Patents

Literature

80results about How to "Reduce filter area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

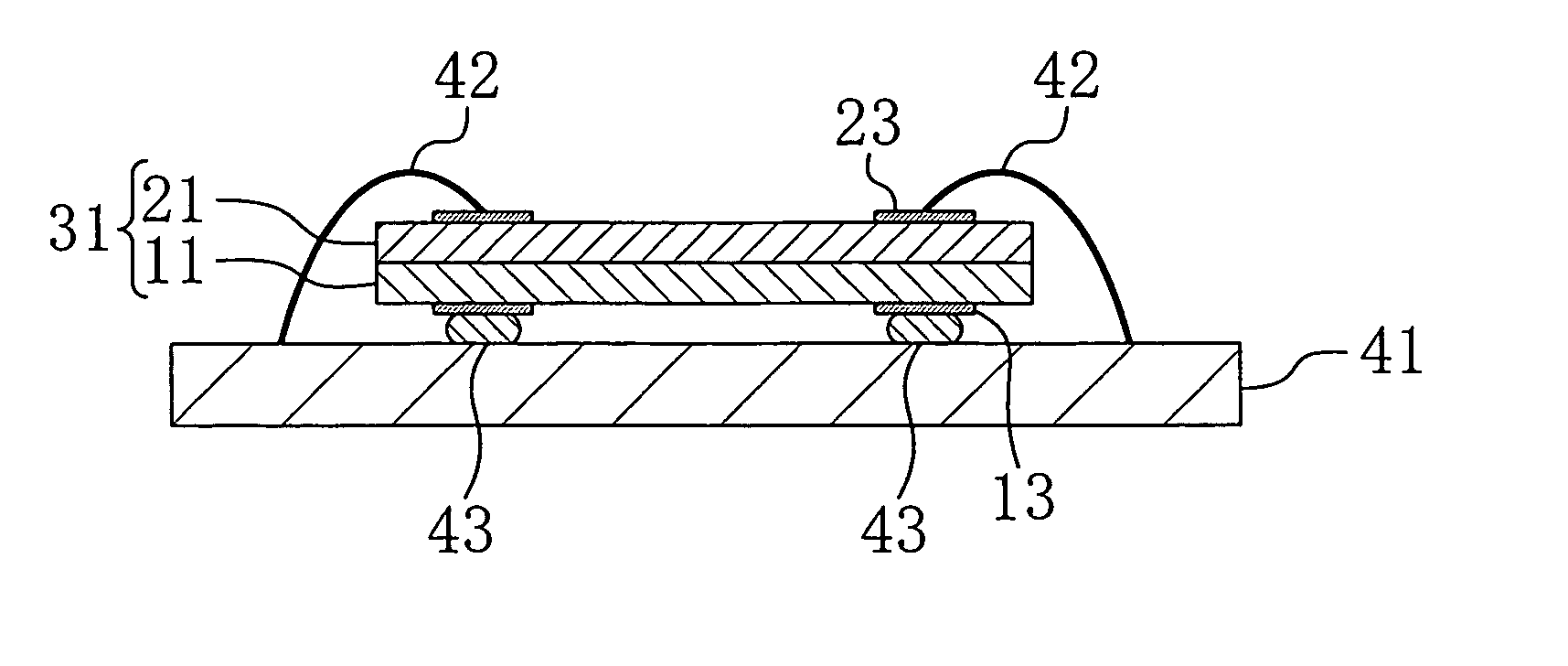

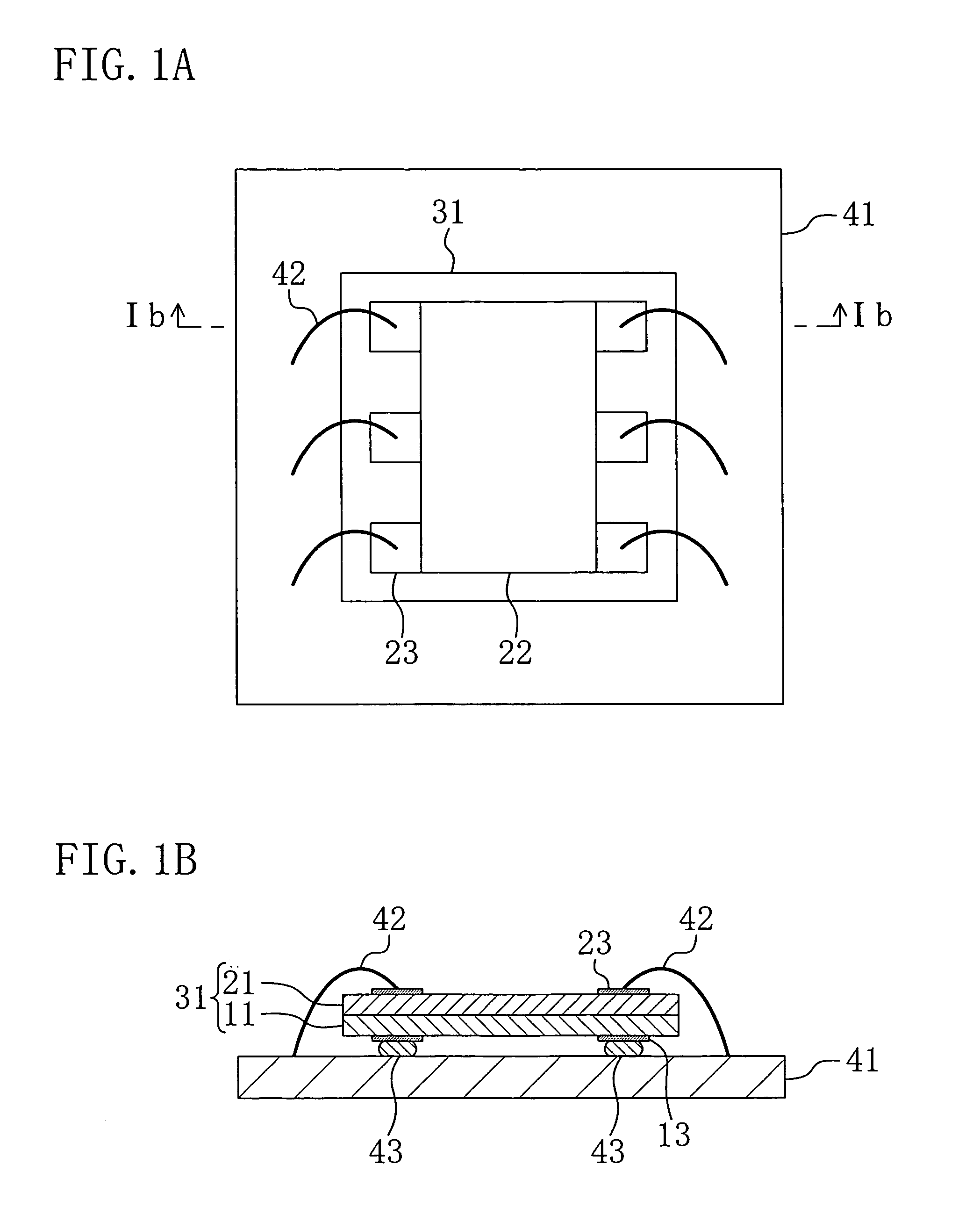

Composite filter chip

InactiveUS20070080757A1Reduce filter areaImpedence networksSolid-state devicesEngineeringComposite filter

A composite filter chip includes a stacked chip made by stacking a first chip and a second chip. The first chip has a first filter circuit formed on the main surface thereof. The second chip has a second filter circuit formed on the main surface thereof.

