Patents

Literature

376results about How to "Reduce cooling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

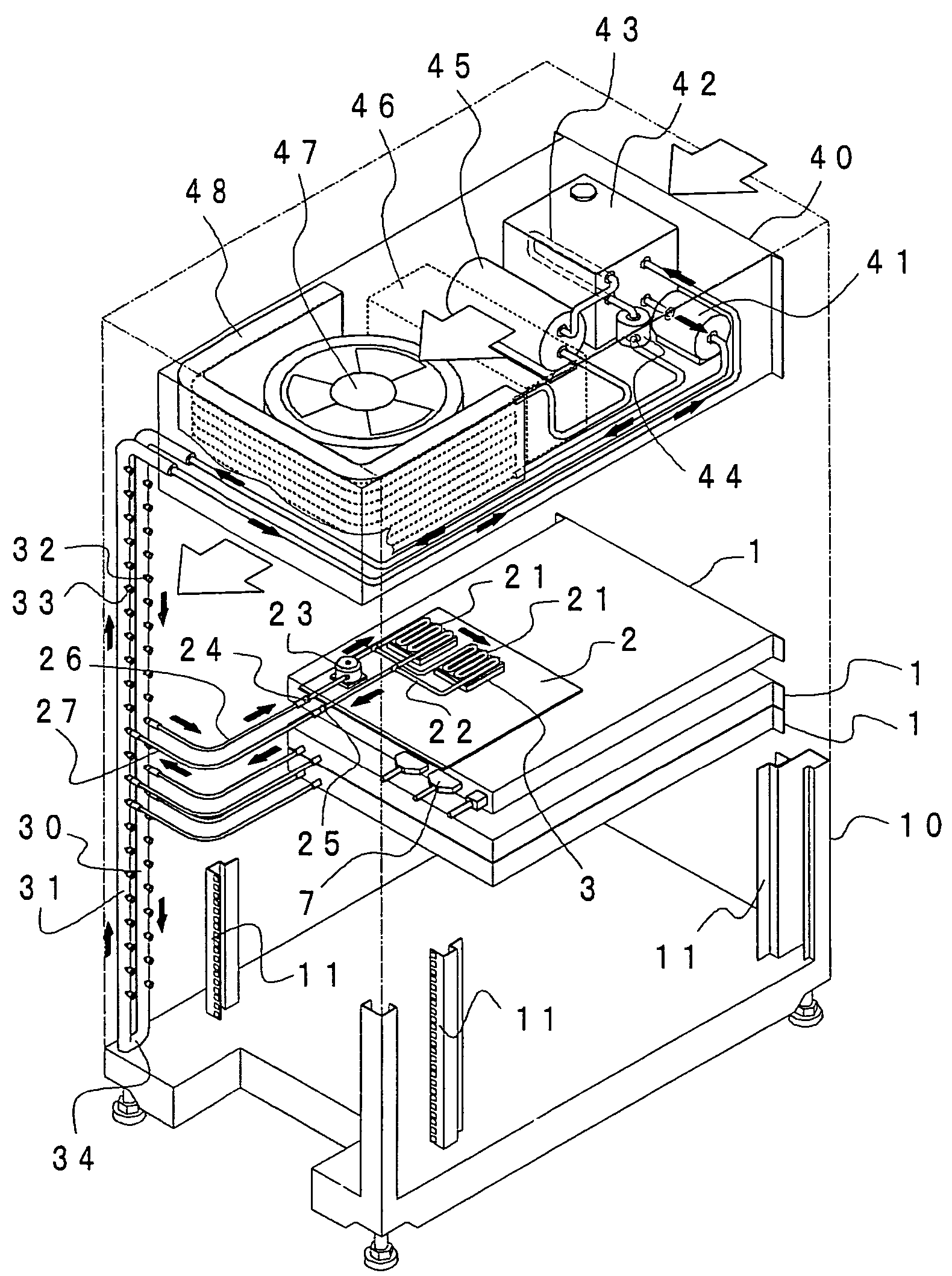

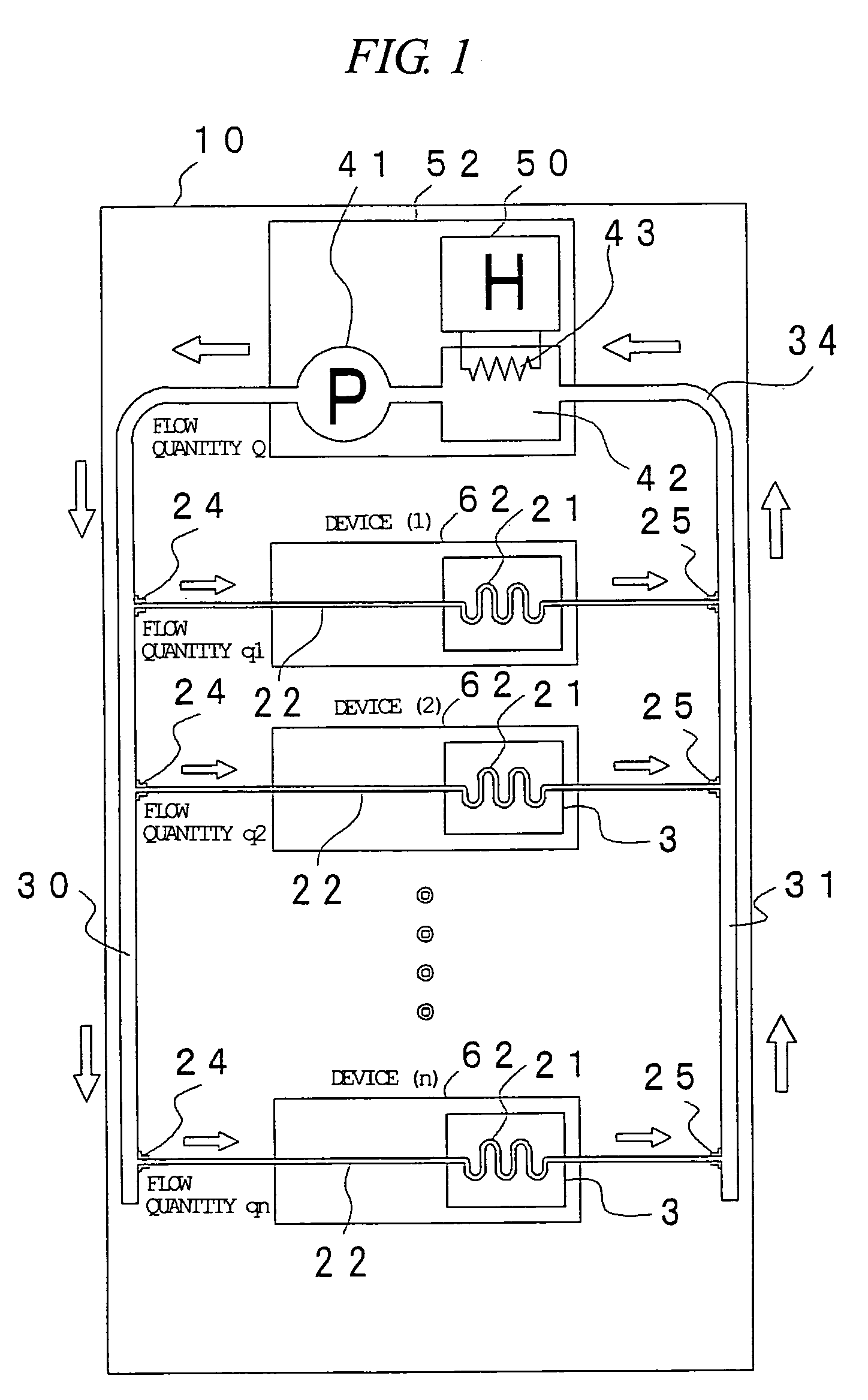

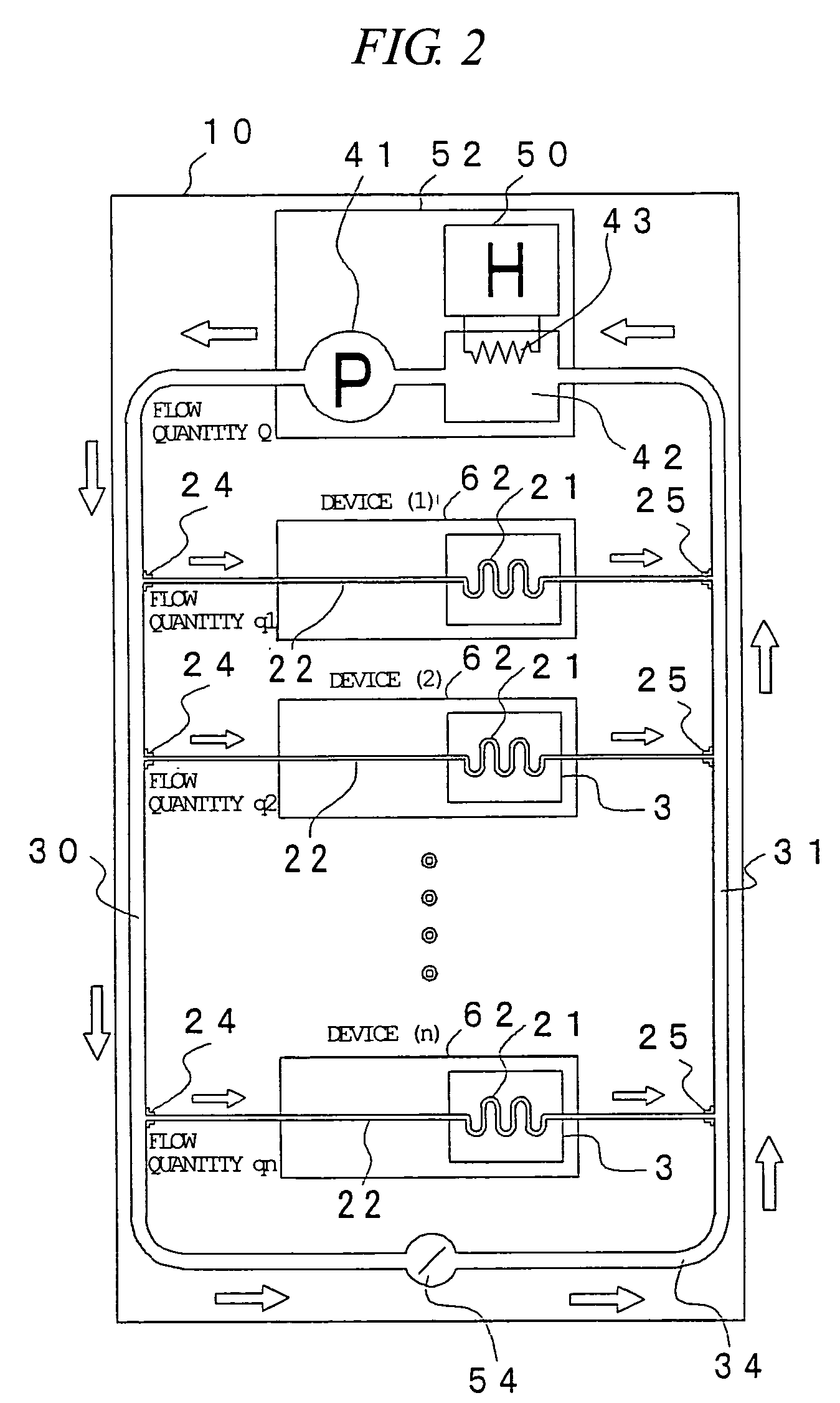

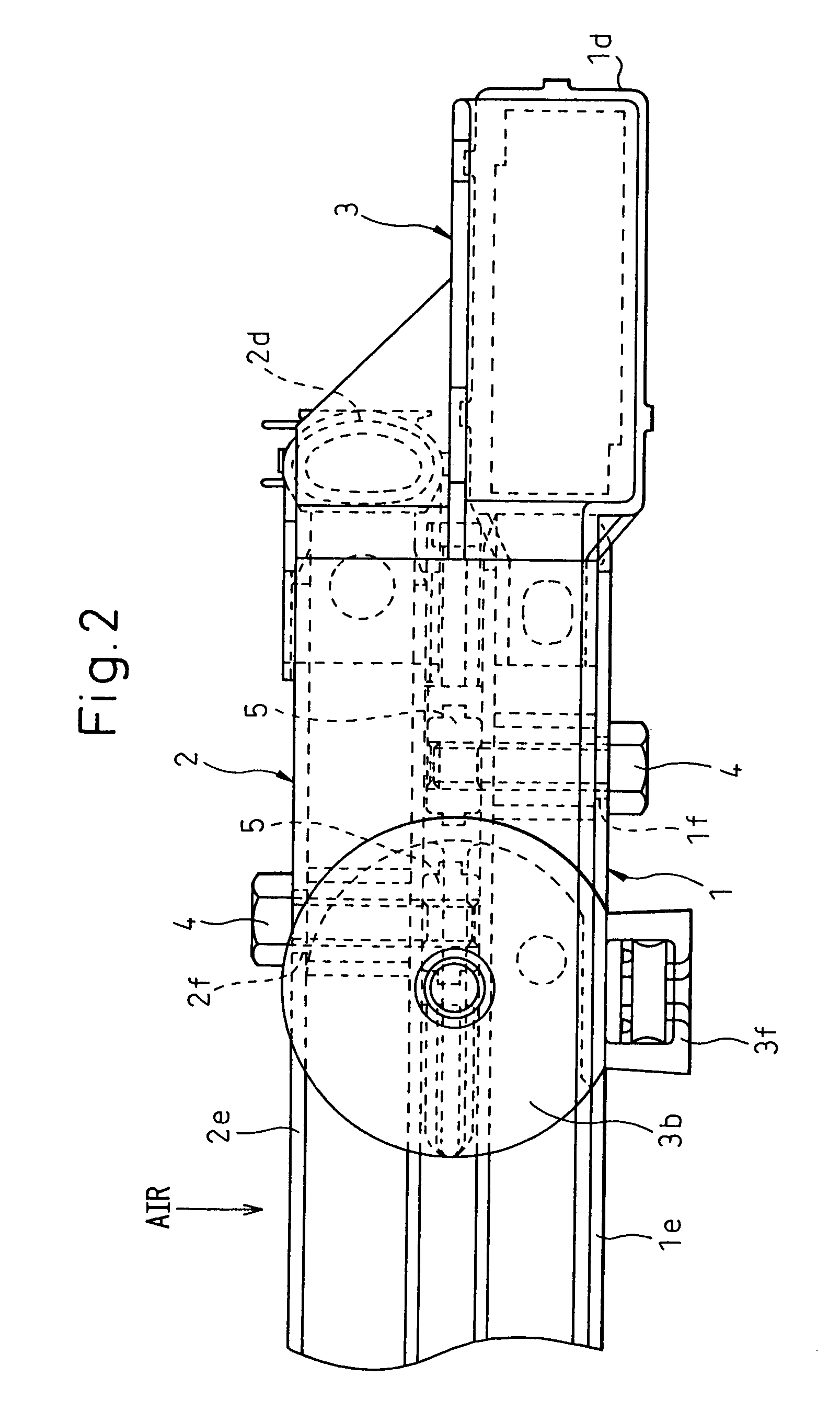

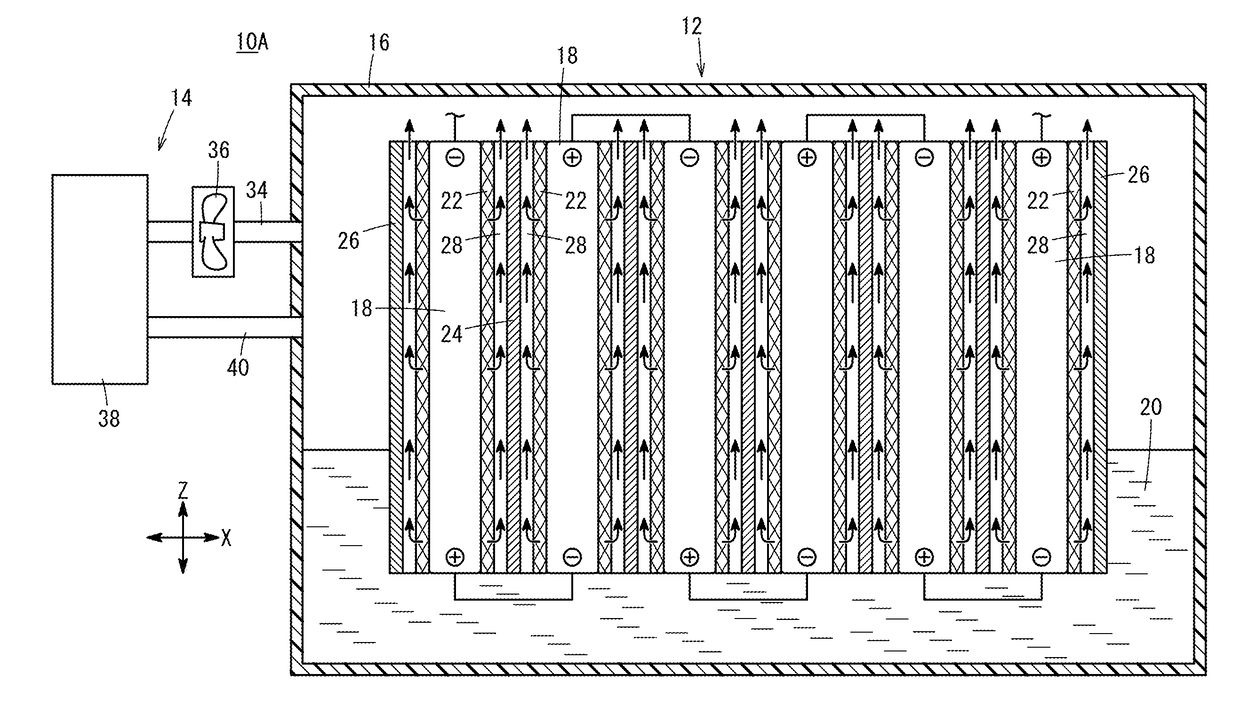

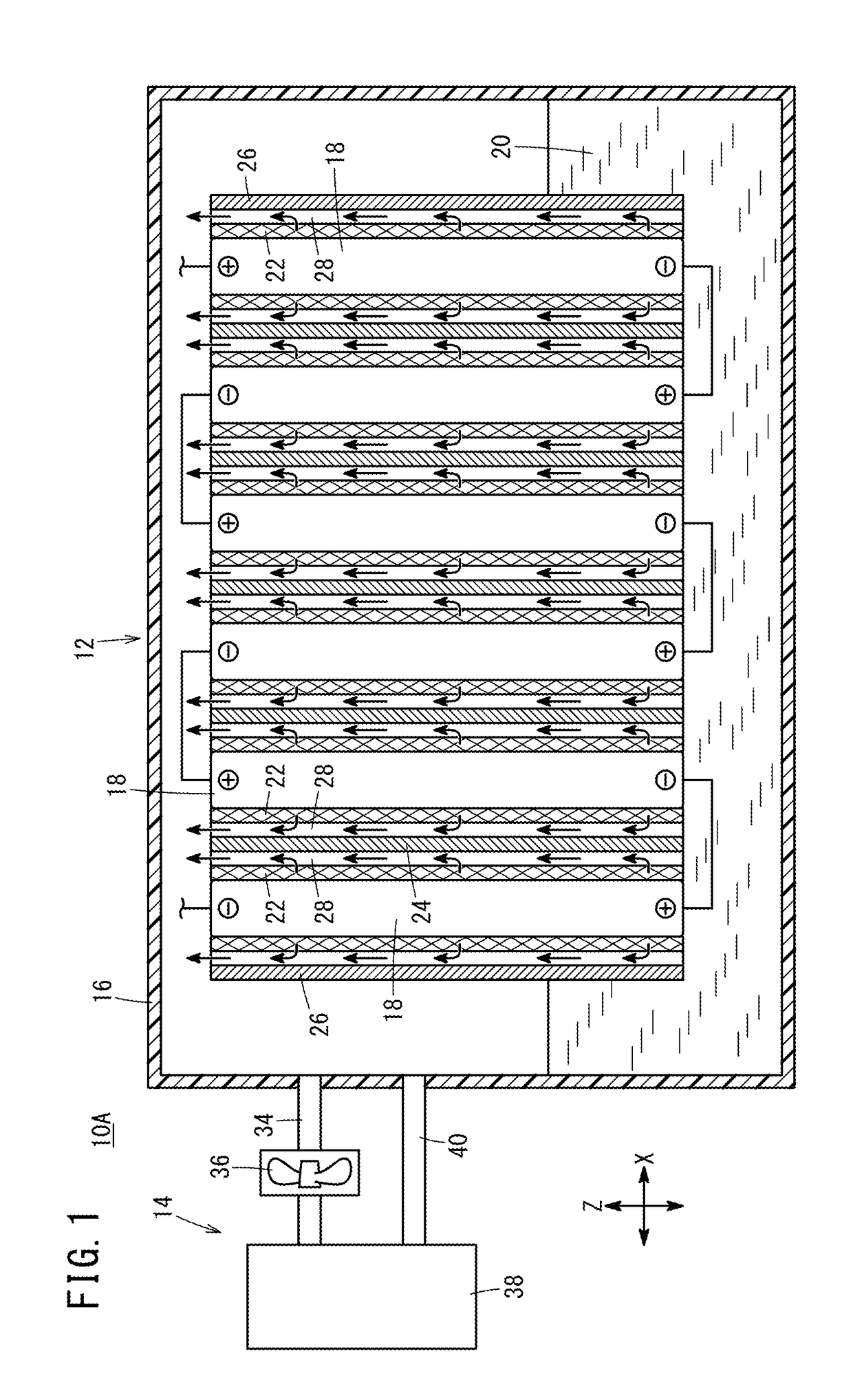

Liquid cooling system for a rack-mount server system

ActiveUS7318322B2Suppress mutationImprove cooling effectDomestic cooling apparatusDigital data processing detailsNuclear engineeringComputer module

A rack-mount server system of a liquid cooling system, in which a heat-generating component such as a CPU is cooled by a coolant has a plurality of server modules with heat-generating components which are cooled by the circulating coolant. The server modules are connected in parallel to a circulation coolant path through which the coolant to cool the server modules is circulated. In the middle of the coolant circulation path is a cooling unit that cools the coolant by radiating its heat to the outside air. Furthermore, a bypass route parallel to the server modules and going around the server modules is provided in the coolant circulation path, and the circulation quantity of the coolant is controlled in the bypass route. Alternatively, the flow quantity of the coolant is controlled in each of the server modules.

