Briquette as material for steel making and method for production thereof

A manufacturing method, iron powder technology, applied in the direction of manufacturing tools, improvement of process efficiency, presses, etc., can solve problems such as high processing cost, environmental degradation, and poor viewpoint of effective resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

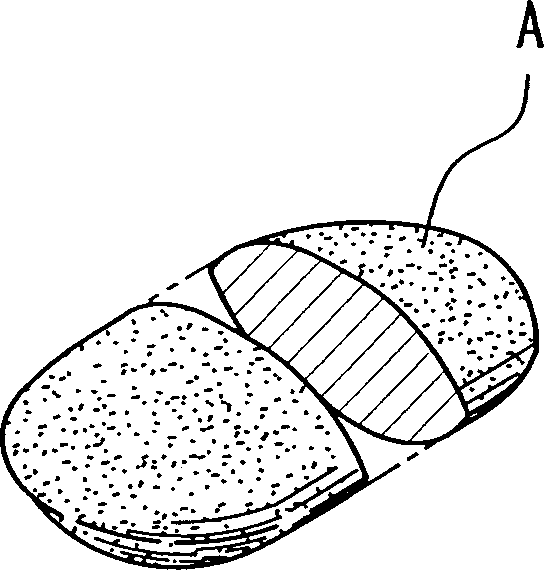

[0040] figure 1 It is a partially cutaway perspective view of an iron powder brick for steelmaking raw materials according to an embodiment of the present invention. This iron powder brick A contains powdery pure iron and oil, and is made by combining grinding chips of iron-based metals with oil and water. The cotton-like aggregate composed of grinding fluid is finely cut to obtain a powder, which is solidified with a curing auxiliary agent, and then dried to remove the above-mentioned moisture. The shape of this iron powder brick A is made into a substantially pillow shape.