Owner:PANASONIC CORP

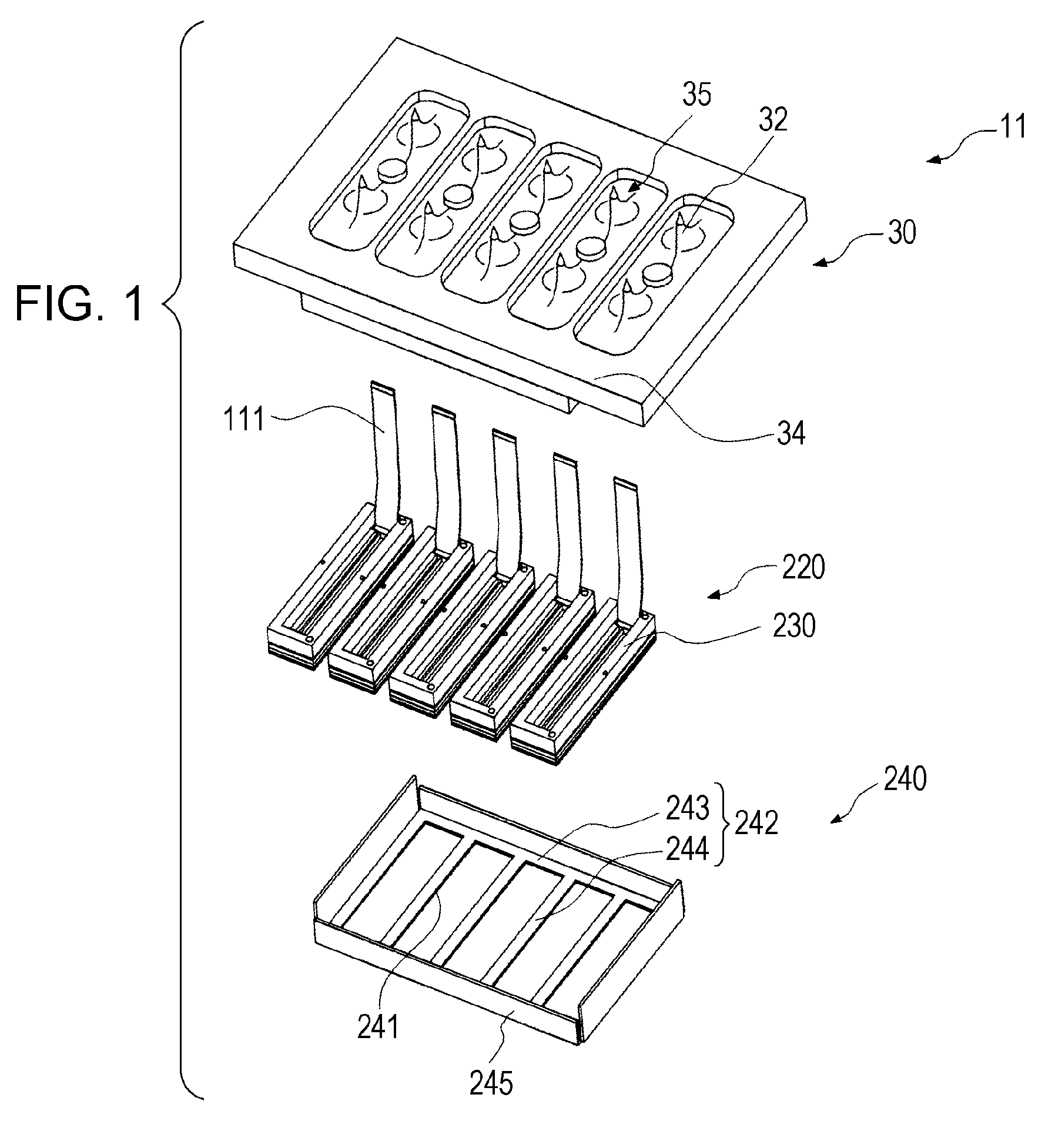

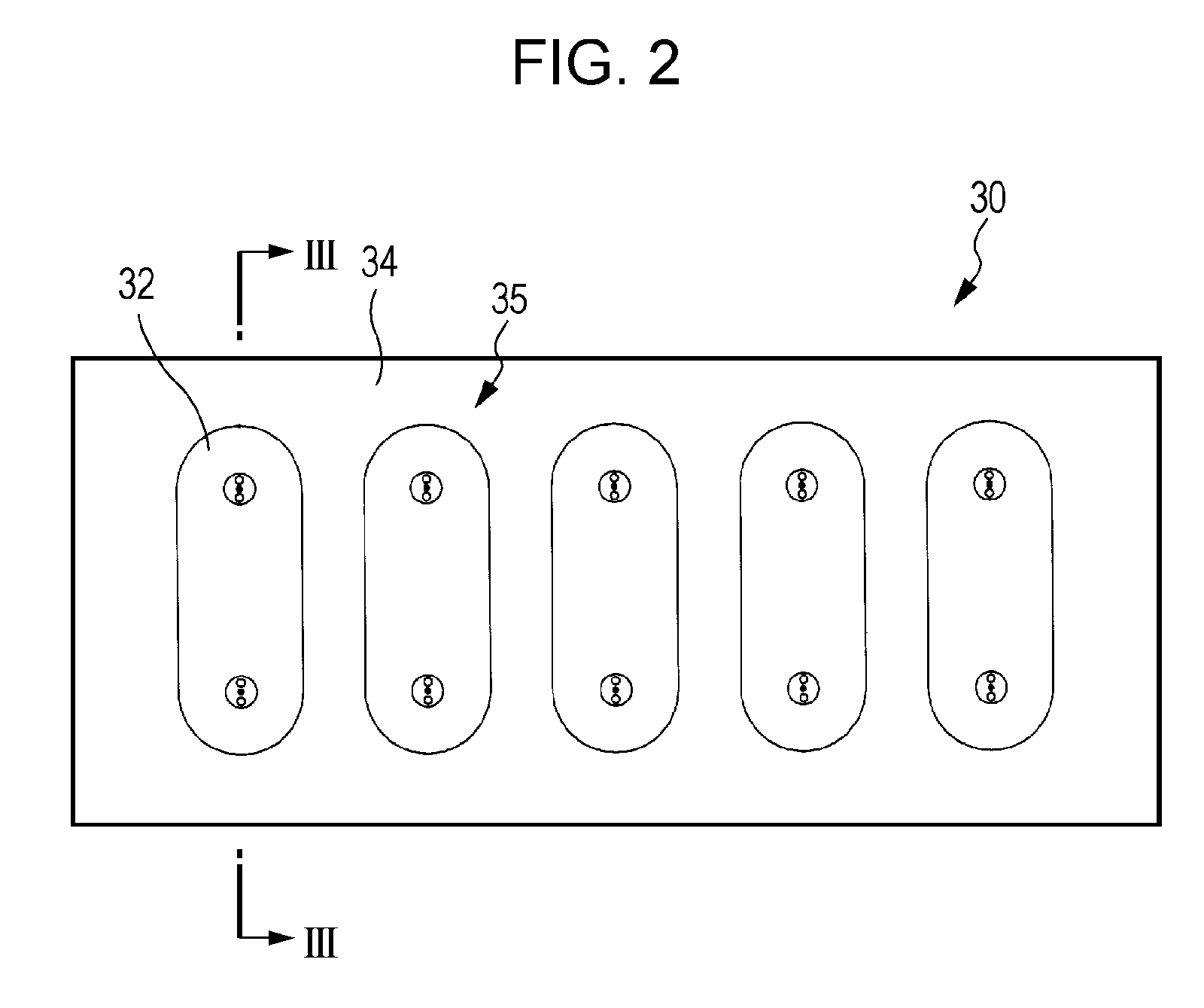

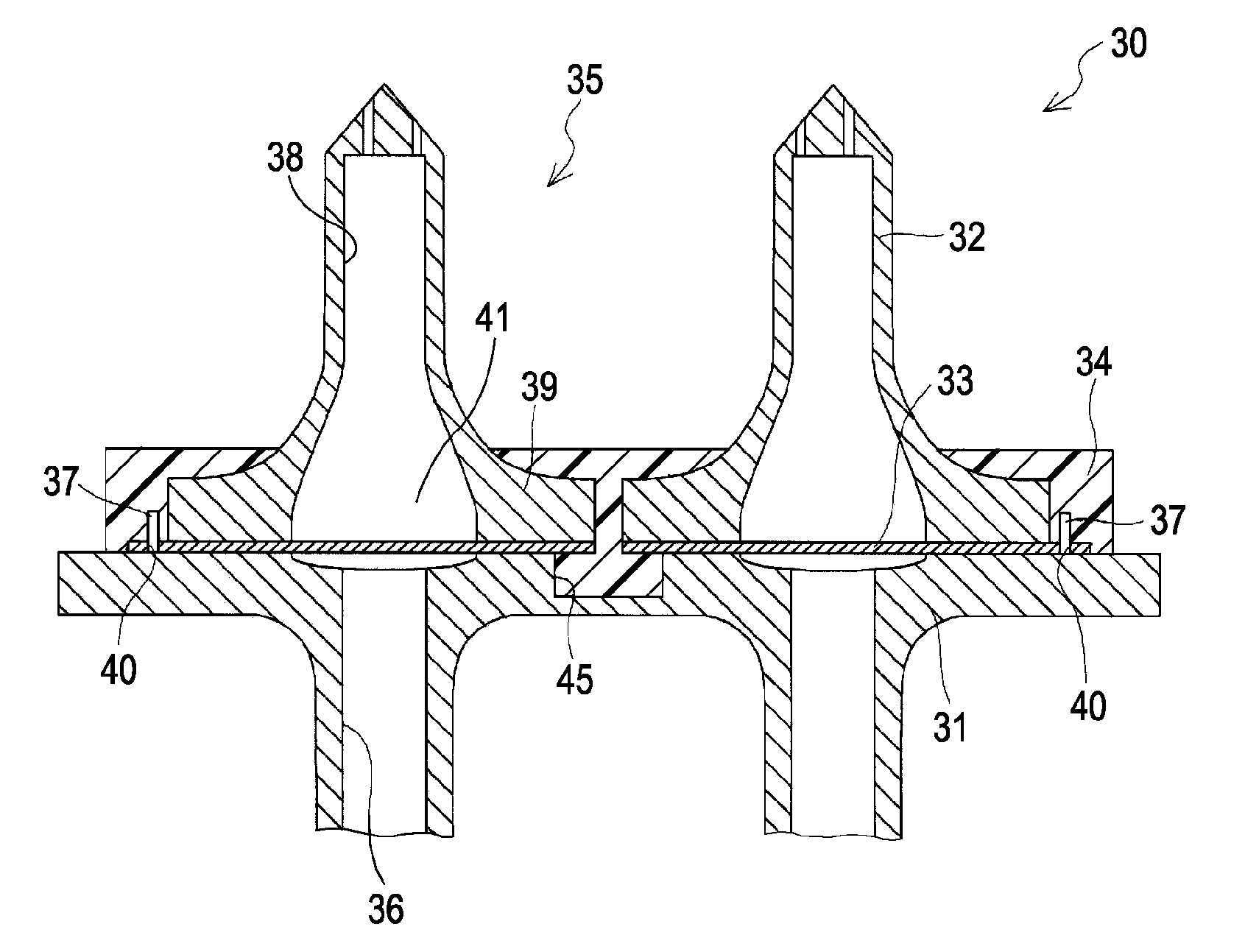

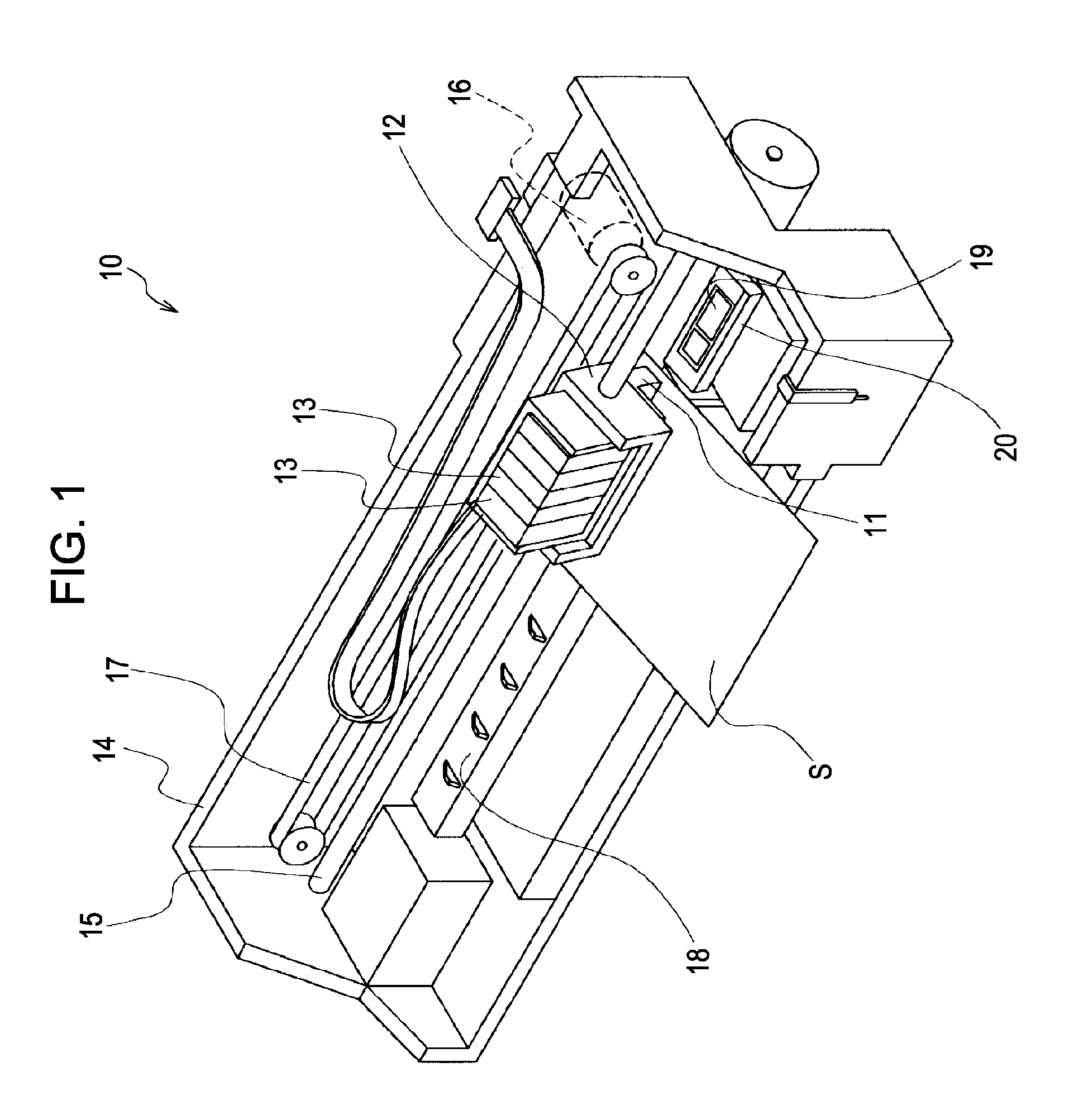

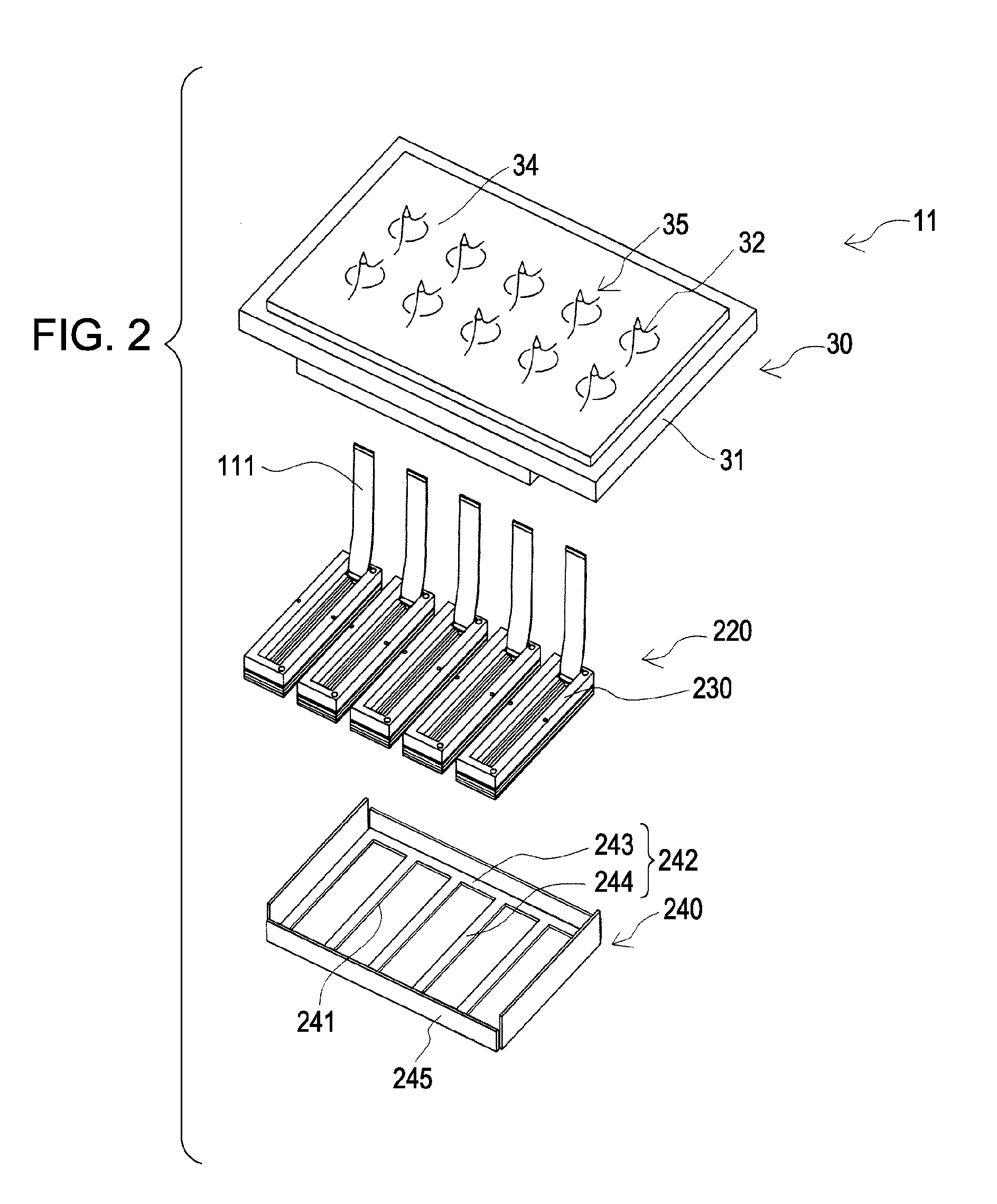

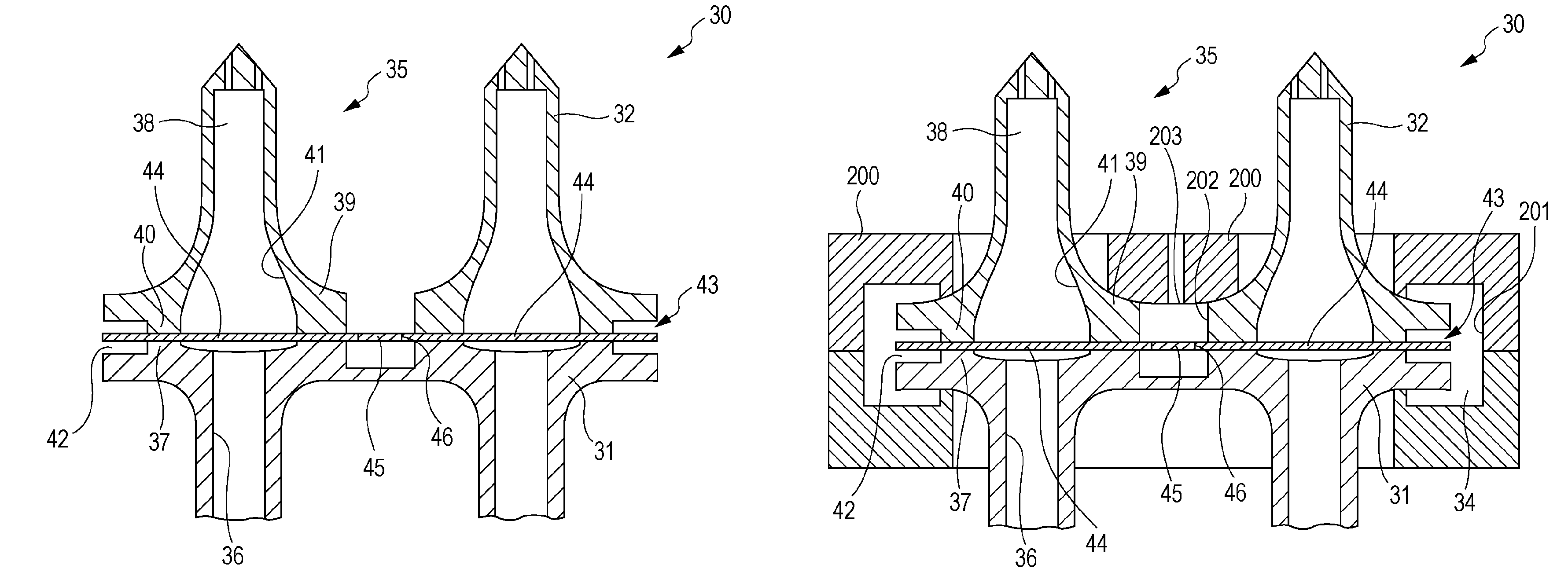

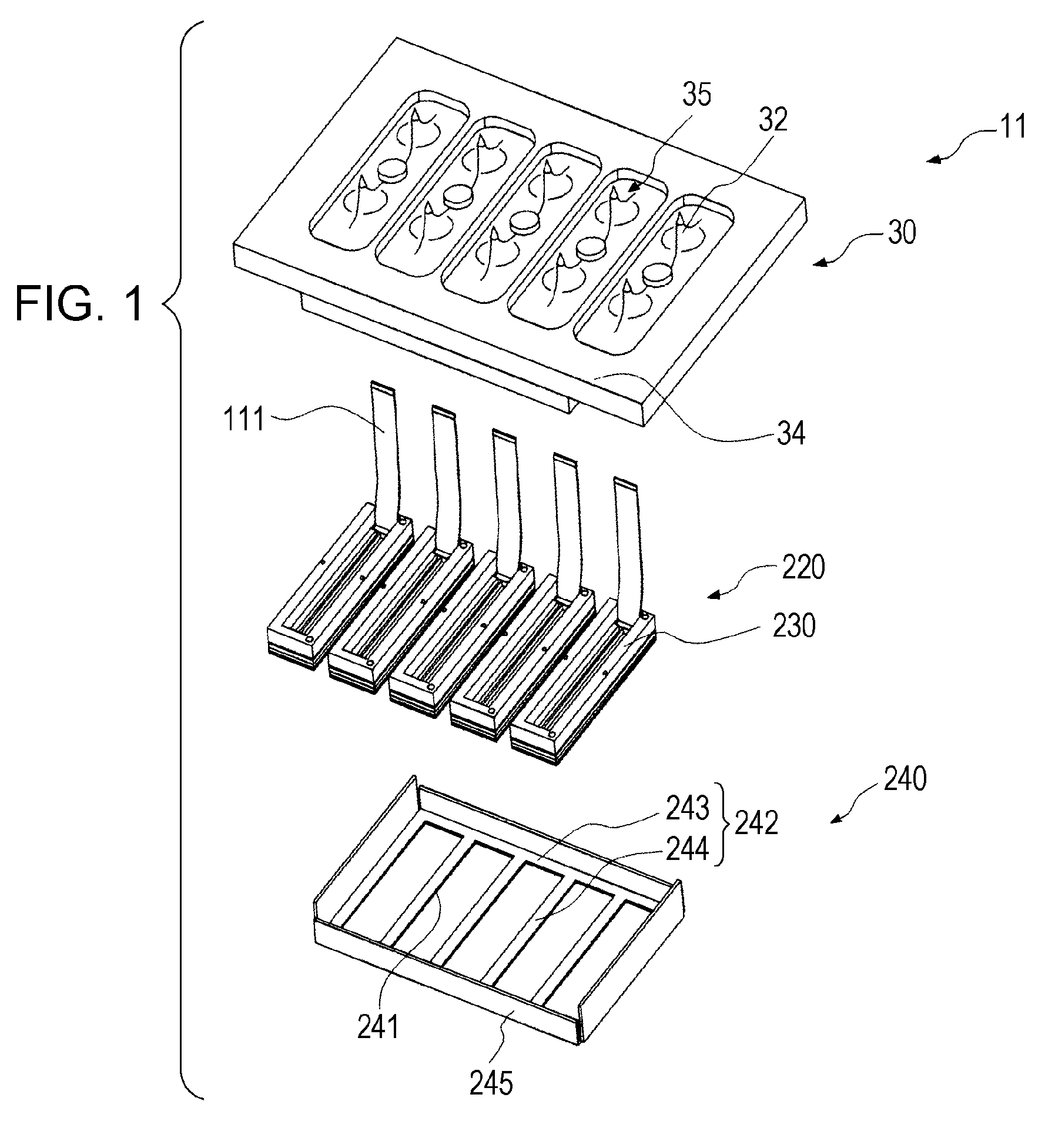

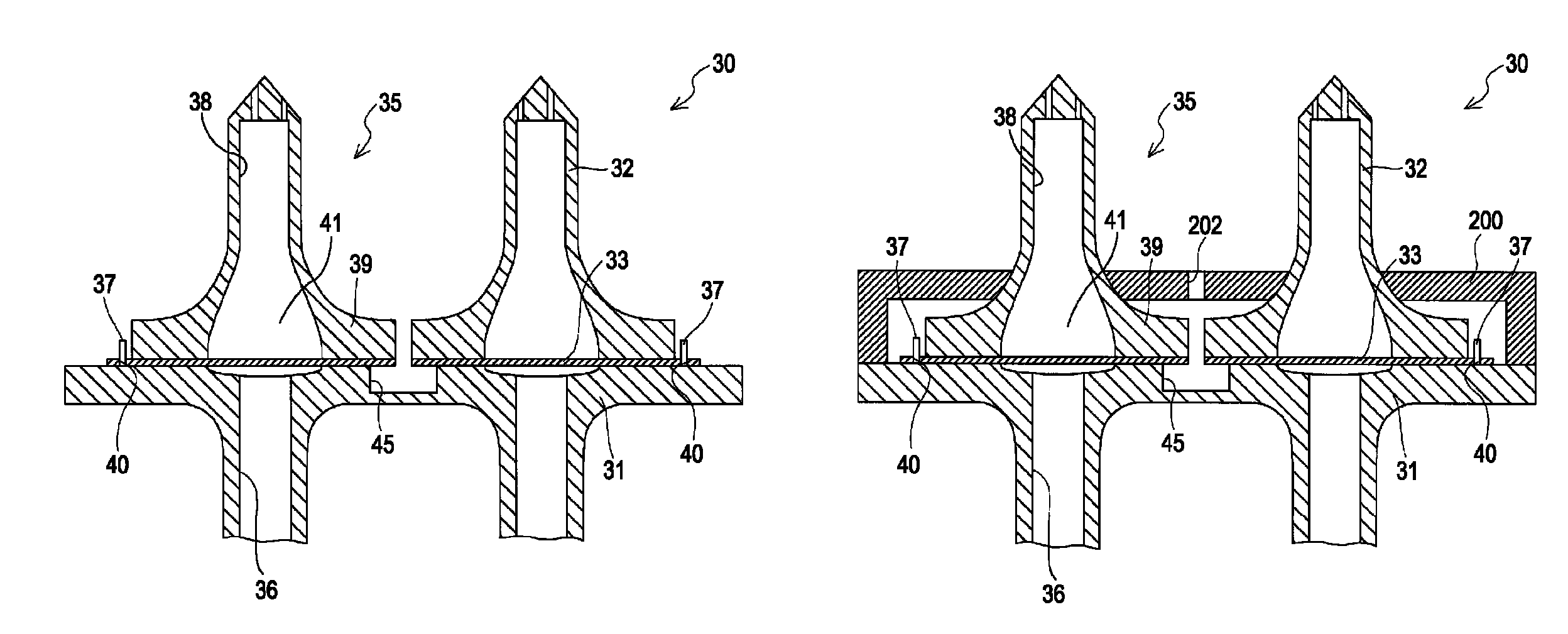

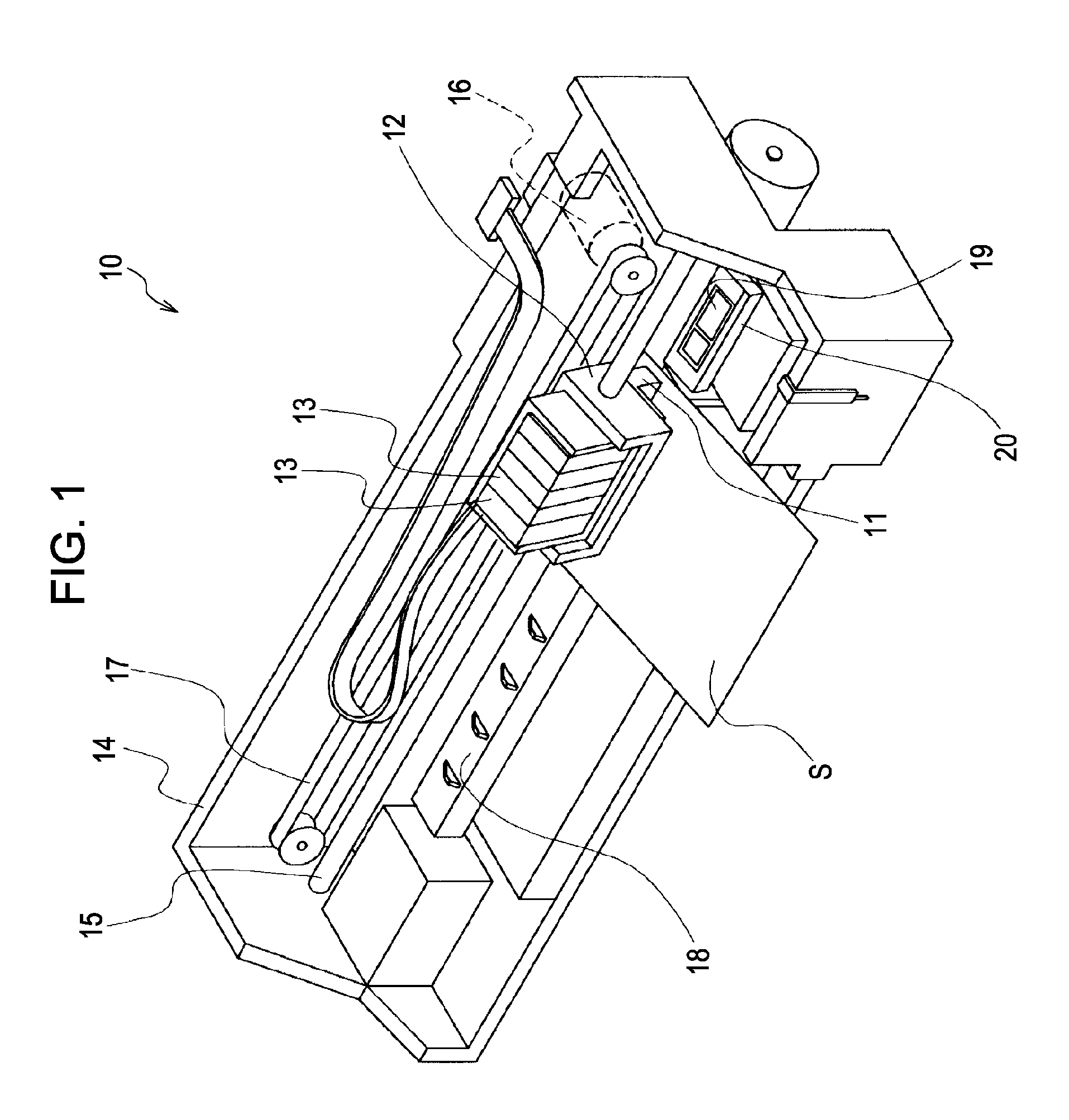

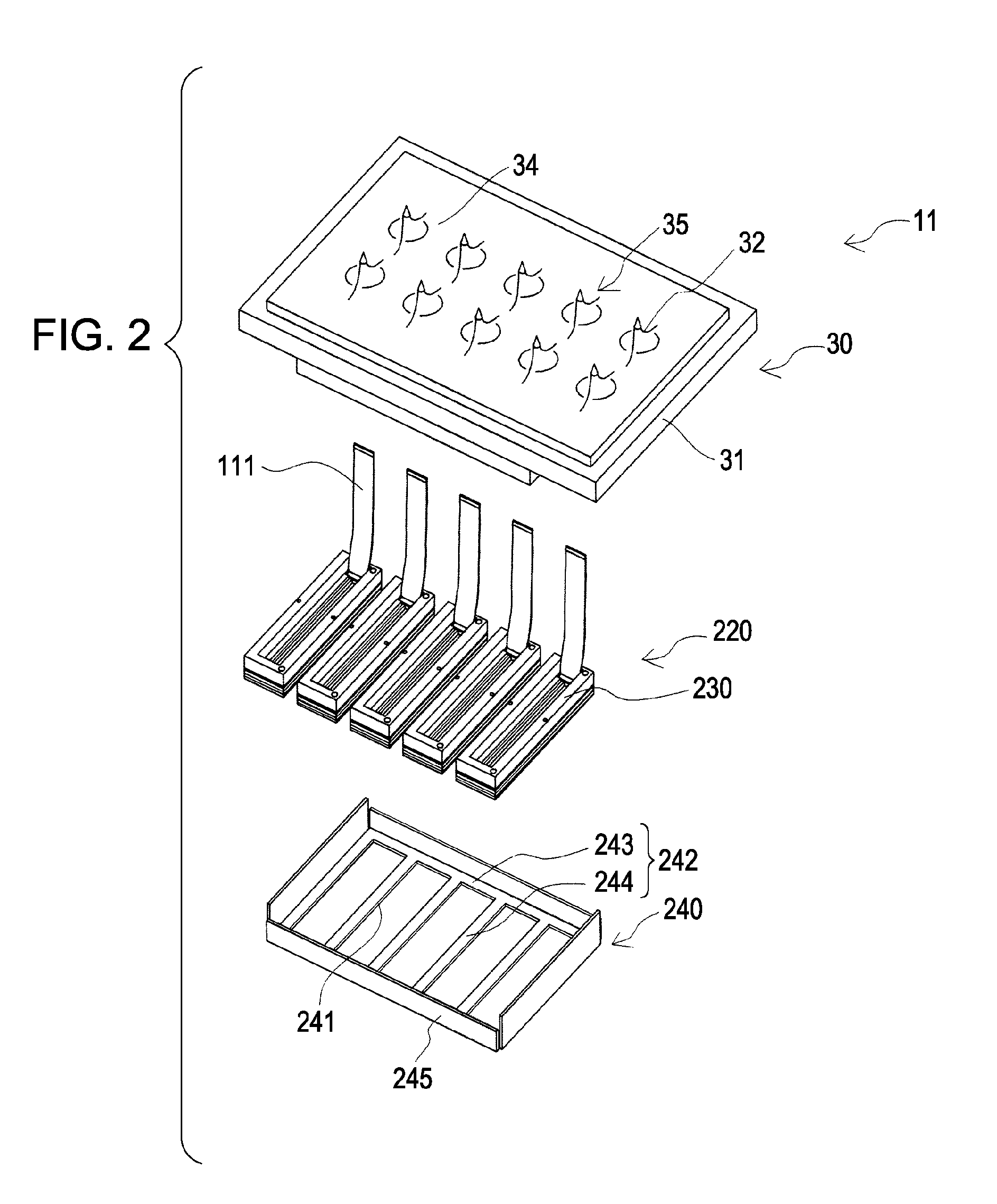

Method of manufacturing liquid ejecting head

InactiveUS20090212460A1Prevent liquid leakageReduce intervalTailstocks/centresConfectioneryMechanical engineeringFilter element

A method of manufacturing a liquid ejecting head and a supply member having a plurality of liquid supply passages is provided. The supply member includes first and second supply members in which liquid supply passages are provided and filters provided between the first supply member and the second supply member. The method includes: preparing a connected filter formed of a plurality of filter element portions corresponding to the plurality of liquid supply passages and a connecting portion that connects the plurality of filter element portions; in a state where the filter element portions of the connected filter are held between the first supply member and the second supply member, charging molten resin from a position corresponding to the connecting portion of the connected filter to separate the connecting portion; and, during the charging, molding.

Owner:SEIKO EPSON CORP

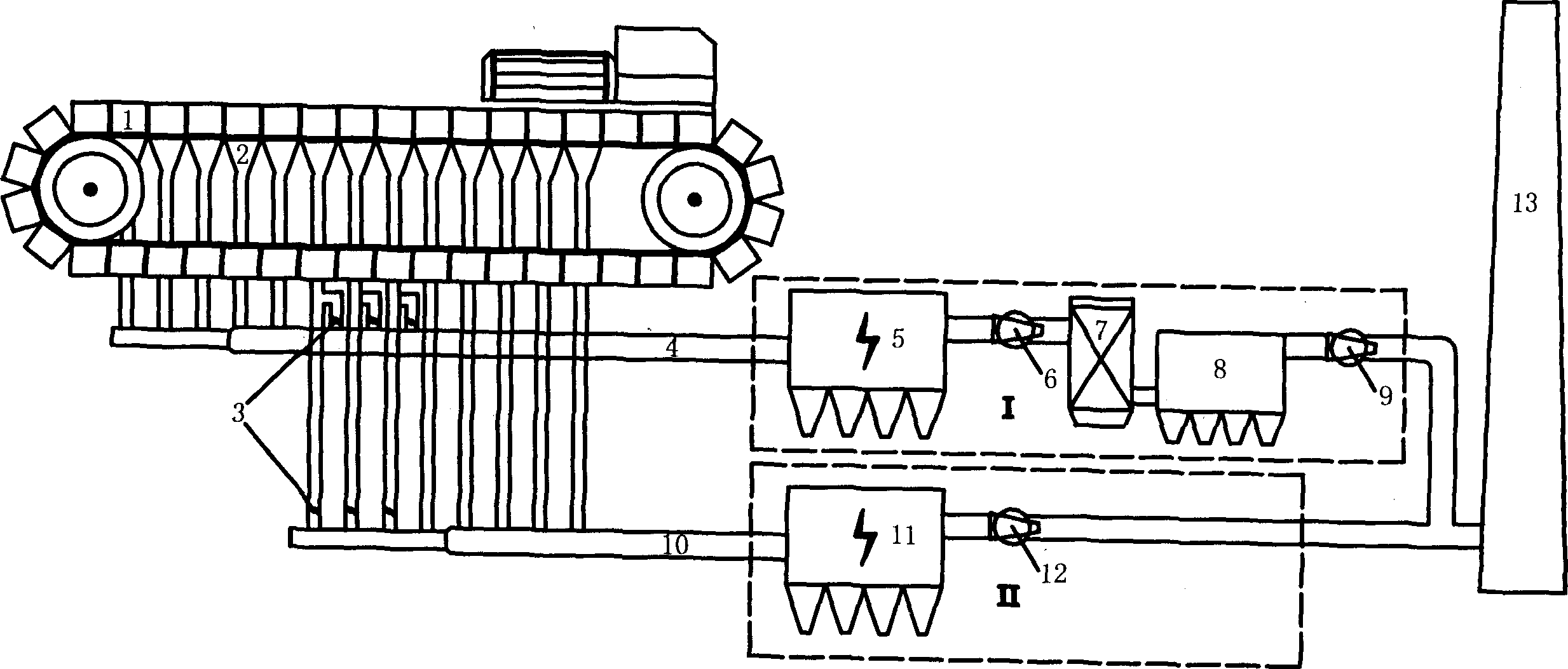

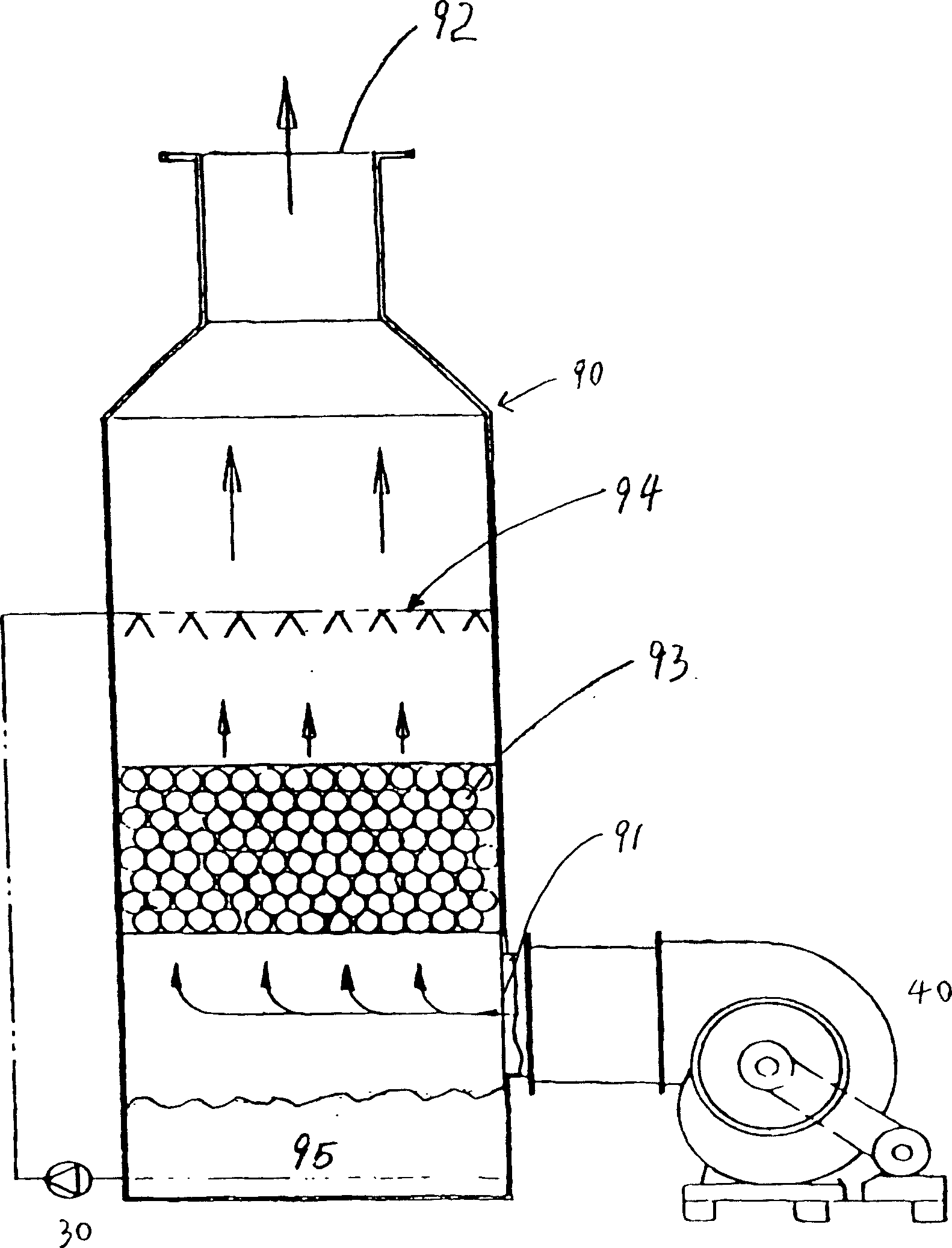

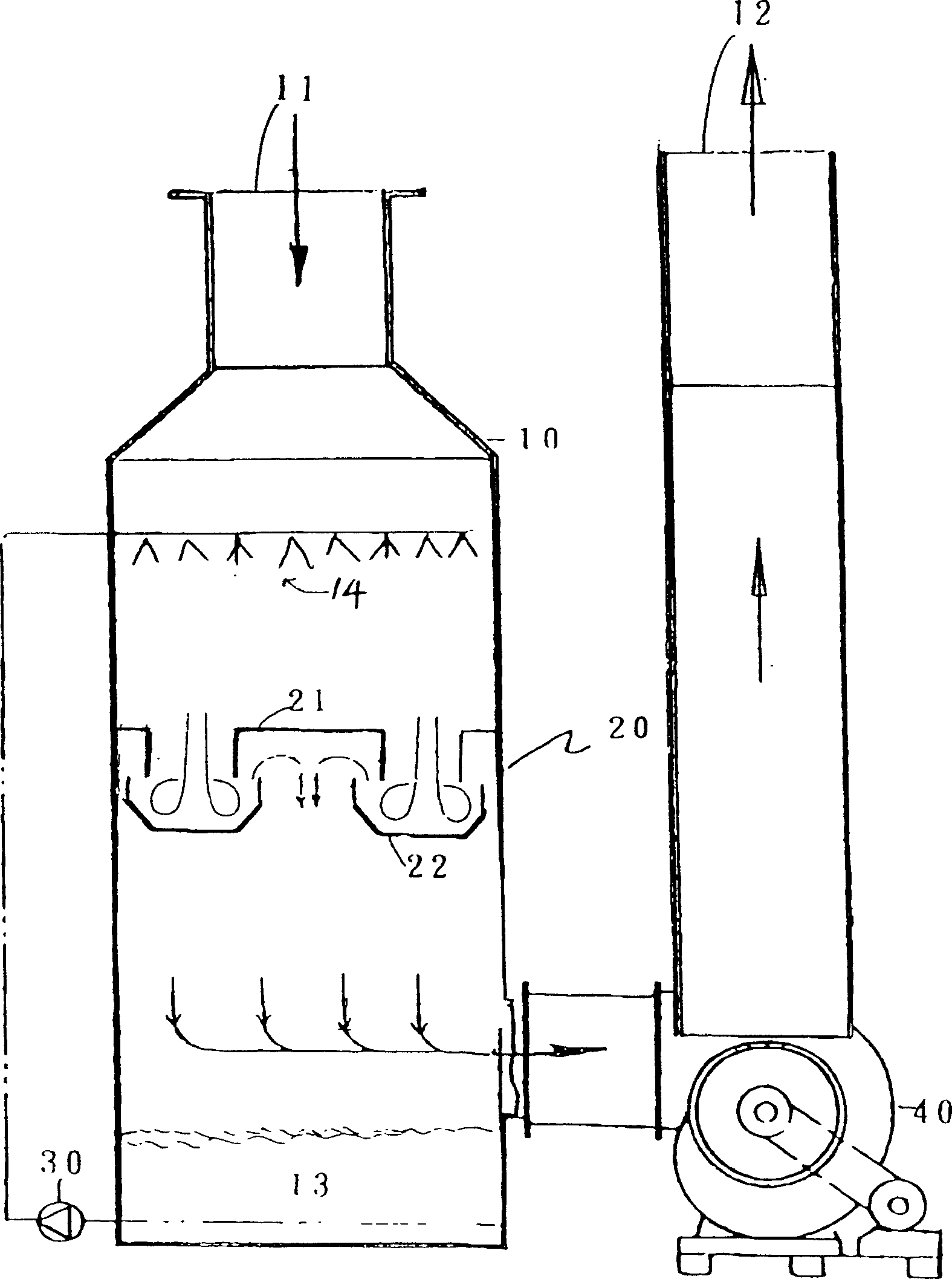

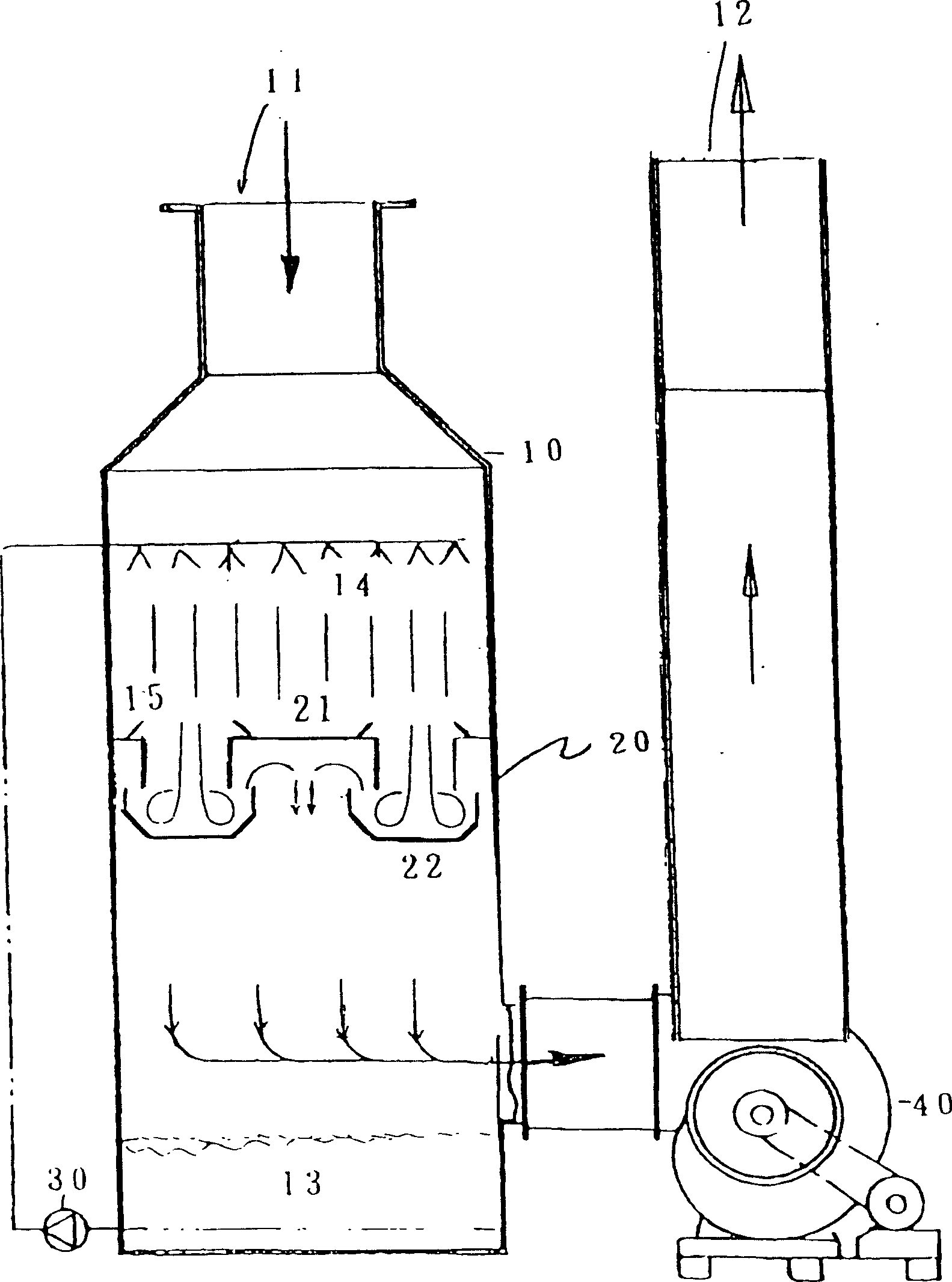

Selectivelly-desulfurized dense-phase tower drier

A closely coherent tower system for selective desulfurizing is composed of a desulfurizing system A and a non-desulfurizing system B, which serve a single sintering motion at same time. Said desulfurizing system A consists of wind gathering hopper, flue valve, flue, electric duster, exhaust blower, closely coherent tower, cloth-bag duster and boosting blower. Said non-desulfurizing system B comprises flue, electric duster and exhaust blower.

