Vanadium titano-magnetite screen method

A technology of vanadium titanomagnetite and screening method, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the problems of high cost, low recovery rate of iron concentrate and titanium concentrate, etc., and improve the recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

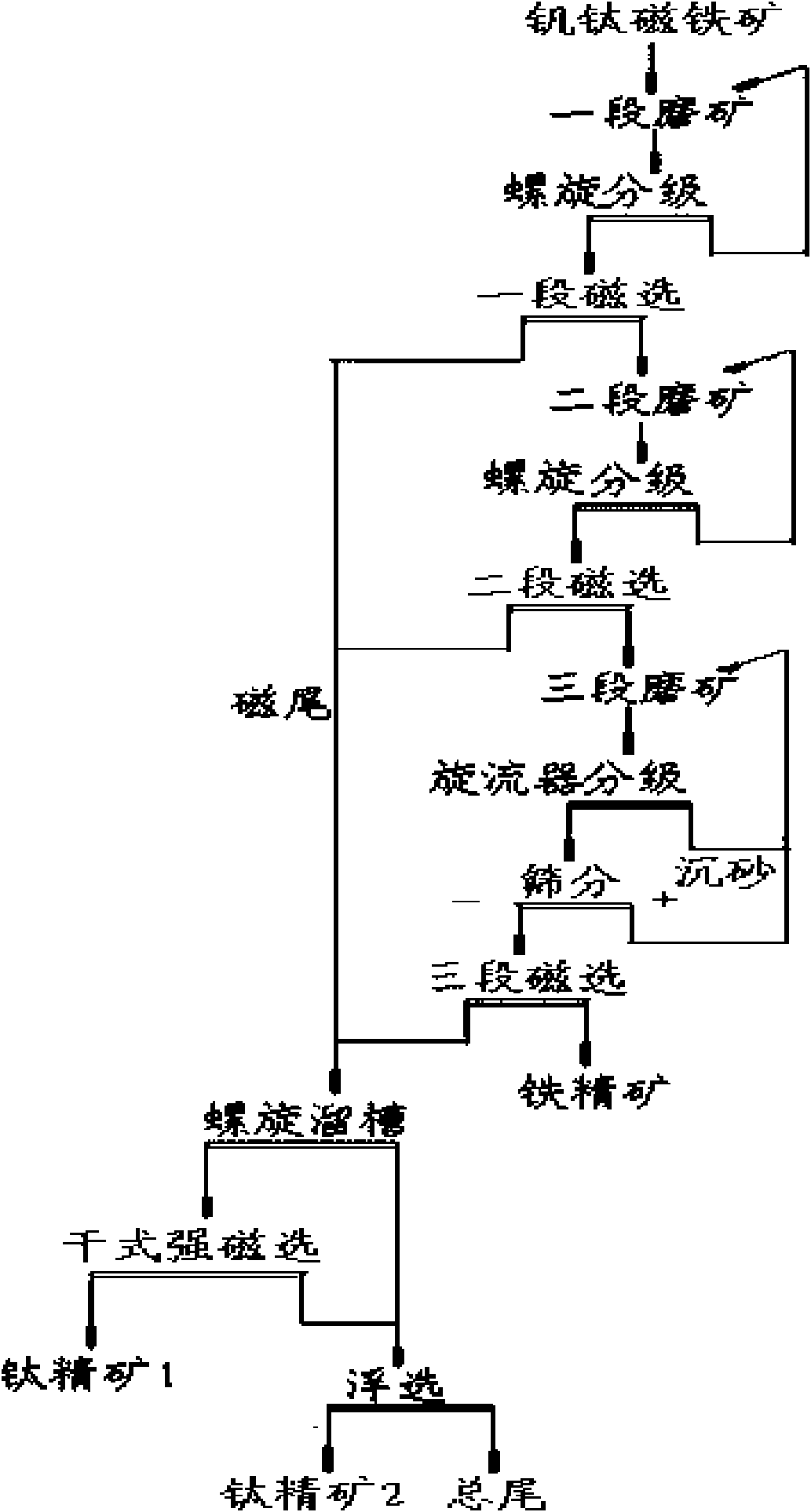

[0033] Embodiment 1 screens low-grade vanadium-titanium magnetite with the inventive method

[0034] Take TFe as 25%, TiO 2 1000t of vanadium-titanium magnetite with a content of 10.5%, the ore is crushed and screened, and the final crushed ore particle size is ≤15mm. The crushed ore enters the ball mill, and cooperates with the spiral classifier to carry out one-stage grinding closed-circuit classification, the pulp-200 mesh particle size reaches 30%, and a weak magnetic separator with a field strength of 3350Gs is used for rough magnetic separation and sweeping magnetic separation; one-stage magnetic separation concentrate After demagnetization, enter the second-stage ball mill, cooperate with the spiral classifier to carry out the second-stage grinding closed-circuit classification, the particle size of -200 mesh reaches 55%, and use the weak magnetic separator with a field strength of 1850Gs for rough magnetic separation and sweep magnetic separation; the second-stage magn...

Embodiment 2

[0039] Embodiment 2 screens low-grade vanadium-titanium magnetite with the inventive method

[0040] Take TFe as 24%, TiO 2 1000t of vanadium-titanium magnetite with a content of 10%, the ore is crushed and screened, and the final crushed ore particle size is ≤15mm. The crushed ore enters the ball mill, and cooperates with the spiral classifier to carry out one-stage grinding closed-circuit classification. The pulp-200 mesh particle size reaches 30%. A weak magnetic separator with a field strength of 3400Gs is used for rough magnetic separation and sweeping magnetic separation; one-stage magnetic separation concentrate After demagnetization, enter the second-stage ball mill, cooperate with the spiral classifier to carry out the second-stage grinding closed-circuit classification, the -200 mesh particle size reaches 55%, use a weak magnetic separator with a field strength of 1900Gs for rough magnetic separation and sweep magnetic separation; the second-stage magnetic separation...

Embodiment 3

[0045] Embodiment 3 screens low-grade vanadium-titanium magnetite with the inventive method

[0046] Take TFe as 22%, TiO 2 1000t of vanadium-titanium magnetite with a content of 9.5%, the ore is crushed and screened, and the final crushed ore particle size is ≤15mm. The crushed ore enters the ball mill, and cooperates with the spiral classifier to carry out one-stage grinding closed-circuit classification. The 200-mesh particle size of the ore pulp reaches 30%. A weak magnetic separator with a field strength of 3450Gs is used for rough magnetic separation and sweeping magnetic separation; After magnetization, it enters the second-stage ball mill, and cooperates with the spiral classifier to carry out the second-stage grinding closed-circuit classification. The particle size of -200 mesh reaches 55%. A weak magnetic separator with a field strength of 2000Gs is used for rough magnetic separation and sweep magnetic separation; the second-stage magnetic separation fine After dem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com