Patents

Literature

8637 results about "Iron ore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in colour from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (Fe₃O₄, 72.4% Fe), hematite (Fe₂O₃, 69.9% Fe), goethite (FeO(OH), 62.9% Fe), limonite (FeO(OH)·n(H₂O), 55% Fe) or siderite (FeCO₃, 48.2% Fe).

Anti-seepage burnon casting paint made from alcohol base or aqueous sand powder

InactiveCN1666828AExcellent anti-seepage and sticky sand effectSmall specific surface areaFoundry mouldsFoundry coresWater basedAlcohol

The invention relates to the melting coating of alcohol-base or water-base anti-penetrating sands, which uses the fireproofing bone materials, the floating agent, the felting agent, the reinforcing agent and the carrier as the preparing coating. The weight shares of the said coating are: 100,3-8,3-7,0.2-1.0 and 30-40. The invention uses chrome iron minerals as the main materials and is prior to any kinds of the traditional coating.

Owner:HUBEI UNIV OF TECH

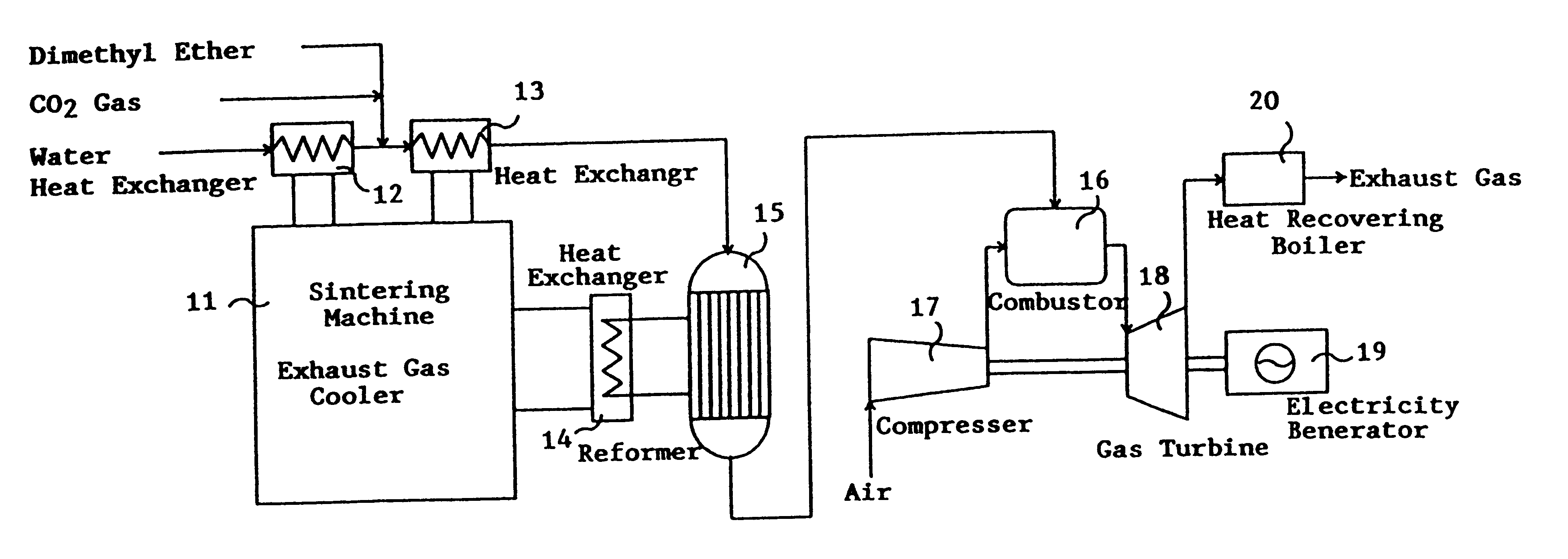

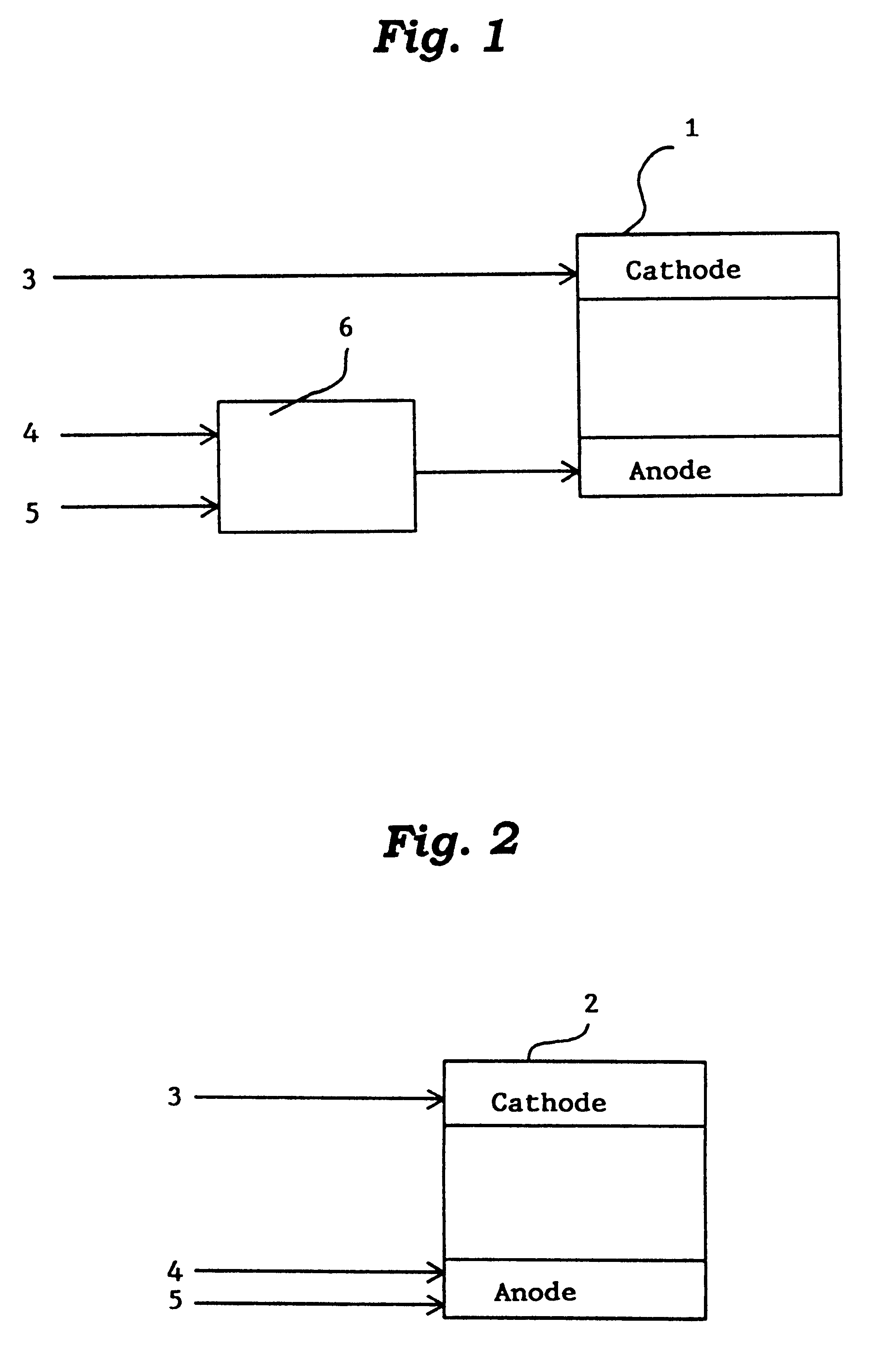

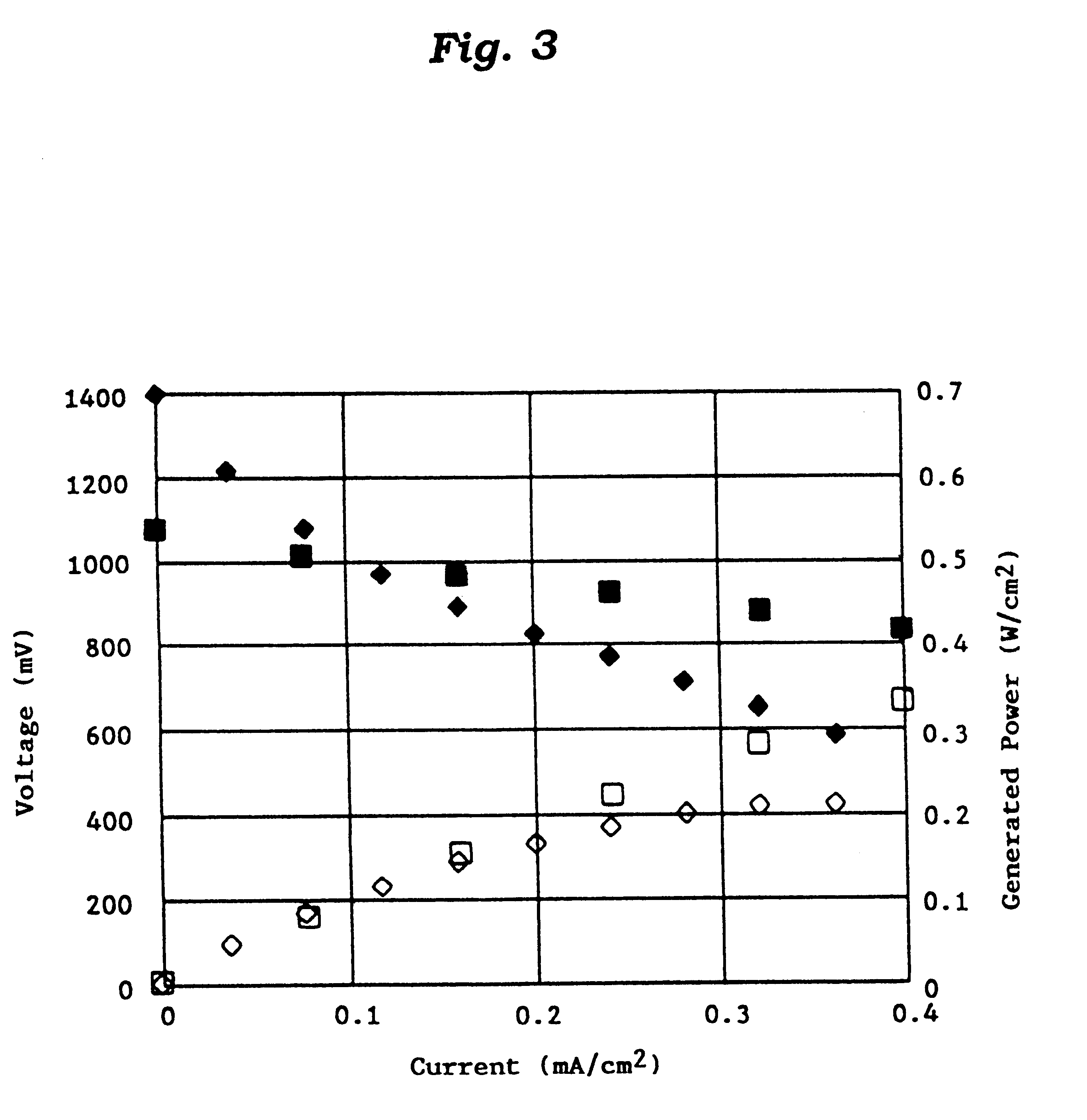

Catalyst for manufacturing hydrogen or synthesis gas and manufacturing method of hydrogen or synthesis gas

InactiveUS6361757B1Produce hydrogenEfficient productionIron compoundsCobalt compoundsIridiumForming gas

This invention provides a catalyst for producing hydrogen gas from a mixed gas comprising dimethyl ether and water vapor or carbon dioxide gas, which comprises copper, iron, cobalt, palladium, iridium, platinum, rhodium, or nickel as an active component, and a method of producing synthesis gas or hydrogen gas in a high yield at a low temperature. By using the catalyst, a fuel cell, electricity generation, reduction of iron ore and the like can be carried out.

Owner:NIPPON KOKAN KK

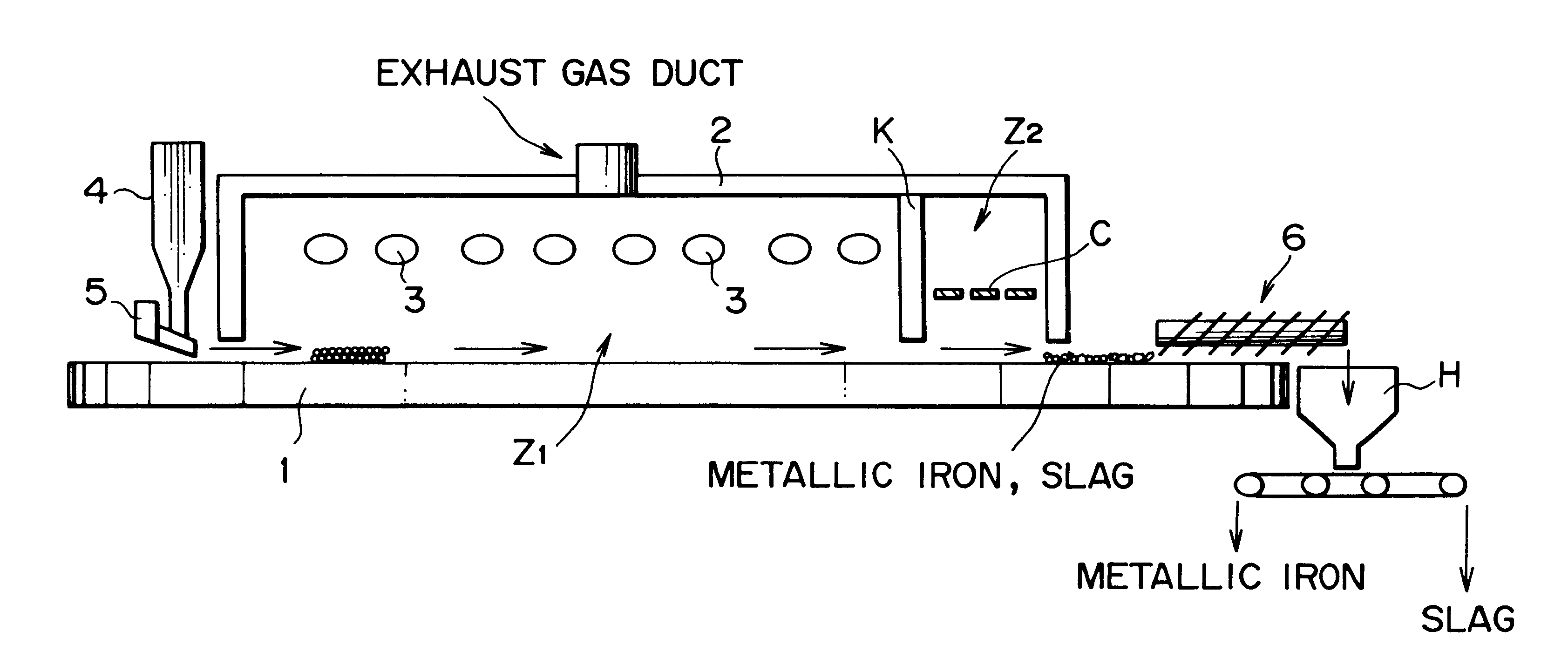

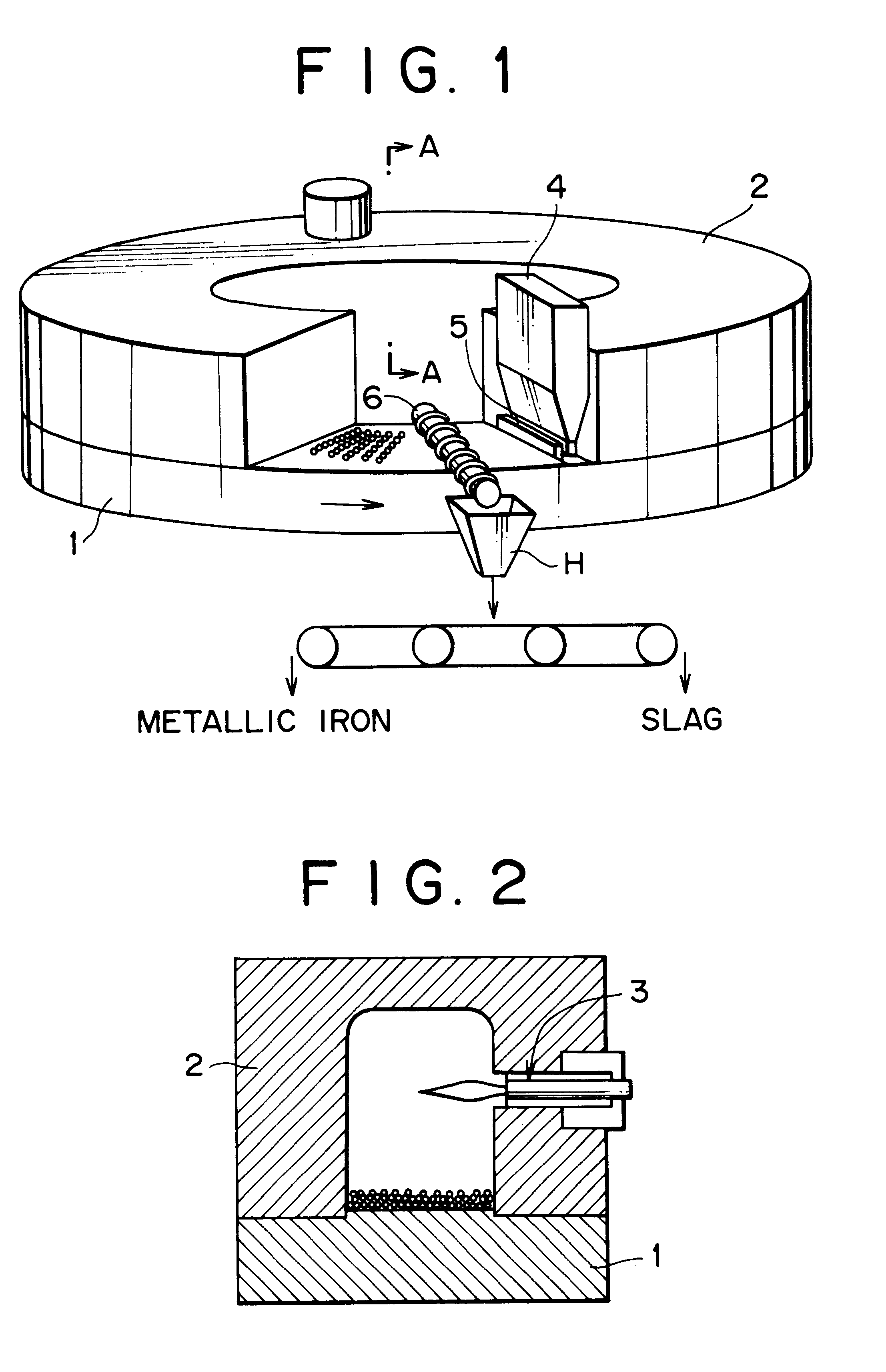

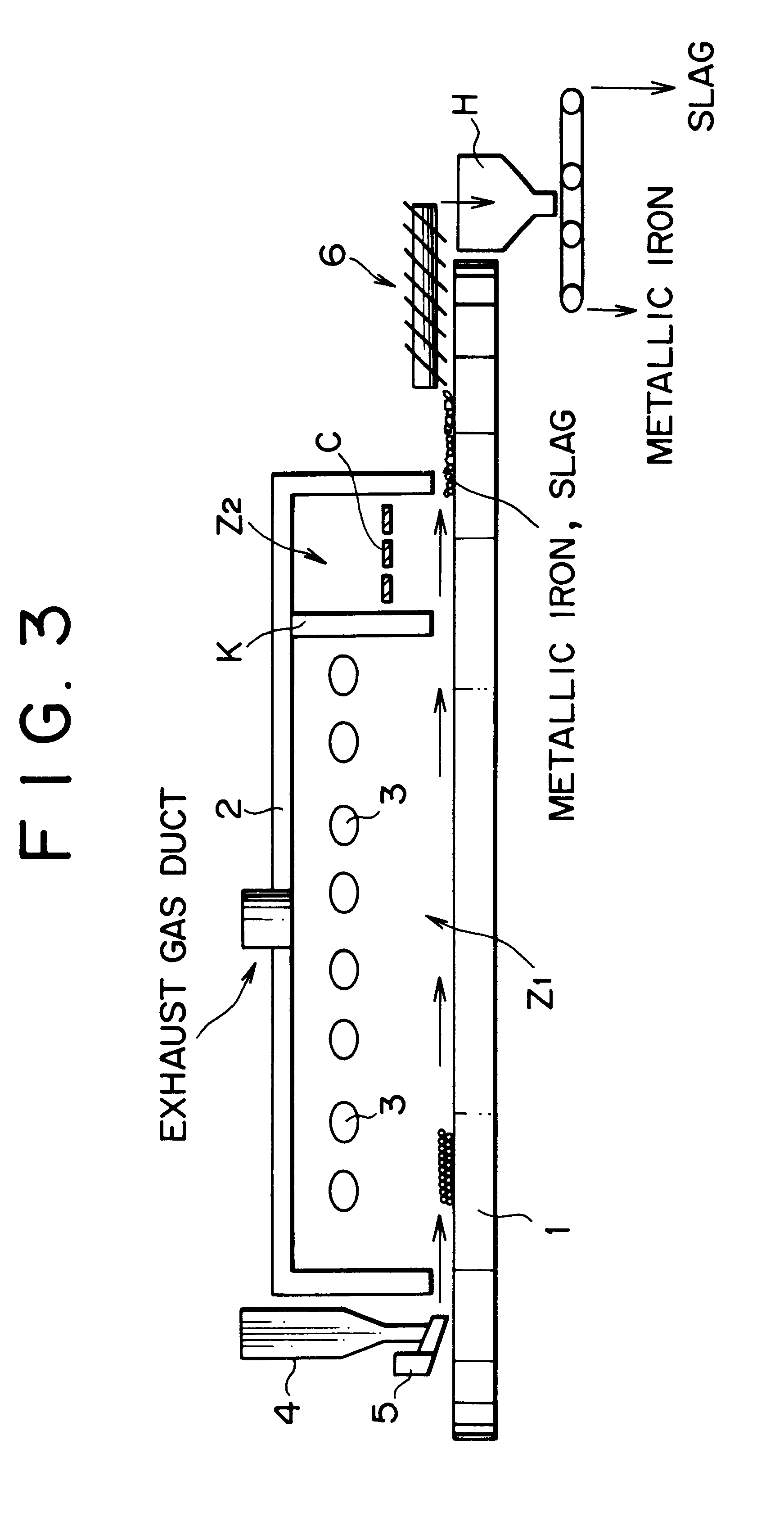

Method and apparatus for making metallic iron

InactiveUS6036744AHigh purityReadily and efficiently madeBlast furnace componentsRotary drum furnacesMolten slagCoal

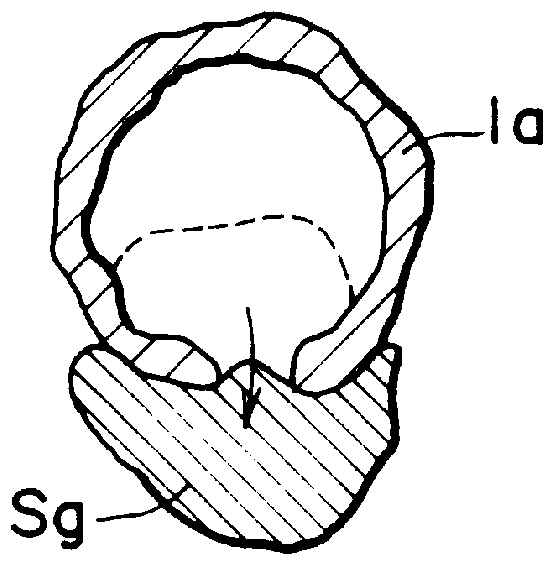

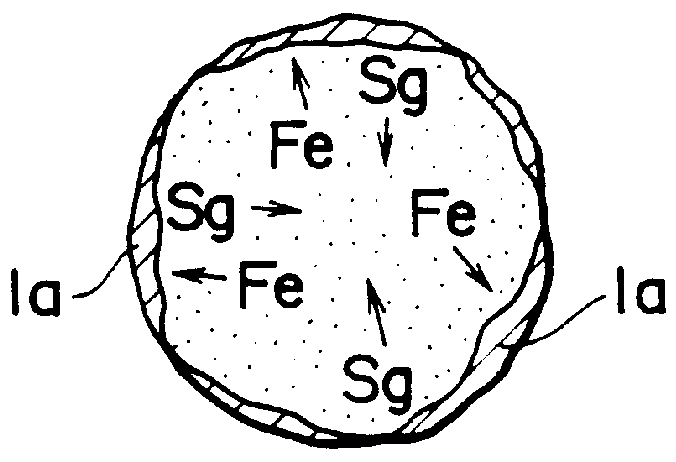

A method of making metallic iron in which a compact, containing iron oxide such as iron ore or the like and a carbonaceous reductant such as coal or the like, is used as material, and the iron oxide is reduced through the application of heat, thereby making metallic iron. In the course of this reduction, a shell composed of metallic iron is generated and grown on the surface of the compact, and slag aggregates inside the shell. This reduction continues until substantially no iron oxide is present within the metallic iron shell. Subsequently, heating is further performed to melt the metallic iron and slag. Molten metallic iron and molten slag are separated one from the other, thereby obtaining metallic iron with a relatively high metallization ratio. Through the employment of an apparatus for making metallic iron of the present invention, the above-described method is efficiently carried out, and metallic iron having a high iron purity can be made continuously as well as productively not only from iron oxide having a high iron content but also from iron oxide having a relatively low iron content.

