Patents

Literature

149 results about "Zero waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zero Waste is a set of principles focused on waste prevention that encourages the redesign of resource life cycles so that all products are reused. The goal is for no trash to be sent to landfills, incinerators, or the ocean. Currently, only 9% of plastic is actually recycled. Zero waste system, material will be reused until the optimum level of consumption. The definition adopted by the Zero Waste International Alliance (ZWIA) is...

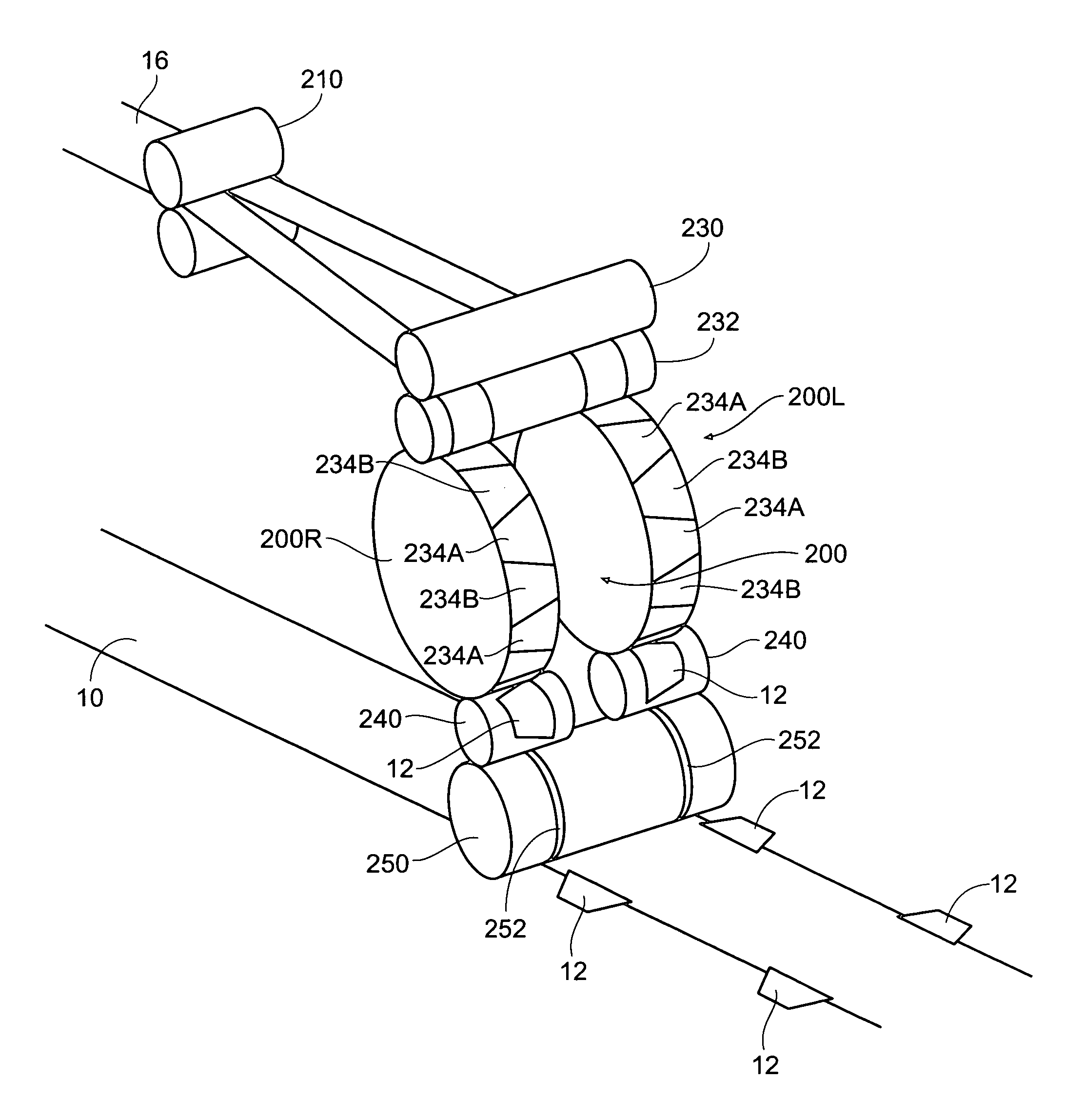

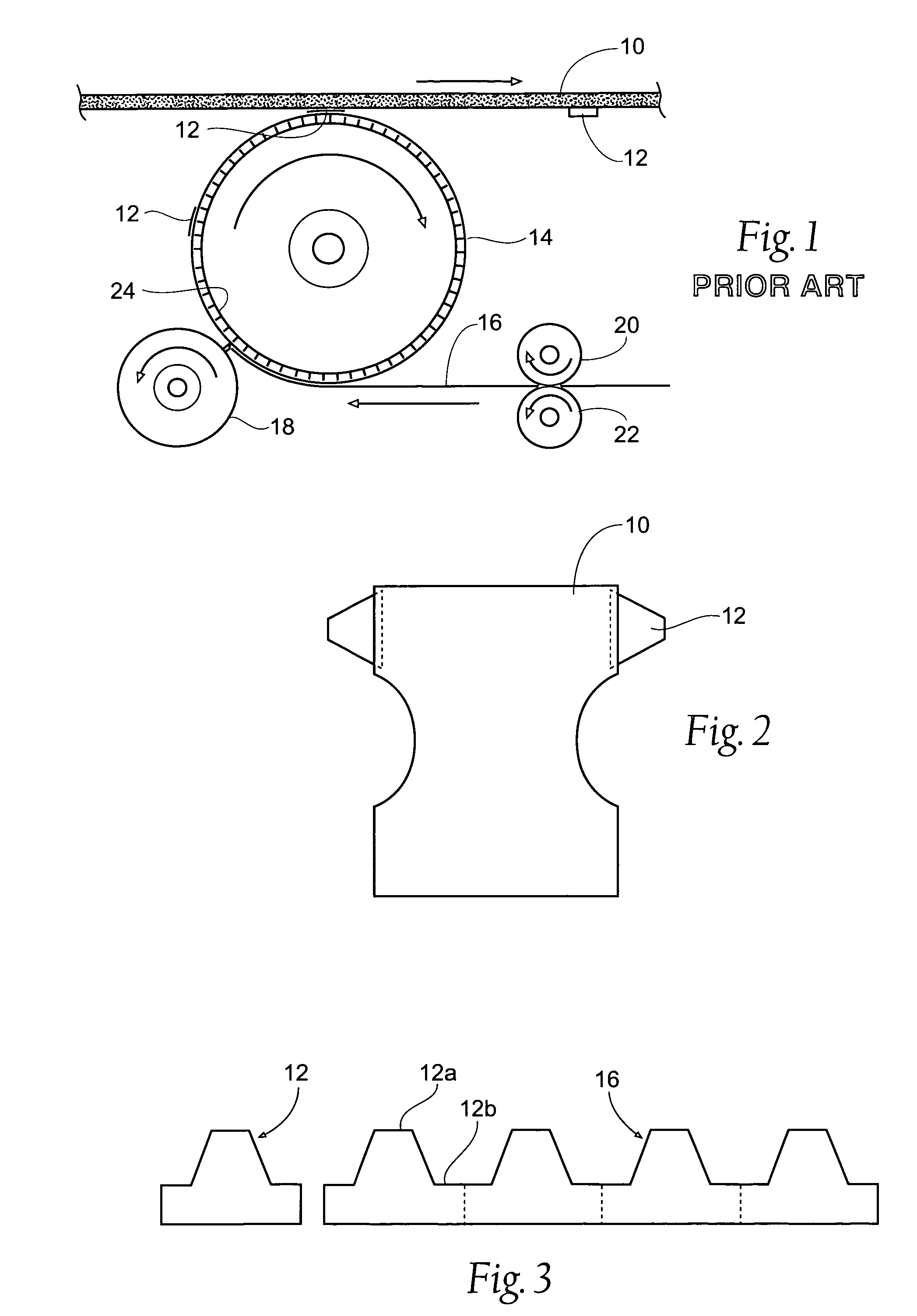

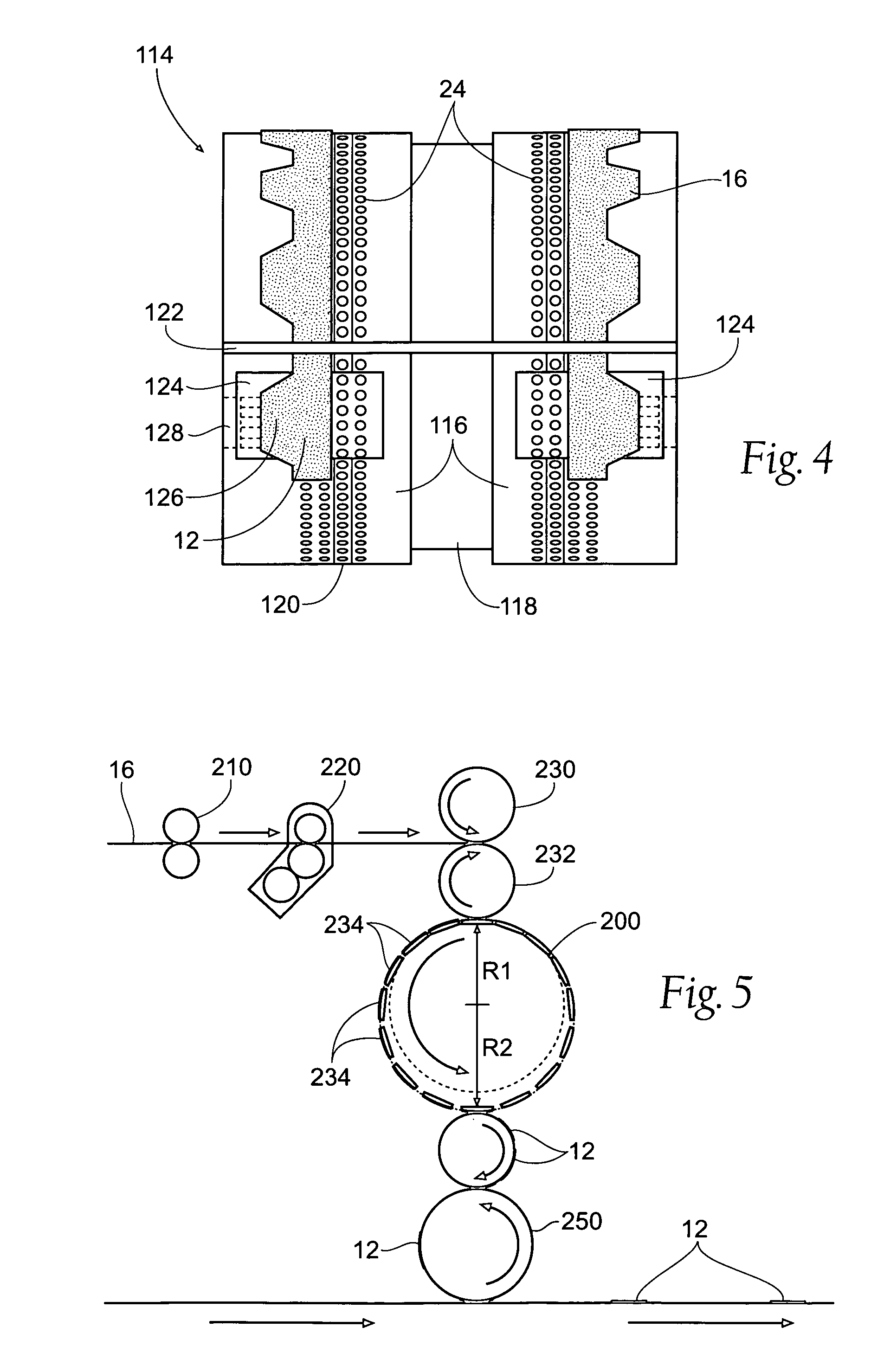

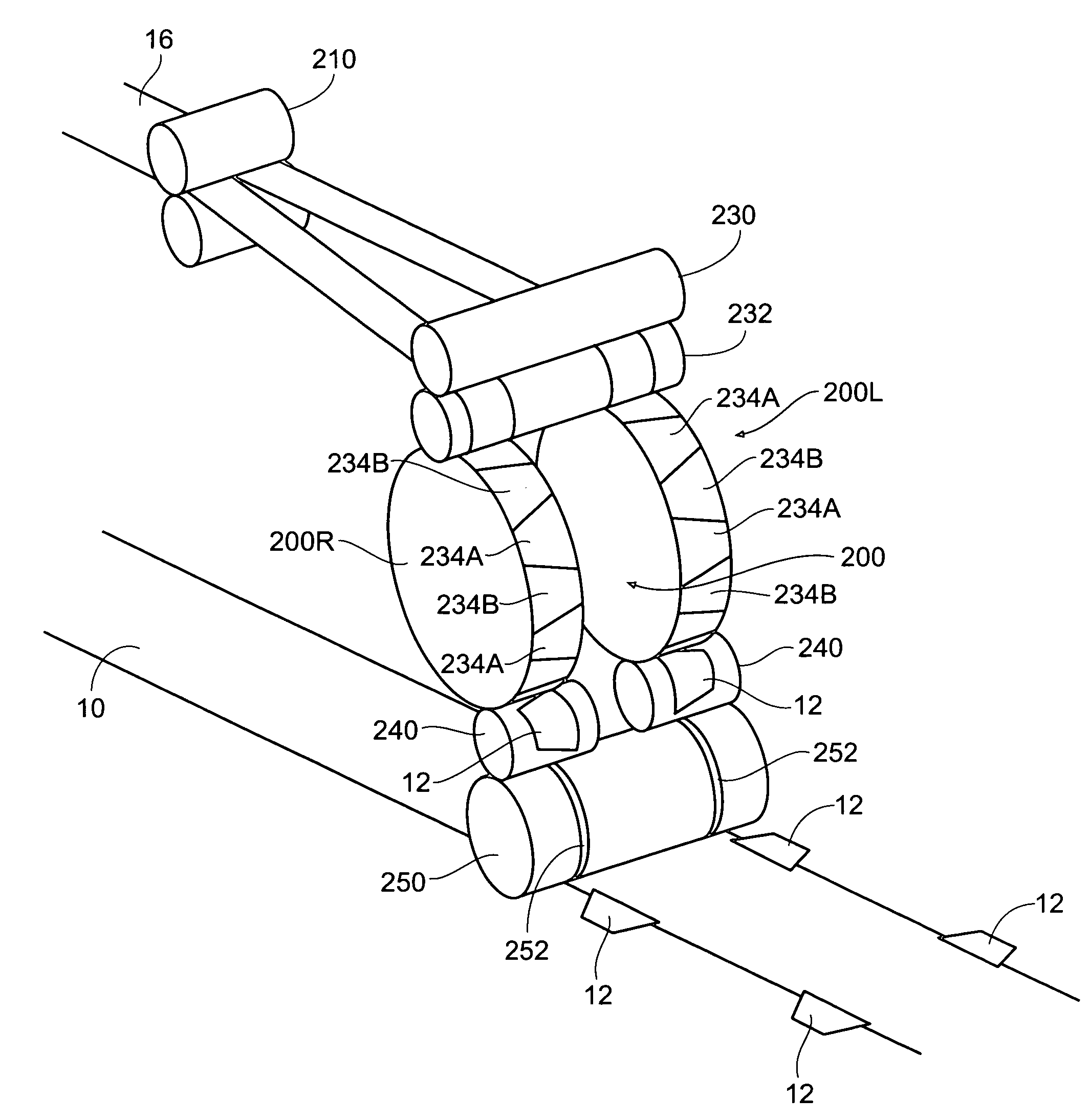

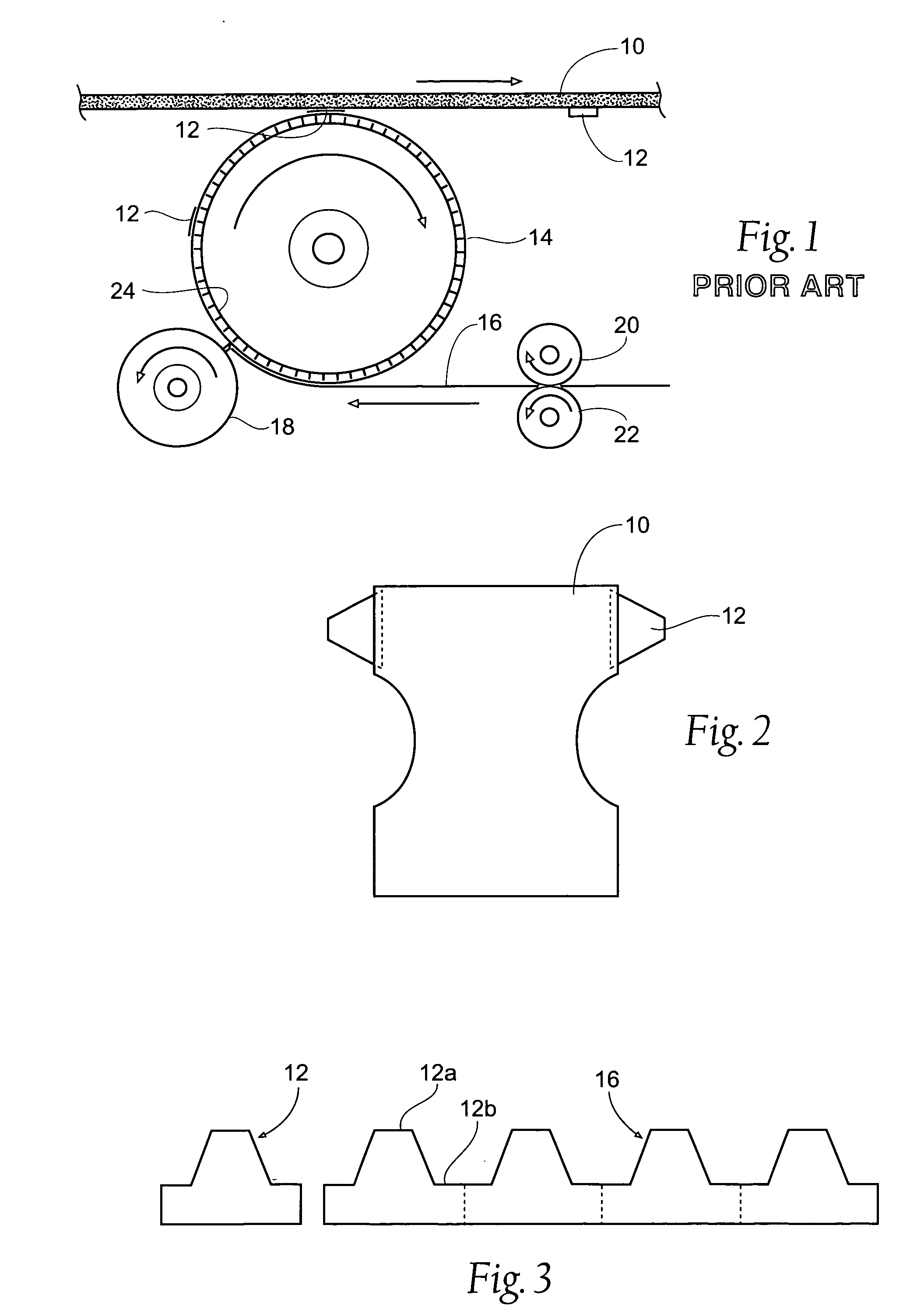

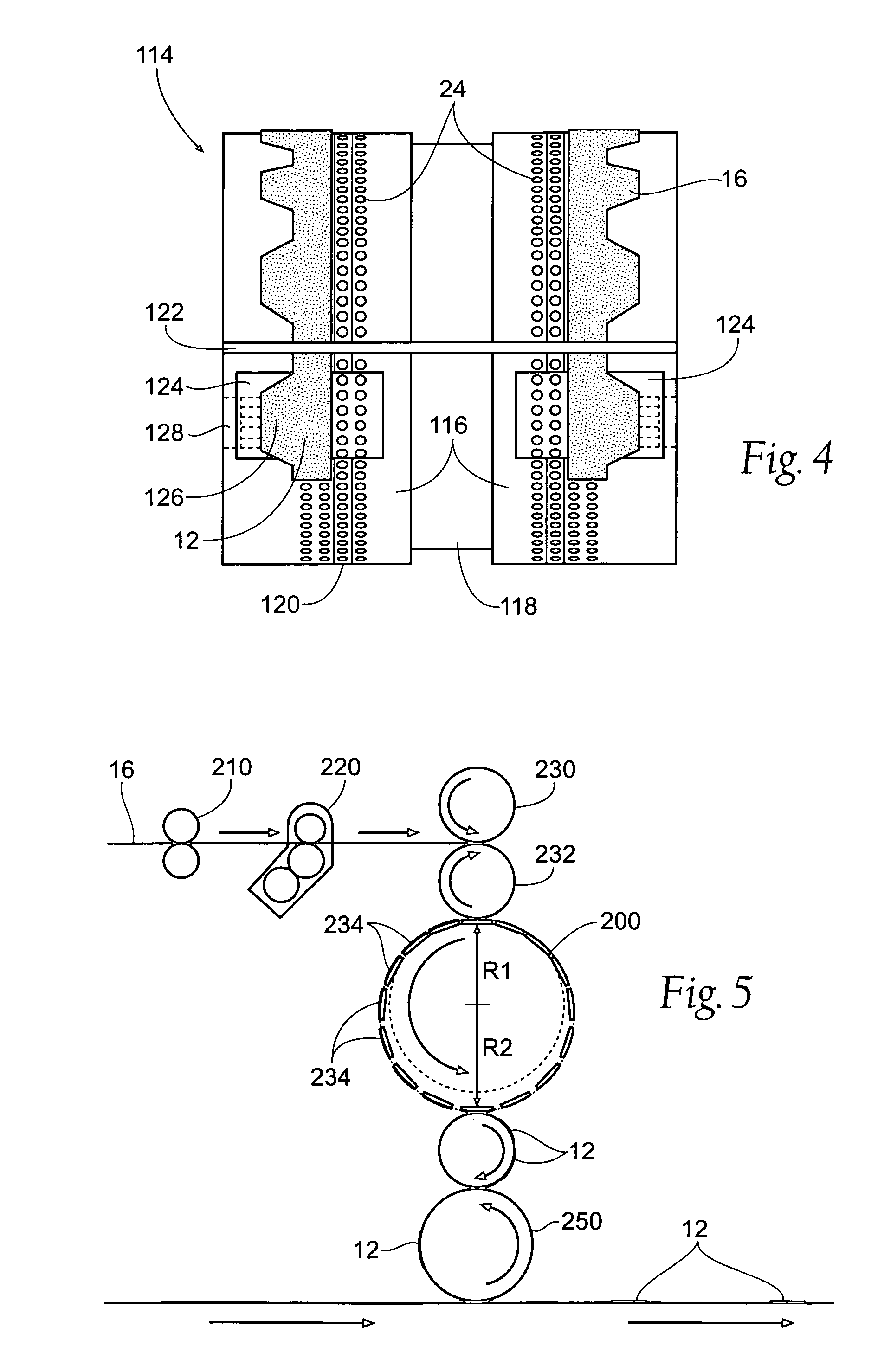

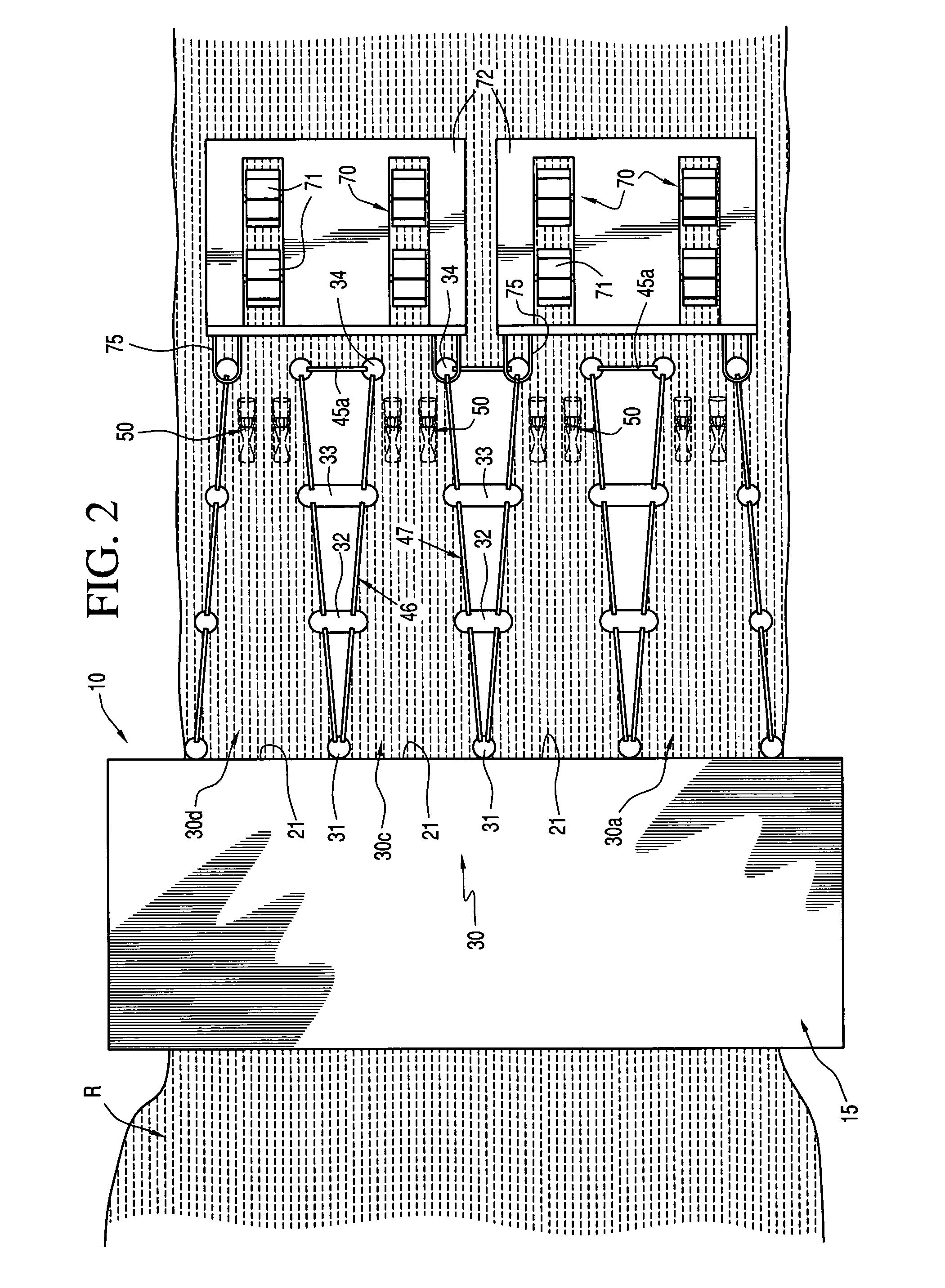

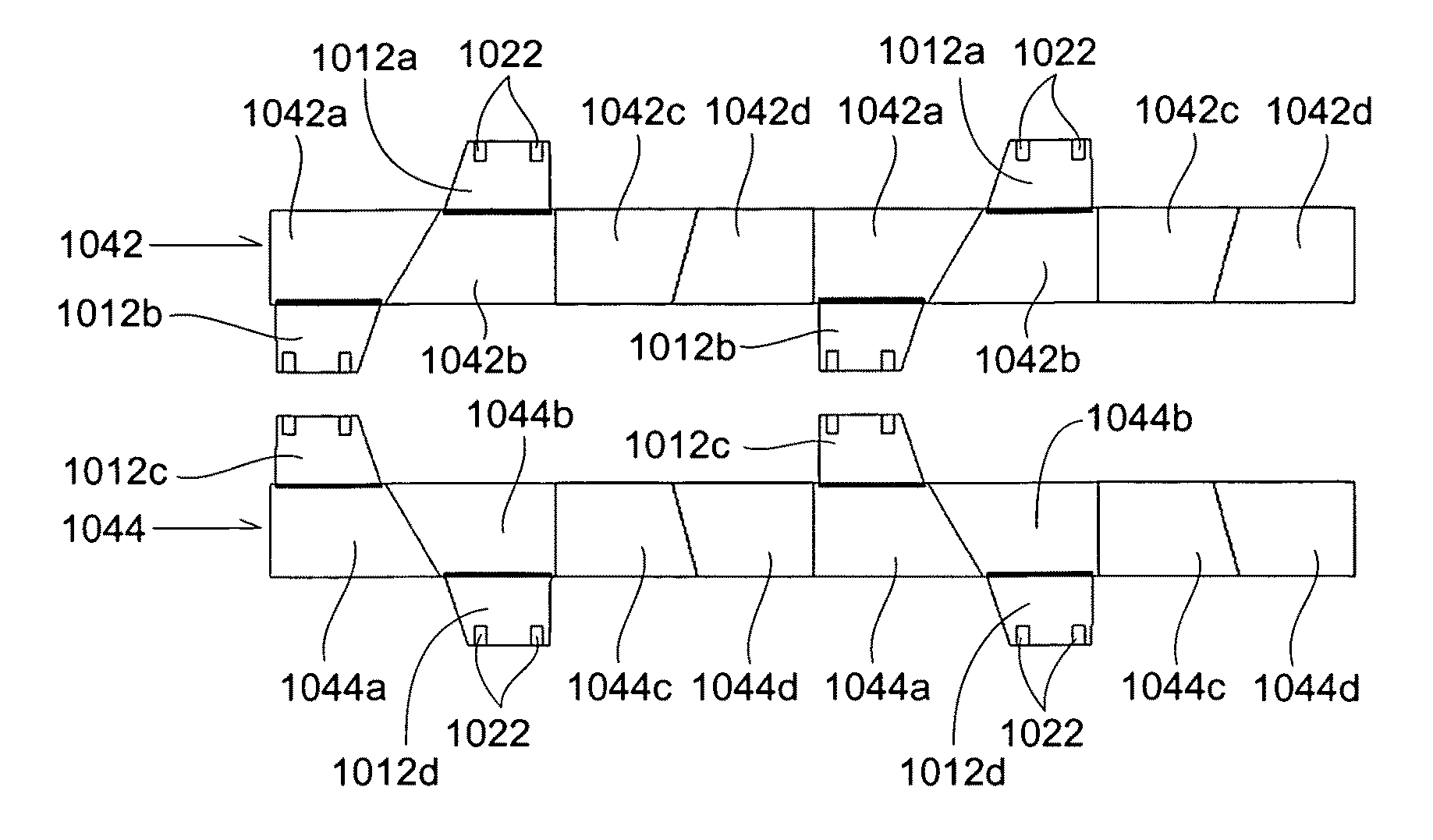

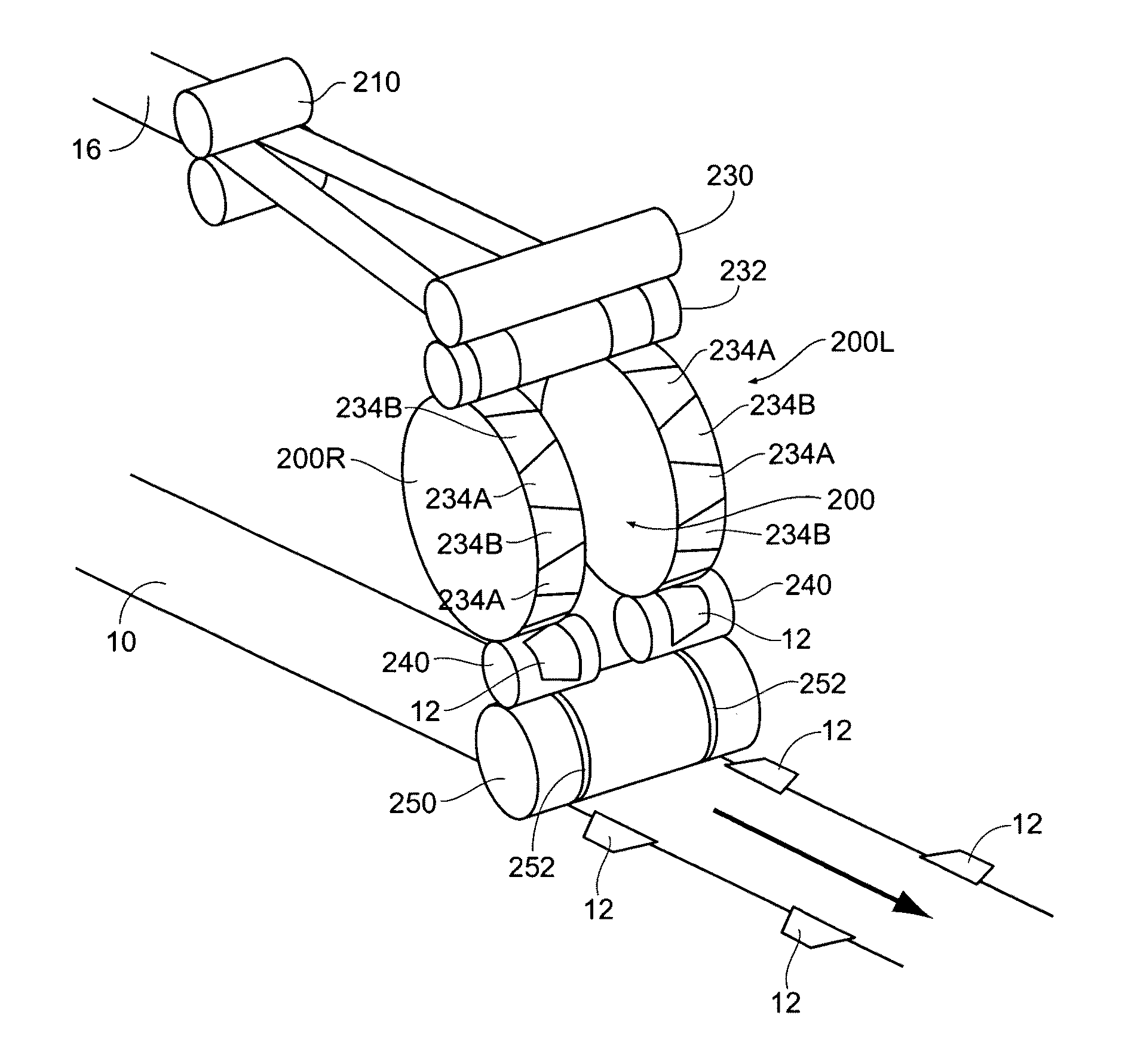

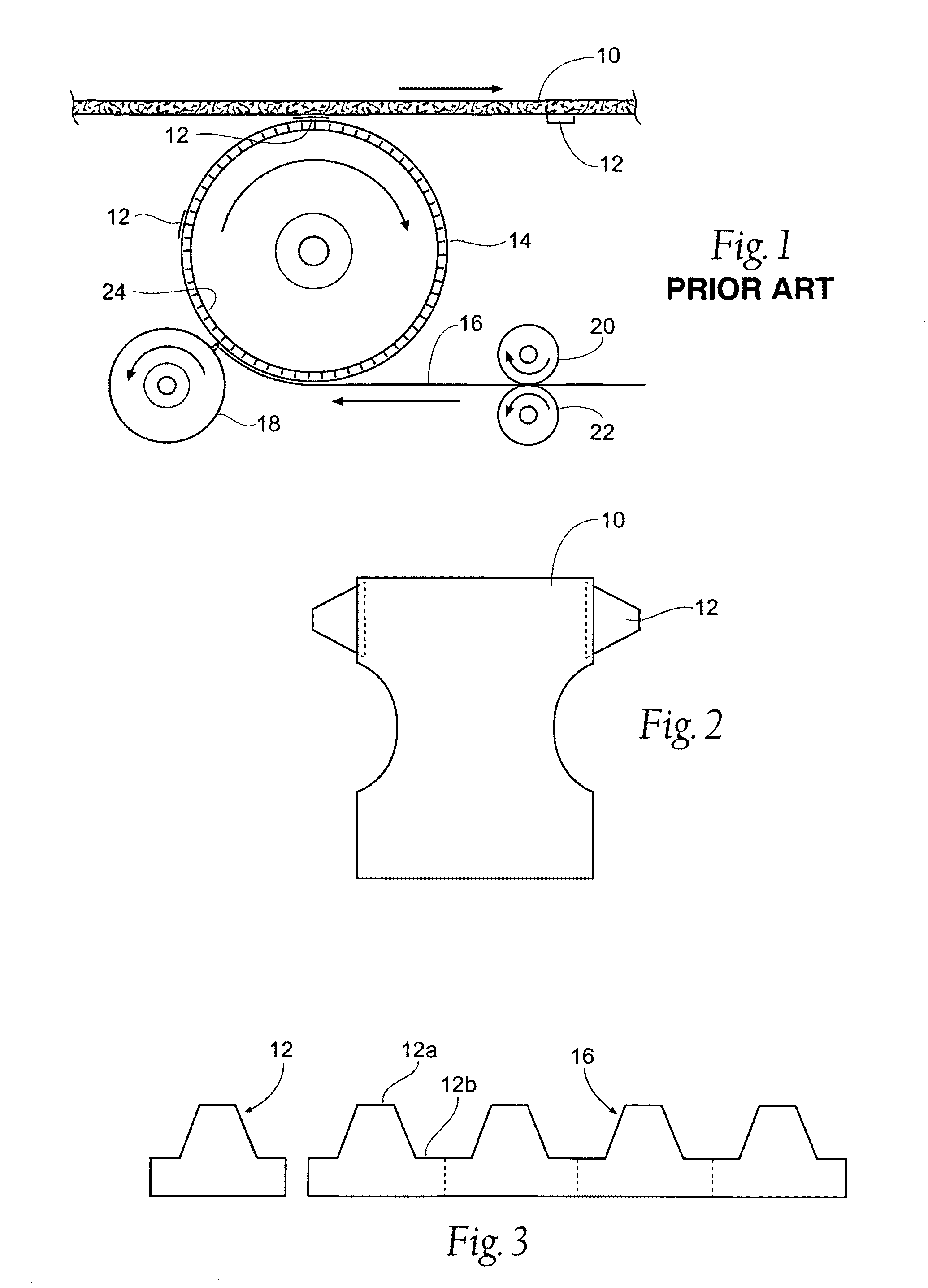

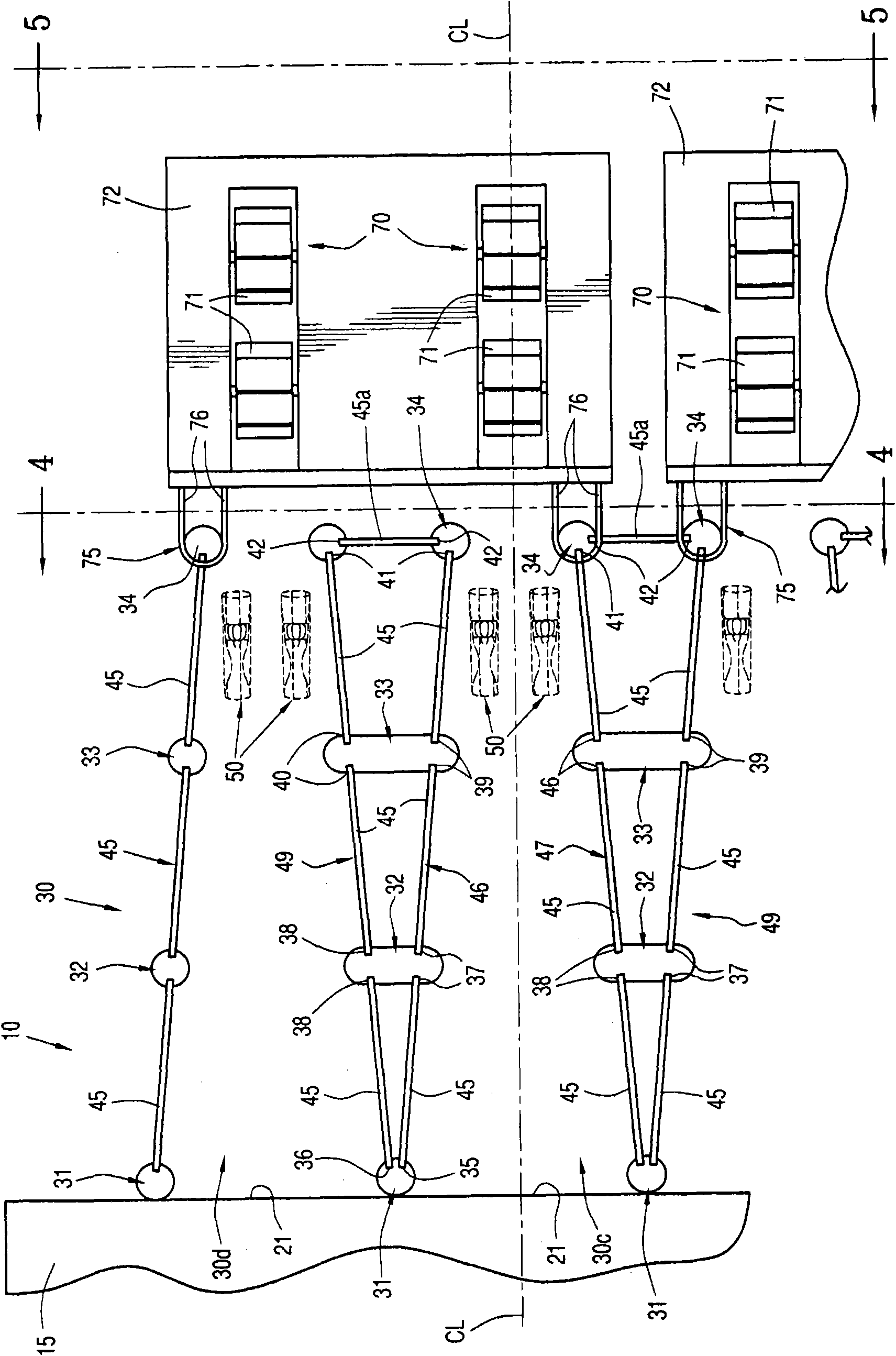

Methods and apparatus for application of nested zero waste ear to traveling web

The present invention provides a process wherein a rotary knife or die, with one or more cutting edges, turns against and in coordination with a corresponding cylinder to create preferably trapezoidal ears. Ear material is slit into two lanes, one for a left side of a diaper and the other for a right side of a diaper. Fastening tapes are applied to both the right and the left ear webs. The ear material is then die cut with a nested pattern on a synchronized vacuum anvil. The resulting discrete ear pieces however, due to the trapezoidal pattern of the ears, alternate between a correct orientation and an incorrect (reversed) orientation. The reversed ear is required to be rotated 180° into the correct orientation such that the ears and associated tape present a left ear and a right ear on the diaper.

