Sawing machine clamp

A fixture and sawing machine technology, which is applied in the field of fixtures, can solve the problems of difficult inspection and maintenance, lower production efficiency, and easy to cause work-related injuries, so as to avoid manual pressing, improve work efficiency, and ensure life safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

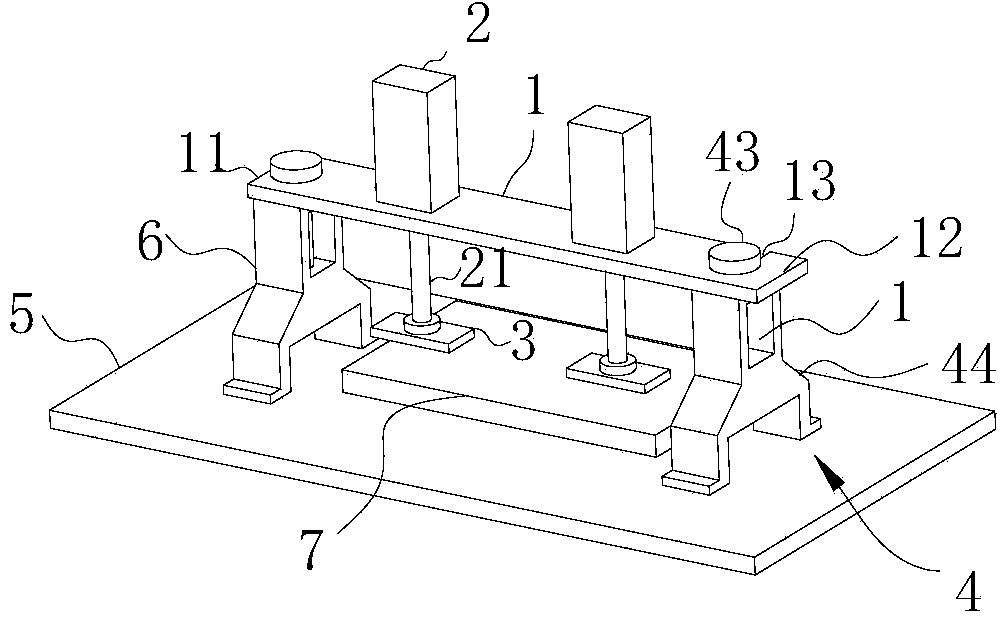

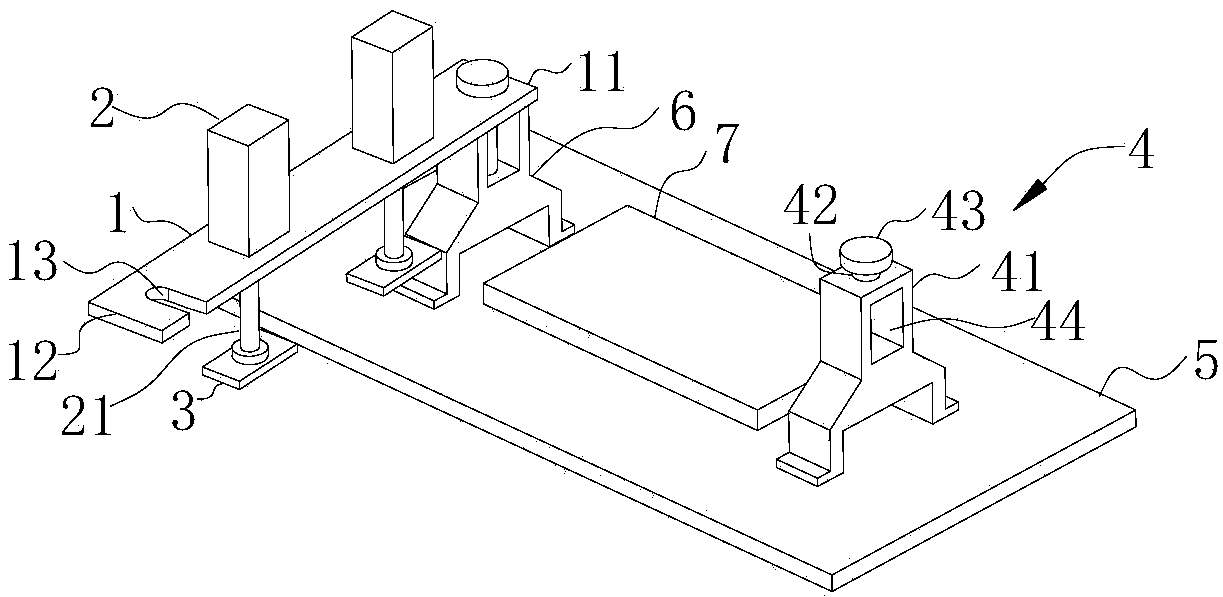

[0026] Such as Figure 1~2 As shown, in this embodiment, a kind of sawing machine clamp described in the present invention comprises the rotating crossbeam 1 that is arranged on the top of workbench 5, and rotating crossbeam 1 comprises hinged end 11 and free end 12, and the hinged end 11 of rotating beam 1 The first fixing device 6 hinged with the rotating beam 1 is arranged below, and the second fixing device 4 that can fix the end is arranged below the free end 12 of the rotating beam 1, and the first fixing device 6 and the second fixing device 4 can be disassembled fixed on the workbench 5, and at least one pressing device is arranged on the rotating beam 1 along its length direction for automatically pressing the materials 7 placed on the workbench 5.

