Patents

Literature

92results about How to "Easy to chop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

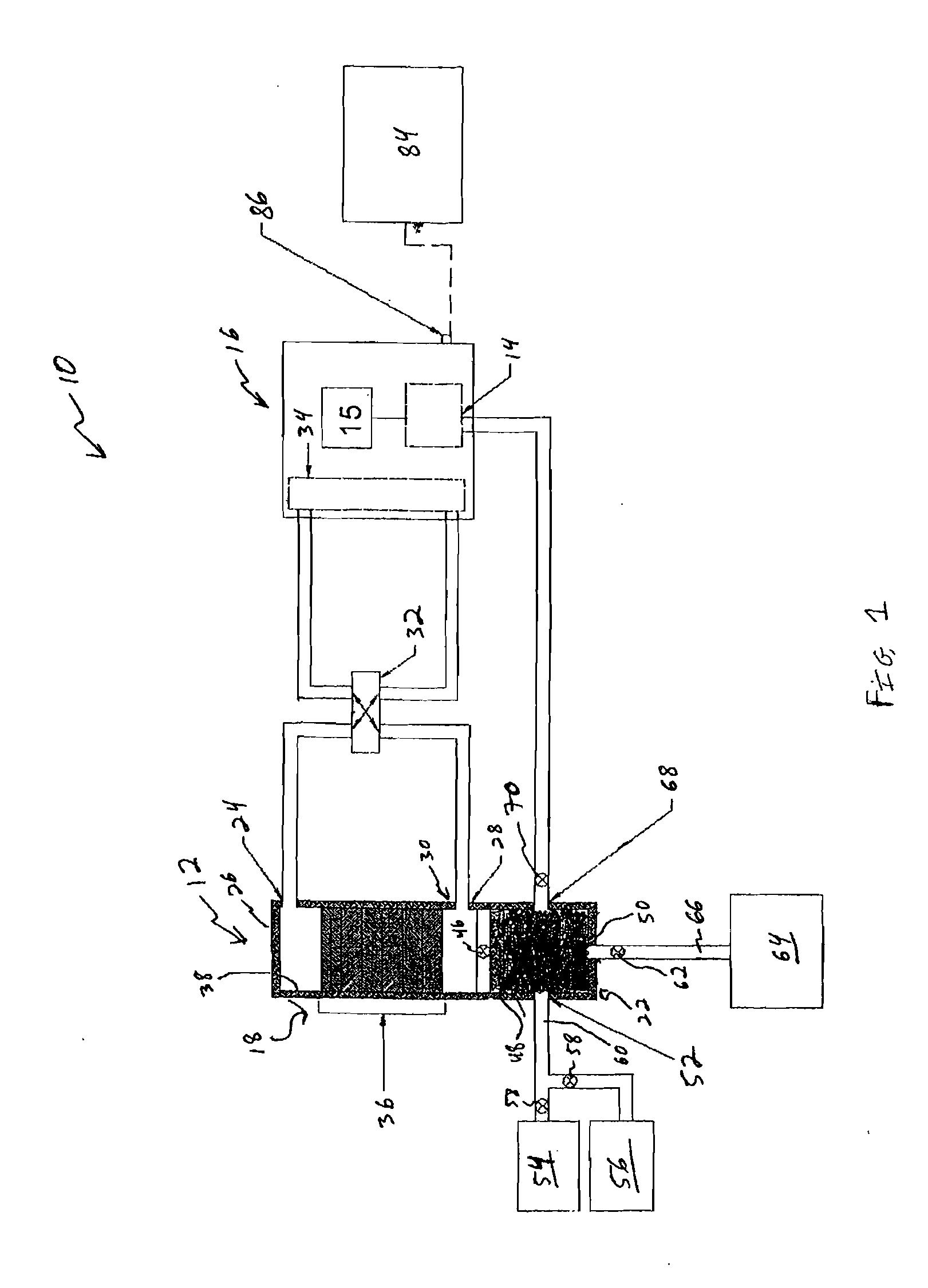

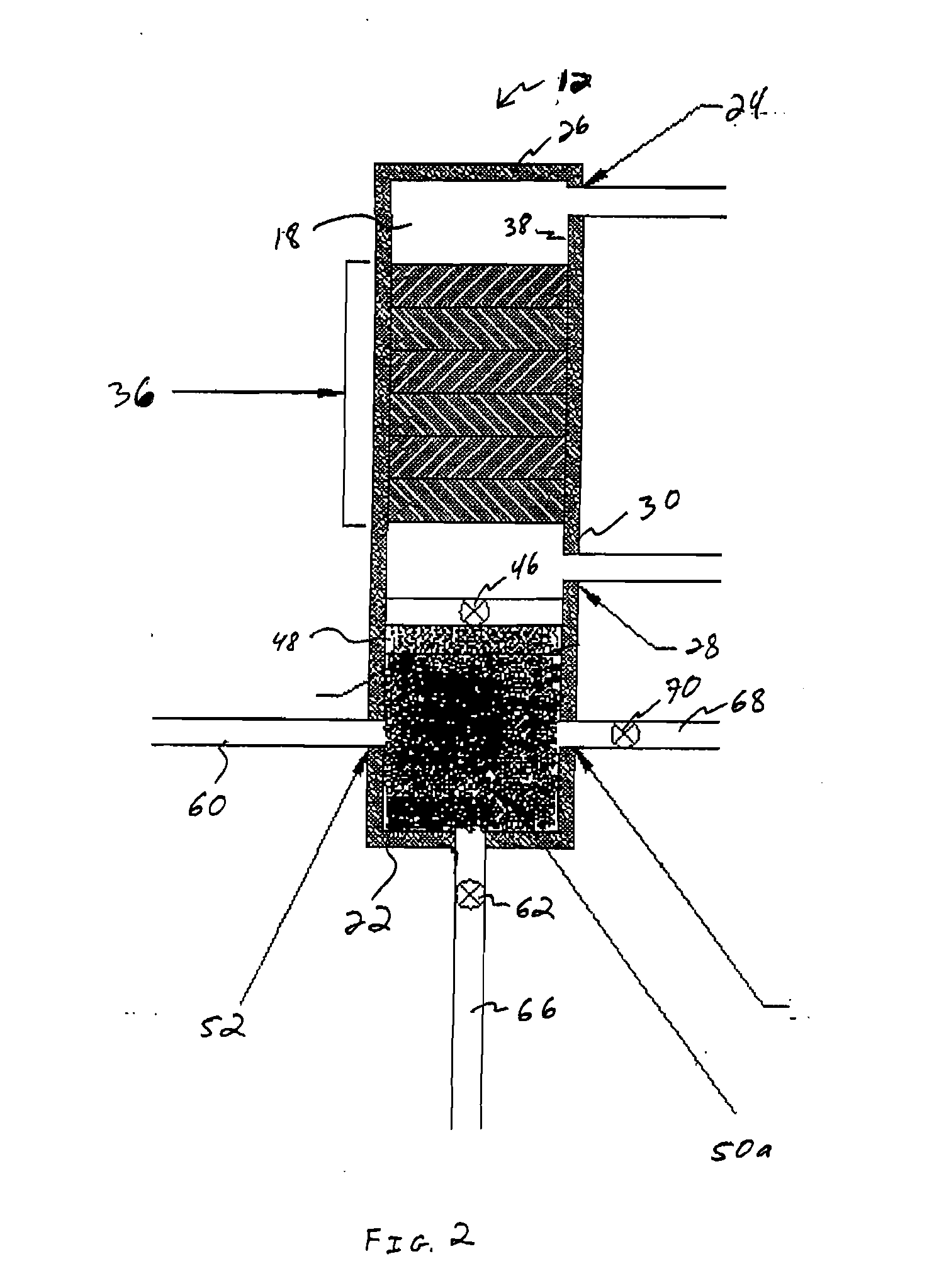

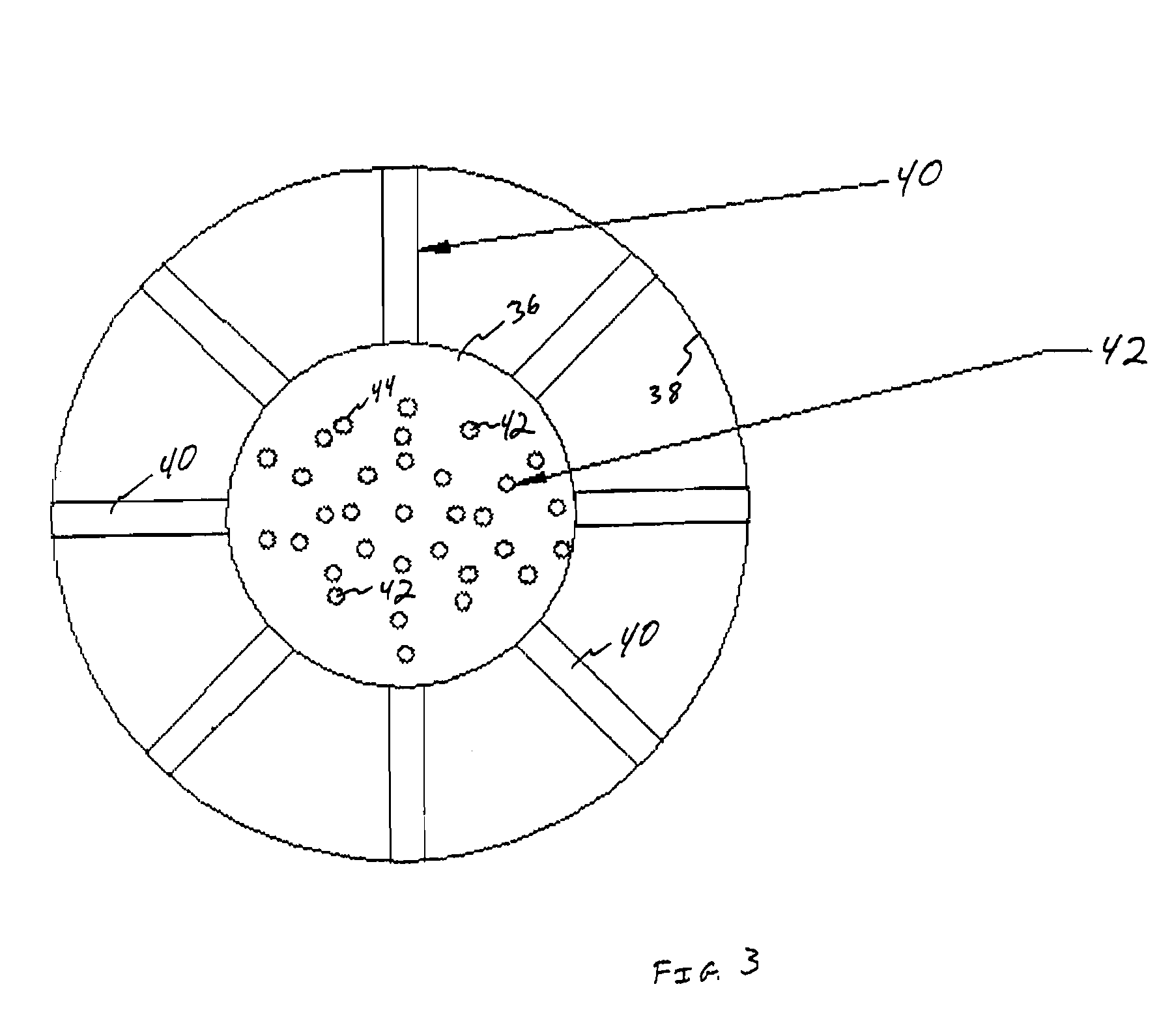

Portable microorganism detection unit

InactiveUS20100216225A1Easy to chopSmall apertureBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismDNA extraction

The present invention is a portable device for detecting microorganisms in a food sample. The device includes a DNA extraction tube, a chip, and a portable control unit. The DNA extraction tube extracts DNA from the sample in an aqueous solution. The extraction tube includes successive chambers that are configured to mince, filter, and purify DNA in the form of an aqueous eluate. The chip includes reaction chambers disposed for a polymerase chain reaction to amplify a specific DNA fragment in the eluate for detection, and the portable control unit is configured to receive the chip and analyze the amplified DNA on the chip.