Owner:KOBE STEEL LTD

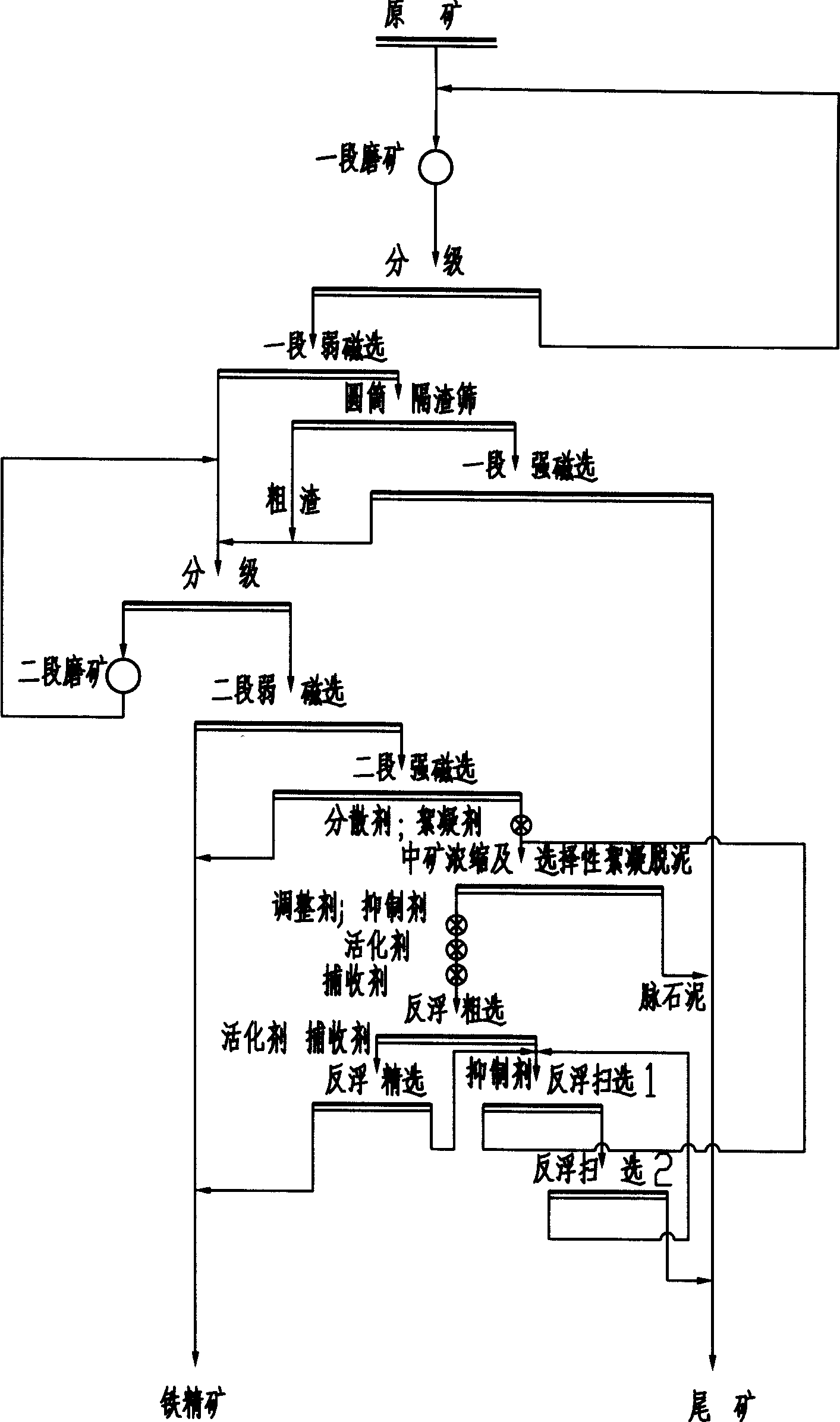

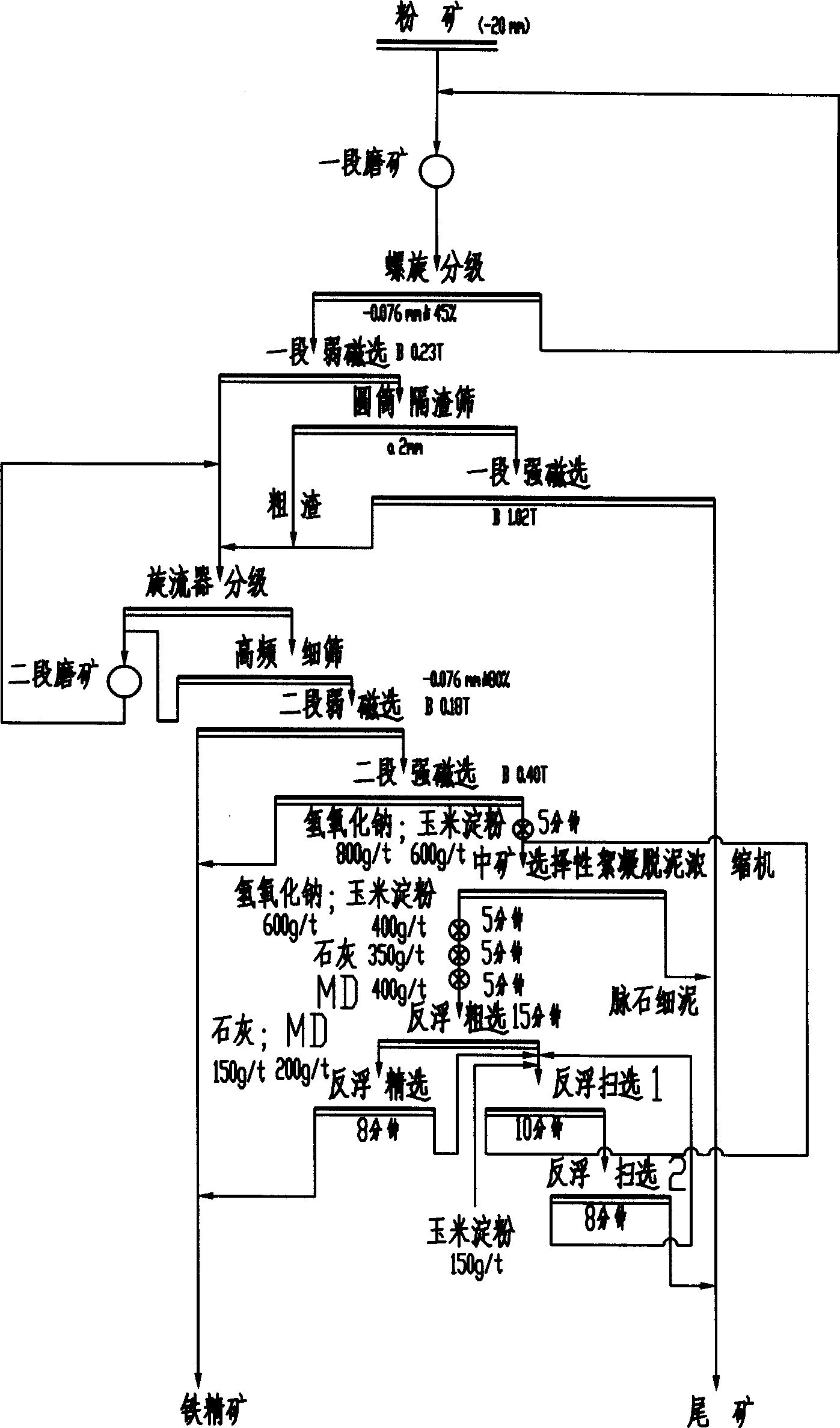

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method of making iron and steel

InactiveUS6149709AEasy to getLess impurity contentProcess efficiency improvementElectric furnaceHigh energyRefractory

Molten iron is prepared by (1) providing iron oxide and a carbonaceous reducing agent, (2) preparing a shaped product from the carbonaceous reducing agent and the iron oxide, (3) preparing solid reduced iron from the shaped product, wherein the solid reduced iron has a metallization of at least 60%, a specific gravity of at least 1.7, and a carbon content of at least 50% of the theoretical amount required for reducing the iron oxide remaining in the solid reduced iron, and, (4) before substantial cooling occurs, heating the solid reduced iron in an arc heating-type melting furnace at a high temperature. The molten iron can be prepared efficiently from iron ores of relatively low iron content without causing erosion of refractories, at high energy and high reduction efficiencies, and by a simple operation in a simple facility.

Owner:KOBE STEEL LTD

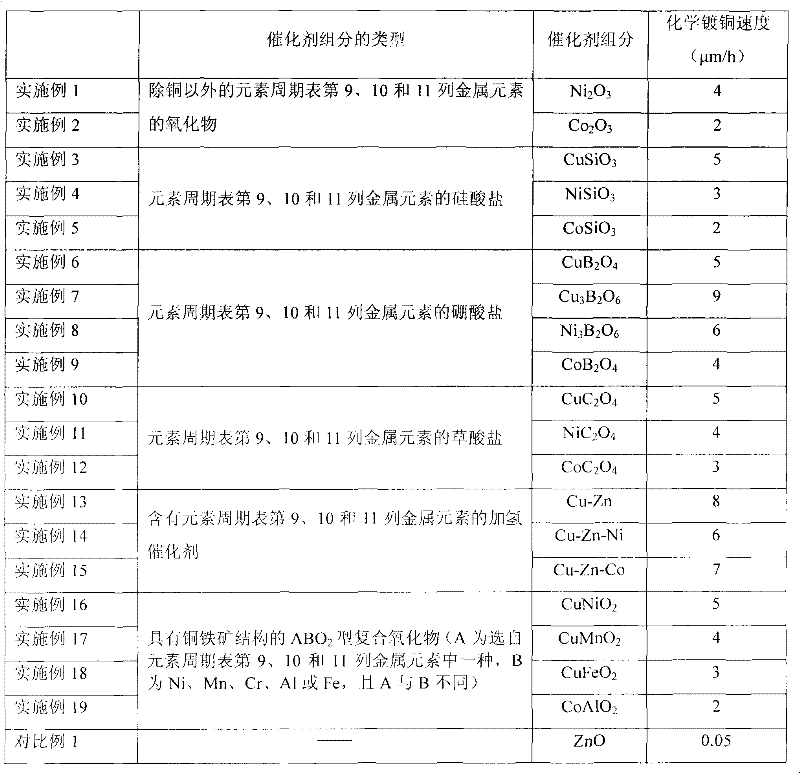

Plastic compound, application thereof and method of selective metallization of plastic surface

ActiveCN101747650AFacilitates electroless copper platingReduced stabilityLiquid/solution decomposition chemical coatingOxalateCopper

The invention provides a plastic compound, which comprises a plastic substrate component and a catalyst component, wherein the catalyst component is selected from one kind or two or more kinds of oxides of the metal elements in the ninth line, the tenth line and the eleventh line of the periodic table of elements except copper, silicates, borates and oxalates of the metal elements in the ninth line, the tenth line and the eleventh line of the periodic table of elements, hydrogenation catalysts with the metal elements in the ninth line, the tenth line and the eleventh line of the periodic table of elements and ABO2 type compound oxides with a delafossite structure; A is selected from one kind of the metal elements in the ninth line, the tenth line and the eleventh line of the periodic table of elements, B is Ni, Mn, Cr, Al or Fe, and A and B are different from each other. The invention also relates to application of the plastic compound in the selective metallization of a plastic surface. Moreover, the invention provides a method of the selective metallization of the plastic surface. When the method is applied, the circuit can be further easily formed.

Owner:BYD CO LTD

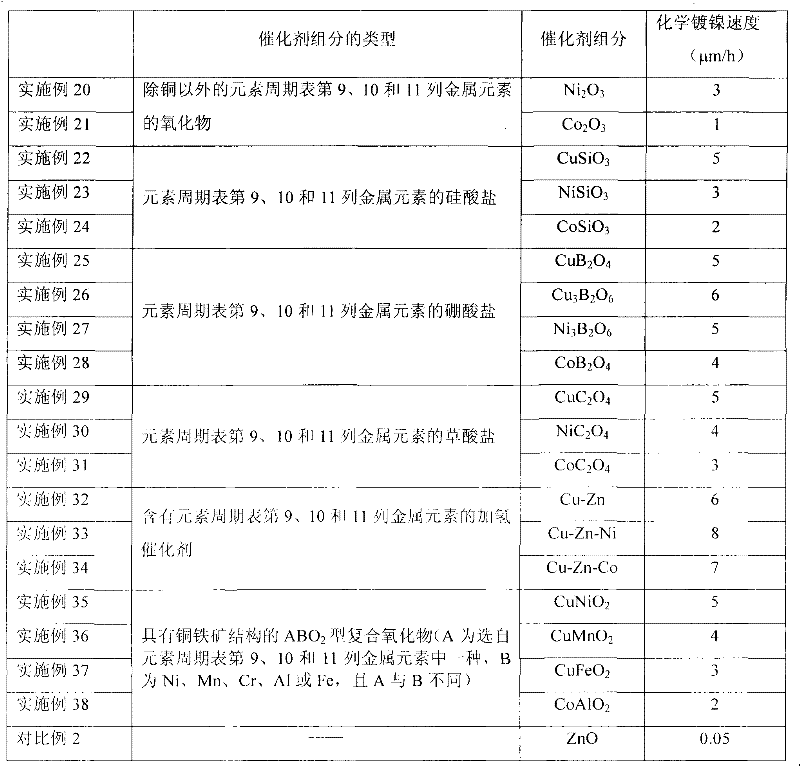

Vanadium titano-magnetite screen method

ActiveCN101564707AQuality improvementHigh recovery rateFlotationMagnetic separationMagnetiteMaterials science

The invention relates to a screen method for vanadium titano-magnetite with high quality, belonging to the ore screen field. The method adopts three stage-grinding and stage-concentration process for magnetic separation, wherein the field intensity of one-stage magnetic separation is 3000-4000 Gs; the field intensity of two-stage magnetic separation is 1800-2200 Gs; and the field intensity of three-stage magnetic separation is 1300-1700 Gs. The recovery rate of the screened iron ore concentrate and the titanium ore concentrate is high and the screened cost of the screened iron ore concentrate and the titanium ore concentrate is low, thus providing a new selection for the low grade vanadium titano-magnetite resource and having a broad application prospect.

Owner:四川安宁铁钛股份有限公司

Iron coke for blast furnace and preparing method thereof

InactiveCN103468289AEnsure Strength IndexBest heating speedCoke ovensBlast furnace detailsCoke ovenUltimate tensile strength

The invention relates to iron coke for a blast furnace and a preparing method thereof. The iron coke comprises 5wt%-20wt% of iron ore powder and 80wt%-95wt% of mixed coal; the mixed coal is formed by mixing 25wt%-29wt% of one third of coking coal, 40wt%-44wt% of coking coal, 7wt%-11wt% of lean coal, 6wt%-10wt% of gas-fat coal and 12wt%-16wt% of fat coal; the iron ore powder and the mixed coal are mixed uniformly with water and tamped before entering the blast furnace, and are placed into the blast furnace when the temperature is 800 DEG C, the temperature is increased at the speed of 2 DEG C per minute to 3 DEG C per minute, the iron ore powder and the mixed coal are discharged from the blast furnace when the temperature is 950-1050 DEG C, and the iron coke is obtained by adopting a wet way of quenching the coke. According to the iron coke and the preparing method, the performance, the ratio, the particle size and the composition and the like of the iron ore powder and the mixed coal are optimized, and the strength and the reactivity of the iron coke can meet the requirement of the blast furnace process under the circumstance of not adding binding agents.

Owner:WUHAN UNIV OF SCI & TECH

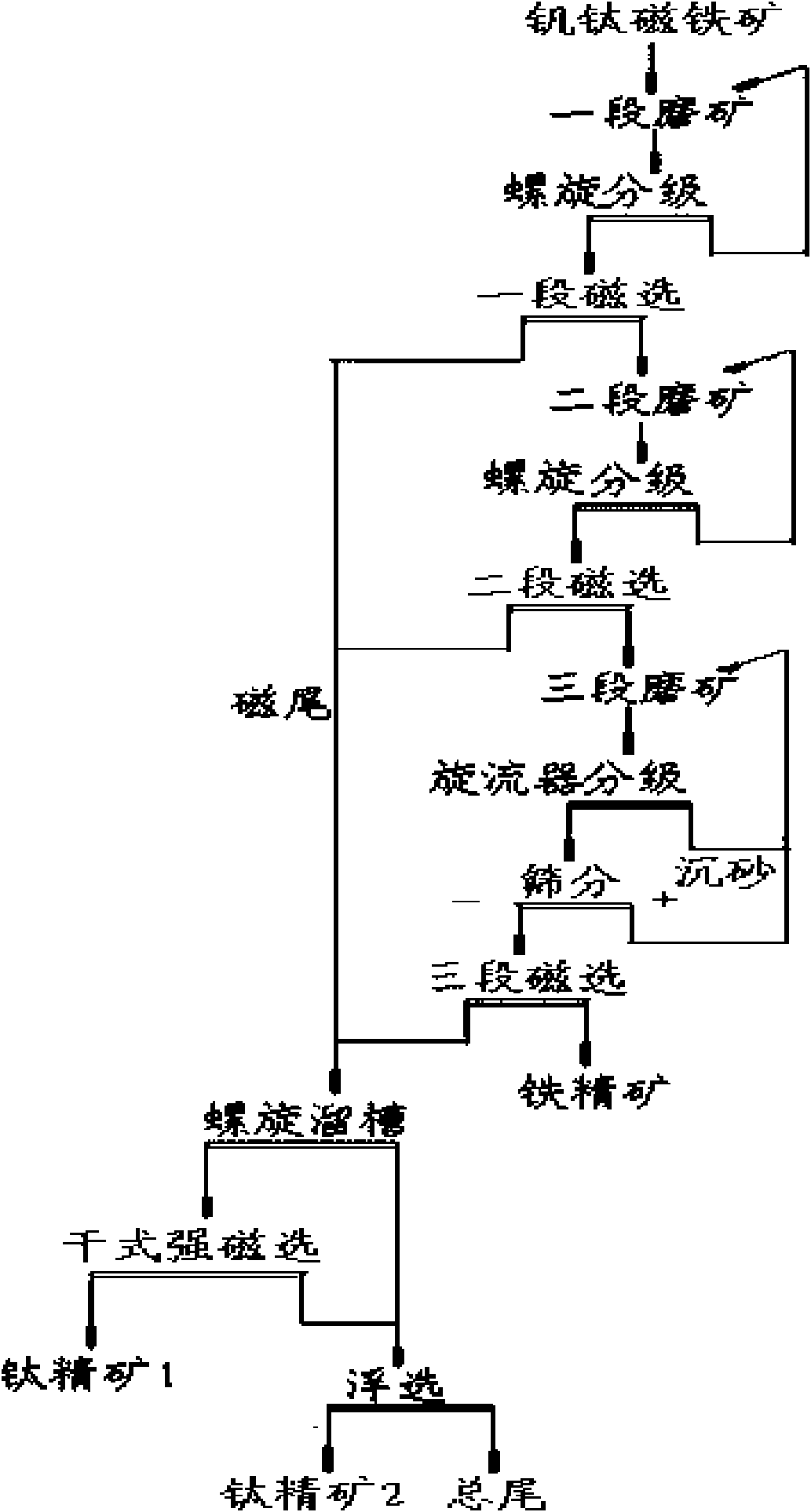

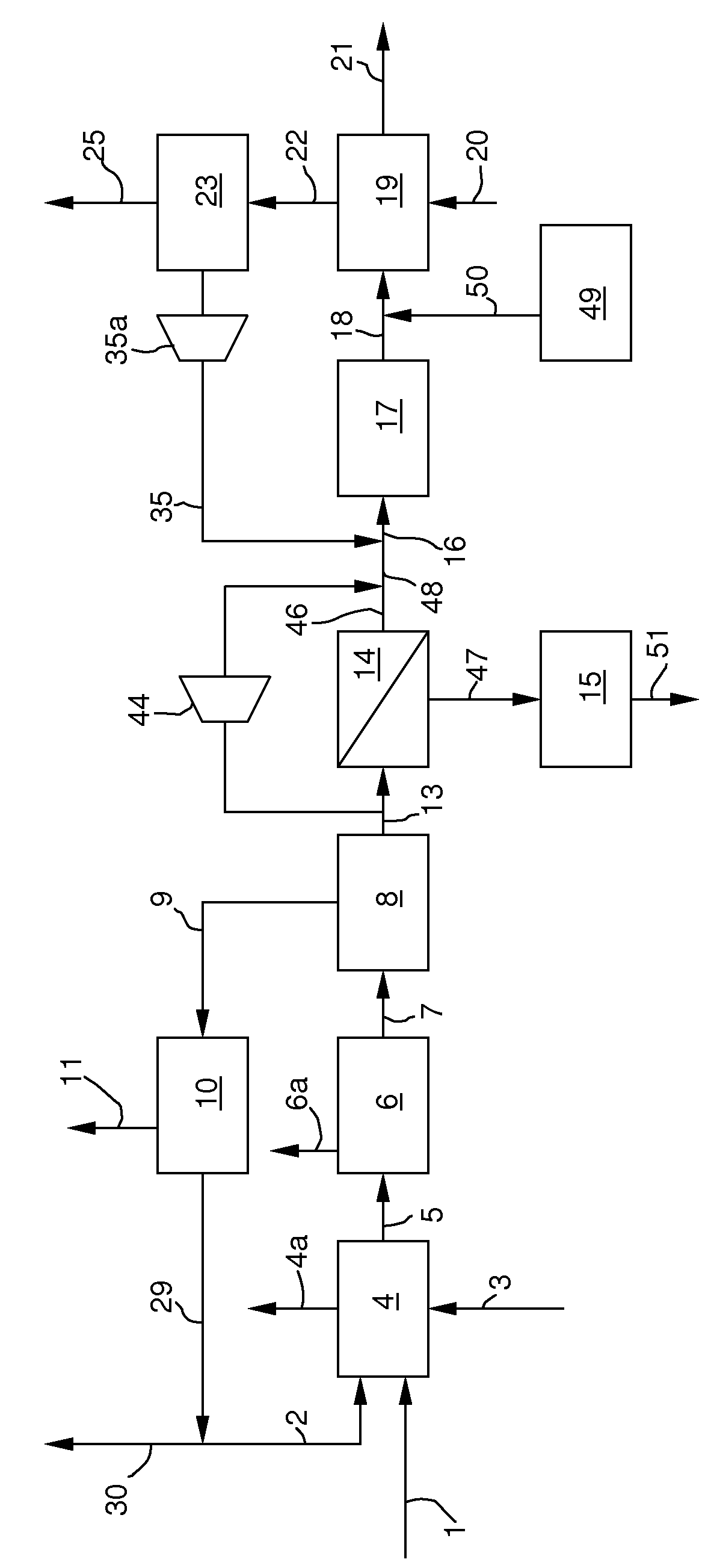

Pre-selection method of low-ore grade magnetic iron ore

InactiveCN101502819ASolve the costSolve the problem of large tailingsSievingScreeningSeparation technologyMagnetite

