Patents

Literature

401 results about "Existing Treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benign prostatic hyperplasia: An overview of existing treatment Neelima Dhingra and Deepak Bhagwat 1 Pharmaceutical Chemistry Division, University Institute of Pharmaceutical Sciences, Panjab University, Chandigarh - 160 014, India

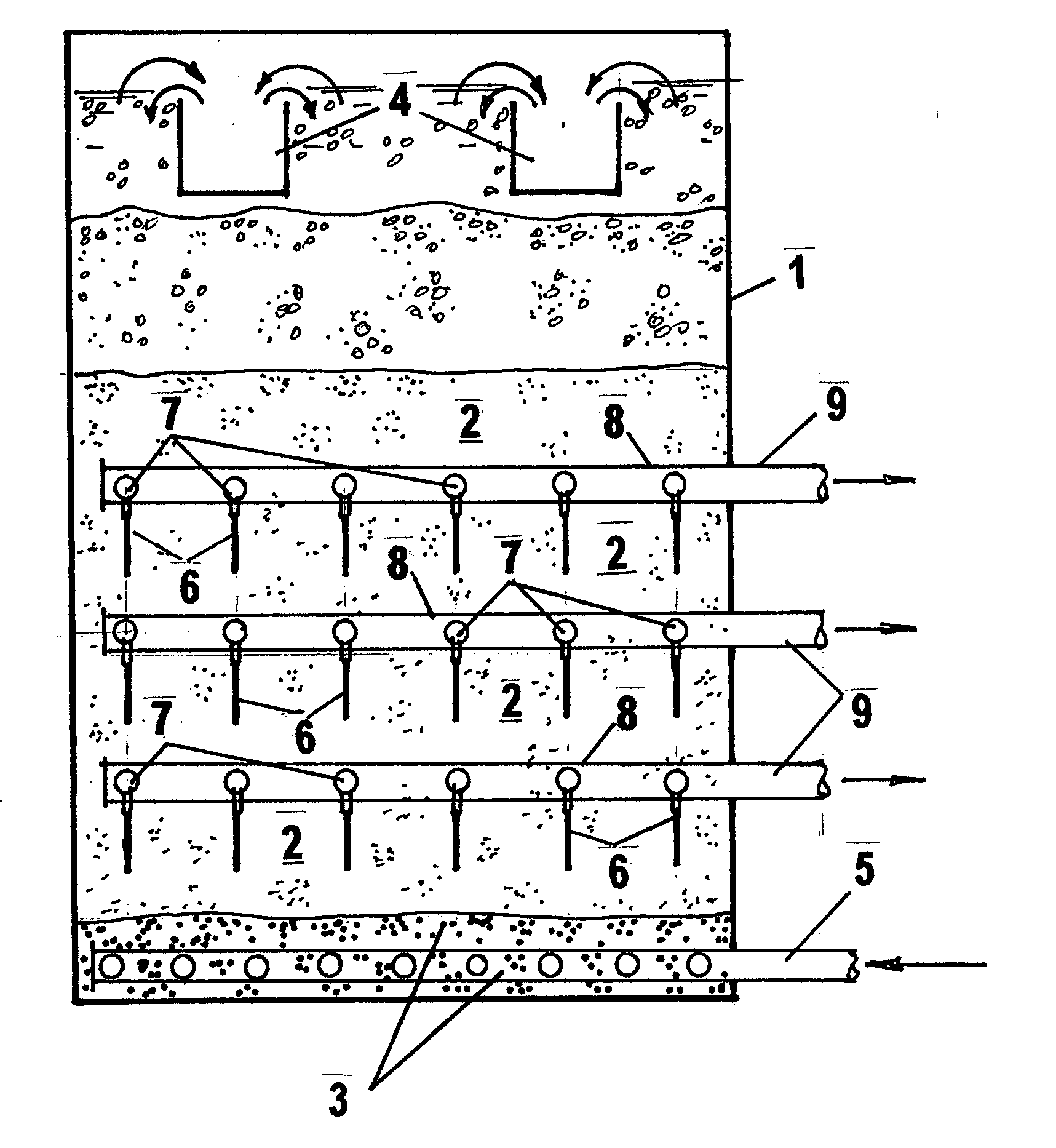

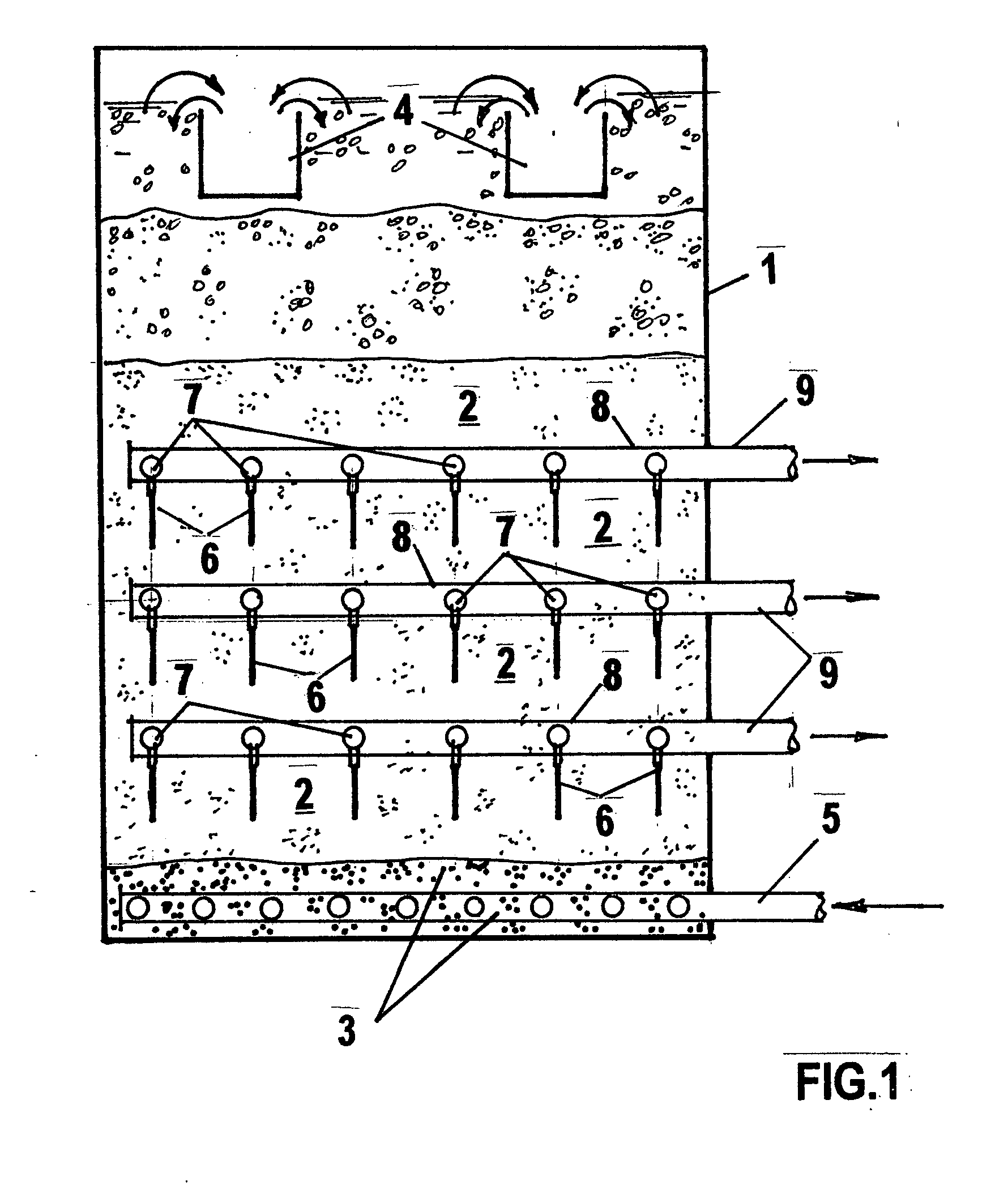

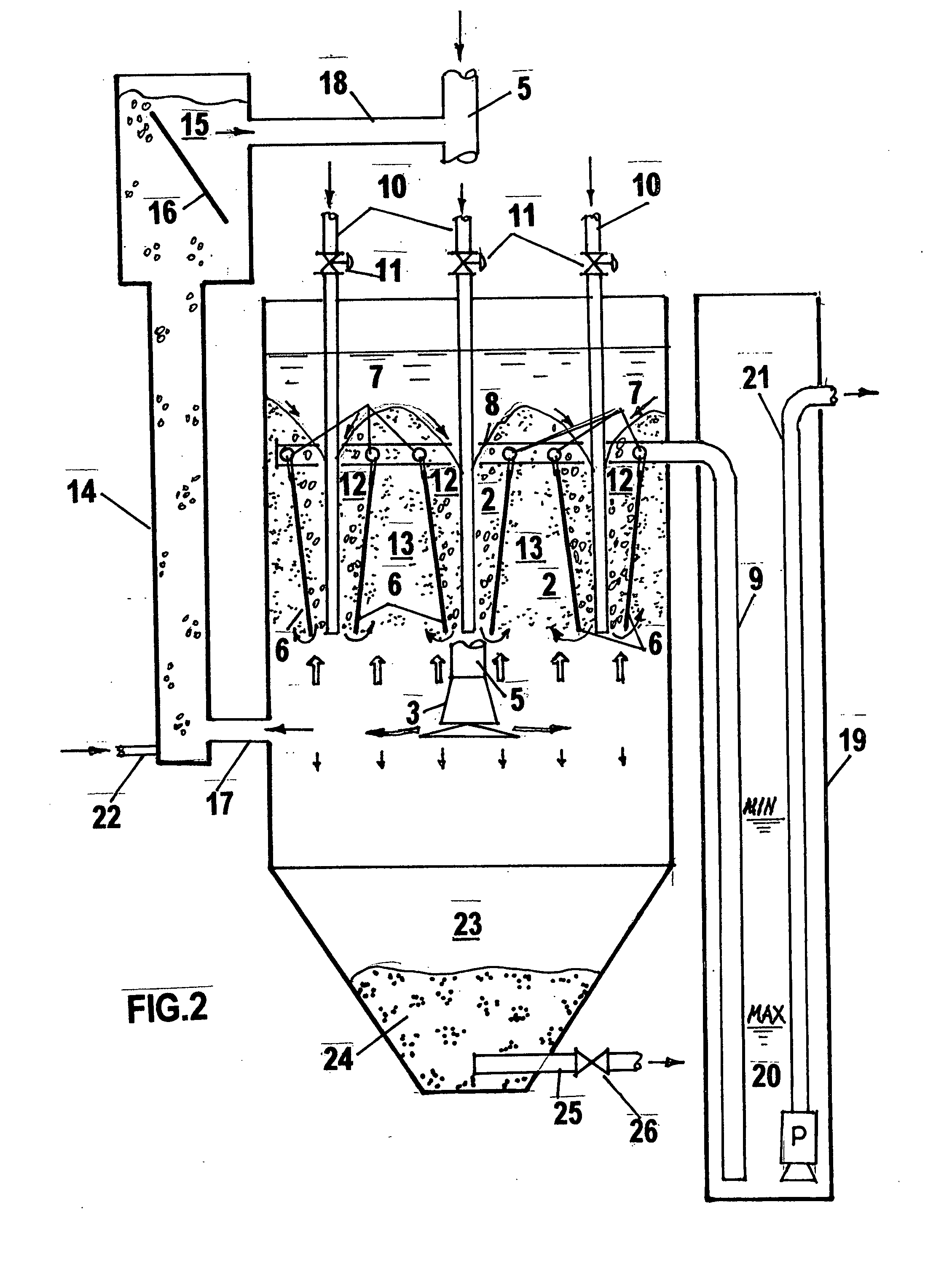

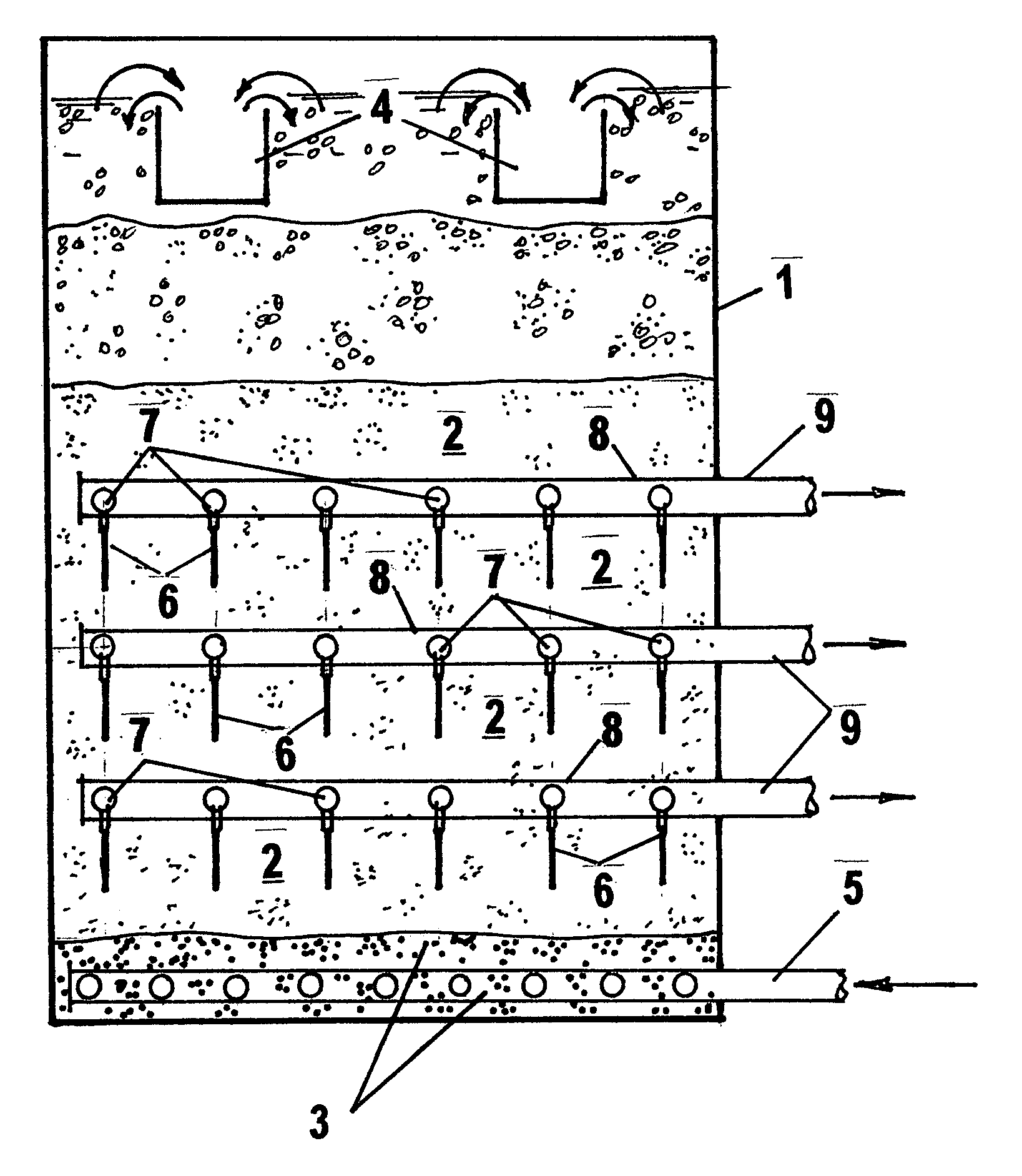

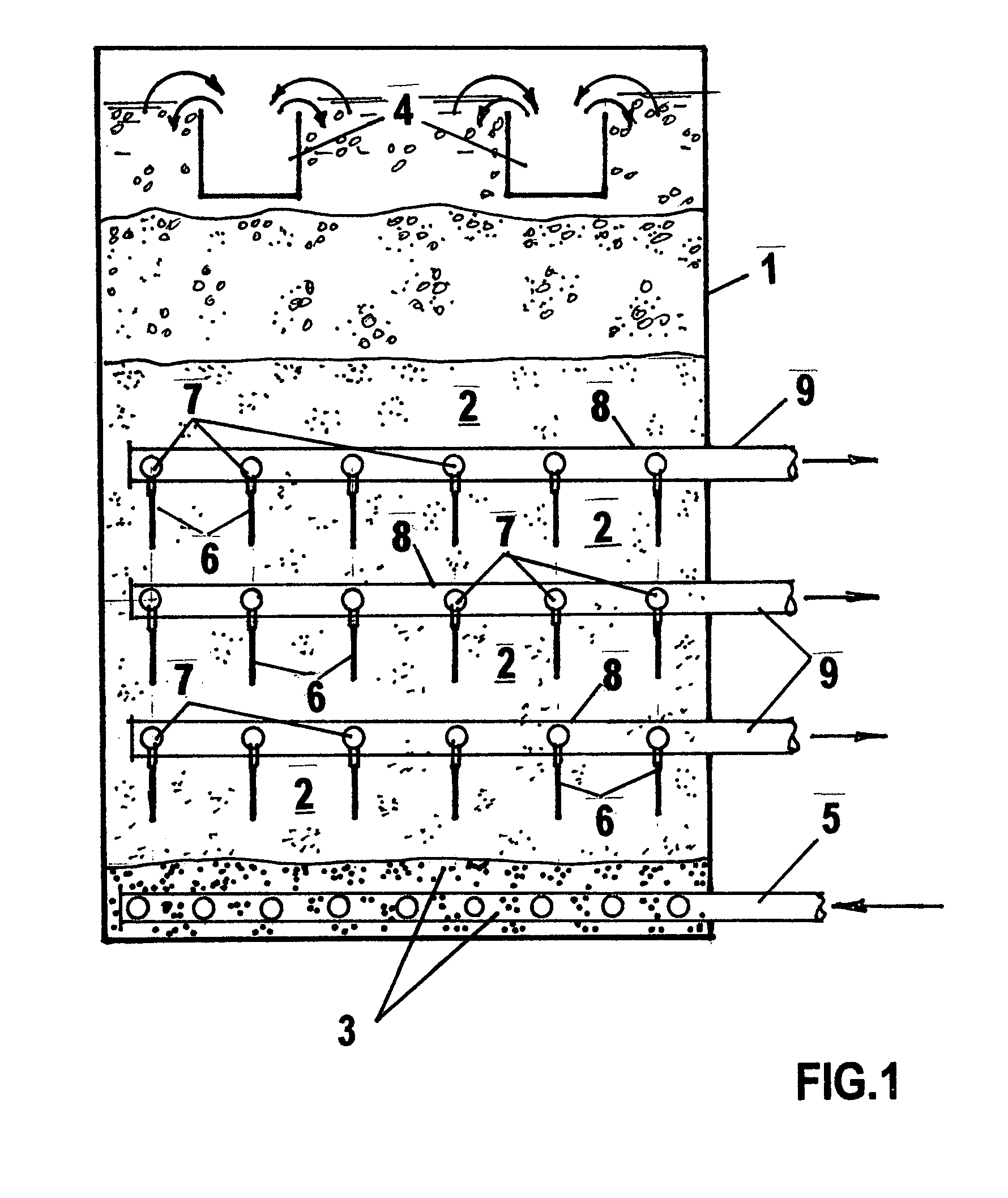

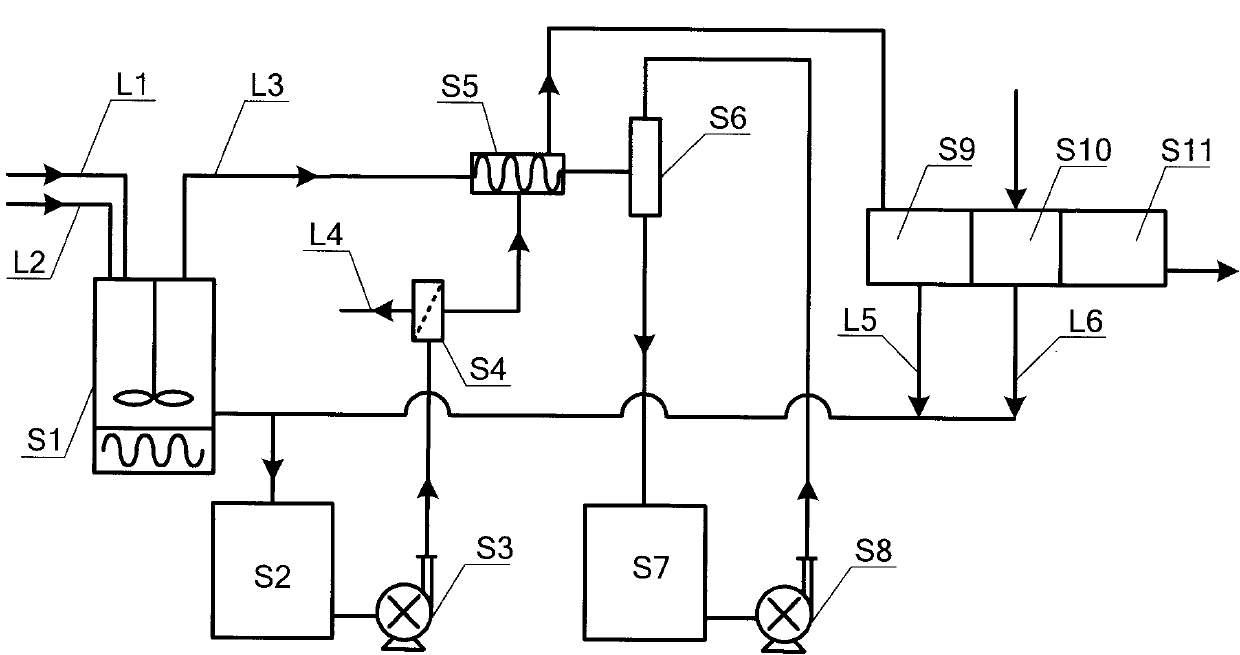

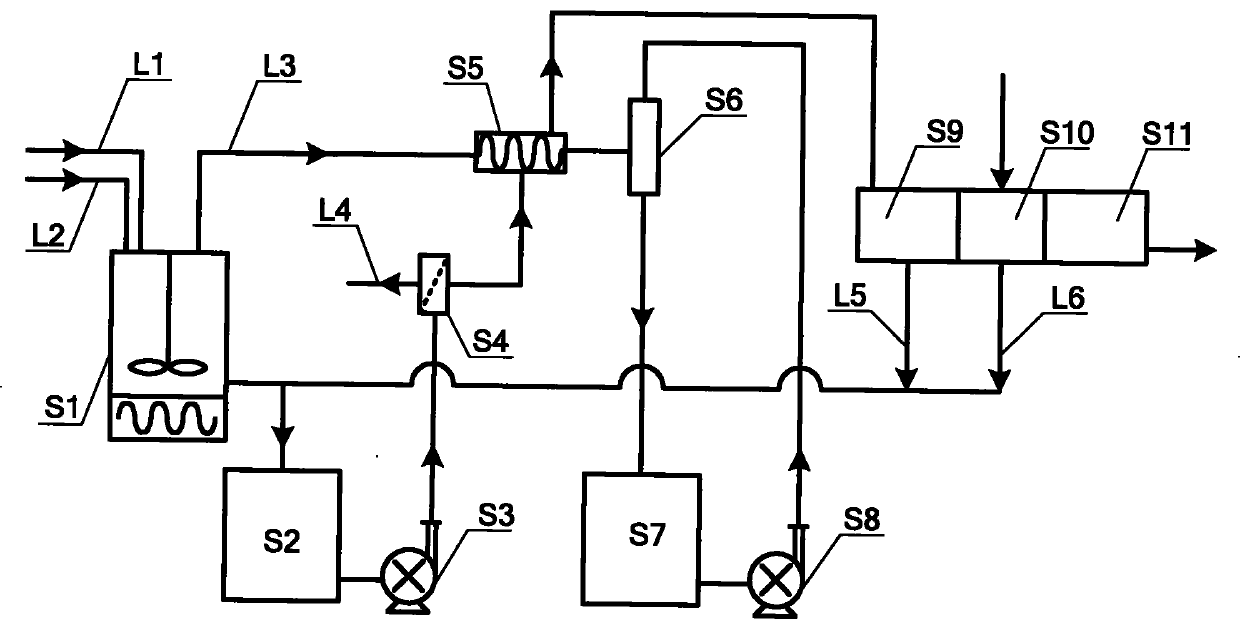

Method for water filtration

InactiveUS20090045135A1Great hydraulic resistancePromote circulationTreatment using aerobic processesTreatment involving filtrationNatural sourceSuspended particles

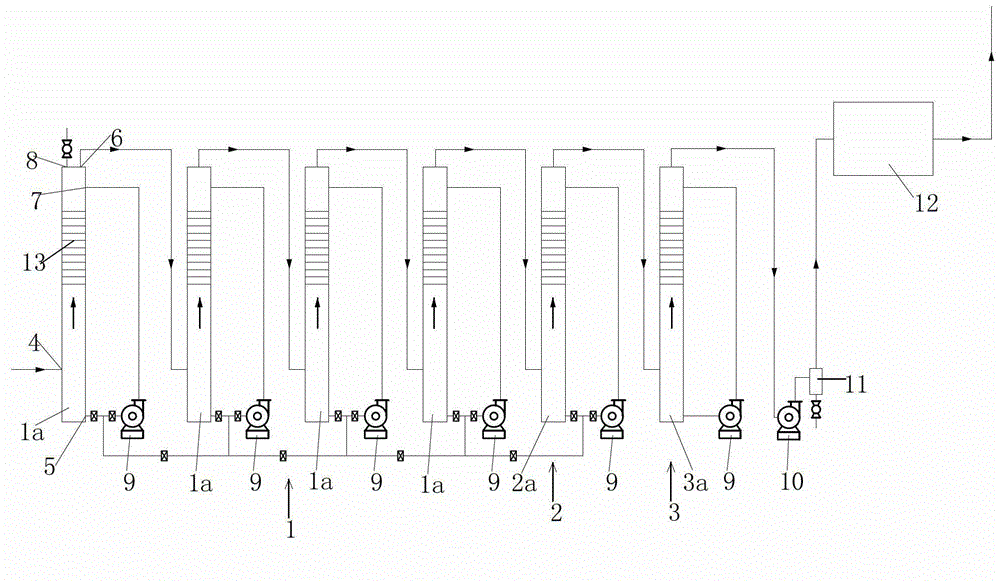

This is a method of filtration of a liquid comprising steps of sequential filtration of said liquid through at least one deep bed medium producing at least one first filtrate followed by at least one membrane medium filtration producing at least one second filtrate, wherein said membrane medium is at least periodically within said deep bed media Many types of deep bed and membrane media can be used. The domain of using contact clarification (direct filtration) can be expanded towards greater solids concentration. Operation and backwash, is simplified, continuous filtration becomes possible. Water can be water from natural source water, process water, wastewater, aqueous or non-aqueous suspensions, emulsions, solutions. Treatment can include mechanical interception of suspended particles, chemical, physical chemical, electrochemical, and biological processes. In water and wastewater processing, control over suspended solids, BOD, COD, nitrogen and phosphorus compounds, bacteria and viruses, heavy metals, color, and other constituents can be dramatically improved as compared to conventional processes. The method can be accommodated in new and modified existing treatment systems.

