Patents

Literature

4878 results about "Chain transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

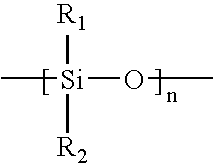

Chain transfer is a polymerization reaction by which the activity of a growing polymer chain is transferred to another molecule. Chain transfer reactions reduce the average molecular weight of the final polymer. Chain transfer can be either introduced deliberately into a polymerization (by use of a chain transfer agent) or it may be an unavoidable side-reaction with various components of the polymerization. Chain transfer reactions occur in most forms of addition polymerization including radical polymerization, ring-opening polymerization, coordination polymerization, and cationic polymerization, as well as anionic polymerization.

Novel Polymers

ActiveUS20080015315A1Sufficient amountReduce the amount requiredOrganic compound preparationCarboxylic acid esters preparationHydrophilic monomerPolymer science

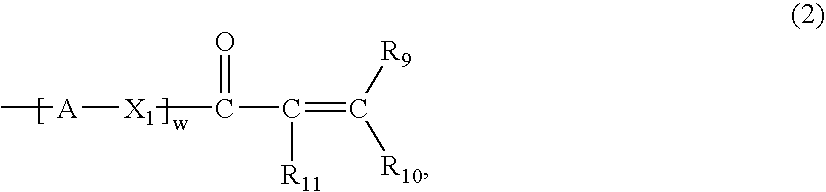

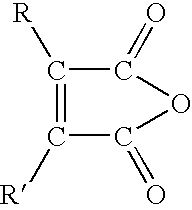

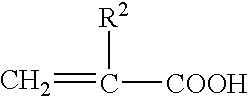

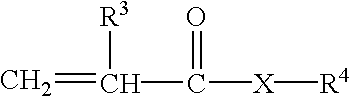

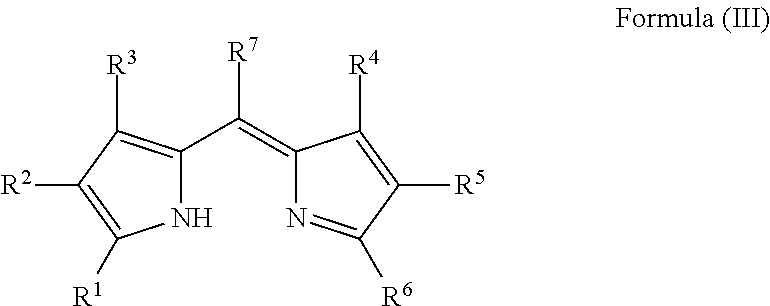

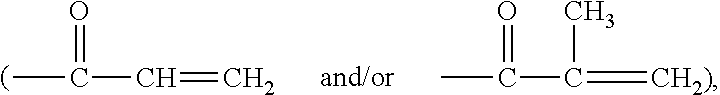

The invention relates to novel crosslinkable copolymers which are obtainable by (a) copolymerizing at least two different hydrophilic monomers selected from the group consisting of N,N-dimethyl acrylamide (DMA), 2-hydroxyethyl acrylate (HEA), glycidyl methacrylate (GMA), N-vinylpyrrolidone (NVP), acrylic acid (AA) and a C1-C4-alkoxy polyethylene glycol (meth)acrylate having a weight average molecular weight of from 200 to 1500, and at least one crosslinker comprising two or more ethylenically unsaturated double bonds in the presence of a chain transfer agent having a functional group; and (b) reacting one or more functional groups of the resulting copolymer with an organic compound having an ethylenically unsaturated group.

Owner:ALCON INC

Rheology modifying copolymer composition

A rheology modifying copolymer composition containing a cross-linked copolymer of unsaturated carboxylic acid, a hydrophobic monomer, a hydrophobic chain transfer agent, a cross linking agent, and, optionally, a steric stabilizer, provides increased viscosity in aqueous electrolyte-containing environments.

Owner:NOVEON IP HLDG CORP

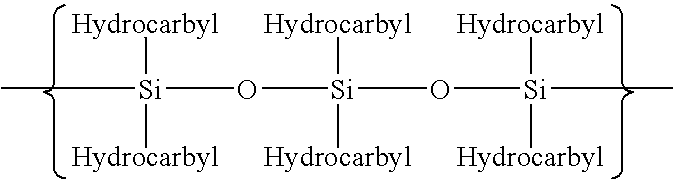

Polymerization of halogen-containing monomers using siloxane surfactant

Halogenated polymers are prepared by a process comprising polymerizing at least one halogen-containing monomer in an aqueous medium containing monomer, radical initiator, and siloxane surfactant. The medium may optionally contain one or more of an antifoulant, a buffering agent and a chain-transfer agent.

Owner:ARKEMA INC

Radiation curable and jettable ink compositions

The present invention is directed to radiation curable and jettable ink compositions and particularly to such compositions which exhibit enhanced elongation, when cured at low doses, and are advantageously used, for example, in digital inkjet printing. The compositions include a polyfunctional component and a monofunctional monomer, and may optionally include an additional monofuctional component and / or chain transfer agent. The compositions have a viscosity at 25° C. of not greater than about 70 cP and are radiation curable to form a cured ink having an elongation of between about 40 and about 150%. In addition, the compositions, when cured at low dose, exhibit a tack free surface and a low coefficient of friction.

Owner:COLLINS INK CORP

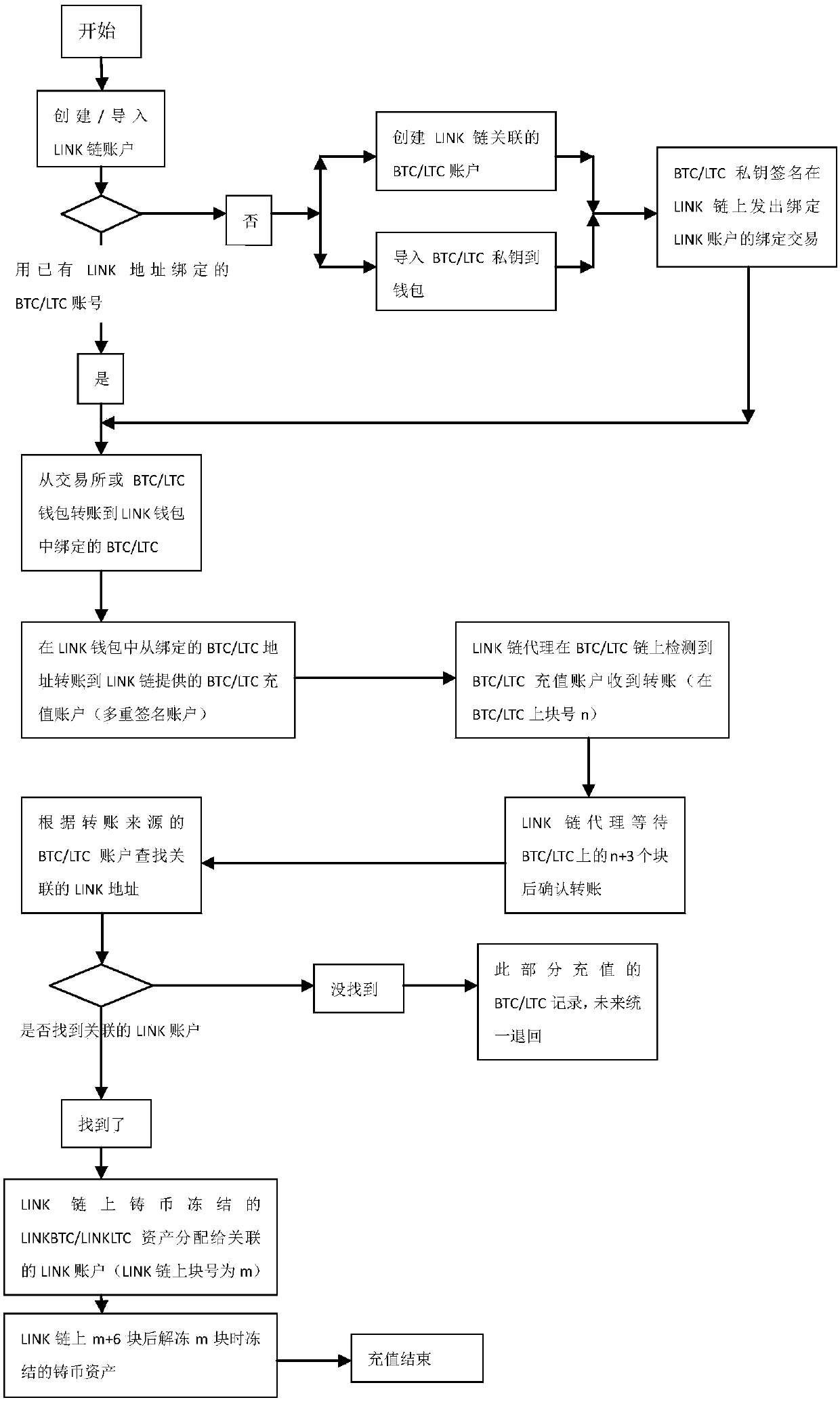

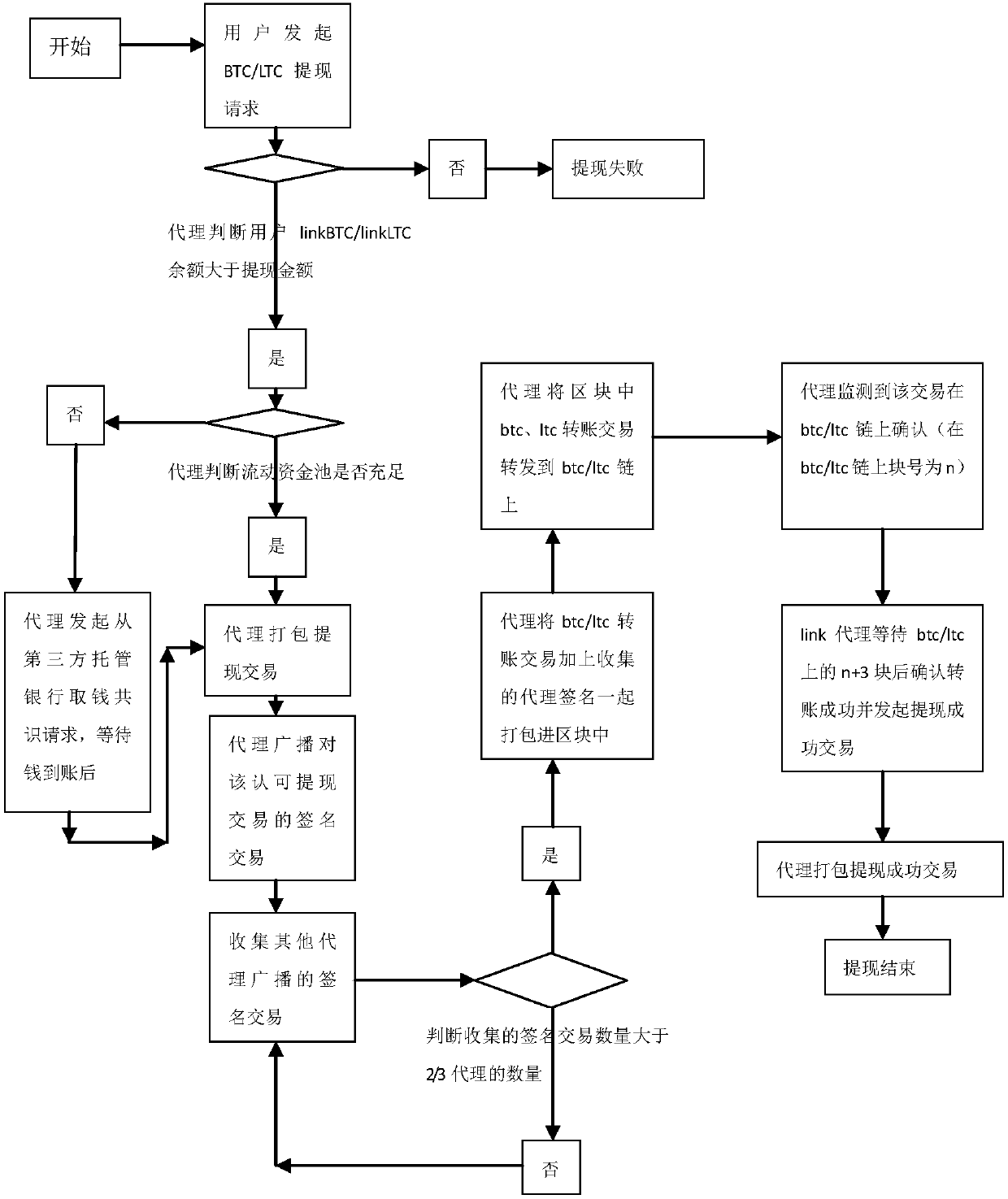

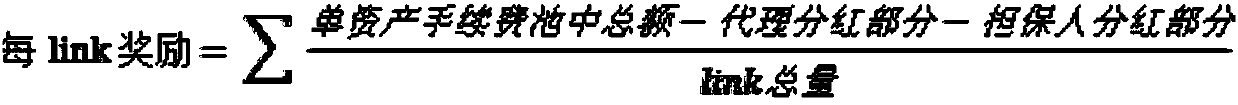

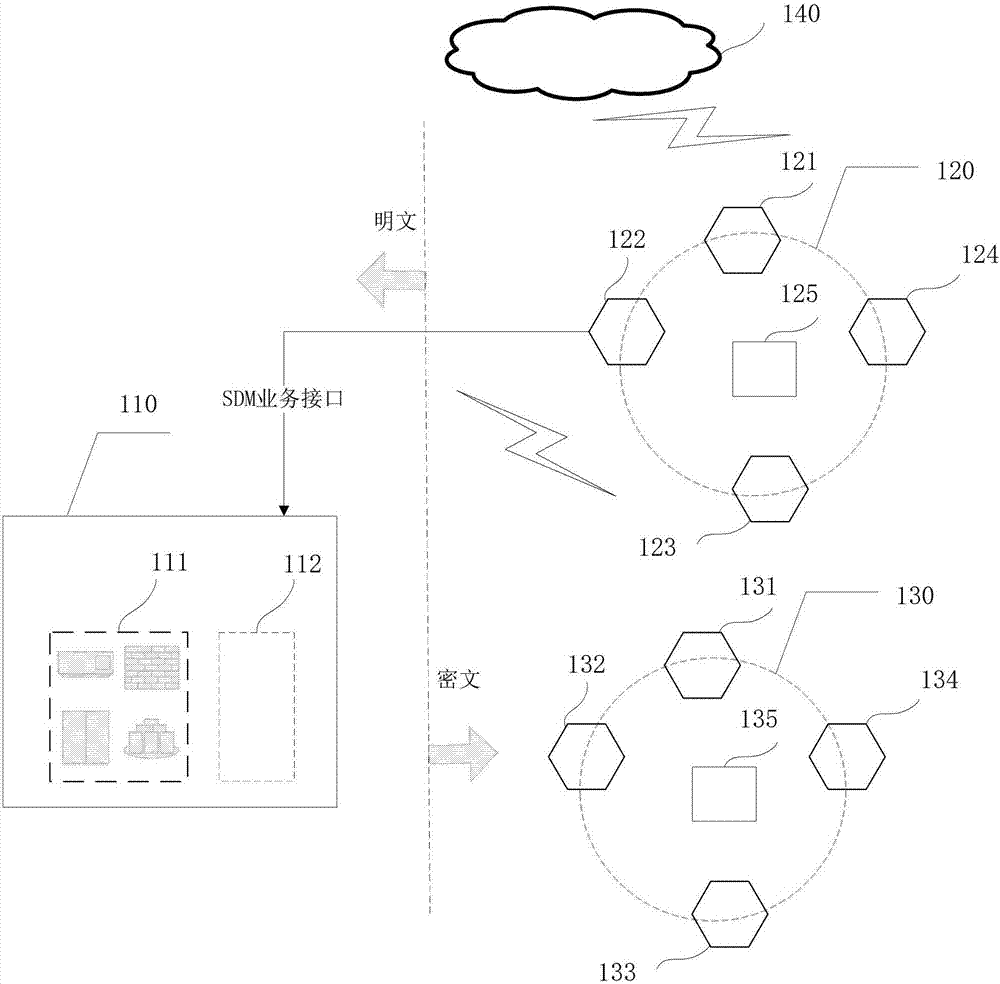

Blockchain-based cross-chain transaction method and storage medium

The present invention discloses a blockchain-based cross-chain transaction method. The method comprises the following steps that: a first account is created on a first block chain, wherein the first block chain is used for managing the circulation of cross-chain assets; the first account is bound with a second account on a second blockchain; assets on the second blockchain comprise assets to be subjected to cross-chain transfer; and consensus modification is performed on the circulation of the assets between the first blockchain and the second blockchain, thus the transfer of the cross-chain assets can be realized. The present invention also provides a storage medium for implementing the method. With the method adopted, asset transfer between different chains can be realized in a trust-free manner.

