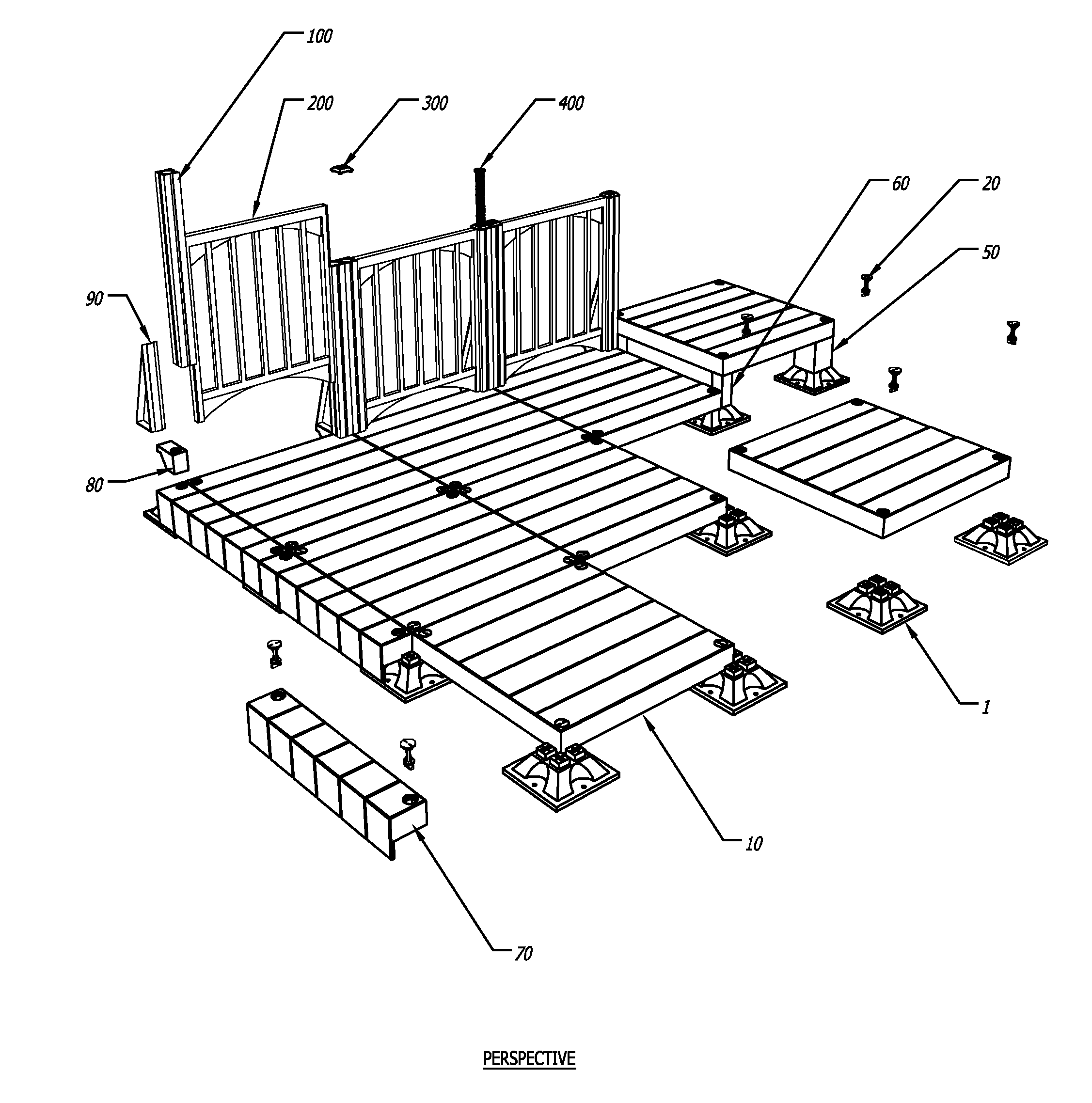

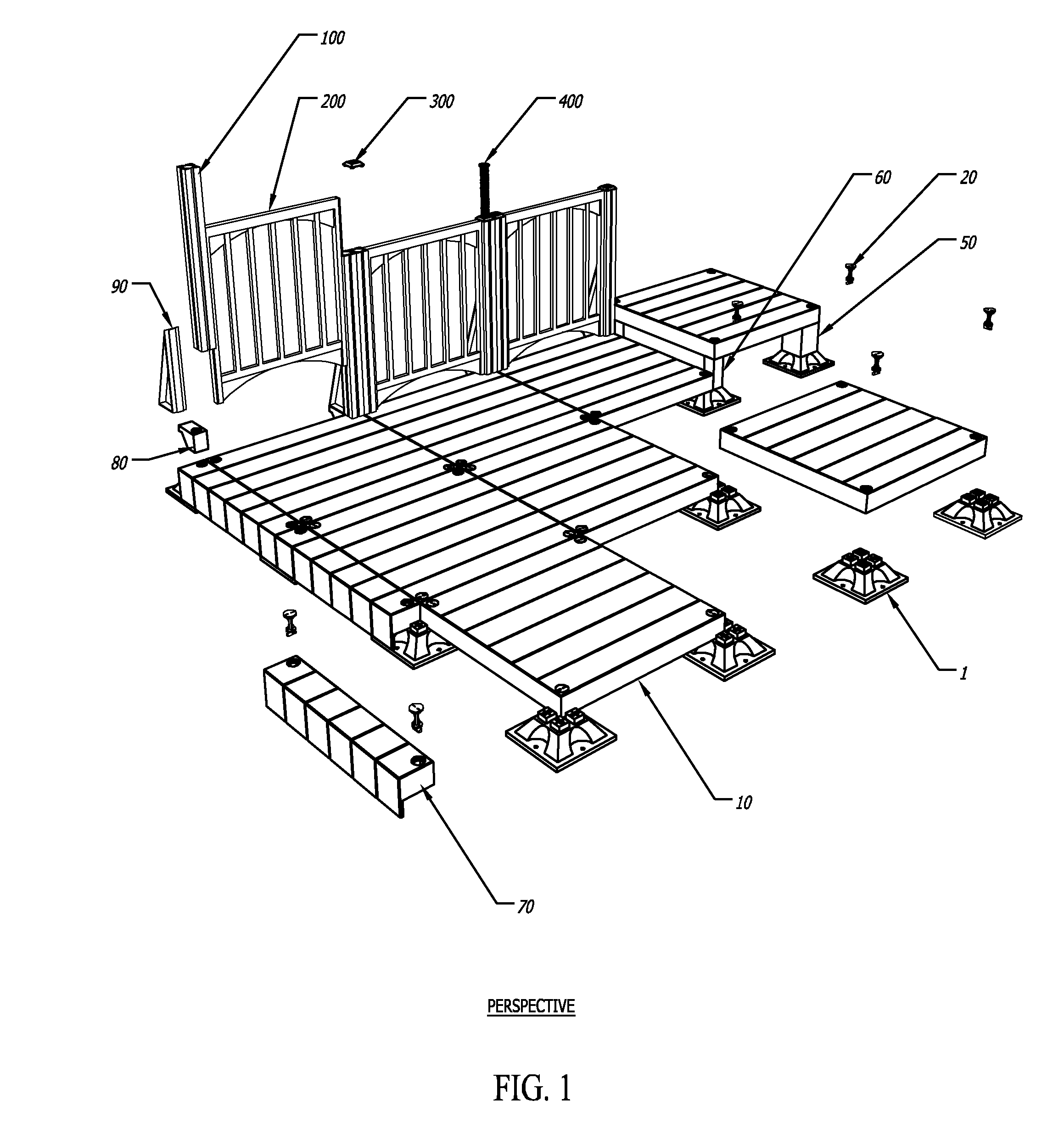

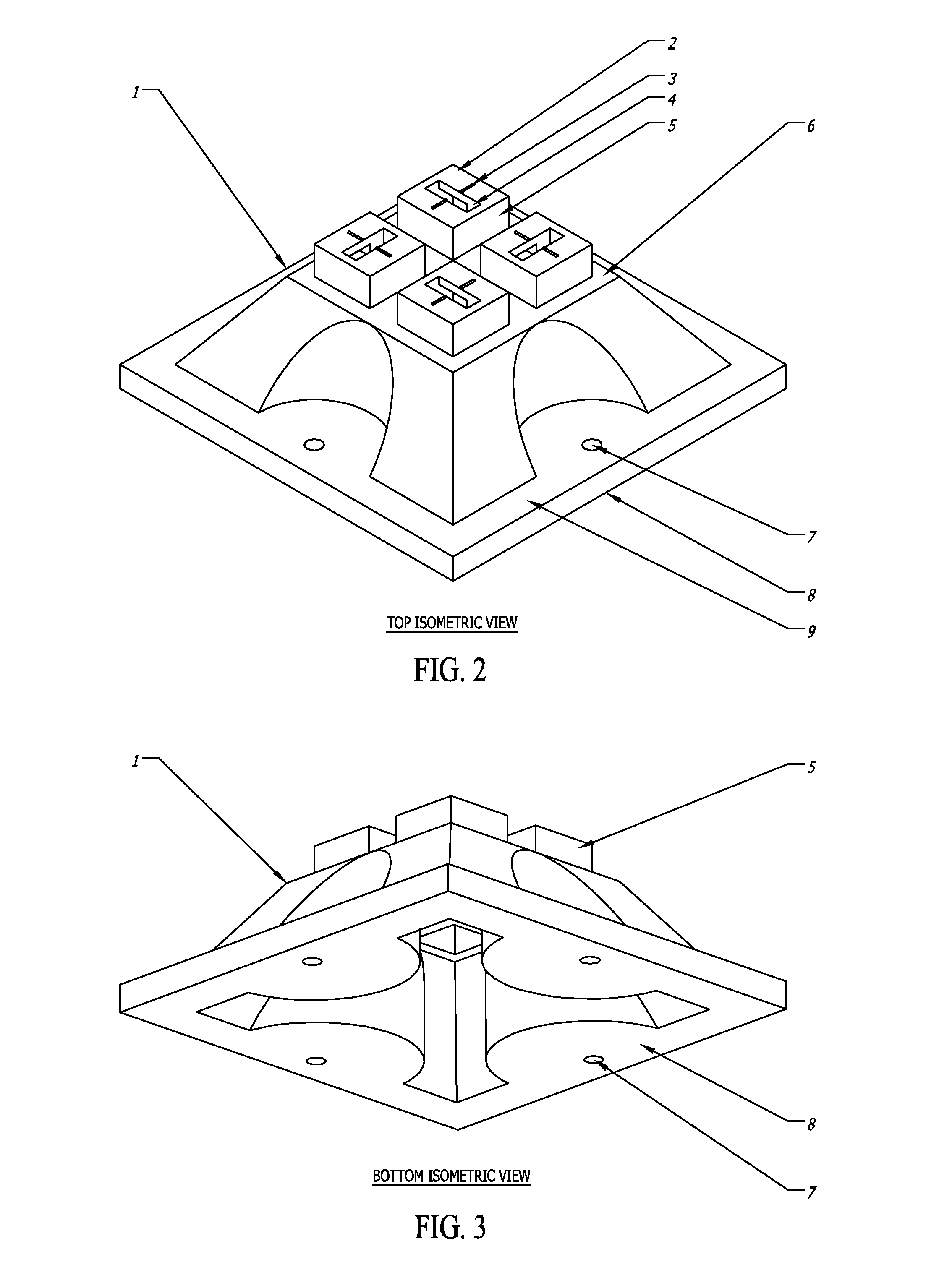

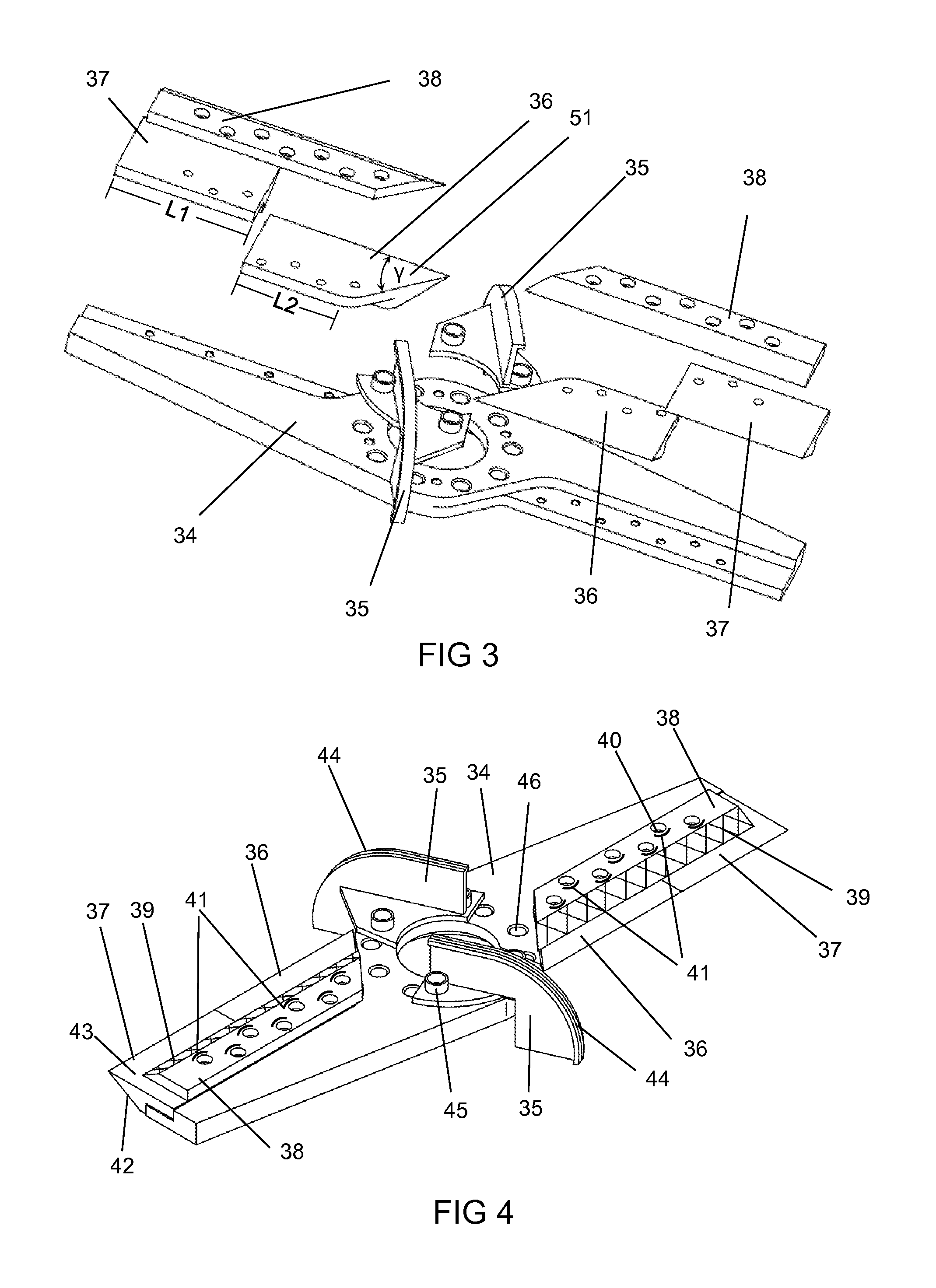

Modular, Portable, Interlocking Decking System

ActiveUS20100257796A1Simple and easy assembly processSimple designBuilding roofsCeilingsSystems designMarine engineering

Components for use in the assembly and installation of a modular decking system, comprised of structural free floating piers which distributes loads of deck pad to ground, piers have a pad bearing surface and four uniformly placed receiver blocks which interlock with corresponding recesses at four pad corners, an interlocking cam passes through pad recesses at deck surface and locks to piers by rotating cam with custom designed tool.The system is designed to be assembled without permanent fasteners to allow for expansion, reconfiguration or relocation, or addition of traditional and contemporary deck accessories that engage and interlock with the piers, pads and cams. One ideal manufacturing method of one or any of the system components is compression molded post-consumer and / or industrial thermo-plastic waste.

