Patents

Literature

181results about How to "Curing stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

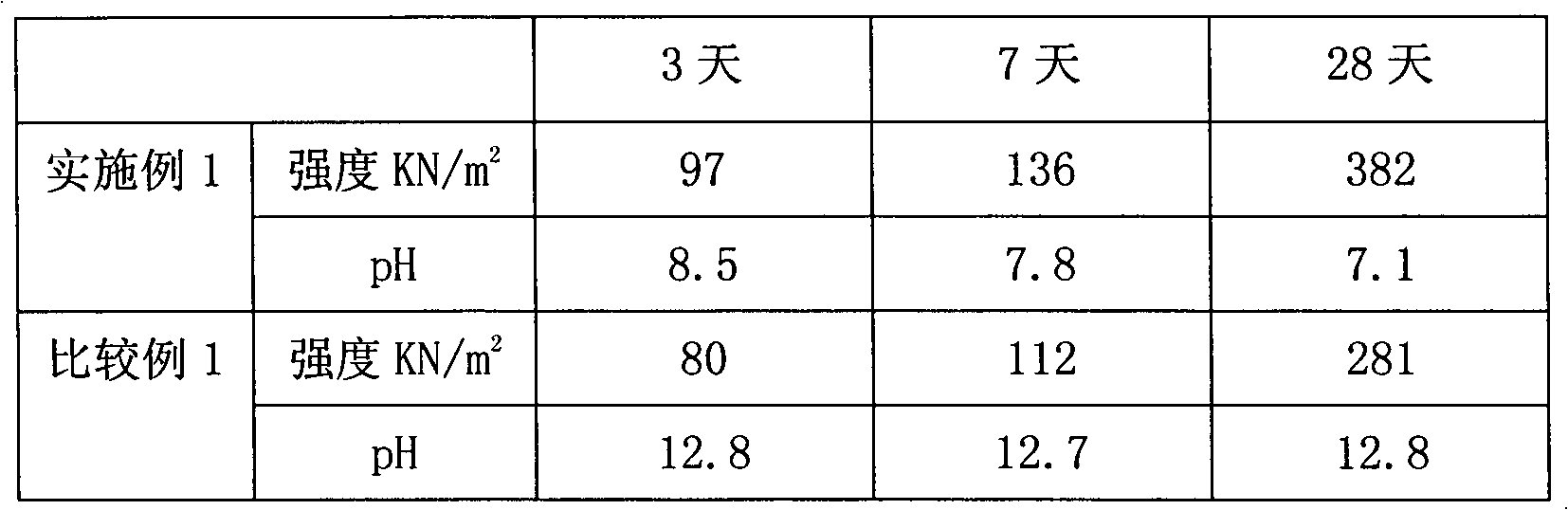

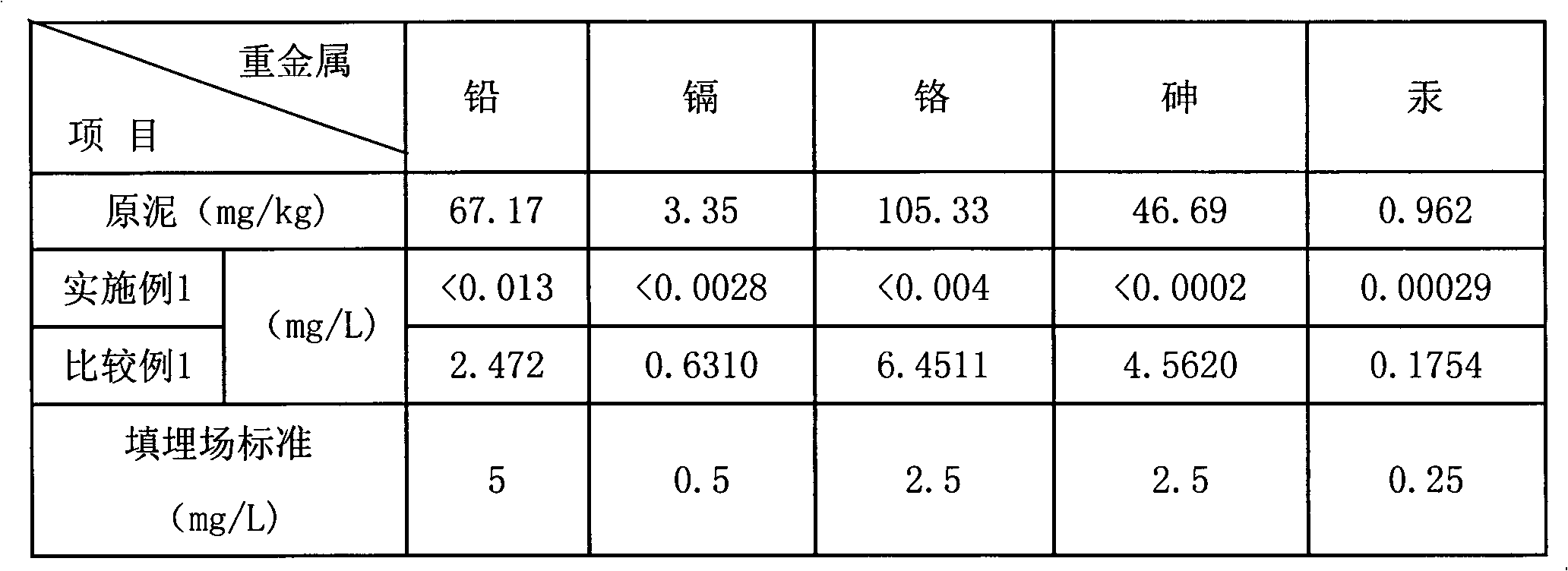

Neutral inorganic composite material for dehydration, solidification and modification of high water content sludge

ActiveCN101955345ASolving Alkaline ProblemsHigh compressive strengthSludge treatment by de-watering/drying/thickeningSolid waste managementHazardous substanceHigh water content

The invention discloses a neutral inorganic composite material for dehydration, solidification and modification of high water content sludge. The composite material comprises a powdery mixture consisting of the following components in part by weight: 100 parts of water hardened solidifying material consisting of hydrated gypsum and magnesium oxide, 80 to 120 parts of inorganic water absorption ash material, 20 to 40 parts of inorganic substance aid hardened material, 1 to 10 parts of high polymer coagulant and 1 to 5 parts of modifying functional agent. After being treated by the neutral inorganic composite material, the solidified sludge has high compressive strength; the pH of the lixivium is neutral, and meanwhile, harmful substances such as heavy metal and the like in the sludge can be effectively solidified; the treated sludge meets the requirement of landfill soil, soil for earthwork or soil for greening and farmlands; and the neutral inorganic composite material can be widely applied to the dehydration, solidification and modification of the high water content sludge such as sludge from waterworks, dredged bottom mud of rivers and lakes, residual building soil and the like.

