Patents

Literature

33results about How to "Avoid overshoot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

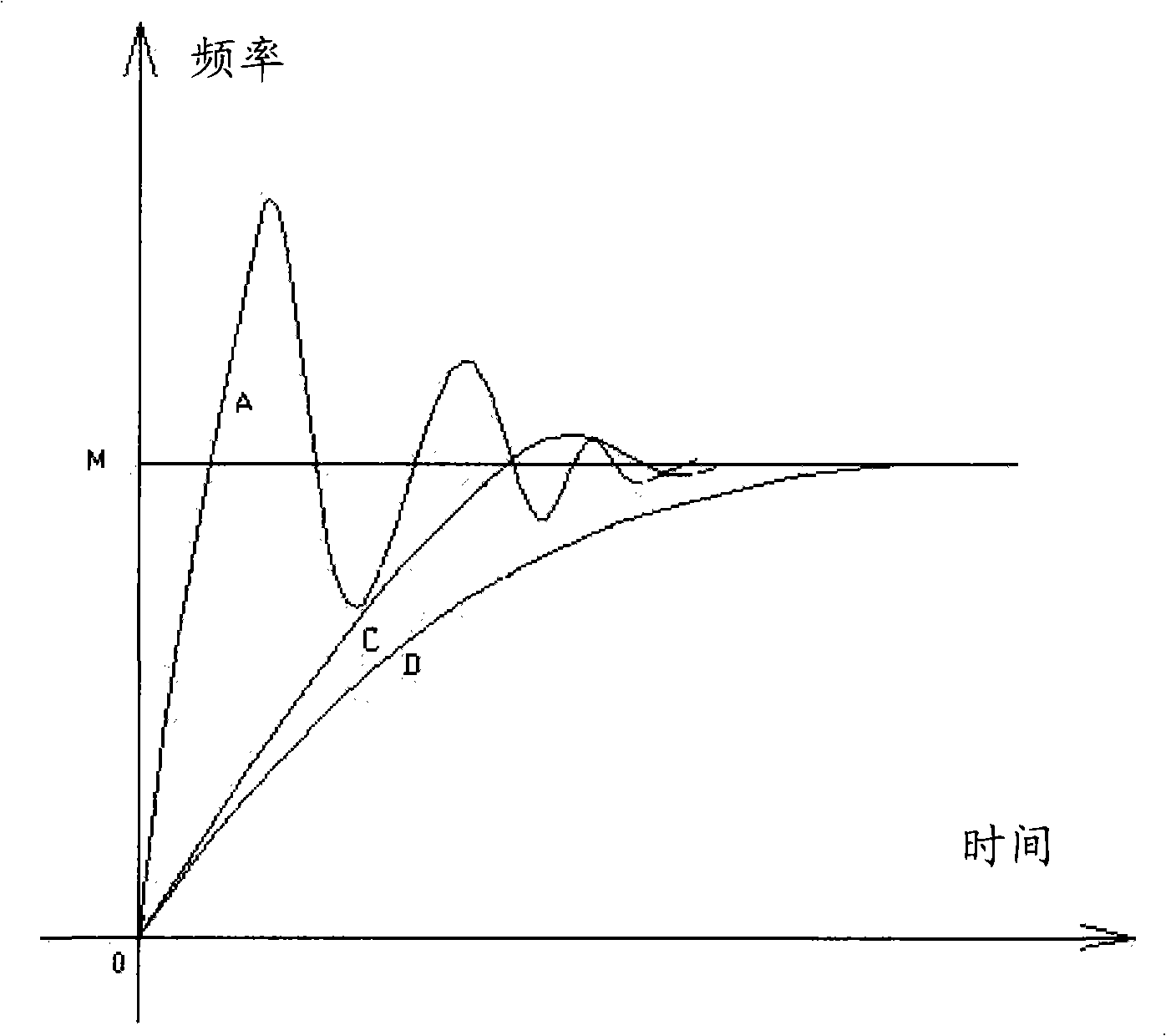

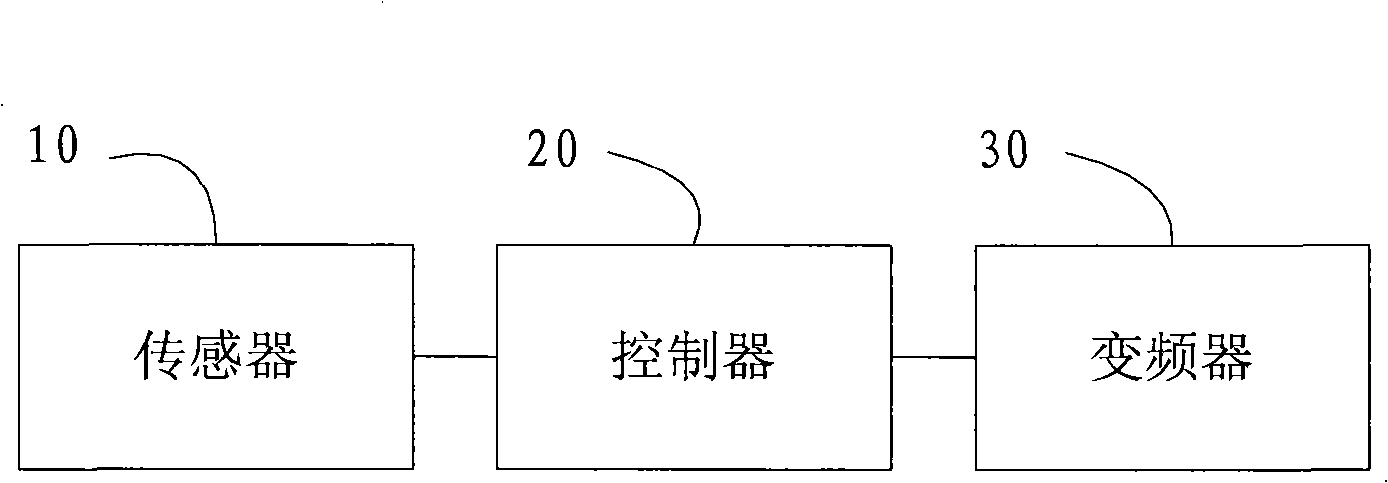

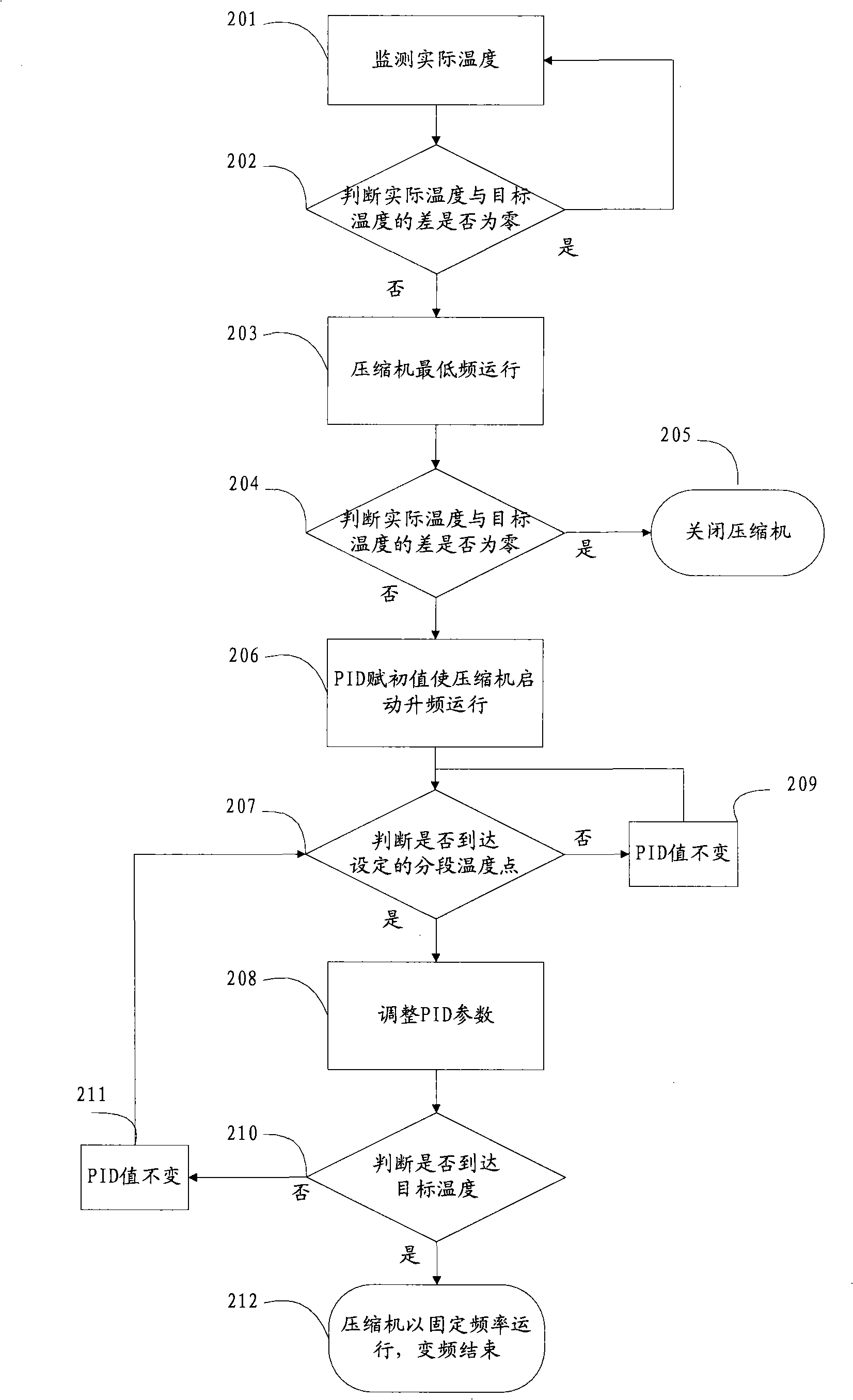

Method and device for controlling inverter compressor

InactiveCN101539151AImprove cooling efficiencyAvoid overshootPump controlRefrigeration safety arrangementConstant frequencyEngineering

The invention discloses a method for controlling an inverter compressor. According to the method, a target temperature and a dividing temperature point are preset, and a sensor monitors an actual temperature value. The method comprises the following steps that: a controller judges whether the difference between an actual temperature and the target temperature is zero, and the compressor operates at a minimum frequency for a certain period if the difference between an actual temperature and the target temperature is zero; the controller judges whether the target temperature is reached, and thecompressor stops operation if the target temperature is reached, or the controller initializes a PID parameter to allow an inverter to make the compressor start to raise frequency quickly if the target temperature is not reached; the controller judges whether the preset dividing temperature point is reached, and the PID parameter is adjusted if the preset dividing temperature point is reached, orthe PID parameter is kept constant if the reset dividing temperature point is not reached; and the controller judges whether the target temperature is reached, and the compressor operates at a constant frequency and the frequency inversion is finished if the target temperature is reached, or the compressor raises frequency while keeping the original PID parameter if the target temperature is not reached. Correspondingly, the invention also provides a device for controlling the inverter compressor. The method and the device can realize a quick, energy-saving and stable frequency inversion process at the same time.

Owner:HAIER GRP CORP +1

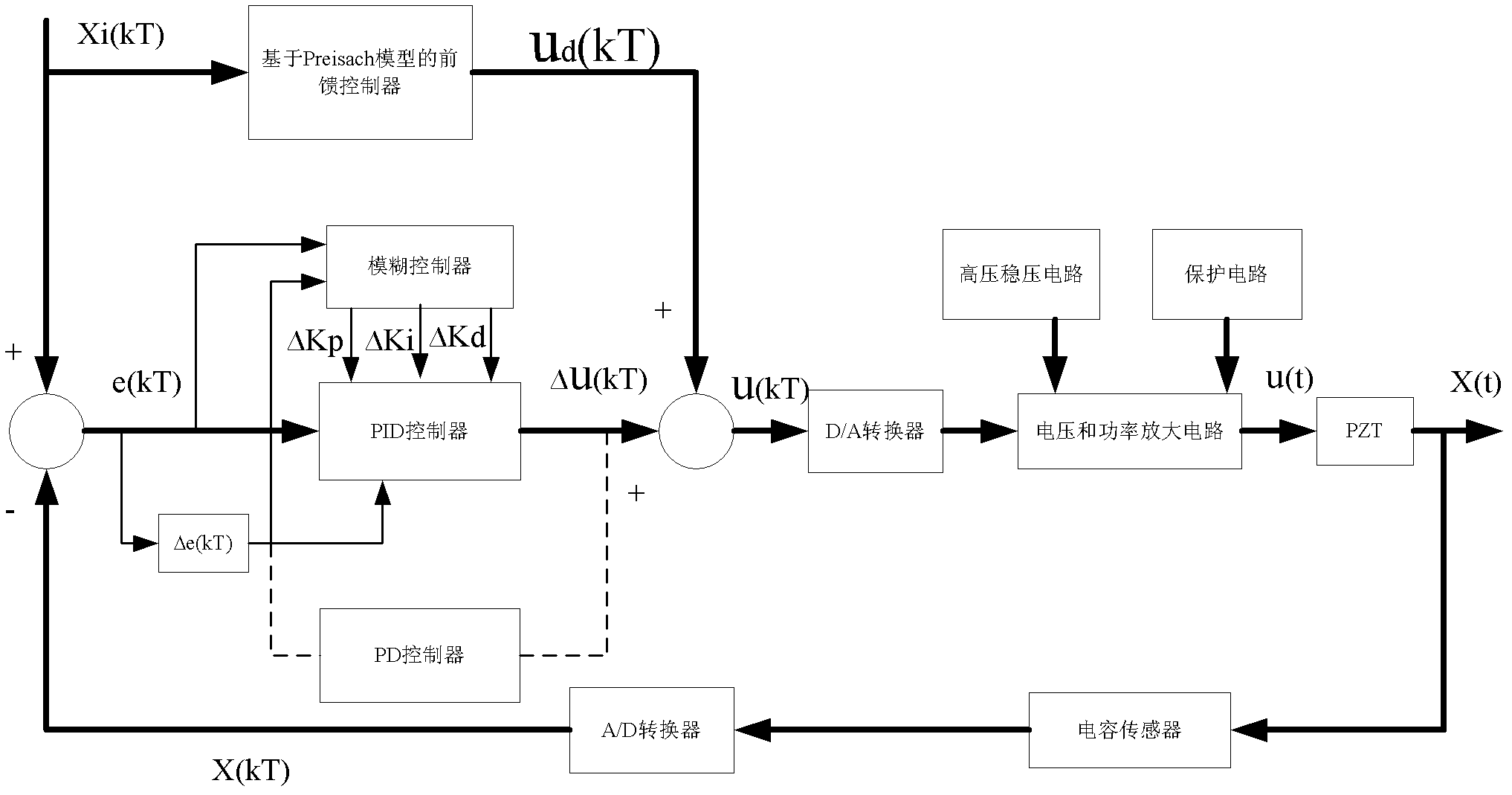

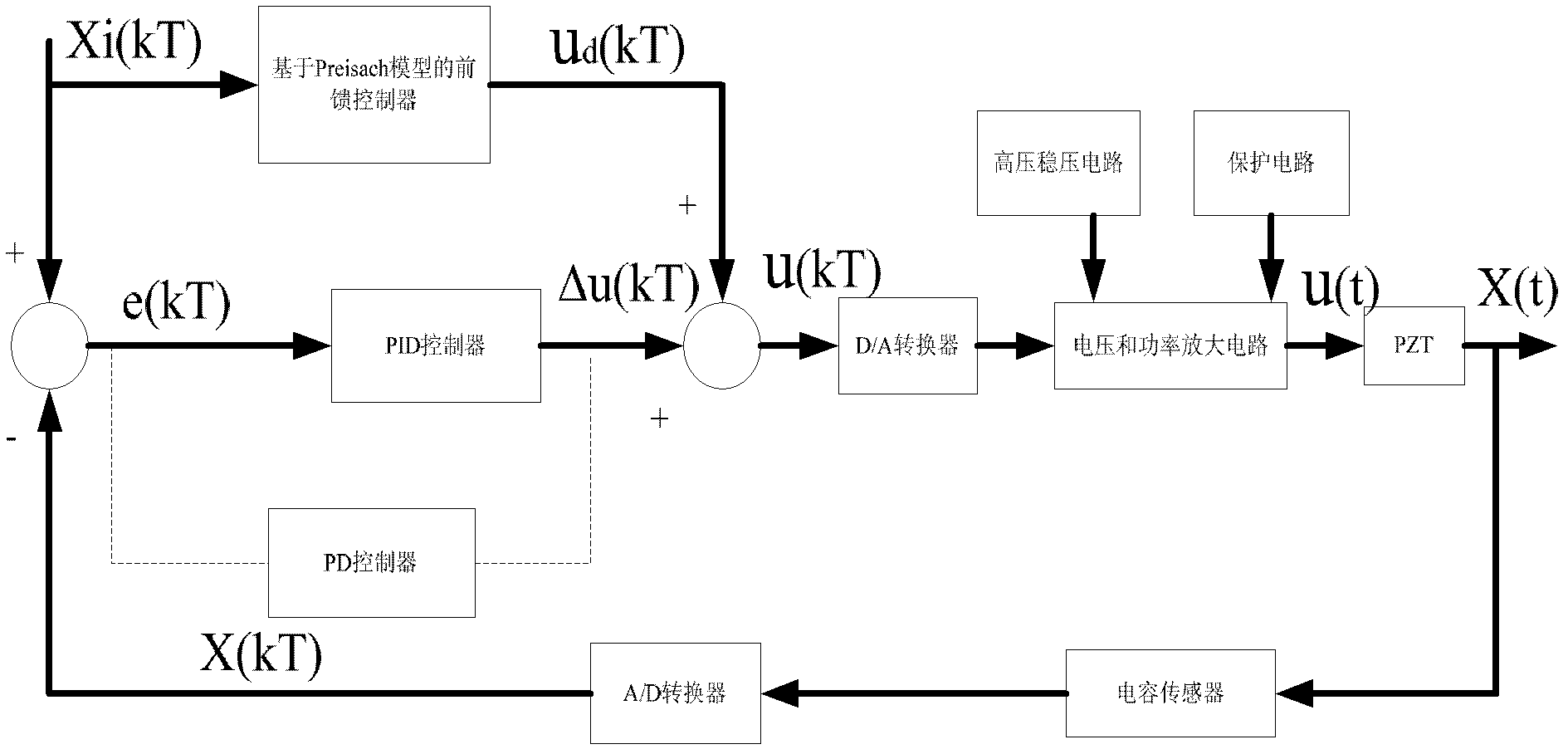

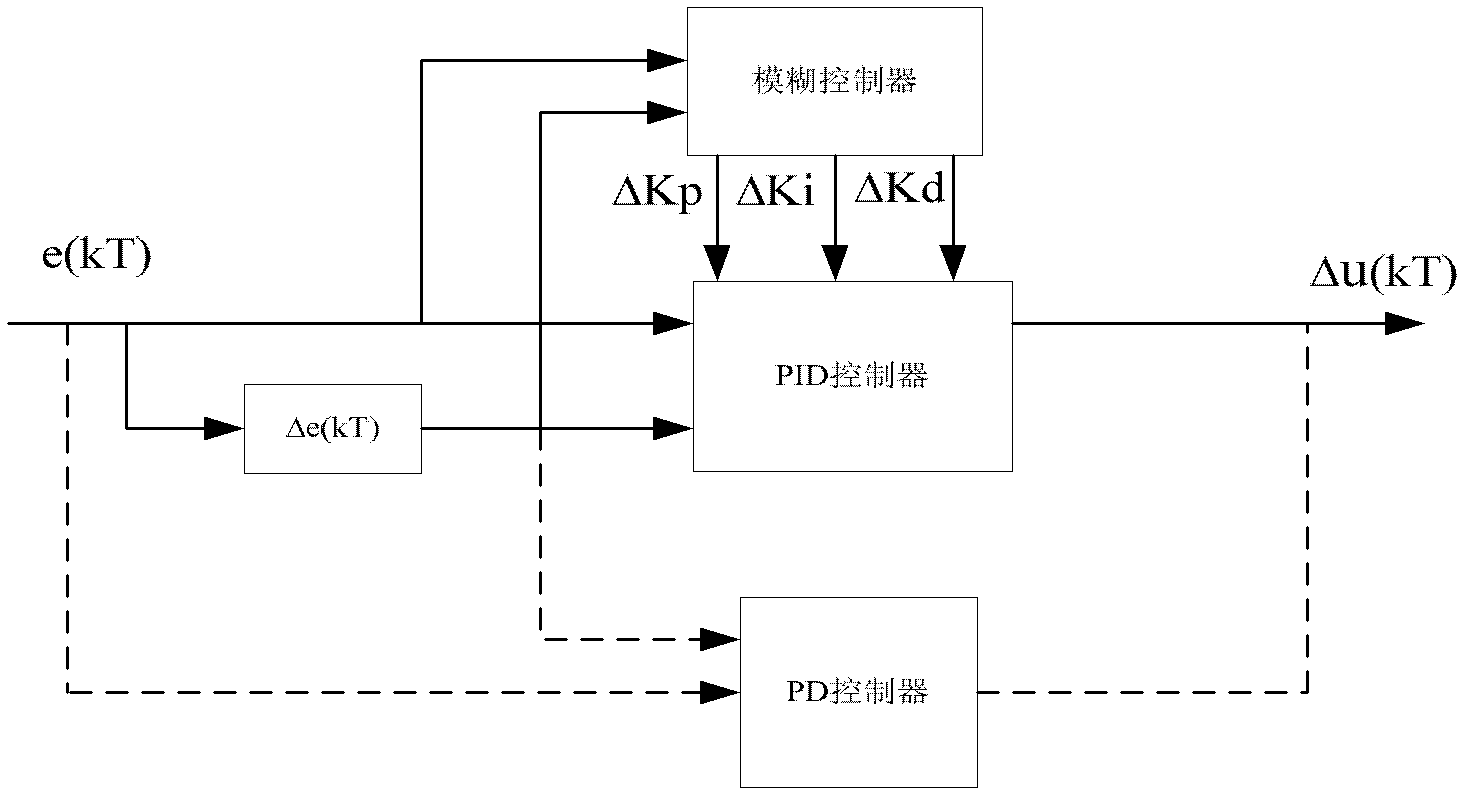

Composite control method for piezoelectric ceramic positioning

The invention provides a composite control method for piezoelectric ceramic positioning. In the method, different control combination ways are adopted in an entire process; a threshold value delta is set; composite control of feedback control and PID (Proportion Integration Differentiation) control, or composite control of feedback control and PD (Proportion Differentiation) control is used selectively according to the magnitude relation between a displacement deviation e (kT) and the threshold value delta. According to the method, a mathematical model is required to be established, the lag and nonlinearity of a piezoelectric ceramic driver are described by adopting the conventional Preisach model, and the parameter of PID or PD is self-tuned on line by using fuzzy control, so that optimal control of a system can be realized, and the system has the advantages of flexibility, high adaptability and the like of fuzzy control. In the method, a selective control method combination is used for the first time, so that the positioning accuracy of piezoelectric ceramic is increased effectively, the stability and interference resistance are enhanced, the response rise time is shortened, and lag and creepage are eliminated effectively simultaneously.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