The invention discloses a preselecting method of low-grade magnetic iron ore, comprising the steps of crushing the raw ore of the magnetic iron ore by coarse crushing, intermediate crushing and fine crushing operations, conveying to subject to ultra-fine crushing operation, and then crushing by a high-pressure roller mill, scattering the crushed product by a wet cylindrical sieve, conveying the ore on the cylindrical sieve to the vibrating sieve by a belt to perform wet gradation, conveying the ore on the vibrating sieve to a dry magnetic separator by the belt to discard the waste, returning the ore concentrate of the dry magnetic separator to the high-pressure roller mill to crush the ore concentrate again, perform magnetic separation and discarding tailings of the ore concentrate below the vibrating sieve and the ore concentrate below the cylindrical sieve in a wet coarse grain intermediate-field intensity magnetic separator, and selecting the coarse ore concentrate of the intermediate-field intensity magnetic separator by a grinding separation technology. The invention has the advantages that the invention selects quantities of qualified mine tailings by wet magnetic separation before grinding ore, reduces ore grinding work, reduces ore grinding energy consumption and has high system processing capacity; the invention can be widely used in magnetic ore dressing plant, and in particular suitable for treatment of preselecting low-grade magnetic iron ore with the iron grade lower than or equal to 22%.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

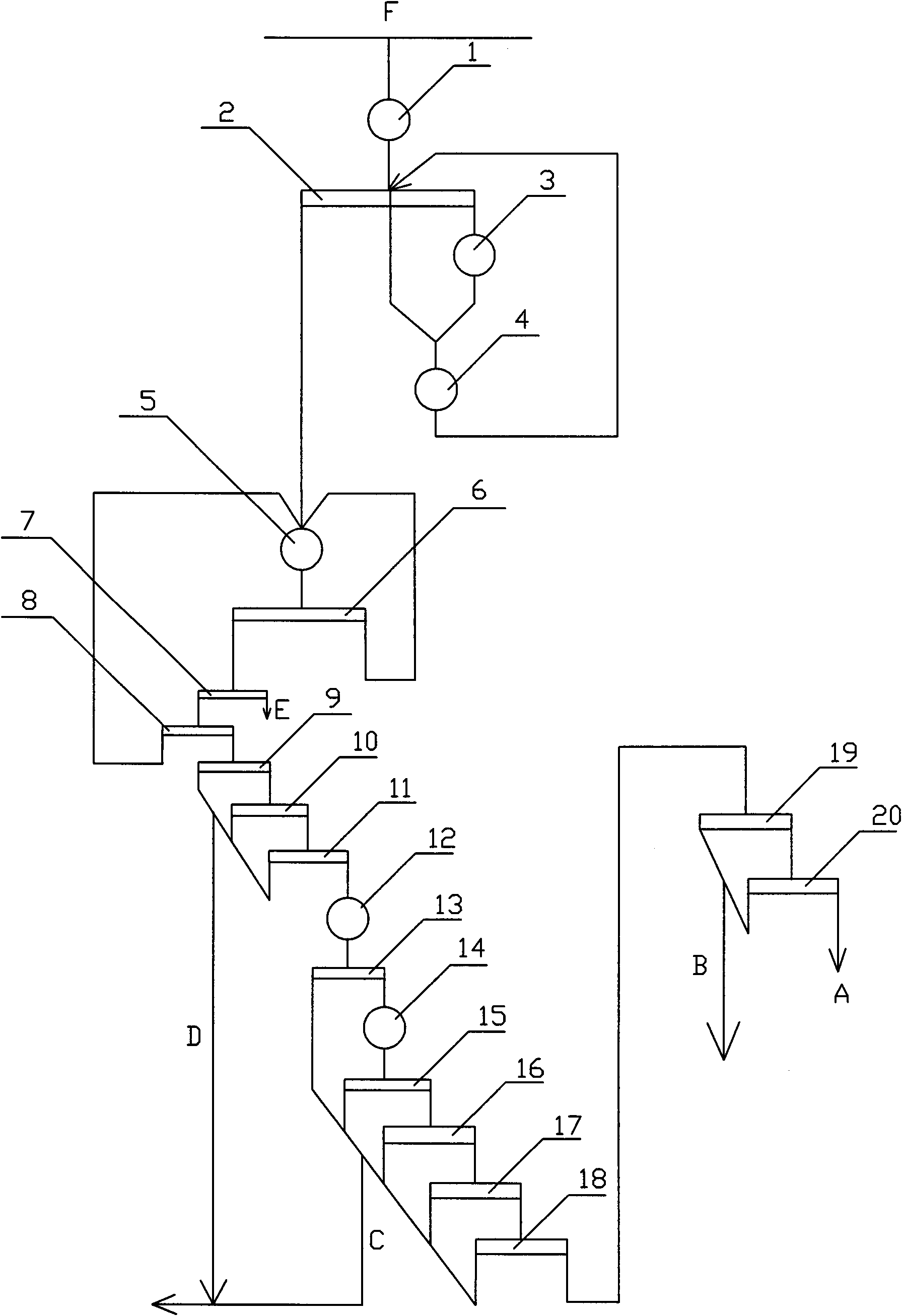

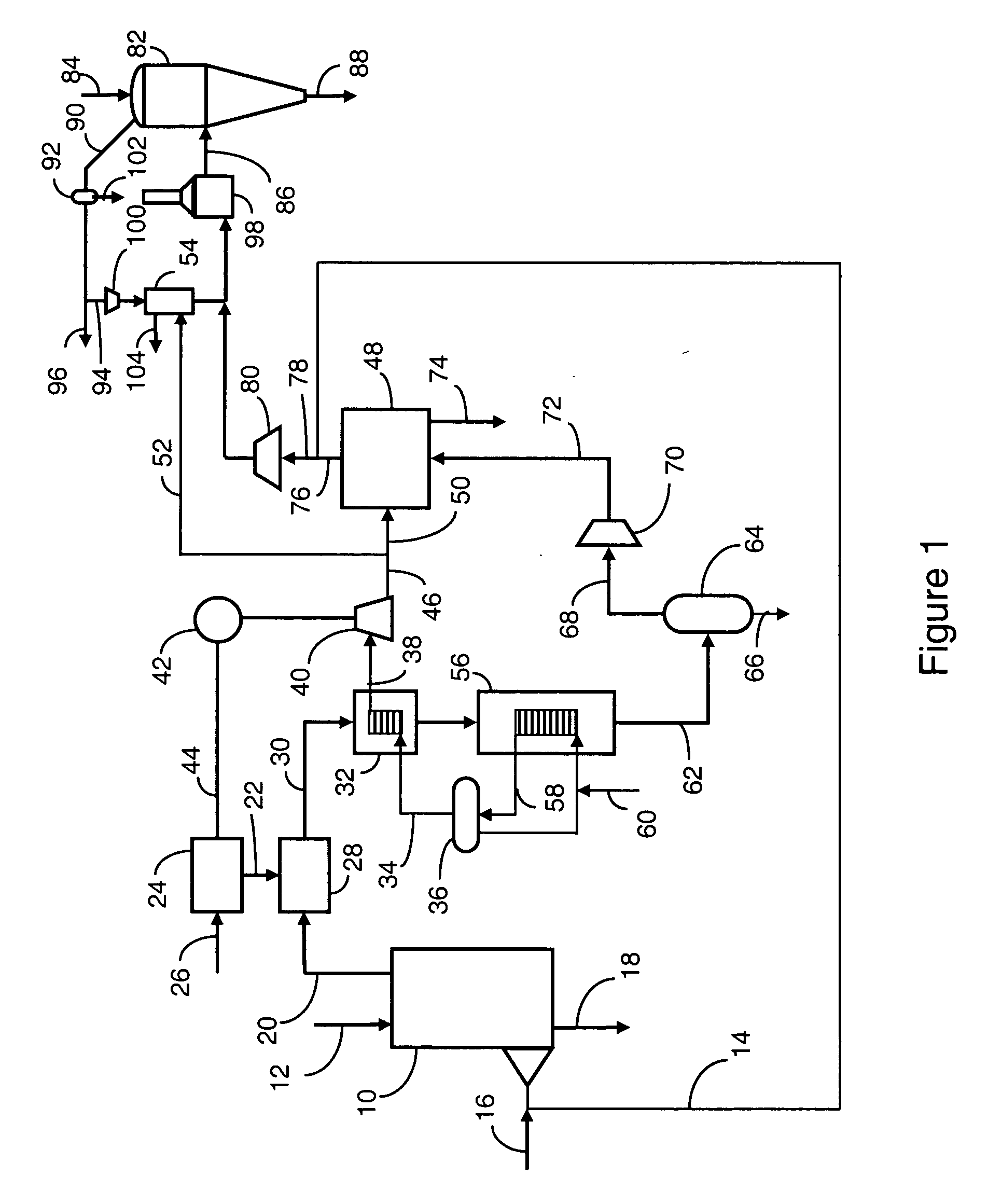

Process for production of elemental iron

InactiveUS7931731B2Easy to processIsotope separationHydrogen/synthetic gas productionPartial oxidationFerric

A process to prepare elemental iron by contacting an iron ore feed with a reducing gas at a pressure of between 1 and 10 bar to obtain iron and an off-gas includes preparing the reducing gas by performing the following steps: (a) partially oxidizing a mixture comprising a solid or liquid carbonaceous fuel and oxygen at a pressure of between 10 and 80 bar, thereby obtaining a gas comprising H2 and CO; (b) removing CO2 and H2S from the gas obtained in step (a) to obtain an intermediate gas comprising H2 and CO; (c) supplying the intermediate gas obtained in step (b) to a H2-selective membrane to obtain a H2-rich permeate gas and a CO-rich retentate; and (d) heating H2-rich permeate to obtain a heated H2-rich permeate as the reducing gas.

Owner:SHELL OIL CO

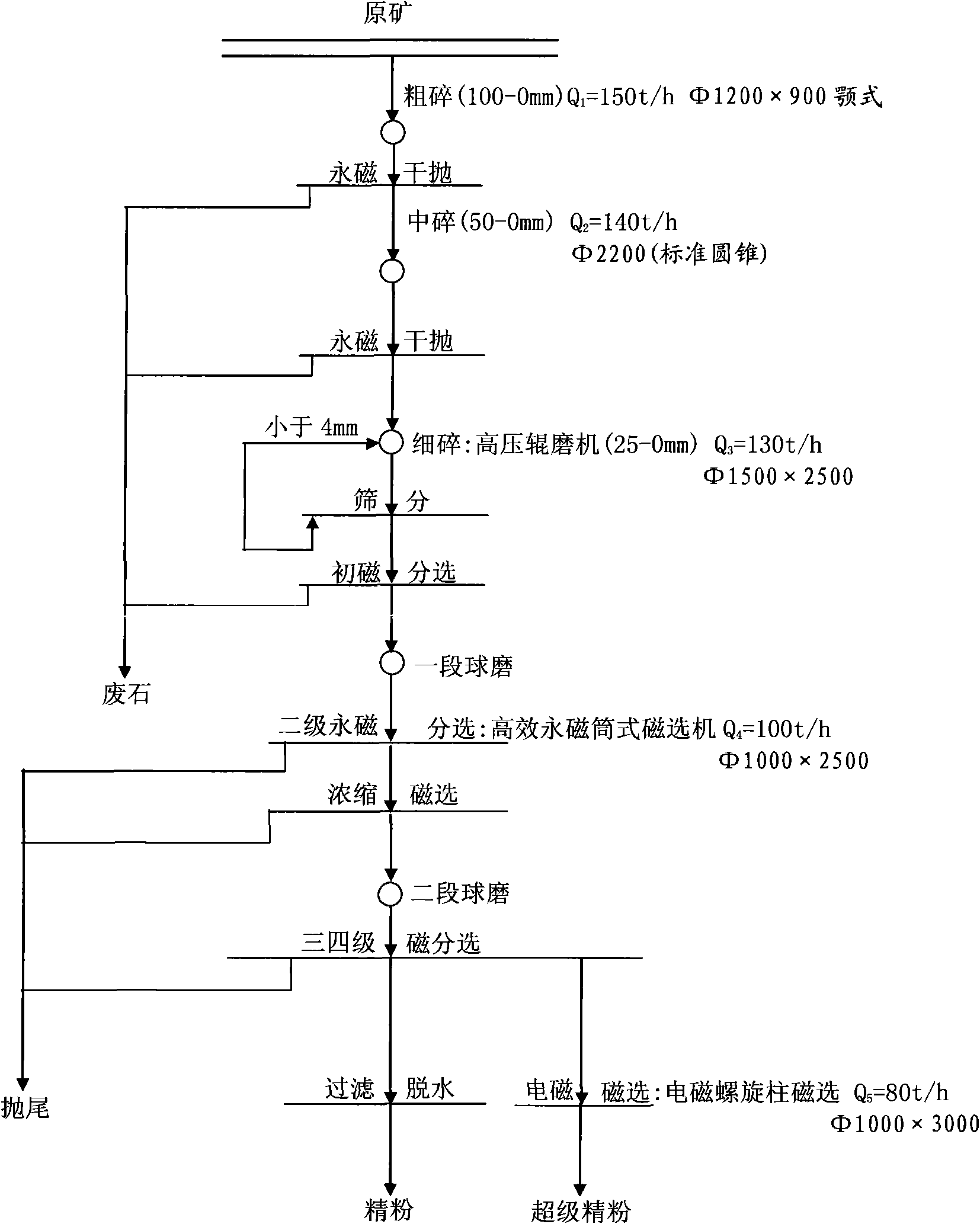

Method for concentrating extremely low-grade refractory magnetite

ActiveCN101559403AIncrease productionImprove product indicatorsMagnetic separationGrain treatmentsLower gradeRefractory

The invention discloses a method for concentrating extremely low-grade refractory magnetite to achieve higher-grade iron ore concentrate. The process proposal comprises the following steps of: dry type magnetic separation and tailing rejecting, stage grinding, wet type magnetic separation, magnetic concentrate fine screening classification, minus sieve magnetic separation, plus sieve regrinding and recleaning and concentrate extraction directly through magnetic separation of an electromagnetic wreathed column. Namely, on the basis of conducting stage grinding separation on crude ore, electromagnetic concentration, fine screening and plus sieve regrinding and recleaning are implemented to improve the final iron ore concentrate grade. With the method adopted, the production cost is reduced,the concentrate grade is raised up to 71.96 percent, the tailings grade is decreased to 4.50 percent and the secondary pollution to the environment is also avoided.

Owner:安徽大昌矿业集团有限公司

Beneficiation method for removing long quarry impurities by adopting strong magnetic flotation

InactiveCN101898168AIncrease production capacityImprove grinding efficiencyFlotationMagnetic separationEngineeringBall mill

The invention relates to a beneficiation method for removing long quarry impurities by adopting strong magnetic flotation, comprising the steps of crushing, grinding, sieving, desliming, strong magnetically floating, floating, concentrating and dewatering. The concrete beneficiation method comprises the following steps of: breaking and grinding ore in a ball mill; grading ground minerals by a spiral grader and a hydraulic hydrocyclone twice; combining with the ball mill into a closed cycle; respectively mounting high-frequency linear vibration sieves in overflows graded twice; respectively removing impurities over 3 mm and 1 mm, such as mica, grass-roots bark, and the like; removing most of muddy substances from minerals through desliming equipment after the impurities are removed; removing mechanical iron, weakly magnetic iron ore, tourmaline and partial mica in a strong magnetic flotation machine; floating the minerals passing through the strong magnetic flotation machine again to remove residual iron minerals, mica and black minerals; and finally, concentrating and dewatering the minerals to form a product.

