Patents

Literature

115 results about "Brown seaweed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

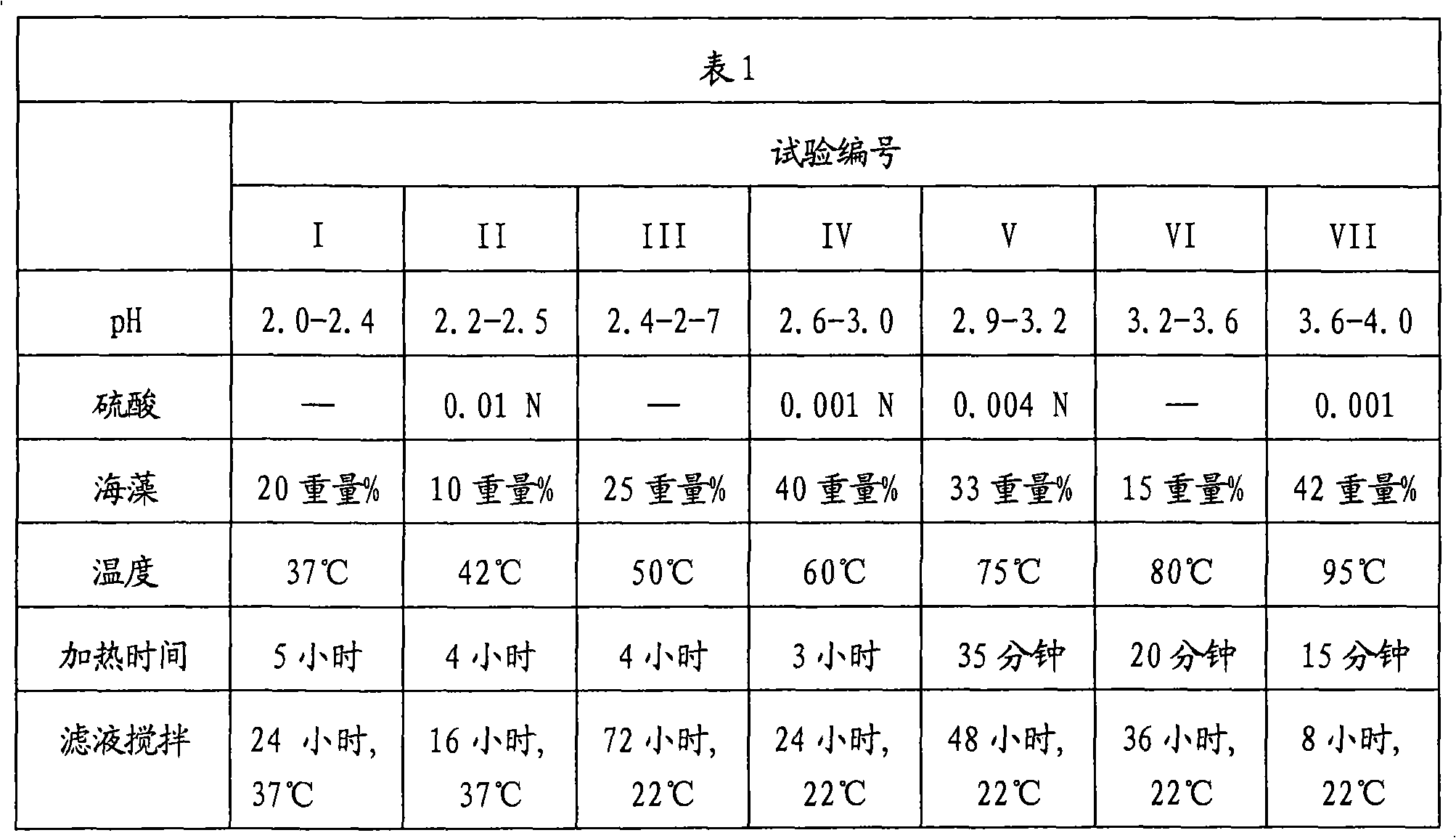

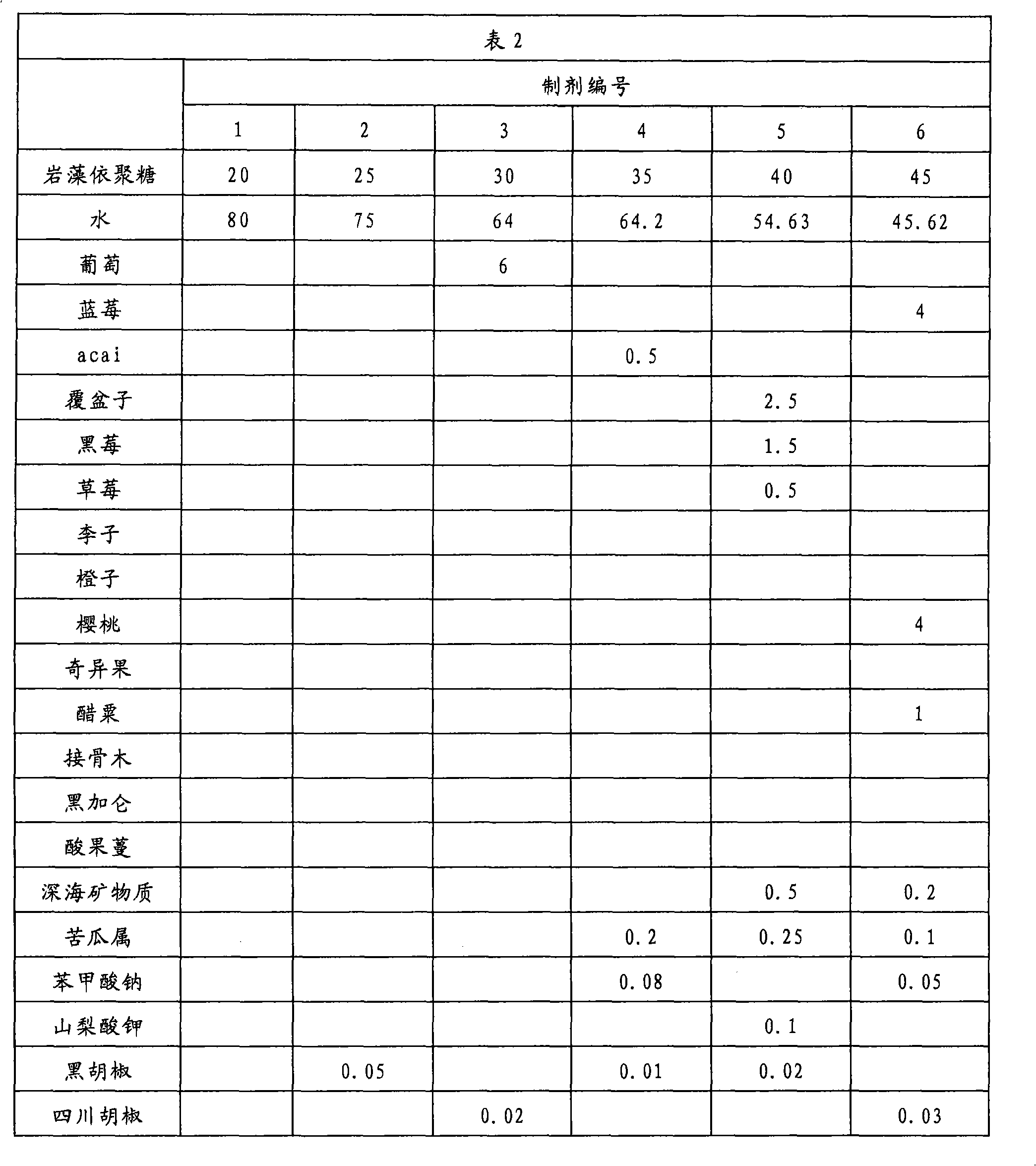

Fucoidan compositions and methods for dietary and nutritional supplements

ActiveUS20060210609A1Promote growthHigh energyCosmetic preparationsBiocideDietary supplementAdditive ingredient