Owner:MAXELL HLDG LTD

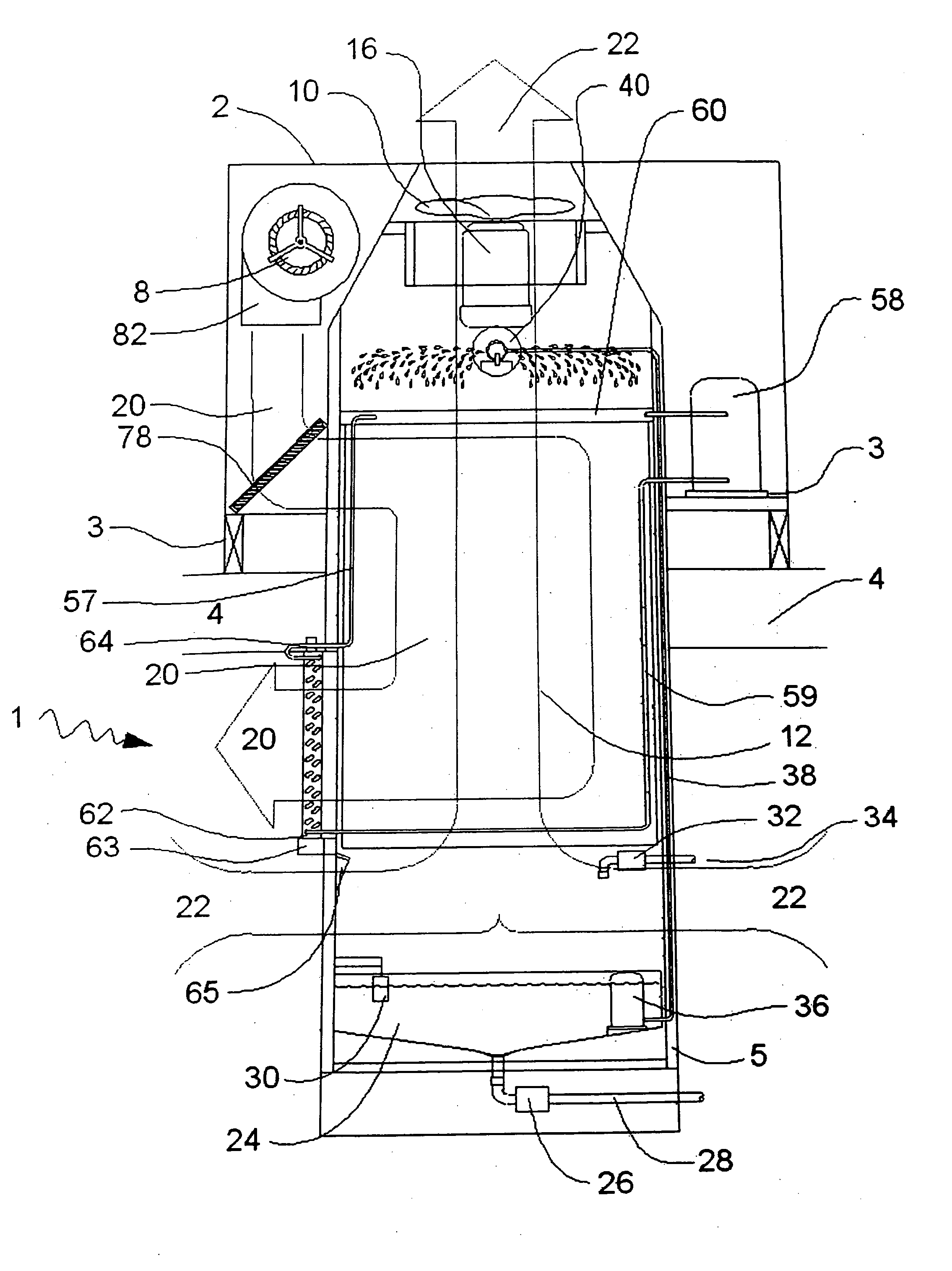

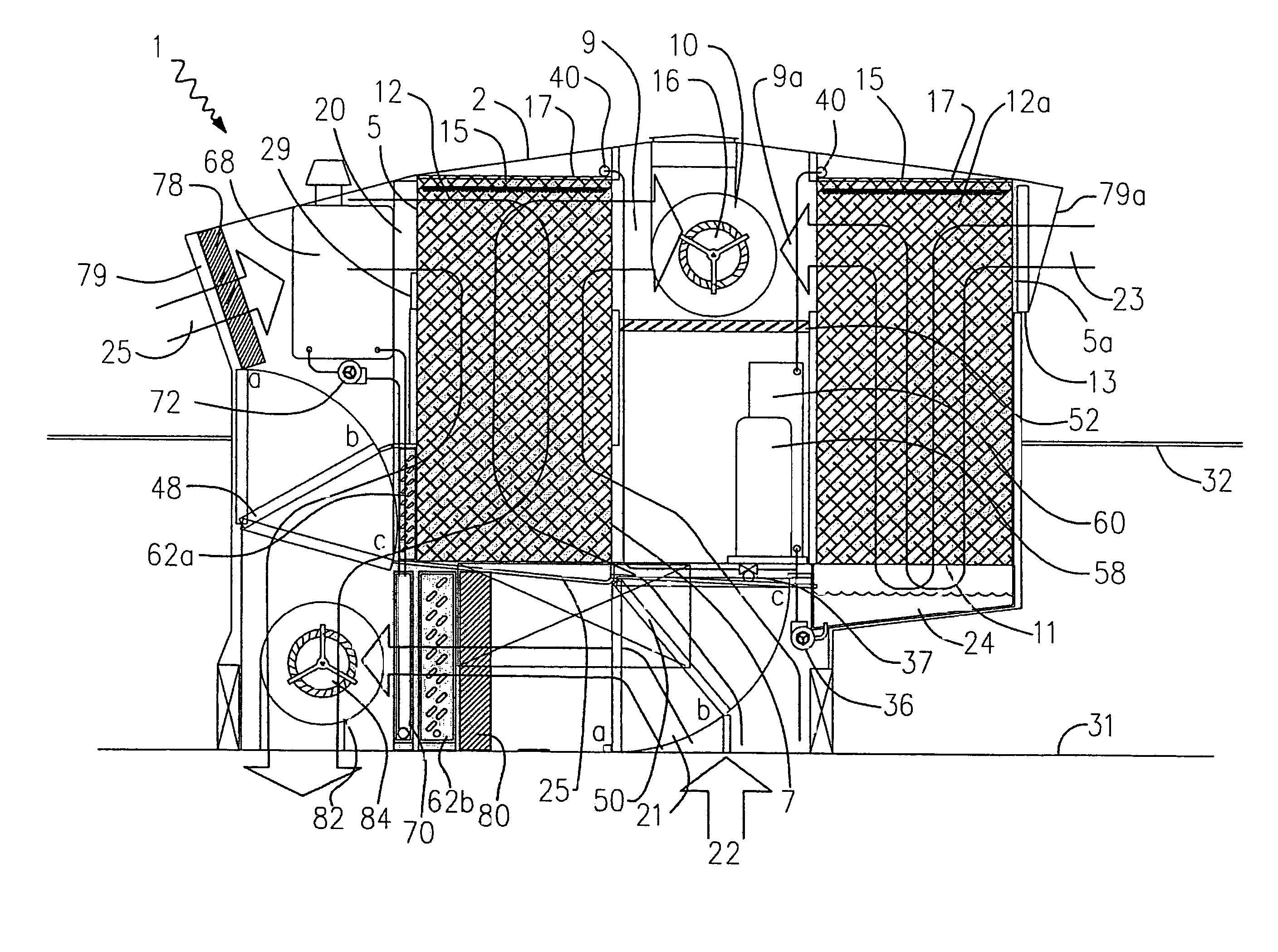

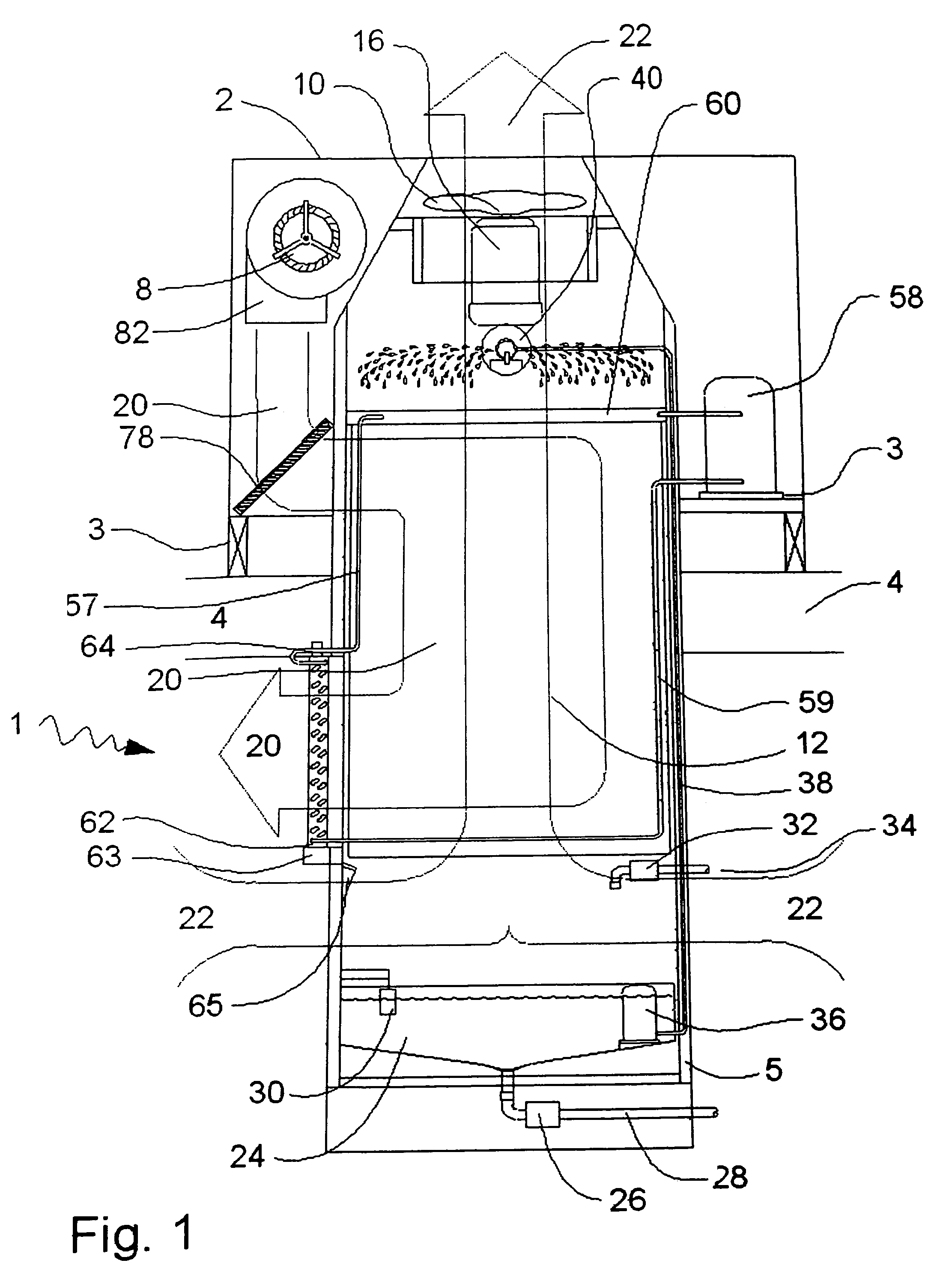

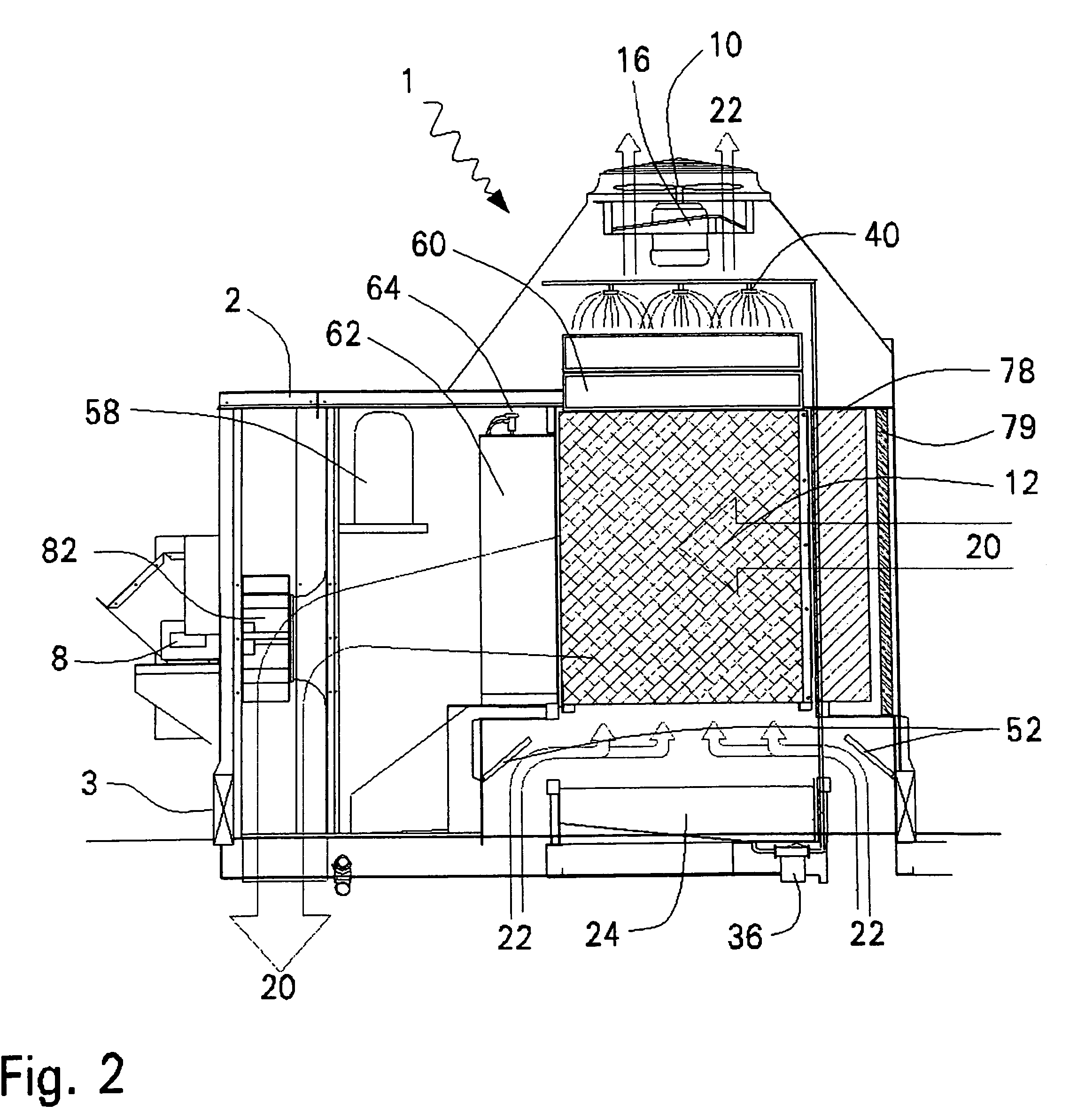

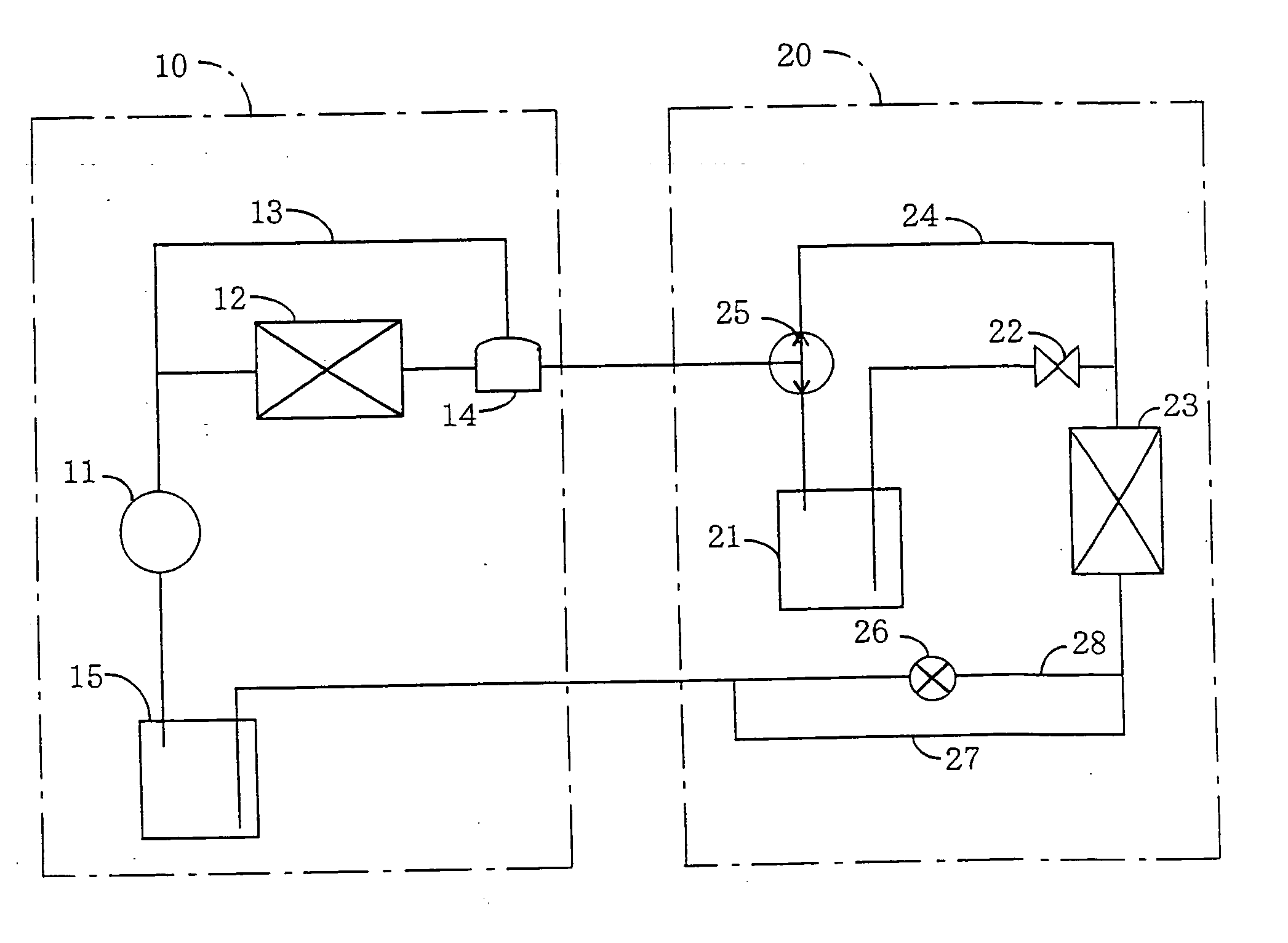

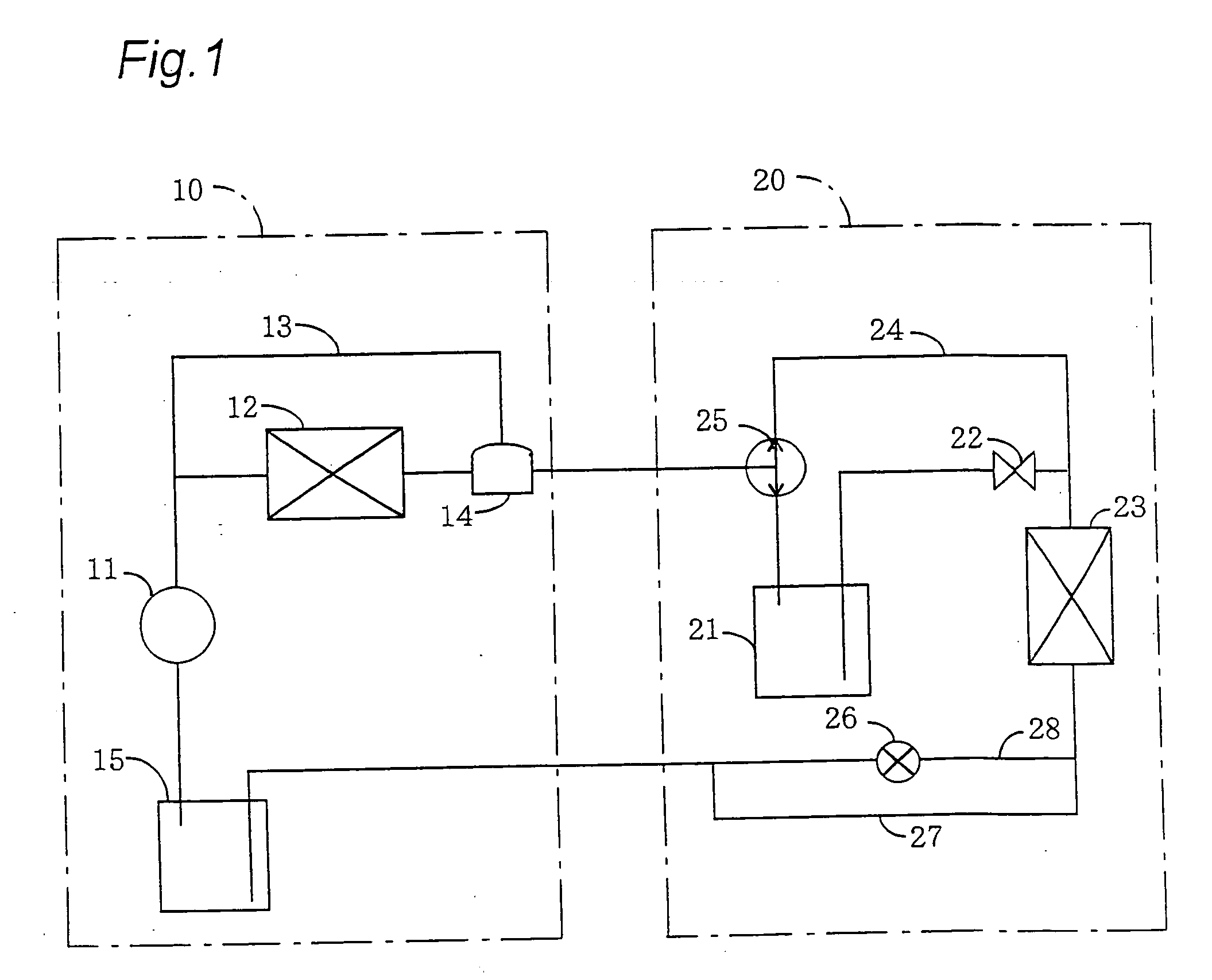

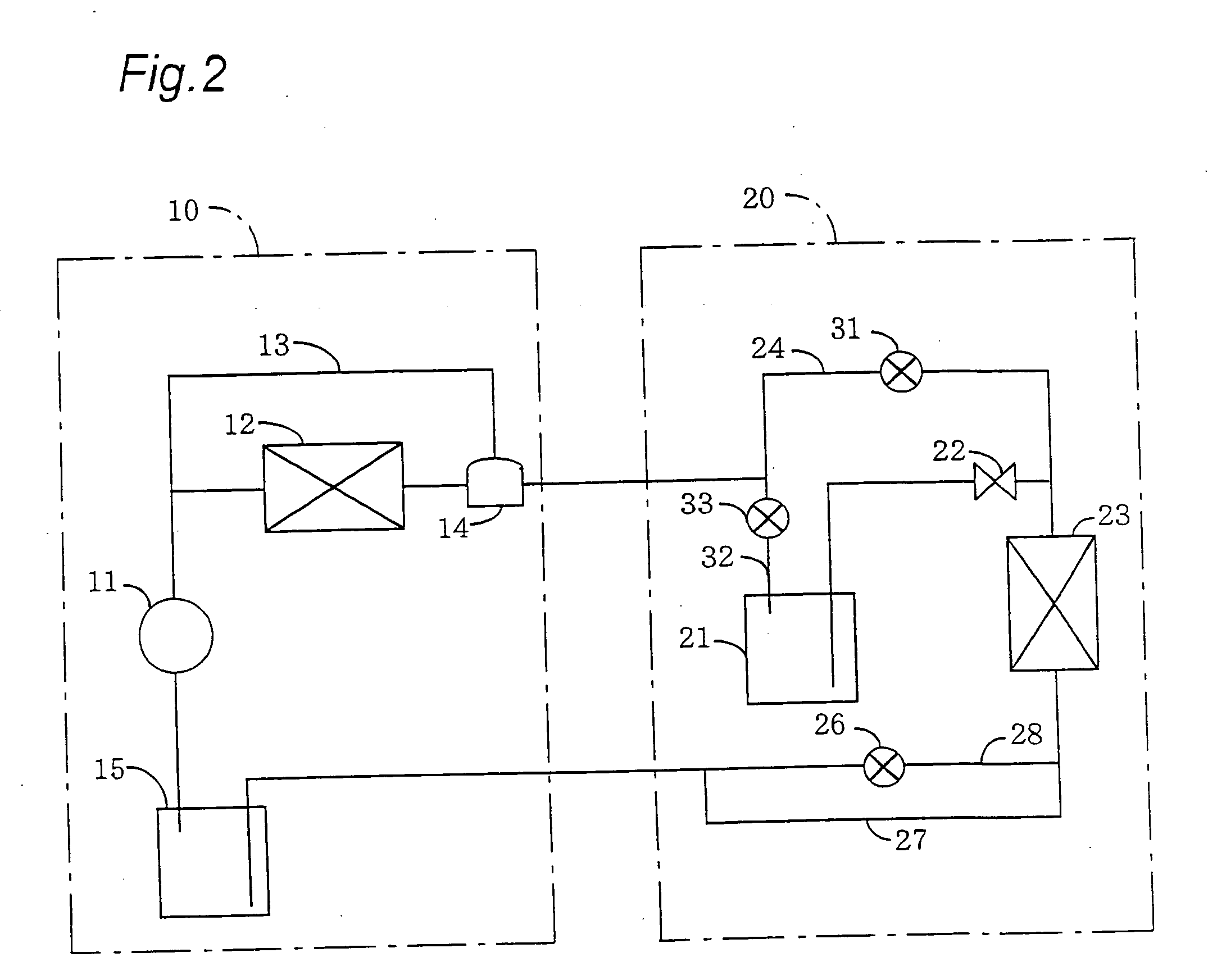

Hydronic rooftop cooling systems

InactiveUS20050056042A1Improve RTU efficiencyEnhanced evaporative cooling effectEnergy recovery in ventilation and heatingHeat recovery systemsAir filterEngineering

A roof top cooling unit has an evaporative cooling section that includes at least one evaporative module that pre-cools ventilation air and water; a condenser; a water reservoir and pump that captures and re-circulates water within the evaporative modules; a fan that exhausts air from the building and the evaporative modules and systems that refill and drain the water reservoir. The cooling unit also has a refrigerant section that includes a compressor, an expansion device, evaporator and condenser heat exchangers, and connecting refrigerant piping. Supply air components include a blower, an air filter, a cooling and / or heating coil to condition air for supply to the building, and optional dampers that, in designs that supply less than 100% outdoor air to the building, control the mixture of return and ventilation air.

Owner:DAVIS ENERGY GROUP

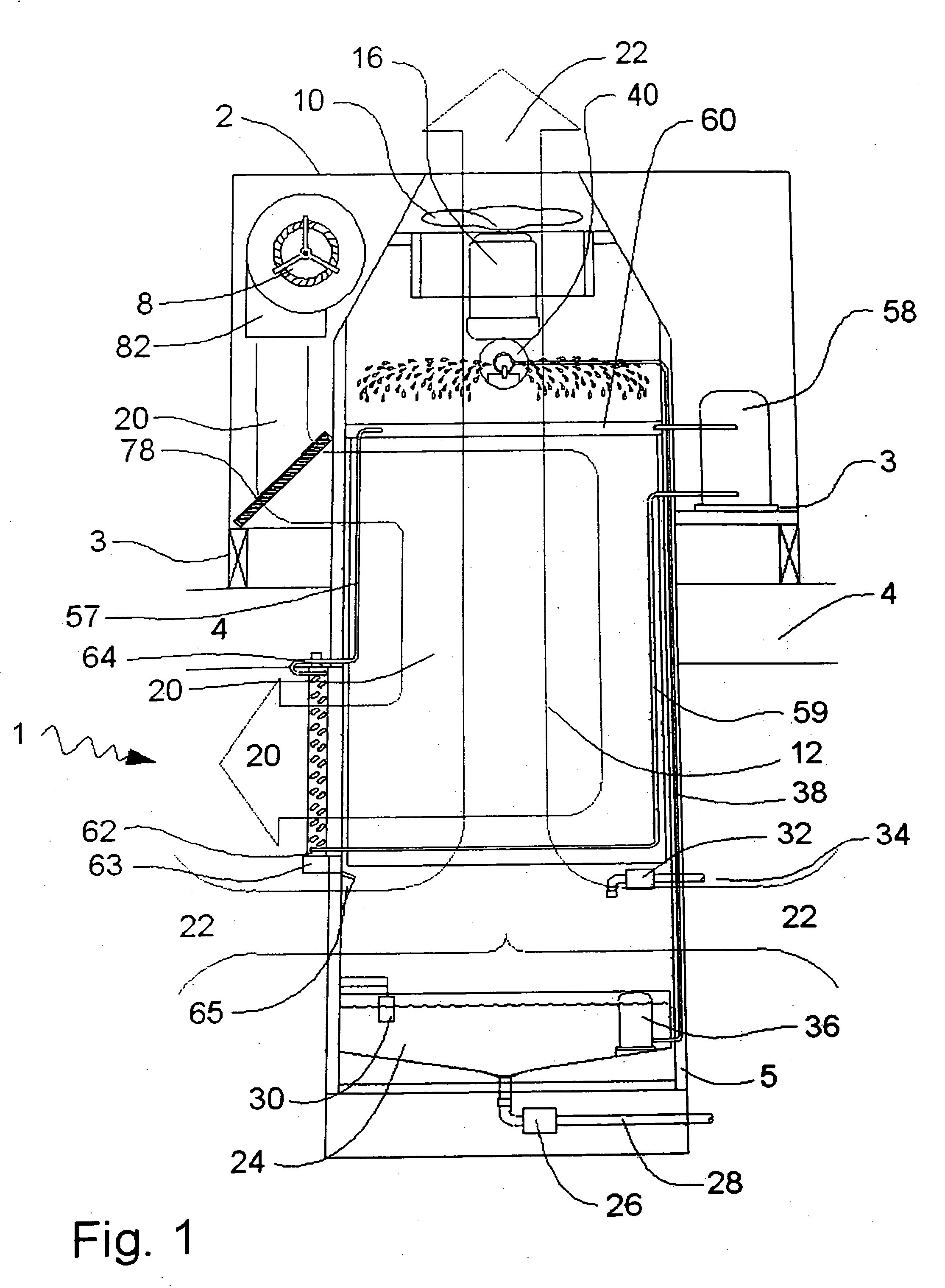

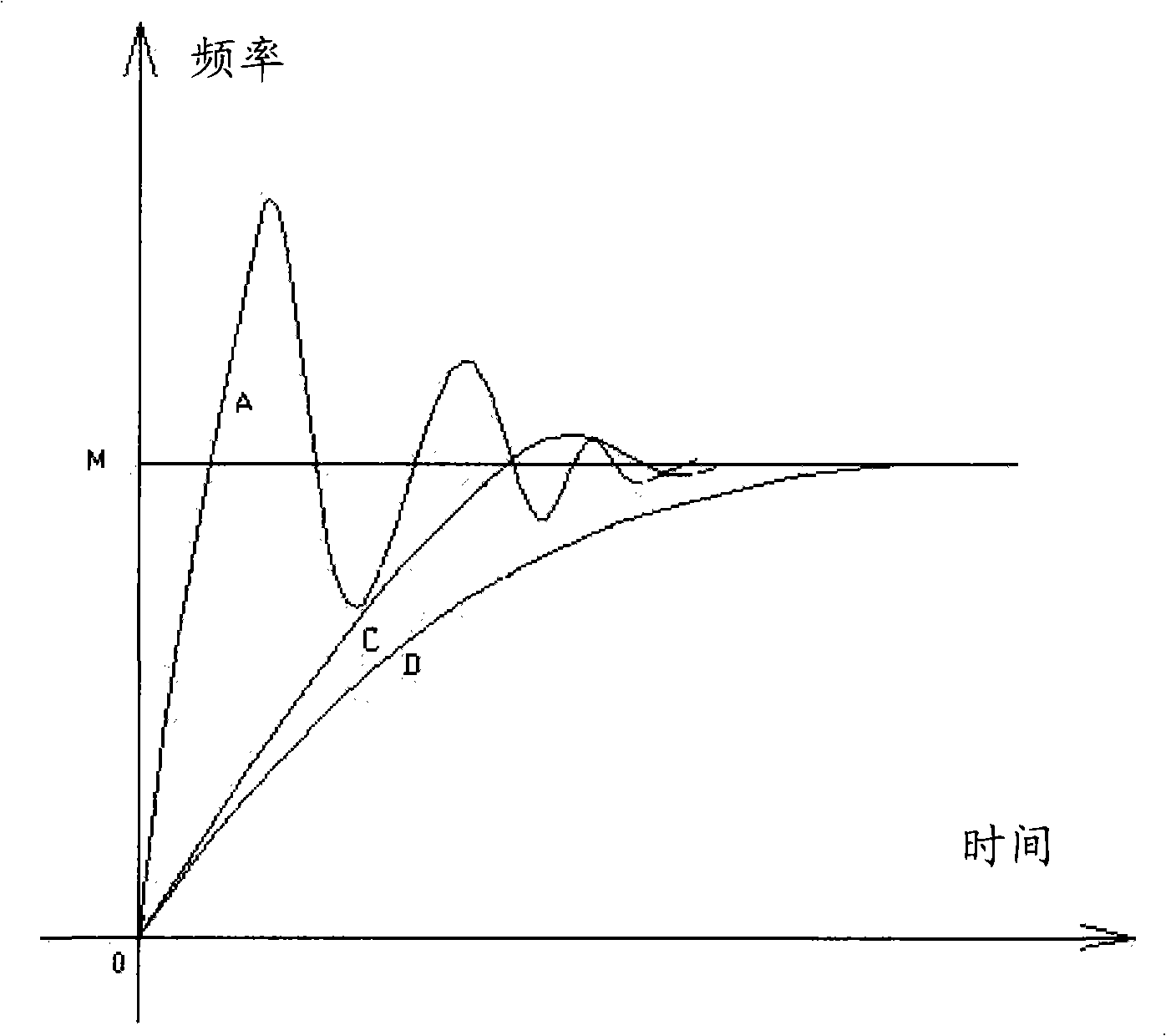

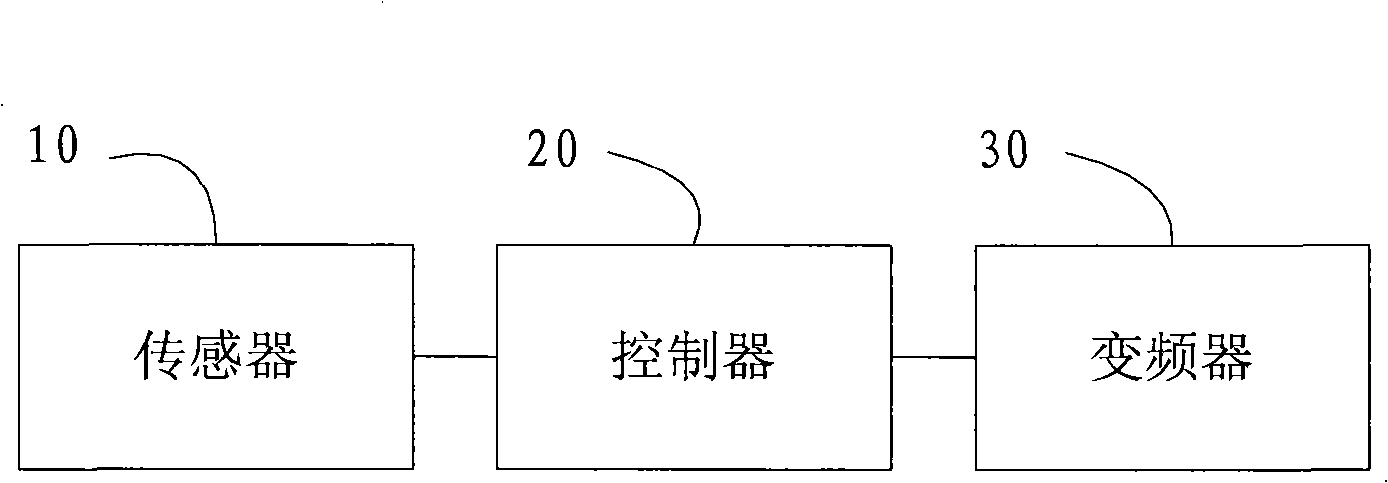

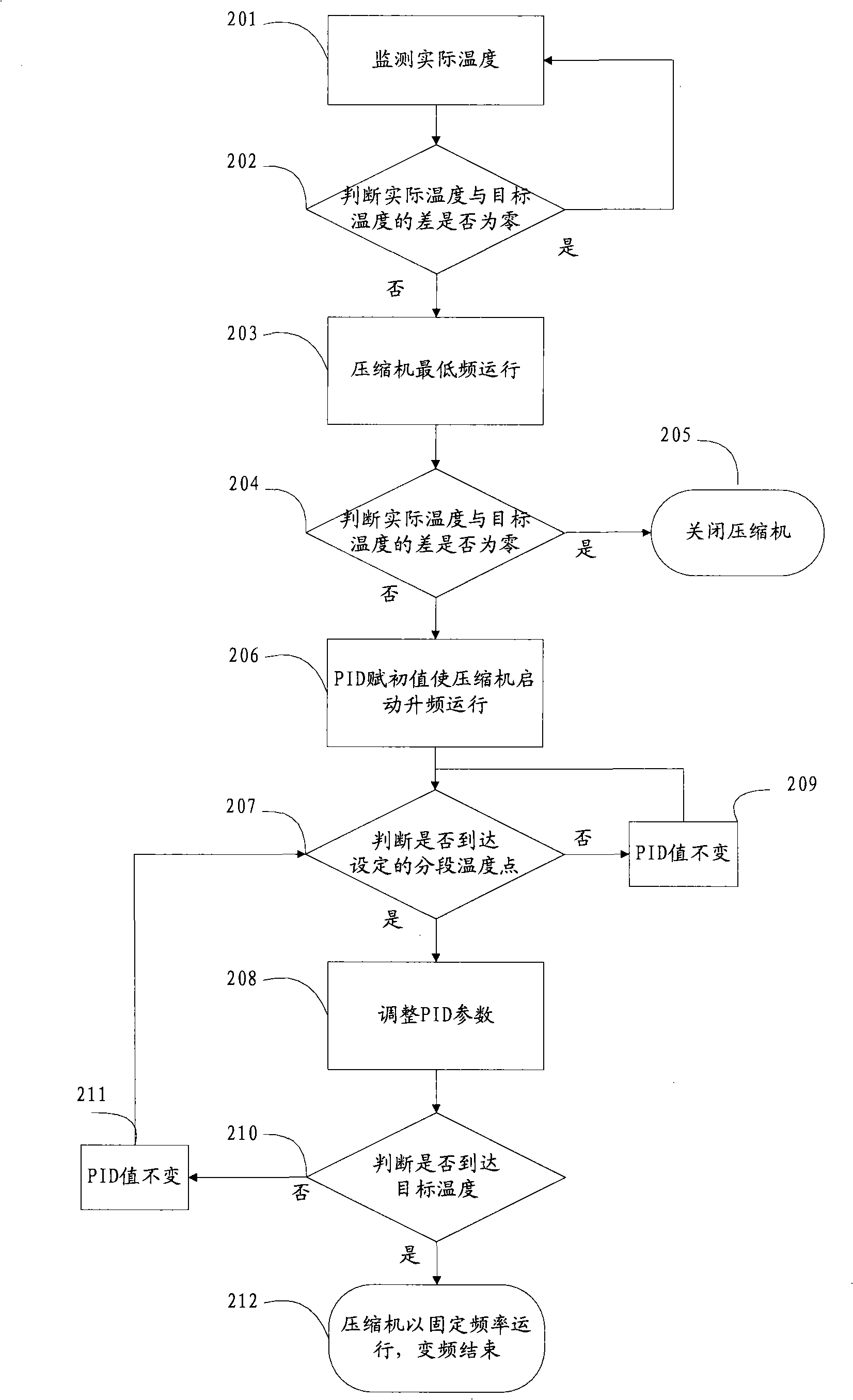

Method and device for controlling inverter compressor

InactiveCN101539151AImprove cooling efficiencyAvoid overshootPump controlRefrigeration safety arrangementConstant frequencyEngineering

The invention discloses a method for controlling an inverter compressor. According to the method, a target temperature and a dividing temperature point are preset, and a sensor monitors an actual temperature value. The method comprises the following steps that: a controller judges whether the difference between an actual temperature and the target temperature is zero, and the compressor operates at a minimum frequency for a certain period if the difference between an actual temperature and the target temperature is zero; the controller judges whether the target temperature is reached, and thecompressor stops operation if the target temperature is reached, or the controller initializes a PID parameter to allow an inverter to make the compressor start to raise frequency quickly if the target temperature is not reached; the controller judges whether the preset dividing temperature point is reached, and the PID parameter is adjusted if the preset dividing temperature point is reached, orthe PID parameter is kept constant if the reset dividing temperature point is not reached; and the controller judges whether the target temperature is reached, and the compressor operates at a constant frequency and the frequency inversion is finished if the target temperature is reached, or the compressor raises frequency while keeping the original PID parameter if the target temperature is not reached. Correspondingly, the invention also provides a device for controlling the inverter compressor. The method and the device can realize a quick, energy-saving and stable frequency inversion process at the same time.

Owner:HAIER GRP CORP +1

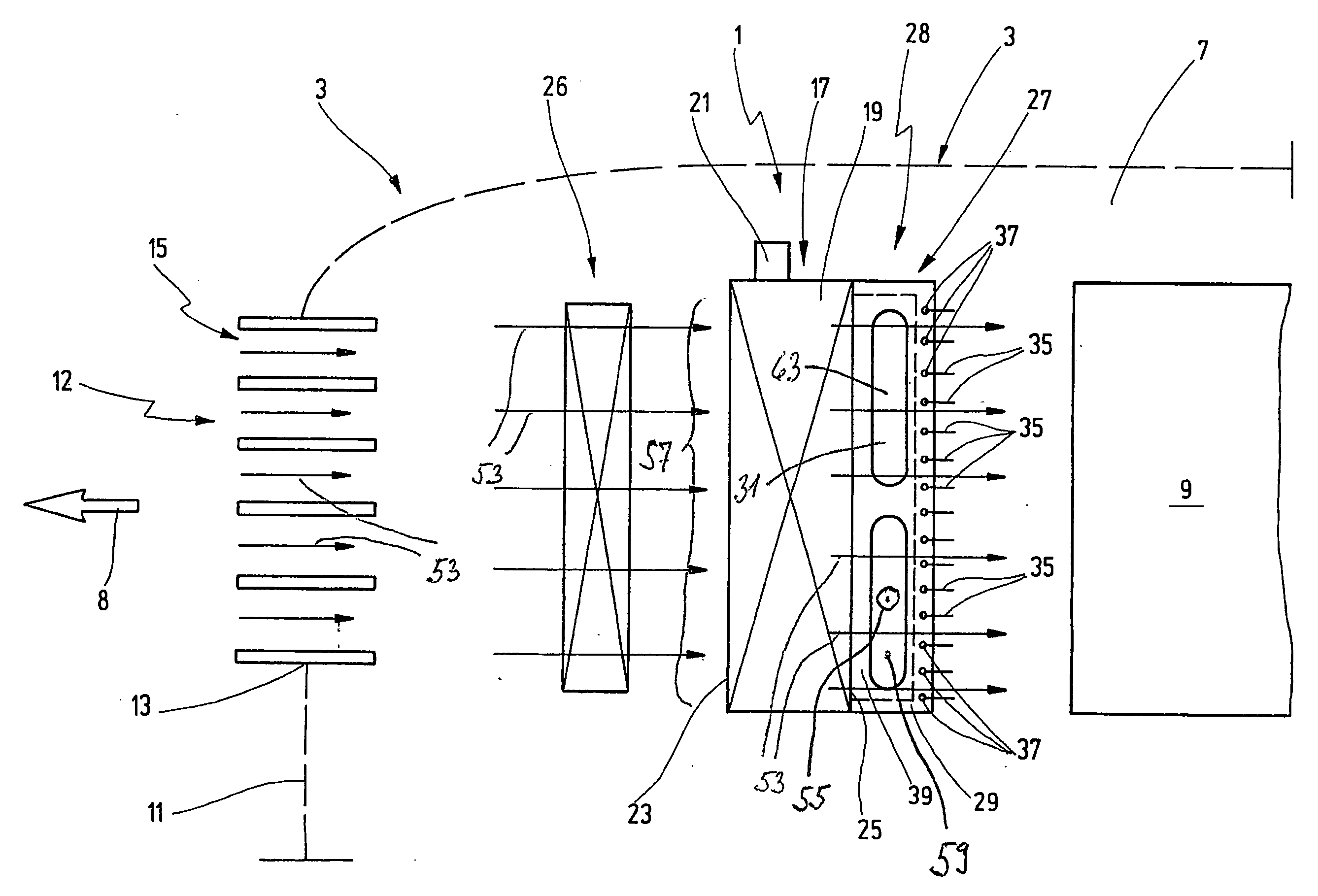

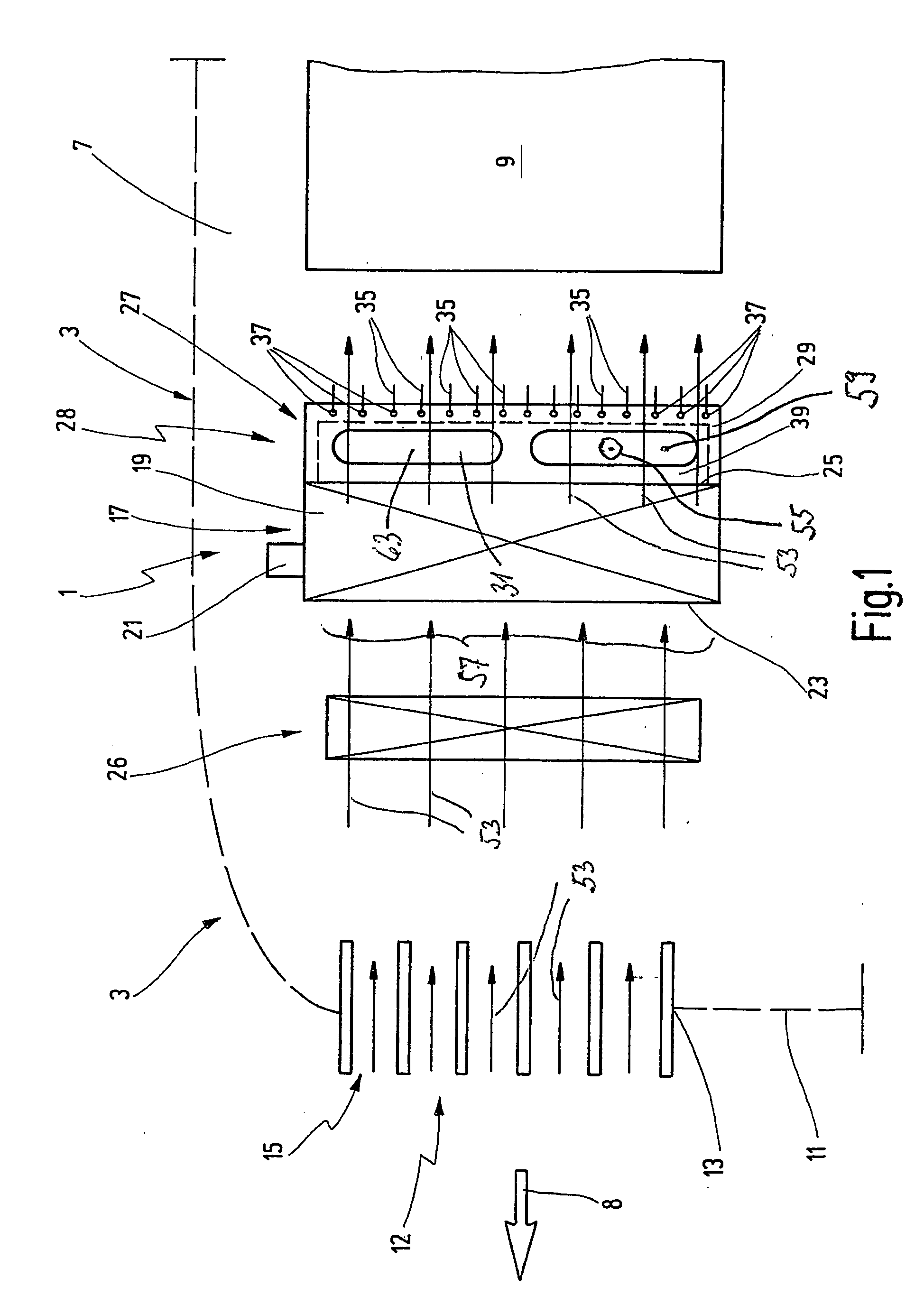

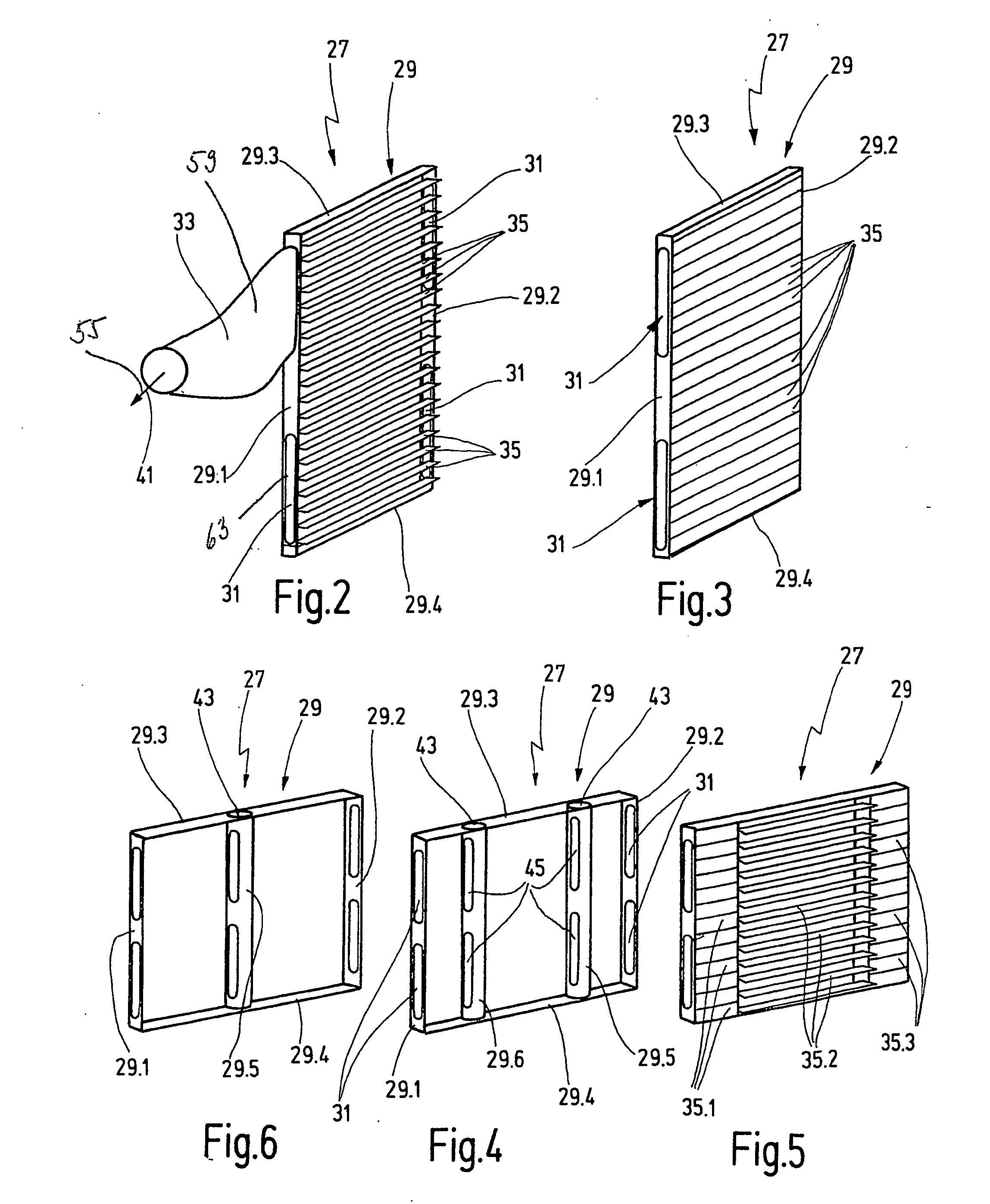

Cooling system for motor vehicles and method for controlling at least one air mass flow through a radiator

InactiveUS20060211364A1Easy to controlHeating up fastDucting arrangementsCoolant flow controlMobile vehicleEngineering

Cooling system for motor vehicles with at least one radiator to which in a first operating phase, particularly in the ram pressure phase, a first air stream can be supplied via a first air flow path and which in an alternative or simultaneous second operating phase, particularly during fan operation, can be supplied by means of at least one air-conveying device, with a second air stream flowing along a second air flow path. Among other things, it is also provided that at least in some regions the two air flow paths are oriented at an angle to each other so that the air-conveying device is disposed outside or essentially outside the first air flow path. The invention also related to a corresponding method.

