Patents

Literature

173results about How to "Reduce work accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

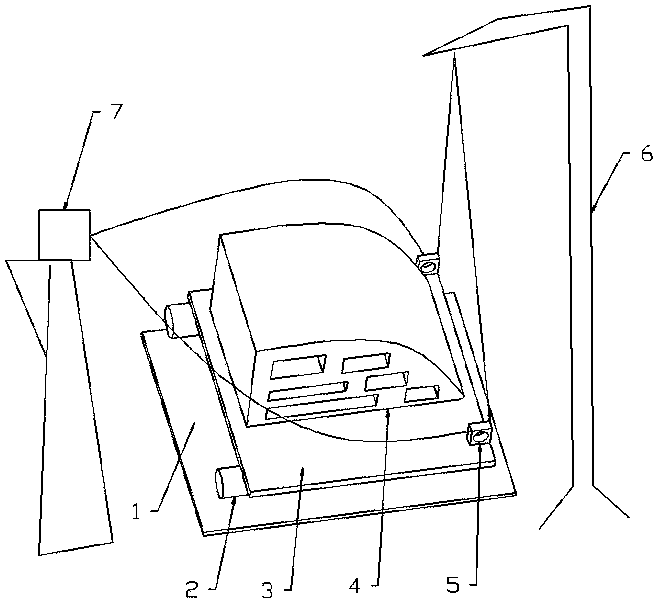

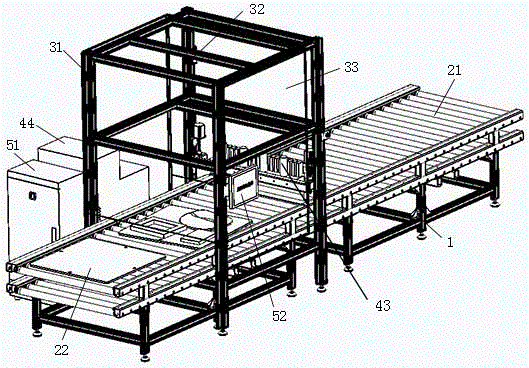

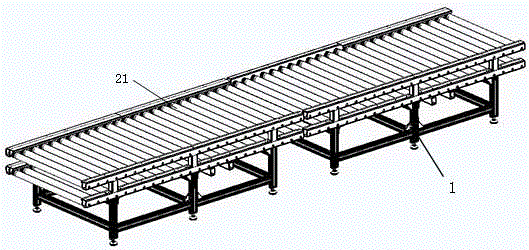

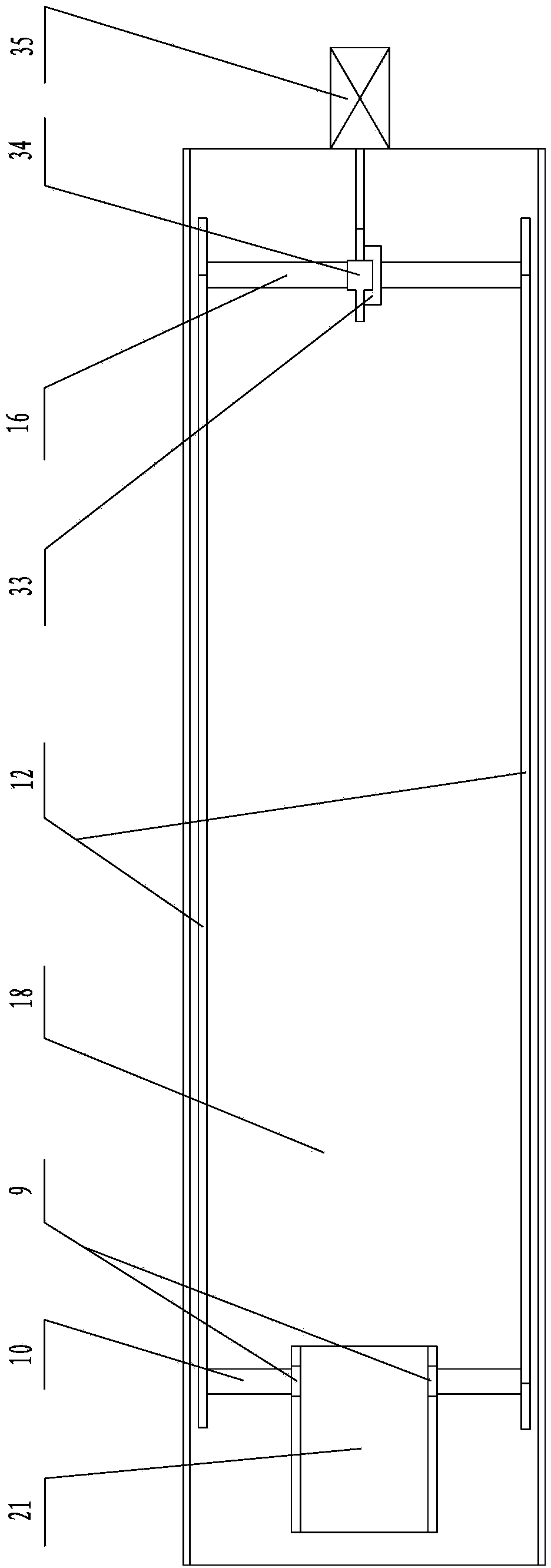

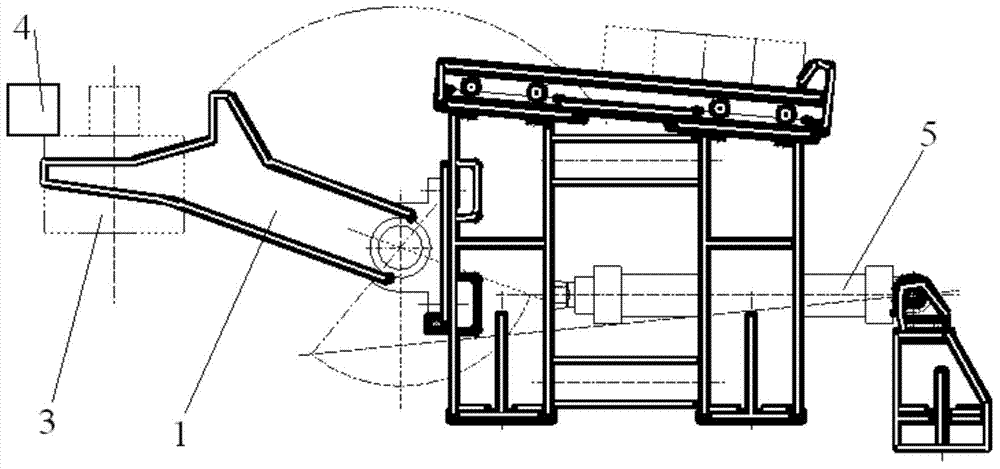

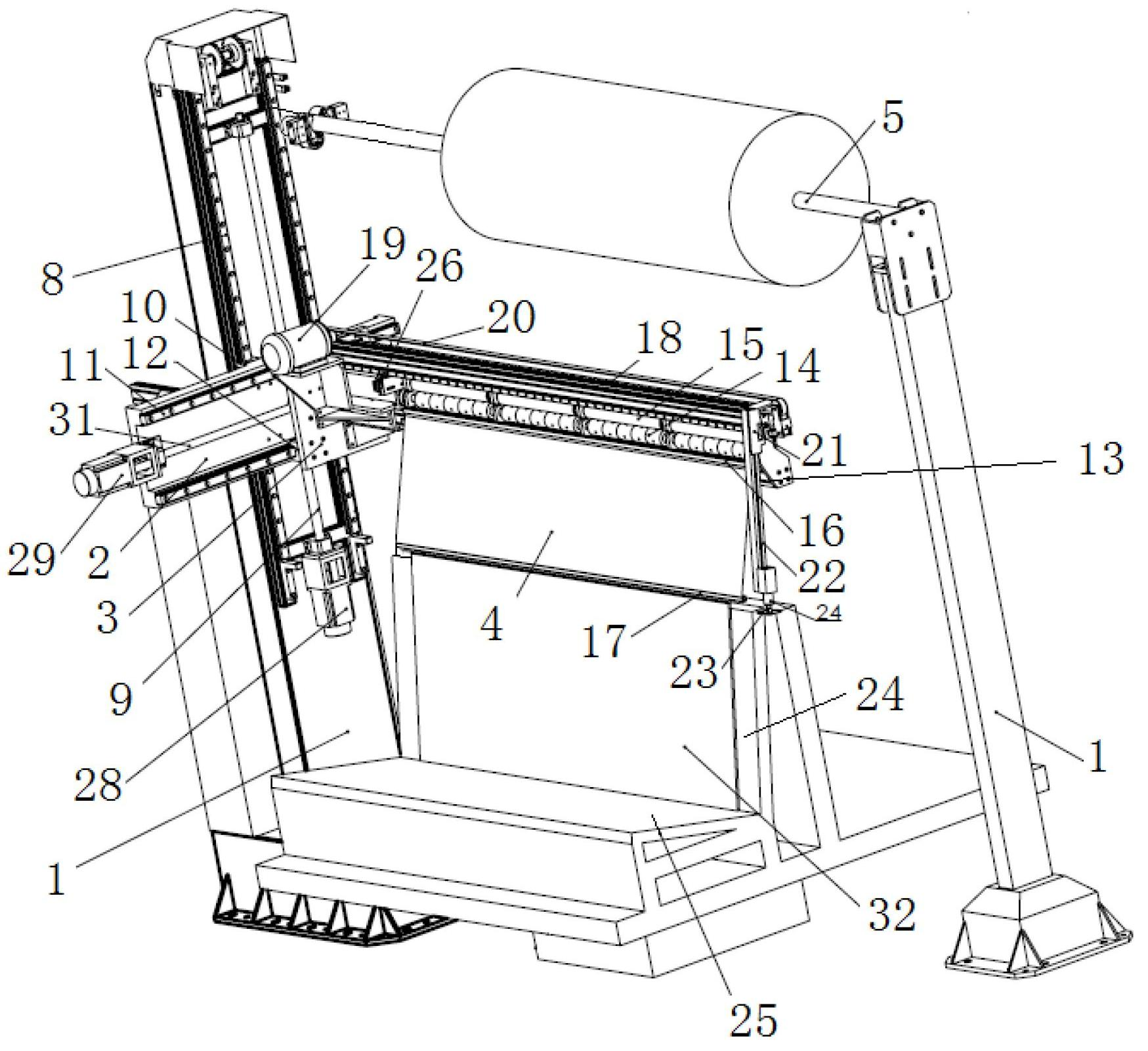

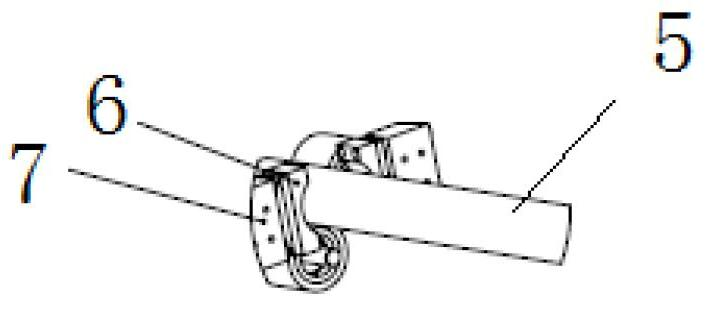

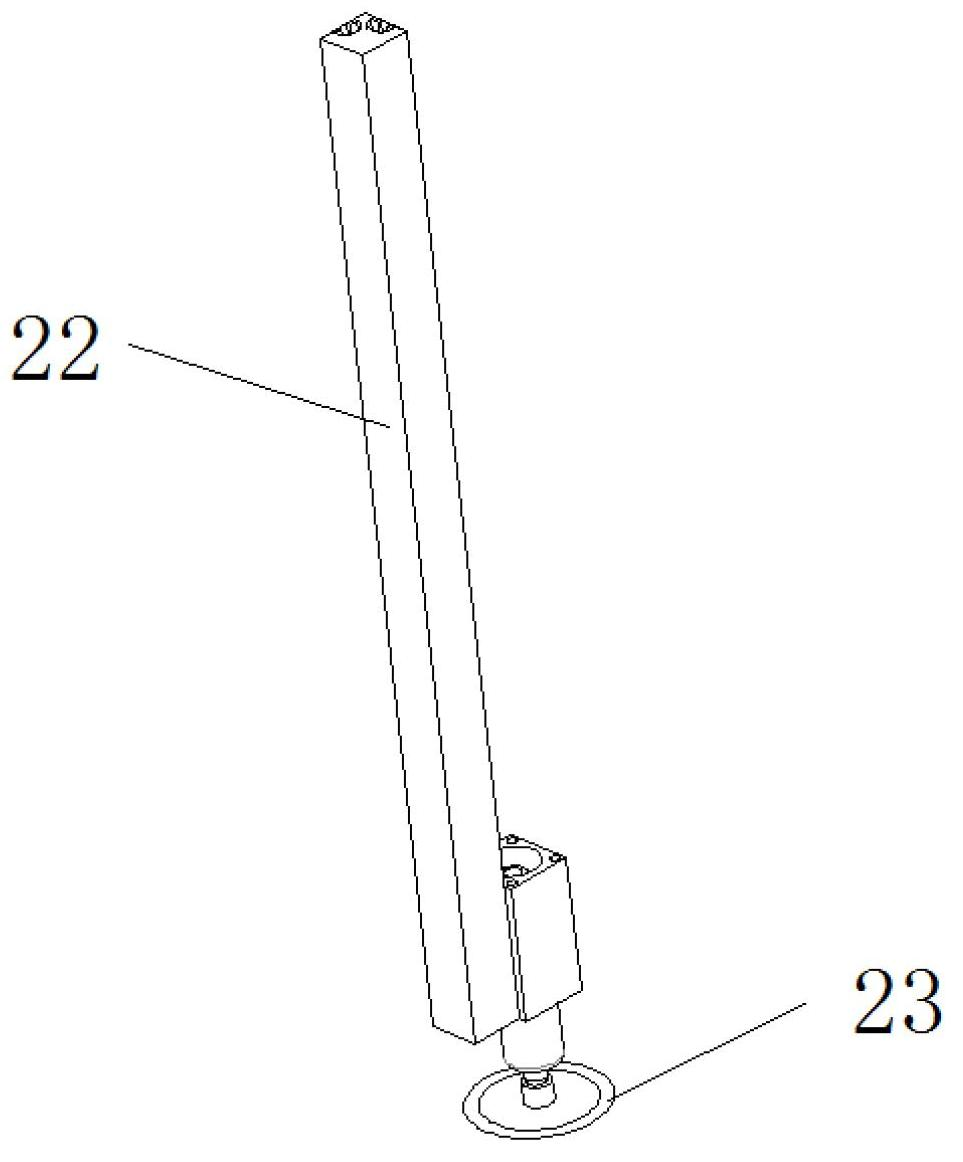

Architectural glass encasement device

ActiveCN105668235AReduce breakage rateEfficient handlingConveyorsCharge manipulationArchitectural glassProduction line

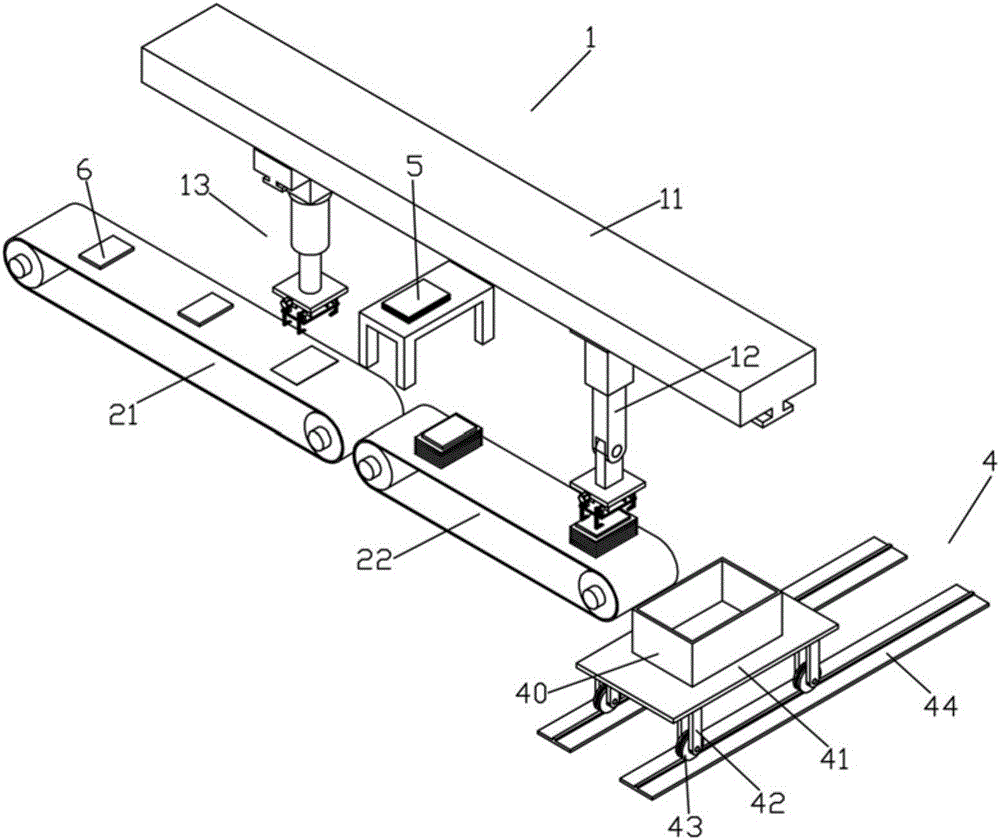

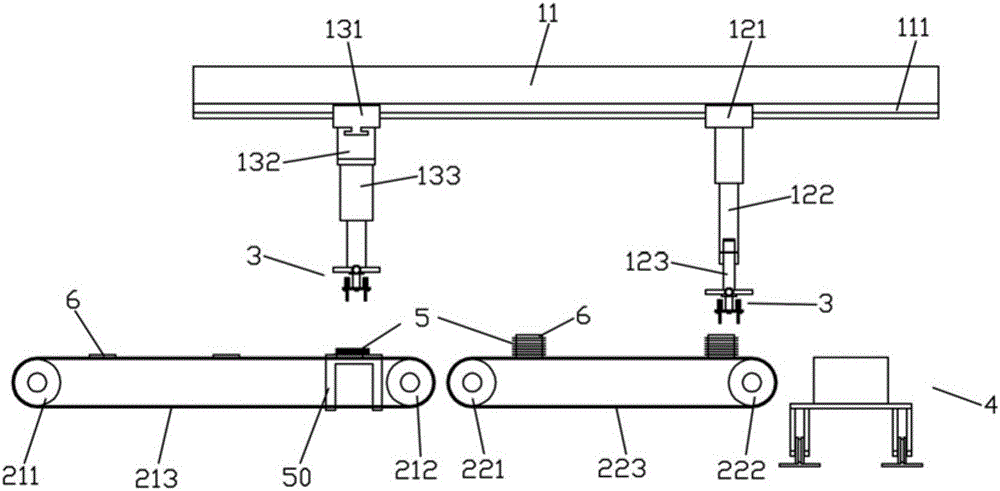

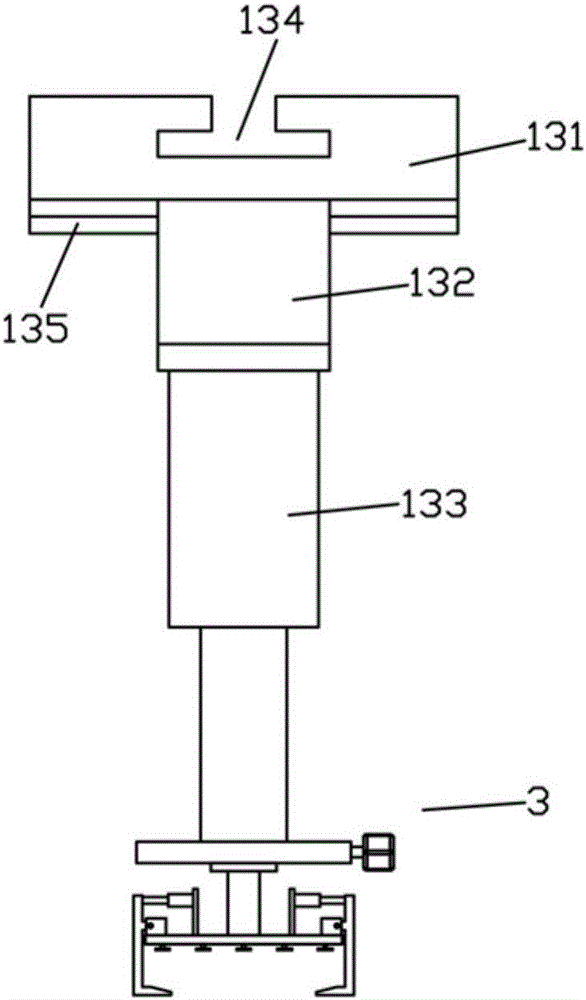

The invention discloses an architectural glass encasement device. The architectural glass encasement device comprises a stacking and packaging unit, a conveying unit, a finished product conveying unit, a protective layer supplying unit and a control unit, wherein the control unit is electrically connected to the stacking and packaging unit, the conveying unit and the finished product conveying unit and guarantees that each unit can complete corresponding operation on architectural glass. The architectural glass is conveyed to the conveying unit through a production line, and the stacking and packaging unit carries out stacking before encasing and encasing after stacking. According to the encasement device, carrying, packaging-protecting and stacking-encasing of the glass can be carried out efficiently and quickly, workers are prevented from working for a long time, the labor force is liberated greatly, the production efficiency is improved, the production cost is lowered, the breakage rate of the architectural glass is lowered, and the work accidents of the workers are greatly reduced.

