Patents

Literature

8687results about "Flotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

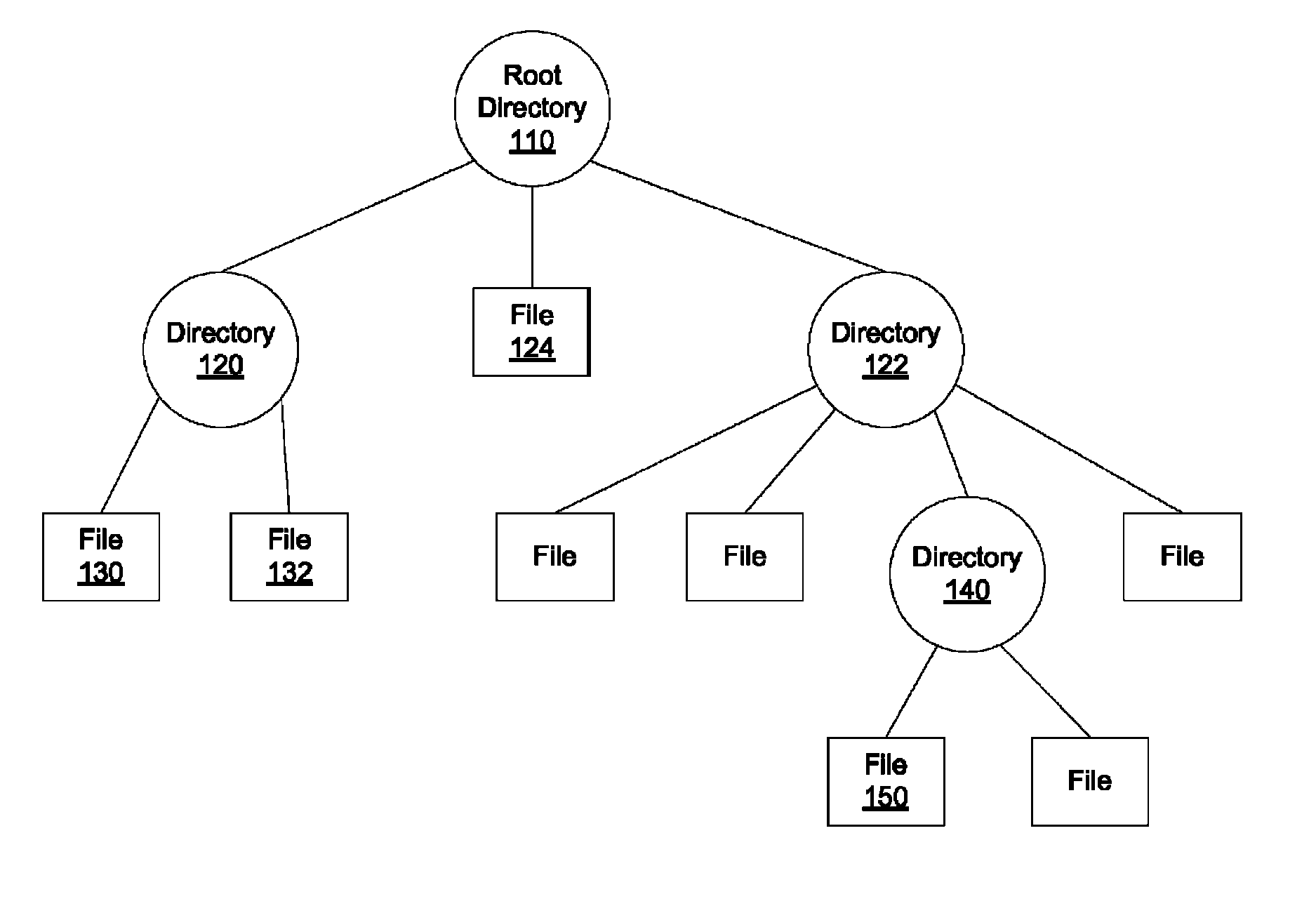

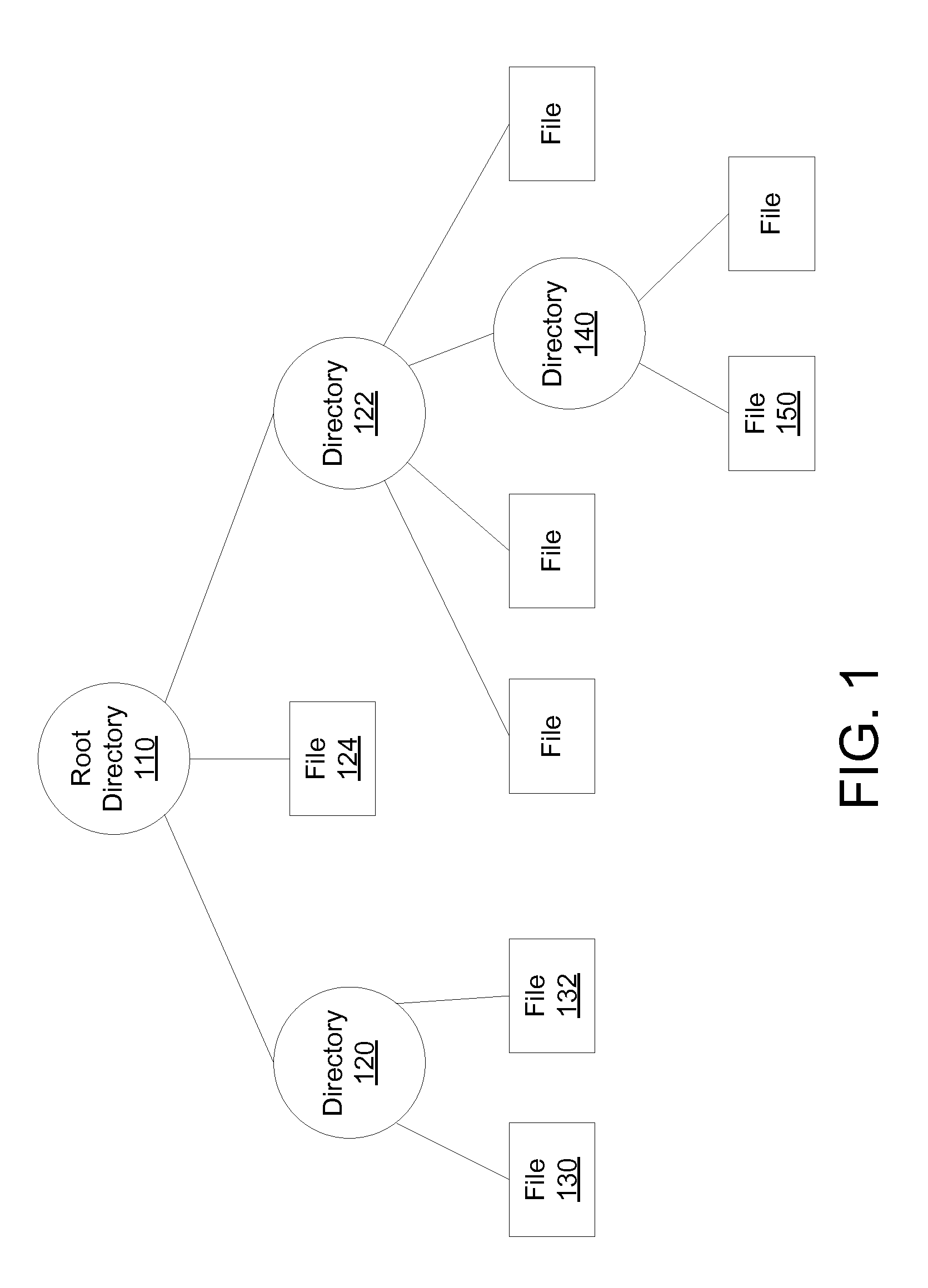

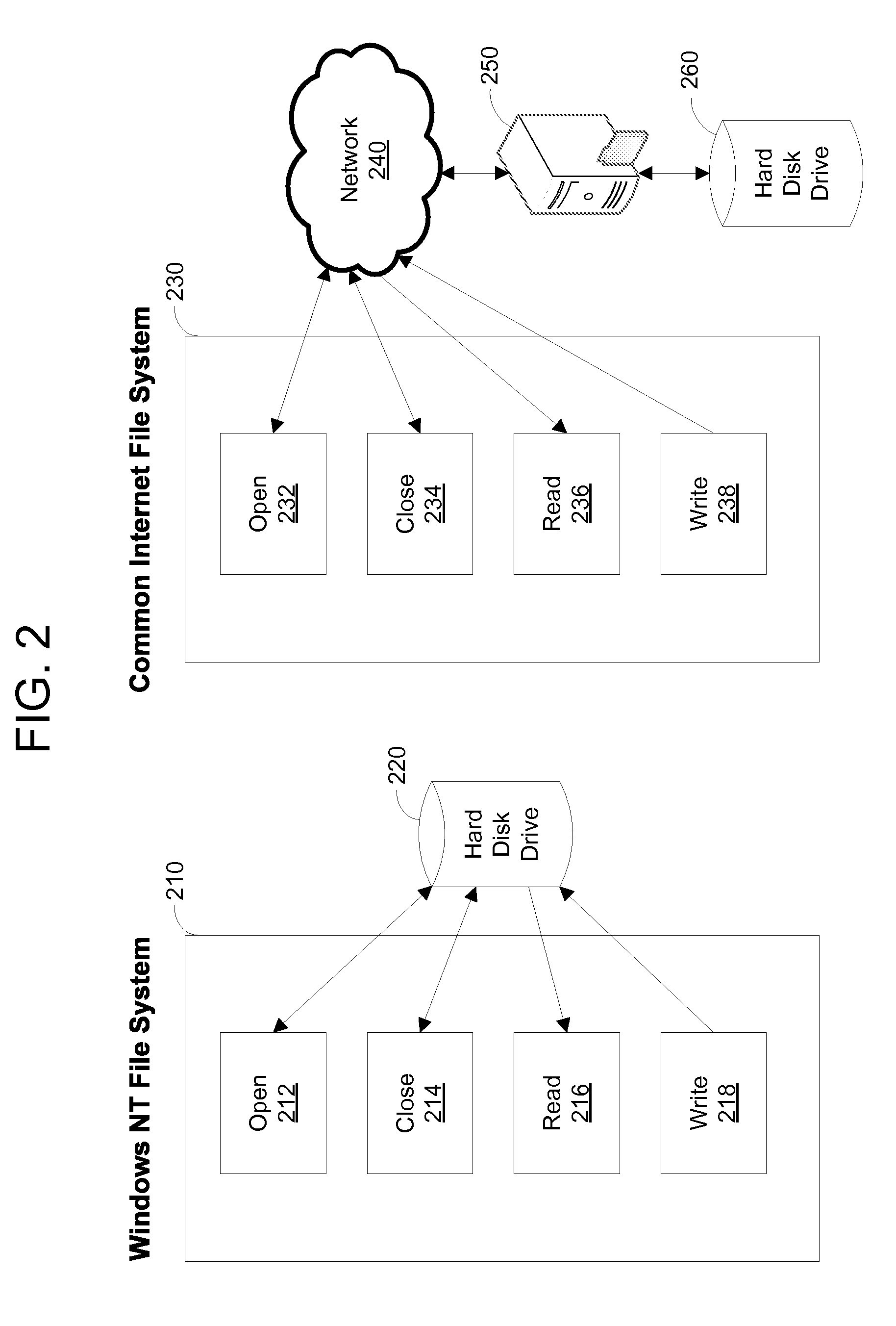

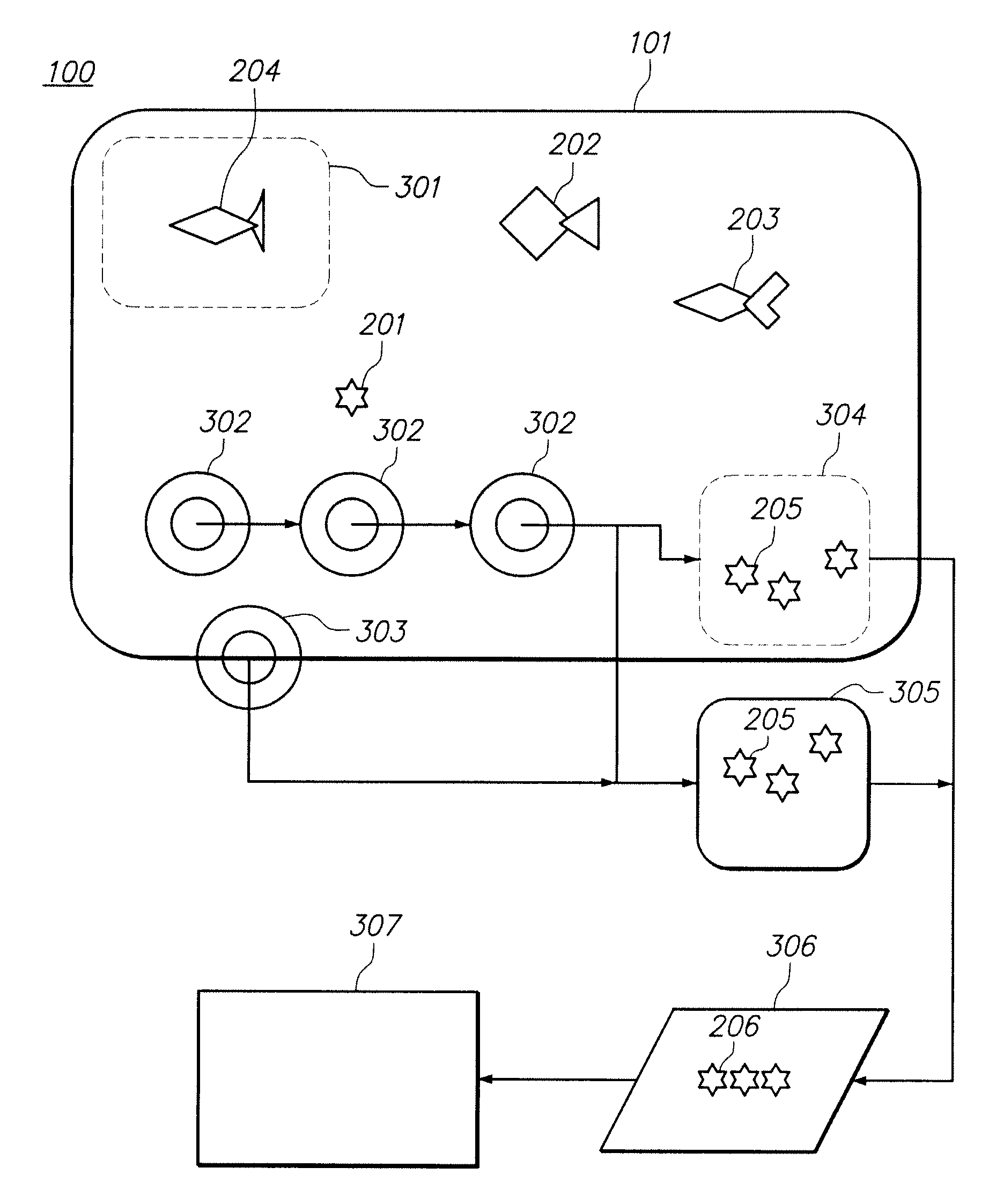

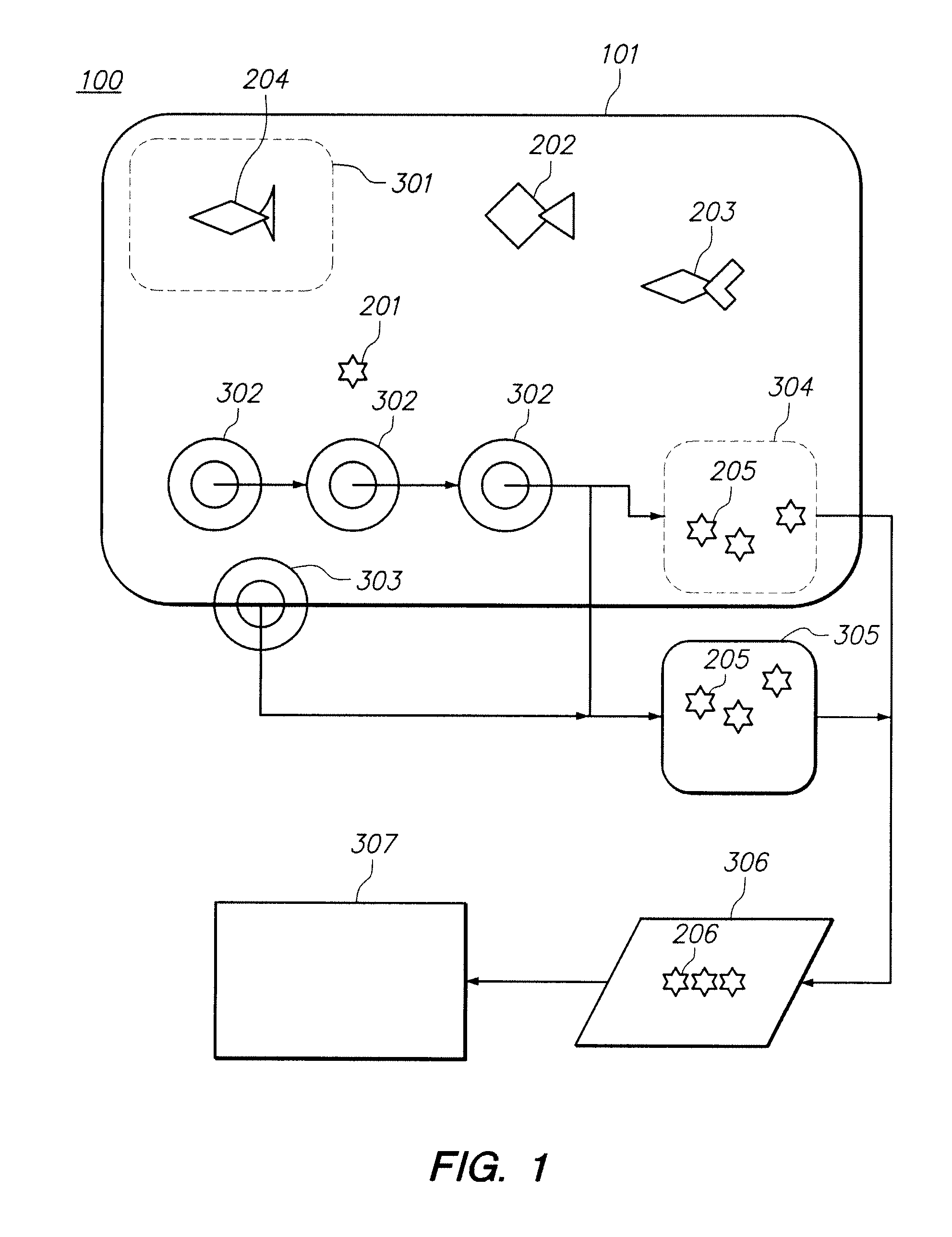

Peer-to-Peer Redundant File Server System and Methods

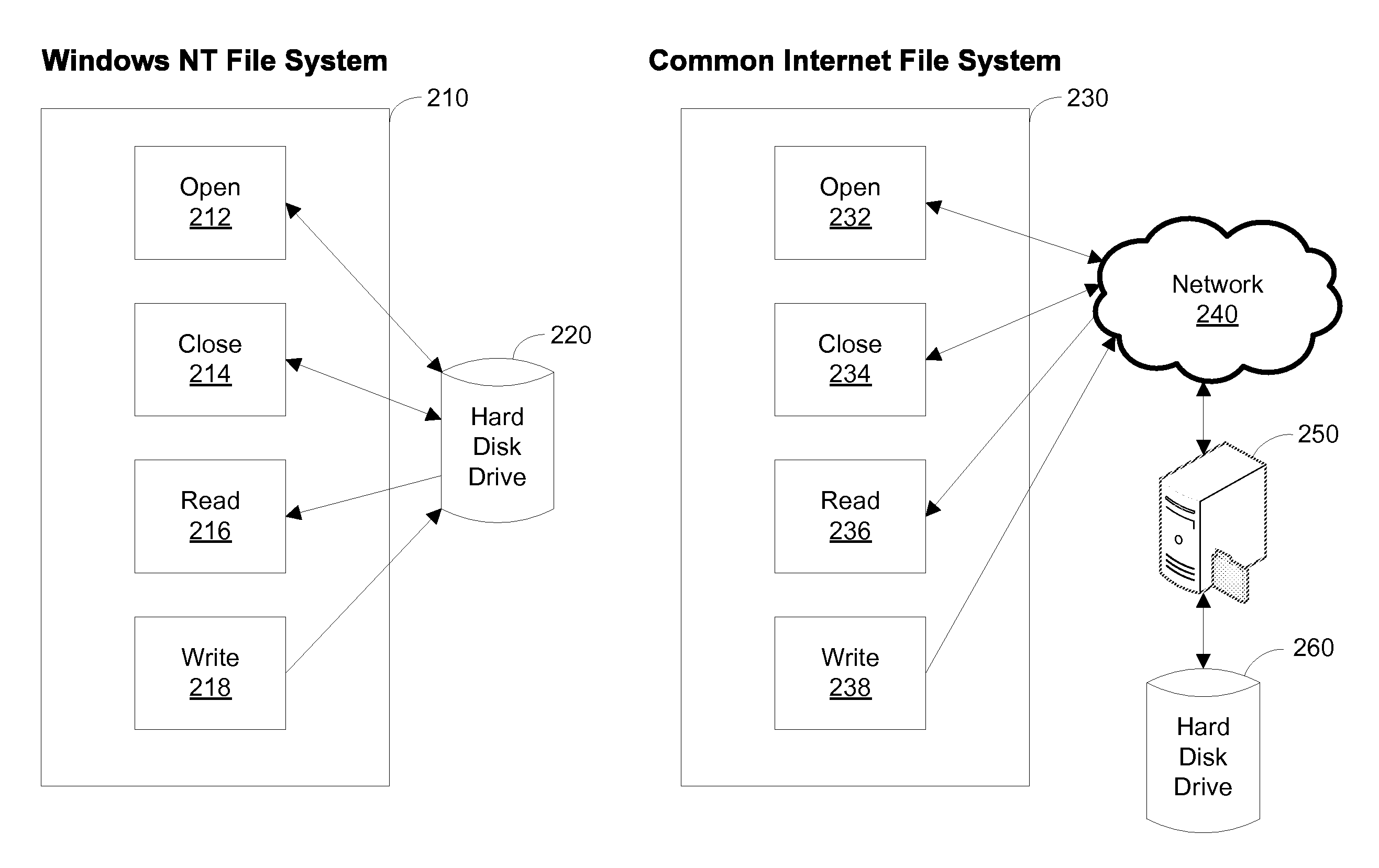

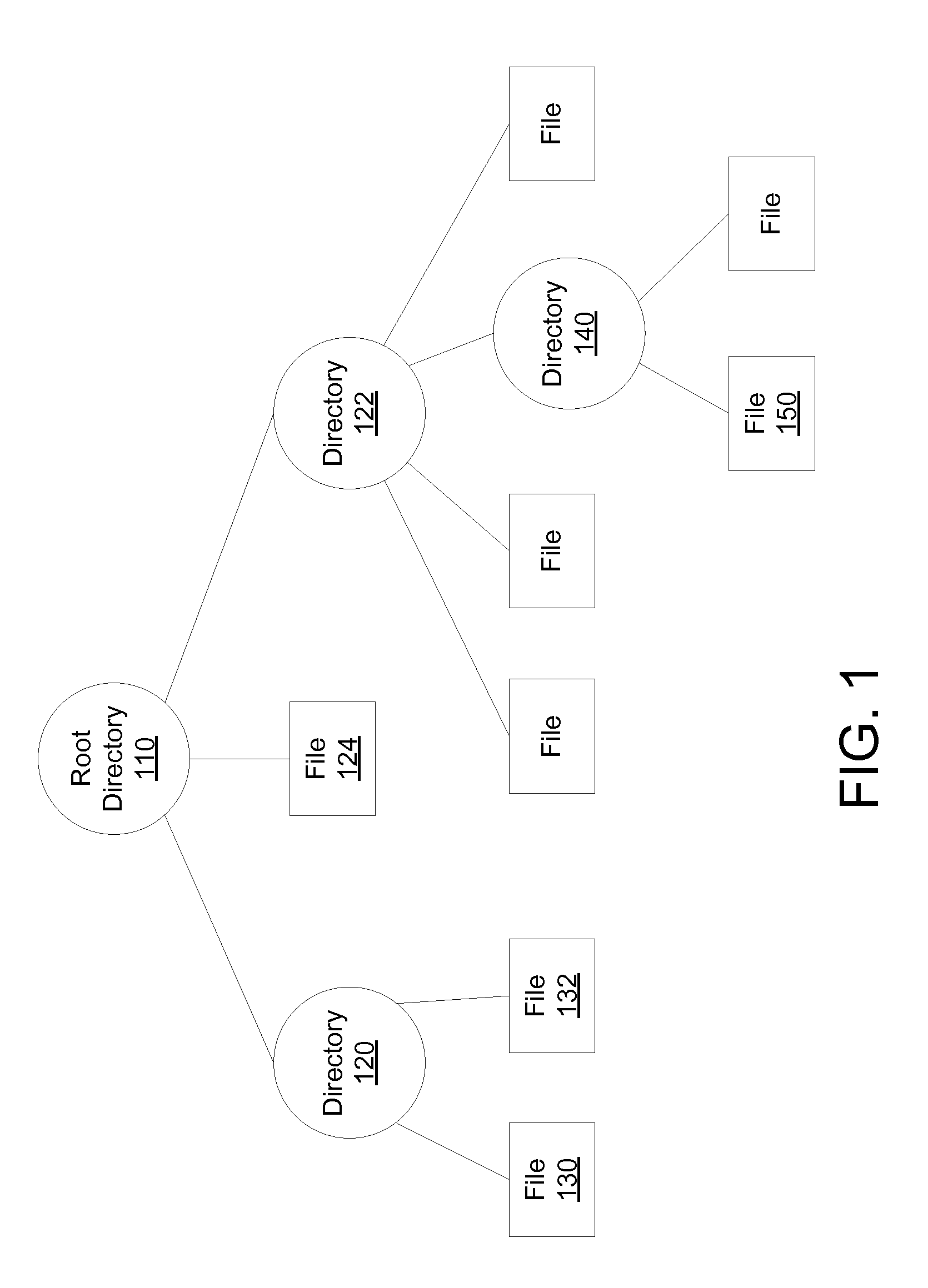

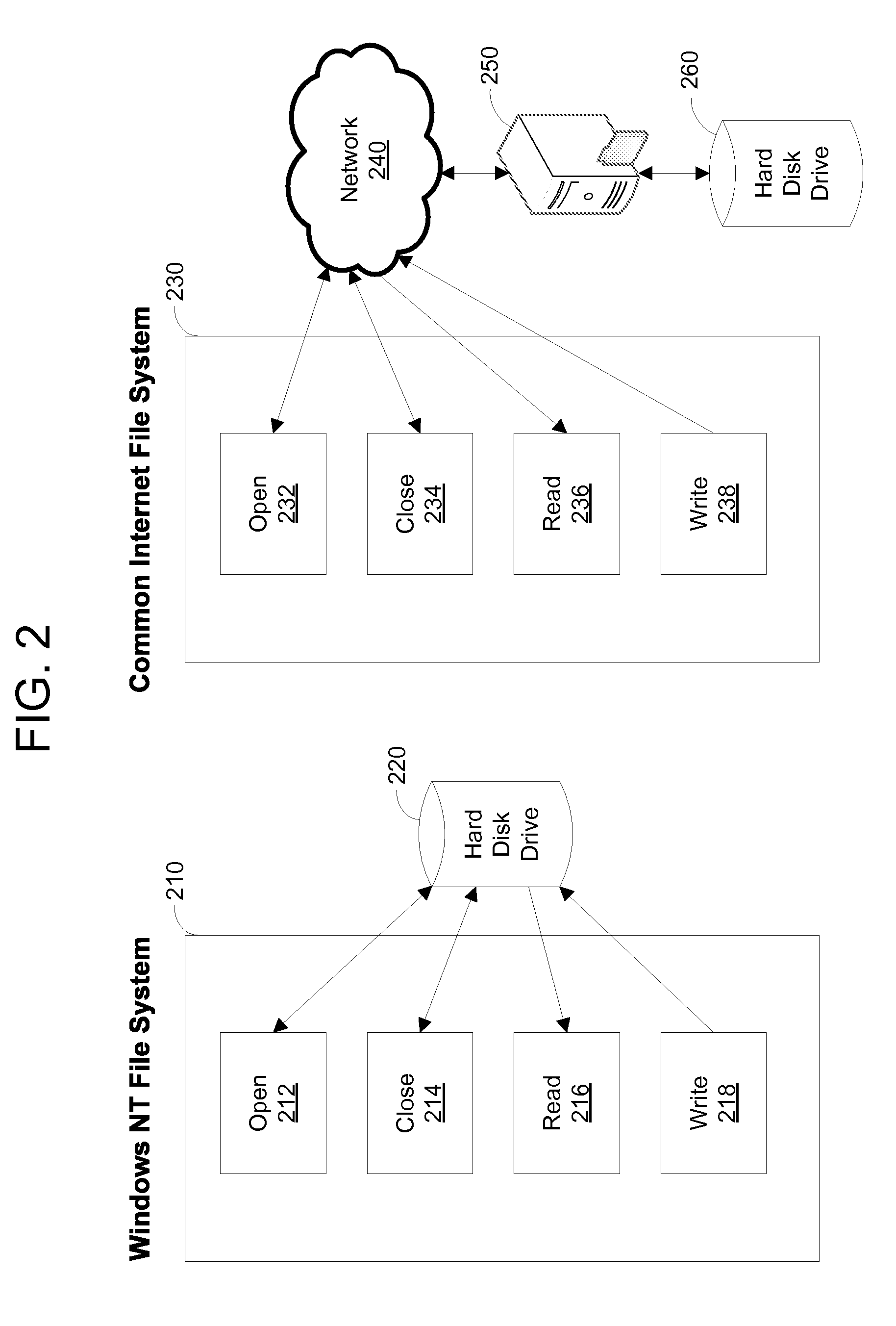

InactiveUS20090271412A1Digital data information retrievalMultiple digital computer combinationsHash functionFile system

Peer-to-peer redundant file server system and methods include clients that determine a target storage provider to contact for a particular storage transaction based on a pathname provided by the filesystem and a predetermined scheme such as a hash function applied to a portion of the pathname. Servers use the same scheme to determine where to store relevant file information so that the clients can locate the file information. The target storage provider may store the file itself and / or may store metadata that identifies one or more other storage providers where the file is stored. A file may be replicated in multiple storage providers, and the metadata may include a list of storage providers from which the clients can select (e.g., randomly) in order to access the file.

