Patents

Literature

262 results about "Industrial Accident" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An accident taking place on the site of a commercial enterprise.

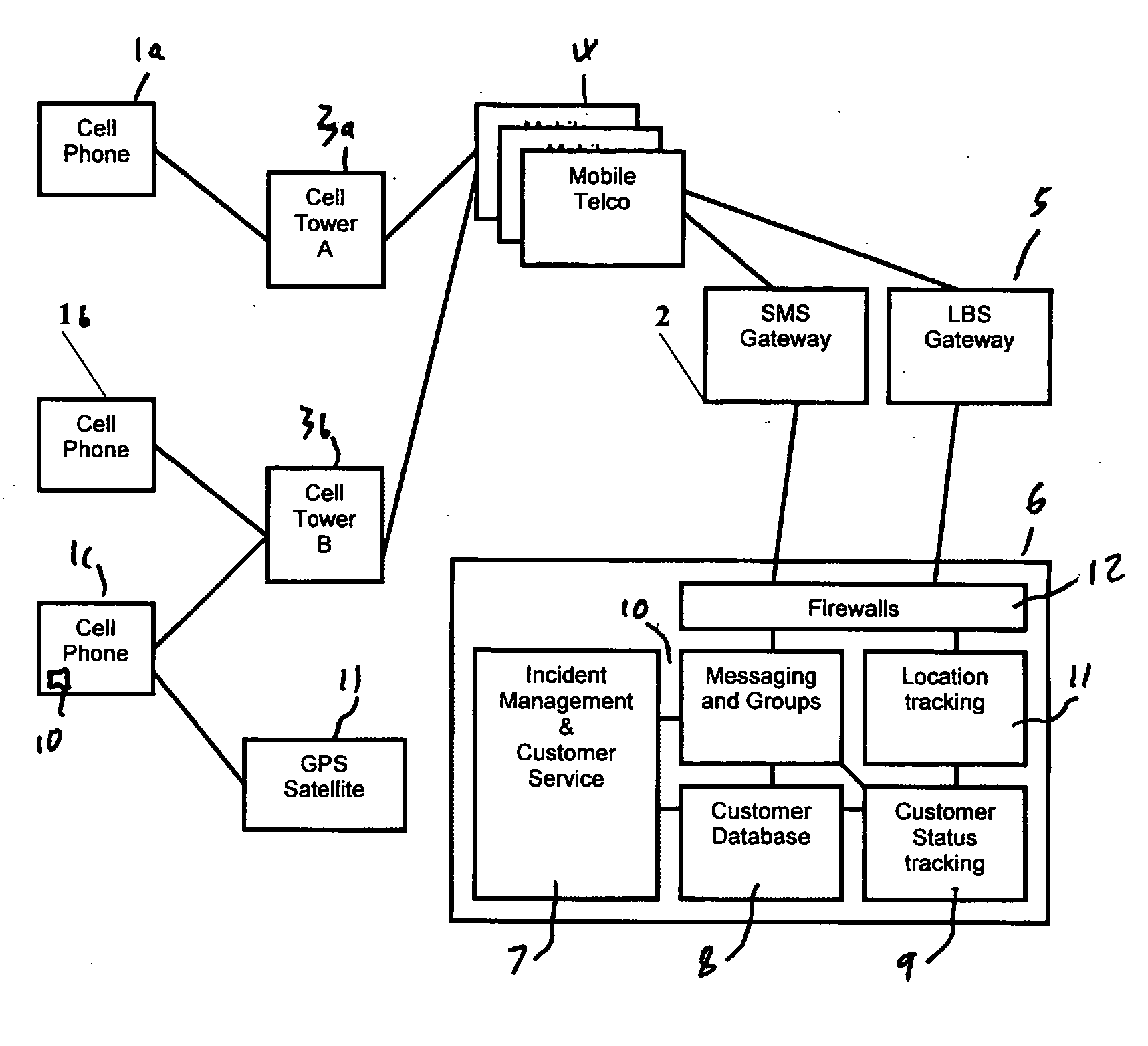

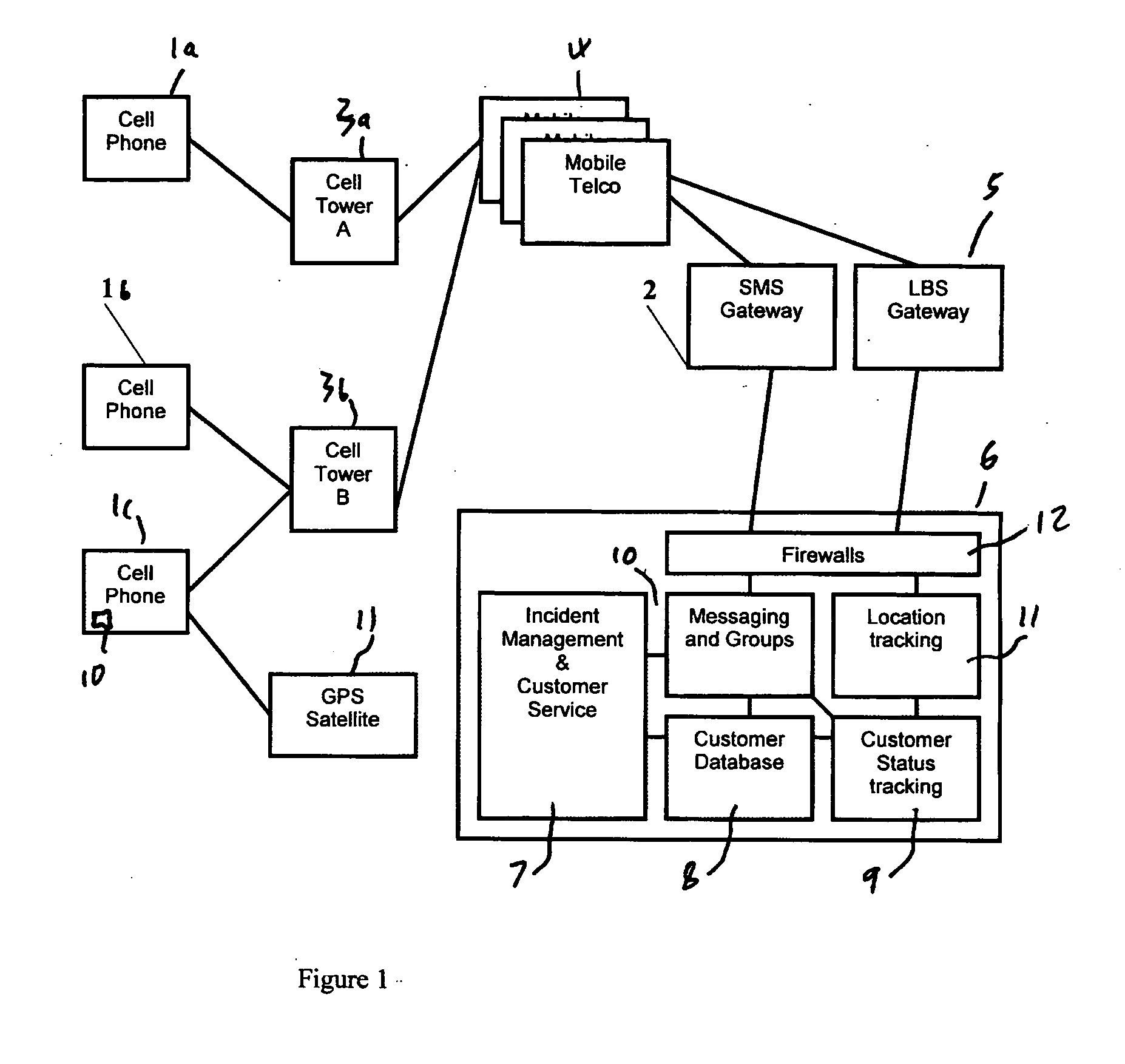

Location, tracking and alerting apparatus and method

InactiveUS20070159322A1Position fixationRadio/inductive link selection arrangementsExtreme weatherIndustrial Accident

This invention describes a product that is used during emergency incidents where the location of people can be used to track who could have been involved in the incident for example Industrial Accidents, Extreme Weather, Natural Disasters, Terrorist Attacks etc. The service locates people using devices they carry with them typically their mobile phone (1). The people's locations are compared to the location and radius of the incident and the probability that they may have been involved in the incident is determined (possible or low probability). People are also automatically contacted by a verity of means for example SMS (2) to their mobile and asked to confirm their status. Their status is automatically updated and available to people who they have linked themselves to via the service.

Owner:GRIFFIN IAN

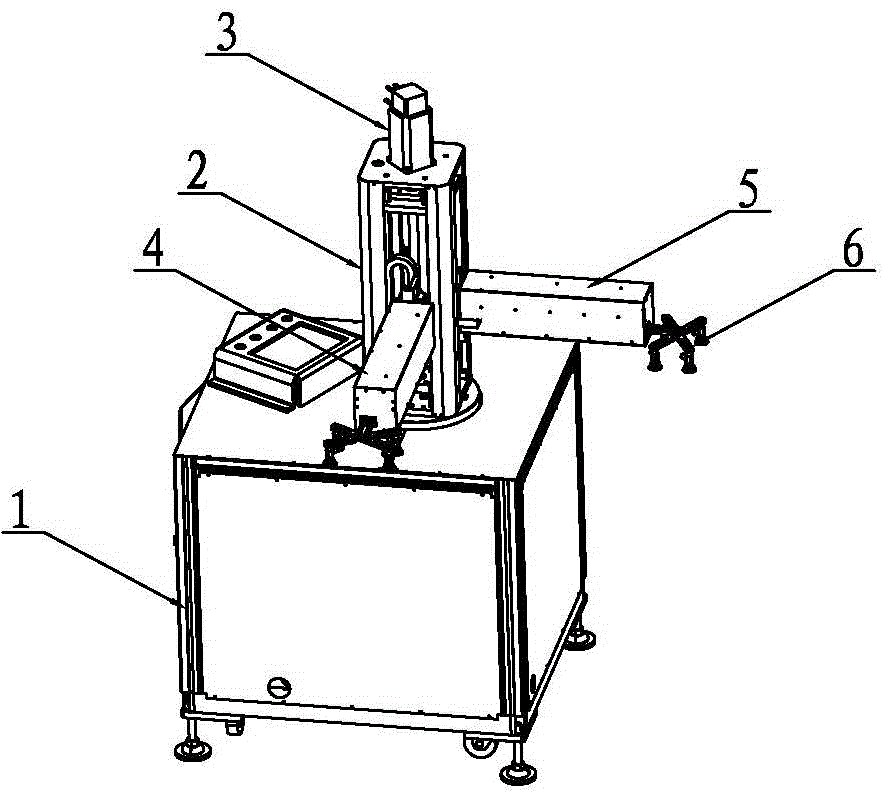

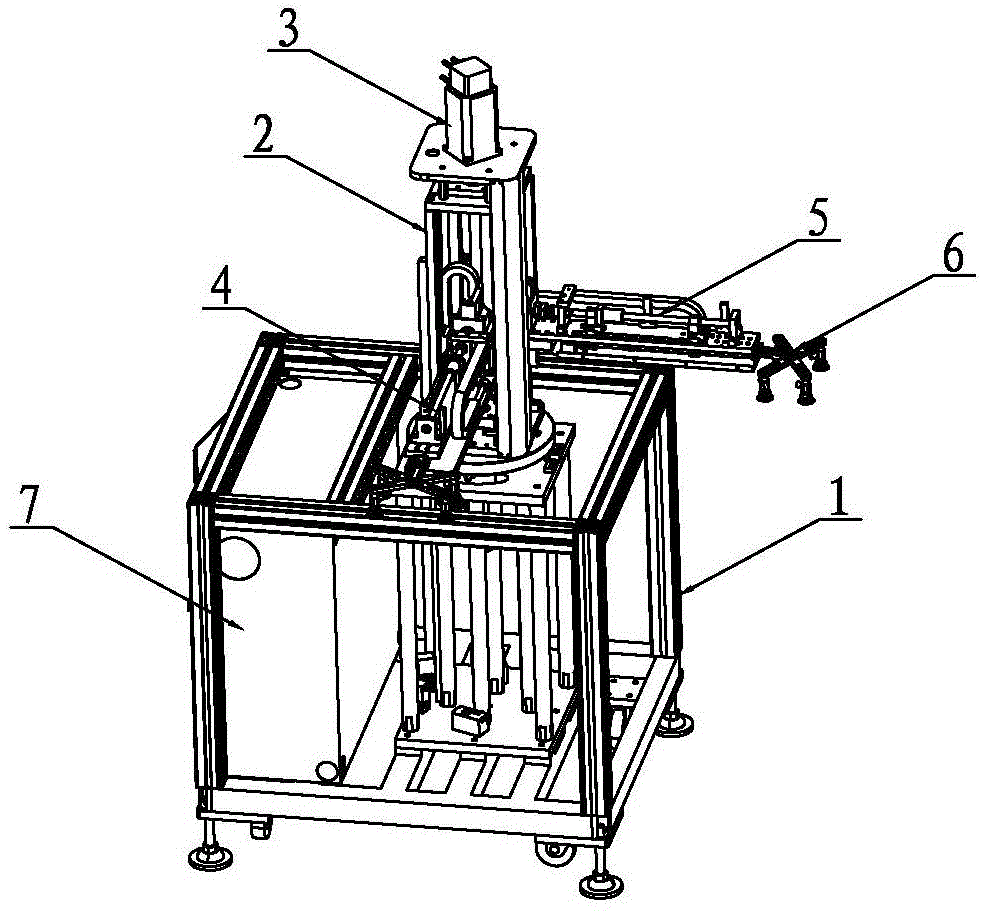

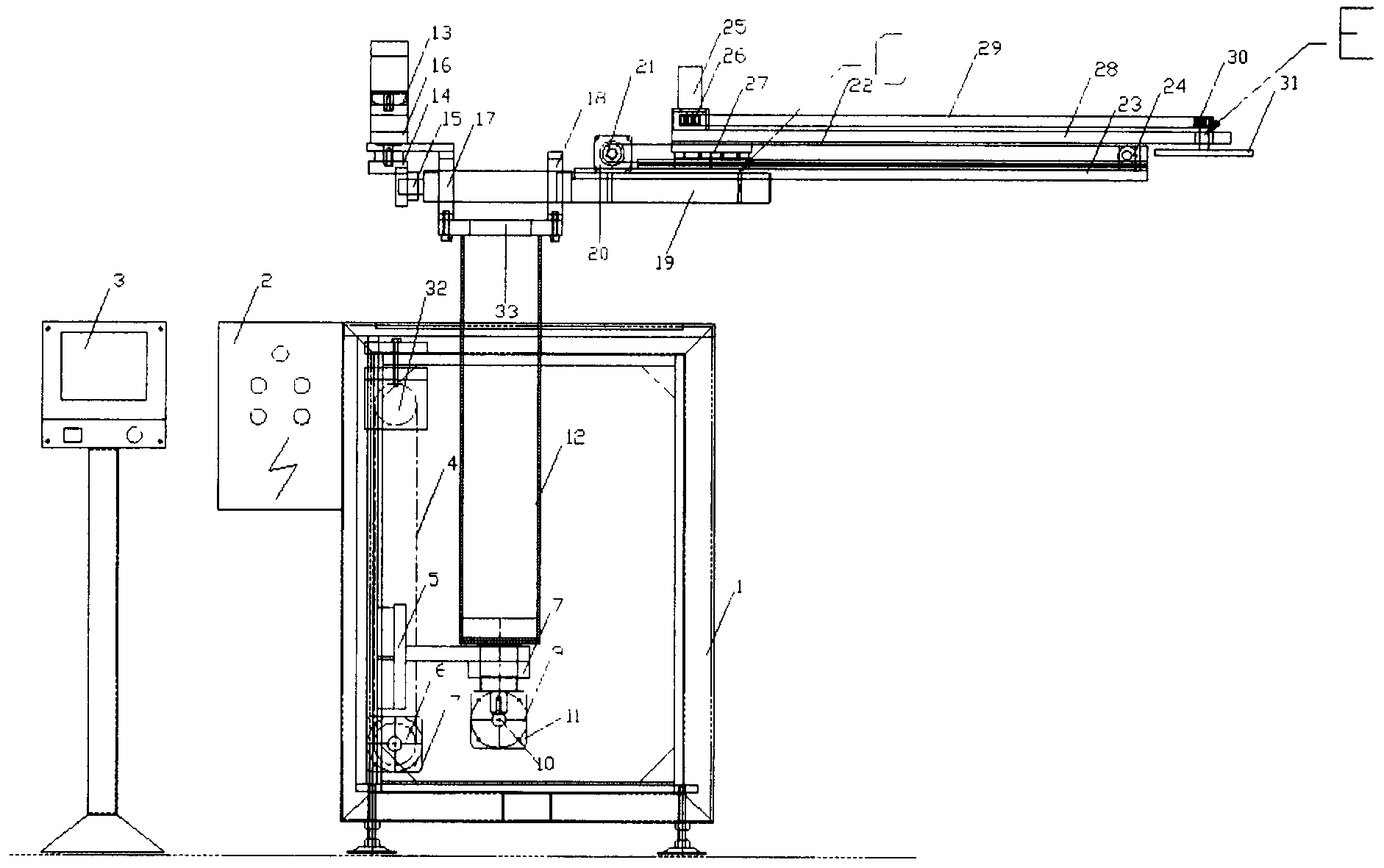

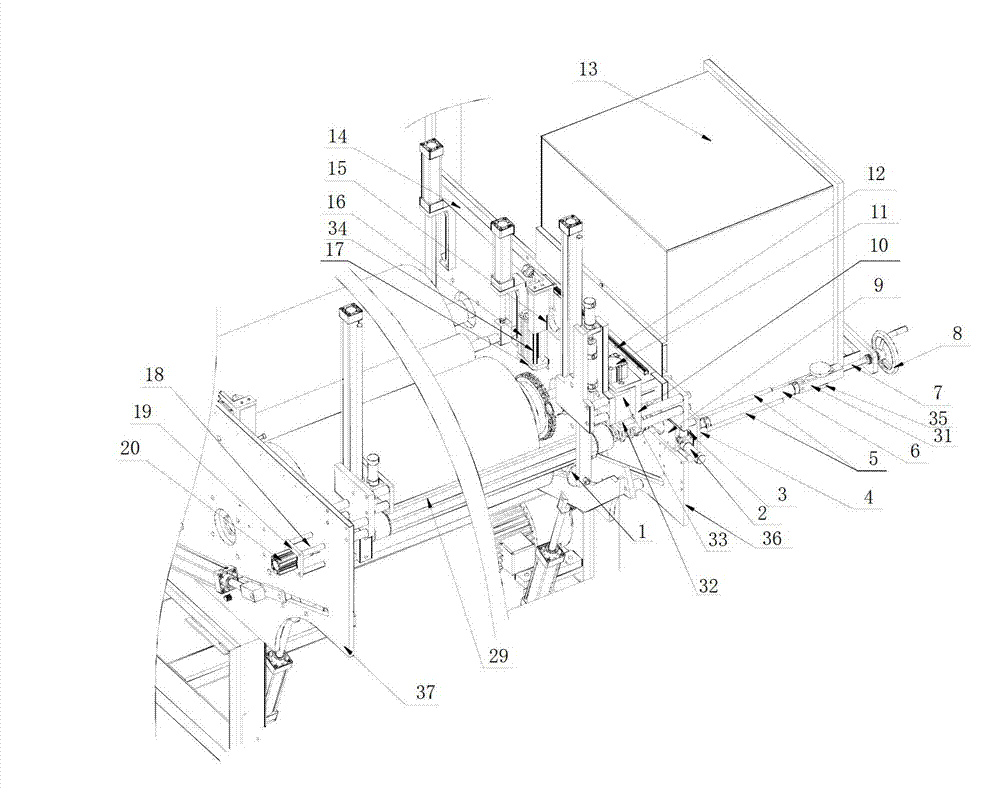

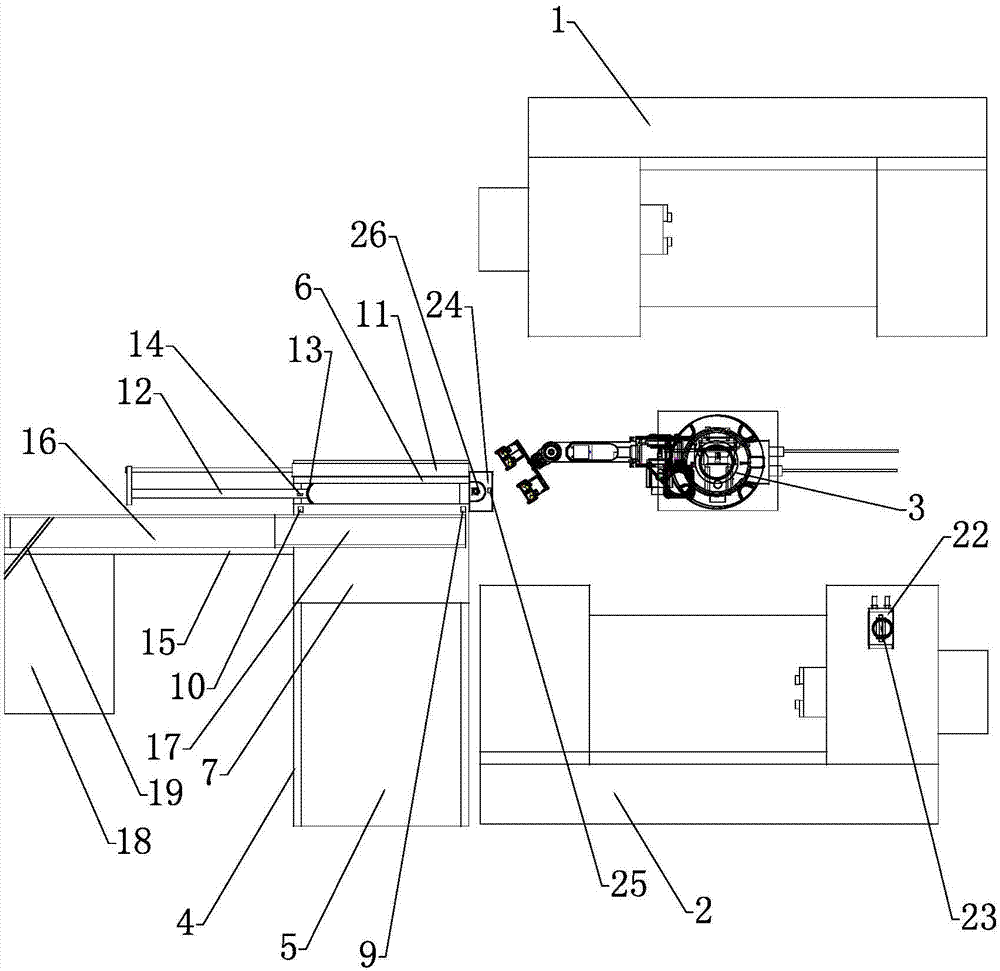

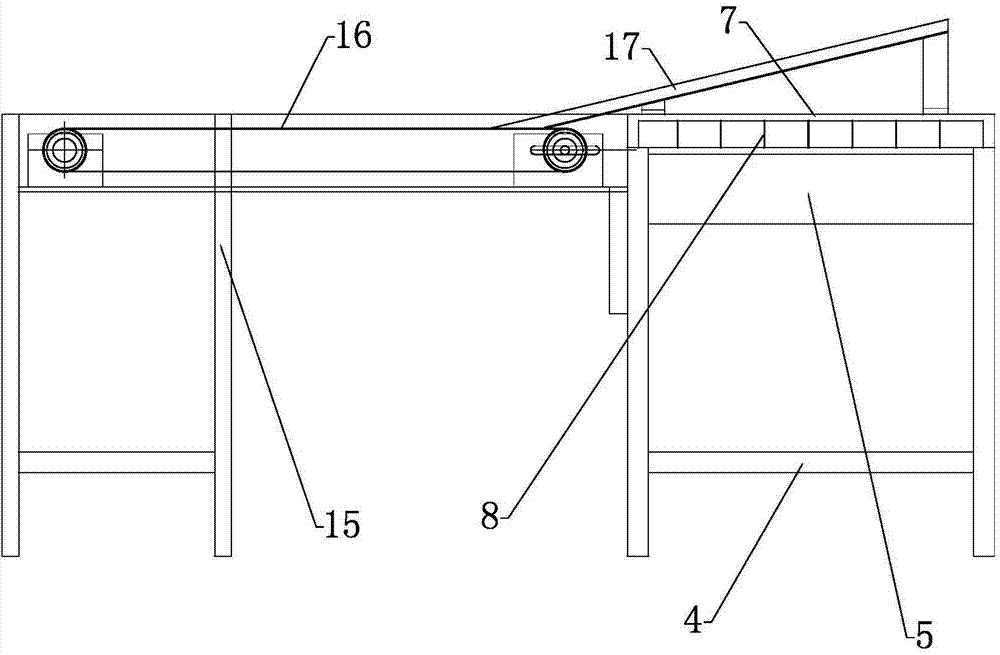

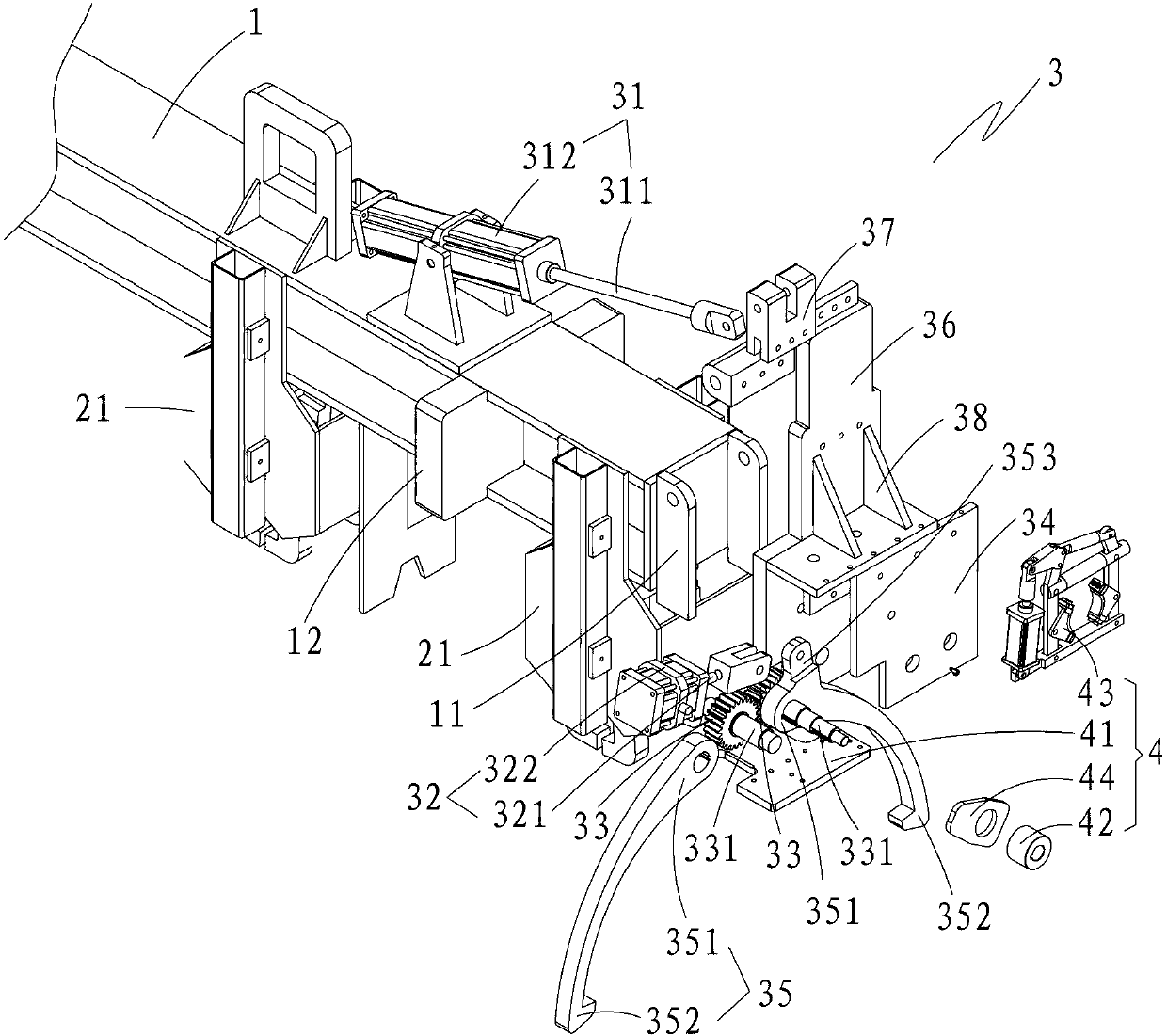

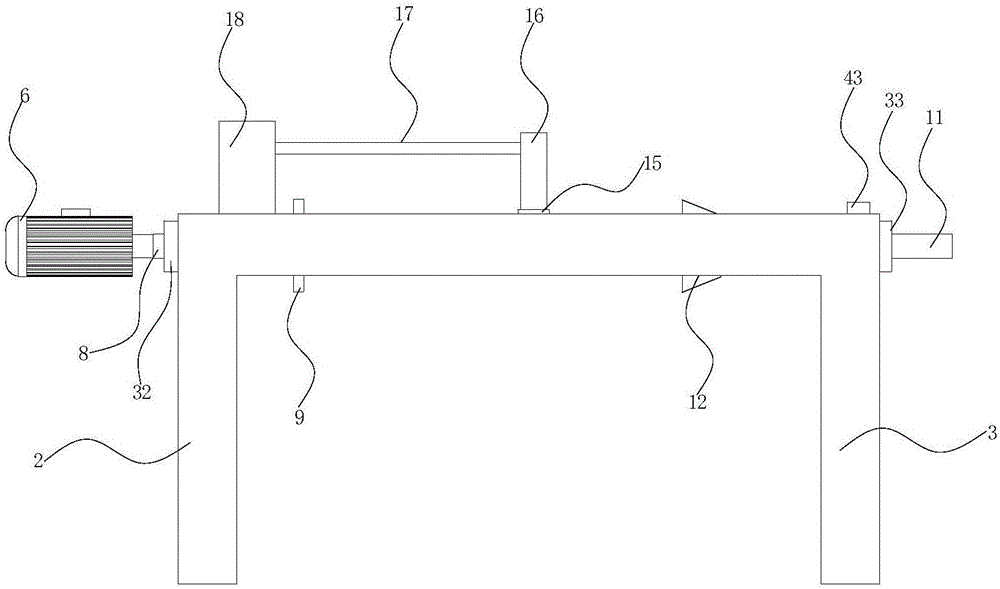

Feeding and discharging mechanical arm and device for stamping process

InactiveCN104785655AAutomatic and flexible reclaimingAutomatic and flexible feedingProgramme-controlled manipulatorMetal-working feeding devicesElectricitySingle process

The invention discloses a feeding and discharging mechanical arm and device for the stamping process. The feeding and discharging mechanical arm structurally comprises an electric control cabinet, a rack, a main rotating shaft, a fixing base, a vertical shaft, a first mechanical arm body, a second mechanical arm body, a first mechanical claw and a second mechanical claw. The included angle between the first mechanical arm body and the second mechanical arm body ranges from 90 degrees to 120 degrees, and the first mechanical arm body and the second mechanical arm body can move vertically along with the vertical shaft. The vertical shaft and the fixing base can rotate horizontally along with the main rotating shaft. The main rotating shaft, the vertical shaft, the first mechanical arm body and the second mechanical arm body are driven by different motors, and all the motors are electrically connected with the electric control cabinet. The feeding and discharging mechanical arm has the functions of taking and placing materials automatically and flexibly, is suitable for single-process stamping as well as whole-line multi-station stamping, solves the technical problems that existing equipment is low in applicability, low in working efficiency and likely to cause industrial accidents, and improves working efficiency, flexibility and safety.