Owner:江苏艾特克环境工程有限公司

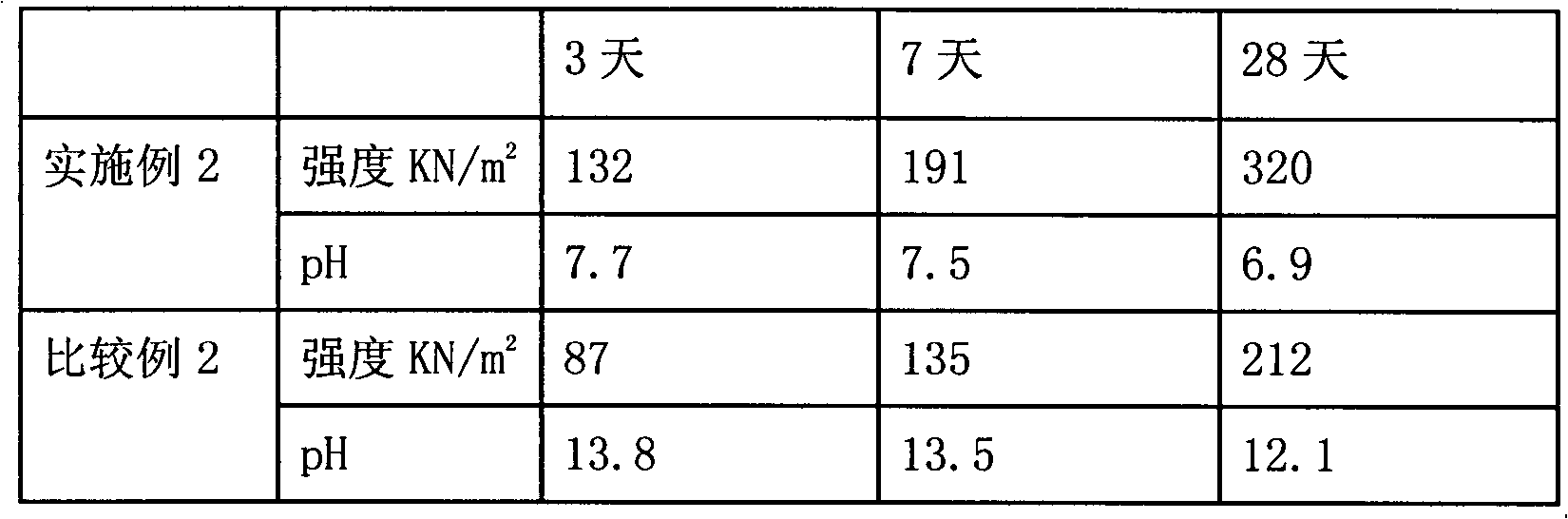

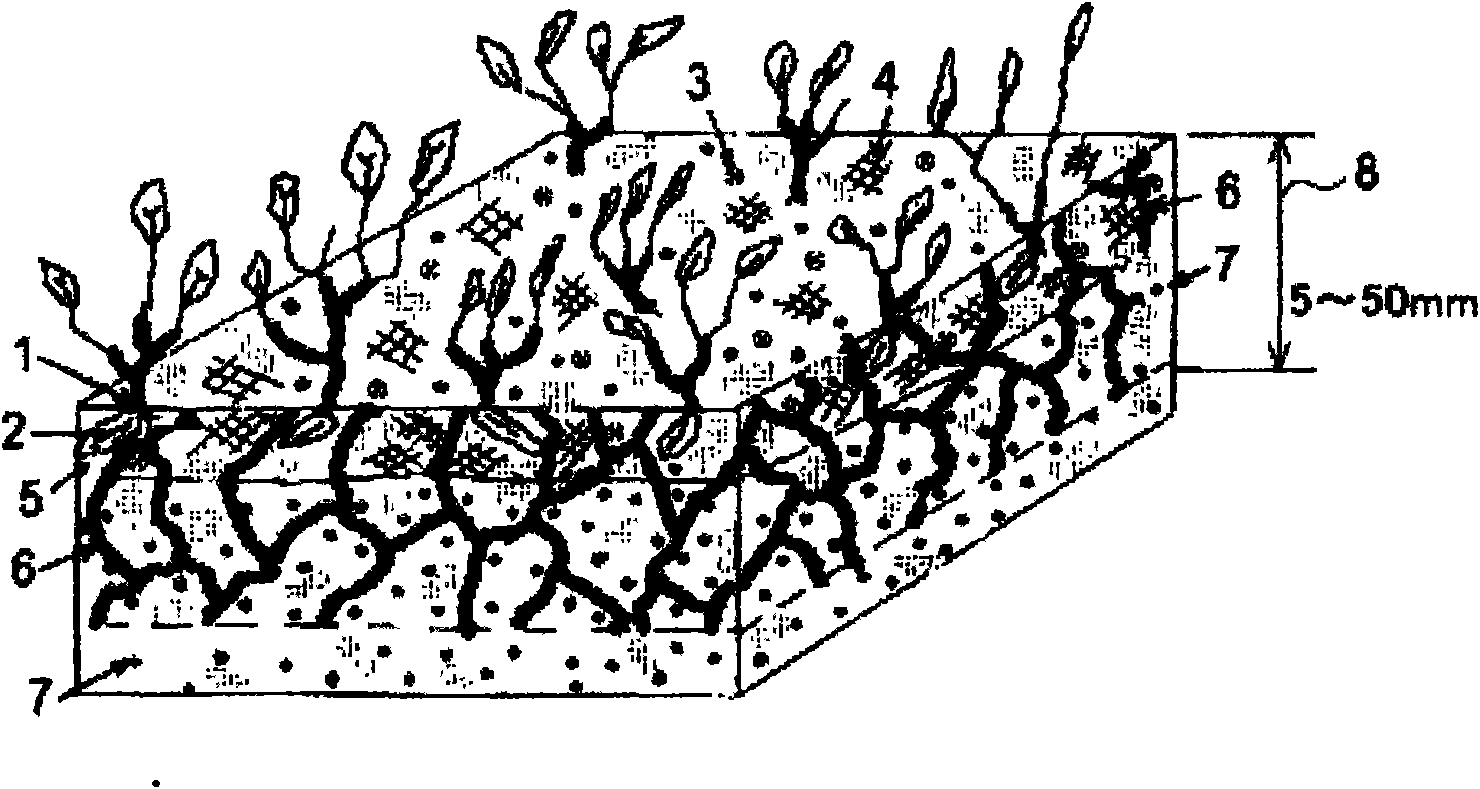

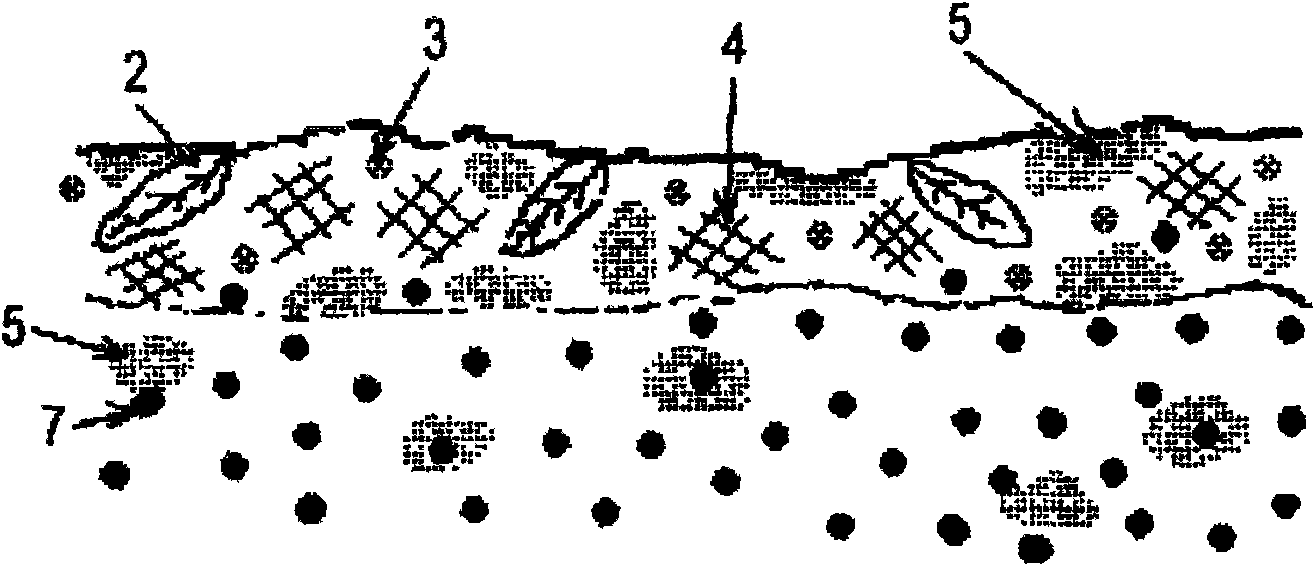

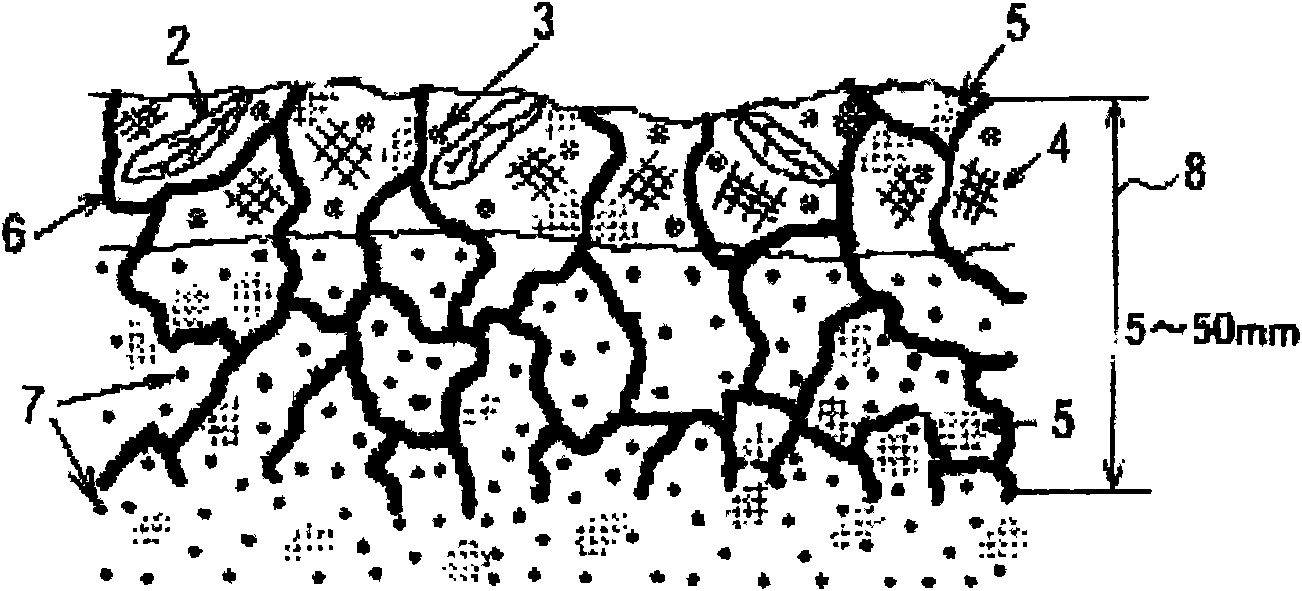

Desert control method of chemical sand-fixing greening technology based on organic composite materials

ActiveCN101548595AAvoid flowModerate thicknessClimate change adaptationAfforestationThermal insulationSoil horizon

The invention discloses a desert control method of a chemical sand-fixing greening technology based on organic composite materials, and the desert control method is characterized in that hydrophilic polyurethane resin curing agent solution is sprayed on a sand or soil layer of greening objects for sowing the vegetation for forming a porous fixed sand layer. The fixed sand layer formed by the method has appropriate thickness and strength, good durability, good anti-freeze and melt properties and functions of water retention, thermal insulation, ventilation, vegetation and the like. According to the method of the invention, the stable and effective solidifying can be carried out on sand even under the specific desert environments of no abundant groundwater sources and strong wind erosion, and the purpose of vegetation greening can be also realized. The method has large-scale construction properties and good economic performances, thereby being applicable to the needs of large-scale chemical sand fixing and vegetation greening of the vast desert and realizing the plant greening function and the ecological restoration and the control of desertified land.

Owner:江苏艾特克环境工程设计研究院有限公司 +2

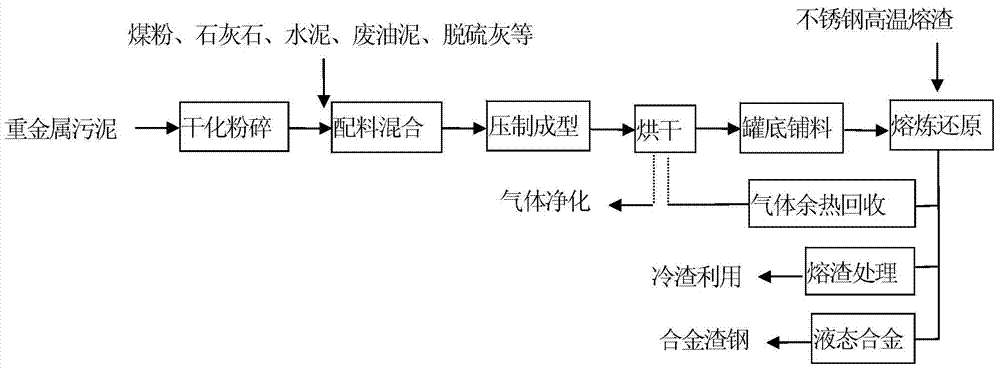

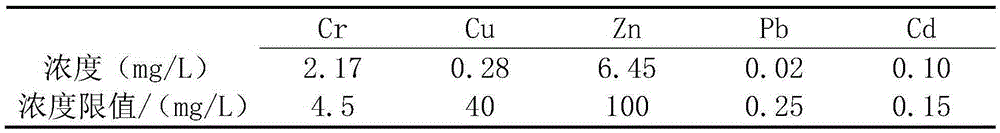

Method for treating heavy metal sludge by using stainless steel molten slag

InactiveCN104512988AIncrease productionIncrease temperatureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeMetallurgy

The present invention discloses a method for treating heavy metal sludge by using stainless steel molten slag. The method comprises drying crushing, material matching mixing, pressing molding, drying, tank bottom material spreading, smelting reduction, gas purification, molten slag treating, metal recovery and other steps, and specifically comprises that: after heavy metal sludge is subjected to pre-treatment, a certain proportion of ingredients are matched, and the sludge agglomerate is adopted as the bottom spreading material and is placed into a stainless steel molten slag tank to carry out a harmless treatment on the sludge agglomerate. According to the present invention, the characteristics of high production amount, high temperature and rich sensible heat resource of the stainless steel molten slag are adopted, and the stainless steel molten slag is adopted to treat the heavy metal sludge, such that the harmless treatment on the hazardous components and the resource on the valuable material are achieved, the method is the new attempt crossing the industry, and the waste heat resource can be effectively utilized so as to achieve the waste treatment adopting the waste.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Stabilization and solidification method of highly toxic waste residues

The invention relates to a stabilization and solidification method of highly toxic waste residues containing one or more of mercury, arsenic, chromium, cadmium and cyanide. Heavy metal is stabilized through chemicals, and then the highly toxic waste residues are sequentially wrapped with gypsum plus paraffin and epoxy resin. After four times of wrapping and two times of solidification, highly toxic substances in the waste residues are fully solidified into a solidified body, and the generated solidified body is high in strength and long in stability, and can be buried conveniently later.

Owner:扬州杰嘉工业固废处置有限公司

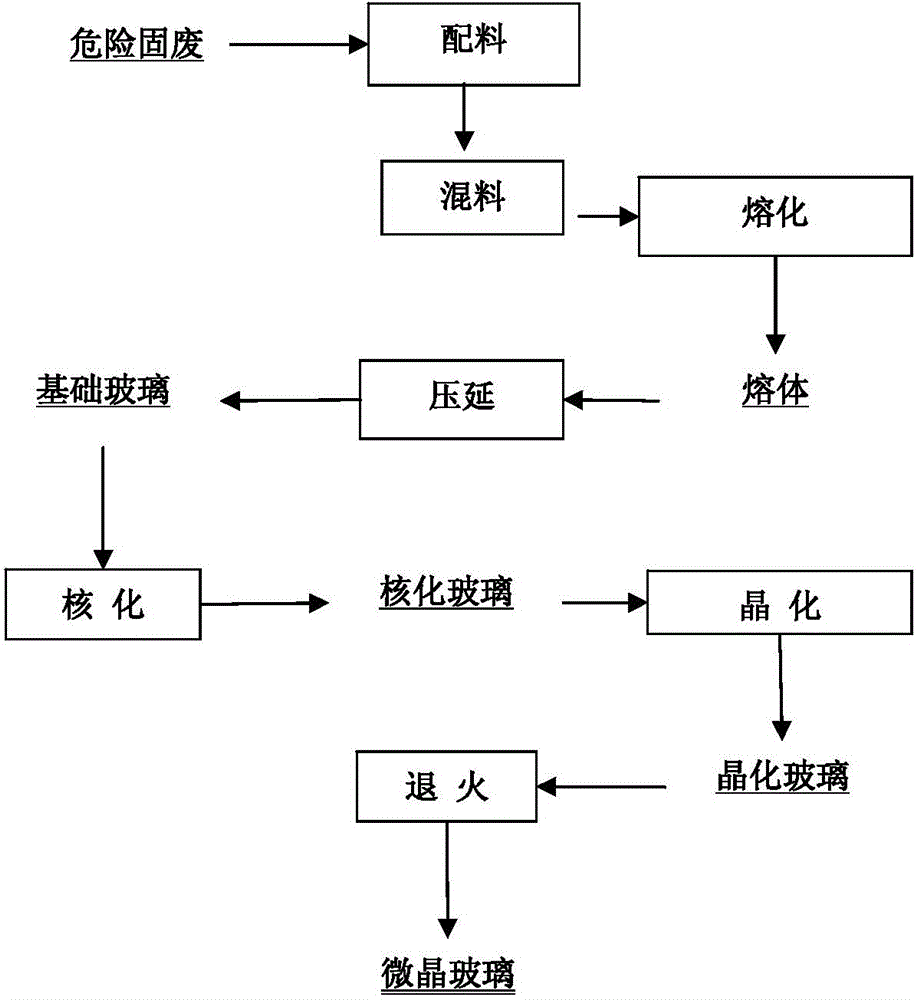

Method for preparing microcrystalline glass from hazardous solid wastes

The invention discloses a method for preparing microcrystalline glass by taking hazardous solid wastes which are hazardous solids for short. The method is characterized by taking heavy metals in the hazardous solids as nucleating agents, mixing, fusing, rolling, nucleating, crystallizing and annealing to obtain the microcrystalline glass. The method has the advantages that the heavy metal elements in waste incineration ash, stainless steel slag, stainless steel acid pickling sludge, electroplating sludge, chromium slag, lead-zinc smelting slag and coal ash can be stably solidified; the pollution is avoided; meanwhile, high-additional-value microcrystalline glass is prepared; the harmless high-value application of the hazardous solids is realized; and the method has remarkable environmental and economic benefits and wide market prospects.