Owner:UNIV OF SCI & TECH BEIJING +1

Liquid ejecting head manufacturing method

ActiveUS20100071211A1Decrease in sizeSmall sizeWriting implementsMetal-working apparatusEngineeringHead parts

Owner:SEIKO EPSON CORP

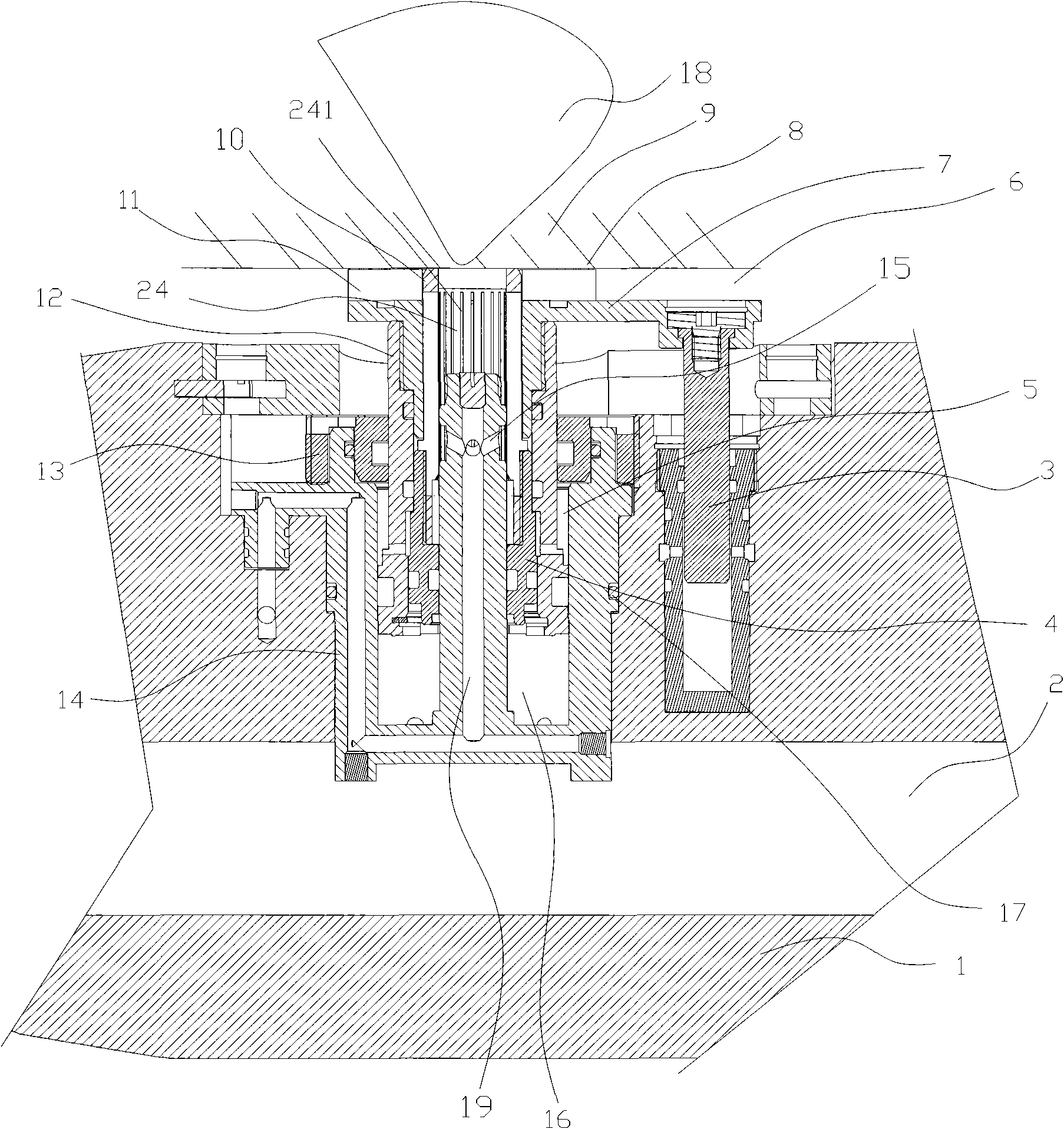

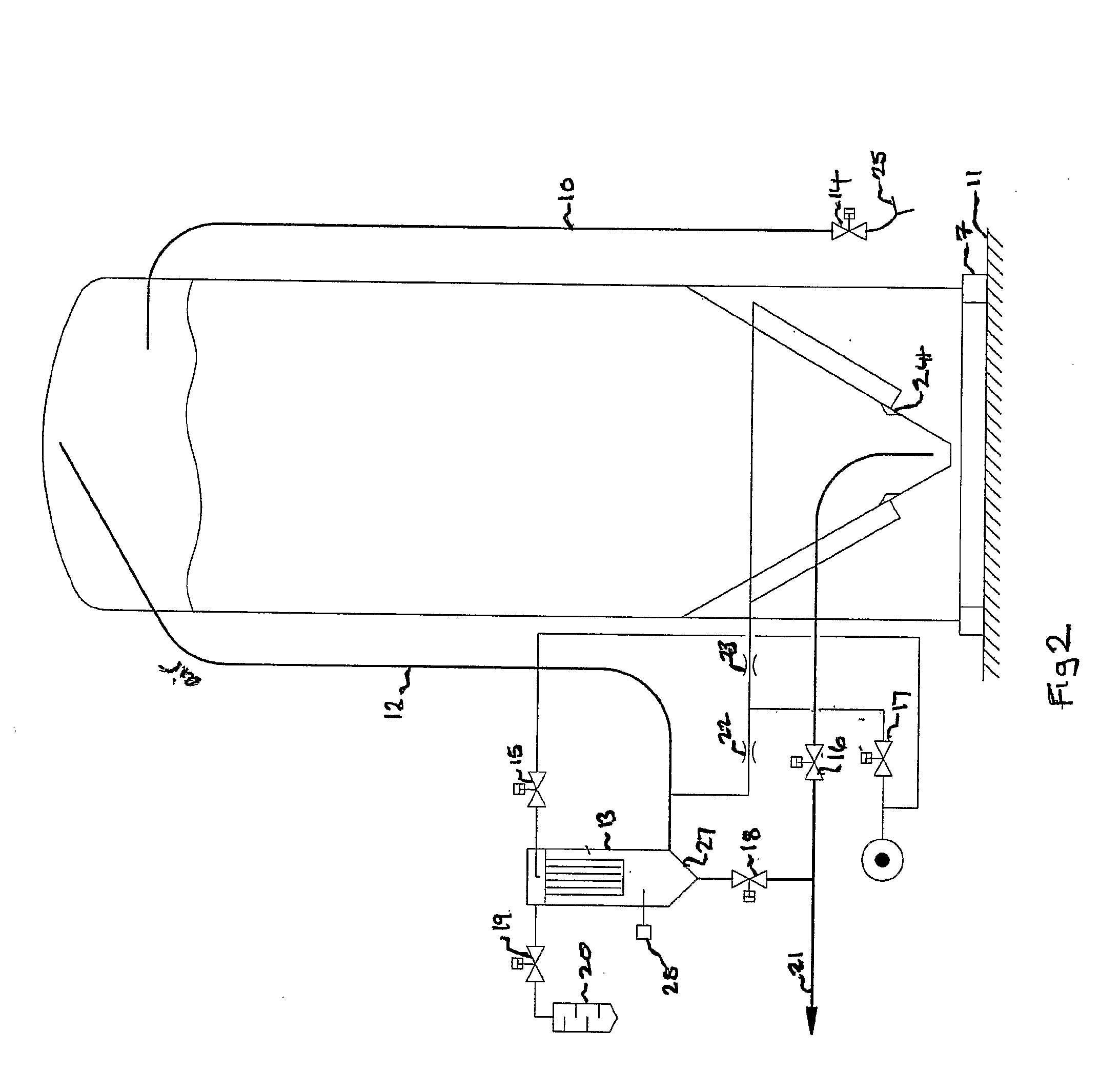

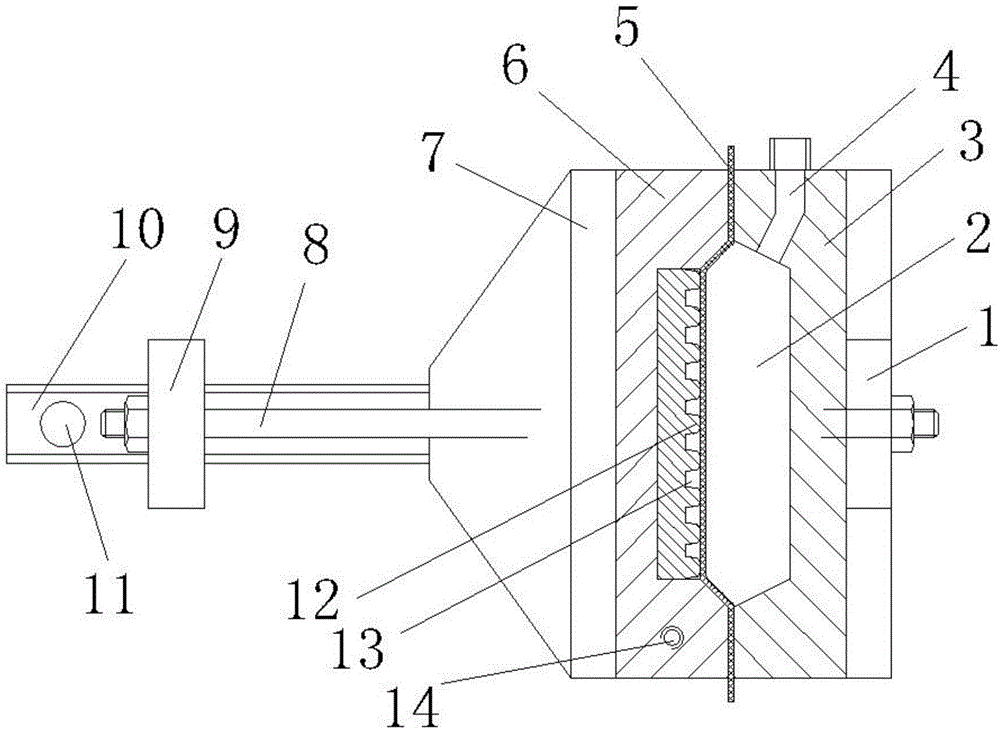

Pushing device for extraction of formation fluid

The invention discloses a pushing device for the extraction of formation fluid, which comprises a main cylinder, and the bottom of the main cylinder is provided with an axially extended central guide rod, on which a first pushing piston and a second pushing piston are sequentially sleeved; the sidewall of the main cylinder is provided with an extension oil port, a formation fluid oil port and a retraction oil port, the extension oil port is communicated with an extension oil chamber of the main cylinder through an extension oil passage axially arranged in the sidewall of the main cylinder, the formation fluid oil port is communicated with a fluid inlet of the central guide rod via a fluid passage, the fluid passage consists of a first passage a second passage and a third passage, wherein the first passage sequentially runs through and is axially arranged in the sidewall of the main cylinder, the second passage is radially arranged in the bottom of the main cylinder, the third passage is axially arranged in the central guide rod, and the retraction oil port is communicated with a retraction oil chamber of the main cylinder through a retraction oil passage of the sidewall of the main cylinder. The pushing device has the advantages of high integration degree and small occupied space, and the arrangement of the control oil passages and the fluid passage of the pushing device is more reasonable.

Owner:CHINA NAT OFFSHORE OIL CORP +1

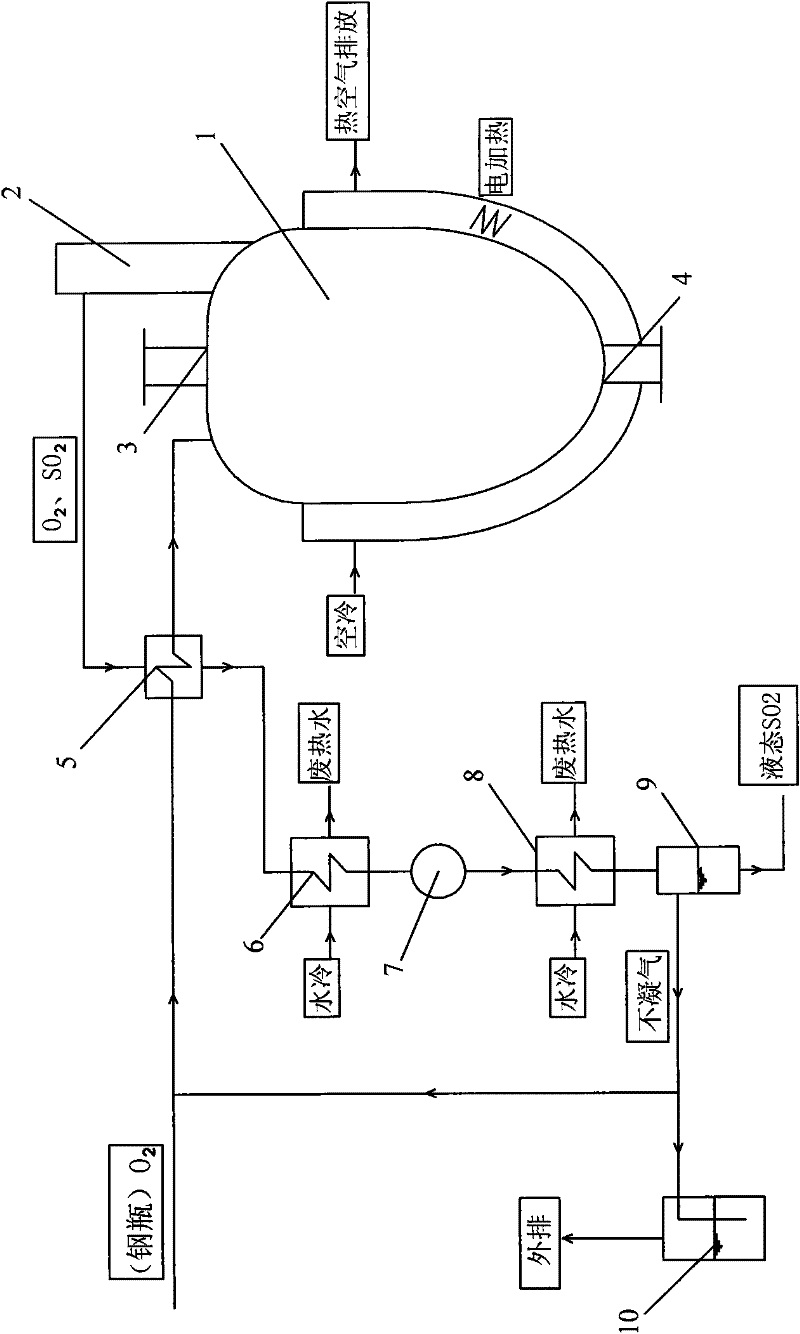

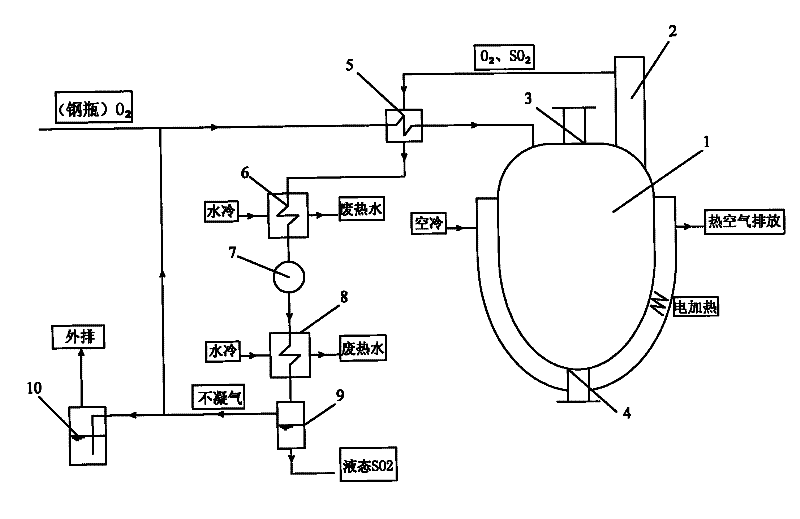

Method for pollution-free production of molybdenum oxide

InactiveCN102126757AFast oxidationReduce filter areaMolybdenum oxides/hydroxidesHigh concentrationChemical reaction

The invention provides a method for pollution-free production of molybdenum oxide, which comprises the following steps of: adding molybdenum sulfide into a sealing reactor and introducing oxygen into the reactor, and heating, so that the molybdenum sulfide reacts with the oxygen to generate molybdenum oxide and sulfur dioxide; and filtering generated high-temperature gas by a dust collector, and cooling, compressing and separating to obtain high-concentration liquid sulfur dioxide. In the method, the molybdenum oxide is produced by adopting the closed oxygen-enriched combustion technology, so the production efficiency of the product is improved, and mineral resources are saved; energy consumption is saved by utilizing heat in a chemical reaction; and the SO2 generated in the production process can be recycled to realize the resource utilization of exhaust gas and reduce atmosphere pollution, so the method has a bright application prospect.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

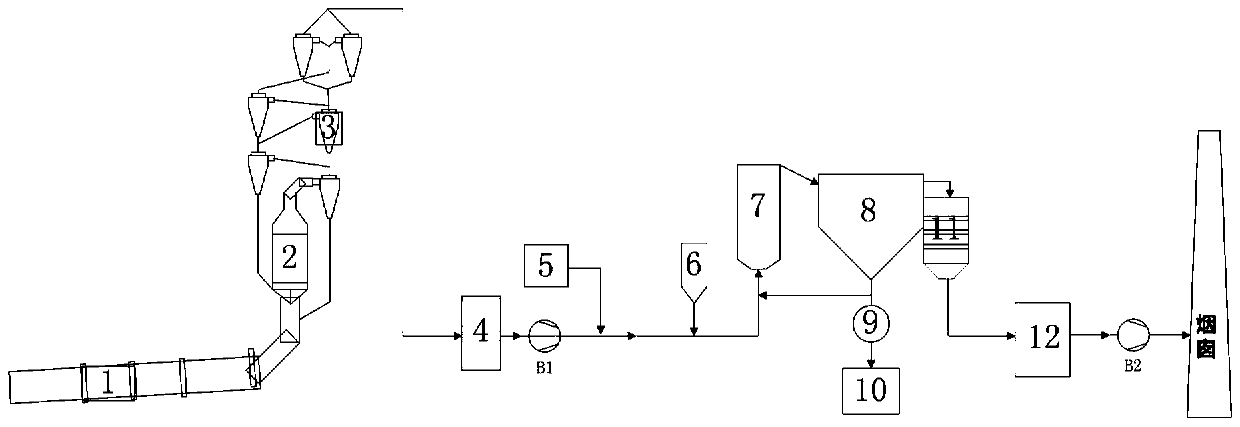

Dry desulfurization, denitration and dust removal device and method for low-sulfur flue gas in cement kiln tail

PendingCN110665352AReduce filter areaReduce resistanceGas treatmentDispersed particle filtrationDust controlCement kiln

The invention relates to a dry desulfurization, denitration and dust removal device for low-sulfur flue gas in cement kiln tail. The dry desulfurization, denitration and dust removal device includes acement kiln, a decomposing furnace, a suspension preheater, a cooling device, a desulfurization tower, a dust remover and a medium-temperature SCR denitration device, wherein the cement kiln, the decomposing furnace, the suspension preheater and the cooling device are successively connected, an air inlet pipeline of the desulfurization tower is connected with a flue gas outlet of the cooling device, and the desulfurization tower is a circulating fluidized bed dry desulfurization tower with the low density, a low bed and no water spraying; the air inlet pipeline is provided with a high-temperature fan, and connected with a raw mill, a desulfurizer bin and a smoke dust return device; a flue gas inlet of the dust remover is connected with a flue gas outlet of the desulfurization tower, and aby-product outlet of the dust remover communicates with the air inlet pipeline through the smoke dust return device, and is connected with a raw material warehouse through a by-product conveying device; and a flue gas inlet of the medium-temperature SCR denitration device is connected with a flue gas outlet of the dust remover, an air outlet pipeline of the medium-temperature SCR denitration device is successively provided with a waste heat boiler and an induced draft fan, and discharges purified gas through a chimney. According to the dry desulfurization, denitration and dust removal device,synergistic removal of multi-component contaminants can be achieved while high-efficiency desulfurization, denitration and dust removal are achieved, corrosion prevention is not needed, zero waste water discharge and transparent chimney discharge are achieved, and meanwhile long-term stable operation can be achieved.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

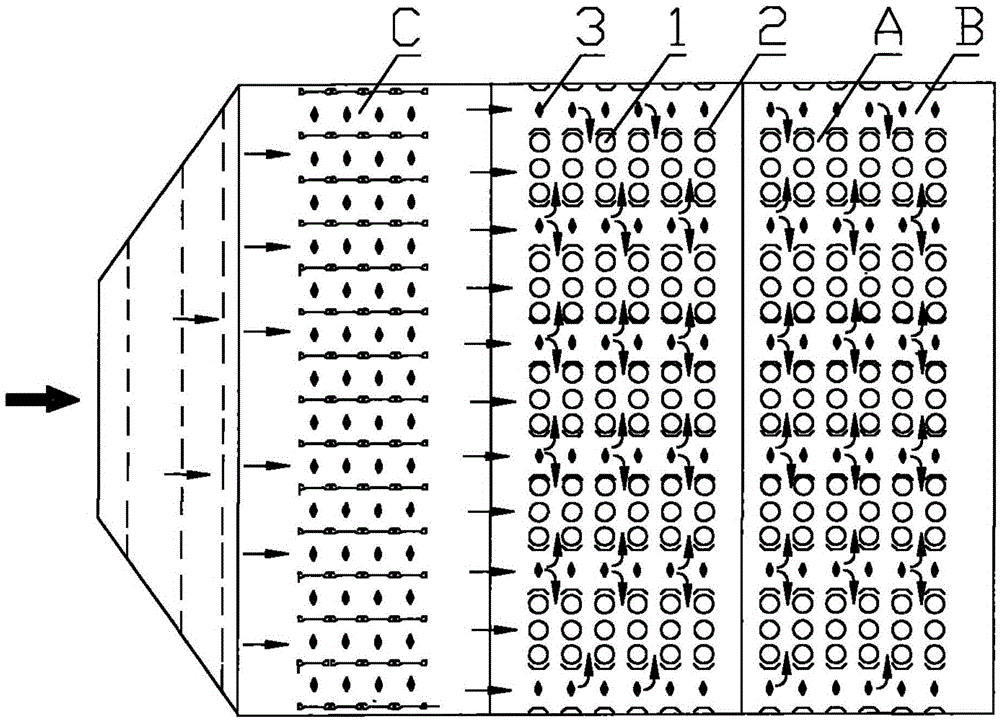

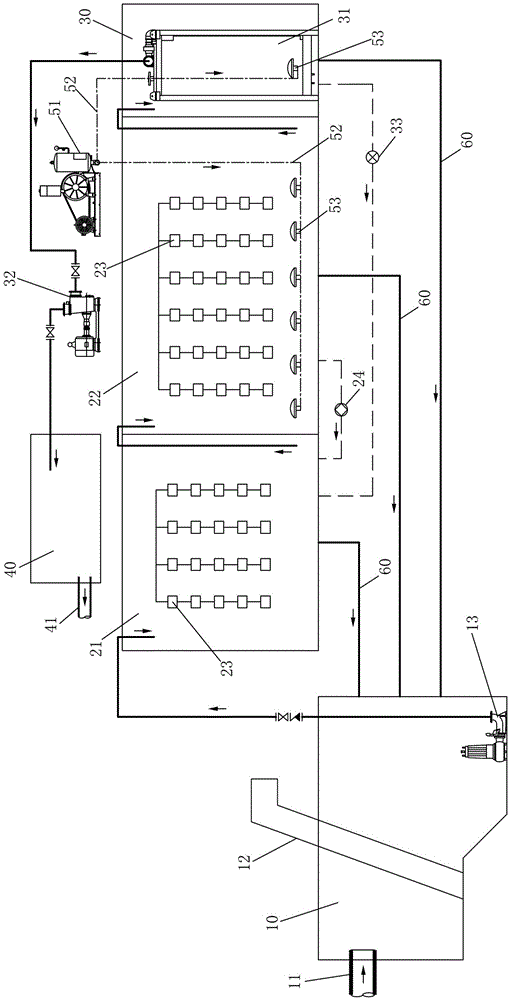

Electrostatic-bag composite dust collector

ActiveCN106552469AGuaranteed service lifeImprove charging effectCombination devicesAir velocityFlue gas

The invention discloses an electrostatic-bag composite dust collector which includes an electrostatic-bag mixing area provided with a filter bag and electric field. The filter bag is a metal filter bag. A negative discharge pole is arranged on the periphery of the metal filter bag. A positive pole plate is disposed in the electrostatic-bag mixing area and is corresponding to the negative discharge pole, so that the electric field is formed by the discharge pole and the positive pole plate. A negative pole system is formed by the metal filter bag, which is corresponding to the positive pole plate, so that friction on the filter bag is avoided in the technical scheme and service life of the filter bag is ensured. The electric field is formed by the metal filter bag and the discharge pole, so that charging property of dust is improved, and when the dust is captured by the filter bag, a loose dust layer is formed on the surface of filter bag due to the principle of like charge repelling each other, thereby preventing dust caking and improving dust removal efficiency. The metal filter bag is a negative pole system, so that under the constraint of electric field force, speed of the charged dust is reduced and the dust is remained in and even deposited in the electric field, while flue gas can flow towards the metal filter bag at high speed, so that the dust collector also can increase the air flowing speed in the filter bag area, thereby increasing utilization ratio of the filter bag and utilization ratio of space.

Owner:FUJIAN LONGKING

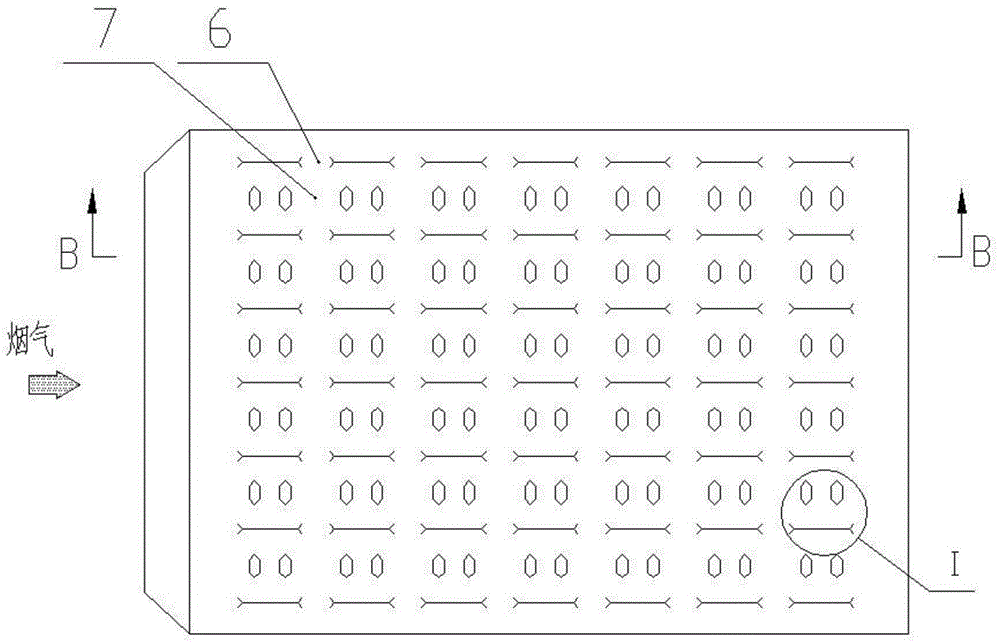

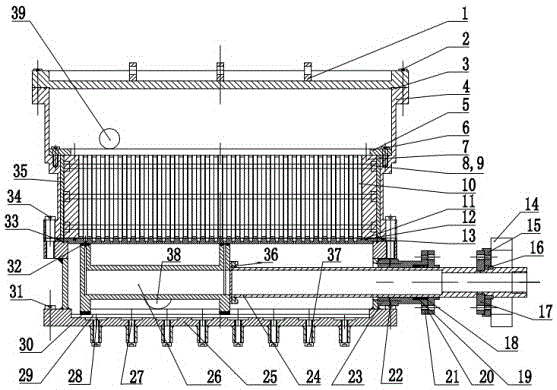

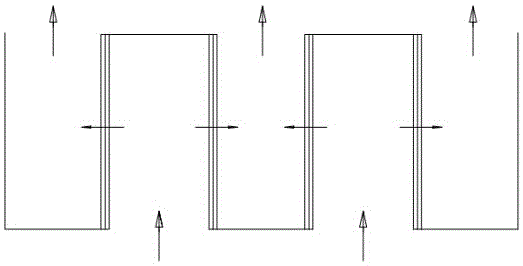

Automatic back-washing plate frame filter

ActiveCN105126402ASave human effortReduce energy consumptionFiltration separationFiltrationStructural engineering

The invention discloses an automatic back-washing plate frame filter which comprises a main engine, a back-washing device and a plate frame filter rack, wherein the main engine comprises an upper body cover plate, a filter element body, an intermediate plate and a base in sequence from top to bottom; the filter element body is divided into a clear liquid tank positioned at the upper part and a filter element tank positioned at the lower part; a plurality of filter element filter plates are arranged in the filter element tank at uniform intervals; intervals of front and back adjacent filter element filter plates are formed into filter seams, the lower ends of the front filter seams are in sealed connection with the plate surface of the intermediate plate, the upper ends of the front filter seams are communicated with the clear liquid tank, the lower ends of the back filter seams are communicated with a to-be-filtered liquid through hole in the intermediate plate, and the upper ends of the back filter seams are sealed, so as to form a staggered connection structure; a piston cavity structure is formed by the intermediate plate and the base; a back-washing device is arranged in the piston cavity, and comprises a piston, a hydraulic device connected with the piston and a back washing outlet; the piston and the plate surface of the intermediate plate are connected in a sliding and sealed manner; a back-washing inlet corresponding to the to-be-filtered liquid through hole in position is formed in the piston. According to the automatic back-washing plate frame filter, automatic back-washing can be realized in the use process, and the filtration quality is high.