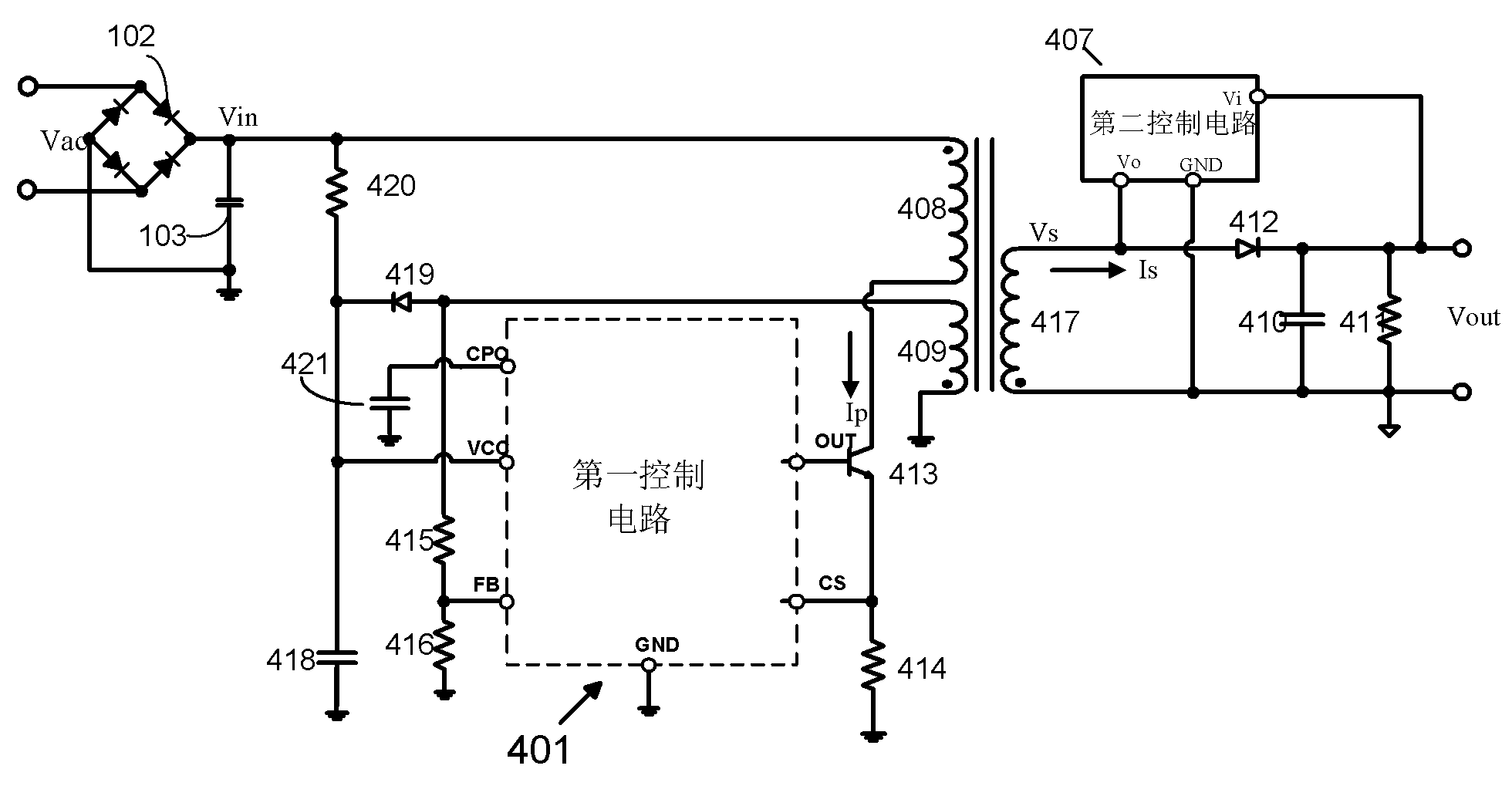

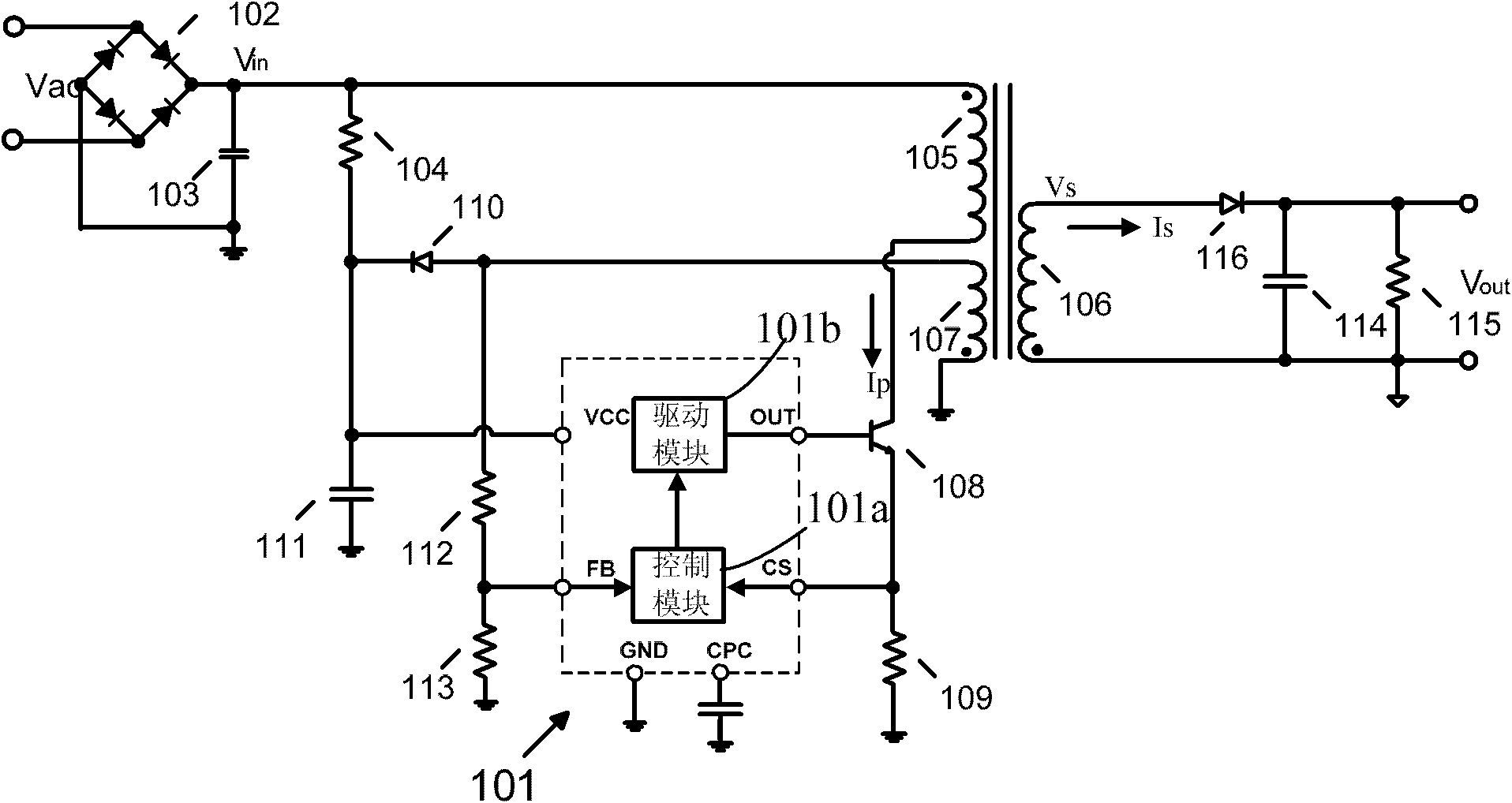

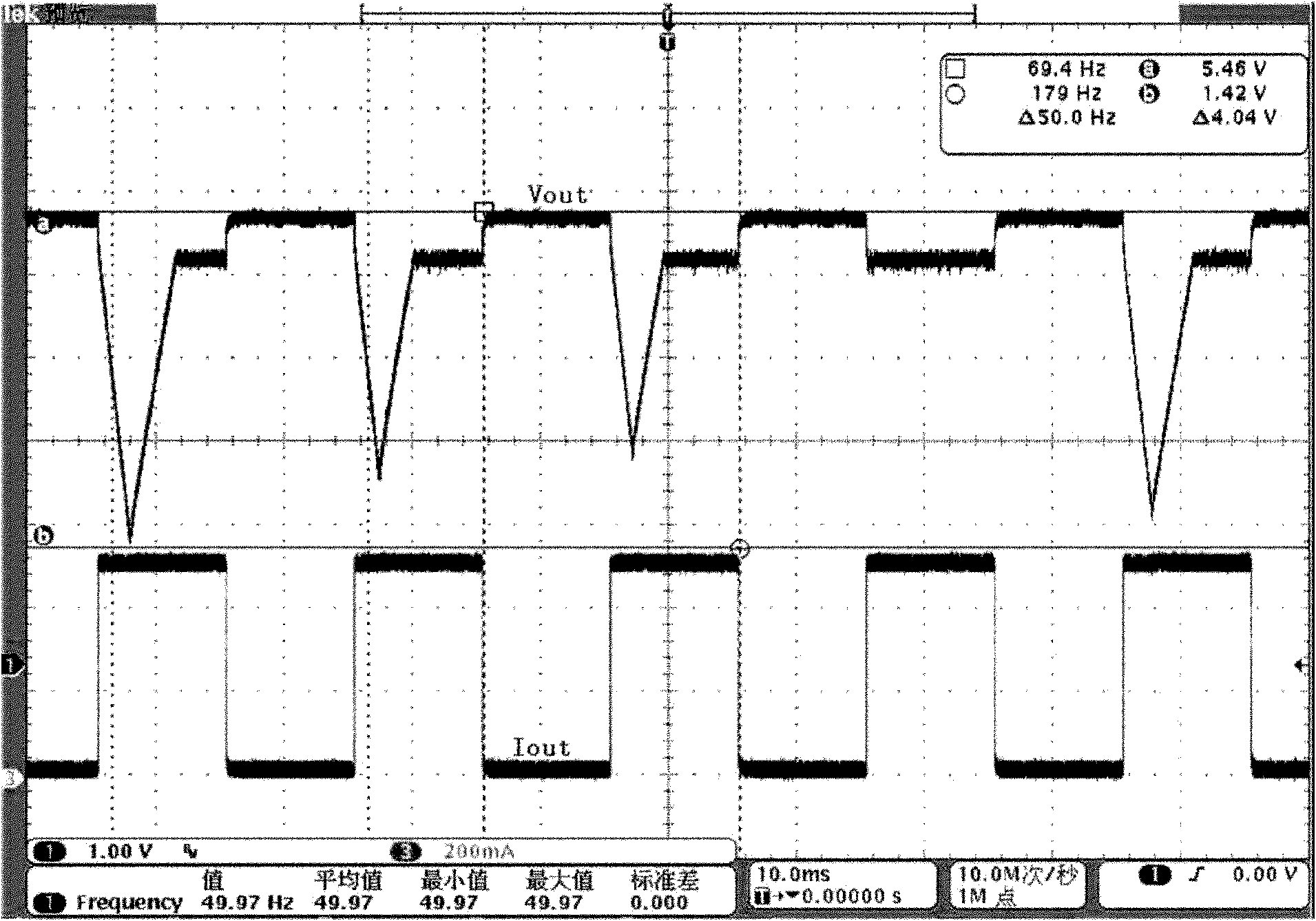

Switching power supply and controlling method thereof

ActiveCN102097949AAvoid overshootPrevent overshootEfficient power electronics conversionDc-dc conversionStandby powerEngineering

The invention discloses a switching power supply, which comprises a transformer primary side winding, a transformer auxiliary winding, a transformer secondary side winding, and a first control circuit coupled to the transformer primary side winding. The base electrode of a power transistor is connected with the output end of the first control circuit, the collector electrode is connected with the different end of the transformer primary side winding, and the emitter is earthed. The switching power supply further comprises a second control circuit coupled to the transformer secondary side winding, wherein the input end of the second control circuit is connected with the output end of the switching power supply, and the output end of the second control circuit is connected with the different end of the auxiliary winding. When the input voltage Vout of the switching power supply is lower than a first set voltage value, the second control circuit transmits a pulse signal to the first control circuit, and the first control circuit controls the power transistor to be conducted in order to transfer energy to the output end of the switching power supply through the transformer primary side winding. By the invention, the standby power consumption can be improved, and the output voltage precision in the light load and idle load range can be increased.

Owner:BCD (SHANGHAI) MICRO ELECTRONICS LTD

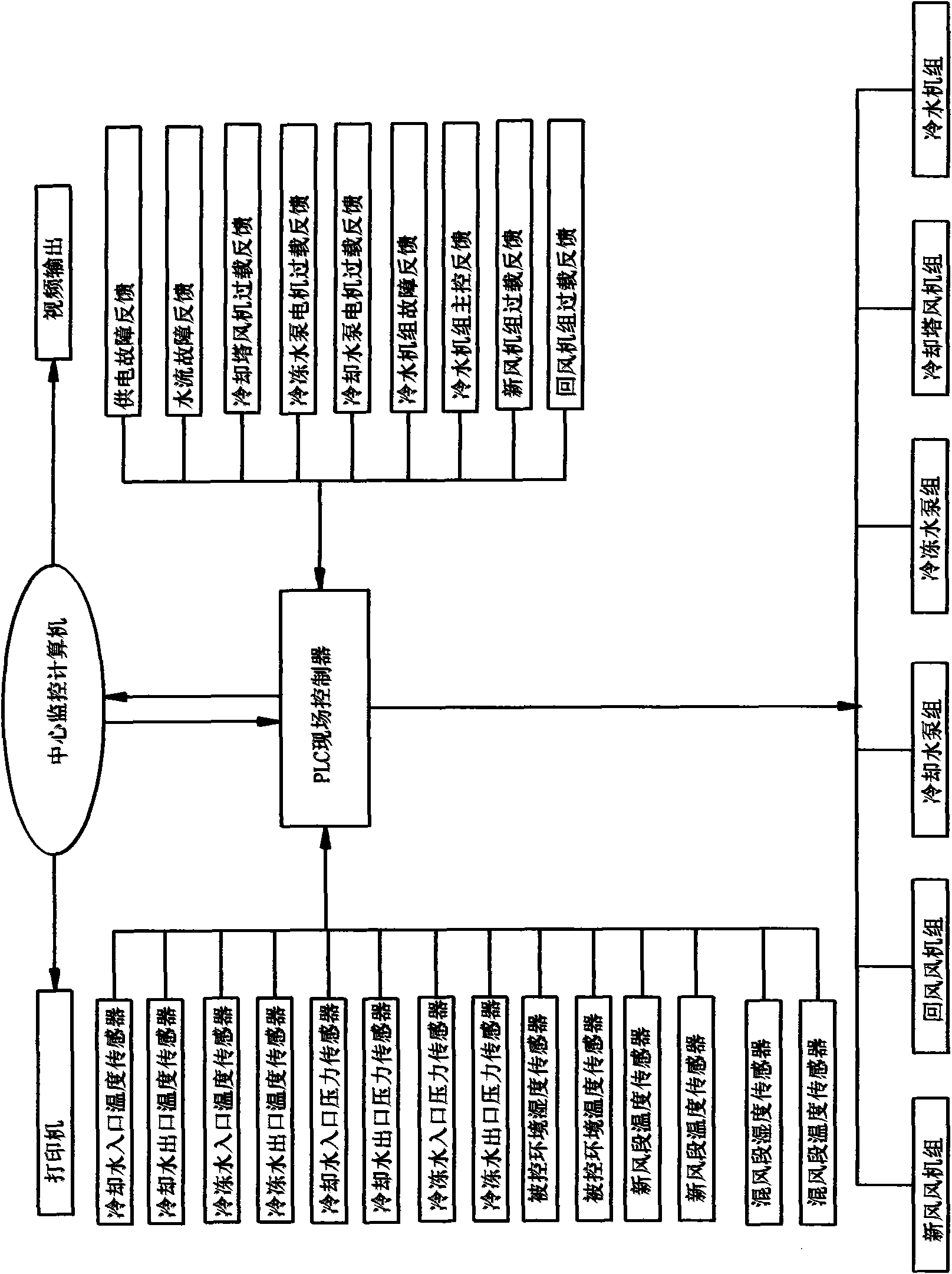

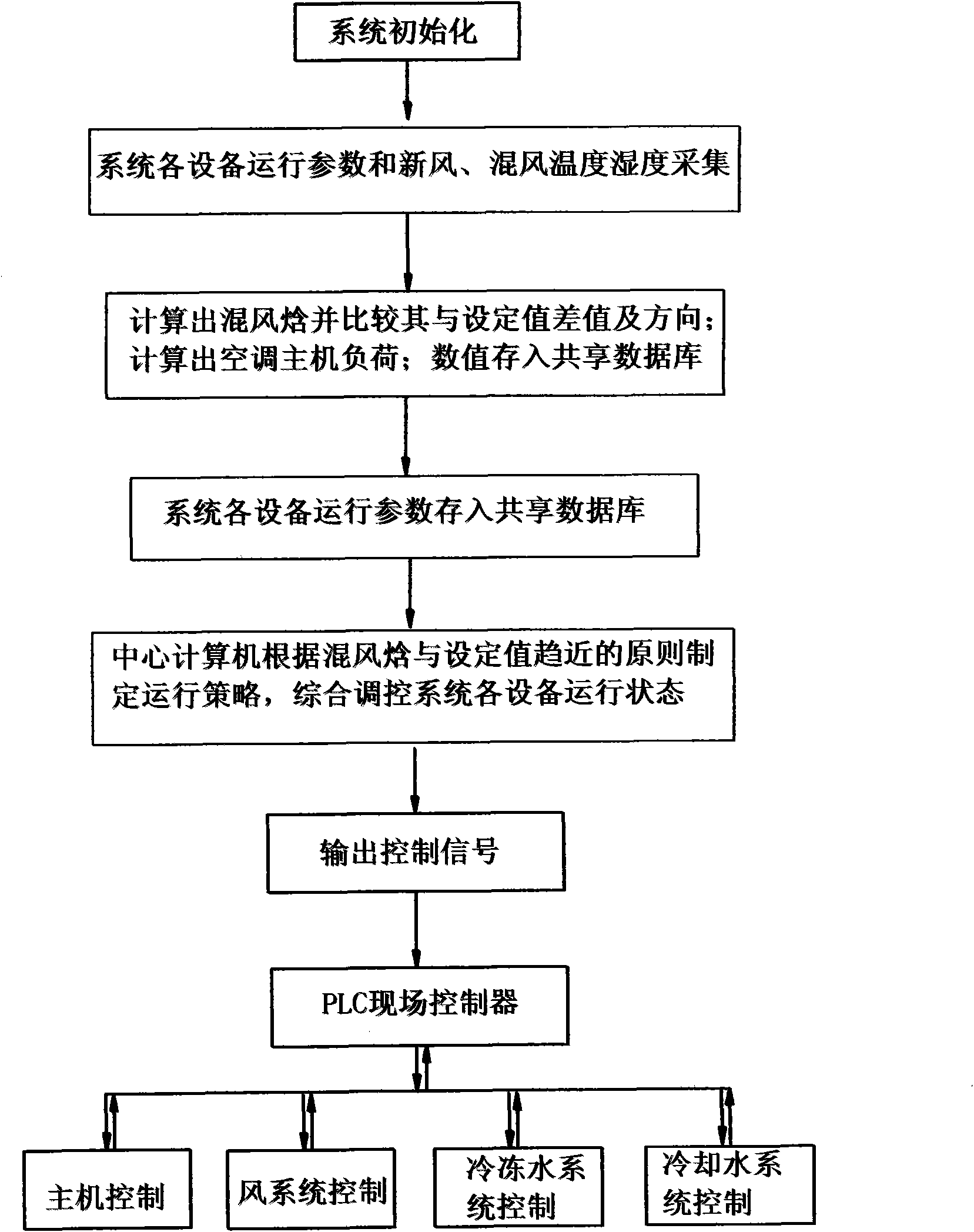

Enthalpy control-based method and system for controlling energy conservation of air conditioner

InactiveCN101922783ADirect controlShortcut controlSpace heating and ventilation safety systemsLighting and heating apparatusBusiness efficiencyProcess engineering

The invention relates to an enthalpy control-based method and an enthalpy control-based system for controlling energy conservation of an air conditioner. The method comprises the following steps of: increasing and decreasing the load of an air-conditioning system according to the difference values and directions of an enthalpy of an air mixing section and a control target value; making a system operating strategy according to the load of a main unit of the air conditioner and the running state data of each point in the system, an optimal energy efficiency ratio curve of a refrigerating main unit and a principle that the air enthalpy of the air mixing section is close to the control target value so as to comprehensively adjust the chilled water of a central air-conditioning system, cooling water temperature, flow rate, controlled environment end fresh air, air return fan and main unit running load; and therefore, the sum of refrigeration / heat demand of each point and the supply amount of a central air conditioner are balanced.

Owner:CHONGQING TONGFANG SCI & TECH DEV

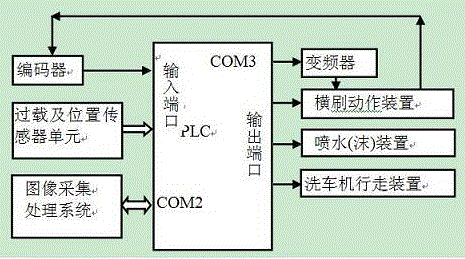

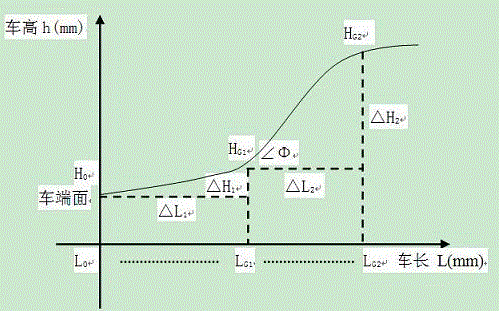

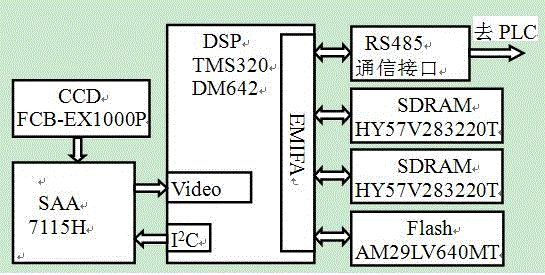

Vehicle cleaning machine profiling control method and apparatus based on machine vision

ActiveCN105955188AAvoid overshootImprove reliabilityCleaning apparatus for vehicle exteriorsProgramme control in sequence/logic controllersAutomotive engineeringControl function

The invention discloses a vehicle cleaning machine profiling control method and apparatus based on machine vision. An intelligent clearing supplement control function is employed, vehicle body images are acquired and processed by use of an image processing system so as to determine whether a vehicle is well cleaned, if cleaning requirements are not met, an intelligent clearing supplement control program is activated, and a control system carried out cleaning supplement operation. According to the invention, the cleaning quality is improved, an intelligent washing intensity control function is realized, vehicle cleanliness data is acquired by a CCD pick-up head, and the data is taken as a basis of washing intensity control; and for dirty positions of a vehicle body, a control brush is closer to the vehicle body for washing, at the same time, the discharge rate of a cleaning agent and water spray pressure are correspondingly increased, the cleaning intensity is increased, and otherwise, the cleaning intensity is reduced.

Owner:安徽创研新材料有限公司

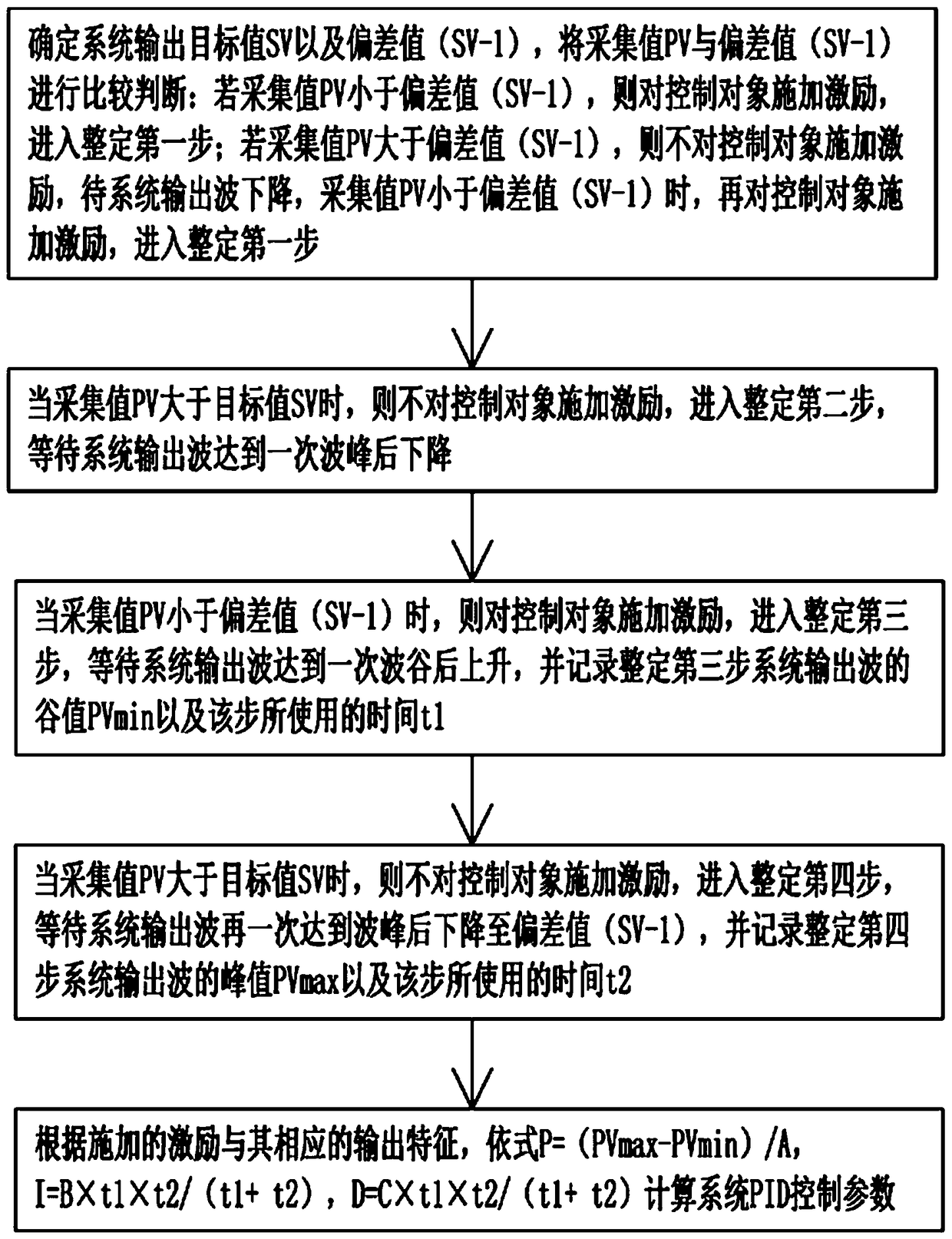

Parameter self-tuning method for PID system

ActiveCN109062033AAvoid shockAvoid overshootControllers with particular characteristicsIndustrial AccidentSelf-tuning

The invention discloses a parameter self-tuning method for a PID system. The parameter self-tuning method for the PID system effectively prevents oscillation of a system output wave near a target value SV or deviation value (SV_n) in a self-tuning process, and excitation application on a control object is stopped only when a system sampling value PV reaches the target value SV, thereby guaranteeing that the system output wave always can reach and control the target value SV, and PID control parameters calculated by a controller are more accurate; besides, the self-tuning method respectively firstly acquires a working condition signal no matter how is a system initial state and then judges whether an excitation is applied to the control object according to comparison of an acquired value PVwith the deviation value (SV_n), namely working condition judgment of the method is prior to control output, the overshoot situation is effectively prevented from appearing, and an industrial accident is avoided from occurring; and a complete waveform, namely a corresponding period, is not required in the self-tuning process, and time of the self-tuning process is shortened, thus system self-tuning detection speed is improved, and the industrial accident is avoided from occurring.