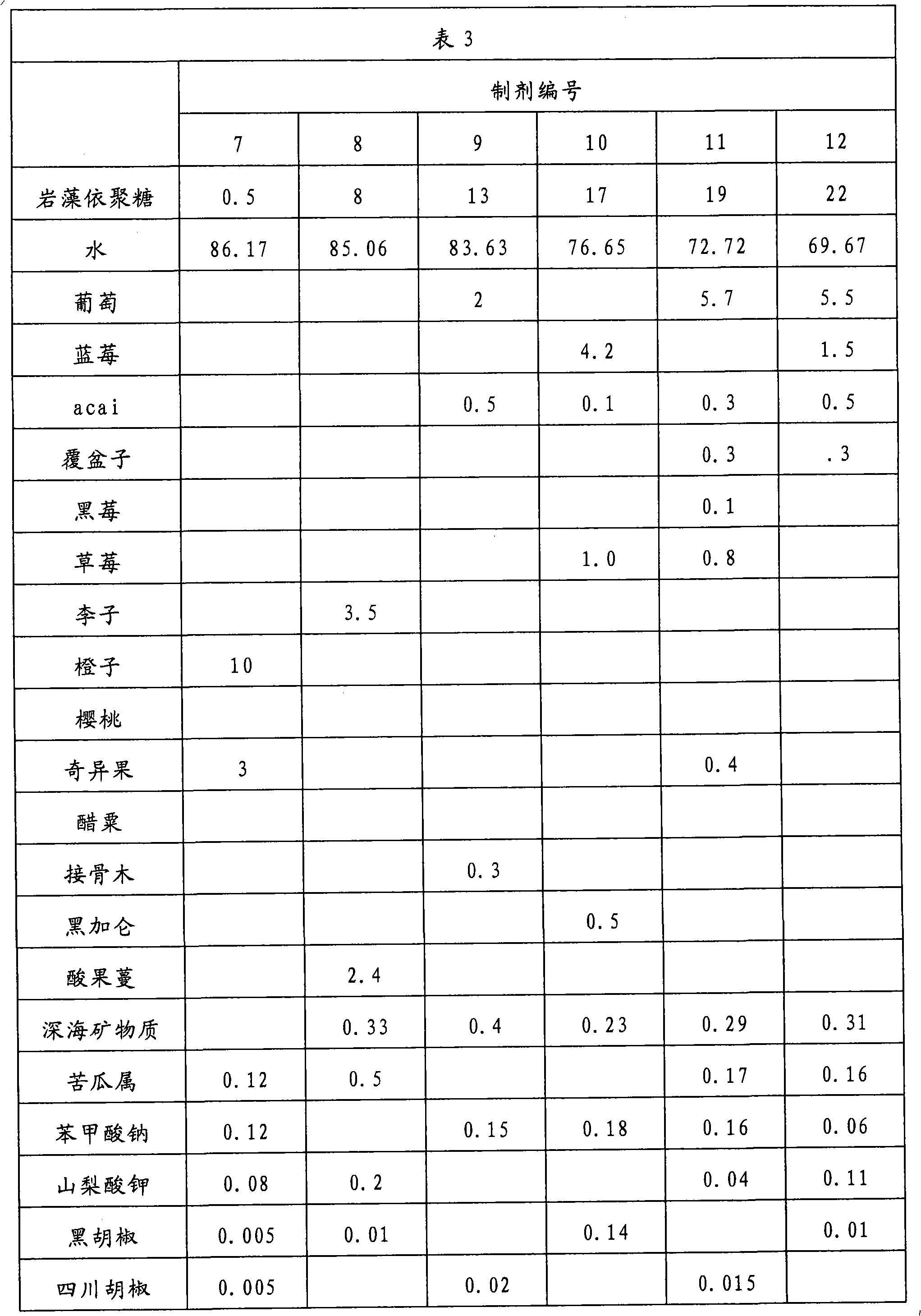

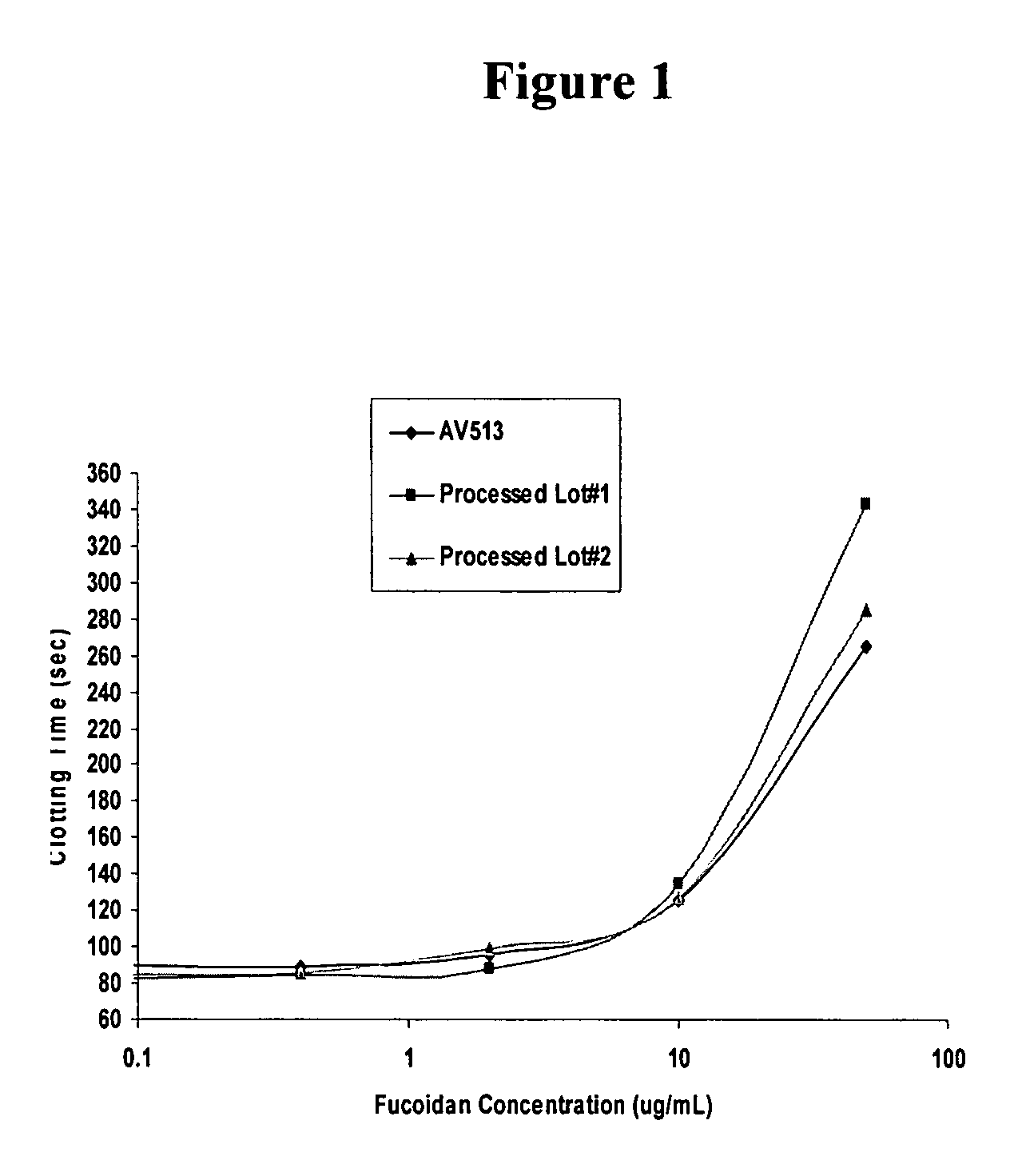

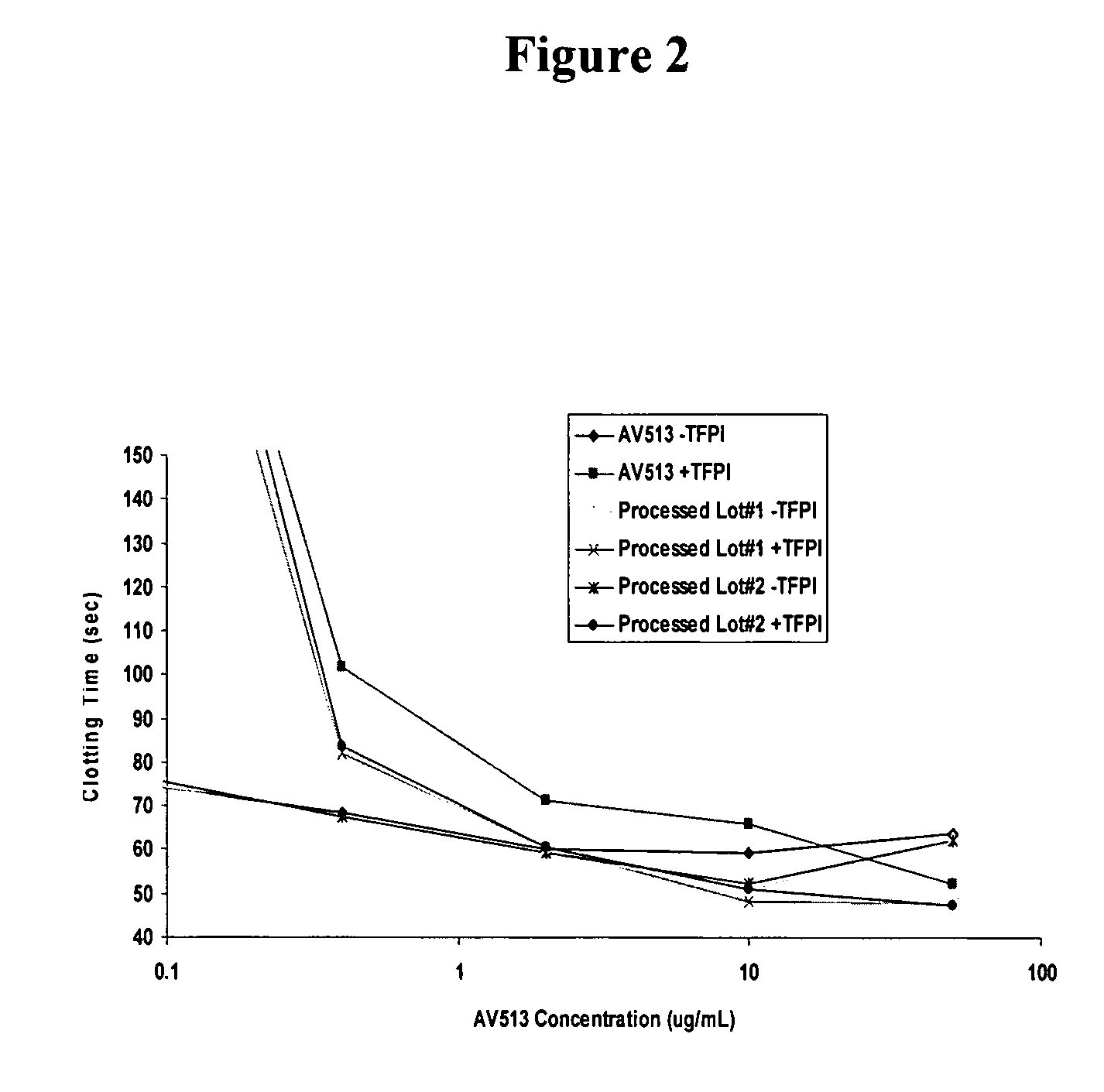

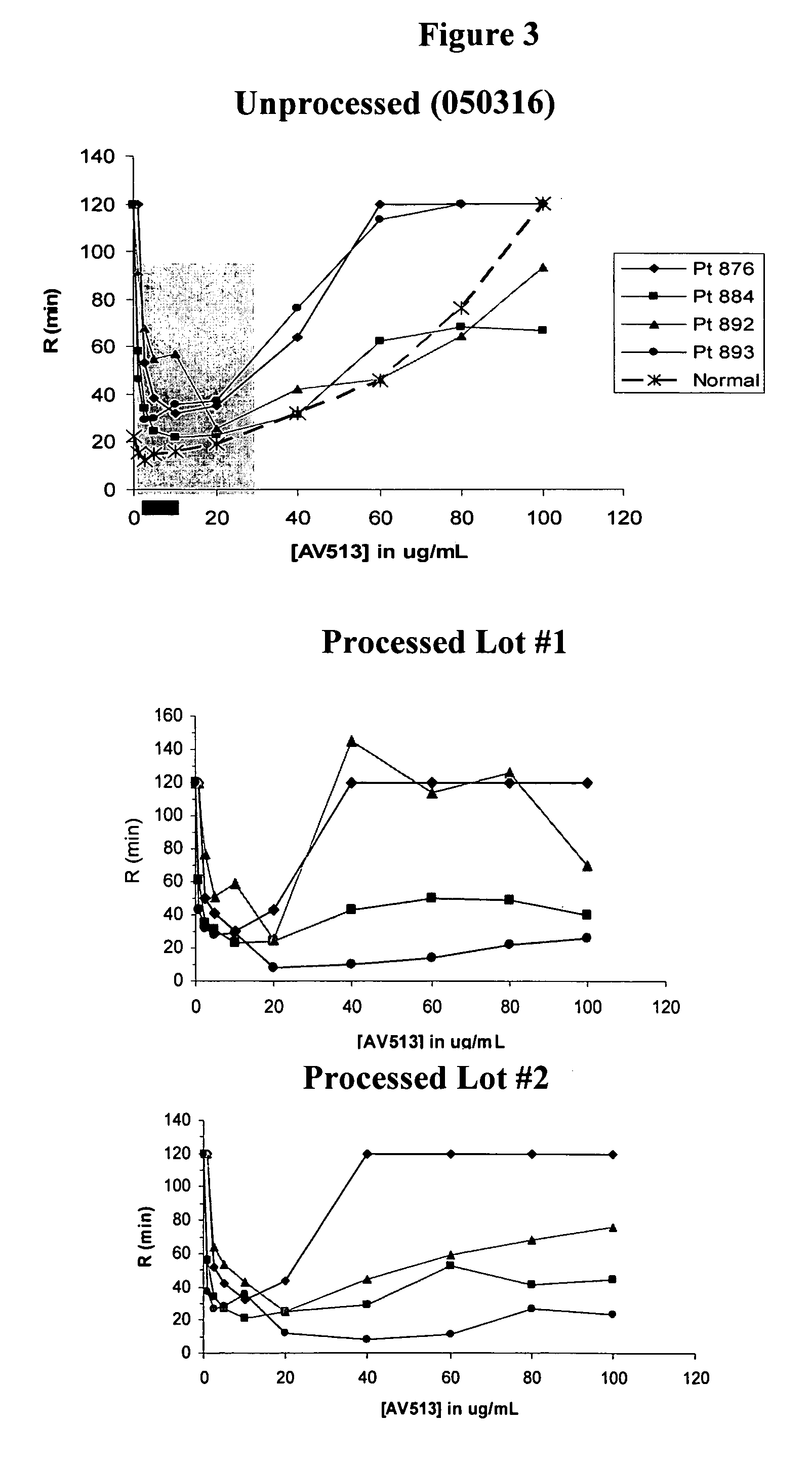

Compositions and methods relating to partially hydrolyzed fucoidan for use in dietary supplements are described. Fucoidan from brown seaweeds is partially hydrolyzed and then mixed with other ingredients for use as a dietary supplement in beverage, capsule, or tablet form. The fucoidan is partially hydrolyzed with acid and heat. The partially hydrolyzed fucoidan can also be sulfonated. Other ingredients that can be included in the dietary supplement include high-ORAC-value antioxidants, minerals, pepper extract, flavoring agents, coloring agents, and preservatives. The compositions can be in the form of beverages, tablets, capsules, powders, and the like.

Owner:SAKURA PROPERTIES LLC

Fucoidan compositions and methods

InactiveUS20080089941A1Effective treatmentPromote healingOrganic active ingredientsCosmetic preparationsAdditive ingredientDietary supplement

Compositions and methods relating to partially hydrolyzed fucoidan for use in dietary supplements and skin-care products are described. Fucoidan from brown seaweeds is partially hydrolyzed and / or sulfonated and then mixed with other ingredients for use as a dietary supplement in beverage, capsule, or tablet form or for use as a skin-care product. Other ingredients that can be included in the dietary supplements include vitamins, minerals, amino acids, carotenoids, flavonoids, antioxidants, aminosugars, glycosaminoglycans, and botanicals. Skin care products according to the present invention comprise partially hydrolyzed fucoidan and a base.

Owner:SAKURA PROPERTIES LLC

Method for preparing low molecular weight brown seaweed fucoidan sulfate

InactiveCN101962415AAutomatically consumed completelyEffective separation and purificationAntiviralsAntineoplastic agentsSulfated polysaccharidesSeparation technology

The invention relates to a method for preparing low molecular weight brown seaweed fucoidan sulfate. The method comprises a step of oxidatively degrading brown seaweed sulfated polysaccharides by hydroxyl radical and a step of ultrafiltration membrane separation and purification, wherein raw sugar of the brown seaweed sulfated polysaccharide is used as a raw material, the hydroxyl radical generated by the reaction of copper ions and hydrogen peroxide is adopted to oxidatively degrade the raw sugar of the brown seaweed sulfated polysaccharide, and the membrane separation technology is combined in the method for preparing the low molecular weight fucoidan sulfate from the brown seaweeds. In the preparation process, the oxidizing speed is uniform, the reacting condition is mild, and the controllability and repeatability are good; the copper ions are removed by a chelating column after the oxidation reaction is finished, so the operation process is simple. Furthermore, the pH value is adjusted by adding little acid and alkali, so the salt content in the product is low, and can be completely removed by a 300Da ultrafiltration membrane in the ultrafiltration membrane separation and purification process. The ultrafiltration membrane can effectively separate and purify the brown seaweed fucoidan with different molecular weights along with high separating speed and large treatment amount. The method is suitable for industrial production.