Owner:DEFENSE SYSTEMS

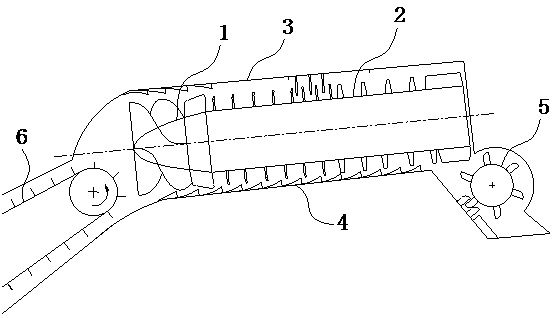

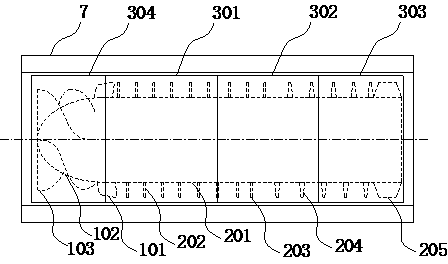

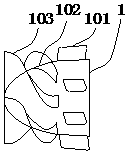

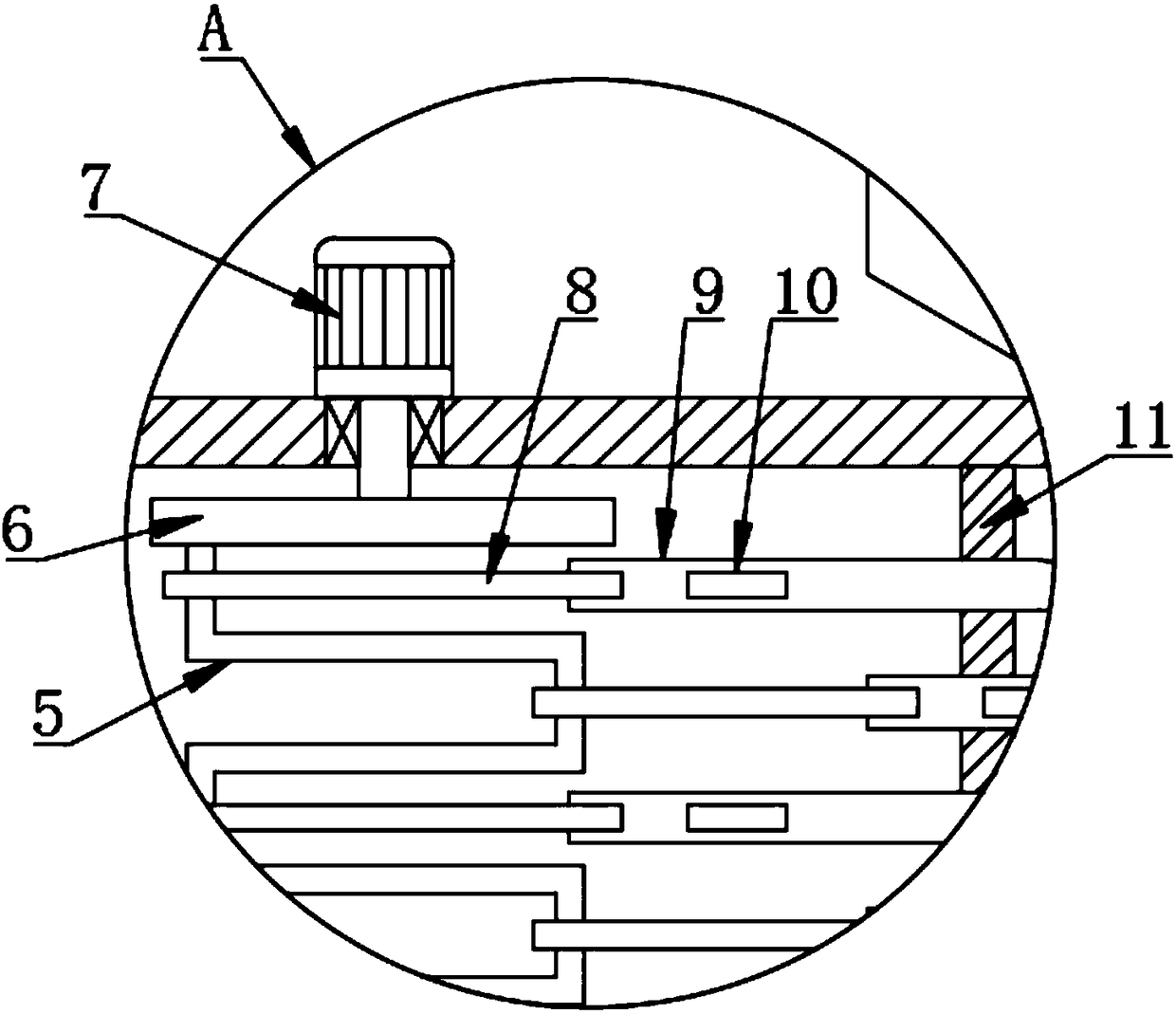

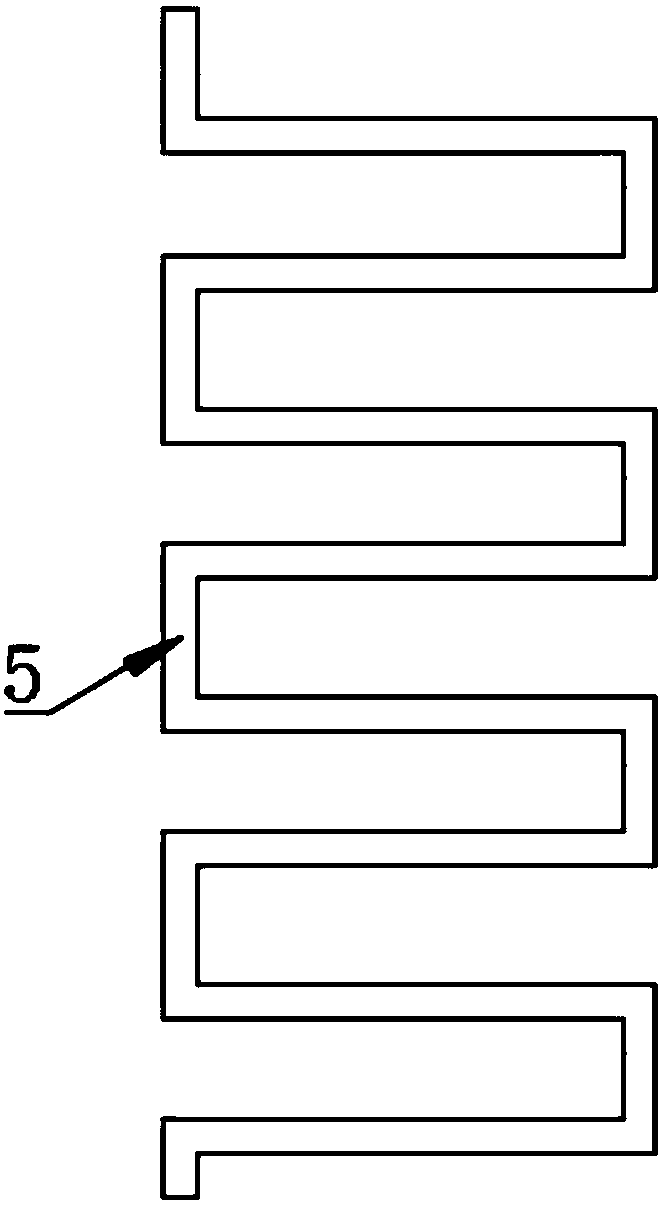

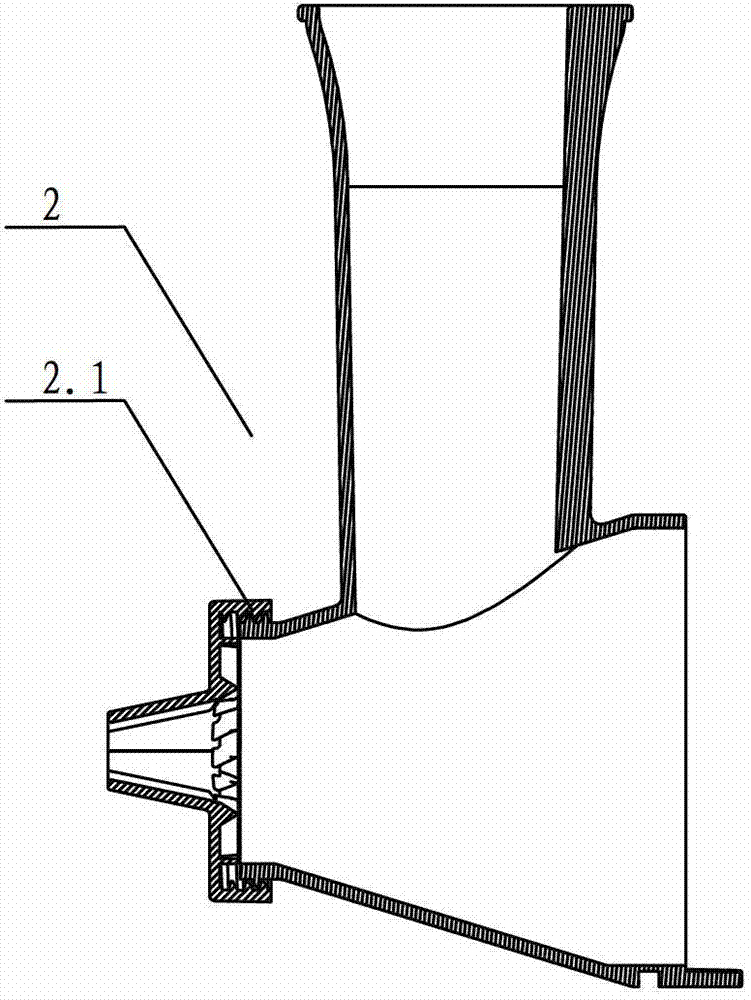

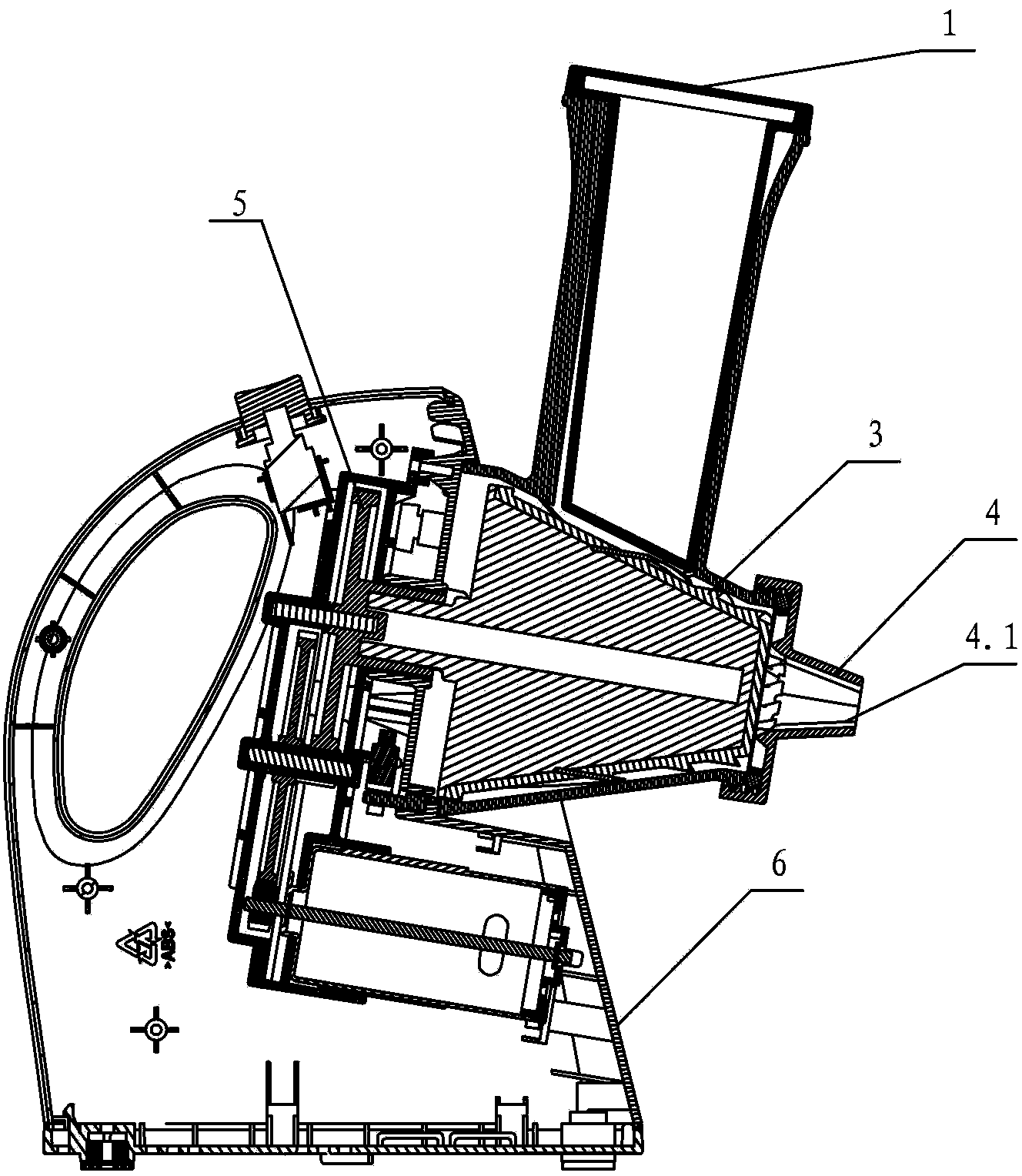

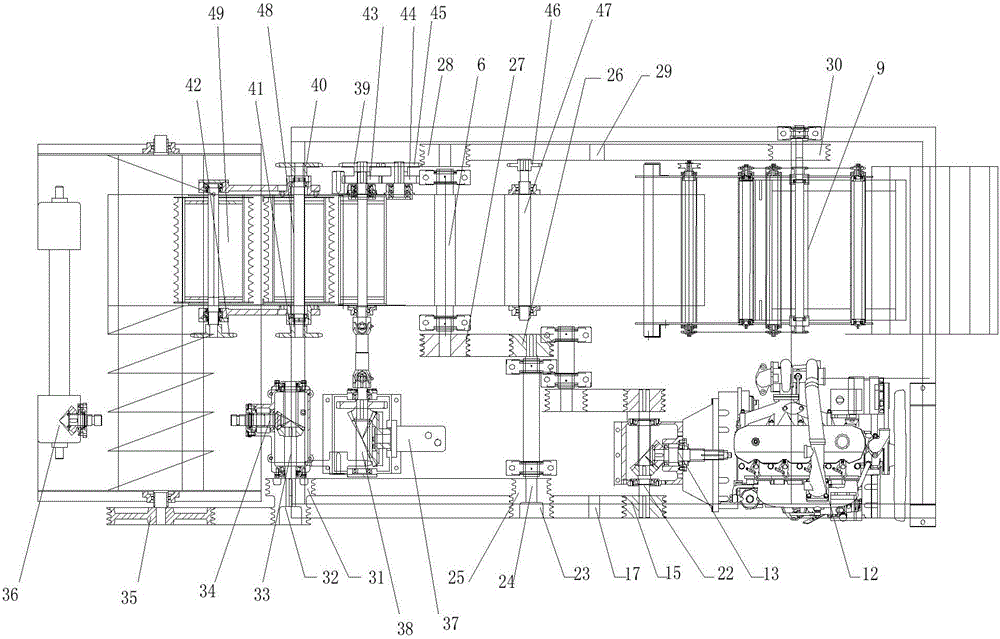

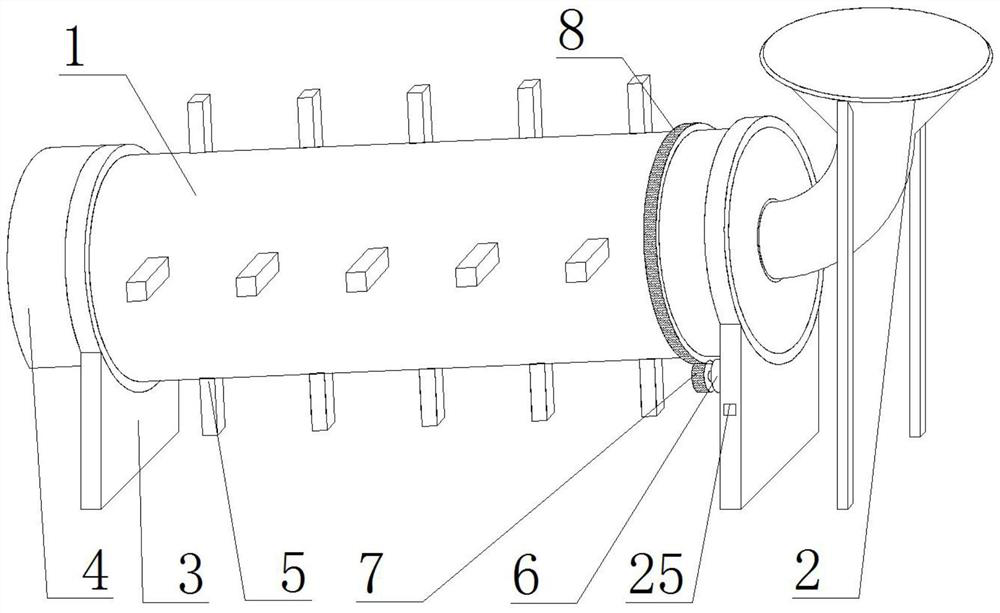

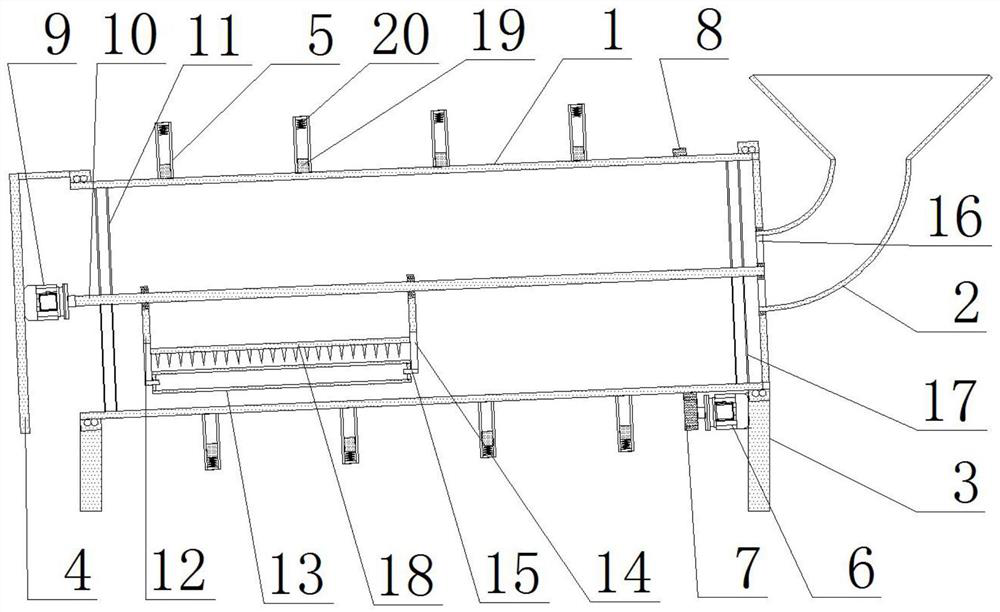

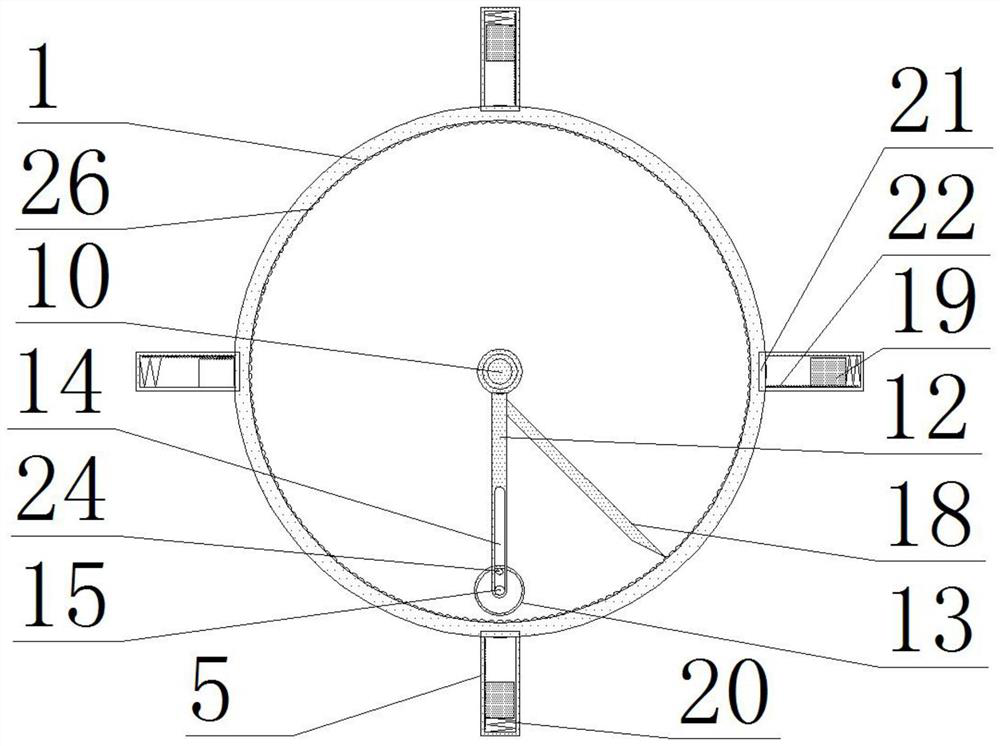

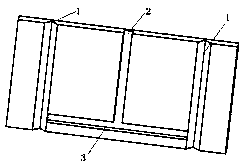

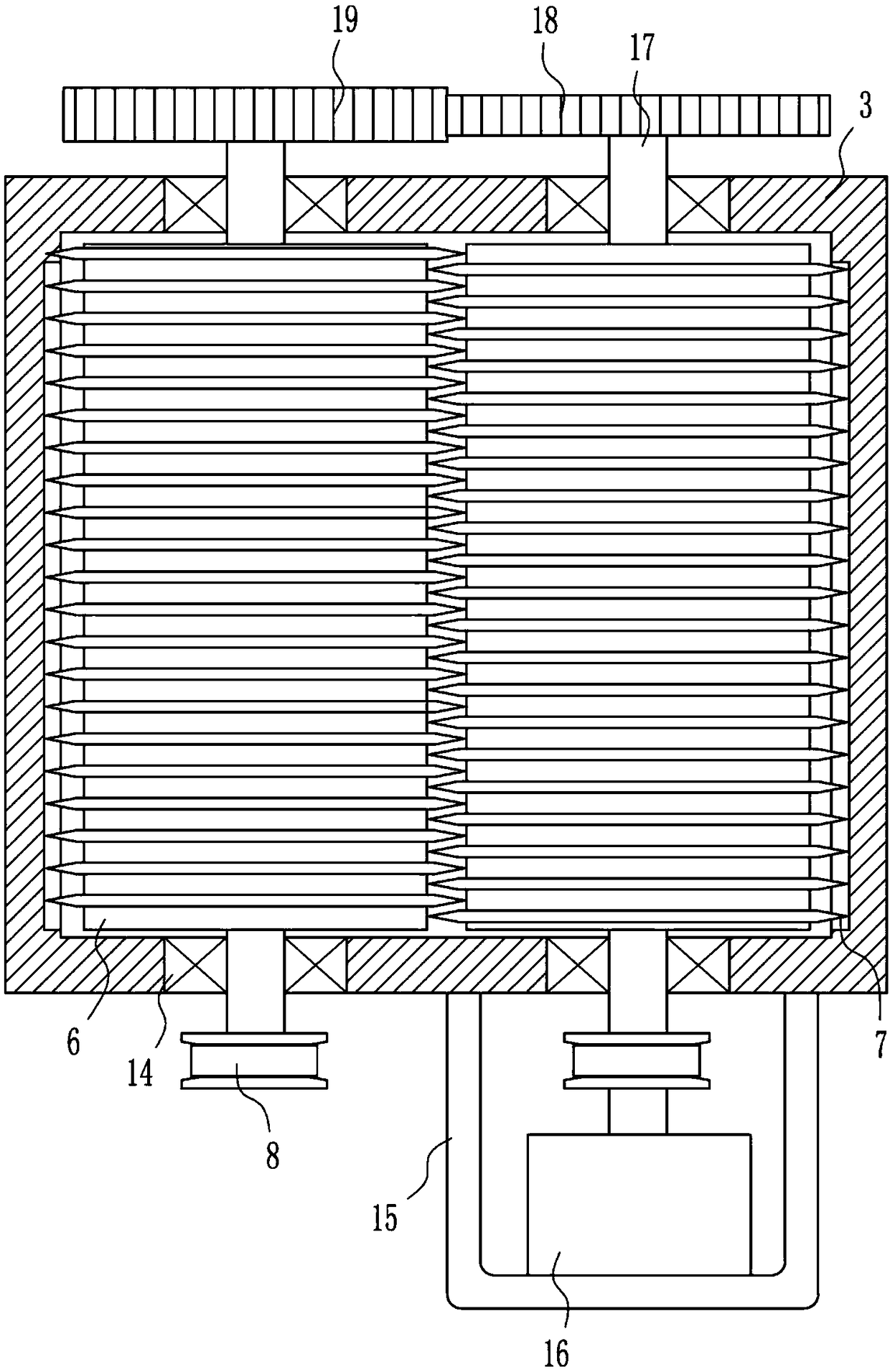

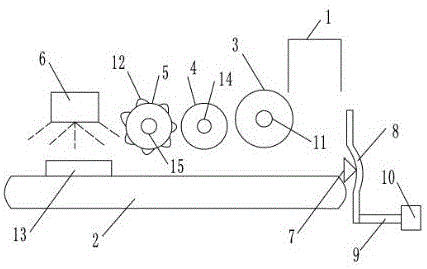

Axial-feeding type rice and wheat threshing and separating integrated device

ActiveCN103718733AShorten the lengthSimple structureCrop conditionersMowersAgricultural engineeringIntegrated devices

The invention relates to an axial-feeding type rice and wheat threshing and separating integrated device which comprises a feed head (1), a longitudinal axial-flow threshing and separating drum (2), a threshing gridded cover plate (3) and a separating concave grate (4). The feed head (1) is arranged at the front end of the longitudinal axial-flow threshing and separating drum (2), the threshing gridded cover plate (3) is arranged on the upper side of the longitudinal axial-flow threshing and separating drum (2), the separating concave grate (4) is arranged on the lower side of the longitudinal axial-flow threshing and separating drum (2), and the threshing gridded cover plate (3) and the separating concave grate (4) encircle to form a barrel capable of accommodating the longitudinal axial-flow threshing and separating drum (2). The axial-feeding type rice and wheat threshing and separating integrated device can realize high-feed harvesting of rice or wheat, and is high in harvesting efficiency and high in threshing capacity. As the length of the longitudinal axial-flow drum is reduced effectively, straws smashed by smashing and throwing mechanism are smashed effectively and thrown uniformly, and then can be returned to fields directly after harvesting.

Owner:JIANGSU UNIV

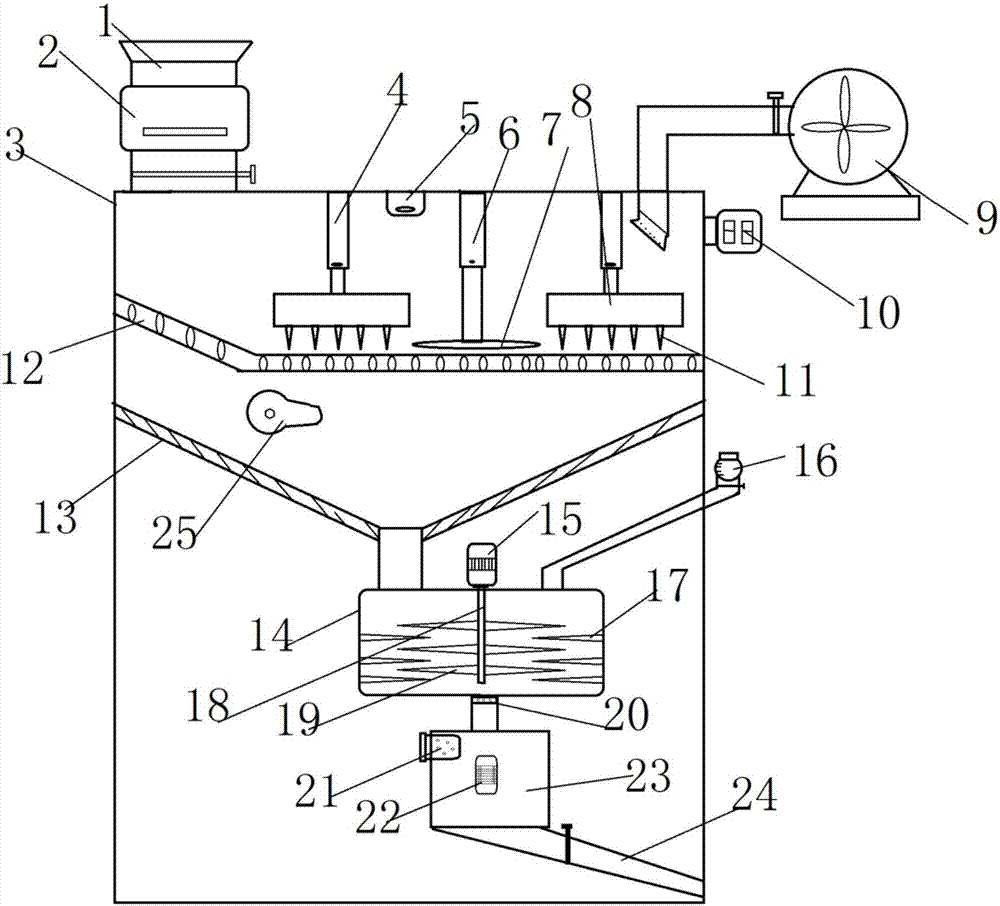

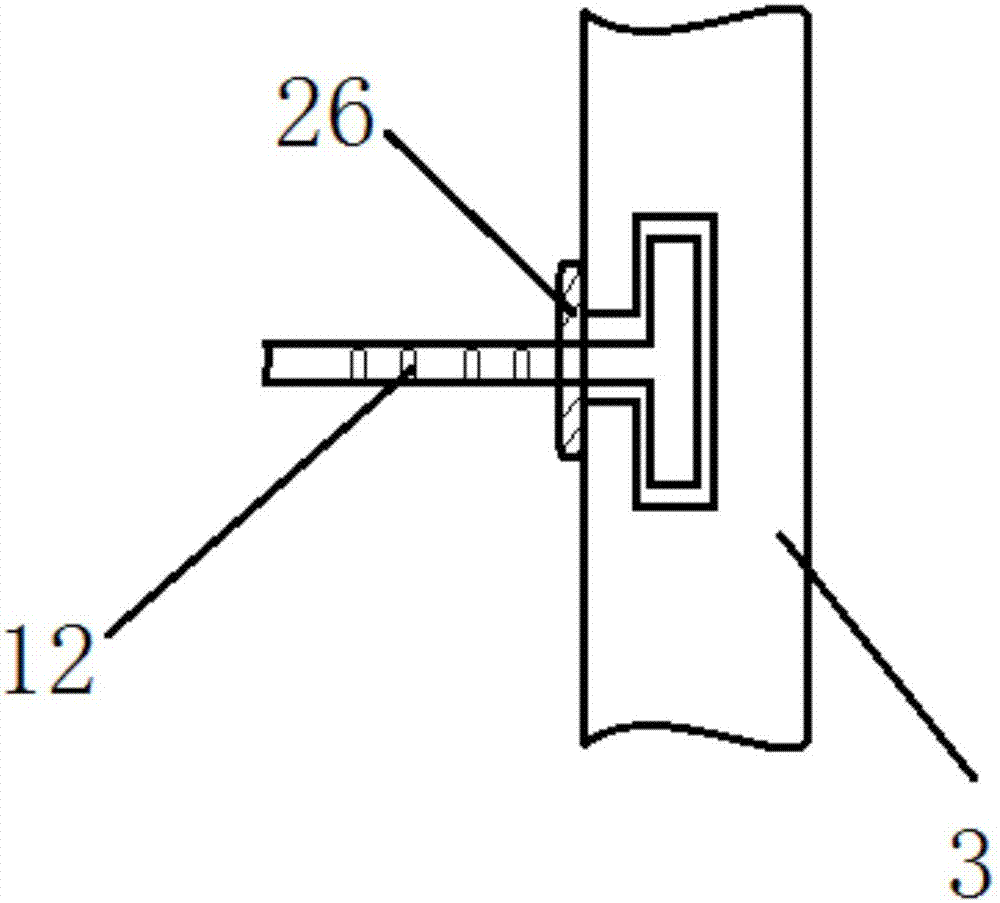

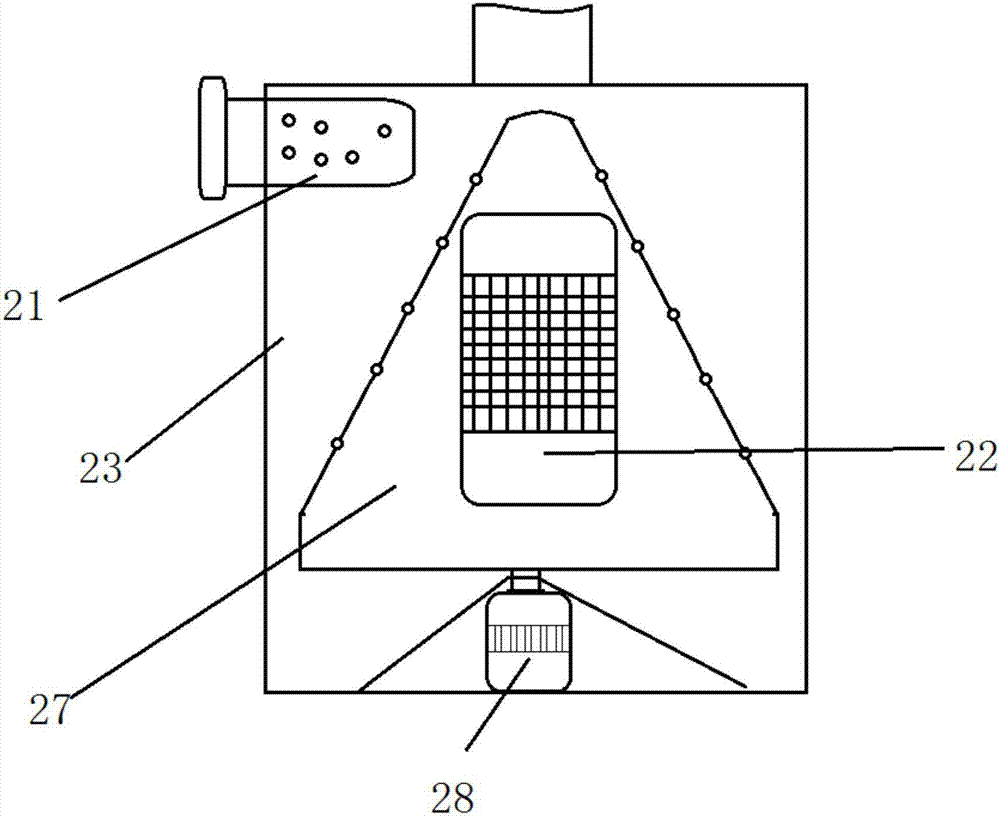

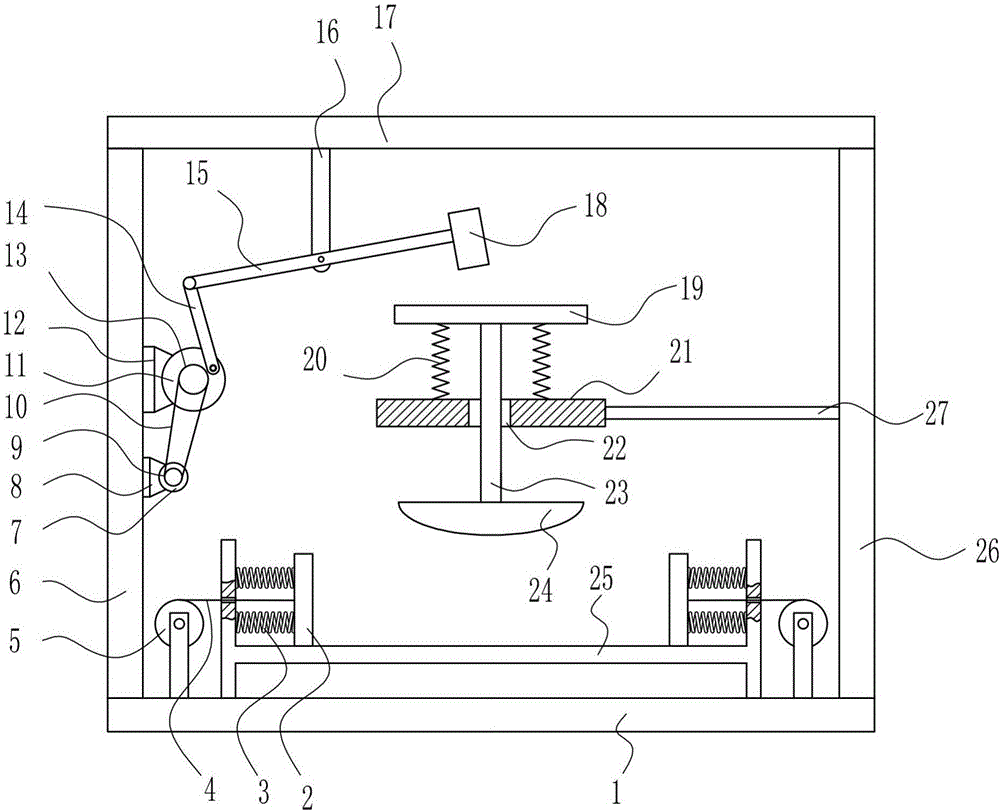

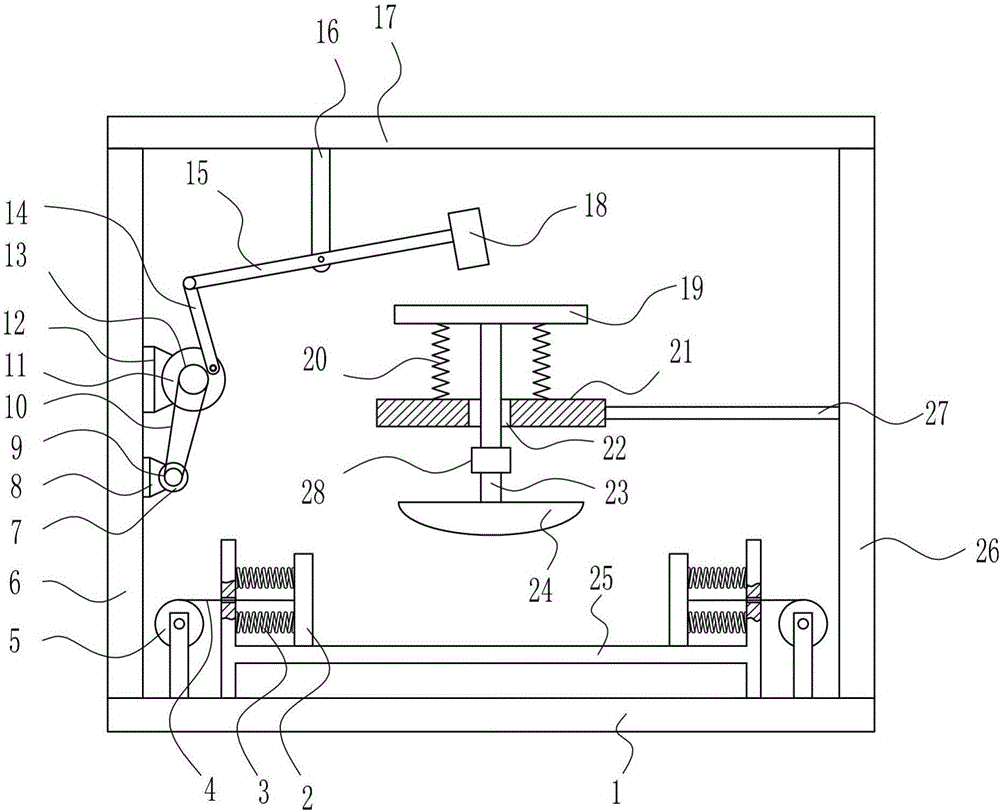

Environment-friendly straw feed manufacturing equipment

The invention discloses environment-friendly straw feed manufacturing equipment. The equipment comprises a feeding pipe, a box body, an electric telescopic rod, a camera, a stir-frying knife, a pressing plate, an air blower, a crushing box, a heater, a drying box and a rotary conical roller, wherein the feeding pipe is arranged on the top of the box body, the electric telescopic rod is arranged on the top of the box body, and the pressing plate is arranged at the bottom of the electric telescopic rod; a cutter is arranged on the lower surface of the pressing plate, a rotating shaft is arranged in the box body, and the stir-frying knife is arranged at the bottom of the rotating shaft; a pressure bearing plate is arranged in the box body, a cam is arranged at the bottom of the pressure bearing plate, and a timer is arranged on the outer wall of the box body; the top of the box body is communicated with the air blower, an inclined guide plate is arranged below the pressure bearing plate, and the crushing box is arranged at the outlet end of the inclined guide plate; the bottom of the crushing box is connected with the drying box, and a discharging pipe is arranged at the bottom of the drying box. The equipment guarantees reasonable utilization of straw, straw feed particles can be conveniently stored, the breeding feed cost is reduced, and the equipment is simple in structure, convenient to use and easy to popularize.