Owner:UDECX

Dog leash handle

The invention is a multi-compartmented dog leash handle assembly. The handle assembly has a compartment capable of carrying keys, money and / or plastic waste bags. The handle also has provisions for the easy transport of dog food and water. The handle also has a mechanism for attaching to the loop handle of a typical dog leash. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:RABELLO BILLY

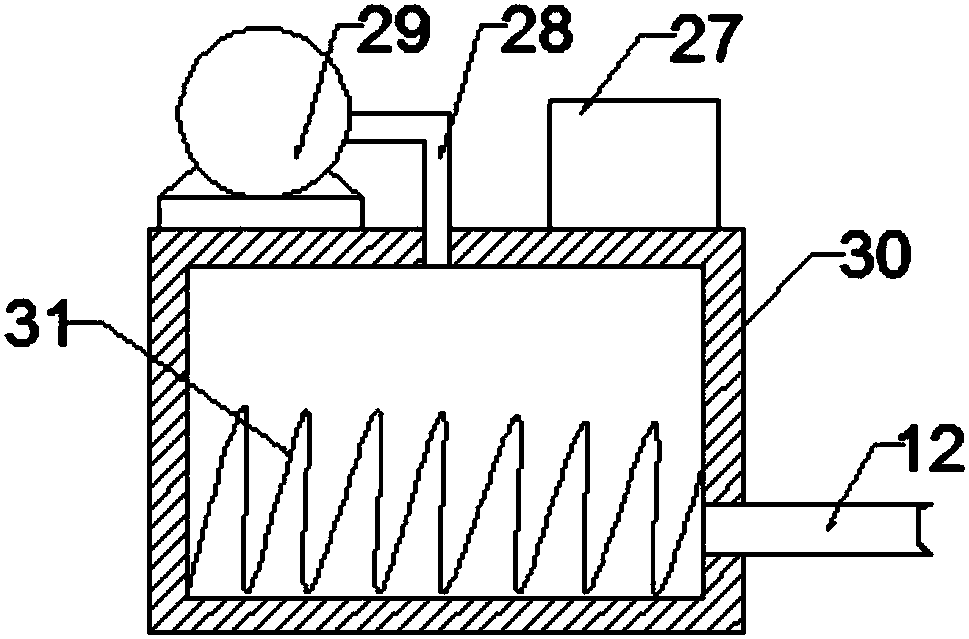

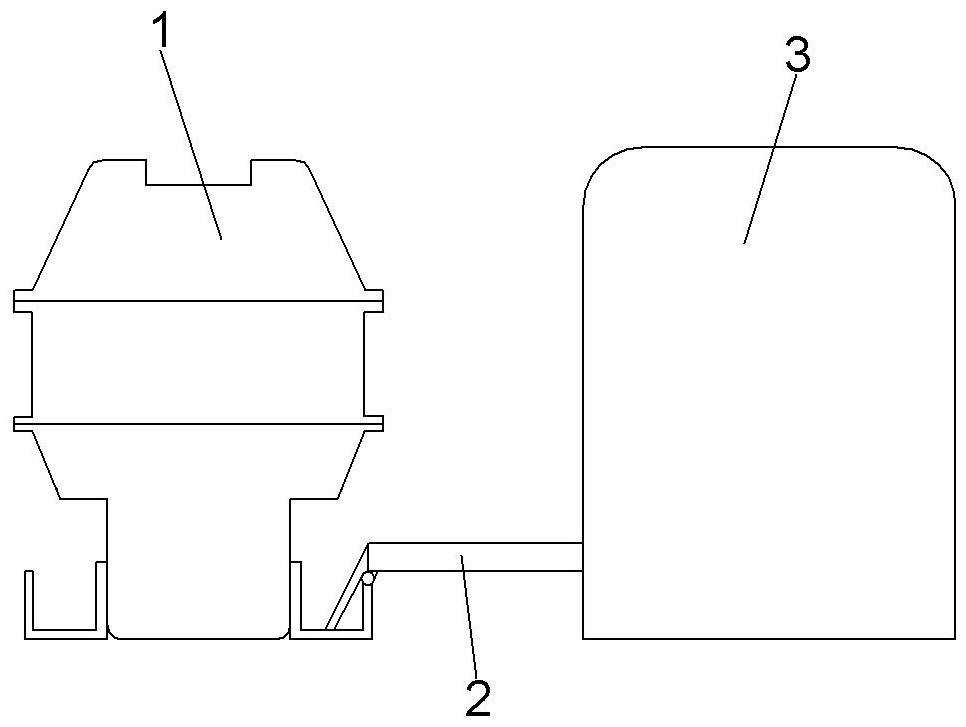

Domestic waste treatment device

InactiveCN109940023AFacilitate solid-liquid separationImprove filtering effectDispersed particle filtrationSolid waste disposalLiquid wasteInlet channel

The invention relates to the technical field of domestic waste treatment equipment and discloses a domestic waste treatment device which comprises a box body; one side of the top of the box body is provided with a feeding hole; the top of one side of the box body is fixedly provided with a first motor; an output shaft of the first motor is fixedly provided with a dewatering device in a sleeved manner; and the top of an inner cavity of the box body is provided with a material conveying box. For the domestic waste treatment device, liquid sewage collected in a liquid collecting tank is drained into the a collecting box through a flow guide pipe, so that liquid wastes produced in the waste treatment process is collected in a centralized manner, and centralized treatment is facilitated; a second motor is used for driving a stirring device to crush the wastes subjected to filter pressing, and the crushed wastes are dried by starting a hot air blower and utilizing an air outlet pipe, then asuction fan is started to suck relatively light plastic wastes, such as plastic bags, in the wastes through an air inlet channel, and the plastic wastes are collected by utilizing a collecting bin after being intercepted with a filter screen in an air inlet pipe, so that classified collection treatment of the wastes is realized.

Owner:周新光

Composite board produced with waste and old plastic and industrial gypsum, and producing method thereof

The invention discloses a composite board produced by waste plastics and industrial gypsum and a production method thereof. The composite board is prepared by the waste plastics and the industrial gypsum according to certain weight ratio. The invention adopts waste plastics such as waste polypropylene plastic, waste polyethylene plastic, waste polystyrene plastic, waste polyvinyl chloride plastic and so on discarded by industrial production and human life and the industrial gypsum as main raw materials to produce the composite board through the crushing and hot pressing, the composite board achieves the standard of the national building formwork, reduces the pollution of the industrial gypsum and plastic wastes to the environment, can also be used to substitute a wood building formwork or a steel building formwork which is widely used for the prior building construction, has low production cost, light weight, high strength, shock resistance, and easy mold stripping, can turn the harmful into the beneficial and turn waste into valuables, and greatly accelerate the progress of waste resource recovery in our country.

Owner:GUIZHOU UNIV

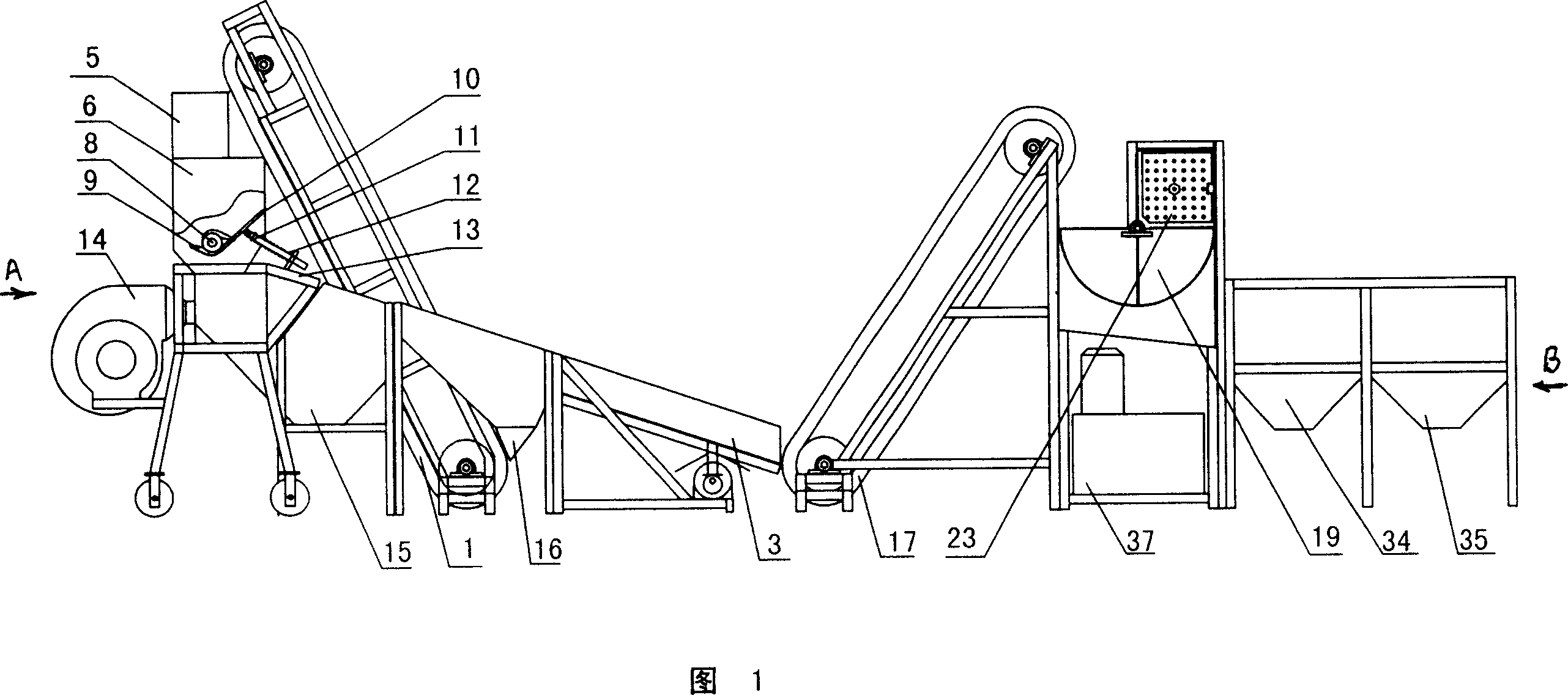

City domestic refuse plastic sorting process and device

InactiveCN1966233AWith back-off protection functionAvoid entanglementGas current separationSolid waste disposalWeight changeLitter

The invention relates to a method for separating the life plastic waste, and relative device, wherein it comprises that: transmitting waste, breaking waste and wind selecting. The invention is characterized in that: the wind selection uses two-stage wind selection, with screening, weight change, as waste transmission, waste breaking, first-stage wind selection, screening, weight change and second-stage wind selection. The light waste, via broken, first-stage wind selection and vibration screen will be transmitted to weight changer, to immerge and squeeze the plastic and paper, to change their specific weight; and the second-stage wind selection will separate them. The invention can effectively separate plastic and paper, with low cost.

Owner:SHANDONG UNIV OF TECH

Separation of hydrocarbons from hydrocarbon containing liquid

InactiveUS20030047522A1Avoid dischargePrevents back wash of any liquidLiquid suspension thickening by filtrationPaving gutters/kerbsPolyolefinFiltration

A novel filtration media employing polymeric absorbents comprising a material selected from the group consisting of styrene, pentadiene, cyclopentadiene, butylene, ethylene, isoprene, butadiene, propylene and mixtures thereof; and a filtration enabler intimately mixed with the polymeric absorbent. Preferably, the filtration enabler comprises clay, ground glass, talc, mica, recycled rubber, sand, gravel, vermiculite, recycled plastic chips, an inert, non-absorbent material, or mixtures thereof. Preferably, the polymeric absorbent may be further compounded to incorporate about 10 to 50% recycled or waste plastic scrap, scrap polyolefins, inorganic fillers, or other inexpensive, relatively inert solids. Other compounding materials may include clay, talc, mica, ground glass, silica, and mixtures thereof. Upon contact with a hydrocarbon containing liquid, the liquid partially dissolves the polymeric absorbent forming a partial filtration barrier prior to the filtration media substantially absorbing the hydrocarbons, and allowing hydrocarbon-free liquid to flow through the filtration media. In situations of a leak or spill wherein an excess of hydrocarbons are present, the filtration media forms a plug to seal and prevent further discharge of the hydrocarbons. The filtration media may be placed inside a portable container for insertion into an existing drain such that hydrocarbon containing liquid is filtered through the device allowing hydrocarbon-free liquid to flow from the device. The filtration media has a thickness within the container adapted to substantially filter out hydrocarbons while capable of forming a plug in an excess of hydrocarbons. The filtration media of the present invention may be employed in pits, pipes, and self-contained cartridges of various sizes to remove and contain hydrocarbons from a hydrocarbon containing liquid or a hydrocarbon spill or leak, and that the absorbent will form a plug in an excess of hydrocarbons entering the pit, pipe or cartridge. Also described are methods of filtering and preventing discharge of a hydrocarbon containing liquid.

Owner:SPI FILTRATION

Process for making modified cellulosic filler from recycled plastic waste and forming wood substitute articles

InactiveUS20070007682A1Lower melting and softening temperatureImprove compatibilityPlastic recyclingWood working apparatusThermoplasticPolyvinyl chloride

A low cost process of making modified cellulosic materials by melt blending with at least 30% recycled and commingled plastic waste stream at higher temperature and pressure where at least 70% of plastics melts and encapsulate the filler. The plastic encapsulated filler can be used as a feed stock for continuous or discontinuous process of compression, extrusion, coextrusion and injection molded structural (e.g. profiles, stake, panel) and non-structural (e.g. sheet, thin-board) articles by mixing with a thermoplastic (e.g. polyethylene, polypropylene, polyvinyl chloride, polystyrene) or a hybrid mixture of said thermoplastics, bonding agents, plastic processing additives, impact modifiers, colorant and with / without a lightner.