Owner:CURT G JOA

Special-purpose board for building and producing method thereof

ActiveCN101168610AProtect the environmentOvercome fear of waterBuilding constructionsSlagPolyvinyl chloride

The invention relates to a building product and the generating method thereof, in particular to a construction special-purpose plate and the manufacturing method thereof. The invention is made of the following raw material according to the parts by weight: 20 to 50 percent of thermoplastic resin comprising polyvinyl chloride, polyethylene and polypropylene, 50 to 80 percent of bulking agent comprising iron ore waste tailing sand, calcium carbonate and slag, and additive occupying 0.05 to 5 percent of the gross weight of the thermoplastic resin and the bulking agent and comprising plasticizer, heat stabilizer and lubricating agent. The product is made by adopting a stone molding and extrusion moulding way, no pollution is produced, no distortion exists, the product is moistureproof and fireproof, the processing waste and the disposed plate of the product can be recycled and newly processed to ensure zero waste, the damage to the environment cannot be caused, and the product is made into a hollow plate structure which has the advantages that the elasticity and the sound insulation effect are good and the heat transfer effect is good, therefore, the invention is very suitable for the heating of a geothermic pipeline, and the difficult problem that a wooden compound floor plate in the present market cannot be used for the heating of the northern geothermic building because of the distortion due to the heating or poor heat insulation heating effect is solved.