[0027] By setting the rotating beam 1, when the staff needs to check or clean the cutting material device, they only need to separate the free end of the rotating beam 1 from the first fixing device 6, and then rotate the...

Embodiment 2

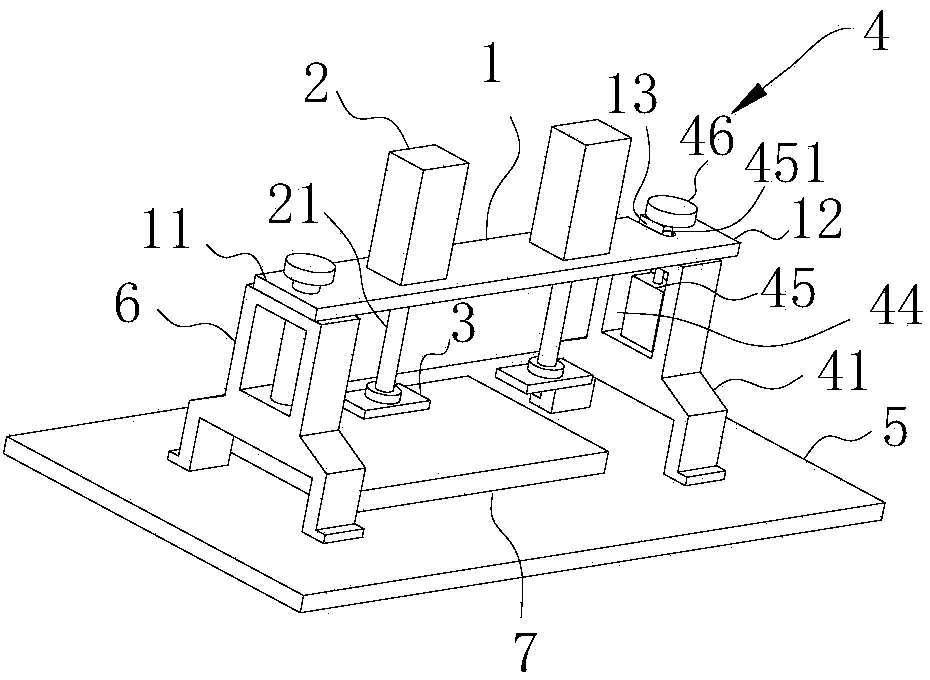

[0038] Such as image 3As shown, the difference between this embodiment and Embodiment 1 is only that the fixing member is a power compression mechanism, and the power compression mechanism includes a power device 45 and a pressing block 46, and the power device 45 is fixed in the cavity 44 near the workbench 5. On the side, the briquetting block 46 is arranged on the side of the fixed block 41 away from the workbench 5, the power unit 45 has an output shaft 451, and the end of the output shaft 451 passes through the fixed block 41 and is connected with the briquetting block 46 for driving the briquetting block 46 Press the rotating beam 1, and the rotating beam 1 is provided with a clamping hole 13 for the output shaft 451 to pass through. The clamping hole 13 has an opening through which the output shaft 451 can pass.

[0039] By setting the fixing member as a power pressing mechanism, after the free end 12 of the rotating beam 1 is clamped, the pressure block 46 can be comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com