Patents

Literature

1647results about How to "Improve straightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

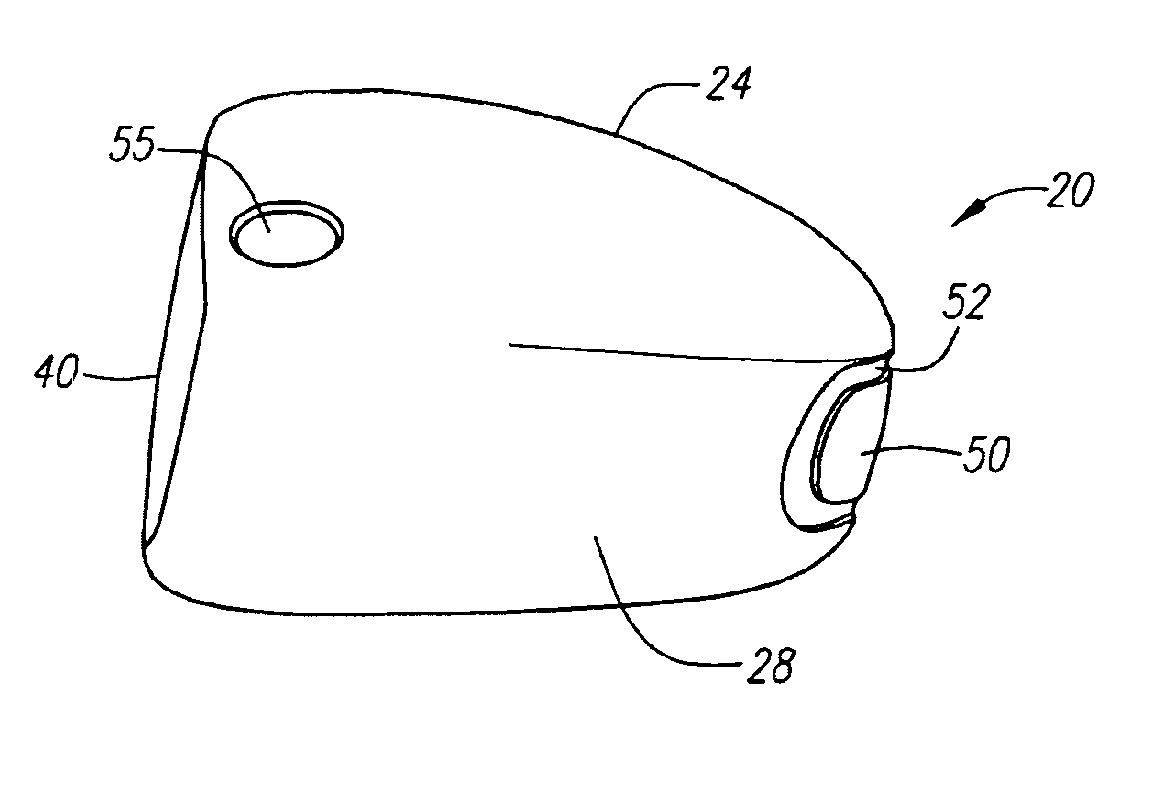

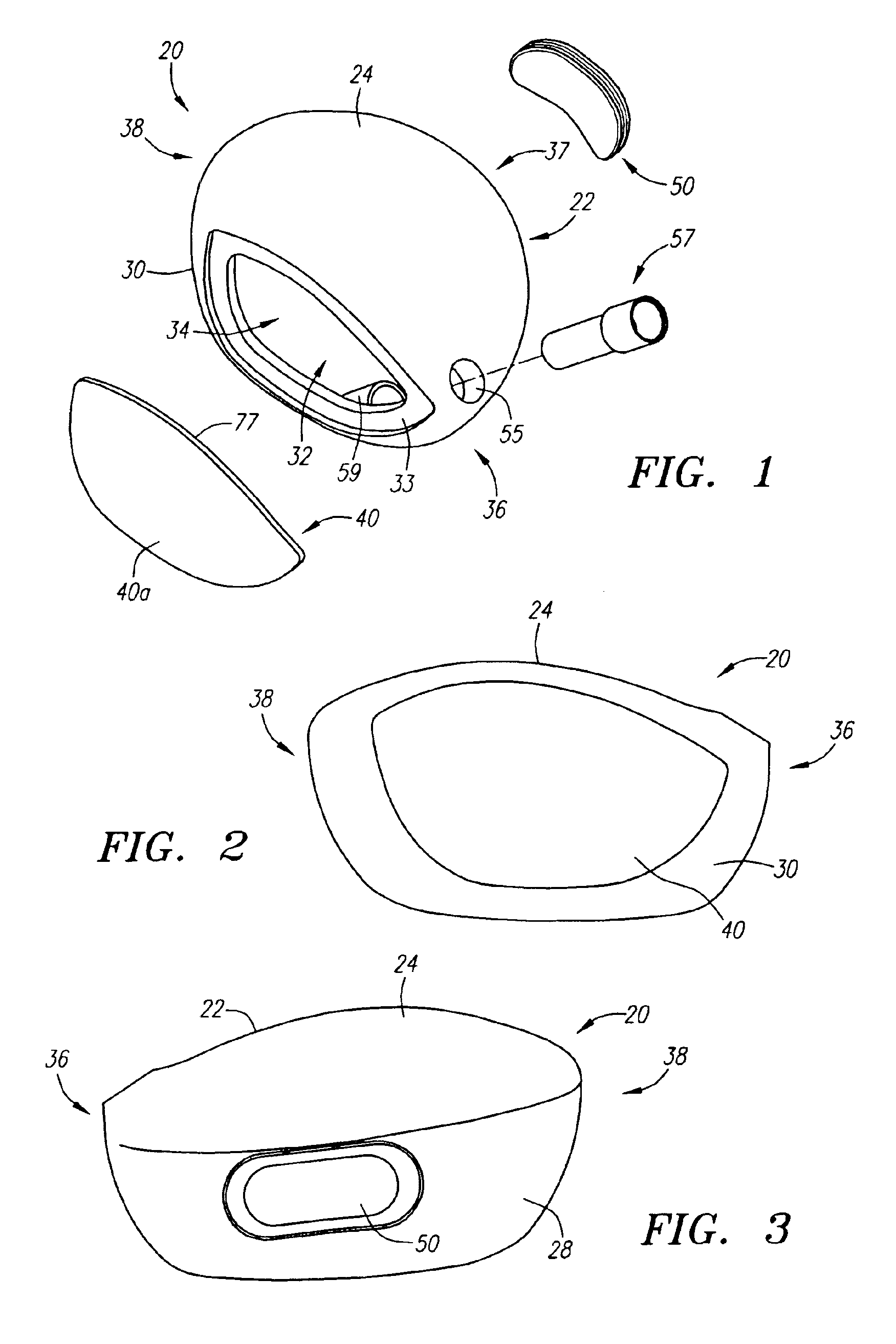

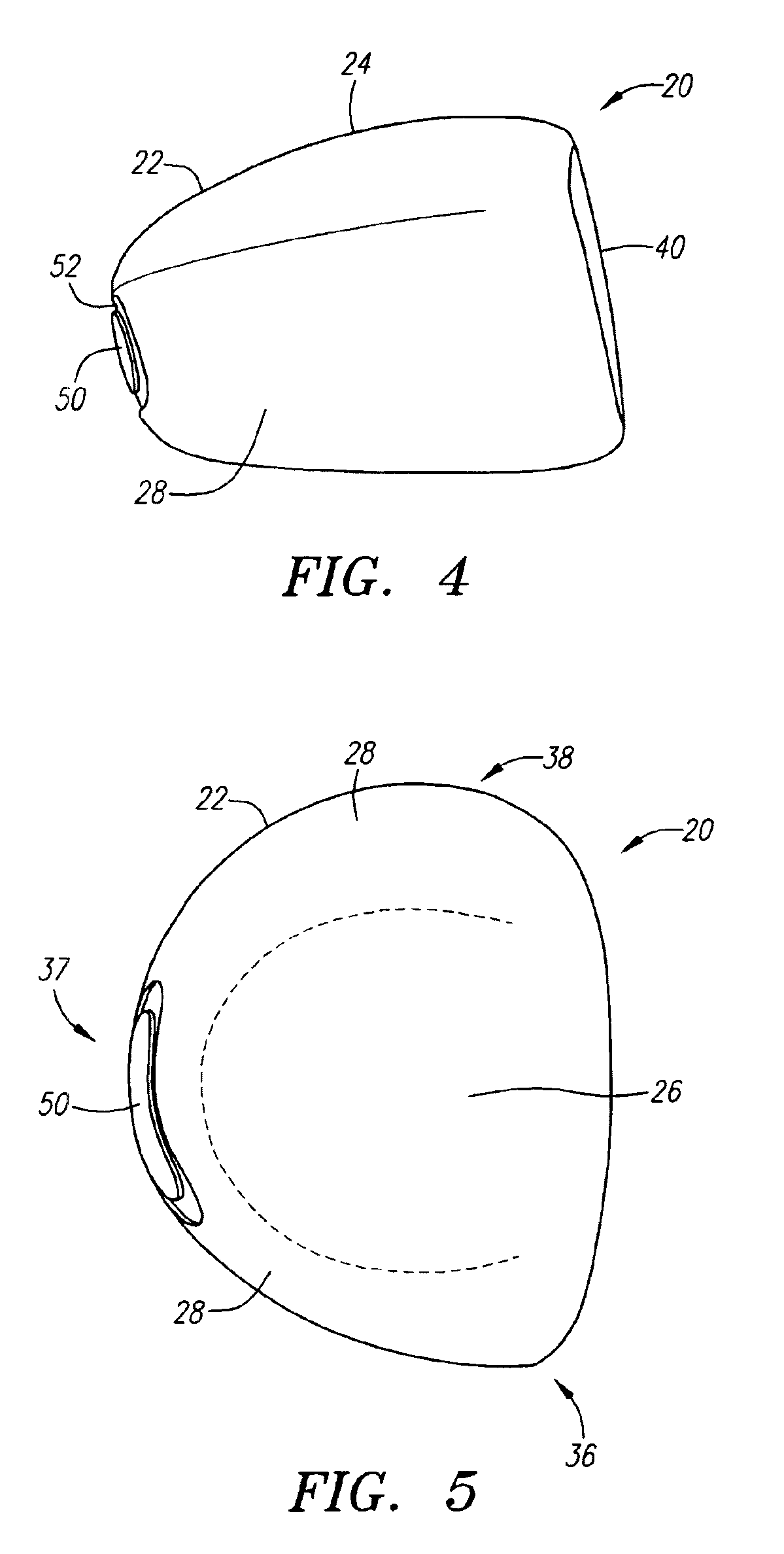

Golf club head (Corporate Docket PU2150)

A golf club head (20) having a center of gravity located relatively forward toward the front wall (30) or striking plate (40) of the golf club head (20), and a relatively high moment of inertia about the Iyy axis through the center of gravity of the golf club head (20) is disclosed. The golf club head (20) preferably has a volume between 300 cubic centimeters and 500 cubic centimeters. The golf club head (20) preferably has a mass between 105 grams and 300 grams. The positioning of the of the center of gravity of the golf club head (20) and the relatively high moment of inertia Iyy through the center of gravity provide for a golf club with greater robustness and better performance.