Owner:JIUJIANG HENGSHENG CHEM FIBER

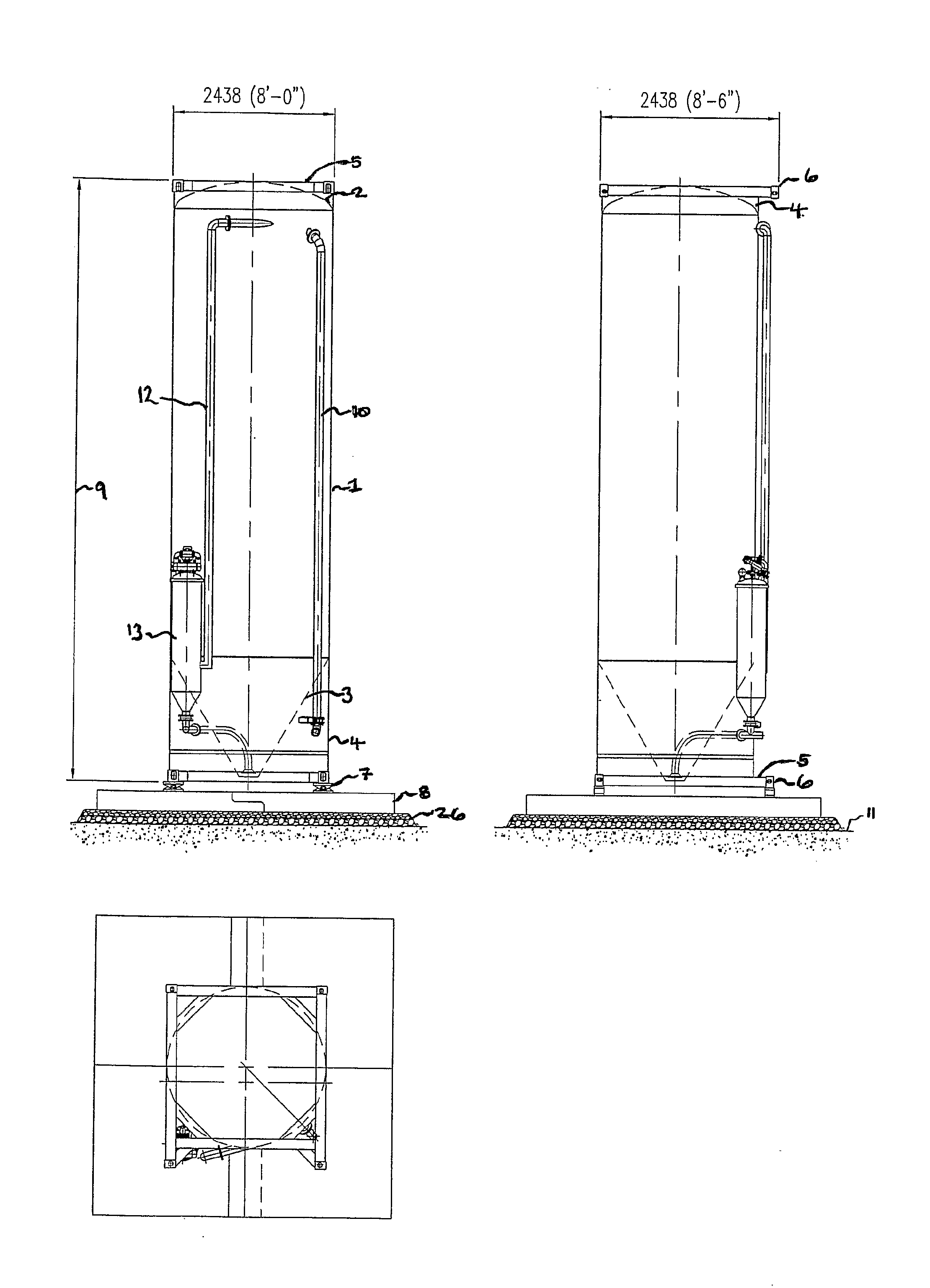

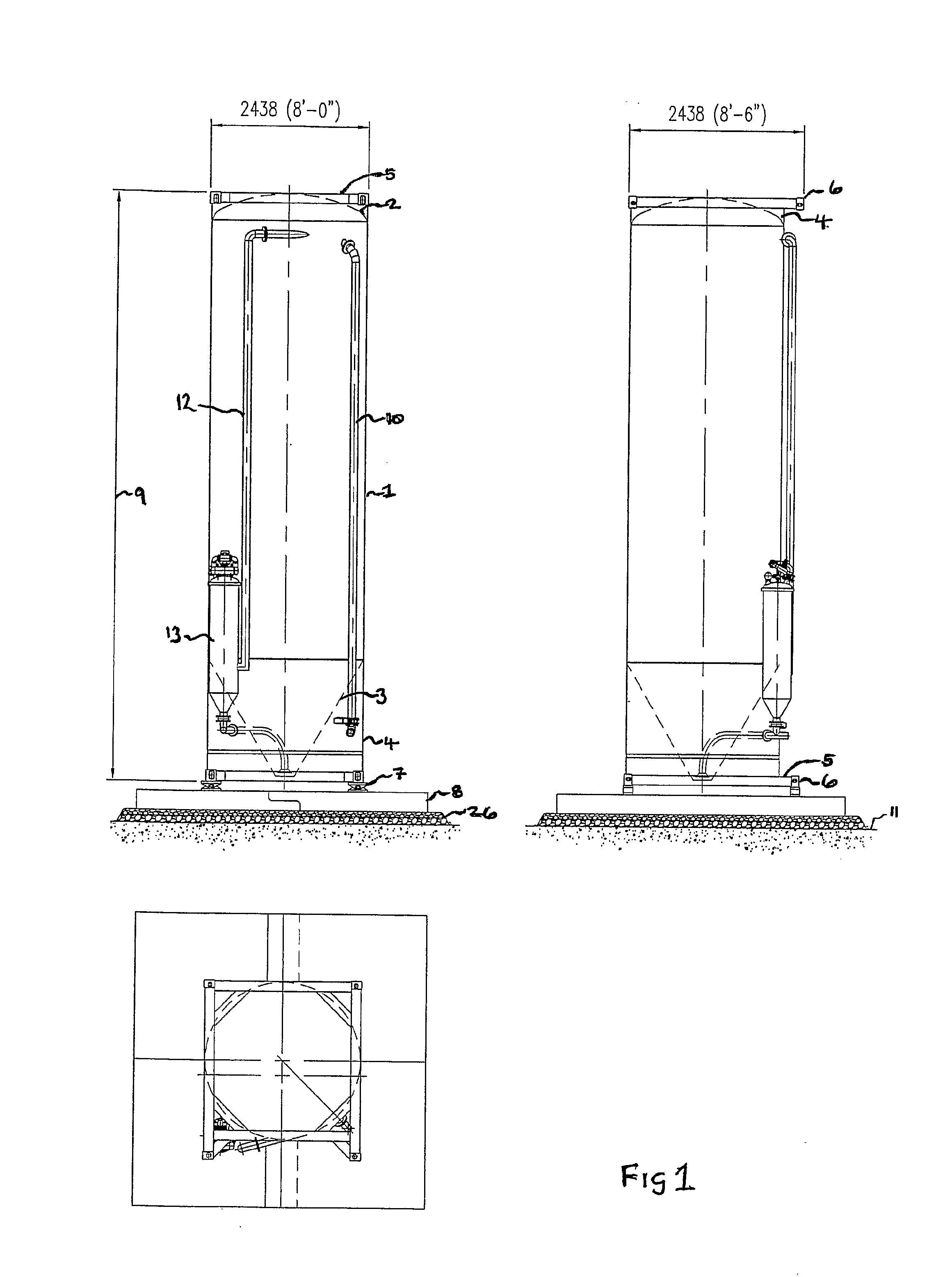

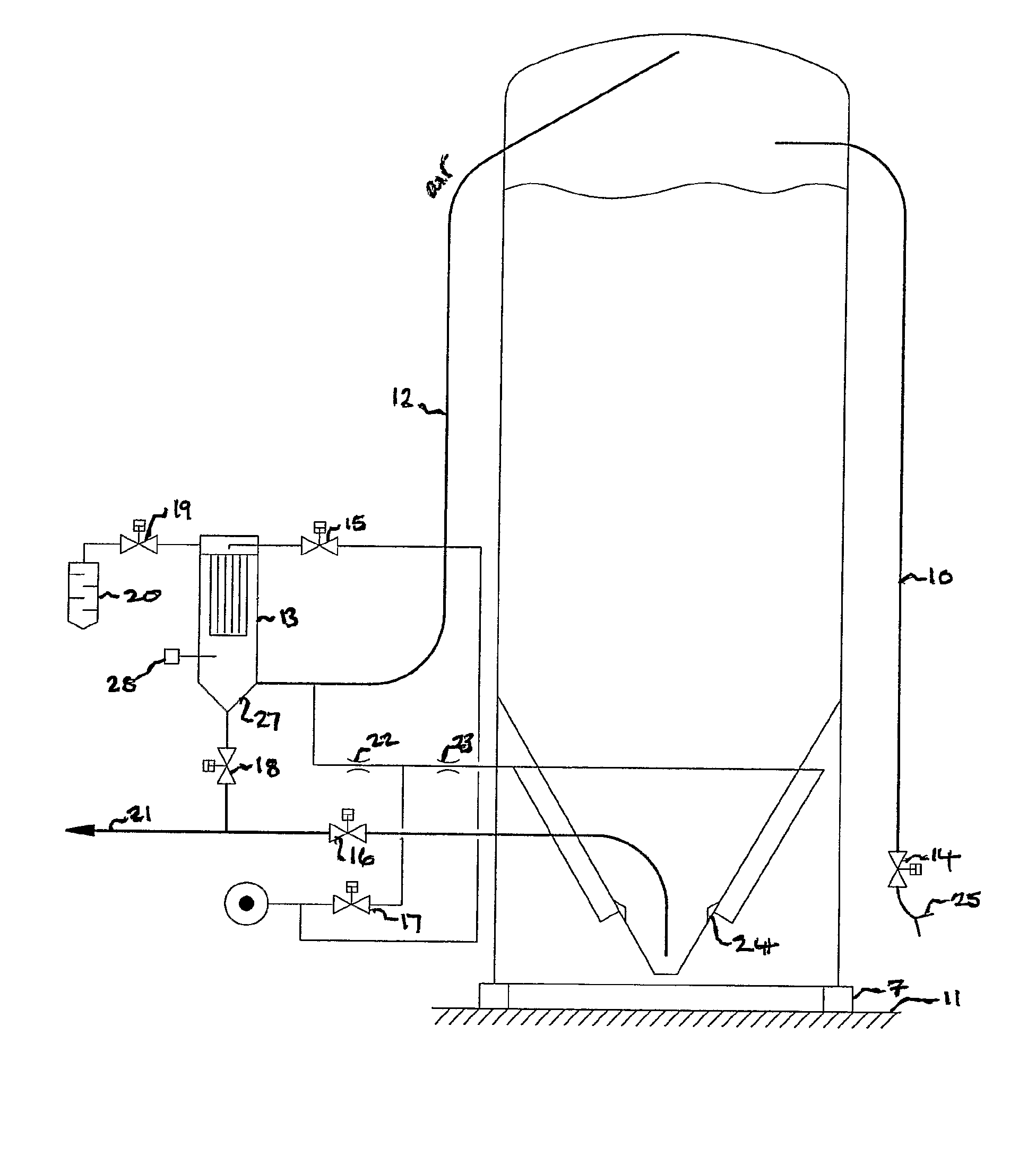

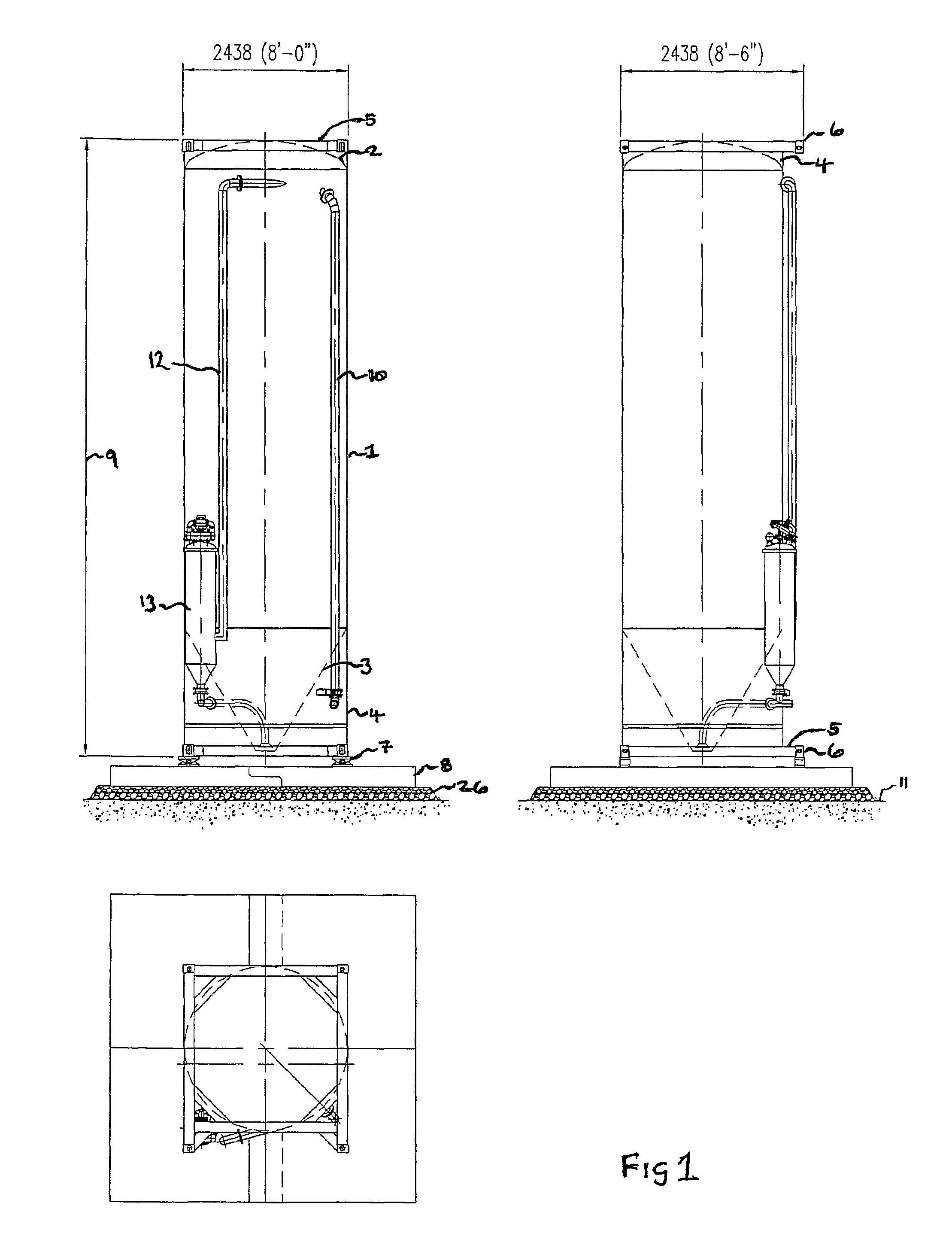

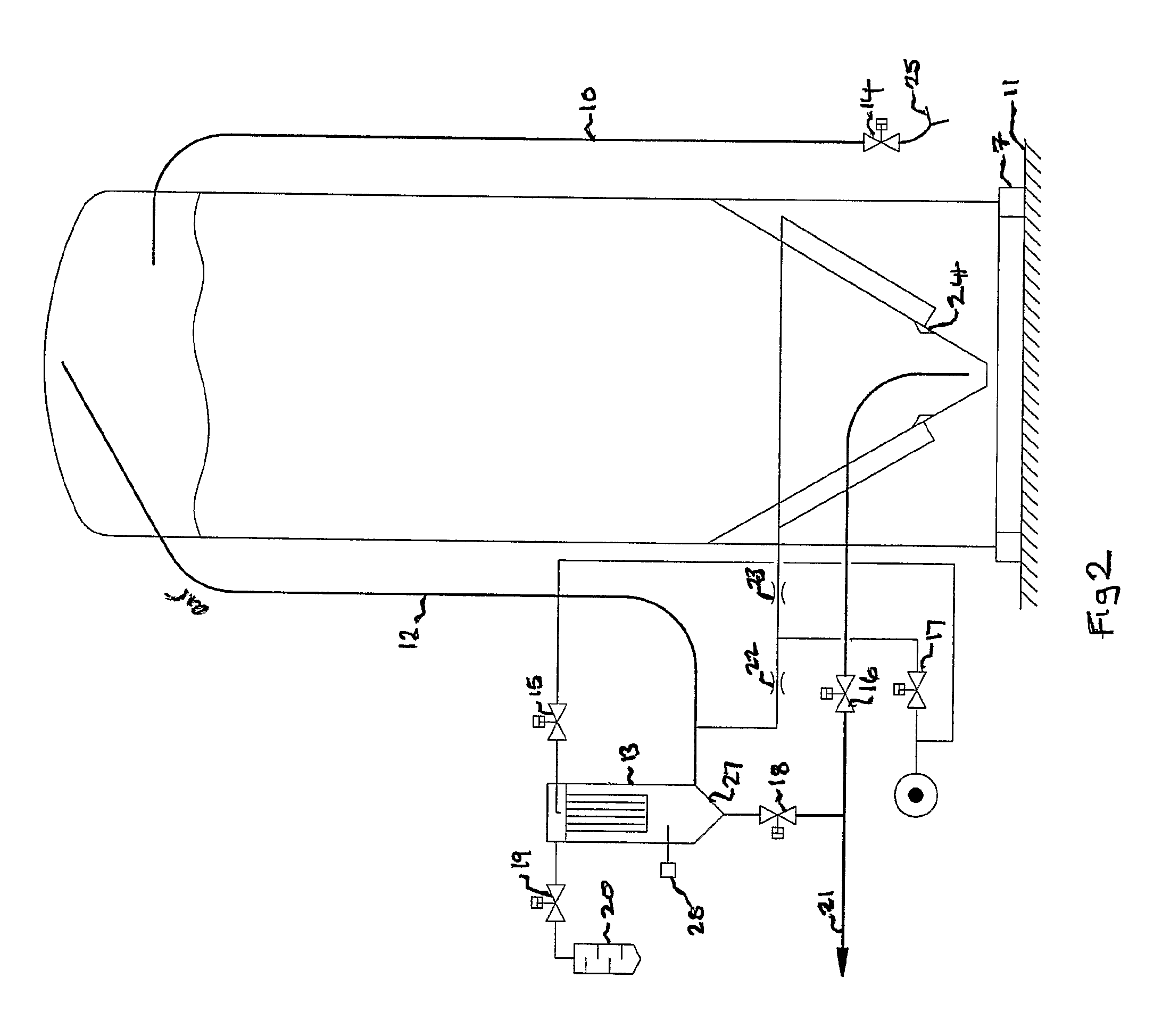

Container

InactiveUS20080210093A1Lower ground loadAvoid overall overturningCombination devicesLiquid fillingEngineeringSilo

Owner:INBULK TECH

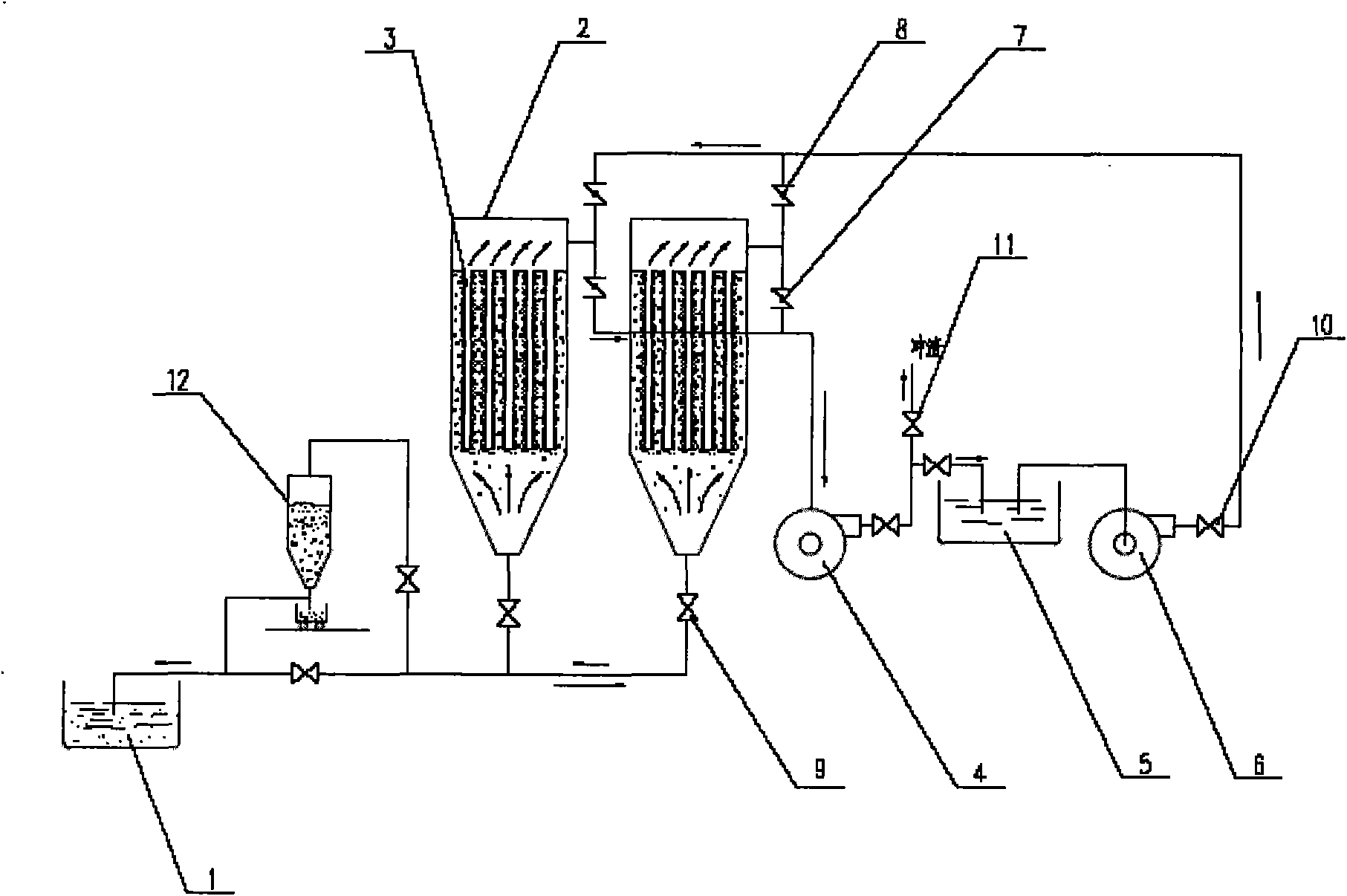

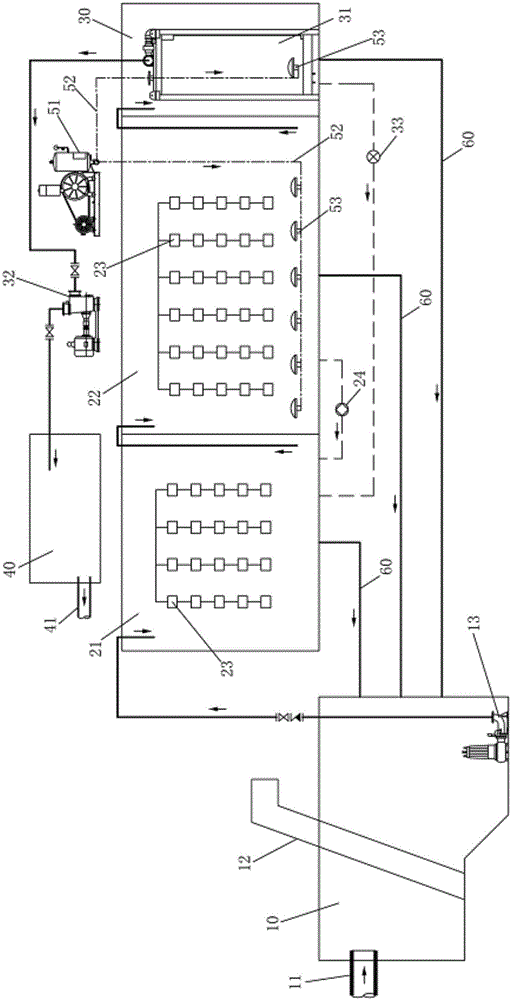

Blast furnace slag flushing water purification system and method thereof

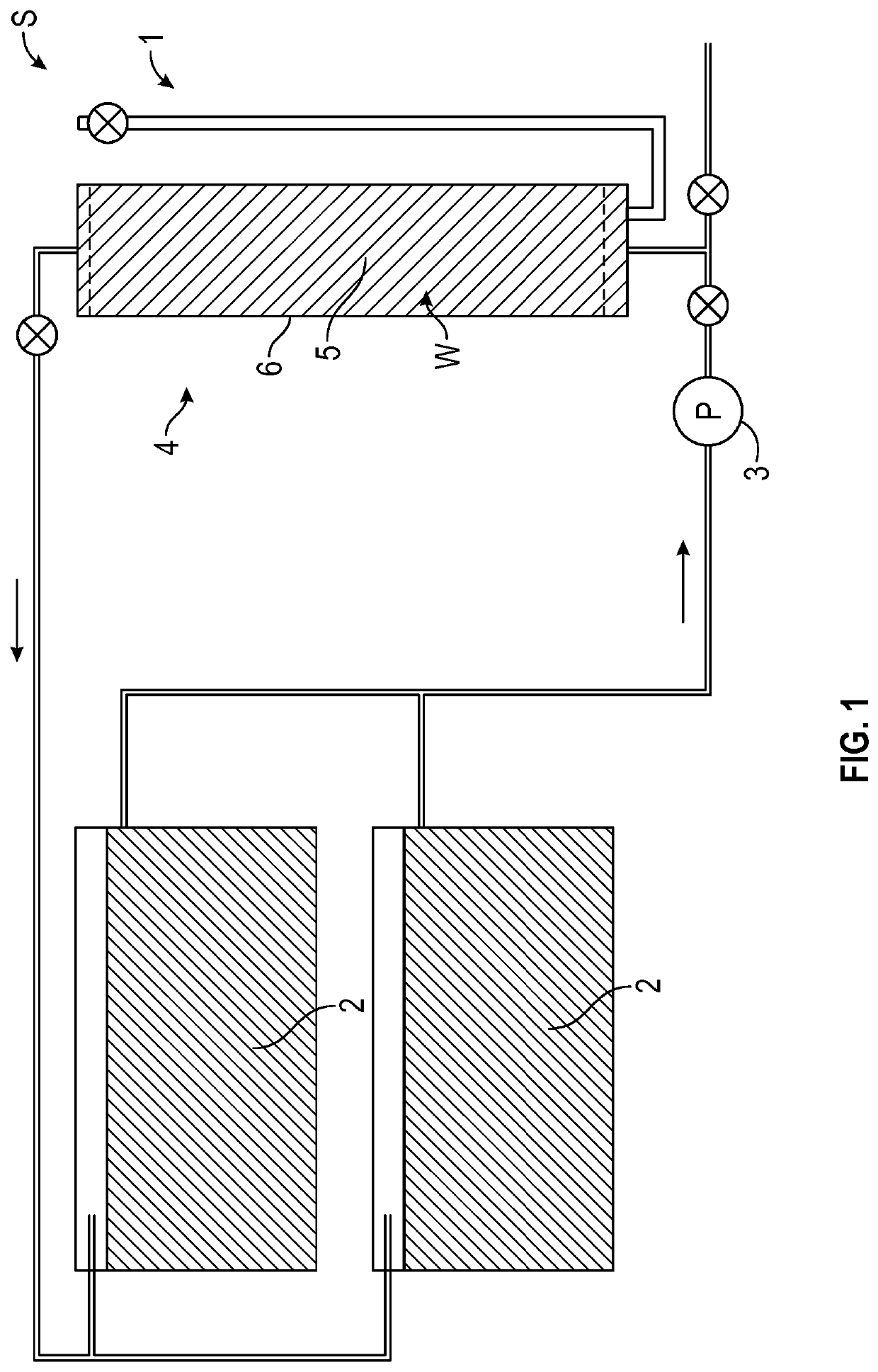

ActiveCN101564616ASolve water quality problemsPerfect slag flushing processGravity filtersFiltration circuitsSlagWater flow

The invention discloses a blast furnace slag flushing water purification system and a method thereof, pertaining to the technical field of blast furnace ironmaking in the iron and steel industry. The system comprises a slag water tank, a filter, a filter pump, a clear water reservoir, a back flush water pump, a filter butterfly valve, a back flush butterfly valve and a matched valve and a slag bin for back flushing. One or a plurality of filters are arranged for purifying slag flushing water containing suspended fine slag and are internally provided with filter elements which are arranged in order; though the equipment is small, the filter area is much larger than that in a bottom filter method; the back flush water pump is used for reversely injecting the clear water in a clear water flow flushing filter element for removing the slag on the surface and recovering the filtering quality. The filter pump can be integrated with the slag flushing pump in the existing slag treatment system, thus being capable of filtering and flushing slag simultaneously with one pump. The blast furnace slag flushing water purification system and the method thereof have the advantages of good purification effect and high filter velocity, therefore, the filter area is small, the volume of the equipment is small, the operation is easy and the maintenance is convenient.

