Mud resisting and slump retaining type polycarboxylic acids water reducer and preparation method thereof

A slump-preserving, polycarboxylic acid technology, applied in the field of superplasticizers, can solve the problems of large concrete slump loss, complex process, concrete segregation, etc., and achieve the effects of easy industrial production, simple preparation process and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

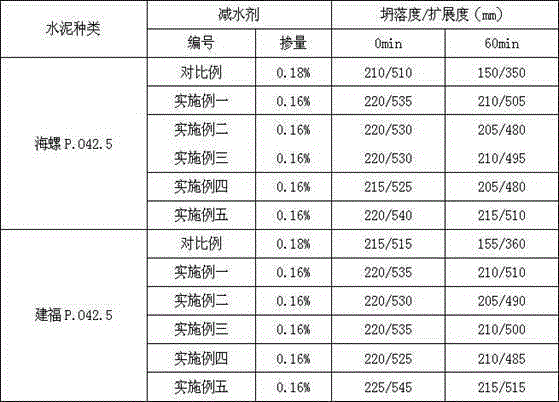

Examples

Embodiment 1

[0037] Example 1: Preparation of mud-resistant and slump-proof polycarboxylate superplasticizer

[0038] Raw materials: see Table 1.

[0039] Preparation:

[0040] (1) Weigh each raw material according to the data in Table 1.

[0041] (2) Add the unsaturated polyoxyethylene ether and water into the reactor, stir at room temperature until the unsaturated polyoxyethylene ether is completely dissolved, add the oxidizing agent, stir for 5-10 minutes, and then add the unsaturated carboxyl The mixed solution composed of acid, functional monomer and cross-linking agent and the mixed solution composed of chain transfer agent and reducing agent are added dropwise for 3-5 hours, and the reaction is continued for 1-2 hours after the drop is completed.

[0042] (3) After the reaction is completed, use an alkaline regulator to neutralize to a pH of 6-7 to obtain a polycarboxylate superplasticizer solution with a concentration of 40%.

Embodiment 2

[0043] Example 2: Preparation of mud-resistant and slump-proof polycarboxylate superplasticizer

[0044] Raw materials: see Table 1.

[0045] See Example 1 for the preparation method.

Embodiment 3

[0046] Example 3: Preparation of mud-resistant and slump-proof polycarboxylate superplasticizer

[0047] Raw materials: see Table 1.

[0048] See Example 1 for the preparation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com