Owner:马晶瑶

Cross-block chain digital asset transfer method and device

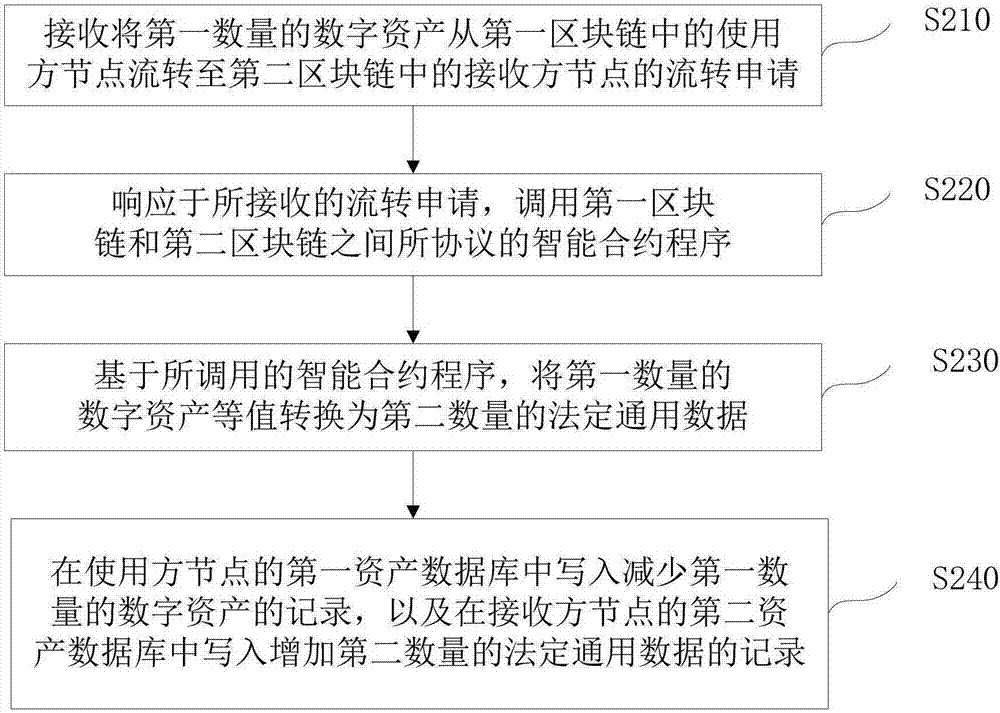

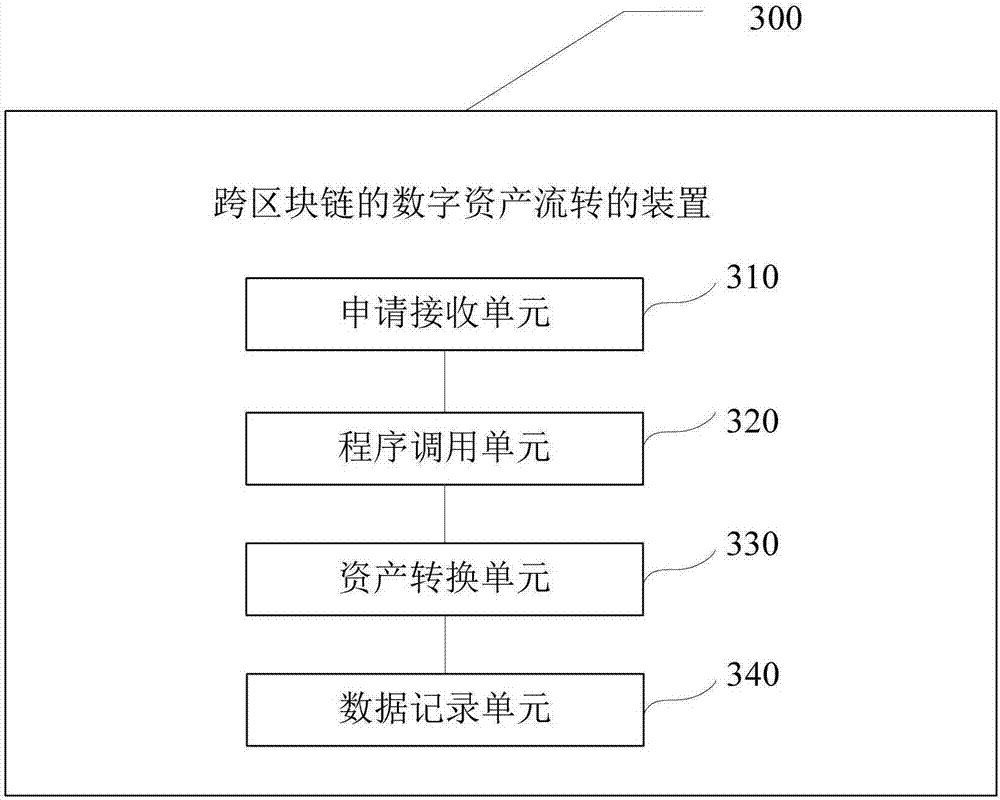

InactiveCN106960388APrevent problems such as voting fraudPrevent flow lossFinancePayment circuitsSmart contractDatabase

The invention discloses a cross-block chain digital asset transfer method and device; the method comprises the following steps: receiving a transfer application requesting to transfer first quantity digital asset from a user party node in the first block chain to a receiver party node in a second block chain; responding to the received transfer application, and invoking an agreed intelligent contract program between the first and second block chains; equivalently converting the first quantity digital asset into the second quantity legal general data according to the invoked intelligent contract program; writing a digital asset record deducting the first quantity into the first asset database of the user party node, and writing a legal general data record adding the second quantity into the second asset database of the receiver party node. The method and device can ensure the digital asset total quantity remaining unchanged in a different block chain transfer process, thus preventing transfer losses, ensuring fast transfer, and preventing participation party fake voting problems.

Owner:中钞信用卡产业发展有限公司杭州区块链技术研究院 +1

Formaldehyde free insulation binder

An aqueous binder composition containing a water-soluble and substantially infinitely water-dilutable free radical polymerized adduct of a monomeric carboxylic acid component and a monomeric hydroxyl component, polymerized in the presence of a chain transfer agent, and the related method of its use for making glass fiber products, especially fiberglass insulation.

Owner:GEORGIA PACIFIC CHEM LLC

Multi-purpose polymers, methods and compositions

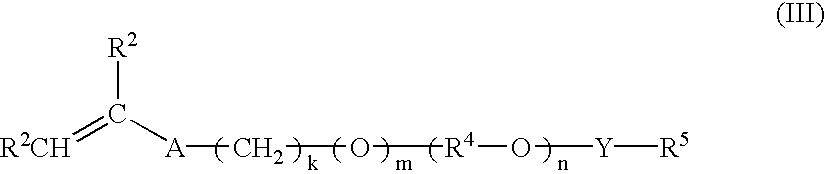

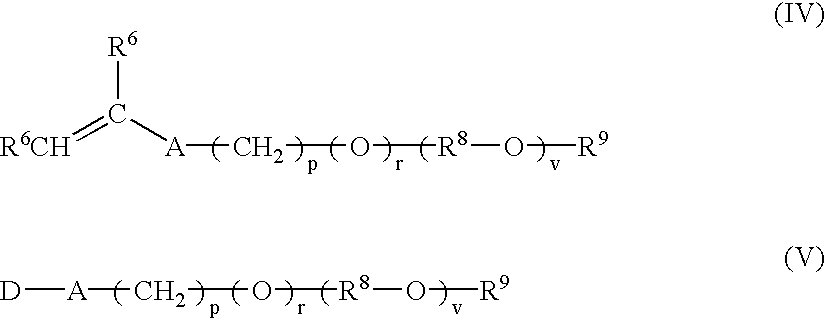

Disclosed are multi-purpose alkali-swellable and alkali soluble associative polymers, which are the polymerization product of a monomer mixture comprising: (a) at least one acidic vinyl monomer; (b) at least one nonionic vinyl monomer; (c) a first associative monomer having a first hydrophobic end group; (d) a monomer selected from the group consisting of a second associative monomer having a second hydrophobic end, a semihydrophobic monomer and a combination thereof; and, optionally, (e) one or more crosslinking monomers or chain transfer agents. When monomer (d) is an associative monomer, the first and second hydrophobic end groups of monomers (c) and (d) have significantly different hydrophobic and / or steric character from one another. The multi-purpose associative polymers surprisingly provide desirable Theological and aesthetic properties in aqueous media.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Polycarbonate polyol compositions and methods

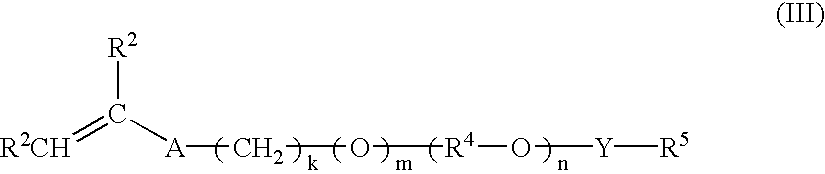

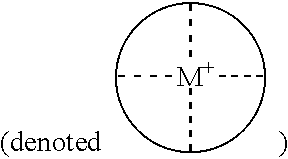

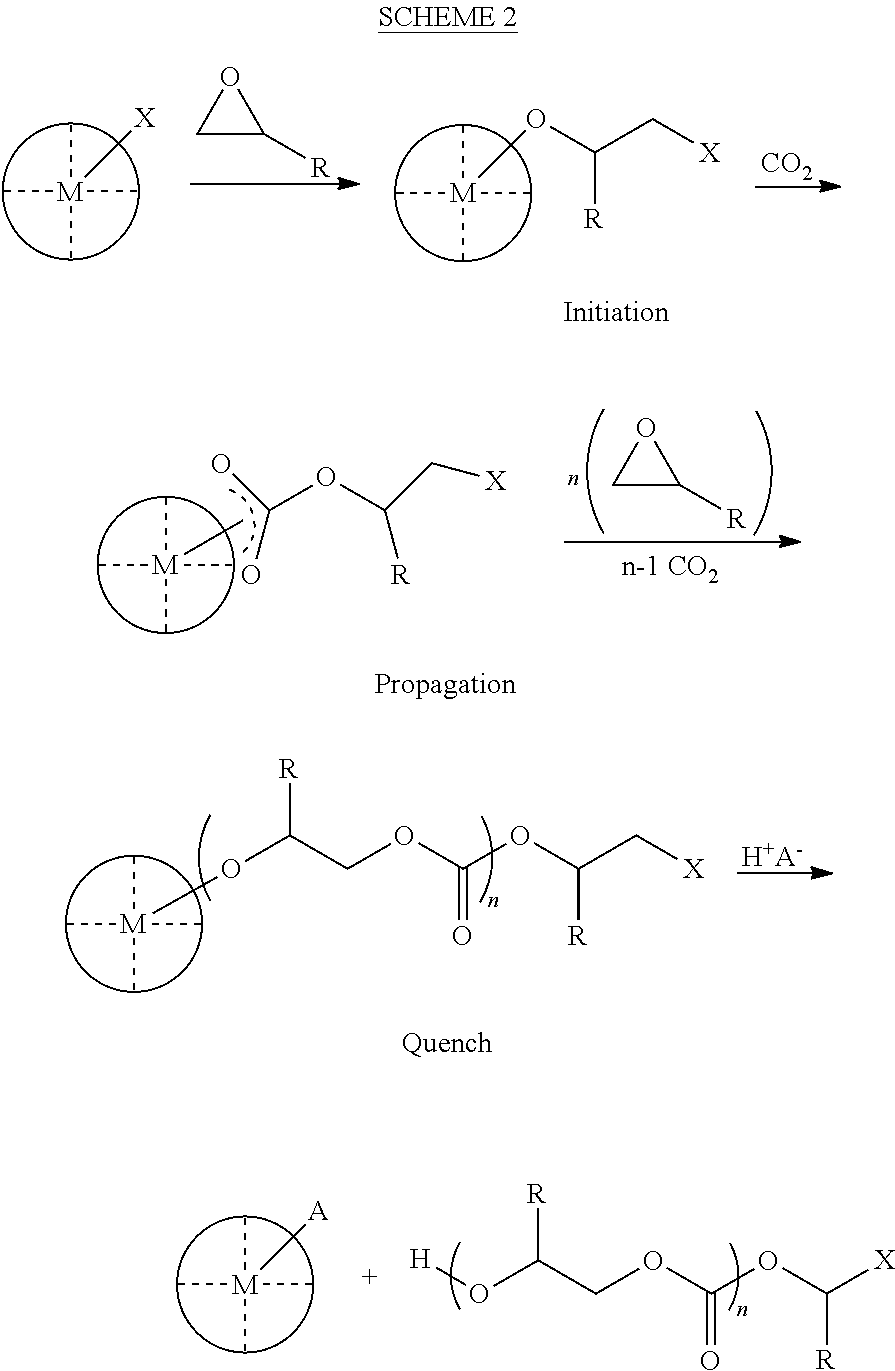

ActiveUS8247520B2Increase ratingsIncreases extentOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEnd-groupPolycarbonate