Owner:FOSHAN IROBOT AUTOMATIC

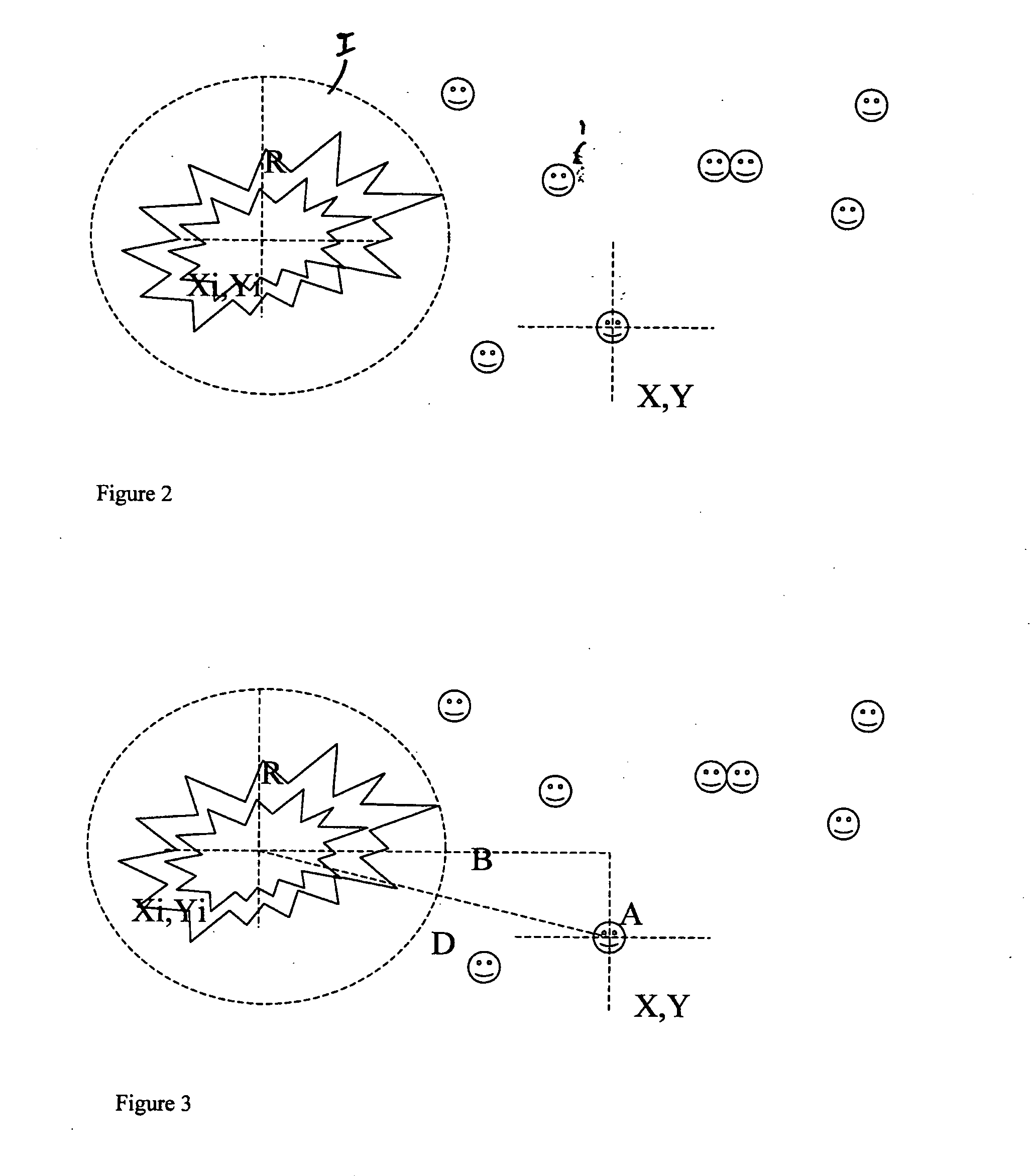

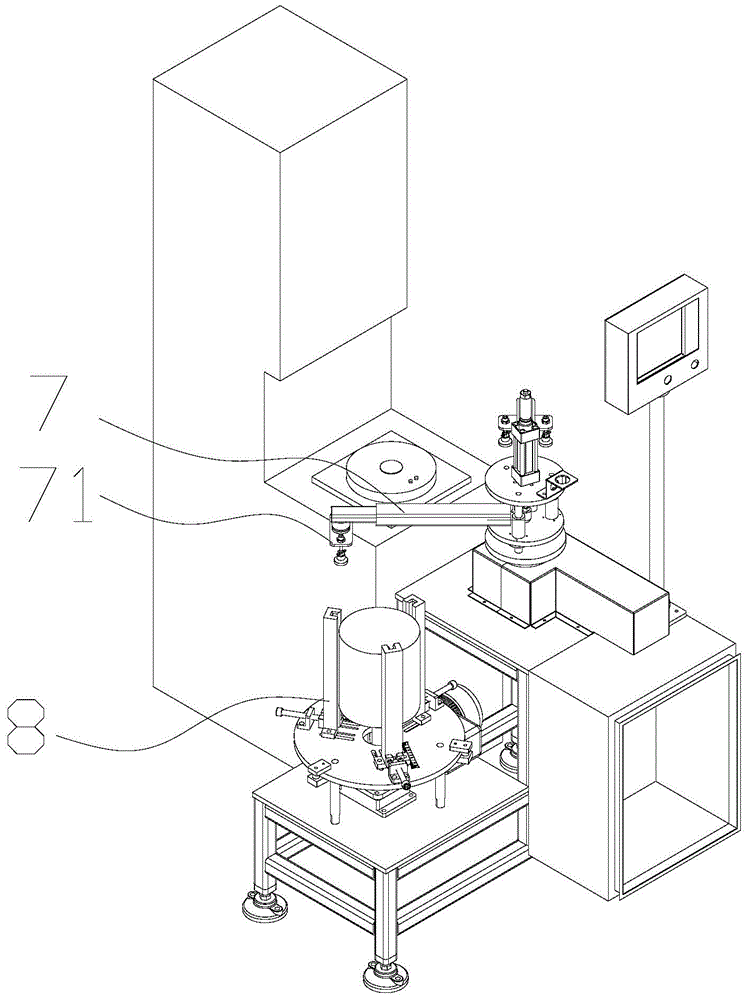

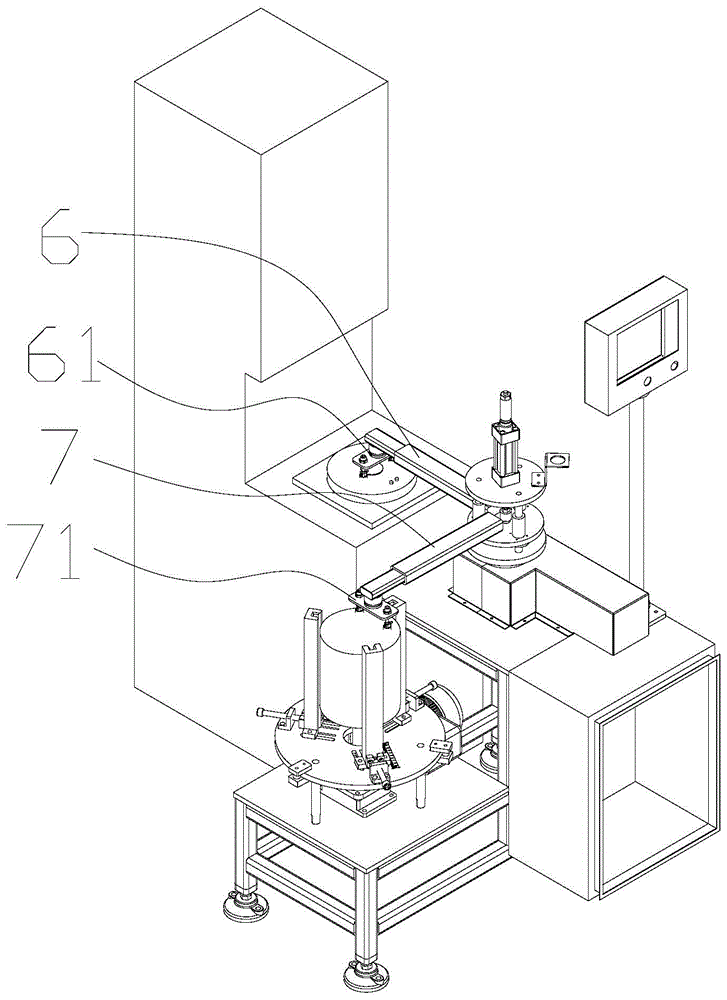

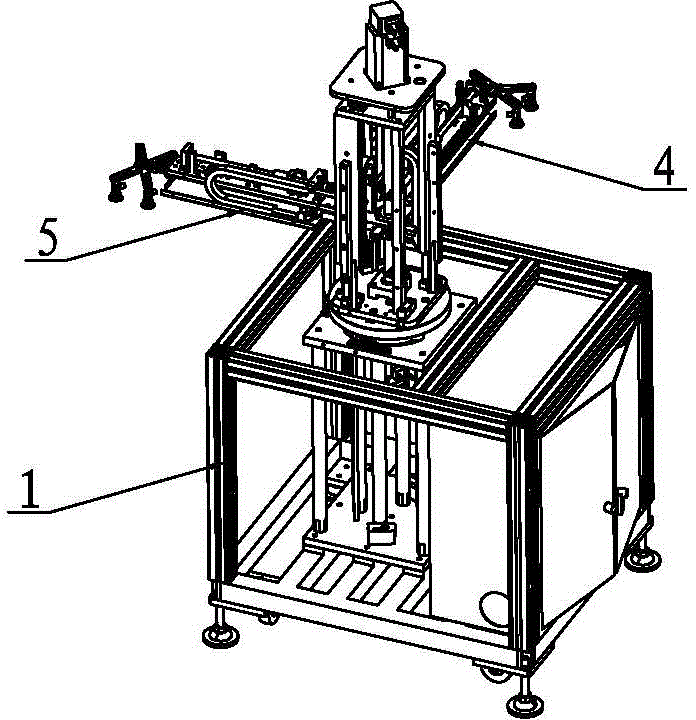

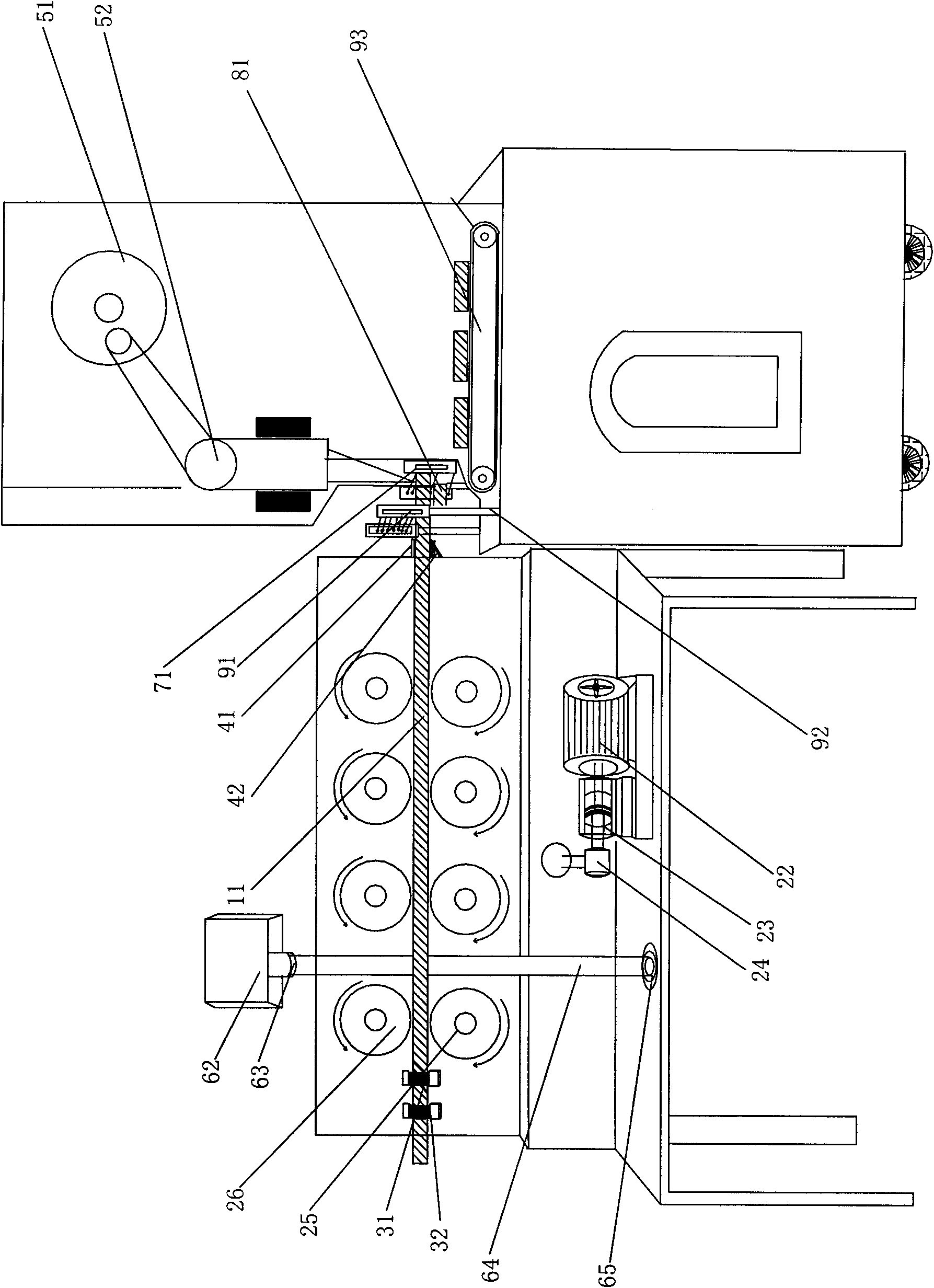

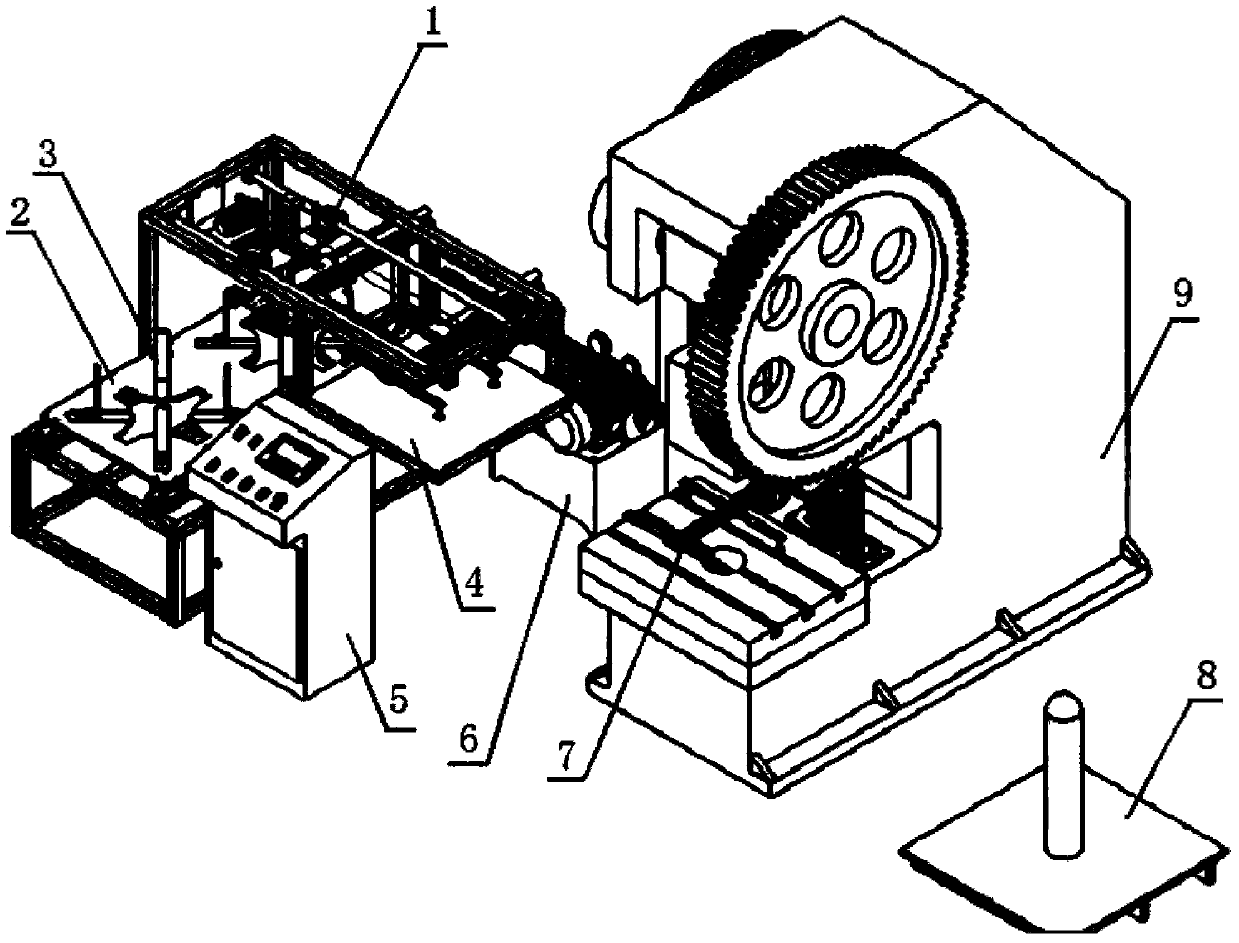

Rotating-disc type automatic feeding-discharging machine

ActiveCN104016131AReduce the number of employeesImprove continuityConveyor partsIndustrial AccidentRotating disc

The invention relates to the technical field of conveying devices, and discloses a rotating-disc type automatic feeding-discharging machine. When the rotating-disc type automatic feeding-discharging machine works, a first stretchable arm is stretched out, sucks up a product to be machined through a sucker device and then is drawn back, a wheel disc rotates by a certain angle to enable the first stretchable arm to be aligned with a machining device with the requirement for feeding, the first stretchable arm is stretched out, places the product to be machined into a machining position and is drawn back, and the feeding work is completed; while the first stretchable arm carries out feeding, a second stretchable arm is stretched into the machining position to suck up a machined product, then is drawn back to exit from the machining position, synchronously rotates by a certain angle along with the wheel disc, and then releases the machined product, and the discharging work is completed. In conclusion, by means of the rotating-disc type automatic feeding-discharging machine, automatic feeding-discharging work is achieved, the work continuity is good, the production efficiency is improved, manual intervention is avoided in the operation process, the safety is improved, and industrial accidents are greatly avoided; meanwhile, the number of employees of an enterprise is decreased, and the production cost is saved.

Owner:东莞市恒技精密机械设备有限公司

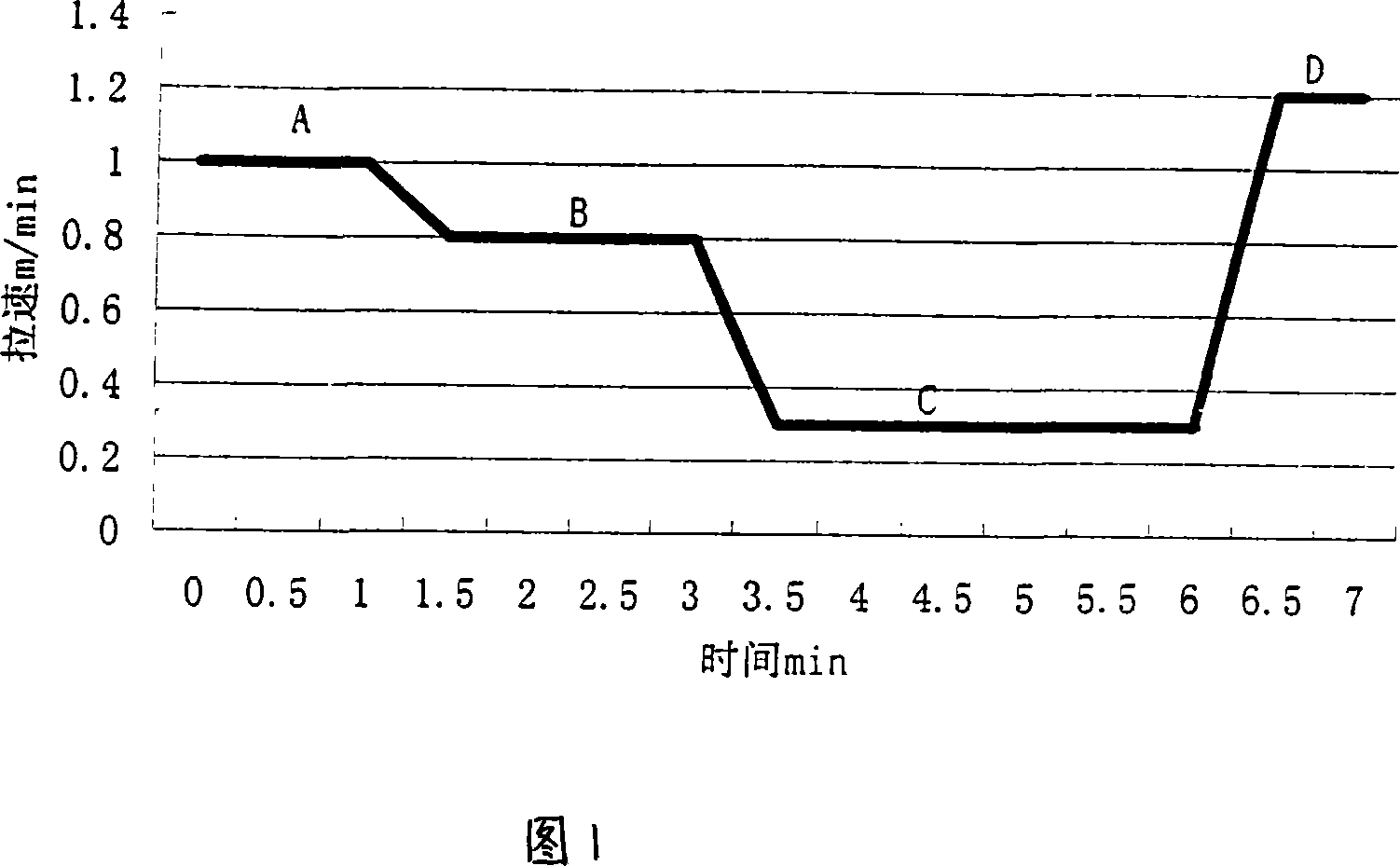

Flat blank continuous casting closed-top technology for preventing steel liquid roof-falling

A slab continuous casting capping process for preventing molten steel from badly bleeding relates to a continuous casting field for smelting, comprises: section decelerating, adding with aluminum bar and raising speed of tailing slab. The section decelerating after bale pouring is to prevent decelerating too fast in final period and too large of the forward-shift in cogging region, thus it has no time to form the slab shell. Agitating oxygen pipe and water drilling for cooling are to ensure the empty slab shell have enough length so that the molten steel moving upwards has enough space. In order to continue desoxy a wild molten steel and prevent rising caused by tail part ebullition, 1-2 kilogram aluminum bar is inserted into open steel. During the final period, drawing tailing slab is carried out by raising speed to a speed higher than that of 0.2-0.3m / min during generally drawing strips, when the speed is too low, defects such as crack,etc., may appear, while the speed is too high, badly bleeding of the molten steel may occurs. The advantages of the invention are in that industrial accident of badly bleeding of the molten steel in the final period of the slab continuous casting process so that incidence rate of the molten steel badly bleeding can be reduced from 5 times / month to 0 time / month, meanwhile, incidence rate of tailing slab transverse crack during pouring peritectic steel and alloy steel can be reduced to 50% or more.

Owner:WUHAN IRON & STEEL (GROUP) CORP

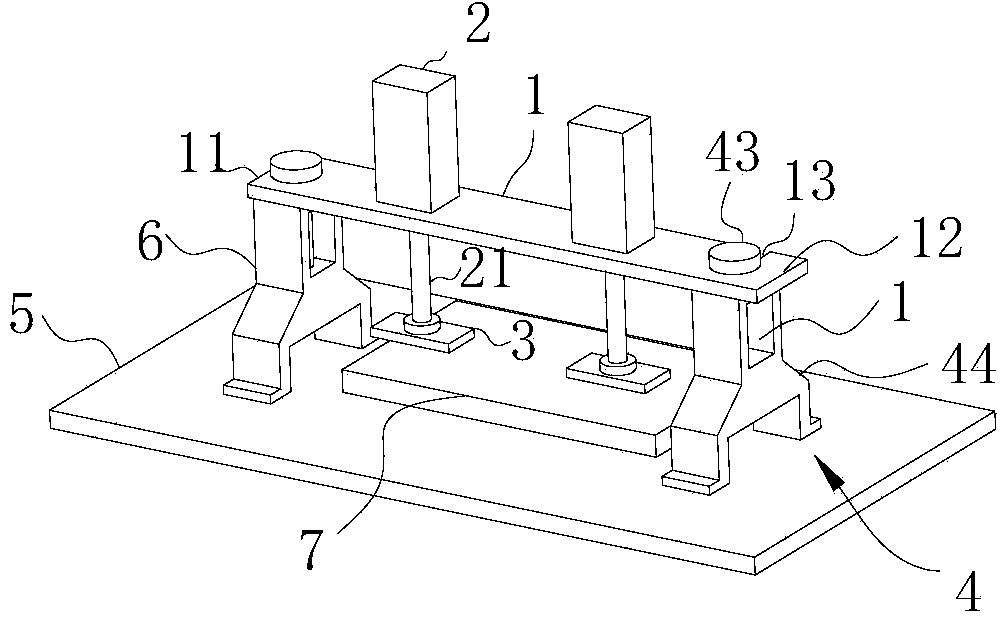

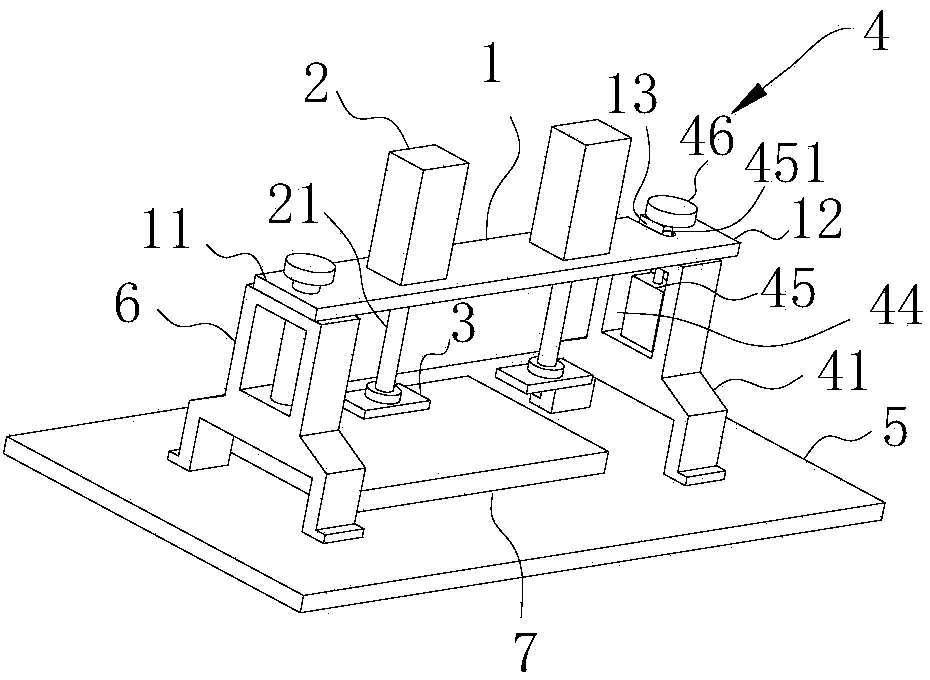

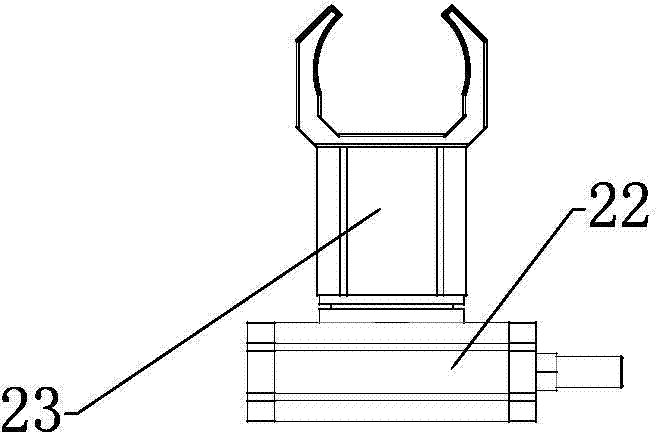

Sawing machine clamp

ActiveCN103862311AEnsure life safetyEasy to carryWork clamping meansPositioning apparatusIndustrial AccidentEngineering

The invention discloses a sawing machine clamp. The sawing machine clamp comprises a rotating cross beam arranged above a worktable, wherein the rotating cross beam comprises a hinging end and a free end, a first fixing device which is hinged to the rotating cross beam is arranged under the hinging end of the rotating cross beam, a second fixing device capable of fixing the free end is arranged under the free end of the rotating cross beam, both the first fixing device and the second fixing device can be detachably fixed on the worktable, and the rotating cross beam is provided with at least one material-pressing device used for automatically pressing materials placed on the worktable in the length direction of the rotating cross beam. Through the arranged rotating cross beam, when a material cutting device needs to be checked, unimpeded check can be achieved by rotating the rotating cross beam, and further the rotating cross beam brings convenience to carrying of the materials. Besides, through the arranged material-pressing device, the sawing machine clamp can achieve material pressing without handwork, improve work efficiency, reduce industrial accidents and guarantee life safety of workers.