Owner:衡阳县湘雁矿业有限公司

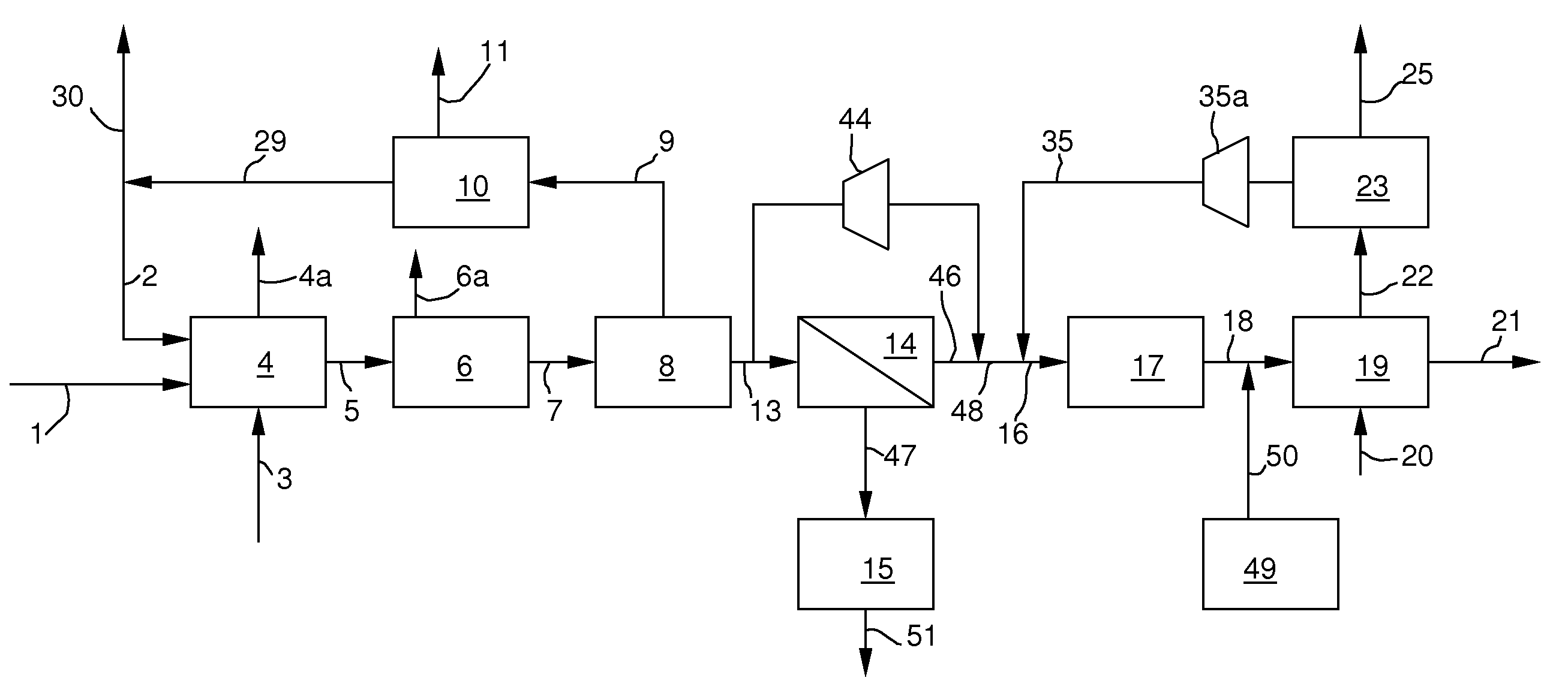

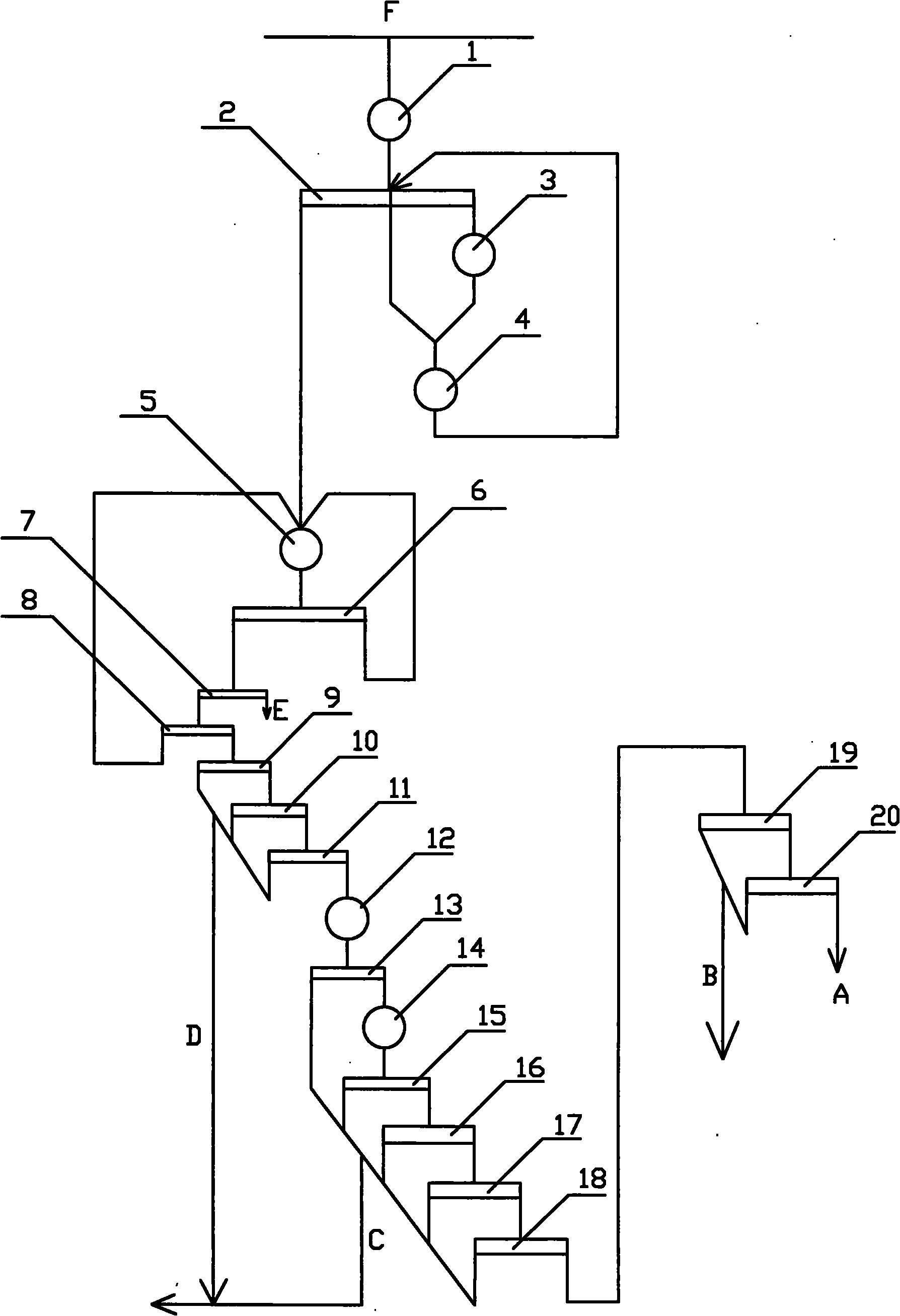

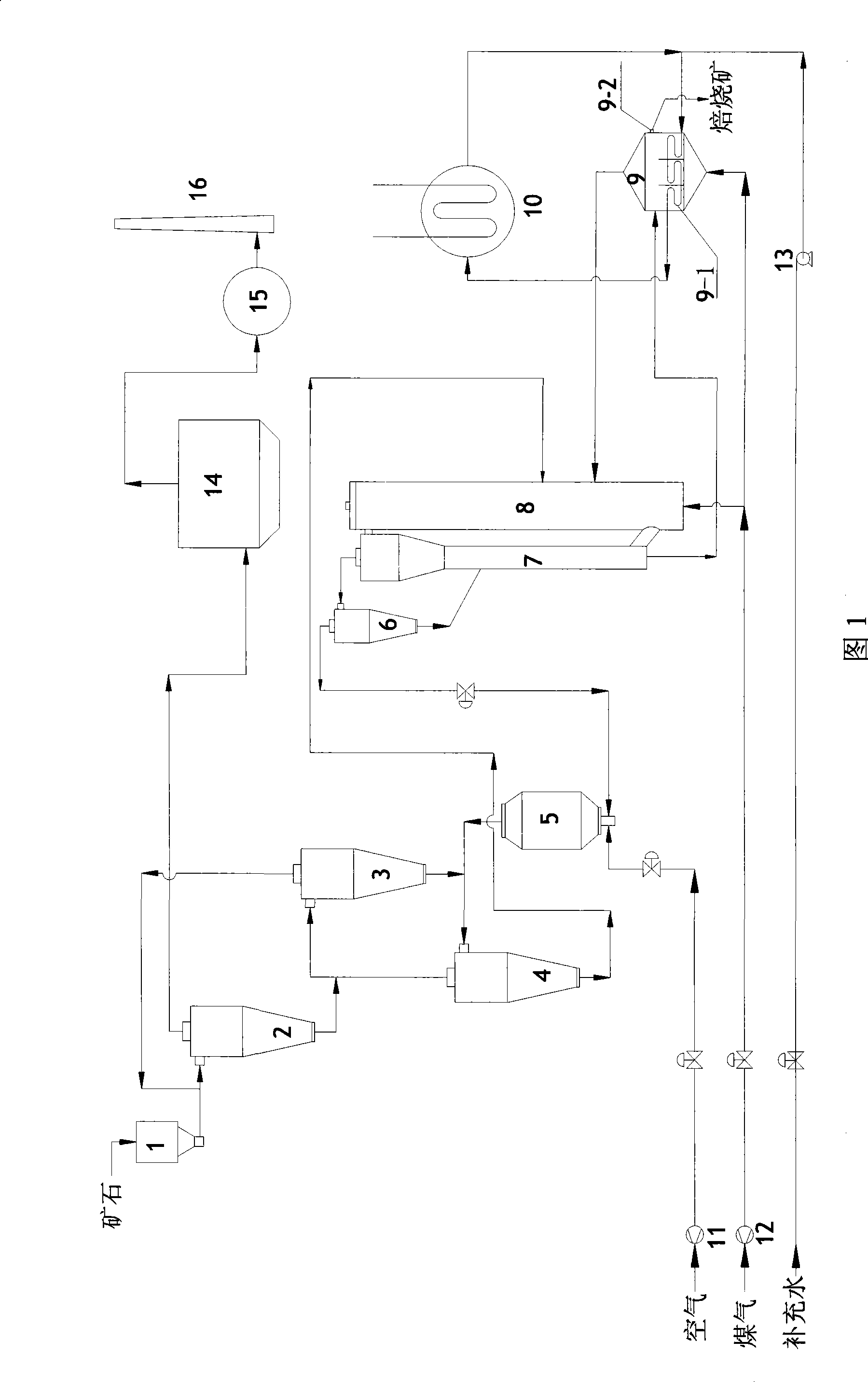

Magnetization roasting technique system for refractory iron ore powder and roasting technology

The invention belongs to the fields of chemical engineering and metallurgy and in particular relates to a process system which adopts a circulating fluid bed to carry out magnetization roasting on limonite, siderite, sedimentary hematite and other refractory iron ore powder bodies. The process system adopts a high-efficiency low-resistance reactor of the circulating fluid bed to carry out the magnetizing roasting to the iron ore powder body; firstly, roasted tail gas in a combustion chamber releases latent heat of unreacted reducing gas through combustion; secondly, the roasted tail gas exchanges heat with the cold iron ore powder body through a multilevel cyclone preheater to reclaim heat; and finally a fluidizing cooler is adopted to reclaim sensible heat of high-temperature roasting ore. The process system has the advantages of high magnetizing roasting efficiency and full heat reclaiming and utilization in the roasting process and the like, can reduce energy consumption of the refractory iron ore powder body in the process of magnetizing roasting and improve the economical efficiency of the refractory iron ore in the process of magnetizing roasting.

Owner:深圳市中科九台资源利用科技产业股份有限公司

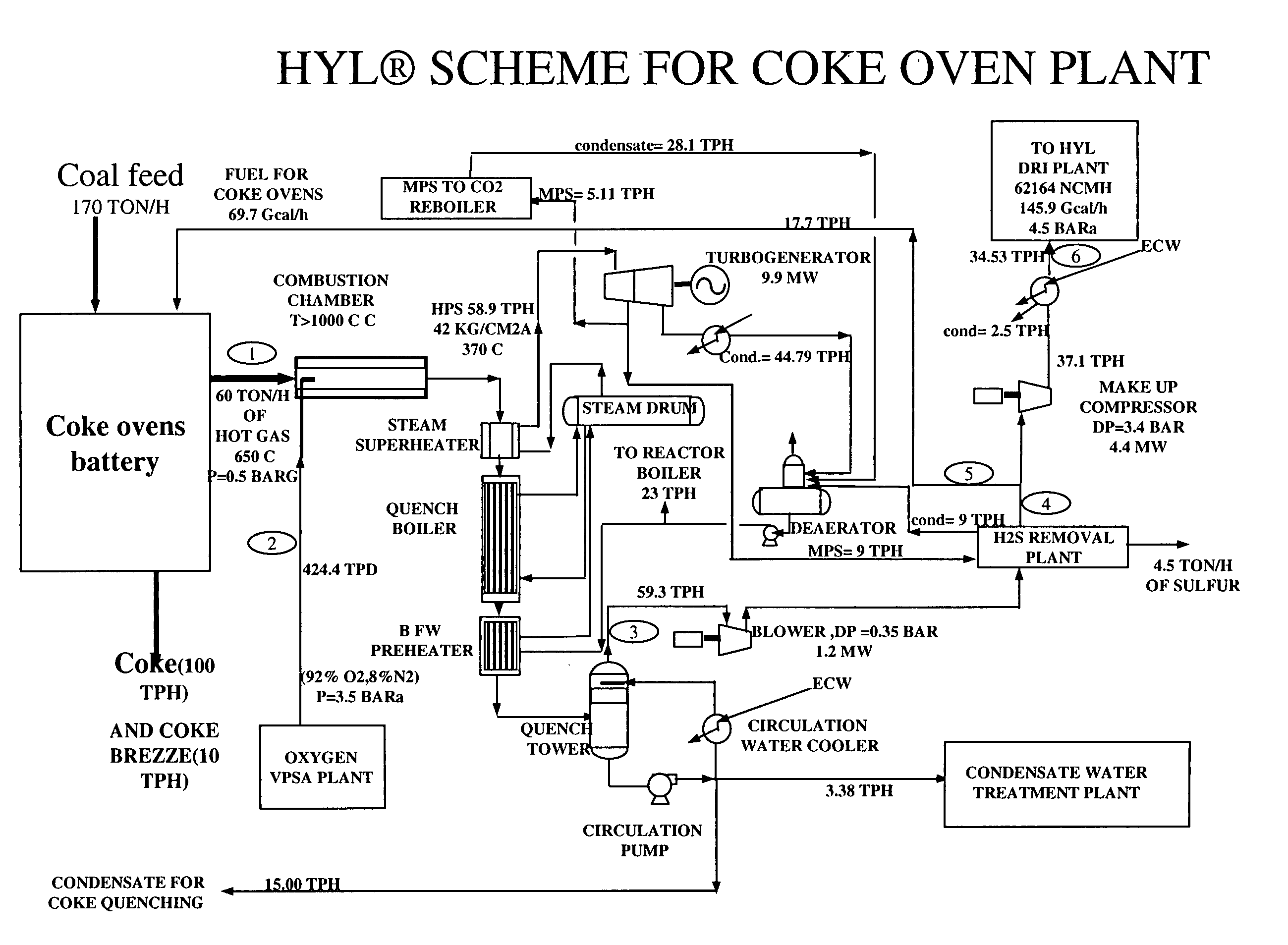

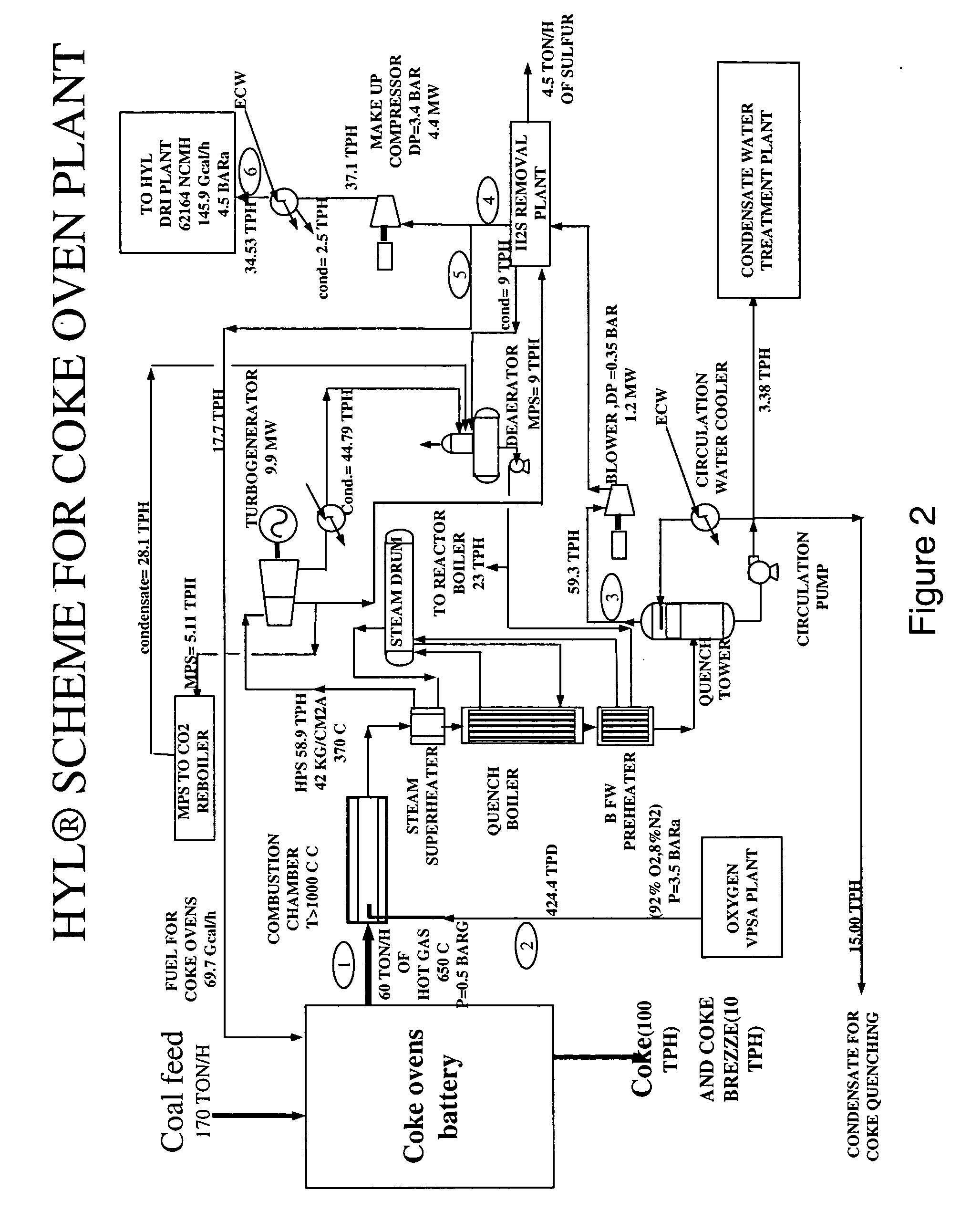

Method and apparatus for producing clean reducing gases from coke oven gas

InactiveUS20060027043A1Avoiding complex and expensiveOxygen/ozone/oxide/hydroxideHydrogen separationProcess engineeringCoke oven

A process and system for producing reducing gases are disclosed, wherein volatile components derived from coal are transformed into reducing gases suitable for utilization as synthesis gas, as a reducing agent for the direct reduction of iron ores and / or as a clean fuel.