Owner:YANGZHOU STRVALUE INFORMATION TECH CO LTD

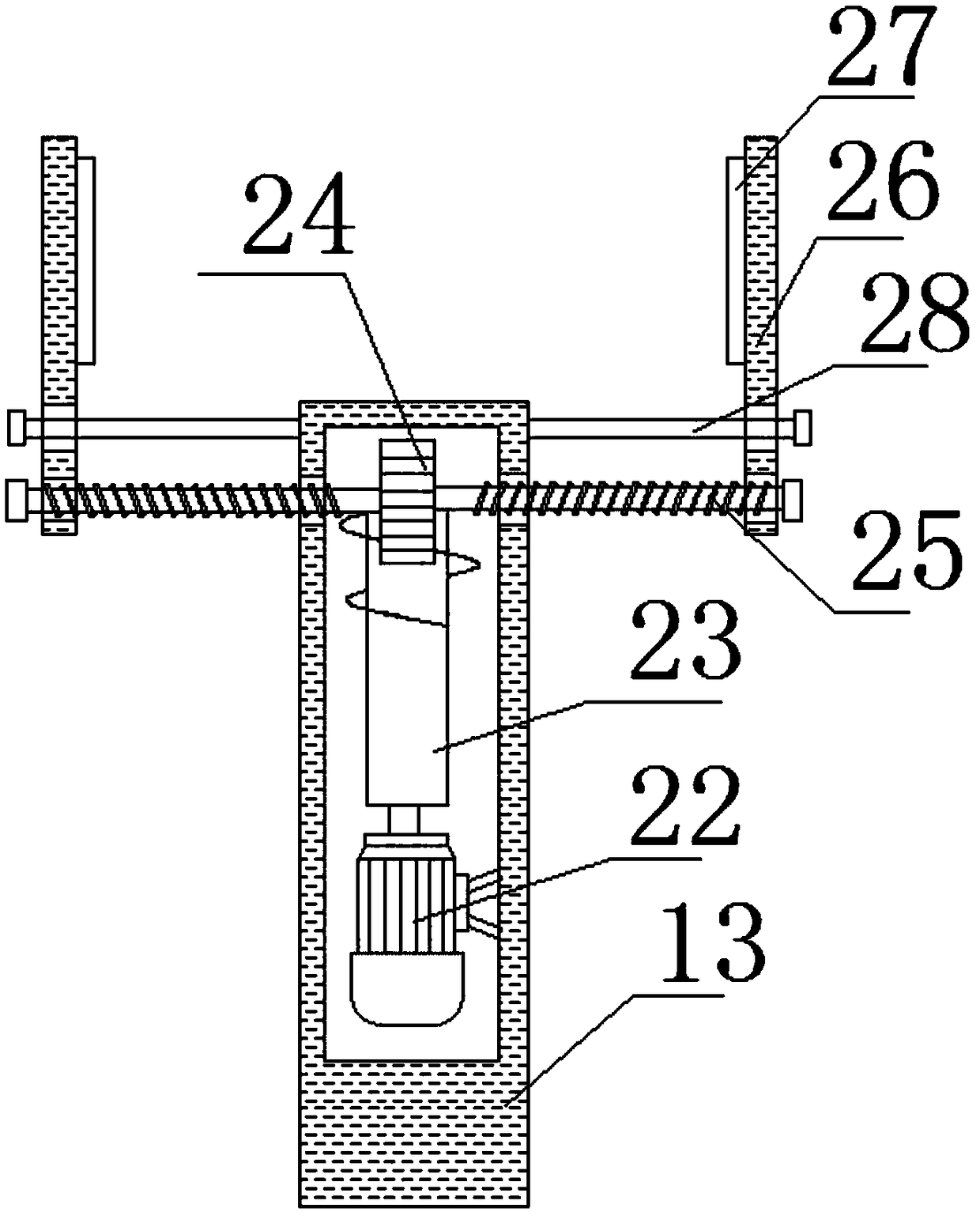

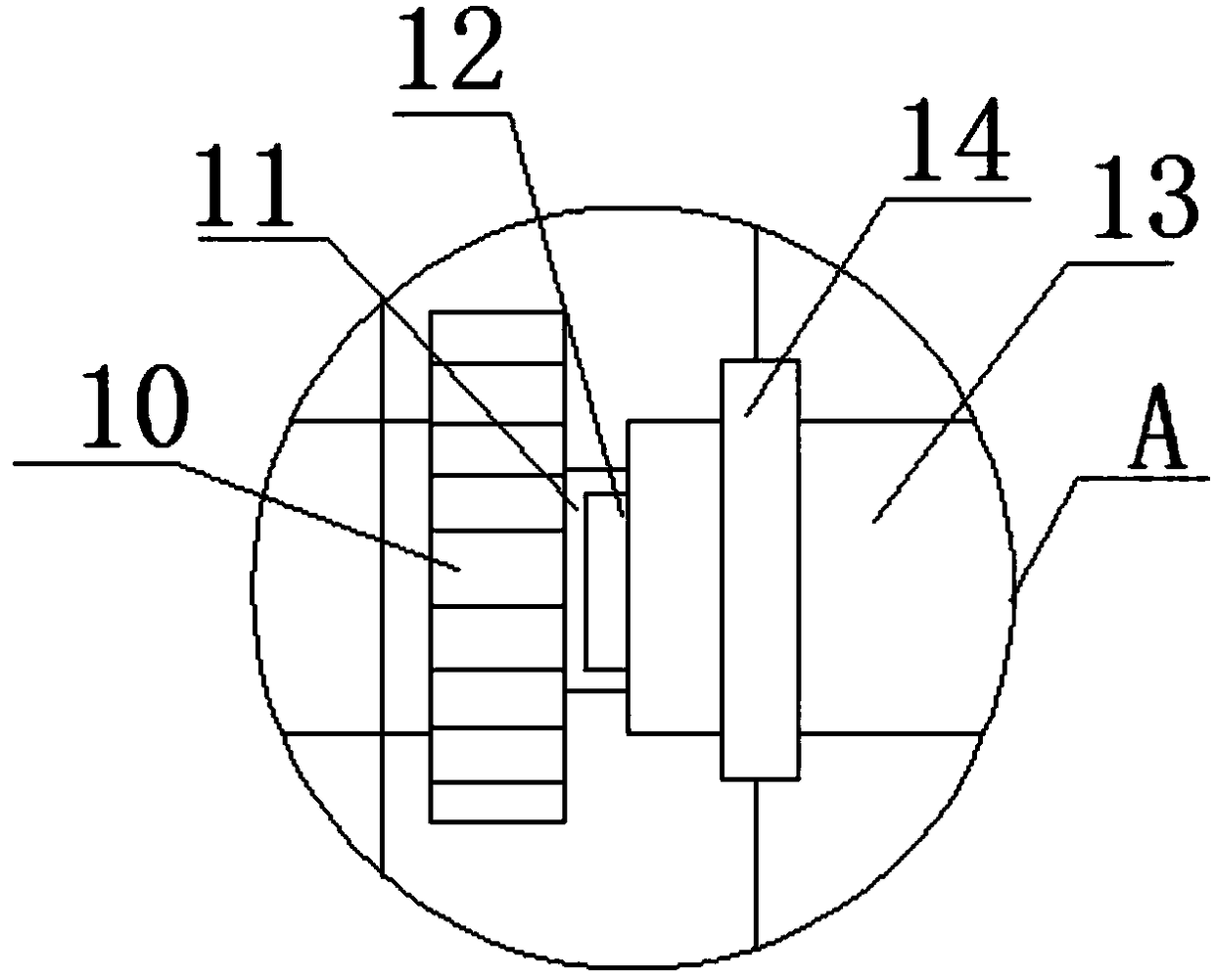

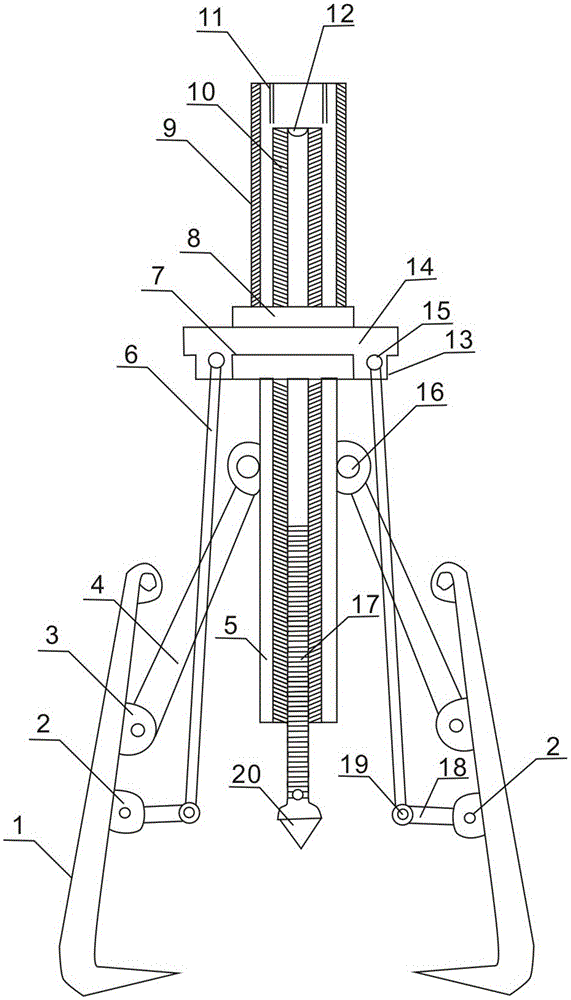

Turnable forging device for production of environment-friendly materials

InactiveCN108213309AReduce work accidentsReduce manual laborForging/hammering/pressing machinesMotor driveEngineering

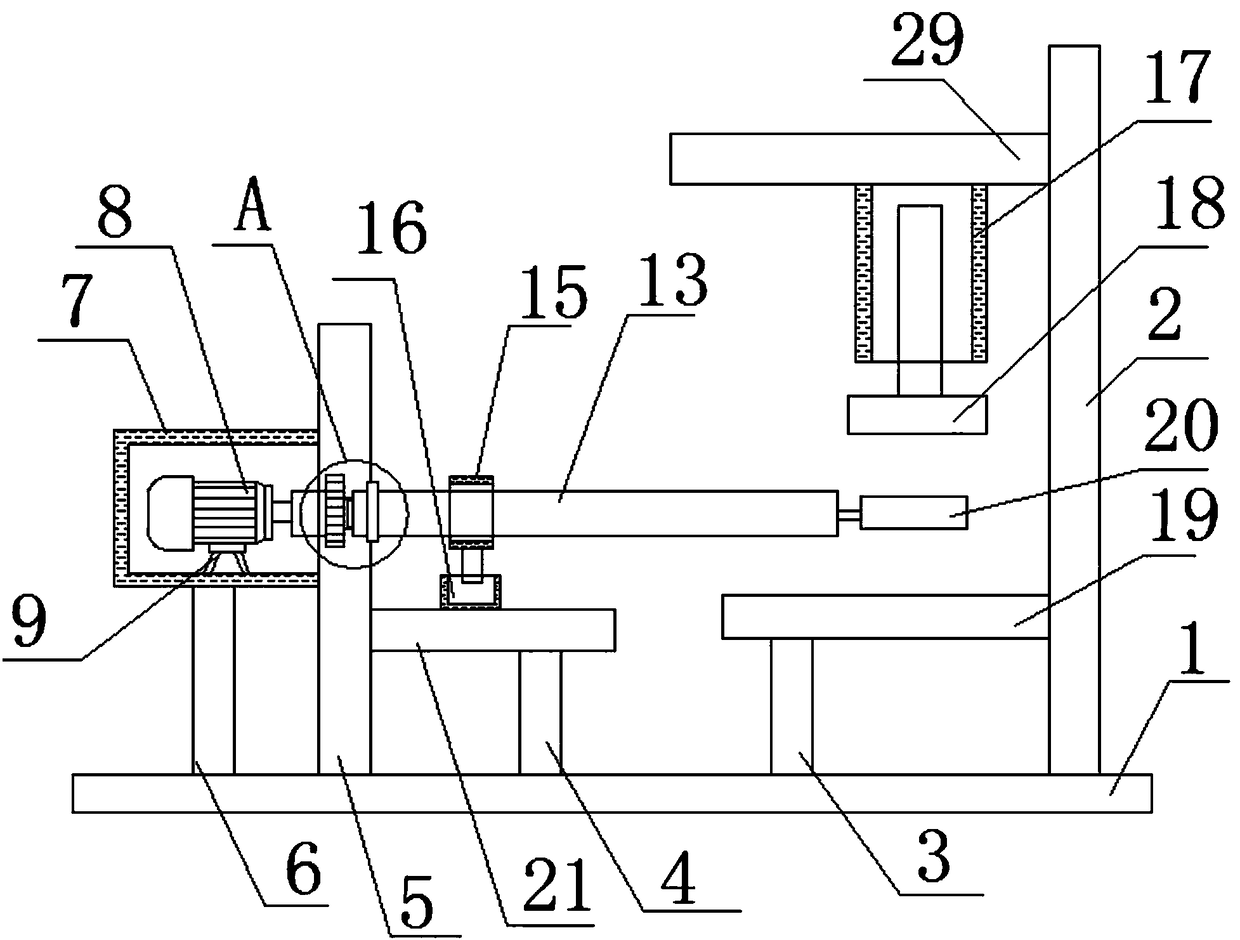

The invention discloses a turnable forging device for production of environment-friendly materials. The turnable forging device comprises a base. A first fixing plate, a first support plate, a secondsupport plate, a second fixing plate and a third support plate are connected to the upper end face of the base sequentially. A mounting box is fixedly connected to the other end of the third support plate. A first motor is arranged in the mounting box. A support frame is connected to the lower end face of the first motor fixedly. A rotating rod is fixedly connected with one end of a rotating shaftof the first motor. The turnable forging device has the advantages that a second motor drives a worm to rotate, a clamping plate moves close to the middle on a screw rod until a workpiece is clamped,the clamping plate completely enters a clamping groove through movement of a first hydraulic elongator, the rotating rod is rotated by 180 degrees through rotation of the first motor to turn over theworkpiece, and the workpiece falls off through retraction of the first hydraulic elongator and reverse rotation of the second motor, so that the workpiece is turned over by 180 degrees mechanically,labor is reduced, working efficiency is improved, and accidents of workers are reduced.

Owner:合肥信比欣新材料有限公司

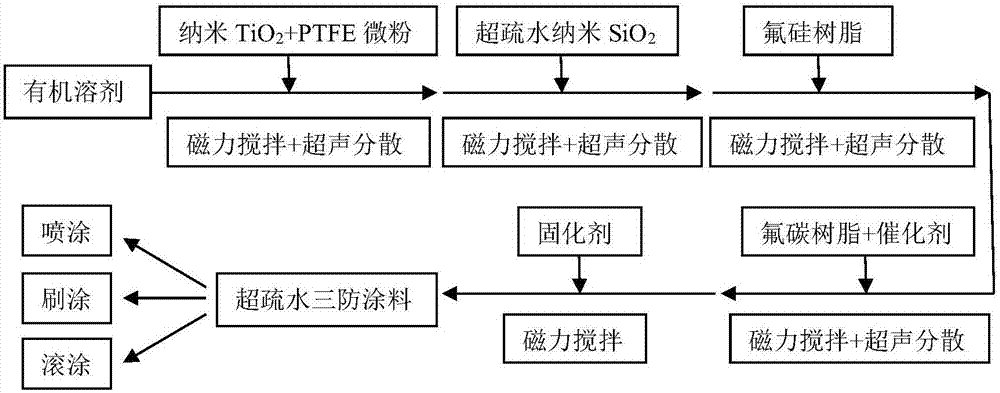

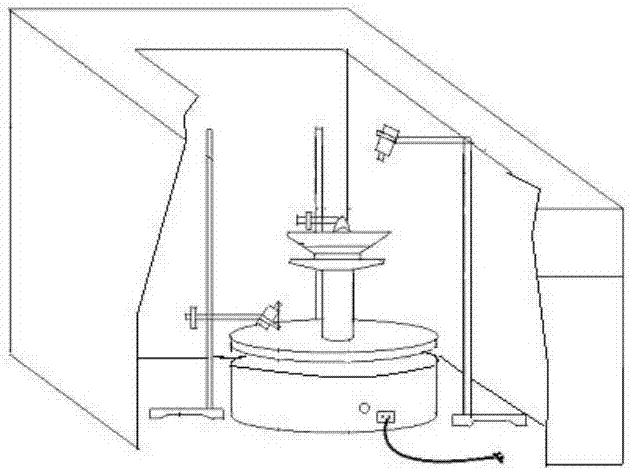

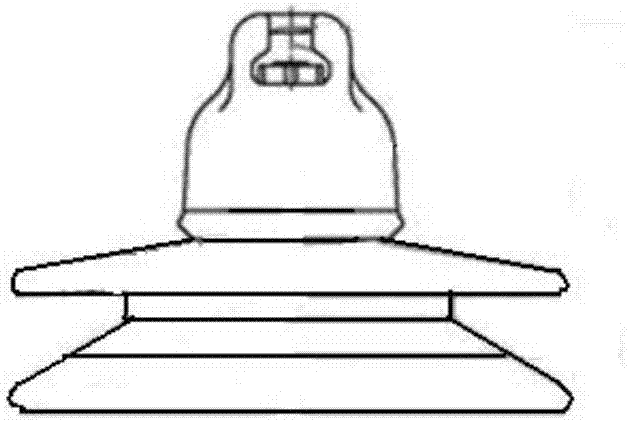

Super-hydrophobic conformal coating, and preparation method and application method thereof

InactiveCN107446424AImprove overall performanceGood weather resistanceAntifouling/underwater paintsPretreated surfacesChemistryNanometre

The invention discloses a super-hydrophobic conformal coating, and a preparation method and an application method thereof. The super-hydrophobic conformal coating is composed of, by mass, 5 to 40% of fluorocarbon resin, 10 to 30% of fluorosilicon resin, 20 to 60% of an organic solvent, 10 to 30% of silica, 1 to 10% of titanium dioxide, 1 to 10% of polytetrafluoroethylene, 0.1 to 0.5% of a catalyst, and 1 to 5% of a curing agent. According to the preparation method, the ingredients are subjected to stirring mixing and ultrasonic uniform dispersion in sequence at a certain ratio. According to the application method, the super-hydrophobic conformal coating is subjected to direct spraying or brush coating onto the surfaces of insulators and outdoor electric power facilities; the thickness of obtained coating layers is controlled to be 0.1 to 0.5mm preferably; and 20 to 60min of normal temperature curing is needed. The preparation method is simple; the cost is low; the super-hydrophobic conformal coating is convenient to use, possesses extremely high hydrophobicity and weatherability, is capable of realizing self cleaning, is a nanometer composite hybrid normal-temperature cured fluorocarbon coating, is capable of realizing stain prevention, pollution flashover prevention, and corrosion prevention of insulators and outdoor electric power facilities effectively, and is promising in application prospect.