Owner:OVERLAND STORAGE

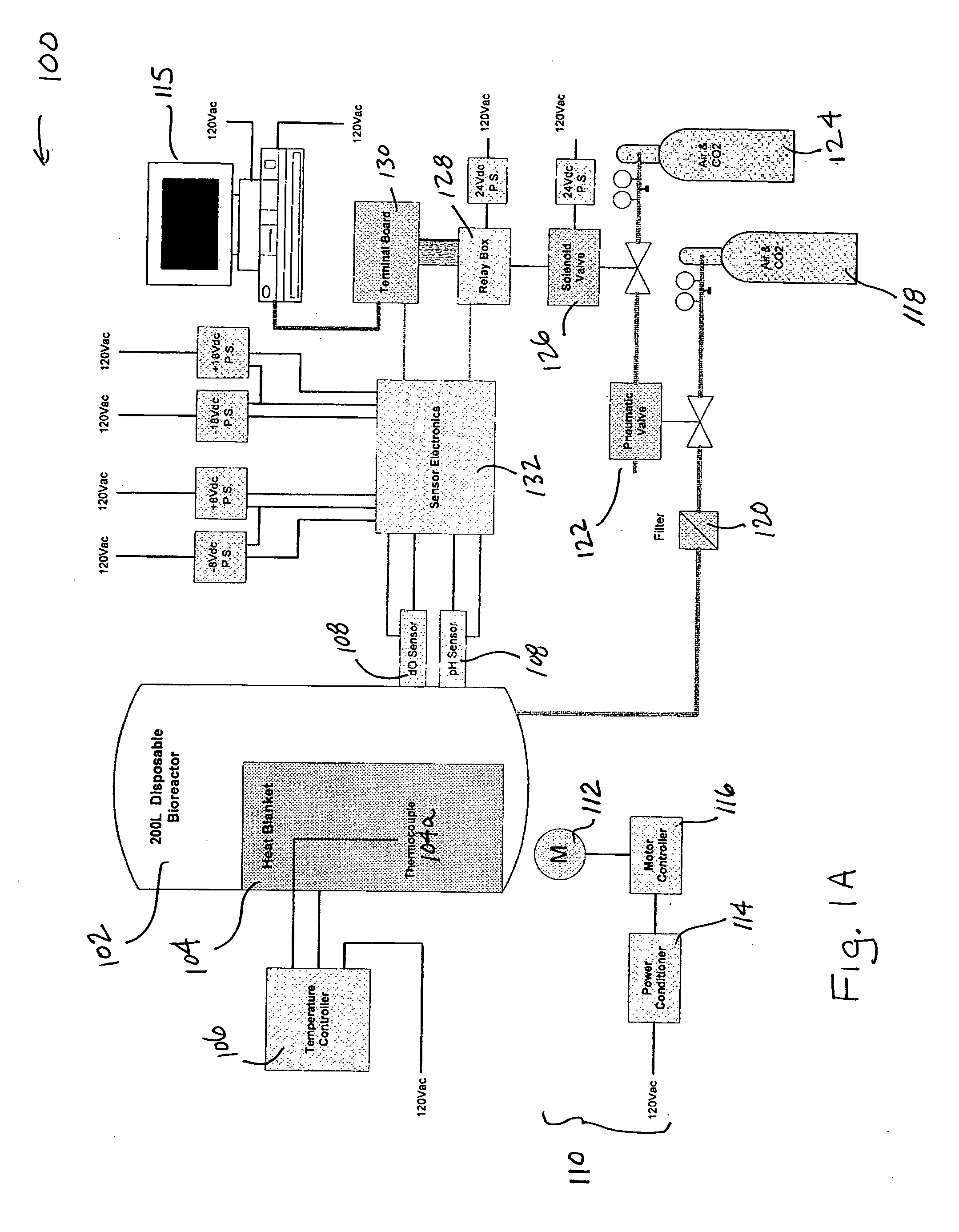

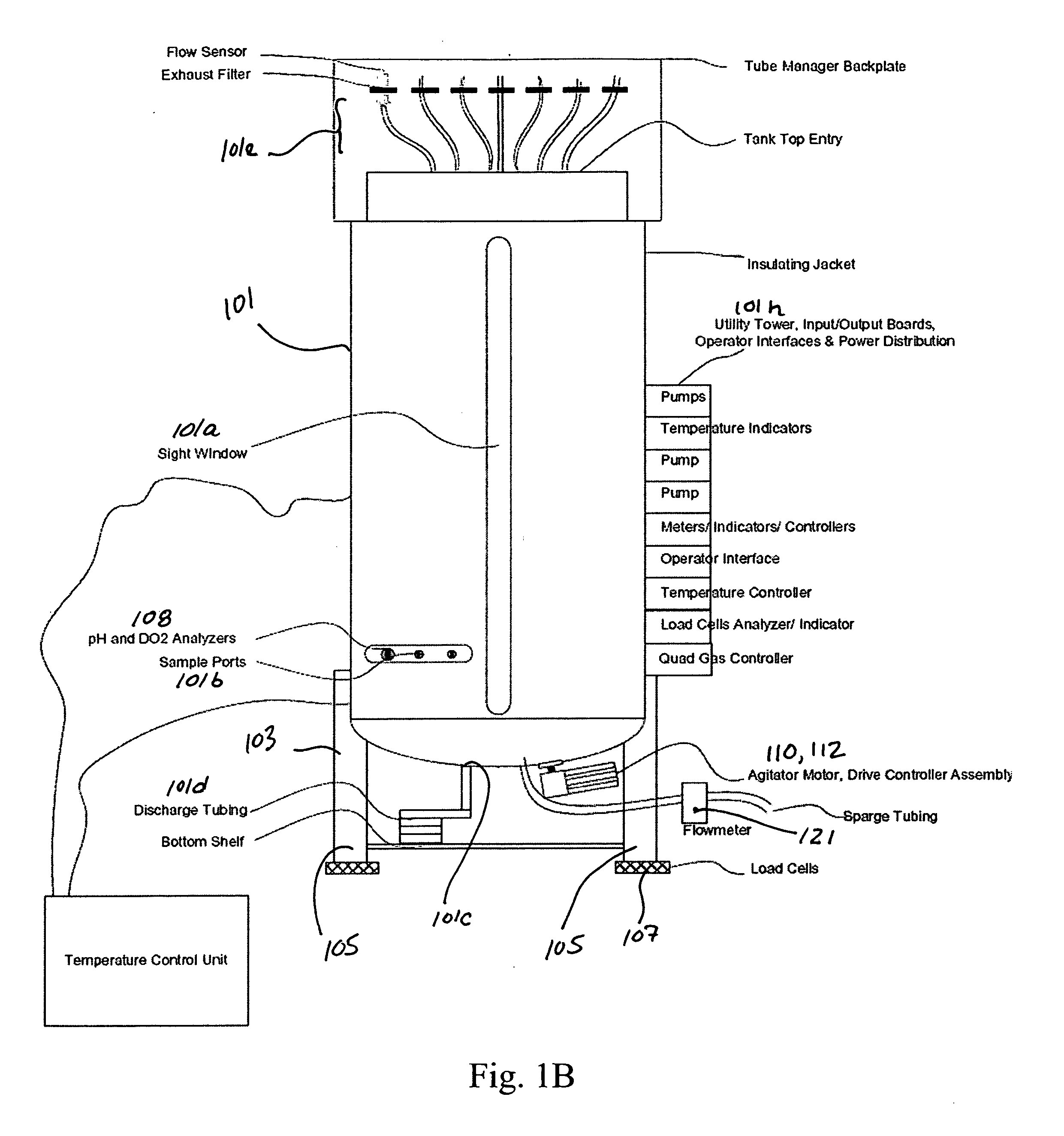

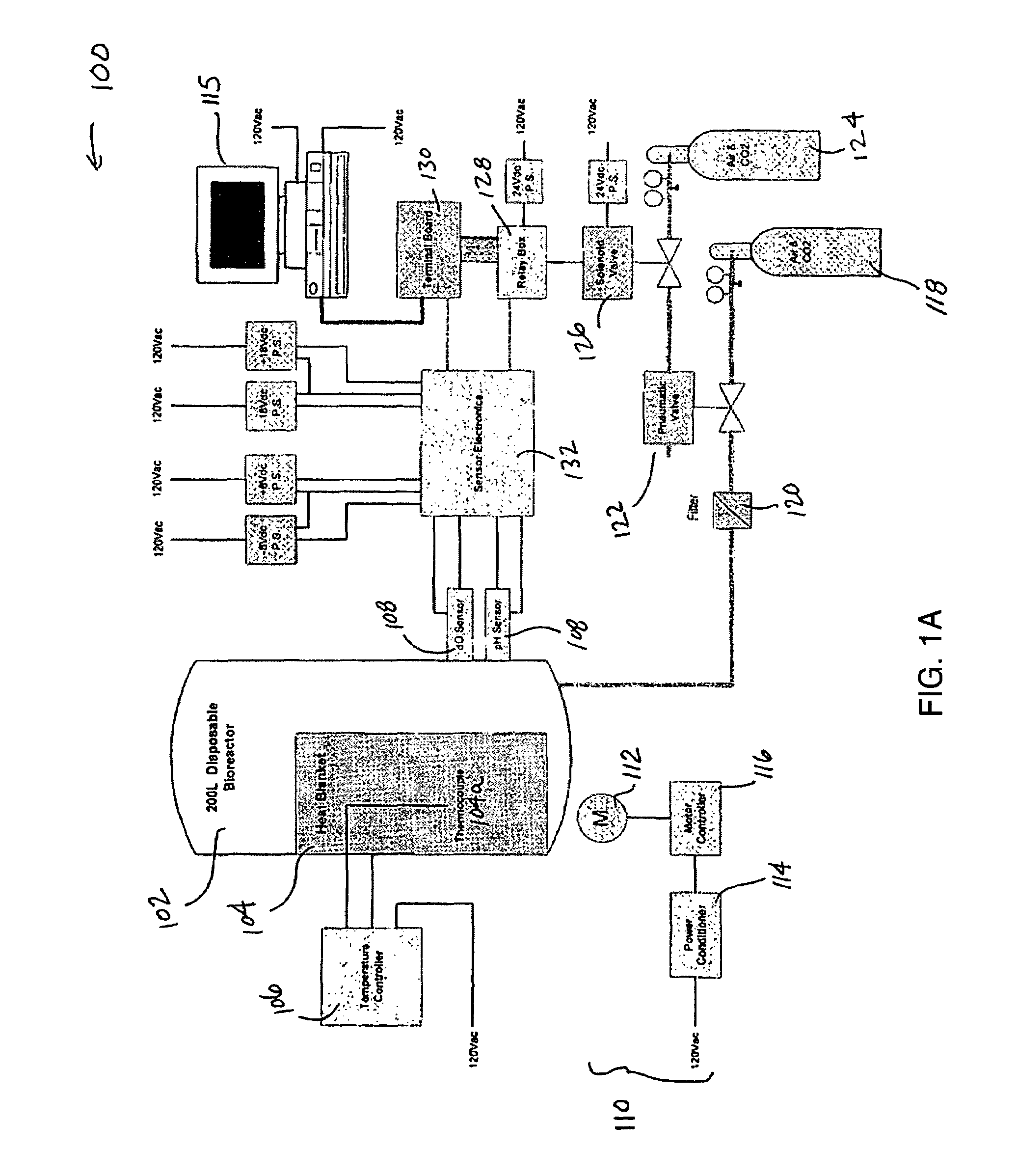

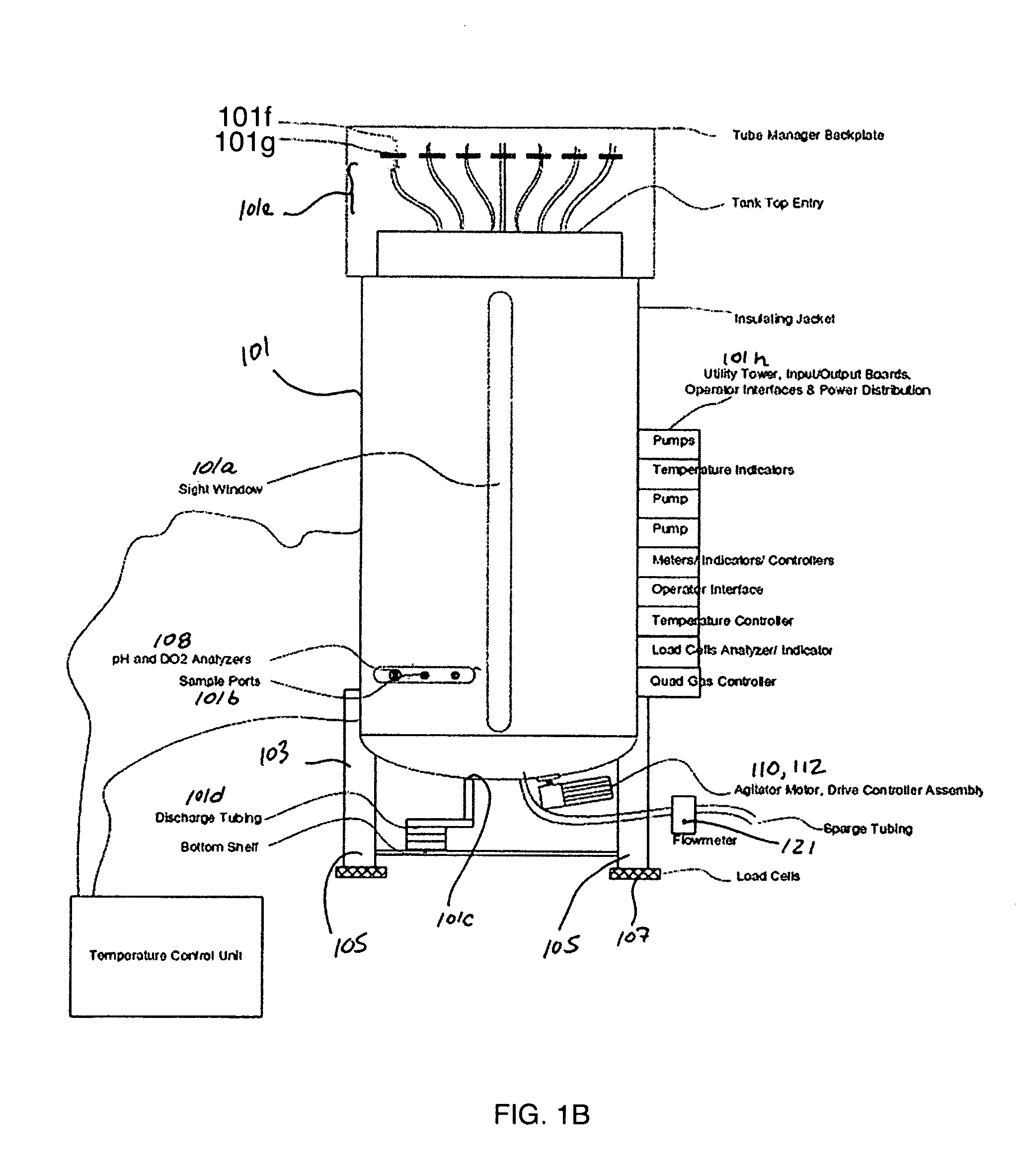

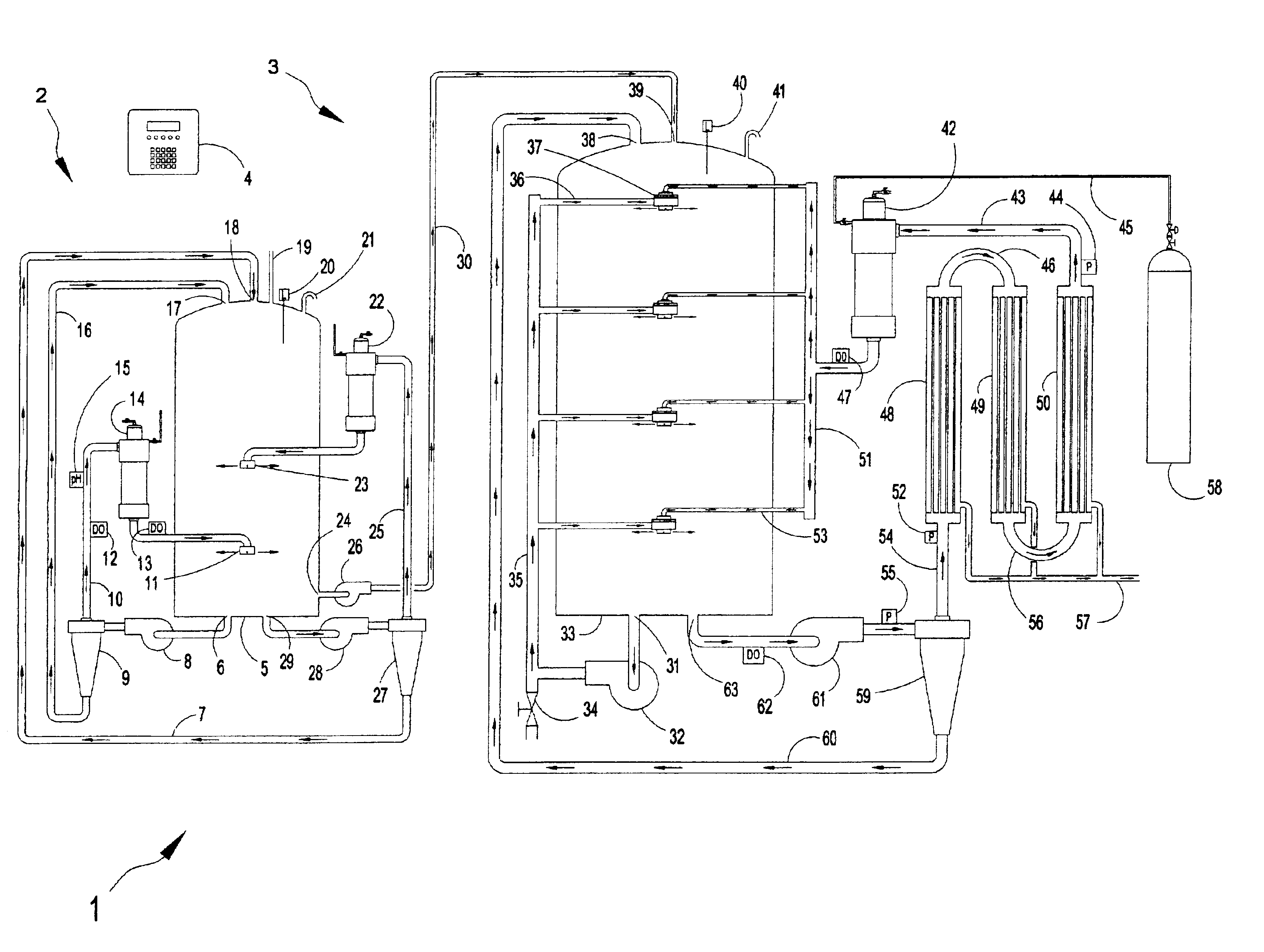

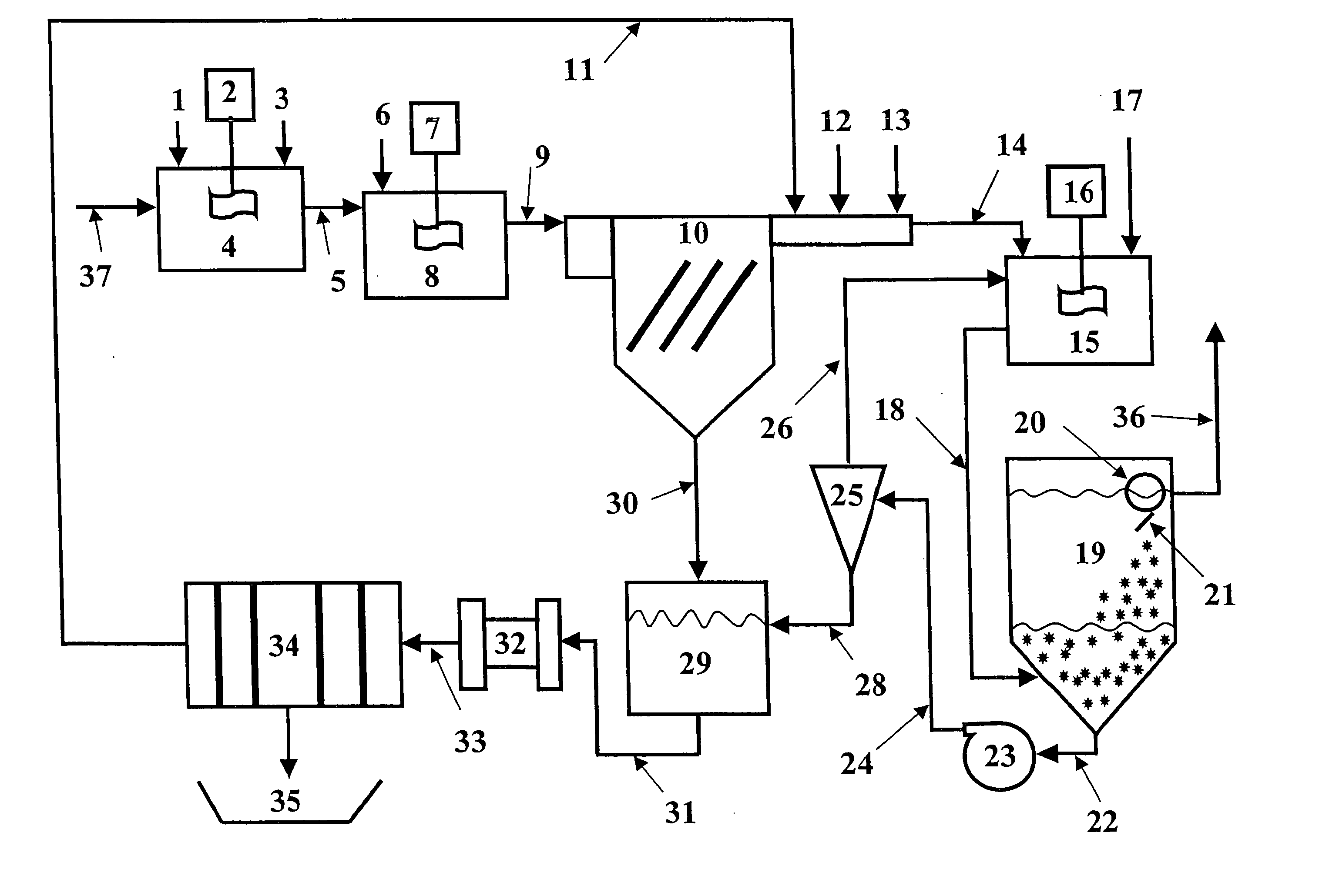

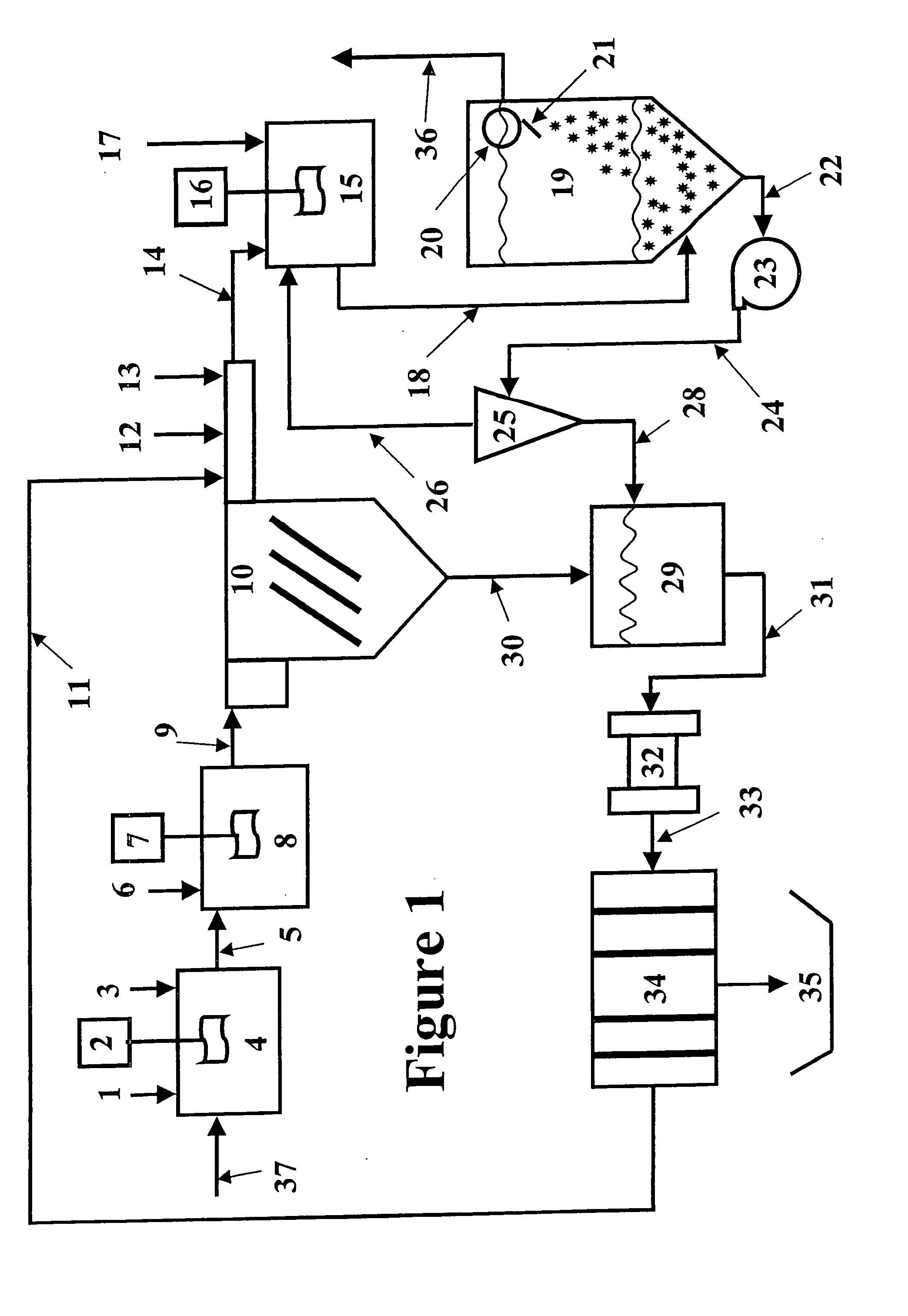

Disposable bioreactor systems and methods

ActiveUS20050272146A1Reduce wearReduce tearingBioreactor/fermenter combinationsBiological substance pretreatmentsOpen portSterile environment

Accordingly, in one embodiment of the invention, a bioreactor system is presented and includes a disposable container for housing biomaterials for processing, the disposable container including at least one input port, at least one exhaust port, at least one harvest port, and the integrity of the sterile environment is protected with sterile filters attached to all external open ports a structure for supporting the disposable container, one or more sensors for sensing one or more parameters of the biomaterials in the container, a heater for heating the contents of the container, the heater having a thermostat and mixing system arranged with the system such that biomaterials contained in the disposable container are mixed.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

Disposable bioreactor systems and methods

ActiveUS7629167B2Reduce wearReduce chanceBioreactor/fermenter combinationsBiological substance pretreatmentsSterile environmentHybrid system

Accordingly, in one embodiment of the invention, a bioreactor system is presented and includes a disposable container for housing biomaterials for processing, the disposable container including at least one input port, at least one exhaust port, at least one harvest port, and the integrity of the sterile environment is protected with sterile filters attached to all external open ports a structure for supporting the disposable container, one or more sensors for sensing one or more parameters of the biomaterials in the container, a heater for heating the contents of the container, the heater having a thermostat and mixing system arranged with the system such that biomaterials contained in the disposable container are mixed.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

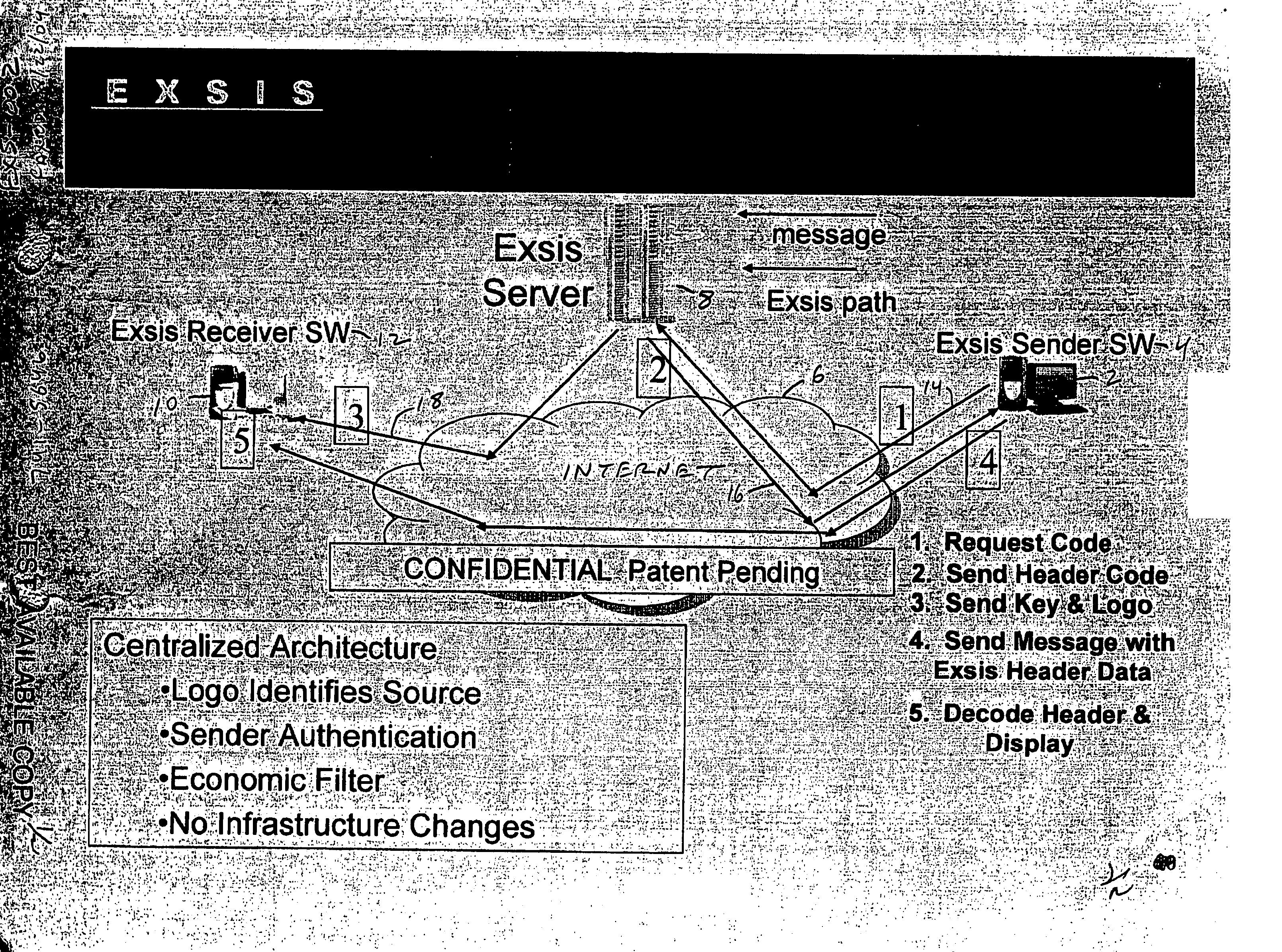

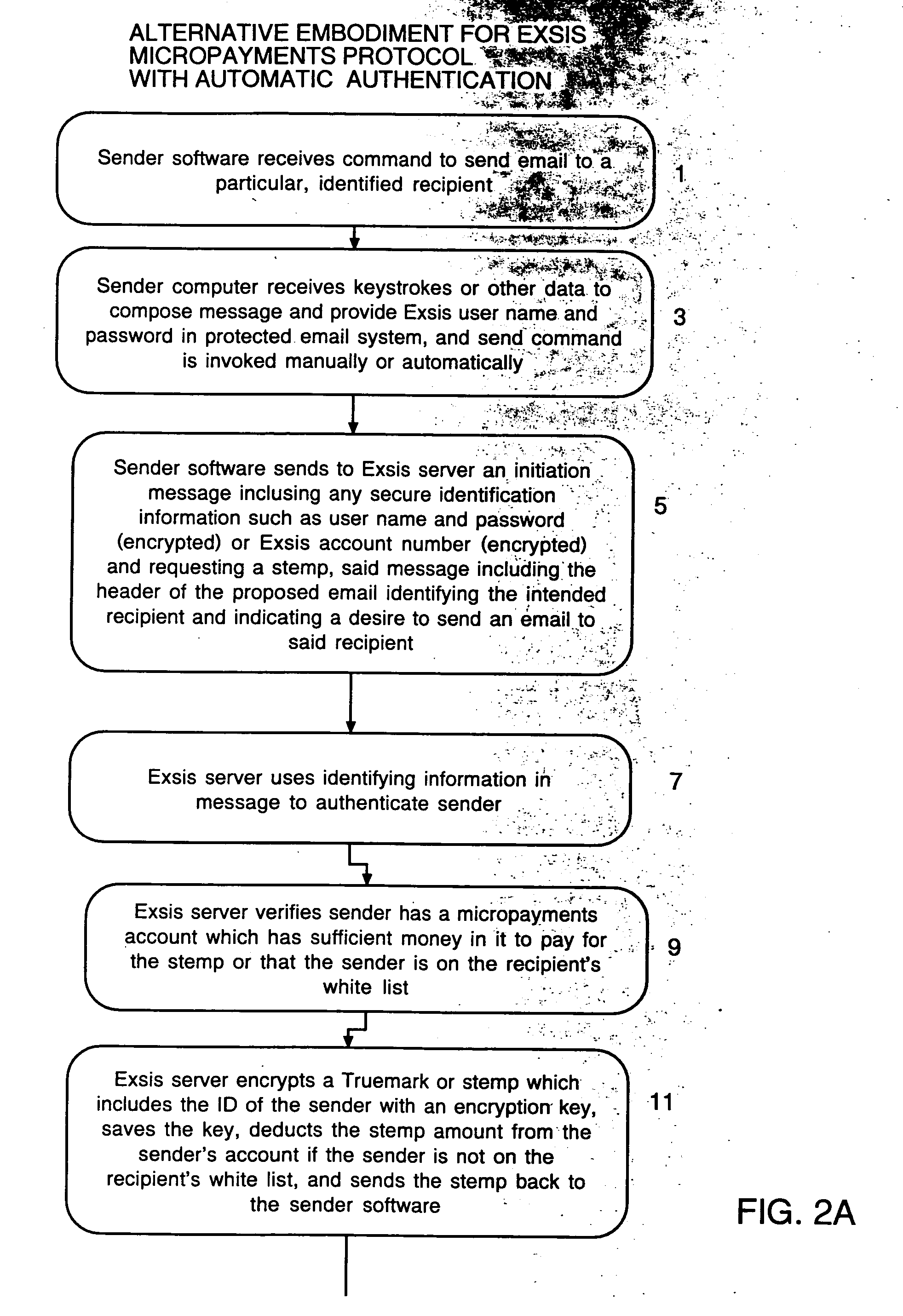

User interface and anti-phishing functions for an anti-spam micropayments system

ActiveUS20060075028A1Control contentEffective controlMultiple digital computer combinationsFlotationTrademarkSpamming