Owner:ILLINOIS TOOL WORKS INC +1

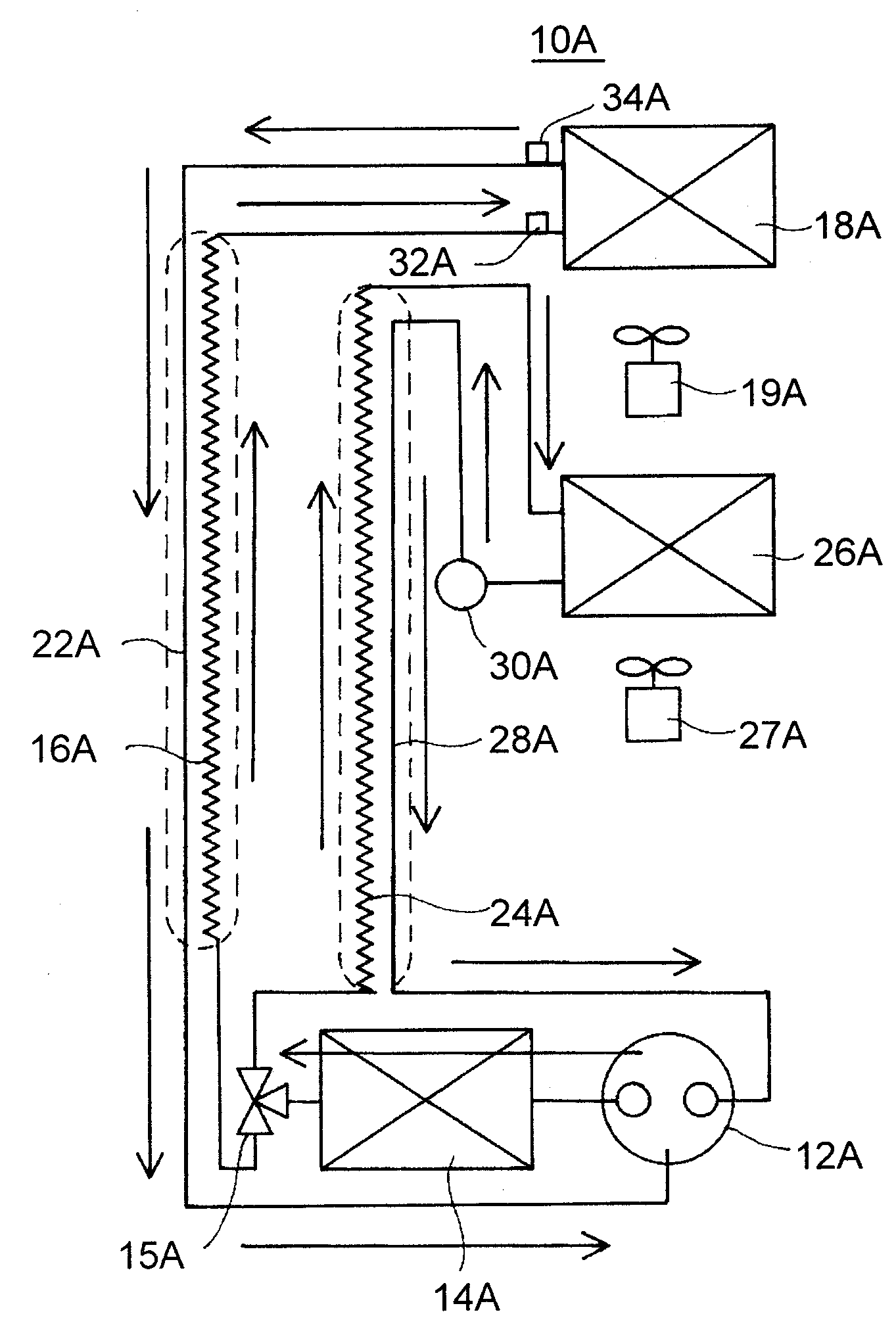

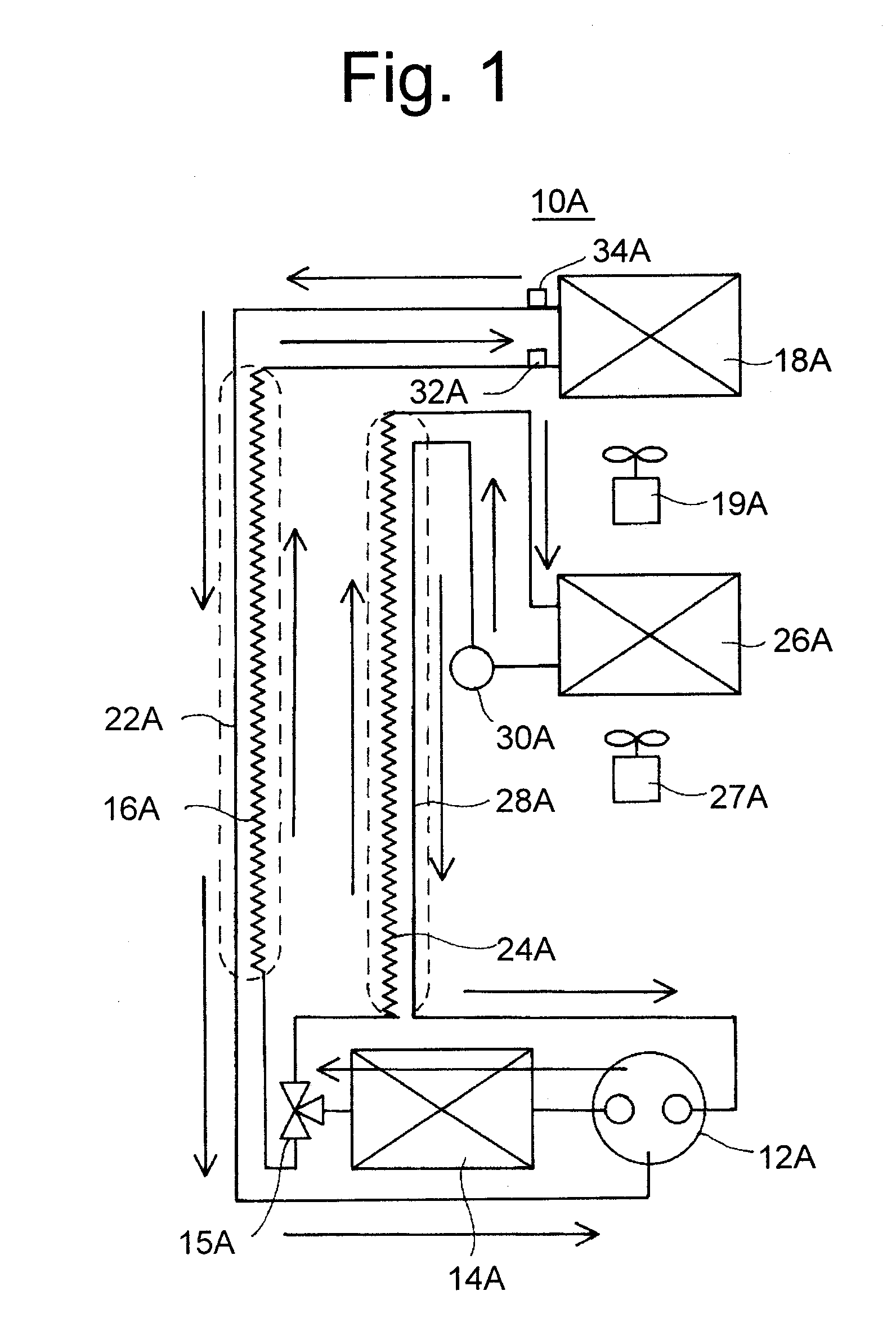

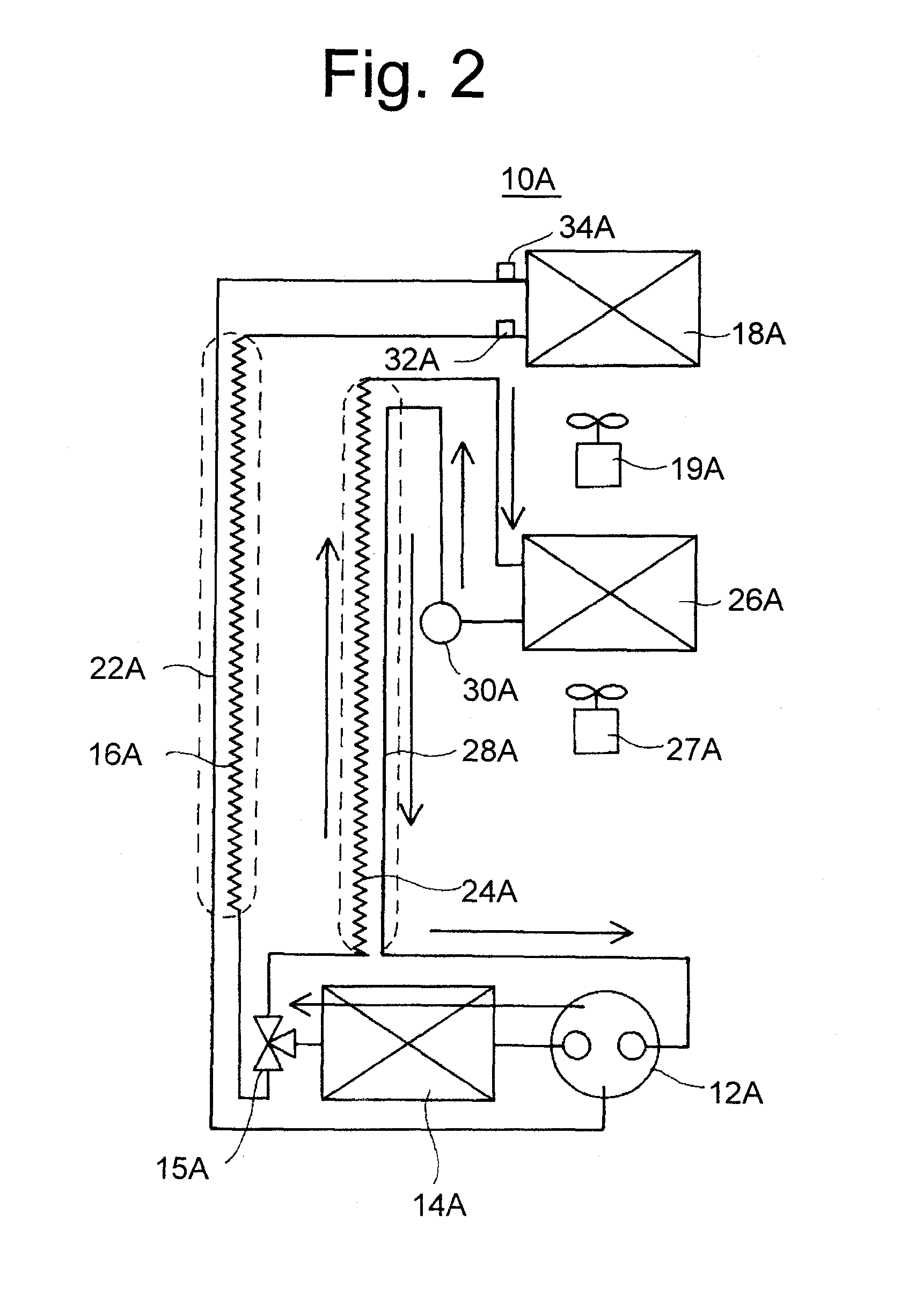

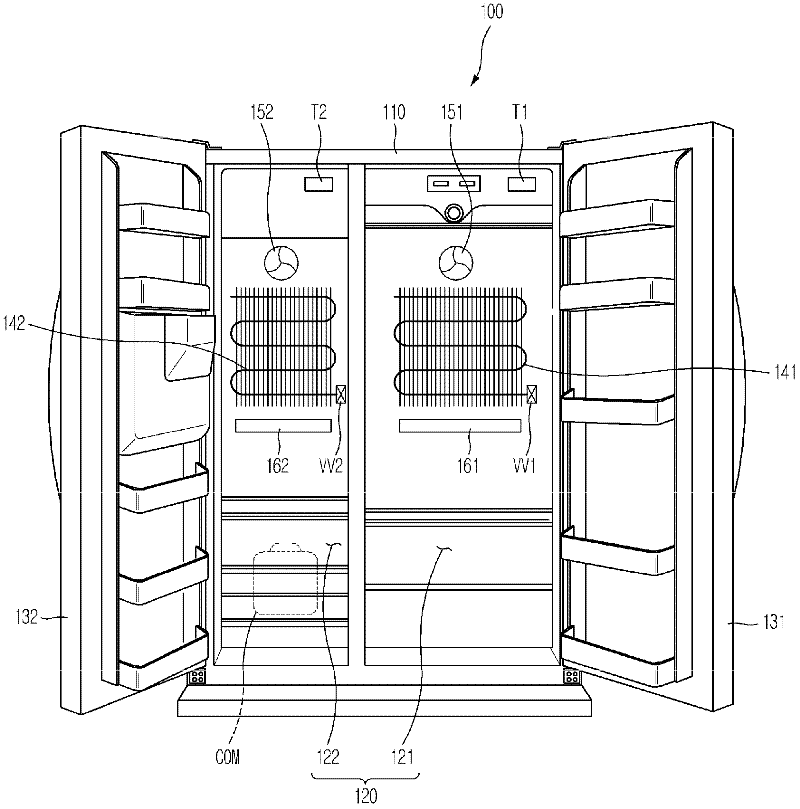

Refrigerator

InactiveUS20080190125A1Easy to controlReduce cooling efficiencyCompression machines with non-reversible cycleDomestic refrigeratorsEngineeringTemperature difference

A high-pressure side discharge port of a two-stage compressor (12A) and a condenser (14A) are connected, condenser (14A) and a PMV (15A) are connected, a refrigerating side exit of PMV (15A) is connected to a medium pressure side suction port of two-stage compressor (12A) via an R capillary tube (16A) and an F evaporator (18A), connected to an F evaporator (26A) via an F capillary tube (24A), F evaporator (26A) is connected to a low-pressure side suction port of two-stage compressor (12A) via a low-pressure suction pipe (28A), PMV (15A) can switch a simultaneous cooling mode and a freezing mode, and in the simultaneous cooling mode, a refrigerant flow rate toward R evaporator (18A) is adjusted by PMV (15A), and thereby a temperature difference control is performed so as to make a difference between an entrance temperature and an exit temperature of R evaporator (18A) equal to a preset temperature difference (for example, 4° C.).A controller (22), on the basis of the detection condition of a temperature sensor (23) for a freezing chamber and a temperature sensor (24) for a refrigerating chamber, controls a freezing cycle device (10). Here, controller (22) controls an opening of a regulating valve (12) so as to make a superheat amount which is a difference between an exit temperature and an entrance temperature of a refrigerating evaporator (5) equal to a target superheat amount, and thereby adjusts a refrigerant flow rate to refrigerating evaporator (5) in a limited state.In this case, when a power is turned on, the entrance temperature and the exit temperature of refrigerating evaporator (5) are the same, so that controller (22), when the power is turned on, calibrates detected temperatures of an entrance temperature sensor (27) and an exit temperature sensor (26) so as to coincide with each other, and thereby can execute surely the subsequent limiting adjustment of regulating valve (12) on the basis of the superheat amount.Further, in this case, when a refrigerant supply to refrigerating evaporator (5) is stopped and the temperature of refrigerating evaporator (5) rises suddenly, controller 22 increases an opening of a valve opening (42) to refrigerating evaporator (5) of regulating valve (12) to a predetermined return value, so that the refrigerant supply amount to refrigerating evaporator (5) is increased at a stretch, and thus the refrigerating evaporator can be cooled quickly.A refrigerator having a two-stage compressor (12A) for cooling efficiently both a refrigerating chamber (2A) and a freezing chamber (5A) will be provided.When limiting and adjusting a refrigerant flow rate to one evaporator according to an opening of a valve body so as to make a superheat amount of one evaporator appropriate on the basis of the superheat amount which is a difference between an exit temperature and an entrance temperature of one evaporator, a refrigerator for detecting accurately the entrance temperature and the exit temperature of one evaporator will be provided.When limiting and adjusting a refrigerant flow rate to one evaporator according to an opening of a valve body, a refrigerator for causing no delay in a refrigerant supply to one evaporator will be provided.

Owner:TOSHIBA HA PROD +2

Hydronic rooftop cooling systems

InactiveUS7322205B2Improve efficiencyEasy to controlEnergy recovery in ventilation and heatingHeat recovery systemsAir filterRefrigerant

Owner:DAVIS ENERGY GROUP

Cooling device

InactiveUS20060107671A1Reduce cooling efficiencyDecrease of defrosting efficiencyMechanical apparatusEvaporators/condensersEvaporationEngineering

In a cooling system having a compressor for supplying refrigerant under pressure, a condenser for condensing the refrigerant supplied from the compressor, a liquid receiver arranged to temporarily store the condensed refrigerant supplied from the condenser, an expansion valve for expanding the refrigerant supplied from the liquid receiver, and an evaporator arranged to effect evaporation of the expanded refrigerant for cooling the surrounding thereof, a bypass conduit is arranged to bypass the liquid receiver and expansion valve, and an electrically operated flow passage changeover valve is provided to selectively connect a supply passage of refrigerant to the liquid receiver and expansion valve and to the bypass conduit so that the supply passage of refrigerant is connected to the liquid receiver and expansion valve during operation at a cooling mode and is connected to the bypass conduit during operation at a defrost mode.

Owner:HOSHIZAKI ELECTRIC CO LTD

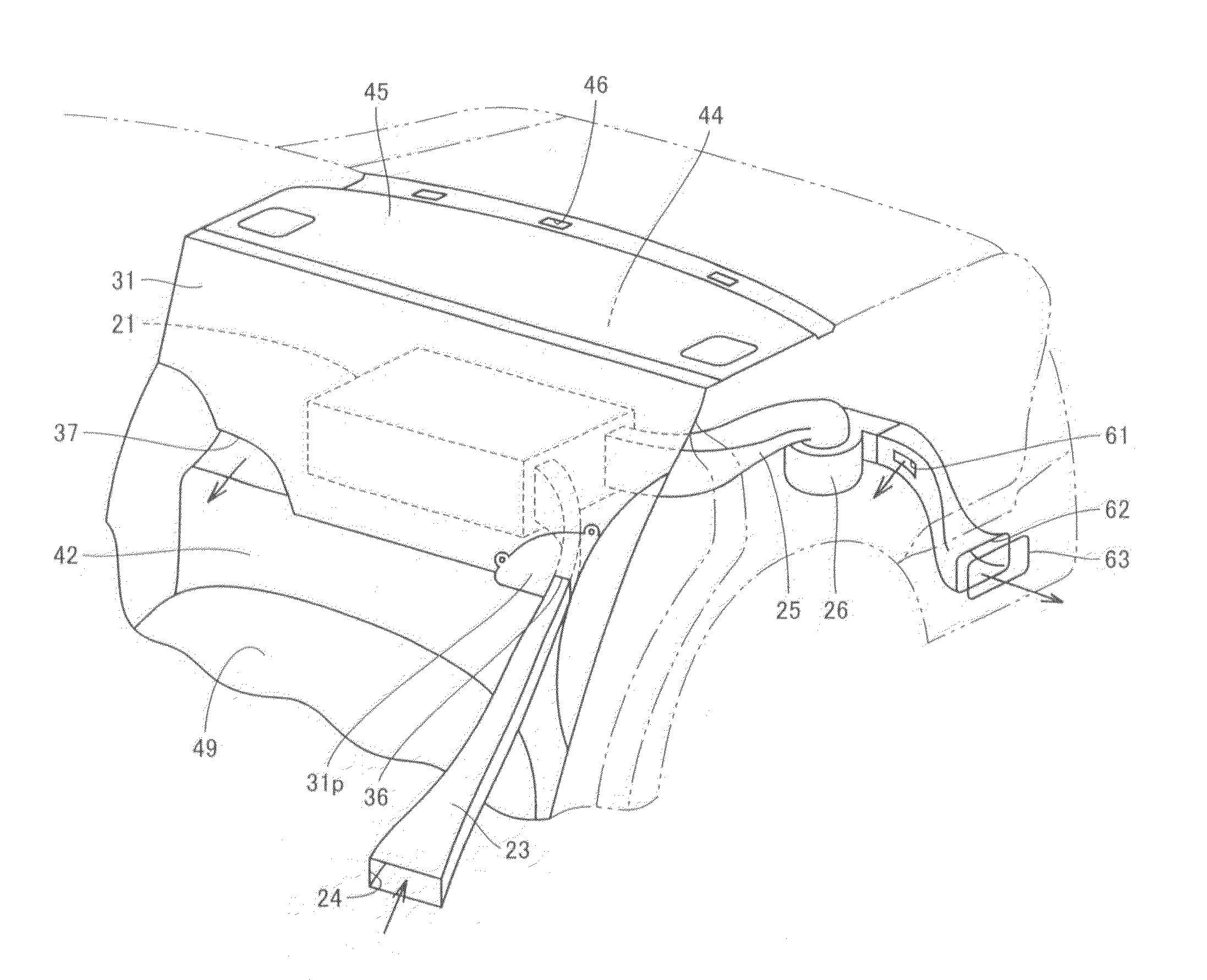

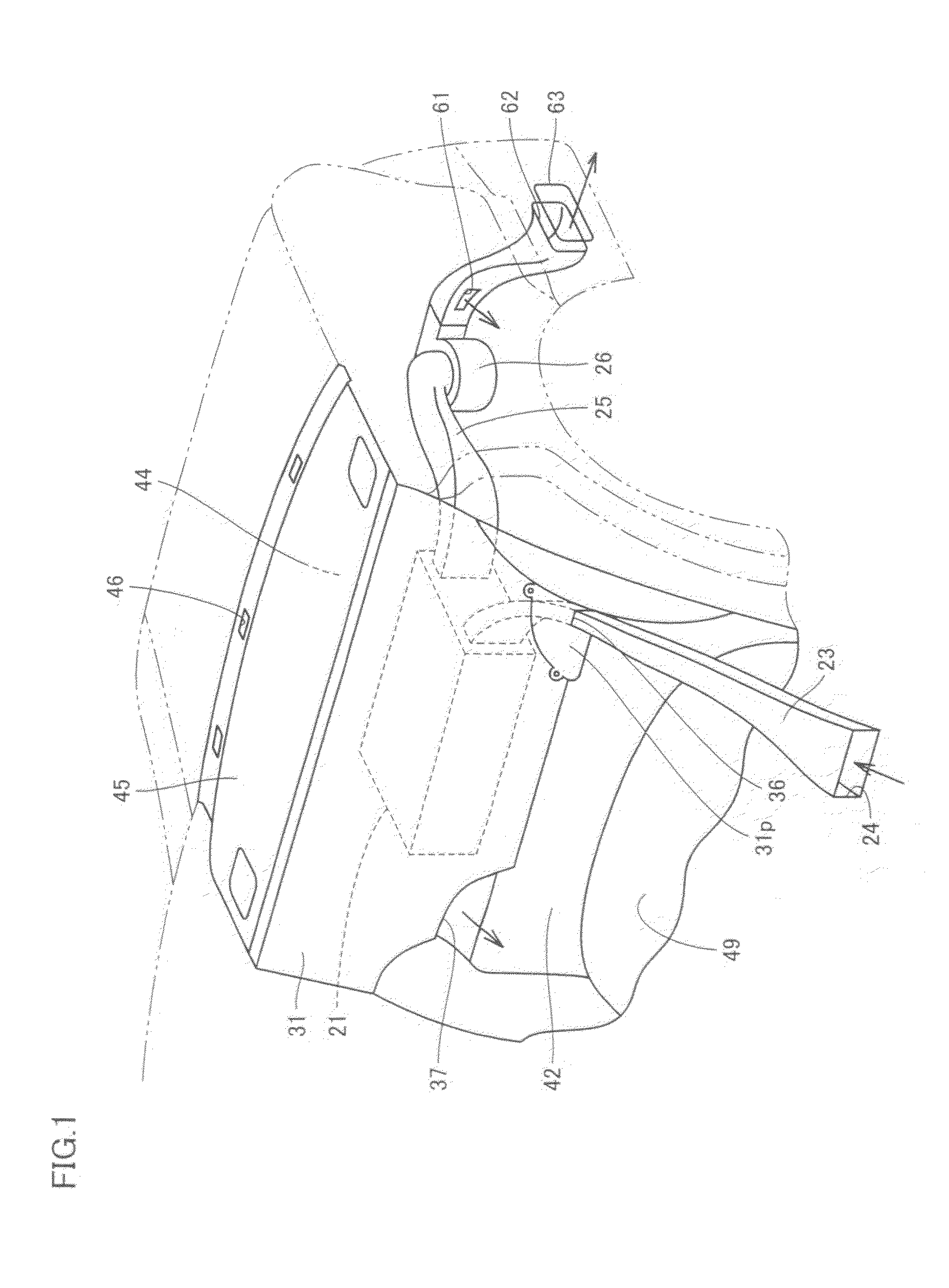

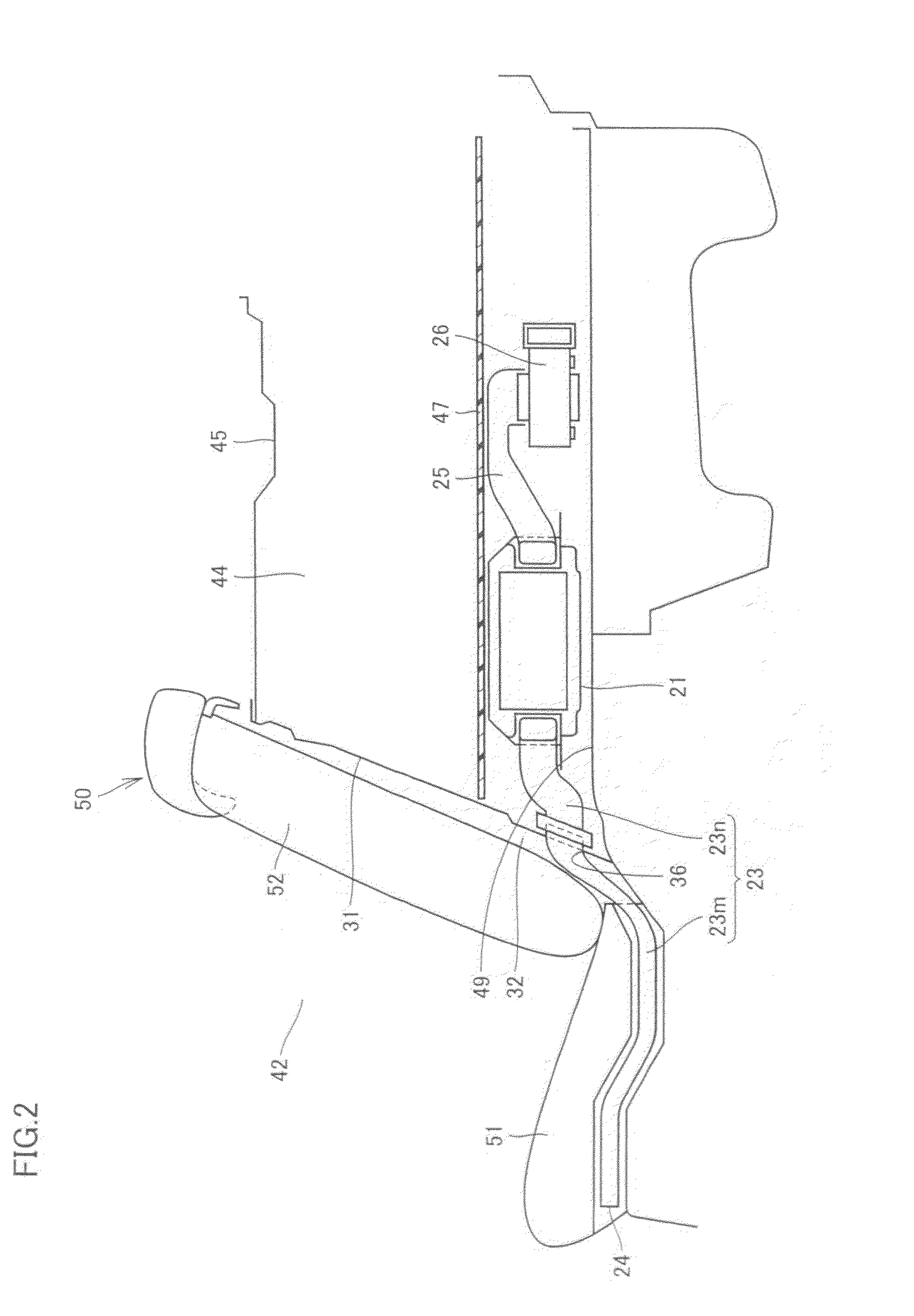

Battery cooling structure

InactiveUS20100099019A1Reduce cooling efficiencyImprove workabilityCell temperature controlElectric propulsion mountingEngineeringAdverse effect

A battery cooling structure includes: a battery provided in a luggage room of a vehicle; an air intake duct, including an air inlet open in a vehicular cabin, for supplying air in the vehicular cabin to the battery as cooling air; and a partition panel standing away from a rear seat with a clearance therebetween so as to section the luggage room and the vehicular cabin and provided with a duct hole in which the air intake duct is inserted. The partition panel is provided with an air exhaust hole for exhausting air in the luggage room to the vehicular cabin. The air exhaust hole is formed at a location spaced away from the duct hole. Such a configuration provides a battery cooling structure suppressing an adverse effect caused by exhaust of heated cooling air.