Owner:WANSHITAI METAL IND KUNSHAN

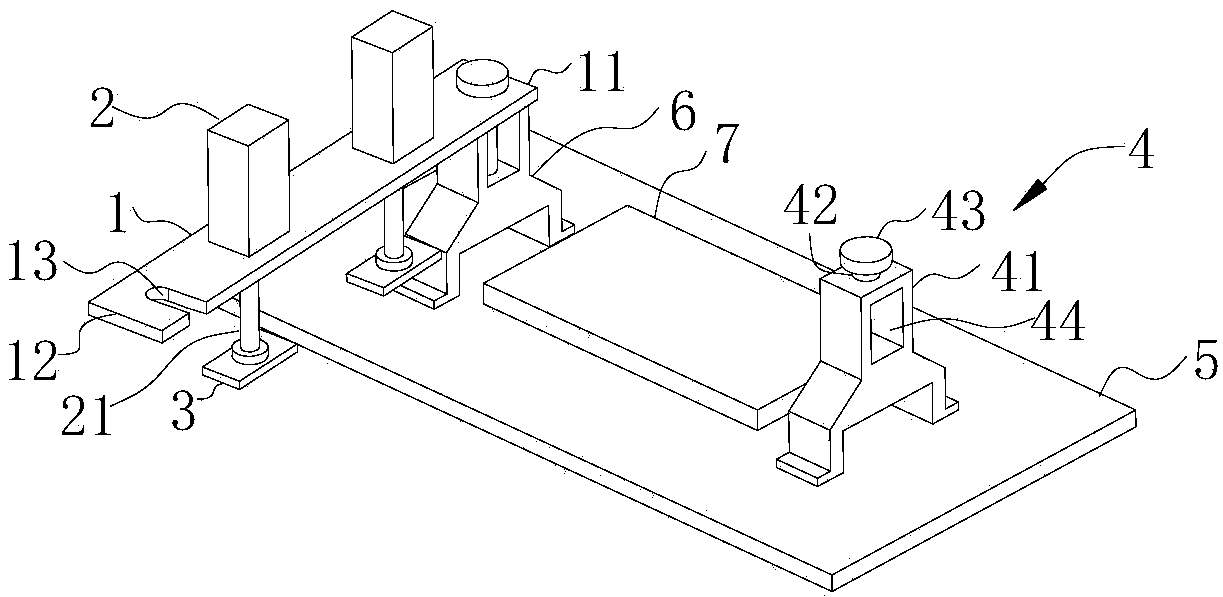

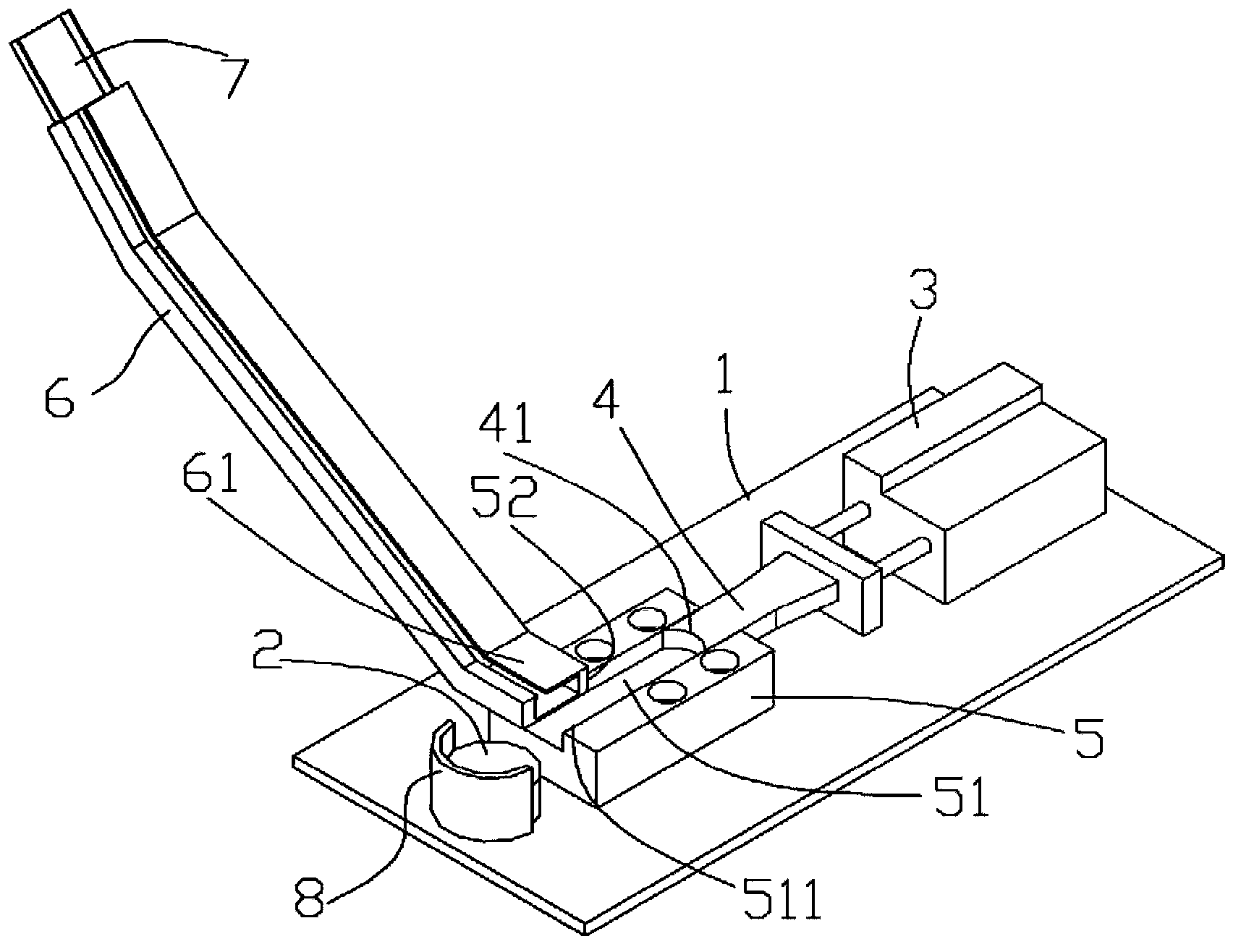

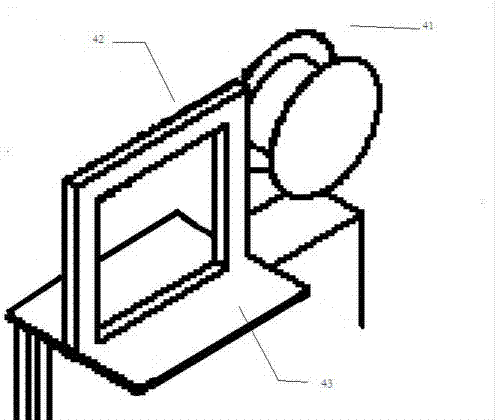

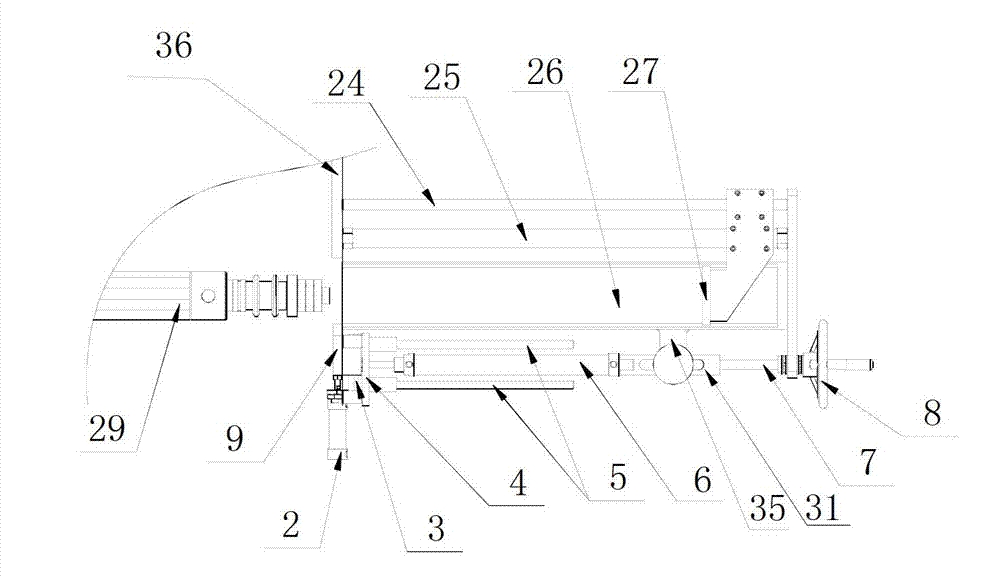

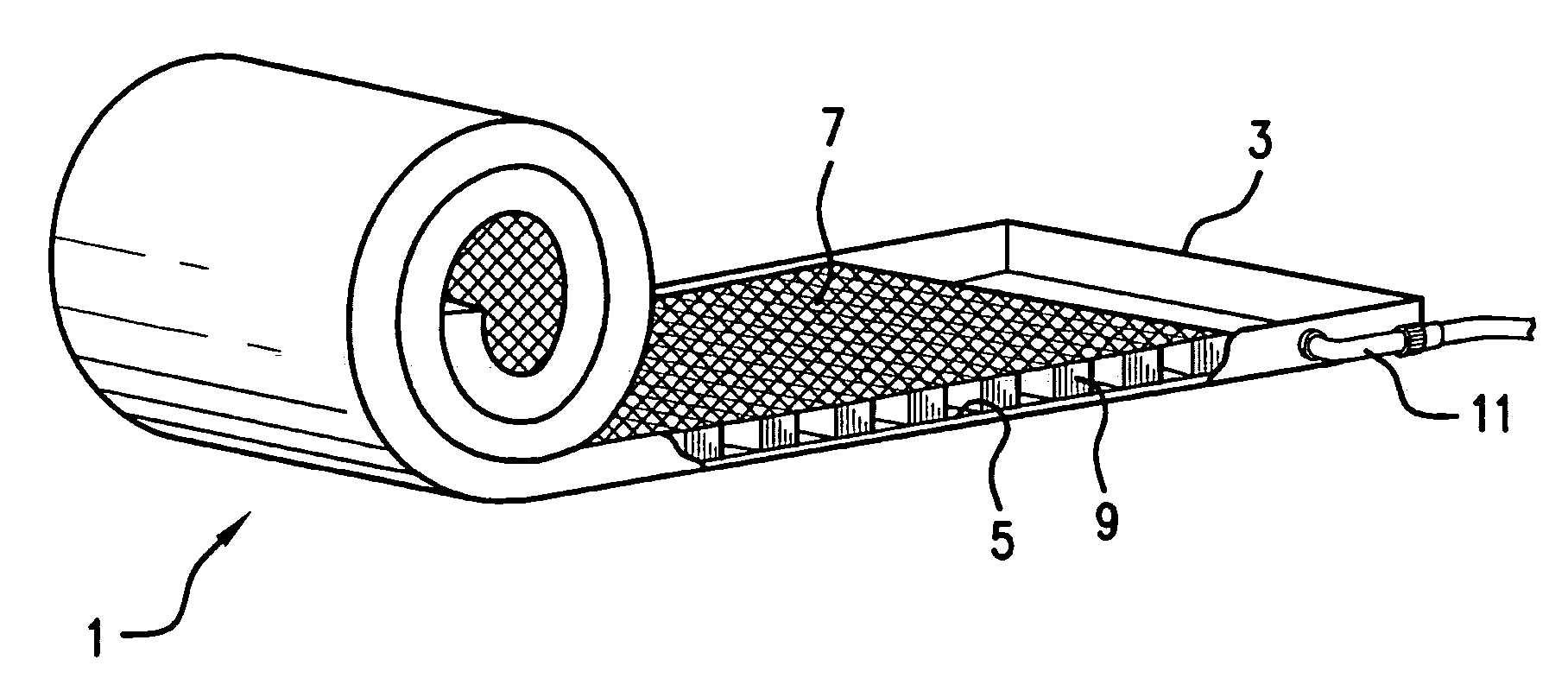

Stamping feeding device for circular workpieces

InactiveCN103406468AImprove processing efficiencyImprove stamping yieldShaping toolsMetal-working feeding devicesIndustrial AccidentPiston rod

A stamping feeding device for circular workpieces comprises a punch workbench (1); a stamping lower die (2) is fixed on the punch workbench (1); a workpiece pushing cylinder (3) is fixed on the punch workbench (1); an ejection plate (4) is fixed on a piston rod of the workpiece pushing cylinder (3); a through groove (51) and a notch (52) are formed in a square block (5); a discharge hole of a material channel (6) is connected with the through groove (51) in a communicating mode; the ejection plate (4) is inserted into the through groove (51) in a sleeve mode; a semicircular blocking piece (8) is fixed on the stamping lower die (2); a semicircular vice jaw (41) is formed at the front end of the ejection plate (4); the upper surface of the stamping lower die (2) and the bottom surface of the through groove (51) are in the same plane. The stamping feeding device for the circular workpieces has the advantages of improving the machining efficiency, avoiding industrial accidents and improving the rate of stamping finished products.

Owner:吴江市钱氏纺织有限公司

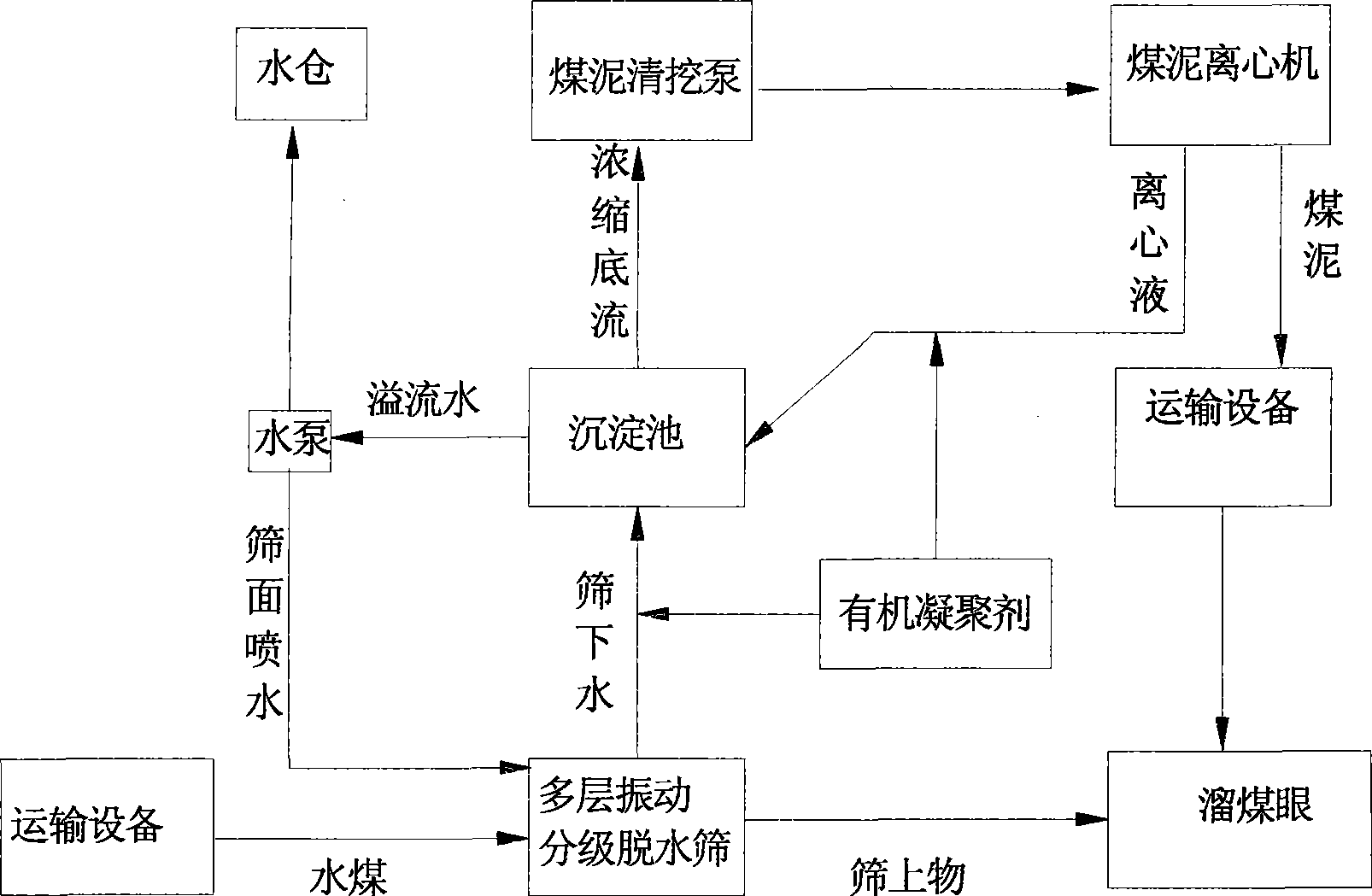

Coal dehydration technology under hole for coal mine

InactiveCN101387204AEasy to joinQuick and easy to joinRotary centrifugesDrainageIndustrial AccidentEnvironmental engineering

The invention discloses a water coal underground dewatering technology for a coal mine, wherein a multi-layered vibration-classifying dewatering sieve is arranged on an unloading position of a first water coal conveying unit; materials on the sieve are conveyed to a coal milling hole through the conveying unit, and slime water below the sieve flows into a sedimentation tank; a slime cleaning pump is utilized for pumping slime at the bottom of the sedimentation tank into a slime centrifuge for dewatering treatment; centrifugate returns to the sedimentation tank for concentration; the dewatered slime is conveyed to the coal milling hole through the conveying unit; and overflow water in the sedimentation tank flows into an underground drain sump, so as to prevent industrial accidents in the steps of belt transportation, lifting, storage and so on caused by water coal. The water coal underground dewatering technology for the coal mine has the characteristics of low labor intensity of workers, good dewatering effect and so on.

Owner:HENAN POLYTECHNIC UNIV

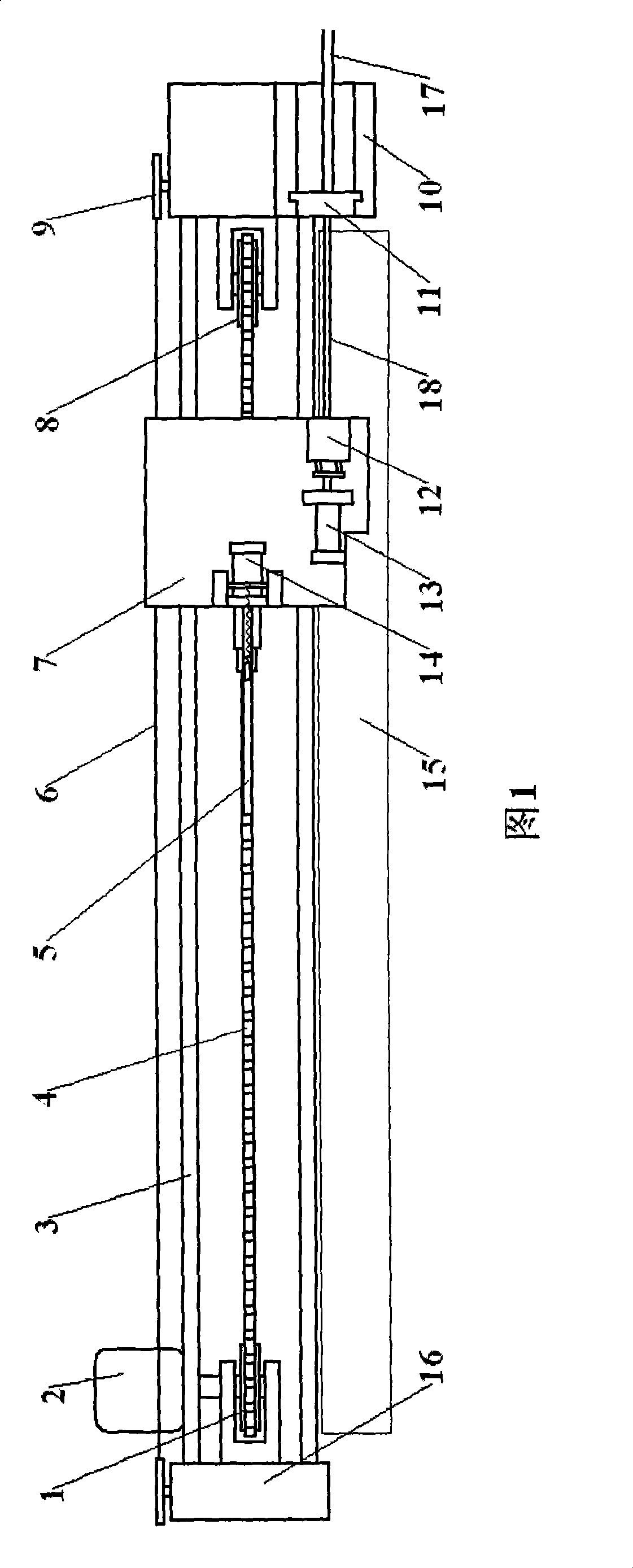

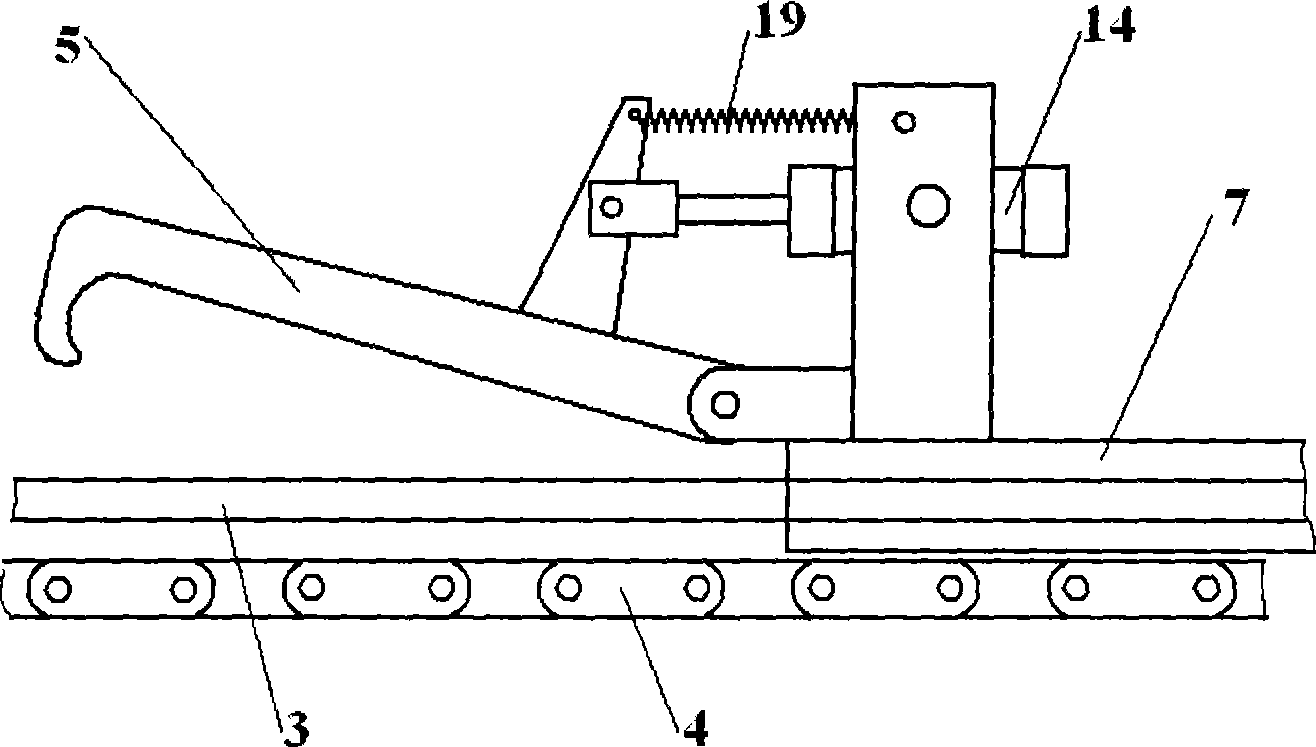

Intellectualized material cutting-off machine

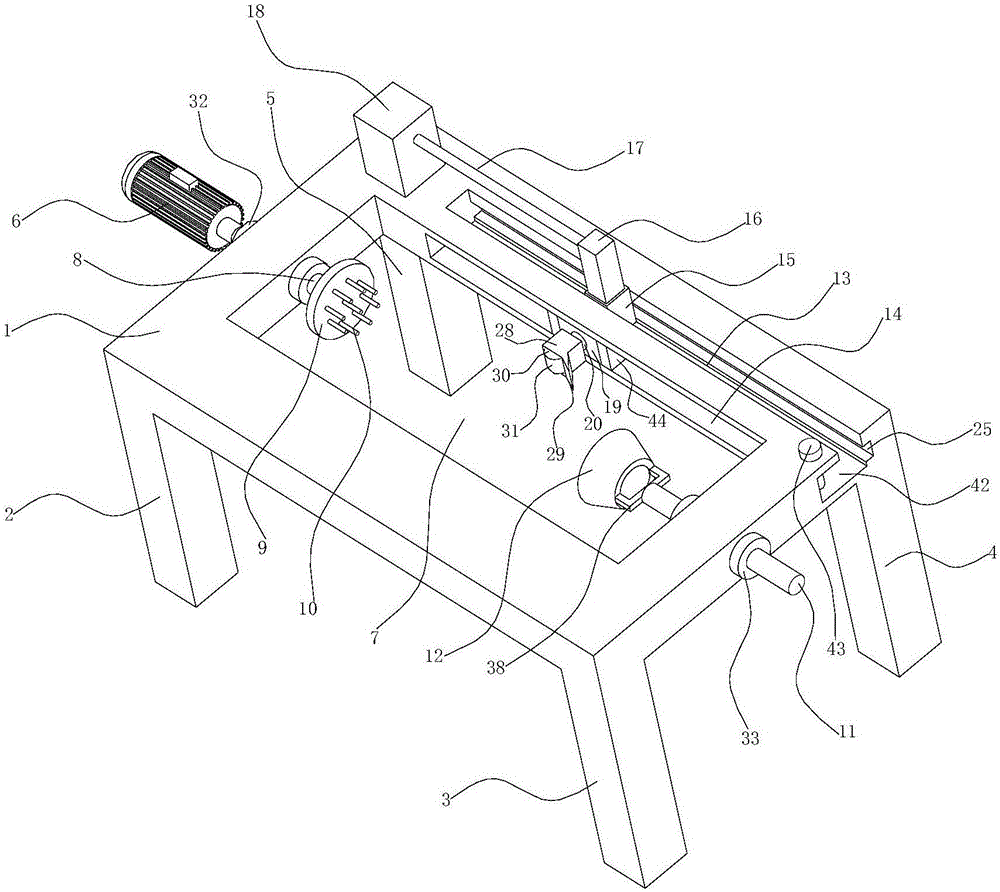

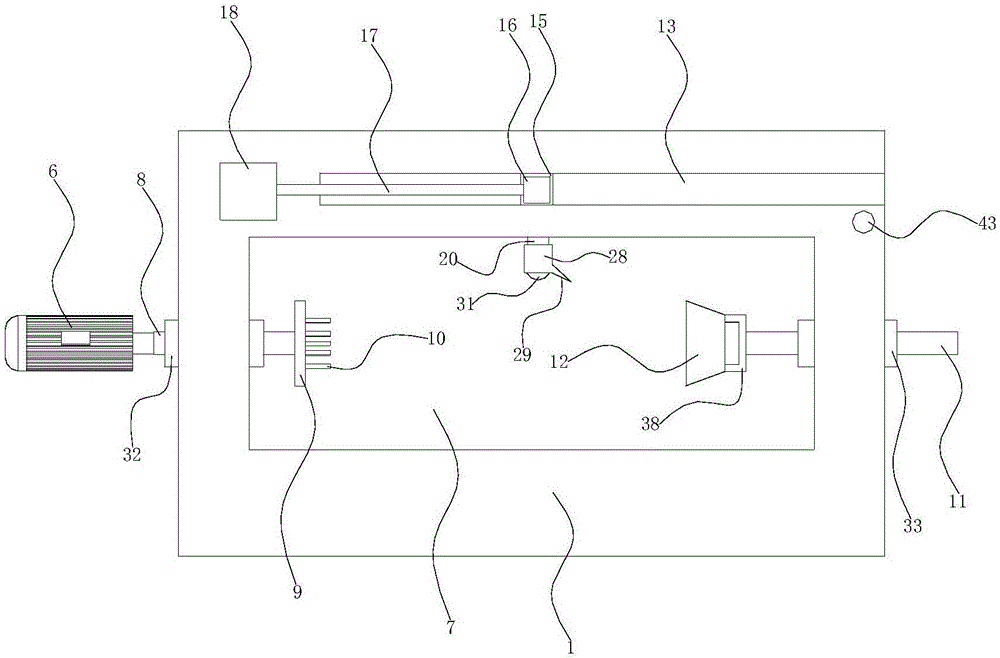

InactiveCN101791720AGuaranteed not to deformEffective alignmentShearing machinesShearing machine accessoriesDrive wheelMotor drive

The invention provides an intellectualized material cutting-off machine which comprises a conveying mechanism, a cutting-off mechanism and a control mechanism; the conveying mechanism comprises a conveying motor, a conveying transmission unit and a plurality of driving wheels, wherein the conveying motor drives the driving wheels by the conveying transmission unit so as to drive a material contained in a conveying passage to move; the inlet position of the conveying passage is provided with a speed sensor, and the outlet position of the conveying passage is provided with a fixed block used for restricting the swing of the material; the cutting-off mechanism comprises a cutting-off motor, a cutting-off transmission unit and a die cutting knife; and the control mechanism comprises a controller and a human-computer interface which are mutually connected. The invention has the advantages that after the material is output by the conveying mechanism, the material is cut off by the momentary action of the die cutting knife and is cut off into a set length, and this cutting-off mode ensures no deformation of the material and the glossiness of the surface of the material; the conveying mechanism comprises the driving wheels and driven wheels, which are in pairs, the material is driven by the driving wheels and the driven wheels to move, and the driving wheels and the driven wheels also have an alignment function; and by arranging a barrier inductor, industrial accidents can be effectively prevented, and the operational safety is enhanced.