Owner:HYLSA SA DE CV

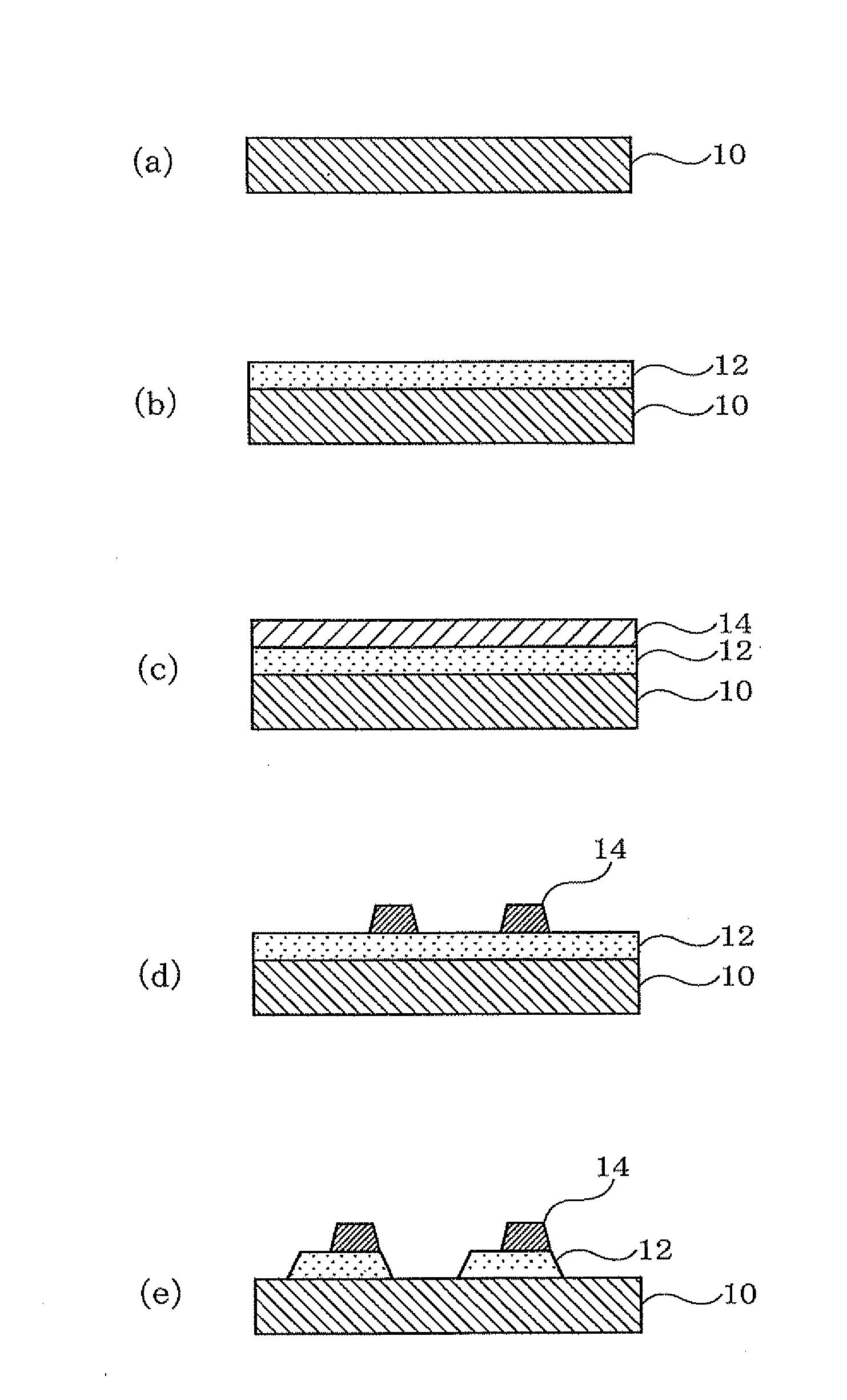

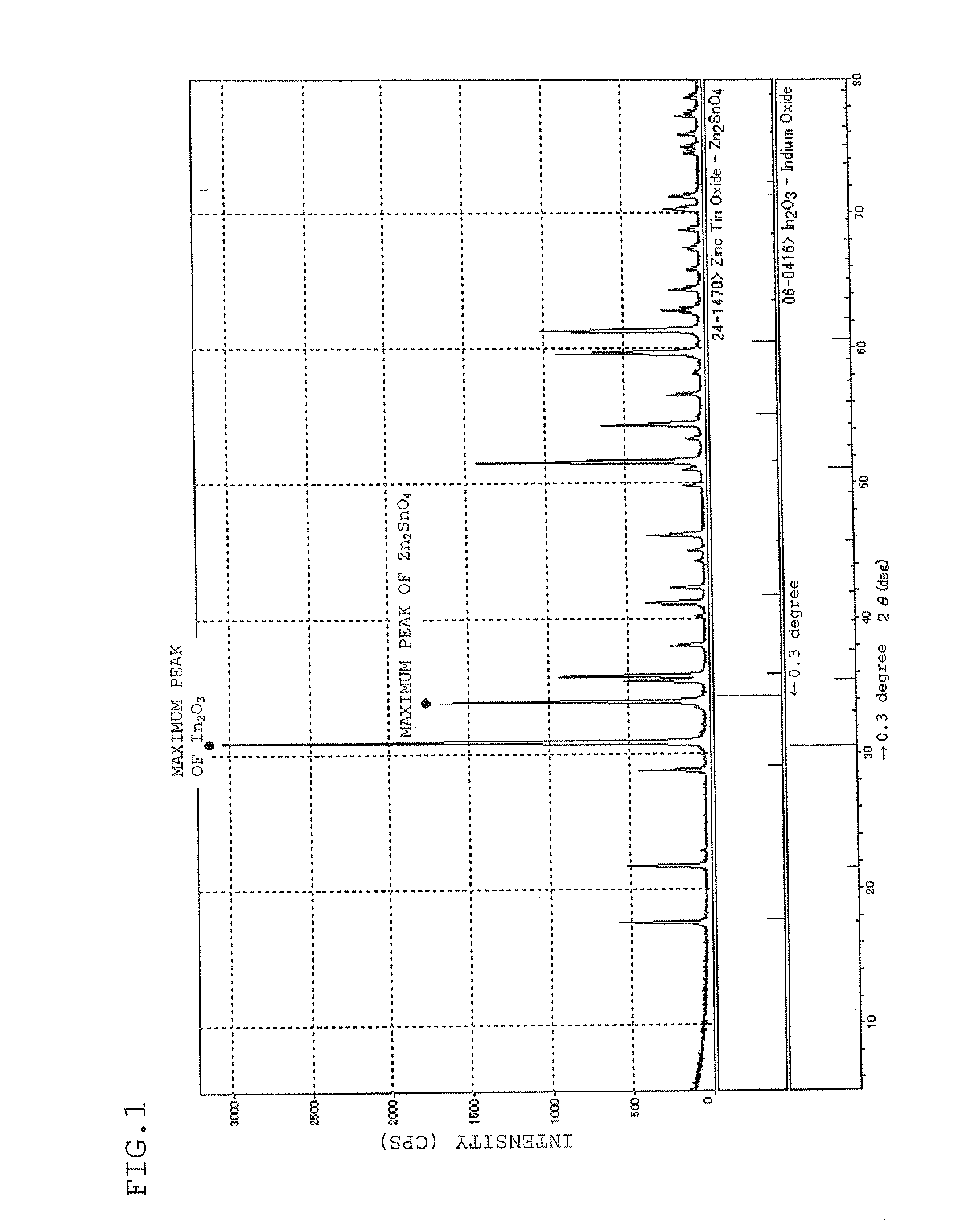

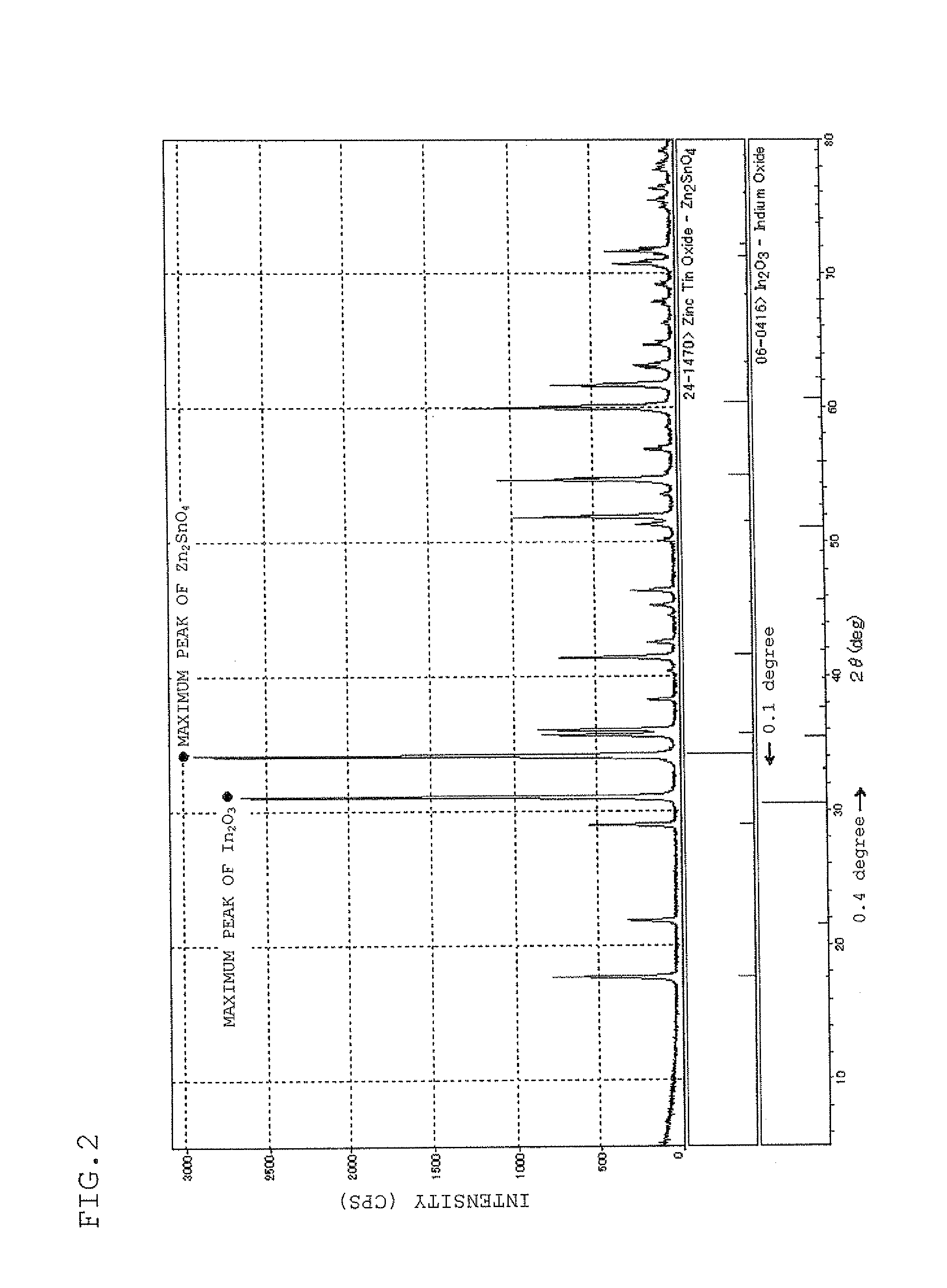

Sputtering target, transparent conductive film and transparent electrode

ActiveUS20100170696A1Lower resistanceHigh densityNon-insulated conductorsConductive materialIndiumX-ray

A sputtering target which is composed of a sintered body of an oxide which contains at least indium, tin, and zinc and includes a spinel structure compound of Zn2SnO4 and a bixbyite structure compound of In2O3. A sputtering target includes indium, tin, zinc, and oxygen with only a peak ascribed to a bixbyite structure compound being substantially observed by X-ray diffraction (XRD).

Owner:IDEMITSU KOSAN CO LTD

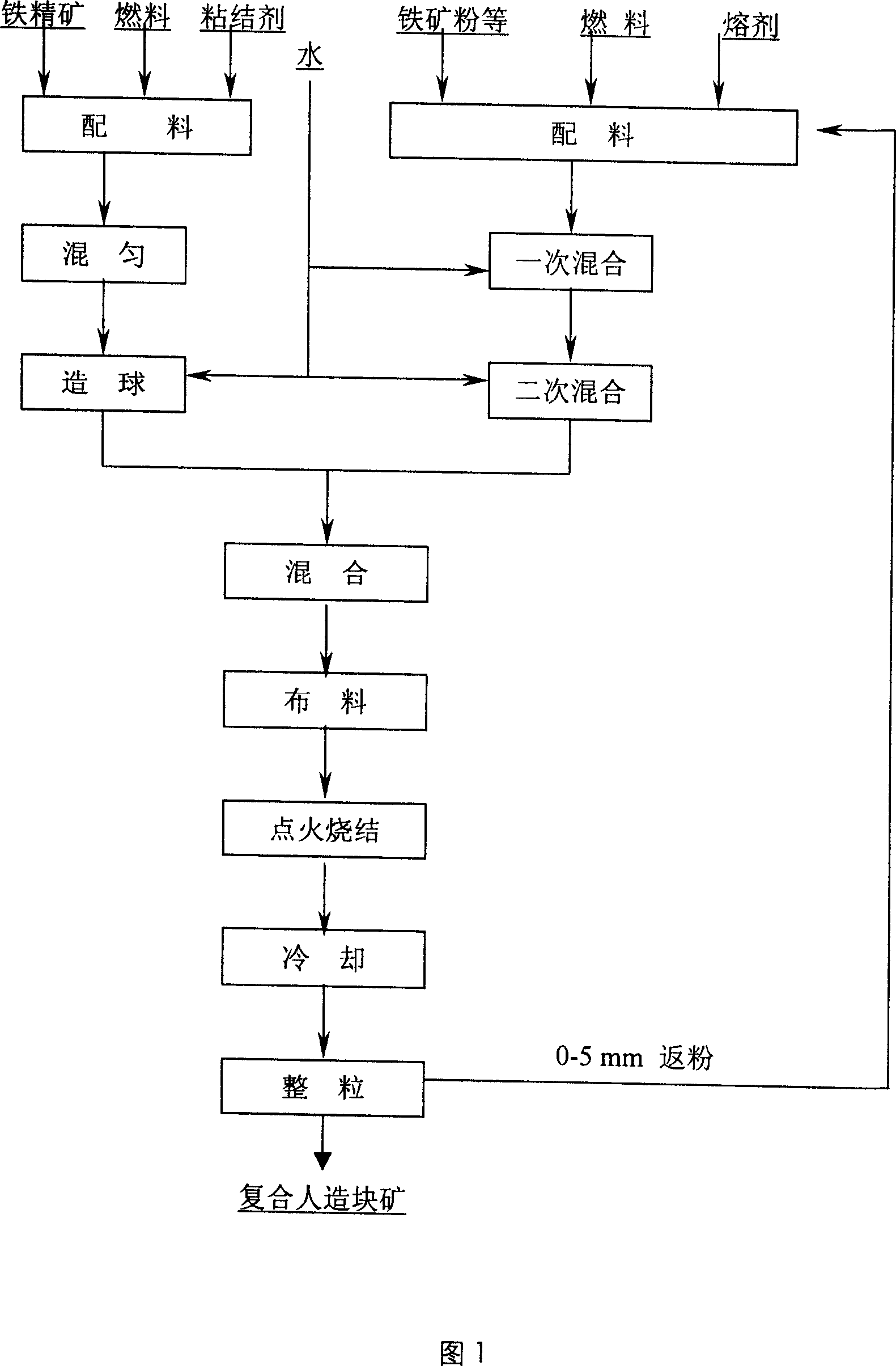

Composite agglomeration technology of iron powdered ore

The invention discloses a ferric powder composite block preparing technology, which is characterized by the following: separating fine ferric ore individually; preparing ball; blending rough particle with ferric powder and other raw materials; paving on the traditional sintering machine; inserting high-alkaline sintering ore of acid ball ore.

Owner:CENT SOUTH UNIV

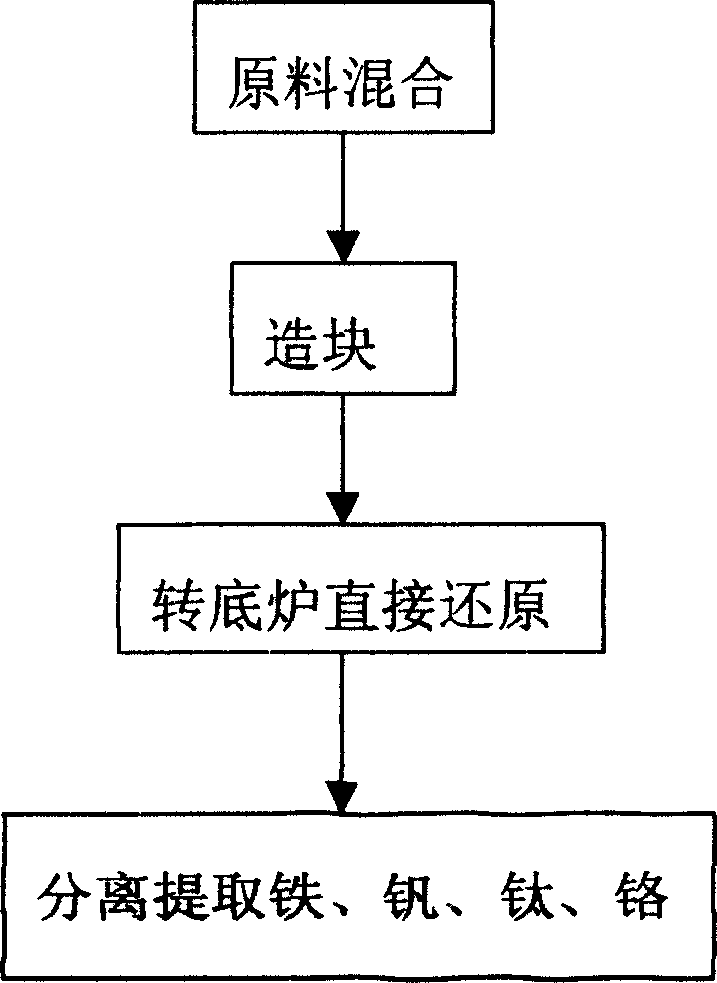

Method for separating and extracting metal element from varadium-titanium magnetite

InactiveCN1641045AFast reduction reactionShort recovery timeRecycling and recovery technologiesProcess efficiency improvementSlagAdhesive

The technological process of separating and extracting metal elements from V-Ti iron ore includes the steps of: agglomerating ore powder of mixing V-Ti iron ore powder, reductant, additives and adhesive, pressing the mixture into 10-25 mm diameter agglomerates and drying at 80-90 deg.c; reducing inside one bottom rotating furnace to obtain metal products; smelting the metal products in an electric furnace to obtain molten iron and V-Ti slag component, and smelting the V-Ti slag component to obtain V-Cr oxide and Ti slag as the material for producing titanium while. The present invention has high reduction temperature, fast reduction speed, short reduction time, high production efficiency, high metal and V-Ti recovering rate and less environmental pollution.

Owner:SICHUAN LOMON MINING & METALLURGY

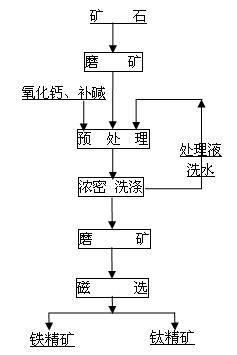

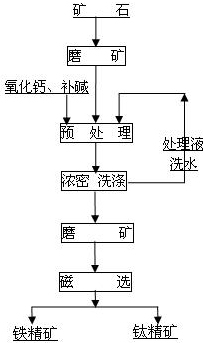

Beneficiating method for ilmenite

ActiveCN102181626AIncrease alkali concentrationHigh in ironBlast furnace detailsProcess efficiency improvementMagnetiteIlmenite

The invention discloses a beneficiating method for ilmenite, relating to a method for preparing titanium concentrate and iron concentrate by beneficiating crude ilmenite. The method is characterized in that: a beneficiating process of the method orderly comprises the following steps of: (1) grinding the crude ilmenite; (2) performing alkaline leaching pretreatment under the conditions of heating, oxygenating and pressurizing; (3) filtering pulp which is subjected to the alkaline leaching pretreatment; (4) washing filter residue and grinding; and (5) performing magnetic separation to obtain the titanium concentrate and the iron concentrate. In the method provided by the invention, the characteristic of iron and titanium compact symbiosis and the isomorphism occurrence characteristic of vanadium are damaged from the source of vanadium titano-magnetite by adopting the pretreatment process, so that mineral transformation of the vanadium titano-magnetite is realized, dissociation on lattice layers of titanium and iron is realized, high-quality iron concentrate and titanium concentrate with lower iron content are obtained through grinding and the magnetic separation process, an alkaline medium used in the pretreatment can be recycled, and the process has a small influence on environment and a bright application prospect.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

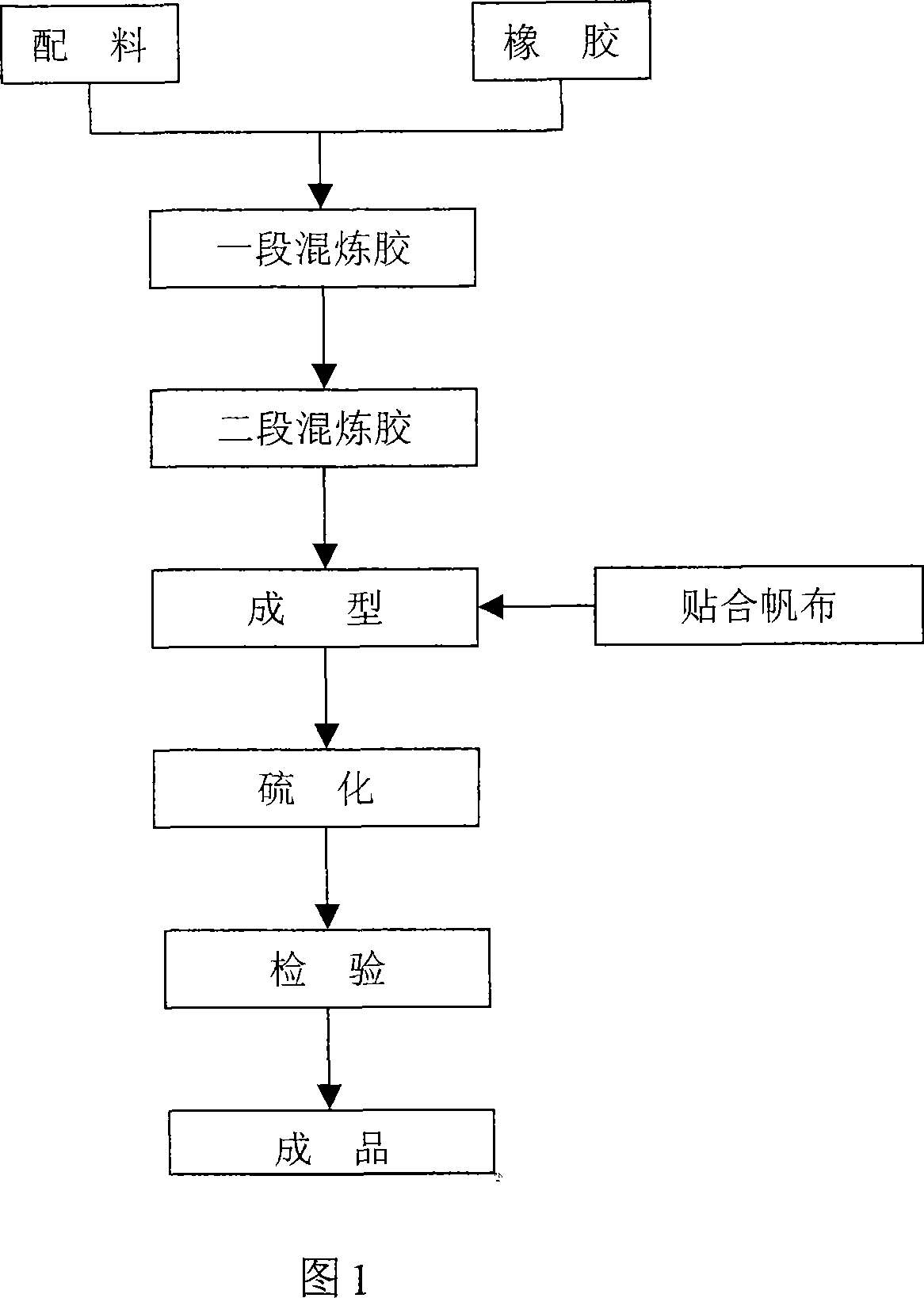

Tearproof antiwear conveying belt

The present invention relates to one kind of tearproof antiwear conveying belt, and belongs to the field of rubber product technology. The tearproof antiwear conveying belt is produced through pre-pressing and mixing natural rubber, styrene butadiene rubber and cis-butadiene rubber inside a Banbury mixer; adding promoter, activator, leveler and antiaging agent before further mixing; adding reinforcing agent, softening agent and aramid fiber before further mixing to obtain mixed rubber; mixing for the second time and adding cross-linking agent inside a Banbury mixer after being set for some time; discharging batch to obtain mixed rubber; rolling to form rubber sheet; combining rubber sheet with tension element belt blank, rolling up and sulfurizing; and trimming to obtain the product. The tearproof antiwear conveying belt has excellent tearproof performance, excellent antiwear performance and long service life, and is suitable for use in mines.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