Owner:MALDAS DEBESH +1

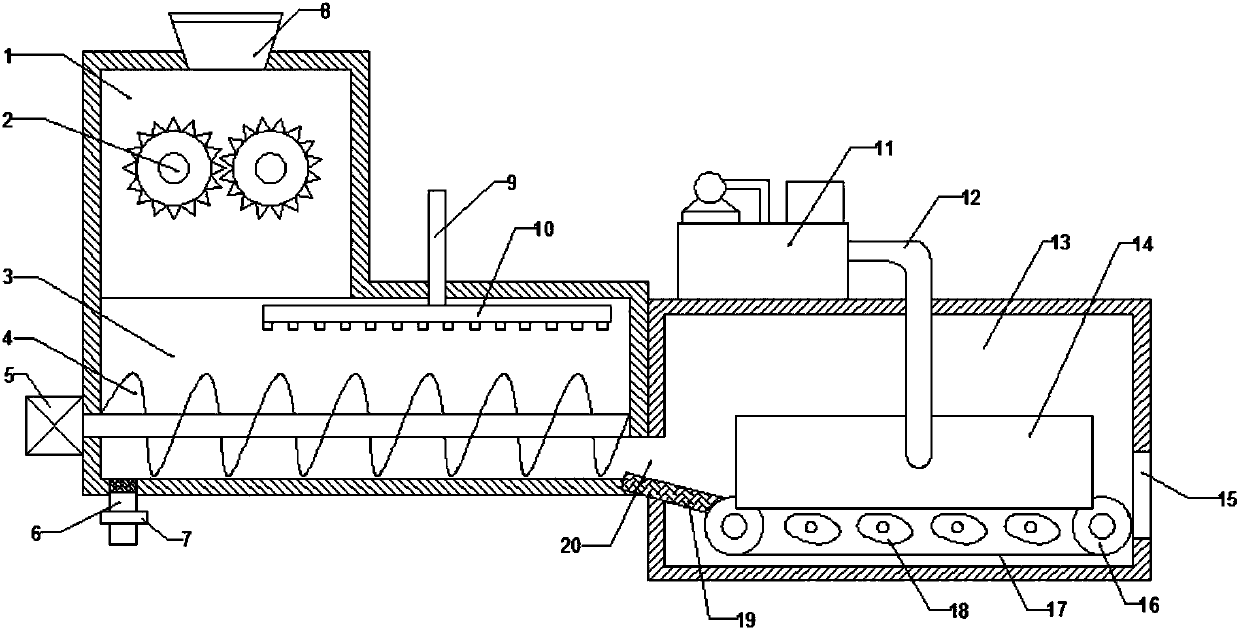

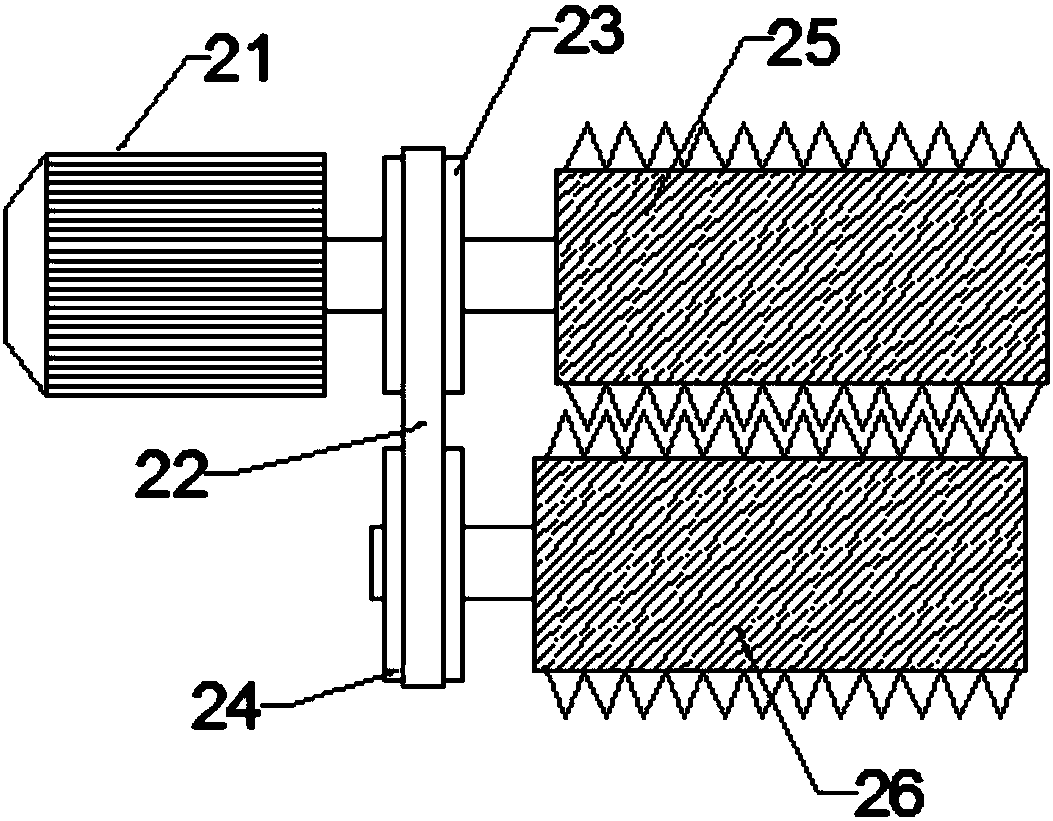

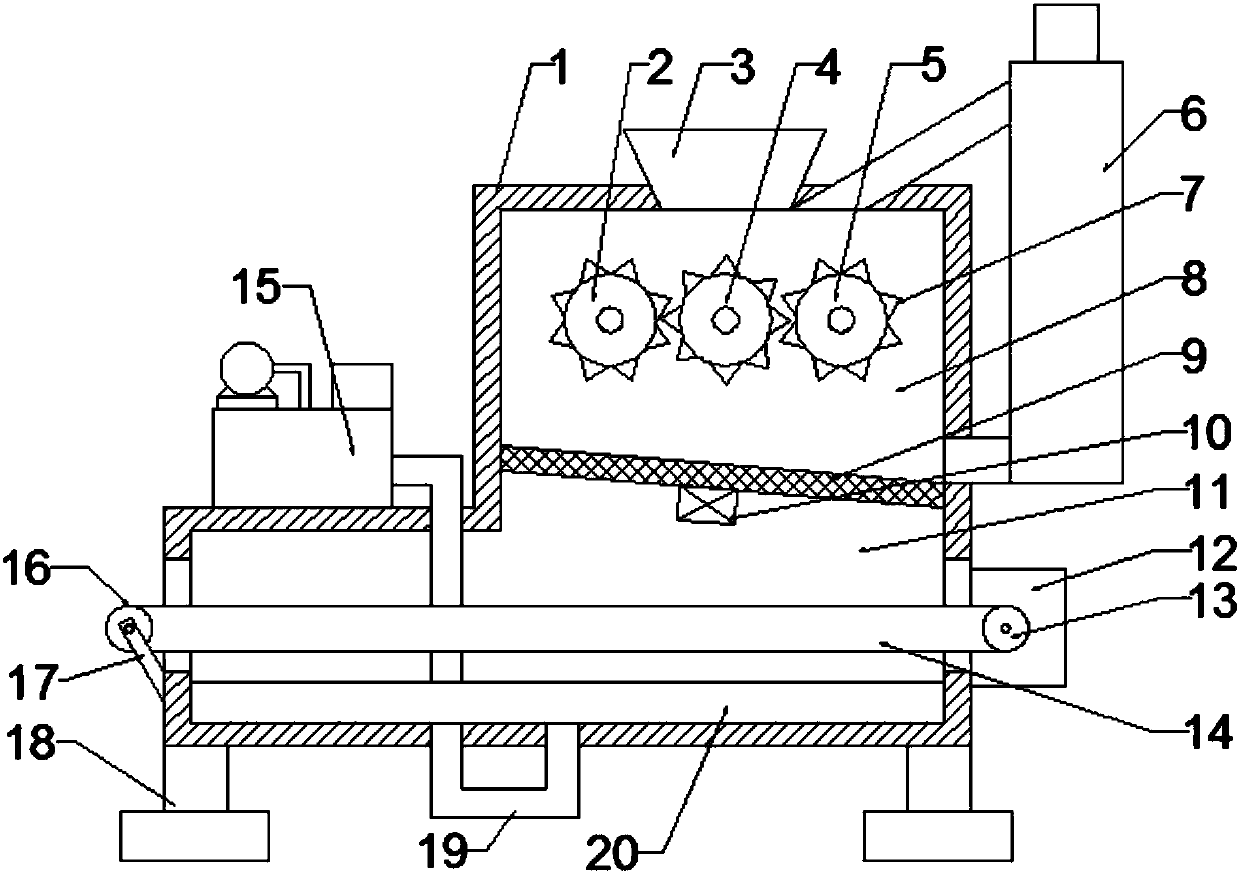

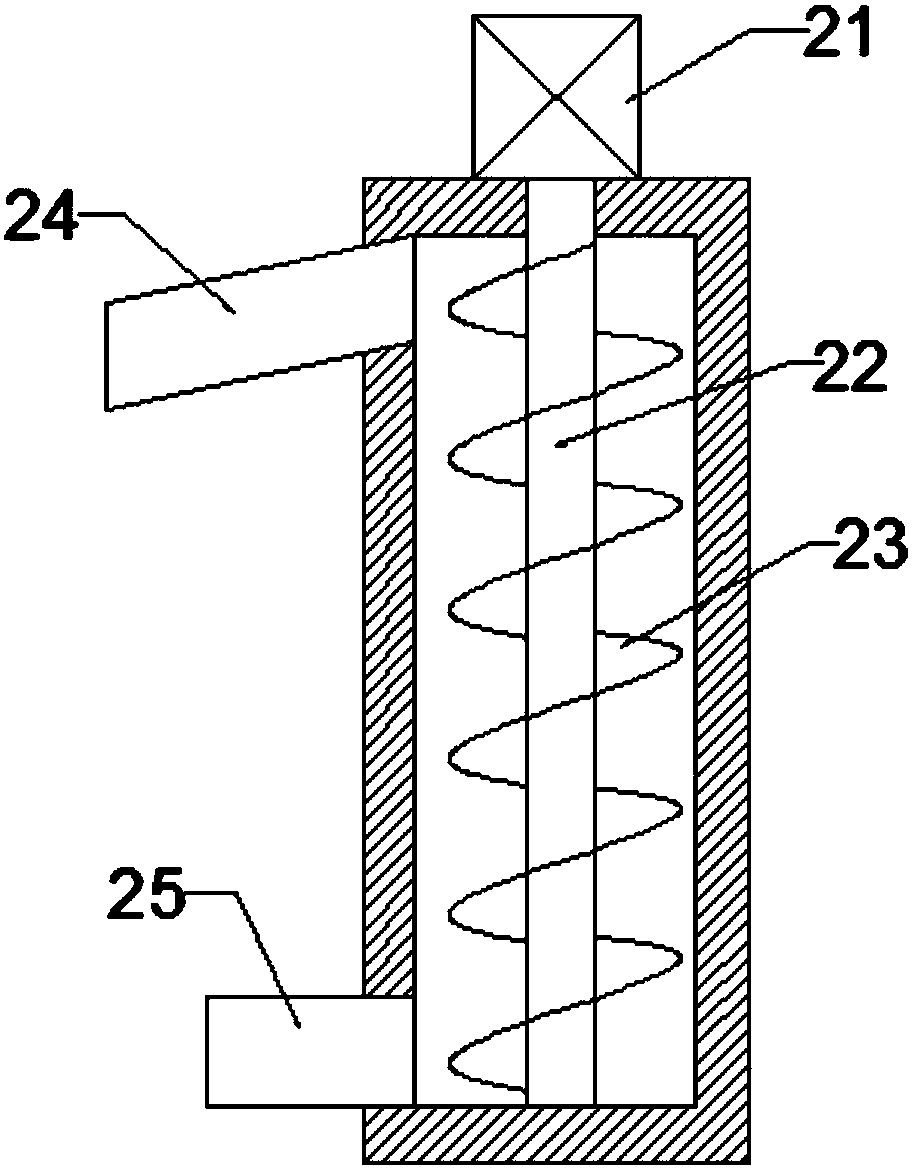

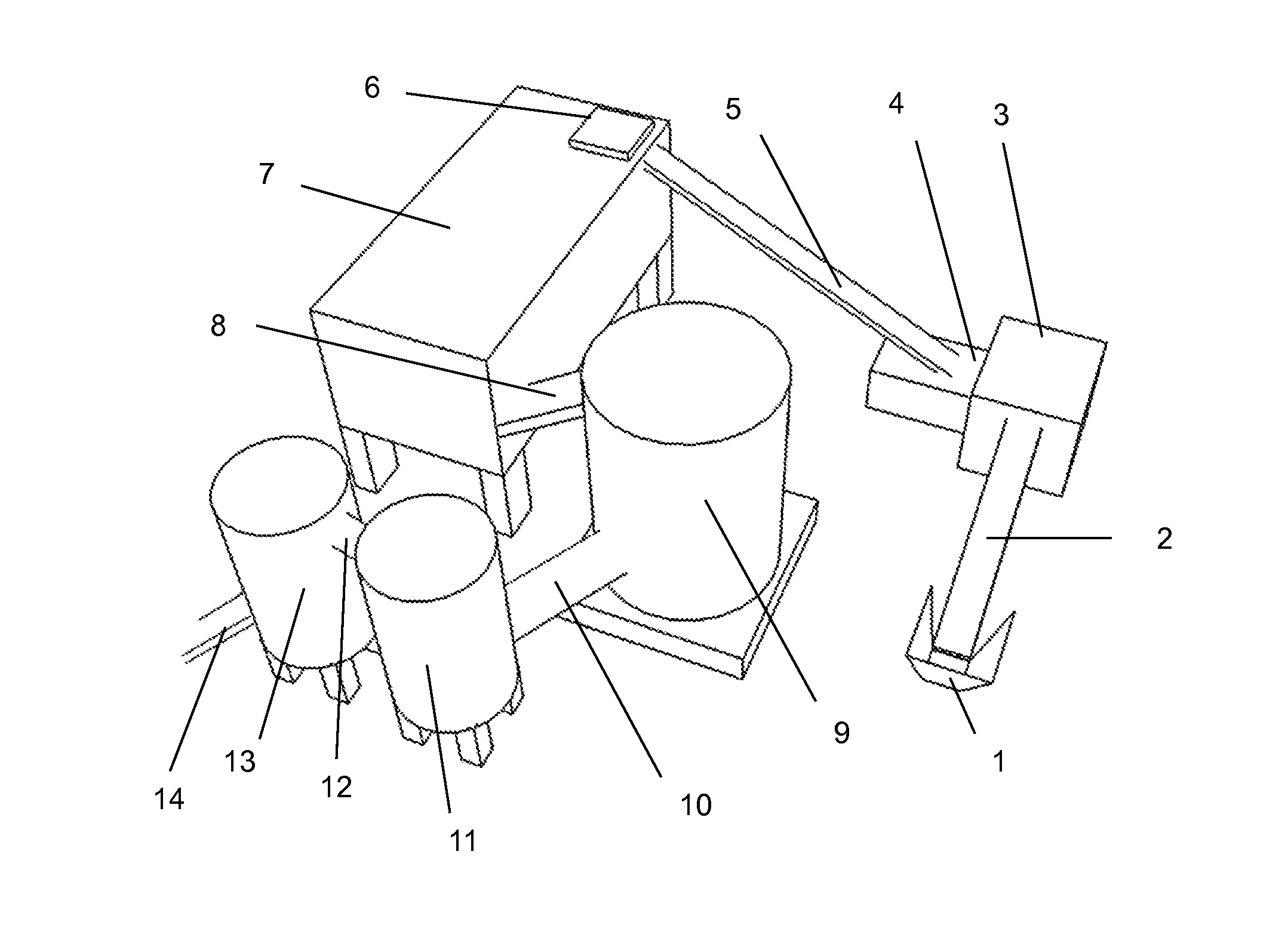

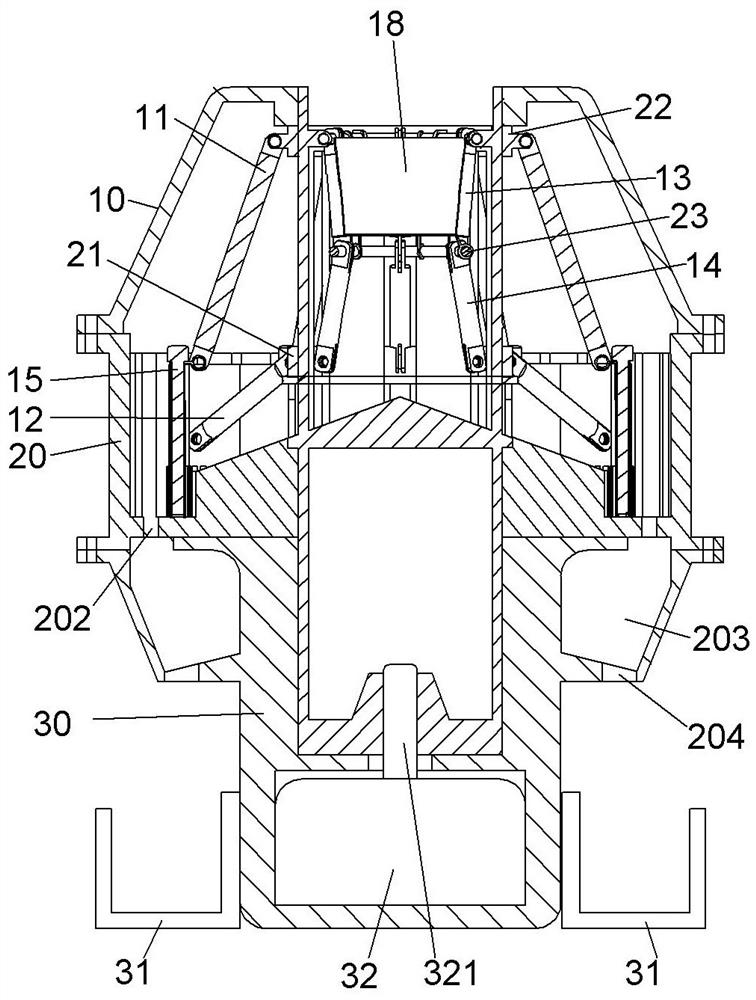

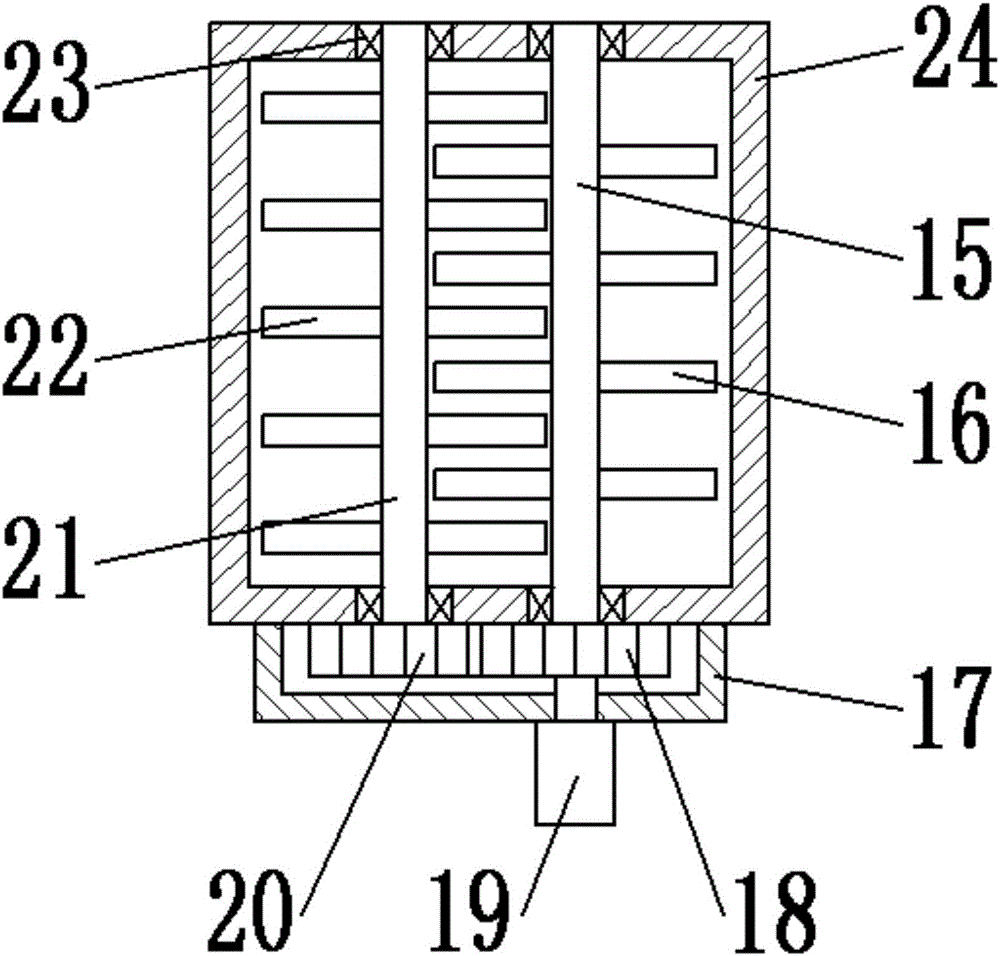

Horizontal plastic waste recovering granulator

InactiveCN104859067AAvoid it happening againImprove working environmentPlastic recyclingThermodynamicsPlastic waste

A horizontal plastic waste recovering granulator is composed of a hopper, a box cover, a melting chamber, a fan, an arc-shaped screen, a heating tube, a mouth mold, a pelletizing mechanism, an extrusion screw, a machine cylinder, a frame, a driving mechanism, a transmission mechanism, a V-shaped receiving hopper, a hot air circulating box body, a separator plate and a stirring mechanism. The granulator adopts hot air to directly melt plastic wastes, so the crushing and cleaning processes of traditional technologies are omitted, the working environment is improved, and secondary pollution is avoided; and the temperature of the hot air is controllable, so the overheating decomposition of plastics is avoided, cycle use of the hot air is realized, and the heat efficiency is high.

Owner:NANCHANG UNIV

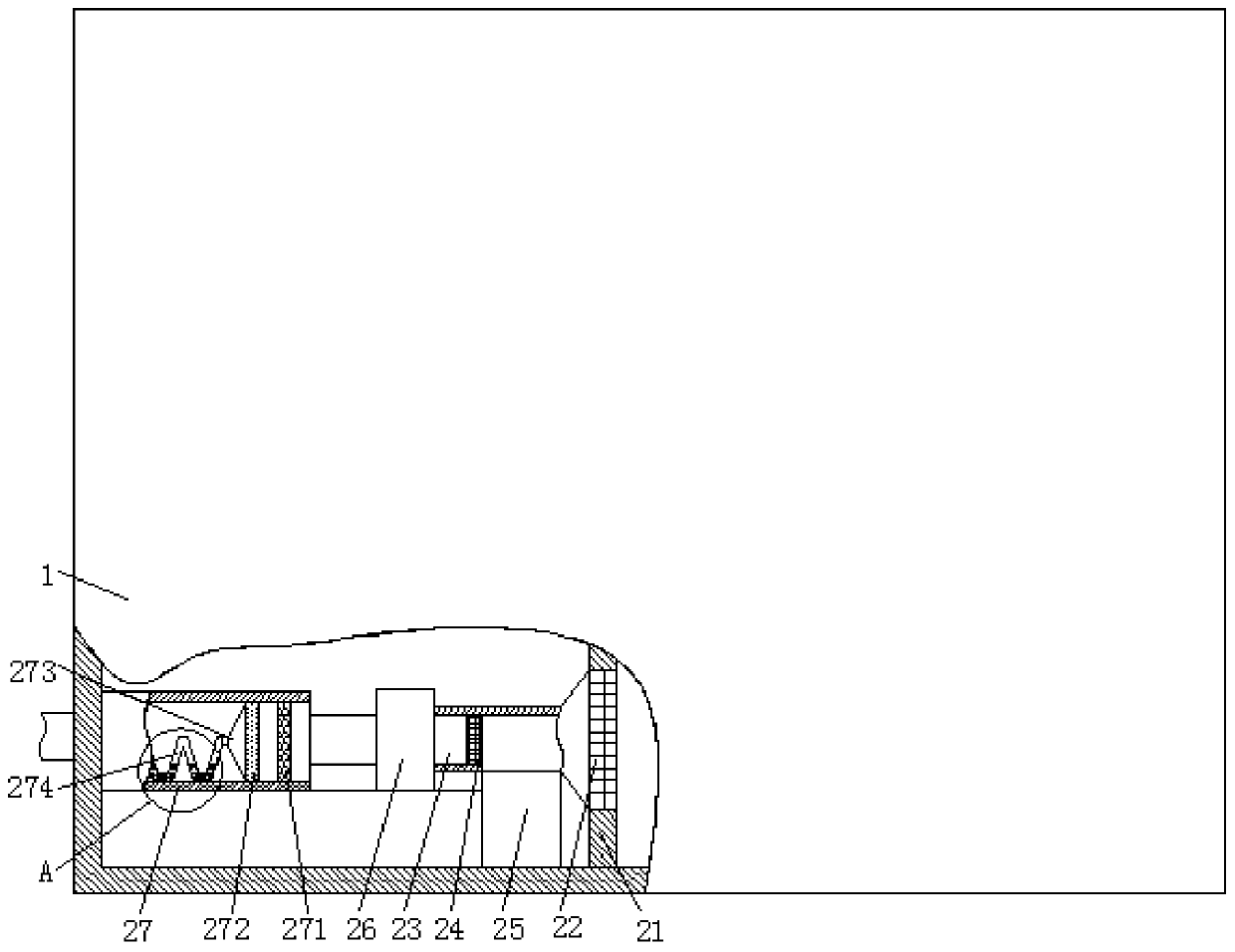

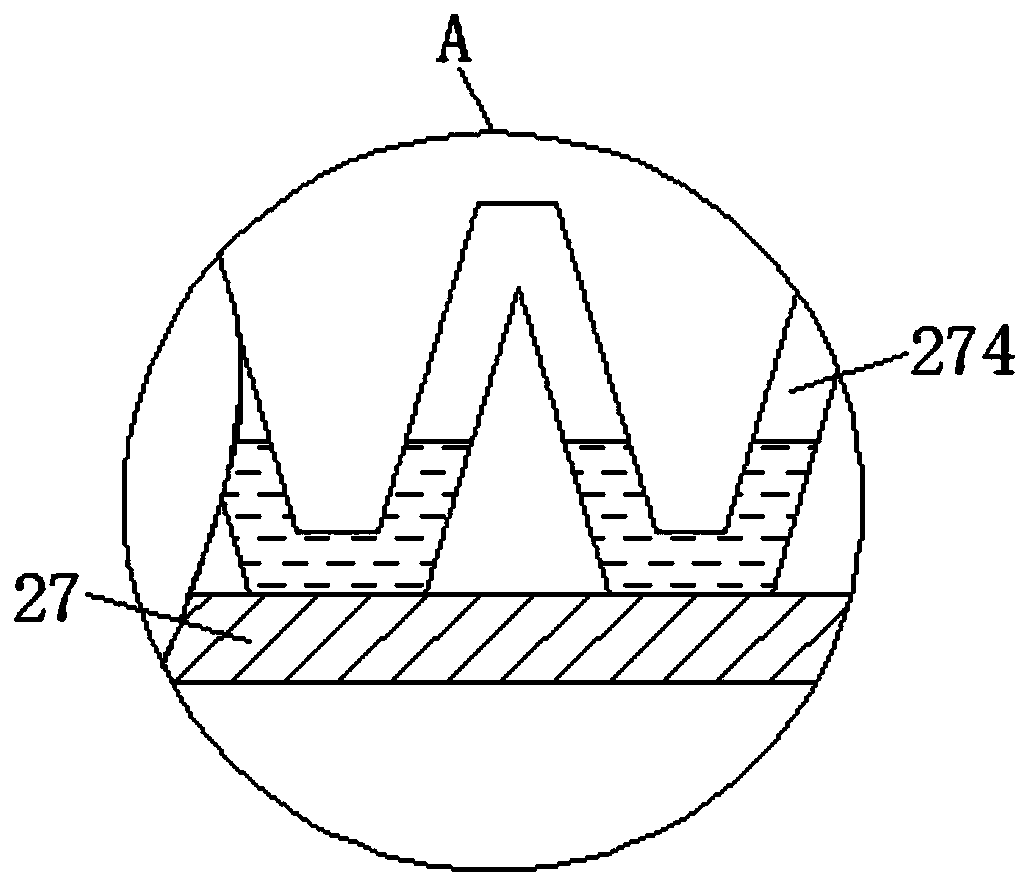

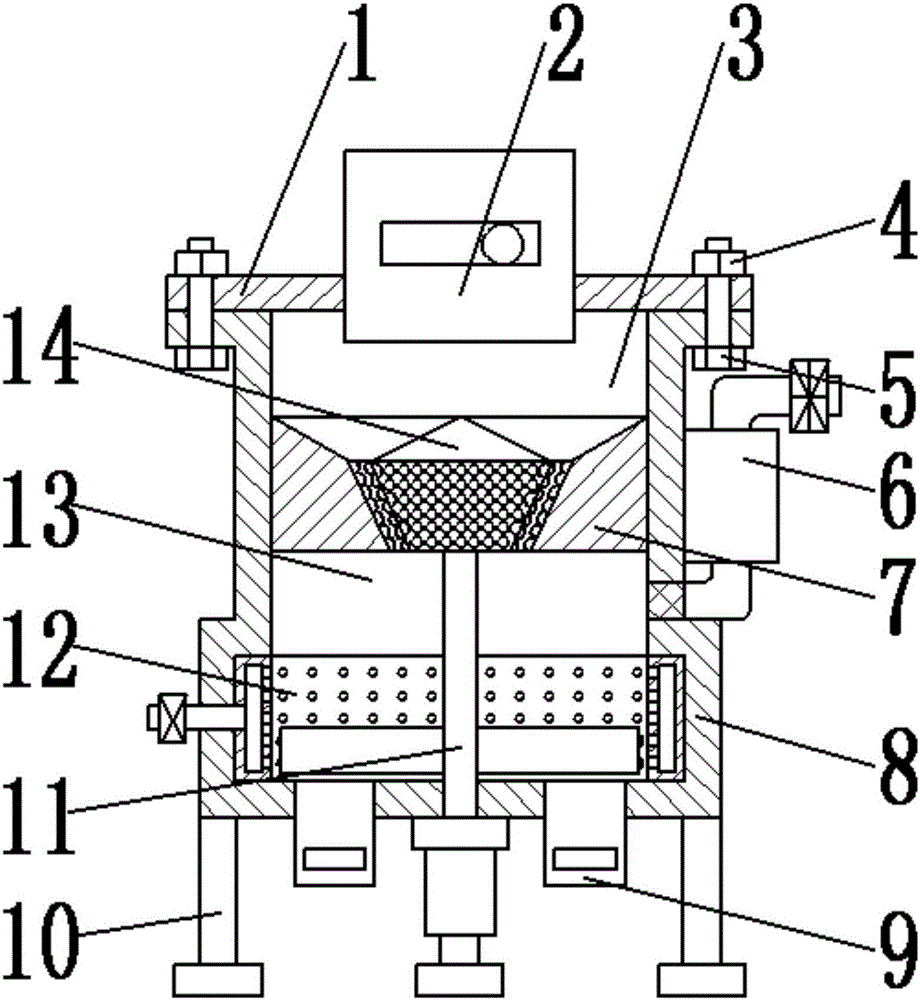

Plastic waste treatment equipment with crushing and drying functions

The invention discloses plastic waste treatment equipment with crushing and drying functions, and belongs to the field of plastic treatment equipment. The plastic waste treatment equipment comprises abox body, wherein the box body is provided with support legs, and the support legs are fixedly connected with the box body; the interior of the box body is partitioned into a crushing cavity and a drying cavity through a sieve plate; a charge hopper is arranged at the top end of the box body, and is conical; crushing teeth are arranged on a right driven wheel, a drive wheel and a left driven wheel; a second rotary wheel is arranged at the left end of the box body through a support, and the support is fixedly connected with the box body; a drive motor is fixedly arranged at the right end of the box body, and a first rotary wheel is arranged on the drive motor; and an air diffusion box is fixedly arranged at the bottom of a drying cavity, and is connected with an air heating device throughan air inlet pipe. The plastic waste treatment equipment disclosed by the invention is reasonable in structural design, capable of realizing cyclic crushing, and thorough in crushing; and moreover, the plastic waste treatment equipment is capable of carrying out drying treatment on the crushed plastic waste.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