Owner:SHENZHEN SUNXING LIGHT ALLOYS MATERIALS CO LTD

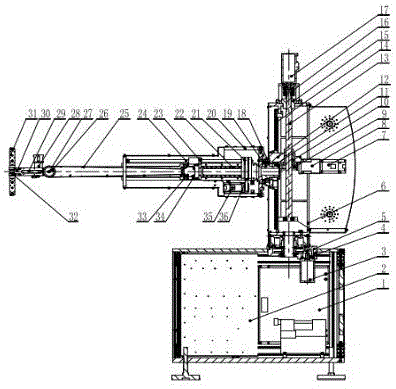

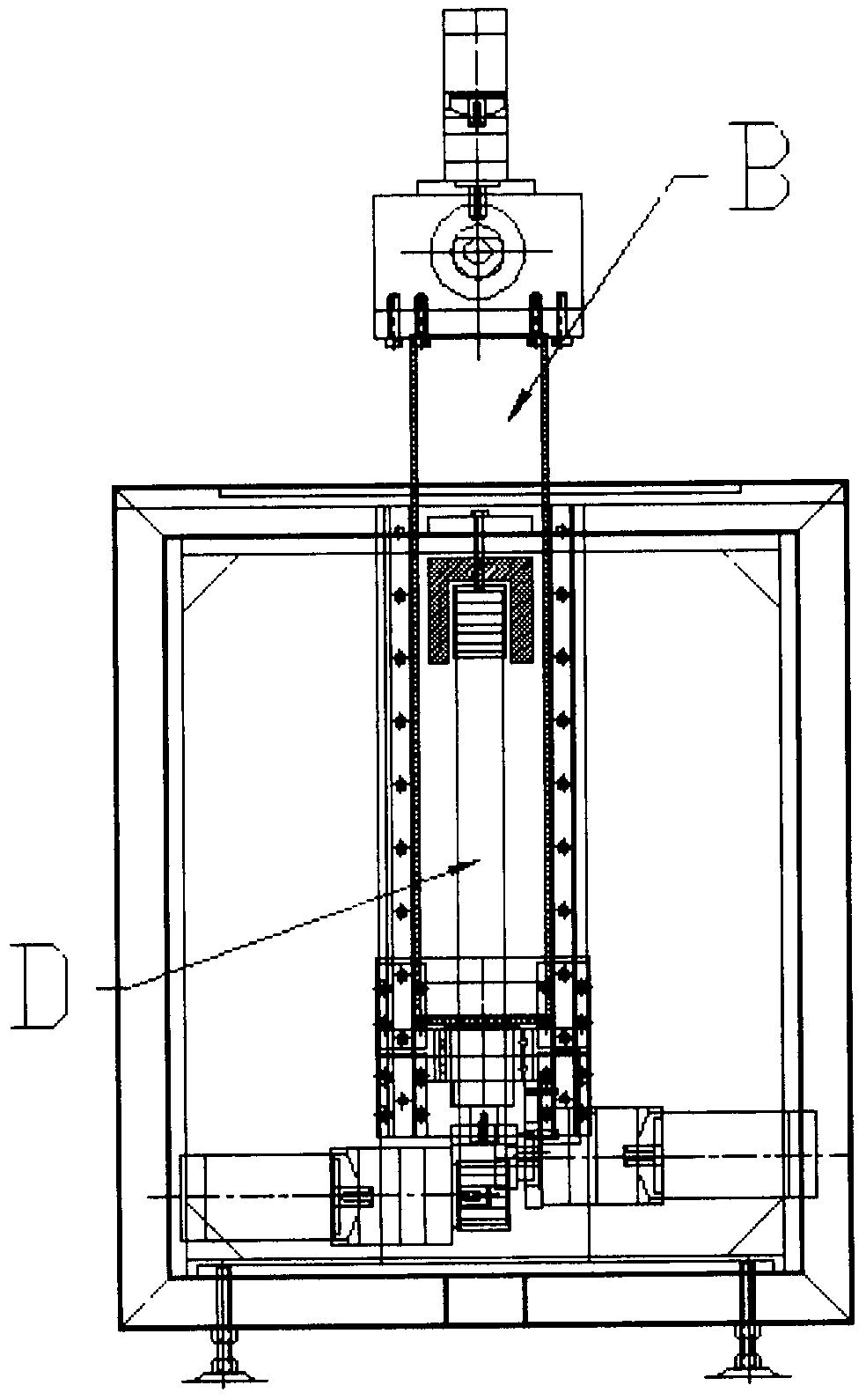

Six-axis intelligent carrying mechanical hand for stamping

InactiveCN105798905ARealize mechanized workAvoid safety hazardsProgramme-controlled manipulatorArmsIndustrial AccidentEngineering

The invention discloses a six-axis intelligent carrying mechanical hand for stamping, and the six-axis intelligent carrying mechanical hand has six degrees of freedom and high sensitivity. The six-axis intelligent carrying mechanical hand for stamping comprises a swing arm rotation motion mechanism, a lifting motion mechanism, a turnover motion mechanism, a horizontal telescopic motion mechanism, a tail end rotation motion mechanism and a gripper pitching motion mechanism, wherein the lifting motion mechanism is fixedly connected with the swing arm rotation motion mechanism; the turnover rotation motion mechanism is fixedly connected with the lifting motion mechanism; the horizontal telescopic motion mechanism is fixedly connected with the turnover motion mechanism; the tail end rotation motion mechanism is fixedly connected with the horizontal telescopic motion mechanism; and the gripper pitching motion mechanism is fixedly connected with the tail end rotation motion mechanism. The six-axis intelligent carrying mechanical hand for stamping can meet material getting and placing requirements in any directions and at any positions within a stroke range, and replaces manual operation, so that the labor intensity is reduced, the efficiency is improved, and the occurrence of industrial accidents is reduced to a greater extent, and the six-axis intelligent carrying mechanical hand for stamping is safe and reliable.

Owner:安徽六联智能科技有限公司

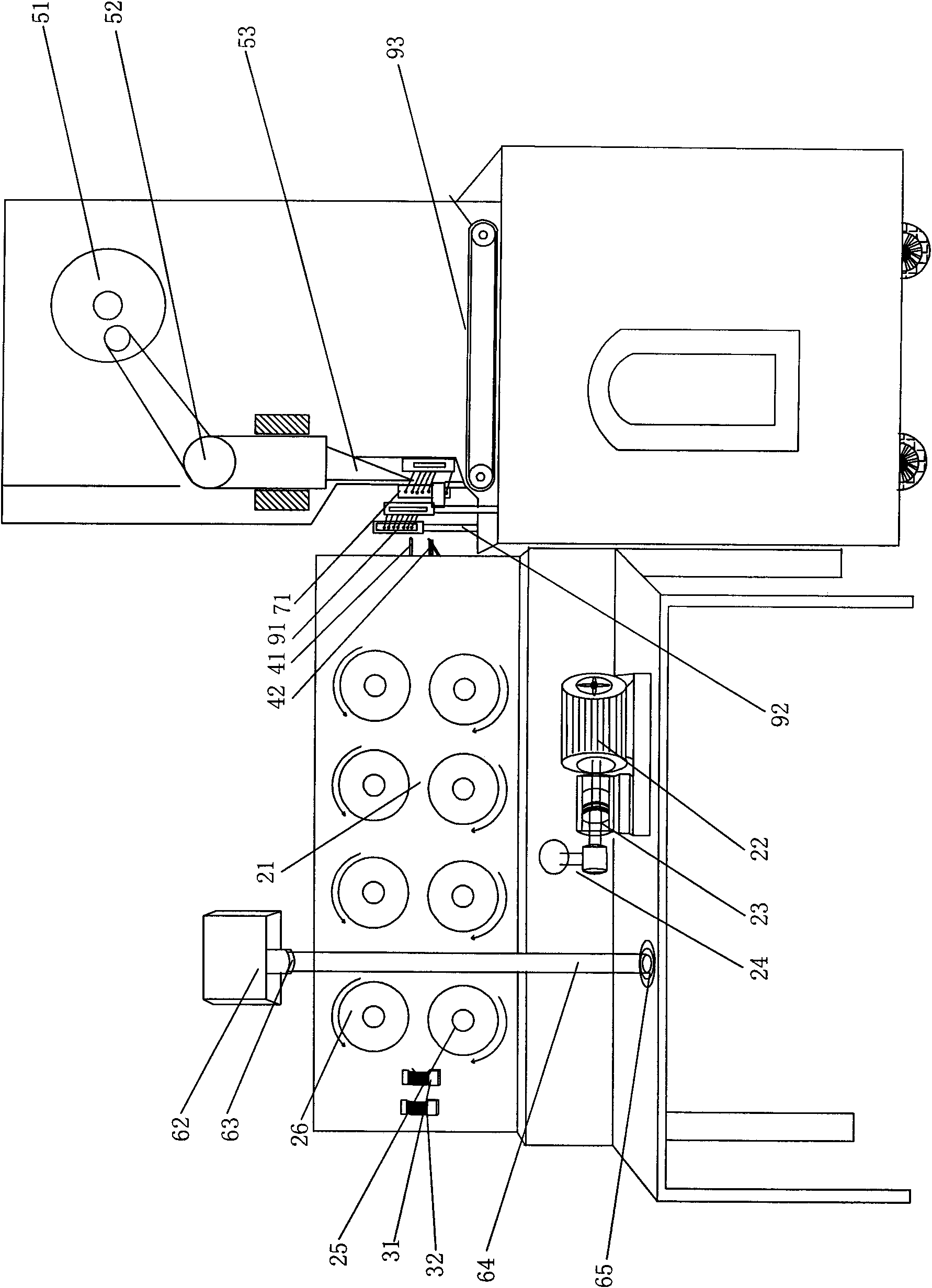

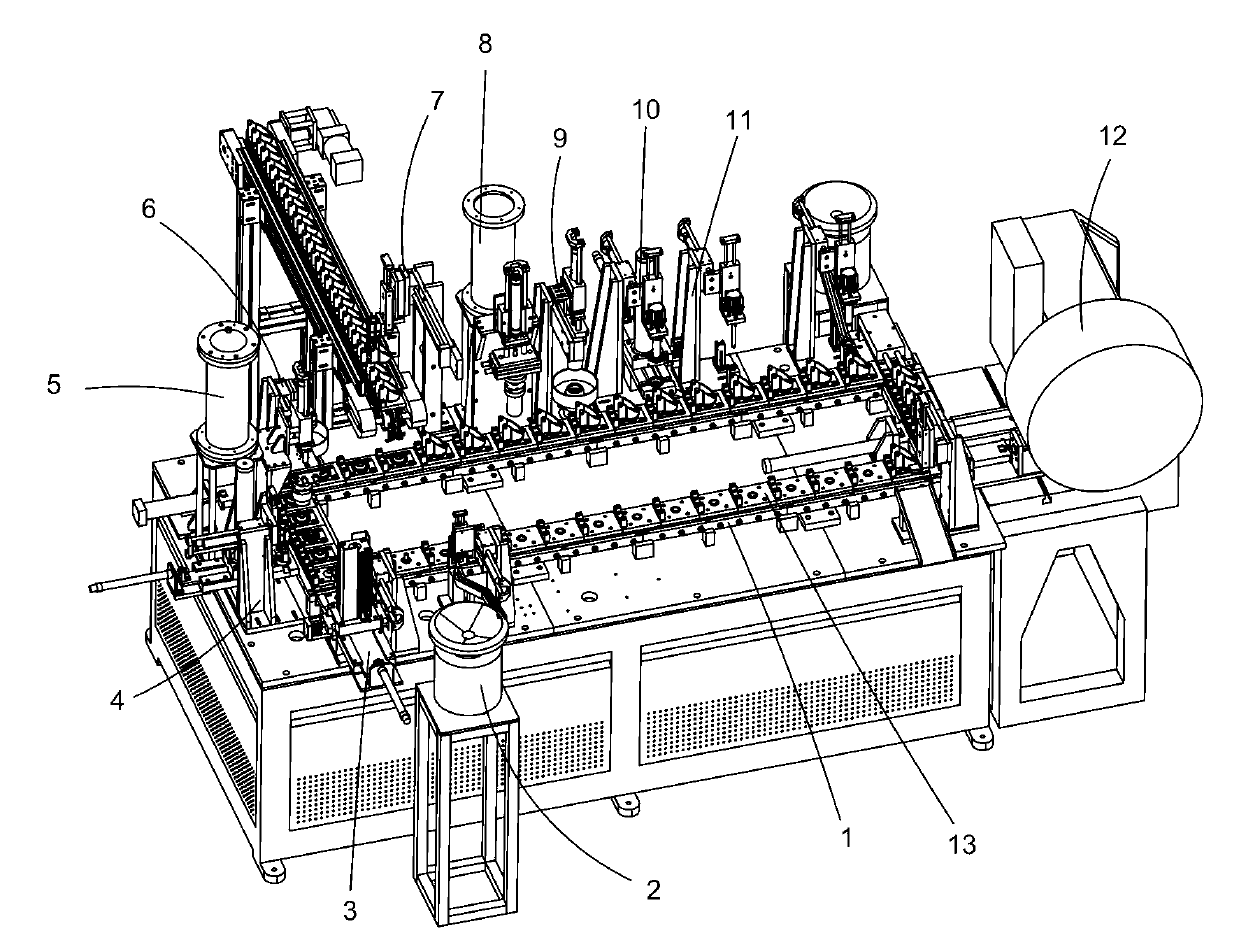

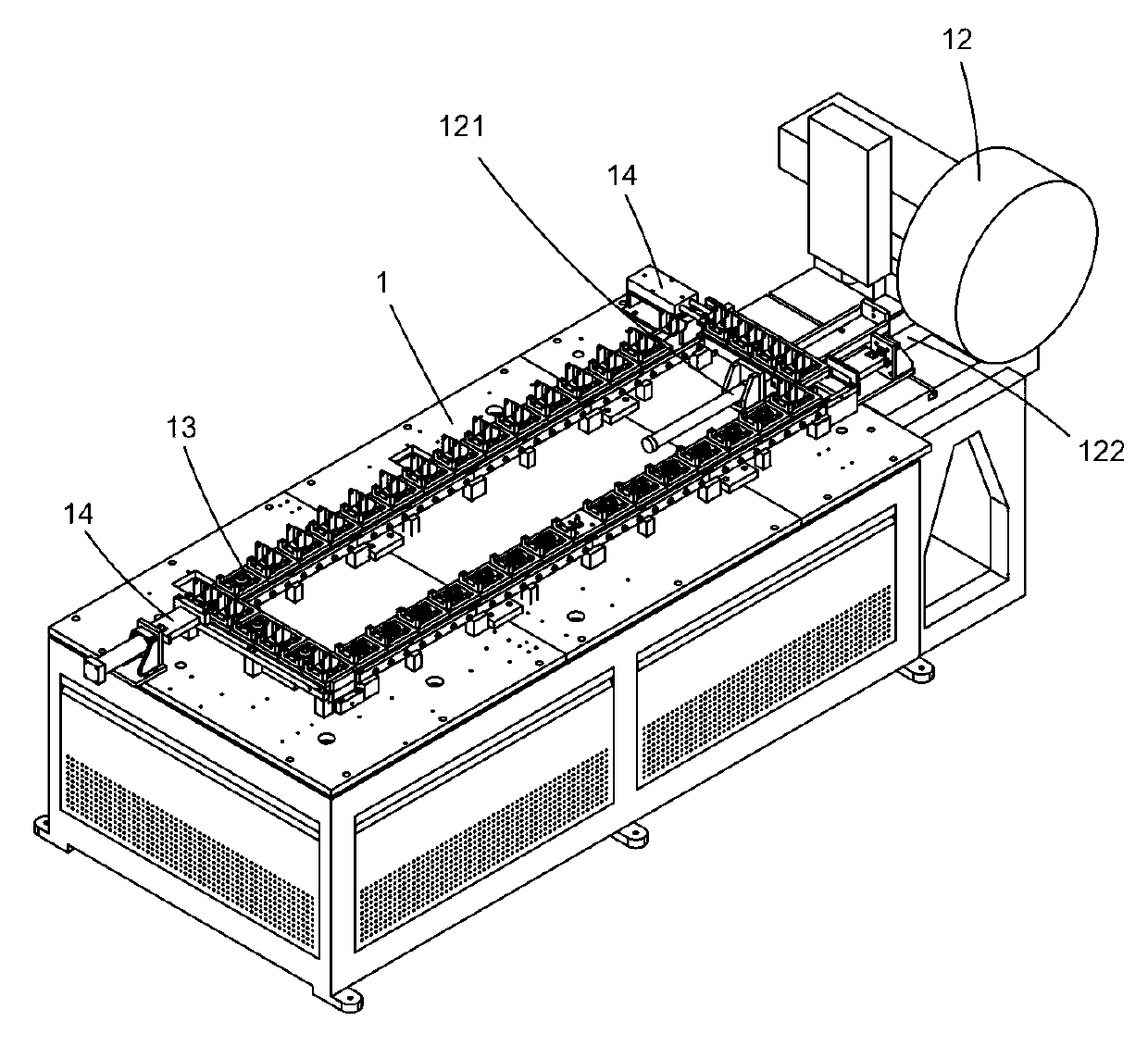

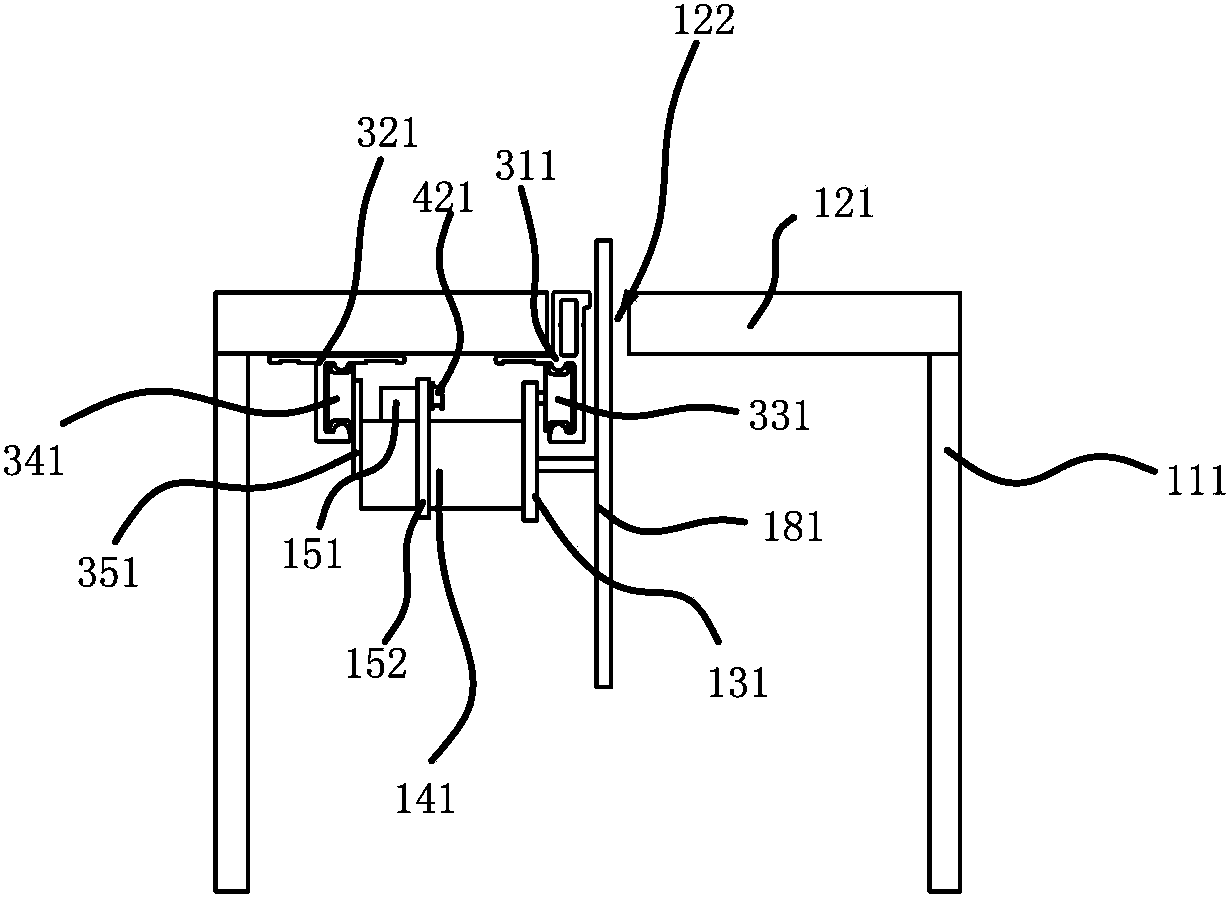

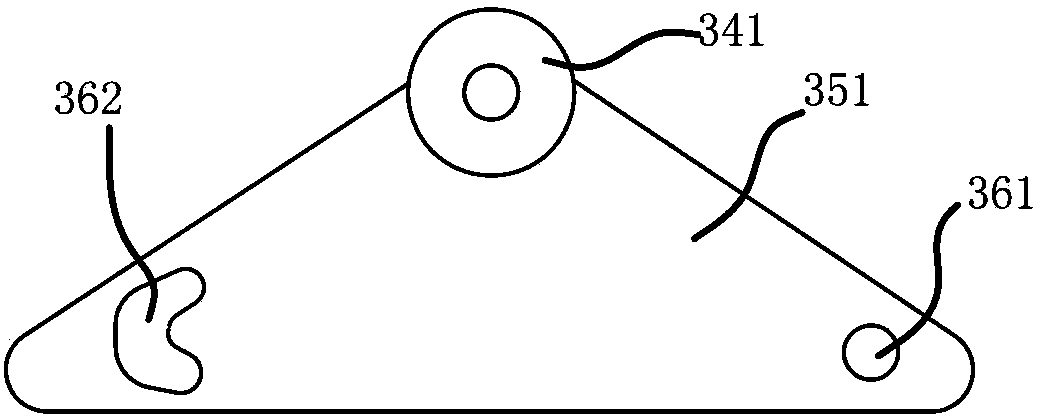

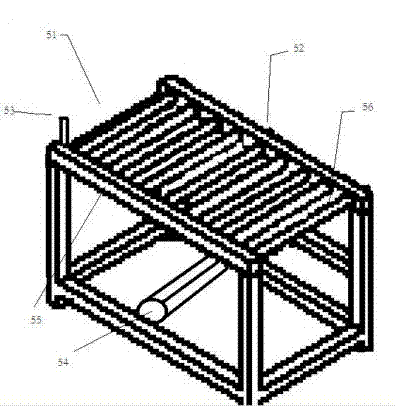

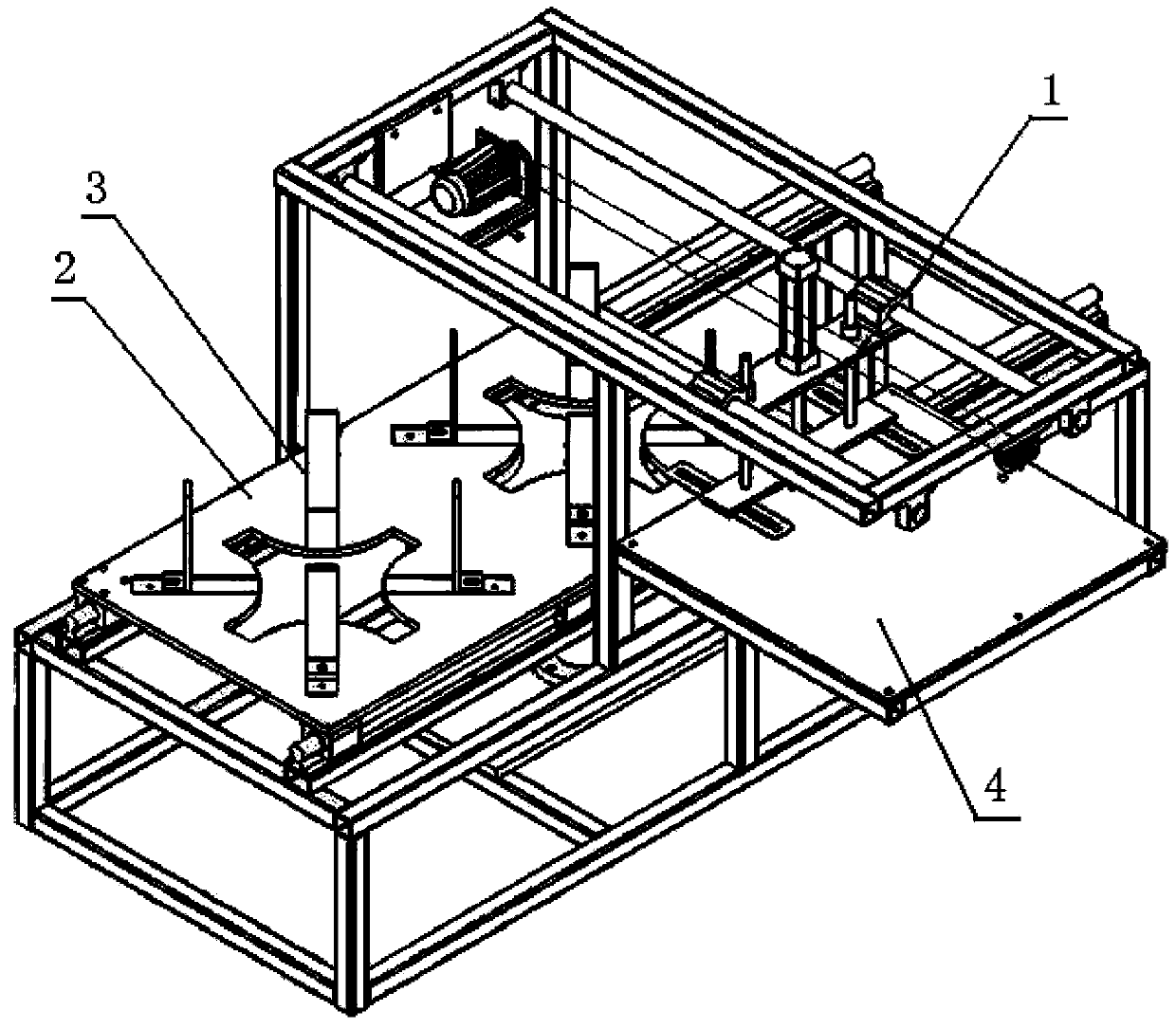

Intelligent trundle automatic assembling machine

InactiveCN103128546AIncrease productivityStreamlined manual operationsAssembly machinesElectricityIndustrial Accident

The invention provides an intelligent trundle automatic assembling machine. The intelligent trundle automatic assembling machine comprises a revolving platform, a rivet holding device, a big base plate device, a big steel ball tray device, a first oiling device, a big steel ball bunch device, a bracket system, a second oiling device, a small steel ball bunch device, a small wave plate device, a spacer device and a punch press device, wherein all the devices can be respectively installed on the revolving platform independently, also can be respectively electrically connected one by one, and are driven and controlled by a master control circuit, and simultaneously all the devices can be selectively installed on the revolving platform. Due to a purpose of achieving intelligent trundle production, the intelligent trundle automatic assembling machine can simplify hand operations on the premise of improving production efficiency, and avoids unnecessary industrial accidents.

Owner:佛山奔宇脚轮股份有限公司

Woodworking sawing machine

ActiveCN103358360AQuick cutImprove cutting efficiencyPortable power driven sawsBark-zones/chip/dust/waste removalIndustrial AccidentEngineering

The invention provides a woodworking sawing machine, and belongs to the technical field of woodworking machines. The technical problems that industrial accidents can occur easily when an existing woodworking sawing machine is operated, and thus personal safety is seriously affected are solved. The woodworking sawing machine comprises a machine frame, an electric saw and a workbench which is fixed on the machine frame. The electric saw comprises a driving motor and a saw blade which is fixed on an output shaft of the driving motor. The workbench is provided with a bar-shaped channel which allows the saw blade to pass through, and the driving motor is placed below the workbench and can slide in the direction of the channel. The upper end of the saw blade passes through the channel and is placed above the workbench. A driving structure which can drive the driving motor to move is arranged between the driving motor and the machine frame. The woodworking sawing machine has the advantages of being capable of reducing the contacting probability of the saw blade and workers and improving the safety.

