Patents

Literature

170 results about "Right convex" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

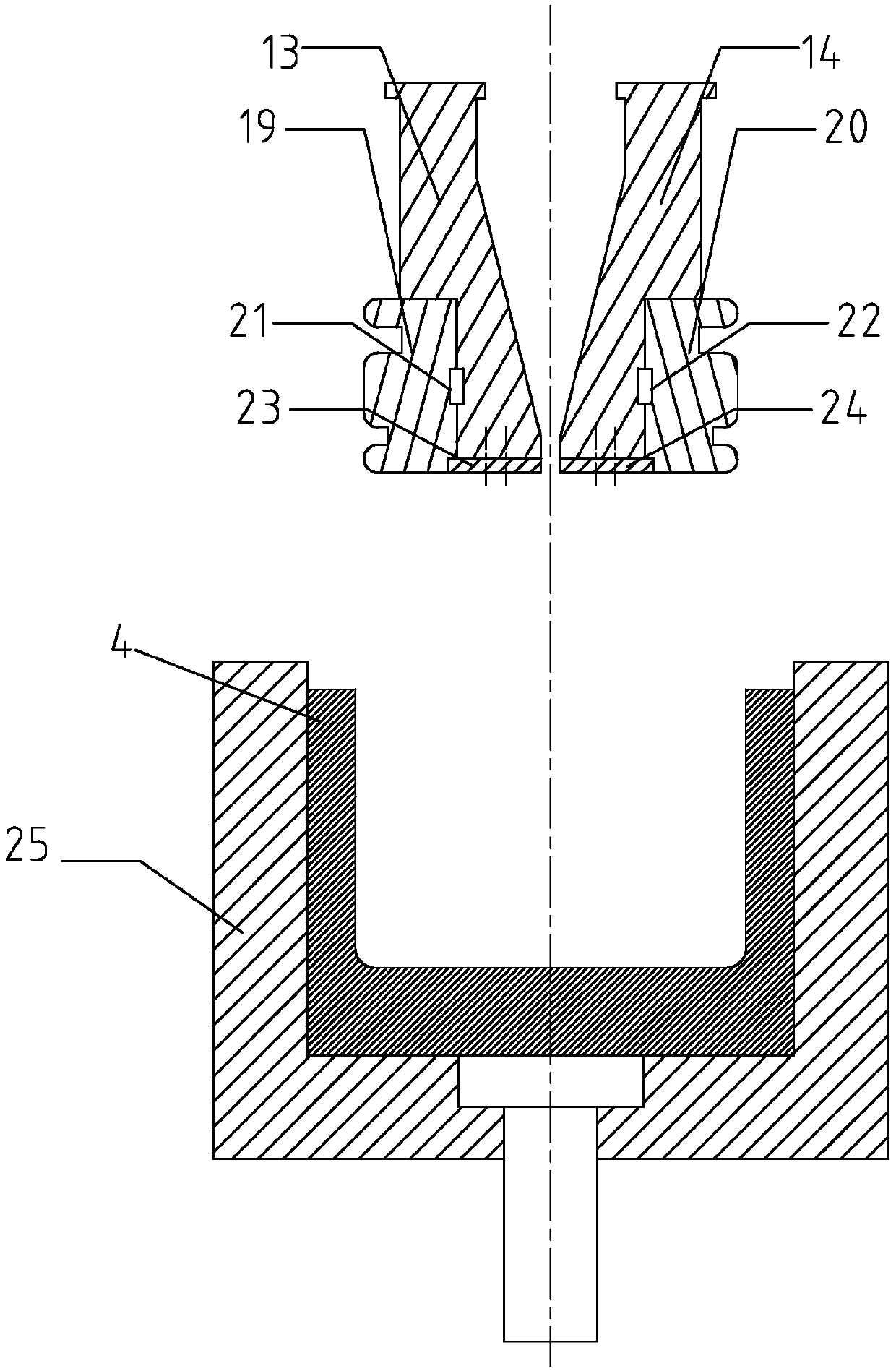

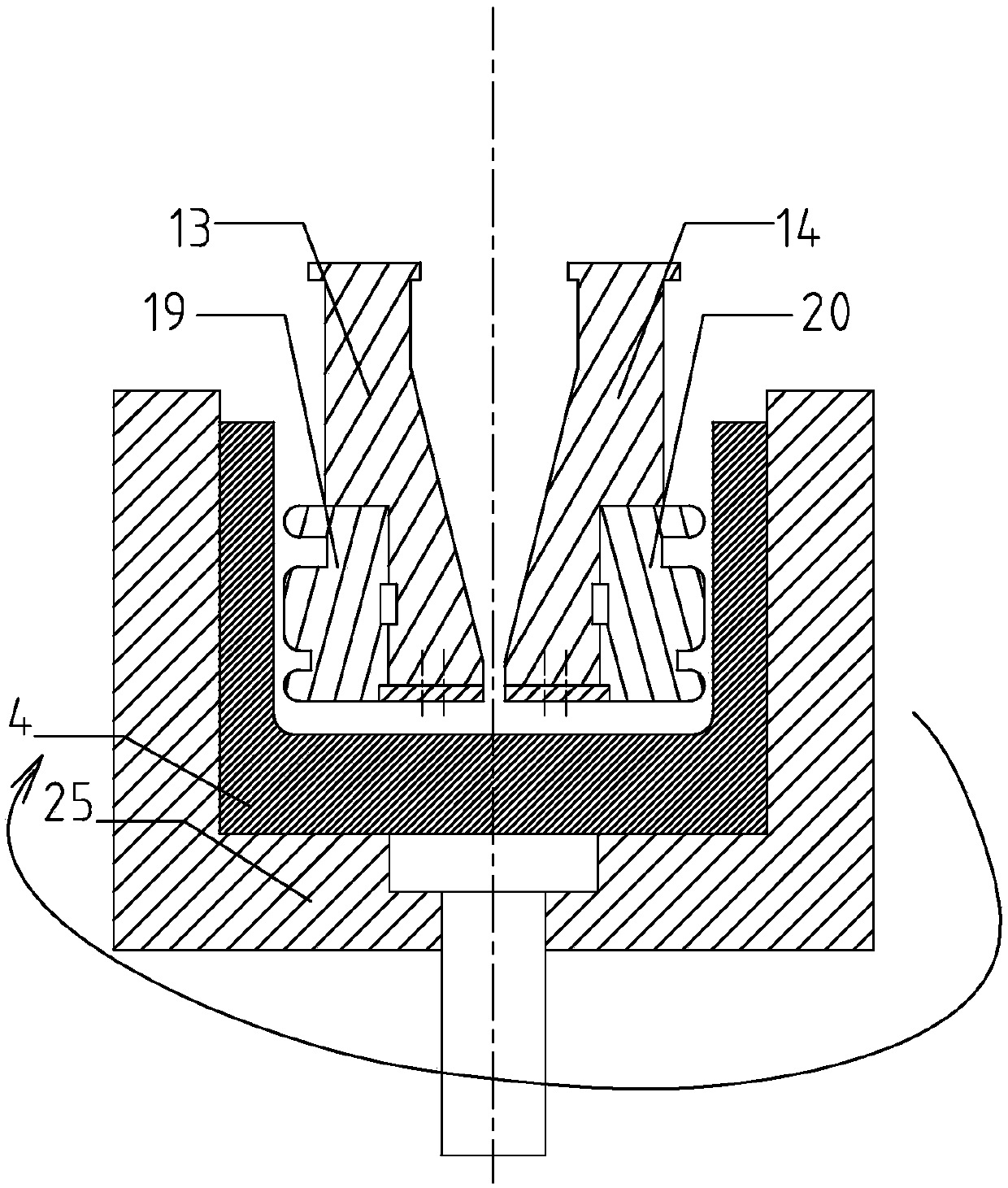

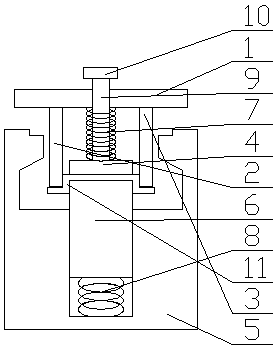

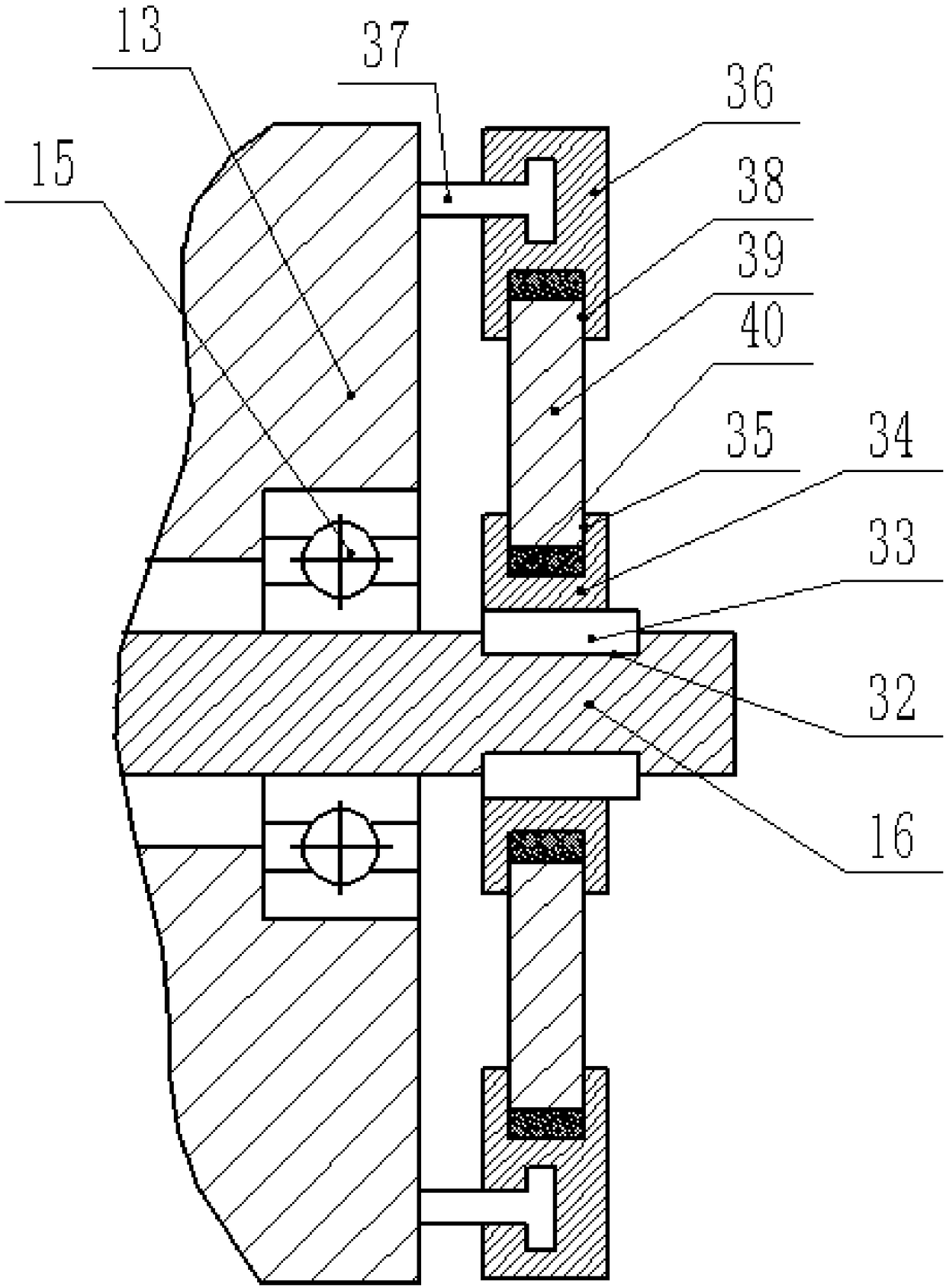

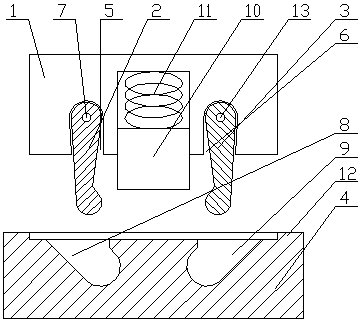

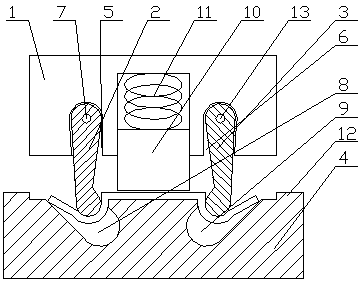

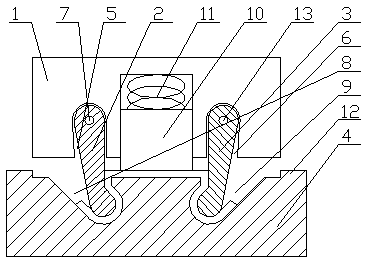

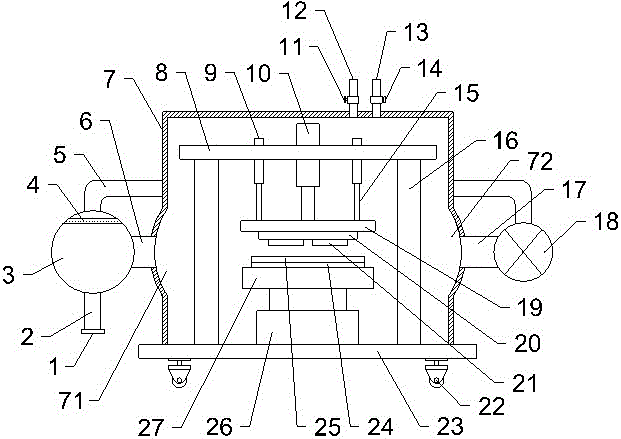

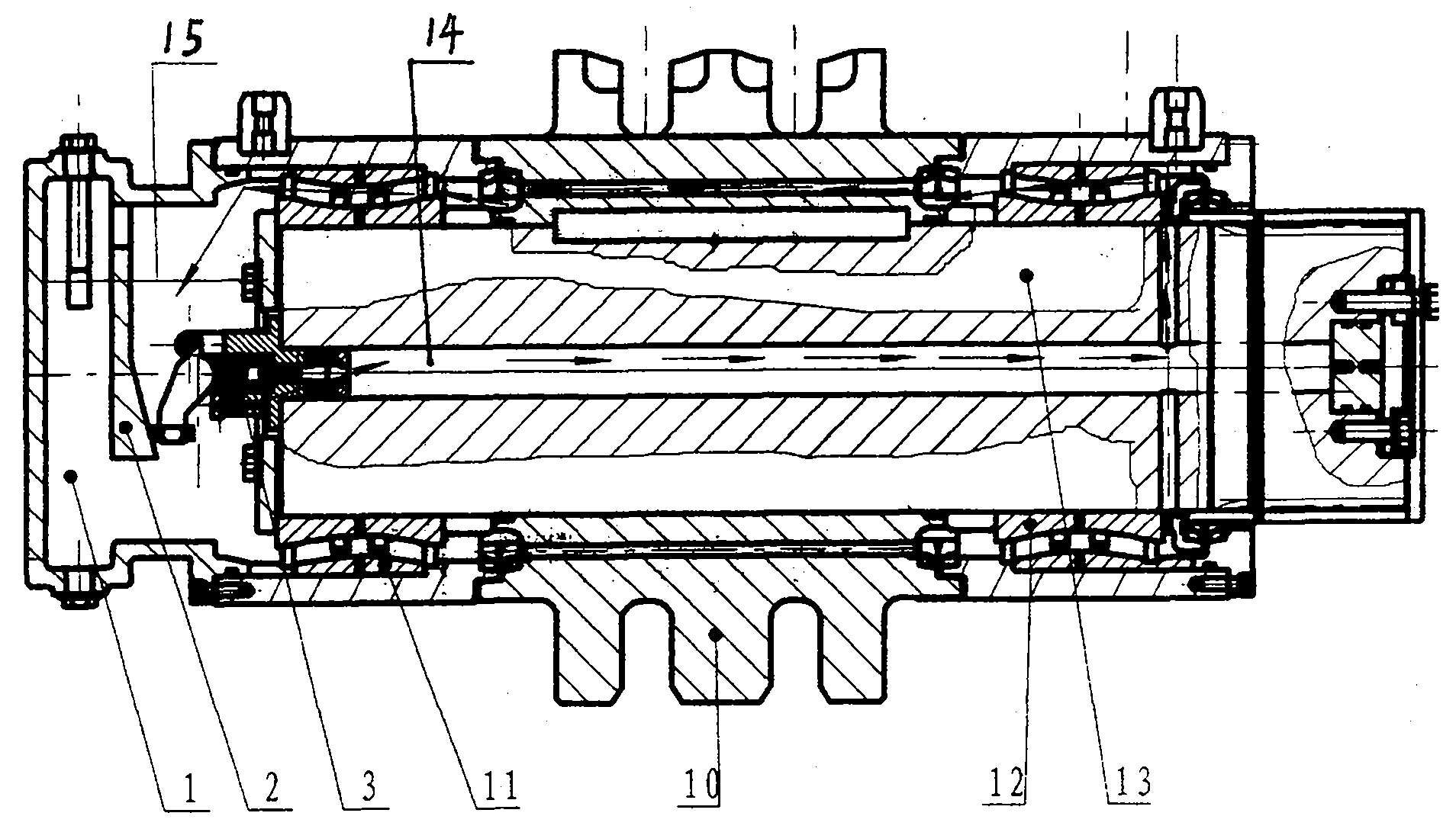

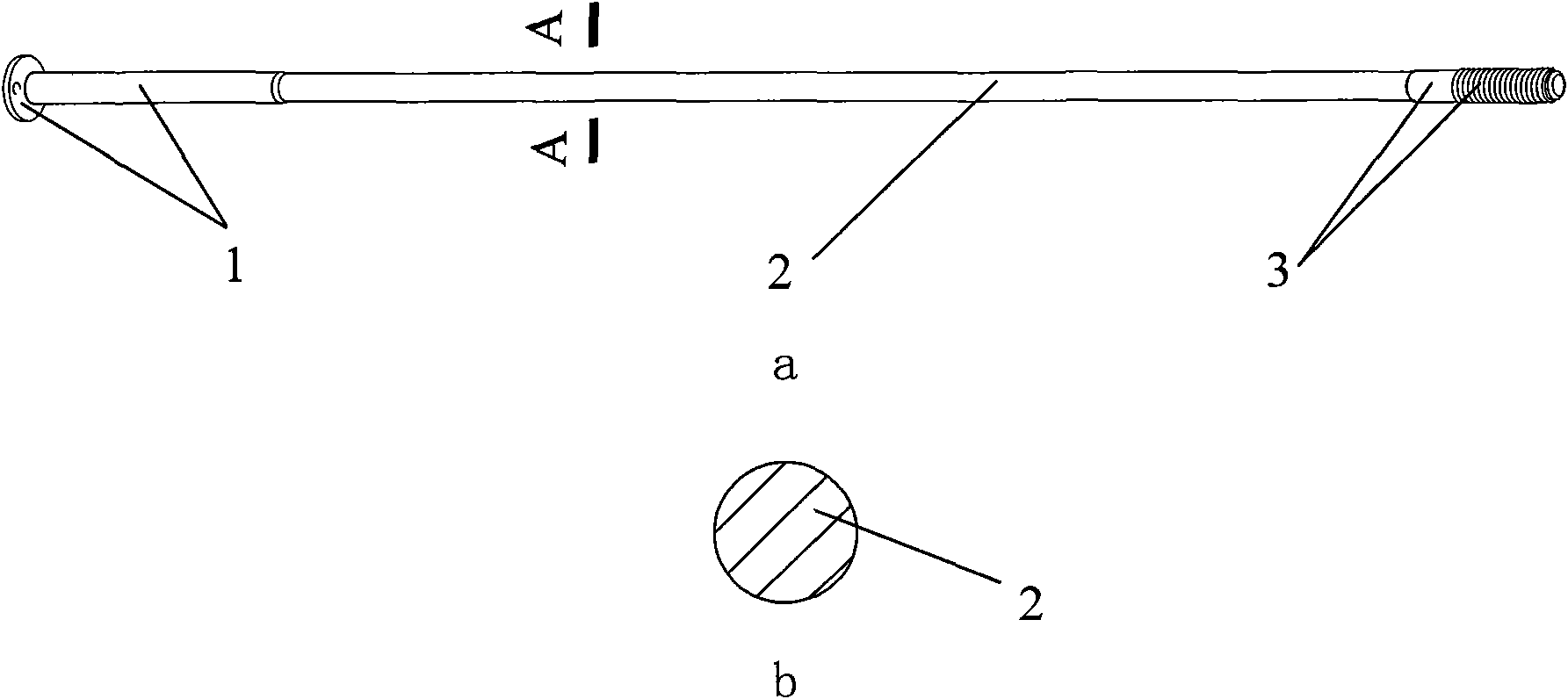

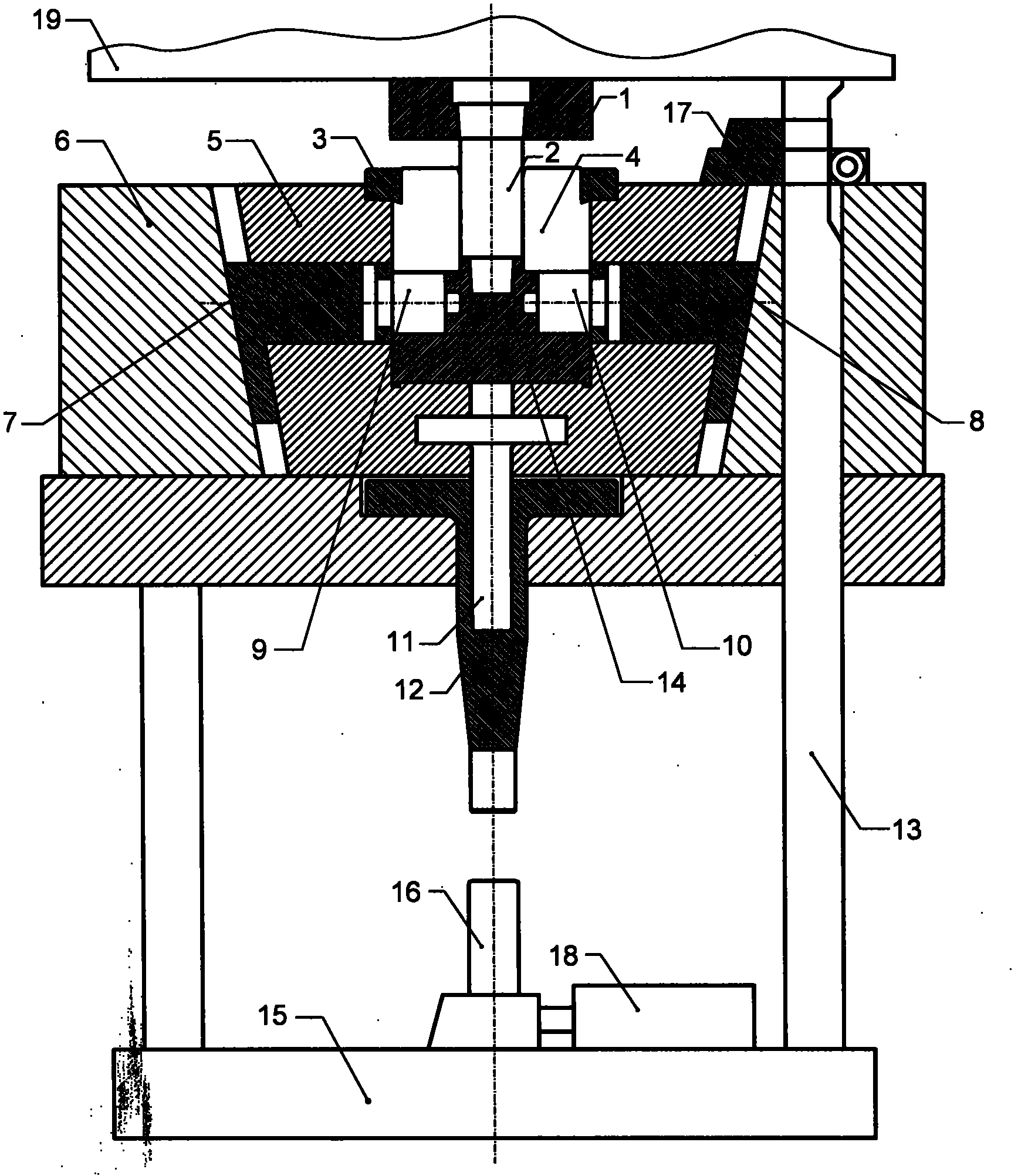

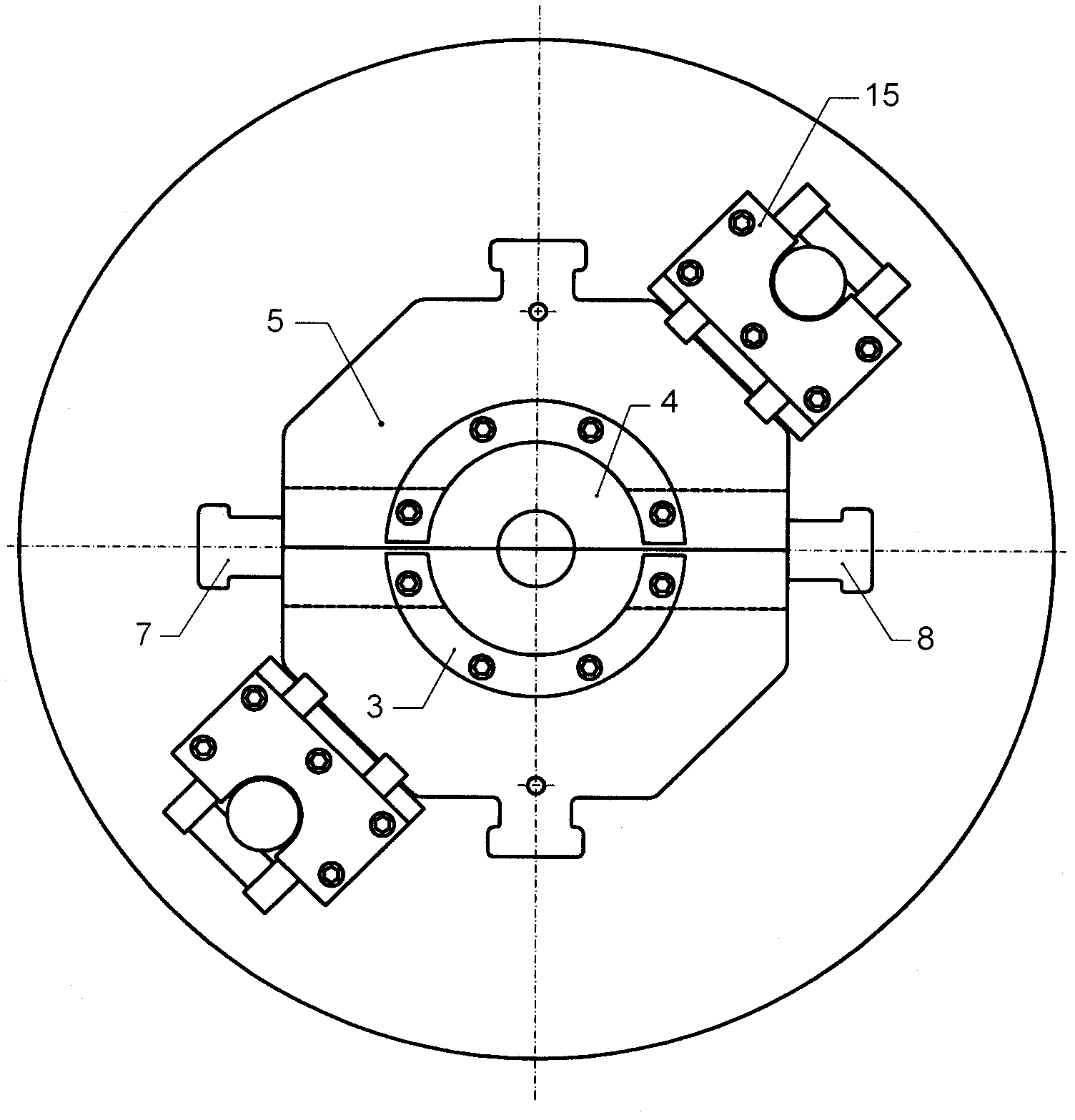

Inner transverse bar extrusion die for cylindrical component

The invention discloses an inner transverse bar extrusion die for a cylindrical component. The inner transverse bar extrusion die comprises an upper die base, a wedge, a left convex die, a right convex die, a left convex die fixing plate, a right convex die fixing plate, a hydraulic cylinder of a left push-pull fixing plate, a hydraulic cylinder of a right push-pull fixing plate, a concave die, a stopper, a lower die base, a thrust bearing plate, a steel ball bearing bracket, a steel ball, a spring and a rotating device, wherein the left and the right convex dies are mounted on the upper die base and can slide left and right, the opposite side walls of the left and the right convex dies are slopes, and the wedge is embedded between the slope of the left convex die and the slope of the right convex die; the concave die is fixed on the lower die base through the stopper, and the upward and downward floatation of the concave die is realized on the lower die base through the spring. According to the inner transverse bar extrusion die provided by the invention, the separable convex dies and the floating type concave die are adopted, a workblank is vertically pressed down by the convex dies and driven to rotate by the concave die, a cylindrical wall is formed in a way that the workblank spirally flows upwards in the twisting process, cylinder fibers are spirally distributed and diagonally arranged, isotropy is realized, and the lateral and longitudinal comprehensive performance of the extruded component is improved.