Owner:BEIJING SHOUGANG INT ENG TECH

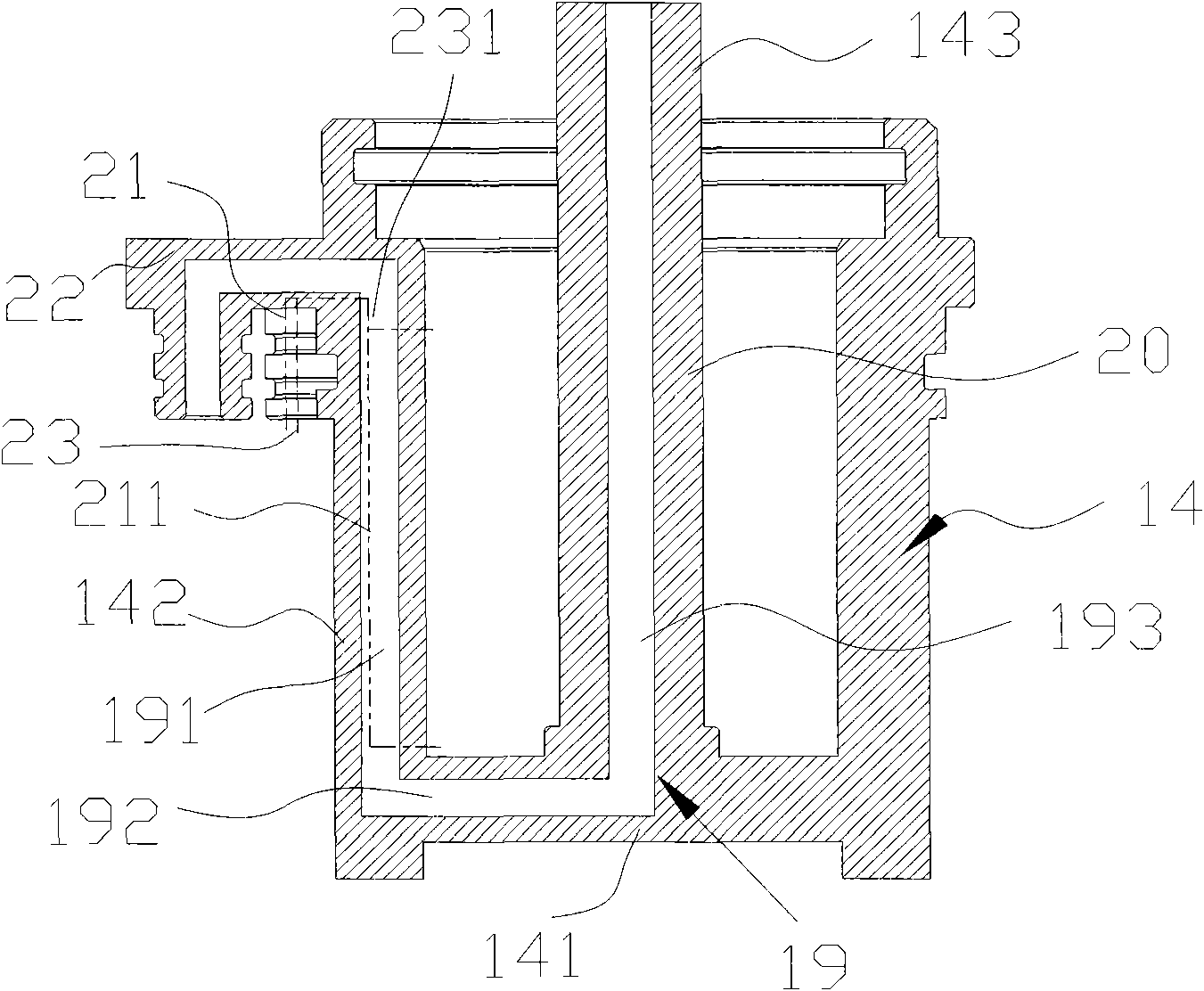

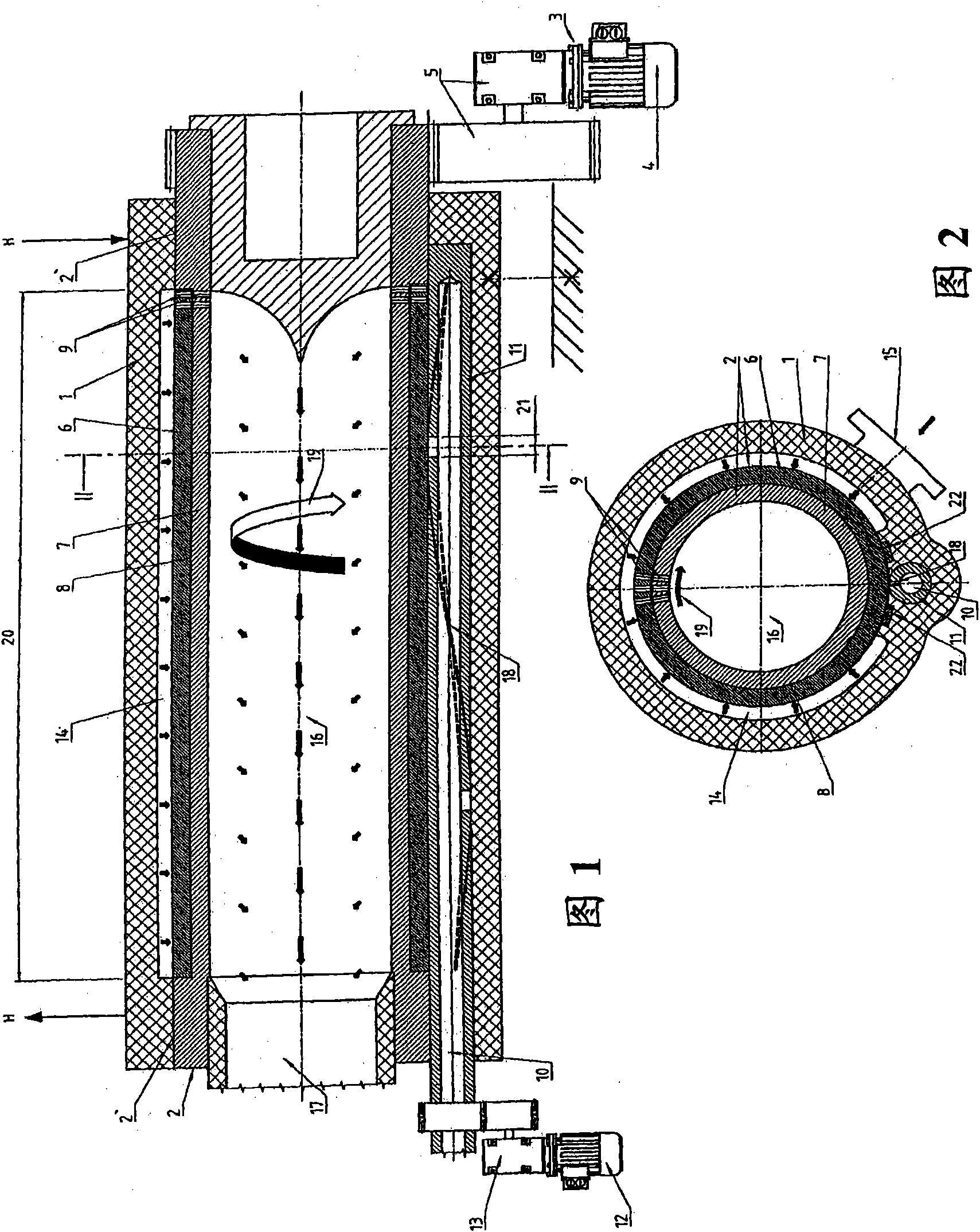

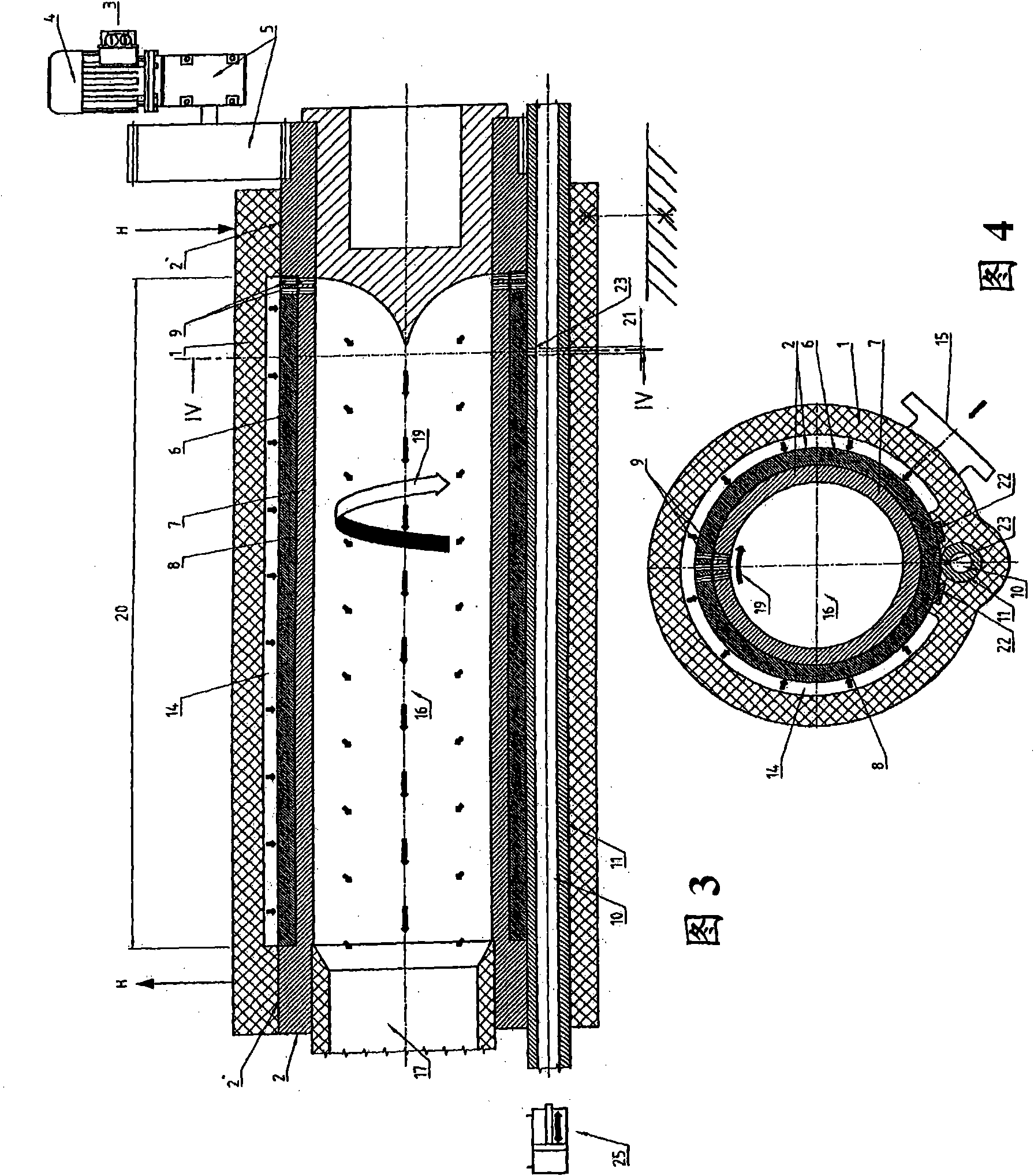

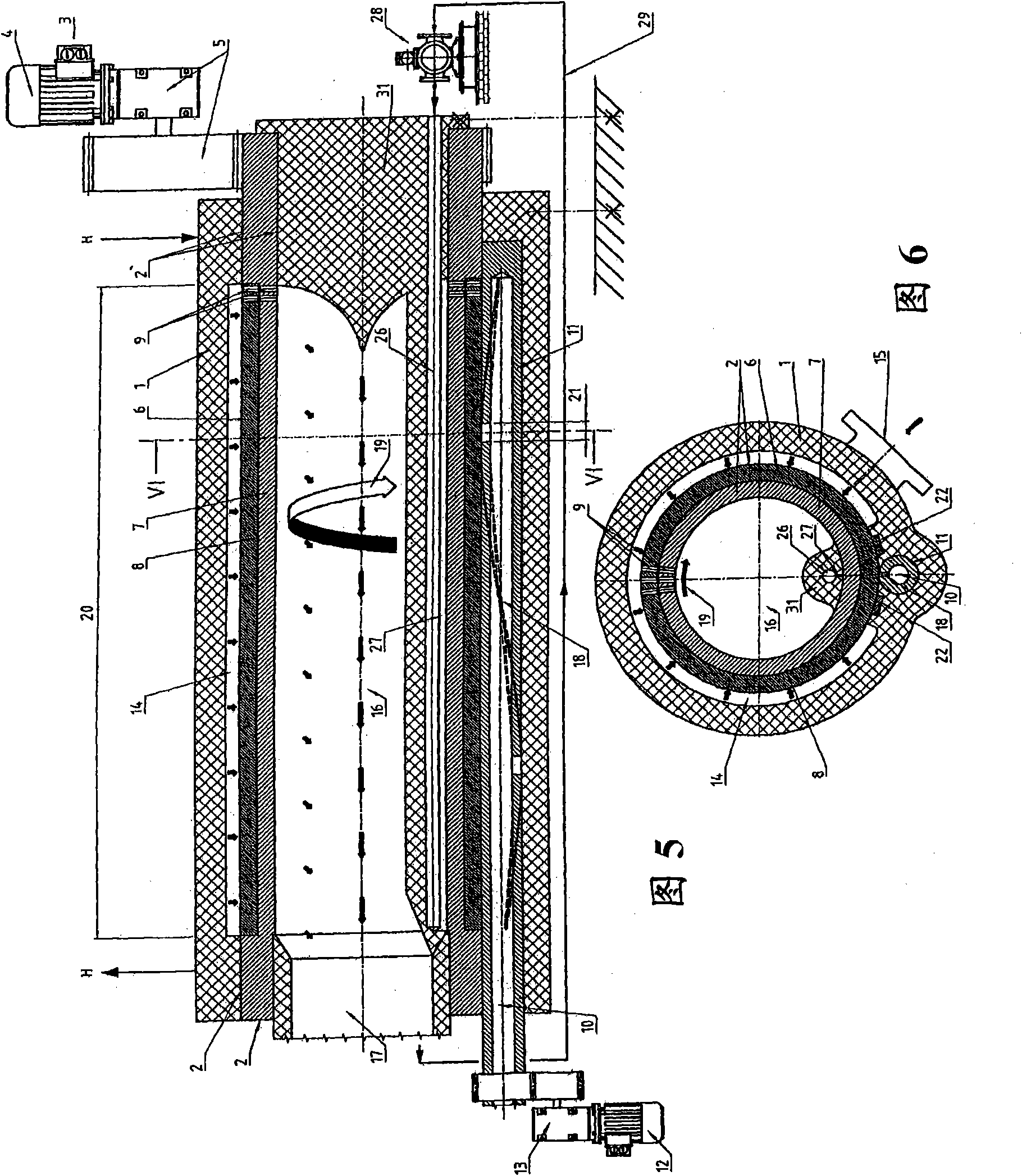

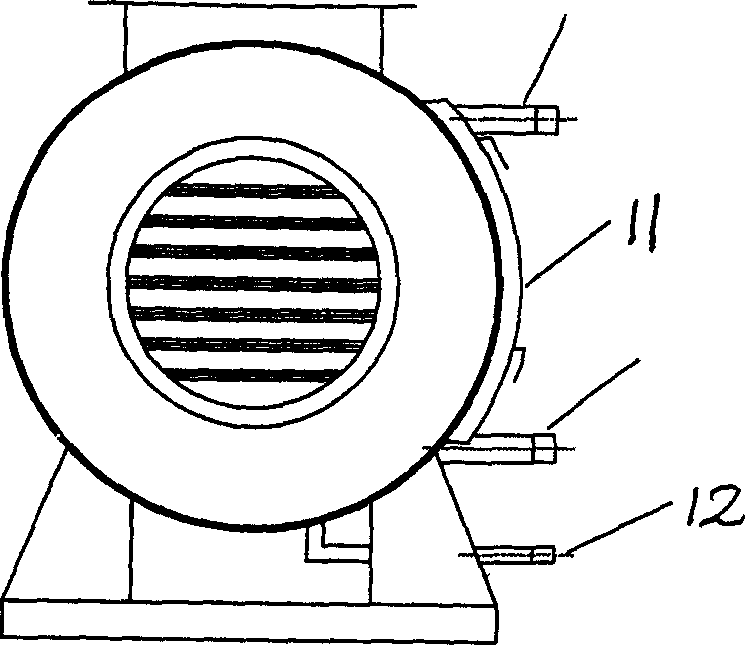

Backwash filter

InactiveCN101610826AShorten the lengthAchieve connectionMoving filtering element filtersFilter materialBiomedical engineering

The invention relates to a backwash filter, especially for highly viscous media, comprising a filter body (2) forming a cylinder sheath in a housing (1), characterized in that the housing (1) and the filter body (2) can be rotated relative to each other about the axis of the filter body (2), wherein the filter body (2) separates a media supply chamber (14) from a media discharge chamber (16) and comprises a washing agent discharge channel (10) that extends along a generatrix of the filter body (2). According to the invention, said washing agent discharge channel can be moved relative to the filter body (2) and is in fluid connection with the filter body (2) over the entire length and the entire circumference thereof, thus forming a flow path opening into the washing agent discharge channel (10). In order to achieve an increased backwash efficiency, a higher throughput and in order to protect the filter material, said backwash filter is characterized in that the fluid connection is only established via a partial region of the longitudinal extension (20) of a generatrix of the filter body (2).

Owner:LENZING AG

Method of manufacturing liquid ejecting head

InactiveUS7862759B2Prevent liquid leakageReduce intervalTailstocks/centresConfectioneryEngineeringMechanical engineering

A method of manufacturing a liquid ejecting head and a supply member having a plurality of liquid supply passages is provided. The supply member includes first and second supply members in which liquid supply passages are provided and filters provided between the first supply member and the second supply member. The method includes: preparing a connected filter formed of a plurality of filter element portions corresponding to the plurality of liquid supply passages and a connecting portion that connects the plurality of filter element portions; in a state where the filter element portions of the connected filter are held between the first supply member and the second supply member, charging molten resin from a position corresponding to the connecting portion of the connected filter to separate the connecting portion; and, during the charging, molding.

Owner:SEIKO EPSON CORP

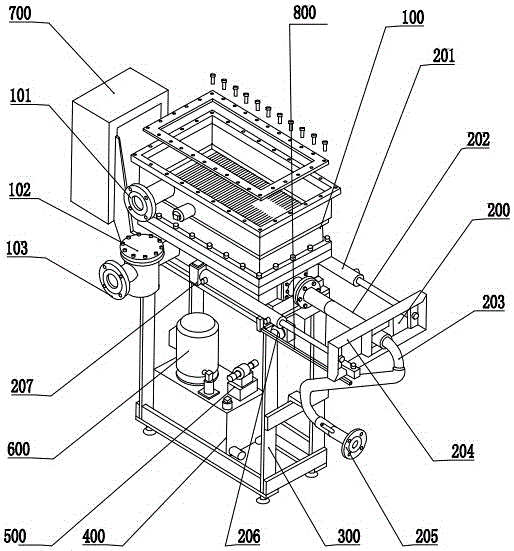

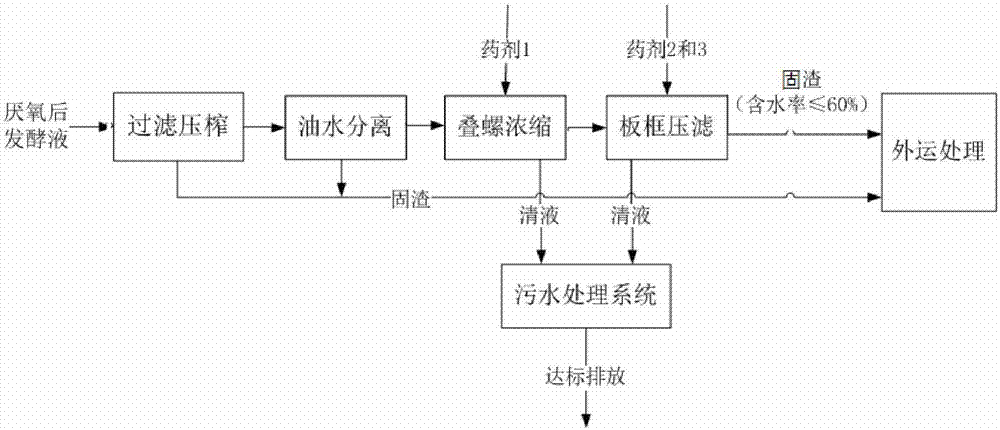

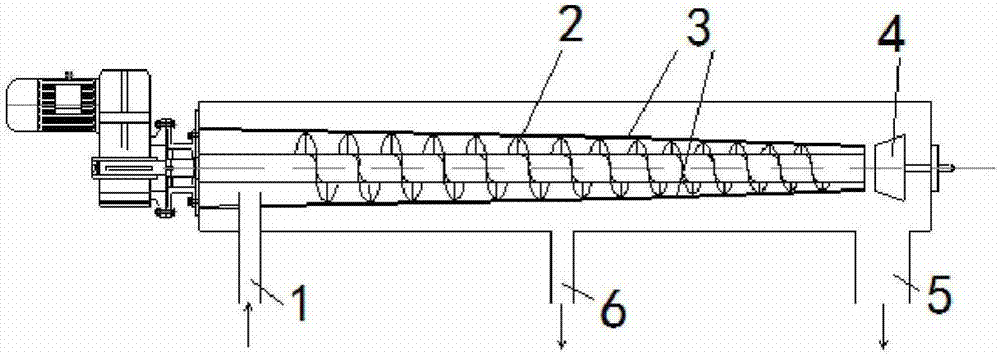

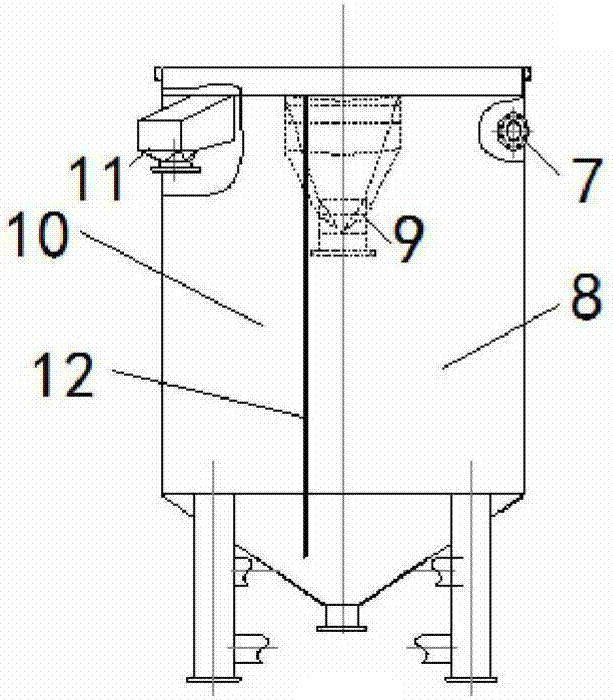

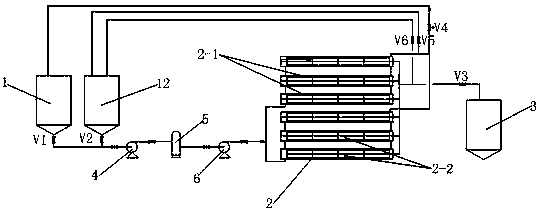

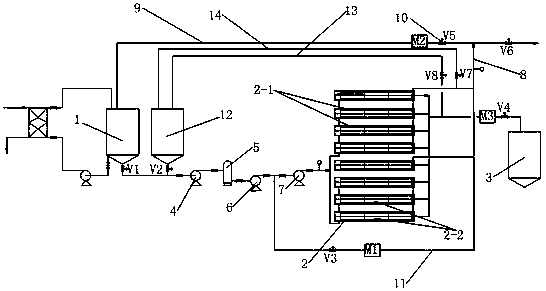

Solid-liquid separation method and device for multi-material anaerobic fermentation liquid containing kitchen wastes

PendingCN108002599AReduce workloadReduce filter areaFatty/oily/floating substances removal devicesTreatment involving filtrationPlunger pumpMulti material

The invention discloses a solid-liquid separation method and device for multi-material anaerobic fermentation liquid containing kitchen wastes and belongs to the technical field of kitchen waste treatment. A first discharging hole of a filter press is connected with a feeding hole of an oil-water separation tank by virtue of a pipeline; an overflow port of the oil-water separation tank is connected to a first conditioner by virtue of a pipeline; a submersible sewage pump is arranged in the first conditioner; the discharging hole of the submersible sewage pump is connected with a feeding hole of a multi-disk screw thickener; a second discharging hole of the multi-disk screw thickener is connected to a second conditioner by virtue of a pipeline; the second conditioner is connected with a feeding hole of a plunger pump by virtue of a pipeline; a discharging hole of the plunger pump is connected with a feeding hole of a plate-and-frame filter press; a residue outlet collection bucket of the plate-and-frame filter press is connected with the feeding hole of a residue delivery screw; the discharging hole of the residue delivery screw is connected with a residue box. Aiming at the material characteristics, the problems generated during operation of the original anaerobic fermentation liquid solid-liquid separation equipment with participation of kitchen wastes are gradually solved, the operating stability is improved, the treatment effect is ensured, the operating cost is reduced, secondary pollution is reduced, and the solid residues obtained by solid-liquid separation meet the national standard.