Owner:KHUDENKO ENG

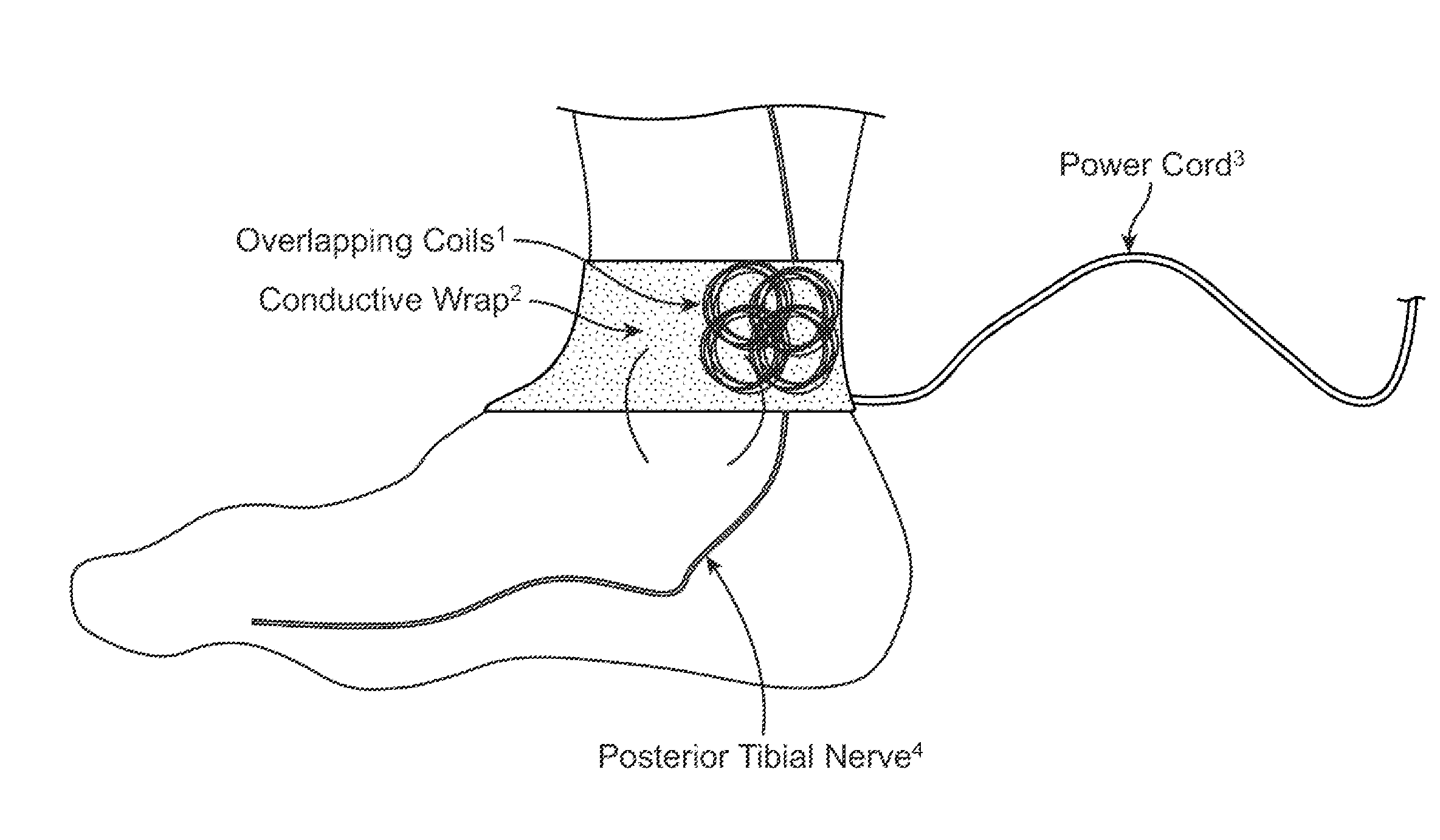

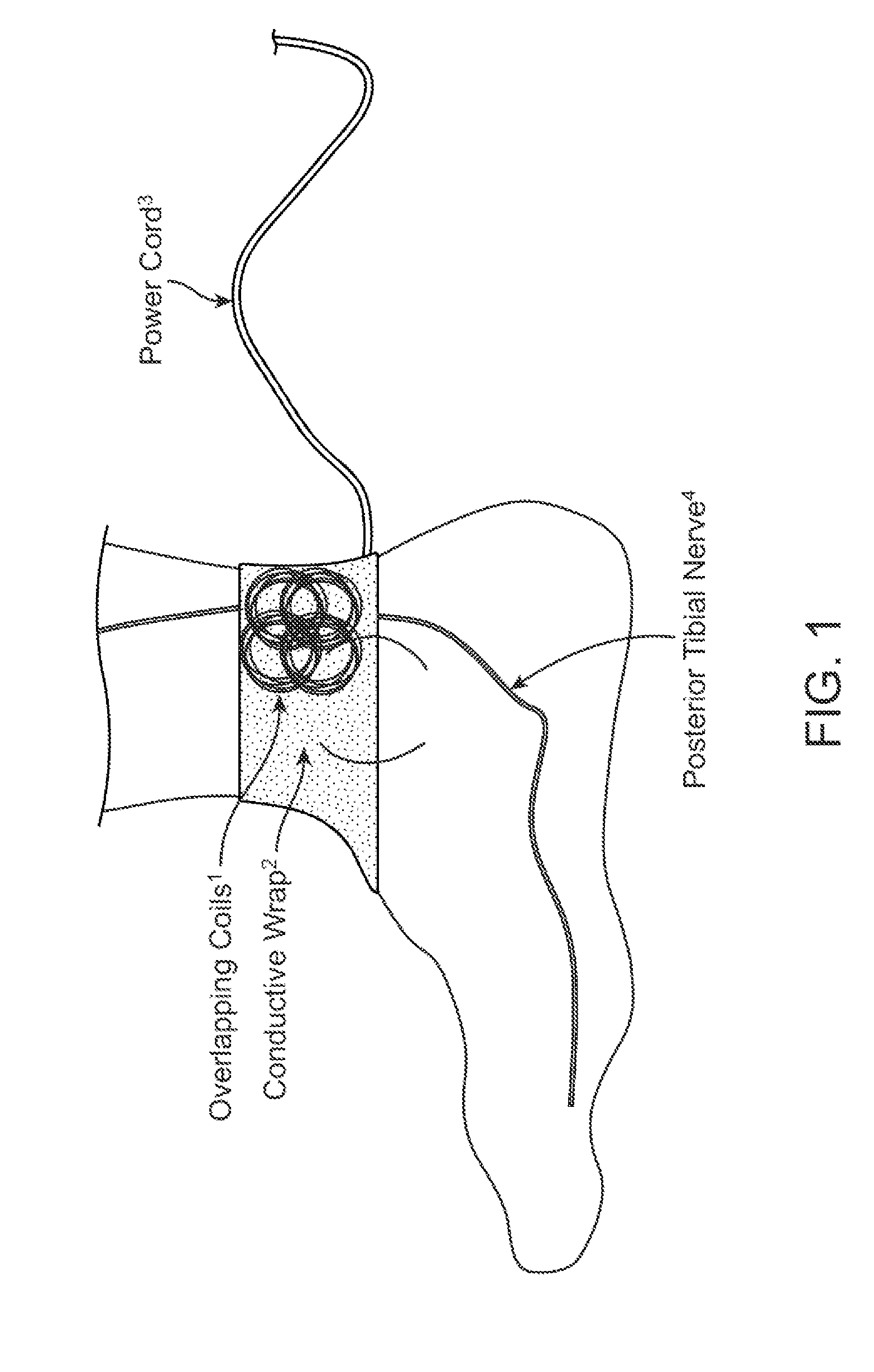

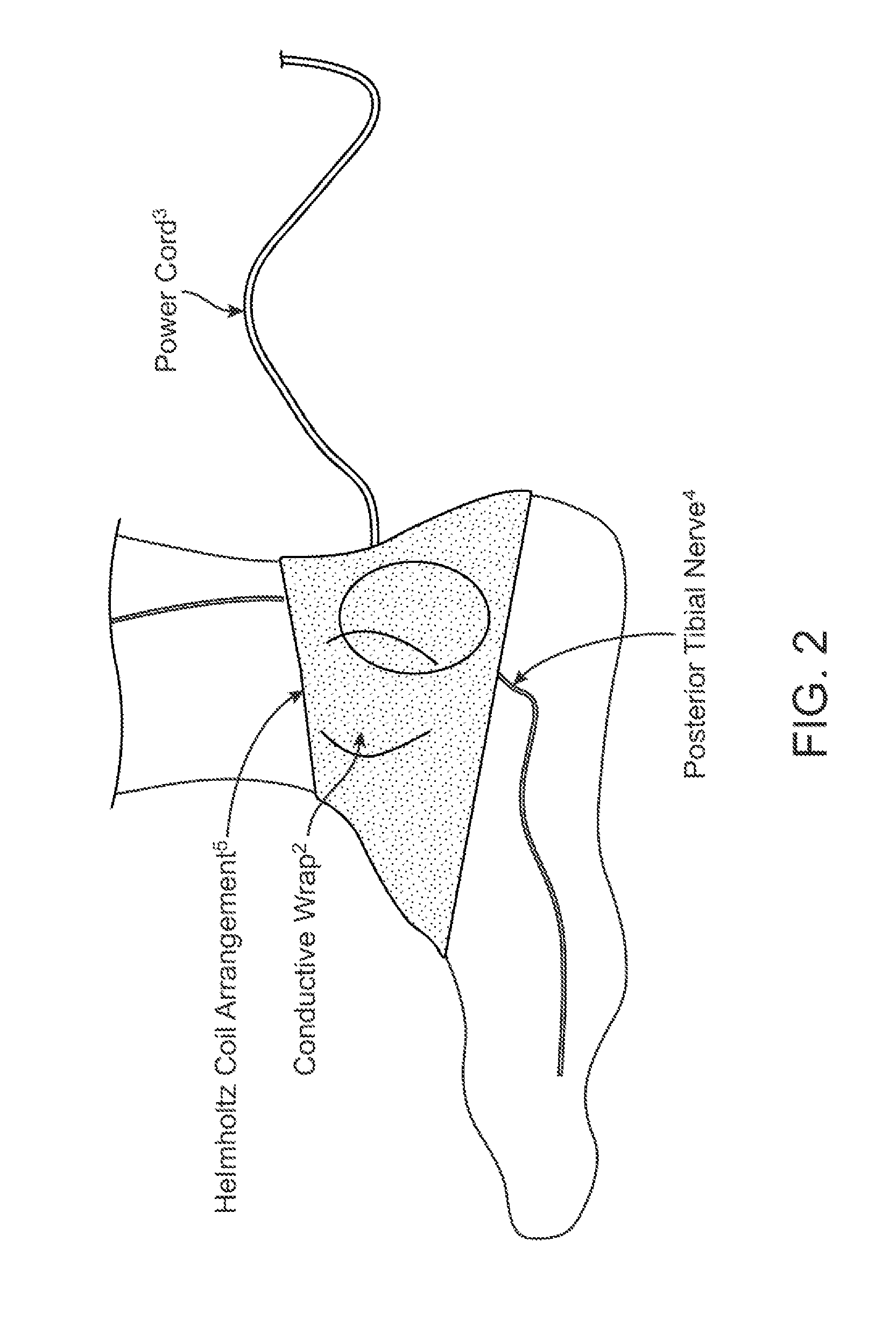

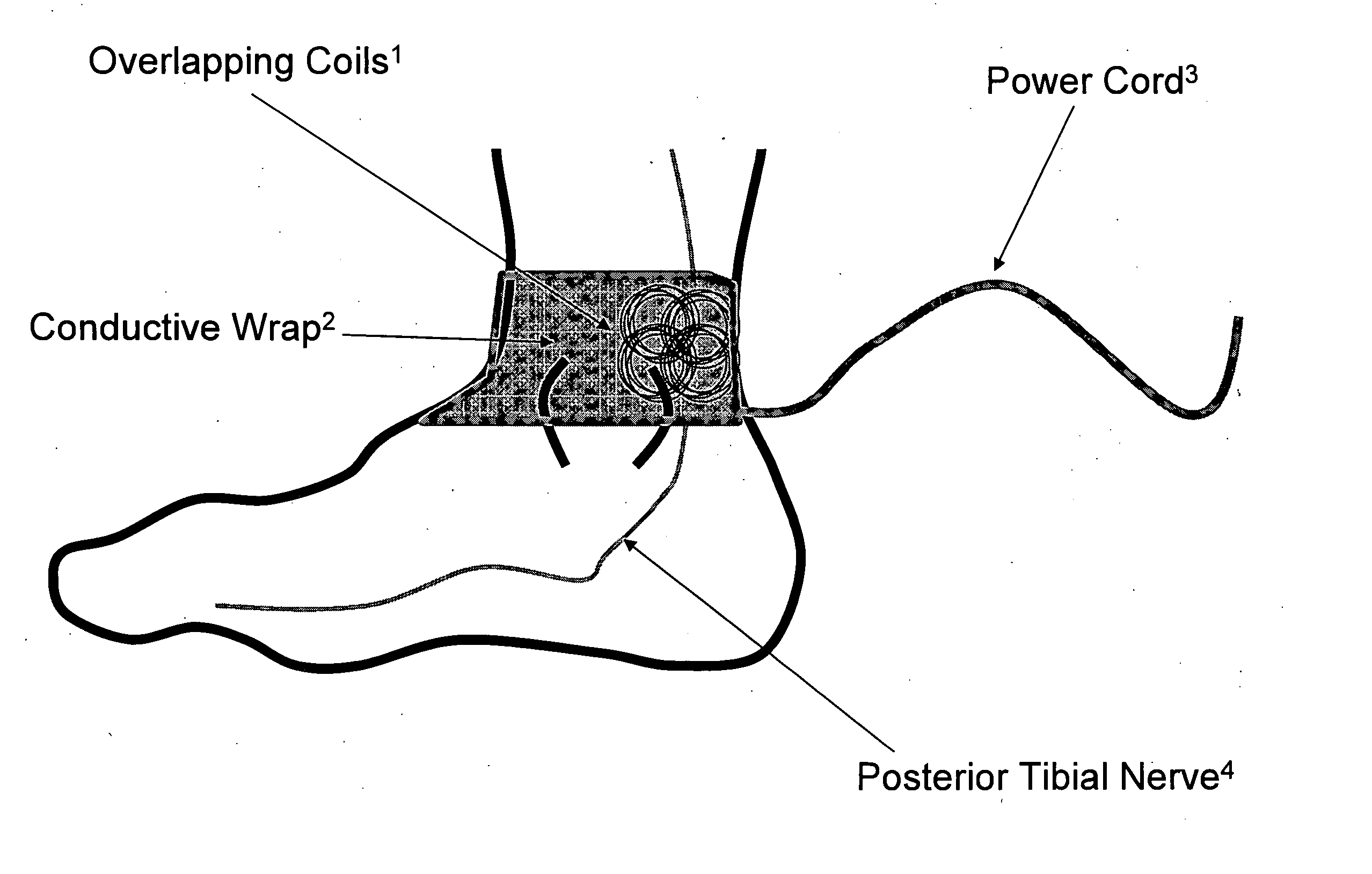

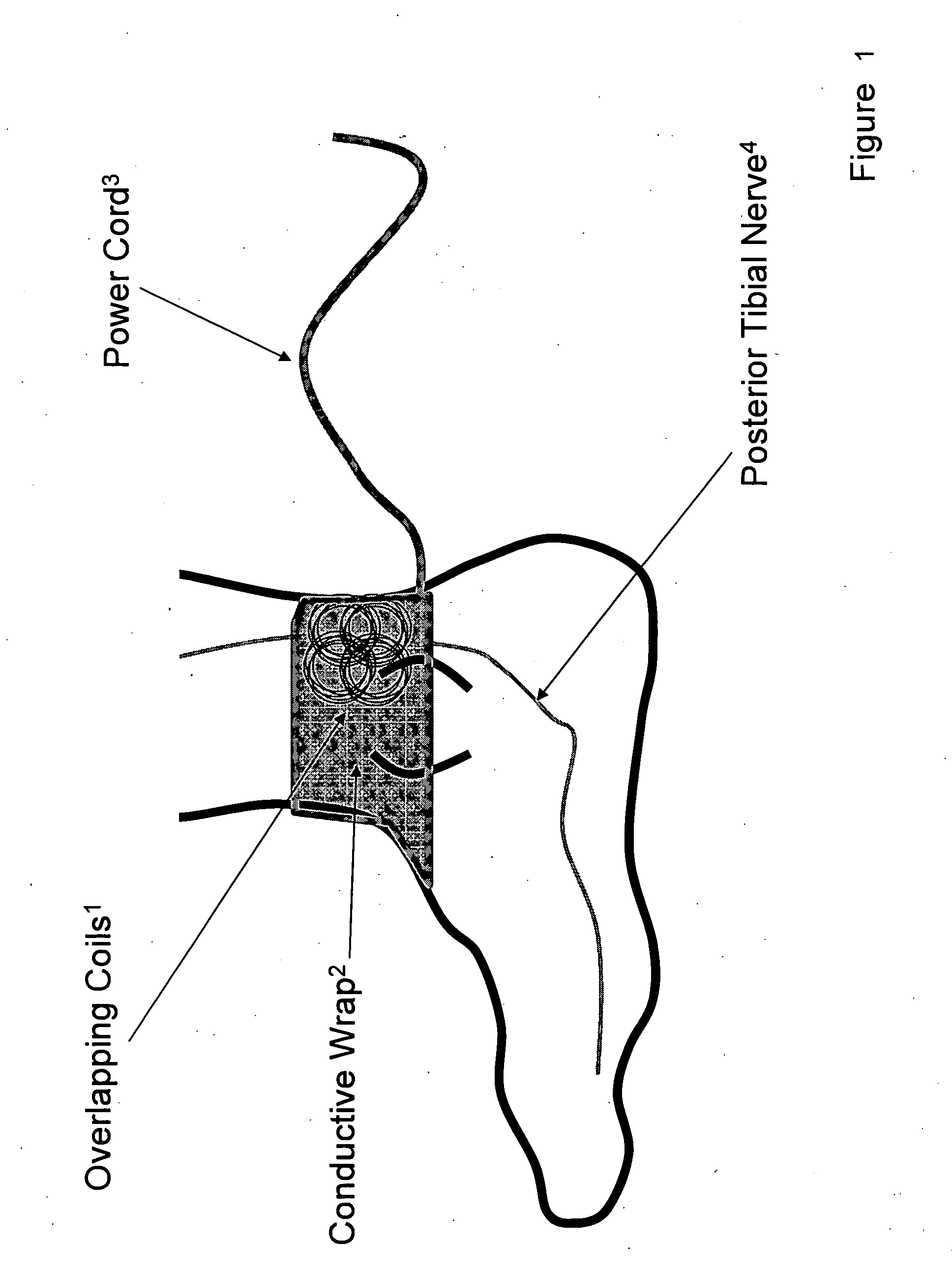

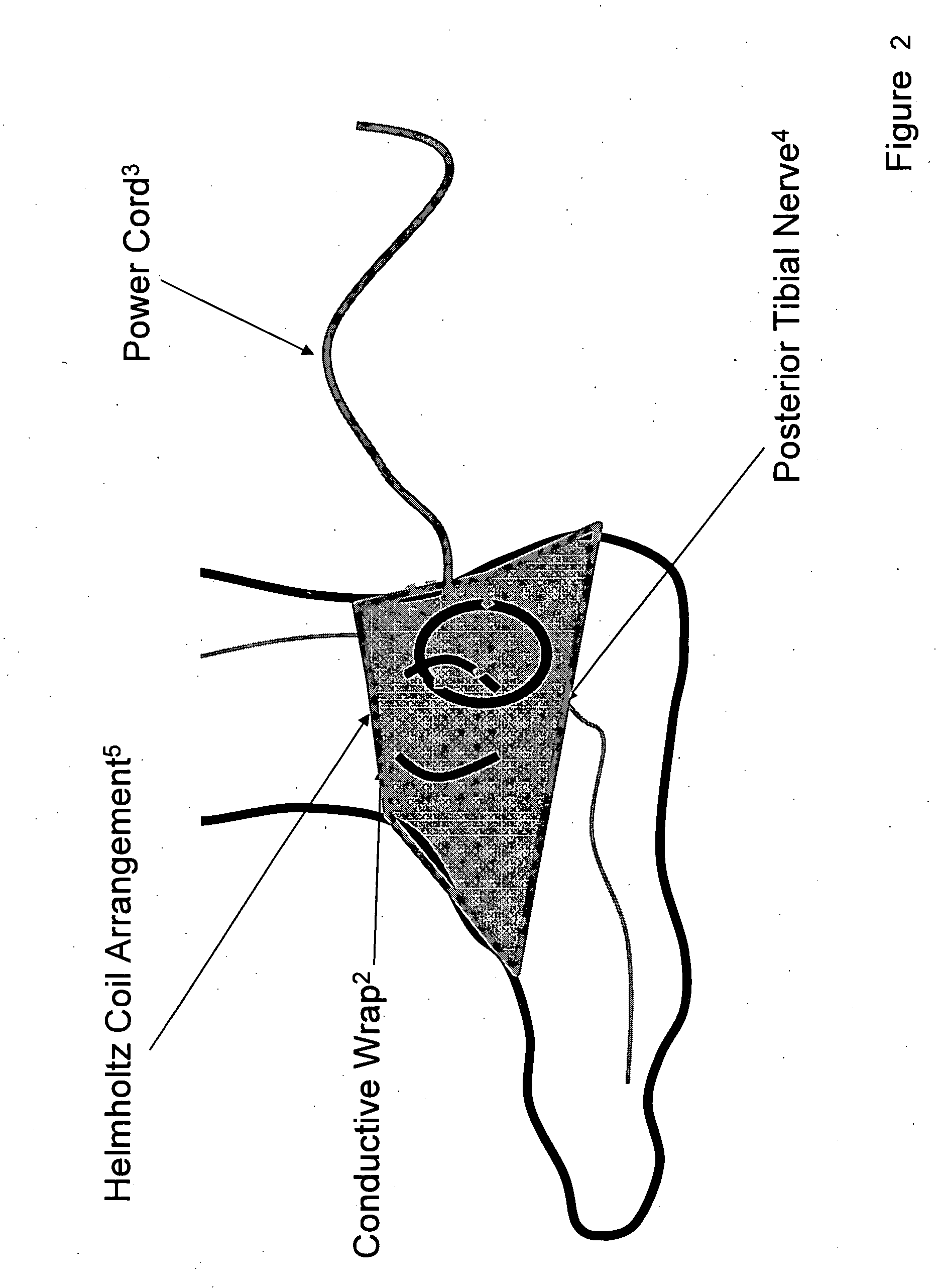

Method and apparatus for low frequency induction therapy for the treatment of urinary incontinence and overactive bladder

InactiveUS20100222630A1Easy to useEasy to placeElectrotherapyMagnetotherapy using coils/electromagnetsTreatment choicesTreatment options