Owner:邹铁梅

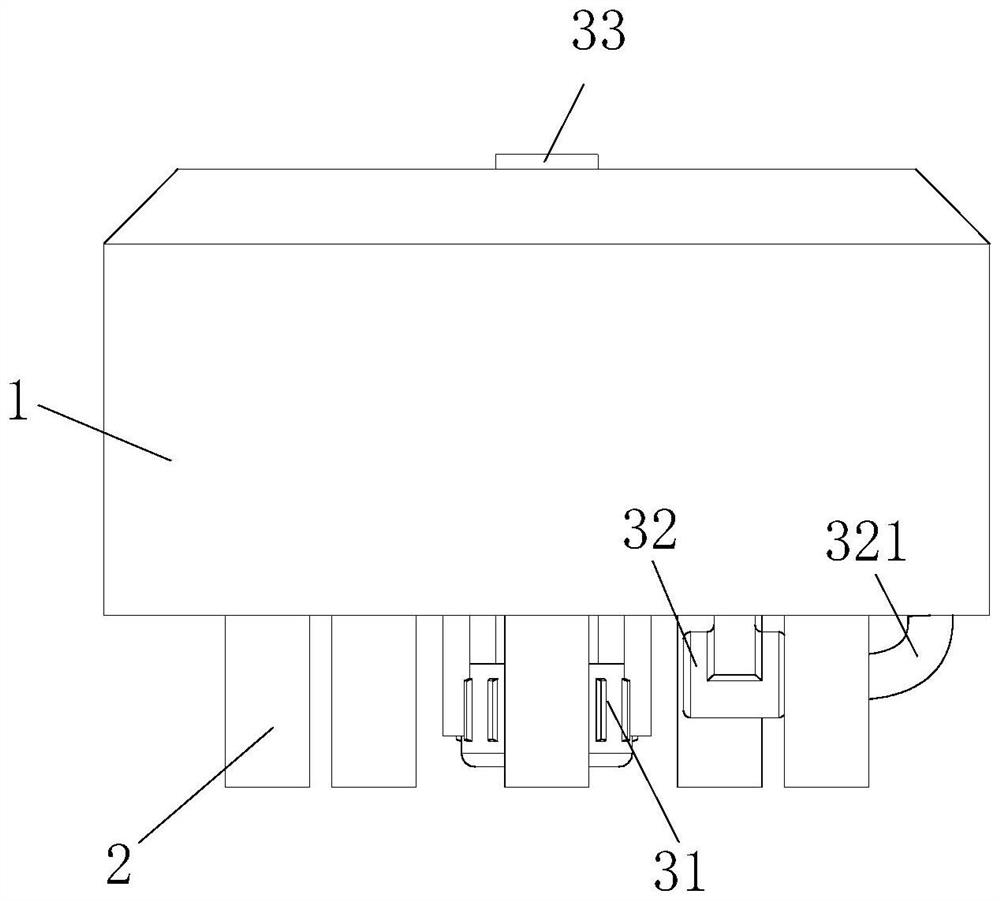

Medical plastic waste rapid-treatment device

ActiveCN106393497AImprove chopping effectEasy to chopPlastic recyclingGrain treatmentsDrive wheelPlastic waste

The invention relates to a plastic waste treatment device, in particular to a medical plastic waste rapid-treatment device. The medical plastic waste rapid-treatment device is high in treatment efficiency, easy to operate and reasonable in design. The medical plastic waste rapid-treatment device comprises a bottom plate, a left side plate, a first pulley, a first sliding rail, a top plate, a second pulley, a guide plate, a first sliding block, a spring, a cutting-up frame, a wire spool, a second sliding rail, a driven wheel, a second sliding block, a rack, blades, a first baffle, a first pulling rope, a second baffle, a first motor, a driving wheel, a flat belt, a supporting rod, a gear, a rolling shaft and a second pulling rope. The left side plate, the first pulley and the first sliding rail are sequentially arranged on the bottom plate from left to right. The medical plastic waste rapid-treatment device has the effects of being high in treatment efficiency, easy to operate, and reasonable in design.

Owner:宁夏红远汇达实业集团有限公司

Edible cat toy

InactiveUS20150164047A1Easy to manageHealth and safetyMilk preparationMeat/fish preservationFlavorWater soluble polysaccharides

An edible toy for cats is made from a base material made of edible material; and an edible coating for the base material. The base material can be any of hypromellose; an edible, water-soluble polysaccharide; fermented tapioca; fish gelatin, beef gelatin, catnip, valerian root or a combination thereof. The base material is combined with water, an inorganic pH buffer and a metal-ion bonding agent. A coating has flavors such as chicken, turkey, beef, pork, lamb, duck, seafood, freshwater fish, grass, catnip, valerian root, lemon grass, sweet grass or a combination thereof. Also disclosed is a method of making edible and medicated toys.

Owner:URBAN PET HAUS

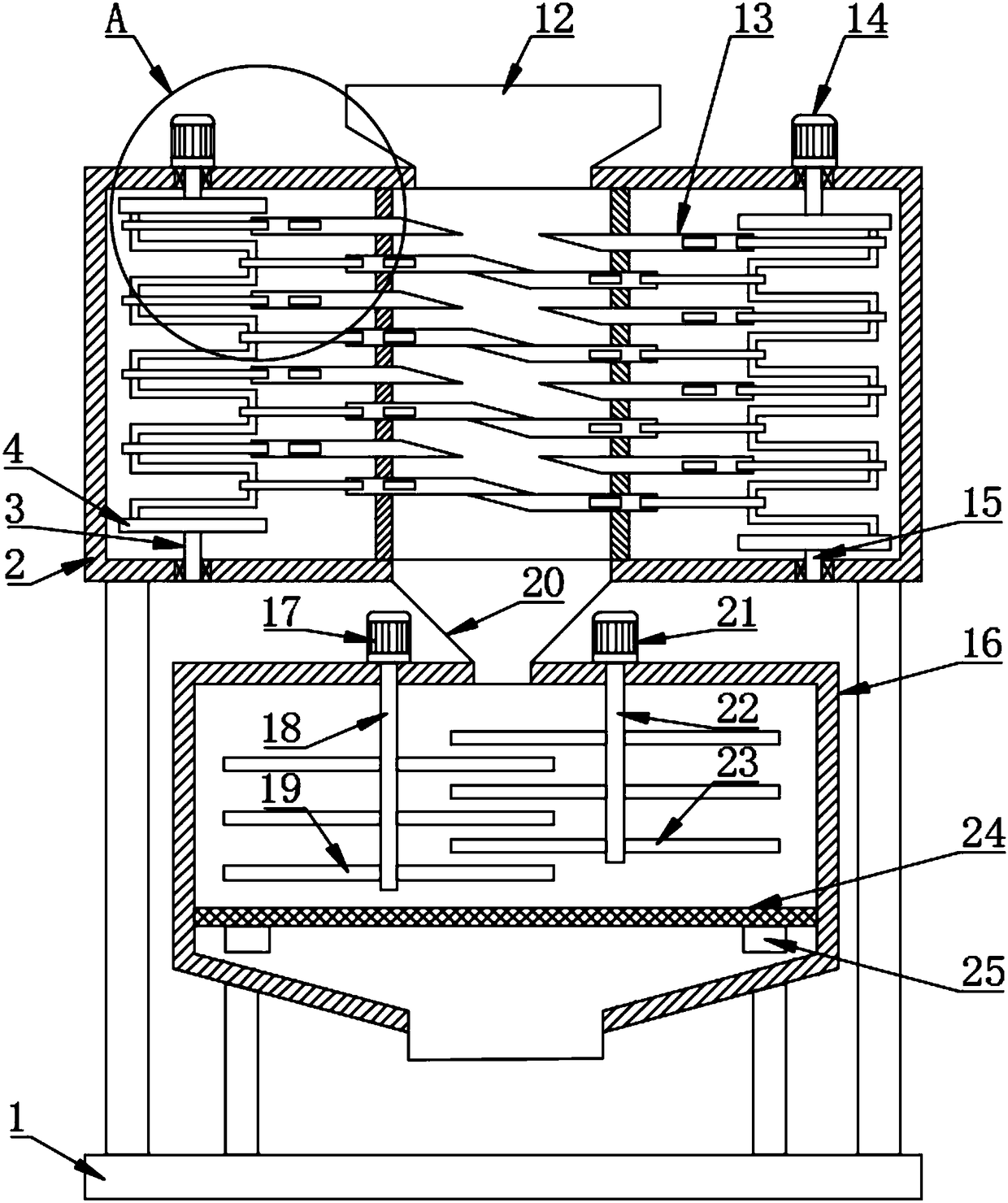

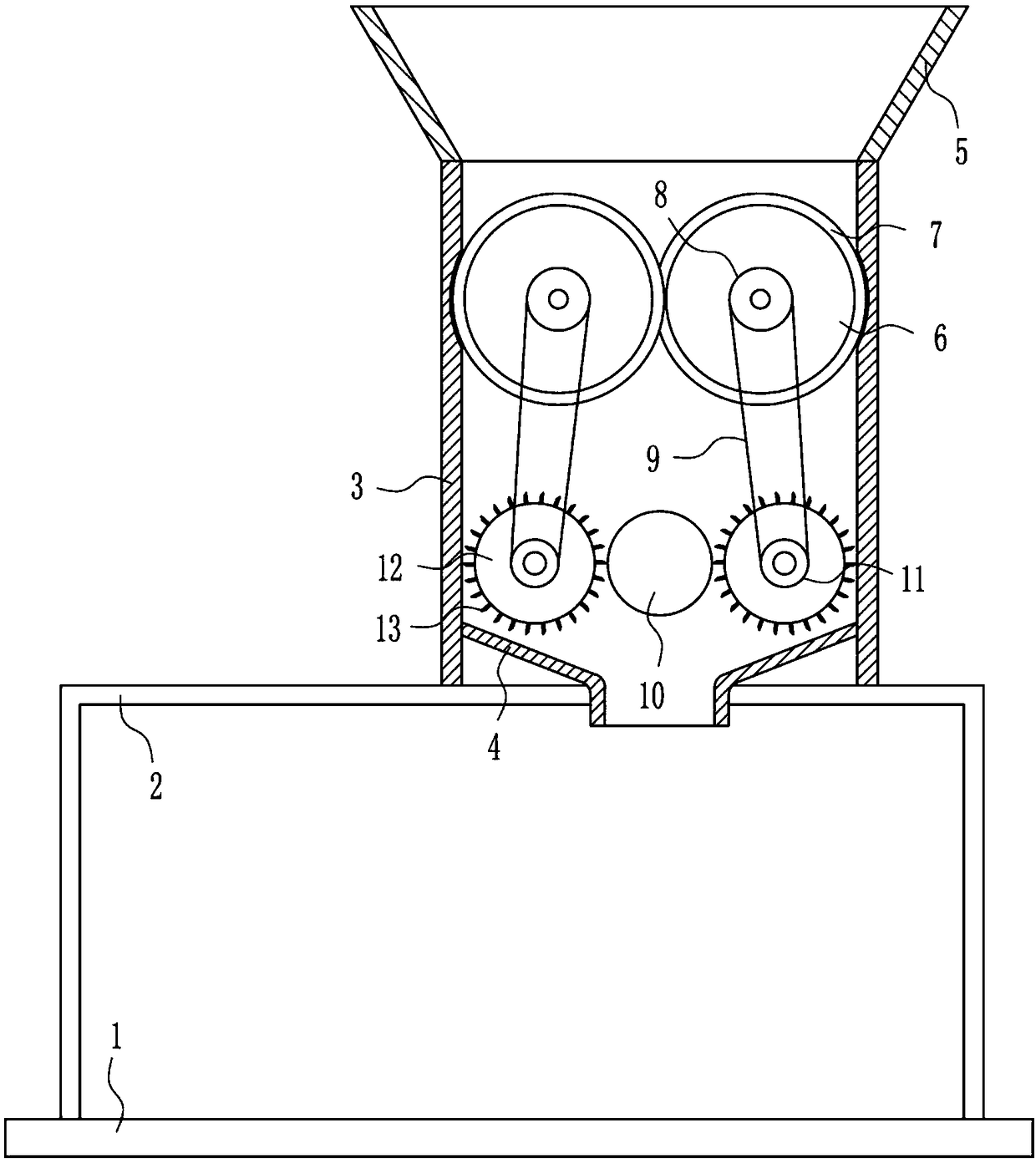

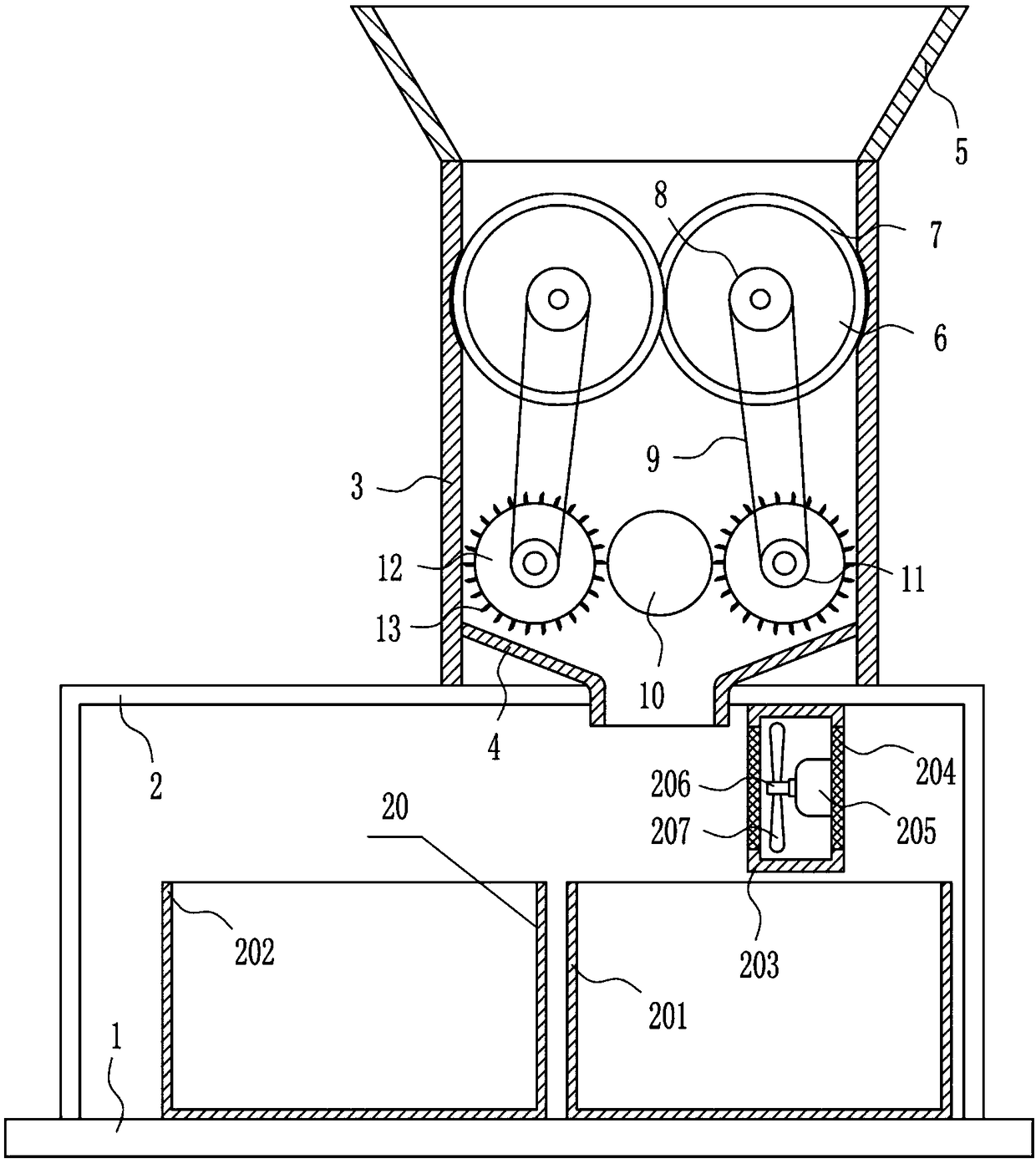

Device for quickly cutting and crushing forage of animal husbandry

PendingCN108093893AAvoid a direct fallConvenient for subsequent crushingCuttersEngineeringAnimal husbandry

The invention discloses a device for quickly cutting and crushing forage of animal husbandry. The device comprises a base; the top of the base is fixedly provided with a cutting box through a supportframe; the left side and the right side of the inner bottom of the cutting box are respectively rotatably connected with one lower round plate through a first rotating shaft and a second rotating shaft; the left side and the right side of the top of the cutting box are respectively fixedly provided with a first speed reduction motor and a second speed reduction motor; the motor shafts at the bottom ends of the first speed reduction motor and the second speed reduction motor pass through the top wall of the cutting box and are respectively fixedly connected with one upper round plate; a crankshaft is fixedly connected between the lower round plate and the upper round plate at the left side, and a crankshaft is fixedly connected between the lower round plate and the upper round plate at theright side; a plurality of connecting rods are respectively rotatably connected at the positions of the crankshaft journals; the right end of the connecting rods at the left side are hinge with a plurality of first cutting blades; the left ends of the connecting rods at the right side are hinged with a plurality of second cutting blades; and the first cutting blades are matched with the second cutting blades. According to the invention, forage is crushed by a plurality of cutting blades matched with each other, and vertically adjacent cutting blades move back and forth to cut the forage, so that the forage is prevented from falling directly after cutting for one time, so that the cutting effect is better and the efficiency is high.