Owner:ZHONGBEI UNIV

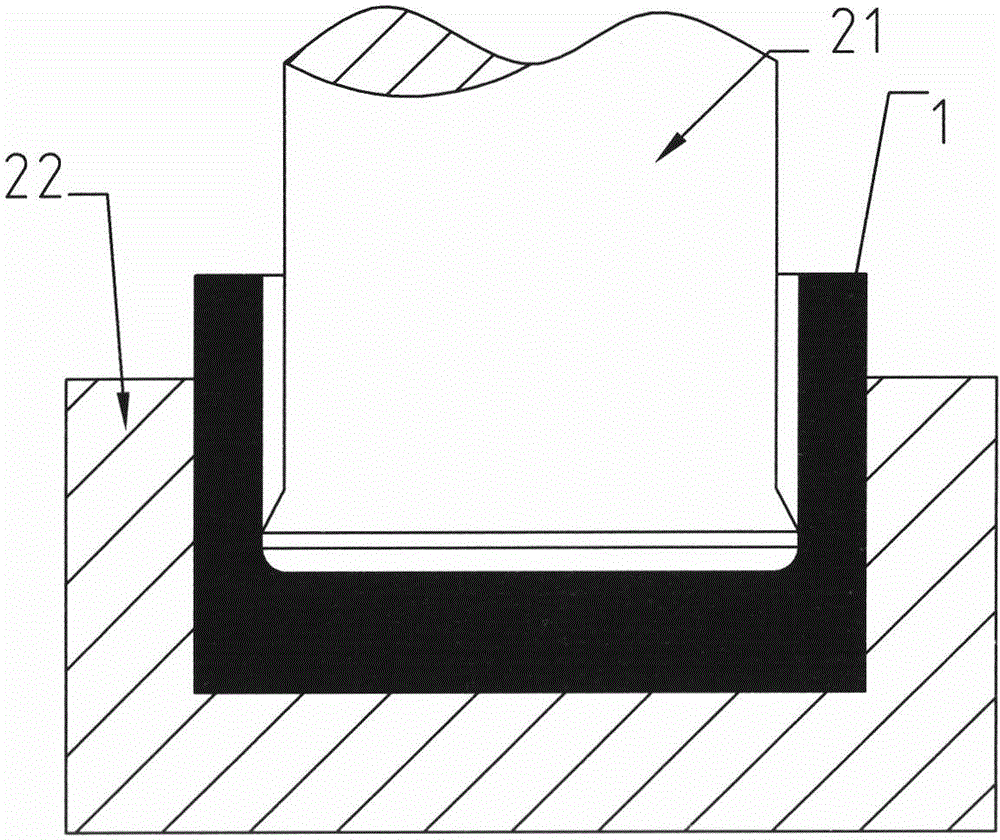

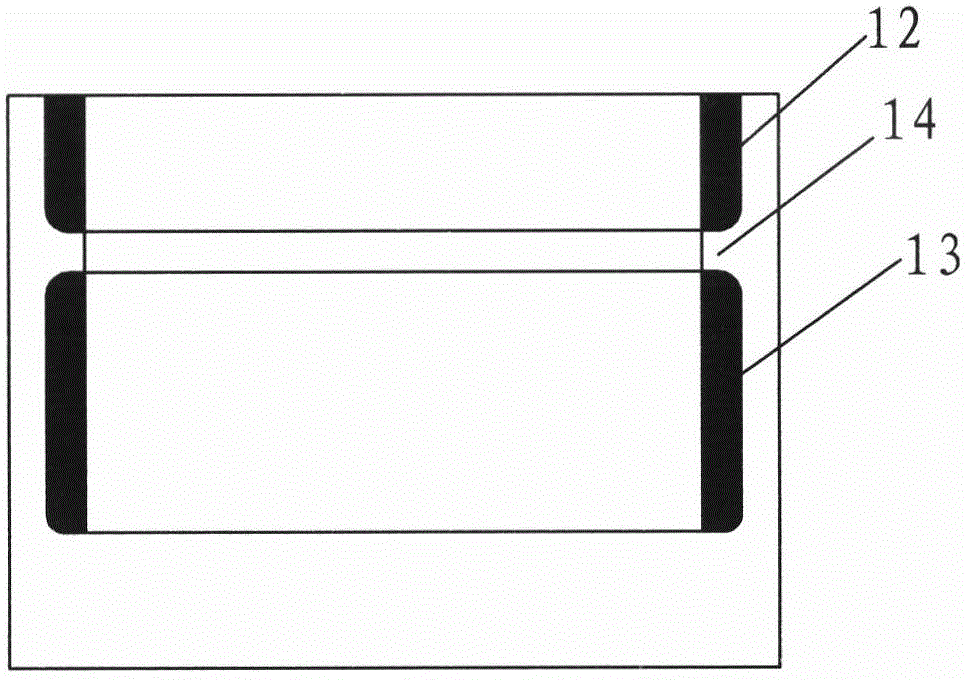

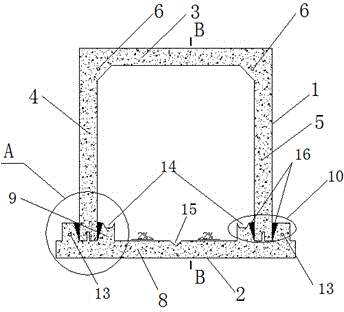

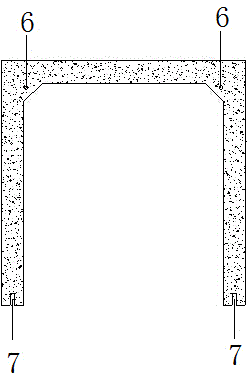

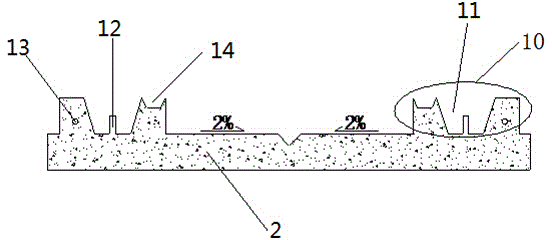

Novel assembling type precast concrete urban comprehensive pipe gallery and construction method thereof

ActiveCN104674847AImprove waterproof performanceImprove drainage capacityArtificial islandsUnderwater structuresWater dischargeArchitectural engineering

The invention discloses a novel assembling type precast concrete urban comprehensive pipe gallery and a construction method thereof. The novel assembling type precast concrete urban comprehensive pipe gallery comprises a plurality of inverted u-shaped cover plates and a plurality of substrate plates, wherein each inverted u-shaped cover plate comprises a cross plate, a left vertical plate and a right vertical plate; each substrate plate comprises a bottom plate, a left convex plate and a right convex plate; the middle position of each left convex plate and each right convex plate is provided with troughs; each left vertical plate and each right vertical plate are respectively installed in each left convex plate and each right convex plate; the middle position of each bottom plate is provided with a central drain. The construction method of the novel assembling type precast concrete urban comprehensive pipe gallery comprises the following steps: preparing prefabticated members; excavating and timbering a foundation pit; laying a cushion ply; connecting the inverted u-shaped cover plates with the substrate plates; connecting the inverted u-shaped cover plates, and connecting the substrate plates; tensioning, smearing gaps, backfilling and carrying out form stripping. The novel assembling type precast concrete urban comprehensive pipe gallery has the advantages of convenience in transportation, construction and maintenance, simpleness in operation and high construction efficiency, and the structural integrity and stability of a gallery body can be improved, and the water resistance and water discharging performances of the pipe gallery can be improved.

Owner:NORTHEASTERN UNIV

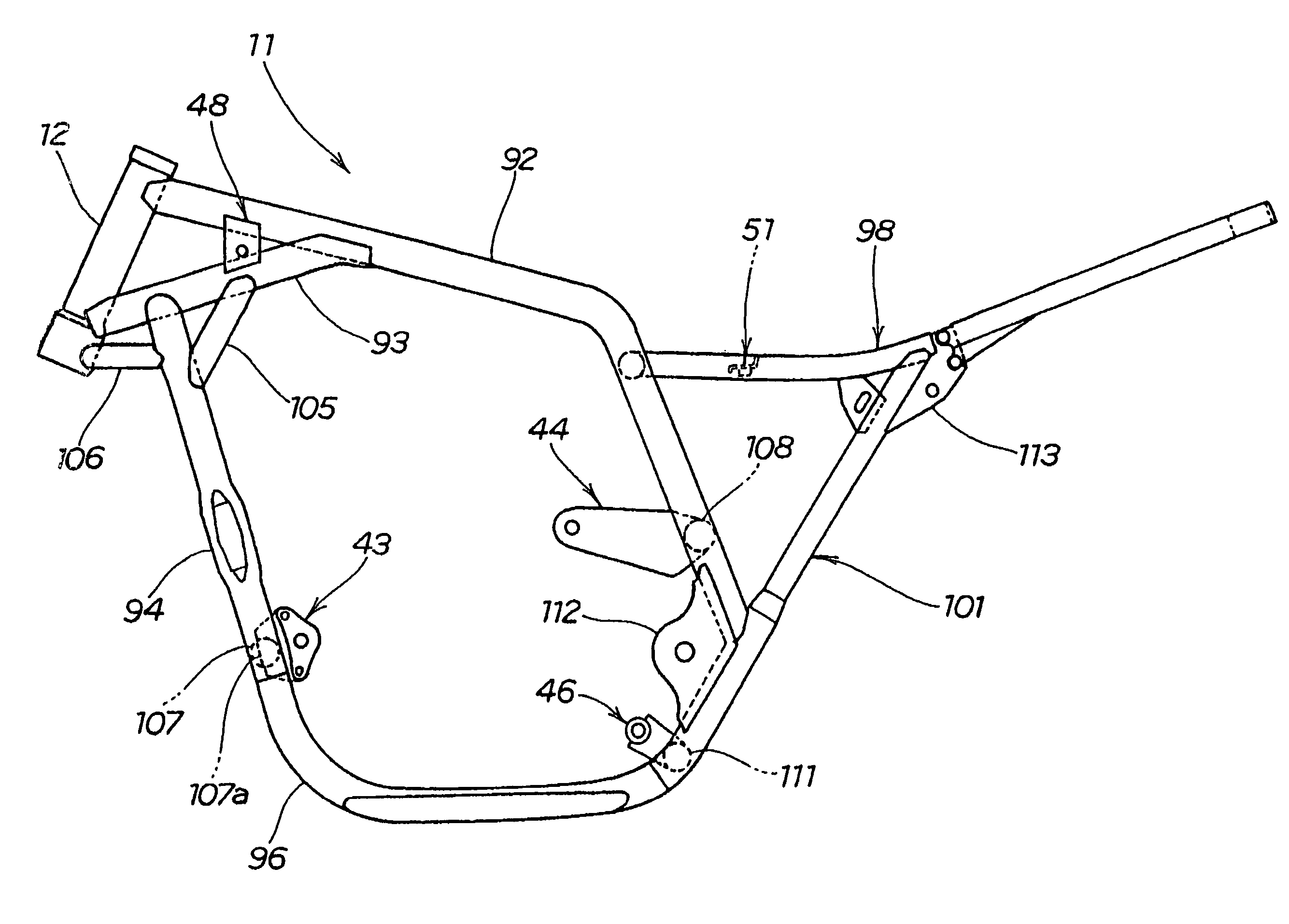

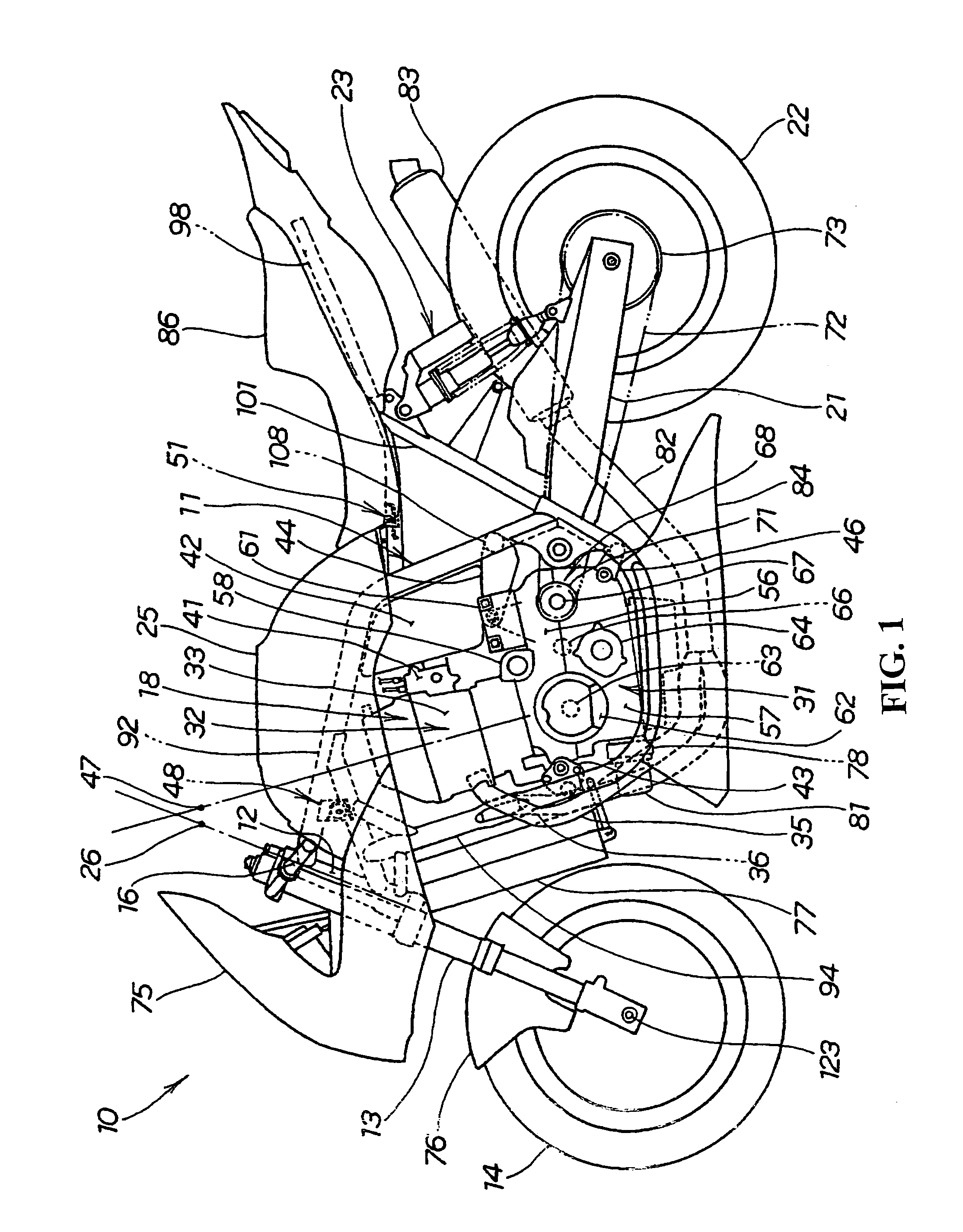

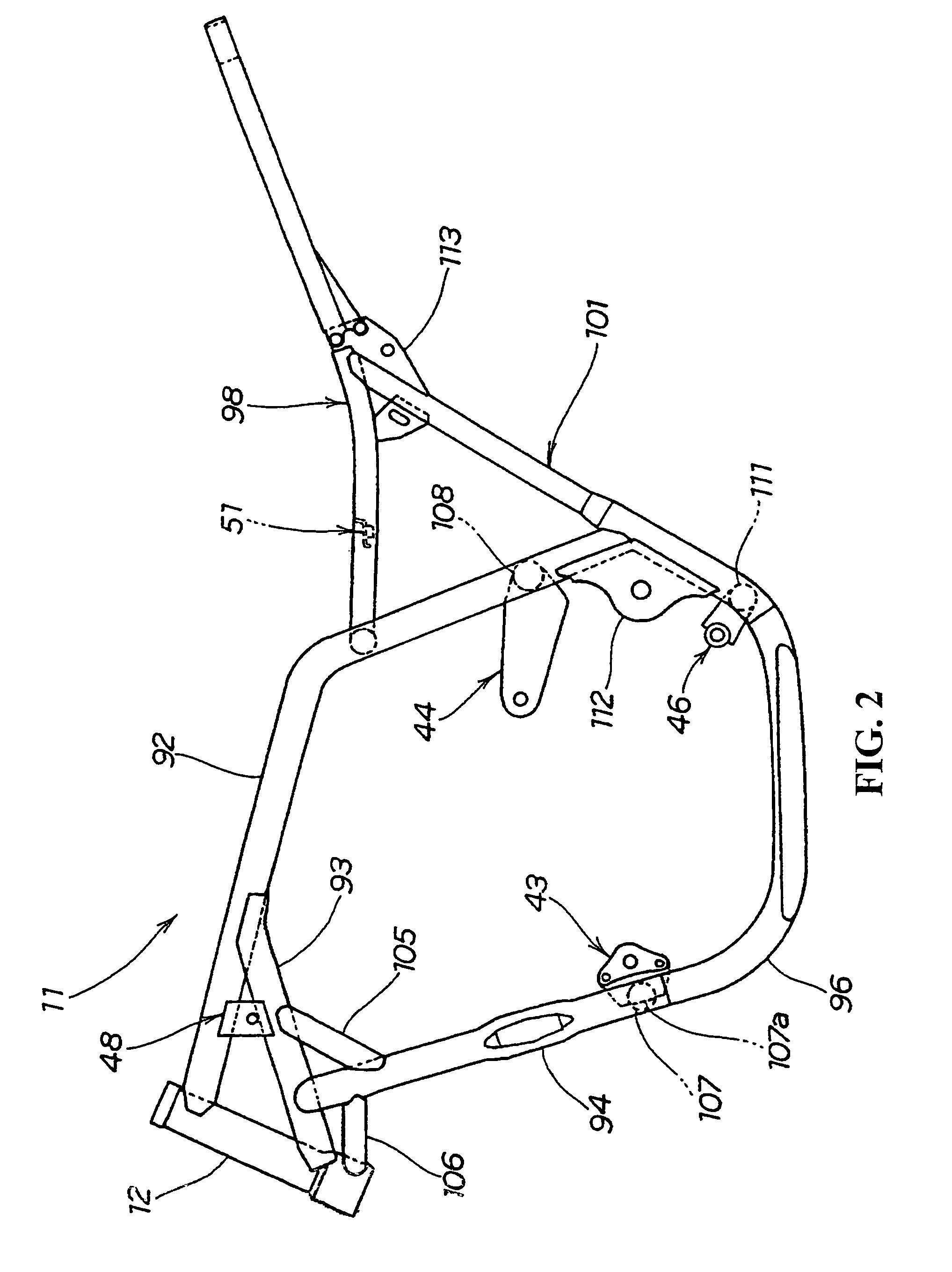

Structure of fuel pump installation area for two-wheeled vehicle

InactiveUS7422243B2Increase stiffnessTank vehiclesUsing liquid separation agentVehicle frameFuel tank