Owner:OCEAN UNIV OF CHINA

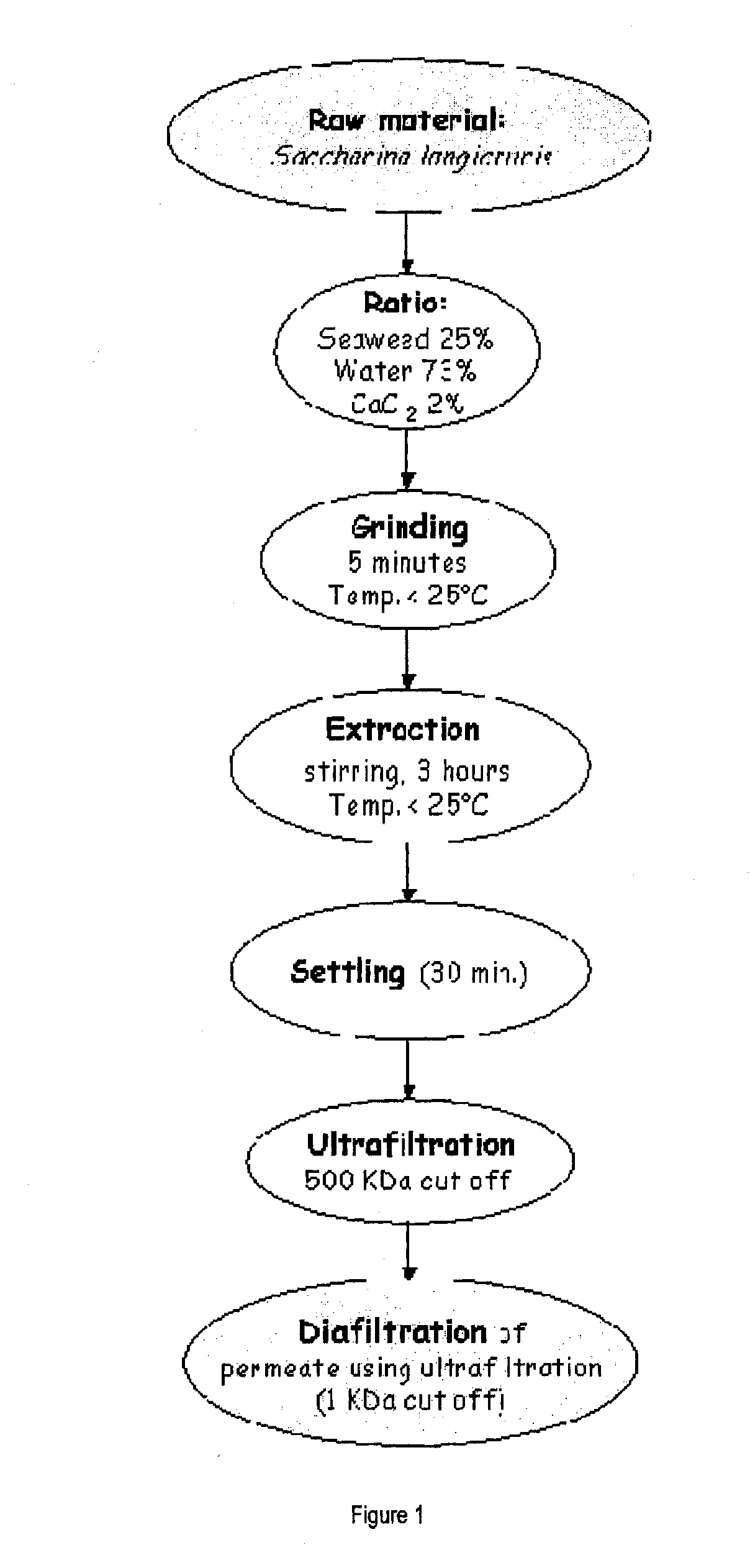

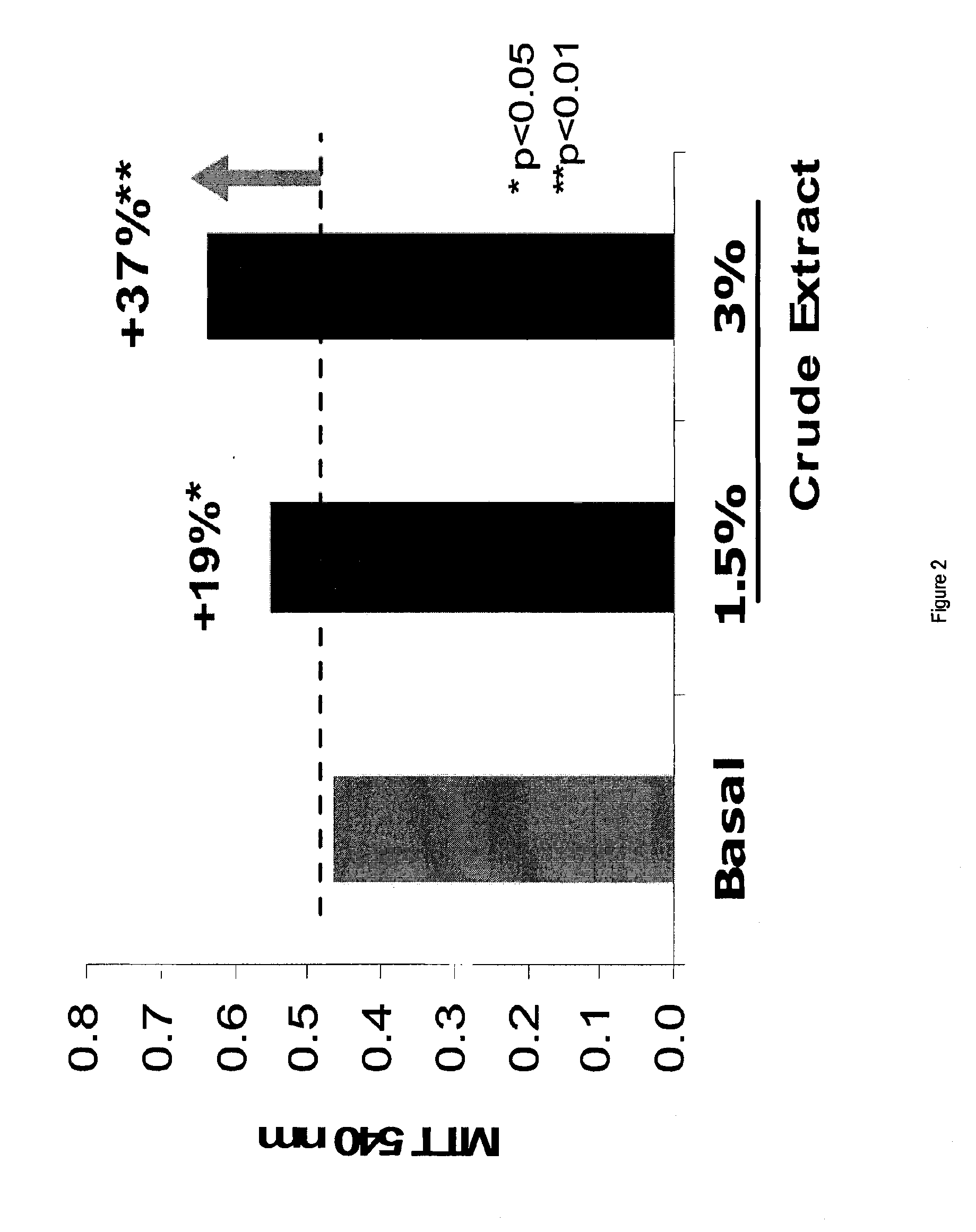

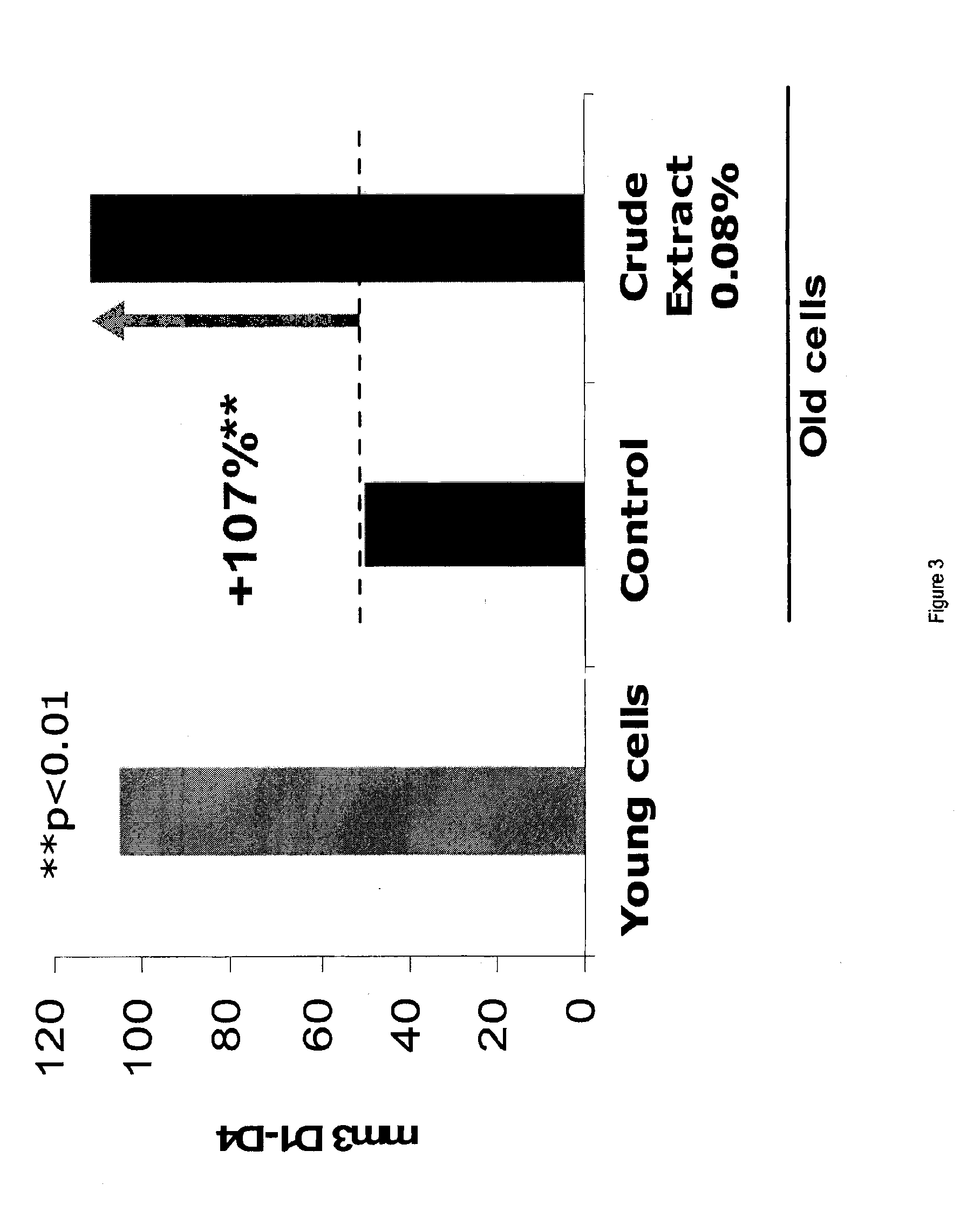

Use of skin care compositions comprising laminariacea extract for treatment of skin aging signs

InactiveUS20120195923A1Extend your lifeImprove propertiesBiocideCosmetic preparationsCellular AgingSeaweed extract

This invention is directed to a skin care composition comprising a laminriacea (brown seaweed) extract and the use of said composition in the treatment of skin aging signs Specifically, it was discovered that a crude extract of the laminariacea Saccharina Longicruris has a strong potential for anti-senescence and anti-cellular aging effect and is efficient to restore the contraction of the collagen network of aged cell lattices to the level of contraction of young cells.

