Patents

Literature

445 results about "Brown algae" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The brown algae (singular: alga), comprising the class Phaeophyceae, are a large group of multicellular algae, including many seaweeds located in colder waters within the Northern Hemisphere. Most brown algae live in marine environments, where they play an important role both as food and as habitat. For instance, Macrocystis, a kelp of the order Laminariales, may reach 60 m (200 ft) in length and forms prominent underwater kelp forests. Kelp forests like these contain a high level of biodiversity. Another example is Sargassum, which creates unique floating mats of seaweed in the tropical waters of the Sargasso Sea that serve as the habitats for many species. Many brown algae, such as members of the order Fucales, commonly grow along rocky seashores. Some members of the class, such as kelps, are used by humans as food.

Marine algae extract and glycosidase inhibitor containing the same

InactiveUS20070122493A1Enhanced inhibitory effectTreat and/or prevent diabetes more effectivelyBiocideMetabolism disorderAscophyllumGlycoside

A glycosidase inhibitor comprising as an active ingredient an extract of Ascophyllum nodosum which is a kind of brown algae can be used as a useful healthy food or food for specified health uses for the treatment and / or prevention of diabetes.

Owner:RIKEN VITAMIN COMPANY

Fucoidin ester as antiviral immunoregulator and its prepn

InactiveCN1344565AHigh yieldSimple and fast operationPharmaceutical non-active ingredientsImmunological disordersShrimpReverse osmosis

Owner:汤洁 +1

Method for extracting active polysaccharides from brown algae

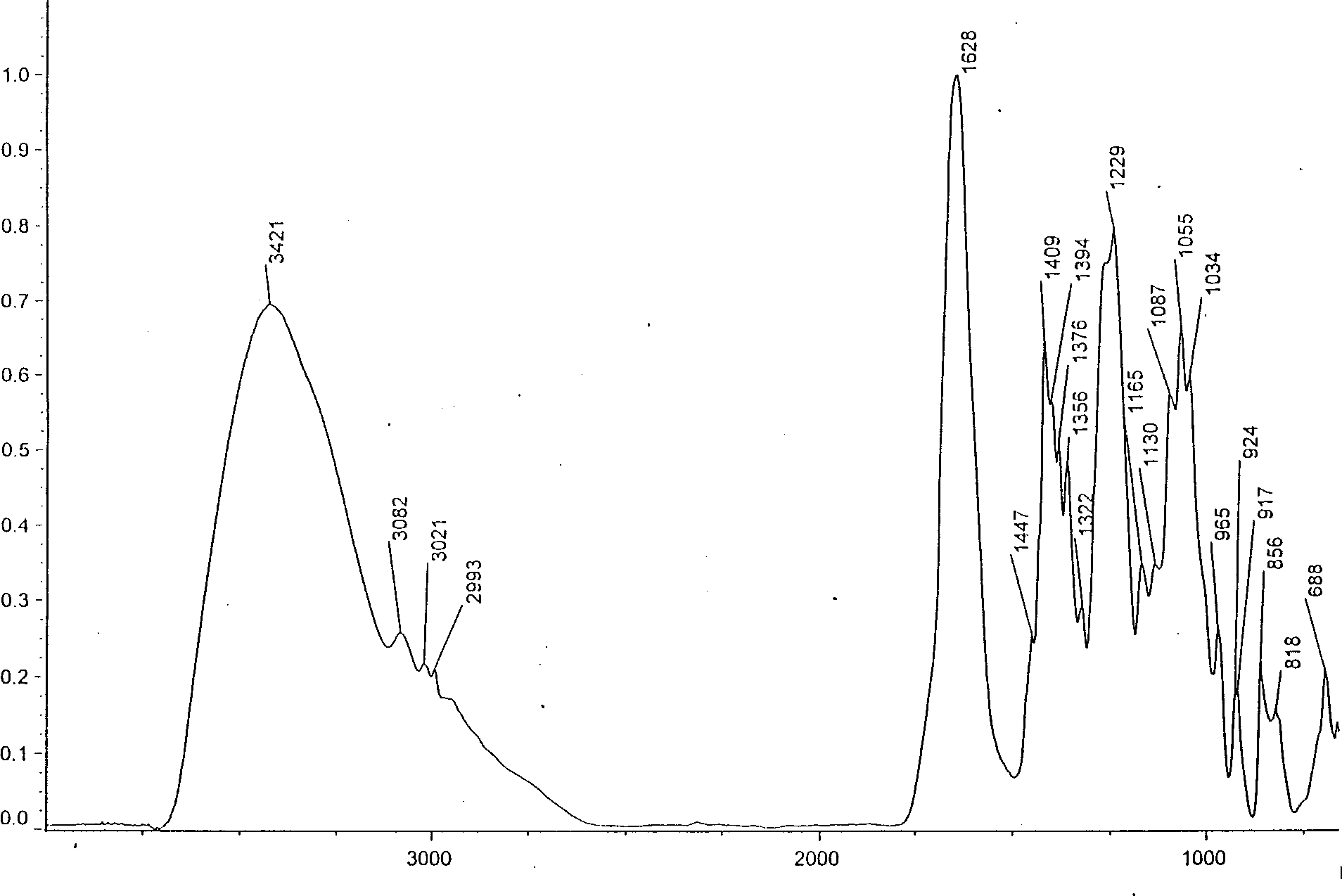

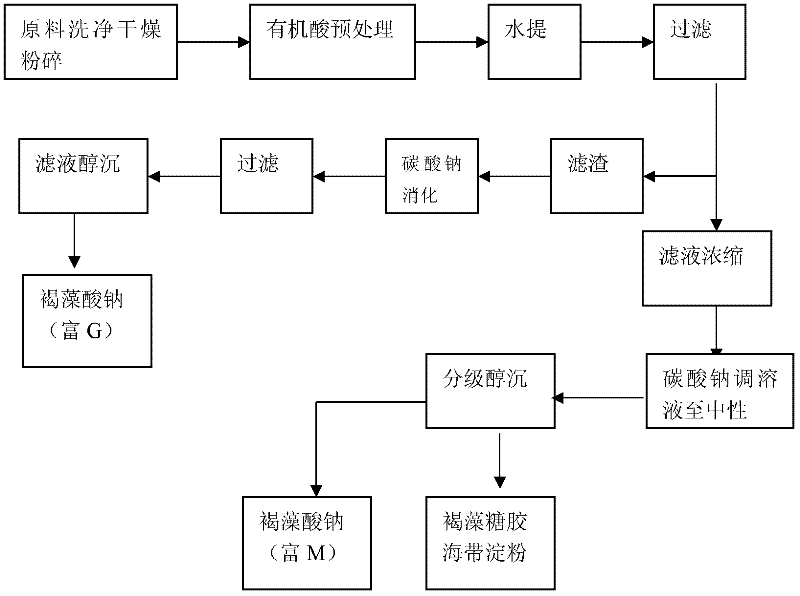

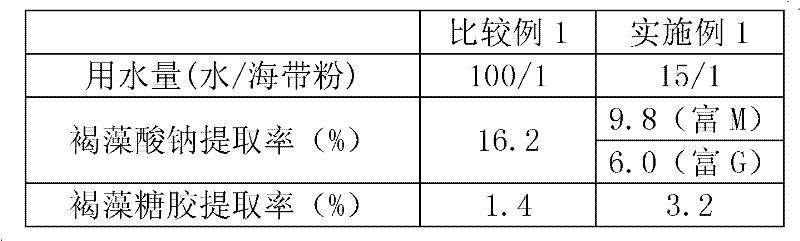

The invention relates to a method for extracting active polysaccharides from brown algae. The method comprises the following specific steps of: putting a cleaned, dried and smashed alga raw material into an extraction container, and adding an organic acid solution or organic-inorganic mixed acid solution; heating a stirred and wetted material to 50-150 DEG C to realize partial degradation of highpolymer polysaccharide substances of brown algae; fully washing with an organic solvent till the acid solution in the material is discharged completely; adding 5-8 times of volume of water for extracting, concentrating an extracting solution, regulating the PH value to neutral, and gradually depositing in alcohol to obtain align, fucoidin and laminaran which are rich in mannuronic acid fragments (rich in M) respectively; and pretreating brown alga raw material residues with water-extracted organic acid according to an alkali digestion process to obtain align which is rich in guluronic acid fragments (rich in G). By adopting the method, the defects of high water consumption, severe pollution and the like existing in the conventional align production process are overcome; and the method has the advantages of saving in energy, reduction in emission, high product yield, small extraction solvent dosage, and the like.

Owner:张劲松

Method for preparing low molecular weight brown seaweed fucoidan sulfate

InactiveCN101962415AAutomatically consumed completelyEffective separation and purificationAntiviralsAntineoplastic agentsSulfated polysaccharidesSeparation technology

The invention relates to a method for preparing low molecular weight brown seaweed fucoidan sulfate. The method comprises a step of oxidatively degrading brown seaweed sulfated polysaccharides by hydroxyl radical and a step of ultrafiltration membrane separation and purification, wherein raw sugar of the brown seaweed sulfated polysaccharide is used as a raw material, the hydroxyl radical generated by the reaction of copper ions and hydrogen peroxide is adopted to oxidatively degrade the raw sugar of the brown seaweed sulfated polysaccharide, and the membrane separation technology is combined in the method for preparing the low molecular weight fucoidan sulfate from the brown seaweeds. In the preparation process, the oxidizing speed is uniform, the reacting condition is mild, and the controllability and repeatability are good; the copper ions are removed by a chelating column after the oxidation reaction is finished, so the operation process is simple. Furthermore, the pH value is adjusted by adding little acid and alkali, so the salt content in the product is low, and can be completely removed by a 300Da ultrafiltration membrane in the ultrafiltration membrane separation and purification process. The ultrafiltration membrane can effectively separate and purify the brown seaweed fucoidan with different molecular weights along with high separating speed and large treatment amount. The method is suitable for industrial production.

Owner:OCEAN UNIV OF CHINA

Method for extracting fucoxanthin from brown algae

The invention relates to a method for extracting fucoxanthin from brown algae, which is characterized by comprising the following steps: pulping fresh brown algae, adding an organic reagent into the brown algae, and then adding 0.05 to 0.1 mass permillage of antioxidant into the brown algae; leaching the mixture for 22 to 26 hours, and performing suction filtration to obtain leaching solution; leaching the mixture repeatedly until an organic layer is colorless; combining the organic layer liquid of each time into a dark brown bottle; performing rotary evaporation on the organic layer liquid to remove an organic solvent; adding ethyl acetate and water according to a volume ratio of 1:1-2 into an adherence material obtained in a rotary evaporation utensil, oscillating the mixture for layering after dissolving the adherence material, collecting the organic layer, and repeating the operations for 3 to 6 times; combining each organic layer liquid and then performing rotary evaporation and concentration to obtain a total pigment of the brown algae; and separating and purifying the total pigment by using silica gel column chromatography to obtain the high-purity fucoxanthin. The fucoxanthin prepared by the method has high purity, and the method has simple and practical operation, is convenient for industrial production, and provides a basic condition for further development of correlative industrial products and medicines and health care products aiming at the market vacancy of the high-purity fucoxanthin at home and abroad.