Owner:ICONIX INC

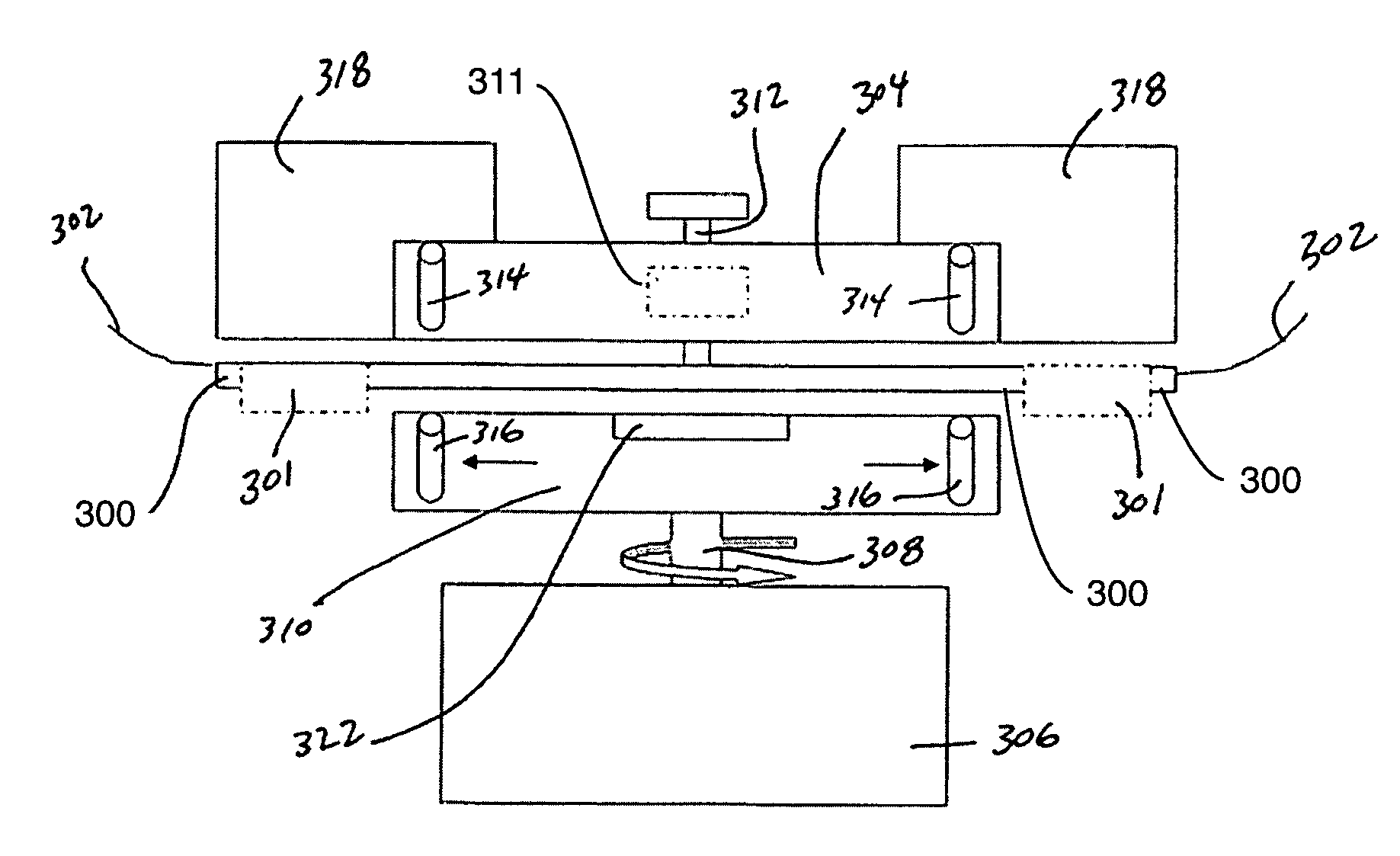

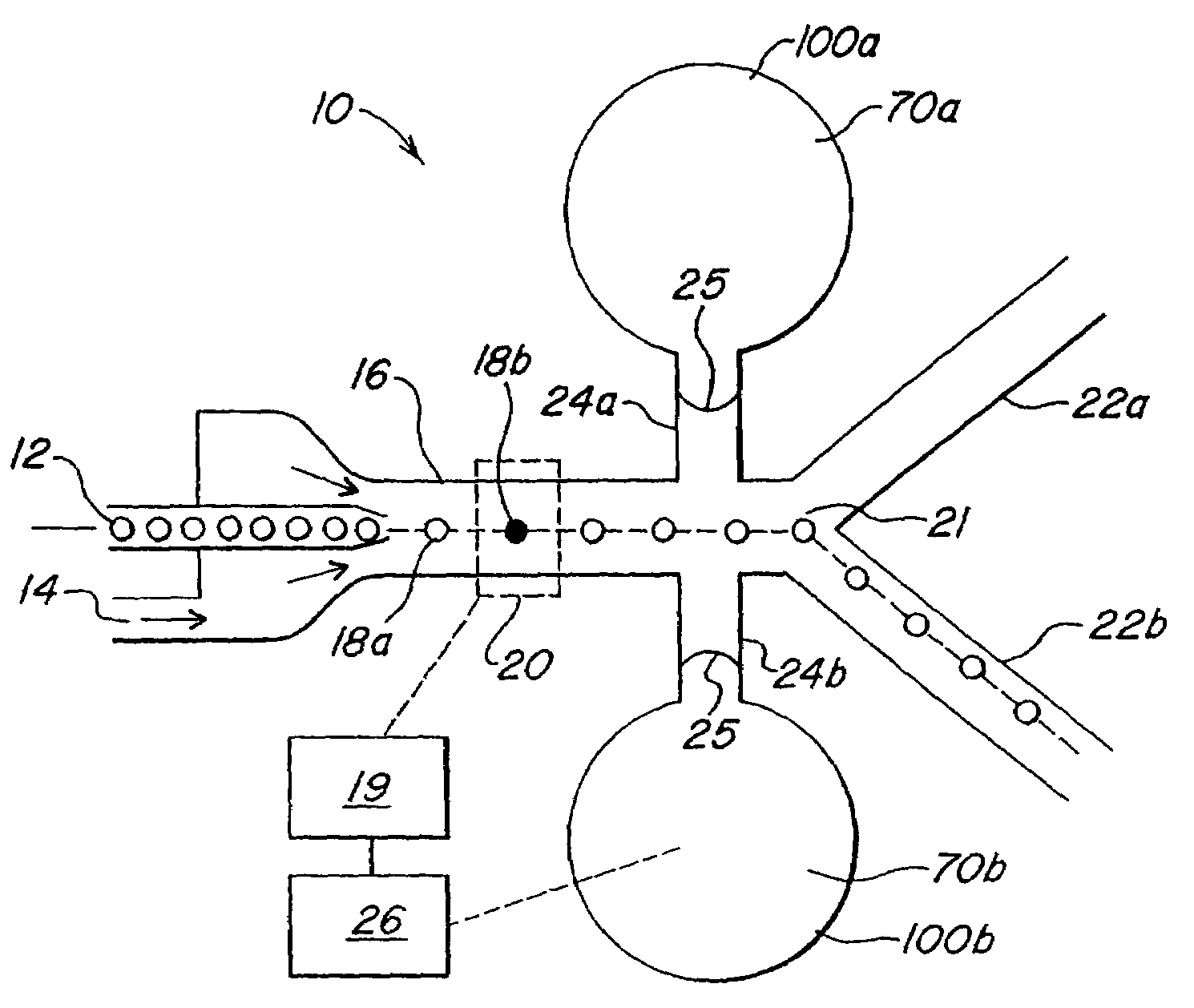

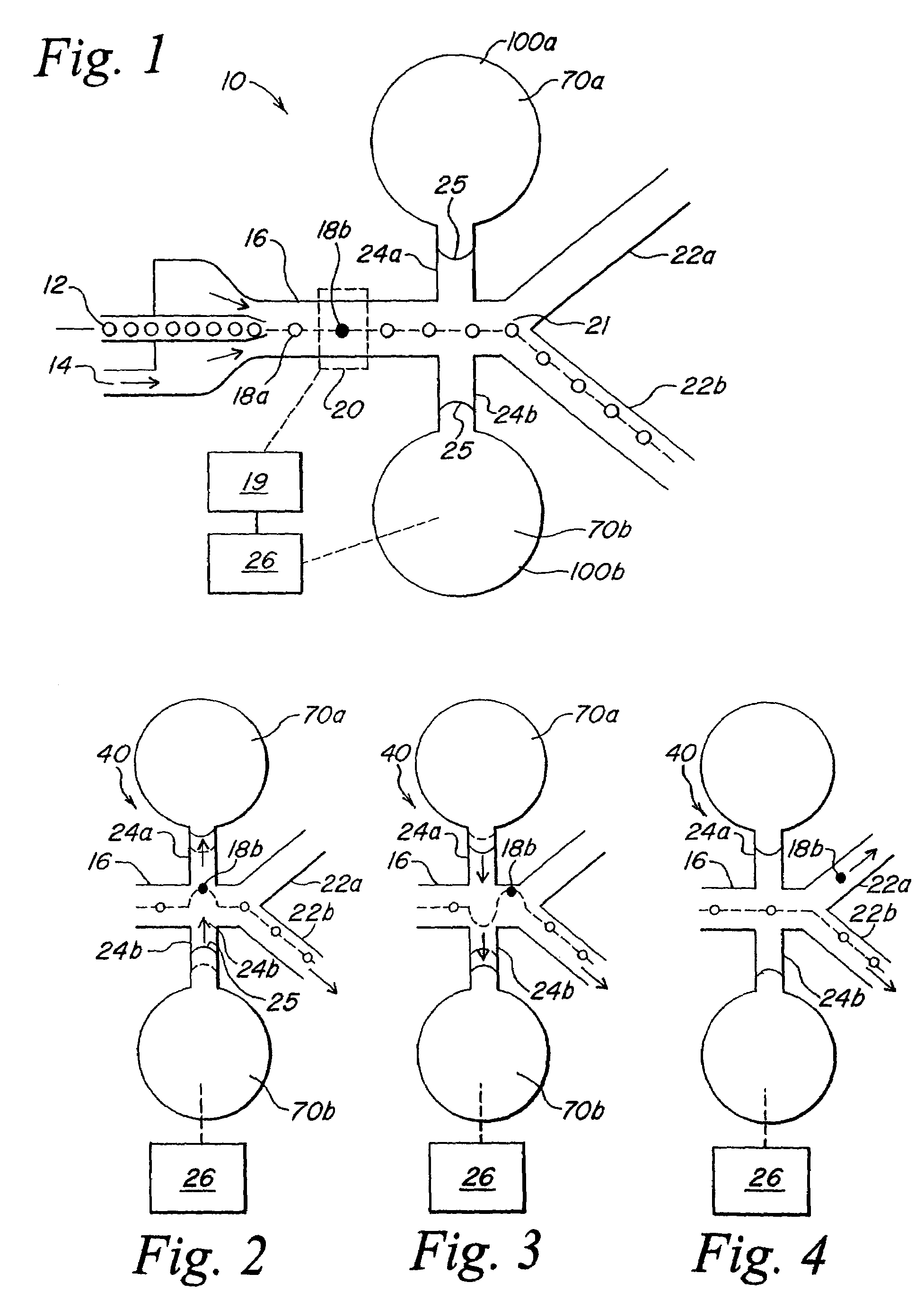

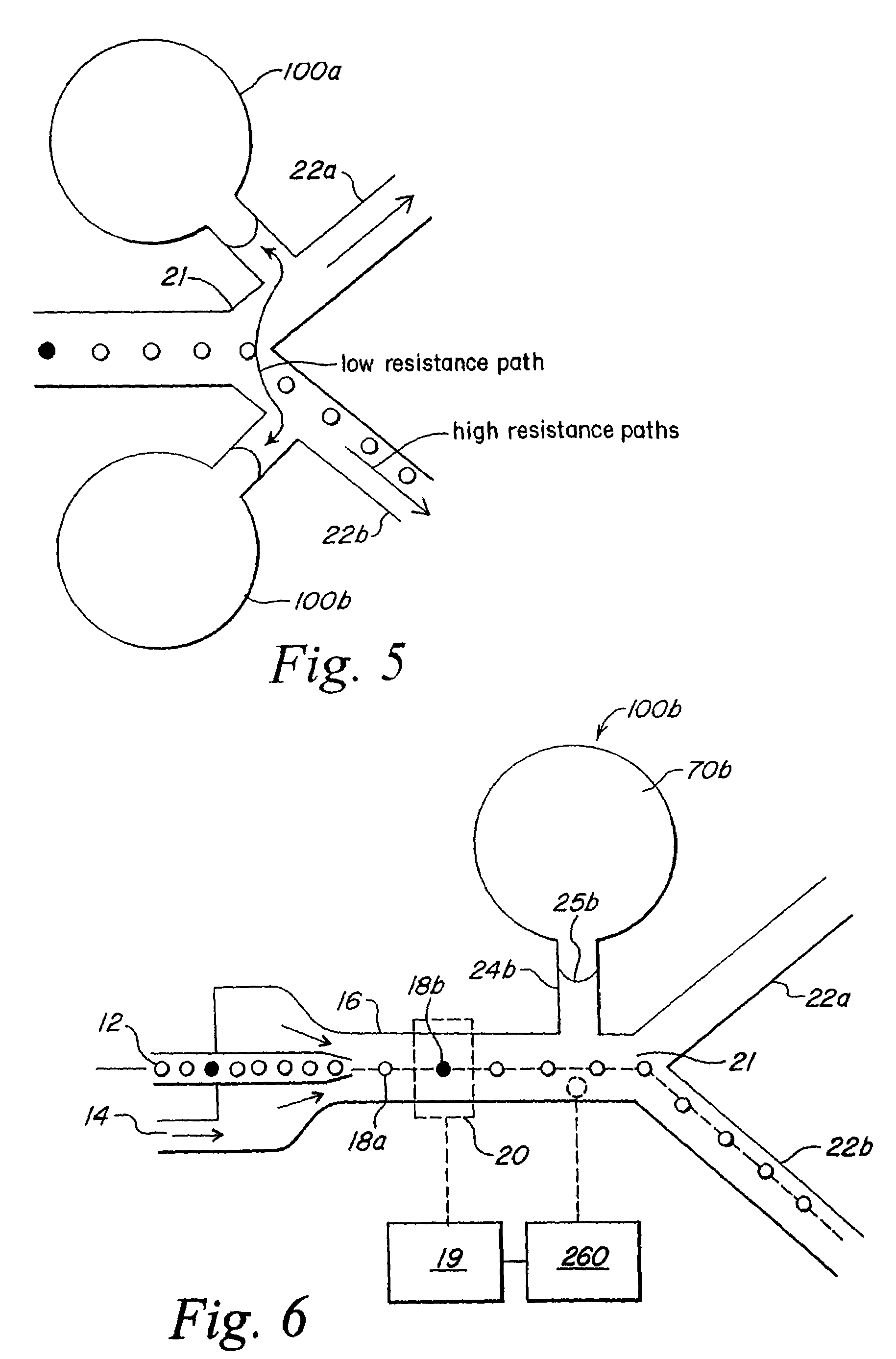

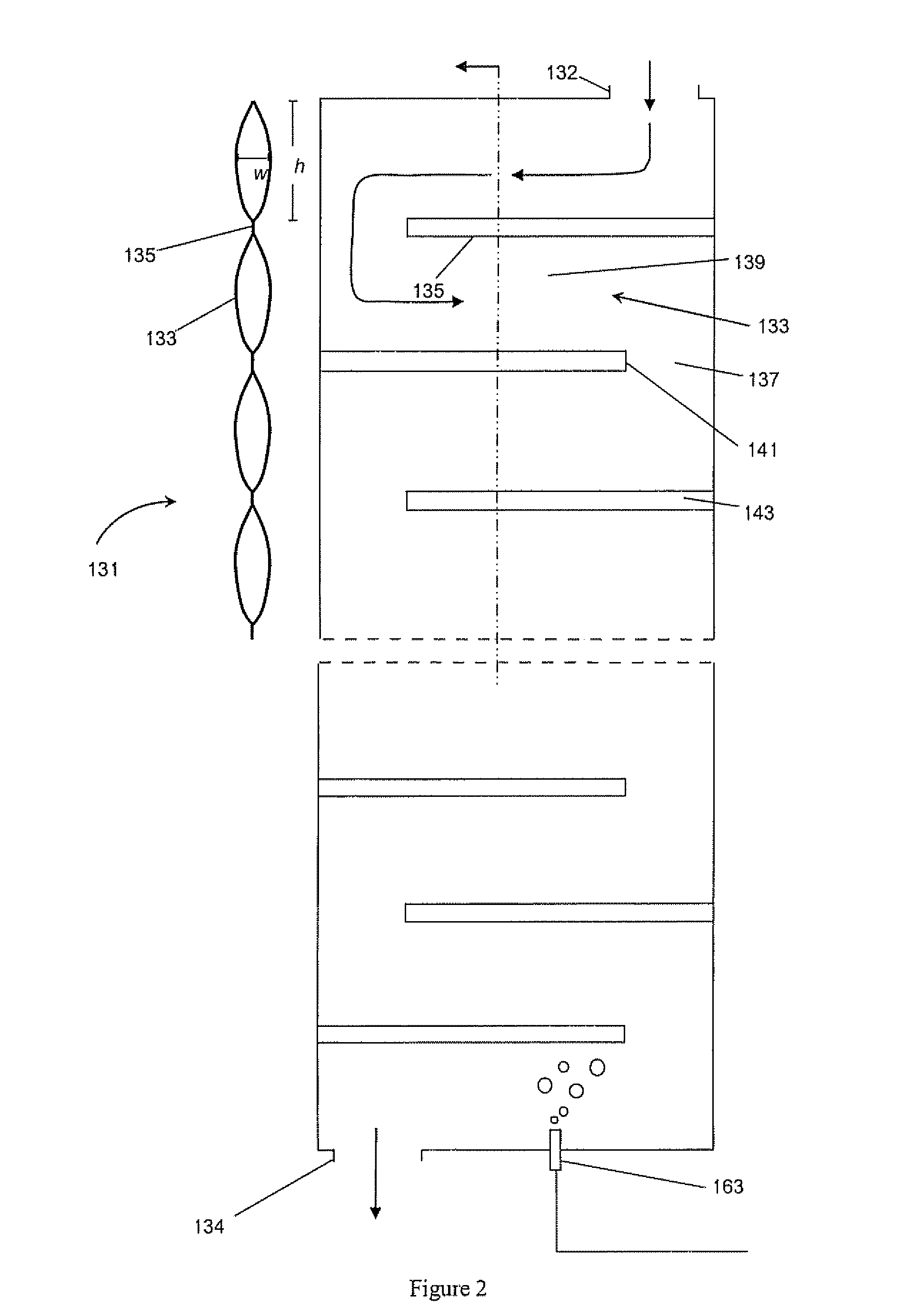

Method and apparatus for sorting particles

InactiveUS7157274B2Low costImprove sorting rateBioreactor/fermenter combinationsBiological substance pretreatmentsParticle sortingComputer module

A method and apparatus for sorting particles moving through a closed channel system of capillary size comprises a bubble valve for selectively generating a pressure pulse to separate a particle having a predetermined characteristic from a stream of particles. The particle sorting system may further include a buffer for absorbing the pressure pulse. The particle sorting system may include a plurality of closely coupled sorting modules which are combined to further increase the sorting rate. The particle sorting system may comprise a multi-stage sorting device for serially sorting streams of particles, in order to decrease the error rate.

Owner:CYTONOMEST

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

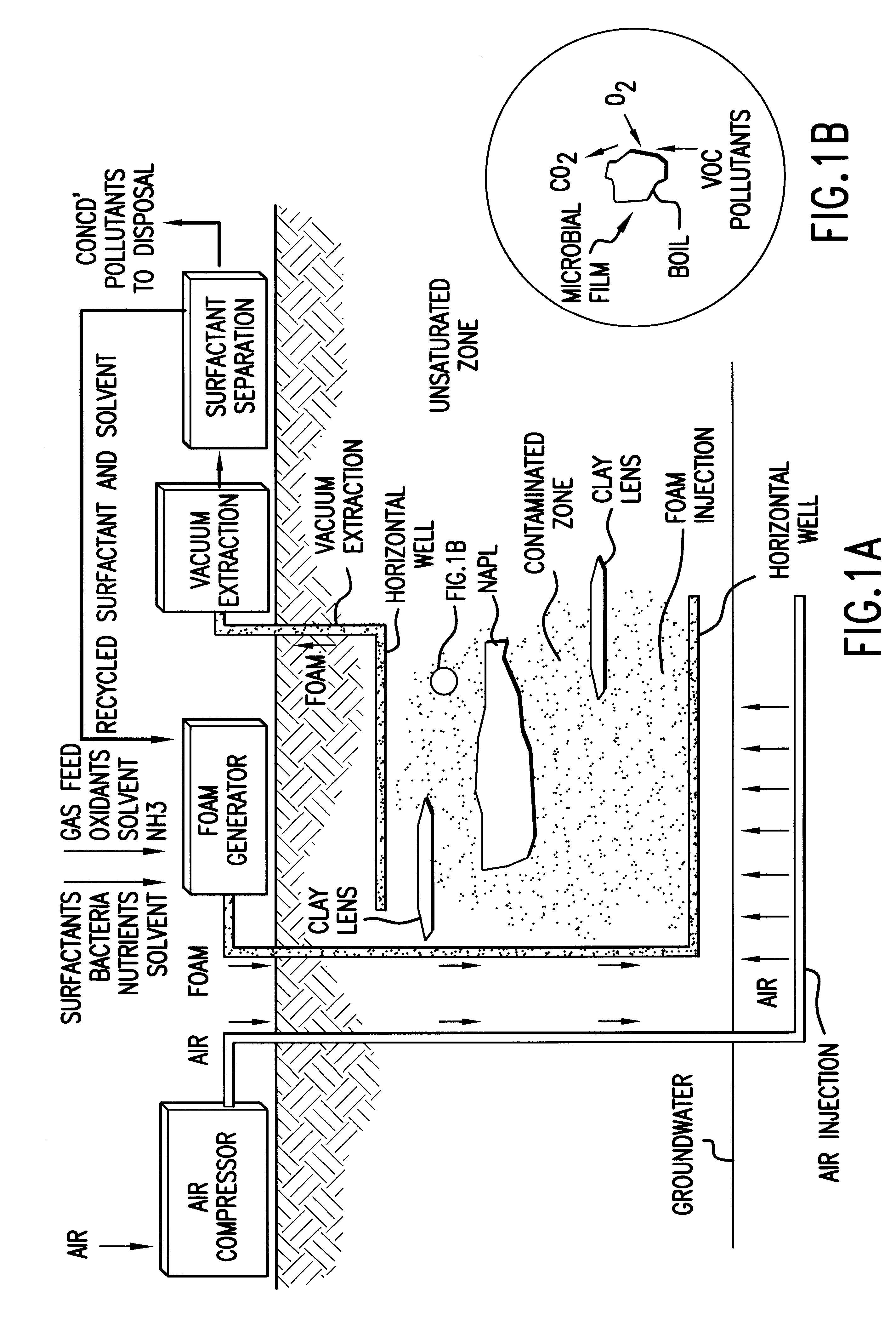

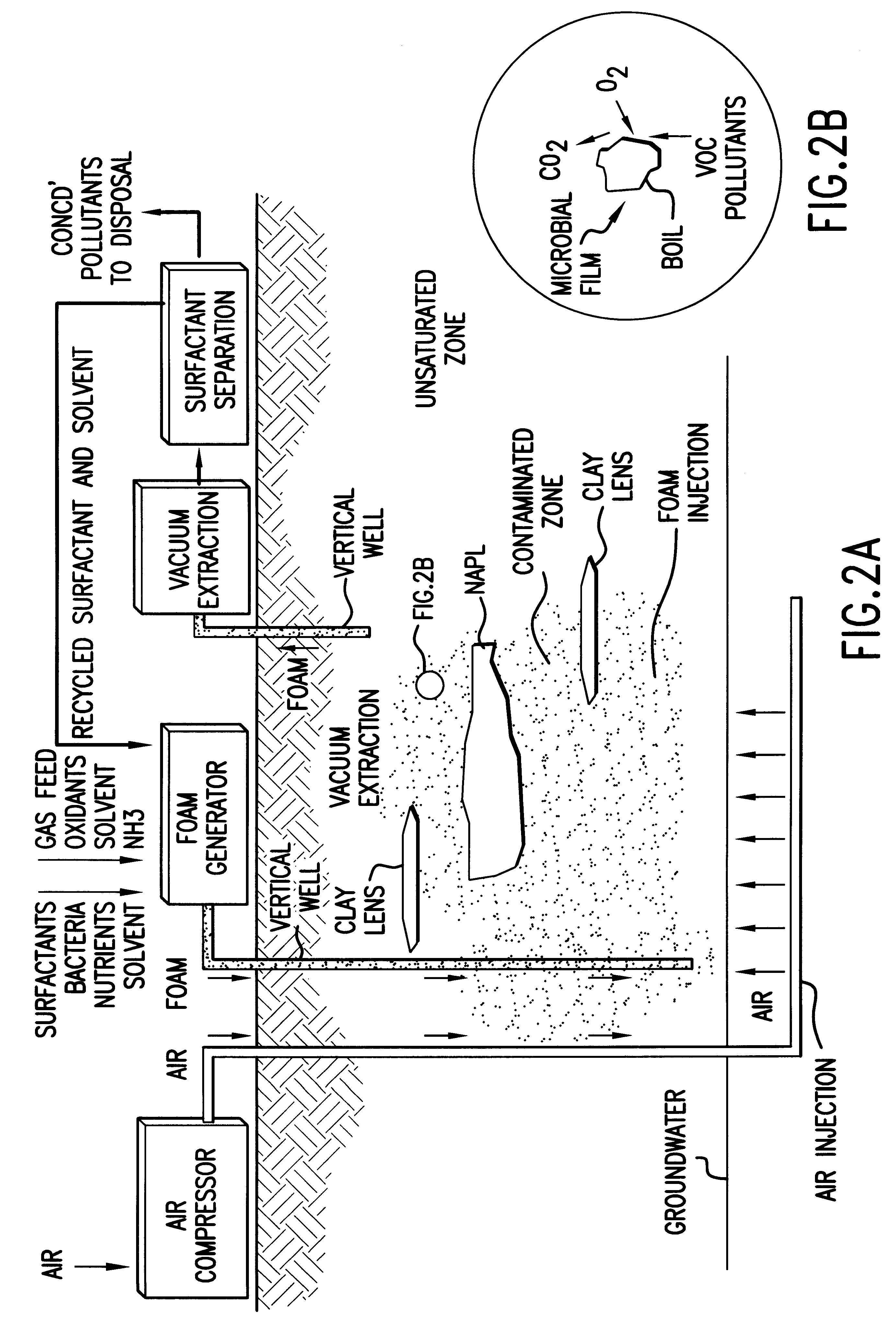

Foam transport process for in-situ remediation of contaminated soils

Owner:GAS TECH INST

Peer-to-peer redundant file server system and methods

InactiveUS8296398B2Digital data information retrievalMultiple digital computer combinationsHash functionFile system

Peer-to-peer redundant file server system and methods include clients that determine a target storage provider to contact for a particular storage transaction based on a pathname provided by the filesystem and a predetermined scheme such as a hash function applied to a portion of the pathname. Servers use the same scheme to determine where to store relevant file information so that the clients can locate the file information. The target storage provider may store the file itself and / or may store metadata that identifies one or more other storage providers where the file is stored. A file may be replicated in multiple storage providers, and the metadata may include a list of storage providers from which the clients can select (e.g., randomly) in order to access the file.

