Treatment method for surface of bag cage framework

A processing method and skeleton technology, applied in the processing field, can solve problems such as complicated operation, and achieve the effect of simplifying operation steps, curing stability and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0051] The processing method of this bag cage skeleton surface, it comprises the steps:

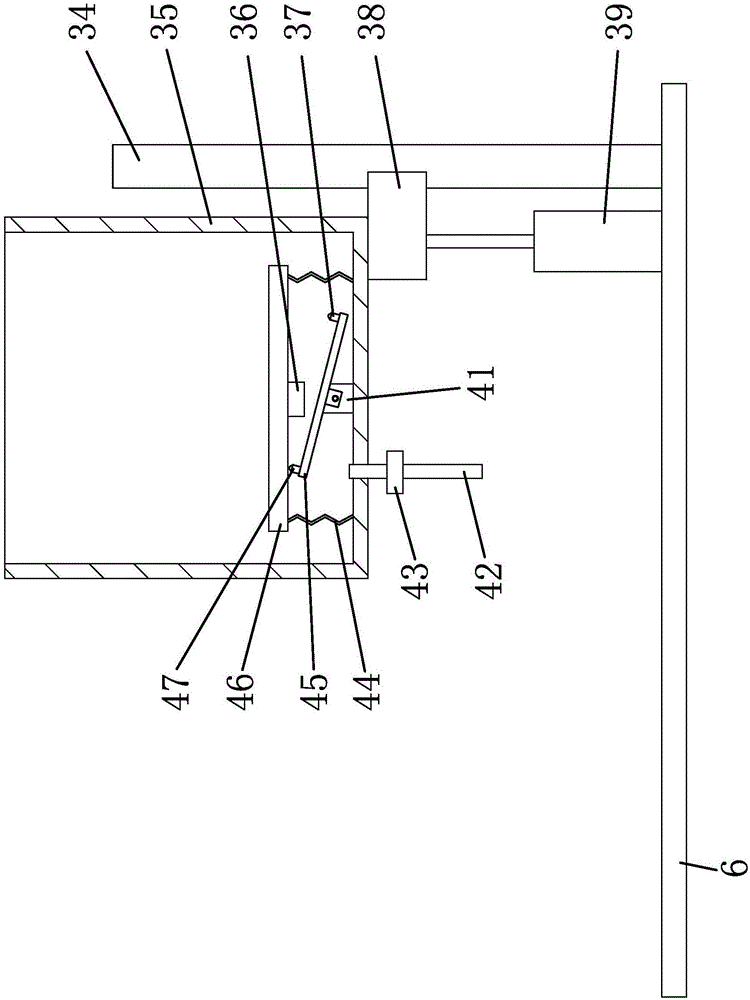

[0052] a. Weld the frame of the bag cage to remove the oxide skin at the weld;