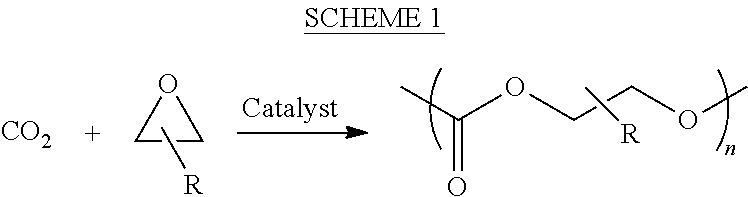

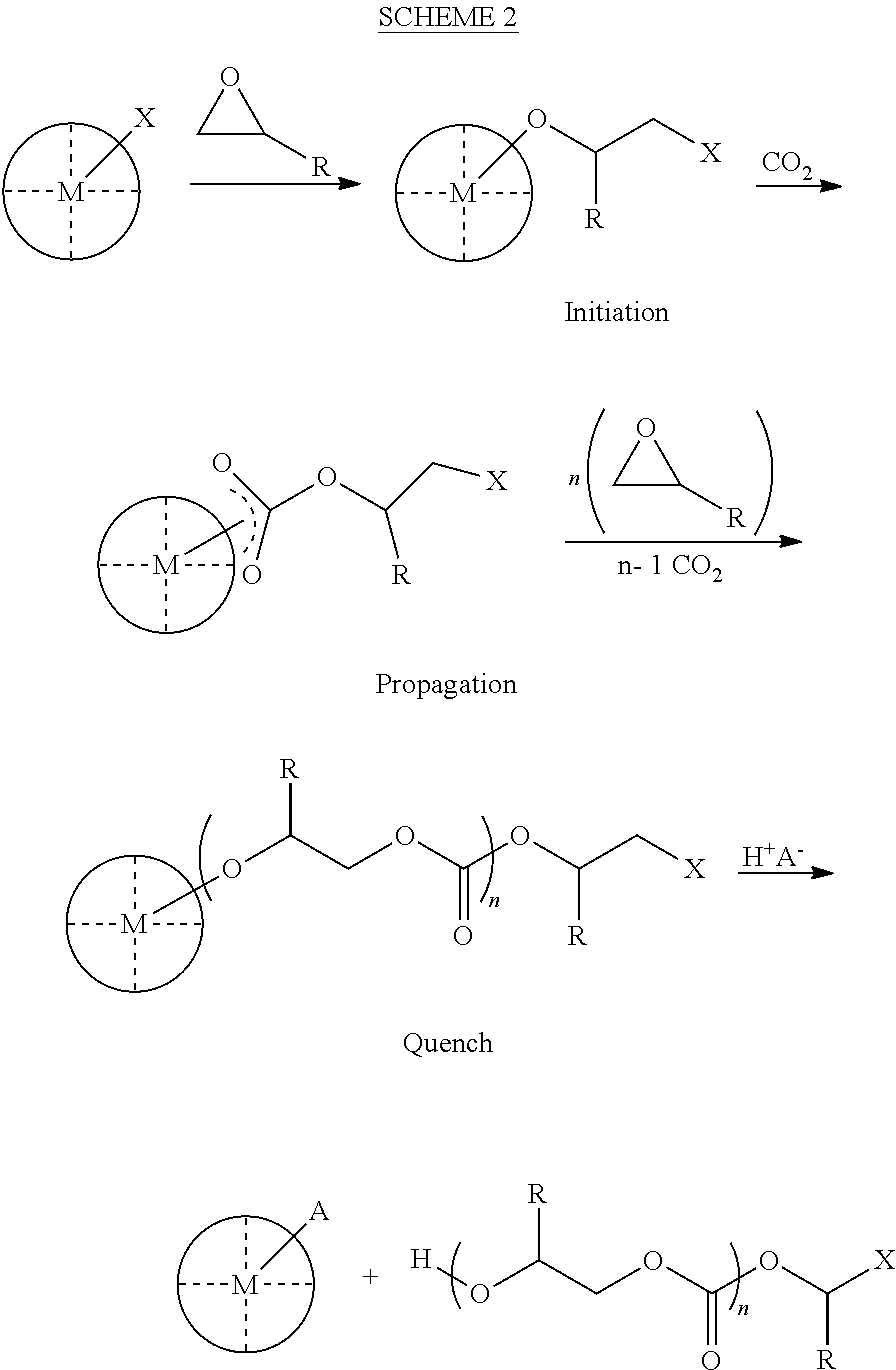

In one aspect, the present disclosure encompasses polymerization systems for the copolymerization of CO2 and epoxides comprising 1) a catalyst including a metal coordination compound having a permanent ligand set and at least one ligand that is a polymerization initiator, and 2) a chain transfer agent having two or more sites that can initiate polymerization. In a second aspect, the present disclosure encompasses methods for the synthesis of polycarbonate polyols using the inventive polymerization systems. In a third aspect, the present disclosure encompasses polycarbonate polyol compositions characterized in that the polymer chains have a high percentage of —OH end groups and a high percentage of carbonate linkages. The compositions are further characterized in that they contain polymer chains having an embedded polyfunctional moiety linked to a plurality of individual polycarbonate chains.

Owner:SAUDI ARAMCO TECH CO

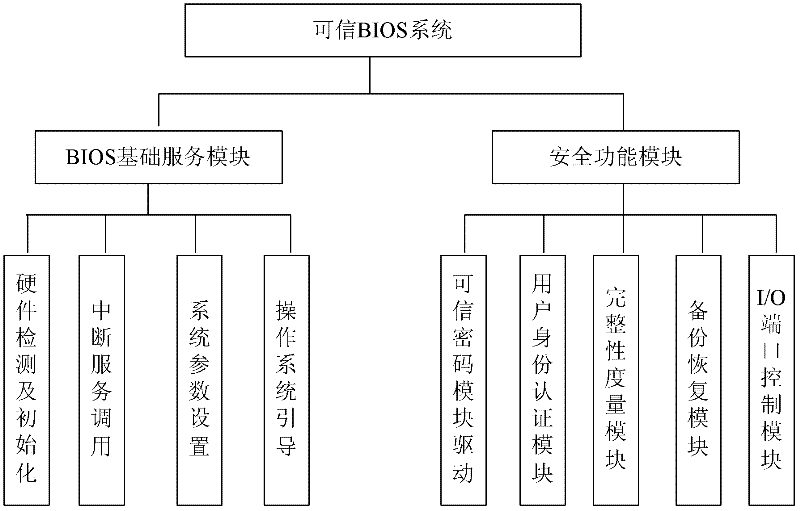

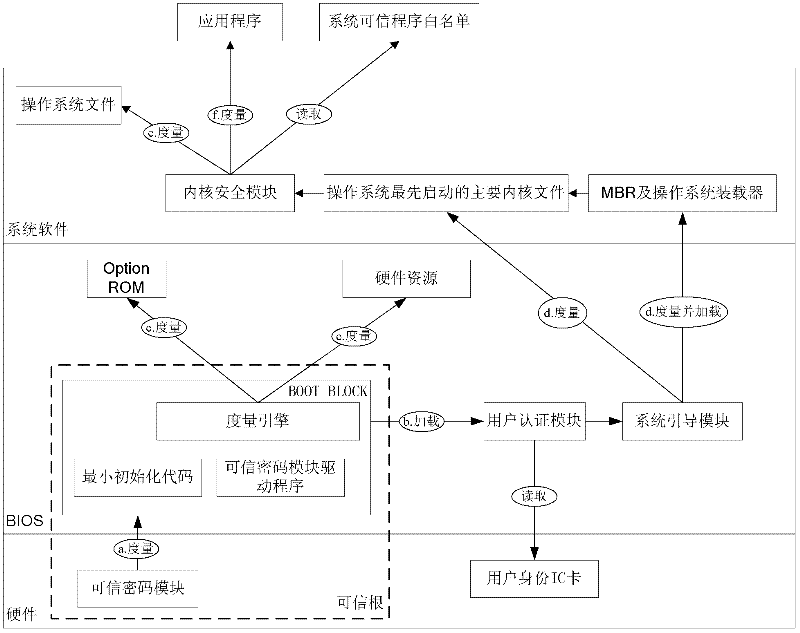

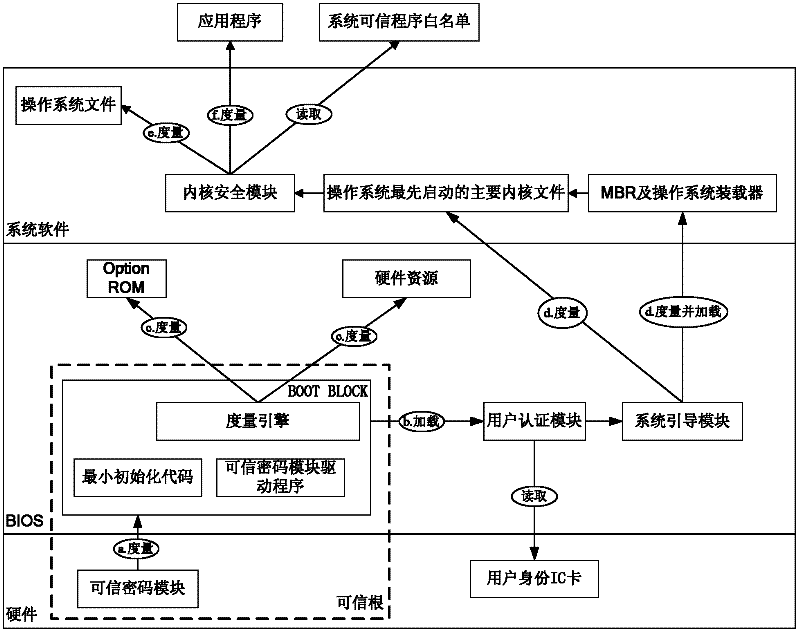

Trust chain transfer method for trusted computing platform

InactiveCN102332070ANot easy to tamper withNot easy to attackPlatform integrity maintainanceOperational systemTrusted Computing

The invention discloses a trust chain transfer method for a trusted computing platform. A trusted computing module (TCM) serving as a starting point of starting a trust chain is started and actively initiated at first to verify the trustiness of a BIOS (basic input output system) chip; after the trusted BIOS chip is started, a MAIN BLOCK of the BIOS chip performs concentrated integrity verification on key files of an MBR (master boot record), an operating system loader and an operating system kernel; in the starting process of an operating system, the starting and running of an unauthorized program are prevented in a way of combining the integrity verification based on a white list and running program control; and hashing operations for the integrity verification are finished by a hardware computing engine. When a user starts any executable program, a security module in the operating system kernel checks the integrity of the program and checks whether the program is in the trusted program white list or not, and only application programs which are in the trusted program white list of the system and have integrity measures consistent with an expected value are permitted to be run. High-efficiency and fine-grained trust chain transfer is realized, the damages of viruses to system files and program files can be prevented, and the execution of the unauthorized program can be prevented.