Owner:周兰芝

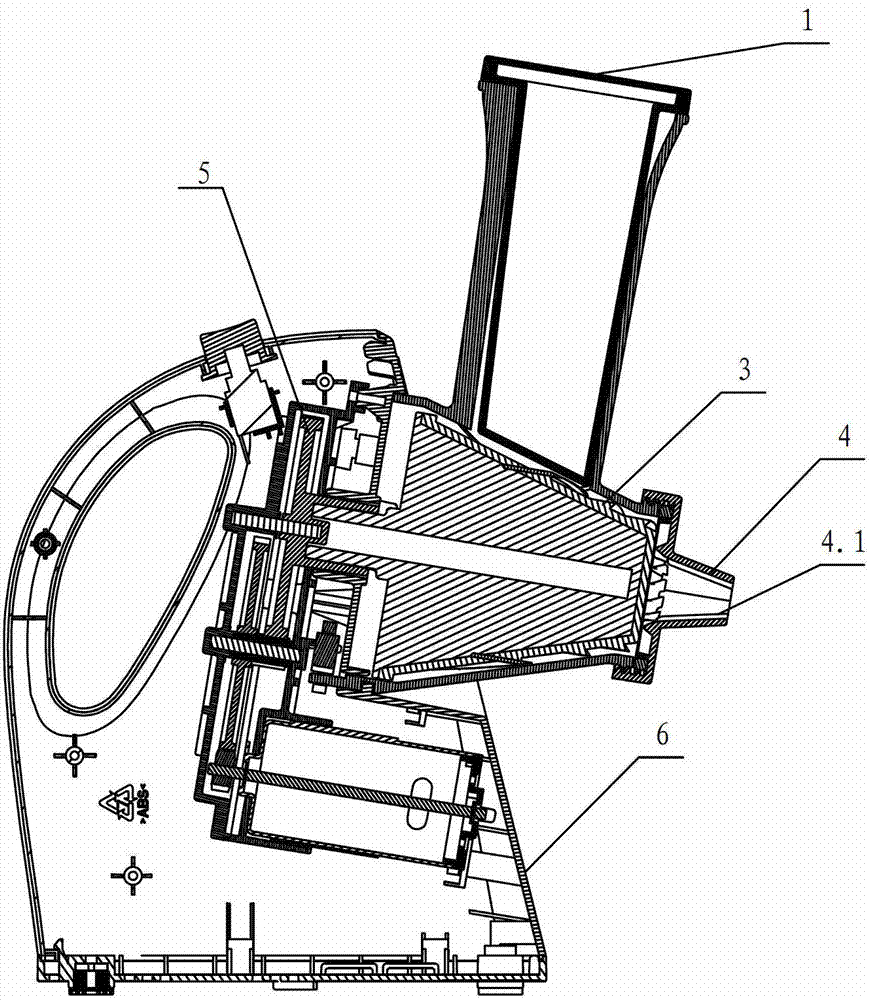

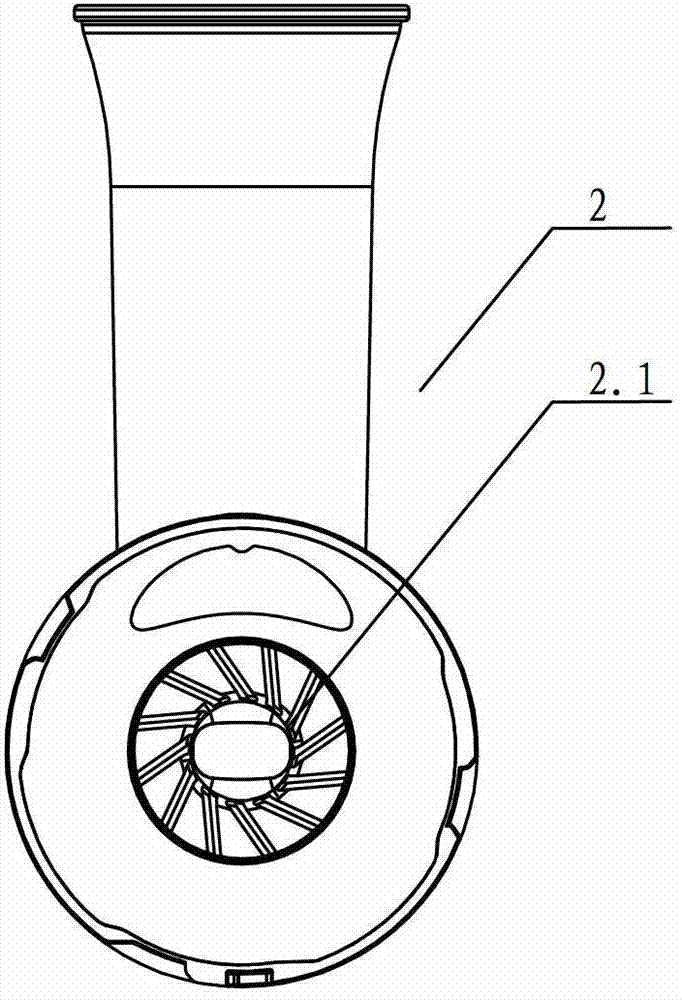

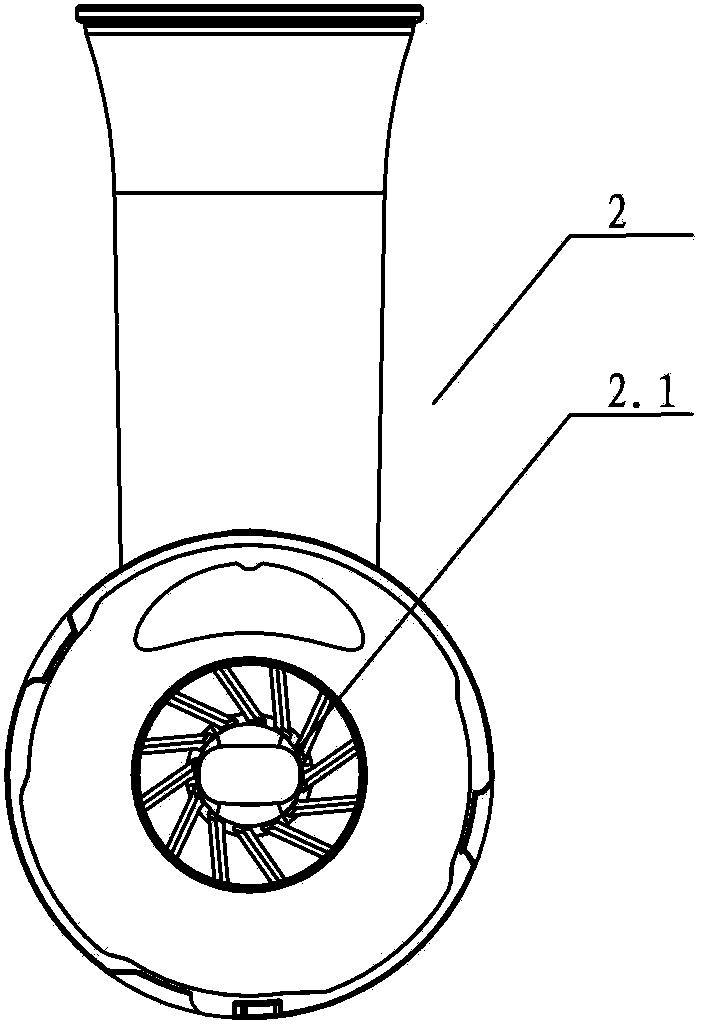

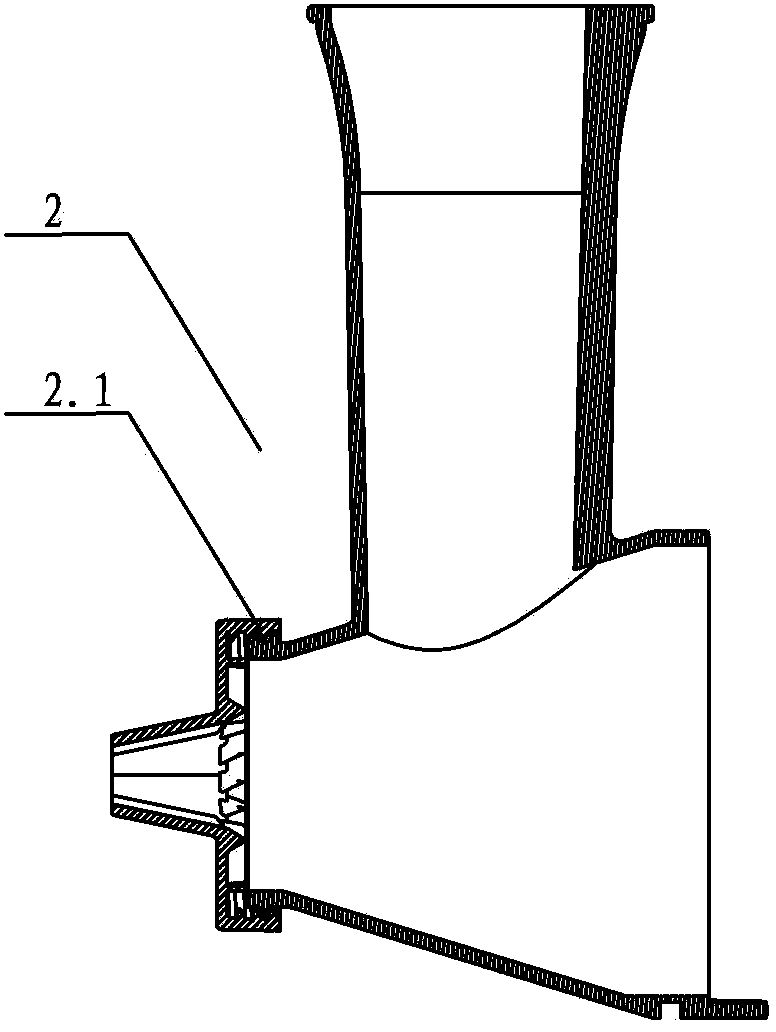

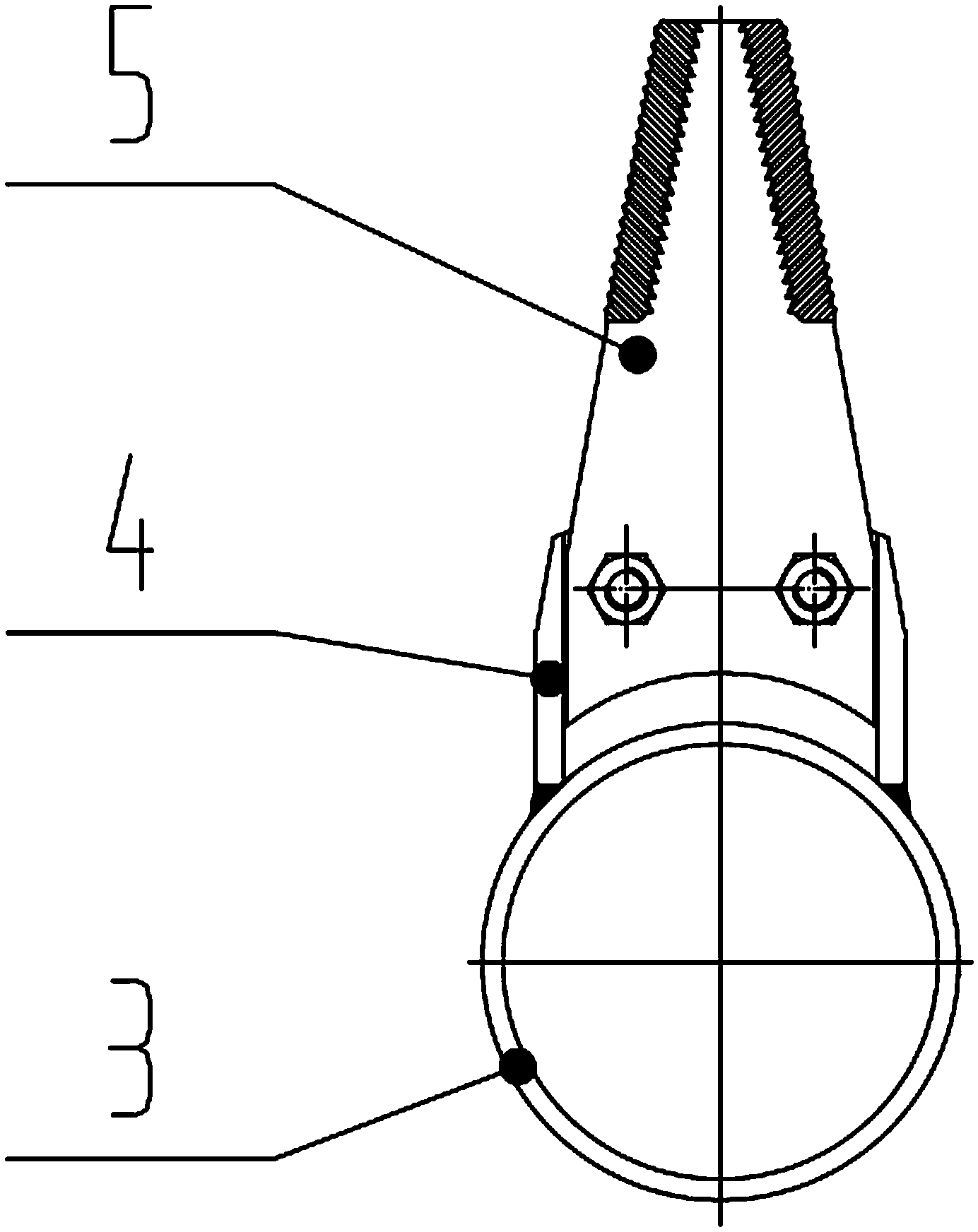

Extrusion head and ice cream machine employing same

The invention provides an extrusion head and an ice cream machine employing the extrusion head. The extrusion head comprises a conical body with cutting knives and extrusion threads, wherein continuous cuts respectively formed by merging more than two cutting knives and extrusion screw heads are formed on the surface of the extrusion head; a plane is arranged at the top of the extrusion head; the extrusion screw heads positioned at the upper part of the extrusion head have small inclination; the cutting knives positioned at the lower part of the extrusion head have large inclination; the whole inclination transits gradually; a rotary shaft is arranged at the base part of the extrusion head; the cutting knives are manufactured by adopting plastic or metal; and more than two flow guide grooves evenly distributed in the radial direction are formed in the plane at the top of the extrusion head. The ice cream machine with the extrusion head comprises a material feed cylinder arranged on a machine stand, wherein the extrusion head is inserted into the material feed cylinder transversely or obliquely; and a grinding cover with a material discharge opening is formed in one side surface of the material feed cylinder. The ice cream machine has the characteristics of simple and reasonable structure, low vibration, low noise and wide application range.

Owner:NINGBO BORINE ELECTRIC APPLIANCE

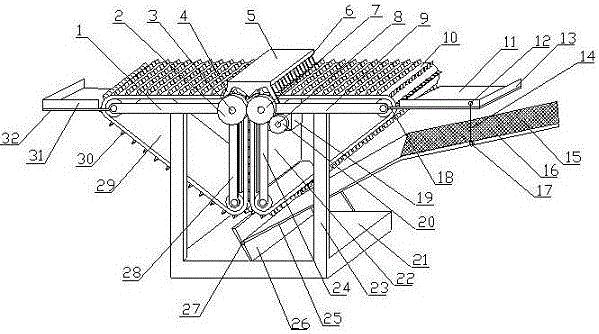

Vegetable cutting and filling stirring integrated machine

InactiveCN104172948AAchieve cutting effectRealize the stuffing actionKitchen equipmentReciprocating motionGear wheel

The invention discloses a vegetable cutting and filling stirring integrated machine which comprises a framework, a vegetable cutting motor, a rotary table, a vegetable knife, a filling stirring knife and a filling stirring motor. The vegetable cutting and filling stirring integrated machine is characterized in that a vegetable cutting driving mechanism comprises a left driven gear, a left rotary disc, a driving rod, a left slide rail, a right slide rail and a telescopic rod, the left driven gear is meshed with a driving gear, and the left rotary disc is coaxially fixed to the left driven gear; a left slide rod and a right slide rod which can slide along the length directions of the left slide rail and the right slide rail are respectively arranged in the left slide rail and the right slide rail, the lower end of the driving rod is hinged to the edge of the left rotary disc, and the upper end of the driving rod is connected with the bottom of the left slide rod. The vegetable cutting and filling stirring integrated machine has the advantages that the vegetable knife can reciprocate up and down, so that cutting effects can be realized for foods in a vegetable basin; the vegetable cutting and filling stirring integrated machine is provided with the filling stirring knife, the filling stirring motor, a guide rod, a lifting rack and a lifting motor, the filling stirring knife can extend to the bottom of the vegetable basin under the driving effect of the lifting motor, and filling stirring actions can be implemented under the driving effect of the filling stirring motor.

Owner:BINZHOU UNIV +1

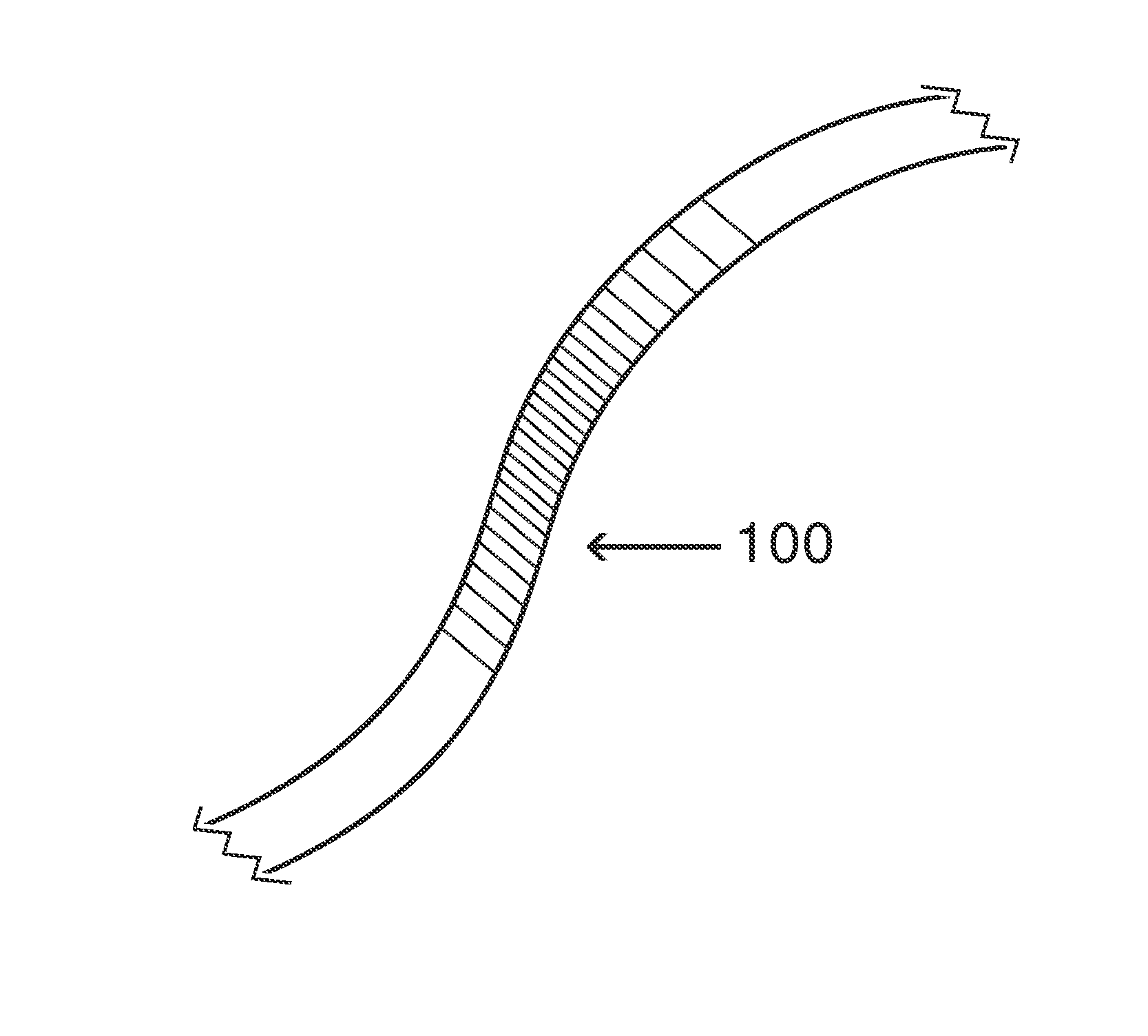

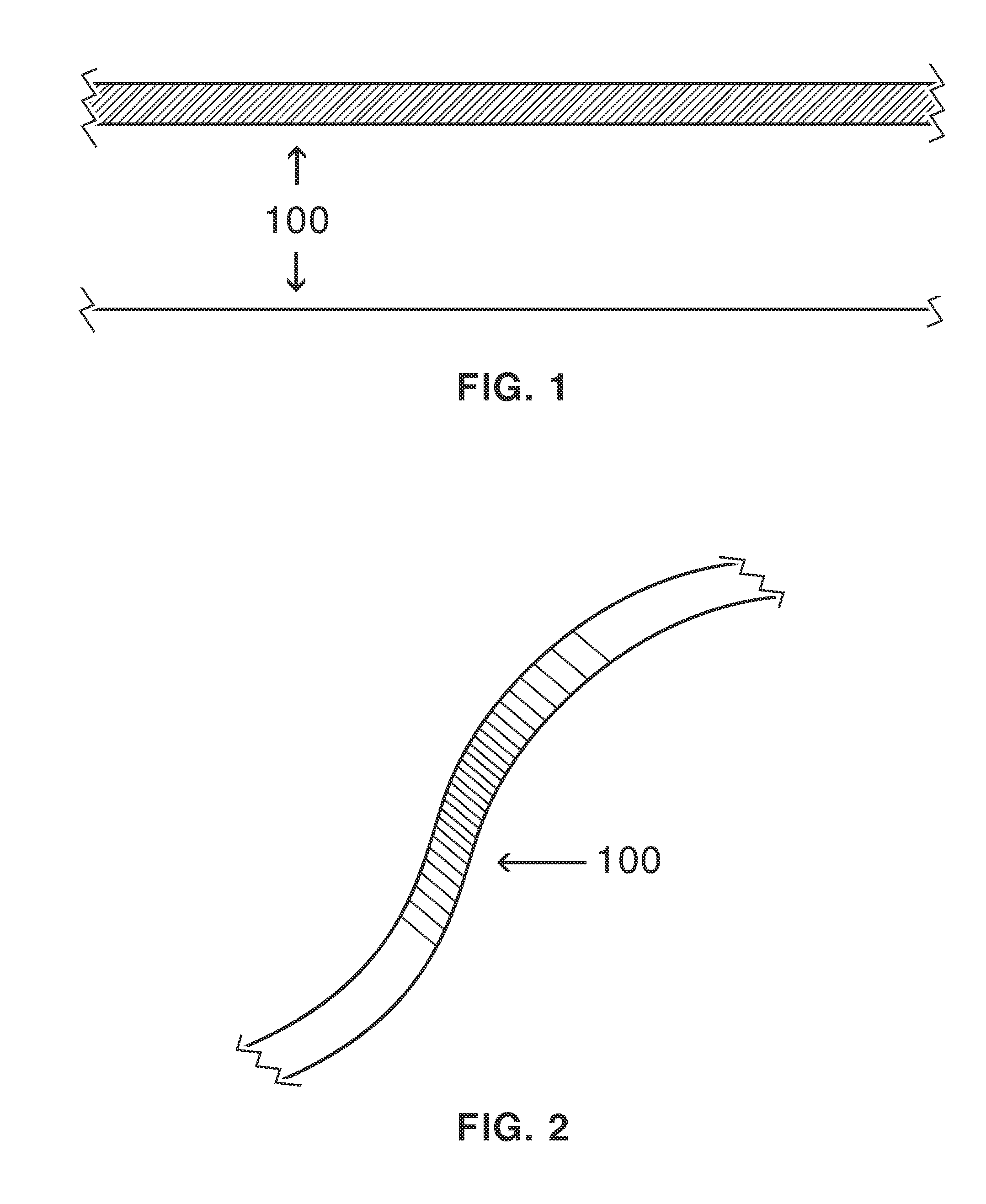

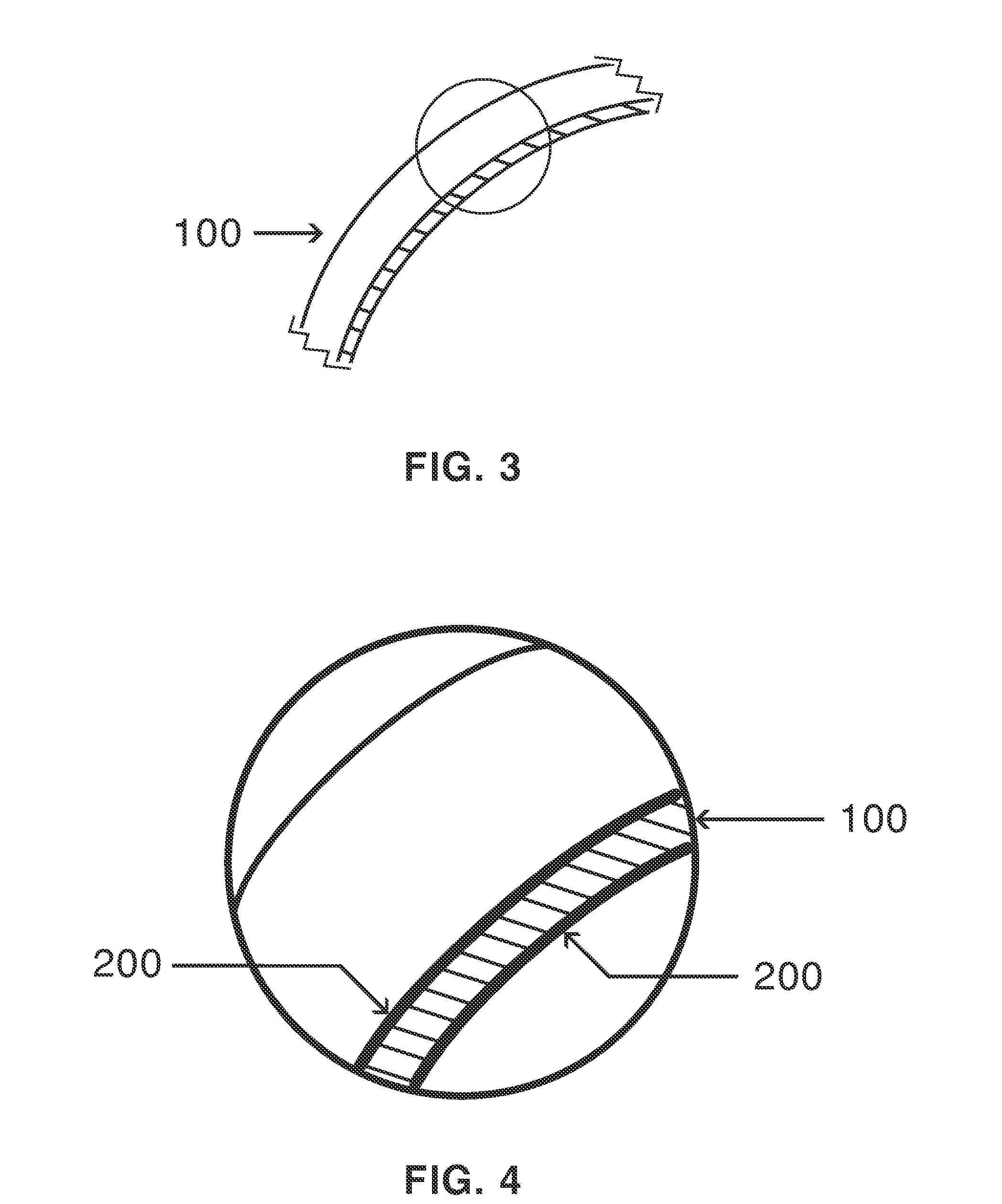

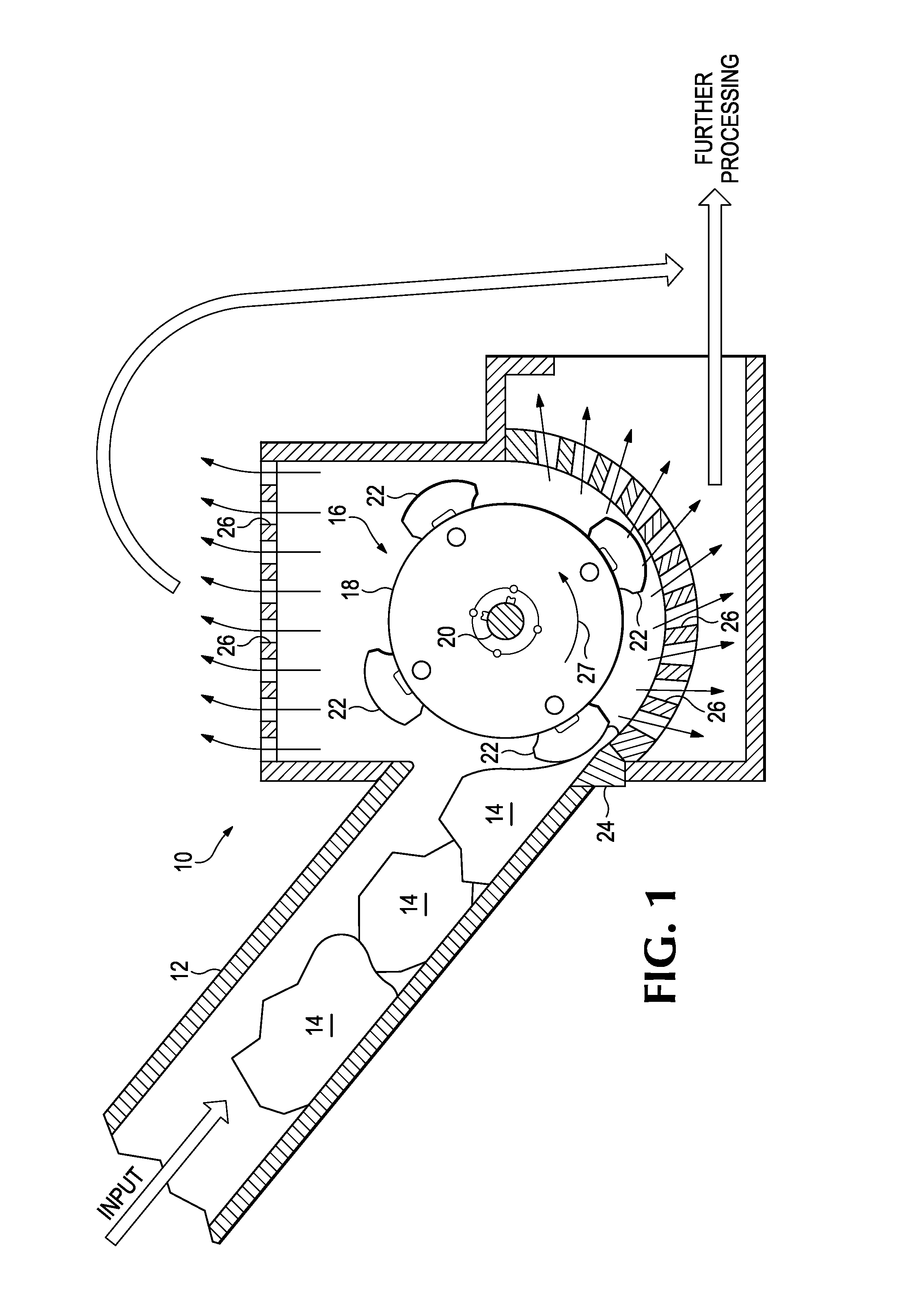

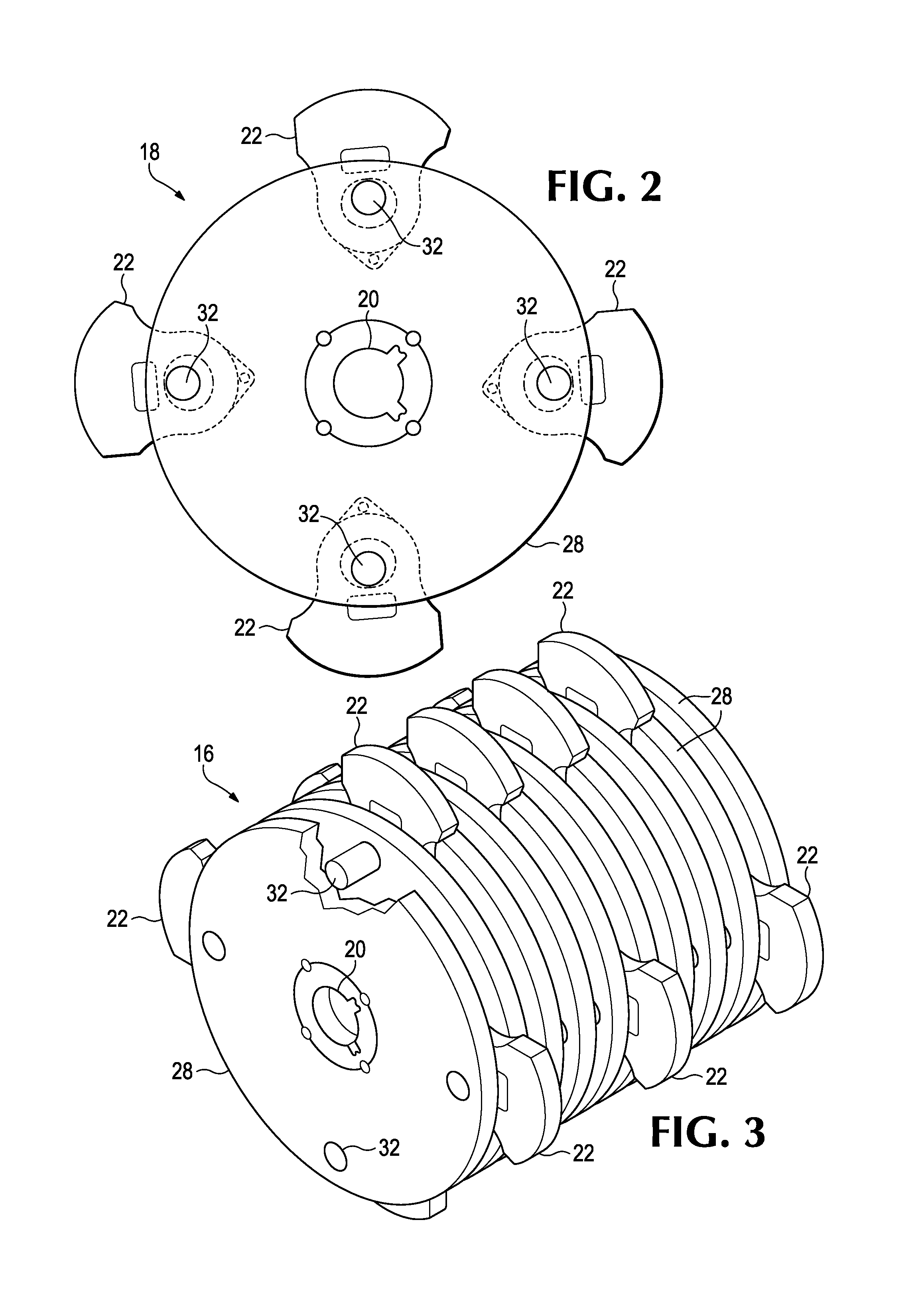

Production of whole grain shredded products

InactiveUS20060246193A1Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsTortilla chipsGluten

