Patents

Literature

84results about How to "Enhanced steric hindrance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

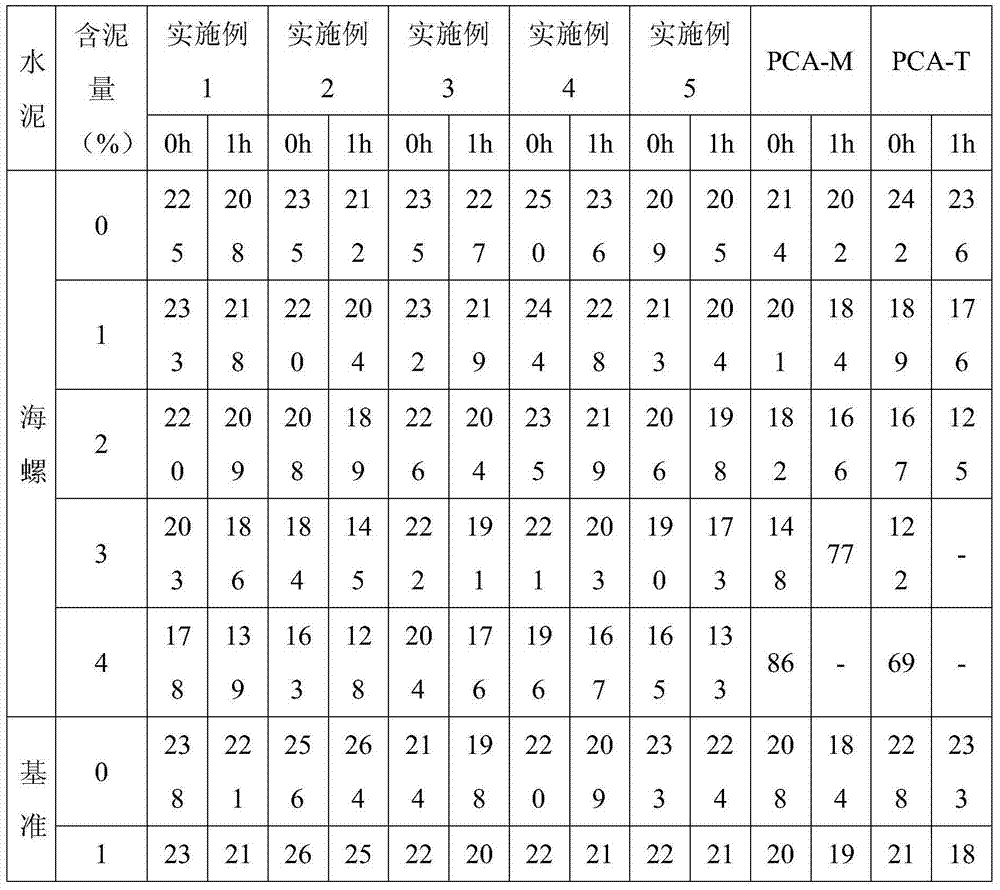

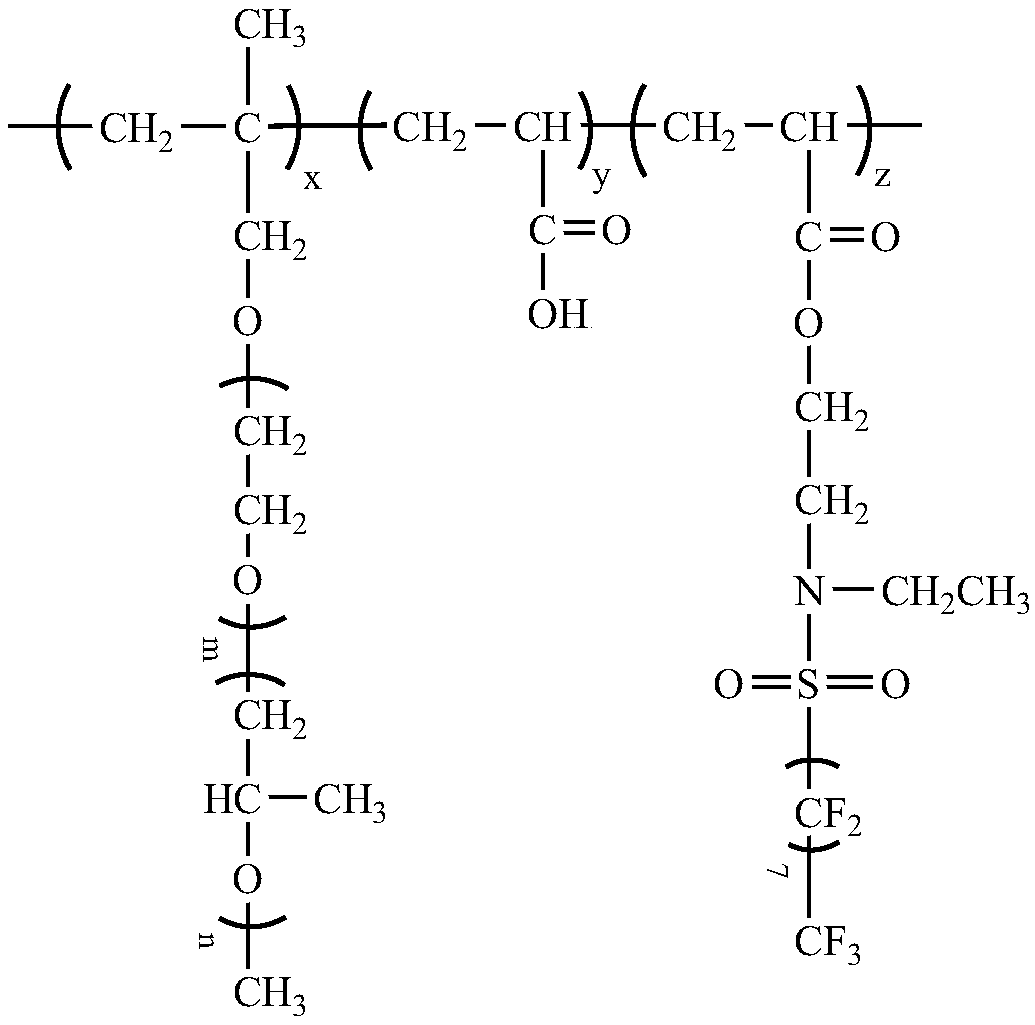

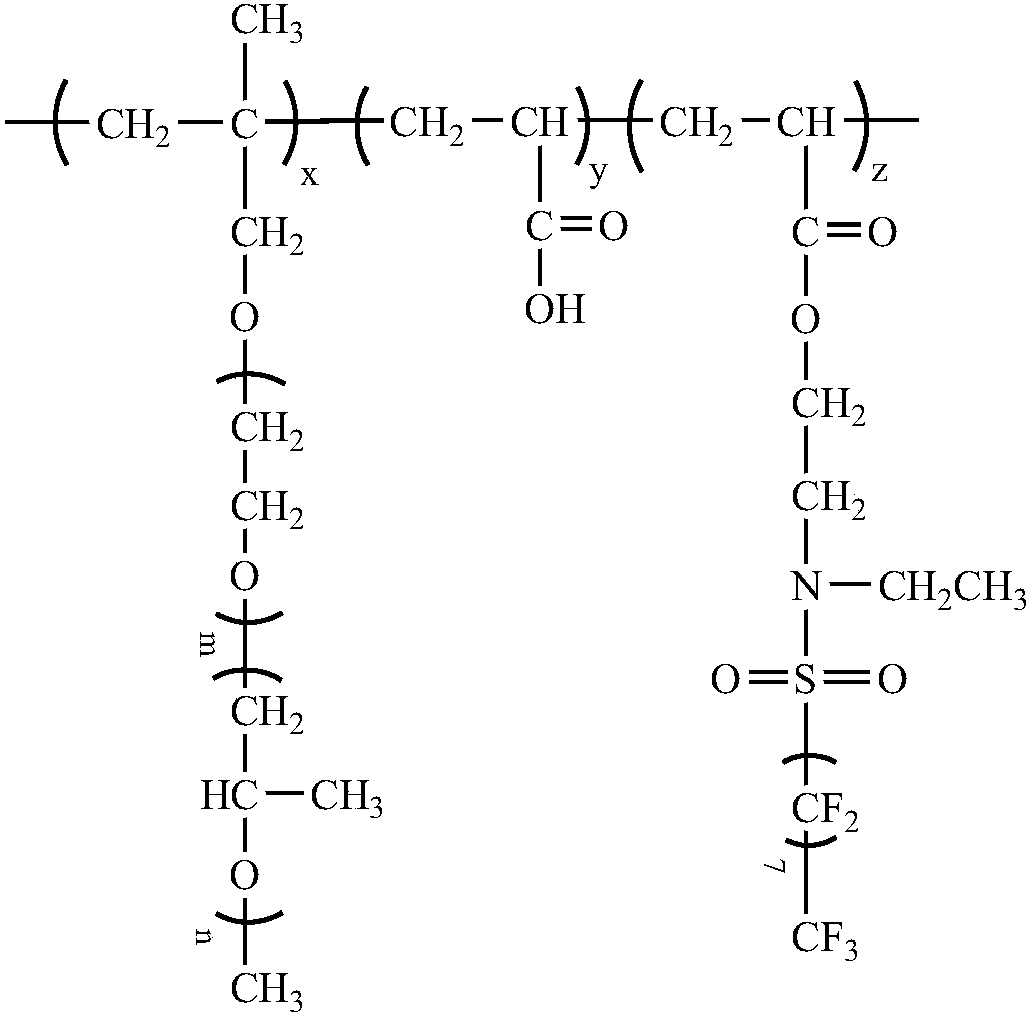

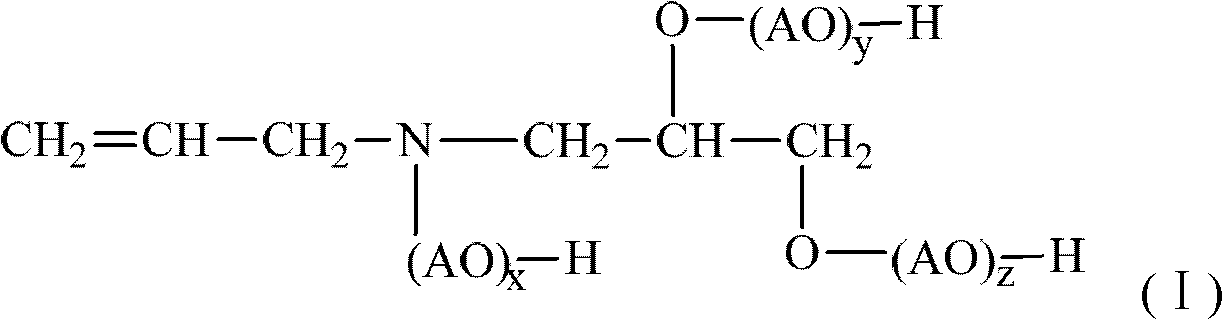

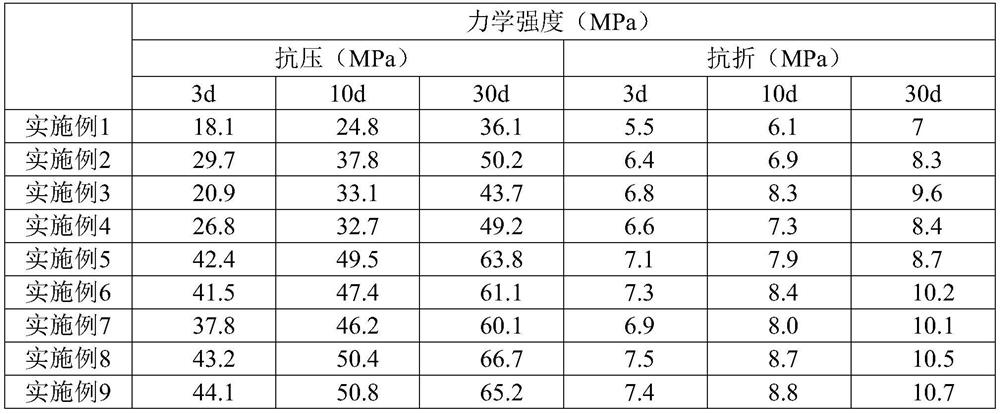

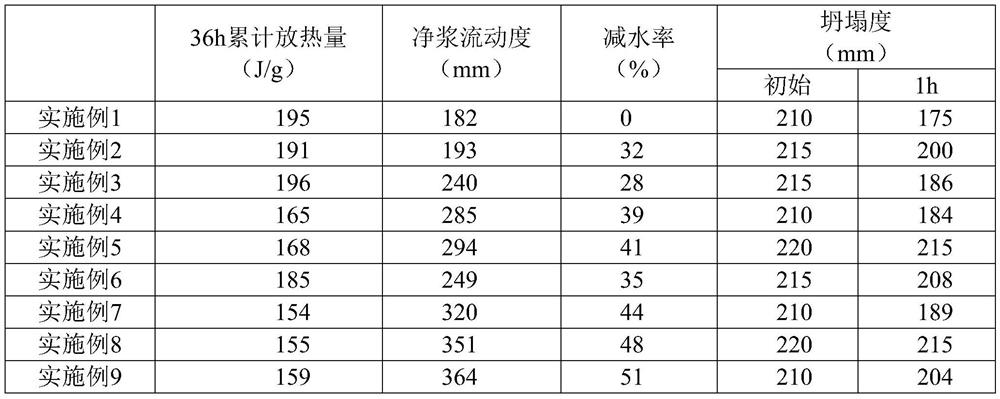

Unsaturated polyether monomer, comb-like branched copolymer cement dispersant prepared by the same, and preparation method thereof

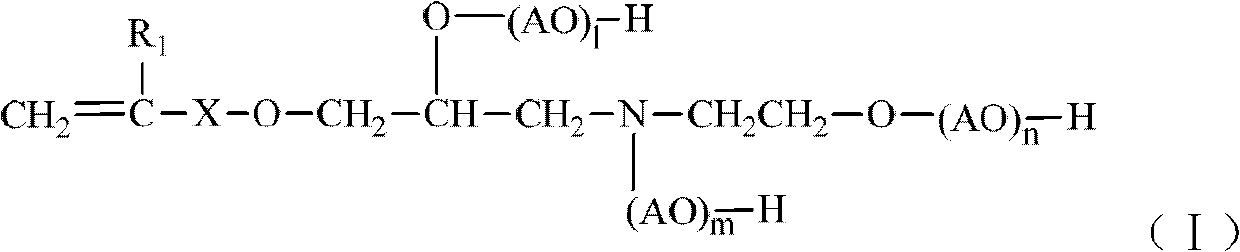

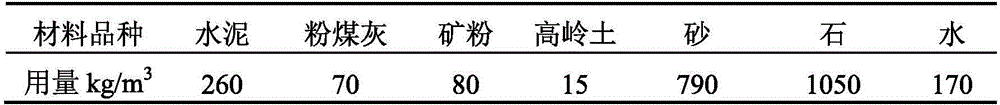

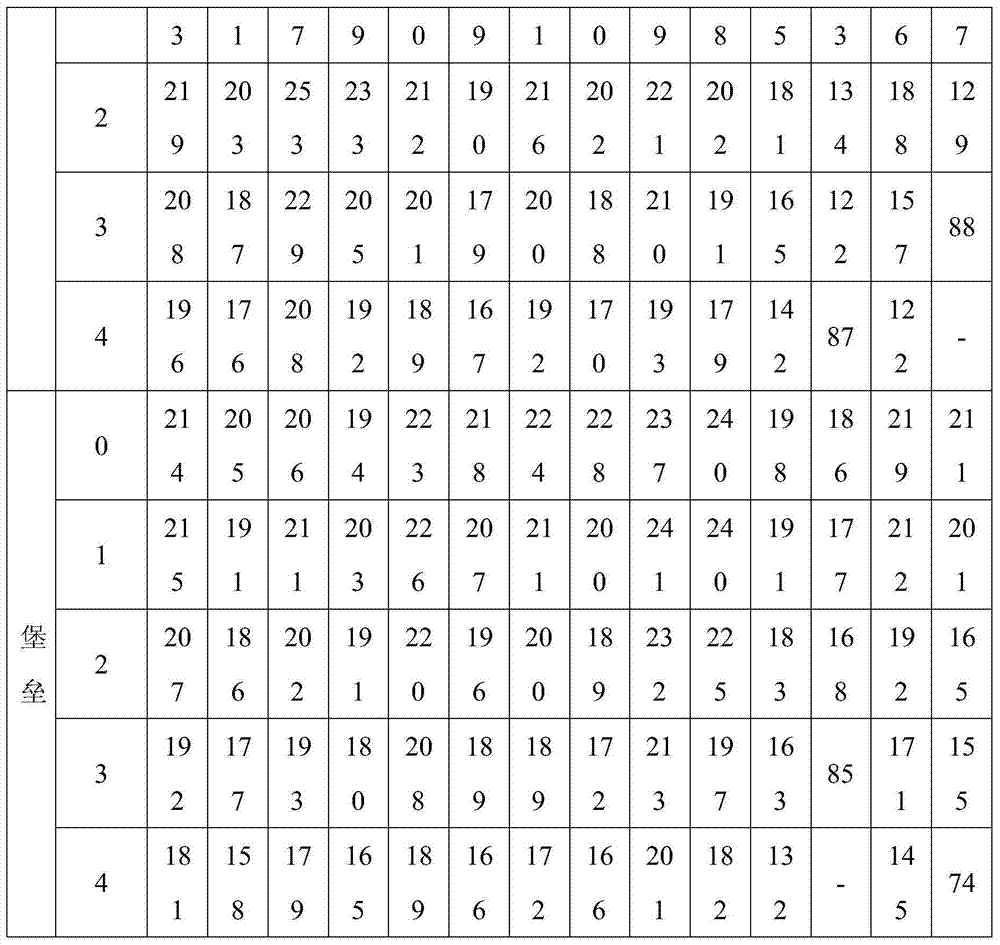

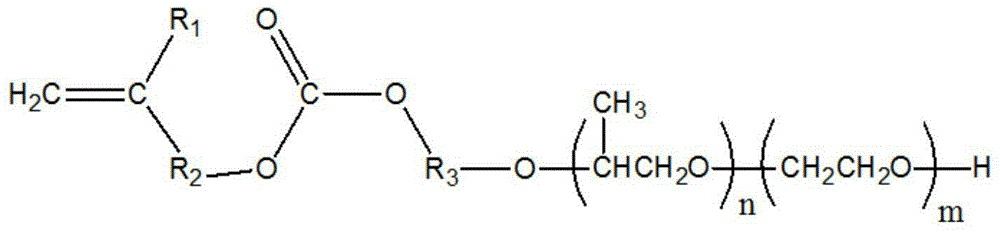

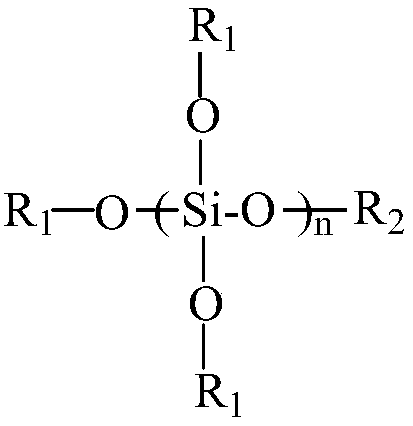

The invention relates to an unsaturated polyether monomer, a comb-like branched copolymer cement dispersant prepared by the monomer, and preparation methods of the monomer and the dispersant. The unsaturated polyether monomer has the general formula (I), wherein R1 is H or -CH3; X is a linking group selected from -CH2-, -CH2CH2-, -OCH2CH2-, -OCH2CH2CH2CH2-; AO is ethylene oxide group and / or propene oxide group; l, m and n are all repeating units of AO; and the sum of l, m and n is an natural number of 10 to 50. The dispersant has the following chemical structure (VI), wherein x, y and z represent mole percentages of three structural units in the copolymer, and the sum of x, y and z is 100%. Preferably, x is 10% to 50%, y is 40% to 80% and z is 0% to 30%. The preparation method of the dispersant is simple and does not need organic solvents or complex esterification. The dispersant is advantageous in low dosage, good dispersibility and small slump loss.