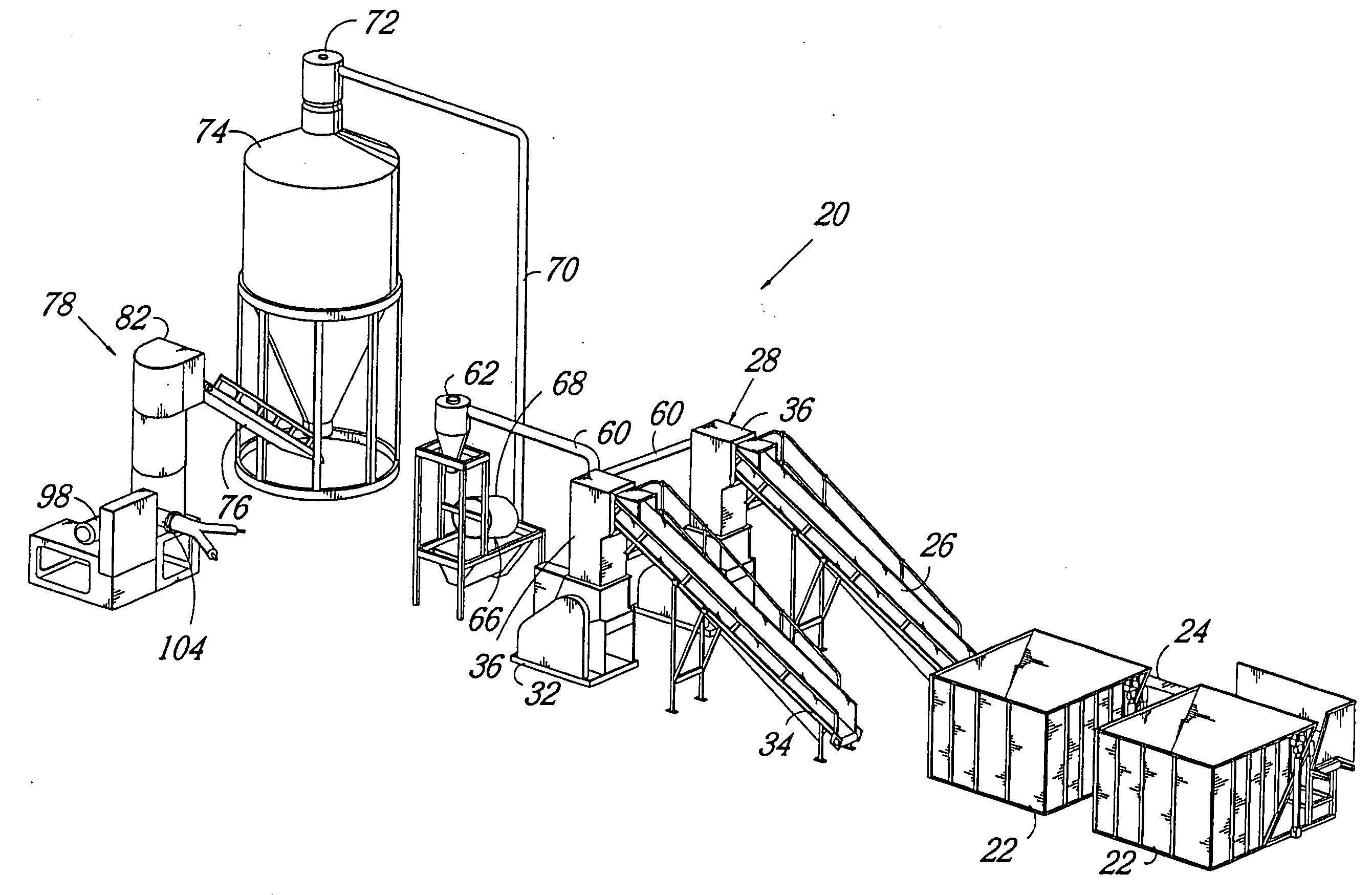

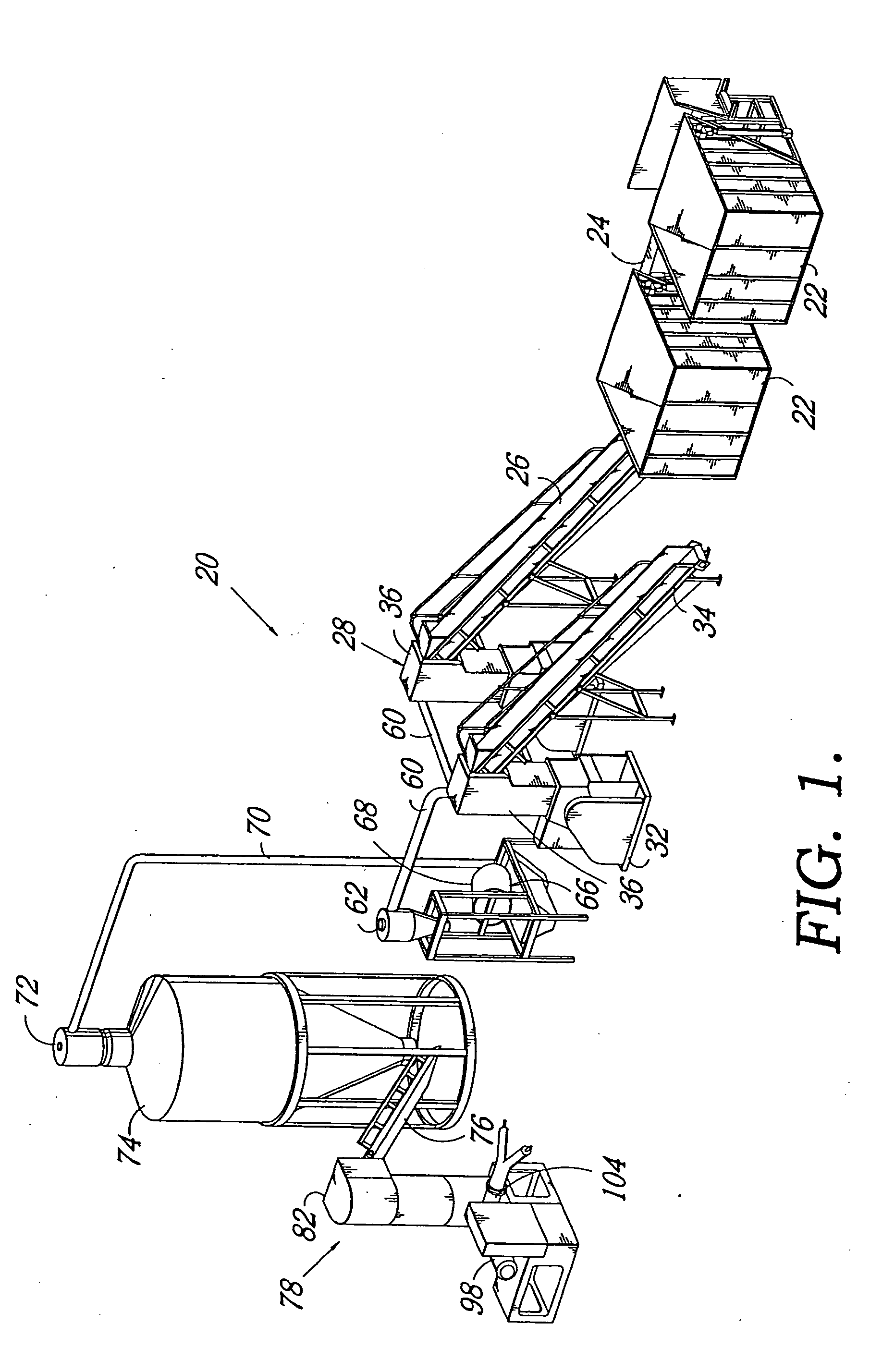

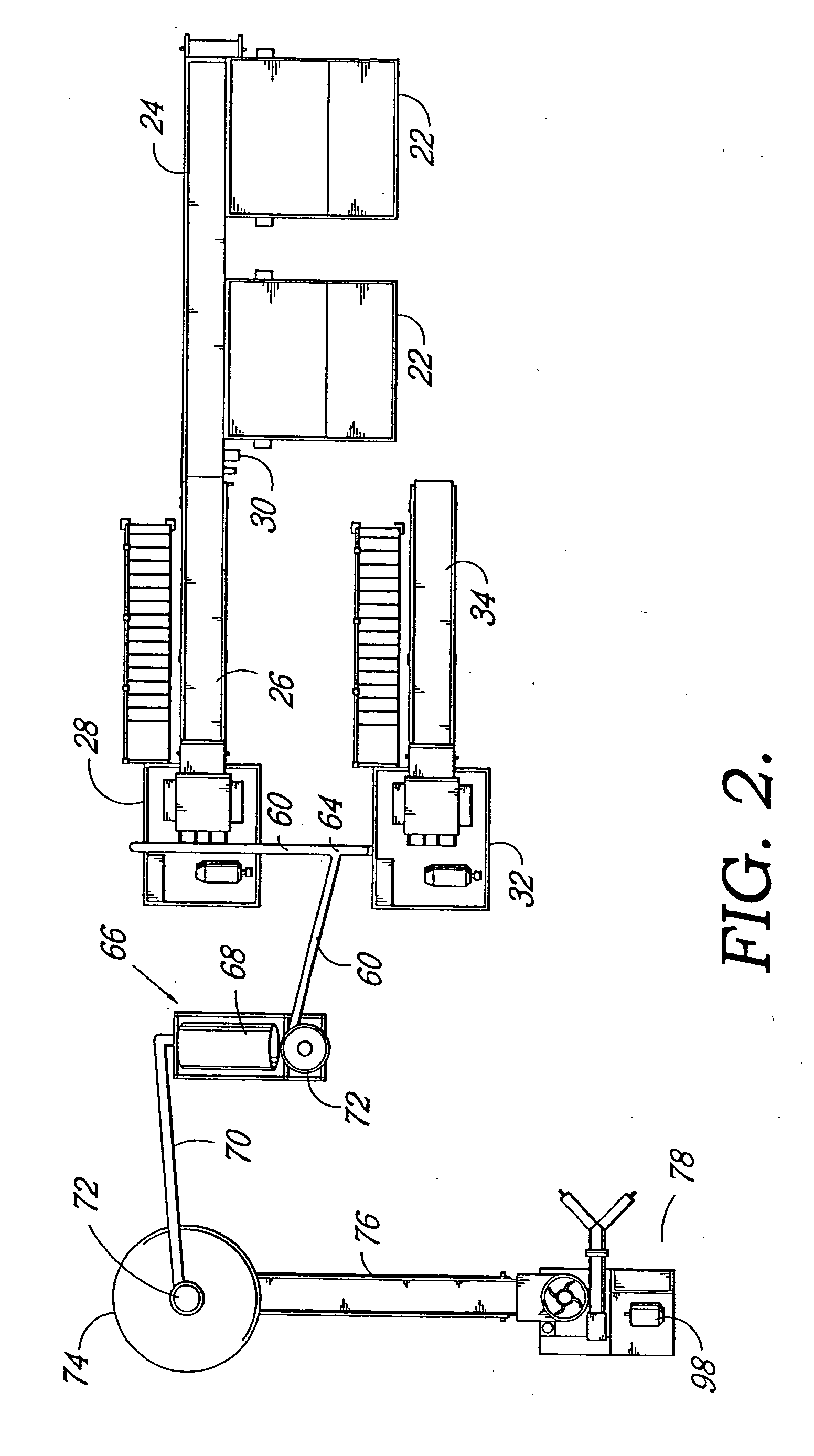

Plastic recycling system and process

InactiveUS20050051646A1Increase frictionIncrease wastePlastic recyclingGrain millingPlastic wasteEngineering

The present invention provides a plastic recycling system, including a first granulator for reducing plastic waste to a first particle size. The system also includes a second granulator for reducing plastic waste to a second particle size. A frictional melting stricture is provided which melts the first particles and the second particles via use of a rotating plate.