Owner:OCEAN UNIV OF CHINA

Topical skin care composition

Topical skin care compositions containing a combination of ascorbic acid or a derivative thereof, brown algae extract, and a blend of botanical extracts comprising cucumber extract, watercress extract, birch leaf extract, red clover extract, and St. John's wort extract, and, optionally, ginseng extract, as well as methods of using the same, are disclosed.

Owner:ARBONNE INT

Method for preparing calcium alginate

The invention provides a method for preparing calcium alginate, comprising the following steps: soaking brown algae, and adding soda ash to digest and extract an alginic acid; washing and dehydrating; granulating; carrying out cryogenic grinding; calcifying; dehydrating; drying and grinding. The flocculent alginic acid is changed into powder in the process of preparing to be convenient for subsequent processing. The prepared calcium alginate has good stability, safety and flowability and is easy to disperse when in use. As the processes of cryogenic grinding and liquid-phase calcifying are adopted, the quality of the product can be improved, the drying can be carried out easily, and the scale production can be achieved. As the alga powder is dispersed into an organic solvent, and a calcifying agent is added to calcify, the purifying can be carried out while calcifying. The final product can be used for producing pharmaceutical products, cosmetic products and other high-end products.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Process for preparing fucoidan by enzymatic hydrolysis of brown algae

The enzymically hydrolysis process of preparing fucan sulfate with brown algae includes the following steps: compounding composite cellulase with cellulase and pectase; enzymolyzing brown algae material via adding the composite water and cellulase at pH 6.0-8.0 for 50-80 min; heating at 90-100 deg.c in water bath for 3-4 hr, cooling to room temperature and centrifuging to obtain supernatant; adding alcohol to the supernatant to produce precipitate and centrifuging to obtain the second supernatant; adding alcohol to the second supernatant to produce precipitate and collecting the precipitate; washing the precipitate and vacuum freeze drying to obtain white powder. The said process has high extraction rate, low product cost, and less environmental pollution.

Owner:DALIAN FISHERIES UNIVERSITY

Method for extracting brown algae polysaccharide sulfated

The invention relates to ocean chemical engineering technique field, concretely is a method for extracting fucoidan from a kelp soak solution, which includes steps: adding 1-10 ml flocculant to kelp soak solution per 150 ml, stirring for 2-10 min, flocculating for 10 min to 8 h, swelling for 1-24 h under condition that pH is 2-6 after centrifuging and depositing, stirring for 1-4 h to dissolve, filtrating and adjusting the filtrate to neutrality, decompressing and concentrating, adding ethanol to the concentrated solution, filtrating to obtain deposition, washing and drying the deposition to obtain the fucoidan. The invention relates to employs chitosan and its derivative as flocculant to flocculate and deposit ''sugar glue'' from kelp soak solution, and then extracts fucoidan from the ''sugar glue''. The advantages of the invention are: resources are utilized comprehensively, operation is simply, quantity of used acid and base is reduced, and quantity of the obtained fucoidan reaches 5-16% of quantity of the deposition.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Preparation method of low-molecule brown seaweed glucan

ActiveCN102153669ARealize comprehensive utilizationPlant growth regulatorsAmyrisHydrogen peroxide degradation

The invention belongs to a preparation method of low-molecule brown seaweed glucan. Alkali carbonate solution is used for breaking up seaweed tissue and cells, acid is used for adjusting a pH value to be proper, alginic acid, brown seaweed polysaccharide and brown seaweed starch are extracted from the seaweed tissue and the cells, and the starch is degraded with hydroxide to turn into the brown seaweed glucan with the average molecular weight being 800-1000 Dalton. As reported, the brown seaweed glucan with the low molecular weight can enhance the immunity of a human body and the stress resistance of plants.

Owner:北京雷力联合海洋生物科技有限公司

Method for producing sodium alginate by applying brown algae

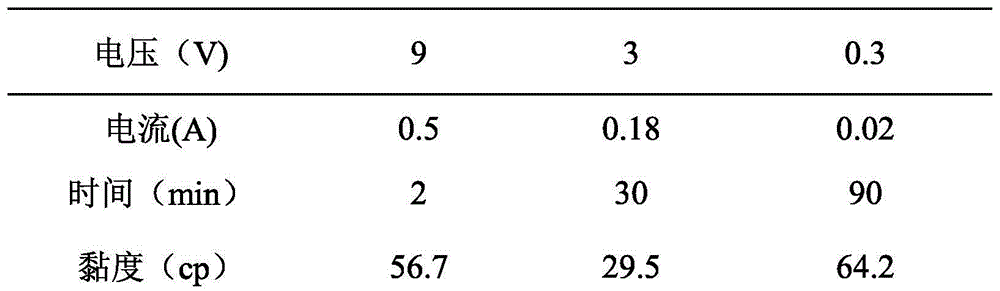

The invention discloses a method for producing sodium alginate by applying brown algae. The method is characterized by treating the brown algae by utilizing a fenton method to obtain a treatment product and extracting the sodium alginate from the treatment product, wherein the particular process of treating the brown algae by utilizing the fenton method comprises the following steps of soaking the brown algae in a ferrous ion solution, wherein the weight ratio of the brown algae and ferrous ions in the ferrous ion solution is (500:1)-(10:1); then adding a hydrogen peroxide solution to the ferrous ion solution, and treating for 1-100 minutes, wherein the amount of substance ratio of the ferrous ions and hydrogen peroxide in a mixed solution is not lower than 1:1. The method disclosed by the invention has the advantages of low energy consumption, convenient operation, low water consumption and fast degradation, is used for increasing the output of the sodium alginate produced by applying the brown algae and especially provides a simple, convenient and effective method for producing the low-viscosity sodium alginate.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Sea weed polysaccharide and its derivatives used for cigarette filter tip additives

InactiveCN1682614AReduce alkoxy radicalsTobacco smoke filtersFree Radical SuppressionCigarette filter

The present invention discloses the application of algal polysaccharide and its derivatives as cigarette filter tip additive. The said algal polysaccharide is polysaccharide of brown algae, red algae and blue-green algae; and the algal polysaccharide derivatives are algal polysaccharide Simth degrading product or aldehyde decomposing product. The algal polysaccharide and its derivatives may be loaded with carrier, active carbon, diatomite or molecular sieve, and the weight ratio between algal polysaccharide and its derivatives and the carrier is preferably 1-3. The cigarette filter tip with the additive has free alkoxyl radical inhibiting rate up to 20-63 % and certain tar eliminating effect.