Owner:连云港苏博特新材料有限公司 +2

Preparation method of synthetic type polycarboxylic acid water reducer

The invention discloses a preparation method of a synthetic type polycarboxylic acid water reducer. The synthetic type polycarboxylic acid water reducer has a solid content of 40-50%, and is prepared from the following raw materials in parts by weight: 100 parts of unsaturated polyoxyethylene ether, 7-15 parts of unsaturated acid, 4-10 parts of unsaturated ester, 1-3 parts of an amide derivative, 0.5-2 parts of an oxidant, 0.2-1.2 parts of a chain transfer agent, 0.3-2 parts of a reducing agent, 0.1-1 part of a crosslinking agent, 0.01-0.1 part of ferrous sulfate heptahydrate, 5-10 parts of a commercially available mud-resistant auxiliary agent, 90-130 parts of deionized water and an appropriate amount of liquid caustic soda. The preparation method disclosed by the invention adopts a normal-temperature oxidation-reduction initiating system to synthesize the synthetic type polycarboxylic acid water reducer which not only has functions of water reduction and slump loss resistance, but also has functions of mud resistance and early strength, heating is not needed for reaction, the energy consumption is reduced, and the production cost is greatly reduced.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

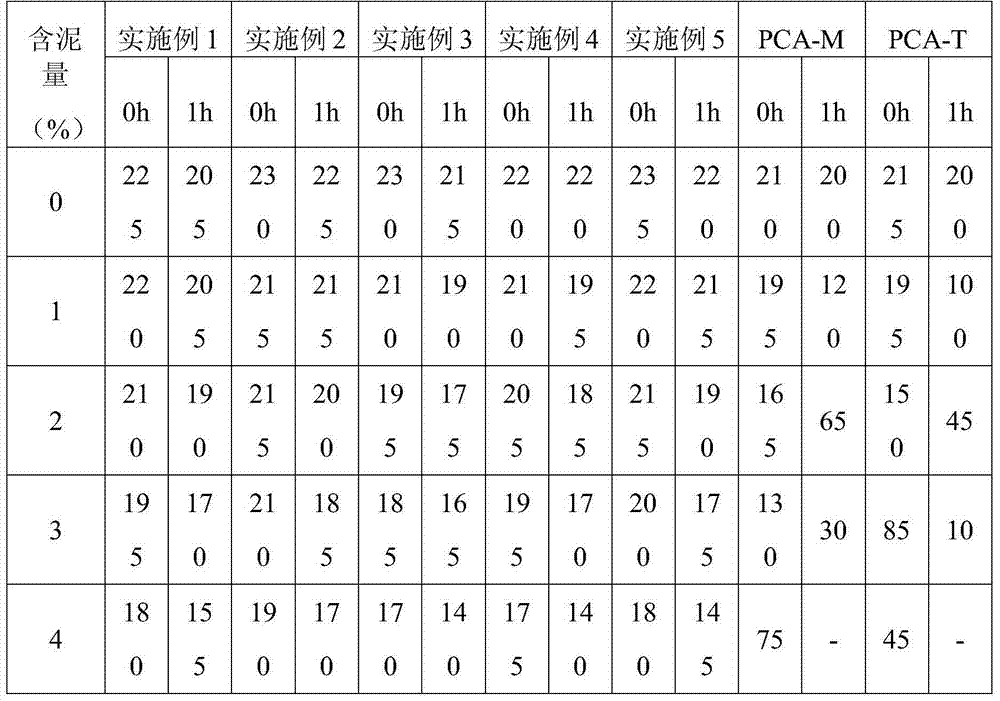

Polycarboxylate-type water reducing agent suitable for mud-containing aggregates and preparation method therefor

ActiveCN103641963AShield adsorptionGuarantee water reduction and slump protectionCarboxylic acidWater reducer

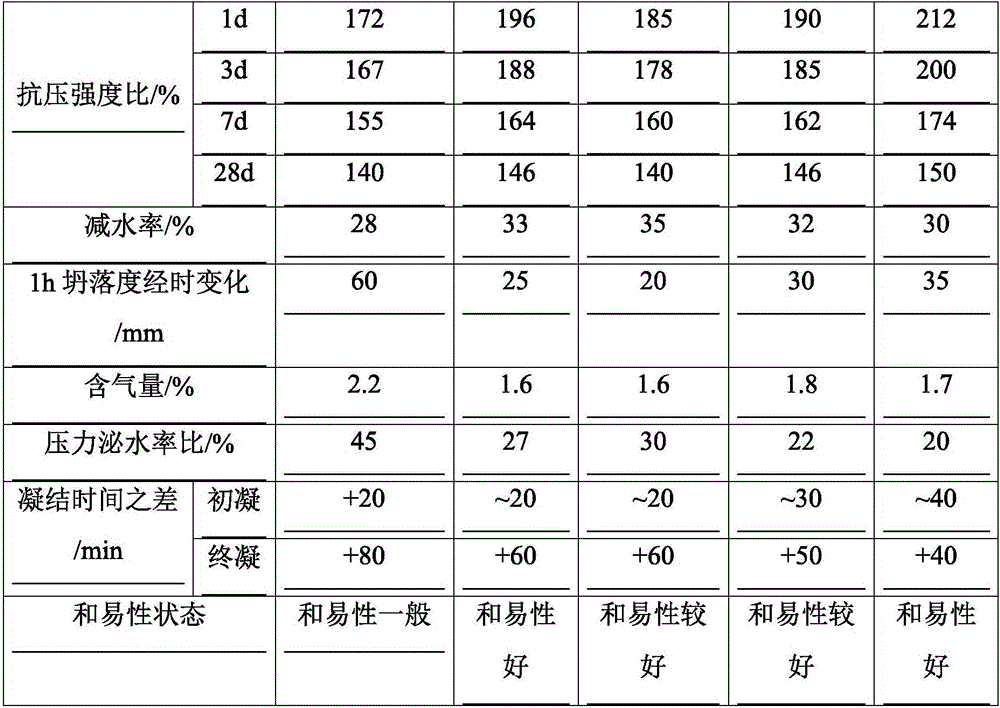

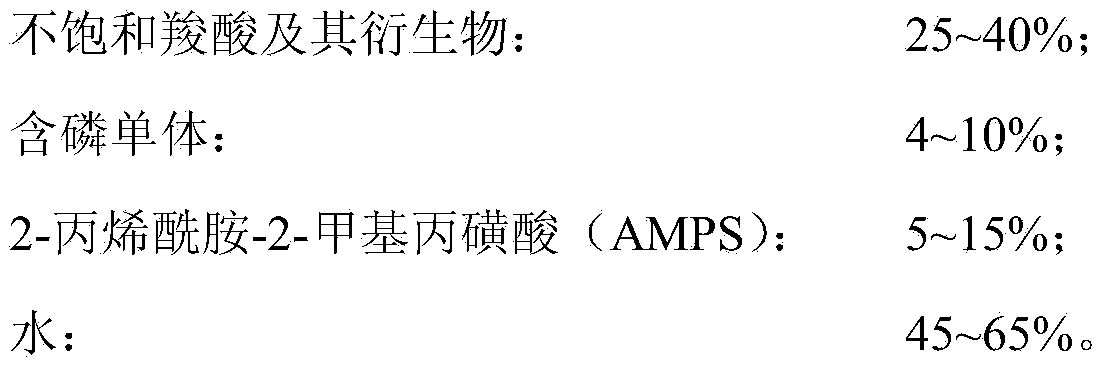

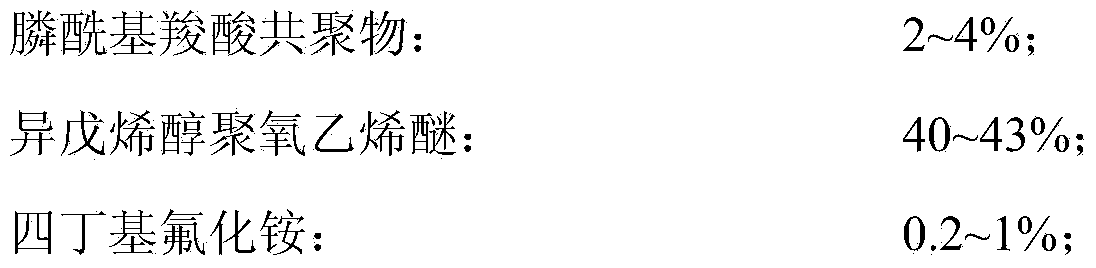

The invention discloses a preparation method for a polycarboxylate-type water reducing agent suitable for mud-containing aggregates and belongs to the water reducing agent field. First, nonsaturated monocarboxylic acid and derivatives thereof, and / or nonsaturated dicarboxylic acid and derivatives thereof, phosphorus-containing monomers, and 2-acrylamide-2-methyl propanesulfonic acid (AMPS) are subjected to copolymerization under action of initiators and a kind of phosphono carboxylic acid copolymers are obtained; then the obtained phosphono carboxylic acid copolymers, isoamyl enol polyethenoxy ether, tetrabutyl ammonium fluoride, nonsaturated monocarboxylic acid and derivatives thereof are subjected to free radical copolymerization under action of initiators and chain transferring agents and the polycarboxylate-type water reducing agent is obtained. The adsorption of high valent metal ions to the polycarboxylate-type water reducing agent can be reduced, the adverse influences of the mud content of aggregates in concrete to the polycarboxylate-type water reducing agent can be avoided, and the problems of insufficient water reducing of concrete, low intensity and the like can be solved without raising mixing amount of the polycarboxylate-type water reducing agent.

Owner:NANJING RUIDI HIGH TECH

Low-melting point polyester synthesis method

The invention discloses a synthesizing method of low-fusing point polyester, which comprises the following steps: adopting terephthalic acid and ethandiol as raw material; possessing 15-40% m-phthalic acid, 5-25% azelaic acid and 2-10% neopentyl glycol with the molar rate of acid and alcohol at 1: 1.1-1.3; allocating even slurry; esterifying; condensing to synthesize low-fusing point polyester with fusing point at 100-160 Deg C.

Owner:厦门翔鹭化纤股份有限公司 +1

Ceramic ink and preparation method and applications thereof

ActiveCN105384449AEnhanced steric hindranceAvoid reunionImpression capsCeramic shaping apparatusSolid phasesGlycerol

The invention discloses a ceramic ink, which comprises the following raw materials in percentage by mass: 57-57% of ceramic powder, 1-5% of a dispersant, 8-30% of glycerol, 8-35% of water and 5-20% of an organic solvent; and the pH value of the ceramic ink is 8-12, and the dispersant is composed of ammonium polyacrylate and polyvinylpyrrolidone in a mass ratio of 1:5 to 5:1. The invention also discloses a preparation method of the ceramic ink and the application of the ceramic ink in the ink-jet printing of false teeth. According to the invention, the dispersion and ink stability of the ceramic ink are improved by a binary dispersant, and then the solid phase content of the ceramic ink is increased to 20-40 vol. %, so that the ceramic ink can be used for directly printing ceramic products such as false teeth and the like through ink-jet printing, and the relative density of ceramic products is more than 98%.

Owner:HUAZHONG UNIV OF SCI & TECH

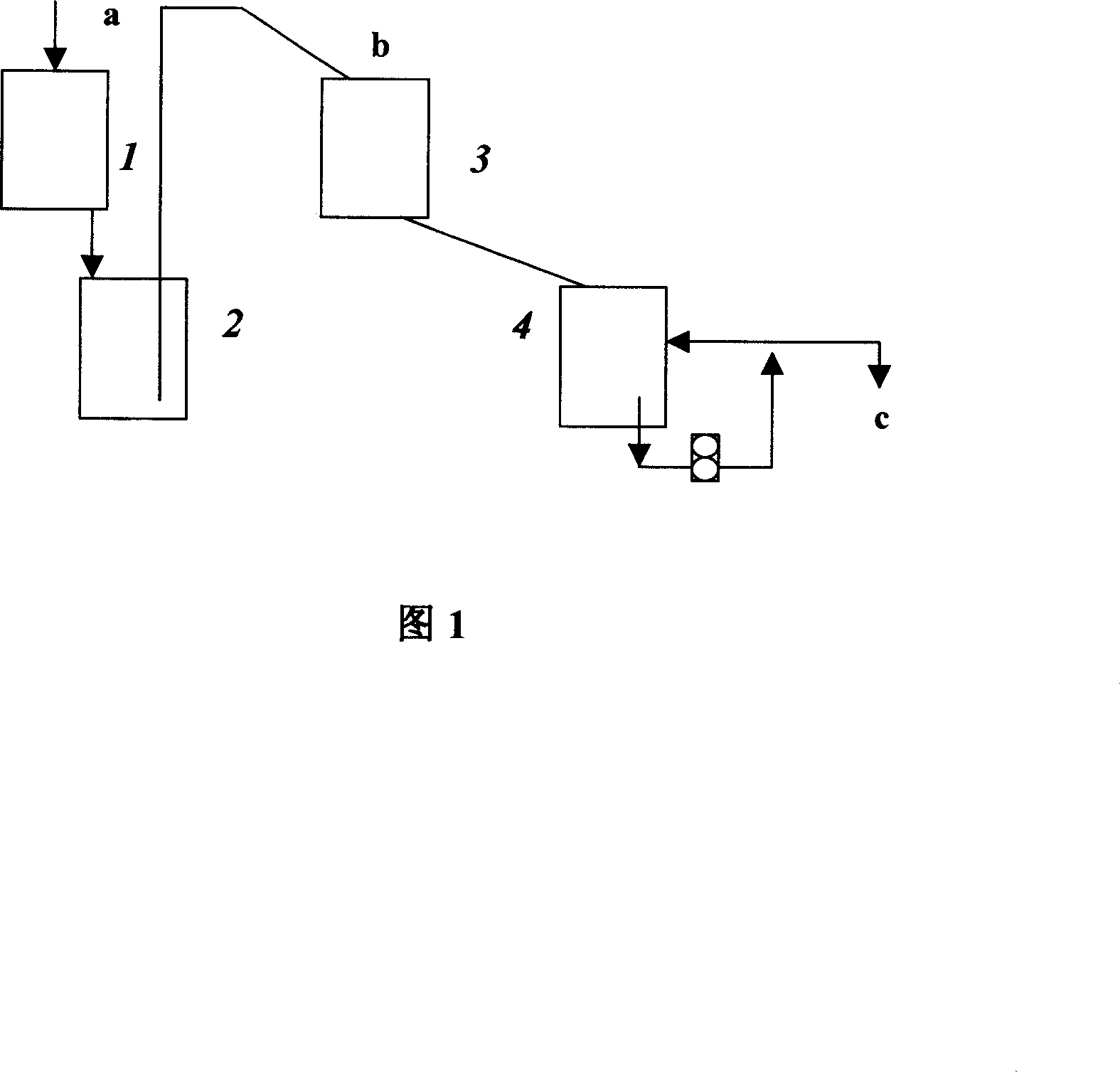

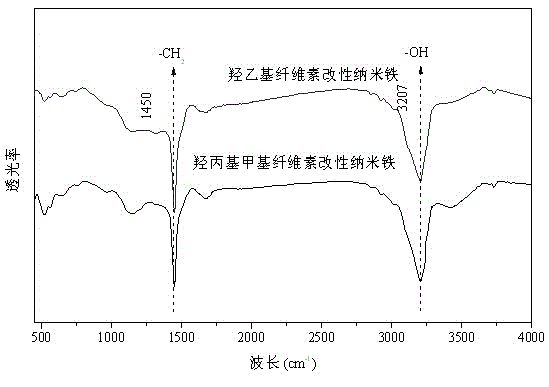

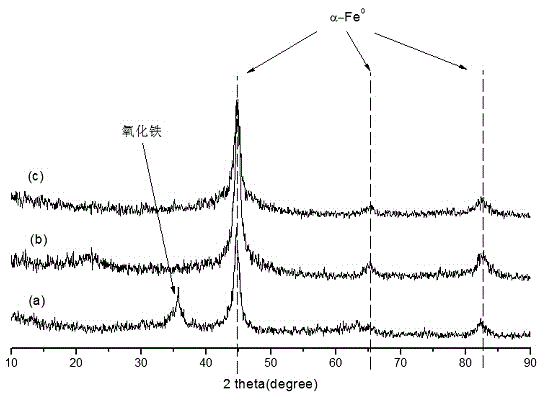

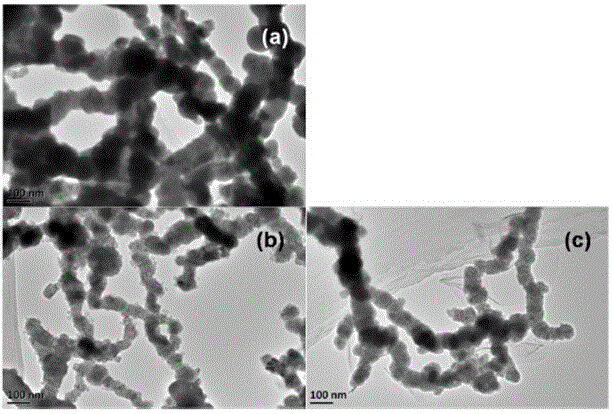

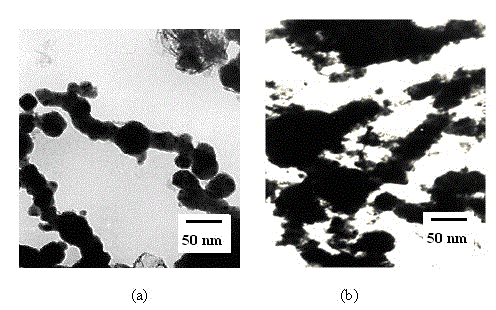

Preparation method for cellulose modification nano iron particles

ActiveCN104785793AFacilitate adaptation to in situ and heterotopic repairSimple processWater/sewage treatmentCelluloseNitrate salts

The invention discloses a preparation method for cellulose modification nano iron particles. According to the preparation method, two kinds of environment-friendly non-poisonous and innocuous cellulose are taken as dispersing agents to conduct surface modification on particles in the preparation process of the nano iron particles, and the cellulose dispersing agent modified nano iron particles are obtained. According to the preparation method for the cellulose modification nano iron particles, the process is simple and convenient, the operation is easy, the cost is low, the dispersity of the nano iron particles is good, the agglomeration of the particles in water can be reduced, and the removal efficiency of the particles to organic pollutants, dyestuff, pesticides, nitrate and heavy metal is improved.