Owner:HONDA MOTOR CO LTD

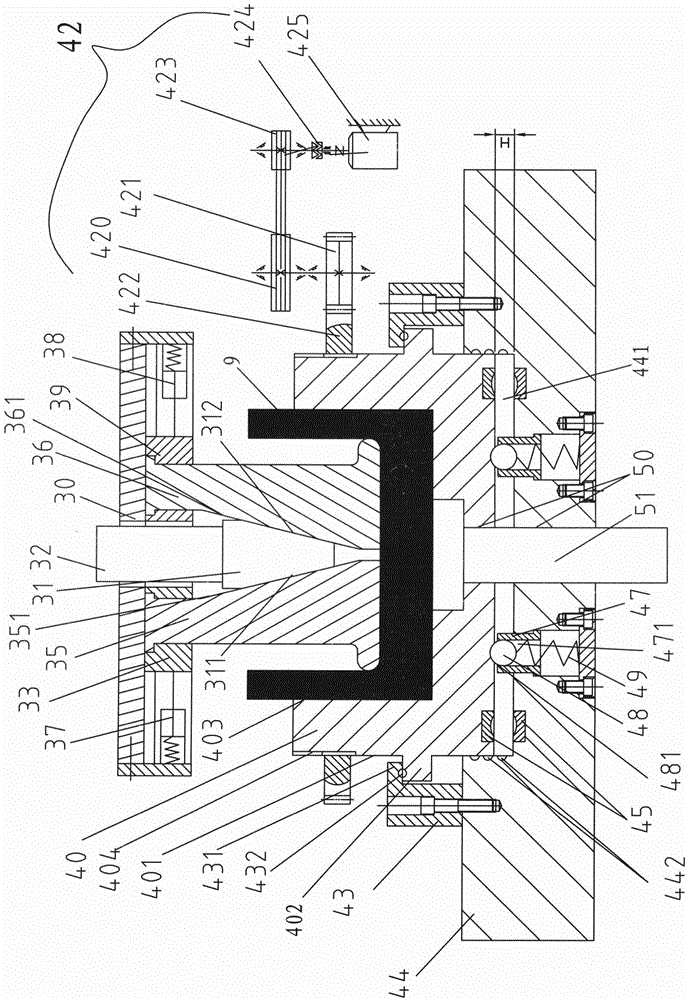

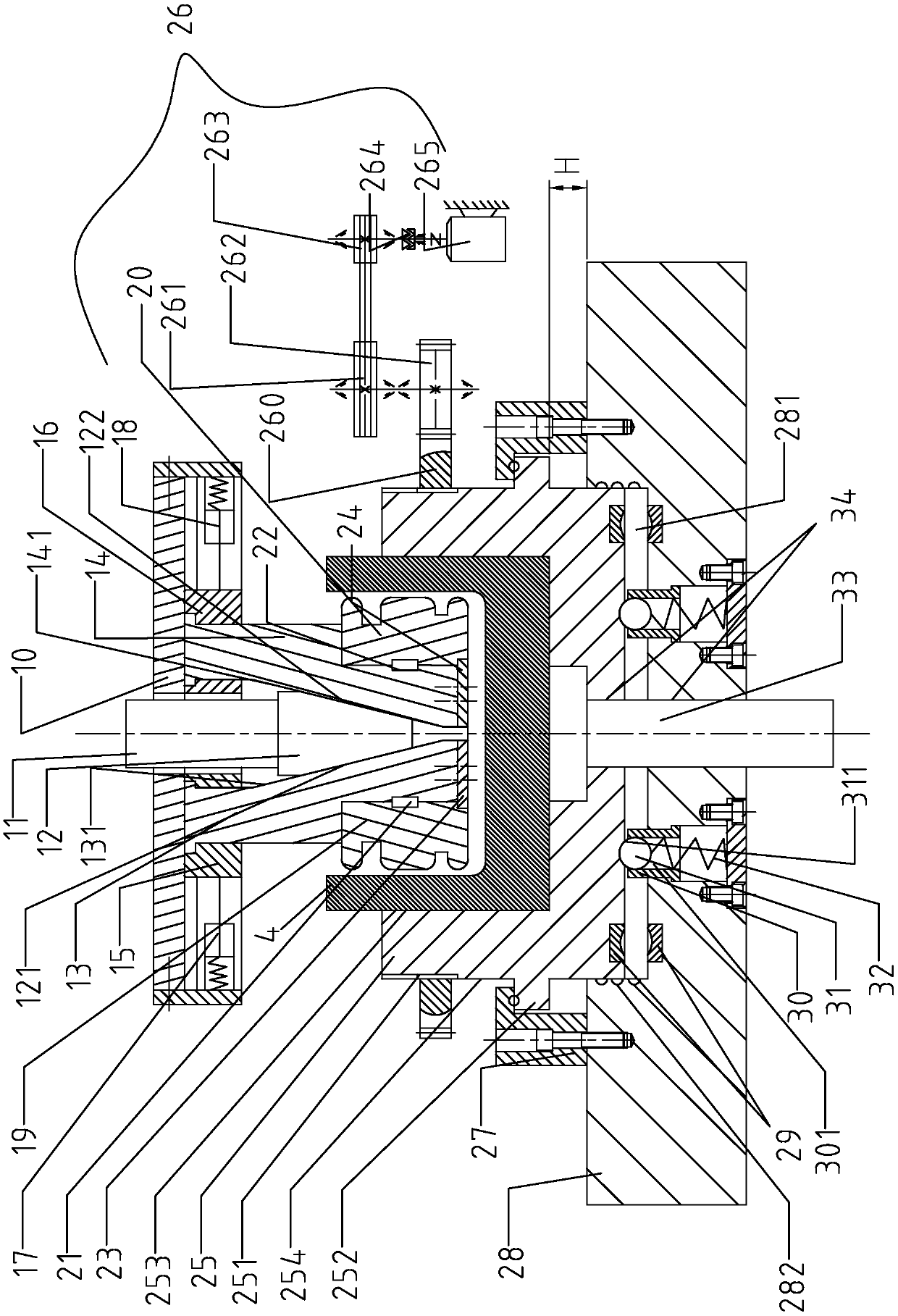

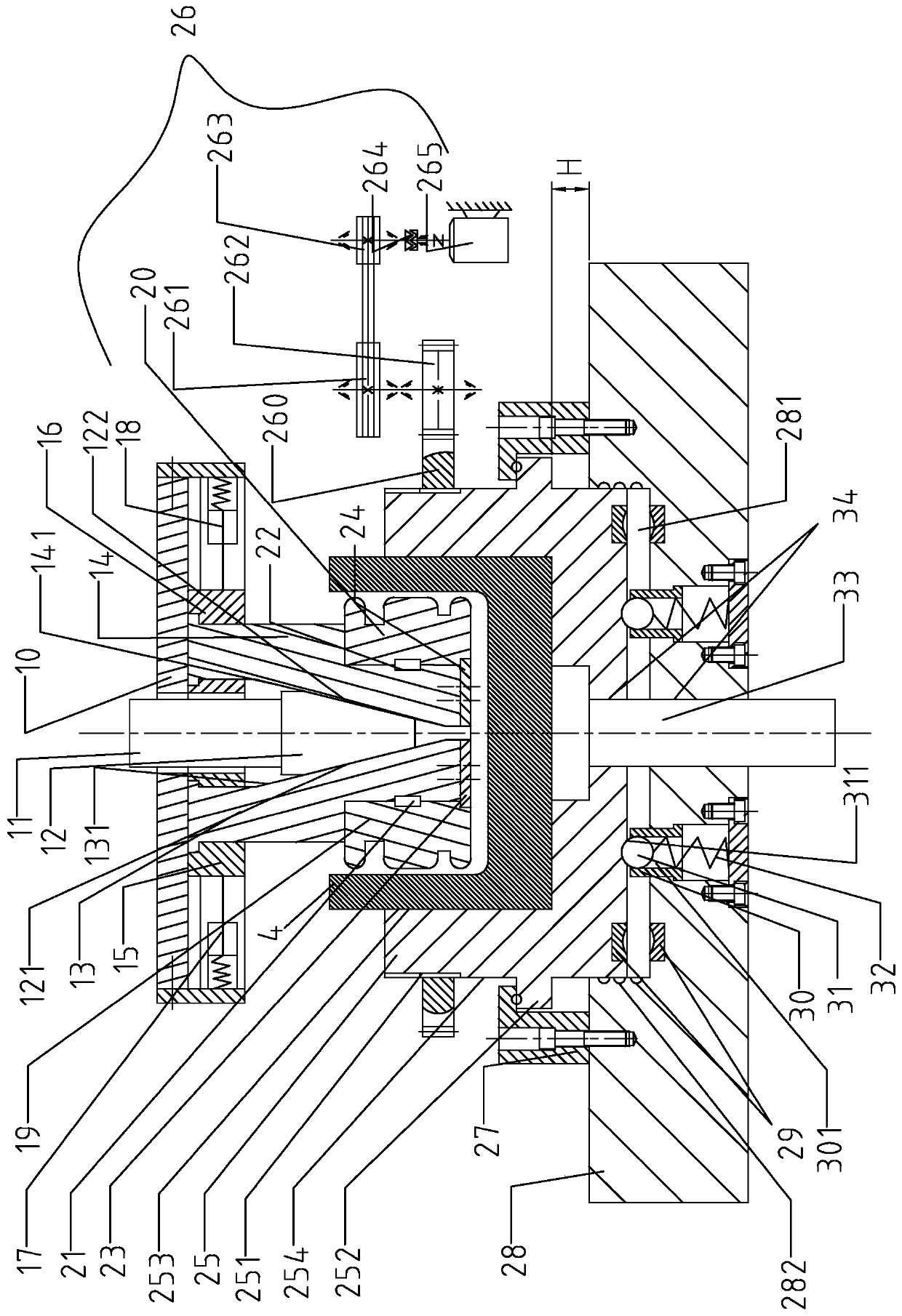

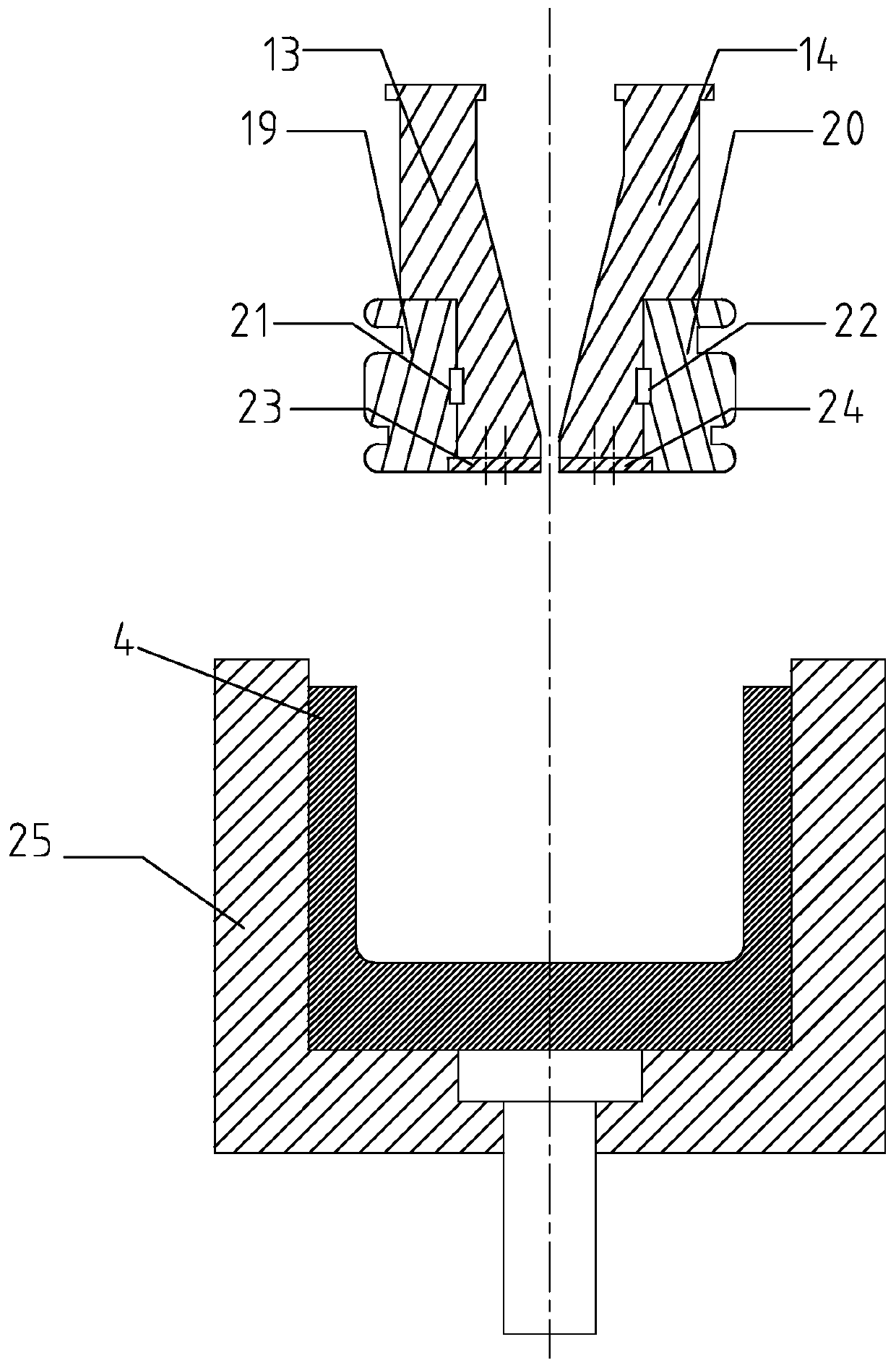

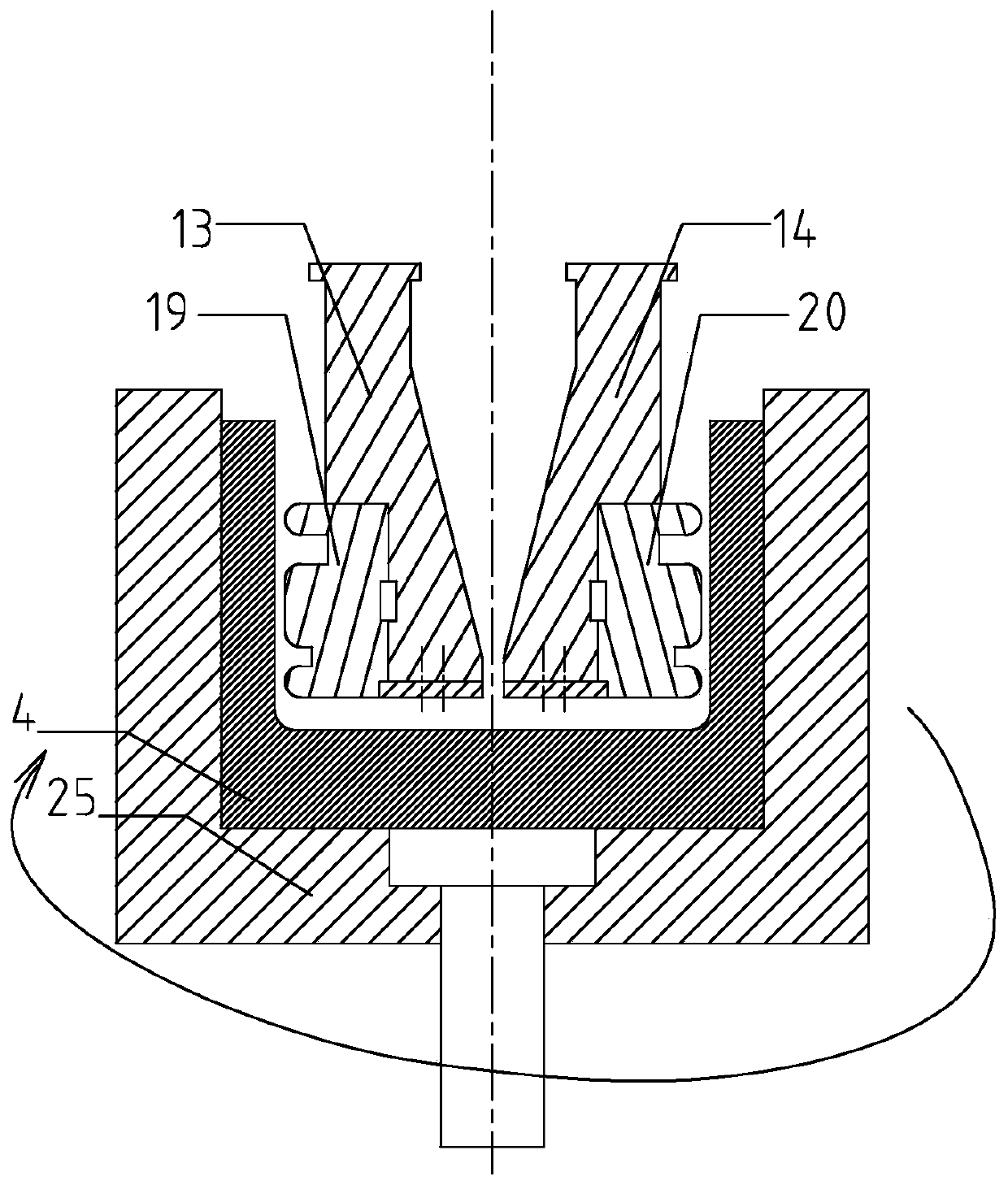

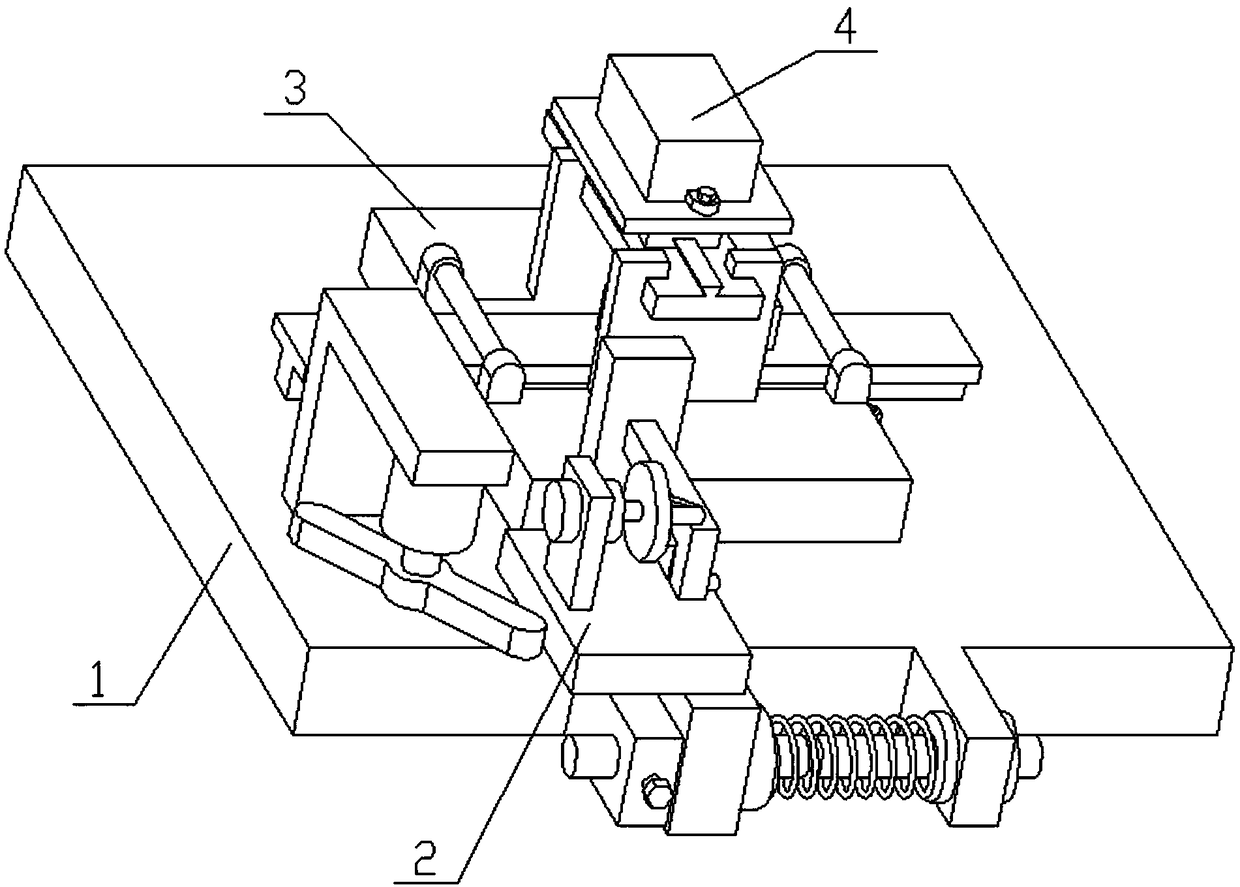

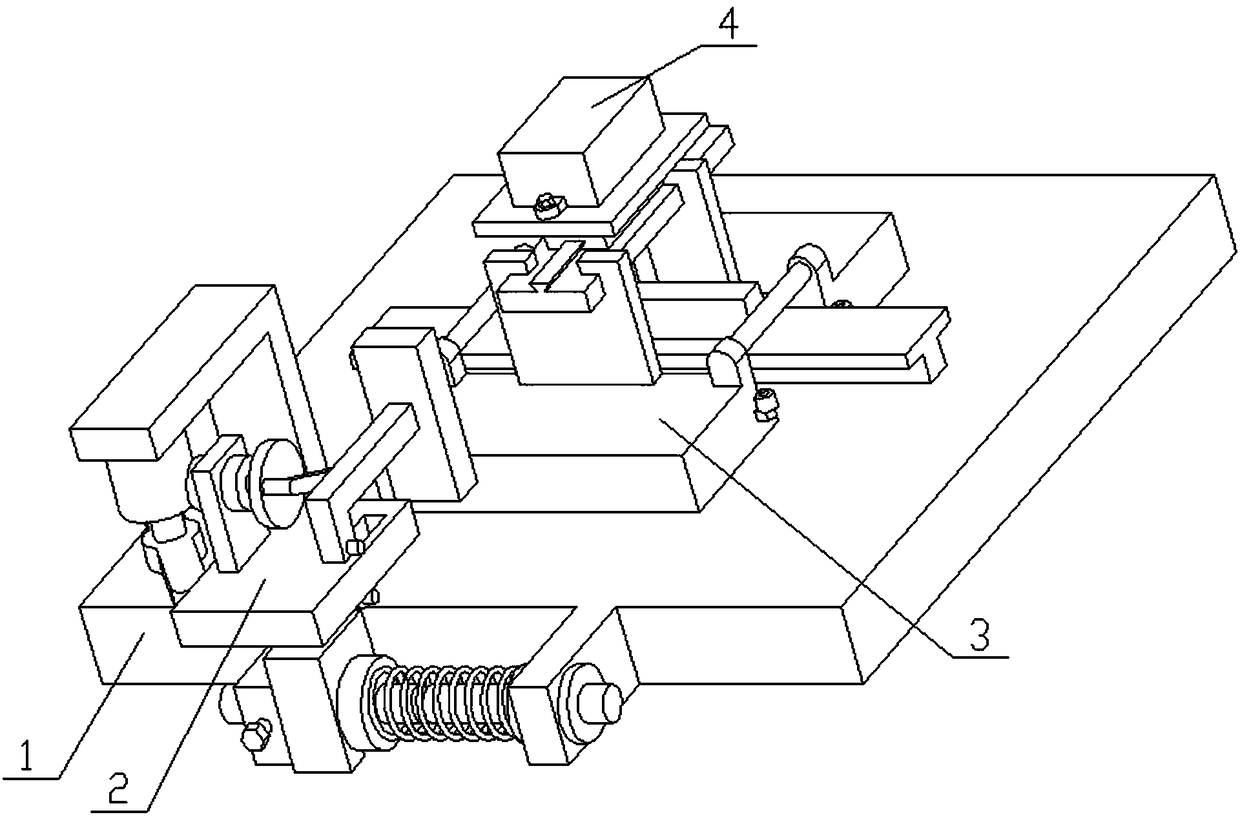

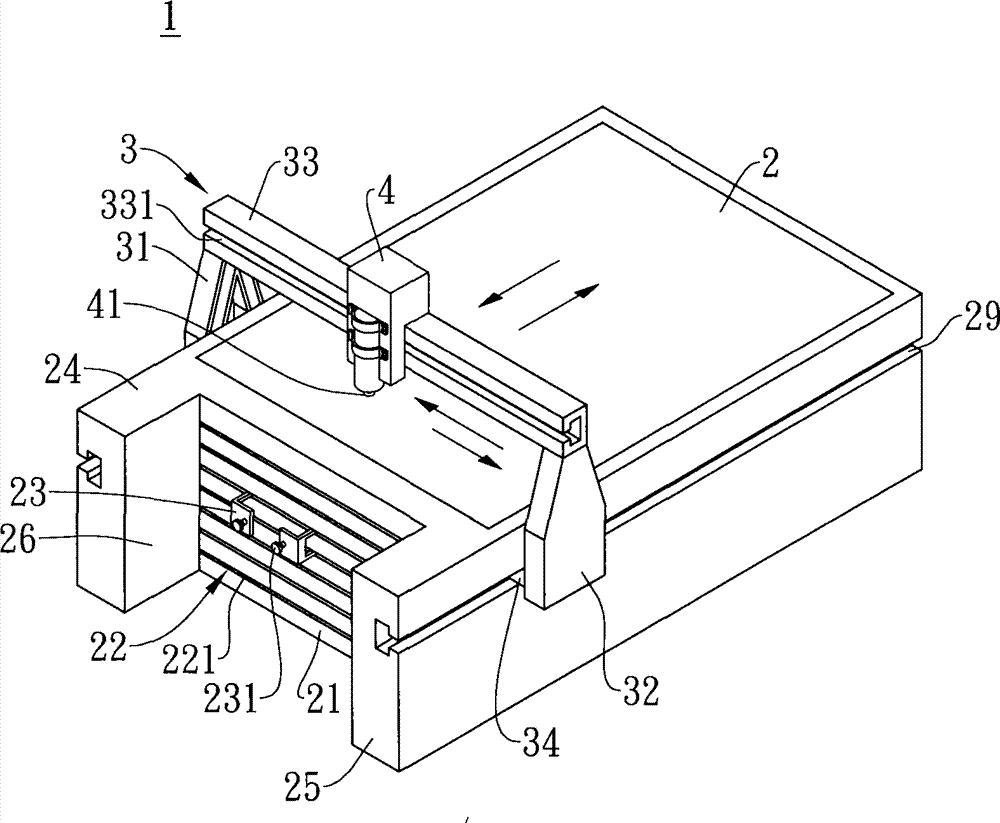

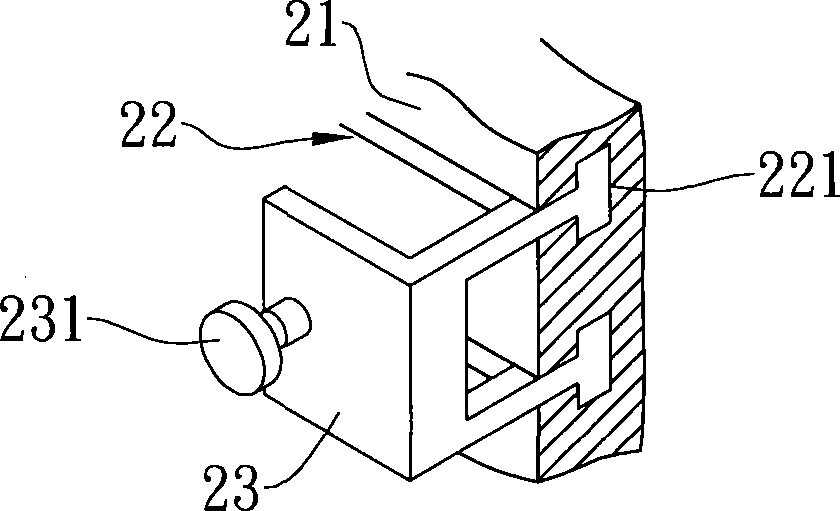

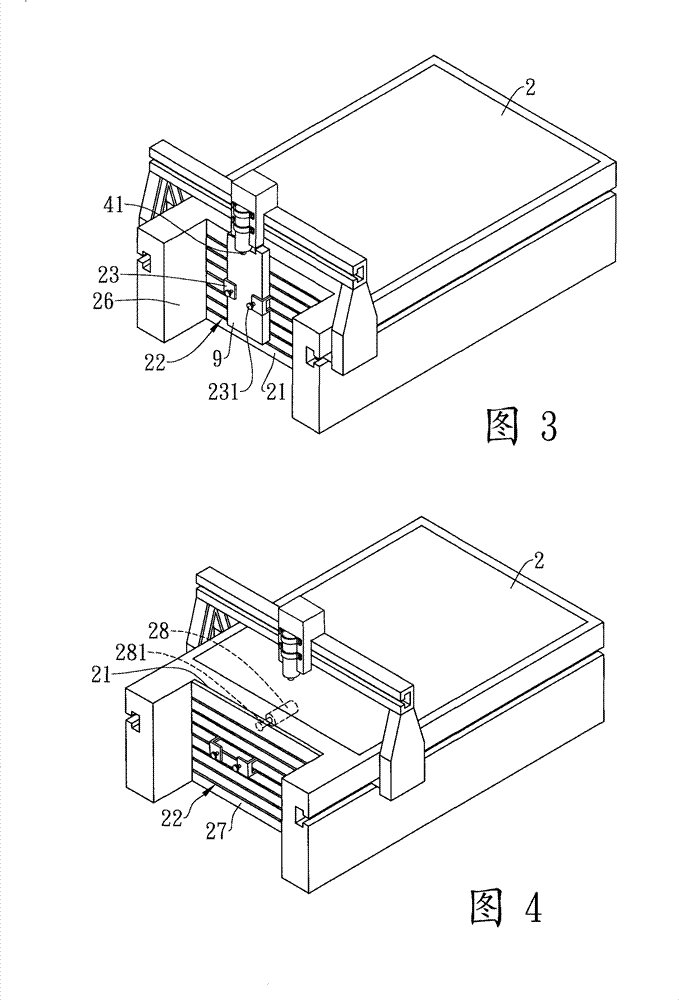

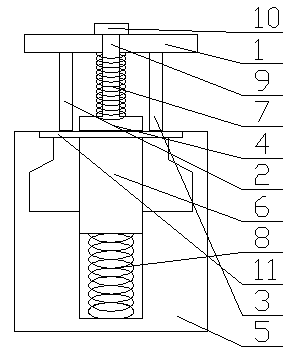

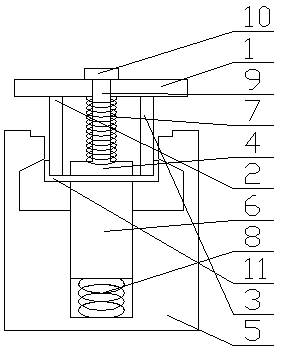

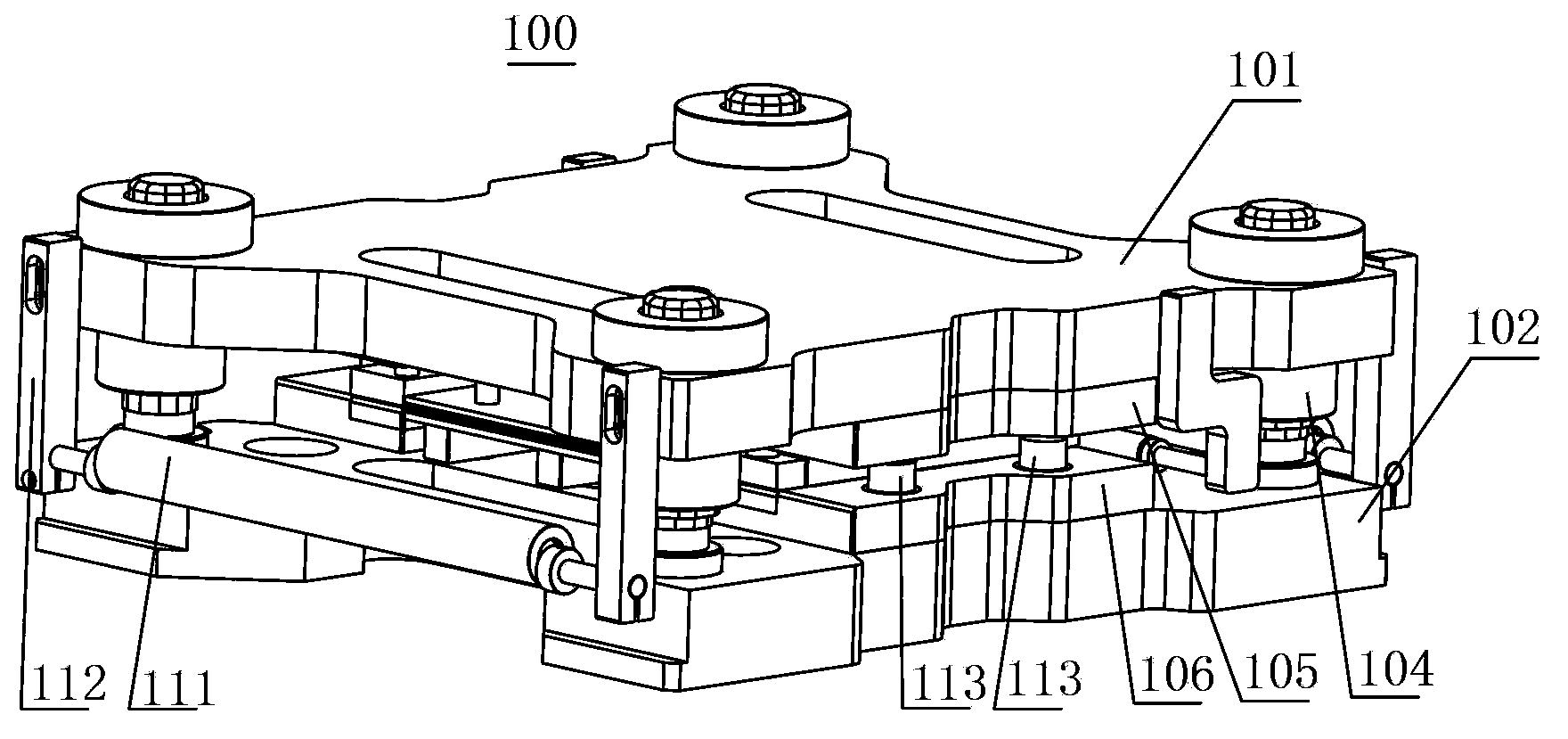

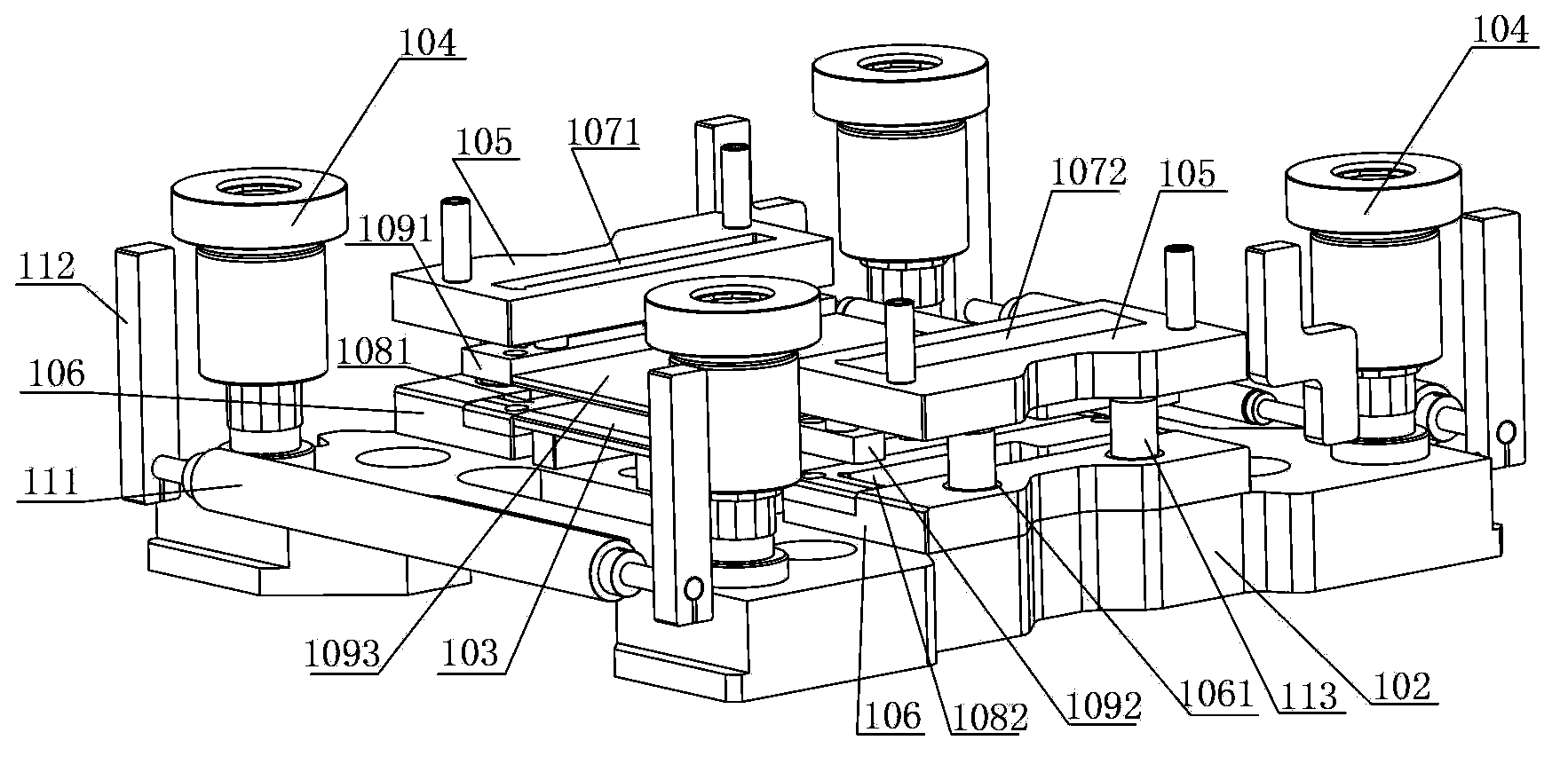

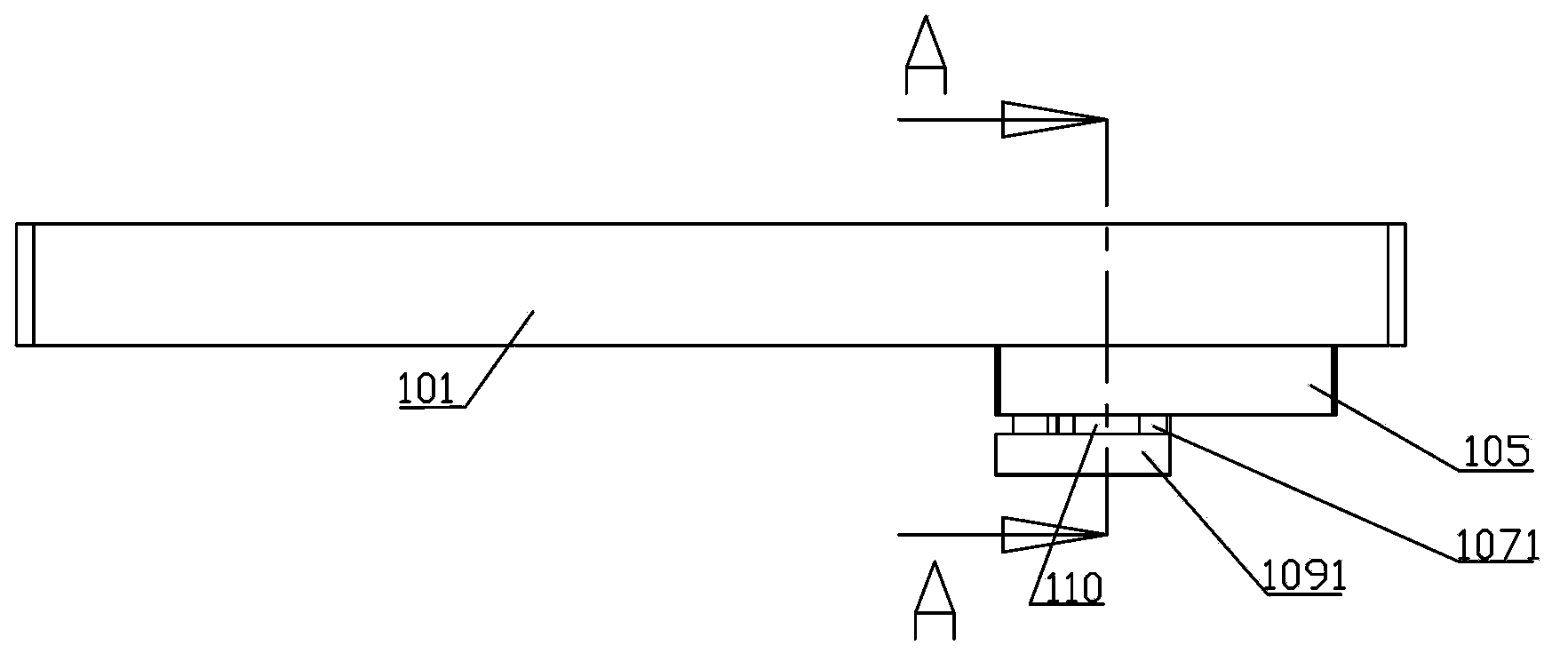

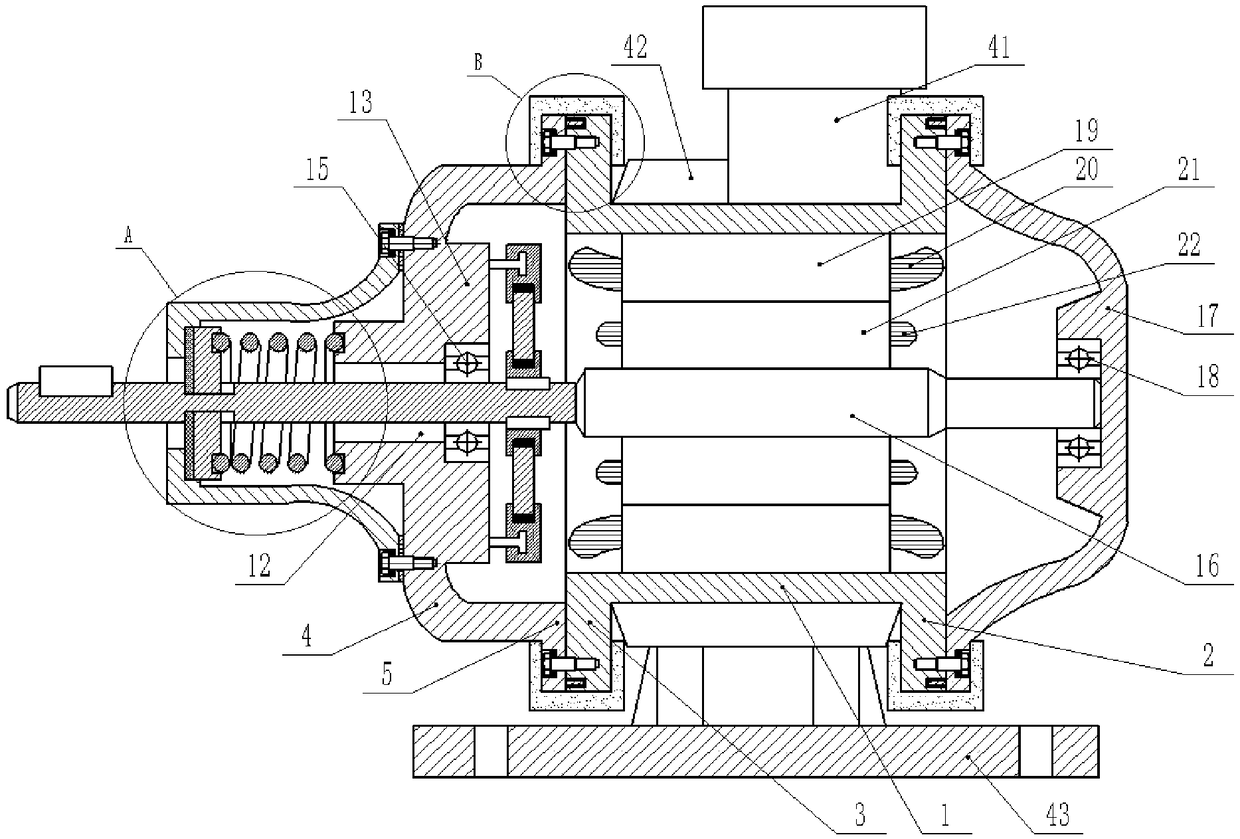

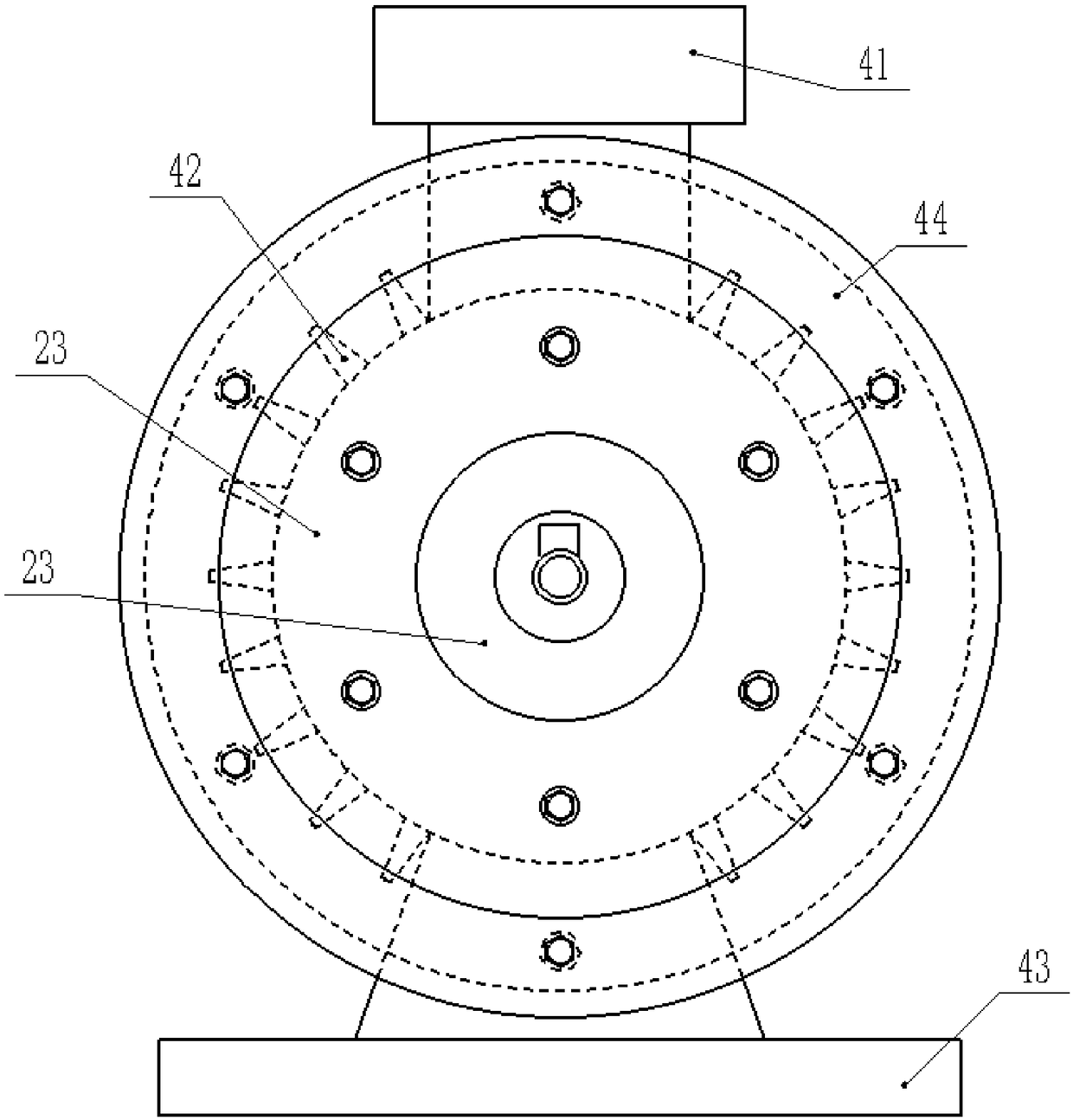

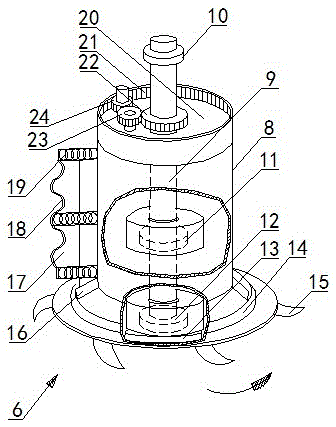

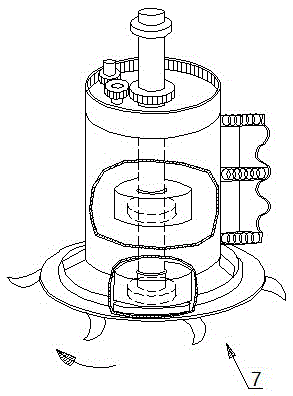

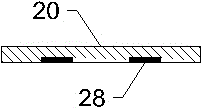

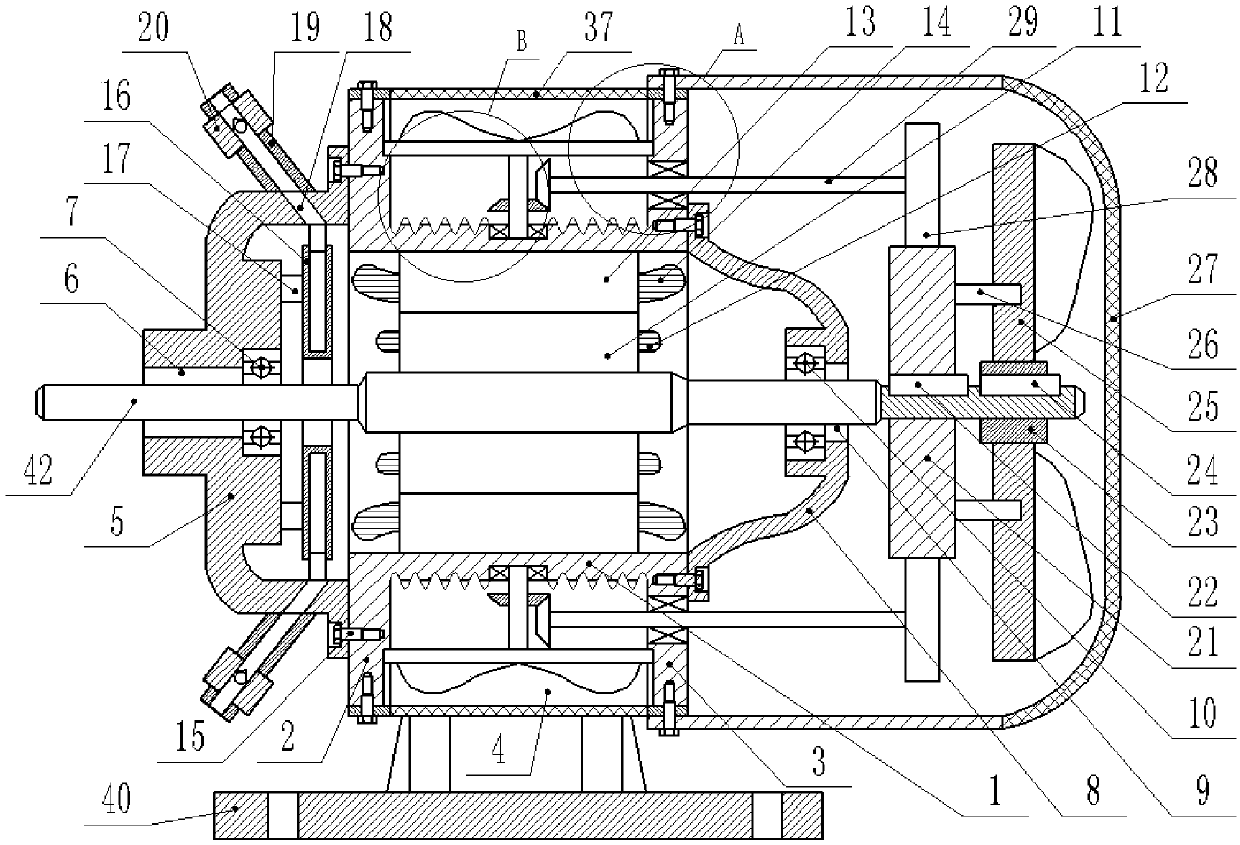

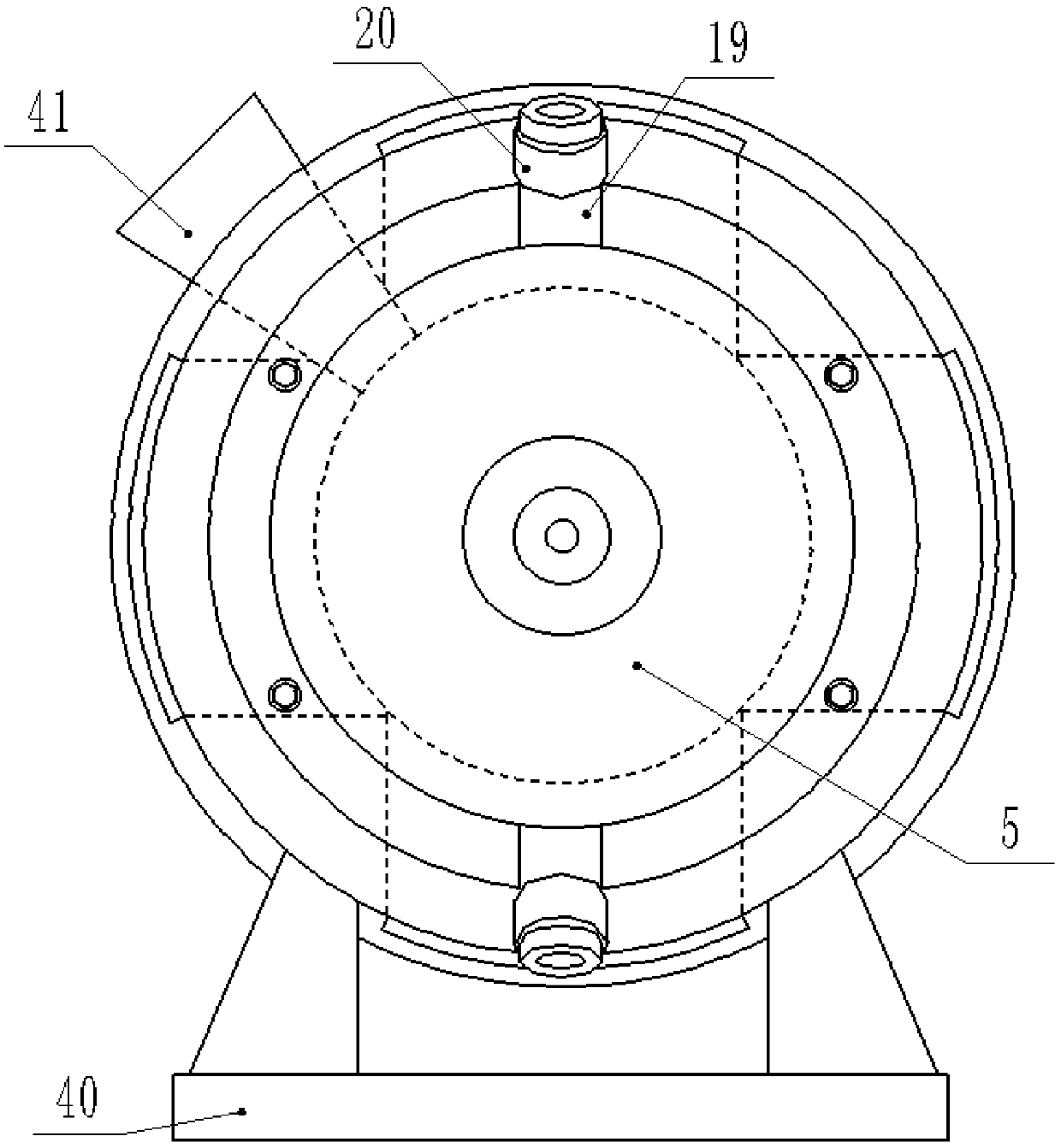

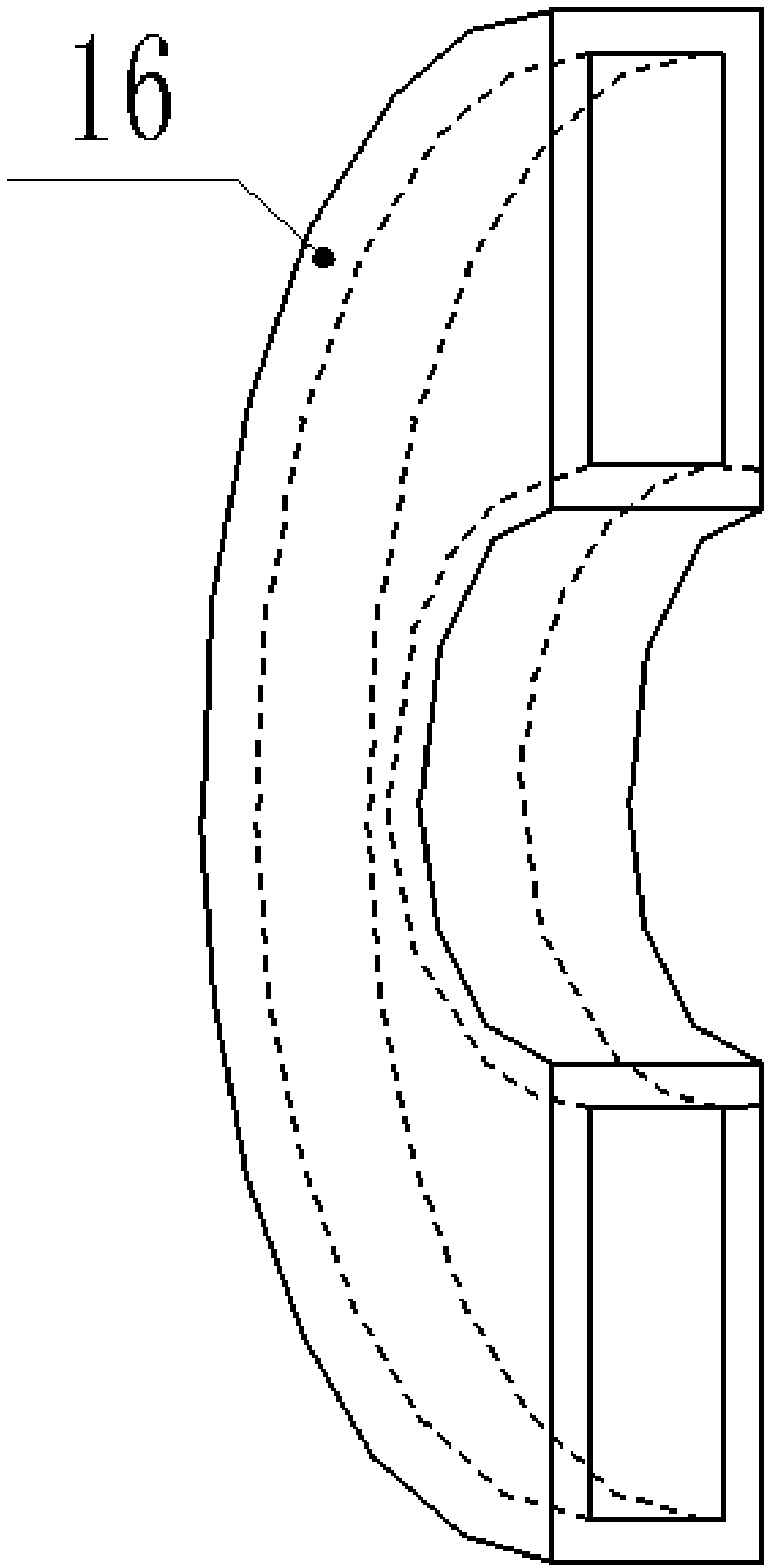

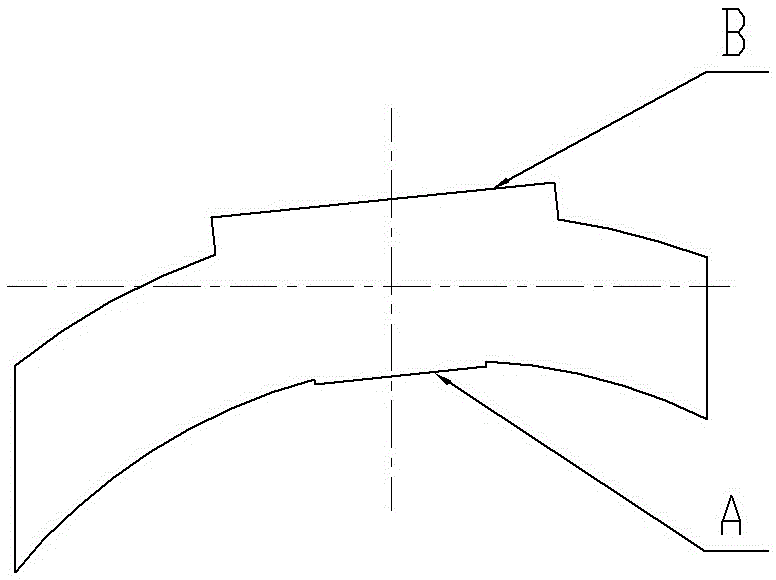

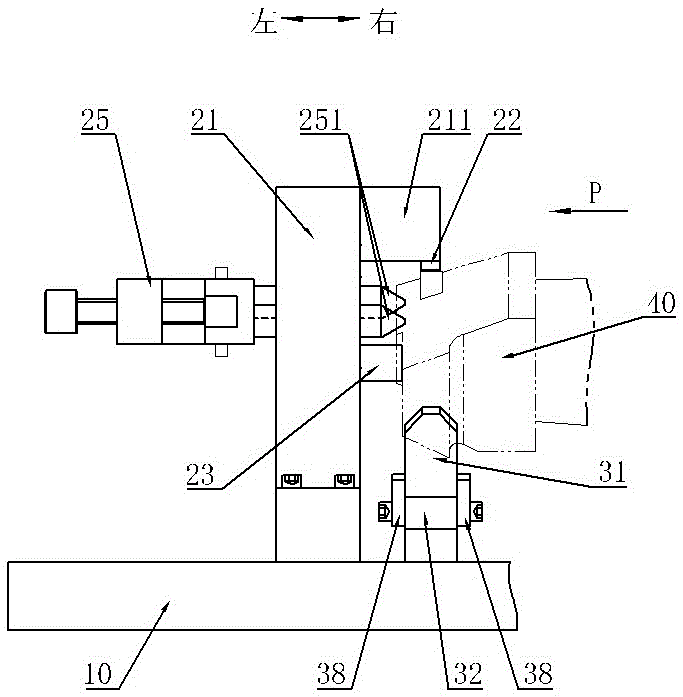

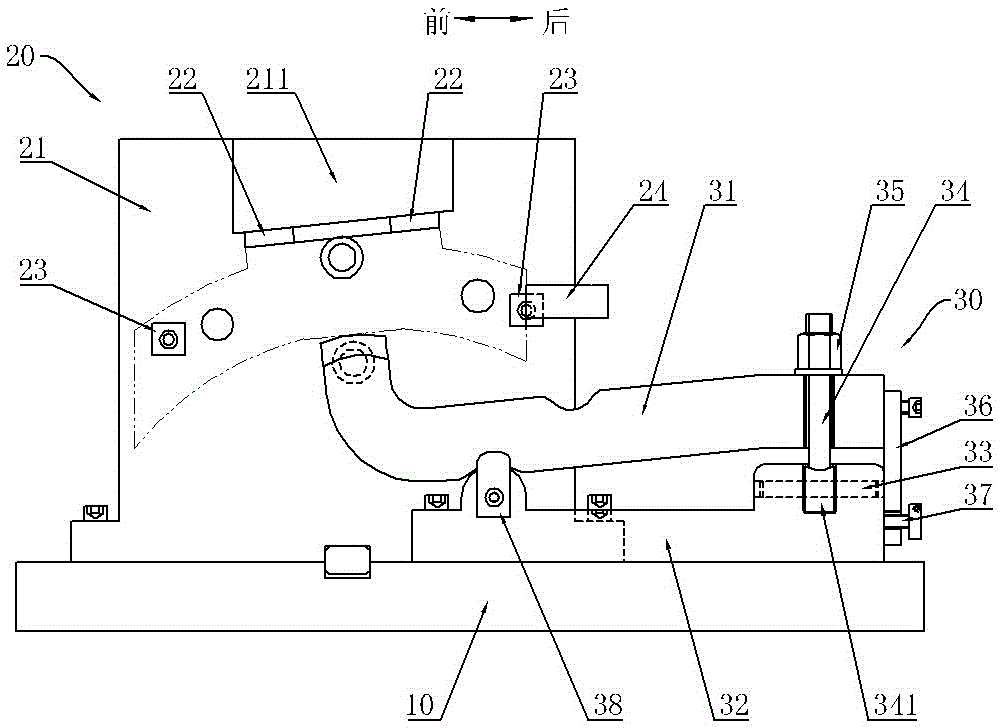

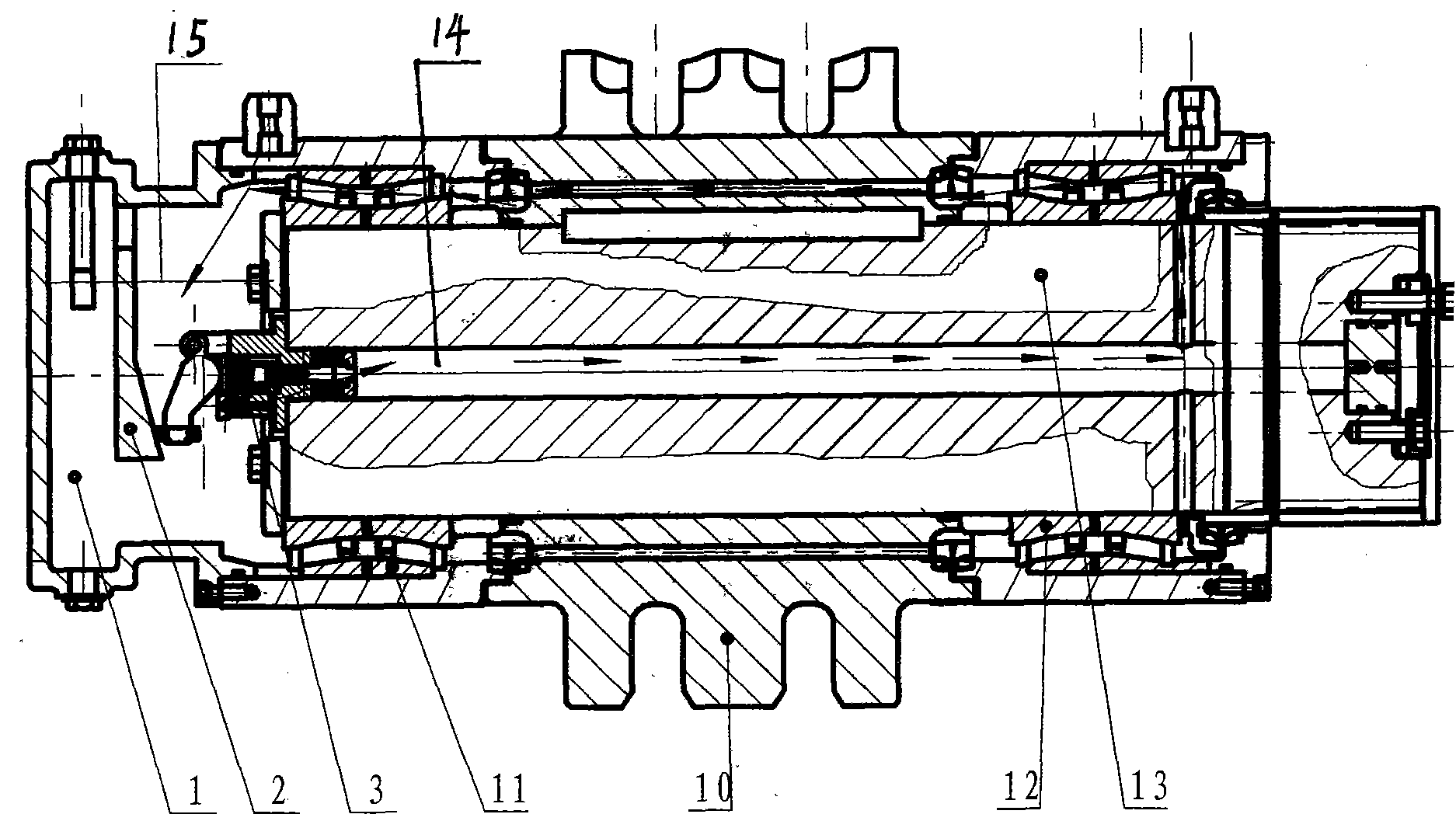

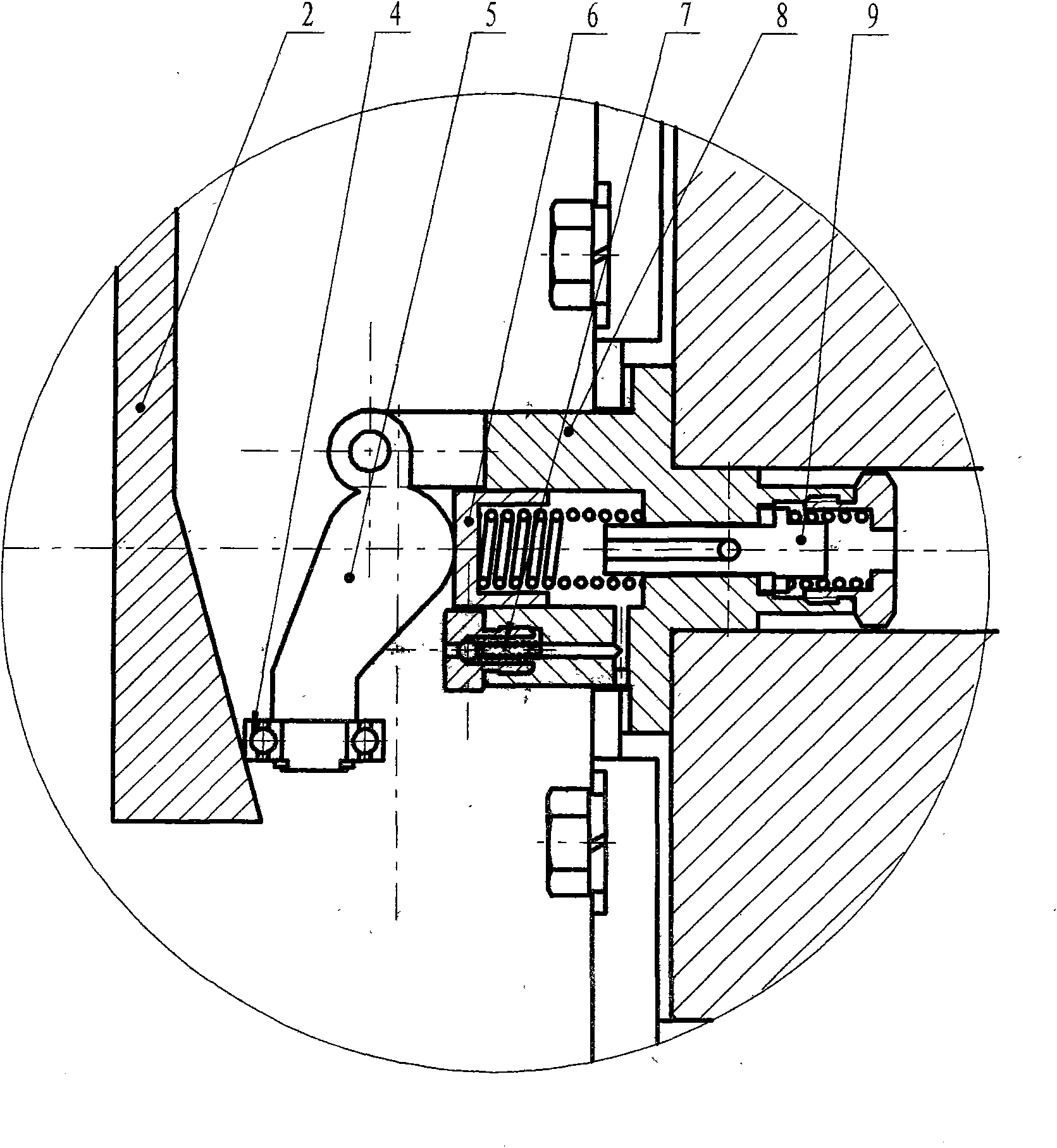

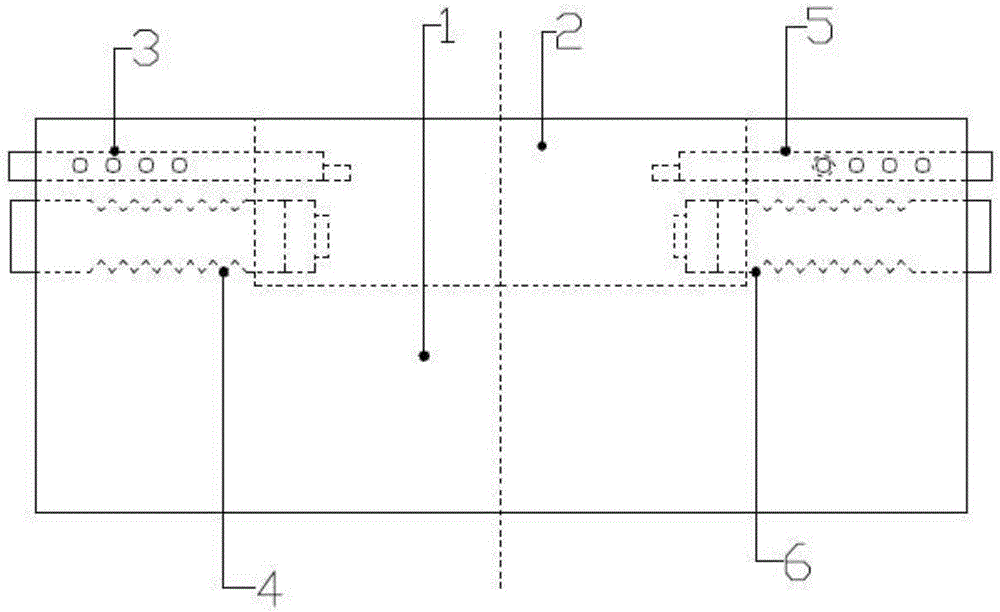

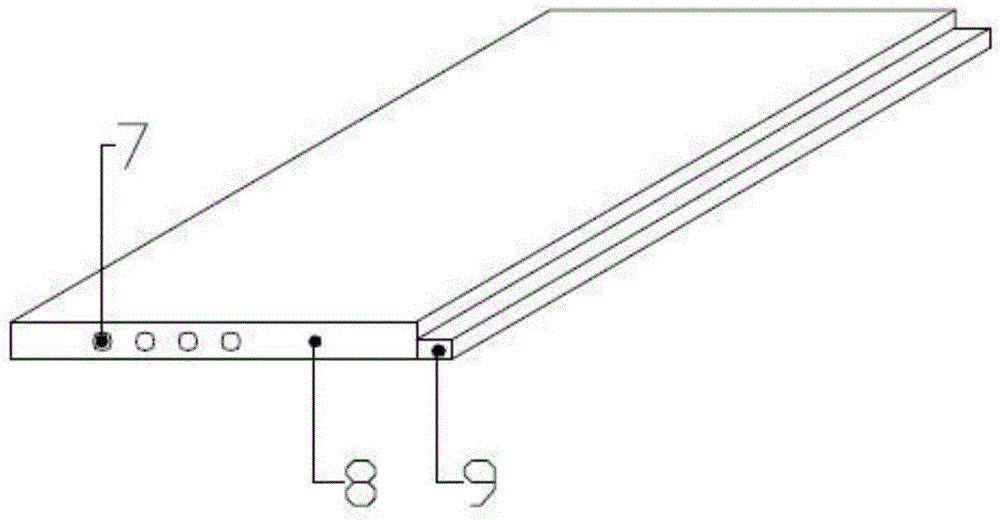

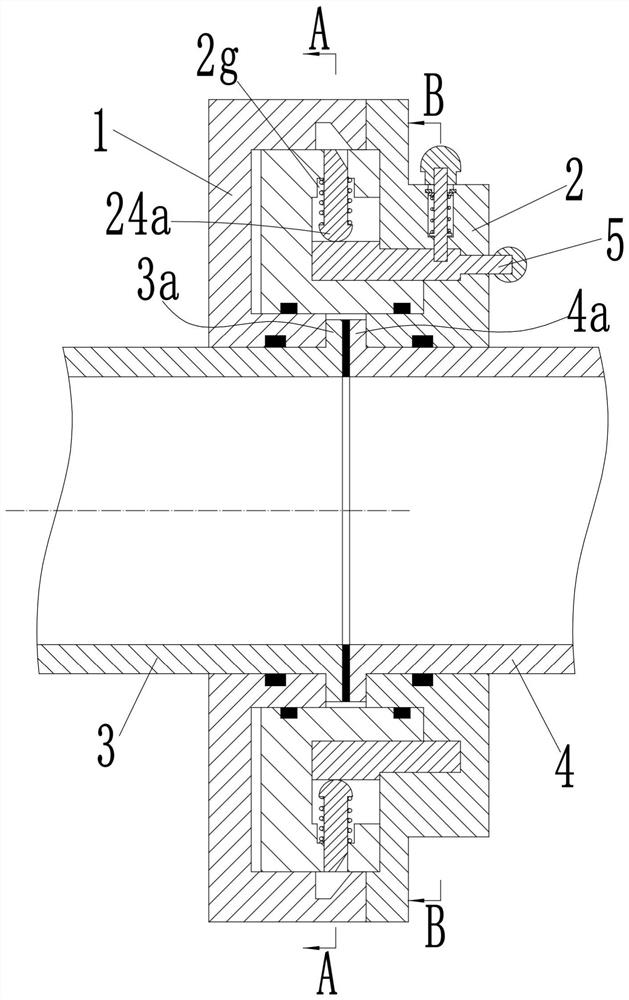

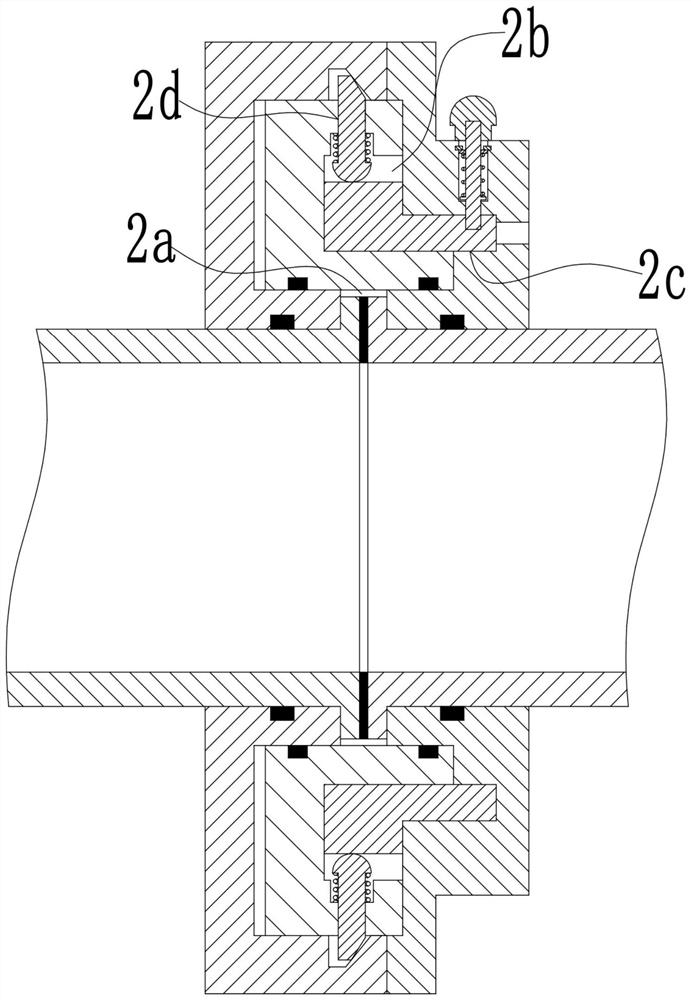

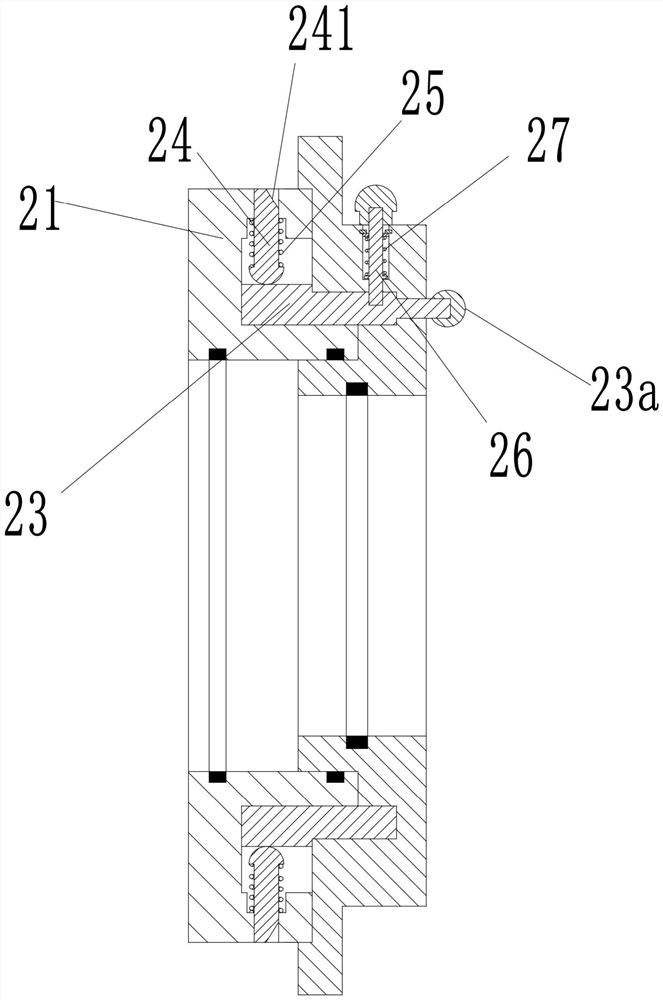

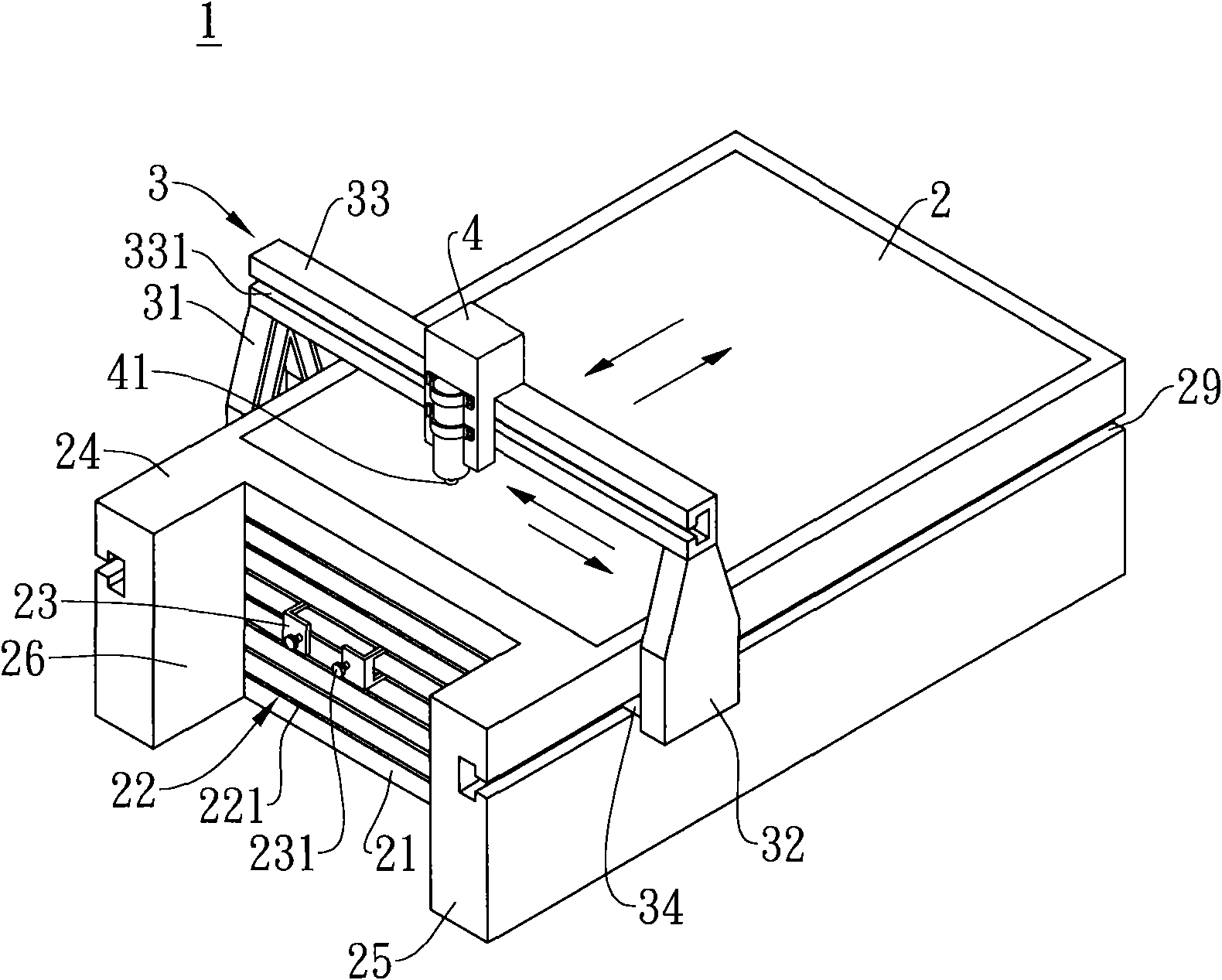

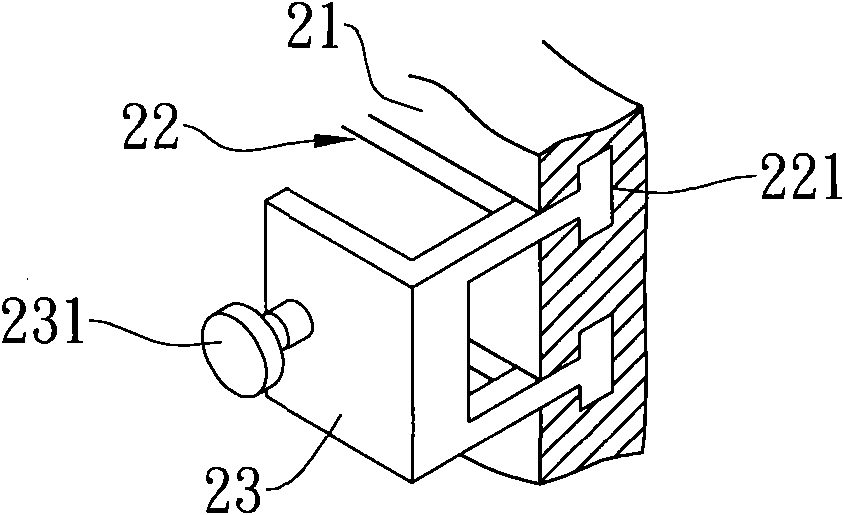