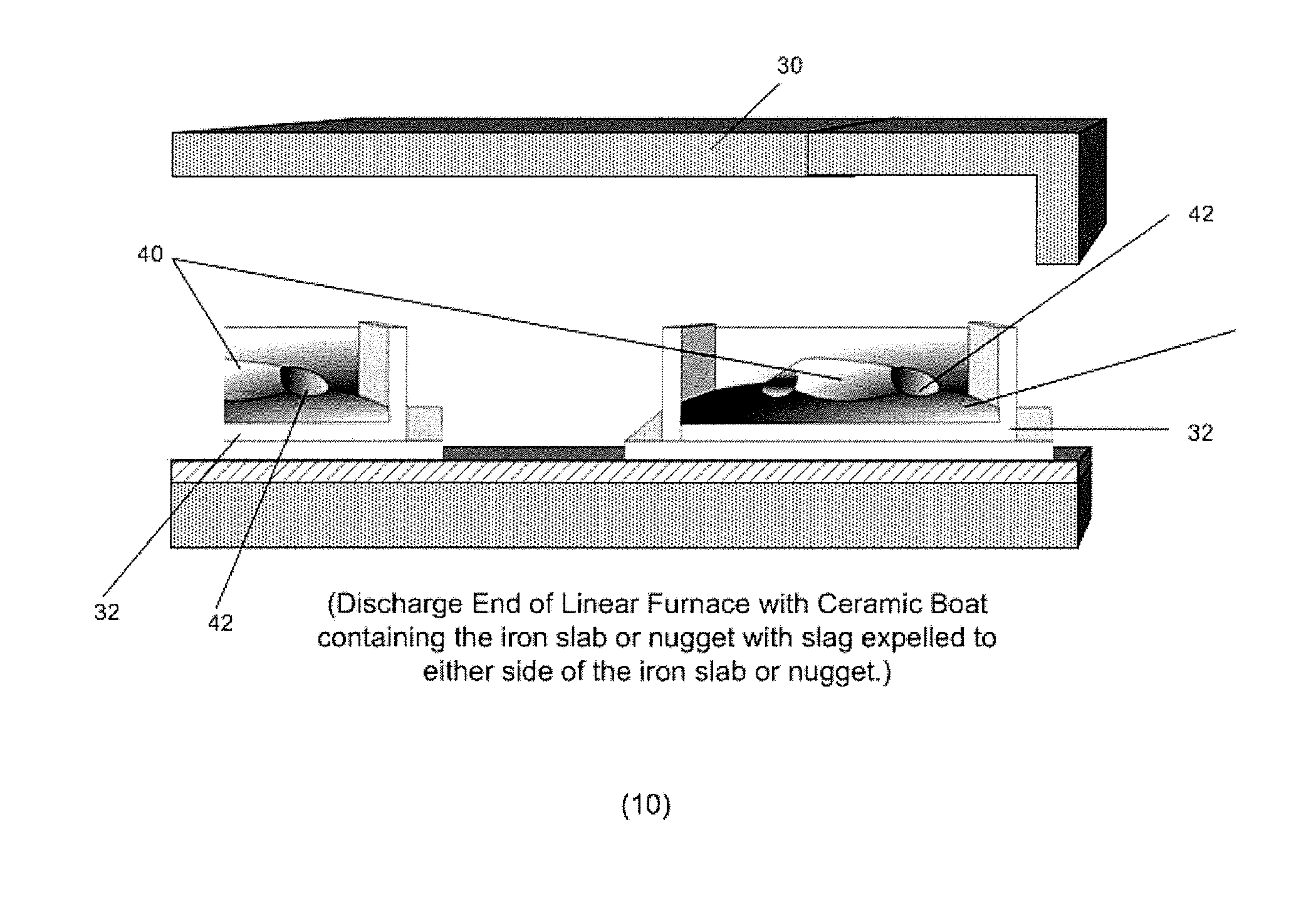

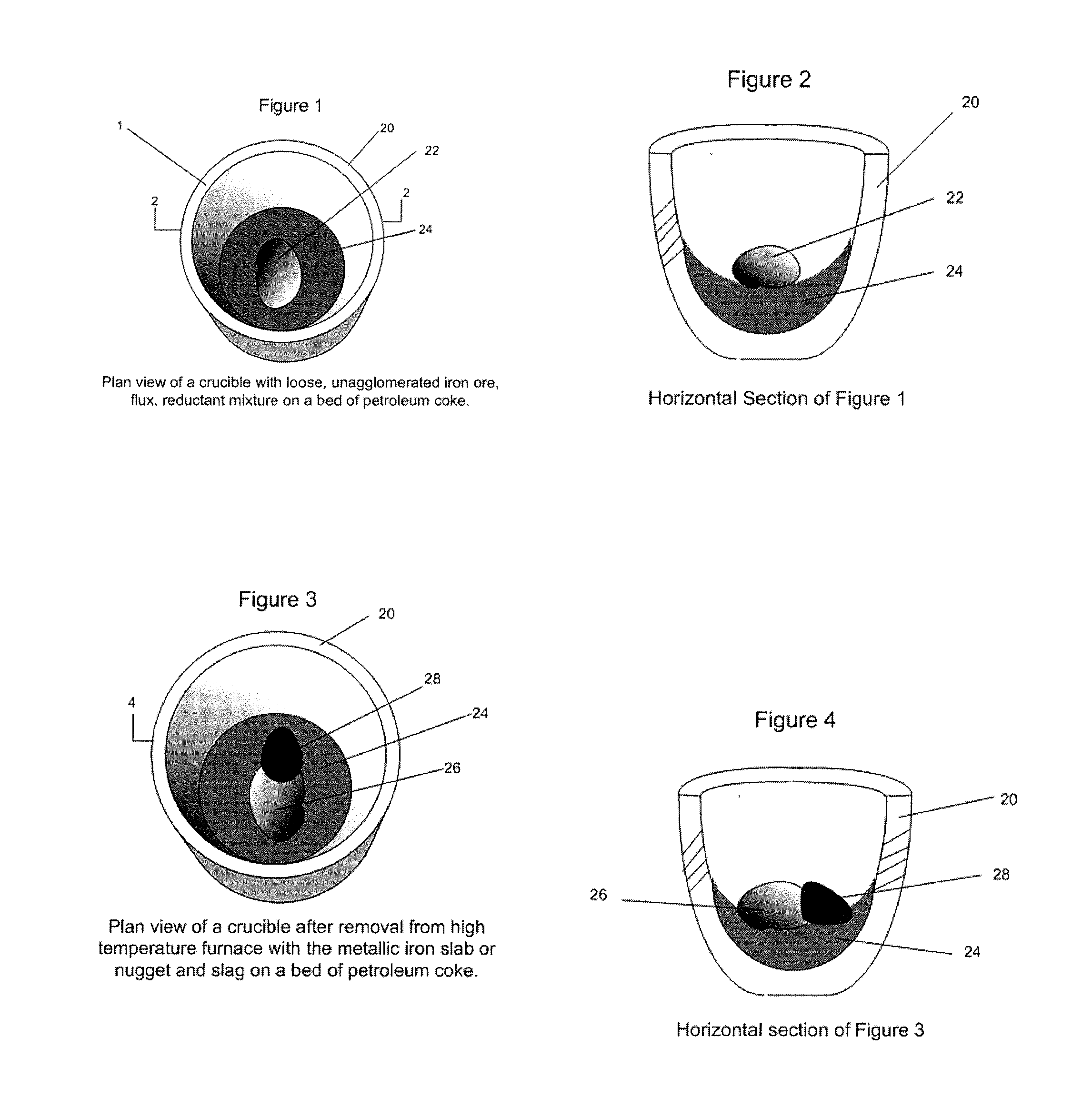

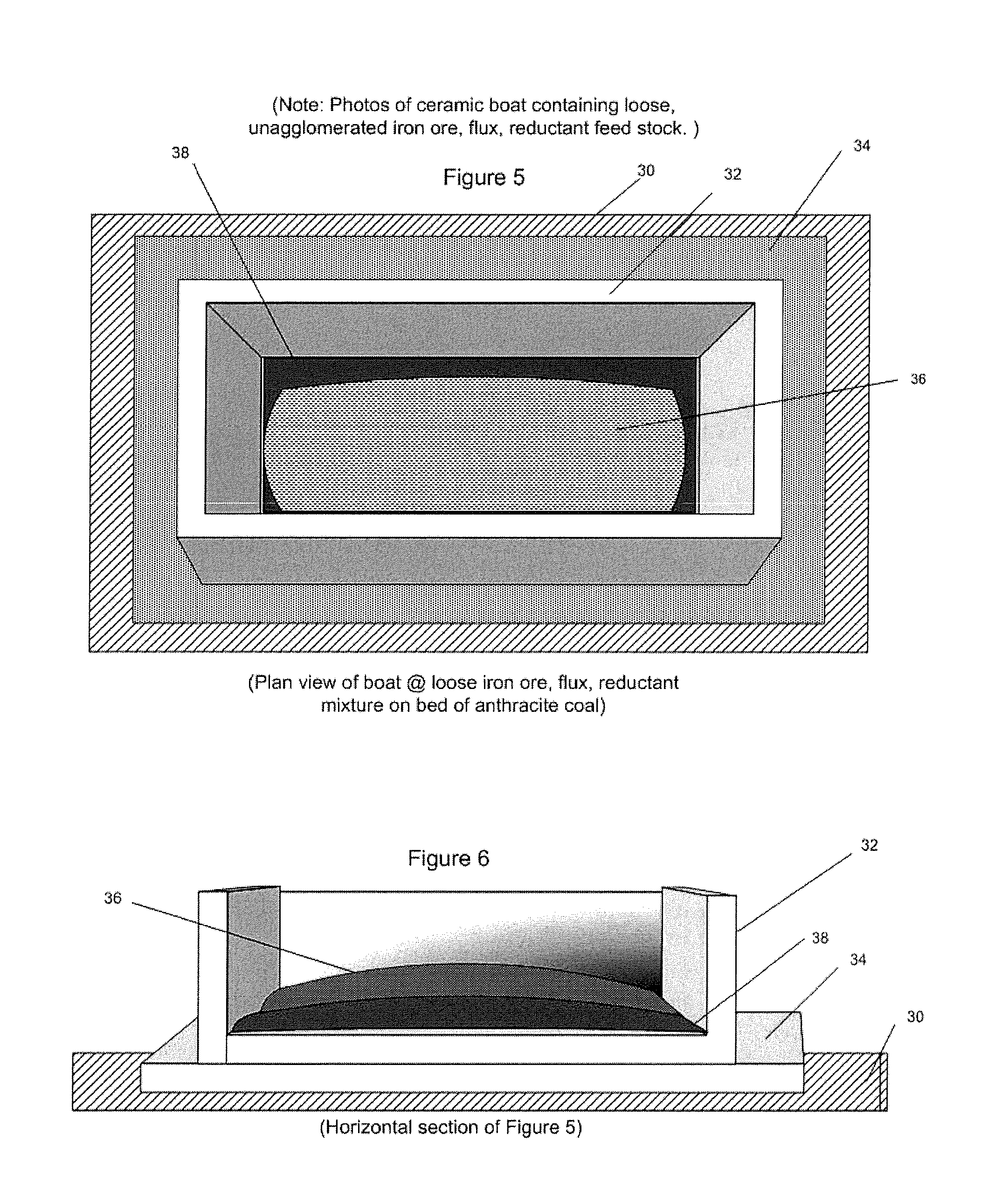

Direct Production of Iron Slabs and Nuggets From Ore Without Pelletizing or Briquetting

ActiveUS20130081516A1Lower cost of capitalReduce operating costsExhaust gas handlingGas emission reductionParticulatesIronstone

Metallic iron is produced from a composition formed from a mixture of iron ore particles and particles of a reductant made of a biomass material, a coal or coke in a particulate form together with a flux and is processed in a loose, un-agglomerated non-pelletized, non-briquetted form in a reducing furnace to produce metallic iron directly from the ore. An excess of biomass or coal or coke reductant can be used to provide CO and H that can be recovered as a synthetic gas and converted to electrical or other energy. Metallic iron nuggets or slabs can be produced from manganiferous ores or concentrates. Manganese can be caused to enter the nugget or slab or the slag by adjusting the furnace temperature. Titaniferous ores or concentrates can be used to produce metallic iron slabs or nuggets and a titanium-rich slag.

Owner:SIMMONS JOHN J

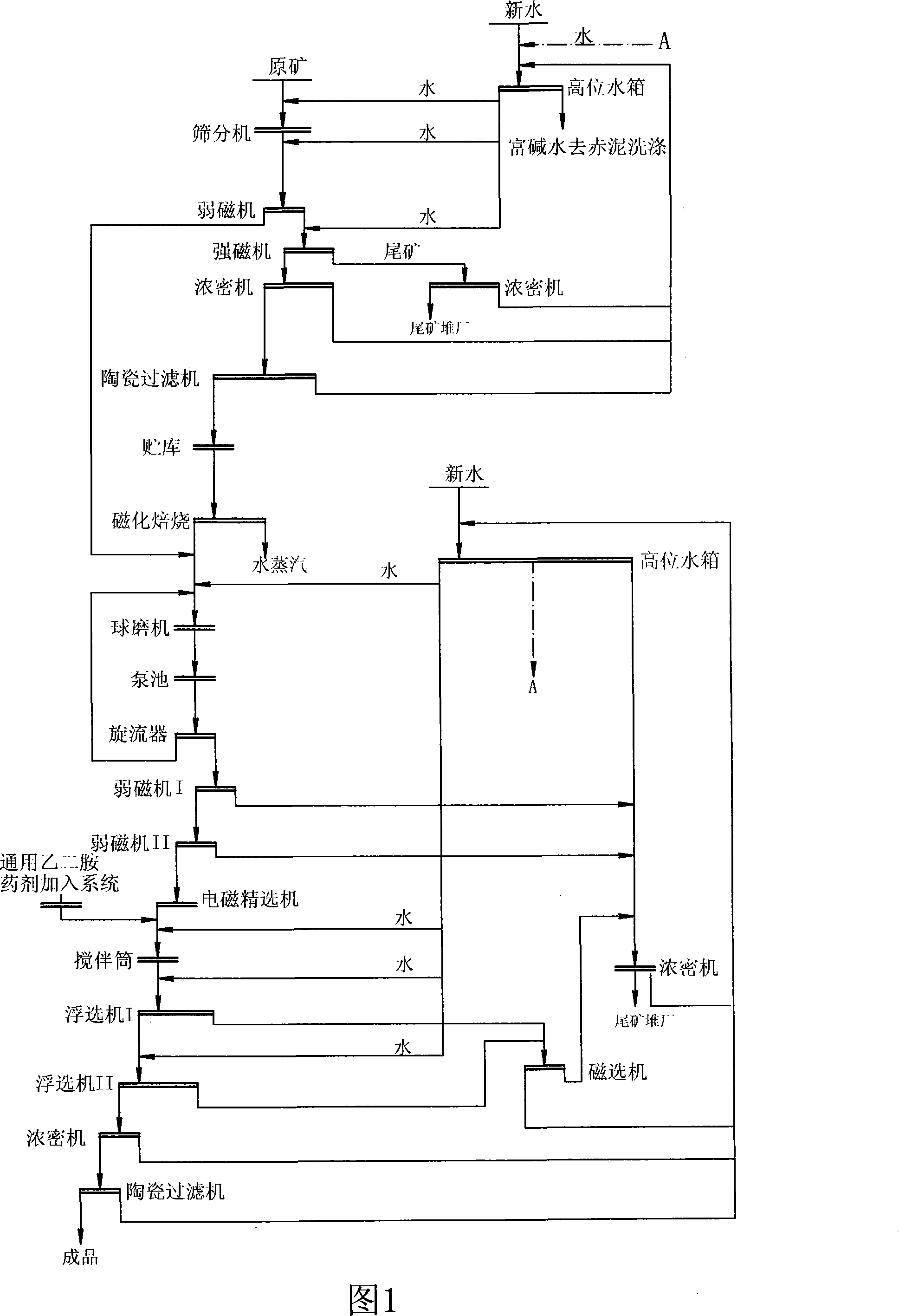

Method of refining iron ore from alkaline red mud and making gangue neutral

The invention relates to a method to select refined iron ore from alkaline red mud and neutralize mine tailings. The method consists of red mud pretreatment and technological process of preparing refined iron ore. The red mud pretreatment is that water is added into the red mud slurry discharged from aluminum factory; the red mud slurry is diluted to the solid concentration of 30 to 40 percent and then is screened and put into a low intensity magnetic separator for selecting ferromagnetic substance. The ferromagnetic substance is dehydrated and directly selected as the product. The remaining red mud is watered down to 30 percent solid concentration and put into a high intensity magnetic separator for magnetic separation and desliming. The obtained coarse ore is washed to a coarse ore settling tank or a thickener to be concentrated while the undercurrent is sent into a vacuum ceramic filter and a filter cake is roasted in a suspended magnetic roasting furnace. The roasted materials are crushed into a ball mill and then are milled. The water is overflown until 95 percent of the solid material granularities are less than 75m and then is treated by the third stage magnetic separation and the second flotation. The undercurrent is filtered by the ceramic filter, and then the refined iron ore with a purity of 58 to 65 percent is obtained. The refined iron ore is recycled from the red mud by the invention so as to fully employ aluminum ore, save resources and energy consumption and neutralize the whole red mud. The invention reduces environmental pollution and has good economic and social benefits.

Owner:SHENYANG XINBO IND TECH

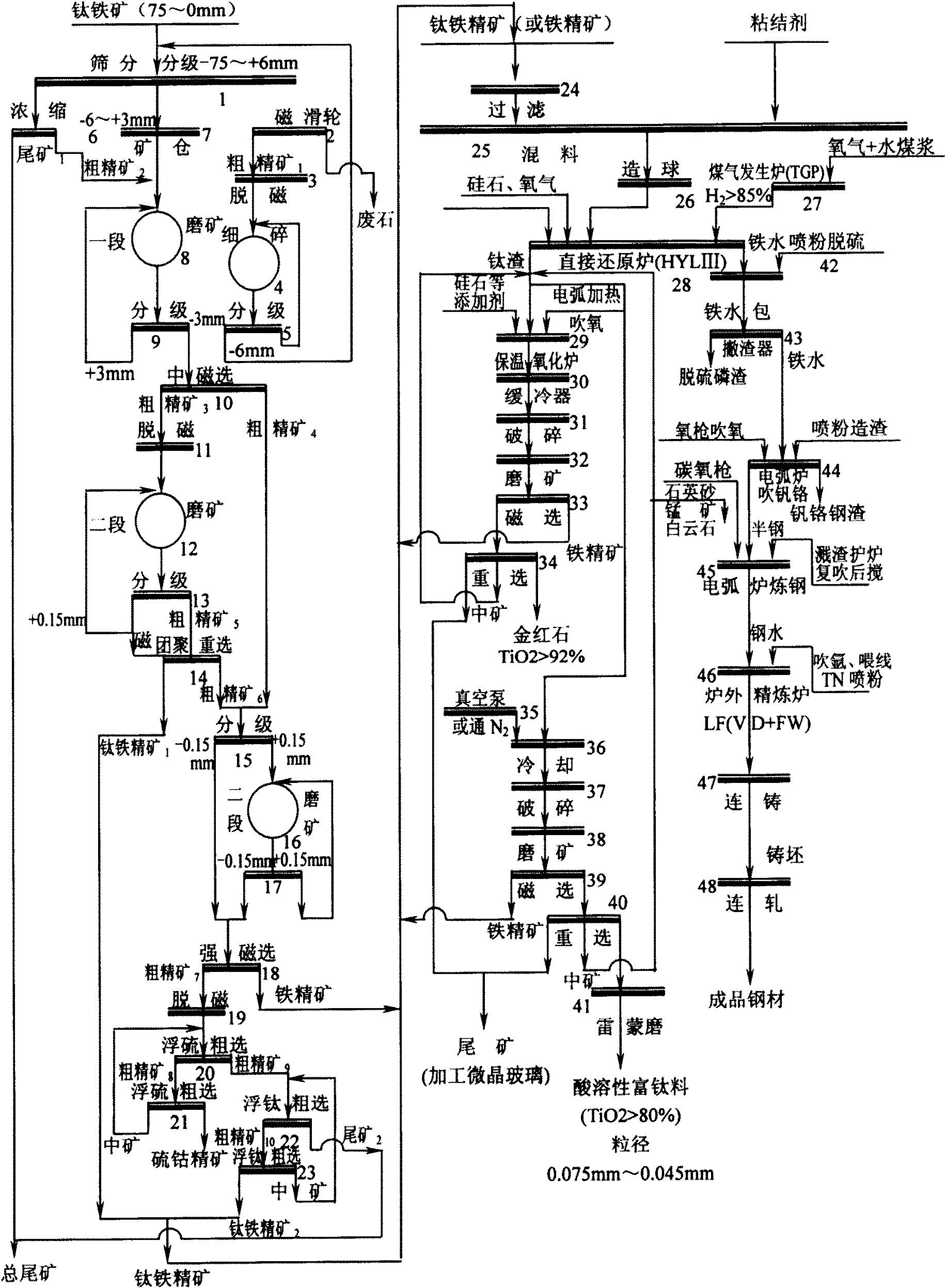

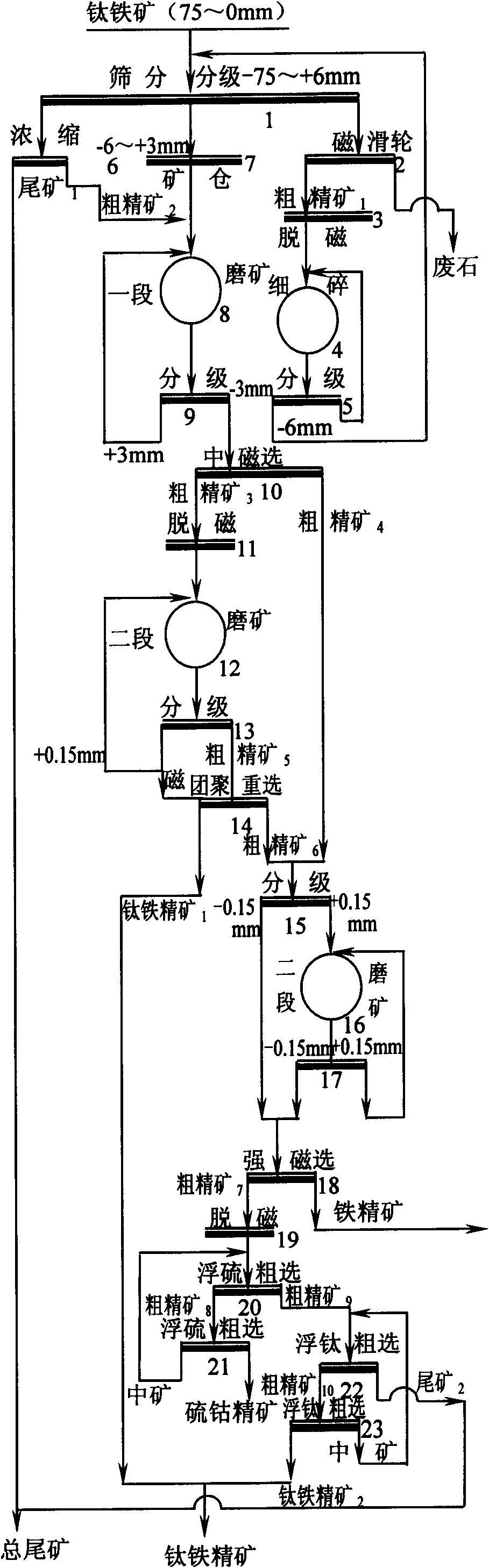

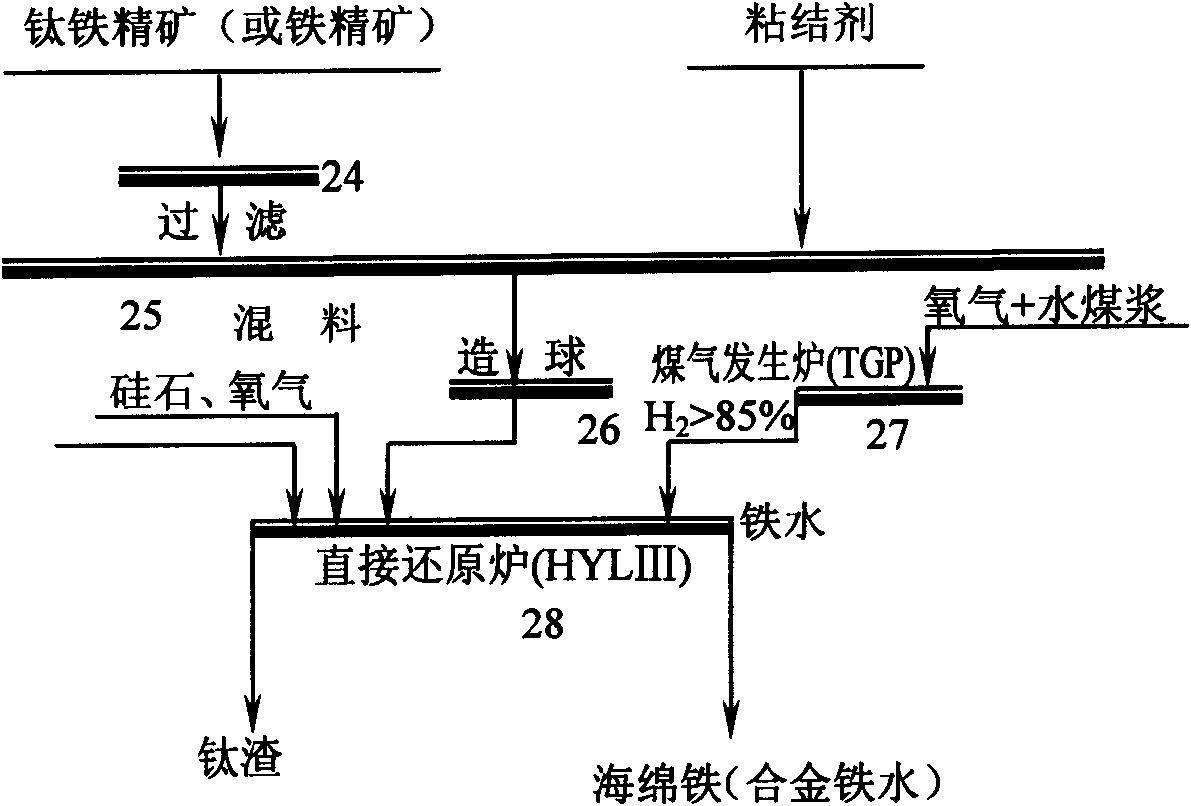

Method for producing titanium and steel products by utilizing titanium and iron ores

InactiveCN101613825AIncrease profitHigh recovery rateProcess efficiency improvementElectric furnaceRutileContinuous rolling

The invention discloses a method for producing titanium and steel products by utilizing titanium and iron ores, which belongs to the field of technical innovation of mining, dressing and smelting full process flow of the titanium and iron ores. Ordinary blast furnaces are not suitable for the smelting of high-titanium and medium-titanium schreyerite; and schreyerite mining, dressing and smelting enterprises in Panxi region extract rich parts and discard poor parts, and discard weathered ore of submarginal ore which accounts for over 95 percent of that of raw ore and is taken as mining mullock. The method comprises the following step: directly reducing titaniferous iron concentrate dressed from the mining mullock (TiO2 is over 5 percent, and TFe is over 13 percent) of the schreyerite, electric furnace melt producing titanium slag and molten water with electric furnace melt components, and producing a titanium-rich material and rutile with the titanium slag through mineral dressing by a fire method; producing alloy molten iron with the molten iron through electric smelting and vanadium-chrome steel slag blowing; and producing various alloy steel products the alloy molten iron in a continuous casting and continuous rolling mode through the electric smelting. The recovery rates of titanium, iron and vanadium are improved to 80 percent from 3.86 percent, improved to 70 percent from 34.5 percent and improved to 70 percent from 20.90 percent respectively.