Owner:OVERLAND STORAGE INC

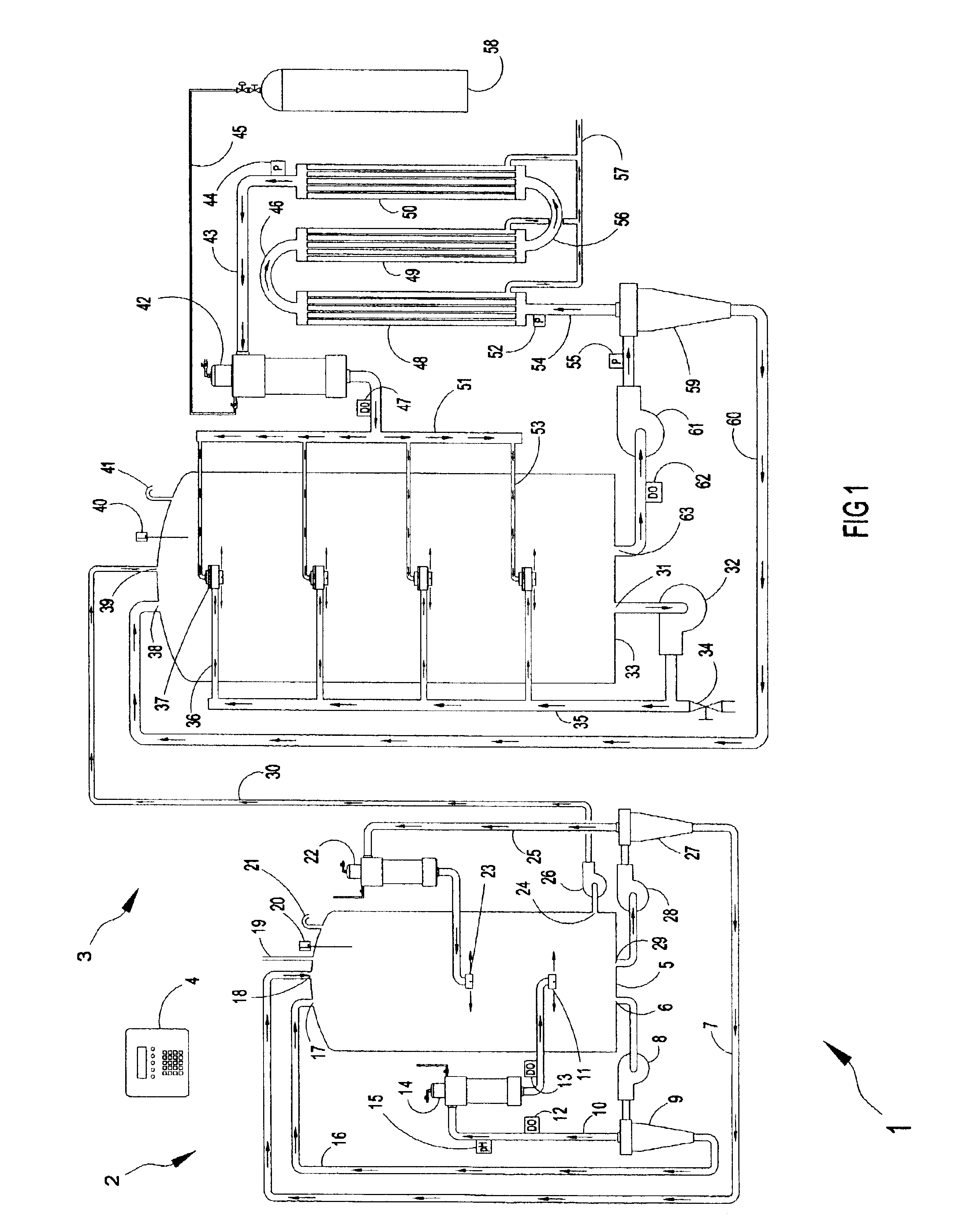

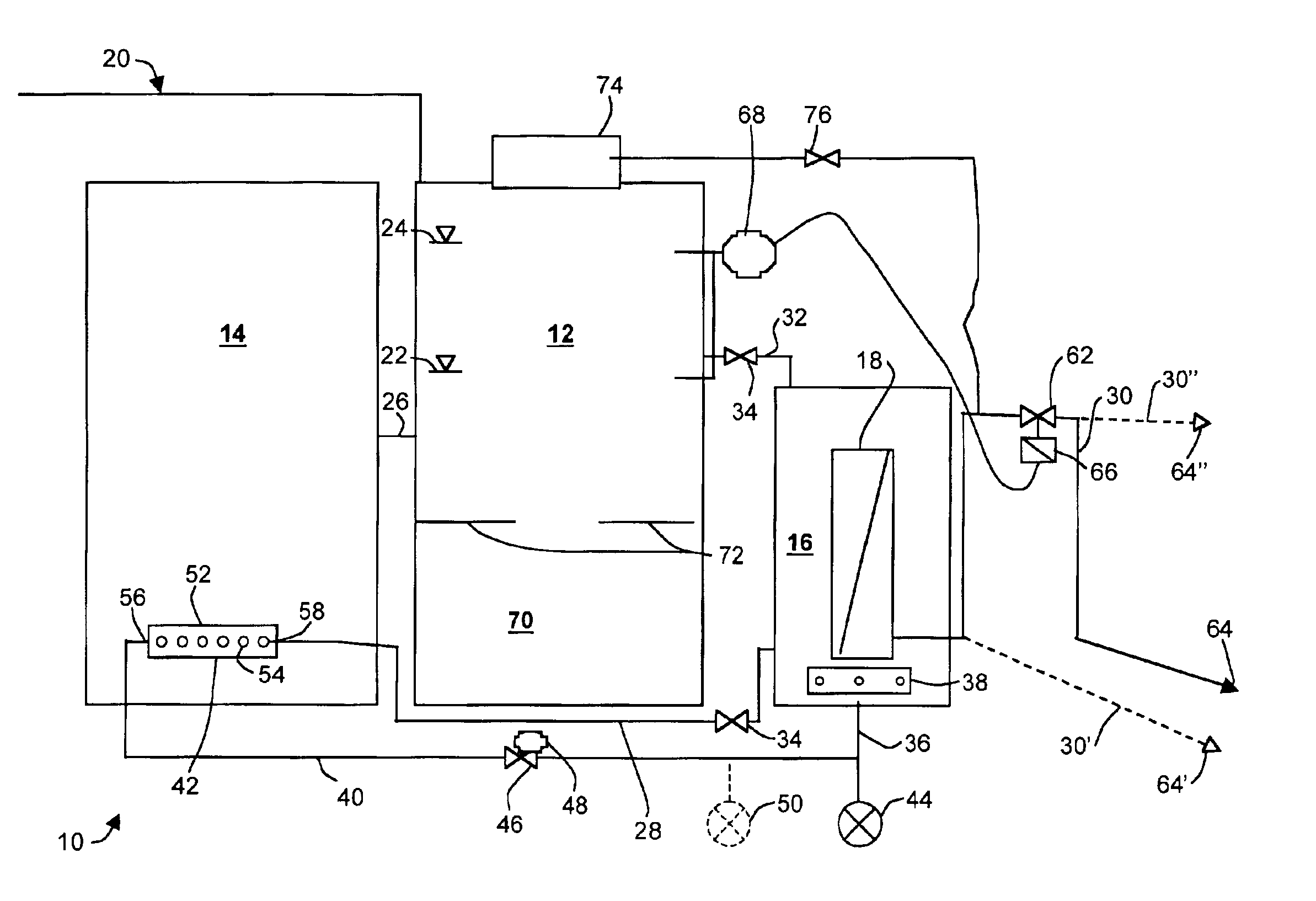

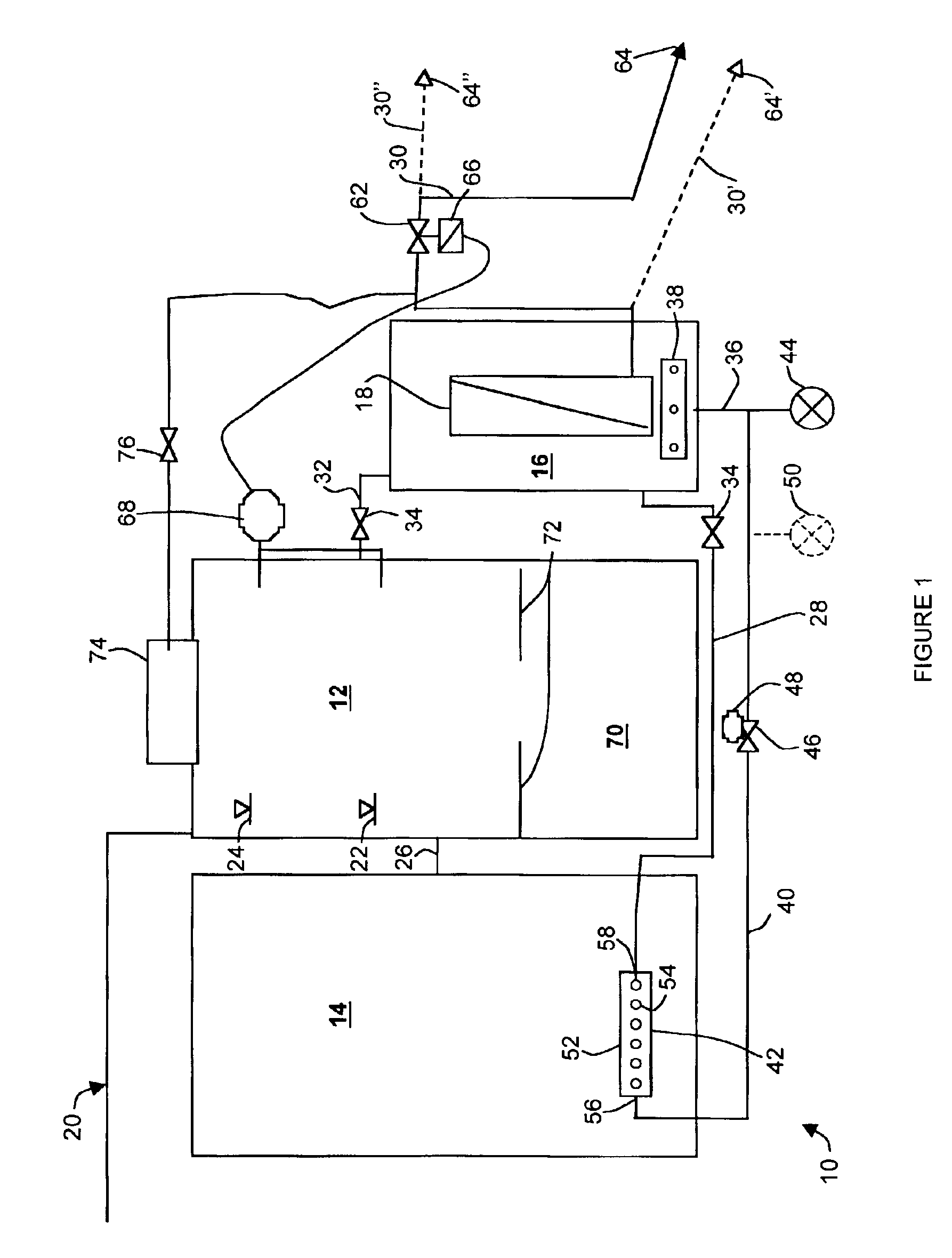

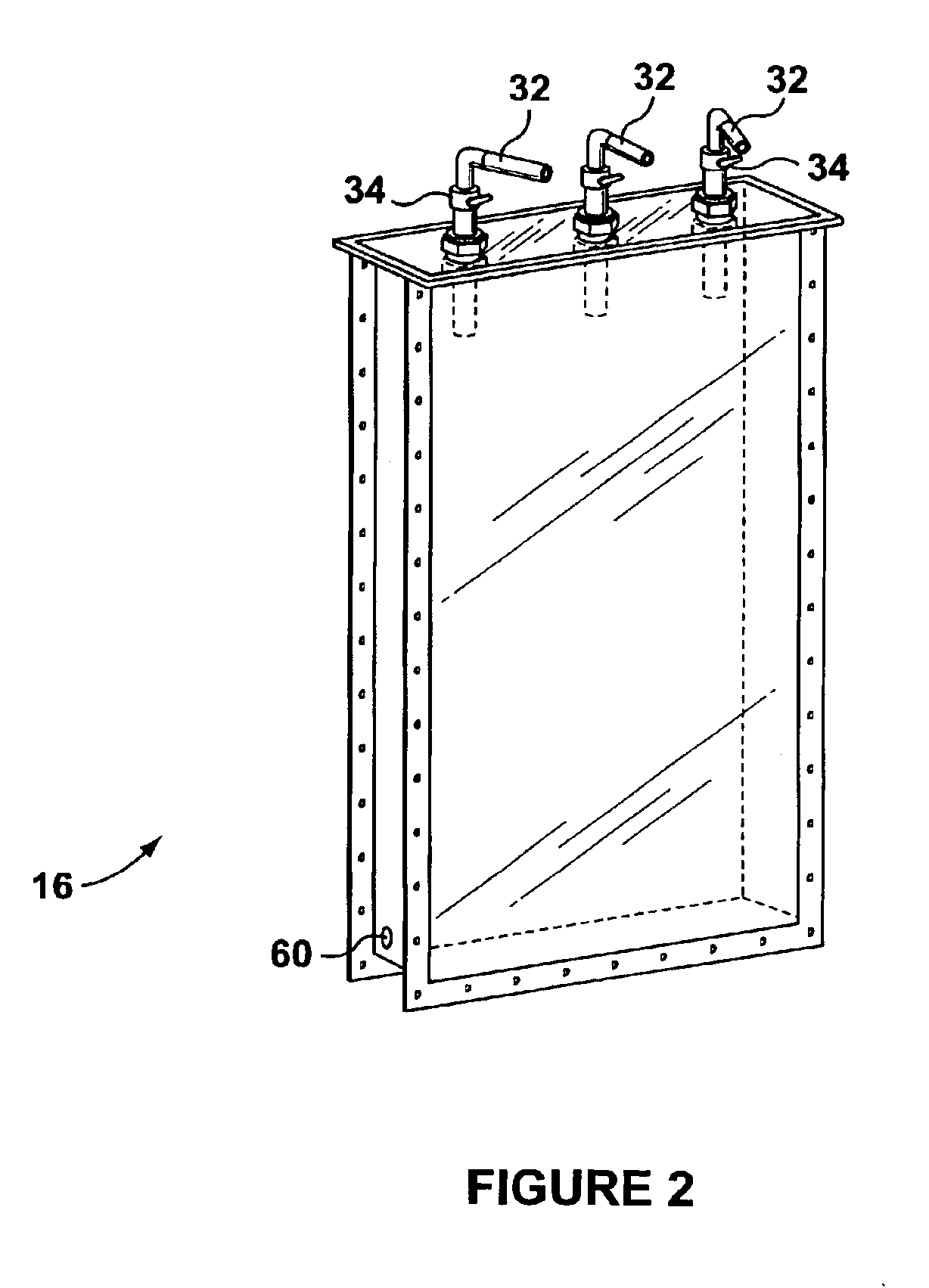

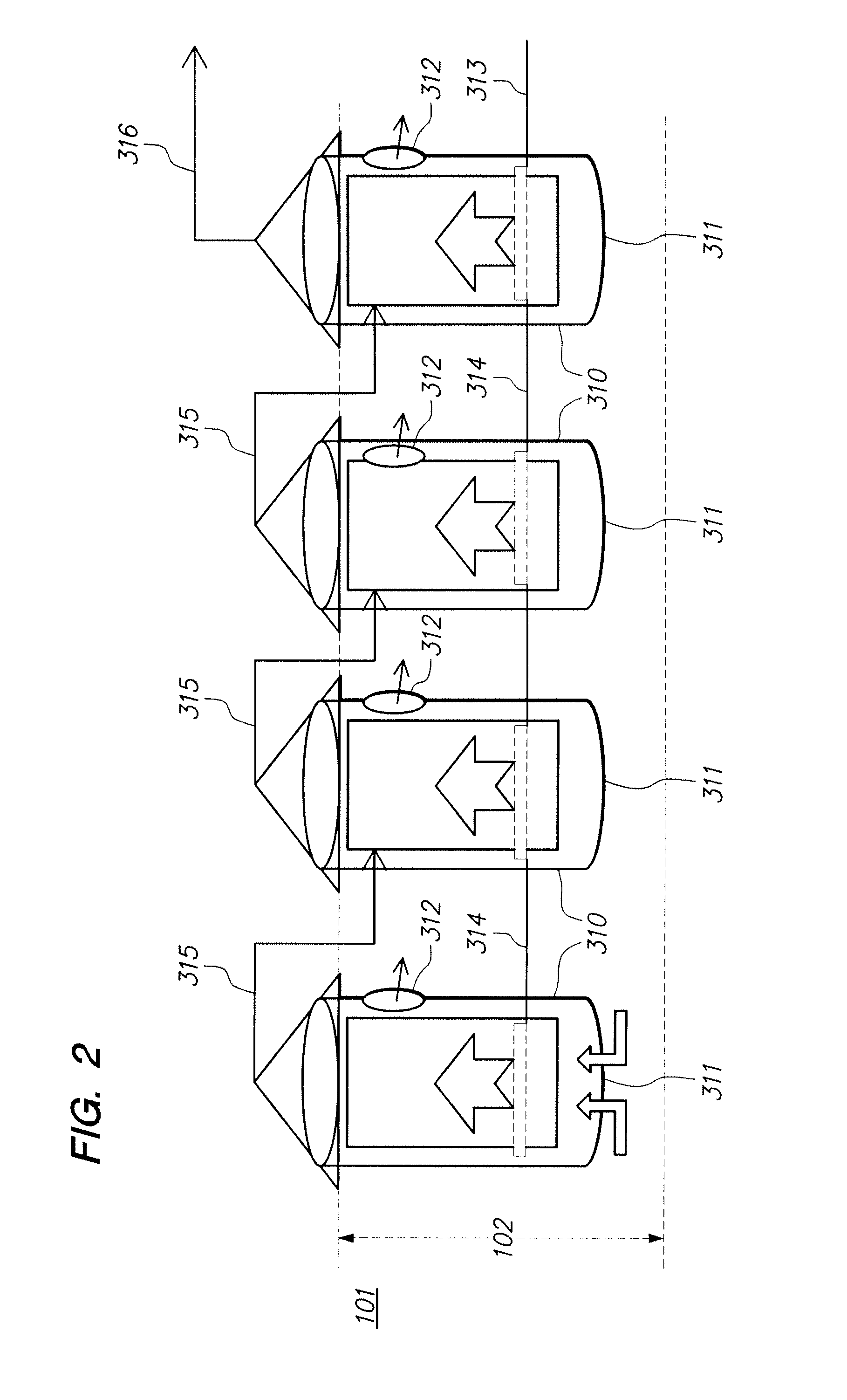

Method and apparatus for treatment of wastewater employing membrane bioreactors

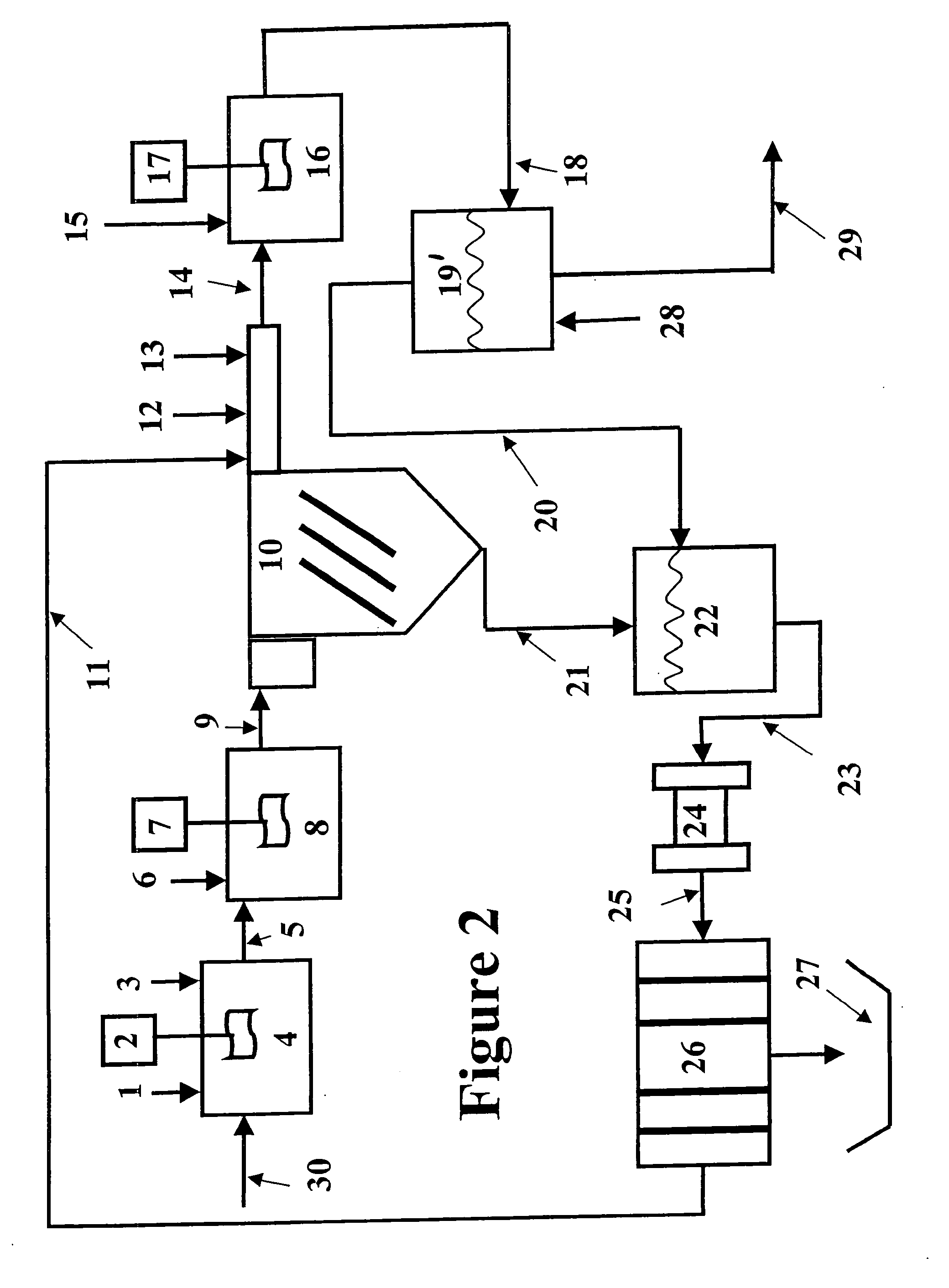

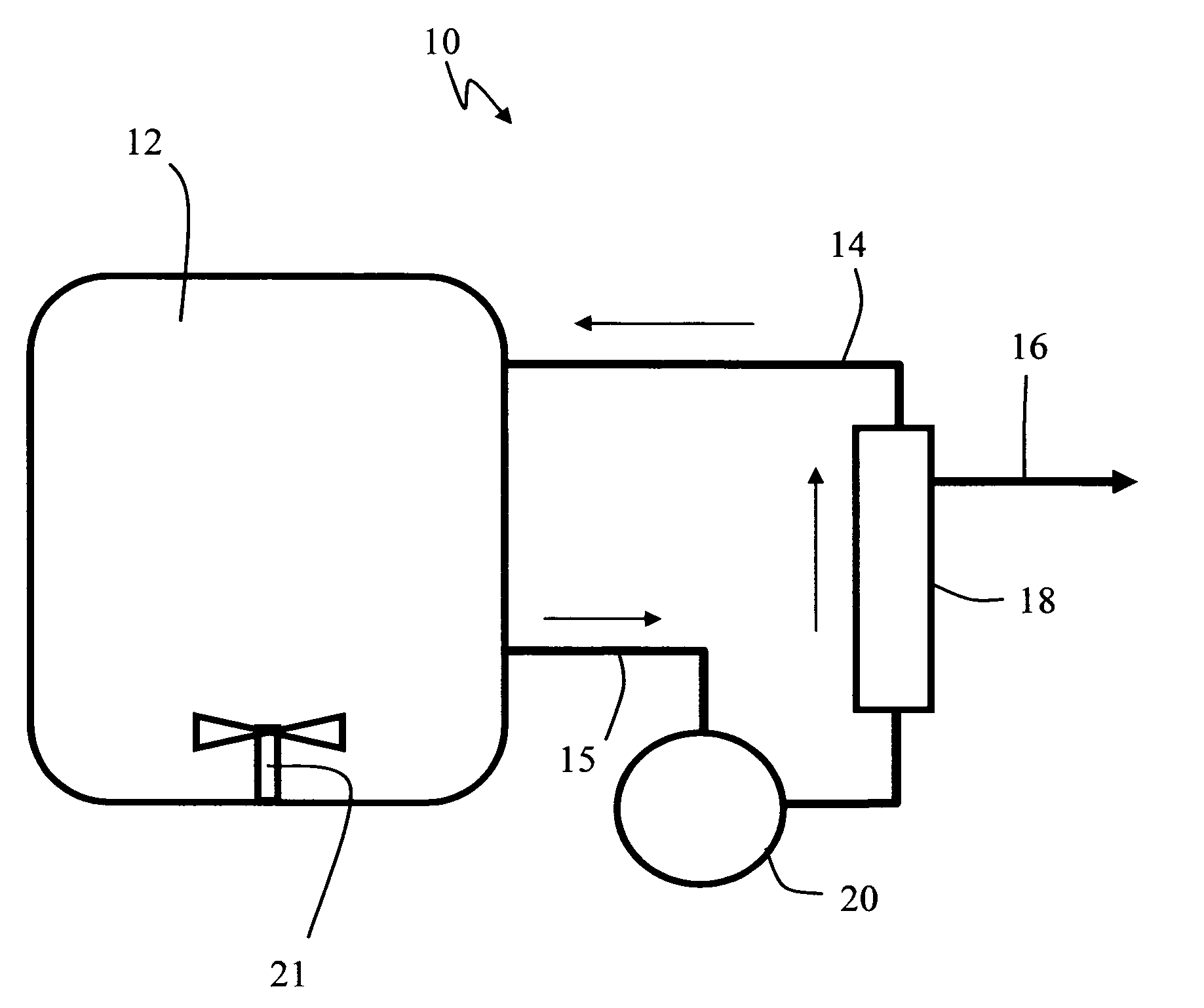

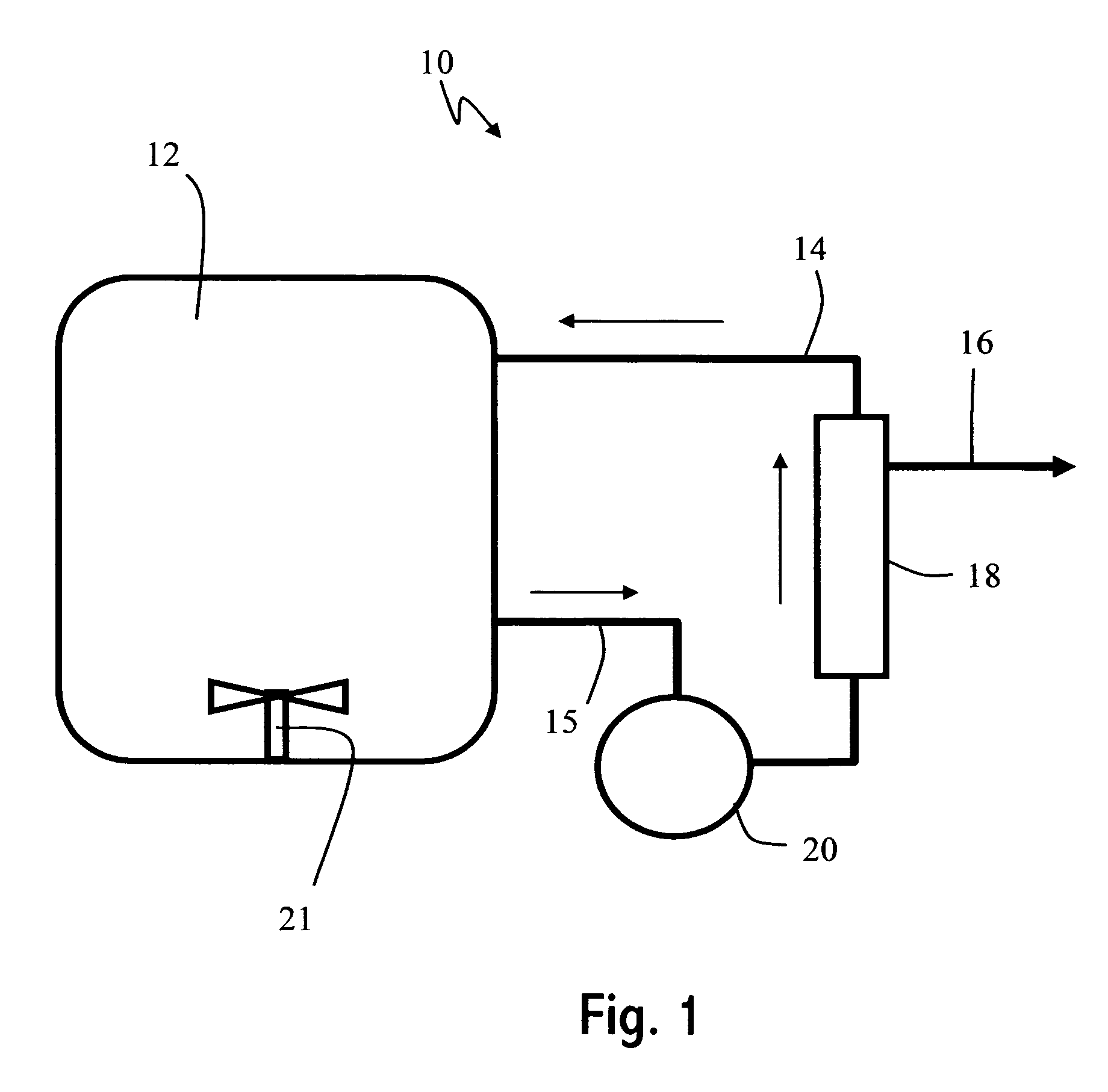

InactiveUS6805806B2Accelerates the biodegradation processAvoid cloggingLiquid separation auxillary apparatusTreatment using aerobic processesAeration systemFiltration

Methods and apparatus employing membrane filtration in biodegradation processes for treatment of wastewater are described. A bioreactor system is described having an equalization system, a membrane bioreactor system, and a controller. Aeration systems for a membrane bioreactor, such as a mixer, and an ultrafilter subsystem are also described, as is a rotary membrane ultrafilter.

Owner:HYDROTREAT

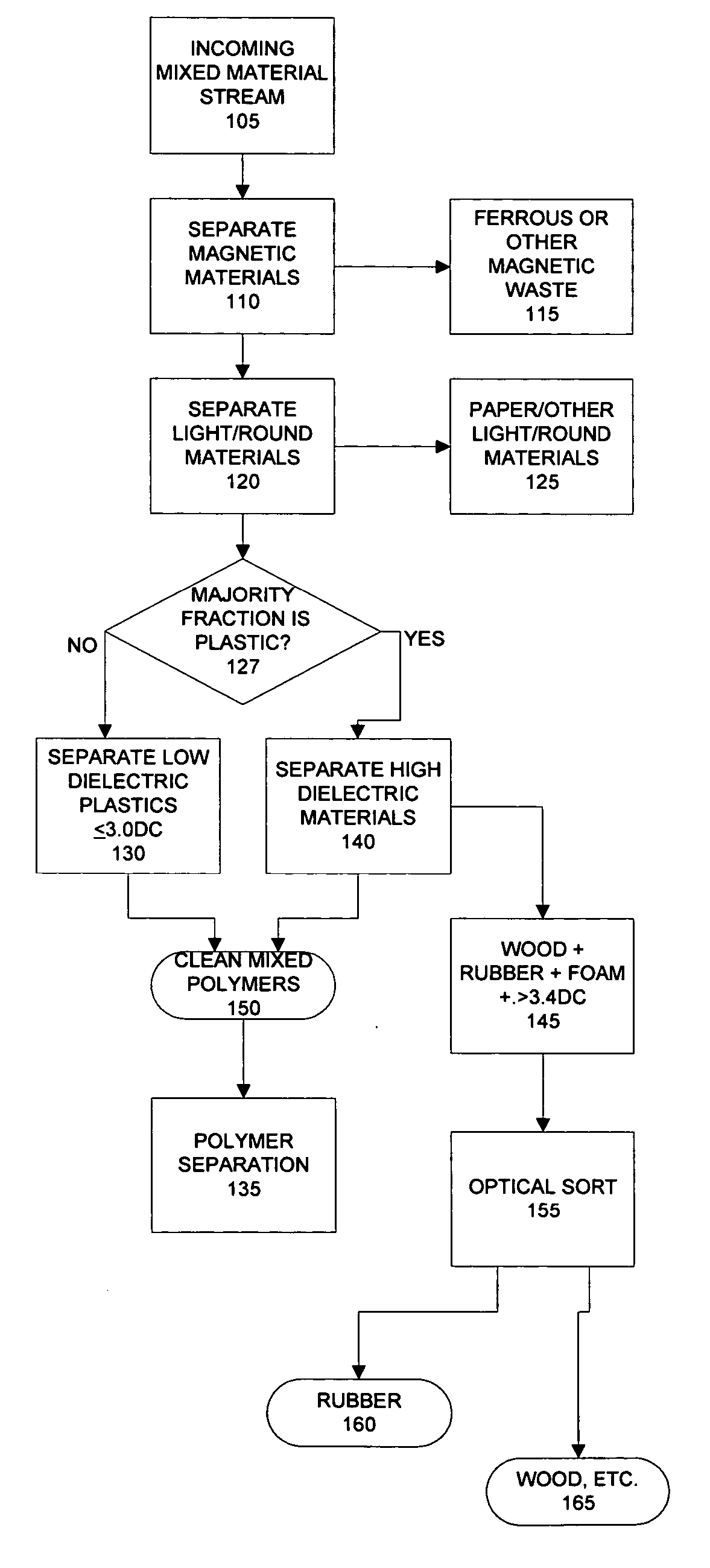

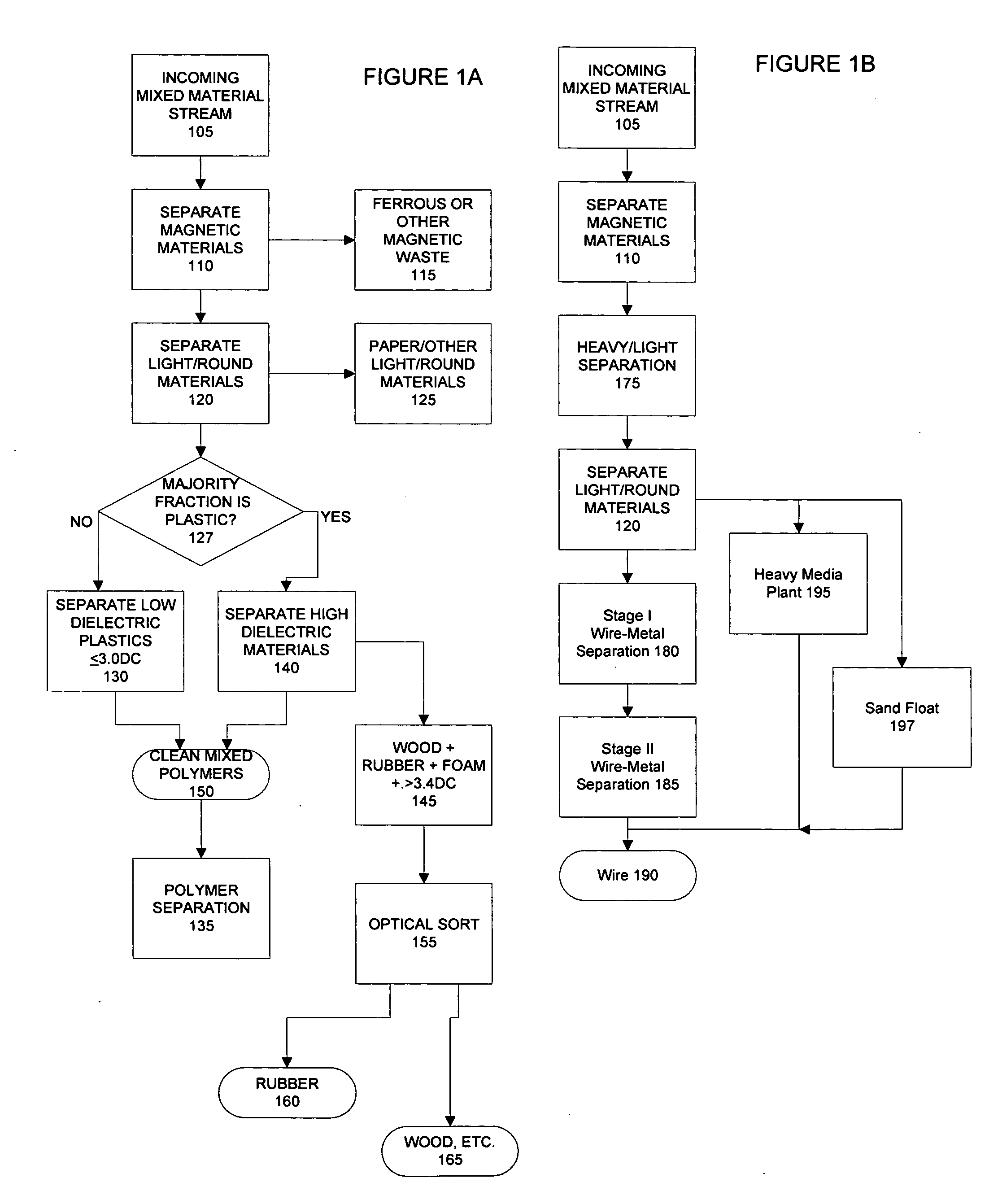

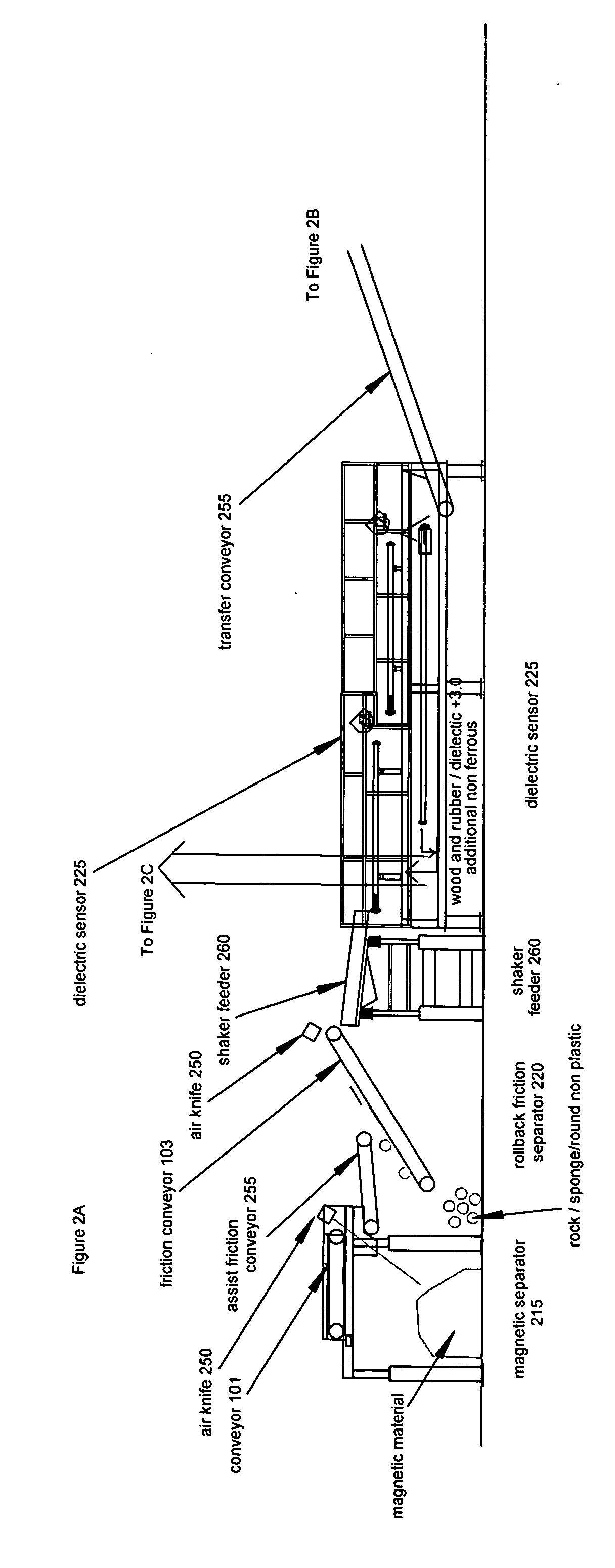

Dissimilar materials sorting process, system and apparata

InactiveUS20070187299A1Improve uniformityUnified operationGas current separationSolid waste disposalElectricityMagnetic separator

An automated system for sorting dissimilar materials, and in particular for sorting plastics from other materials and for sorting different types of plastics from one another comprises, depending upon the embodiment, combinations of a sizing mechanism, a friction separation, an air separator, a magnetic separator, a dielectric sensor sortation bed, shaker screening, a ballistic separator, an inductive sensor sortation system and a float / sink tank. The dielectric sensor sortation system may be either analog or digital, depending upon the particular implementation. One or more float / sink tanks can be used, depending upon the embodiment, each with a media of a different specific gravity. The media may be water, or water plus a compound such as calcium chloride. In addition, multiples of the same general type of module can be used for particular configurations. A heavy media system or a sand float process can be used either alternatively or additionally.

Owner:VALERIO THOMAS A

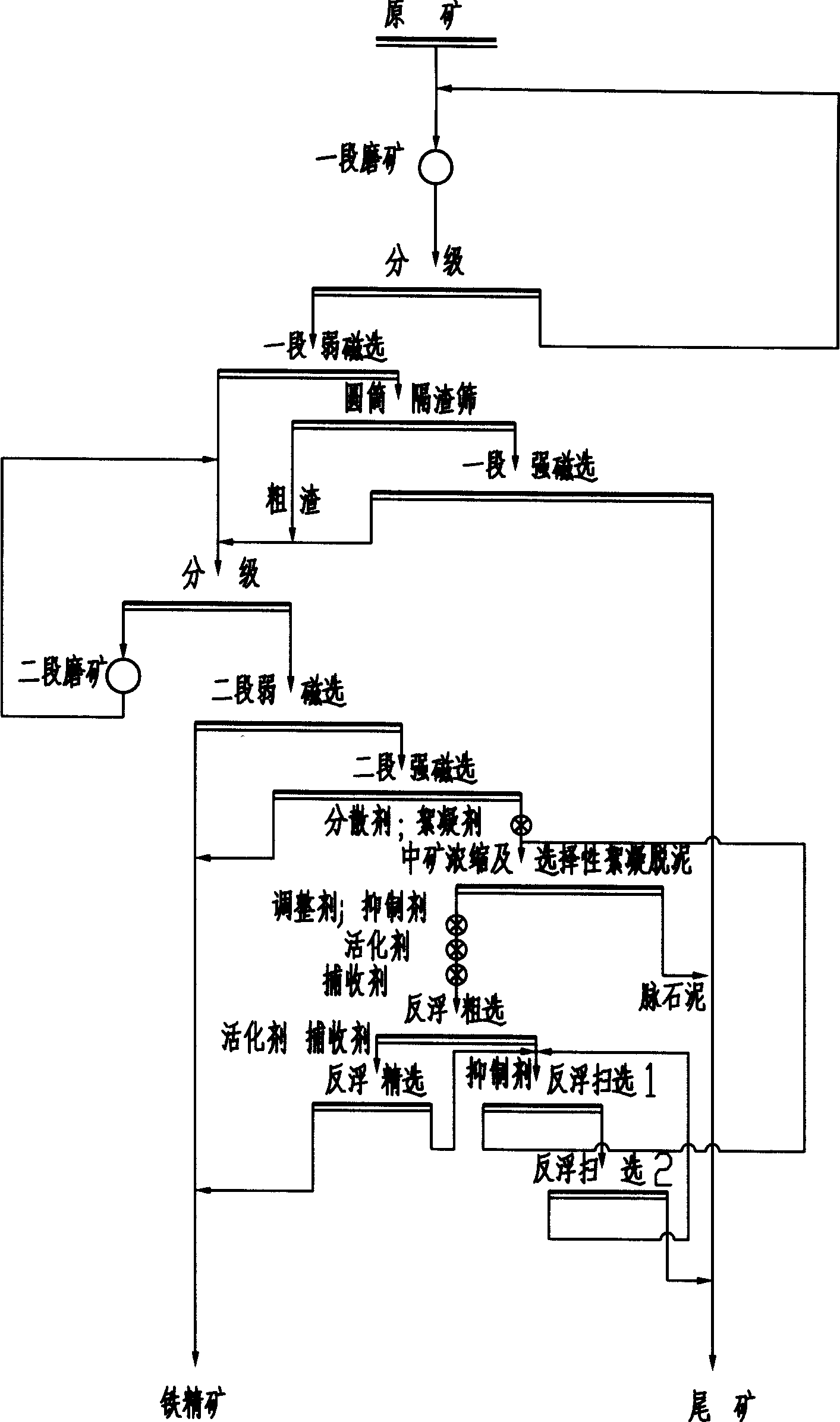

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

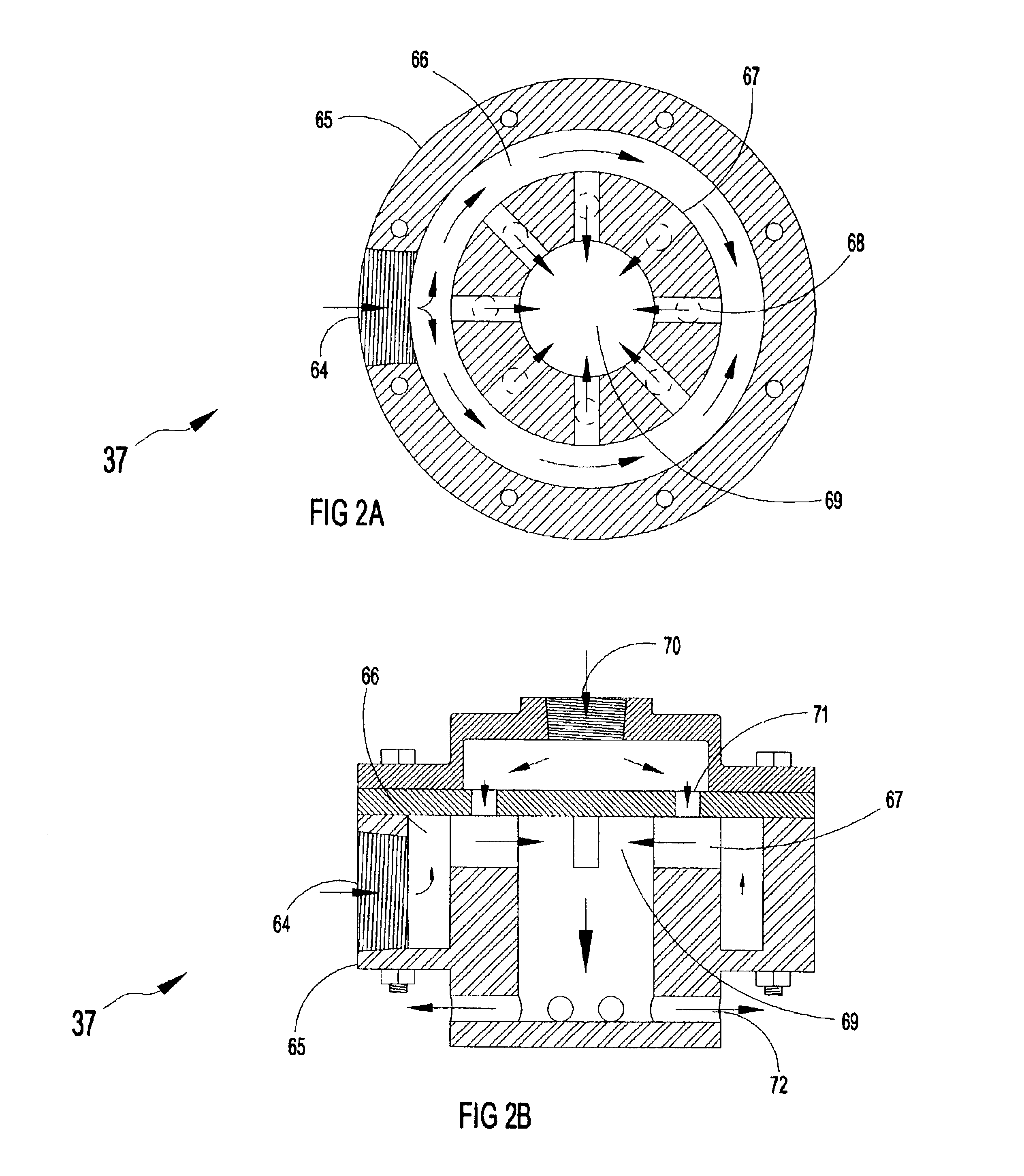

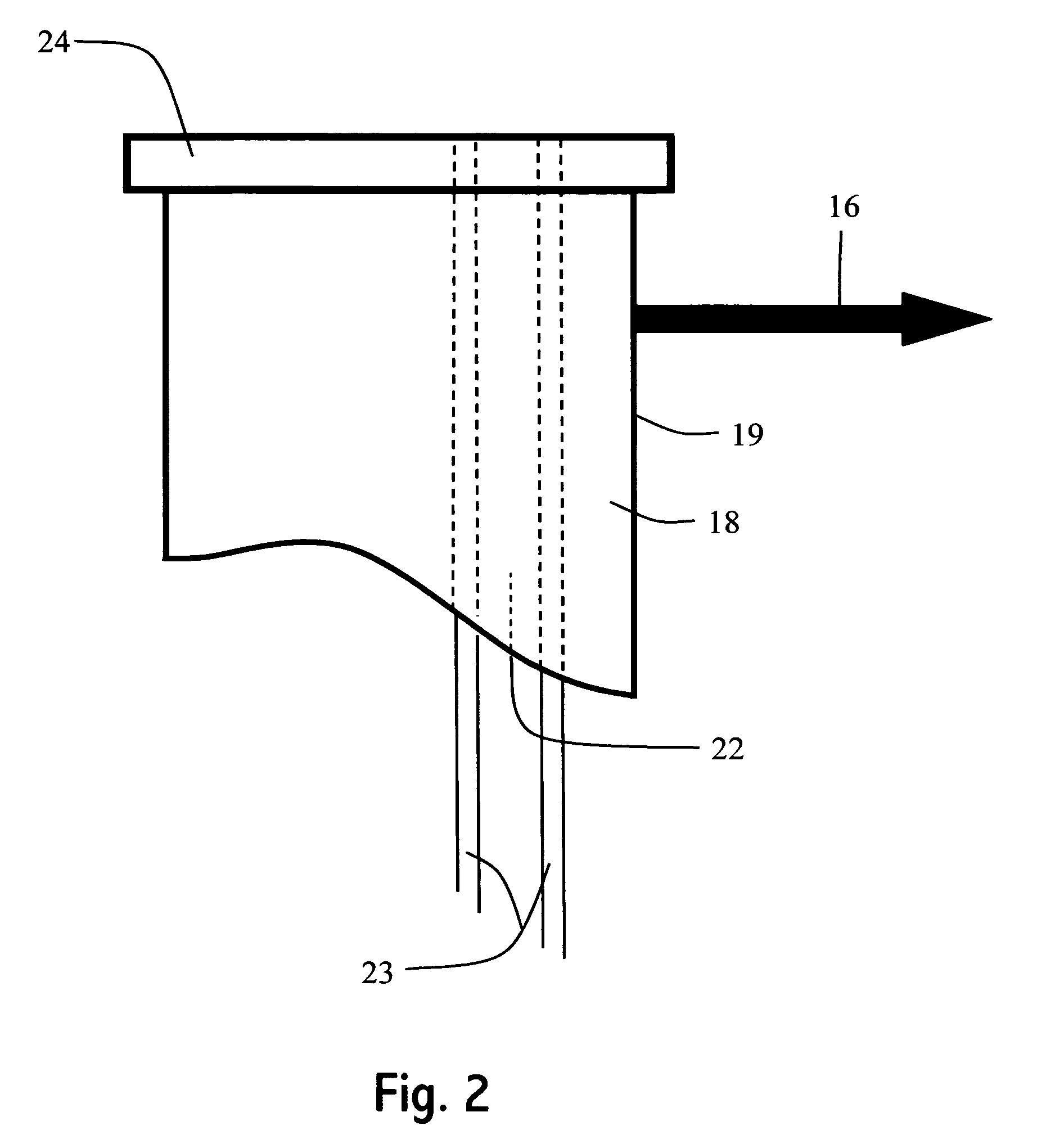

Membrane bioreactor, process and aerator

InactiveUS6863817B2Increase pressureEasy to moveTreatment using aerobic processesUsing liquid separation agentSiphonGravity flow