Owner:昆明理工大电力工程技术有限公司

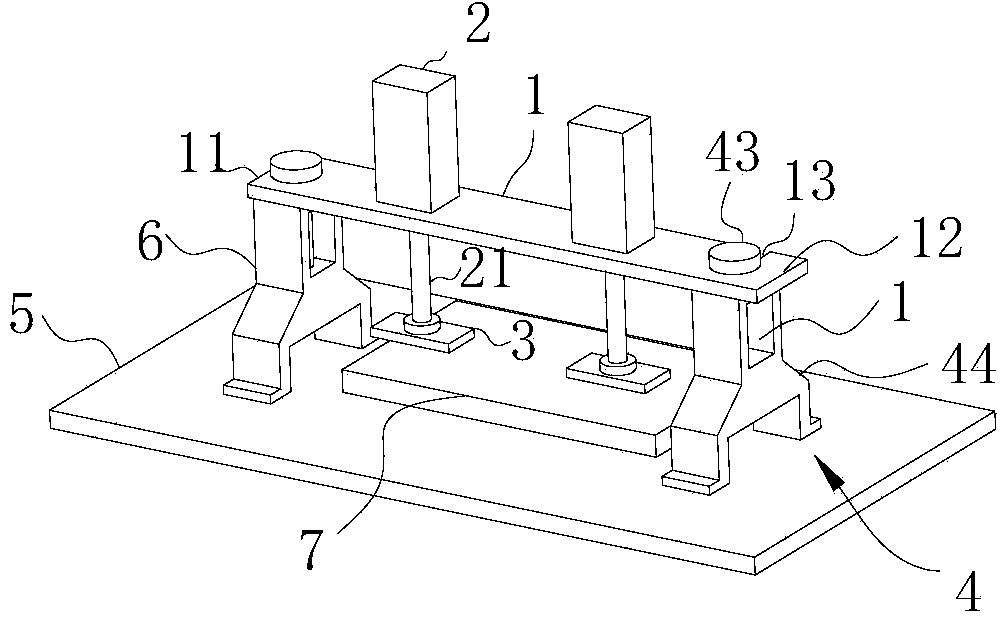

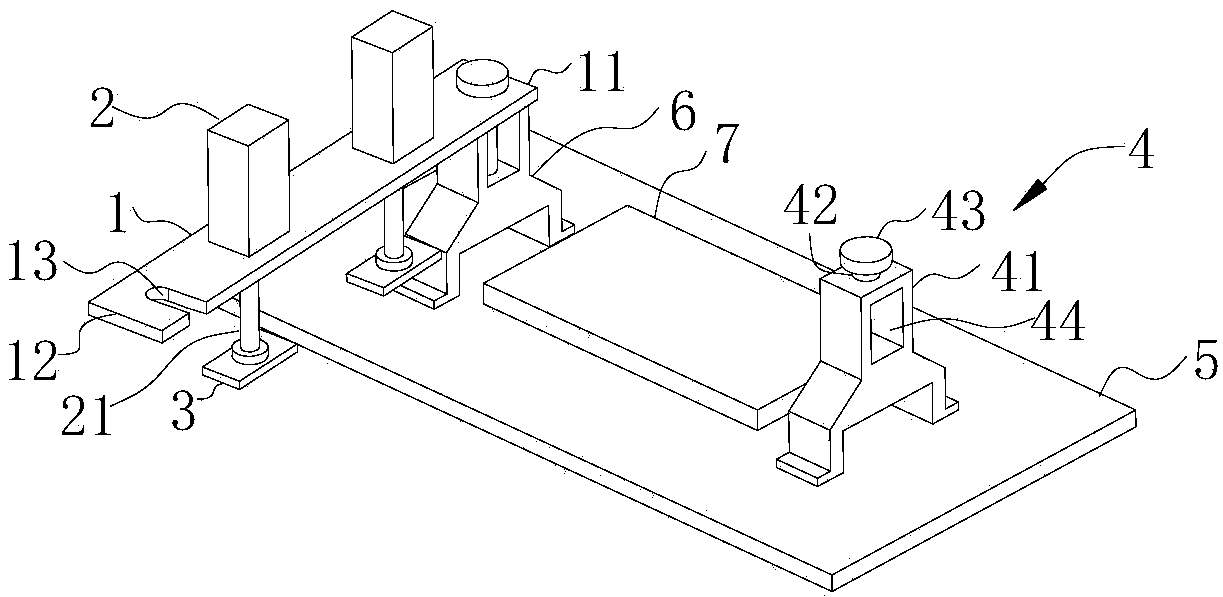

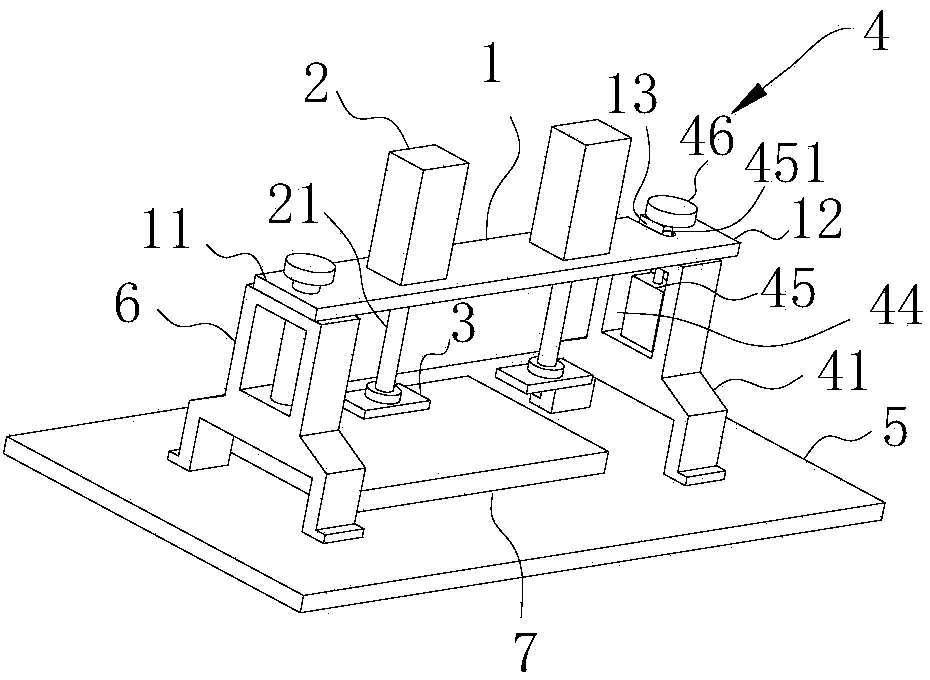

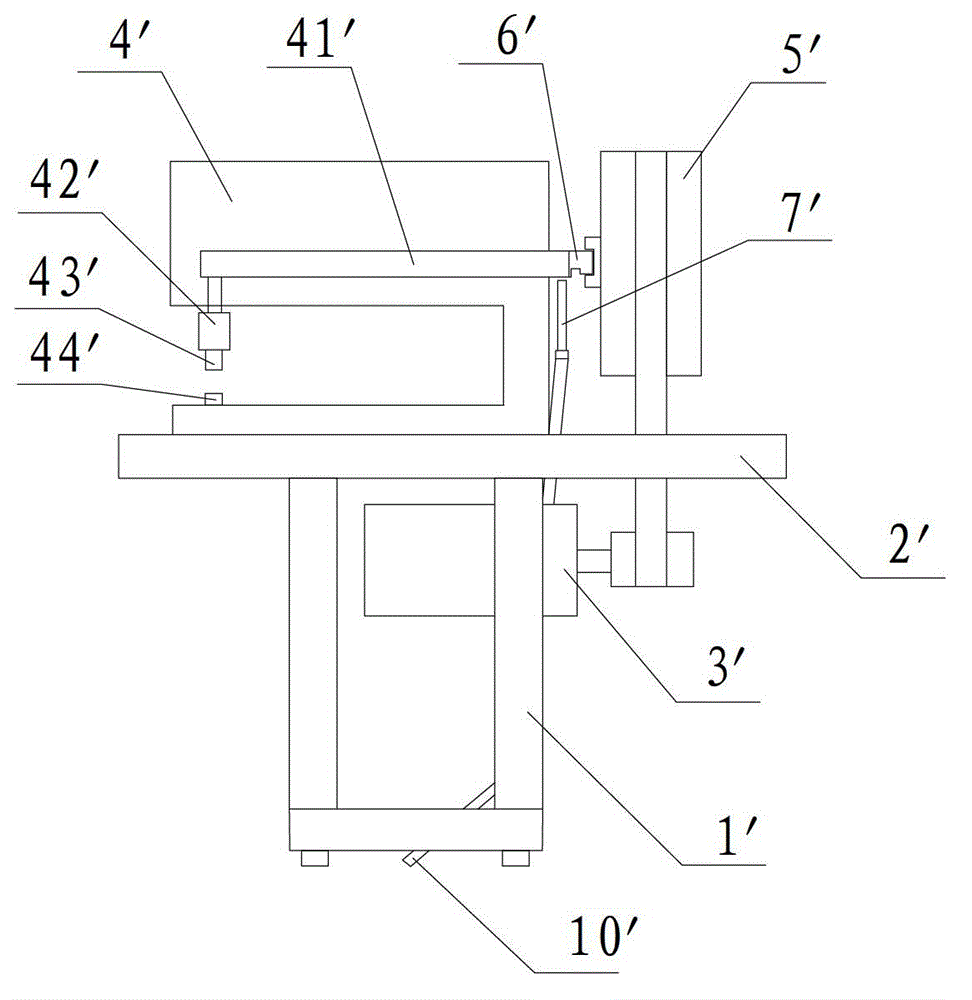

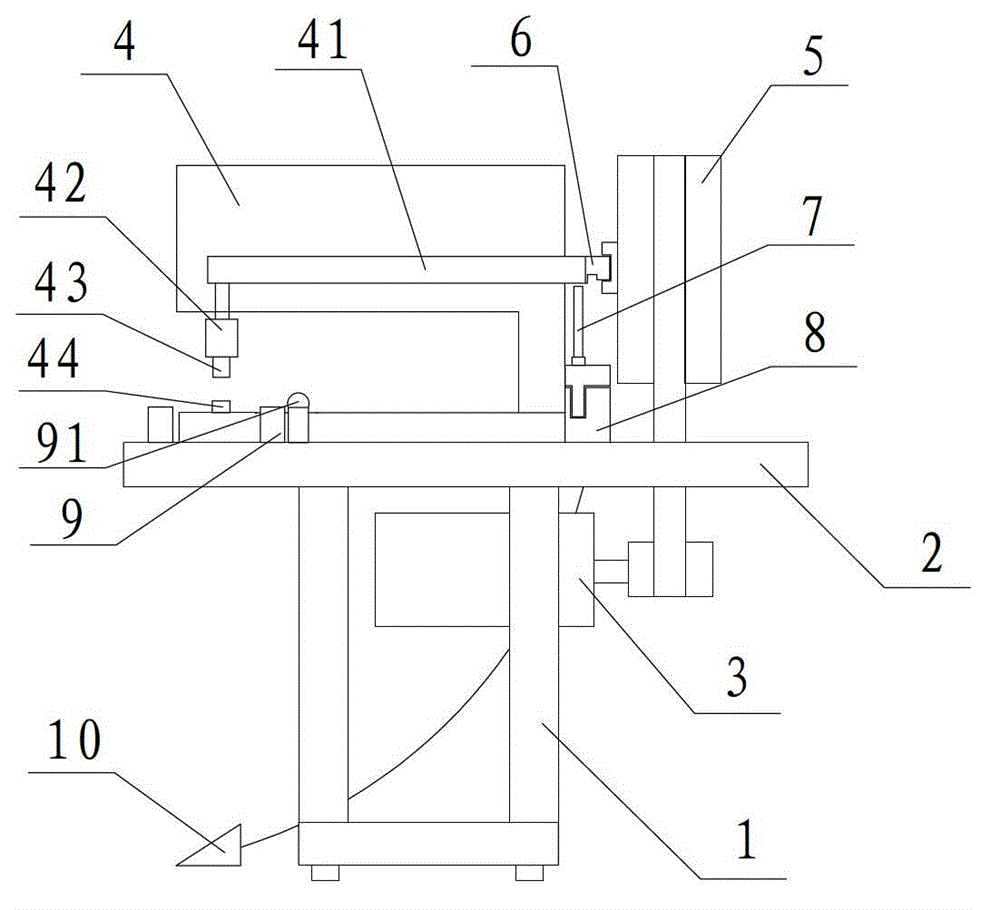

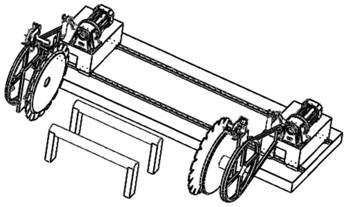

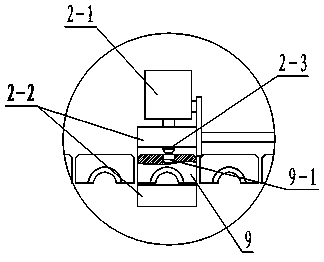

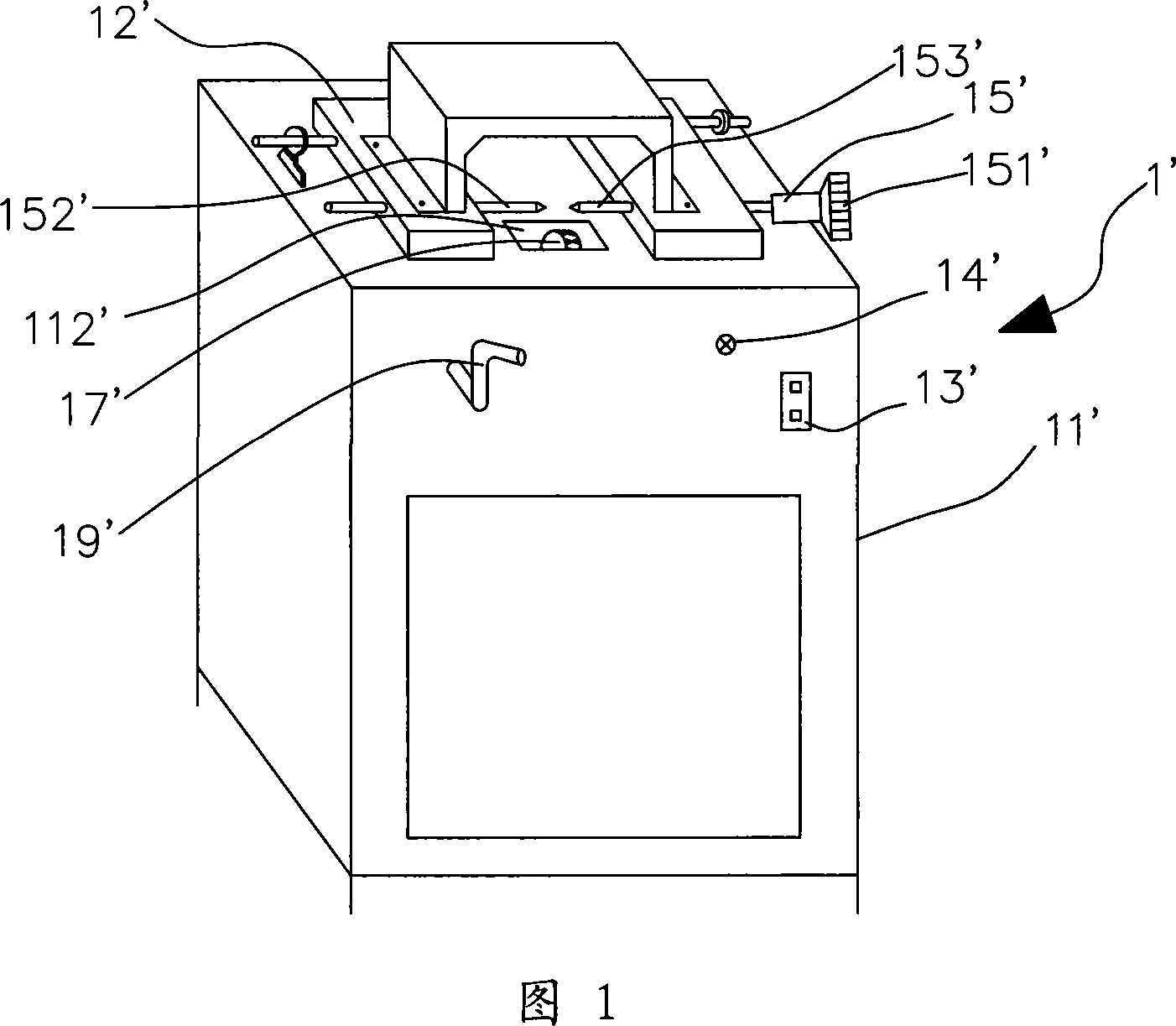

Sawing machine clamp

ActiveCN103862311AEnsure life safetyEasy to carryWork clamping meansPositioning apparatusIndustrial AccidentEngineering

The invention discloses a sawing machine clamp. The sawing machine clamp comprises a rotating cross beam arranged above a worktable, wherein the rotating cross beam comprises a hinging end and a free end, a first fixing device which is hinged to the rotating cross beam is arranged under the hinging end of the rotating cross beam, a second fixing device capable of fixing the free end is arranged under the free end of the rotating cross beam, both the first fixing device and the second fixing device can be detachably fixed on the worktable, and the rotating cross beam is provided with at least one material-pressing device used for automatically pressing materials placed on the worktable in the length direction of the rotating cross beam. Through the arranged rotating cross beam, when a material cutting device needs to be checked, unimpeded check can be achieved by rotating the rotating cross beam, and further the rotating cross beam brings convenience to carrying of the materials. Besides, through the arranged material-pressing device, the sawing machine clamp can achieve material pressing without handwork, improve work efficiency, reduce industrial accidents and guarantee life safety of workers.

Owner:WANSHITAI METAL IND KUNSHAN

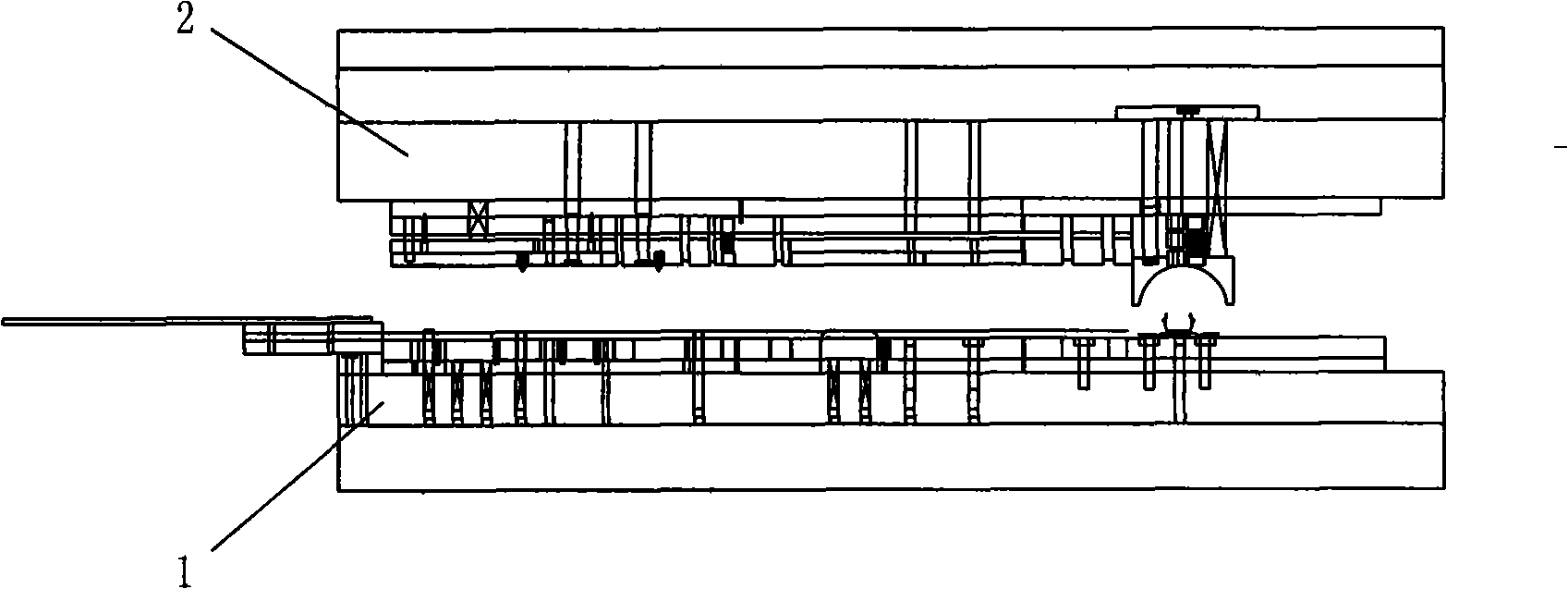

Rack lamp, panel type lamp stamping machine and stamping technique thereof

InactiveCN101357385ASimple equipment manufacturing and maintenanceImprove flexibility and adaptabilityShaping toolsMetal-working feeding devicesSizingMachine tool

The invention relates to a bracket lamp and a machine tool for processing and punching lamp panel and lamp and a punching processing technology thereof. The machine tool comprises a lower die bed and an upper die bed for installing a punching die. Dies are installed at the inner sides of the lower die bed and the upper die bed. The lower die bed and the upper die bed are installed on a driving mechanism. The lower die bed and the upper die bed are all an integral structure. The dies comprise a blank lance, a reinforcing rib striking die, a blanking guide die, a downwards baling die, a convex hull sizing die, a punched hole, the reinforcing rib striking die, a punching die, a Z-shaped bending die and a bending and molding and a cutting die which are arranged orderly, and each die is arranged transversely. The punching processing technology has the following steps: a) collecting material, b) feeding the material and c) punching transversely and continuously. The equipment is simple for manufacturing and maintaining, improves the flexibility and adaptability of the die structure and has high production efficiency and comparatively stable quality; in the practical production, the existing proposal can only produce 2 to 12 lamps per minute, while the machine tool can produce 48 lamps per minute, so the efficiency is increased by more than 2 times, and the processing cost is reduced by more than 2 times.