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 120° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

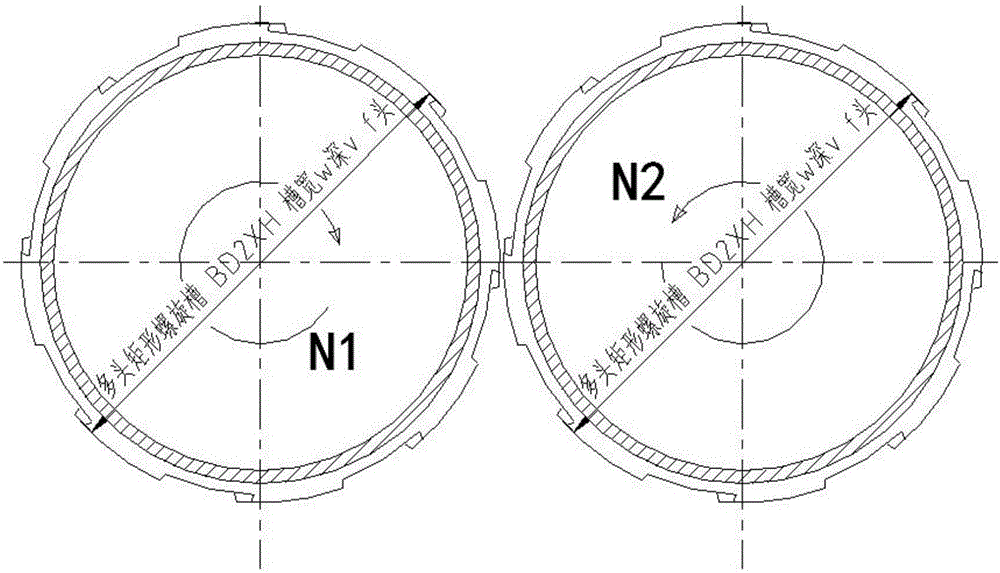

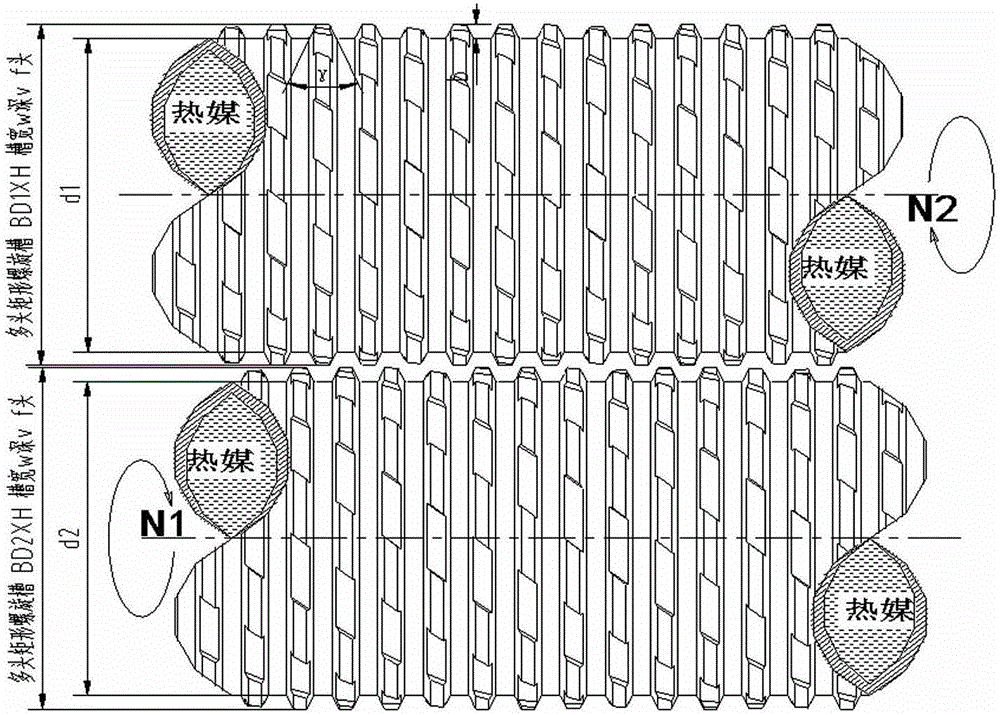

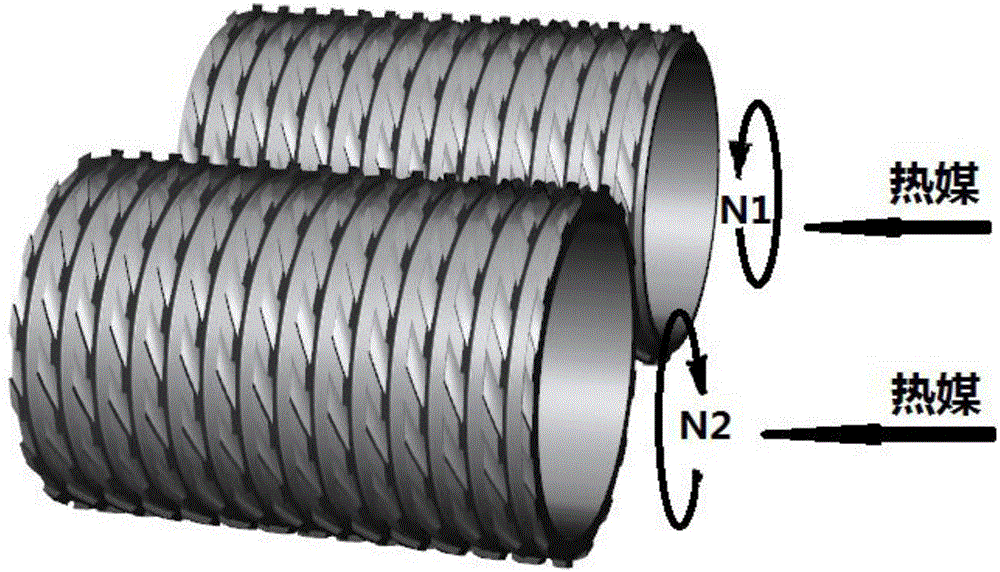

Combined-type granulator

ActiveCN106422974AAchieve maximum surfaceAchieve superficialityGranulation by pressingForeign matterSoft materials

The invention belongs to a wet material granulation principle and an equipment combination process, and particularly relates to a combined-type granulator. The combined-type granulator comprises a plurality of layers of combined box bodies, a temporary storage feed bin and a plurality of layers and groups of roller mills. Each group of roller mills is equipped with a rotary joint, a cleaning blade, an elastic stripping frame, a material baffle and a guide plate; a waste gas emptying interface is also arranged on each of the box bodies, and an air inlet at a lowest layer of the granulator is arranged on a bracket. The linear velocity of a tooth surface and the flow rate of volume of a rotary drum of each of the roller mills at a second layer are higher than those of a rotary drum of each of the roller mills at a first layer, and the linear velocity of a tooth surface and the flow rate of volume of a rotary drum with a reticular tooth socket or a single radial tooth socket of each of the roller mills at an adjacent lower layer are designed according to the volume properties of materials in the area. According to the granulator disclosed by the invention, hard foreign matters can be stripped, and simple granulation of soft materials in a cream state, a paste state, a slurry state and the like can be realized; meanwhile, caky and blocky materials can be pulled into monomer granules, soft and hard materials can simultaneously enter into the granulator, and granules at an outlet have a plurality of pores and are in an irregular shape.

Owner:张元才

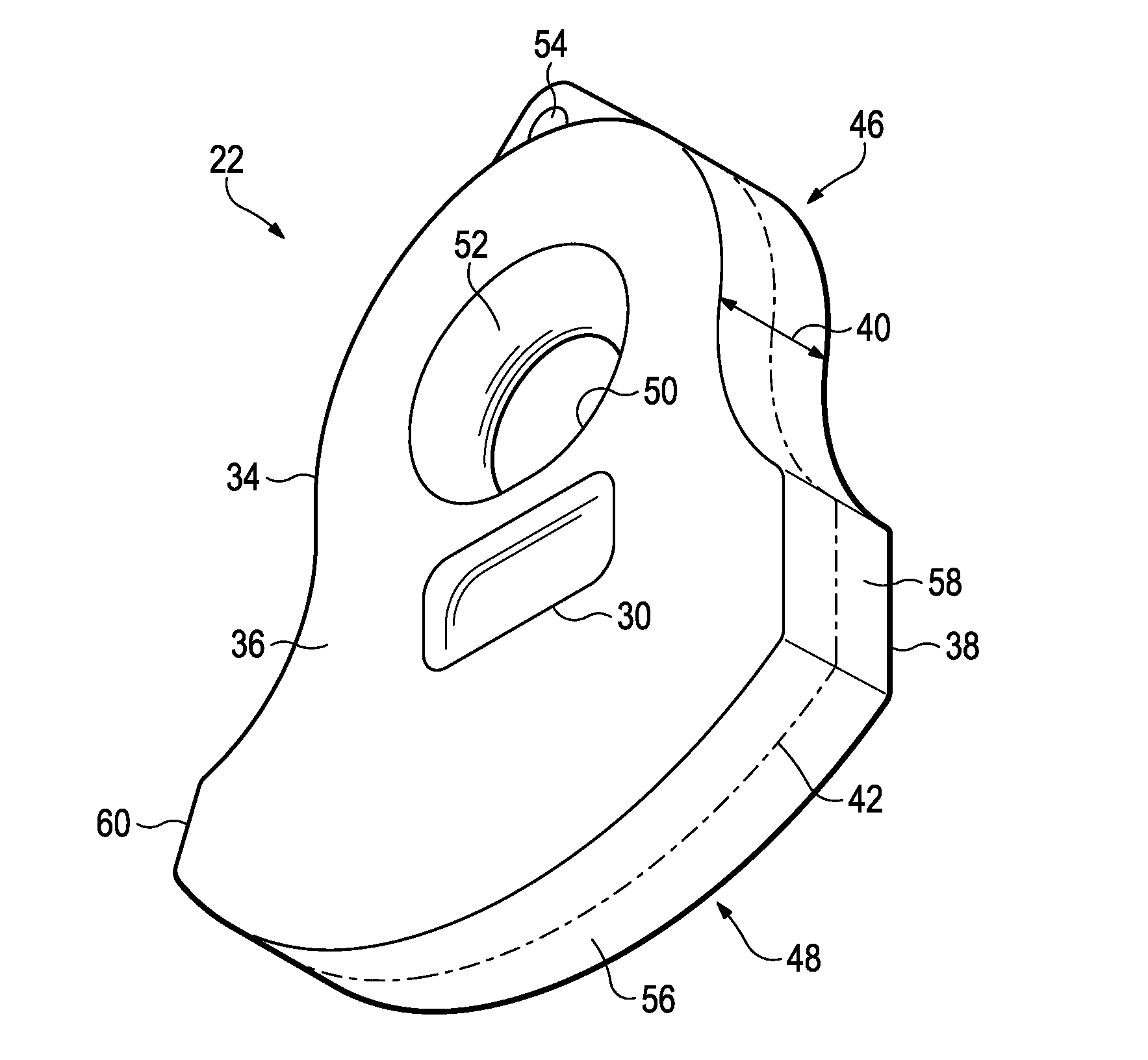

Hammer for shredding machines

InactiveUS20140151475A1Easy to chopEffective wearGrain treatmentsEngineeringElectrical and Electronics engineering

Shredder hammers having first and second major surfaces on opposing sides, and a circumferential edge. A mounting portion includes a mounting hole that extends from the first major surface to the second major surface, and is configured to receive a hammer mounting pin for mounting in a reducing system. The circumferential edge includes a primary impact face to initially impact materials to be reduced and a wear edge to subsequently crush and shear the material against a wall of the equipment. The hammer is biased forward on the pin to admit more material to be crushed between the wear edge and the grates.

Owner:ESCO GRP LLC

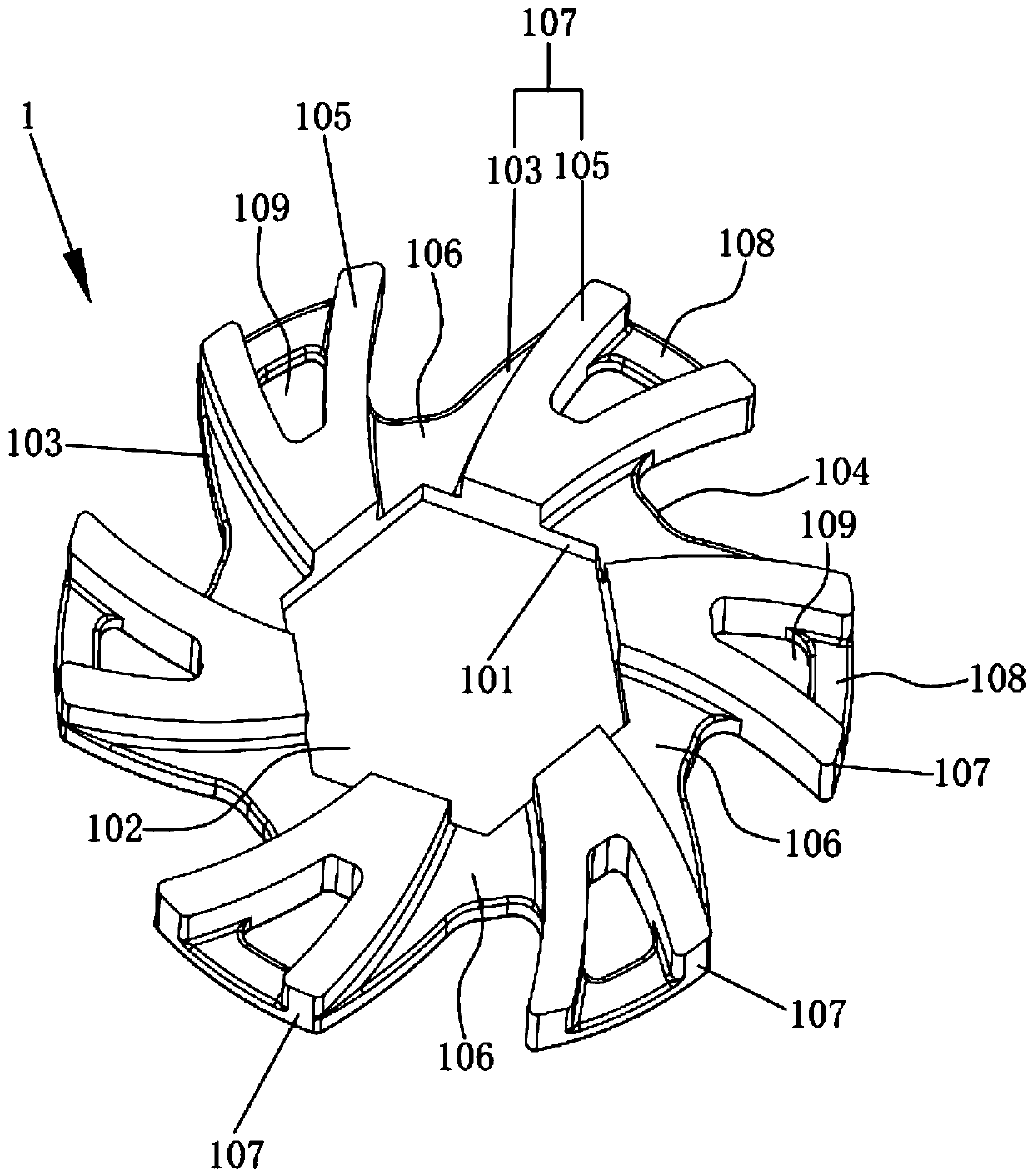

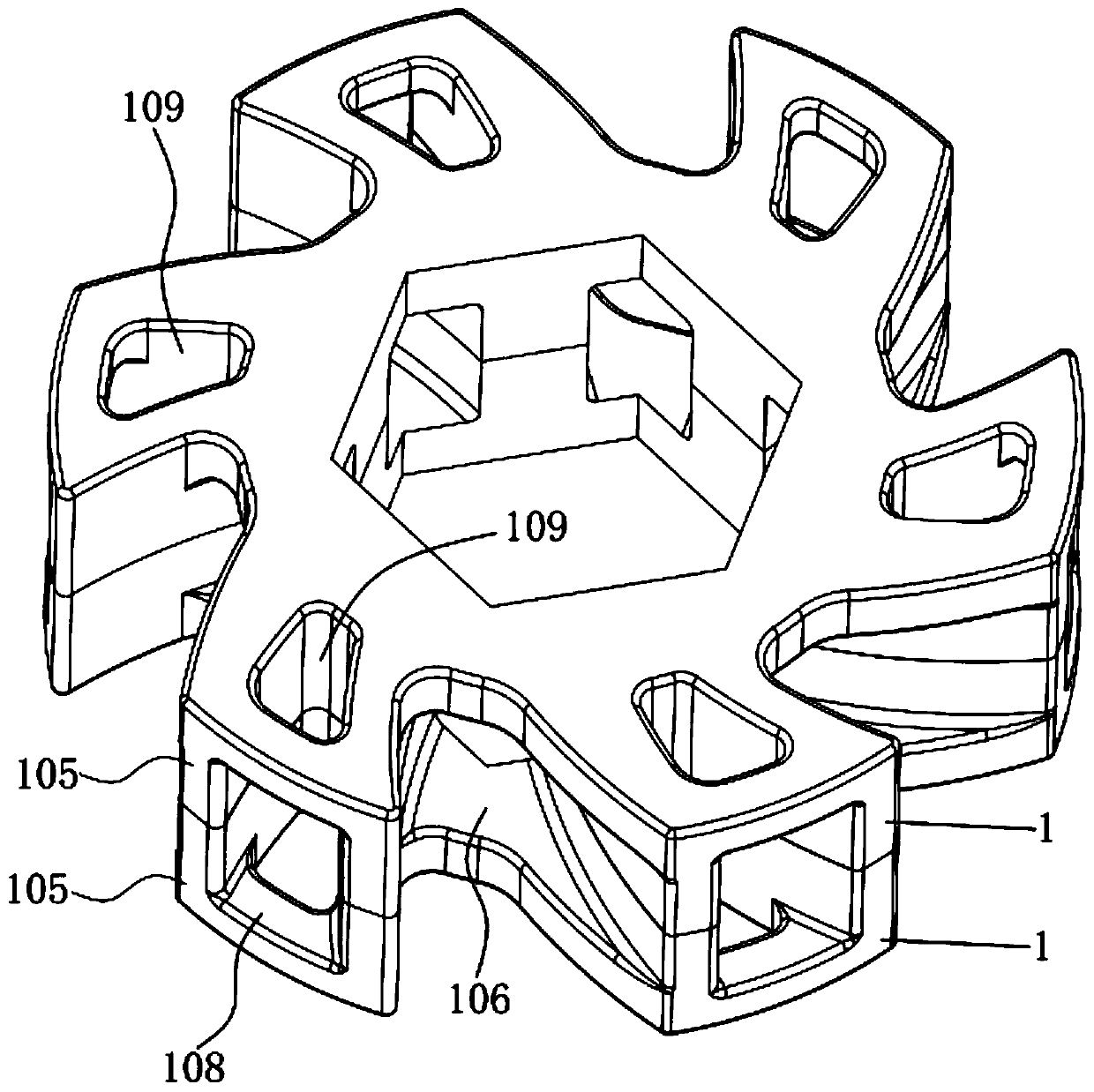

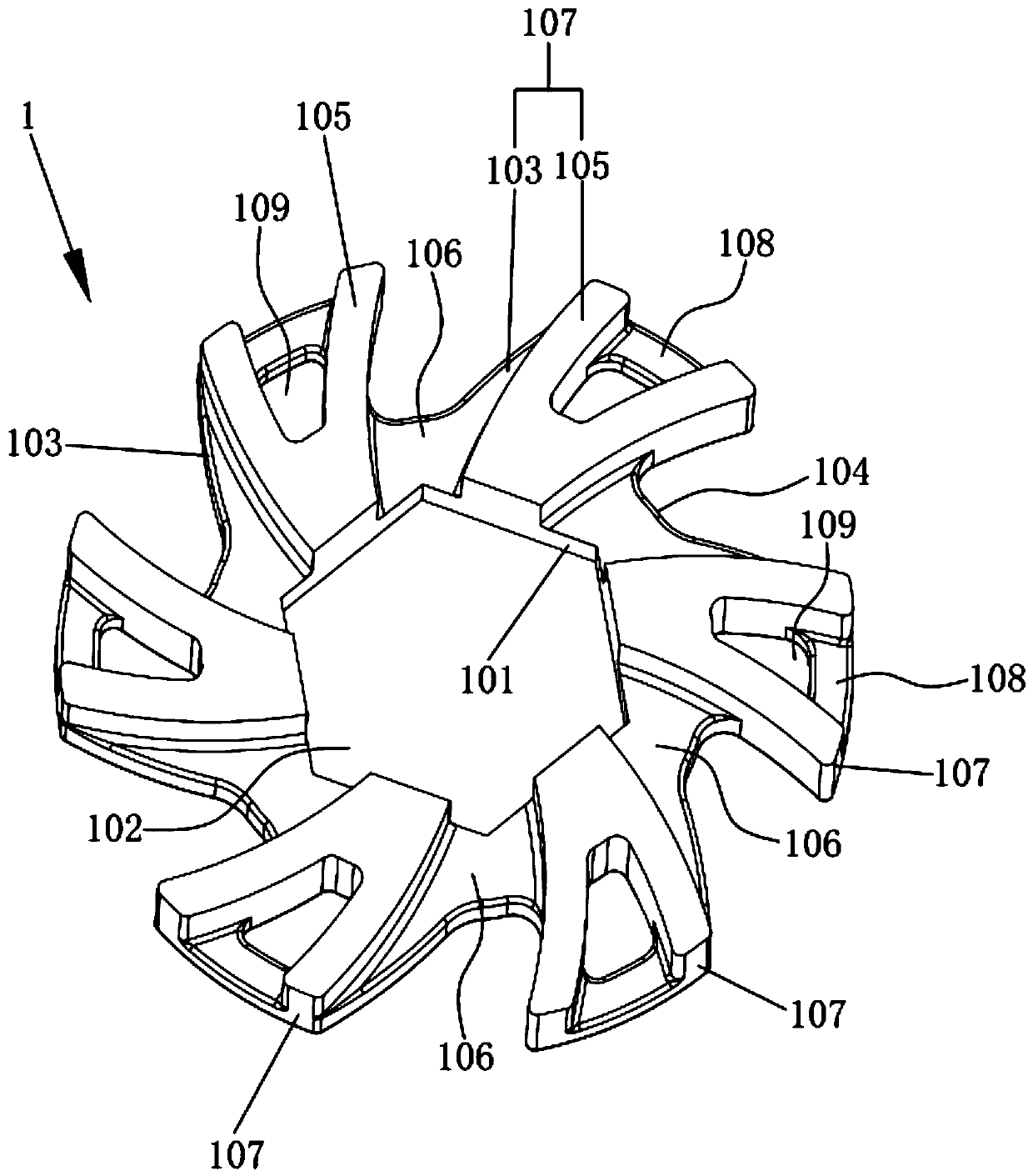

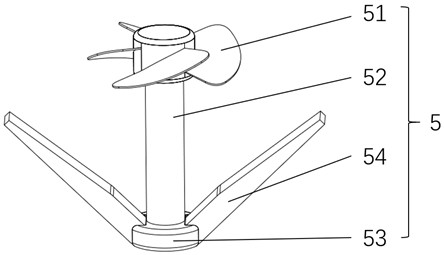

Turbine blade, grinding turbine and grinding device

The invention discloses a turbine blade, a grinding turbine and a grinding device. The turbine blade comprises a turbine body and grinding teeth. A center through hole formed in the axial direction ofthe turbine body is formed in the middle of the turbine body, multiple convex pins being convex outwards are formed in the circumferential direction of the periphery of the turbine body, and an opengroove is formed between every two adjacent convex pins. The multiple grinding teeth are arranged on at least one surface of the turbine body in the circumferential direction of the center through hole. The multiple grinding teeth are formed on the multiple convex pins in one-to-one correspondence. A radial hollowed channel allowing a grinding medium to flow in or out of the center through hole inthe radial direction of the turbine body is formed on one surface of the turbine body by every two adjacent grinding teeth. The radial hollowed channels of the turbine blade have no end faces stopping outflow motion of the grinding media, kinetic energy losses are low in the process that the grinding media flow out, grinding of the grinding media is more sufficient in the radial direction, exchange of the grinding media at different positions is more frequent, and grinding efficiency is greatly improved.

Owner:GUANGZHOU HONGKAI MACHINERY CO LTD

Production of whole grain shredded products

InactiveUS7964233B2Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsGlutenCereal grain

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 120° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Extrusion head and ice cream machine employing same

The invention provides an extrusion head and an ice cream machine employing the extrusion head. The extrusion head comprises a conical body with cutting knives and extrusion threads, wherein continuous cuts respectively formed by merging more than two cutting knives and extrusion screw heads are formed on the surface of the extrusion head; a plane is arranged at the top of the extrusion head; the extrusion screw heads positioned at the upper part of the extrusion head have small inclination; the cutting knives positioned at the lower part of the extrusion head have large inclination; the whole inclination transits gradually; a rotary shaft is arranged at the base part of the extrusion head; the cutting knives are manufactured by adopting plastic or metal; and more than two flow guide grooves evenly distributed in the radial direction are formed in the plane at the top of the extrusion head. The ice cream machine with the extrusion head comprises a material feed cylinder arranged on a machine stand, wherein the extrusion head is inserted into the material feed cylinder transversely or obliquely; and a grinding cover with a material discharge opening is formed in one side surface of the material feed cylinder. The ice cream machine has the characteristics of simple and reasonable structure, low vibration, low noise and wide application range.