Owner:TOYOTA JIDOSHA KK

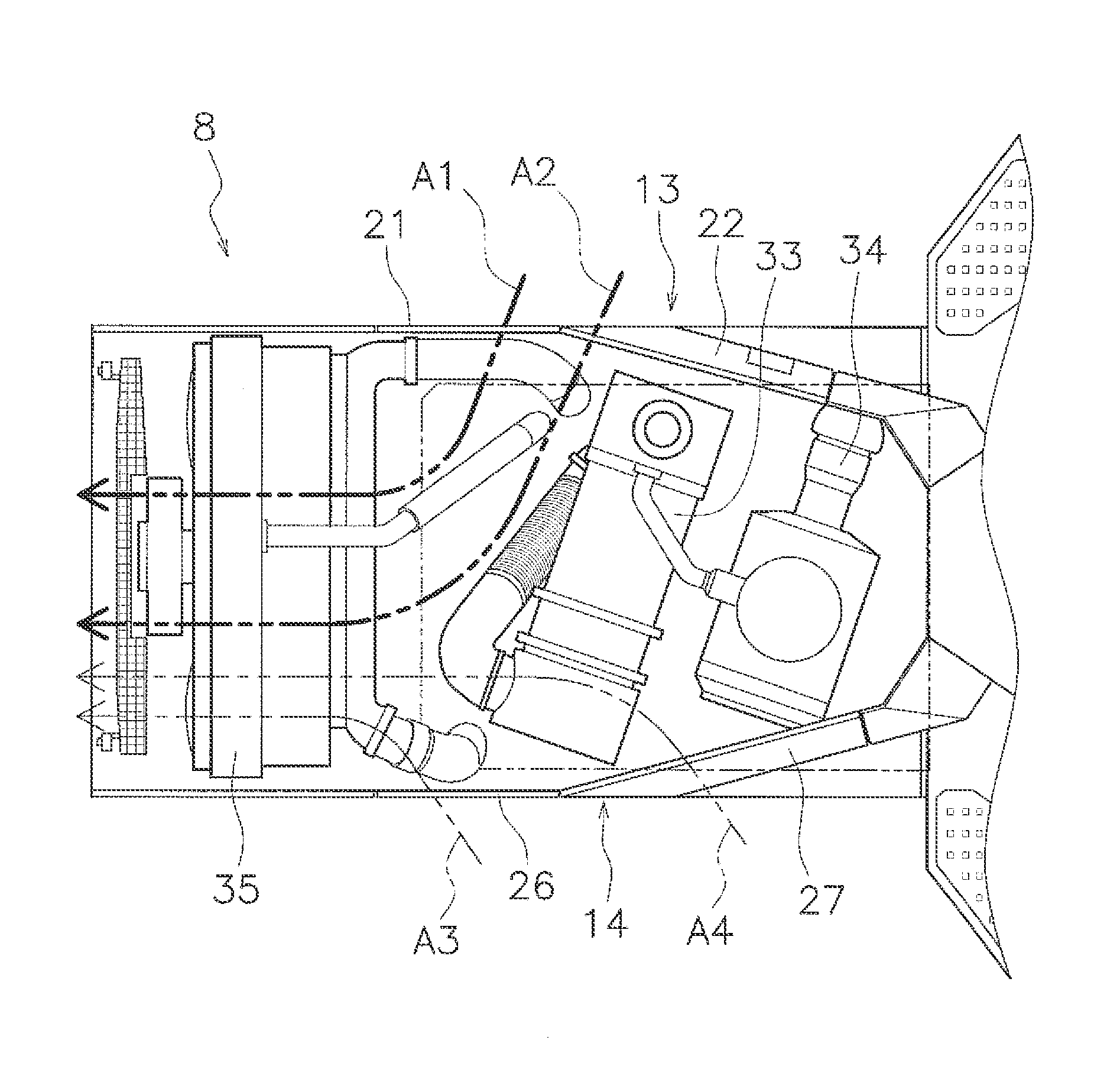

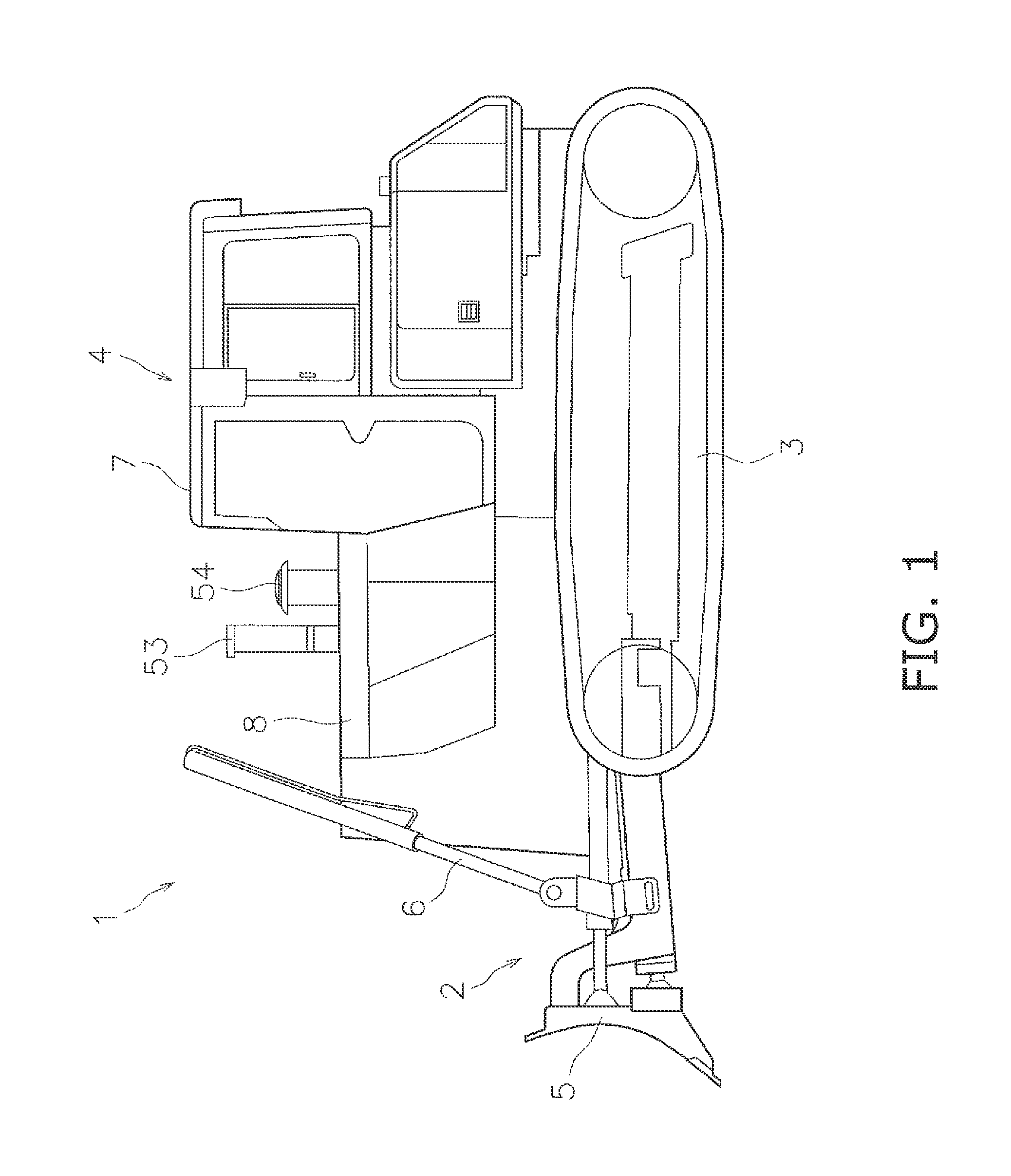

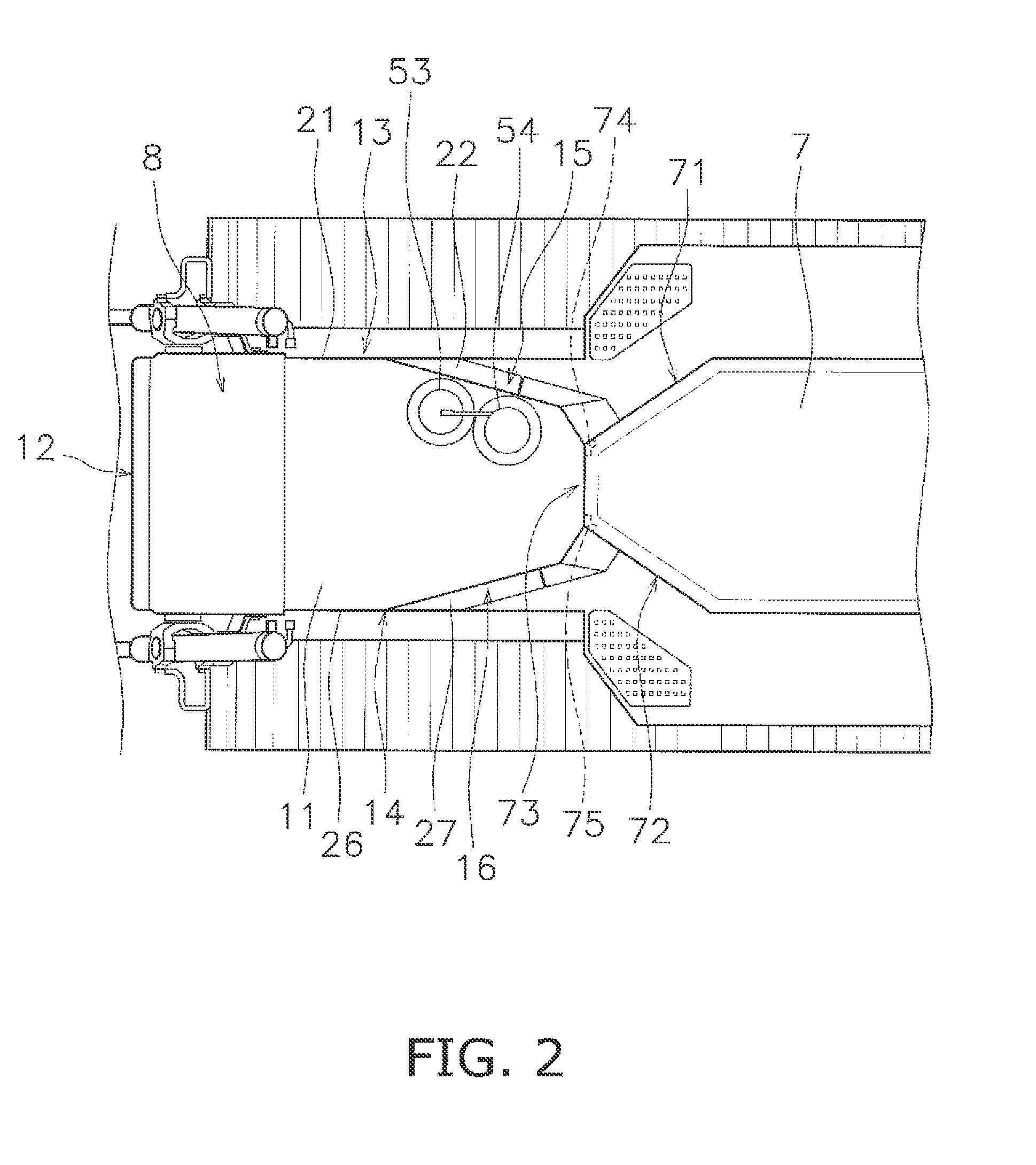

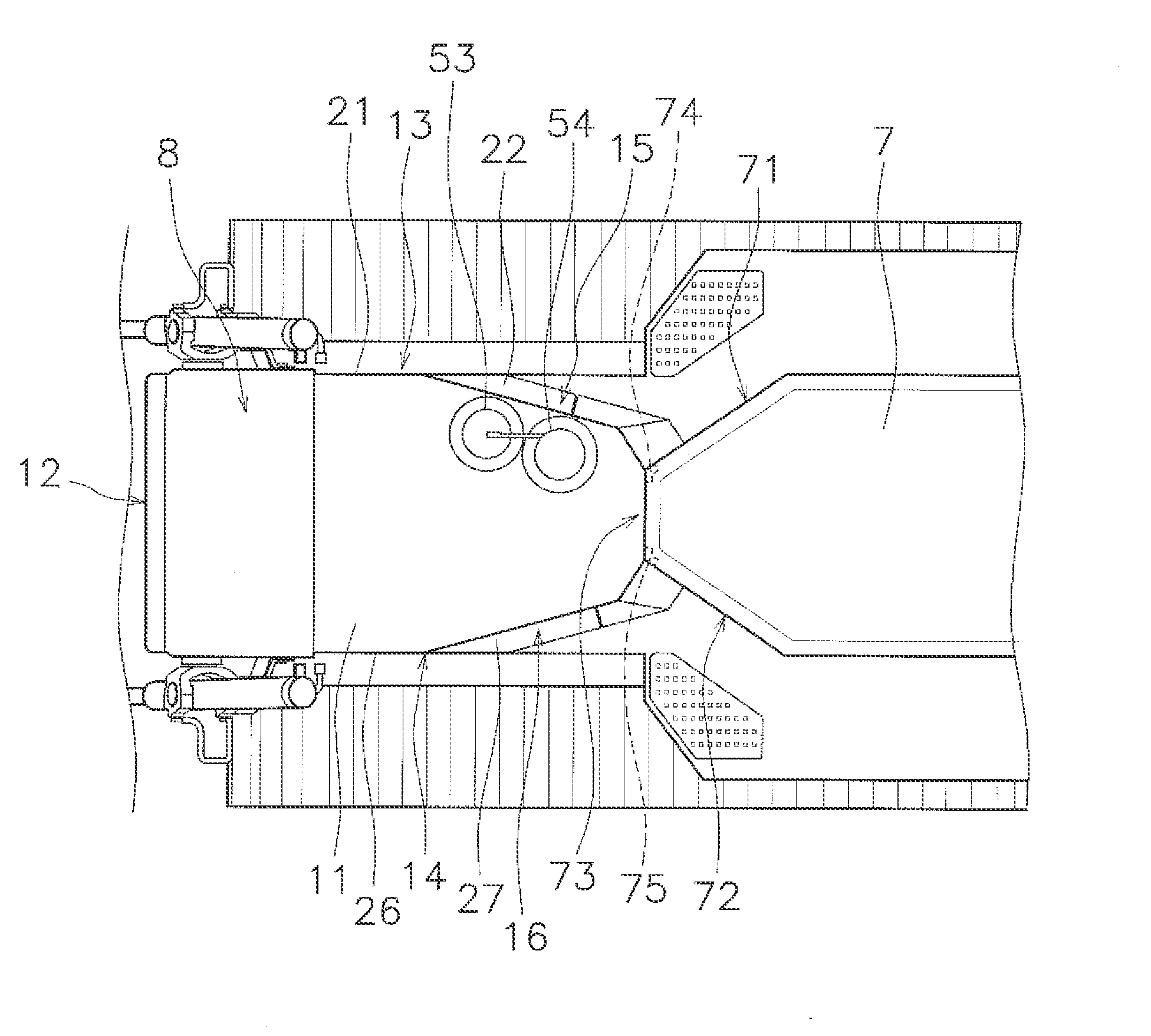

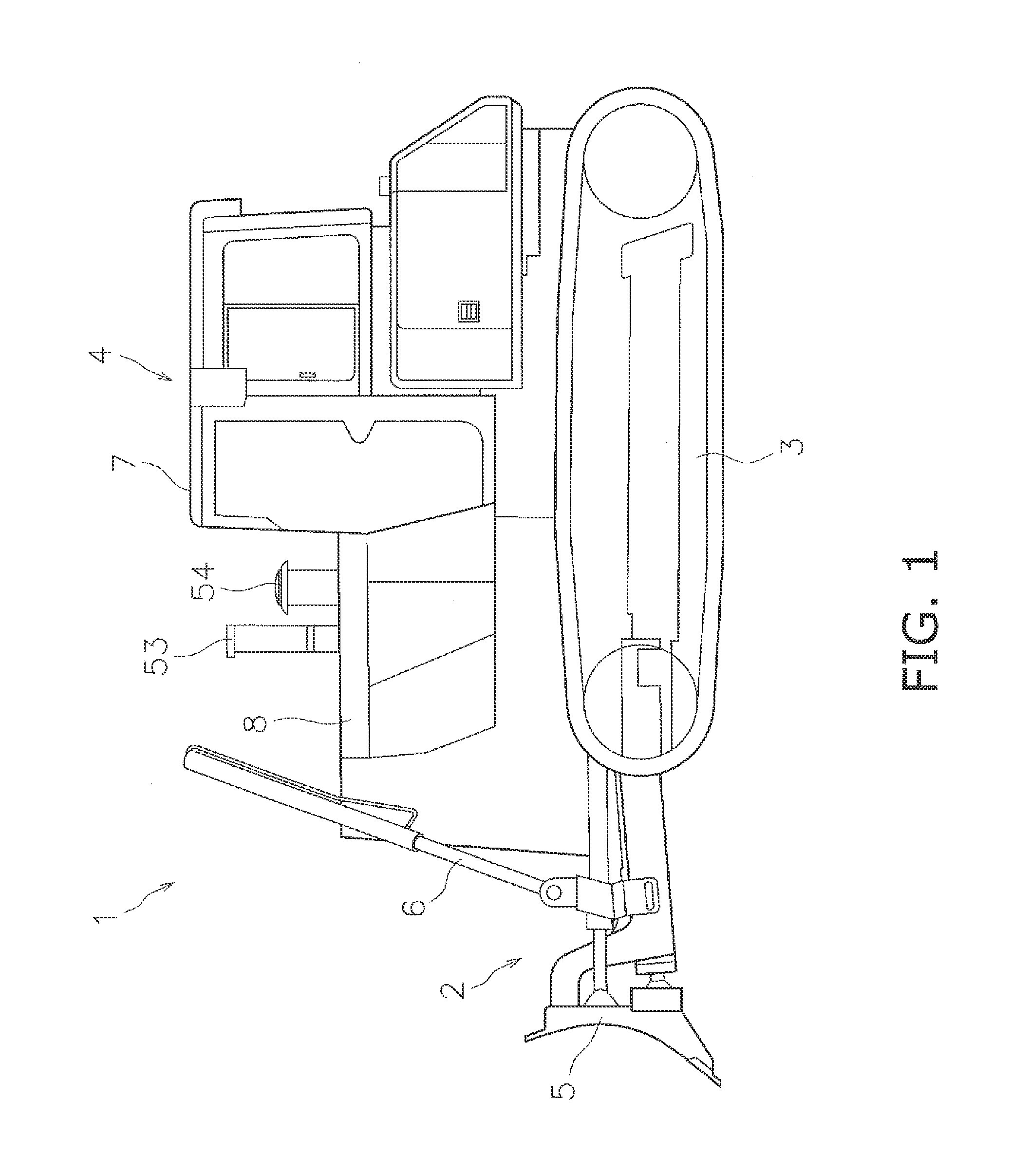

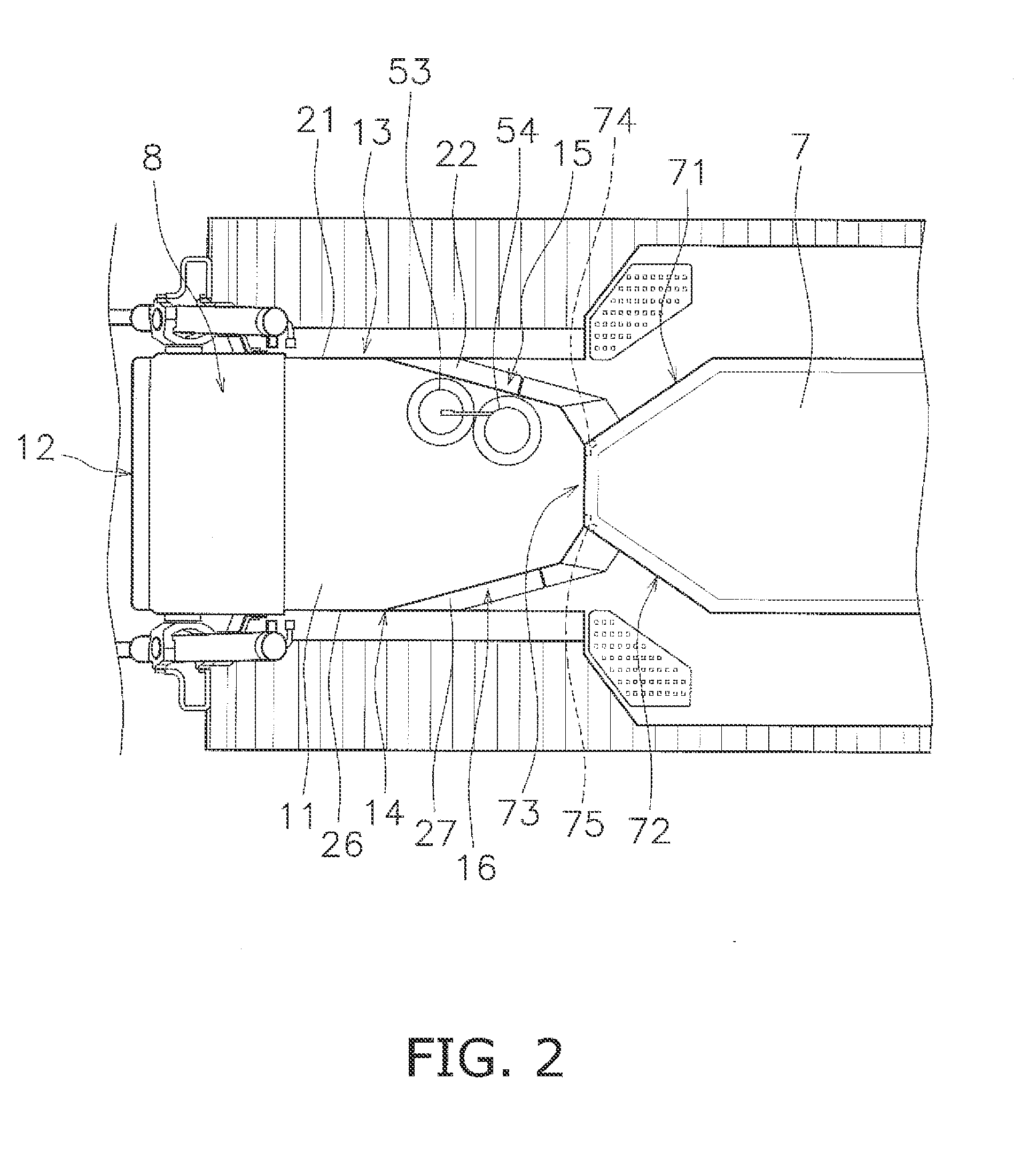

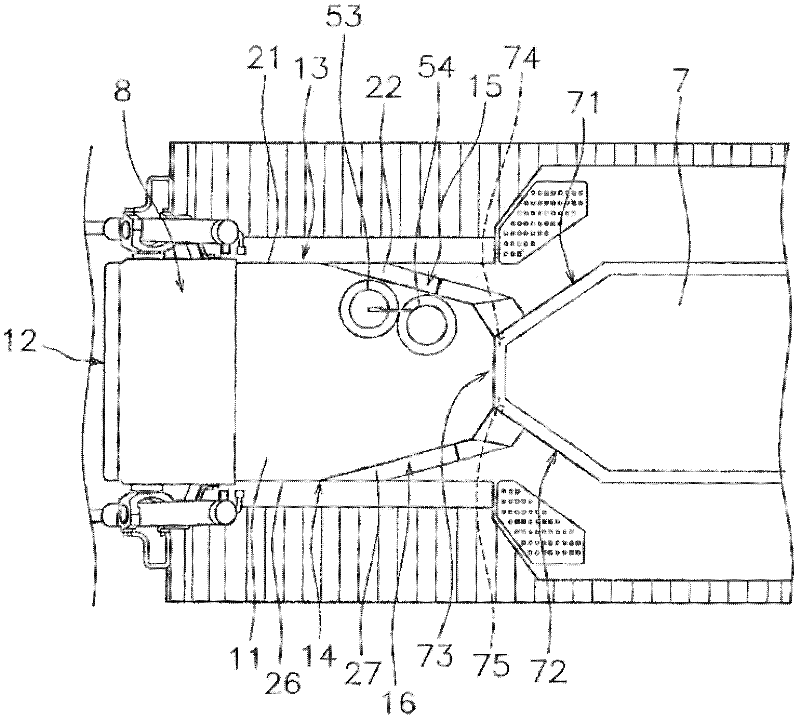

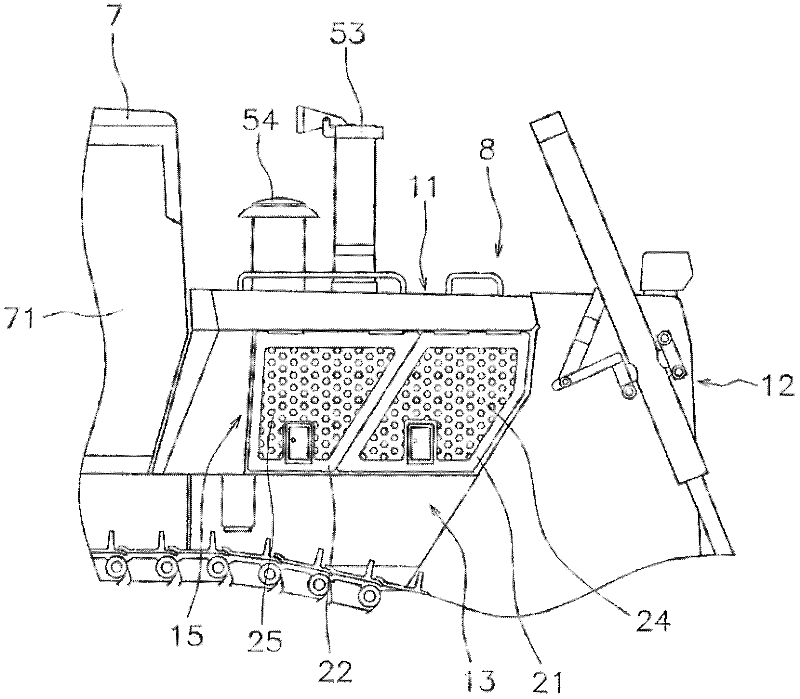

Work vehicle with engine compartment and exhaust gas treatment arrangement

ActiveUS8505661B2Reduce cooling efficiencySufficient reliabilityExhaust apparatusSilencing apparatusExhaust fumesAir blast

In a work vehicle, an engine compartment is disposed forwards of a cab. An exhaust gas treatment device is disposed over an engine in the engine compartment. A radiator is disposed forwards of the exhaust gas treatment device (33) in the engine compartment. A blower is configured to generate an airflow passing through the radiator from back to front of the radiator. The exhaust gas treatment device is slanted with respect to a vehicle width direction for increasing a distance between the exhaust gas treatment device and the radiator towards a first lateral face portion. Further, the first lateral face portion includes air inlets facing a space between the exhaust gas treatment device and the radiator.

Owner:KOMATSU LTD

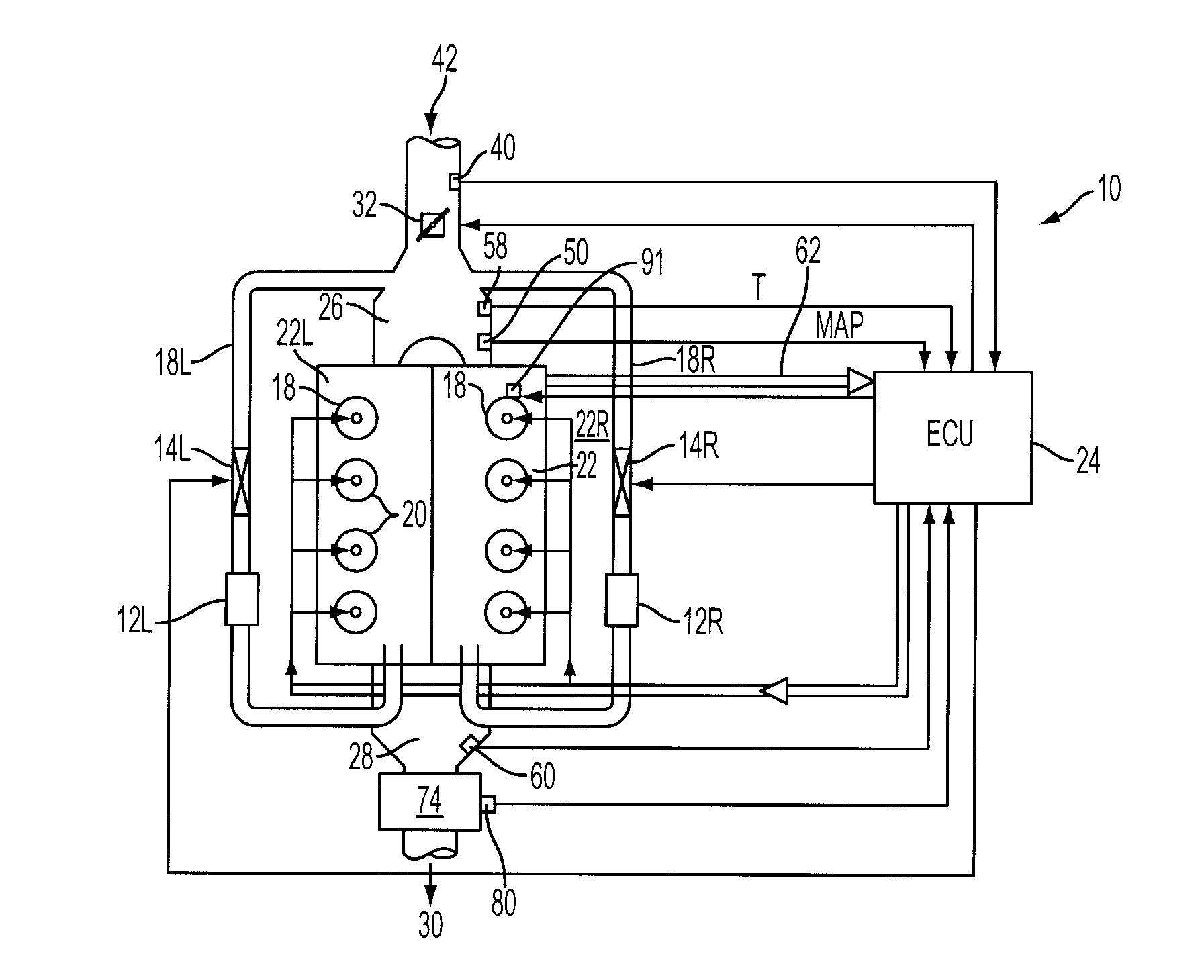

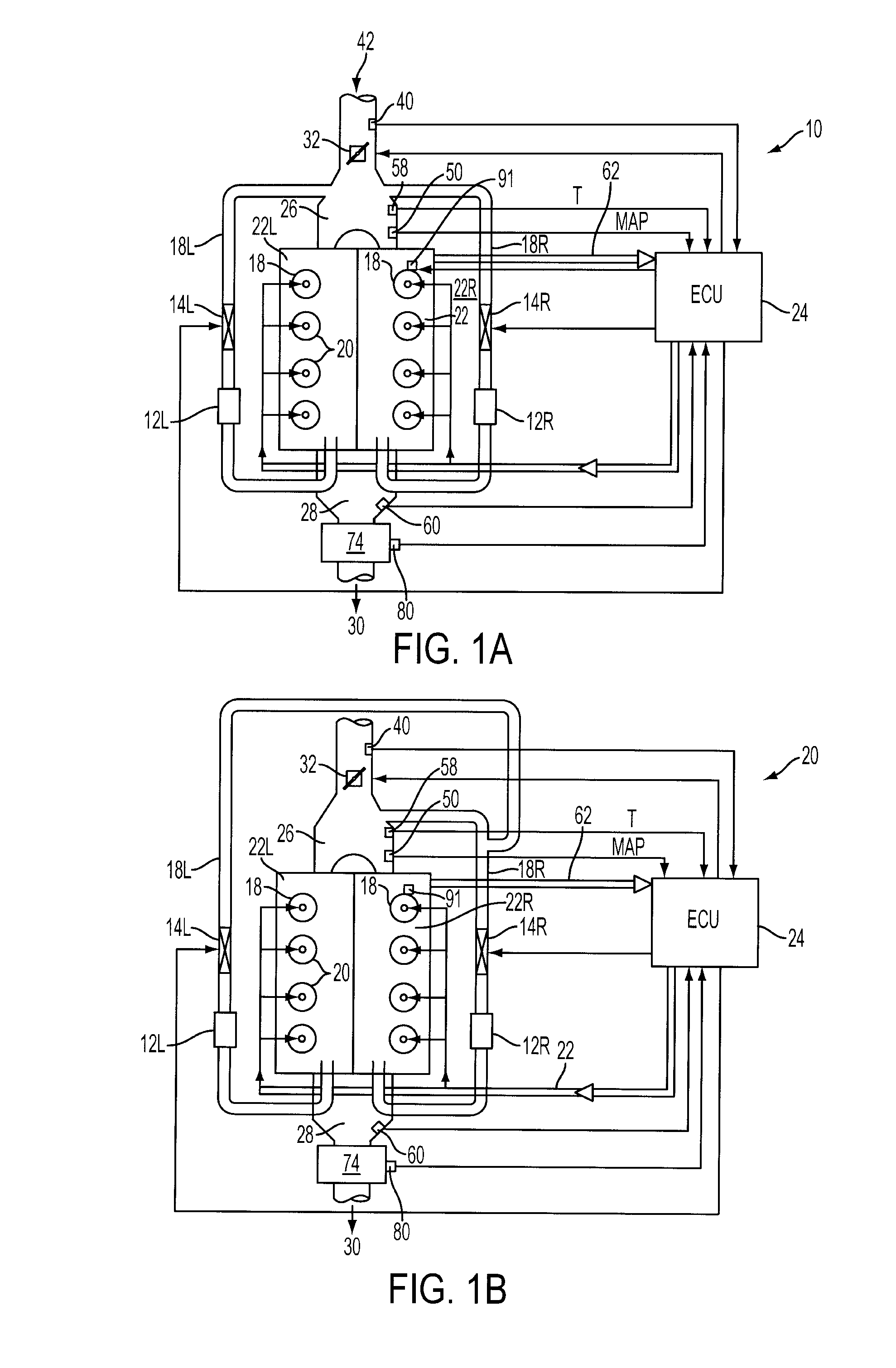

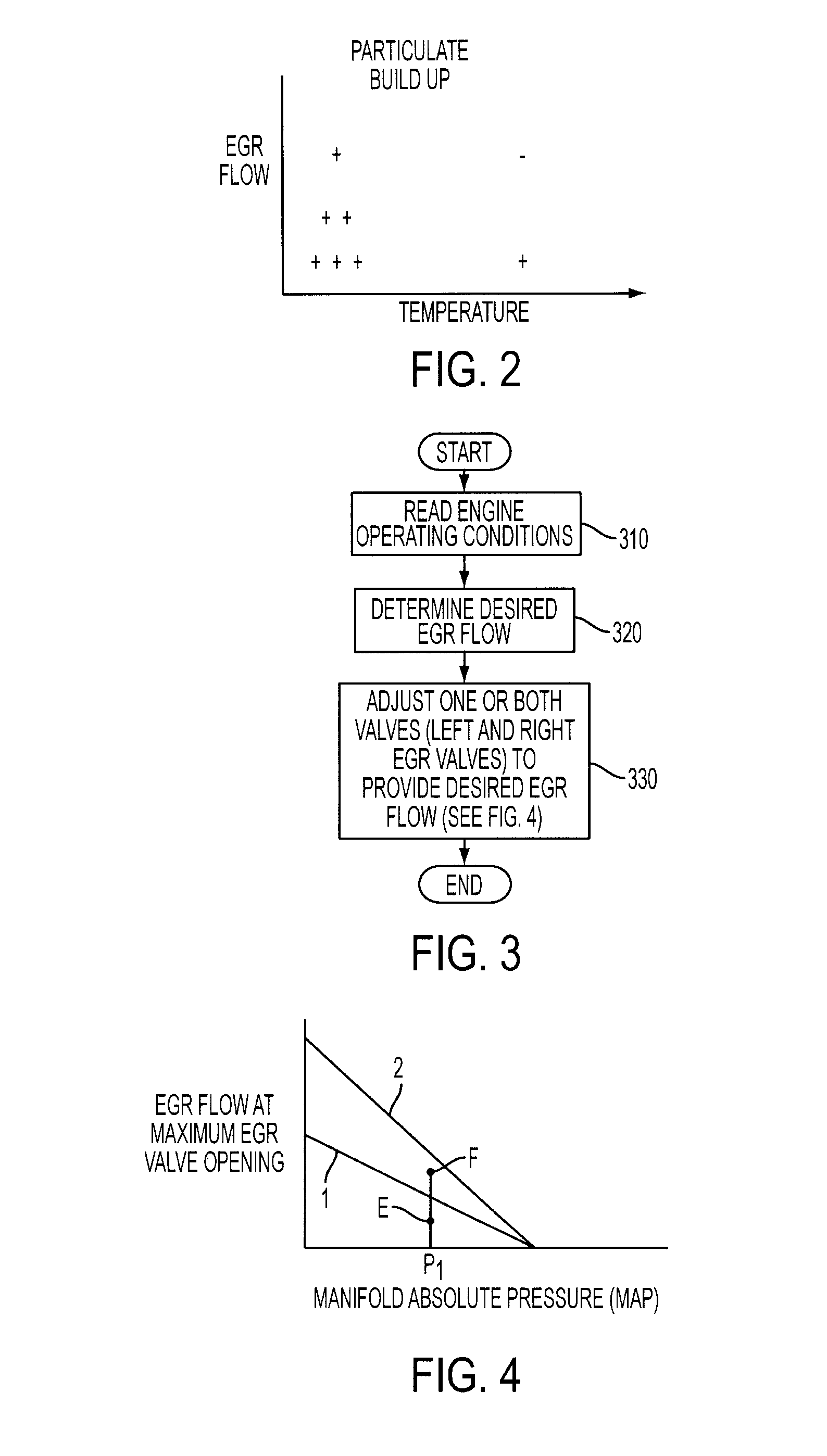

Alternative Left/Right Bank EGR Loop Operation to Improve Fouling Resistance During Low Mass Flow Engine Mode

InactiveUS20080060624A1Reduce formationReduce nitrogen oxide emissionsElectrical controlInternal combustion piston enginesControl systemDiesel engine

A system for a vehicle, comprising of a diesel engine having an intake system and an exhaust system, a first EGR loop coupled between said intake system and said exhaust system and having a first valve and a first cooler located therein, a second EGR loop coupled between said intake system and said exhaust system and having a second valve and a second cooler located therein, and a control system operating the first and second valves in a first condition where both valves provide EGR flow to the engine, and at least temporarily increasing flow in the first EGR loop and decreasing flow in the second EGR loop when EGR flow is decreased to a condition where buildup in one of said coolers is increased.