Owner:惠州雷士光电科技有限公司

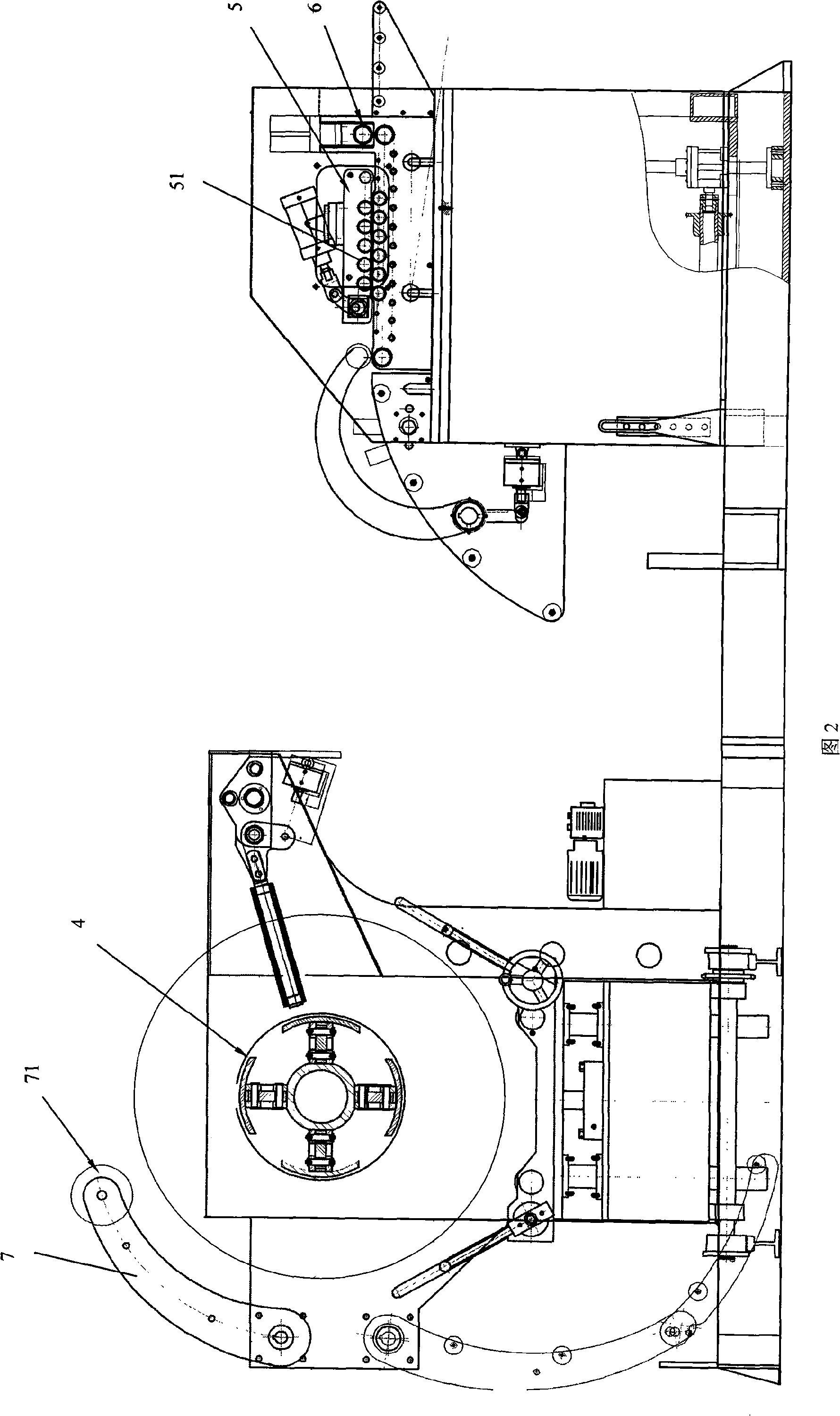

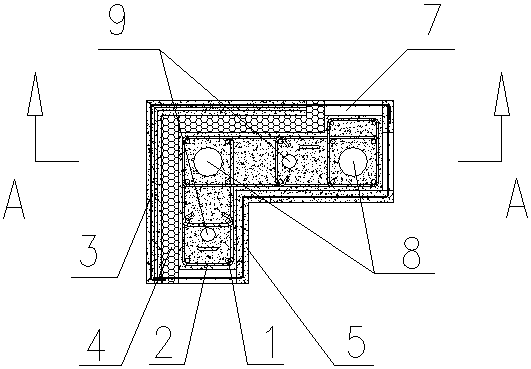

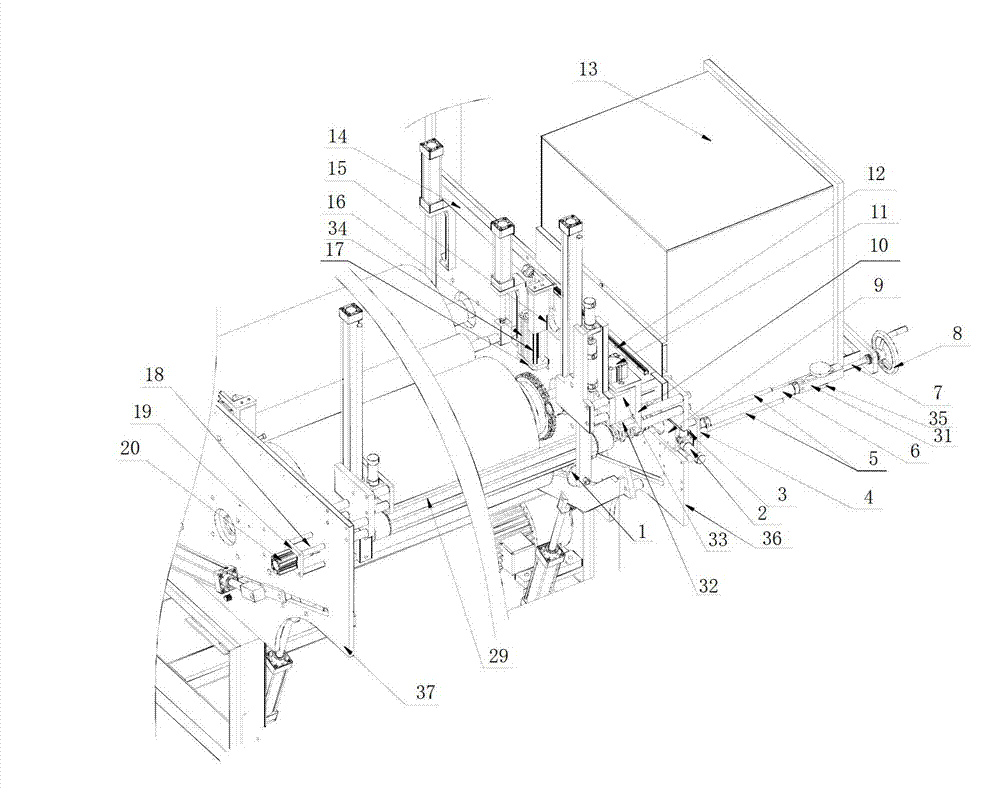

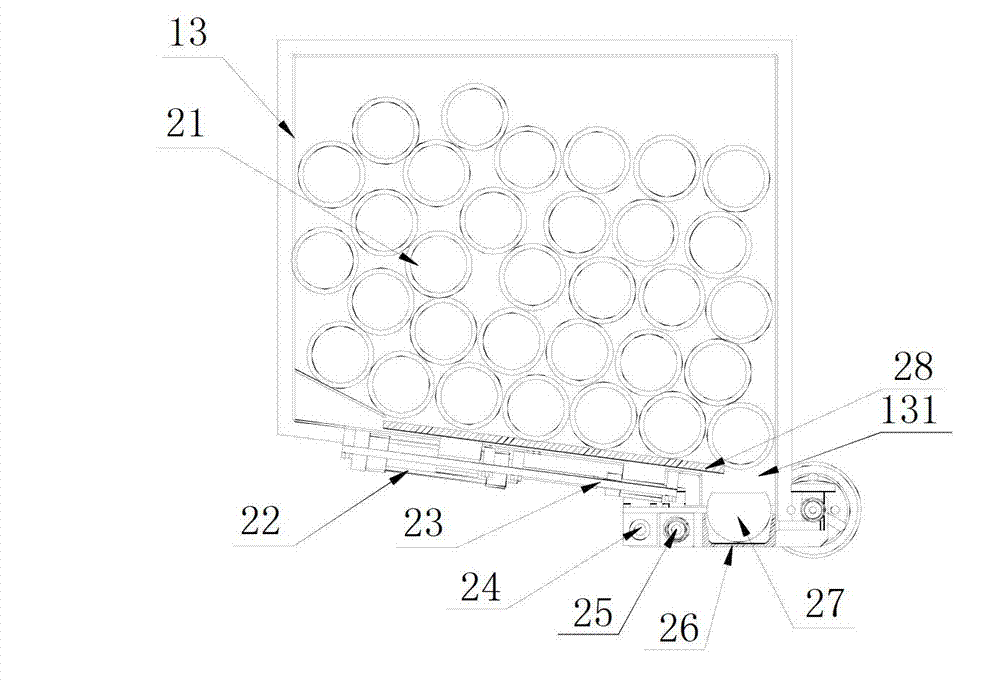

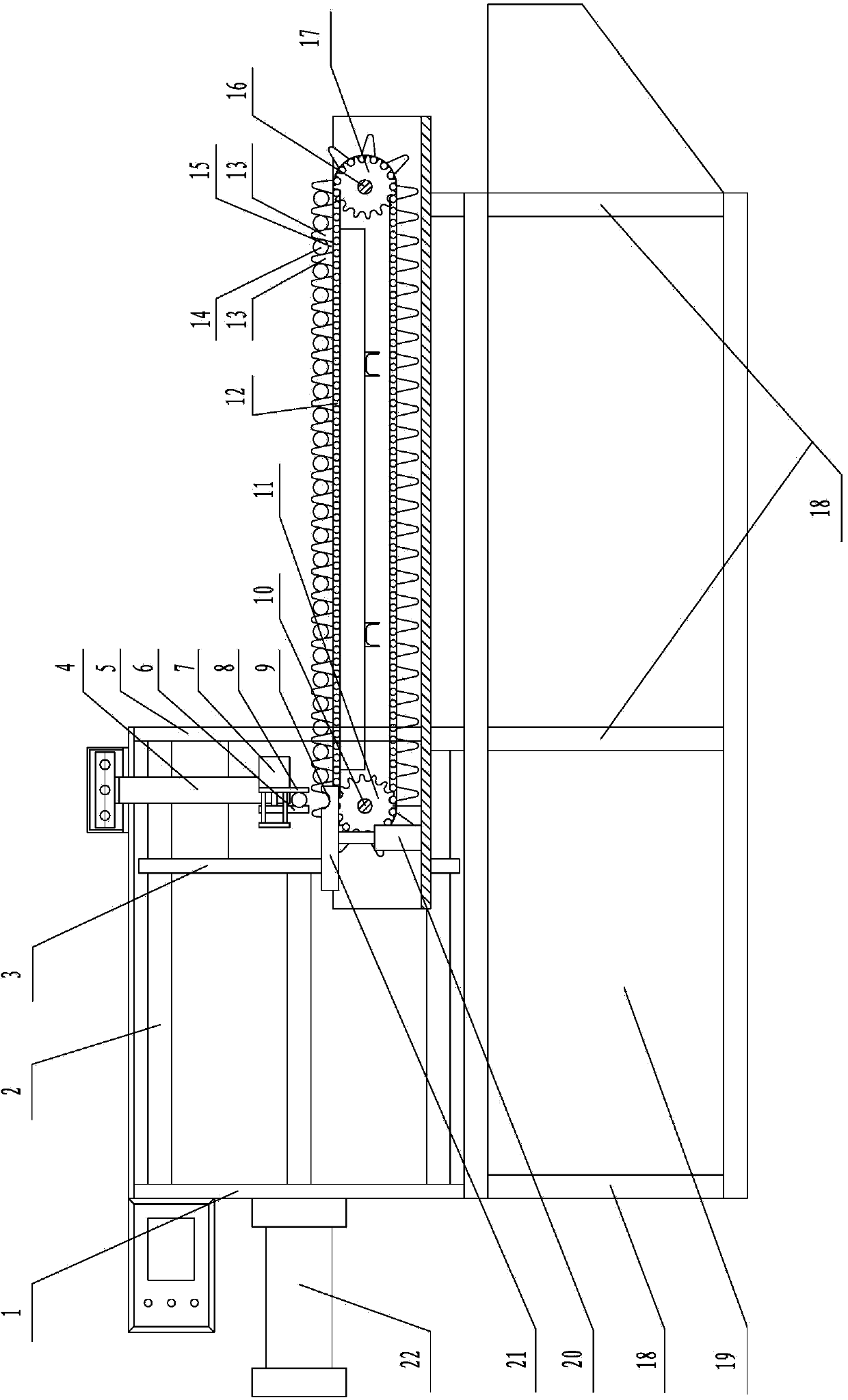

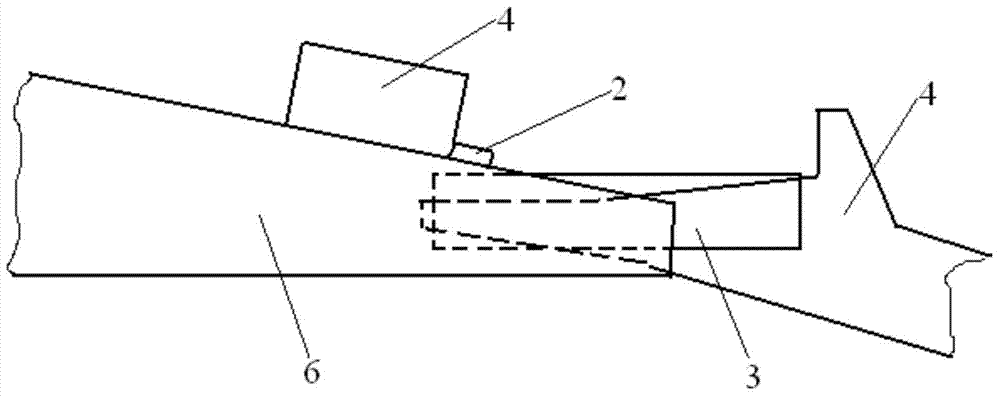

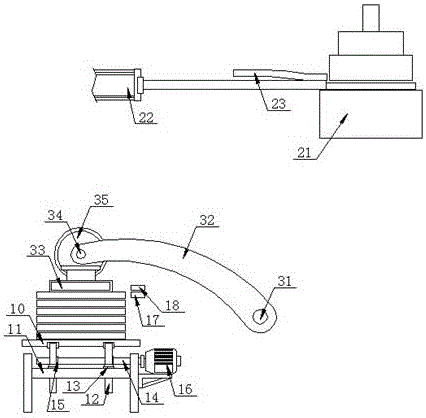

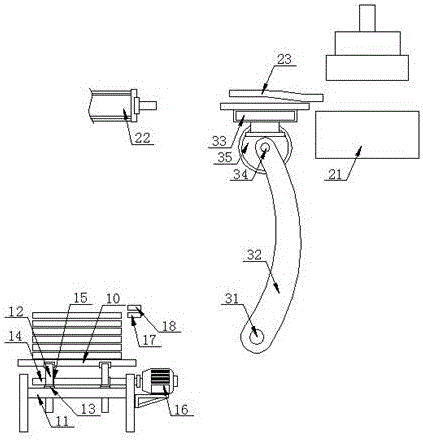

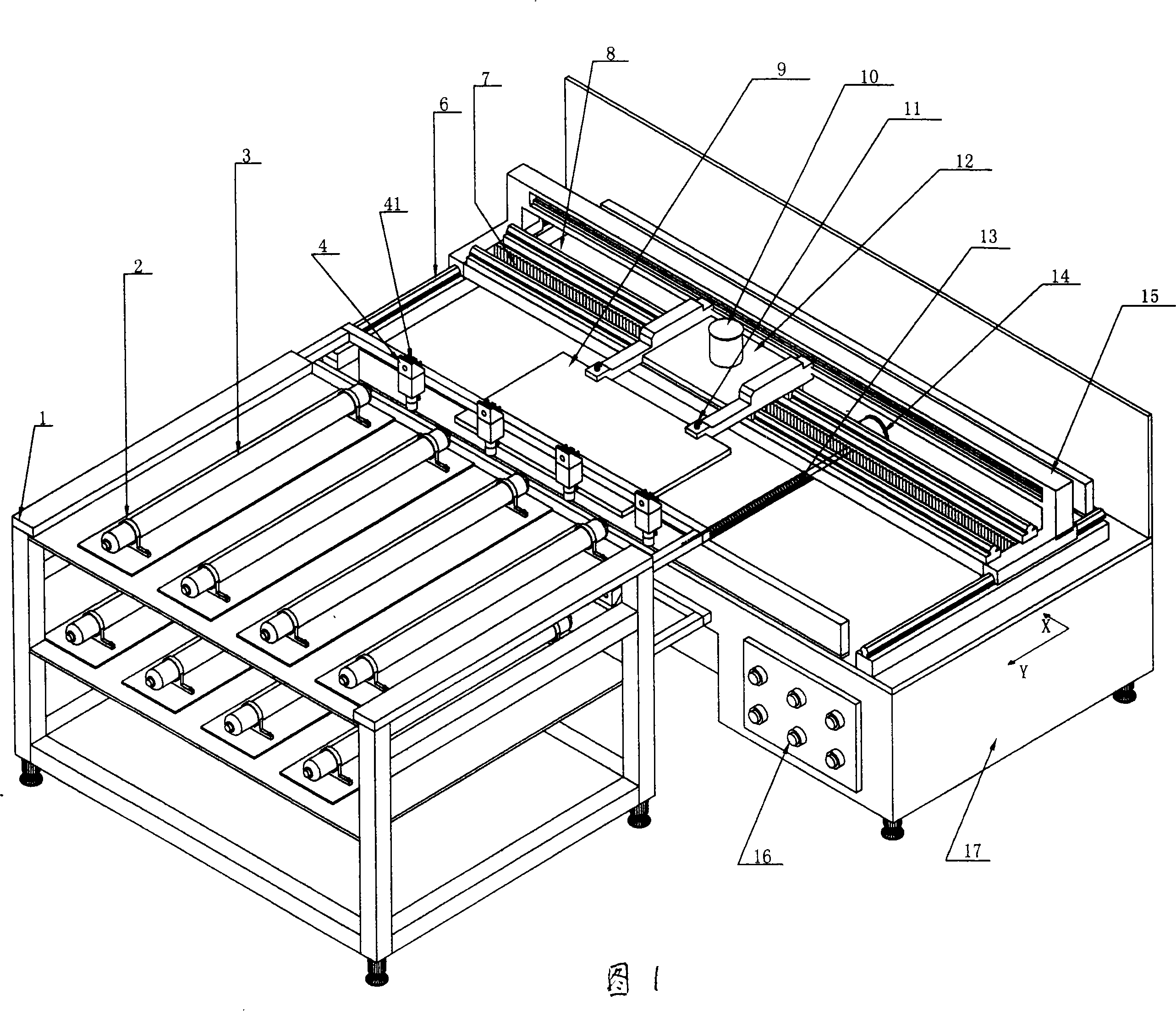

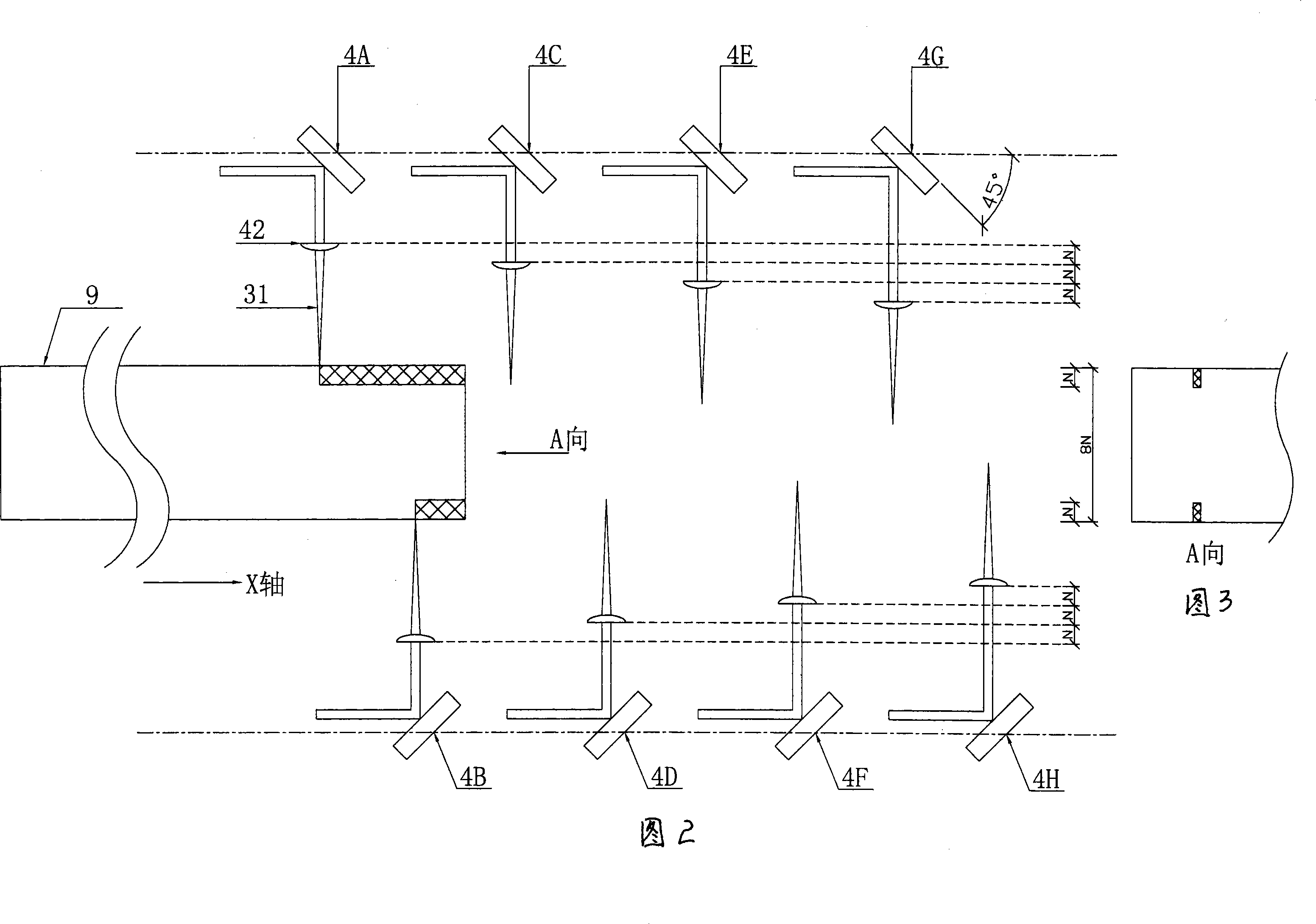

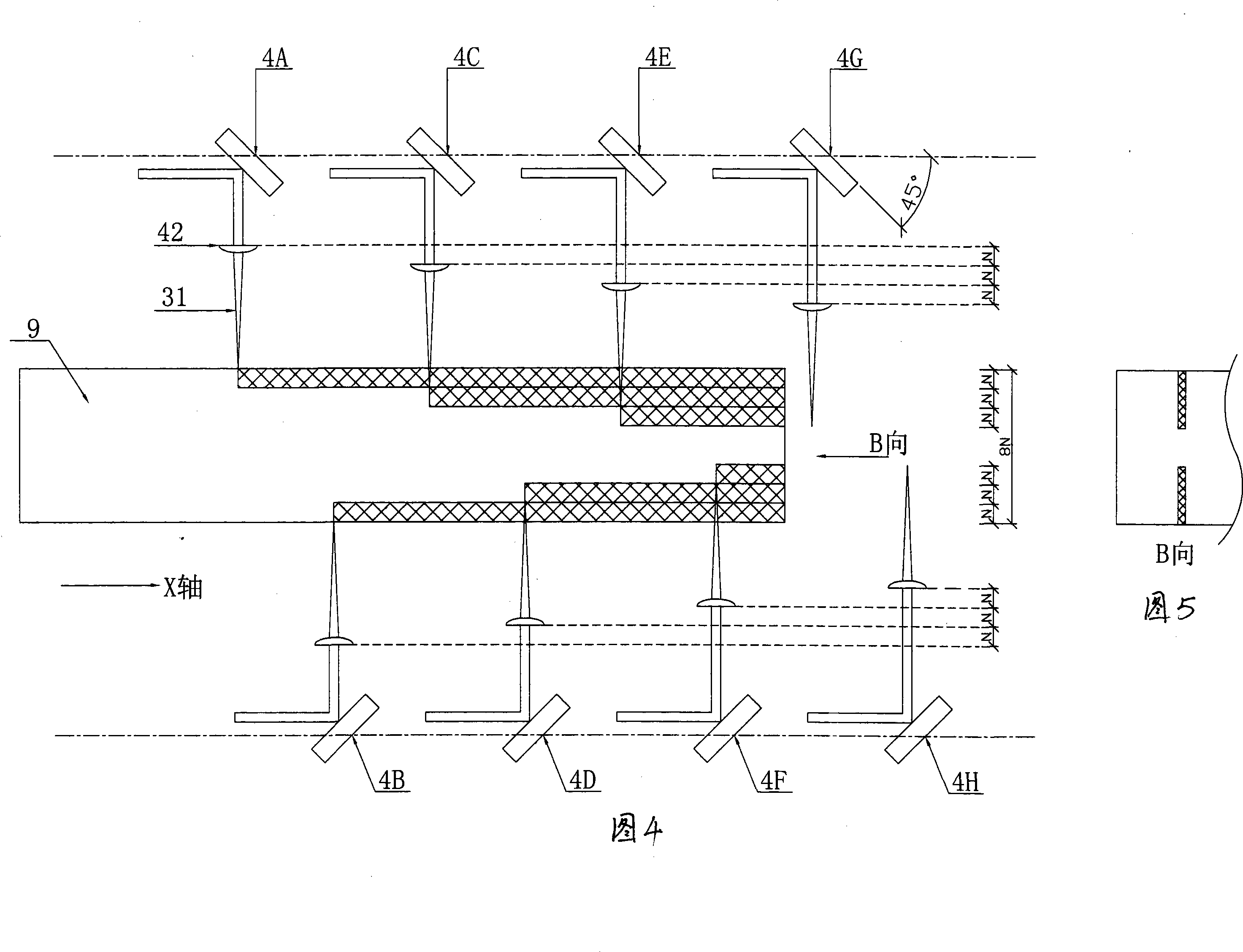

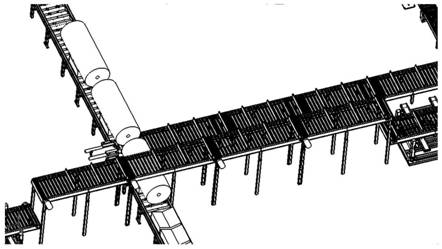

Automatic stacking paper-laying machine and paper laying method thereof

ActiveCN102862855AAdequate restGuaranteed aestheticsPile receiversArticle deliveryHigh volume manufacturingEngineering

The invention discloses an automatic stacking paper-laying machine which comprises a glass transiting mechanism, a glass overturn mechanism, a tray lifting mechanism, a glass tray, a paper cutting mechanism and a paper feeding mechanism. The glass transiting mechanism is arranged on one side of the glass overturn mechanism, and the glass tray is arranged on the other side of the glass overturn mechanism. The automatic stacking paper-laying machine with the structure has the advantages that paper can be automatically laid on glass; attractiveness of a whole stack of products can be guaranteed under the condition that the requirement on plate grabbing speed of a robot is met, so that a paper laying process is improved; labor is reduced, consistency and quality of the products are improved, the automatic stacking paper-laying machine is suitable for batch production, production cost is lowered, and production efficiency is improved; and the automatic stacking paper-laying machine is humanized, work intensity of staff is relieved, and industrial injury accidents can be reduced.

Owner:芜湖金三氏数控科技有限公司

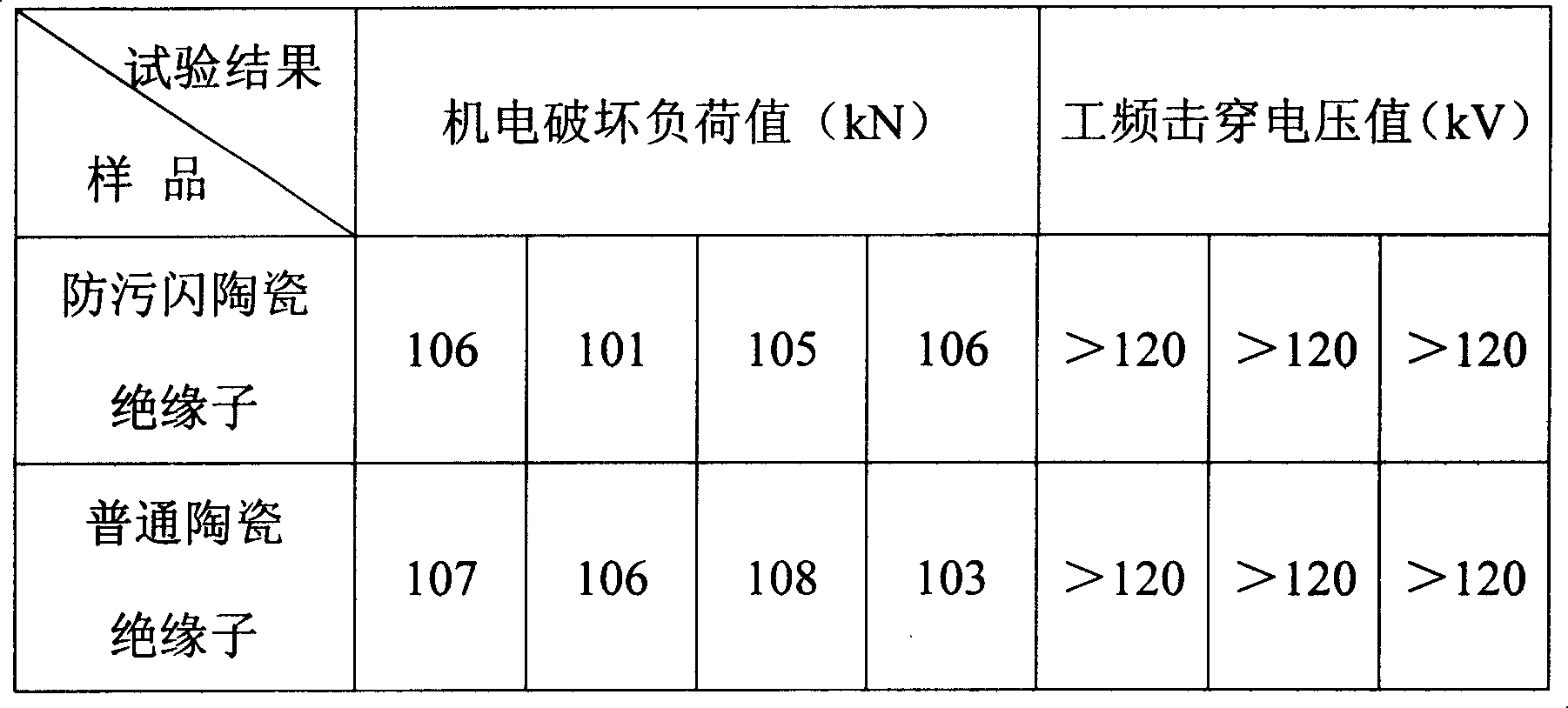

Method for manufacturing anti pollution flashover high tension ceramic and glass insulators

ActiveCN1686951AAnti-agingBest integrated anti-fouling flash functionQuartz/glass/vitreous enamelsHigh pressureSurfactant free

The present invention discloses a high voltage ceramic and glass insulator with the function of resisting pollution flashover and its preparation method. Said method includes the following processes: firstly, preparing titanium dioxide base sol, adding surfactant into the sol, then applying the titanium dioxide sol containing the above-mentioned surfactant or containing no surfactant on the surface of high-voltage ceramic and glass insulator, low-temperature heat treatment to make the titanium dioxide sol be solidified on the insulator surface so as to form a layer of nano inorganic film capable of raising pollution flashover resisting function of genral ceramic insulator.

Owner:FUZHOU UNIV +2

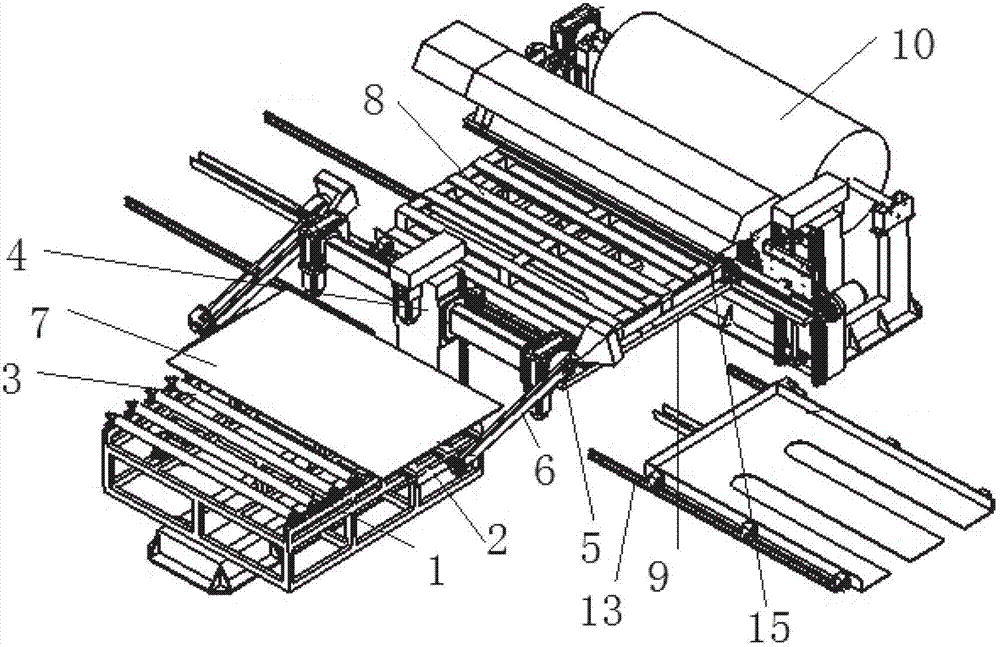

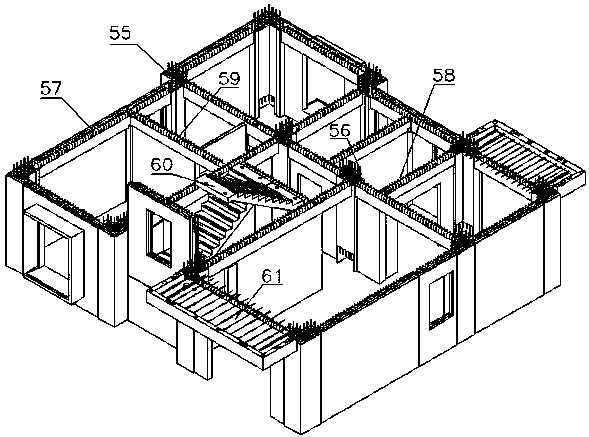