Owner:PANZHIHUA JINTAI HI TECH

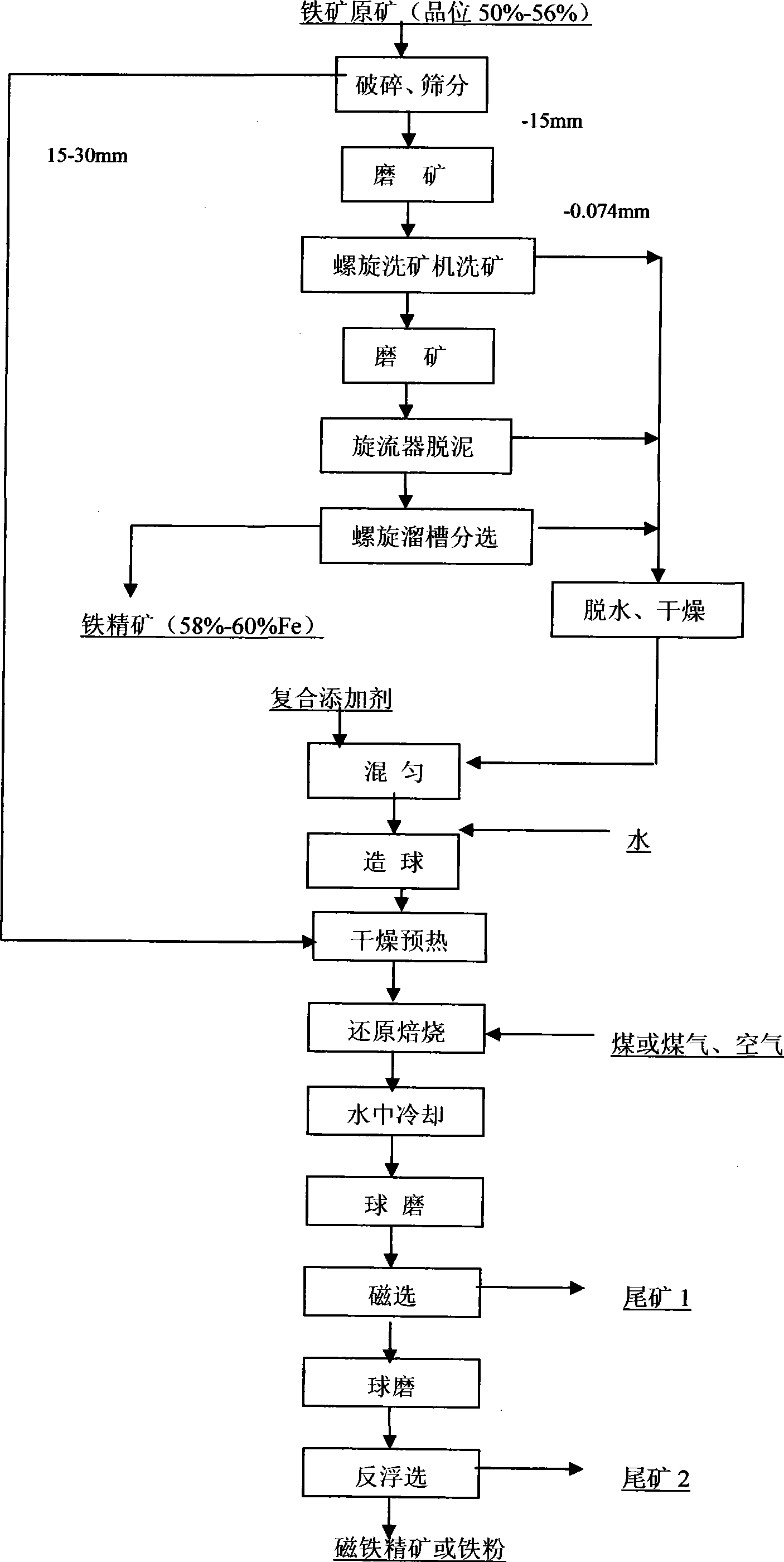

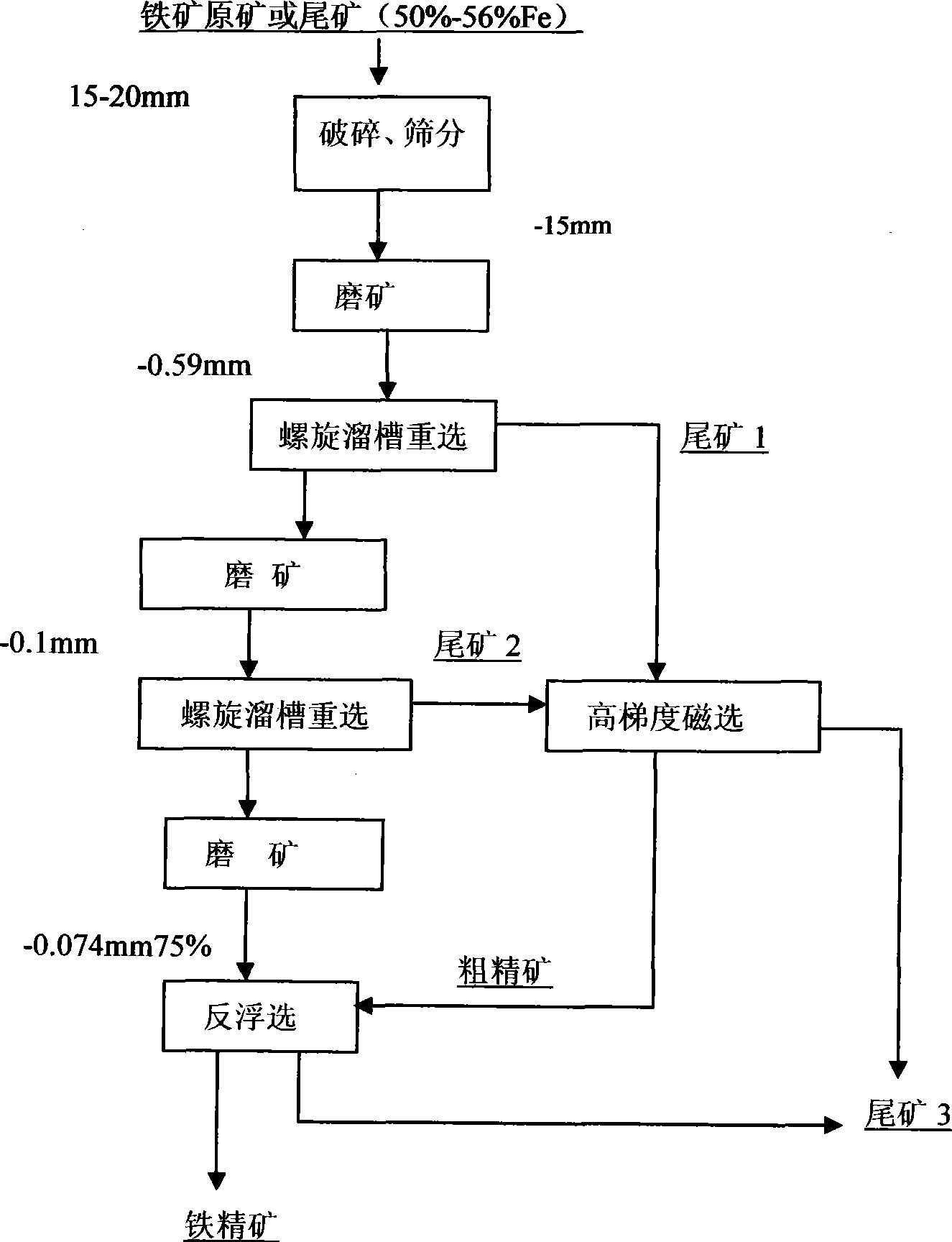

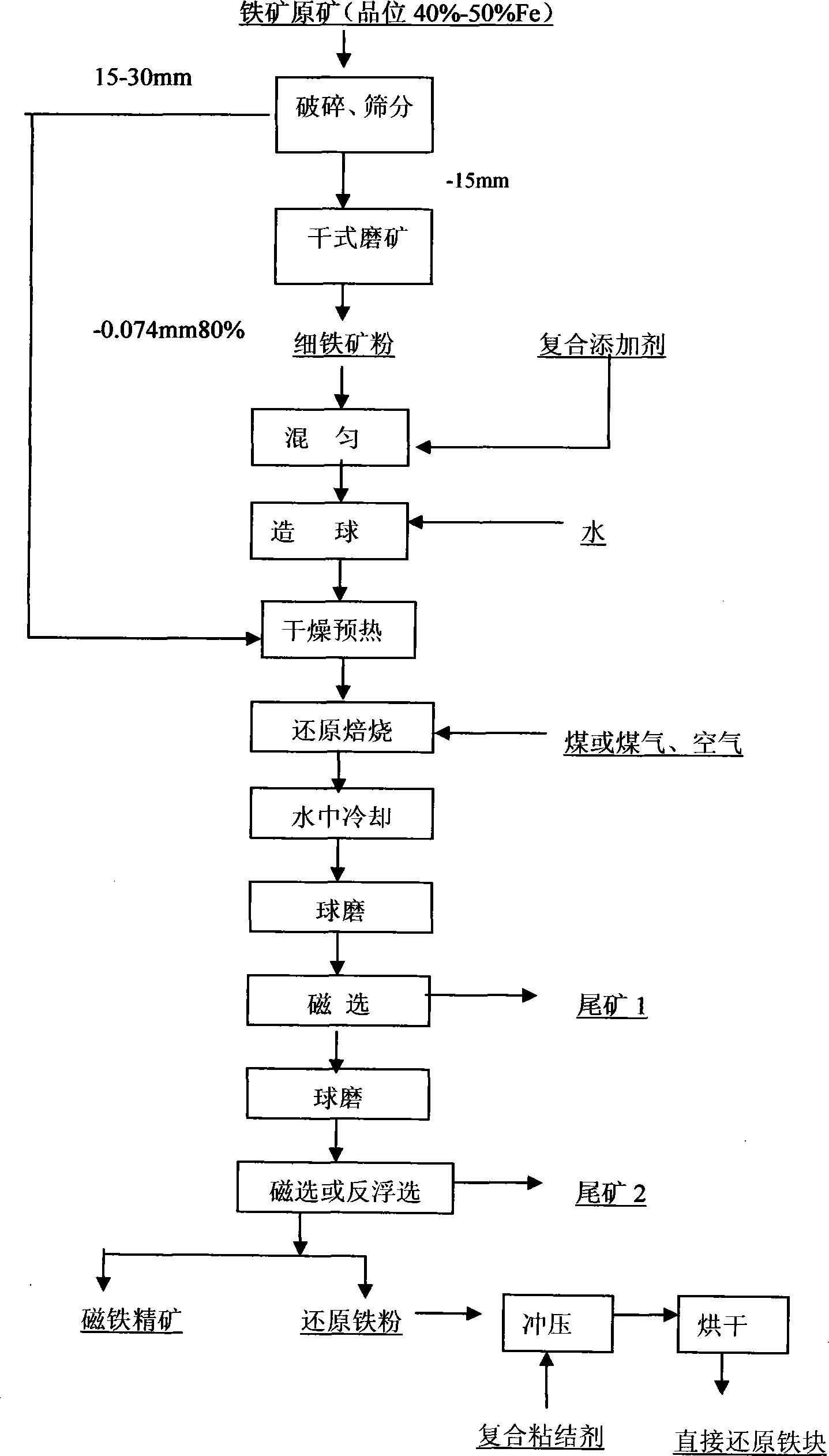

Method for efficiently separating low-ore grade and complicated iron ore

ActiveCN101413057ALow grain sizeHigh content of water of crystallizationProcess efficiency improvementIronstoneIron powder

The invention provides an efficient separation method for low-grade and complex iron ores. The method is characterized in that the complex iron ores of different grades and species are classified, so as to obtain lump ores and mineral powder which are balled, dried and preheated; reduction roasting, cooling, ball milling, magnetic separation, ball milling and magnetic separation or reverse flotation are performed in turn, so as to obtain iron ore concentrate or reduced iron powder; classification treatment is to crush and screen the iron ores with iron-containing grade between 50 and 56 percent and then dry and preheat obtained ores; fine-grained mineral powder is ground, washed, ground, deslimed and separated so as to obtain the iron ore concentrate and slime containing 58 to 60 percent of iron; the slime which is washed, deslimed, and separated is dewatered and dried and is added to and well mixed additives, so as to be balled then; the iron ores with the iron-containing grade between 40 and 50 percent are crushed and screened so as to obtain the lump ores which are directly dried and preheated, while the fine-grained mineral powder is obtained through dry-type grinding and then is added to and well mixed the additives so as to be balled then; and the iron ores with the iron-containing grade between 25 and 40 percent are crushed and screened so as to obtain the lump ores which are dried and preheated, while the fine-grained mineral powder is subjected to grinding, gravity separation or high-gradient magnetic separation and reverse flotation, so as to obtain coarse iron concentrate powder which is added to and well mixed with the additives and then is balled.

Owner:CENT SOUTH UNIV

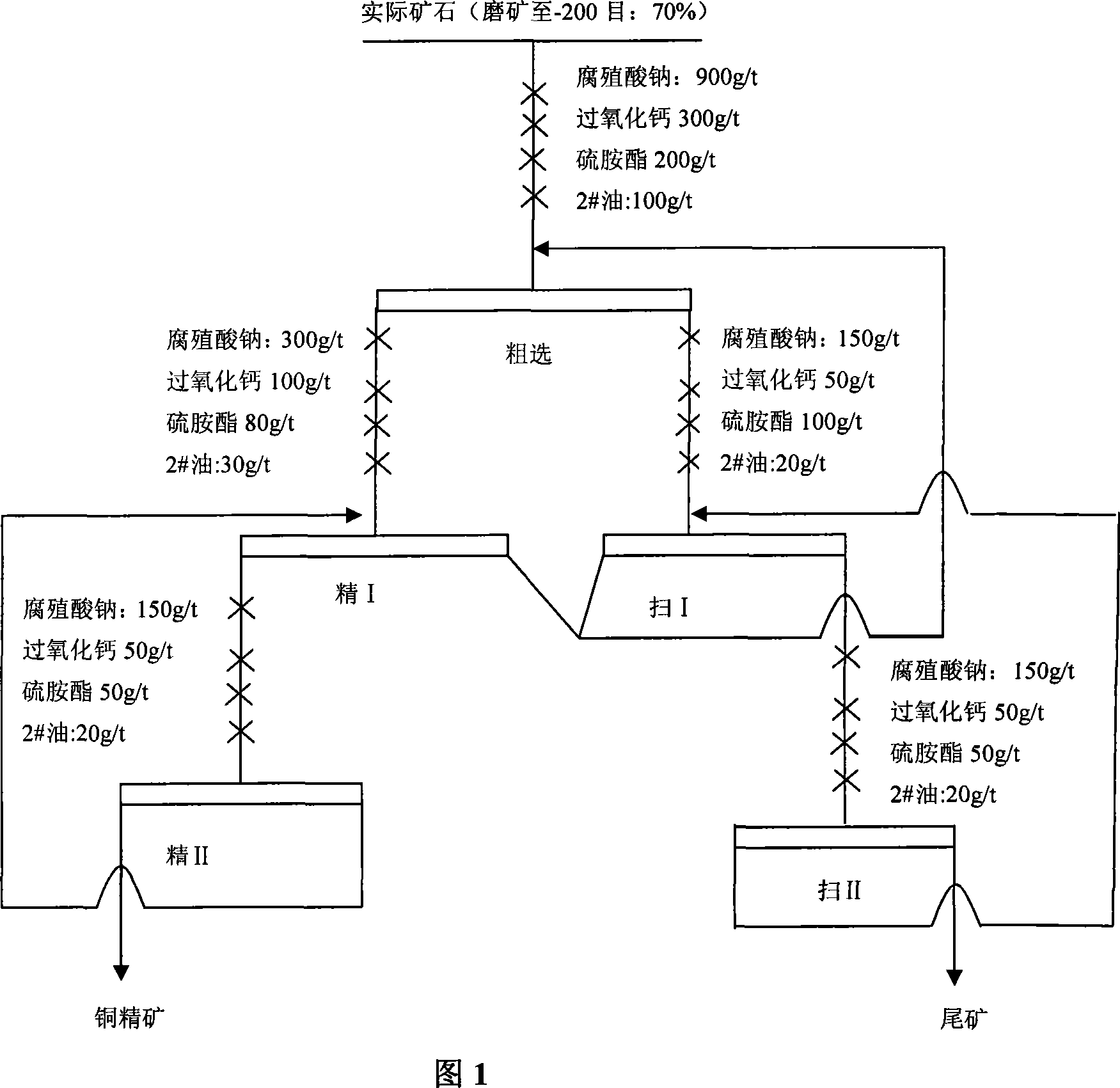

Highly effective composite restrainer of ferro-sulphur ore in complex vulcanizing ore and method of use thereof

The invention relates to a high-efficient combined inhabitor for pyrite in complex sulfide ores and the application method of the inhabitor. The inhabitor comprises calcium superoxide and HA-Na. The inhabitor of the invention can inhibit complex vulcanized iron-bearing minerals selectively, has better inhibition properties for magnetic pyrite, pyrite and arsonopyrite, and is an inhabitor of high selectivity. Compared with the prior inhibitors such as lime, cyanide, bichrome, potassium permanganate, sodium sulfide, sulphite, zinc sulphate and trisodium phosphate, the invention has the advantages of lower use level, good effects, no pollution, and other advantages.

Owner:CENT SOUTH UNIV

Special-purpose board for building and producing method thereof

ActiveCN101168610AProtect the environmentOvercome fear of waterBuilding constructionsSlagPolyvinyl chloride

The invention relates to a building product and the generating method thereof, in particular to a construction special-purpose plate and the manufacturing method thereof. The invention is made of the following raw material according to the parts by weight: 20 to 50 percent of thermoplastic resin comprising polyvinyl chloride, polyethylene and polypropylene, 50 to 80 percent of bulking agent comprising iron ore waste tailing sand, calcium carbonate and slag, and additive occupying 0.05 to 5 percent of the gross weight of the thermoplastic resin and the bulking agent and comprising plasticizer, heat stabilizer and lubricating agent. The product is made by adopting a stone molding and extrusion moulding way, no pollution is produced, no distortion exists, the product is moistureproof and fireproof, the processing waste and the disposed plate of the product can be recycled and newly processed to ensure zero waste, the damage to the environment cannot be caused, and the product is made into a hollow plate structure which has the advantages that the elasticity and the sound insulation effect are good and the heat transfer effect is good, therefore, the invention is very suitable for the heating of a geothermic pipeline, and the difficult problem that a wooden compound floor plate in the present market cannot be used for the heating of the northern geothermic building because of the distortion due to the heating or poor heat insulation heating effect is solved.

Owner:唐山金三顺装饰材料有限公司

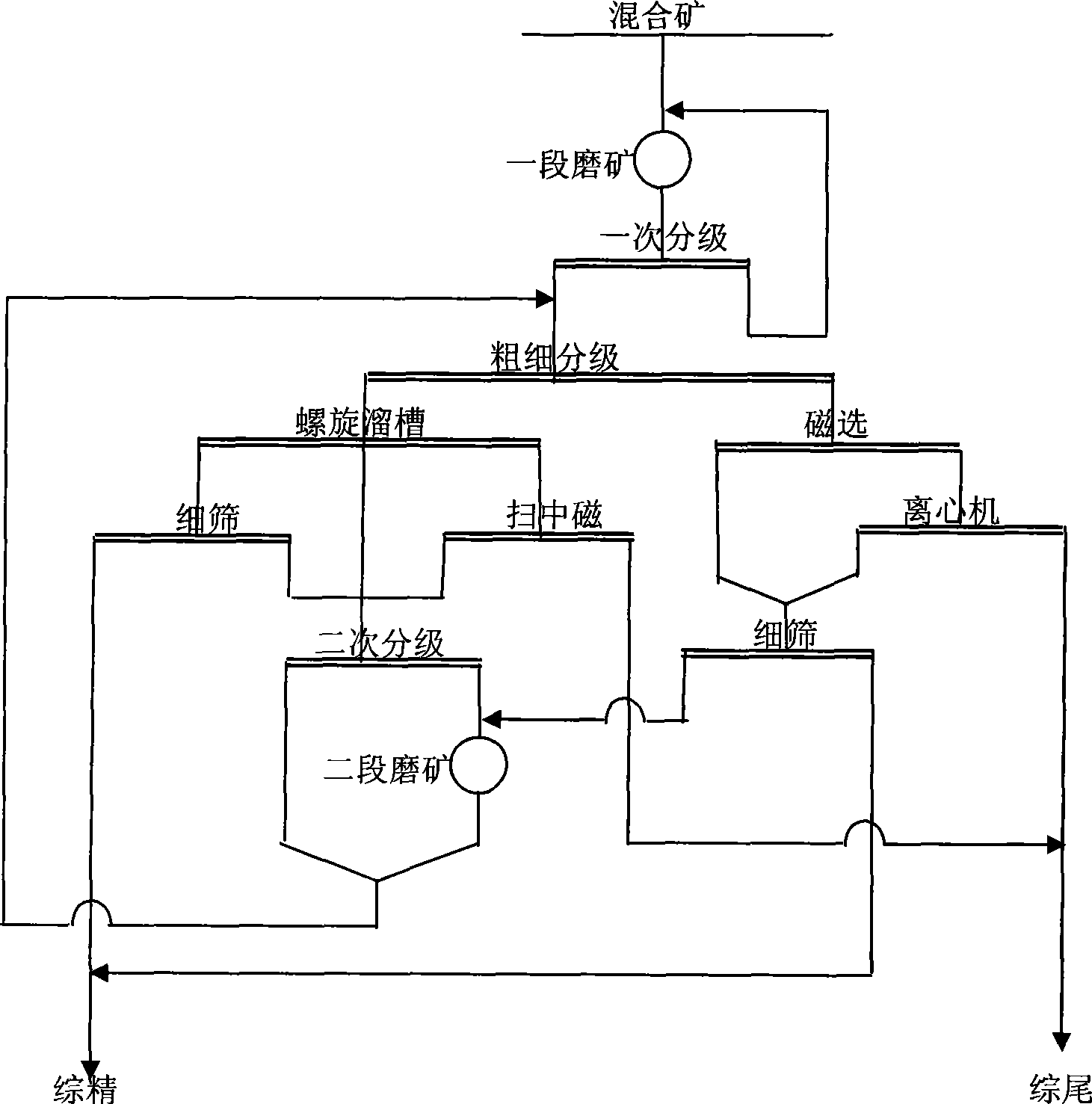

Technique for processing mixed type iron ore

ActiveCN101468330AEfficient recyclingOvercome the complex system and the shortcomings of being easily interfered by other mineralsSievingScreeningHybrid typeGravity separation

The invention discloses a process for treating mixed-type iron ore. The process comprises the following steps: raw ore is crushed and then subjected to primary grinding and primary grading which form closed circuit grinding; after primary overflow is subjected to crudeness / fineness grading and coarse grains are sorted through a gravity separation device, spiral chute concentrate is fed into a fine screen with large mesh size, and undersize products are coarse-grain concentrate; after gravity separation tailings are subjected to tailings discarding through intermediate-magnetism sweeping, intermediate-magnetism sweeping concentrate, gravity separation middlings and oversize products are merged into coarse-grain middlings; the middlings are fed into an open-circuit grinding system consisting of secondary grading and secondary grinding and reground, and then return to crudeness / fineness grading; fine grains after crudeness / fineness grading are sorted through a magnetic separation device; magnetic separation concentrate is fed into the fine screen with small mesh size, and the undersize products are fine-grain concentrate, while the oversize products are fine-grain middlings which are directly fed into two-stage grinding so as to be reground; fine-grain concentrate and the coarse-grain concentrate are merged into final concentrate; and intermediate-magnetism sweeping tailings and the magnetic separation tailings are merged into final tailings. The process has the advantages of good flow stability, easy operation and capability of effectively recovering the mixed-type ore and fully utilizing mixed-type ore resources.