Owner:UNIV OF SCI & TECH BEIJING

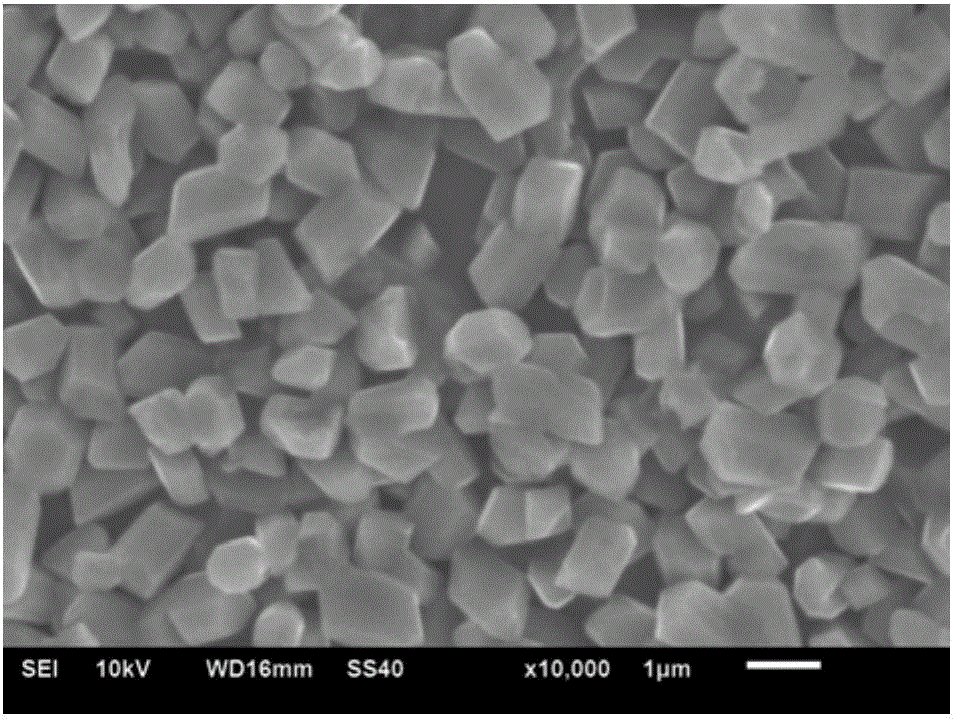

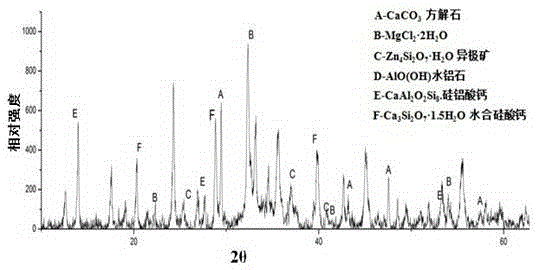

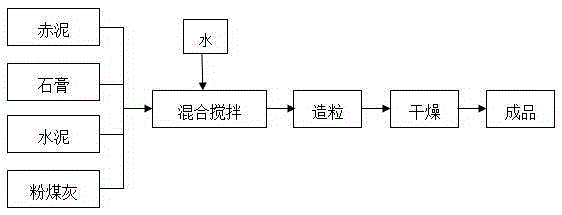

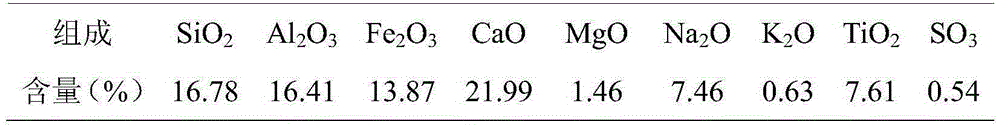

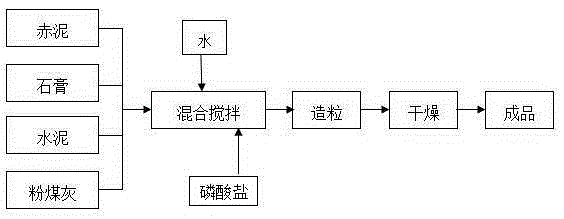

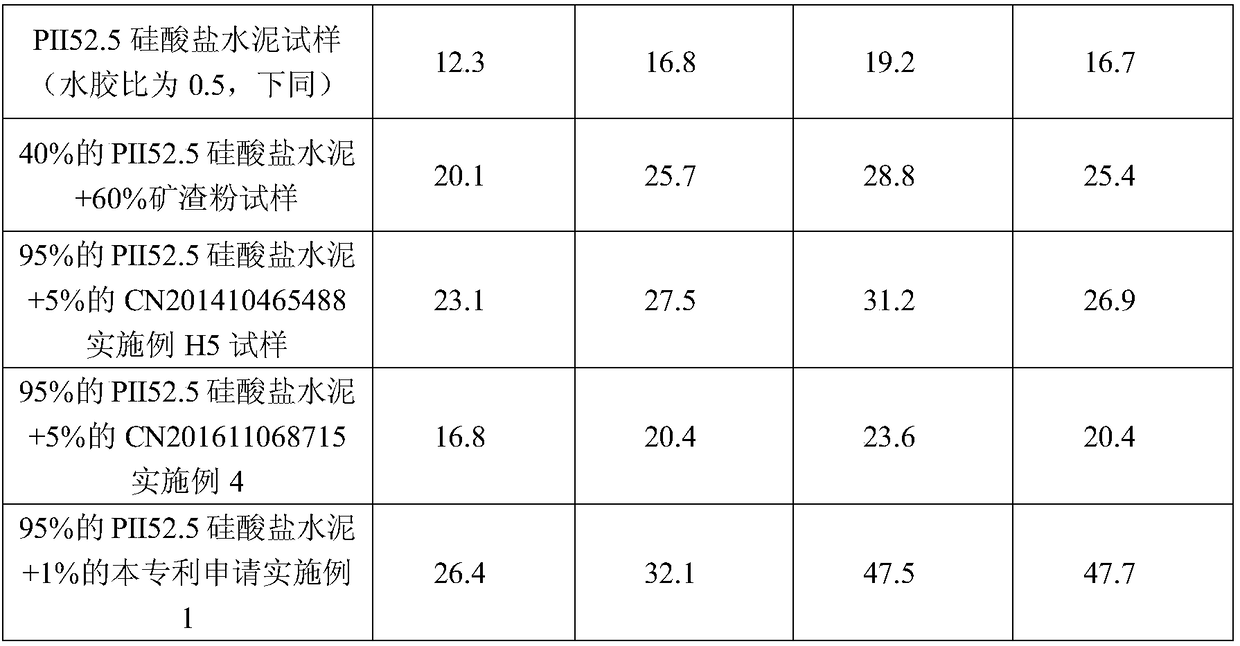

Red mud particle soil repairing adhesives and preparation method thereof

The invention discloses red mud particle soil repairing adhesives and a preparation method and application thereof. The red mud particle soil repairing adhesives are prepared through a series of steps of water adding, mixing, ball forming, room-temperature drying and solidifying by using red mud as the raw material, mixing gypsum into the red mud and using binding material Portland cement and powdered coal in a compound mode to achieve the synergistic interaction result and remarkably improve the red mud gelling property. Red mud powder is granulated and prepared at a room temperature, the obtained red mud particle soil repairing adhesives have certain mechanical strength and quite good heavy metal stabile solidifying performance, soil or mud polluted by heavy metal can be effectively treated, and meanwhile OH radical ions can be slowly released; the pH of soil is kept between 6.7 and 8.1 after soil is repaired through the repairing adhesives, the problems that when soil is repaired through red mud powder, the pH of soil rises too fast and plant growth is not facilitated can be effectively solved, and high application value and environment benefits are achieved.

Owner:国家电投集团山西铝业有限公司 +1

Ceramic exhaust gas sensor

InactiveUS20110139618A1Improved dimensional stabilityReduce occurrenceMaterial analysis by electric/magnetic meansAir quality improvementMetallurgyExhaust gas sensor

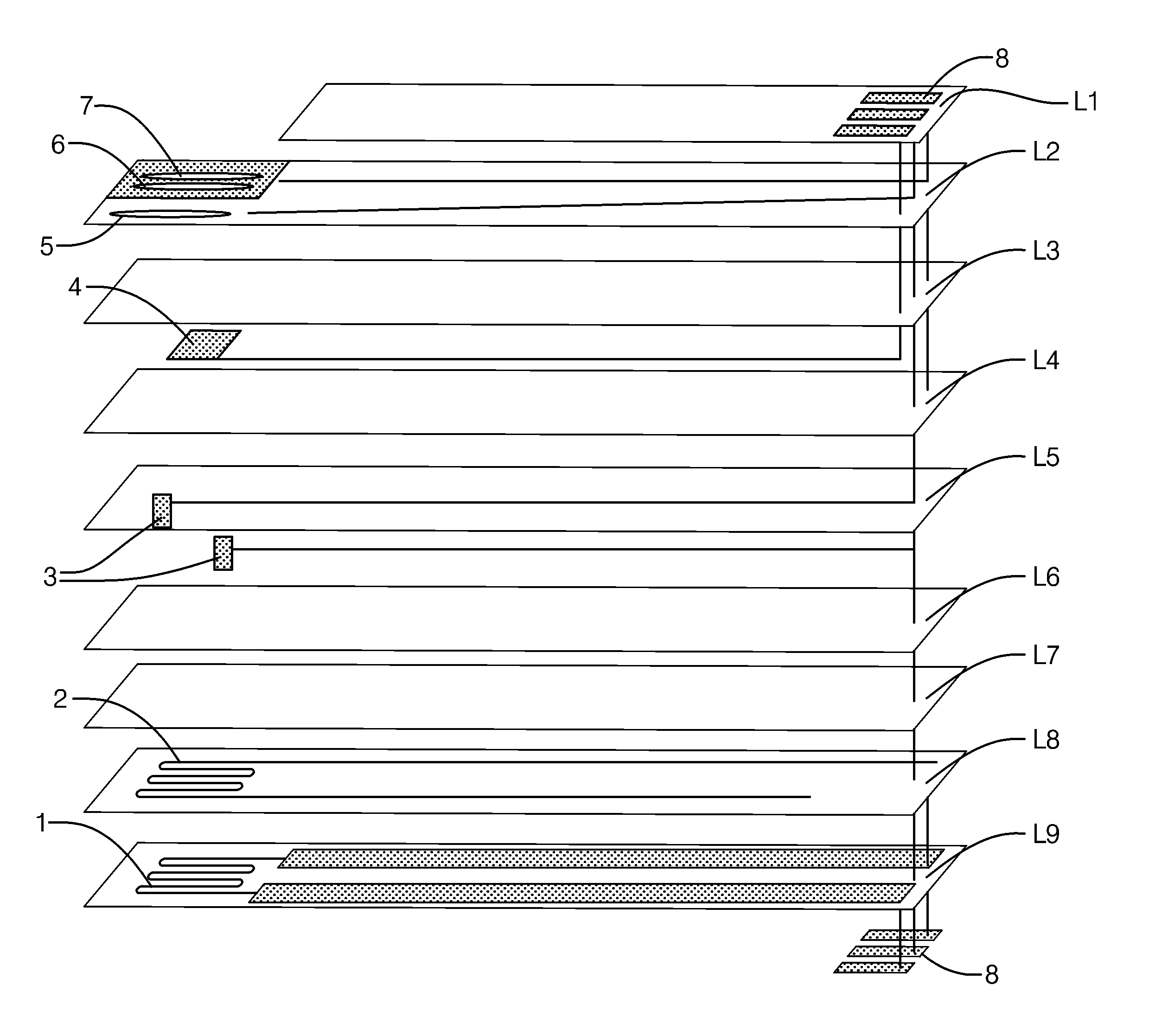

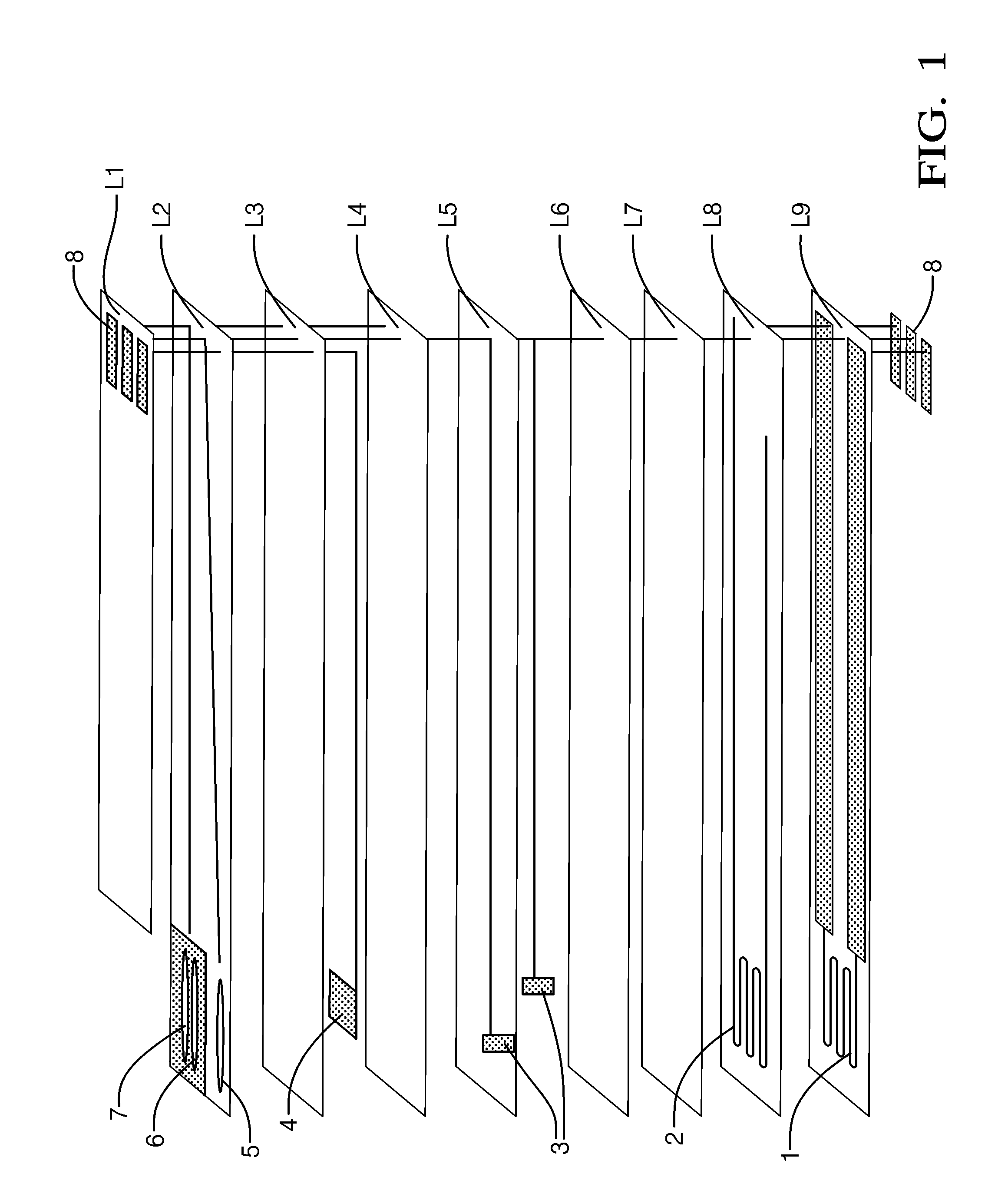

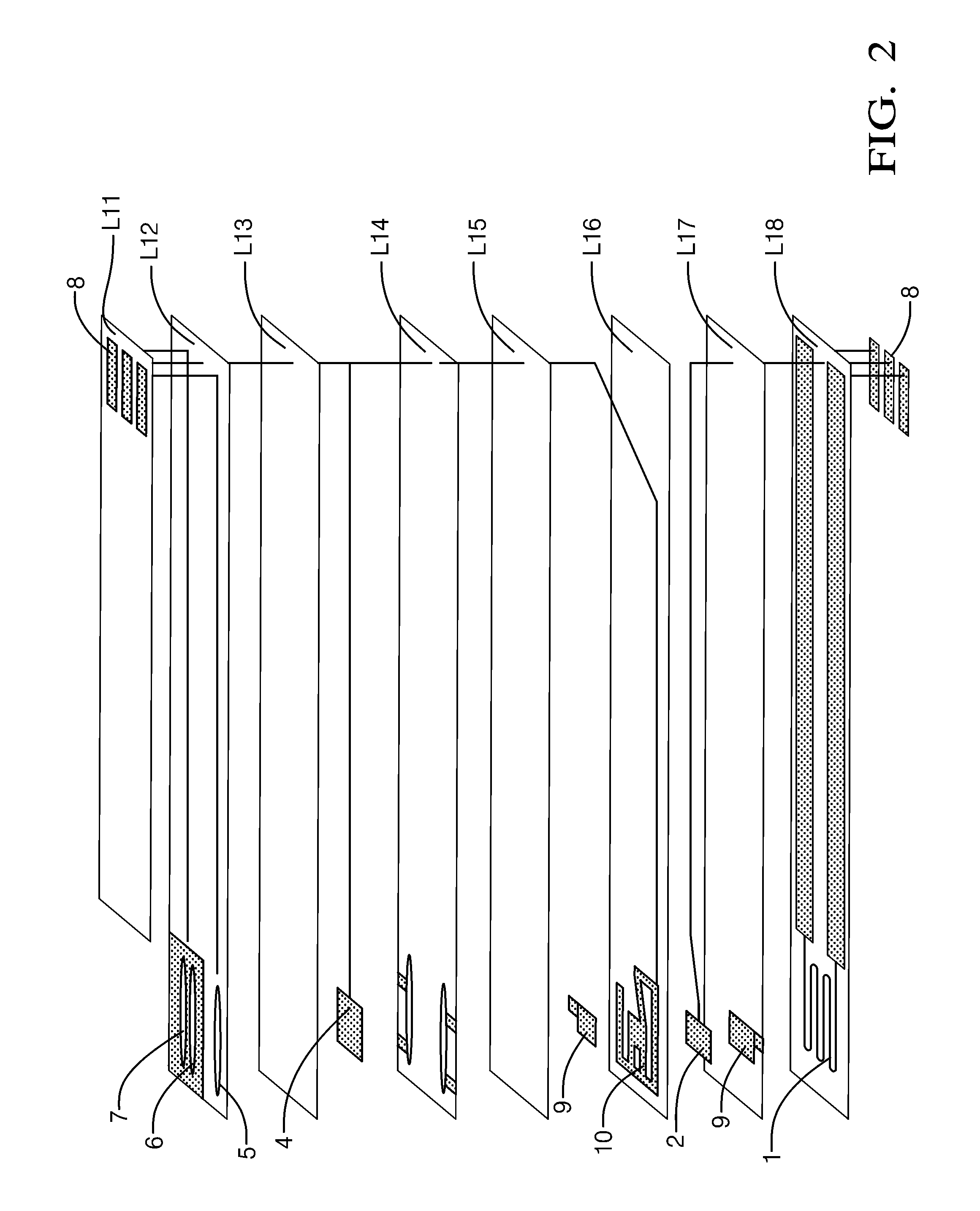

Ceramic exhaust gas sensors are disclosed that offer enhanced dimensional stability during curing, with reduced occurrence of deformations like bending or warping, and can be used in a variety of exhaust gas component sensing applications. The sensors of the invention utilize appropriate selection and orientation of the various layers of green ceramic tape that make up the sensor structure to provide enhanced dimensional stability.