Owner:中国人民解放军海军计算技术研究所

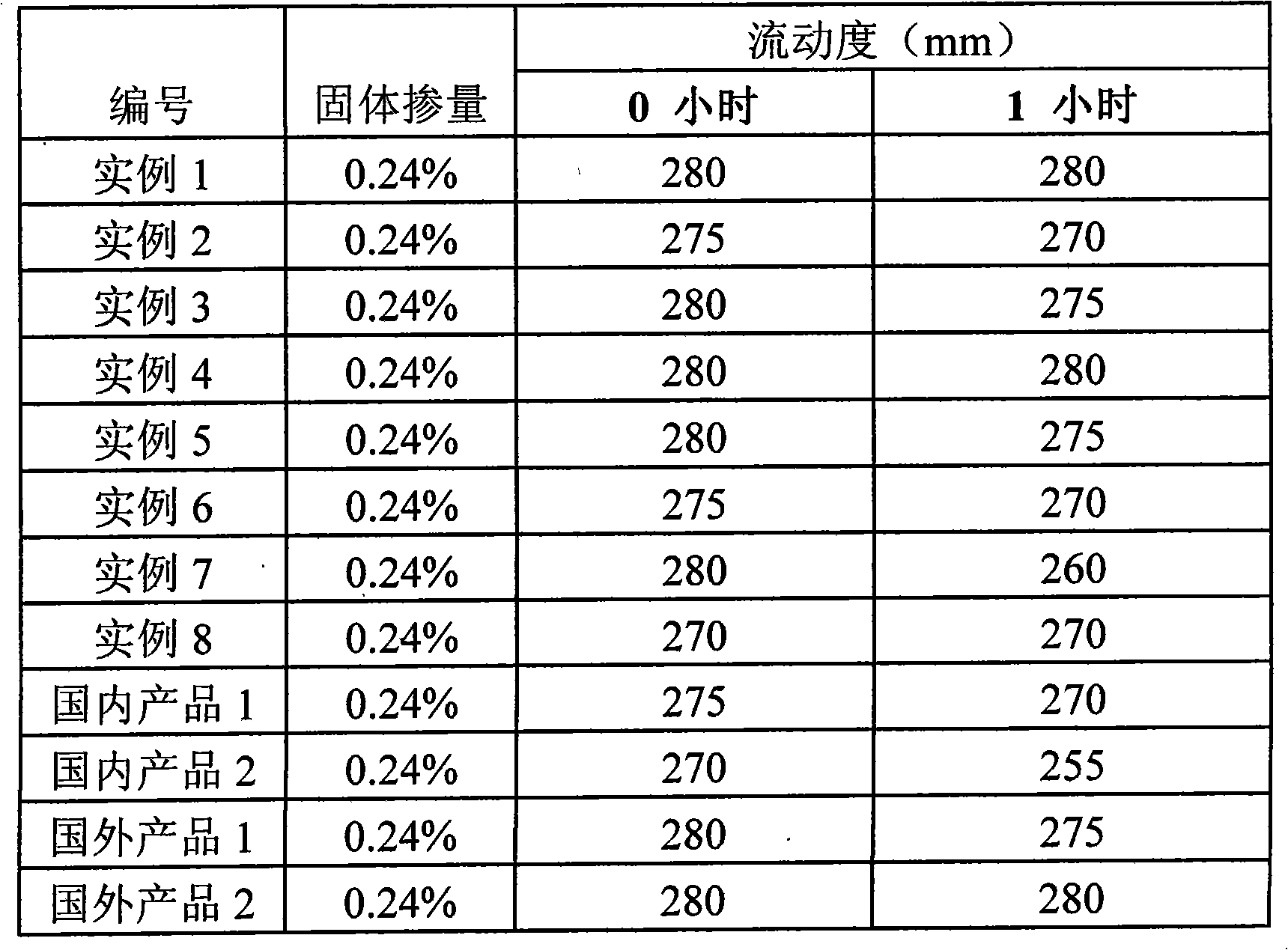

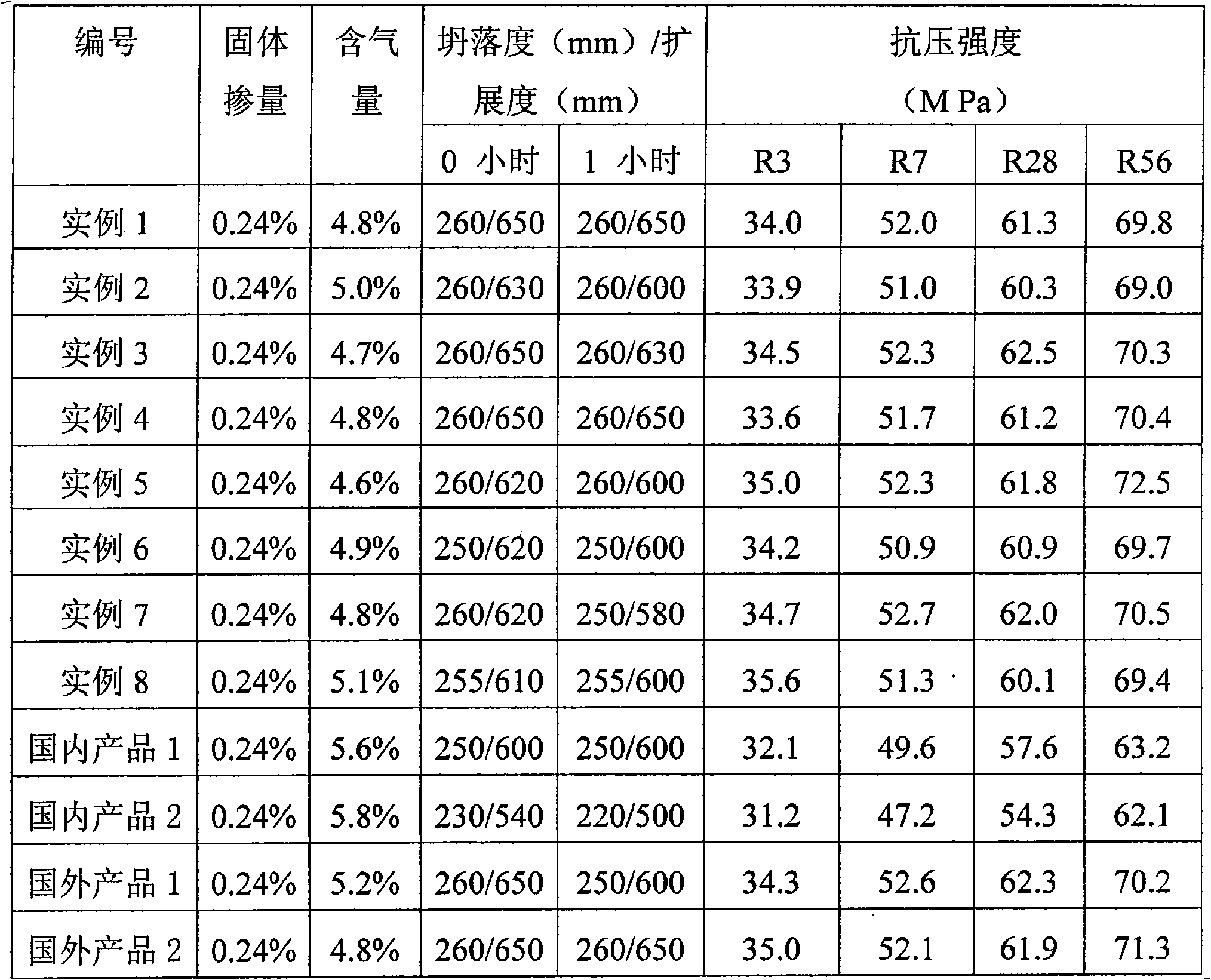

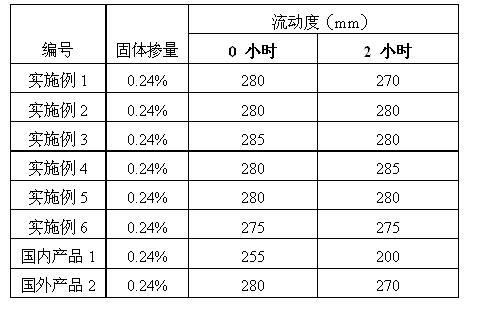

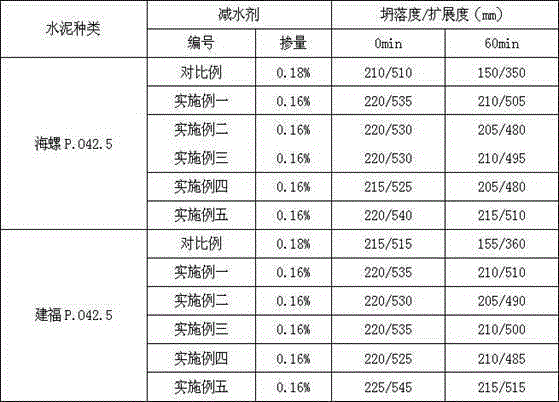

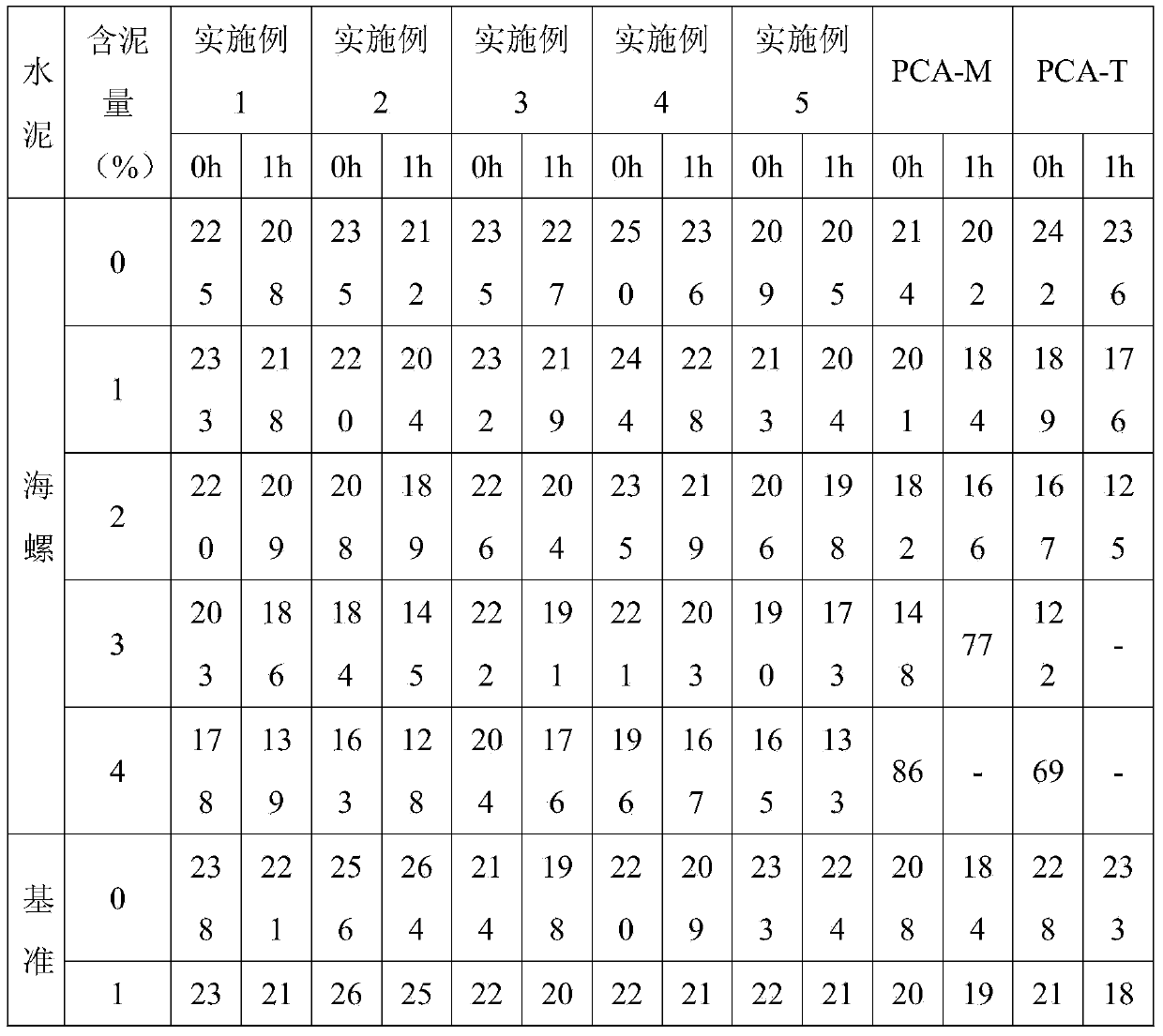

Polyether class polycarboxylic acid high-efficiency water reducing agent and preparation method thereof

The invention relates to a polyether class polycarboxylic acid high-efficiency water reducing agent and a preparation method thereof, belonging to the field of concrete materials, structures and engineering of building materials. The polyether class polycarboxylic acid high-efficiency water reducing agent raises the temperature of water solutions of 15-55 mass percent of allyl polyethenoxy ether and 0-6 mass percent of chain transfer agent is raised to 50-90 DEG C, one side is dropwise added with a water solution of 0.01-0.9 mass percent of an evocating agent, one side is dripwise added with miscible liquids of 3-15 mass percent of unsaturated acids and one or more than one derivative thereof, the temperature is kept unchanged, and the water solution and the miscible liquids are completely dropped within 2-6 hours, the temperature is preserved for 1-6 hours and naturally cooled to room temperature, and the mixed solution is neutralized by sig water till a PH value reaches 6.8-7.2 so as to obtain the polyether class polycarboxylic acid high-efficiency water reducing agent. The polyether class polycarboxylic acid high-efficiency water reducing agent and the preparation method thereof have simple technique, low cost and good property, can effectively reduce the water-cement ratio of concrete, improves the compaction rate of a pore structure of the concrete, enhances the strength and the durability of the concrete and has great significance on enhancing the engineering quality, prolonging the service life, reducing the engineering cost, reducing the environment pollution, and the like.

Owner:大连华健科技有限公司

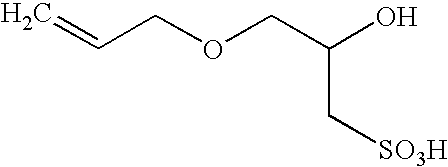

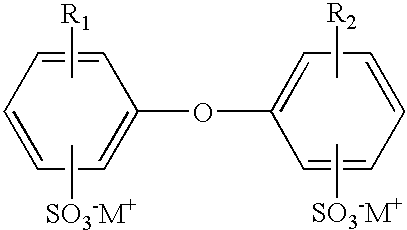

Polymerization of fluoromonomers using a 3-allyloxy-2-hydroxy-1-propanesulfonic acid salt as surfactant

InactiveUS6869997B2Reduce the binding forceOrganic chemistryFibre treatmentFluoropolymerBuffering agent

Fluoropolymers are prepared by a process comprising polymerizing at least one fluoromonomer in an aqueous reaction medium containing monomer, a radical initiator and a 3-allyloxy-2-hydroxy-1-propanesulfonic acid salt as surfactant. The medium may optionally contain one or more of an antifoulant, a buffering agent and a chain-transfer agent.

Owner:ARKEMA INC

Polycarbonate polyol compositions and methods

ActiveUS20110230580A1Efficient productionIncrease ratingsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEnd-groupPolycarbonate

In one aspect, the present disclosure encompasses polymerization systems for the copolymerization of CO2 and epoxides comprising 1) a catalyst including a metal coordination compound having a permanent ligand set and at least one ligand that is a polymerization initiator, and 2) a chain transfer agent having two or more sites that can initiate polymerization. In a second aspect, the present disclosure encompasses methods for the synthesis of polycarbonate polyols using the inventive polymerization systems. In a third aspect, the present disclosure encompasses polycarbonate polyol compositions characterized in that the polymer chains have a high percentage of —OH end groups and a high percentage of carbonate linkages. The compositions are further characterized in that they contain polymer chains having an embedded polyfunctional moiety linked to a plurality of individual polycarbonate chains.

Owner:SAUDI ARAMCO TECH CO

High water reduction high collapse protection type polycarboxylate high-performance water reducer and pyrogen-free preparation method thereof

The invention belongs to the technical field of concrete additives in building materials. The high water reduction high collapse protection type polycarboxylate high-performance water reducer mainly comprises the following monomer components: unsaturated methyl vinyl polyoxyethylene ether (A), a chain transfer agent (B), a mixture (C) of one or more of unsaturated acid and unsaturated acid derivatives, an oxidant (D) and a reducing agent (E), wherein the molar ratio A: B: C: D: E of the monomers is 1:0.01-0.5:2-8:0.08-0.5:0.02-0.3. The high water reduction high collapse protection type polycarboxylate high-performance water reducer is prepared by regulating the polymer mass concentration to between 20 and 40 percent by using water, and polymerizing a redox initiator system at normal temperature. The water reducer has the advantages of low doping amount, high water reducing ratio, excellent slump retaining capacity, and high cement adaptability, and the technology has the advantages of no need of extra heat source, implementation at normal temperature, low equipment investment, low cost and suitability for large area popularization and application.

Owner:大连华建科技有限公司

Radiation-sensitive colored composition, color filter, method for producing a color pattern, method for producing color filter, solid-state imaging device, and liquid crystal display apparatus

ActiveUS20120242940A1Improve hydrophilicityImproved development propertyPhotosensitive materialsSolid-state devicesLiquid-crystal displayRadiation sensitivity

Provided is a radiation-sensitive colored composition that enables formation of color cured films in which color concentration unevenness is inhibited and which have uniform color and exhibit a superior development property and excellent pattern formability in the formation of color patterns.The radiation-sensitive colored composition contains (A) a dye polymer containing a structural unit having a dye structure polymerized using a chain-transfer agent having a LogP value of 5 or less, and (B) a solvent.

Owner:FUJIFILM CORP

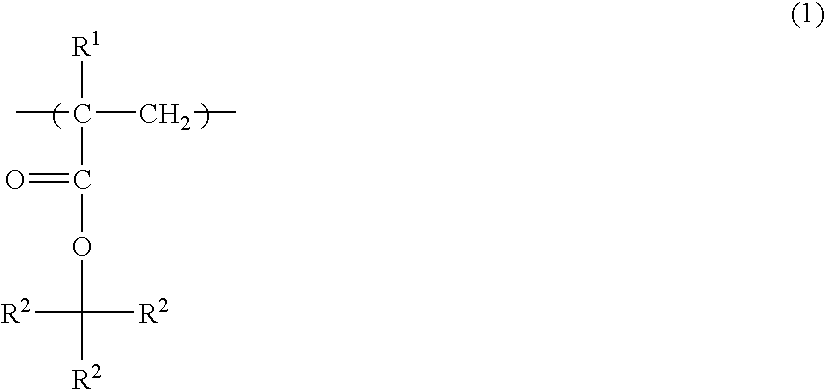

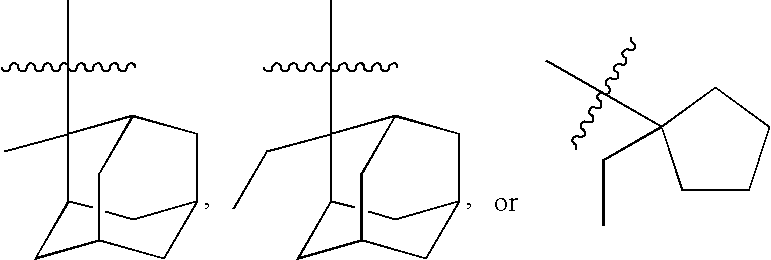

Photoresist polymer compositions

ActiveUS20060257781A1Overcomes drawbackPhotosensitive materialsPhotomechanical apparatusPolymer scienceEnd-group

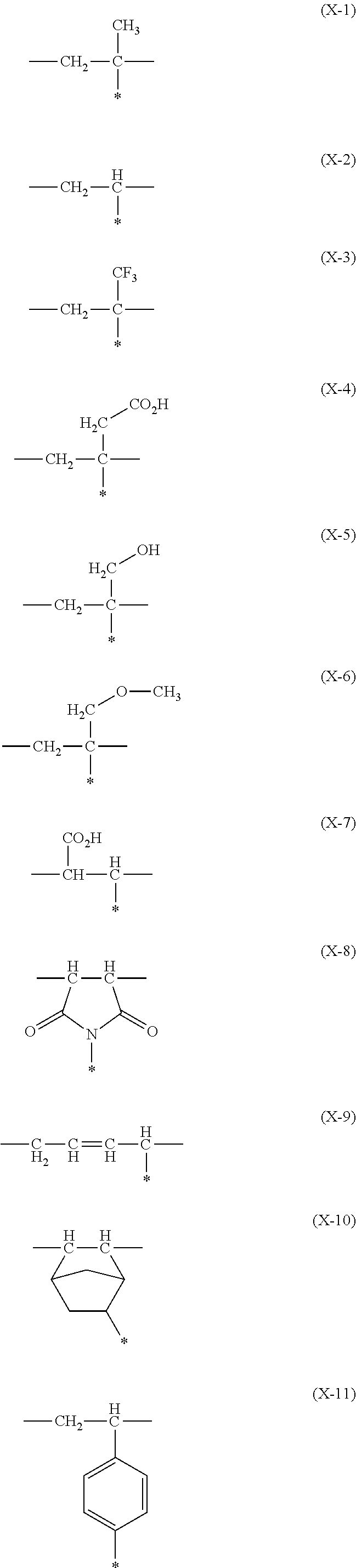

The present invention is directed to the preparation of photoresist polymers via living free radical polymerization techniques. Sterically bulky ester monomers are utilized as the polymerization components. Use of chain transfer agents is included in polymerization processing conditions. Cleavage of polymer terminal end groups that include a heteroatom are described.