A reactor has an aerobic tank, an anoxic tank and a sealed membrane tank with conduits for circulating mixed liquor between them. Permeation starts when the mixed liquor reaches a high level and stops when the mixed liquor reaches a low level. A sensor, for detecting the mixed liquor level, may stop and start permeation. Pressure builds in the membrane tank when membrane air is on. Transmembrane pressure is also provided by gravity flow or siphon. Membrane air generates an air lift which drives the mixed liquor circulation. The total amount of air provided by an air source is divided and varied in time between the membrane aerator and the process aerator. The process aerator acts as a screening inlet to the conduit to the membrane tank. Chemical maintenance cleaning is provided by gravity flow.

Owner:ZENON TECH PARTNESHIP

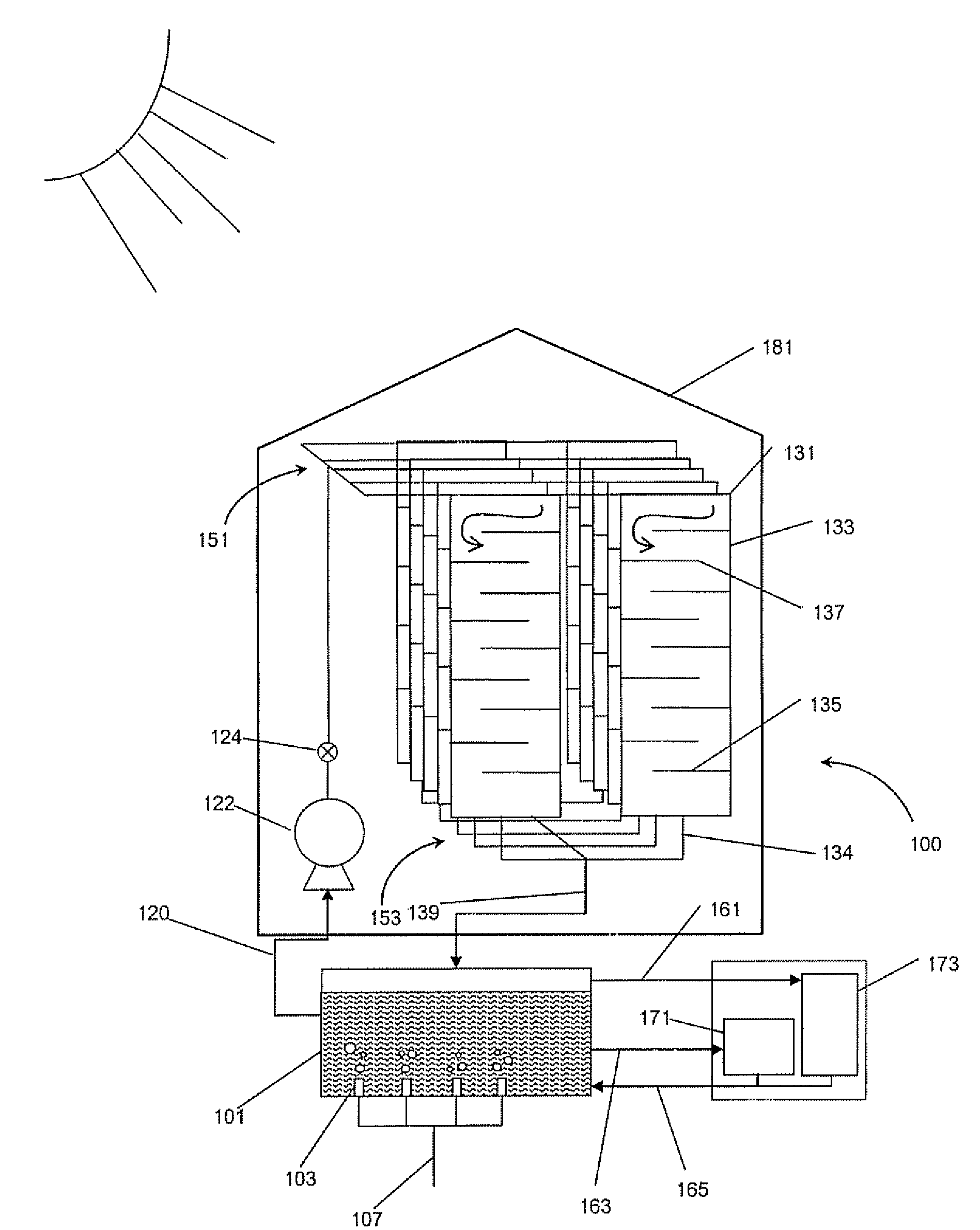

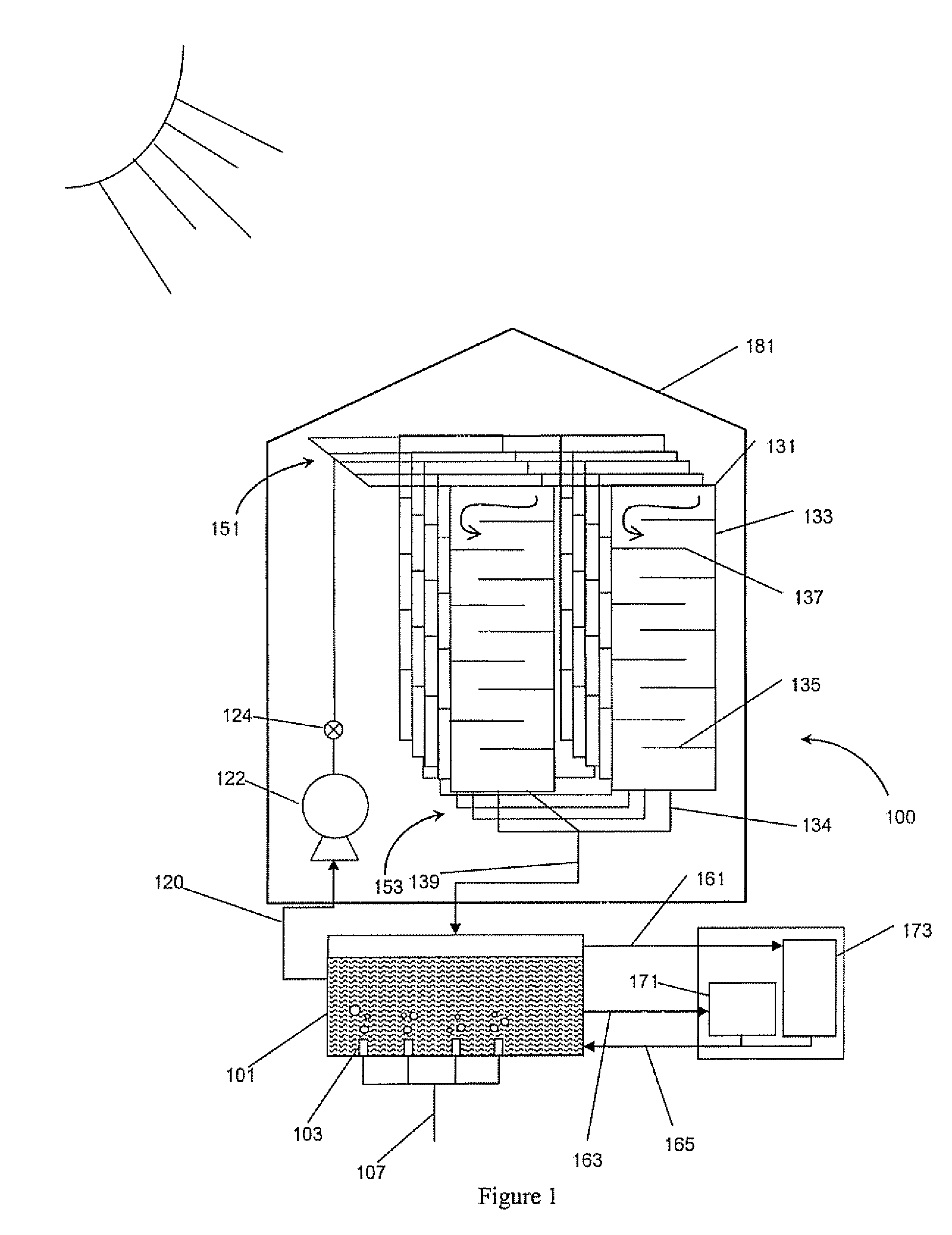

Method and apparatus for co2 sequestration

InactiveUS20070289206A1Easy to manufactureIncrease surface areaBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaeBioreactor

A method and apparatus for sequestering CO2 using algae comprises a plurality of vertically suspended bioreactors, each bioreactor being translucent and including a flow channel formed by a plurality of baffles. A culture tank contains a suspension of water and at least one algae and includes a plurality of gas jets for introducing a CO2-containing gas into the suspension. The culture tank is in fluid communication with an inlet in each channel for flowing the suspension through the channel in the presence of light. A pump pumps the suspension into the channel inlet.

Owner:KERTZ MALCOLM GLEN

Systems and methods for producing biofuels from algae

InactiveUS20100077654A1Promotes algae growthEnergy efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiofuelOedogonium

The invention provides systems and methods for producing biofuel from algae wherein the algae and fishes are co-cultured in a body of water. The methods further comprise inducing the algae to accumulate lipids by environmental stress, and concentrating the algae prior to extraction of the algal oil. The systems of the invention comprise at least one growth enclosure, means for concentrating algae, and means for subjecting algae to environmental stress.

Owner:LIVEFUELS

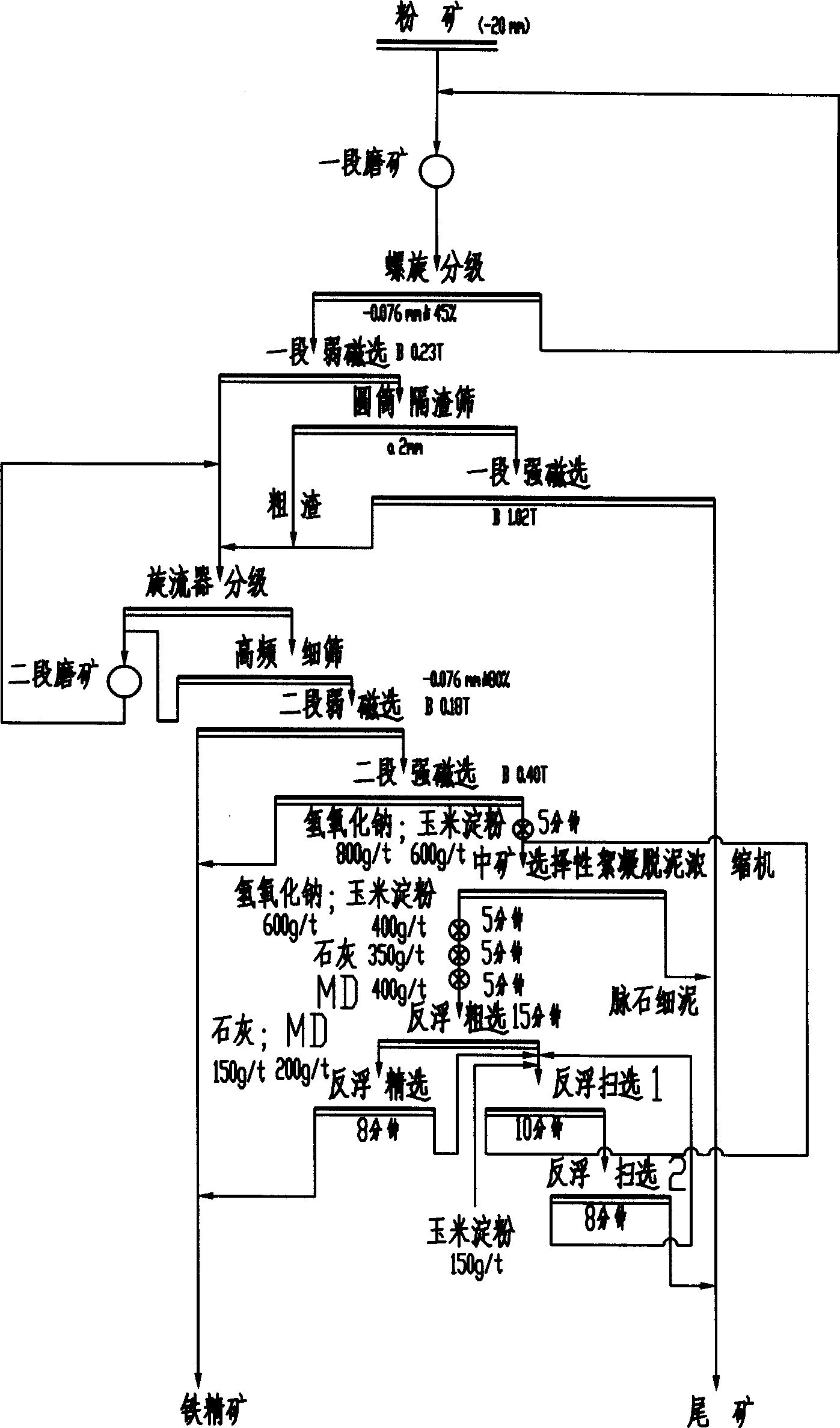

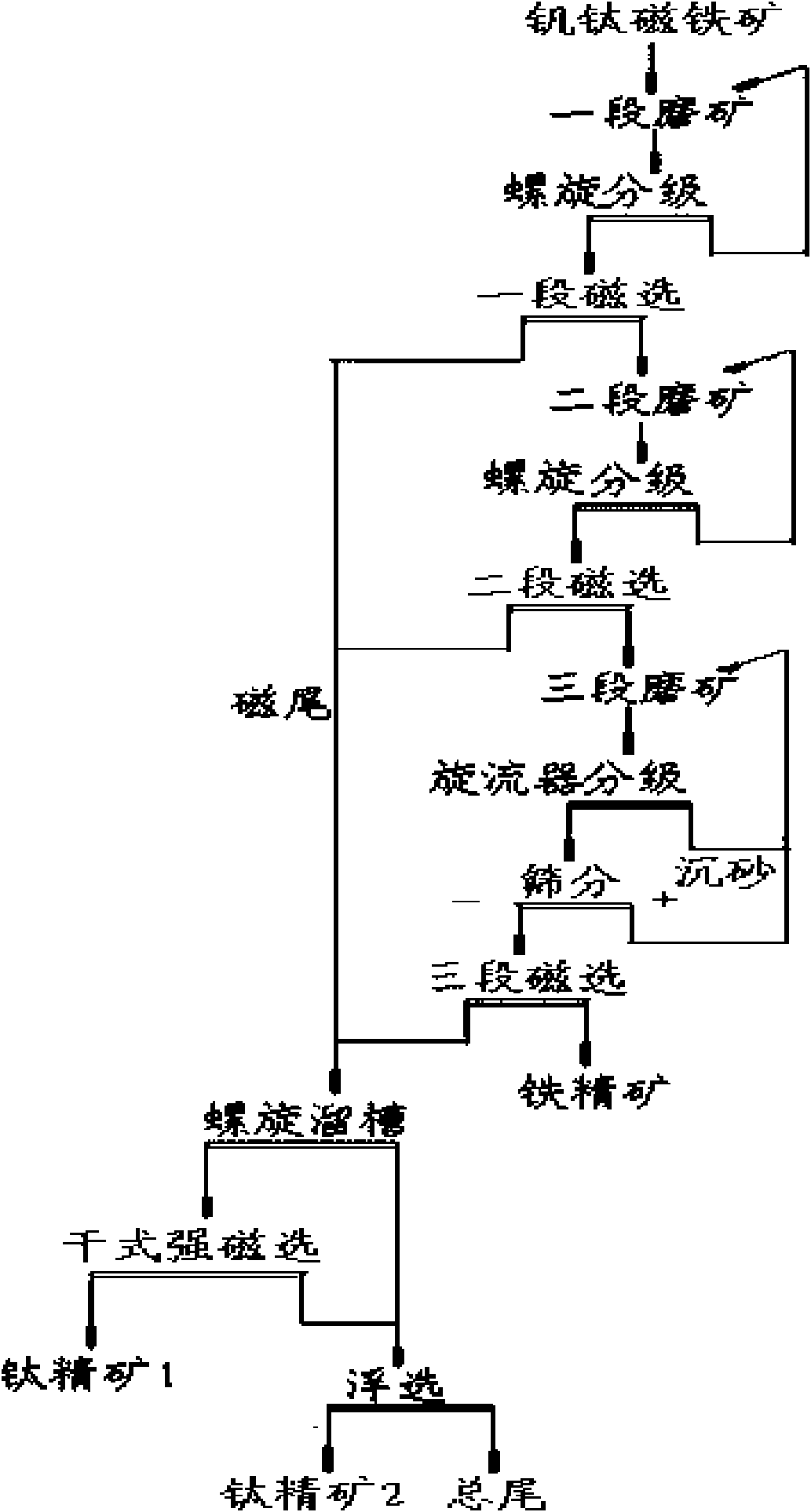

Vanadium titano-magnetite screen method

ActiveCN101564707AQuality improvementHigh recovery rateFlotationMagnetic separationMagnetiteMaterials science

The invention relates to a screen method for vanadium titano-magnetite with high quality, belonging to the ore screen field. The method adopts three stage-grinding and stage-concentration process for magnetic separation, wherein the field intensity of one-stage magnetic separation is 3000-4000 Gs; the field intensity of two-stage magnetic separation is 1800-2200 Gs; and the field intensity of three-stage magnetic separation is 1300-1700 Gs. The recovery rate of the screened iron ore concentrate and the titanium ore concentrate is high and the screened cost of the screened iron ore concentrate and the titanium ore concentrate is low, thus providing a new selection for the low grade vanadium titano-magnetite resource and having a broad application prospect.

Owner:四川安宁铁钛股份有限公司

Systems, apparatuses, and methods for extracting non-polar lipids from an aqueous algae slurry and lipids produced therefrom

InactiveUS20110095225A1Increase volume flowEasy extractionLiquid separation by electricityMicroorganism lysisLipid formationPhospholipid

Methods, systems, and apparatuses for extracting non-polar lipids from microalgae are achieved using a lipid extraction device having an anode and a cathode that forms a channel and defines a fluid flow path through which an aqueous slurry is passed. An electromotive force is applied across the channel at a gap distance in a range from 0.5 mm to 200 mm to cause the non-polar lipids to be released from the algae cells. The non-polar lipids can be extracted at a high throughput rate and with low concentrations of polar lipids such as phospholipids and chlorophyll.

Owner:ORGINOIL INC

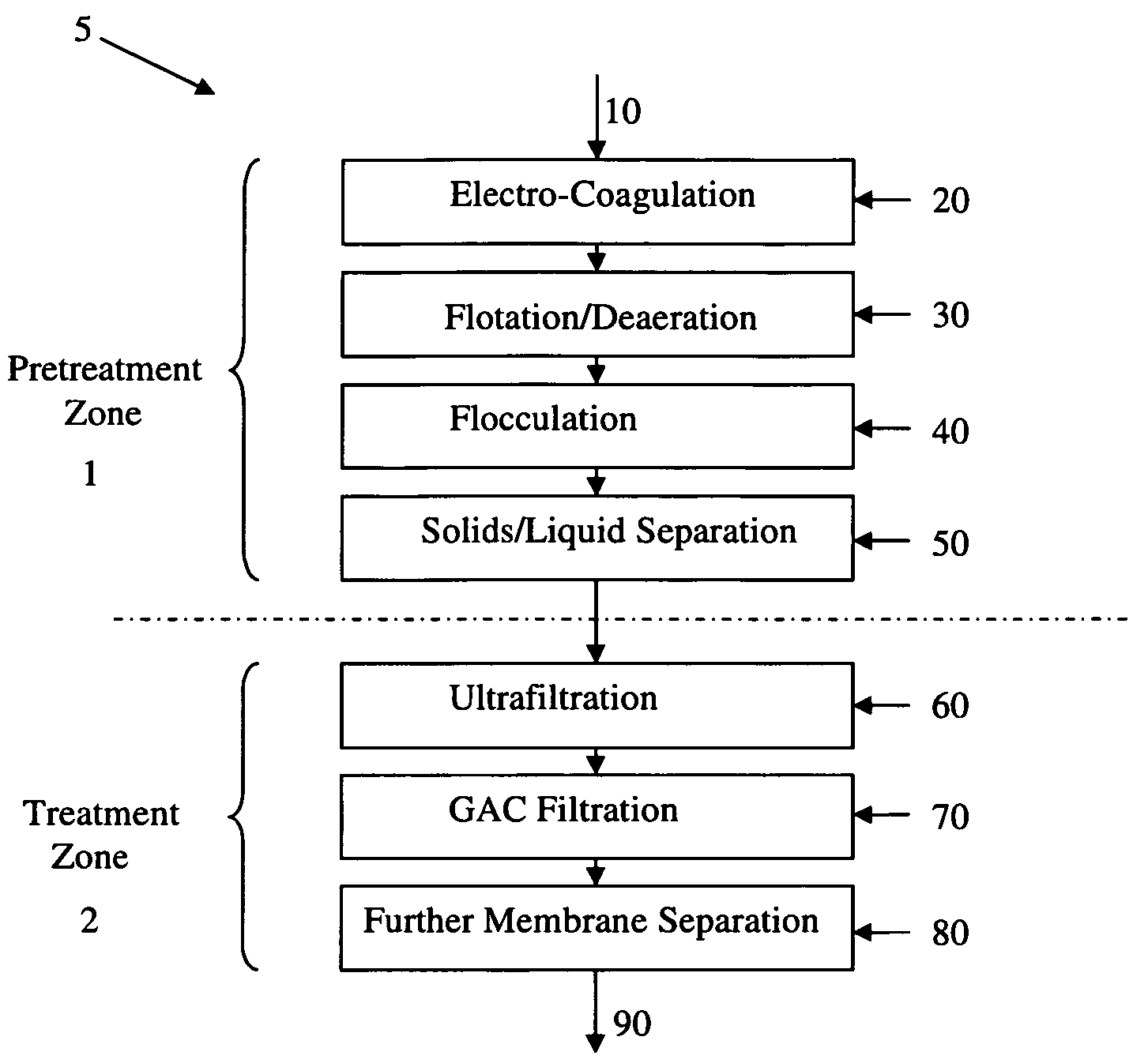

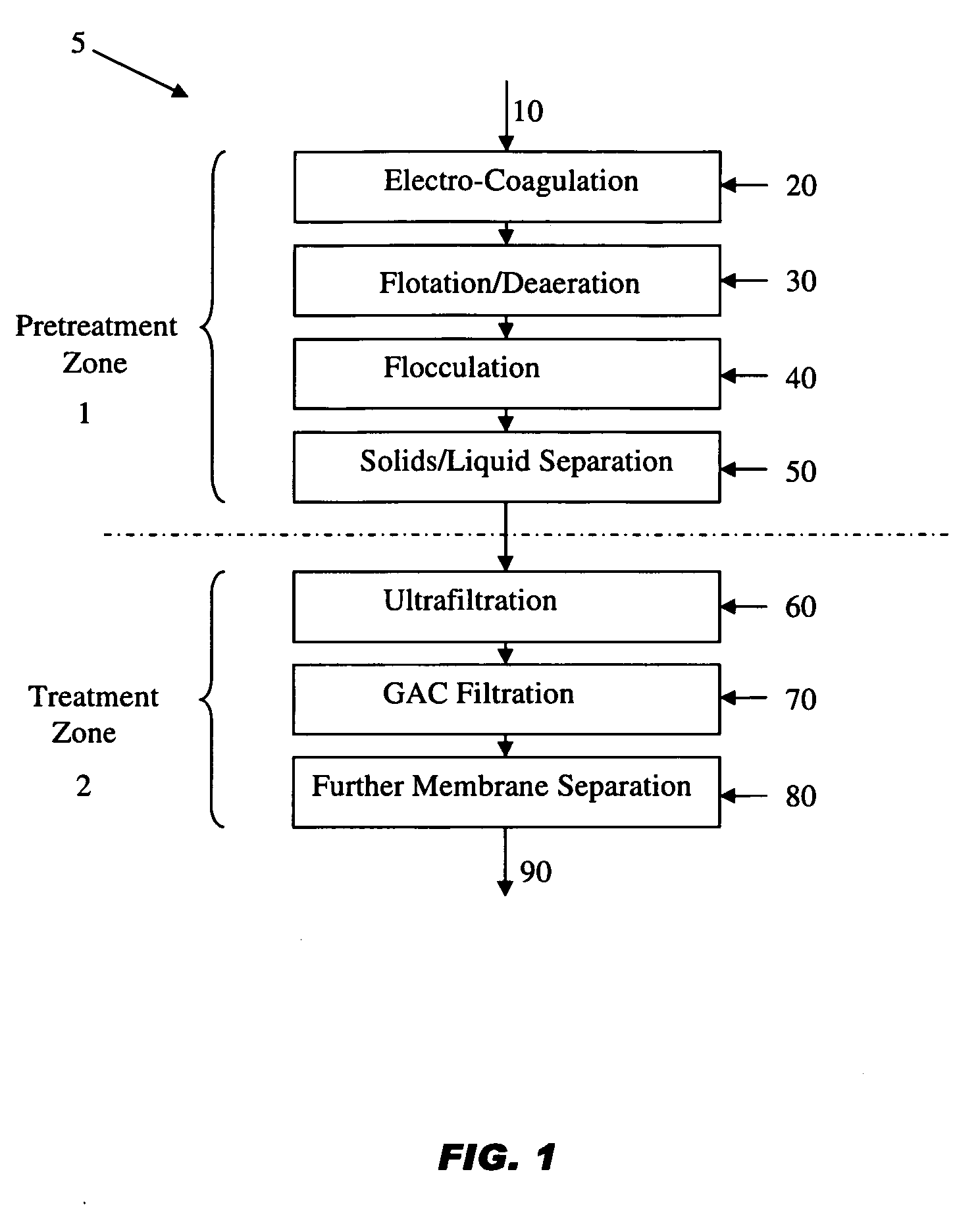

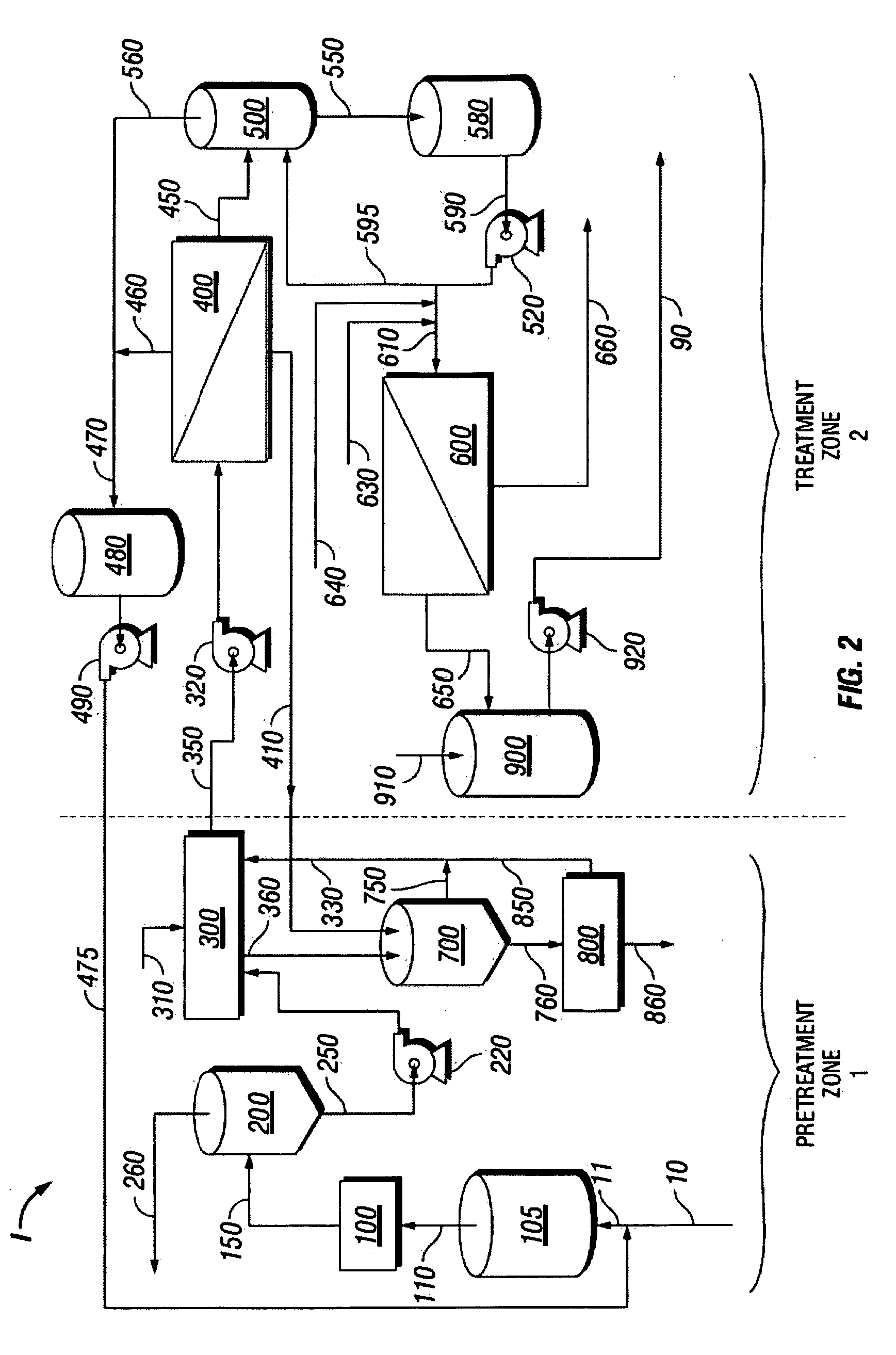

Treatment process and system for wastewater, process waters, and produced waters applications

A method for the removal of contaminants from a contaminated water stream, by pretreating the contaminated water stream to yield a pretreated water stream, wherein pretreating comprises passing the contaminated water stream to at least one electrocoagulation cell wherein coagulation of contaminants is promoted, yielding an electrocoagulated stream; and separating coagulated contaminants from the electrocoagulated stream.An electrocoagulation reactor comprising a plurality of electrodes positioned parallel to each other and provided with a means of energizing each electrode; a fluid inlet for an inlet stream comprising contaminated water; a fluid outlet for an outlet stream comprising electrocoagulated products; a flow distributor system; and a gas distribution system for injecting a gas into the electrocoagulation reactor. An electrocoagulation system for treating a contaminated water stream, the system comprising at least one electrocoagulation reactor.

