System for repairing heavy metal contaminated soil and processing method

A heavy metal-contaminated soil and heavy metal technology, applied in the restoration of polluted soil, etc., can solve the problems of low cost, low investment, short electromigration time, etc., to reduce repair cost, avoid secondary pollution, and facilitate quality control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

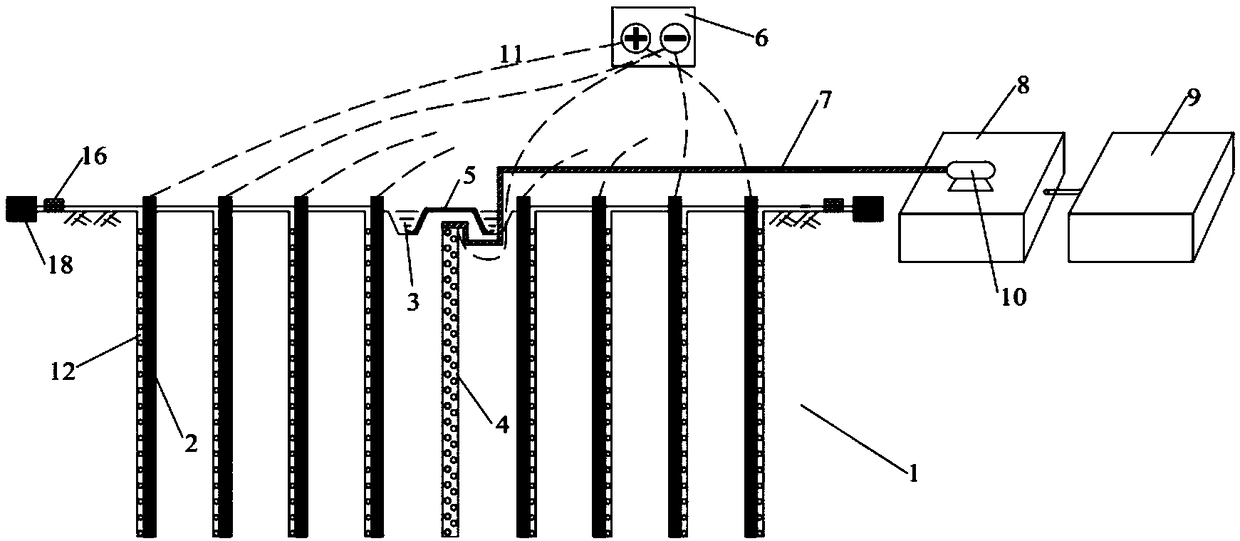

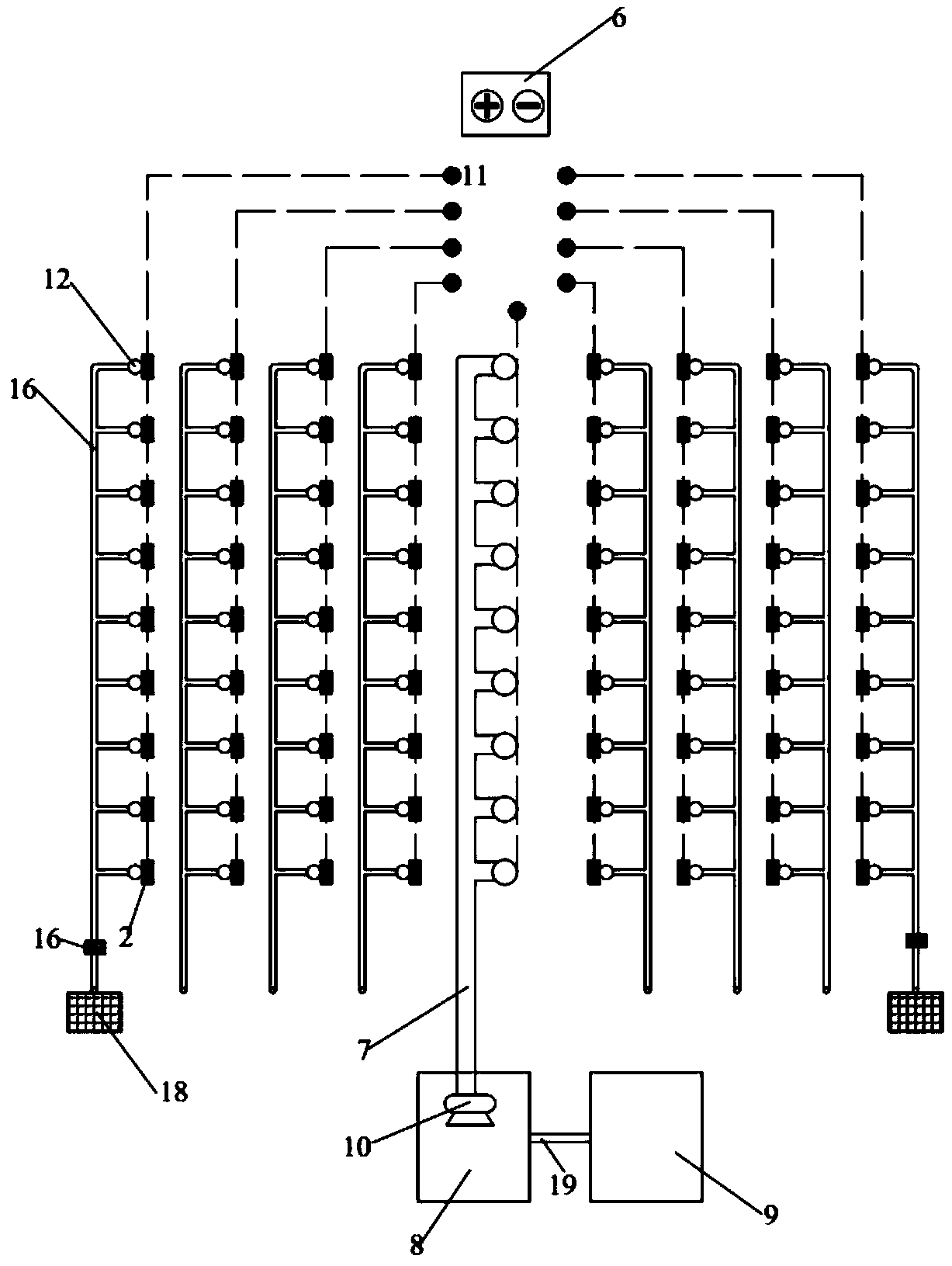

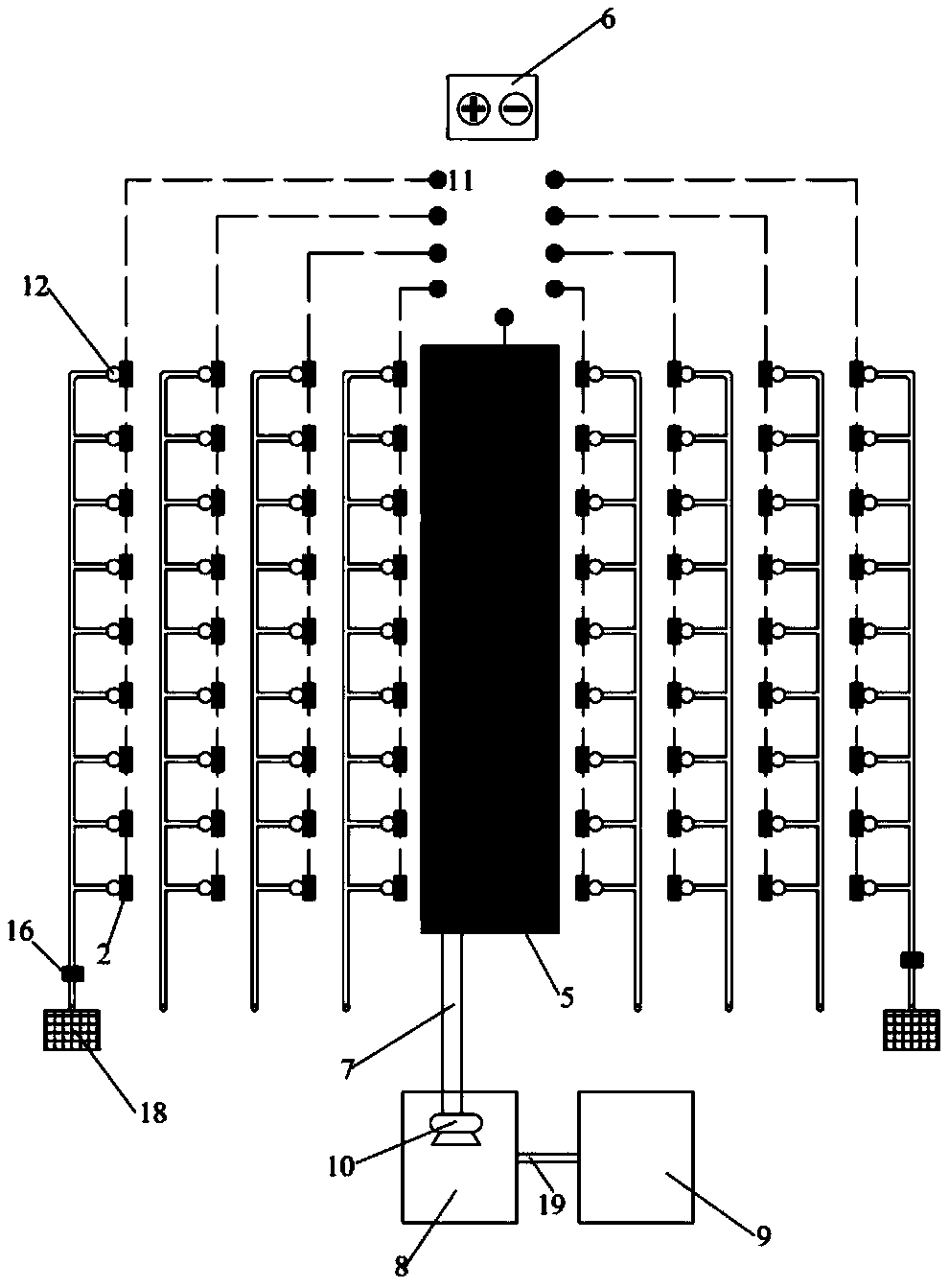

[0039] Such as figure 1 As shown, a system for remediating heavy metal-contaminated soil is provided, which mainly includes a progressive electric remediation system, a liquid injection system, a vacuum drainage system and a solidification stabilization system.

[0040] Among them, the progressive electric repair system includes several electrodes arranged in a rectangular, quincunx or ring shape. Each layer of electrodes is connected to the positive and negative electrodes of the power supply in turn, and the heavy metals in the polluted soil are transferred from the outside to the inside or from the inside to the outside. The liquid injection system includes a liquid injection pipe driven into the soil together with the electrode, and the other end of the pipe is connected to the liquid storage tank, and the flow and velocity are controlled by a peristaltic pump; the vacuum drainage system includes a suction pipe connected to the cathode tube in the enrichment area , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com