Owner:FREESLATE +1

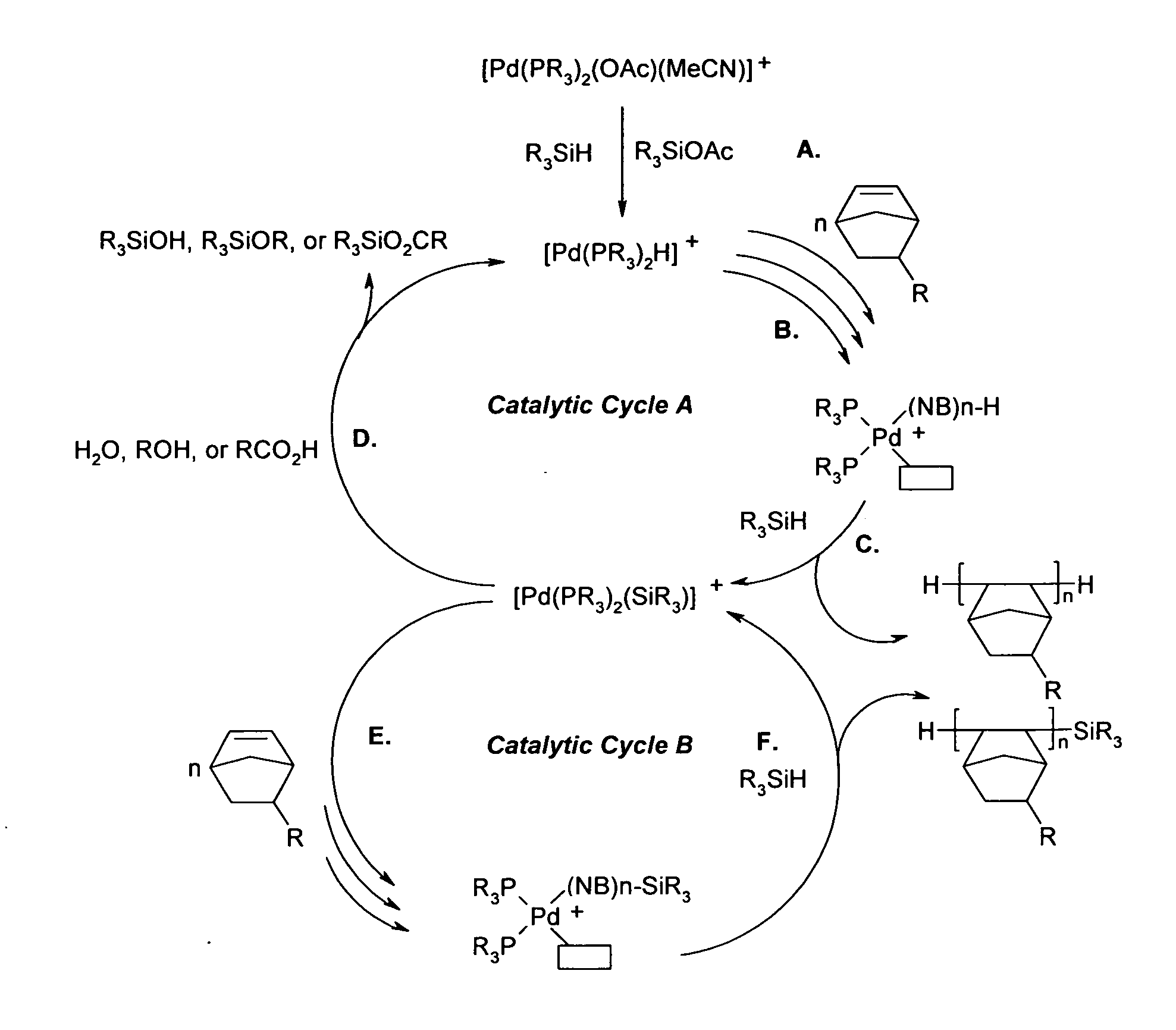

Vinyl addition polycylic olefin polymers prepared using non-olefinic chain transfer agents and uses thereof

ActiveUS20070066775A1Photosensitive material auxillary/base layersPhotosensitive materials for photomechanical apparatusMonomer compositionHydrogen

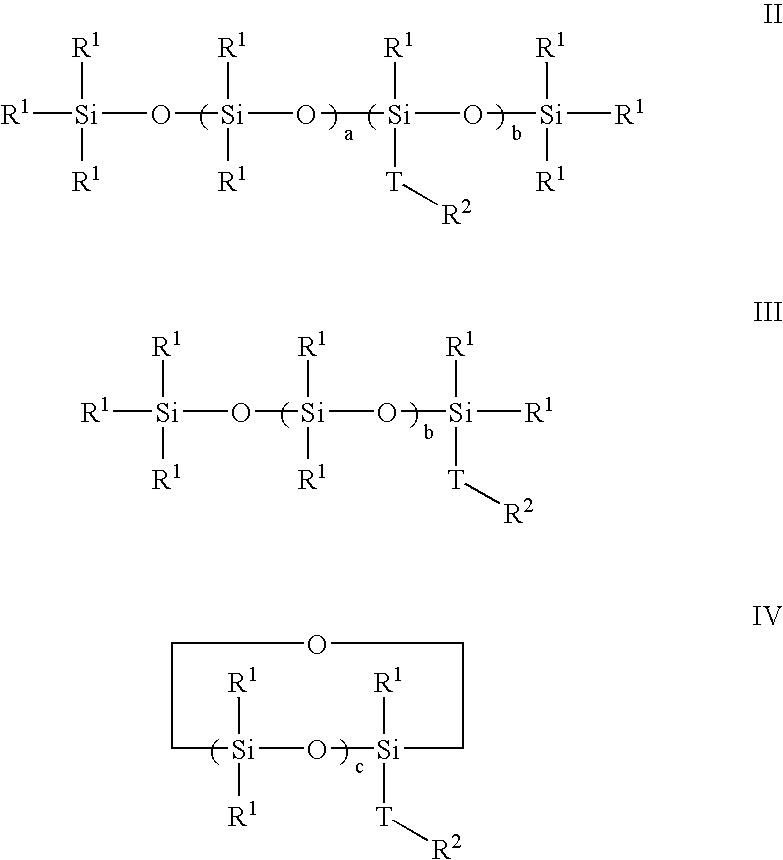

A method of polymerizing poly(cyclic)olefin monomers encompassing (a) combining a monomer composition containing the poly(cyclic)olefin monomers, a non-olefinic chain transfer agent and an activator compound to form a mixture; (b) heating the mixture; and (c) adding a polymerization catalyst containing Ni and / or Pd. The non-olefinic chain transfer agent includes one or more compounds selected from H2, alkylsilanes, alkylalkoxysilanes, alkylgermanes, alkylalkoxygermanes, alkylstannanes, and alkylalkoxystannanes. The activator is characterized as having an active hydrogen with a pKa of at least 5. The resulting poly(cyclic)olefin polymers can be used in photoresist compositions.

Owner:SUMITOMO BAKELITE CO LTD

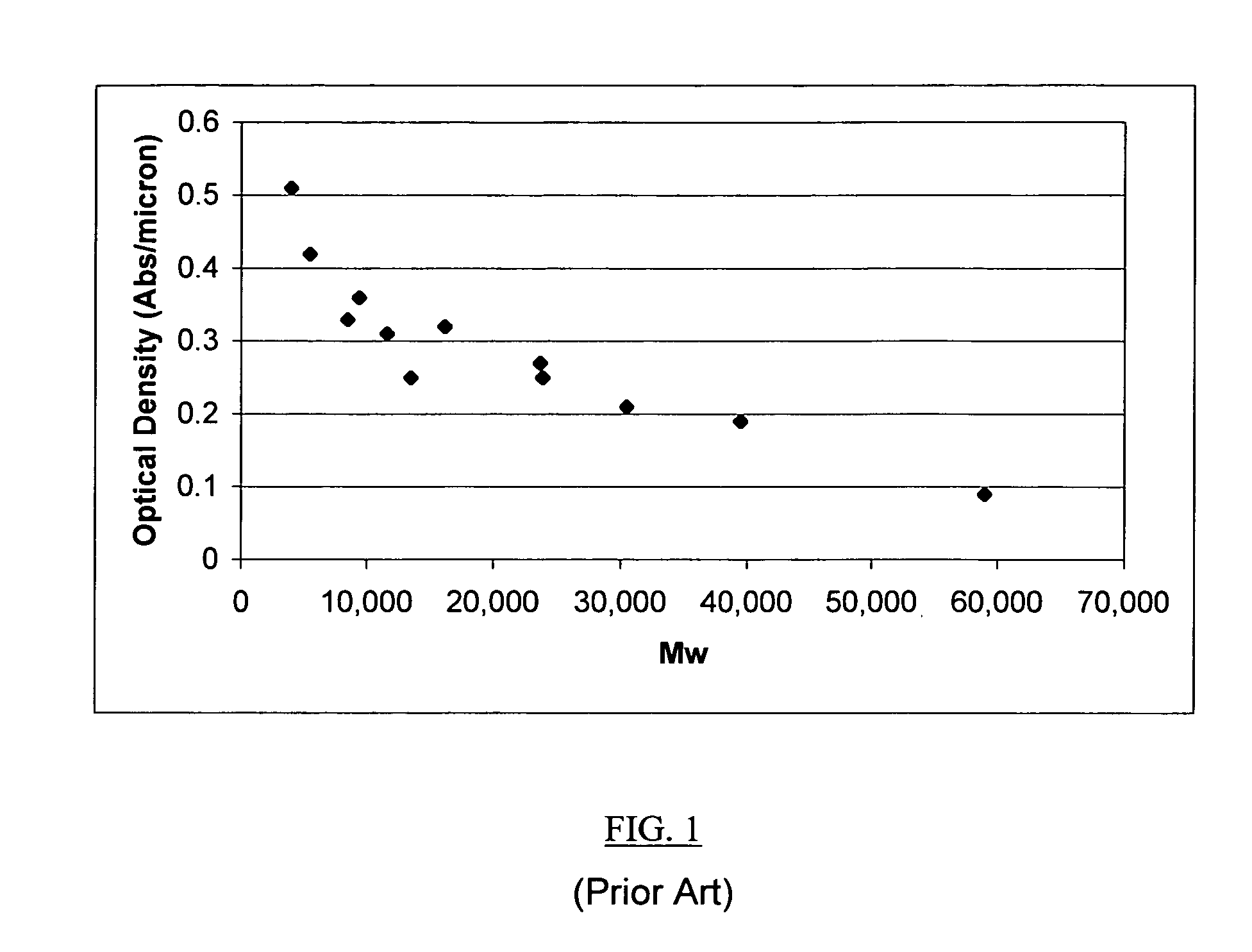

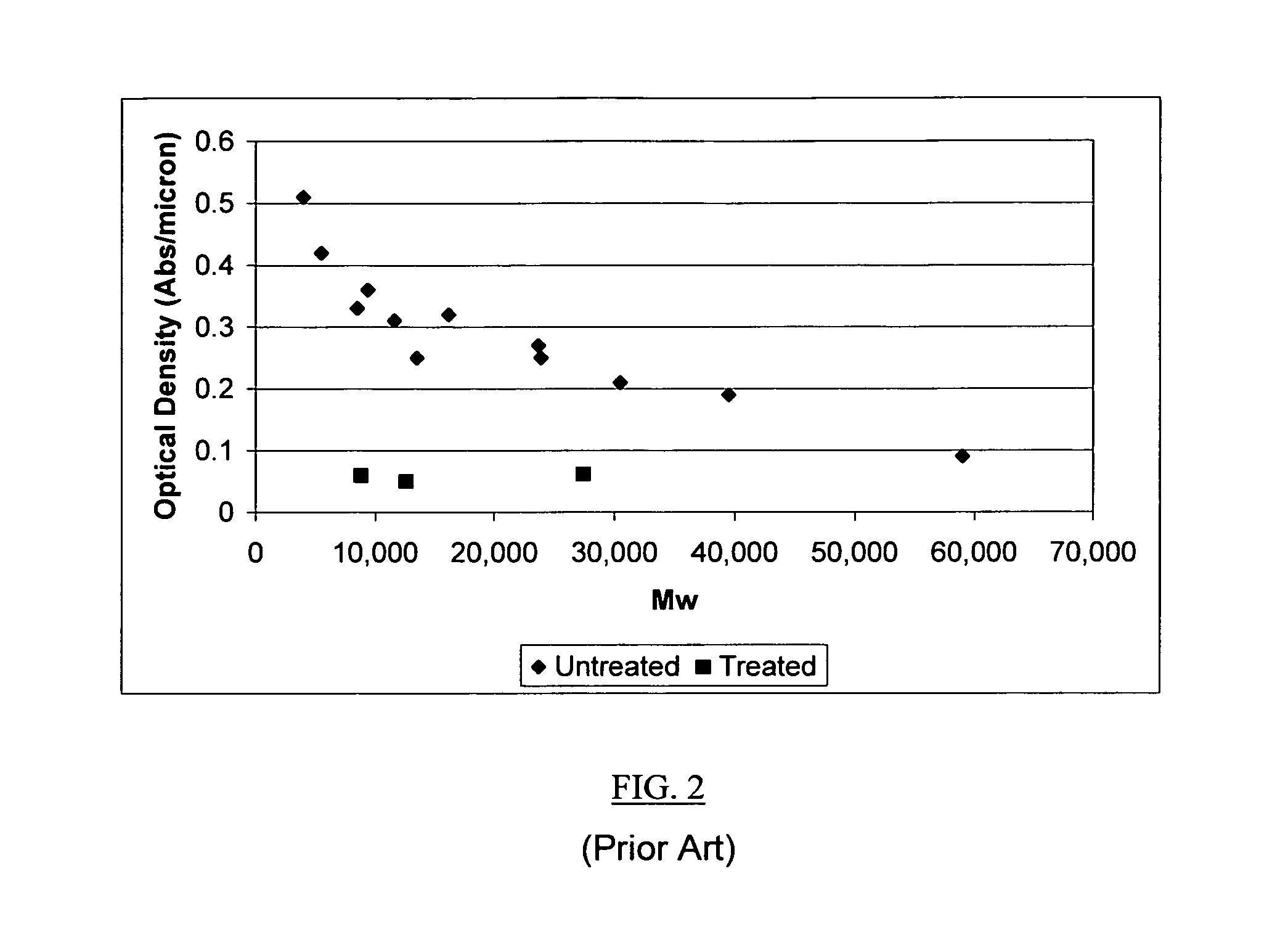

Latex processes

InactiveUS6503680B1Improve performanceImprove featuresDevelopersEmulsion paintsGlass transitionPolymer chemistry

A process for the preparation of a latex polymer consistent with E / A (emulsion / aggregation / coalescence) toner manufacture. The process utilizes a standard (universal) latex composition and involves chain-transfer agent partitioning, emulsion polymerization that provides a latex polymer with a wide range of molecular properties. In particular, the process customizes a wide range Mw (weight average molecular weight) latex, without substantially varying the Mn (number average molecular weight) and hence, without substantially varying Tg (glass transition temperature) such that good toner performance is maintained. In a preferred process, a latex polymer is prepared by mixing a seed particle latex, generated by aqueous emulsion polymerization of a first portion of a monomer emulsion, with a second portion of the monomer emulsion and at least one chain-transfer agent. The mixing is done in the presence of a free-radical initiator and heated, and wherein the monomer emulsion comprises a mixture of polymerization reagents of at least one monomer, at least one chain-transfer agent, at least one surfactant, and water. This process may be applied to core-shell polymerization as well. These latex polymers are ideally suited in the manufacture of toner and developer for electrophotographic imaging and printing.