Owner:DELPHI TECH INC

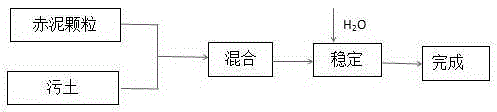

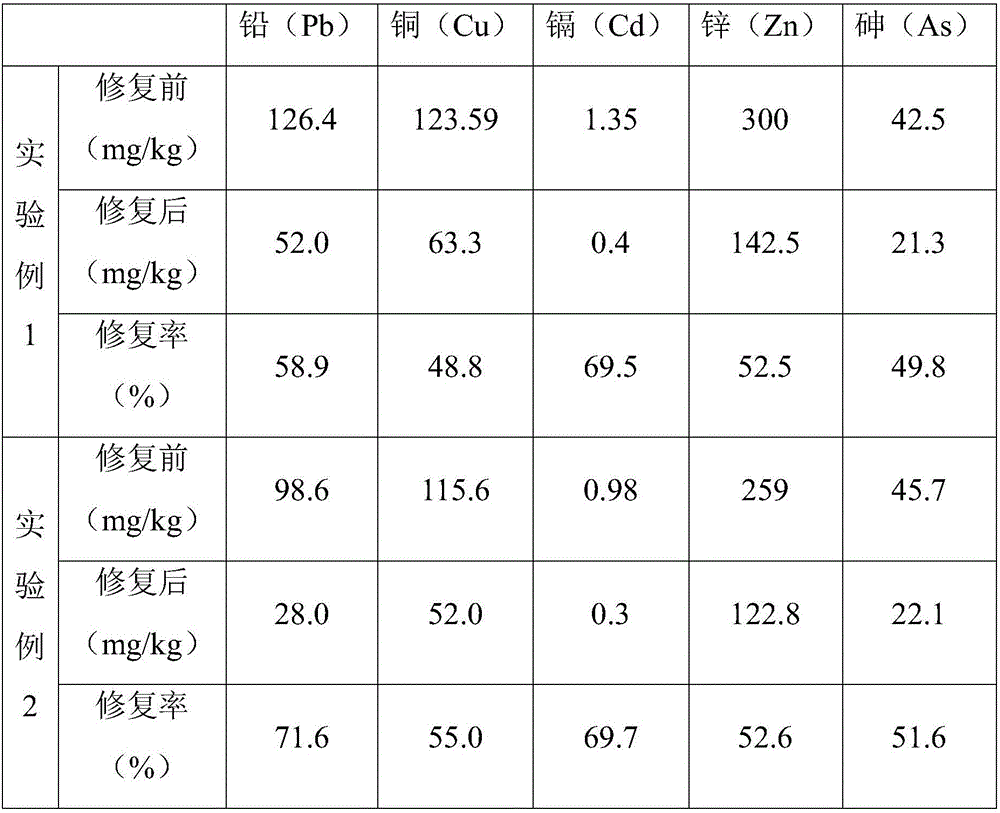

Method for repairing heavy metal-polluted soil by using red mud granular material

The invention discloses a red mud granular material and an application thereof. A red mud particle soil repairing agent takes red mud powder, gypsum, cement and fly ash as main materials, phosphate is doped as an activation material, thereby, gelling capability of red the mud powder and capability for fixing heavy metal ions in a stable mode can be increased, a series of processes of mixing by adding water, balling, and drying solidification at normal temperature can be carried out, so that the spherical particle soil repairing agent can be obtained by composite moulding of the red mud raw ore powder material. The method realizes preparation of the red mud powder with granulation at normal temperature, the obtained red mud particle soil repairing agent has certain mechanical strength and good heavy metal stable solidification performance, the heavy metal-polluted soil or sludge can be effectively processed, OH radical ions can be slowly released simultaneously, a pH value of the soil after restoration by the repairing agent is basically stabilized below 7.5, problems of fast increase of the pH value of the soil and poor growth condition for plants during a soil restoration process by the red mud powder can be effectively overcome, and the method has high application value and environment benefit.

Owner:SUN YAT SEN UNIV

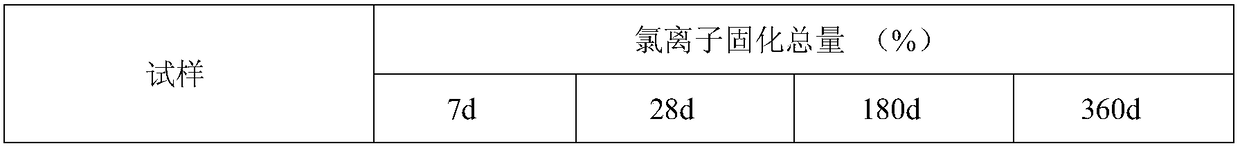

Concrete additive capable of solidifying chlorions efficiently for long time as well as application

ActiveCN108129051AEnhance physical adsorption capacity and stabilityLow transfer rateSodium BentoniteSilicon

The invention discloses a concrete additive capable of solidifying chlorions efficiently for a long time as well as a preparation method. A silicon aluminum phase component is added in the concrete additive capable of solidifying chlorions efficiently for a long time and accounts for 20 to 46.75 percent of the total mass of the concrete additive capable of solidifying chlorions efficiently for a long time; the silicon aluminum phase component is bentonite and / or kaolin which is calcined at 400 to 800 DEG C, the particle diameter is 80-um square hole sieve residue less than or equal to 10 percent and the mass percentage of Al2O3 is more than or equal to 35 percent; furthermore, the silicon aluminum phase component can generate Friedel salt (calcium chloraluminate hydrate) with the purity being more than 90 percent under the concrete alkaline environment. According to the concrete additive, the chlorions in the concrete can be solidified efficiently and stabilized for a long time, and the transmission speed of the chlorions in the concrete is effectively reduced. In conclusion, the technology has the technical advantages of low mixing amount (1 to 5 percent by mass of substituted gelmaterial), high chlorion solidification efficiency and long-term stable solidification effect.

Owner:JIANGSU SOBUTE NEW MATERIALS

Repair agent for treating compound pollution of heavy metal in soil and preparation method of repair agent

InactiveCN106800939AIncrease surface areaReduce agglomerationAgriculture tools and machinesOther chemical processesSoil heavy metalsAgricultural residue

The invention discloses a repair agent for treating compound pollution of a heavy metal in soil and a preparation method of the repair agent. The repair agent is prepared from the following components in parts by weight: 6-8 parts of modified nano-carbon black, 2-5 parts of sodium bentonite-loaded nano zero-valent iron, 1-2 parts of phosphate mineral and 5-10 parts of decomposed forestry and agricultural residues. The preparation method comprises the steps of (1) crushing the phosphate mineral and the decomposed forestry and agricultural residues into powder of which the particle size is 100-200 meshes separately and drying for later use; and (2) mixing the modified nano-carbon black, the phosphate mineral, the sodium bentonite-loaded nano zero-valent iron and the decomposed forestry and agricultural residues according to the formula, and stirring in a closed container to prepare the repair agent for treating compound pollution of the heavy metal in the soil.

Owner:四川省有色冶金研究院有限公司

Sewage treatment agent and preparation method and applications thereof

ActiveCN110563162AImprove efficiencyGood effectWater contaminantsWaste water treatment from animal husbandrySodium BentoniteMicrobial agent

The invention relates to a sewage treatment agent. The sewage treatment agent is prepared from the following components: chitosan solidified tannin, a sodium bentonite-loaded microbial agent, graphene, a biological compound enzyme, an organic-inorganic flocculant, a flocculation aid, sodium hydrogen sulfite, coconut shell powder and sawdust. The sewage treatment agent disclosed by the invention ishigh in bioactive substance stability and high in activity, has good adsorption capacity, flocculation capacity and biodegradation capacity, is applied to river sewage and aquaculture wastewater treatment, can effectively remove most of heavy metals, complexes and organic matters in sewage, effectively reduce the nitrogen and phosphorus content in sewage, and purifiy water, and is efficient and environmentally friendly; and no secondary pollution is caused.

Owner:HUIZHOU UNIV +1

Method for producing cement clinker from stainless steel cold rolling dewatered sludge ingredient

InactiveCN101475325ACalcination temperature is lowBurn completelySludge treatmentWaste water treatment from metallurgical processAdditive ingredientPulverized fuel ash

The invention relates to a method for producing cement clinker through utilization of a stainless steel cold-rolled dehydrated sludge ingredient. The method comprises that: stainless steel cold-rolled dehydrated sludge and other materials of a cement green stock are evenly mixed to prepare the cement green stock; the cement green stock comprises the following compositions in percentage by weight: 70 to 79 percent of limestone, 10 to 14 percent of clay, 1 to 8 percent of the stainless steel cold-rolled dehydrated sludge, 5.3 percent of coal ash, 0 to 3 percent of iron ore powder and 0 to 0.5 percent of gypsum; and the prepared cement green stock is sintered to form silicate cement clinker. The obtained cement clinker and a corresponding cement product have no essential difference with the prior silicate cement clinker and a cement product in composition and performance; the quality of the cement clinker and the corresponding cement product meets the index requirement of national corresponding product standard and can be used as a normal high-quality commodity; and the method effectively utilizes and processes industrial sludge containing harmful metal elements, achieves the effects of resource optimization and utilization and has remarkable environment-friendly benefit.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD +1

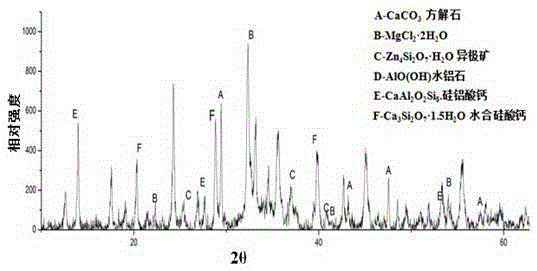

Method for solidifying and cementing tannery sludge containing heavy metals by bacillus pasteurii

ActiveCN108675585ASimple processEasy to operateWater contaminantsWaste water treatment from animal processingChemistryIndustrial waste

The invention provides a method for solidifying and cementing tannery sludge containing heavy metals by bacillus pasteurii. The method comprises the following steps: mixing a bacteria solution of thebacillus pasteurii with tannery sludge to be treated under an aerobic condition, adding urea and calcium chloride into the bacteria solution, and solidifying at 20 to 30 DEG C for 12 to 15 days to finish solidification treatment of the tannery sludge containing heavy metals; generating calcium carbonate precipitate in the presence of the urea and calcium chloride by urease-producing bacteria to fix and cement the heavy metals in the tannery sludge and achieve harmless treatment of industrial waste residue. The method provided by the invention has the advantages of simple process, convenience in operation, obvious effect, low treatment cost, wide application range, freeness from secondary pollution and the like. Through the method provided by the invention, solidification and cementation ofthe tannery sludge containing heavy metals are realized, obtained solidified heavy metals have small leaching amount and high compressive strength, and can be taken as a building material.

Owner:ZHEJIANG UNIV OF TECH

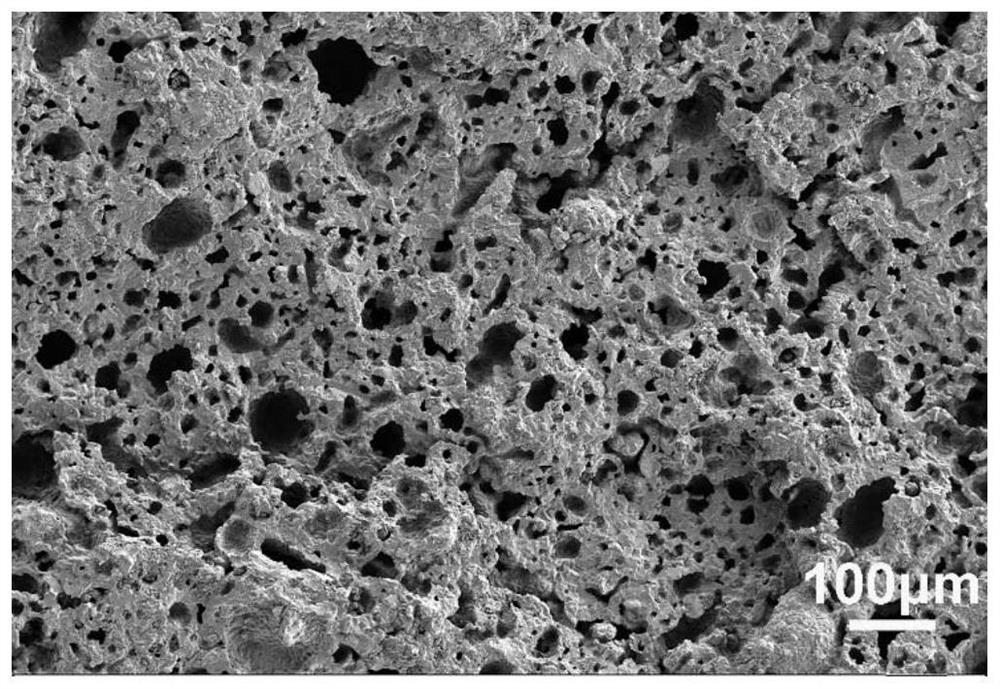

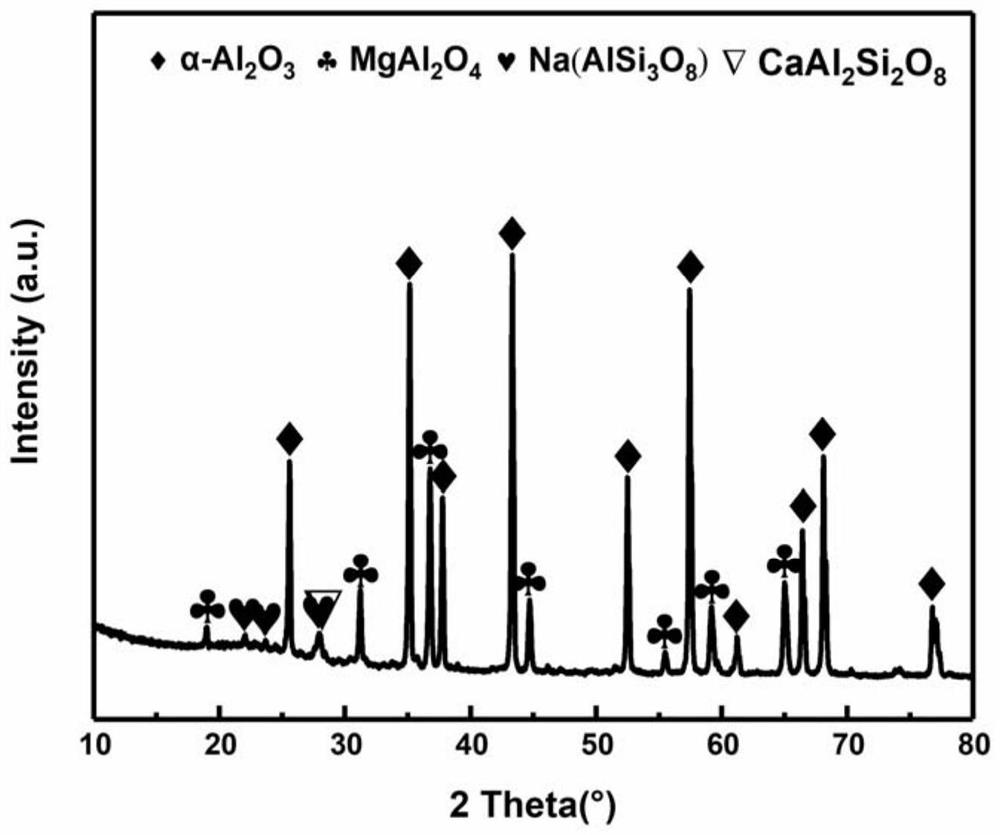

Method for preparing low-shrinkage porous ceramic through high-temperature self-foaming of aluminum ash

ActiveCN113735611ASolve pollutionSolve the hazardCeramic materials productionCeramicwareSpray GranulationThermal insulation

The invention relates to the technical field of comprehensive utilization of solid waste resources, and discloses a method for preparing low-shrinkage porous ceramics through high-temperature self-foaming of aluminum ash residues. Secondary aluminum ash residues obtained after aluminum extraction are used as main raw materials, and the aluminum ash residues do not need to be subjected to desalting and denitrifying treatment; and the secondary aluminum ash is subjected to spray granulation, dry pressing forming and high-temperature sintering, and finally the low-shrinkage porous ceramic material is obtained. According to the method, the technological process is simple and easy to implement, the complex desalting and denitrifying process is omitted, the high-temperature self-foaming process is achieved by fully utilizing the component characteristics of the secondary aluminum ash residues, then a porous structure is obtained, harmless treatment of the secondary aluminum ash residues and resource utilization of solid waste can be achieved, and the prepared porous ceramic material has the characteristics of low shrinkage, high strength, excellent heat insulation performance and the like, and can be applied to the fields of thermal insulation materials and the like.