Owner:FORD GLOBAL TECH LLC

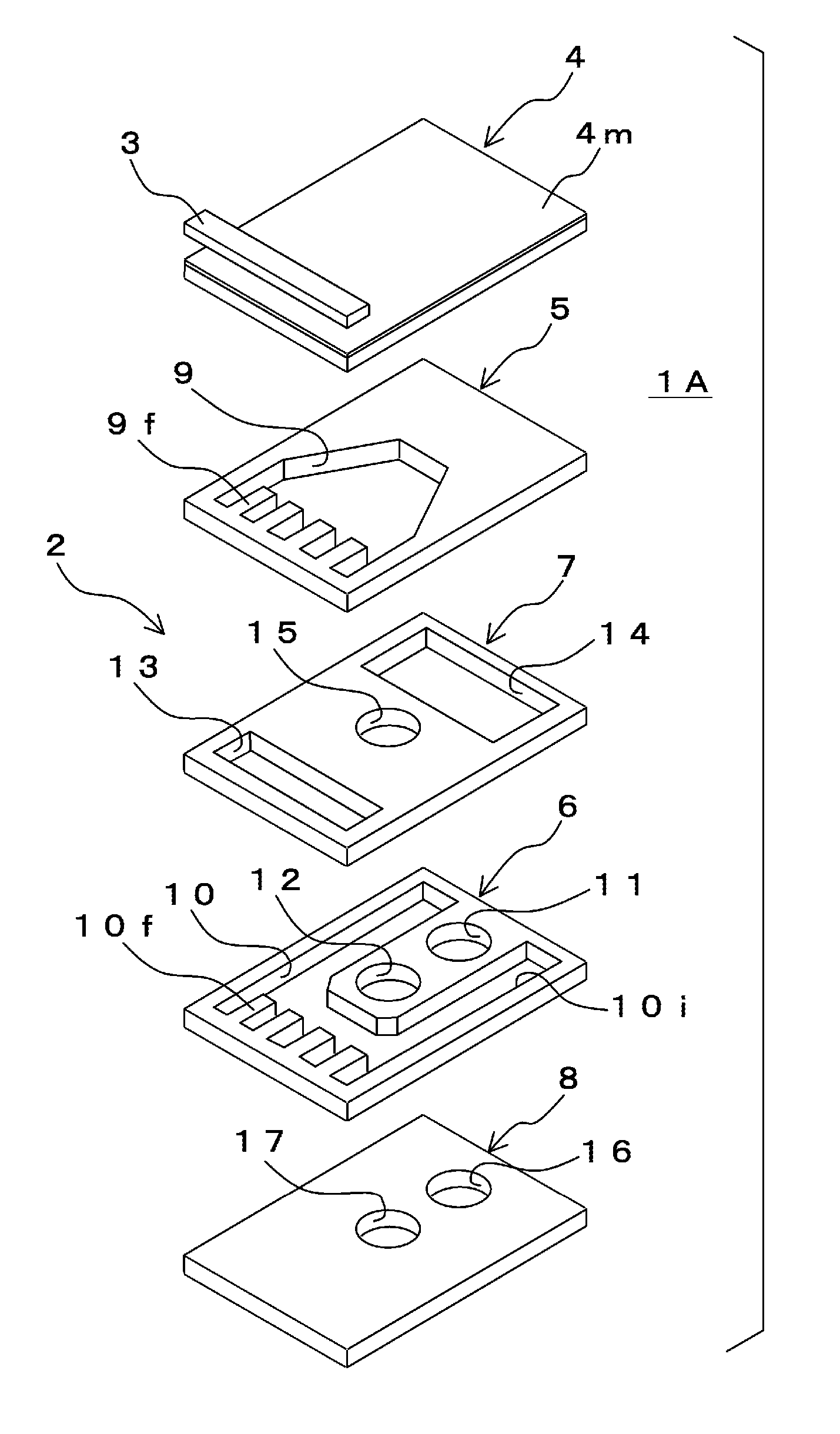

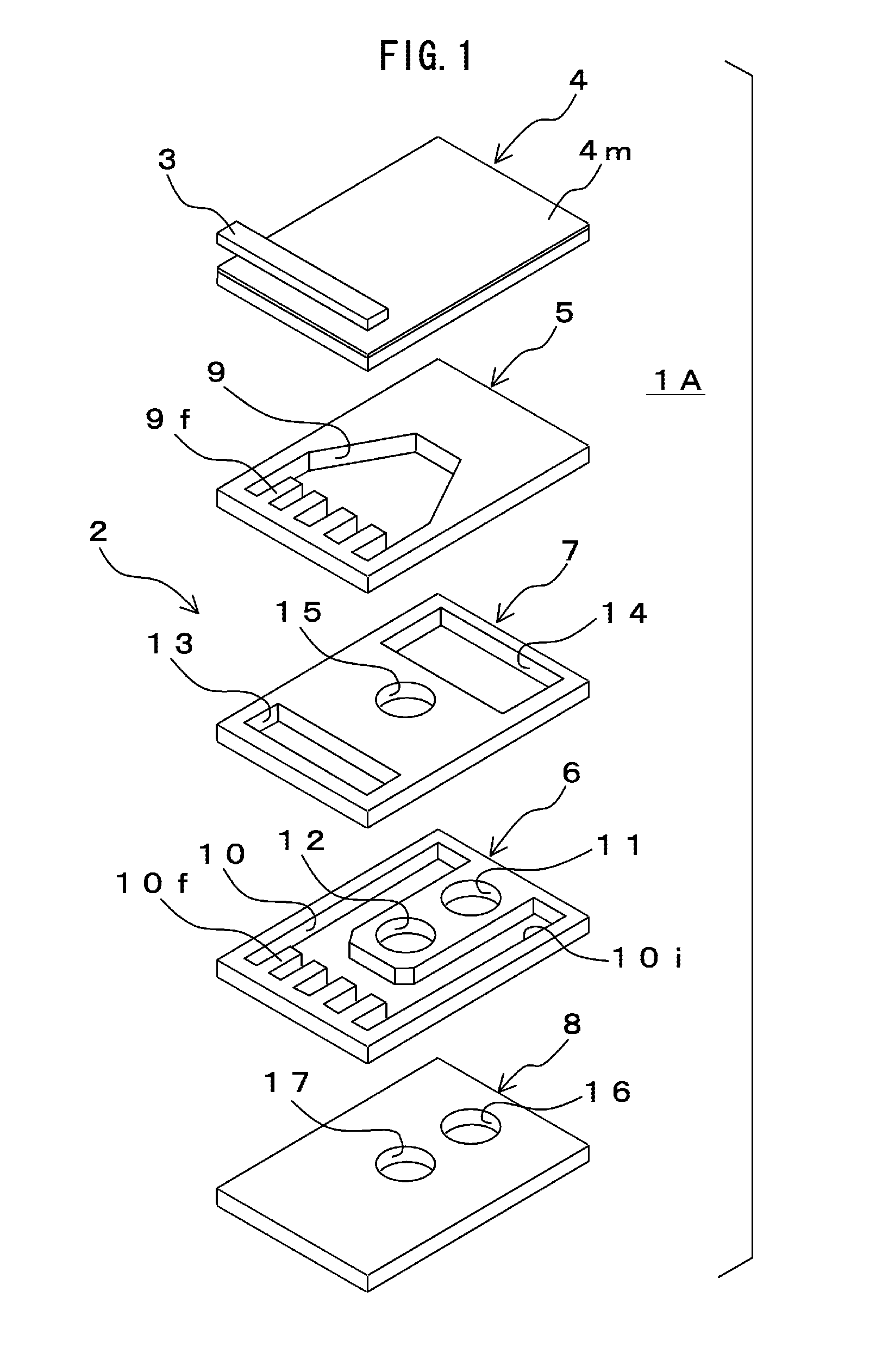

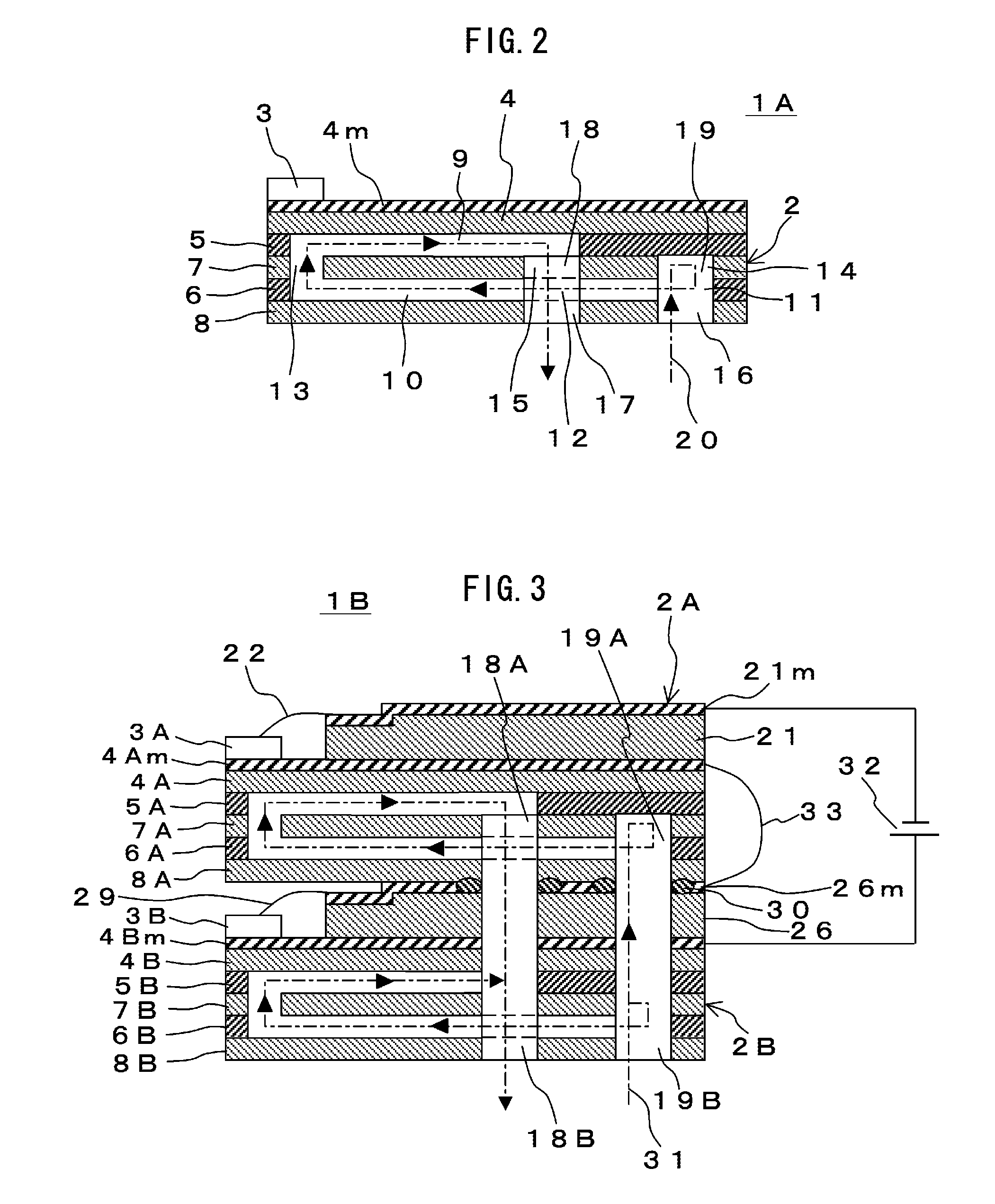

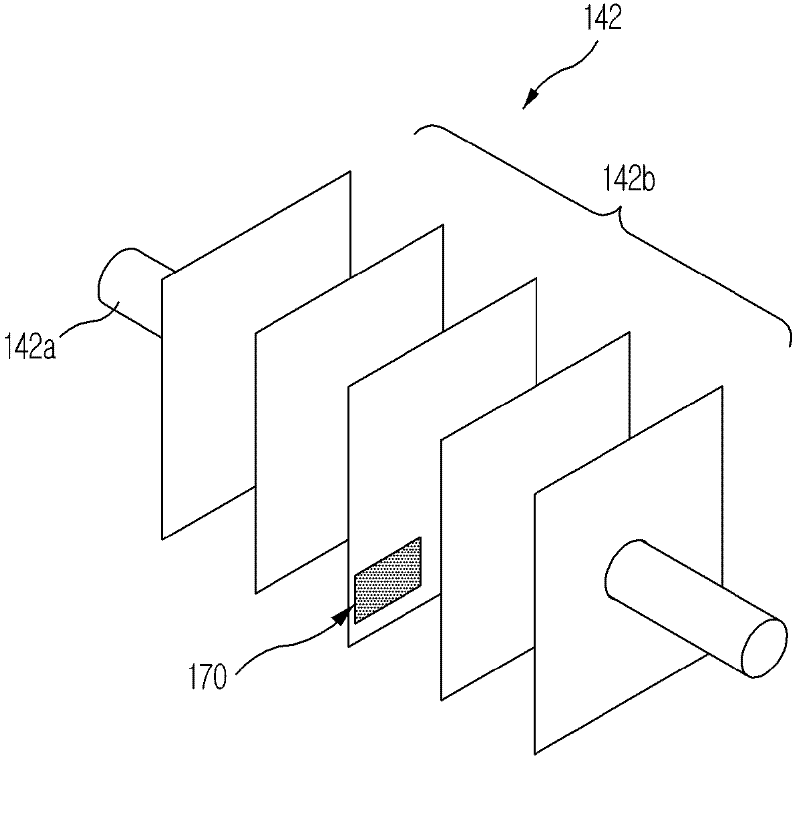

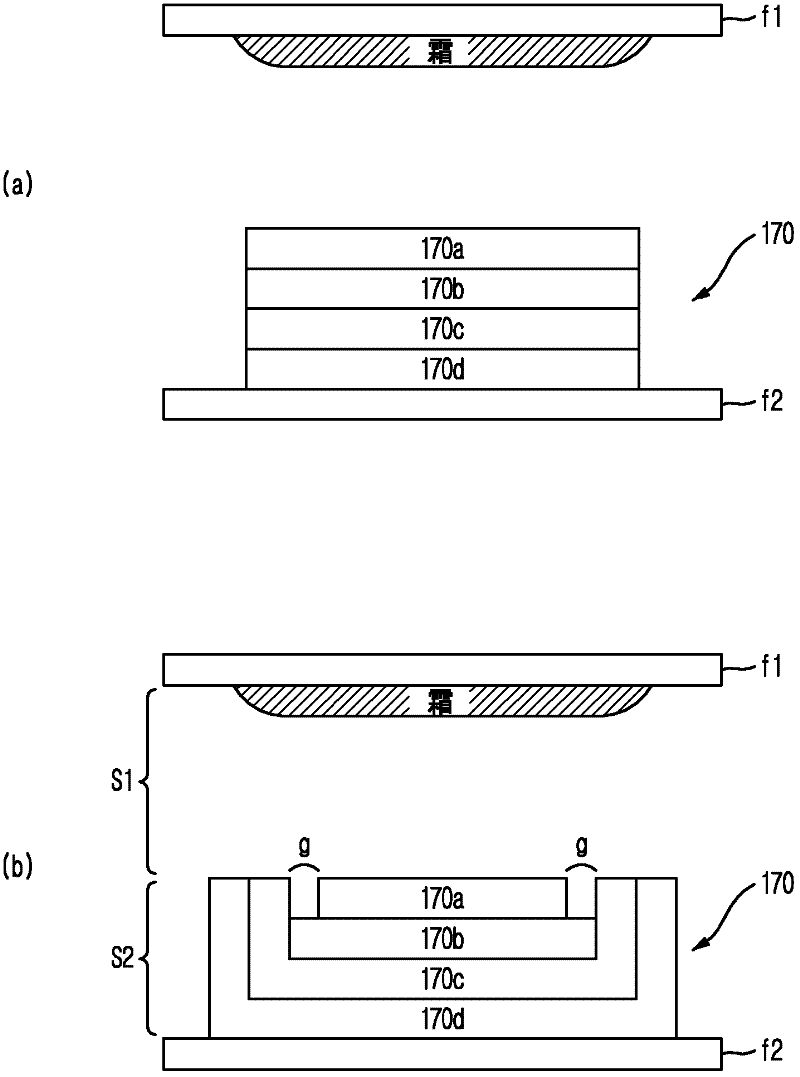

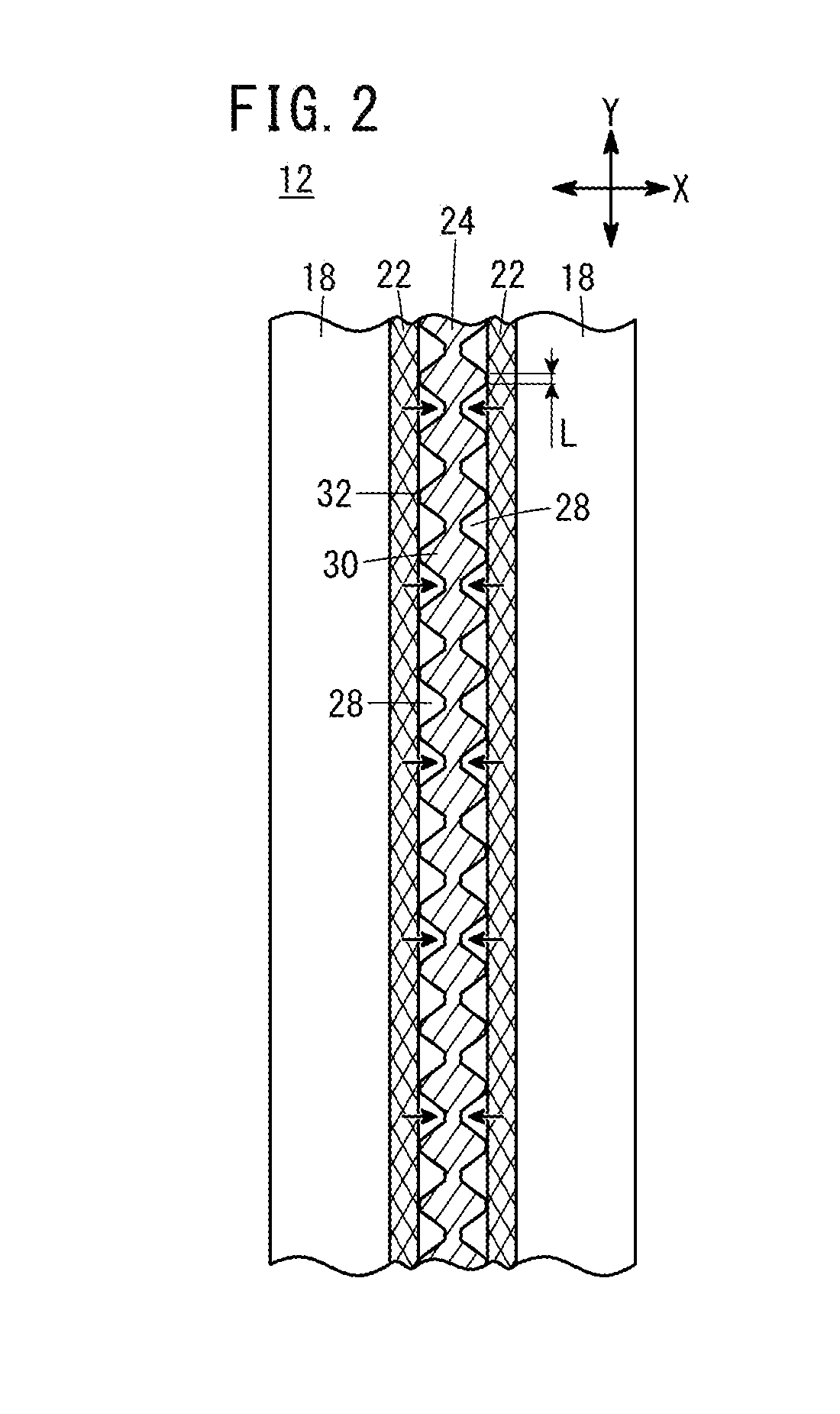

Semiconductor laser device and heat sink used therein

InactiveUS20060227827A1Remove heatReduce stress generateSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringCoolant flow

A semiconductor laser device has a heat sink of which laminated plural plates are constituted and a semiconductor laser element mounted on upper surface of the heat sink. The heat sink has a channel in which a coolant flows inside thereof. The heat sink includes a channel-forming plate portion that forms the channel and a mounting plate portion that forms an upper surface of the heat sink that comes into contact with the channel. The mounting plate portion is made of material having a thermal expansion coefficient, which is nearer that of the semiconductor laser element than that of the channel-forming plate portion.

Owner:SONY CORP

Element for emission of thermal radiation

InactiveUS20100155043A1Reduction of exchange of thermal energyReduce cooling efficiencyDoor/window protective devicesHeat-exchange elementsThermal radiationWavelength range

The present disclosure provides an element for emission of thermal radiation. The element comprises particles arranged for receiving thermal energy and emitting at least a portion of the received thermal energy in the form of the thermal radiation. The thermal radiation predominantly has a wavelength or wavelength range within an atmospheric window wavelength range in which the atmosphere of the Earth has a reduced average absorption and emission compared with an average absorption and emission in an adjacent wavelength range whereby absorption by the element of radiation from the atmosphere is reduced.

Owner:SYDNEY UNIV OF TECH

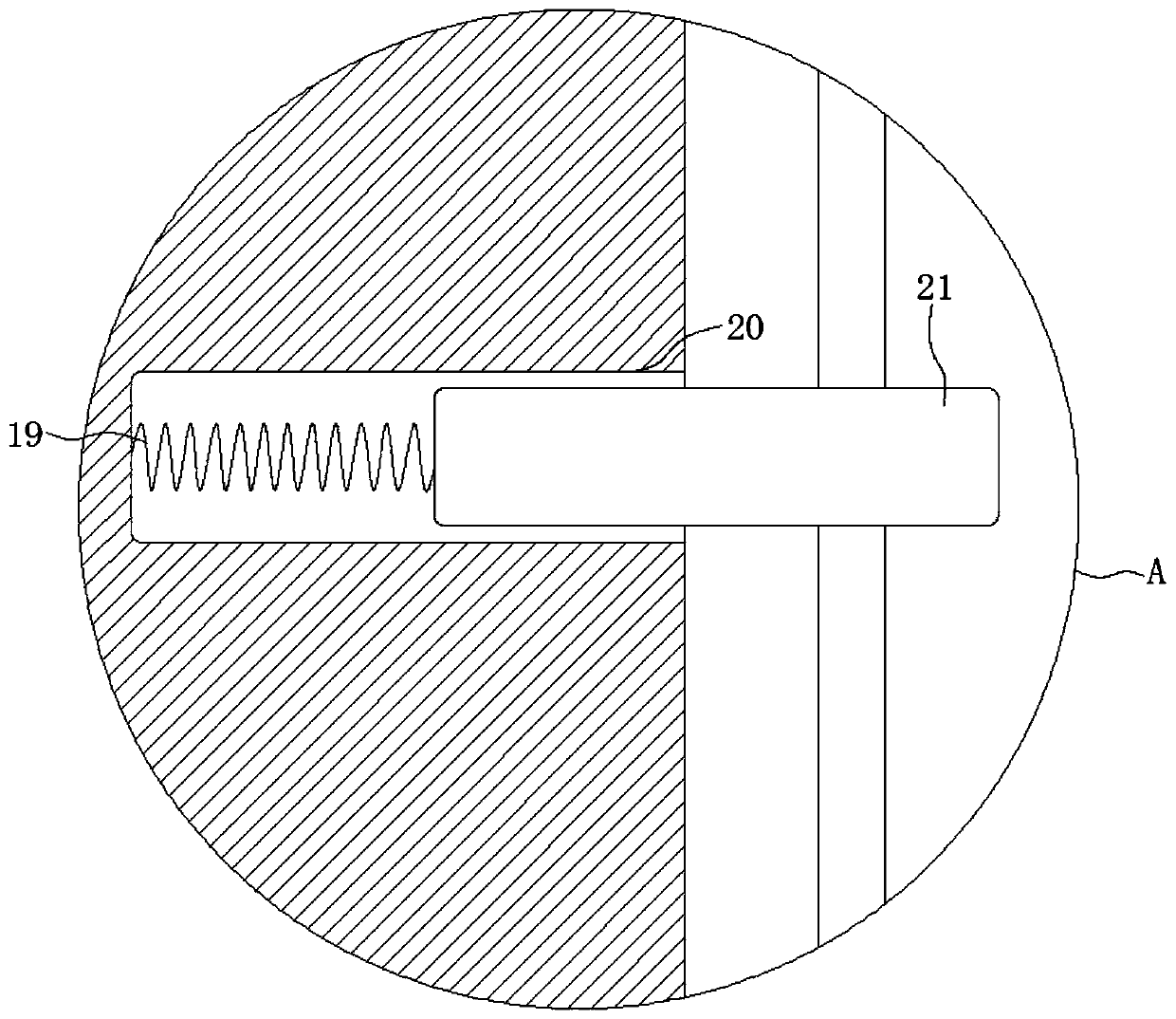

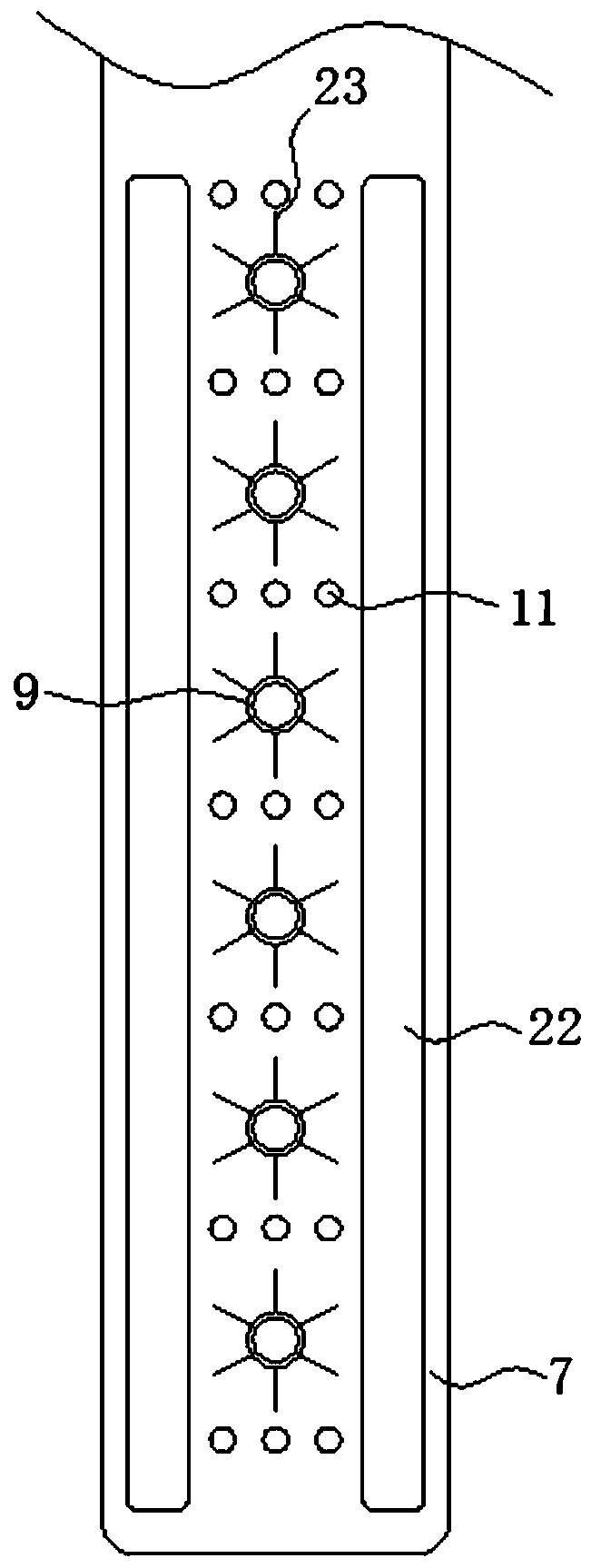

Solar photovoltaic panel dust clearing equipment

InactiveCN111069131AReduce manufacturing costLess power consumptionPhotovoltaicsCleaning using toolsPhysicsEngineering

The invention discloses solar photovoltaic panel dust clearing equipment. The equipment comprises a mounting frame whose upper surface is obliquely arranged, wherein a photovoltaic panel is arranged at the upper end of the mounting frame, a groove is formed in the upper end of the mounting frame, a reciprocating lead screw is rotationally connected to the side wall of the groove, a sliding block is in threaded connection with the reciprocating lead screw, a transverse plate which is obliquely arranged is fixedly connected to the side wall of the sliding block, and a clearing device for clearing the surface of the photovoltaic panel is mounted on the transverse plate. According to the equipment, through arrangement of fan blades fixedly connected to the side wall of the reciprocating lead screw, the fan blades can be driven to rotate when outside air blows, so that the reciprocating lead screw drives the sliding block to reciprocate back and forth, the transverse plate is driven to perform automatic clearing on the surface of the photovoltaic panel, a stretchable airbag fixed to the sliding block and the side wall of the groove is set, so that rainwater in a water tank is extruded into a cavity when the sliding block reciprocates back and forth, and water is sprayed on the surface of the photovoltaic panel through a water outlet hole for clearing.

Owner:张俊鹏

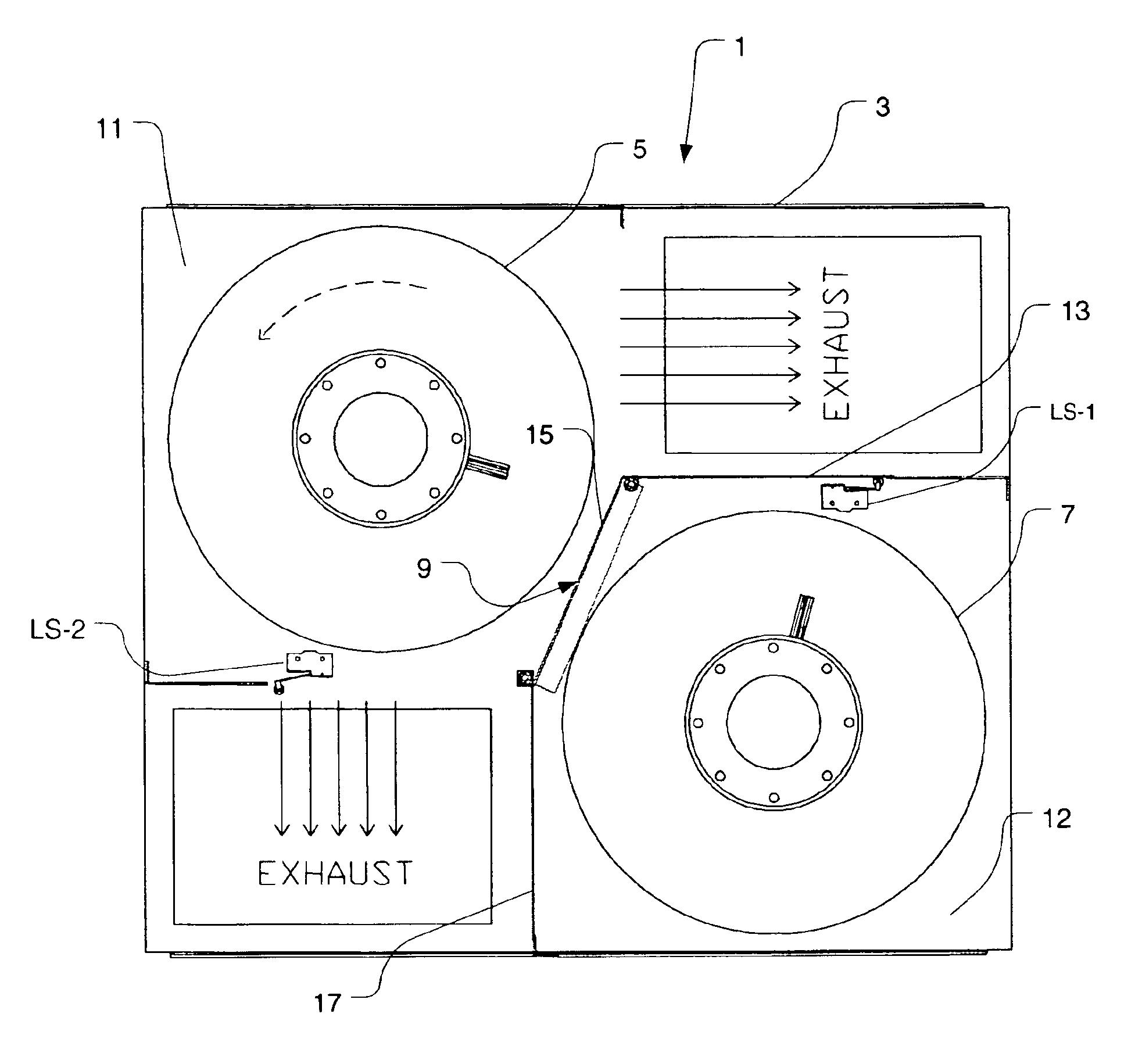

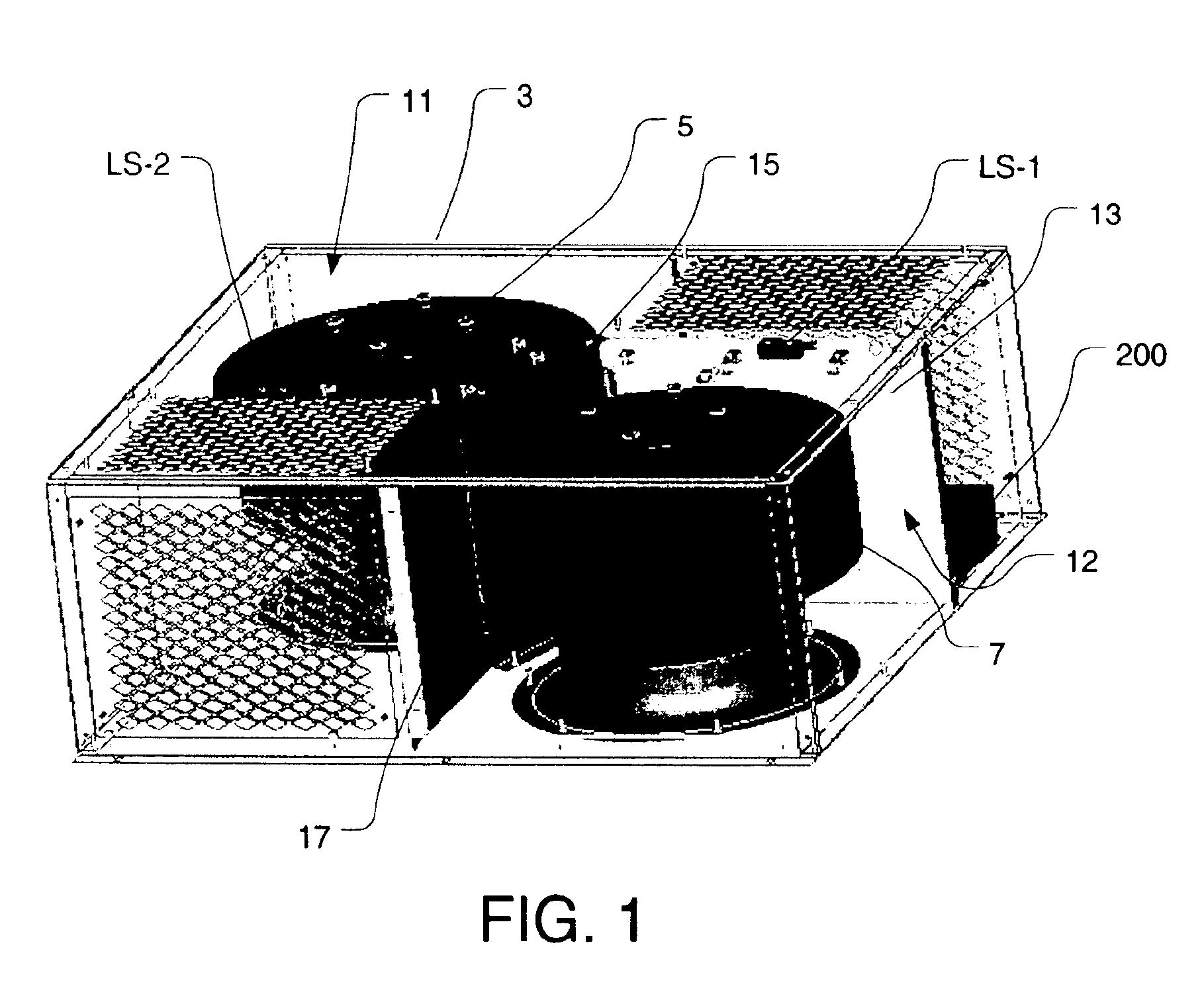

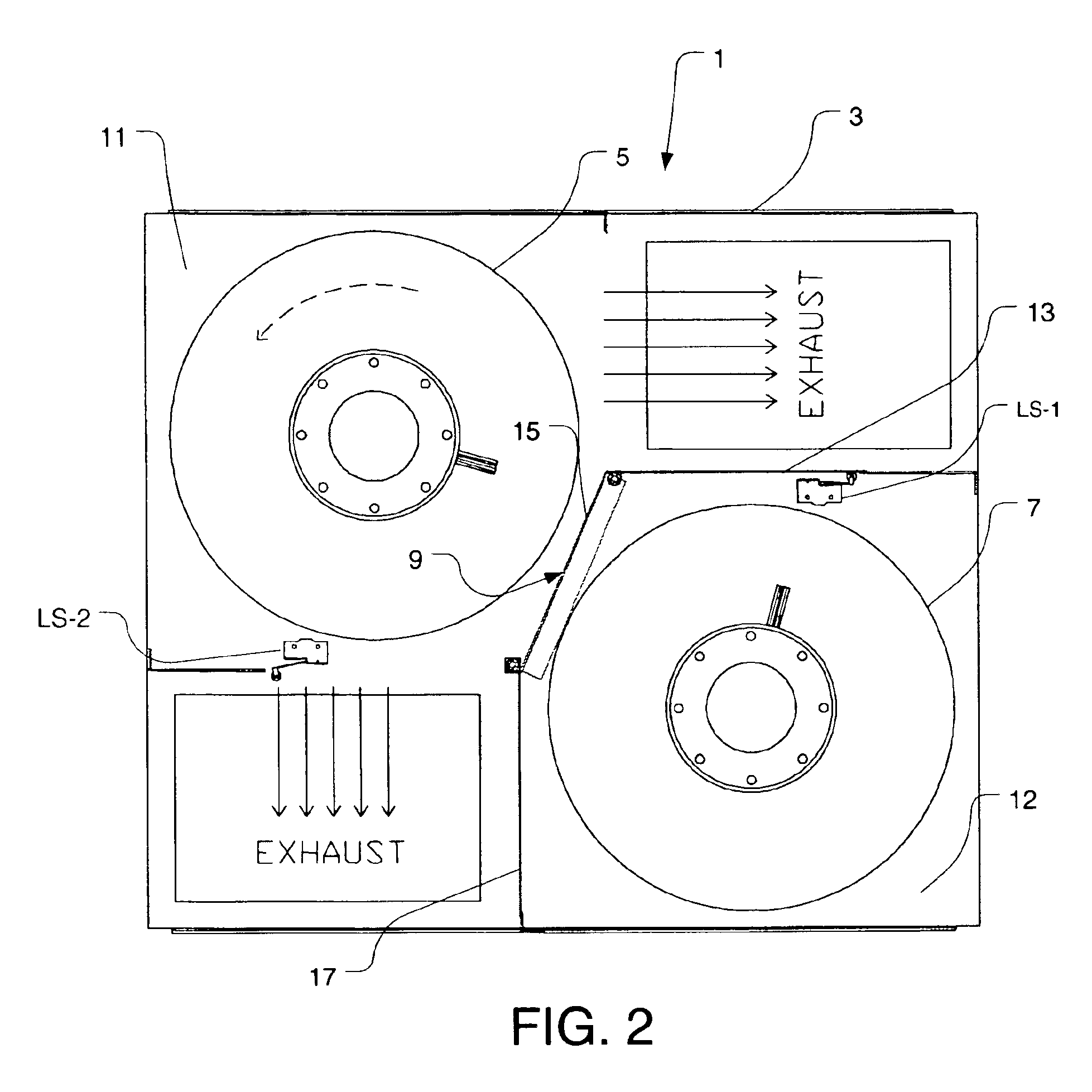

Apparatus for continuous cooling of electrical powered equipment

ActiveUS6936767B2Promote recoveryReduce harmDigital data processing detailsGaseous cathodesControl signalEngineering

A fluidic cooling assembly for removing heat from electrical equipment includes operational diversity features in which multiple fluid moving devices are mounted in a single housing. The assembly may include a first fluid baffle and a second fluid baffle disposed within the housing so as to define a first and a second control compartment. A first fan and a second fan may be disposed within the first control compartment and the second control compartment, respectively. A first sensor and a second sensor may be configured to sense changes in operation of the first fluid moving device and the second fluid moving device, respectively; and a controller unit configured for receiving signals generated by the first sensor and the second sensor go as to the transmit control signals to the first fan and the second fan.

Owner:TOSHIBA INT

Work vehicle

ActiveUS20120138379A1Sufficient distanceReduce the heating effectExhaust apparatusSilencing apparatusHeat spreaderAirflow

In a work vehicle, an engine compartment is disposed forwards of a cab. An exhaust gas treatment device is disposed over an engine in the engine compartment. A radiator is disposed forwards of the exhaust gas treatment device (33) in the engine compartment. A blower is configured to generate an airflow passing through the radiator from back to front of the radiator. The exhaust gas treatment device is slanted with respect to a vehicle width direction for increasing a distance between the exhaust gas treatment device and the radiator towards a first lateral face portion. Further, the first lateral face portion includes air inlets facing a space between the exhaust gas treatment device and the radiator.