Owner:XEROX CORP

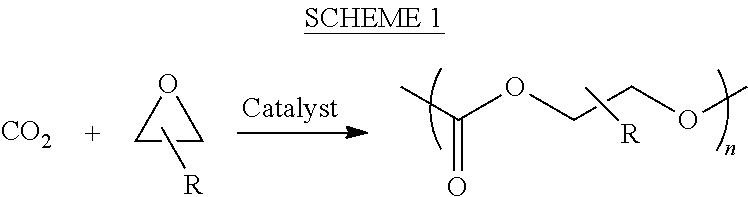

Preparation method of poly(carbonic ester-ether) glycol and preparation method of catalyst thereof

The invention discloses a preparation method of rare earth-doped double metal cyanide catalyst and a method for preparing low molecular weight poly (carbonic ester-ether) glycol by using the catalyst to catalyze the copolymerization of carbon dioxide and epoxy compounds. The preparation method of poly (carbonic ester-ether) glycol comprises the following steps: using rare earth-doped double metalcyanide based on Zn3[Co(CN)6]2 as a catalyst, and letting carbon dioxide and epoxy compounds be subject to polymerization in the presence of chain transferring agent to obtain the poly(carbonic ester-ether) glycol. According to the invention, compared with the prior art, the rare earth-doped double metal cyanide based on Zn3[Co(CN)6]2 used herein efficiently catalyzes the copolymerization of carbon dioxide and epoxy compounds under the effect of chain transferring agent; and compared with double metal cyanide without doping, the rare earth-doped double metal cyanide based on Zn3[Co(CN)6]2 used herein has higher catalytic activity and better product selectivity.

Owner:南通华盛高聚物科技股份有限公司

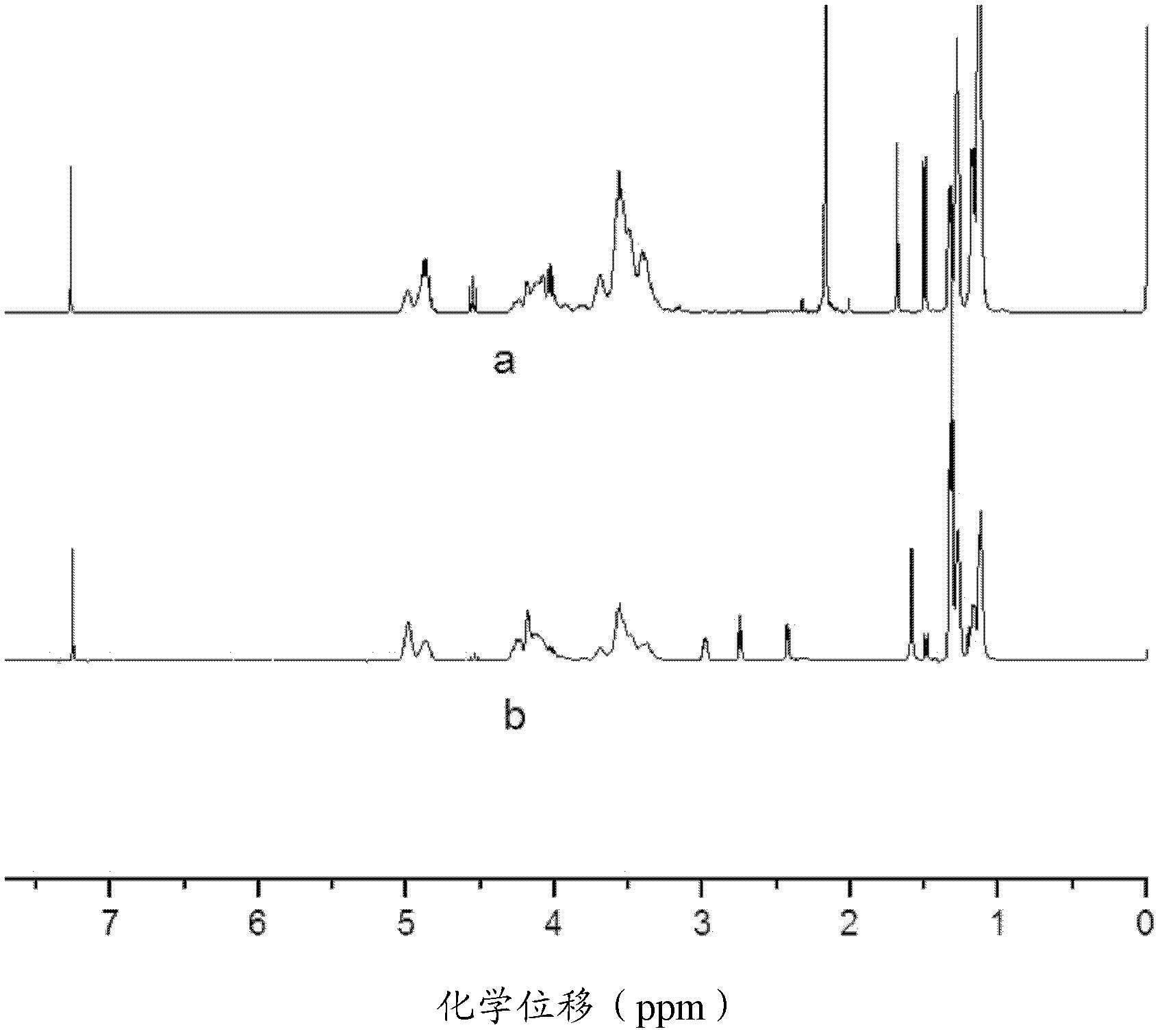

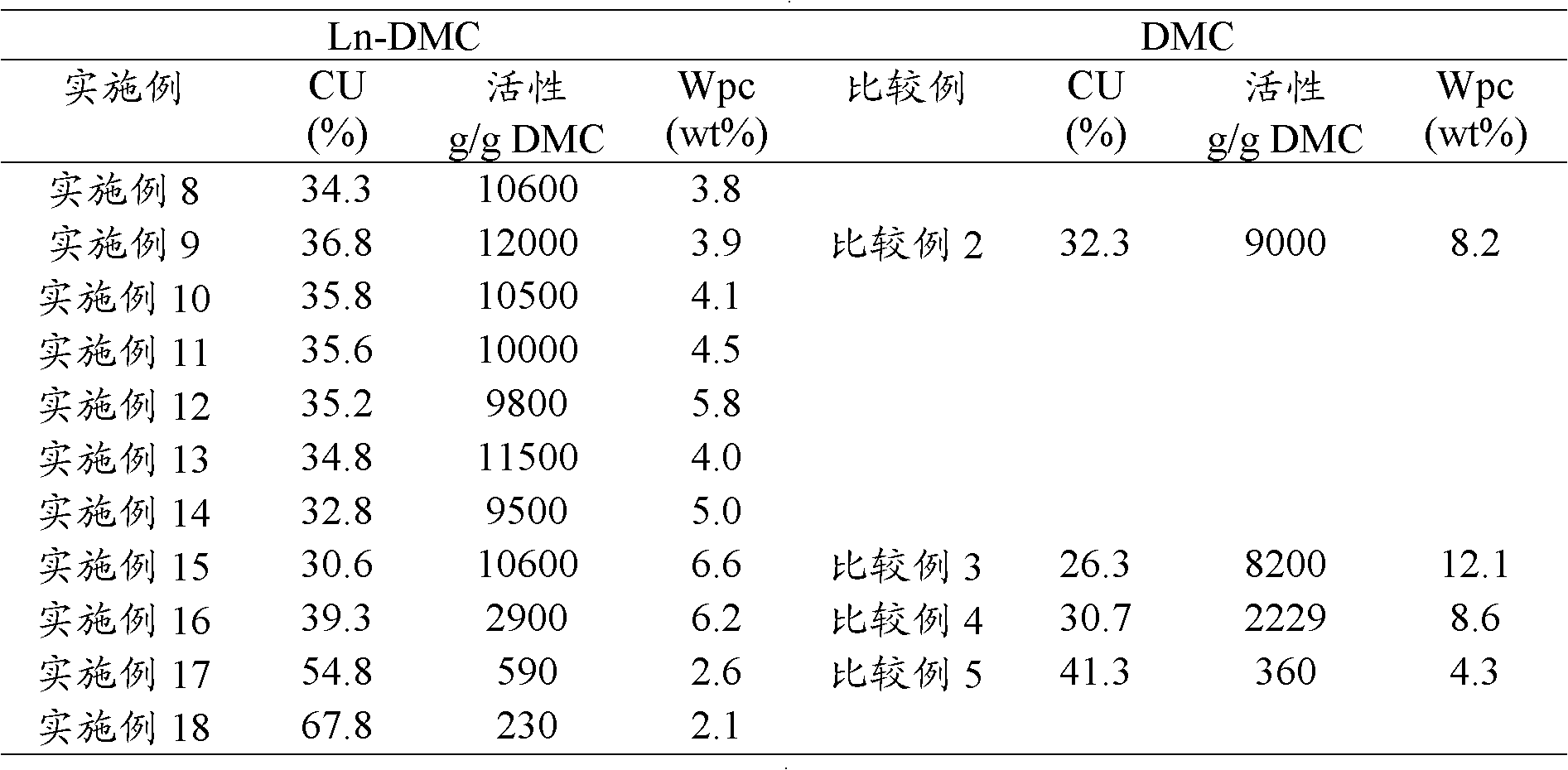

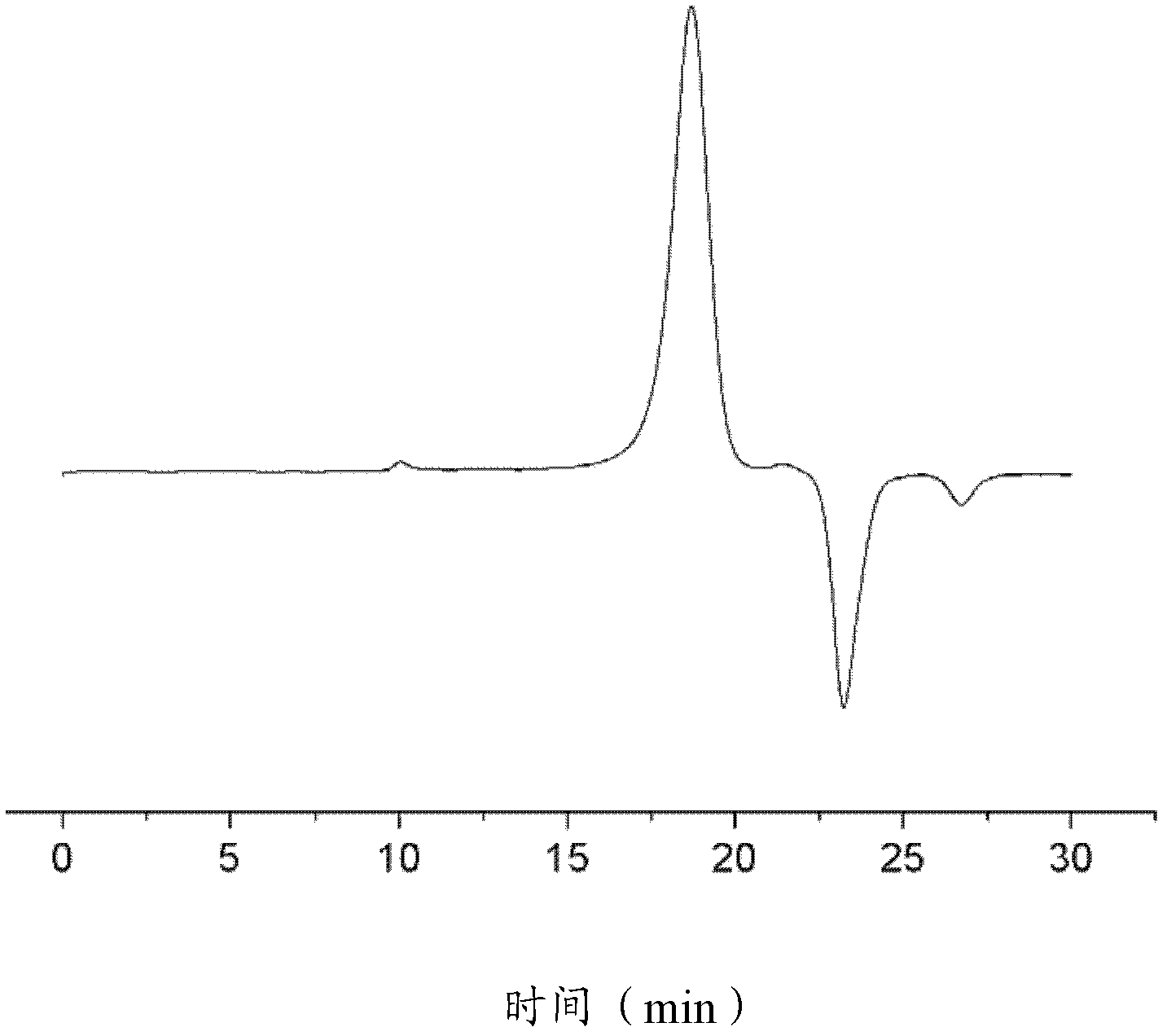

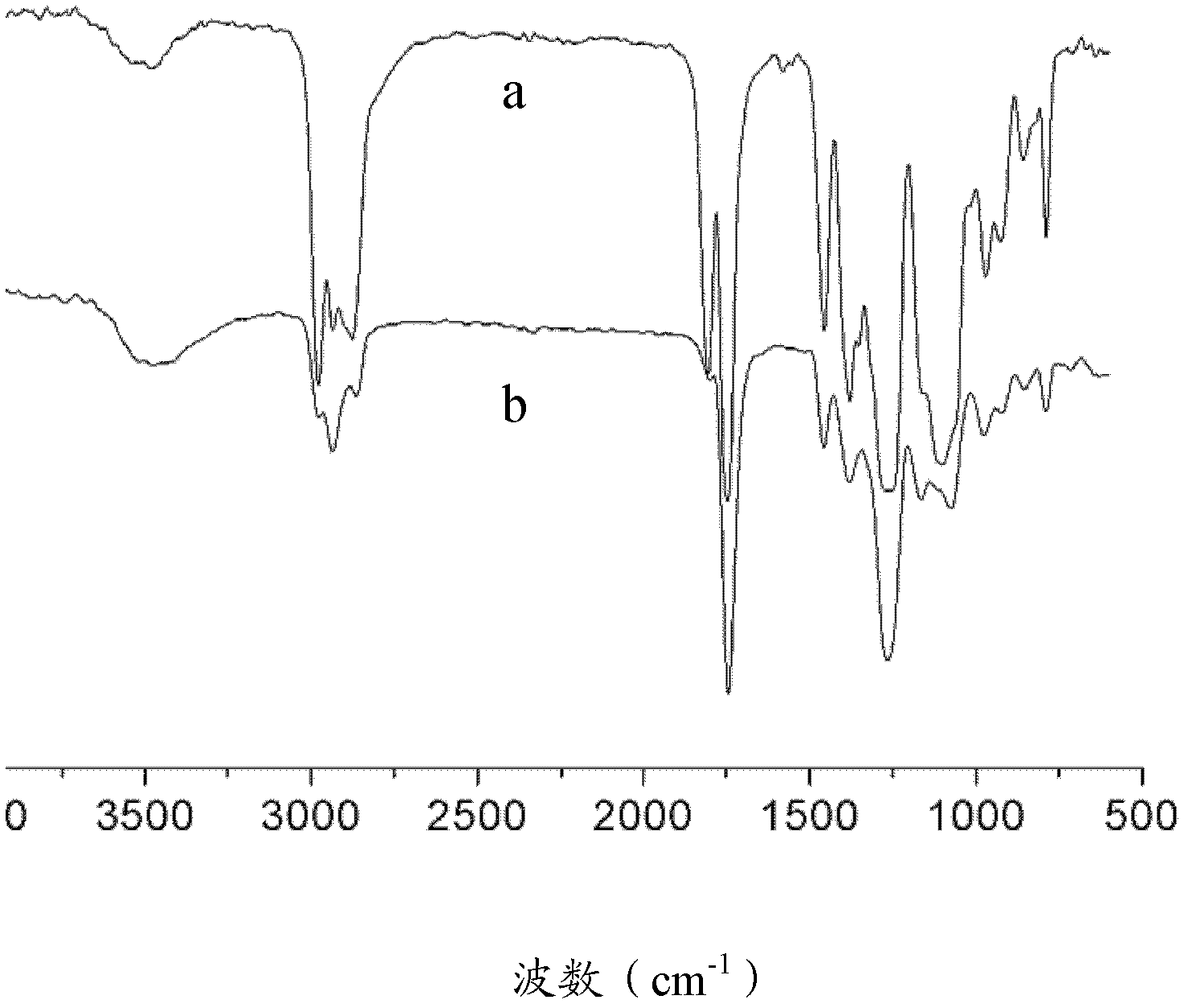

Preparing method of poly (carbonic ester-ether) polyalcohol

ActiveCN102617844AIncreased content of carbonate unitsSuppression of continuous insertionCyanidePolyol