Owner:INST OF CHEM CHINESE ACAD OF SCI

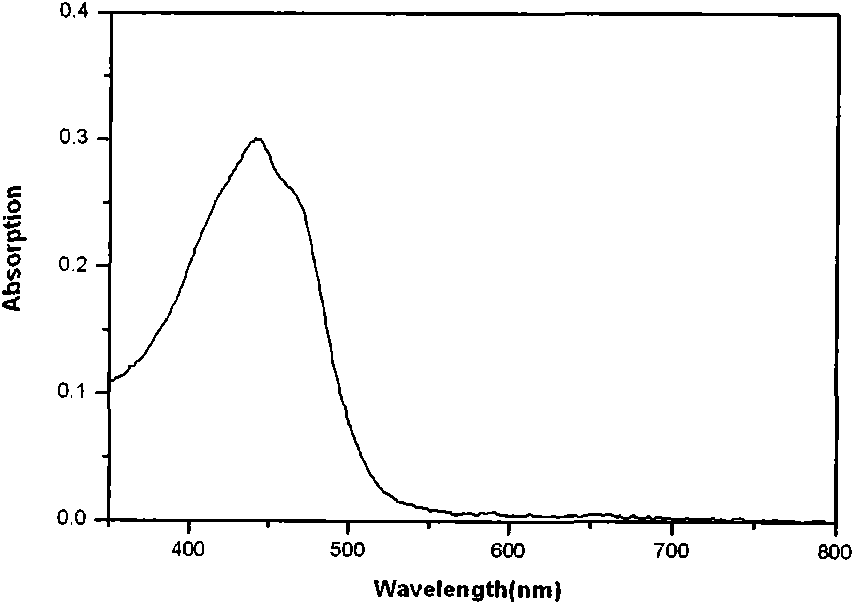

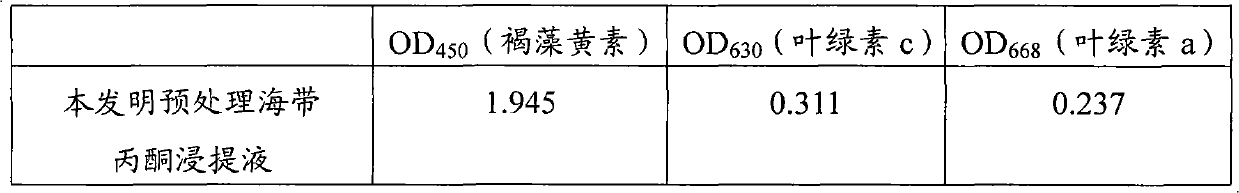

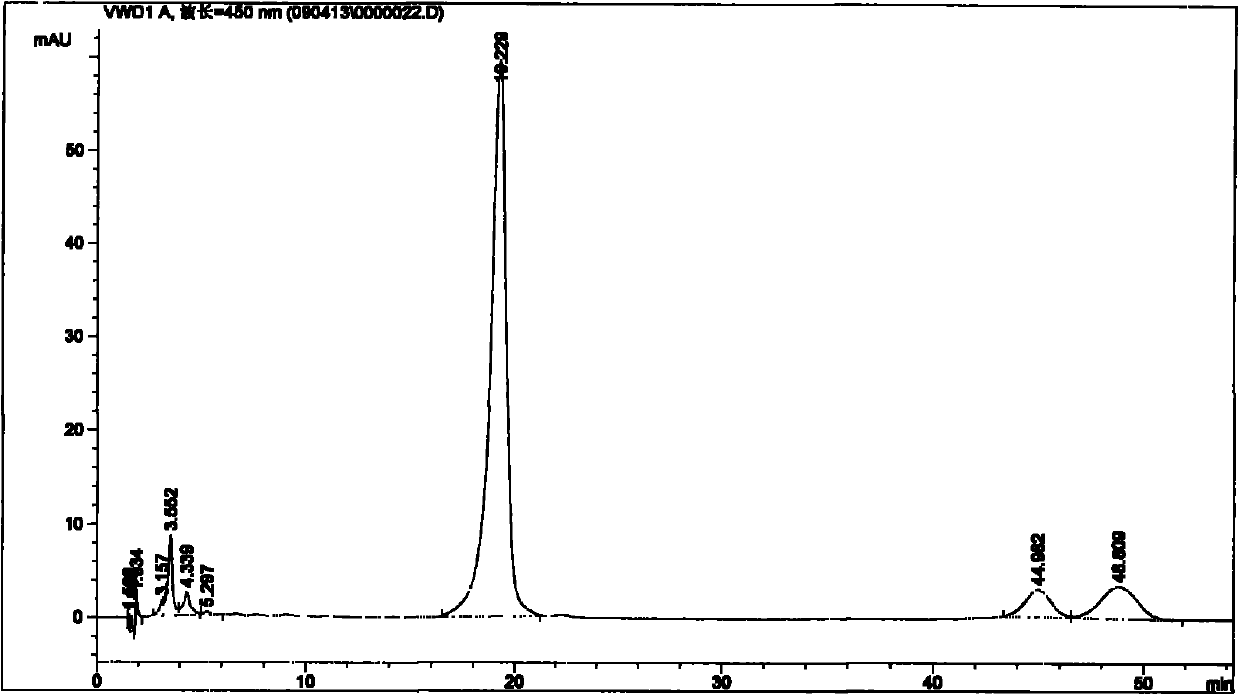

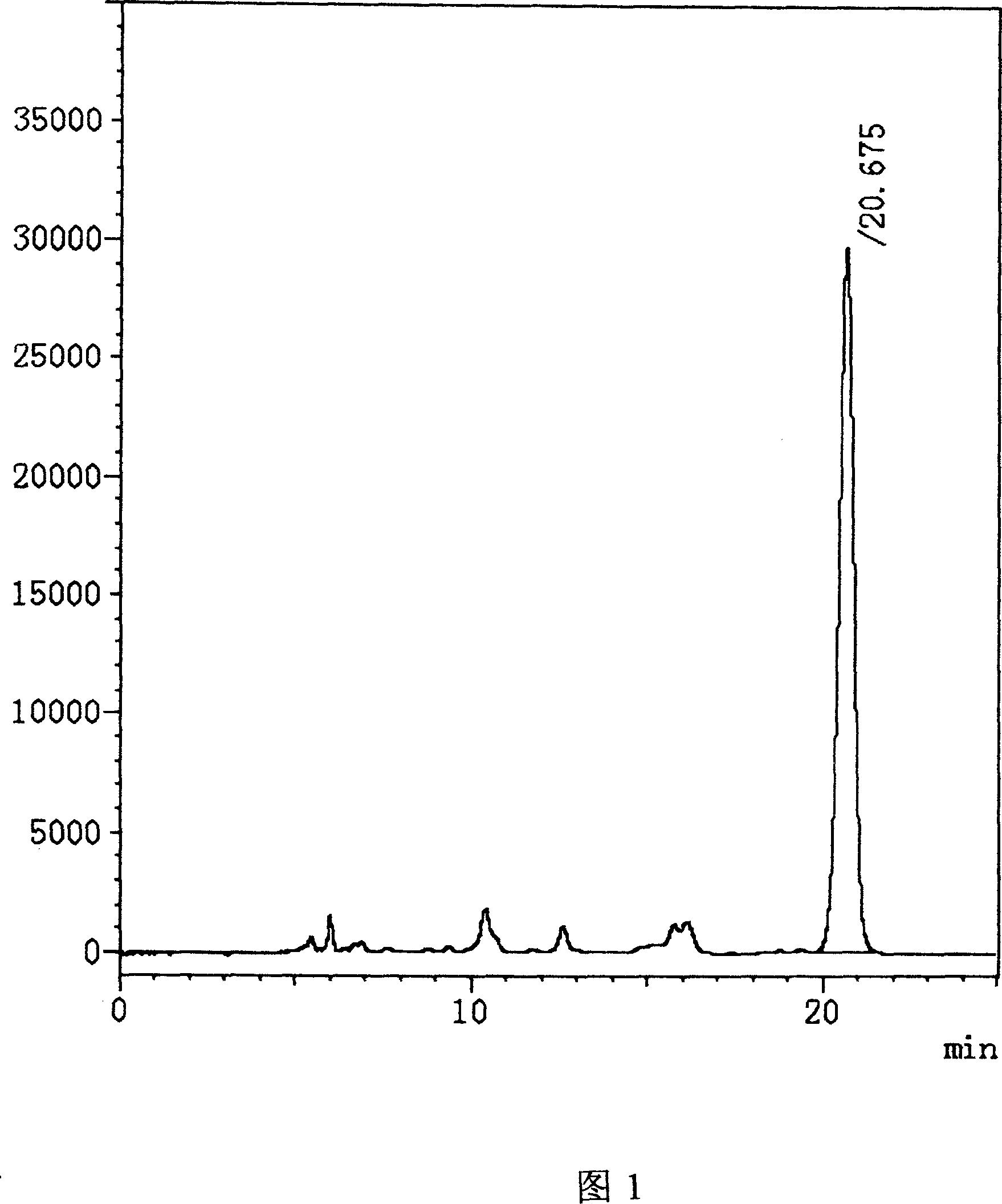

Method for extracting fucoxanthin from brown algae

The invention relates to a method for extracting fucoxanthin from brown algae. The method comprises the following steps of: performing water swelling pretreatment on the crushed brown algae, and leaching the brown algae by using a water-soluble organic solvent; purifying fucoxanthin in leaching solution by adopting an extraction method and twice column chromatography in turn; and finally, further purifying to obtain a fucoxanthin standard substance with the purity of over 90 percent or over 99 percent through preparative thin-layer chromatography or preparative high performance liquid chromatography. The method for extracting the fucoxanthin has the advantages of simple, economic and efficient technology, and capacity of providing an experimental basis for industrial production of the fucoxanthin and improvement of industrial utilization rate of the algae.

Owner:秦皇岛惠恩生物技术有限公司

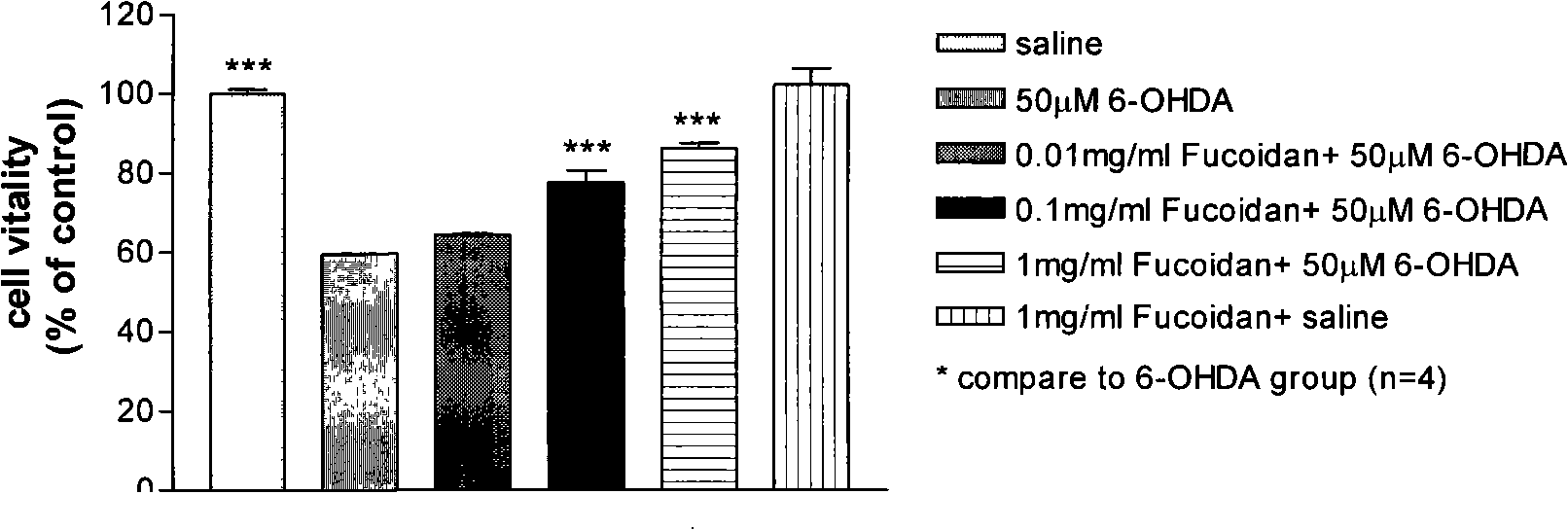

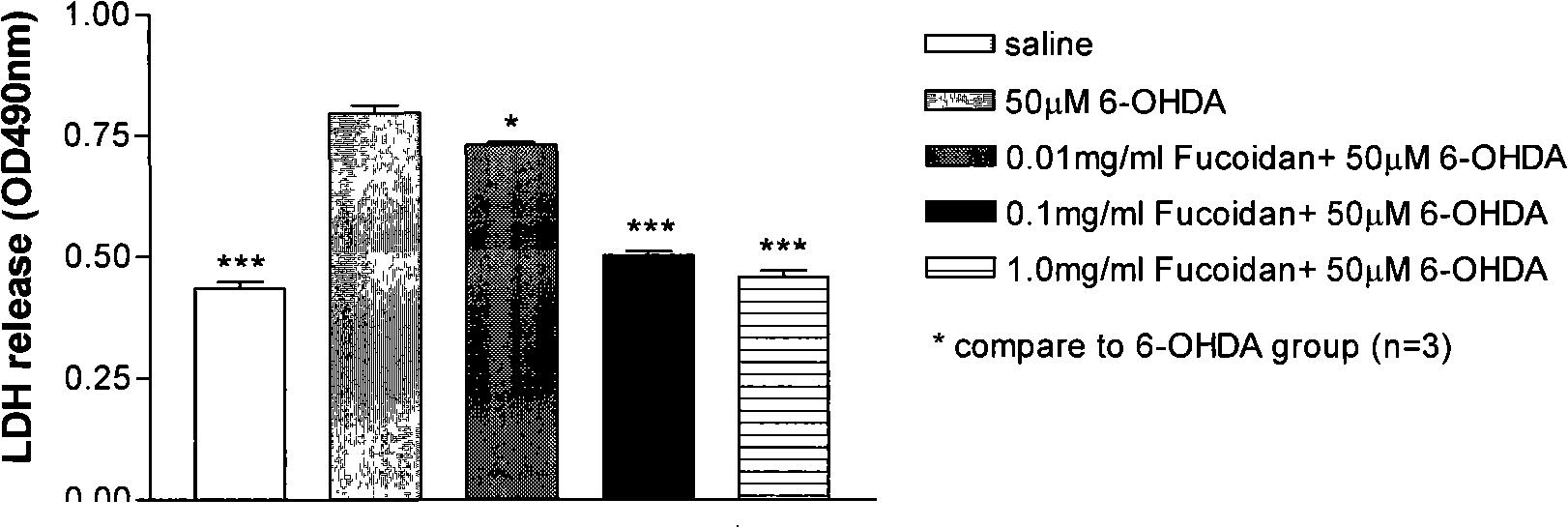

Use of brown alga polysaccharide sulfate in preventing and treating Parkinson's disease