Owner:NINGBO ELECTROMECHANICAL IND RES & DESIGN INST CO LTD

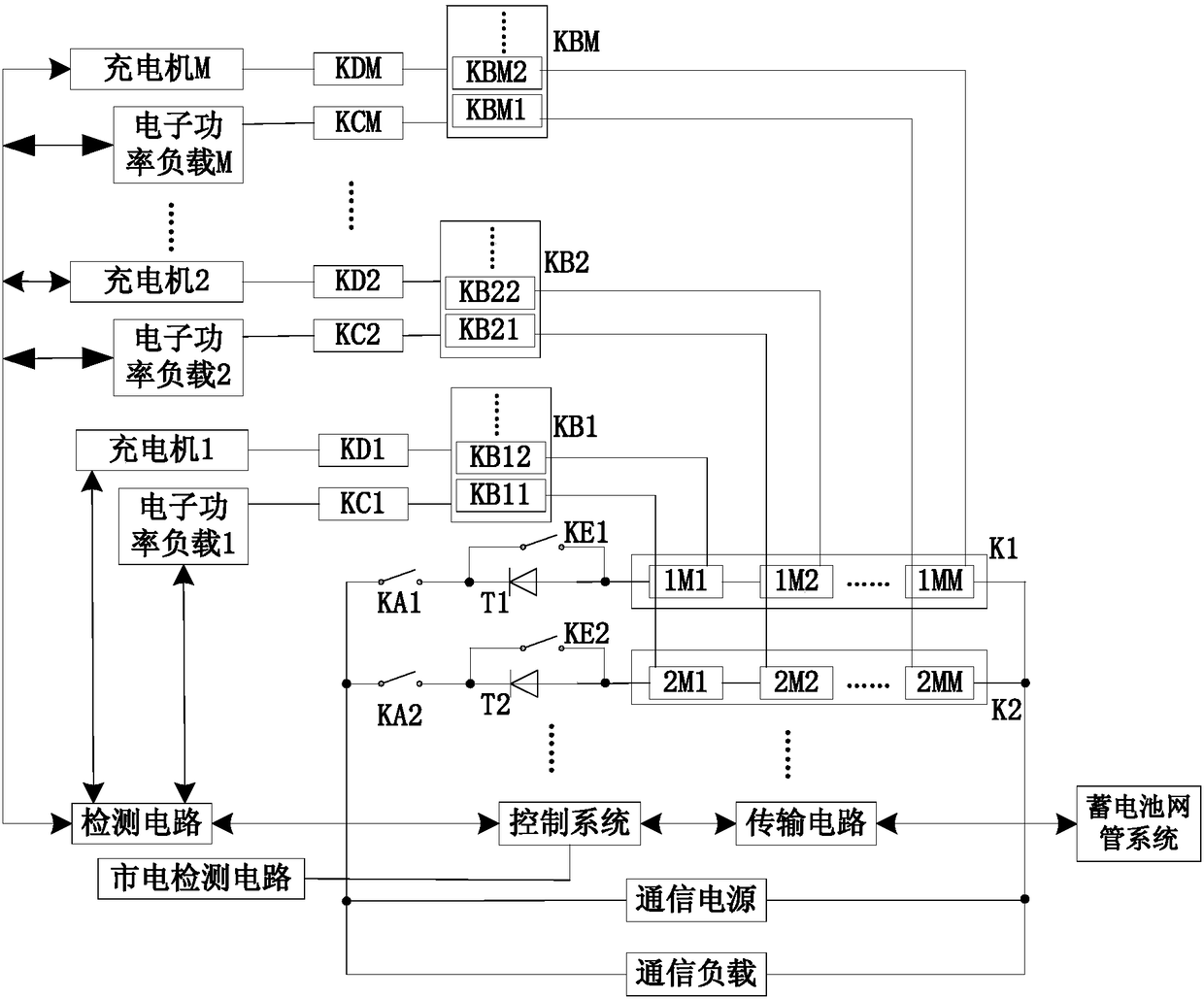

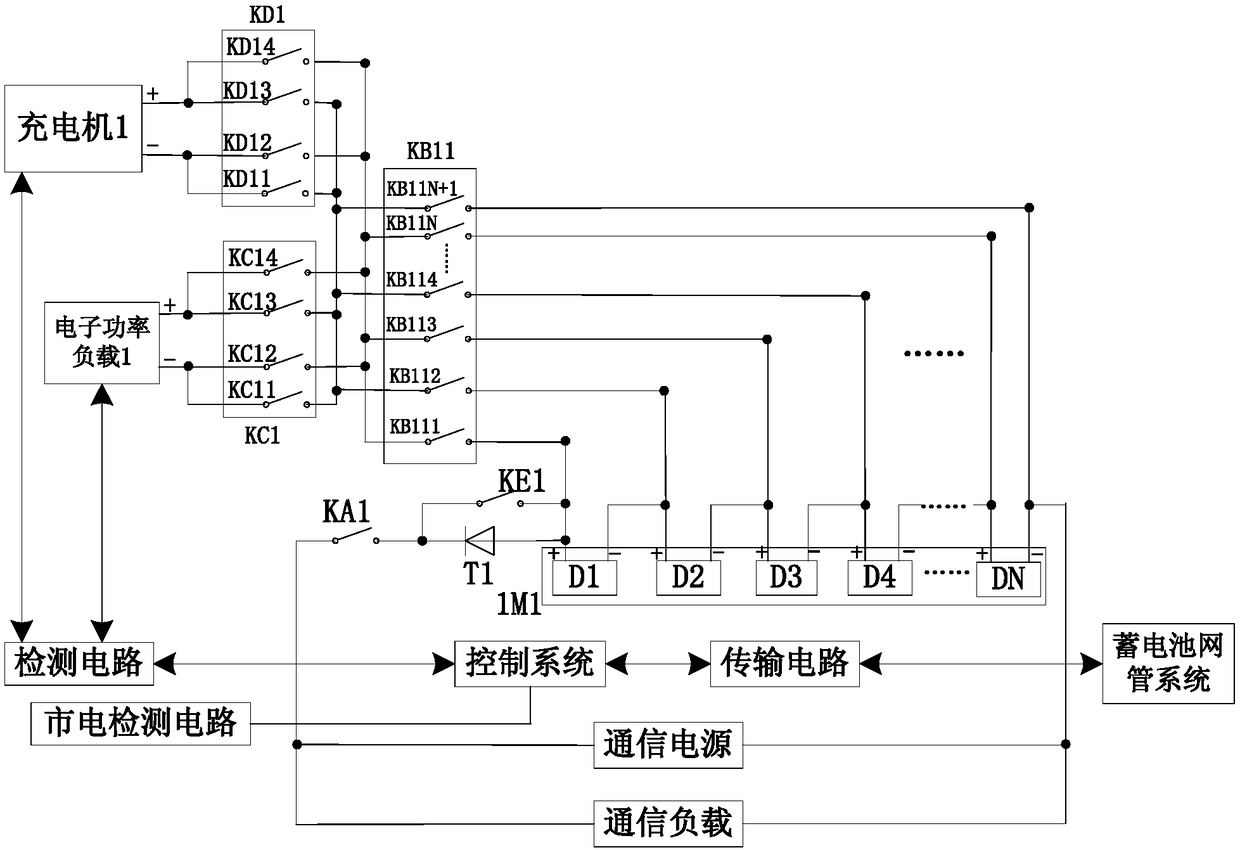

Online charging and discharging system for communication storage battery

InactiveCN108233478AAvoid overshootPut an end to over-dischargeCharge equalisation circuitIndicating/monitoring circuitsElectrical batteryControl system

The invention relates to the field of communication storage battery management and discloses an online charging and discharging system for a communication storage battery. When the communication storage battery is charged or discharged online, the interior of a communication storage battery pack is subjected to online active balancing, and the situation is avoided that a single battery is overshotand over-discharged and cannot be completely charged. According to the online charging and discharging system, in the discharging process of the storage battery pack, a control system controls a switch network, a charger is in parallel connection with a single storage battery which is low in capacity in the storage battery pack, the discharging speed of the single storage battery which is low incapacity is lowered accordingly, and it is guaranteed that all the single batteries in the storage battery pack complete discharging at the same time; in the charging process of the storage battery pack, the control system controls the switch network, the electronic power load is in parallel connection with the single storage battery which is low in capacity in the storage battery pack, the charging speed of the single storage battery which is low in capacity is lowered accordingly, it is guaranteed that all the single batteries in the storage battery pack complete charging at the same time, and accordingly active balancing of online discharging is achieved. The online charging and discharging system is suitable for the communication storage battery pack.

Owner:成都捷先科技有限公司

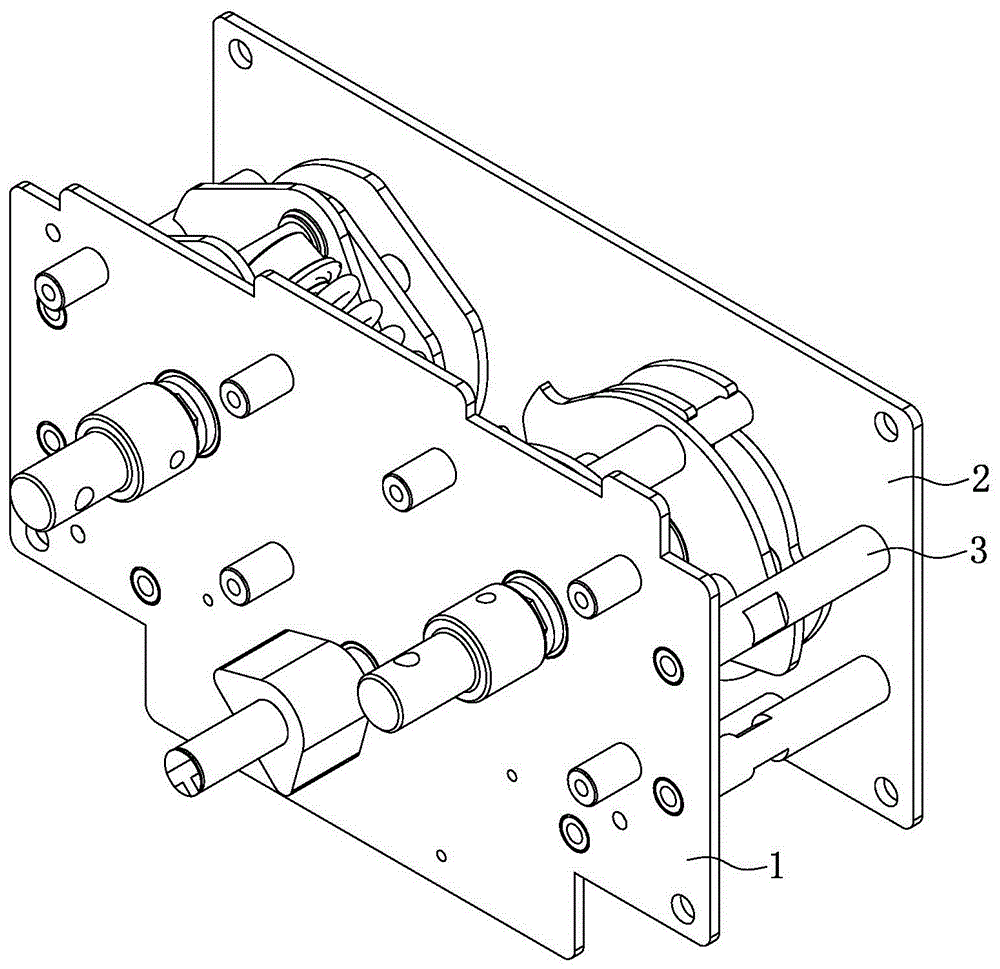

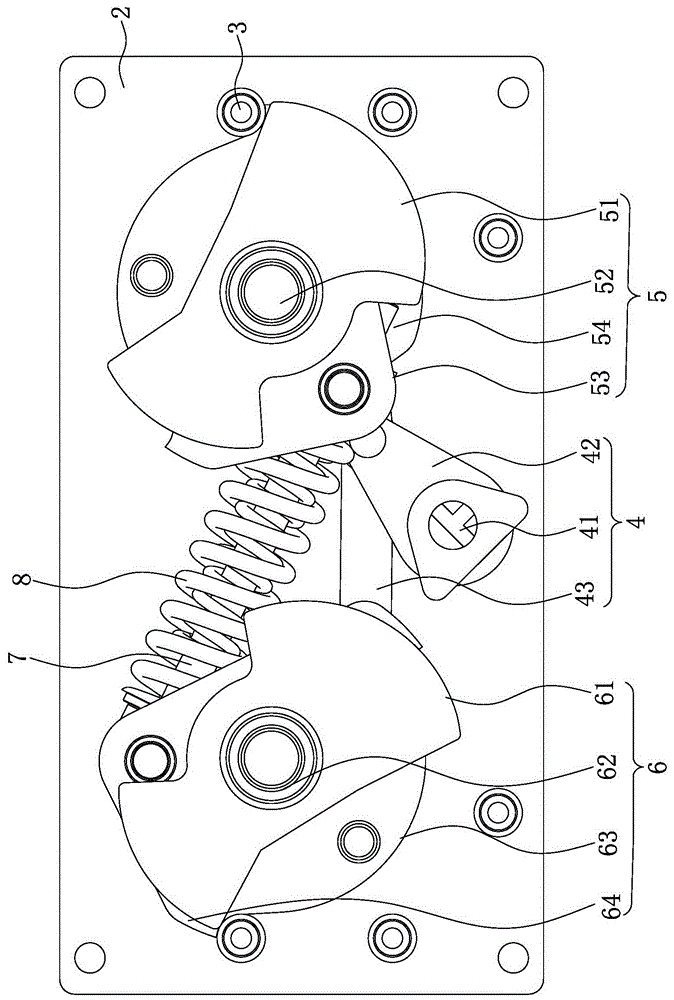

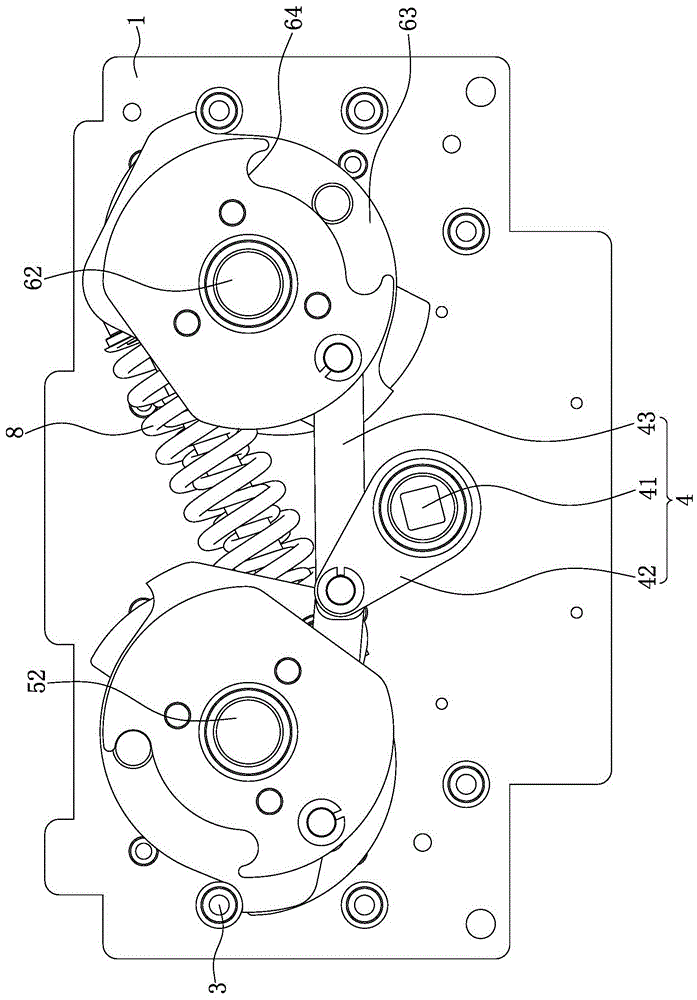

Three-position operating mechanism with buffering function

InactiveCN105977069AAvoid overshootAvoid insulation failureContact vibration/shock dampingEngineeringMechanical engineering

The invention discloses a three-position operating mechanism with a buffering function. The three-position operating mechanism comprises a mechanism front plate, a mechanism rear plate, an output shaft module, a grounding side closing and separating module, an isolation side closing and separating module, a spring module and a buffering module. All the modules are assembled between the mechanism front plate and the mechanism rear plate. The output shaft module comprises an output shaft, an output shaft crank arm and a driving pull rod. The output shaft is arranged on the middle part of the mechanism rear plate. The grounding side closing and separating module and the isolation side closing and separating module are distributed at the two sides of the output shaft with the output shaft acting as the center. The output shaft crank arm is pivotally connected on the output shaft. The buffering module is fixed on the mechanism rear plate. One end of the buffering module abuts against the external side of the output shaft crank arm. An insulation fault caused by overshooting in separating can be prevented so that the safety of operation can be enhanced.

Owner:SOUTH CHINA ELECTRIC DEV XIAMEN

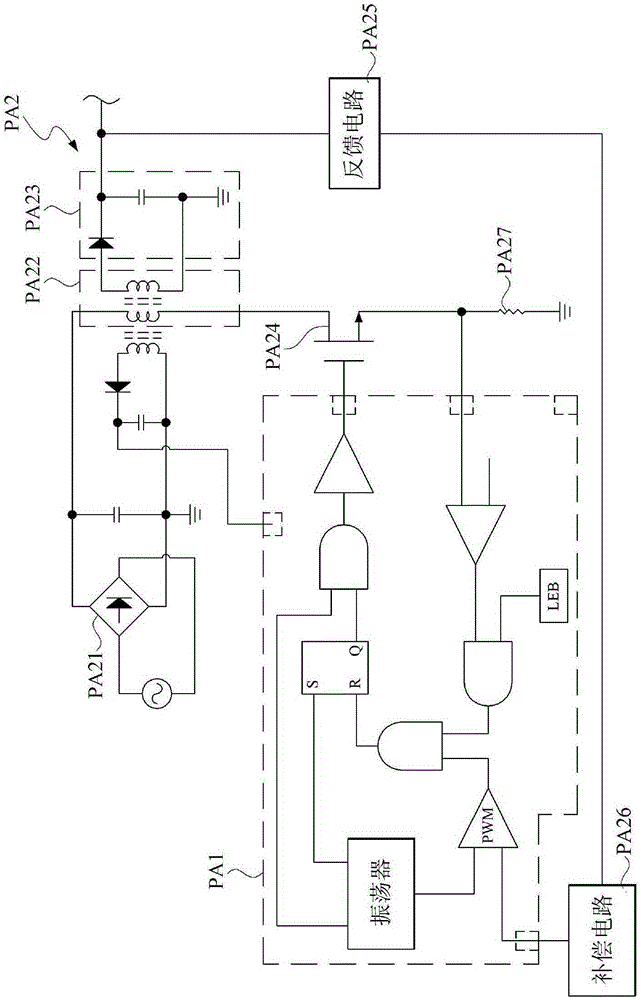

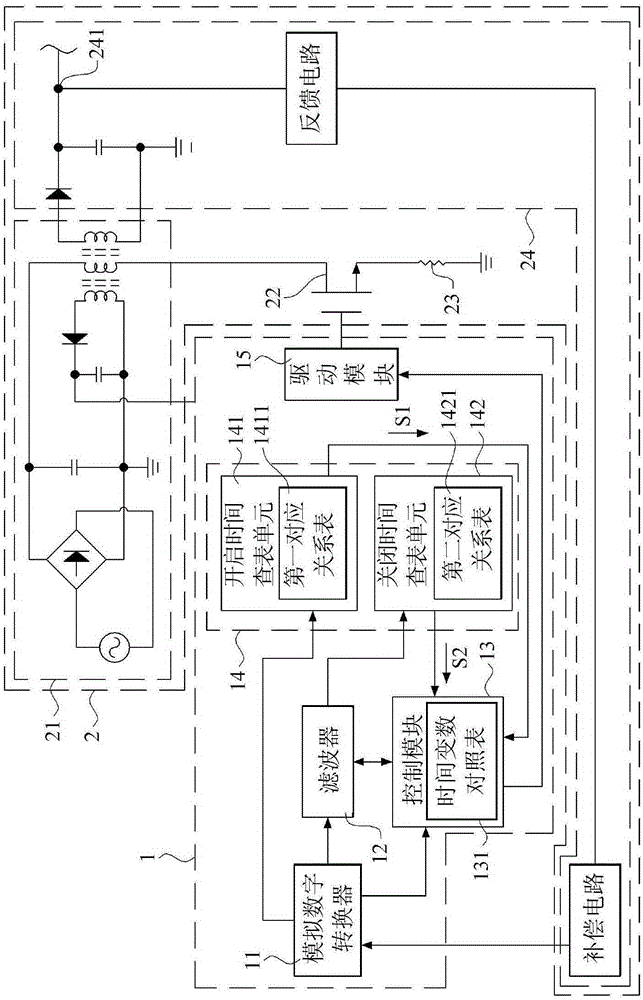

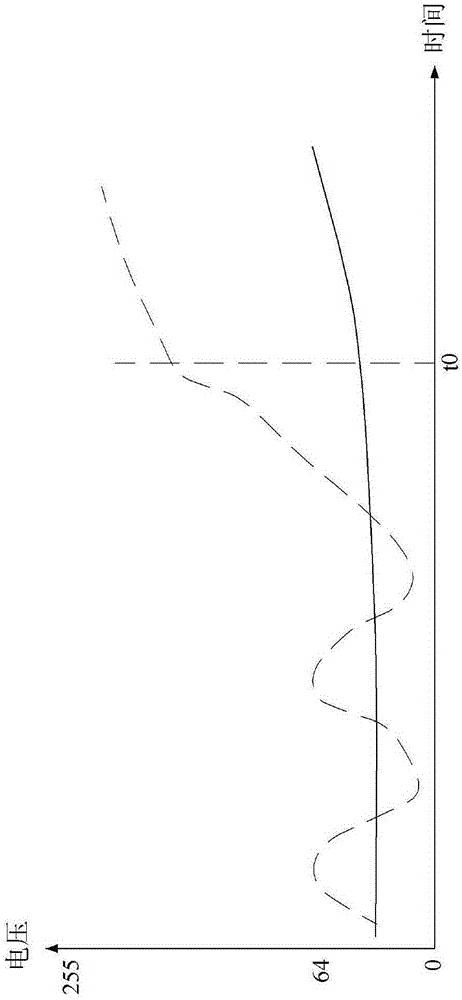

Circuit converter control system

InactiveCN106559002AAvoid overshootAvoid loadAc-dc conversion without reversalCycle controlControl system

The invention provides a circuit converter control system which is electrically connected to a circuit converter including an input stage circuit, a load switch and an output stage circuit. In the circuit converter control system, a filter is sued for sampling a historical feedback average voltage according to feedback output voltages at different times for digital signals output by an output end at different times; a control module is provided with a voltage threshold, and is used for receiving immediate feedback output voltages for the digital signals output by the output end and detecting the load state of the circuit converter based on the historical feedback average voltage; and the control module controls the load switch at a control duty cycle, increases the control duty cycle for controlling the load switch when the load state is changed from a light load state to a heavy load state and the voltage difference value reaches the voltage threshold, otherwise reduces the control duty cycle. Therefore, the need for time-consuming circuit redesign is not required, and the problem of overshoot and load reduction of the circuit converter can be effectively solved.

Owner:JOINT POWER EXPONENT

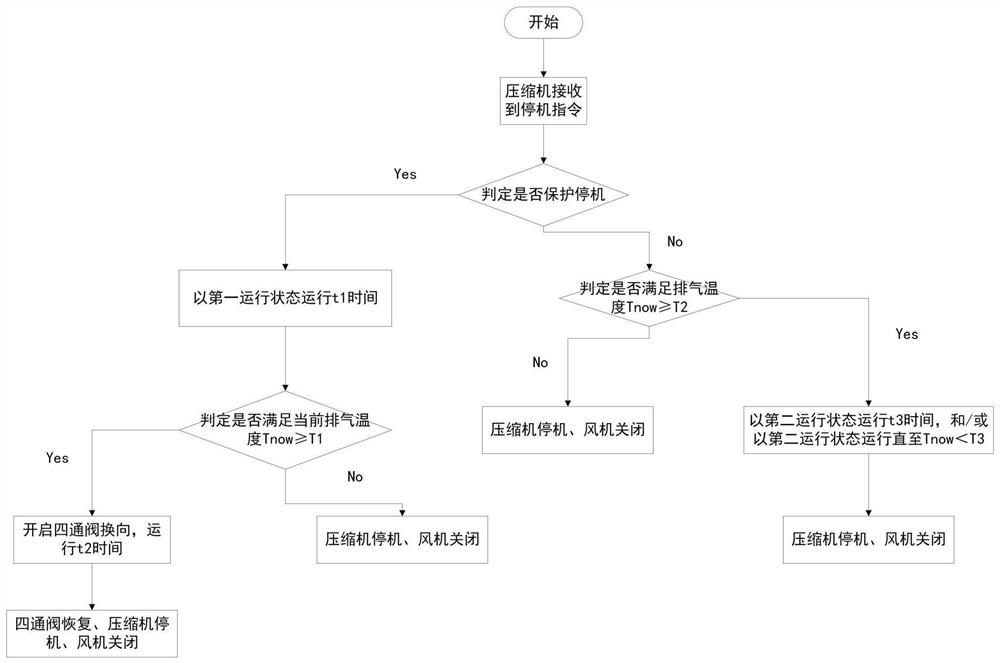

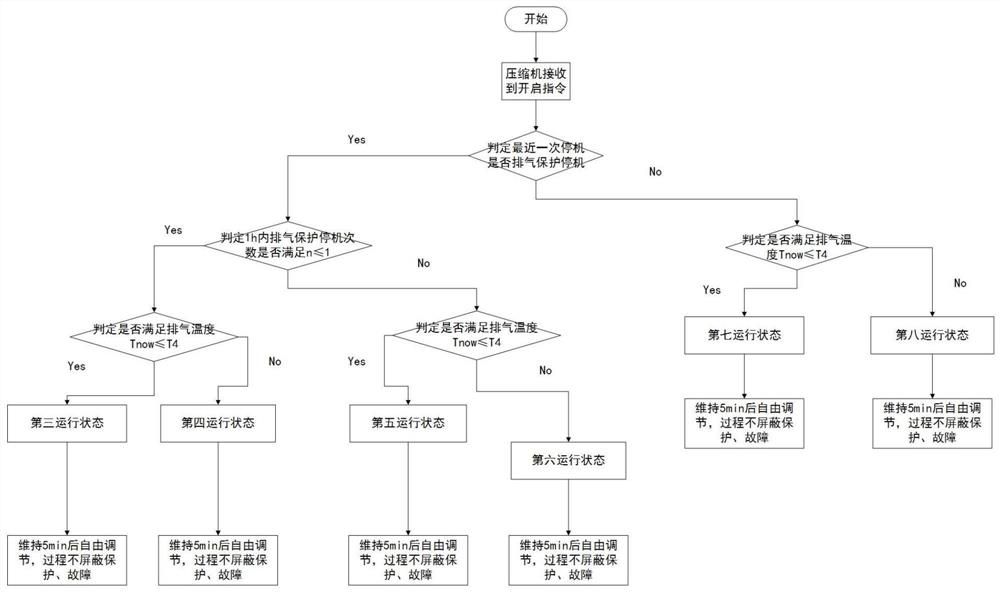

Compressor shutdown control method, compressor startup control method and air conditioner

ActiveCN113483444AImplement downtime control methodsImplement the boot control methodMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsFour-way valve

The invention provides a compressor shutdown control method, a compressor startup control method and an air conditioner. The compressor shutdown control method comprises the steps that S1, a compressor receives a shutdown instruction; S2, whether the shutdown instruction is an exhaust protection shutdown instruction or not is judged, if yes, S3 is carried out; S3, the air conditioner runs according to the first running state and runs for t1 time; S4, the current exhaust temperature T<now> is detected, and whether T<now> is larger than or equal to the first preset temperature T1 or not is judged, if yes, S5 is carried out, if not, the compressor is shut down, and an outer fan is shut down; S5, a four-way valve is controlled to reverse, and operation is conducted for t2, then the four-way valve is controlled to restore to the forward reversing state, the compressor is stopped, and the outer fan is closed. According to the compressor shutdown control method, the balance of the refrigerant pressure difference of the compressor is accelerated, and the compressor can be quickly cooled, so that the temperature is reduced to a proper temperature as far as possible before the compressor is started next time, the pressure is balanced, the influence on next starting is reduced, the time interval of next starting of the compressor is shortened, and the use feeling of a user on the air conditioner is enhanced.