Owner:KOMATSU LTD

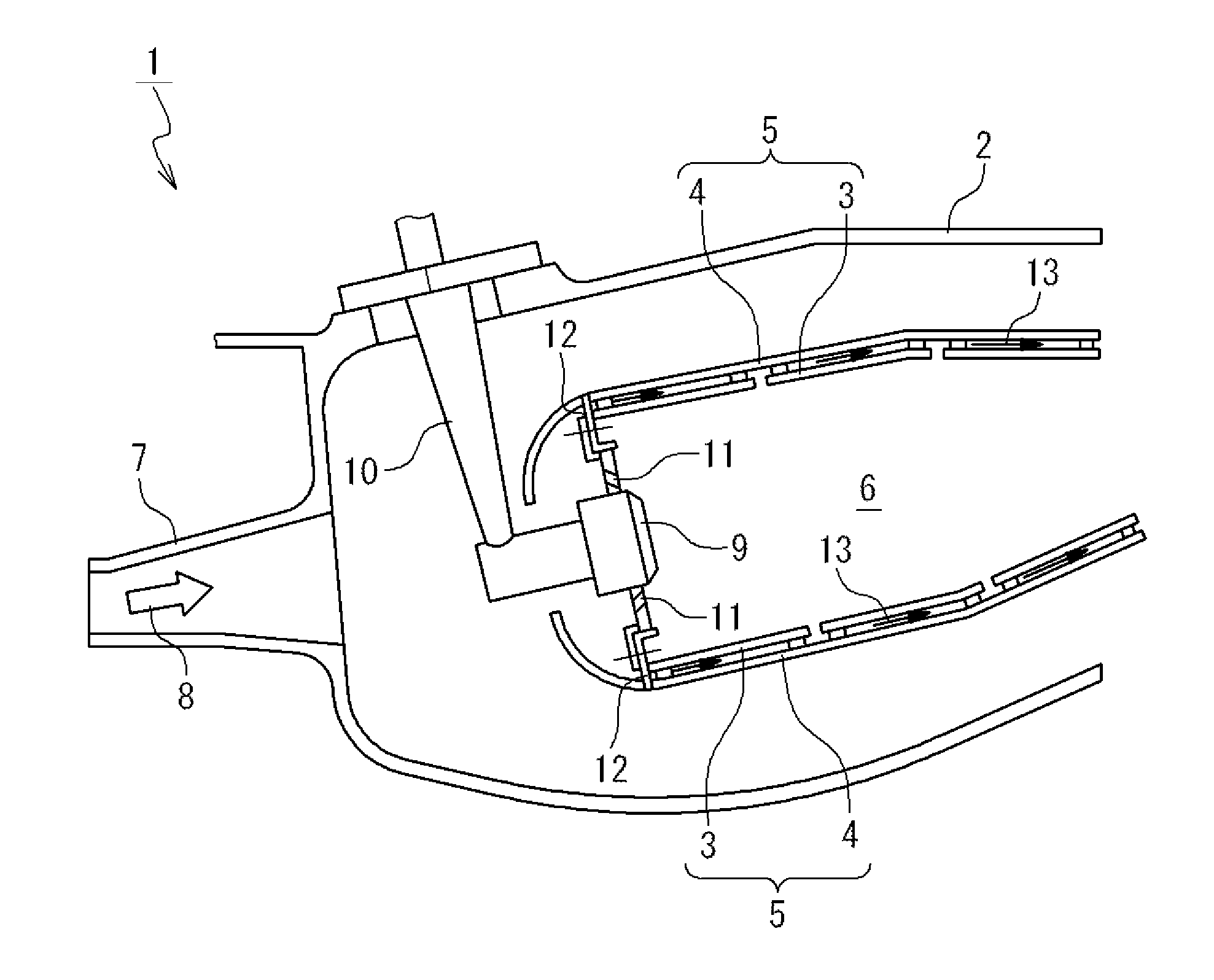

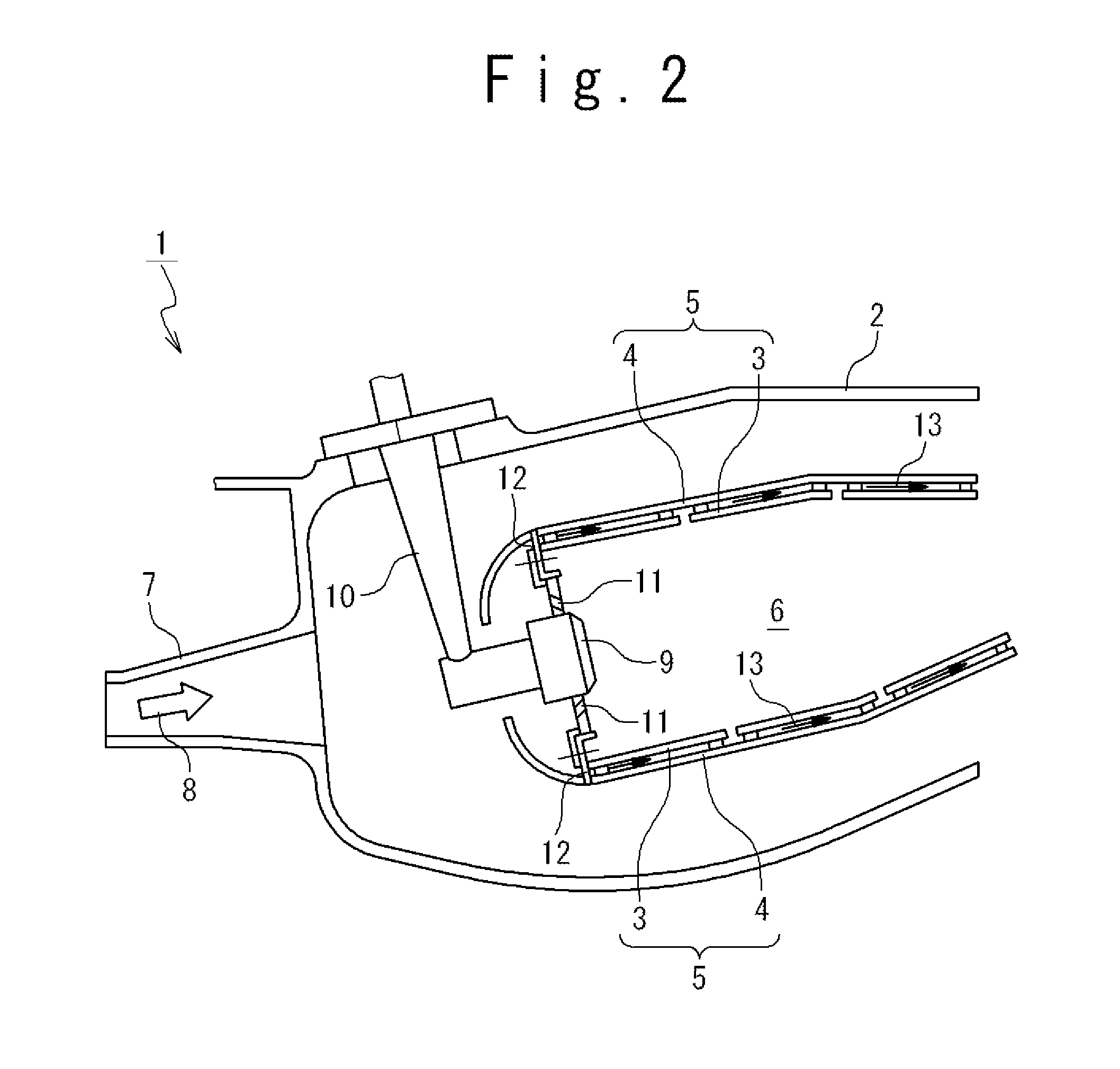

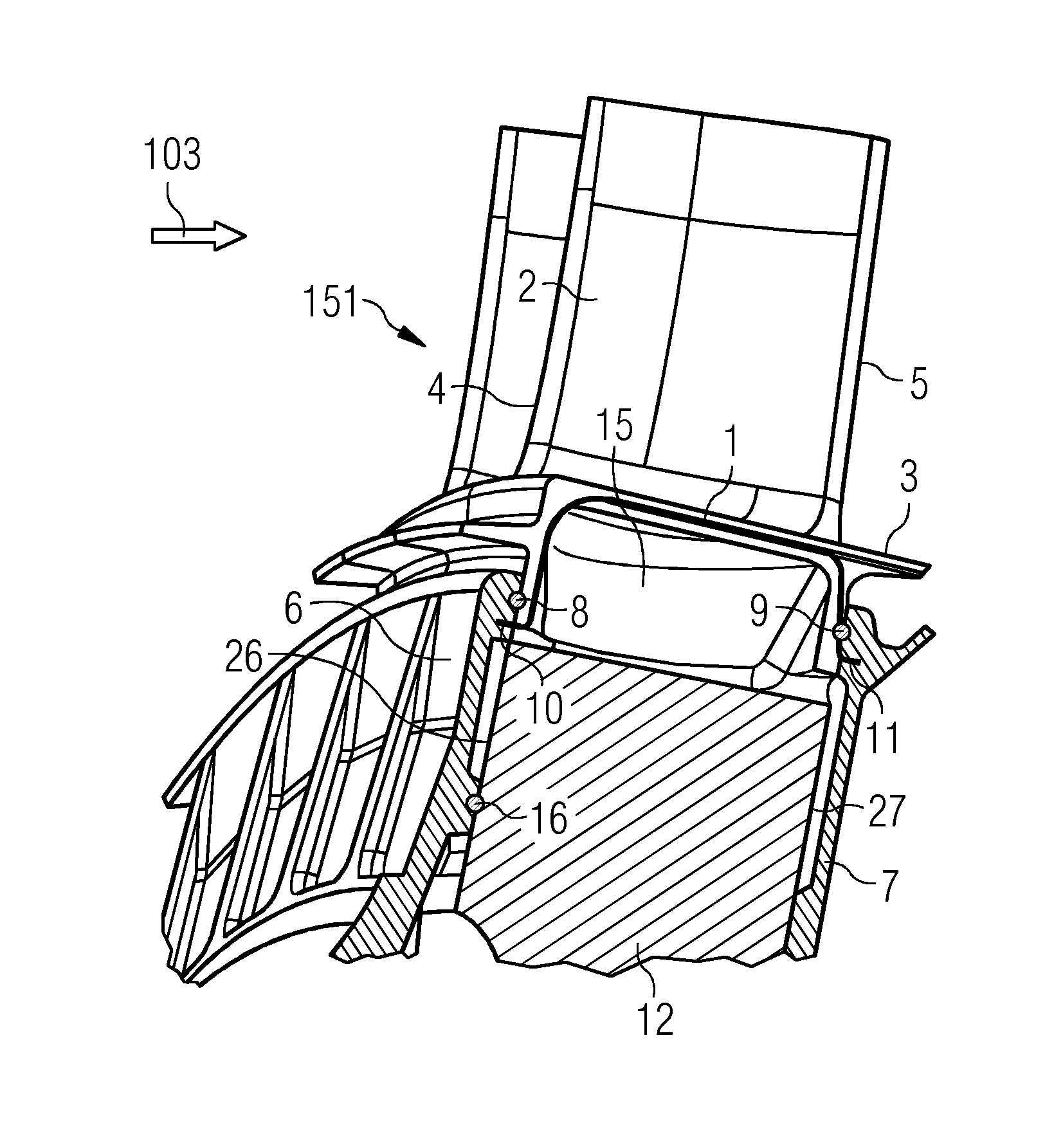

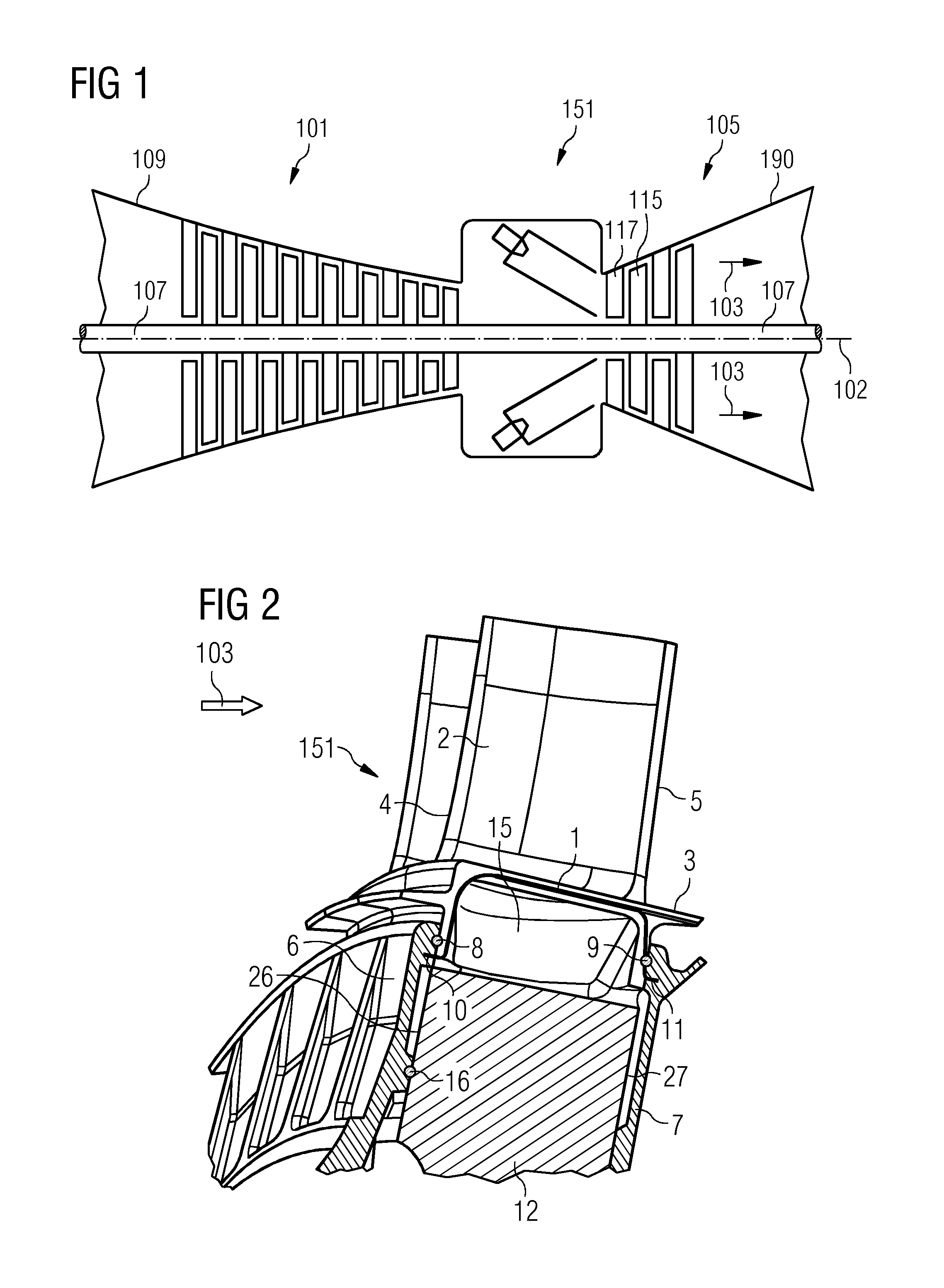

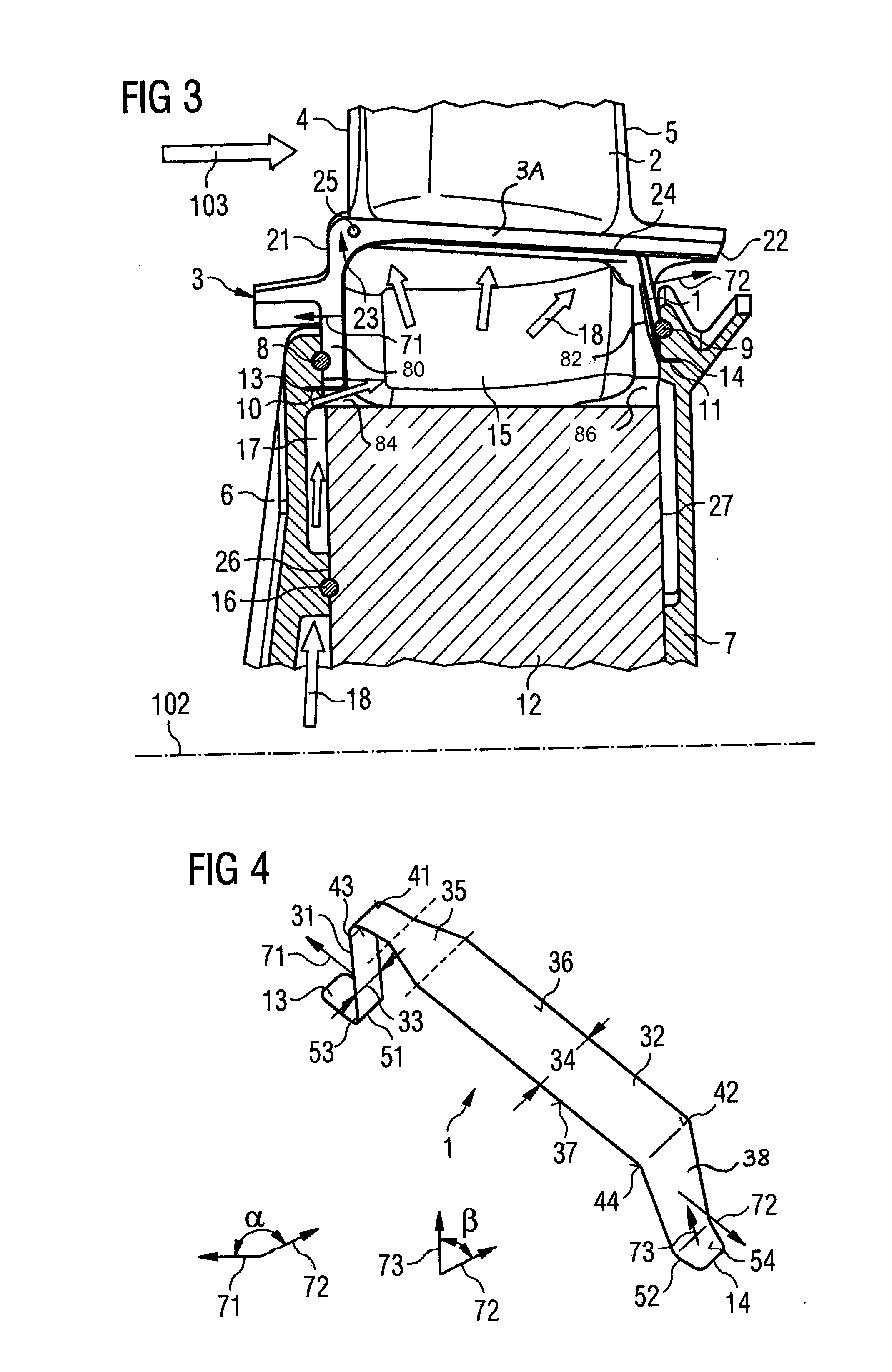

Cooling structure, gas turbine combustor and manufacturing method of cooling structure

InactiveUS20120255311A1Improve cooling efficiencyAvoid it happening againContinuous combustion chamberTurbine/propulsion engine coolingCombustorGas turbines

A cooling structure, a gas turbine combustor, and a method of manufacturing the cooling structure attain a high cooling efficiency without increasing manufacturing cost. The cooling structure includes a first member as a cooling object having a first plane, and a second member arranged above the first plane and having an opposing second plane such that a passage is formed between the first plane and the second plane for a cooling medium to flow. The first member has a plurality of prominences each of which extends upwardly from the first plane, and extends to be inclined along a direction in which the cooling medium flows. A clearance between the second plane and a tip of each prominence is set such that a heat transfer rate between the cooling medium and the first member becomes larger than that when each prominence extends vertically upward from the first plane.

Owner:MITSUBICHI HEAVY IND AERO ENGINES LTD

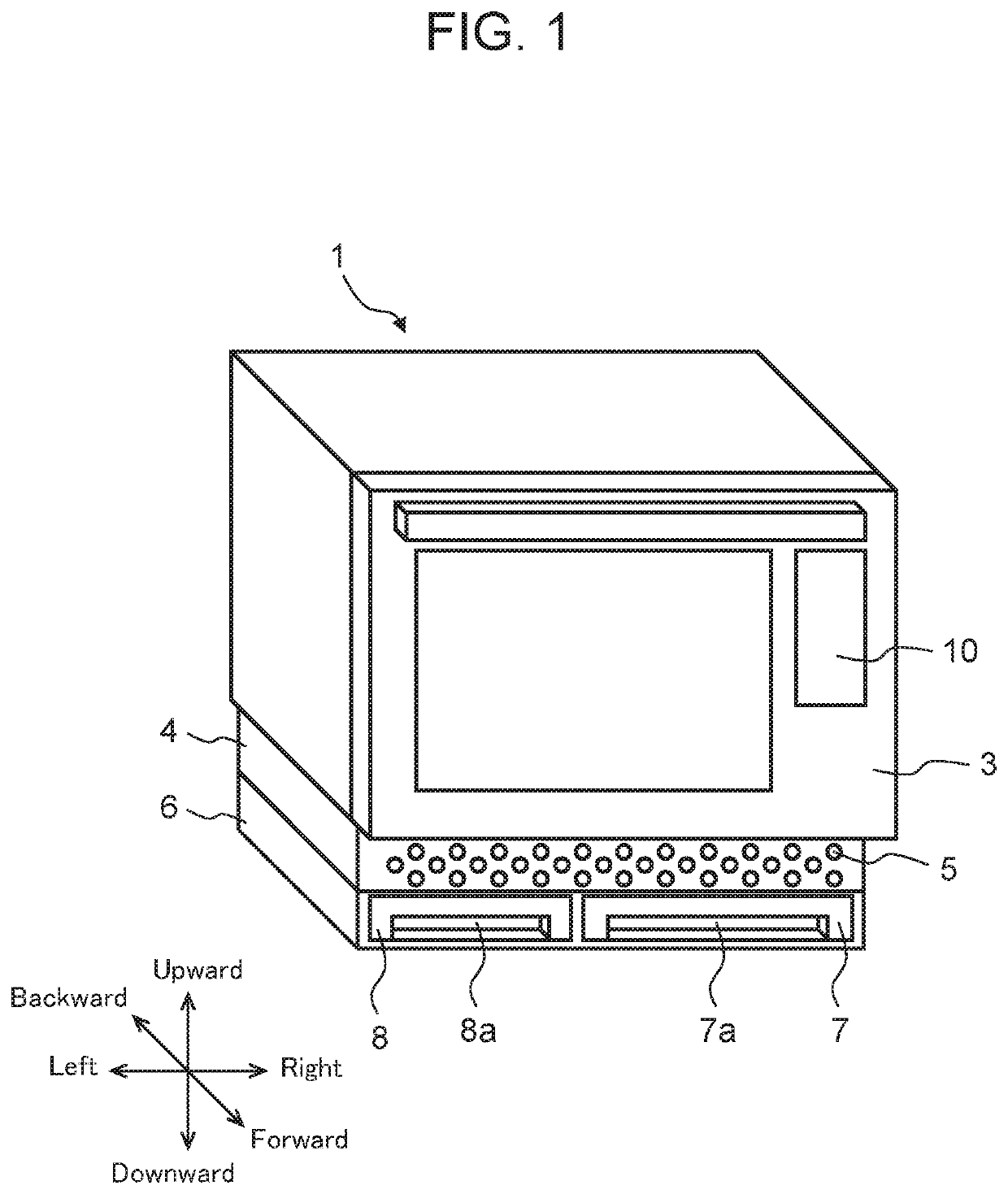

Cooking device

ActiveUS10645765B2Increased pressure lossReduce cooling efficiencyCooking-vessel materialsDomestic stoves or rangesThermodynamicsWater storage tank

Cooking device includes heating chamber with door for housing object to be heated, vapor generator for supplying vapor into heating chamber, and water storage tank. Cooking device further includes cooling air passage provided between heating chamber and water storage tank and allowing cooling air to pass therethrough, and air inlet provided to the side of door and introducing cooling air into cooling air passage. This enables cooling, using a smaller and more inexpensive cooling fan. As a result, cooking device is made shorter in overall height.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

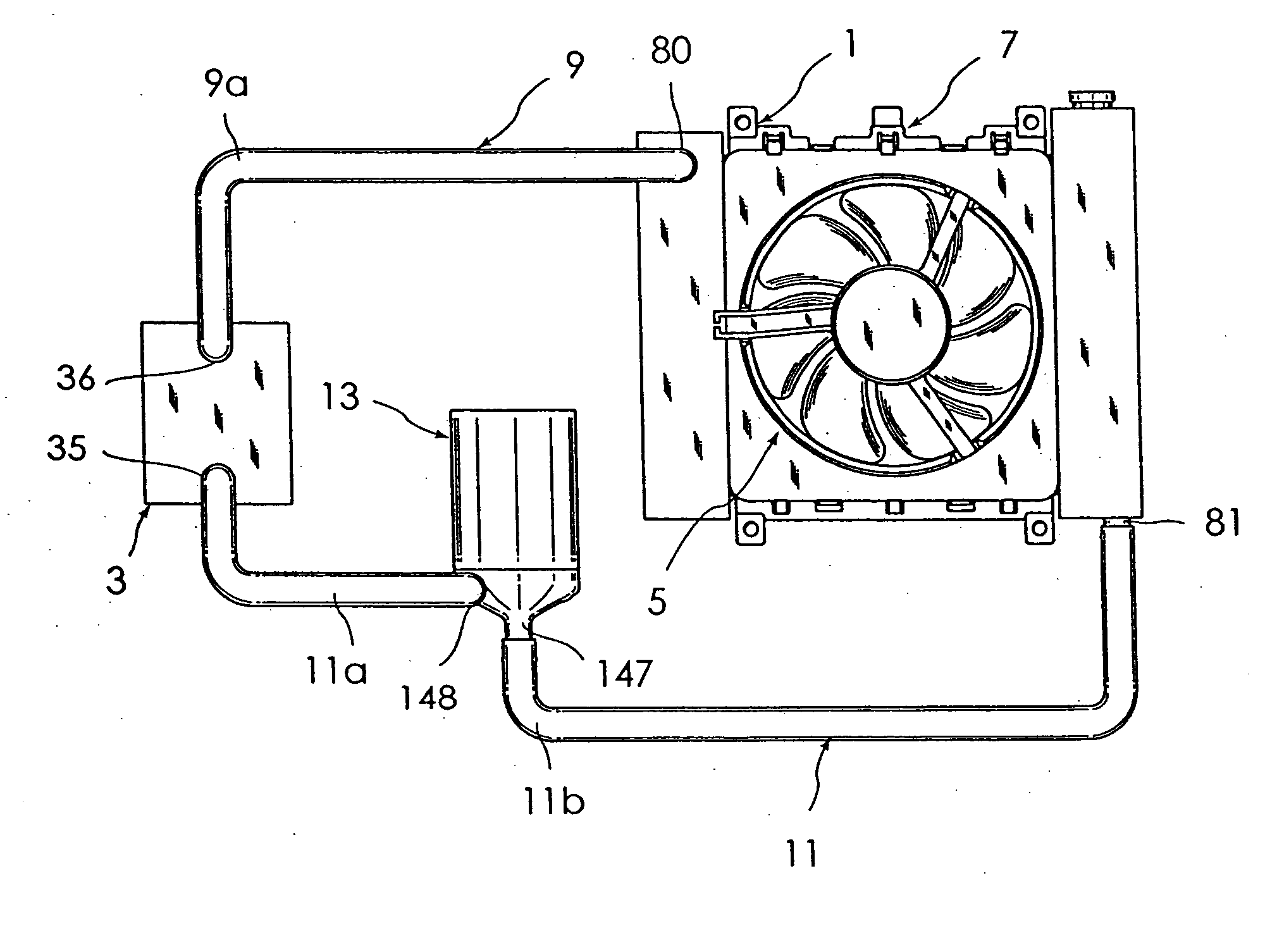

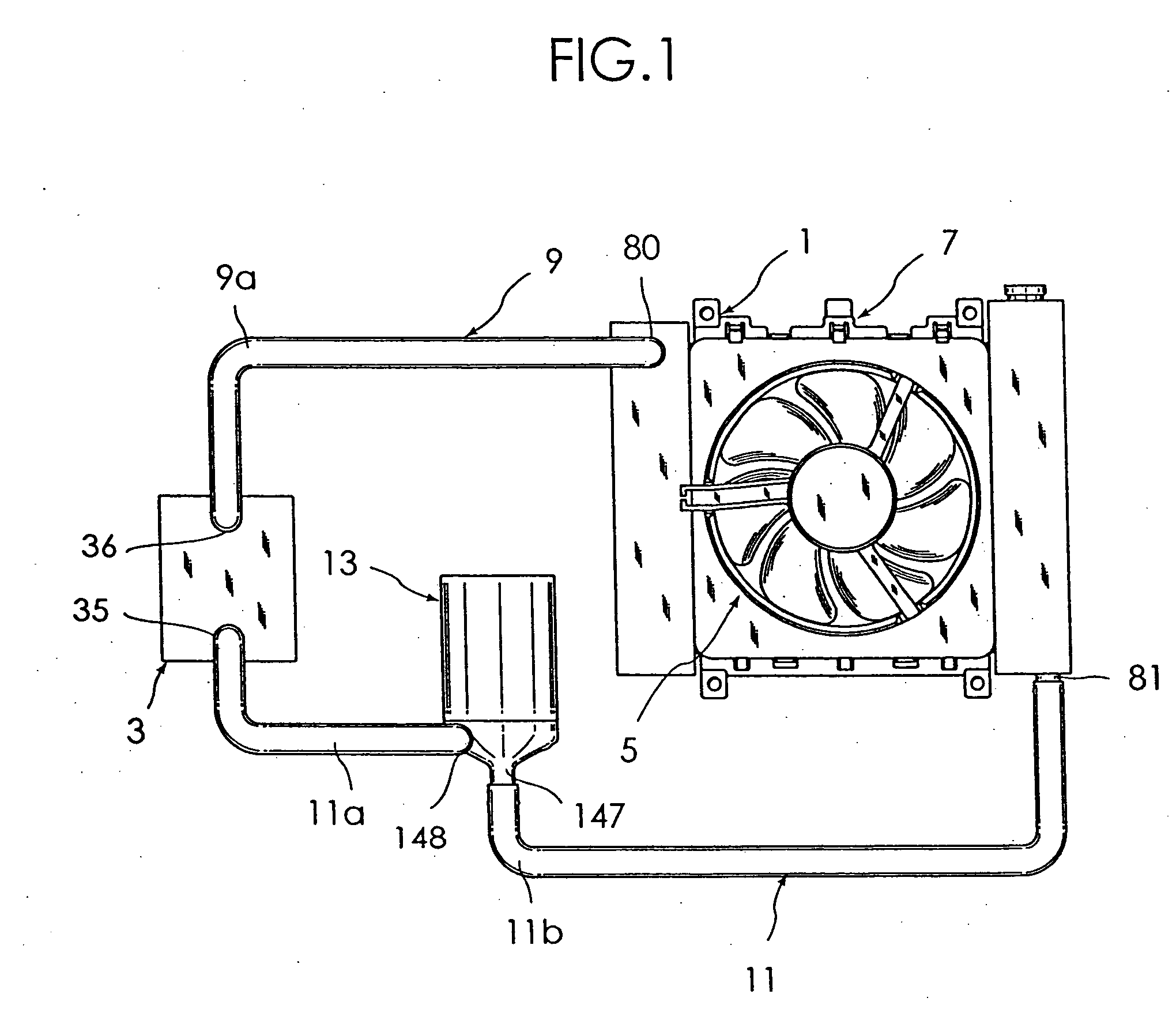

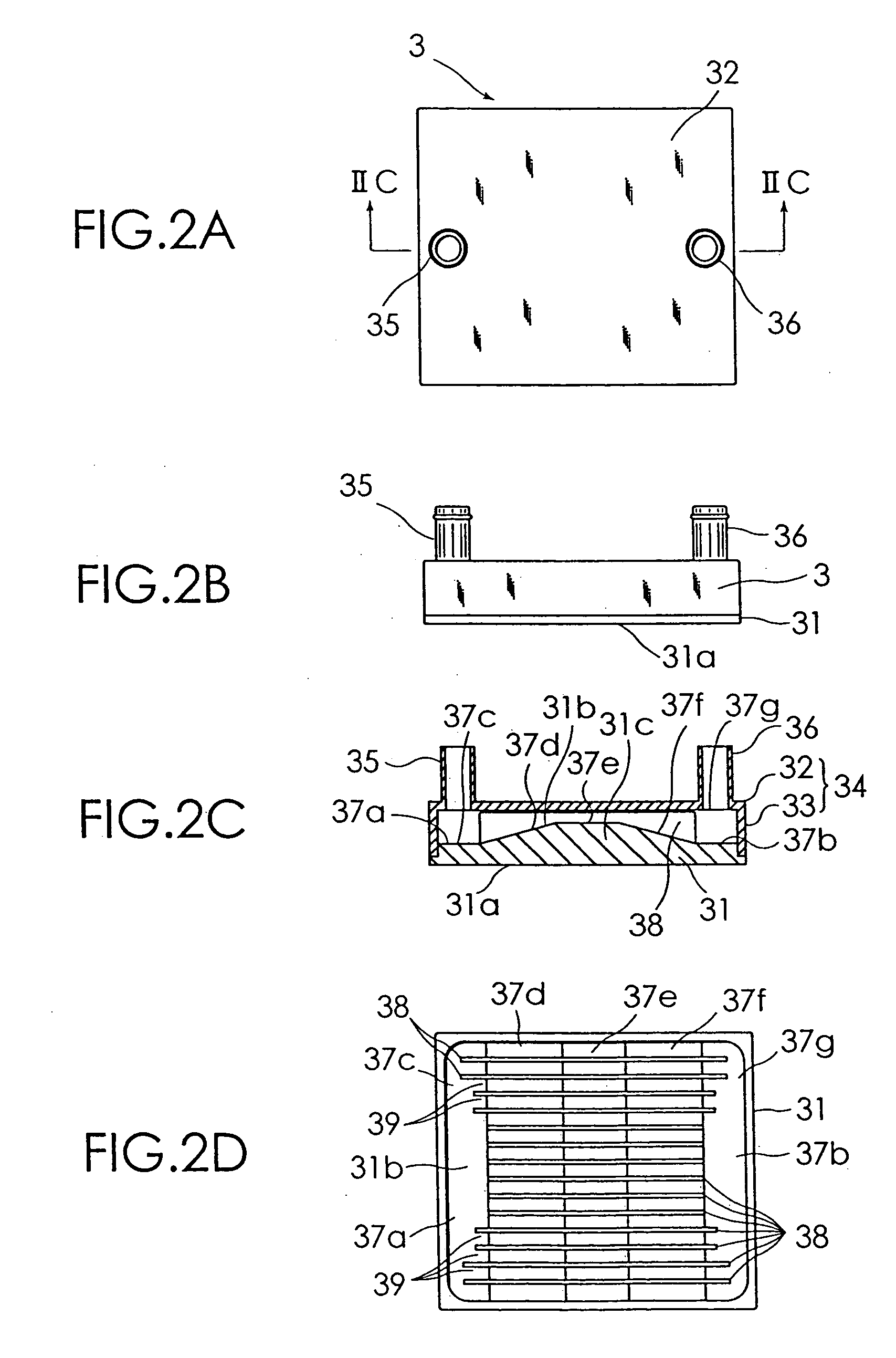

Heat exchanger module

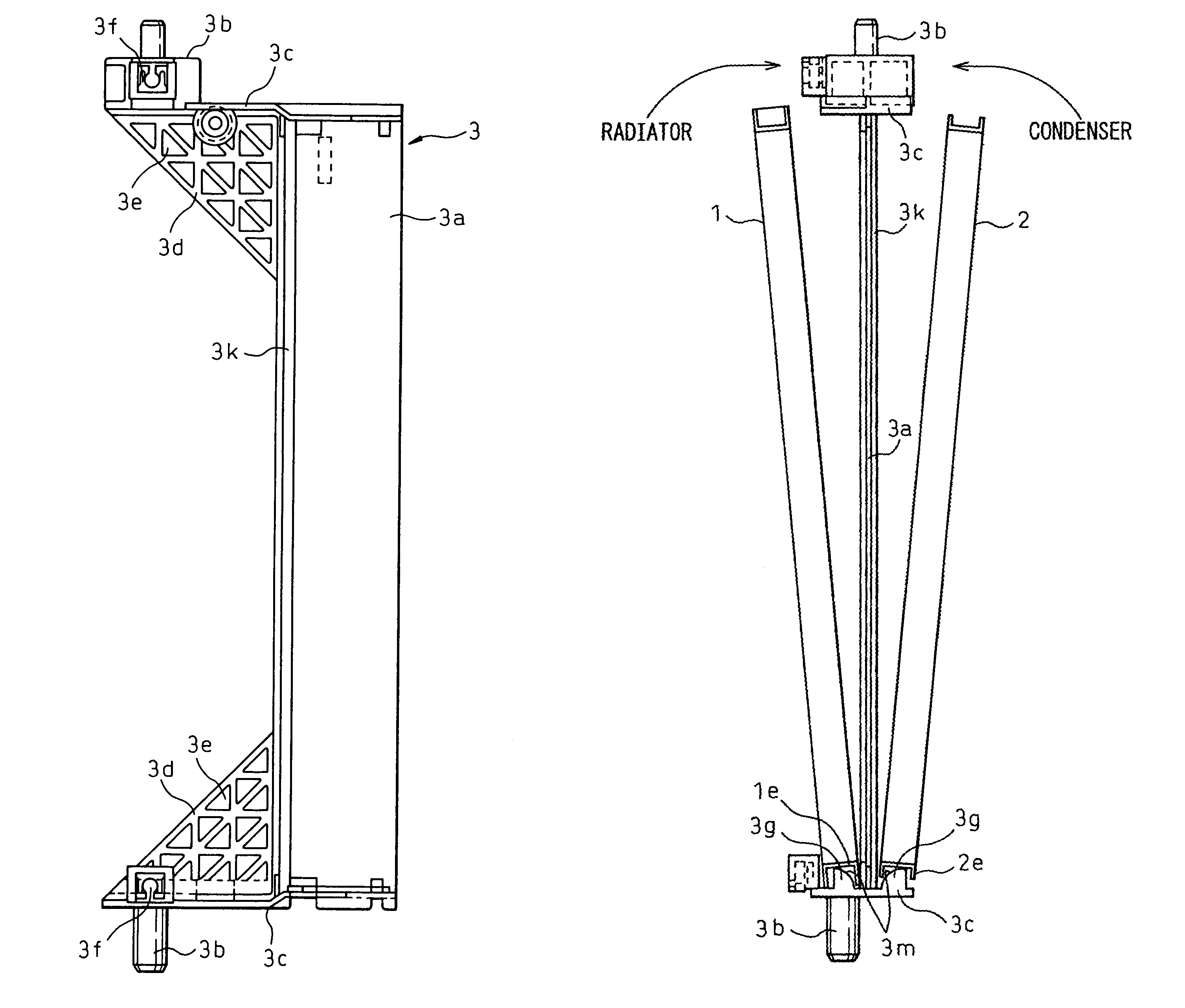

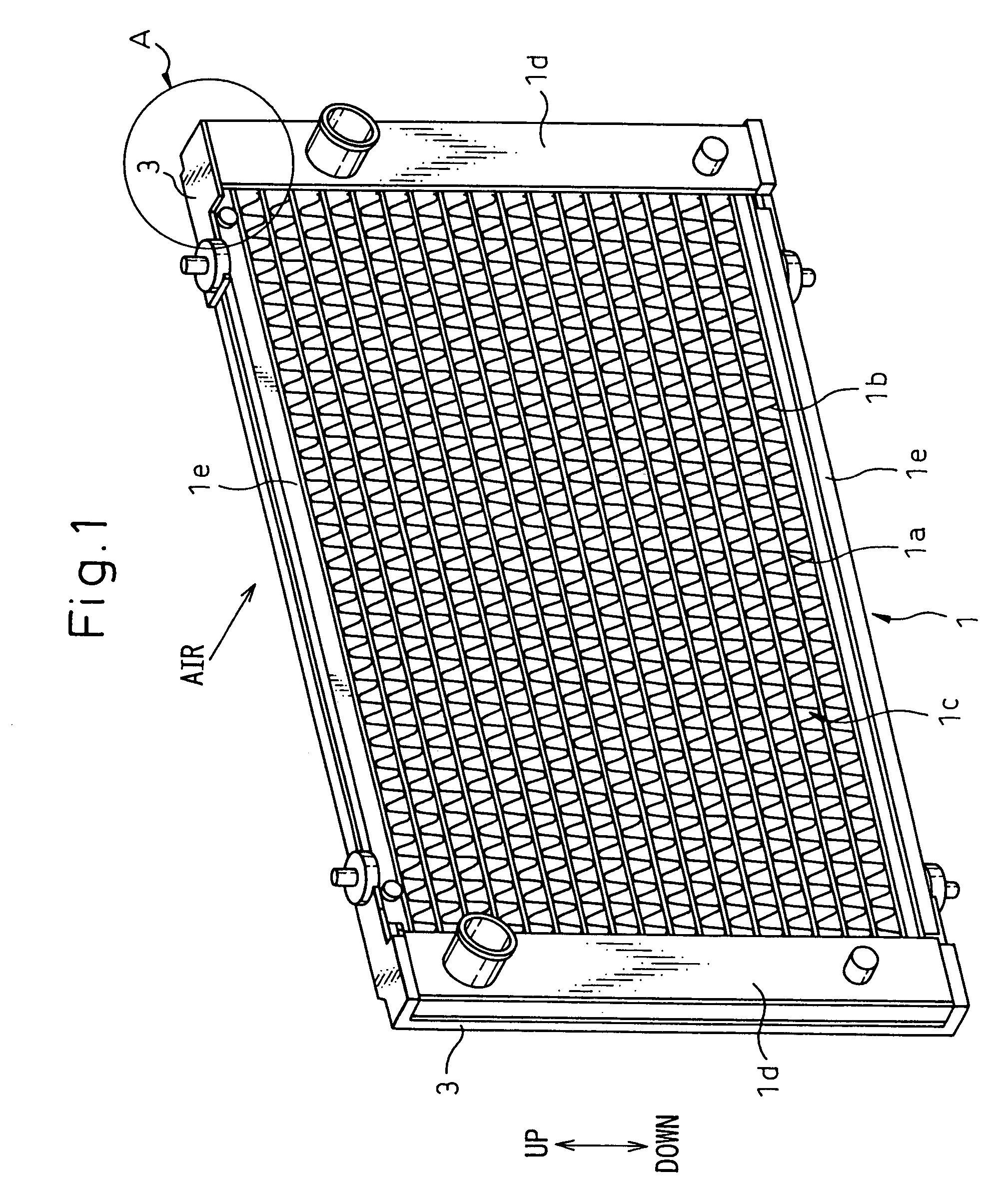

InactiveUS7036561B2Promote absorptionEasy to installAir-treating devicesSemiconductor/solid-state device detailsEngineeringCooling efficiency

Brackets 3 made of resin are provided between the radiator 1 and the condenser 2, and the heat exchangers 1 and 2 are secured to the brackets 3, so that heat transfer from the radiator 1 to the condenser 2 can be restricted and reduction of the cooling efficiency of the condenser 2 can be prevented. The radiator 1 and the condenser 2 are assembled with and secured to the brackets 3 so that the position of the condenser 2 with respect to the radiator 1 can be easily determined. Therefore, the assembling of the cooling module can be facilitated and no heat exchange between the radiator 1 and the condenser 2 can be restricted due to a predetermined space provided between the core 1c of the radiator 1 and the core 2c of the condenser 2.

