Method of refining iron ore from alkaline red mud and making gangue neutral

A technology for iron ore concentrate and red mud, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of high capital construction and maintenance costs, occupation of large land, etc., and achieve good economic and social benefits, Small footprint, saving resources and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

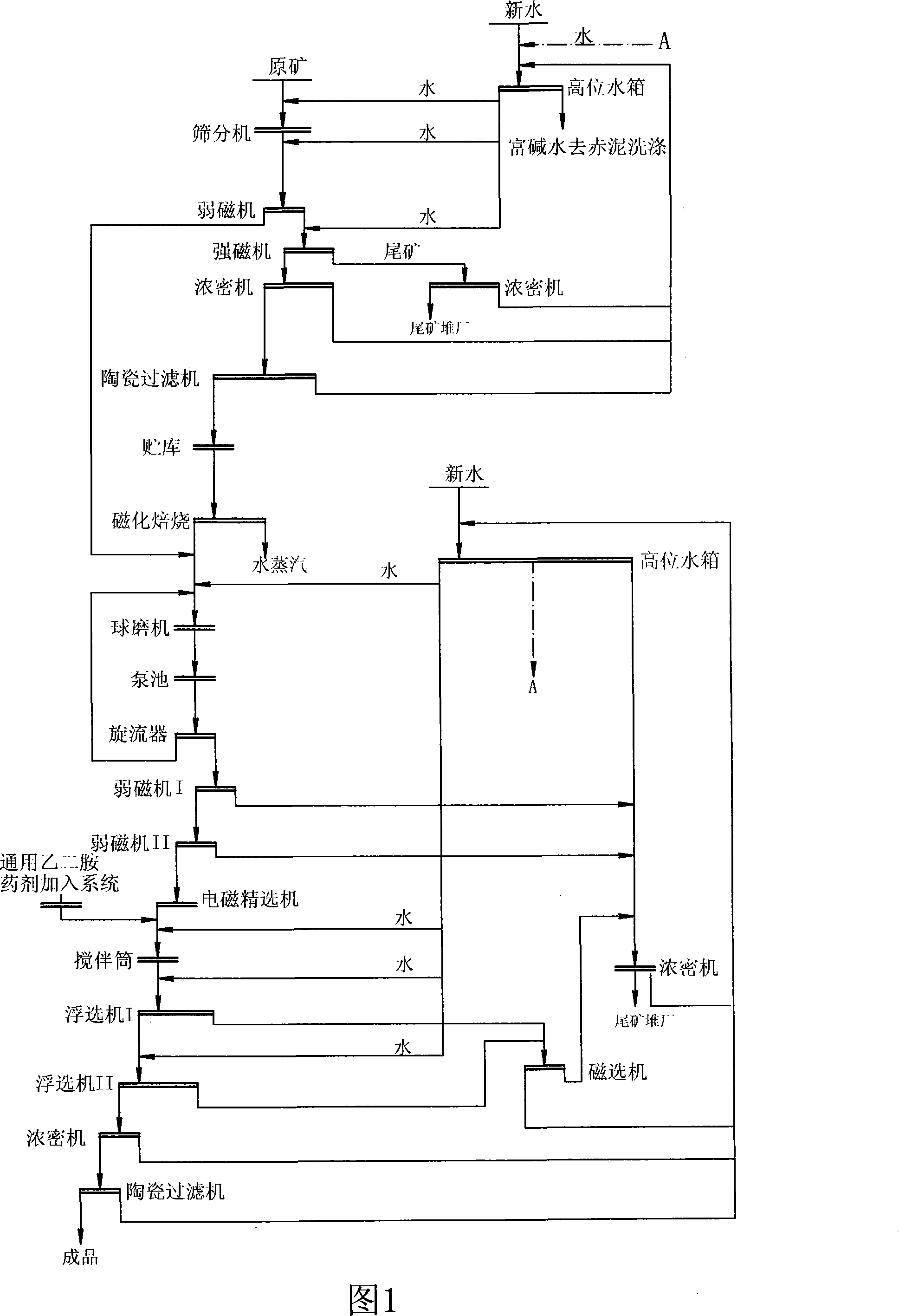

Image

Examples

Embodiment Construction

[0024] A method for selecting iron concentrate from alkaline red mud and making tailings neutral, comprising the following process steps:

[0025] 1. Red mud pretreatment

[0026] The red mud slurry with a solid concentration of 60% from the alumina production plant is sent to the mixing tank, diluted with water to a solid concentration of 30% to 40%, pumped to the high-level tank, and then distributed to the screening machine by the high-level tank to remove foreign matter . Screening machines include rotary screens, vibrating screens, curved screens, bar screens, etc.

[0027] The material under the sieve enters the CTB weak magnetic separator to select the strong magnetic material. According to the test analysis results, it can be sent to the ball mill process for further processing, or it can be sent to the product filtration process to be directly used as a product after dehydration. The remaining red mud is diluted with water to a solid concentration of about 30%, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com