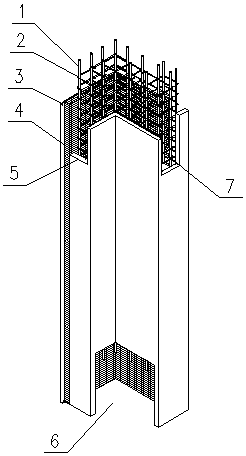

Cast-in-place superposed formwork integrated structure of prefabricated building and construction method

The invention relates to a cast-in-place superposed formwork integrated structure of a prefabricated building and a construction method and belongs to the field of building engineering. The structurecomprises shear wall members, superposed column members, superposed beam members, superimposed slab members, inner partition members, peripheral guard wall members, stair members and balcony members.The members are connected through sleeve grouting and then connected into a whole by grouting concrete from grouting holes, so that the cast-in-place superposed formwork integrated structure of the prefabricated building is formed. The integrated structure is used for constructing the prefabricated building; all nodes of the building have the same performance as cast-in-place nodes; and the prefabricated building has the same integrity as cast-in-place building and excellent shock resistance, water resistance and sound insulation performance.

Owner:江西万盟建筑科技有限公司

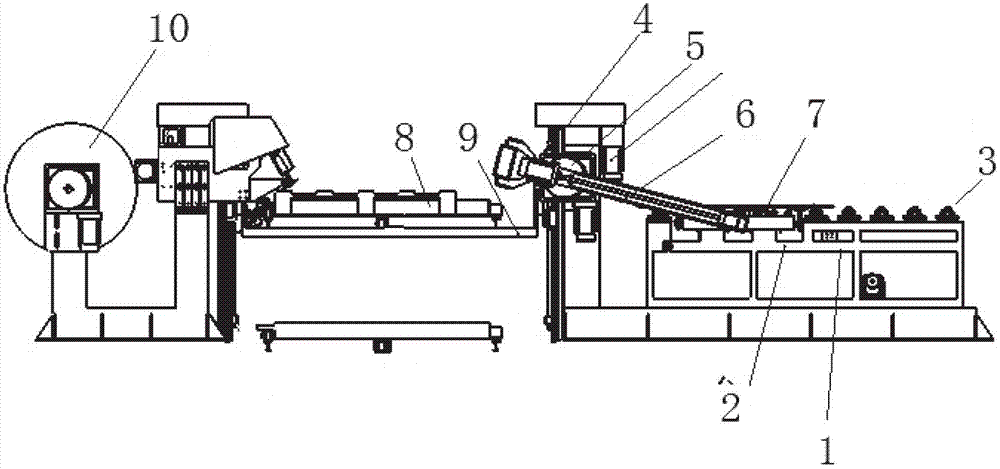

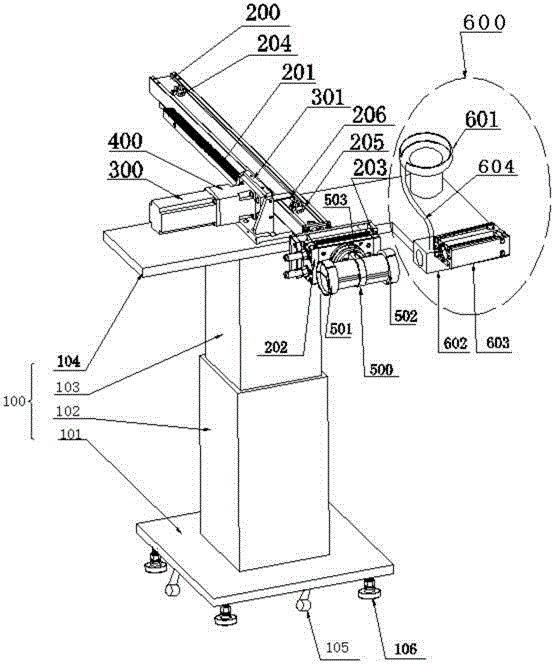

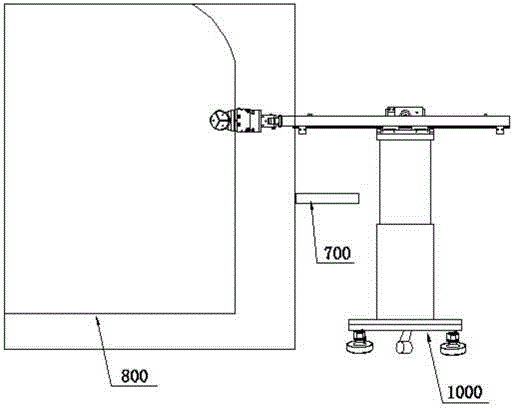

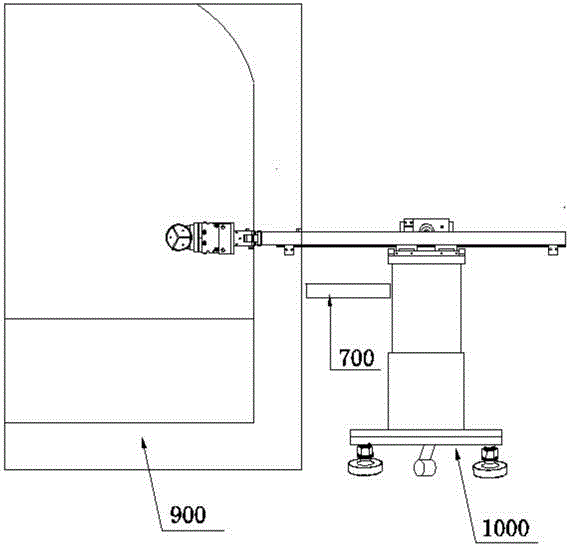

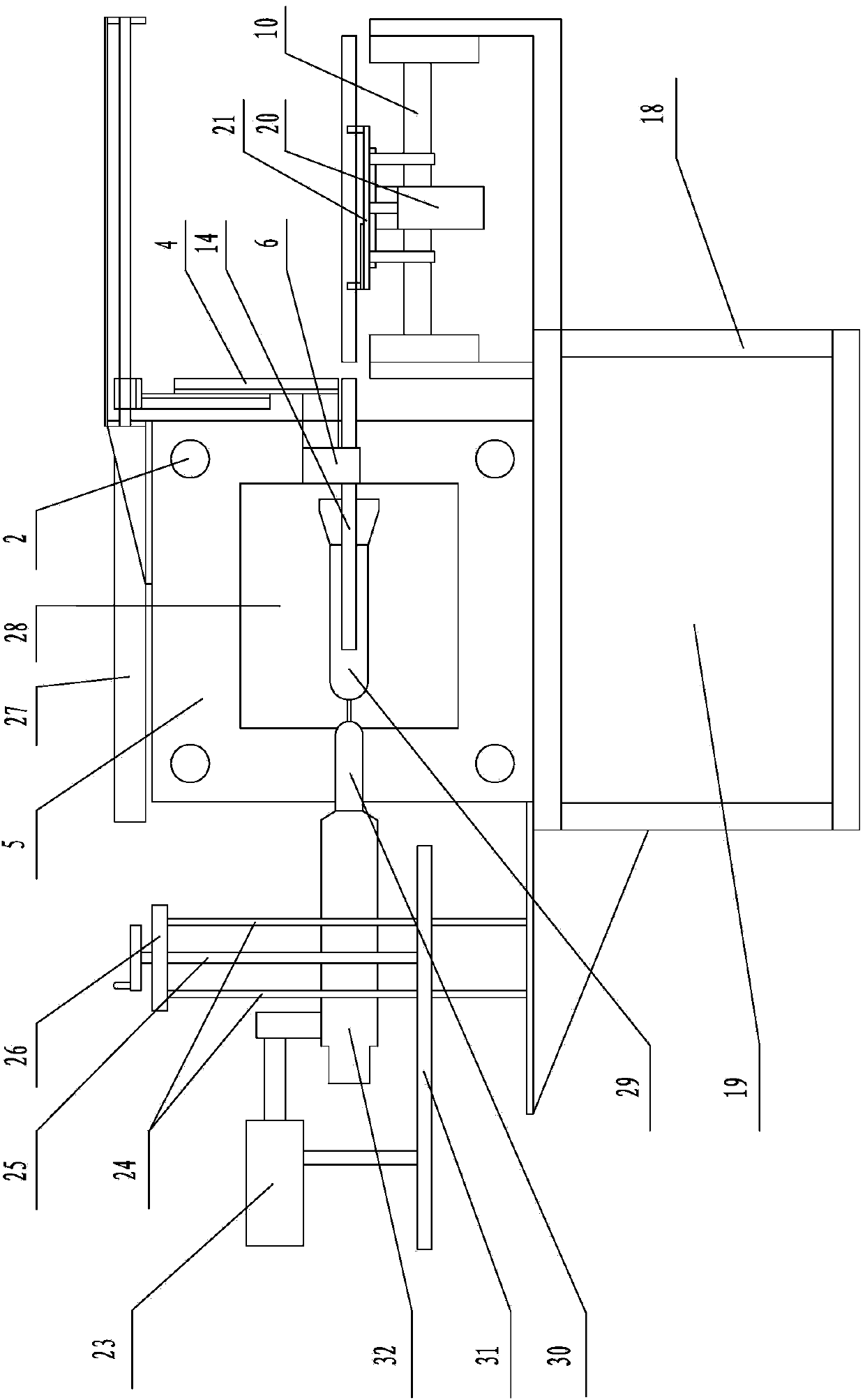

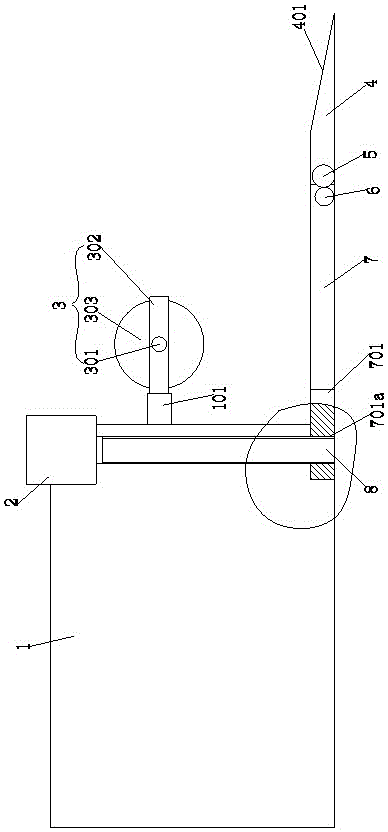

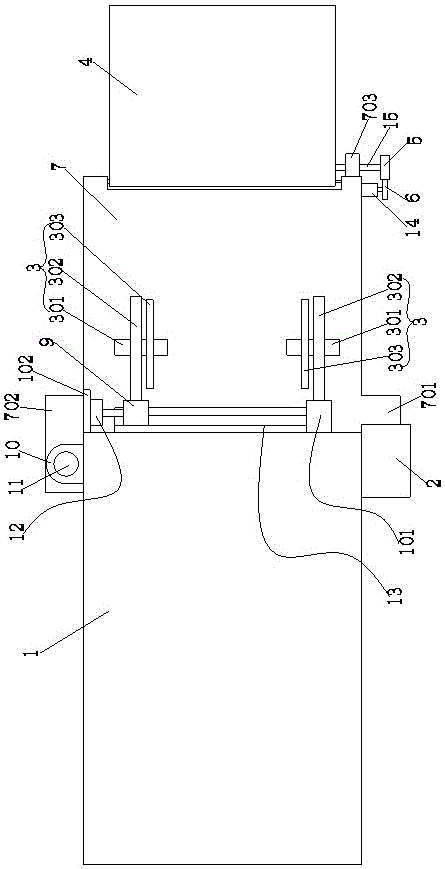

Automatic mechanical arm

ActiveCN104607992AReduce work accidentsImprove efficiencyAutomatic workpiece supply/removalGrinding feedersEngineeringConcertina movement

The invention belongs to the technical field of mechanical arm, and relates to an automatic mechanical arm specifically. The automatic mechanical arm comprises a rack (100), a servo motor (300) is arranged on the rack (100), a mechanical arm (200) is arranged on the rack (100), and the mechanical arm (200) conducts concertina movement driven by the servo motor (300). A fixture holder (500) is arranged at the end of the mechanical arm (200), and a feeding fixture (501) and a reclaiming fixture (502) are arranged on the fixture holder (500). A first cylinder (202) and a second cylinder (203) are arranged on the mechanical arm (200), the first cylinder (202) is used for controlling the rotation of the fixture holder (500), and the second cylinder (203) is used for controlling the horizontal moving of the fixture holder (500). The fixture holder of the mechanical arm can rotate driven by the cylinder, and the translocation of an intermittence between the feeding fixture and the reclaiming fixture is controlled correspondingly, perform bodied that needs processing and the processed elements are clamped respectively, the corresponding processing is conducted, the automatic material clamping, the feeding and reclaiming are achieved, and manual labor is replaced greatly.

