Polyamide film and preparation method thereof

A polyamide film, polyamide technology, applied in chemical instruments and methods, flexible covers, packaging, etc., can solve problems such as poor yield and film wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Film preparation

[0033] The preparation process of the heat-resistant cooking polyamide film of the present invention is specifically as follows:

[0034] The dried raw resin is melted and extruded through three independent single-screw extruders at a temperature of 240~260℃. The melt flows through a filter, a metering pump, a static mixer, and a coat hanger die to reach 20~20. Molding on the cooling drum at 40℃, it can be well attached to the cold drum under the action of the electrostatic attaching device, which can minimize the generation of crystals, avoid the generation of large-sized crystal nuclei, and make a good thickness Sheet. The sheet is stretched in the longitudinal direction (length direction) at a temperature of 45 to 75°C, and the longitudinal stretching ratio is 2.0 to 3.5. After stretching, the film is cooled at a temperature of about 30°C, and then it is stretched in the transverse direction (width direction). Width machine. After passing through a ...

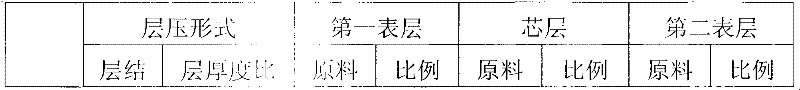

Embodiment 1

[0052] By using the co-extrusion method, the polyamide-based mixed resin formula of Example 1 shown in Table 1 was mixed and proportioned, the mixed nylon 6 resin was dried, put into the corresponding hopper and sent to the corresponding extruder, and heated to It is melted in the barrel at 265°C and extruded in a sheet form from the T-die. Using a high-voltage electrostatic film attachment device, it was attached to a cold drum with a surface temperature of 24°C and quenched to obtain an unstretched thick film. Then, the extruded thick sheet is heated through a series of high-precision metal rollers, and under a certain speed gradient, the sheet is elongated longitudinally, so that the polymer molecules are longitudinally oriented, shaped and cooled. The stretching in this process is carried out in two times, the stretching ratio used in both times is the same, which is 1.70 times, and the stretching temperature is 58°C and 62°C, respectively. Then, this MD stretched film was...

Embodiment 2

[0055] Except that the B / A ratio of the core layer material was changed to 90 / 10, the other process conditions were the same as those in Example 1, to obtain a biaxially oriented polyamide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com