Owner:唐山金三顺装饰材料有限公司

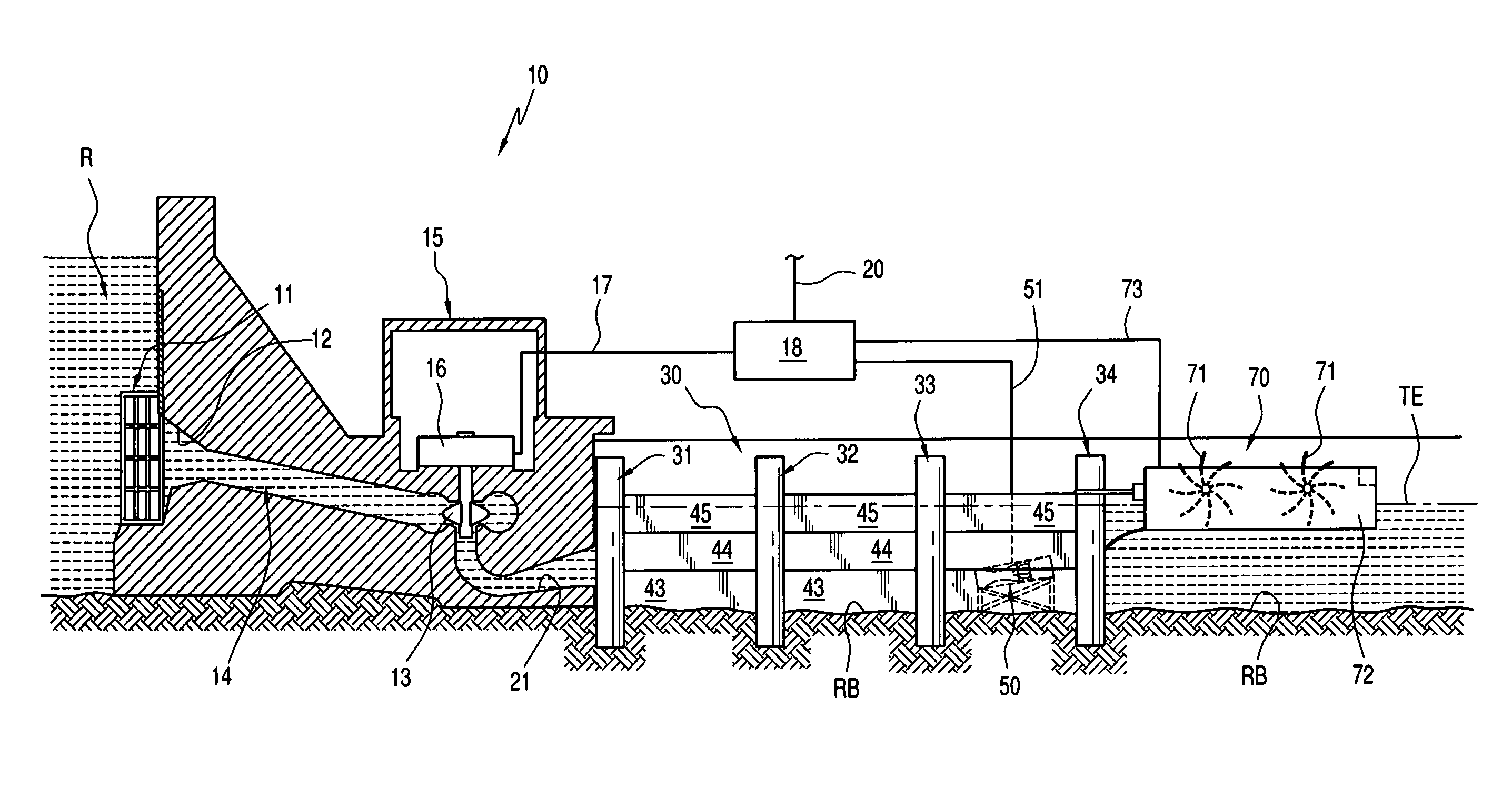

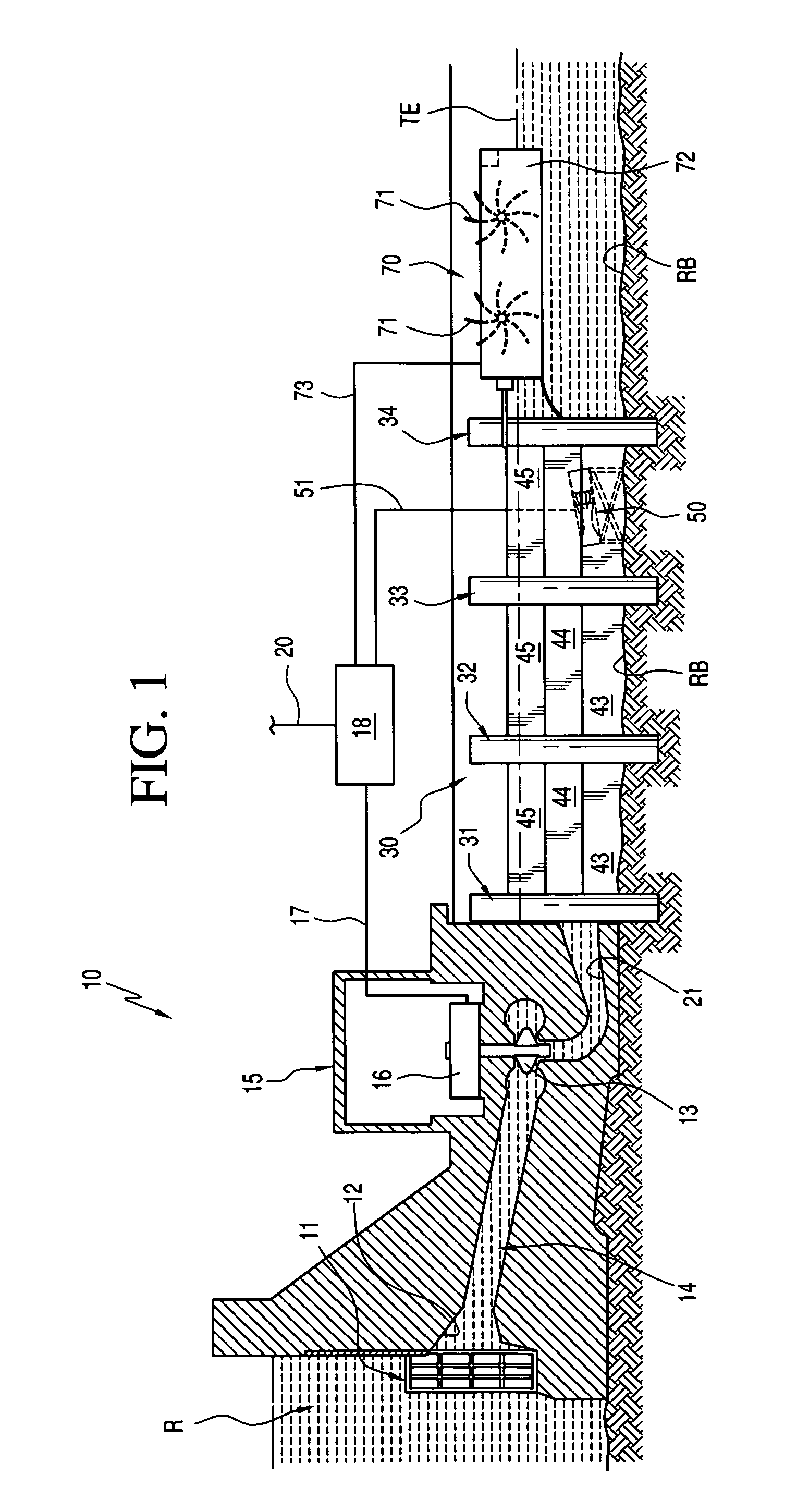

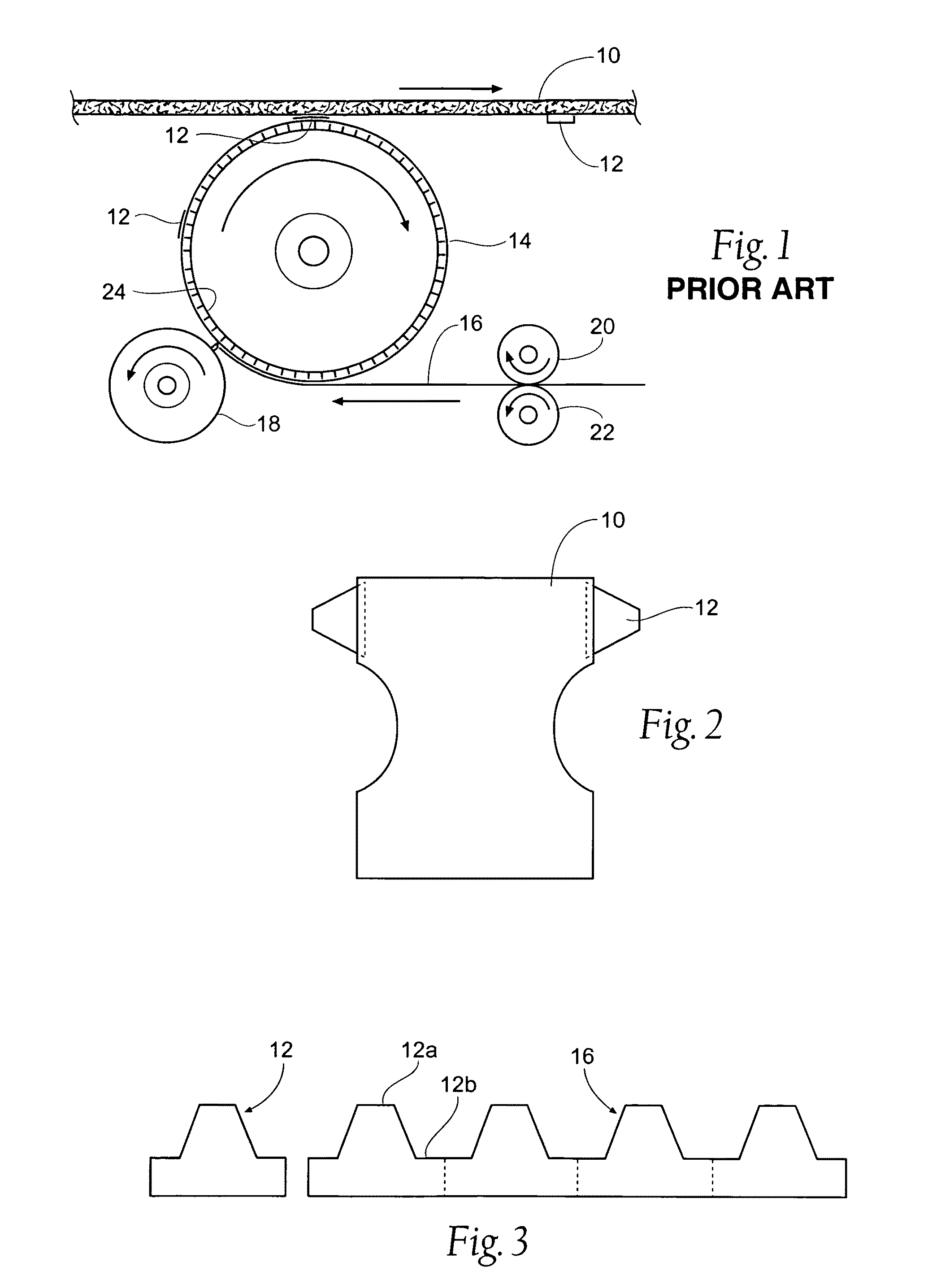

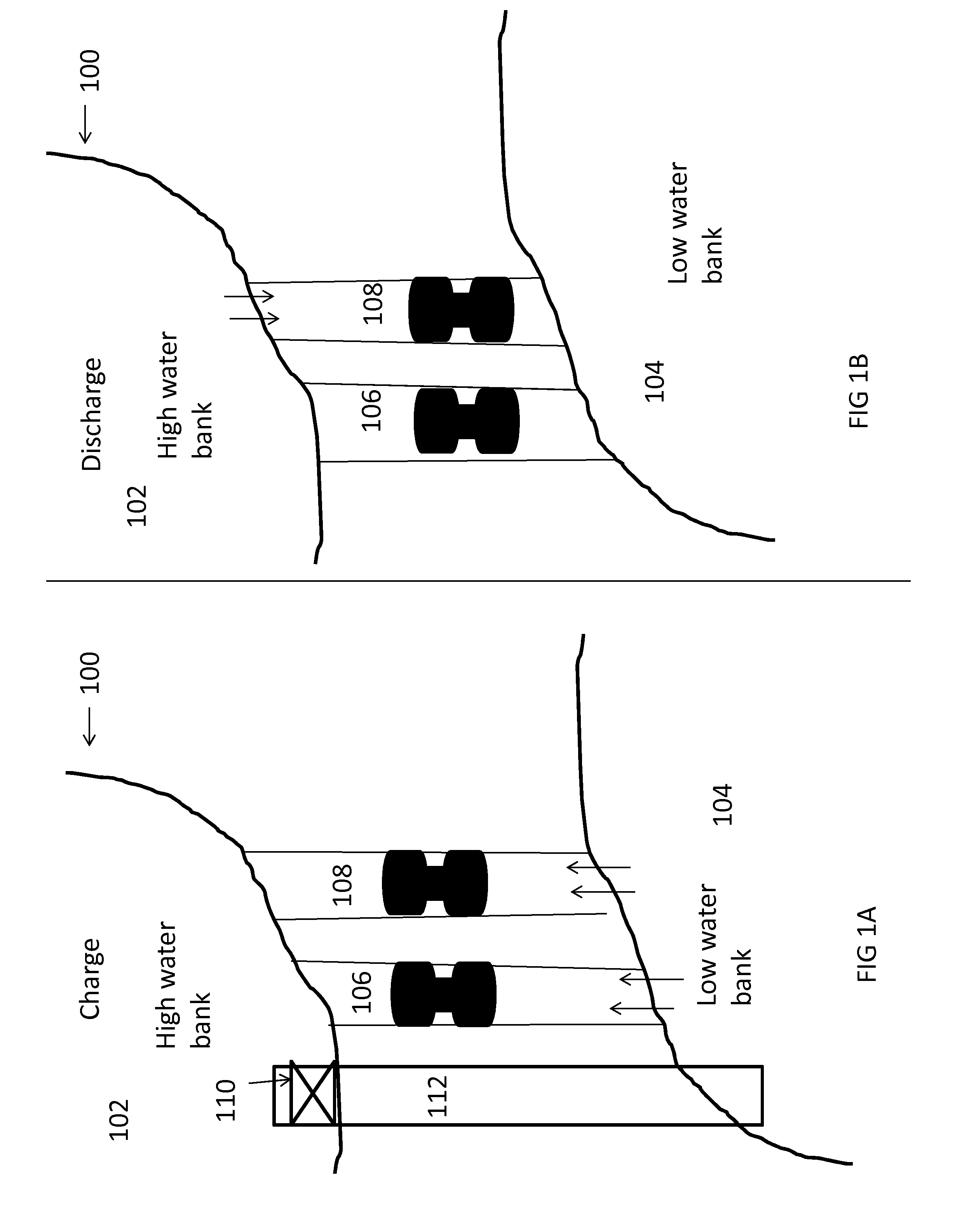

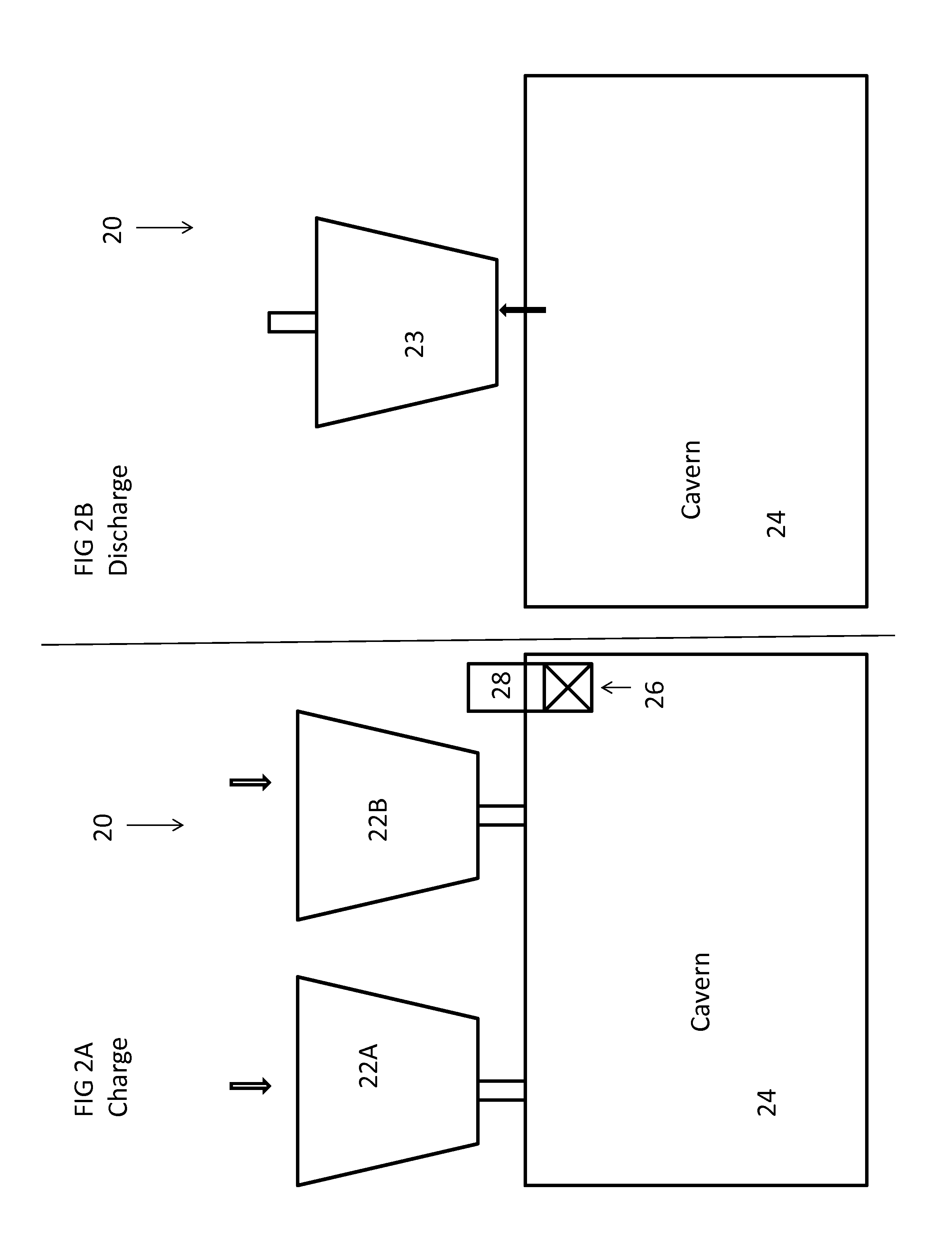

Apparatus for hydroelectric power production expansion

InactiveUS7478974B1Maximize productionLower life cycle costsWater-power plantsReaction enginesEngineeringElectric power

Normally hydroelectric dam powerhouses use river flow once before discharging it as turbulent tailwater, ineffective to spin turbines. The present invention uses tapered channels to confine and constrict turbulent tailwater into laminar flow that drives turbines both submersible and floatable utilizing the same water three times concurrently to generate new electricity. Channels originate adjacent to draft tube outlets, constrict in the downstream direction to create narrow necks where turbine / generators benefit from debris free, increased velocity and laminar flows to generate electricity. Hydroelectricity uses zero fuel, creates zero waste and has zero carbon dioxide emissions. Structures are uncomplicated, construction is within project boundaries minimizing environmental impacts and speeding projects coming online. New facilities are protected by existing dam security. Hydroelectricity replaces less dependable renewable energy systems.

Owner:KELLY WILLIAM LOWELL

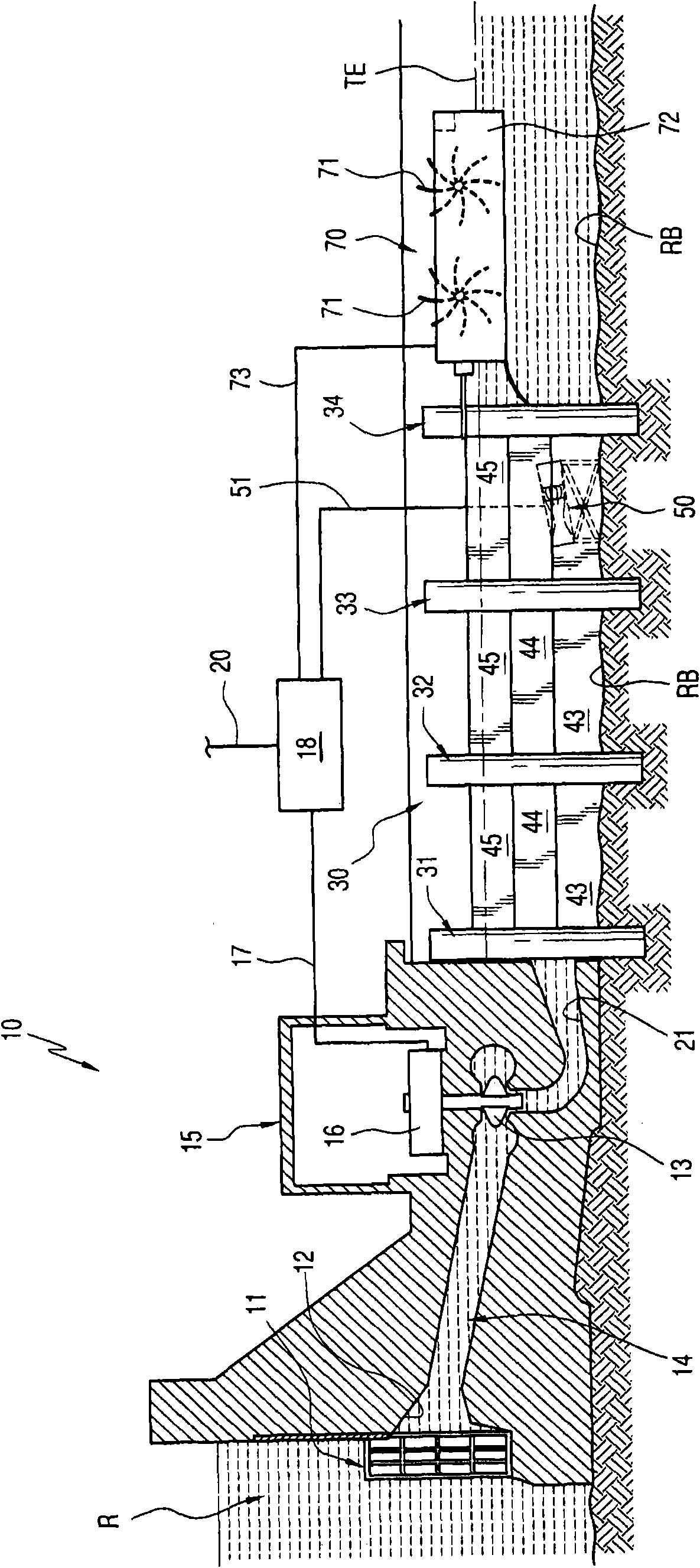

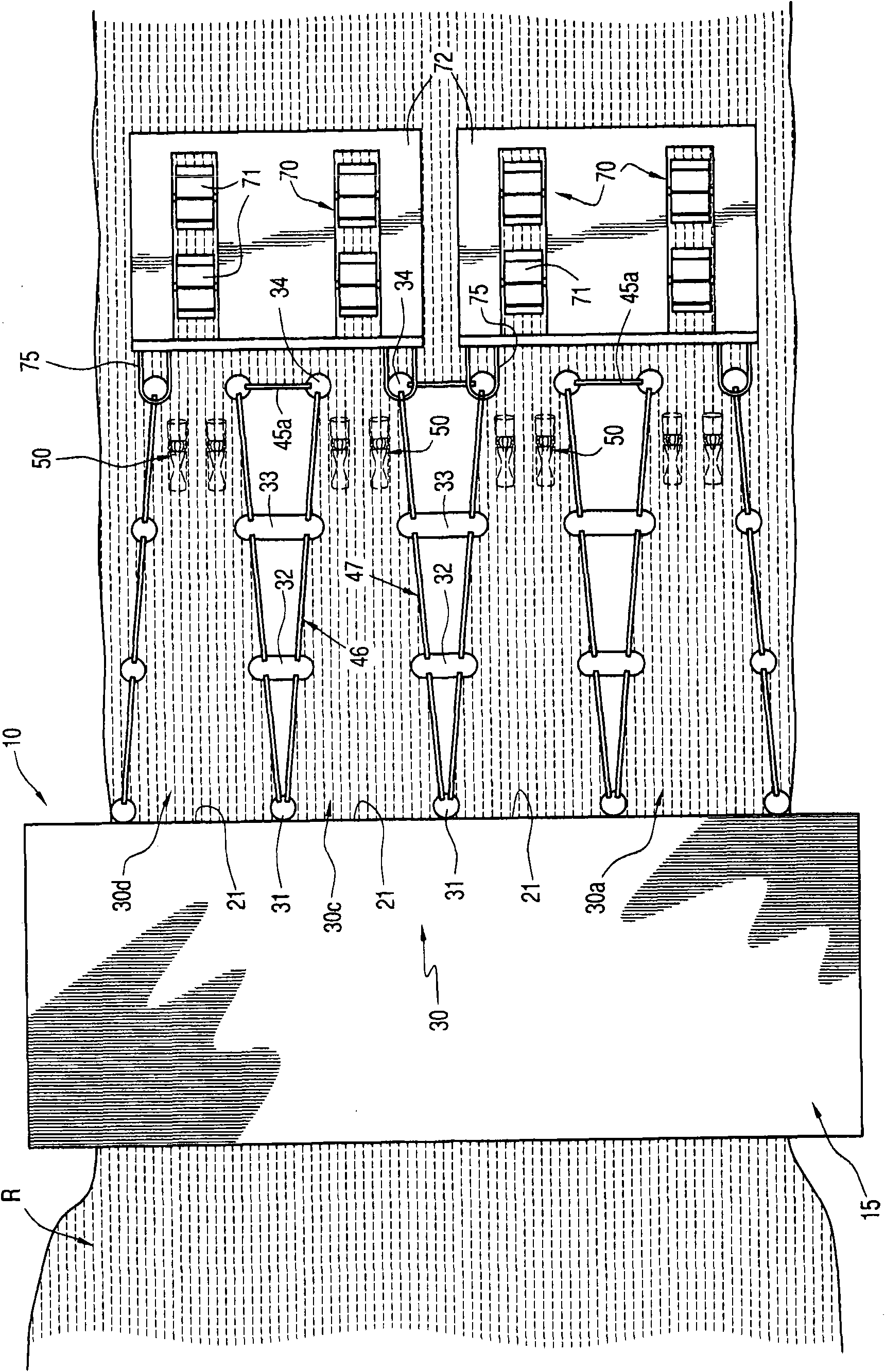

Methods and apparatus for application of nested zero waste ear to traveling web

The present invention provides a process wherein a rotary knife or die, with one or more cutting edges, turns against and in coordination with a corresponding cylinder to create preferably trapezoidal ears. Ear material is slit into two lanes, one for a left side of a diaper and the other for a right side of a diaper. Fastening tapes are applied to both the right and the left ear webs. The ear material is then die cut with a nested pattern on a synchronized vacuum anvil. The resulting discrete ear pieces however, due to the trapezoidal pattern of the ears, alternate between a correct orientation and an incorrect (reversed) orientation. The reversed ear is required to be rotated 180° into the correct orientation such that the ears and associated tape present a left ear and a right ear on the diaper.

Owner:CURT G JOA

Methods and apparatus for application of nested zero waste ear to traveling web

The present invention provides a process wherein a rotary knife or die, with one or more cutting edges, turns against and in coordination with a corresponding cylinder to create preferably trapezoidal ears. Ear material is slit into two lanes, one for a left side of a diaper and the other for a right side of a diaper. Fastening tapes are applied to both the right and the left ear webs. The ear material is then die cut with a nested pattern on a synchronized vacuum anvil. The resulting discrete ear pieces however, due to the trapezoidal pattern of the ears, alternate between a correct orientation and an incorrect (reversed) orientation. The reversed ear is required to be rotated 180° into the correct orientation such that the ears and associated tape present a left ear and a right ear on the diaper.

Owner:CURT G JOA

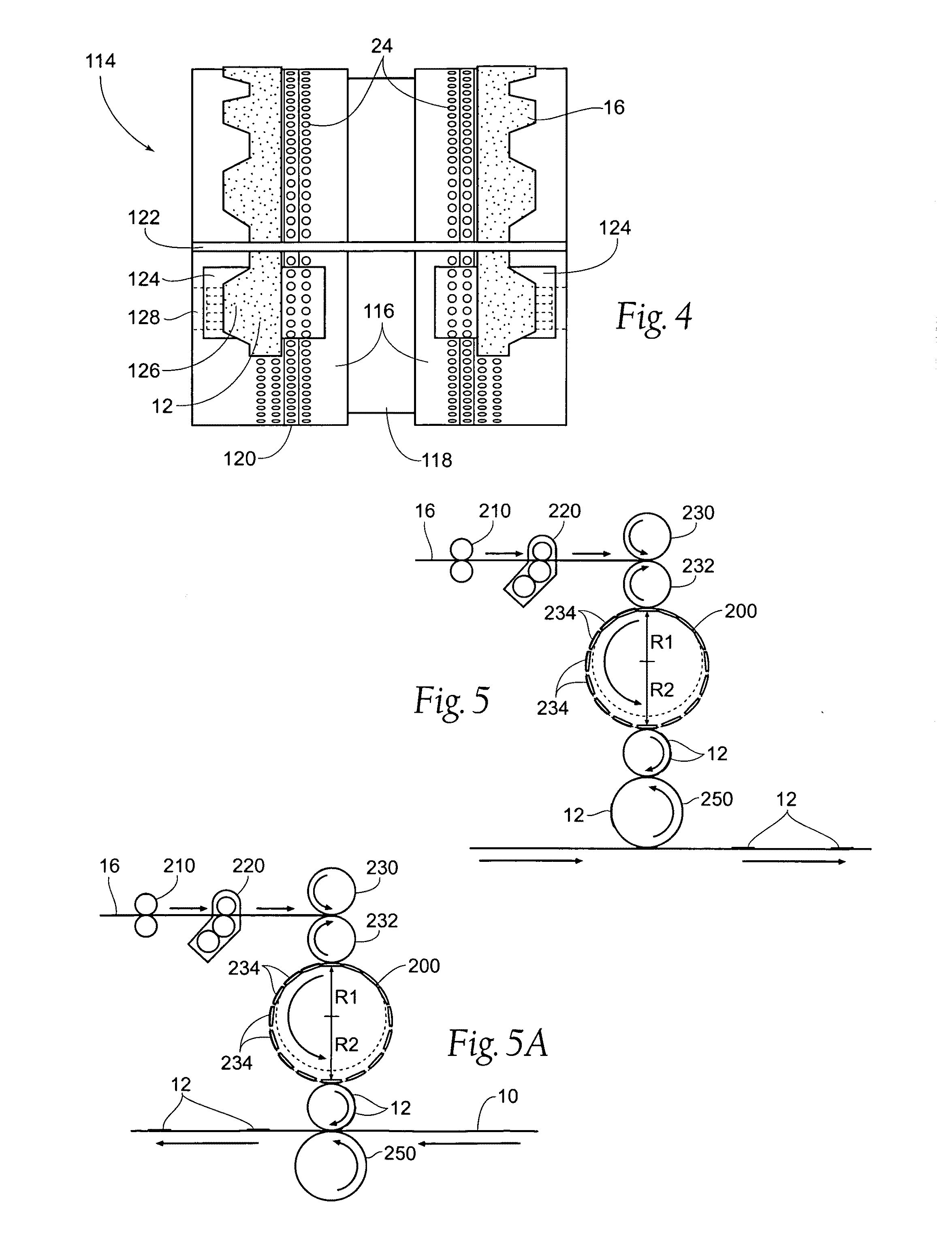

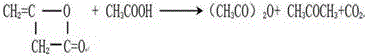

Method for extracting ketene dimer by rectifying residues and pumped liquid

The invention relates to a method for extracting ketene dimer by rectifying residues and pumped liquid. The method comprises the following steps that firstly, hydrolysis is carried out, wherein primary residues and the pumped liquid are mixed in the proportion of 2:1 and heated to 65-75 DEG C through a membrane type evaporator, ketene dimer is evaporated out, crude ketene dimer obtained through cooling of a primary condenser and a secondary condenser enters a high-order storage tank and is mixed with crude ketene dimer generated in a polymerization section, and then mixed crude ketene dimer enters a rectifying section; secondly, secondary residues formed in the membrane type evaporator and acetic anhydride in the condensers enter a hydrolysis section for hydrolysis, and acetone, dilute acetic acid and solid waste residues are obtained; thirdly, tail gas at the hydrolysis section is fed to a water scrubber to be absorbed. The method has the advantages that crude ketene dimer is recycled through heating of the membrane evaporator, the yield of crude ketene dimer is increased inside the system, consumption of glacial acetic acid is reduced, waste gas and residues generated in the production process are digested and absorbed, solid waste is greatly reduced, and zero waste water emission is achieved.