Owner:颜夏根

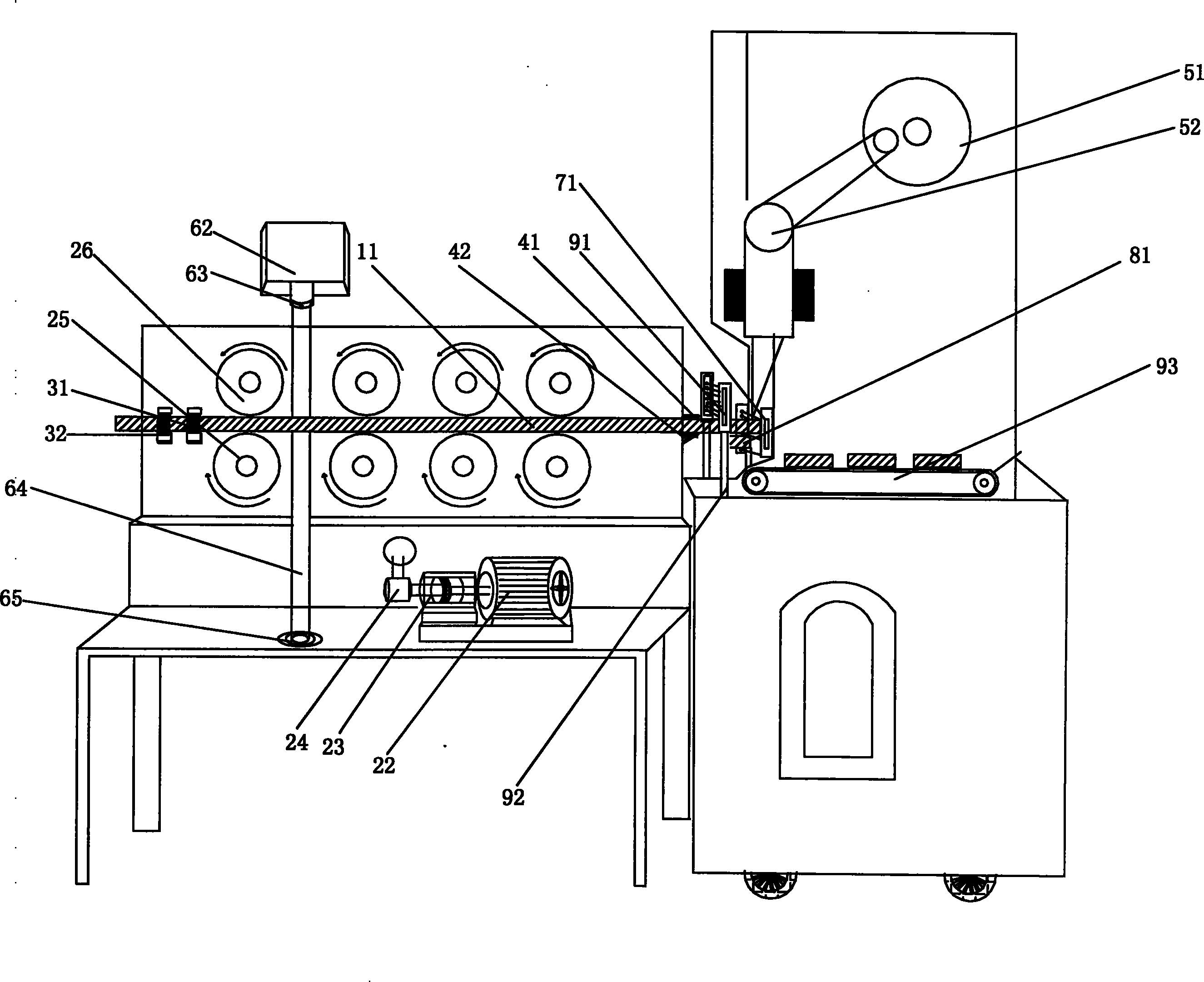

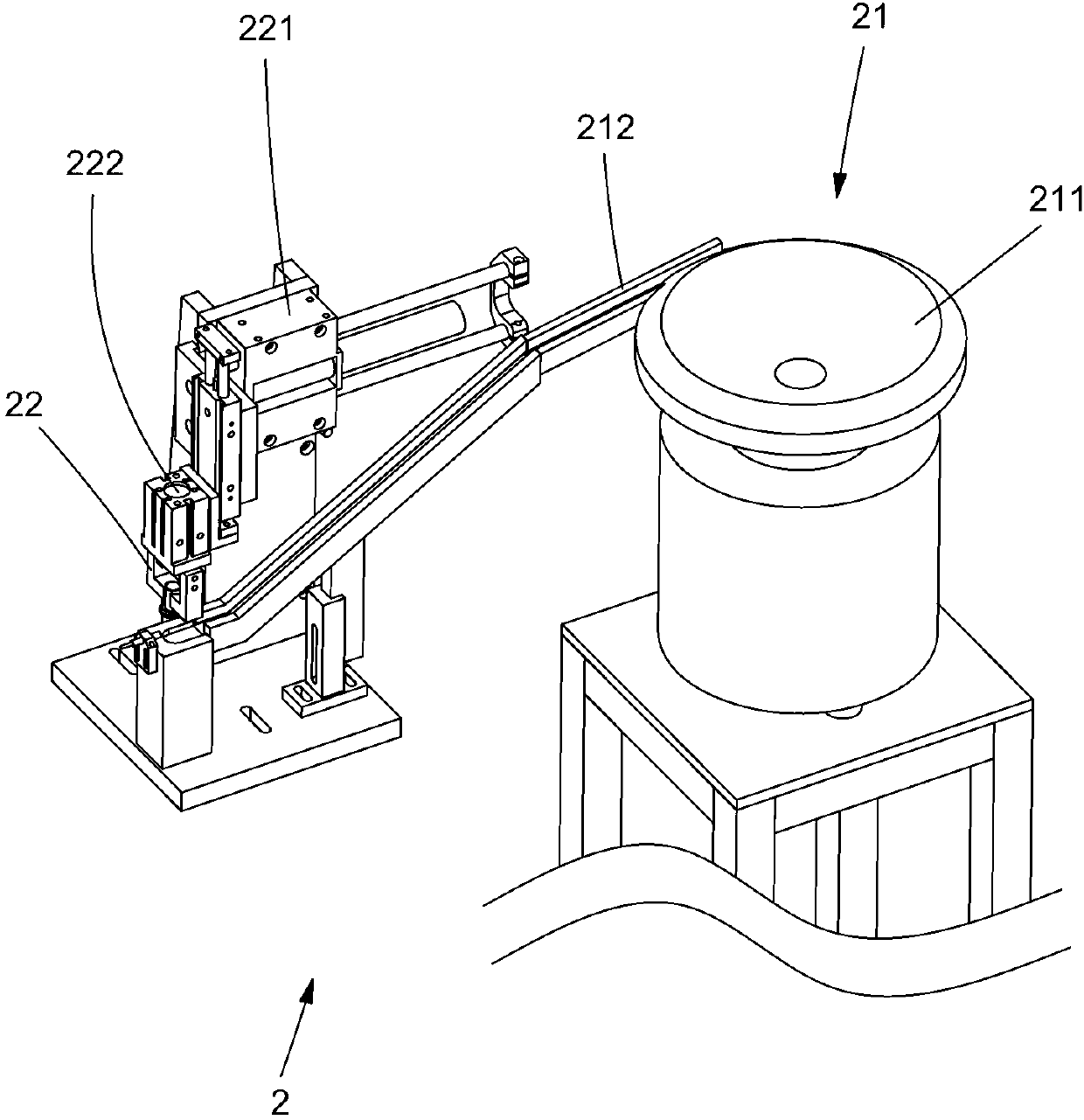

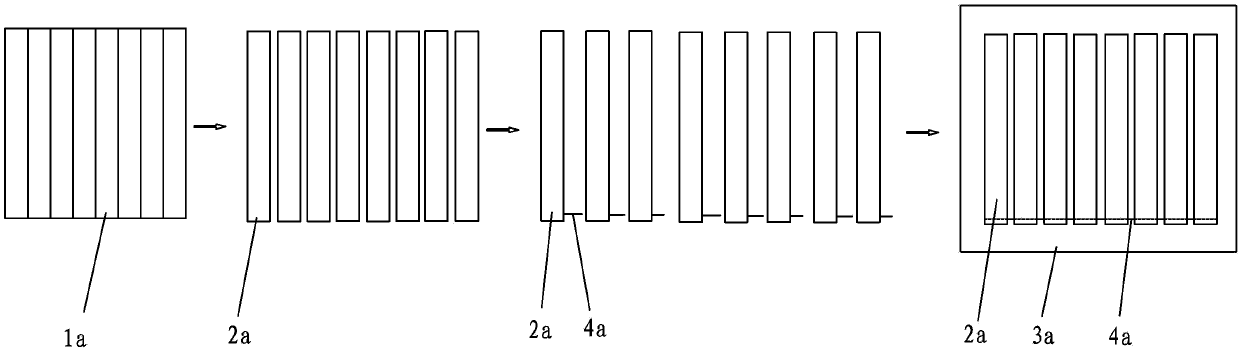

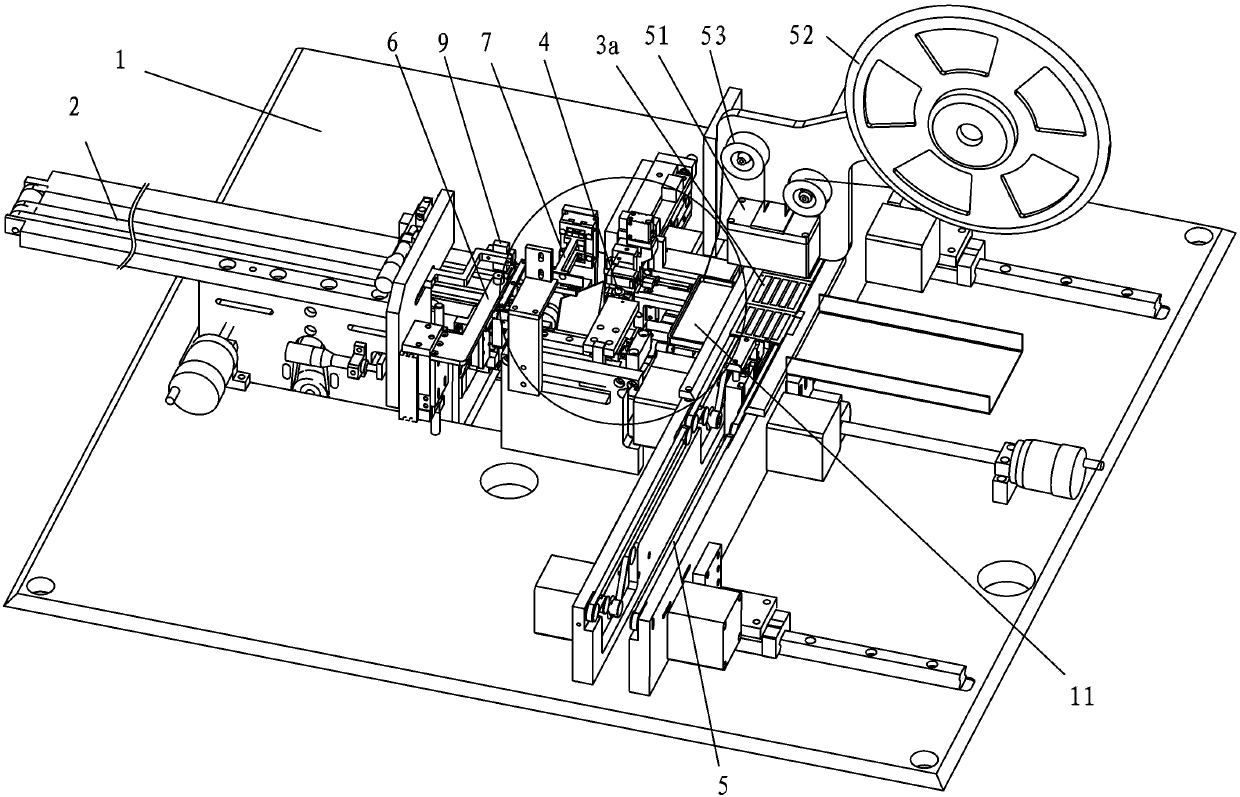

Automatic cell welding machine for small solar component

ActiveCN103386555AEasy to operateIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesIndustrial AccidentCell separation

The invention discloses an automatic cell welding machine for a small solar component. The automatic cell welding machine comprises a conveyor belt and a cell separation mechanism, which are sequentially connected along the feeding direction of a solar cell component. The automatic cell welding machine also comprises a welding strip conveying mechanism, a first suction mechanical hand, a welding mechanism, a second suction mechanical hand and a placement output mechanism. According to the automatic cell welding machine for the small solar component, the solar cell component is separated into independent solar cells through the cell separation mechanism, and a welding strip is welded on the back surfaces of the solar cells through the welding mechanism to connect electrodes of circuits in the solar cells. A staggered cell separation mode is adopted, so that the automatic cell welding machine is easy to operate, the production efficiency and the welding yield can also be improved, the labor intensity can be reduced, and the problems of high breaking rate of manual cell separation of the conventional small cell component, high pseudo welding rate and high component damage rate of the small component and high industrial accident rate are solved.

Owner:WINCHANCE TECH

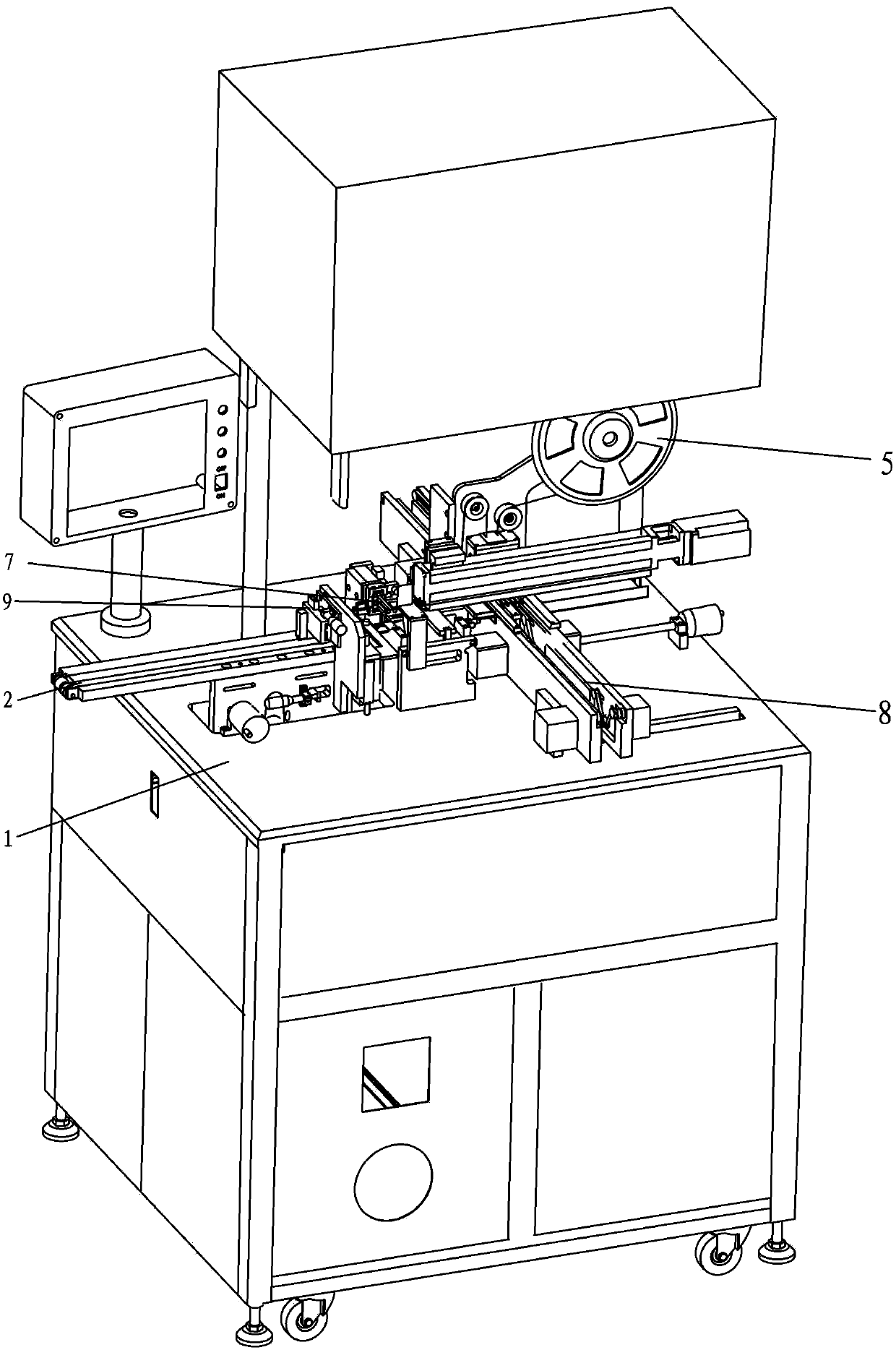

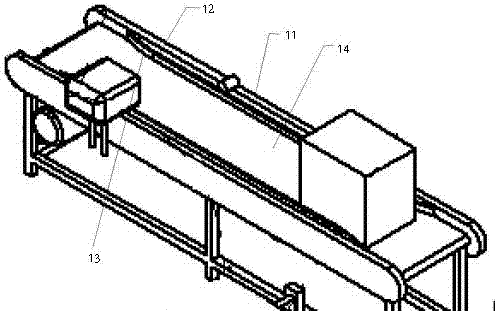

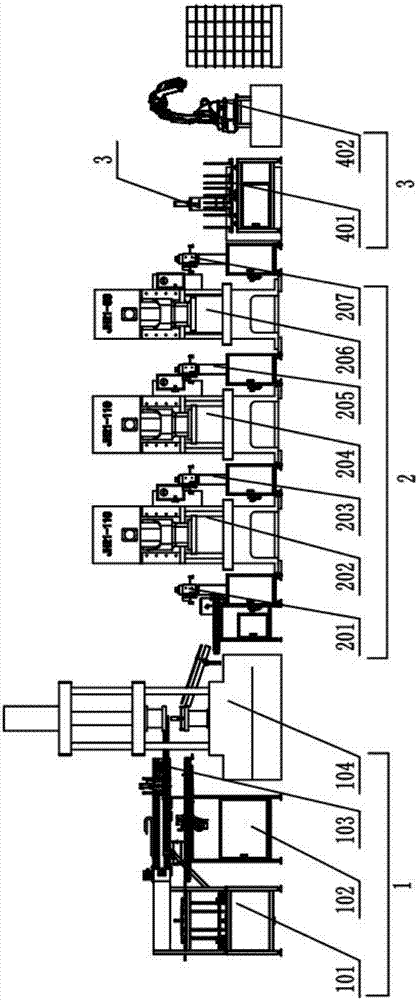

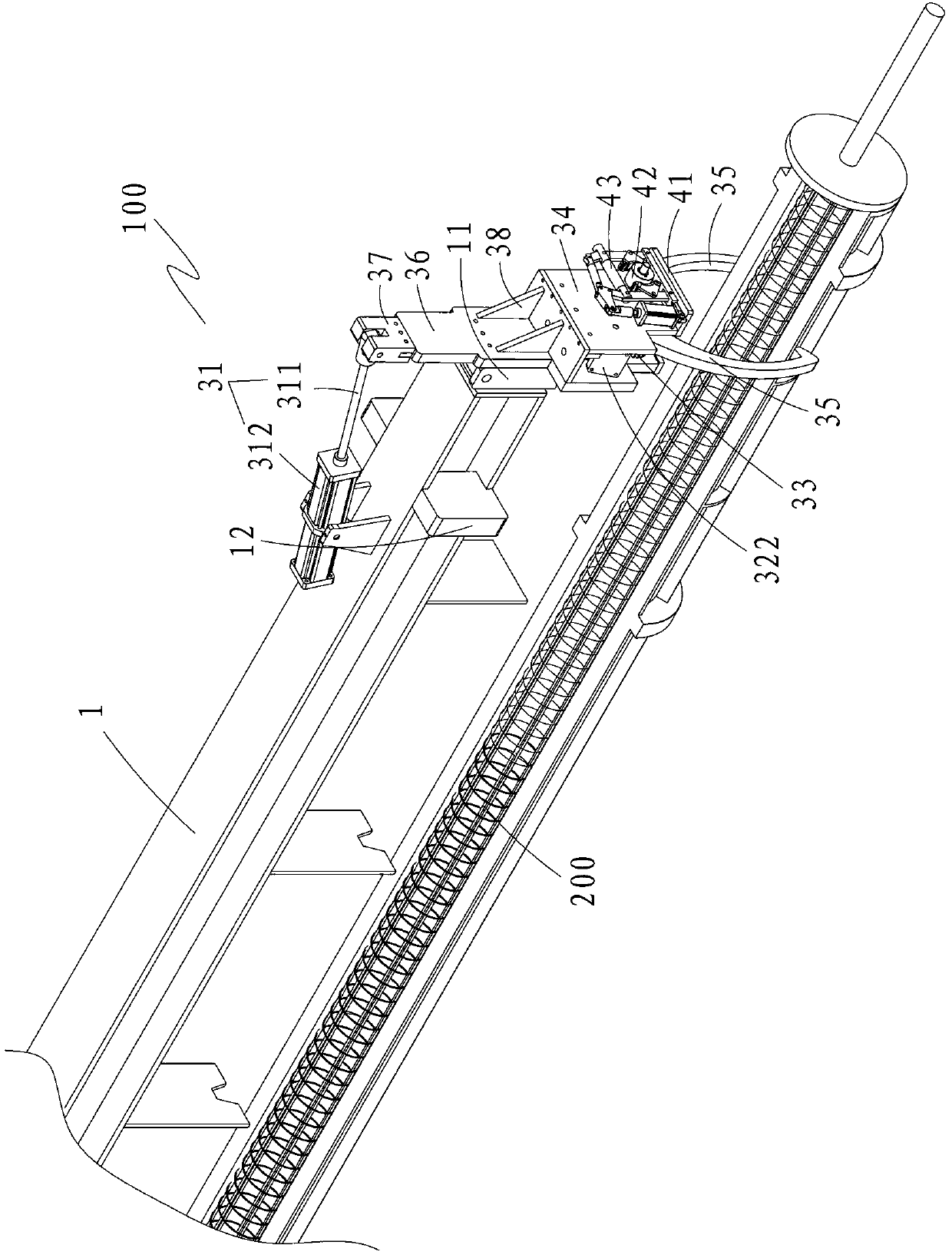

Integral automatic packing and sealing code-spraying and piling production line

The operation of packing, code-spraying, sealing and piling of the conventional medical instruments is basically finished manually. Due to certain weights of the medical instruments plus the weights of packing cases, the consumption of labor force is very high in a turnover process, and rise in the industrial accidents of workers, extremely low production efficiency, occupation of a large space and waste of resources are caused. The invention provides an integral automatic packing and sealing code-spraying and piling production line. The production line comprises a middle packing and automatic code-spraying unit 1, an automatic packing unit 2, an automatic cover folding and sealing unit 3, an automatic packing unit 4, a large packing and code-spraying unit 5 and a piling unit 6 in sequence, wherein each unit is connected with a PLC (Programmable Logic Controller). The PLC is used for acquiring signals and performing mechanical control, mechanical automatic packing, sealing, code-spraying and piling operation can be realized, the labor cost is reduced, and the production efficiency is increased.

Owner:WUHAN W E O SCI & TECH DEV

Automatic absorbing feeding device

InactiveCN103769491AReduce labor intensityAvoid work accidentsMetal-working feeding devicesPositioning devicesHydraulic cylinderPunch press

The invention provides an automatic absorbing feeding device. The feeding device comprises a feeding mechanism, a material taking mechanism, a control cabinet and a hydraulic station; wherein the feeding mechanism comprises a lateral feeding device, a material supporting platform, material supporting bins and a positioning platform; the lateral feeding device, the material supporting bins and the positioning platform are fixedly connected with the material taking platform respectively; a hydraulic cylinder is arranged at the lower part of one material supporting bin; the hydraulic cylinder is connected with the motor output end of the hydraulic station; the hydraulic station is connected with the output end of the control cabinet. The feeding device has the benefits as follows: by the arrangement of mechanical arms used for grabbing and putting down the materials, feeding and taking of stator and rotor plates can be accomplished accurately; manual participation is not needed in the whole process, so that labor intensity of workers is greatly reduced, and industrial accidents are avoided; since the feeding position is more accurate, the machining precision of the stator and rotor plates can be increased, the service life of a punching mould is prolonged, and the investment cost is reduced at the same time.

Owner:SHIJIAZHUANG LIANCHUANGZHONG NEW TECH

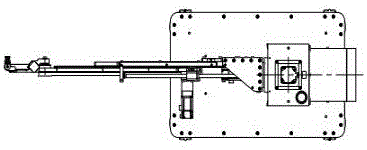

Punching manipulator

InactiveCN103658433AWork fasterOperating speed and power savingProgramme-controlled manipulatorMetal-working feeding devicesIndustrial AccidentPunching

A punching manipulator comprises a vertical moving mechanism, a horizontal moving mechanism, a turning moving mechanism, a swinging moving mechanism and an executing end rotating moving mechanism. The defect that human hands are broken and crippled due to frequently-occurring industrial accidents in the prior art is effectively overcome.

Owner:冯华仁

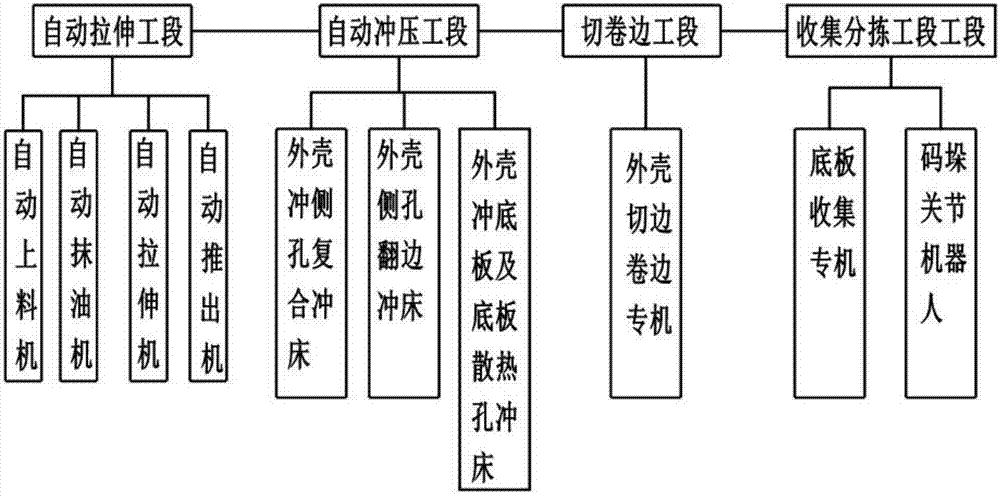

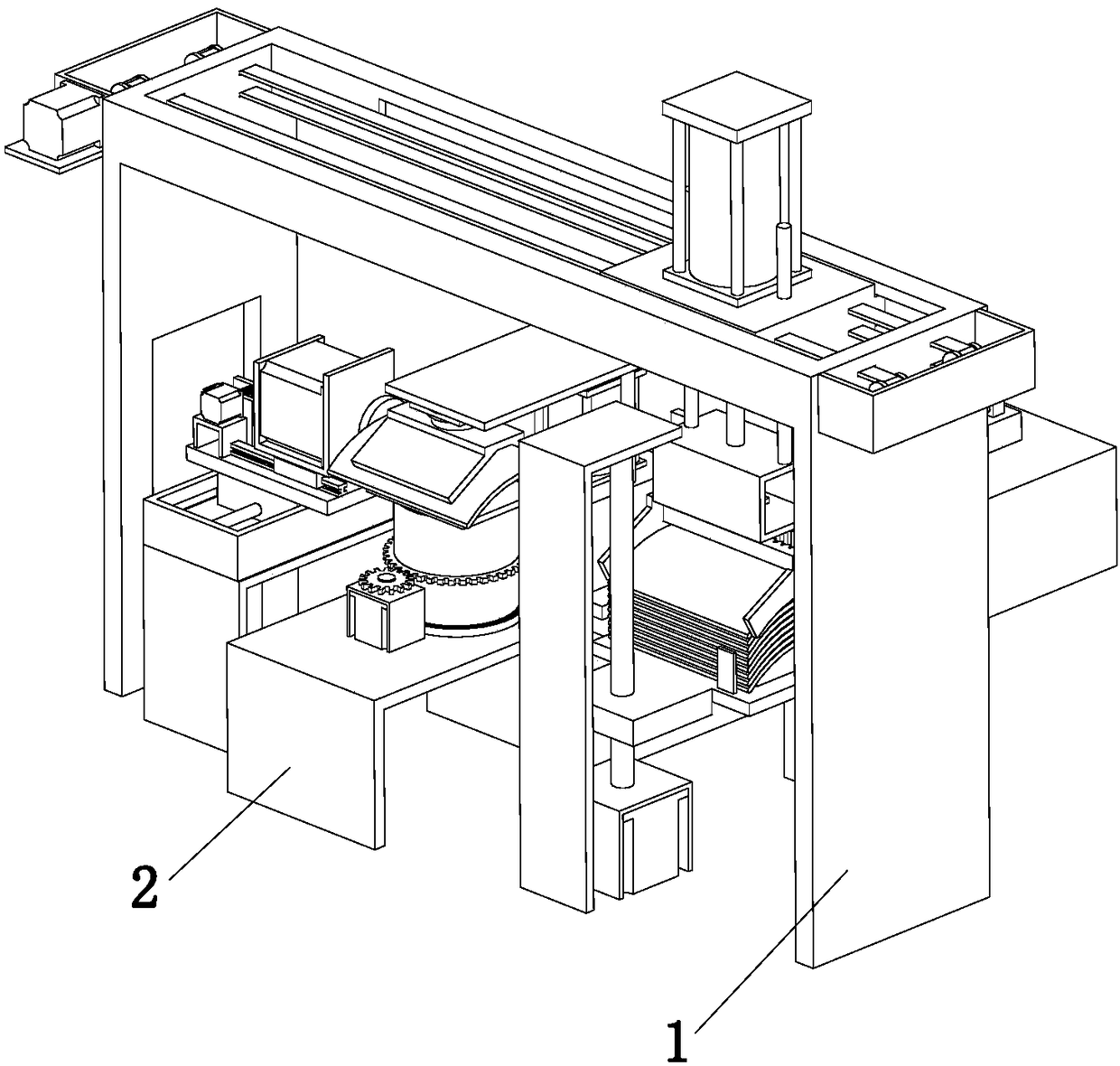

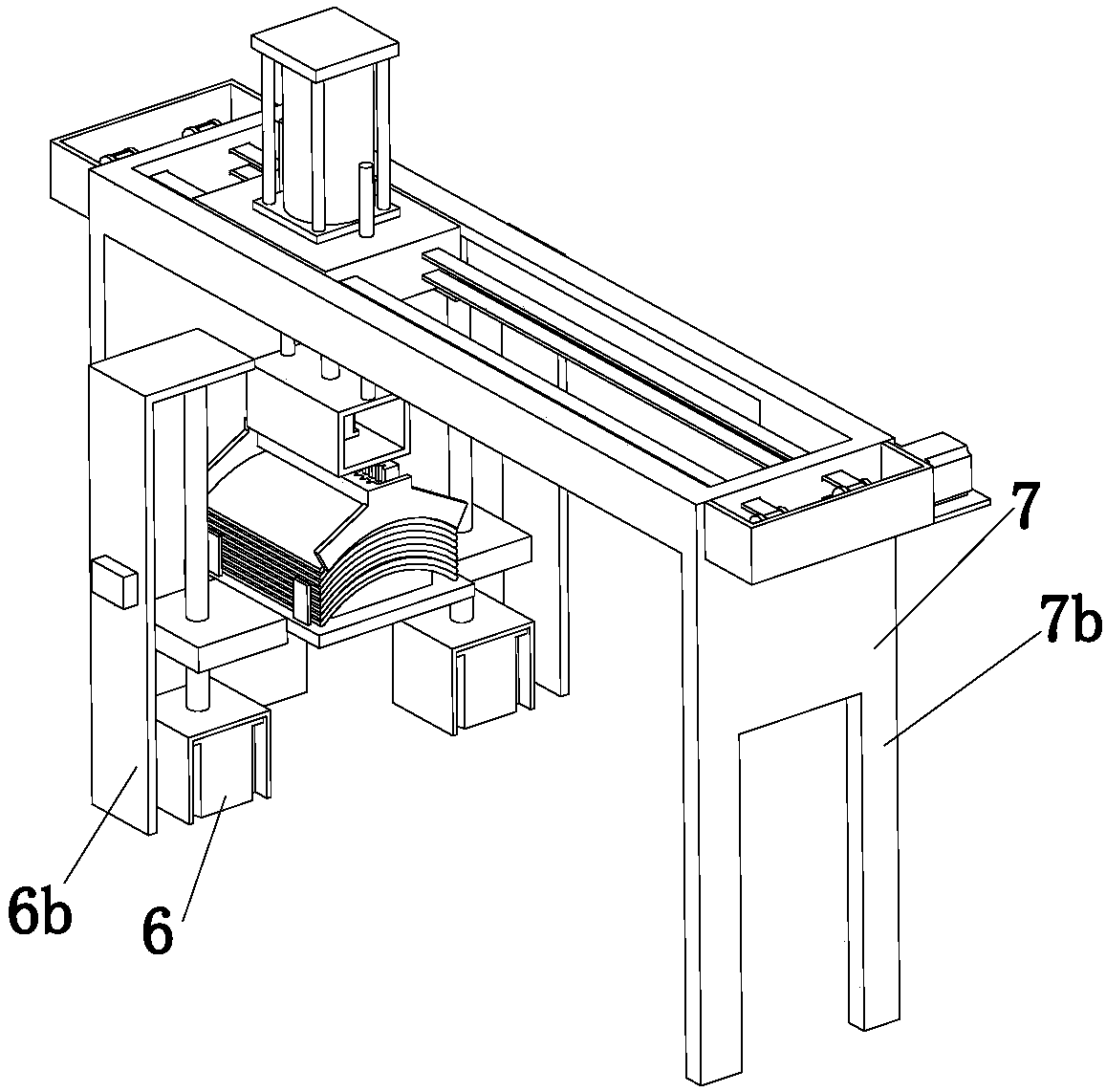

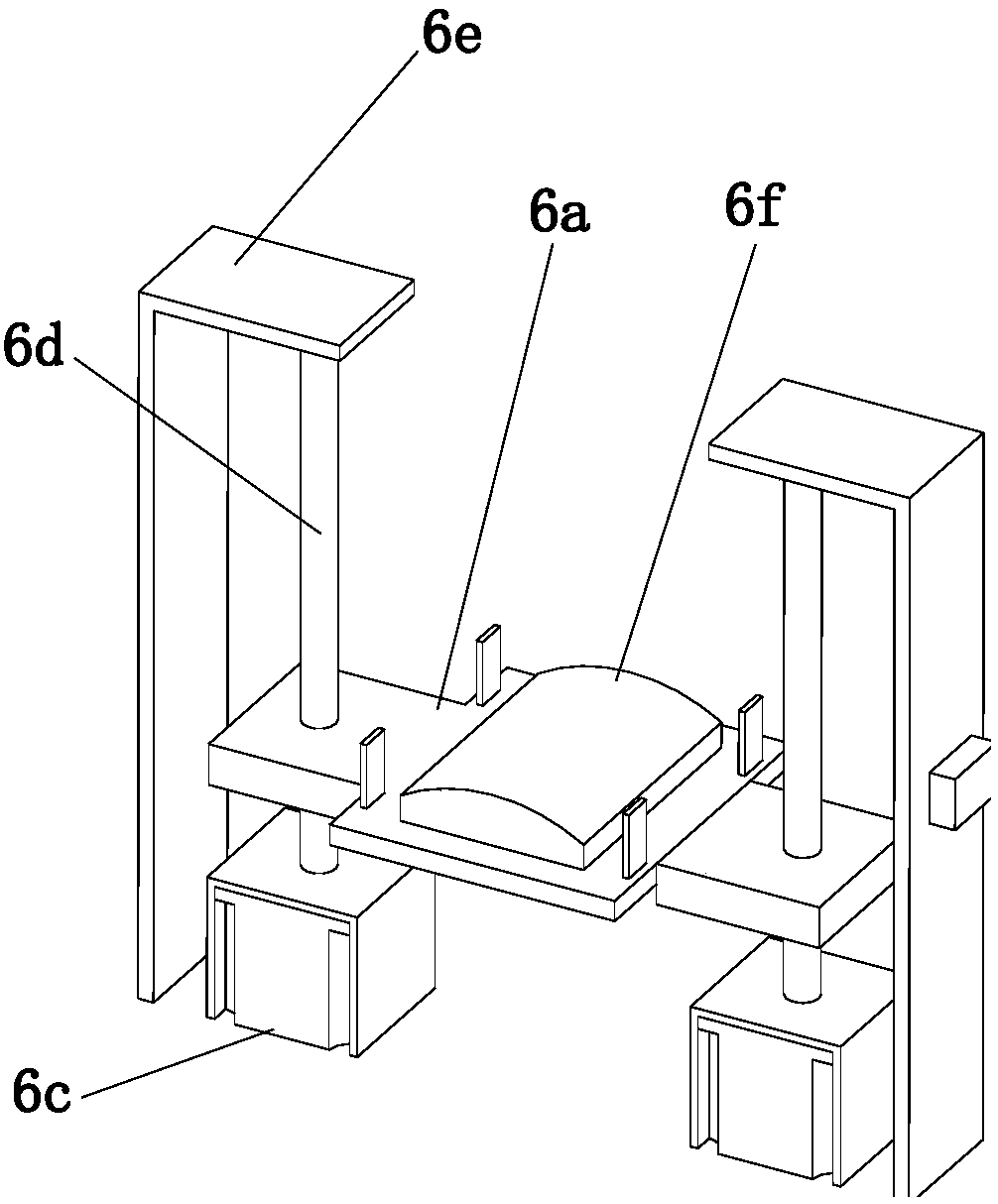

Full automatic production line for integral shell of electric cooker

ActiveCN107186113AIncrease productivityIncrease flexibilityHollow articlesProduction lineIndustrial Accident

