Combine harvester

A technology for combine harvesters and harvesting devices, which is applied to harvesters, cutters, agricultural machinery and implements, etc. It can solve the problems of loss of adsorption force, easy overheating of the engine, and inability to remove dust, so as to suppress the reduction of the filtration area and improve the efficiency of the filter area. Work efficiency and the effect of ensuring the suction air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

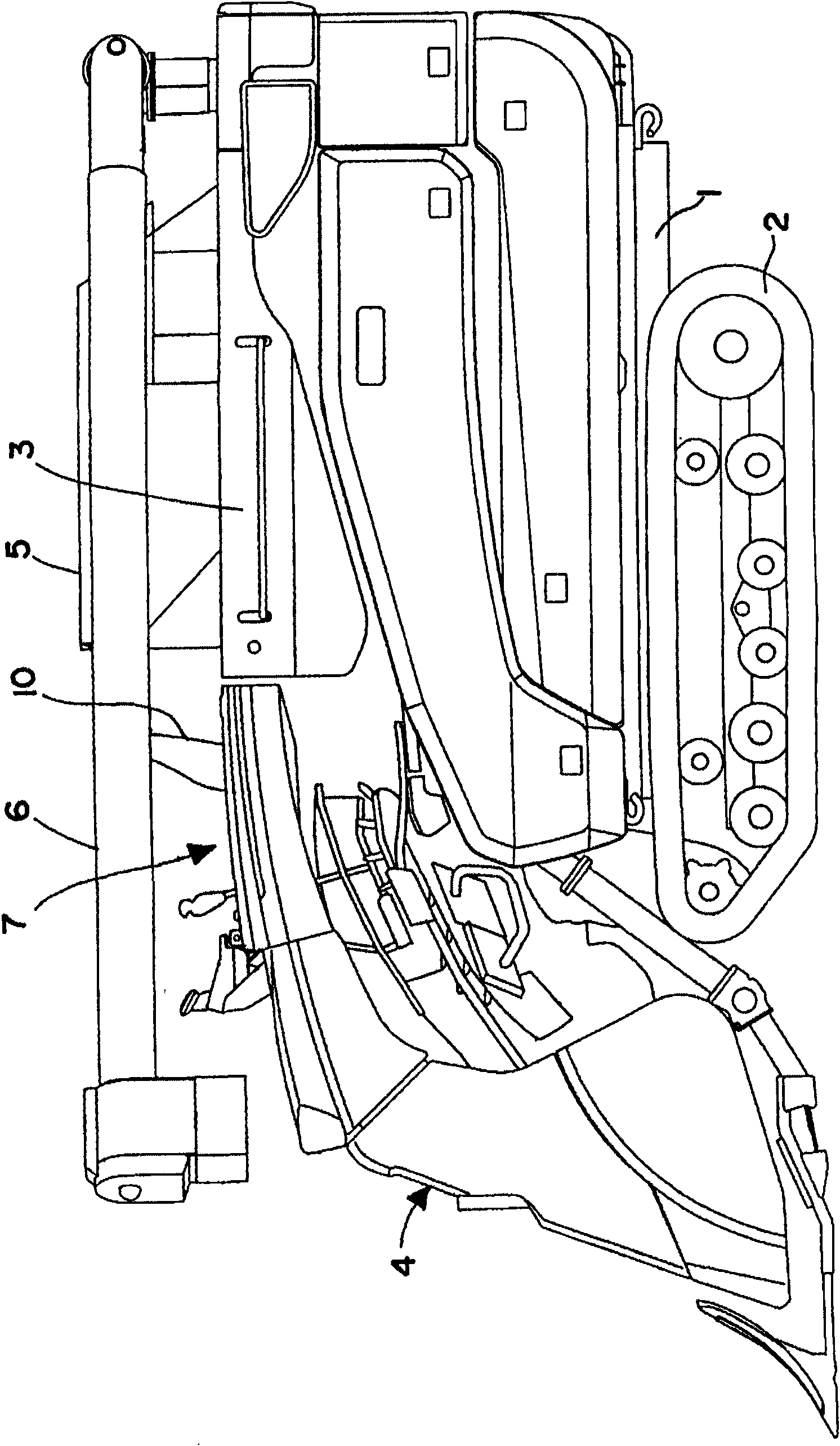

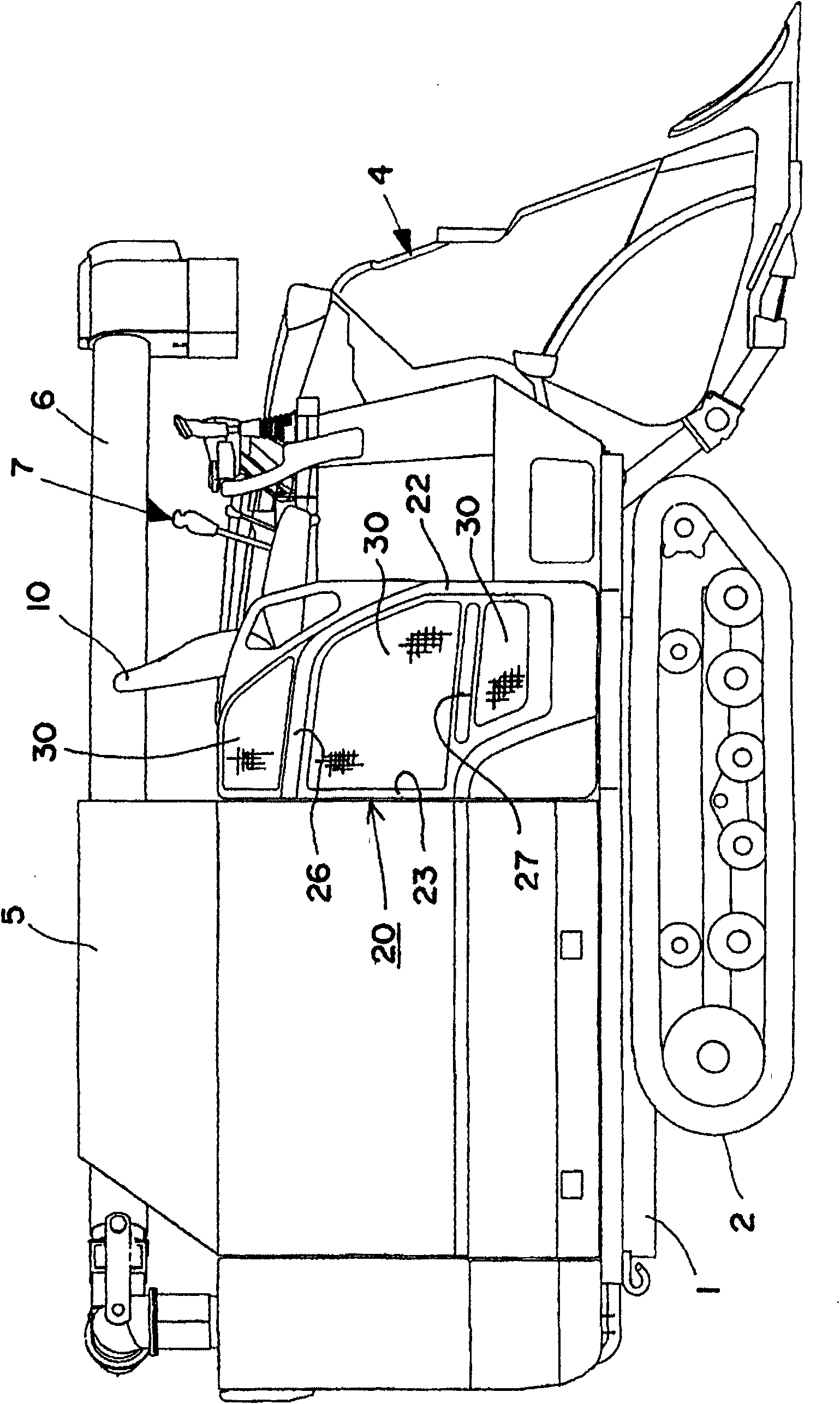

[0038] Such as figure 1 , figure 2 As shown, the body structure of the combine harvester of the present invention is such that a crawler-type traveling device 2 is provided on the lower side of the body frame 1, and a threshing device 3 and a grain threshing device 3 equipped with an auger 6 are mounted side by side on the upper side of the body frame 1. The storage device 5 is provided with the manipulation part 7 on the front side of this grain storage device 5, and the reaping device 4 is provided in the front side of the body frame 1 so that it can move up and down freely.