Owner:ITS ENGINEERED SYST

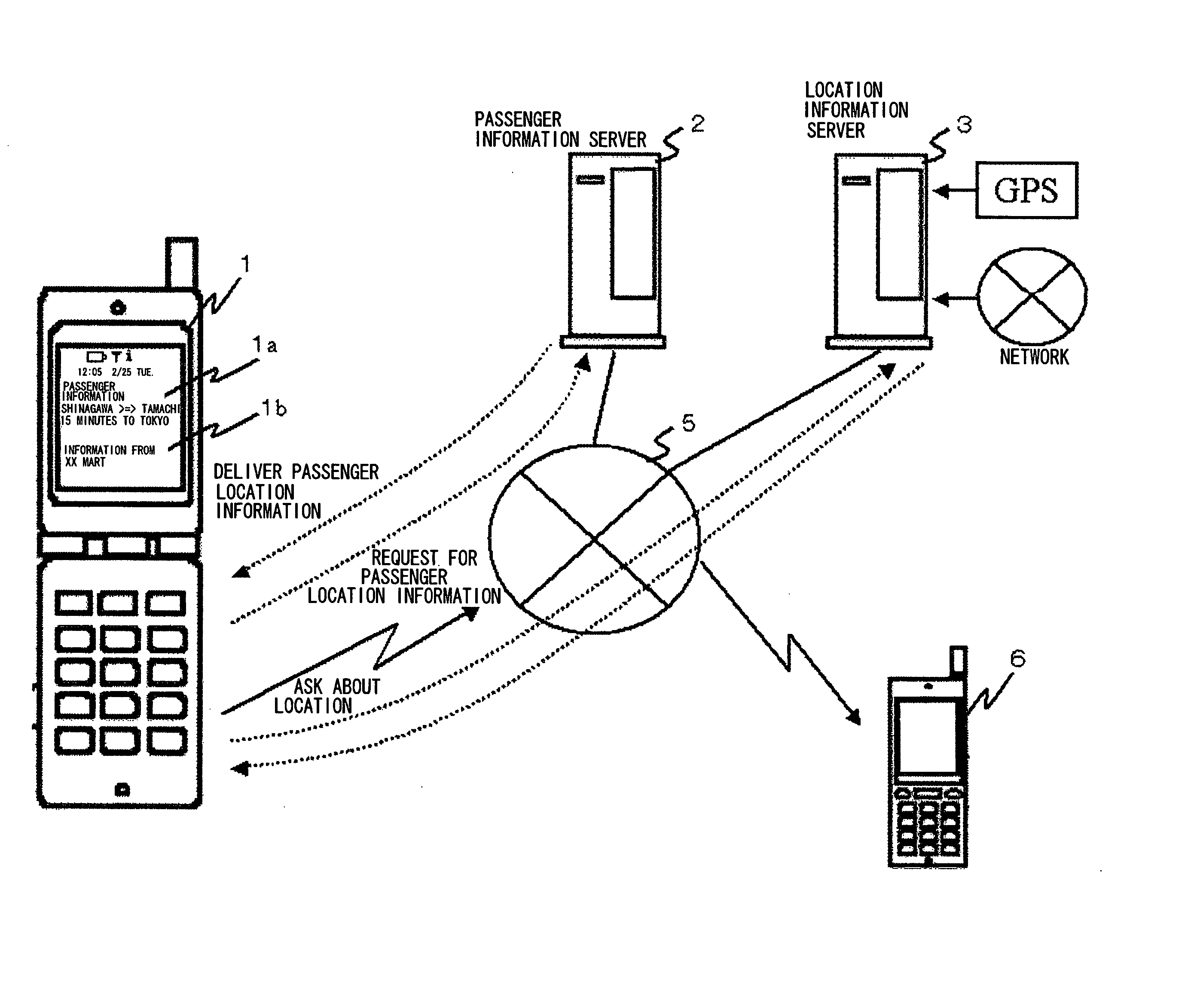

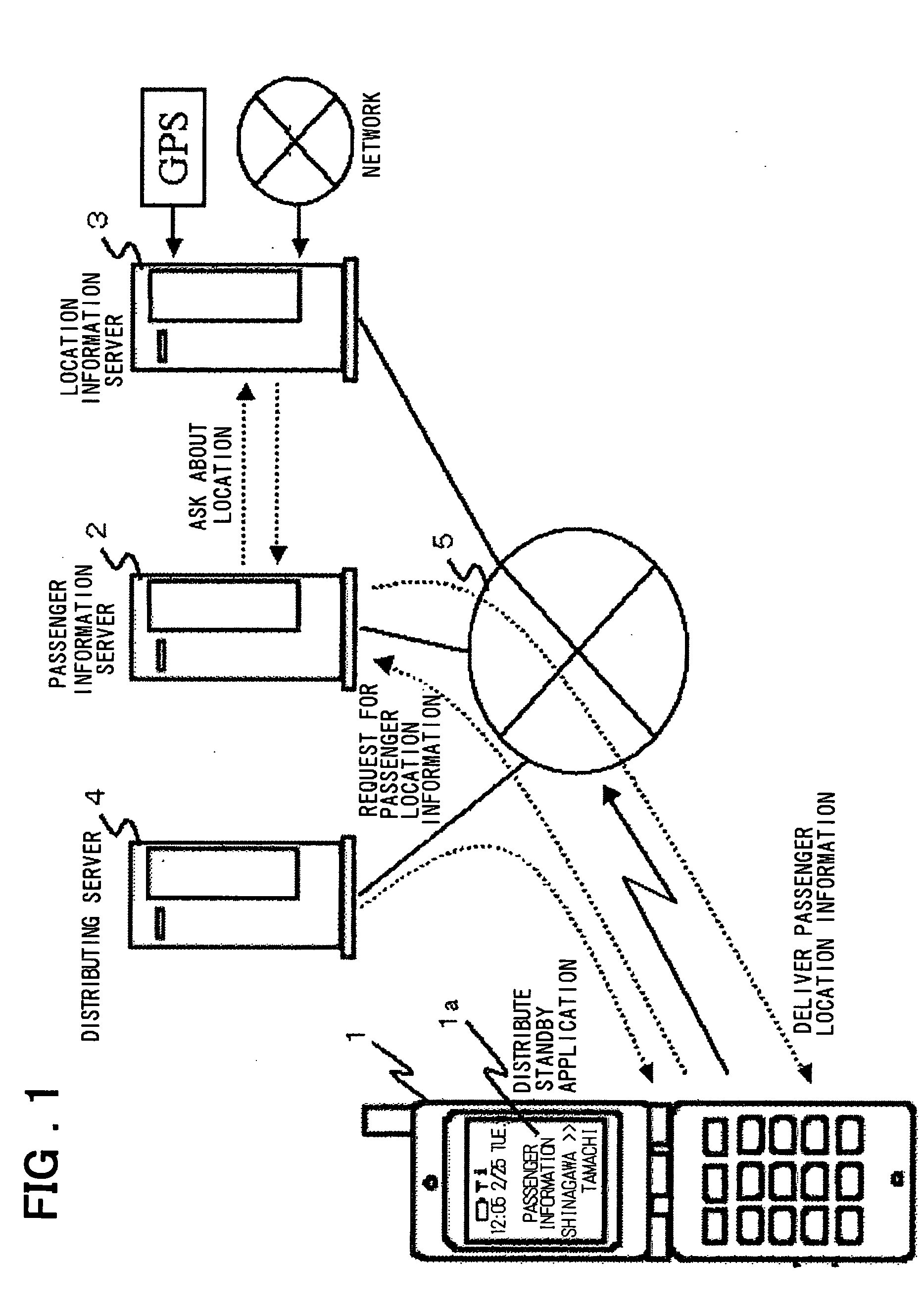

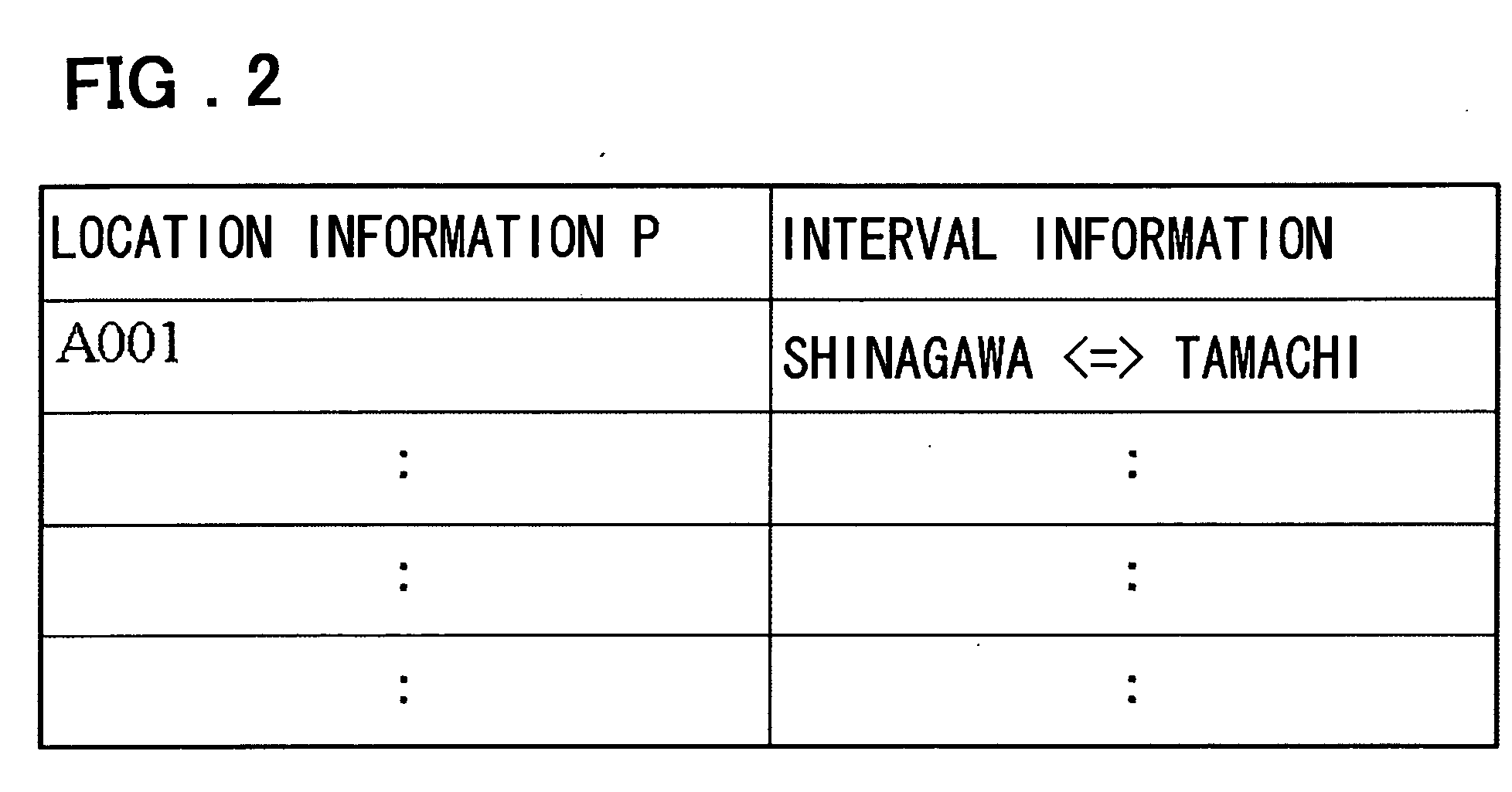

Passenger location information system, portable information terminal, and server

ActiveUS20060041374A1Reduce the impactEasy to receive informationInstruments for road network navigationData processing applicationsMobile phoneInformation system

The present invention provides a passenger location information system that provides information on the current location of a user during a trip in real time and in a mode suitable for each user. A configuration is provided in which passenger location information, at least including information on the ends (station, stop, etc.) of a transportation line interval in which a portable information terminal is located, is output at a predetermined time on a user terminal 1 such as a mobile phone terminal connectable to a network. In addition, using notification means such as a ringing tone or a vibrator, the user terminal 1 notifies the user, under a condition set by the user in advance, that the user is approaching a destination to prevent the user from riding past a destination due to dozing.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Methods for removing heavy metals from water using chemical precipitation and field separation methods

InactiveUS20050258103A1Efficient removalEasy to disassembleSedimentation separationDifferential sedimentationParticulatesSulfide

A two-step chemical precipitation process involving hydroxide precipitation and sulfide precipitation combined with “field separation ” technology such as magnetic separation, dissolved air flotation, vortex separation, or expanded plastics flotation, effectively removes chelated and non-chelated heavy metal precipitates and other fine particles from water. In the first-step, the non-chelated heavy metals are precipitated as hydroxides and removed from the water by a conventional liquid / solids separator such as an inclined plate clarifier to remove a large percentage of the dissolved heavy metals. The cleaned water is then treated in a second precipitation step to remove the residual heavy metals to meet discharge limits. In the second precipitation step, any metal precipitant more effective than hydroxide for metal precipitation can be used. The invention improves metal removal, lowers cost because fewer chemicals are used, produces less sludge, and reduces the discharge of toxic metals and metal precipitants to the environment. Magnetic separation is preferred for the separation of particles precipitated in the second stage. Similar methods can be employed for separation of other particulates from water. Particulates can also be removed by causing them to adhere to particles of expanded plastic, forming a floc lighter than water, so that the floc can be removed by flotation.

Owner:CORT CHERYL J

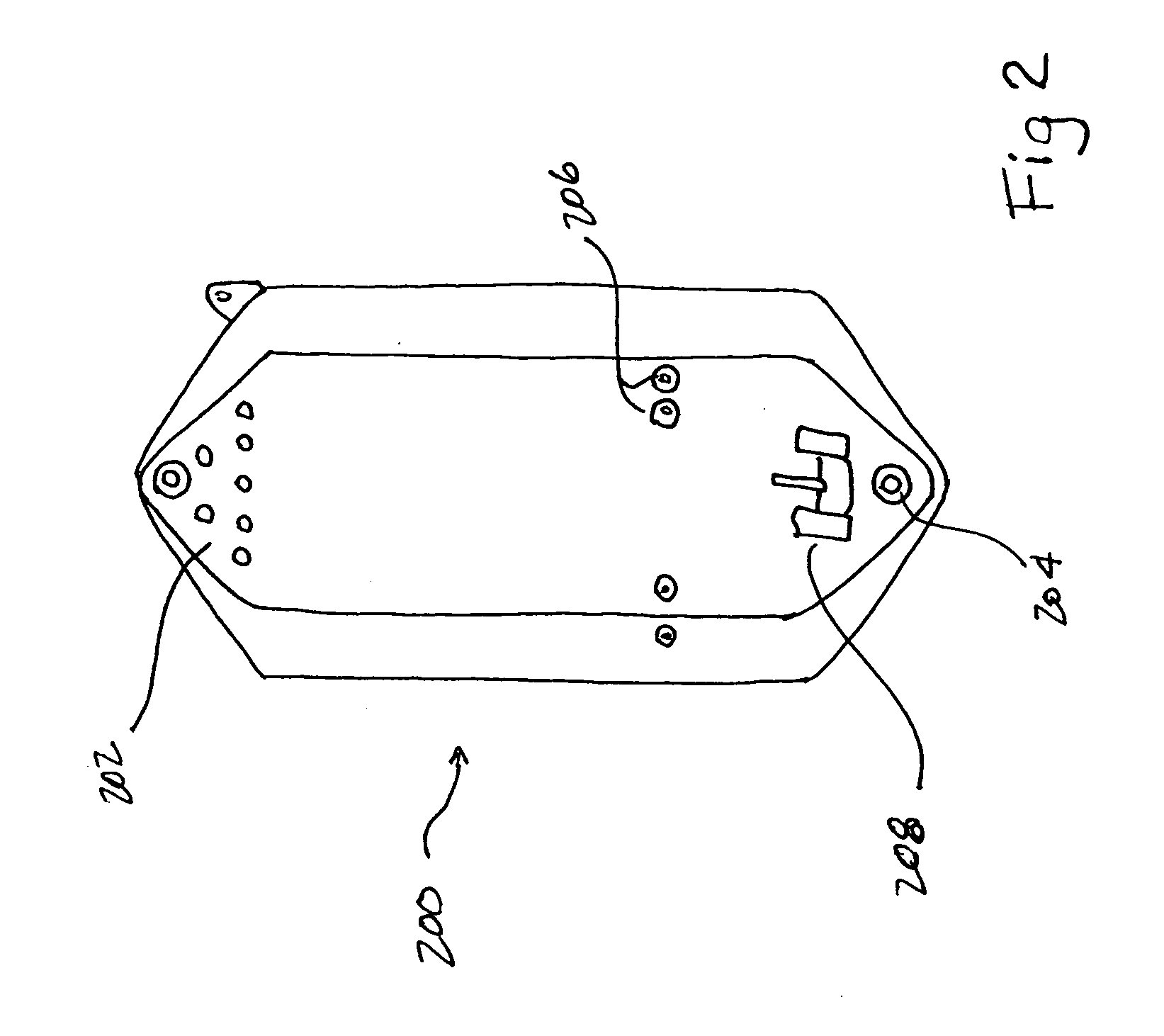

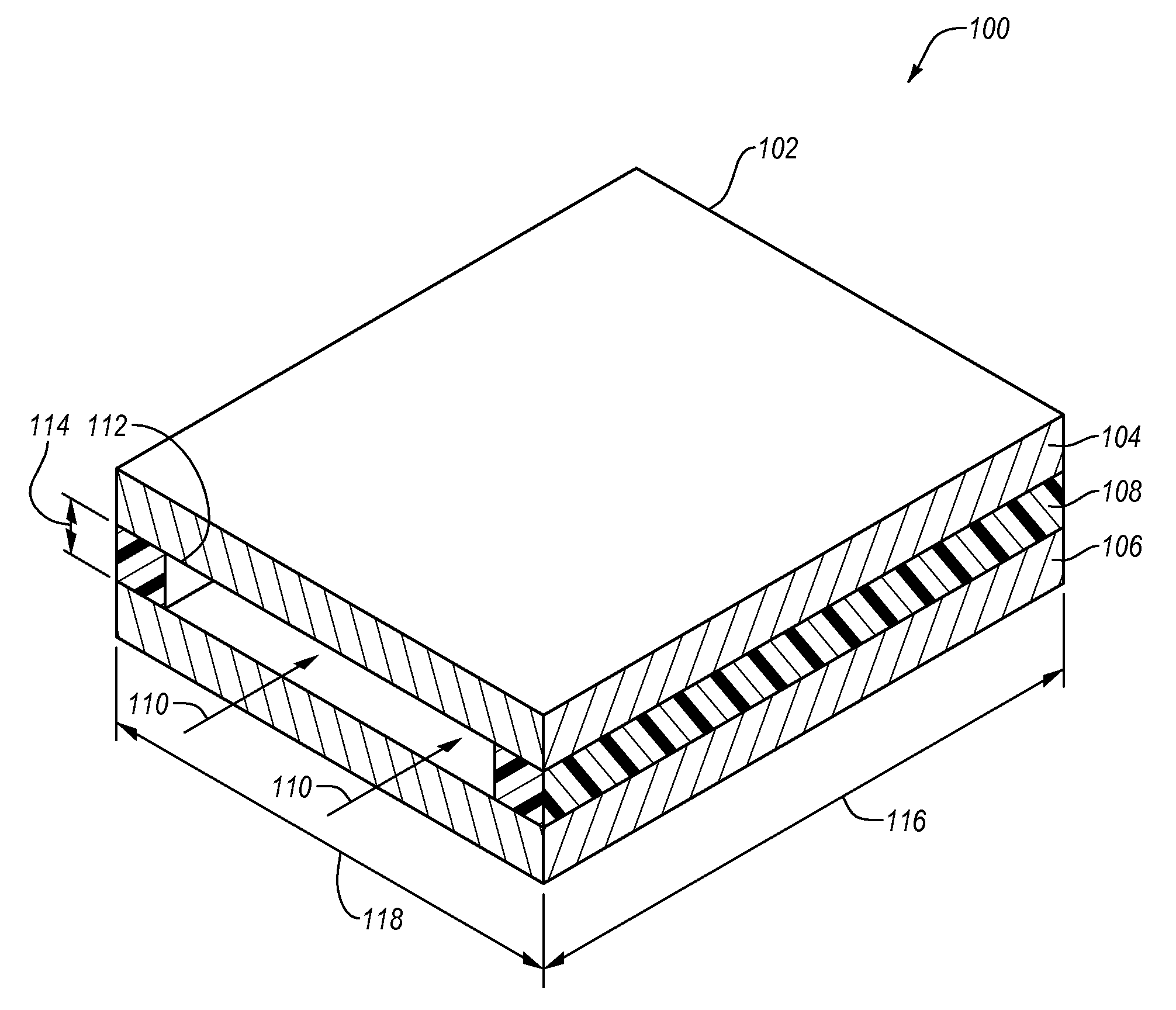

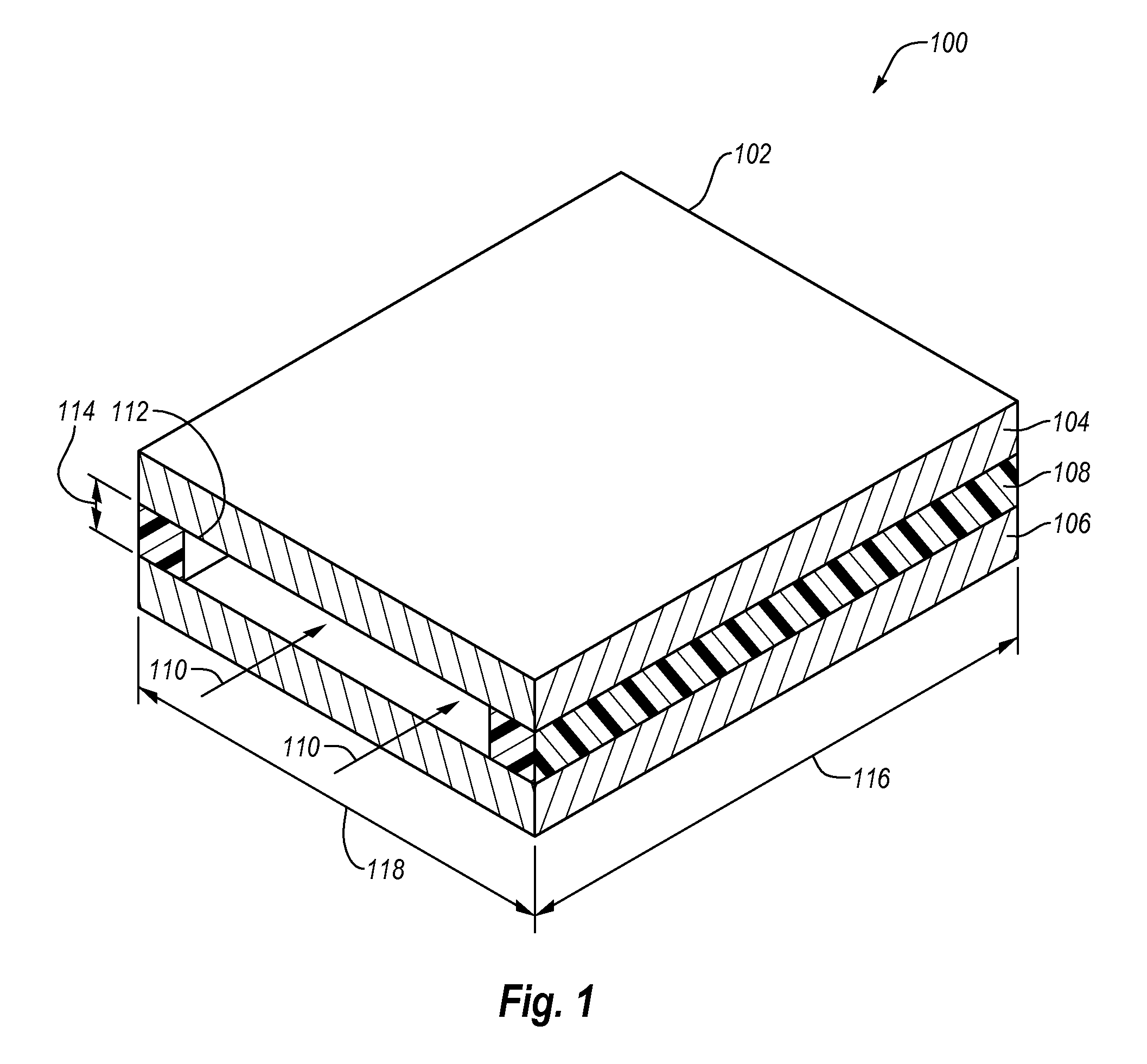

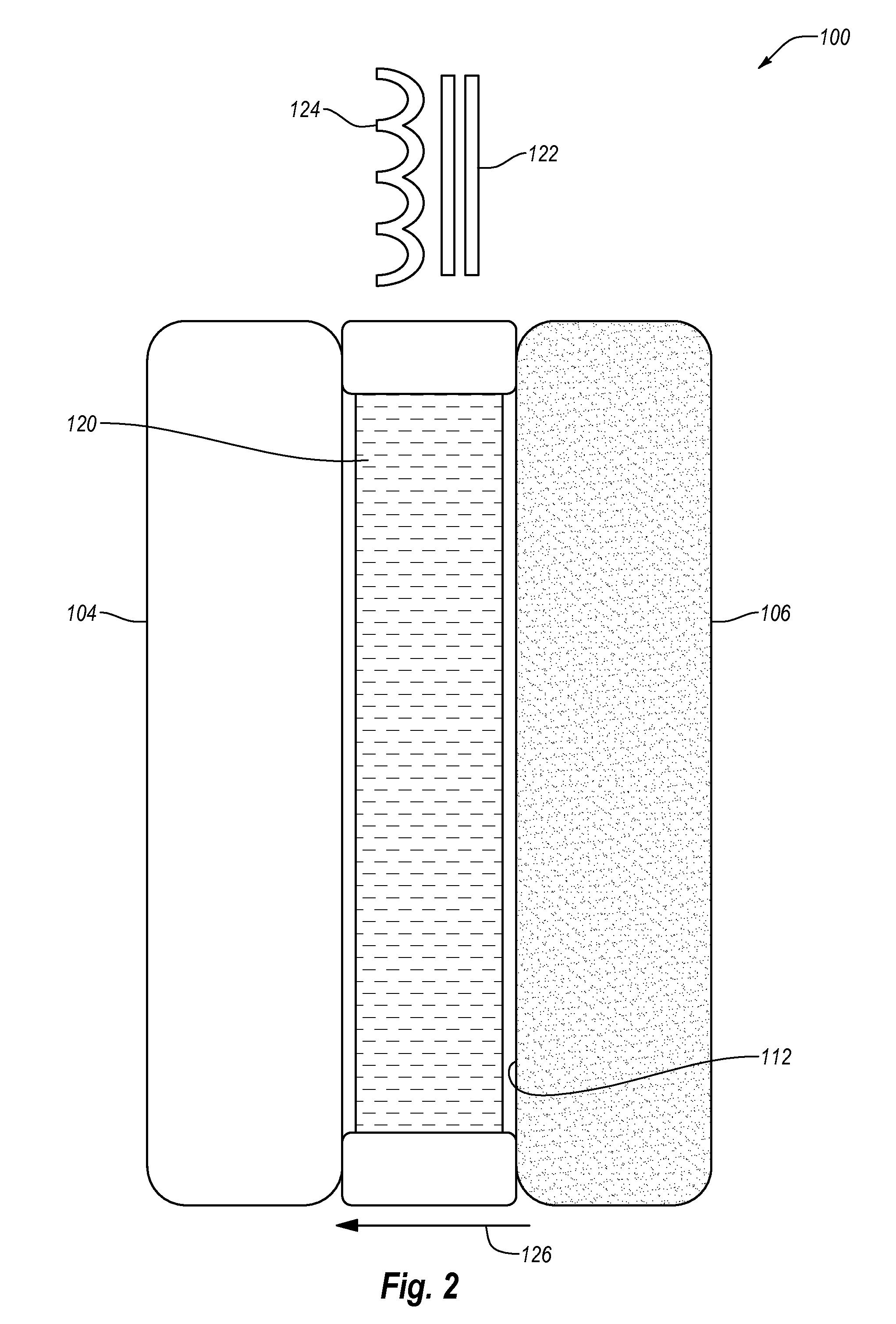

Bioreactor systems and disposable bioreactor

ActiveUS20050158851A1Efficient use ofEasily and economically usedBioreactor/fermenter combinationsBiological substance pretreatmentsCell biologyDisposable bioreactors

The present invention is in the field of cell bioreactors, and specifically in the field of disposable bioreactors.

Owner:CP BIOTOOLS LLC

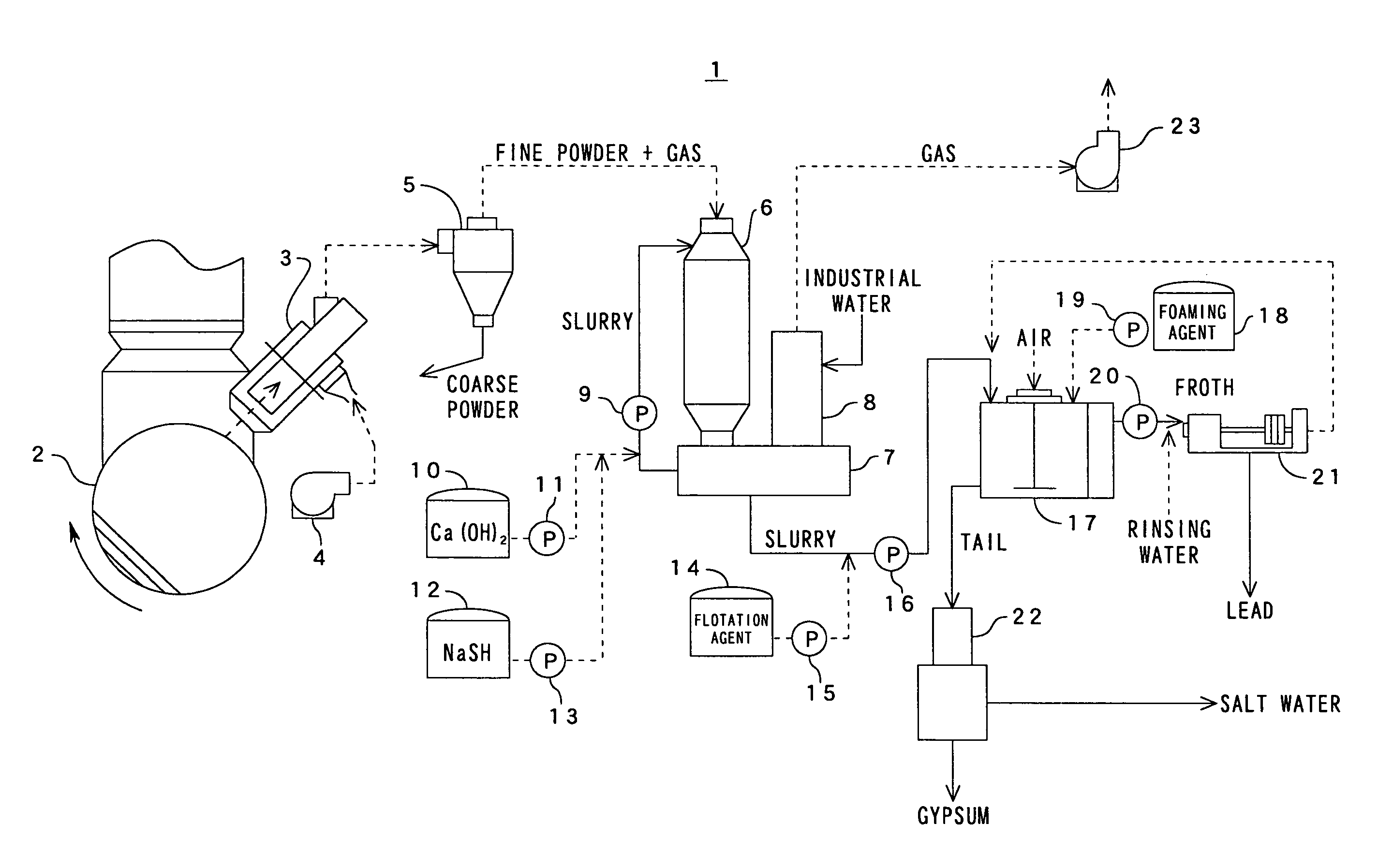

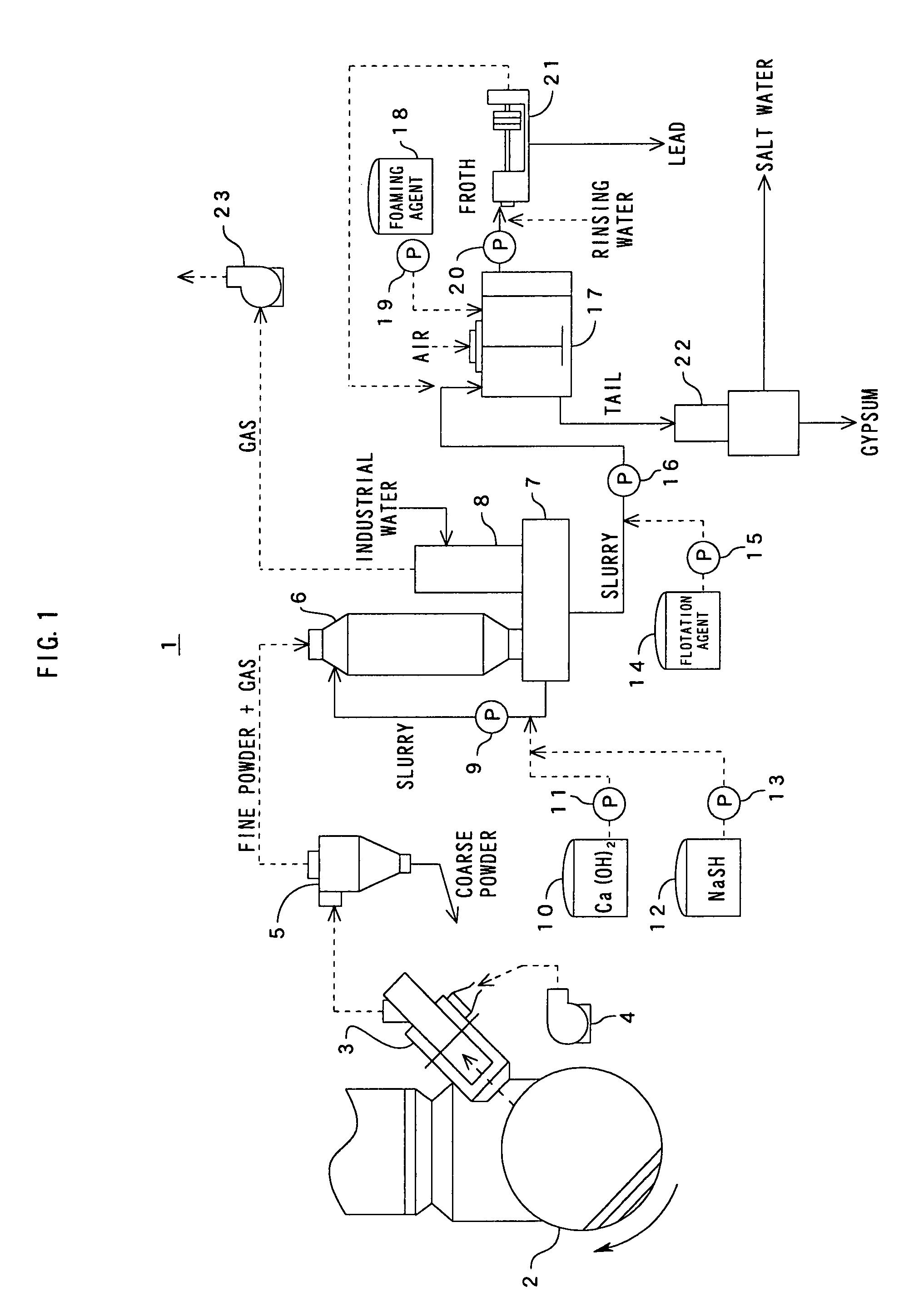

System and method for treating dust contained in extracted cement kiln combustion gas

InactiveUS7789944B2Effectively remove dustLow facility requirementsCombination devicesUsing liquid separation agentCycloneSlurry

A treatment system to efficiently remove lead from dust contained in extracted cement kiln combustion gas while reducing facility and running costs. A treatment system 1 comprising: a probe 3 for extracting a part of combustion gas, while cooling it, from a kiln exhaust gas passage, which runs from an inlet end of a cement kiln to a bottom cyclone; a classifier 5 for separating coarse powder from dust contained in the combustion gas extracted by the probe 3; a wet dust collector 6 for collecting dust from the extracted gas containing fine powder discharged from the classifier 5; and devices 12, 13 for feeding sulfurizing agent for sulfurizing lead contained in the kiln exhaust gas to the wet dust collector 6, and others. From the sulfurizing-agent feeders 12, 13 are preferably added the sulfurizing agents to a circulation liquid tank 7 or a pump 9 for circulating slurry. The slurry obtained by the wet dust collector 6 is separated into froth including lead and tail side slurry including gypsum by a flotation facility 14, 17, 18.