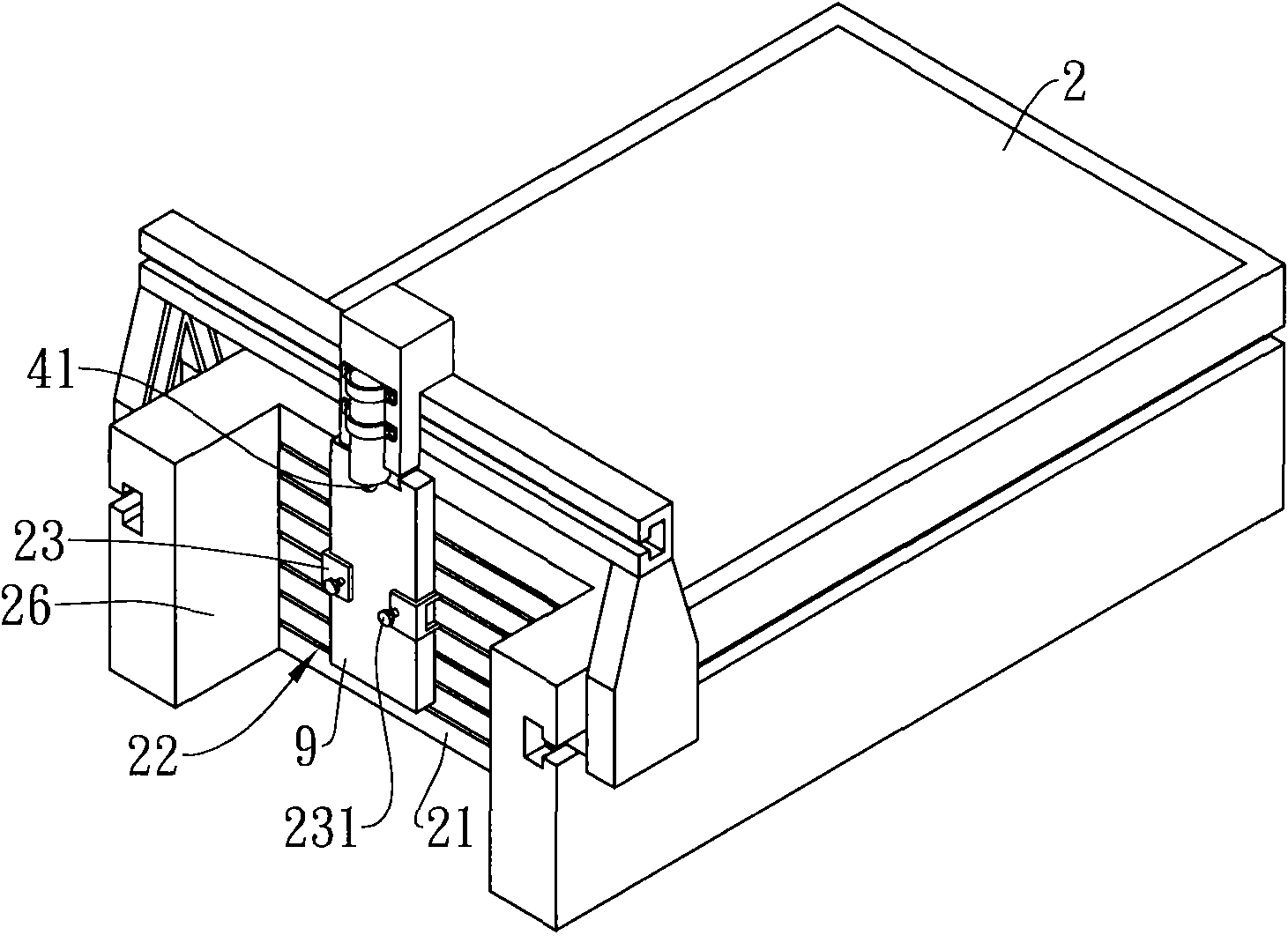

Rotary extrusion forming die for multiple inner annular ribs of cylindrical workpiece

The invention discloses a rotary extrusion forming die for multiple inner annular ribs of a cylindrical workpiece. The rotary extrusion forming die comprises a split convex die, an inner shape imitating forming sleeve, a rotating device, a floating device, an upper die assembly connected with the upper die holder and a concave die connected with a lower die holder; the split convex die comprises aleft convex die body and a right convex die body, the opposite side walls of the left convex die body and the right convex die body are slopes, and the inner shape imitating forming sleeve is fixed to the side walls outside the slopes of the left convex die body and the right convex die body; the upper die assembly comprises a double action press perforated cylinder connector, a wedge block and apush-pull device, the wedge block is embedded between the slopes of the left convex die body and the right convex die body, the double action press perforated cylinder connector is connected to the wedge block, and the push-pull device is used for controlling the left convex die body and the right convex die body to slide on the upper die holder left and right; and the rotating device and the floating device are used for driving the concave die to rotate and vertically float on the lower die holder separately. According to the rotary extrusion