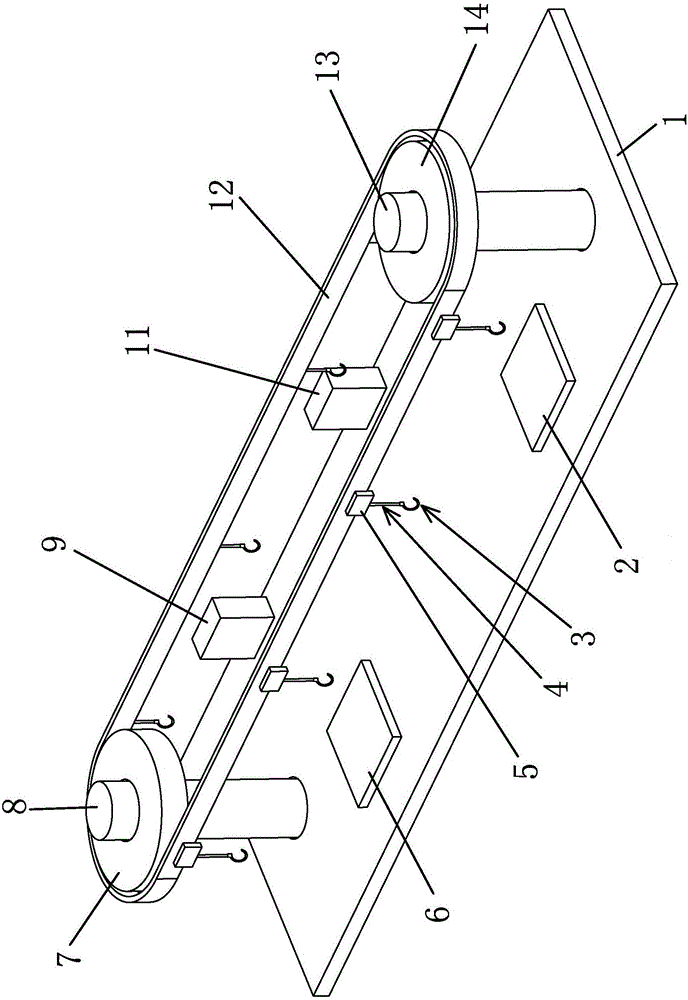

[0053] b. Sandblasting the bag cage skeleton:

[0054] c. Use a sandblasting machine to remove scale and rust from the bag cage skeleton;

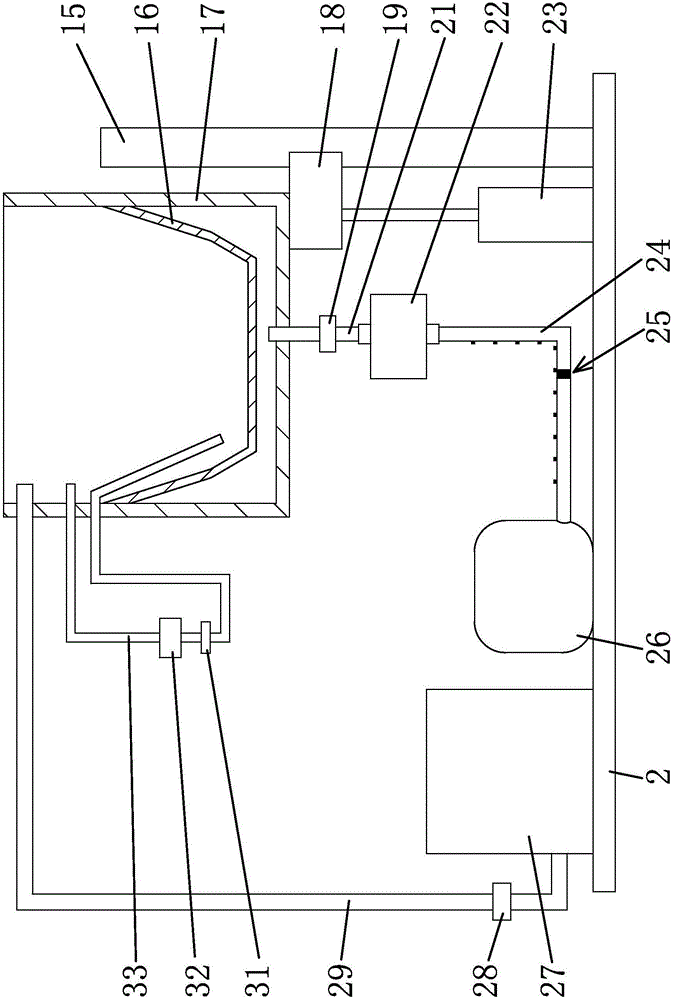

[0055] d. The organic silicon powder is evenly sprayed on the surface of the cage by spraying equipment, and the coating thickness is 150-180 μm; in this embodiment, the coating thickness is 160 μm, and the organic silicon powder adopts existing products available on the market .

[0056] By adopting the above method, the operation steps can be greatly simplified, the time required for processing can be saved, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com