Patents

Literature

608results about How to "Reduce anisotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

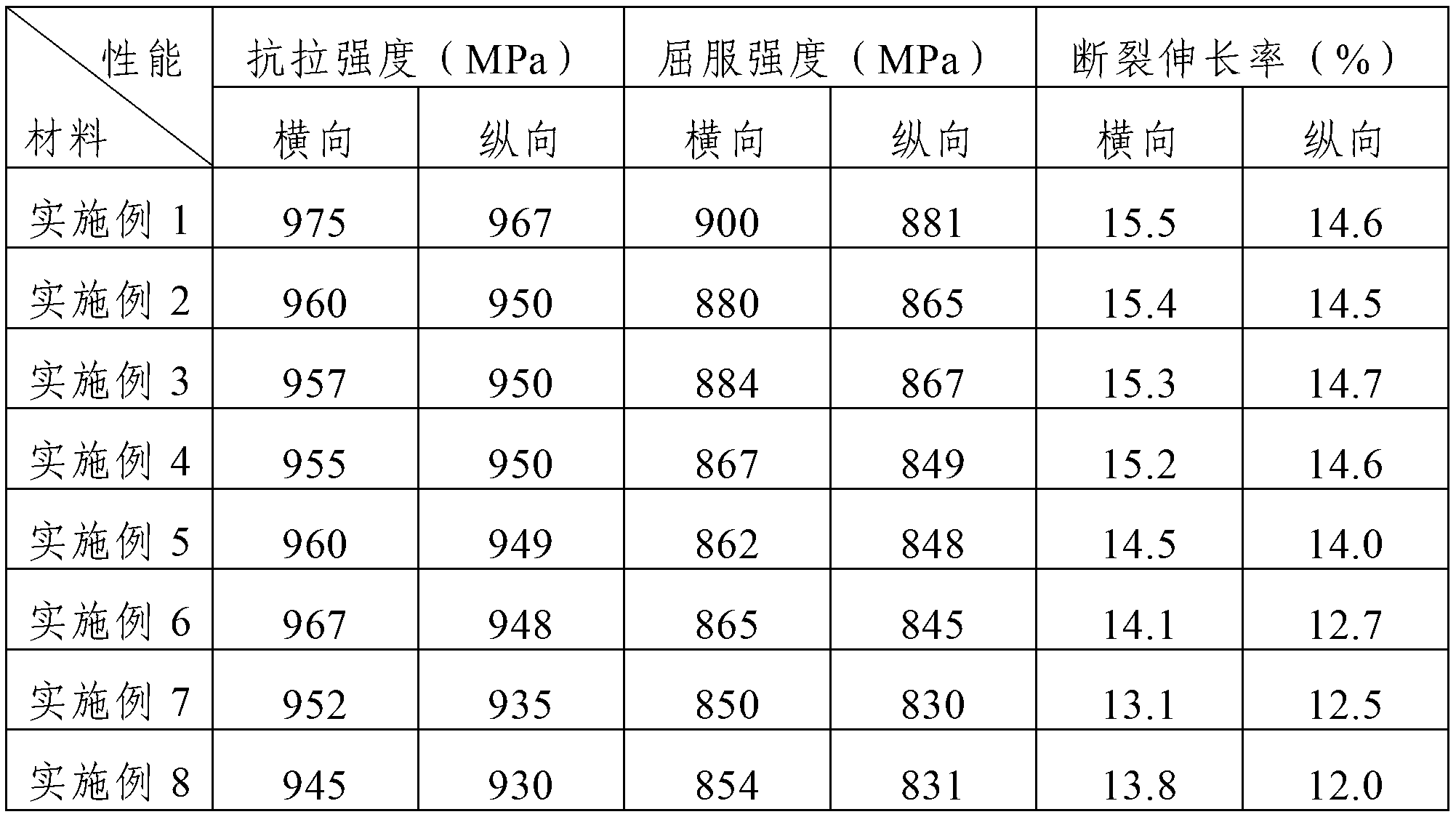

Damage-resistant aluminum-lithium alloy and preparation method thereof

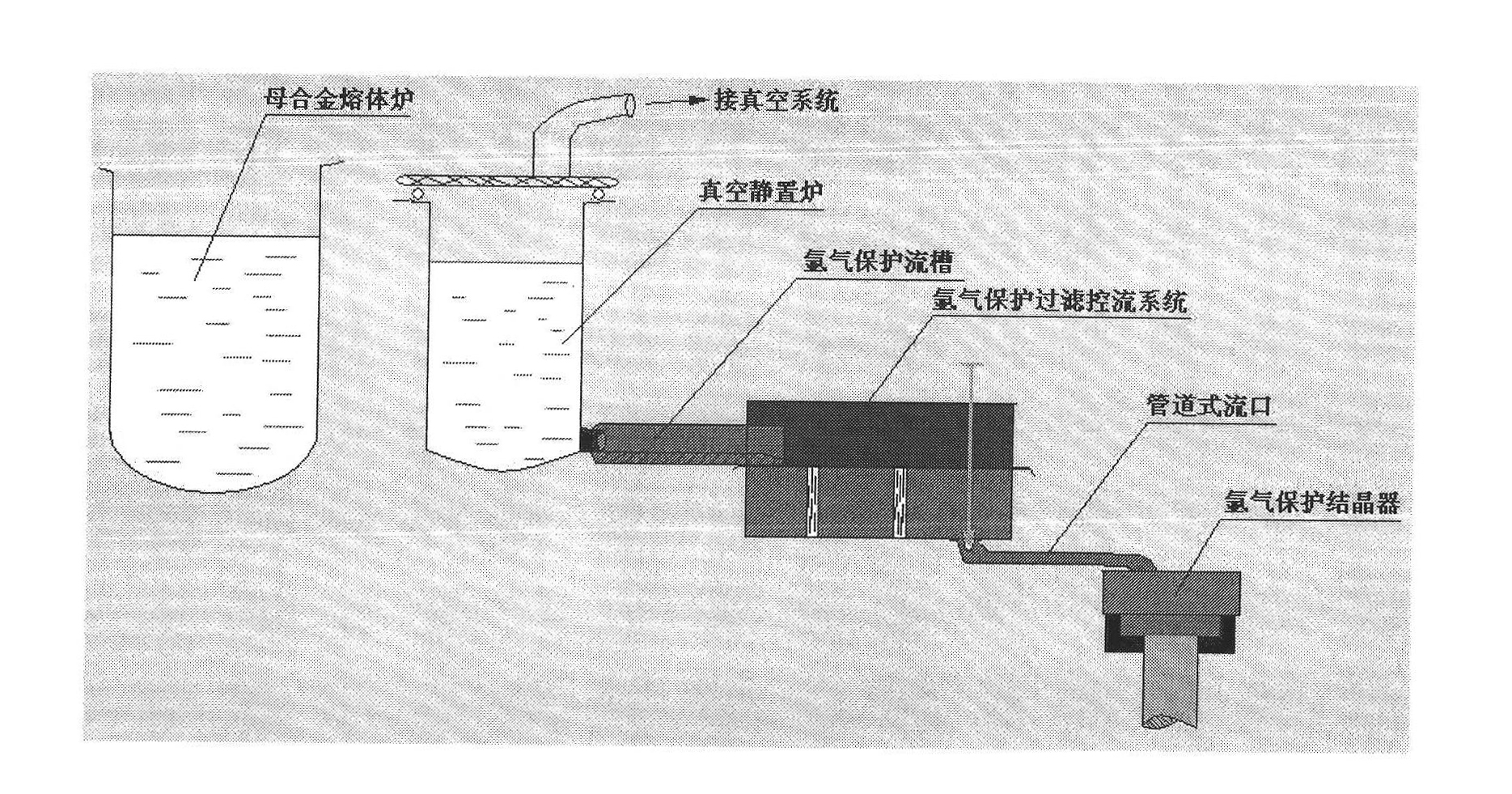

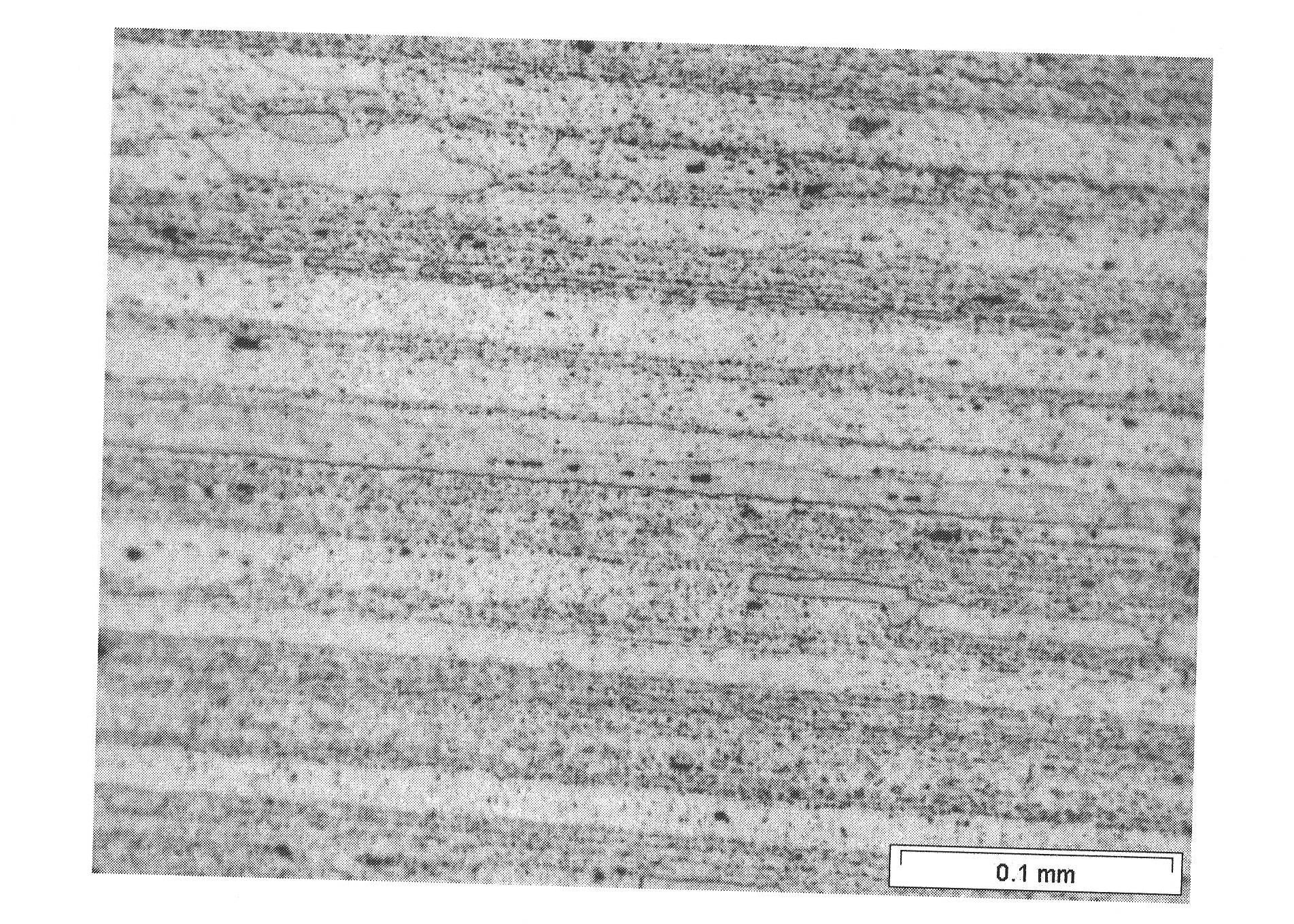

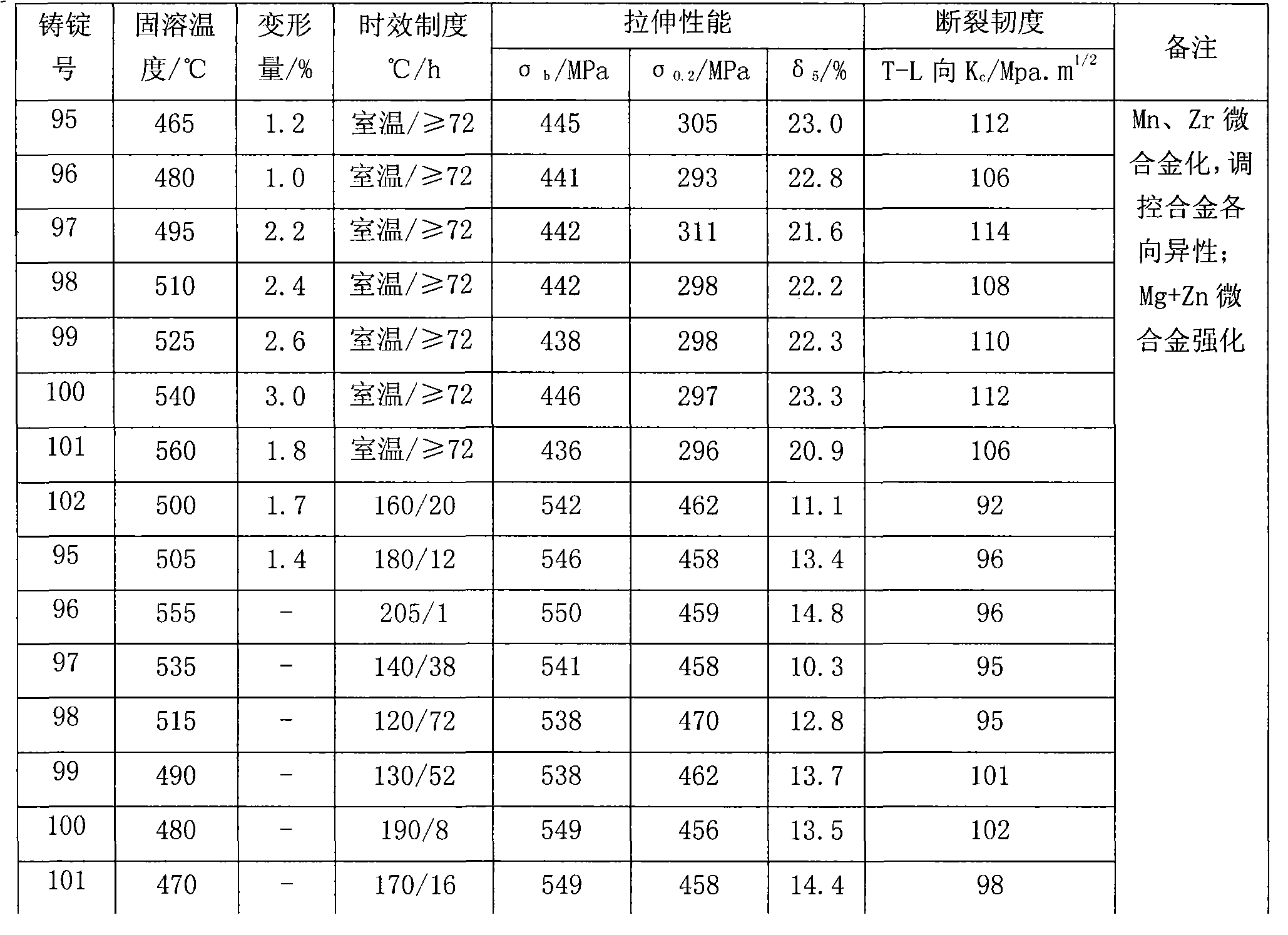

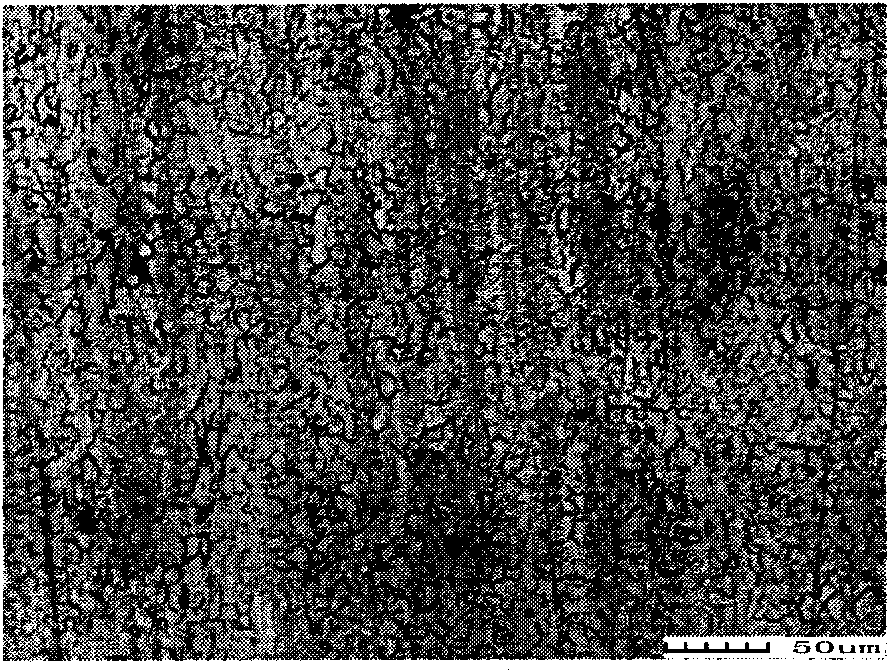

The invention relates to a novel damage-resistant aluminum-lithium alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.8 to 4.0 percent of Cu, 0.8 to 1.9 percent of Li, 0.20 to 0.60 percent of Mn, 0.20 to 0.80 percent of Zn, 0.04 to 0.20 percent of Zr, 0.20 to 0.80 percent of Mg, 0.1 to 0.7 percent of Ag, less than or equal to 0.10 percent of Si, less than or equal to 0.10 percent of Fe, less than or equal to 0.12 percent of Ti, less than or equal to 0.15 percent of other impurities, and the balance of Al, wherein a single impurity accounts for less than or equal to 0.05 percent of the weight of the alloy; and one to five of alloy elements Mn, Zn, Mg, Ag and Zr can be selectively added. The preparation method comprises the following steps of: mixing the alloy elements, melting raw materials, performing furnace refining, standing, and pouring to form alloy ingots with required specifications. The alloy ingots are formed by hot extrusion, hot rolling and cold rolling after being optimized and homogenized and are used for machined parts after being subjected to heat treatment by an optimal process. The novel damage-resistant aluminum-lithium alloy material of the invention has a uniform microstructure and stable performance and is suitable for manufacturing sheets. Products made of the material can be used for structural elements in the fields such as aerospace, nuclear industry, transportation, sports goods, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof

The invention relates to a low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof. The composite material comprises the following components (wt%): 10-35% of polycarbonate, 20-45% of polybutylece terephthalate, 1-10% of flexibilizer, 3-10% of kaolin and 15-38% of glass fiber; 0.1-1% of antioxidant, 0.1-0.5% of ester exchange inhibiting agent and 0.1-3% of processing agent are prepared, silane coupling agent is utilized to process kaolin, then raw materials are placed into a mixing machine to be mixed for 2-5min, then mixture is placed into a screw machine for extrusion granulation, and meanwhile side charging is carried out on the glass fiber, the rotating speed of screw machine is 180-600rpm, and temperature is 240-280 DEG C, thus obtaining the product. The invention can obtain products with high surface gloss, excellent comprehensive mechanical properties and dimensional stability and especially ensures low warping property of product when being produced into injection moulding product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

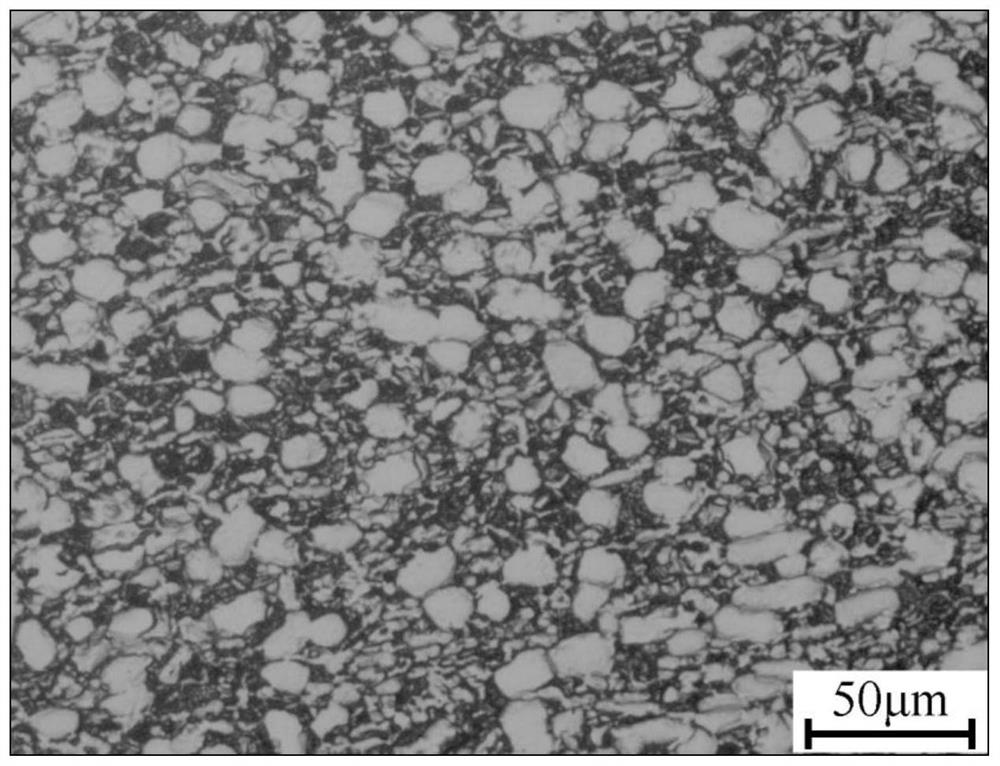

Hot rolling process of high-plasticity and low-anisotropy magnesium alloy and sheet thereof

ActiveCN101857933ASimple processEasy to controlTemperature control deviceProcess efficiency improvementZincMetal