Owner:NINGBO AUX ELECTRIC +1

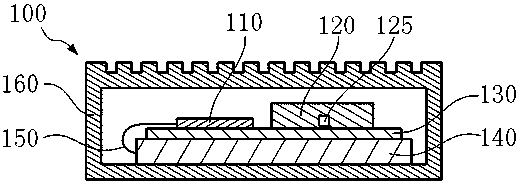

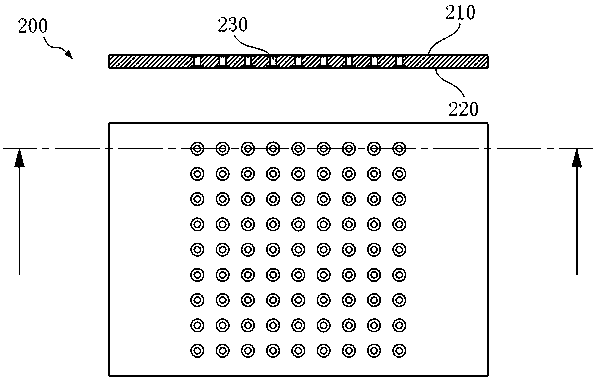

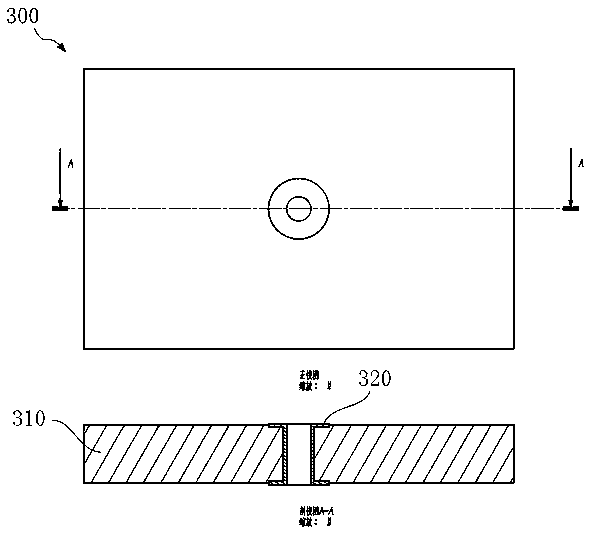

Inertial measurement module

ActiveCN109827570AQuick responseAvoid overshootNavigation by speed/acceleration measurementsInertial measurement unitEngineering

The present invention provides an inertial measurement module. The inertial measurement module (100) comprises a control unit (110), an inertial element (120), a temperature sensor (125), a substrate(130), a temperature control element (140) and a housing (160), and the control unit (110) monitors the temperature of the inertial element (120) through the temperature sensor (125) and controls thetemperature control element (140) to control the temperature of the inertial element (120). The control unit (110) and the inertial element (120) are installed at the same surface of the substrate (130), the temperature control element (140) is installed at the other surface of the substrate (130), and the temperature control element (140) is installed on the housing (160).

Owner:上海戴世智能科技有限公司

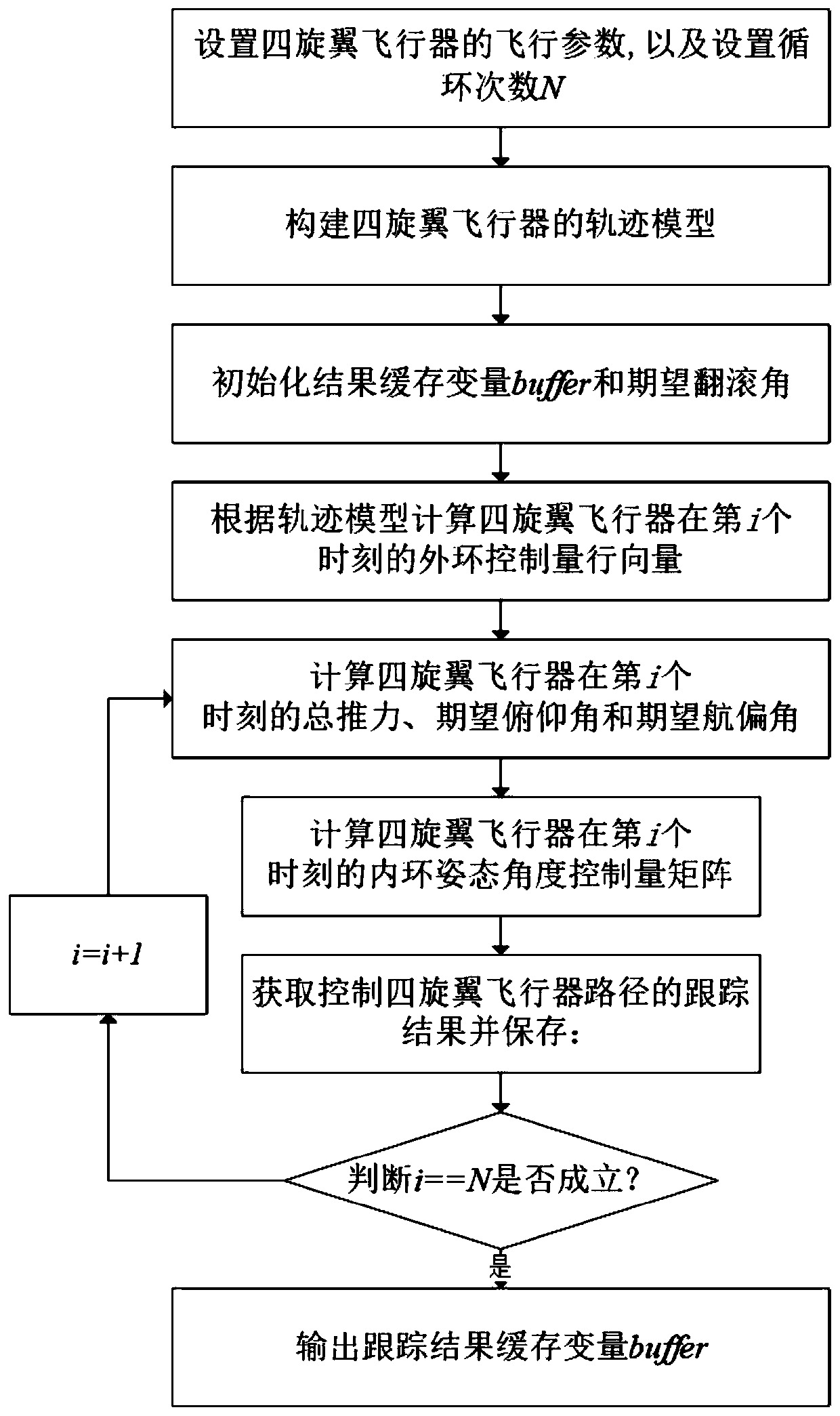

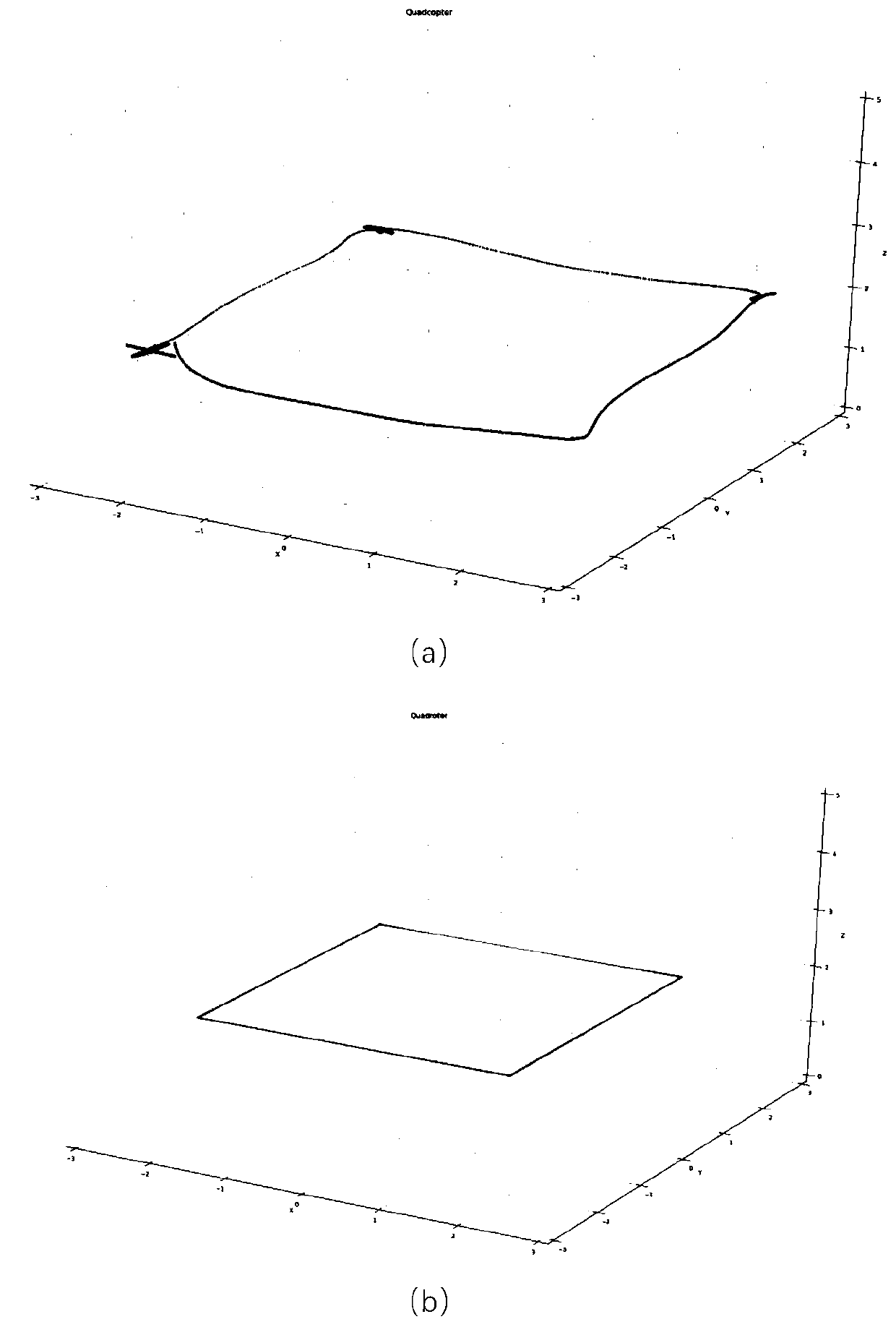

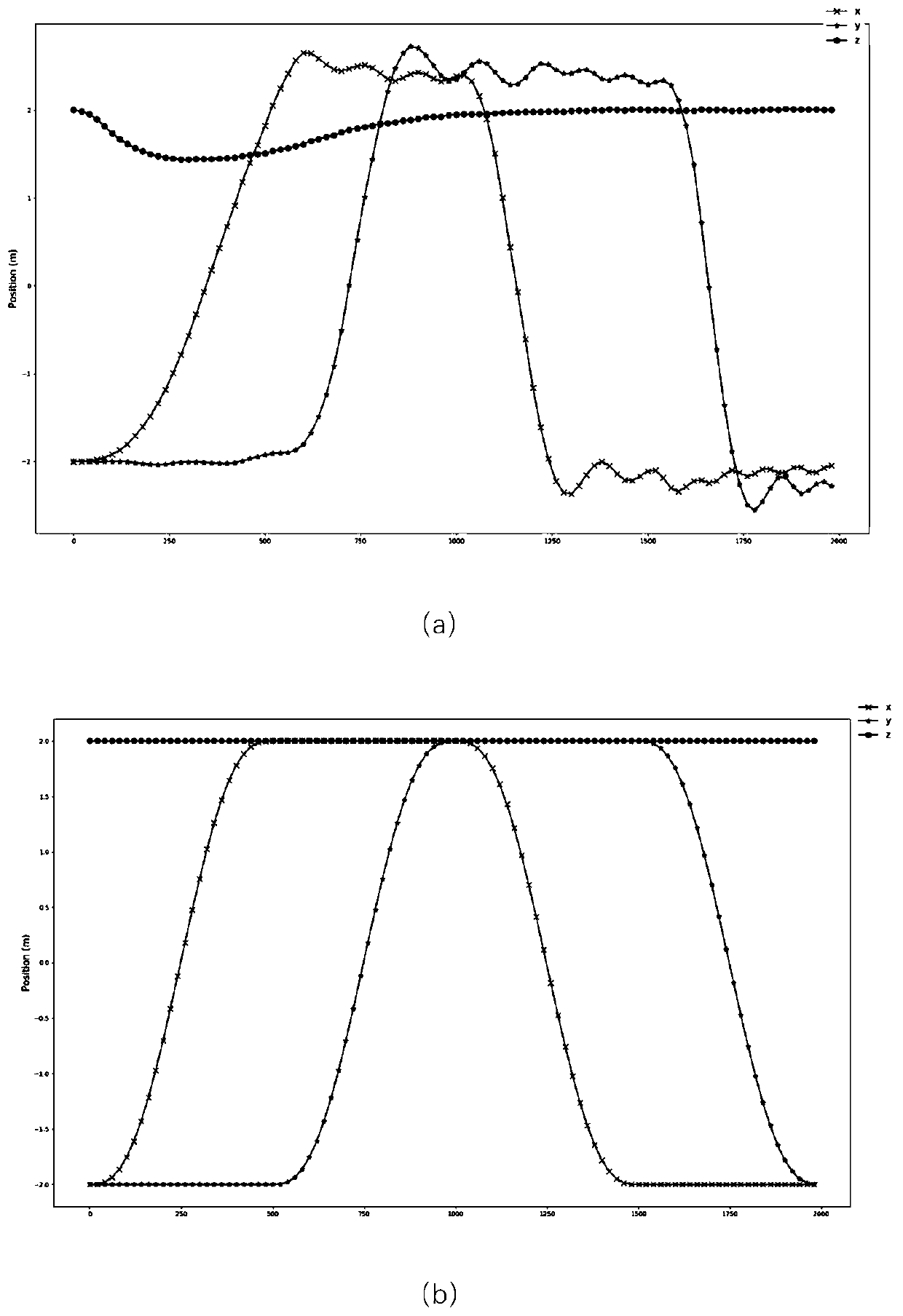

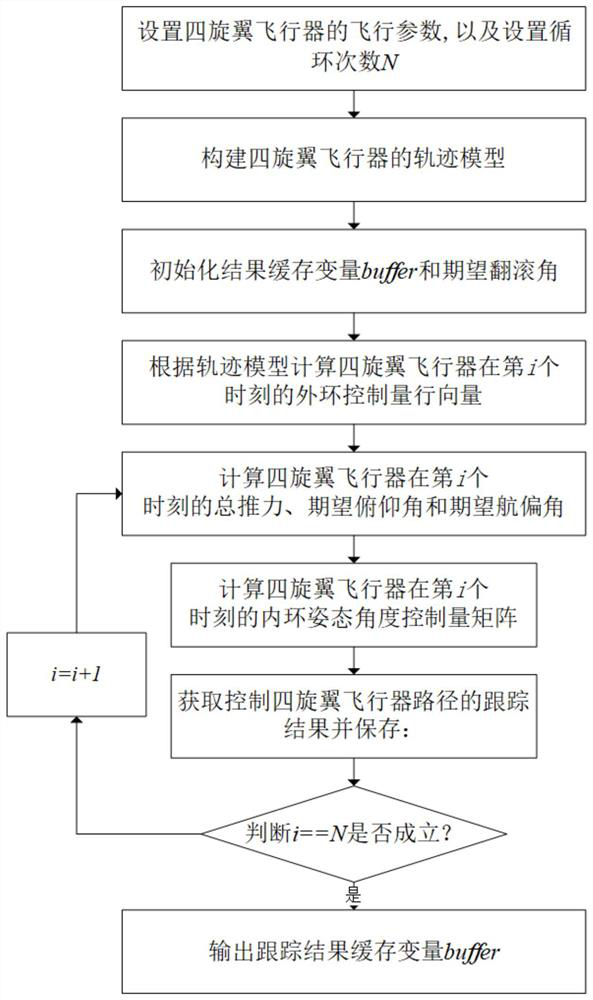

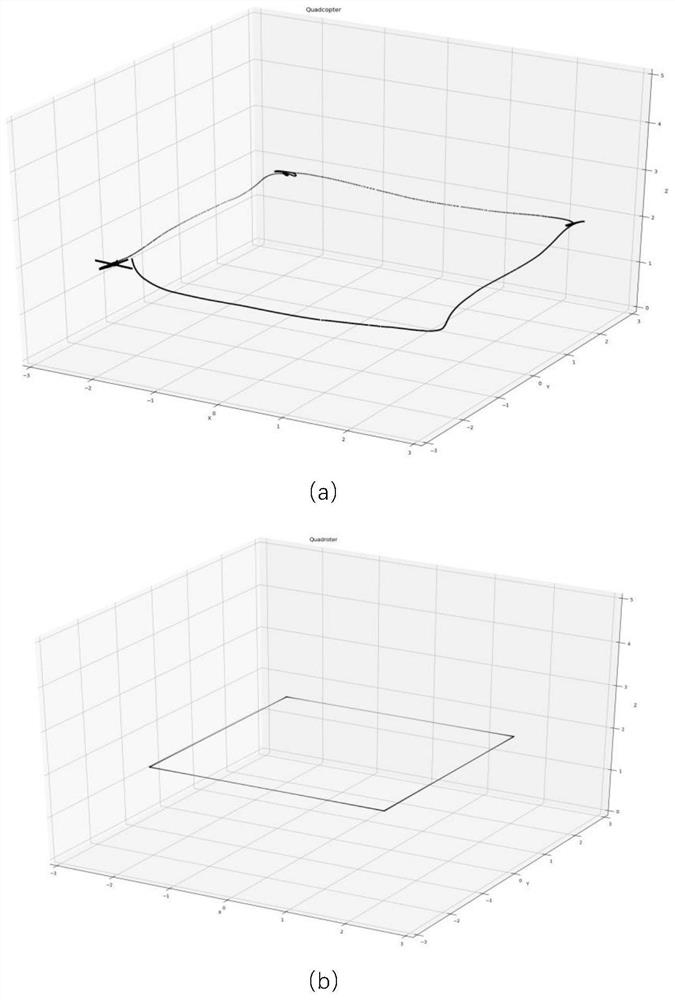

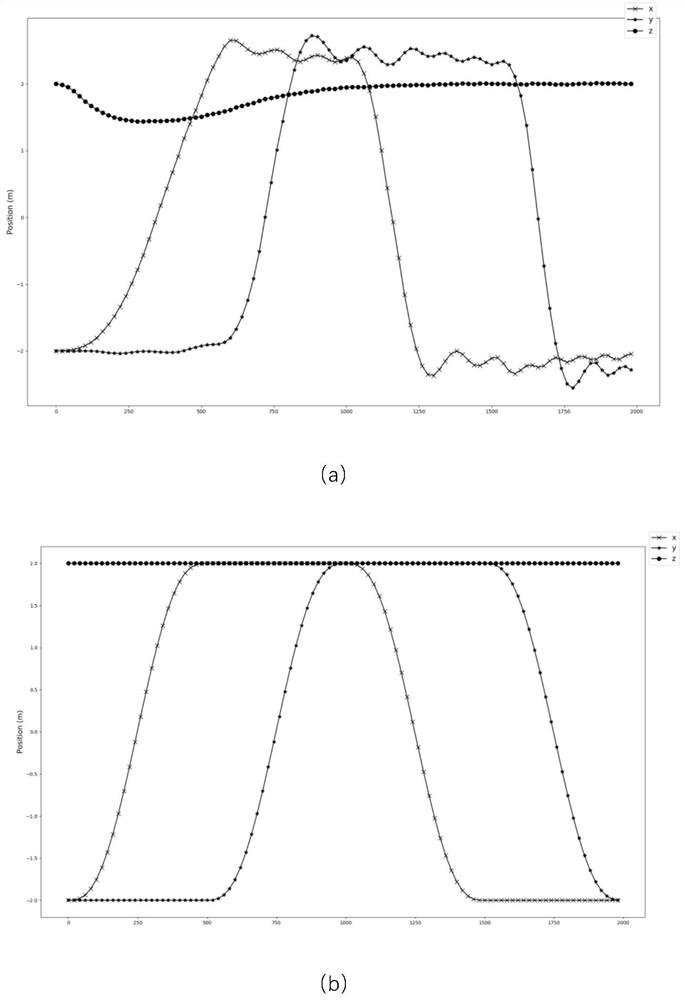

Four-rotor 3D path tracking method based on nonlinear PD double closed-loop control

ActiveCN110888447AHigh precisionImprove stabilityPosition/course control in two dimensionsLoop controlFlight vehicle

The invention discloses a four-rotor 3D path tracking method based on nonlinear PD double closed-loop control. The method comprises the following steps: to begin with, setting flight parameters of a four-rotor aircraft, constructing a trajectory model Pc of the four-rotor aircraft, and initializing a result buffer variable buffer and an expected roll angle [psi]c; then, calculating an outer loop control quantity row vector pu of the four-rotor aircraft at the ti moment according to the trajectory model Pc; calculating total thrust Tu, an expected pitch angle and an expected drift angle of the four-rotor aircraft at the ti moment through the outer ring control quantity; calculating an inner ring attitude angle control quantity matrix of the four-rotor aircraft at the ti moment by combining expected attitude; calculating and obtaining a tracking result for controlling the path of the four-rotor aircraft according to the total thrust Tu; and finally, performing cyclic control onthe trajectory model Pc through the set parameters. According to the invention, the stability of four-rotor aircraft can be effectively controlled, a high-accuracy tracking result can be obtained, anda path tracking flight control task of four-rotor unmanned navigation can be completed.

