Structurally-modified polymer flocculants

A structure modifier, water-soluble polymer technology, applied in the direction of flocculation/sedimentation water/sewage treatment, separation methods, chemical instruments and methods, etc., can solve problems such as flocculation of unknown polymer flocculants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] The water soluble modified polymers prepared herein above may be cationic, anionic or nonionic. They can be emulsion polymers, dispersion polymers, or gel polymers.

[0053] "Emulsion polymer" and "latex polymer" mean water-in-oil polymer emulsions, comprising cationic, anionic or nonionic polymers according to the invention in the water phase, for hydrocarbon oil and water-in-oil emulsification of the oil phase agent. The opposite emulsion polymers are continuous hydrocarbons and water soluble polymers dispersed in a hydrocarbon matrix. The opposite emulsion polymer is then "inverted" or activated by releasing the polymer from the particle using shear, dilution, and generally another surfactant. See U.S. Pat. No. 3,734,873, incorporated herein by reference. Representative preparations of high molecular weight inverse emulsion polymers are described in U.S. Patent nos. 2,982,749, 3,284,393, and 3,734,873. See also, "Mechanism, Kinetics and Modeling of Acrylamide Rev...

Embodiment 1

[0113] Polymer 1, a control polymer of 15% polymer solids, 90 / 10 mol% AcAm / DMAEA·BCQ dispersion, was synthesized as follows:

[0114] To a 1500 ml reaction flask equipped with a mechanical stirrer, thermocouple, condenser, nitrogen purge tube, and addition port, was added 213 g of acrylamide 49.6% in water (Nalco Chemical Company, Naperville, IL), 56.6 g of dimethylaminoethyl acrylate Ester benzyl chloride quaternary salt (70.9% aqueous solution, Nalco Chemical Company, Naperville, IL), 9 g glycerin, 59 g copolymer of dimethylaminoethyl acrylate benzyl chloride quaternary salt and diallyl dimethyl ammonium chloride (15% aqueous solution, Nalco Chemical Company, Naperville, IL), 0.4 g diethylamine tetraacetic acid, tetrasodium salt, 157 g ammonium sulfate, and 424 g deionized water. The mixture was then heated to 48°C while stirring at 900 rpm. After reaching 48°C, 1.2 g of a 1.0% aqueous solution of 2,2'-azobis(2-amidinopropane) dihydrochloride (V-50, Wako Chemicals, Dallas, ...

Embodiment 2

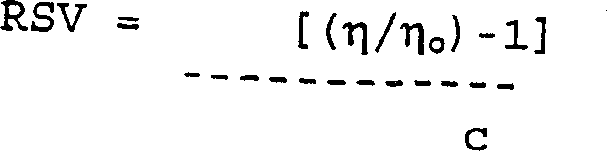

[0115] Polymer 2 was synthesized using the general procedure described in Example 1, vinyltrimethoxysilane modified 15% polymer solids, 90 / 10 mol% AcAm / DMAEA·BCQ dispersion polymer. The standard procedure was modified by adding 0.25 g of vinyltrimethoxysilane (Huls America, Inc., Bristol, PA) to the reaction mixture 3.5 hours after initiation (approximately 88% conversion). No further improvements were made. The reduced viscosity of the product is 18.3dl / g (in 0.125N NaNO 3 0.045% polymer in solution). Example 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Reduced viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com