Owner:KUNMING UNIV OF SCI & TECH

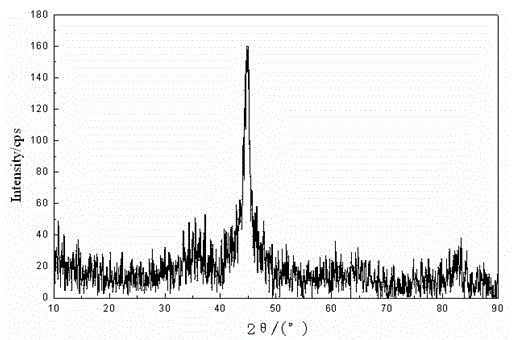

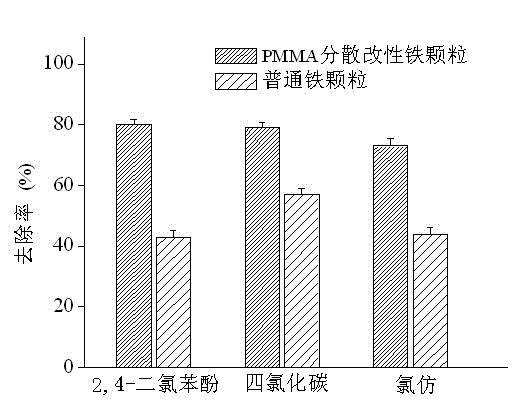

Preparation method of dispersant modified iron nanoparticles

InactiveCN102614918AImprove stabilityLow degree of reunionOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsEnvironmental mediaOrganic compound

The invention discloses a preparation method of dispersant modified iron nanoparticles. According to the preparation method, high polymer, a cationic surfactant or anionic polymer electrolyte is used as a dispersant to perform surface modification on particles in a preparation process of the iron nanoparticles so as to prepare the dispersant modified iron nanoparticles. The iron nanoparticles prepared by the method have good dispersion stability; the hard agglomeration of the iron nanoparticles in an aqueous medium is reduced; the dispersion degree of the iron nanoparticles is increased; the method can also be used for performing dispersion modification on iron base bimetallic particles; and the method can be applied to pollution remediation of chlorinated organic compounds in an environmental medium and has broad application prospect.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of anti-mud polycarboxylic water reducer

ActiveCN103467670BGuarantee water reduction and slump protectionEnhanced steric hindranceDistillationCarboxylic acid

The invention relates to an anti-mud polycarboxylic water reducer and a preparation method thereof and belongs to the field of water reducers. The preparation method of the water reducer comprises the steps of (1) preparing quaternary ammonium salt oligomer: allowing epibromohydrin and tertiary amine compound aqueous solutions to react by the action of a composite initiator in a mixed solvent of low alcohol and water when a system pH (potential of hydrogen) value is 1-2, then performing reduced pressure distillation, and obtaining light yellow viscous quaternary ammonium salt oligomer, and (2) preparing the anti-mud polycarboxylic water reducer, performing radical copolymerization on quaternary ammonium salt oligomer, isopentene alcohol ethoxylate, amino trimethylene phosphonic acid, unsaturated monocarboxylic acid and a derivative of unsaturated monocarboxylic acid by the action of an initiator and a chain transfer agent to form the colorless to light yellow transparent polycarboxylic water reducer. An adverse effect of a mud content of aggregate in concrete on the polycarboxylic water reducer can be avoided, and the problems of insufficient water reduction, great slump loss and lower strength of the concrete are solved on the premise that the mixing amount of the polycarboxylic water reducer is not increased.

Owner:NANJING RUIDI HIGH TECH

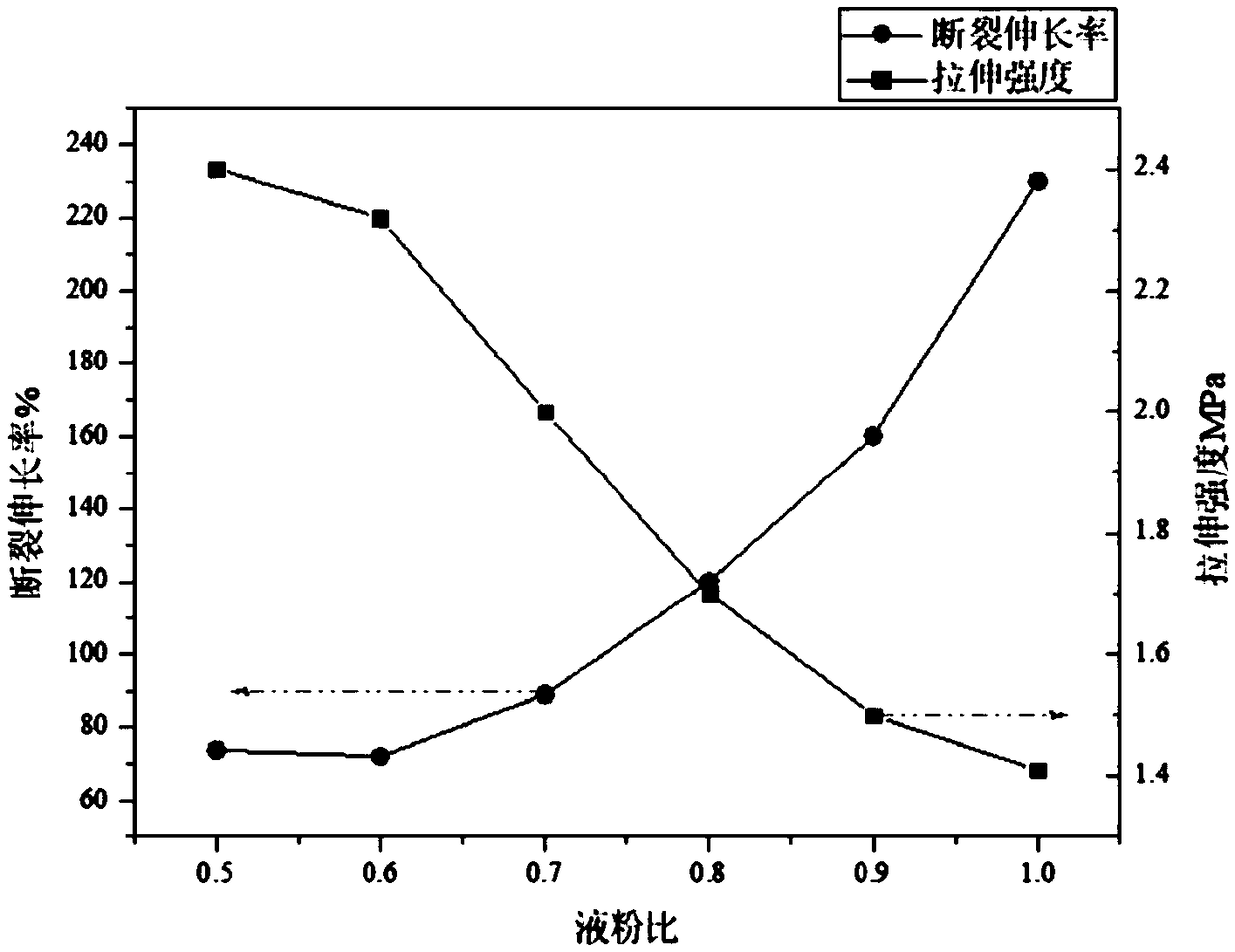

Zero-VOC (volatile organic compound) cement-based water-proof material copolymer emulsion and preparation method thereof

The invention discloses zero-VOC (volatile organic compound) cement-based water-proof material copolymer emulsion and a preparation method thereof. The preparation method adopts a zero-VOC copolymer emulsion component A and an inorganic powder component B, the zero-VOC copolymer emulsion component A is prepared from deionized water, alkyl acrylate, styrene, acrylic acid functional monomers, emulsifying agents, initiators, a buffer agents, polymerization inhibitors, oxidizing agents, reducing agents, sterilizing agents and defoaming agents through polymerization of pre-emulsification semi-continuous seed emulsion, and the inorganic powder component B comprises ordinary portland cement, quartz sand and water reducers. The prepared emulsion is high in solid content, low in viscosity, uniformin particle size and good in stability and has excellent rheological property and coating water absorption, the content of a residual monomer in an emulsion product is lower than 300ppm and meets national zero-VOC emulsion standards, the emulsion is environmentally friendly and free from toxicity and pollution, the compatibility of the emulsion and cement is good, and a prepared polymer cement waterproof coating is excellent in water resistance, good in low-temperature flexibility and low in water absorption.