ActiveCN101301310AImprove securityEnsure long-term medication needsOrganic active ingredientsNervous disorderCholinergic cellsSulfated polysaccharides

The invention discloses a novel application of fucoidan sulfate in prevention and cure of a parkinson disease. According to the experiments of an isolated PD cell model and an in vivo animal model, fucoidan sulfate has a certain neuroprotection effect on DA cholinergic neurons of the PD cell model and animal model and can prevent and cure the PD disease. The fucoidan sulfate of the invention can be natural polysaccharide extracts obtained form brown alga such as kelp, focus, bladder wrack, sea-tangle or chorda filum and also can be materials such as low molecular weight SSPSA or oligosaccharide which are obtained through the degradation of fucoidan sulfate.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES +1

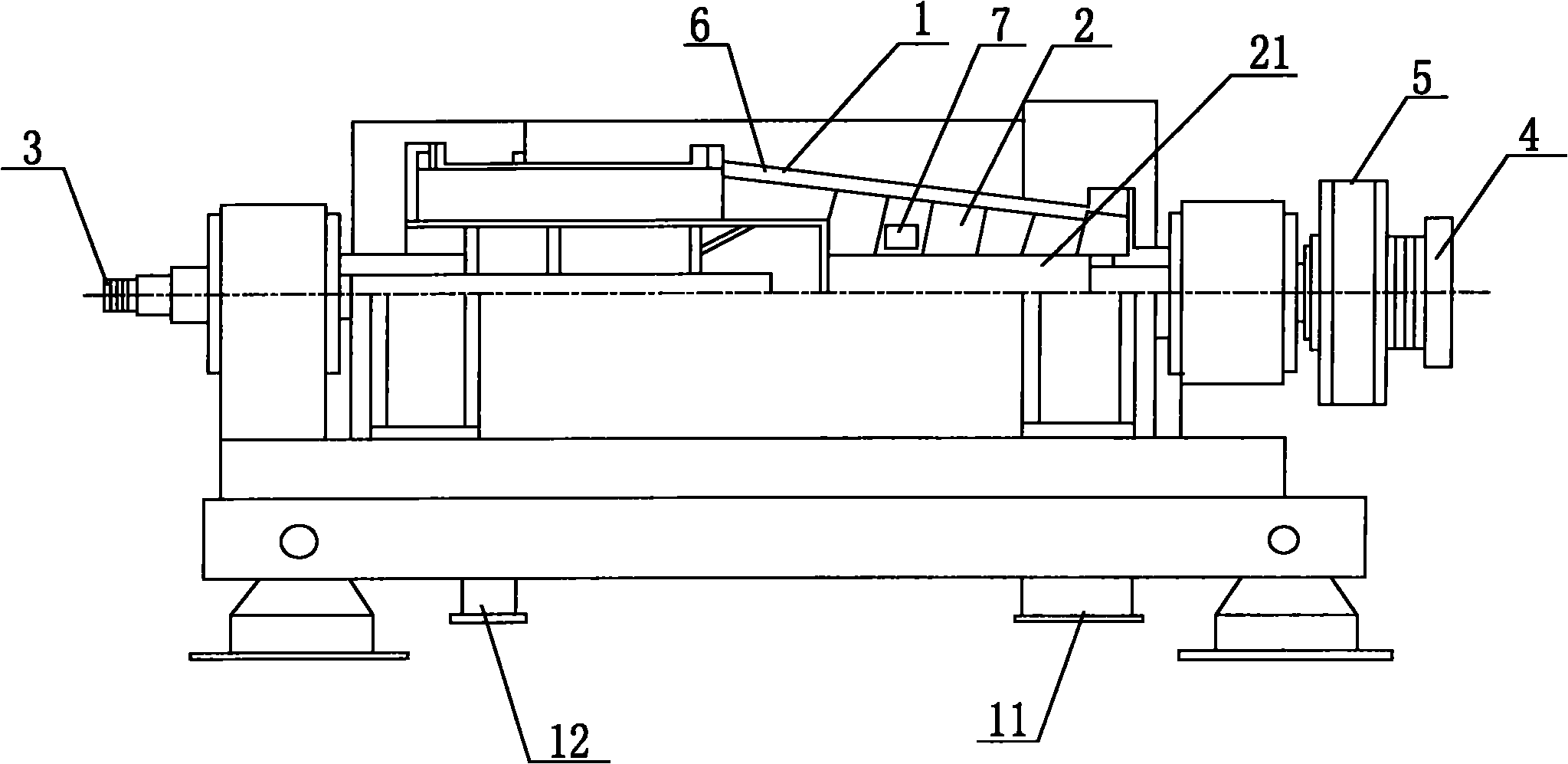

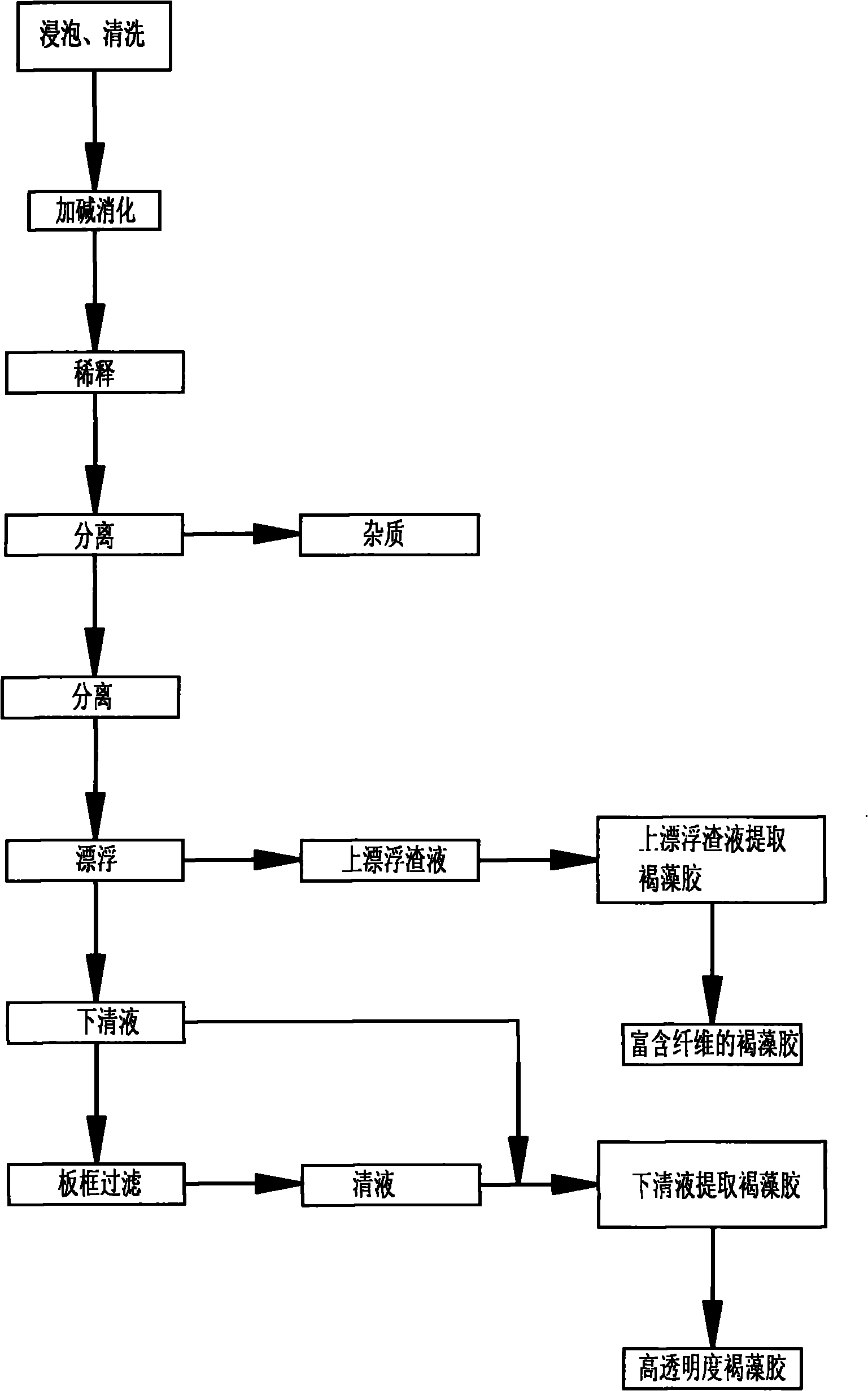

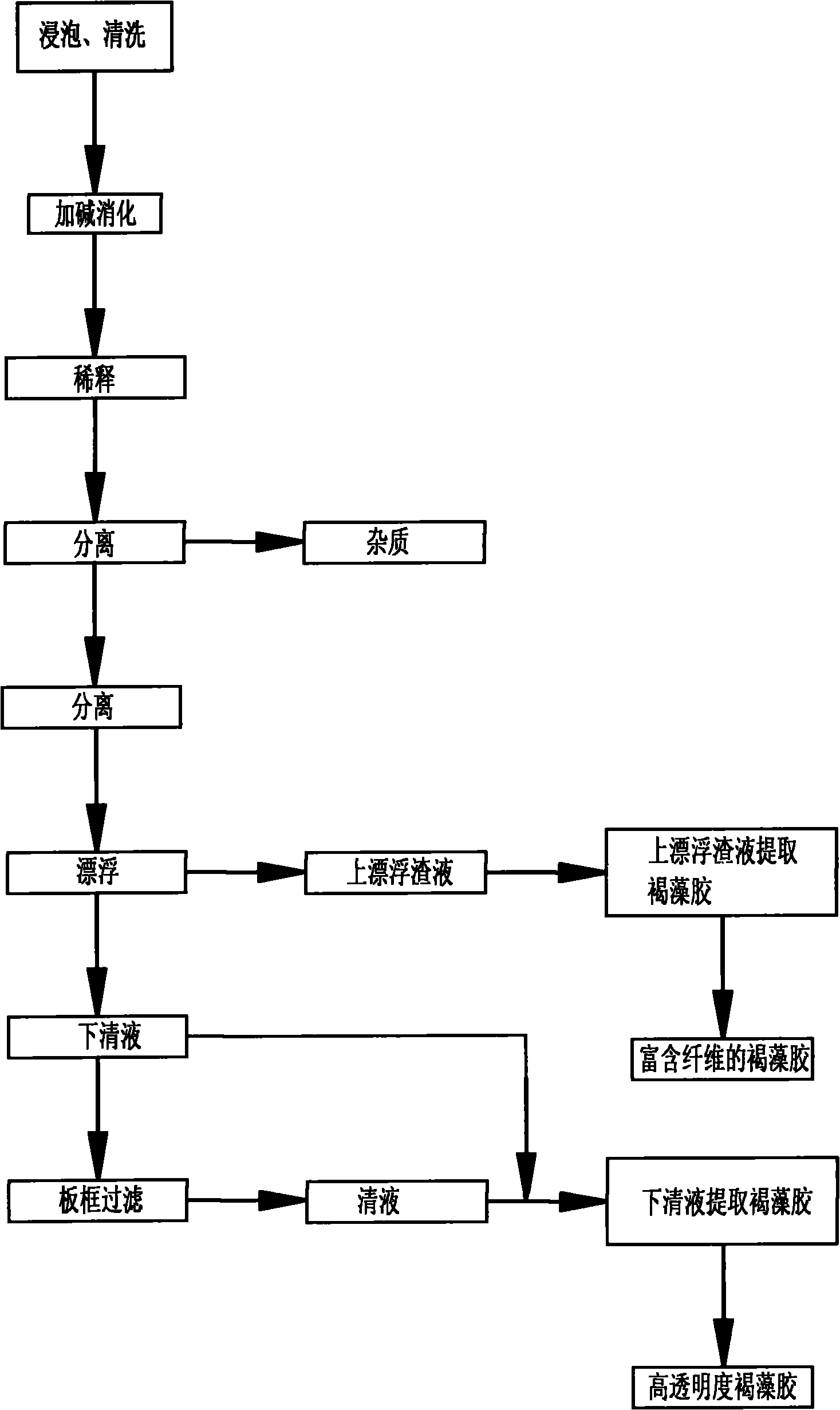

Method for extracting algin through comprehensively utilizing brown algae

The invention provides a method for extracting algin through comprehensively utilizing brown algae, which comprises the following process steps of: soaking and washing; adding sodium carbonate for digestion to obtain a digested glue solution; adding water to the digested glue solution and diluting to Engler viscosity of 110-200 seconds so as to obtain a diluted digested glue solution; separating and removing brown algae skin, silt and other impurities from the diluted digested glue solution with a horizontal spiral centrifuge to obtain a separating solution, and settling and floating the