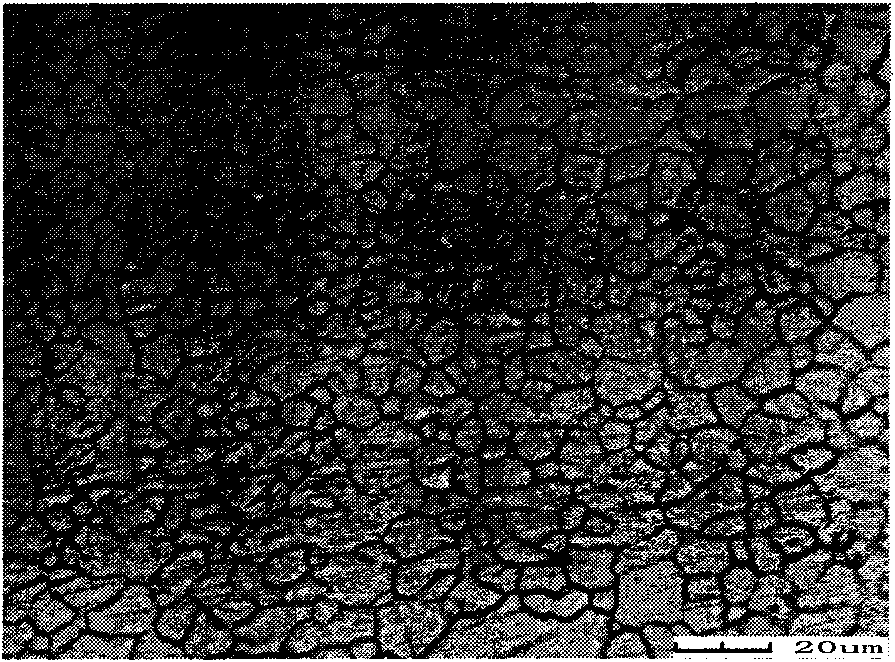

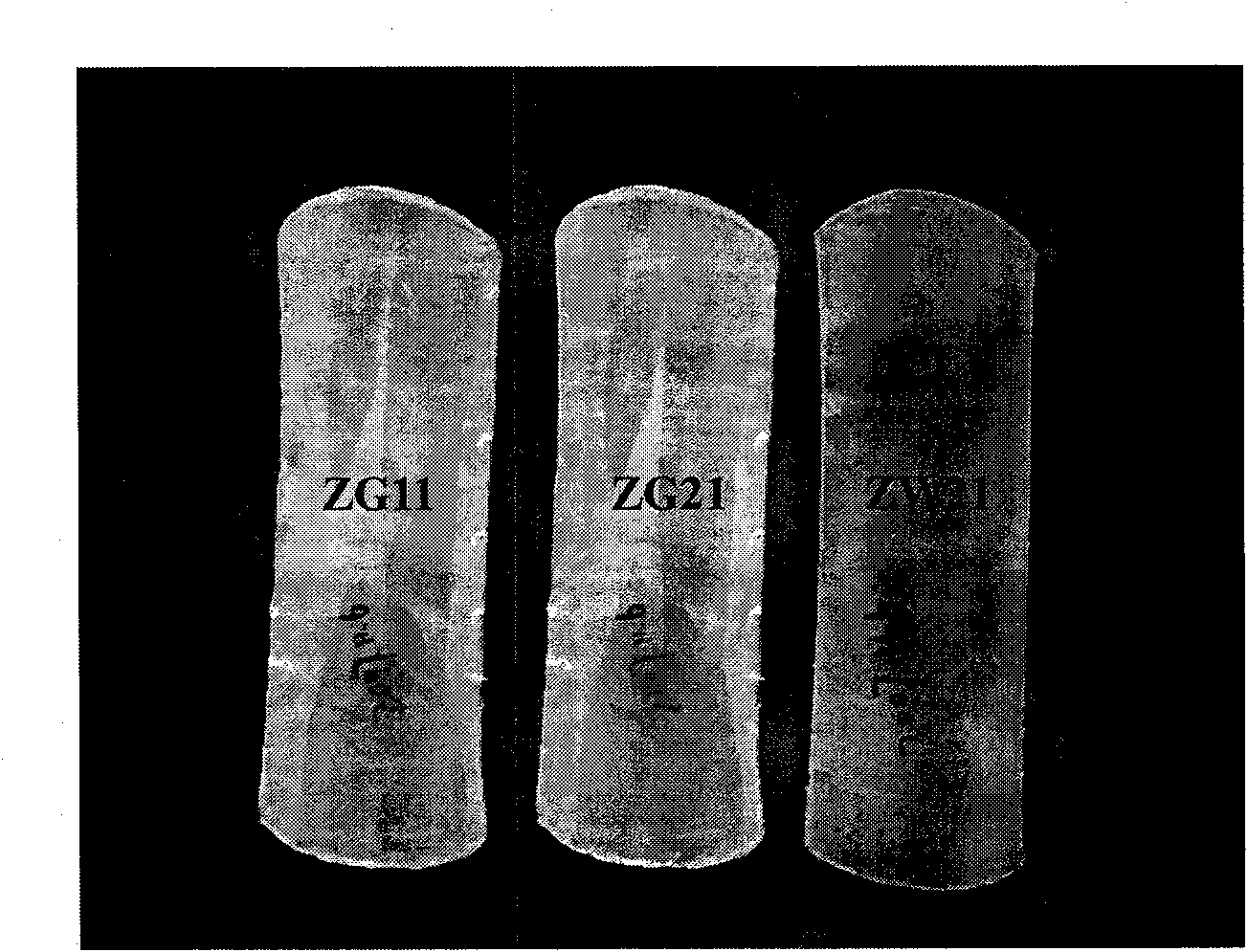

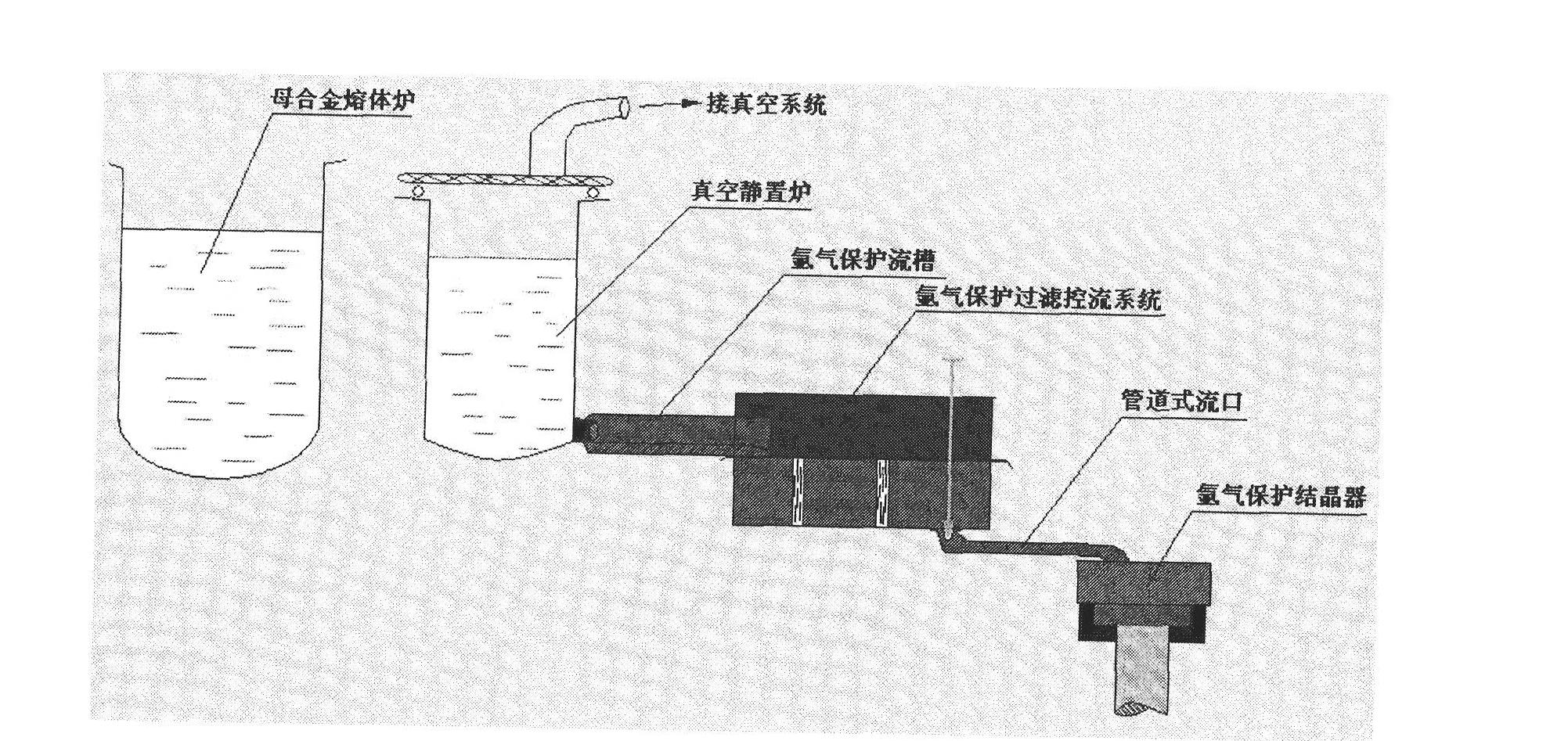

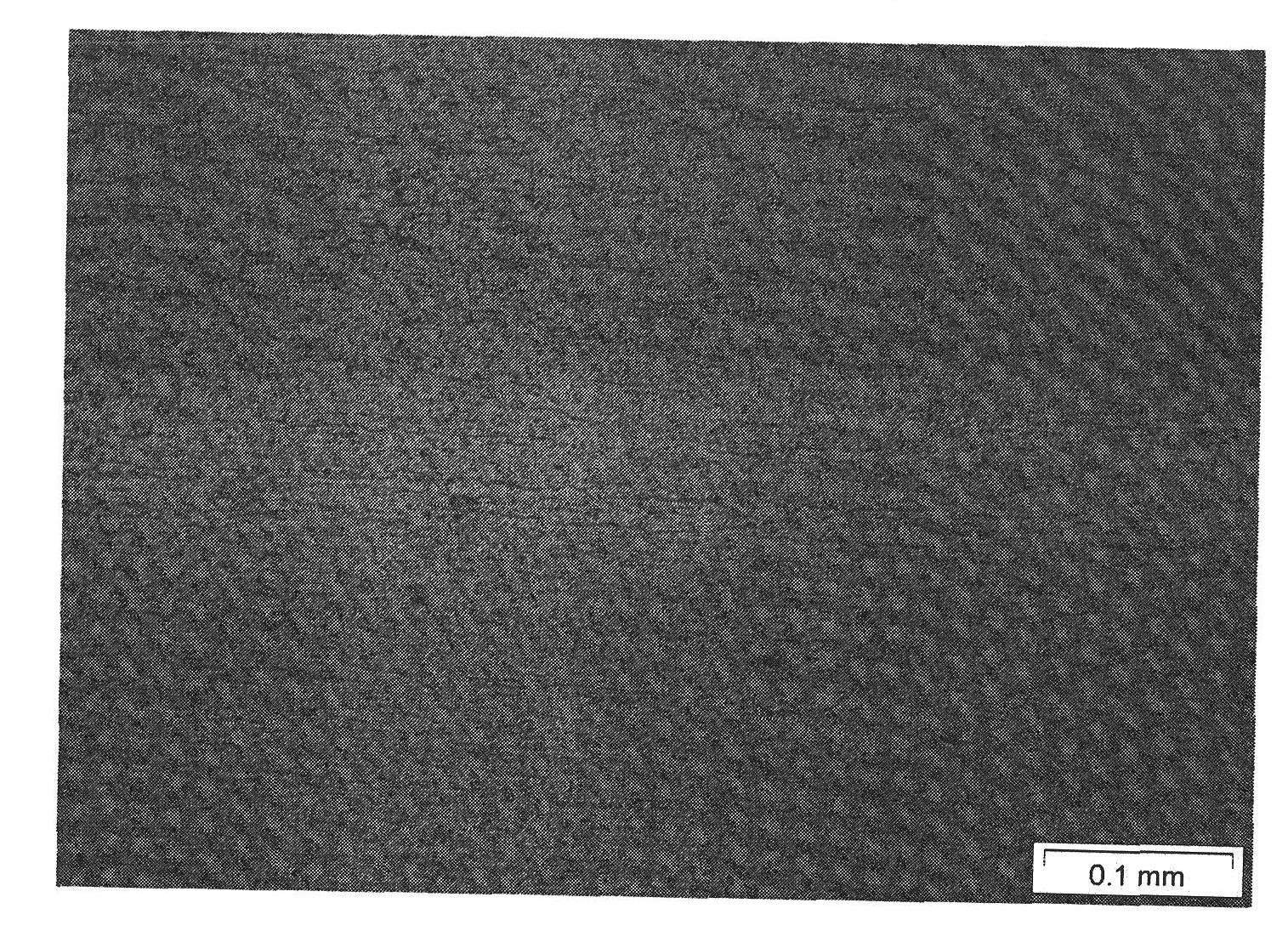

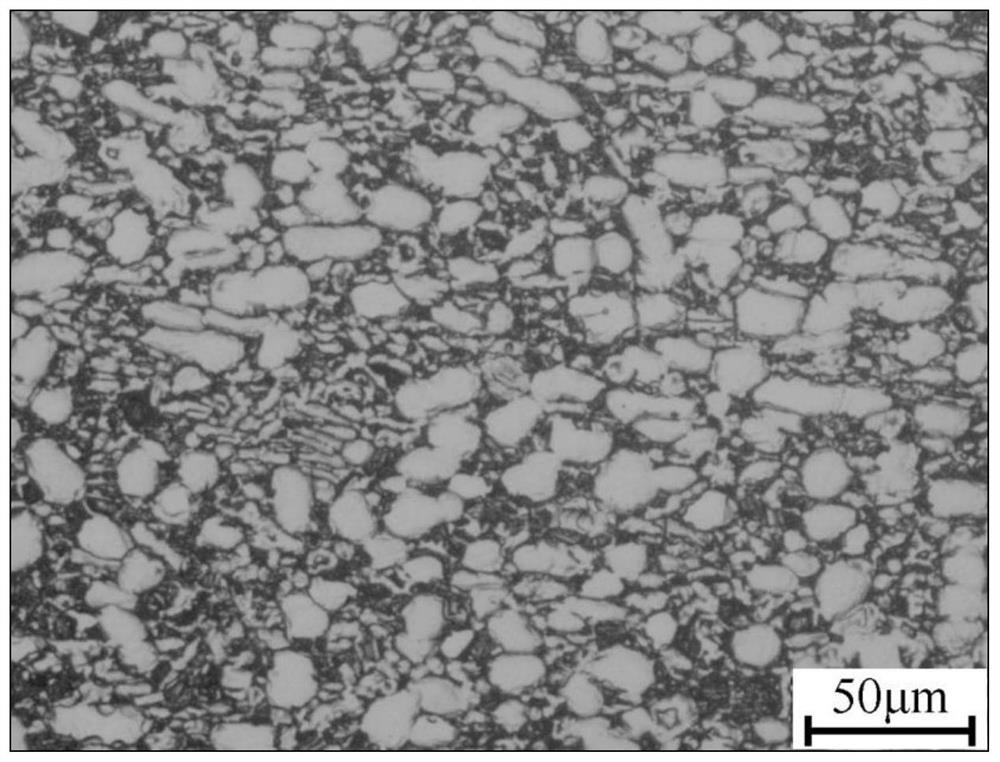

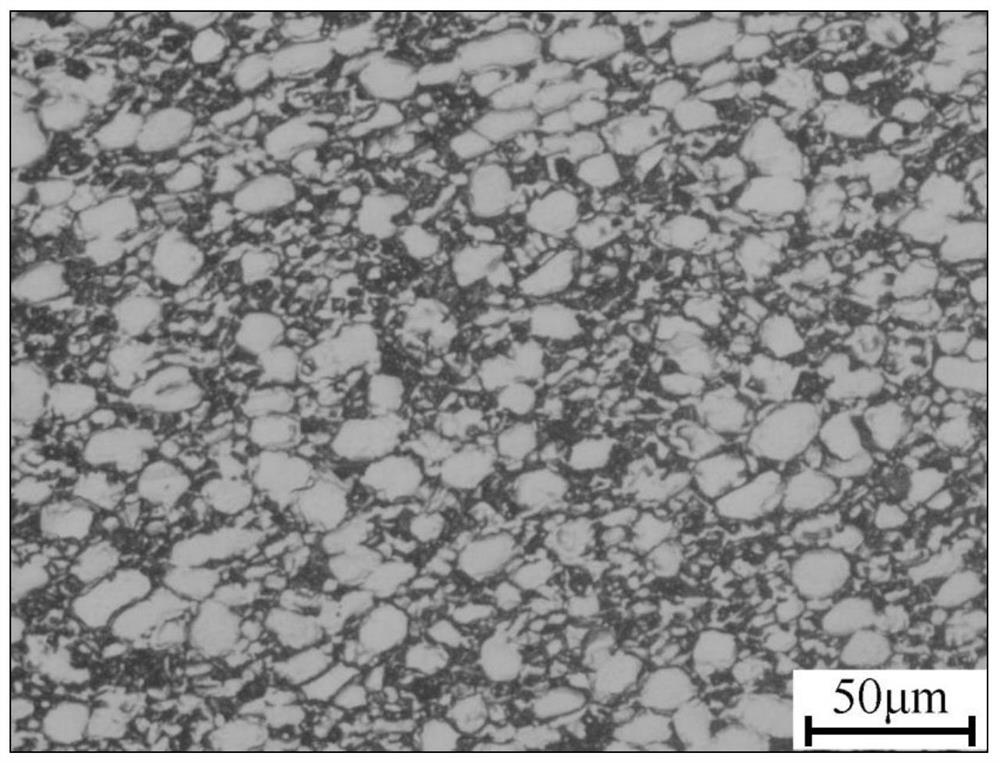

The invention relates to a hot rolling process of a high-plasticity and low-anisotropy magnesium alloy and a sheet thereof, which belongs to the technical field of metal materials. The magnesium alloy is an Mg-Zn-RE system and comprises the following components in percentage by weight: 0-5 percent of zinc, 0.1-10 percent of rare earth (RE) and the balance of Mg. The hot rolling process comprises the following steps: producing cast ingots by adopting a metal mould and a sand mould gravity casting or semicontinuous casting method; carrying out homogenized annealing treatment and face milling on the cast ingots; preserving the heat and then starting rolling; rolling sheets with the thickness of 10-600mm into sheets of 0.1-5mm; and carrying out heat treatment. The elongation percentage delta of the sheet after rolled or rolled and annealed along the rolling direction is more than or equal to 30 percent and the elongation along the transverse direction is more than or equal to 36 percent. The prepared sheet has the characteristics of weaker basal face texture, low anisotropy (average anisotropic factors are between 0.8 and 1.3) and higher hardening index (0.2-0.4). The favorable forming performance at room temperature of the sheet is ensured.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-toughness aluminum lithium alloy and preparation method thereof

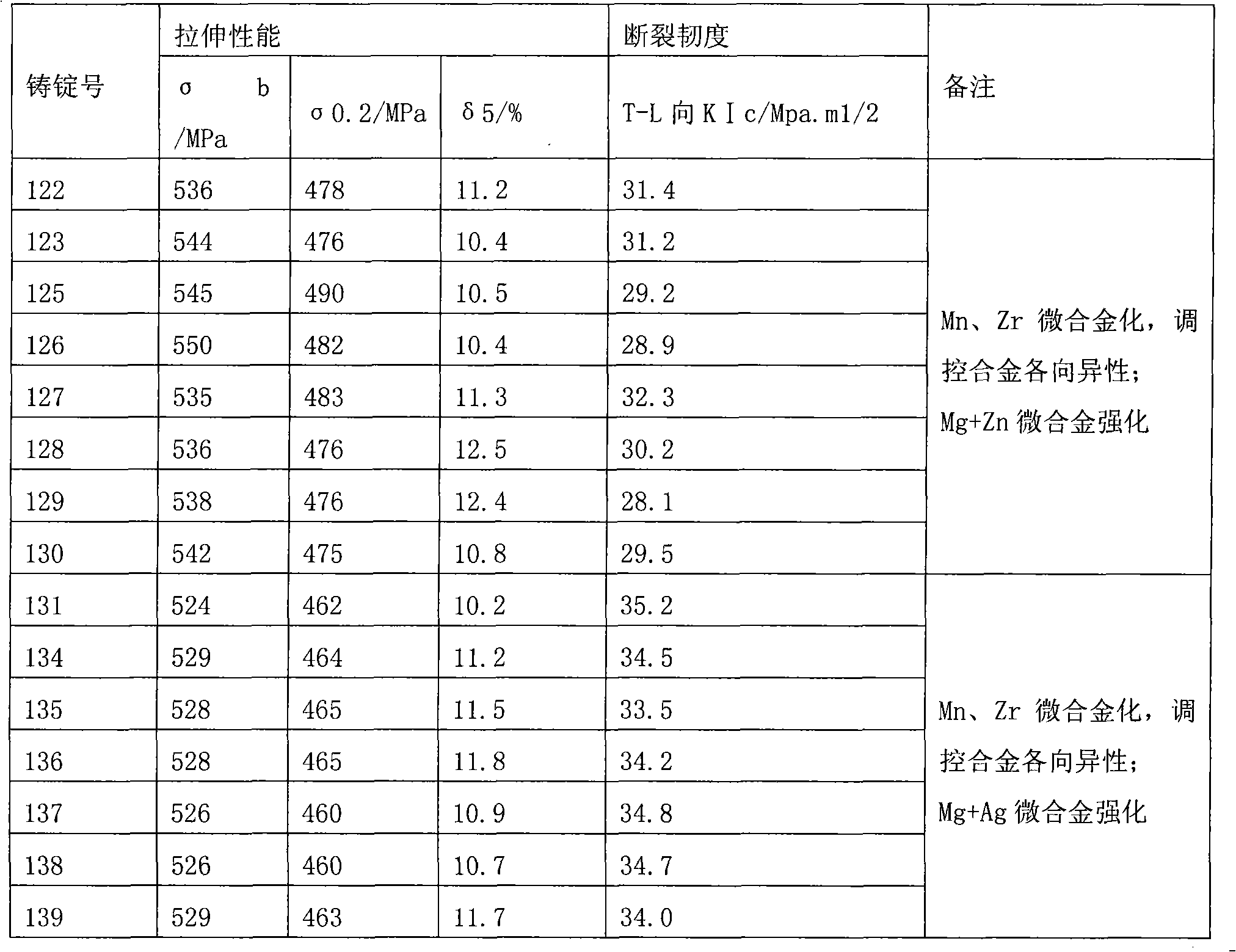

The invention discloses a high-toughness aluminum lithium alloy and a preparation method thereof. The alloy comprises the following chemical components in percentage by weight: 3.2 to 4.2 percent of Cu, 0.7 to 1.8 percent of Li, 0.20 to 0.60 percent of Mn, 0.20 to 0.60 percent of Zn, 0.06 to 0.20 percent of Zr, 0.20 to 0.80 percent of Mg, 0.2 to 0.7 percent of Ag, less than or equal to 0.10 percent of Si, less than or equal to 0.10 percent of Fe, less than or equal to 0.12 percent of Ti, less than or equal to 0.15 percent of other impurities (single impurity is less than or equal to 0.05 percent) and the balance of Al. One or five of alloy elements Mn, Zn, Mg, Ag and Zr can be selectively added. Proportioning is performed according to the alloy components, the raw materials are melted, then furnace refining and standing are performed, and alloy ingots with required specifications are cast. The alloy ingots are preferably homogenized and then molded by any process of hot extruding, hot rolling and the like, and the alloy ingots thermally treated by the preferable process can be used for processing parts. The high-toughness aluminum lithium alloy material has uniform microscopic structure and stable performance, and is suitable for manufacturing thick plates and extruded materials. The ultimate tensile strength can reach over 510MPa, and meanwhile, the elongation rate is more than 8 percent and the KIc can reach over 30MPam1 / 2. The material product can be used for structural elements of the fields of aerospace, nuclear industry, traffic and transportation, sports goods, weapons and the like.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