Owner:UNIV LAVAL

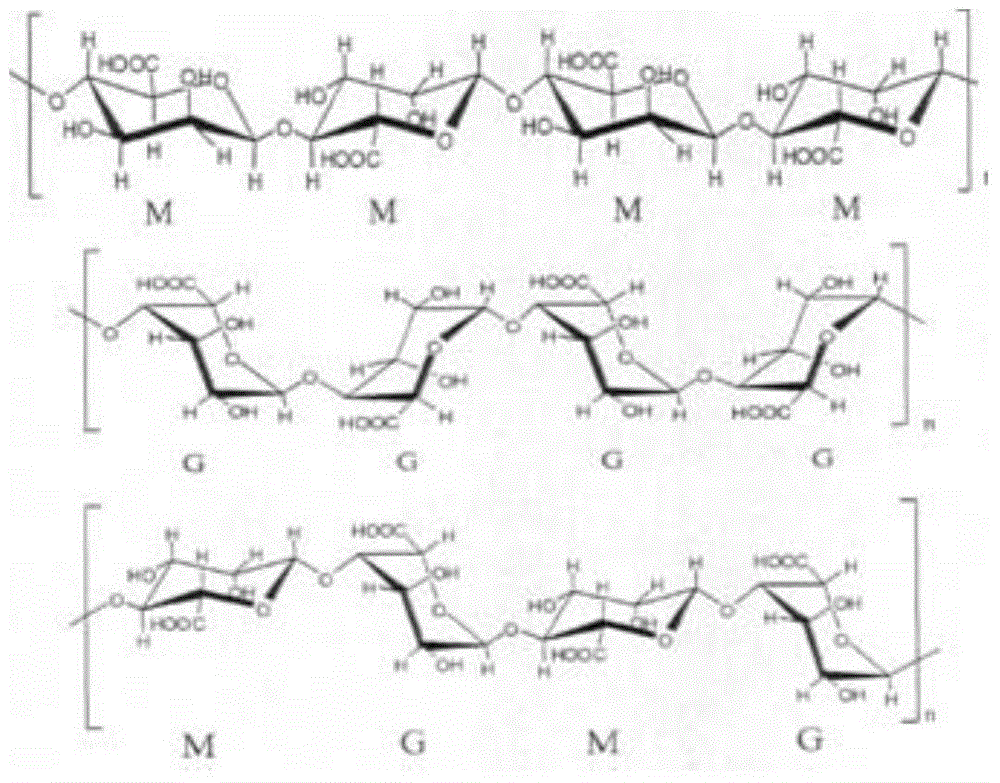

Preparation method of low-molecule brown seaweed glucan

ActiveCN102153669ARealize comprehensive utilizationPlant growth regulatorsAmyrisHydrogen peroxide degradation

The invention belongs to a preparation method of low-molecule brown seaweed glucan. Alkali carbonate solution is used for breaking up seaweed tissue and cells, acid is used for adjusting a pH value to be proper, alginic acid, brown seaweed polysaccharide and brown seaweed starch are extracted from the seaweed tissue and the cells, and the starch is degraded with hydroxide to turn into the brown seaweed glucan with the average molecular weight being 800-1000 Dalton. As reported, the brown seaweed glucan with the low molecular weight can enhance the immunity of a human body and the stress resistance of plants.

Owner:北京雷力联合海洋生物科技有限公司

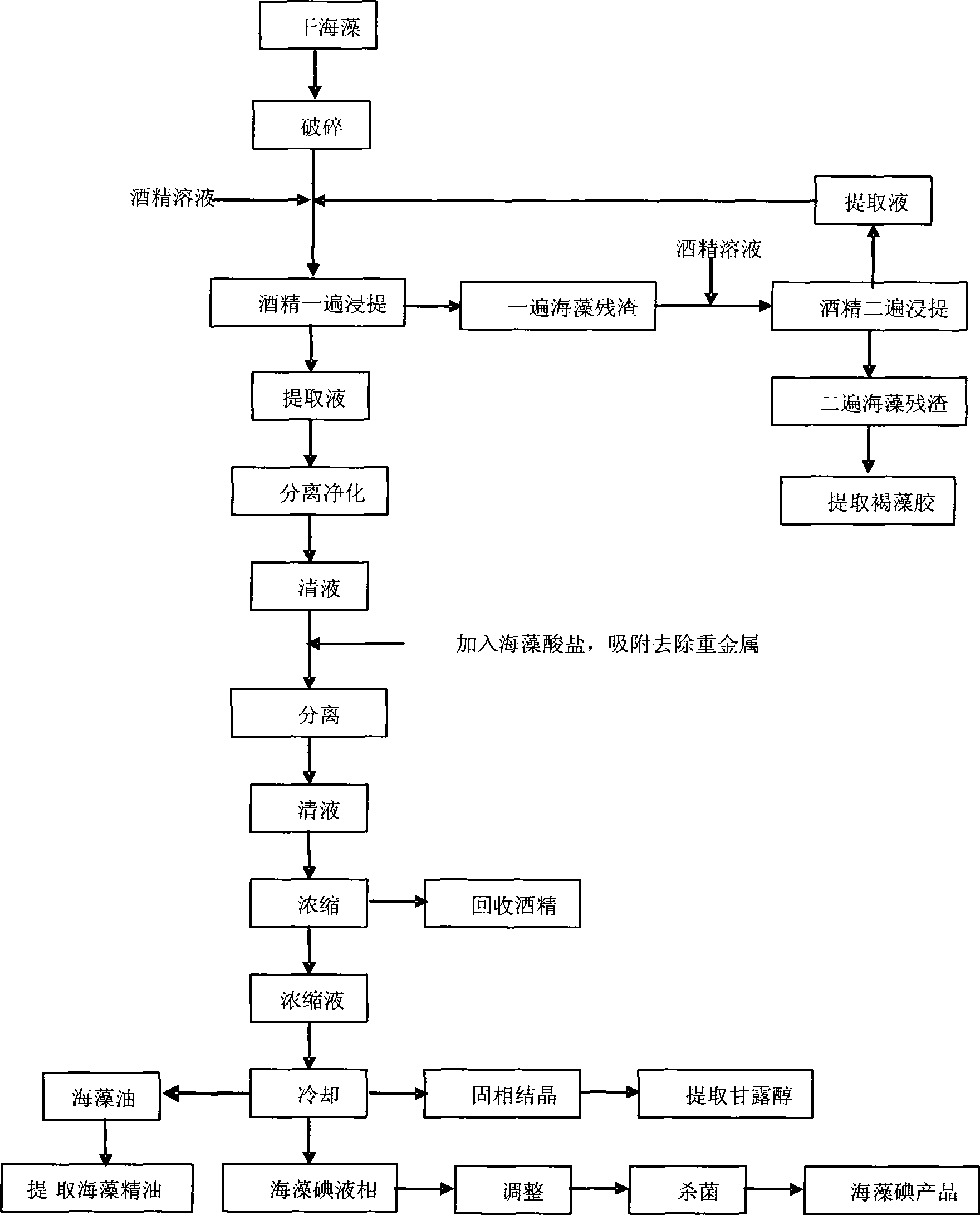

Method for extracting kelp iodine with comprehensive utilization of brown seaweed

ActiveCN101428761ARealize comprehensive utilizationSolve the problem of heavy metal residueHalogen/halogen-acidsBrown seaweedIodine

The invention provides a method for extracting iodine from kelp by comprehensively utilizing brown algae, and can solve the problems in the prior art that heavy metal is remained in the iodine from kelp. The invention adopts the brown algae as raw materials to prepare the iodine from kelp; in an extraction process, a principle that alginate from the brown algae absorbs the heavy metal is utilized, so as to solve the residue problem of the heavy metal in the iodine from kelp during the physical extraction process; and on the premise of ensuring the content of the iodine from kelp, the active ingredients of the kelp are remained to the maximum. At the same time of extracting the iodine from kelp, algae fine oil, algin and mannite are extracted by comprehensive utilization, so that the utilization rate of the kelp is increased to the maximum.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Fucoidan compositions and methods

Compositions and methods relating to partially hydrolyzed fiicoidan for use in dietary supplements and skin-care products are described. Fucoidan from brown seaweeds is partially hydrolyzed and / or sulfonated and then mixed with other ingredients for use as a dietary supplement in beverage, capsule, or tablet form or for use as a skin-care product. Other ingredients that can be included in the dietary supplements include vitamins, minerals, amino acids, carotenoids, flavonoids, antioxidants, aminosugars, glycosaminogrycans, and botanicals. Skin care products according to the present invention comprise partially hydrolyzed fiicoidan and a base.

Owner:SAKURA PROPERTIES LLC

Methods for fucoidan purification from sea weed extracts

Methods for purifying fucoidan in extracts from brown seaweed are disclosed. In particular, methods of purifying fucoidan in the extract to remove heavy metal ions, bacterial and endotoxin contaminants, and other impurities are disclosed. The methods include the use of a chelating agent, selective precipitation, and filtration.

Owner:TAKEDA PHARMA CO LTD

Pig feed for latter fattening period and preparation method thereof

InactiveCN105901378APromote absorptionHigh activityFood processingAnimal feeding stuffAnimal scienceRapeseed

The invention belongs to the field of feed and in particular relates to a pig feed for the latter fattening period. The pig feed disclosed by the invention comprises corn flour, distillers' grains of Baijiu, wheat bran, soybean meal, peanut meal, peanut vine meal, sesame seed meal, rapeseed dregs, palm meal, rice bran, sweet potatoes, potatoes, sweet potato vine meal, brown seaweed, a complex enzyme preparation, a complex-probiotic agent, citric acid, sodium carboxymethyl cellulose, edible salt, fishbone dust, shell powder, calcium carbonate, lysine, methionine, ginger powder, premix, soybean dietary fiber flour, green feed and chitosan. The feed formula disclosed by the invention has the innovation that the green feed is added, so that the absorption and digestion ability of pigs in the latter fattening period is improved, the growth speed of the pigs is improved, and the disease resistance of the pigs in the latter fattening period is improved. In addition, a variety of feeds which are difficult to digest and absorb are fermented and transformed into components which are easy to digest and absorb, and the growth of the pigs in the latter fattening period is facilitated.

Owner:JINAN ZHENGCHI BIOTECH CO LTD

Preparation method of soft hygroscopic composite alginate dressing

InactiveCN106894111AGood flexibilityImprove antibacterial propertiesAbsorbent padsConjugated artificial filamentsBrown seaweedPolymer science

The invention discloses a preparation method of a soft hygroscopic composite alginate dressing. The preparation method includes: subjecting sodium alginate extracted from brown seaweed and carboxymethyl chitosan to cross-linking modification to form carboxymethyl chitosan / sodium alginate mixed liquid; adding propylene glycol alginate, stirring, and mixing well to form wet-process spinning dope; taking calcium chloride solution as solidification liquid for first solidification bath and one of zinc chloride solution, magnesium chloride solution and copper chloride solution as solidification liquid for second solidification bath for wet-spinning to obtain fiber; subjecting the fiber to needle-punched nonwoven cloth processing, slitting, packaging and sterilizing processes to obtain the soft hygroscopic composite alginate dressing. The alginate dressing prepared by the method has functions of absorbing liquid, maintaining moisture, resisting bacteria and stopping bleeding; due to spatial effect of carboxymethyl in the dressing, acting force among fiber macromolecules is weakened, so that flexibility of the fiber is enhanced, personalized needs of patients on the dressing are met better, and the alginate dressing has good application prospect.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Pig feed for early stage of fattening and preparation method of pig feed

InactiveCN105995071APromote absorptionHigh activityFood processingAnimal feeding stuffAnimal scienceAdditive ingredient

The invention belongs to the field of feed, and particularly relates to pig feed for the early stage of fattening. The pig feed comprises corn flour, beer vinasse, wheat bran, soybean meal, peanut meal, peanut vine bran, sesame seed meal, rapeseed meal, palm meal, rice bran, sweet potatoes, potatoes, sweet potato vine bran, brown seaweed, complex enzyme preparations, compound probiotic preparations, citric acid, sodium carboxymethylcellulose, salt, fishbone meal, shell powder, calcium carbonate, lysine, methionine, ginger powder, premix, soybean dietary fiber flour, green feed and chitosan. The pig feed has the advantages that the green feed is added into the formula of the feed innovatively, digestion and absorption capabilities of pigs in the early stage of fattening are improved, growth speed of the pigs is increased, and disease resistance of the pigs in the early stage of fattening is improved; various kinds of feed not easy to digest and absorb is fermented into ingredients easy to digest and absorb, and growth of the pigs in the early stage of fattening is facilitated.