separating solution under the dissolved air foaming action of the centrifuge per se to obtain an upper floating slag solution and a lower clear solution; then extracting the upper floating slag solution to obtain algin rich in fibers; and directly extracting the lower clear solution or extracting after filtering with an added filter aid to obtain algin with different purities and qualities. Compared with the prior art, the method simplifies separation process, saves diluting water and improves the quality and the yield of the algin, and simultaneously can produce the algin rich in fibers as a byproduct. The method has cost advantage over comprehensive utilization.

Owner:江苏明月海洋生物科技有限公司

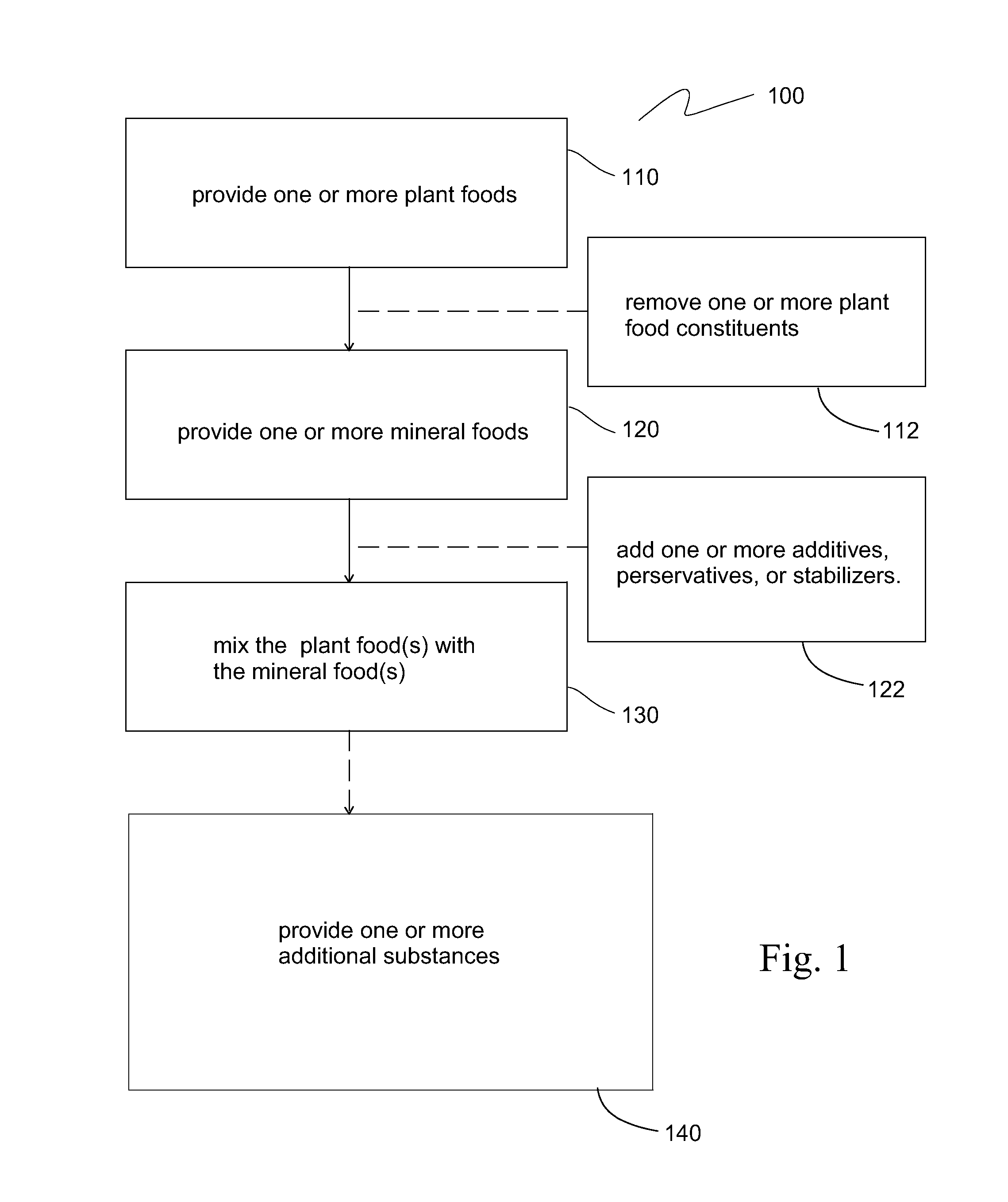

Nutritional composition

InactiveUS20130337116A1Improve overall utilizationConvenient oralOrganic active ingredientsMilk preparationSodium BentoniteCarrageenan

A nutritional composition containing a plant food and a mineral food, where the plant food includes at least one of aloe, green algae, red algae, brown algae, blue-green algae, kelp, kombu, hijiki, nori, arame, sea palm, bladderwrack, wakame, dulse, carrageenan, fungi, and bacteria. The mineral food includes at least one of shilajit, humic acid, fulvic acid, bentonite clay, charcoal, diatomaceous earth, dolomite, fossilized remains, rocks, gems, sodium chloride, sea salt, and derivatives or combinations thereof. In one embodiment of the composition, the plant food is a juice of aloe vera and the mineral food is fulvic acid.

Owner:PETRALIA ROSEMARY C

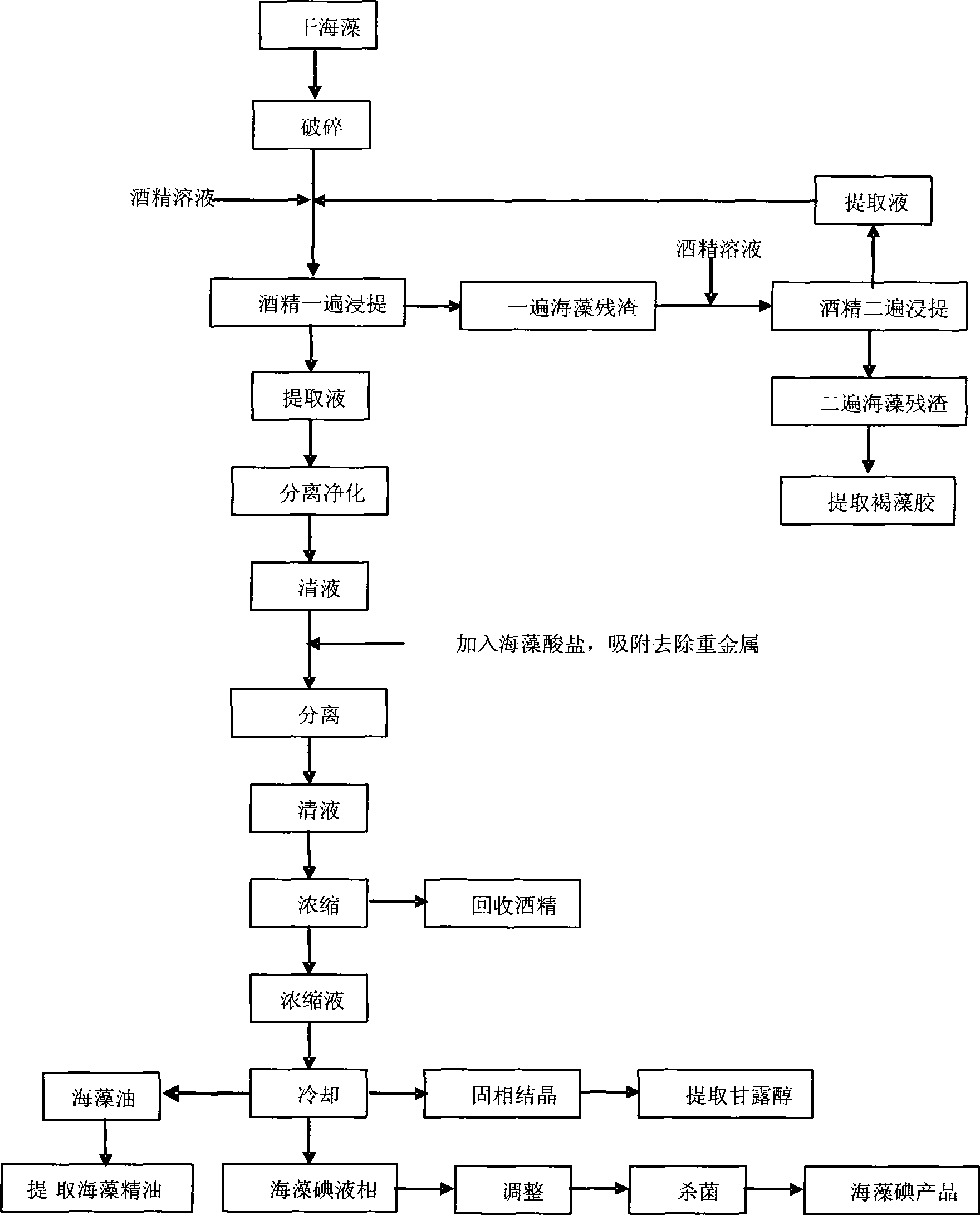

Method for extracting kelp iodine with comprehensive utilization of brown seaweed