The invention discloses a preparing method of poly (carbonic ester-ether) polyalcohol. Rare-earth doped bi-metal cyanides based on Zn3[Co(CN)6]2 serve as catalysts, carboxylic acids serve as chain transfer agents, and carbon dioxide and epoxy compounds are performed with a copolymerization reaction to obtain the poly (carbonic ester-ether) polyalcohol. Compared with the prior art, the carboxylic acids serve as chain transfer agents, and due to the fact that the carboxylic acids are strong in coordination capability, faster in chain transfer, capable of restraining continuous inserting of epoxy monomers and free of ether structure, unit content of carbonic ester is improved, and the prepared poly (carbonic ester-ether) polyalcohol has higher carbonic ester unit content. Experimental results indicate that molecular weight of the prepared poly (carbonic ester-ether) polyalcohol is 1500g / mol-5000g / mol, molecular weight distribution is 1.11-1.50, unit content of the carbonic ester is 40%-80%, catalytic activity is larger than 1.0kg / gLn-DMC, and cyclic carbonic ester content is less than 10wt%.

Owner:南通华盛高聚物科技股份有限公司

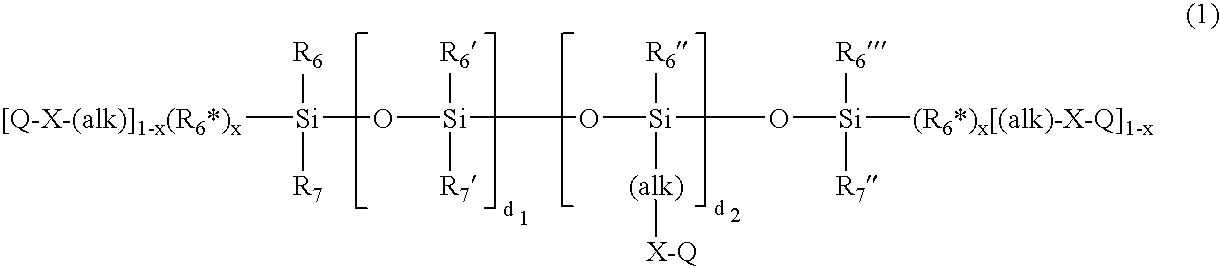

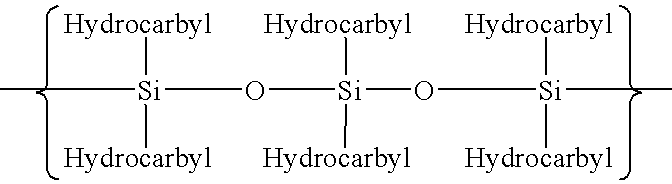

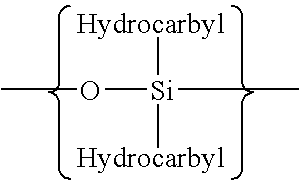

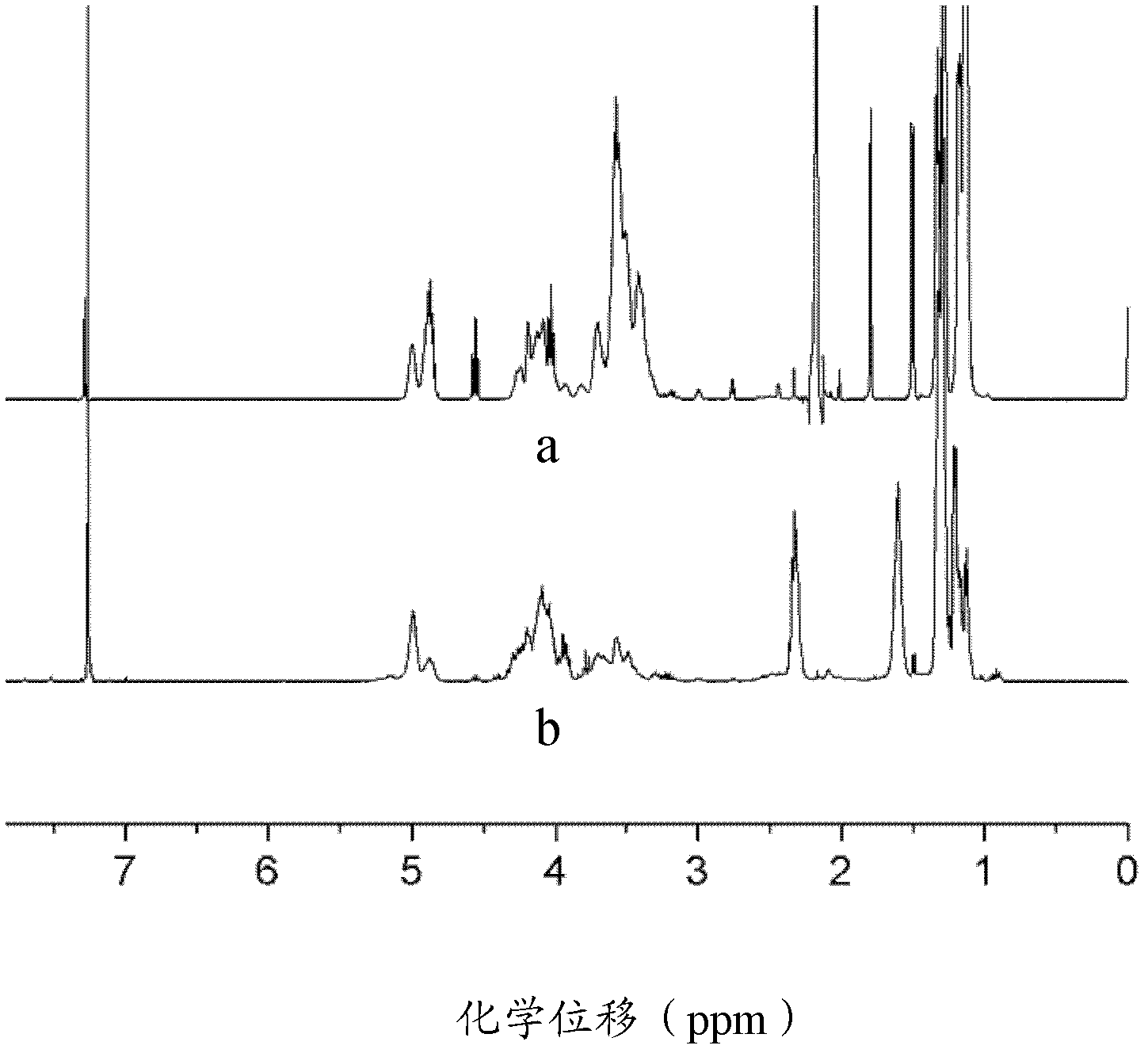

Amphiphilic polysiloxane prepolymers and uses thereof

The present invention provides an amphiphilic polysiloxane prepolymer which comprises hydrophilic monomeric units derived from at least one hydrophilic vinylic monomer, polysiloxane crosslinking units derived from at least one polysiloxane crosslinker having at least two terminal ethylenically-unsaturated groups, dangling polysiloxane chains each of which is terminated with one ethylenically unsaturated group, and chain-transfer units derived from a chain transfer agent other than a RAFT agent. A prepolymer of the invention is suitable for making hydrogel contact lenses. The present invention is also related to hydrogel contact lenses made from an amphiphilic polysiloxane prepolymer of the invention and to processes for preparing an amphiphilic polysiloxane prepolymer of the invention and for making silicone hydrogel contact lenses.