Owner:TAIHEIYO CEMENT CORP

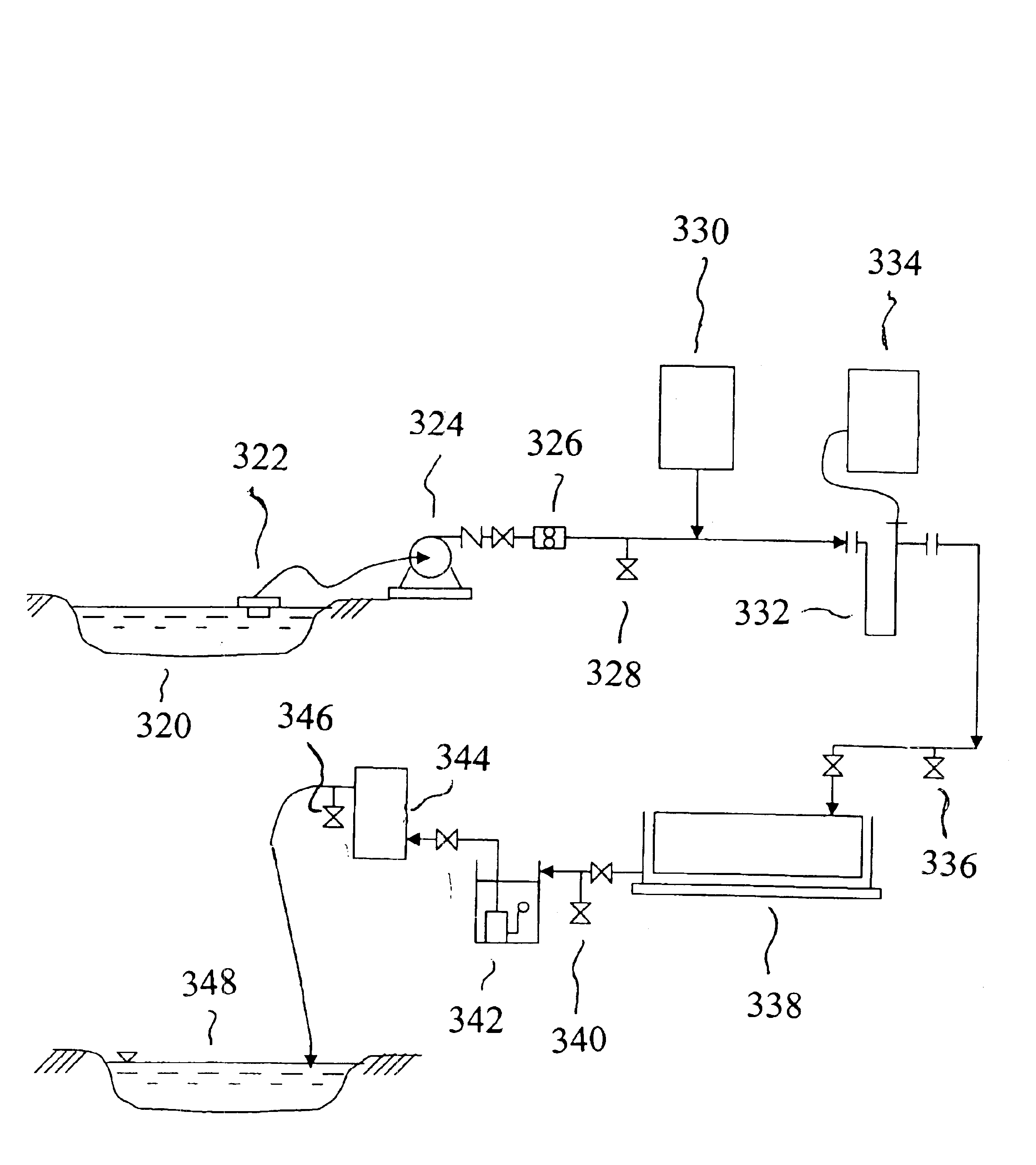

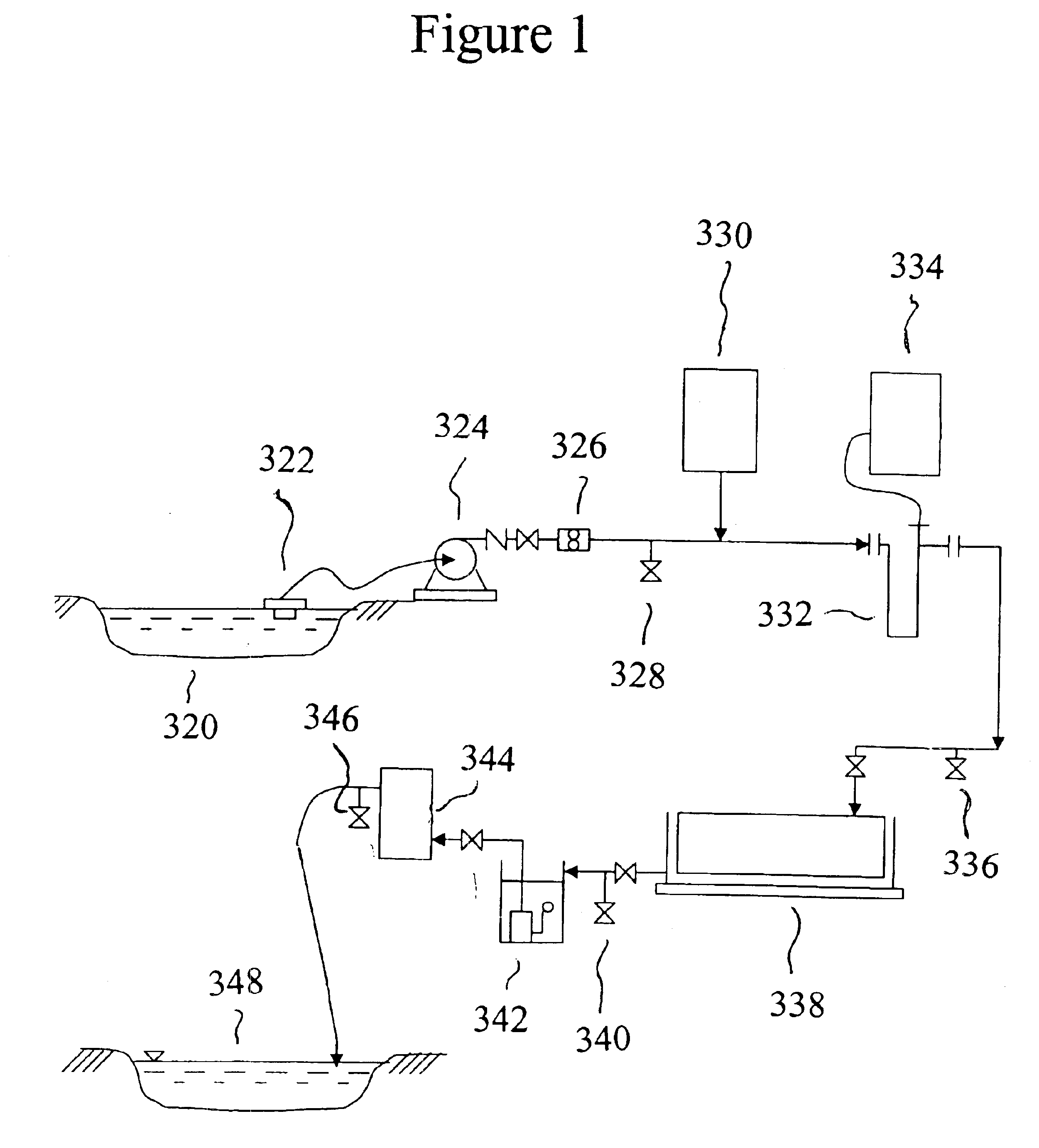

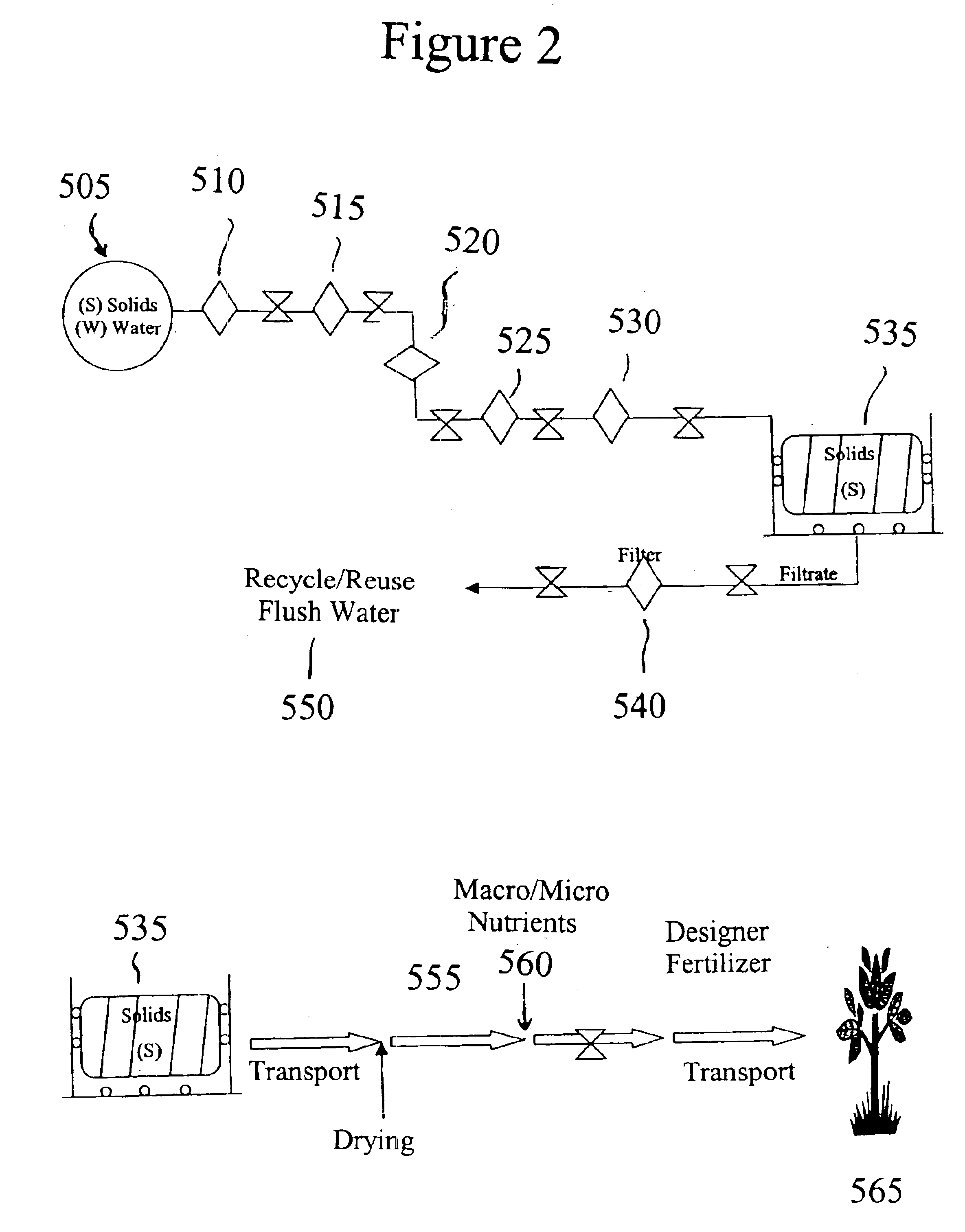

Animal waste effluent treatment

Animal waste such as fecal material from swine, chicken, turkey, and cattle is converted into useful forms such as fertilizer, other types of soil builders, and even nutrient feed additives. Devices, systems, and methods are provided that allow economical conversion and in many instances, alleviate the production and release of undesirable gases such as sulfide and ammonia. In one embodiment, undesirable anaerobic and facultative anaerobic bacteria are killed at a greater rate than desirable soil compatible aerobic bacteria. The use of low temperature killing diminishes off gassing commonly associated with other techniques, and the use of gas trapping additives such as zeolites provides enhanced soil building qualities such as slow release of nitrogen and slow release of moisture to soil. The methods allow convenient adjustment of composition, allowing conversion of waste into tailored designer fertilizer suited for particular soils. Other embodiments provide other soil building qualities as well as nutrient qualities for feedstock used in animal husbandry such as aquaculture.

Owner:SHEETAB SR RICHARD G

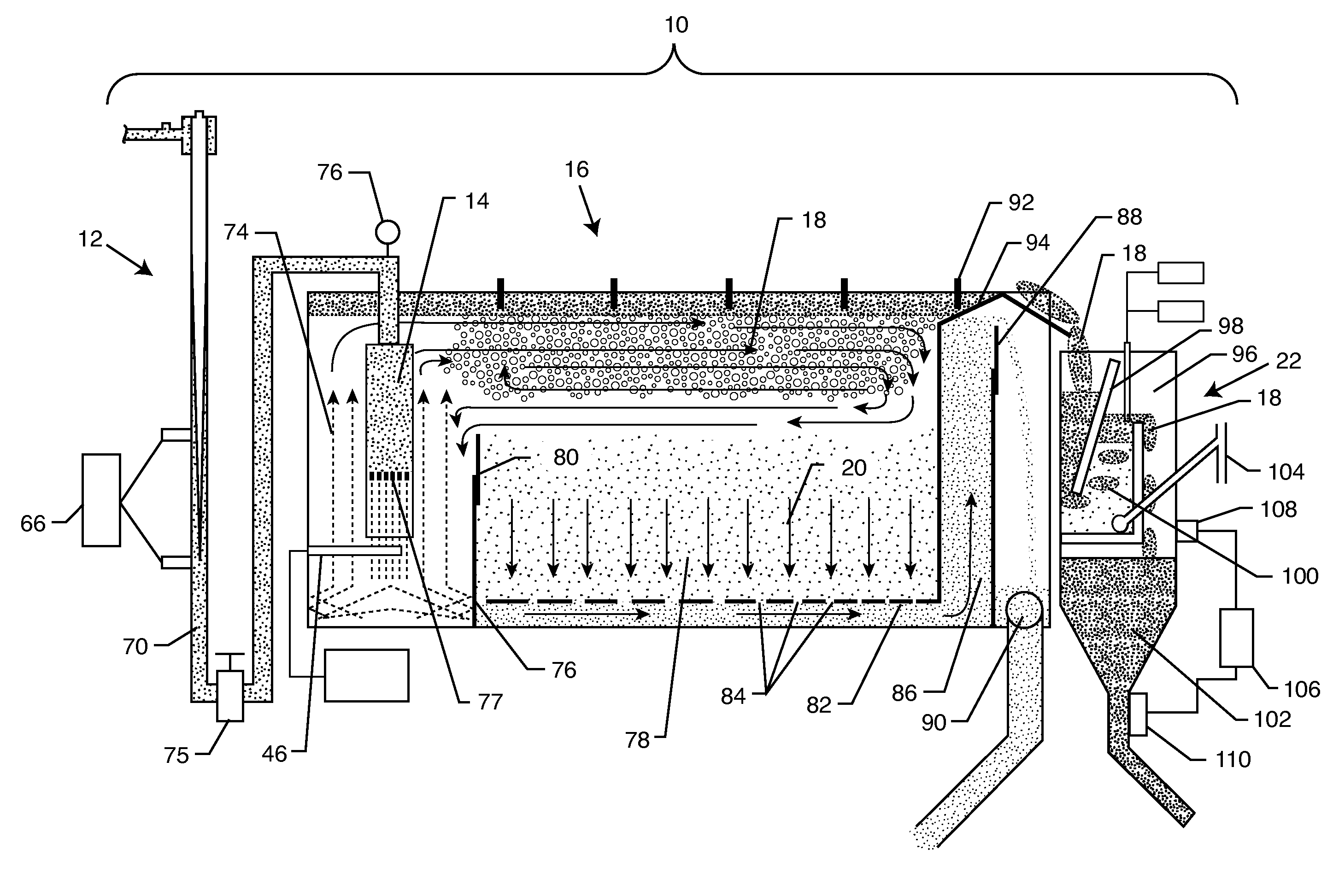

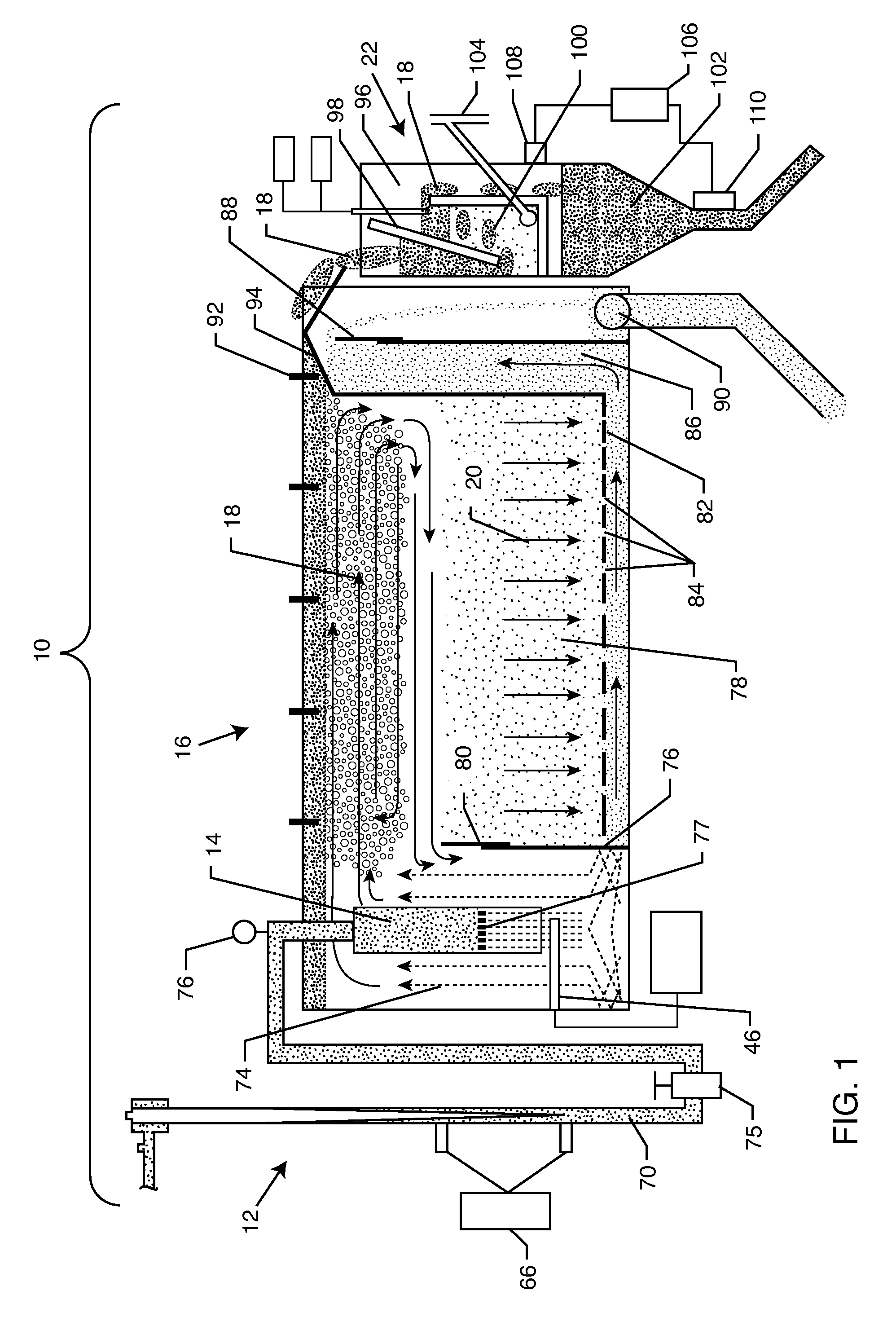

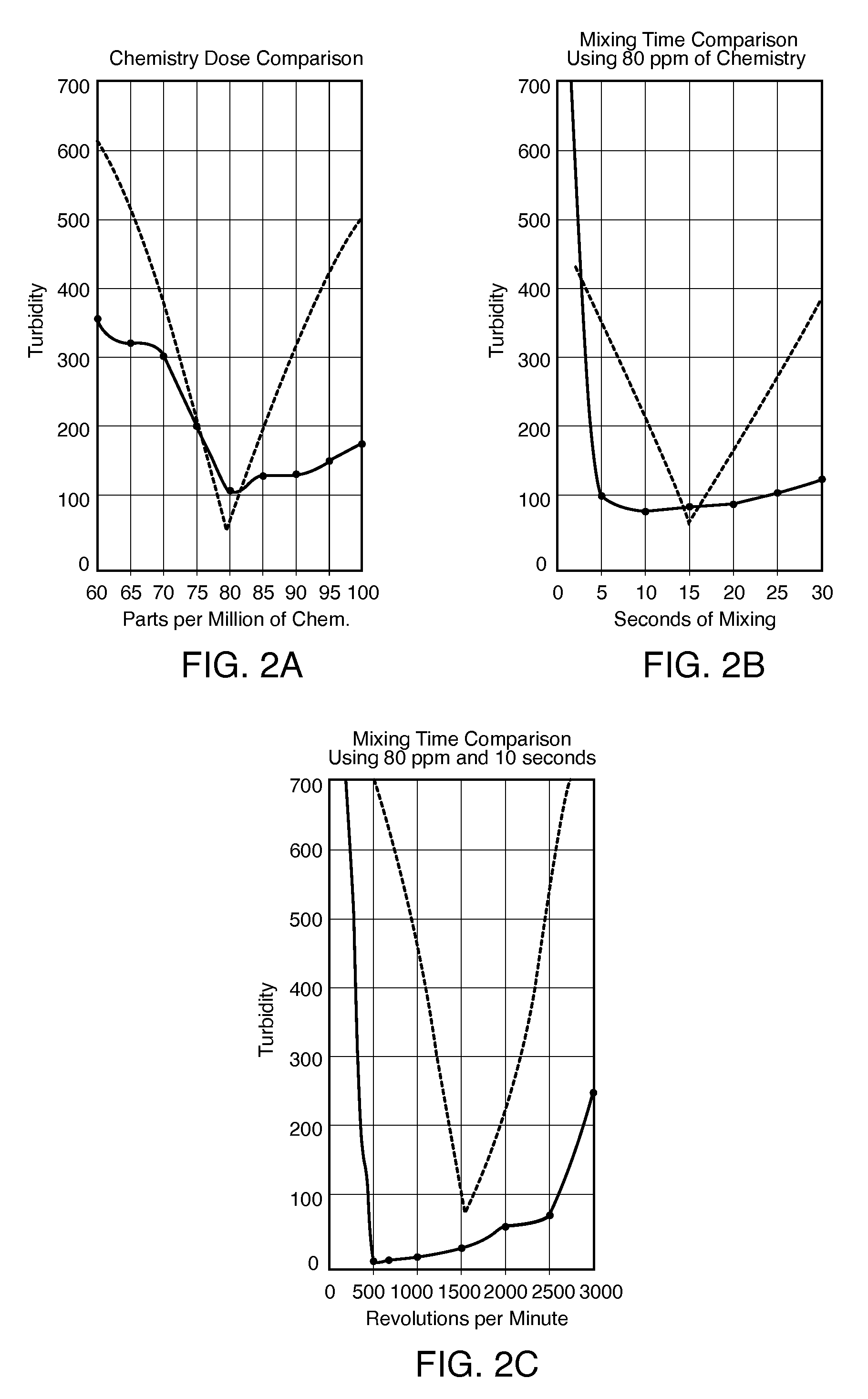

Control system and process for wastewater treatment

InactiveUS20080047903A1Effective positioningEasy to drainWater treatment parameter controlFlow mixersControl systemWastewater

A system and process is provided for optimizing chemical additions, mixing energy, mixing time, and other variables while treating a contaminated liquid stream. Samples from the contaminated liquid stream are tested to determine the optimal parameter for each variable, including type and amount of the chemicals to be added, chemical sequence, mixing energy, mixing time, temperature, and pressurization. A system of mixers, a flotation chamber, and a dewatering subsystem are designed to achieve optimal turbidity of the wastewater stream. The system can be modified in real-time in response to a continually changing contaminated liquid stream via a controller and set of sensors, valves, and ports.

Owner:WORLD WATER TECH

Structurally-modified polymer flocculants

InactiveCN1426429ASludge treatment by de-watering/drying/thickeningSedimentation separationCross-linkStructural Modifier

This invention is directed to structurally-modified water-soluble polymers prepared by initiating polymerization of an aqueous solution of monomers under free radical polymerization conditions to form a polymer solution and adding at least one structural modifier to the polymer solution after at least 30 % polymerization of the monomers has occurred, and to use of the water-soluble cross-linked polymers as flocculating agents.

Owner:ONDEO NALCO

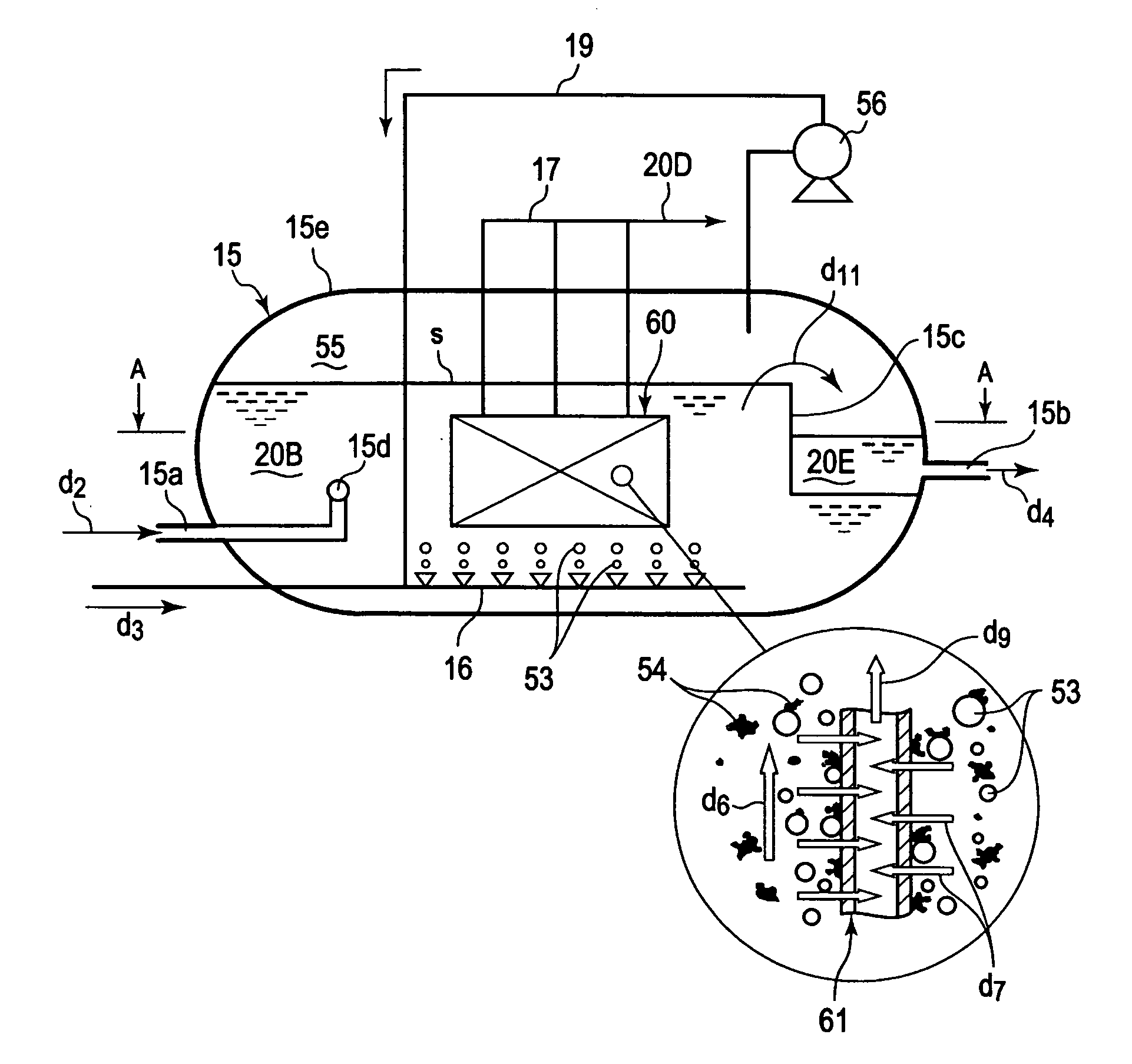

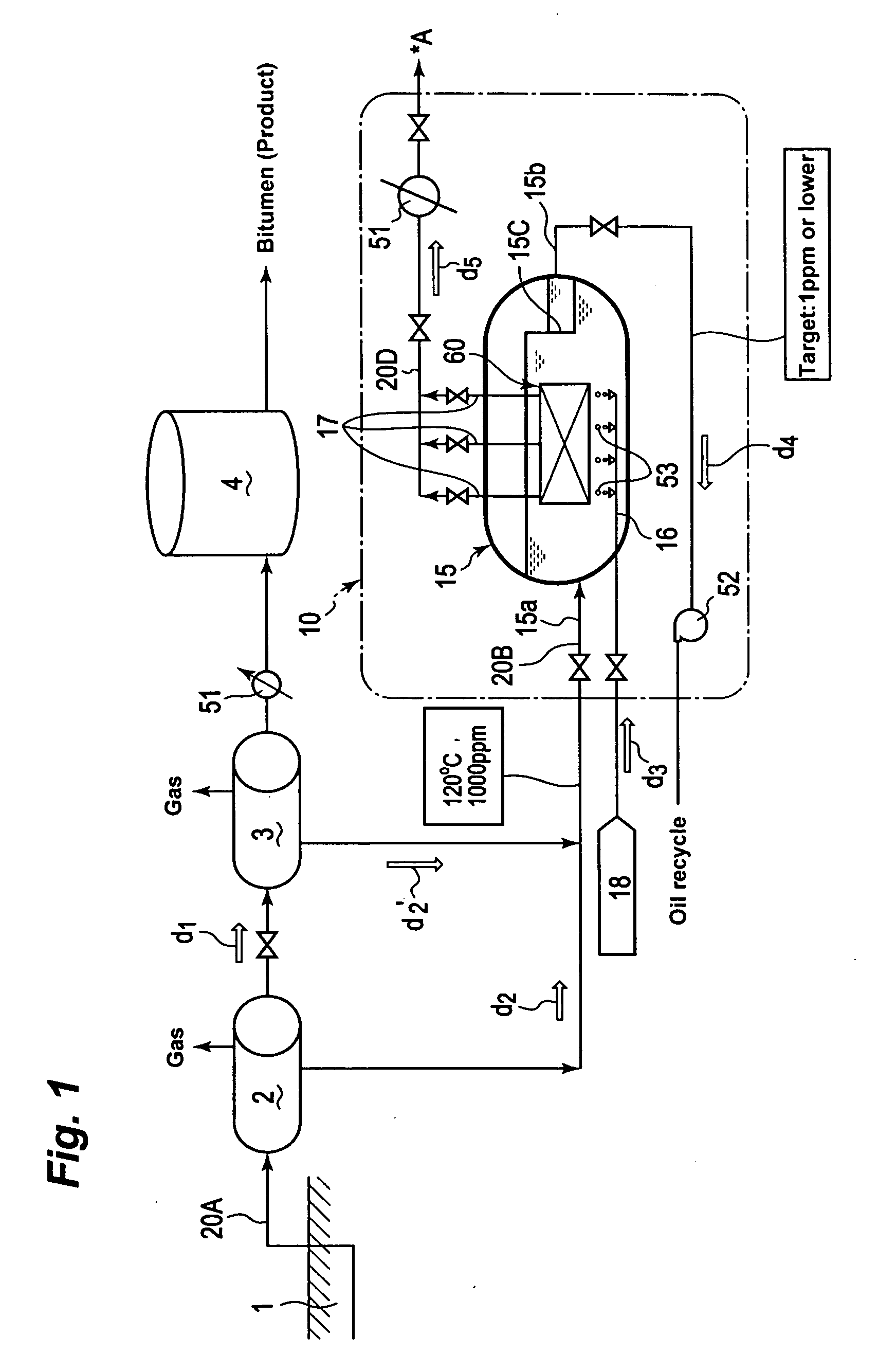

Apparatus of produced water treatment, system and method of using the apparatus, and method of water reuse by using the same

An apparatus of produced water treatment, to be adopted in an in-situ recovery method of producing bitumen from oil sand, the apparatus capable of removing the oil from produced water, the produced water of being left by separating the bitumen from bitumen-mixed fluid having been recovered from the oil sand, the apparatus having: a vessel for receiving the produced water; a submerge type filtration membrane module, installed in the vessel, for filtering the produced water in the condition of the membrane being submerged in the produced water; and a bubble generator for generating bubbles to be forwarded toward the submerged filtration membrane in the produced water.

Owner:TOYO ENG CORP +1

Azetidinium-functional polysaccharides and uses thereof

The present invention relates to polysaccharides that have been modified by providing azetidinium functionality thereto. Such functionality can be provided by crosslinking a polysaccharide with a resin having azetidinium functional groups. In one or more aspects, the polysaccharide can comprise one or more of starch, guar gum, alginate or derivatives thereof. Polysaccharides having azetidinium functionality according to the present invention are suitable for multiple uses. Such uses include, but are not limited to, removal of one or more solid materials from a liquid, beneficiation of an ore, removal of metallic ions from a liquid; providing oil from bitumen; and removal of mercury from synthetic gypsum. Other uses of the functionalized polysaccharides of the present invention include hydroseeding, dust control and corosion control.

Owner:GEORGIA PACIFIC CHEM LLC

Ink set, ink container, inkjet recording method, recording device, and recorded matter

ActiveUS20080182085A1High metallic mirror surface glossMaterial nanotechnologyMeasurement apparatus componentsPolymer chemistryPigment

An ink set, comprising: an oil based ink composition containing a metallic pigment; and at least one or more oil based ink compositions selected from a group consisting of a chromatic color ink composition containing chromatic color pigment, a black ink composition containing black pigment, and a white ink composition containing white pigment.