Owner:COLLEX

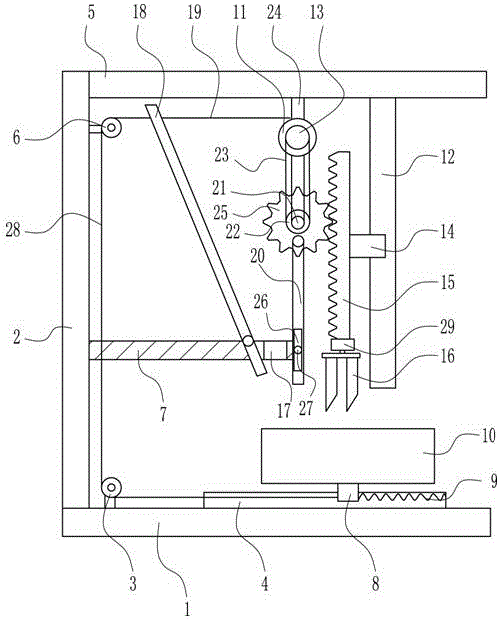

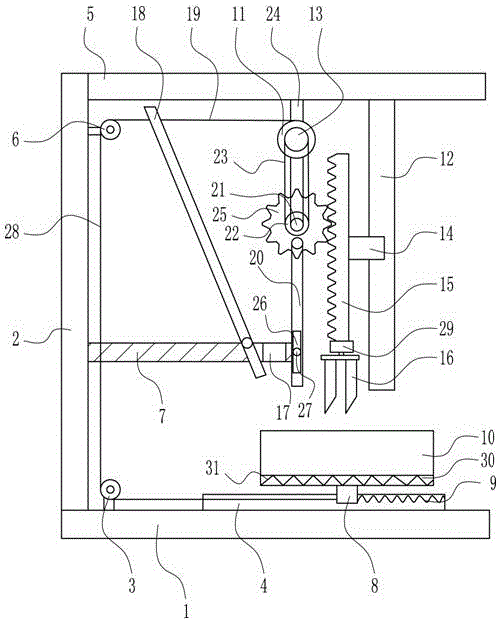

Medical plastic waste rapid-treatment device

ActiveCN106393497AImprove chopping effectEasy to chopPlastic recyclingGrain treatmentsDrive wheelPlastic waste

The invention relates to a plastic waste treatment device, in particular to a medical plastic waste rapid-treatment device. The medical plastic waste rapid-treatment device is high in treatment efficiency, easy to operate and reasonable in design. The medical plastic waste rapid-treatment device comprises a bottom plate, a left side plate, a first pulley, a first sliding rail, a top plate, a second pulley, a guide plate, a first sliding block, a spring, a cutting-up frame, a wire spool, a second sliding rail, a driven wheel, a second sliding block, a rack, blades, a first baffle, a first pulling rope, a second baffle, a first motor, a driving wheel, a flat belt, a supporting rod, a gear, a rolling shaft and a second pulling rope. The left side plate, the first pulley and the first sliding rail are sequentially arranged on the bottom plate from left to right. The medical plastic waste rapid-treatment device has the effects of being high in treatment efficiency, easy to operate, and reasonable in design.

Owner:宁夏红远汇达实业集团有限公司

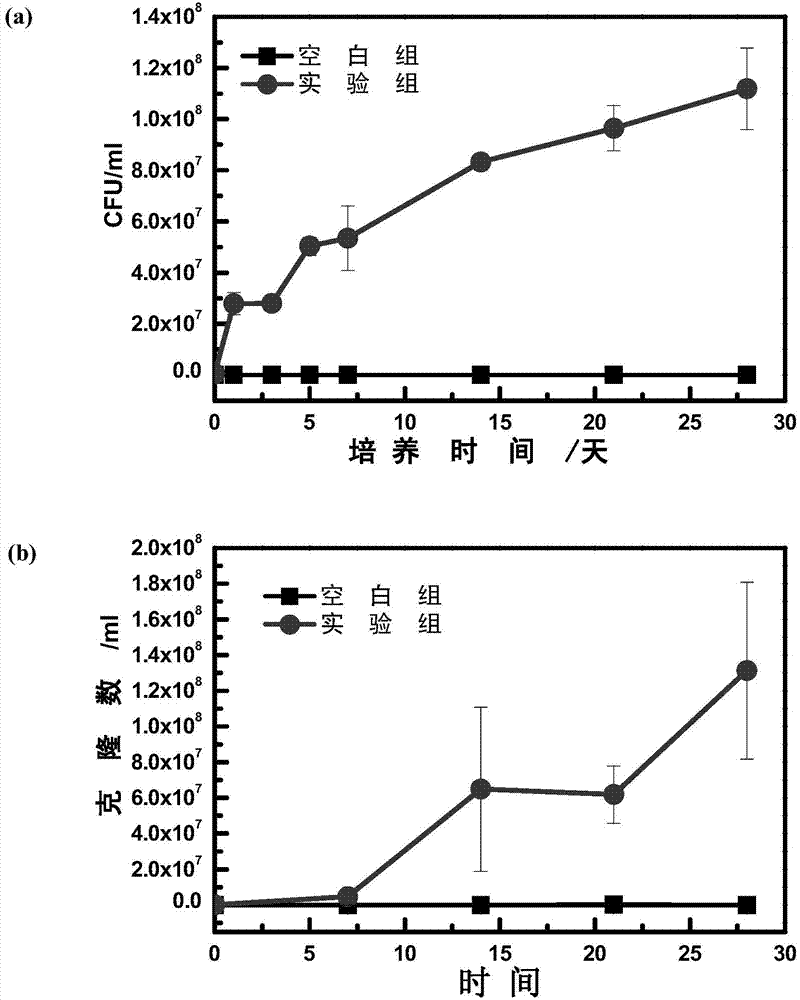

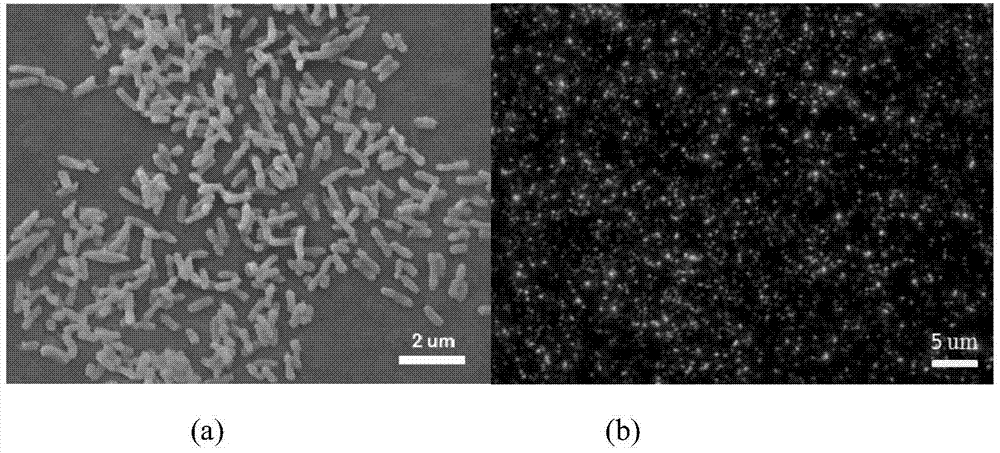

Enterobacter cancerogenus for degrading polyethylene and application of enterobacter cancerogenus

ActiveCN104232501AEfficient degradationIncrease landfill capacityBacteriaSolid waste disposalMicrobial agentPlastic waste

The invention discloses an enterobacter cancerogenus for degrading polyethylene and an application of the enterobacter cancerogenus. The bacterial strain disclosed by the invention is enterobacter cancerogenus YZ1 CGMCC No.6816. The active component of a microbial agent disclosed by the invention is enterobacter cancerogenus YZ1 CGMCC No.6816. The bacterial strain disclosed by the invention is capable of effectively corroding and degrading polyethylene plastic. The microbial agent disclosed by the invention is low in production cost, and can degrade 5% (mass percent) of polyethylene within 60 days. The bacterial strain and the microbial gent disclosed by the invention can be suitable for polyethylene wastes in refuse landfills and various water body and soil environments, and can ensure that the polyethylene can be biodegraded. According to the method disclosed by the invention for efficiently degrading microorganisms of plastic, the microorganisms of degradable plastic with high purity and high activity can be quickly obtained. A technique and a method can be provided for solving the problems that the existing polyethylene plastic wastes pollute the environment and occupy great landfill capacity of the landfill, and the enterobacter cancerogenus is of great importance in environmental protection and reduction of garbage disposal cost.

Owner:BEIHANG UNIV +1

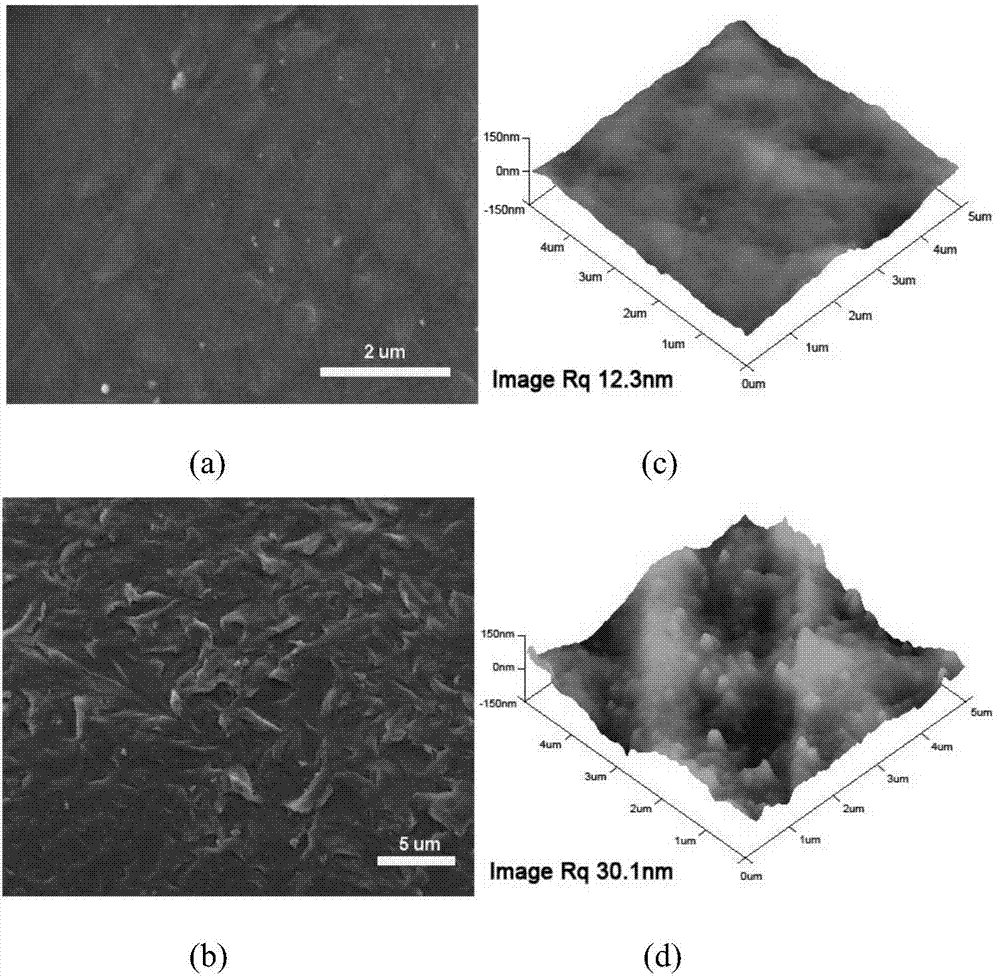

Device for recycling mixed plastic waste, a blade system for said device and a method for recycling mixed plastic waste

ActiveUS20150258713A1Thicker and durableReducing surface structureSolid waste disposalPlastic recyclingMolten statePlastic waste

A blade system for device for recycling mixed plastic is disclosed. Furthermore, a device and a method for recycling unidentified, unclean, and unsorted mixed plastic into reusable plastic mixture is disclose. The present solution allows the recycling of mixed plastic waste outdoors, both in warm and cold climate conditions. In the course recycling mixed plastic waste the mixed plastic waste is taken to a melting temperature, at which the mixed plastic waste is mixed in a molten state, and the organic and bacterial material is destroyed during the thermal processing. After the melting, mixing and thermal processing of the mixed plastic waste, the compaction process of the molten mixed plastic waste is performed. Volume compacting is performed, and the mass of mixed plastic waste in a molten state is rapidly cooled down, crushed, after-cooled and homogenized.

Owner:ROLAN INVESTMENT OU

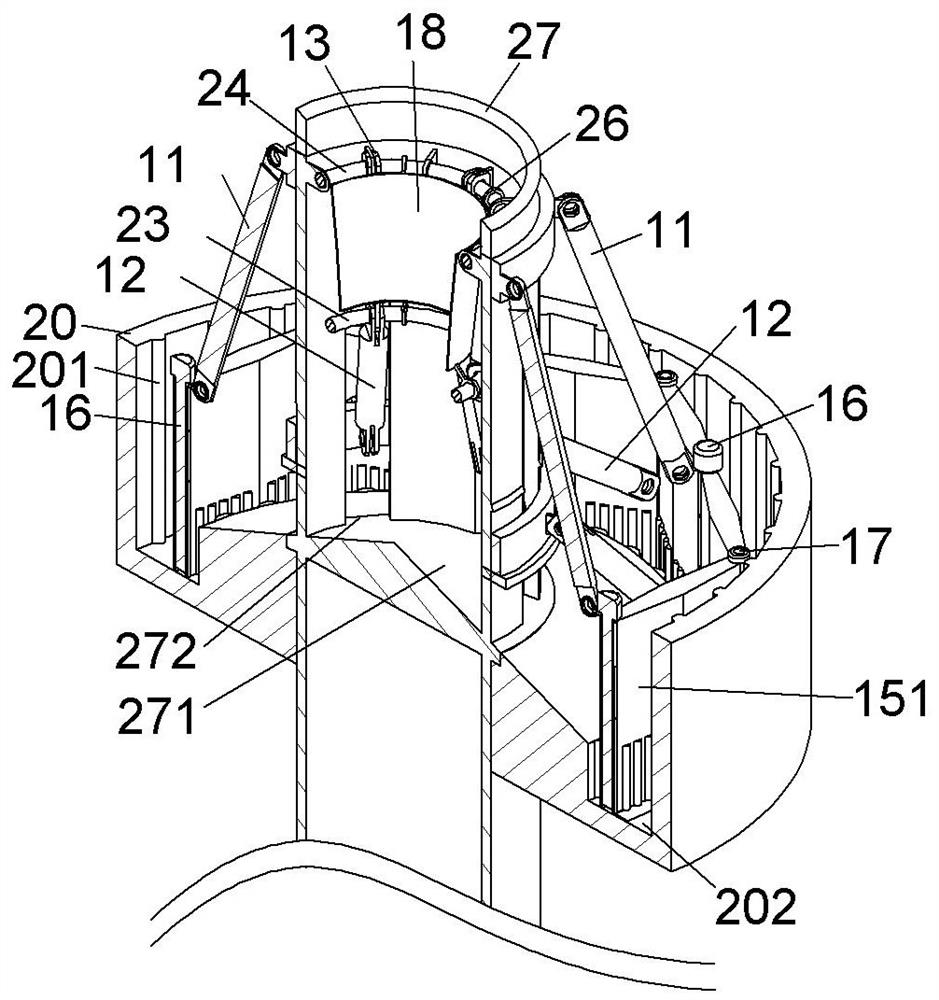

Glass fiber reinforced plastic decomposition and recovery equipment and recovery method

The invention relates to the technical field of glass fiber reinforced plastic recovery, in particular to glass fiber reinforced plastic decomposition and recovery equipment and a recovery method. The glass fiber reinforced plastic decomposition and recovery equipment comprises a grinding device, a high-temperature heat treatment device, a cooling device, a dust removal device and a catalysis device. The grinding device comprises a base, a rotating cylinder, a grinding ring groove body, a feeding hopper, a grinding cylinder and an adjusting device. An annular grinding cavity with an upward opening is defined in the grinding ring groove body, and a discharging opening is formed in the bottom of the grinding ring groove body. The grinding cylinder is arranged in the grinding cavity and comprises a plurality of grinding plates, a plurality of first hinge shafts and a plurality of second hinge shafts. The adjusting device comprises a sliding ring, an elastic rope, a plurality of first connecting rods, a plurality of second connecting rods and a plurality of third connecting rods. During normal work, the lower end of the feeding hopper is opened, the lower end of the feeding hopper is closed when the feeding hopper is clamped, the grinding cylinder is in a dynamic change process in the grinding process and cannot be clamped till glass fiber reinforced plastic waste is ground to the preset size, manual unclamping is not needed, and the grinding efficiency is further improved.