Owner:JINAN ZHENGCHI BIOTECH CO LTD

Ascophyllum Compositions and Methods

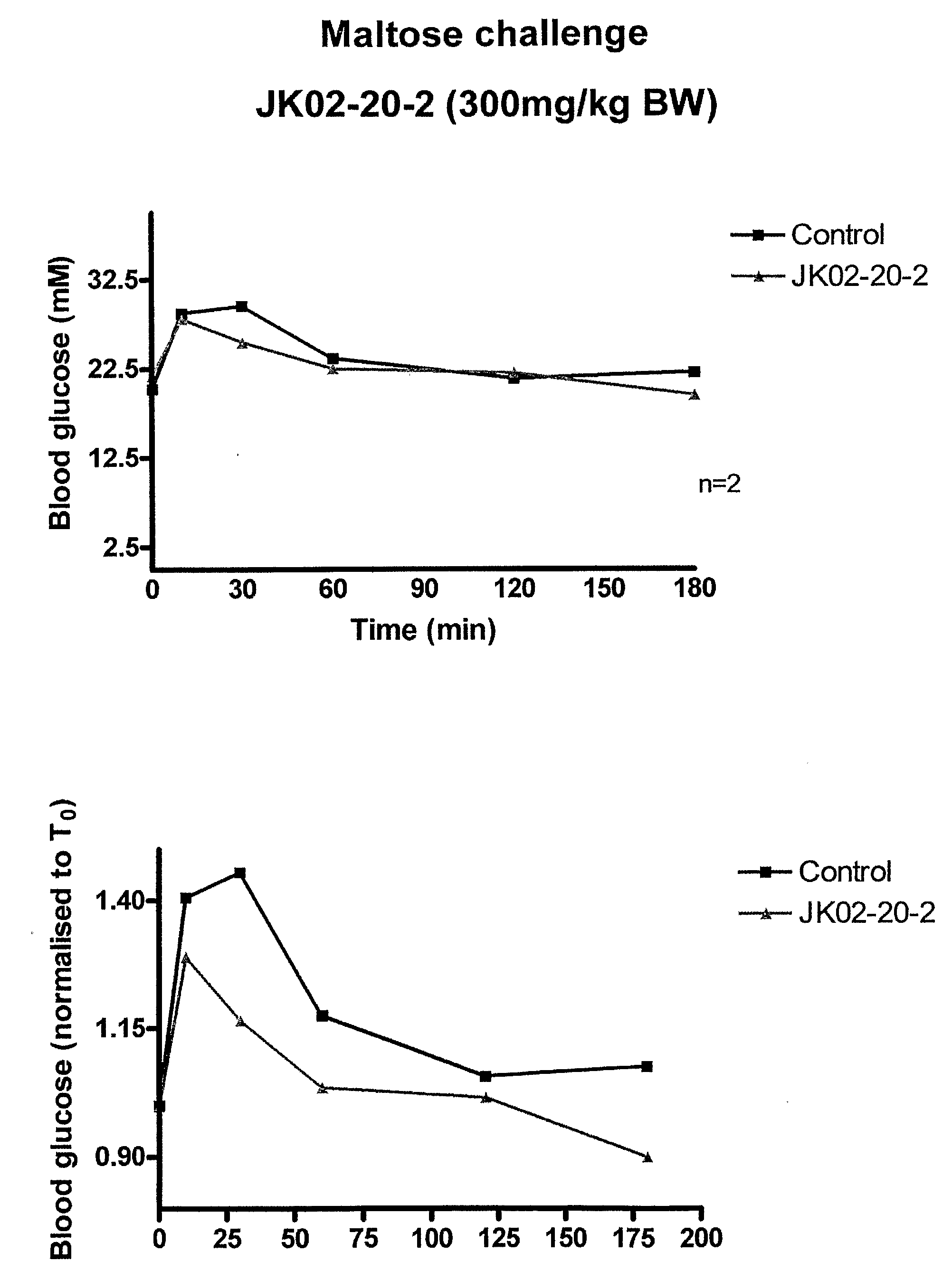

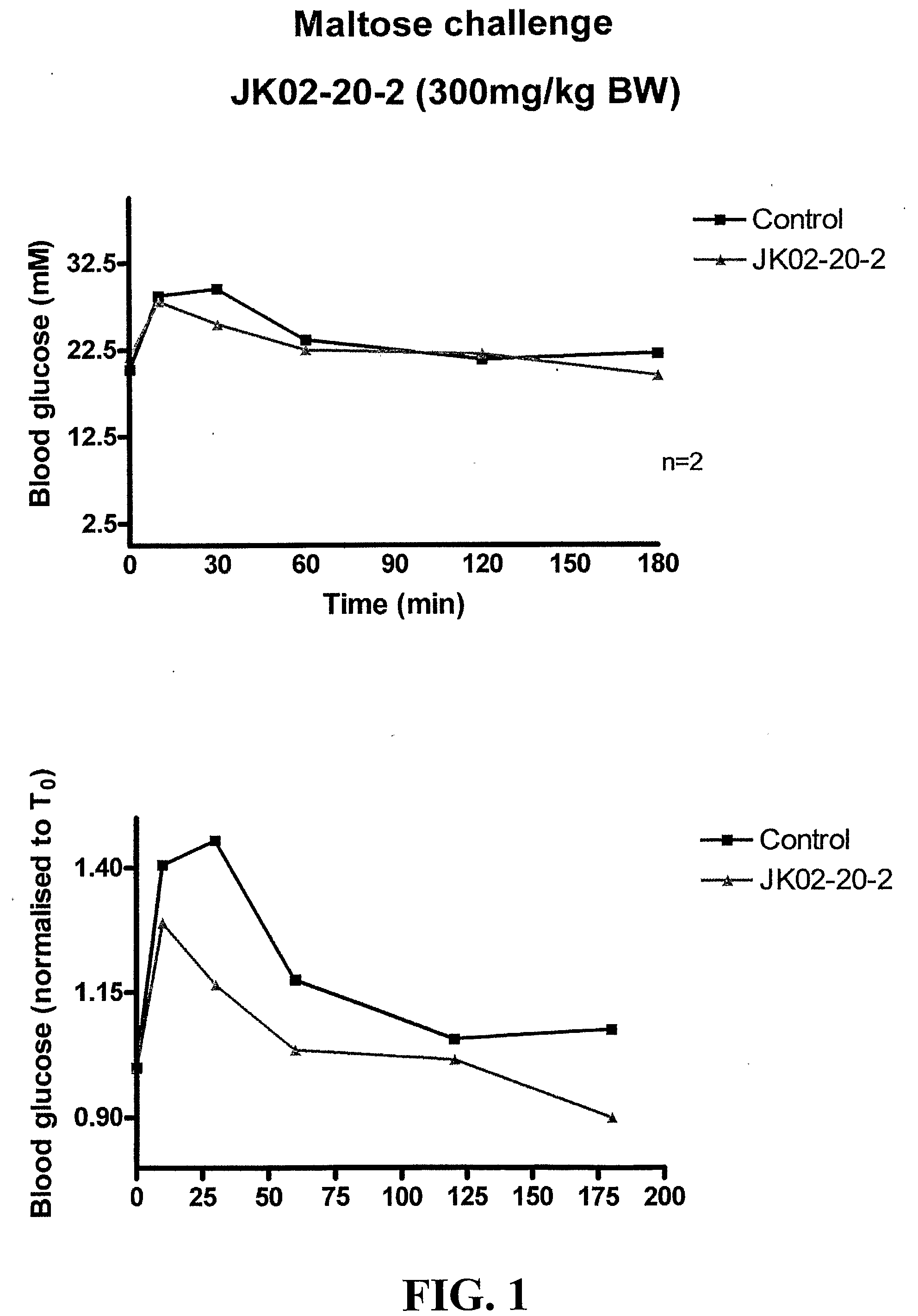

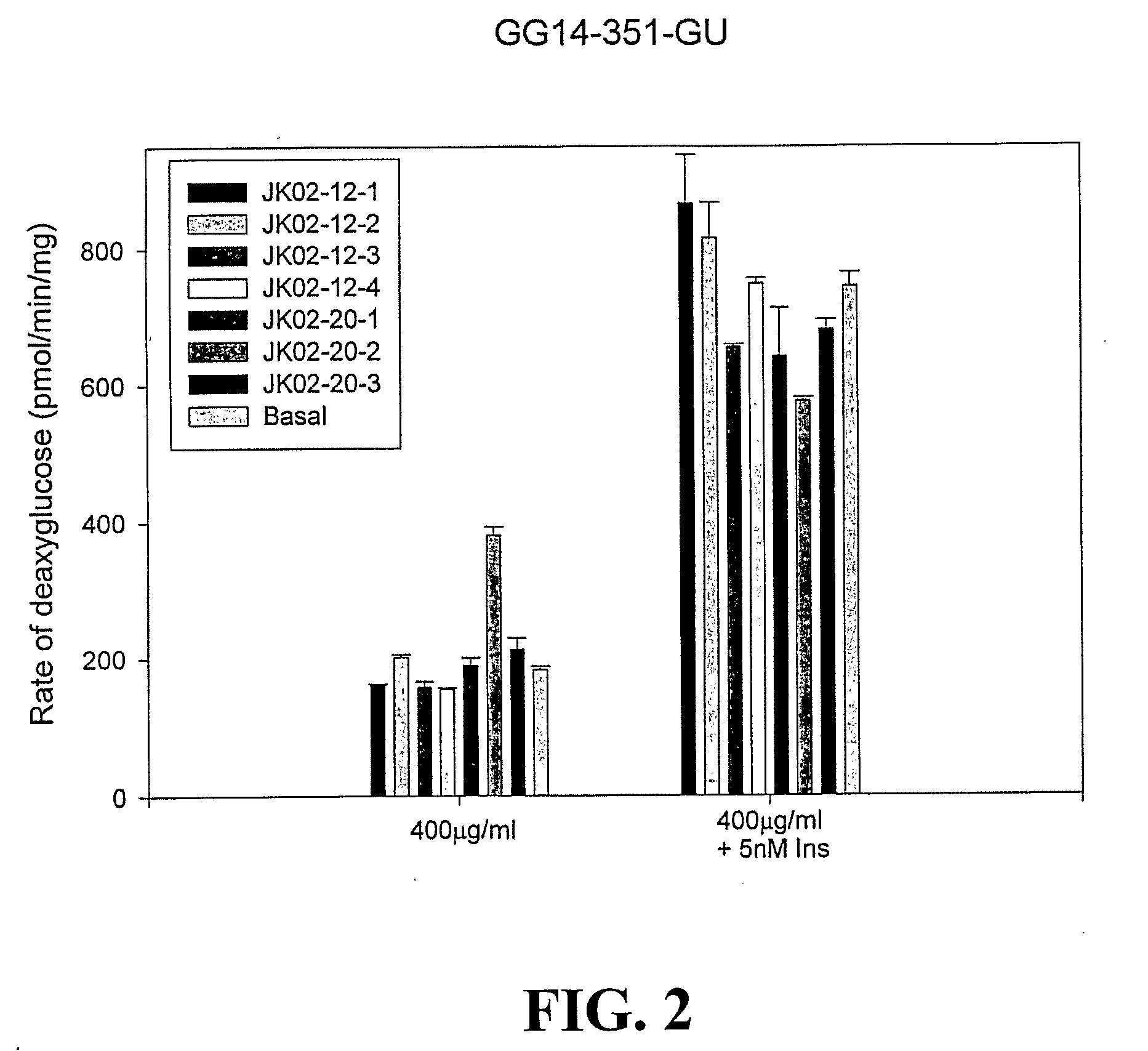

InactiveUS20080280994A1Valuable medicinal propertyBiocideSugar derivativesAscophyllumAlpha-glucosidase activity

The invention provides extracts of brown seaweed of the genus Ascophyllum that have valuable pharmacological properties. In particular, compositions of the invention are useful for e.g.: inhibiting alpha-glucosidase activity; preventing or treating conditions mediated by alpha-glucosidase activity; reducing blood glucose levels; preventing or treating diabetes; modulating glucose uptake in adipocytes; preventing or treating obesity; scavenging free radicals; stimulating the immune system; activating macrophages; preventing or treating condition mediated by macrophage activation; and modulating nitric oxide production by macrophages. Methods for using the Ascophyllum extracts of the invention are provided, as are kits comprising Ascophyllum extracts of the invention and instructions for using the extracts.

Owner:OCEAN NUTRITION CANADA

Method for extracting fucoidan for brown seaweed

The invention relates to a fucoidan extract method, in particular to a method for extracting fucoidan for brown seaweed, comprising the following steps: 1. desalting: adopting fresh brown seaweed or unfreezed frozen brown seaweed to soak in pure water to remove salt; 2. enzymolysis: adding enzyme in the desalted brown seaweed to perform enzymolysis at 40-60 DEG C for 1-3h; 3. abstraction: adding calcium chloride in enzymatic hydrolyzate obtained by enzymolysis, and heating the solution to 90-100 DEG C for 1-4h to obtain the fucoidan extract. The invention is characterized of simple operation, high application security, high extraction efficiency, high extraction purity and the like and the extraction process is applicable to factory mass production.