Owner:ANHUI JINGHE IND

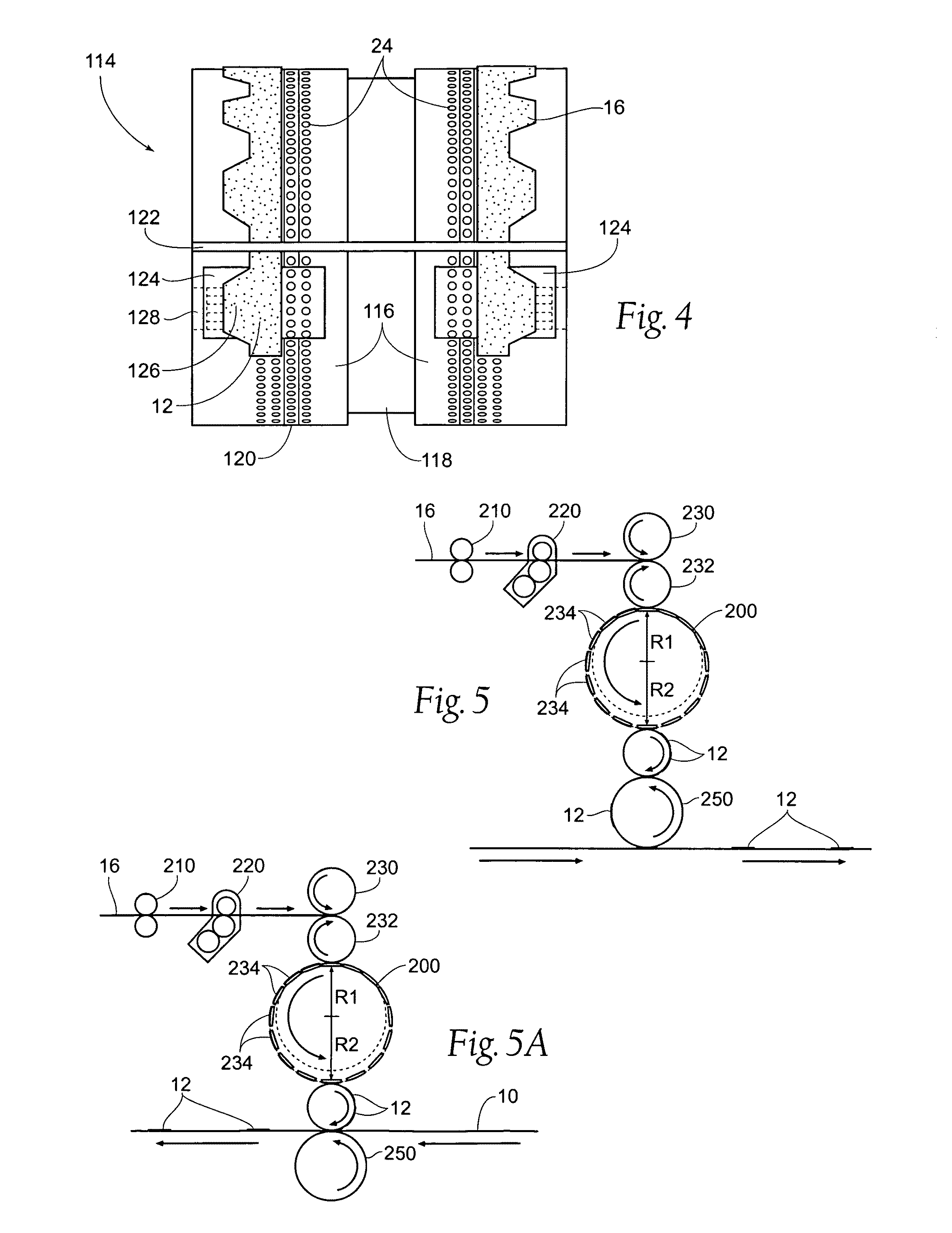

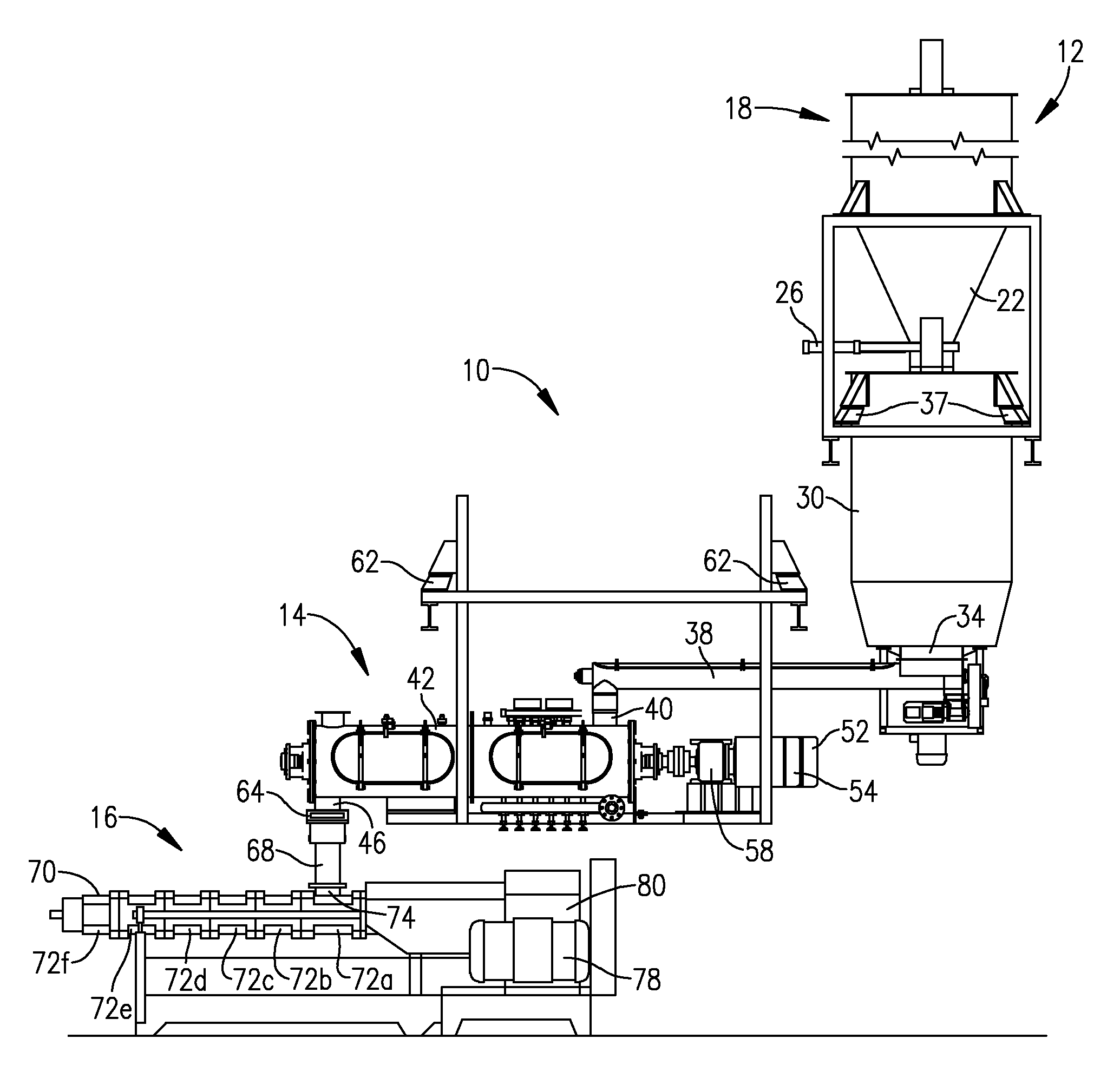

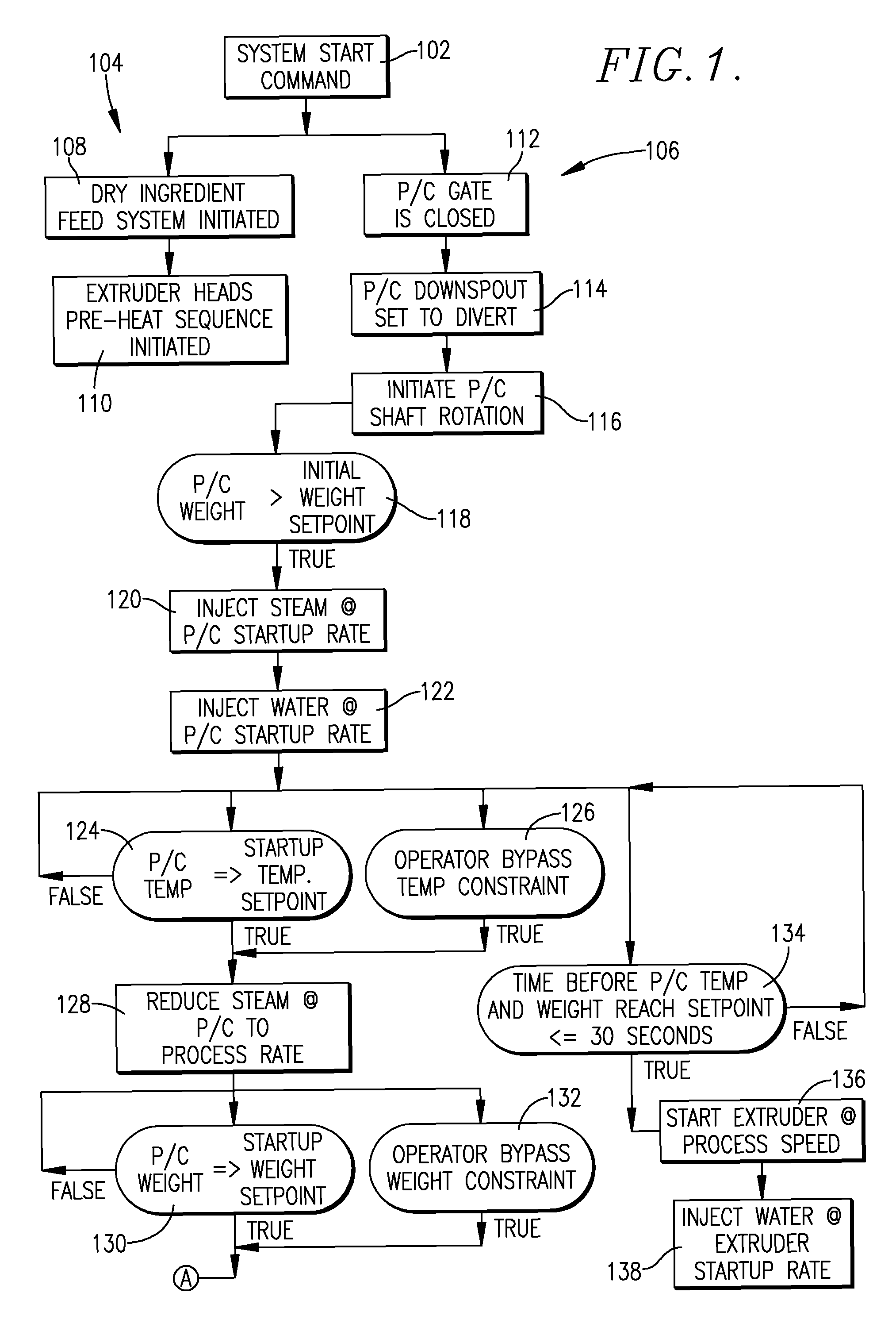

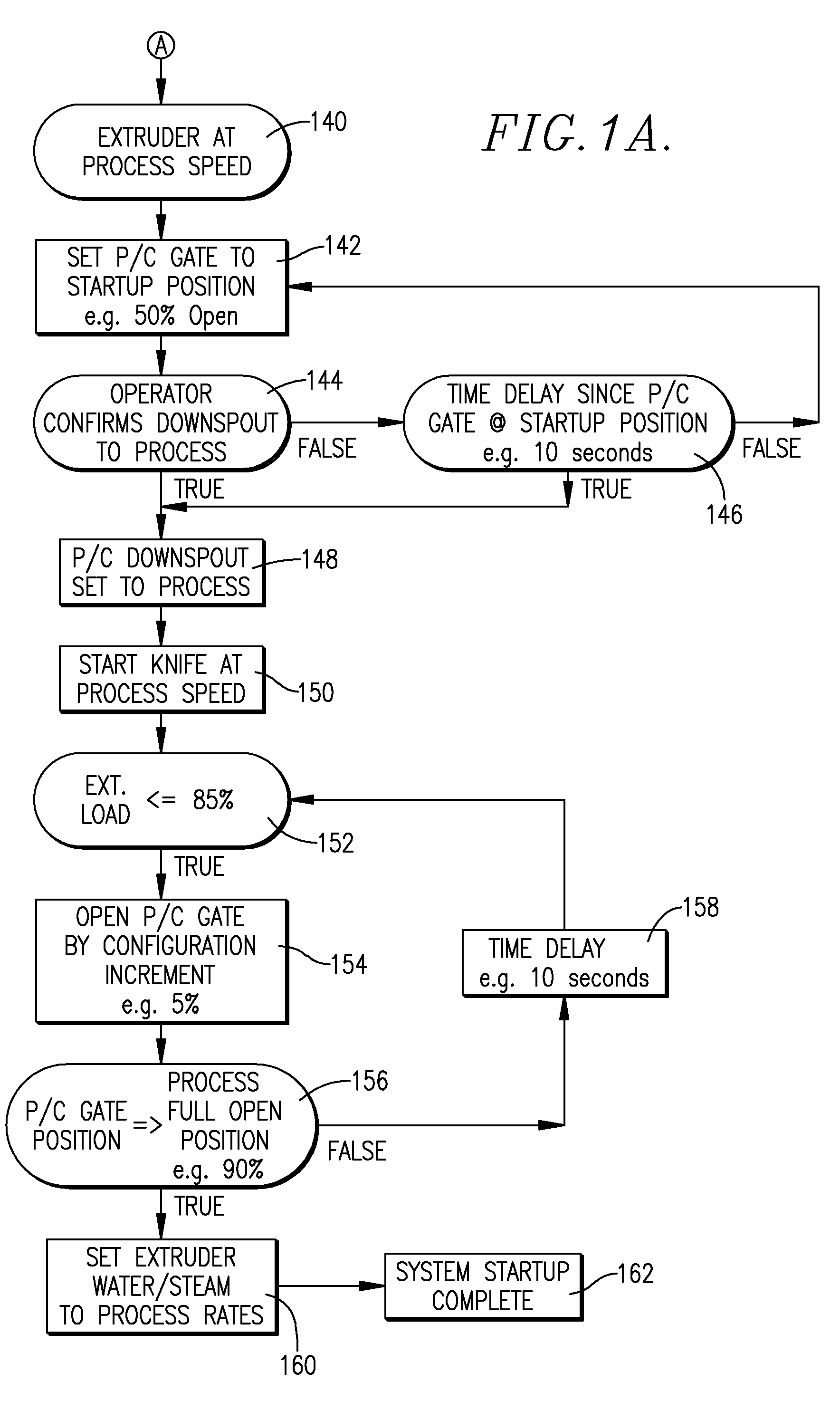

Method of preconditioner control with reduced or zero waste

ActiveUS7794134B1Easy to disassembleSignificant to useOther chemical processesFeeding-stuffDownstream processingProcess engineering

Improved, low- or no-waste control methods for food processing systems including a preconditioner (14) and a downstream processing device such as an extruder (16) are provided. The control methods include both startup and shutdown sequences, and an optional flush sequence. During startup, a gate (64) of preconditioner (14) is initially closed and is thereafter sequentially opened to a full open, normal operating position after predetermined preconditioner temperature and / or weight set points are achieved. Shutdown involves terminating the flow of ingredients to the preconditioner (14) while the gate (64) remains open, with the preconditioner operated to deliver the preconditioned material within the preconditioner (14) to the extruder (16) for as long as possible in order to minimize any residual waste within the preconditioner.

Owner:WENGER MFG LLC

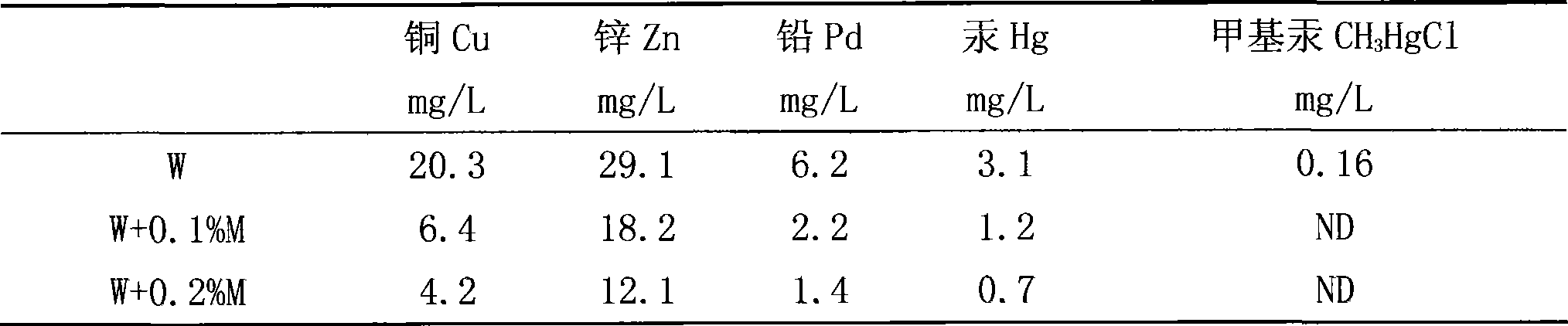

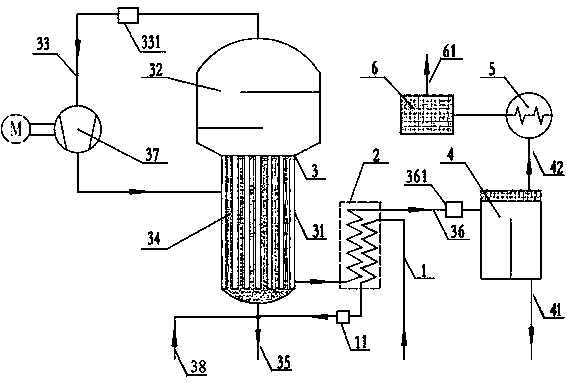

Zero sludge and resource handling arrangement and recovery method of heavy metal waste water

InactiveCN101357809AZero wasteZero pollutionMultistage water/sewage treatmentCopper oxides/halidesRecovery methodHigh concentration

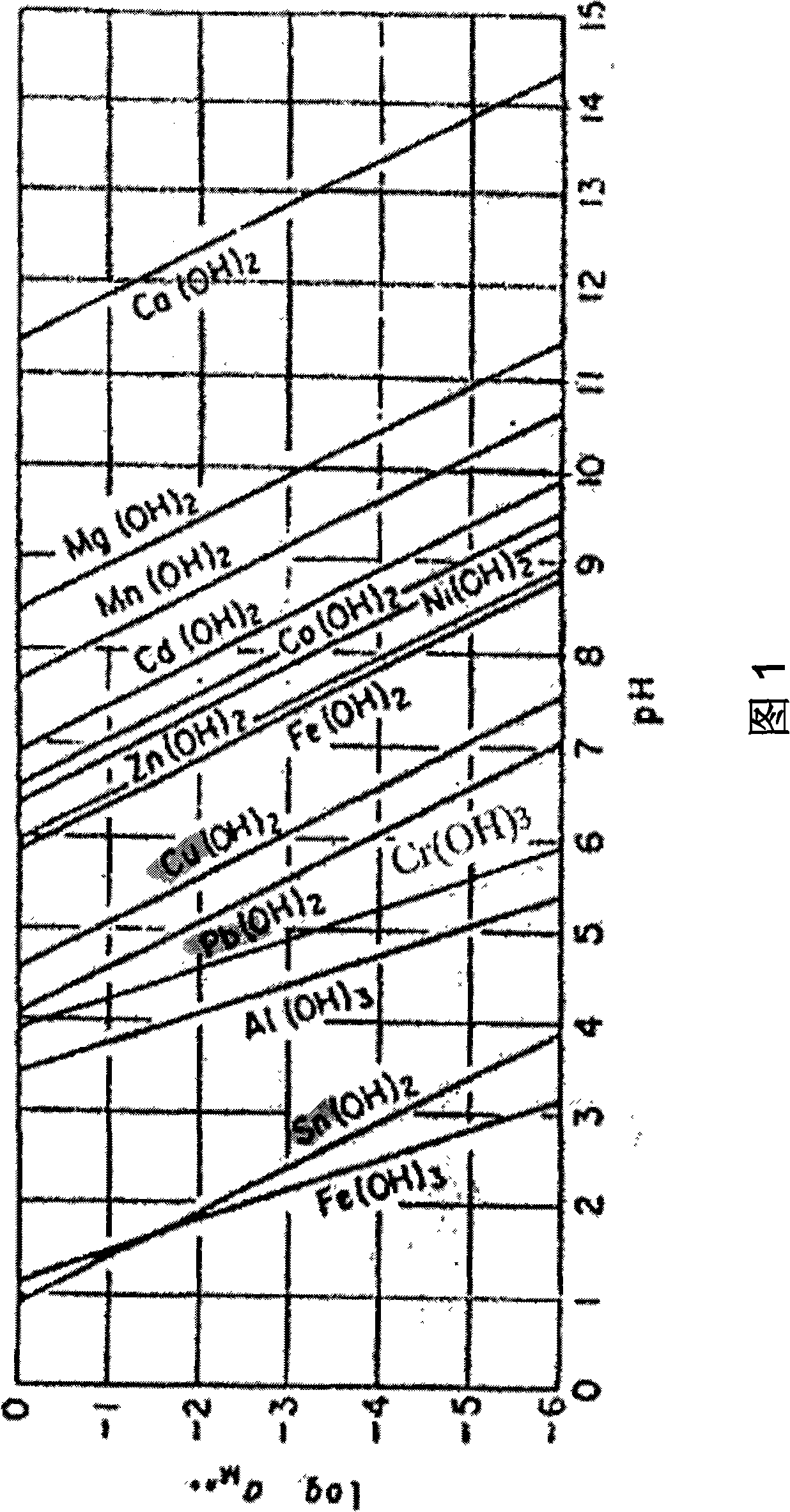

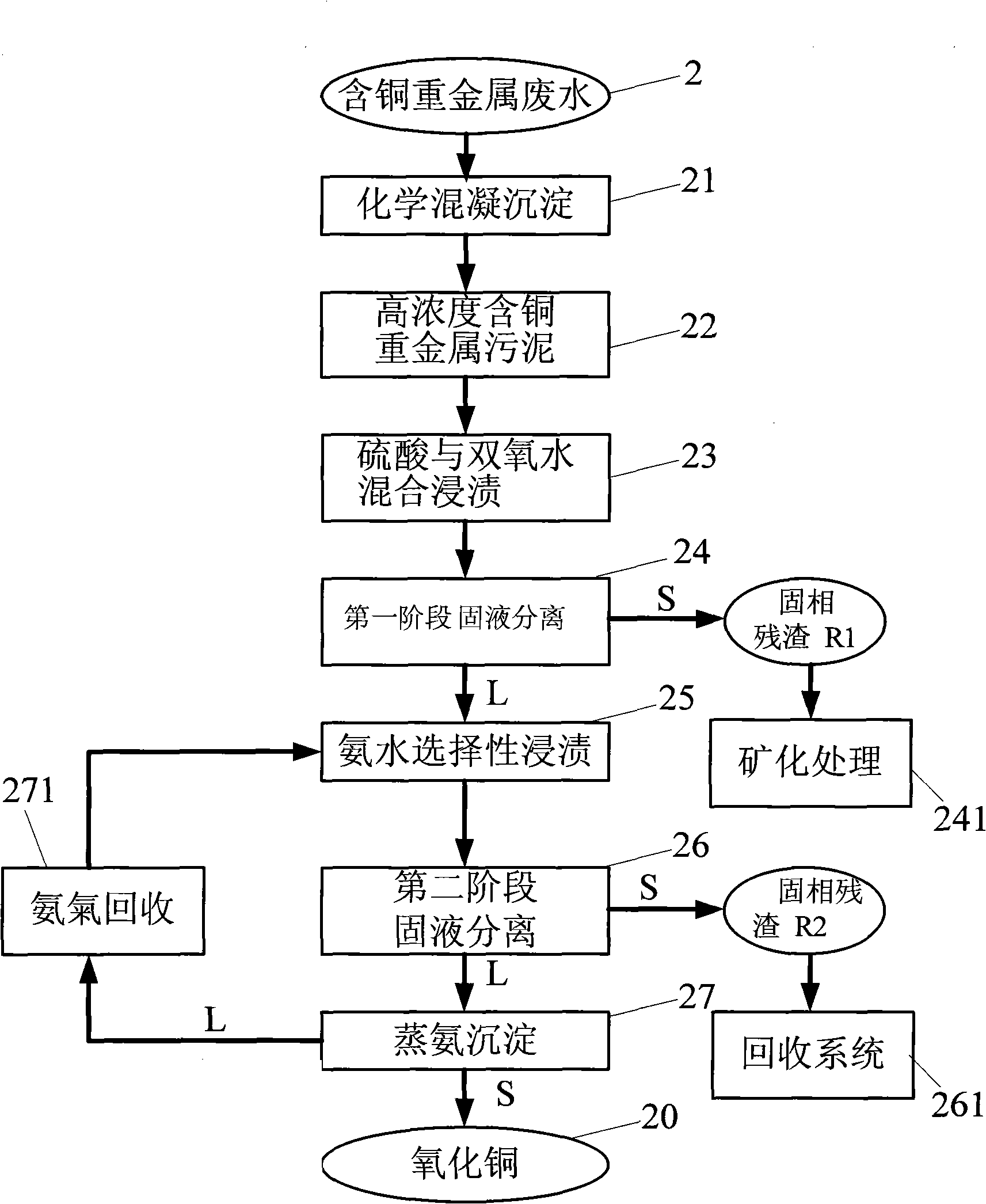

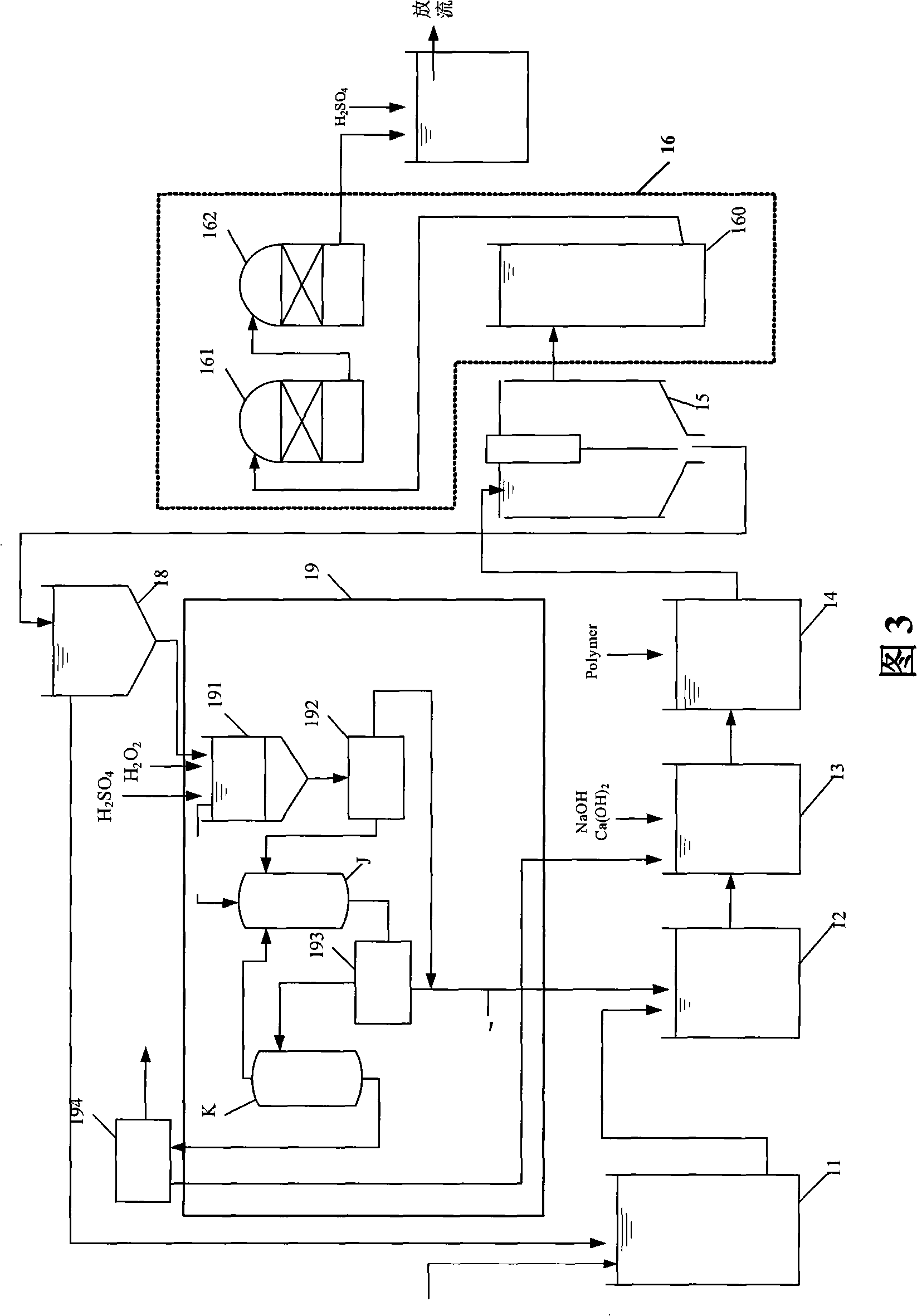

The invention relates to a treatment device and a recovery method for zero sludge resource recovery of heavy metal wastewater, the heavy metal wastewater which mainly contains copper is coagulated and sedimented chemically, after that, sludge with high-concentration copper ions is formed by concentration, the heavy metal sludge is dipped in mixed liquid of sulfuric acid and hydrogen peroxide, thereby obtaining impregnation liquid with the high-concentration copper ions; ammonia water is further used for adjusting the pH value of the impregnation liquid, the selective impregnation is carried out, ammonia copper solution and residues which are rich in iron or aluminium can be obtained after the solid-liquid separation, the ammonia copper solution is done with the procedure of heating and ammonia distillation, then copper oxide and ammonia with very high utilization values can be obtained by recovery, wherein, the generated residues are recovered to be directly added in a rapid mixing tank during the wastewater treatment process as a coagulating agent, the harmless treatment is carried out by wet treatment, or the resource recovery is carried out by using the dry smelting method to recover the iron or the aluminium, and the generated ammonia during the procedure of heating and ammonia distillation can be recovered and reused. The purposes of zero sludge, zero waste and zero emission output can be achieved.