Owner:UNIV OF SCI & TECH BEIJING

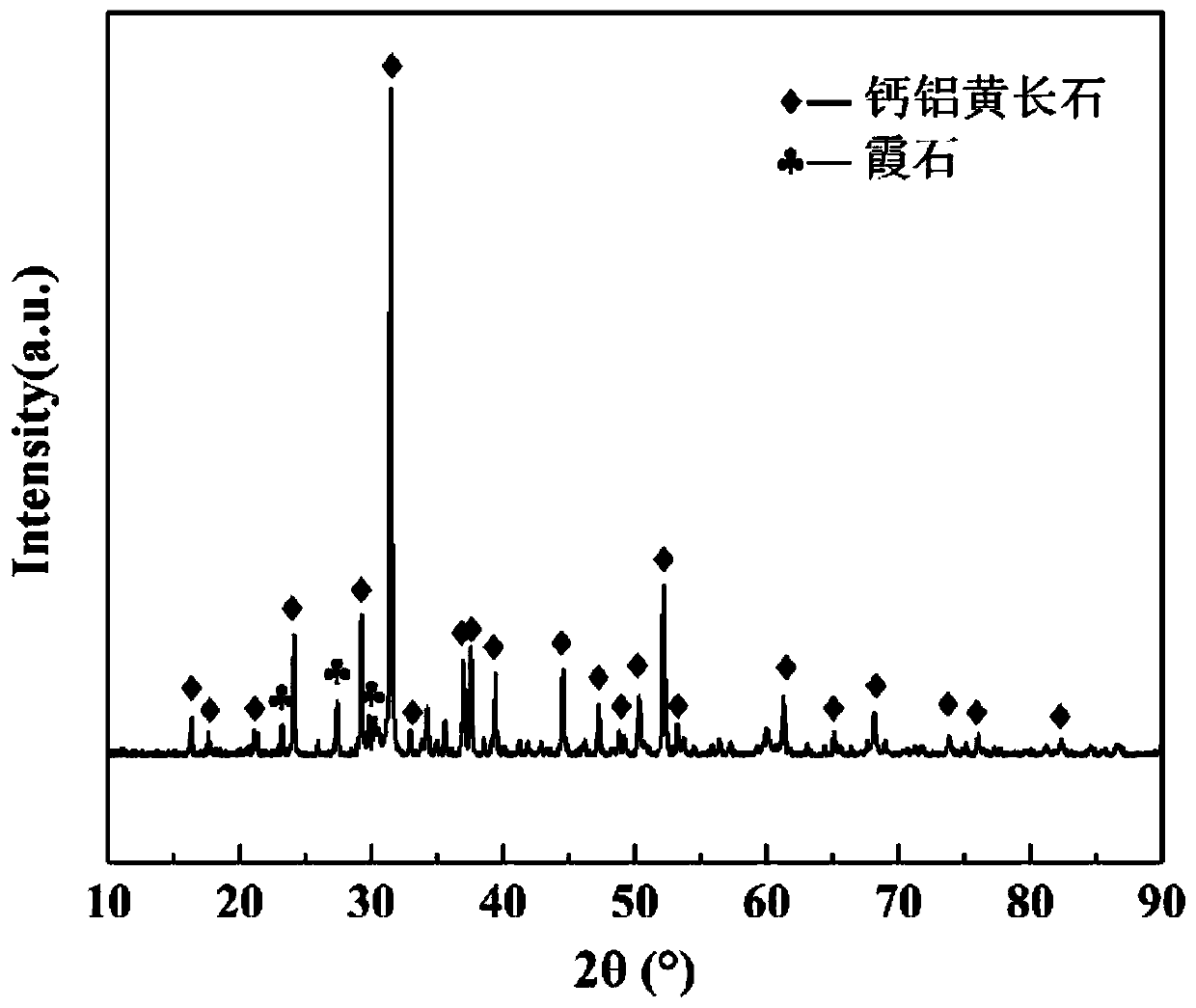

Harmless and resourceful treatment method for smelting slag generated during iron capture of waste catalysts

The invention relates to the technical field of harmless and resourceful treatment of solid waste and provides a harmless and resourceful treatment method for smelting slag generated during iron capture of waste catalysts. The method comprises the following steps: directly carrying out casting and calendering to obtain base glass by using glassy-state smelting slag generated by capturing a waste catalyst with iron as a raw material and heavy metals such as Fe2O3, Cr2O3, TiO2, NiO and PbO in the smelting slag as nucleating agents without adding any other reagent; subjecting the base glass to synchronous nucleation and crystallization at a certain temperature; and performing annealing to eliminate stress so as to obtain a microcrystalline glass product. The method has the advantages that heavy metal in the smelting slag generated smelting slag generated during iron capture of waste catalysts is solidified, so pollution is avoided; nucleation and crystallization heat treatment are synchronously carried out, so the method has the advantages of short flow, low energy consumption and easiness in industrial production; the harmless and resourceful utilization of the smelting slag is realized; the added value of the obtained microcrystalline glass is high; obvious environmental protection and economic benefits are obtained; and the method has good market prospects.

Owner:UNIV OF SCI & TECH BEIJING

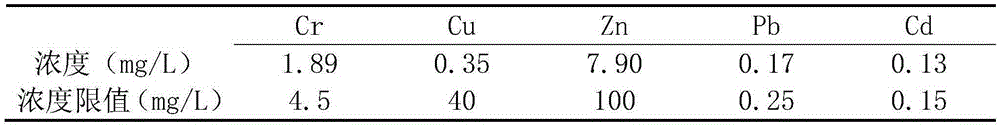

Method for synergistically treating heavy metal sludge

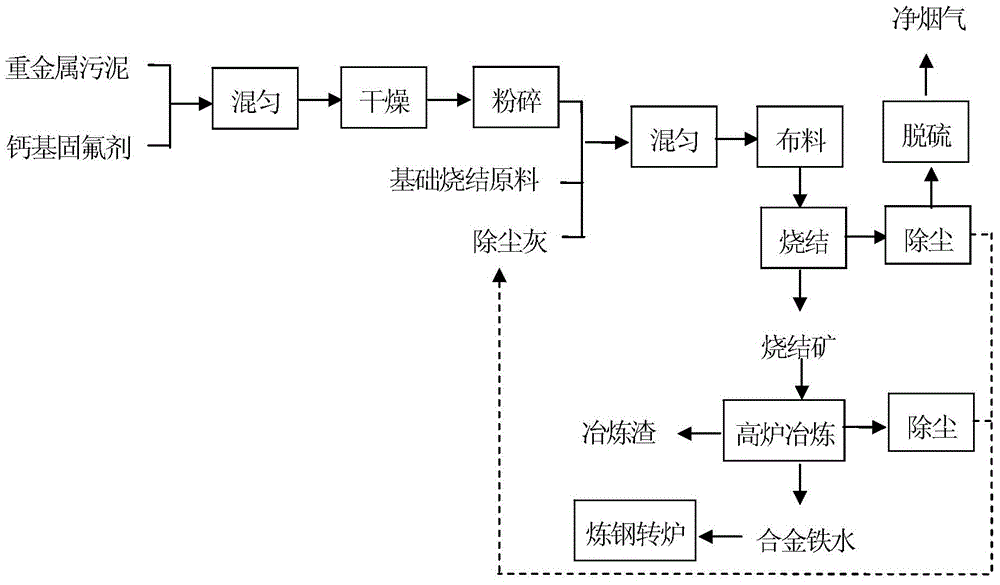

ActiveCN105271624AEfficient recyclingNo slag effectSludge treatmentWaste water treatment from metallurgical processSteelmakingSludge

The present invention provides a method for synergistically treating heavy metal sludge. The method comprises: uniformly mixing heavy metal sludge with a water content of 20-50% and a calcium-based fluorine fixing agent, drying, crushing to obtain calcium-based sludge, uniformly mixing with a base sintering raw material and dust removing ash, granulating, and distributing the material, wherein a mass ratio of the base sintering raw material to the heavy metal sludge to the calcium-based fluorine fixing agent to the dust removing ash is 50-120:0.3-20:0.1-2:0.5-5; sintering the granulated mixing material to obtain sintered ore, wherein the flue gas produced during the sintering process passes through a dust removing and desulfurization device, and the purified flue gas is externally discharged through a chimney; and conveying the sintered ore into a blast furnace, and smelting, wherein the flue gas is externally discharged after the dust removing, the smelting residue is comprehensively utilized, and the alloy hot metal enters the steelmaking converter of the stainless steel enterprise. According to the present invention, dust, gas and wastewater can be discharged into the existing facilities so as to be treated; and with the synergetic treatment of the sintering process and the blast furnace smelting, most of the metal elements can be effectively recovered so as to achieve harmlessness and resources.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Glue-dispensing and laminating method for touch display module

InactiveCN109968790ACuring stabilityImprove the bonding yieldLamination ancillary operationsPretreated surfacesRubber ringEngineering

The invention discloses a glue-dispensing and laminating method for a touch display module. The method comprises the following steps: S1, providing a first substrate and a second substrate; S2, dispensing a glue on the laminating surface of the first substrate to form a rubber ring at the edge of the laminating surface of the first substrate; S3, pre-curing the glue ring; S4, dispensing the glue on the laminating surface of the first substrate and the inner surface formed by the rubber ring; S5, laminating the first substrate and the second substrate; S6, pre-curing the glue-dispensed area obtained in step S4; and S7, carrying out full-surface main curing on the laminated first substrate and second substrate to completely cure the glue between the first substrate and the second substrate.In the invention, the glue is dispensed on the laminating surface of the first substrate to form the rubber ring at the edge of the laminating surface of the first substrate, the rubber ring is pre-cured, the glue is dispensed on the inner surface formed by the rubber ring, and the glue flows in the area formed by the glue ring, so the method can effectively avoid the problem of glue spilling in the laminating process.

Owner:TRULY OPTO ELECTRONICS

Two-component colorful flexible polysulfide ammonia ester sealant and preparation method thereof

InactiveCN105111996AColor stableNot easy to yellowNon-macromolecular adhesive additivesOther chemical processesPolymer scienceVulcanization

The invention discloses a two-component colorful flexible polysulfide ammonia ester sealant and a preparation method thereof. The sealant consists of a component A and a component B; expressed by weight part, the component A is prepared from 15 to 60 parts of PSU type liquid rubber, 10 to 30 parts of a plasticizer, 10 to 60 parts of a filler, 0.1 to 5 parts of a tackifier, 0.1 to 5 parts of an antiager and 0.1 to 5 parts of a premature vulcanization retarder; the component B is prepared from 10 to 40 parts of a vulcanizing agent, 0.1 to 5 parts of a vulcanization accelerator, 10 to 50 parts of a plasticizer, 1 to 20 parts of a colorant and 10 to 50 parts of a filler; the mass ratio of the component A to the component B is 5 to (15 to 1). The component A and the component B are respectively ground to be pasty and then are mixed uniformly, thus obtaining a product. The product is stable in storage, excellent in physical and mechanical properties, and easy to blend into multiple colors, and the defect of color singleness of an existing flexible sealant is overcome.

Owner:HENAN YONGLI CHEM

Anticorrosion fireproof coating for ships

InactiveCN105017920AIncrease stickinessGood weather resistanceFireproof paintsAnti-corrosive paintsPhenyl EthersPyrophosphate

The invention discloses an anticorrosion fireproof coating for ships. The anticorrosion fireproof coating comprises, by weight, 63-79 parts of modified melamine resin, 36-62 parts of phenolic resin, 23-45 parts of ketone-aldehyde resin, 12-24 parts of hydroxyethyl cellulose, 4.5-8.7 parts of attapulgite, 6-12 parts of lignocellulose, 3.5-6.8 parts of calcium stearate, 2.3-4.5 parts of zinc stearate, 1.6-3.4 parts of sodium pyrophosphate, 2.1-4.3 parts of nanometer titanium dioxide, 1.2-3.6 parts of nanometer magnesium hydroxide, 1.1-3.4 parts of asbestos powder, 0.6-1.6 parts of meerschaum powder, 0.5-2.3 parts of sodium lauryl sulfate, 1.4-2.6 parts of silicon carbide, 2.3-4.5 parts of metakaolin, 1.3-2.6 parts of propylene glycol phenyl ether, 0.6-1.8 parts of powdered steatile, 2.3-4.5 parts of mica powder, 0.6-1.8 parts of zinc borate, 1.8-3.6 parts of montmorillonite, 1.6-6.8 parts of a curing agent, 1.2-2.6 parts of an antifoaming agent, 0.6-2.6 parts of a pigment and 52-68 parts of water. The anticorrosion fireproof coating has high hardness, good toughness and good anticorrosive and fireproof performances.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