ActiveCN101428761ARealize comprehensive utilizationSolve the problem of heavy metal residueHalogen/halogen-acidsBrown seaweedIodine

The invention provides a method for extracting iodine from kelp by comprehensively utilizing brown algae, and can solve the problems in the prior art that heavy metal is remained in the iodine from kelp. The invention adopts the brown algae as raw materials to prepare the iodine from kelp; in an extraction process, a principle that alginate from the brown algae absorbs the heavy metal is utilized, so as to solve the residue problem of the heavy metal in the iodine from kelp during the physical extraction process; and on the premise of ensuring the content of the iodine from kelp, the active ingredients of the kelp are remained to the maximum. At the same time of extracting the iodine from kelp, algae fine oil, algin and mannite are extracted by comprehensive utilization, so that the utilization rate of the kelp is increased to the maximum.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Method for producing sodium alginate and co-producing ethanol and seaweed organic fertilizer

InactiveCN103232554ARealize high-value comprehensive utilizationHigh extraction rateFermentationOrganic fertilisersIon exchangeDigestion

The invention discloses a method for producing sodium alginate and co-producing ethanol and a seaweed organic fertilizer. The method comprises the following steps of: with brown algae kelp serving as a raw material, pre-processing through cellulase and compound protease in an enzymolysis manner; decomposing cellulose in the kelp into microbially available monosaccharide and oligosaccharide in order to ferment to produce ethanol; preparing the seaweed organic fertilizer through the rest fermentation broth with little kelp residue; extracting and separating sodium alginate from the pre-processed kelp; and then performing a dilute alkali digestion technology and a calcium coagulating-ion exchange method to obtain high-quality sodium alginate. According to the method, the preprocessing is performed through bio-enzyme, and the main components, namely, cellulose, protein and the like in the kelp, are separated in advance through the cellulose and protease, thus high extraction rate of the sodium alginate is grained; simultaneously, wastes generated in processing are utilized to prepare a fuel, namely, ethanol; and the waste liquid and waste residues remained in ethanol preparation are utilized to prepare the seaweed organic fertilizer, therefore, high-valued utilization of the kelp is realized, and marine biomass energy is developed.

Owner:QINGDAO BETTER BIO TECH

Process of extracting algal brown pigment from brown alga and use thereof

InactiveCN100999508ABoost gene expressionAnti-cancerCosmetic preparationsOrganic chemistryFiltrationBrown pigment

This invention involves separation of brown algae; is a method of extract phycophacin from brown algae. The specific process is: brown algae as raw material, by 60-100% ethanol extraction, concentration, filtration to gain precipitation, macroporous resin column chromatography, spray drying to obtain products. Products content of 1% -20% (HPLC: High Performance Liquid Chromatography, HPLC). This invention is simple, separation result nice, and suitable for industrial production. The invention also involves brown algae in the health-food products, food and cosmetics field applications.

Owner:宋云飞

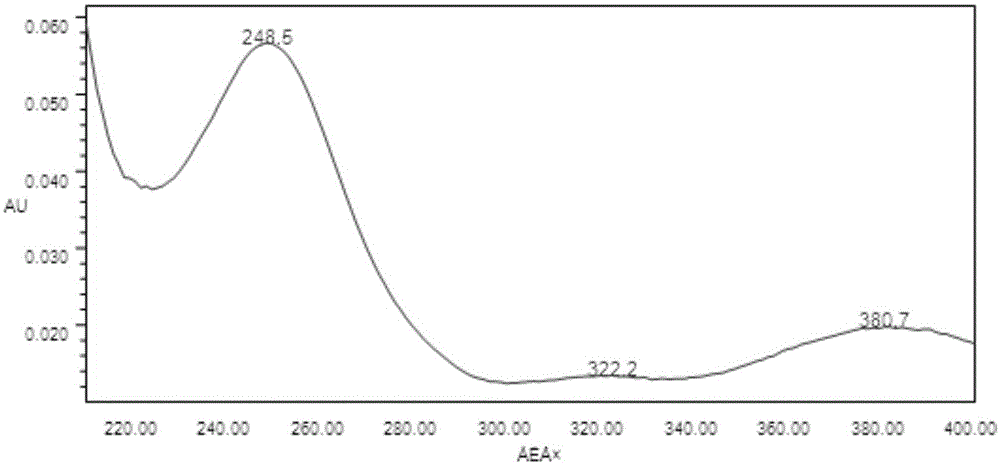

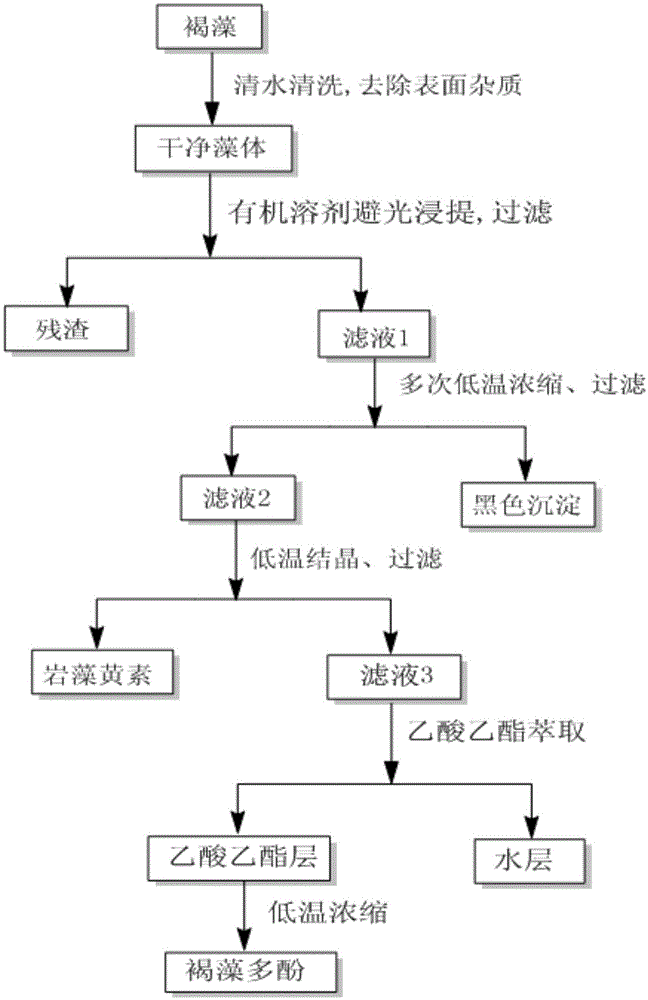

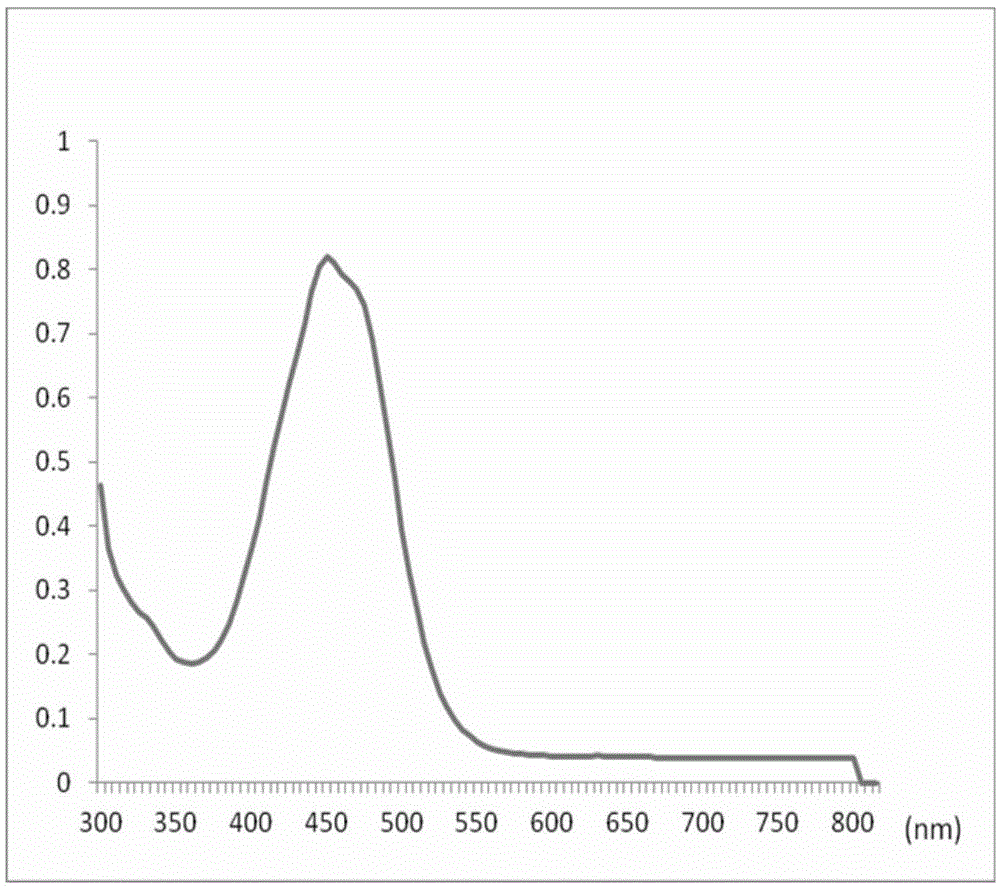

Method for comprehensively extracting fucoxanthin and brown alga polyphenol from gulfweed

ActiveCN105037300AEasy to operateLow costOrganic chemistryColor/spectral properties measurementsFreeze thawingFucoxanthin

Owner:NINGBO UNIV

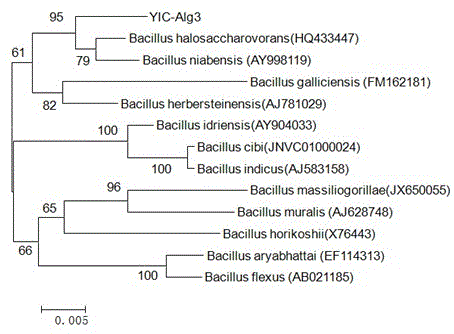

Bacillus saccharophila used for degrading alginic acid, and application method thereof

ActiveCN105936881AIncrease productionPromote growthBacteriaAlkali orthophosphate fertiliserLiquid mediumBacillus psychrosaccharolyticus

The invention relates to a Bacillus saccharophila used for degrading alginic acid, and an application method thereof. The application method comprises the following steps: 1, milling dried alga to form powder, adding water to the alga powder according to a certain ratio, filling a fermentation tank with the obtained solution, and sterilizing the solution at a certain temperature for a period of time; 2, preparing a seed liquid: screening a fermentation strain YIC~ALG3 capable of degrading alginic acid, inoculating the fermentation strain YIC~ALG3 to a 2216E liquid medium, and culturing the fermentation strain YIC~ALG3 overnight; and 3, adding the obtained seed liquid to the fermentation tank according to a certain mass ratio, fermenting the seed liquid under certain conditions, and processing a brown alga raw material through using microbial fermentation to prepare an alga liquid. The fermentation process is stable and controllable, the fermentation period is short, and the alga liquid has substantial efficacy, and is suitable for large-scale production.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI +1

