Rotary extrusion forming die for multiple inner annular ribs of cylindrical workpiece

A technology for extrusion forming and cylindrical parts, applied in the direction of metal extrusion dies, etc., can solve the problems of reducing the connection strength between the inner ring rib and the body wall, long production process, and deflection, etc., to achieve fewer types of equipment and higher production efficiency High, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

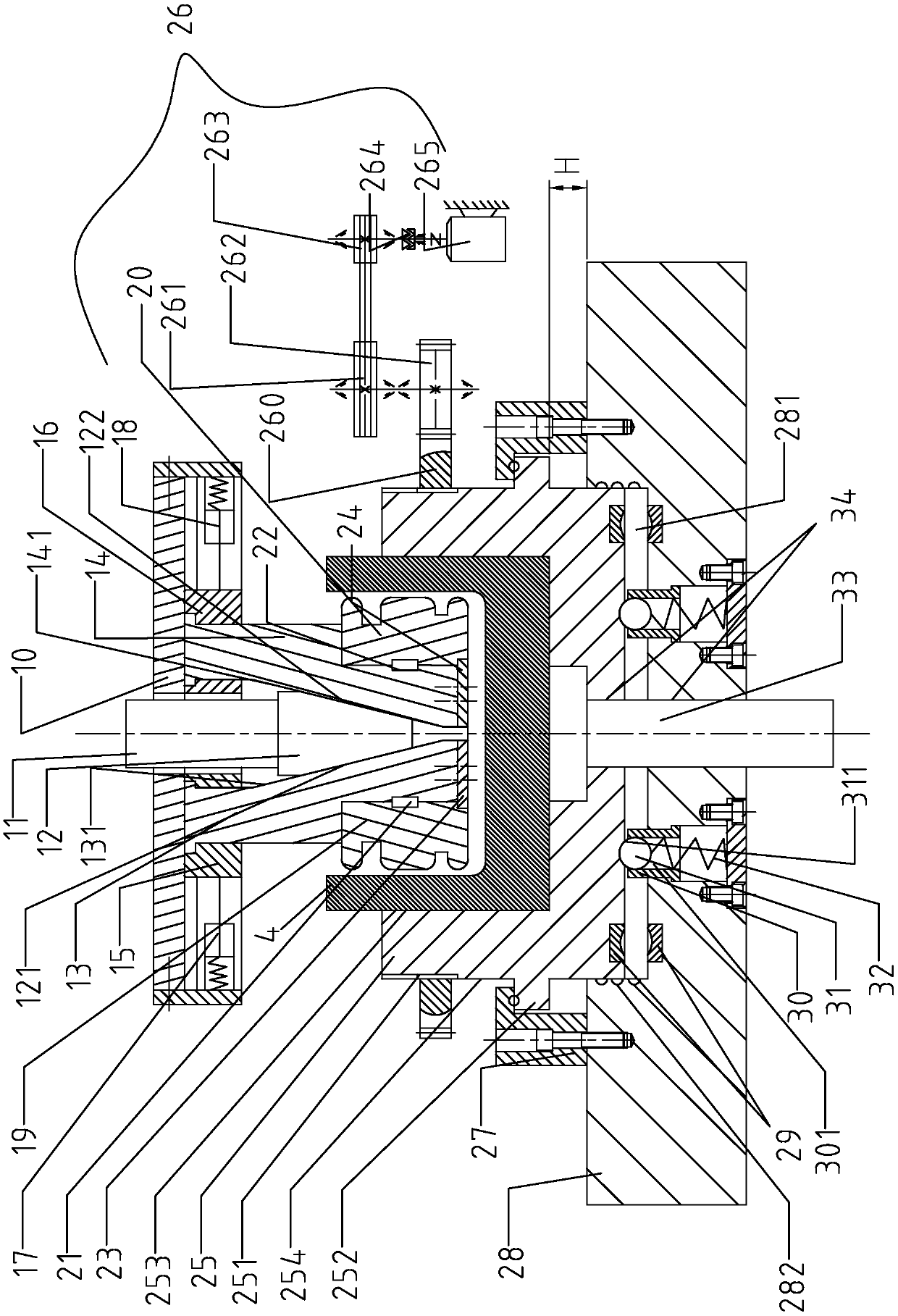

[0036] The present invention discloses a rotary extrusion molding die with multiple inner ring ribs for cylindrical parts, see Figure 1-10 ,