Owner:江苏华纳环保科技有限公司

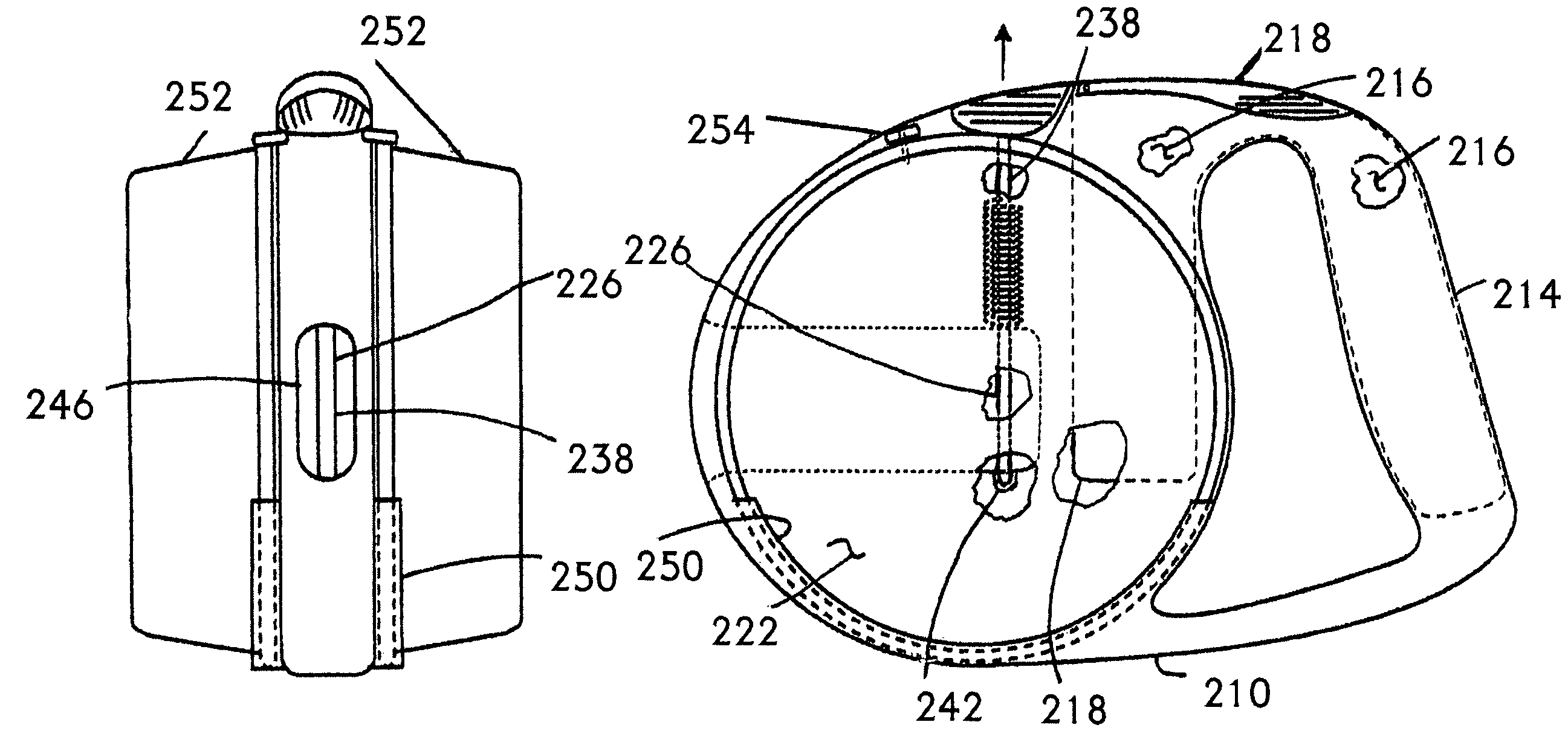

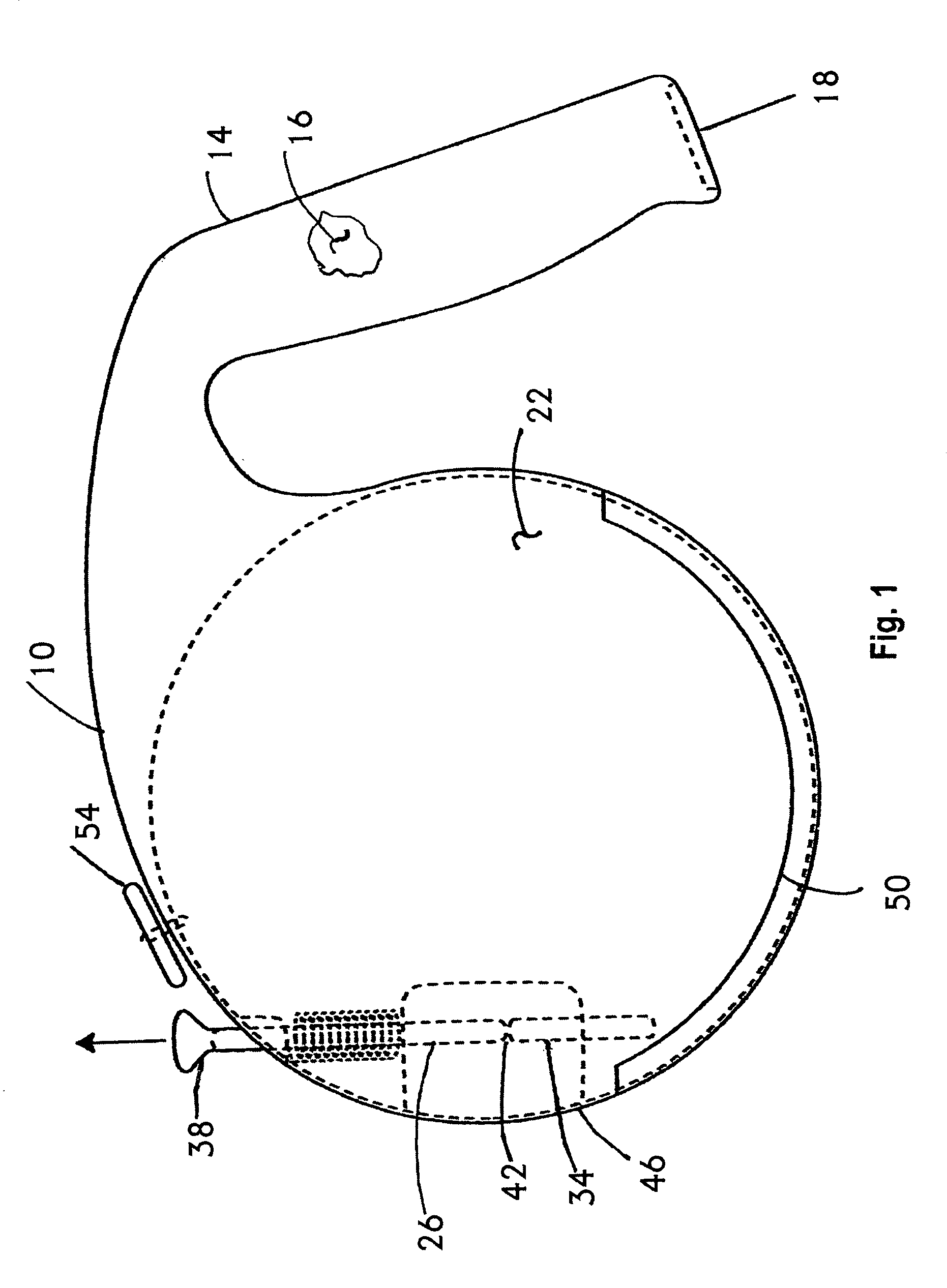

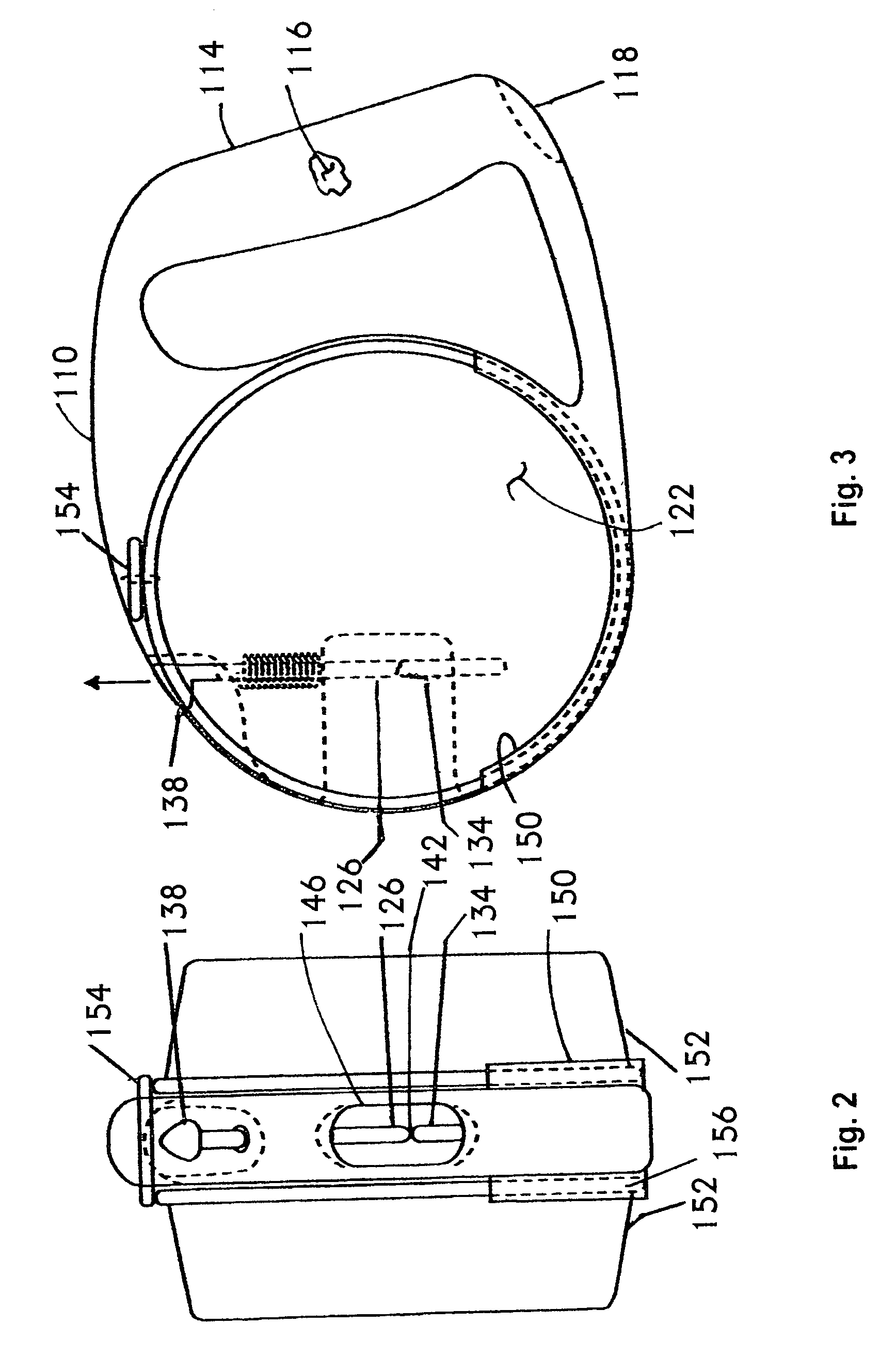

Pet leash and waste pick-up device

InactiveUS8100445B1Conveniently disposedConveniently removedRoad cleaningOther apparatusLitterPlastic waste

A pet leash and waste pick-up device comprises a retractable waste pick-up tool which is conveniently disposed in a sheath housing compartment on the leash device. When it is necessary to pick up and dispose of pet waste, the tool is removed from the sheath housing, expanded to a usable orientation, and fitted with a plastic waste bag. The device is then maneuvered so that the center of the bag is positioned over the waste to be removed. At this point, the tool is retracted, thereby closing the bag over the waste. The bag can then be simply removed from the tool, sealed appropriately, and stored for disposal, without risk of the user directly contacting the waste.