Owner:DENSO CORP

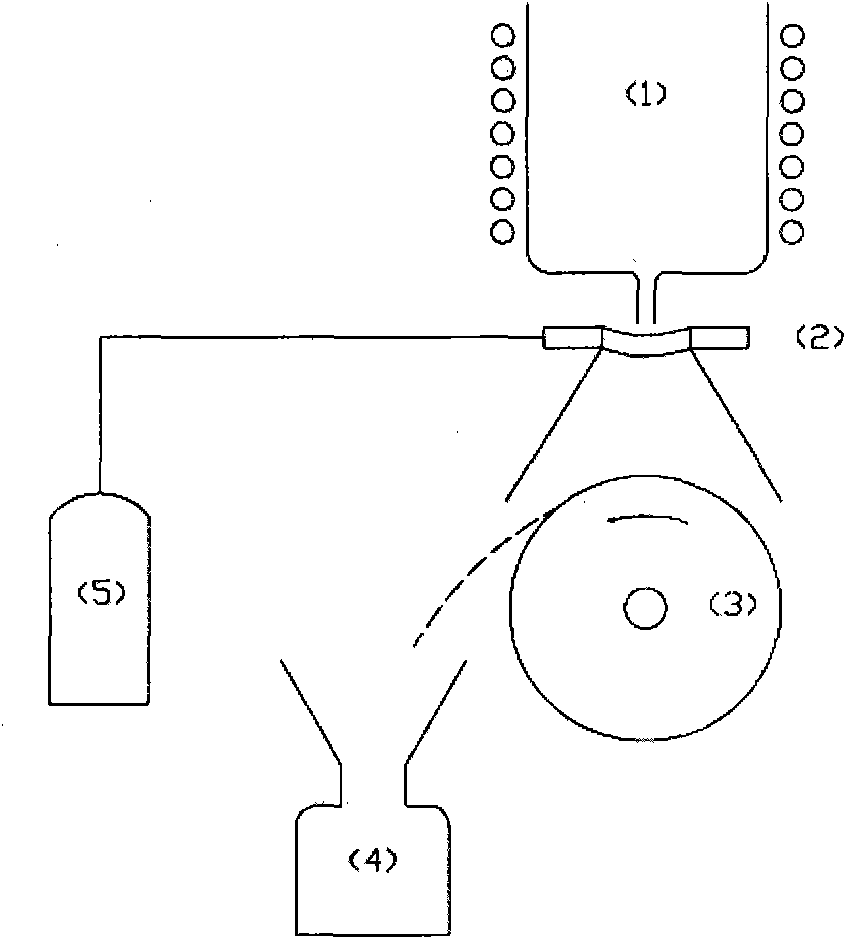

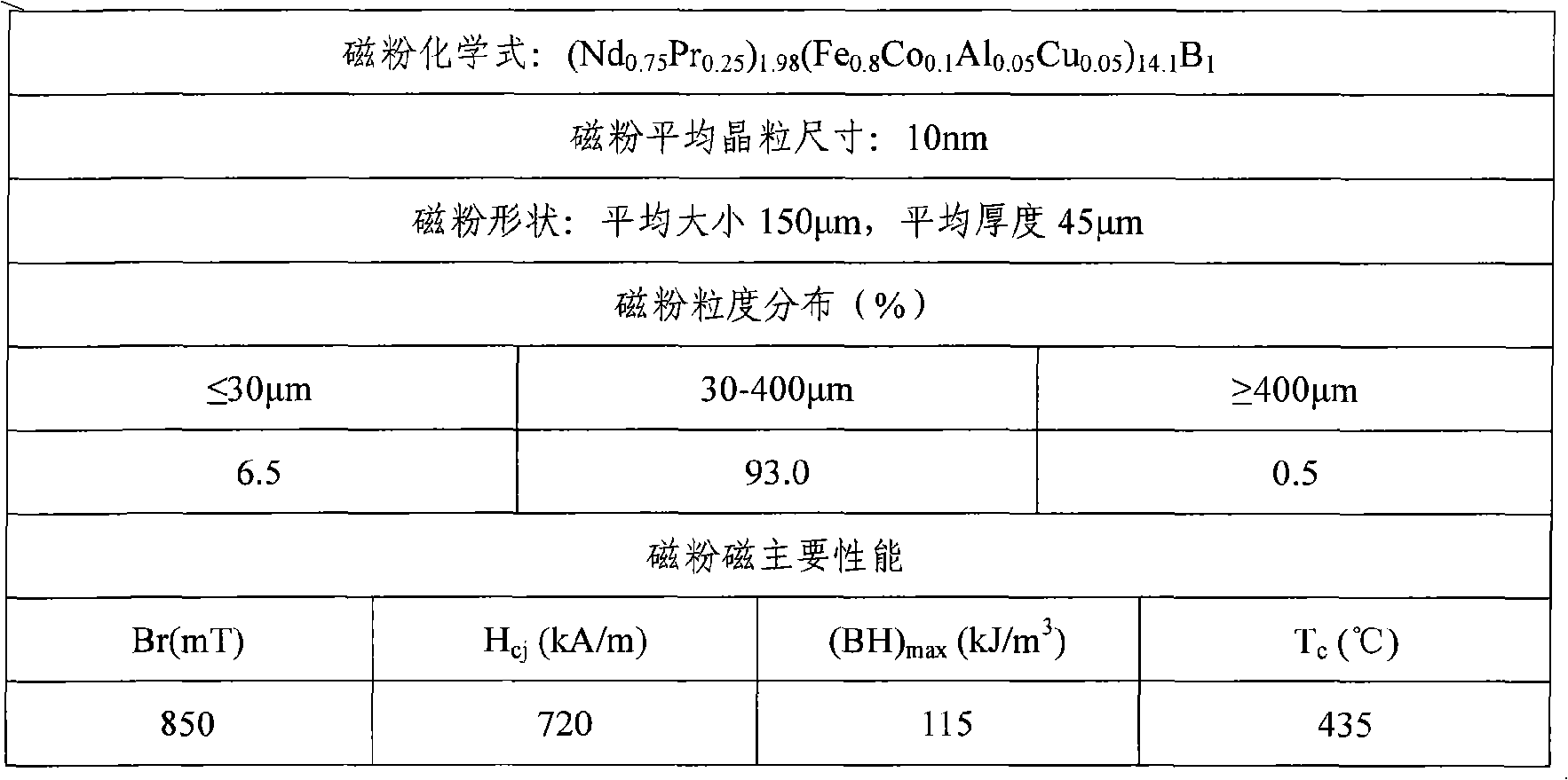

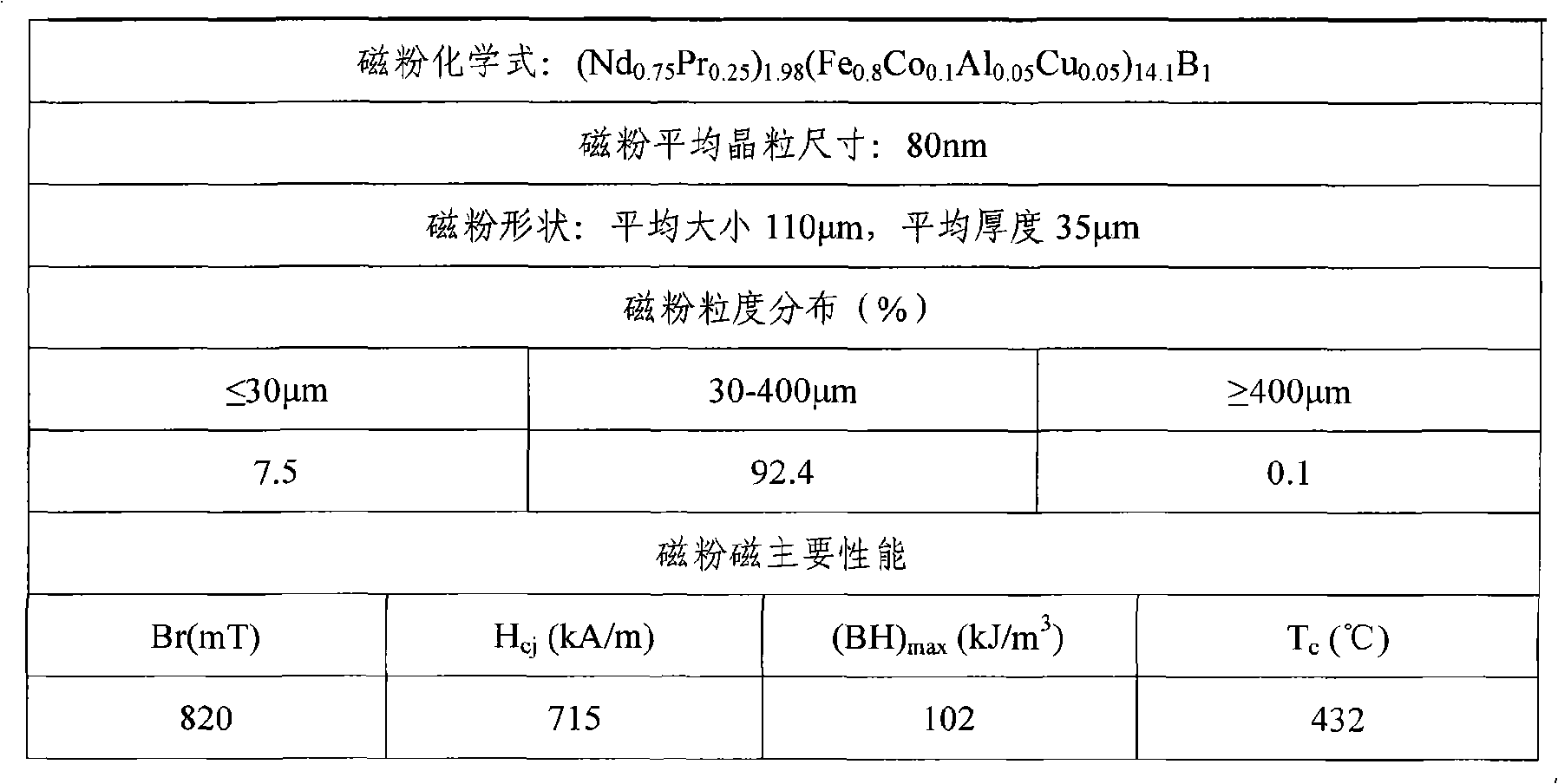

Flaky rare earth permanent magnet powder and preparation method thereof

InactiveCN101572145AReduce cooling efficiencyEasy to understandInorganic material magnetismRare earthHigh pressure

The invention relates to a flaky rare earth permanent magnet powder and a preparation method thereof, belonging to the fields of magnetic functional material and preparation technology. The invention provides the flaky rare earth permanent magnet powder used for bonded permanent magnet and the preparation method thereof. The magnet powder has round, elliptic or irregular flakiness, the average size of 60-300mum, average thickness of 20-60mum and granules formed by nanocrystal or amorphous structure with the average size of 30-120nm. Compared with a rapid quenching belt, the magnet powder is not needed to be ground and can be directly used for preparing magnet. Molten alloy is atomized by high pressure gas to form droplet flow, the liquid drops are sputtered onto a water-cooling substrate for rapid quenching, and the magnet powder is prepared after crystallization heat treatment. Compared with the traditional rapid quenching technique for preparing powder, the method has simple technique, high efficiency and low cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Electronic component cooling apparatus

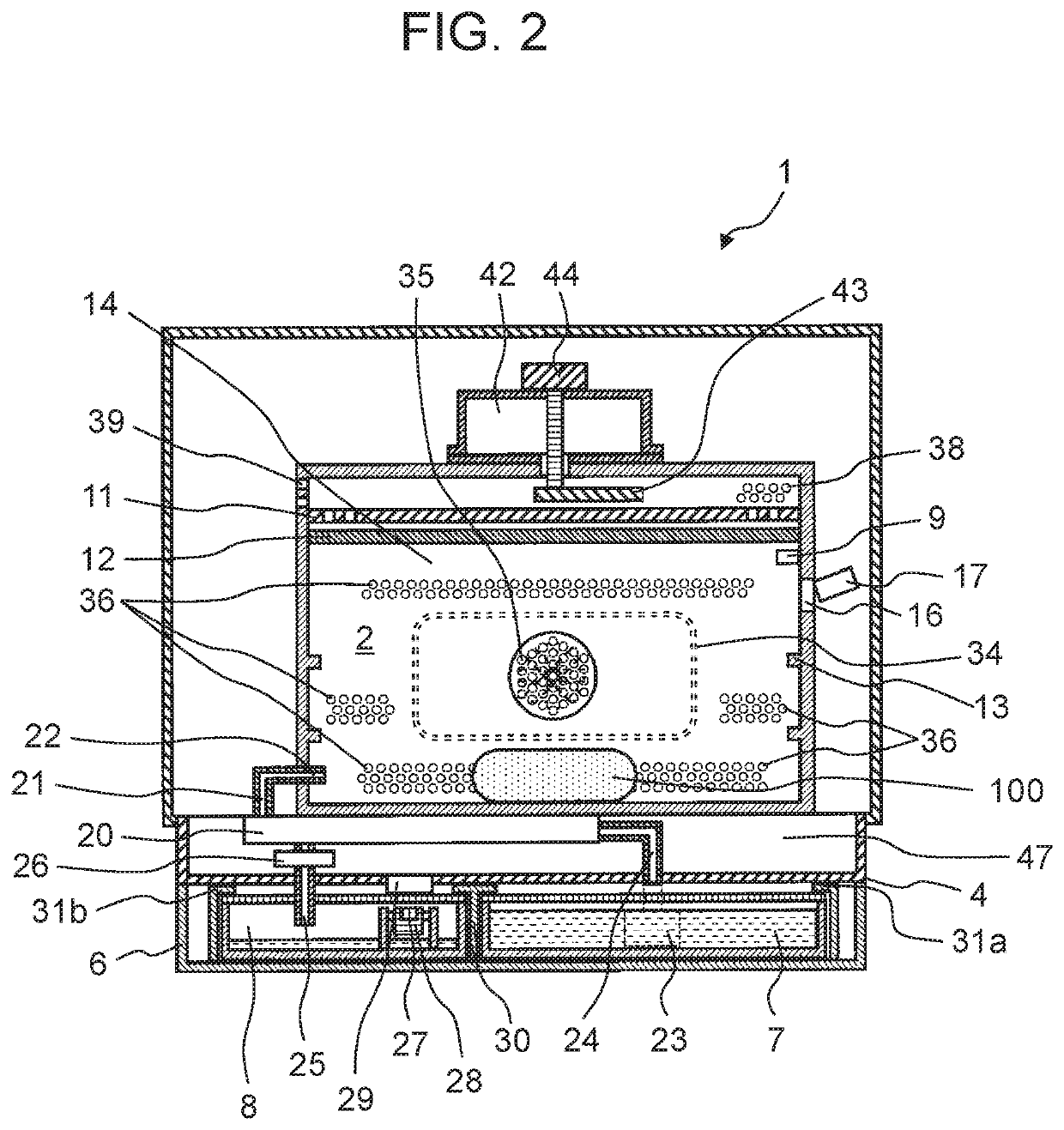

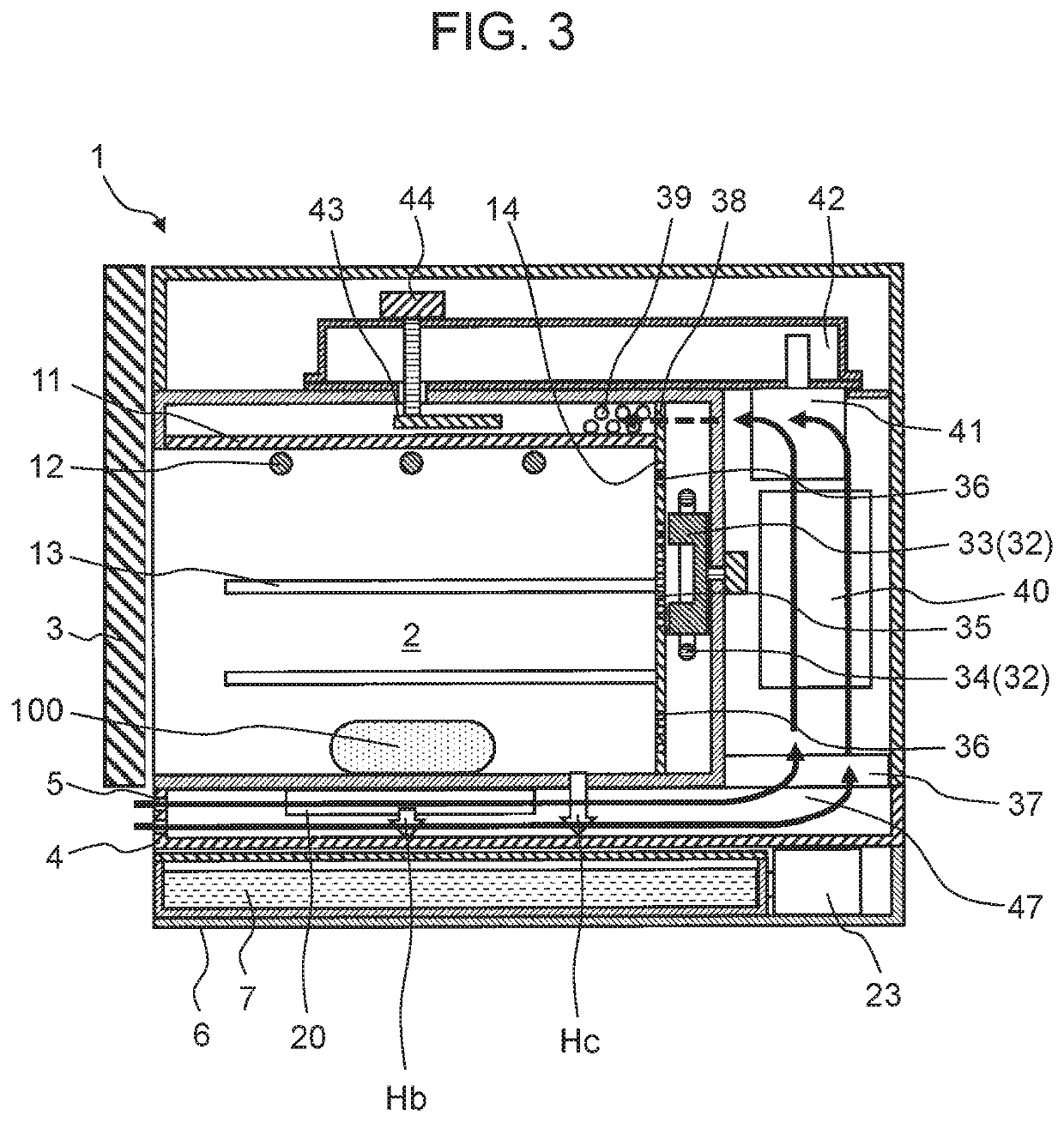

InactiveUS20050280995A1Reduce cooling efficiencyAdequate levelLiquid coolingPump componentsNuclear engineeringMotor drive

An electronic component cooling apparatus comprises a so-called water-cooled heat sink, a radiator to be cooled by a motor-driven fan, first and second coolant paths for circulating a coolant between the heat sink and the radiator, and a motor-driven pump for giving a moving energy to the coolant. A plurality of engaging pieces of the motor-driven fan and a plurality of engaged portion of the radiator are engaged to connect the motor-driven fan and the radiator.

Owner:SANYO DENKI CO LTD

Eutectic salt cold-storage material

InactiveCN101434830AApplicable temperature rangeReduce cooling efficiencyHeat-exchange elementsCool storageAir conditioning

The invention provides an eutectic-salt cool-storage material, comprising sodium sulfate decahydrate (Na2SO4 question mark 10H2O), ammonium chloride (NH4Cl), sodium borate decahydrate (Na2B4O7 question mark 10H2O), and silica gel (mSiO2 question mark nH2O); the eutectic-salt cool-storage material is characterized in that: according to the mass percentage, the eutectic-salt cool-storage material comprises 72.86 percent of Na2SO4 question mark 10H2O, 12.86 percent of NH4Cl, 2.86 percent of Na2B4O7 question mark 10H2O and 11.42 percent of mSiO2 question mark nH2O. The transformation temperature of the eutectic-salt cool-storage material is 8.47 DEG C, the undercooling degree thereof is 2.41 DEG C and the transformation latent heat thereof is 136.07-182.73Kj / kg. Owning to low transformation temperature and small undercooling degree, the material is the eutectic-salt cool-storage material applicable to cold accumulation air-conditioning systems.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Cooling system and defrosting control method thereof

InactiveCN102384614AOutput voltage changeAccurate detectionCorrosion preventionRefrigeration safety arrangementFrostEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

Battery device

ActiveUS20180034116A1Smooth bootReduce cooling efficiencyCell temperature controlCell component detailsEvaporationEngineering

A battery device is provided with cooling bodies for contacting the outer surfaces of a plurality of battery cells arranged inside a battery case, and spacers provided adjacent to the cooling bodies. The cooling bodies absorb or are impregnated with a cooling fluid inside the battery case. Cooling medium vapor flow channels in which cooling medium vapor circulates are formed on the surfaces of the spacers facing the cooling bodies, the cooling medium vapor being generated by the evaporation of the cooling fluid of the cooling bodies.

Owner:IKUYO +1

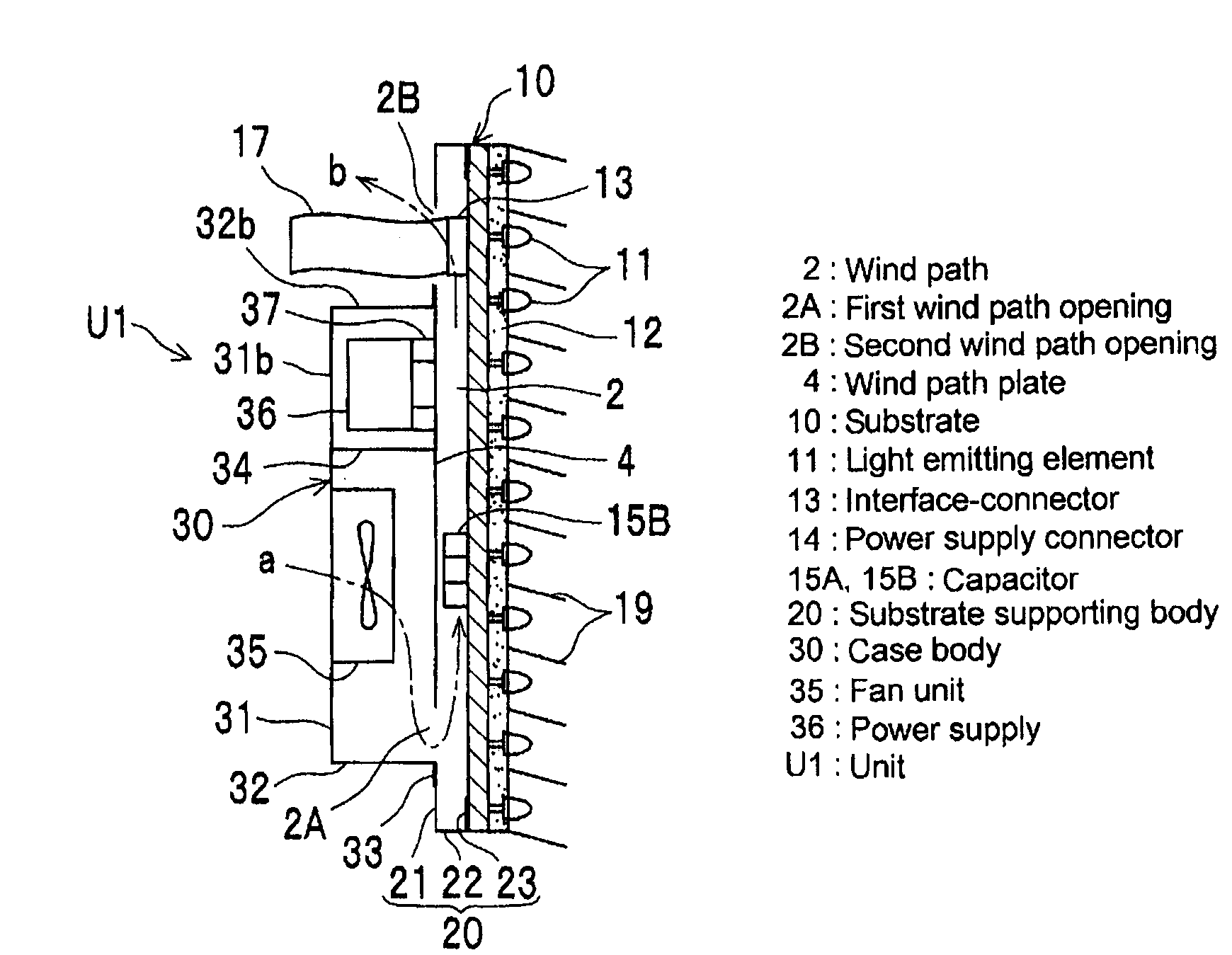

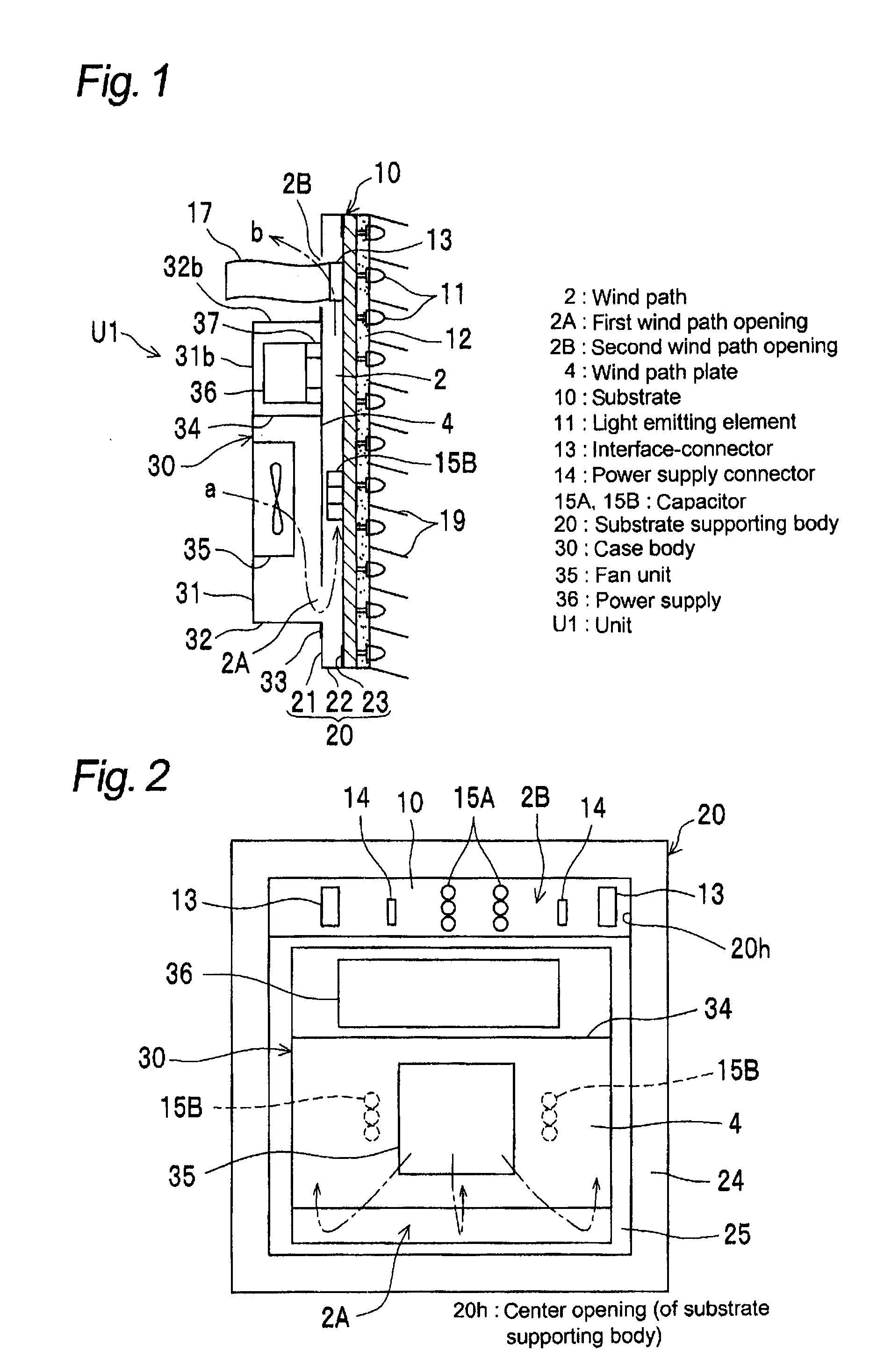

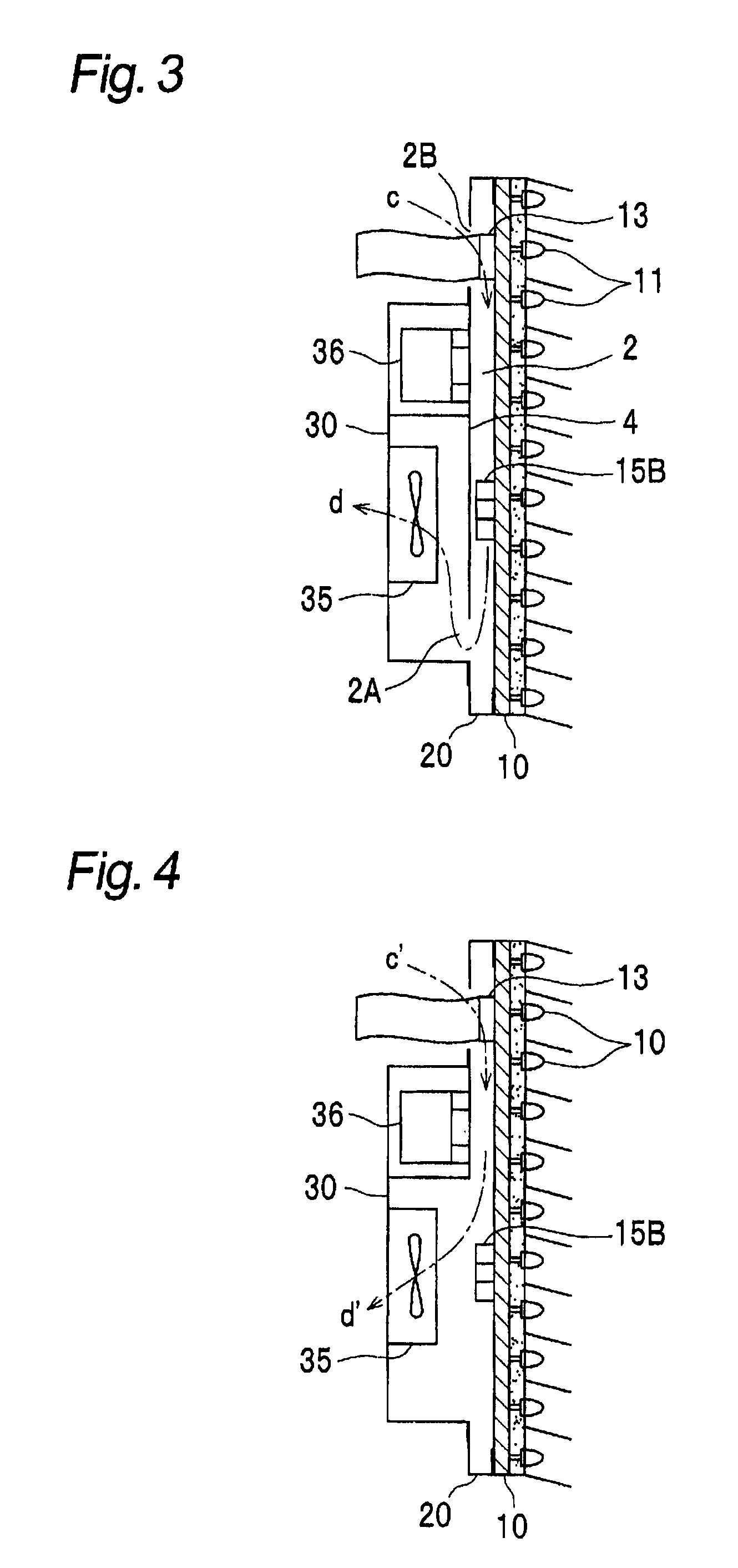

Display device

ActiveUS20080170015A1Improve cooling effectAvoid simple structuresStatic indicating devicesDigital data processing detailsDisplay deviceEngineering

A display device includes a substrate having light emitting elements for display on a front surface; a substrate supporting body having an opening in the center and positioned on the back surface side of the substrate to support a peripheral region of the substrate; a case body positioned on the back surface side of the substrate supporting body and covering a part of the center opening; a fan unit arranged in the case body; a wind path plate arranged between the fan unit and the back surface of the substrate and forming a wind path to pass airflow generated by driving the fan unit only on the back surface side of the substrate; and a power supply arranged in the case body and on the back surface of the wind path plate; and wherein the airflow impinges the wind path plate through the fan, thereafter passes through the wind path and is discharged to the outside from the back side of the wind path plate. According to the present invention, it is possible to cool down a substrate uniformly and efficiently in a display device using light emitting elements arranged on the substrate without raising cost or complicating the structure.

Owner:MITSUBISHI ELECTRIC CORP

Platform seal strip, turbine blade assembly and method for assembling it

InactiveUS20150125301A1Improve sealingImprove cooling effectPropellersPump componentsTurbine bladeEngineering

A platform seal strip, in particular for use in a gas turbine blade assembly, is provided. The platform seal strip includes an upper side, a lower side, a first portion and a second portion. The width of the first portion is smaller than the width of the second portion. The first portion and the second portion are at least partially bent downwards such that the upper side includes a convex surface portion and the lower side includes a concave surface portion.

Owner:SIEMENS AG

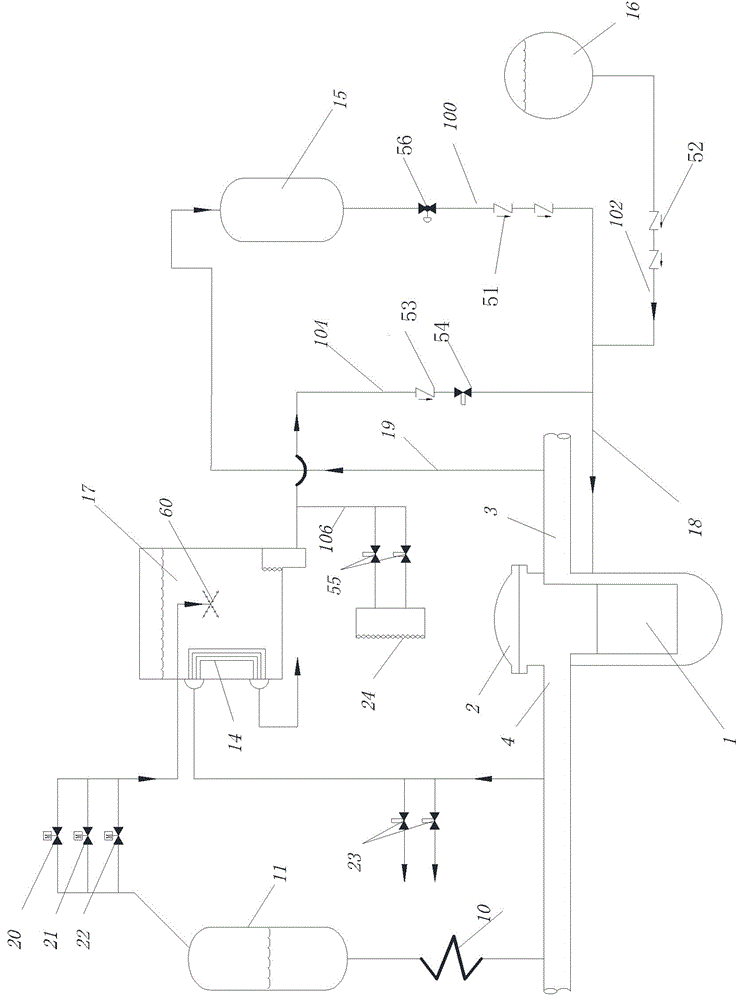

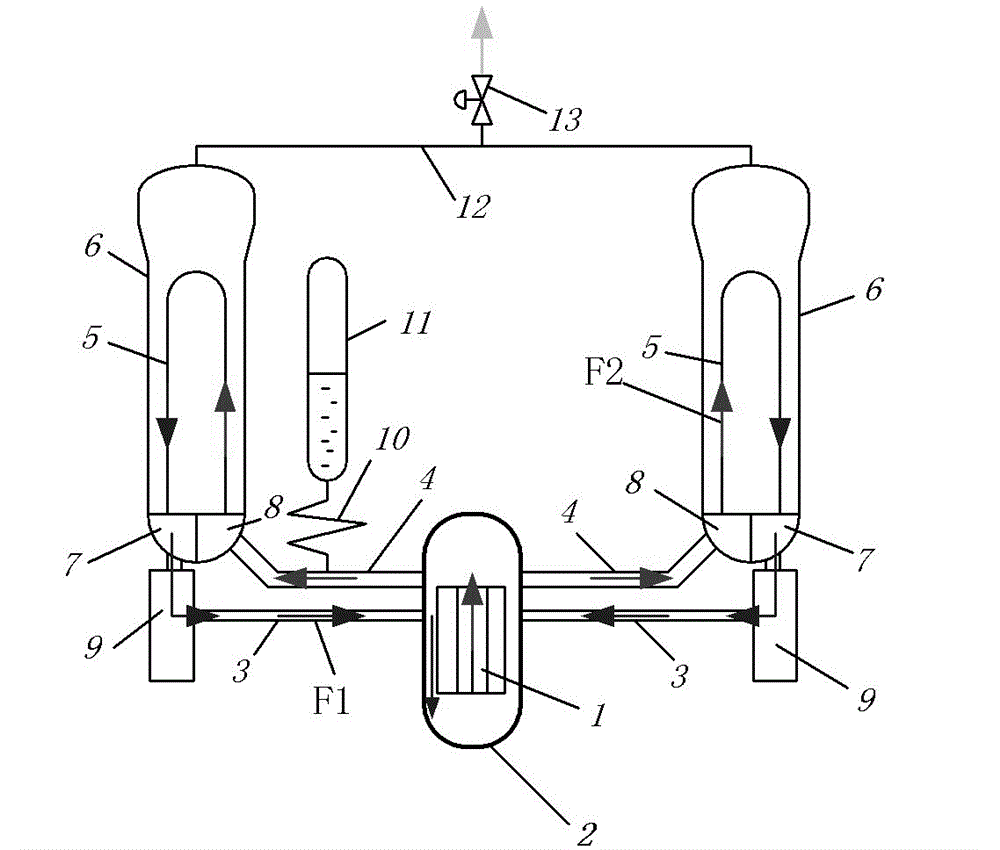

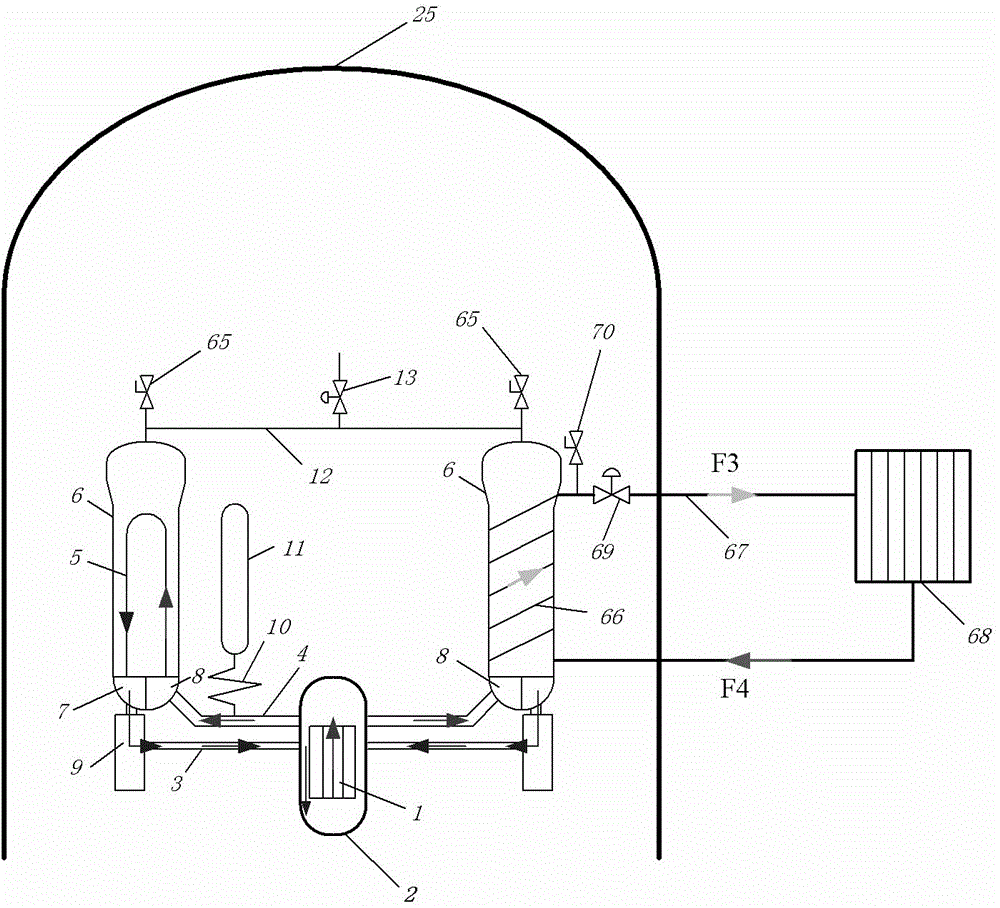

Passive residual heat removal system for nuclear power plant

ActiveCN105810256AConducive to production recoveryRelieve pressureNuclear energy generationCooling arrangementIsolation valveNuclear power

The invention relates to a passive residual heat removal system for a nuclear power plant. The passive residual heat removal system for the nuclear power plant comprises a steam generator shell heat exchanger, a heat exchange loop pipeline, a shell exterior heat exchanger, a pressure maintaining valve, an isolating valve and a heat transferring medium, wherein the heat exchange loop pipeline penetrates through a containment; the steam generator shell heat exchanger is distributed on a steam generator and is communicated with the heat exchange loop pipeline; the shell exterior heat exchanger is arranged outside the containment and is communicated with the heat exchange loop pipeline; the shell exterior heat exchanger is arranged at a high position relative to the position of the steam generator shell heat exchanger; the pressure maintaining valve and the isolating valve are arranged in the containment and are sequentially arranged between the steam generator shell heat exchanger and the shell exterior heat exchanger along a first flow direction of the heat transferring medium in the heat exchange loop pipeline; the passive residual heat removal system for the nuclear power plant is maintained in a relatively low pressure level by virtue of the pressure maintaining valve; and the isolating valve and a shutdown safety signal of a reactor are subjected to interlock opening to be used for continuously taking away heat in the steam generator during an accident.