Owner:大连海宝生物技术有限公司

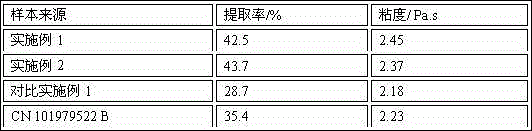

Process for extracting sodium alginate

The invention discloses a process for extracting sodium alginate. The process comprises the following steps: performing enzyme treatment on kelp or brown seaweed by virtue of a complex enzyme, and extracting sodium alginate by virtue of a classic chemical method. The process comprises the following steps: performing pretreatment; performing enzymolysis; digesting; separating; performing acidification; and performing alkali dissolution and acidification. The extraction process disclosed by the invention is high in extraction rate, and the extracted sodium alginate is high in viscosity and has industrial application prospects.

Owner:HAINAN OPEARL BIOLOGICAL ENG

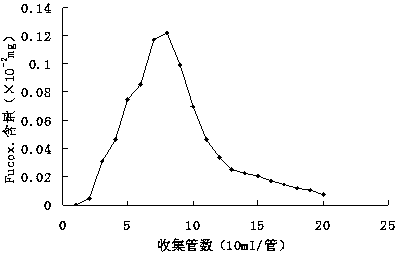

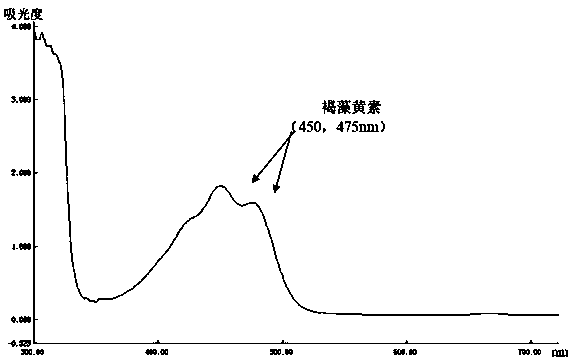

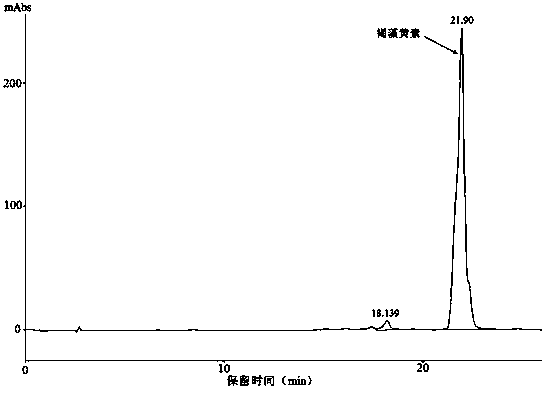

Method for extracting and purifying fucoxanthin

The invention discloses a method for extracting and purifying fucoxanthin. According to the method, a microwave assisted extraction technology is utilized, and ethanol serves as a solvent, so that fucoxanthin in brown seaweed raw materials can be rapidly extracted; and a liquid-liquid extraction and column chromatography two-step separation process is adopted, so that the fucoxanthin can be effectively separated from chlorophyll and other impurity components. The fucoxanthin is low in toxicity, safe and environment-friendly, ethanol is taken as an extraction solvent, and the use amount of a toxic organic solvent is effectively reduced; and moreover, a microwave extraction method is adopted, extraction can be finished within 5 minutes only, and the extraction time is greatly shortened. The method disclosed by the invention is simple, rapid and high-efficiency in the whole extraction and purification process, the operation is convenient, large-scale production is easily realized, and a foundation is laid for development and utilization of natural health food additives such as the fucoxanthin with extremely high values and biological drug resources.

Owner:WUHAN UNIV

Application of brown seaweed polysaccharide, brown seaweed oligosaccharide as well as derivatives of brown seaweed polysaccharide and brown seaweed oligosaccharide in preparation of adsorbent for adsorbing atmospheric pollutants

The invention provides the application of brown seaweed polysaccharide, brown seaweed oligosaccharide as well as derivatives of the brown seaweed polysaccharide and the brown seaweed oligosaccharide in preparation of an adsorbent for adsorbing atmospheric pollutants, wherein the brown seaweed polysaccharide has the degree of polymerization more than 30, and the brown seaweed oligosaccharide has the degree of polymerization of 2-30; the absorbent is prepared by preparing the seaweed polysaccharide, the brown seaweed oligosaccharide as well as the derivatives of the brown seaweed polysaccharide and the brown seaweed oligosaccharide into a water solution or glycerin solution with the mass volume concentration of 0.1mu g / mL-2000mg / mL. The prepared adsorbent is very wide in application field. The using method of the adsorbent is as follows: the adsorbent is arranged in the nasal cavity in any acceptable way; for instance, the adsorbent can be arranged on safety appliances such as a mask, a face mask, a head sleeve, a helmet; the adsorbent is arranged close to an outlet of equipment for discharging the atmospheric pollutant in a room, a factory, an automobile and the like in any acceptable way; therefore, the adsorbent has good market application prospect.

Owner:MARINE BIOMEDICAL RES INST OF QINGDAO CO LTD

Clean production method of seaweed fertilizer

InactiveCN101439995AAvoid bringing inZero emissionFertiliser formsOrganic fertilisersBrown seaweedPotassium hydroxide

The invention relates to a clean production method for seaweed fertilizer, which comprises the following steps: 1) adding water and potassium hydroxide into a reaction kettle, heating the mixture, and then adding dry brown seaweed into the mixture, preserving temperature and digesting the mixture; 2) filtering the digested brown seaweed solution; 3) neutralizing the filtrate by phosphoric acid to obtain seaweed extract to be directly used as liquid seaweed fertilizer; and 4) mixing filter residue and furfural residue, and then pelletizing and drying the mixture to be used as solid soil fertilizer. When preparing the brown seaweed extract, the method neutralizes the brown seaweed filter residue and the furfural residue to prepare the solid soil fertilizer, so as to change waste into valuable and achieve resource conservation, environmental protection and zero discharge.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Alginate fiber spunlace non-woven fabric and manufacturing method thereof

InactiveCN105401337AReduce tensionSimple production processNon-woven fabricsBrown seaweedCalcium alginate

The invention discloses an alginate fiber spunlace non-woven fabric with an efficacy of absorbing heavy metals and a manufacturing method thereof. The non-woven fabric is made of alginate fibers and plant mixed fibers in a blending manner. Weight ratio of the alginate fibers and the plant mixed fibers is x: y, wherein 10<=x<100, 0<y<=90, and dimension of the fiber is 1.5 D, 38 mm. The alginate fibers are made of raw materials of calcium alginate which is extracted from brown seaweeds. The method is simple in production process, convenient in material drawing, and low in cost, and mixing proportion of the alginate fibers and other plant mixed fibers can be adjusted in a targeted manner in a processing process. The alginate fiber non-woven fabric can be used as a material base cloth of a mask. In a use process, through soaking the fabric in essences in different efficacies, the fabric becomes a good functional component carrier. The materials are safe and do not contain toxic and harmful substances, a mask cloth can stand long-time immersion of an essence, and the fabric can be naturally degraded after use, so the fabric is more friendly to environment.

Owner:JIANGSU GREAT CREATIVITY NEW MATERIALS CO LTD

Method for coproducing fucoidan and seaweed fertilizer

InactiveCN103755831ASolve high water consumptionSolve the problem of waste water and residueOrganic fertilisersPlant growthFermentation

The invention discloses a method for coproducing fucoidan and a seaweed fertilizer. The method comprises the following steps: (1) extracting a brown seaweed component having a plant growth promoting function; (2) extracting the fucoidan; (3) preparing a seaweed fertilizer component 2; and (4) blending the seaweed fertilizer, namely completely adding the seaweed fertilizer component 1 obtained in the step (1) into the seaweed fertilizer component 2 obtained in the step (3), stirring and mixing uniformly, standing for precipitating for 2 hours, filtering and centrifuging to perform liquid-solid separation, wherein the obtained liquid and solid refer to a liquid seaweed fertilizer base and a solid seaweed fertilizer base respectively. According to the method for coproducing the fucoidan and the seaweed fertilizer, resources are fully utilized, and the fucoidan product and the seaweed fertilizer are produced by means of the processes of ethanol soaking extraction, probiotics fermentation and the like, so that the problems of high water consumption as well as generation of waste water and waste residues in the production of the fucoidan are solved fundamentally, the additional value of the brown seaweed industry is increased remarkably, and a remarkable ecologic benefit is achieved.