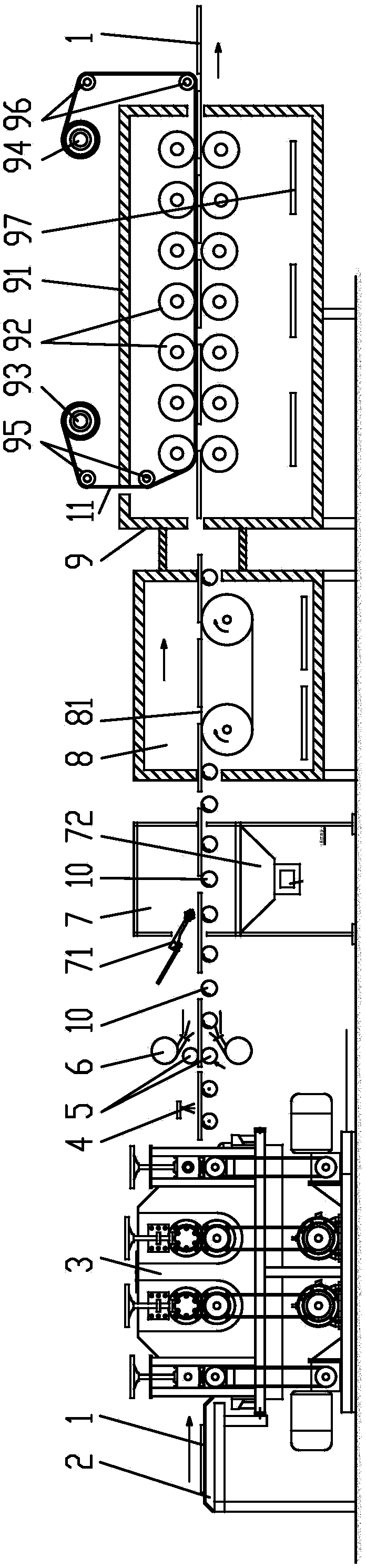

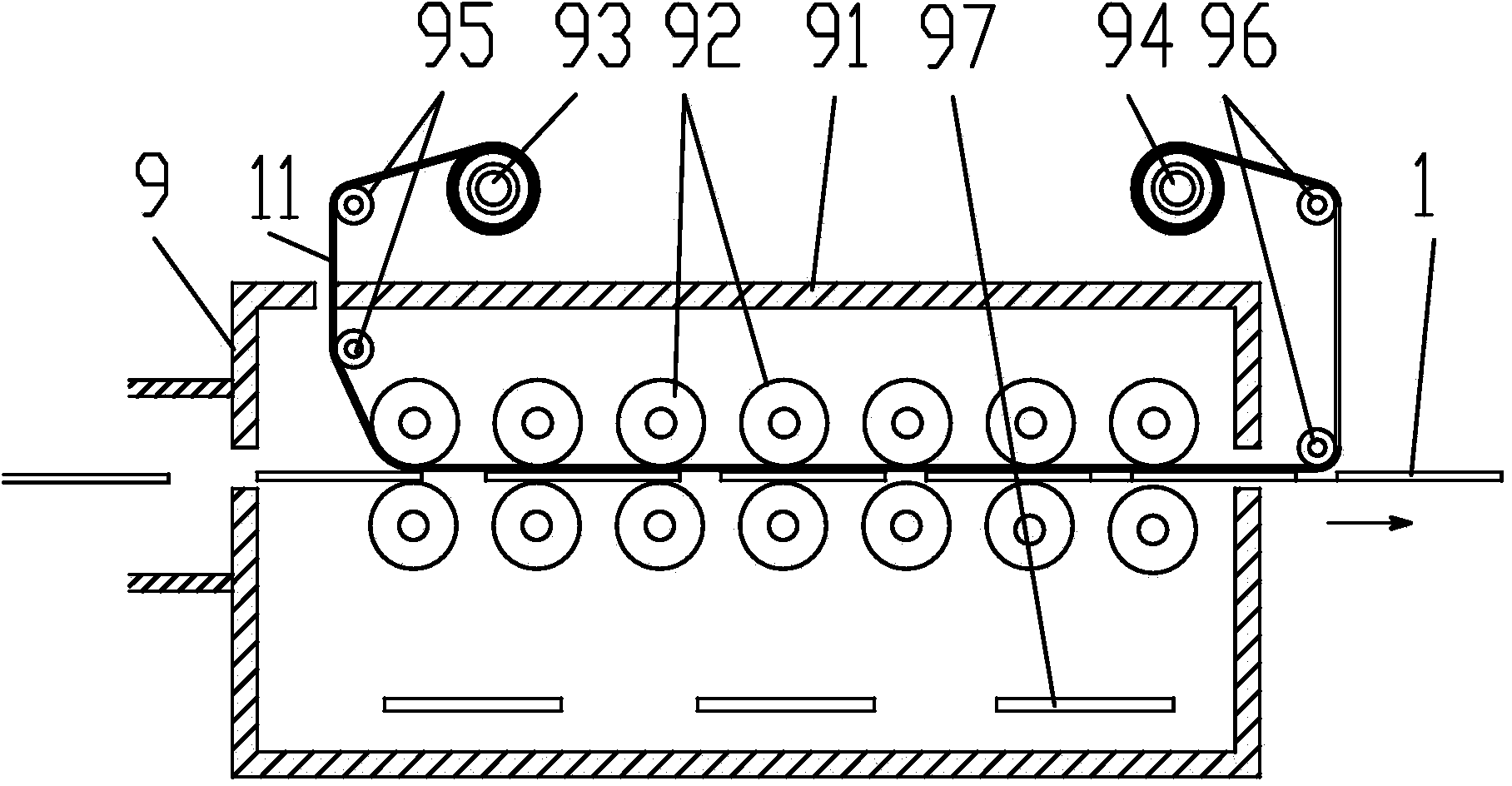

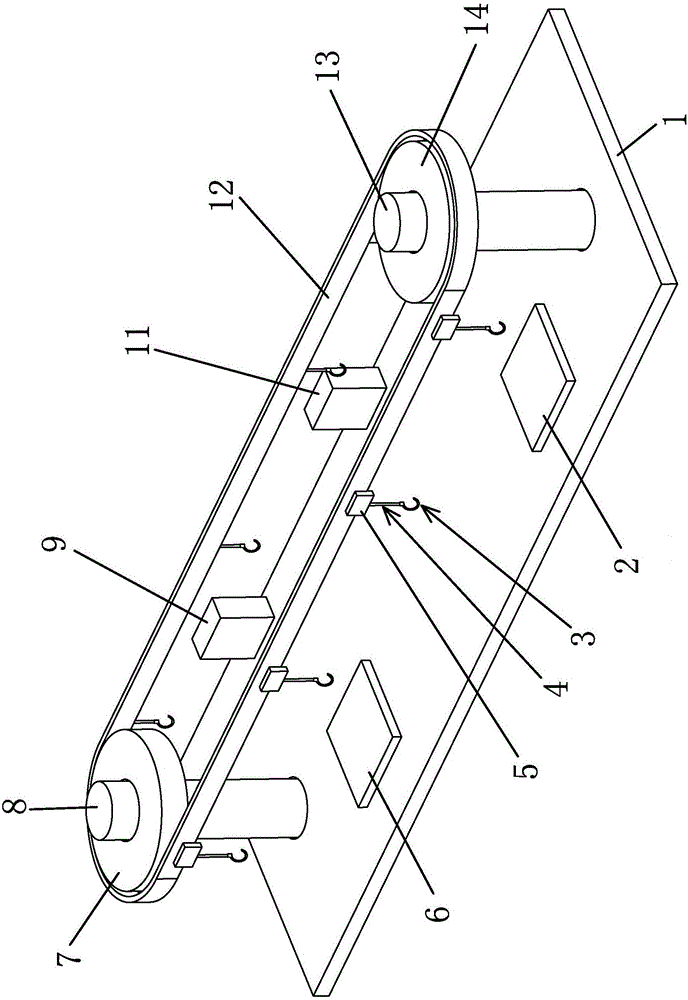

Production process and system applicable to steel plate heat transfer printing

InactiveCN103818138ARealize continuous thermal transfer operationSimple processTransfer printingDuplicating/marking methodsSheet steelEngineering

The invention discloses a production process and a system applicable to steel plate heat transfer printing. The production process and the system are applicable to continuous heat transfer printing operation of a single steel plate; a flat steel plate is fed into an operation system through a feeder to finish process steps through a washing and air-drying device, a powder spraying pretreatment device and a roll-type continuous heat transfer printing device in sequence. The process comprises the following steps: A, washing, degreasing and preprocessing the flat steel plate and air-drying the flat steel plate; B, carrying out powder spraying pretreatment on the upper surface of the flat steel plate, heating, curing and molding powder; and C, carrying out continuous heat transfer printing on the flat steel plate by using a heat transfer paper coil. Through the production process and the system, the continuous heat transfer printing of the single steel plate is realized; the continuous operation of the steel plate can be carried out; compared with a conventional platform type printing device, the production process and the system have the advantages that the transfer printing efficiency is greatly improved; the transfer printing effect is easily controlled; meanwhile, the flat steel plate does not need to be heated and cooled for multiple times; the energy is greatly saved.

Owner:殷殿荣 +1

Impact-resistant rust-proof heat-resistant coating for building steel

InactiveCN104946094AImprove water resistanceImprove corrosion resistanceAntifouling/underwater paintsPaints with biocidesMagnesiumMelamine phosphate

The invention discloses an impact-resistant rust-proof heat-resistant coating for building steel. The impact-resistant rust-proof heat-resistant coating comprises, by weight parts, 74 parts of modified epoxy acrylate resin, 29 parts of chlorosulfonated polyethylene, 25 parts of melamine formaldehyde resin, 6 parts of methyl hydroxyethyl cellulose, 3 parts of sodium hexametaphosphate, 4 parts of nano-titanium dioxide, 3 parts of nano-magnesium hydroxide, 4 parts of organic bentonite, 2 parts of nano-sepiolite powder, 3 parts of diatomaceous earth, 4 parts of talc powder, 2 parts of modified attapulgite, 3 parts of titanate coupling agents, 3.5 parts of chlorinated paraffin, 9 parts of ethyl acetate, 4 parts of citroflex, 2 parts of zinc oxide, 4 parts of zinc borate, 5.5 parts of antimony trioxide, 2.5 parts of melamine phosphate, 4 parts of polypropylene glycol, 4 parts of curing agents, 6.5 parts of leveling agents, 7.5 parts of mould inhibitor, 6 parts of pigment and 42 parts of solvents. The impact-resistant rust-proof heat-resistant coating for building steel has good impact resistance, rust resistance and heat resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

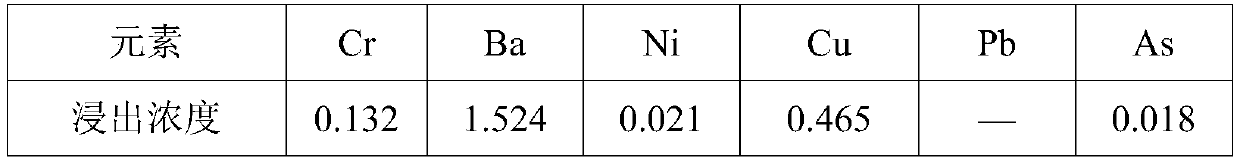

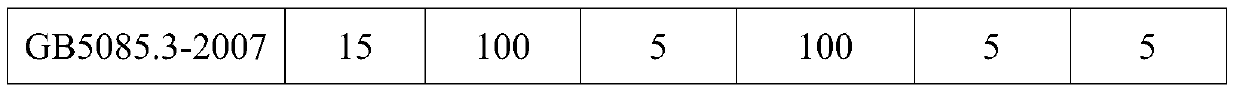

Co-processing method for red mud and household garbage incineration fly ash

The invention discloses a co-processing method for red mud and household garbage incineration fly ash. The co-processing method is characterized by comprising the following steps that (1) the red mud is ground into powder after being dried, 10wt%-15wt% of strong base is added, and calcined activation is carried out between 750 DEG C and 850 DEG C, and a heavy metal curing agent is obtained after cooling; (2) the heavy metal curing agent and the household garbage incineration fly ash are mixed to obtain mixture powder, the mass proportion of the heavy metal curing agent in the mixture powder ranges from 45% to 60%, and net paste is obtained by adding water to the mixture powder according to the water-ash ratio ranging from 0.4 to 0.6 and evenly mixing the water and the mixture powder; and (3) the net paste is cured for 14 to 28 days under the normal temperature and the normal pressure, and a garbage incineration fly ash composite solidified body is obtained. Through the method, the red mud and the household garbage incineration fly ash can be processed at the same time, the solidification effect is stable, the steps are simple and easy to implement, and the method is suitable for being popularized on a large scale.

Owner:HUAZHONG UNIV OF SCI & TECH

Immobilizing and stabilizing agent for arsenic-contaminated soil and application thereof

ActiveCN104774619ASimple componentsEasy to manufactureContaminated soil reclamationOrganic fertilisersContaminated soilsChemistry

The invention relates to an immobilizing and stabilizing agent for arsenic-contaminated soil and application thereof. The immobilizing and stabilizing agent comprises, by weight, 20 to 50 parts of a ferric salt, 30 to 40 parts of an aluminum salt, 5 to 10 parts of permanganate and 10 to 20 parts of calcium carbonate. The application of the immobilizing and stabilizing agent to arsenic-contaminated soil comprises the following steps: adding, by weight, 0.1 to 5 parts of the immobilizing and stabilizing agent and 20 to 30 parts of water into each 100 parts of the arsenic-contaminated soil; and carrying out uniform mixing under stirring and then carrying out standing and maintenance for more than 3 d. The immobilizing and stabilizing agent has simple composition, is convenient to prepare and is especially applicable to soil contaminated by high-concentration arsenic.

Owner:YONKER ENVIRONMENTAL PROTECTION

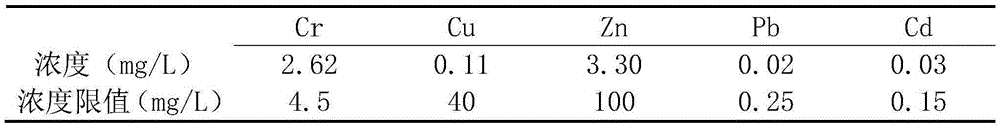

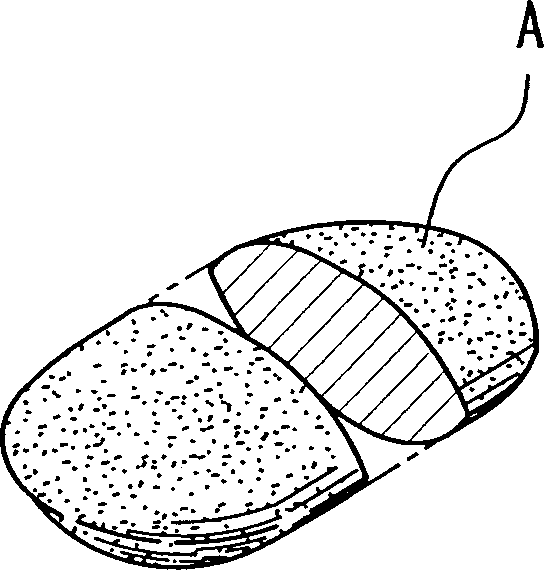

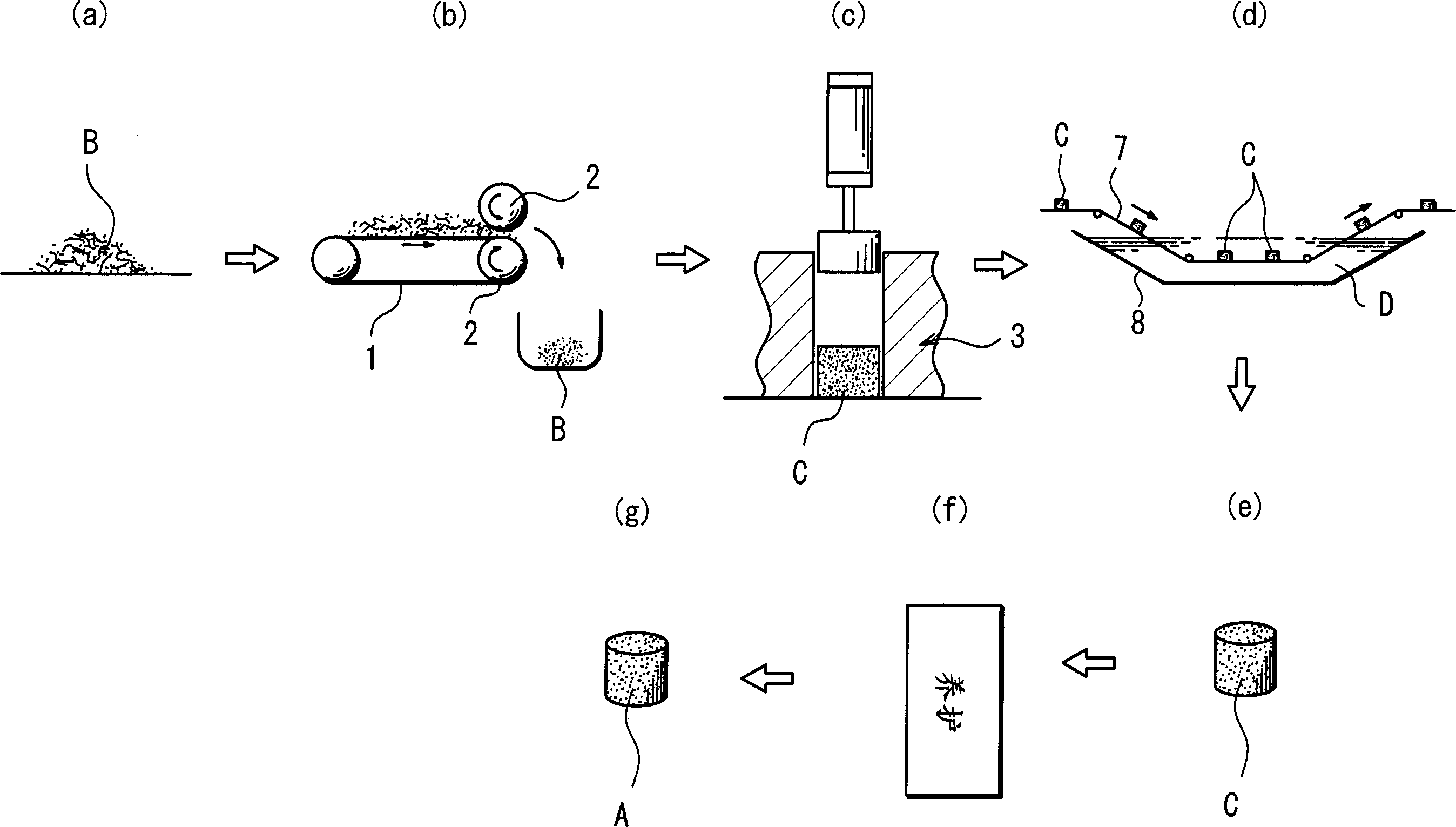

Briquette as material for steel making and method for production thereof

InactiveCN1388832ACuring stabilityProcess efficiency improvementPressesCompression moldingSteelmaking

Cotton-like aggregates (B) containing grinding chips from an iron-based metal and a grinding fluid containing oil and water are compression molded thereby forming a brittle compact (C) in which the fibrous grinding chips are roughly sheared and which is removed of excessive water and oil. The brittle compact (C) is crushed for further finely shearing the grinding chips and then, the resultant grinding chips are mixed with a solidification assistant(D) for obtaining powder (E) containing the solidification assistant(D). The powder (E) is solidified by compression molding, thereby forming a water-containing briquette (F). A briquette (A) for use as steelmaking material, which contains powdery pure iron and oil, is obtained by removing the water from the water-containing briquette (F). Without crushing the brittle compact (C), it is also possible to form the briquette (A) for use as steelmaking material by impregnating the brittle compact (C) with the solidification assistant(D) and then drying the compact.