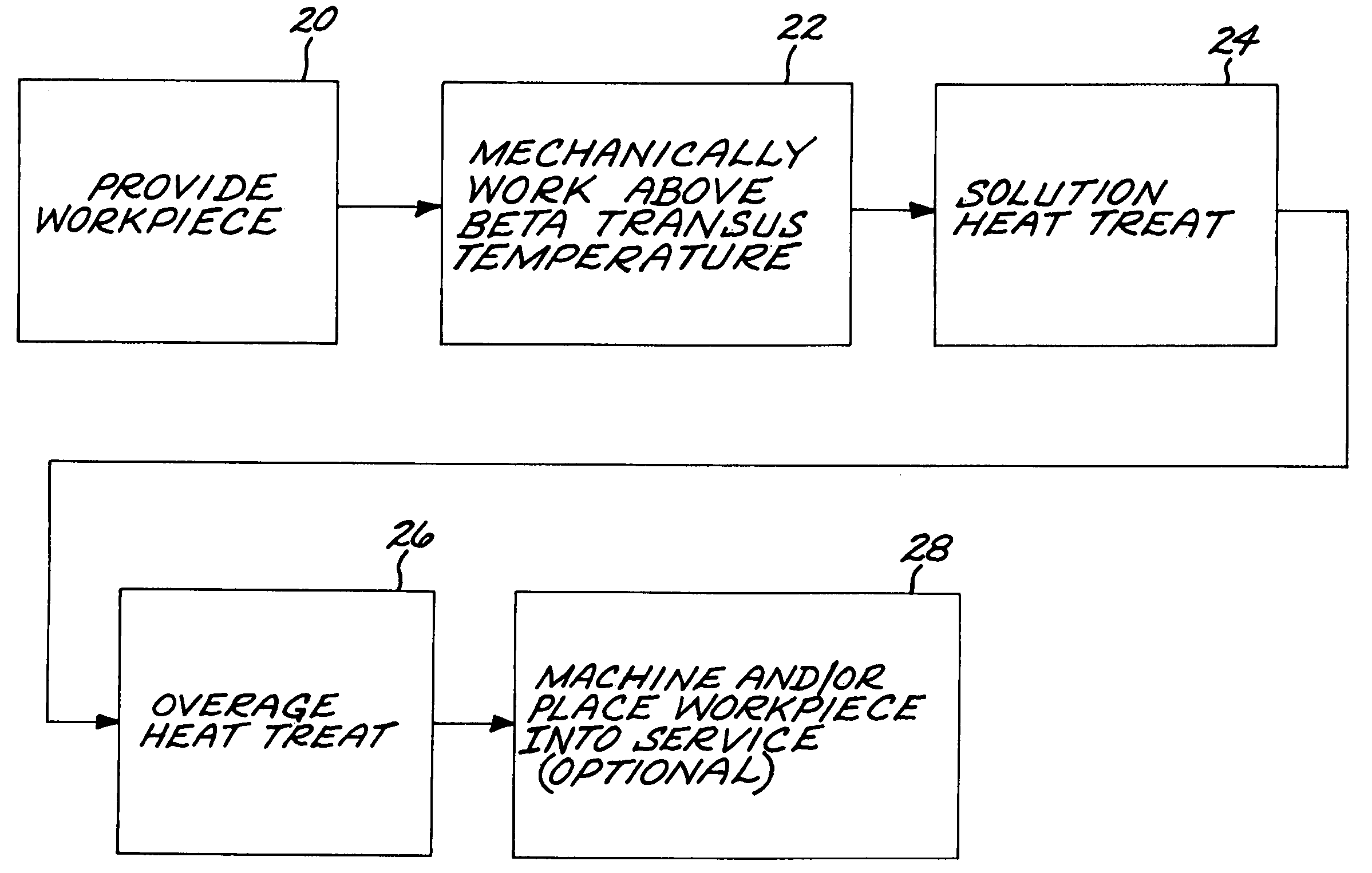

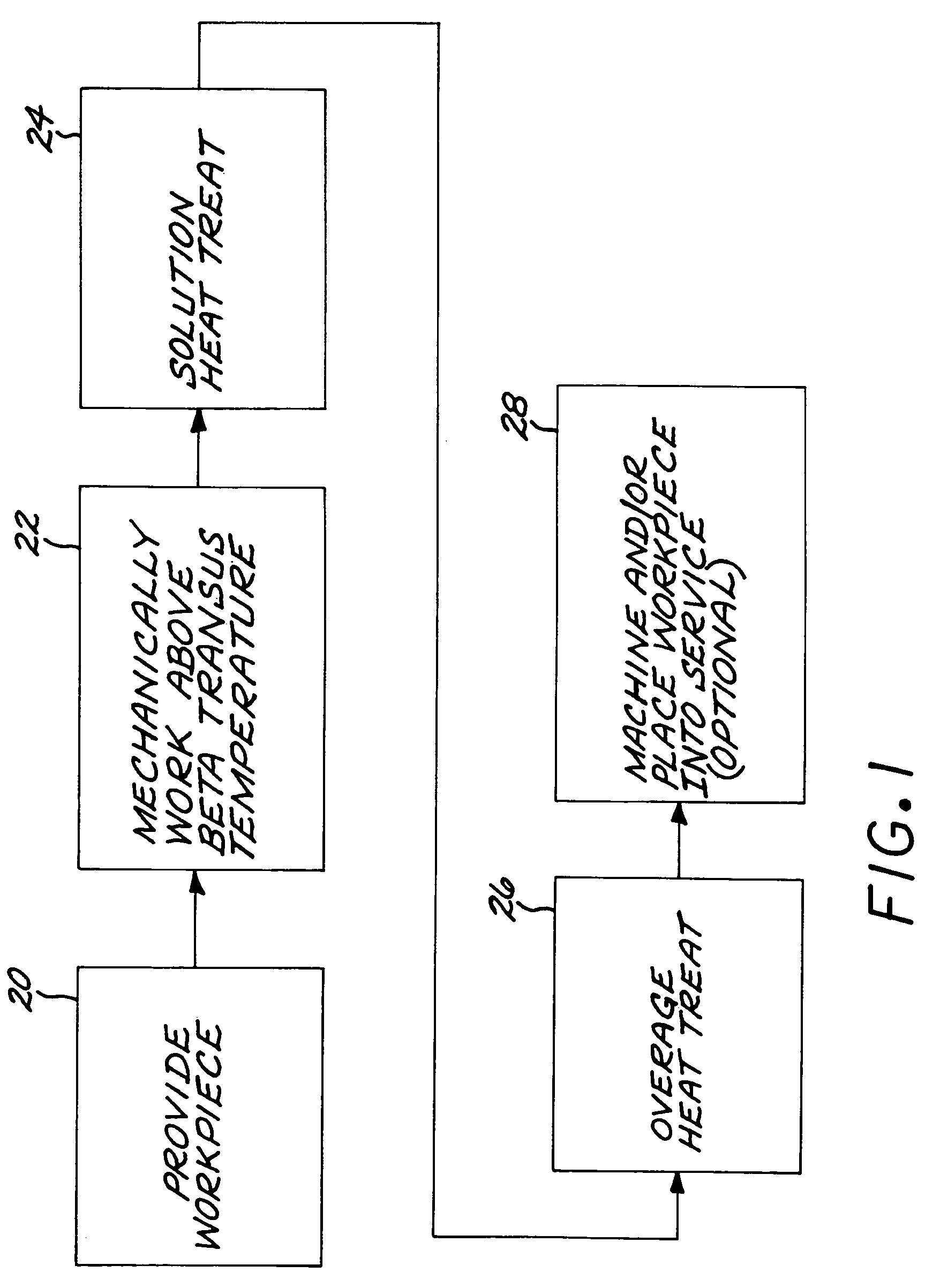

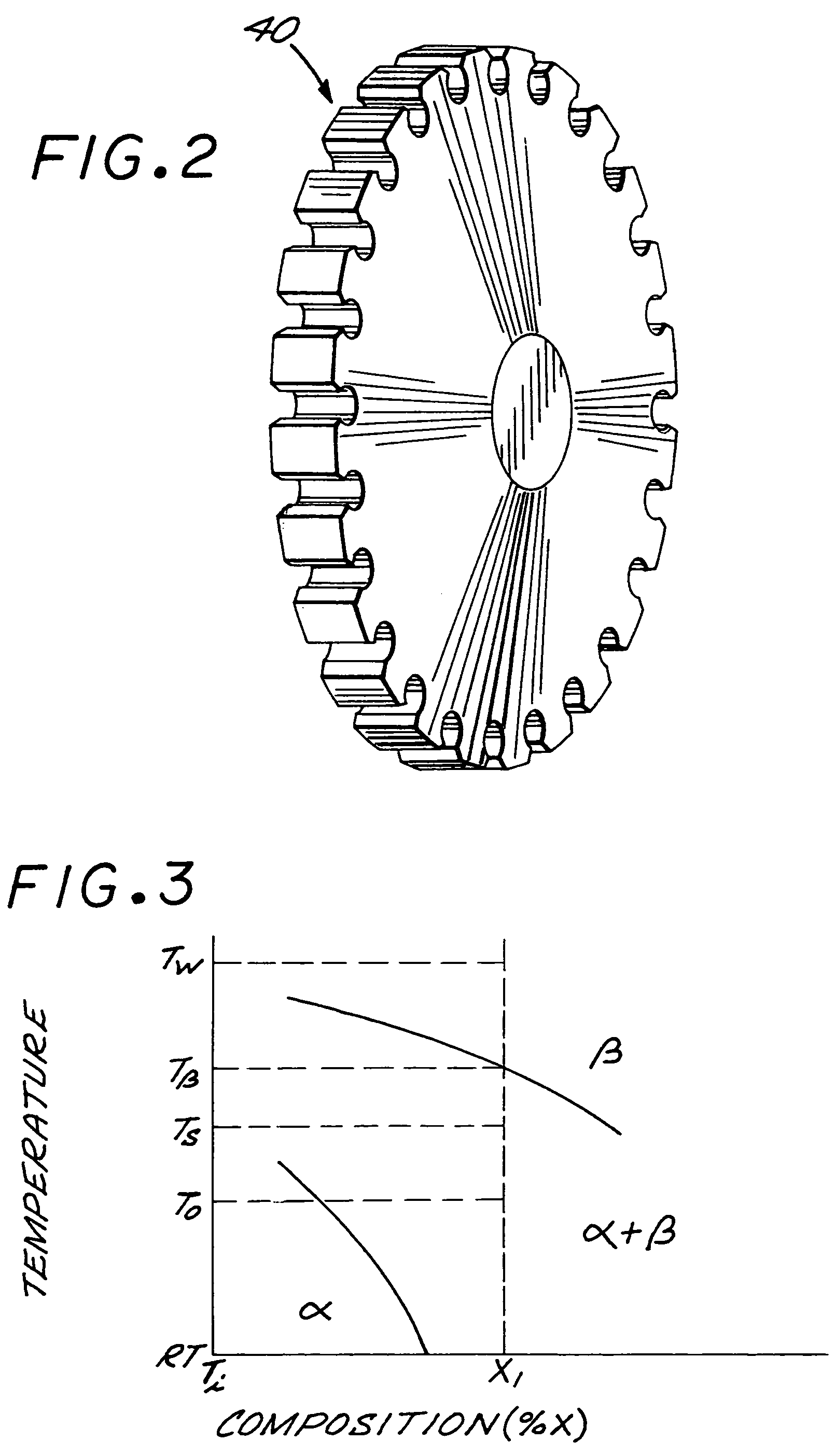

Method for producing a beta-processed alpha-beta titanium-alloy article

InactiveUS7449075B2Improve mechanical propertiesReduce anisotropyGreek letter betaWorking temperature

A titanium-alloy article is produced by providing a workpiece of an alpha-beta titanium alloy having a beta-transus temperature, and thereafter mechanically working the workpiece at a mechanical-working temperature above the beta-transus temperature. The mechanically worked workpiece is solution heat treated at a solution-heat-treatment temperature of from about 175° F. below the beta-transus temperature to about 25° F. below the beta-transus temperature, quenched, overage heat treated at an overage-heat-treatment temperature of from about 400° F. below the beta-transus temperature to about 275° F. below the beta-transus temperature, and cooled from the overage-heat-treatment temperature.

Owner:GENERAL ELECTRIC CO

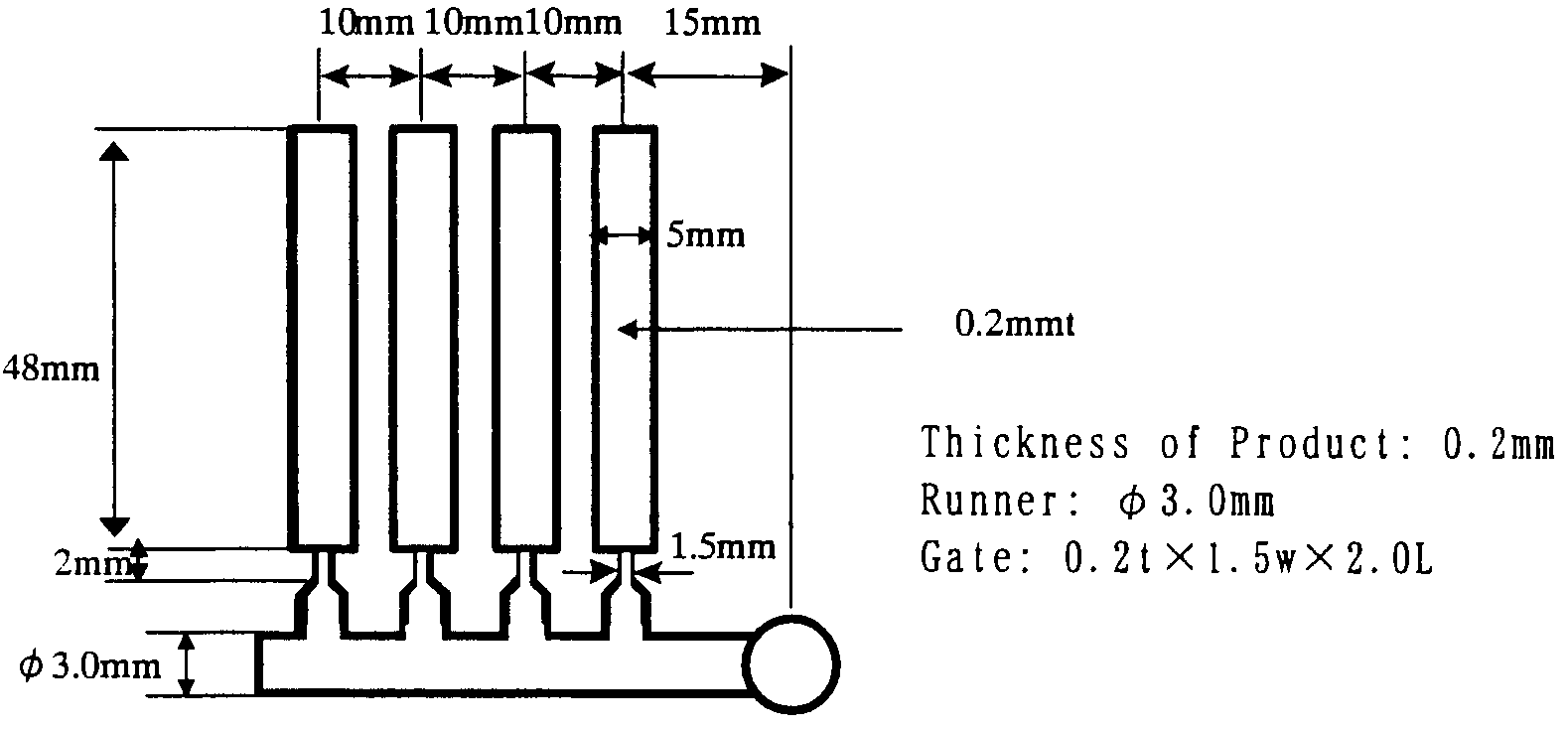

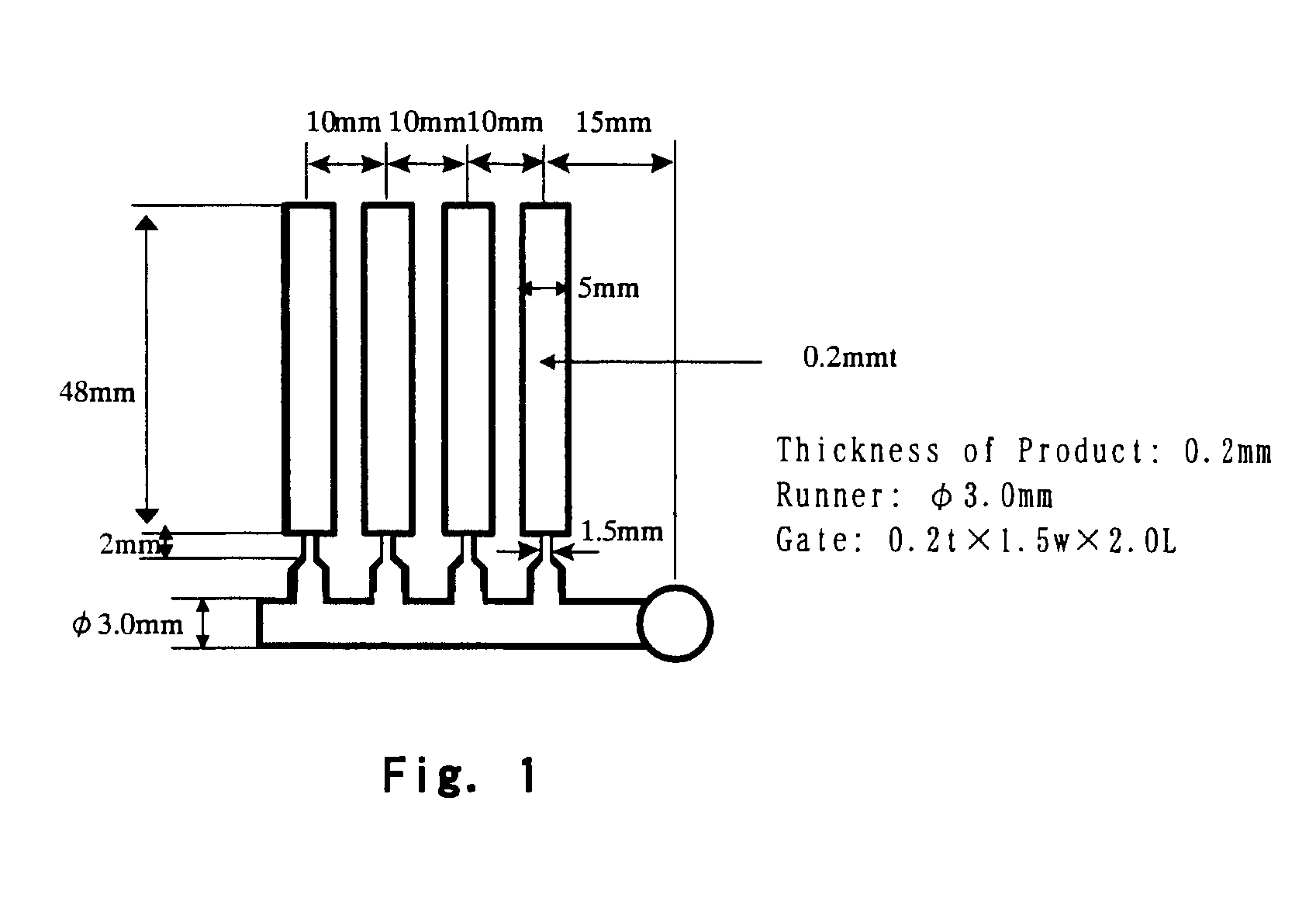

Liquid crystalline polyester composition

InactiveUS7824572B2High heat resistanceReduce anisotropyLiquid crystal compositionsSynthetic resin layered productsPolyesterLiquid crystalline

The present invention provides a liquid crystalline polyester composition comprising a terphenyl and a liquid crystalline polyester, wherein the terphenyl substantially consists of p-terphenyl, and the p-terphenyl is contained in the composition in the amount of 0.3 to 15 parts by weight on the basis of 100 parts by weight of the liquid crystalline polyester. The liquid crystalline polyester composition has high flowability and low anisotropy, which can also suppress generation of gases when molded.

Owner:SUMITOMO CHEM CO LTD

Rolling method of TC4 titanium alloy wide cut medium-thickness plates

ActiveCN103230936AReduce anisotropyReal-time monitoring of rolling deformation temperatureTemperature control deviceProfile control deviceWork in processTitanium alloy

The invention provides a rolling method of TC4 titanium alloy wide cut medium-thickness plates. The rolling method includes the following steps: 1, first heating treatment is performed on TC4 titanium alloy plate blank with thickness ranging from 80mm to 150mm and length and width ranging from 800mm to 1200mm; 2, first rolling is performed on the TC4 titanium alloy plate blank to obtain semi-finished plate blank; 3, surface scale is removed after the semi-finished plate blank is sheared, and then second heating treatment is performed; and 4, second rolling is performed on the semi-finished plate blank to obtain TC4 titanium alloy wide cut medium-thickness plates with thickness ranging from 5mm to 30mm and width ranging from 1000mm to 2600mm. Through comprehensive control of rolling temperature, rolling heating number, heating number deformation and rolling directions, finally the TC4 titanium alloy wide cut medium-thickness plates with small anisotropism, high mechanical properties, strong plastic comprehensive matching are manufactured.