Owner:蔡敏行

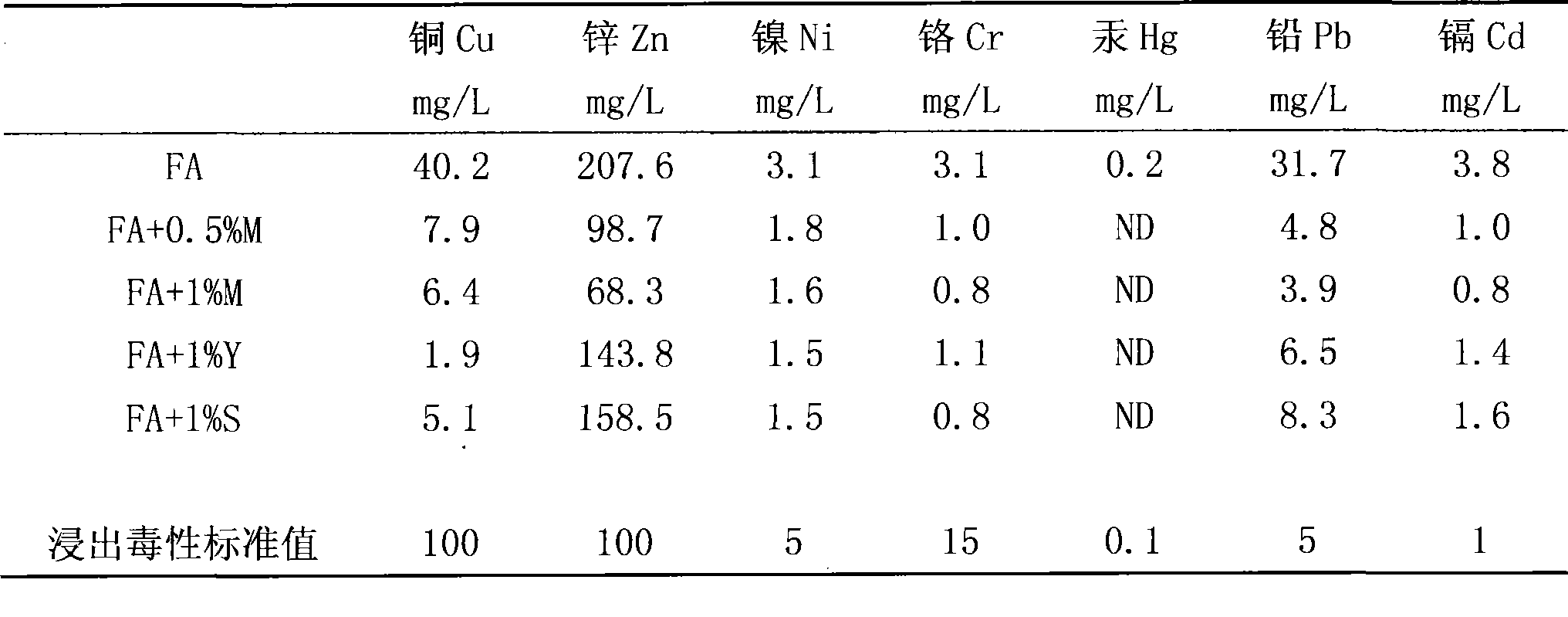

Water-soluble high molecule intercalating agent containing thiourea group and preparation method

ActiveCN101456939AImprove responseReduce investmentSludge treatmentOther chemical processesSolubilityLiquid waste

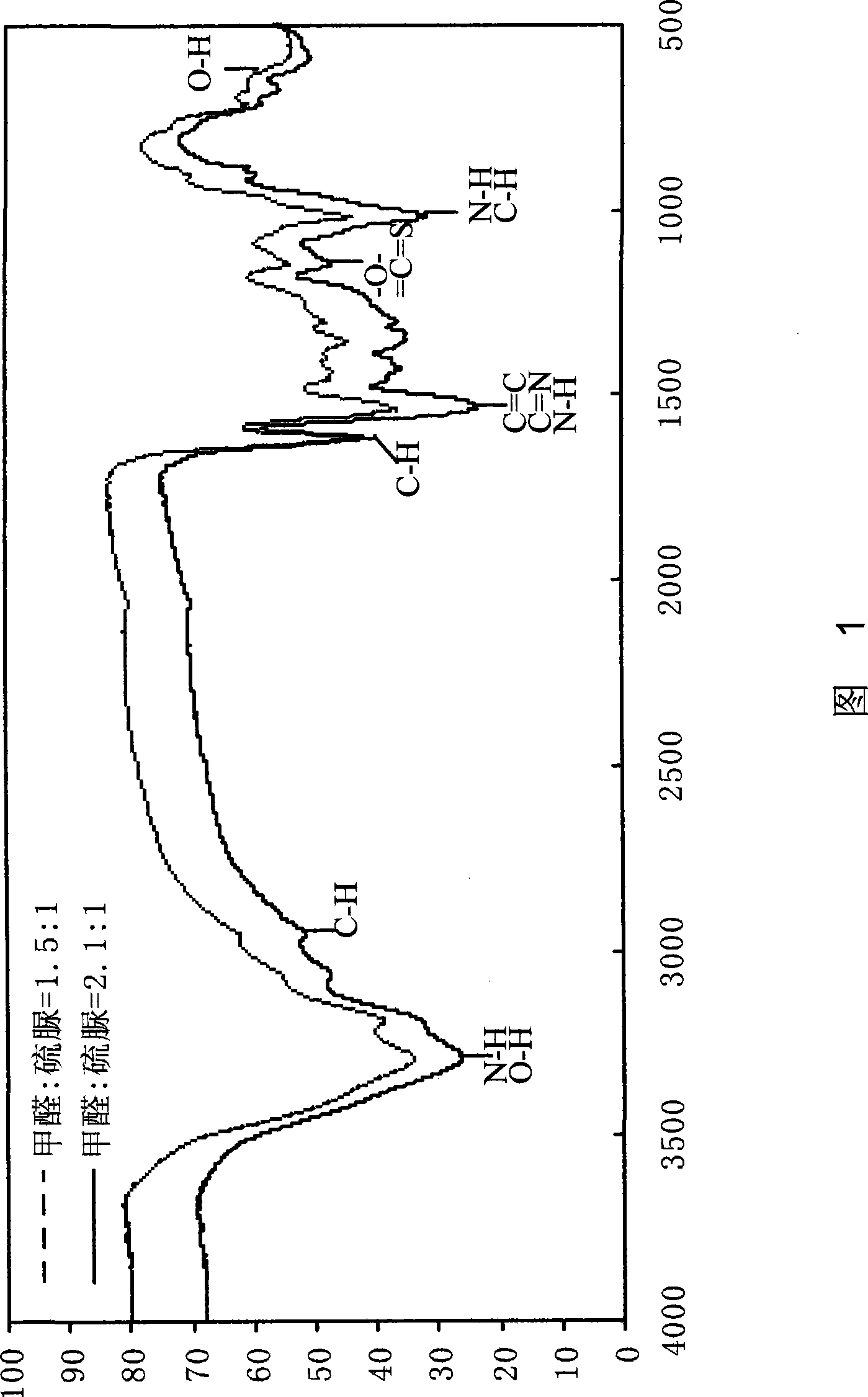

The invention discloses a water-solubility macromolecular chelant containing sulfourea group and a preparation method thereof. The chelant of the invention is prepared by the following method: (a) adjusting the pH value of formaldehyde with acid liquor to activate the formaldehyde; (b) adding the sulfourea, adjusting the pH value with alkali, and reacting at the temperature of 75-90 DEG C; (c) adjusting the pH value with the acid, adding the alcoholic solution of benzene sulfonyl chloride to react at 70-90 DEG C; (d) reducing temperature to 50-60 DEG C, adjusting the pH value with the alkali, and reducing the temperature to below 40 DEG C to prepare the chelant. The chelant of the invention has chelation sedimentation function to almost all of the transition stated heavy metals, which can not only be used in the treatment of the heavy metal sewage containing copper, zinc, nickel, mercury, cadmium, and the like, but also can be used in the stabilization treatment of the heavy metal in the solid wastes such as mud, waste incineration flying ashes, and the like. The preparation method of the invention has the advantages of no need of high temperature and high voltage, low one-time investment, easy availability of raw materials, and zero waste gas, waste liquid and waste residue in the production process.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

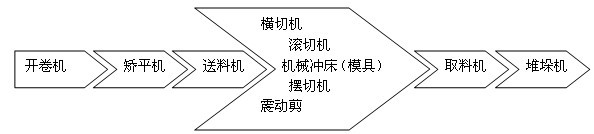

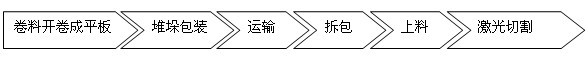

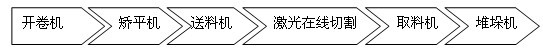

Processing method of automatic-feeding laser cutting

InactiveCN102490070ACancel noiseEliminate vibrationMetal working apparatusLaser beam welding apparatusLaser processingDevice material

The invention relates to the technical field of laser processing, in particular to a processing method of automatic-feeding laser cutting, which comprises the following steps of 1 uncoiling a coiled material into a flat plate through an uncoiler, and leveling the coiled material uncoiled into the flat plate through a leveler; and 2 pushing the coiled material leveled in the step 1 into a laser cutting work area through an automatic feeder, and cutting and processing the coiled material into a plurality of workpieces through laser. Therefore, the processing method of the automatic-feeding laser cutting has the advantages of 1 being free of noise, vibration and greasy dirt, safe and environment-friendly; 2 being capable of randomly being cut in a suit mode, and completely cutting the material in the suit mode theoretically to achieve zero waste material; 3 saving device materials and reducing problems of investment waste and environment pollution caused by casting of large-sized devices and corresponding moulds; 4 greatly improving production efficiency and rate of finished products of relevant industries; 5 being capable of obtaining high accuracy and good quality and being wide in application range; and 6 reducing operation and maintenance costs of the devices, energy consumption and invested operation cost of large-sized coil feed lines.

Owner:余小刚

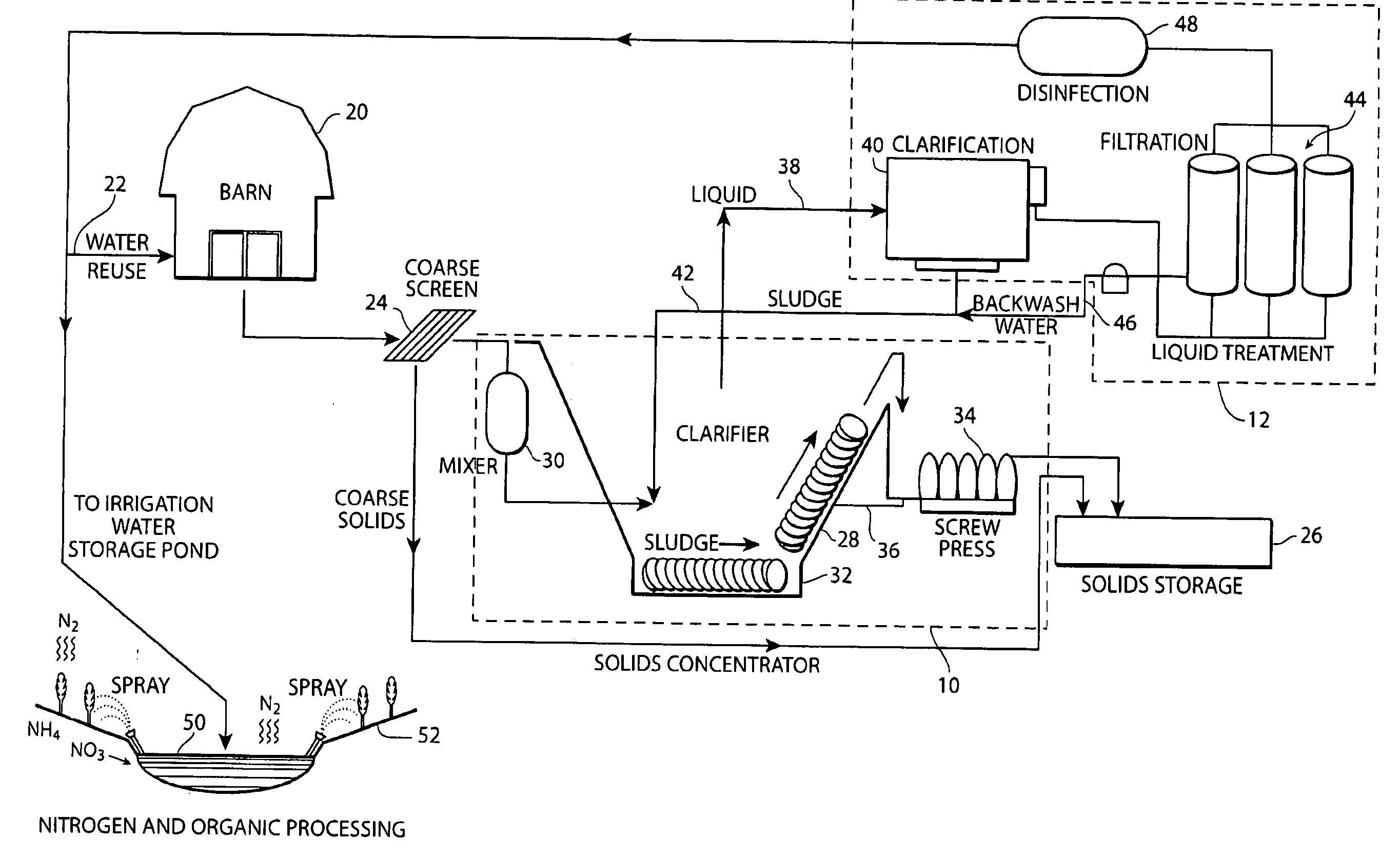

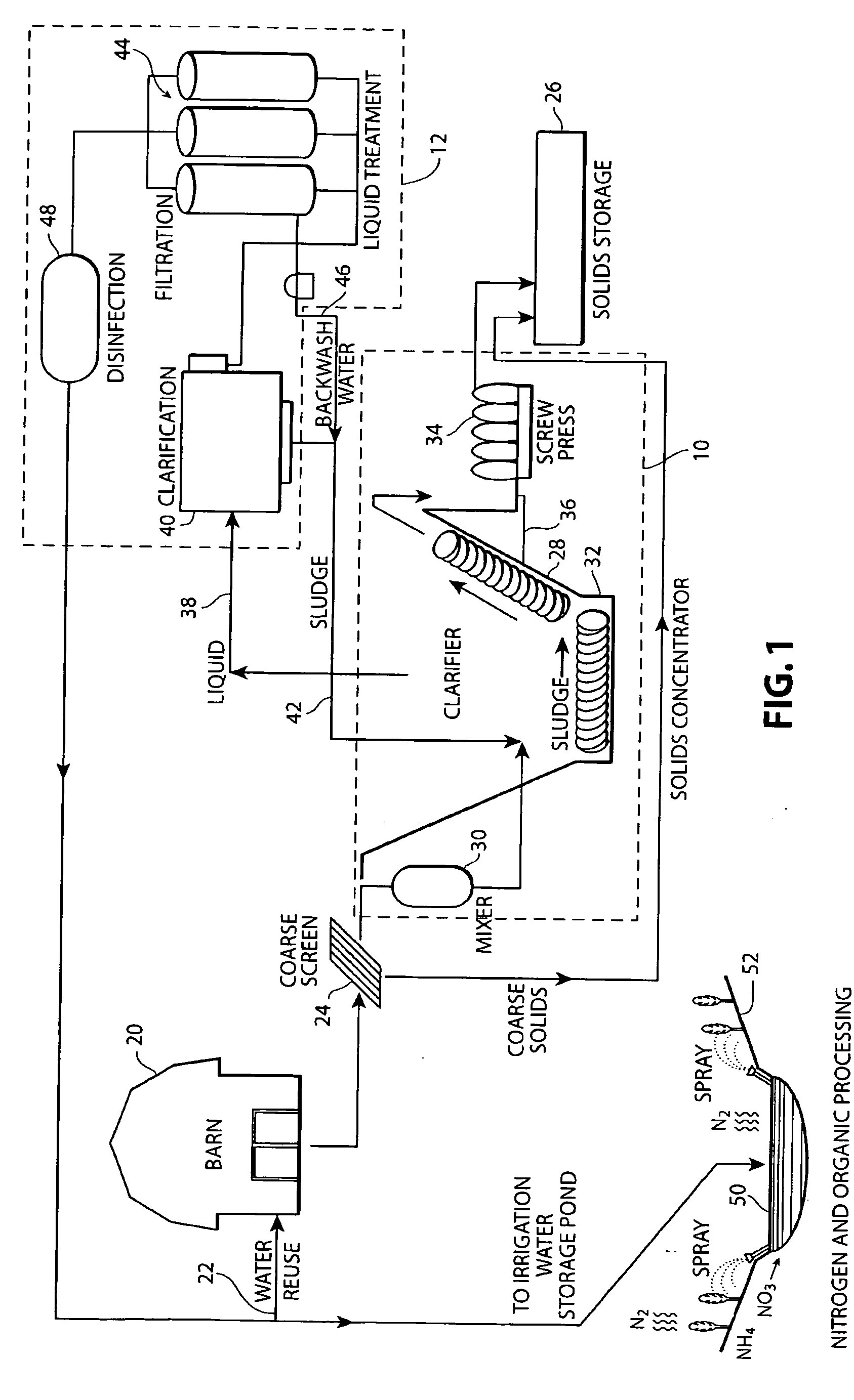

Animal waste treatment system with reusable recovered water and solids

InactiveUS20040226895A1Easy to operateLow impurity contentProductsOther chemical processesWater usePotable water

A high content recovery system which allows for the processing of animal waste and the reuse of the nutrient rich solids and water used in the processing of such animal waste. The recovery system includes a solids concentrator section which concentrates solids and aids in removal of the liquids, a liquid treatment section which treats the water in such manner to allow the same to be reused as potable water and an organic waste processing area. The system is efficient in using substantial portions of the animal waste, both as the nutrient rich solids for fertilizer and other applications and reuse of the water for further processing and other uses and thus effectively constitutes a zero waste discharge system.

Owner:BROMLEY DAVID

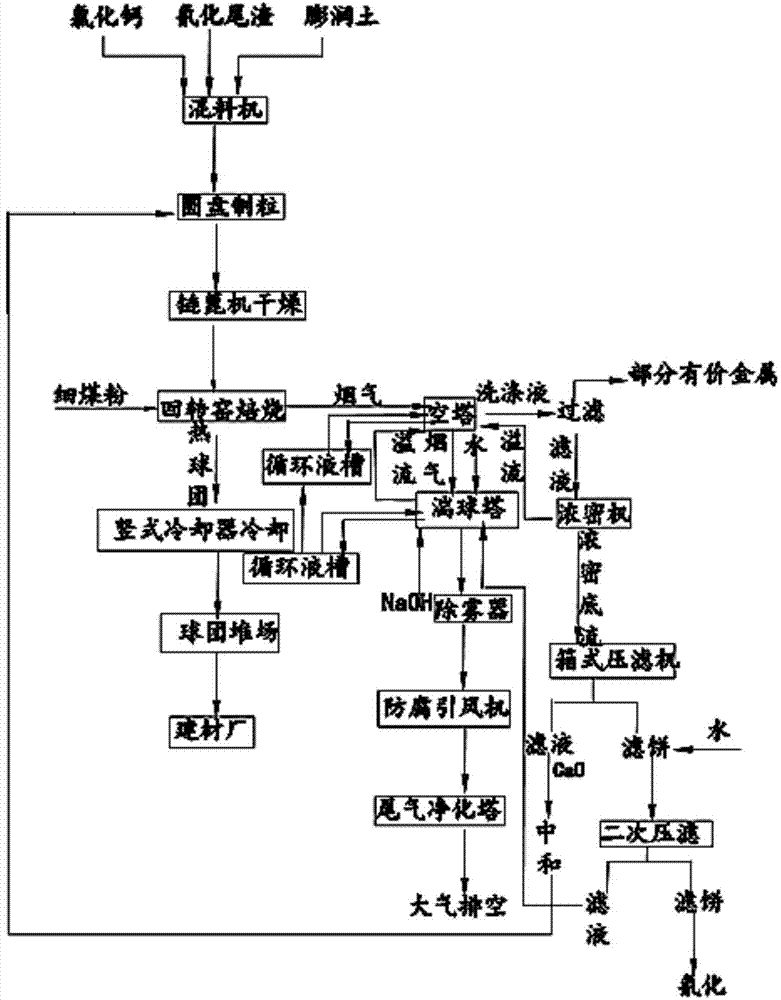

Method for extracting gold from cyanidation tailings

InactiveCN104726716AHigh recovery rateHigh strengthProcess efficiency improvementSodium BentoniteResource utilization

The invention belongs to the technical field of metallurgy, and particularly relates to a method for extracting gold from cyanidation tailings. The method comprises the following steps that the cyanidation tailings, bentonite and calcium chloride are proportionally mixed, pelletized, dried and roasted; metal gold and chlorine form a chemical compound; the chemical compound is volatilized in a form of smoke; the smoke is subjected to spray washing and concentrated by a thickener; ore pulp is subjected to filter pressing; an obtained filter cake is cyanidation leaching; and the gold is extracted. The method is simple in process, low in raw material requirement and high in gold recovery rate; the pellet strength is high; the phenomenon of rotary kiln accretion is avoided; the gold in the cyanidation tailings is recovered with lower production cost; in addition, 'zero waste emission' is realized in a whole production flow; environmental pollution is reduced; and a resource utilization rate is increased.

Owner:ZHAOJIN MINING +1

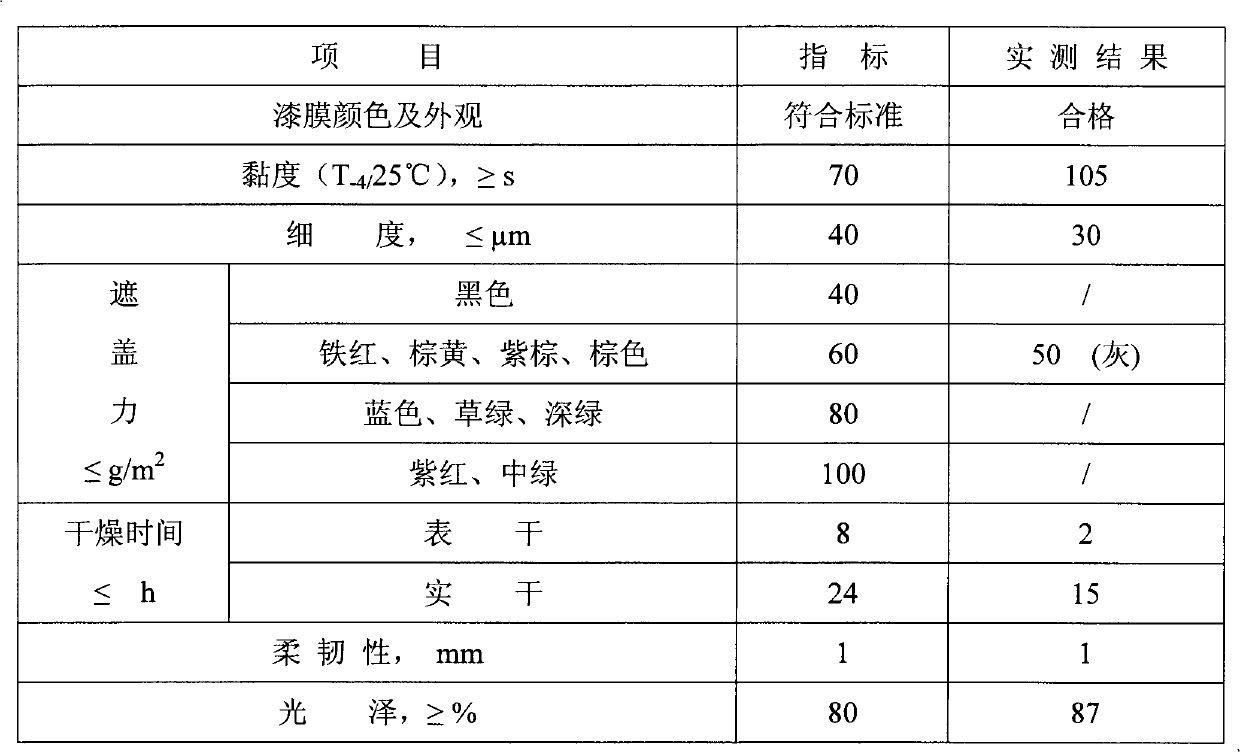

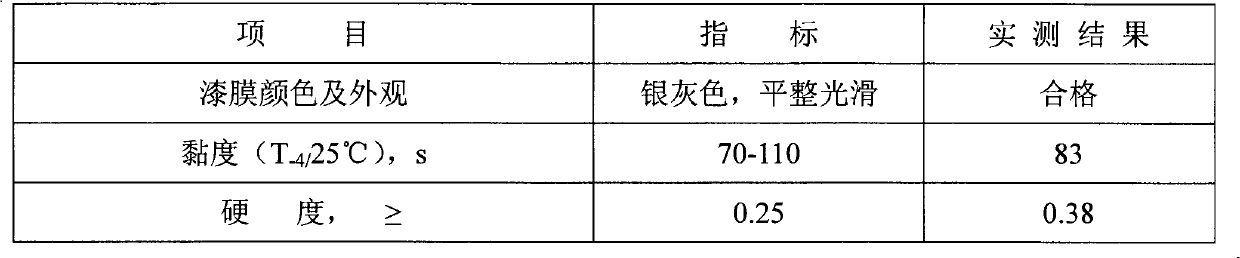

Method for preparing modified phenolic resin for coating with cresol residue

InactiveCN102002139AFast dryingImprove adhesionEpoxy resin coatingsPolyester coatingsCresolChemical reaction

The invention provides a method for preparing modified phenolic resin for coating with cresol residue, belonging to the technical field of treatment and comprehensive use of cresol residues. The method uses effective functional groups of each compound in the cresol residue to prepare the cresol residue into modified phenolic resin which can be industrially prepared through a serial of chemical reactions. The modified phenolic resin can be directly used for preparing the corresponding coating so as to realize the zero waste exhaust in the production of the cresol, thereby fundamentally solving the pollution problem of the cresol, achieving the purpose of comprehensive treatment and changing waste into valuable; and simultaneously, the quality of the prepared coating product is better than the traditional industry standard, but the production cost is lower than that of the existing corresponding product. The method is simple in production technique, little in device investment, strong in enablement, low in comprehensive cost, and obvious in economical benefit.

Owner:LANZHOU PETROCHEM COLLEGE OF VOCATIONAL TECH

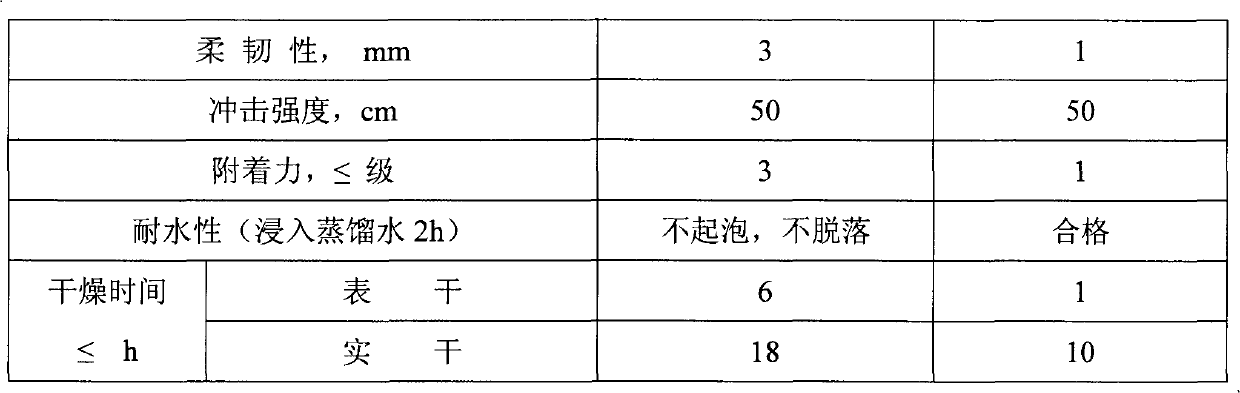

Method for recycling metal from waste acid etching liquid

InactiveCN106282567ANothing producedFull recoveryPhotography auxillary processesProcess efficiency improvementAcid etchingFiltration

The invention belongs to the field of copper-containing industrial waste resource comprehensive utilization and particularly relates to a method for recycling metal from waste acid etching liquid. The method includes the following steps of (1) mixed alkali neutralization and sedimentation, (2) suction filtration and elution for dechlorination, (3) leaching controlling, and (4) electro-deposition. Compared with existing waste acid etching liquid resource treatment technologies, the method has the advantages that alkali consumption is low, one-time construction investment cost is low, and the adaptability is wide; and a selective electro-deposition technology adopted at the end can adapt to high copper sulfate solution residual chlorine, the quality of produced products is stable, and operation is simple. Besides, no waste water is generated except that filtration concentrated saltwater is evaporated and independently treated in the whole treatment process; the adoption of selective electro-deposition equipment guarantees unified treatment of acid mist generated in the electro-deposition process, and harmless discharge is achieved; and no superfluous waste residues are generated in the whole process, printed circuit board (PCB) acid etching waste liquid treatment zero waste can be achieved, Cu and Cl in the acid waste liquid are fully recycled, and the environment can be effectively protected.