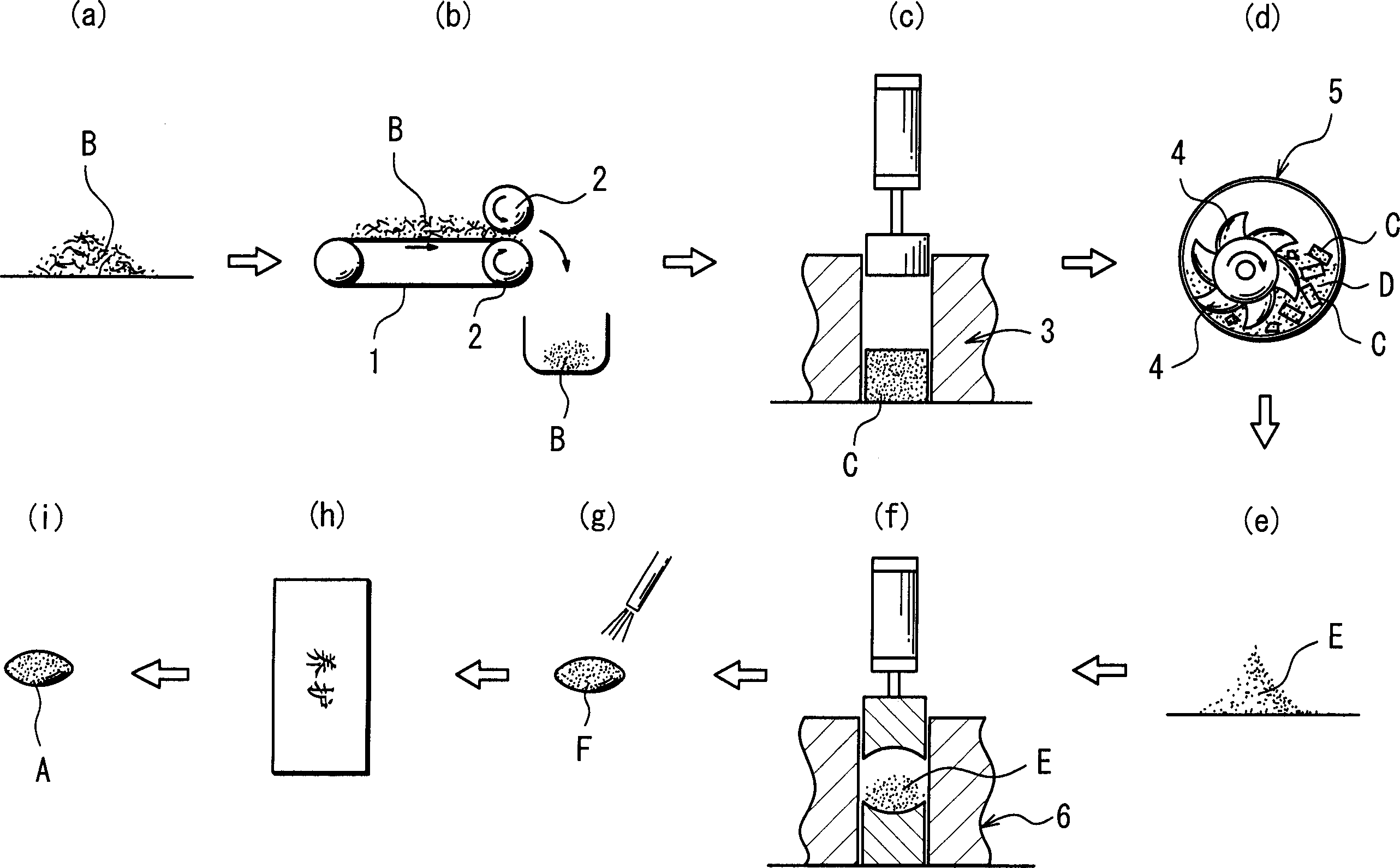

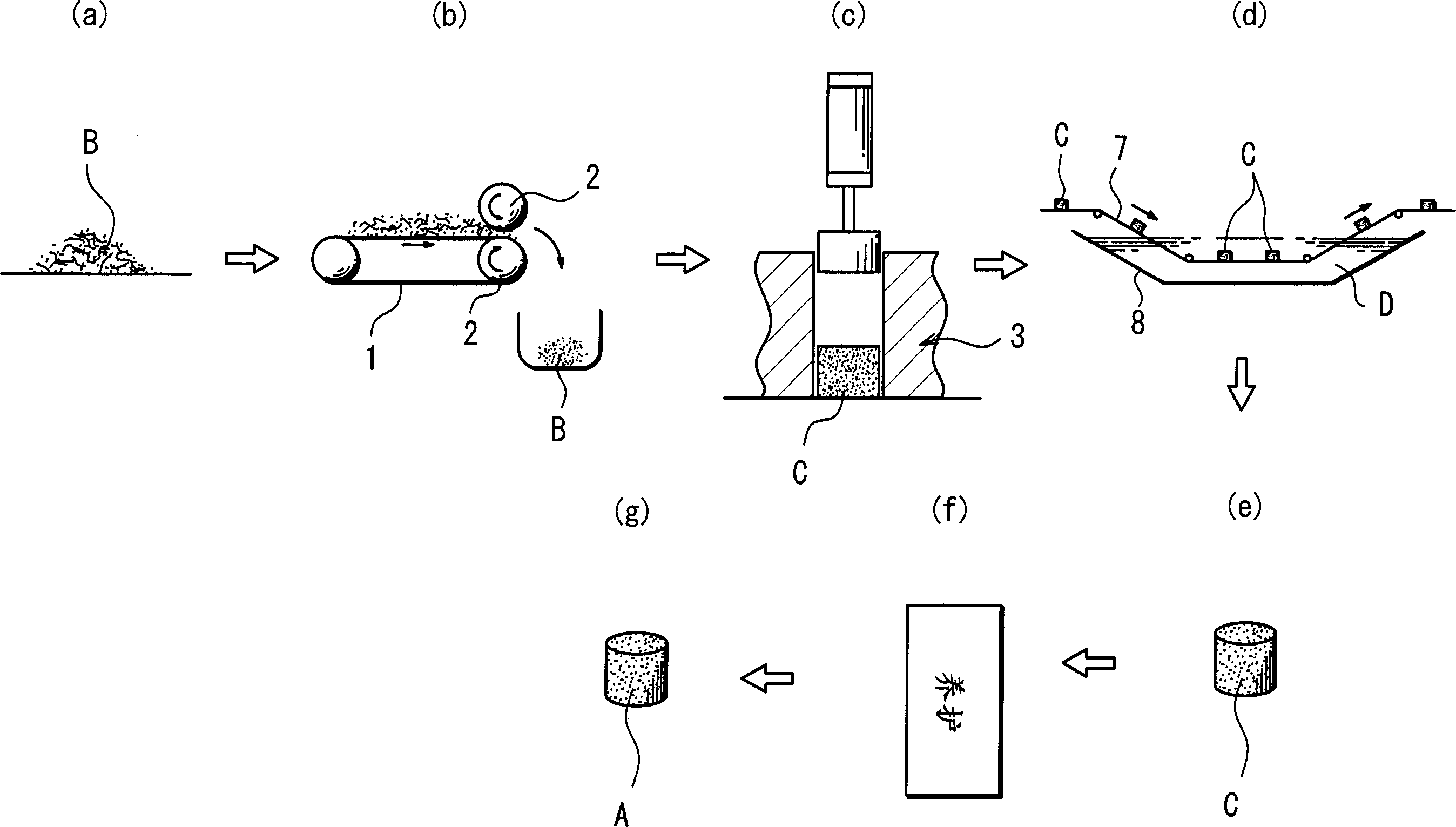

[0041] figure 2 It is a process drawing which shows the manufacturing method of the said iron powder brick A. In the manufacture of this iron powder brick A, the spongy agglomerate B of the grinding chips generated when the iron-based metals are first pressurized and compressed (refer to figure 2 (a)), and then preliminarily adjust the content of water and oil as components of the grinding fluid con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com