Environment-friendly type pavement heating sealant material as well as preparation method and application thereof

A sealant and heating-type technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of reducing the service life of the road surface, poor low-temperature performance, loss of waterproof effect, etc., and achieve full elasticity and excellent adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

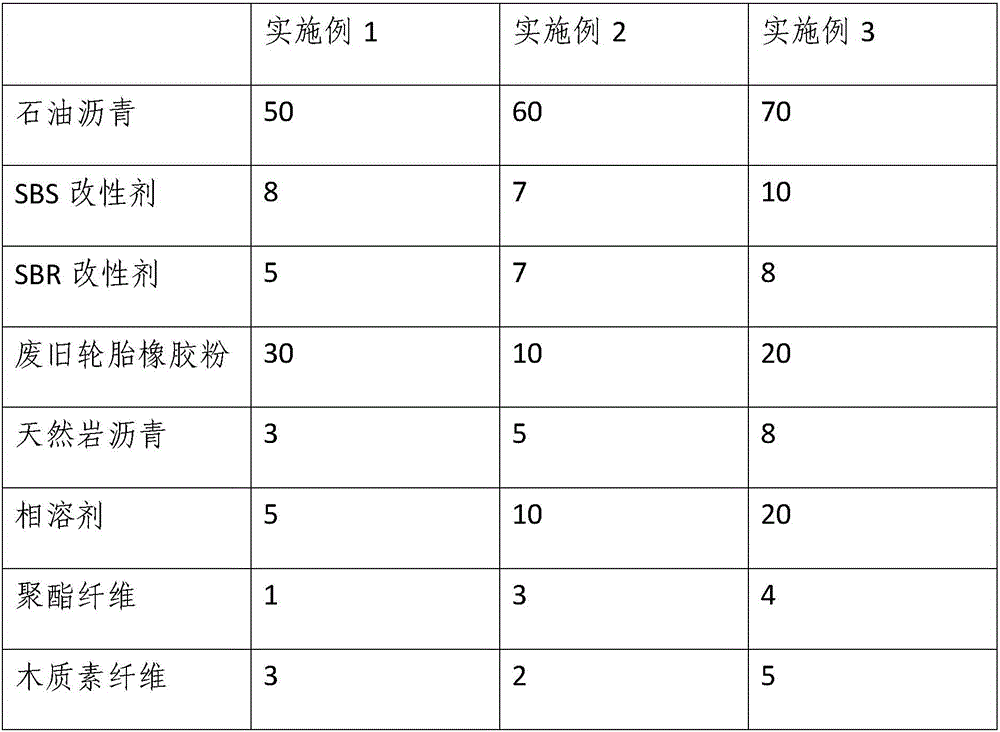

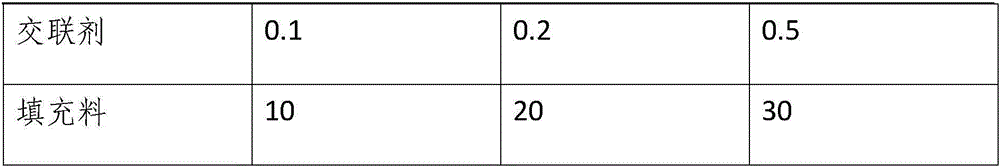

[0024] Example: Unit: parts by weight

[0025] 1) Formula:

[0026]

[0027]

[0028] 2) Preparation method:

[0029] 1) According to the formula in any one of Examples 1-3, preheat the road petroleum asphalt to 180-200℃ and add it to the batching tank. Under continuous stirring, add the SBS modifier and SBR modifier to fully mix and swell 10 minute;

[0030] 2) After shearing and grinding by colloid mill for 2-3 times to make the modifier particle fineness less than 5μm, transport to the development tank to add crosslinking agent, keep 180-200℃ for circulation and stir for 3-5h to form a stable system High-temperature premix;

[0031] 3) Transport the premix to the premix tank, add waste tire rubber powder, natural rock asphalt, phase solvent, polyester fiber, and lignin fiber in sequence under continuous stirring in the premix tank. The temperature is raised to and maintained at 180-200℃ After stirring and developing for 1-2h until the mixing is uniform, add sodium-based bentonite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com