Owner:SHAANXI RUIKAI ENVIRONMENTAL PROTECTION & TECH CO LTD

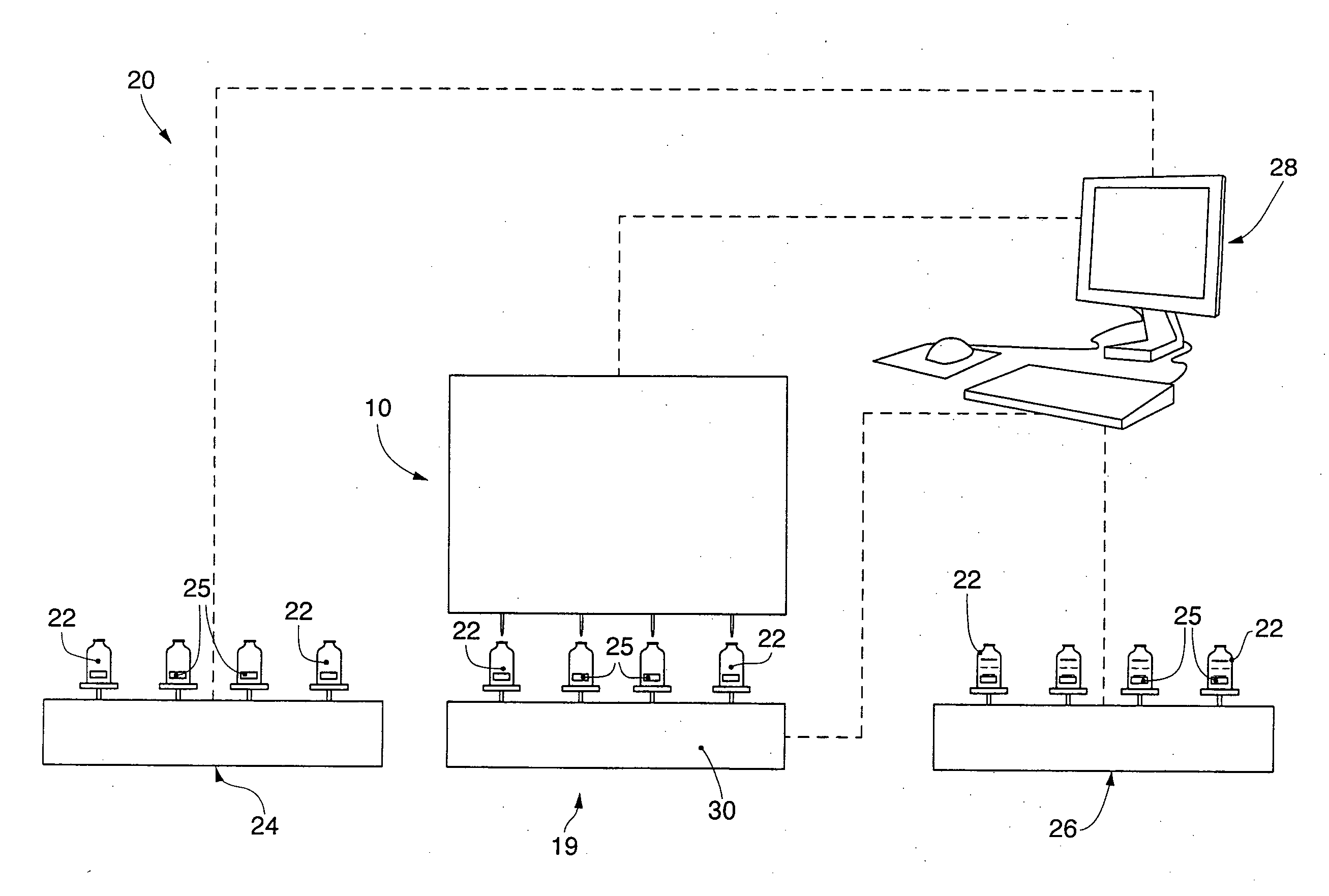

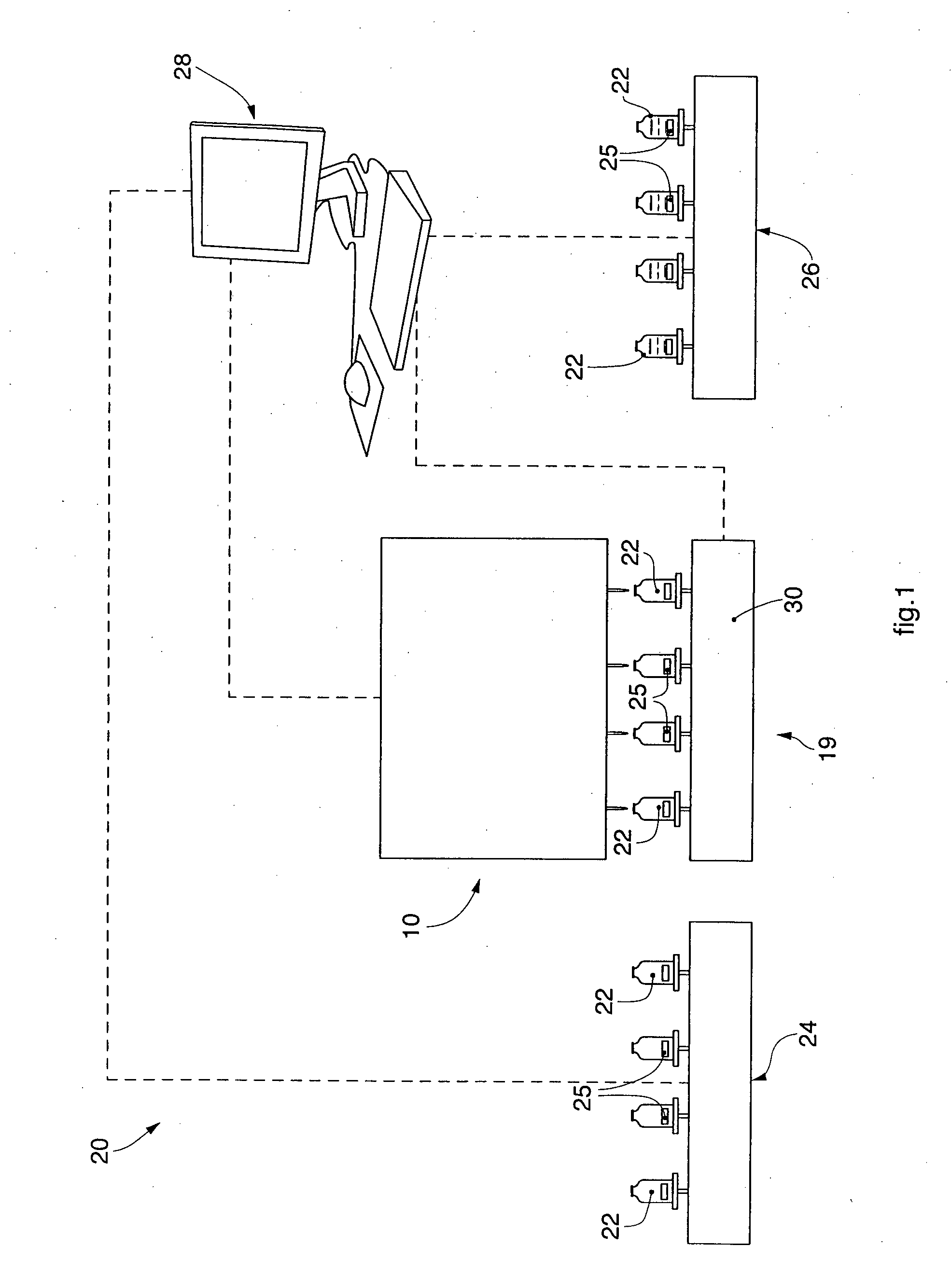

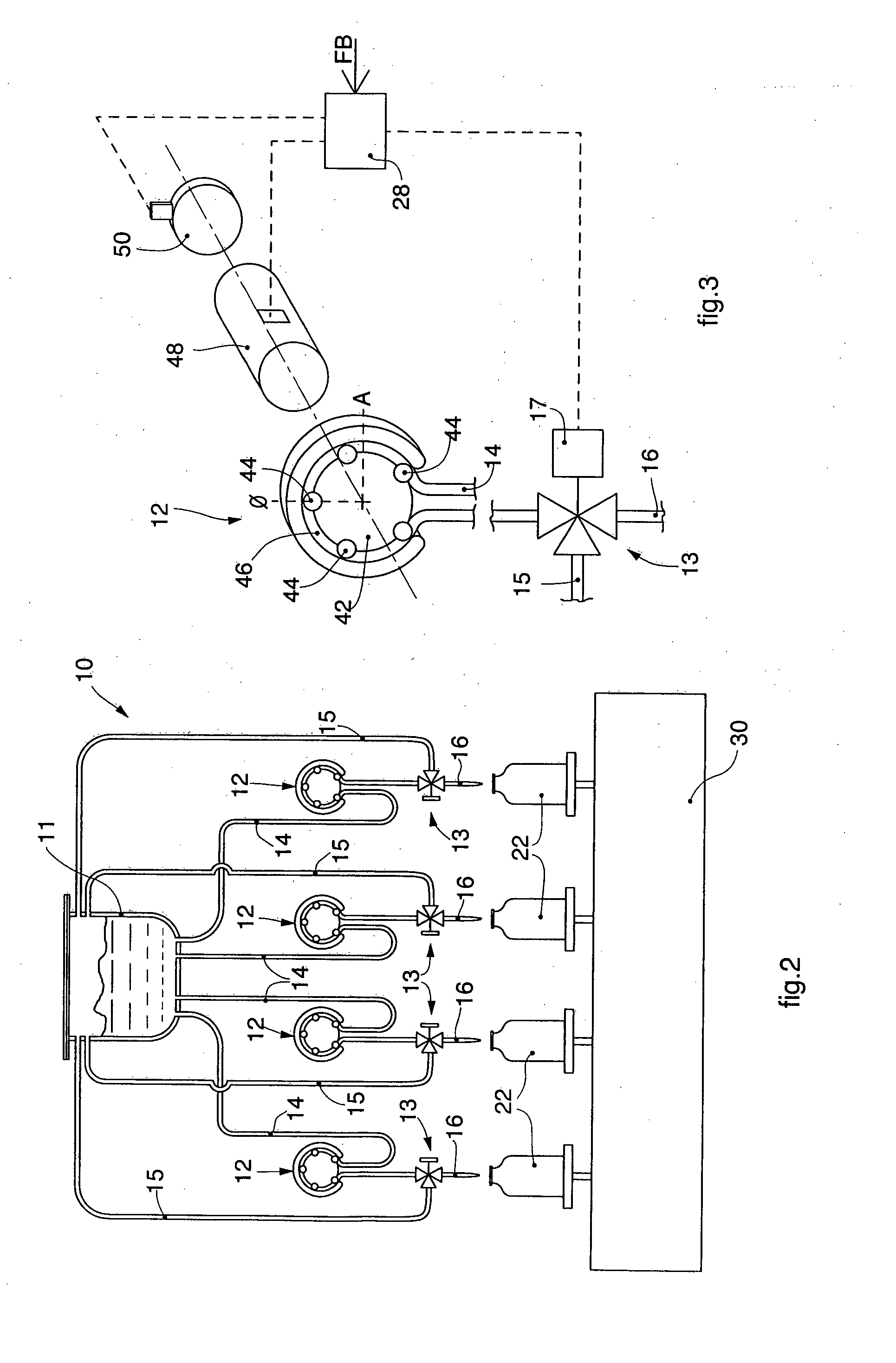

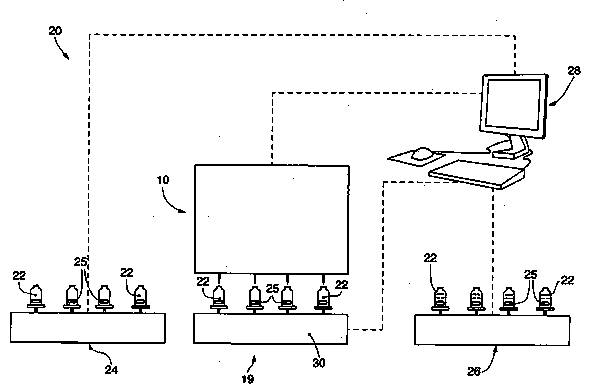

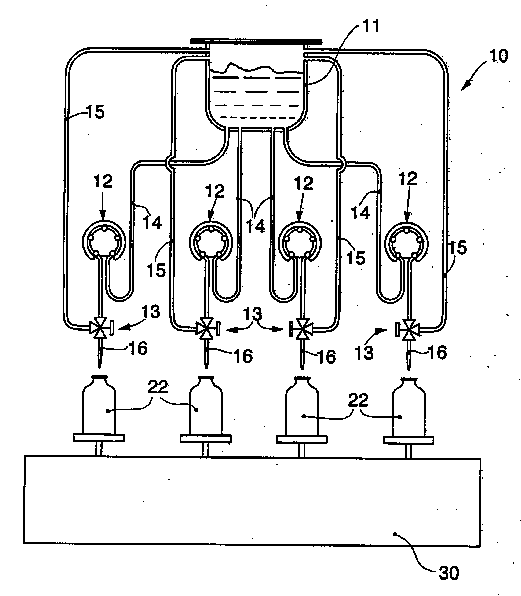

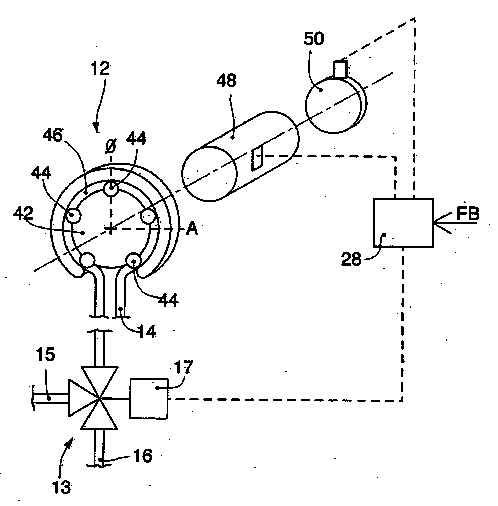

Zero waste dosing method and apparatus for filling containers of liquids

ActiveUS20150013825A1Eliminate the effects ofLiquid fillingFlexible member pumpsLiquid productZero waste

Zero waste dosing method for filling containers of liquids which provides to use, at a delivery station of the liquid product, at least a volumetric pump with a rotor and stator, associated with a tank of the liquid to be introduced into said containers.

Owner:IMA IND MASCH AUTOMATICHE SPA

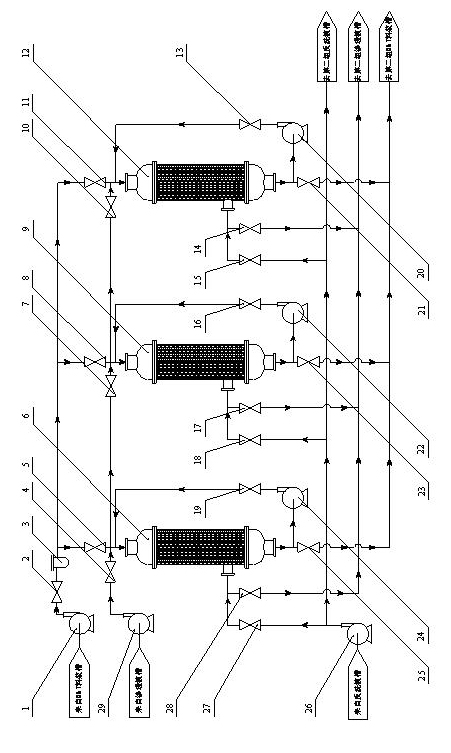

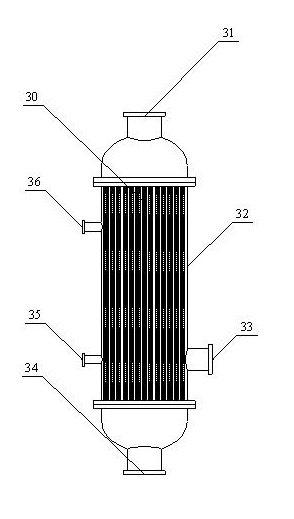

A method and equipment for treating melamine wastewater by ultrafiltration membrane

InactiveCN102276074AAvoid it happening againImprove economyWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentSlagUltrafiltration

The invention relates to a method and equipment for treating tripolycyanamide waste water by using ultrafiltration membranes and belongs to the field of waste water treatment. In the invention, waste water from tripolycyanamide production is treated by using the ultrafiltration membranes, an ultrafiltration system consists of three ultrafiltration membrane modules which are connected in series, each ultrafiltration membrane module has three sets of parallelly working ultrafiltration membrane equipment, ornithine aminotransferase (OAT) pulp enters the three ultrafiltration membrane modules in turn, and the ultrafiltration membranes divide the OAT pulp into concentrated OAT pulp, resident fluid and pure tripolycyanamide and penetrating fluid. The resident fluid enters a resident fluid tank from the third ultrafiltration membrane module and is subjected to high-temperature and high-pressure treatment; and the OAT and tripolycyanamide are decomposed into ammonia and carbon dioxide, which are recovered and reduced. The penetrating fluid is discharged from each set of ultrafiltration membrane equipment and recycled as process circulating water, and thus, the zero waste discharge of a tripolycyanamide device is realized. The production of waste slag in a tripolycyanamide production process is avoided, the process is environment-friendly, the process atom economy is high, limited resources are saved, and energy consumption and cost are reduced.

Owner:ZHENGZHOU UNIV

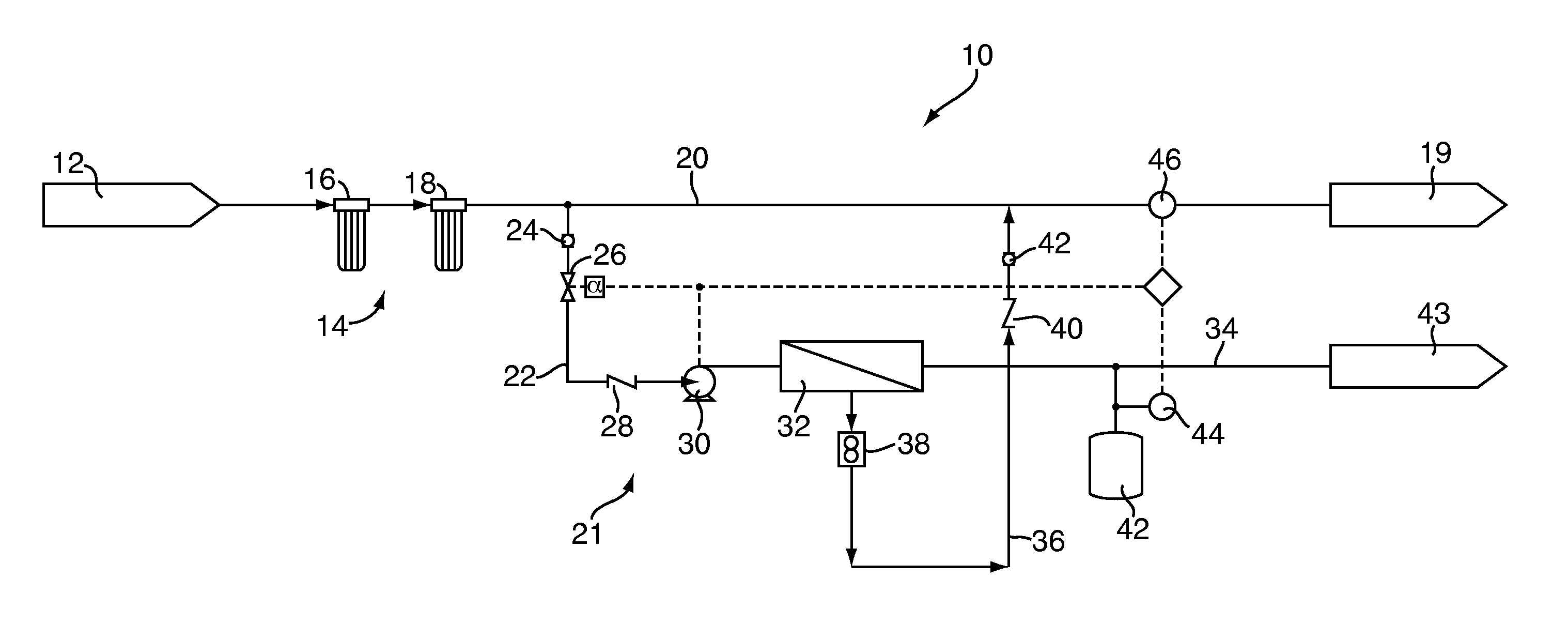

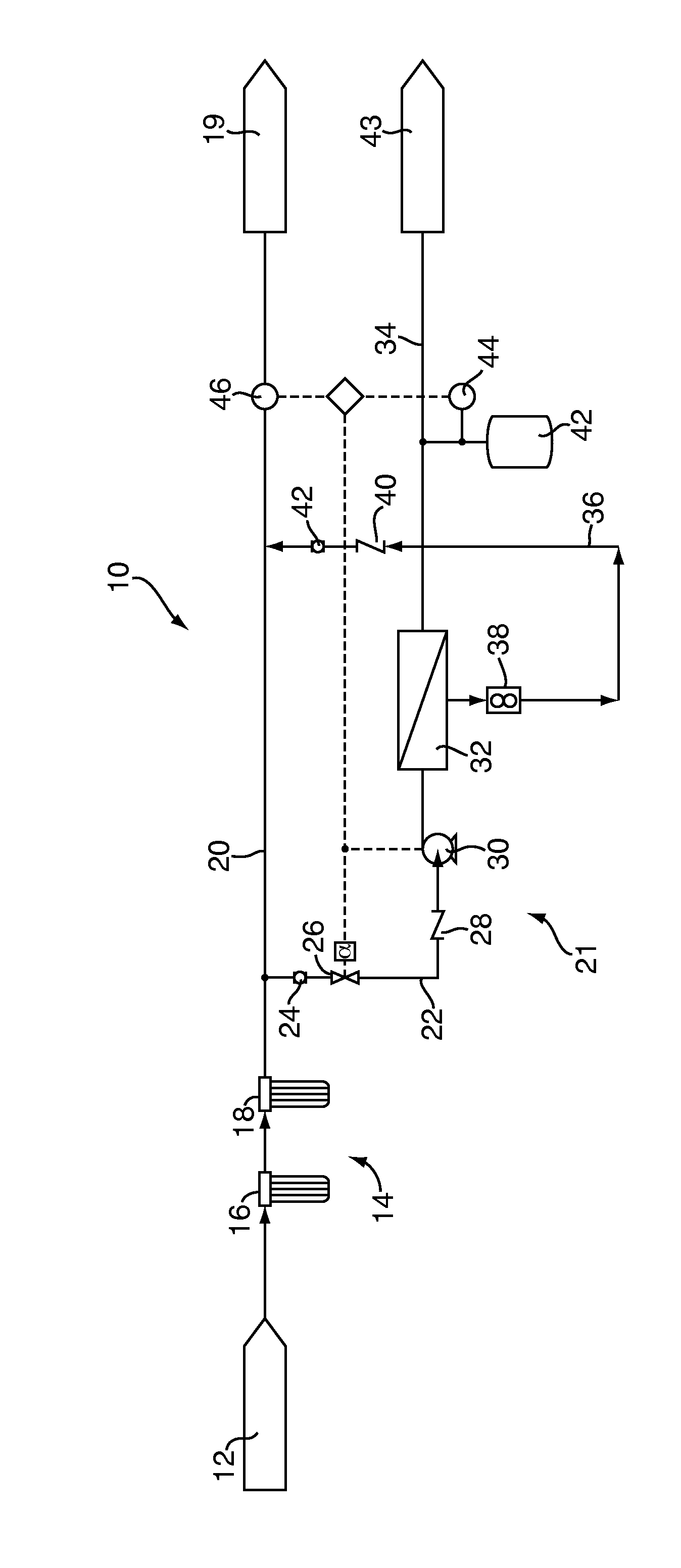

Flow-switch-controlled, zero waste reverse osmosis water treatment system

InactiveUS20120031844A1Avoids potential high pressure buildupInstantly dilutesWater treatment parameter controlMembranesWater treatment systemWater flow

A flow-switch controlled, zero waste reverse osmosis water treatment system having a first conduit for providing a supply of water, a second conduit having an inlet in fluid communication with the first conduit for selectively receiving a flow of water from the first conduit, a reverse osmosis element positioned along the second conduit, the reverse osmosis element separating the flow of water within the second conduit into a purified water stream and a reject water stream, a purified water conduit having an inlet configured to receive the purified water stream and a reject water conduit having an inlet configured to receive the reject water stream and an outlet in fluid communication with the first conduit.