Owner:SOUTH CHINA UNIV OF TECH

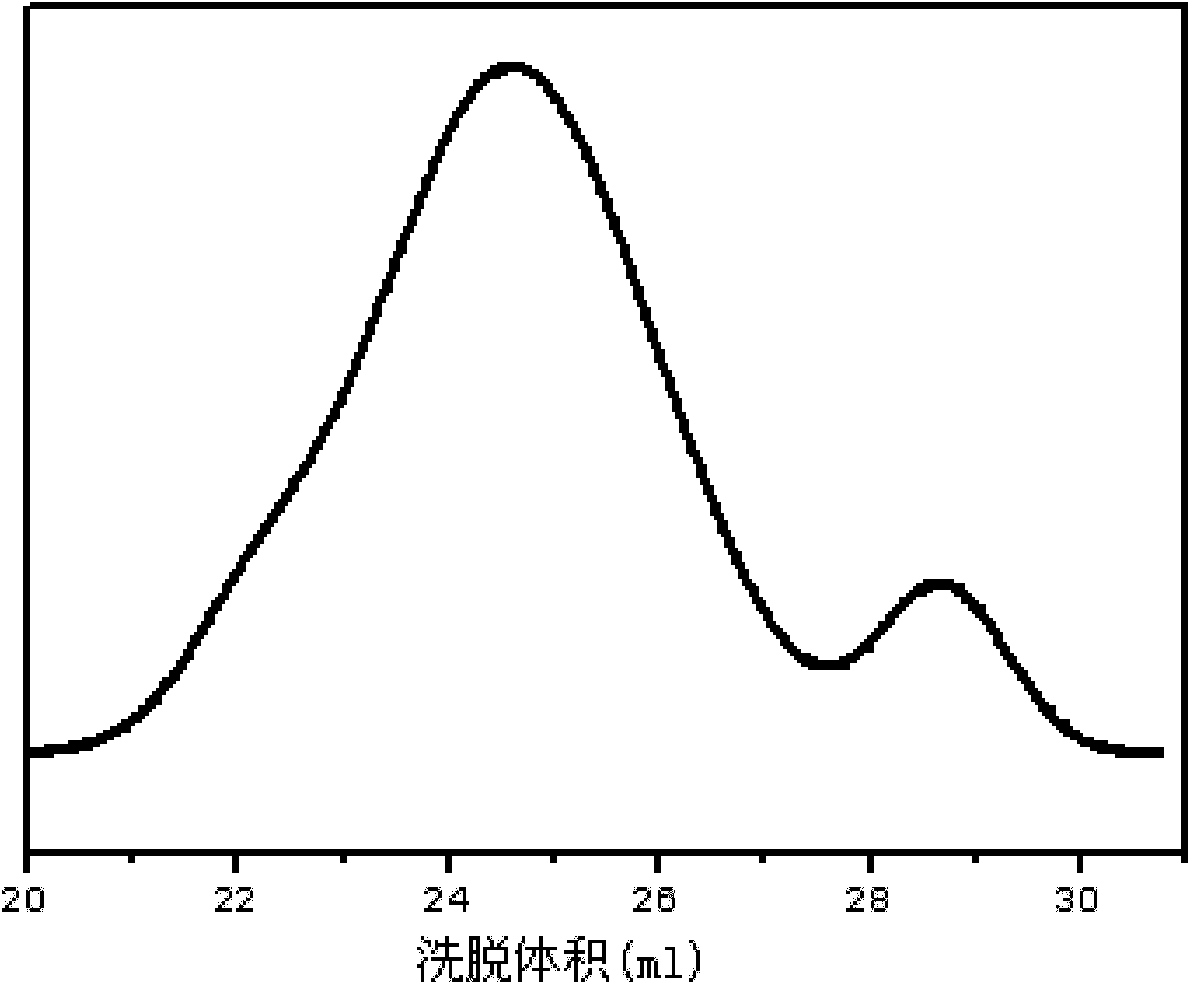

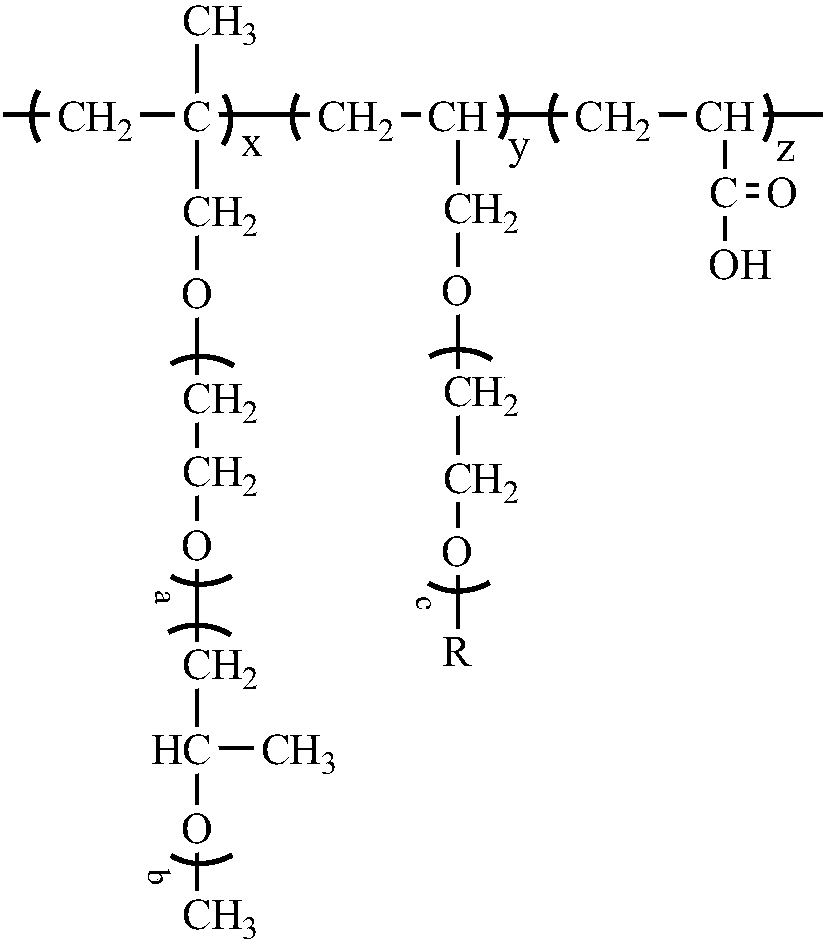

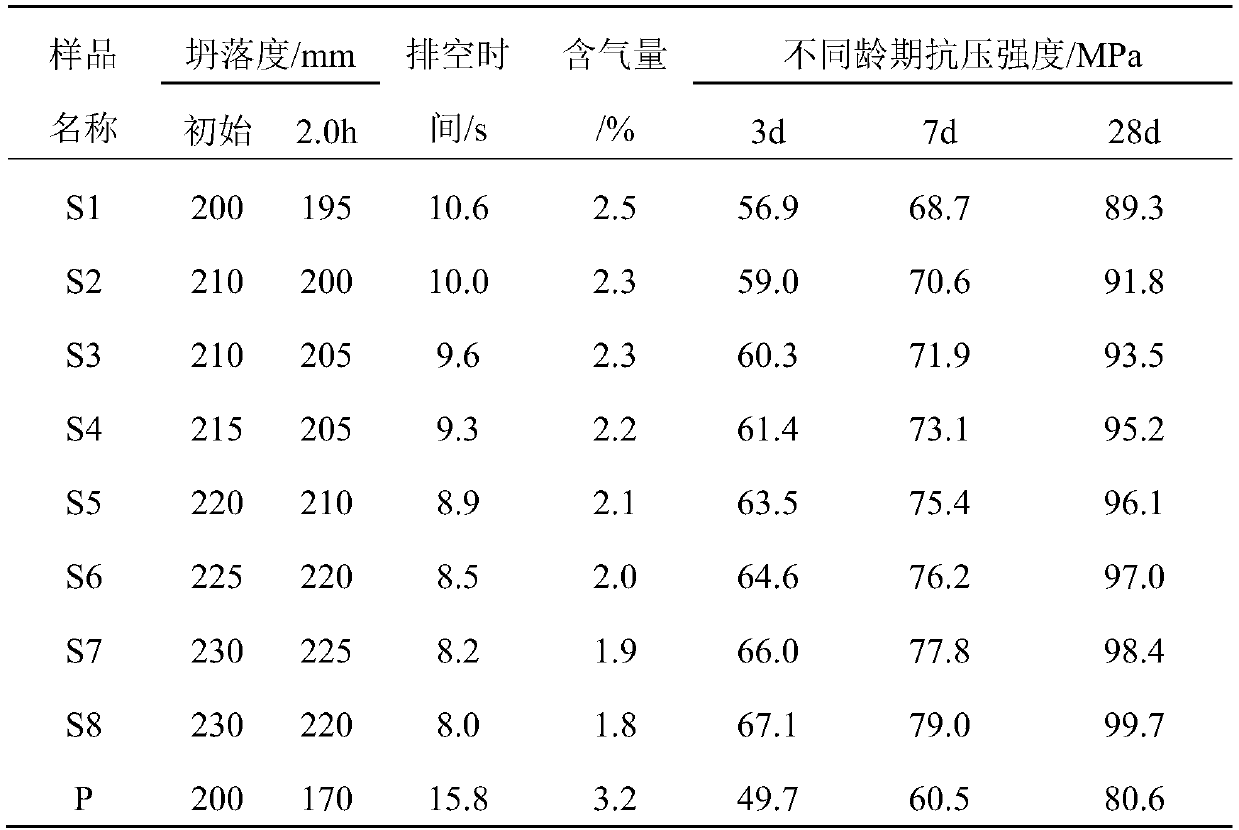

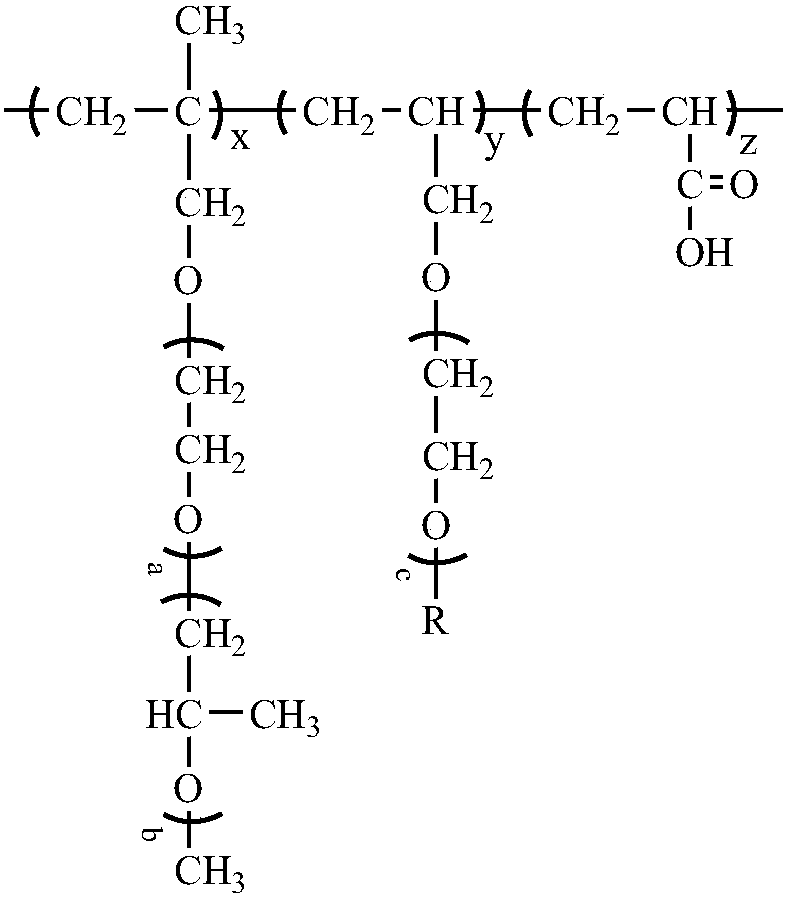

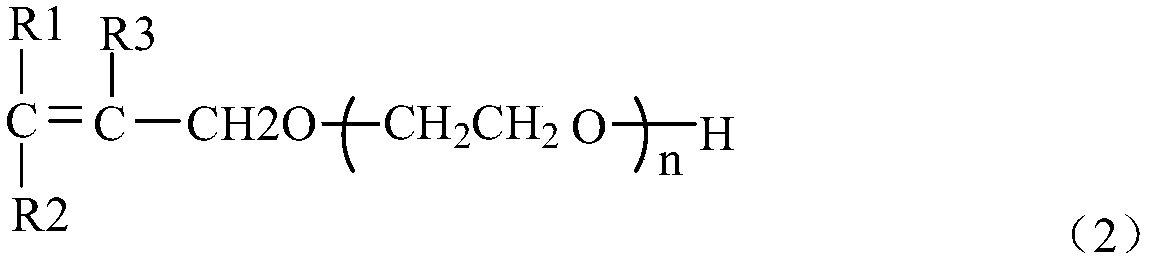

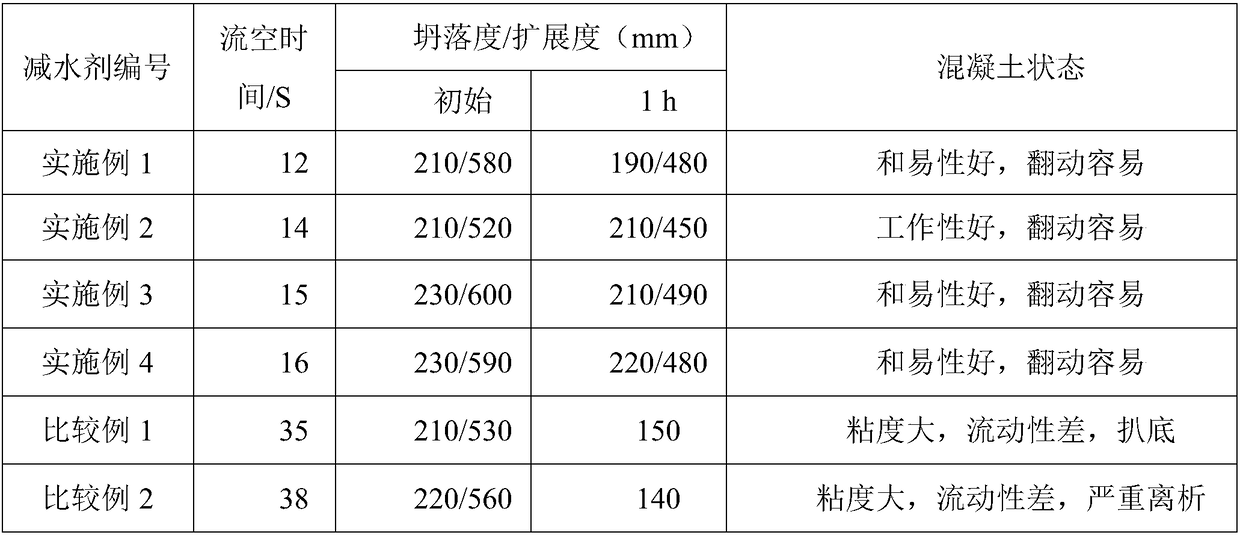

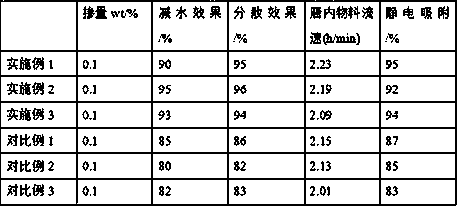

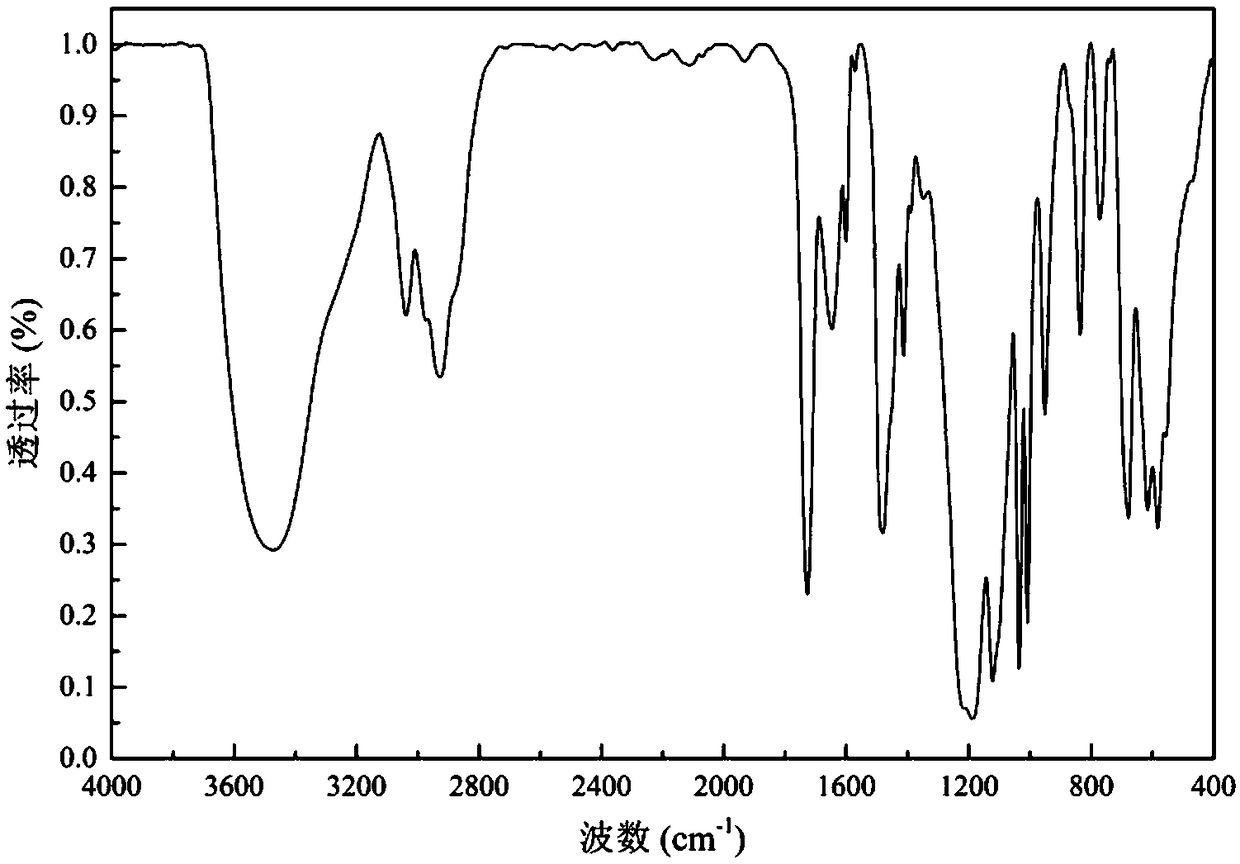

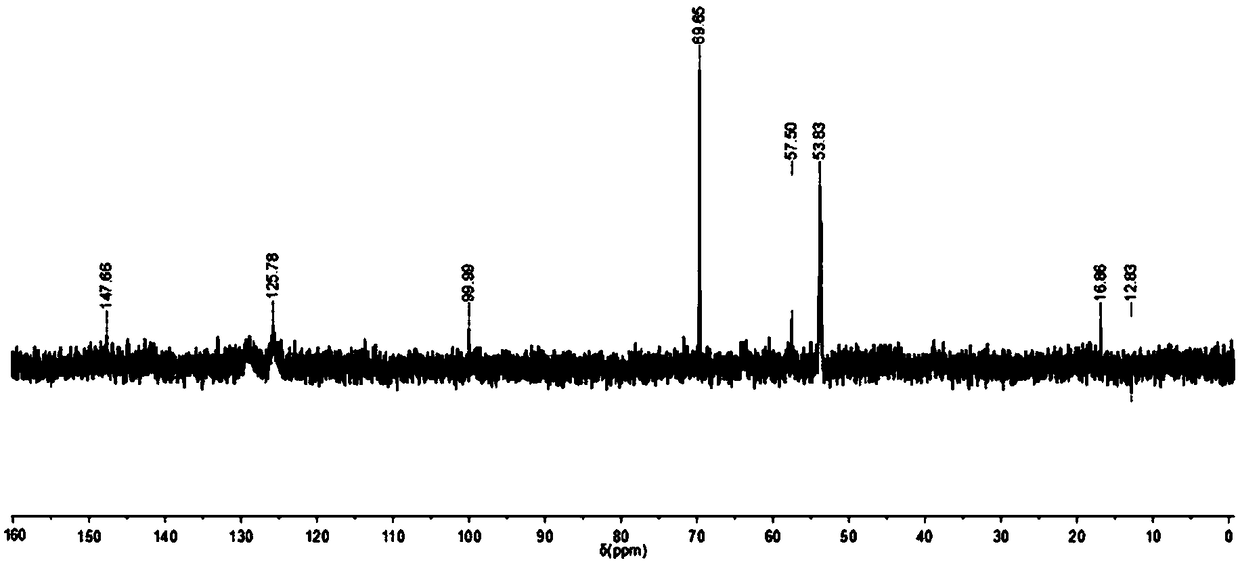

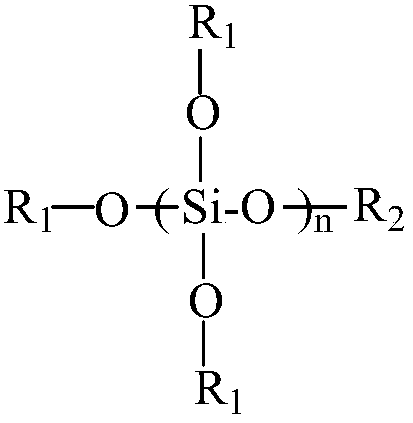

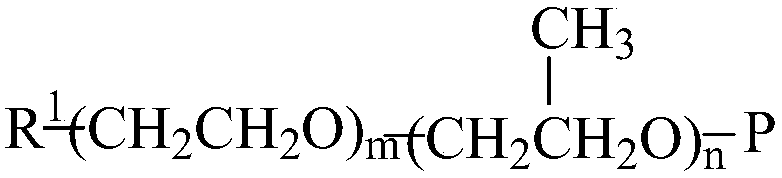

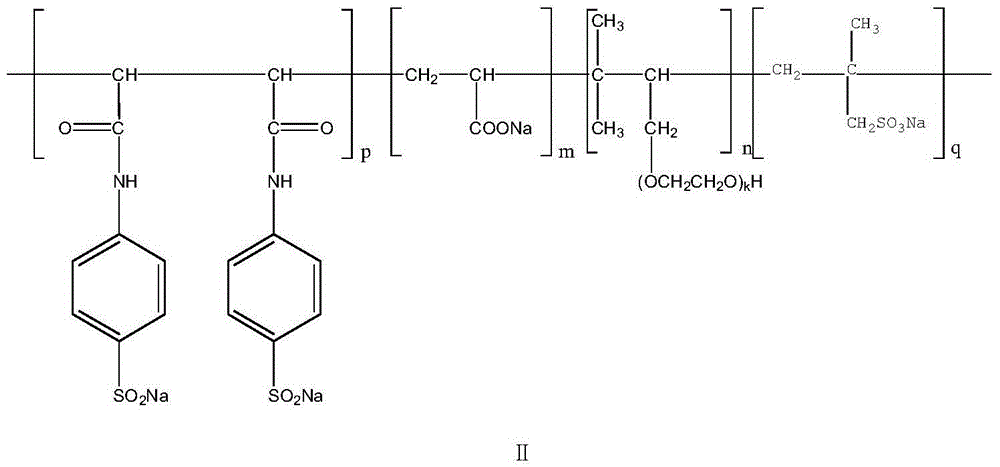

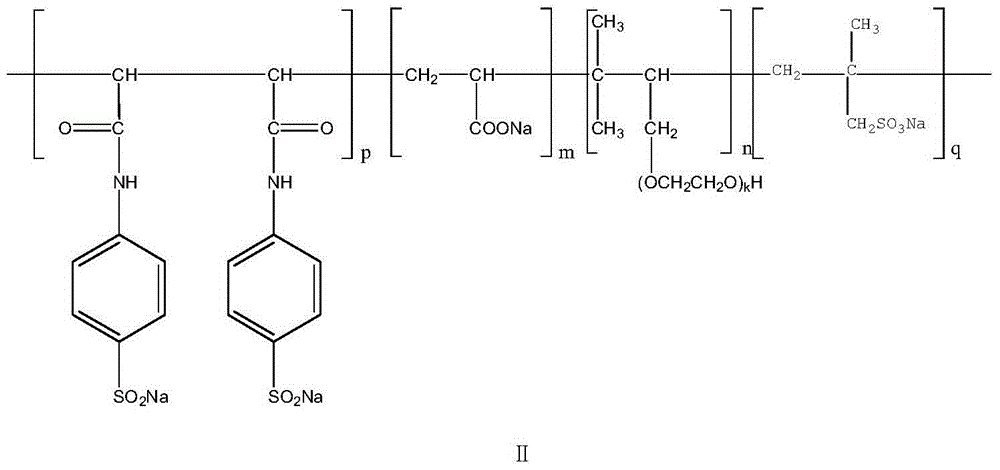

Preparation method for comb-shaped copolymer cement dispersant, monomer used therein and prepared comb-shaped copolymer cement dispersant