Owner:BMEI +1

Liquid ejecting head manufacturing method

Owner:SEIKO EPSON CORP

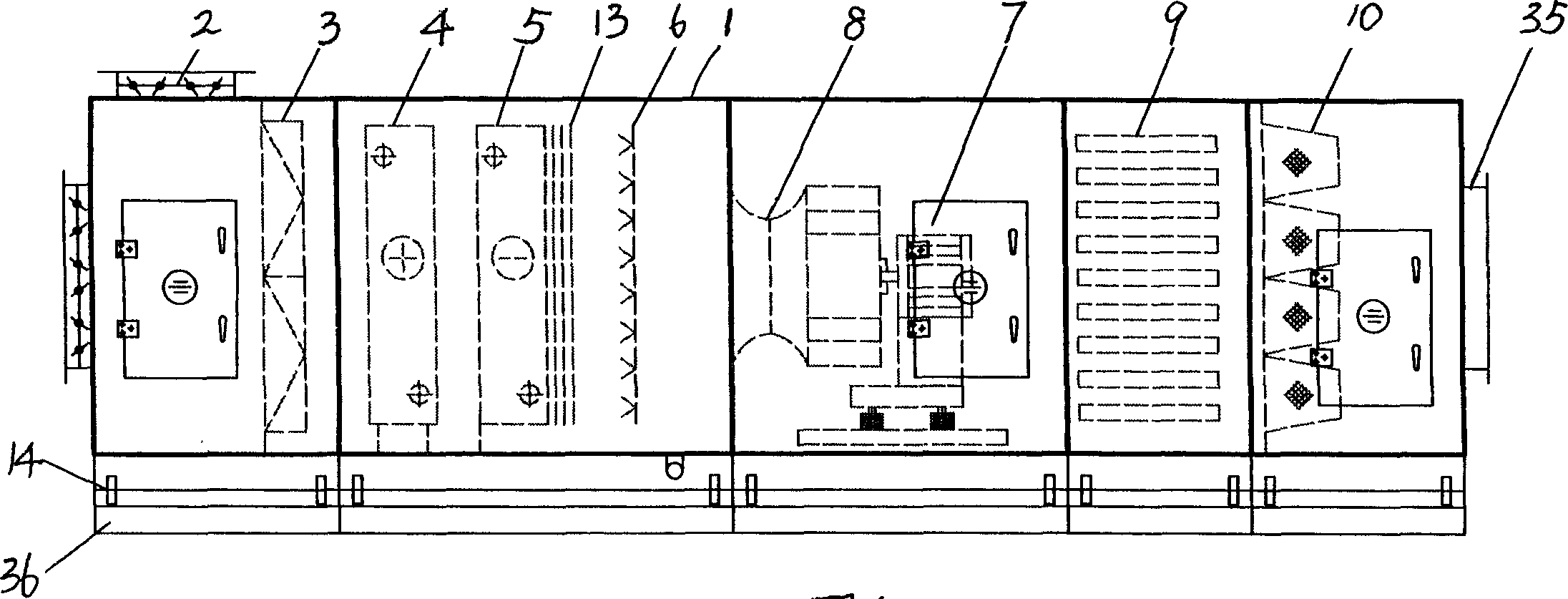

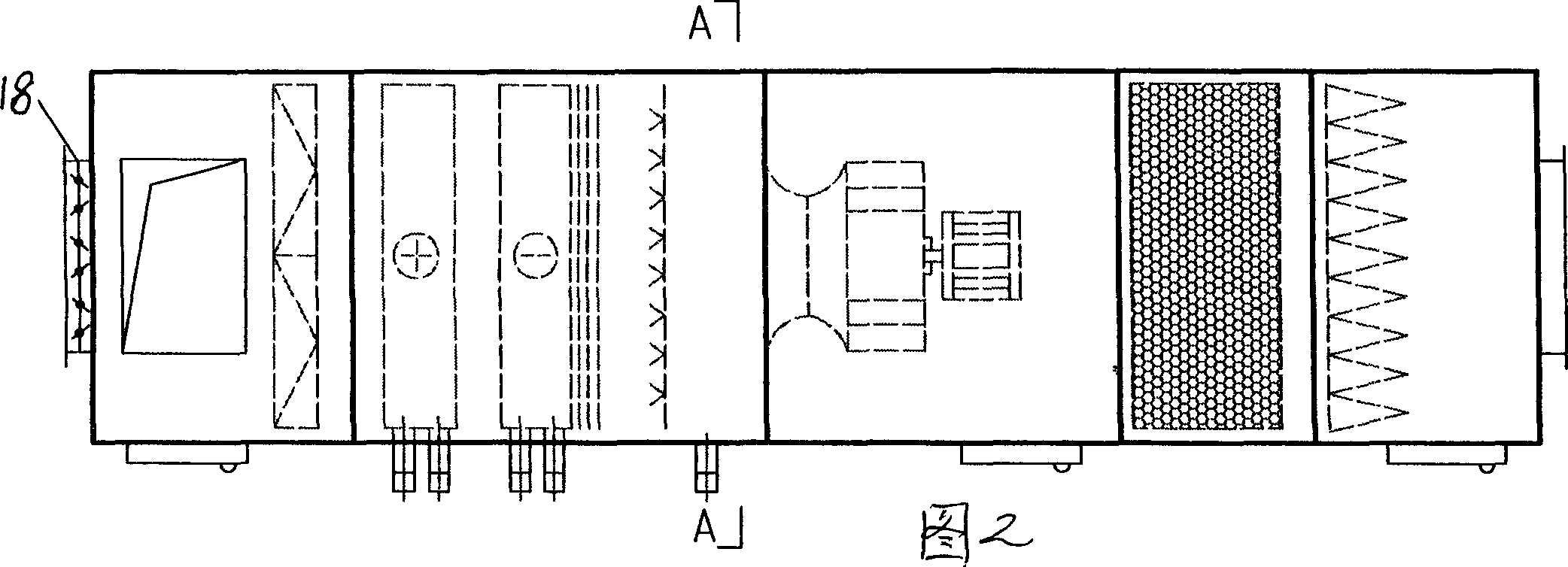

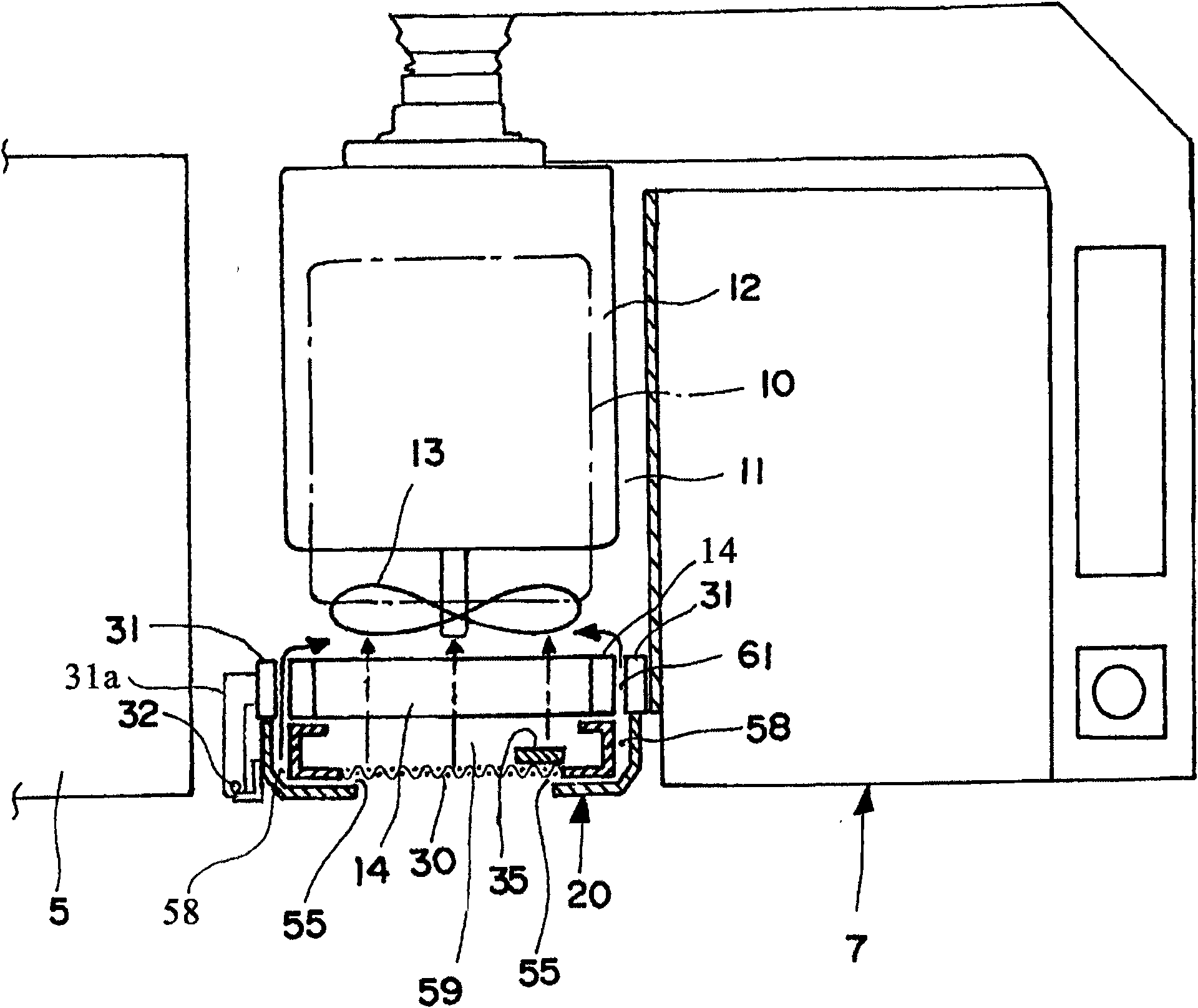

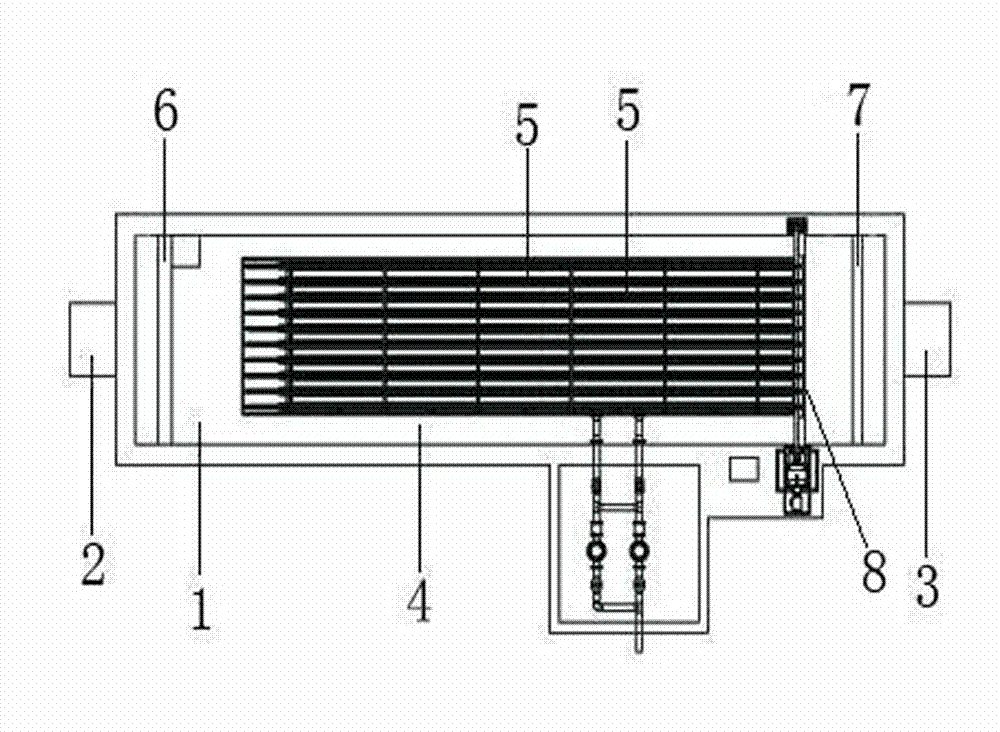

Drum type air treating machine set

InactiveCN1815095AIncrease airflowImproves airflow uniformityLighting and heating apparatusAir conditioning systemsElectric machineAir treatment

Present invention discloses a drum type air handling assembly. It includes cylinder shape horizontal shell, round multi-leaf damper, fan-shaped or tube type primary filter, round surface heater, primary filter surface air coolers, humidifier, circular arc shape service door, and condensate pipe. Said invention has reasonable structure and fine working performance.

Owner:JIANGSU FENGSHEN AIR CONDITIONING GRP

Container

InactiveUS7833318B2Reduce filter areaFilter area can be halvedCombination devicesLiquid fillingAir filterAtmospheric pressure

Owner:INBULK TECH

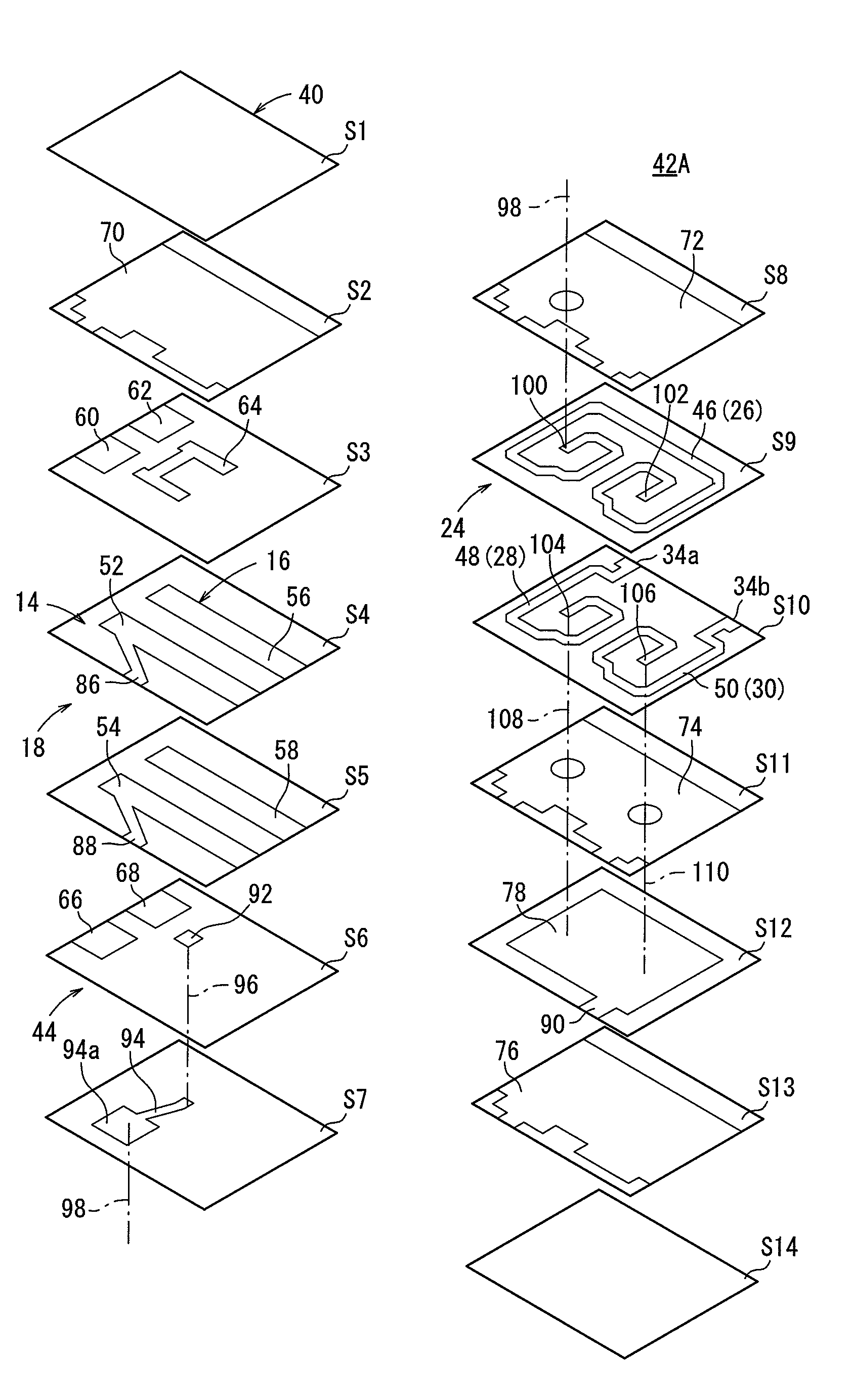

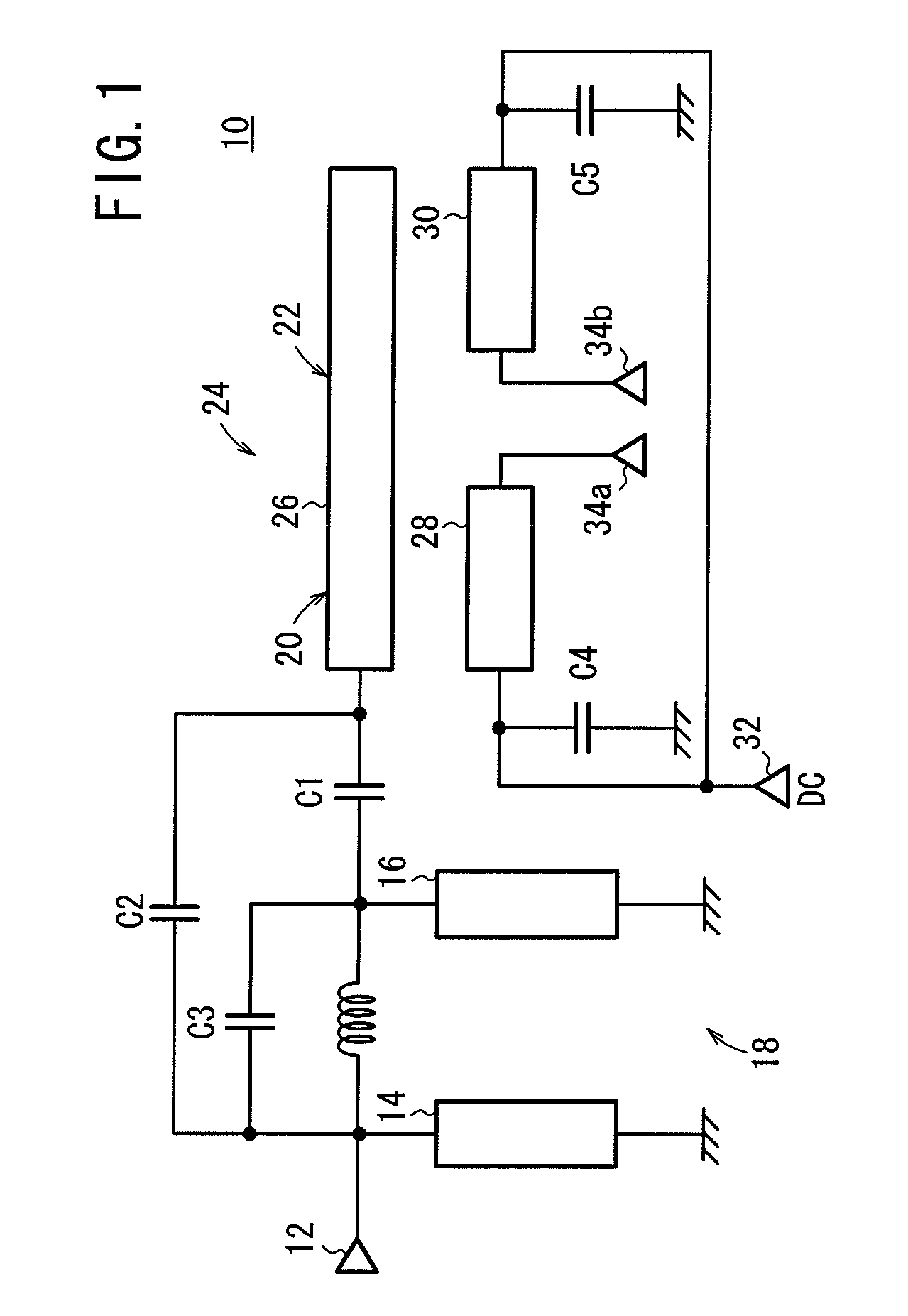

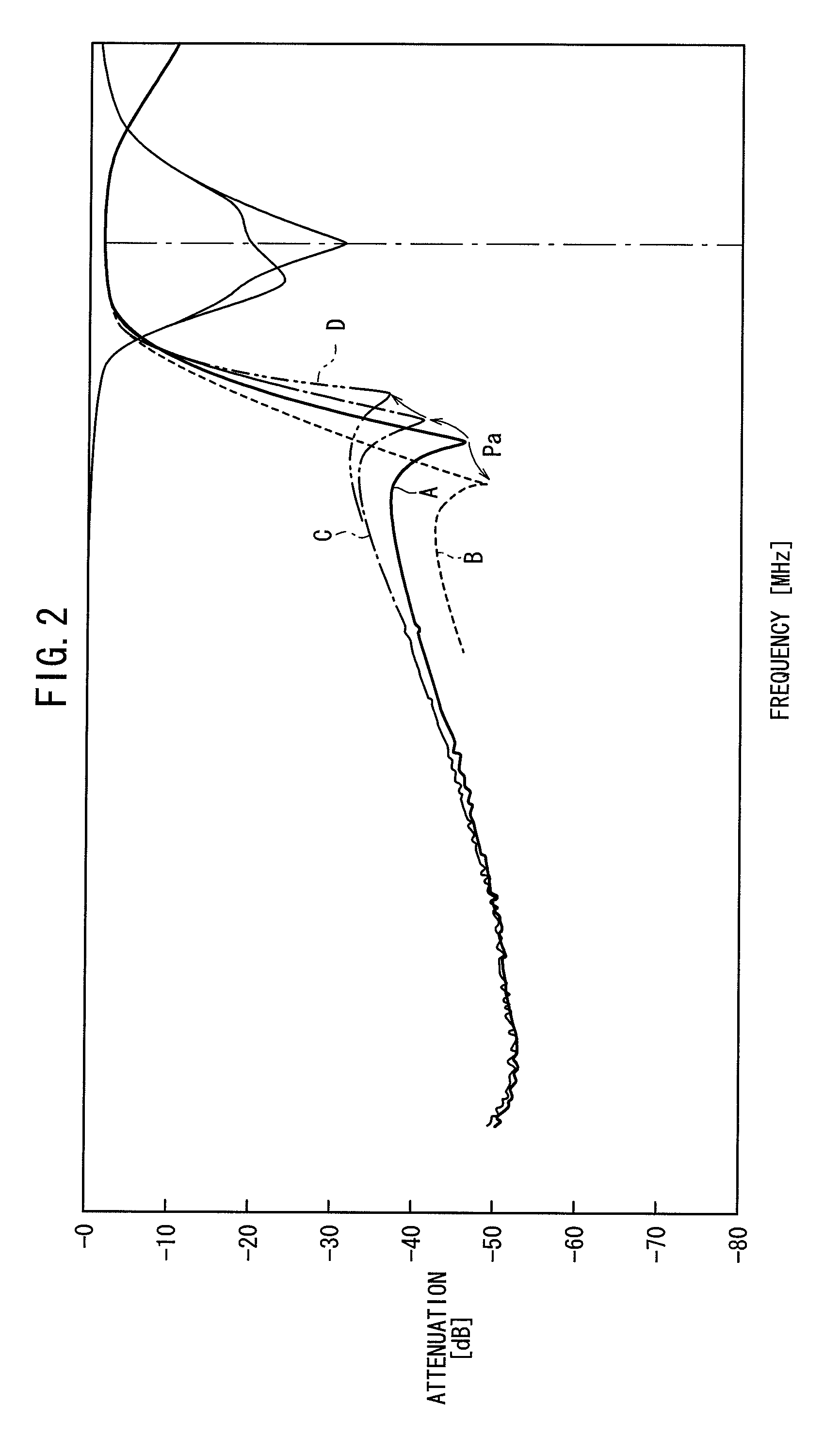

Passive component

ActiveUS20090134950A1Large attenuation levelSharp attenuation characteristicMultiple-port networksOne-port networksUltrasound attenuationEngineering

A passive component is provided with a filter section employing a nonequilibrium input / output system, which has an input side resonator connected to a nonequilibrium input terminal, and an output side resonator coupled with the input side resonator; and a converting section having two double line coupled lines. An output stage of the filter section is connected with an input stage of the converting section through a first capacitor, and an input stage of the filter section is connected with the input stage of the converting section through a second capacitor. Namely, the second capacitor functions as a jump capacitor. The position of an attenuation pole is permitted to be adjusted by a second capacitor in a region low in frequency characteristics.

Owner:SOSHIN ELECTRIC

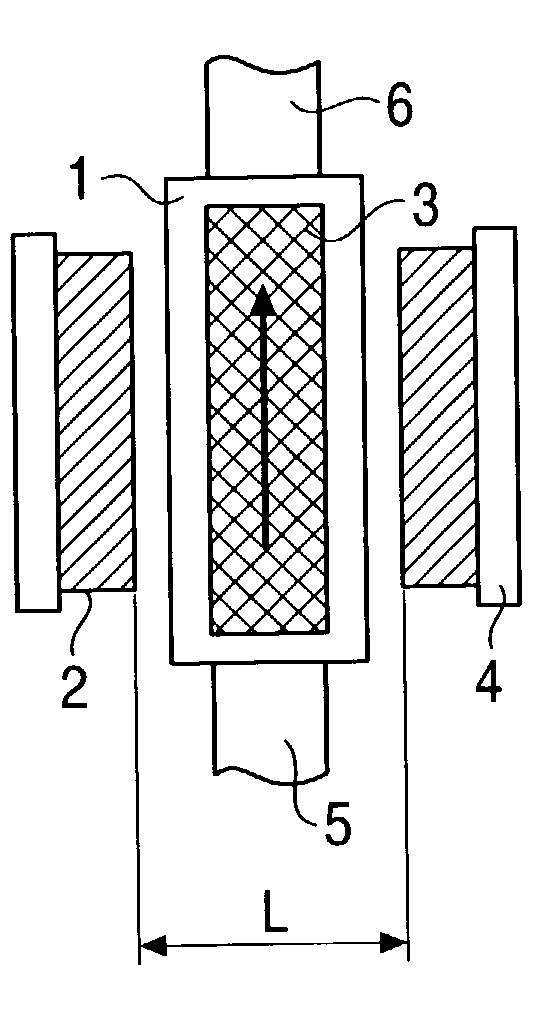

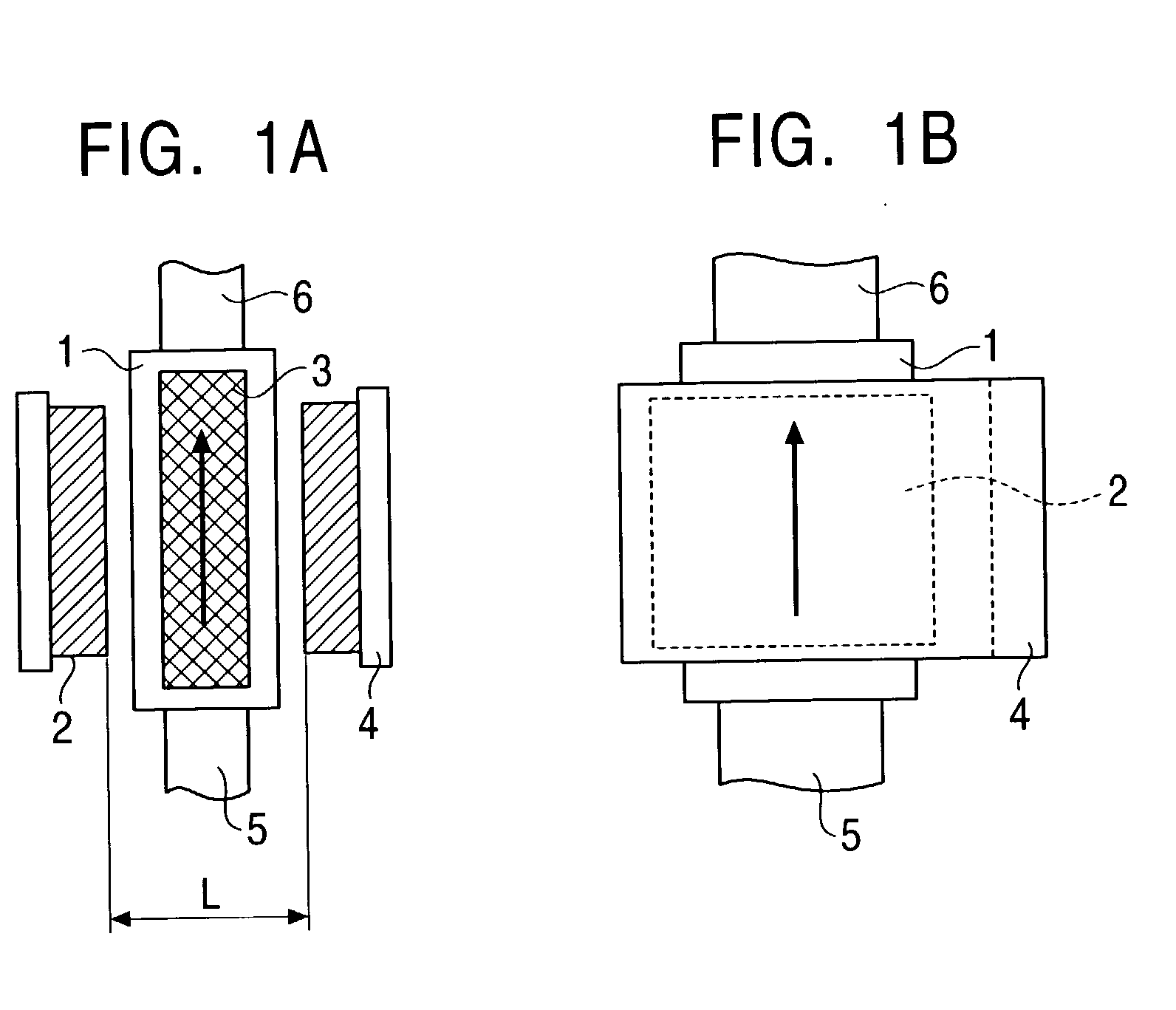

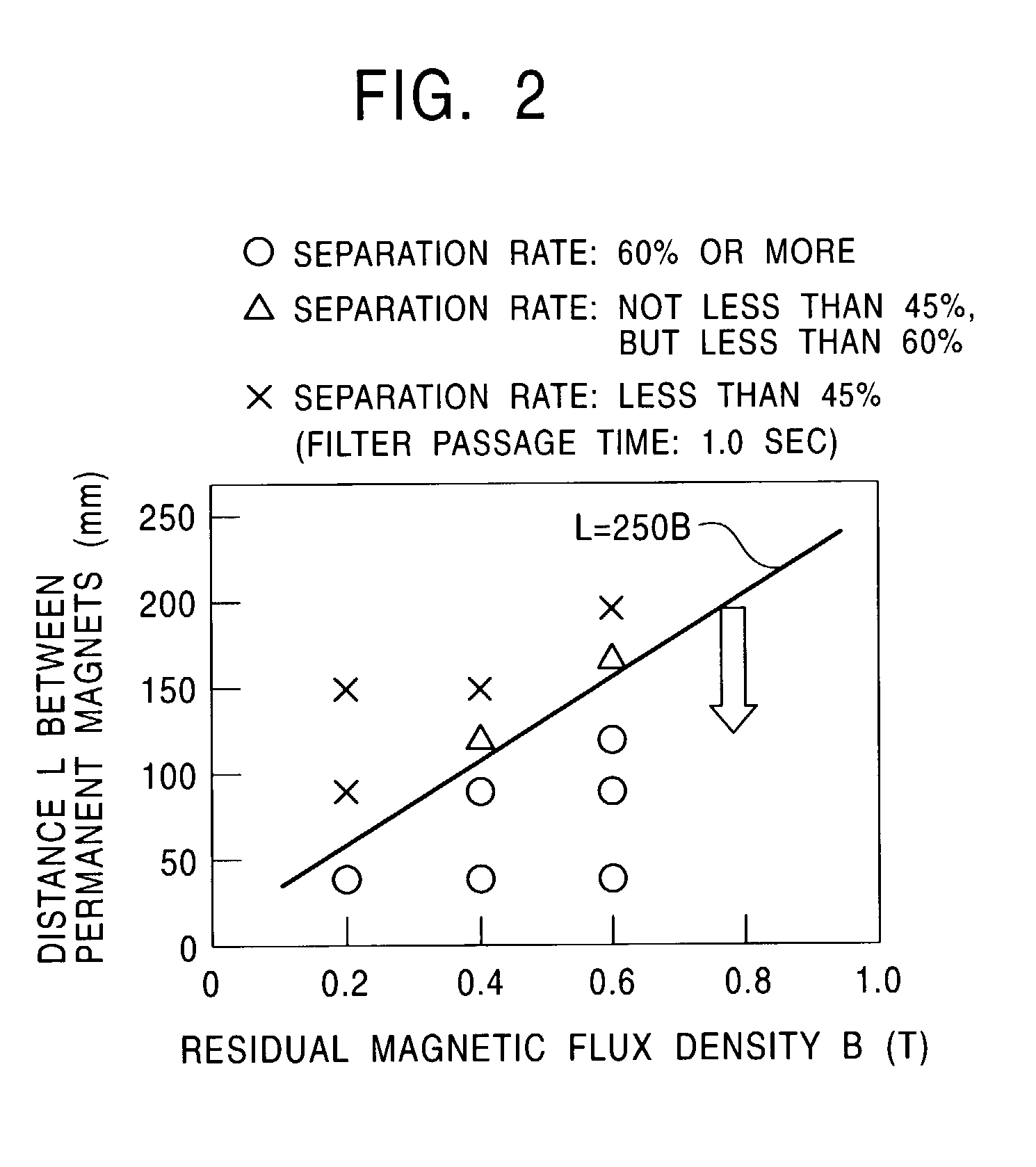

Magnetic filter device

InactiveUS20020189990A1Small sizeLow costHigh gradient magnetic separatorsWater/sewage treatment by magnetic/electric fieldsGeneral purposeNeodymium magnet

In a magnetic filter apparatus in which permanent magnets are arranged to oppose each other with a container therebetween so as to generate a magnetic line of force in a direction substantially orthogonal to the moving direction of the fluid in the interior of the container, while regulating a filter passage time of the fluid in the range of 0.5 to 1.5 seconds, the permanent magnets are arranged so that the distance L (mm) between the permanent magnets in relation to the residual magnetic flux density B (T) of the permanent magnets satisfies the relationship: <paragraph lvl="0"><in-line-formula>Bx100<=L<=Bx250 < / in-line-formula>In this manner, the highest possible performance can be obtained from the filter using general-purpose permanent magnets such as ferrite or neodymium magnets, thereby achieving size reduction of the apparatus at low equipment cost.