The invention relates to an automatic production line, in particular to a full automatic production line for an integral shell of an electric cooker. The full automatic production line comprises an automatic stretching workshop section, an automatic stamping workshop section and a control device, wherein the automatic stretching workshop section is connected to the automatic stamping workshop section, a curled edge cutting workshop and a collecting sorting workshop section, and the collecting sorting workshop section is connected to the curled edge cutting workshop section. In the whole process, automatic operation of automatic charging, conveying, stretching, stamping and stacking is combined and applied to the production line for the integral shell of the electric cooker, the production efficiency is improved, the cost is reduced, artificial participation is reduced, the technical problems of high production cost, low efficiency, overlarge labor intensity, frequent industrial accidents, low product percent of pass and the like of a traditional artificial transfer manner caused by high artificial participation degree and low automatic degree in the existing production process of the electric cooker are solved, and the production line can be arranged in a matching manner according to different production demands, and the flexibility is high.

Owner:GUANGDONG HUAQIANG ELECTRICAL APPLIANCE GROUP

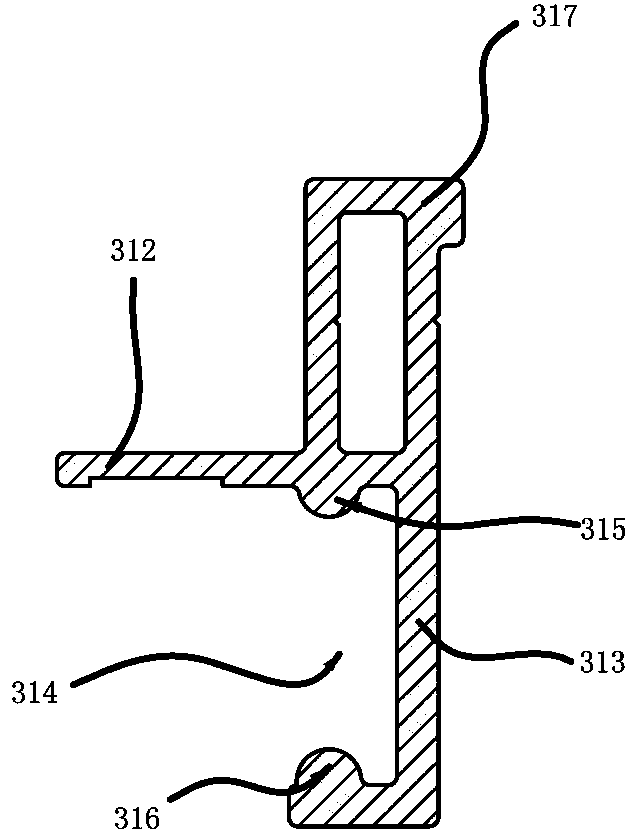

Charging mechanism of automatic magnetic shoe deburring device

InactiveCN108356697AIncrease productivityAvoid affecting the loading operationGrinding feedersIndustrial AccidentMachining

The invention relates to the technical field of machining, in particular to a charging mechanism of an automatic magnetic shoe deburring device. The charging mechanism comprises a material lifting assembly, a charging assembly and a material taking assembly. The material taking assembly and the charging assembly are located above the material lifting assembly. The charging assembly comprises a sliding block of a cuboid structure, and a bearing assembly used for supporting the sliding block. The bearing assembly comprises a mounting frame and two supporting plates which are located at the bottom of the mounting frame and used for supporting the bottom of the mounting frame. The sliding block is located in the mounting frame and is in sliding fit with the mounting frame. The material takingassembly comprises a lifting assembly located at the top of the sliding block, and a clamping assembly located below the sliding block. Workpieces can be automatically moved to a machining waiting area, the production efficiency of enterprises is improved, the labor intensity of workers is relieved, in addition, the workpieces can be clamped through the material taking assembly, and industrial accidents caused by manual charging by the workers are avoided.

Owner:ANHUI NORMAL UNIV

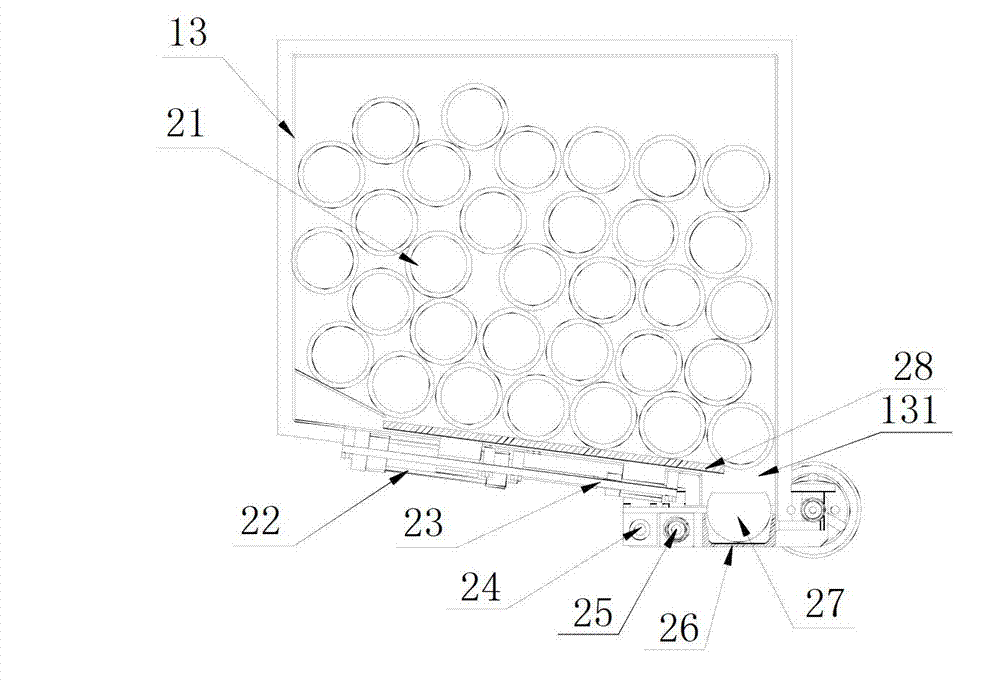

Device for automatically penetrating paper pipe by air bulking shaft of cast film machine

ActiveCN103303720ACancel manual operationReduce labor intensityLoading/unloadingWebs handlingIndustrial AccidentPulp and paper industry

The invention relates to a device for automatically penetrating a paper pipe by an air bulking shaft of a cast film machine. The device comprises a paper sleeve hopper mechanism, a paper sleeve base, a paper pipe pushing mechanism, an air bulking shaft inflating mechanism and an air bulking shaft support mechanism; the paper sleeve hopper mechanism is arranged above the paper sleeve base; the paper sleeve base is fixedly connected with the outer side of a first wall plate of a machine body; the paper pipe pushing mechanism is fixedly connected with the outer side of the first wall plate of the machine body; the paper pipe pushing mechanism comprises a paper sleeve push plate arranged in the paper sleeve base; the air bulking shaft inflating mechanism is fixedly connected to the outer side of a second wall plate of the machine body; the air bulking shaft support mechanism comprises a first support mechanism and a second support mechanism; the first support mechanism is fixedly connected with the inner side of the first wall plate of the machine body; the second support mechanism is connected to the inner side of the second wall plate of the machine body; the air bulking shaft is movably arranged on the first support mechanism and the second support mechanism. The air bulking shaft can automatically penetrate the paper pipe without being moved at a reel alternation and feed preparation position, so that the automation degree is high, the production efficiency is greatly improved, and the labor strength of production personnel is alleviated; and manual operation of penetrating the water pipe is omitted, so that the safety is improved, and the occurrence of industrial accidents is reduced.

Owner:CHANGLONG TECH YANGJIANG CO LTD

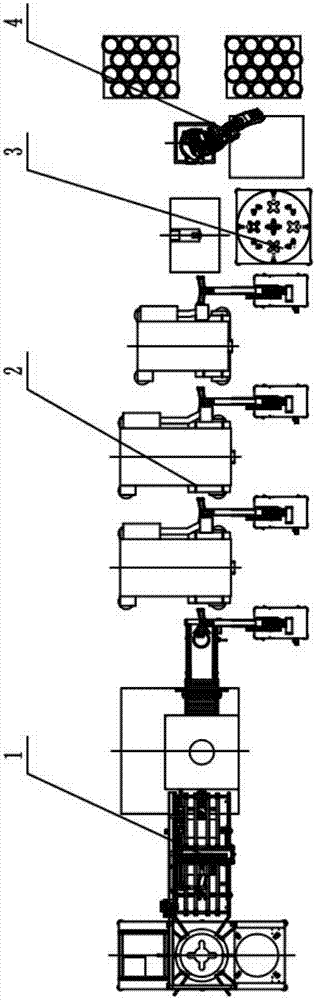

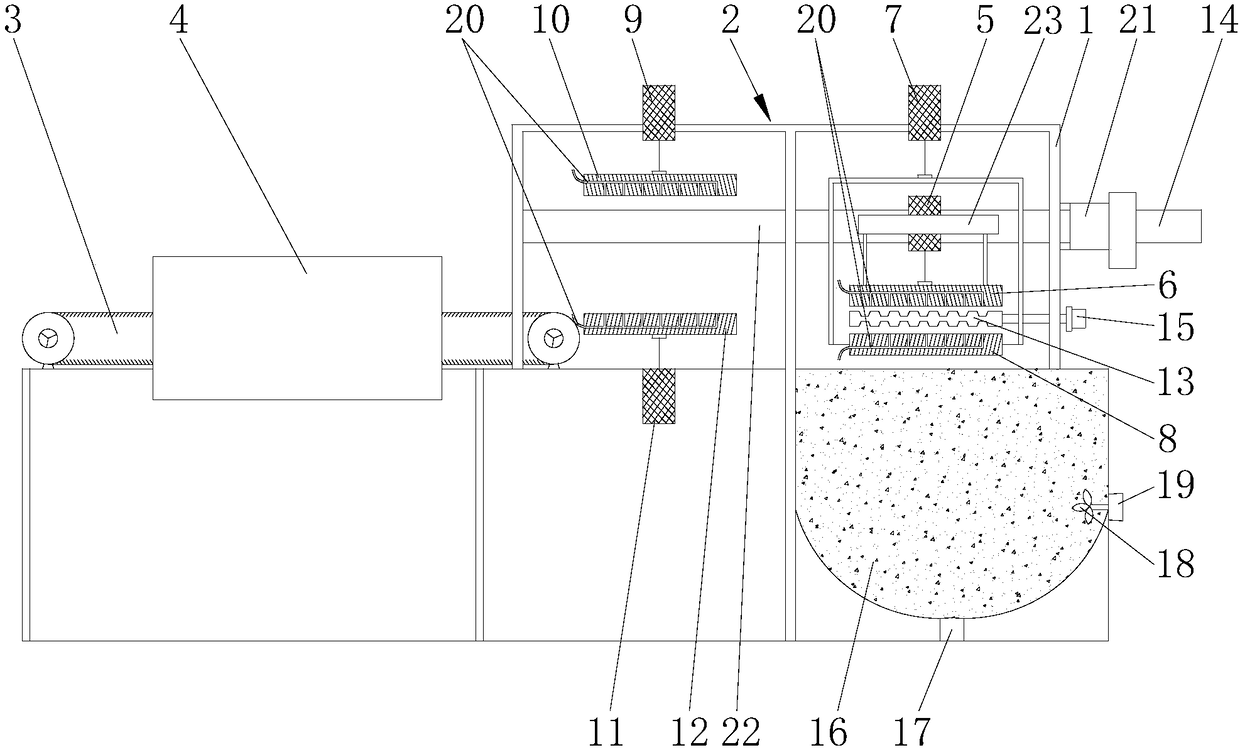

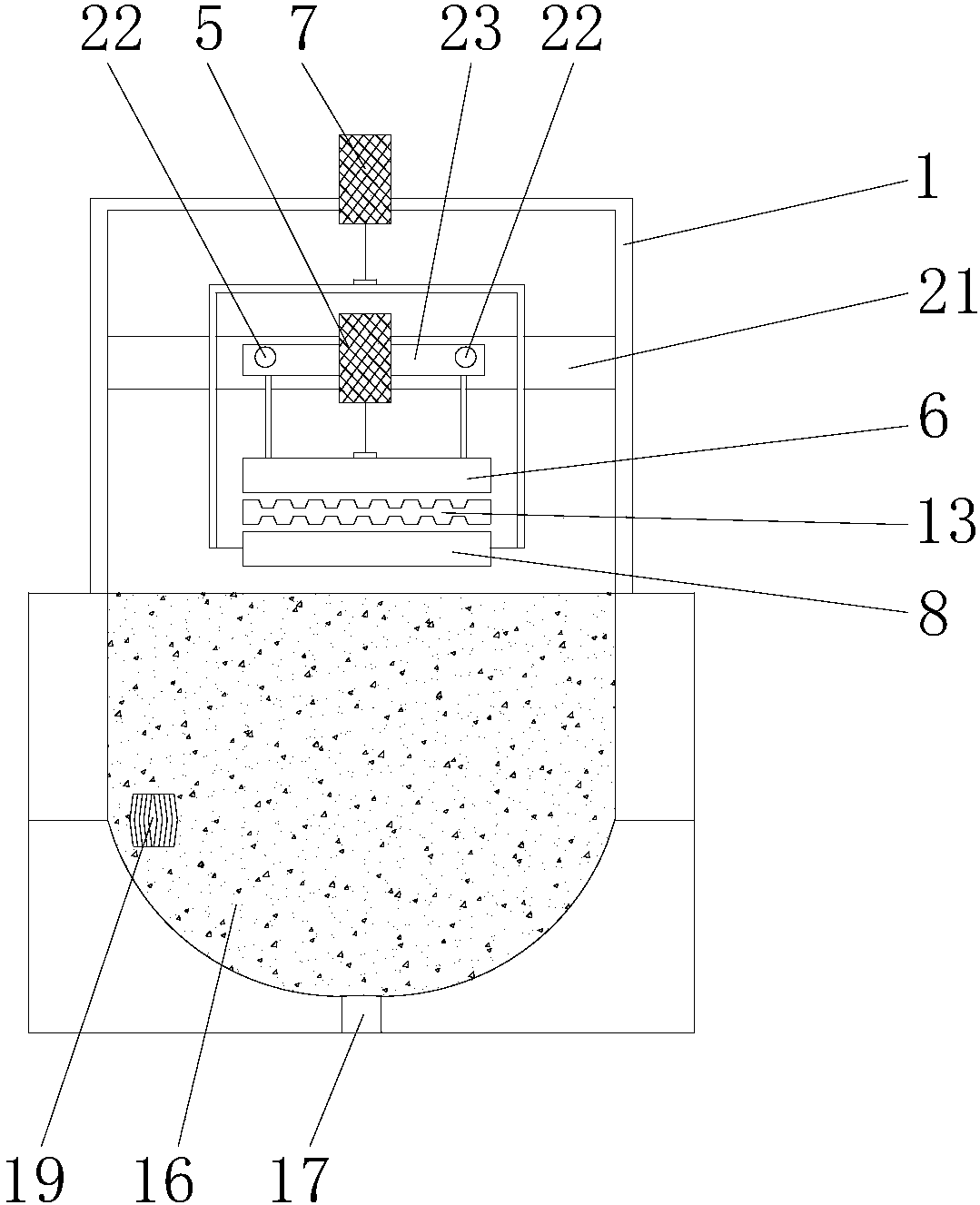

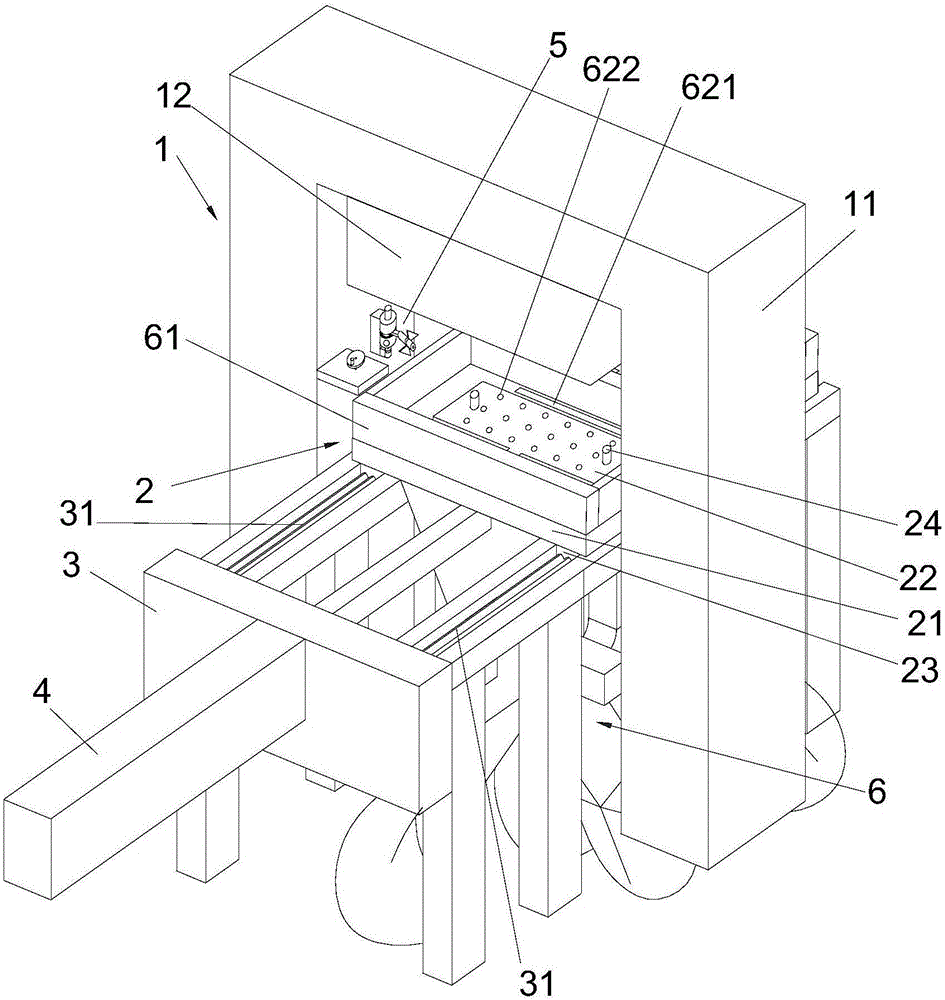

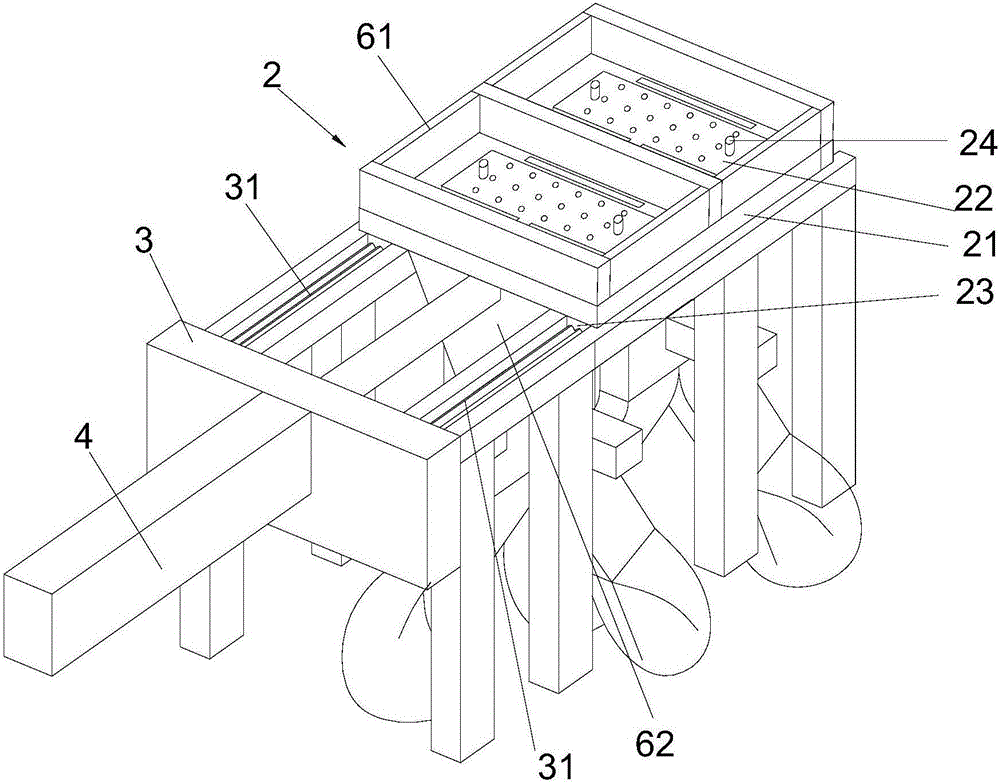

Integrated paper pulp molding equipment and method

PendingCN108517724AReduce work accidentsImprove quality and efficiencyTextiles and paperIndustrial AccidentSlurry

The invention relates to integrated paper pulp molding equipment, in particular to integrated paper pulp molding equipment and method. The integrated paper pulp molding equipment comprises a rack (1),a molding mechanism (2), delivery equipment (3), a drying mechanism (4) and a slurry pool (16), wherein the molding mechanism (2), the delivery equipment (3) and the drying mechanism (4) are all arranged on the rack (1), the delivery equipment (3) and the drying mechanism (4) are located at one side of the molding mechanism (2), the delivery equipment (3) is partially located in the drying mechanism (4), and the slurry pool (16) is located below the molding mechanism (2). Through a designed pulp absorbing mode, the paper pulp molding product thickness is increased, industrial accidents can bereduced, and the product quality and the production efficiency can be improved. The invention further provides an integrated paper pulp molding method. A top-bottom two-sided slurry absorbing mode isadopted, and the product compactness is improved.