forming die for the multiple inner annular ribs of the cylindrical workpiece, the inner shape imitating forming sleeve can be quickly replaced according to the shape and the quantity of the formed inner annular ribs, and the cylindrical workpiece with the large height-diameter ratio, the multiple cross section shape varieties and the high inner annular rib and body strength requirement can be formed at a time.

Owner:ZHONGBEI UNIV

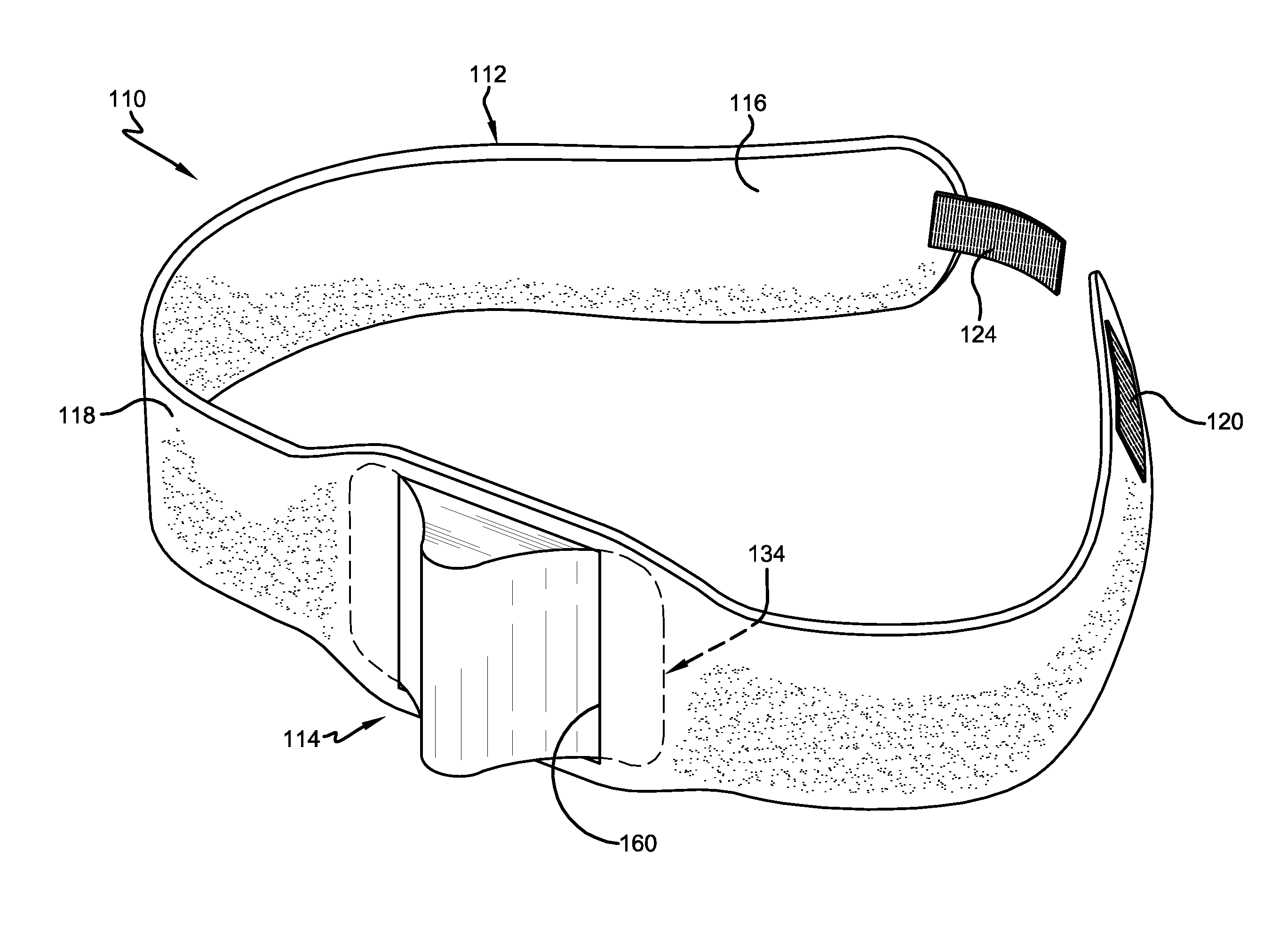

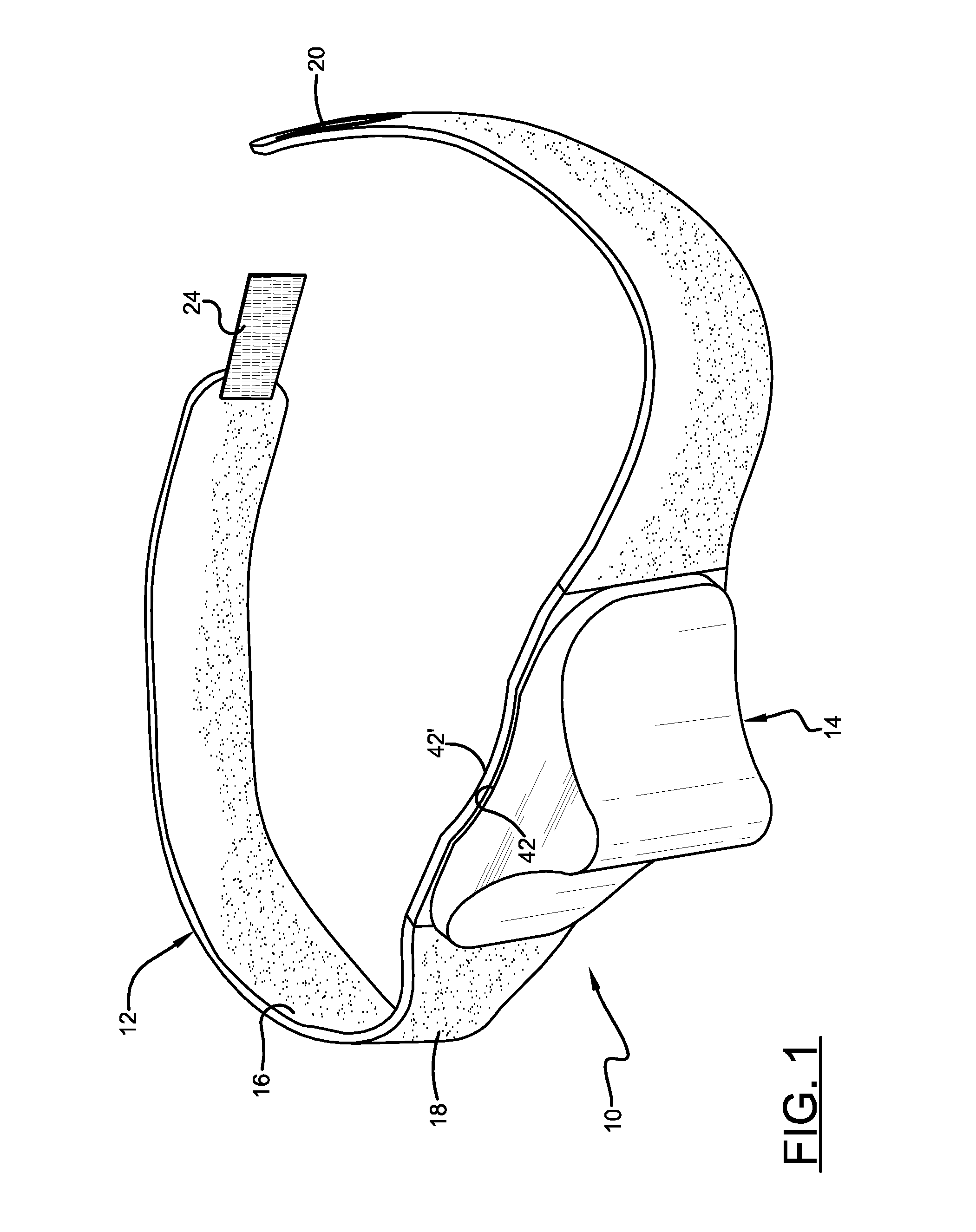

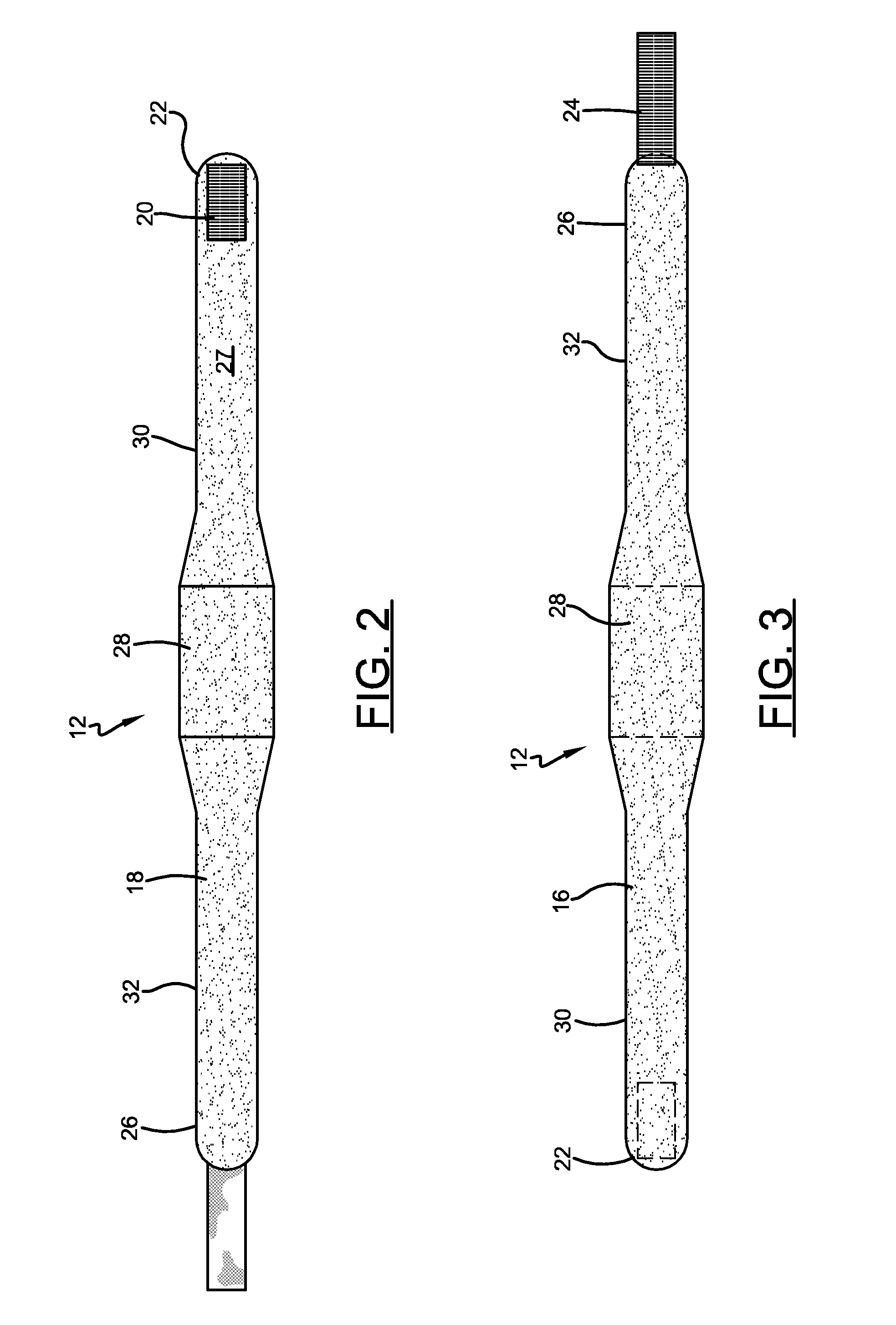

Therapeutic sleep device for discouraging sleeping in a supine position

InactiveUS20120167895A1Reduce back pressureOperating chairsSnoring preventionRight convexSupine position

A therapeutic sleep device worn about an individual's torso and intended to discourage an individual from sleeping in a supine position includes a body securing member and a sleep fin. The body securing member has an interior side and a posterior side. The sleep fin includes a supine-suppression fin providing a right convex surface and a left convex surface tapering from a wider base region to a narrower peak region at which the right and left convex surfaces join at an apex. The apex and at least a portion of the right and left convex surfaces extend beyond said posterior side of the body securing member. A spine indentation formed in the sleep device can help to increase the comfort and improve the securing of the device to a individual.