Owner:JFEENG CORP

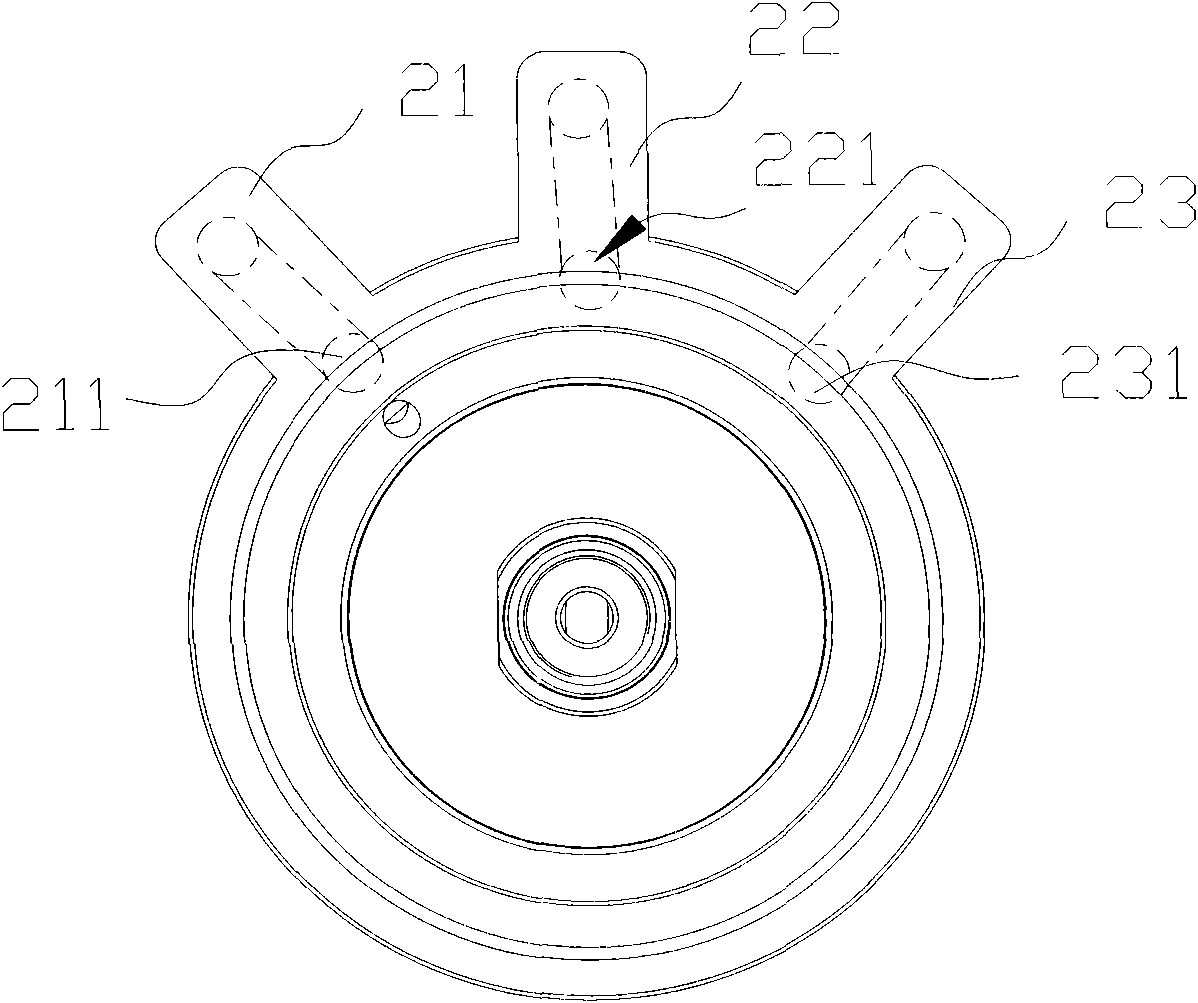

Filter cloth model selection experiment machine

ActiveCN104874215AReduce lossShorten the timeFiltration separationModel selectionPulp and paper industry

The invention discloses a filter cloth model selection experiment machine. The filter cloth model selection experiment machine comprises a supporting base plate, a compressing plate and a bolt pull rod. The filter cloth model selection experiment machine is characterized in that the inner side of the supporting base plate is fixedly provided with a charge plate; the inner side of the compressing plate is fixedly provided with a filtering plate; filter cloth is installed between the charge plate and the compressing plate and is compressed by matching so as to form an enclosed filtering chamber. The filter cloth model selection experiment machine is compact in structure, is simple to operate, is small in size, is convenient to transport, is less in materials required for experiments, reduces loss, and solves a series of problems of insufficient materials, limited field, high transportation cost, high filter cloth loss and the like which are normally encountered by the filter cloth model selection.

Owner:HANGZHOU LVDING FILTER PRESS MFG

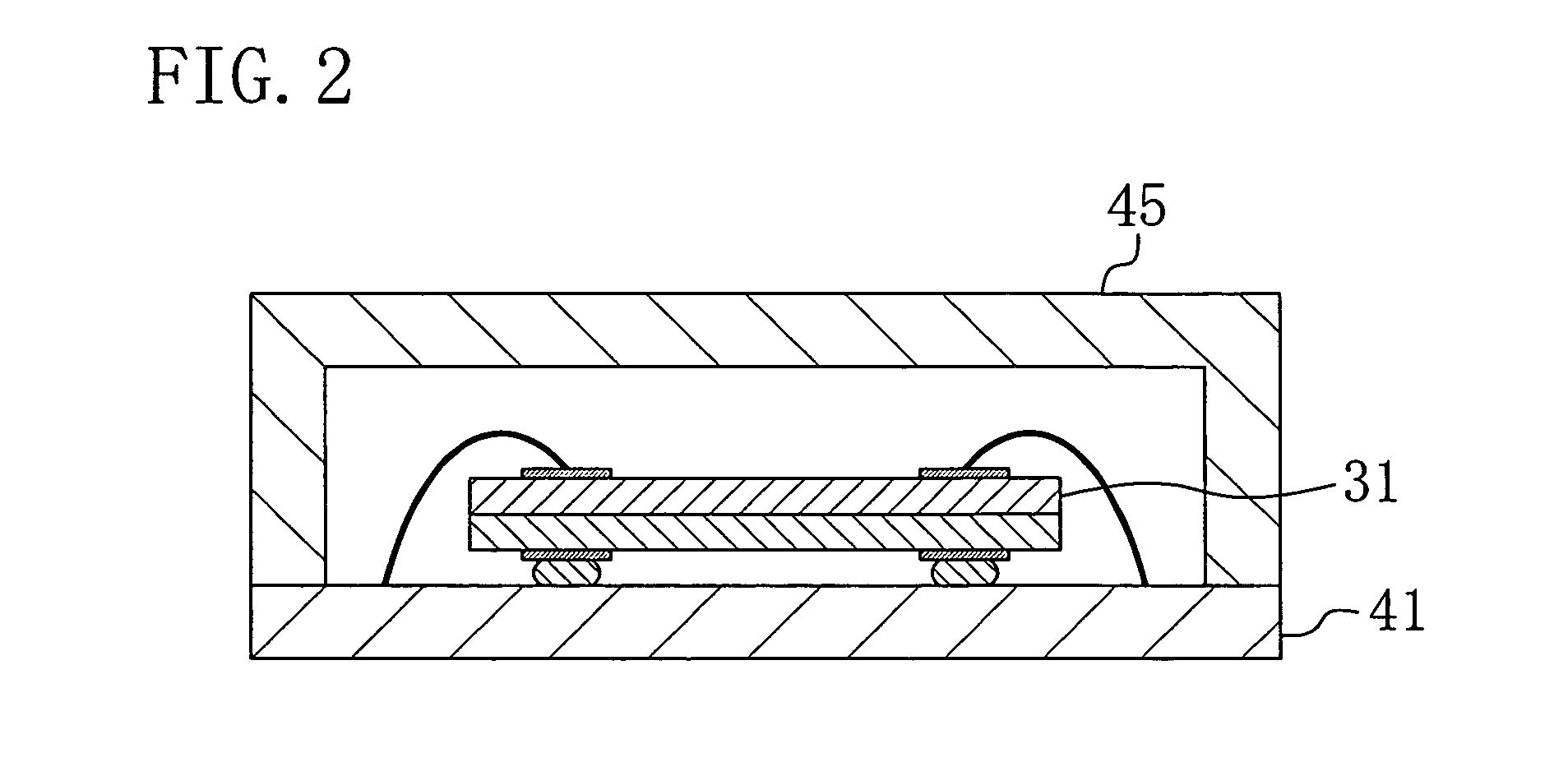

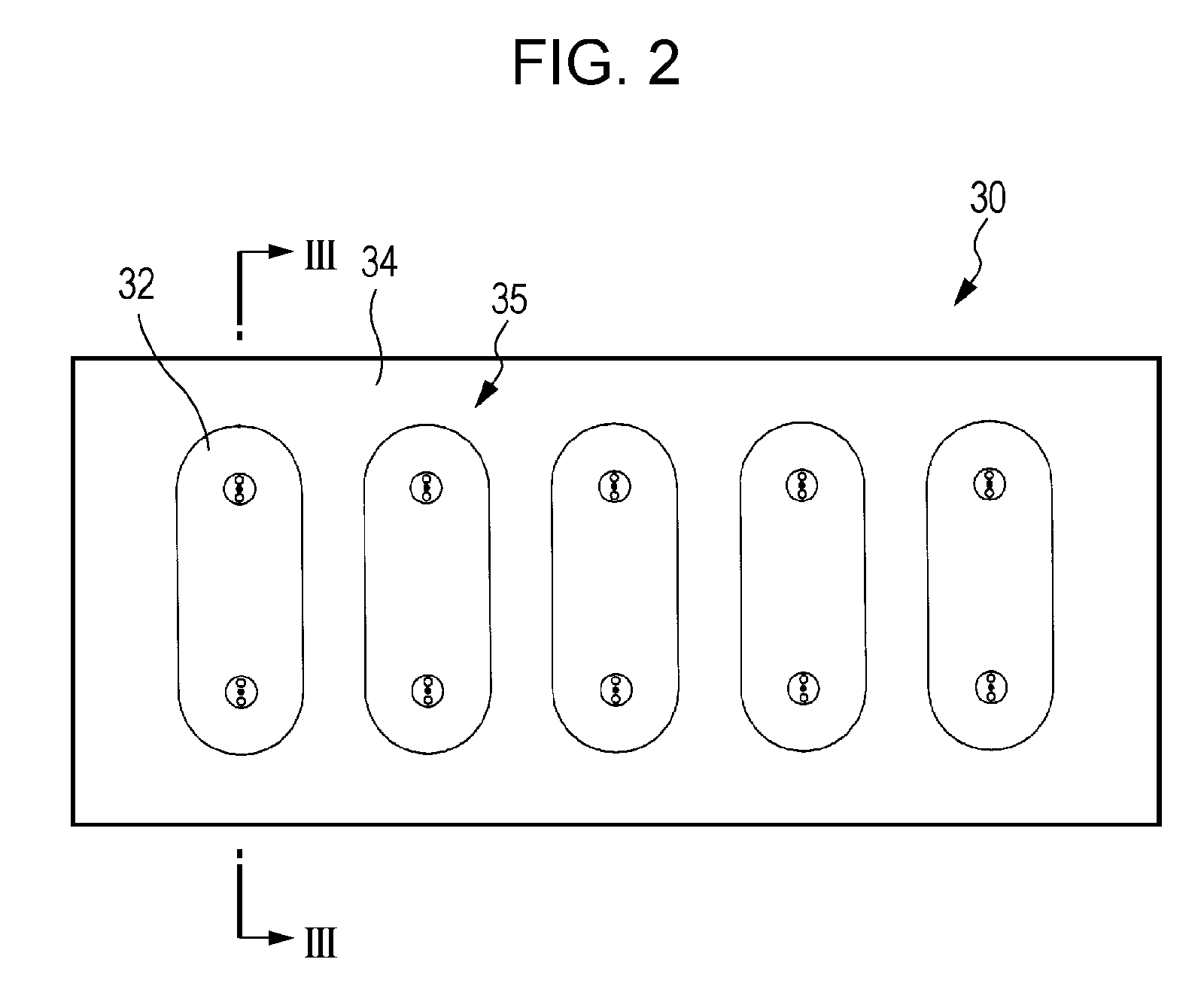

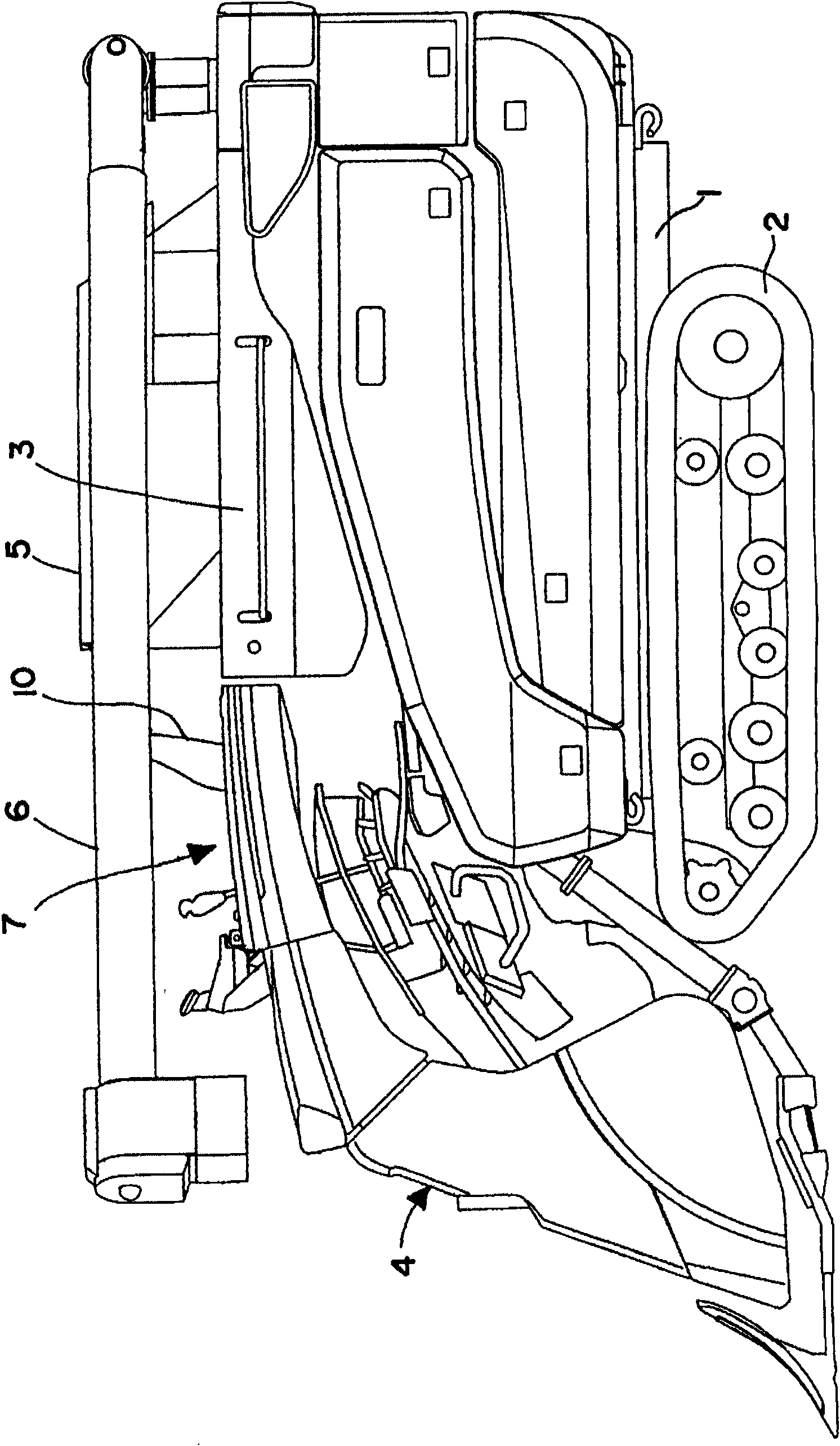

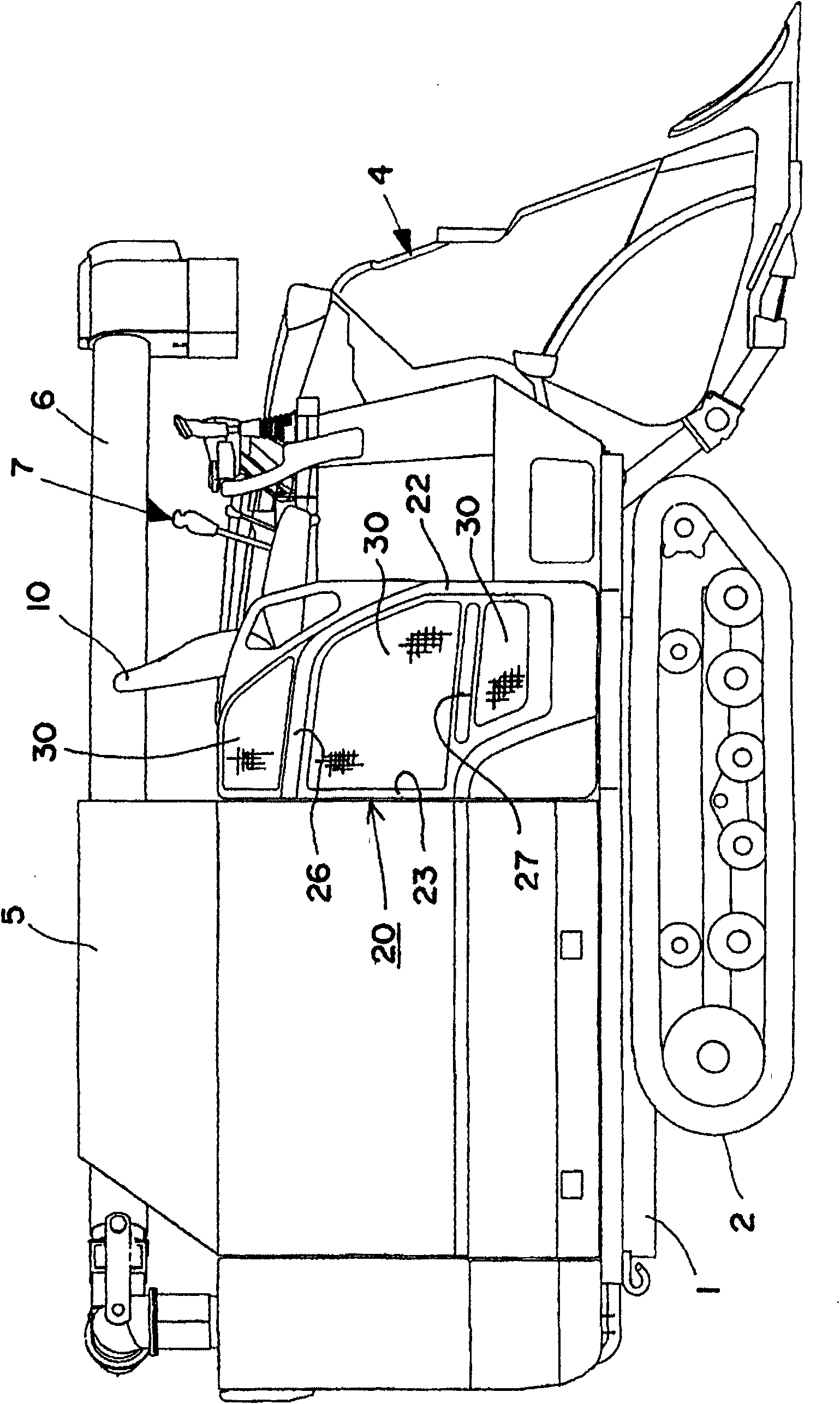

Combine harvester

InactiveCN101563974APromote sheddingAvoid overall overheatingMowersPropulsion coolingReciprocating motionCombine harvester

The invention relates to a combine harvester, ensures the intake air quantity passing through the dustproof net for cooling, prevents the engine from overheating, and improves the work efficiency of the combine harvester. an intake air shield plate (35) for shielding part of the intake air passing through the dustproof net (30) is disposed near the inner side surface of the dustproof net (30); and a driving device is disposed for driving the intake air shield plate (35) to perform a reciprocating motion linearly along the inner side surface of the dustproof net (30); in addition, a dust attraction mouth (55) for attracting the dust on the outer surface of the dustproof net (30) is disposed on the end of the reciprocating motion path of the intake air shield plate (35); additionally, an accessory attraction duct (58) from the dust attraction mouth (55) to the cooling fan (13) is separated from the main attraction duct (59) from the dustproof net (30), through the radiator (14) to the cooling fan (13).

Owner:ISEKI & CO LTD

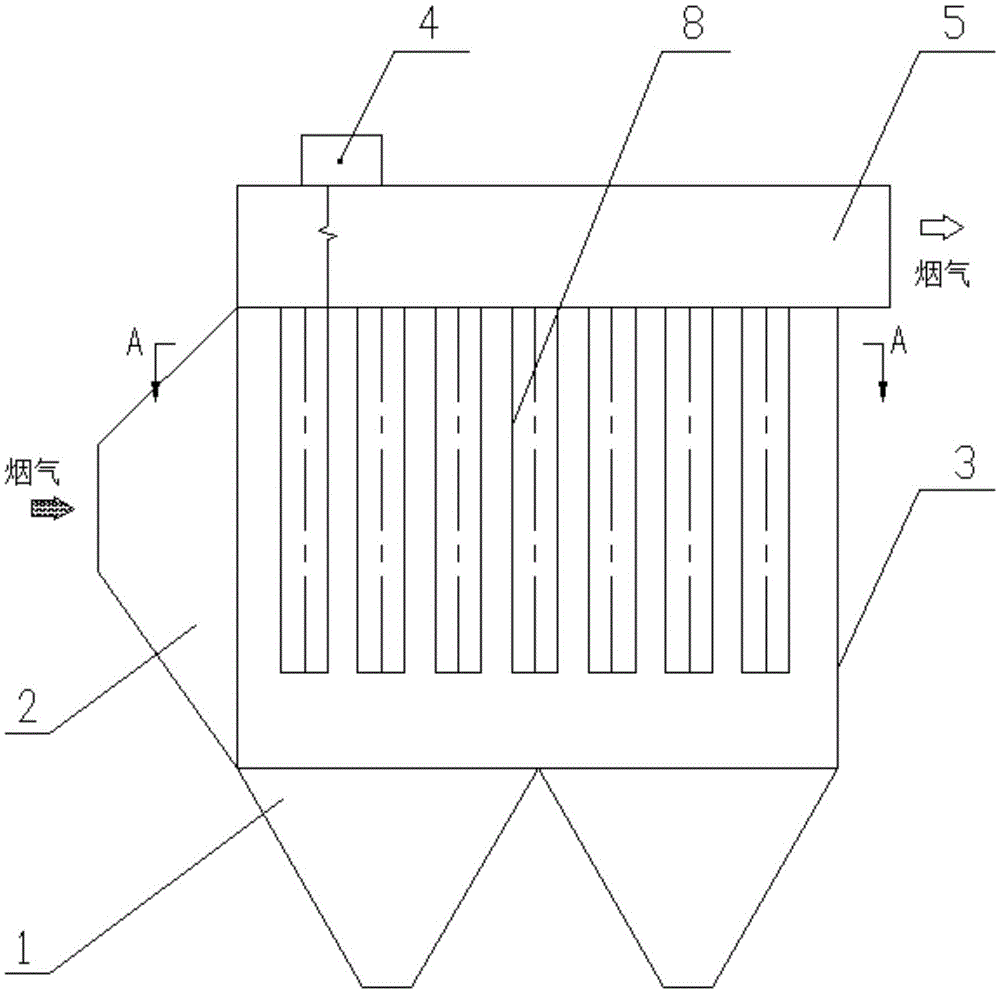

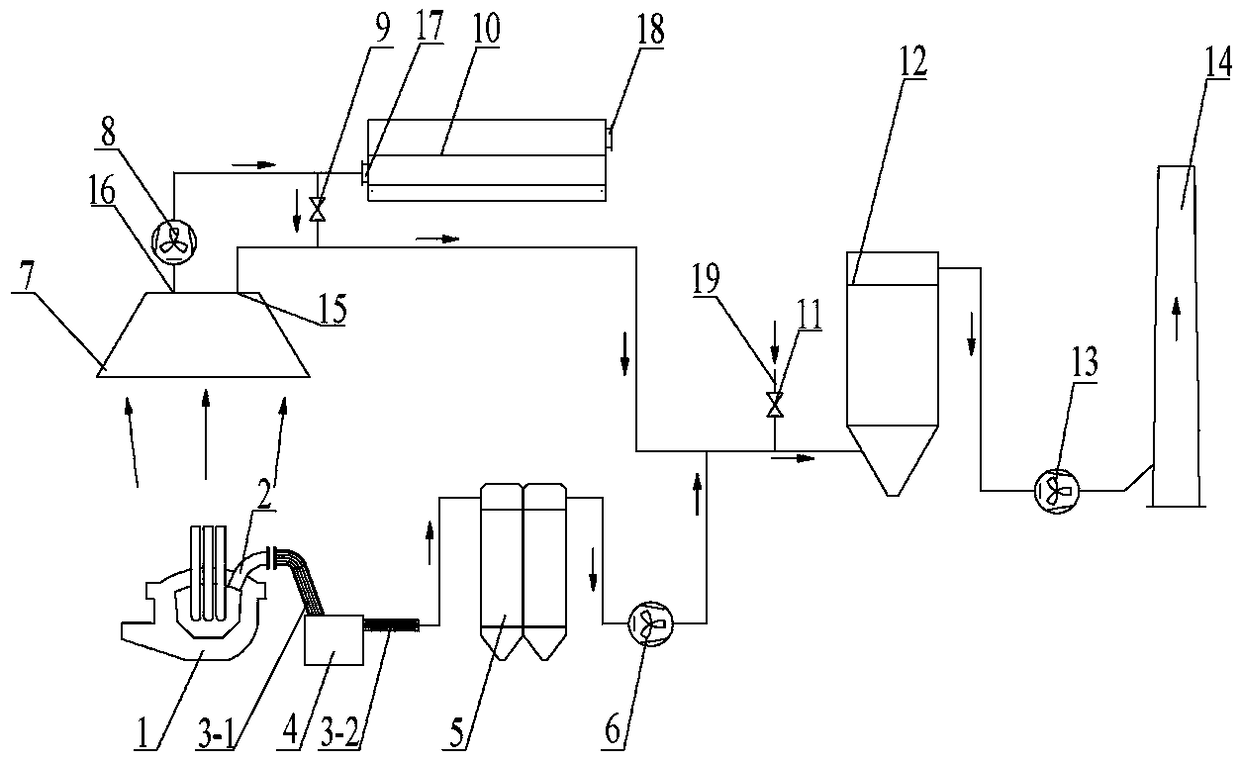

Electric furnace flue gas dust removal device capable of storing flue gas

InactiveCN109163572AReduce the amount of smokeReduce filter areaIncreasing energy efficiencyWaste heat treatmentElectric arc furnaceSafety valve

The invention provides an electric furnace flue gas dust removal device capable of storing flue gas. According to the electric furnace flue gas dust removal device, flue gas treatment can be effectively performed, moreover, the size of the equipment can be reduced, then the consumption of materials can be reduced, and the investment cost and the operation energy consumption can be reduced. The electric furnace flue gas dust removal device comprises an electric furnace, a furnace hole smoke discharging pipe, a water cooling flue, a combustion settling chamber, an air cooler and a booster fan which are connected in sequence, a roof cover is arranged above the electric furnace, moreover, a direct-discharge opening of the roof cover is connected with the booster fan and then is sequentially connected with a bag-type dust collector, a dust removal fan and a chimney, a safety valve is arranged between the roof cover and the bag-type dust remover, the electric furnace flue gas dust removal device further comprises a smoke storage fan, a bypass valve and a flue gas storage pipe, a bypass opening is formed in the roof cover, the bypass opening is connected with the flue gas storage pipe through the smoke storage fan, and the bypass valve is connected between the flue gas storage pipe and the direct-discharge opening.