Owner:WESTERN METAL MATERIAL

Hot-rolled steel sheet and process for manufacturing same

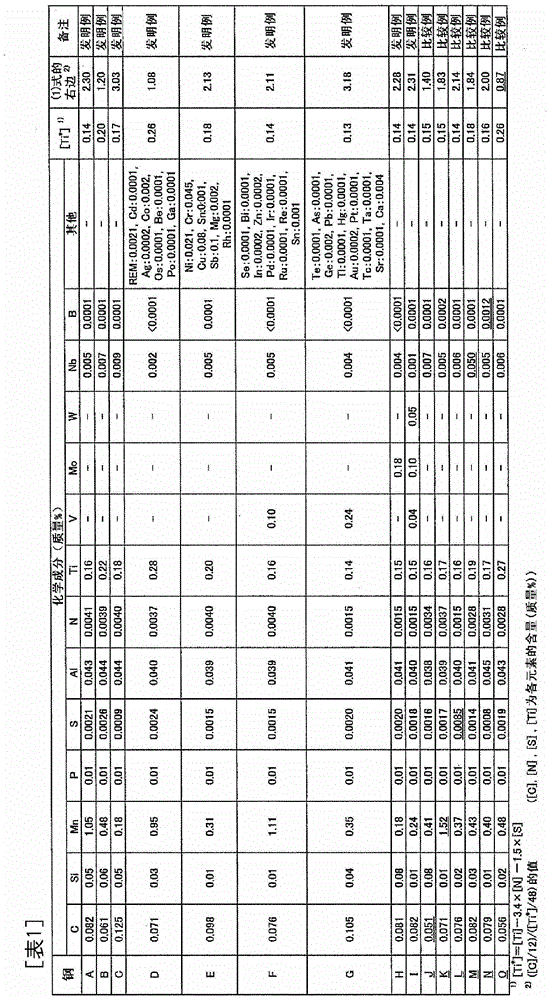

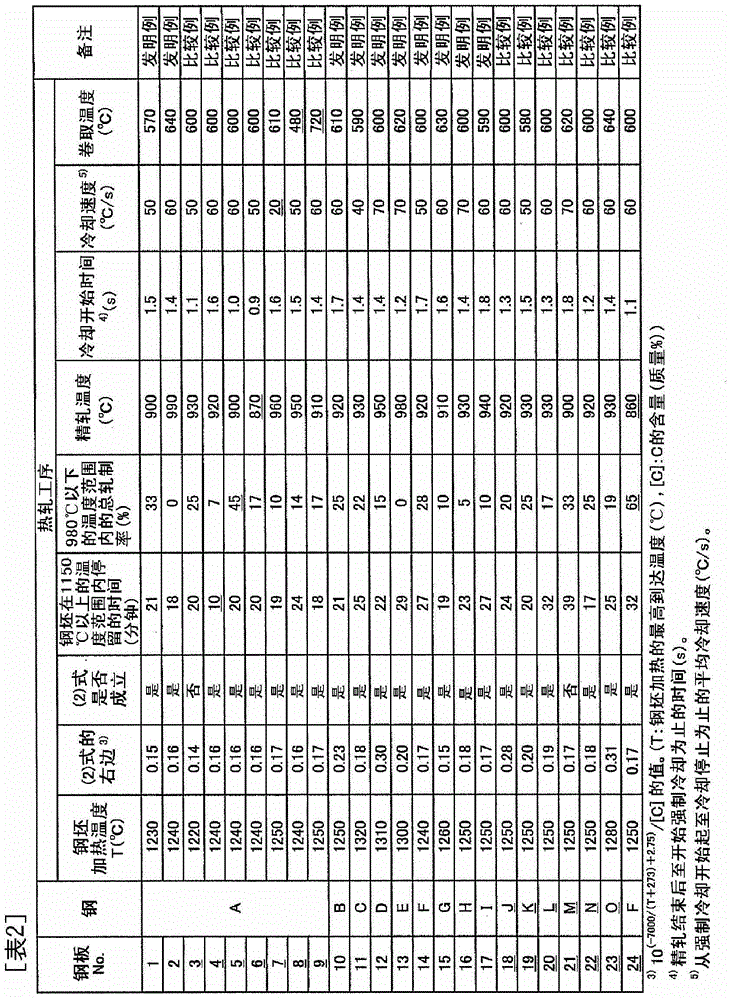

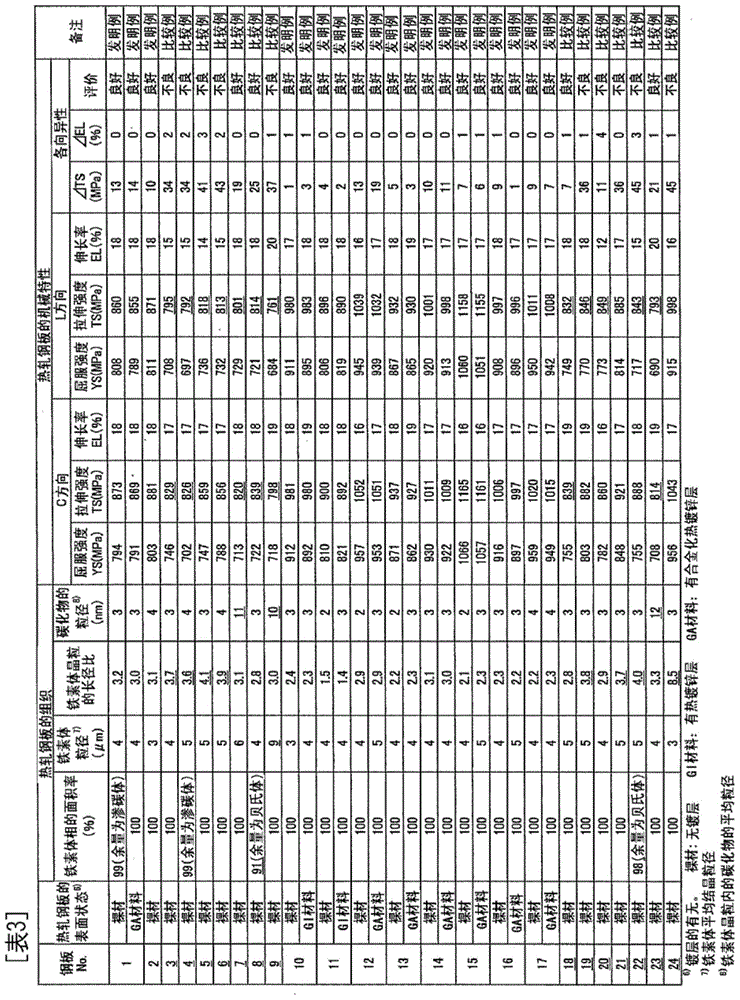

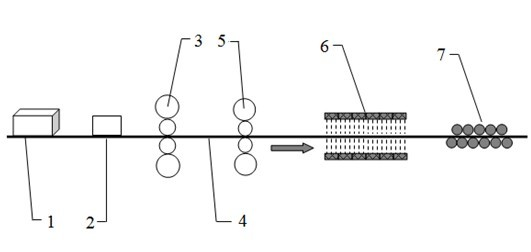

ActiveCN104011234ALow tensile strengthSmall mechanical propertiesHot-dipping/immersion processesFurnace typesSheet steelHot rolled

The present invention pertains to a process for manufacturing a hot-rolled steel sheet which comprises: heating a steel raw material that contains, in mass%, 0.055 to 0.15% of C, at most 0.2% of Si, at most 1.3% of Mn, at most 0.03% of P, at most 0.007% of S, at most 0.1% of Al, at most 0.01% of N and 0.14 to 0.30% of Ti so as to satisfy the relationship 1.0 <= ([C] / 12) / ([Ti*] / 48) (wherein [Ti*] = [Ti]-3.4[N]-1.5[S]) to a temperature (T) ( DEG C) which is equal to or higher than 1150 DEG C and which satisfies the relationship [Ti*] < 10{-7000 / (T+273)+2.75 / [C]; keeping the steel raw material in a temperature range down to 1150 DEG C for at least 15 minutes; subjecting the resulting steel raw material to hot rolling wherein the total rolling reduction in a temperature range up to 980 DEG C is 40% or less and the finish rolling temperature is 880 DEG C or higher; cooling the hot-rolled steel sheet at a cooling rate of 40 to 200 DEG C / s within three seconds after the completion of the finish rolling; and winding up the cooled steel sheet in a temperature range of 500 to 680 DEG C.

Owner:JFE STEEL CORP

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941AGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

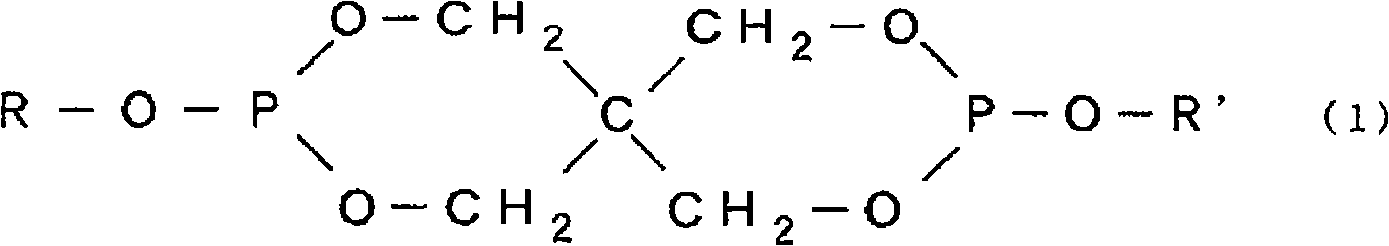

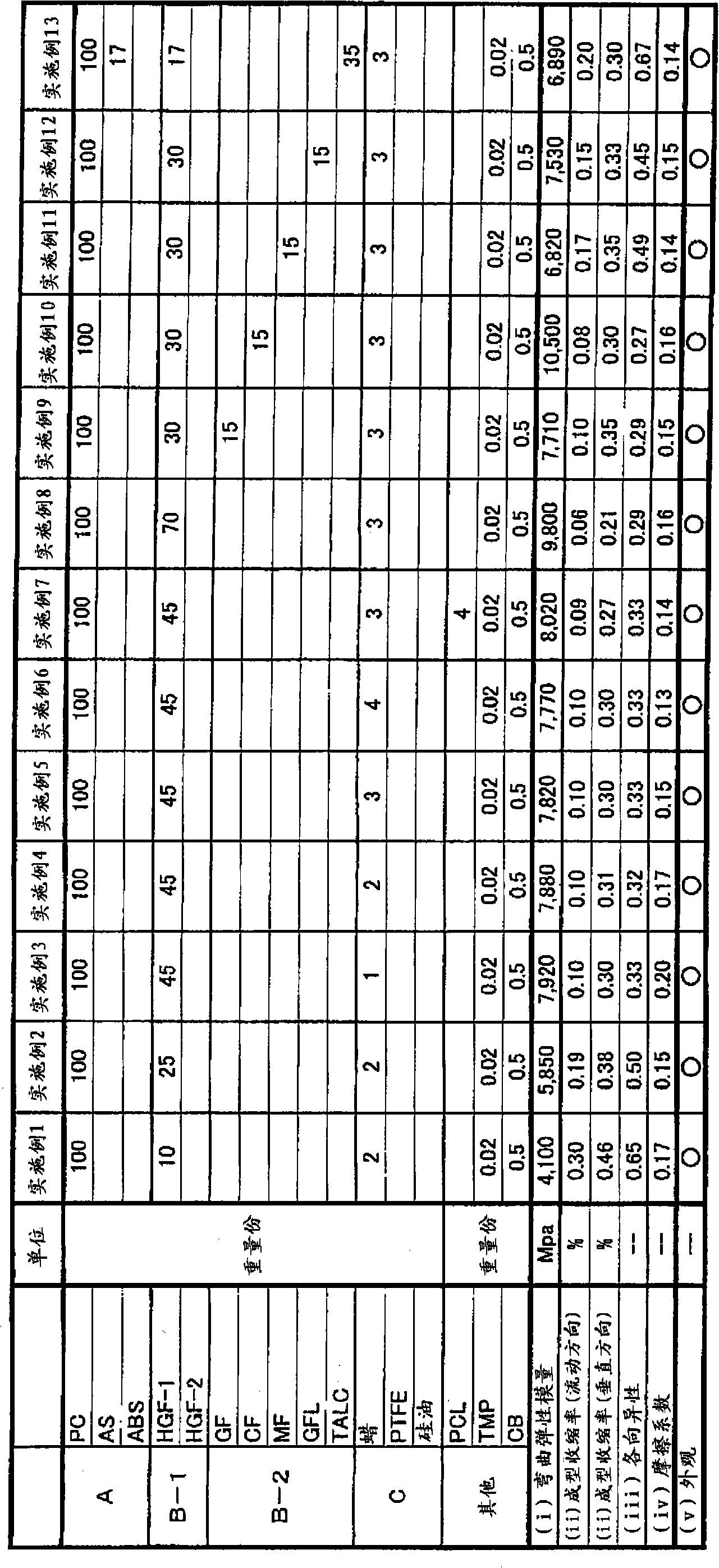

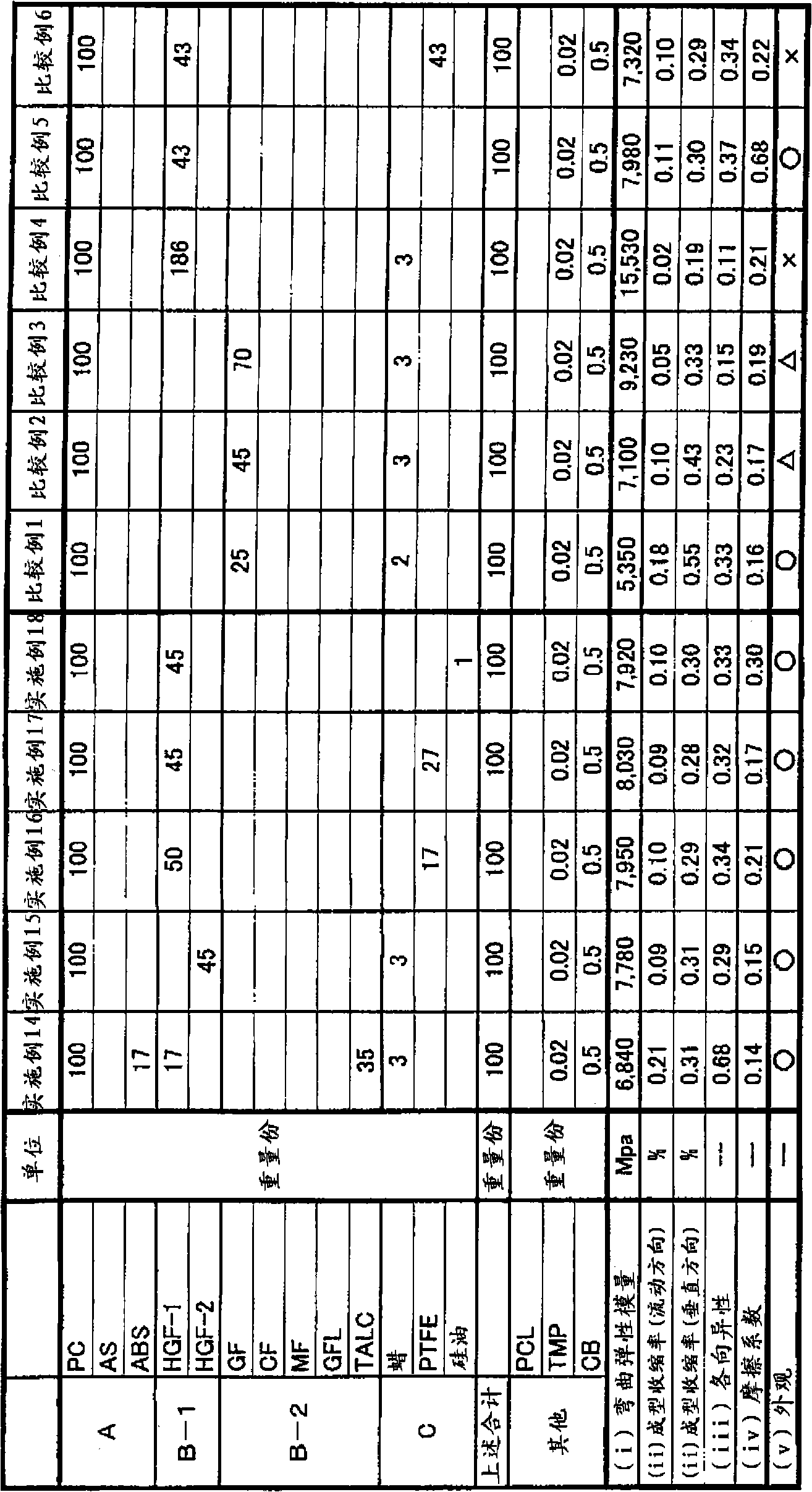

Glass fiber reinforced resin composition

The present invention relates to a glass fiber reinforced resin composition. The objective is to provide a resin composition based on flat cross section glass fiber reinforced thermoplastic resin and having excellent mechanical strength, small aeolotropism of mold shrinkage, good appearance and sliding characteristic. The resin composition contains (A) thermoplastic resin (component A) containing aromatic polycarbonate resin (component A-1); (B) flat cross section glass fibre (component B-1) that an average value of long diameters of the fibre cross section is 10-15[Mu]m, an average value of ratios of the long diameters and short diameters is 1.5-8, and filler material (component B-2), and (C) slide endowing agent (component C), wherein relative to 100 parts of component A by weight, the resin composition contains 1-150 parts of B-1 by weight, 0-150 parts of B-2 by weight, and 0.1-30 parts of C by weight.

Owner:TEIJIN KASEK KK

Liquid crystalline polyester composition

InactiveUS20120135228A1Difficult to formGood molding effectLiquid crystal compositionsGlass/slag layered productsPolyesterLiquid crystalline

Disclosed is a liquid crystalline polyester composition which contains a liquid crystalline polyester and mica and which provides a molded article hard to form blisters therein under a high temperature condition, even when it is molded at a high temperature. The liquid crystalline polyester composition is prepared by incorporating the mica and a fluorocarbon polymer whose flow start temperature is 330° C. or lower into the liquid crystalline polyester. The content of the mica in the liquid crystalline polyester composition is preferably from 15 to 100 parts by mass per 100 parts by mass of the liquid crystalline polyester, and the content of the fluorocarbon polymer in the liquid crystalline polyester composition is preferably from 0.2 to 10 parts by mass per 100 parts by mass of the liquid crystalline polyester.

Owner:SUMITOMO CHEM CO LTD

Method for manufacturing ultra-fine crystal magnesium/titanium layered polystyrene-plywood laminate

InactiveCN101244429AImprove performanceHigh bonding strengthRoll force/gap control deviceTemperature control devicePolystyreneTitanium

The invention relates to a production method of ultra-fine crystal magnesium / titanium laminated composite panel, which comprises the following steps: firstly, cleaning the surfaces of the metal materials; secondly, stacking the metal materials; thirdly, annealing the stacked sheets; fourthly, rolling the sheets after annealing; fifthly, cutting the rolled sheets into two identical parts, trimming and deburring; repeating the first step to the fourth step for lamination and ply rolling; sixthly, annealing the composite panel obtained from lamination and ply rolling to obtain the ultra-fine crystal magnesium / titanium laminated composite panel. The production method solves the problems of complicated technology, high cost, poor corrosion resistant performance of material and poor interface binding performance of the magnesium / titanium laminated composite panel existing in the prior art. The production method has the advantages of simple technology, low cost as well as good corrosion resistant performance and good interface binding performance of the composite panel.