Owner:TEWARI SANJIV +2

Rotating extrusion molding method of multi-inner ring ribs of cylindrical part

PendingCN109692907ASubstantiveReduce connection strengthShaping toolsHollow articlesPush and pullDiameter ratio

The invention discloses a rotating extrusion molding method of multi-inner ring ribs of a cylindrical part, and relates to a rotating extrusion molding die of the multi-inner ring ribs of the cylindrical part. The rotating extrusion molding die comprises a fission convex die, an inner-imitation forming molding sleeve, a rotating device, a floating device, an upper die assembly and a concave die; the fission convex die comprises a left convex die and a right convex die, and the upper die assembly comprises a double-acting press machine perforated cylinder joint, a wedge block and a push-and-pull device; after blanking, preparation of a cylinder body or a tube blank and molding preparation are carried out, the concave die drives the blank to rotate, the fission convex die moves down into thecylinder body, the wedge block moves down to separate the left convex die and the right convex die, the left convex die and the right convex die are moved by the push-and-pull device, and the inner-imitation forming molding sleeve extrudes the side wall of the cylinder body, after the extrusion molding is carried out, the wedge block moves up, the fission convex die moves up, and demolding of a workpiece is carried out. According to the rotating extrusion molding method of the multi-inner ring ribs of the cylindrical part, the inner-imitation forming molding sleeve can be quickly replaced according to the shapes and the number of the molded inner ring ribs, and cylindrical workpieces with a large height-diameter ratio, various cross-section shapes and high-strength requirements of the inner ring ribs and the cylinder body can be once-molded.

Owner:ZHONGBEI UNIV

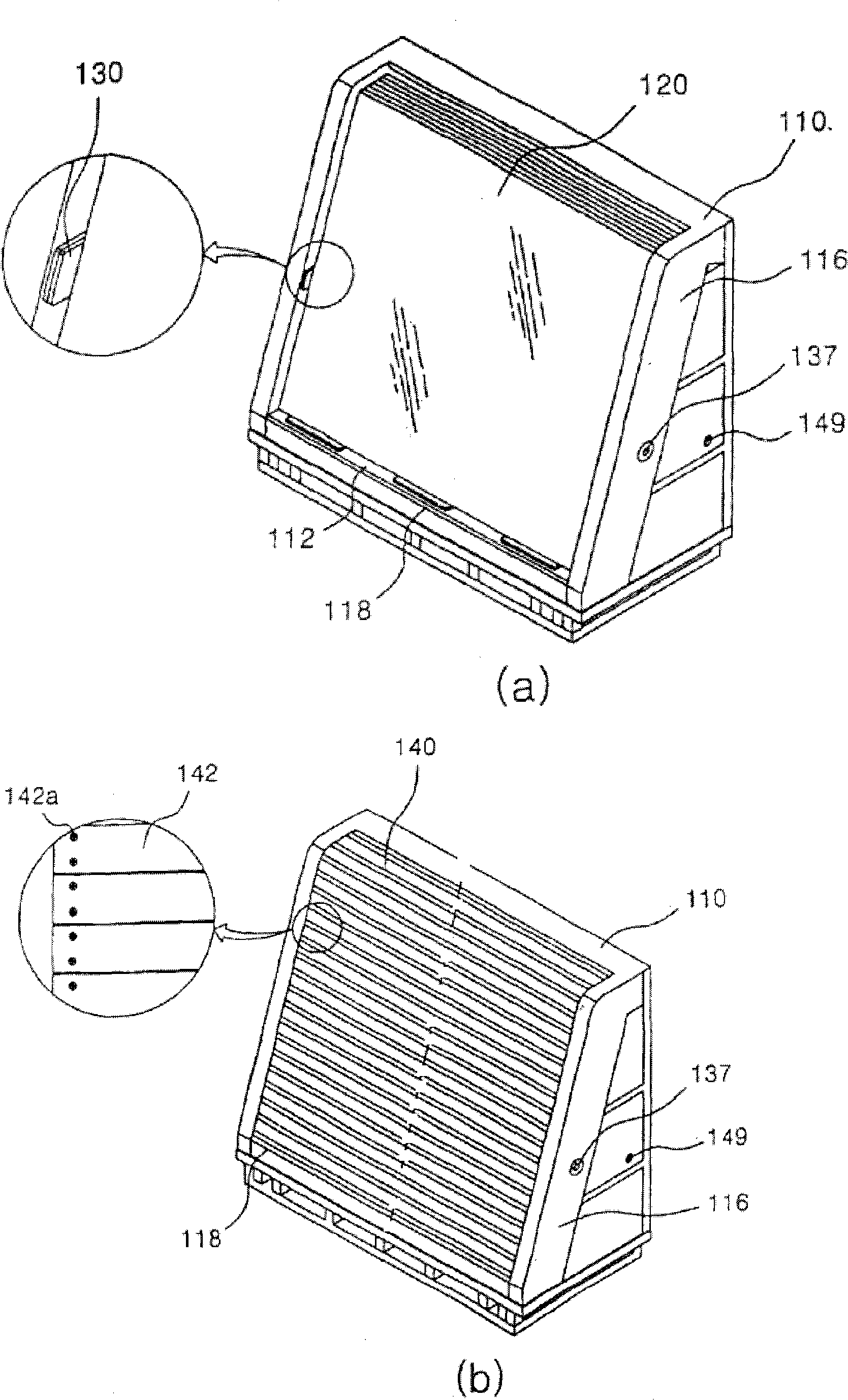

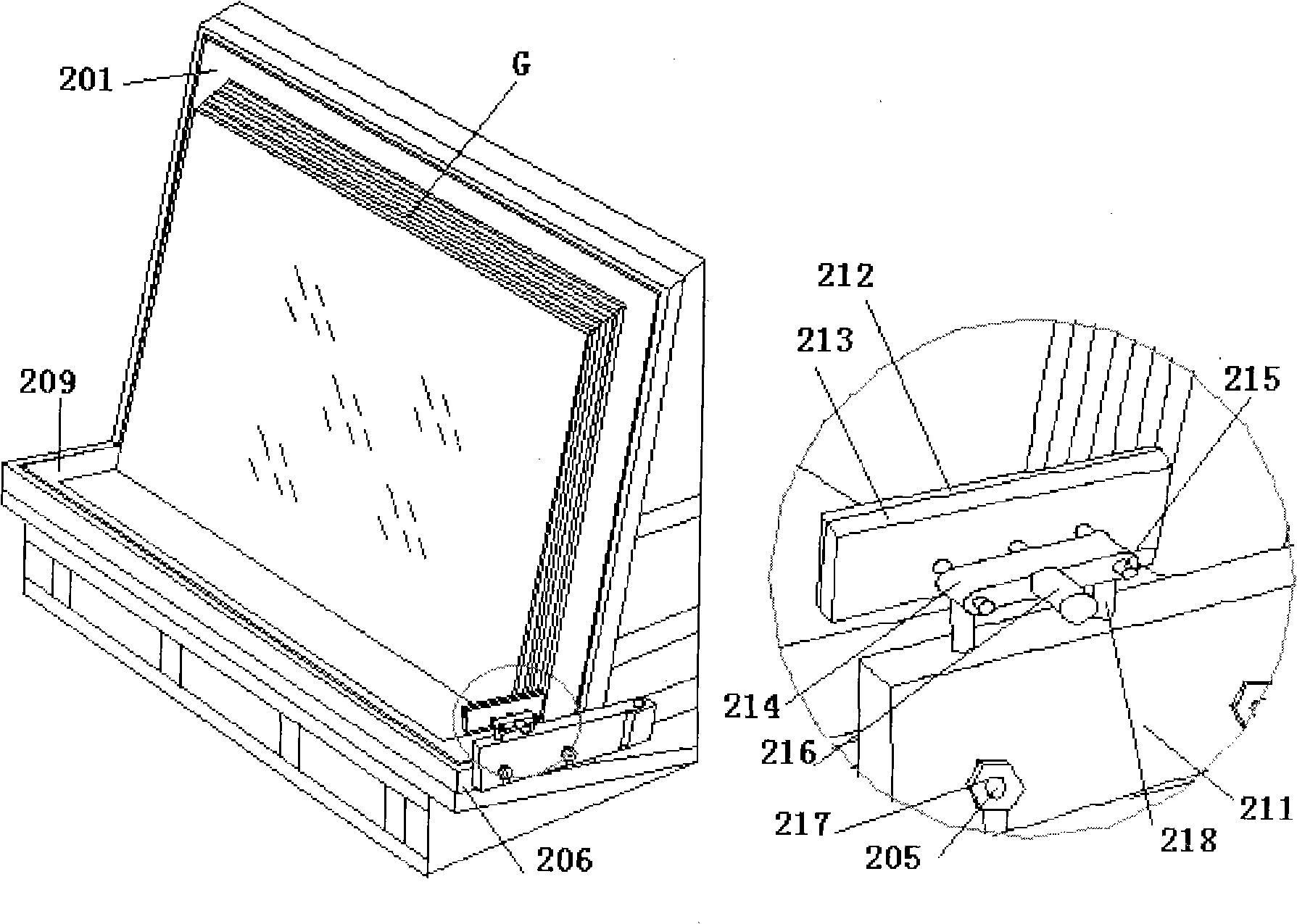

Packaging device and box of flat glass plate for displaying

InactiveCN101357704AEasy to assemble and disassembleEasy to installRemovable lids/coversContainers to prevent mechanical damageFlat glassDisplay device

The invention relates to a packaging device and a packaging box of a plane glass plate used for displaying; wherein, the packaging device comprises an arranging frame; two sides of the arranging frame are fixed with a left convex platform and a right convex platform respectively; the left convex platform and the right convex platform are respectively provided with a left rotation block and a right rotation block which rotate correspondingly to a pin; the rotation blocks are provided with plane glass plate correcting devices used for displaying; the plane glass plate correcting device used for displaying comprises a frame, a motion block, a motion block damping material and a driving cylinder; the packaging box comprises an arranging frame and a packaging box cover; the left rotation block and the right rotation block are provided with a left side surface ejecting device and a right side surface ejecting device respectively; the left side surface ejecting device and the right side surface ejecting device respectively comprise an ejecting device frame, an ejecting block, an ejecting block damping material and an ejecting bolt and can arrange a plurality of plane glass plates used for displays; by using the correcting device, the side edges of the glass plates are orderly piled during the piling process of the glass plate; subsequently, the glass plates are fixed by a side surface ejecting device and an enlacing belt; the packaging device and a packaging box of a plane glass plate used for displaying have the advantages of preventing the damage of the glass plates due to mutual staggering caused by the vibration of the glass plates during the long-distance transport.

Owner:HENAN GUOKONG YUFEI ELECTRONICS GLASS

Cell oscillation device for cell engineering

The invention relates to the field of cell engineering and in particular to a cell oscillation device for cell engineering. A sliding base inside the device can be moved forwards and backwards, and leftwards and rightwards as well, so that a cell solution can be oscillated in multiple directions, and the consequence that cells are damaged since the cell solution is directly stirred by using stirring blades can be avoided. A vertical plate is fixedly connected with the upper end of a bottom plate; a transverse plate is fixedly connected with the upper end of the vertical plate; a long-convex strip is fixedly connected with the upper end of the transverse plate; a left convex block and a right convex block are respectively fixedly connected with the left end and the right end of the front end of the bottom plate; a fixing round rod is fixedly connected with the left end of the right convex block; a moveable round rod is connected with the left convex block in a sliding manner; a fastening screw is in threaded connection with the front end of the left convex block; the fastening screw is connected with the moveable round rod; the moveable round rod is coaxial with the fixed round rod;the radius of the cross section of the moveable round rod is equal to that of the cross section of the fixed round rod; the right end of the moveable round rod is fitted to the left end of the fixedround rod; a sliding ring is connected with the combined rod of the moveable round rod and the fixed round rod in a sliding manner.

Owner:居李生物科技(北京)有限公司

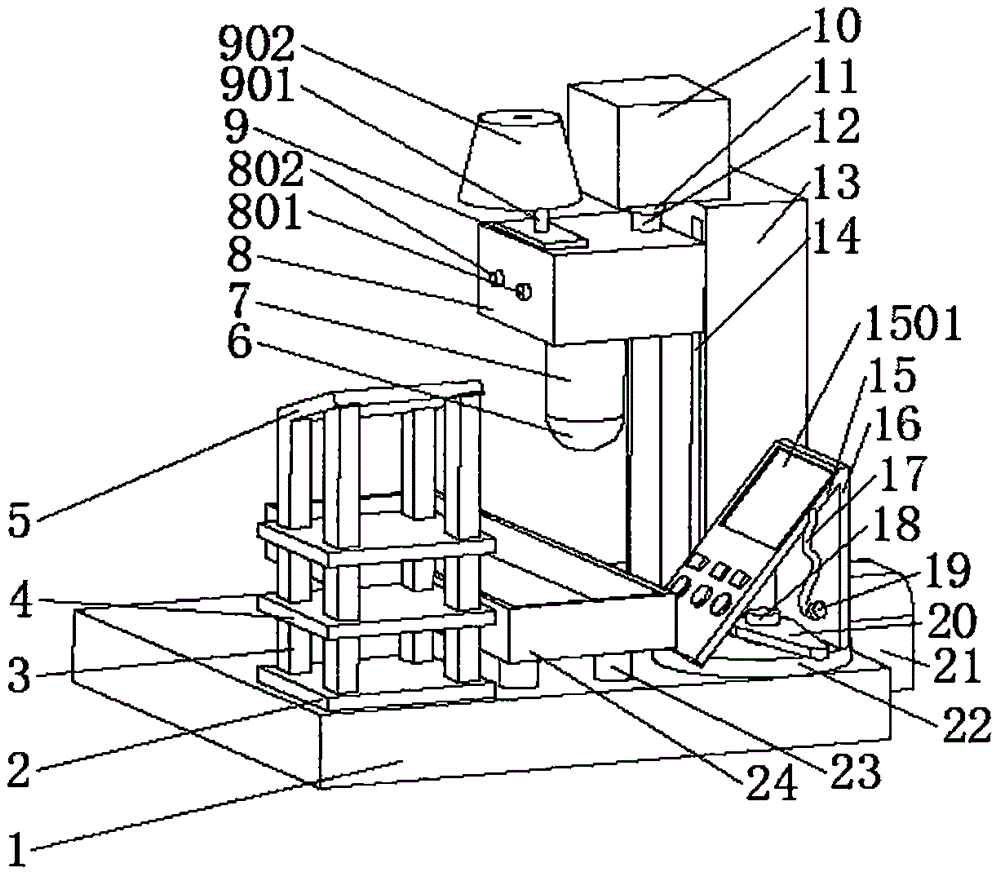

Tenon engraving machine

InactiveCN101879727BIncreased tenoning speedReduce human production costsTongue/grooves making apparatusTenon making apparatusRight convexEngineering

The invention relates to a tenon engraving machine. A left convex part is arranged at the left side of the front end surface of a stand, a right convex part corresponding to the left convex part is arranged at the right side of the front end surface of the stand, and a groove is formed among the front end surface, the left convex part and the right convex part of the stand; the front end surface of the stand is provided with a positioning part; and in addition, an inverted U-shaped hanging bracket which can move back and forth and oppositely parallel to the stand is arranged on the stand, a cutter seat which can slide left and right opposite to the hanging bracket is arranged on the hanging bracket, and a cutter is arranged below the cutter seat. Thus, when an article to be processed is located on the positioning part at the front end of the stand, a tenon joint on the article to be processed can be cut by moving the cutter.

Owner:李尚民

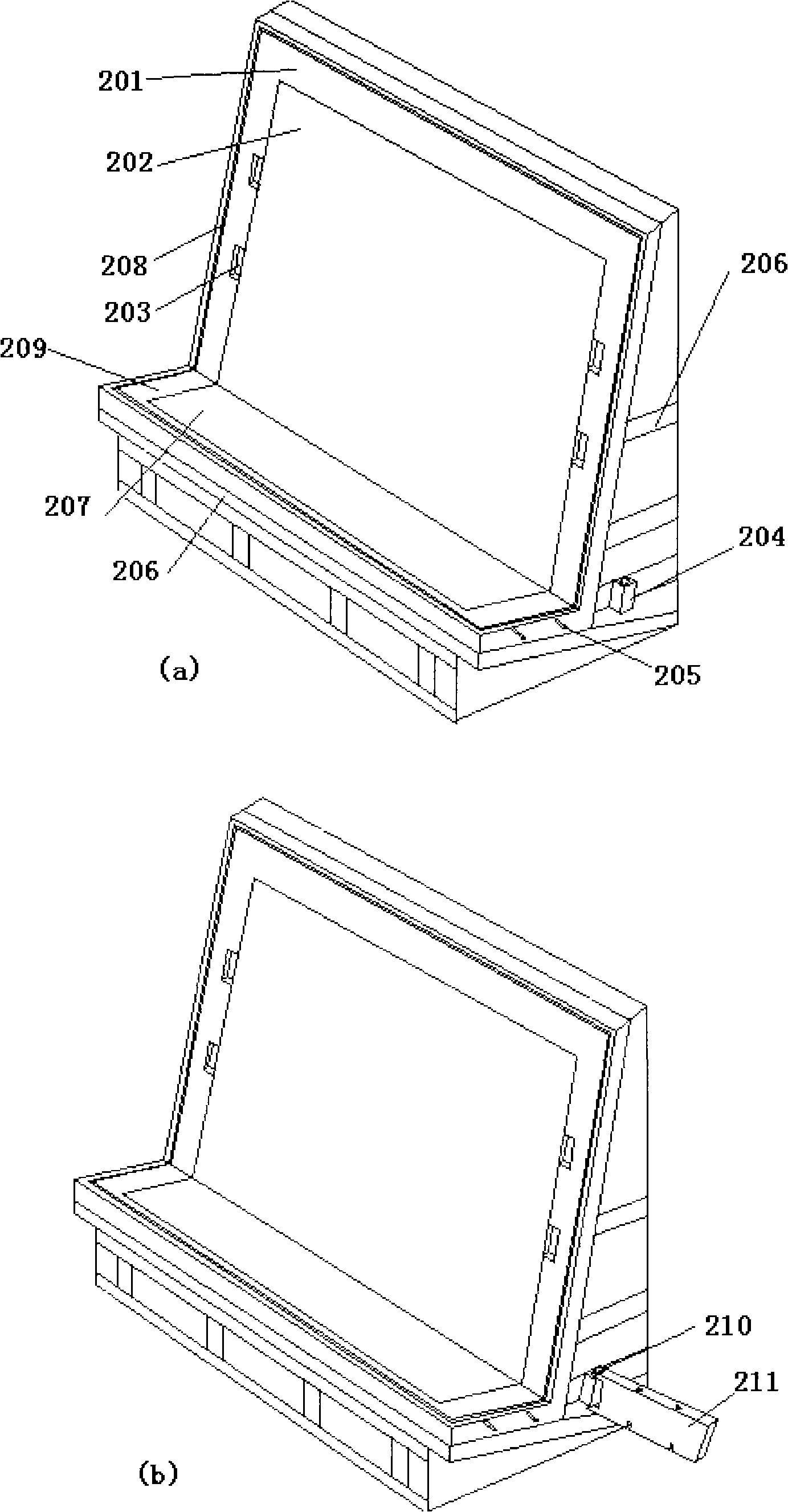

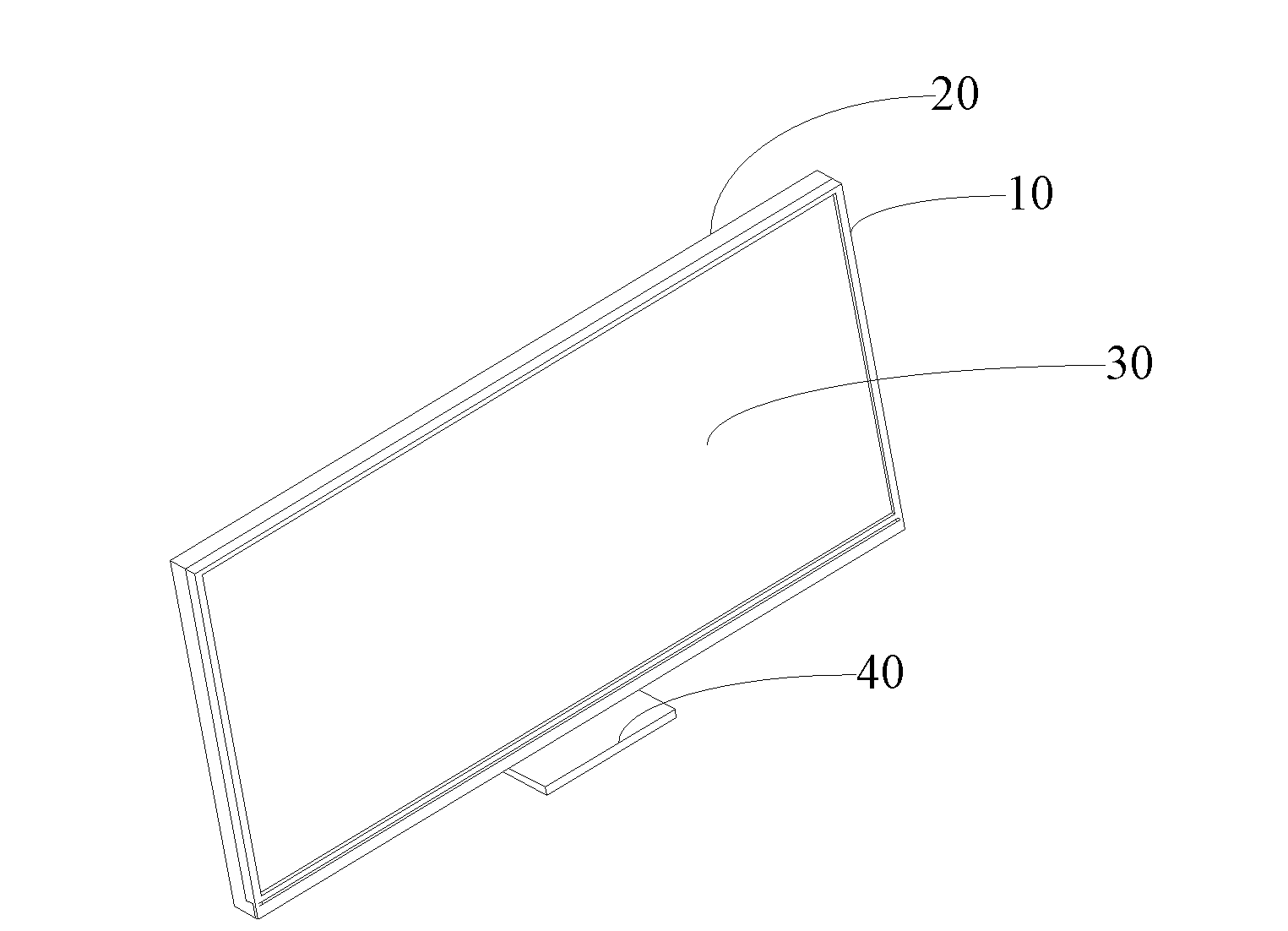

Housing of flat panel television and flat panel television

ActiveCN102638664AAchieve narrow bezel designSimple assembly structureTelevision system detailsColor television detailsRight convexEngineering

The invention discloses a housing of a flat panel television. The housing comprises a surface shell in a square frame structure and a rear cover connected with the surface shell, as well as a decorative clamping strip clamped at a lower side frame of the surface shell, wherein an upper convex edge, a left convex edge and a right convex edge are arranged in the surface shell corresponding to an upper side frame, a left side frame and a right side frame, the upper, left and right convex edges and the upper, left and right side frames constitute a clamping groove for clamping a glass substrate of a liquid crystal screen, the upper edge, left edge and right edge of the glass substrate of the liquid crystal screen are clamped in the clamping groove, the lower end surface of the glass substrate of the liquid crystal screen is in contact with the decorative clamping strip, and after the rear cover is connected with the surface shell, the lower end of the rear cover pushes against the decorative clamping strip. The invention further provides a flat panel television with the housing. According to the invention, the design of narrow side frames of the flat panel television can be realized.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