Owner:SEIKO EPSON CORP

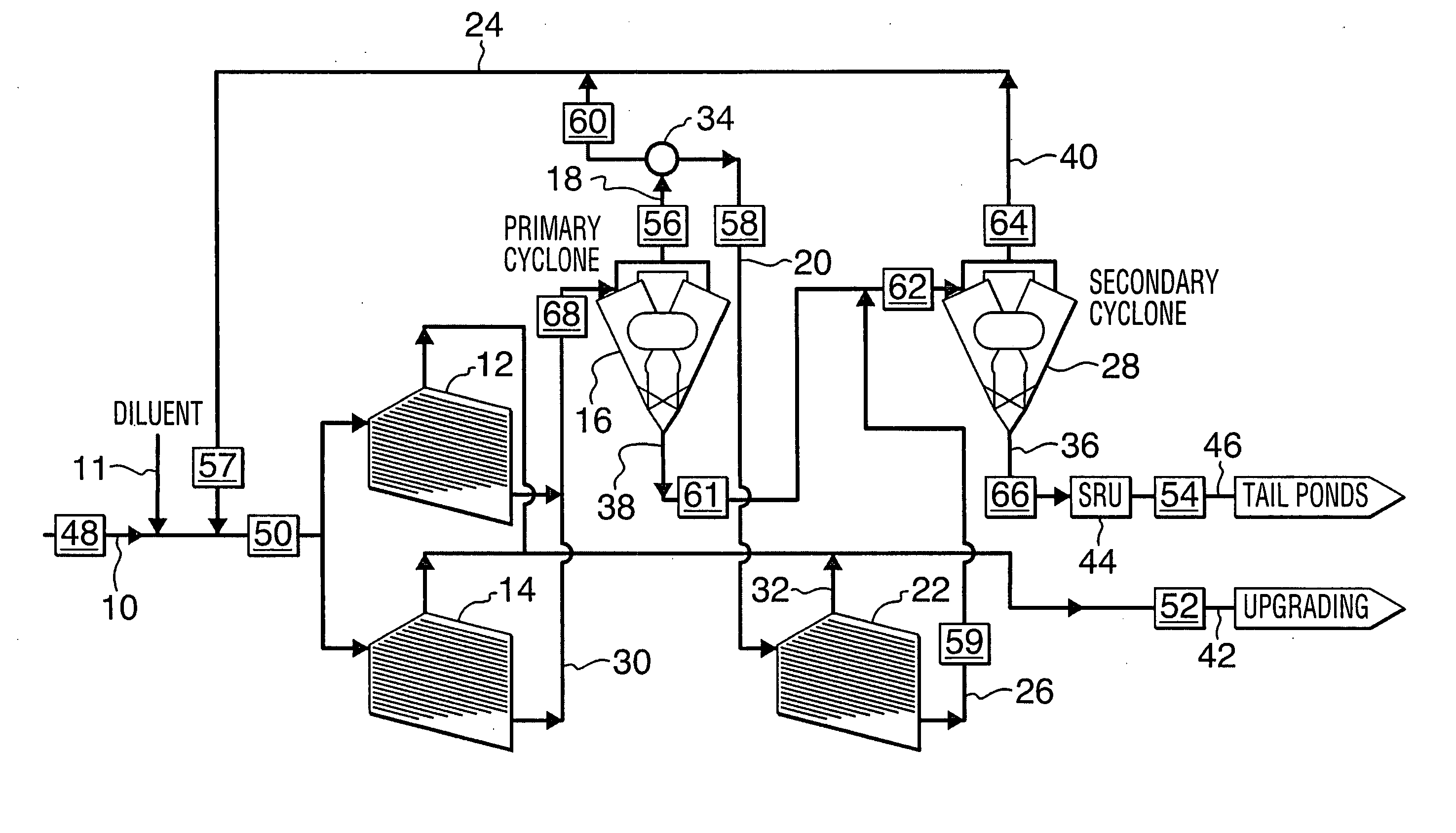

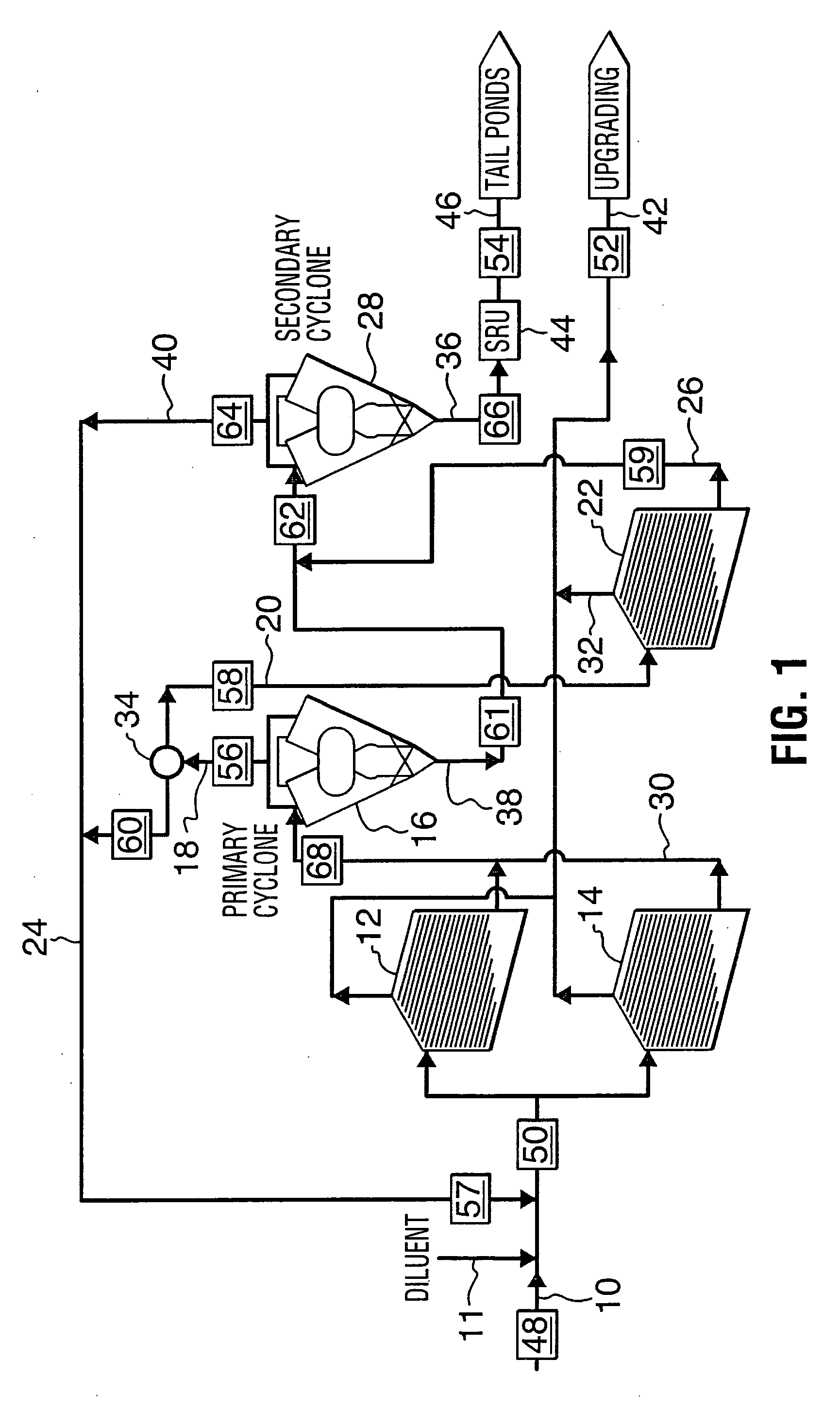

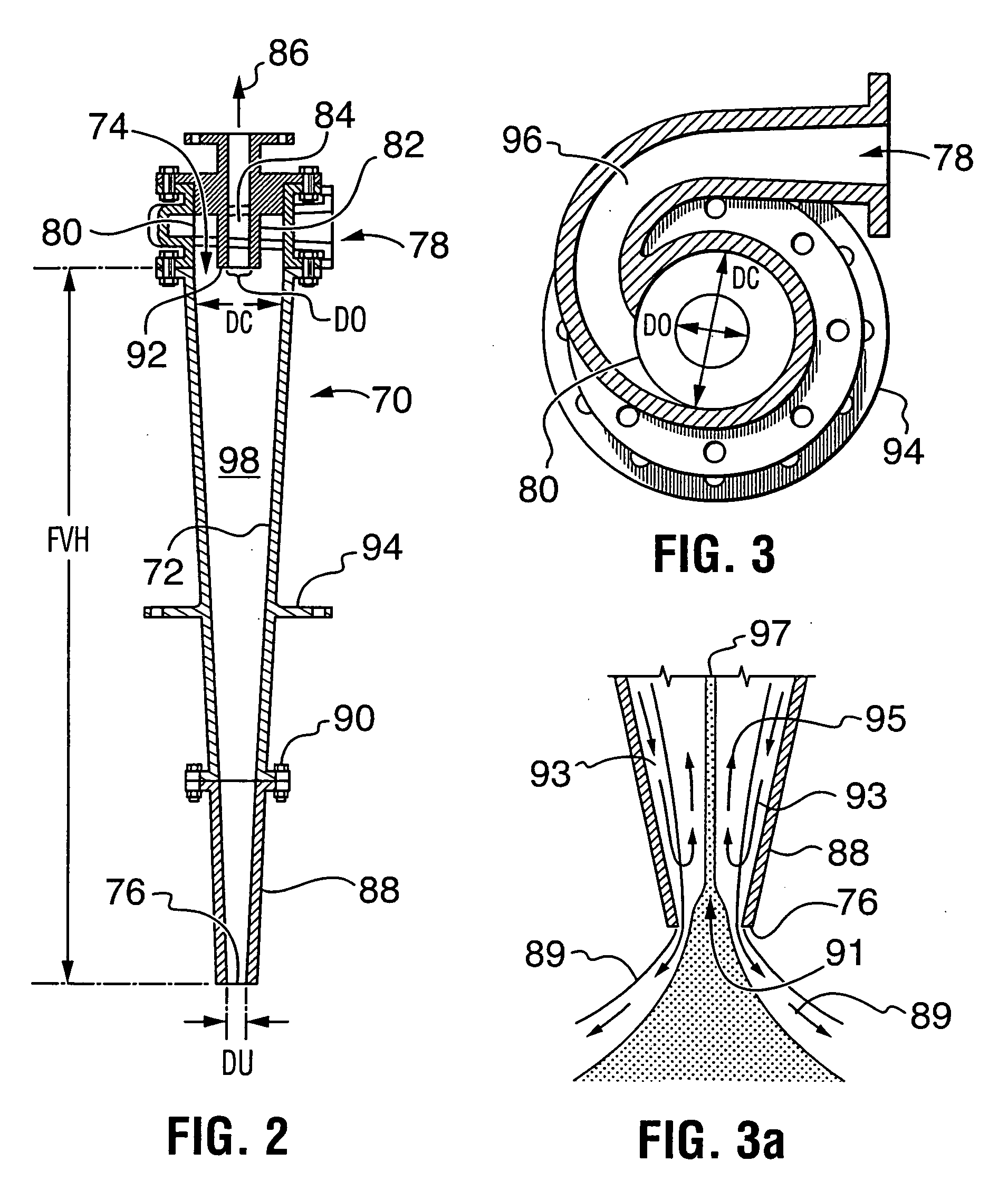

Bituminous froth hydrocarbon cyclone

InactiveUS20060138055A1Poor separationEasy to separateReversed direction vortexCentrifugal force sediment separationCycloneHydrocotyle bowlesioides

An apparatus to perform a process to remove water and minerals from a bitumen froth output of a oil sands hot water extraction process comprises: (i) a cyclone body having an elongated conical inner surface defining a cyclone cavity extending from an upper inlet region with a diameter DC to a lower apex outlet with a diameter DU; (ii) an inlet means forming an inlet channel extending into the upper inlet region of the cyclone cavity; and (iii) a vortex finder forming an overflow outlet of a diameter (DO) extending into the upper inlet region of the cyclone cavity toward the lower apex outlet and having a lower end extending an excursion distance below the inlet channel; wherein a fluid composition entering the inlet channel into the cyclone cavity is urged by force of gravity and velocity pressure downward toward the lower apex and variations in density of the constituent components of the fluid composition cause the lighter component materials to be directed toward the overflow outlet of the vortex finder.

Owner:GARNER WILLIAM NICHOLAS +2

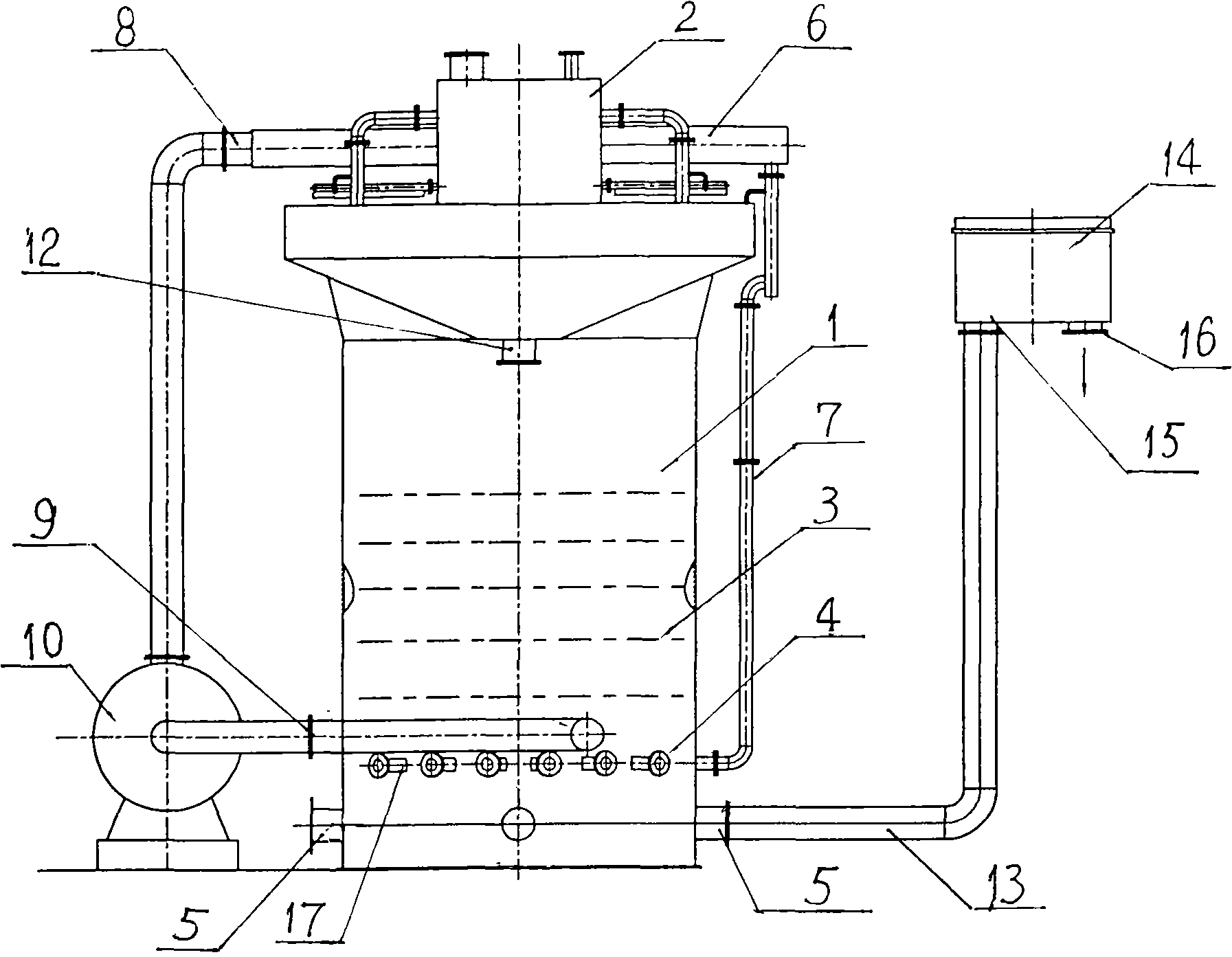

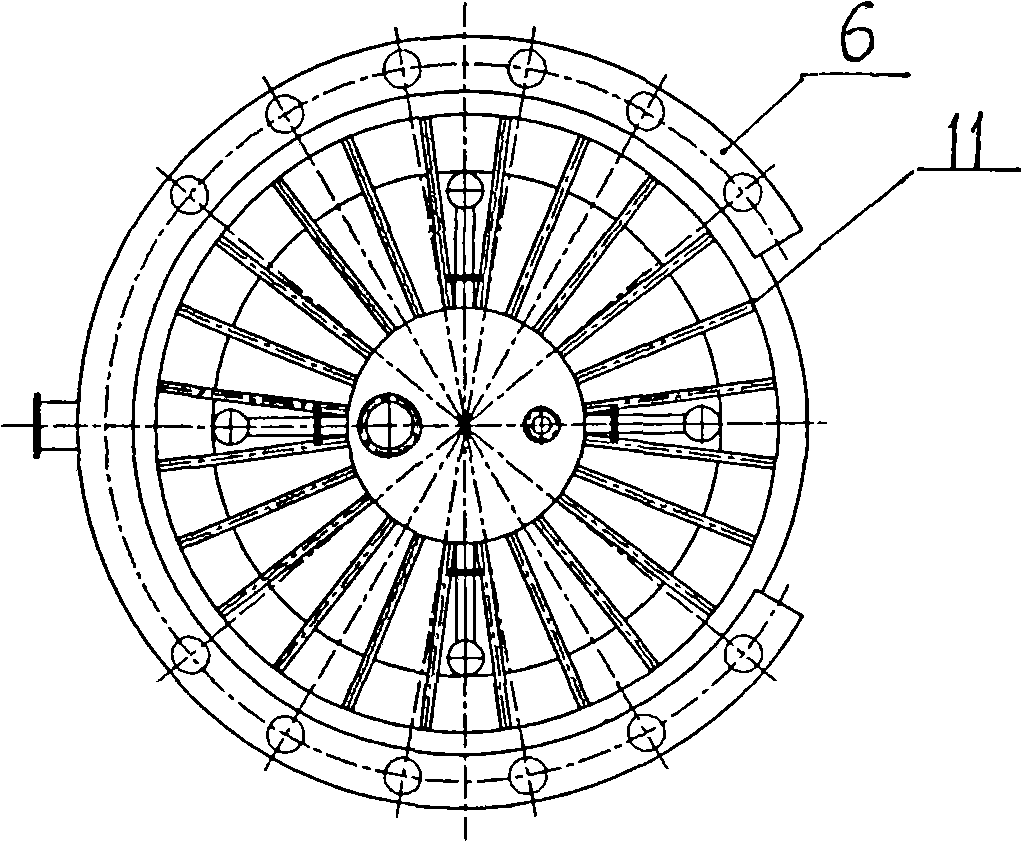

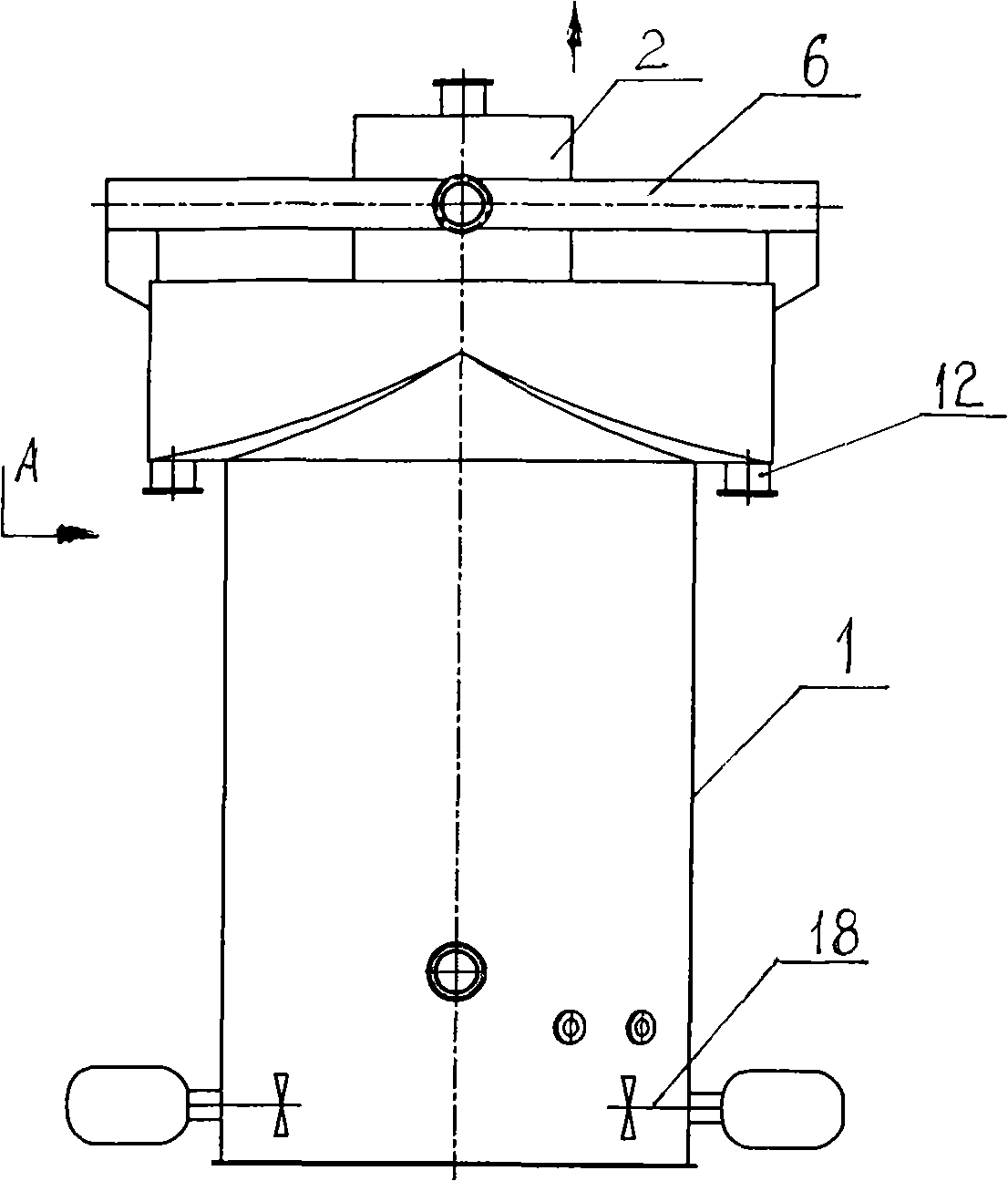

Flotation pillar special for fly ash

The invention relates to a special flotation column of coal fly ash, an ore pulp distributor is arranged at the top part of a cylinder body of the special flotation column, a plurality of layers of bubble plates are arranged in the cylinder body, a multi-point rotary flow device and a multi-point fly ash overflow hole are arranged at the lower part of the cylinder body, an ore pulp distributing pipe is arranged at the periphery of the ore pulp distributor, a circulating pipeline is arranged at the periphery of the cylinder body, the upper end of the circulating pipeline is connected and communicates with the ore pulp distributing pipe, the lower end is connected and communicates with the rotary flow device, an interface of the ore pulp distributing pipe and a feed and discharge port are respectively connected with the both ends of a circulating pump, a high carbon ash balance overflow plate and a high carbon ash overflow collection port are further arranged at the upper part of the flotation column, and the fly ash overflow hole is provided with a fly ash automatic regulation box by the connection of the pipeline. The special flotation column is applicable to various requirements, the decarburization effect is good, the continuous operation is stable and reliable, the quality of fine coal is high and the processing ability is great, thus saving energy, increasing efficiency and saving investment.

Owner:贵州安顺惠海粉煤灰开发有限公司

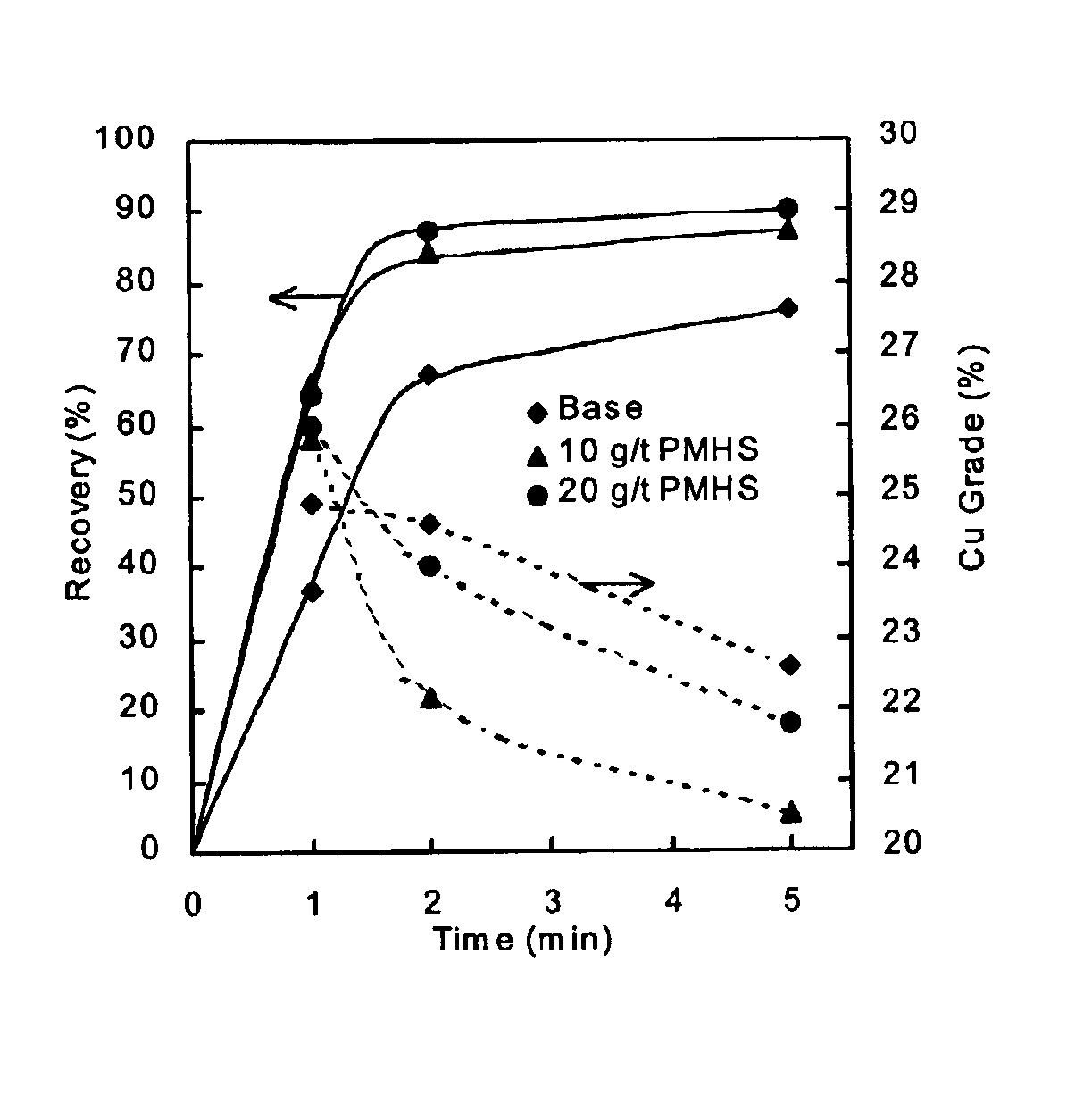

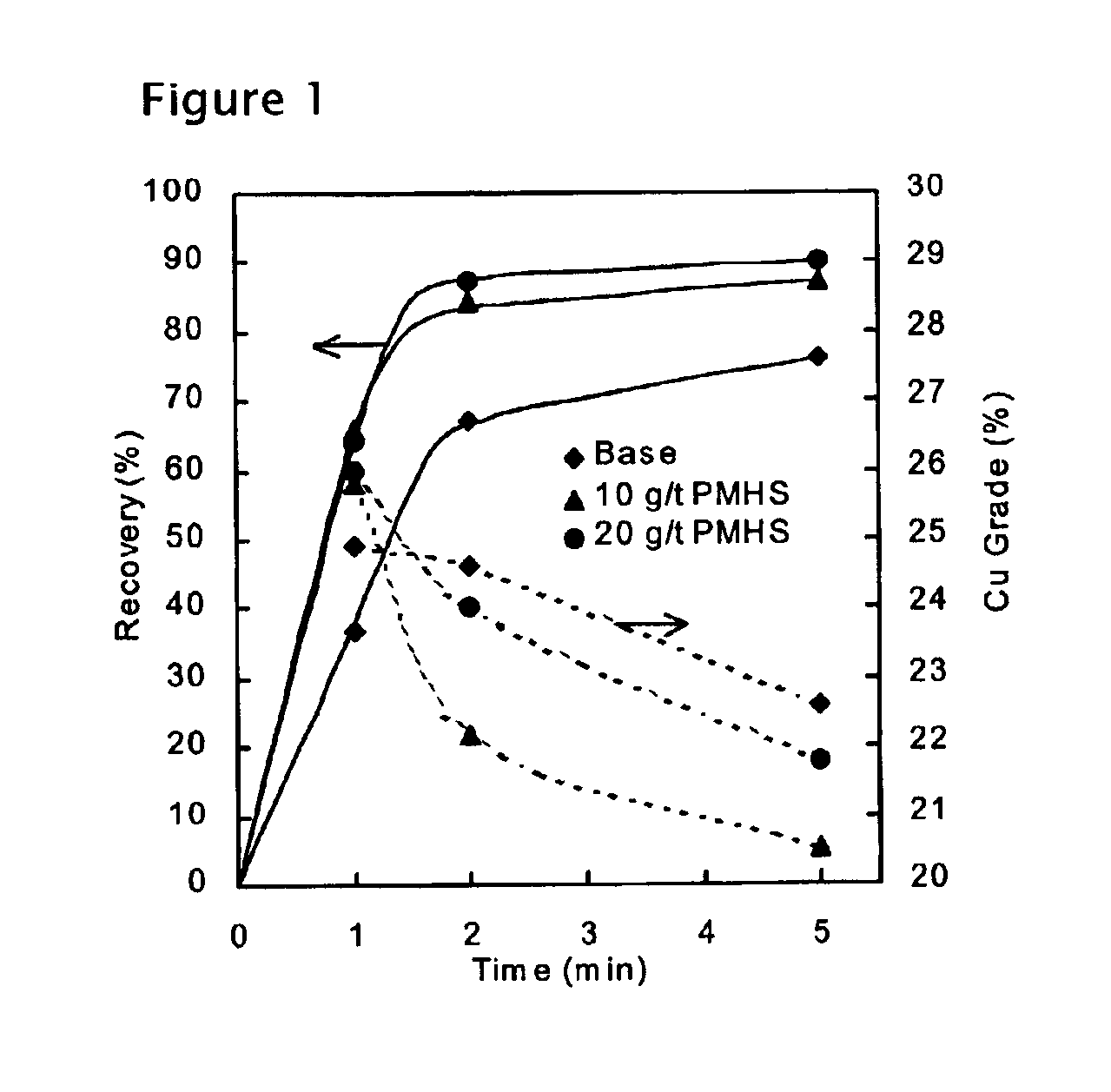

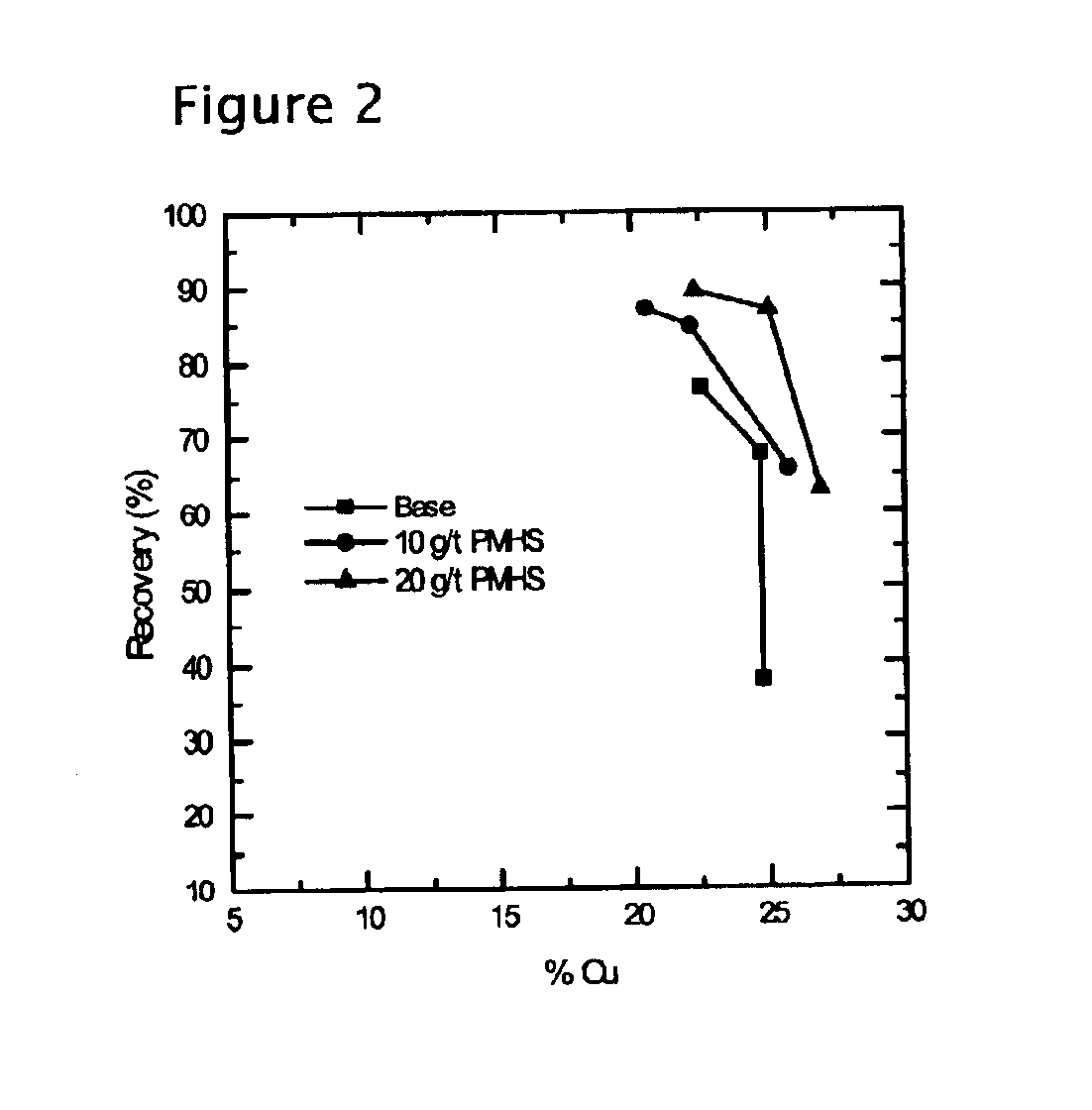

Methods of increasing flotation rate

Methods of increasing the rate of separating hydrophobic and hydrophilic particles by flotation have been developed. They are based on using appropriate reagents to enhance the hydrophobicity of the particles to be floated, so that they can be more readily collected by the air bubbles used in flotation. The hydrophobicity-enhancing reagents include low HLB surfactants, naturally occurring lipids, modified lipids, and hydrophobic polymers. These methods can greatly increase the rate of flotation for the particles that are usually difficult to float, such as ultrafine particles, coarse particles, middlings, and the particles that do not readily float in the water containing large amounts of ions derived from the particles. In addition, new collectors for the flotation of phosphate minerals are disclosed.

Owner:MINERAL & COAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com