Method for preparing oligosaccharide-containing seaweed organic fertilizers by graded enzymolysis

A technology of organic fertilizer and enzymatic hydrolysis, applied in the direction of organic fertilizer, nitrogen fertilizer, phosphate fertilizer, etc., can solve the problems of low content of effective substances, unclear enzymatic hydrolysis products, low enzyme production efficiency, etc., to increase content, shorten reaction time, improve The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

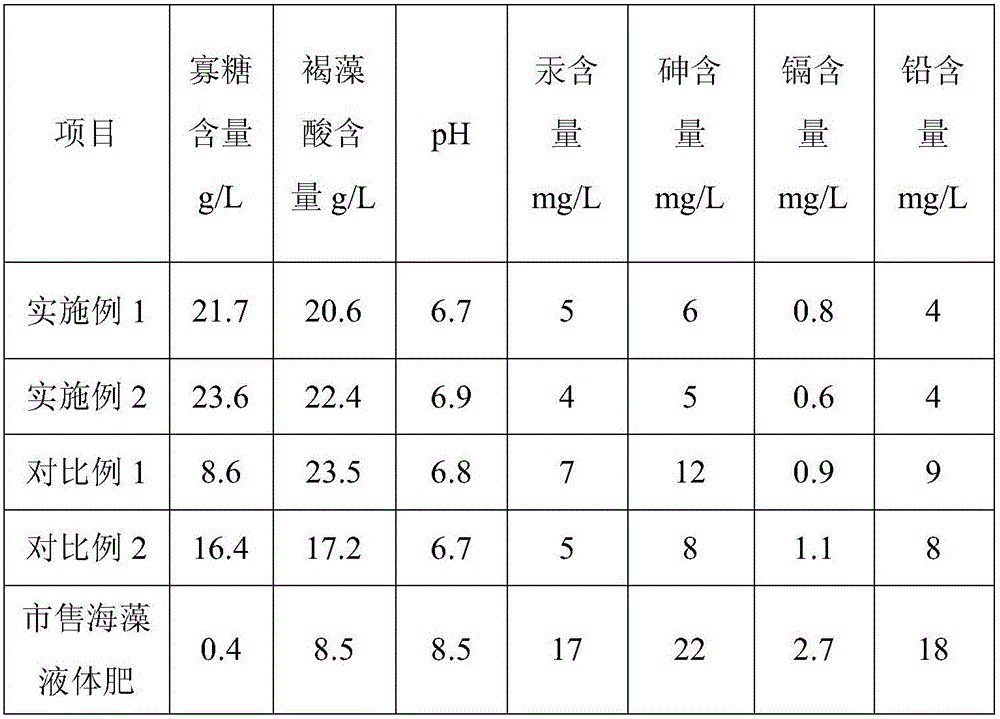

Embodiment 1

[0031] 1) Preparation of Product A: Wash and remove fresh copper algae and kelp (mass ratio: 1:1), soak for 24 hours, refine, transfer to a fermenter, sterilize at 115°C for 30 minutes, and cool to 20 ℃ to get the product A, set aside.

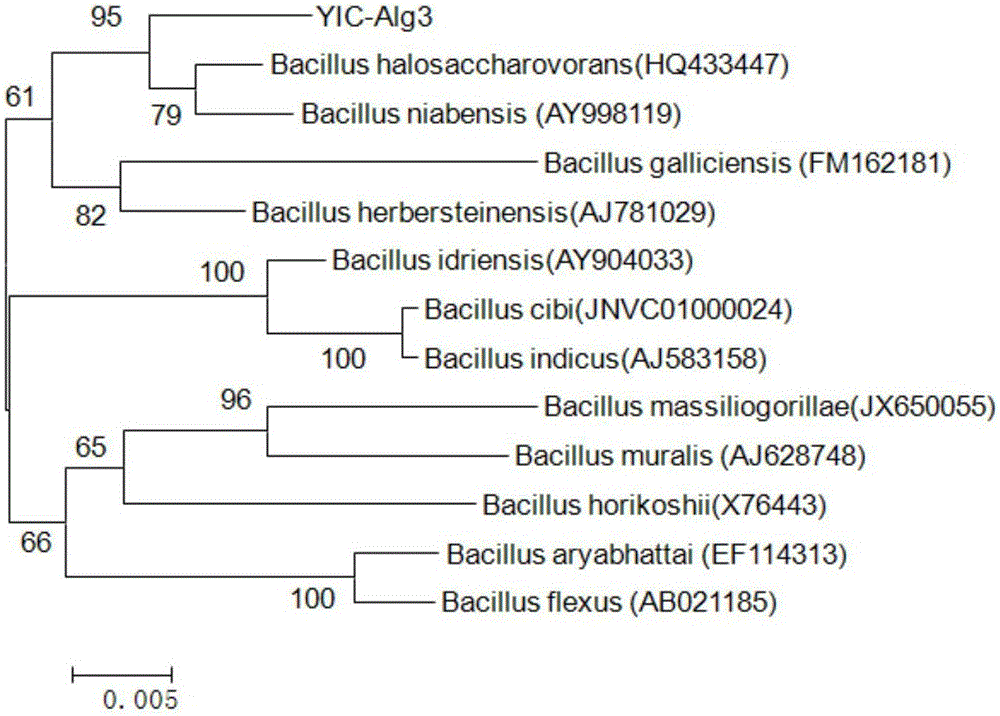

[0032] 2) Preparation of enzyme solution: respectively activate Bacillus cereus and Bacillus megaterium and inoculate them into the same seed fermenter for mixed enrichment culture, the inoculum size is 10%, the temperature is 37°C, cultivate for 15 hours, and centrifuge the fermentation broth Cellulolytic enzyme solution A is obtained by membrane filtration to remove the bacteria; activate Bacillus saccharophilus and transfer to a seed fermentation tank for enrichment culture, the inoculum size is 10%, the temperature is 30°C, cultured for 12 hours, and the fermented liquid is centrifuged The bacterial cells were removed by membrane filtration to obtain alginic acid degrading enzyme solution B.

[0033] The inoculum size refers to the mass p...

Embodiment 2

[0041] 1) Preparation of product A: Wash fresh Sargassum and Sargassum (mass ratio 1:1), remove impurities, soak for 36 hours, grind, transfer to a fermenter, sterilize at 121°C for 30 minutes, and cool To 30 ℃ to obtain product A, set aside.

[0042] 2) Preparation of enzyme solution: activate Bacillus cereus and Bacillus megaterium and inoculate them into the same seed fermenter for mixed enrichment culture, the inoculum size is 15%, the temperature is 37°C, cultivate for 18 hours, centrifuge the fermentation broth Cellulolytic enzyme solution A is obtained by membrane filtration to remove the bacteria; activate Bacillus saccharophilus and transfer to a seed fermentation tank for enrichment culture, the inoculum size is 15%, and the temperature is 35 ° C, cultured for 14 hours, and the fermentation liquid is centrifuged The bacterial cells were removed by membrane filtration to obtain alginic acid degrading enzyme solution B.

[0043] The inoculum size refers to the mass pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com