Owner:ALCON INC

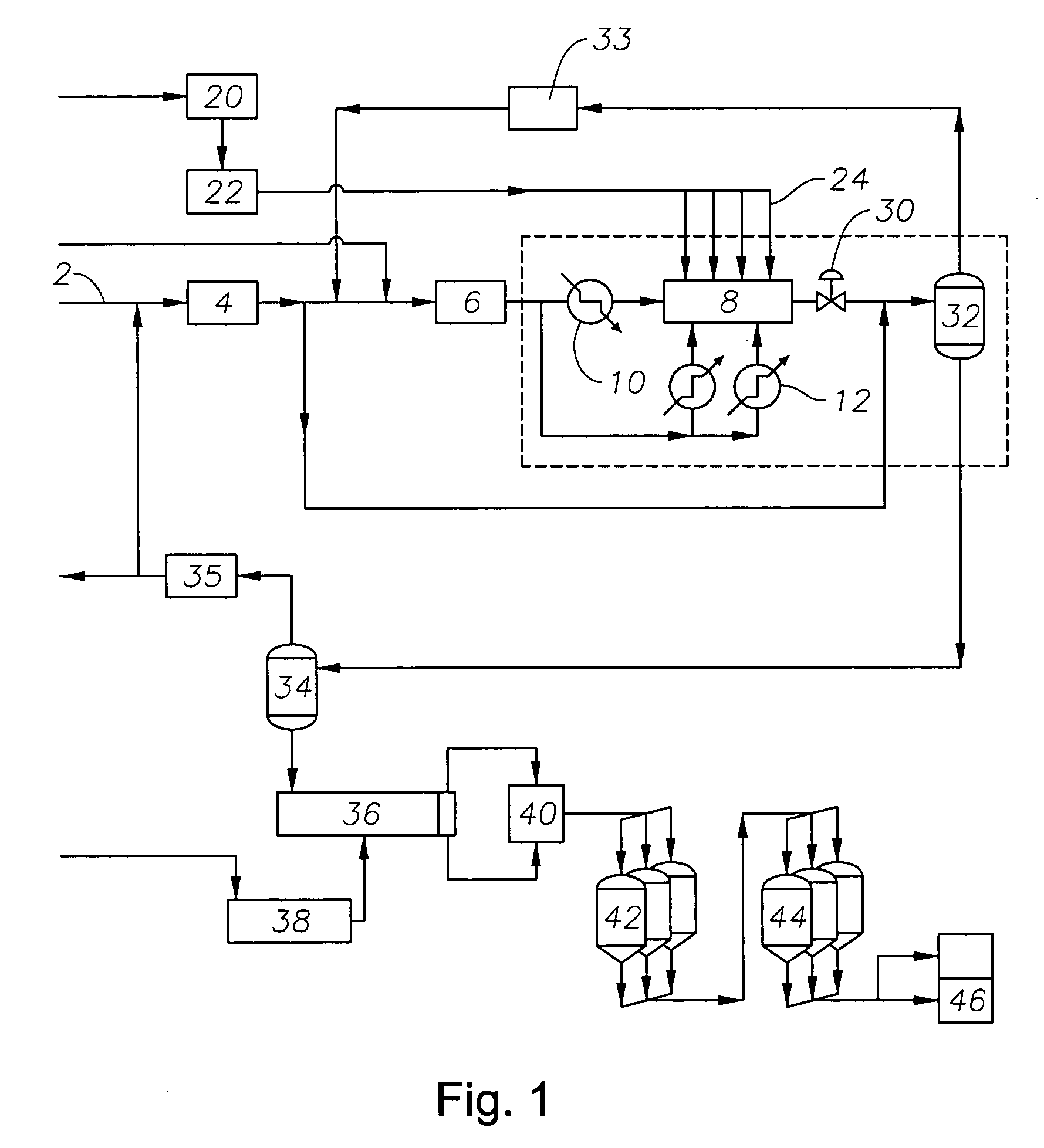

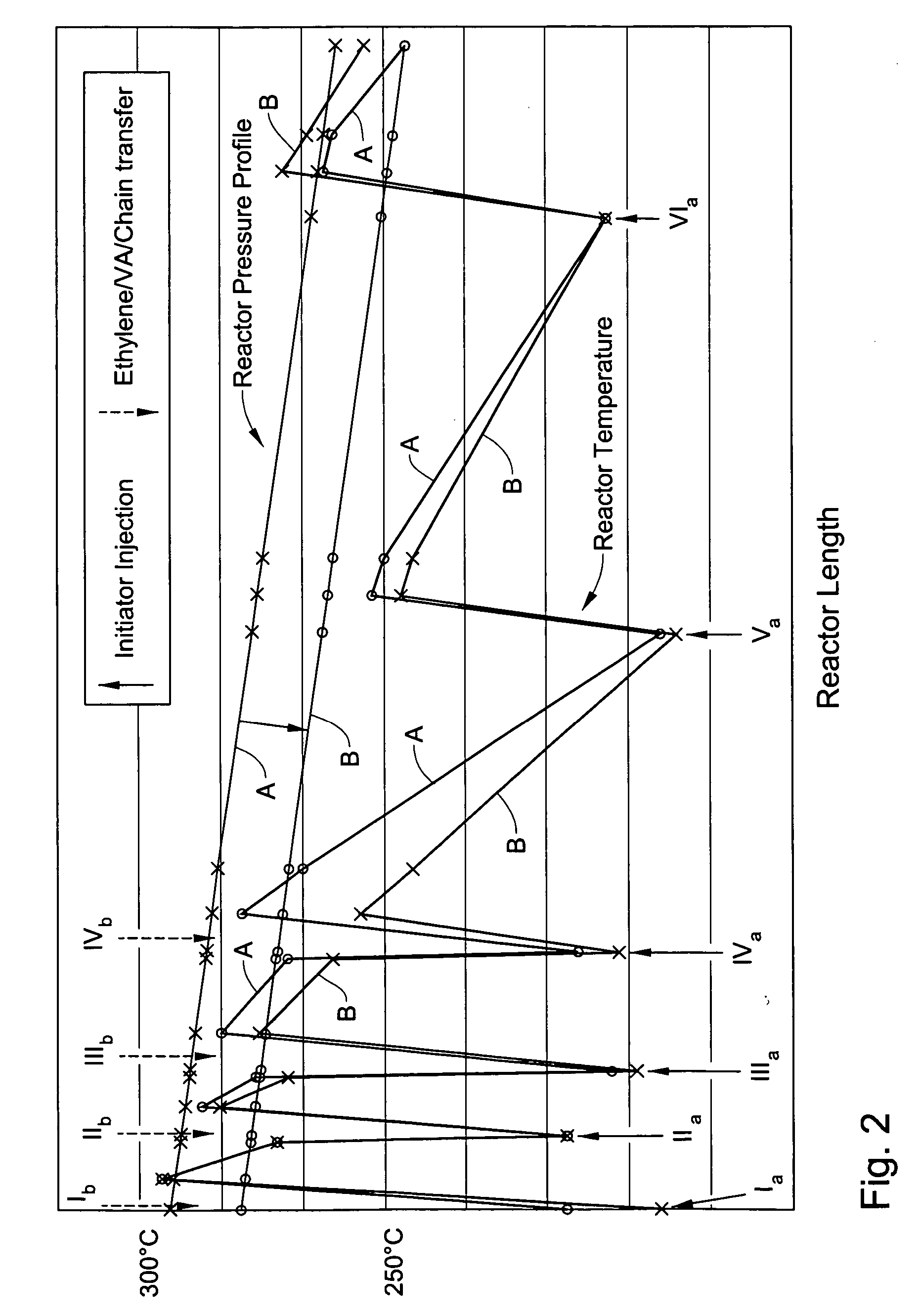

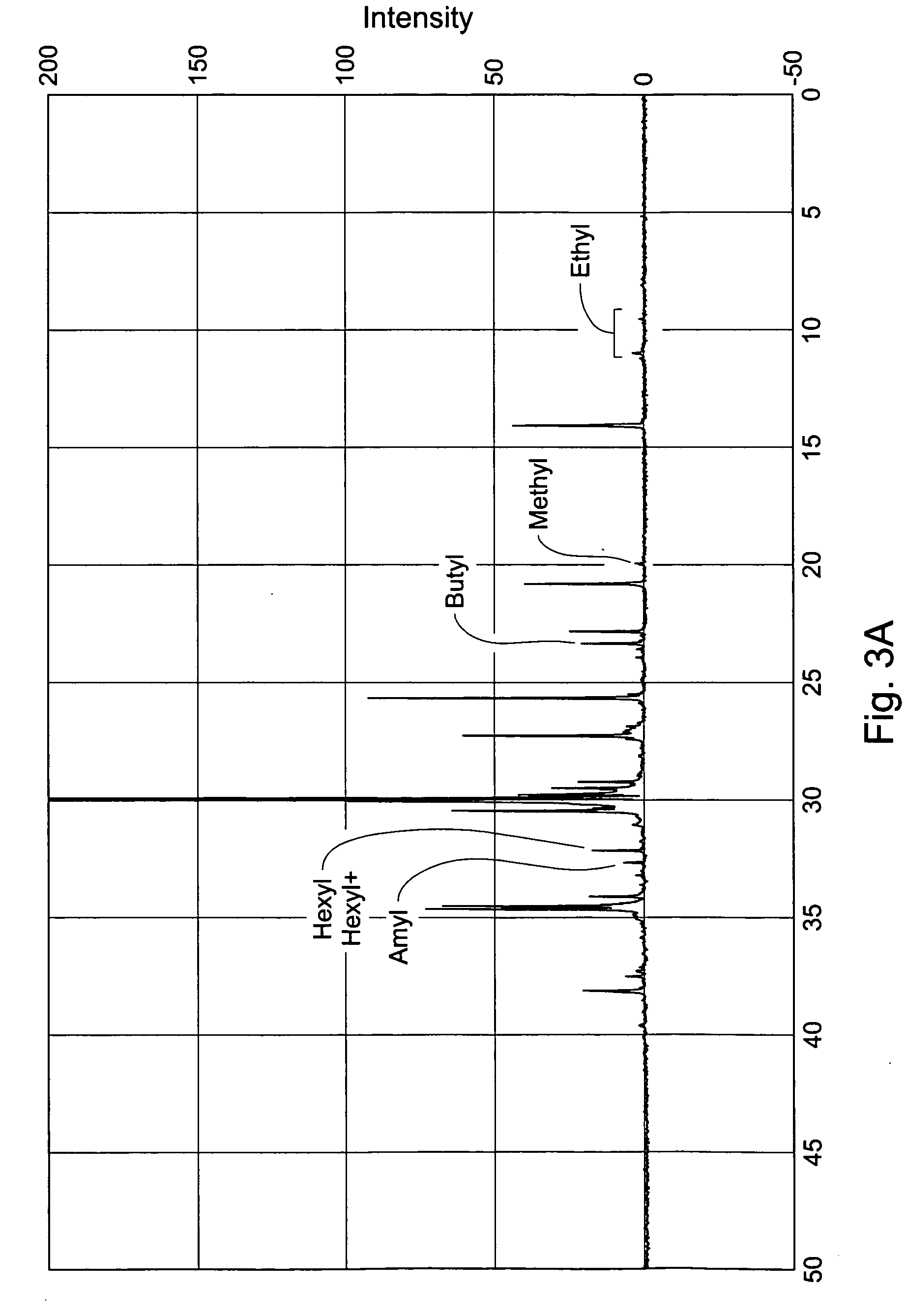

Polymers of ethylene and, optionally, copolymerizable esters, films using such polymers and stretch hood packaging processes using such films

ActiveUS20050037219A1Excellent film performanceSynthetic resin layered productsDomestic containersParticulatesMelt flow index

The invention relates to a polymer comprising units derived from ethylene, said polymer having: a) a Melt Index of from 0.05 to 20 g / 10 min as determined by ASTM-1238 Condition E; b) at least 10 per 1000 C-atoms of short chain branches, containing five carbon atoms or less, as determined by C13 NMR, and less than 3.5 mol %, of units derived from a copolymerizable ethylenically unsaturated ester, c) a density of from 0.90 to 0.94 g / cm3, preferably 0.91 to 0.935 g / cm3, especially 0.92 to 0.93 g / cm3 as determined by ASTM D1505, and d) a relaxation time as described herein of at least 10 s. Such polymers are obtainable by polymerization by free radical polymerization using a chain transfer agent that incorporates into the polymer chain such as an alpha-olefin, preferably propylene, as a chain transfer agent, preferably in a tubular reactor under circumstances to favor LCB formation in a down stream part of the tubular reactor. The polymer may be used for stretch hood film, preferably as a blown film coextruded tube comprising: a) a core of the above polymer; and b) a skin layer, on each side of the core which may be of the same or different composition, comprising at least 60 wt % of an LLDPE having density of 0.91 to 0.94 g / cm3 as determined by ASTM-D 1238 Condition E and hexane extractables less than 1.5 wt %, said skin layer containing less than 7500 ppm of anti-block particulates and said film having an elastic recovery after a 100% stretch of at least 40% and providing a normalized holding force per 100 μm thickness pre-stretch at 85% stretch after an initial stretch of 100% of at least 20 N / 50 mm at a deformation rate of less than 10% of the starting length per second.

Owner:EXXONMOBIL CHEM PAT INC

Amphiphilic diblock, triblock and star-block copolymers and their pharmaceutical compositions

This invention relates to novel amphiphilic diblock, triblock copolymers and star-shaped block copolymers comprising a biodegradable polymer covalently attached at the polymer ends, to a hydrophilic vinyl polymer, via divalent sulfur atom; to a process for producing the block polymers; to a polymerization process which comprises subjecting the monomers capable of radical polymerization to radical polymerization in the presence of a macromolecular biodegradable chain-transfer agent; and to pharmaceutical compositions comprising the block copolymers loaded with therapeutic agents.

Owner:PALADIN LABS INC

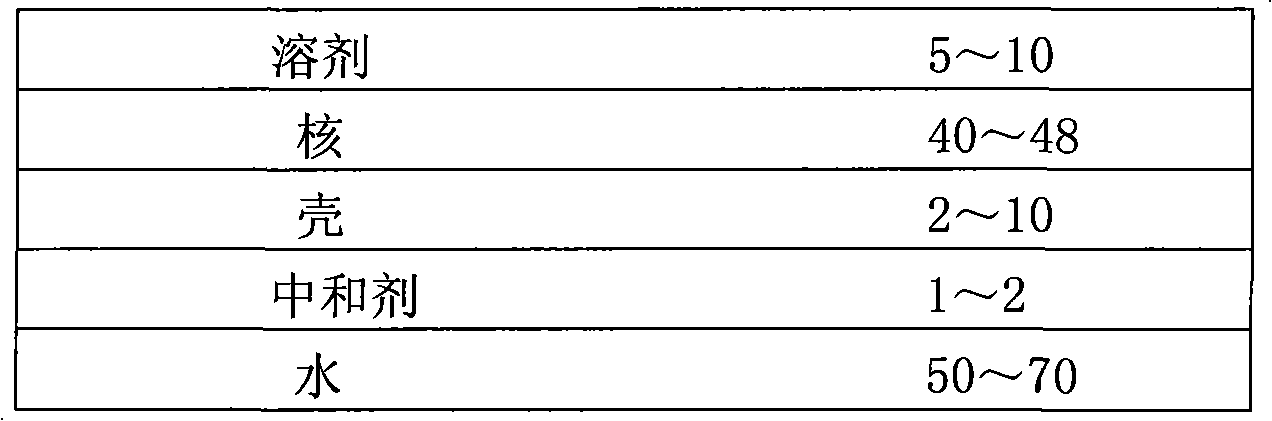

Hydroxy acrylic resin aqueous dispersion and water-based coating prepared therefrom

ActiveCN101914185AImprove anti-corrosion performancePolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses a method for preparing a hydroxy acrylic resin aqueous dispersion and the hydroxy acrylic resin aqueous dispersion prepared by the same and water-based coating using the hydroxy acrylic resin aqueous dispersion as a film forming matter. The hydroxy acrylic resin aqueous dispersion is prepared by a step free radical solution polymerization process and obtains a nucleus-shell structure by using an initiator of a specific type and a chain transfer agent and by a high-temperature polymerization reaction. The nucleus has weak hydrophilicity and no carboxyl, and the shell has a strong hydrophilicity and is rich in carboxyl, so stable storage can be realized. The obtained hydroxy acrylic resin aqueous dispersion has the characteristics of low solution content, high solid content and low viscosity. The coating prepared from the hydroxy acrylic resin aqueous dispersion and a water-based amino resin or a water-based polyurethane cross-linking agent has the characteristics of high brightness, good water resistance and excellent weather resistance. The hydroxy acrylic resin aqueous dispersion can be used for preparing an excellent base material of high-performance environment-friendly industrial protective coatings and widely applied to topcoats and primer-topcoat coatings in various fields.

Owner:LANGFANG JINHUILI INDAL PAINT

Polymer polyols with ultra-high solids contents

The present invention relates to ultra-high solids content polymer polyols which have good filterability while maintaining a reasonable viscosity, and to a process for the preparation of these ultra-high solids contents polymer polyols. These polymer polyols comprise the free-radical polymerization product of (A) a base polyol, (B) a pre-formed stabilizer, (C) at least one ethylenically unsaturated monomer, (D) at least one free-radical polymerization initiator, and (E) at least one chain transfer agent. The solids contents varies from 60% to about 85% by weight.

Owner:COVESTRO LLC

Method for preparation of lithographic printing plate and lithographic printing plate precursor

InactiveUS20070020563A1Improve discriminationHigh sensitivitySemiconductor/solid-state device manufacturingPhotosensitive material processingHexaarylbiimidazolePlanographic printing

A method for preparation of a lithographic printing plate comprising: exposing a lithographic printing plate precursor comprising a hydrophilic support, a photosensitive layer containing (A) a sensitizing dye having an absorption maximum in a wavelength range of from 350 to 450 nm, (B) a hexaarylbiimidazole compound, (C) a polymerizable compound, (D) a hydrophobic binder polymer and (E) a chain transfer agent and a protective layer in this order, with a laser beam of from 350 to 450 nm; and rubbing a surface of the exposed lithographic printing plate precursor with a rubbing member in a presence of a developer having pH of from 2 to 10 in an automatic processor equipped with the rubbing member to remove the protective layer and an unexposed area of the photosensitive layer.

Owner:FUJIFILM CORP +1

Mud resisting and slump retaining type polycarboxylic acids water reducer and preparation method thereof

ActiveCN105110687ASimple preparation processNo pollution in the processFunctional monomerCross linker

The invention discloses a mud resisting and slump retaining type polycarboxylic acids water reducer and a preparation method thereof. The mud resisting and slump retaining type polycarboxylic acids water reducer comprises, by weight, unsaturated polyoxyethylene ether 32.5% to 33.6%, unsaturated carboxylic acid 1.7% to 2.5%, functional monomer 3.25% to 3.36%, cross-linking agent 0.08% to 0.13%, oxidizing agent 0.12% to 0.32%, reducing agent 0.09% to 0.17%, chain transferring agent 0.03% to 0.06%, alkalinity modifier 0.86% to 1.22%, and water 60%. The water reducer in the invention has quite strong adaptability for sandstone with high silt content, good effect on mud resisting, large initial dispersibility, low cost and good slump retaining performance. Moreover, the preparation method in the invention reacts at normal temperature; has short reaction time, low energy consumption, low cost, high security coefficient, and no need to control the temperature in the whole production process; and is simple, without pollution, and suitable for commercial production.

Owner:厦门路桥翔通建材科技有限公司

High-solid hydroxyl fluorine-containing acrylic resin and preparation method thereof

The invention relates to high-solid hydroxyl fluorine-containing acrylic resin and a preparation method thereof. The high-solid hydroxyl fluorine-containing acrylic resin comprises the following components in parts by weight: 10-25 parts of fluorine-containing acrylic ester monomer, 10-30 parts of hydroxyl group-containing acrylic ester monomer, 5-20 parts of methyl acrylic alkyl ester monomer, 5-15 parts of acrylic alkyl ester monomer, 0.3-6 parts of initiator, 0.2-4 parts of chain transfer and 30-50 parts of solvent. According to the hydroxyl fluorine-containing acrylic resin, the solid content reaches up to 75-90 percent, the viscosity is only 900-3,000 mPa.s, the number-average molecular weight is 1,200-6,000, and the molecular weight distribution index is 1.4-2.5; and the resin has the advantages of superior performance, high transparency, no odor of mercaptan, low VOC (Volatile Organic Compound) content, a fluorine carbon group included on a polymer chain and superior corrosion resistance of the resin and can be applied to the fields such as heavy anticorrosive coatings, marine antifouling coatings, aircraft surface coatings, anti-doodling coatings, exterior wall coatings of high weathering resistance and the like.

Owner:SOUTHEAST UNIV

Radiation curable and jettable ink compositions

Radiation curable and jettable ink compositions comprise ethylenically unsaturated oligomer and an ethylenically unsaturated monofunctional monomer. The compositions may optionally include additional ethylenically unsaturated polyfunctional component and / or chain transfer agent. The compositions have a viscosity at 25° C. of not greater than about 70 cPs and are radiation curable to form a cured ink having an elongation of at least 150%.

Owner:KAO CORP

Preparation method of anti-mud polycarboxylic water reducer

ActiveCN103467670AGuarantee water reduction and slump protectionEnhanced steric hindranceDistillationCarboxylic acid

The invention relates to an anti-mud polycarboxylic water reducer and a preparation method thereof and belongs to the field of water reducers. The preparation method of the water reducer comprises the steps of (1) preparing quaternary ammonium salt oligomer: allowing epibromohydrin and tertiary amine compound aqueous solutions to react by the action of a composite initiator in a mixed solvent of low alcohol and water when a system pH (potential of hydrogen) value is 1-2, then performing reduced pressure distillation, and obtaining light yellow viscous quaternary ammonium salt oligomer, and (2) preparing the anti-mud polycarboxylic water reducer, performing radical copolymerization on quaternary ammonium salt oligomer, isopentene alcohol ethoxylate, amino trimethylene phosphonic acid, unsaturated monocarboxylic acid and a derivative of unsaturated monocarboxylic acid by the action of an initiator and a chain transfer agent to form the colorless to light yellow transparent polycarboxylic water reducer. An adverse effect of a mud content of aggregate in concrete on the polycarboxylic water reducer can be avoided, and the problems of insufficient water reduction, great slump loss and lower strength of the concrete are solved on the premise that the mixing amount of the polycarboxylic water reducer is not increased.

Owner:NANJING RUIDI HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com