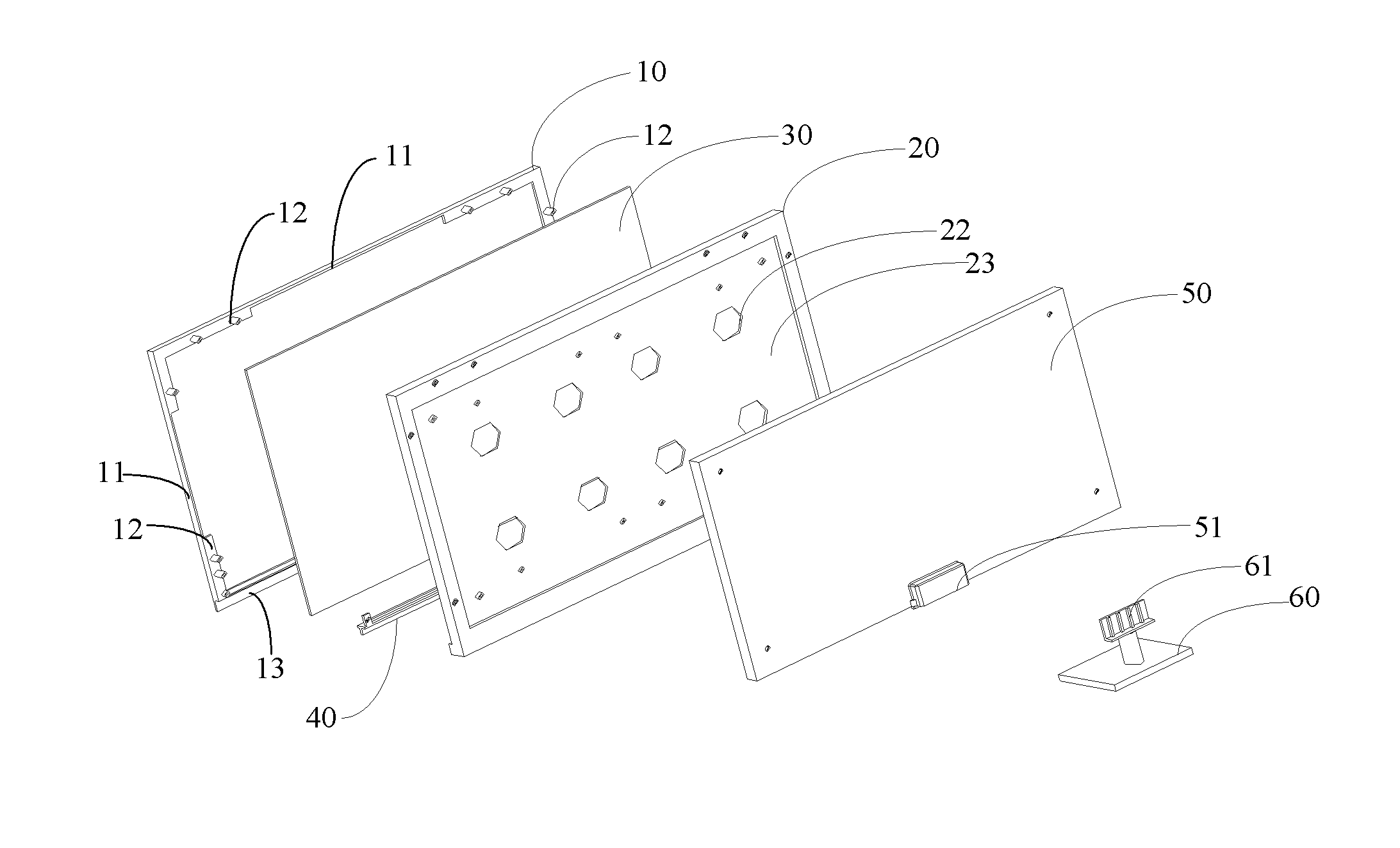

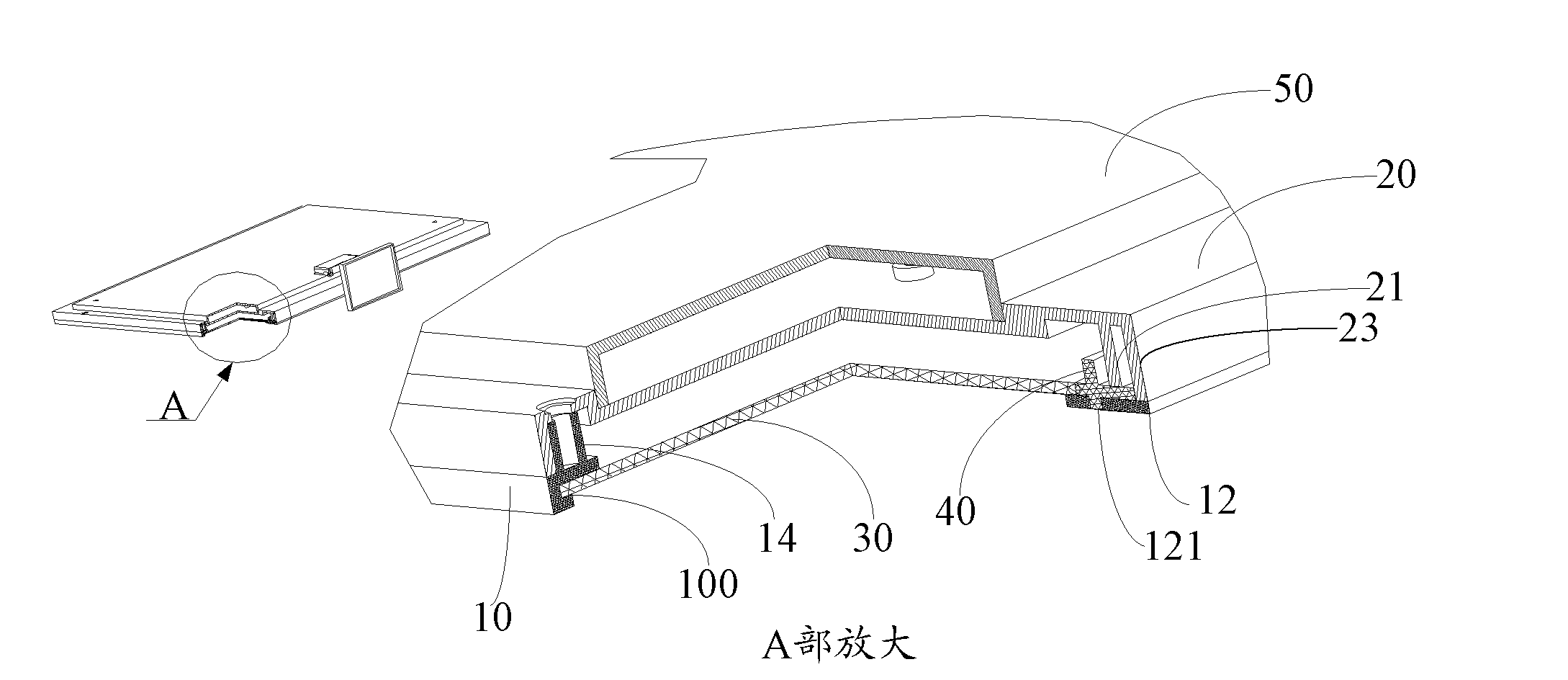

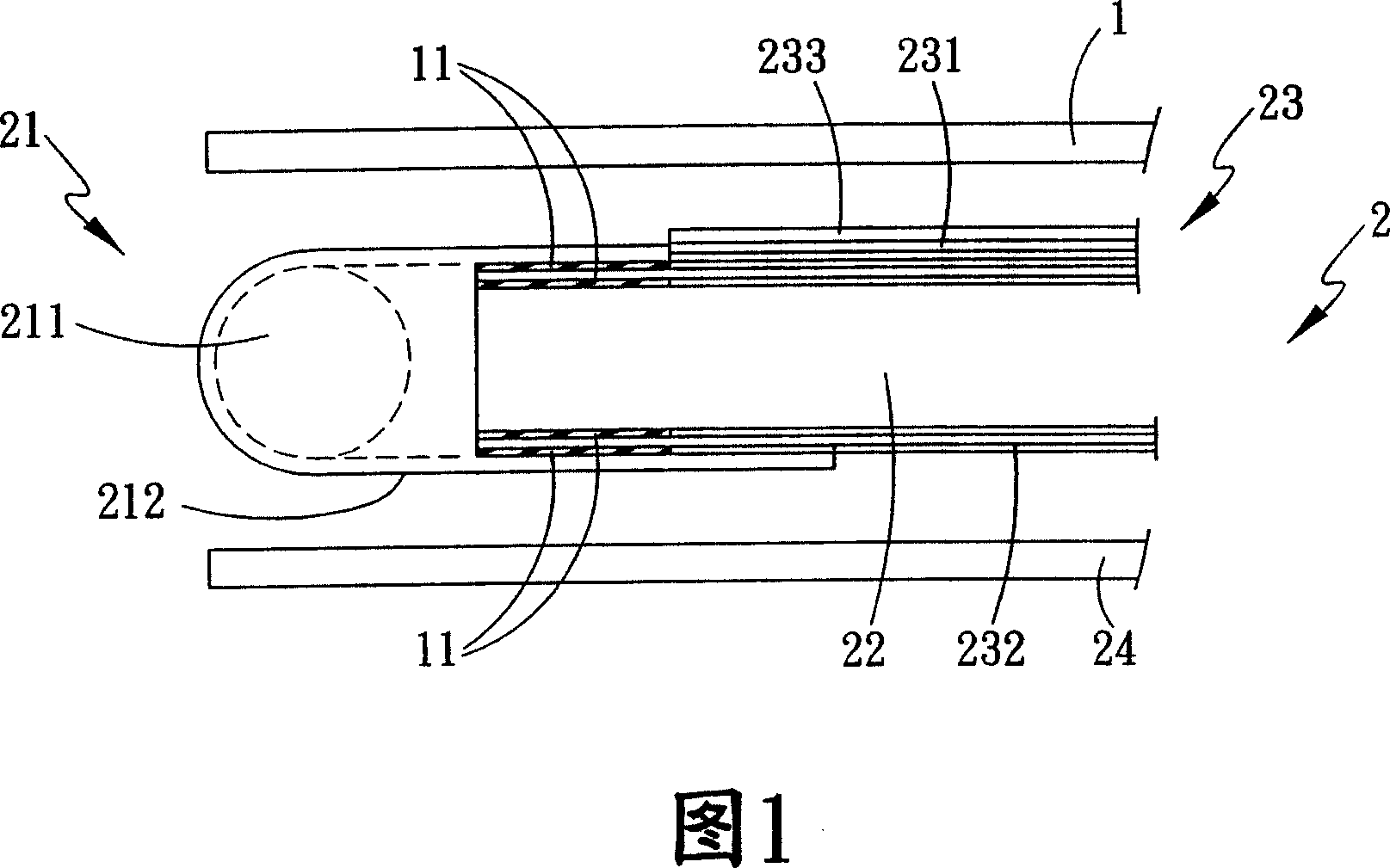

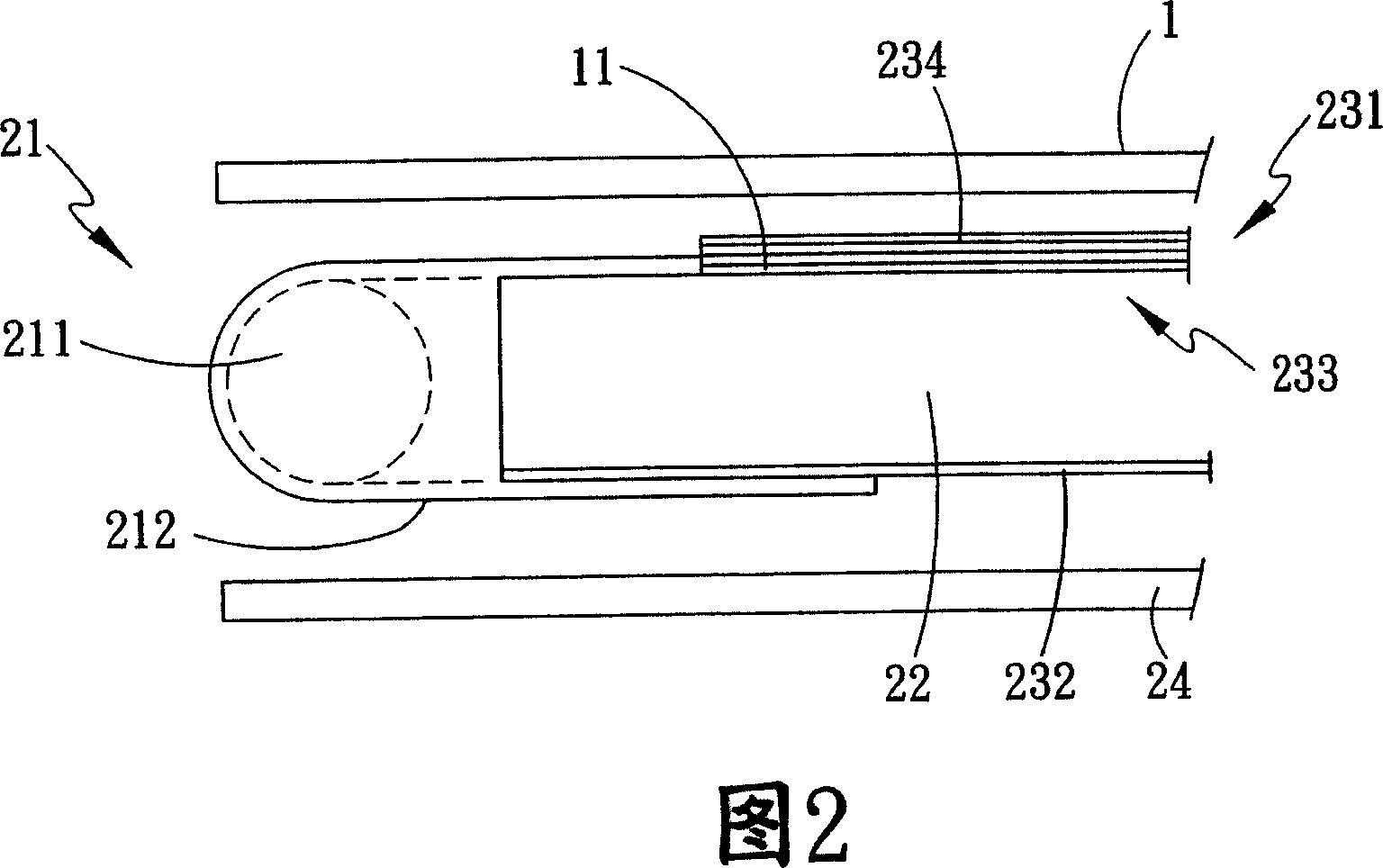

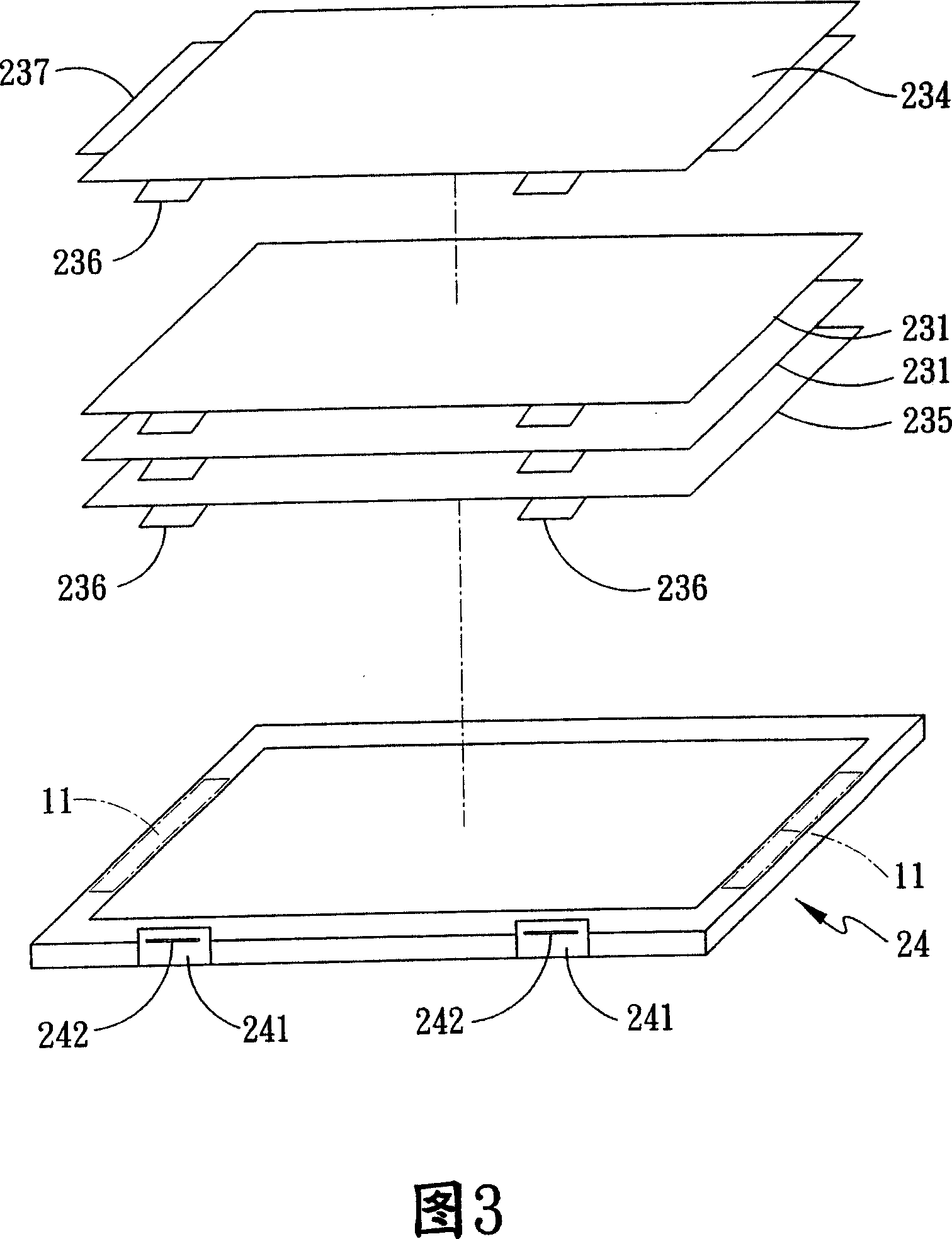

Frame combination of back light module and backlight module using said frame

InactiveCN1945397ARapid replacementEasy to assembleNon-linear opticsComputer hardwareLiquid-crystal display

The invention relates to a backlight module frame composition and the backlight module using the frame. The frame body composition contains a framework and two card button devices. The framework has a left and a right surface, which can be installed with a convex left ear and a convex right ear of at least one optical patch. Such cards are used to restraint each ear to a corresponding surface that can be released with a scheduled tolerance to allow the ear to displace on the corresponding surface. The backlight module includes the frame composition, an optical patch group and a light resource. The optical patch group has a left and right convex ear that is put on the left and right surface. When the optical patch group is heated and extends to the side with such ears, the cards provide a distance for their expanding.

Owner:CHUNGHWA PICTURE TUBES LTD

Combined examination and diagnosis device for ultrasonic department

InactiveCN105662469APromote resultsEasy to operatePatient positioningInfrasonic diagnosticsMotor driveRight convex

The invention discloses a combined examination and diagnosis device for the ultrasonic department. The combined examination and diagnosis device comprises a supporting frame. A rectangular groove is formed in the right side of the supporting frame, rectangular guide rail grooves are formed in the two side faces of the rectangular groove, a left convex surface and a right convex surface of a transverse sliding table are connected in the rectangular guide rail grooves in a sleeved mode, a rectangular longitudinal guide rail groove is formed in the front side face of the transverse sliding table, a protruding part of a longitudinal sliding table is connected in the longitudinal guide rail groove in a sleeved mode, a thread is arranged in the longitudinal sliding table, and a lead screw is connected to the longitudinal sliding table in a sleeved mode through the thread. According to the combined examination and diagnosis device for the ultrasonic department, a driving motor drives the transverse sliding table to move front and back in the rectangular guide rail grooves, a stepping motor drives the longitudinal sliding table to move up and down in the longitudinal guide rail groove, and thus the front-back and up-down positions of an ultrasonic diagnostic apparatus can be adjusted; an operating panel is arranged, and thus a medical worker can observe detection results and perform operation conveniently. When the device is used for performing ultrasonic examination and diagnosis on a patient, the working difficulty of the medical worker is lowered.

Owner:于朝霞

Bent compound die

InactiveCN102989898ASimple structureReduce manufacturing costShaping toolsStructural engineeringRight convex

The invention discloses a bent compound die which comprises an upper die holder, a left convex die, a right convex die, a pressure plate, a concave die and an ejection block, wherein the left convex die and the right convex die are symmetrically and fixedly arranged on the upper die holder, the pressure plate is arranged between the left convex die and the right convex die and movably arranged on the upper die holder, and an elastomer 1 is arranged between the pressure plate and the upper die holder; and the concave die is provided with a narrow-mouth cavity, the bottom of the narrow-mouth cavity is provided with a blind hole, the ejection block is movably arranged in the blind hole, and an elastomer 2 is arranged between the ejection block and the bottom of the blind hole. The die disclosed by the invention can realize the one-time forming of flanging U-shaped bending, and is simple in structure, low in production costs, easy to maintain and long in service life, therefore, the die can reduce the production cost.

Owner:安徽吉峰技研有限公司

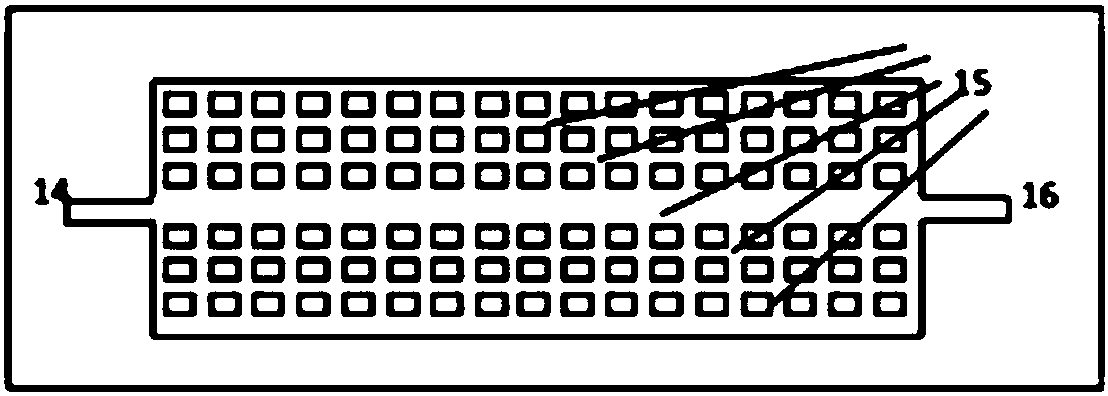

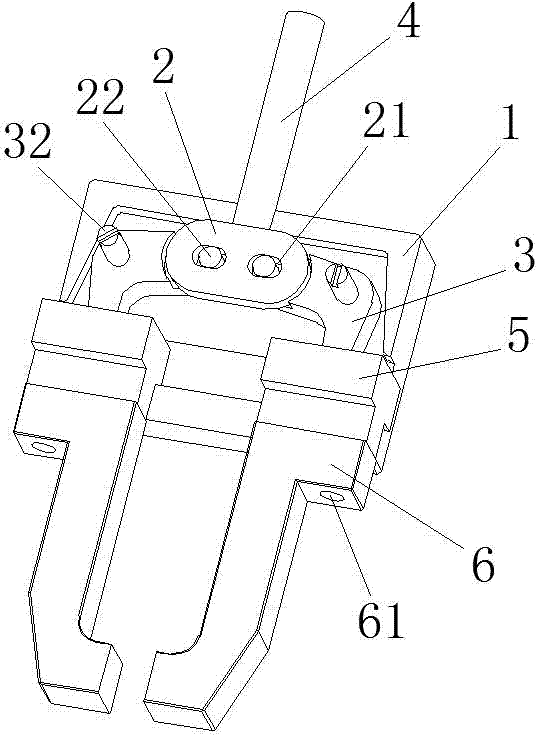

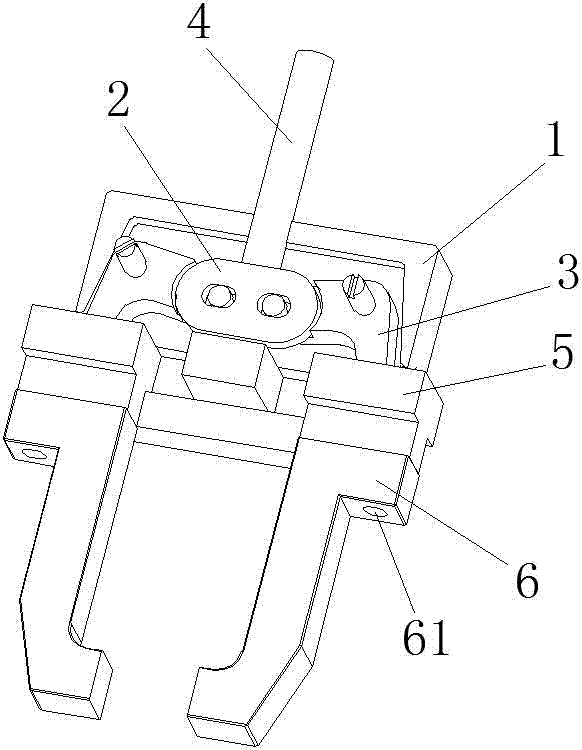

Pole piece punching mechanism and pole piece manufacturing device

ActiveCN103367698AShort strokeGuaranteed to affect punching accuracyElectrode manufacturing processesPunchingRight convex

The invention discloses a pole piece punching mechanism and a pole piece manufacturing device. The pole piece punching mechanism comprises a punching driving mechanism, an upper fixed plate, a lower fixed plate, a supporting platform, an external guide post, an upper template, a lower template, convex molds, concave molds, pressure plates and elastic parts, wherein the elastic part is arranged between the upper fixed plate and the pressure plate so as to apply downward elastic acting force to the pressure plate; the convex molds comprise a left convex mold and a right convex mold; the concave molds comprise a left concave mold and a right concave mold; the pressure plates comprise a left pressure plate, a right pressure plate and a middle pressure plate; the elastic parts comprise a left elastic part, a right elastic part and a middle elastic part. When at a mold opening state, the lower surfaces of the left and the right pressure plate are lower than those of the left and the right convex mold, and the height difference of the lower surfaces of the left and the right pressure plate and the lower surfaces of the left and the right convex mold is between 0.05mm and 0.1mm; the lower surface of the middle pressure plate is lower than the lower surfaces of the left and the right pressure plate, and the height difference of the lower surface of the middle pressure plate and the lower surfaces of the left and the right pressure plate is smaller than 1mm. The pole piece punching mechanism has the advantages of high punching efficiency, high precision and little burring.

Owner:SHENZHEN YINGHE TECH

Novel motor having waterproof performance

InactiveCN108768047AImprove sealingGuaranteed reliabilitySupports/enclosures/casingsRight convexEngineering

The invention discloses a novel motor having waterproof performance. The novel motor comprises an enclosure, a front end cover, a rear end cover and a plurality of bolts, wherein a left convex ring and a right convex ring are respectively arranged at two ends of the enclosure and are integrated, a front end cover convex ring is arranged at one end of the front end cover and is integrally formed with the front end cover, a cover is arranged at the other end of the front end cover, the front end cover convex ring is fixed with the left convex ring by the plurality of bolts, the rear end cover isfixed with the right convex ring by the bolts, an end cover through hole is formed in one end, aside the cover, of the front end cover, an inner convex ring is arranged on an inner wall of the end ofthe front end cover and is integrally formed with the front end cover, an outer convex ring is arranged on an outer wall and is integrally formed with the outer wall, the end cover through hole communicates with inner circles of the inner convex ring and the outer convex ring, a front bearing is arranged at the inner circle of the inner convex ring, a rotation shaft is arranged in the enclosure,one end of the rotation shaft is rotatably connected with the rear end cover by a rear shaft, the other end of the rotation shaft sequentially penetrates through the front bearing, the end cover through hole and the outer convex ring, and the rotation shaft is rotatably connected with the front end cover by the front bearing. The motor has favorable waterproof sealing performance.

Owner:张志通

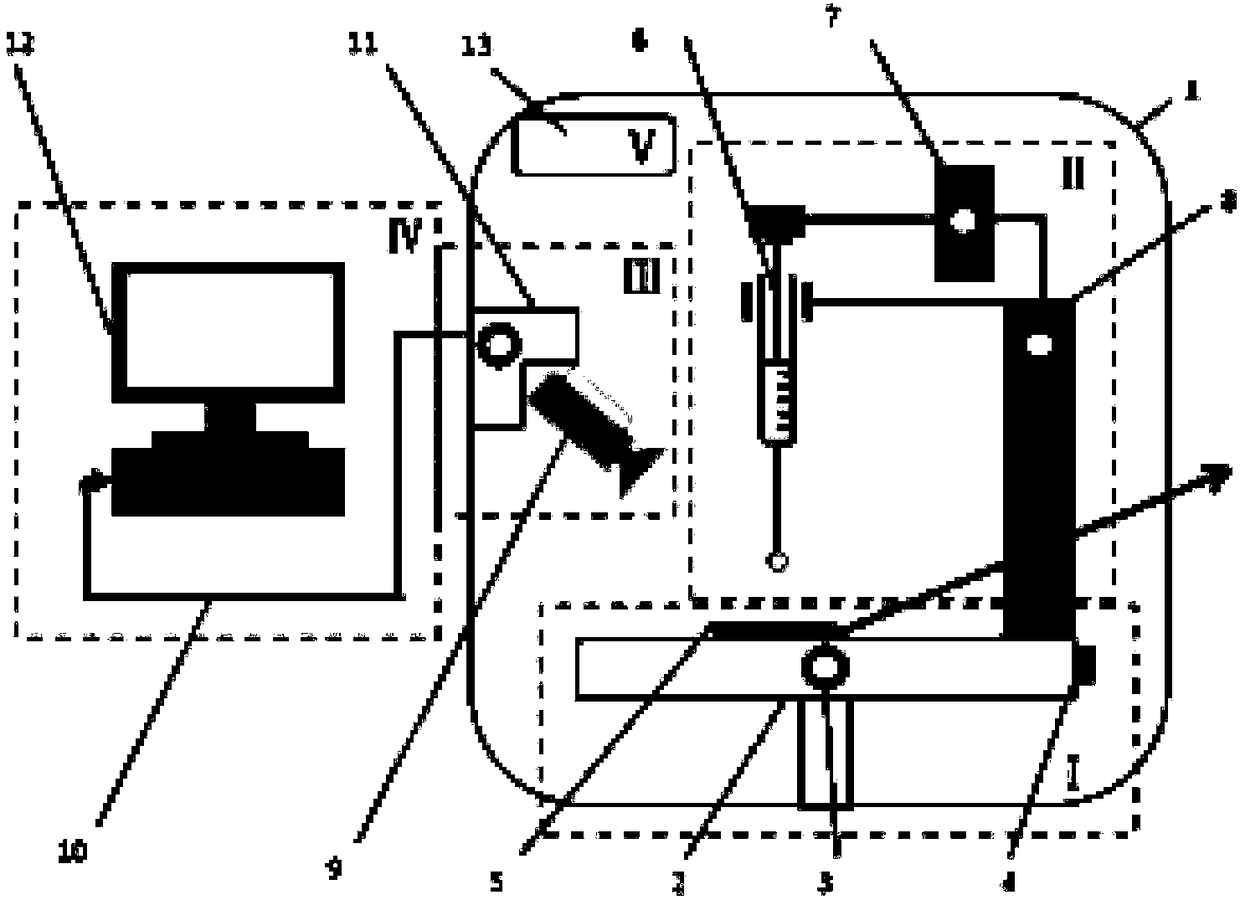

Experimental system and method suitable for macro-molecule crystallization process accurate regulation and control

ActiveCN108165486AGuaranteed crystalline microenvironmentCrystalline microenvironment precisionBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringPosition control

The invention belongs to the technical field of crystallization, and relates to an experimental system and a method suitable for macro-molecule crystallization process accurate regulation and control.The experimental system is an enclosed space under normal pressure, and is mainly composed of a platform arrangement horizontal moving tank and a runner special-purpose backwashing module, a liquid drop dropwise adding control module, an observation module, a user observation computer system, and an experimental condition control module. In applications, a system x and y axis platform high precision moving turn button and syringe needle accurate position control are capable of ensuring a molecular solution is added at right convex or concave positions, ensuring crystal crystallization micro environment and later crystal backwashing accurate operation; a high-power camera is adopted for real-time data measuring of target crystal form crystallization induction period, realizing real-time adjusting of crystal culture environment based on experimental conditions, increasing crystallization efficiency and success rate. The experimental system and the method are simple; the yield is relatively high; the experimental system and the method can be used for routine experiment repetition, and limit crystallization condition exploration.

Owner:DALIAN UNIV OF TECH

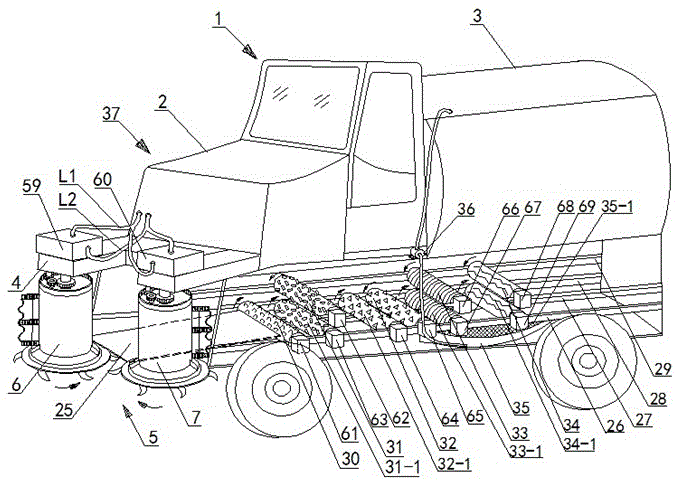

Sugarcane reaping and squeezing machine

ActiveCN105474879AReduce transportation linksConducive to return to fieldLoadersCrop conditionersHydraulic motorSolenoid valve

The invention discloses a sugarcane reaping and squeezing machine. The sugarcane reaping and squeezing machine comprises a diesel power main engine, a main engine head box and a rear storage tank, wherein a left-right convex arm is arranged at the front end of the main engine head box, a sugarcane reaping device is arranged below the left-right convex arm, four cross beams are arranged below the main engine head box and the rear storage tank respectively, a sugarcane feeding roller, leave stripping rollers, leave smashing rollers, crushing rollers and squeezing rollers are arranged on the cross beams, a reaping and squeezing power allocation system is arranged in the main engine head box and composed of a hydraulic oil pump power machine, a hydraulic oil pump, an oil storage tank, an oil path block, a solenoid valve block and a hydraulic motor, the power of the hydraulic oil pump power machine drives the hydraulic oil pump, the hydraulic oil pump drives the hydraulic motor, and the hydraulic motor drives the sugarcane reaping device and the rollers to rotate for reaping and squeezing. The sugarcane reaping and squeezing machine has the advantages that power consumption is low, labor intensity is lowered, use is convenient, the sugarcane transporting process is omitted, economic benefits are increased for sugarcane farmers and sugar production enterprises, and sugarcane leaves and residues can be returned to field easily.

Owner:唐强

Symmetrical S-shaped flanging die

The invention discloses a symmetrical S-shaped flanging die, which comprises an upper die plate, a left convex die, a right convex die and a concave die, wherein the upper die seat is symmetrically provided with a left moving groove and a right moving groove, the left convex die is movably arranged in the left moving groove by a shaft 1, the right convex die is movably arranged in the right moving groove by a shaft 2, the concave die is provided with a left forming groove and a right forming groove, the left side wall of the left forming groove is an inclined edge which is provided with an upper narrow part and a lower wide part, the right side wall of the left forming groove is an inclined edge which is provided with an upper wide part and a lower narrow part, the left side wall and the right side wall of the left forming groove are connected by a semicircular bottom edge, the right forming groove structure and the left forming groove are in a mirror symmetrical way, the left forming groove is matched with the left convex die, and the right forming groove is matched with the right convex die. The symmetrical S-shaped flanging die has the advantage that the S-shaped bending and forming can be completed in a one-time way, and the two times of material return are not needed, so the processing efficiency is high, and the processing performance is high.