Owner:重庆凯成科技有限公司

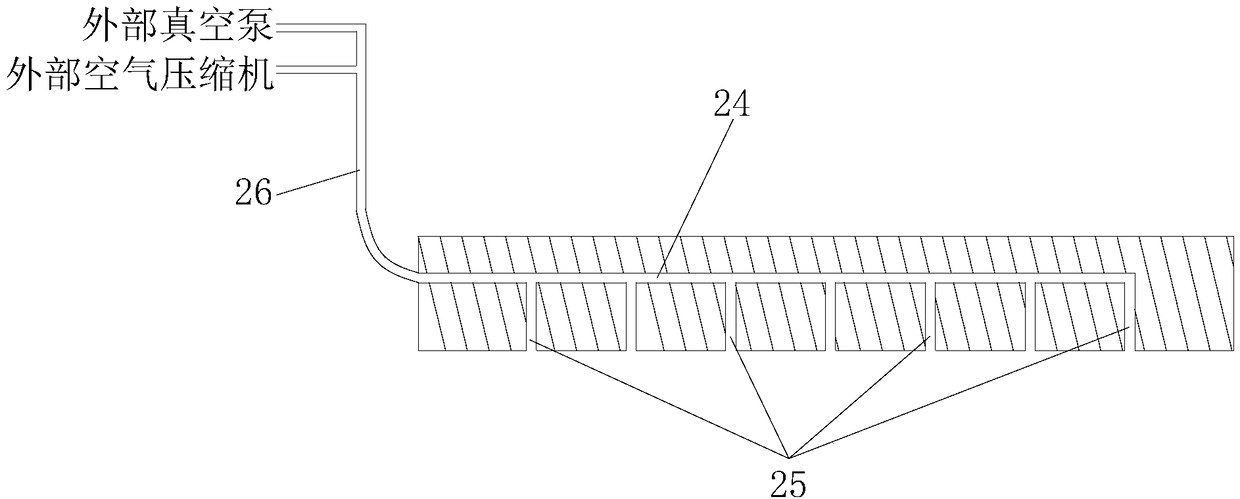

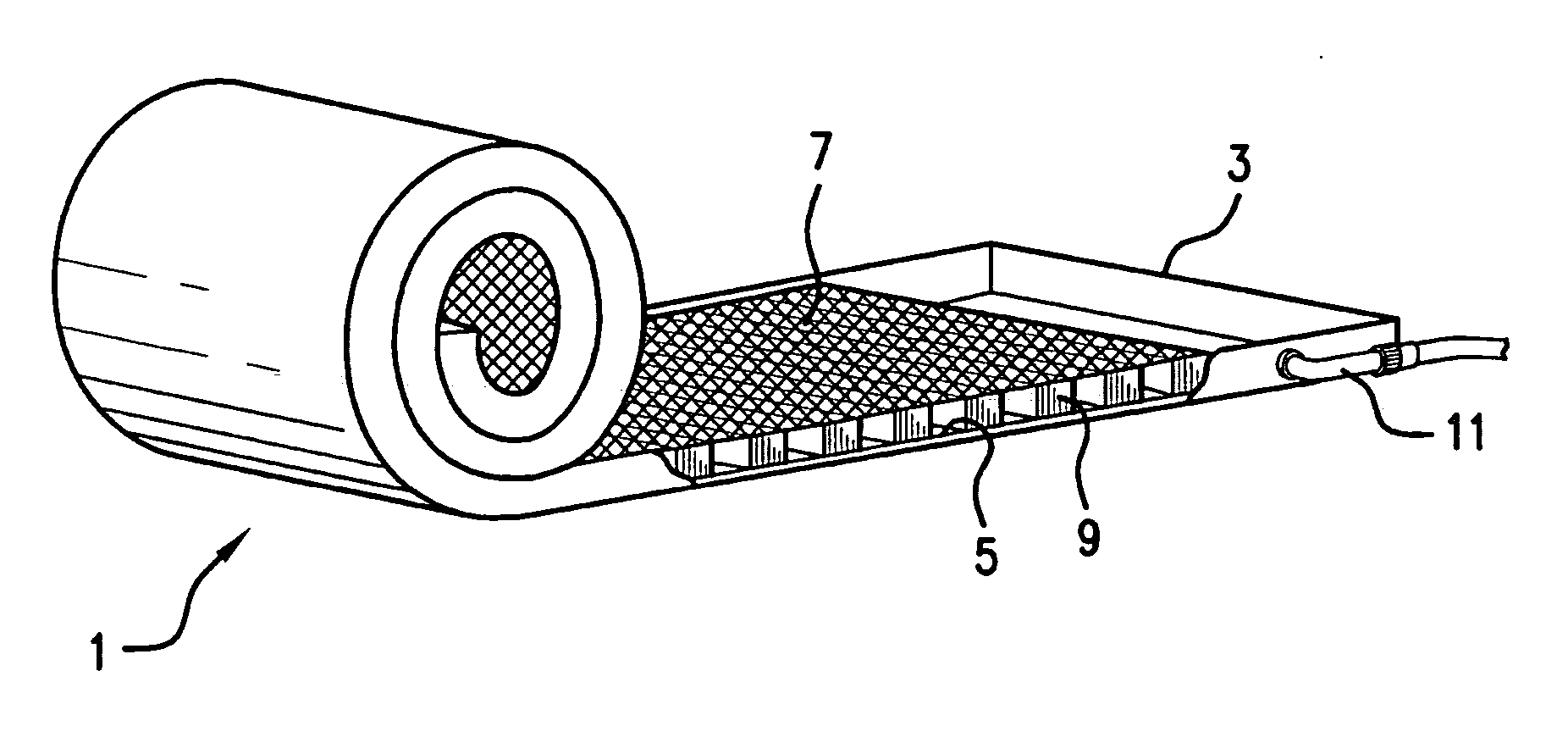

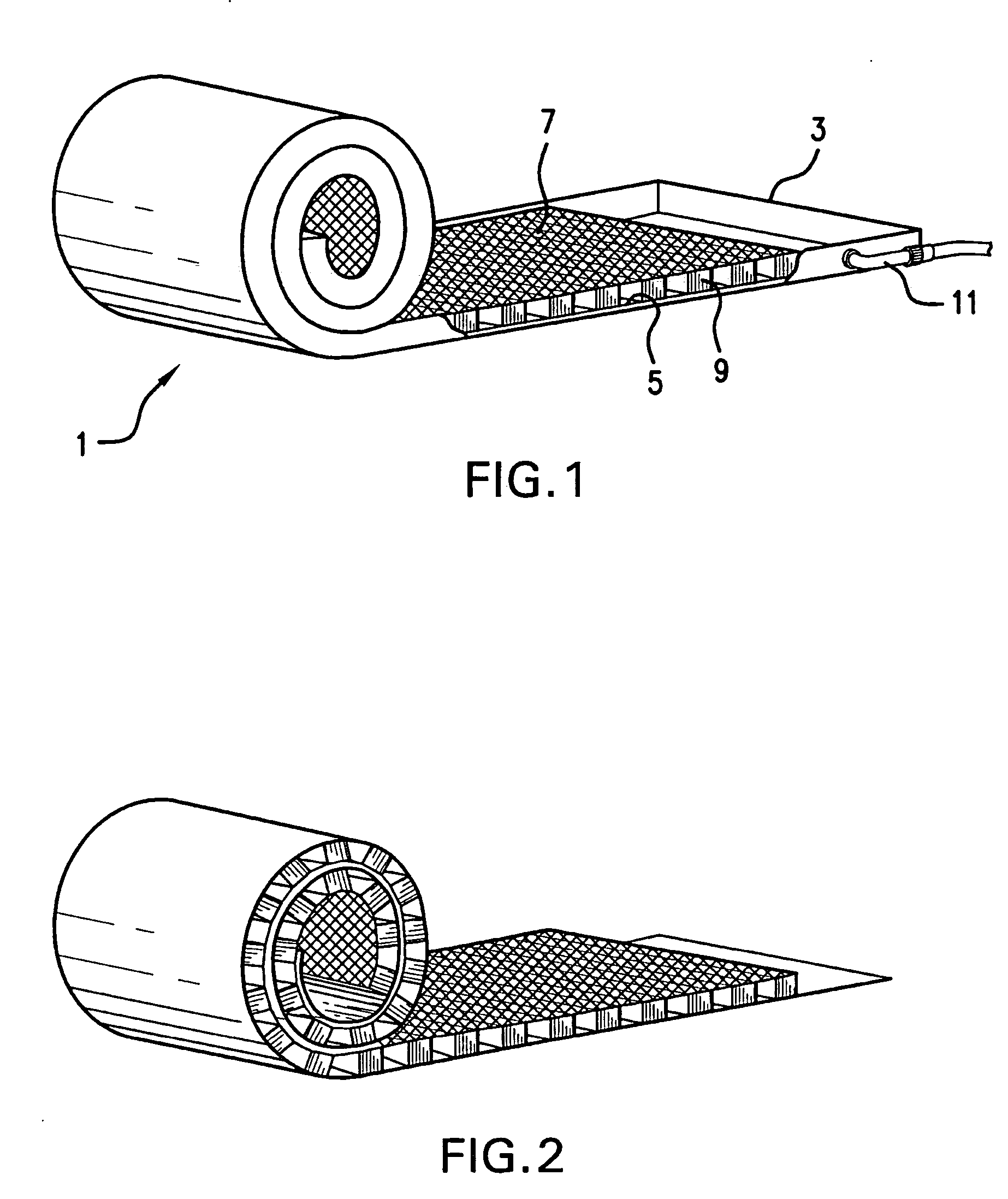

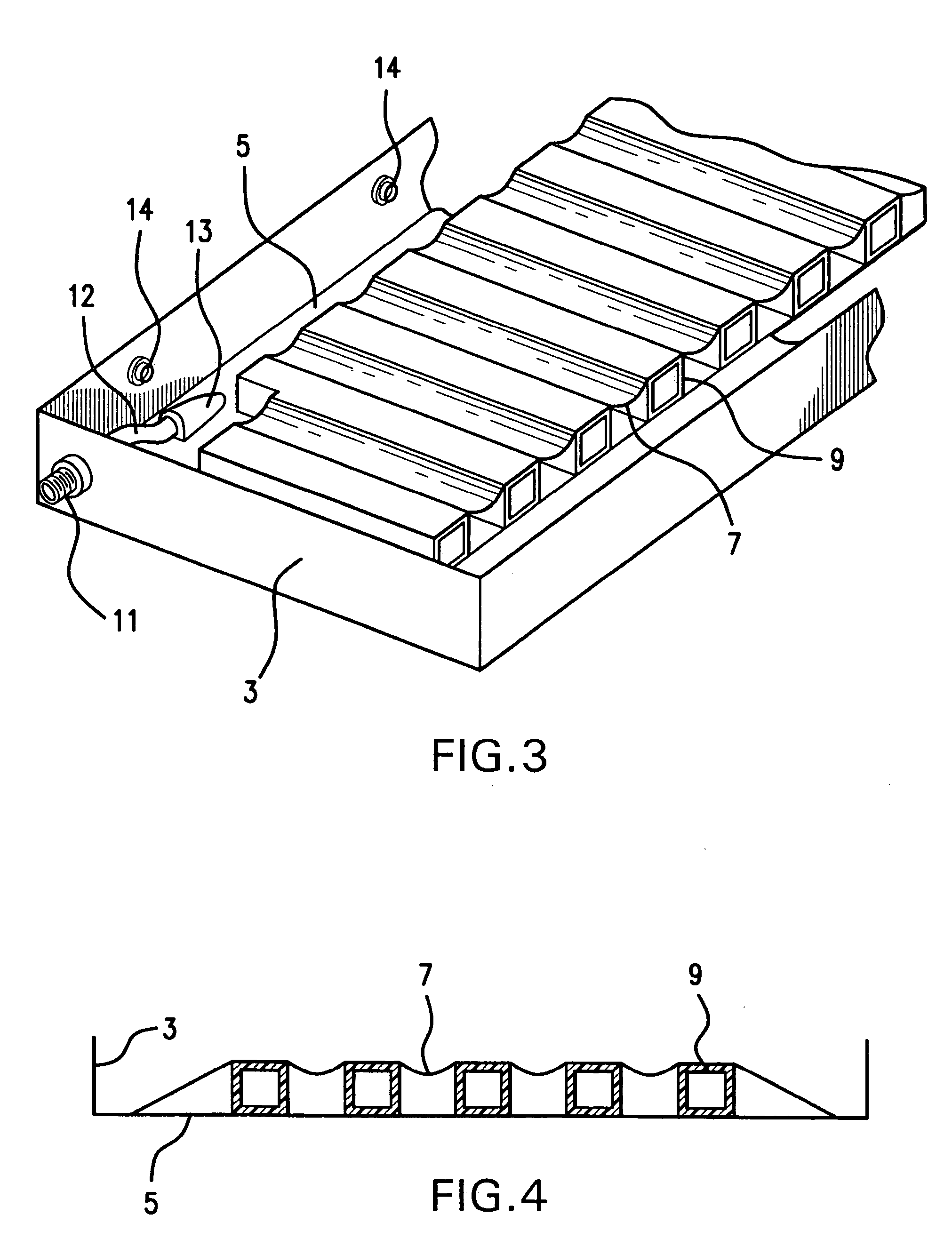

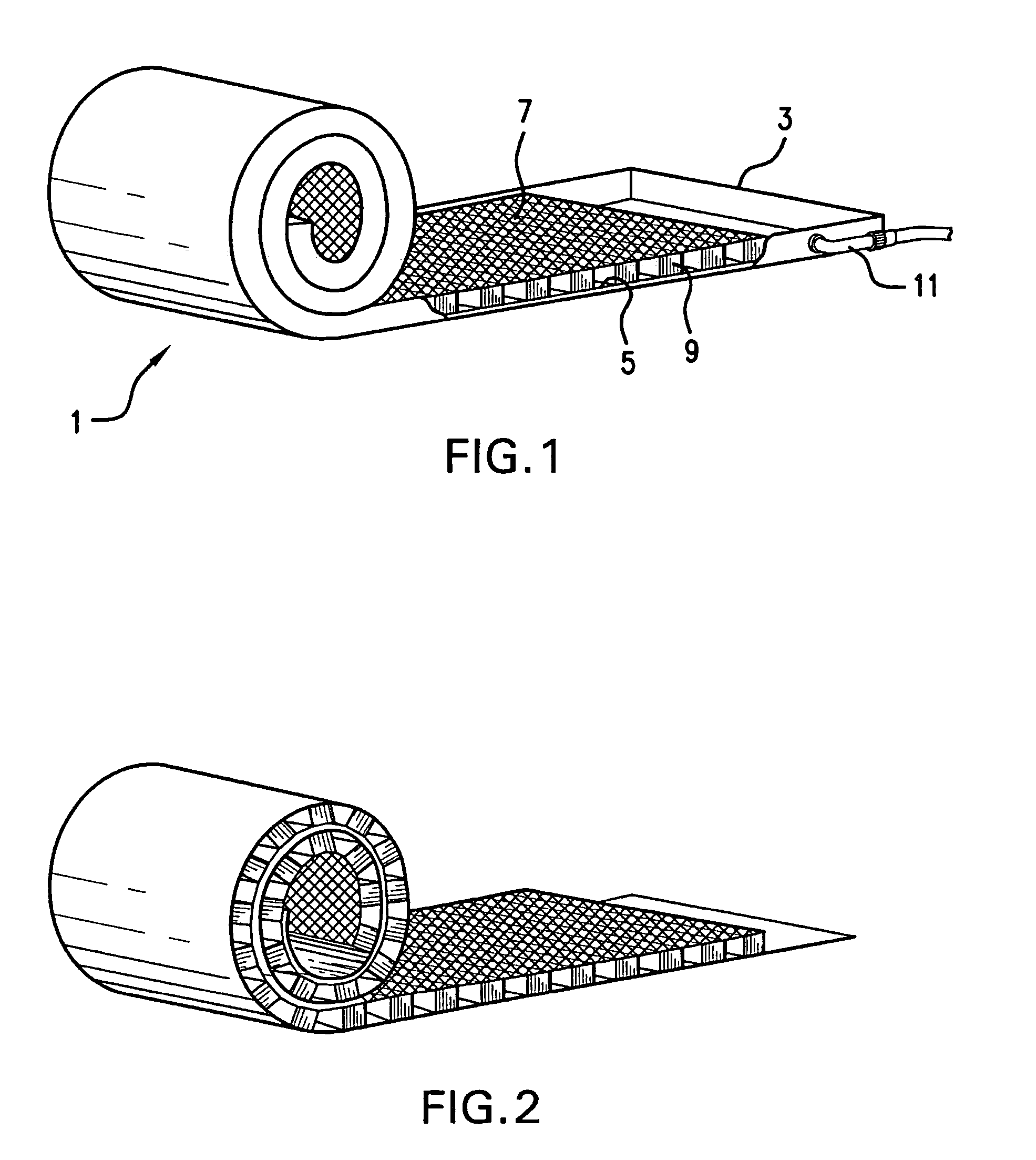

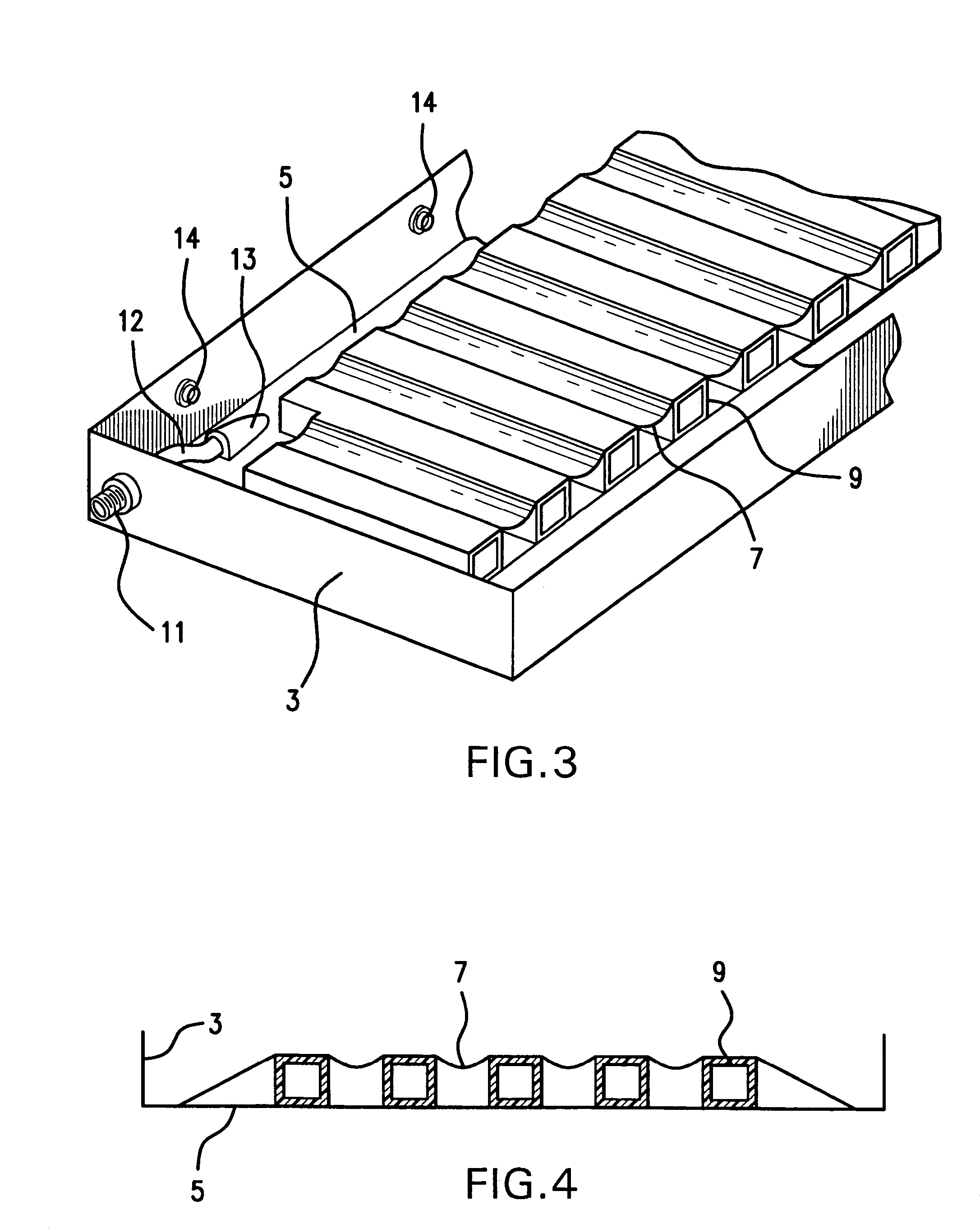

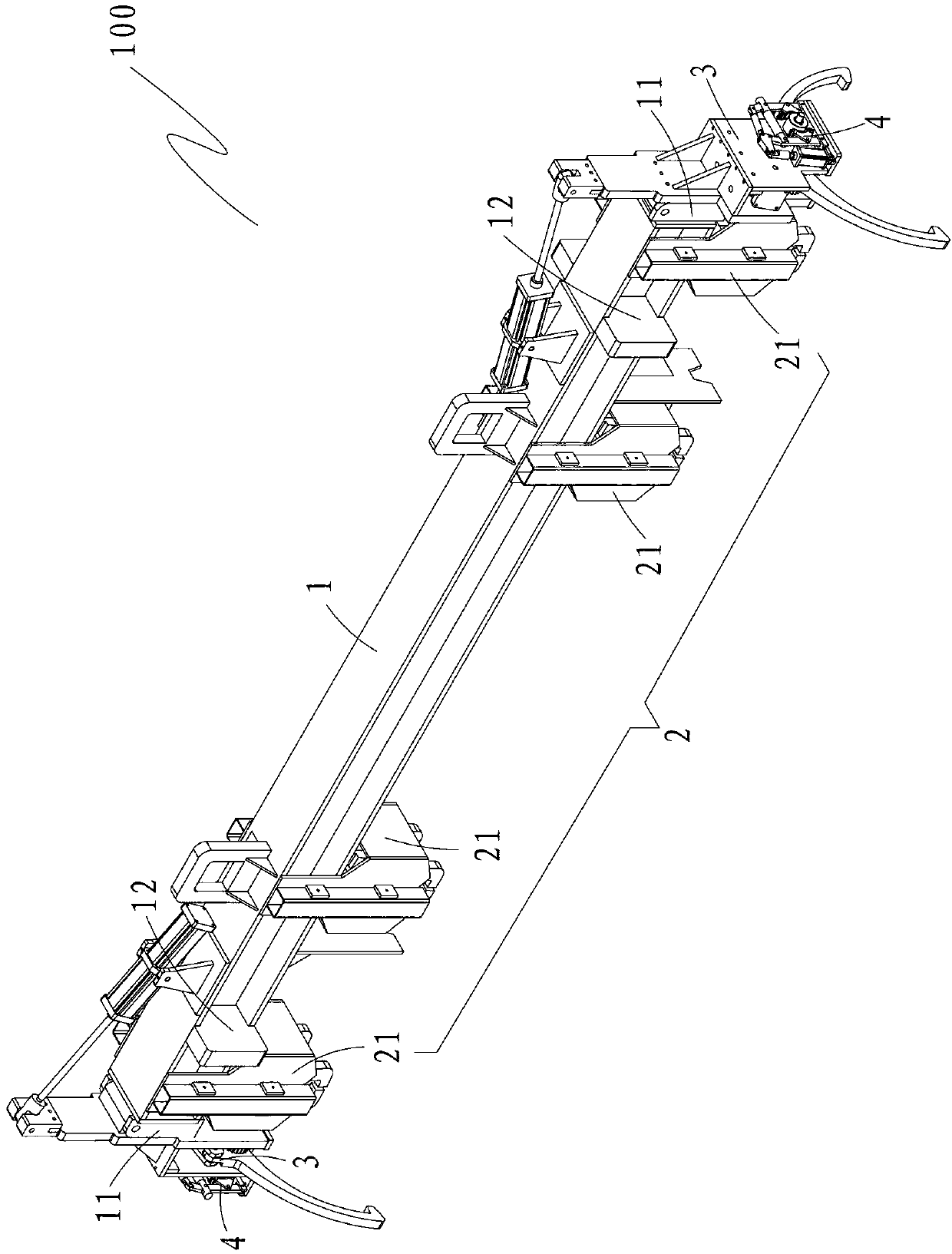

Roll-up pool for a decontamination system

InactiveUS20060070654A1Shorten the timeReduce the possibilityBathsDouchesIndustrial AccidentCompound (substance)

A roll-up pool combines a collection basin and an elevation grid system into one unit that can be set up for use in seconds. The roll-up pool includes a bottom portion and wall portions, as well as an upper surface. A set of elevation pieces are located between the upper surface and the bottom portion, and are bonded to these components. All of these components are made of a material which is sufficiently flexible to allow the structure to be wound into a roll. When decontamination is required, the roll is unwound to provide a collection basin having an elevation grid system. In another embodiment, the rolled structure includes only the elevation grid system, and is intended for deployment in a collection basin that already exists. The invention substantially reduces the time and effort required to decontaminate victims of industrial accidents or chemical or biological attack.

Owner:VANBASTEN WILLEM F

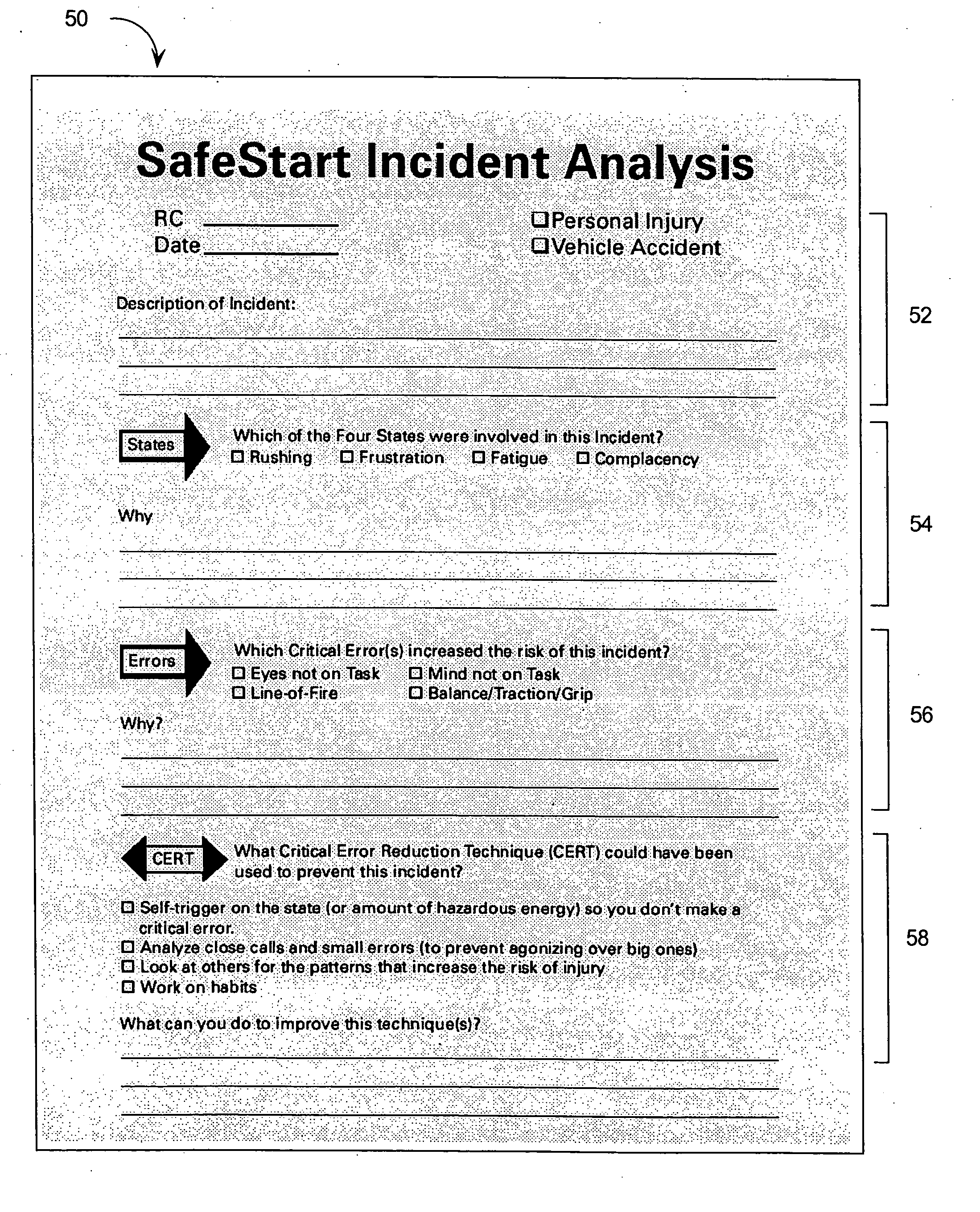

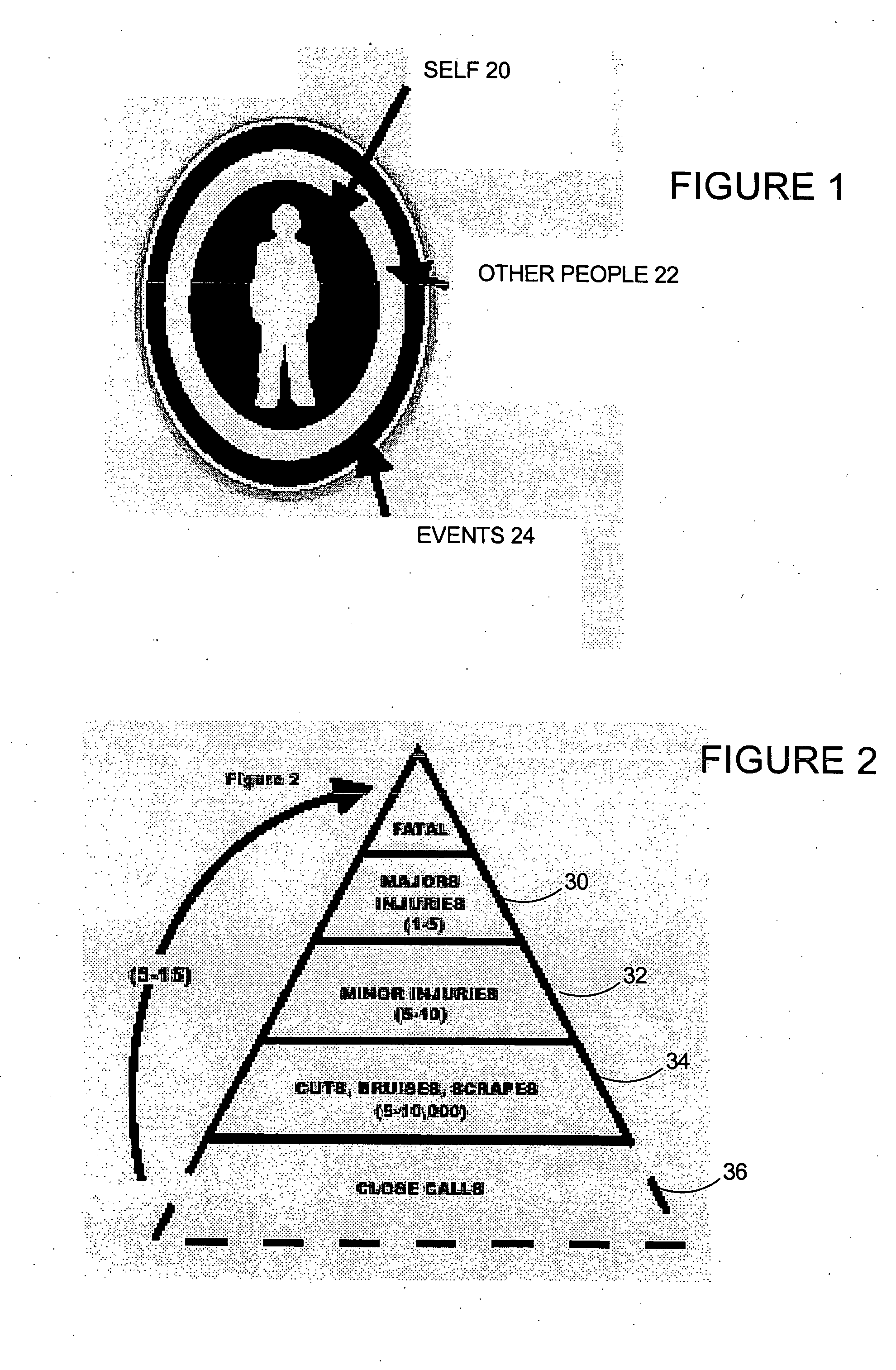

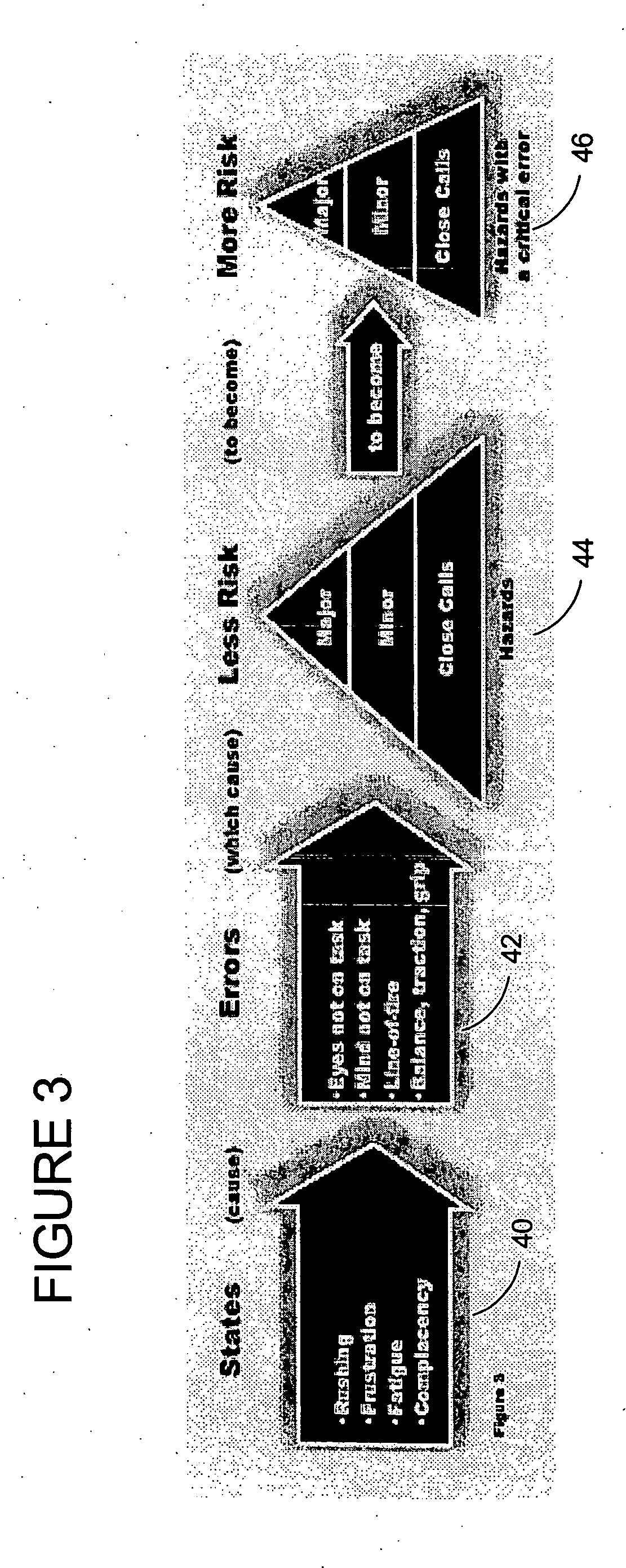

Method and system for reducing accident occurrences

InactiveUS20050147949A1Reduce accidentsReduce frequencyEducational modelsTeaching apparatusMental stateIndustrial Accident

The present invention relates generally to accident prevention, and more specifically, to a method of, and system for training individuals which reduces the frequency and / or severity of accident occurrences. The invention provides a method of reducing the frequency of industrial accidents comprising the steps of: determining the mental state of an individual at the time of an accident or close call; classifying the cause of the accident as being due to the individual being in one of four hazardous mental states; identifying the state-to-error risk pattern; and teaching the individual to effect critical error reduction techniques, to avoid future occurrences of accidents. The invention also provides a checklist outlining this methodology, for use in accident investigation.