Owner:KOYO SEIKO CO LTD

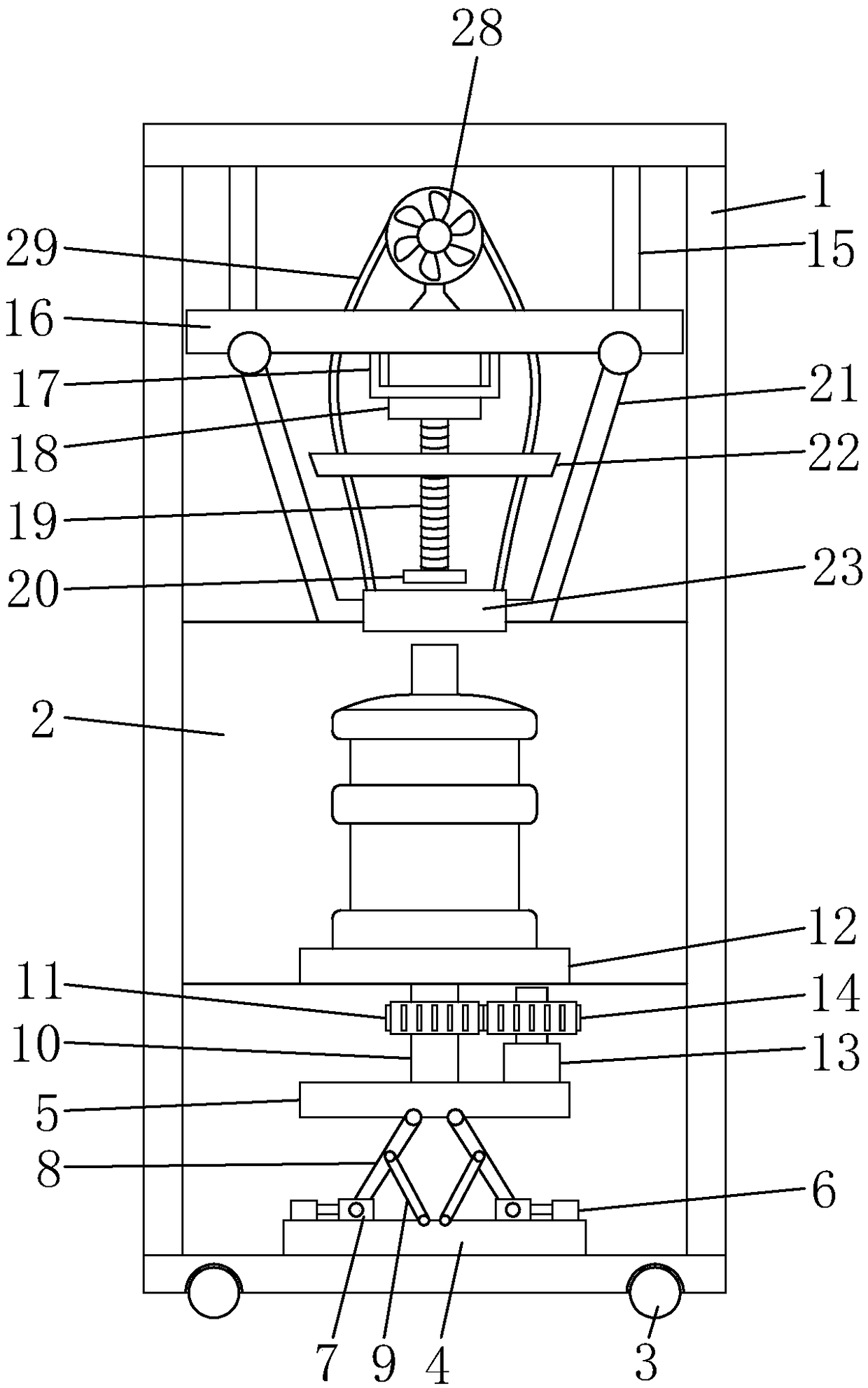

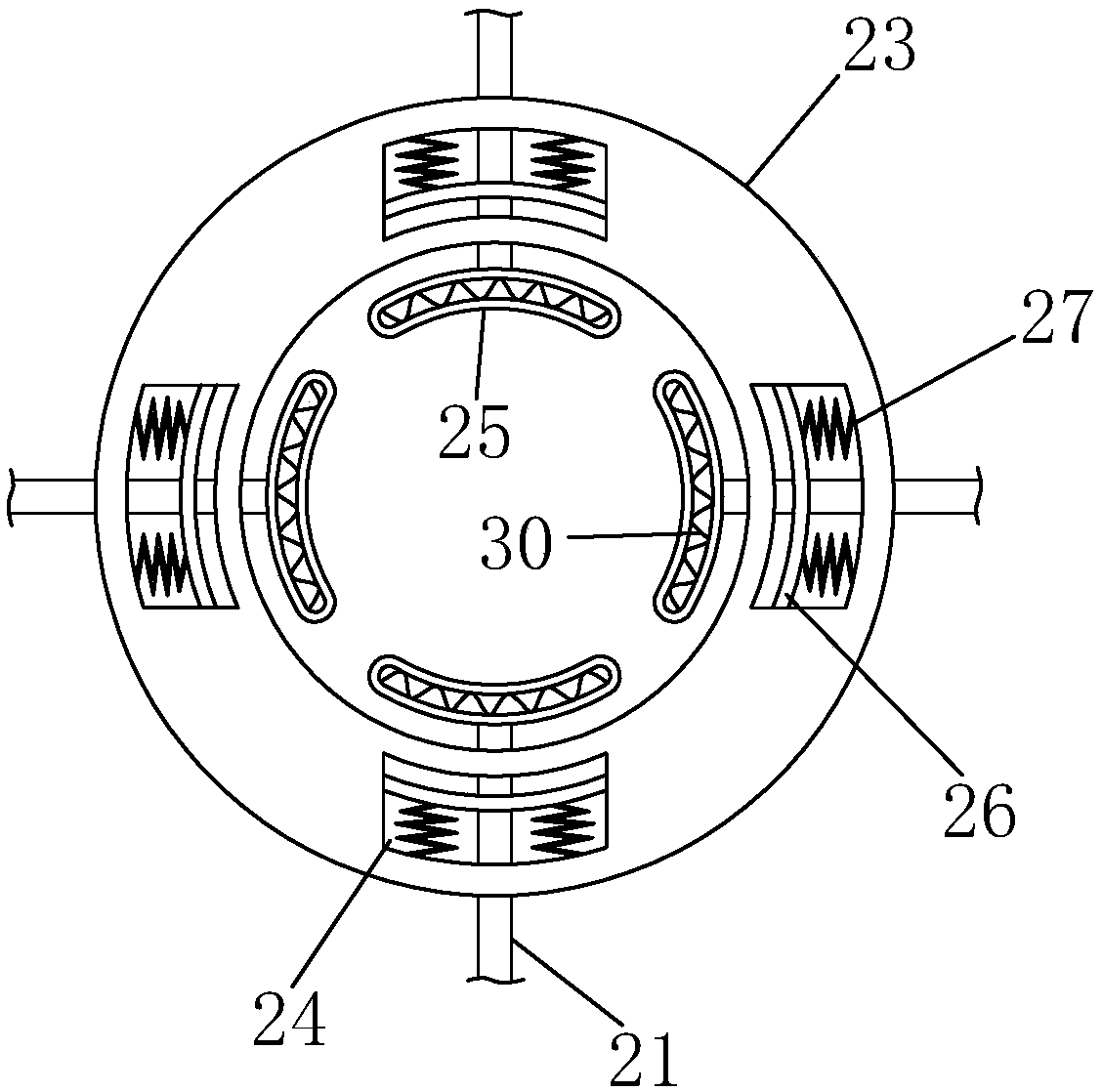

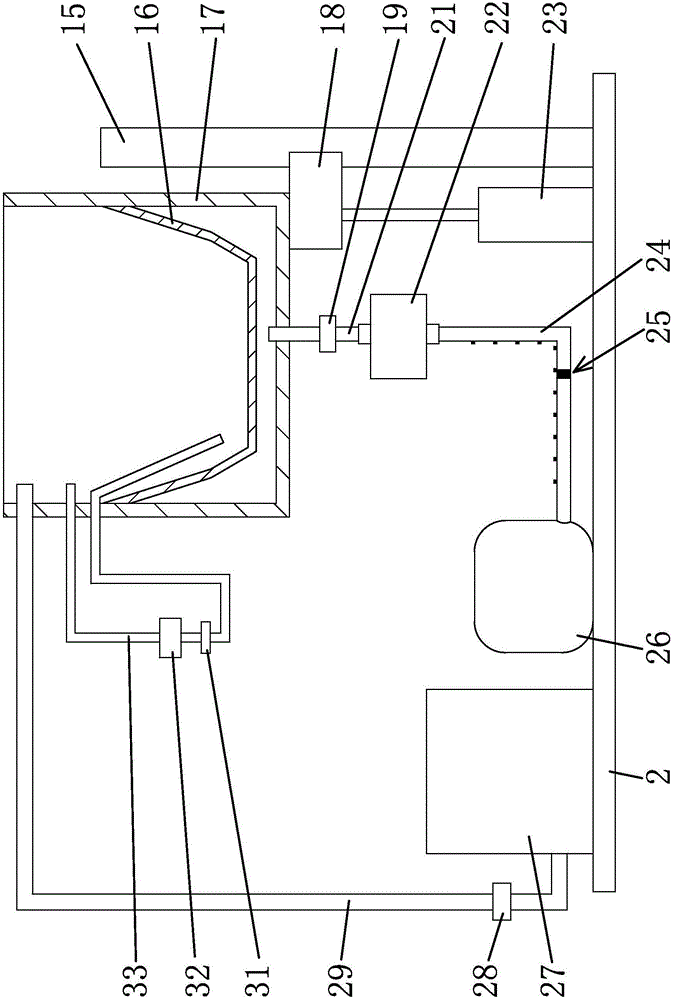

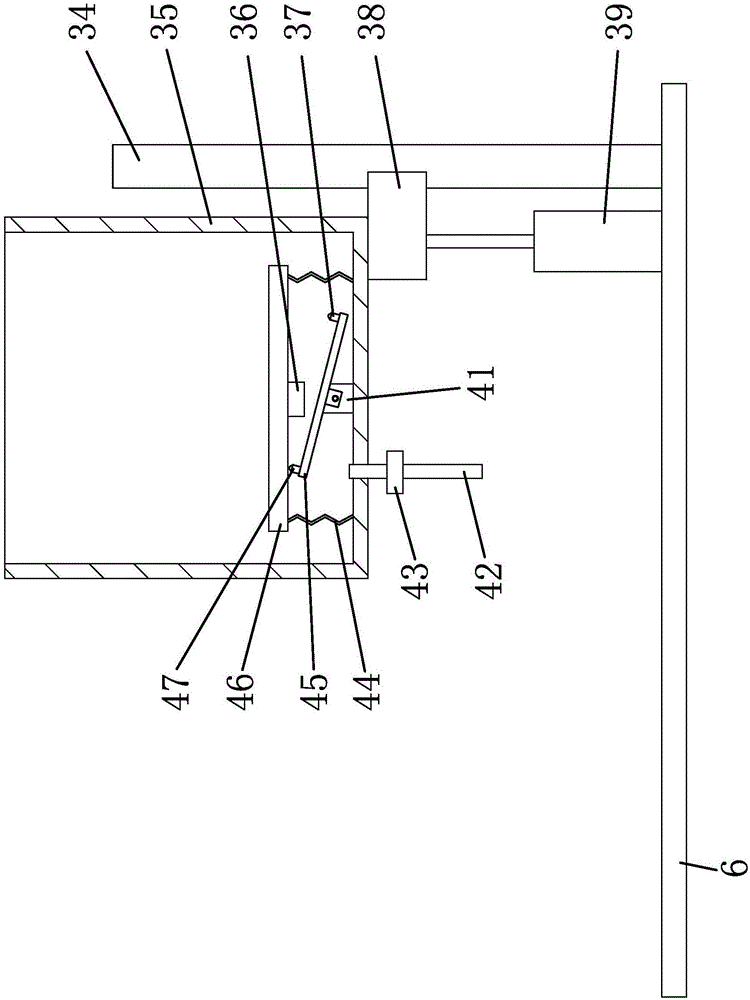

Bottled water sealing device

The invention provides a bottled water sealing device, comprising a body, wherein the outer side wall of the body is provided with a placement opening, the inner bottom wall of the body is provided with a lifting mechanism, and the inner top wall of the body is provided with a sealing mechanism. The bottled water sealing device can quickly solidify a sealing film at an opening of bottled water, saves time and labor compared with manual sealing, and has good sealing consistency, ensures the sealing quality of bottled water, and has high sealing efficiency.