Owner:SHENZHEN KING TEAM PRECISION TECH

Turnover method for overweight block of ship

The invention discloses a turnover method for an overweight block of a ship. The turnover method comprises the following steps: cleaning steel plate ground, and hoisting the block by a large-sized gantry crane; laying a rubber plate below the block, mounting two turbine propellers on one side of the rubber plate, and mounting two lifting lugs on the other side of the rubber plate; slowly placing the block on the rubber plate, wrapping the block with a rubber cover, and mutually bonding the rubber cover and the rubber plate to form a sealing element; enclosing the block on the steel plate ground by using the steel plate and forming a tank body, pouring water into the tank body to enable the block to float; hooking the lifting lug and upwards pulling by an upward-pulling hoist on the right side, and meanwhile, enabling the turbine propellers to propel rightwards for enabling the whole block to turnover anticlockwise; when the upward-pulling hoist elevates to a 90-degree turnover orientation, starting a horizontal-pulling hoist to leftwards pull for smoothly turning the section; draining off water in the tank body, dismantling the enclosed steel plate, taking off the rubber plate, and enabling the section to be directly closed.

Owner:舟山长宏国际船舶修造有限公司

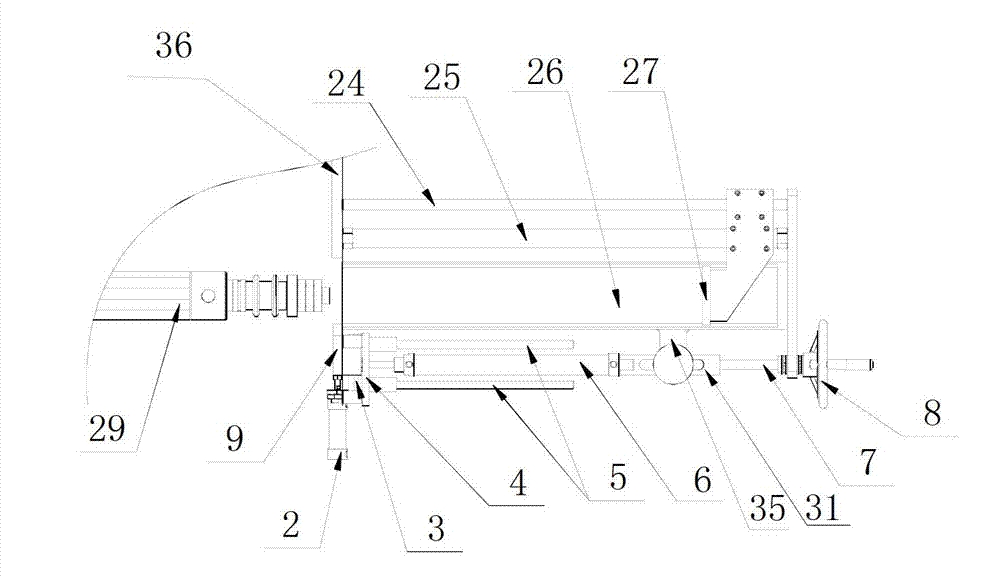

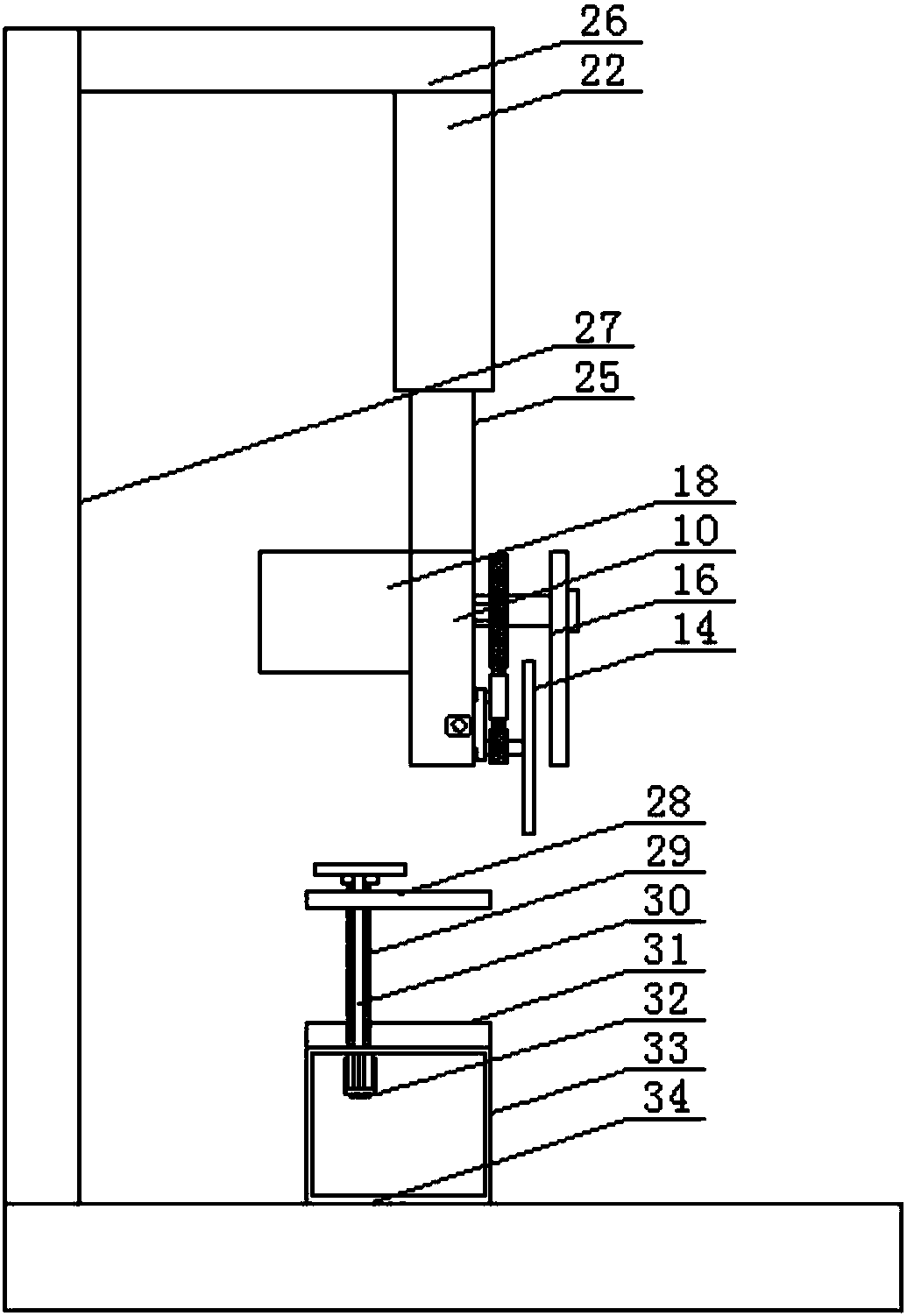

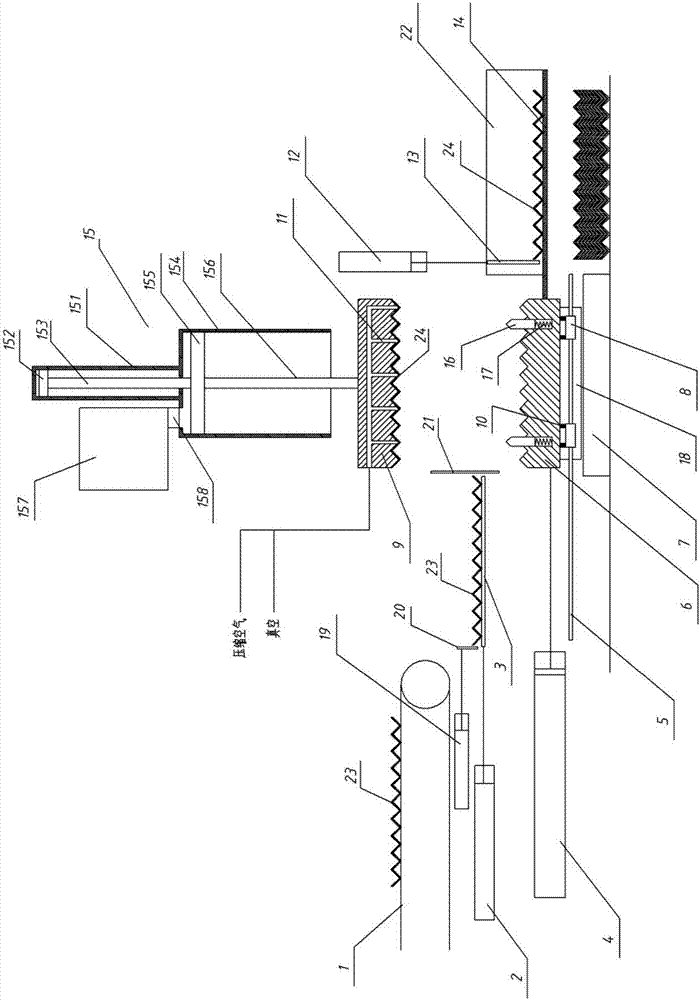

Device for automatically penetrating paper pipe by air bulking shaft of cast film machine

ActiveCN103303720ACancel manual operationReduce labor intensityLoading/unloadingWebs handlingIndustrial AccidentPulp and paper industry

The invention relates to a device for automatically penetrating a paper pipe by an air bulking shaft of a cast film machine. The device comprises a paper sleeve hopper mechanism, a paper sleeve base, a paper pipe pushing mechanism, an air bulking shaft inflating mechanism and an air bulking shaft support mechanism; the paper sleeve hopper mechanism is arranged above the paper sleeve base; the paper sleeve base is fixedly connected with the outer side of a first wall plate of a machine body; the paper pipe pushing mechanism is fixedly connected with the outer side of the first wall plate of the machine body; the paper pipe pushing mechanism comprises a paper sleeve push plate arranged in the paper sleeve base; the air bulking shaft inflating mechanism is fixedly connected to the outer side of a second wall plate of the machine body; the air bulking shaft support mechanism comprises a first support mechanism and a second support mechanism; the first support mechanism is fixedly connected with the inner side of the first wall plate of the machine body; the second support mechanism is connected to the inner side of the second wall plate of the machine body; the air bulking shaft is movably arranged on the first support mechanism and the second support mechanism. The air bulking shaft can automatically penetrate the paper pipe without being moved at a reel alternation and feed preparation position, so that the automation degree is high, the production efficiency is greatly improved, and the labor strength of production personnel is alleviated; and manual operation of penetrating the water pipe is omitted, so that the safety is improved, and the occurrence of industrial accidents is reduced.

Owner:CHANGLONG TECH YANGJIANG CO LTD

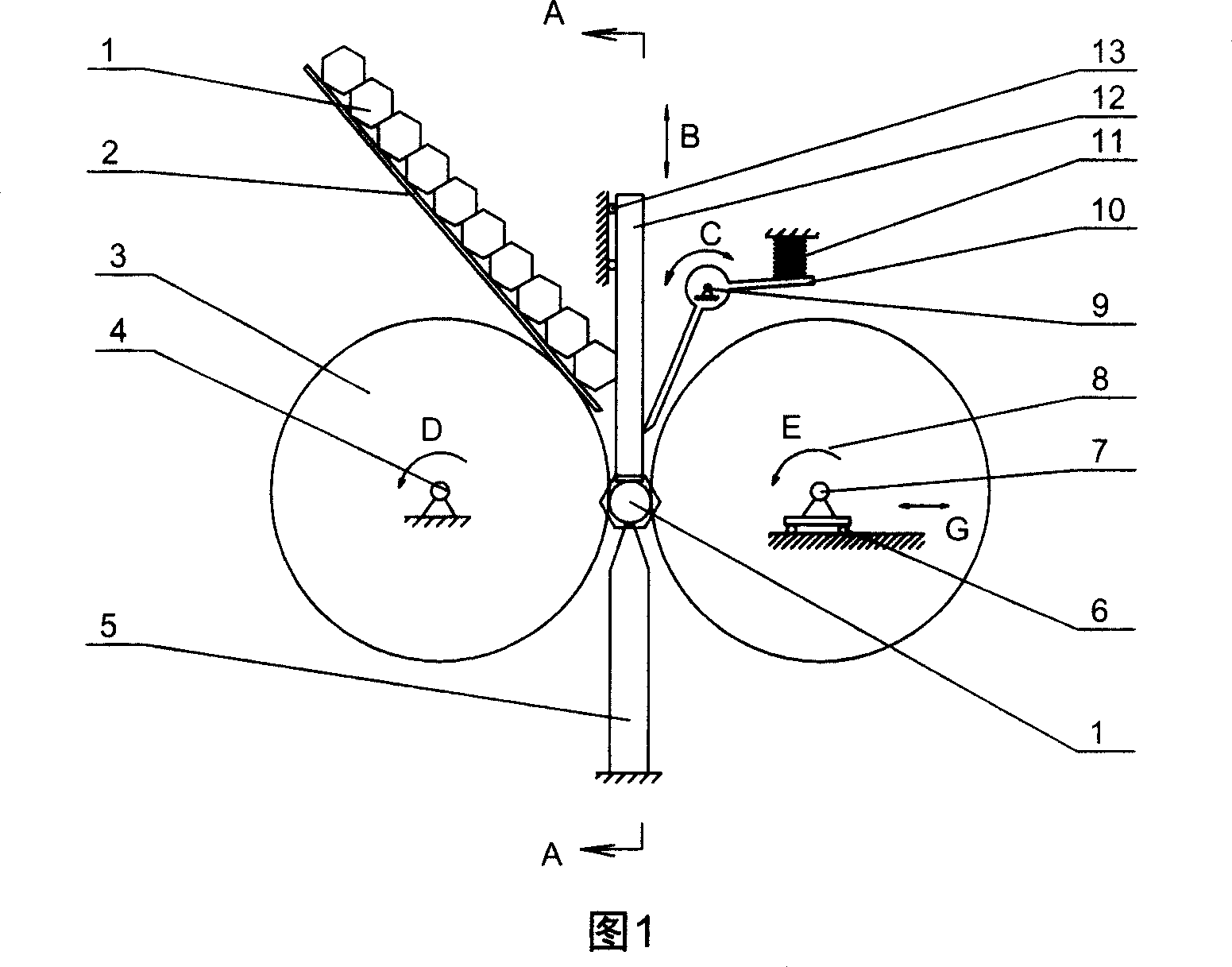

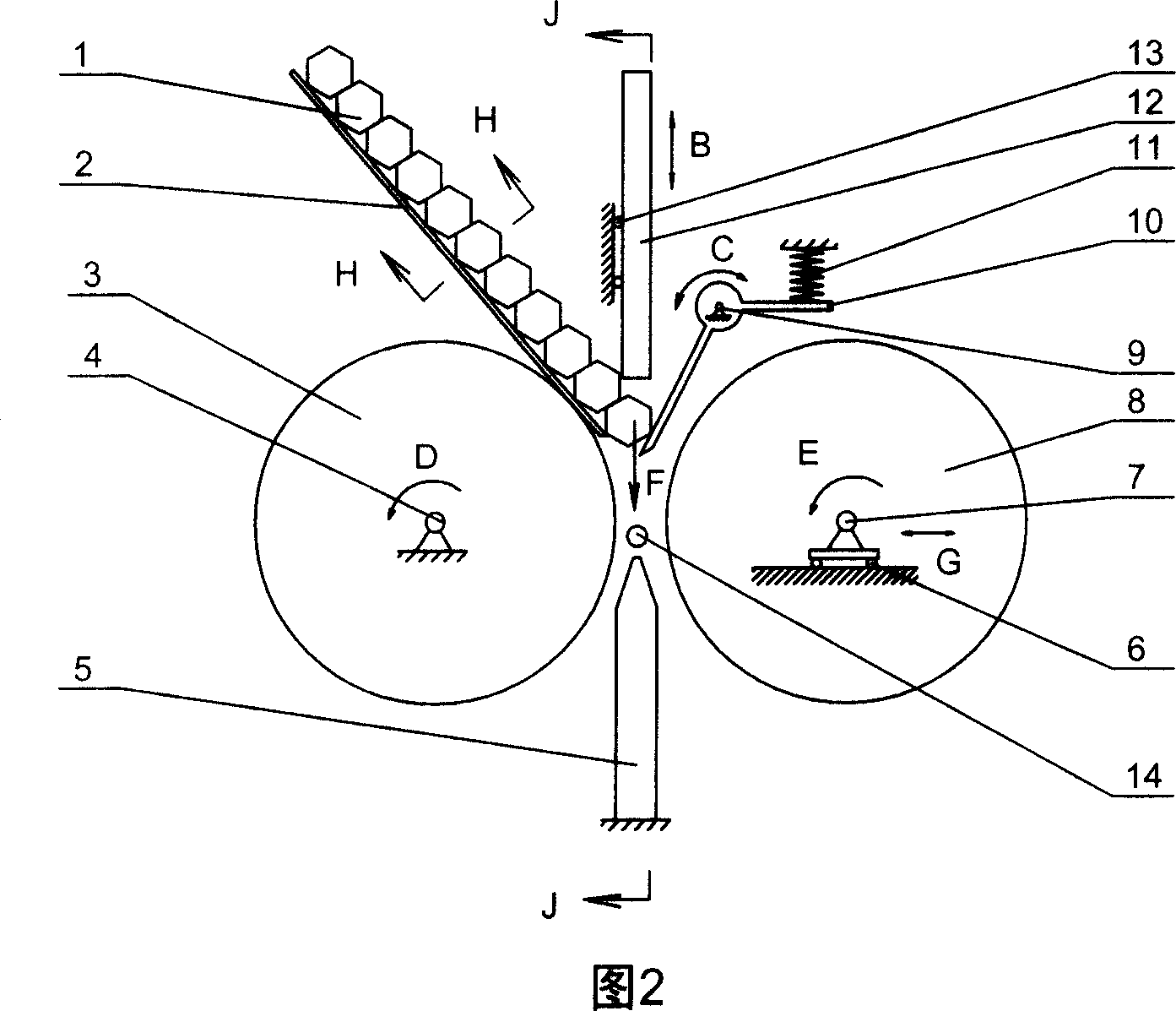

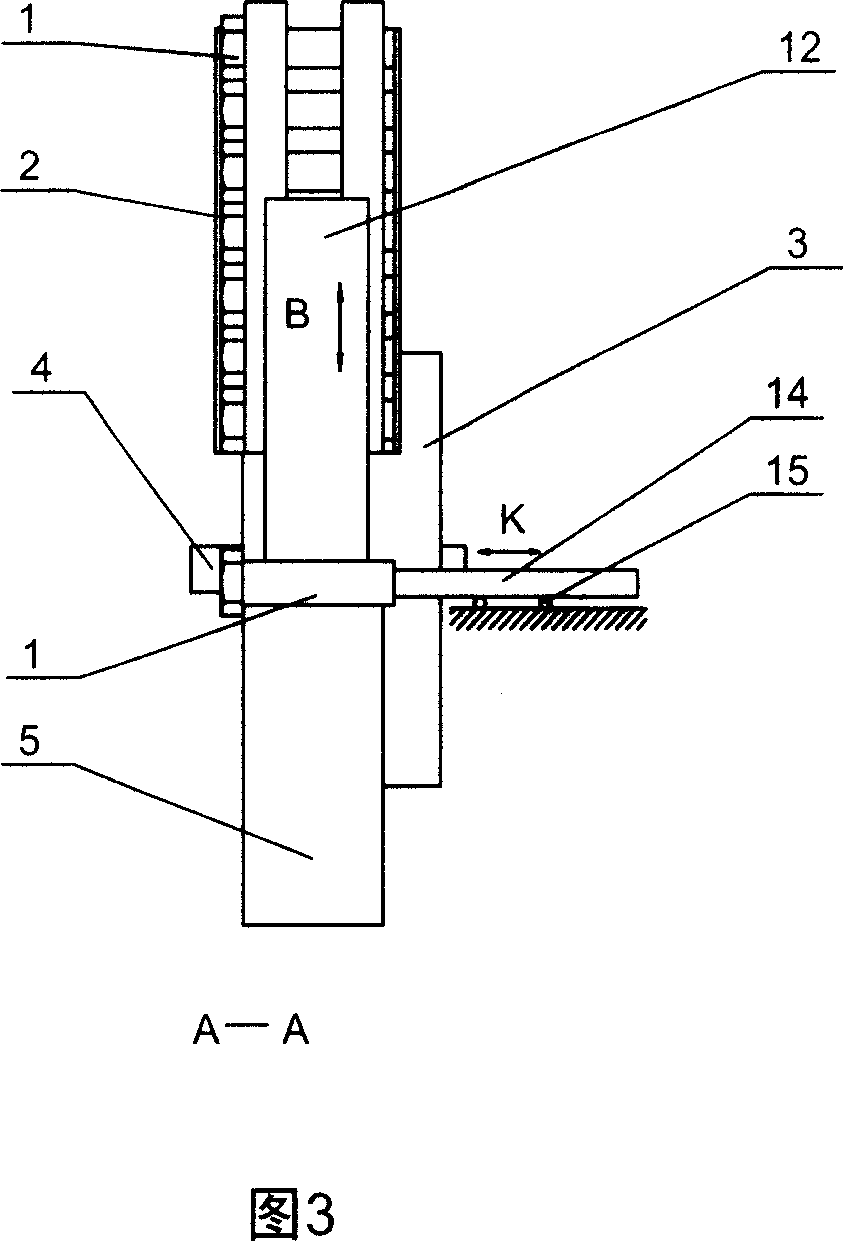

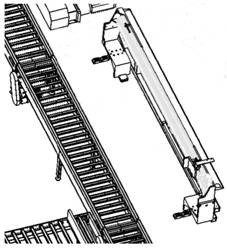

Automatic skip blanking apparatus of thread rolling machine

InactiveCN101028642AReduce labor intensityLow failure rateThread cutting feeding devicesMetal-working feeding devicesLevel lineFastener