Owner:HARBIN INST OF TECH

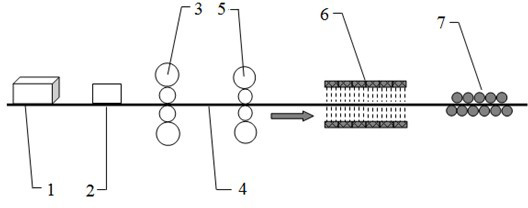

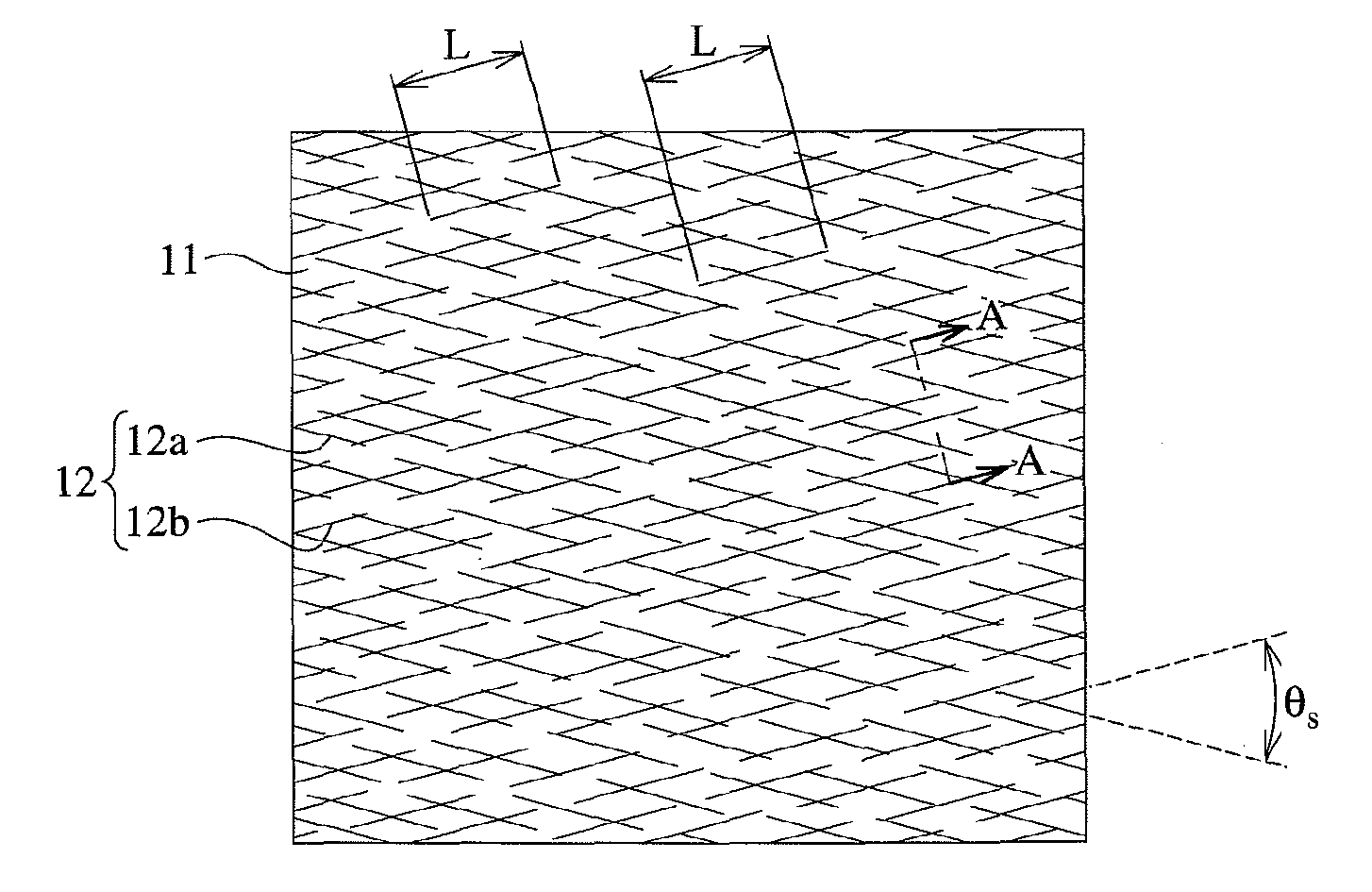

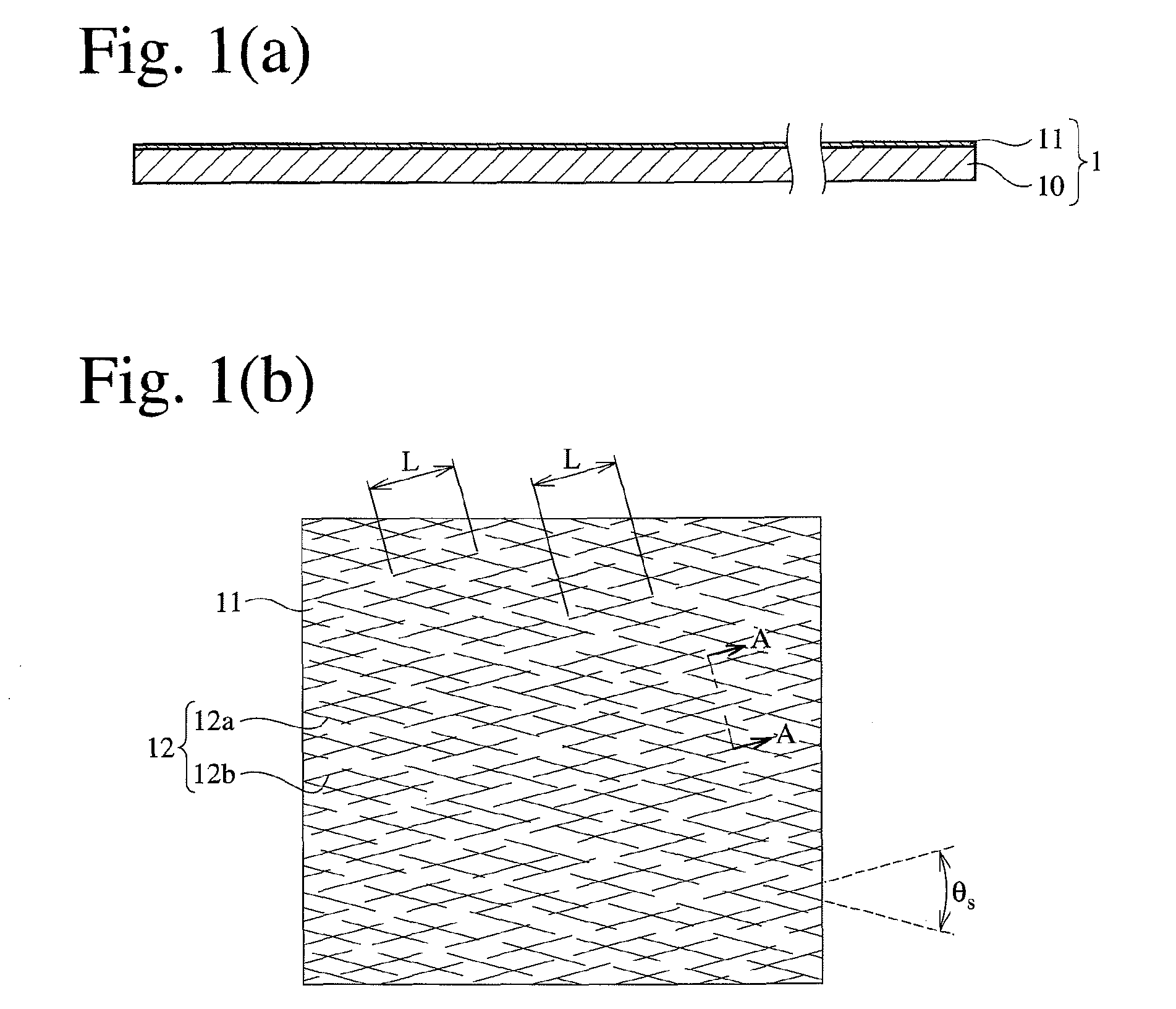

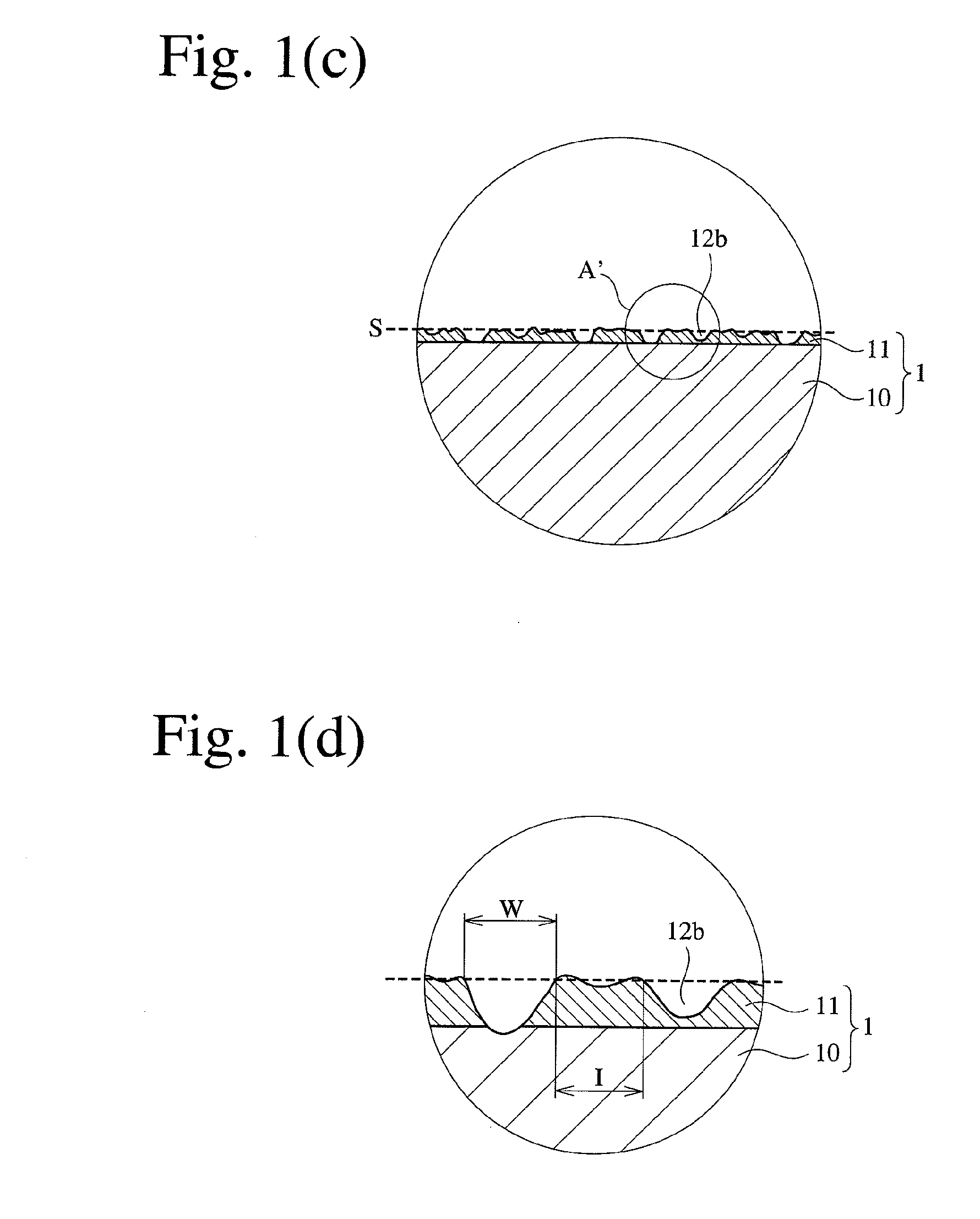

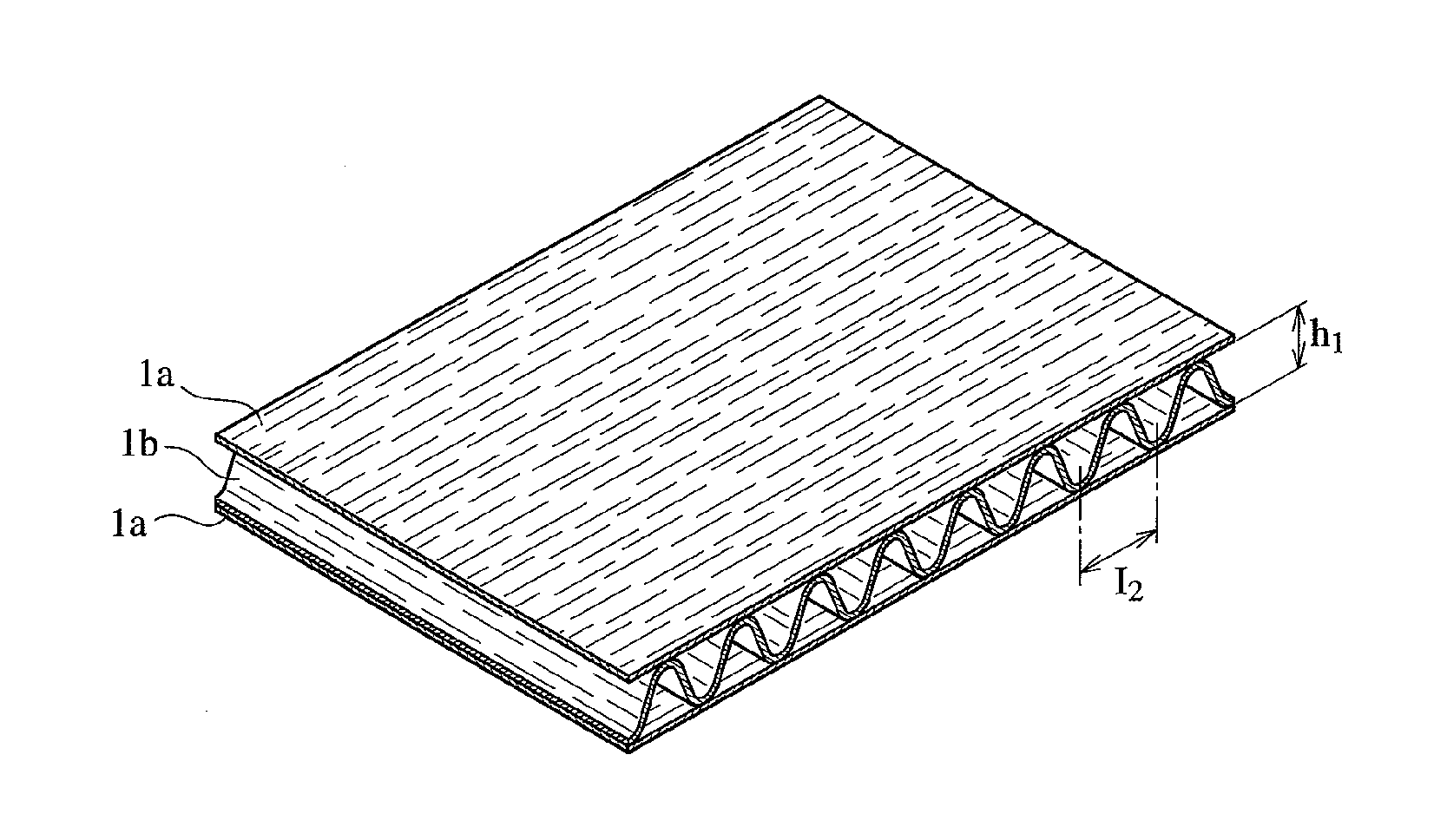

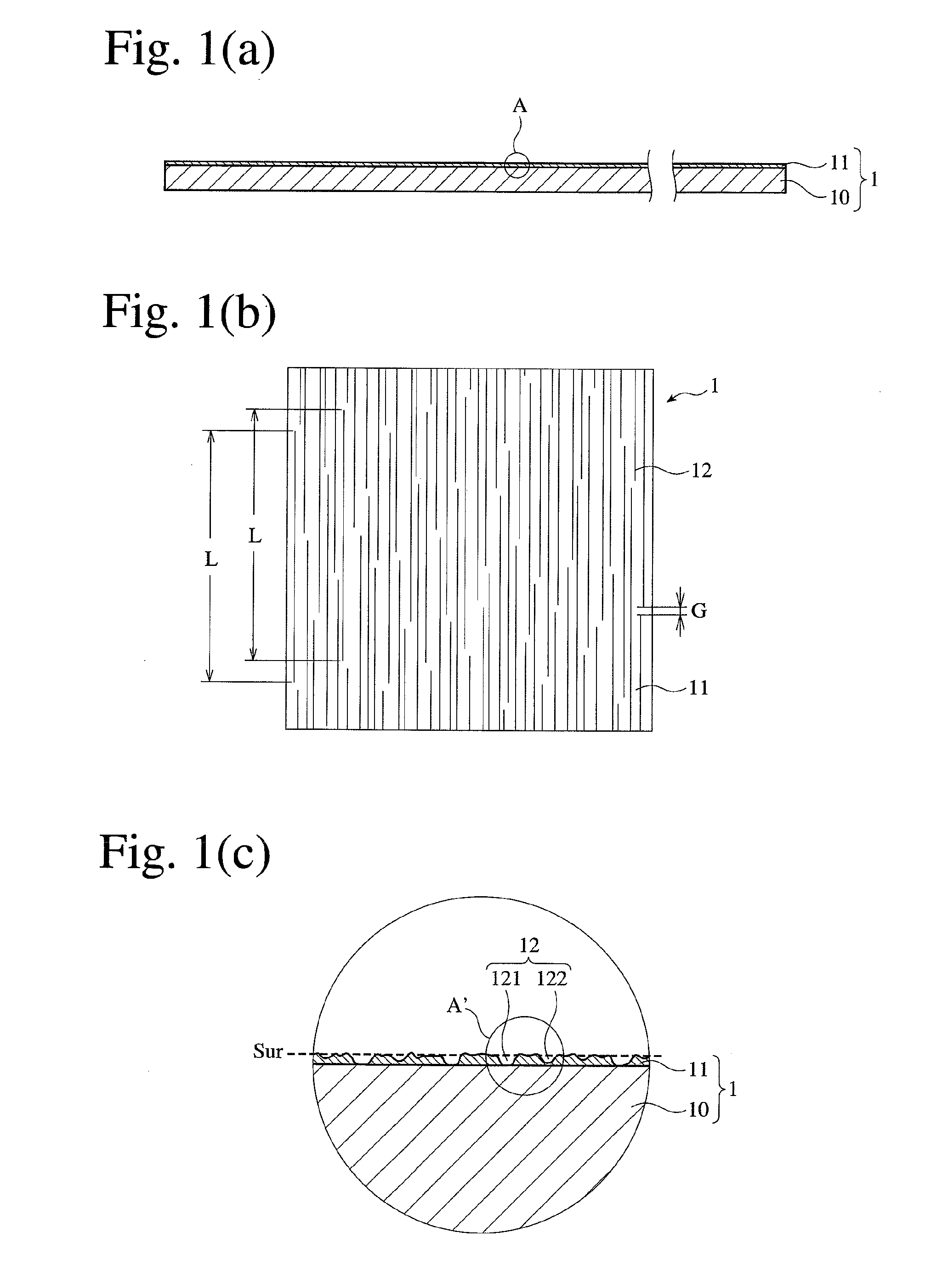

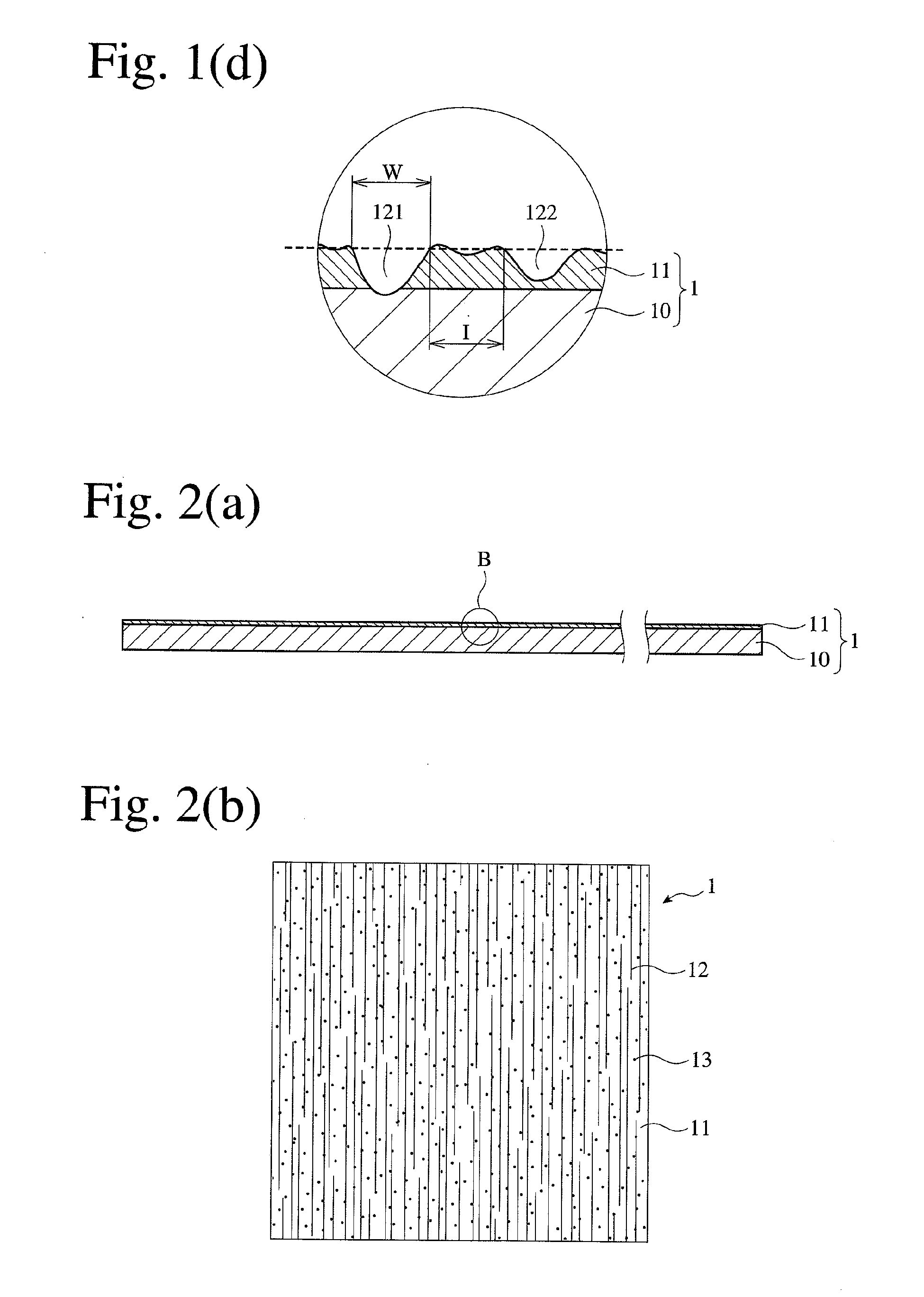

Composite film of linearly-scratched, thin metal film and plastic film, and its production apparatus

ActiveUS20110008580A1Promote absorptionReduce anisotropyMagnetic/electric field screeningSynthetic resin layered productsElectromagnetic wave absorberThin metal

The present invention provides a composite film having a linearly-scratched, thin metal film and a plastic film, which has good absorbability to electromagnetic waves in various frequencies, as well as reduced anisotropy in electromagnetic wave absorbability, suitable for electromagnetic wave absorbers, and its production apparatus. The composite film having a linearly-scratched, thin metal film and a plastic film according to the present invention comprises a plastic film, and a single-or multi-layer, thin metal film formed on at least one surface of the plastic film, the thin metal film being provided with large numbers of substantially parallel, intermittent, linear scratches with irregular widths and intervals in plural directions. Its production apparatus comprises pluralities of pattern rolls each having large numbers of fine, high-hardness particles on the surface, which are arranged to form linear scratches on the thin metal film side of a thin metal film-plastic composite film, and means each pressing the pattern roll to the composite film, and pluralities of the pattern rolls being oriented in different directions in a plane in which they are in sliding contact with the thin metal film of the composite film.

Owner:KAGAWA SEIJI

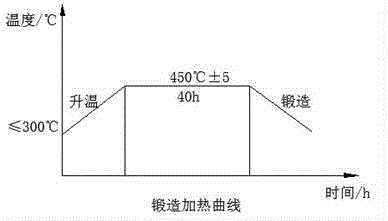

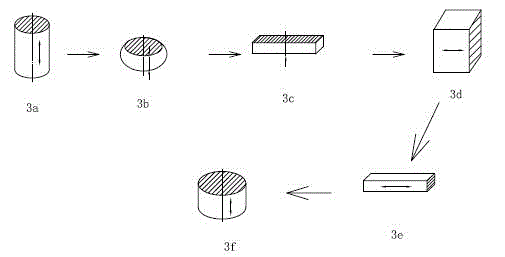

Forging forming technology of aluminum alloy straight-flanked ring with extra-large specification

The invention relates to a forging forming process of an aluminum alloy straight-flanked ring with an extra-large specification. The forging forming process comprises the fist step of blanking; the second step of a first heating before forging, wherein two heating stages are included; the third step of billet fabricating, wherein four stages are included; the fourth step of machining and damage removing; the fifth step of a second heating before forging; the sixth step of forging and ring rolling; the seventh step of heat treatment, wherein two heat treatment stages are included; the eighth step of machining to appropriate dimensions. By means of the forging forming process of the aluminum alloy straight-flanked ring with the extra-large specification, forging formability and mechanical performance of the aluminum alloy straight-flanked ring with the extra-large specification are improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

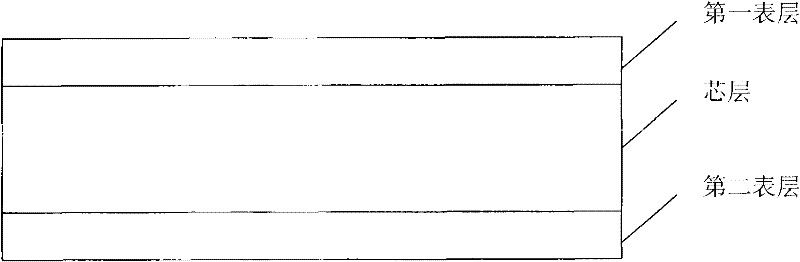

Polyamide film and preparation method thereof

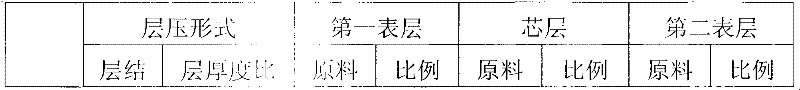

InactiveCN102190120AReduce anisotropyGap between macromolecular chainsFlexible coversWrappersSurface layerPolyamide

The invention discloses a polyamide film which comprises a first surface layer, a core layer and a second surface layer, wherein the first surface layer and the second surface layer contain fatty polyamide. The polyamide film is characterized in that the core layer contains 10-20 percent by weight of amorphous semi-aromatic polyamide and 80-90 percent by weight of fatty polyamide. The polyamide film can be cooked at high temperature of 121 DEG C or even 135 DEG C and no S-shaped warping or delamination is generated after the cooking. The polyamide film can be widely applied to food package, in particular to the field of high-temperature resistant cooked food package. The invention further discloses a method for preparing a polyamide film which is resistant to high-temperature cooking.