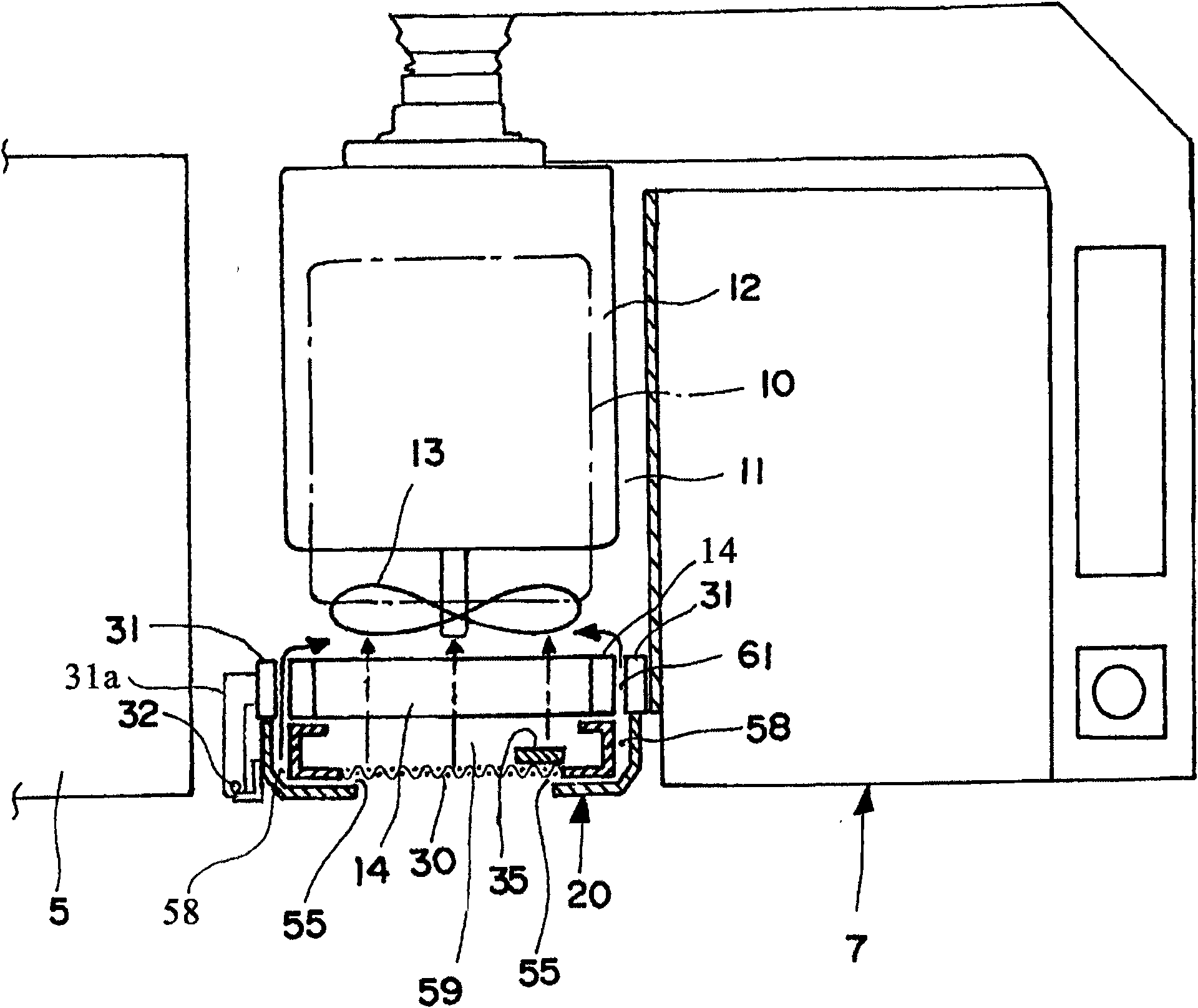

[0039] Furthermore, an engine 12 is mounted on the upper side of the body frame 1 below the driver's seat 10 of the control unit 7 , and the engine 12 is surrounded by a partition wall to form an engine room 11 . An engine cooling fan 13 driven by the engine 12 is provided on the body frame 1 on the outer side of the body than the engine 12 . A radiator 14 for cooling the engine 12 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com