Owner:TOPGOLF CALLAWAY BRANDS CORP

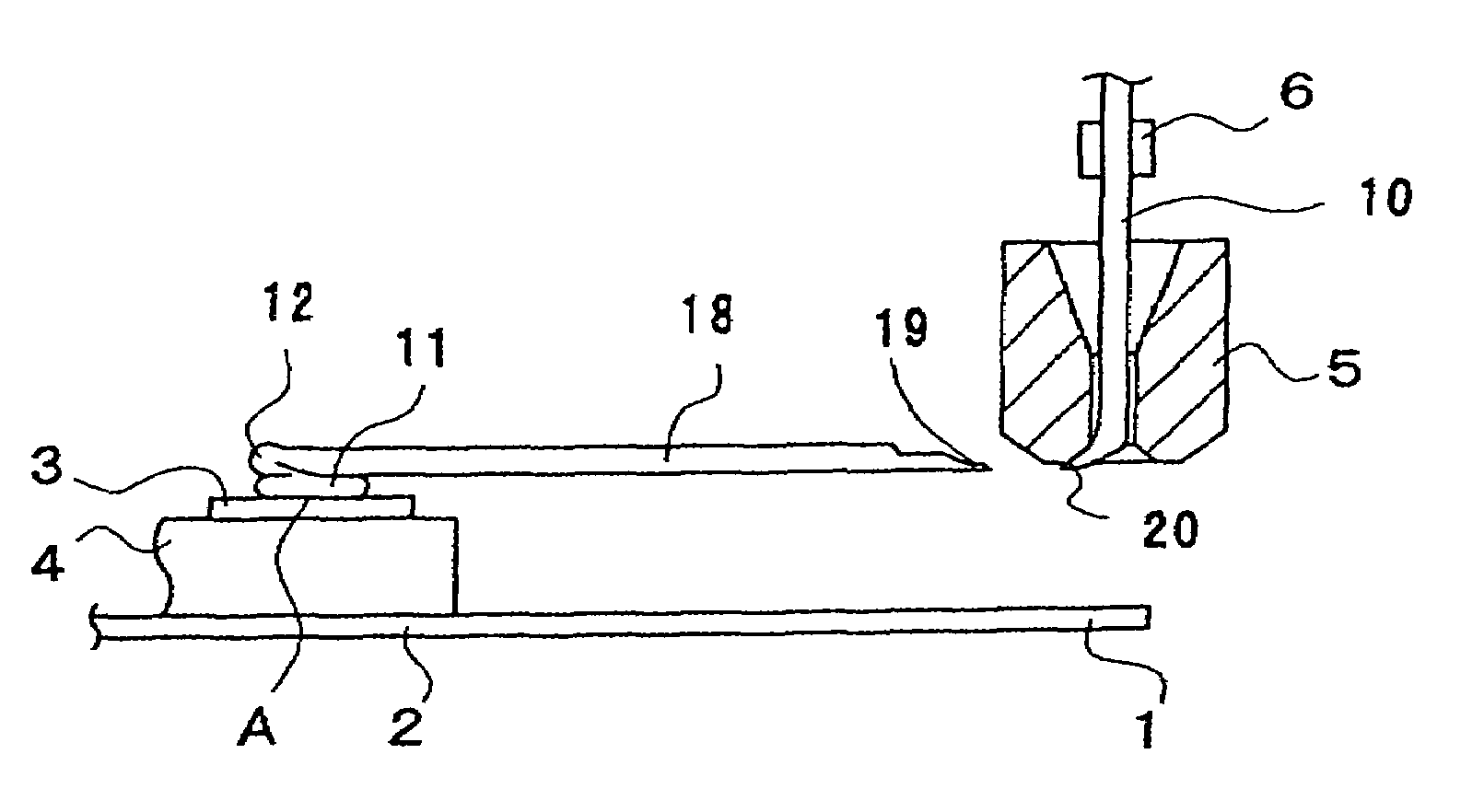

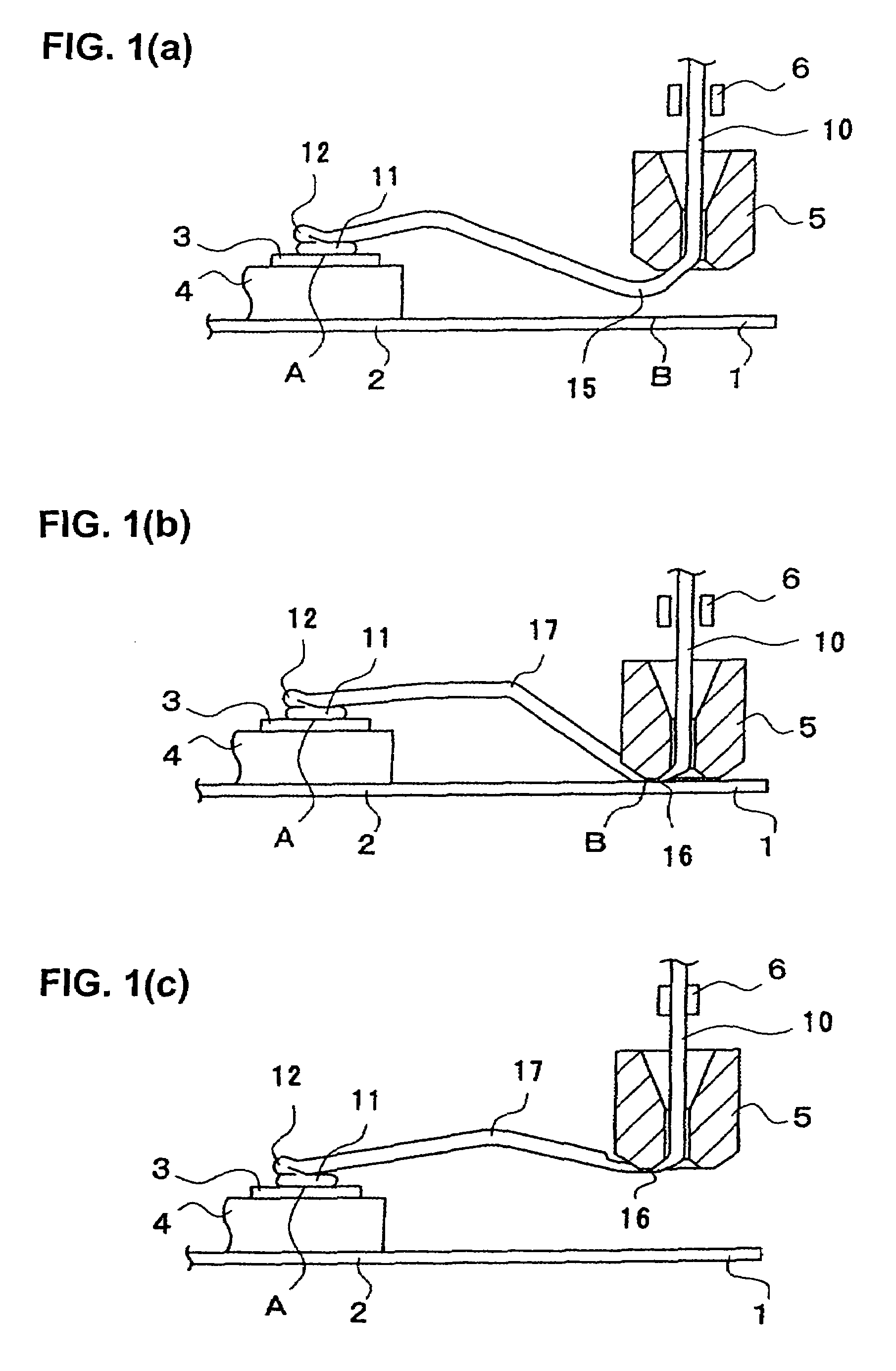

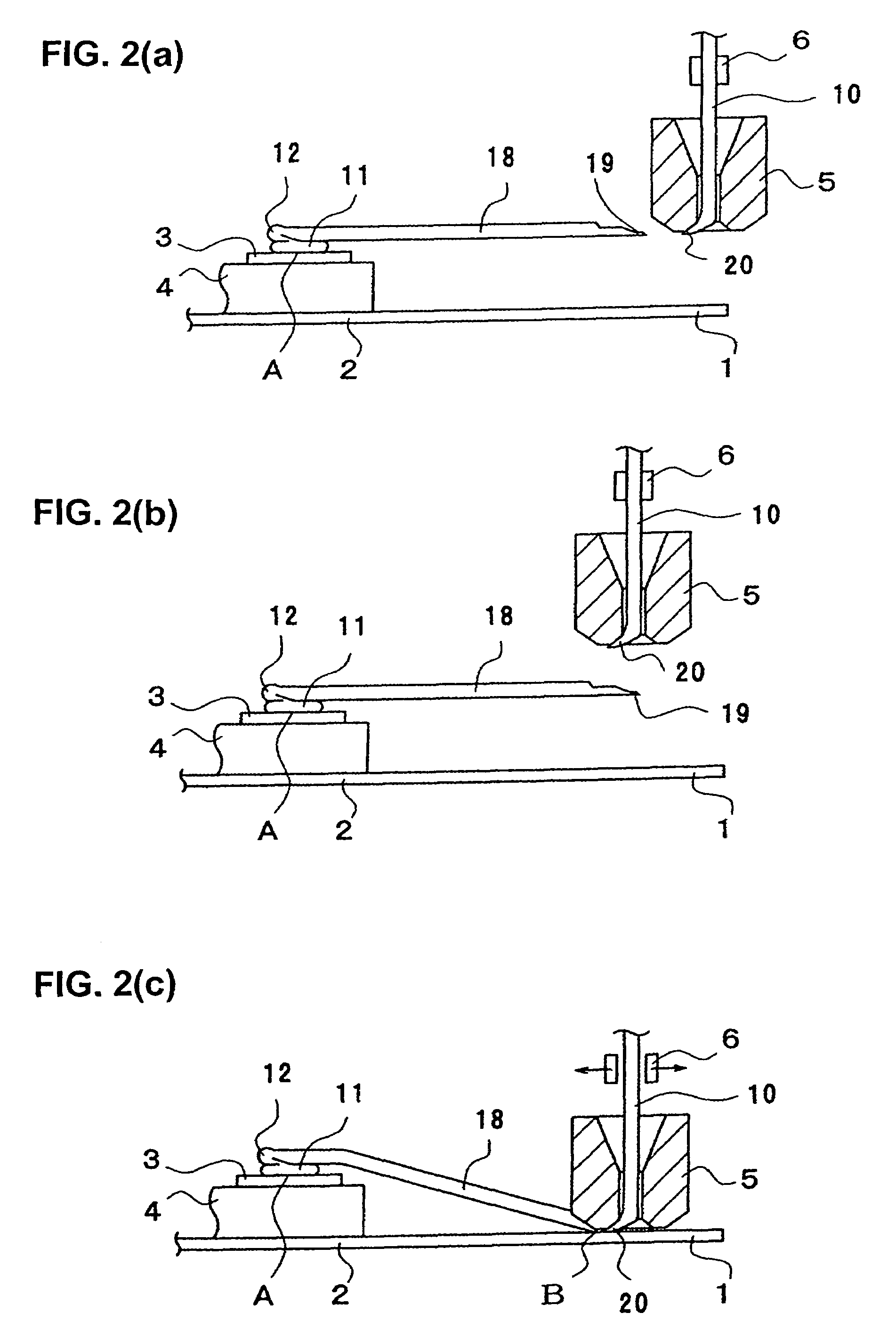

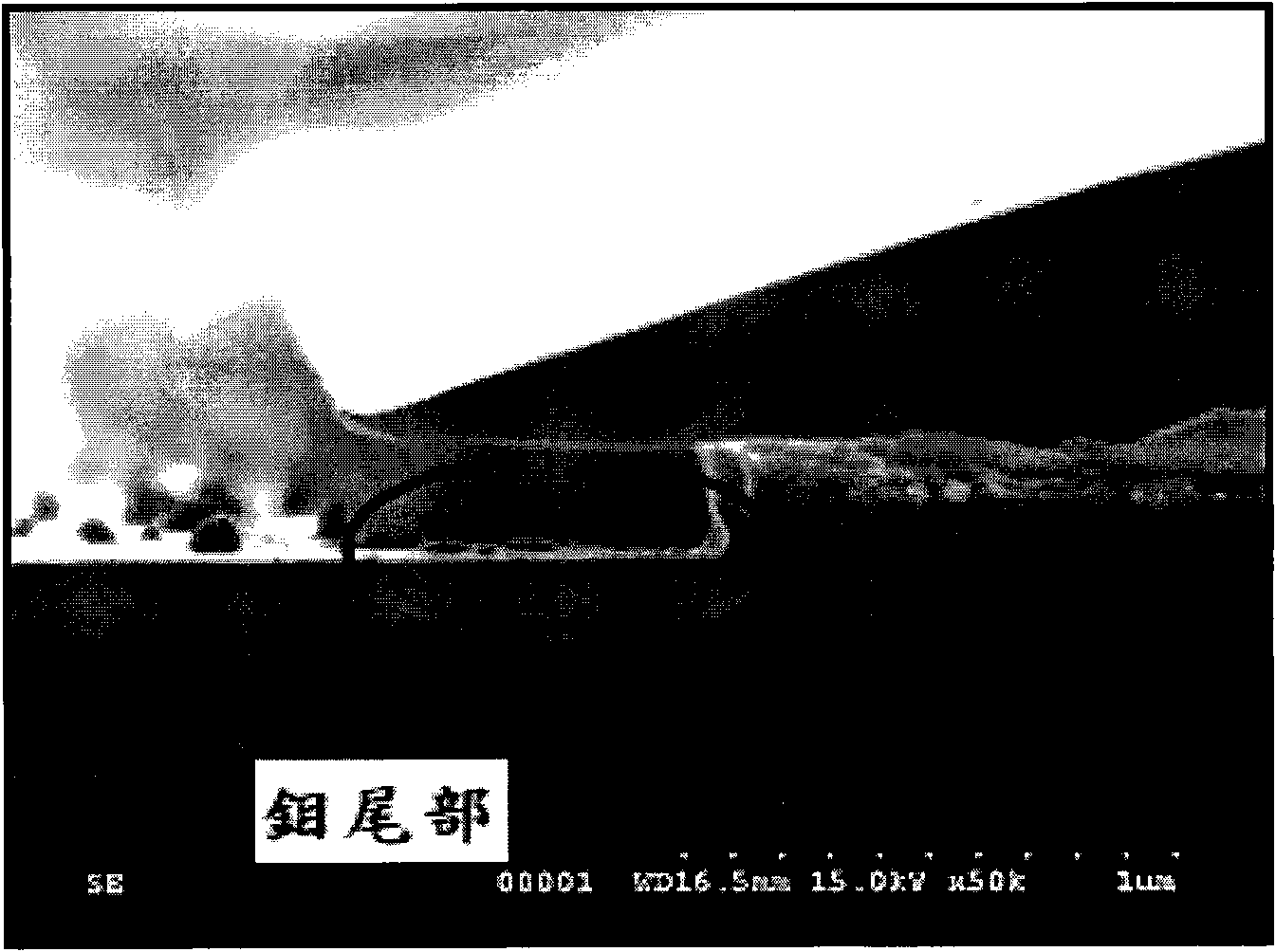

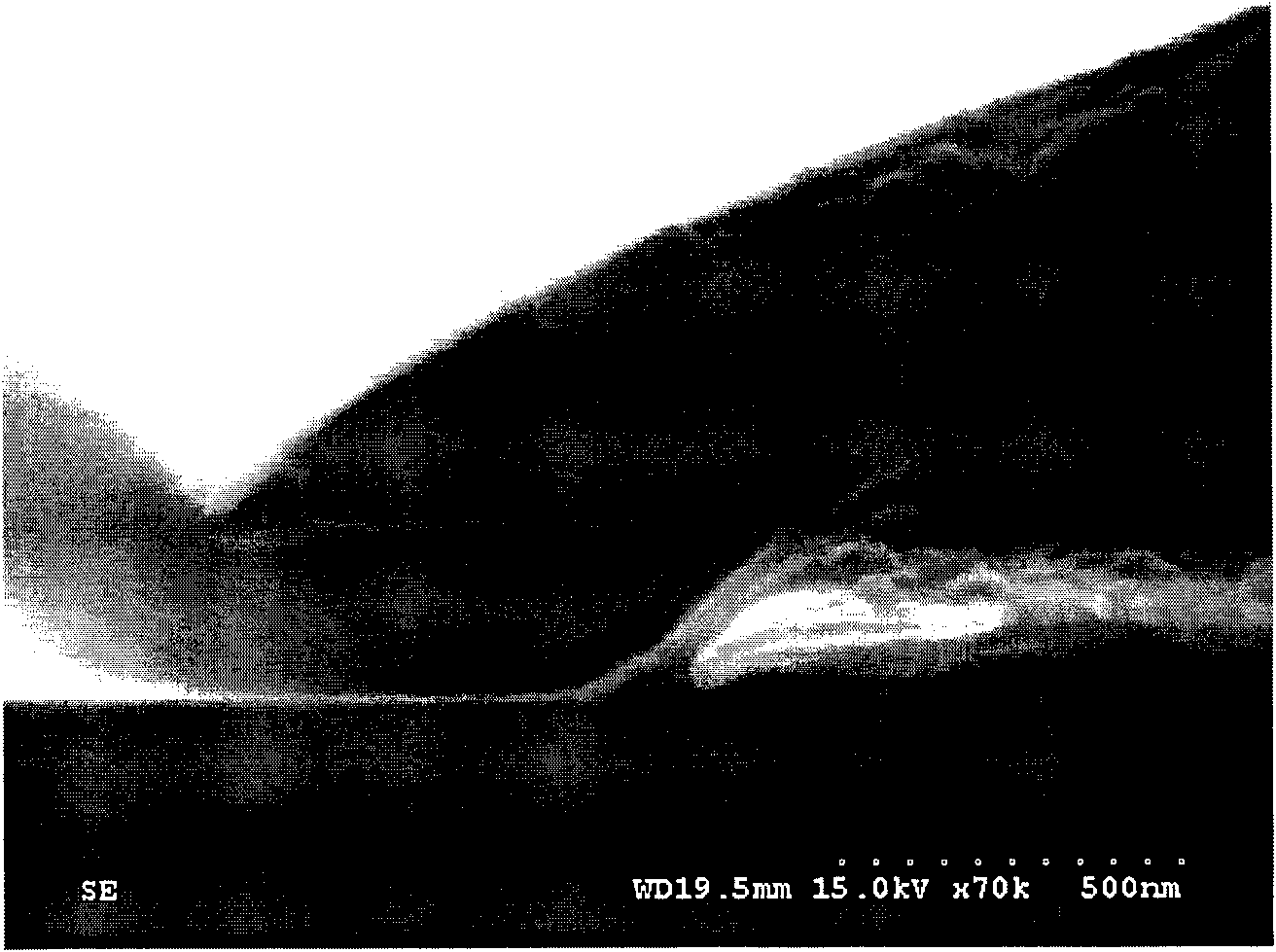

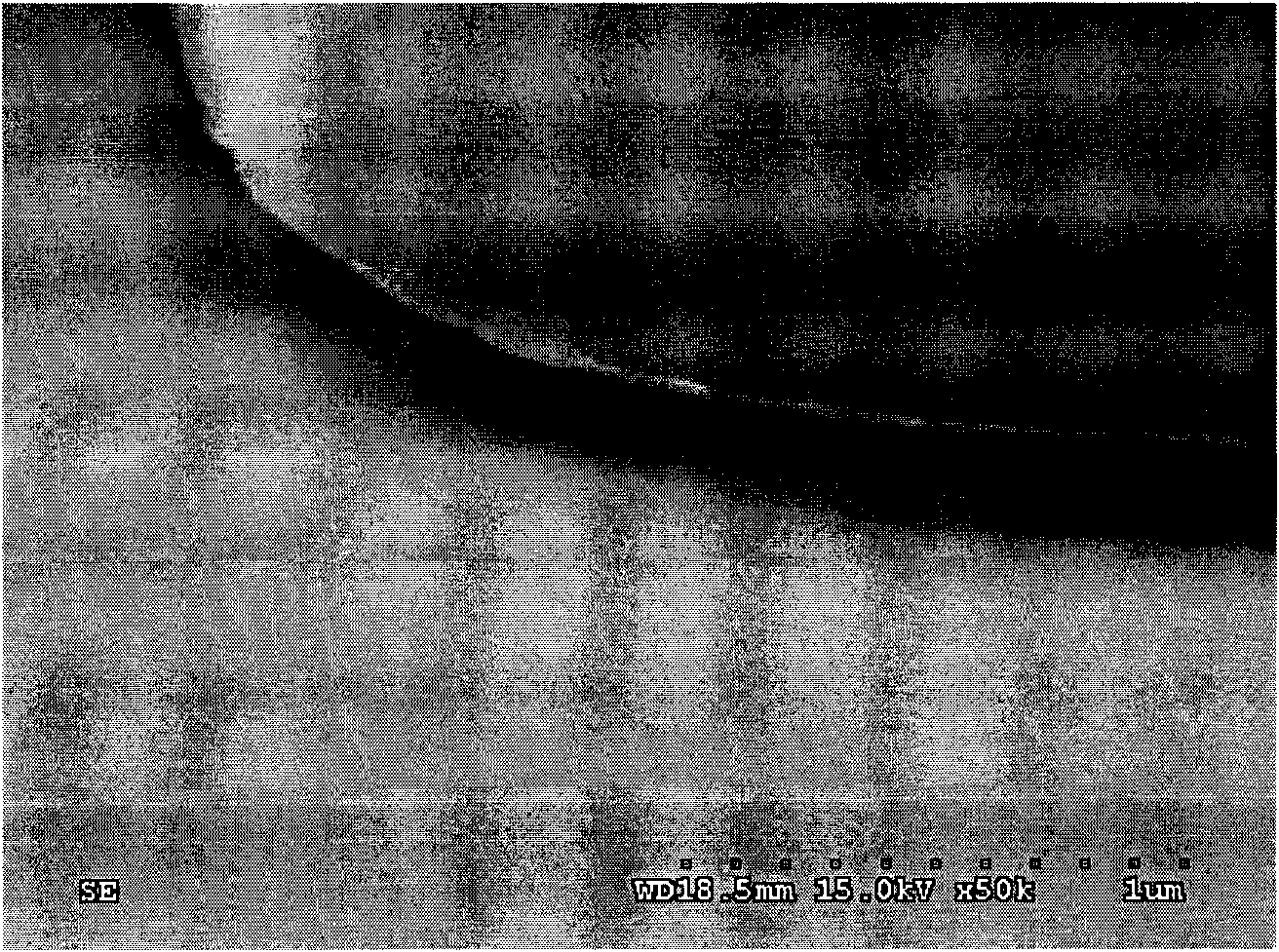

Wire bonding method

InactiveUS7621436B2Inhibit swellingImprove straightnessSolid-state devicesWelding/cutting auxillary devicesEngineeringWire bonding

A wire bonding method including the steps of: descending a capillary 5 from above an external lead 1 to press a wire 10 to such an extent that the wire is not completely connected to the external lead 1, thus forming a thin part 16 in the wire; next ascending the capillary 5 and the thin part 16 to substantially the same height as a first bonding point A, then moving the capillary 5 in a direction away from the first bonding point A, thus making a linear wire portion 18 and then cutting the wire at the thin part 16; then connecting the end 19 (thin part) of the linear wire portion 18 and the wire tip end 20 at the lower end of the capillary 5 are connected to the external lead 1; and then separating the wire tip end 20 from the external lead 1.