Owner:SHANDONG UNIV

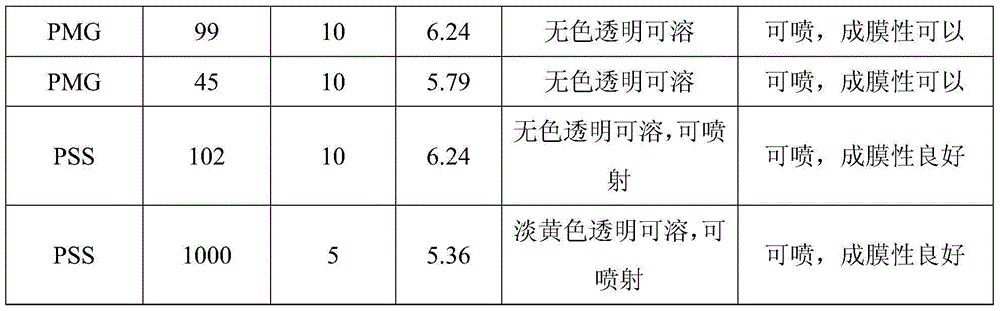

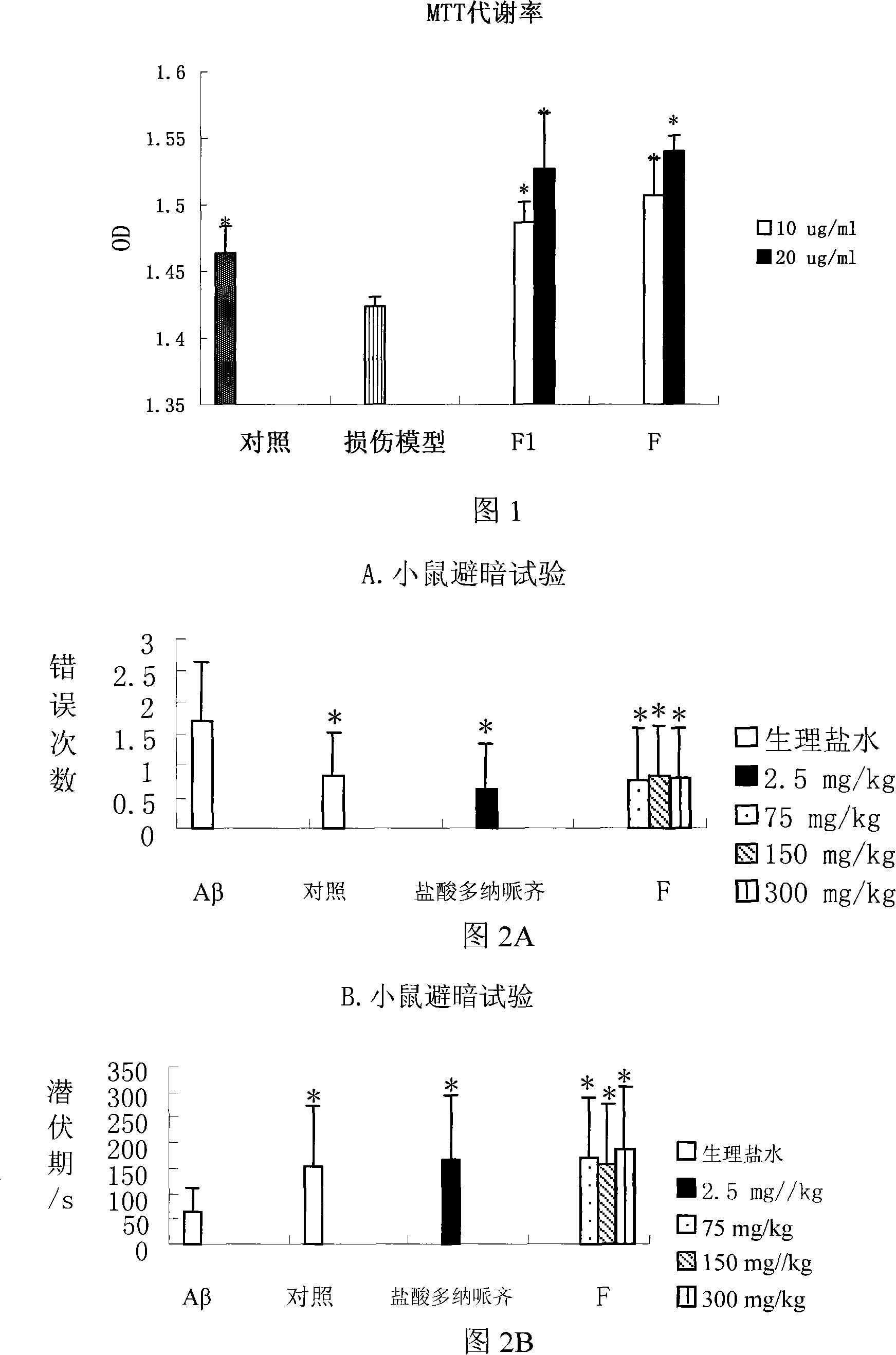

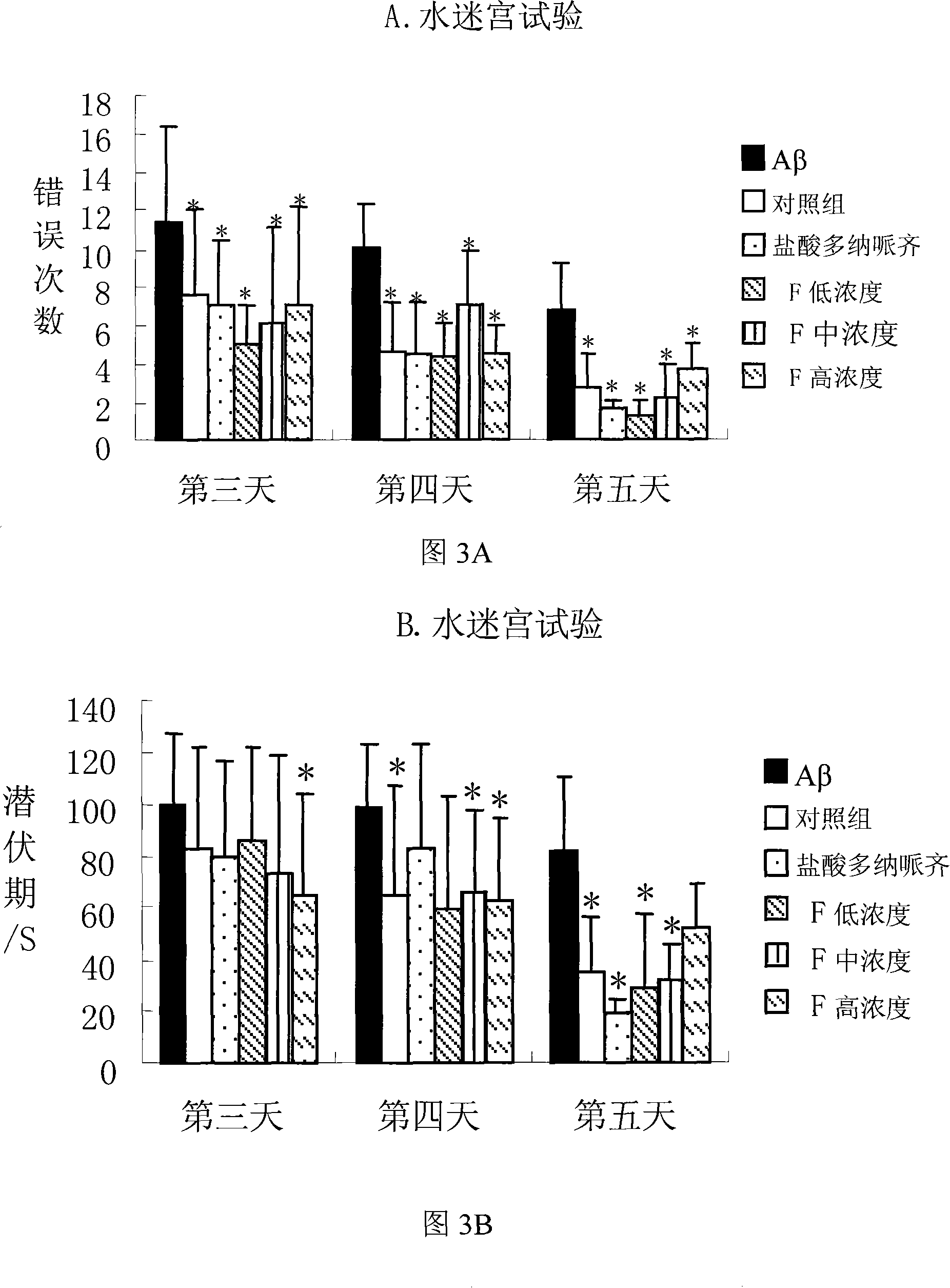

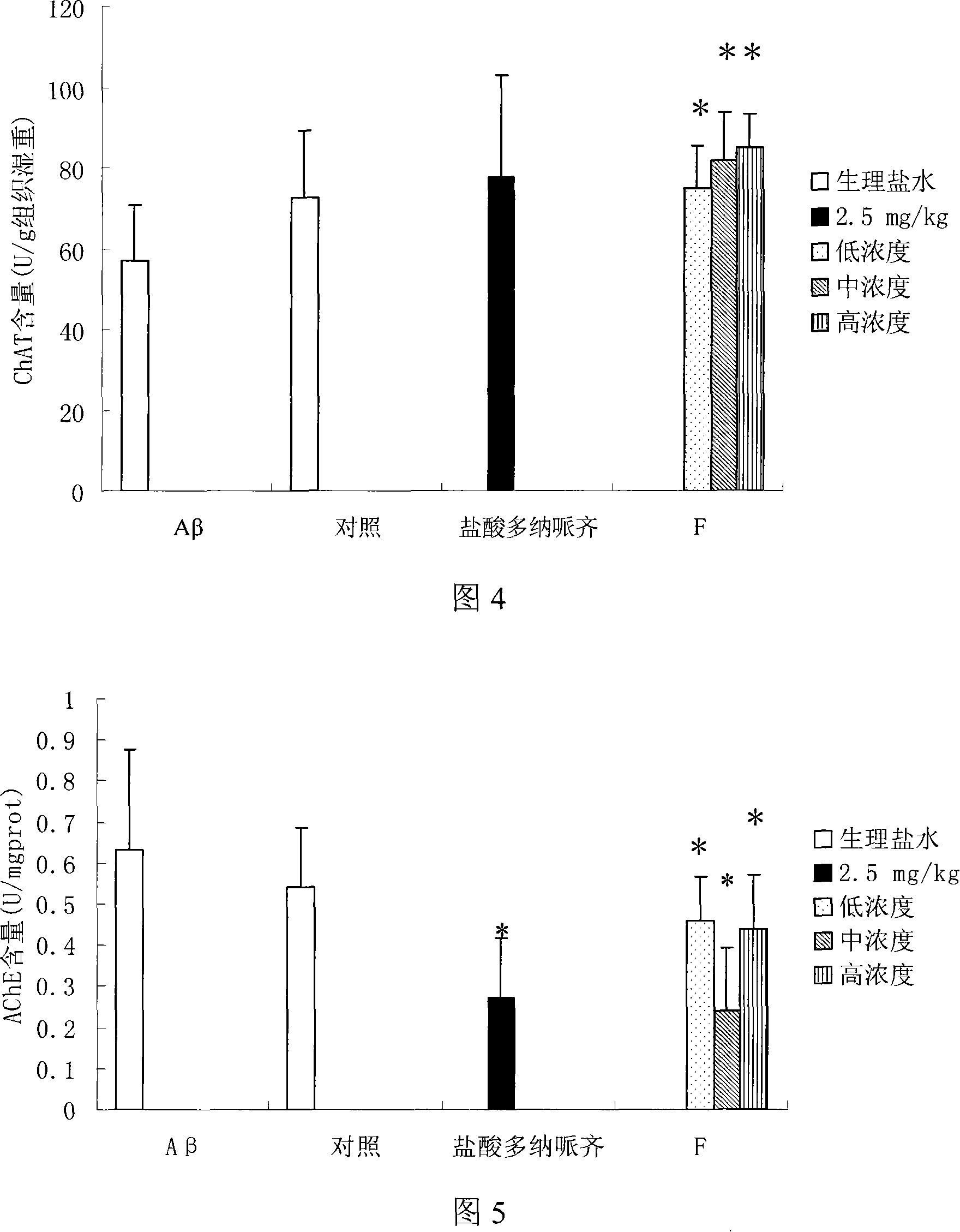

Application of brown seaweed polyoses sulfate in preparing medicament for treating senile dementia

InactiveCN101152208AImprove securityEnsure long-term medication needsOrganic active ingredientsNervous disorderBrown seaweedLaminaria japonica

The invention provides a brown seaweed polysaccharide sulfate with the purpose of preventing and treating senile dementia. The brown seaweed polysaccharide sulfate of the invention can be natural polysaccharide extracts from brown algae like kelp, focus, asophyllum, laminaria japonica or chorda filum, etc, or low molecular weight sulfuric acid polysaccharide or oligosaccharide material prepared by degradation of brown seaweed polysaccharide sulfate. The product of the invention has high safety and can be taken for a long term.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Preparation method for alginate with ultra-low viscosity

The invention discloses a preparation method for alginate with ultra-low viscosity. The preparation method includes the steps that 1, brown seaweed, as a raw material, is soaked, fixed, washed, digested, diluted, filtered, floated, and subjected to refined filtration to obtain colloidal fluid; then through calcification or acidification, decalcification and dehydration, alginic acid is obtained and then smashed; 2, the alginic acid is degraded through heating, and low-boiling-point substances obtained through steaming are discharged, and during heating, the alginic acid is stirred continuously; 3, the degraded alginic acid is cooled, alcohol is added for uniform stirring, neutralizing is carried out with alkali, and the alginate with ultra-low viscosity is obtained after drying and smashing. The problems that in an existing hydrogen peroxide degrading or irradiation degrading technology, the stability of product viscosity is low, the smell of an oxidizing agent remains, and irradiation is limited are solved; the application effect of the product is improved, and the alginate is suitable for industrialized production and application.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Heavy metal sewage treatment method

InactiveCN106007118ASimple processImprove removal efficiencyWater/sewage treatment by irradiationSpecific water treatment objectivesIon exchangeEtidronic acid

The invention discloses a method for treating heavy metal sewage, which is extracted by polymerizing ferrosilicon sulfate, polyacrylamide, aluminum tripolyphosphate, petroleum ether, octadecyl dimethyl, manganese sulfate, hydroxyethylidene diphosphonic acid and brown algae Compound sewage treatment agent formulated with alum, tertiary butyl hydroquinone, pyrrolidone, thiabendazole, and ethyl naphthol reacts with sewage by stirring, after ultrasonic treatment, the ion exchange column is eluted through the column, and the flocculant is stirred, flocculated and precipitated , the flocculation supernatant is passed through a column adsorption resin, filtered through a membrane filter, and sterilized to obtain discharge standard treated water. The method has high removal efficiency for heavy metals in sewage, simple and easy process, strong operability, no pollution to the environment, can meet the requirements of the industry, and has good application prospects.

Owner:陈昌

Sea cucumber seed and processing method thereof

The invention relates to a sea cucumber feed and a processing method thereof, and belongs to the technical field of feed and processing method thereof. A sea cucumber feed comprises the following raw materials by weight: 20-40 parts of a big leaf powder, 10-20 parts of a sweet potato leaf powder, 10-15 parts of a gulfweed powder, 20-30 parts of a sargassum thunbergii powder, 10-15 parts of an ulva powder, 15-18 parts of a degumming brown seaweed powder, 10-20 parts of a soybean protein powder, 10-15 parts of a defatted fish meal, 10-12 parts of a scallop skirt powder, 12-15 parts of a shrimp powder, 5-10 parts of a yeast, 8-15 parts of elecampane, 5-10 parts of solanum lyratum, 5-10 parts of angelica, and 5-8 parts of fritillaria. The sea cucumber feed provided by the invention is added with big leaf powder, sweet potato leaf powder and traditional Chinese herbal medicines such as elecampane and angelica, so that the feed has more balanced and rich nutrition, is more conducive to the production of sea cucumber, and can shorten growth cycle of sea cucumber and improve nutritional value of the sea cucumber.