Owner:EMKINETICS

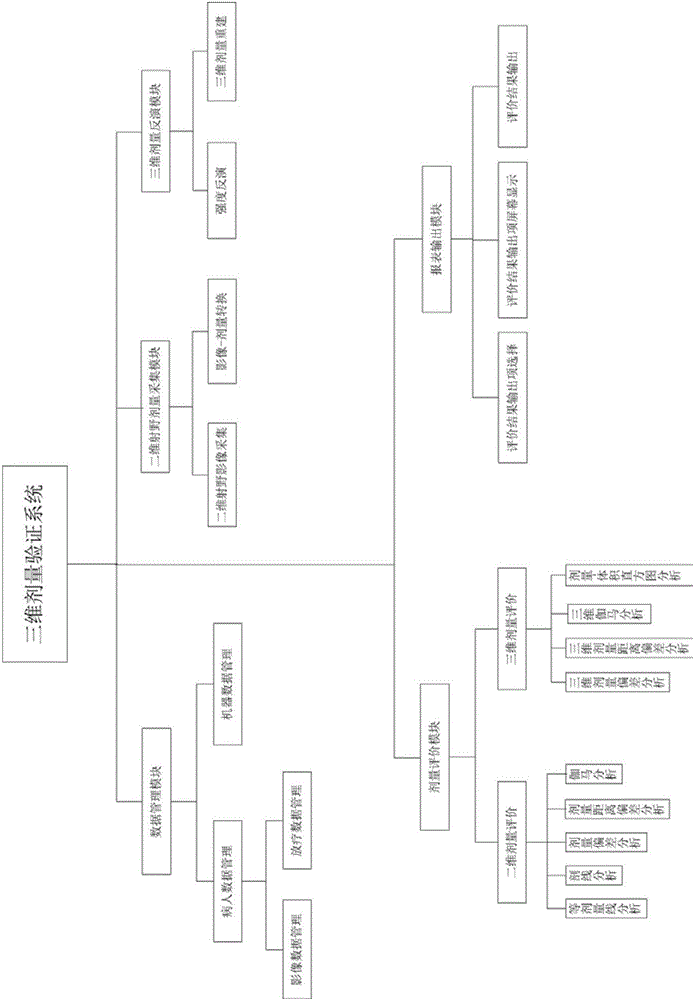

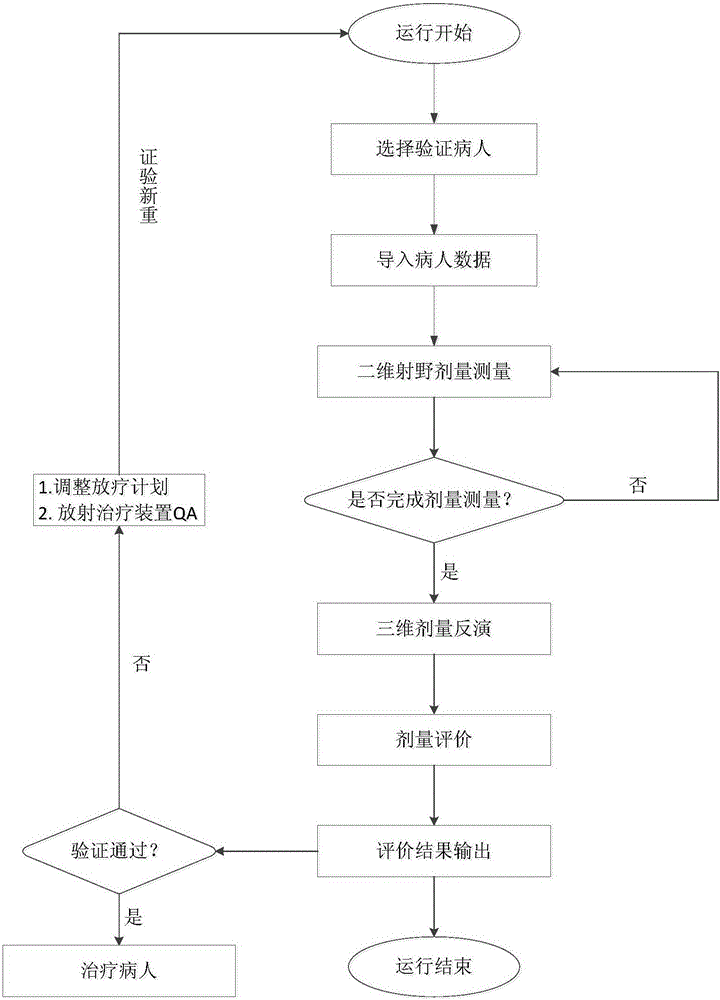

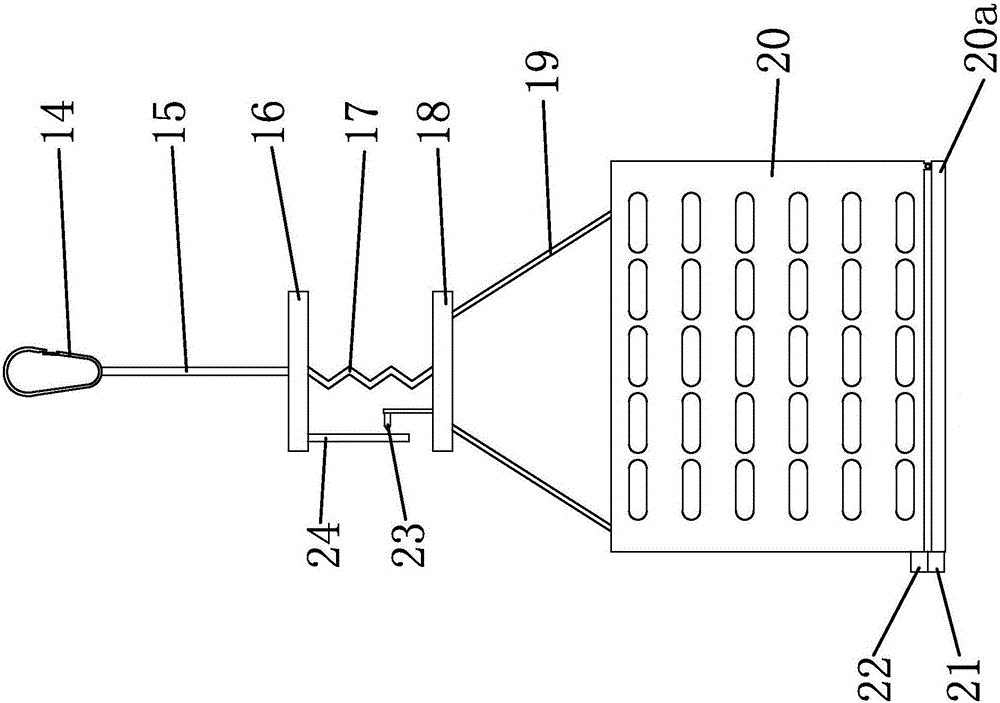

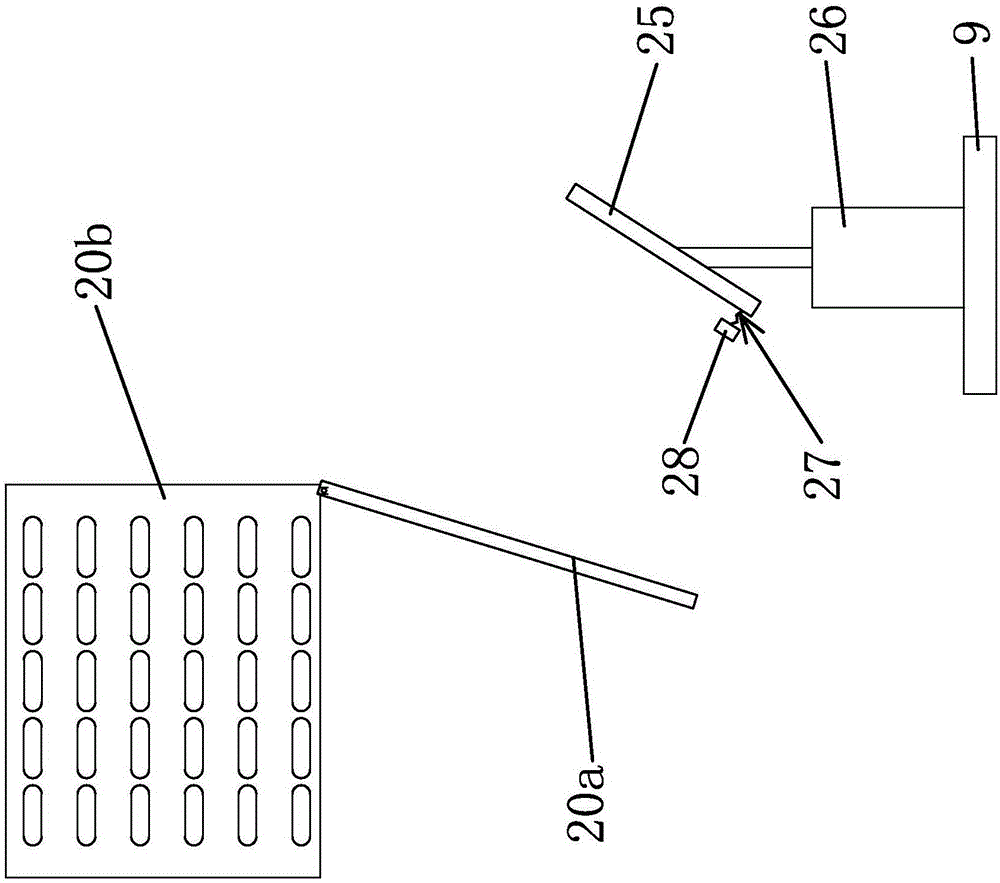

System and method for three-dimensional dose verification in radiosurgery

InactiveCN105854191AVerify accuracyImprove Dose Verification AccuracyX-ray/gamma-ray/particle-irradiation therapyRadiosurgeryDose verification

The invention provides a system and method for three-dimensional dose verification in radiosurgery. First a patient's image data and radiotherapy planning data are led in through a data management module, a patient's actual illuminated three-dimensional dose field distribution during the treatment is quickly reconstructed by utilization of a two-dimensional field size dosage collecting module and a three-dimensional dose inversion module; three-dimensional evaluation analysis is performed on a irradiation dose and a planning dose through a dose evaluation module; whether an error is in a permissible range is judged; if the error is in the permissible range, the patient is treated according to a radiotherapy plan, or else the radiotherapy plan is adjusted or a radiosurgery accelerator is subjected to quality control detection, irradiation is not performed on the patient until the dose verification passes, and the consistency between the irradiation dose and the planning dose is guaranteed finally. According to the system and method for three-dimensional dose verification in radiosurgery, the shortcoming of two-dimensional plane dose verification of using water instead of a person prior to existing treatment is overcome, and precise dose verification of three-dimensional space dose field distribution in the patient prior to fractionated treatment and during the fractionated treatment can be implemented.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for water filtration

InactiveUS7553418B2Simple in-situ restoration of membrane surfaceEfficient removalTreatment using aerobic processesTreatment involving filtrationNatural sourceSuspended particles

This is a method of filtration of a liquid comprising steps of sequential filtration of said liquid through at least one deep bed medium producing at least one first filtrate followed by at least one membrane medium filtration producing at least one second filtrate, wherein said membrane medium is at least periodically within said deep bed media Many types of deep bed and membrane media can be used. The domain of using contact clarification (direct filtration) can be expanded towards greater solids concentration. Operation and backwash, is simplified, continuous filtration becomes possible. Water can be water from natural source water, process water, wastewater, aqueous or non-aqueous suspensions, emulsions, solutions. Treatment can include mechanical interception of suspended particles, chemical, physical chemical, electrochemical, and biological processes. In water and wastewater processing, control over suspended solids, BOD, COD, nitrogen and phosphorus compounds, bacteria and viruses, heavy metals, color, and other constituents can be dramatically improved as compared to conventional processes. The method can be accommodated in new and modified existing treatment systems.

Owner:KHUDENKO ENG

Method and apparatus for low frequency induction therapy for the treatment of urinary incontinence and overactive bladder

Current treatment options for Overactive Bladder and Urinary Incontinence include exercise and behavioral modifications, pharmacological therapies, surgical intervention, and neuromodulation. Although each of these treatments is used in the treatment of individuals with these conditions, each has severe limitations. Building on the limitations of existing therapies, and with the distillation of lessons learned from the field of pulsed electric stimulation, the present invention employs Low Frequency Induction Therapy for the delivery of an effective, cost efficient, noninvasive alternative to available treatment options. The device of the present application allows for consistent, user-friendly modulation of the pudendal nerve and the sacral plexus, via pulsed electromagnetic stimulation of the posterior tibial nerve, on an outpatient basis. The device has two primary components: a programmable Logic Controller (LC), which generates the required current, and a Conductive Wrap (CW), through which the current is channeled in generating the pulsed electromagnetic fields.

Owner:EMKINETICS

Nutritionally Fortified Honey

Nutritionally strengthened honey improves its health care and therapeutic effects and pertinence, and uses it as a daily health food to overcome the shortcomings of existing honey in the treatment of existing superficial diseases and lack of prominent targets. It is composed of honey and one or several kinds of plant extracts that are recognized by the state as medicine and food. , choose the extracts of homologous plants of medicine and food as additive ingredients, carry out the effect targeting formed by scientific compatibility, cooperate with the original inherent effect of honey to strengthen the specific effect of honey, and obtain honey as the main ingredient, and the health care and treatment effects are significantly higher than Health food with honey. It is used to enhance immunity, improve sleep, promote lead discharge, clear throat, lose weight, remove chloasma, assist in lowering blood pressure, assist in lowering blood sugar, promote digestion, improve nutritional anemia, relieve visual fatigue, and assist in improving memory.

Owner:吉林省鼎健天然植物基地有限公司

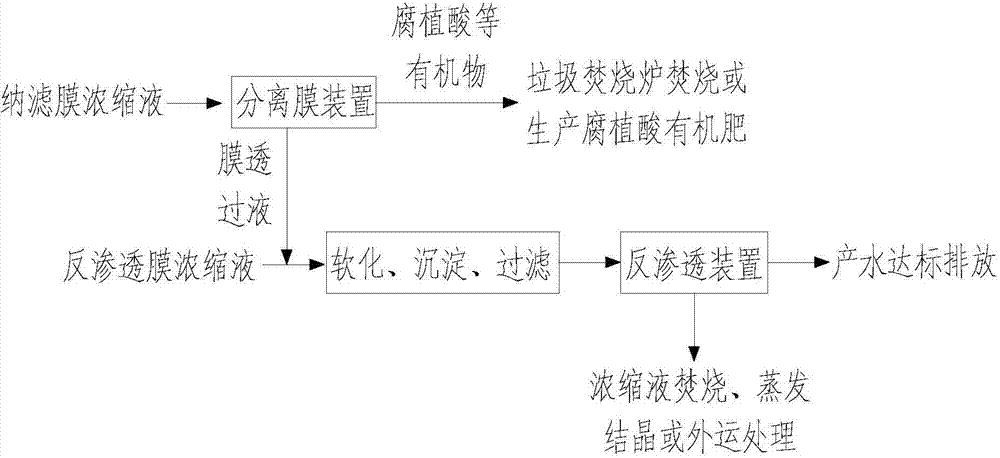

Treatment method for garbage leachate membrane concentrated solution

InactiveCN104496079AEasy to handleOrganic matter such as humus that is easy to process and recover has been safely and effectivelyMultistage water/sewage treatmentExisting TreatmentReverse osmosis

The invention discloses a treatment method for a garbage leachate membrane concentrated solution. The treatment method comprises the following steps: feeding the garbage leachate membrane concentrated solution into a membrane separating device to remove degradation-resistant organic substances such as humic acid in the concentrated solution, mixing the outlet water of the concentrated solution with a reverse osmosis concentrated solution, then removing scaling ions such as Ca<2+> and Mg<2+> and other inorganic substances in the concentrated solution by softening, precipitating and filtering, introducing the outlet water into the reverse osmosis membrane to further concentrate, and realizing up-to-standard release of produced water; and finally, spraying back the concentrated water back to an incinerator for incineration, evaporative crystallization or outward processing. The treatment method can be used for realizing efficient treatment of the garbage leachate membrane concentrated solution, and has the advantages of being stable in operation, high in treatment efficiency, low in operation cost, convenient to maintain and manage, and the like in comparison with the existing treatment method for the garbage leachate membrane concentrated solution.

Owner:BEIJING SOUND ENVIRONMENTAL ENG +1

Method for producing regenerated aggregate and regenerated cement from discarded concrete

Disclosed is a method for producing regeneration skeletal materials and regeneration cement with abandoned concrete, which relates to a method for regeneration of the abandoned concrete. The invention resolves the recycling and utilizing problem of the abandoned concrete and the problem of producing secondary pollution in existing treatment process. The method of the invention comprises as follows that firstly, grinding and handling the abandoned concrete, secondly, calcining the abandoned concrete in the condition of 750-800 DEC G, thirdly, separating sandstone materials and grout from the lump materials of the abandoned concrete via mechanical workout, fourthly, obtaining stones, sands and regeneration skeletal materials after screen separation of the sandstone materials which are obtained by separation in the third step, fifthly, mixing the cement paste separated from the third step, silicate cement clinker and thickening time control agent to skive to obtain regenerate cement. The invention has the advantages of saving resource, protecting environment, saving energy, reducing costs, simple technology, and being not easy to make secondary pollution for environment.

Owner:HARBIN INST OF TECH

Health care tea of ganoderma lucidum medicinal herbs

InactiveCN101152341AImprove immunityReduce high blood pressureMetabolism disorderCardiovascular disorderMedicinal herbsSide effect

A ganoderma herbal health tea comprises the raw materials by following ratio: ganoderma, mongolian milkvetch, ciwujia, jiaogulan, epimedium, eucommia, Chinese wolfberry, atractylodes, laminaria japonica and root kudzuvine. The invention overcomes the defects of great toxic side effect and bad curative effect for the existing treatment a ''two high cases''. The compound recipe for the ganoderma herbal health tea of the present invention adopts pure green Chinese herbs, can not only nourish the physical fitness of people and tone up body, but also prevent and cure diseases. For middle and old aged people in a sub-health or health state, long-term use of the prescription health tea changes the people with illness into the people without illness and with a stronger body, thereby prolonging the life of the people.

Owner:陈宏刚

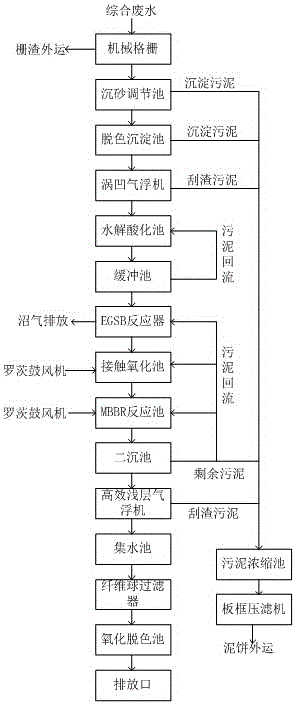

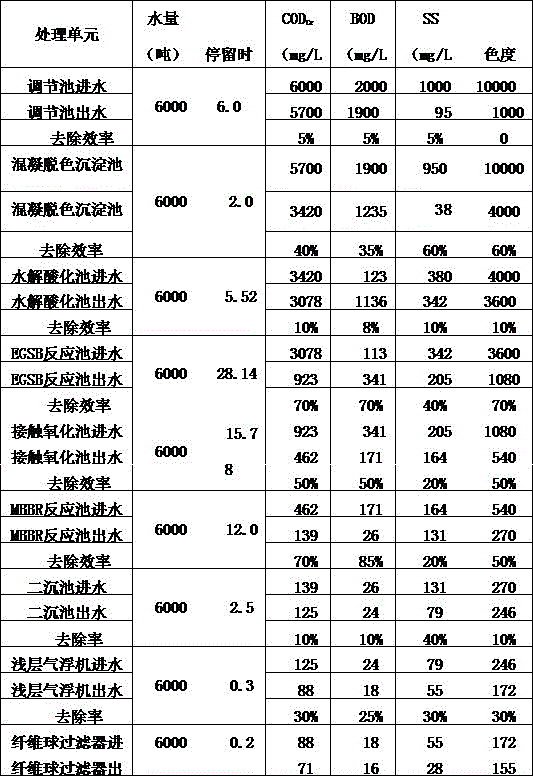

Printing and dyeing waste water treatment process

InactiveCN106630472AEasy to handleEasy to trainSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsExisting TreatmentWastewater

The invention discloses a printing and dyeing waste water treatment process, and solves the problem the existing treatment effects of the printing and dyeing waste water are not good. The printing and dyeing waste water treatment process comprises the steps that 1, in the pretreatment process, impurities in the waste water are removed, and the decoloration process is conducted to a certain degree, and loads of subsequent treating processes are reduced; 2, in the biochemical treatment process, organic pollutants in waste water are degraded; 3, in the advanced treatment process, the impurities, the organic pollutants and chroma in the waste water are further removed. The problems in the prior art are well solved by the above scheme.