Owner:STATE NUCLEAR HUAQING BEIJING NUCLEAR POWER TECH R & D CENT +1

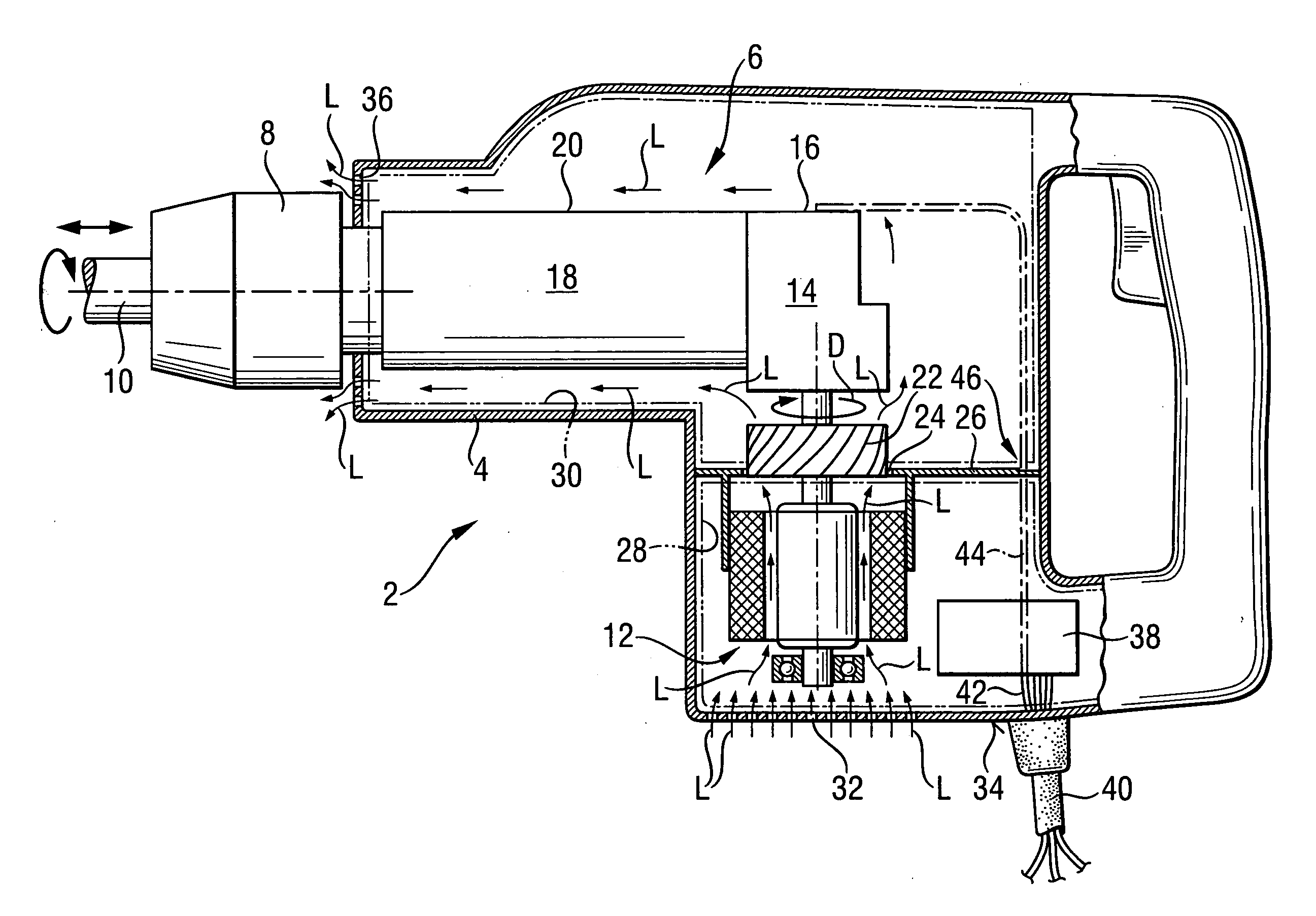

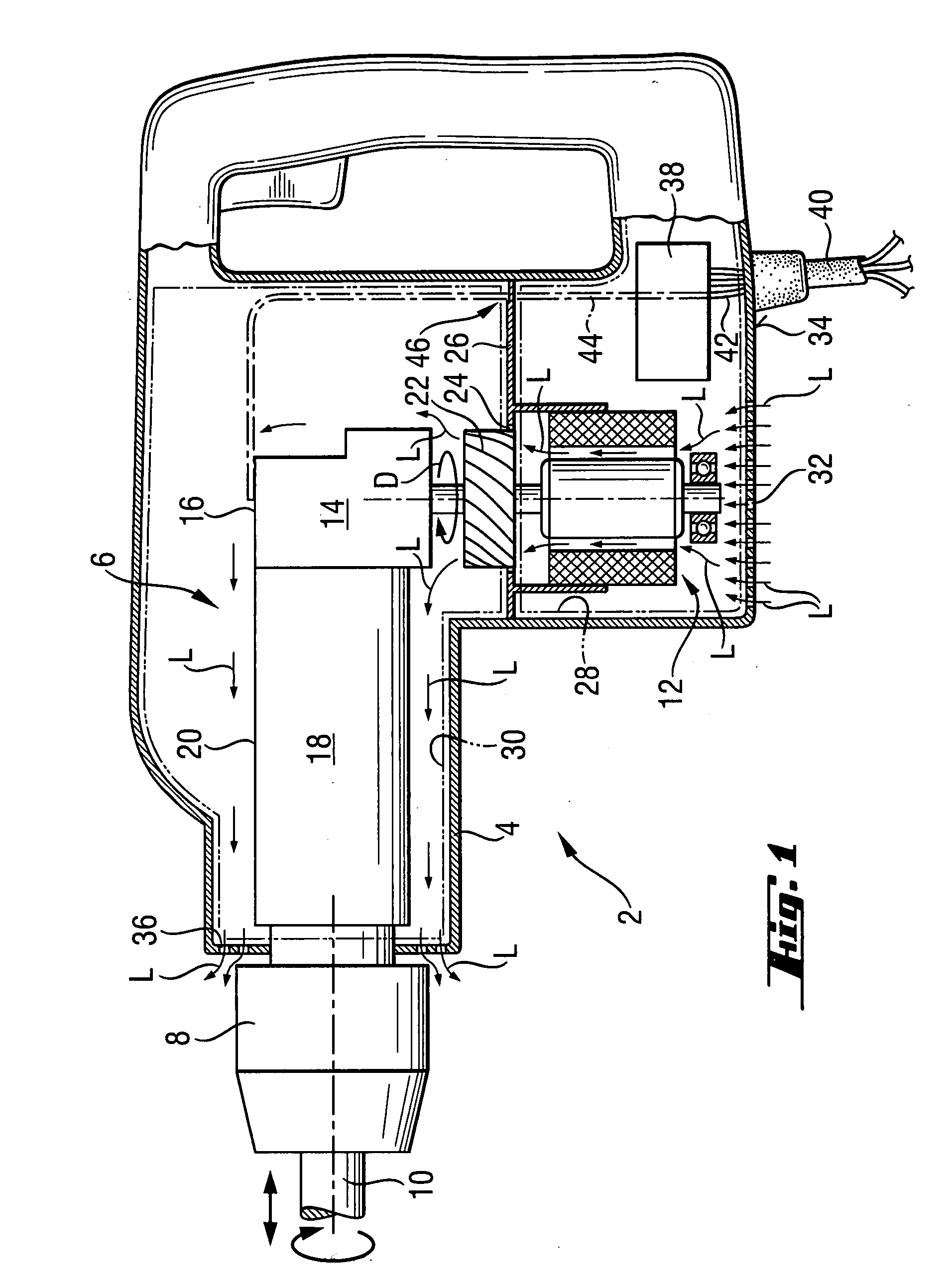

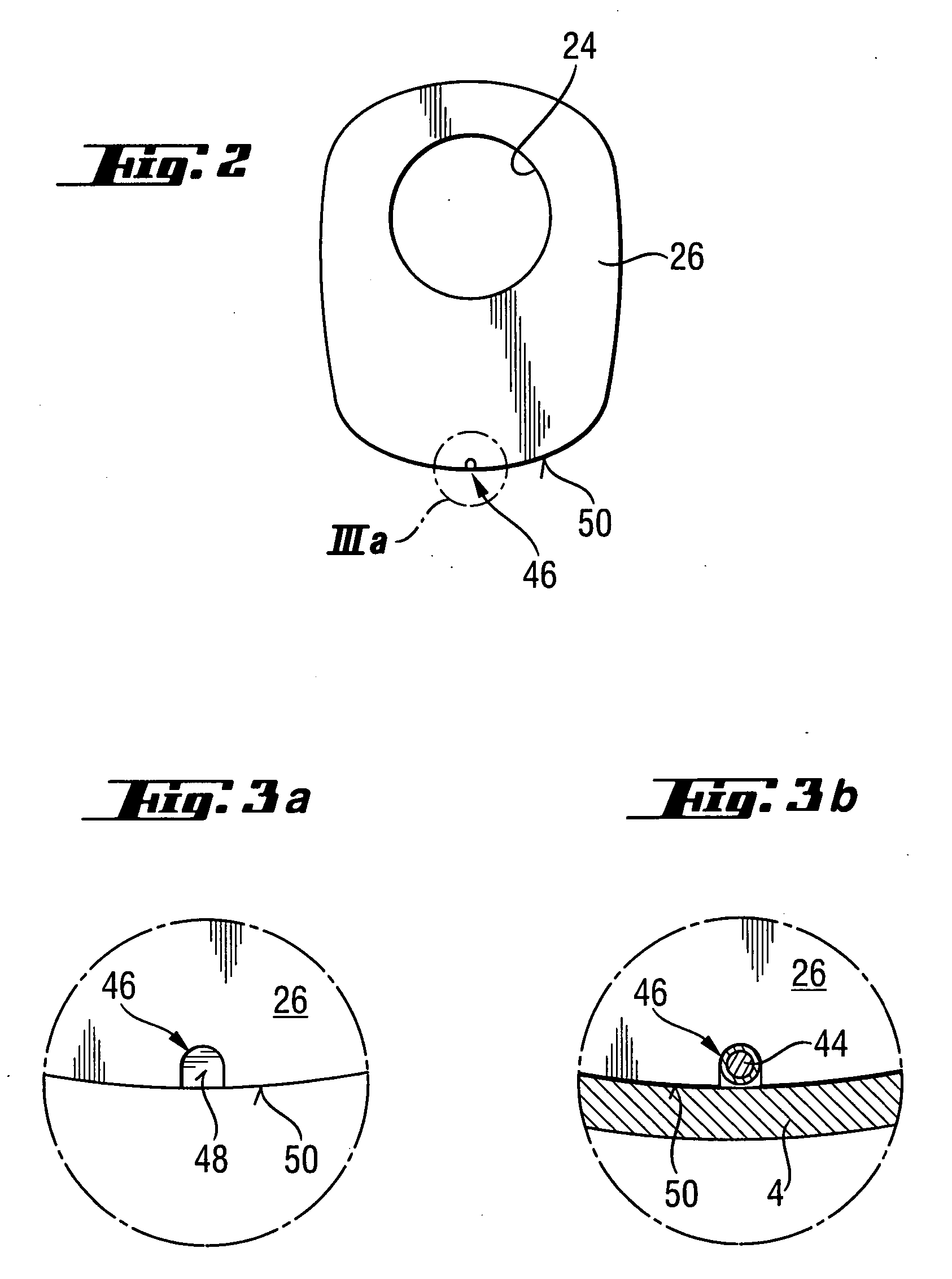

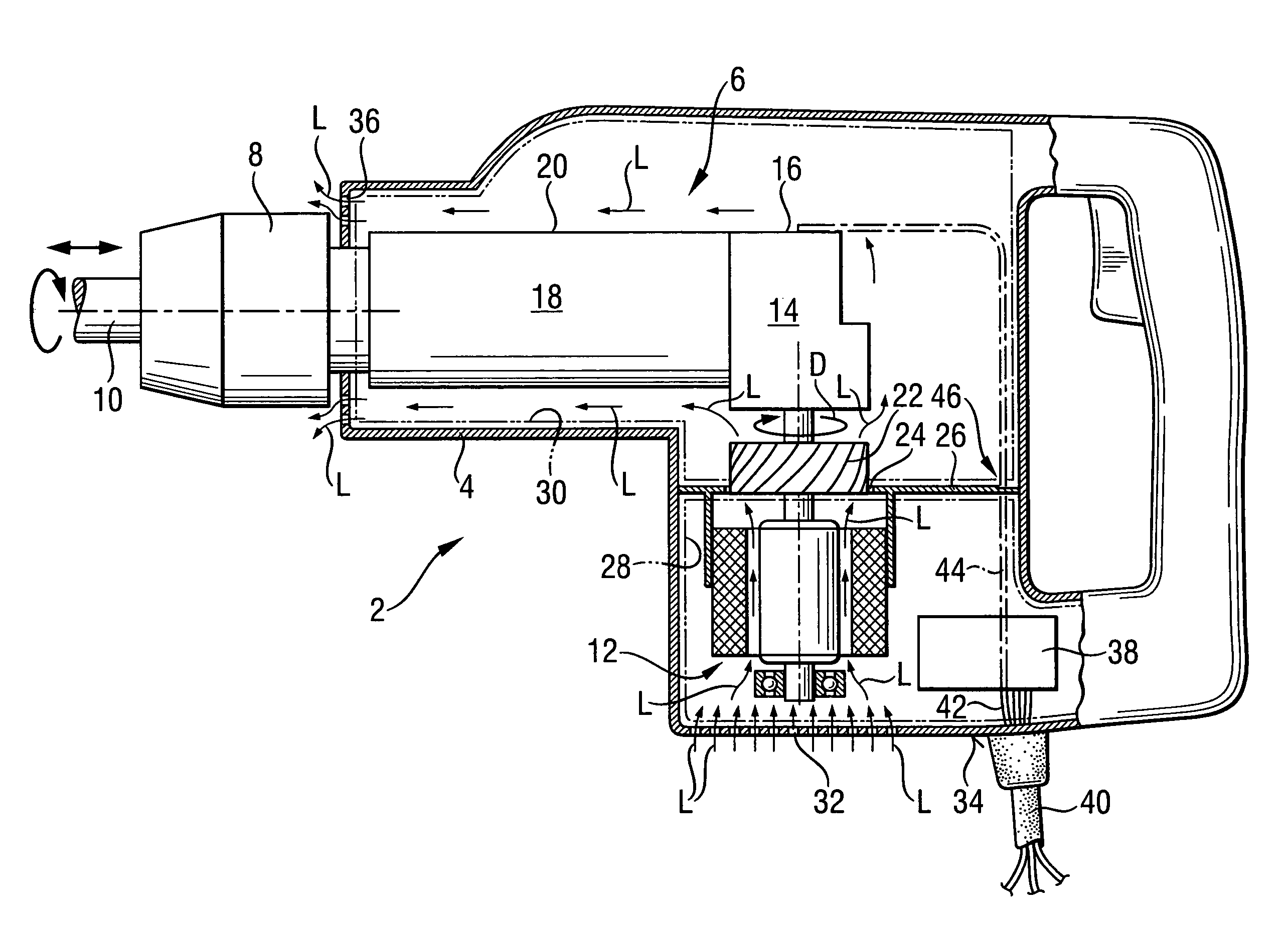

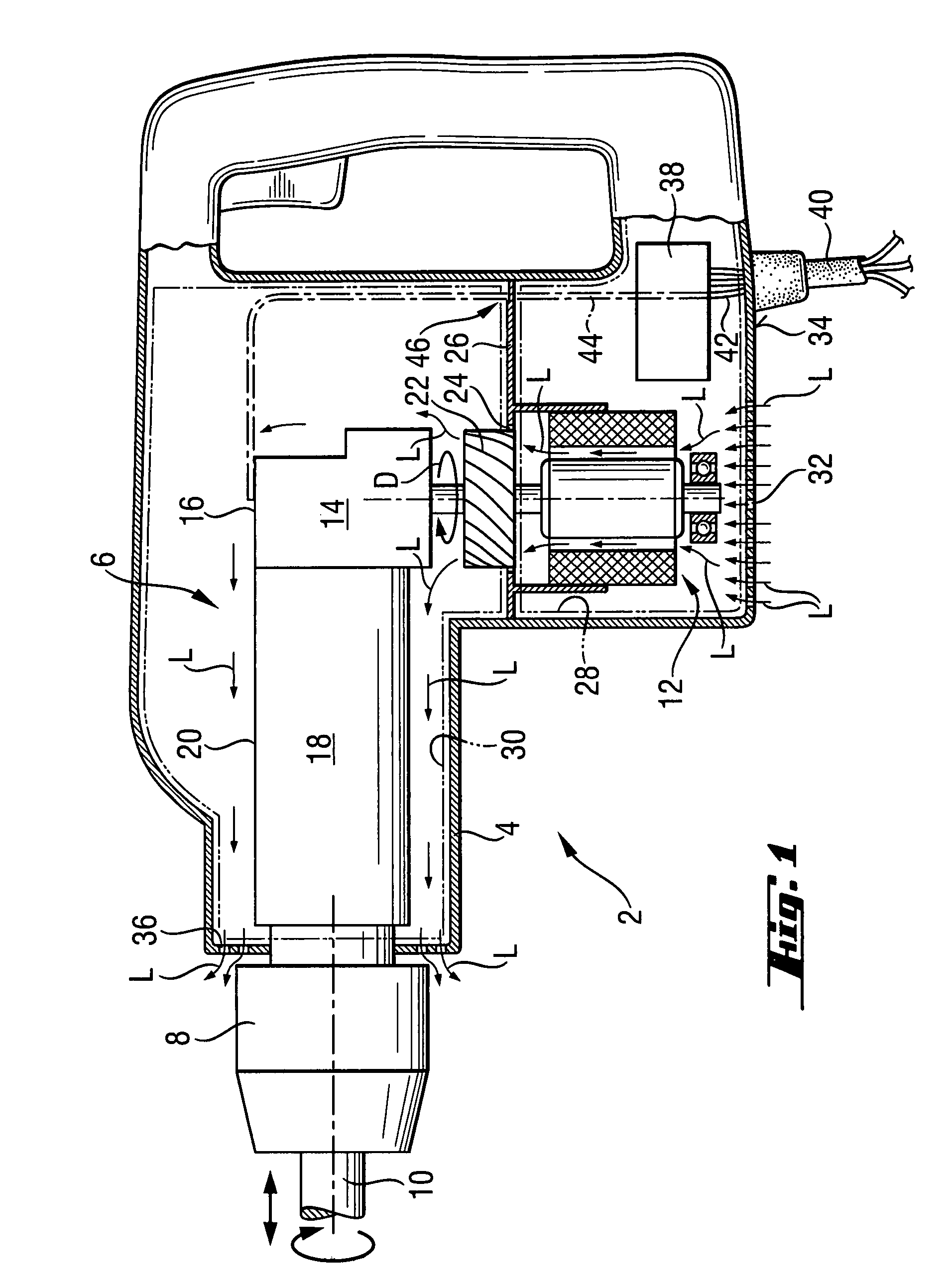

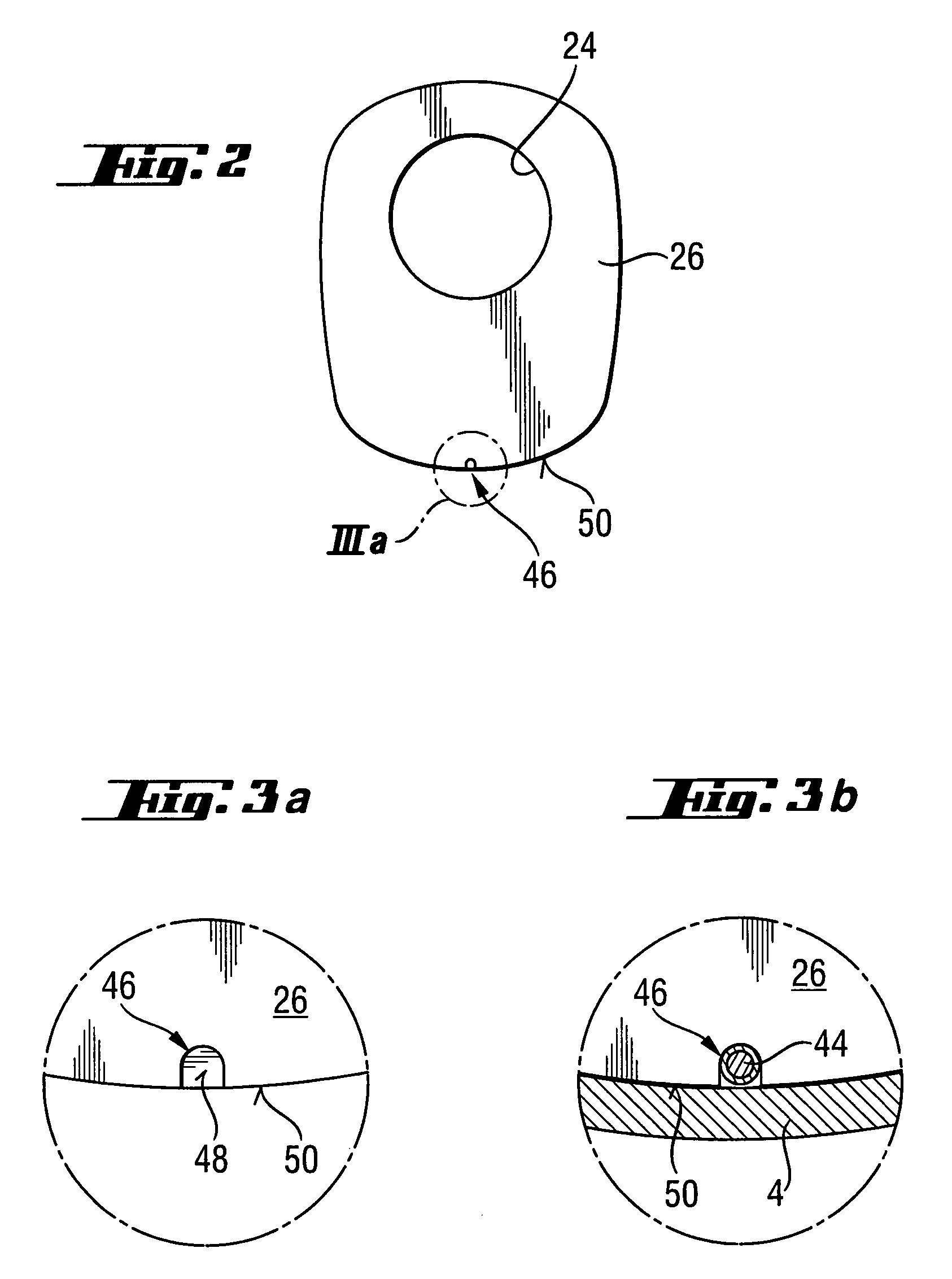

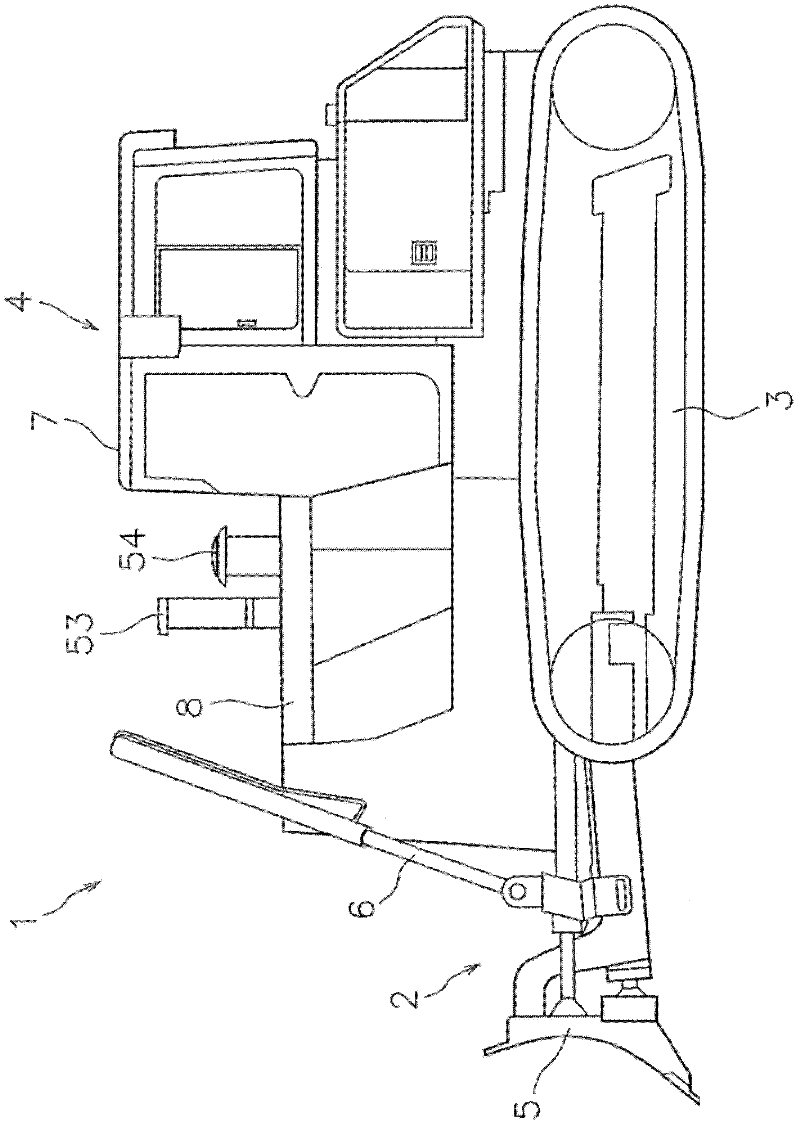

Hand-held power tool with grounding

An electrical hand-held power tool (2) includes a housing (4) in which a drive (6) is located, a ventilator (22) for forming a suction region (28) and a pressure region (30) in the housing (4) which provide for an air flow (L) that serves for cooling at least parts of the drive (6), and a separation element (26) arranged between the suction region (28) and the pressure region (30) and fixedly secured in the housing (4), the separation element (46) having an opening for forming a limited wire passage region (46) from the suction region (28) into the pressure region (30).

Owner:HILTI AG

Hand-held power tool with grounding

Owner:HILTI AG

Work vehicle

ActiveCN102666174AReduce cooling efficiencyGreat accessExhaust apparatusSilencing apparatusEngineeringHeat spreader

In a work vehicle, an engine compartment is disposed forwards of a cab. An exhaust gas treatment device is disposed over an engine in the engine compartment. A radiator is disposed forwards of the exhaust gas treatment device (33) in the engine compartment. A blower is configured to generate an airflow passing through the radiator from back to front of the radiator. The exhaust gas treatment device is slanted with respect to a vehicle width direction for increasing a distance between the exhaust gas treatment device and the radiator towards a first lateral face portion. Further, the first lateral face portion includes air inlets facing a space between the exhaust gas treatment device and the radiator.

Owner:KOMATSU LTD

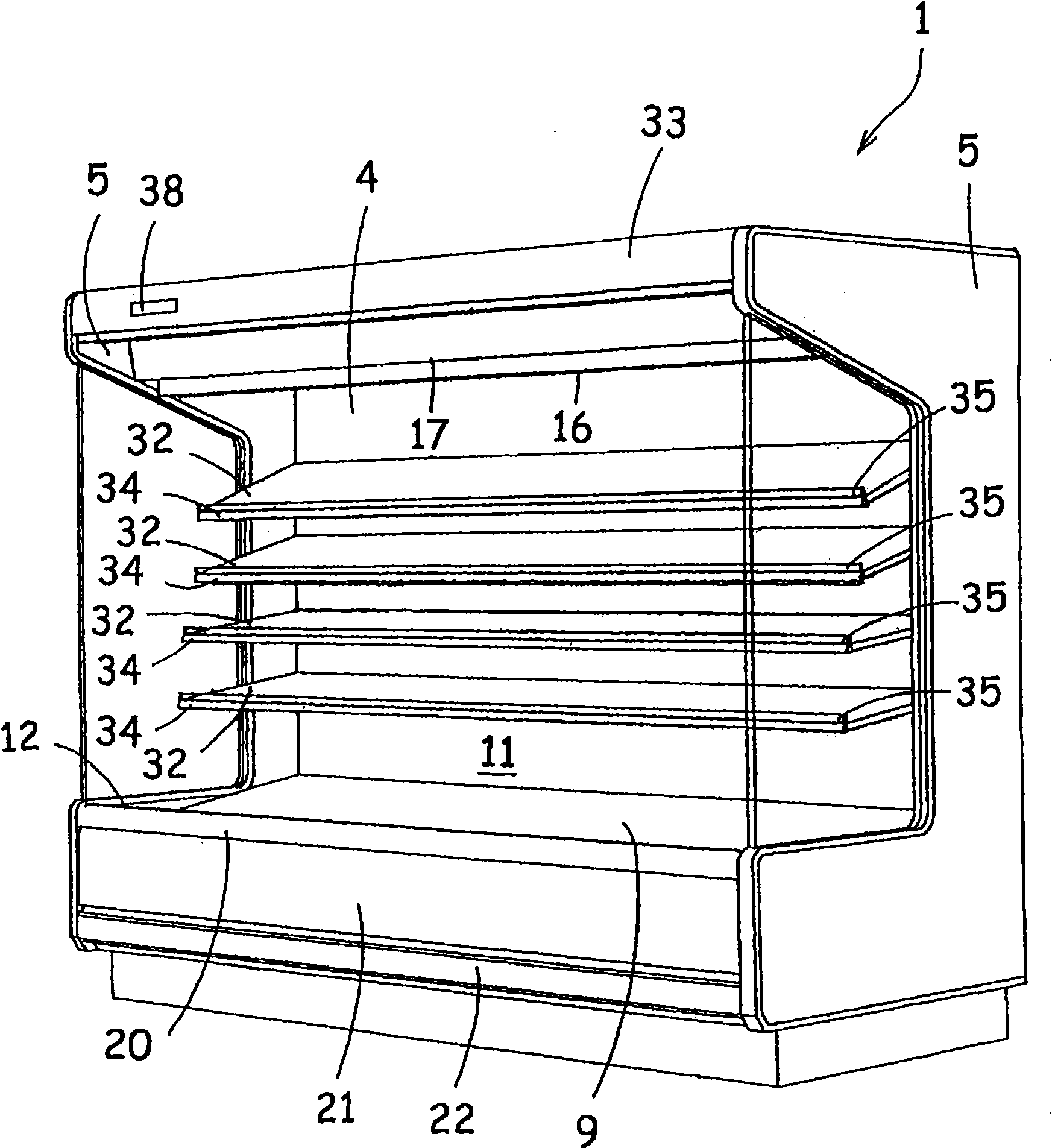

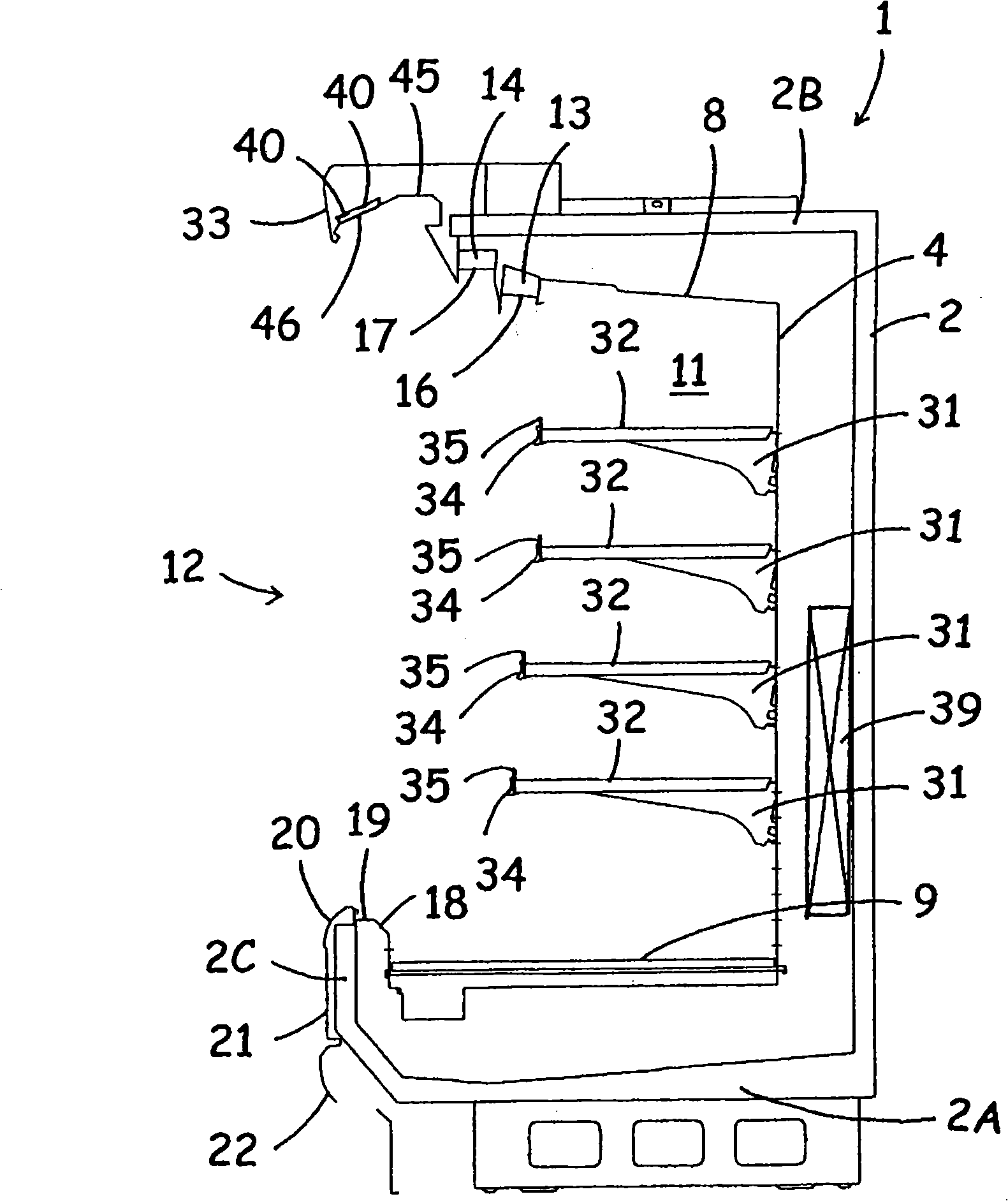

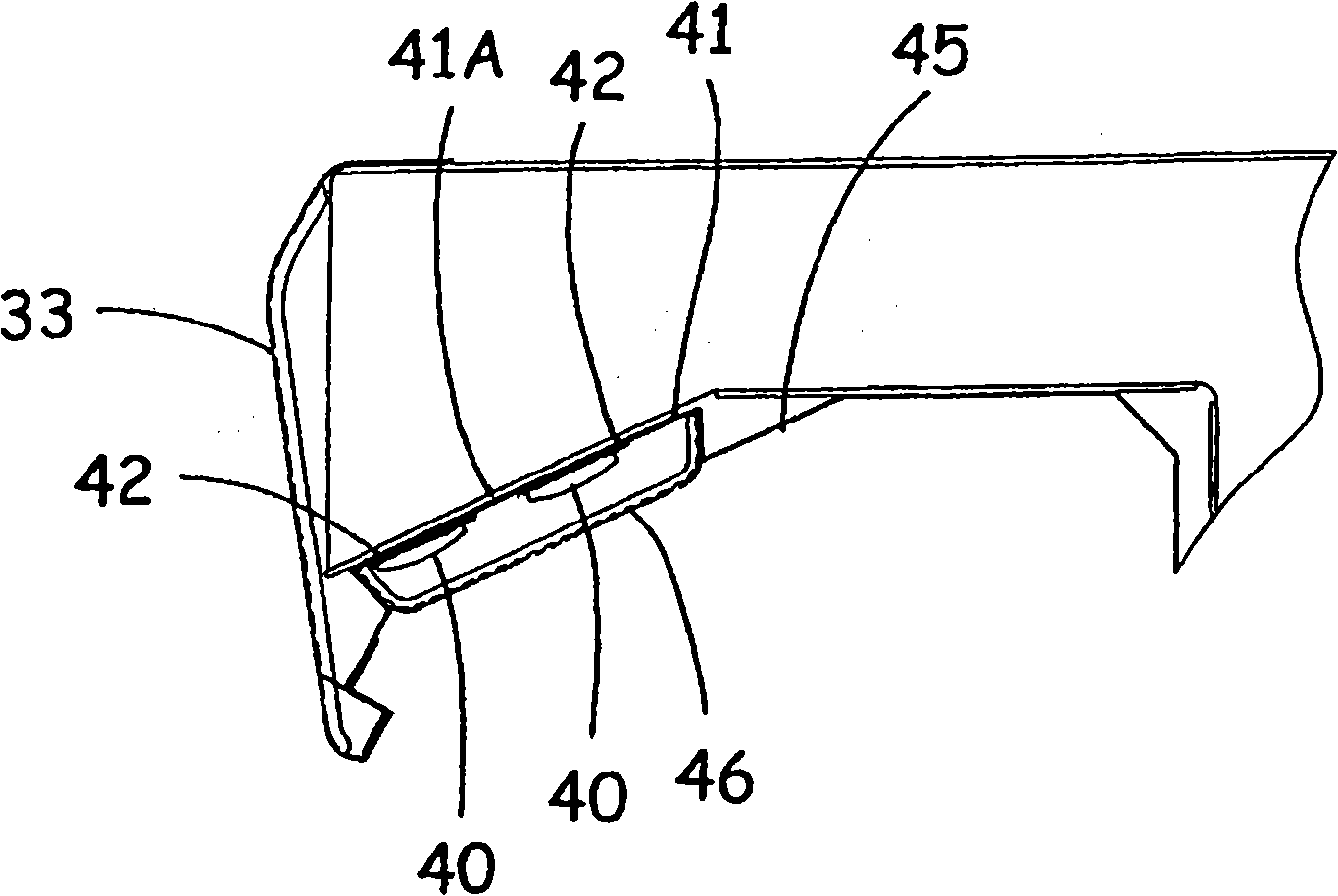

Open showcase

InactiveCN101254058AEffective lightingLess power consumptionLighting applicationsShow cabinetsEngineeringReflective layer

In an open showcase 1 of the present invention, a display chamber 11 is formed in an insulating wall 2 to display commodities in the display chamber 11 while cooling the commodities, the showcase includes a reflective plate 45 which extends externally from a front surface opening 12 of the display chamber 11, and LED lights 40 attached to the reflective plate 45, and the inside of the display chamber 11 is illuminated with light emitted from the LED lights 40. Thus, the invention provides an open showcase provided with a light device capable of simplifying a maintenance operation and improving a cooling efficiency in a display chamber.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com