Owner:NINGBO BORINE ELECTRIC APPLIANCE

Production of whole grain shredded products

InactiveUS7939122B2Avoid insufficient frictionEnsure adequate heatingMilk preparationBakery productsTortilla chipsGluten

Shredded whole grain products, such as ready-to-eat cereals, and sweet and savory snacks, such as whole grain shredded corn chips are continuously produced by pelletizing agglomerates of cooked, tempered, whole cereal grain particles. Cooked whole grains, such as corn and other non-gluten or low-gluten containing grains have a tendency to become hard and rubbery after cooking during the cooling and tempering process. The pelletization results in the production of whole grain pellets having a soft, pliable texture, which are shreddable into continuous net-like sheets on a mass production basis. The pelletizing may be at a pressure of about 200 psig to about 600 psig, preferably from about 400 psig to about 500 psig. The pelletizing temperature may be controlled to provide a pellet temperature of about 80° F. to about 135° F., preferably from about 90° F. to about 110° F., upon exiting the pelletizer.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

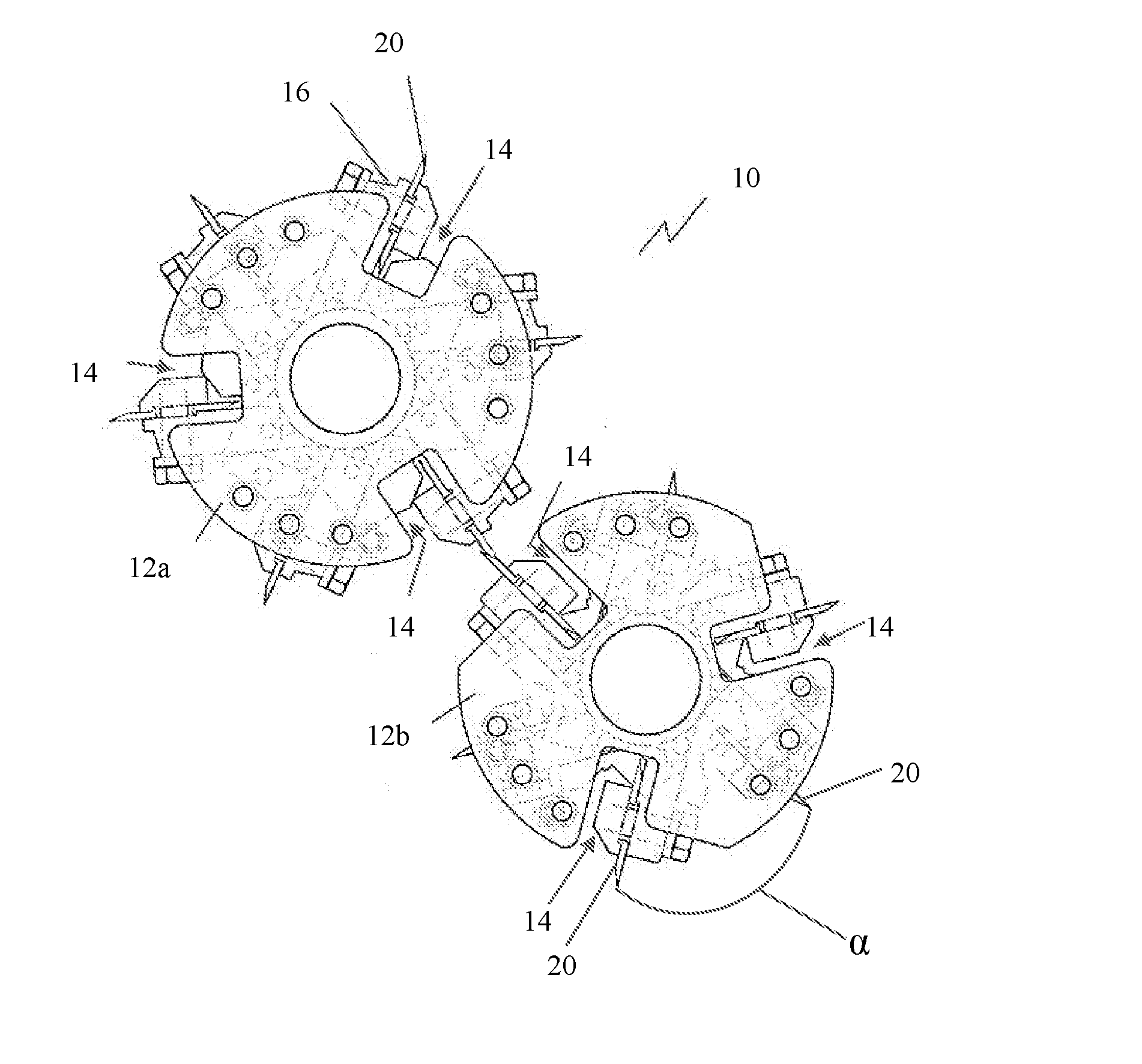

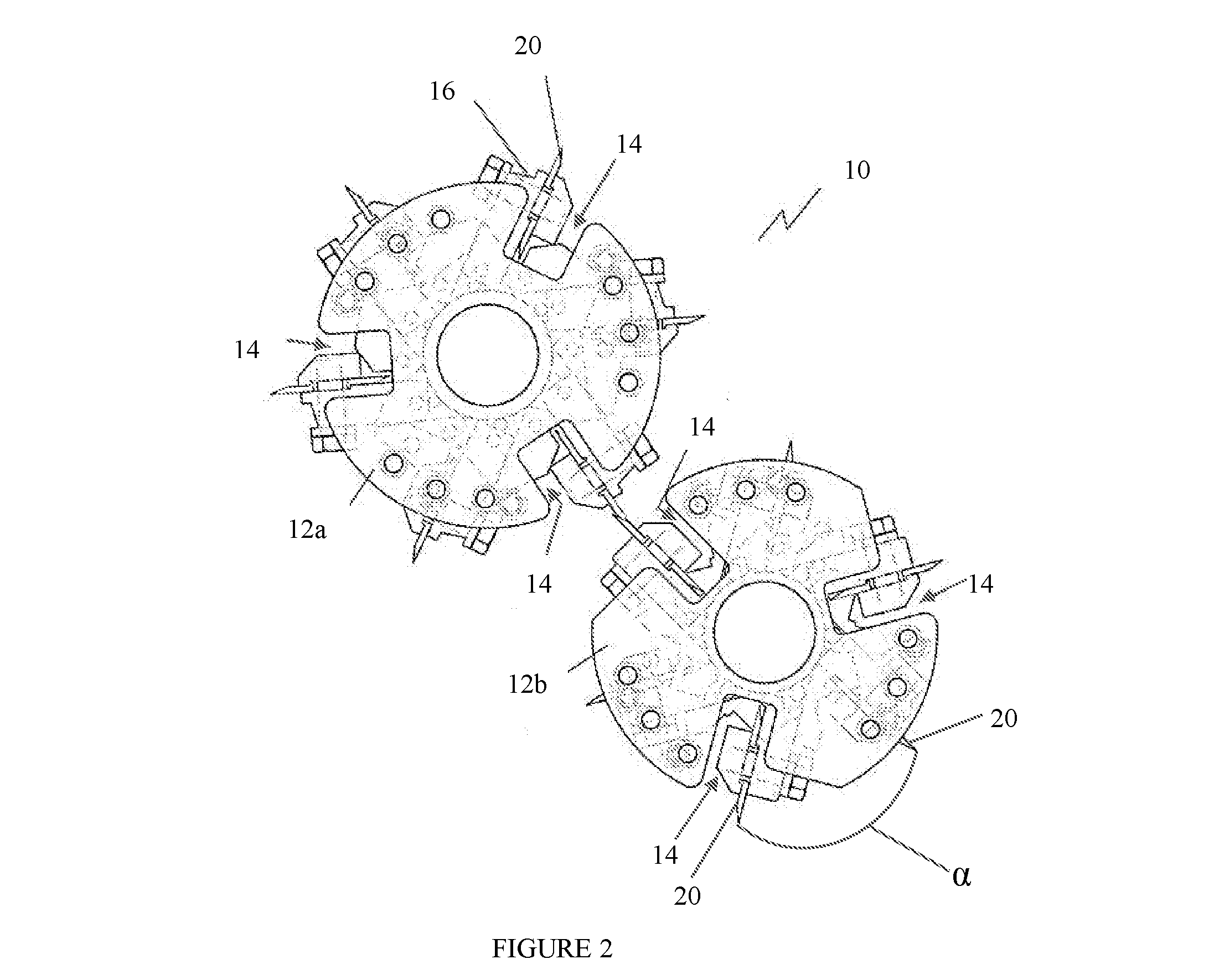

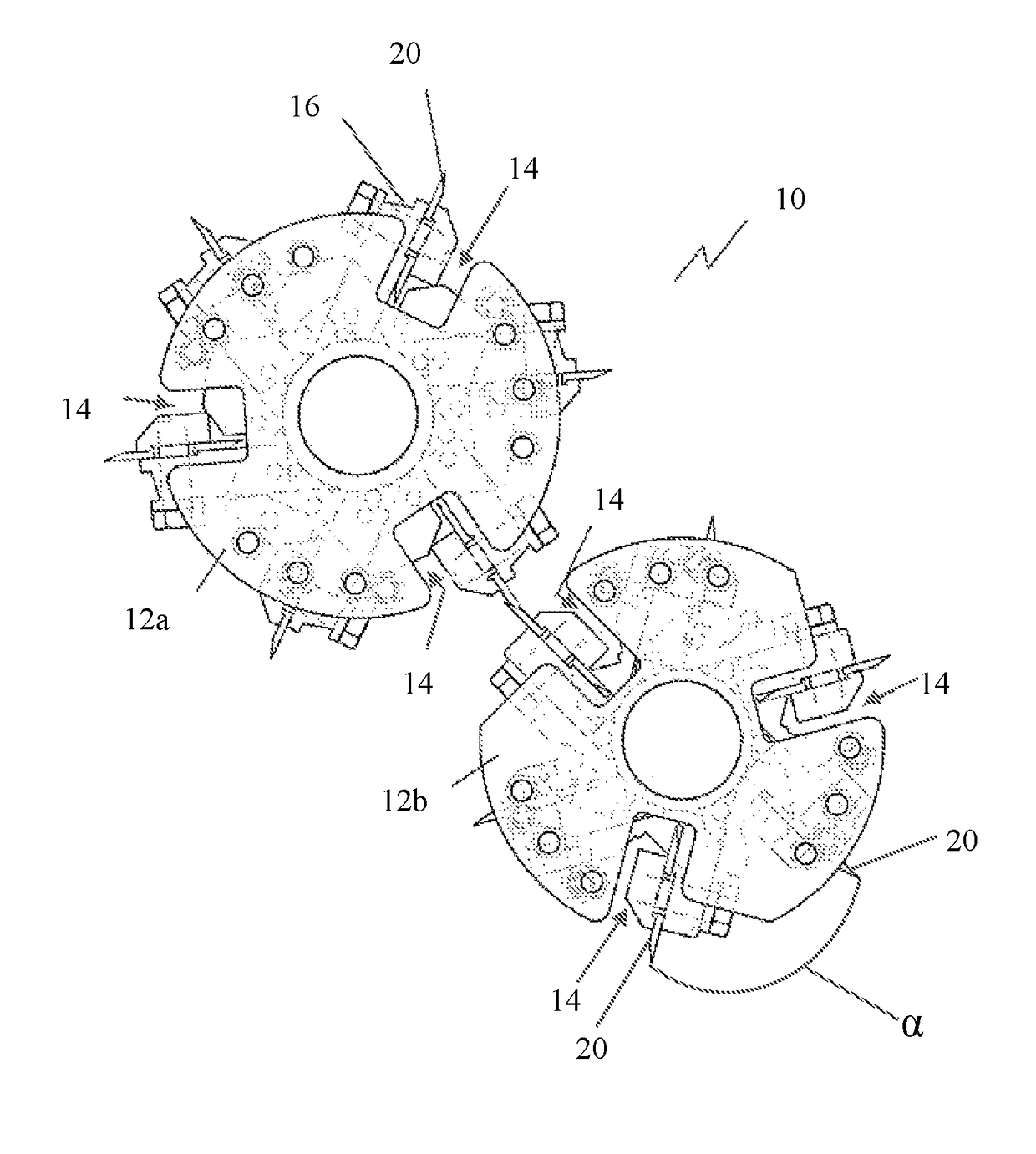

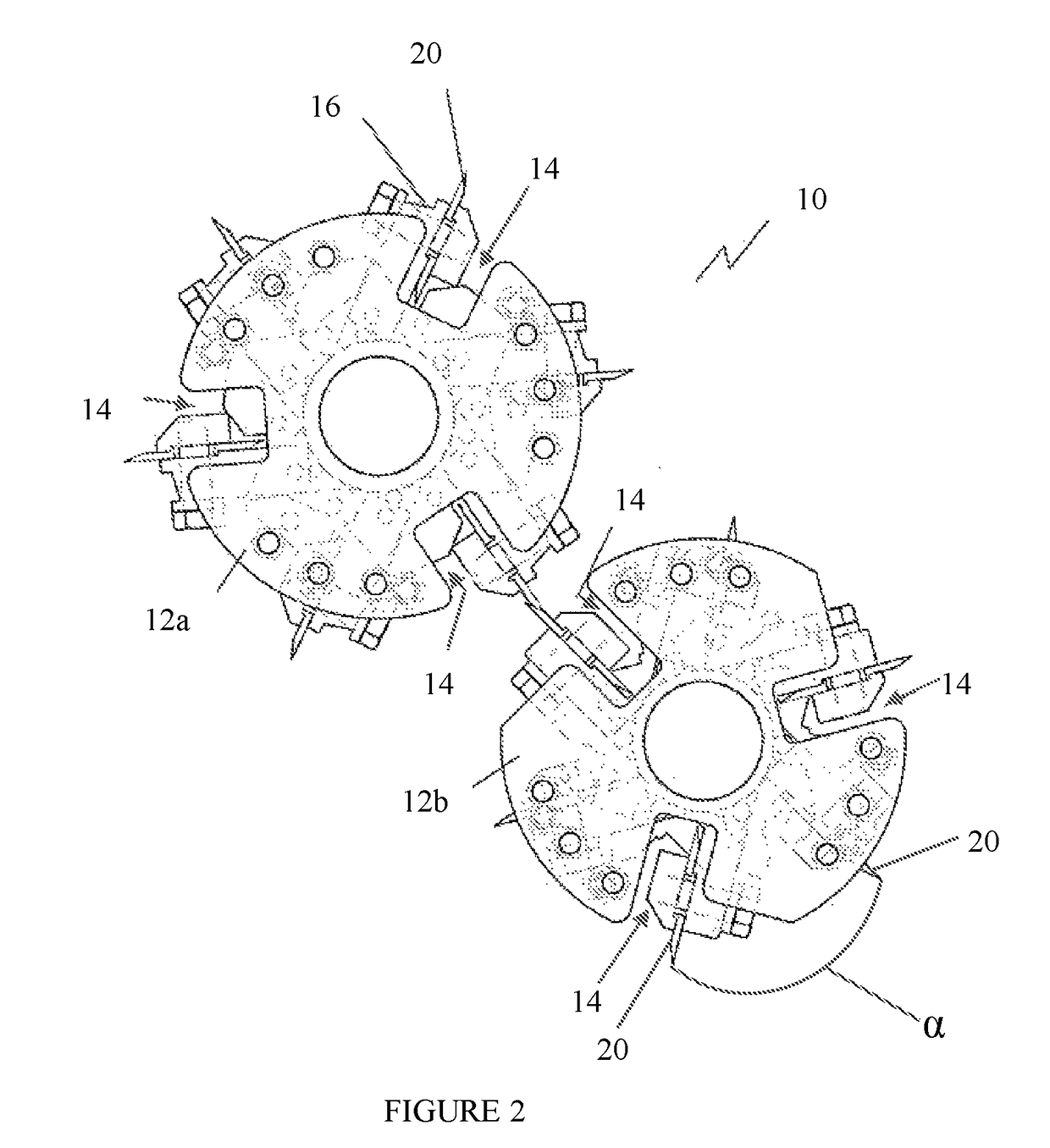

Chopper mechanism

ActiveUS20160235010A1Easy to chopReduces effective usageMowersCuttersEngineeringMechanical engineering

A chopper mechanism for chopping stalk-like plant wherein the chopper mechanism includes a plurality of chopping elements that are removably mounted on the pair of chopper drums via associated holders. The chopping elements are mounted on the chopper drums circumferentially spaced apart and define a predetermined radial angle (α) therebetween. Each of the chopping elements having a pair of substantially parallel cutting edges spaced apart by substantially parallel mounting surfaces. One of the cutting edges is selectively engaged in the chopping while the other cutting edge is enclosed within the holder. The parallel cutting edge of the chopping elements facilitates in reversing each chopping element depending on the degree of abrasion of the cutting edge.

