Preparation method of brown algae oligosaccharide monomers and brown algae oligosaccharide

A brown algae oligosaccharide and monomer technology, applied in the field of food processing, can solve the problems of increasing the difficulty of separation and purification of sugar monomers and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

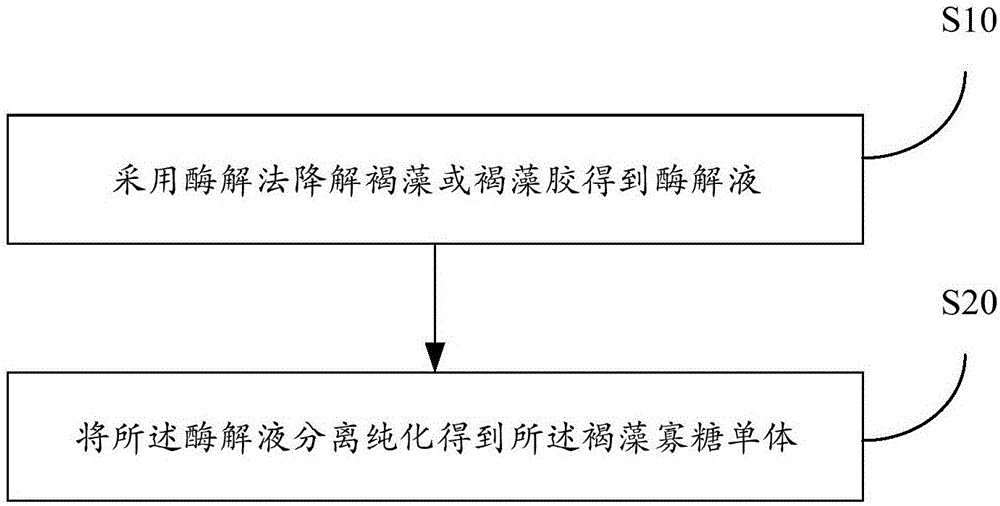

[0038] Such as figure 1 Shown, the preparation method of the fucoidan oligosaccharide monomer of one embodiment, comprises the following steps:

[0039] S10. Using enzymatic hydrolysis to degrade brown algae or alginate to obtain an enzymatic hydrolysis solution, and

[0040] S20. Separating and purifying the enzymolysis solution to obtain the fucoidan oligosaccharide monomers; the fucoidan oligosaccharide monomers include mannuronodisaccharides and mannuronotrioses.

[0041] The preparation method of the above-mentioned fucoidan oligosaccharide monomers uses enzymatic hydrolysis to degrade brown algae or alginate to obtain an enzymolysis solution, and then separates and purifies the enzymolysis solution to obtain fucoidan oligosaccharides including mannuronic acid disaccharides and mannuronic acid trisaccharides. sugar monomers.

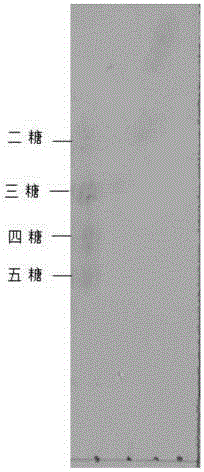

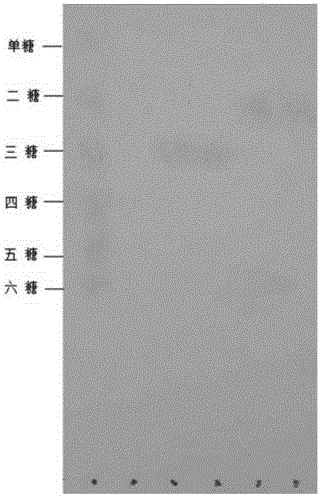

[0042] see figure 2 , step S10, using an enzymatic method to degrade brown algae or alginate to obtain an enzymatic solution, comprising the fo...

Embodiment 1

[0066] 1. Preparation of Crude Enzyme Solution

[0067] Take the Bacillus saccharophilus YIC-Alg 3 cryopreservation tube at -80°C, thaw naturally at room temperature, inoculate it in 100ml seawater medium in an ultra-clean bench, and culture it in a shaker at 30°C at 200rpm for 12h.

[0068] Take 4ml of the above-mentioned bacterial solution, inoculate it in 200ml of modified Alg medium, culture at 30°C for 30h, and obtain a fermentation broth. The formula of the improved Alg medium is 20g sodium alginate, 5g ammonium sulfate, 1g magnesium sulfate, 2g dipotassium hydrogen phosphate, add deionized water to 1000ml, pH 7.2-7.4.

[0069] Centrifuge at 12000r / min for 15min to remove the bacteria, take the supernatant and add ammonium sulfate to 80% saturation, put it in a refrigerator at 4°C for 12h to fully precipitate the sodium alginate lyase, and then store it at 4°C Centrifuge for 15 minutes to save the precipitate. After the precipitate is fully dissolved with 1.5ml of phos...

Embodiment 2

[0081] 1. Preparation of Crude Enzyme Solution

[0082] Take the Bacillus saccharophilus YIC-Alg 3 cryopreservation tube at -80°C, thaw naturally at room temperature, inoculate it in 100ml seawater medium in an ultra-clean bench, and culture it in a shaker at 30°C at 200rpm for 12h.

[0083] Take 4ml of the above bacterial solution, inoculate it in 200ml of Alg medium, incubate at 30°C for 24h to obtain a fermentation broth, centrifuge at 12000r / min for 15min to remove the bacteria, add ammonium sulfate to the supernatant until the saturation is 80%, put it in 4°C Stand in the refrigerator for 12 hours to fully precipitate the sodium alginate lyase, and then centrifuge at 4°C for 15 minutes to retain the precipitate. After the precipitate is fully dissolved with 1.5ml of phosphate buffer (pH=7.2), it becomes the crude enzyme solution.

[0084] 2. Preparation of enzymatic hydrolysis solution

[0085] Add 1ml of crude enzyme solution to 40ml of brown algae slurry with a concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com