Owner:XIDIAN UNIV

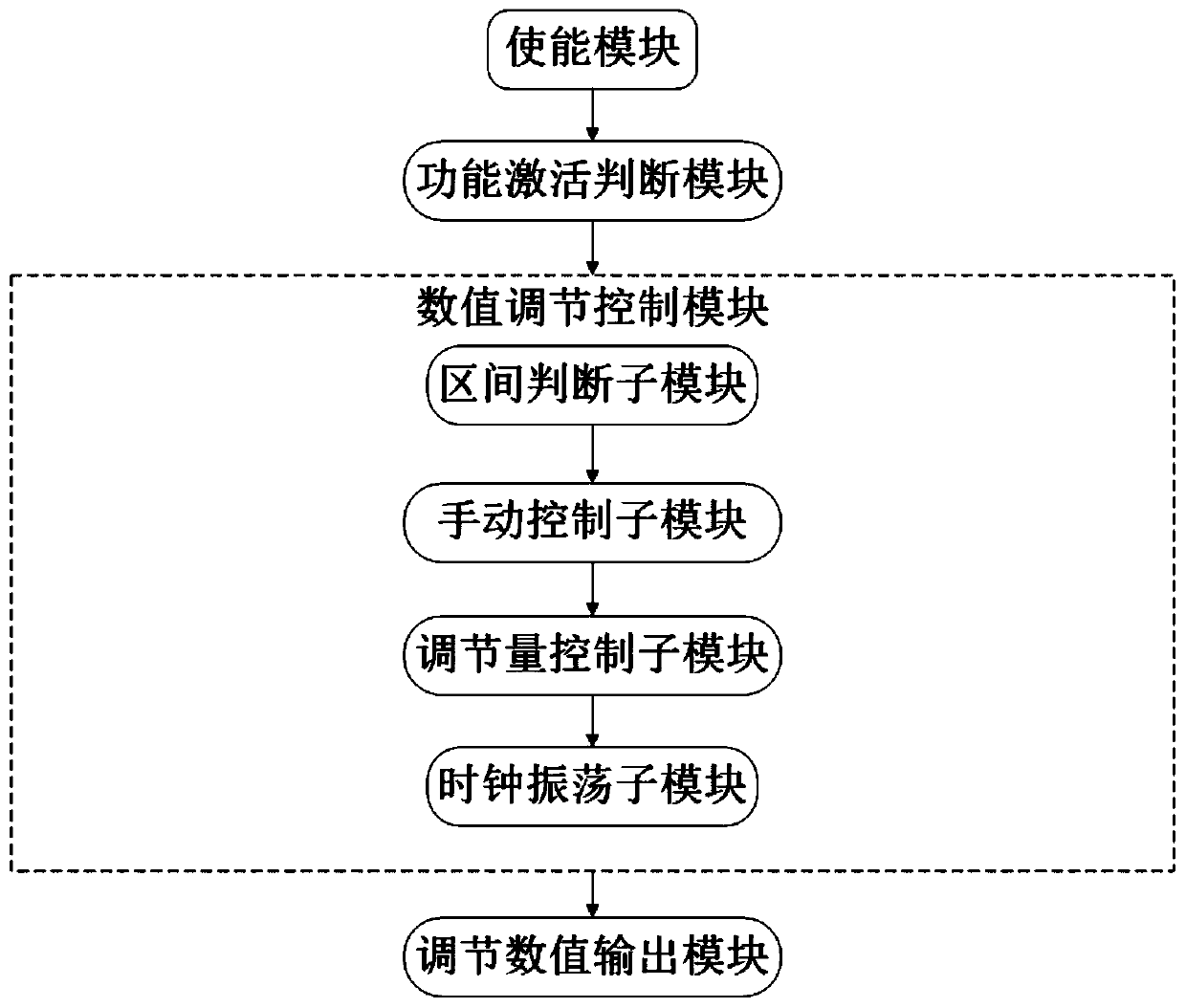

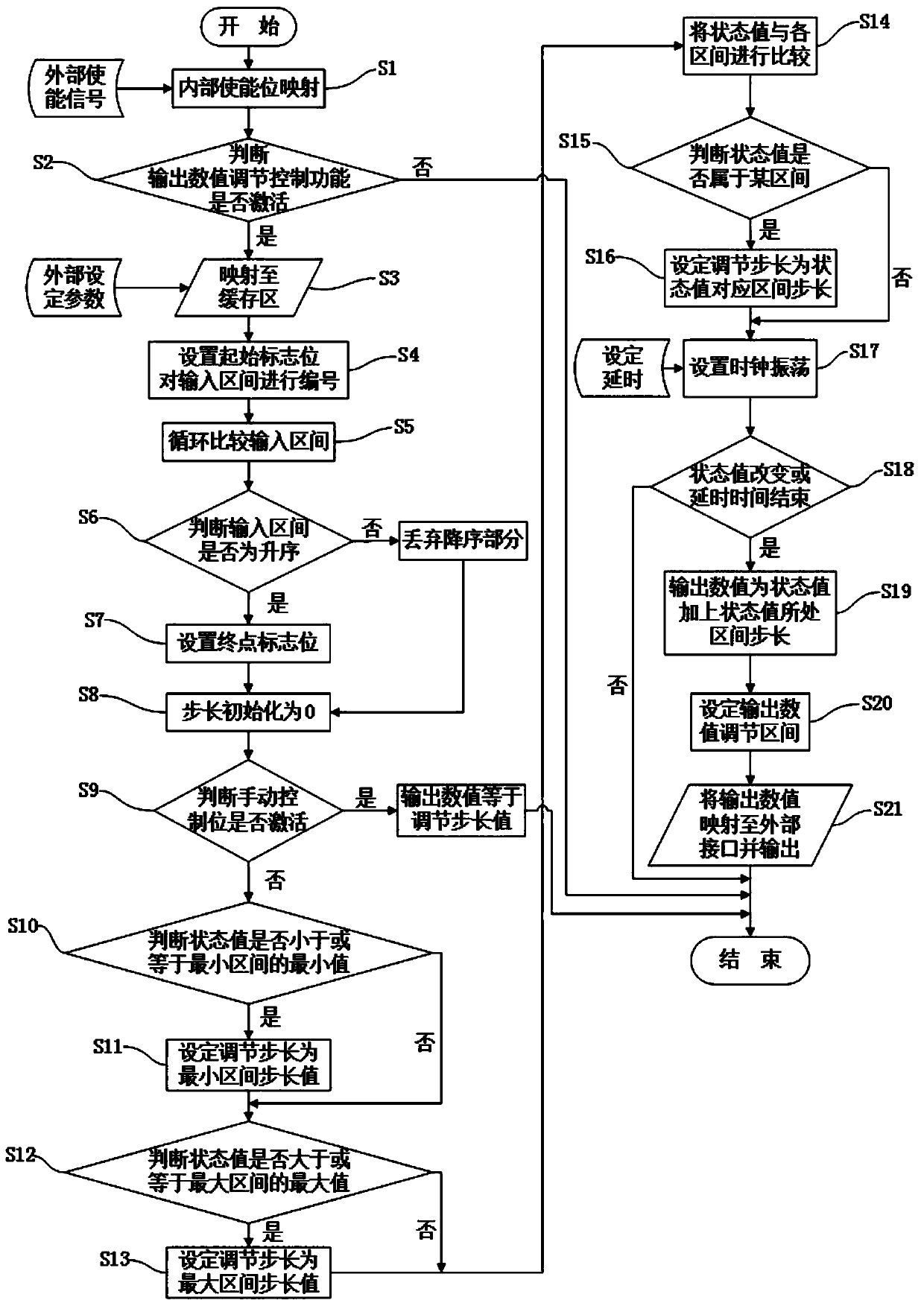

Dedusting equipment air door opening degree adjustment interval control output method and control system

PendingCN111061190ARealize coordinated controlAvoid overshootProgramme controlComputer controlControl systemControl engineering

The invention relates to a dedusting equipment air door opening degree adjusting interval control output method and a control system. A required opening degree numerical value adjusting interval is maintained according to an opening degree state of an air door of dedusting equipment. Through a numerical value adjustment control module, a set value required by the opening degree of the air door ofthe dedusting equipment increases or decreases a numerical value needing to be adjusted in set time according to a set adjustment quantity in a numerical value adjustment interval so that the openingdegree of the air door of the dedusting equipment is effectively controlled. Problems that common manual control is complex and equipment overshoot is easily caused in an air door opening degree interval control adjustment output process of existing dedusting equipment are solved, coordination control of an interval control adjustment output numerical value is achieved, and an overshoot situationof a control target is avoided.

Owner:JIANGSU YUANPU AUTOMATION SYST

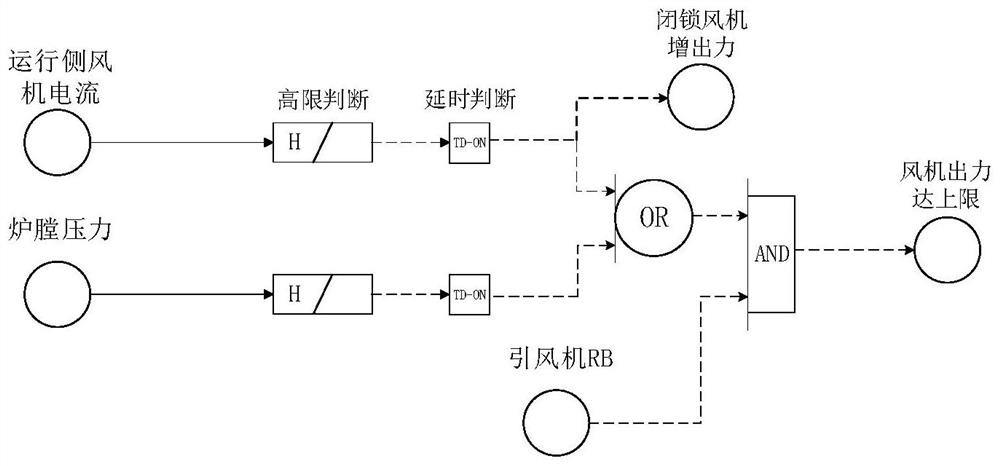

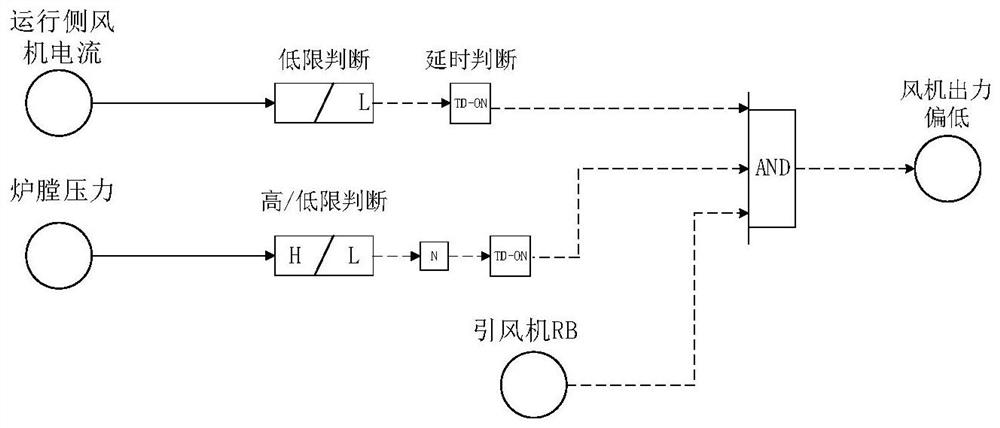

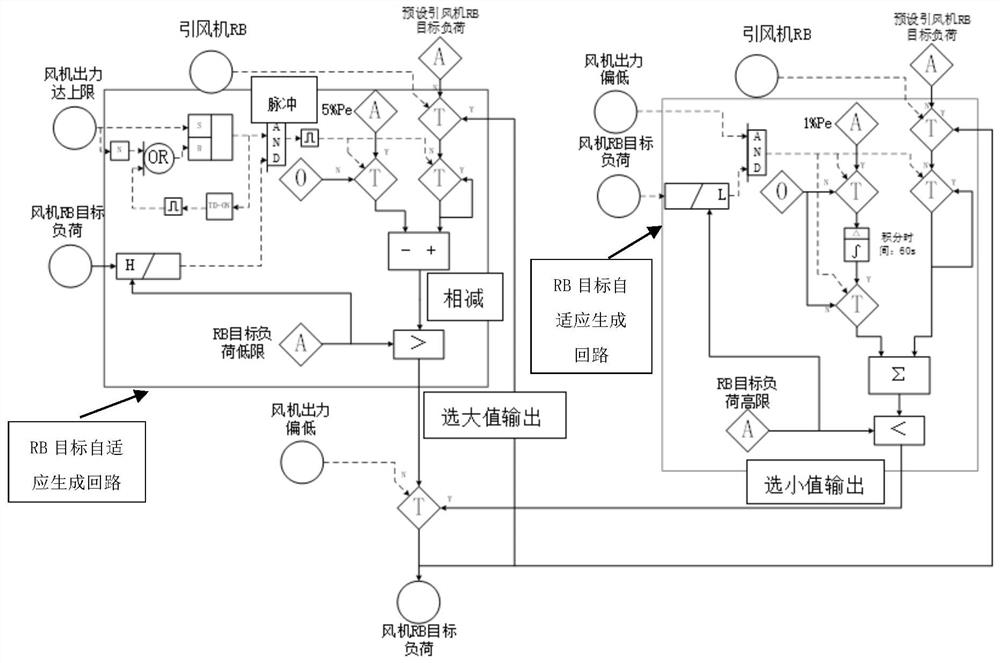

Unit RB target load self-adaptive generation method based on auxiliary machine state

ActiveCN112540537AEnsure safetyGuaranteed economyFuel supply regulationAdaptive controlControl engineeringAir blower

The invention relates to a unit RB target load self-adaptive generation method based on an auxiliary machine state, wherein the method comprises the steps: step 1, a control logic obtains a preset control parameter when an important auxiliary machine of a unit has an air blower tripped and triggers an RB, and the load reduction operation is carried out through employing a preset unit RB target load as an instruction; and step 2, in the load reduction process, the control logic monitors the operation state of the auxiliary machine, and whether the output of the auxiliary machine reaches the upper limit or not is judged in real time. The method has the beneficial effects that on the basis of the original control logic, the running state and output of the auxiliary machine after the unit RB occurs are monitored and judged according to the selected state parameters, and the target load is adjusted in real time on the basis of the running state and output. Through self-adaptive generation and flexible adjustment of the RB target load, the actual loading capacity of the auxiliary machine can be matched, so that over-adjustment or under-adjustment in the RB process is avoided, the accuracy and reliability of overall RB control are improved, and the safety and economy of unit operation after tripping of the auxiliary machine are guaranteed.

Owner:ZHEJIANG ZHENENG TECHN RES INST

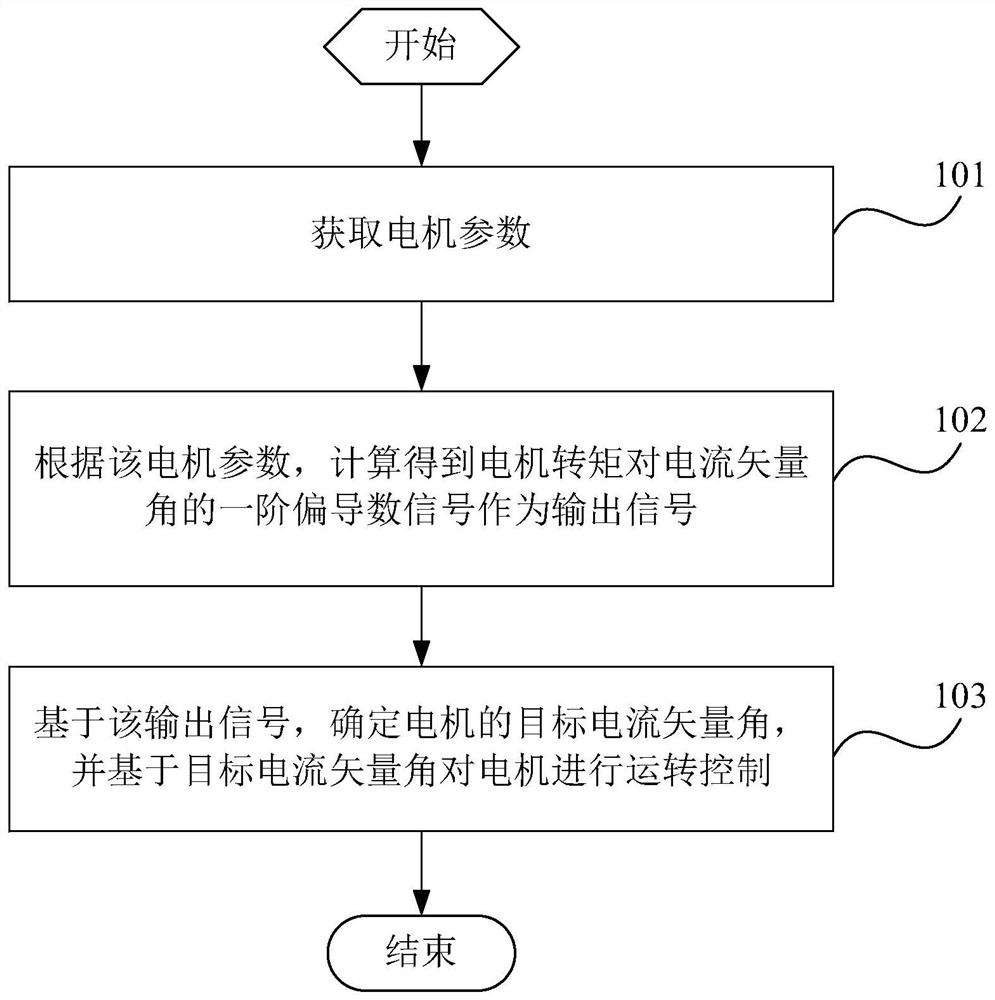

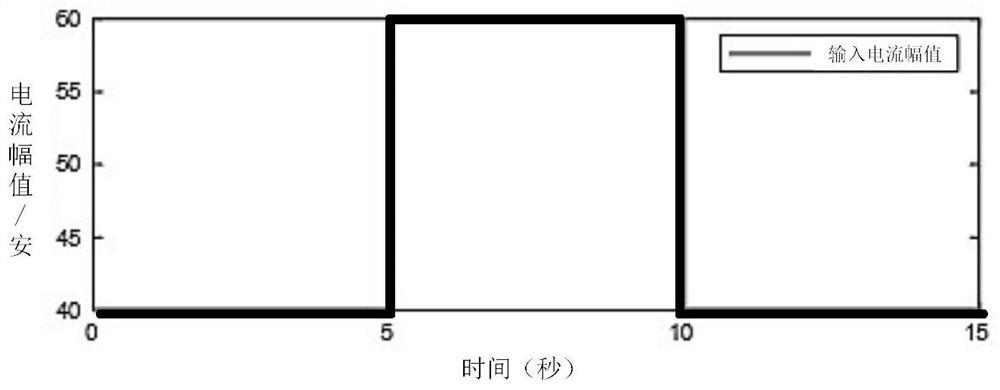

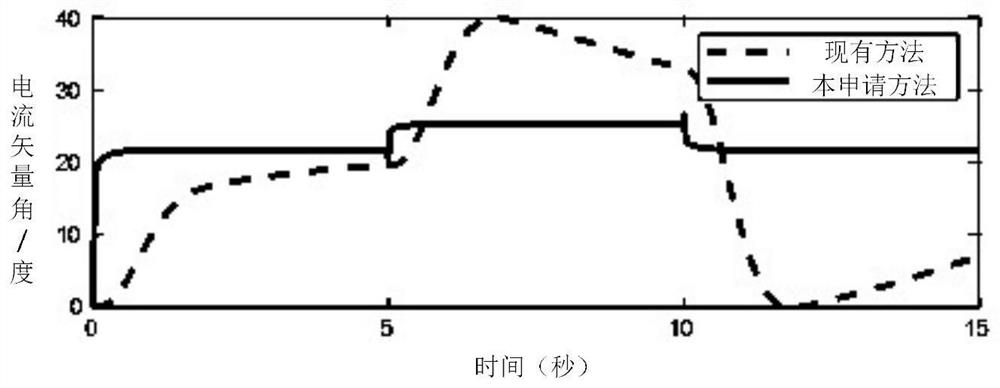

Motor control method and device, terminal and storage medium

ActiveCN113346815AFast dynamic responseAvoid overshootElectronic commutation motor controlVector control systemsPhysicsShaft voltage

The invention belongs to the technical field of motor control, and provides a motor control method and device, a terminal and a storage medium. The method comprises the steps of: obtaining motor parameters including the d-axis voltage, q-axis voltage, d-axis current, q-axis current and d-axis inductance of a motor, the mechanical angular speed of a rotor in the motor, the stator resistance of the motor, and the number of pole pairs of permanent magnets in the motor; and calculating a first-order partial derivative signal of a motor torque to a current vector angle according to the motor parameters; taking the first-order partial derivative signal as an output signal, determining a target current vector angle of the motor based on the output signal; and and performing operation control on the motor based on the target current vector angle. According to the motor control method and device, terminal and storage medium of the invention, the state stability of the motor running at the optimal state running point can be ensured.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Quadrotor 3D Path Tracking Method Based on Nonlinear PD Dual Closed-loop Control

ActiveCN110888447BHigh precisionImprove stabilityPosition/course control in two dimensionsLoop controlFlight vehicle

The invention discloses a quadrotor 3D path tracking method based on nonlinear PD double closed-loop control. Firstly, the flight parameters of the quadrotor aircraft are set, and the trajectory model P of the quadrotor aircraft is constructed. c , and initialize the initialization result cache variable buffer and the expected rollover angle ψ c , and then according to the trajectory model P c Calculate the quadrotor at t i Row vector p of outer loop control quantity at time u i , and calculate the quadrotor at t through the outer loop control quantity i The total thrust of time T u i , the expected pitch angle and the expected yaw angle combined with the expected attitude to calculate the quadrotor aircraft at t i Inner loop attitude angle control matrix at time and according to the total thrust T u i Calculate and obtain the tracking result of controlling the path of the quadrotor aircraft, and finally adjust the trajectory model P through the set parameters c Carry out cycle control; the invention can effectively control the stability of quadrotor flight and obtain high-accuracy tracking results, and complete the path tracking flight control task of quadrotor unmanned navigation.

Owner:XIDIAN UNIV

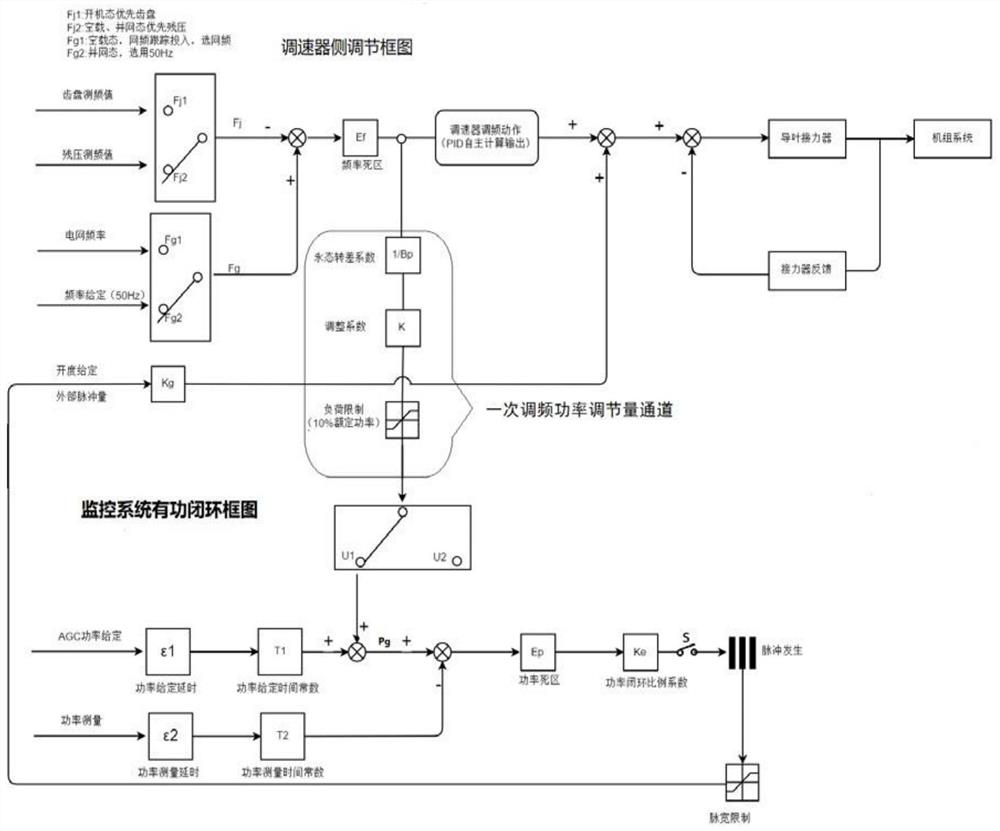

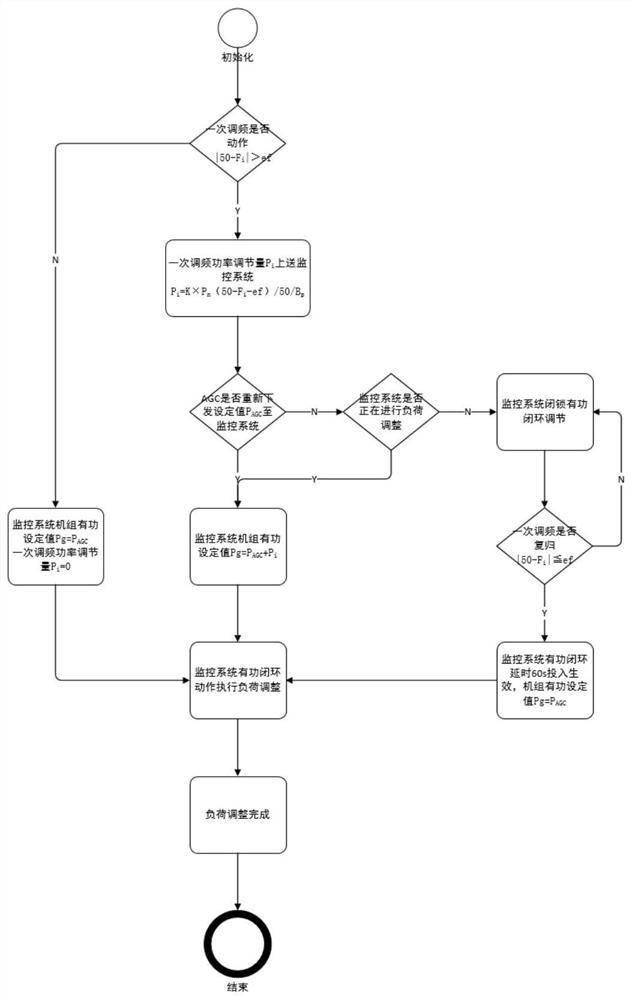

Hydro-generator active power cooperative control method based on power grid frequency

PendingCN113991756ASolve the problem of active closed-loop conflictReduce the probability of being assessed by the gridSingle network parallel feeding arrangementsPower oscillations reduction/preventionWater turbineClosed loop

The invention discloses a hydro-generator active power cooperative control method based on power grid frequency, relates to the technical field of power system automation, and effectively solves the problem that primary frequency modulation and AGC are not coordinated through the design of a primary frequency modulation function and AGC cooperative control logic, and improves the active power control accuracy of a water turbine. The primary frequency modulation power regulation quantity is uploaded to the monitoring system and superposed to the active closed-loop power given set value by adopting a mode of superposing the primary frequency modulation power regulation quantity with AGC, so that the condition that the primary frequency modulation action quantity is counteracted by the active closed loop of the monitoring system is avoided. A primary frequency modulation action / reset signal is used as a judgment condition for effective cooperative control of the active power of the water turbine, and targeted primary frequency modulation and AGC cooperative control logic is executed under different working conditions of steady state and dynamic state of the power of the water turbine unit. In other words, when the unit is in a stable state, the primary frequency modulation action of the speed regulator is prior to AGC control; when the unit is dynamically adjusted, the primary frequency modulation action quantity of the speed regulator and the AGC are subjected to superposition control.