Owner:DEERE & CO

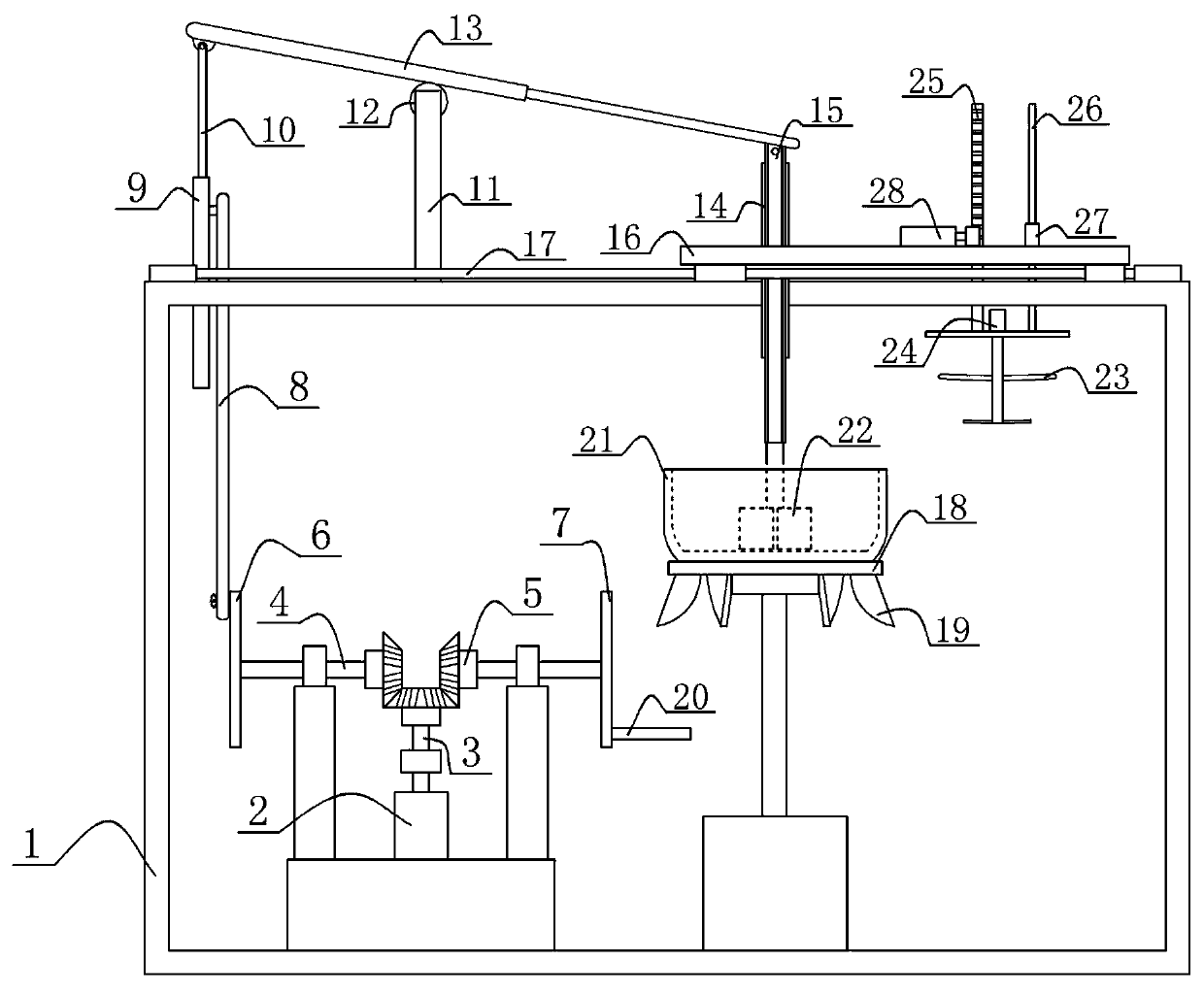

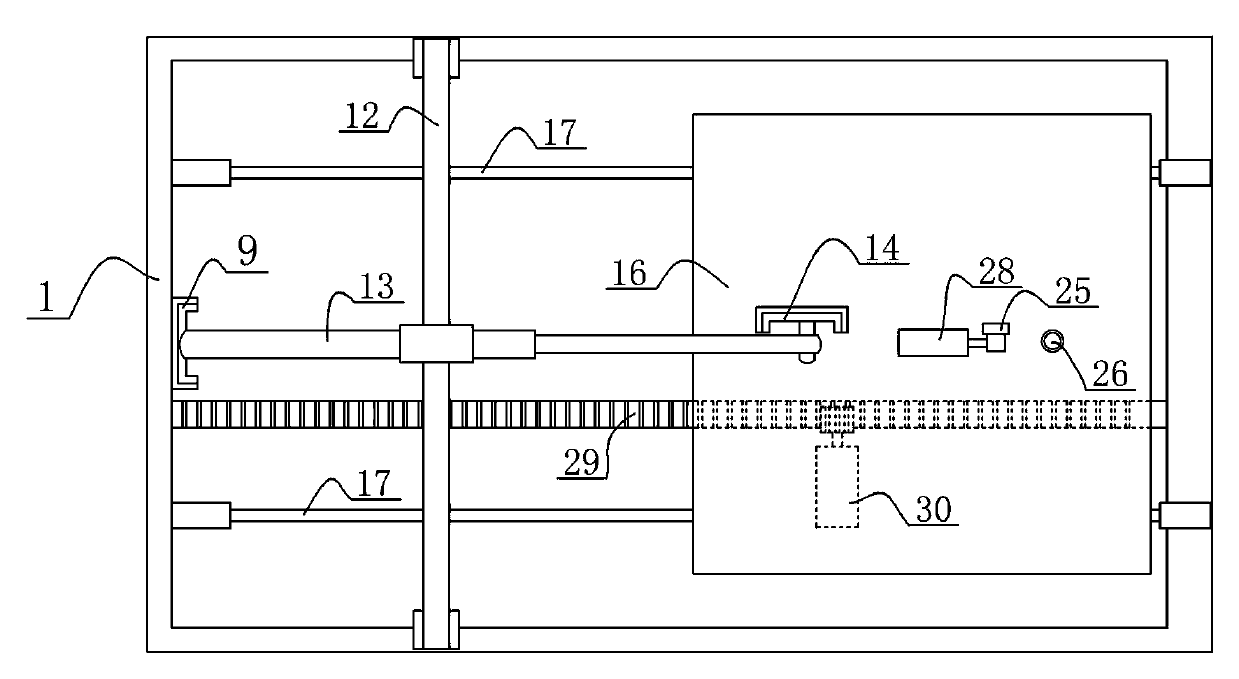

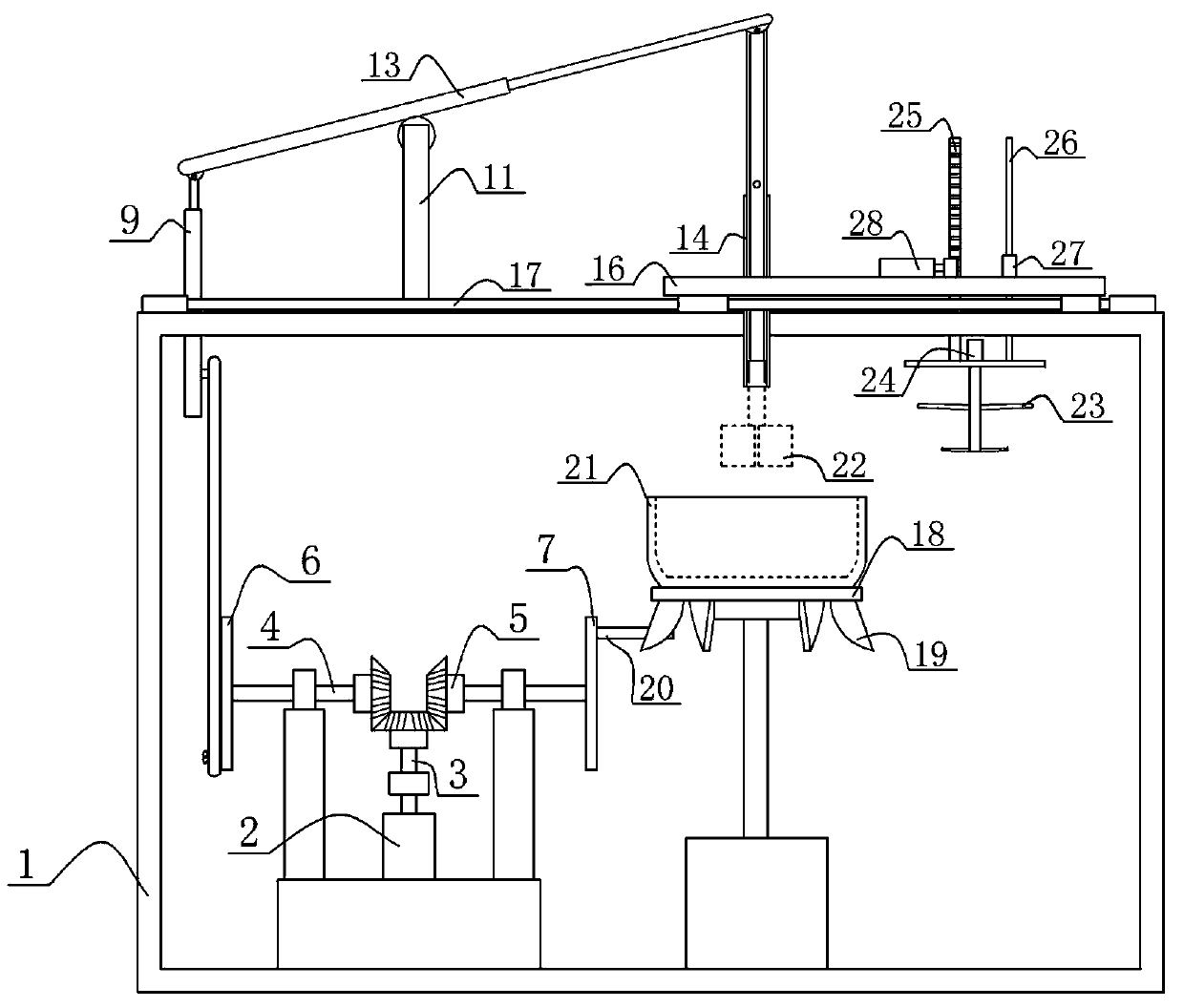

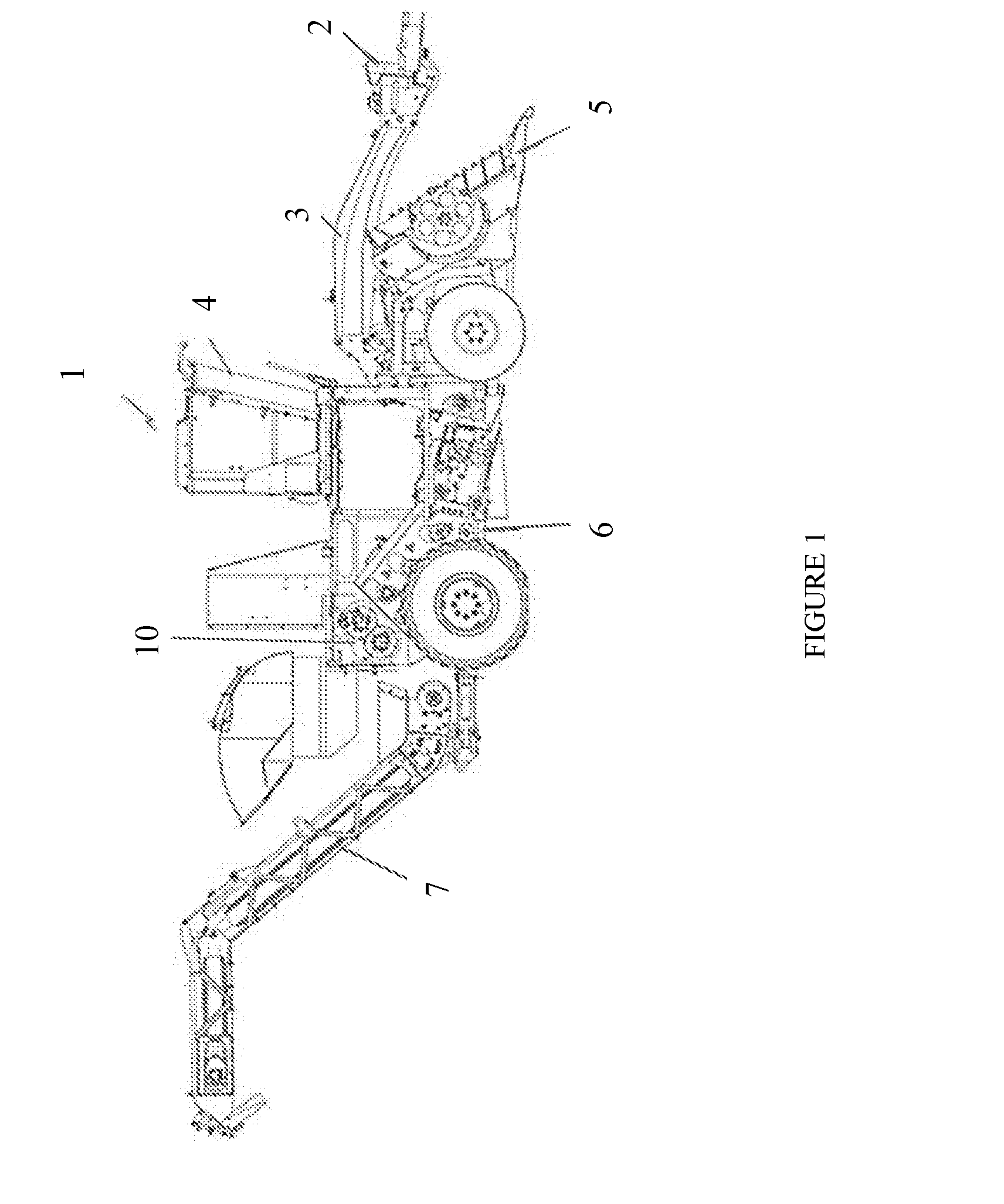

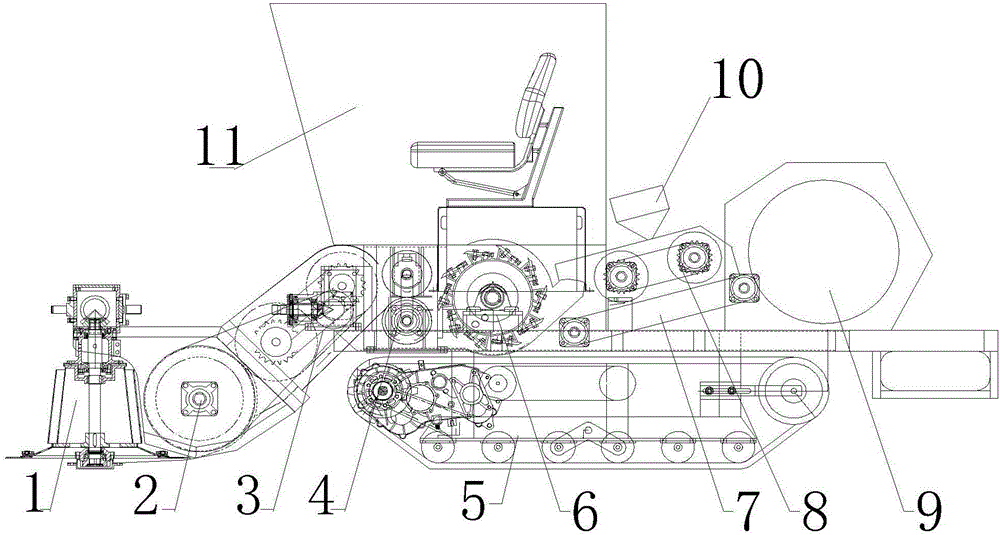

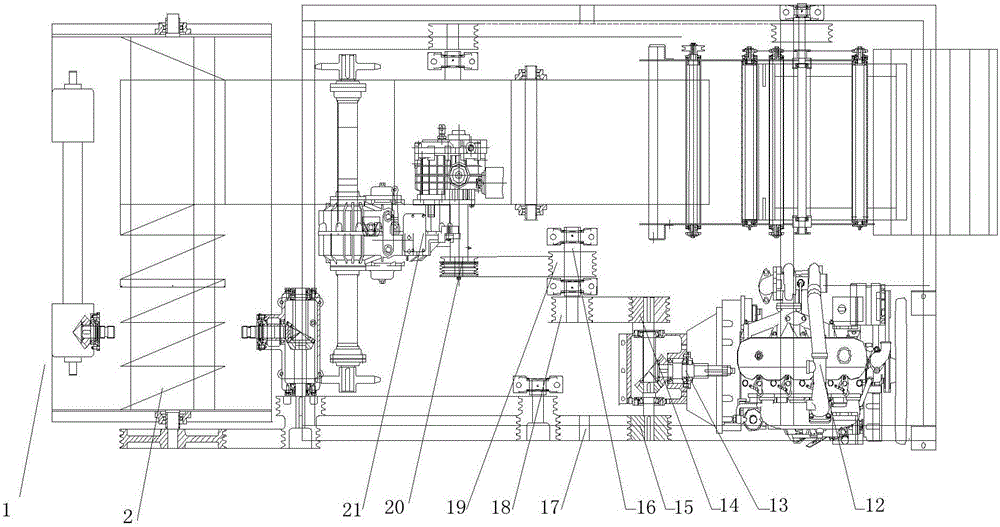

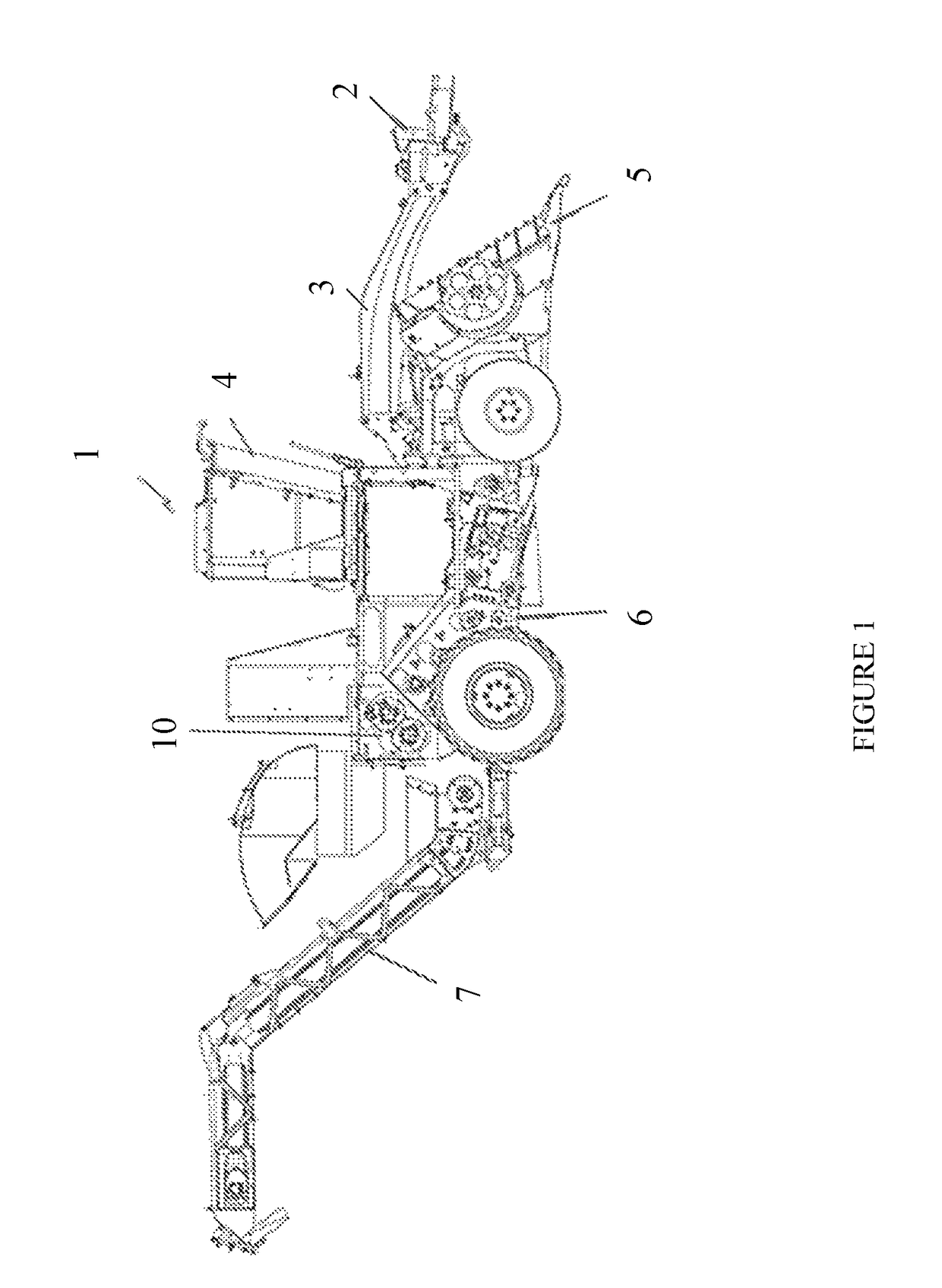

Self-propelled forage harvesting and baling machine

The invention discloses a self-propelled forage harvesting and baling machine.The machine comprises a vehicle chassis, a traveling system arranged on the vehicle chassis, a cutting device arranged at the front end of the vehicle chassis, a feeding mechanism close to the cutting device, a forage clamping device located behind the feeding device, a chopping device close to the forage clamping device, a chopped material conveying mechanism used for conveying chopped forage backwards, and a forage baling device located behind the chopped material conveying device.The self-propelled forage harvesting and baling machine integrates sectional work of forage cutting, forage conveying, forage chopping, forage baling and the like, cutting, conveying, chopping and baling combined work of forage is achieved, the machine is multifunctional, contact of forage and soil and other impurities affecting the quality of the forage is reduced, and forage quality is guaranteed.

Owner:SHIJIAZHUANG XINNONG MACHINERY +1

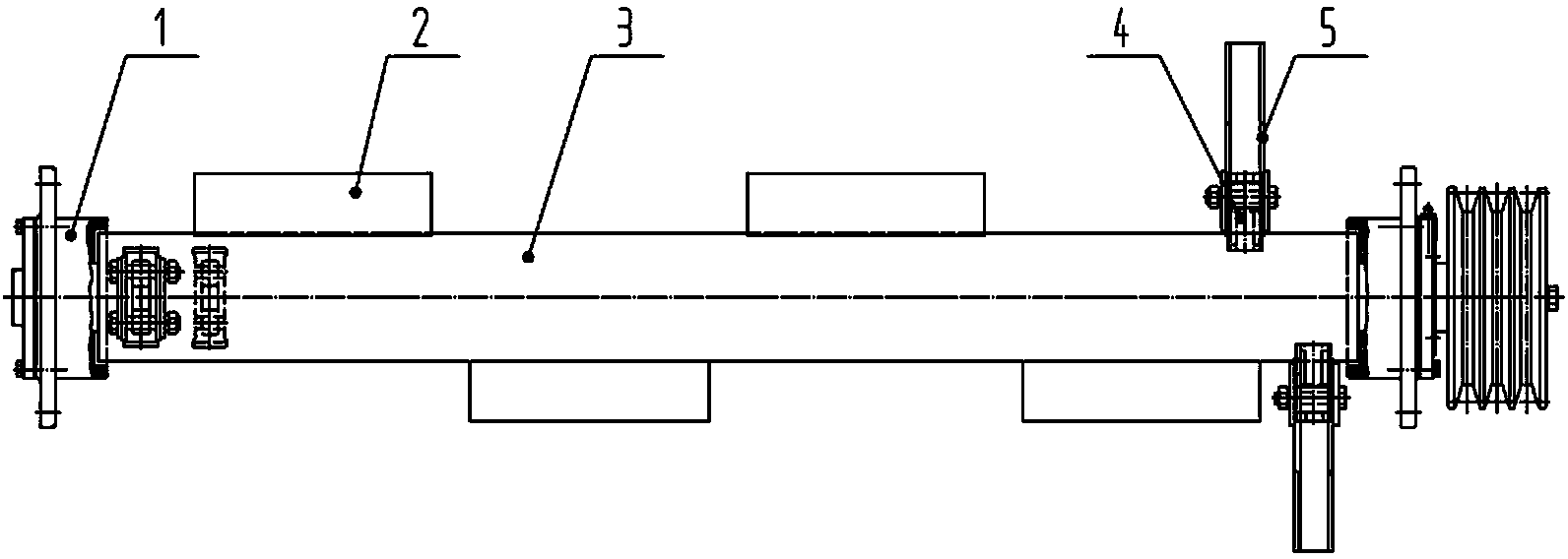

Shredding cutter shaft with air drafting effect

ActiveCN104012252AEasy to chopSmall amount of dynamic balanceCrop conditionersMowersRice strawEngineering

The invention relates to a shredding cutter shaft with the air drafting effect, and belongs to crop straw processing devices. The shredding cutter shaft with the air drafting effect is composed of a bearing base, air drafting blades, a shredding cutter shaft body, a movable cutter base and a movable cutter, the bearing base is located at the two ends of the shredding cutter shaft body, the air drafting blades are evenly arranged outside the shredding cutter shaft body in a staggered mode, and the upper portion and the lower portion of the position, attached to the bearing base, of one end of the shredding cutter shaft body are provided with the movable cutter base and the movable cutter respectively. Through the technological improvement, the shredding cutter shaft has the advantages that crop straws, in particular to crop straws (rice straws) with the high shredding tenacity, are easily shredded; the movable equilibrium amount of the shredding cutter shaft is decreased, and the shredding cutter shaft is stable during high-speed rotation; vibration of a whole machine is reduced, and other components are easily protected.

Owner:黑龙江红兴隆机械制造有限公司

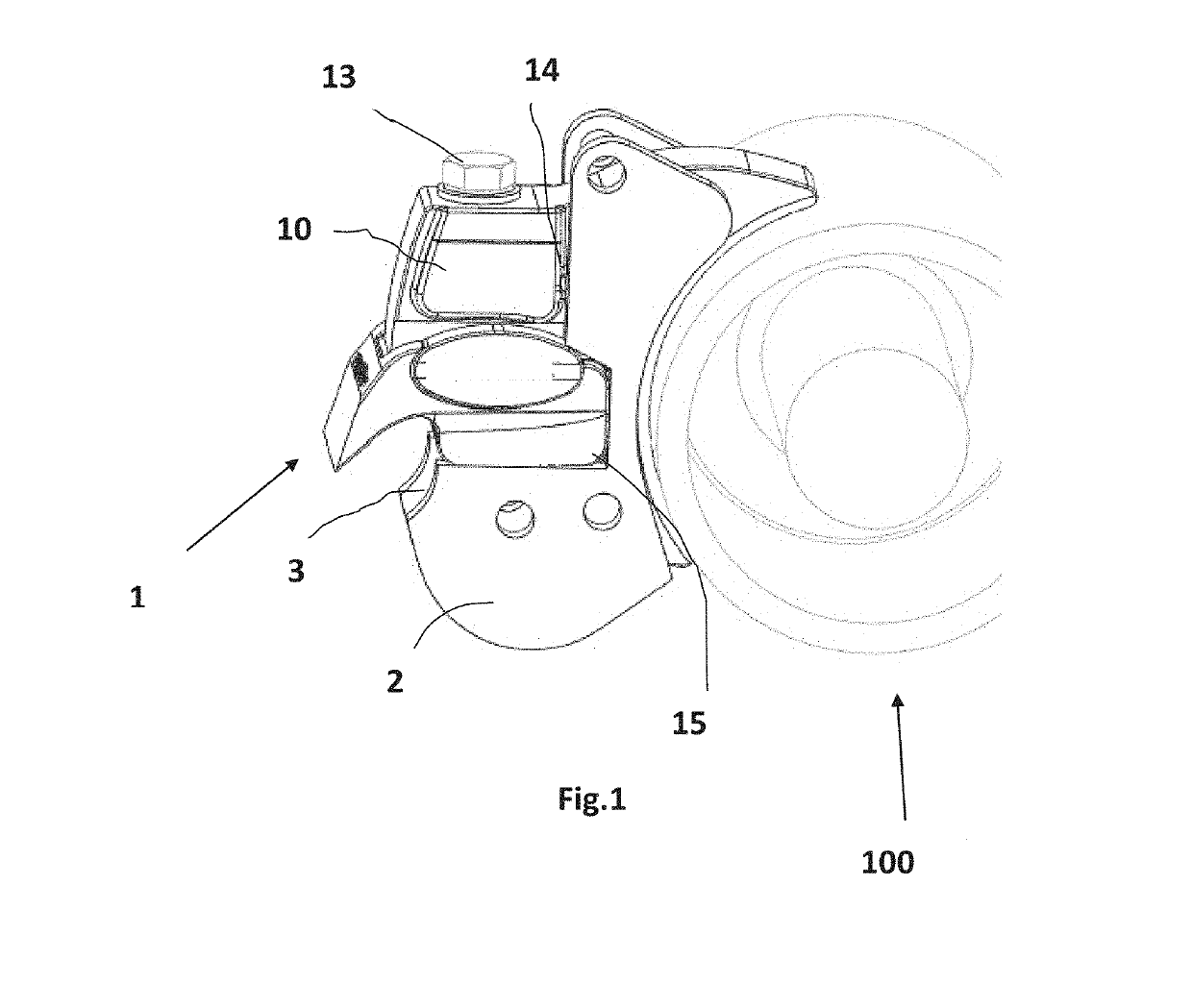

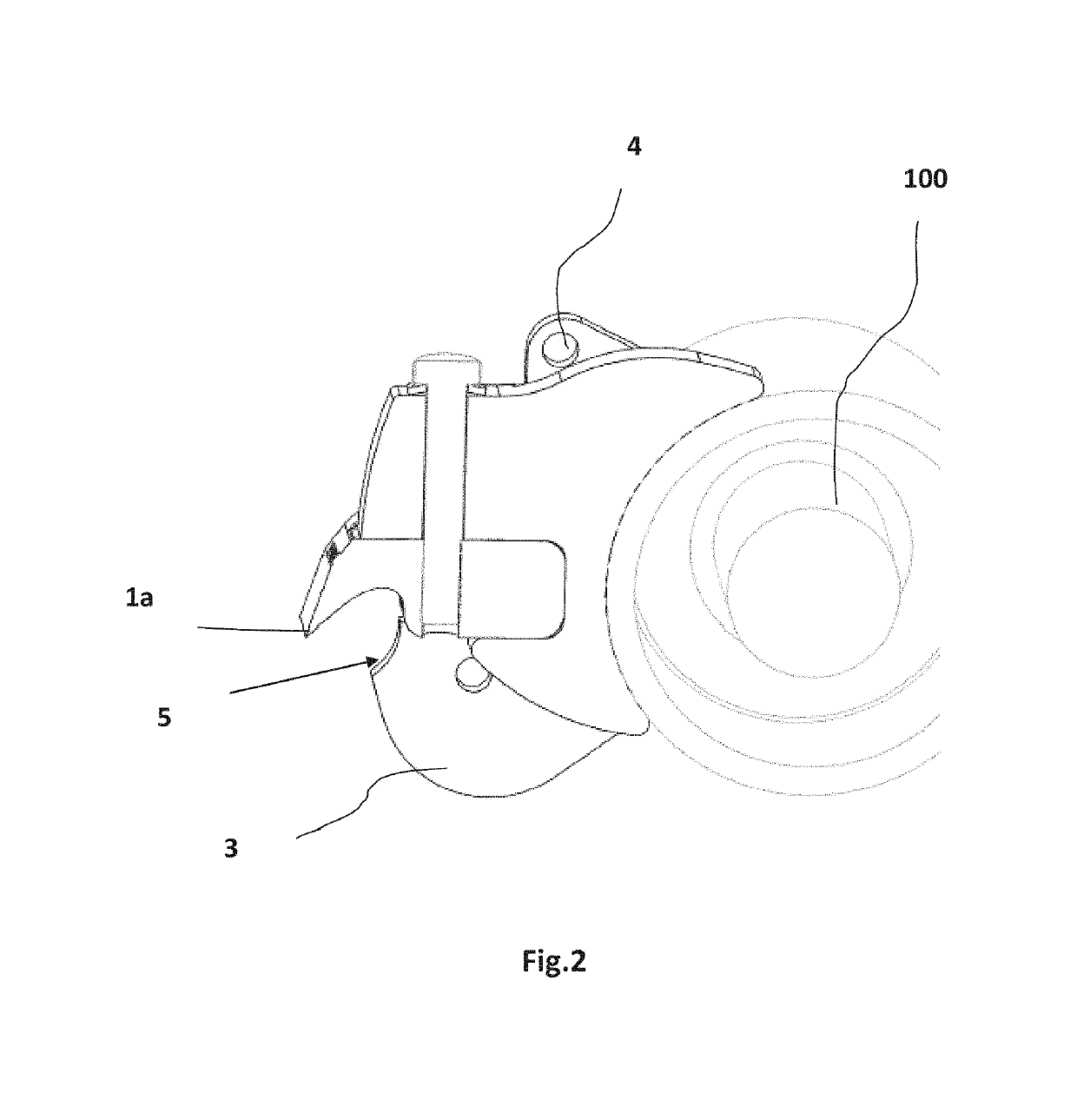

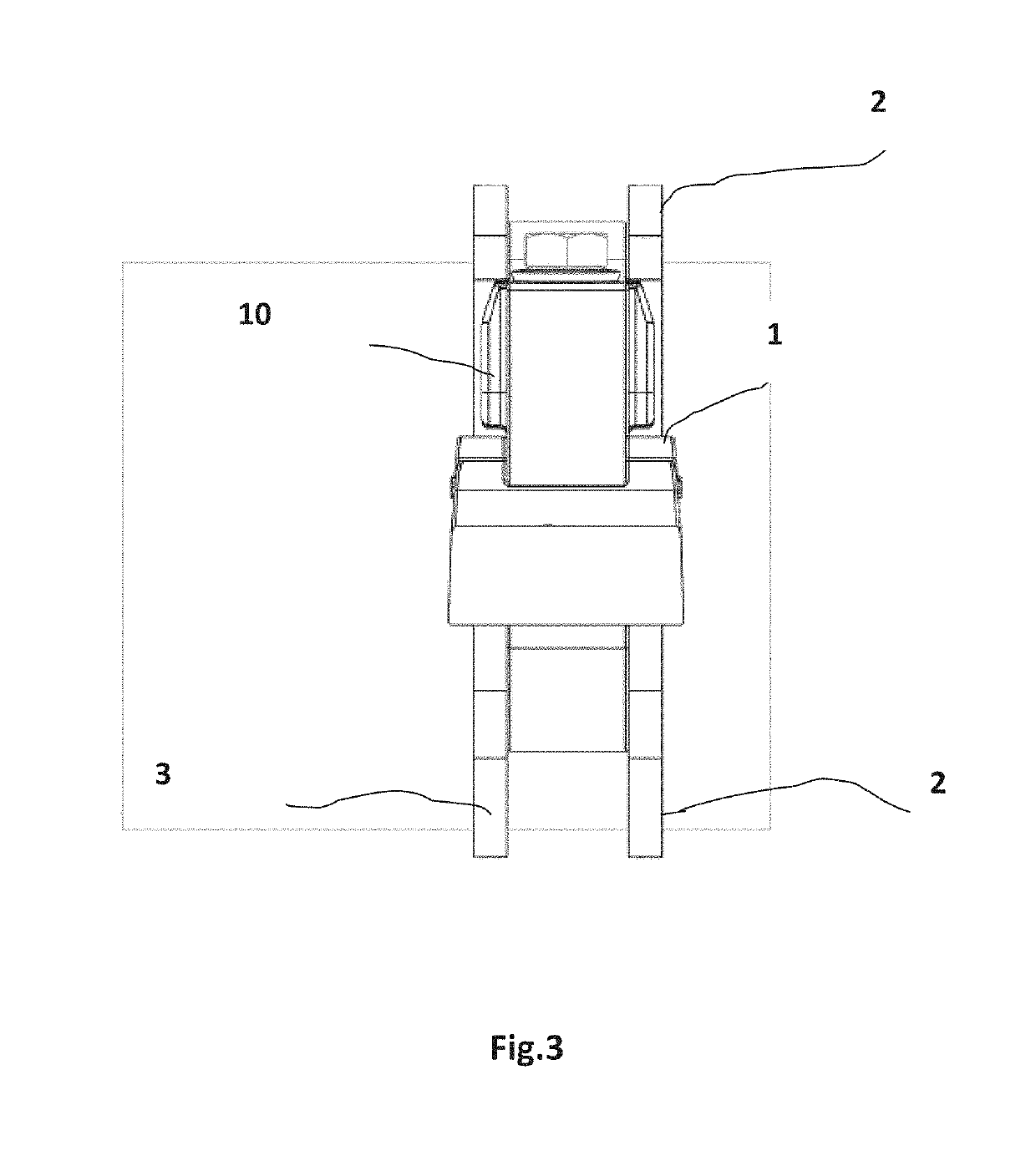

Protection device for tool-holders for tools for shredding, cutting and collecting material

A protection device for tools for cutters and shredders and the like, arranged on a tool-holder seat for a tool-holder rotor rotatable about the axis of the rotor, said tool being housed in a seat arranged on the tool-bolder rotor, and formed by a first surface arranged at the front in the cutting direction and a second surface onto which the tool is fixed with its opposite surface to the cutting direction, the tool having a body that has a front surface in the rotation direction of the rotor, and a rear surface opposing the front surface. The tool and / or the seat having lateral projections and a protection device is dismountable connected to the seat of the tool, laterally as a protection for the tool and the plates being arranged partially between the lateral projections, of the tool and / or the seat of the tool, and the tool-holder rotor.