Owner:四川亿龙环保工程有限公司

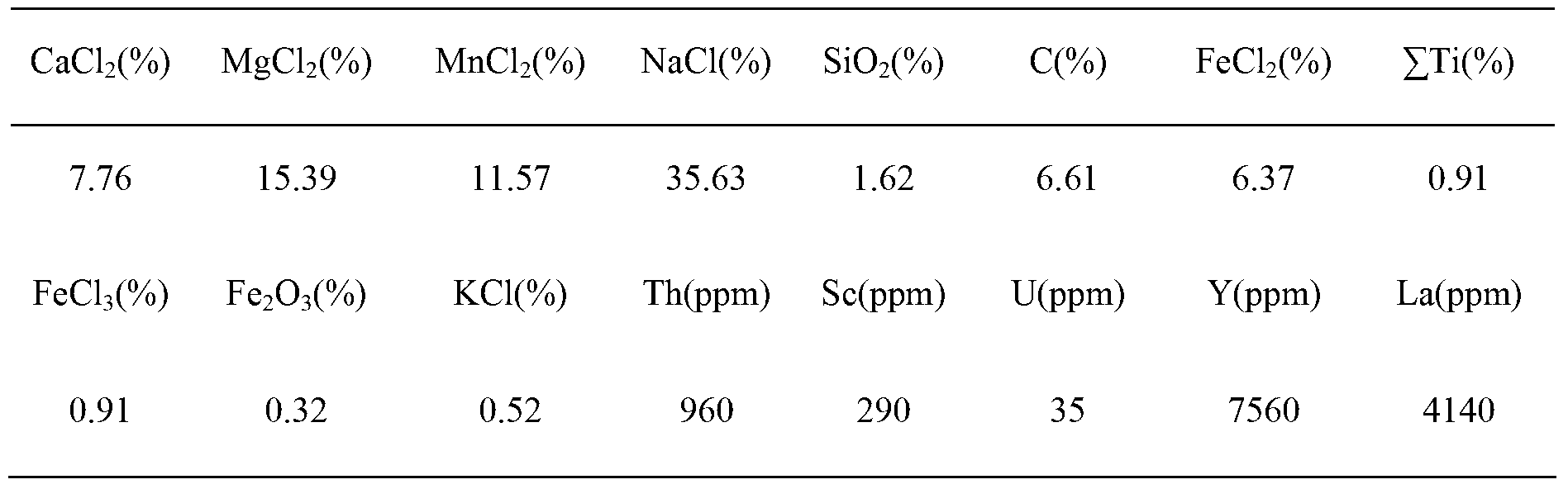

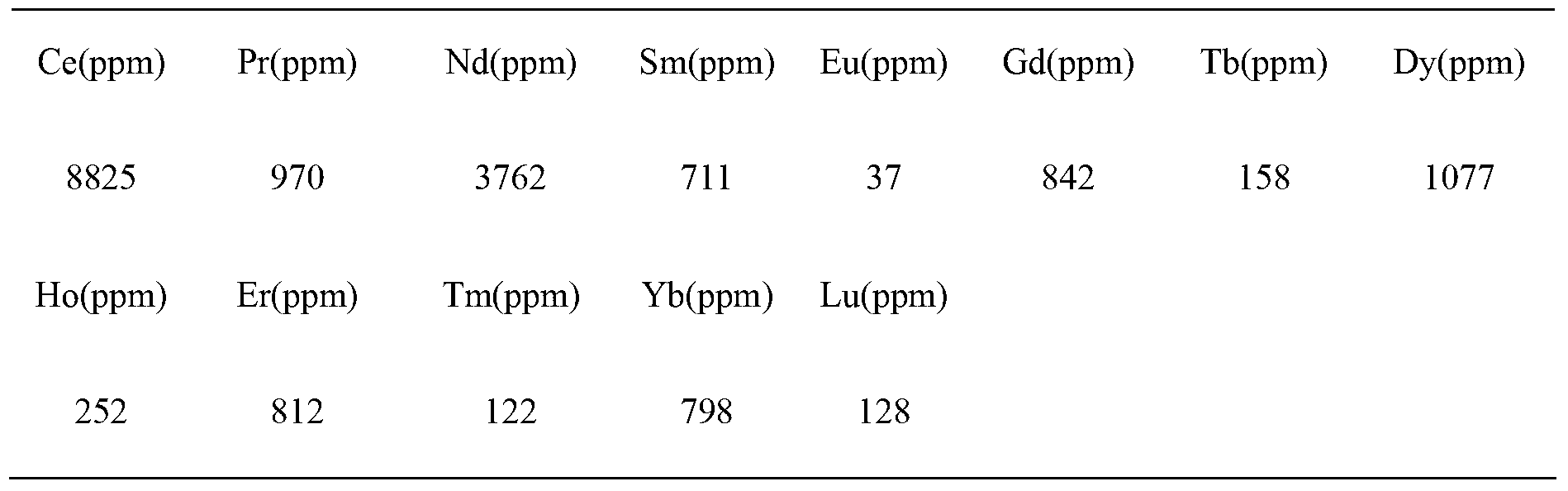

Treatment method of fused salt chlorination slag

The invention provides a treatment method of fused salt chlorination slag. The method comprises the following steps: leaching fused salt chlorination slag by water or a dilute acid solution; then, extracting and back-extracting the leaching liquid by using a blank organic phase I as an extractant and an alkaline solution I as a back-extractant so as to obtain a back-extract I; after adjusting the acidity of the back-extract I by acid, extracting and back-extracting the back-extract I by using a blank organic phase II as the extractant and an alkaline solution II as the back-extractant so as to obtain a residual extraction solution II and a back-extract II; adding a scandium precipitator to the residual extraction solution II and filtering and calcining to obtain scandium oxide; and mixing the back-extract II and a thorium and uranium precipitator, and filtering to obtain a thorium and uranium enriched substance. Compared with existing treatment of fused salt chlorination slag, the method provided by the invention not only extracts scandium with high additional value, but also recovers thorium and uranium in waste residue, so that radioactive contamination is eliminated. Meanwhile, chemical materials used in the treatment method provided by the invention are simple and easy to obtain, and the method is lower in cost and simple in process.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

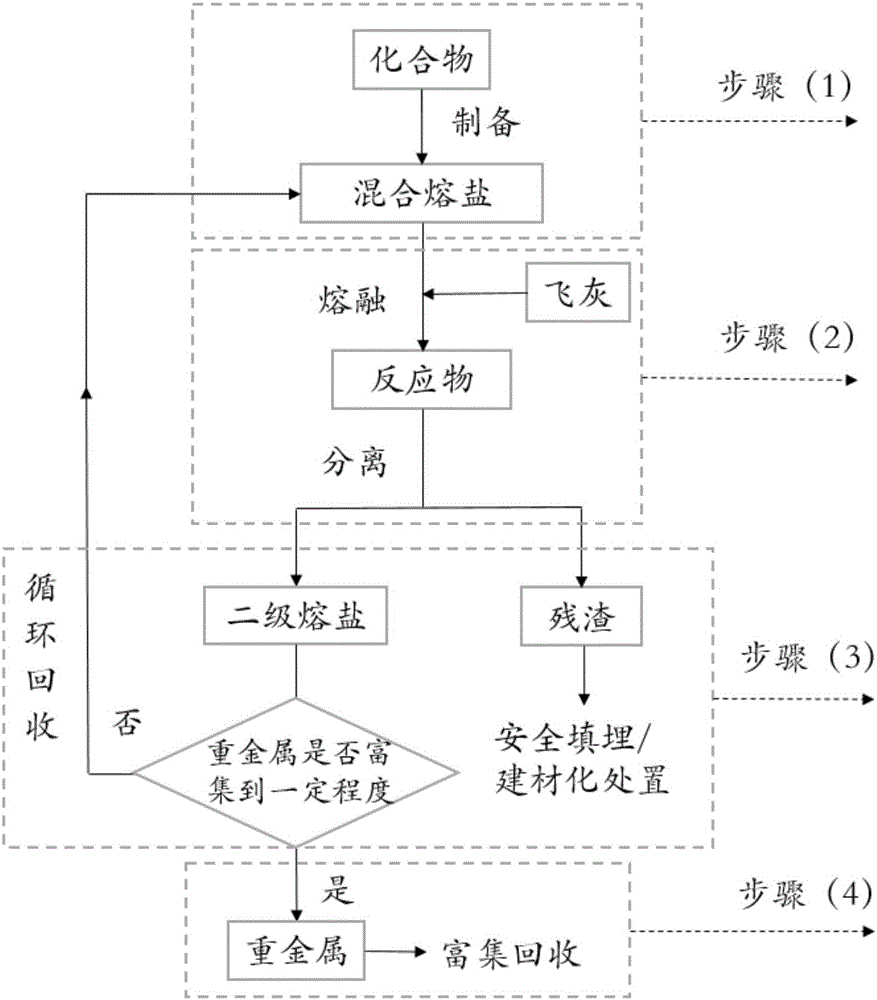

Fused salt heat treatment method for rubbish incineration fly ash

ActiveCN106378352AFull conductionAchieve dissolutionSolid waste disposalTransportation and packagingResource utilizationExisting Treatment

The invention discloses a fused salt heat treatment method for rubbish incineration fly ash, and belongs to ash treatment methods. The method solves the problems that the treatment temperature is high, the energy consumption is large and poisonous trace elements cause secondary pollution through existing treatment methods for the rubbish incineration fly ash. The method includes the steps of preparing mixed fused salt, carrying out fusing heat treatment, detecting the content of heavy metal and extracting and recovering the heavy metal. According to the method, chlorides, sulfate and partial heavy metal in the fly ash can be dissolved out through the fusing, heat storing and reacting characteristics of the fused salt, processes are relatively simple, reaction conditions are mild and easy to control, leaching of the heavy metal in the fly ash can be effectively controlled in an environment, the treated fused salt can be recycled, deep enrichment and recovery of the dissolved heavy metal can be carried out, the harm level of treated residues is greatly lowered, building material utilization and secure landfill of the treated residues can be conveniently carried out, secondary pollution is effectively reduced, the resource utilization efficiency is improved, and light reduction, harmlessness and resource utilization of the rubbish incineration fly ash can be realized synchronously.

Owner:HUAZHONG UNIV OF SCI & TECH

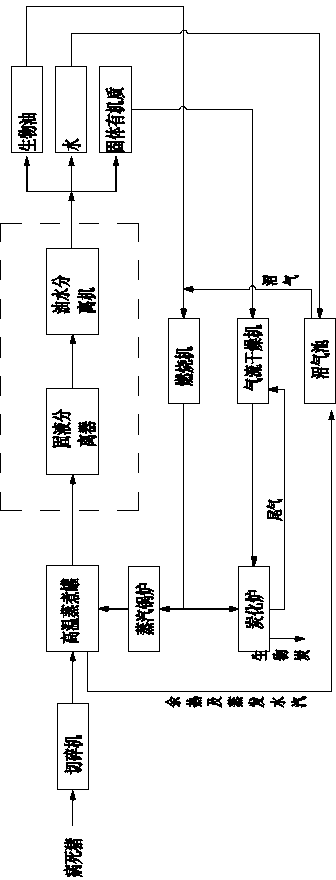

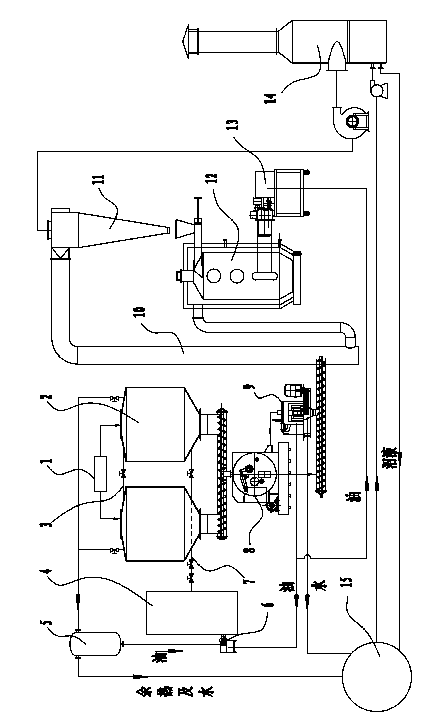

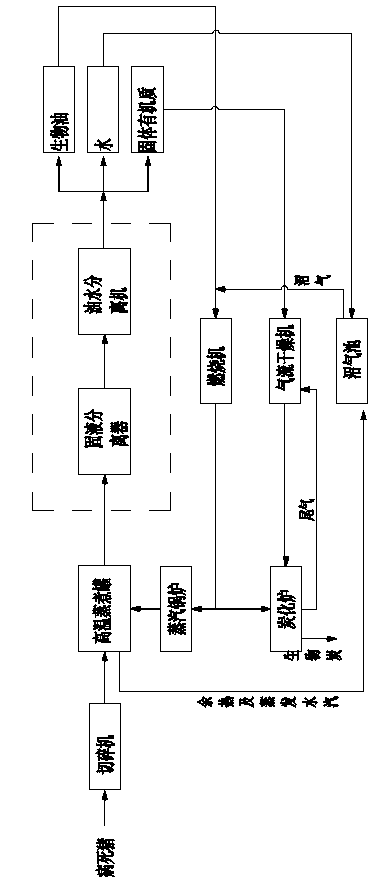

Treatment process of livestock died of epidemic diseases

ActiveCN103264037AGood sealingReduce the risk of transmissionSolid waste disposalClimate change adaptationProcess systemsExisting Treatment

The invention related to a treatment process of livestock died of epidemic diseases. The invention solves problems which disease the transmission and the environmental pollution caused by a improper treatment of existing livestock died of epidemic diseases while existing treatment ways have a high cost and a low energy utilization rate. The process comprises following steps: step 1: livestock died of epidemic diseases will be cut up by a chopping machine; step 2: chopped livestock are cooked under high temperature in a closed container in order for the homogenization of dead livestock; step 3: solid organic matters, biological oil and water after high-temperature cooking are separated by a separator; step 4: solid organic materials separated in step 3 are delivered to a charring furnace for the high-temperature, anaerobic and closed charring to form charcoal; step 5: water separated in step 3 is delivered to a biogas digester for biogas fermentation to create biogas; step 6: biological oil separated in step 3 is used as the heating fuel of the high-temperature cooking in step 2 and the charring in step 4. The complete process system in the invention has a good closure, reducing risks in the disease transmission; reducing the consumption of fuel provided externally.

Owner:ZHEJIANG BULAIMENG AGRI SCI & TECH

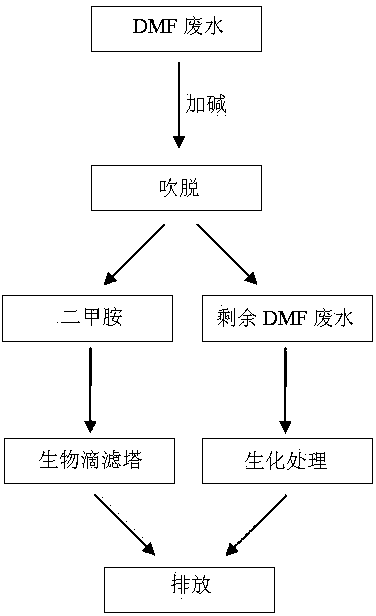

Combined treatment method of N, N-dimethylformamide (DMF) wastewater

InactiveCN103449662AAvoid secondary pollutionImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentN dimethylformamideExisting Treatment

The invention discloses a combined treatment method of N, N-dimethylformamide (DMF) wastewater, relates to the field of environment protection and water pollution treatment, and in particular relates to a combined treatment method for treating the N, N-DMF wastewater. The method specifically comprises the following steps: firstly decomposing the DMF wastewater into dimethylamine and formate under an alkali condition, then carrying out air stripping, introducing the dimethylamine waste gas generated in the air stripping into a bio-trickling tower for treatment, and directly carrying out biochemical treatment on the air-stripped wastewater. According to the combined treatment method disclosed by the invention, a physic-chemical method and a biological method are combined, a feasible process for treating the DMF wastewater is provided, the toxicity of the DMF wastewater is reduced by means of the physical-chemical method, the biodegradability of the DMF wastewater is improved, and the generated dimethylamine organic waste gas and wastewater are subjected to advanced treatment by means of the bio-chemical method. By adopting the combined treatment method disclosed by the invention, the effective and economical treatment of the DMF wastewater is achieved, and the problems of secondary pollution, difficult regeneration, low efficiency and the like easily caused by the existing treatment methods of adsorption, extraction, chemical oxidization and the like are solved.

Owner:NANJING TECH UNIV

Processing apparatus of livestock died of epidemic diseases

ActiveCN103264038AReduce the risk of transmissionReduce consumptionSolid waste disposalClimate change adaptationThermal energyCarbonization

The invention related to a processing apparatus of livestock died of epidemic diseases. The invention solves problems that disease transmission and environmental pollution caused by improper treatment of existing livestock died of epidemic diseases while existing treatment ways have high cost and low energy utilization rate. The apparatus comprises a shredder and a high temperature cooking kettle connected with the shredder, characterized in that the outlet port of the high temperature cooking kettle is connected with a separating apparatus for separating solid organic matter, bio-oil and water; the solid organic matter outlet of the separator is connected with a carbonization furnace; the bio-oil outlet of the separator is connected with a burner that provides thermal energy for the high temperature cooking kettle and the carbonization furnace; the water outlet of the separator is connected with a methane tank. The whole system of the invention has good sealing property, little contact with outside, which reduces the risk of disease propagation. The apparatus employs an inner cycle energy supply mode, and takes the bio-oil separated during processing as fuel, which not only reduces fuel consumption of external supply, and reduces the risk of disease propagation by not outputting the bio-oil as a kind of product.

Owner:ZHEJIANG BULAIMENG AGRI SCI & TECH

Comprehensive treatment method of acidic etching waste liquid

InactiveCN101792220AImprove resource recoveryGuaranteed emission standardsChlorine/hydrogen-chlorideWaste water treatment from metallurgical processLiquid wasteDistillation

The invention relates to a comprehensive treatment method of acidic etching waste water. Tail water treated by the existing treatment method can not conform to the standard. The method comprises the following steps: firstly adding oxydol to an acidic etching waste liquid to be treated for breaking and regeneration; then adding 98% concentrated sulfuric acid, distilling by heating, and absorbing the distilled steam with clean water to obtain dilute hydrochloric acid; dissolving residues after the distillation in a solution to generate a mother solution, throwing nano filter membranes and reverse osmosis membranes for concentration and separation, cooling and crystallizing the condensed mother solution, rinsing with water, and drying to obtain a copper sulfate crystal product. The method comprehensively uses the resources of the acidic etching waste liquid, produces the industrial dilute hydrochloric acid and copper sulfate products, ensures that the discharged waste water conform to the standard, improves the resource recovery rate of copper, and also raises the distillation speed.