Owner:QUENCH USA

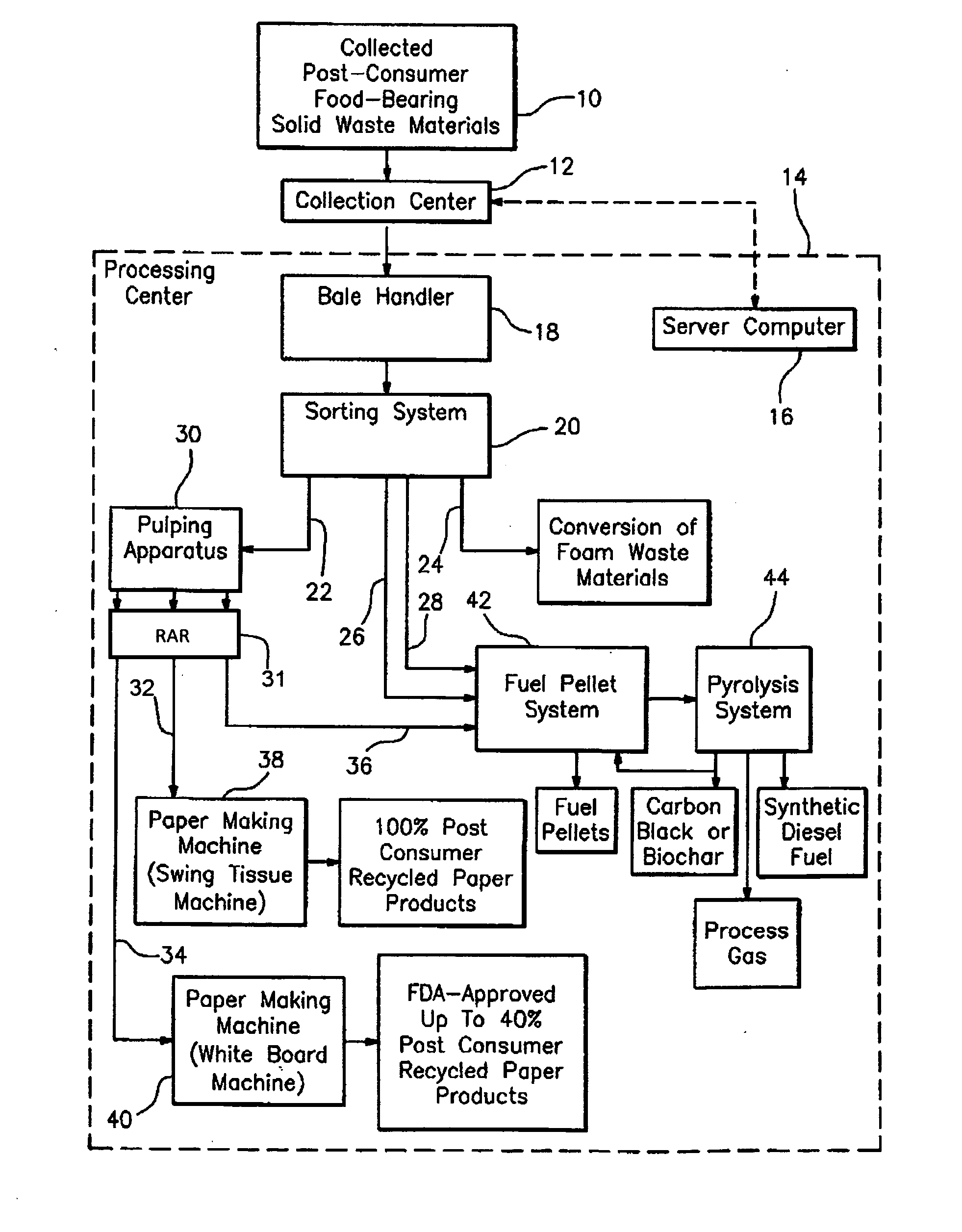

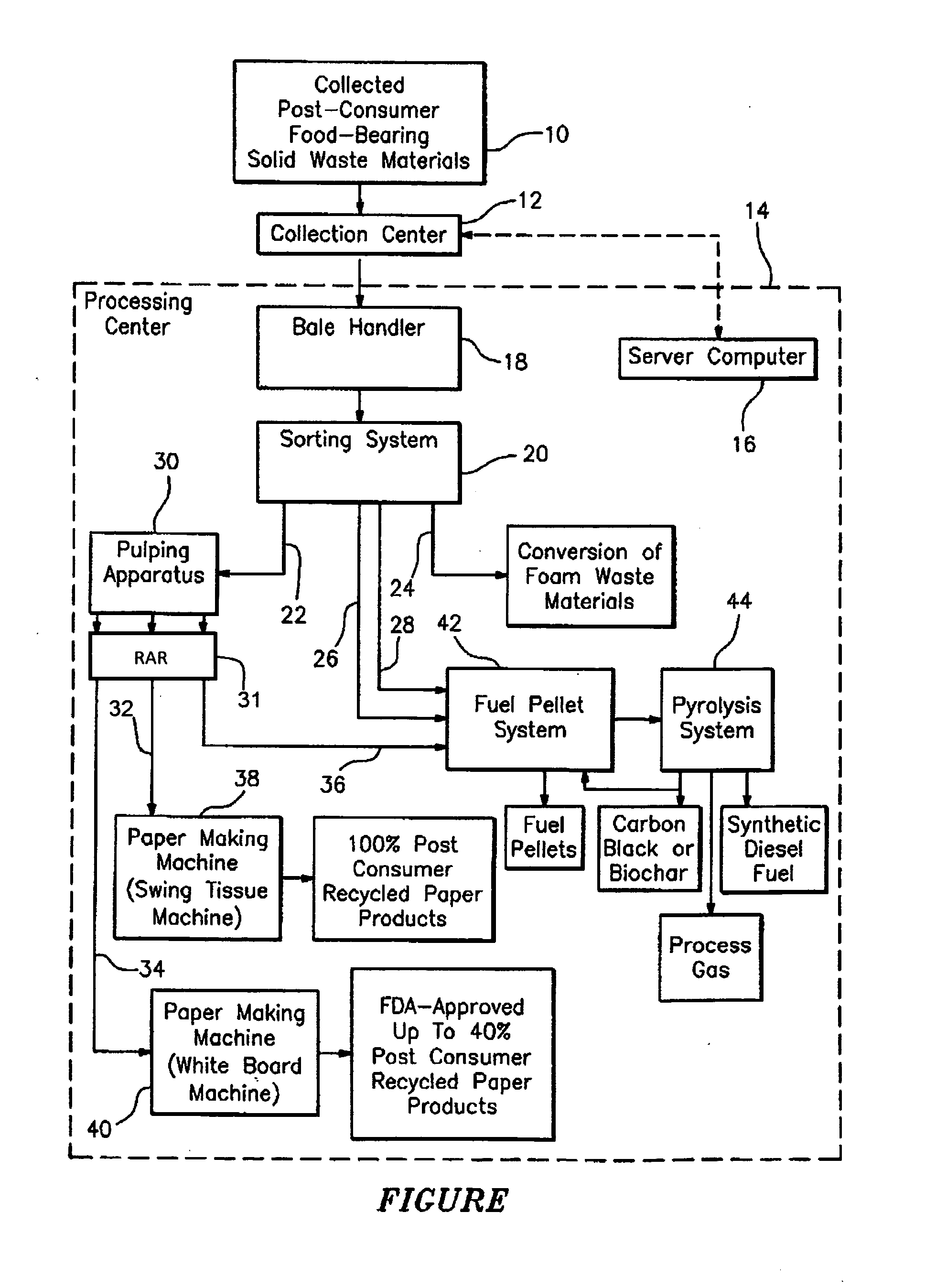

Solid waste reclamation process

A process for reclaiming food-contaminated solid waste streams from fast food restaurants, casual dining restaurants, cafeterias, schools, colleges and universities, concession stands, arenas, stadiums, movie theaters, large city street trash bins and other entertainment venues, and other places that offer simple food items for dine in or carry-out that are currently sent to a land fill. The inventive process offers total solid waste reclamation with zero waste water discharge, zero landfill and minor source air emissions, resulting in 100% reclamation and a 100% sustainable process. This process can also be used on solid waste from reclamation centers and manufacturers who currently land fill their waste.

Owner:PC FIBER TECH

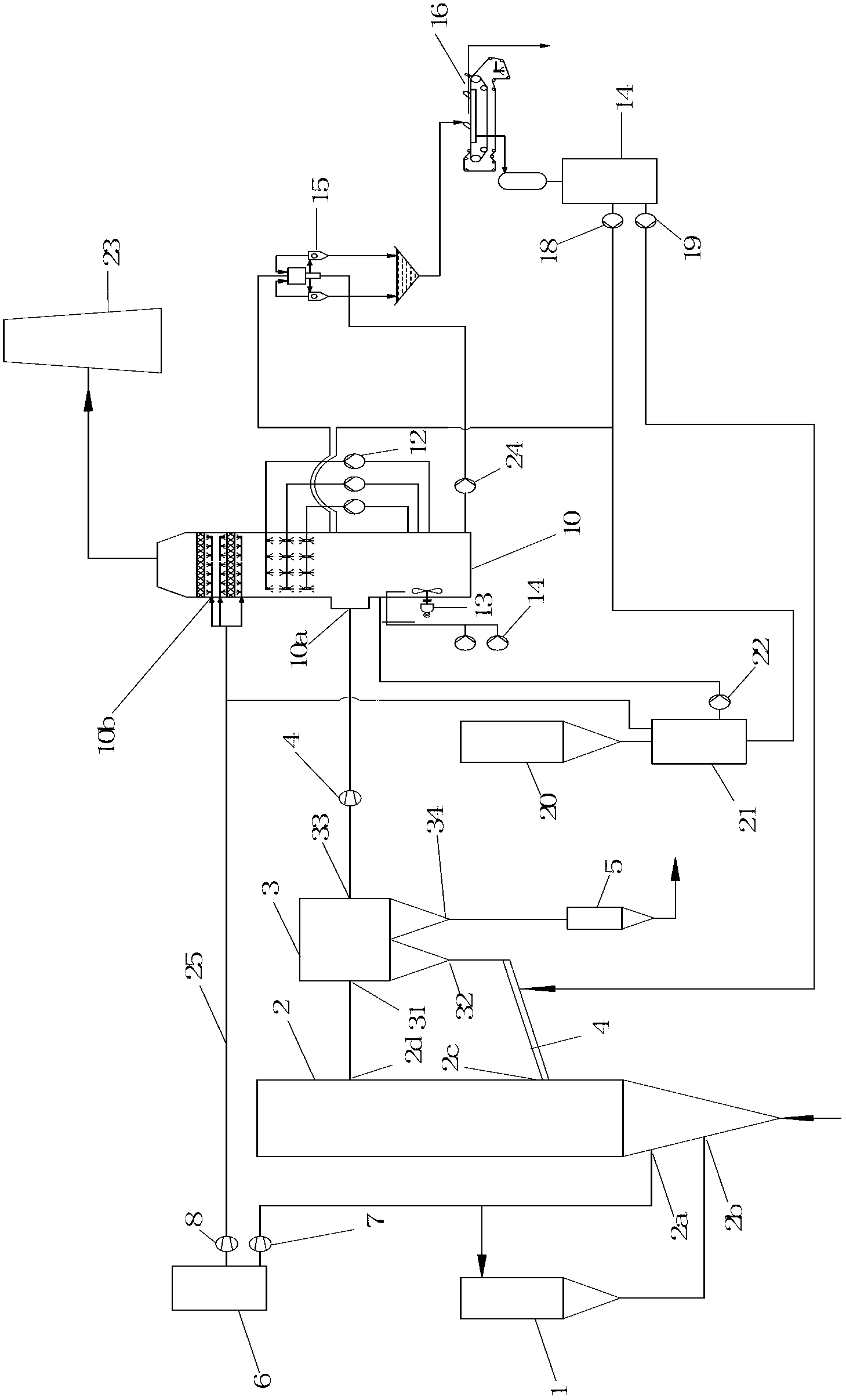

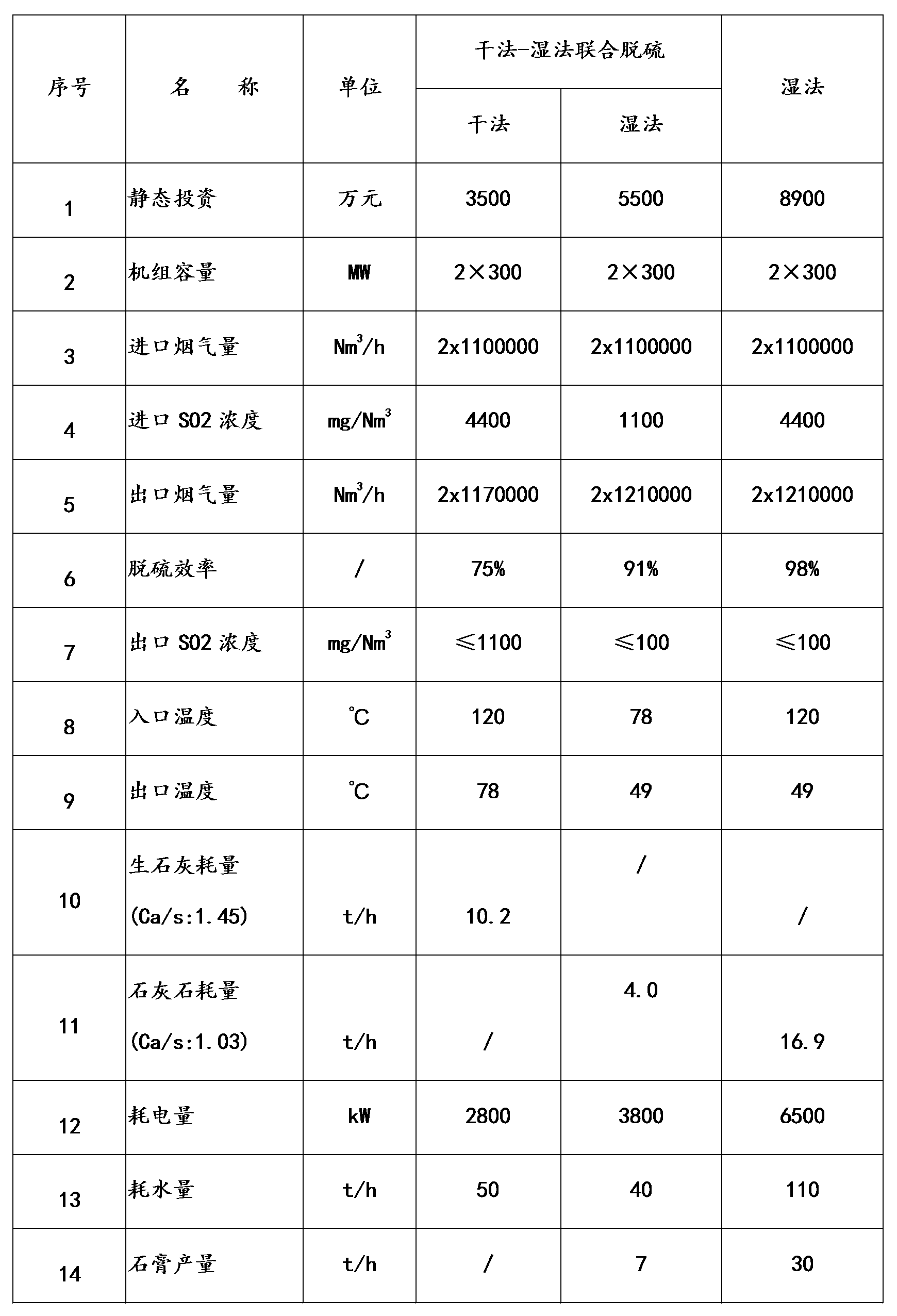

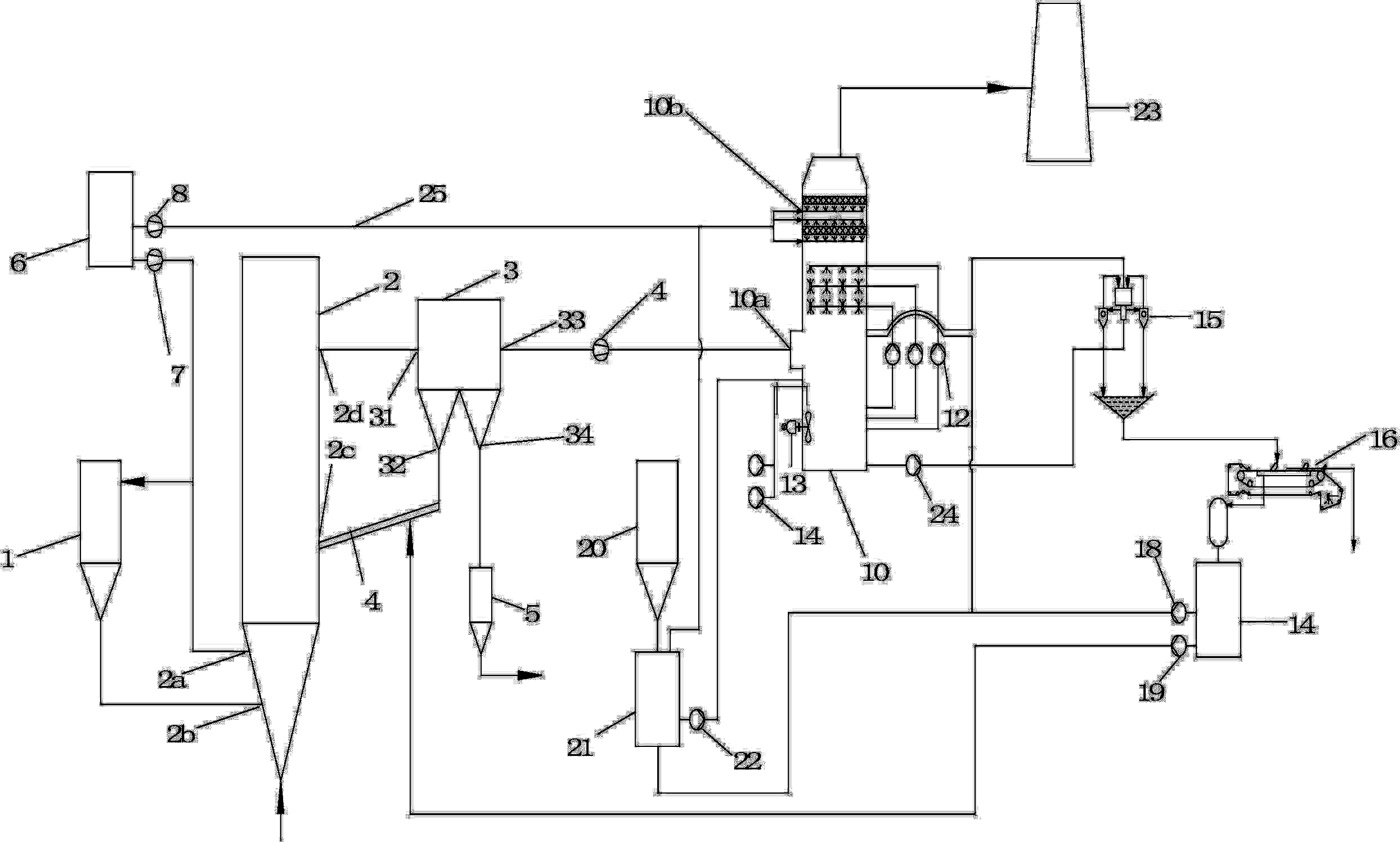

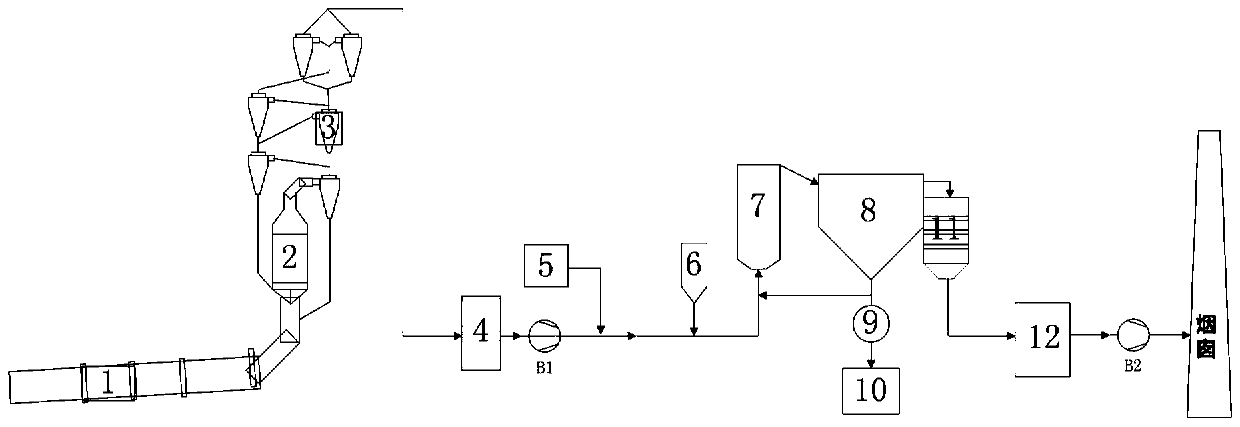

Dry process and wet process combined smoke gas desulfuration system

ActiveCN102698590AReduce the temperatureReduce corrosionDispersed particle separationWastewaterSlurry

The invention discloses a dry process and wet process combined smoke gas desulfuration system, which consists of a dry process desulfuration system and a wet process desulfuration system, wherein the wet process desulfuration system comprises a backflow water tank, a wet process absorption tower and a limestone slurry box, the dry process desulfuration system comprises a dry process absorption tower, a water tank, a slaked lime cabin and an electric dust remover, the dry process absorption tower is connected with the backflow water tank, the water tank is respectively connected with the wet process absorption tower and the limestone slurry box, and the electric dust remover is connected with the wet process absorption tower. The dry process and wet process combined smoke gas desulfuration system has the advantages that the redundancy of the sulfur content of firing coal in an electric plant is improved, the tail end wet process desulfuration liquid-gas ratio can be reduced, and the generated waste water can be used as process water for semi-dry process desulfuration, so the zero waste water discharge is realized.

Owner:WUHAN LONGKING ENVIRONMENTAL PROTECTION CO LTD

Zero waste dosing method and apparatus for filling containers of liquids

ActiveCN104245561ASolve the problem of angular displacementFlexible member pumpsLiquid transferring devicesLiquid productEnvironmental engineering

Zero waste dosing method for filling containers (22) of liquids which provides to use, at a delivery station (19) of the liquid product, at least a volumetric pump (12) with a rotor and stator, associated with a tank (1 1) of the liquid to be introduced into said containers (22).