An automatic feeding-discharging mechanism for a screw rolling machine is composed of a feeding chute with an inclined angle (0-90 deg.), a vertical feeding push rod and its driver, a feeding barrier with a spring, a horizontal discharging push rod, and the driver for horizontal discharging push rod.

Owner:陈显国

Cutting device for building construction

The invention discloses a cutting device for building construction. The cutting device for the building construction comprises a base, wherein a support rod is fixed to the upper end of the base, anda bearing plate is fixed to the upper end of the support rod. A fixing rod is fixed to the lower end of the bearing plate, and a brake cavity is formed in the fixing rod. A third drive motor is fixedto one side of the fixing rod, and the tail end of an output shaft of the third drive motor penetrates through one end of the fixing rod and extends into the brake cavity. A second bevel gear is fixedto the tail end of the output shaft of the third drive motor, and a second screw is rotatably connected to the opposite side walls of the brake cavity. The upper end of the second screw is fixedly sleeved with a first bevel gear. According to the cutting device for the building construction, pipelined cutting is realized, the quality and speed of cutting are ensured, and cutting of various materials can be realized. The spacing of conveying gaps can be adjusted according to the sizes of the materials, the noise pollution is reduced, the manpower is relieved, the work accident is reduced, andthe work efficiency is improved.

Owner:吕彬

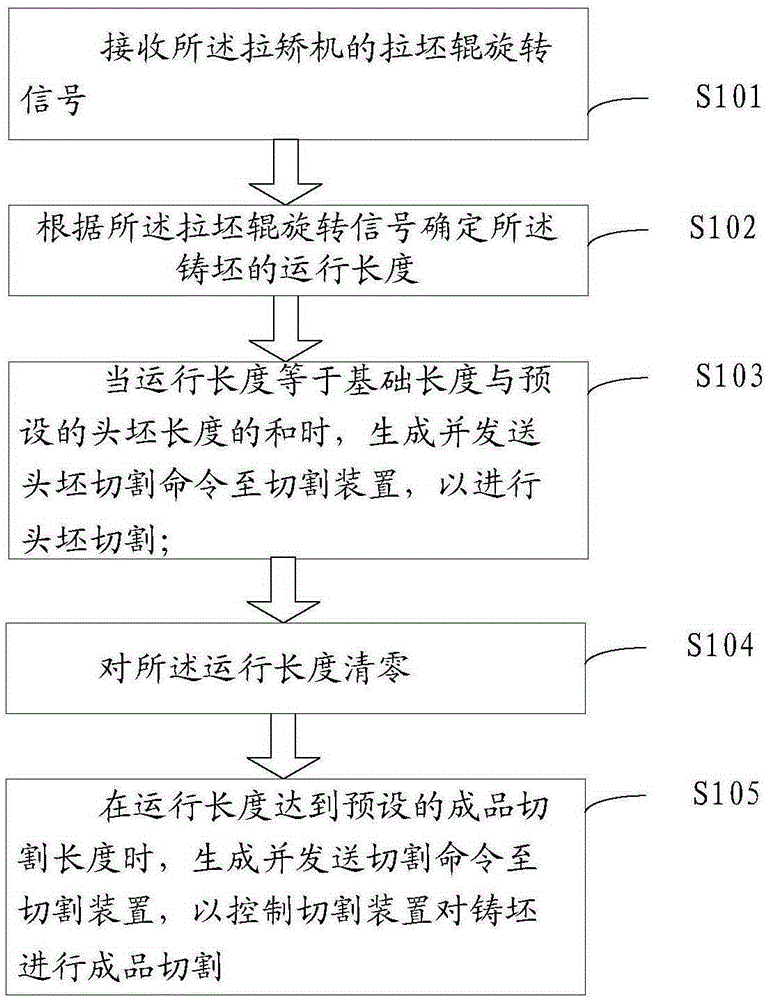

Casting blank cutting positioning method and system

ActiveCN105328154AAvoid technical issues that are greatly influenced by the outside world and therefore impreciseImprove cutting positioning accuracyEngineeringMechanical engineering

The invention discloses a casting blank cutting positioning method and a system. The method comprises the steps of: receiving a drawing roller rotating signal of a withdrawal and straightening machine; determining an operation length of a casting blank according to the drawing roller rotating signal; generating and sending a head blank cutting command to a cutting device so as to control the cutting device to perform the head blank cutting for the casting blank when the operation length is equal to a sum of a basic length and a preset head blank length, wherein the basic length is a distance from a liquid level of a crystallizer to an original position of a cutting car; zeroing the operation length; and generating and sending a cutting command to the cutting device so as to control the cutting device to perform the finished-product cutting for the casting blank when the operation length reaches a preset finished-product cutting length. The casting blank cutting positioning method and system, provided by the invention, are used for solving the technical problems of low precision and high equipment maintenance cost in a casting blank cutting positioning method of the prior art, and realize the technical effects of improving the cutting positioning precision and reducing the equipment maintenance cost.

Owner:BEIJING SHOUGANG CO LTD

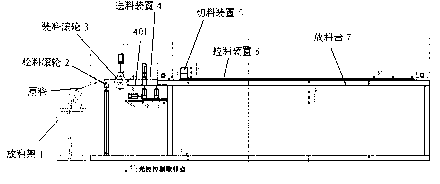

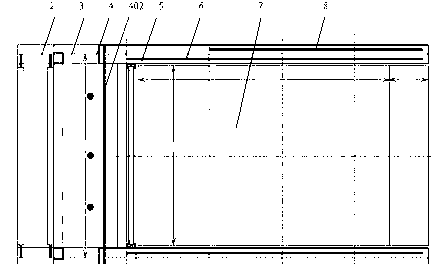

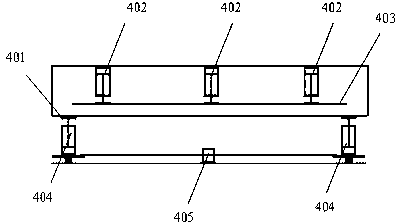

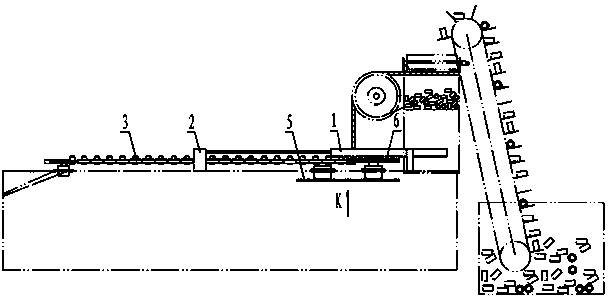

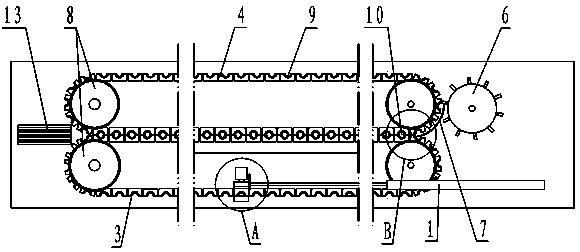

Fully automatic material cutting machine

ActiveCN102700990AReduce work accidentsImprove securityArticle deliveryIndustrial AccidentEngineering

The invention relates to a fully automatic material cutting machine, which comprises a material placing frame, a material loosening rolling wheel, a material loading rolling wheel, a material conveying device, a material cutting device, a material pulling device and a material placing table in sequential arrangement and also comprises a length regulating device connected with the material cutting device through a circuit. The fully automatic material cutting machine has the advantages that the labor consumption during the production can be greatly reduced, the occurrence of industrial accidents is reduced, the safety and the reliability are improved, and the maintenance is convenient.

Owner:SHANGHAI JILONG SPORT & LEISURE PROD CO LTD

Plate type workpiece glue injection robot system and glue injection method thereof

ActiveCN106733479AHigh degree of automationRealize the memory functionLiquid surface applicatorsCoatingsRobotic systemsManufacturing technology

The invention relates to the technical field of machining and manufacturing of plate type workpieces, in particular to a plate type workpiece glue injection robot system and a glue injection method thereof. The plate type workpiece glue injection robot system comprises multiple glue injection mechanisms. Each glue injection mechanism comprises a rack, a conveying device arranged on the rack, a visual processing room, a glue injection device and a control device. The conveying device comprises multiple sets of linear plane transmission mechanisms which are sequentially connected end to end, and trays arranged on the upper surfaces of the linear plane transmission mechanism. According to the plate type workpiece glue injection robot system and the glue injection method thereof, glue can be sprayed to plate type workpieces efficiently and accurately, and the beneficial effects that the production efficiency is high, glue is saved, operation is simple, the defective rate is low, the quality is stable, safety and reliability are achieved, and the automation degree is high are achieved.

Owner:ANJI BATA ROBOT CO LTD

Automatic shaping machine for pulp molding product

ActiveCN107012747AReduce work accidentsReduce labor costsTextiles and paperIndustrial AccidentShell molding

The invention discloses an automatic shaping machine for a pulp molding product. The automatic shaping machine comprises a stamping and shaping mold, a blanking device and a discharge device, wherein the blanking device and the discharge device are arranged at two sides of the stamping and shaping mold separately; the stamping and shaping mold comprises matched upper template and lower template; the upper template is driven to carry out vertical motion through a stamping drive cylinder; an air passage is formed in a molding surface of the upper template; the air passage is connected with an external vacuum pump for adsorbing a shaped product; the lower template is driven to carry out horizontal motion through a feeding drive cylinder; one end of the lower template is connected with the feeding drive cylinder and the other end is connected with a receiving plate; and when the feeding drive cylinder drives the lower template to move to a position right below a blanking position of the blanking device from a position right below the upper template, the receiving plate just moves to a position right below the upper template. The automatic shaping machine is high in automatic degree, an industrial accident in the production process can be effectively reduced, the human cost is reduced and the production efficiency is improved.

Owner:肇庆市敏捷图文快印有限公司

Automatic wax injection machine for producing wax sticks

InactiveCN103624920AReduce labor intensityEnsure personal safetyFoundry moulding apparatusWaxUltimate tensile strength

The invention discloses an automatic wax injection machine for producing wax sticks. The automatic wax injection machine comprises a rack, a first fixed plate, a second fixed plate, an arranging and conveying device for conveying wax stick stems, a lifting device for lifting the wax stick stems, a feeding device for feeding the wax stick stems into a mold cavity, and a wax injection device for injecting wax slurry into the mold cavity, wherein the wax injection device, the lifting device and the arranging and conveying device are all arranged on the rack; the feeding deice is arrange on the top of the second fixed plate and is positioned above the lifting device; the lifting device is positioned on the left side of the arranging and conveying device; both the first fixed plate and the second fixed plate are connected with the rack; a guide column is arranged between the first fixed plate and the second fixed plate and is connected with a movable plate in a sliding manner; the first fixed plate is connected with a pressing cylinder for driving the movable plate to slide; a cooling water tank is arranged on the rack and is positioned below the first fixed plate, the movable plate and the second fixed plate. According to the automatic wax injection machine, the production efficiency can be greatly improved, the labor intensity is reduced, and the personal safety of production workers can be guaranteed.

Owner:郏银芳

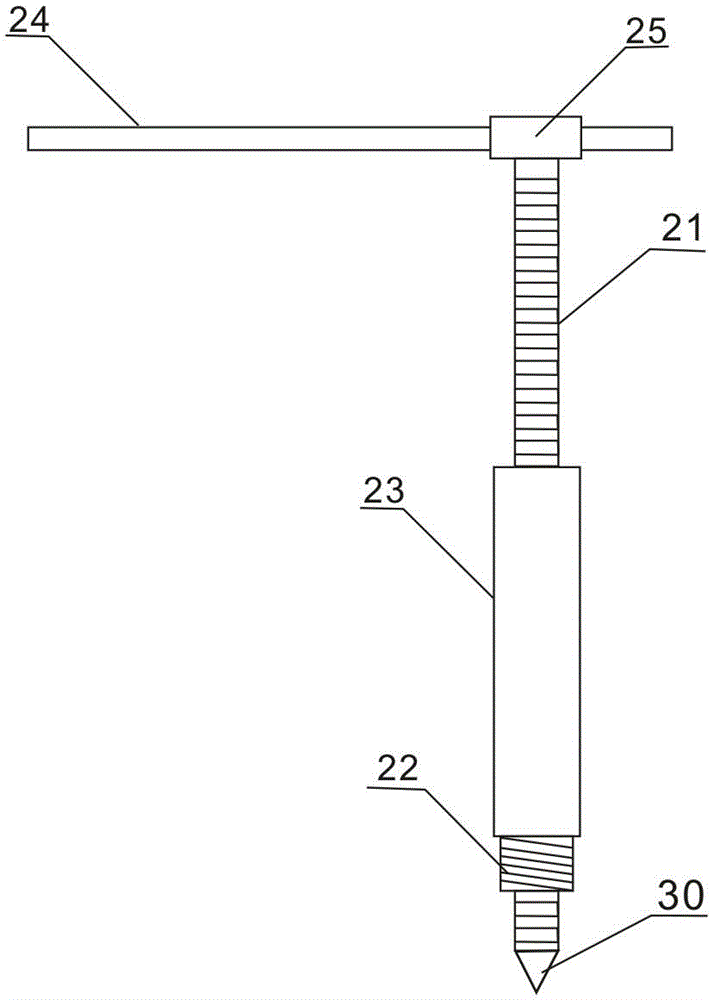

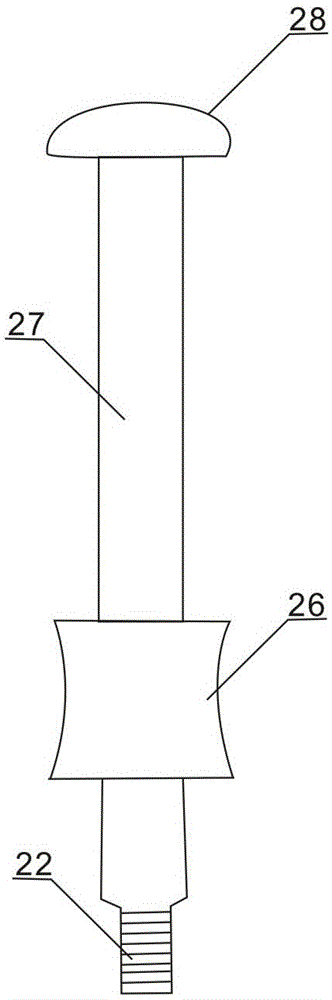

Multi-purpose bearing extractor

Owner:陈大才

Defective product rejecting stand with steel tilting function

ActiveCN104492817AReduce labor intensityHigh speedSortingMetal rolling arrangementsIndustrial AccidentEngineering

The invention discloses a defective product rejecting stand with a steel tilting function. The defective product rejecting stand comprises a steel rejecting machine arm (1), a roller way (3), a cold blank stand movable beam and a cold blank stand static beam (6), wherein a positioning stop block (2) is arranged on the cold blank stand static beam, when a steel blank (4) is arranged on the cold blank stand static beam and is in contact with a positioning surface of the positioning stop block (2), the end part of the steel rejecting machine arm (1) is in contact with the lower surface of the steel blank (4), and the gravity center on the cross section of the steel blank (4) is beyond the end part of the steel rejecting machine arm (1). The technical scheme is adopted, during the steel tilting, one steel loader can operate in an indoor position, the work intensity of a worker is reduced; in addition, the speed is high, and the steel tilting efficiency is improved; the occurrence of industrial accidents is reduced, and the safety factor is improved.

Owner:WUHU XINXING DUCTILE IRON PIPES

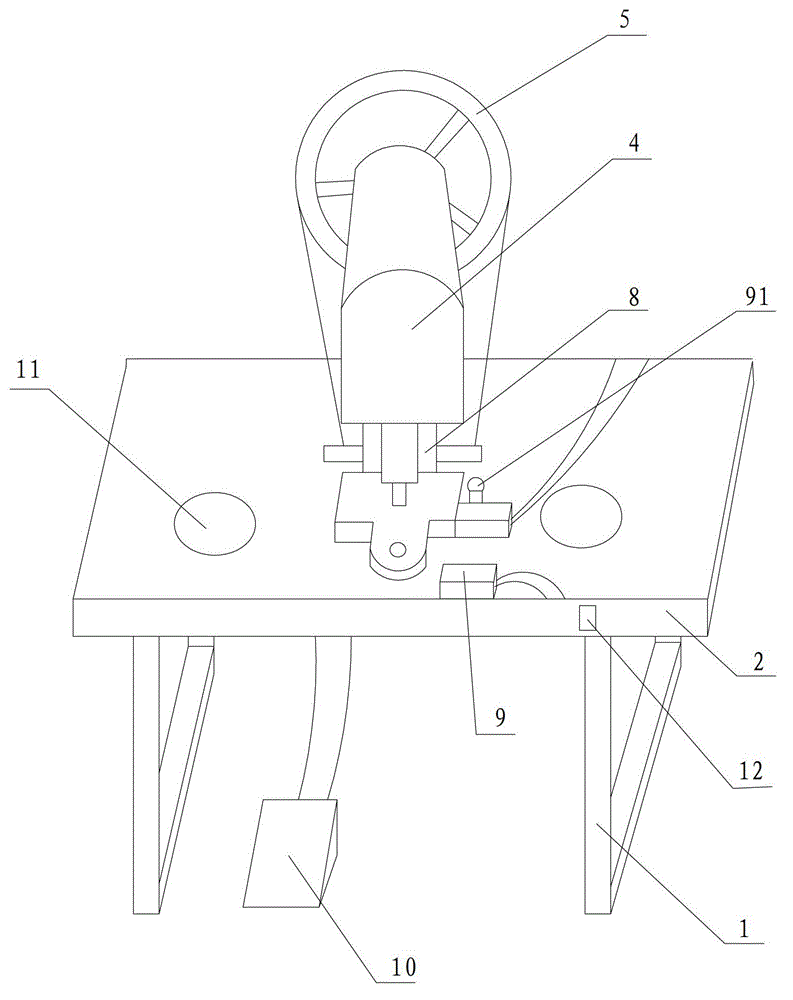

Photoelectric protection type button set-in machine

InactiveCN103330316AAvoid misuseReduce work accidentsEngineering safety devicesClothes making applicancesFoot SwitchIndustrial Accident

The invention relates to a photoelectric protection type button set-in machine. The photoelectric protection type button set-in machine comprises an electromagnetic module fixed on a work table and connected with a pull rod, a photoelectric sensing module installed beside a button set-in machine body and on the same side as the hand placing a button upper die, and a foot switch placed on the ground. The photoelectric sensing module, the foot switch and the electromagnetic module are sequentially connected for forming a switch circuit. According to the photoelectric protection type button set-in machine, the photoelectric sensing module and the foot switch are arranged at the same time and control the electromagnetic module together, when one of the photoelectric sensing module and the foot switch is in the disconnected state, the electromagnetic module cannot work, so that misoperation by working personnel during the long-time work process is prevented effectively, and the industrial accidents are reduced.