Owner:XIAMEN CHANGTIAN ENTERPRISE

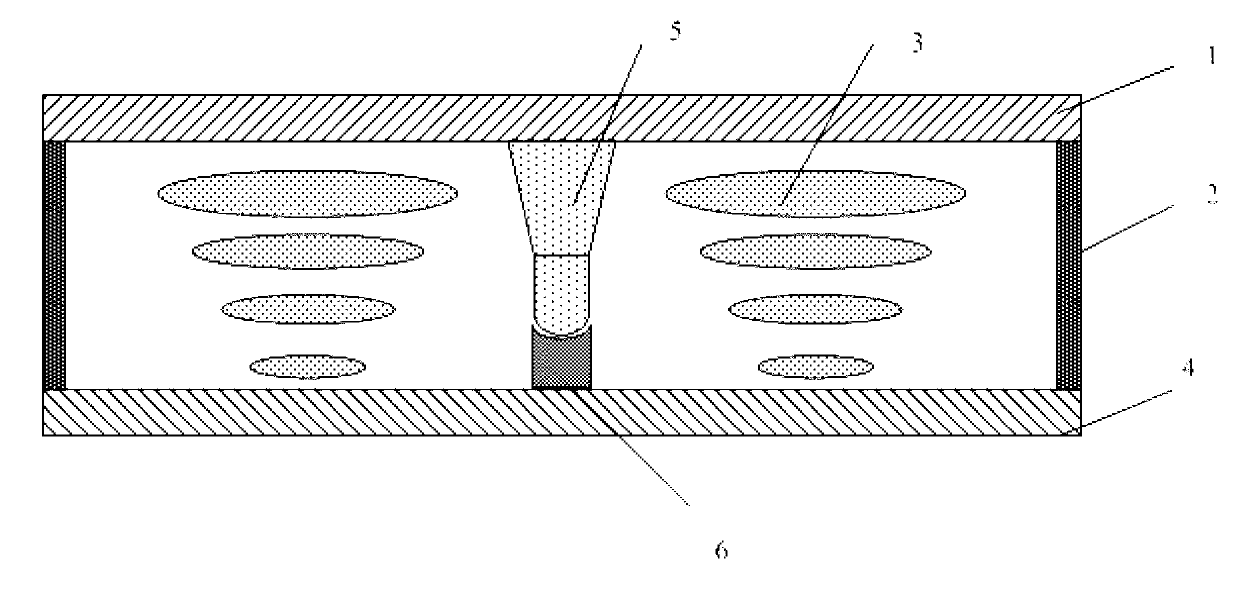

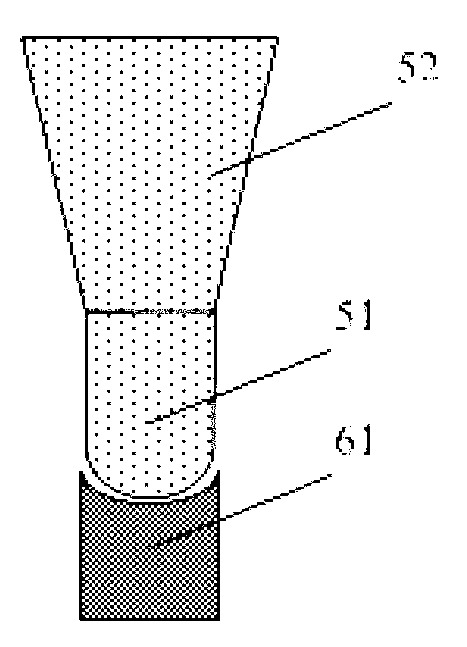

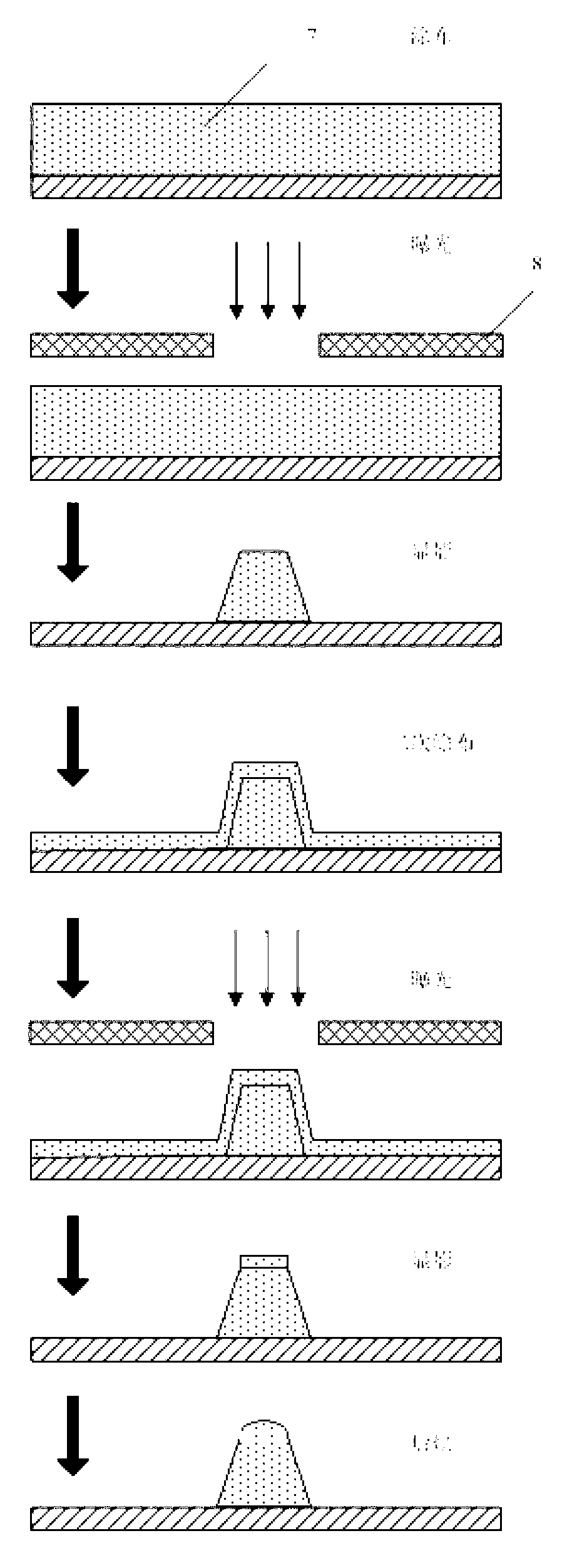

Cushion isolating material, liquid crystal panel, liquid crystal display device and preparation method of cushion isolating material

ActiveCN102998852AReduce anisotropyLow birefringencePhotomechanical apparatusNon-linear opticsLiquid-crystal displayColor film

The invention relates to a cushion isolating material which is arranged between a color film base panel and an array base panel of a liquid crystal panel. The cushion isolating material comprises a first component and a second component, wherein the first component comprises a first top part; the second component comprises a second top part; and the structures of the first top part and the second top part are matched concavely and convexly. Accordingly, the invention provides a preparation method of the cushion isolating material, the liquid crystal panel comprising the cushion isolating material, and a liquid crystal display device. The cushion isolating material can be used for effectively decreasing the stress between glass as a substrate in the liquid crystal panel, so that the anisotropy of the glass is decreased effectively, and the birefringence phenomenon of the glass is reduced. Therefore, the influence of the effective phase delay quantity (delta n*d) of the liquid crystal due to the phase delay quantity caused by the glass is eliminated, and the light leak of the liquid crystal panel is lightened correspondingly, i.e., the uniformity of luminance of light rays penetrating the liquid crystal panel is ensured, and the poor luminance effects such as a dark state Mura are decreased effectively. Consequently, the good display effect of the liquid crystal display device is realized.

Owner:BOE TECH GRP CO LTD

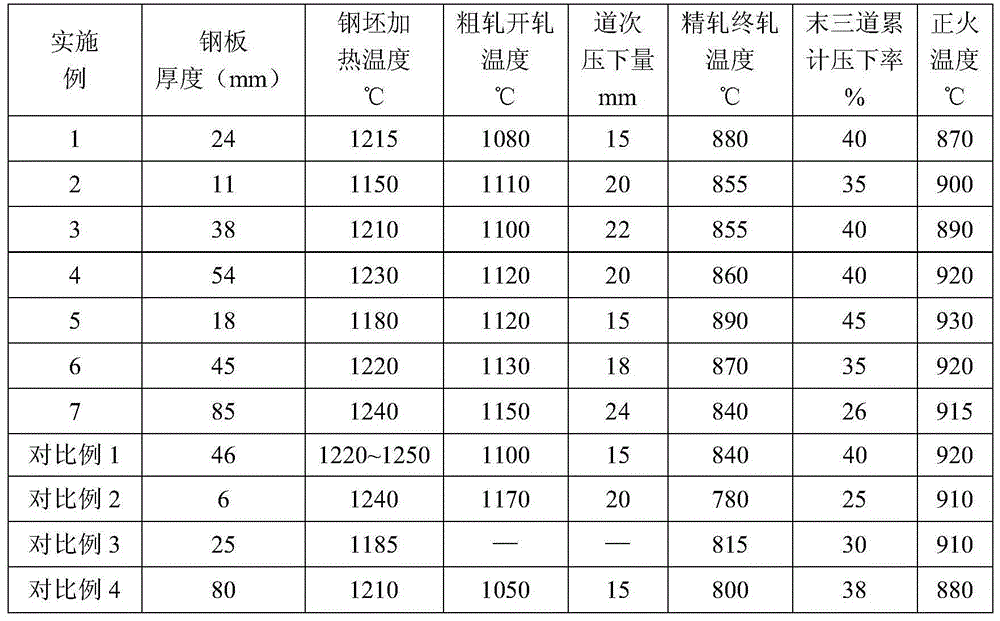

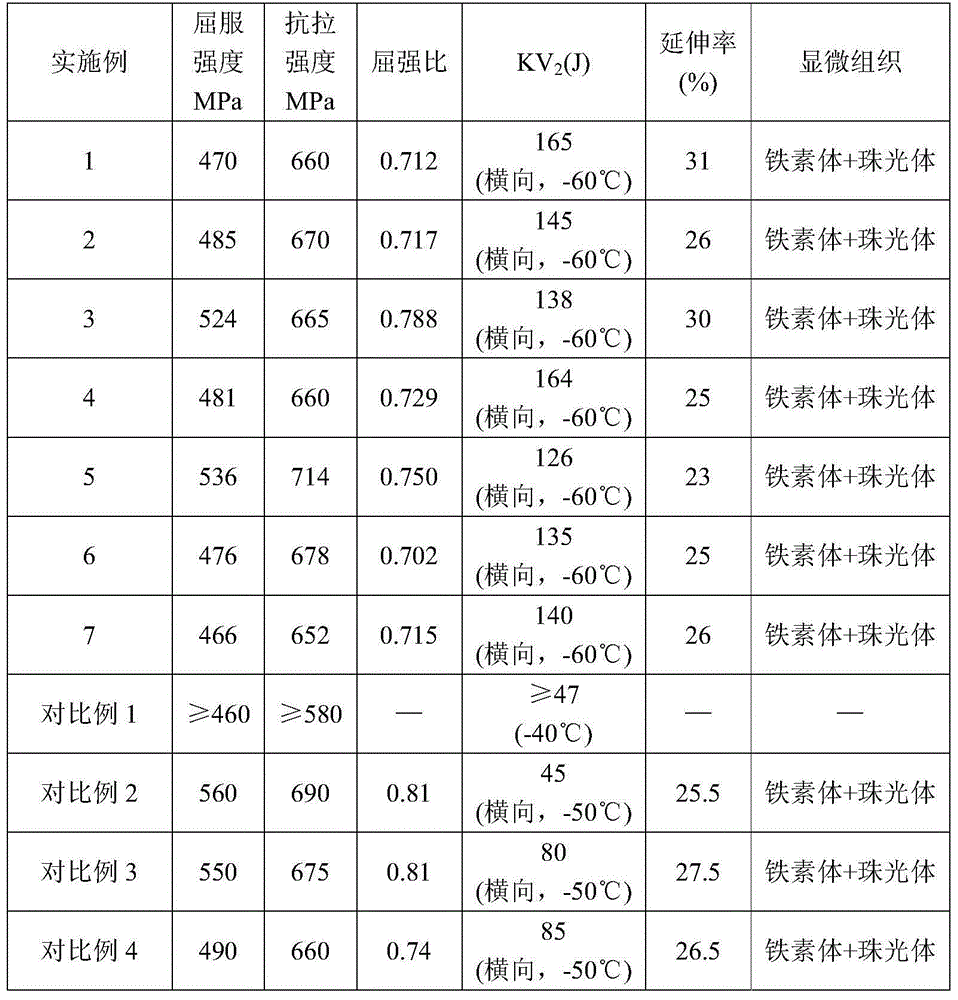

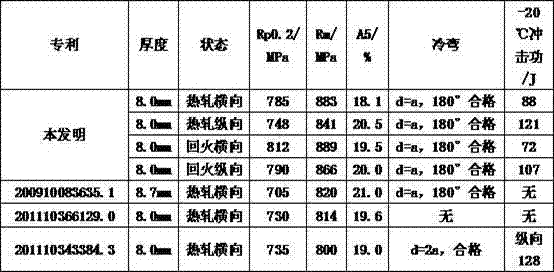

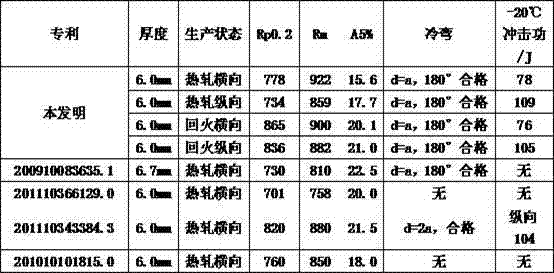

Good low-temperature high-toughness normalizing type high-strength pressure container steel plate and manufacturing method thereof

The present invention discloses a good low-temperature high-toughness normalizing type high-strength pressure container steel plate, wherein the chemical components comprise, by weight, 0.10-0.22% of C, less than or equal to 0.40% of Si, 1,10-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, less than or equal to 0.40% of Ni, less than or equal to 0.035% of Nb, less than or equal to 0.17% of V, 0.0070-0.0190% of N, 0-0.025% of Als, 0-0.018% of Ti, and the balance of Fe and unavoidable inclusion, wherein (V+Ti+Nb) / N is more than or equal to 3.5 and is less than or equal to 15, and (C+V+2Ti) is more than or equal to Ti+Nb / (3.5N) and is less than or equal to 5V / (C+V+Nb). The good low-temperature high-toughness normalizing type high-strength pressure container steel plate has the following characteristics that: the yield strength is more than or equal to 460 MPa, the tensile strength is 630-725 MPa, the elongation is more than or equal to 25%, the yield ratio is less than or equal to 0.85, the weldability is good, and the production cost is low.

Owner:武汉钢铁有限公司

Hot rolling steel plate for automobile girder, and manufacturing method thereof

The present invention provides a manufacturing method of a hot rolling steel plate for an automobile girder. The production method comprises a steelmaking step, a continuous casting step, a heating step, a hot continuous rolling step and a coiling step, and is characterized in that components of the molten steel after steelmaking comprise 0.05-0.1 wt% of C, 0.15-0.35 wt% of Si, 1-2 wt% of Mn, 0.01-0.1 wt% of Nb, 0.03-0.12 wt% of Ti, less than or equal to 0.025 wt% of P, less than or equal to 0.01 wt% of S, and the balance of Fe and unavoidable impurities, a finish rolling temperature in the hot continuous rolling step is 830-900 DEG C, and a coiling temperature is 600-700 DEG C. The present invention further provides the hot rolling steel plate prepared by using the method and provided for the automobile girder. With the manufacturing method, production cost is reduced, and rolling process control is simple. With the hot rolling steel plate for the automobile girder, hot rolling product structures are substantially enriched and improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Glass cloth for printed wiring board

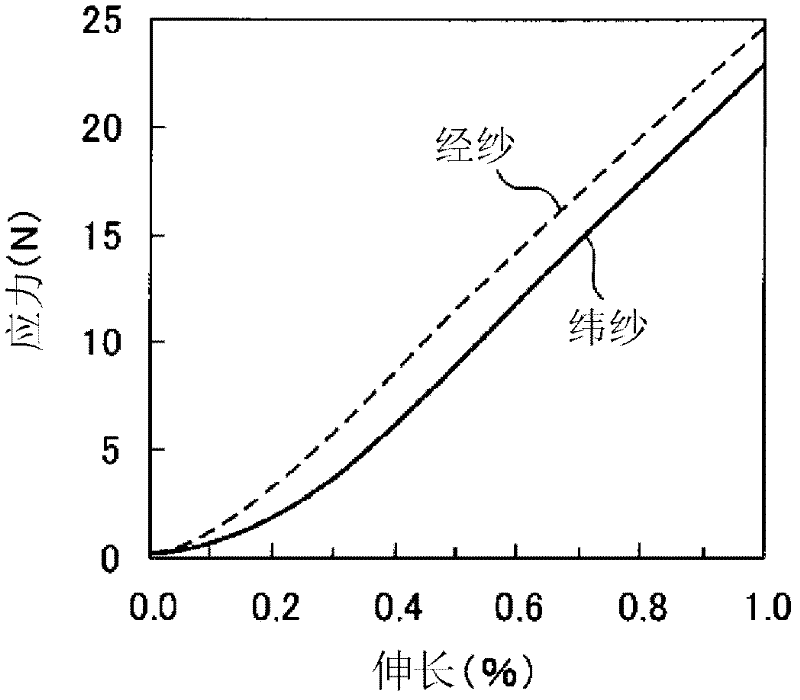

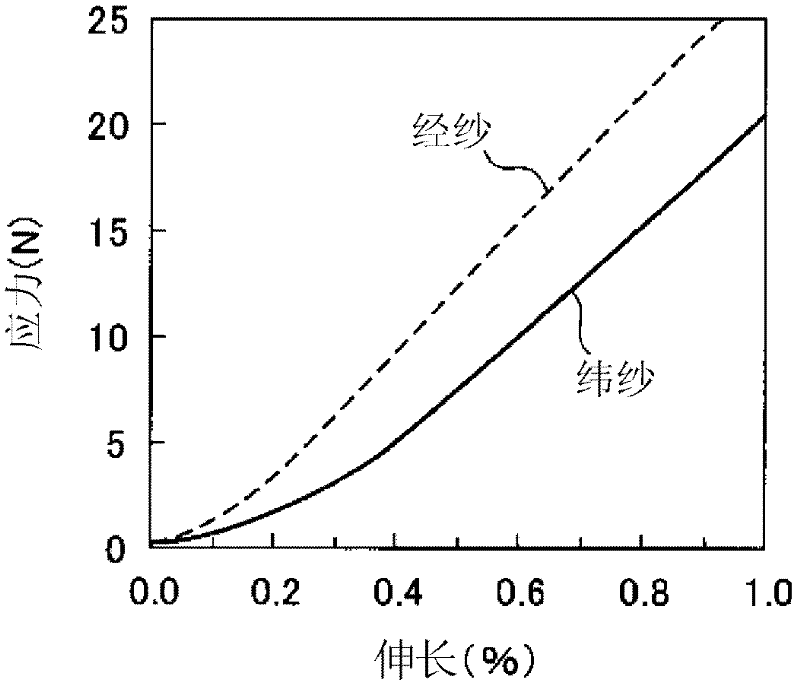

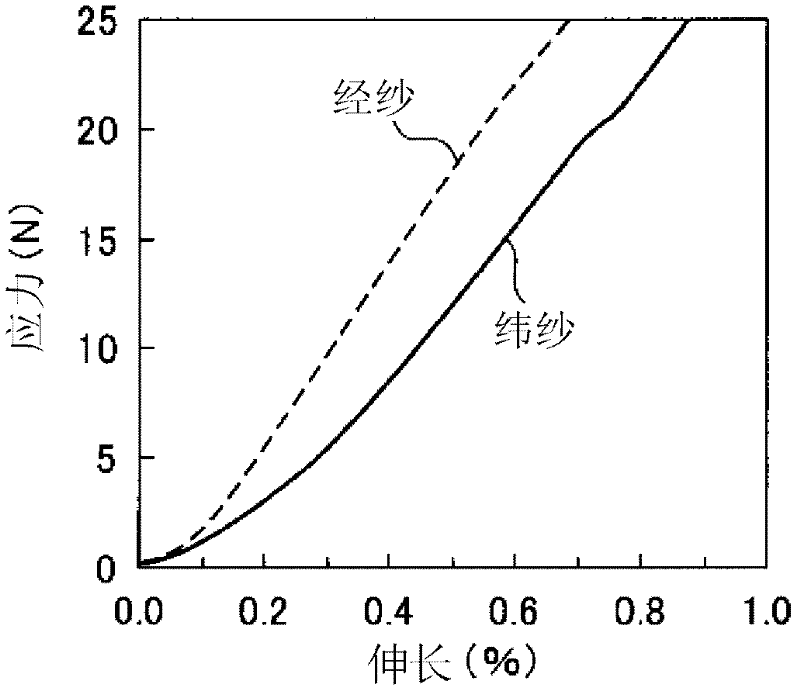

ActiveCN102482809AIncreased anisotropyNo warping/twistingPrinted circuit aspectsWoven fabricsGlass fiberYarn

Disclosed are: a glass cloth, which has small anisotropy of dimensional change, while being free from warp and twist, and which is suitable for the production of a printed wiring board that is used in electronic / electrical fields; a prepreg using the glass cloth; and a printed wiring board using the glass cloth. The glass cloth is characterized in that the warp and the weft are configured of glass yarn of from 1.8 10-6 kg / m to 14 10-6 kg / m, the ratio of the average filament diameter of the weft to the average filament diameter of the warp (the weft / warp ratio) is 1.01 or more but less than 1.27, and the glass cloth has a thickness of 10-40 [mu]m (inclusive).

Owner:ASAHI KASEI KK

Processing method of fine-grain superplastic TA15 titanium alloy medium-thickness plate

The invention discloses a processing method of a fine-grain superplastic TA15 titanium alloy medium-thickness plate. The processing method comprises the following steps that 1, vacuum consumable arc melting is carried out to obtain a TA15 titanium alloy cast ingot; 2, after heat preservation, a primary forging stock is obtained through upsetting, drawing, cogging and forging; 3, after heat preservation, a second-stage forging stock is obtained through beta-phase region upsetting and drawing forging; 4, upsetting and drawing forging in an alpha + beta two-phase region is carried out to obtain afourth-stage forging stock; 5, a forge piece is obtained through upsetting, drawing and finish forging; 6, after heat preservation, a first-fire rolled plate blank is obtained through first-fire rolling; 7, after heat preservation, a second-fire rolled plate blank is obtained through second-fire rolling; and 8, the TA15 titanium alloy medium-thickness plate is obtained through annealing treatment. According to the processing method of the fine-grain superplastic TA15 titanium alloy medium-thickness plate, the corresponding deformation temperature is selected and combined with multi-heating-number large-deformation upsetting and drawing forging, so that the TA15 titanium alloy cast ingot with a coarse structure is crushed under the large deformation, driving force is provided for recrystallization, the grain refinement and homogenization degree is improved, and the fine-grain superplasticity TA15 titanium alloy medium-thickness plate is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Electromagnetic-wave-absorbing film and electromagnetic wave absorber comprising it

InactiveUS20110031008A1Excellent electromagnetic wave absorption performanceReduce anisotropyMagnetic/electric field screeningSynthetic resin layered productsElectromagnetic wave absorberThin metal

An electromagnetic-wave-absorbing film comprising a plastic film, and a single- or multi-layer, thin metal film formed on at least one surface of the plastic film, the thin metal film being provided with large numbers of substantially parallel, intermittent, linear scratches with irregular widths and intervals.