Owner:鞍钢集团矿业设计研究院有限公司

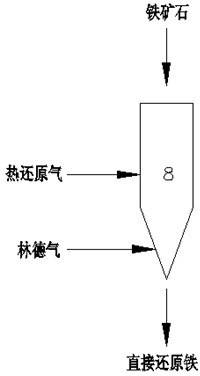

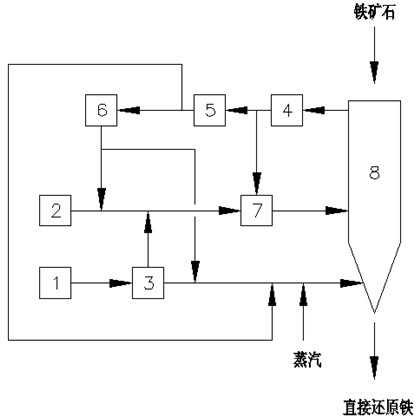

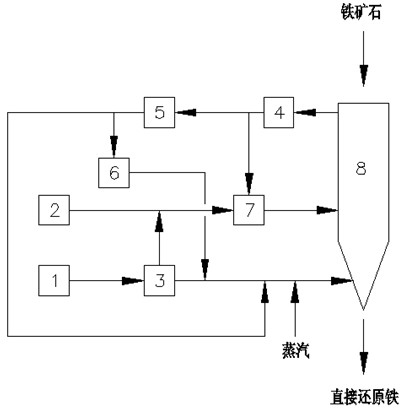

Method and device for producing direct reduced iron by using gas-based reduction shaft furnace

The invention discloses a method and device for producing direct reduced iron by using a gas-based reduction shaft furnace. Coal reducing gas and coke oven gas are mixed and supplied to a shaft furnace so as to produce direct reduced iron. The method comprises the following steps: separating the coke oven gas into hydrogen gas and linde gas, mixing the hydrogen gas with the coal reducing gas and using as reducing gas to reduce iron ores, and using the linde gas as cooling gas to cool direct reduced iron. The device for realizing the method comprises a shaft furnace, a coke oven gas source, a coal gasification device, a coke oven gas hydrogen-extracting device and a gas heating device. In the invention, coal gasification devices of different sizes can be flexibly used with a coke oven gas supply device, thereby reducing the size of the coal gasification device and effectively using the coke oven gas. Meanwhile, the invention cancels the minor cycle of a cooling section of a common shaft furnace, saves the equipment and investment, and brings the heat of direct reduced iron to a reducing section, thereby saving the heating load of the system reducing gas.

Owner:CISDI SHANGHAI ENG CO LTD +1

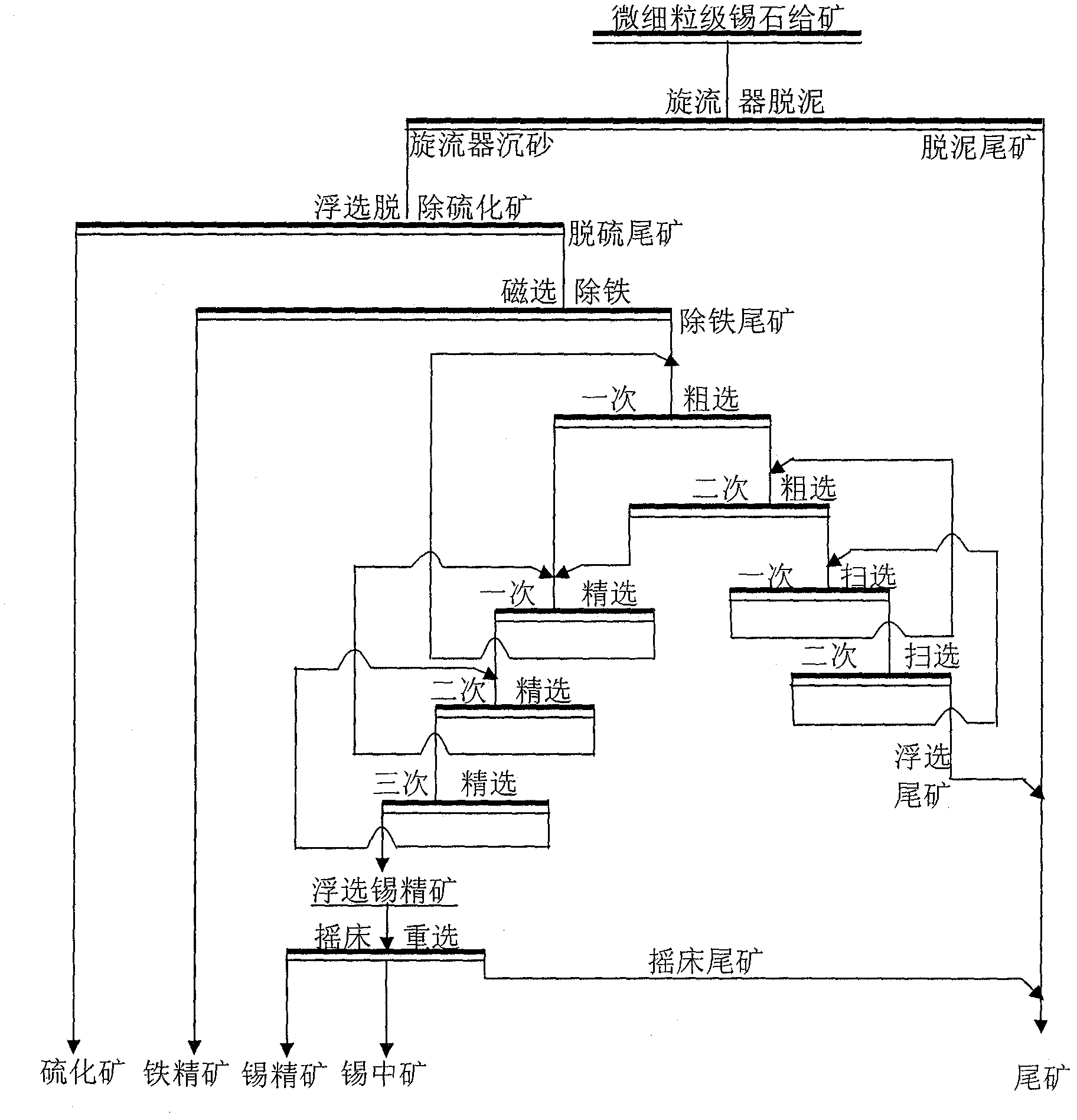

Beneficiation method for ultrafine fraction cassiterite

InactiveCN102631977AMineral processing method to solveEfficient recyclingFlotationWet separationCassiteriteMaterials science

A beneficiation method for ultrafine fraction cassiterite is characterized in that a swirler is used for desliming to obtain swirler settled sand and deslimed tailings; sulfide ores are separated from the swirler settled sand so that the sulfide ores and desulfurized tailings are obtained; iron is removed from the desulfurized tailings by means of magnetic separation to obtain iron ore concentrate and deironed tailings; flotation tin concentrate and flotation tailings are obtained after secondary roughing flotation, secondary scavenging flotation and tertiary blank concentration flotation for the deironed tailings; and a table concentrator is used for performing gravity concentration for the flotation tin concentrate to obtain tin concentrate, tin middlings and table concentration tailings. The grade of the tin concentrate is higher than 40%, the tin recovery rate of the tin concentrate is higher than 50%, the grade of the tin middlings ranges from 1% to 3%, the tin recovery rate of the tin middlings is higher than 15%, and the overall tin recovery rate of the tin concentrate and the tin middlings is higher than 65%. The beneficiation method for the ultrafine fraction cassiterite is high in recovery rate, low in production cost, high in tin grade and applicable to recovery of the ultrafine fraction cassiterite with the silt content ranging from 10% to 30%.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

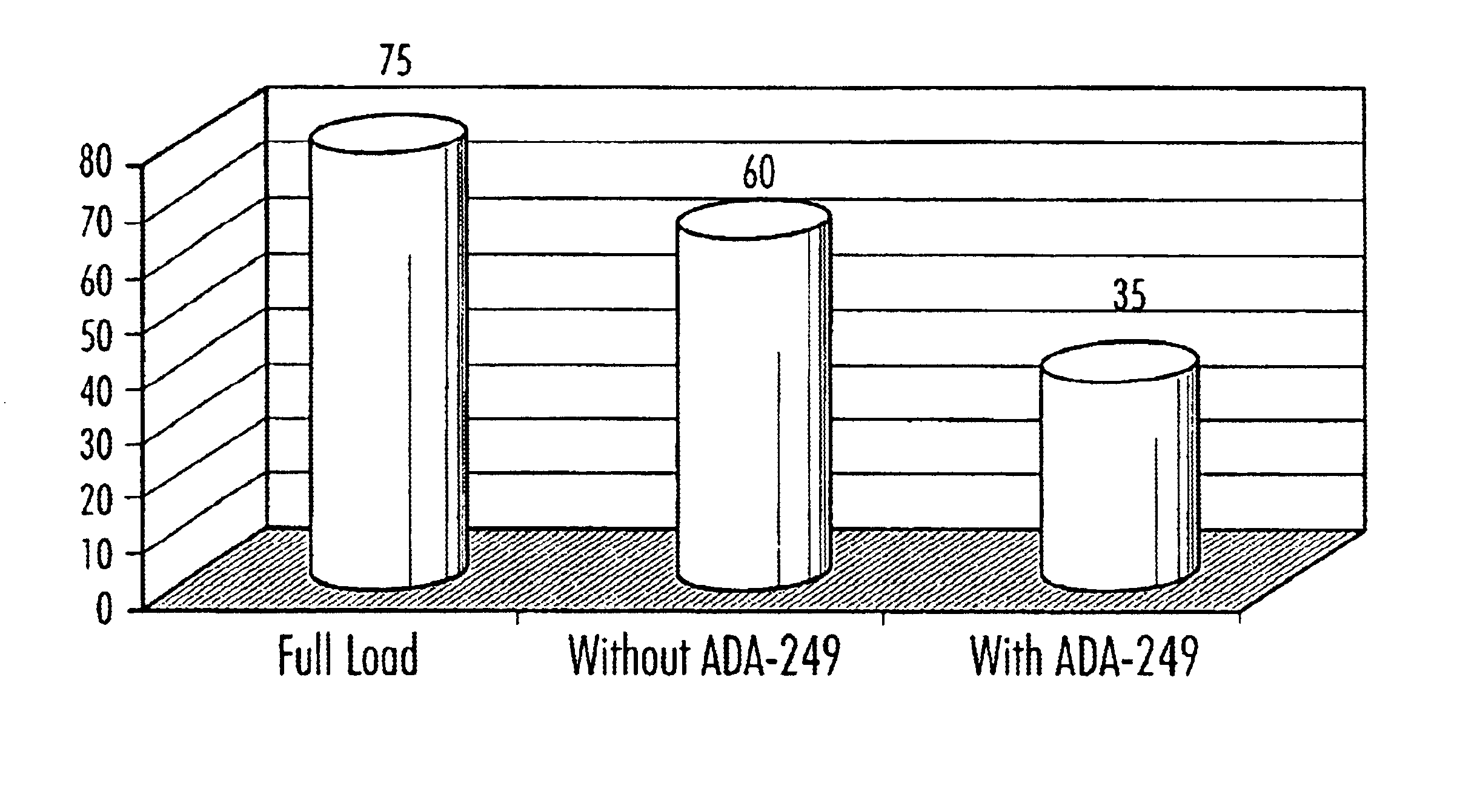

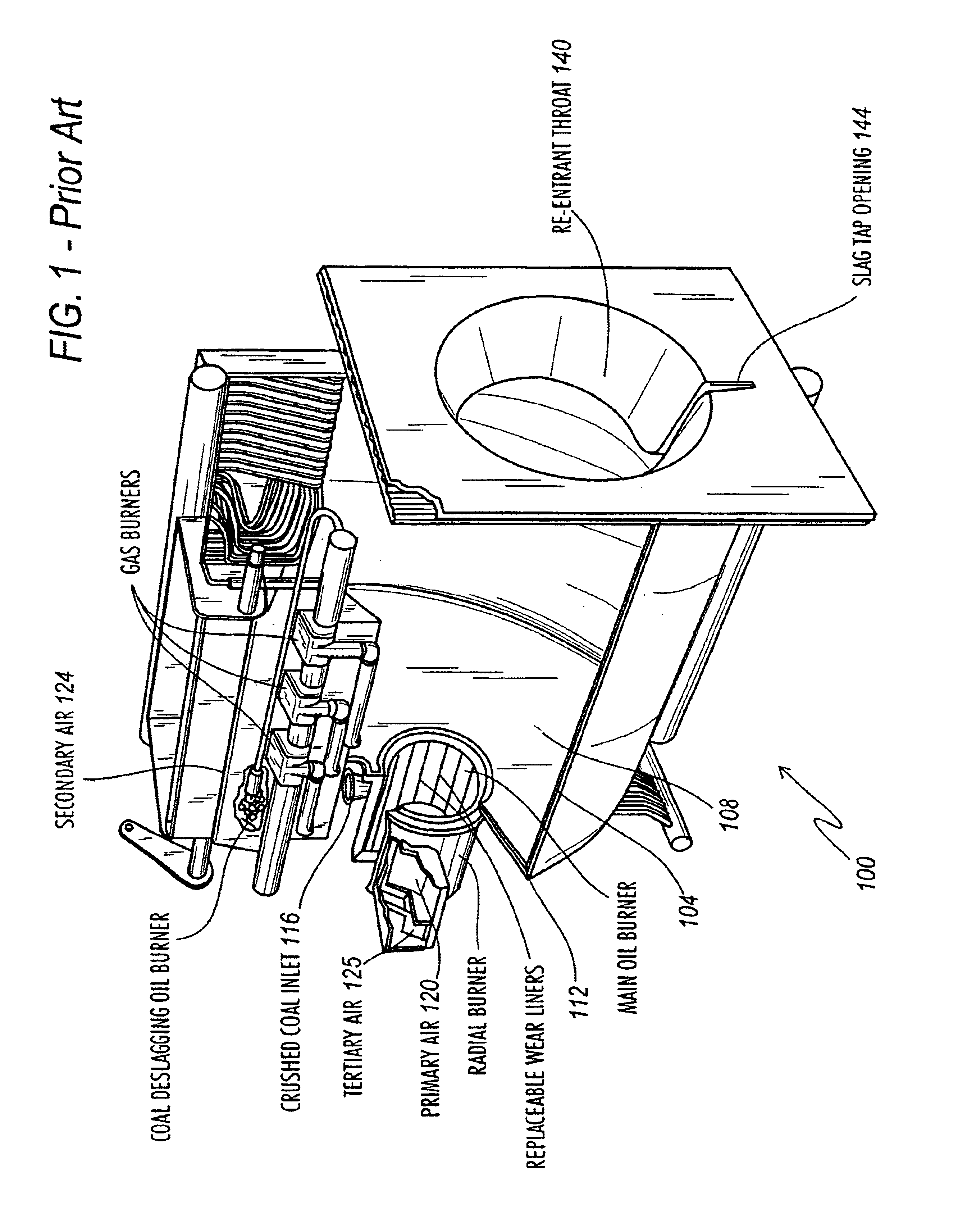

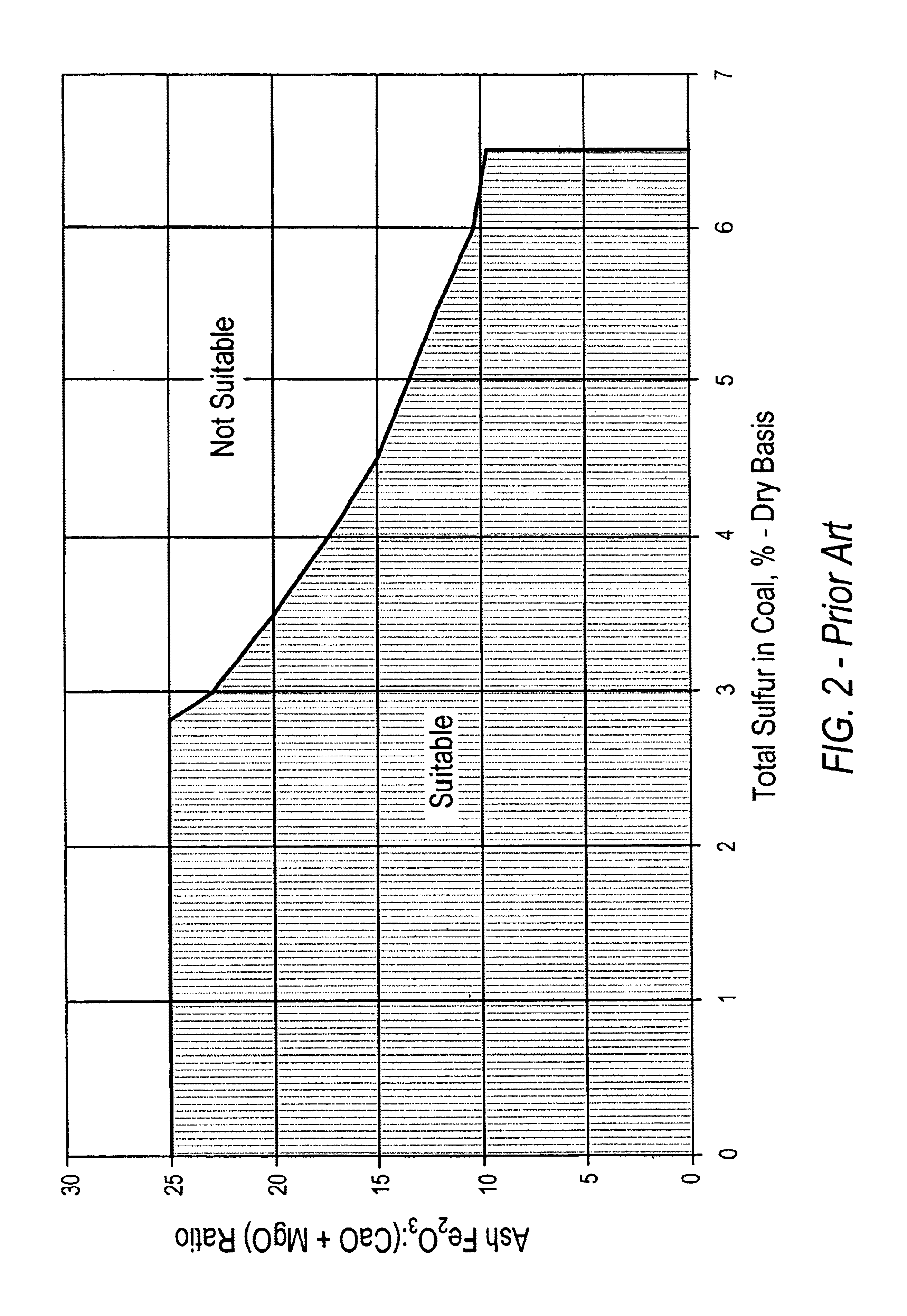

Low sulfur coal additive for improved furnace operation

InactiveUS7332002B2Improve featuresLower melting temperatureSolid fuel pretreatmentSolid fuelsSlagMelt temperature

The present invention is directed to additives for coal-fired furnaces, particularly furnaces using a layer of slag to capture coal particles for combustion. The additive(s) include iron, mineralizer(s), handling aid(s), flow aid(s), and / or abrasive material(s). The iron and mineralizers can lower the melting temperature of ash in low-iron, high alkali coals, leading to improved furnace performance.

Owner:ADA ES

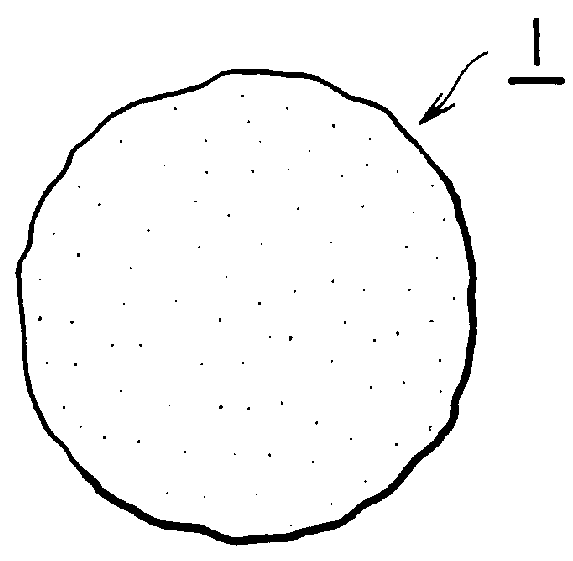

Method of producing iron nuggets

InactiveUS6592649B2Avoid smallImprove productivityProcess efficiency improvementGas emission reductionProduction rateSlag

The present invention provides a method of producing metallic iron nuggets with a high yield and good productivity, and more particularly a method which can produce metallic iron nuggets which have a high Fe purity and are excellent in transporting and handling due to a large grain diameter with a high yield and good productivity, when they are produced by reducing and melting raw material containing iron oxide such as iron ore and carbonaceous reducing agent such as coke. The method of producing metallic iron nuggets comprises steps of: heating raw material containing carbonaceous reducing agent and iron oxide-containing material in a reducing / melting furnace, reducing iron oxide in the raw material, and then heating and melting the metallic iron produced by the reduction and simultaneously making it coalesce while separating the metallic iron nuggets from slag components characterized in that the fixed carbon content ratio as the carbonaceous reducing agent is at least 73% and the volatile matter content in the raw material is not more than 3.9% are used, and the mixing content of carbonaceous reducing agent is restrained to be not more than 45% in relation to the iron oxide components, which is contained in the iron oxide-containing material of the raw material.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com