Owner:BRAR BALBIR S

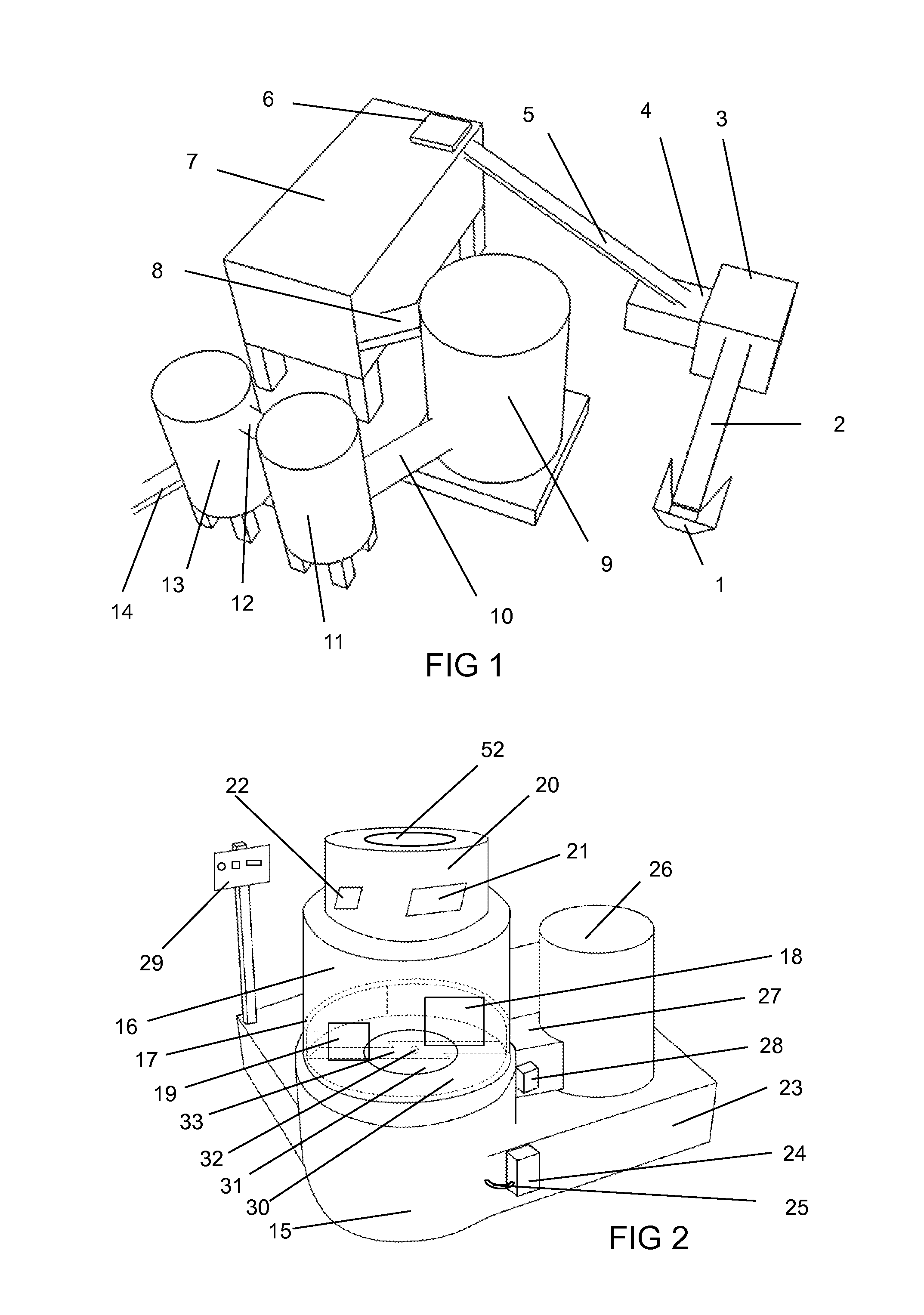

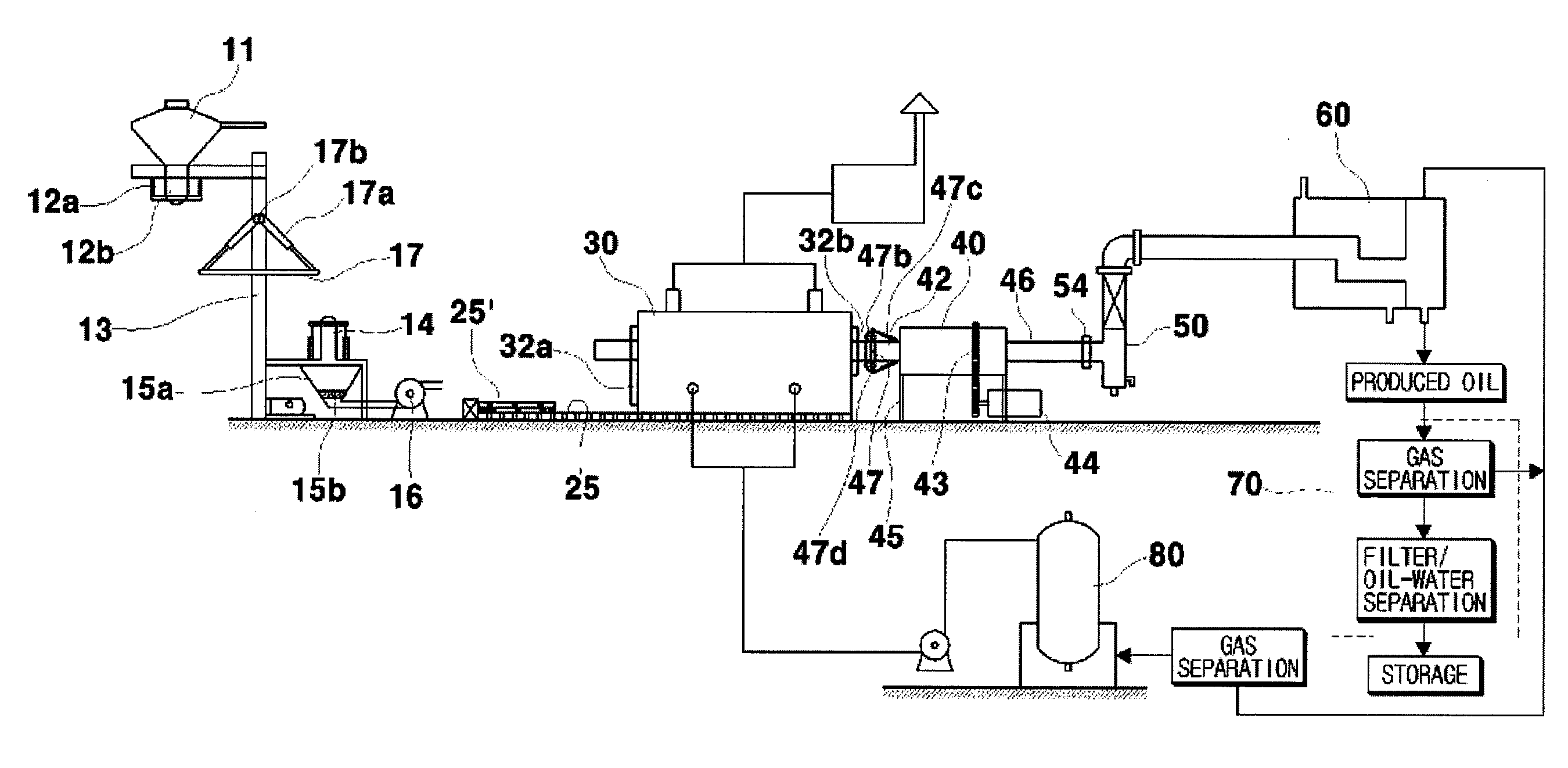

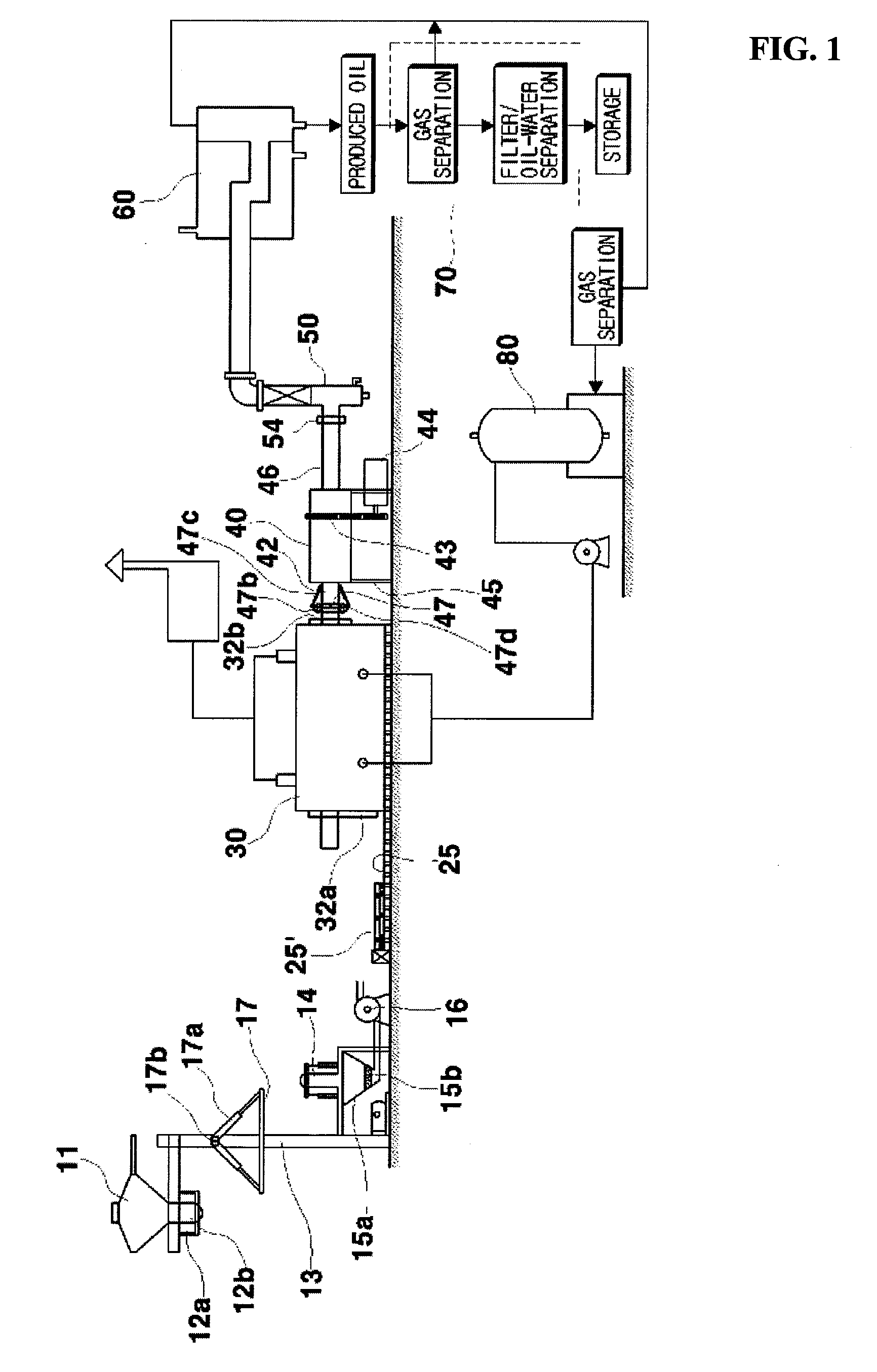

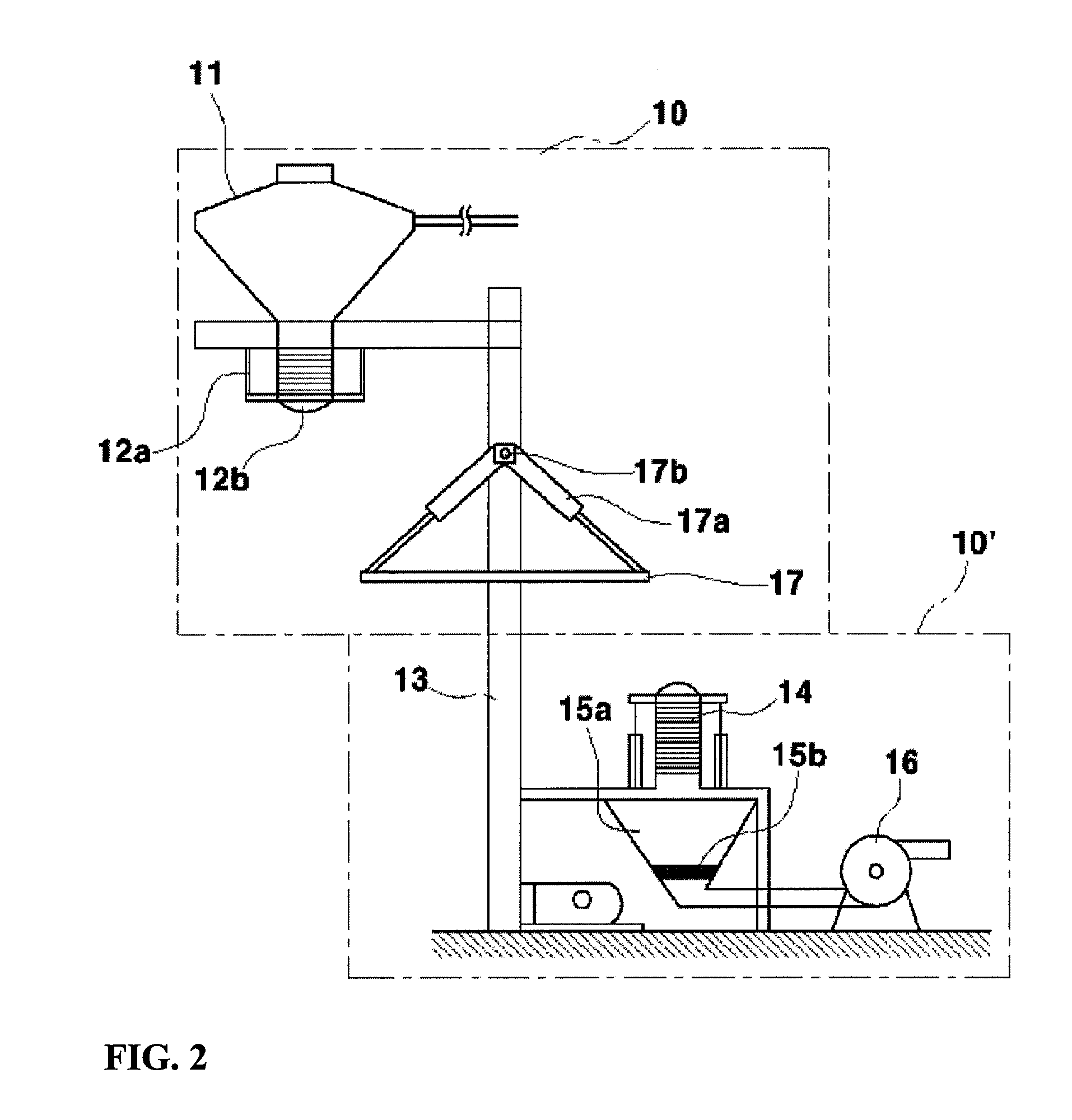

Oil extraction device for pyrolysis of plastics waste material and extraction method thereof

InactiveUS20090314622A1Economical efficiencyEfficiently collecting the pyrolyzed gasDispersed particle filtrationTransportation and packagingCombustion chamberCombustor

An oil extraction system and method for pyrolyzing waste plastic materials are disclosed. The oil extraction system includes: a waste feeding device for supplying waste plastic materials contained in a hopper to a primary pyrolysis chamber through a feed inlet, wherein the primary pyrolysis chamber pyrolyzes the supplied waste plastic materials; a double jacket furnace having a burner and for heating the primary pyrolysis chamber loaded into a burning room of the furnace; a rotation device for rotating the primary pyrolysis chamber loaded into the burning room of the furnace; a secondary pyrolysis chamber for re-pyrolyzing gas produced in the primary pyrolysis chamber, and for separating carbides and residue; a condenser for liquefying the gas separated from the secondary plyrolysis chamber by compression and forming oil; and an oil-water separator for separating oil and water condensed in the condenser.

Owner:PULSE ENERGY

Plastic waste efficient crushing and quick drying equipment

InactiveCN106738480AEasy to passExpand the spraying areaPlastic recyclingDrying gas arrangementsPlastic wasteAir heater

The invention provides plastic waste efficient crushing and quick drying equipment. The equipment comprises a tank body; the internal of the tank body is divided into a crushing cavity and a drying cavity through a fixed grinding disc; an upper cover is arranged in a top opening of the tank body; a crushing device is fixed on the upper cover, and consists of a crushing tank and a transmission box; a stirring device and a drying device are arranged in the drying cavity; the stirring device consists of a stirring motor, a stirring shaft and a stirring blade; the stirring blade is fixed at the bottom of the stirring shaft; the top of the stirring shaft is fixedly connected with a rotary grinding disc; the drying device consists of an air spraying disc, an intake pipe and an air heater; and a dehumidifying device is arranged on the side wall of the tank body at the top of the drying cavity. The equipment shears and crushes plastic wastes through the crushing device to facilitate improvement of the crushing quality, is convenient to transfer heat through the stirring device to facilitate quick drying of the wastes, and facilitates efficient crushing of the wastes through relative rotation of the fixed grinding disc and the rotary grinding disc.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com