Owner:HANGZHOU DIANZI UNIV

Integrated treatment method for high-salinity and high-concentration refractory organic wastewater resulted from cellulose ether production

ActiveCN106746198ASolve processingSolve the costTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationExisting Treatment

The invention discloses an integrated treatment method for high-salinity and high-concentration refractory organic wastewater resulted from cellulose ether production. The method comprises the steps of (1) carrying out pretreatment on to-be-treated wastewater through coagulating sedimentation and fenton reaction in sequence; (2) carrying out biochemical treatment on fenton reaction effluent through cellulase hydrolysis, anaerobic treatment, first-stage contact oxidation and second-stage contact oxidation in sequence, feeding cellulose to carry out degradation, anaerobic treatment, first-stage contact oxidation and second-stage contact oxidation processes on the wastewater in the cellulose hydrolysis process, adding a salt-tolerant fungicide of producing the cellulose ether to carry out strengthened treatment on the wastewater; and (3) carrying out deep treatment on second-stage contact oxidation effluent through the fenton reaction and finally discharging the effluent. Compared with an existing treatment method, the integrated technology has the characteristics of being high in pertinence, economic and environment-friendly; and problems that the wastewater is high in salinity, high in concentration and refractory are solved for enterprises that produce the cellulose ether.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

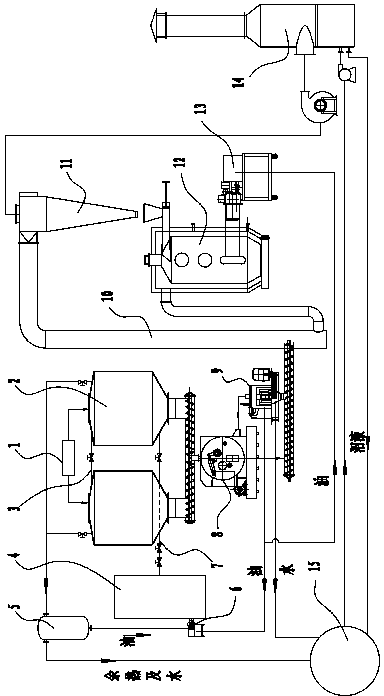

Oxynitride waste gas treatment device and oxynitride waste gas treatment method

ActiveCN102974200ASolve secondary pollutionDispersed particle separationAir quality improvementVapor–liquid separatorAcid washing

The invention belongs to the technical field of waste gas treatment, and particularly relates to an oxynitride waste gas treatment device and an oxynitride waste gas treatment method. The oxynitride waste gas treatment device comprises an acid washing unit, a water washing unit, an alkali washing unit and a draft fan, wherein the acid washing unit is provided with a plurality of acid washing absorption towers which are connected in series; the water washing unit is arranged at the latter station of the acid washing unit and connected with the acid washing unit in series, and comprises a water washing absorption tower; the alkali washing unit is arranged at the latter station of the water washing unit and connected with the water washing unit in series, and comprises an alkali washing absorption tower; the bottom of each absorption tower is respectively provided with a waste gas inlet and a liquid outlet, and the top is respectively provided with a waste gas discharge port and a liquid inlet; the top of the first acid washing absorption tower is provided with an air inlet; each absorption tower is provided with a suction pump of which the inlet and outlet are respectively connected with the liquid outlet and the liquid inlet; an inlet of the draft fan is connected with a waste gas discharge port of the alkali washing absorption tower, and an inlet of the draft fan is connected with an inlet of a gas-liquid separator; and a gas outlet of the gas-liquid separator is connected with a gas inlet of a dry-type adsorption tower. The invention solves the following problems: the existing treatment device can not absorb NO, but only can absorb NO2, and abundant industrial waste salts generated in the waste gas treatment process can bring about secondary pollution.

Owner:SHOUGUANG FUKANG PHARMA

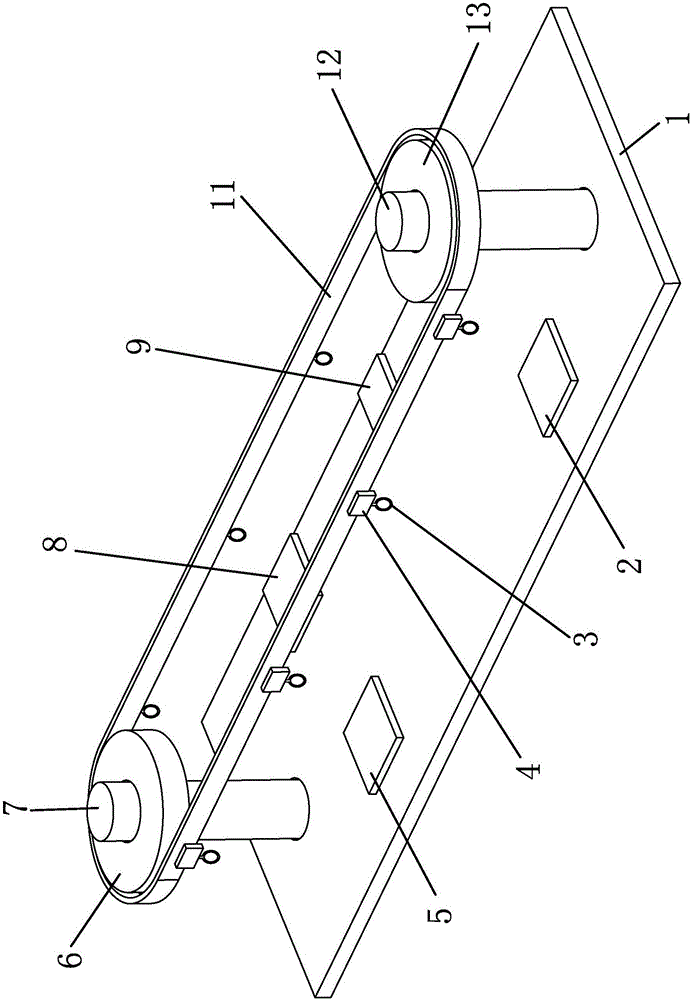

Treatment system for cabinet-wood corrosion prevention

ActiveCN106182254AExtended service lifeExtended use timeWood treatment detailsOpen tank impregnationTransmission beltDrive shaft

The invention provides a treatment system for cabinet-wood corrosion prevention. The technical problems that existing treatment equipment is too simple in structure, is provided with no blanking device, needs to be manually operated and low in treatment speed are solved. The treatment system for cabinet-wood corrosion prevention comprises a rack, a driving shaft and a driven shaft are vertically arranged at the two ends of the rack correspondingly, the driving shaft is connected with a power mechanism capable of driving the driving shaft to rotate, and a diving chain wheel is fixedly arranged on the driving shaft; a driven chain wheel corresponding to the driving chain wheel is fixedly arranged on the driven shaft, a transmission belt is arranged between the driving chain wheel and the driven chain wheel, and a plurality of mounting blocks are fixedly arranged on the transmission belt; and fixed rings are fixed to the mounting blocks, storage mechanisms for storing wood are detachably arranged on the fixed rings, and a soaking device, a shaking device and a blanking device are further arranged on the rack in sequence. The treatment system has the beneficial effect of being high in treatment speed.

Owner:海宁恒森家具有限公司

Skin-touch matte washing and brightening treatment agent for synthetic leather and preparation method thereof

ActiveCN103031728AComply with environmental standardsGood effectGrip property fibresCyclohexanoneButyl acetate

The invention relates to a skin-touch matte washing and brightening treatment agent for synthetic leather. The skin-touch matte washing and brightening treatment agent comprises the following components: modified polyurethane resin, cyclohexanone, dimethyl benzene, butyl acetate, nano-elastic powder, silicon dioxide matting powder, aminosilicone and castor oil. The invention further relates to a preparation method of the skin-touch matte washing and brightening treatment agent for synthetic leather. Compared with the existing treatment agent for ordinary synthetic leather, the skin-touch matte washing and brightening treatment agent for synthetic leather, which is disclosed by the invention, has excellent fog degree and degree of blackness and further has unique skin-touch hand feeling after water washing and graining treatment, the bottom of a surface channel is foggy, the top layer is bright, the bright-fog contrast effect of the leather surface is unique, and the leather treated by using the treatment agent has the advantages of natural luster, clear color and luster, smooth hand feeling, strong true leather effect and excellent comprehensive effects.

Owner:JIANGSU BAOZE POLYMER MATERIAL

Chemical repair method for cyanide polluted soil

ActiveCN101417287AEasy to repairLow costContaminated soil reclamationChlorine dioxideRestoration method

The invention relates to a soil cyanide pollution treatment technique and discloses a chemistry restoration method used for soil with cyanide pollution. The existing treatment of the soil with cyanide pollution mostly focuses on plant restoration methods which are limited by growth conditions of plants and have long treatment period. The technique utilizes a chemistry method which takes a chlorine dioxide disinfector as an oxidant for treating the soil with cyanide, thus leading the cyanide in the soil to be up to environment safety standard. Aiming at the different contents of the cyanide in the soil, parameters of oxidant concentration, treatment time and temperature, and the like can be regulated in certain range until the soil with cyanide pollution comes up to the standard of state soil environmental quality assessment.

Owner:SUN YAT SEN UNIV

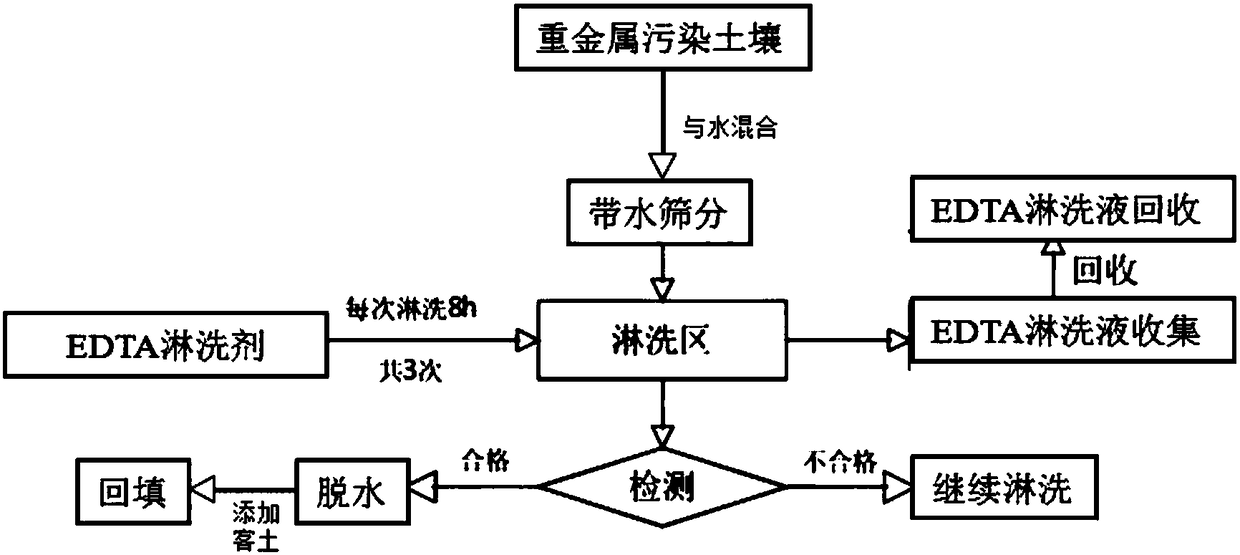

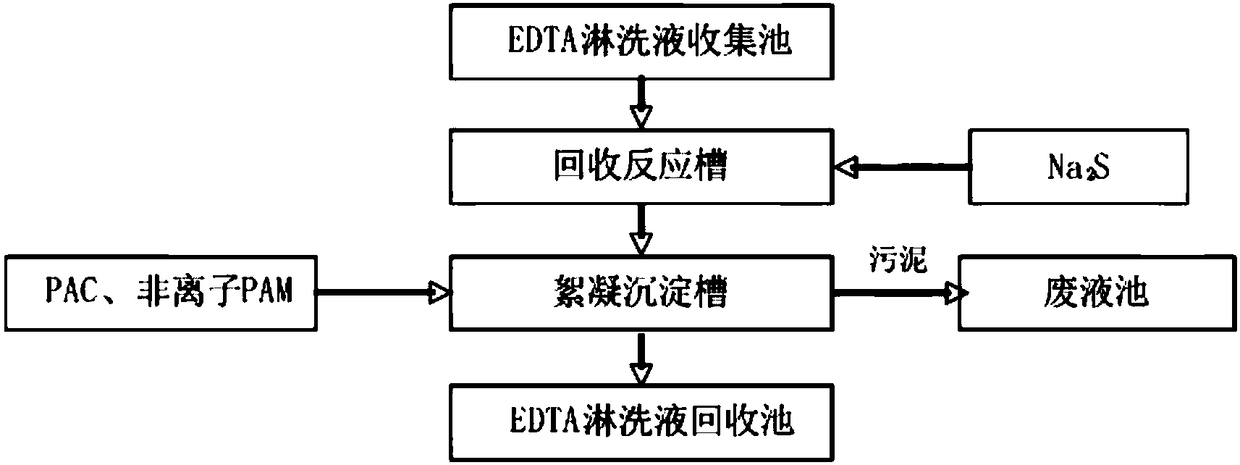

Washing treatment method for heavy metal contaminated soil

InactiveCN108311538AEasy to operateLow implementation costContaminated soil reclamationSoil-working methodsExisting TreatmentSoil fertility

The invention provides a washing treatment method for heavy metal contaminated soil. The method comprises the following steps: mixing the heavy metal contaminated soil and water, sieving the heavy metal contaminated soil with water, feeding the sieved soil to a washing tank, injecting a washing solution, performing circulation stirring, detecting the washed soil till the soil is qualified, dehydrating the qualified soil which is treated in the previous step, adding borrowed soil to the dehydrated soil, and then performing backfilling. The method is simple to operate, adopted reagents are common and available, the implementation cost is low, the removal rates of Cd, Zn, Pb and Cu in the soil can respectively reach 65.1, 47.5, 43.2 and 35.1 percent, the removal rates are superior to that inthe existing treatment technology, and the method is flexible to use, can achieve the effects of improving the physical and chemical properties of soil and enhancing the soil fertility through addition of organic fungi-manure to the treated soil according to the requirements, overcomes the deficiency of long phytoremediation cycle on the heavy metal contaminated soil, and is low in environmental risk.

Owner:湖南新九方科技有限公司

Method for preparing recycled cement by using waste concrete

InactiveCN104446042AEmission reductionReduce recycling costsCement productionIron powderExisting Treatment

The invention discloses a method for preparing recycled cement by using waste concrete. The method is specifically carried out according to the following steps: 1 preparing raw cement powder from waste concrete, limestone, clay, iron powder and coal; 2 calcining the raw cement powder prepared in the step 1 twice to prepare a cement clinker; and 3 taking gypsum powder and mixing the cement clinker obtained in the step 2 with the gypsum powder, so as to obtain the recycled cement. By using the method for preparing the recycled cement by using the waste concrete, the problems that the existing treatment mode of waste concrete is high in cost and not environment-friendly are solved; a new way for recycling the waste concrete is also provided; the cost is reduced; and the environment protection is facilitated.

Owner:XI'AN POLYTECHNIC UNIVERSITY

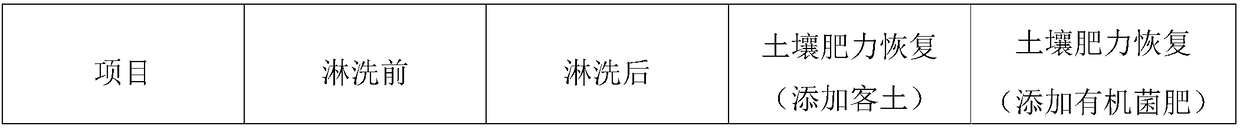

Treatment method for direct flotation water of bauxite

The invention relates to a treatment method for direct flotation water of bauxite, aiming at solving the problems that the existing treatment method is not thorough in the treatment of the mineral separation backwater of bauxite, high in cost, complex in treatment process, and available in secondary pollution. The treatment method adopts a water treatment system which consists of a main water system, a first water treatment passageway and a second water treatment passageway. The treatment method comprises the following steps of: firstly, producing tailings pulp and concentrate pulp by the main water system; respectively carrying out water treatment on the tailings pulp and the concentrate pulp by a double-passageway pH valve balancing purifying method; and keeping the pH value balance of the water in a circulating water tank. The treatment method adopts three water treatment systems such as the main water system, the first water treatment passageway and the second water treatment passageway, so that the problems that the existing treatment method is not thorough in the treatment of the mineral separation backwater of bauxite, high in cost, complex in treatment process, and available in secondary pollution can be solved.