InactiveCN102115516AImprove dispersion stabilityEasy to operateOrganic chemistryDispersion stabilityDouble bond

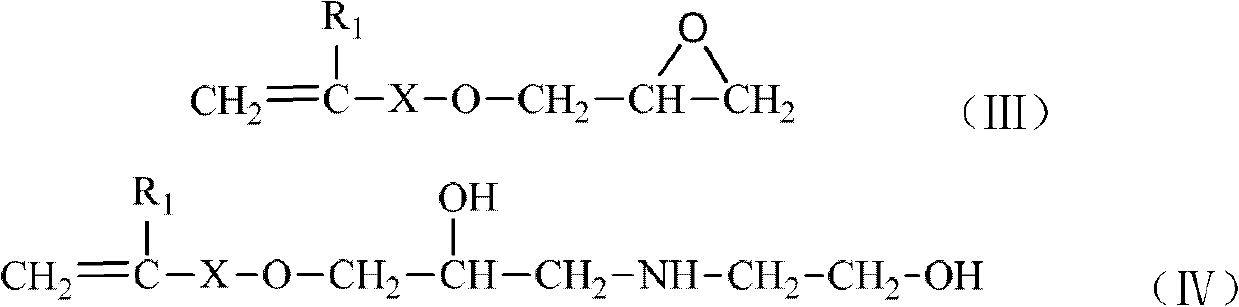

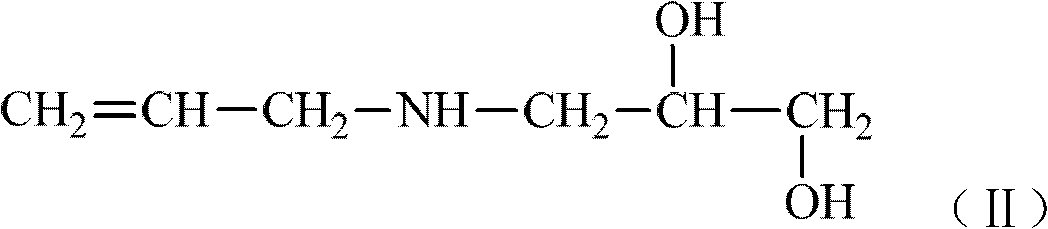

The invention relates to a preparation method for a comb-shaped copolymer cement dispersant, a monomer used in the comb-shaped copolymer cement dispersant and the prepared comb-shaped copolymer cement dispersant. The preparation method for the comb-shaped copolymer cement dispersant comprises the following steps: a monomer (a) and a monomer (b) are subjected to free-radical copolymerization in aqueous medium, wherein the monomer (a) is expressed with a general formula (I), and the monomer (b) is expressed with a general formula (II); and the mol ratio of the monomer (a) and the monomer (b) is preferably 1:(1 to 10). The structure formula of the comb-shaped copolymer cement dispersant obtained by the preparation method is shown in (VI). The new monomer (a) is introduced in the comb-shaped copolymer cement dispersant, and the molecular structure of the monomer (a) has an unsaturated reactive double bond and two branching polyoxyalkylene long chains, so that the steric hindrance among cement particles can be greatly enhanced, and the dispersion stability of cement can be enhanced. The preparation method for the comb-shaped copolymer cement dispersant is simple and convenient for production operation, and meanwhile, the prepared comb-shaped copolymer cement dispersant has the advantages of low dosage, good dispersivity, high water-reducing rate, small slump loss and low gas content.

Owner:JIANGSU SUBOTE MATERIAL +2

Preparation method for anti-mud polycarboxylate water reducing agent used for polyether with molecular weight of 3,000

The invention provides a preparation method for an anti-mud polycarboxylate water reducing agent used for polyether with a molecular weight of 3,000. The preparation method comprises the following steps: 1) adding polyether macromonomers with a molecular weight of 3,000, phenylcarboxylic acid functional monomers, phosphate functional monomers and water in a certain mass ratio a reaction kettle, and carrying out stirring and heating to dissolve the above substances; 2) controlling a temperature at 46-52 DEG C, and then beginning to add a certain amount of hydrogen peroxide; 3) in 5 minutes, adding a solution B drop by drop, and starting dropwise addition of a solution A within 10 minutes after the completion of addition of the solution B, wherein the dropwise addition time of the solution Ais a hours, a is in a range of 2 to 4, the dropwise addition time of the solution B is (a+0.5) hours, the solution A is composed of acrylic acid, unsaturated sulfonate and water in a certain mass ratio, and the solution B is composed of ascorbic acid, a chain transferring agent and water in a certain mass ratio; and 4) after the completion of the dropwise addition, keeping a temperature constant,carrying out curing for 1-3 hours, slowly adding a certain amount of a neutralizer when the temperature of a reaction solution is lower than 30 DEG C, and supplementing water to 1000 parts so as to obtain the anti-mud polycarboxylate water reducing agent used for polyether with a molecular weight of 3,000 and having a mass fraction of 40%.

Owner:HUBEI UNIV OF TECH

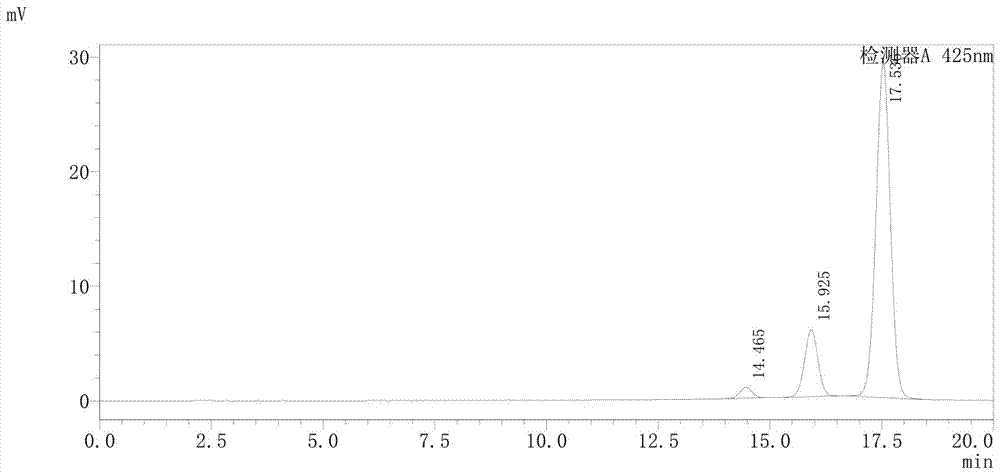

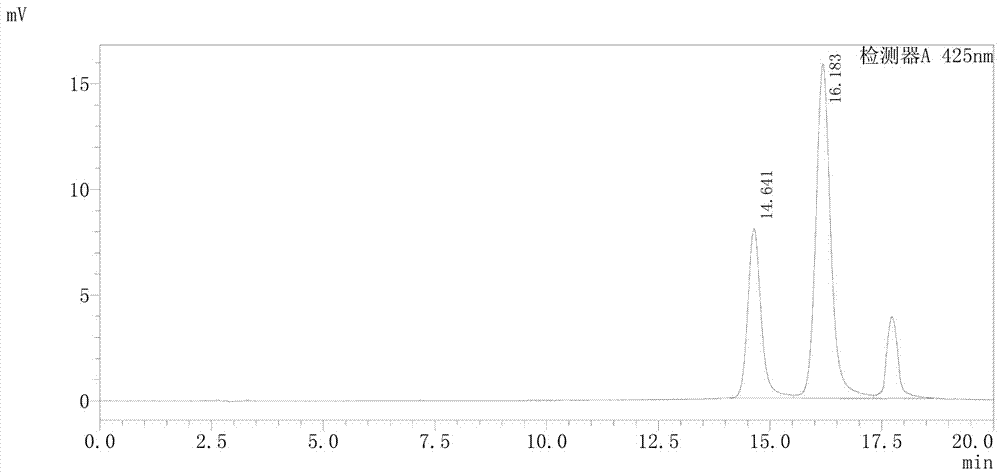

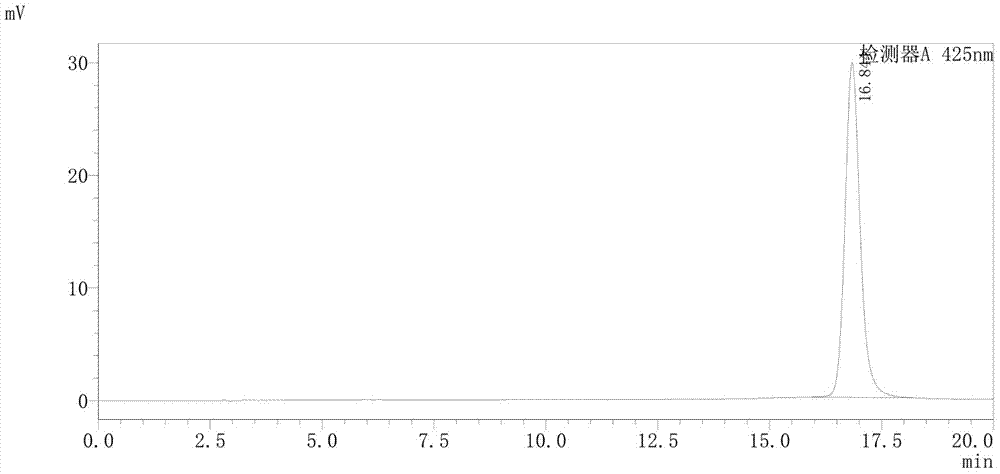

Low-cost and high-efficiency curcumin extraction method

ActiveCN106866397AEfficient separationEasy to operateCarbonyl compound separation/purificationEthyl acetateAdsorption separation

The invention belongs to the technical field of extraction of plant effective components, and concretely relates to a low-cost and high-efficiency curcumin extraction method. The method sequentially comprises the following steps: taking crushed dry turmeric, carrying out extraction on the crushed dry turmeric by using ethanol, concentrating obtained extraction filtrate, extracting the concentrated filtrate with petroleum ether, re-concentrating the obtained extract, dissolving the obtained concentrate in an aqueous sodium hydroxide solution, extracting the obtained solution with ethyl acetate, and concentrating the obtained ethyl acetate layer to obtain a primary turmeric extract; and dissolving the primary turmeric extract in ethanol, and carrying out high-matching adsorption separation by adopting specially-produced modified attapulgite to respectively obtain a demethoxycurcumin and bisdemethoxycurcumin mixture and highly pure curcumin. The method fully utilizes the structural characteristics of the curcumin and the attapulgite, realizes high matching against the molecular difference, and has the advantages of convenience in operation, no large device demands, high extraction efficiency, low cost, effective separation of the curcumin from the demethoxycurcumin and the bisdemethoxycurcumin, high purity, and realization of industrial production.

Owner:广州市科虎生物技术有限公司

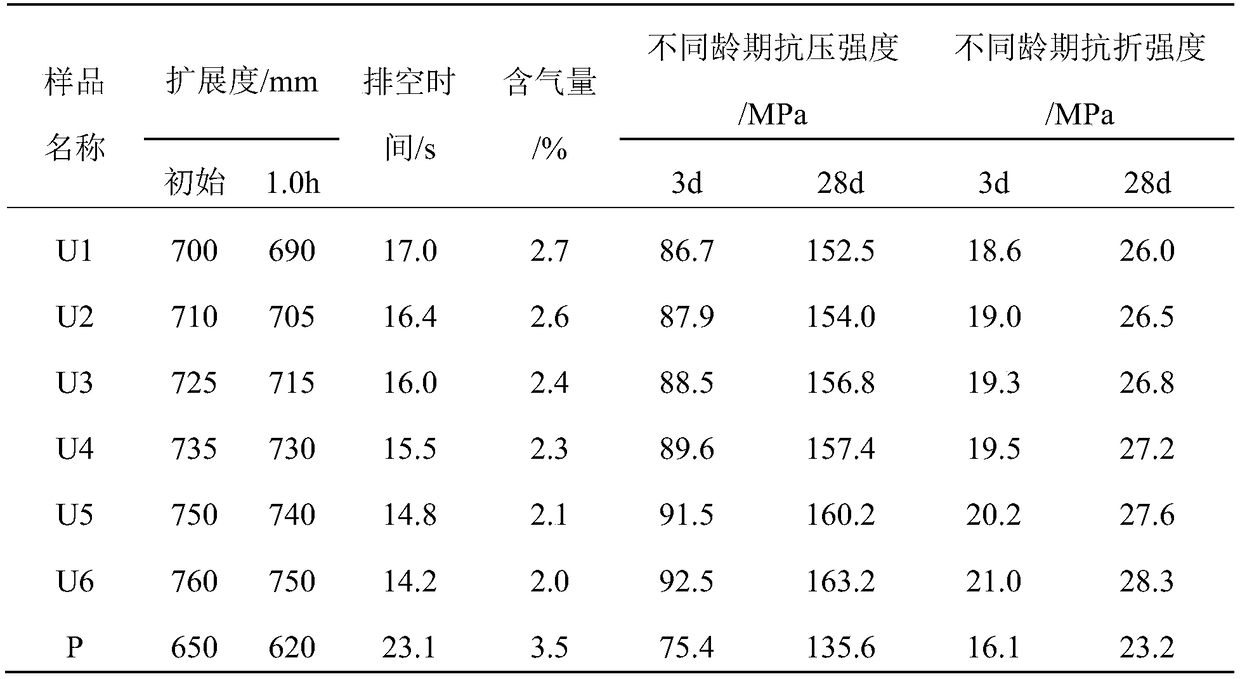

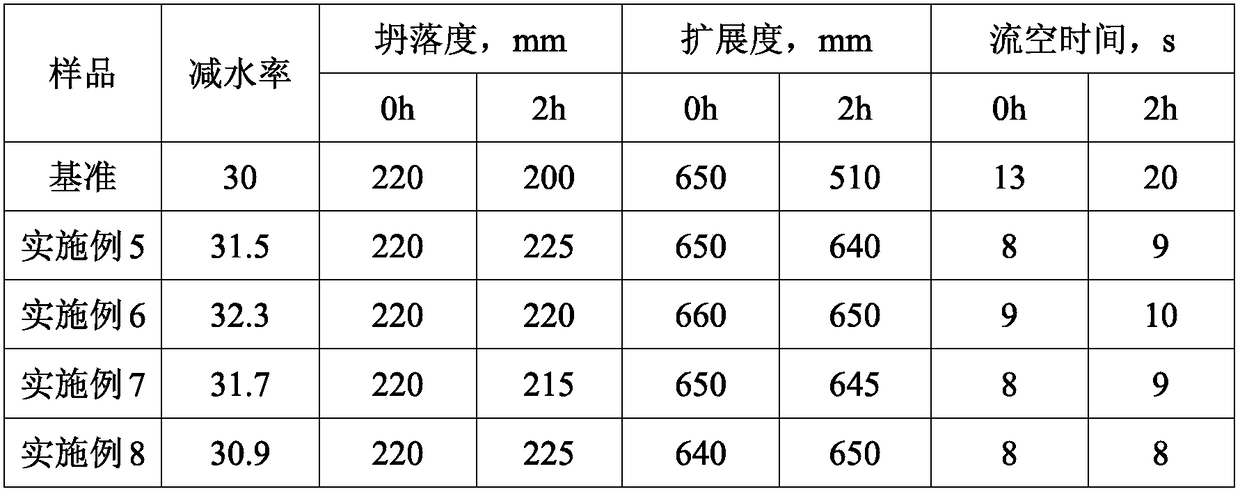

Special high performance concrete polycarboxylate superplasticizer and preparation method thereof

InactiveCN108623756ASuper high water reductionUltra high viscosity reductionSuperplasticizerReducing agent

The invention discloses a special high performance concrete polycarboxylate superplasticizer and a preparation method thereof. The preparation method comprises the following steps: firstly, heating and dissolving methyl allyl polyoxyethylene polyoxypropylene ether and water in a reaction kettle so as to obtain a solution A; adding hydrogen peroxide into the solution A, respectively dropping a solution of a Bruggolite FF6 reducing agent and a mixed water solution of acrylic acid and N-ethyl perfluorooctyl sulfamide acrylate, carrying out a heat-preservation reaction, and cooling to a room temperature so as to obtain a solution B; finally adding sodium hydroxide into the solution B, and adjusting a pH value to 6-8, so as to obtain the special high performance concrete polycarboxylate superplasticizer. The special high performance concrete polycarboxylate superplasticizer disclosed by the invention has functions of super water reduction, viscosity reduction, slump loss resistance, early strength, and the like, is capable of comprehensively improving comprehensive properties of high performance concrete, and is beneficial to promotion of application and development of the polycarboxylate superplasticizer in the field of concrete.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS +1

Hydrophobically modified viscosity-reducing polycarboxylate superplasticizer and preparation method thereof

The invention discloses a hydrophobically modified viscosity-reducing polycarboxylate superplasticizer and a preparation method thereof. The method includes the steps of: adding methyl allyl polyoxyethylene polyoxypropylene ether, hydrophobically modified allyl polyethylene glycol, acrylic acid and deionized water into a reaction kettle, and performing stirring and dissolving to obtain a solutionA; adding hydrogen peroxide into the solution A, also adding a deionized water mixed solution of acrylic acid and ascorbic acid dropwise, and then carrying out heat preservation reaction to obtain a solution B; adding liquid alkali into the solution B, and adjusting the pH value to 6-8, thus obtaining the hydrophobically modified viscosity-reducing polycarboxylate superplasticizer. The hydrophobically modified viscosity-reducing polycarboxylate superplasticizer prepared according to the invention has good dispersibility, slump retention and reinforcement, also has excellent viscosity-reducingperformance, and can greatly improve the comprehensive performance of high-performance or ultrahigh performance concrete.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

Physical modification method and preparation of soluble soybean polysaccharide

The invention discloses a physical modification method and preparation of a soluble soybean polysaccharide (SSPS), and belongs to the field of agricultural and sideline product processing. According to the physical modification method, octenyl succinic anhydride and the soybean polysaccharide are subjected to chemical reaction so as to obtain a novel soybean polysaccharide with amphipathic characteristics. The physical modification method comprises following steps: firstly, a hexametaphosphate is taken as a cross-linking agent to realize crosslinking esterification of the soluble soybean polysaccharide; at a pH value ranging from 8.0 to 8.5, octenyl succinic anhydride (OSA) is used for hydrophobic modification of an obtained crosslinked soybean polysaccharide; an obtained ocentyl succinic anhydride-soluble soybean polysaccharide ester (OSA-SSPS) crude product is extracted with ethyl acetate, and is subjected to rotary evaporation, and freeze drying or spray drying, and then is smashed so as to obtain a finished product. After appropriate physical modification, the obtained soybean polysaccharide possesses both hydrophilicity and hydrophobicity, and the stabilizing effect of steric hindrance is achieved preferably. Application range can be widened further; and the obtained product is widely applied to the fields such as food, cosmetic, weaving, papermaking, and pharmacy industry.

