Preparation method of heavy metal contaminated soil passivator

A technology of polluted soil and passivating agent, applied in chemical instruments and methods, soil conditioning materials, and other chemical processes, can solve the problems of poor passivation effect, unstable adsorption and fixation of heavy metal ions, and single passivation mechanism. Achieve the effects of improving physical adsorption performance, improving cation exchange capacity, and best passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

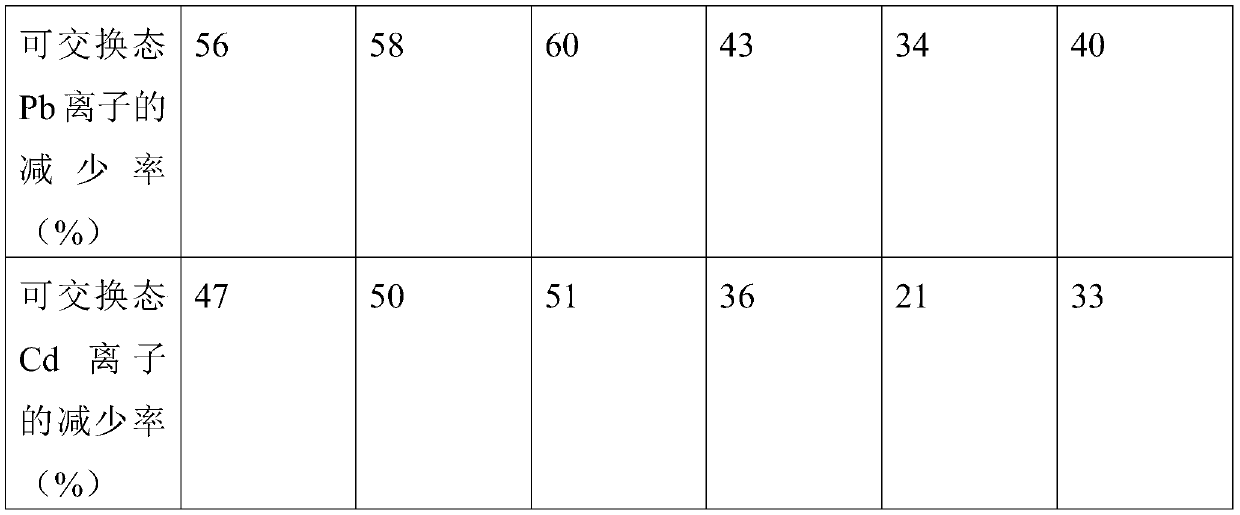

Examples

preparation example Construction

[0030] A preparation method of heavy metal polluted soil passivation agent, the specific preparation steps are:

[0031] (1) Weigh the zeolite and put it into a pulverizer to pulverize for 20-30 minutes, collect the pulverized zeolite, mix the pulverized zeolite with a hydrochloric acid solution with a mass fraction of 5% at a mass ratio of 1:10, and put it into ultrasonic vibration In the instrument, immerse with ultrasonic vibration at a frequency of 20-30kHz for 10-20min. After the ultrasonic vibration is completed, filter and separate to obtain the filter residue, which is the modified zeolite;

[0032] (2) Mix the above-mentioned modified zeolite, mussel mucin and deionized water at a mass ratio of 1:1:8, put them in a stirrer, and stir at a speed of 200-300r / min for 20-30min to obtain mixture;

[0033] (3) Put the mixture obtained above into the reactor, then add catechol oxidase of 9% of the mixture mass in the reactor, seal the reactor, and use 100 to 200 r / h under th...

example 1

[0037](1) Preparation of modified zeolite: Weigh zeolite and put it into a pulverizer to pulverize for 20 minutes, collect the pulverized zeolite, mix the pulverized zeolite with 5% hydrochloric acid solution in a mass ratio of 1:10 Put it into an ultrasonic oscillator, and impregnate it with ultrasonic oscillation at a frequency of 20kHz for 10 minutes. After the ultrasonic oscillation is completed, filter and separate to obtain a filter residue, which is the modified zeolite;

[0038] (2) Preparation of the mixture: mix the modified zeolite obtained above with mussel mucin and deionized water in a mass ratio of 1:1:8, put them in a stirrer, and stir at a speed of 200r / min for 20min to obtain mixture;

[0039] (3) Preparation of pre-treated modified zeolite: put the mixture obtained above into a reactor, then add catechol oxidase with a mass of 9% of the mixture into the reactor, seal the reactor, and set the temperature at 40°C Stir and react at a speed of 100r / min for 3h, ...

example 2

[0043] (1) Preparation of modified zeolite: Weigh zeolite and put it into a pulverizer to pulverize for 25 minutes, collect the pulverized zeolite, mix the pulverized zeolite with 5% hydrochloric acid solution in a mass ratio of 1:10 Put it into an ultrasonic oscillator, and impregnate it with ultrasonic oscillation at a frequency of 25kHz for 15 minutes. After the ultrasonic oscillation is completed, filter and separate to obtain a filter residue, which is the modified zeolite;

[0044] (2) Preparation of the mixture: mix the modified zeolite obtained above with mussel mucin and deionized water in a mass ratio of 1:1:8, put them in a stirrer, and stir at a speed of 250r / min for 25min to obtain mixture;

[0045] (3) Preparation of pre-treated modified zeolite: put the mixture obtained above into a reactor, then add catechol oxidase with a mass of 9% of the mixture into the reactor, seal the reactor, and set the temperature at 44° C. Stir and react at a speed of 150r / min for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com