Owner:HENAN DONGDA TECH CO LTD

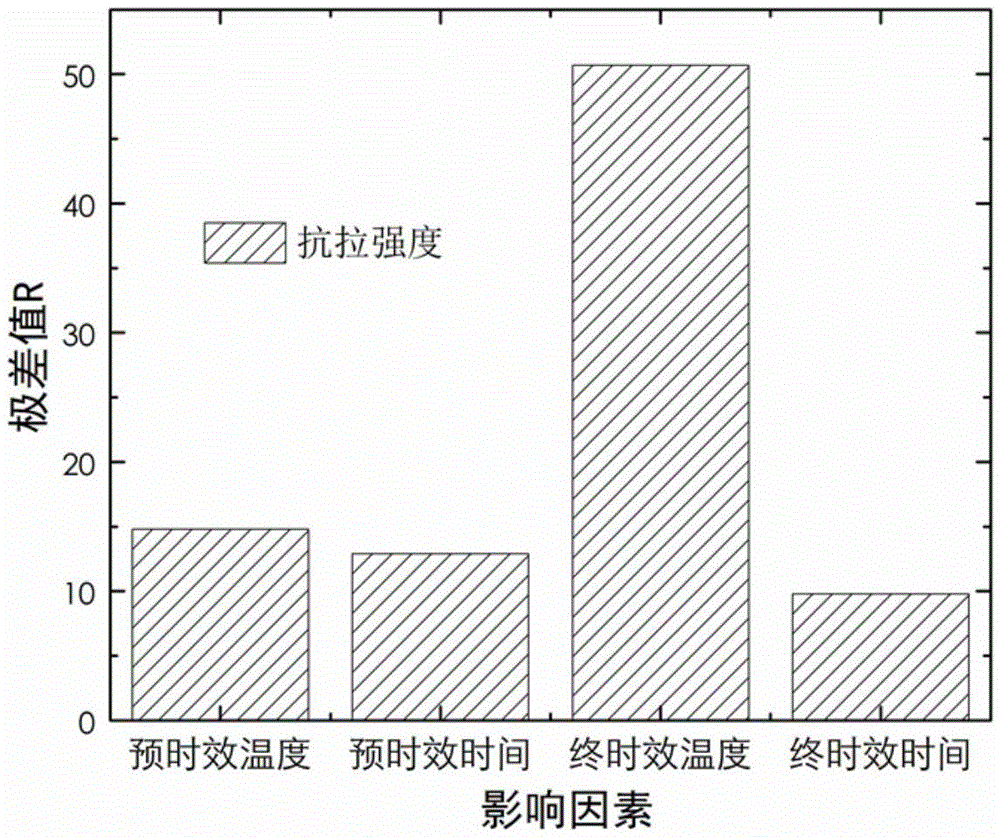

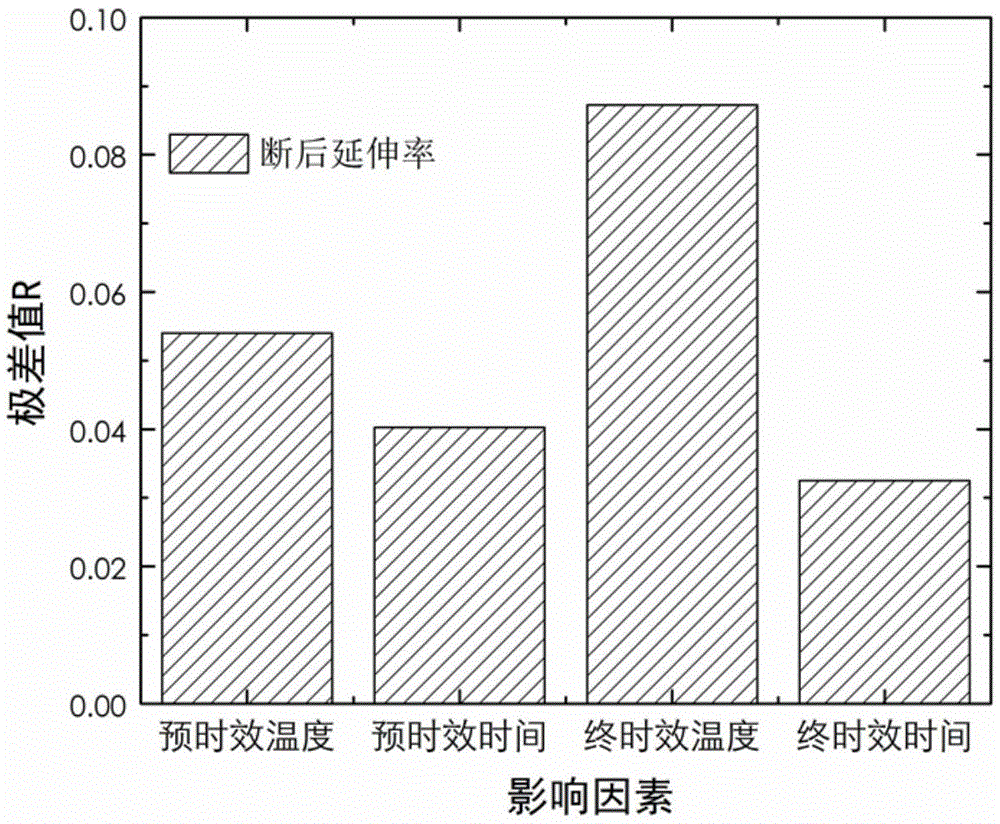

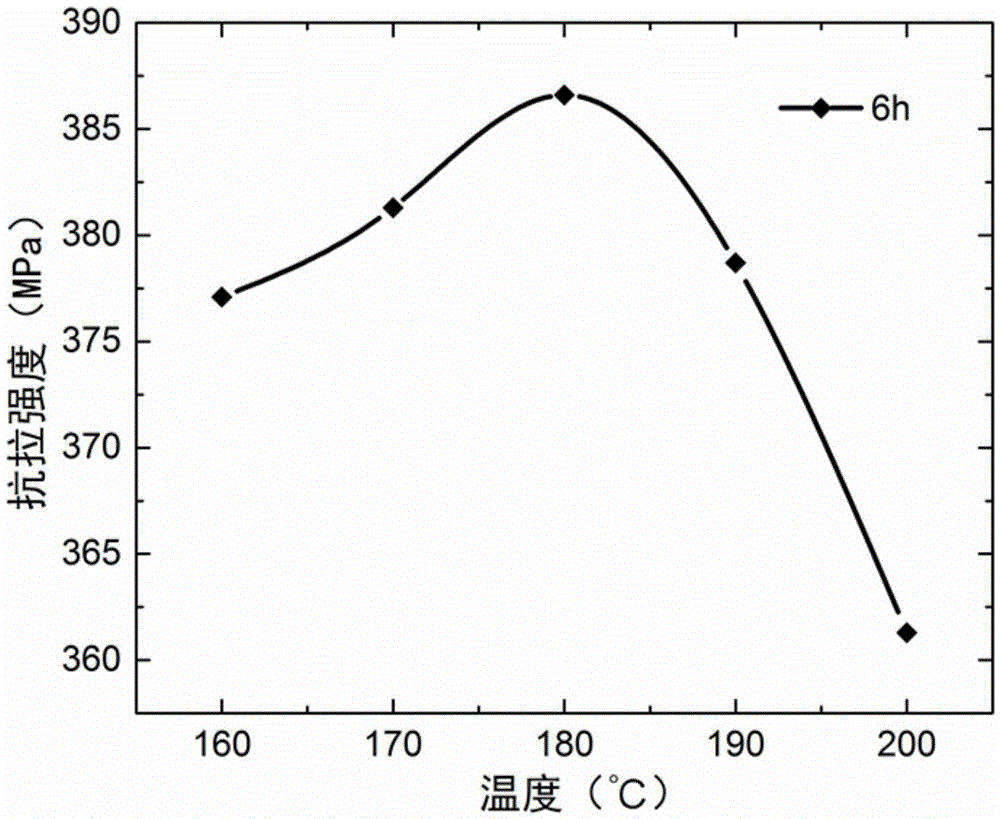

Thermo-mechanical treatment method for aluminum alloy

ActiveCN105543738ASimplify Manufacturing RoutingImprove fine dispersionPre deformationExisting Treatment

The invention discloses a novel electromagnetic forming and aging thermal treatment combined method for improving the strength and toughness of an aluminum alloy and belongs to the technical field of thermo-mechanical treatment of the aluminum alloy. The method includes the following steps of solution-and-quenching treatment, two-stage aging treatment and electromagnetic forming. Compared with an existing process including the steps of pre-deformation, solution and quenching, final deformation and artificial aging, the novel electromagnetic forming and aging thermal treatment combined method has the beneficial effects that the defects that the existing treatment process is complex, secondary deformation is likely to be caused, and use performance is lowered are overcome, the manufacturing process route for strengthening the aluminum alloy through thermal treatment is simplified, and the phenomena of secondary deformation and performance degradation in a traditional manufacturing process are avoided; and it is proved by tests that an aluminum alloy component formed through the method is free of obvious secondary deformation, and the intensity and plasticity of materials are improved compared with materials obtained through the traditional process. The thermo-mechanical treatment method of the aluminum alloy can be widely used for the fields of aerospace and the industry.

Owner:HUAZHONG UNIV OF SCI & TECH

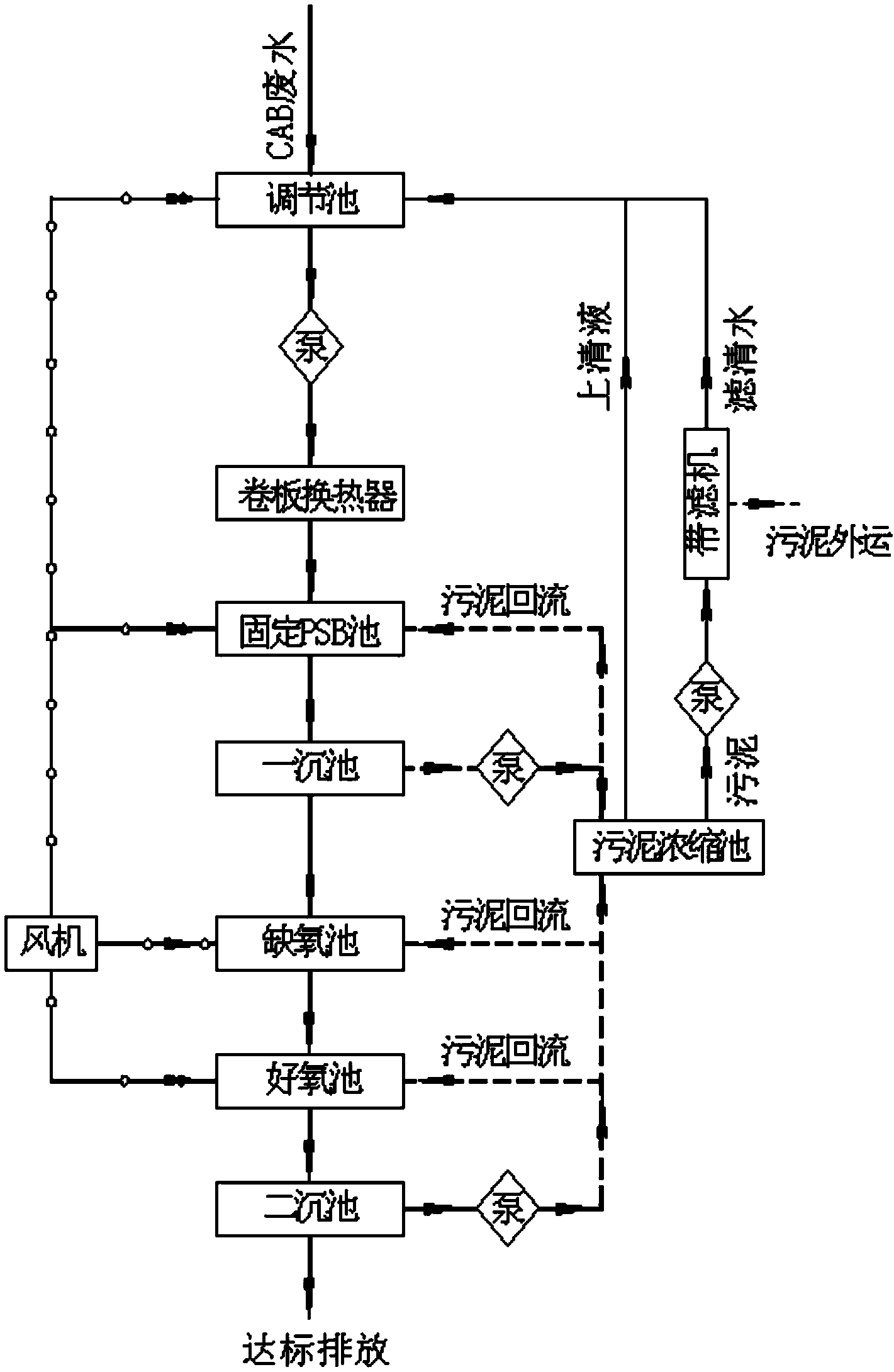

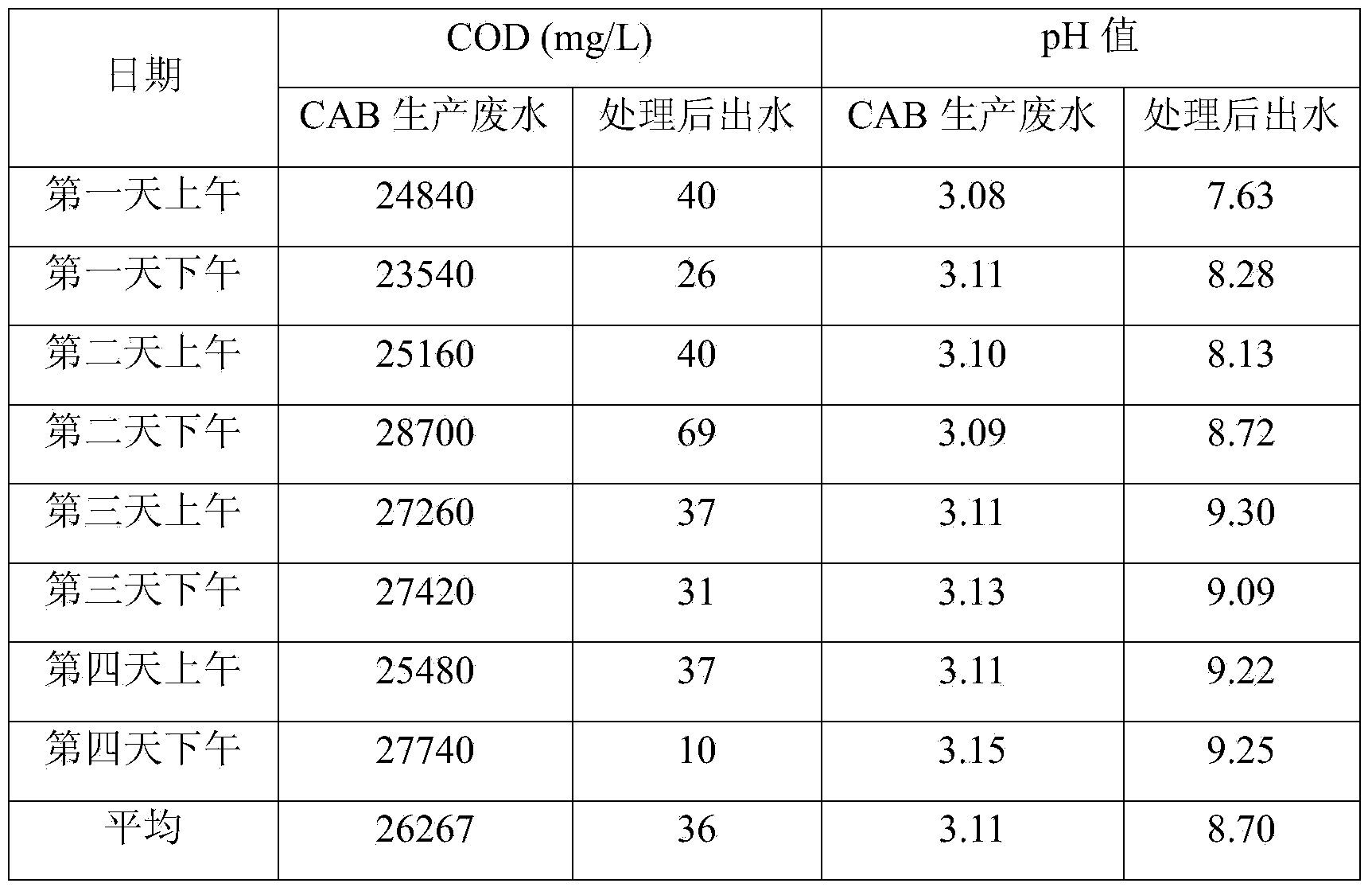

Method for treating cellulose acetate butyrate production wastewater

InactiveCN104129893ASolve non-ChineseSolve difficult problems that cannot be biochemicallyMultistage water/sewage treatmentNature of treatment waterTreatment effectSludge

The invention belongs to the field of wastewater treatment, and in particular relates to a method for treating cellulose acetate butyrate production wastewater. The method solves the technical problems of complex flow, high running cost and large sludge quantity of an existing treatment process. For solving the technical problems, the invention provides the method for treating the cellulose acetate butyrate production wastewater and the method comprises the steps of 1) treating the cellulose acetate butyrate production wastewater in an adjusting tank for 12-16h, and then treating the wastewater in an immobilized photosynthetic bacteria tank for 46-52h; 2) settling the effluent of the immobilized photosynthetic bacteria tank in a primary settling tank for 2-3h; 3) treating the supernate obtained after settling in the primary settling tank in an anaerobic tank for 20-28h; 4) treating the effluent coming from the anaerobic tank in an aerobic tank for 20-28h; 5) settling the effluent coming from the aerobic tank for 2-3h in a secondary settling tank, and then discharging the supernate reaching standards through a discharge opening or recycling the supernate. The method disclosed by the invention has the advantages of good treatment effect and low running cost, and can stably realize up-to-standard discharge.

Owner:SICHUAN NITROCELLULOSE CORP +1

Pharmaceutical Composition for Treatment of Diabetic Complications

ActiveUS20110021526A1High activityImprove the level ofBiocideSenses disorderCollagen accumulationBeta blocker