Method for extracting brown algae polyphenols

InactiveCN103610704AReduce the degree of oxidationPrevent oxidationInorganic non-active ingredientsAlgae medical ingredientsBiological bodyFreeze-drying

Owner:WEIHAI YUWANG GROUP

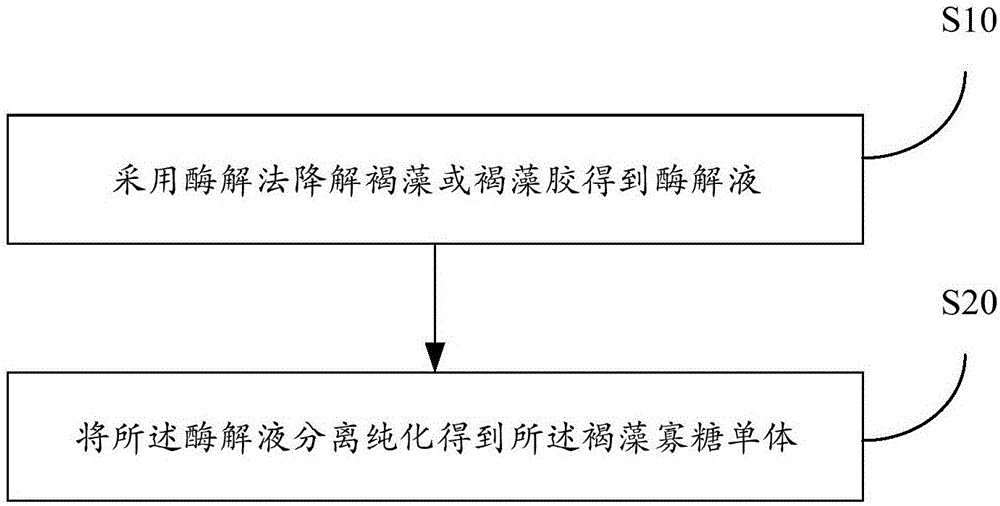

Preparation method of brown algae oligosaccharide monomers and brown algae oligosaccharide

The invention provides a preparation method of brown algae oligosaccharide monomers. The method comprises the following steps: degrading brown algae or brown algae colloid by using an enzymolysis method to obtain an enzymolysis solution, separating and purifying the enzymolysis solution to obtain the brown algae oligosaccharide monomers such as dimannuronic acid disodium salt and trimannuronic acid trisodium salt and the like. The method is characterized by degrading the brown algae by using the enzymolysis method; compared with the conventional chemical method, the method is mild in condition, clean and environment-friendly in preparation process, free of addition and residue of harmful chemical materials and simple in process.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

Method for extracting fucoidan for brown seaweed

The invention relates to a fucoidan extract method, in particular to a method for extracting fucoidan for brown seaweed, comprising the following steps: 1. desalting: adopting fresh brown seaweed or unfreezed frozen brown seaweed to soak in pure water to remove salt; 2. enzymolysis: adding enzyme in the desalted brown seaweed to perform enzymolysis at 40-60 DEG C for 1-3h; 3. abstraction: adding calcium chloride in enzymatic hydrolyzate obtained by enzymolysis, and heating the solution to 90-100 DEG C for 1-4h to obtain the fucoidan extract. The invention is characterized of simple operation, high application security, high extraction efficiency, high extraction purity and the like and the extraction process is applicable to factory mass production.

Owner:大连海宝生物技术有限公司

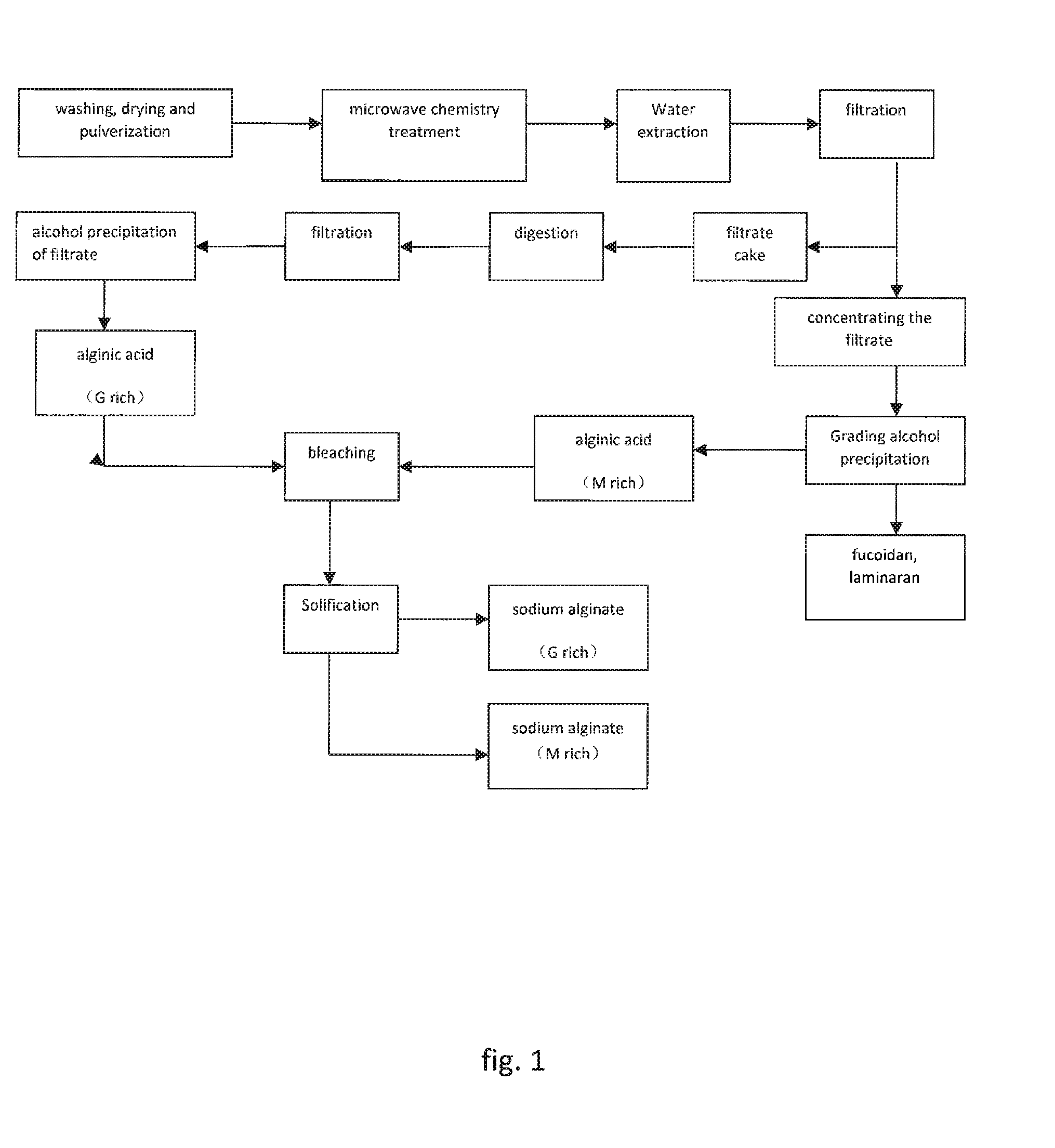

Method for extracting brown algae polysaccharide via microwave chemical process

ActiveUS20140296496A1Narrow molecular weight distributionHigh puritySugar derivativesImmunological disordersDigestionDrug biological activity

This invention relates to an extraction process of brown algae polysaccharides in a field of pharmaceutical chemistry. This invention particularly discloses a process of extracting brown algae polysaccharides based on a microwave chemistry method and brown algae polysaccharides obtained by said process. The process of the invention comprises: 1) putting pulverized brown algae powder into a microwave reaction chamber, adding acid solution to conduct reaction; optionally concentrating the mixer, and then washing with organic solvent to remove excess acid; conducting grading alcohol precipitation after water extract to obtain mannuronic acid rich fragment (M rich) algin, fucoidan and / or laminaran respectively; and adding an alkali solution to the brown algae residue to conduct alkaline digestion, filtering the residue off, adjusting pH of the filtrate to neutral, conducting alcohol precipitation to obtain guluronic acid rich fragment (G rich) algin precipitates. The present invention has significant advantages like fast processing rate, high yield of polysaccharides, strong controllable polysaccharide degradation, using less organic acid and efficient recovery, small water consumption, low power consumption, etc., the active polysaccharides has high yield and content, better water-soluble, and good biological activities.

Owner:SHENYANG KESI HIGH TECH

Novel Crop Fortification, Nutrition and Crop Protection Composition

ActiveUS20190014788A1Maintain good propertiesImprove stabilityBiocideAnimal repellantsNutritionPlant propagation

The invention relates to an algal composition in the form of an aqueous suspension. More particularly the invention relates to aqueous suspension composition including one or more algae selected from green algae, red algae, golden algae, brown algae, golden-brown algae, blue algae, blue-green algae or their species in the range of 0.1%-65% by weight with one or more surfactants in the range of 0.1%-50% by weight; with one or more structuring agent in the range of 0.01%-5% by weight, where the composition has a particle size range of from 0.1 micron to 60 microns. Furthermore, the invention relates to a process of preparing the algal composition comprising at least one alga and at least one agrochemically acceptable excipient in the form of an aqueous suspension. The invention further relates to a method of treating the plants, seeds, crops, plant propagation material, locus, parts thereof or the soil with the algal composition in the form of aqueous suspension.

Owner:SAWANT ARUN VITTHAL

Large seaweed extract sunscreen skin care emulsion and preparation method thereof

InactiveCN104224650AAvoid harmGood stabilityCosmetic preparationsToilet preparationsBiotechnologyInonotus obliquus

The invention discloses large seaweed extract sunscreen skin care emulsion and a preparation method thereof. The large seaweed extract sunscreen skin care emulsion is prepared by mixing the following components in parts by weight: 30-35 parts of decolorized brown algae extract solution, 30-35 parts of decolorized red alga extract solution, 3-5 parts of nanoscale barium sulfate powder, 3-5 parts of nanoscale silicon dioxide powder, 3-5 parts of glycerin monostearate, 5-7 parts of white oil, 7-8 parts of Vaseline, 2-3 parts of beewax, 1-3 parts of chitosan, 1-3 parts of polysaccharide of inonotus obliquus, 0.3-0.6 part of royal jelly, 1-2 parts of olive oil, 0.5-0.6 part of lauryl sodium sulfate, 0.5-0.6 part of triethanolamine and 15-25 parts of deionized water. The large seaweed extract sunscreen skin care emulsion has high stability and safety, is good in sunscreen property and has the effects of whitening, efficiently supplementing water, nourishing and moisturizing, balancing oil and resisting skin aging.