Owner:FUJIAN QUANZHOU WEIBO FOOD CO LTD

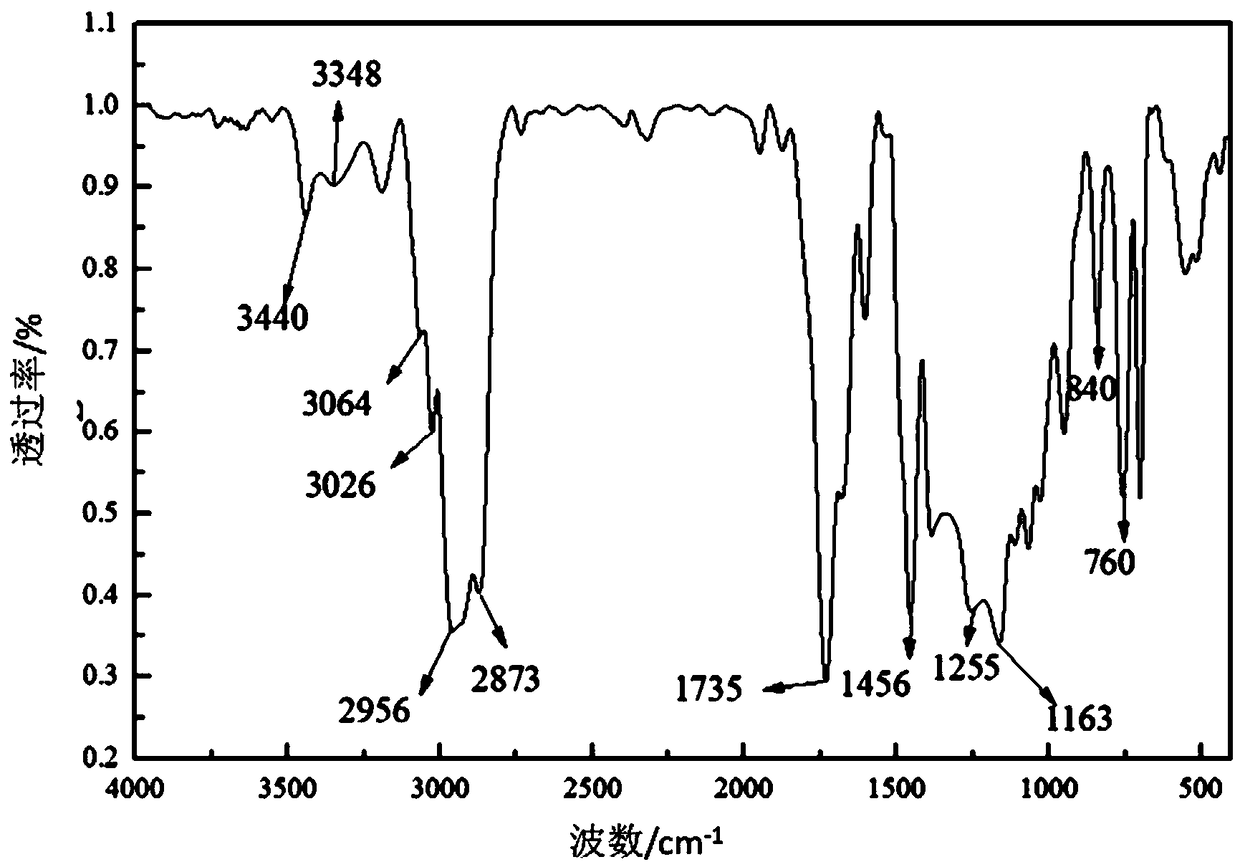

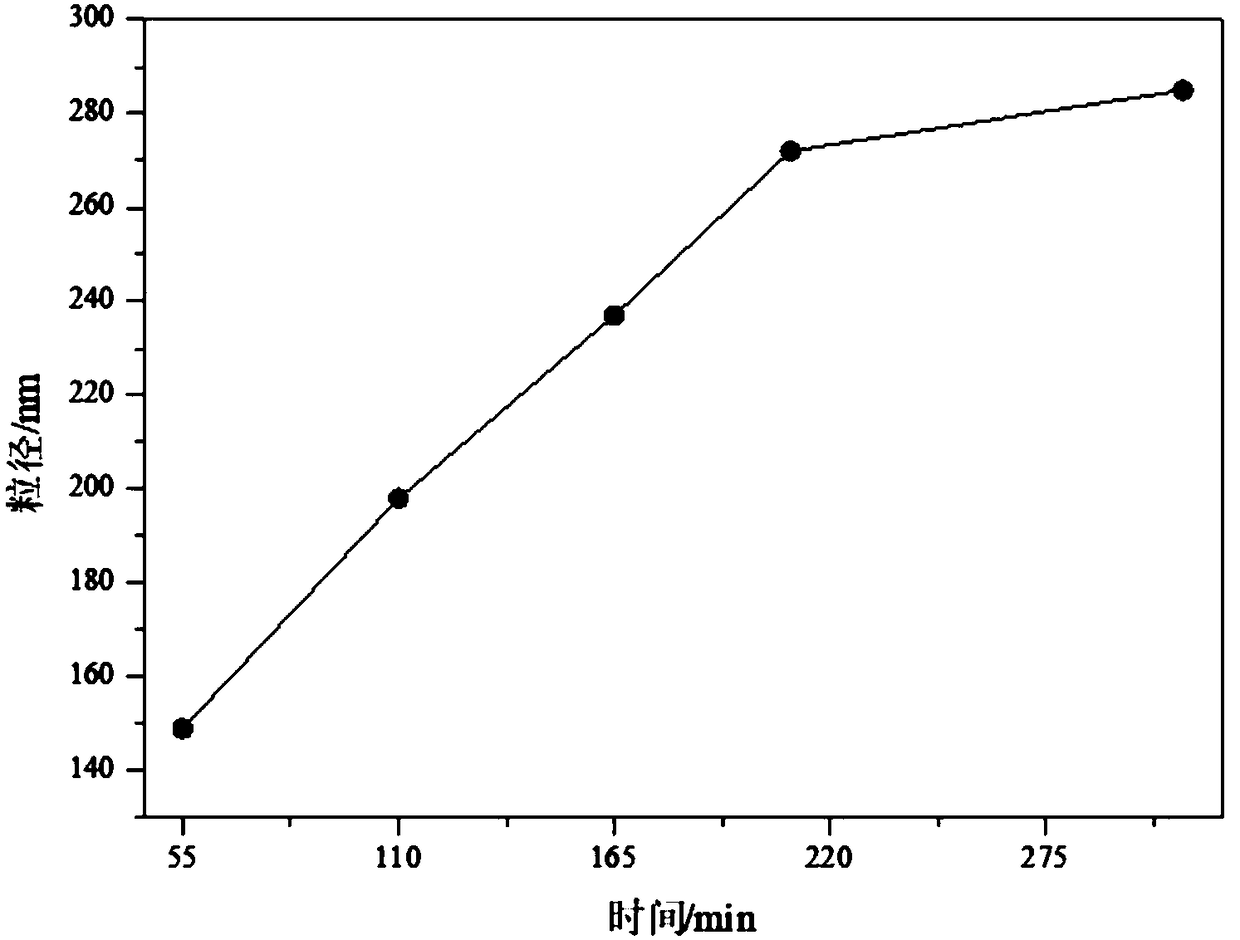

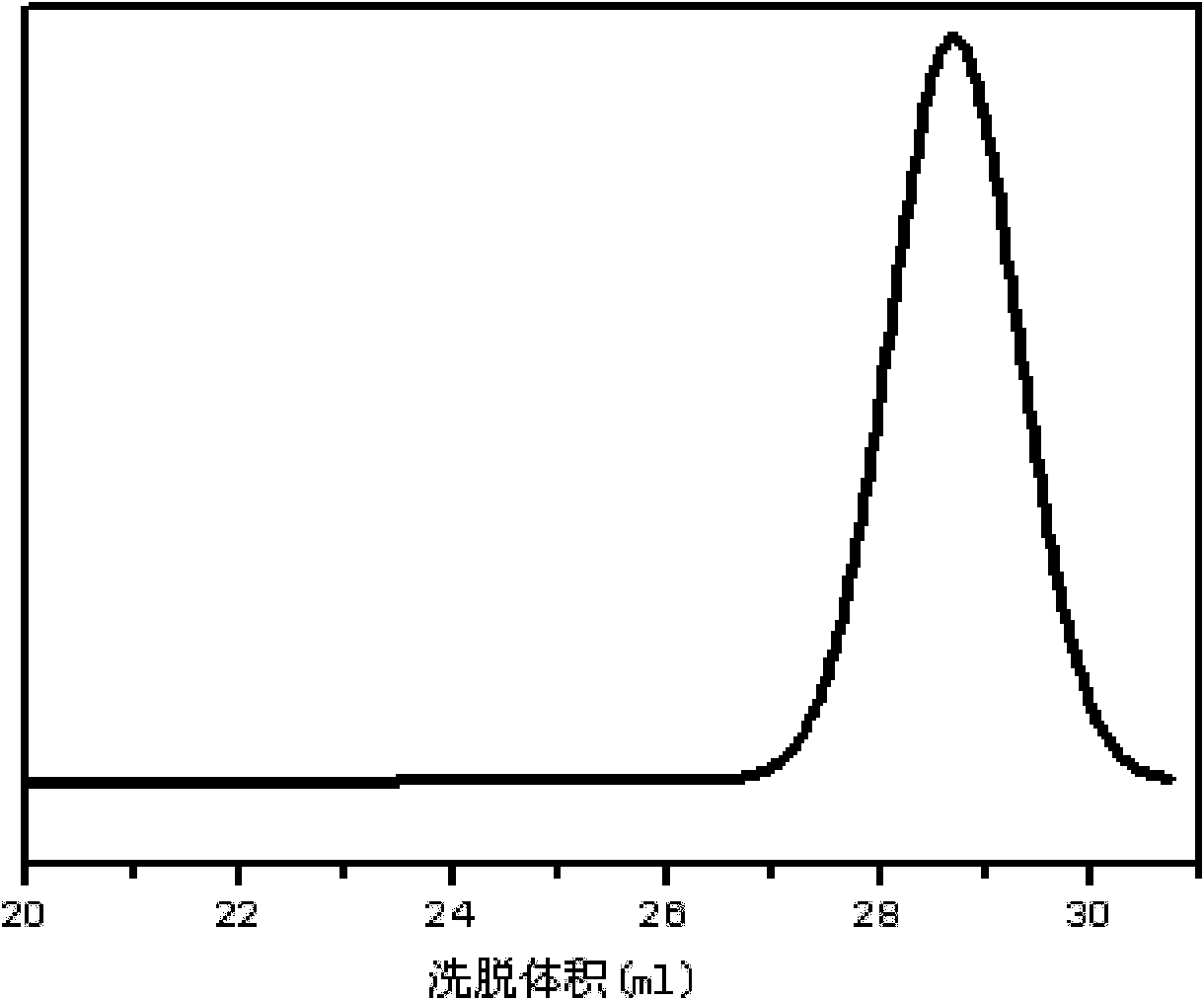

Branching polyether macromonomer and preparation method thereof

The invention provides a branching polyether macromonomer and a preparation method thereof. The structural formula of the branching polyether macromonomer is shown as a formula (I), and the preparation method comprises the following steps of: directly performing quantitative ring-opening addition reaction on allylamine used as a raw material and glycidol to obtain an intermedium of which the tail end contains double hydroxy groups, adding an alkoxylation catalyst by taking the intermedium as initiator, and performing alkoxylation reaction by taking an epoxy compound as a raw material to prepare the branching polyether macromonomer. The preparation method is easy to operate, the branching polyether macromonomer is high in yield, and organic solvents are not used, so environmental pollution is avoided.

Owner:JIANGSU SUBOTE MATERIAL +3

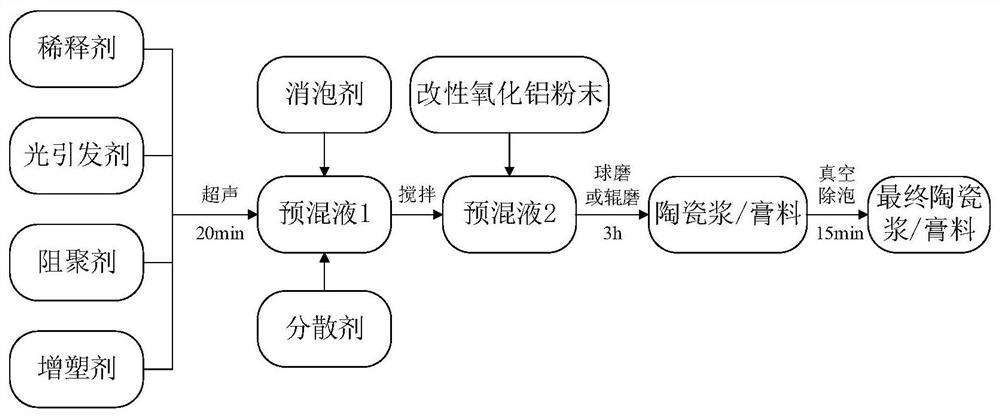

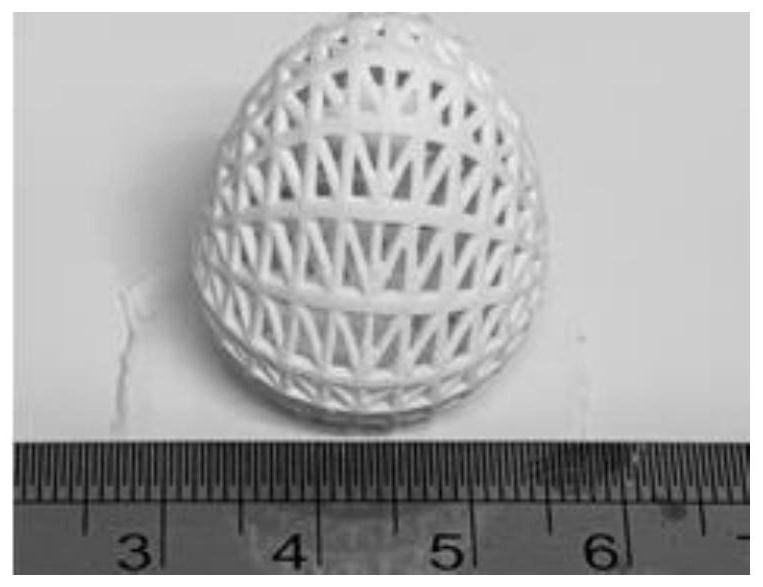

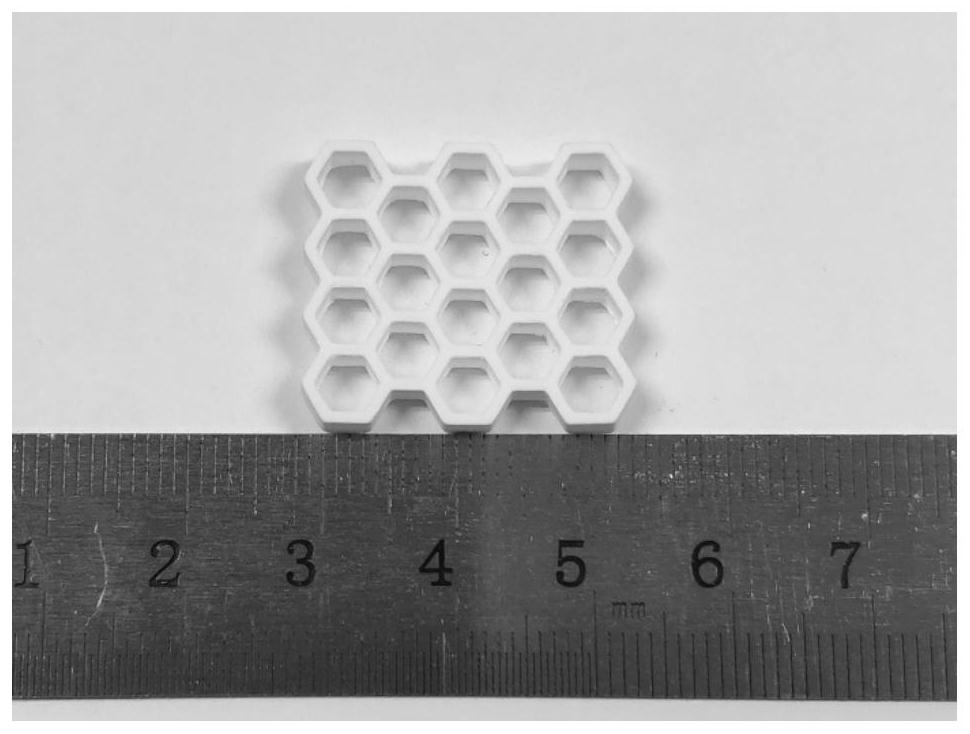

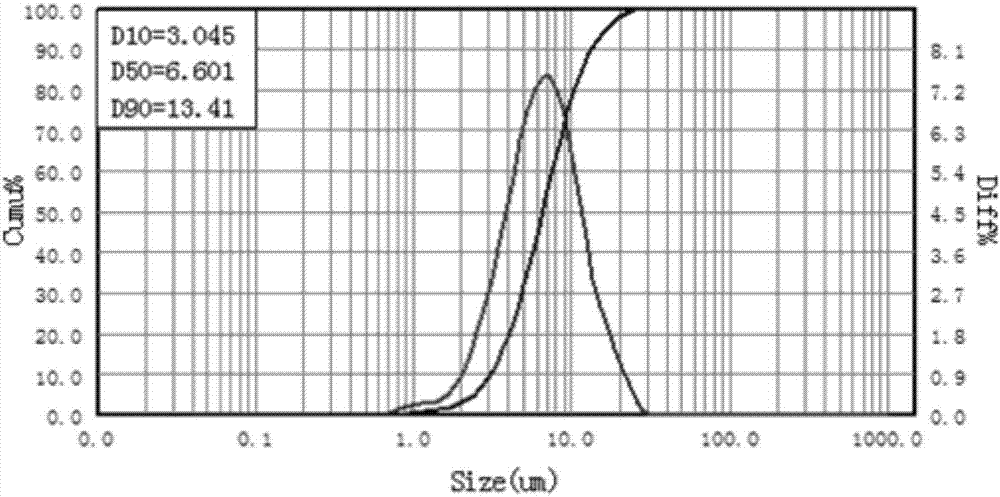

High-solid-phase-content aluminum oxide photosensitive ceramic material and preparation method thereof

ActiveCN112521131AImprove stabilityImprove performanceAdditive manufacturing apparatusPhotoinitiatorOxide ceramic

The invention discloses a high-solid-phase-content aluminum oxide photosensitive ceramic material and a preparation method thereof. The preparation method comprises the following steps of: dispersingaluminum oxide ceramic powder into a surfactant dilute solution for modification treatment, and then performing drying and ball milling to obtain modified ceramic powder; mixing photosensitive resin,a plasticizer, a polymerization inhibitor, a dispersing agent and a photoinitiator to prepare a photosensitive premixed solution; and adding the modified ceramic powder into the premixed solution, fully dispersing the substance, and removing bubbles to obtain the high-solid-phase-content aluminum oxide photosensitive ceramic material. The ceramic photosensitive materials with the same solid phasecontent and different states are prepared so as to meet different requirements of various ceramic 3D printing.