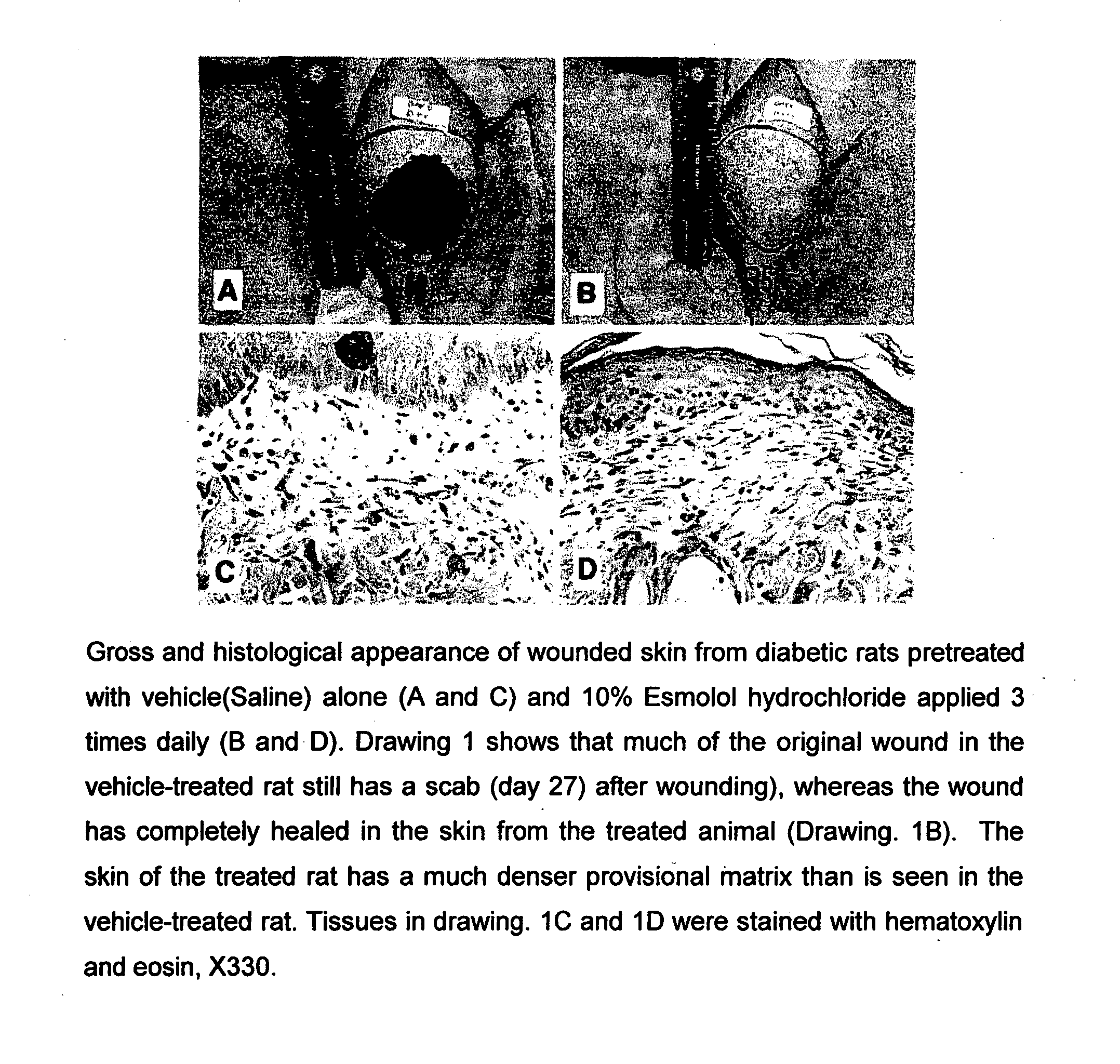

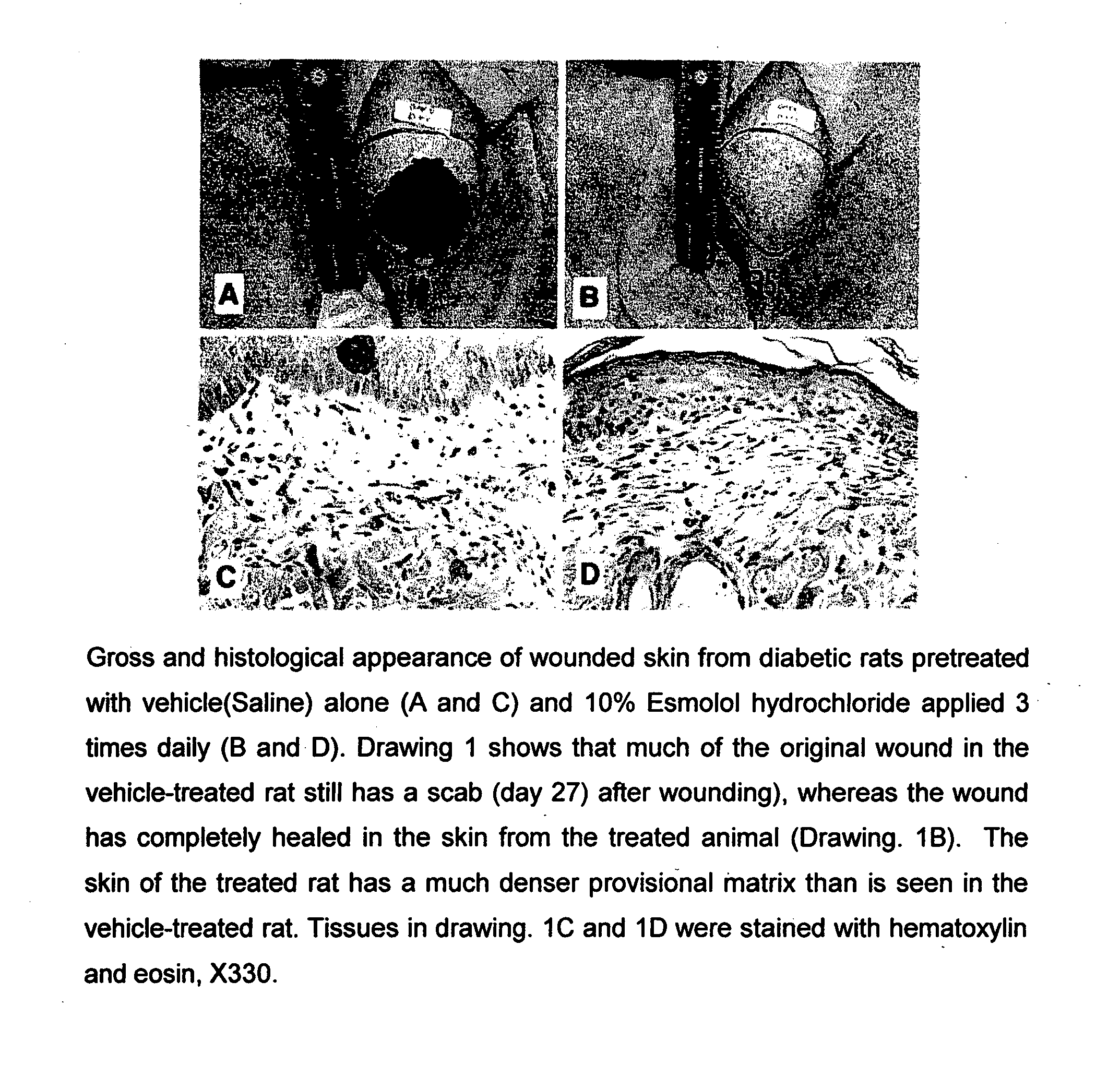

A method for treating diabetic complications by administration of a beta-blocker is disclosed. Diabetic complications arise from diabetes and have few or no existing treatment options. The present invention describes the use of a beta-blocker in the treatment of a diabetic. The present invention also describes the inhibition of aldose reductase, one of the chief causative factors of diabetic complications. Also provided are methods of diabetic wound healing. Compositions for treating diabetic complications, such as diabetic wounds, are disclosed. The present invention includes employing a topical formulation of a beta-blocker, having substantially no antibacterial activity, to improve the process of diabetic wound healing. The present invention also involves increasing the rate of collagen accumulation of the healing epithelialized tissue in the wound of a diabetic individual.

Owner:VLIFE SCI TECH PVT

Treatment method of hexavalent chromium ion containing industrial wastewater

InactiveCN103663661AThe treatment method is economical and practicalNo secondary pollutionWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationIndustrial effluentExisting Treatment

The invention relates to a treatment method of hexavalent chromium ion containing industrial wastewater for innocent treatment of industrial wastewater, which overcomes the deficiency that existing treatment methods of hexavalent chromium ion containing wastewater are high in cost and easy to cause secondary pollution. The technical scheme is that the treatment method comprises the following steps: by taking FeC13.6H2O and FeSO4.7H2O as raw materials and ammonium water as a precipitator, quickly stirring, aging at high temperatures, washing, and drying to prepare magnetic solid particles; preparing polyacrylamide flocculant liquor, putting the magnetic solid particles in the prepared polyacrylamide flocculant liquor, stirring at a high speed, quickly settling the magnetic solid particles under an applied magnetic field, and drying the precipitate to prepare modified magnetic particles; adding the modified magnetic particles into the hexavalent chromium ion containing wastewater, adjusting the pH to 6 by an acid, and stirring and separating, wherein the upper layer is a dechromed clean liquid; and adding alkali liquor into the modified magnetic particles in the lower layer, stirring and separating, and repeatedly using the modified magnetic particles. The method is economical and practical, free from secondary pollution and quick in settling velocity, and hexavalent chromium and the modified magnetic particles can be recovered.

Owner:SOUTHWEST PETROLEUM UNIV

Method for utilizing enhanced pretreatment to promote anaerobic digestion of excess sludge

InactiveCN102424507AGood cracking effectHelp brokenWaste based fuelBiological sludge treatmentSolubilityChemical oxygen demand

Owner:NANKAI UNIV

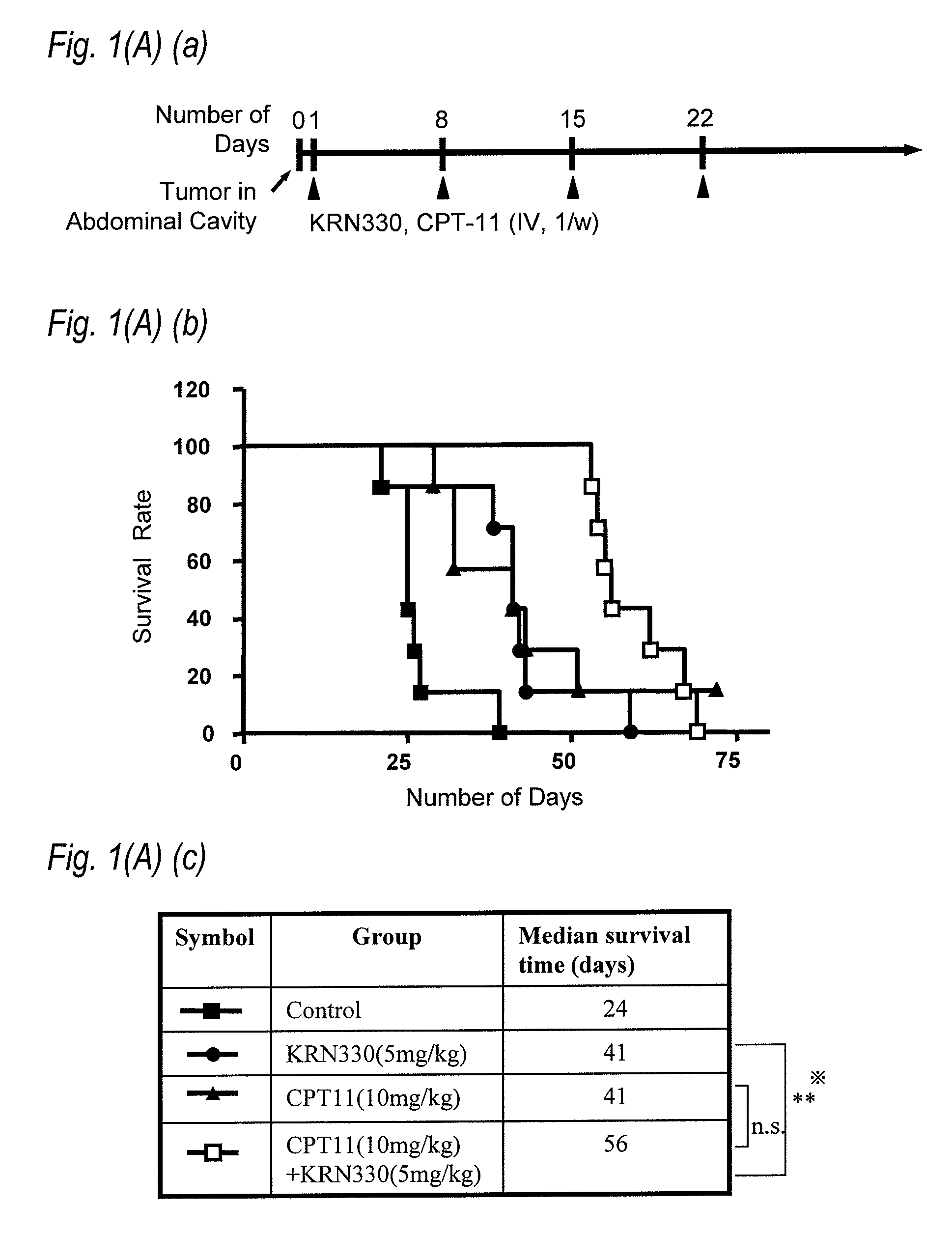

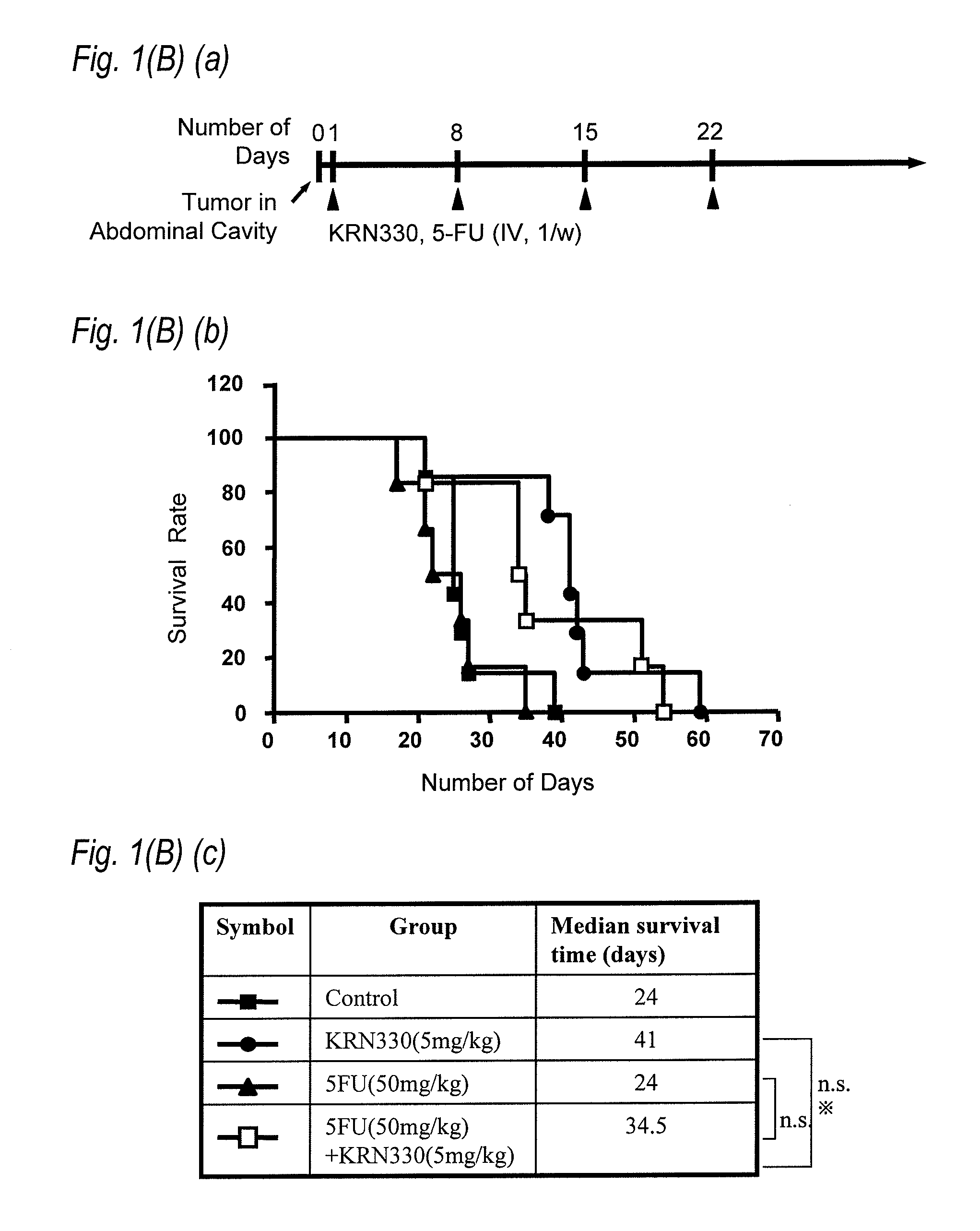

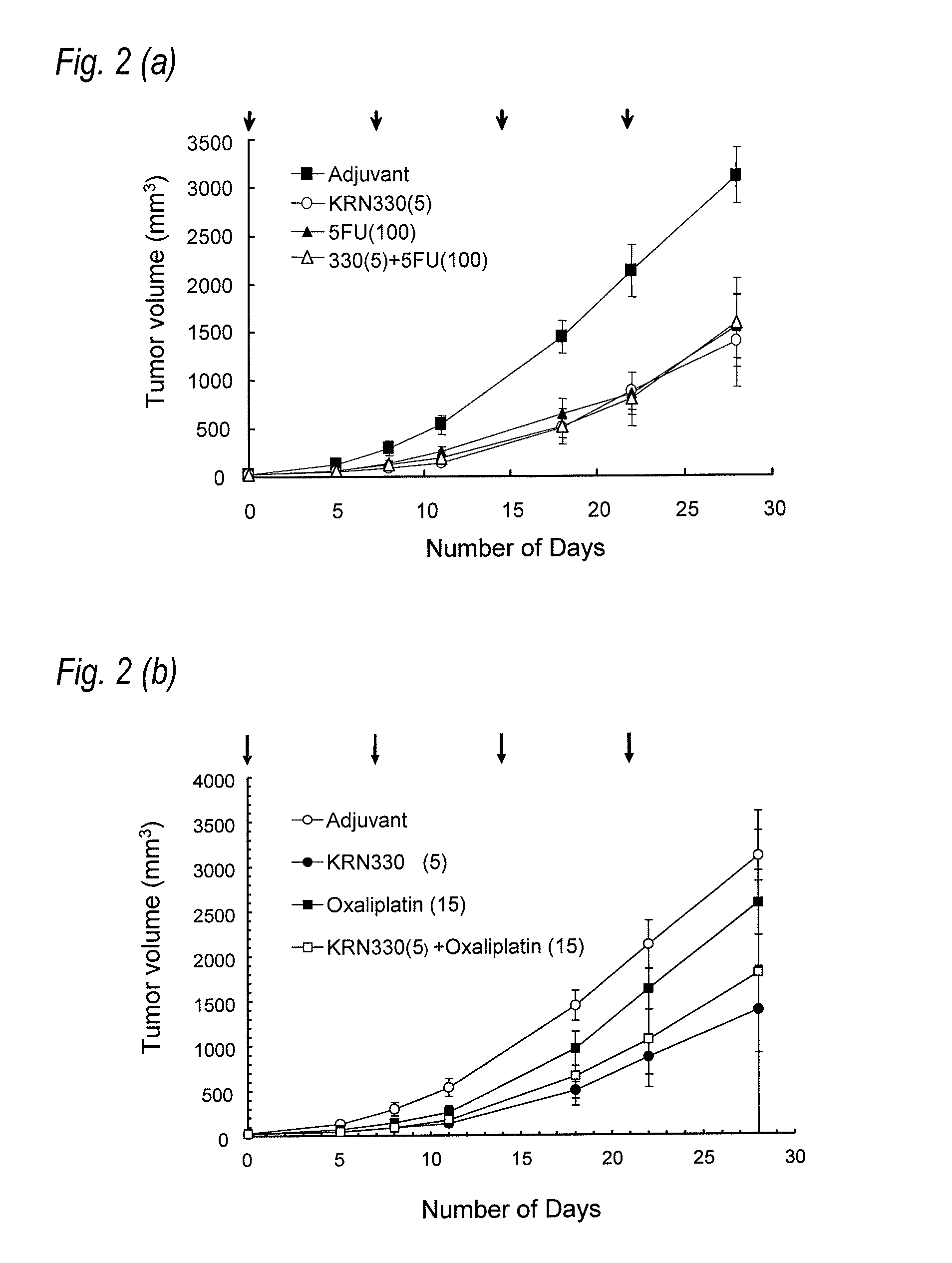

Methods of treating colorectal cancer

InactiveUS20120020989A1Improve clinical symptomsOrganic active ingredientsImmunoglobulins against growth factorsSurgical treatmentExisting Treatment

The present invention provides a pharmaceutical composition and a treating method for colorectal cancer which is difficult for a surgical treatment, comprising an anti-A33 human antibody and a chemotherapy agent in combination. Based on the present invention, a pharmaceutical composition and a treating method comprising the combination of anti-A33 human antibody with CPT-11 (irinotecan) can exhibit a certain degree of antitumor effect on a patient with colorectal cancer who is found recurrence after previously-initiated therapy and / or a patient with colorectal cancer who is difficult to be cured by existing treatments for colorectal cancer.

Owner:KYOWA HAKKO KIRIN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com