Owner:WUXI XUELANG ENVIRONMENTAL TECH CO LTD

Smart two-membrane integrated sewage treatment system

InactiveCN105668952AReduce filter areaSmall footprintWater/sewage treatmentTreatment with aerobic and anaerobic processesGratingAeration system

The invention provides an intelligent dual-membrane integrated sewage treatment system, including a control system, an aeration system, a regulating tank, a membrane bioreactor, an ultrafiltration membrane pond and a clean water pond, a regulating pond, a membrane bioreactor, an ultrafiltration membrane The tank and the clean water tank are connected by pipelines in sequence; the aeration system includes aeration fan, aeration pipeline and aerator; the regulating tank is equipped with a water inlet, a grille and a lift pump; The aerobic tank and the aerobic tank, the anoxic tank and the aerobic tank are provided with combined packing, the aerobic tank is provided with an aerator; the ultrafiltration membrane tank is provided with an ultrafiltration membrane module and an aerator, and the ultrafiltration membrane module includes a hollow fiber Membranes and suction pumps, aerators and hollow fiber membranes are set in the ultrafiltration membrane pool shown, and the suction pump is connected with the ultrafiltration membrane pool and the clear water pool through pipelines; the clear water pool is provided with a water outlet; the control system and aeration system , lift pump and suction pump are electrically connected. The invention has small footprint, low energy consumption and long cleaning cycle.

Owner:DONGGUAN DONGRI WATER TREATMENT TECH

Nanofiltration membrane process system for deep recovery of waste alkaline liquor

PendingCN107855005AExtended service lifeIncrease flushingReverse osmosisProcess engineeringEnvironmental engineering

The invention discloses a nanofiltration membrane process system for deep recovery of waste alkaline liquor. The process system comprises a waste liquid tank, a nanofiltration membrane device and a filter liquid tank in sequential connection, wherein a material pump, a safety filter, a high-pressure pump and a circulation pump are sequentially arranged on a pipeline for connecting the waste liquidtank and the nanofiltration membrane device; the filter liquid tank is connected with a clear liquid outlet of the nanofiltration membrane device; a waste liquid discharging pipe is arranged on a concentration liquid outlet of the nanofiltration membrane device; a concentration backflow pipe connected with the waste liquid tank is arranged on the waste liquid discharging pipe; a concentration backflow valve is arranged on the concentration backflow pipe; a circulation pipe is arranged on the waste liquid discharge pipe positioned at the front end of the concentration back flow valve; the circulation pipe communicates with the pipeline arranged between the high-pressure pump and the circulation pump. During the operation, through the flow rate arrangement of the concentration backflow valve and the circulation pipe, the flow rate entering the nanofiltration membrane device per hour is enabled to be higher than that of the existing device, so that the goals of increasing the membrane layer flushing quantity, lowering the remaining probability of impurities such as separated out hemicellulose, resin and divalent ion complexes, and prolonging the service life of the nanofiltration membrane device are achieved.

Owner:YIBIN GRACE +1

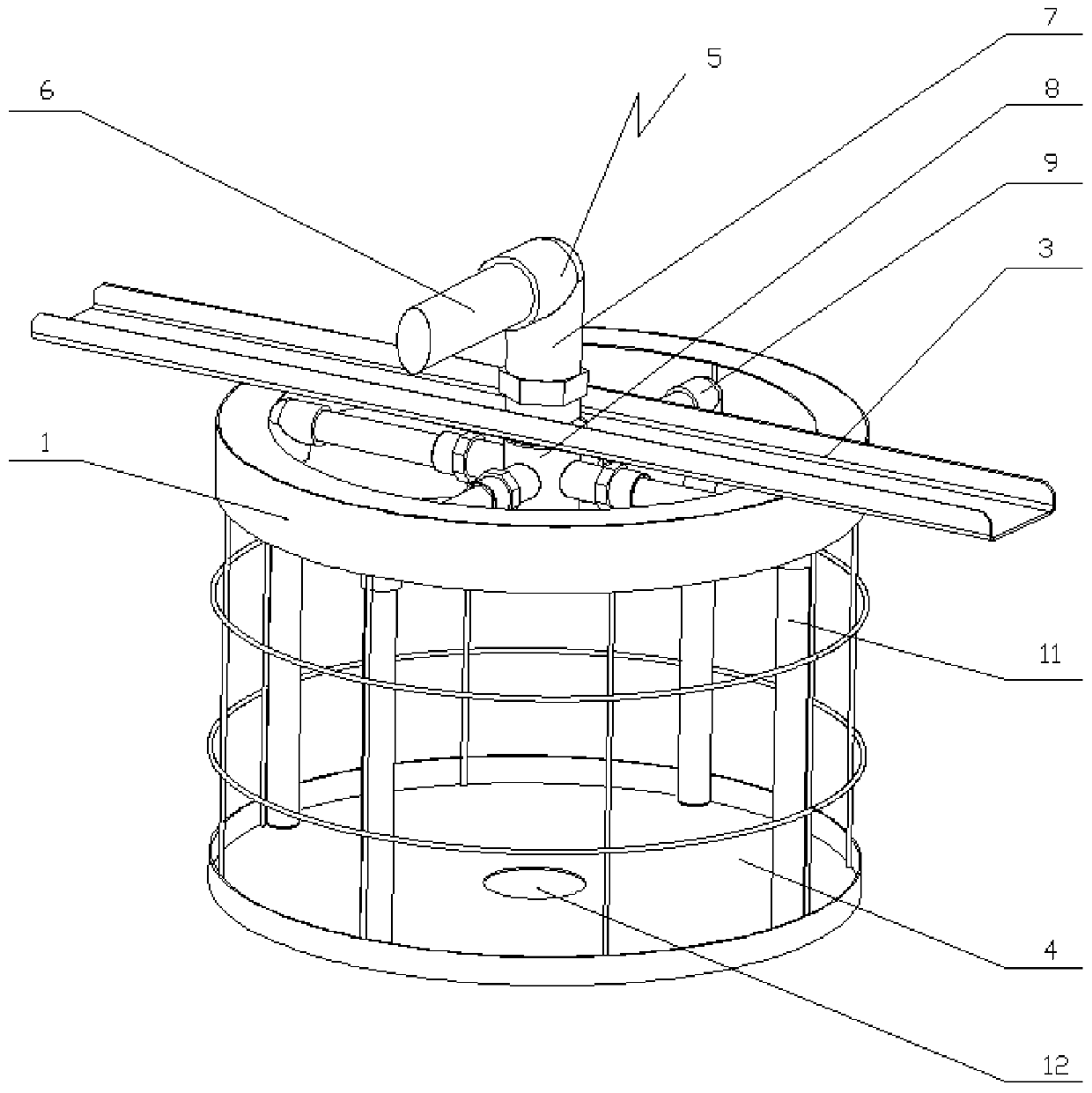

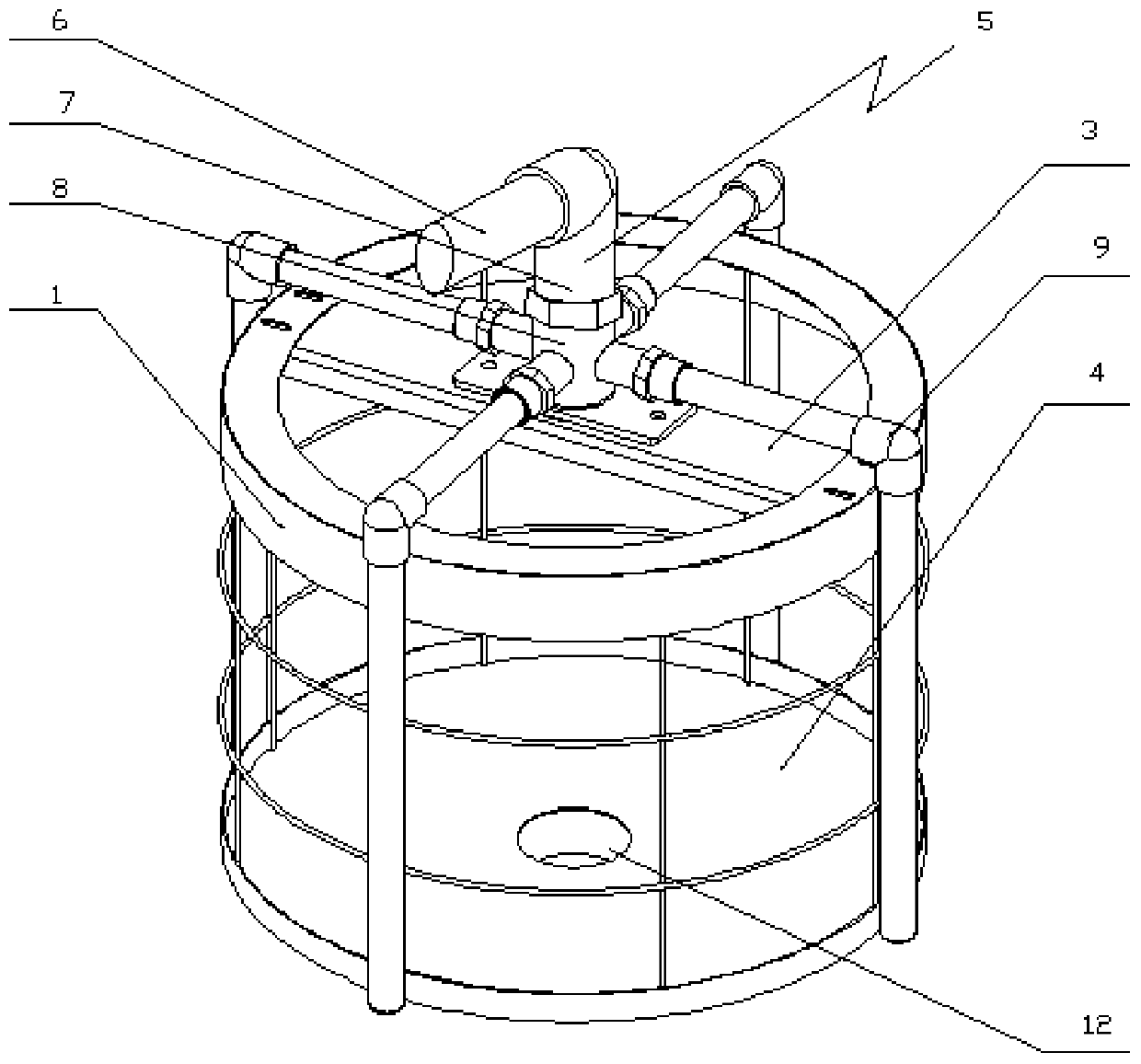

Microfiltration machine with backwashing device, and microfiltration and precipitation integration machine

PendingCN110201444ALarge filter areaSmall footprintFiltration circuitsStationary filtering element filtersWater pipePrecipitation

The invention discloses a microfiltration machine with a backwashing device. The microfiltration machine comprises a filter screen support frame with a filter screen, and the backwashing device, the backwashing device comprises a backwashing water inlet pipe and at least two backwashing water outlet pipes, the water outlet of the backwashing water inlet pipe is communicated with the upper ends ofthe backwashing water outlet pipes, the lower ends of the backwashing water outlet pipes are distributed along the circumference of the filter screen support frame, the filter screen is vertically arranged, and a rotating mechanism capable of automatically rotating the lower ends of the backwashing water outlet pipes around the filter screen support frame is provided between the backwashing wateroutlet pipes and the backwashing water inlet pipe. The microfiltration machine with the backwashing device has the advantages of low control system requirements, good filtering effect, good backwashing effect, and no influences on normal running. The invention also discloses a microfiltration and precipitation integration machine.

Owner:GUANGDONG ISUNGREEN TECH CO LTD

Double-membrane integrated intelligent biological sewage treatment system

InactiveCN105884131AReduce filter areaSmall footprintWater/sewage treatmentTreatment with aerobic and anaerobic processesFiltration membraneWater treatment system

The invention provides a double-membrane integrated intelligent biological sewage treatment system which comprises a control system, an aeration system, a regulating tank, a membrane bioreactor, an ultra-filtration membrane tank and a clear water tank. The regulating tank, the membrane bioreactor, the ultra-filtration tank and the clear water tank are sequentially communicated with one another via pipelines; the aeration system comprises an aeration fan, aeration pipelines and aerators; the ultra-filtration membrane tank is provided with an ultra-filtration membrane assembly and the aerators, the ultra-filtration membrane assembly comprises a hollow fibrous membrane and a suction pump, the aerators and the hollow fibrous membrane are arranged in the ultra-filtration membrane tank, and the suction pump is communicated with the ultra-filtration membrane tank and the clear water tank via pipelines; a water outlet is formed in the clear water tank; the control system is electrically connected with the aeration system, a lift pump and the suction pump. The double-membrane integrated intelligent biological sewage treatment system has the advantages of small occupied area, low energy consumption and long cleaning period.

Owner:郭菲

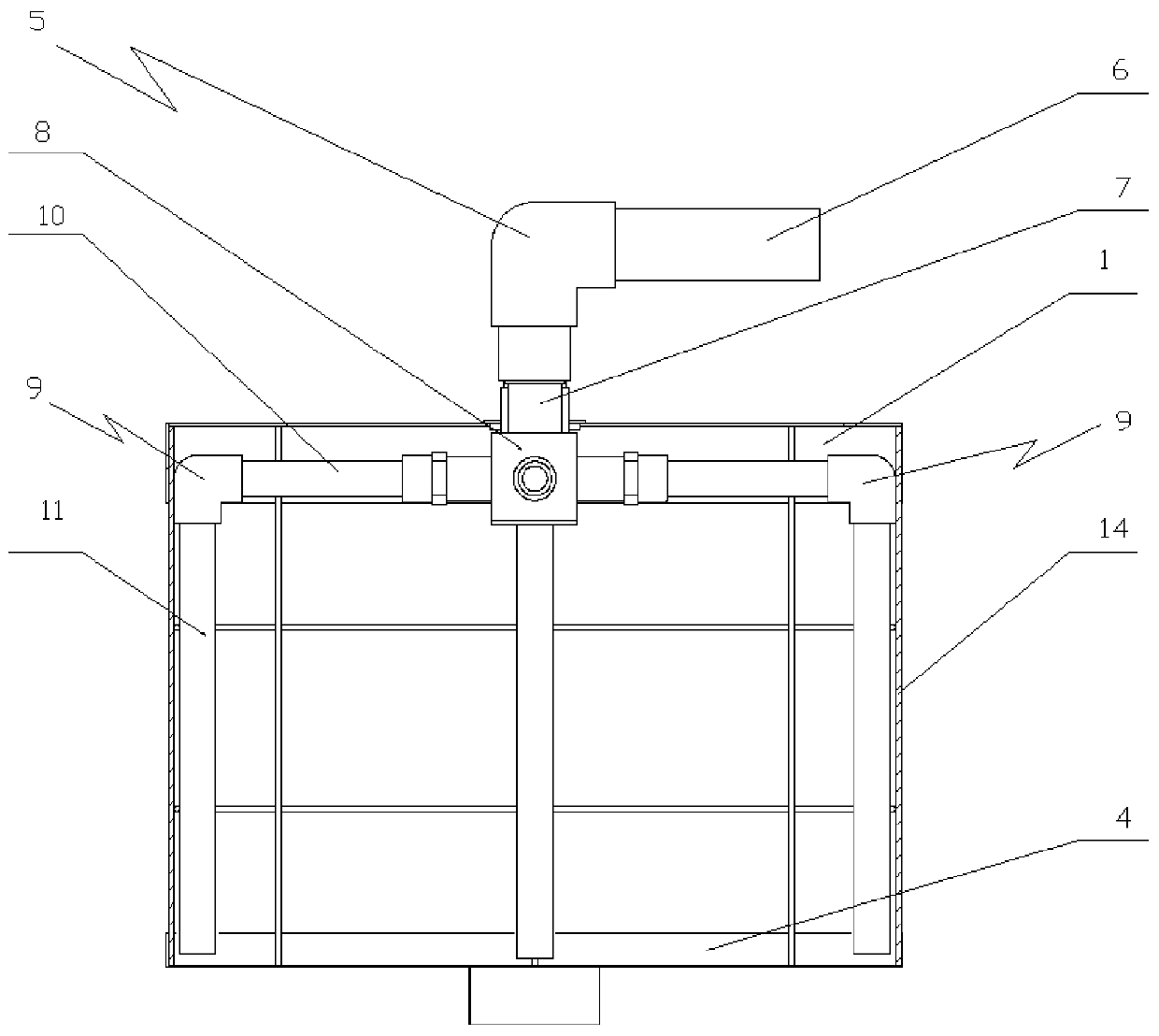

Fixed plate frame microfiltration device

ActiveCN102872632AImprove space utilizationReduce filter areaStationary filtering element filtersMicrofiltrationEngineering

The invention relates to a water treatment device, in particular to a fixed plate frame microfiltration device. The device comprises a filter tank, a water inlet pipeline, a water outlet pipeline and a square filter frame body, wherein the water inlet pipeline and the water outlet pipeline are respectively arranged outside the two ends of the filter tank; and the filter frame body is arranged in the filter tank. The device has the advantages that (1) the effective area of a rectangular filter disc is large, and the space utilization rate is greatly improved; (2) a square plate frame filter disc is fixed and is not required to be rotated, the height of the filter disc is limited by transport dimensions, and the length of the filter disc is not limited; (3) by an immersion design, the utilization efficiency of the filter area under the immersion condition is the highest, and the treatment capacity of the microfiltration device is correspondingly high; and (4) by the scheme, the unit filter area can easily reach more than 300m<2>, even an ultra-large microfiltration device with the unit filter area of more than 600m<2> and the unit treatment capacity of more than 200,000m<3> / d (the treatment capacity in each square meter of filter area in each hour is 15m<3>) can be produced, and the unit scale can be continuously expanded.

Owner:广州市地龙环保技术有限公司

Composition of baffle for generating vortex liquid state flow or vortex l combustive flow

InactiveCN1915484AReduce filter areaReduce volumeCombination devicesChemical/physical/physico-chemical processesCombustionLiquid state

A combined baffle plate structure for generating vortex liquid flow or vortex combustion flow in the washing tower or combustion tower is disclosed. A guide region is arranged at the gas inlet in tower body for making the incoming gas to generate tangent acceleration. The gas is then flowing in the vortex plate region formed by said combined baffle plate structure to generate vortex flow while the water or oil is sprayed for higher vortex effect.

Owner:张才腾

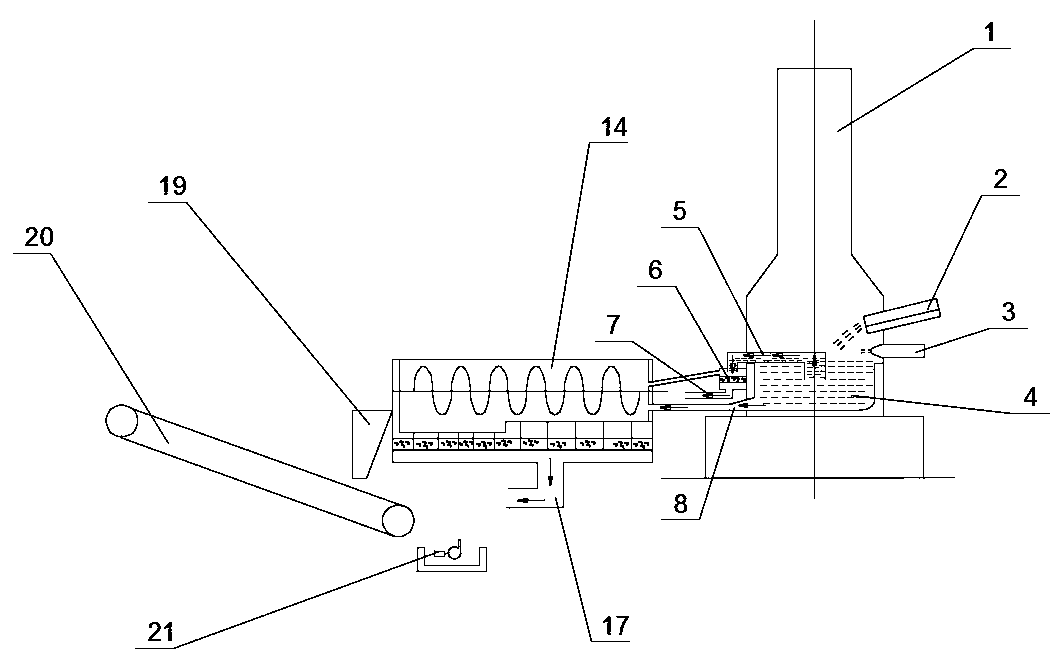

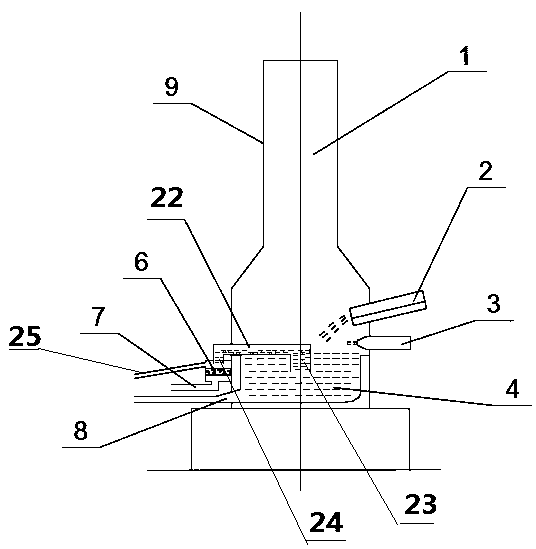

Environmentally-friendly and energy-saving processing method of blast furnace slag and special processing equipment

ActiveCN111575420AReduce the amount of waterReduce filter areaRecycling and recovery technologiesWater savingSewage

The invention relates to an environmentally-friendly and energy-saving processing method of blast furnace slag and special processing equipment, and belongs to the technical field of blast furnace orsubmerged arc furnace slag processing. The technical scheme is that a water slag advancing and conveying device (13) is arranged in a water and slag filter (14), a slag-water mixture outlet (8) of a swirling water-saving granulation tower (1) is connected with the water and slag filter (14), the water and slag filter (14) is connected with an inclined belt conveyor (20) through a discharging chute(19), and the equipment further comprises a sewage slurry pump (21) and a backwater and backwashing system. The equipment has the beneficial effects that according to the swirling water-saving granulation tower arranged at the front end of the water and slag filter, the amount of water entering the water and slag filter is reduced, and the filtering area of the water and slag filter is correspondingly reduced; no situation that a filter tank section has poor filtration performance occurs, and the service life of the water and slag filter is prolonged; the equipment cost is reduced due to theinclined belt conveyor, and the water is further filtered out of the water slag.

Owner:付光明

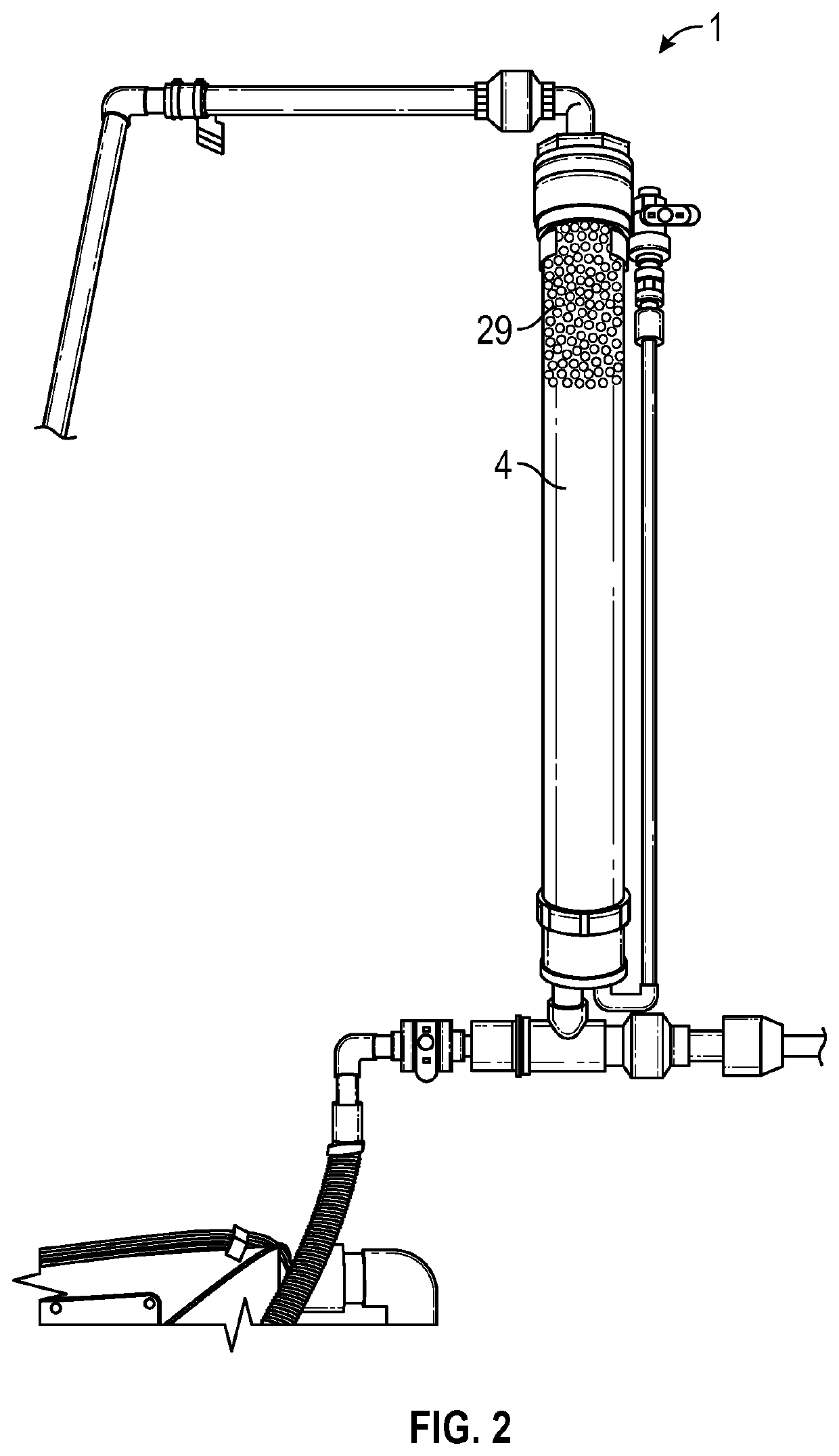

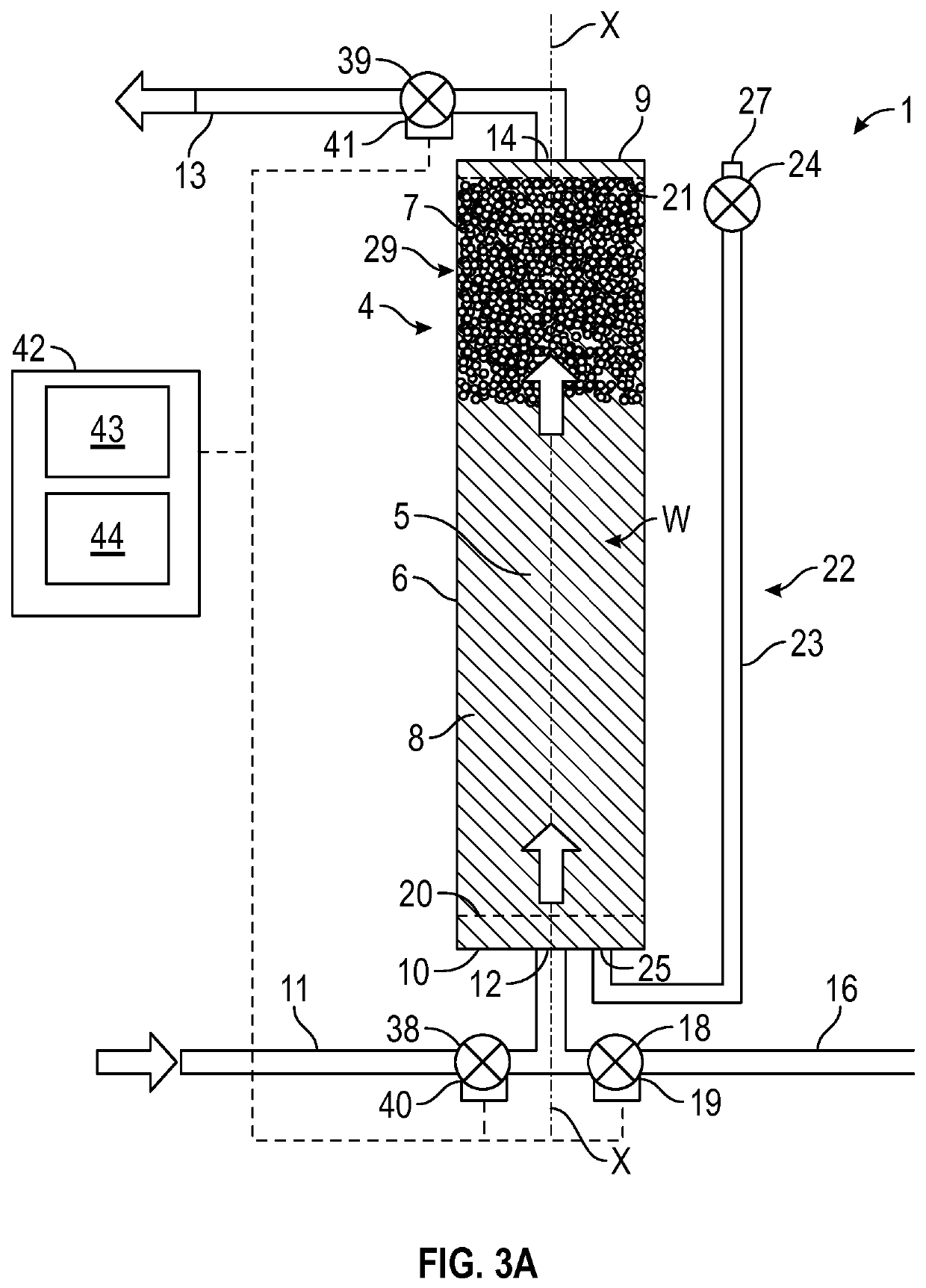

Filter apparatus and method

PendingUS20200269163A1Reduce accumulationStay healthyTreatment using aerobic processesWaste water treatment from animal husbandryEngineeringMechanical engineering

Owner:EVOLUTION AQUA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com