Owner:IMA IND MASCH AUTOMATICHE SPA

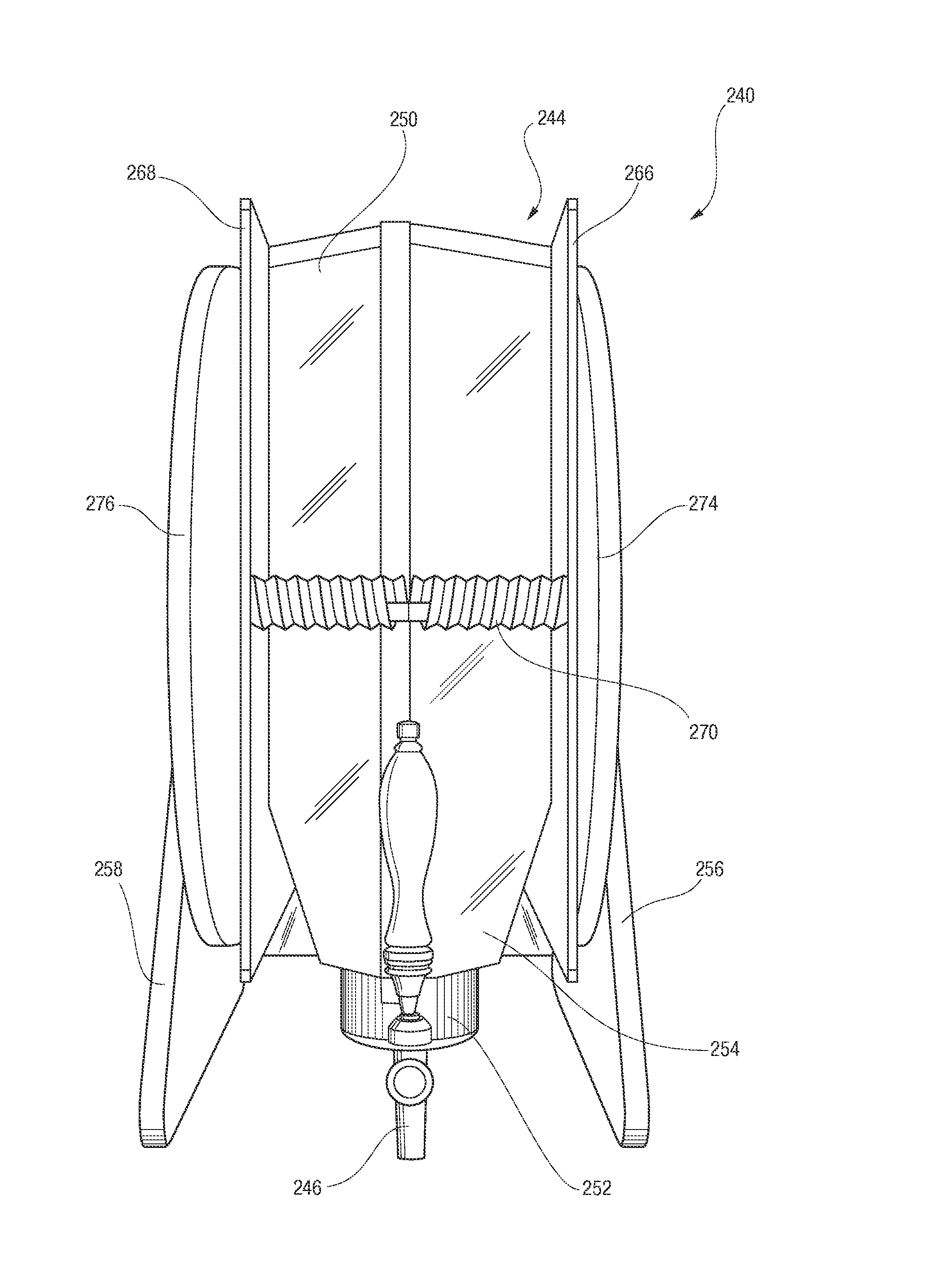

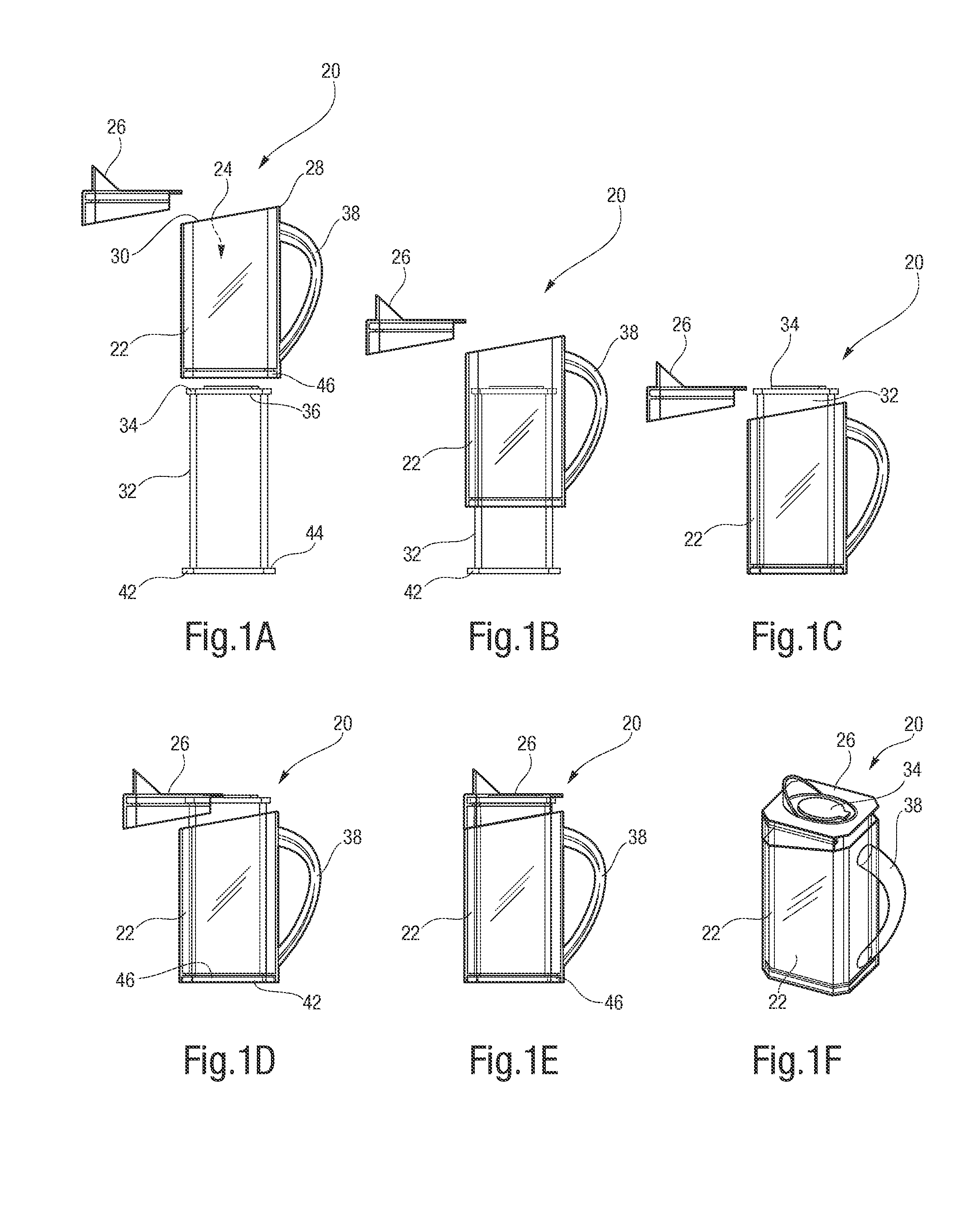

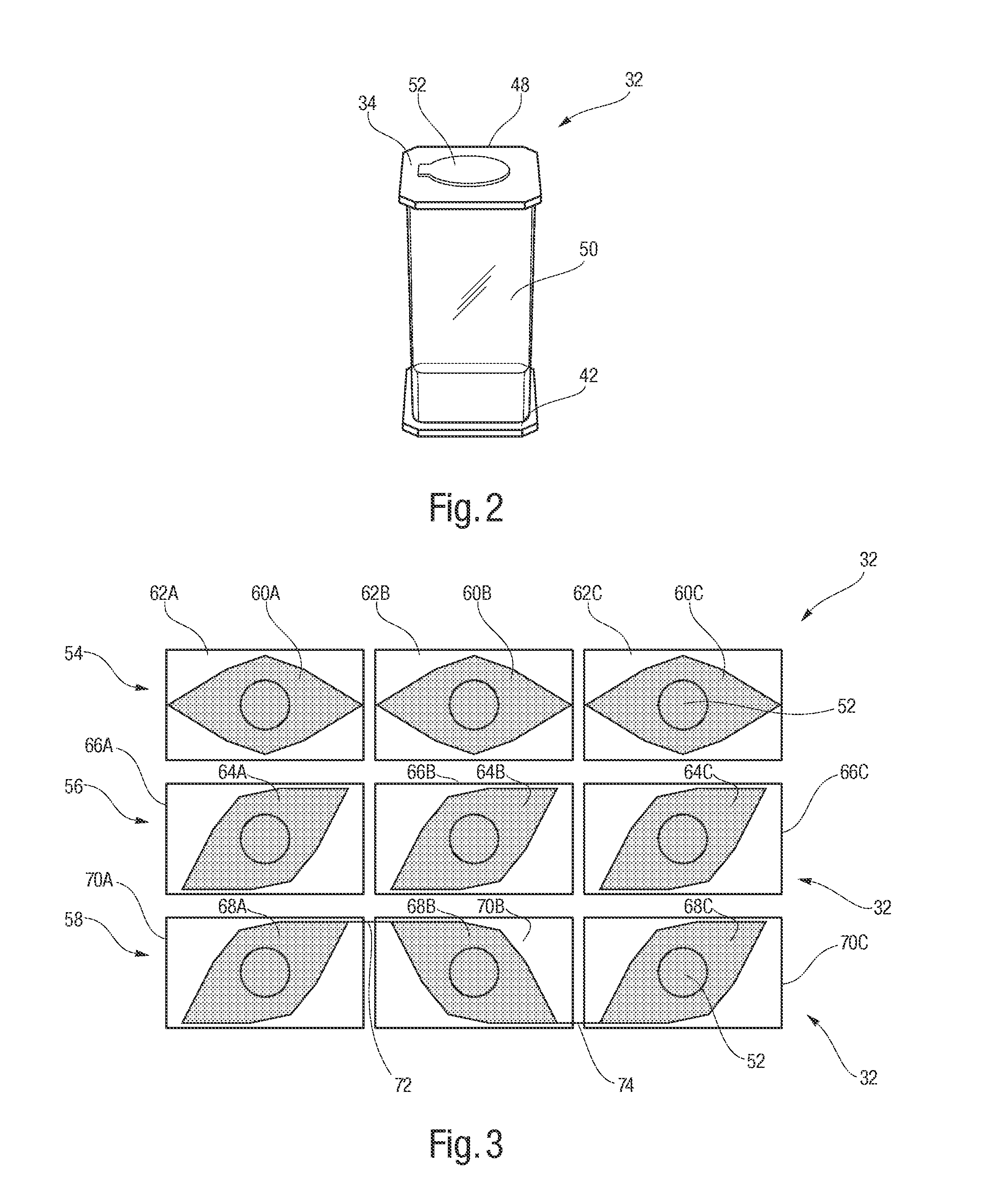

Refillable container with a zero waste dispensing system

InactiveUS20140021221A1Fast processNot to damageDischarging meansMetal working apparatusEngineeringBottle

The refillable container (20) includes a semi-rigid outer shell (22) that defines an interior void (24) and includes a detachable pour spout (26). The container (20) may be refilled with a plurality of collapsible inserts (32). Instead of rigid beverage bottles and other flowable substance containers, the collapsible inserts (32) may be transported from a manufacturing to a filling facility in a collapsed state (76), and do not have to include semi-rigid materials thereby minimizing disposal requirements. A tilt-pouring embodiment (20), a helical track embodiment (100), a helical axle embodiment (240) and an air-bladder embodiment (300) of refillable containers having common components permit dispensing of products from the containers (20, 100, 240, 300) to achieve virtually zero waste of the products.

Owner:PACK FLOW CONCEPTS

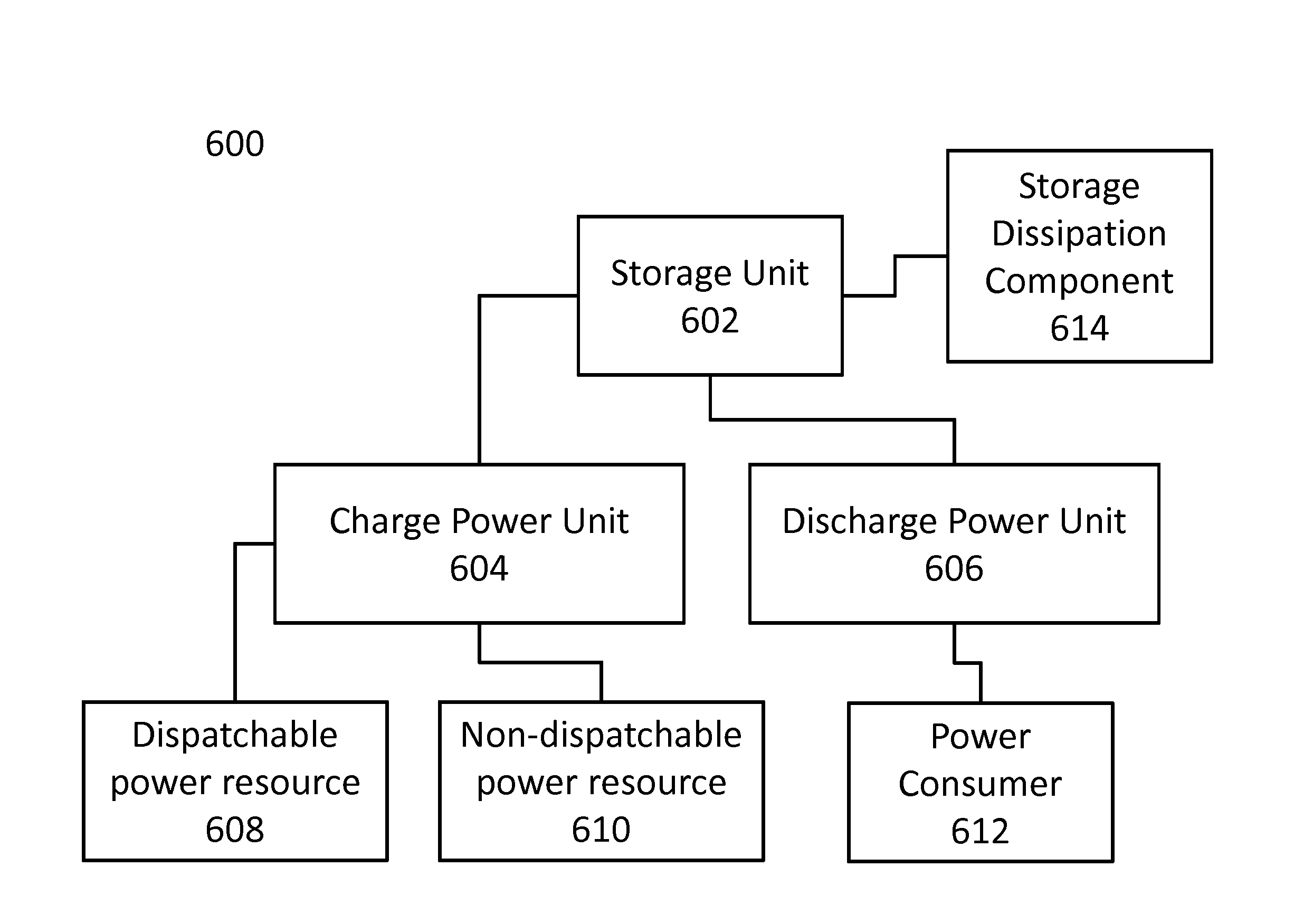

Asymmetric dispatching systems, devices, and methods

InactiveUS20150236527A1Electrical storage systemBatteries circuit arrangementsStored energyEnergy storage

An energy storage apparatus comprising a storage unit, a charge unit, and a discharge power units. The charge unit can have a power capacity that is N / efficiency higher than that of the discharge power unit, where N is significantly greater than unity. The apparatus can comprise a storage dissipation component that can selectively waste stored energy, incoming energy, or withdrawn energy such that the total energy storage capacity or rate capacity of energy storage is increased. Efficiency can be defined as maximum quantity of energy that can be withdrawn for a given quantity stored of the energy storage apparatus with zero waste energy storage selected. The charge unit can be connected to receive power from one or more power sources and the discharge power unit can be connected to dispatch power to a power consumer.

Owner:MADA ENERGIE

Apparatus for hydroelectric power production expansion

InactiveCN101560941AOptimum hydraulic surface flow conditionsWill not emitWater-power plantsReaction enginesEngineeringElectric generator

Normally hydroelectric dam powerhouses use river flow once before discharging it as turbulent tailwater, ineffective to spin turbines. The present invention uses tapered channels to confine and constrict turbulent tailwater into laminar flow that drives turbines both submersible and floatable utilizing the same water three times concurrently to generate new electricity. Channels originate adjacent to draft tube outlets, constrict in the downstream direction to create narrow necks where turbine / generators benefit from debris free, increased velocity and laminar flows to generate electricity. Hydroelectricity uses zero fuel, creates zero waste and has zero carbon dioxide emissions. Structures are uncomplicated, construction is within project boundaries minimizing environmental impacts and speeding projects coming online. New facilities are protected by existing dam security. Hydroelectricity replaces less dependable renewable energy systems.

Owner:威廉・洛厄尔・凯利

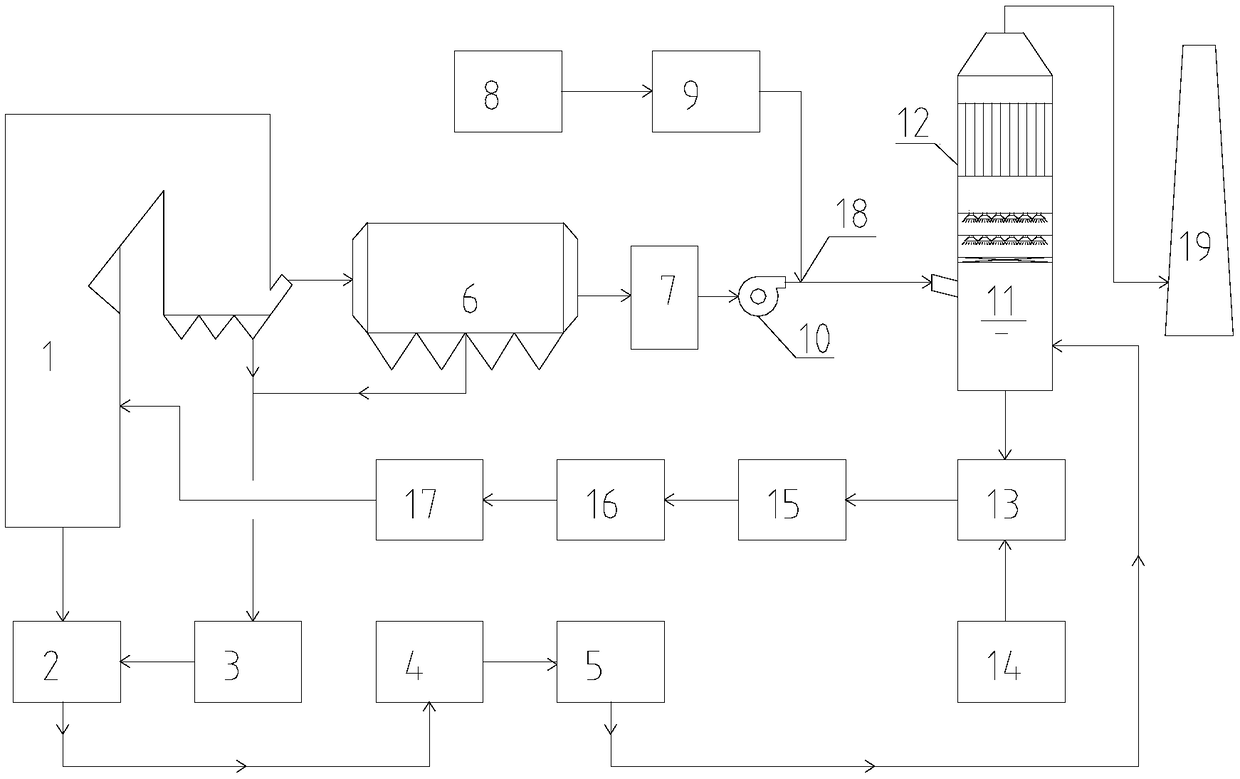

Dry desulfurization, denitration and dust removal device and method for low-sulfur flue gas in cement kiln tail

PendingCN110665352AReduce filter areaReduce resistanceGas treatmentDispersed particle filtrationDust controlCement kiln

The invention relates to a dry desulfurization, denitration and dust removal device for low-sulfur flue gas in cement kiln tail. The dry desulfurization, denitration and dust removal device includes acement kiln, a decomposing furnace, a suspension preheater, a cooling device, a desulfurization tower, a dust remover and a medium-temperature SCR denitration device, wherein the cement kiln, the decomposing furnace, the suspension preheater and the cooling device are successively connected, an air inlet pipeline of the desulfurization tower is connected with a flue gas outlet of the cooling device, and the desulfurization tower is a circulating fluidized bed dry desulfurization tower with the low density, a low bed and no water spraying; the air inlet pipeline is provided with a high-temperature fan, and connected with a raw mill, a desulfurizer bin and a smoke dust return device; a flue gas inlet of the dust remover is connected with a flue gas outlet of the desulfurization tower, and aby-product outlet of the dust remover communicates with the air inlet pipeline through the smoke dust return device, and is connected with a raw material warehouse through a by-product conveying device; and a flue gas inlet of the medium-temperature SCR denitration device is connected with a flue gas outlet of the dust remover, an air outlet pipeline of the medium-temperature SCR denitration device is successively provided with a waste heat boiler and an induced draft fan, and discharges purified gas through a chimney. According to the dry desulfurization, denitration and dust removal device,synergistic removal of multi-component contaminants can be achieved while high-efficiency desulfurization, denitration and dust removal are achieved, corrosion prevention is not needed, zero waste water discharge and transparent chimney discharge are achieved, and meanwhile long-term stable operation can be achieved.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

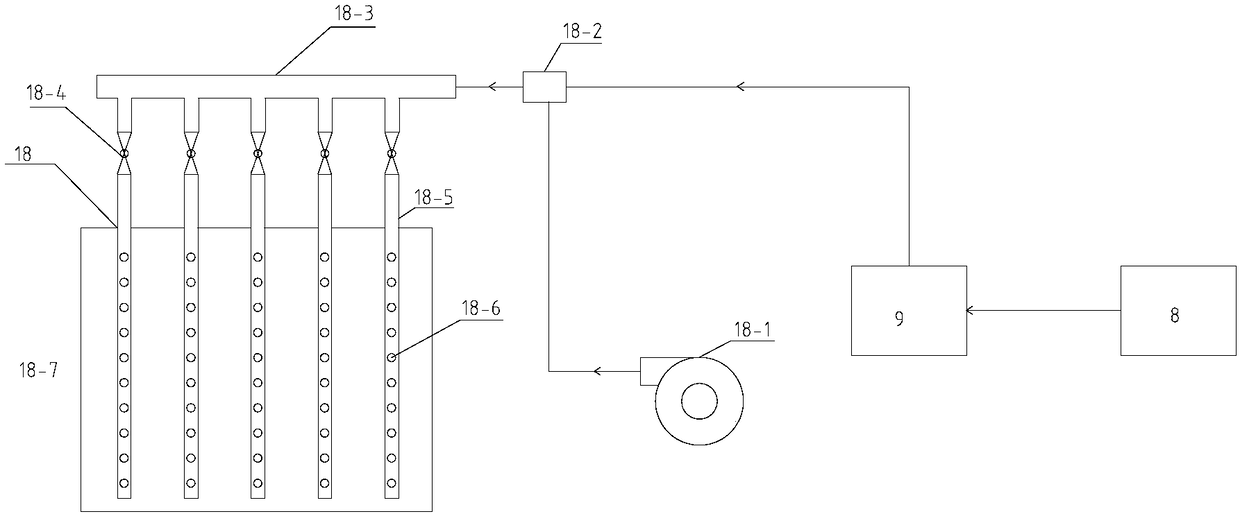

Alkaline furnace flue gas wet process denitration process and device capable of cyclically utilizing absorbent

ActiveCN108380017AMaintain vulcanizationThe recovery rate meetsGas treatmentDispersed particle separationSlurrySodium sulfate

The invention discloses an alkaline furnace flue gas wet process denitration process and device capable of cyclically utilizing an absorbent. The process comprises the following steps that (1) alkaline recovery furnace flue gas is subjected to high-temperature electric dust removal, heat exchange temperature reduction and ozone oxidation, and is then conveyed into a wet process absorption tower; denitration absorption liquid in the absorption tower performs cyclical spraying absorption on flue gas; the purified flue gas is discharged out through a chimney; (2) slurry after the flue gas is subjected to spraying absorption is discharged out of the absorption tower; a denitrification agent is added into the slurry; sodium sulfate slurry after the denitrification treatment is conveyed into a black liquor concentration work procedure of the alkaline recovery furnace; concentrated sodium sulfate and black liquid mixed liquid is sprayed into the alkaline recovery furnace; combustion reductionis performed in the alkaline recovery furnace; a combustion reduction product is discharged and is then dissolved and causticized; denitration absorption liquid is regenerated again. The flue gas wetprocess denitration absorbent can be cyclically utilized; the denitration operation cost is low; the denitration absorbent is not consumed; no ozone escape exists; zero waste water discharging is realized.

Owner:HANGZHOU TIANLAN ENVIRONMENTAL PROTECTION ENG DESIGN

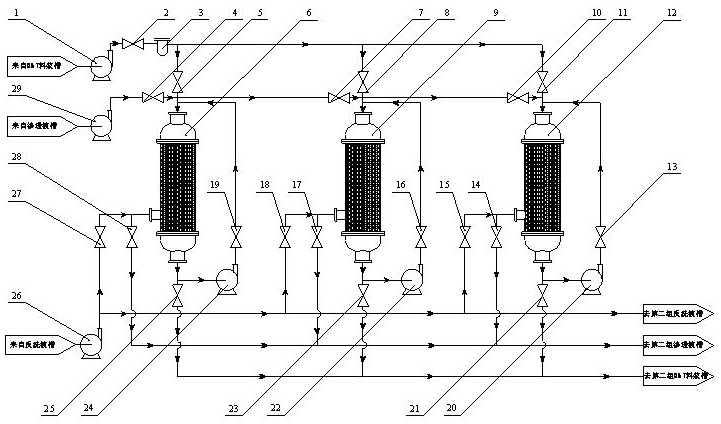

Waste emulsified oil low-temperature separation system

ActiveCN104108822AAchieving zero emissionsAchieve recyclingMultistage water/sewage treatmentWater dischargeDistillation

The invention discloses a waste emulsified oil low-temperature separation system, which comprises a stock solution input pipe, a heat exchanger, an evaporator, an oil / water separating device, a condenser and a smell removal device; the evaporator comprises a heating chamber, an evaporating chamber and a steam conveyer pipe; a vapor compressor is arranged on the steam conveyer pipe; the stock solution input pipe passes through the heat exchanger and is connected to the heating chamber of the evaporator; a distilled water conveyer pipe passes through the heat exchanger and is connected to the oil / water separating device; a distilled water output tube and an oil exit pipe are arranged on the oil / water separating device; and the oil exit pipe is connected to the condenser and the smell removal device in order. Based on a purely physical mode, gasification separation can be carried out according to boiling point difference of different liquid, distilled water and a concentrate are separated through pure distillation, usually, distilled water can be taken as industrial water for recycling, the concentrate can be recovered and reused according to different source, zero waste water discharge in industrial enterprises can be realized, the waste emulsified oil low-temperature separation system is convenient for systematization and equipment, so that land occupation area is greatly reduced by comparing with that in a traditional method.

Owner:SUZHOU DIHILL GREEN TECH

Method for preparing carbon material carrying nanometer multi-element metal

InactiveCN103706805ASimple processNo emissionsNanotechnologyWater/sewage treatment using germicide/oligodynamic-processCarbon nanofiberInorganic chemical compound

The invention provides a method for preparing a carbon material carrying nanometer multi-element metal, and relates to the technical field of carbon materials. The method aims to enable the nanometer multi-element metal to be loaded on the carbon material effectively. The method for preparing the carbon material carrying the nanometer multi-element metal is characterized in that the carbon material is added in deionized water, at least two kinds of organic or inorganic compounds of silver, copper, zinc and iron are added, steep is carried out for 1-24 hours after even mixing, and then heat treatment at 150-1200 DEG C is carried out in an inert gas environment or a reductive gas environment or a vacuum environment, wherein the carbon material is granular active carbon or powdered active carbon or bamboo carbon or rice husk carbon or carbon nano tubes or carbon nanofibers or artificial graphite. According to the method for preparing the carbon material carrying the nanometer multi-element metal, the technology is simple, operation is easy, reduction regents do not need to be added, zero waste water is discharged, no pollution is generated, and the carbon material prepared through the method can be used for purification treatment of drinking water.

Owner:徐剑晖 +1

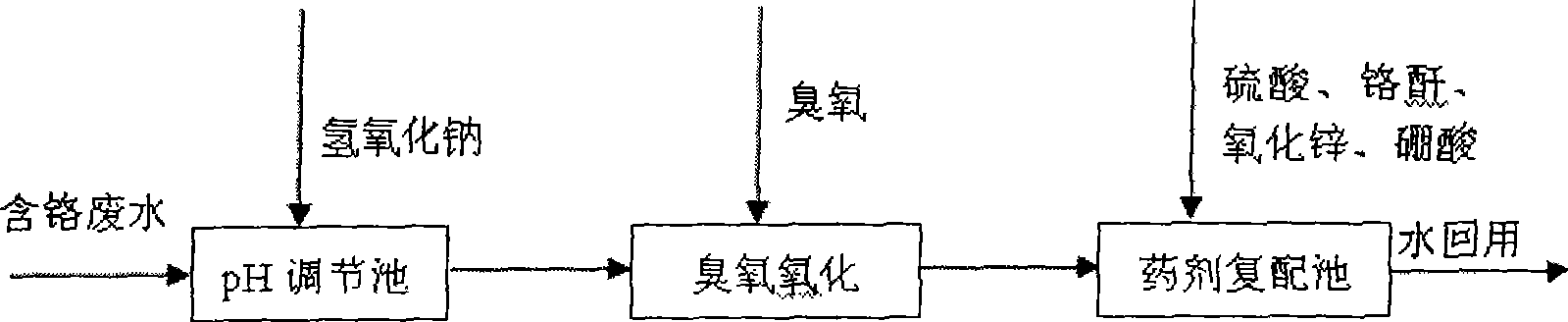

Method for processing chrome wastewater from steel surface passivation process

InactiveCN101481164AEmission reductionRealize resource utilizationWaste water treatment from metallurgical processMultistage water/sewage treatmentWastewaterWater processing

The invention relates to a method for processing chrome-containing waste water generated in steel surface passivating work procedure of steel industry, which solves the problems of complex work procedures, inconvenient running and management, high technical invest, high running cost, unstable discharge, easy secondary environmental pollution and the like of the prior chrome-containing waste water processing. The technical scheme is as following: the chrome-containing waste water is preprocessed and oxidized by ozone to be mixed with medical agent to be compound passivation liquid, and the passivation liquid is sent back to the work procedure of chrome passivation to be used as passivation liquid. The invention has simple technology, low running cost, low technical investment, chrome recovery realization, zero waste water discharge and no environmental pollution.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Instant horseshoe full flour and making method thereof

InactiveCN103637120AFull of nutritionStay nourishedFood shapingFood ingredient functionsNutritionProcess engineering

The invention discloses instant horseshoe full flour and a making method thereof. The making method comprises the following steps: cleaning, drying, coarse grinding, superfine grinding, quick freezing, vacuum drying and sealed packaging. The instant horseshoe full flour and the making method thereof have the advantages that the shortcomings of the nutrition deficiency of the conventional horseshoe processing and production of waste materials are overcome, so that the nutrition of horseshoes can be well retained, and the effects of complete nutrition and zero waste material are achieved; due to the low-temperature superfine grinding, stage drying and irradiation cold sterilization technologies, antibacterial substances in the horseshoes can be biologically stored, and the nutrition and color of the horseshoes are preserved to the maximum extent; the instant horseshoe full flour tastes delicious, is bright in color, has a good shape and rich nutrition, is favorable for digestion and absorption of a human body and is convenient to carry and store.

Owner:HUBEI DAZHAN FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com