Method for extracting brown algae polysaccharide sulfated

A technology of fucoidan and sulfate ester, which is applied in the field of marine chemical engineering, can solve problems affecting product yield, production cost, and waste of resources, and achieve the effect of saving resources and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

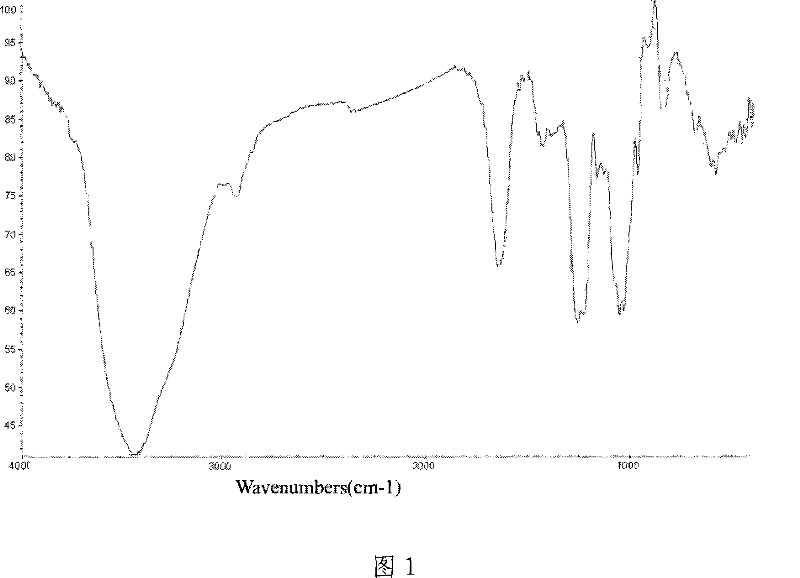

[0014] Add 1ml of chitosan acetic acid solution with an acid solution concentration of 1% and a molecular weight of 2000 to 150ml of kelp soaking liquid, stir for 2 minutes to flocculate for 4 hours, and then centrifuge at a speed of 500 rpm for 2 minutes to separate and obtain a precipitate Swell for 4 hours under the acidic condition of pH 2 (adjust the pH with hydrochloric acid), and stir for 2 hours to dissolve, filter, adjust the filtrate to neutral (use 10% NaOH solution to adjust to neutral), concentrate under reduced pressure, and concentrate The liquid reaches 1 / 10 of the original solution, and then the ethanol concentration is added to the concentrated solution to reach 65%, and the precipitate is filtered, washed twice with anhydrous ether, and freeze-dried with the FD-5N freeze dryer of Tokyo Physical and Chemical Company, namely Fucoidan sulfate was obtained (see Figure 1), and the obtained fucoidan accounted for 10.51% of the precipitated amount.

Embodiment 2

[0016] Add 2ml of chitosan acetic acid solution with an acid solution of 2% and a molecular weight of 760,000 to 150ml of kelp soaking liquid, stir for 4 minutes to flocculate for 0.5 hours, and then centrifuge at a speed of 3000 rpm for 3 minutes to separate and obtain a precipitate Swell for 1 hour under an acidic condition with a pH of 4, stir for 2 hours to dissolve, filter, adjust the filtrate to neutrality, concentrate under reduced pressure, then add ethanol to the concentrated solution to make the concentration reach 70%, filter to obtain a precipitate, and use the free The fucoidan was washed twice with water and ether, and freeze-dried to obtain the fucoidan sulfate, which accounted for 5% of the precipitated amount.

Embodiment 3

[0018] Add 8ml of chitosan hydrochloric acid solution with a molecular weight of 3% and 80,000 to 150ml of kelp soaking liquid, stir for 8 minutes to make it flocculate for 8 hours, and then centrifuge at a speed of 1500 rpm for 5 minutes to separate and obtain a precipitate Swell for 24 hours under an acidic condition with a pH of 6, stir for 4 hours to dissolve, filter, adjust the filtrate to neutrality, concentrate under reduced pressure, then add ethanol to the concentrated solution to make the concentration reach 75%, filter to obtain a precipitate, and use the free Wash twice with water and acetone, and dry in vacuum to obtain fucoidan sulfate, which accounts for 11.1% of the precipitated amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com