[0037] Comprising a split punch, an imitation inner forming sleeve, a rotating device 26, a floating device, an upper die assembly connected to the upper die base 10, and a die 25 connected to the lower die base 28;

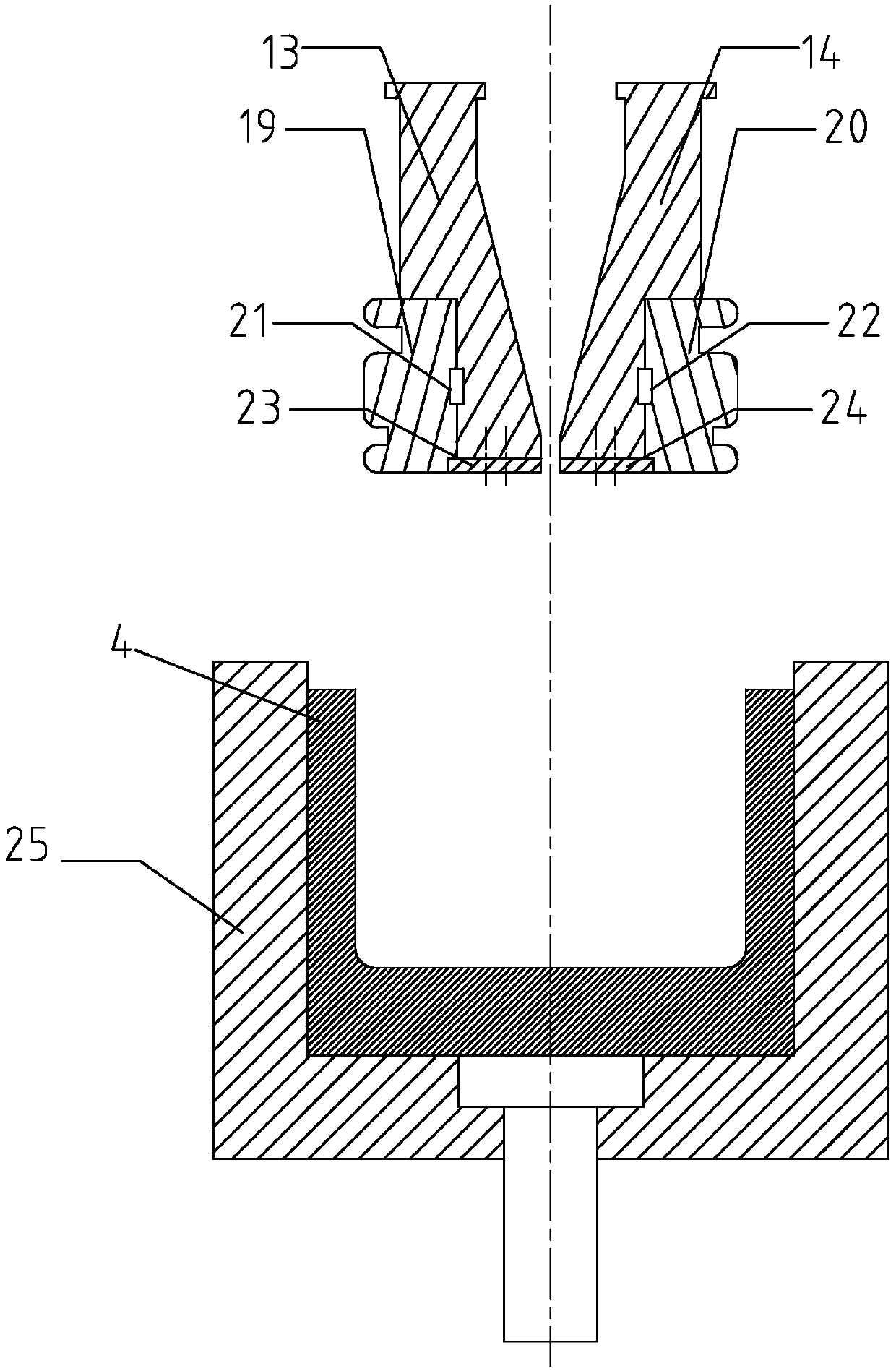

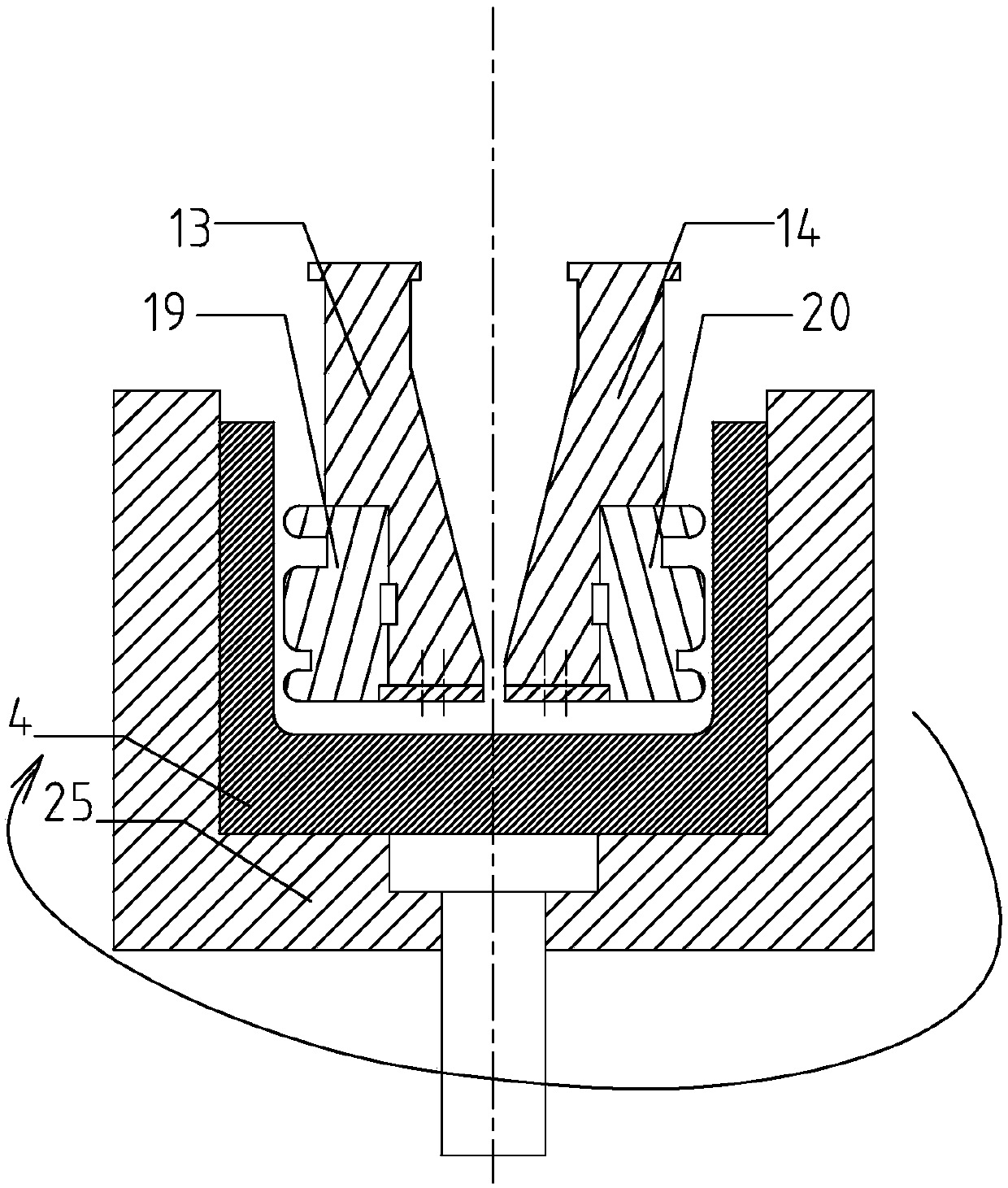

[0038] The split punch includes a left punch 13 and a right punch 14. The opposite side walls of the left punch 13 and the right punch 14 are inclined surfaces 131, 141. The imitation inner forming sleeve includes a left forming sleeve 19 and a right forming sleeve 20; The sleeve 19 and the right forming sleeve 20 are respectively fixed on the side walls outside the slope of the left punch 13 and the right punch 14;

[0039] The upper die assembly includes a double-acting press piercing cylinder joint 11, a wedge 12 and a push-pull device. The wedge 12 is embedded between the slopes 131, 141 of the left punch 13 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com