Owner:SEPPI M

Operating method of food chopping device

Owner:玉环市荣康达机械厂

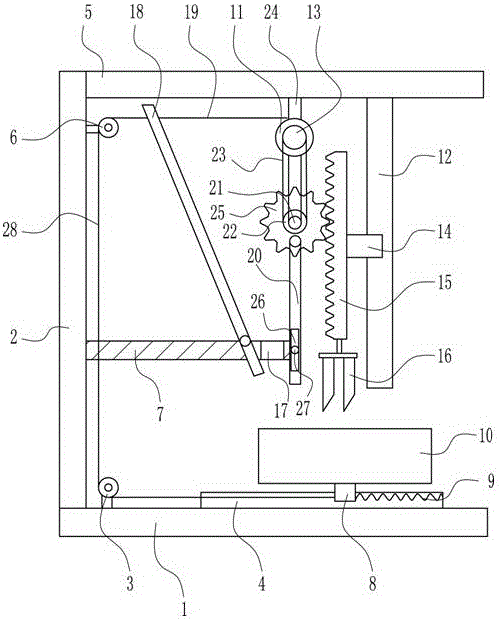

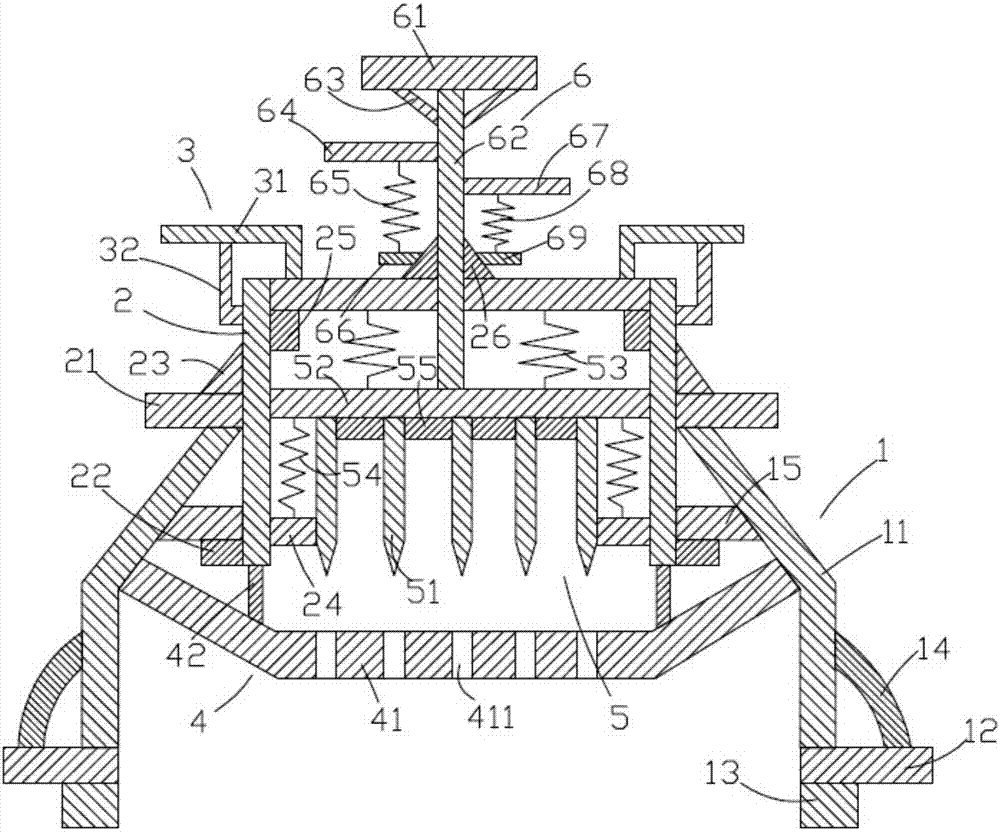

Rapid chopping device of traditional Chinese medicine herbs

The invention relates to a traditional Chinese medicine herb chopping device, and particularly relates to a rapid chopping device of traditional Chinese medicine herbs. The technical problem to be solved in the invention is to provide the rapid chopping device of traditional Chinese medicine herbs, which is good in chopping effect, simple in structure, convenient to operate, and time-saving and labor-saving. In order to solve the technical problems, the rapid chopping device of traditional Chinese medicine herb comprises a bottom plate, a push plate, a spring I, a pulling wire, an electric winding wheel, a left frame, a motor I, a base I, a small belt wheel, a flat belt, a turntable, a base II, a big belt wheel, a link rod I, a link rod II, a fixing rod, a top plate, a rubber hammer, a pressing plate, a spring II, a guide plate, a lifting rod, a cutter, a collecting frame, a right frame, a support rod, and a rotating motor; the left side of the top part of the bottom plate is provided with the left frame, and the right side of the top part of the bottom plate is provided with the right frame. The rapid chopping device of traditional Chinese medicine herbs is good in chopping effect, simple in structure, convenient to operate, and time-saving and labor-saving.

Owner:QINGHAI HUIZHEN BIOTECH CO LTD

Chopper mechanism for stalked crop

A chopper mechanism for chopping stalk-like plant wherein the chopper mechanism includes a plurality of chopping elements that are removably mounted on the pair of chopper drums via associated holders. The chopping elements are mounted on the chopper drums circumferentially spaced apart and define a predetermined radial angle (α) therebetween. Each of the chopping elements having a pair of substantially parallel cutting edges spaced apart by substantially parallel mounting surfaces. One of the cutting edges is selectively engaged in the chopping while the other cutting edge is enclosed within the holder. The parallel cutting edge of the chopping elements facilitates in reversing each chopping element depending on the degree of abrasion of the cutting edge.

Owner:DEERE & CO

Mine greening survival rate improving nutrient soil mixing device

InactiveCN112915871AImprove breathabilityGuaranteed oxygen supplyRotating receptacle mixersTransportation and packagingNutrientElectric machinery

The invention provides a mine greening survival rate improving nutrient soil mixing device, which comprises a roller, a hopper and a support, the other side of the roller is provided with a clamping cover, the outer side of the roller is welded with a sliding sleeve, the support is provided with a motor I through a bolt, one side of the motor I is provided with a gear I, a second gear is welded to the outer edge side of the roller, a second motor is installed on the inner side of the clamping cover through bolts, and a main shaft is installed on one side of the second motor. According to the mine greening survival rate improving nutrient soil mixing device, roots of plants can be fixed to prevent the plants from being blown down by wind when the plants are planted, after watering, more gaps can be reserved in nutrient soil, the breathability of the nutrient soil is improved, oxygen supply to the roots of the plants is guaranteed, the compacted nutrient soil can be scattered through the rake teeth, and the yield of the plants is improved. the cutting efficiency of the nutrient soil is improved, the nutrient soil is prevented from being adhered in the sleeve, the mixing operation of the nutrient soil is guaranteed, energy consumption and equipment investment are reduced, and the device is suitable for uniform mixing use of the nutrient soil.

Owner:陈萍

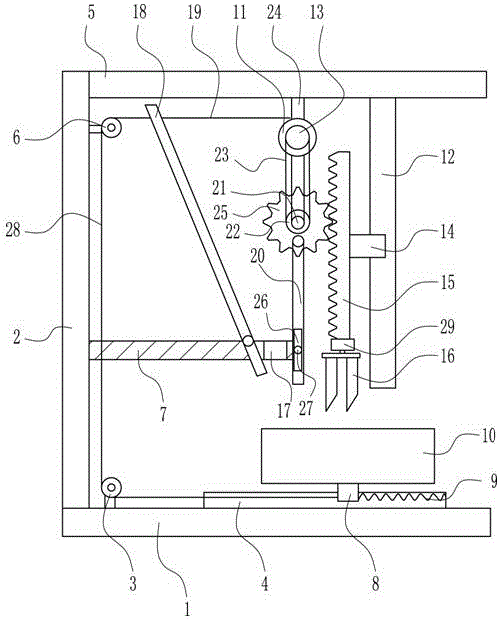

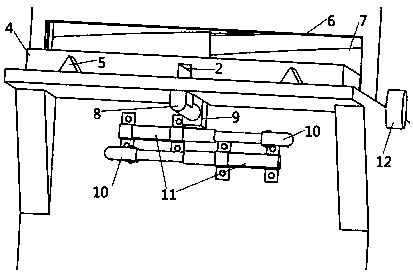

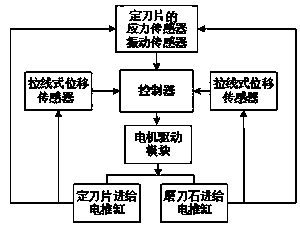

Ensiling machine cutter clearance adjusting and automatic sharpening device

PendingCN110786155AEasy to useImprove work efficiencyGrinding drivesCuttersKnife bladesStress sensors

The invention discloses an ensiling machine cutter clearance adjusting and automatic sharpening device which comprises a clearance adjusting mechanism and an automatic sharpening mechanism. The clearance adjusting mechanism is provided with a fixed blade feeding electric push cylinder, a stay-wire displacement sensor, a stress sensor and a vibration sensor, and a controller controls working of thefixed blade feeding electric push cylinder; the automatic sharpening mechanism is provided with an electro-hydraulic push rod and a sharpening driving electric push cylinder, the driving end of the electro-hydraulic push rod is connected with fixed sharpening stone, the electro-hydraulic push rod pushes the sharpening stone to be close to or away from a movable blade, and the sharpening driving electric push cylinder drives the sharpening stone to be in reciprocating motion along the length direction of the movable blade; the automatic sharpening mechanism is provided with a displacement sensor for monitoring motion of the electro-hydraulic push rod, and the displacement sensor is mounted in hydraulic oil inside the electric push hydraulic cylinder. A clearance between the movable blade and the fixed blade can be adjusted automatically, the sharpening mechanism is controlled by the automatic sharpening system to complete grinding of the movable blade, and cutting-up effect is ensured.

Owner:SHANDONG UNIV OF TECH

Waste paper pulverizing device for carton printing

The invention relates to a pulverizing device and particularly relates to a waste paper pulverizing device for carton printing. The waste paper pulverizing device facilitates recovery of the pulverized waste paper. The waste paper pulverizing device for carton printing comprises a bottom plate, n-shaped rods, a crushing box, a discharging hopper, a feeding hopper, a first roller, a first blade, afirst pulley, a flat belt, a cylinder and a second pulley. The n-shaped rods are installed in the middle of the top of the bottom plate. The right side of the outer top of the n-shaped rod is providedwith a pulverizing box. The top of the pulverizing box is provided with the feeding hopper. The feeding hopper is communicated with the interior of the pulverizing box. The lower part in the pulverizing box is provided with the discharging hopper. The lower part of the discharging hopper is located below the n-shaped rods. A sorting device can collect waste papers so that people facilitates wastepaper treatment. Through a compression device, the waste paper does not fall off from the feeding hopper. The waste paper pulverizing device saves time and labor, has good pulverizing effects and facilitates collection of the waste papers.

Owner:叶财明

Preparation method of environment-friendly and healthy cauliflower yield-increasing fertilizer

InactiveCN107721625ASufficient nutritionReduce usageAlkali orthophosphate fertiliserExcrement fertilisersFiberPotato starch

The invention discloses a preparation method of environment-friendly and healthy cauliflower yield-increasing fertilizer. The preparation method comprises the following steps: uniformly mixing and grinding radish leaves, fermented castor oil meal, manioc waste, fermented horse manure, shrimp shell powder and active carbon, adding water, uniformly stirring, adding urea, potassium poly-phosphate andplant ash, and uniformly mixing to obtain a prefabricated material; mixing borax potassium, zinc humate, borax, urea and iron tri-nitrate ([Fe(H2NCONH2)6](NO3)3), copper humate, calcium humate and manganese humate, adding water, heating and stirring, adding the prefabricated material, zeolite powder, diatomite, attapulgite, rice bran oil, vinasse, composite fiber and potato starch, uniformly mixing, granulating, and drying to obtain the environment-friendly and healthy cauliflower yield-increasing fertilizer. A composite fiber is prepared by adopting the following process: spinning gutta-percha, then sending into a vacuum container, adding gelatin and water, adjusting the temperature, vacuum stirring, vulcanizing by adopting sulfur, and cooling to obtain the composite fiber.

Owner:定远县诚信种植专业合作社

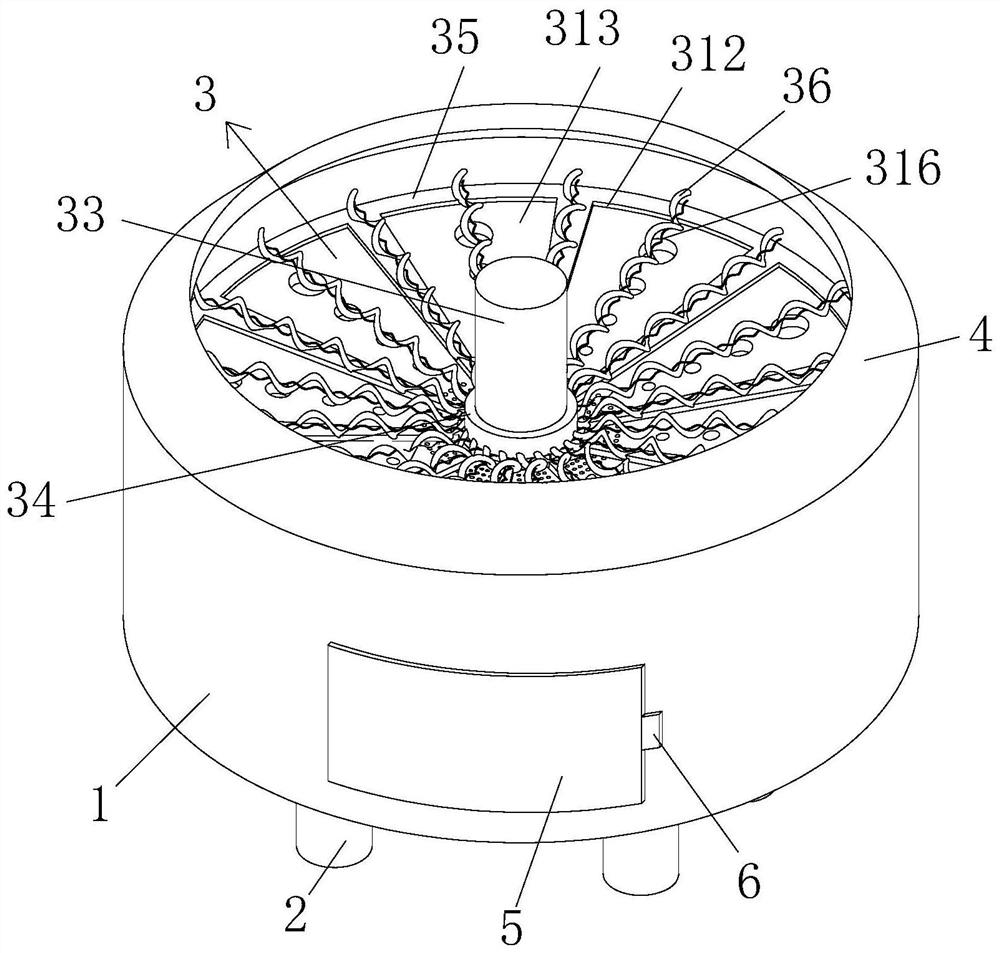

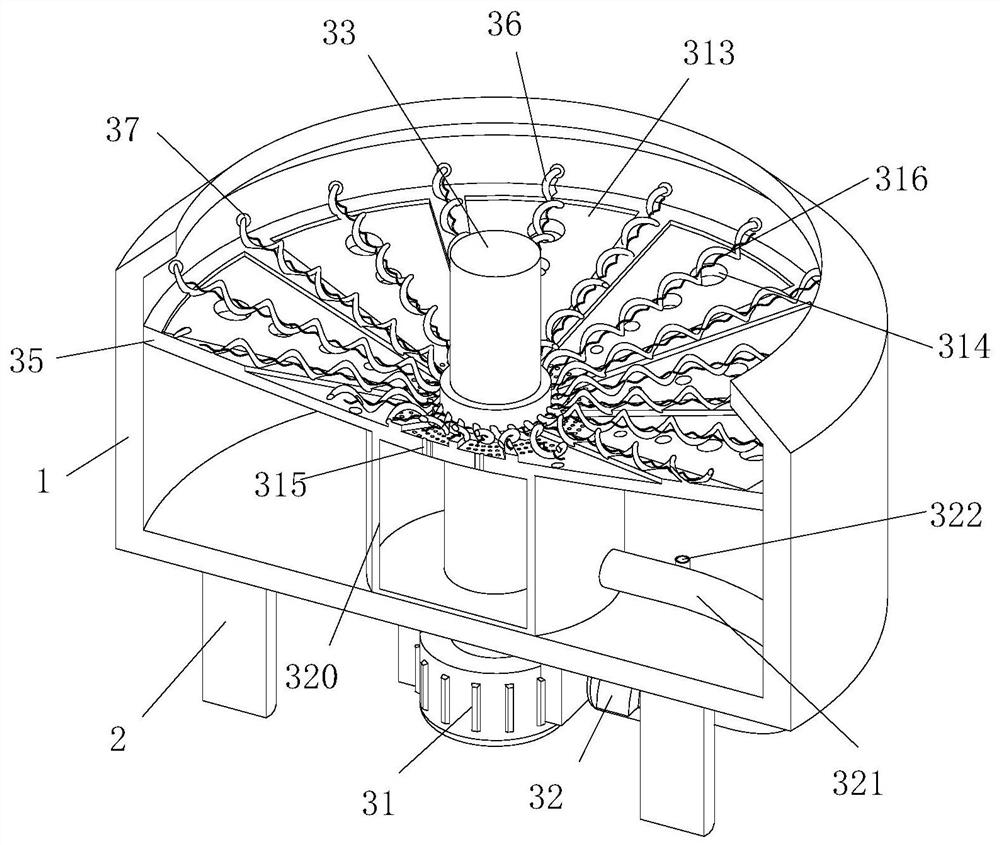

Fresh kelp smashing device

The invention provides a fresh kelp smashing device, and relates to the field of fresh food processing. The fresh kelp smashing device comprises a kelp smashing barrel used for smashing fresh kelp, supporting legs used for supporting the kelp smashing barrel and a spiral cutting and beating mechanism used for cutting and beating the kelp, the supporting legs are fixedly connected to the bottom of the kelp smashing barrel, the spiral cutting and beating mechanism is arranged on the kelp smashing barrel, and the surface of the kelp smashing barrel is in a circular shape. According to the fresh kelp smashing device, a special structure capable of rapidly smashing the kelp is designed to solve the problem of secondary cooking of the kelp in existing kelp food processing, the secondary cooking procedure can be reduced, the food taste is enhanced, and the problems that the order of food processing steps is easily affected, the food processing efficiency is affected, and the food taste is further affected to a certain extent due to the fact that a common fresh kelp smashing device is difficult to damage and smash the structure of the fresh kelp are effectively solved.

Owner:濉溪初新工业设计有限公司

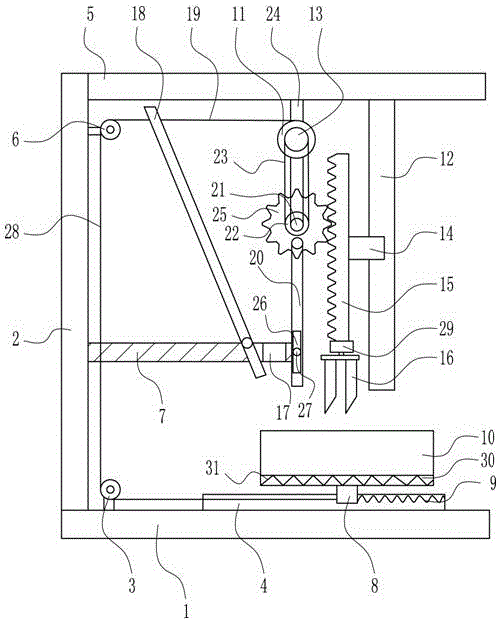

Shredding device for sodium alginate extracting raw material

ActiveCN106799752APrevent fallingIncrease feed rateMetal working apparatusGear wheelTransmission belt

The invention discloses a shredding device for a sodium alginate extracting raw material and discloses a device for shredding a dried brown algae material during sodium alginate extracting, the brown algae shredding efficiency can be effectively improved, and the shredding effect is improved. The shredding device is characterized in that one ends of two supporting rods are perpendicularly arranged on the edge of the base; the middle portion of a main supporting frame is perpendicularly arranged at the other ends of the supporting rods; the middle portion of an auxiliary supporting frame is perpendicularly arranged at the other ends of the supporting rods; a certain gap exists between the main supporting frame and the auxiliary supporting frame; one side of a main floor stand is perpendicularly arranged on one side of the main supporting frame; one side of an auxiliary floor stand is perpendicularly arranged on one side of the auxiliary supporting frame; two transmission rollers are arranged on the two sides of the main supporting frame through fixing shafts, and one transmission roller is arranged on the other side of the main floor stand through a fixing shaft; the three transmission rollers are connected through a main transmission belt; a main driven gear is arranged on the fixing shaft on the side, close to the auxiliary supporting frame, of the main supporting frame; a pressing plate is arranged on the main floor stand; and a clearance is reserved between the pressing plate and the main transmission belt.

Owner:玉环汉普阀门有限公司

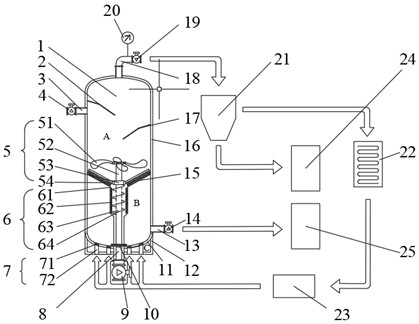

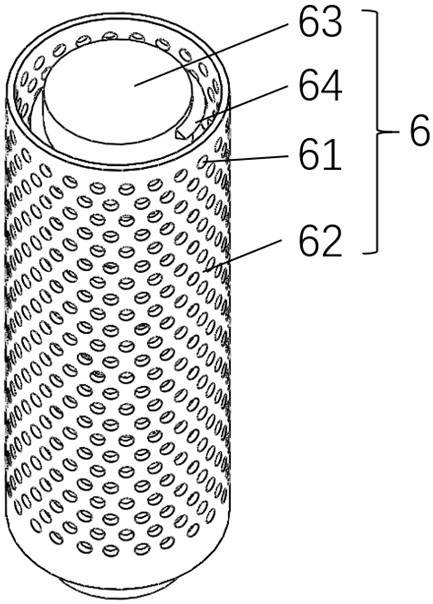

Vertical oil filter

PendingCN112807837AEasy to chopEasy dischargeTreatment with plural serial refining stagesRefining by filtrationFuel oilNitrogen gas

The invention relates to a vertical oil filter, and belongs to the technical field of oil exploitation and separation. The filter comprises a vertical tank body, a fan stirring device, a solid grinding device and a bubbling air inlet device. The vertical tank body is provided with a liquid inlet, an exhaust port, an oil discharge port, a slag discharge port and an inclined filter screen. The inclined filter screen is located in the middle of the vertical tank body and divides the vertical tank body into a solid-liquid mixing area and a gas-liquid mixing area. The fan stirring device is provided with a baffle brush and is connected with the solid grinding device in a concentric circle mode. The inner pipe wall in the solid grinding device surrounds the spiral blade, and the outer pipe and the annular space are provided with fine filter screen openings. The bubbling air inlet device is located at the bottom of the vertical tank body, and filter cotton is arranged in each air hole. According to the vertical oil filter, solid and liquid can be separated, the quality of oil is improved, nitrogen is circularly filled into the oil in a condensation and high-temperature heating mode, light oil and heavy oil are separated according to different boiling points of the oil, production of oil products is better achieved, the viscosity of the oil is reduced, and flowing of the heavy oil is facilitated.

Owner:FUJIAN AGRI & FORESTRY UNIV

Plastic bottle flatting method

InactiveCN106738461AWon't reboundQuality improvementPlastic recyclingEngineeringMechanical engineering

The invention belongs to the field of plastic pressing methods and particularly discloses a plastic bottle flatting method. A plastic bottle falls to a conveying belt and topples toward a first high-temperature roller. The first high-temperature roller rotates to flat the plastic bottle. A rotating second high-temperature roller flats the plastic bottle once more. A rotating rotary roller continues to fully flat the plastic bottle. The plastic bottle which is fully flatted moves to the position below a water spraying device. The plastic bottle is cooled through water sprayed out of the water spraying device. Cutting-up work of the next step can be conducted on the cooled plastic bottle. By means of the plastic bottle flatting method, the plastic bottle can be fully flatted, and the flatted plastic bottle has brittleness.

Owner:重庆市永川区玉江塑料厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com