Steel plate for engineering machinery and production method of steel plate

A technology for construction machinery and production methods, applied in the field of high-strength and high-toughness steel plates, can solve the problems of small strength and low-temperature impact energy value margins, incomplete elimination of internal stress of steel plates, and low flatness of plate shape, etc. The effect of small anisotropy, superior bending performance and high straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The molten steel smelted in a 210-ton converter and refined by LF furnace and RH furnace is poured into a slab in a slab continuous casting machine, and its chemical composition mass percentage is: C 0.076, Si 0.21, Mn 1.81, P 0.011, S 0.0017 , Als 0.032, Ca 0.0005, Nb 0.060, Ti 0.101, Mo 0.19, and the rest are Fe and unavoidable impurities.

[0038] The thickness of the cast slab is 230 mm, and it is rolled on the 2250 conventional hot continuous rolling production line. The heating temperature is 1240 ° C, the finish rolling entrance temperature is 1060 ° C, the thickness of the intermediate billet is 46 mm, the final rolling temperature is 850 ° C, and the target thickness is 4 mm. After rolling, it is cooled by ultra-fast cooling and ACC layer cooling to the target coiling temperature of 600°C, and the steel coil is air-cooled after coiling. After the temperature of the steel coil is lower than 60°C, the steel coil can be flattened on the transverse line, and the fl...

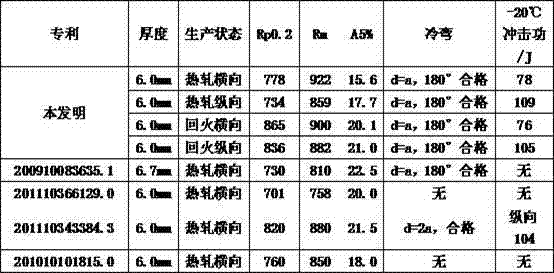

Embodiment 2

[0044] The molten steel smelted in a 210-ton converter and refined by LF furnace and RH furnace is poured into a slab in a slab continuous casting machine, and its chemical composition mass percentage is: C 0.073, Si 0.26, Mn 1.82, P 0.012, S 0.0029 , Als 0.029, Ca 0.0005, Nb 0.063, Ti 0.116, Mo 0.18, and the rest are Fe and unavoidable impurities.

[0045] The thickness of the cast slab is 230mm, and it is rolled on the 2250 conventional hot continuous rolling production line. The heating temperature is 1240°C, the finish rolling entrance temperature is 1030°C, the thickness of the intermediate billet is 51mm, the final rolling temperature is 850°C, and the target thickness is 6mm. After rolling, it is cooled by ultra-fast cooling and ACC layer cooling to the target coiling temperature of 600°C, and the steel coil is air-cooled after coiling. After the temperature of the steel coil is lower than 60°C, the steel coil can be flattened on the transverse line, and the flattened s...

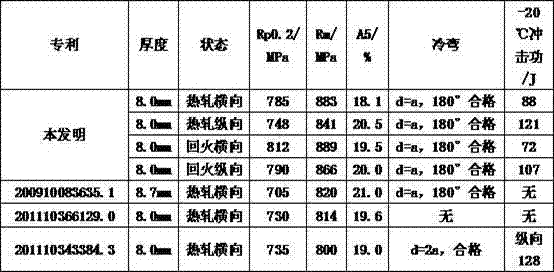

Embodiment 3

[0051] The molten steel smelted in a 210-ton converter and refined by LF furnace and RH furnace is poured into a slab in a slab continuous casting machine, and its mass percentage is: C 0.068, Si 0.0.21, Mn 1.87, P 0.013, S 0.0022 , Als 0.034, Ca 0.0008, Nb 0.061, Ti 0.109, Mo 0.19, and the rest are Fe and unavoidable impurities.

[0052] The thickness of the cast slab is 230mm, and it is rolled on the 2250 conventional hot continuous rolling production line. The heating temperature is 1240°C, the finish rolling entrance temperature is 1030°C, the thickness of the intermediate billet is 54mm, the final rolling temperature is 840°C, and the target thickness is 8mm. After rolling, it is cooled to the target coiling temperature of 580°C by ultra-fast cooling and ACC layer cooling, and the steel coil is air-cooled after coiling. After the temperature of the steel coil is lower than 60°C, the steel coil is flattened on the transverse line, and the flattened steel plate is tempered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com