Owner:孙丽君

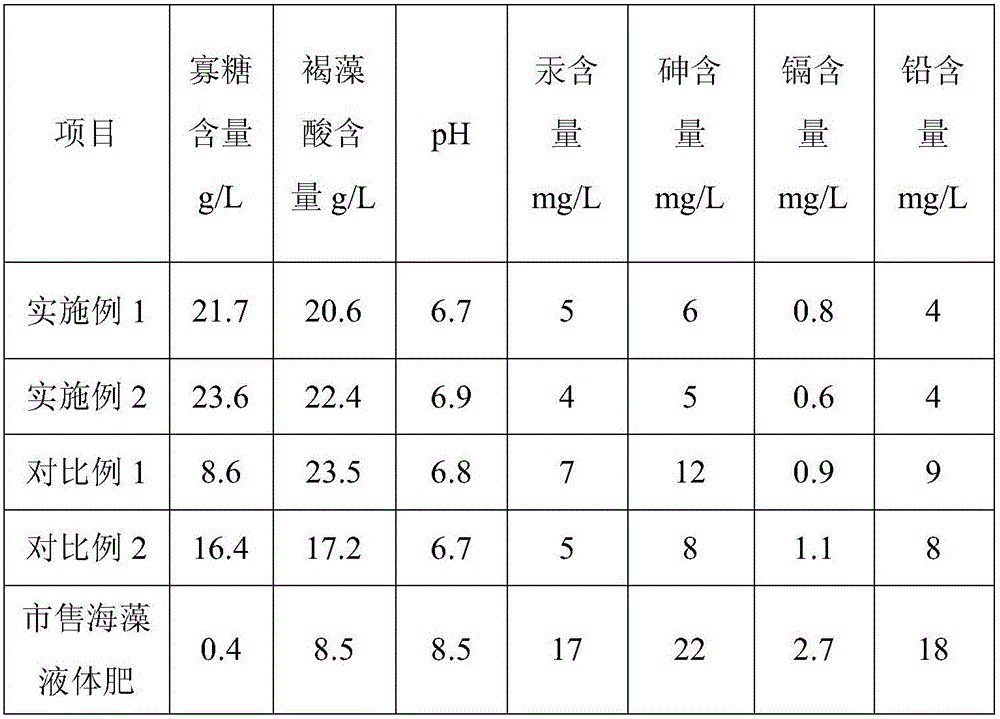

Method for preparing oligosaccharide-containing seaweed organic fertilizers by graded enzymolysis

ActiveCN106278493AShort reaction timeImprove reaction efficiencyAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBrown seaweedOrganic fertilizer

The invention relates to a method for preparing oligosaccharide-containing seaweed organic fertilizers by graded enzymolysis. The method comprises the following steps: washing fresh marine algae plants, removing impurities, soaking, grinding into thick liquid, preparing an enzyme solution, and adding the enzyme solution into a seaweed base material at different times to realize graded enzymolysis. An experiment shows that the technical effect of graded enzymolysis by various enzymes is obviously better than the technical effect of single enzymolysis and the technical effect of a method of simply mixing the various enzymes for enzymolysis, reaction time is short, production efficiency is greatly improved, the contents of active ingredients such as alginic acid and oligosaccharide are high, and the whole process is high in controllability, and is energy-saving and environmentally friendly. The contents of the alginic acid and the brown seaweed oligosaccharide of the prepared oligosaccharide-containing seaweed organic fertilizers are above 20 g / L, pH value is 7.0-8.5, and the ratio of contents of N, P and K is 1-2:1:0.8-1.5.

Owner:WUZHOUFENG AGRI SCI & TECH

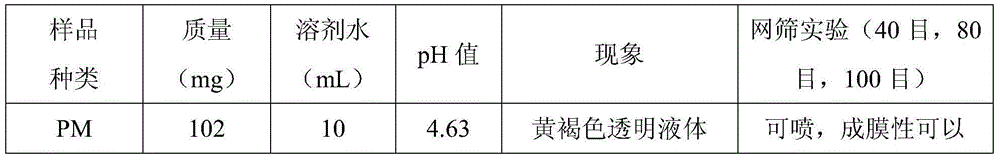

Seaweed polysaccharide medicinal plant film coating and preparation method thereof

InactiveCN102343093AImprove hydrophilicityImprove the coagulation effectPharmaceutical non-active ingredientsFiberSolvent

The invention relates to a drug tablet core coating technology, and specifically, relates to a seaweed polysaccharide medicinal plant film coating and a preparation method thereof. The seaweed polysaccharide medicinal plant film coating comprises a component A, a component B, and a water solvent, wherein the component A comprises seaweed polysaccharide and / or dietary vegetable fibers and the component B comprises one or more of modified starch, guar gum, edible pigment and brown seaweed polysaccharide. Specifically, the seaweed polysaccharide medicinal plant film coating comprises 5 to 15 wt% of the seaweed polysaccharide, 9 to 16 wt% of the dietary vegetable fibers, 1 to 3 wt% of the modified starch, 0.5 to 0.1 wt% of the guar gum, 0.1 to 1 wt% of the brown seaweed polysaccharide, based on the total weight of the seaweed polysaccharide medicinal plant film coating, 0.1 to 0.5ppm of the edible pigment, and the balance the water solvent. A film forming agent and the most of auxiliary additives adopted by the preparation method of the seaweed polysaccharide medicinal plant film coating are all high-molecular materials with excellent physiochemical performances. Therefore, after coating, the seaweed polysaccharide medicinal plant film coating has the effects of proofing moisture, avoiding light, covering peculiar smell and resisting wear, is difficult to mildew, is easy for disintegration, and improves greatly a drug dissolution rate, bioavailability and a period of drug validity.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Sweetener compositions

A sweetener composition comprising xylose, a sugar alcohol and brown seaweed extract in solid form, preferably powdered or crystalline form. The sugar alcohol is preferably an erythritol and the brown seaweed extract is preferably obtained from Laminaria japonica. The sweetener composition can further comprise one or a combination of additional vitamins, minerals, probiotic cultures, and other plant-based extracts.

Owner:BAXCO PHARMA

Method for coproduction of sodium alginate, mannitol and iodine by enzymolysis approach

InactiveCN103193897ASimple extraction processImprove qualityIodineHydroxy compound separation/purificationIon exchangeDigestion

The invention discloses a method for coproduction of sodium alginate, mannitol and iodine by enzymolysis approach. The method comprises the following steps of: taking brown seaweeds as the raw material, pretreating the raw material by a bio-enzymolysis approach, extracting iodine and mannitol from pretreated liquid, removing partial protein and the water soluble component seaweed residues for extraction and separation of sodium alginate, and finally, obtaining high-quality sodium alginate through a dilute alkali digestion process and by calcium solidification-ion exchange method. The method is characterized in that the seaweeds are pretreated by a biological enzyme, so that water soluble matters such as protein and the like therein are dissolved out in advance, which is advantageous for the subsequent extraction process of sodium alginate and the quality of the product and also for improving the product extraction ratio, and in such a way, the recycling of production water is realized finally; the process of extracting iodine and mannitol in the pretreated liquid is simple, and the production cost and the energy consumption are reduced; and compared with the existing industrial production process, more than 90% of water is saved, and the consumption of water resource and sewage drainage are greatly reduced so that environmental pollution is reduced.

Owner:QINGDAO BETTER BIO TECH

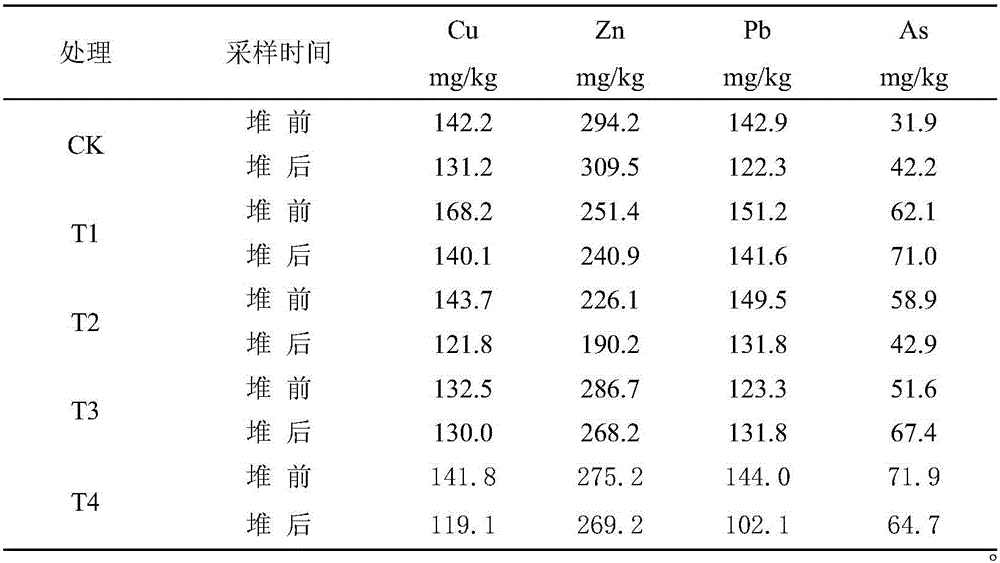

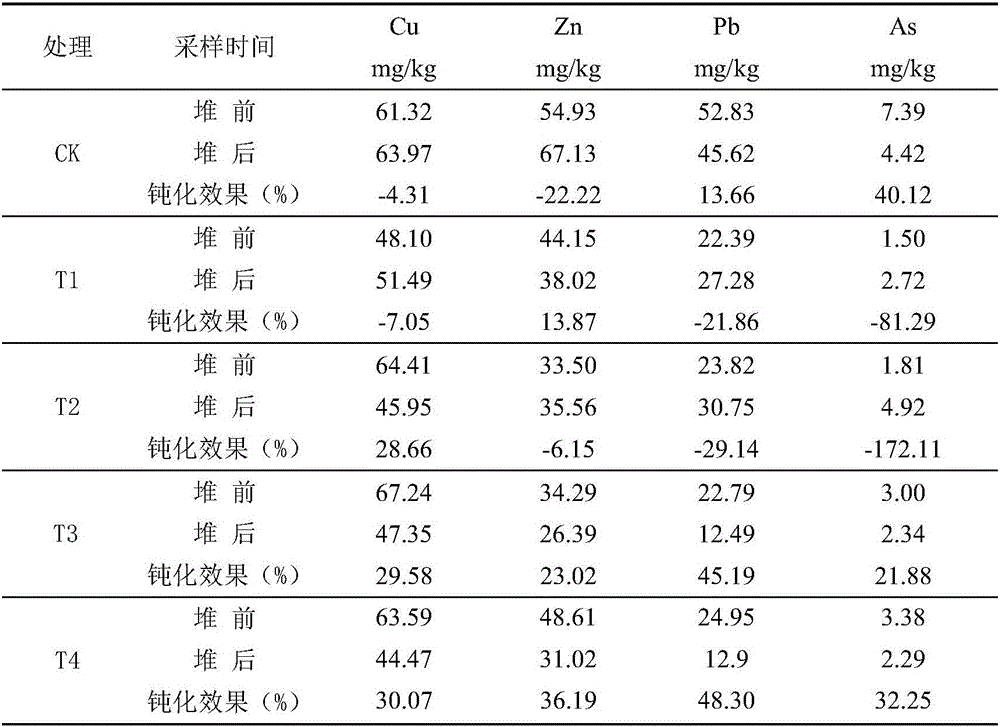

Heavy metal deactivator for chicken manure compost

ActiveCN105906404AImprove passivation effectImprove fat retention capacityFertilizer mixturesBrown seaweedCompost

The invention discloses a heavy metal deactivator for chicken manure compost. The heavy metal deactivator is prepared from 30-50wt% of brown seaweed biochar, 40-60wt% of attapulgite and the balance meerschaum. The heavy metal deactivator utilizes natural raw materials which are environmentally friendly and widely exist in the natural environment and has good passivation effects on heavy metals such as Cu, Zn, Pb and As in chicken manure.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Air purifying composition and preparation method and application method thereof, and formation method for elliptical granules of air purifying composition

InactiveCN105903307AImprove purification effectReduce harmful pollutionGas treatmentDispersed particle separationBrown seaweedMolecular adsorption

The invention provides an air purifying composition and a preparation method and application method thereof, and a formation method for elliptical granules of the air purifying composition. The air purifying composition comprises konjak powder, shell powder, nanometer titanium dioxide and seaweed glue or brown seaweed glue. The plant substance konjak powder, the animal substance shell powder and the mineral substance nanometer titanium dioxide form the mutually bonding granules under the action of the seaweed glue or brown seaweed glue. Under the action of water, purifying factors and a layer of a molecular adsorption surface are formed on the surfaces of the granules, so air purifying effect is improved.

Owner:山东宝梵环保科技有限公司

Laminaria brown seaweed introduction method based on gametophyte cloning line

InactiveCN105165628AAvoid it happening againIncrease in sizePlant tissue cultureHorticulture methodsSporeBrown seaweed

The invention provides a laminaria large-scale economical brown seaweed introduction method based on a gametophyte cloning line, belonging to the technical field of marine organisms. The laminaria large-scale economical brown seaweed introduction method comprises the steps of selecting and pre-treating parent seaweeds, collecting spores, culturing gametophytes, separating female and male gametophytes, transporting the gametophyte cloning line in a long distance, propagating the gametophyte cloning line and preserving the gametophyte cloning line for a long period. According to the laminaria large-scale economical brown seaweed introduction method, by using the characteristics that laminaria seaweed gametophytes have small sizes in all generations and are easy to preserve, the laminaria seaweed gametophytes occupy a small space when being transported in the long distance, and a culture solution does not need to be replaced; and the laminaria large-scale economical brown seaweed introduction method is simple and feasible and the success rate can be up to 100%.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com