Owner:KAGAWA SEIJI

Processing method of anti-fatigue aluminum alloy foaming die cast

The invention discloses a processing method of an anti-fatigue aluminum alloy foaming die cast. The processing method comprises the four steps of compounding, smelting, pouring, and thermal treatment. According to the invention, an appropriate amount of rare earth elements La, Ce and Y are added to the aluminum alloy, so that the hydrogen content in the alloy and the alloy yielding anisotropy can be reduced, the alloy plasticity and the anti-fatigue property of the alloy are obviously increased, and at the same time the wear resistance, thermal resistance and high-temperature strength of the alloy can also be improved. The processed aluminum alloy refrigerator foaming die cast has the advantages of good mechanical properties, high strength, good thermal resistance, good usability, good internal structure compactness, no pore and peeling defects, good wear resistance, good corrosion resistance and oxidation resistance, small expansion coefficient and the like.

Owner:滁州晨润工贸有限公司

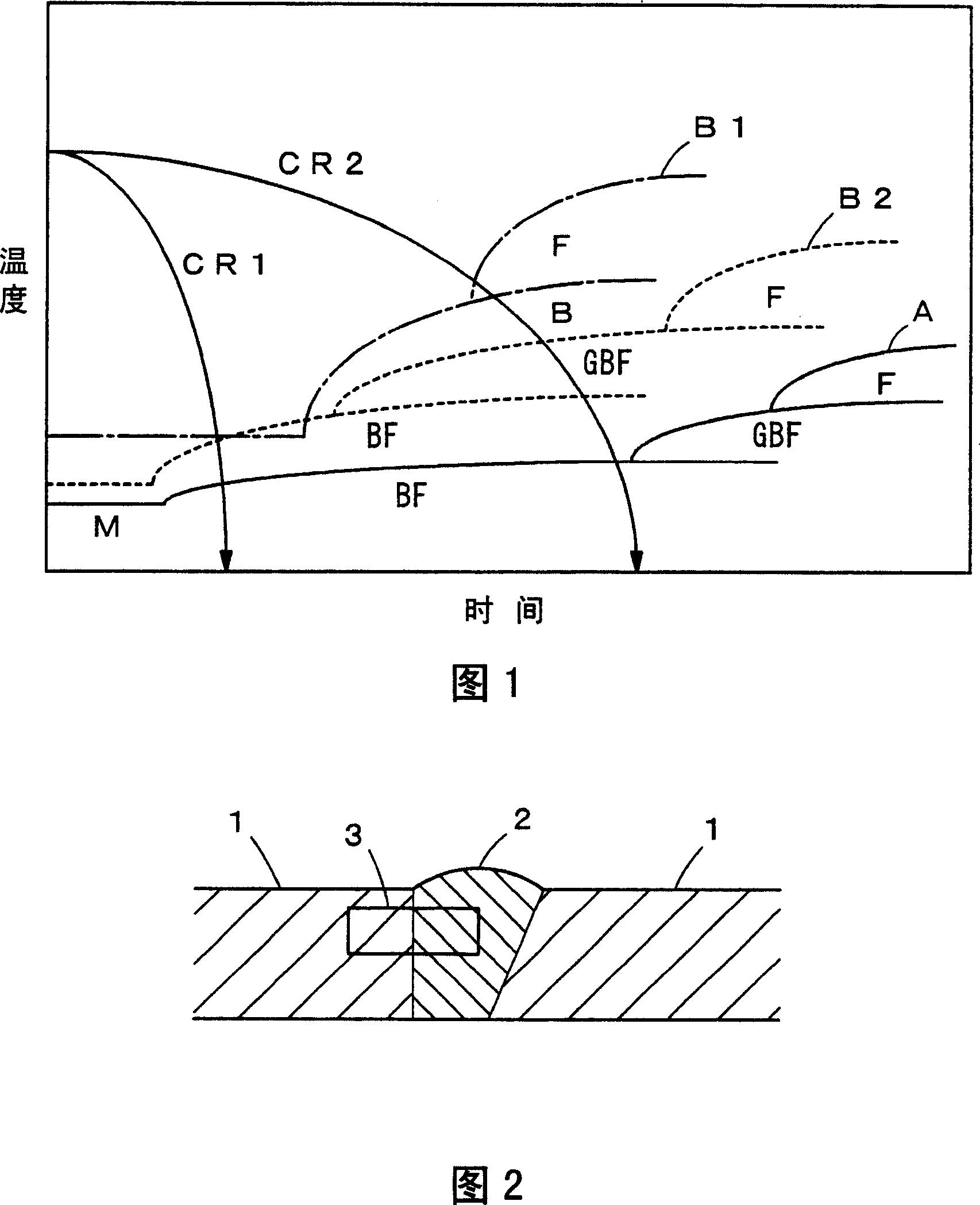

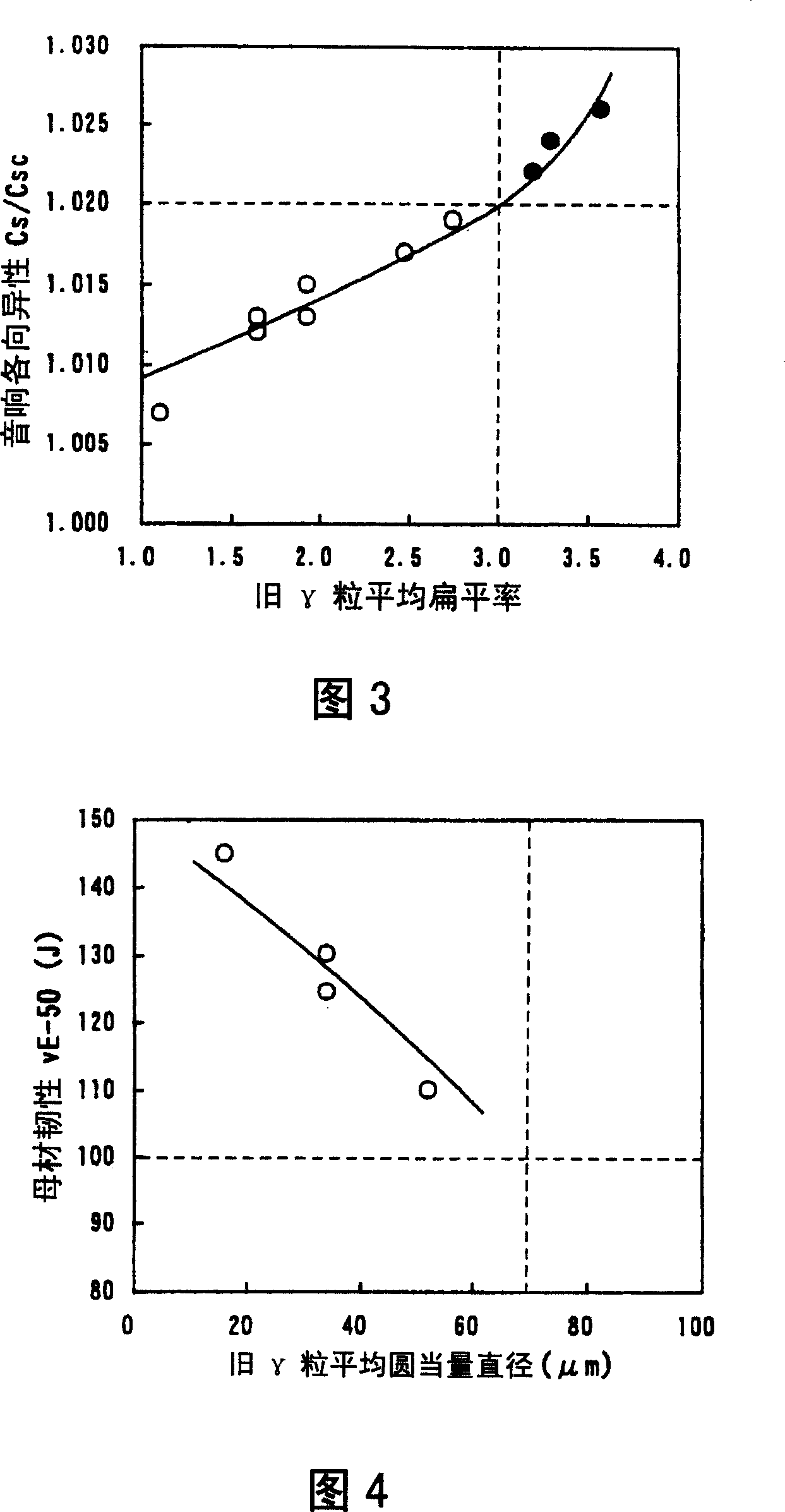

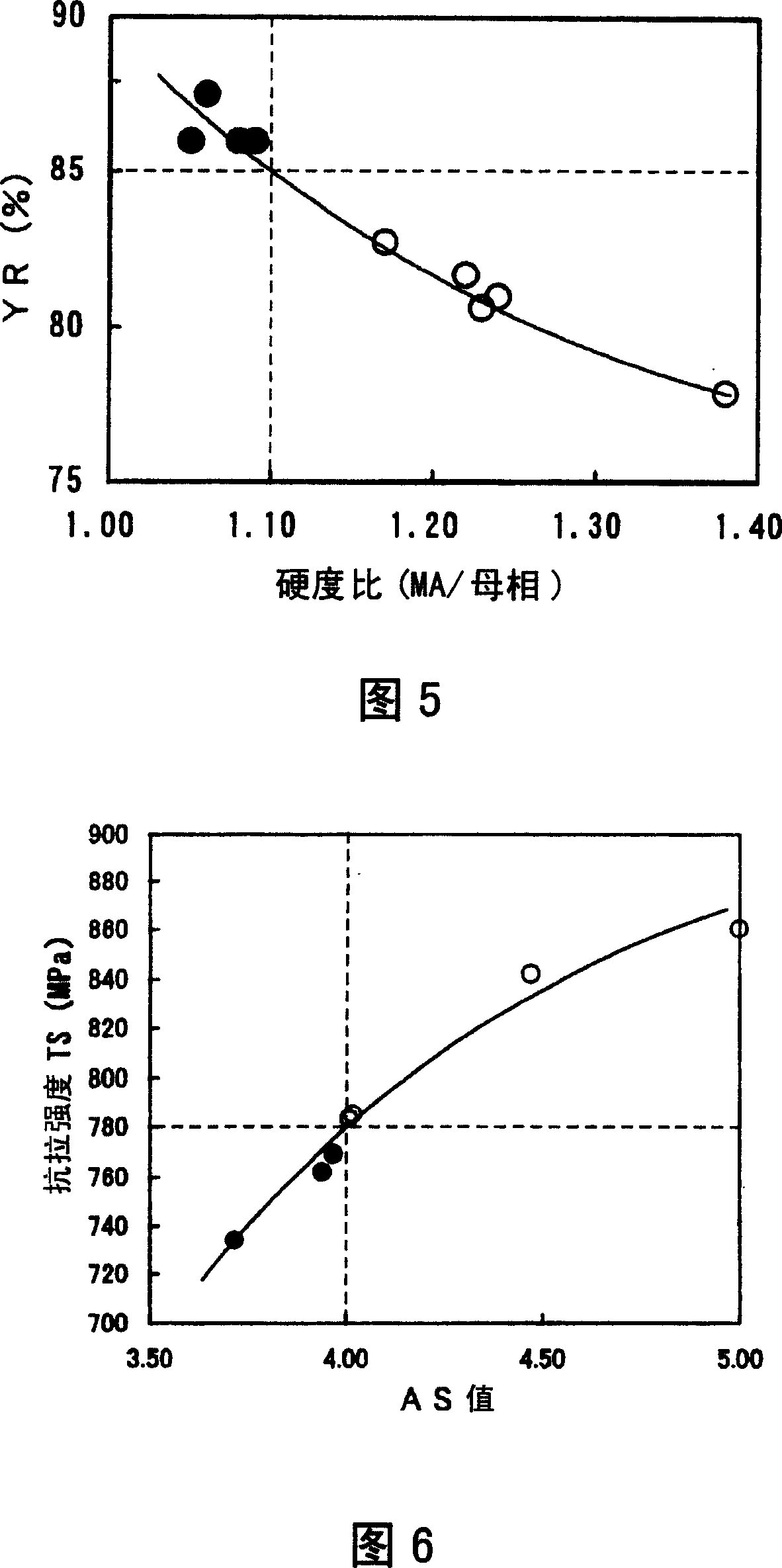

Low yield ratio high tension steel plate and its producing method

InactiveCN1936055AReduce anisotropyHigh strengthFurnace typesHeat treatment furnacesHardness ratioAustenite grain

The invention provides a high tensile steel sheet having a low yield ratio in spite of its tensile strength of >=780 MPa, and having low acoustic anisotropy and excellent weldability, and to provide its production method. The steel sheet has a composition comprising, by mass, 0.010 to 0.080% C, 0.02 to 0.50% Si, 1.10 to 3.00% Mn, <=1.60% Cu, 0.40 to 2.50% Ni, <=0.030% P, <=0.010% S, <=0.200% Al, <=0.0100% N, 0.30 to 2.00% Cr, 0.10 to 1.10% Mo and 0.002 to 0.030% Ti, and the balance Fe with impurities. Further, regarding the following AS and DL, AS>=4.00 and DL<=2.80 are satisfied, the structure in the part of 1 / 4 in the sheet thickness is essentially composed of bainitic ferrite including MA by <=10 area% (excluding 0%), also, the average value of the major axis / manor axis of old austenite grains is 1.0 to 3.0, and further, the hardness ratio of the MA to the bainitic ferrite is >=1.10: AS=[Mn]+[Ni]+2*[Cu], and DL=2.5*[Mo]+30*[Nb]+10*[V]; [X] denotes the content (mass%) of the element X.

Owner:株式会社神户制刚所

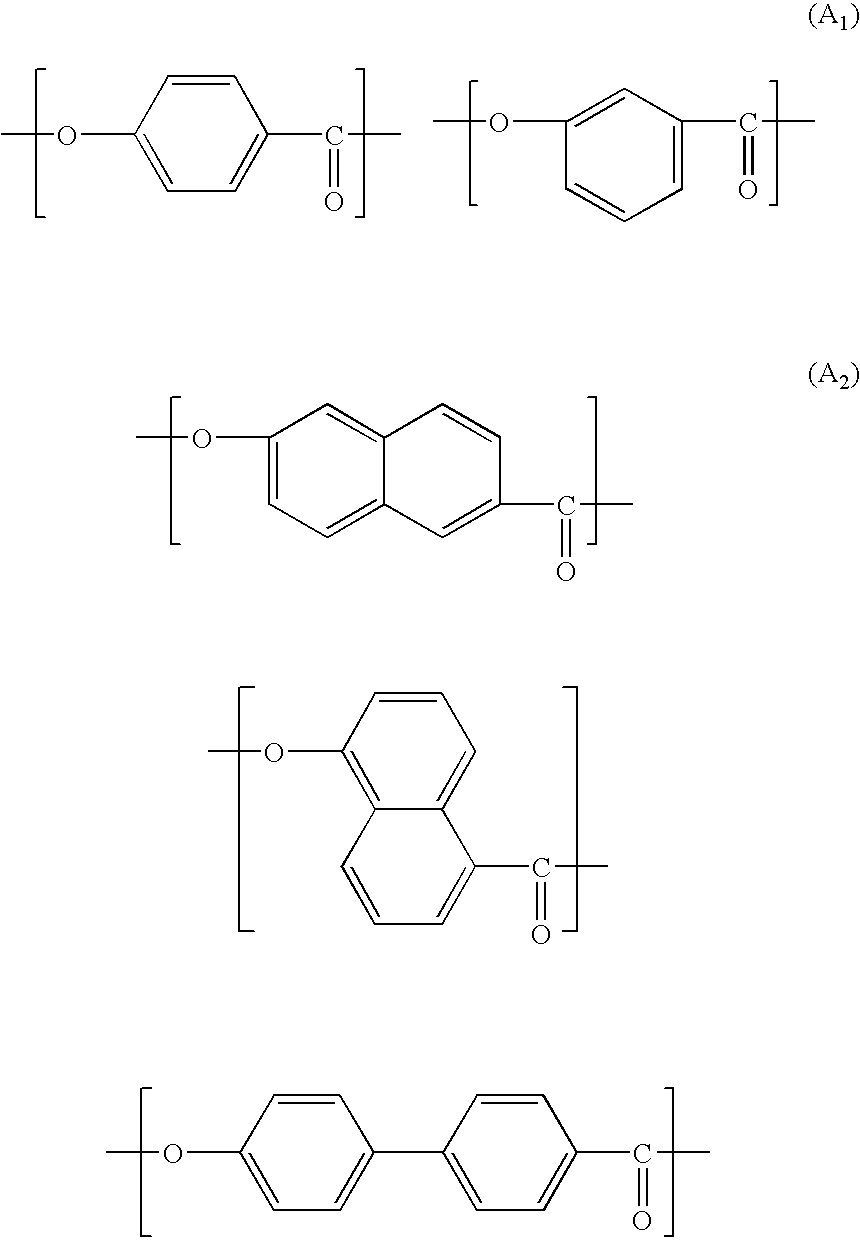

Dendritic polyester, method for producing the same, and thermoplastic resin composition

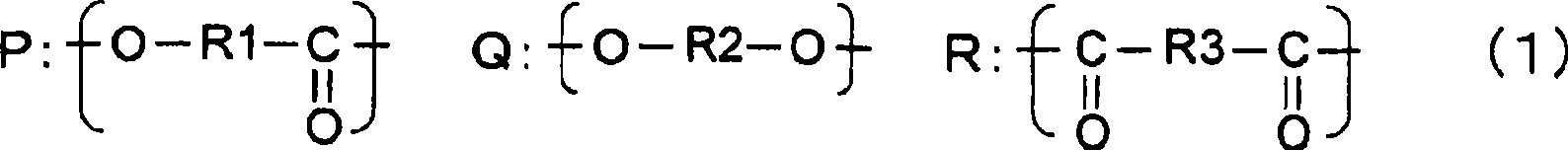

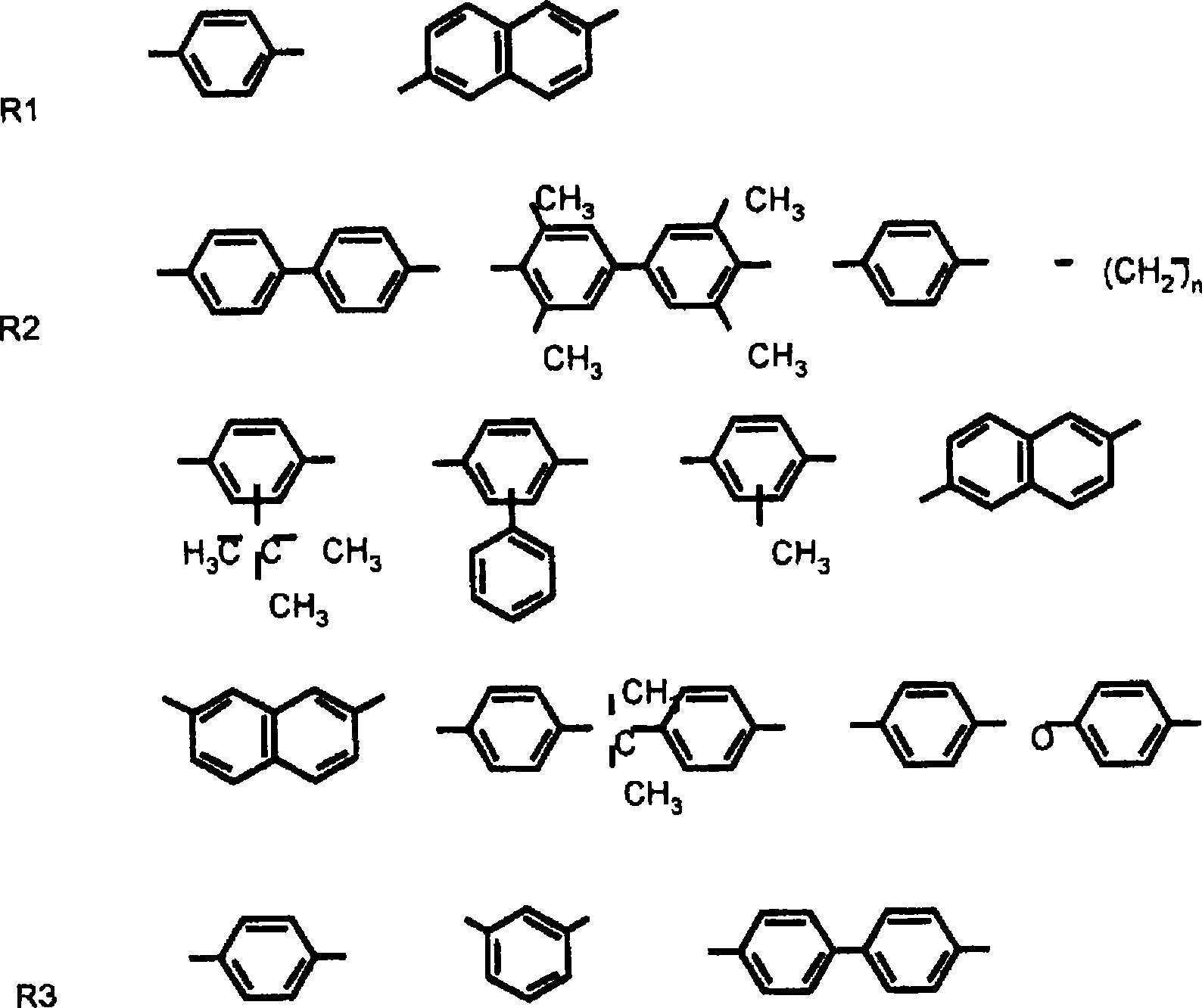

Disclosed is a dendritic polyester containing at least one constituent unit selected from an aromatic oxycarbonyl unit (P), an aromatic and / or aliphatic dioxy unit (Q) and an aromatic dicarboxy unit (R), and a tri- or more-functional organic residue (B). In this dendritic polyester, the content of (B) relative to the total monomers constituting the dendritic polyester is within the range of 7.5-50 mol%. When this dendritic polyester is blended in a thermoplastic resin, the resin can be remarkably improved in thin-wall fluidity, rigidity, gas barrier properties and the like. Also disclosed is a thermoplastic resin composition containing such a dendritic polyester.