Owner:WENZHOU MEDICAL UNIV

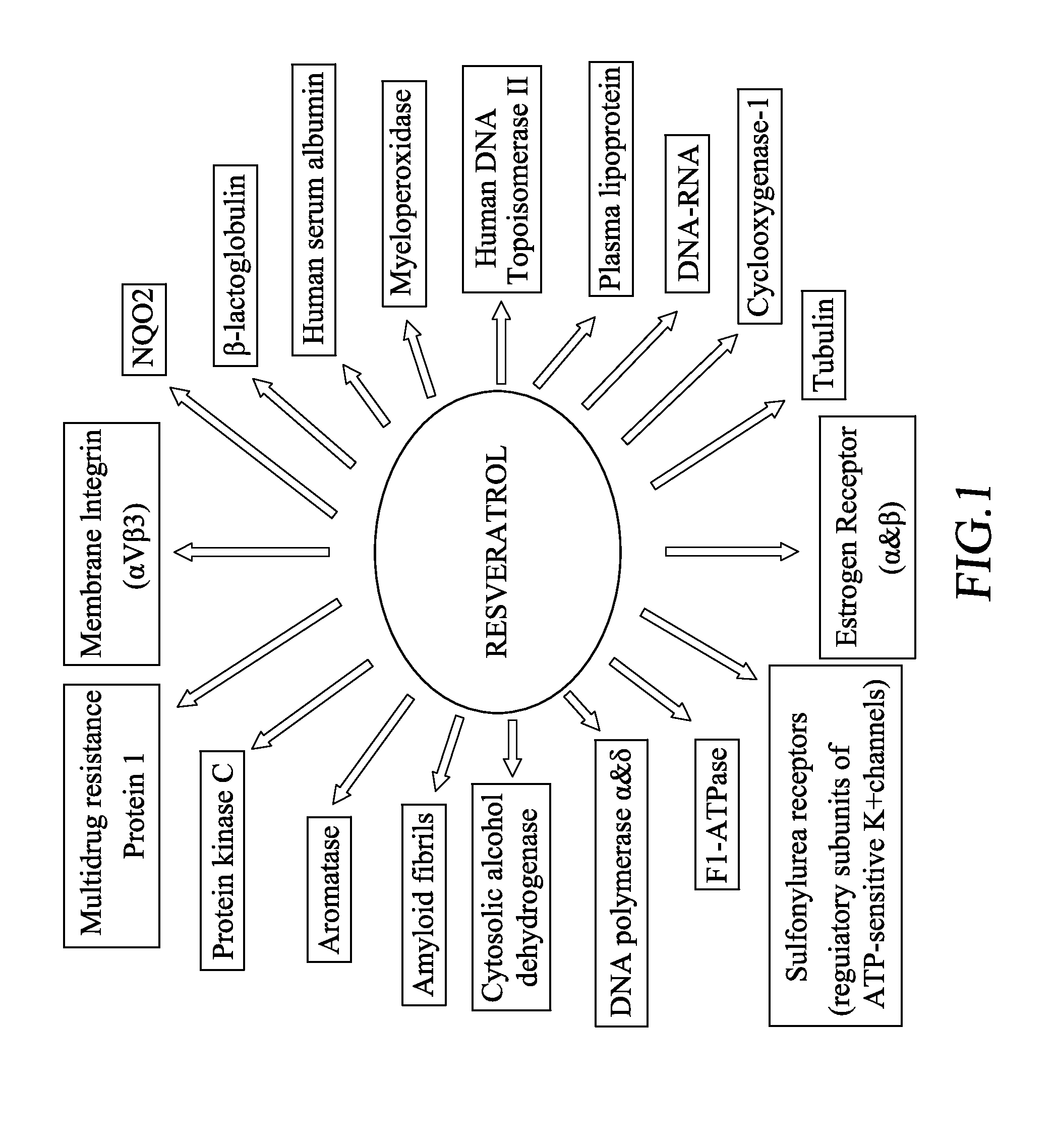

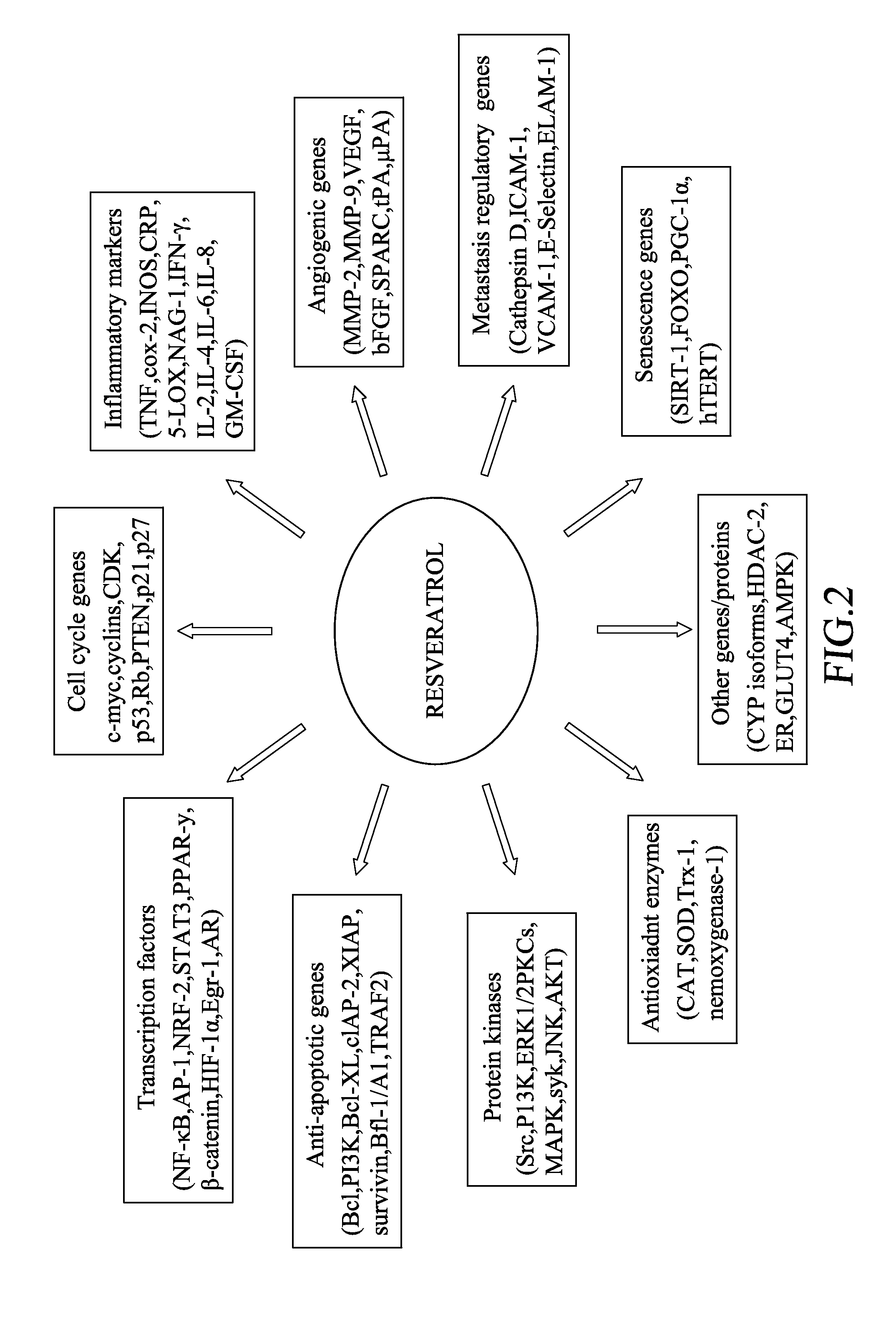

Food recipes for nourishing, maintaining and cultivating a variety of stem cells and a method for manufacturing the same

ActiveUS20130259893A1Low water solubilityReduced stabilityBiocideHydroxy compound active ingredientsBlueberry extractBUTTON MUSHROOM EXTRACT

A food recipes for nourishing, maintaining and cultivating a variety of stem cells, each unit of the food recipes includes grape skin / polygonum cuspidatum root extracts; pseudo-ginseng extracts; cooked polygonum multiflorum thunb extracts; salvia miltiorrhiza bunge extracts; blueberry extracts; bitter melon extracts; soybean extracts; ginseng extracts; rhodiola extracts; yam extracts; licorice extracts; kudzu extracts; brown algae extracts; green algae extracts; szechuan lovage rhizome extracts, Green tea extracts; apple extracts; leek seed extracts; wolfberry extracts; marigold extracts; ganoderma lucidum extracts; caterpillar fungus extracts; agaricus blazei extracts; cistanche deserticola extracts; mushroom extracts; beer yeast; flaxseed oil powder; and vitamin.

Owner:THE WRITER OF RESVERATROL BIOTECH R&D

Preparation method of fucoxanthin

The invention discloses a preparation method of fucoxanthin and relates to the fucoxanthin. The preparation method of the fucoxanthin comprises the steps that a cleaned brown algae material is aired, and soaked by an organic solvent for extraction; an obtained extracting solution is condensed, and a fucoxanthin crude extract is obtained; the fucoxanthin crude extract is subjected to column chromatography separation; a fraction of the fucoxanthin is collected and condensed, and a fucoxanthin raw material is obtained; the obtained fucoxanthin raw material is dissolved by the organic solvent and transferred to a sample introduction bottle of a semipreparative / preparative HPLC (high performance liquid chromatograph); the semipreparative / preparative HPLC is started for separation and purification; fucoxanthin purification liquid is collected automatically through ultraviolet on-line detection or by a fraction collector triggered by a mass spectrum signal; and after the collected fucoxanthin purification liquid is decompressed, condensed, frozen and dried, the high-purity fucoxanthin is obtained. Through testing, the purity of the prepared fucoxanthin is greater than 99%.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

Method for extracting and preparing low molecular weight fucoidin from marine brown algae

The invention relates to the field of seaweed chemicals, in particular to a method for extracting and preparing low molecular weight fucoidin from marine brown algae. The method comprises the following steps of: soaking the brown algae serving as raw materials in water, extracting for 1.5 to 3.0 hours, filtering, desalting filtrate to ensure that the salinity of the filtrate is 0.6 to 1.0 percent, performing ultrafiltration concentration on the desalted filtrate until volume is 1 / 20 to 1 / 30 of the original volume, and taking a concentrated solution as a raw material solution for later use; and adding ethanol into the raw material solution until the concentration of the ethanol in the raw material solution is 60 to 70 percent (v / v), filtering, concentrating the obtained precipitate under reduced pressure until water content is 10 to 15 percent, and thus obtaining low-purity fucoidin. By the method, the low molecular weight fucoidin with the L-fucose content of 15 to 40 percent, the organic sulfate radical content of 20 to 40 percent and the molecular weight of less than 50,000 Daltons is obtained.

Owner:SHANDONG JIEJING GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com