Owner:YALONG RIVER HYDROPOWER DEV COMPANY

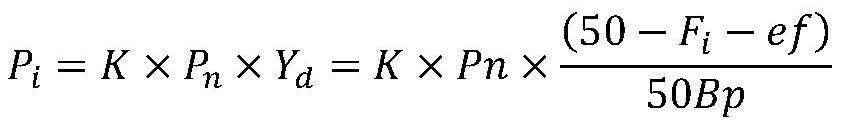

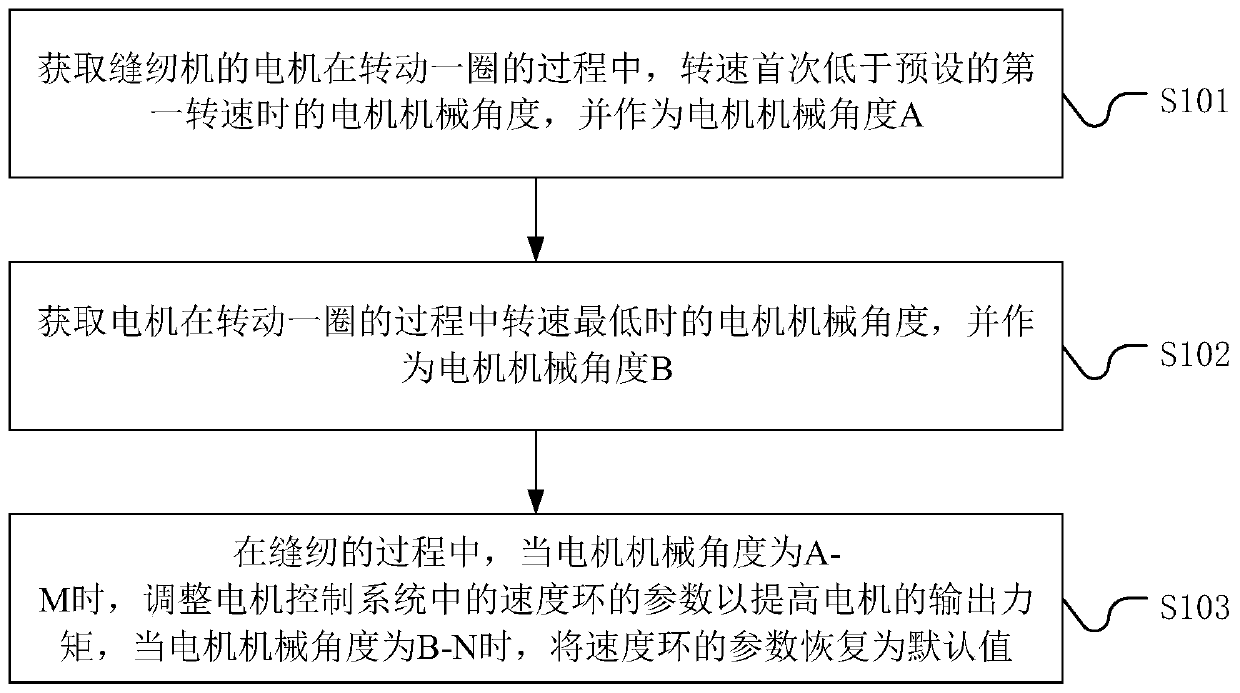

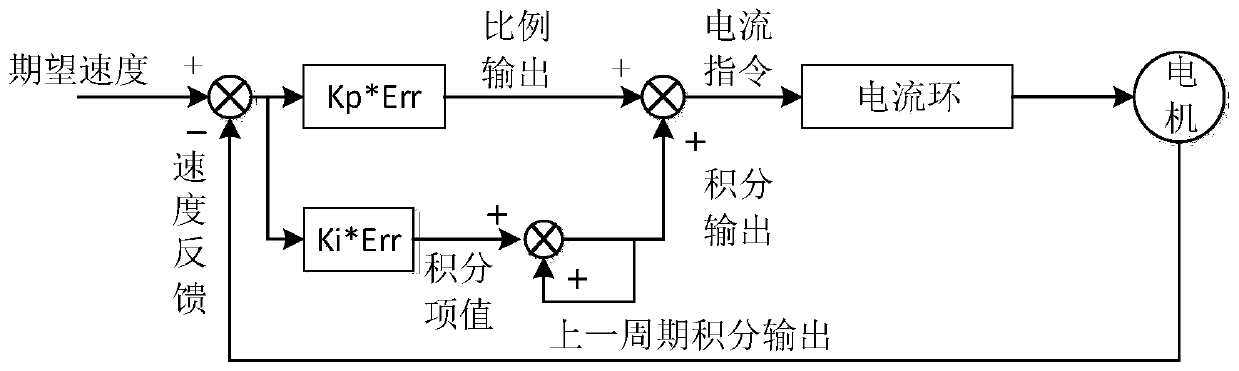

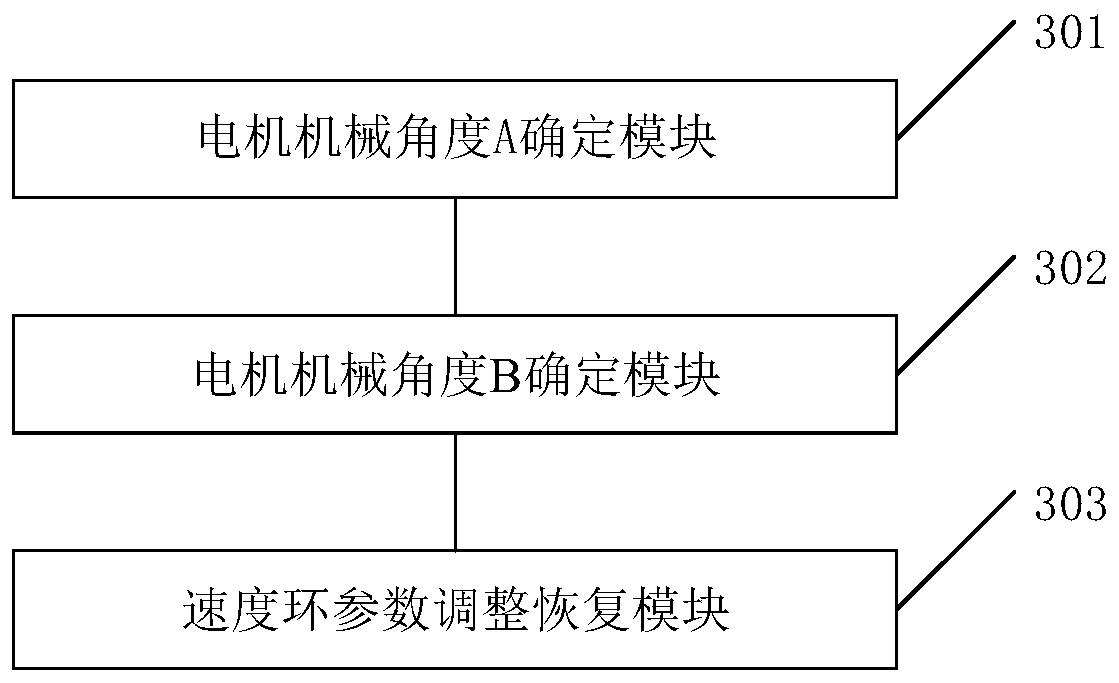

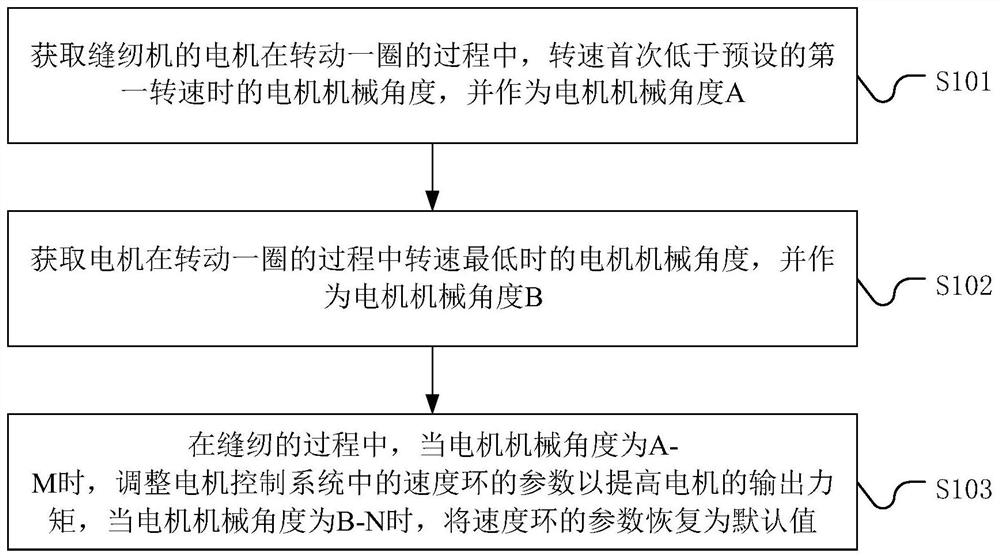

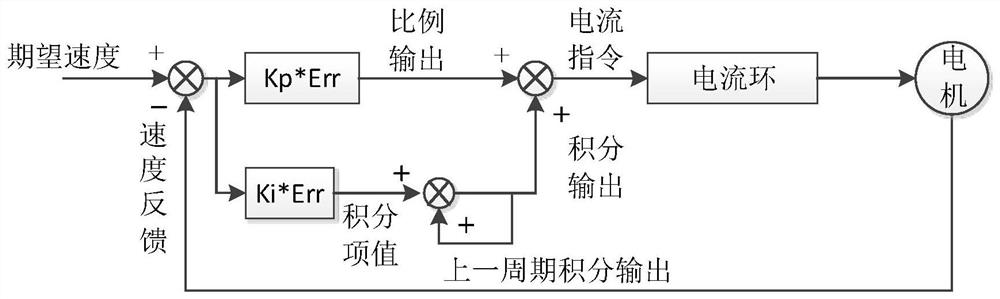

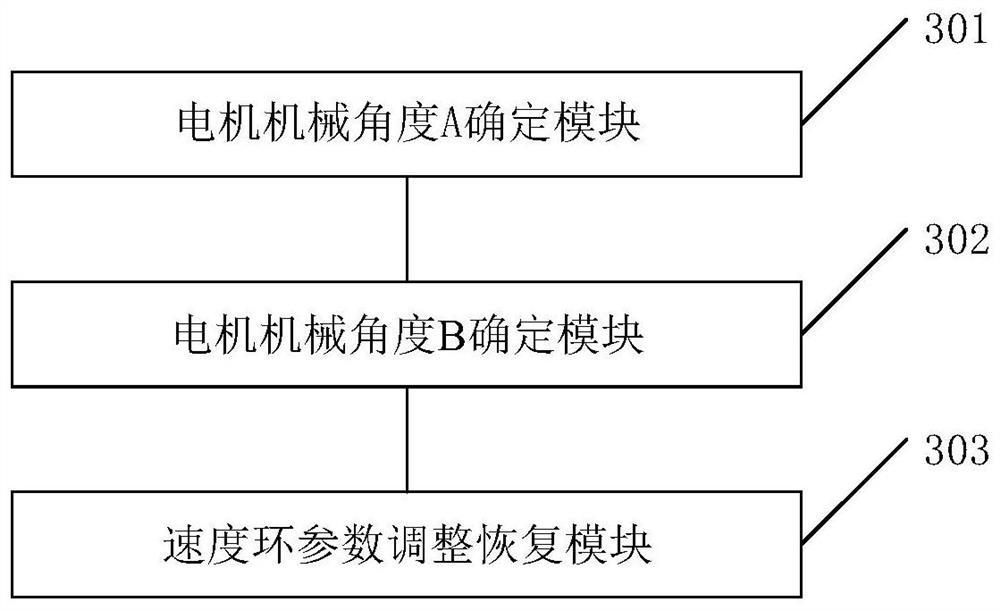

Motor control method, system and equipment of sewing machine and storage medium

ActiveCN110592831AIncrease speedStable speedSewing-machine control devicesControl systemElectric machinery

The invention discloses a motor control method of a sewing machine. The method comprises the steps that the motor mechanical angle when the rotation speed is lower than a preset first rotation speed for the first time in the process that a motor of the sewing machine rotates for a circle is obtained and serves as a motor mechanical angle A; the motor mechanical angle when the rotation speed is thelowest in the process that the motor rotates for a circle is obtained and serves as a motor mechanical angle B; in the sewing process, when the angle of the motor is A-M, parameters of a speed ring in a motor control system are adjusted so as to improve the output torque of the motor, and when the angle of the motor is B-N, the parameters of the speed ring are restored to default values, whereinM is larger than 0 and smaller than A, N is larger than 0 and smaller than B, and B-N is larger than A-M. By applying the scheme, when the sewing machine sews a thick material, the rotation speed of the motor can be more stable, the production efficiency of sewing and the sewing effect can be improved, and the user experience is improved. The invention further provides the motor control system andequipment of the sewing machine and a storage medium which have the corresponding effects.

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

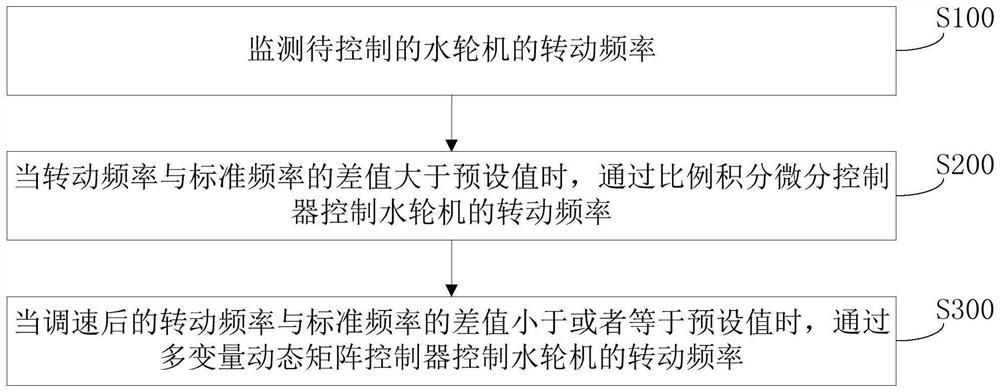

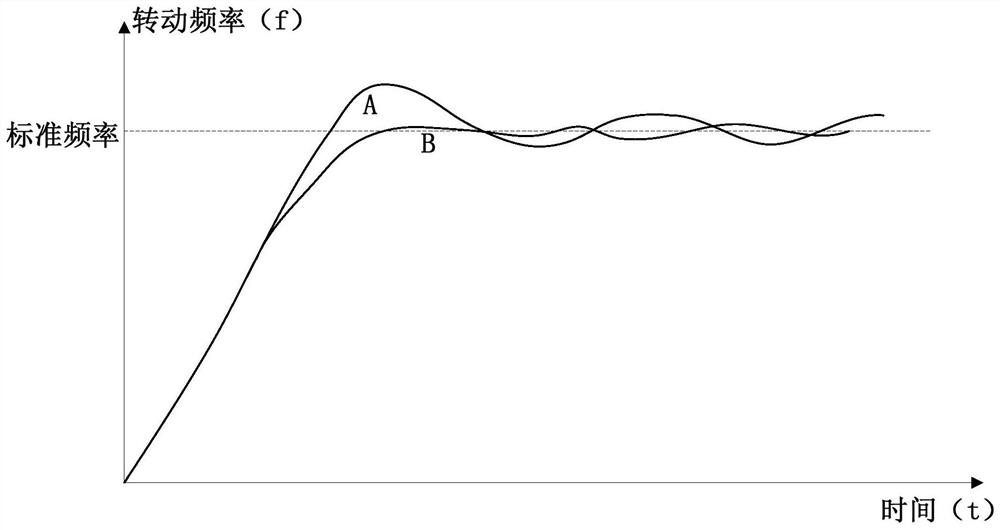

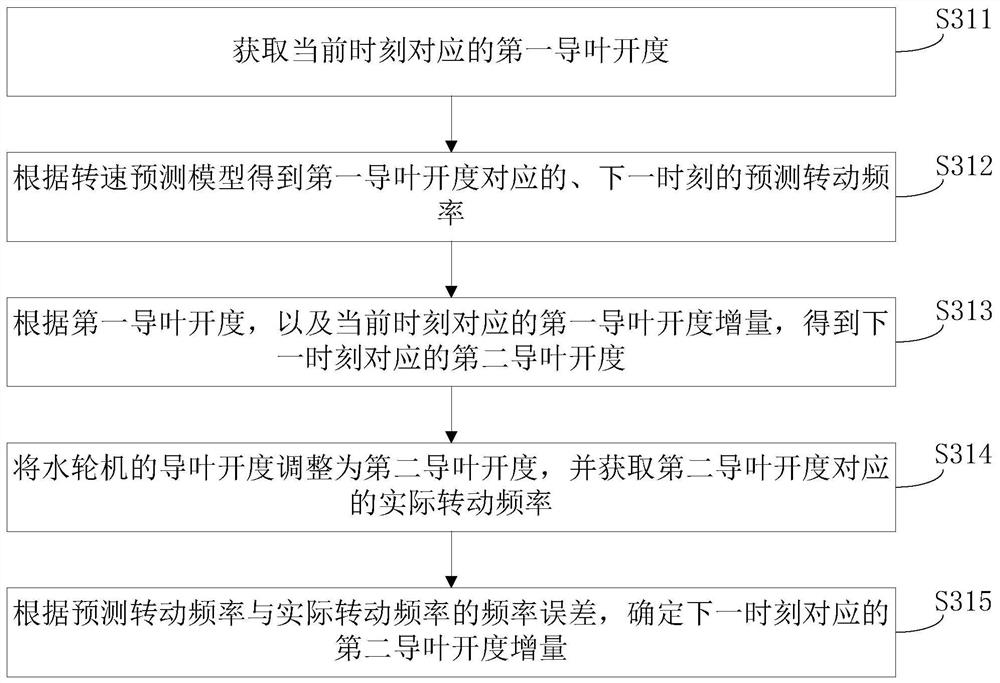

Method, device and system for speed control of hydraulic turbine based on multivariable dynamic matrix

ActiveCN110454322BAvoid overshootHigh control reliabilityEngine fuctionsHydro energy generationProportional integral differentialWater turbine

This application relates to a water turbine speed control method, device and system based on a multivariable dynamic matrix. When performing water turbine speed control, the use of proportional integral differential adjustment can achieve the purpose of quickly approaching a given standard frequency. When the rotation frequency is close to the standard frequency, the multi-variable dynamic matrix adjustment can be used to gradually adjust the rotation frequency to the standard frequency to prevent overshoot, thereby improving control reliability and stability.

Owner:HNAC TECH

An intelligent controller and self-tuning method

ActiveCN105892322BAvoid shockAccurate control parametersProgramme control in sequence/logic controllersIndustrial AccidentSelf-tuning

The invention discloses a self-tuning method of an intelligent controller. A deviation value (SV-m) is set below a control target value SV to prevent oscillation of system output wave nearby the target value SV or the deviation value (SV-m) in the self-tuning process; excitation applied to a controlled object is stopped when the system sampling value PV is greater than the target value SV, thus ensuring that the system output wave can reach the control target value SV all the time, and the PID control parameter calculated by the controller is more accurate; in addition, in the self-tuning method, no matter how the initial state of the system is, a working condition signal is acquired first, and whether excitation is applied to the controlled object is determined by comparing the acquired value PV with the deviation value (SV-m), that is, working condition judgment is prior to control output, so that overshoot is effectively prevented and industrial accidents are avoided.

Owner:SHUNCHANG COUNTY HONGRUN PRECISION INSTR

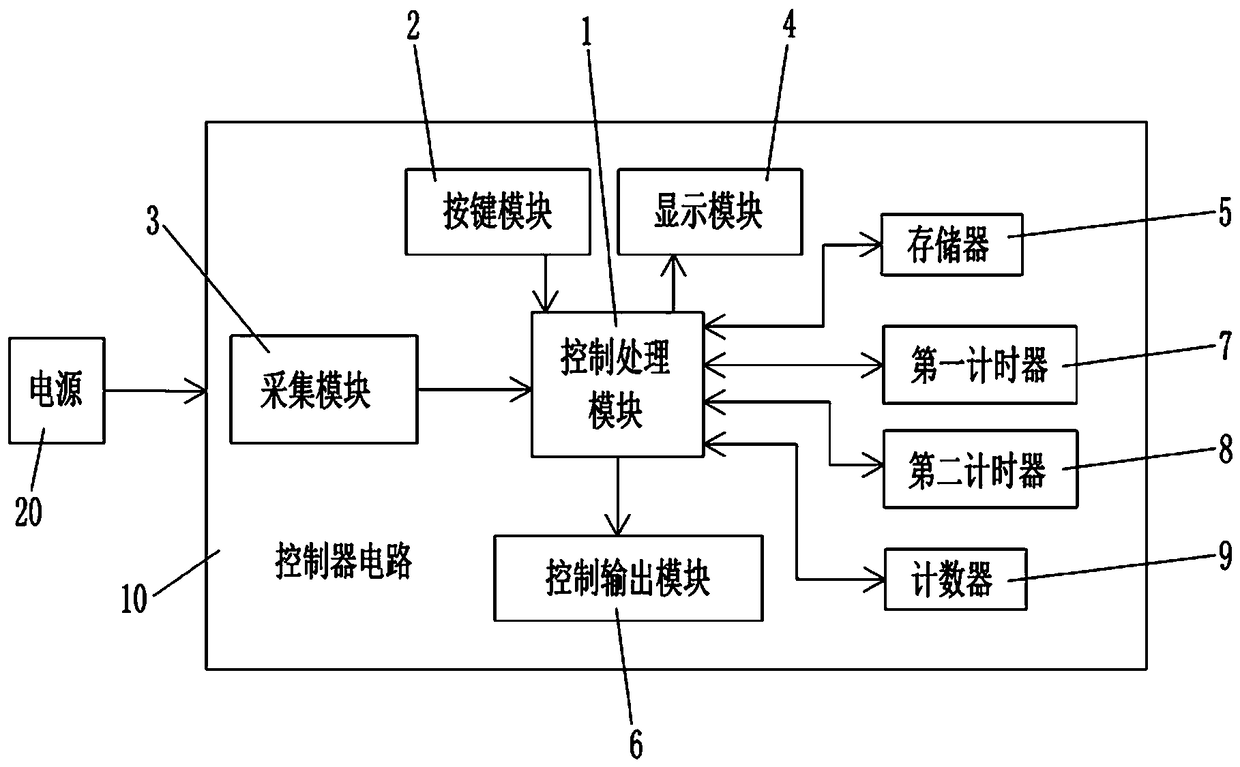

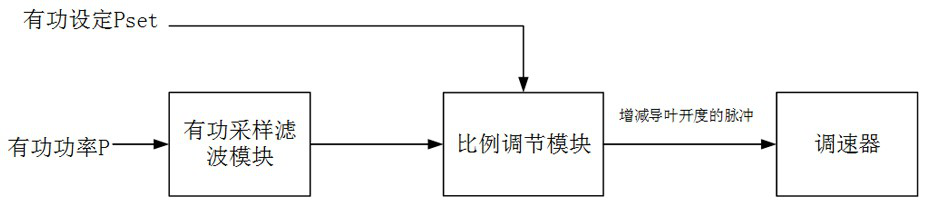

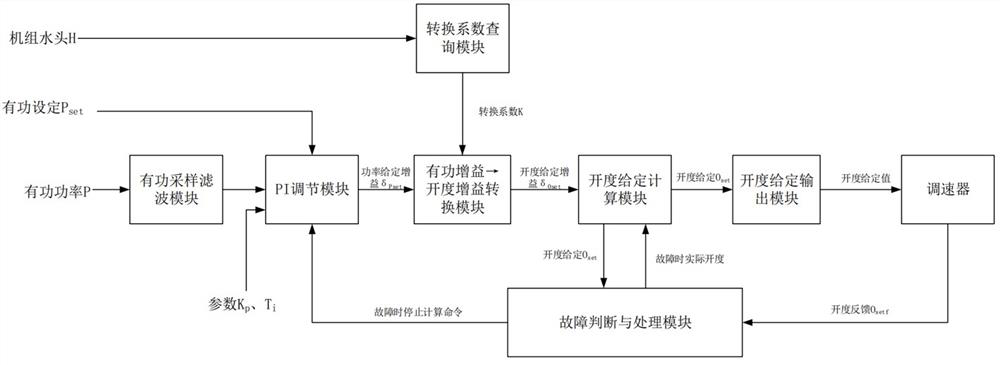

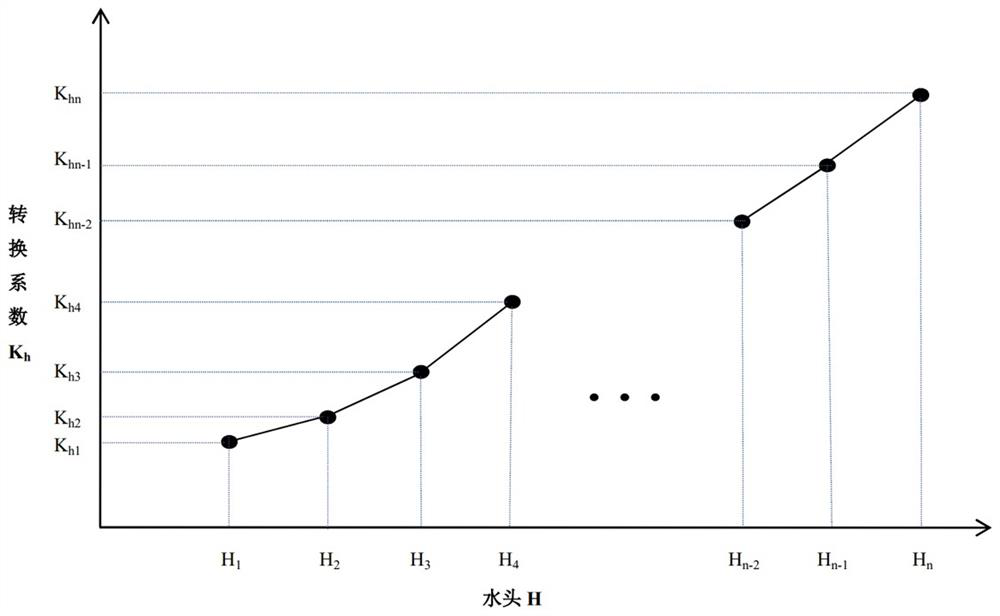

Hydroelectric generating set power control method adopting PI control to adjust given opening degree

PendingCN113864108AImproving the adjustment speed and adjustment accuracy of the unit's active powerAvoid overshootSingle network parallel feeding arrangementsHydro energy generationControl modeLoop control

The invention relates to a hydroelectric generating set power control method adopting PI control to adjust the given opening degree. According to the method, a closed-loop control mode is adopted, a given opening degree value is calculated and obtained to be input into a speed regulator, and the active power of a hydroelectric generating set is adjusted. A control unit of the control method comprises a sampling filter module, a PI adjusting module, an opening gain conversion module, an opening given calculation module and an opening given output module. According to the set power control method, the set power given gain is calculated through proportional-integral control and converted into the given opening degree value of the speed regulator, and compared with an existing method for controlling the opening degree of guide vanes of the set through proportional regulation pulses, the set active power regulation rate and regulation precision in the guide vane opening degree control mode are improved. Large overshoot is avoided. When a speed regulation system breaks down, the open-loop control mode can be switched to, and set power regulation failure or wrong regulation when a monitoring system and the speed regulation system break down is avoided.

