Method for extracting and purifying fucoxanthin

A fucoxanthin and extraction method technology, which is applied in the field of extraction and purification of fucoxanthin, can solve the problems of product safety impact, large amount of organic solvent consumption, time-consuming, etc., achieve product safety guarantee, shorten extraction time, reduce Environmental Risk Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Different solvents and extraction methods compare the extraction efficiency of fucoxanthin in Wakame

[0068] (1) Accurately weigh 1.0g / part of crushed undaria pinnatae dry powder in a 50mL Erlenmeyer flask, divide it into three groups, add 25mL methanol, ethanol and acetone:methanol (volume ratio 7:3), and soak in the dark at room temperature 30min; three repetitions were set for each group.

[0069] (2) Three extraction methods are used for extraction, and the extraction methods and procedures are shown in Table 1 below.

[0070] Table 1 Methods and conditions used in different extraction methods

[0071]

[0072]

[0073] (3) After the extraction, centrifuge at 5000rpm for 5min, and take the supernatant.

[0074] (4) Repeat steps (2) and (3) twice after the precipitation is added to the extraction solvent; respectively merge the supernatants extracted three times in each group, distill under reduced pressure, concentrate to dryness, and dissolve wit...

Embodiment 2

[0083] The extraction of fucoxanthin in embodiment 2 laver

[0084] (1) Weigh 1.0 g of commercially available dried seaweed cake, crush it, add 25 mL of ethanol, and soak for 30 min at room temperature in the dark.

[0085] (2) Put the above materials in a microwave oven, adjust the microwave power to 600W, control each microwave time to 5s, with an interval of 10s, and extract for 90s.

[0086] (3) Centrifuge the extract in (2) at 5000rpm for 5min, take the supernatant, concentrate it to dryness under reduced pressure at 35°C, and dissolve it with 5mL ethanol.

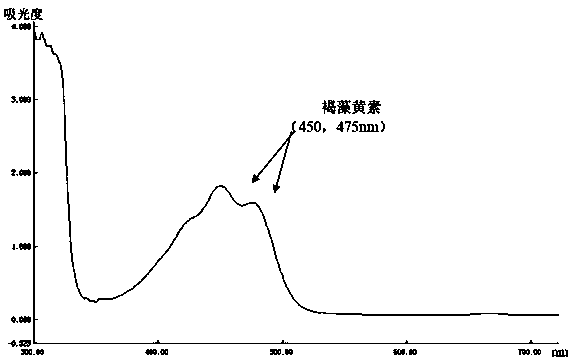

[0087] (4) Measure the absorbance value of the extract at 450 nm with a spectrophotometer, and calculate the content of fucoxanthin according to formula ① to be 0.654 mg.

Embodiment 3

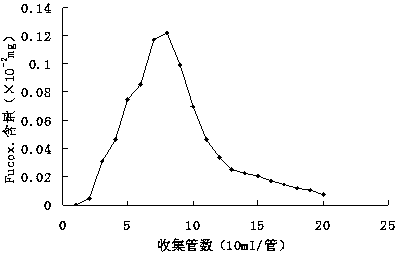

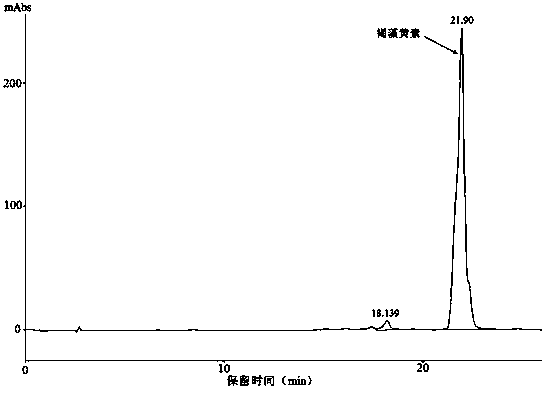

[0088] Extraction and extraction separation of fucoxanthin in embodiment 3 Undaria pinnatae

[0089] (1) Accurately weigh 15 g of dry and pulverized Undaria pinnatifida, add 200 mL of ethanol, soak in dark at room temperature for 30 min, use the microwave extraction method in Example 1 to extract, centrifuge at 5000 rpm for 5 min, take the supernatant, and concentrate under reduced pressure to dryness Afterwards, dissolve with 10 mL ethanol.

[0090] (2) Take 5 mL of the above extract, dilute it with 25 mL of 90% methanol, add 30 mL of n-hexane for extraction, and repeat 3 times. Then add double-distilled water to the methanol / water phase until the concentration of methanol is 70%, and then extract with 25 mL of n-hexane to further separate the pigment. In order to investigate the separation of pigments and the removal of impurities by the number of extractions, each extraction and raffinate were scanned for visible spectrum. The finally obtained n-hexane phase and methanol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com