Owner:WENZHOU HAIDENENG ENVIRONMENTAL PROTECTION EQUIP & TECH

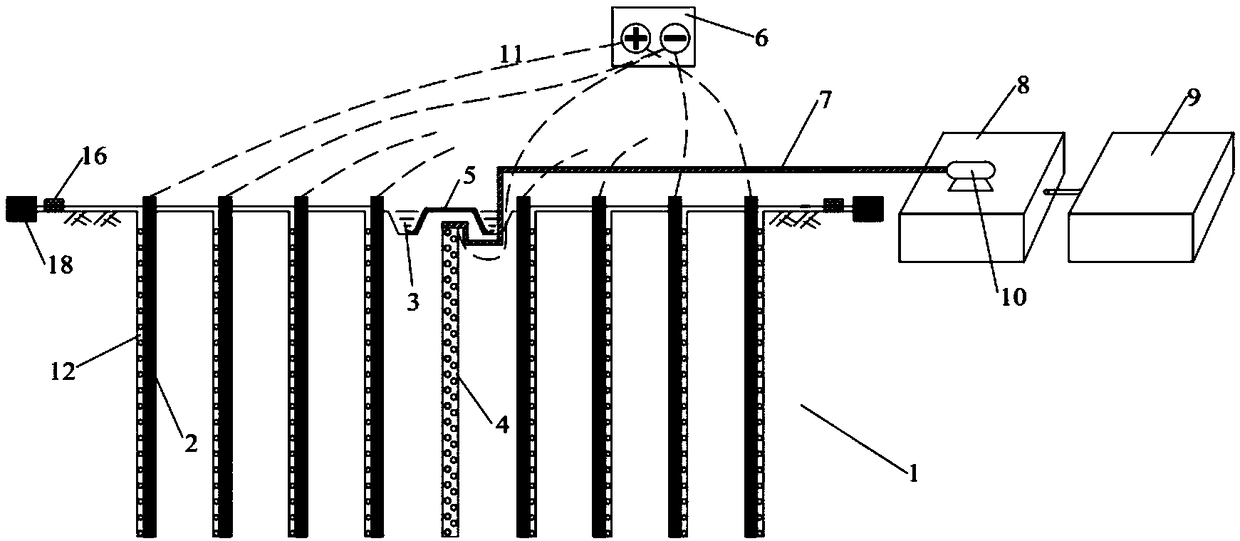

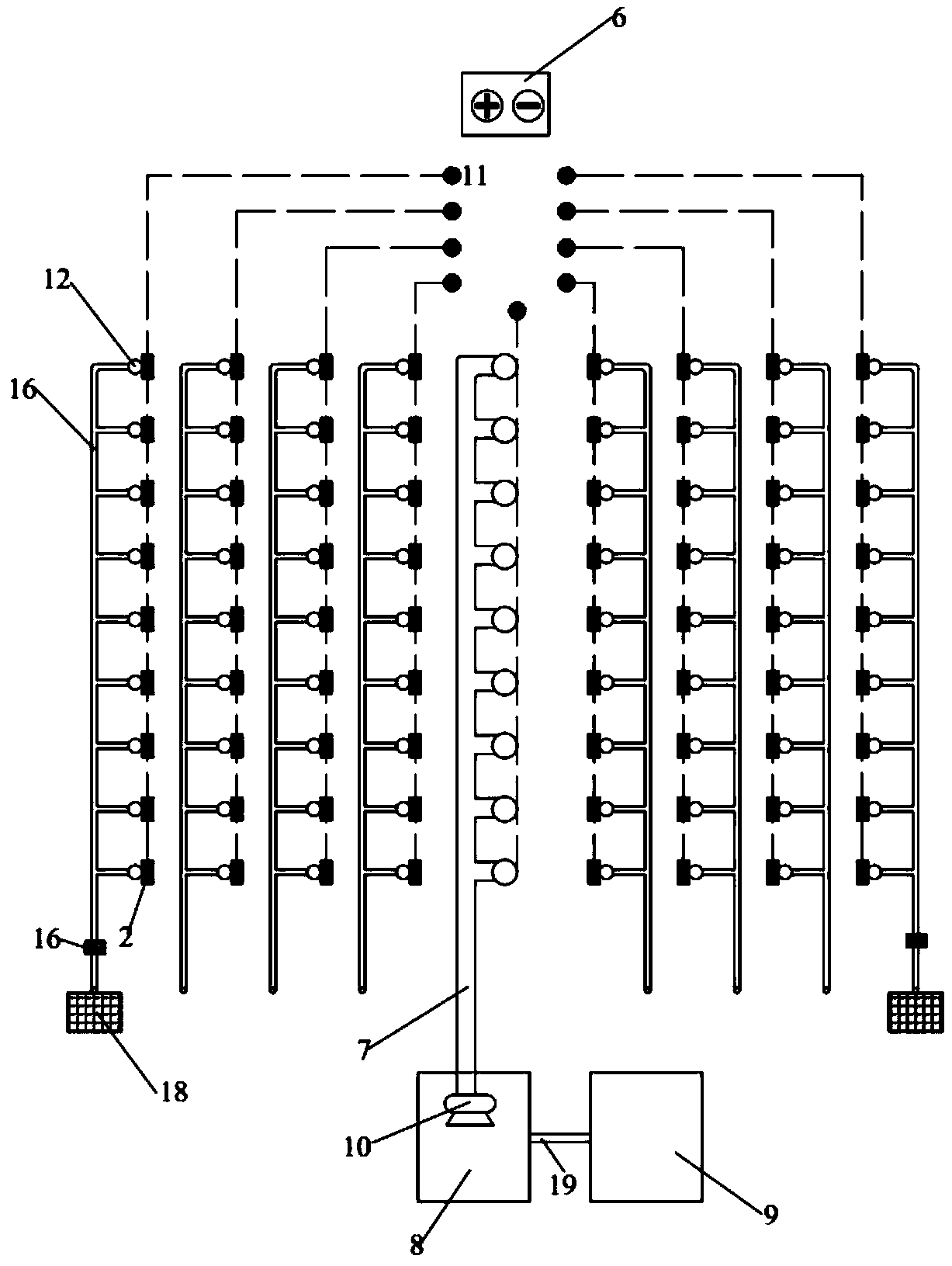

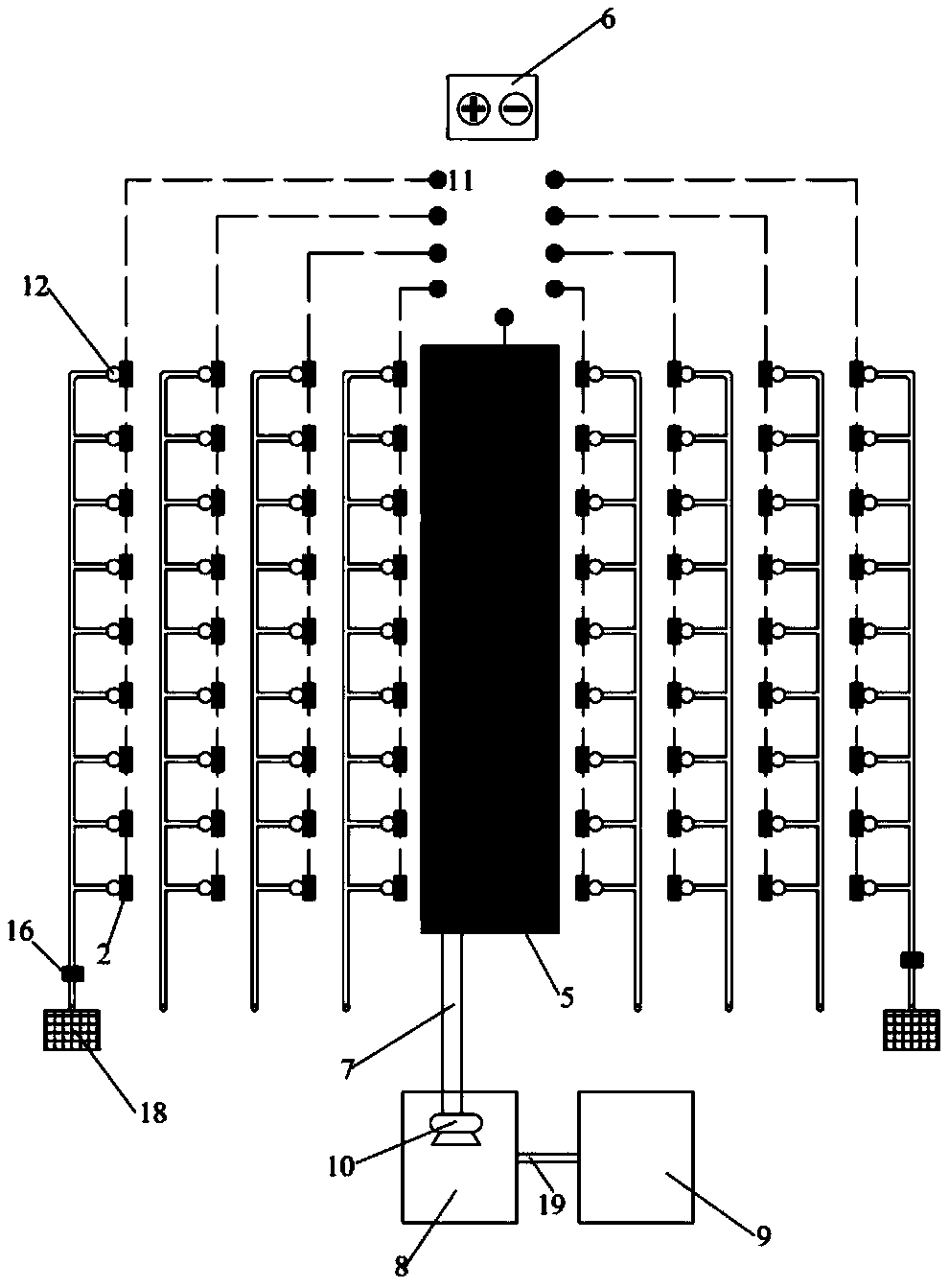

System for repairing heavy metal contaminated soil and processing method

InactiveCN109465290ACuring stabilityHigh removal rateContaminated soil reclamationChemical solutionEngineering

The invention discloses a system for repairing heavy metal contaminated soil and a processing method. The system comprises a progressive electric repair system and a vacuum drainage system, wherein the progressive electric repair system comprises a plurality of lines of electrodes which are laid in to-be-processed soil according to a certain sequence and a direct current power supply which is respectively connected with the electrodes of each layer or each row by virtue of conducting wires; the vacuum drainage system comprises a water pumping pipe which extends to a cathode, a vacuum pump which communicates with the water pumping pipe and a pool which communicates with the outlet end of the vacuum pump; during operation, the electrodes are adjusted to be connected with an anode or the cathode of the direct current power supply according to a preset order, so that the direction of current is the same direction all the time, heavy metal ions are driven to move to the predetermined direction, an enriching area is formed in the preset cathode, and the heavy metal contaminated soil is repaired by injecting a chemical solution, circularly electrifying for many times and solidifying and stabilizing the enriching area. According to the system, secondary pollution caused by the heavy metal contaminated soil to the environment is avoided, the heavy metal removal rate is increased, the repair cost of the contaminated soil is reduced, and the system has the advantages of simple construction process, high operability and convenience in quality control.

Owner:NANTONG UNIVERSITY

Modified epoxy acrylate resin weather-proof exterior wall coating

The invention discloses a modified epoxy acrylate resin weather-proof exterior wall coating, which comprises raw materials with part by weight: modified epoxy acrylate resins 78 parts, polystyrene rubbers 41 parts, mica powder 7.5 parts, nanometer titanium dioxide 5.5 parts, nanometer magnesium hydroxide 3 parts, organophilic bentonite 2.5 parts, nanometer sea-foam stone powder 2 parts, diatomaceous earth 5.5 parts, talcum powder 6 parts, modified attapulgite 4 parts, titanate coupling agents 3 parts, styrene-acrylic emulsions 18 parts, chlorinated paraffin 2 parts, ethylene glycol 3.5 parts, 2,2,4-Trimethyl-1,3-pentanediolmono(2-methylpropanoate) 6 parts, sodium tripolyphosphate 4.5 parts, butyl acrylate resins 3.5 parts, ammonium dihydrogen phosphate 2 parts, diphenylamine 6 parts, deionized water 36 parts, carbamide 14 parts, polyacrylamide 9 parts, propylene glycol methyl ether acetate 6 parts, polyether modified polyester organic siloxane 5 parts and antioxidant trinitrophenyl groups (TNP) 7.5 parts. The modified epoxy acrylate resin weather-proof exterior wall coating has excellent water resistance, cohesive property and weather-proof performance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Treatment method for surface of bag cage framework

ActiveCN106362921AEasy to cleanQuick cleaningPretreated surfacesLiquid spraying apparatusSand blastingExisting Treatment

The invention provides a treatment method for the surface of a bag cage framework and solves the technical problems that an existing treatment method is complex to operate as bag cages need to be gradually picked and placed manually and the like. The treatment method for the surface of the bag cage framework comprises the following steps of: a, welding and forming the bag cage framework and removing oxide skin at a welded junction; b, performing sand blasting on the bag cage framework; c, removing the oxide skin and rust of the bag cage framework through a sand-blasting machine; and d, uniformly spraying organic silicon powder to the surface of the bag cage framework through a spraying device, wherein the coating thickness is 150-180 [mu]m. The treatment method provided by the invention has the advantage of being simple to operate.

Owner:ZHEJIANG JIEYU ENVIRONMENTAL PROTECTION EQUIPCO

Soil restoring agent with heavy metal ion adsorption and immobilization functions, and preparation method thereof

InactiveCN105925268ACuring stabilityImprove adsorption capacityOrganic fertilisersSoil conditioning compositionsAluminum magnesium silicateSoil science

The invention provides a soil restoring agent with heavy metal ion adsorption and immobilization functions, and a preparation method thereof. The raw material formula of the soil restoring agent comprises 60-80 parts of waste soil obtained after oil decolorizing and waste white clay oil extraction, 2-5 parts of a sulfur-containing compound, 8-15 parts of aluminum magnesium silicate and 10-20 parts of humic acid. The preparation method of the soil restoring agent comprises the following steps: 1, reacting the waste soil with the sulfur-containing compound at 500-700DEG C to obtain sulfenyl group-containing modified soil with an octahedral structure; and 2, mixing the modified soil with aluminum magnesium silicate and humic acid to obtain the soil restoring agent. The soil restoring agent has the advantages of recycling of the waste white clay, excellent heavy metal ion adsorption and immobilization functions, high added values, simple preparation and low cost.

Owner:SHANGHAI LICHANG ENVIRONMENTAL ENG

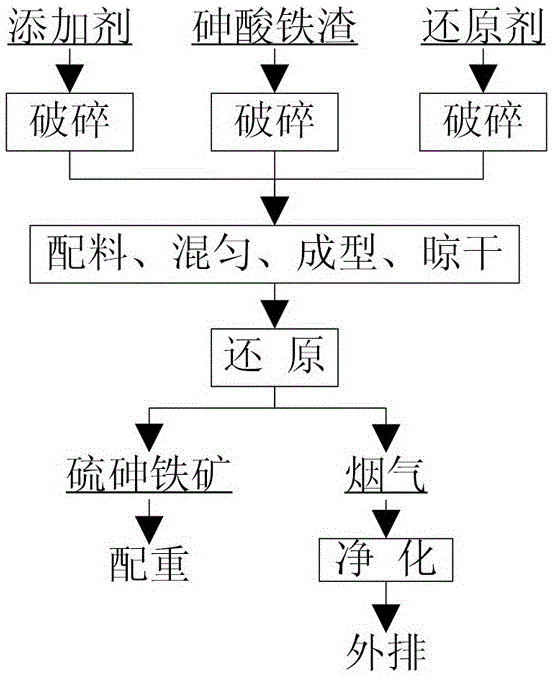

Stable arsenic acid iron slag solidifying method

The invention discloses a stable arsenic acid iron slag solidifying method. The stable arsenic acid iron slag solidifying method comprises the steps that arsenic acid iron slag, an additive and a reducing agent are mixed evenly, geierite is obtained through forming and reduction, and stable solidifying treatment is completed. The method can be used for directly producing geierite, dissolution of arsenic in waste slag can be effectively prevented, bounce does not occur with time, the geierite obtained after stable solidifying is high in strength, large in specific gravity and good in hydrolytic resistance, can be used for balance weight, the environmental environment caused by arsenic-containing slag stockpiling is eliminated, and stable solidifying of arsenic slag is achieved.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com