Owner:ELECTROLAB

Automatic industrial robot feeding and discharging production line for numerically-controlled machine tools

InactiveCN104841957AReduce labor intensityReasonable structural designMetal working apparatusProduction lineNumerical control

The invention discloses an automatic industrial robot feeding and discharging production line for numerically-controlled machine tools. The production line comprises an industrial robot arranged between a first lathe and a second lathe, a feeding rack is arranged on one side of the second lathe, a feeding conveying belt is arranged on the feeding rack, a workpiece retaining plate is arranged at the position, close to the discharge end of the feeding conveying belt, on the feeding rack at the discharge end of the feeding conveying belt, a horizontal guide plate is arranged over the feeding conveying belt, two sides of the guide plate are fixedly connected with the feeding rack on two sides of the feeding conveying belt, a plurality of partitions extending along the length direction of the guide plate are arranged on the lower surface of the guide plate evenly at intervals, and a push mechanism is arranged on the feeding rack on the outer side of the workpiece retaining plate. The production line is rational in structural design and convenient to mount, product machining efficiency is increased, consistency of product machining is guaranteed, product machining precision and quality are improved, labor intensity of workers is lowered, labor is freed, labor cost is lowered, and occurrence rate of industrial accidents is lowered.

Owner:SHANDONG YINGCAI UNIV

Roll-up pool for a decontamination system

A roll-up pool combines a collection basin and an elevation grid system into one unit that can be set up for use in seconds. The roll-up pool includes a bottom portion and wall portions, as well as an upper surface. A set of elevation pieces are located between the upper surface and the bottom portion, and are bonded to these components. All of these components are made of a material which is sufficiently flexible to allow the structure to be wound into a roll. When decontamination is required, the roll is unwound to provide a collection basin having an elevation grid system. In another embodiment, the rolled structure includes only the elevation grid system, and is intended for deployment in a collection basin that already exists. The invention substantially reduces the time and effort required to decontaminate victims of industrial accidents or chemical or biological attack.

Owner:VANBASTEN WILLEM F

Pneumatic sling for dual-purpose full-function automatic grappling hook

ActiveCN102992177ARealize automatic liftingReduce the incidence of industrial accidentsLoad-engaging elementsIndustrial AccidentControl system

The invention provides a pneumatic sling for a dual-purpose full-function automatic grappling hook. The pneumatic sling comprises a sling main beam, a grappling wheel system consisting of four grappling wheel actuating mechanisms, a power source, a control system, two hooking bottom mold systems and two safety brake mechanisms which are respectively arranged on the two hooking bottom mold systems, wherein the two hooking bottom mold systems are respectively connected to two ends of the sling main beam; each hooking bottom mold system comprises a first cylinder arranged on the upper surface of the sling main beam, a second cylinder, two gears with shafts which are meshed with each other, a gearbox used for accommodating the two gears with shafts, and two clamping claws; and each safety brake mechanism comprises a brake fixing plate, a brake hub and a brake rack used for braking the gears with shafts. The pneumatic sling has the advantages that a complete pipe die can be automatically lifted, and a half of pipe die is automatically lifted, so that the industrial accident rate of hooking hands in the pipe pile industry is greatly reduced.

Owner:FUJIAN JIANHUA CONSTR MATERIALS CO LTD

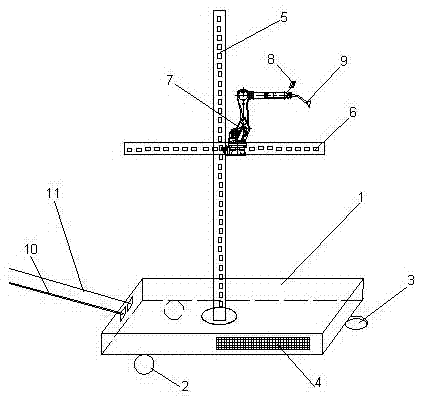

Vessel spraying robot

The invention relates to a ship spraying robot. The robot includes a platform, an electromagnetic adsorption wheel, a steering wheel, a receiving and executing system, a vertical lifting rod, a horizontal moving rod, a painting manipulator, a detection device and a spray gun, and the electromagnetic adsorption wheel and the steering wheel are connected at the lower part of the platform. The receiving and executing system is set in the platform, one end of the vertical lifting rod is fixedly connected to the platform, the horizontal moving rod is connected to the vertical lifting rod, and one end of the painting manipulator is fixedly connected to the horizontal moving rod , the other end of the painting manipulator is provided with a spray gun, and the detection device is provided on the painting manipulator at the rear of the spray gun. The invention has the advantages of simple structure, reduction of industrial accidents, safety and environmental protection, reduction of human injury, high degree of automation and high work efficiency.

Owner:YANGZHOU ZHONGKE FORWANT INTELLIGENT TECH CO LTD

Radish peeling device

InactiveCN106666770AImprove work efficiencyReduce labor intensityVegetable peelingIndustrial AccidentEngineering

Owner:谢洁萍

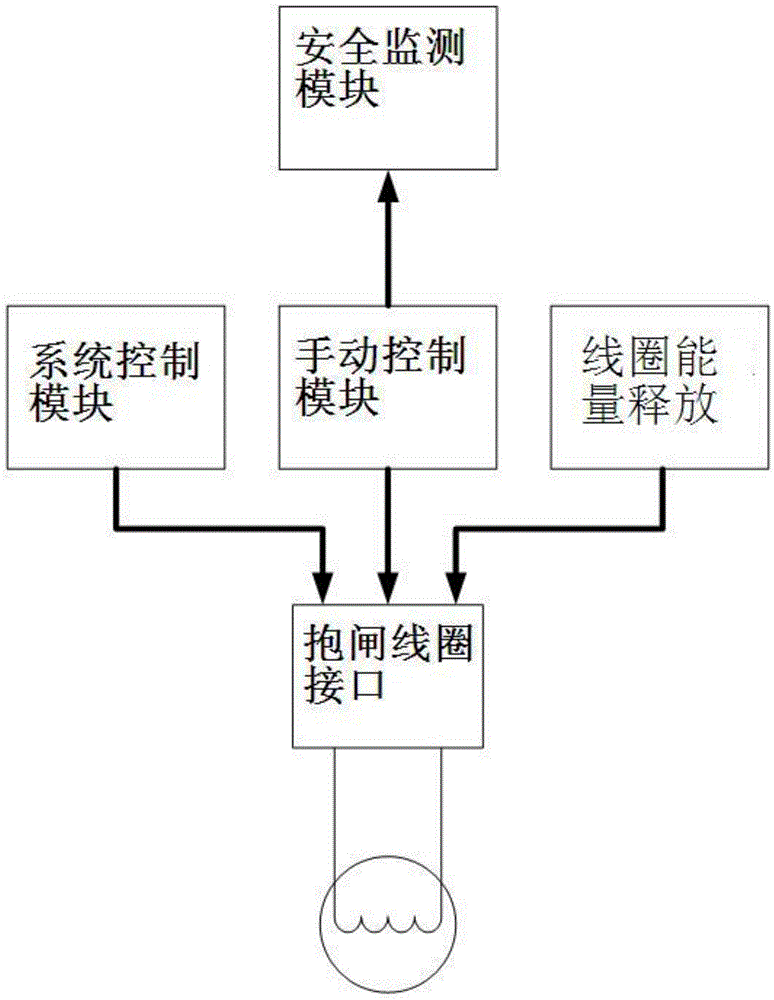

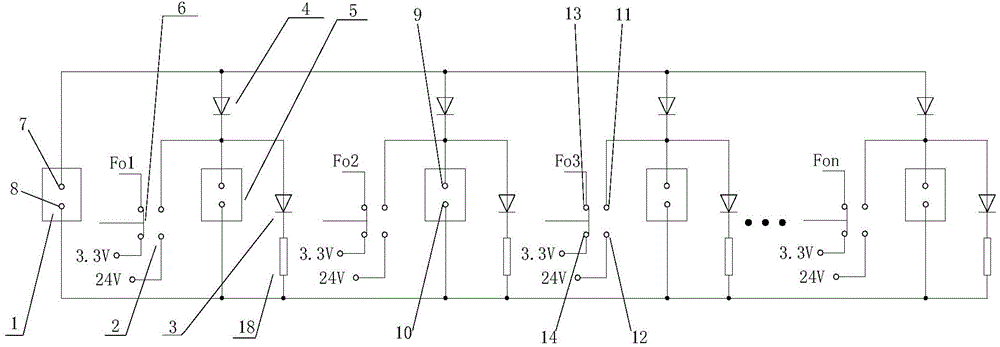

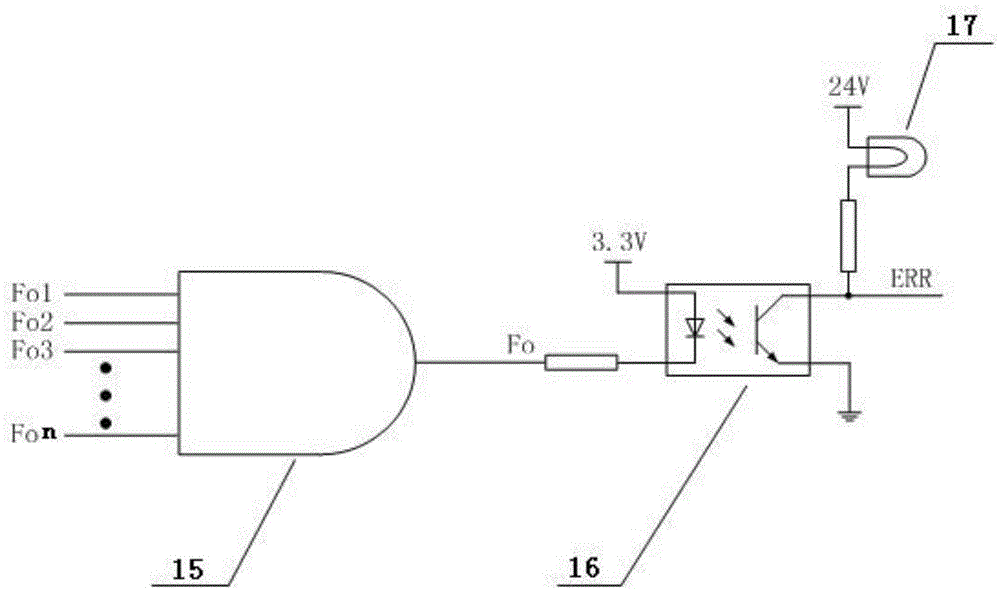

Industrial robot motor band-type brake controller with safety monitoring device

The invention provides an industrial robot motor band-type brake controller with a safety monitoring device. The controller comprises a system control module used for automatic system control, a manual control module used for manually releasing a band-type brake, a coil energy releasing module used for shortening the band-type brake reaction time and a safety detection module used for monitoring whether buttons have faults. The system control module is arranged in a control cabinet of a robot, the manual control module is arranged on the robot, and the system control module, the manual control module and the coil energy releasing module are connected with band-type brake coil interfaces of a motor of the robot correspondingly; the safety monitoring module is connected with the manual control module. According to the controller, a safety detecting device for manually releasing band-type brake control is added, so that industrial accidents caused by mistaken releasing of the band-type brake are avoided.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

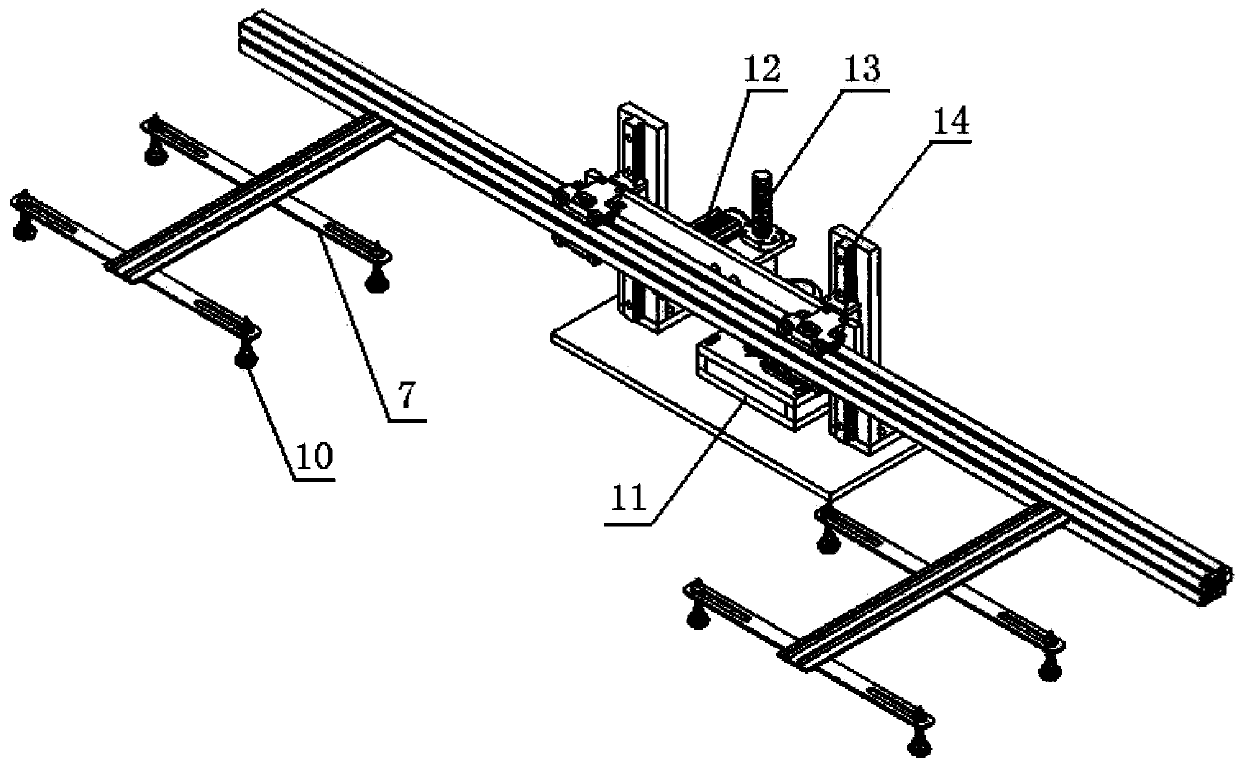

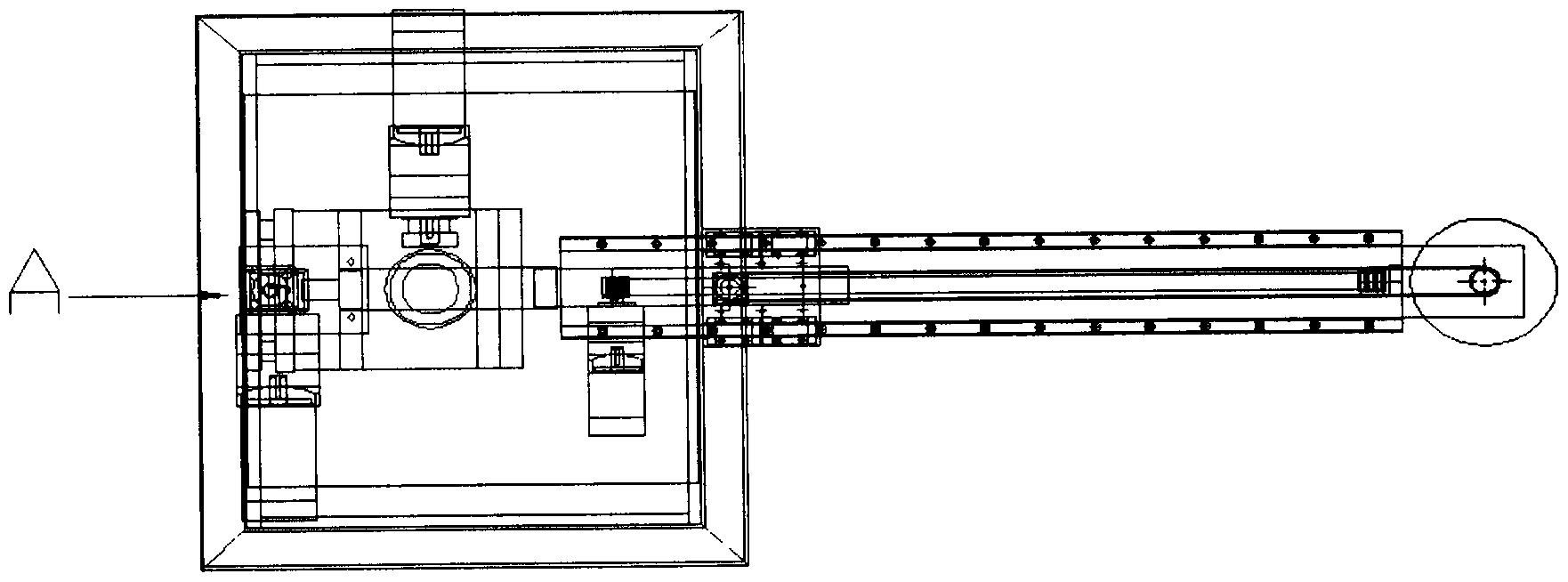

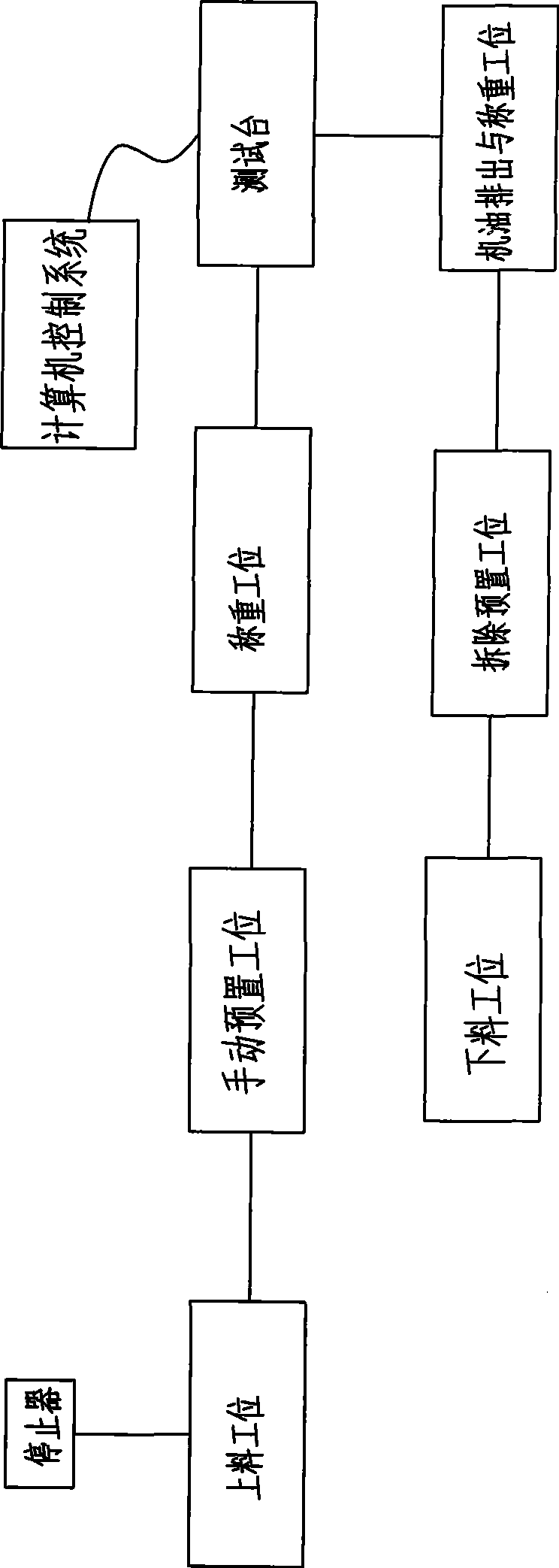

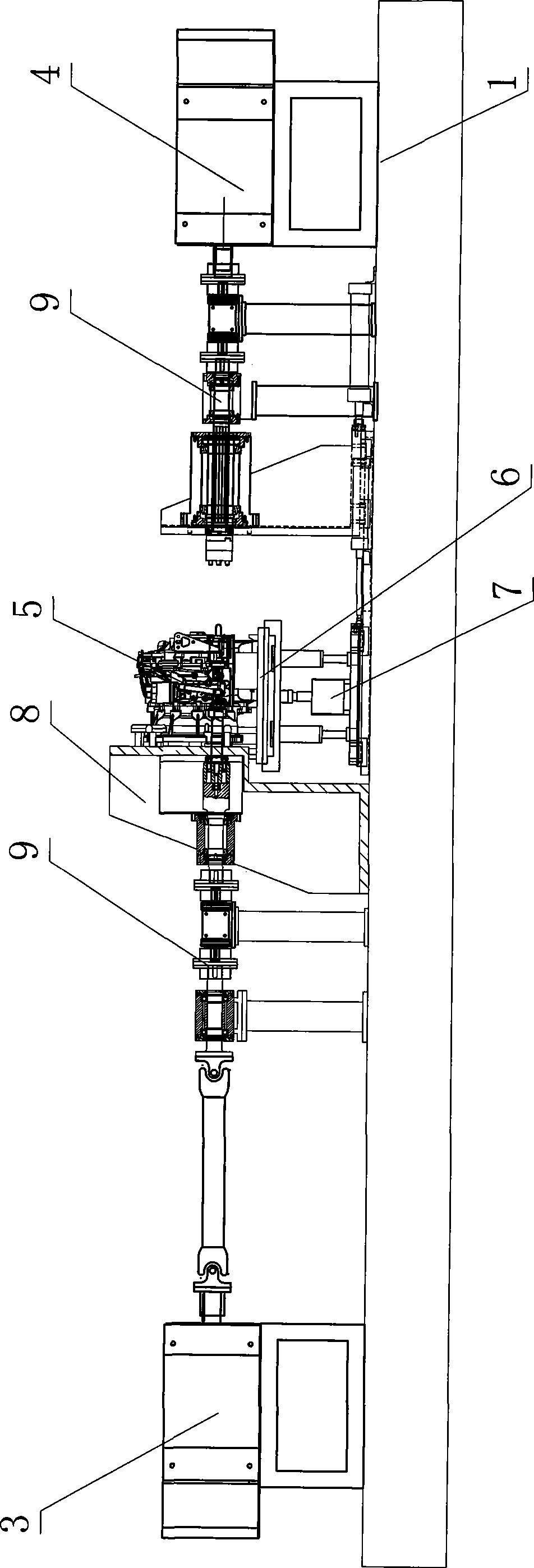

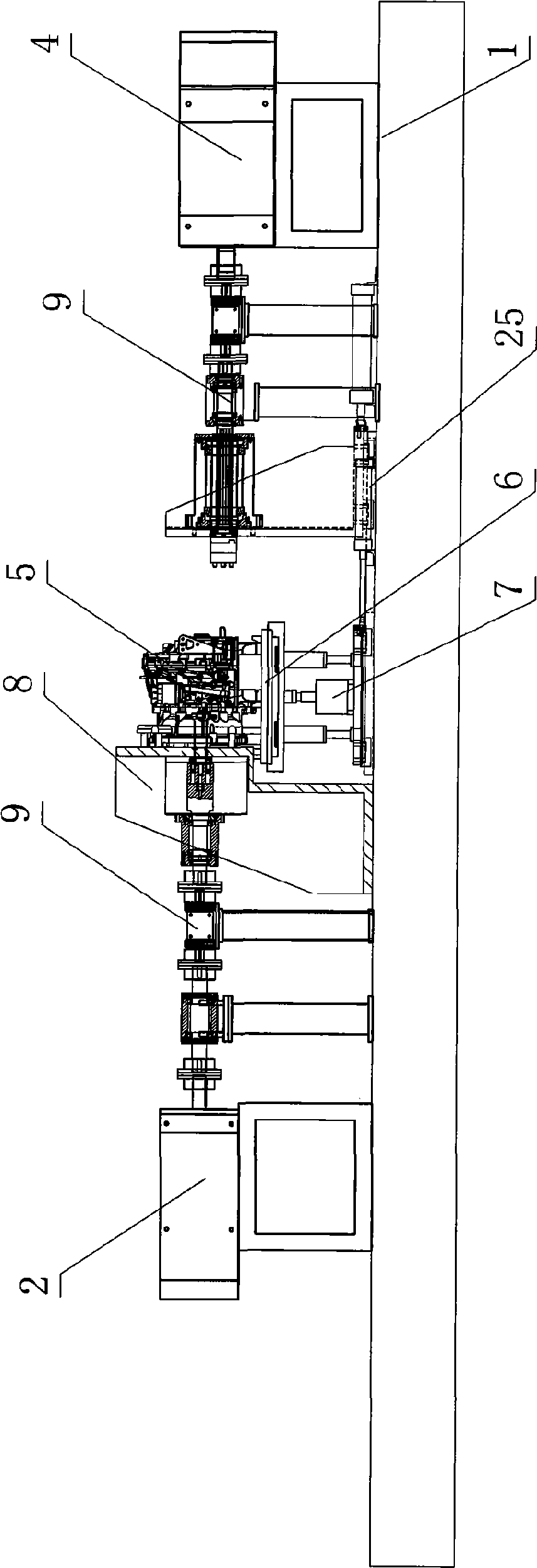

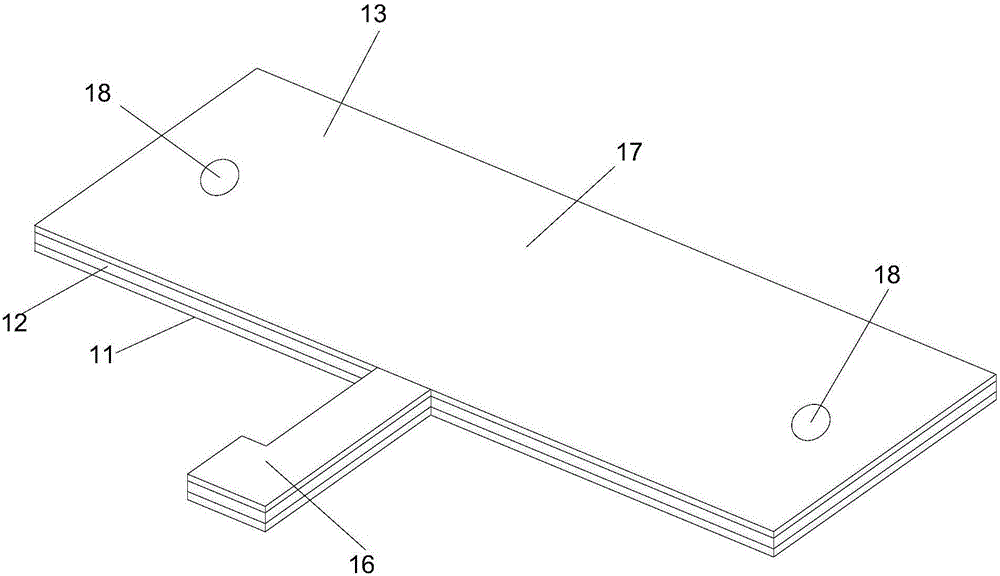

Method for simulation test of self-changing gearbox and test device using same

ActiveCN101520368AAccurately reflectImplement automated testingMachine gearing/transmission testingIndustrial AccidentAutomatic control

The invention provides a method for a simulation test of a self-changing gearbox, which is automatic in the test, low in labor intensity, and high in production efficiency, avoids industrial accidents, meets requirements for large-scale production, accurately reflects performance parameters of the self-changing gearbox, and improves the quality of the test. The invention also provides a test device using the test method. The test device comprises a conveying line and is characterized in that: the conveying line is sequentially provided with a loading station, a manual presetting station, a weighting station, a test desk, an engine oil discharge and weighing station, a dismounting preset station and a discharging station, a stopping device is arranged in front of a conveyor belt, and the test desk is connected with a computer control system. An assembled self-changing gearbox is quickly jointed with an input motor and is positioned and clamped, two output loading motors are quickly jointed with the gearbox, and the computer gives an instruction to simulate a pre-input test curve under real road conditions to do self-change test and to acquire various parameter such as the rotation speed, input torque, various pressures, flow, oil temperature, gear position and the present position of the tested gear box at the same time for analyzing through comparison with a theoretical curve and making an adjustment.

Owner:WUXI DAJINYI TECH CO LTD

Punching machine for producing keyboard circuit

InactiveCN106426384AGuaranteed to proceed normallyImprove securityMetal working apparatusPunch pressIndustrial Accident

The invention provides a punching machine for producing a keyboard circuit. The punching machine comprises a punching mechanism, a station base, a support frame, a transverse driving mechanism and a control box, wherein the punching mechanism includes a portal frame; a punching part is mounted on the portal frame; a punching station is rightly below the punching part; the station base includes a bearing plate and two placing molds; the two placing molds are mounted on the bearing plate, and are both used for placing semi-finished products; after the semi-finished products are placed on the two placing molds, output parts of the semi-finished products are towards the same one direction; four first wire wheels are arranged on the bottom surface of the bearing plate; two slide rails are supported on the upper surface of the support frame, are parallel to each other, and both penetrate through the portal frame; every two of the two first wire wheels are slidingly arranged in one slide rail; the transverse driving mechanism is mounted on the support frame, and an output part thereof is connected with the station base; and the punching mechanism and the transverse driving mechanism are electrically connected with the control box. The punching machine has the following beneficial effects: the punching machine prevents industrial accidents caused by sudden downward pressing of the pressing plate in placement of the semi-finished products.

Owner:重庆淳祥电子科技有限公司

Automatic blanking system of vertical pulling machine of copper pipe

The invention discloses an automatic blanking system for a copper tube straight stretching machine, wherein a stretching slide seat (7) and a copper tube straightening die (11) are arranged outside a guide rail (3) which is arranged on a lathe bed of the directly-stretching machine in the overlooking direction of the copper tube straight stretching machine. Due to adoption of the technical proposal, the automatic straight system for the copper tube directly-stretching machine can effectively solve the problem that the surface of a copper tube is not knocked and damaged under the condition of automatic straight after the copper tube is straightened, lightens the labor intensity of workers, avoids industrial accidents such as scalding and scoring, and avoids mechanical influence and corresponding mechanical failure.

Owner:芜湖浩达金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com