Owner:CHINA YANGTZE POWER

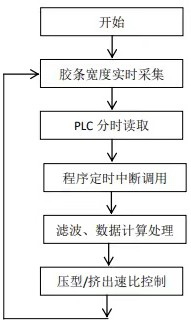

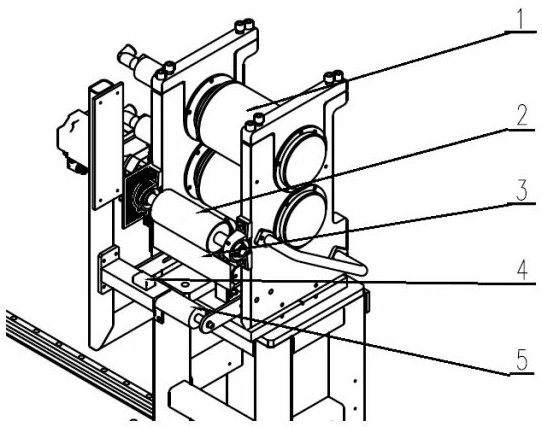

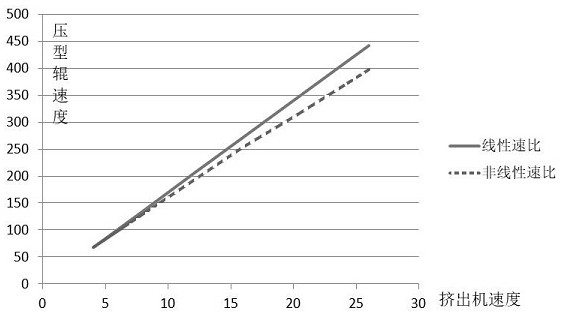

Closed-loop control method and closed-loop control device for width of adhesive tape

The invention discloses a closed-loop control method and a closed-loop control device for the width of an adhesive tape. The method comprises the following steps: a real-time width value of the adhesive tape is acquired; the real-time width value is read in a time-sharing mode, timing interruption is set for PID calculation, the actual speed ratio value between an extruder and a profiling roller is calculated, and the obtained actual speed ratio value is compared with a preset standard speed ratio value; according to the difference value between the actual speed ratio and the preset standard speed ratio, the profiling speed of a profiling roller is adjusted; the real-time width value of the adhesive tape is collected again, and the steps are repeated to achieve closed-loop control over the width of the adhesive tape. The device is used for implementing the method, the width of the adhesive tape is obtained in real time, the width value of the adhesive tape is read in a time-sharing mode, whether the profiling / extrusion speed ratio meets the preset standard value or not is judged according to the width value of the adhesive tape through timing interruption, the profiling roller is adjusted, stretching / stacking of the adhesive outlet profiling adhesive tape is controlled, and therefore the width of the adhesive is controlled to be stable.

Owner:TIANJIN SAIXIANG TECH

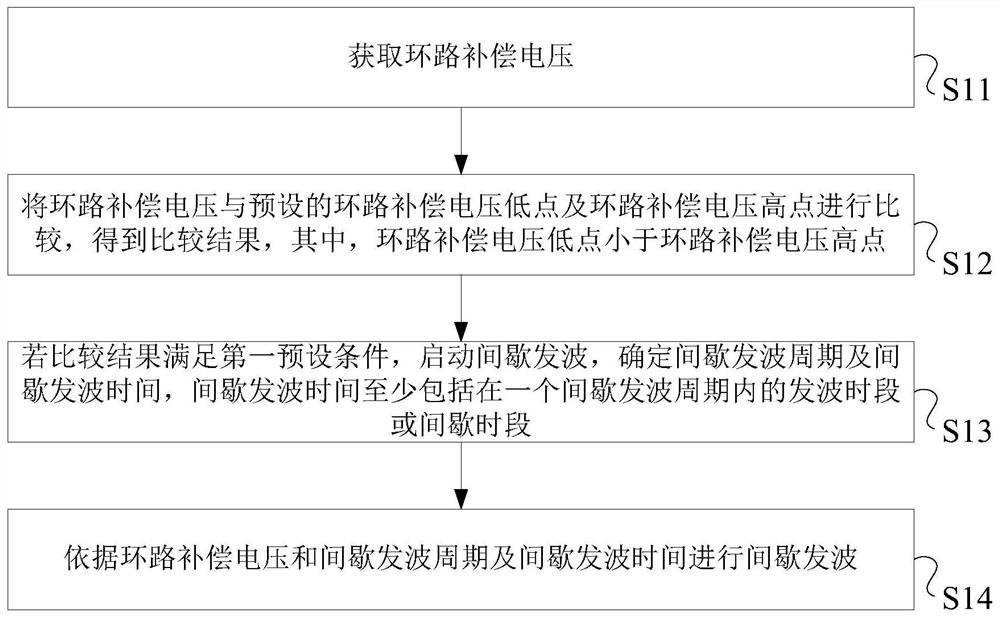

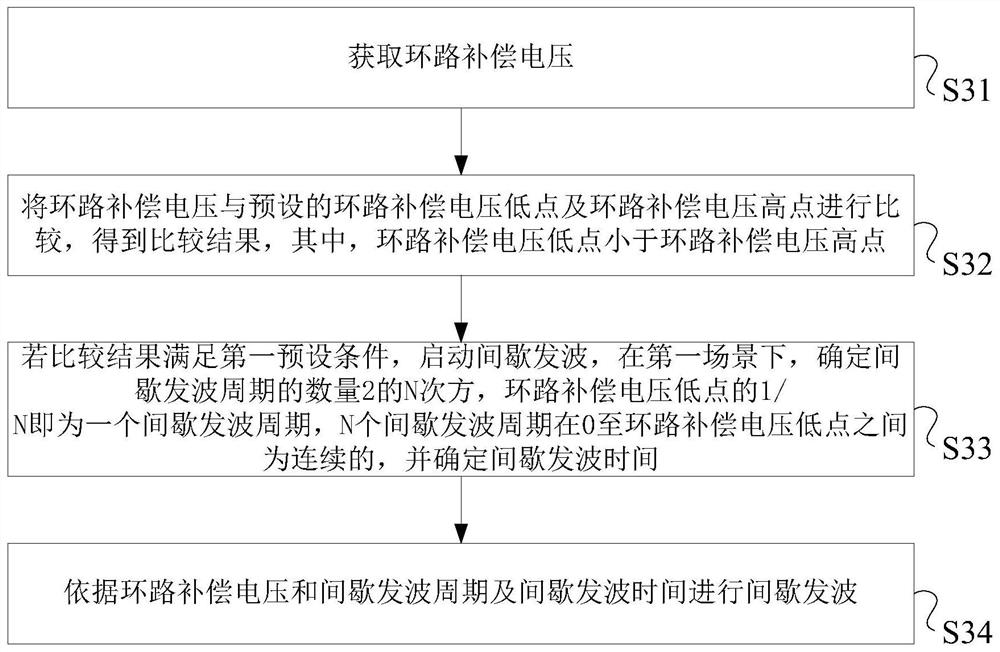

A switching frequency control method and system

ActiveCN110231849BAssurance controlGuaranteed stabilityElectric variable regulationVoltage overshootControl engineering

The invention discloses a switching frequency control method and system. The switching frequency control method comprises the steps of: obtaining loop compensation voltage, comparing the loop compensation voltage with the high point and the low point of the pre-set loop compensation voltage, so that a comparison result is obtained, if the comparison result satisfies a first pre-set condition, starting intermittent wave generation, determining the intermittent wave generation period and the intermittent wave generation time, and performing intermittent wave generation according to the loop compensation voltage, the intermittent wave generation period and the intermittent wave generation time. According to the scheme, when the loop compensation voltage and the pre-set high point and low point satisfy the first pre-set condition, intermittent wave generation is started; therefore, control on switching frequency PWM wave generation is realized; control on transmission energy is controlled;the condition that the output voltage is overshot is avoided; and the stability of the output voltage is ensured.

Owner:SHENZHEN SUPLET

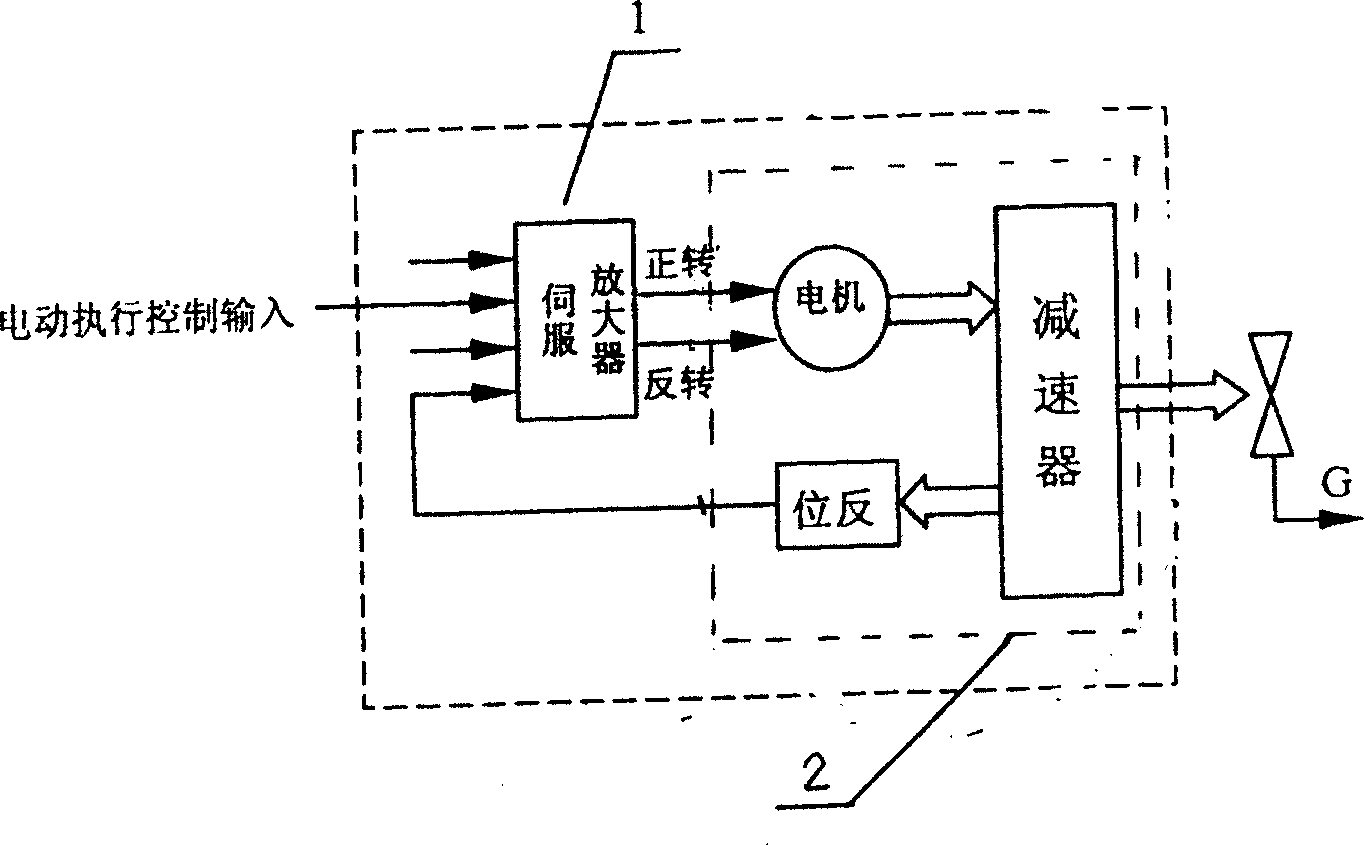

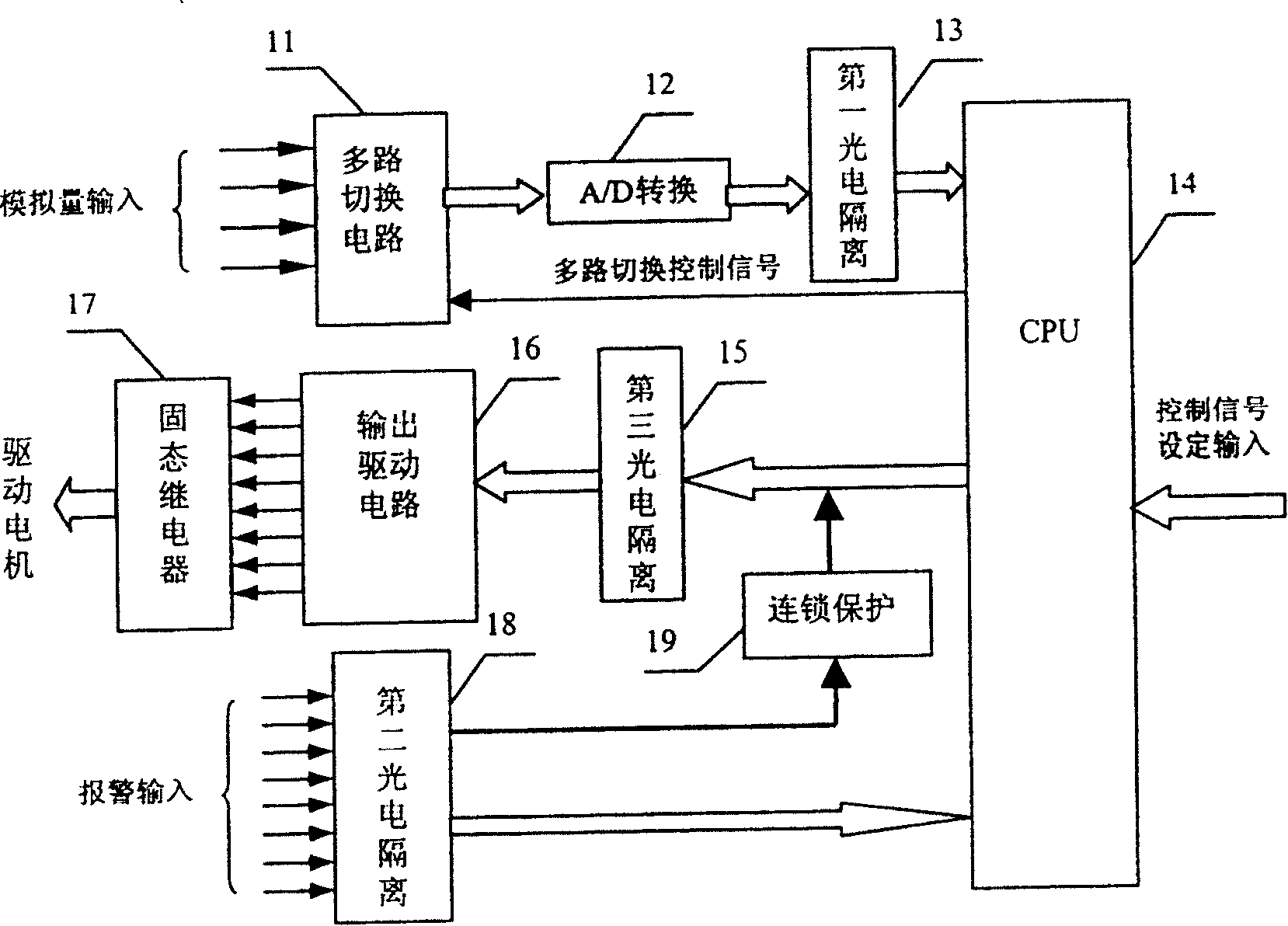

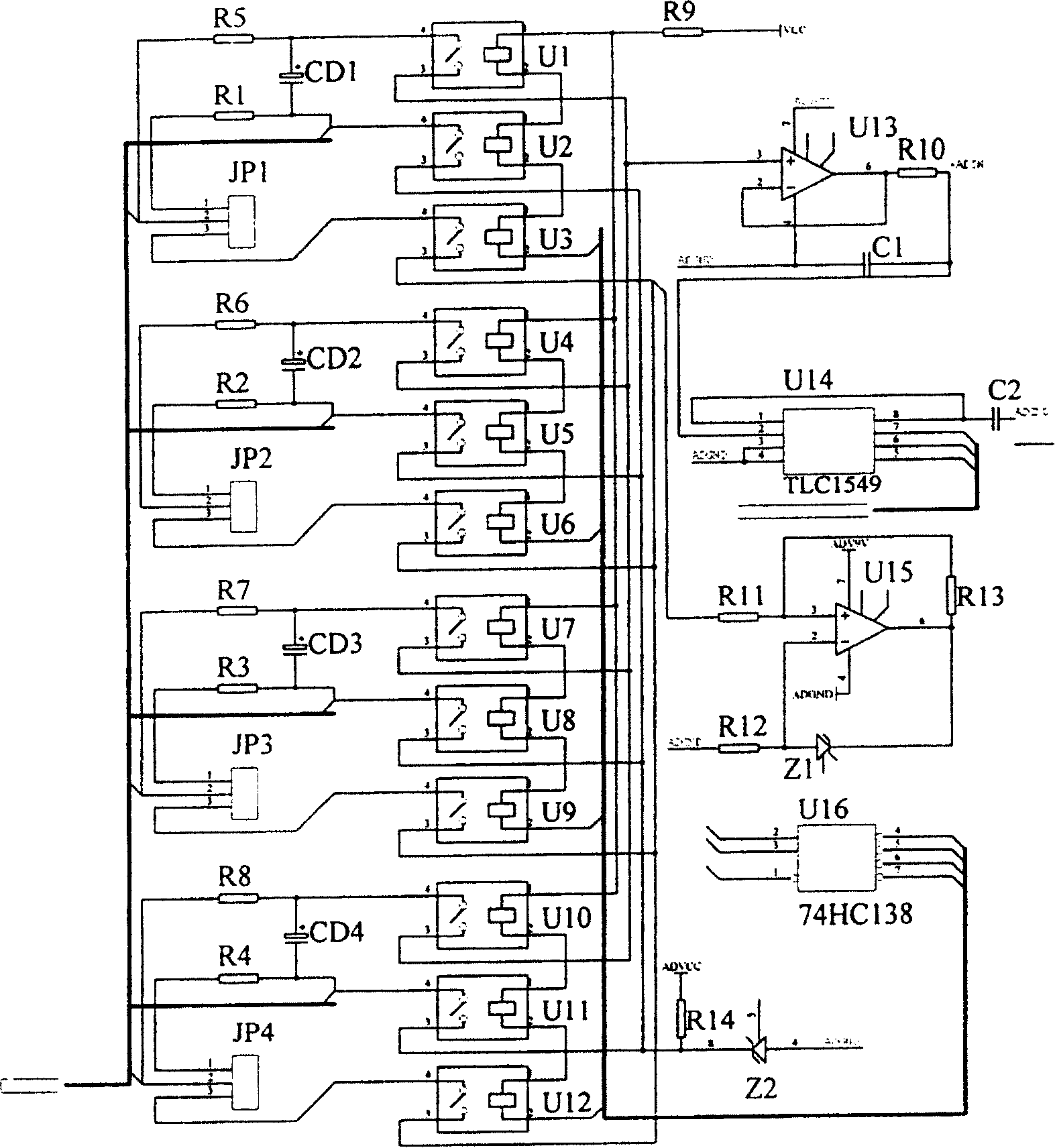

Self-adapting type intelligent electric actuator controller and method for realizing adaptive control thereof

InactiveCN100397262CSimple structureImprove stabilityElectric motor speed/torque regulationAdaptive controlAutomatic controlStudy methods

The present invention belongs to the field of automatic control technology, and is especially one kind of adaptive intelligent controller for electric executing mechanism and its adaptive control method. The controller includes servo amplifying part and electric executing mechanism part, and features that the servo amplifying part consists of microprocessor, multiplexer circuit, A / D converter, photoelectric isolator circuit, output driver circuit, solid relay and linkage protecting circuit. The adaptive control method includes the steps of self-learning characteristic parameters of electric executing mechanism and adaptive intelligent control. Owing to the increased adapting function of the servo amplifier, various characteristic parameters of the electric executing mechanism may be obtained during switching from manual control to automatic control, and this avoids overshoot and raises stability, safety and reliability of the controller.

Owner:ZHEJIANG SUPCON TECH

A Parameter Self-tuning Method of pid System

ActiveCN109062033BAvoid shockAvoid overshootControllers with particular characteristicsSelf-tuningControl objective

The invention discloses a parameter self-tuning method of a PID system. This PID system parameter self-tuning method effectively prevents the system output wave from oscillating near the target value SV or deviation value (SV_n) during the self-tuning process, and the system sampling value PV reaches the target value SV before stopping the control object. The excitation is applied to ensure that the system output wave can always reach the control target value SV, and the PID control parameters calculated by the controller are more accurate. In addition, the self-tuning method, regardless of the initial state of the system, first collects the working condition signal, and then according to the collected value Comparison of PV and deviation value (SV_n) to determine whether to apply excitation to the control object, that is, the judgment of its working condition takes precedence over the control output, effectively preventing the occurrence of overshoot and avoiding the occurrence of industrial accidents; the self-tuning process does not need complete The waveform, that is, the corresponding period, shortens the time of the self-tuning process, thus increasing the detection speed of the system's self-tuning, and avoiding the occurrence of industrial accidents.