Owner:TORAY IND INC

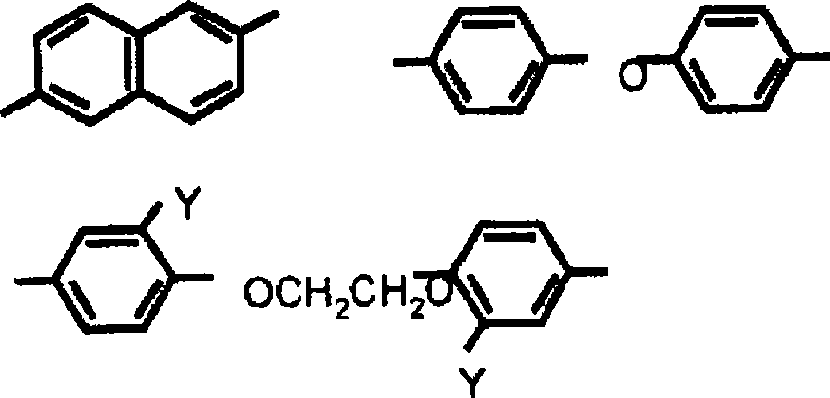

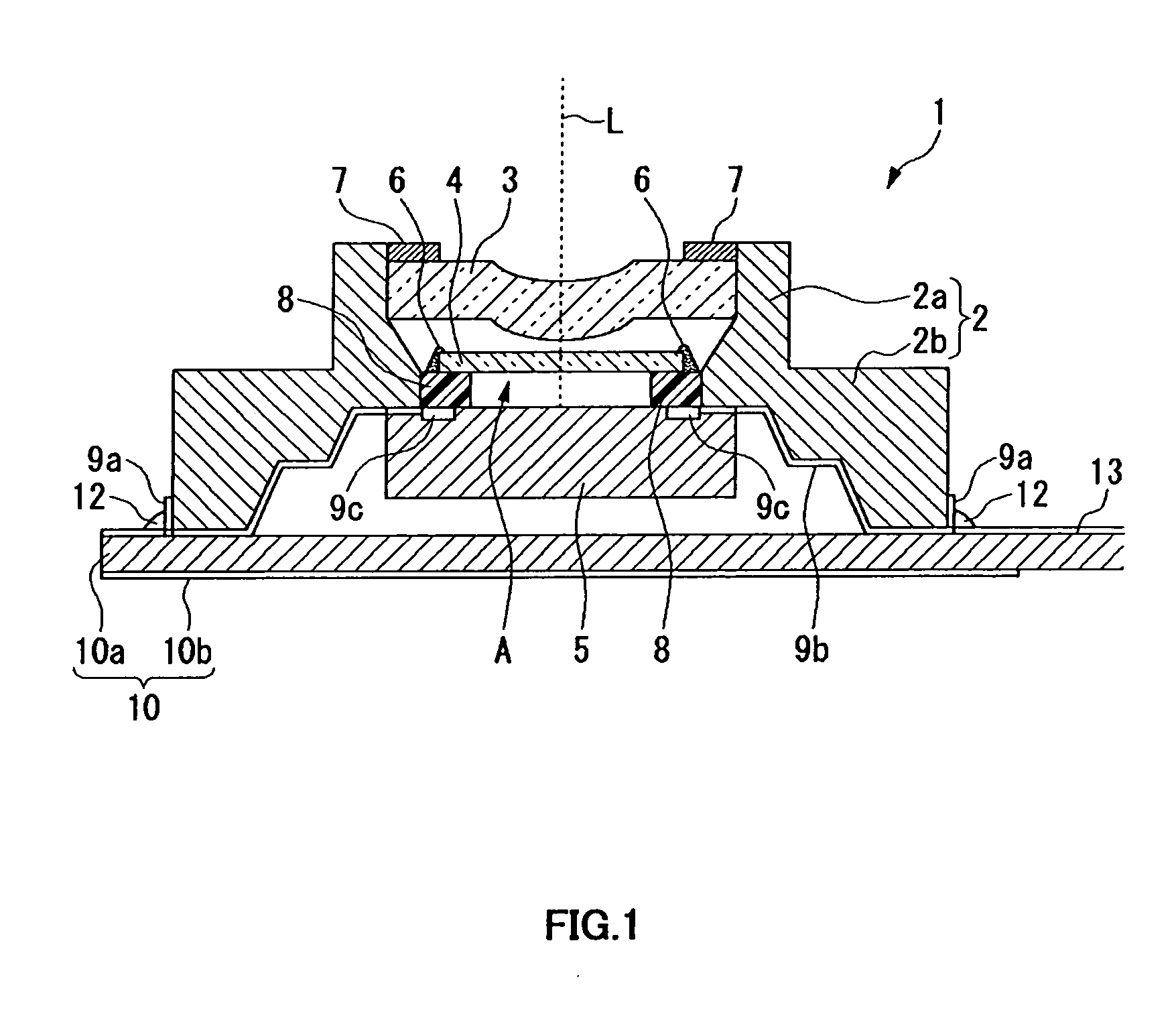

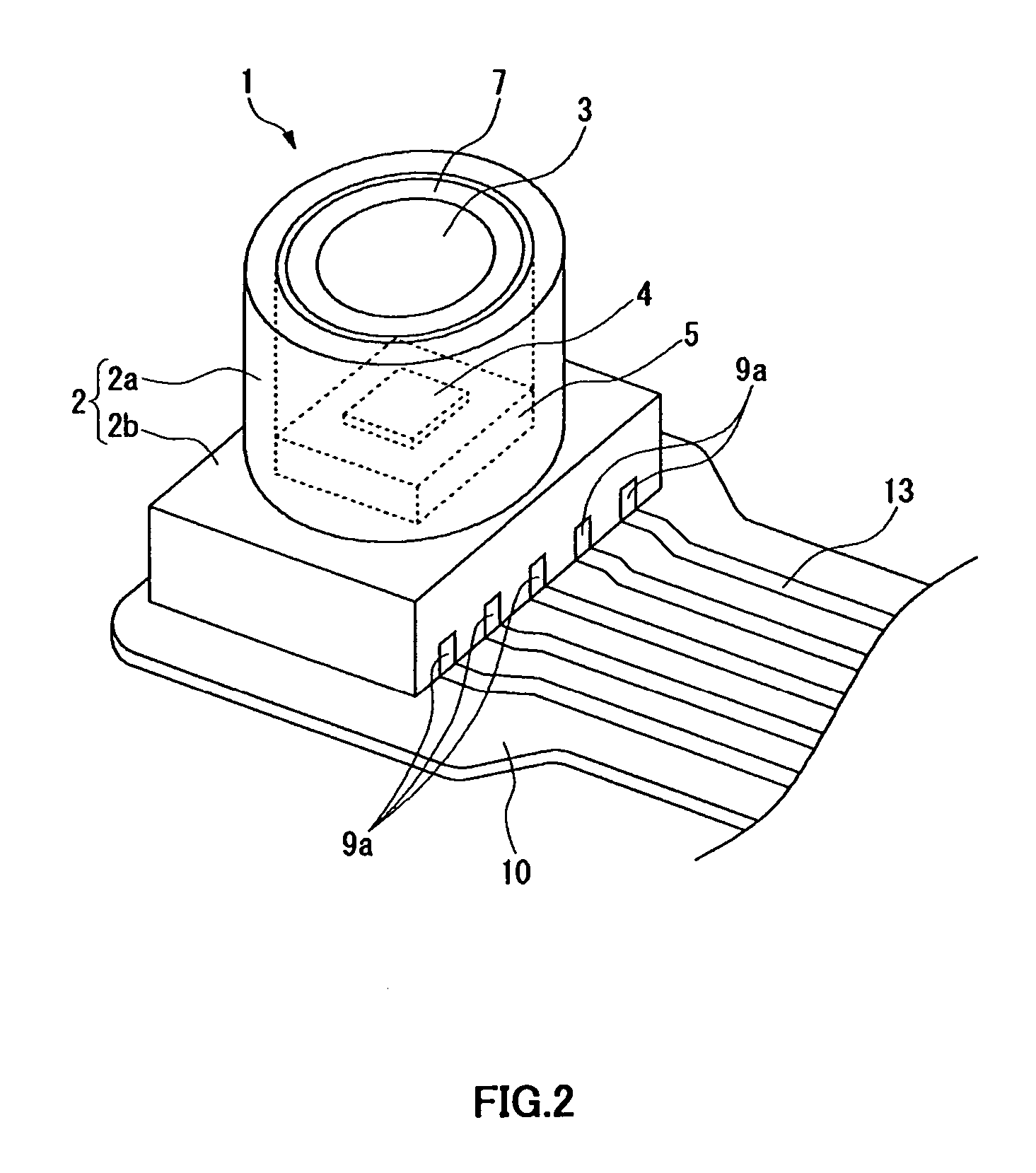

Imaging apparatus

ActiveUS20060251414A1Eliminate thermal expansion anisotropyReduce anisotropyTelevision system detailsSolid-state devicesImaging qualityLength wave

The imaging apparatus 1 comprises: a semiconductor imaging device 5 which converts incident light to an electrical signal; an optical filter 4 which is opposed to an incident surface of the semiconductor imaging device 5 and transmits light of a certain wavelength; and a three-dimensional substrate 2 fixing the optical filter 4 by means of adhesion using a filler-containing adhesive 6; wherein the diameter of the filler is smaller than or equal to the pixel size of the semiconductor imaging device 5. Degradation of image quality of the imaging apparatus 1 caused by the dropped filler can thus be reduced.

Owner:PANASONIC CORP

Aluminum foil used for heat exchanger and manufacturing method thereof

InactiveCN101104900ARelaxed Purity Excessive RequirementsLow costTemperature control deviceMetal rolling arrangementsPlate heat exchangerAluminum foil

The invention relates to an aluminum foil used for heat exchangers and the manufacturing method thereof. The components of the aluminum foil comprise Al, Si, Fe, Cu, Ti and inevitable impurity, and further comprise V. The weight contents of the components are as follows: Al: more than or equal to 98.50 percent, Si: 0.10-0.35 percent, Fe: 0.50-0.90 percent, Cu: 0.01-0.10 percent, V: 0.005-0.05 percent, Ti: 0.01-0.05 percent, and impurity in balance. The inventive aluminum foil used for heat exchangers and the manufacturing method thereof have the advantages of stable performance, good plate shape and good quality of plate surface, low cost, good mechanical property and molding property (even the thickness of aluminum foil is reduced to 0.080-0.094mm).

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

Steel plate for engineering machinery and production method of steel plate

The invention discloses a steel plate for engineering machinery and a production method of the steel plate. The steel plate comprises the following chemical constituents by mass percent: 0.05-0.09% of C, 0.05-0.30% of Si, 1.5-2.0% of Mn, 0-0.025% of P, 0-0.005% of S, 0-0.07% of Nb, 0.08-0.15% of Ti, 0.10-0.30% of Mo, 0.015-0.06% of Als, 0.0010-0.0030% of Ca, 0-0.006% of N, and the balance of Fe. The steel plate is 3.0-8.5 mm in thickness. The steel plate disclosed by the invention is produced by advanced ultra fast cooling equipment and a 2250-mm wide flat steel thermal treatment line, which is unique at home, high in surplus of strength and ductility, excellent in impact toughness, low in postwelding strength loss rate, particularly low in anisotropism and unevenness, excellent in bending performance, and suitable for manufacturing the suspension arm for a crane and other engineering machinery and vehicles.

Owner:湖南华菱涟源钢铁有限公司

Rolling method of TC4 titanium alloy wide thick plate

ActiveCN103203361AReduce anisotropyUniform tissueTemperature control deviceMeasuring devicesThick plateMetallurgy

The invention provides a rolling method of a TC4 titanium alloy wide thick plate. The method comprises the steps of: 1, heating a TC4 titanium alloy plate blank, of which the thickness is 200mm-400mm and the length and the width are both 800mm-1200mm, for the first time; 2, rolling the TC4 titanium alloy plate blank for the first time to get a semi-finished plate blank; 3, cooling the semi-finished plate blank to be below 400 DEG C with water, shearing and eliminating the surface scale, and then, heating for the second time; and 4, rolling for the second time to get the TC4 titanium alloy wide thick plate of which the thickness is 30mm-100mm and the width is 1000mm-2600mm. The rolling method is simple in technology, and can easily realize industrial large-scale volume production; and the TC4 titanium alloy wide thick plate prepared by the rolling method has uniform and fine tissue, and is excellent in comprehensive performance.

Owner:WESTERN TITANIUM TECH

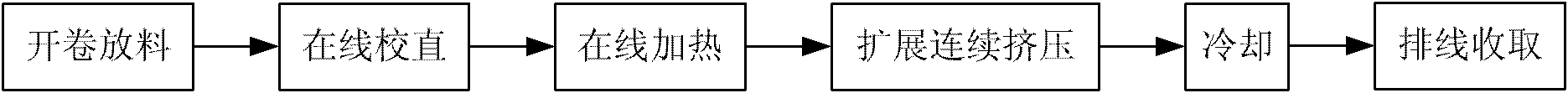

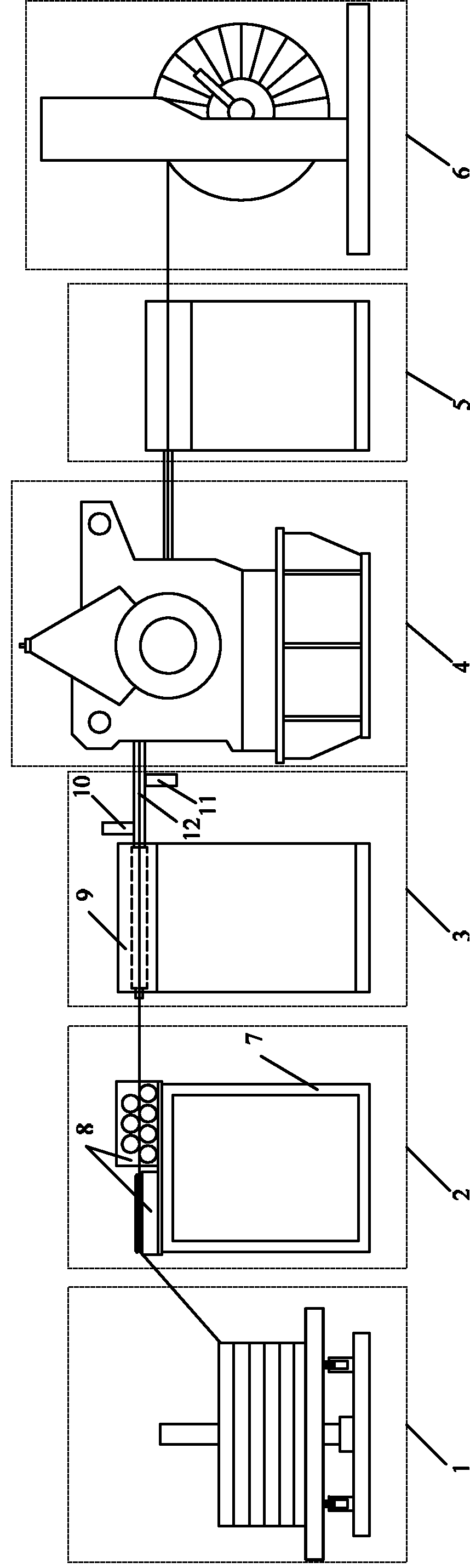

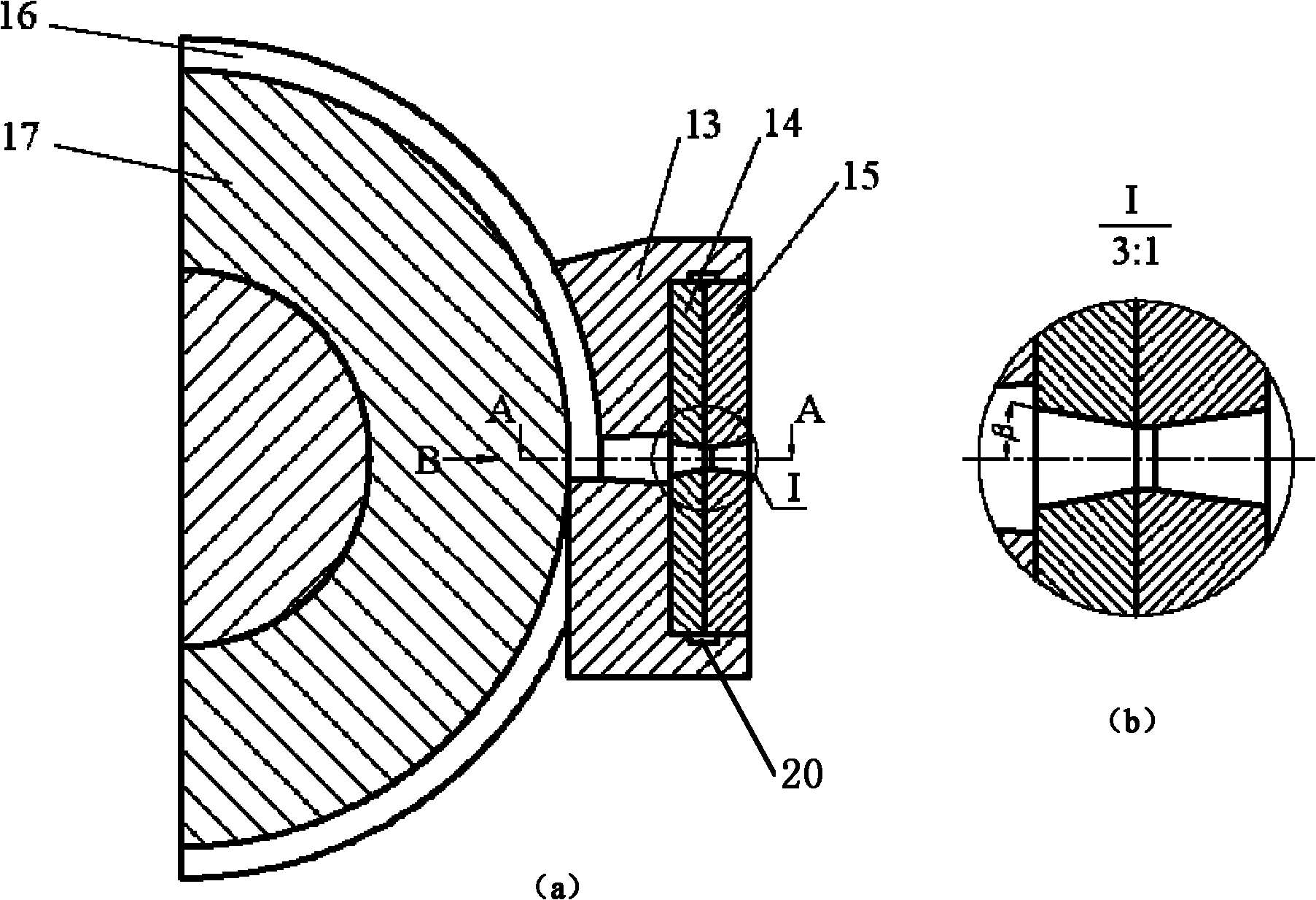

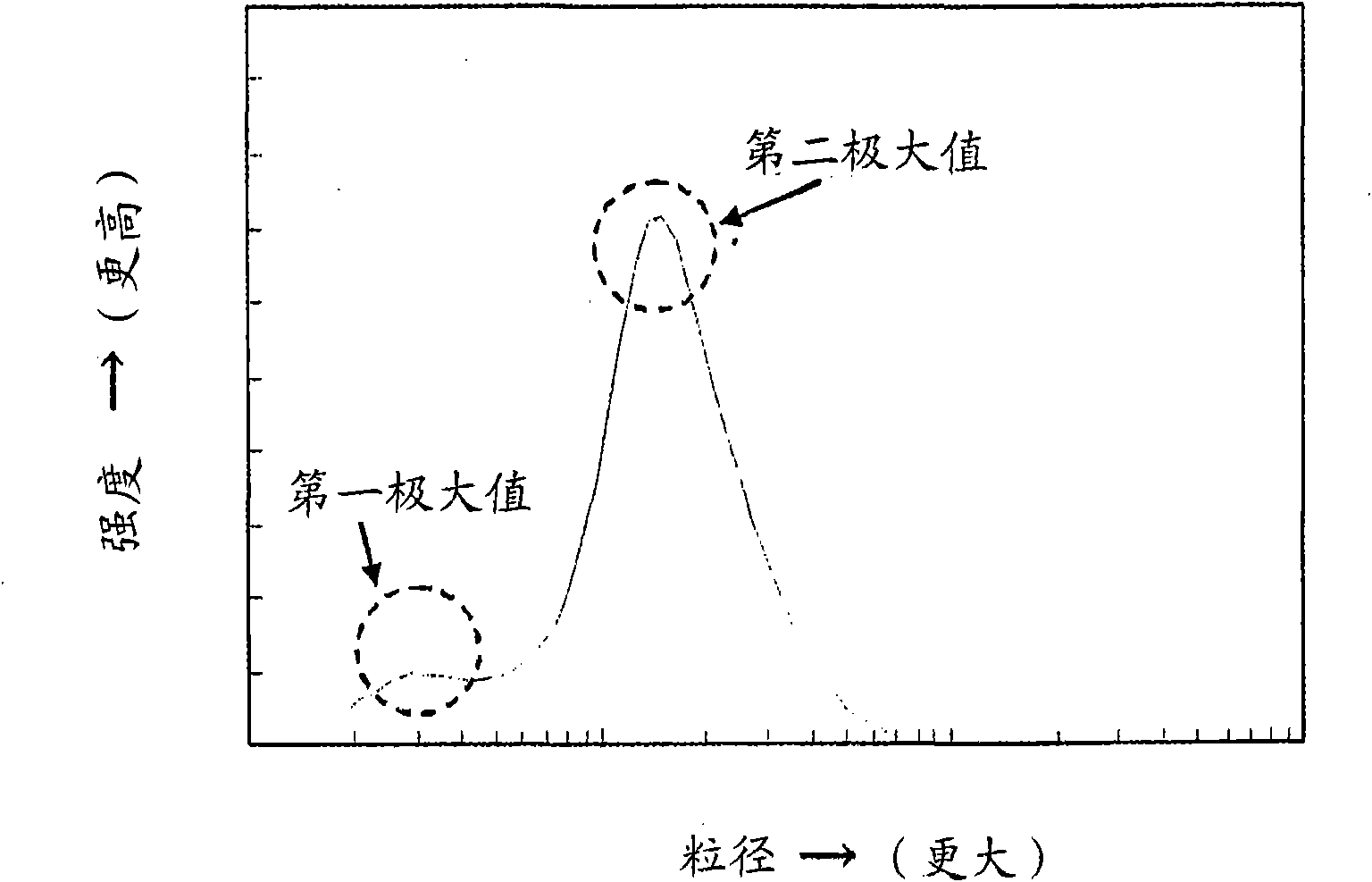

System and method for continuous extrusion production of fine-grain magnesium alloy strip

ActiveCN102688907AShort processIncrease productivityExtrusion control devicesProduction lineLine heating

The invention discloses a system and a method for continuous extrusion production of a fine-grain magnesium alloy strip. The system comprises a decoiling emptying device, an on-line straightening device, an on-line heating device, a continuous extrusion device, a cooling device and a winding displacement collection device. Through control of a temperature of a rod, a good extrusion driving force is produced between the rod and an extrusion wheel groove. Through an expansion mold cavity and a flow-blocking mold, magnesium alloy expansion flowing in a width direction is realized. In order to extrude a plate having larger width, the system adopts a two / three rod feeding-type extrusion mode so that joining and intermetallic welding of multiple rods in a corresponding multi-rod mold cavity are realized. The system and the method have the advantages that a process route is short; production efficiency is high; a grain refinement degree of a product microstructure is high; plate formability is good; and a continuous production line provided by the invention is suitable for industrial application.

Owner:DALIAN JIAOTONG UNIVERSITY

Resin composition and use of the same

InactiveCN101550282ASatisfactory thermal conductivityReduce anisotropyPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsSpecific volumeChemistry

The present invention provides resin composition and use of the same, the resin composition comprising (A) a thermoplastic resin, (B) alumina fine particles and (C) a plate-like filler, wherein the component (B) is contained in the larger amount than the amount of the component (C) in the composition, and the resin composition has a specific volume resistance of 1x1010 Omegam or more.

Owner:SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com