Owner:常熟市海虞镇志宏五金厂

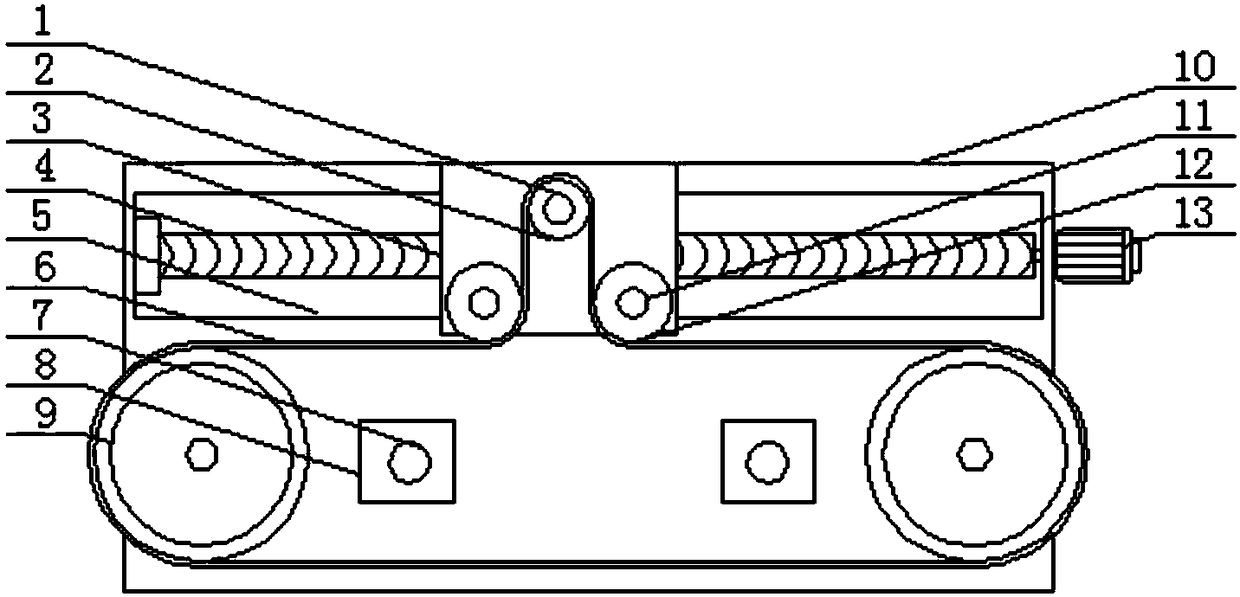

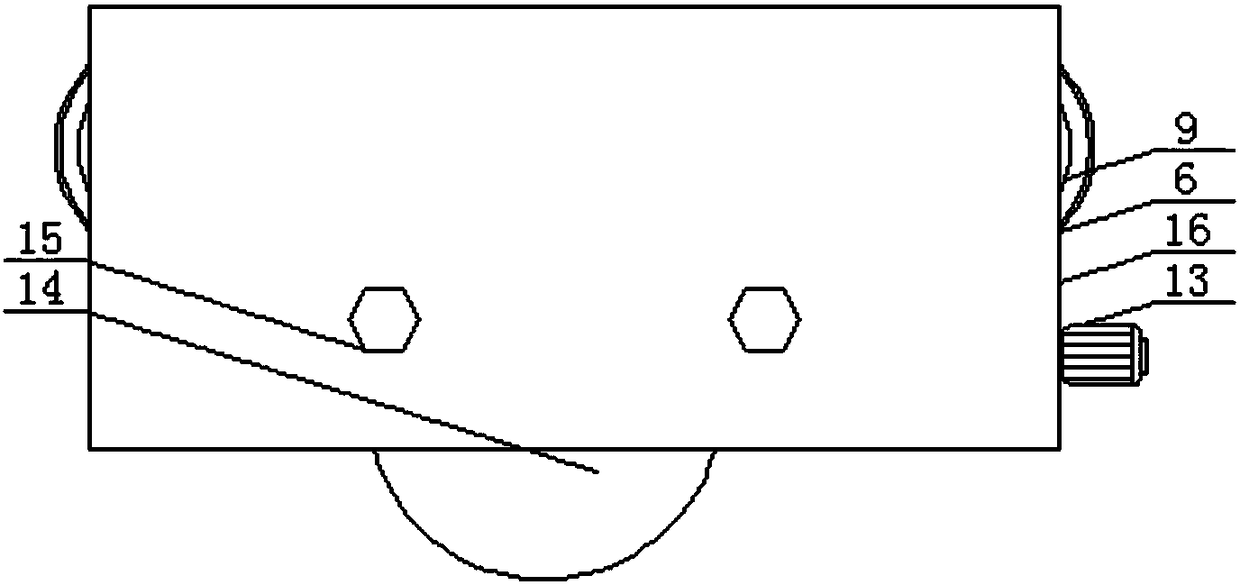

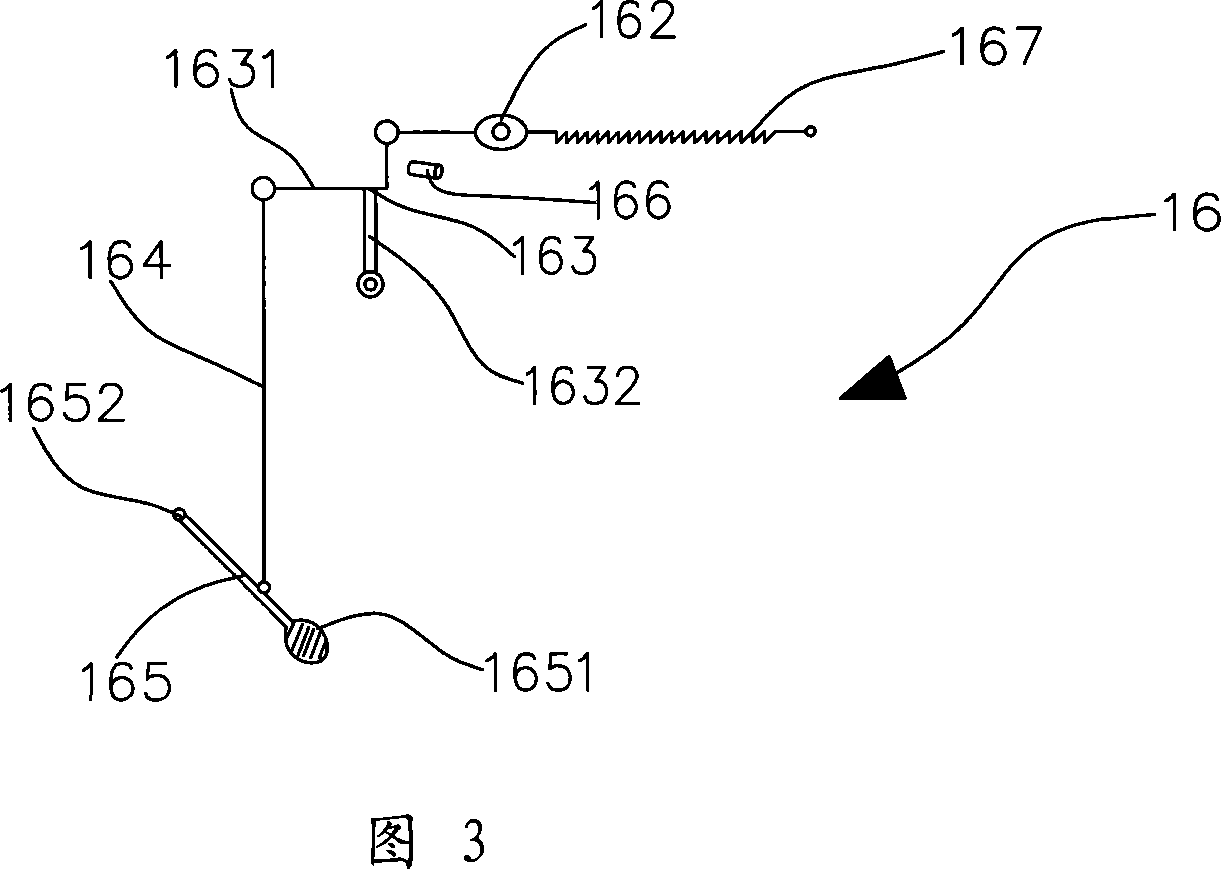

8-shaped winding system and 8-shaped winding method

ActiveCN110060865AReduce manual dependenceReduce work accidentsCoils manufactureWinding machineWind system

The invention provides an 8-shaped winding system and an 8-shaped winding method used by the 8-shaped winding system; the 8-shaped winding system comprises a first winding machine and a second windingmachine; the first winding machine comprises a first feeding device, a first material inputting device, a first winding device, a wire shearing device and a grabbing device; the first winding machineis used for winding a semi-finished product; and the second winding machine comprises a second material inputting device, a second feeding device and a second winding device, wherein the second winding device is used for winding a wire extending out of one end of the semi-finished product into a second set of annular coils to obtain an 8-shaped coil. According to the 8-shaped winding system and the 8-shaped winding method, the dependence of a winding machine on labor is reduced, the production quality is relatively stable, the product precision is high, the production efficiency of the mechanical 8-shaped winding is improved, and the occurrence probability of work injury accidents of a worker is lowered.

Owner:深圳市三通伟业科技有限公司

Sheet-metal working mechanical arm for automatically adjusting height of workpiece

ActiveCN106424421ARealize automatic grabbing and loading operationsReduce labor intensityMetal-working feeding devicesPositioning devicesEngineeringManipulator

The invention discloses a sheet-metal working mechanical arm for automatically adjusting the height of a workpiece, comprising an impact molding mechanism, a transfer mechanical arm and a plate lifting support table. The impact molding mechanism comprises an impact molding lower mold and a molding and material loading air cylinder; the transfer mechanical arm comprises a rotation driving spindle, a rotation piece taking swing arm and an electromagnetic piece taking sucking disc; a fixed supporting base, multiple lifting support lead screws and a horizontally driving spindle are arranged below the plate lifting support table; the fixed supporting base is provided with multiple lead screw installing through holes which are arranged vertically in the axial direction, each of the lead screw installing through holes is provided with one of the lifting support lead screws, each of the lead screw installing through holes is provided with a lead screw lifting wheel gear, the outer sides of the lead screw lifting wheel gears are of bevel gear structures, and the horizontally driving spindle is provided with a spindle driving bevel gear that matches the lead screw lifting wheel gears. The sheet-metal working mechanical arm for automatically adjusting the height of a workpiece can realize automatic grabbing and material loading operation of stacked blanking plates.

Owner:SUZHOU XUANYOU TECH

Intelligent control method for touch screen of sweeping vehicle

PendingCN110398959ASimplify complex operationsAvoid mistakesInput/output processes for data processingPosition/course control in two dimensionsSimulationLarge screen

The invention relates to an intelligent control method for a touch screen of a sweeping vehicle, and belongs to the field of intelligent control of automobiles. An electronic keyboard of the touch screen is used for substituting a mechanical control keyboard of a traditional sweeping vehicle, a one-key operation interface, a running parameter interface, a large-screen monitoring interface and a single-step operation interface are arranged on the touch screen, the one-key operation interface also comprises various types of combination keys and corresponding prompt information, and a driver canoperate and switch among the one-key operation interface, the running parameter interface, the large-screen monitoring interface and the single-step operation interface according to a running condition. By the intelligent control method, the complicated operation process of the traditional keyboard is simplified, the operation error of the traditional keyboard is prevented, the operation efficiency is favorably improved, the operation quality is improved, and the operation accident is reduced.

Owner:SHANGHAI SHENZHOU VEHICLE ENERGY SAVING & ENVIRONMENTAL PROTECTION

A method for processing straight-grained wood using laser cutting

InactiveCN101157234AIncrease profitImprove machining accuracyWood charring/burningLight beamLaser cutting

The invention discloses a method for processing straight line lumber by using a laser. The invention comprises a material feeding mechanism and a laser cutting mechanism, a plurality of groups of laser cutting mechanisms with the power of 10Watt or 100Watt grades which are arranged on the work piece travel, each laser head emits a laser beam simultaneously, and the center points are positioned on the same cutting plane, the work piece is pushed in a straight line to pass through each laser head, a first group laser beam cuts on the work piece to generate a first layer of cutting slot, a second group laser beam cuts to generate a second layer of cutting slot on the base of a first cutting slot of the work piece, a third group laser beam cuts to generate a third layer of cutting slot on the base of a second cutting slot of the work piece, after passing through the plurality of groups of laser heads, the total depth of the cutting slot of the accumulated cutting on the work piece of the laser beam is larger than or equal to the depth of the work piece, the work piece is completely cut, and the next cutting is performed in circulation. The design of the invention has the advantages that the manufacture cost and the price cost are low, the processing precision is high, and the cutting efficiency is high, and the invention is very suitable for the straight line cutting processing of slice material in the decoration and furniture processing industry.

Owner:陈伟良

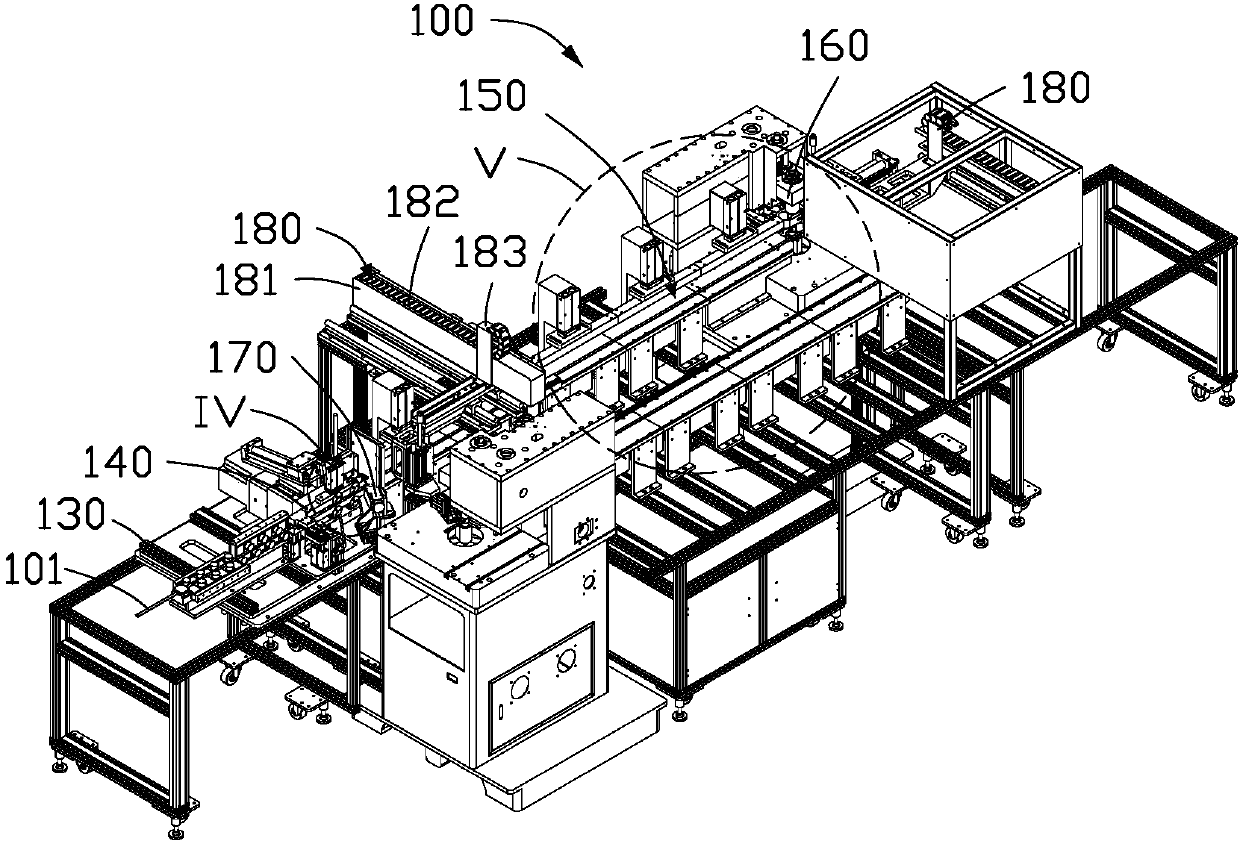

Automatic production line for packaging thin film roll materials

InactiveCN111846485AReduce labor intensityReduce work accidentsWrappingWrapper twisting/gatheringProduction lineAssembly line

The invention discloses an automatic production line for packaging thin film roll materials. The automatic production line comprises a conveying and feeding station, a weighing and measuring station,a packaging, cutting and laminating station, an end cover mounting station, a label pasting station and a stacking and discharging station which are sequentially connected, and an end cover assemblingstation is arranged on one side of the end cover mounting station; and the conveying and feeding station comprises two chain plate type conveying assembly lines, the outer end of each chain plate type conveying assembly line is provided with a transverse coiled material conveying line, and one chain plate type conveying assembly line at the far end bypasses the transverse coiled material conveying line of the other chain plate type conveying assembly line through a lifting conveying platform. The labor intensity of workers and work-related injury accidents can be effectively reduced, and safety operation, working efficiency and intelligent manufacturing are improved.

Owner:BEIJING INST OF COMP TECH & APPL

Oil cylinder drive type feeding device for multi-station internal thread tapping equipment for sleeves

InactiveCN103801769AReduce labor intensityImprove work efficiencyThread cutting machinesMetal working apparatusIndustrial AccidentGear drive

An oil cylinder drive type feeding device for a piece of multi-station internal thread tapping equipment for sleeves belongs to the technical field of thread machining equipment. The oil cylinder drive type feeding device comprises a drive oil cylinder, a clamping unit, a drive chain component, a driven chain component, a gear drive unit and a material stirring wheel, the drive oil cylinder is fixed on a base of the internal thread tapping equipment of the sleeve, the clamping unit is installed on a telescopic boom and is matched with the drive chain component, the drive chain component and the driven chain component are matched to convey a workpiece from an automatic sequencing station to a tapping station, and the gear drive unit is assembled with the driven chain component and the material stirring wheel. According to the oil cylinder drive type feeding device for the multi-station internal thread tapping equipment for the sleeves, the multi-station internal thread tapping equipment for the sleeves automatically feed, so that the labor intensity of an operator is lowered, the working efficiency is improved, the probability of industrial accidents is reduced, and the potential safety hazard in the production process is eliminated.

Owner:夏培信

Pedal control gem shaping machine

The pedal control marble positioning machine comprises the base, sand wheel, locomotive, locomotive alight operation lever and back and forth structure. It also comprises the tumbler device that is composed of tumbler plate, return spring connected to one side of the tumbler plate, motor directing machine connected to the end side of the tumbler plate, pedal fixed to the bottom of the base, pulling line connected to the motor directing machine and the pedal and the return controller, locomotive alighting operation bar installed inside the central hole, return spring not fixed to the base with the tumbler plate, nor of the drive directing machine and the tumbler plate. It is simple in process, operation and low in cost, with reasonable distribution, safe operation, reduced operation time, production cost and improved working efficiency and economical returns with ensured production quality.

Owner:何伟坚 +3

Automatic paper-spreading machine

ActiveCN102673826AAdequate restGuaranteed aestheticsPackaging automatic controlIndustrial AccidentHigh volume manufacturing

The invention discloses an automatic paper-spreading machine. The automatic paper-spreading machine comprises two upright posts, a lifting sliding platform, a transverse sliding platform, a paper feeder, a paper guide plate and a paper cutter, wherein the lifting sliding platform is arranged on one of the upright posts; the paper guide plate is arranged below the paper feeder; the transverse sliding platform is arranged on the lifting sliding platform; and one end of the paper feeder is connected to the transverse sliding platform. By adoption of the structure, the automatic paper-spreading machine has the following steps: 1, paper can be automatically spread on glass; 2, attractive appearance of the whole stack of products can be guaranteed under the condition of meeting the sheet-grabbing speed of a robot, so that the paper-spreading process is perfected; 3, the automatic paper-spreading machine reduces labor, improves the consistency of the products, improves the product quality, is suitable for mass production, reduces the production cost and improves the production efficiency; and 4, the automatic paper-spreading machine is humanized, so that staff get lots of rest and industrial accidents can be reduced.

Owner:芜湖金三氏数控科技有限公司

Packaging machine capable of automatically mounting packaging belt

InactiveCN106697371AReduce labor intensityReduce work accidentsFilament handlingBundling machine detailsLeft convexSlide plate

The invention relates to the technical field of packaging machines, in particular to a packaging machine capable of automatically mounting a packaging belt. The packaging machine is characterized in that a packaging belt clamping mechanism is arranged on one side wall of a packaging machine body; a left convex plate and a right convex plate are correspondingly arranged on the left and right sides of a sliding plate; the top of a guiding shaft penetrates through a guiding sleeve from bottom to top; and a lead screw is fixed at the output end of a lifting motor and in threaded connection with a threaded hole. During the use of the packaging machine provided by the invention, the packaging belt is rolled into the sliding plate when being mounted; then, the lifting motor is utilized for driving the transmission of the lead screw, the packaging belt is taken by the sliding plate to rise, and the packaging belt is clamped and fixed through the packaging belt clamping mechanism; and accordingly, the full-automatic mounting of the packaging belt is achieved, the labor intensity of staff at the post of packaging is reduced, and the industrial accident occurrence probability is lowered.

Owner:黄仕平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com