Owner:NINGBO ELECTROMECHANICAL IND RES & DESIGN INST CO LTD

Motor control method, system, device and storage medium of a sewing machine

ActiveCN110592831BIncrease speedStable speedSewing-machine control devicesControl engineeringElectric machinery

Owner:ZHEJIANG ZOBOW MECHANICAL & ELECTRICAL TECH

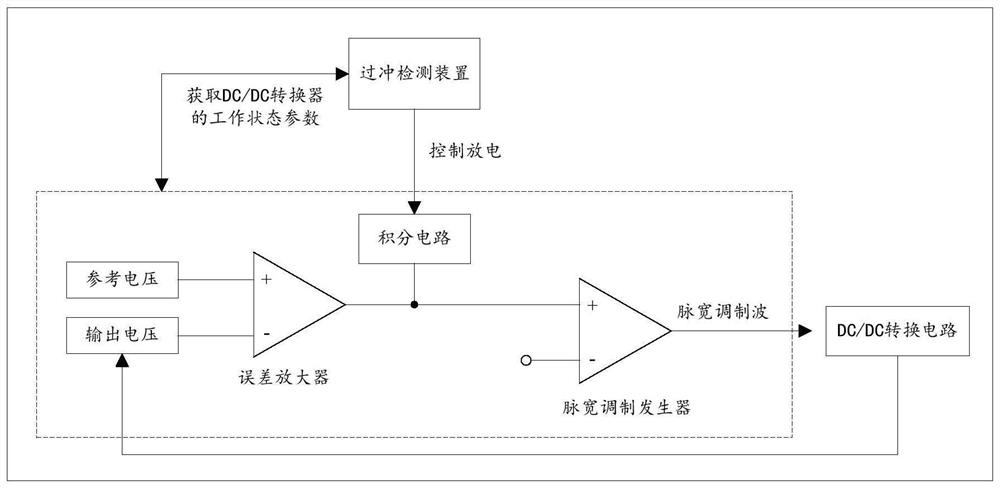

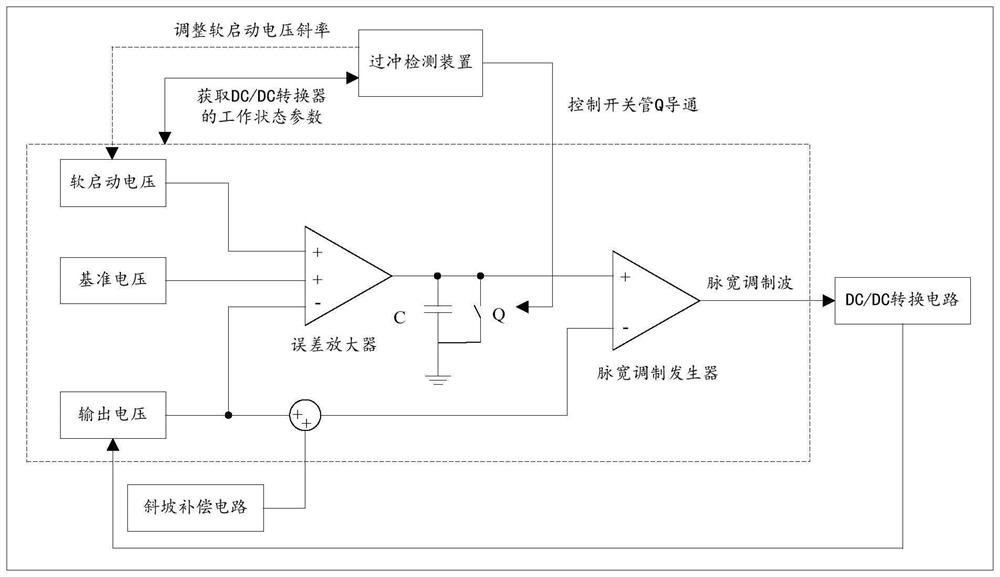

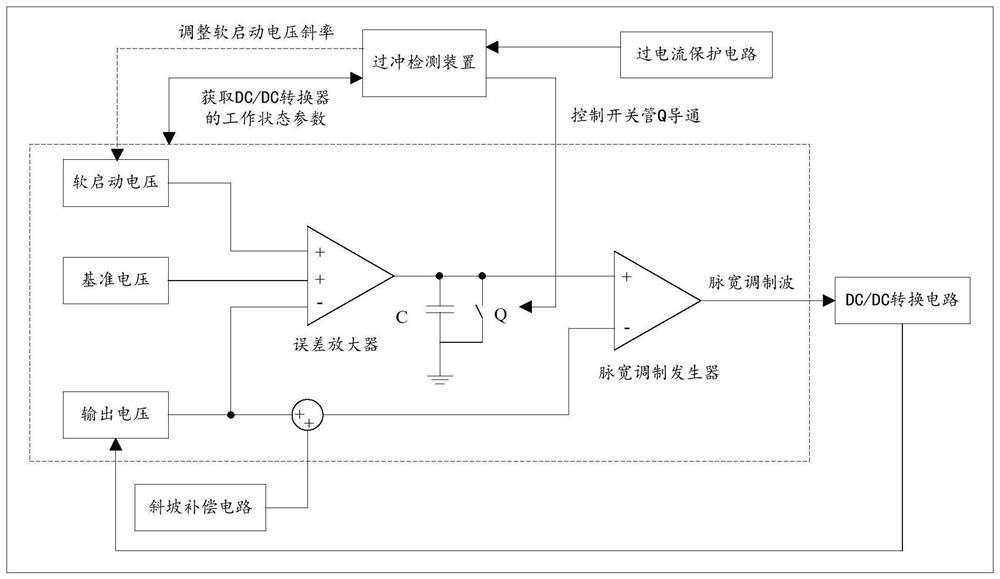

DC/DC converter and its soft-start anti-overshoot method

ActiveCN112803742BImprove accuracySituations where the risk of overshoot is preventedDc-dc conversionConvertersVoltage overshoot

The application provides a DC / DC converter and a soft-start anti-overshoot method thereof. The DC / DC converter includes a DC / DC conversion circuit, an overshoot detection device, a pulse width modulation generator, an error amplifier, and an output of the error amplifier. The integrating circuit is connected to the terminal, wherein the integrating circuit is used to integrate the difference between the reference voltage and the output voltage of the DC / DC conversion circuit, and control the error amplifier to input the pulse width modulation generator. Amplify the magnitude of the voltage. The overshoot detection device acquires the working state parameters of the DC / DC converter, and controls the integrating circuit to discharge when the working state parameters of the DC / DC converter meet the requirements of the working state parameters. The application can effectively avoid the overshoot of the output voltage of the DC / DC converter at the end of the soft start, and has strong applicability.

Owner:HUAWEI TECH CO LTD

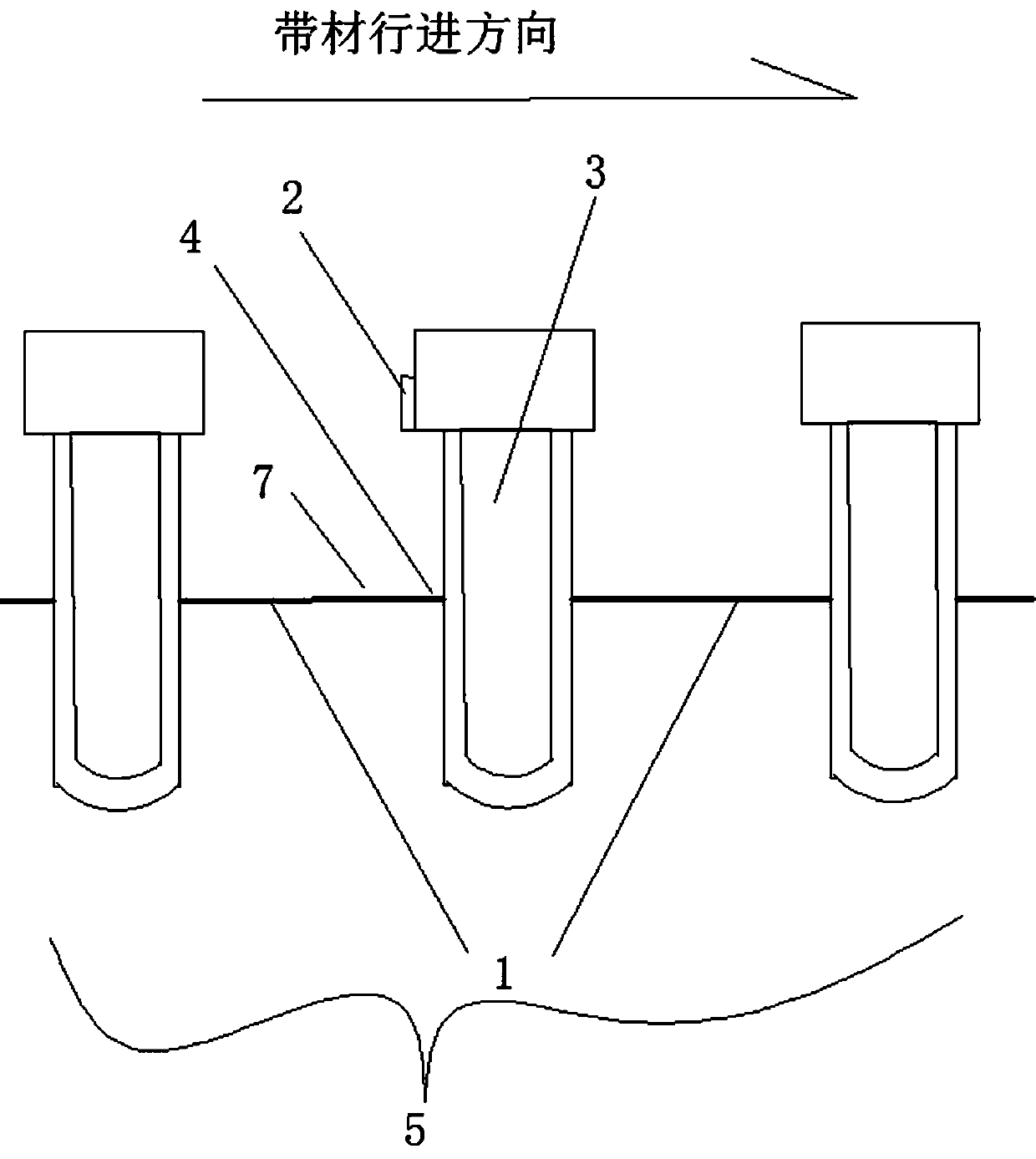

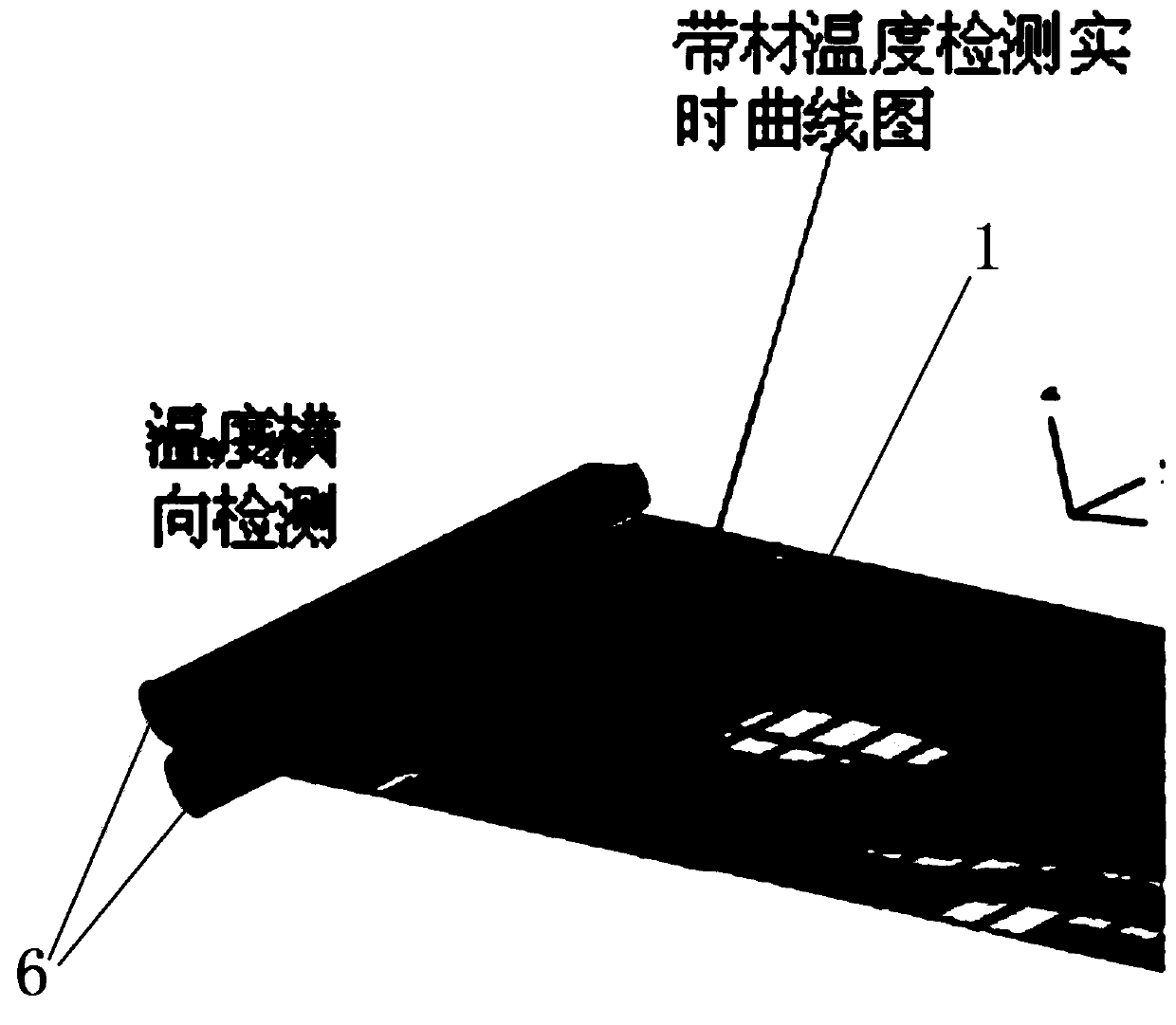

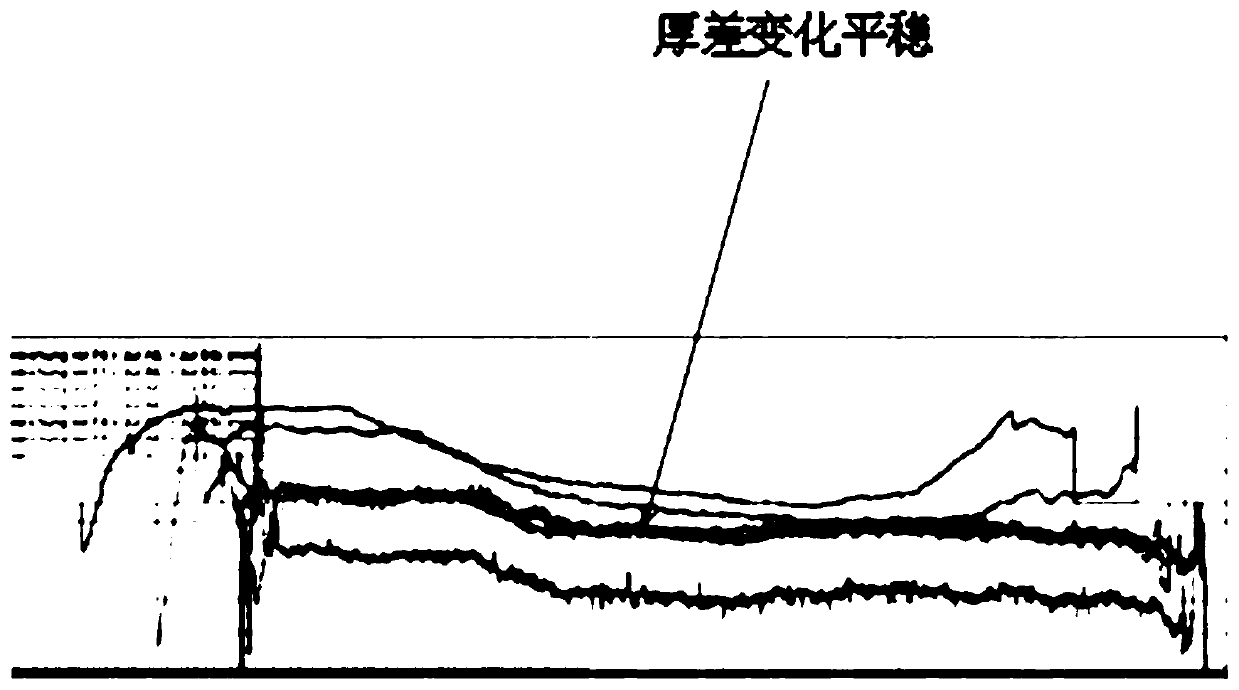

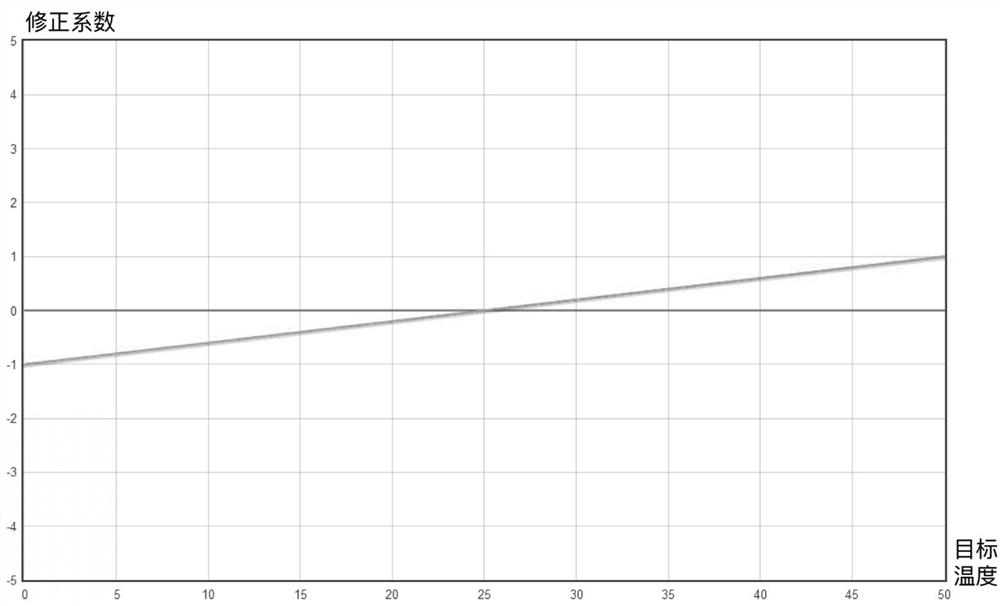

Aluminum alloy hot-rolled strip plate shape control method

ActiveCN109604349AAvoid overshootAvoid phenomena such as overshootingMeasuring devicesProfile control deviceControl systemHot rolled

The invention provides an aluminum alloy hot-rolled strip plate shape control method applied to the aluminum hot finish rolling process of a strip rolling machine plate shape control system. The control method comprises the steps that inlets of one or more rolling racks are selected as strip temperature measuring points in an aluminum rolling channel, high-temperature strip detectors are installedat the strip temperature measuring points, in the aluminum rolling process, when strips pass through the strip temperature measuring points, the high-temperature strip detectors detect the transversetemperature of the strips at the inlets of the rolling racks and feed detected data back to the rolling machine plate shape control system, the rolling machine plate shape control system controls therolling racks in the aluminum rolling channel according to the detected data, feedforward adjusting is conducted on the strip plate shape through the rolling racks, and then the strip finished product plate shape in the aluminum hot finish rolling process can be adjusted and controlled. According to the aluminum alloy hot-rolled strip plate shape control method, the plate shape control precisioncan be high, the cost can not be increased too much, and the control requirements for different quantities of the hot finish rolling racks can be met.

Owner:CHINALCO RUIMIN

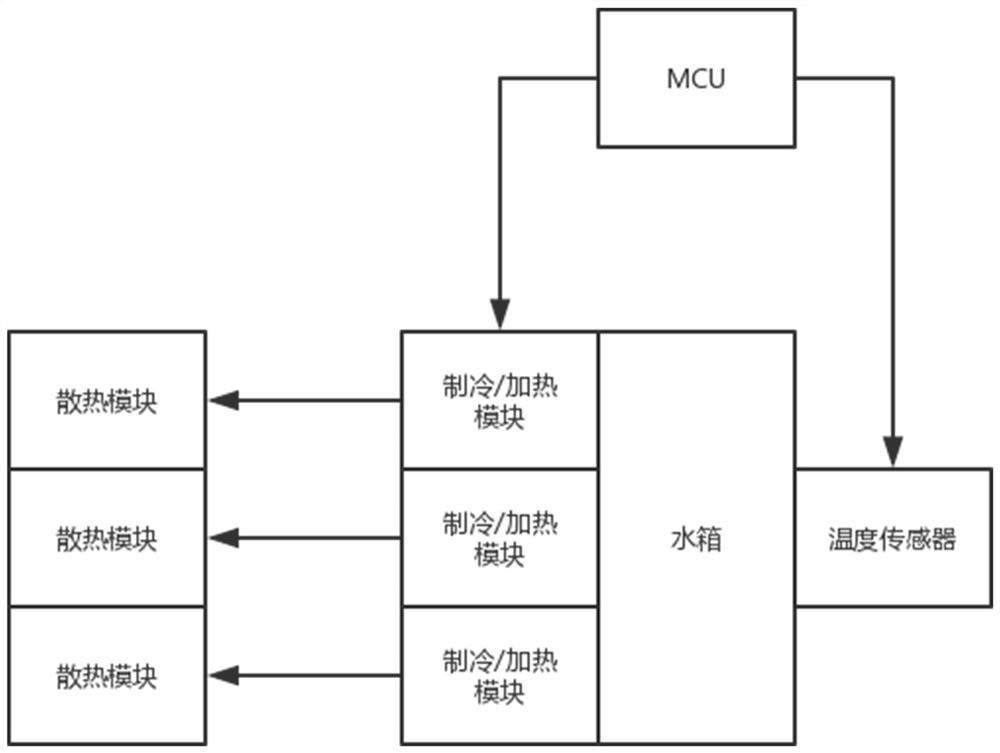

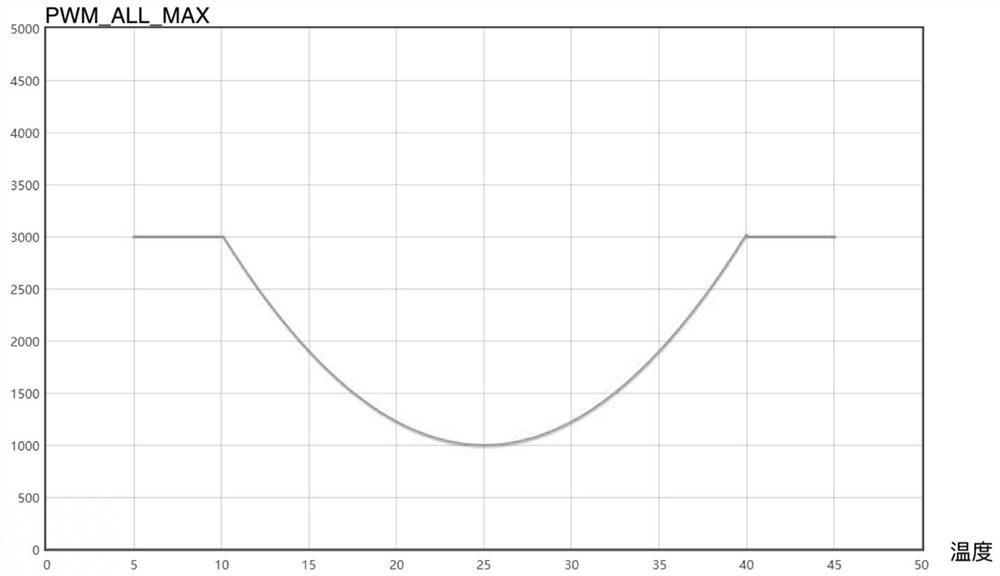

Temperature control method and system for a temperature therapeutic instrument

ActiveCN111474968BGentle temperature change rateAvoid discomfortTemperatue controlTemperature controlMedicine

The invention relates to a temperature control method and system of a temperature therapeutic apparatus, which calculates a PWM_ALL signal according to the current temperature and target temperature of therapeutic water, and compares it with the maximum limit value PWM_ALL_MAX before outputting the PWM_ALL signal, when PWM_ALL When it is greater than PWM_ALL_MAX, set PWM_ALL=PWM_ALL_MAX, and then output PWM_ALL signal to cooling / heating module for cooling or heating. If the current temperature is near room temperature, temperature therapy has a relatively gentle rate of temperature change to prevent discomfort to the patient; Tempering requirements. Therefore, the present invention takes into account both the temperature adjustment requirement and the patient's comfort in the process of using the temperature therapy instrument for temperature therapy.

Owner:厦门中翎易优创科技有限公司

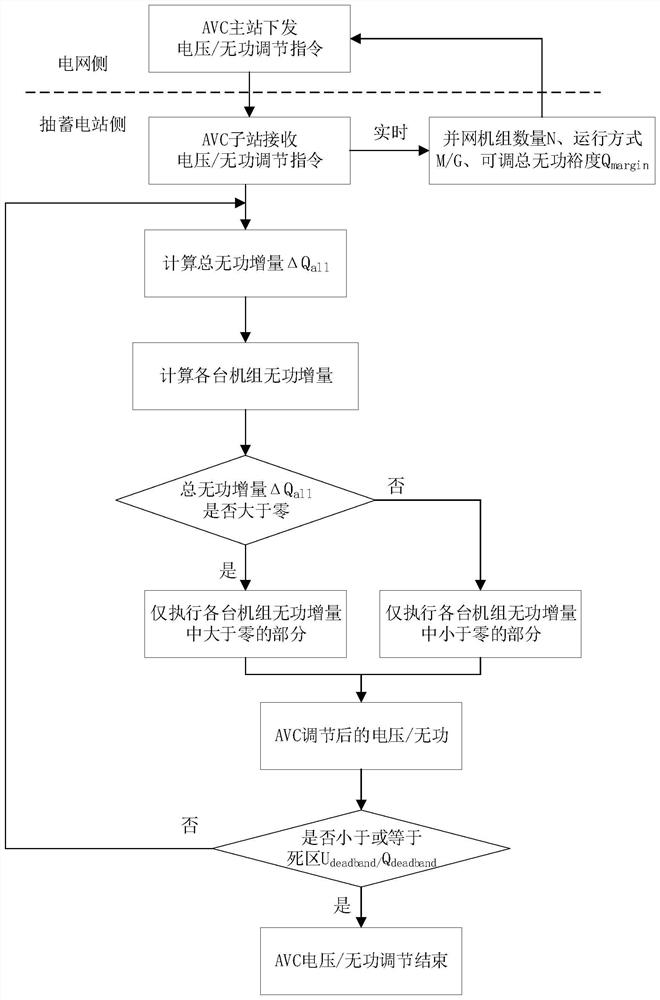

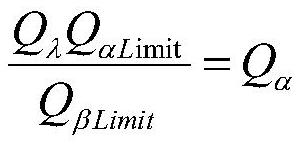

Reactive power margin distribution method for AVC system

ActiveCN112952923AAvoid overshootReasonable distribution of reactive powerSingle network parallel feeding arrangementsAc network voltage adjustmentPower marginPower station

The invention relates to a reactive power margin distribution method for an AVC system. The reactive power margin distribution method balances the reactive power margin of a unit in a pumped storage power station in real time in the AVC adjustment process, and does not need to carry out the reactive power redistribution adjustment of the unit in the station after an adjustment object reaches a target; the reactive power of the units in the station can be reasonably distributed and adjusted under the condition that the reactive power adjustment rates and the reactive power adjustment step lengths of the multiple units in the station are different; and through same-direction judgment, the condition of repeated adjustment when the voltage fluctuates and the target value of the AVC master station is small is avoided. Compared with the prior art, the reactive power margin distribution method has the advantages that reasonable reactive power distribution can be achieved in the mode that the pumped storage power station units run in parallel in multiple working conditions or in different working conditions, and the like.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com