Owner:XI AN JIAOTONG UNIV

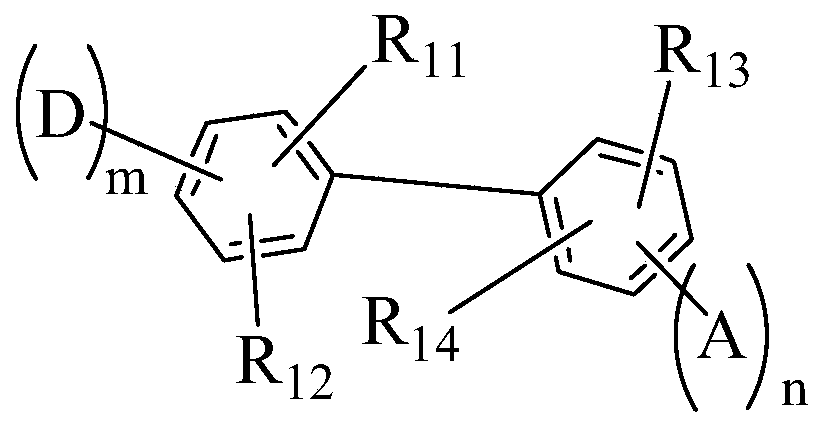

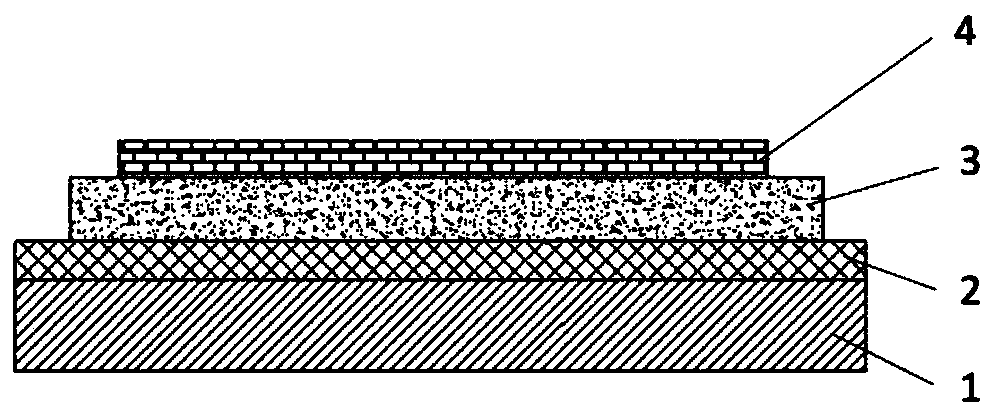

Compound, display panel and display device

PendingCN110003258AReduces the orthosolvochromic effectHigh purity of luminous colorSilicon organic compoundsSolid-state devicesHydrogen atomAlkoxy group

The invention belongs to the technical field of OLED, and provides a compound with a structure shown in a formula (1), wherein D represents an electron donating group containing a nitrogen atom and isconnected to a benzene ring through the nitrogen atom, and A represents an electron accepting group containing a boron atom and is connected to the benzene ring through the boron atom; m and n are respectively selected from 1, 2 and 3; and R11, R12, R13 and R14 are respectively and independently selected from a hydrogen atom, an alkyl group, an alkoxy group, a cyano group, a trifluoromethyl group, the electron accepting group A' or the electron donating group D' containing the nitrogen atom. The compound adopts biphenyl as a connecting unit between the electron donating group D and the electron receiving group A, the D and the A achieve effective separation of HOMO and LUMO at different positions of molecules, and two physical processes of intramolecular charge transfer and space charge transfer can be simultaneously formed in the same molecule through connection of the biphenyl between the D and the A units, so that absorption of the molecules to light is improved, and the oscillatorstrength of the molecules is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

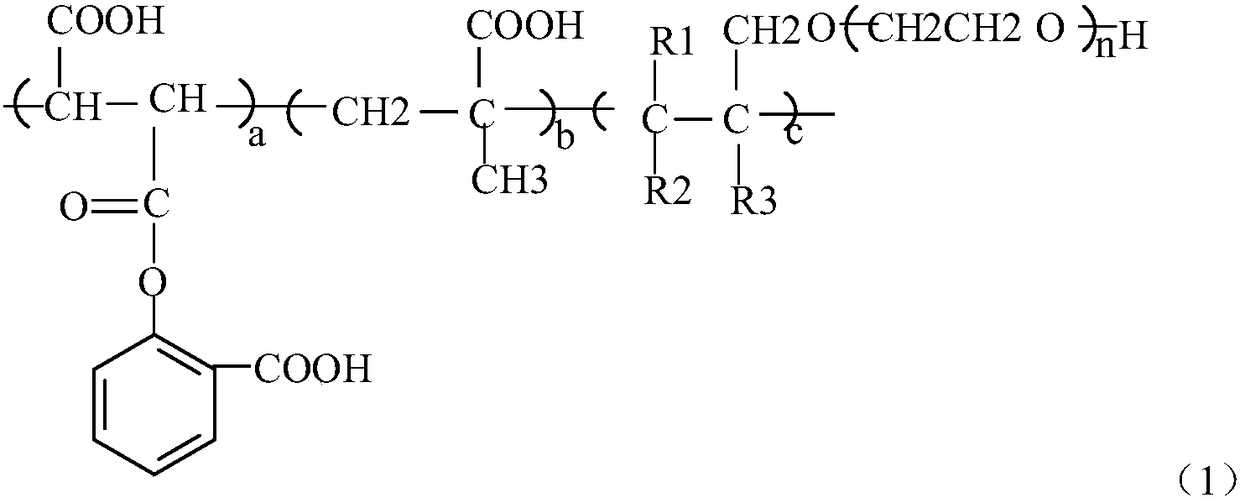

Viscosity-reduction type polycarboxylate water reducer and preparation method thereof

The invention provides a viscosity-reduction type polycarboxylate water reducer and a preparation method thereof, and relates to the technical field of concrete admixtures. Through the technical scheme, the water reducer is essentially formed by copolymerizing unsaturated polyoxyethylene glycol ether macromonomers, unsaturated acid monomers and modified monomers containing ester groups under the effect of a redox system and a chain transfer agent, wherein the modified monomers containing ester groups comprise esters of salicylic acid and maleic anhydride. The viscosity-reduction type polycarboxylate water reducer synthesized in the invention is simple in technology, low in cost and easy to operate, and has good dispersibility and dispersion retainability, so that the requirement of long-distance transportation is met; when the water reducer is applied to high-performance concrete, the viscosity reduction effect is obvious, the viscosity of high grade concrete can be reduced effectively, the slump retainability of concrete is improved, the rheological property and working performance of concrete are improved, and the water reducer is particularly applicable for preparing high-strength, superhigh-strength and self-compact concrete. Moreover, the water reducer has broad adaptability for different cements and aggregates.

Owner:JINAN SHIJIE HUAXIN IND CO LTD

Viscosity-reducing type polycarboxylic acid water reducing agent preparation method

ActiveCN109180876ALightly crosslinkedStructural stretchCross-link2-methacryloyloxyethyl phosphorylcholine

The invention discloses a viscosity-reducing type polycarboxylic acid water reducing agent preparation method, which comprises: (1) preparing an esterification monomer; (2) carrying out a copolymerization reaction; and (3) carrying out a neutralization reaction. According to the present invention, the viscosity-reducing type polycarboxylic acid water reducing agent is prepared by co-polymerizing 2-allyloxyethanol, a blend, VPEG, 2-methacryloyloxyethyl phosphorylcholine and an unsaturated acid, such that the phosphate radical, the carboxylate radical, the quaternary ammonium salt and the estergroup are introduced into the molecular structure of the polymer while the polymer structure is lightly cross-linked, wherein the product obtained by the esterification of the single carboxy in 2-phosphonobutane-1,2,4-tricarboxylicacid prepared by a 2-phosphonobutane-1,2,4-tricarboxylicacid esterification reaction, the product obtained by the esterification of the two carboxy in a small amount of2-phosphonobutane-1,2,4-tricarboxylicacid and the product obtained by the esterification of the three carboxy in a small amount of 2-phosphonobutane-1,2,4-tricarboxylicacid form the blend; and the prepared viscosity-reducing type polycarboxylic acid water reducing agent has advantages of viscosity reducing, water reducing, slump retaining and mud resistance, and can solve the problems of high viscosity, poor workability and rapid loss due to the high mud content in the current concrete raw materials.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

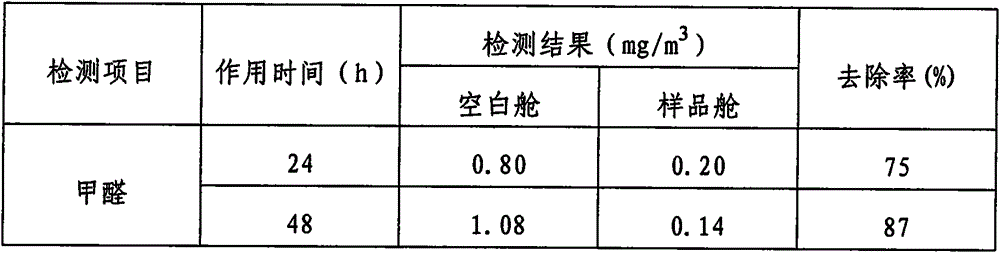

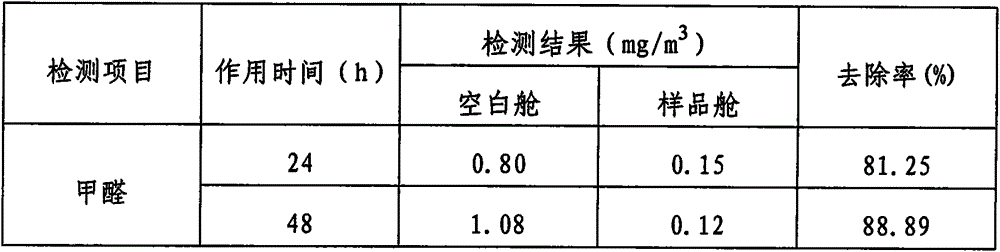

Photocatalyst solution for formaldehyde degradation under visible light, and preparation method thereof

InactiveCN104399532AEvenly dispersedEnhanced steric hindranceOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationSurface modificationPolymer

The present invention discloses a photocatalyst solution for formaldehyde degradation under visible light, and a preparation method thereof. The raw materials comprise, by mass, 0.05-1% of nanometer titanium oxynitride, 1-5% of a silane coupling agent, 1-5% of an anionic or cationic surfactant, 1-5% of an anchor chain polymer dispersant, and 84-96.95% of deionized water. According to the present invention, based on the difficult dispersion of the nanometer titanium oxynitride in the deionized water, the nanometer powder is subjected to surface modification; the coupling agent is adopted to organically modify the nanometer titanium oxynitride, such that the nanometer powder surface is wrapped with a layer of the organic molecular film so as to increase the steric hindrance effect of the nanometer titanium oxynitride during the dispersion; the anionic or cationic surfactant is added to the nanometer titanium oxynitride solution, and the surfactant compounding is adopted to make the nanometer powder can be uniformly dispersed in the solution so as to reduce the sedimentation of the nanometer powder in the water; the photocatalyst solution of the present invention can lastingly and efficiently degrade the formaldehyde under the visible light, and the formaldehyde removal rate can achieve 87%; and the nanometer technology is adopted to degrade the formaldehyde, such that characteristics of stability, no toxicity and no harm on the environment are provided.

Owner:BEIJING MEGA NANO TECH

Ceramic grinding aid

The invention discloses a ceramic grinding aid and belongs to the technical field of ceramic additives. Diisopropanol amine, diethanol amine and succinic anhydride serve as raw materials and are subjected to esterification to form a hyperbranched polymer; the terminals of the raw materials contain large quantity of polar groups, such as hydroxyl group, ester group and the like, so that the ceramicgrinding aid is easy to adsorb on surface of ceramic clinker to form hydrogen bond film that inhibits curing of micro-cracks and increases grinding efficiency; xylitol and acryloyl chloride are subjected to acylating chlorination to synthesize an intermediate, which can partly replace methylallylpolyoxyethylene ether for preparing a modified substance through free radical polymerization with hydroxyethyl methylacrylate and acrylic acid under effect of ammonium persulfate, thereby enhancing flowability of ceramic slurry, improving grinding assisting effect and meanwhile, effectively improvingmaterial flow speed and electrostatic adsorption in a grinding mill. The invention solves problems that a ceramic grinding aid in the prior art does not have excellent water reducing and dispersion effects and cannot improve the material flow speed and electrostatic adsorption in the grinding mill well.

