Treatment method for direct flotation water of bauxite

A water treatment and bauxite technology, applied in flotation, solid separation, etc., can solve the problems of high cost, secondary pollution, complex treatment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

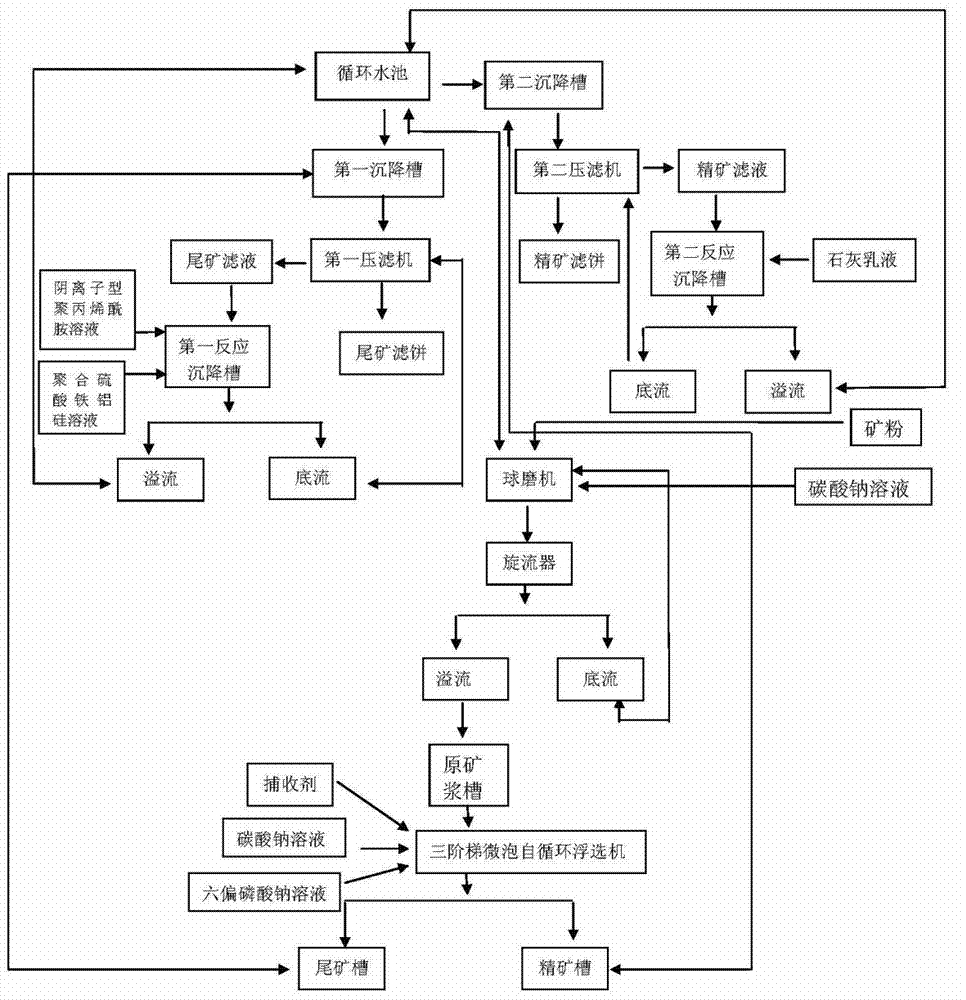

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Depend on figure 1 Provide, the bauxite positive flotation water treatment method of the present invention is:

[0015] 1) In the main water system, the crushed and homogenized bauxite enters the high-pressure roller mill through the upper chamber, and the ore powder after the roller mill passes through the vibrating screen. Among them, the ore powder that cannot pass through the 6-mesh sieve passes through the high-pressure roller mill again Machine roller mill, the ore powder that can pass through the 6-mesh sieve enters the ball mill, and adds circulating water and sodium carbonate solution in the circulating pool. The amount of circulating water added is 1-1.5 times the weight of the ore powder, and the mixture is discharged from the ball mill. The mixture The feeding pump of the cyclone enters the cyclone, and after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com