Owner:安徽吉峰技研有限公司

Temperature control and dust removal die-cutting machine

ActiveCN106584917AReduce scratchesEven by forcePaper-makingBox making operationsHydraulic cylinderTemperature control

The invention discloses a temperature control and dust removal die-cutting machine. The temperature control and dust removal die-cutting machine comprises a box body, a support cross rod, a rack, an upper template, die cutters, a base, a steel plate and a lower template, wherein the box body is arranged at the top of the base; a first hydraulic cylinder is fixed on the support cross rod at the top of the rack; the upper template is fixed at the end part of the piston rod of the first hydraulic cylinder; the plurality of die cutters are mounted on a punching template at the bottom of the upper template; the lower template is arranged under the upper template; an elastic rubber mat and the steel plate are arranged at the top of the lower template; a second hydraulic cylinder is arranged at the bottom of the lower template; a cold air duct and a hot air duct are arranged at the top of the box body; an exhaust duct is connected with a left convex part on the left side of the box body; an intake duct is connected with a right convex part on the right side of the box body; a dust removal ball is connected to the left end of the exhaust duct; and the right end of the intake duct is connected to the air outlet of a circulating fan. By adoption of the temperature control and dust removal die-cutting machine, a paper board is uniformly stressed in the die-cutting process, so that damage of the paper board is reduced; the temperature of the working environment is easy to adjust and control; and the cleaning effect of dust generated by die cutting is excellent.

Owner:中山市丰泽包装制品有限公司

New type of motor with high heat dissipation performance

InactiveCN108683284AImprove cooling effectRapid coolingCooling/ventillation arrangementSupports/enclosures/casingsRight convexEngineering

The invention discloses a new type of motor with high heat dissipation performance, comprising a casing, a front end cover, a rear end cover and a plurality of bolts. The two ends of the casing are respectively provided with a left convex ring and a right convex ring integrally formed with the casing. The front end cover is fixed with the left convex ring through the plurality of bolts. The rear end cover is fixed with the right convex ring by the plurality of bolts. The front end cover is provided with a front end cover through hole, the rear end cover is provided with a rear end cover through hole, and the casing is internally provided with a main shaft. One end of the main shaft passes through the front end cover through hole, and is rotatably connected to the front end cover through afront bearing. The other end of the main shaft passes through the rear end cover through hole and is rotatably connected to the rear end cover through a rear bearing. The main shaft is sleeved with arotor core and fixed thereto. A rotor winding is wound around the rotor core, a stator core fixed to the inner wall of the casing is sleeved on the outer side of the rotor core, a stator winding is wound around the stator core, a plurality of side walls are annularly fixed on the outer surface of the casing, and every two side walls form a cavity. The device has good heat dissipation performance.

Owner:张志通

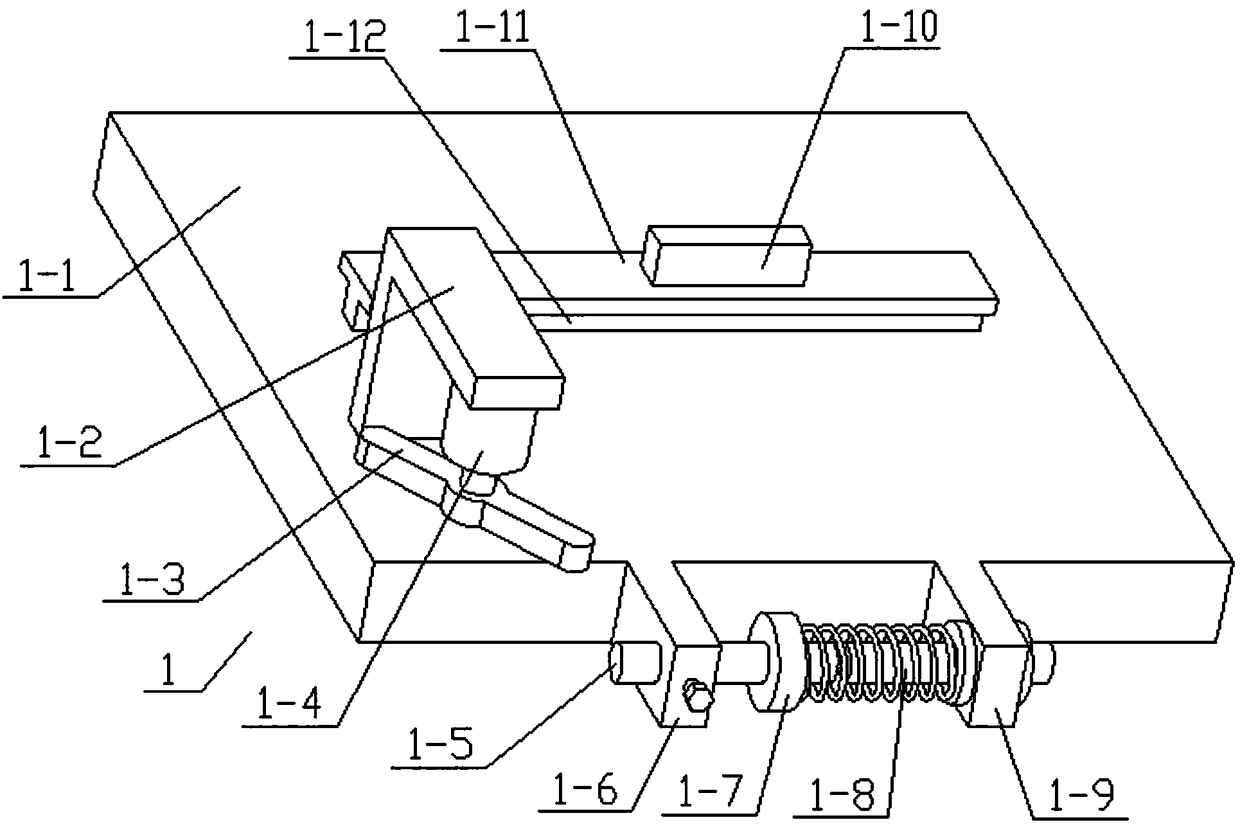

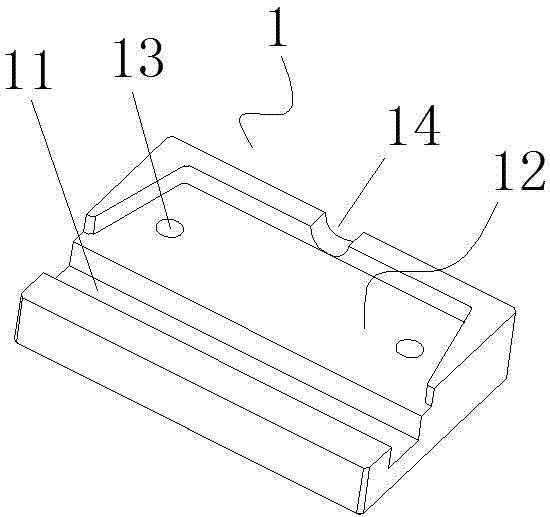

Pre-positioning tightening mechanism for arc tenon tooth blades

ActiveCN106493593AGuaranteed machining accuracyGrinding machinesPositioning apparatusRight convexEngineering

The invention provides a pre-positioning tightening mechanism for arc tenon tooth blades. The pre-positioning tightening mechanism can solve the problems that existing pre-positioning standard is not coincident with a molded surface machining positioning standard, and the blade root machining accuracy is low. The pre-positioning tightening mechanism comprises a base plate which is provided with a positioning mechanism and a tightening mechanism body; the pre-positioning tightening mechanism is characterized in that the positioning mechanism comprises a positioning base, a right convex part is arranged at the top of the positioning base, and a positioning supporting plate used for positioning arc tenon tooth blade root back process lugs is fixedly installed on the bottom face of the right convex part; and the tightening mechanism body comprises a tightening level and a tightening base, the tightening level is rotationally supported to the tightening base, the tightening base is fixedly installed on the base plate and located below the right convex part of the positioning base, the front end of the tightening level is provided with a tightening part upwards cocked to be bent, the back end of the tightening level can be in locked connection with the tightening base, and the tightening part abuts against an arc tenon tooth blade root internal process lug.

Owner:WUXI TURBINE BLADE

Thin oil lubricating device for coal mine conveyor sprocket

ActiveCN101774486AOvercome the defect of easily burnt stripsImprove cooling effectCleaningRight convexSprocket

The invention discloses a thin oil lubricating device for a coal mine conveyor sprocket, and belongs to an underground coal mine machine. The thin oil lubricating device solves the problem that the bearings and the oil seal of the handpiece driving sprocket of a scraper are burned out easily. The thin oil lubricating device comprises a sprocket body (10), a left bearing (11), a right bearing (12), a sprocket central shaft (13) and a lubricating oil way (14) of the bearings, wherein a lubricating oil storage area (1) is arranged on the outside part at the left end of the sprocket central shaft (13) in the sprocket body (10); a plane cam with a convex lower edge is arranged in the outside part at the left end of the sprocket central shaft (13) in the sprocket body (10); an oil pump (3) is fixedly arranged on the outer side at the left end of the sprocket central shaft (13); the left end of the pump body of the oil pump (3) is connected with a cam-shaped rocker arm through a hinge; the right convex part of the cam-shaped rocker arm is arranged on the outer side of an oil pump plunger of the oil pump (3); and the inner side of the oil pump plunger of the oil pump (3) is connected with a plunger spring. The thin oil lubricating device is particularly applied to underground production.

Owner:SHANXI XINZHOU GENERAL MACHINERY

Film sticking device

The invention relates to a film sticking device, and belongs to the technical field of mobile phone film sticking tools. The film sticking device comprises a shell, convex edges and limiting mechanisms. A containing groove is formed in the center of the shell. The convex edges include a left convex edge and a right convex edge. The limiting mechanisms include a left limiting mechanism and a right limiting mechanism. Two convex edge holes used for containing the left convex edge and the right convex edge and two limiting holes used for containing the left limiting mechanism and the right limiting mechanism are formed in the shell. The left limiting mechanism and the right limiting mechanism are connected with the two limiting holes in a clamped mode correspondingly. The two convex edge holes are symmetrically distributed in the two sides of the containing groove, and the two limiting holes are also symmetrically distributed in the two sides of the containing groove. The film sticking device is ingenious in structural design, and a mobile phone is fixed through the left limiting mechanism and the right limiting mechanism, so that the situation that film sticking is affected by mobile phone shaking is avoided; and a screen protector film is accurately positioned through the left convex edge and the right convex edge, the situation that in the prior art, whether the sticking position of the screen protector film is correct or not is identified through human eyes is changed, the film sticking cycle is shortened, the film sticking accuracy is improved, and the working efficiency is improved for enterprises.

Owner:合肥钱锋特殊胶粘制品有限公司

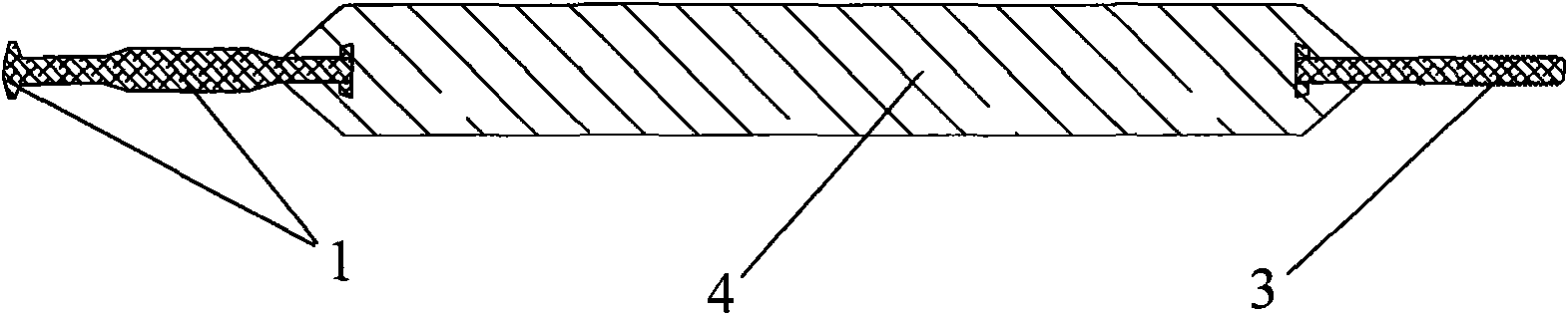

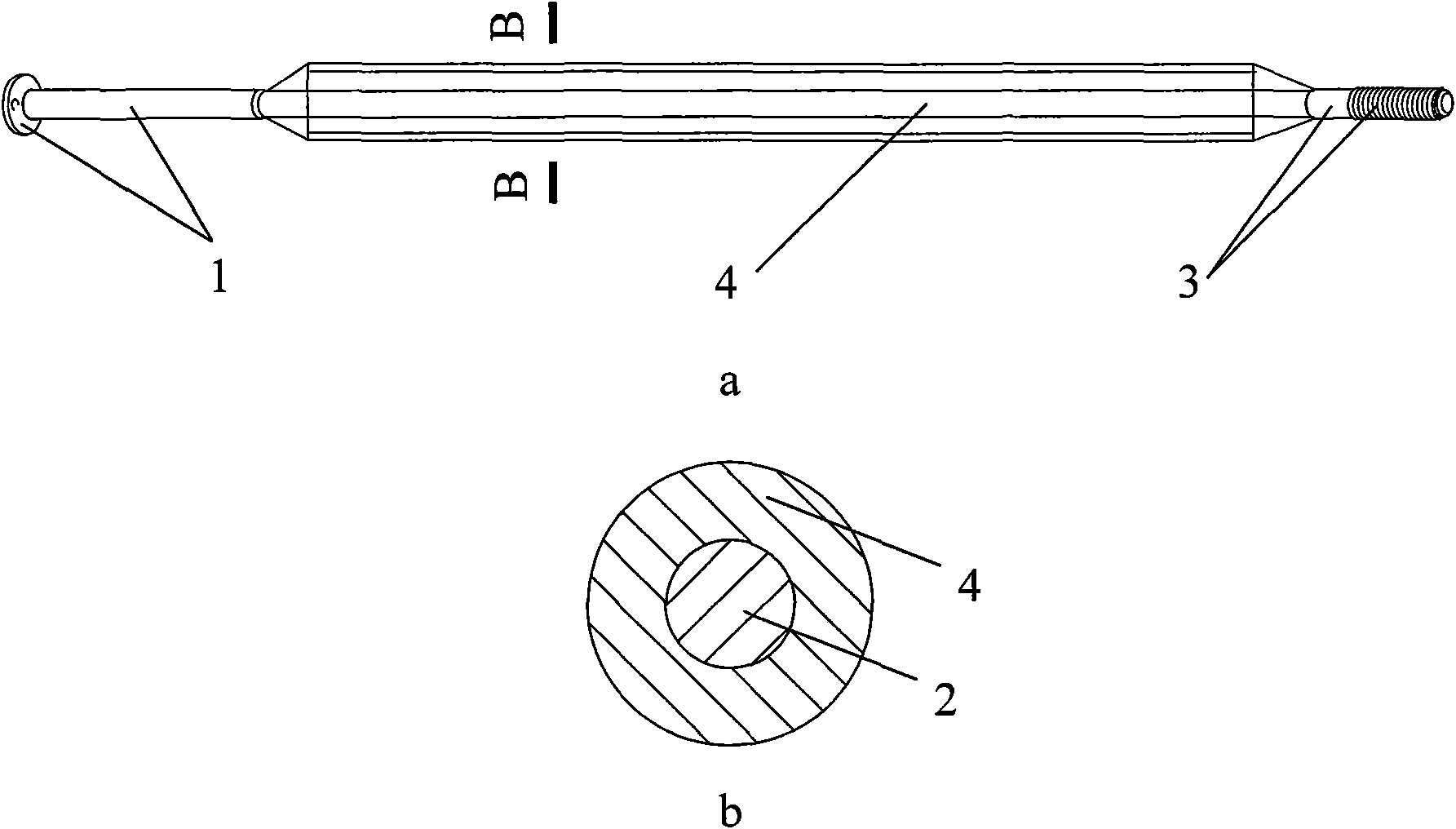

Combined-type spoke

ActiveCN101811416AGuaranteed StrengthReduce weightNon-metallic wheel bodyWheel manufactureRight convexEngineering

The invention relates to a spoke, in particular to a spoke for a wheel rim of a bicycle or a motorcycle. A combined-type spoke comprises an elbow part, a main body part and a screw tooth part, wherein the outer surface of the main body part is coated with a carbon fiber layer; the outer surface of the main body part is provided with a plurality of ring-shaped grooves; the main body part forms a fishbone shape along the section of the length direction; the section shape of the main body part is a rectangle, an oval or a closed figure formed by an upper horizontal straight line and a lower horizontal straight line which are parallel, and a left convex-outward arc line and a right convex-outward arc line; and the main body part is provided with a plurality of small holes. The combined-type spoke reduces the weight on the basis of ensuring the strength, so as to prevent fracture.

Owner:D MAG KUNSHAN NEW MATERIAL TECH CO LTD

Adjustable clamp special for milling plane

InactiveCN106903522AHighlight substantive featuresSignificant progressPositioning apparatusMetal-working holdersRight convexEngineering

The invention relates to a special adjustable clamp for milling plane, comprising a clamp base, a strip-shaped chute and a trapezoidal groove are respectively provided on the clamp base, and the upper surface of the trapezoidal groove is provided with a circular hole that does not penetrate the bottom surface Two left and right corner pieces are embedded on the upper surface of the trapezoidal groove, respectively, a waist-shaped connecting piece is installed above each corner piece, and left and right convex slides are embedded on the strip chute respectively. Each of the convex slider bosses is connected with a clamping arm respectively, and a push handle capable of rotating the left and right corner pieces is installed on the outer side of the waist-shaped connecting piece, on the front side of the upper surface of the fixture base There is also a semi-circular groove in the middle of the edge, and the shape of the semi-circular groove is a sliding tangent matching structure with the journal where the push handle extends. Well, it has the characteristics of being able to adjust, stabilize and clamp the workpiece to be processed effectively and flexibly at any time.

Owner:邓加滨

Combination die used for preparing colorful curbstones

The invention discloses a combination die used for preparing colorful curbstones. The combination die comprises an outer sleeve die, an inner sleeve die and a water discharging hole die; the outer sleeve die is of a groove-shaped structure, and comprises a first front wall, a first back wall, a first left side wall, a first right side wall and a first bottom wall; the first left side wall is provided with a left concave part; the first right side wall is provided with a right convex part; and the right convex part is matched with the left concave part; the inner sleeve die comprises a second front wall, a second back wall, a second left side wall, a second right side wall and a second bottom wall; the second bottom wall is provided with a bottom convex part; the water discharging hole die is matched with the bottom convex part of the inner sleeve die; and surface layers of the colorful curbstones are made of colorful concrete, and inner layers of the colorful curbstones are made of common concrete. The colorful curbstones, which are prepared using the combination die, possess following advantages: intensity is high; color is magnificent; the colorful curbstones are not easy to fade, and are capable of glowing, and realizing water discharging; and self-buckling connection of the colorful curbstones is realized. In addition, solid waste is recycled, so that production cost is reduced, and the combination die can be widely used for preparing the colorful curbstones.

Owner:许春雷

Novel flange

The invention discloses a novel flange. The novel flange is arranged between a left pipeline and a right pipeline and comprises a left flange and a right flange, wherein an annular slot is formed in the right end of the left flange; an annular convex block is fixedly mounted at the left end of the right flange; a mounting groove is formed in an inner hole of the annular convex block; a left convexedge is arranged at the right end of the left pipeline; a right convex edge is arranged at the left end of the right pipeline; an annular locking groove is formed in the inner side wall of the annular slot; a first annular groove is formed in the right end surface of the annular convex block; a second annular groove is formed in the left end surface of the right flange; a plurality of radial holes are formed in the annular convex block; each radial hole is connected with a locking rod in a sliding manner; the inside of the first annular groove and the inside of the second annular groove are rotatably connected with a power ring; arc-shaped protrusions are arranged on the circumference side of the power ring; an arc-shaped groove is formed between two adjacent arc-shaped protrusions; an arc-shaped groove is formed in the right end surface of the right flange; and a handle is arranged at the right end of the power ring. The novel flange is simple in structure and is capable of achievingrapid connection.

Owner:韩国昊

Tenon engraving machine

InactiveCN101879727AIncreased tenoning speedReduce human production costsTongue/grooves making apparatusTenon making apparatusRight convexEngineering

The invention relates to a tenon engraving machine. A left convex part is arranged at the left side of the front end surface of a stand, a right convex part corresponding to the left convex part is arranged at the right side of the front end surface of the stand, and a groove is formed among the front end surface, the left convex part and the right convex part of the stand; the front end surface of the stand is provided with a positioning part; and in addition, an inverted U-shaped hanging bracket which can move back and forth and oppositely parallel to the stand is arranged on the stand, a cutter seat which can slide left and right opposite to the hanging bracket is arranged on the hanging bracket, and a cutter is arranged below the cutter seat. Thus, when an article to be processed is located on the positioning part at the front end of the stand, a tenon joint on the article to be processed can be cut by moving the cutter.

Owner:李尚民

Crosswise-type automatic opening-and-closing mould frame

InactiveCN102836943ANo flash edgeSave raw materialsForging/hammering/pressing machinesRight convexMaterials science

The invention relates to a hot forging process, in particular to a crosswise-type automatic opening-and-closing mould frame capable of saving raw materials and improving the working efficiency. The crosswise-type automatic opening-and-closing mould frame comprises a convex mould punch, a core mould and a pull rod; the convex mould punch comprises an upper convex mould punch, a left convex mould punch and a right convex mould punch; the core mould comprises a first core mould and a second core mould; the upper convex mould punch is fixedly arranged on the upper working panel of equipment through an upper convex mould fixing plate; the left convex mould punch and the right convex mould punch are respectively arranged on a left convex mould fixing oblique plate seat and a right convex mould fixing oblique plate seat correspondingly and fixedly; two octagonal cone cylindrical inner mould sleeves are arranged in cone cylindrical outer mould sleeves and are respectively connected with T-shaped slide ways tightly; the cone cylindrical outer mould sleeves are fixedly arranged on the lower working panel of the equipment; and the lower parts of cone cylindrical inner mould sleeve resetting guide columns are connected with a material jacking support plate on the lower working panel of the equipment in a matching manner. When the crosswise-type automatic opening-and-closing mould frame is used for assembling different moulds, the purposes of extrusion and formation with deep holes, counter bores and holes in a plurality of directions are achieved, no flash is produced, the formation is fast, and the automatic fall-off of a work piece is realized so that the fetching of the work piece is convenient.

Owner:YANCHENG BOYUE PIPE FITTINGS

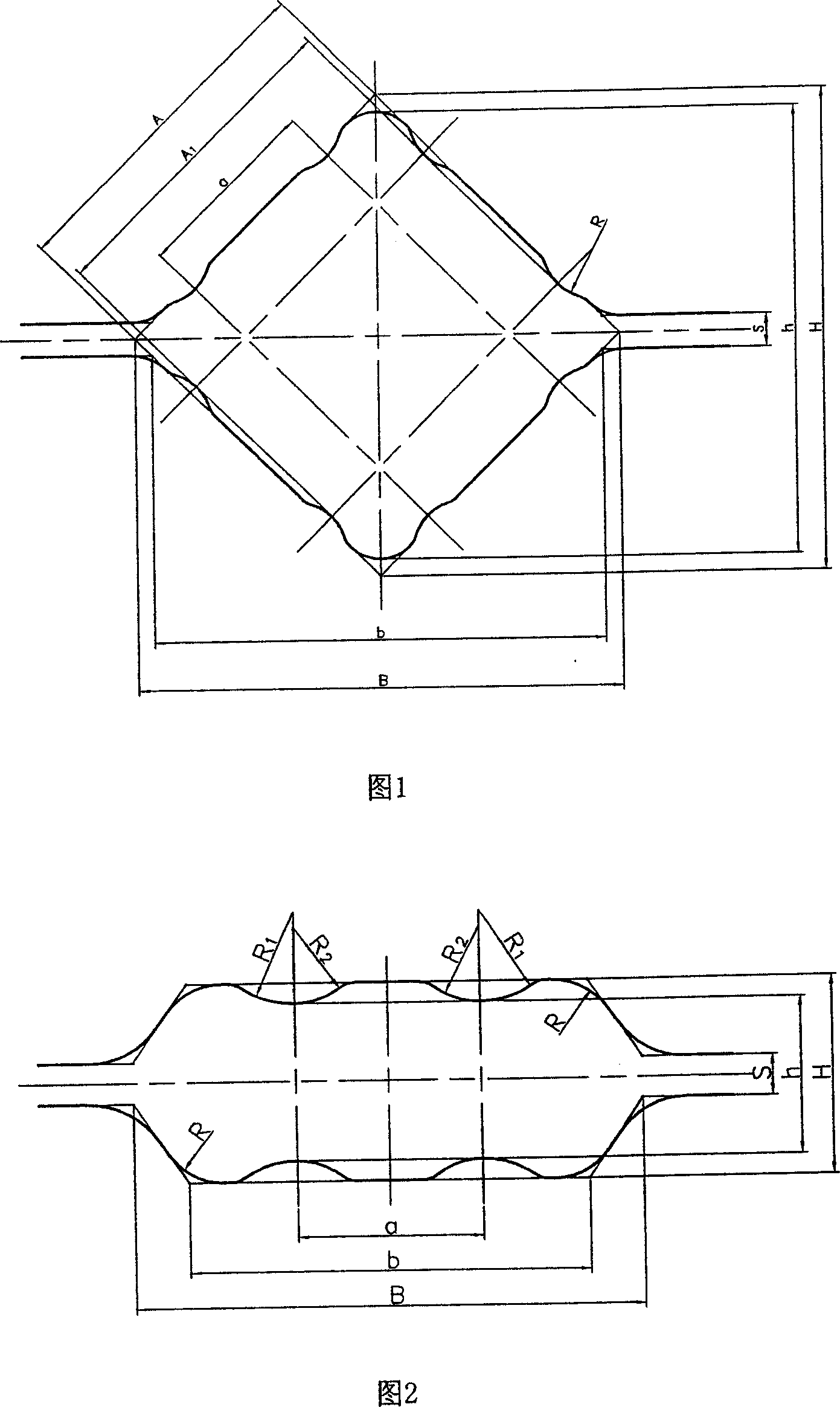

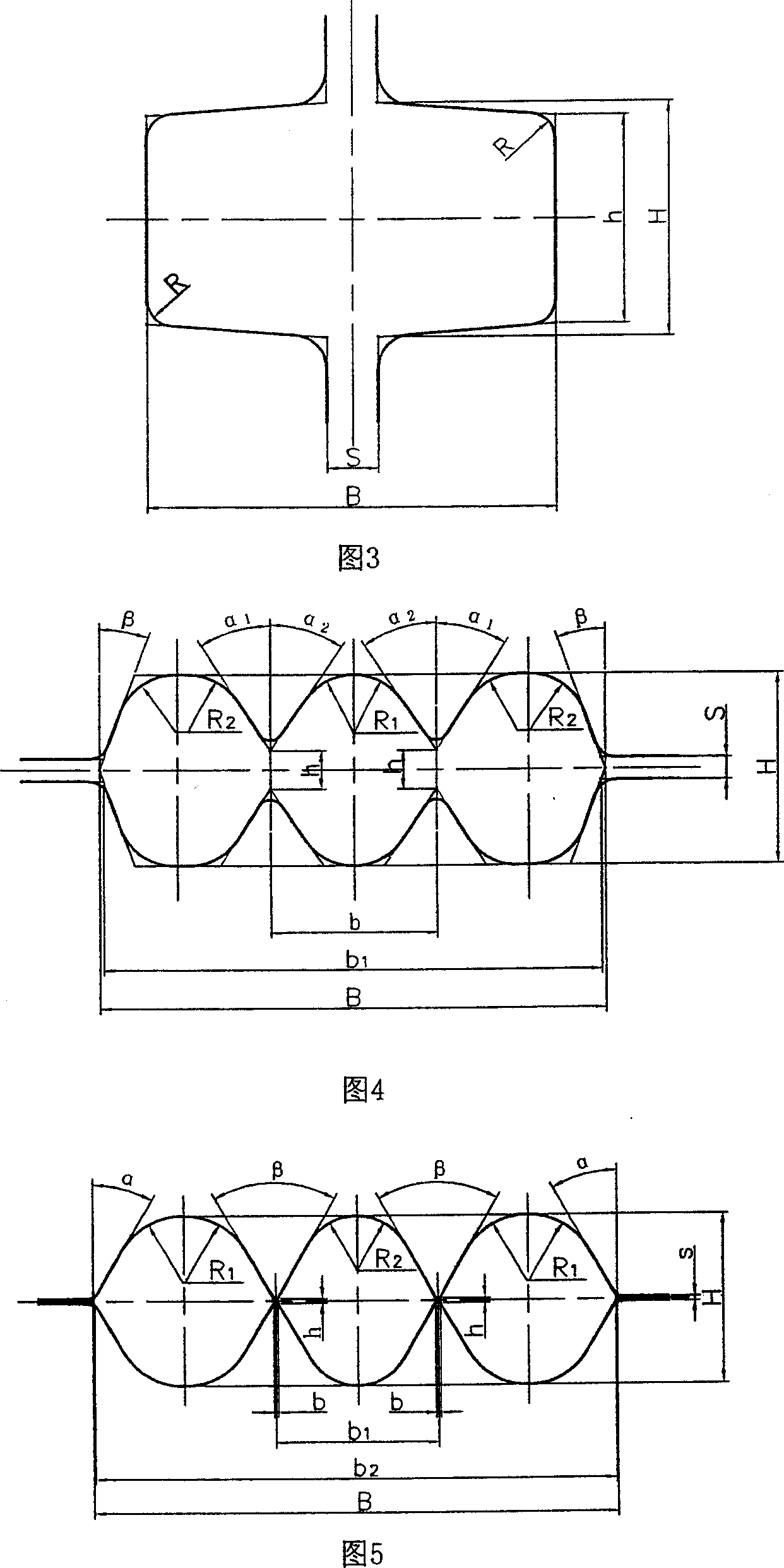

Three-strand splitting rolling method for ribbed steel bar

The invention relates to a method for rolling rib steel bar, wherein it is characterized in that: the last rolling machine at middle roller group uses the square holes as R 6-9mm, depth 1-2mm, and same central distance and convex degree; the first one of fine roller group uses the flat holes with R 7-12mm, depth 2-5mm, unequal arc radials at left and right convex degree, and central distance larger than precutting hole, tangent hole and central distance is 1-2mm; the precutting hole has three same high lines and inner-outer angle difference at 2-4 degree of wedge sharp; the tangent hole is ellipse hole whose height-width ratio is 1. 02-1. 1 and three lines are same high. The invention can uniform rolling abrasion and low section error of tangent three rolled elements.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com