Owner:田秋珍

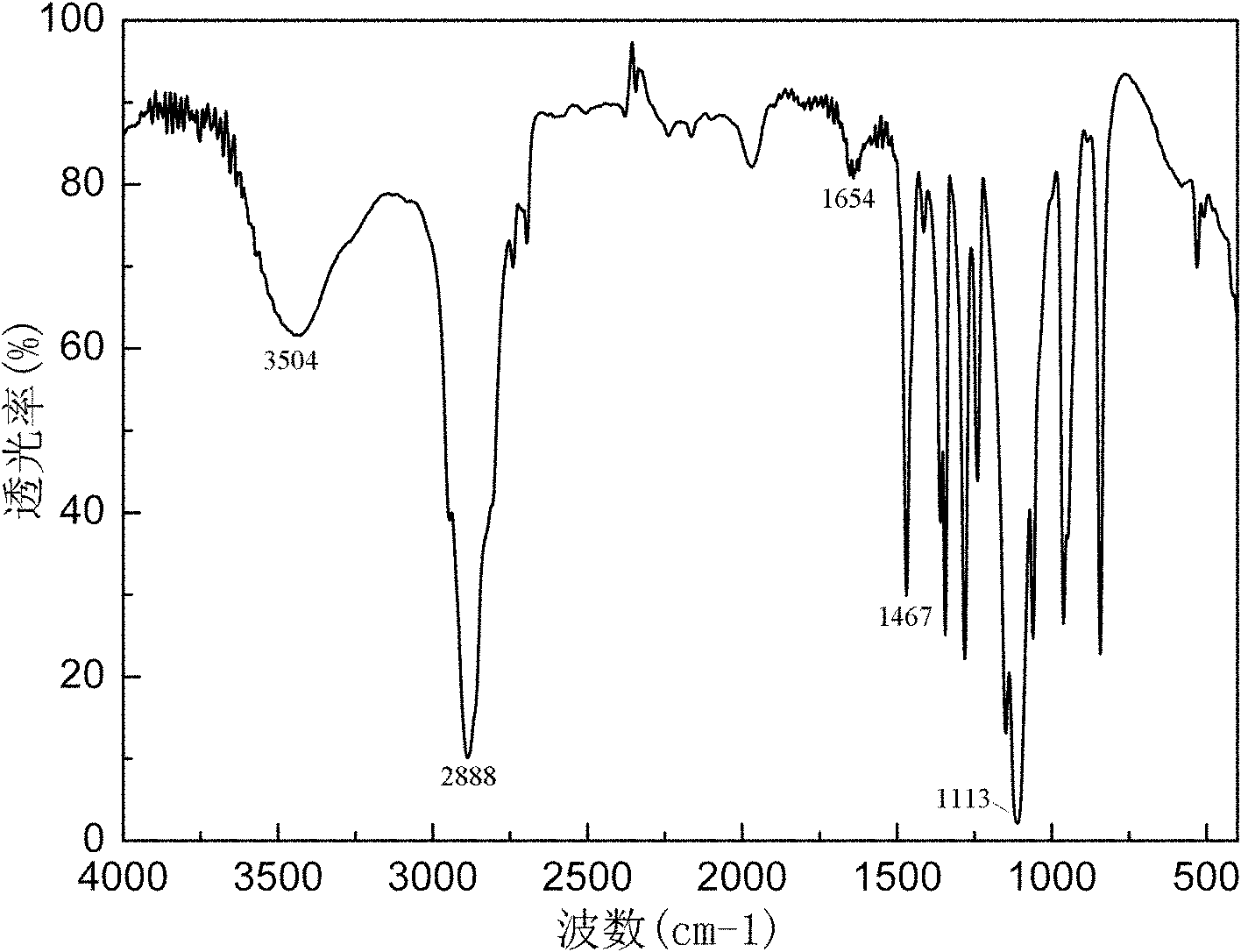

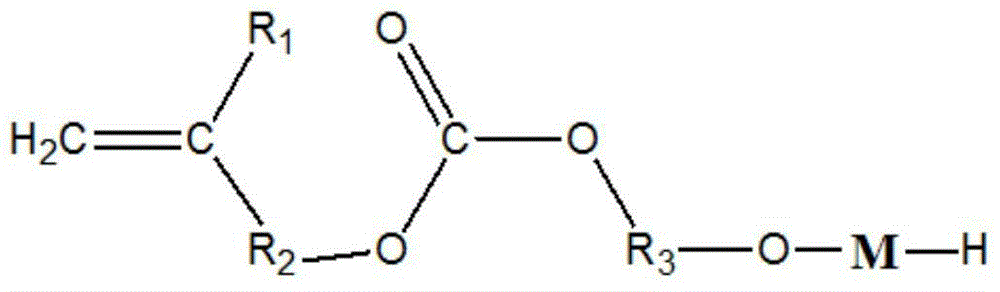

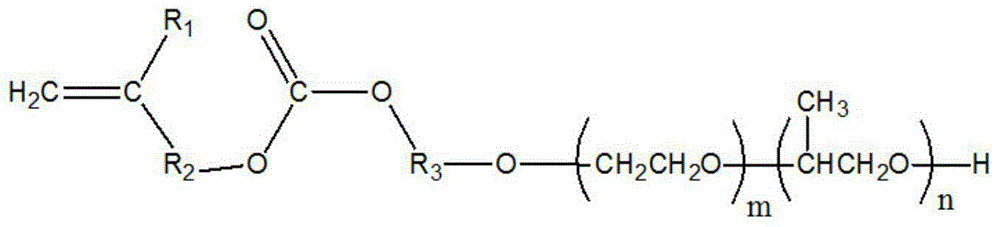

Alkenyl carbonate polyethers, and preparing method and applications thereof

The invention provides alkenyl carbonate polyethers. The general structure of the alkenyl carbonate polyethers is shown as follows, wherein R<1> is H or C1-C3 alkyl, R<2> is a C1-C5 alkylidene group, R<3> is a C2-C4 alkylidene group, a phenylene group or a benzylidene group, M is a polyether chain comprising one or more selected from -CH2CH2O-, -CH(CH3)CH2O- and -CH2(CH3)CHO-. The alkenyl carbonate polyethers comprise a carbonate group, thus facilitating enhancement of molecular chain toughness, and enhancing steric hindrance of synthesized water reducer molecules; and the carbonate group increases the side chain density of synthesized water reducers, and therefore dispersing performance of the water reducers can be improved. The carbonate group in the polyethers is high in electronegativity so that the prepared water reducers have certain functions of resisting slime adsorption. The polyethers are nontoxic, harmless, easily degradable and environmental friendly.

Owner:JIANGSU OXIRANCHEM CO LTD +1

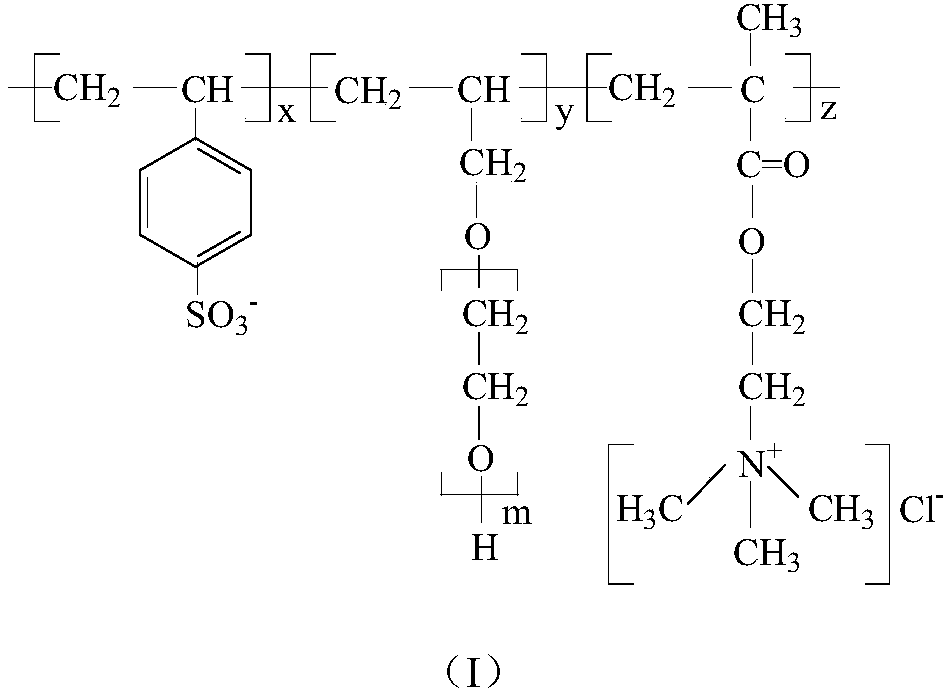

Polycarboxylate flow regulator for water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density and preparation method of polycarboxylate flow regulator

ActiveCN108641686AGood effectInhibition of hydration pulpingDrilling compositionWater basedUltra high density

The invention relates to a polycarboxylate flow regulator for water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density and a preparation method of the polycarboxylate flow regulator. A zwitterionic polycarboxylate multi-polymer with a comb type structure is produced from alkenyl benzene sulfonate, strongly hydrophilic cationic alkenyl quaternary ammonium salt and allyl polyoxyethylene ether containing a specific long chain structure by free radical polymerization in an aqueous solution. A molecular chain of the produced multi-polymer contains 7-20 structural units with weight-average molecular weight in the range of 6,500-12,500. The polycarboxylate flow regulator can greatly reduce viscosity and shear force of the water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density, improve the dispersion state of solid phase weighting materials in the water-based drilling fluid and completion fluid, improve the rheological property of the water-based drilling fluid and completion fluid with ultra-high temperature and ultra-high density, obviously reduce surface tension of the water-based drilling fluid and completion fluid with ultra-high temperature and improve lubricating performance of the water-based drilling fluid with ultra-high temperature and ultra-high density, has shale inhibition performance and high temperature stability performance, and can resist high temperatures of 251 DEG C or higher.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for organic surface modification of nanometer attapulgite

InactiveCN105219126AEasy to precipitate and stratifyEasy separationPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSURFACTANT BLENDSurface modification

The invention provides a method for organic surface modification of nanometer attapulgite. The method comprises the following steps: (1) inorganic surface modification of nanometer attapulgite: a step of heating dispersed and purified nanometer attapulgite aqueous dispersion to 40 to 100 DEG C and carrying out inorganic surface modification on nanometer attapulgite under stirring, wherein a surface coating substance of nanometer attapulgite is one, two or three selected from the group consisting of ZnO hydrate, Al2O3 hydrate and MgO hydrate, and in terms of oxide, a mass ratio of the inorganic coating substance to nanometer attapulgite is 5 to 30%; (2) organic surface modification of nanometer attapulgite: a step of the pH value of the inorganic surface coated nanometer attapulgite aqueous dispersion so as to allow the surface of nanometer attapulgite to be positively charged, then adding desired anionic surfactant under stirring, wherein a mass ratio of the anionic surfactant to nanometer attapulgite is 3% to 20% and the anionic surfactant is added after dissolving in deionized water, and continuing stirring for 5 to 600 min after completion of addition; and (3) post-treatment: a step of subjecting a product to solid-liquid separation, washing, drying and crushing after completion of a reaction so as to eventually obtain the anionic surfactant surface modified nanometer attapulgite.

Owner:蒋寿悟

High-performance polycarboxylate superplasticizer and preparation method thereof

The invention belongs to the technical field of concrete admixtures, and particularly relates to a high-performance polycarboxylate superplasticizer and a preparation method thereof. The preparation method comprises the steps that firstly, in the polymerization process of maleic acid-triethanolamine monoester in alkenyl-terminated polyoxyethylene ether and acrylic acid, the polycarboxylate superplasticizer with the early strength effect is formed; meanwhile, a small amount of nano silicon dioxide is added in the polymerization process, the nano silicon dioxide is grafted into the polycarboxylic acid water reducing agent with the early strength effect through free radical polymerization, then the nano silicon dioxide and the hyperbranched polymer are modified to change the long-chain molecular structure and improve the molecular space volume; as the end of the hyperbranched polymer has a Y-shaped structure, the formed polycarboxylate superplasticizer with the multi-branched Y-shaped structure can increase steric hindrance between side chains of polycarboxylic acid, so that the tail ends of the side chains are in an extended state, and the adsorption thickness and the dispersion performance of the superplasticizer on cement particles are improved.

Owner:湖北恒利建材科技有限公司

Addition compound suitably used as wetting dispersant and preparation method thereof

ActiveCN109666139AImprove wetting abilityEnhanced steric hindranceTransportation and packagingMixingOrganosiliconWetting

The invention relates to an addition compound and a preparation method for the addition compound and a wetting dispersant containing the addition compound used in coating ink. The addition compound isa branched silicon-containing polymer prepared by a monomer mixture through an ester exchange reaction. The branched silicon-containing polymer dispersing auxiliary has a structure as shown in the following formula. An organic silicon component is introduced into the branched polymer, so wetting ability of the dispersant to solid particles is greatly reinforced through a silicon-containing component, and steric hindrance capacity of a branched polyether component to the solid particles is reinforced, an amino residue is bonded and anchored to the surface of the solid particles. While the branched polymer dispersing auxiliary is used for dispersing the solid particles, excellent comprehensive dispersing performance can be provided for an obtained dispersoid.

Owner:博邦新材料科技(广州)有限公司

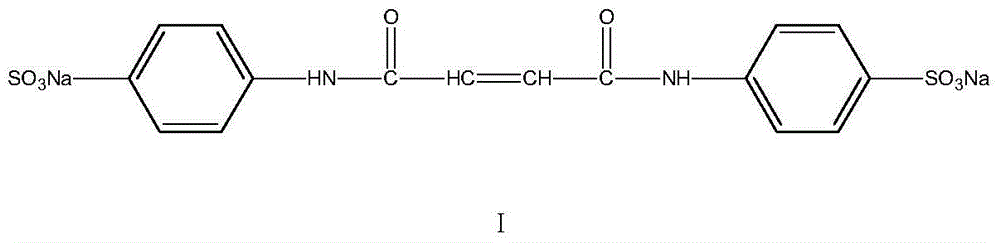

Sodium sulfanilate modified polycarboxylate superplasticizer and preparing method of sodium sulfanilate modified polycarboxylate superplasticizer

The invention relates to a sodium sulfanilate modified polycarboxylate superplasticizer and a preparing method of the sodium sulfanilate modified polycarboxylate superplasticizer, and belongs to the technical field of material synthesis. The effects of reducing the slump losses and improving the mechanical property are achieved. The preparing method includes the following steps: methylbenzene serves as solvents, sodium sulfanilate and maleic anhydride are reacted under the temperature condition ranging from 55 DEG C to 65 DEG C to generate corresponding intermediate products, then the solvents are removed, and water is added to prepare a corresponding intermediate product aqueous solution; polyether macromonomer, crylic acid and sodium methallyl sulfonate are added into the intermediate product aqueous solution to be stirred to be evenly mixed, then oxidizing agents and reducing agents are added, and stirring is carried out to enable the mixture to be reacted to generate the inter polymer sodium sulfanilate modified polycarboxylate superplasticizer. The sodium sulfanilate modified polycarboxylate superplasticizer and the preparing method have the advantages that the dispersing capacity and the concrete peaceability of the polymer can be improved, and the concrete slump losses can be remarkably reduced.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

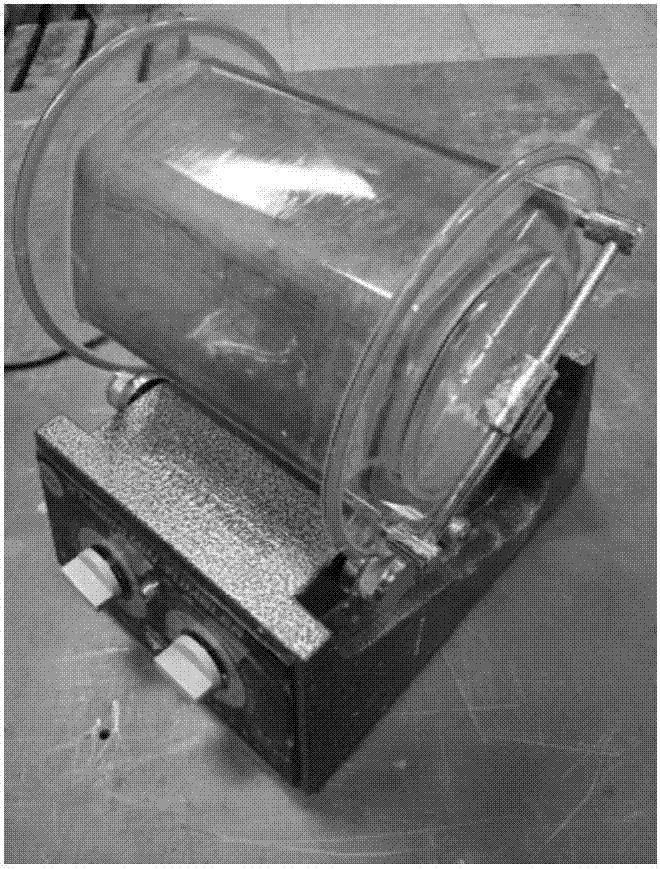

Complex dispersant water-based liquid magnetic grinding tool and manufacturing method thereof

InactiveCN107020582AGood settlement stabilityImprove antioxidant capacityGrinding devicesWater basedAntioxidant

The invention disclose a complex dispersant water-based liquid magnetic grinding tool and a manufacturing method thereof, and belongs to the field of surface finishing of mechanical parts. The high-stability complex dispersant water-based liquid magnetic grinding tool is made of raw materials including, by mass percent, 65% to 80% of magnetic particles, 15% to 25% of deionized water, 0.5% to 3% of a surface active agent, 0.5% to 2% of an antioxidant, 0.3% to 1% of a moisturizing agent, 0.3% to 1.5% of a pH adjusting agent, 1% to 2% of nanoscale particles, and 7% to 10% of abrasive particles. The grinding tool has the beneficial effects the stirring manner based on seal pure rolling is provided, a complex dispersant is used and is combined with other function reagents to replace a single dispersant, the moisturizing agent is added in the formula, the water evaporation is reduced, the nanoscale particles are added, the effect of filling gaps between macromolecules is achieved, the space position resistance effect is improved, and the grinding tool has the beneficial effects of being stable, good in re-dispersion, good in fluidity, low in zero field viscosity, non-poisonous and convenient to recycle.

Owner:TAIYUAN UNIV OF TECH

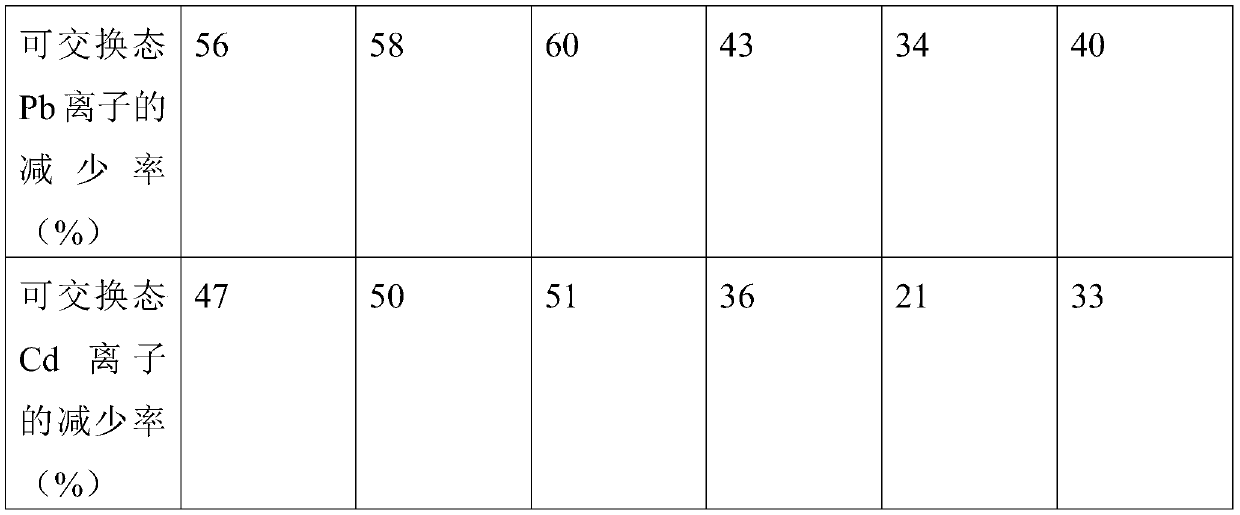

Preparation method of heavy metal contaminated soil passivator

InactiveCN111303898AIncrease cation exchange capacityGood heavy metal ion passivation effectAgriculture tools and machinesOther chemical processesPolyethylene glycolSoil heavy metals

The invention relates to a preparation method of a heavy metal contaminated soil passivator, and belongs to the technical field of soil heavy metal contamination treatment. Silicate mineral zeolite used as a raw material is crushed and then modified through acid dipping to obtain modified zeolite; the modified zeolite is mixed with mussel mucin with a dopa structure, and catechol oxidase is addedfor reaction to prepare pretreated modified zeolite; and then the pretreated modified zeolite, calcium nitrate, polyethylene glycol and sodium silicate are mixed for reaction to obtain the heavy metalcontaminated soil passivator. The prepared soil passivator has an excellent heavy metal passivation effect and a wide application prospect.

Owner:江苏和合环保集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com