Owner:SHINKAWA CO LTD

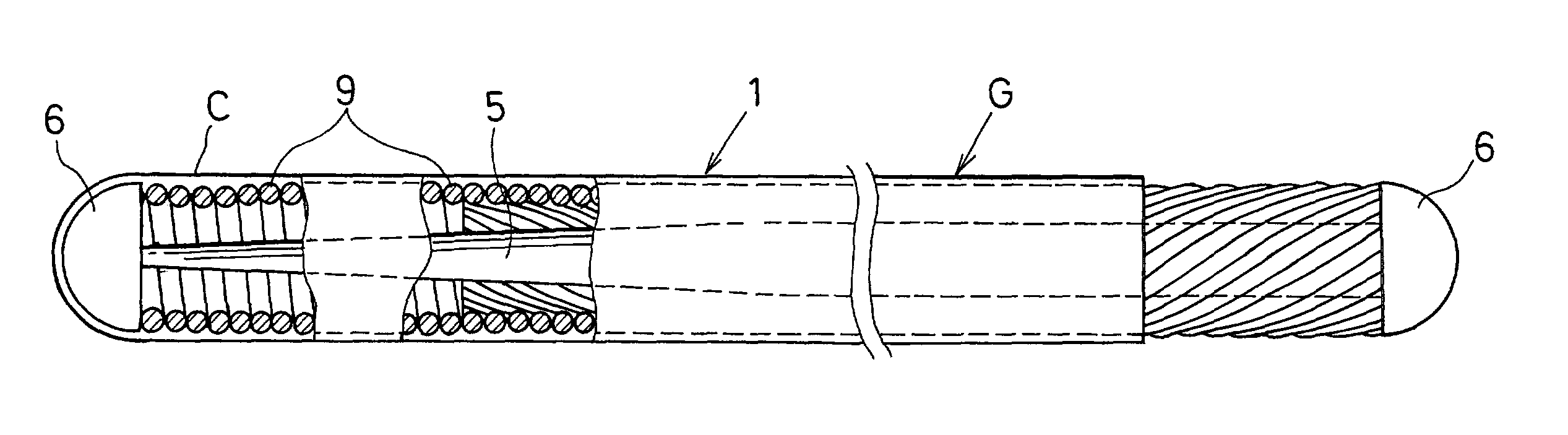

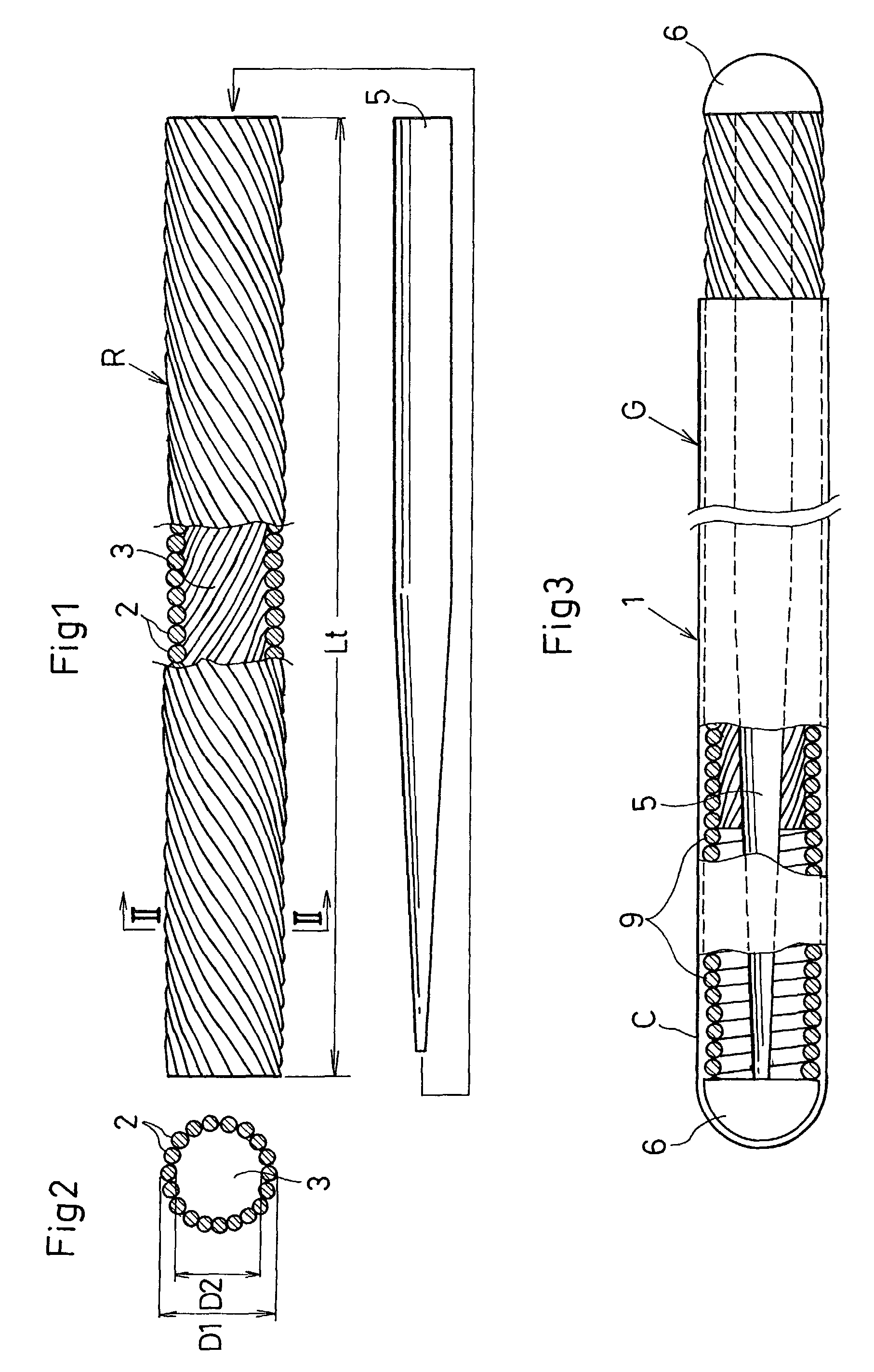

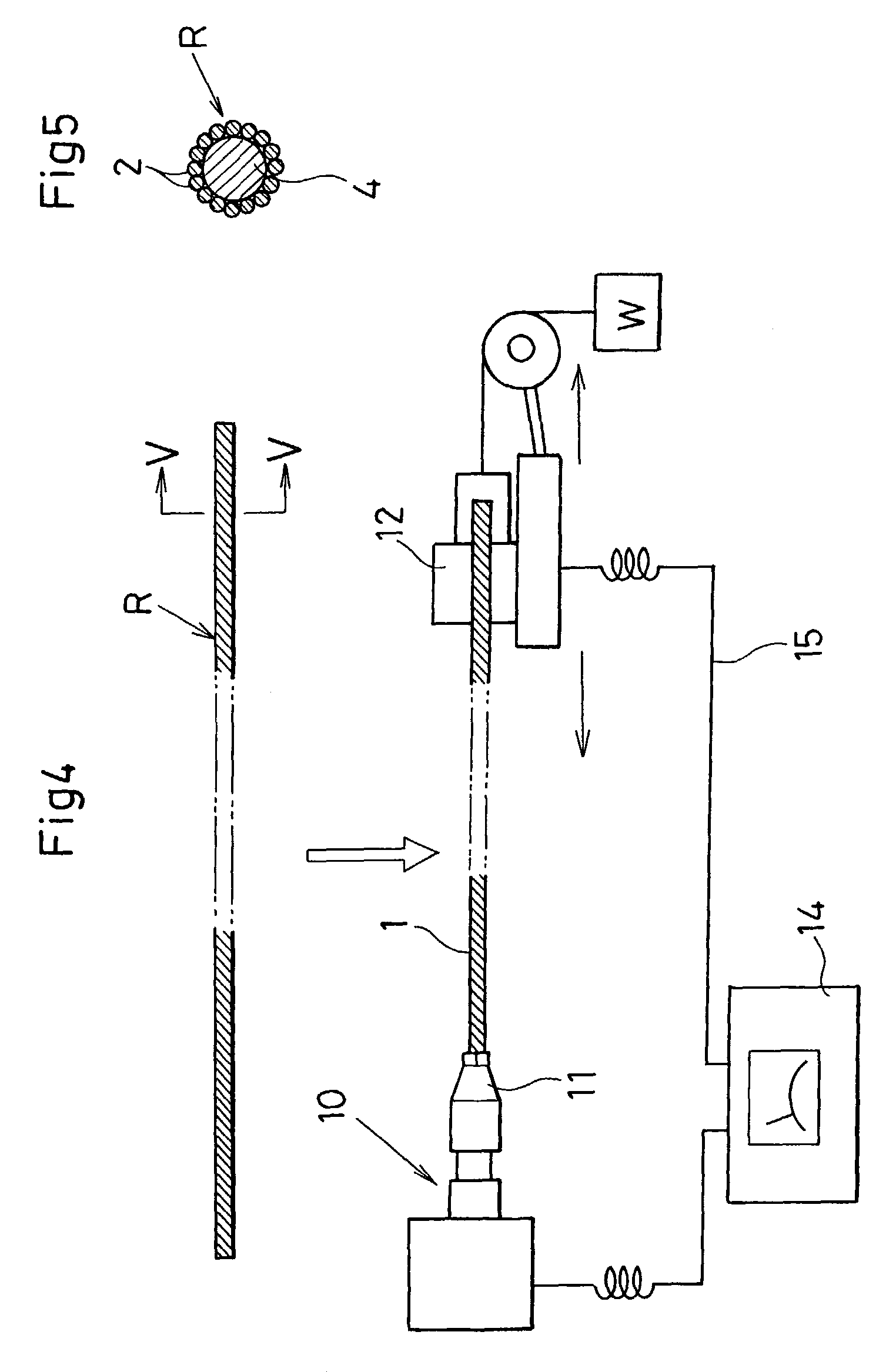

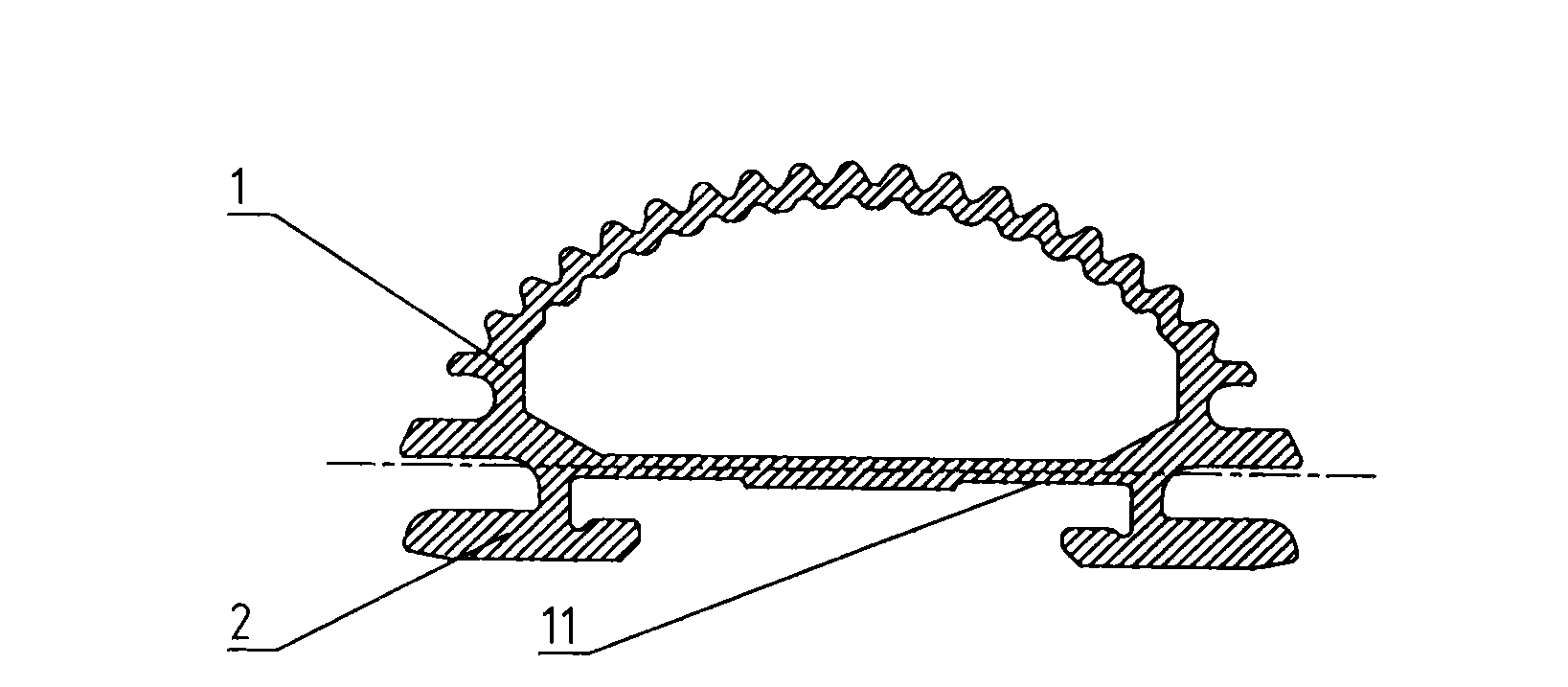

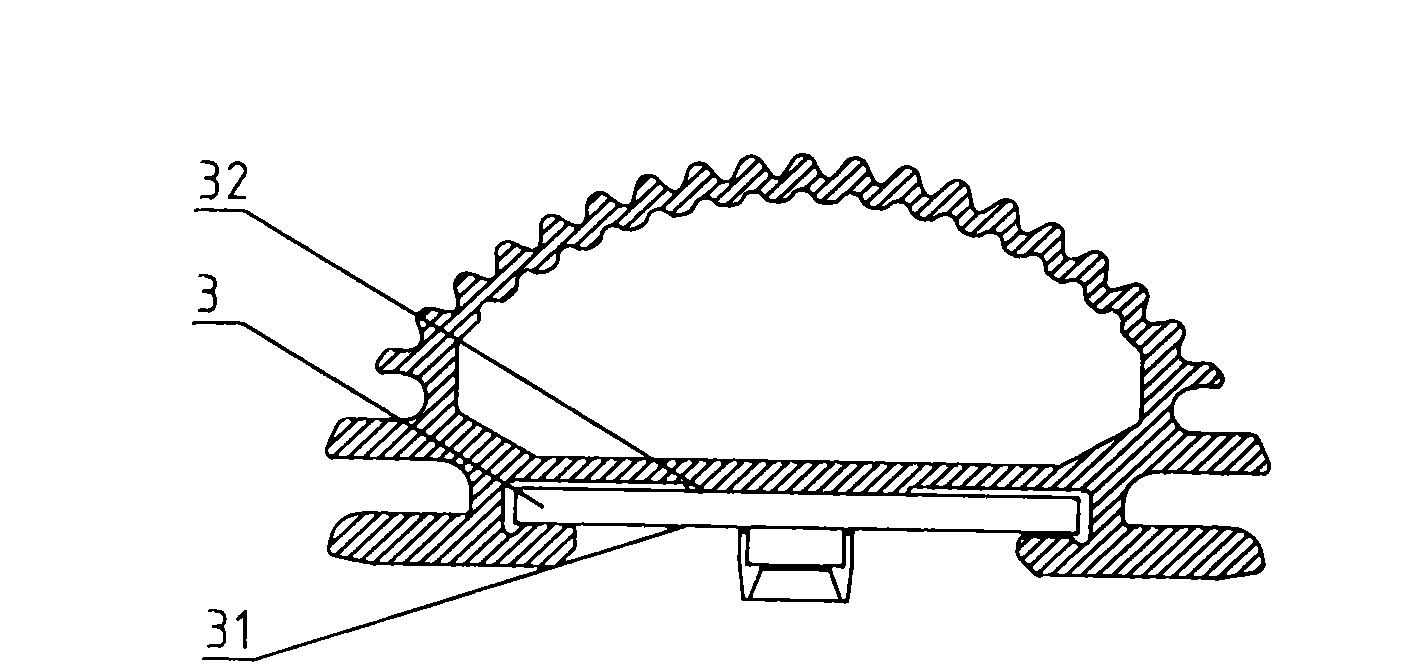

Wire-stranded hollow coil body, a medical equipment made therefrom and a method of making the same

InactiveUS7117703B2Improve rendering capabilitiesImprove straightnessStentsGuide wiresEngineeringMedical device

A wire-stranded hollow coil body (1) has a multitude of coil line elements (2) stranded along a predetermined circular line to form a flexible wire tube having a central axial hollow portion (3), the flexible wire tube is stranded under a strand-turn resistant load and heat treated to remove a residual stress upon formation so as to provide a high rotation-following capability and a high straightness. Further, a method provides a way to strand the coil line elements (2) under a strand-turn resistant load while heat treating the coil line elements (2).

Owner:ASAHI INTECC CO LTD

Copper, copper/molybdenum, or copper/molybdenum alloy electrode etching solution for use in liquid crystal display system

ActiveCN101684557AWith purityGood straightnessSemiconductor/solid-state device manufacturingNon-linear opticsPhosphateMaterials science

The invention relates to a copper, copper / molybdenum, or copper / molybdenum alloy electrode etching solution, comprising: based on the total weight of the etching solution, 12-35 wt% of hydrogen peroxide, 0.5-5 wt% of sulfate, 0.5-5 wt% of phosphate, 0.0001-0.5 wt% of fluorine ion, 0.1-5 wt% of first water-soluble cyclic amine, 0.1-5 wt% of chelating agent, 0.1-5 wt% of second water-soluble cyclicamine, 0.1-5 wt% of diol, and deionized water, the total weight of the etching solution being 100 wt%. The invention relates to the copper, copper / molybdenum, or copper / molybdenum alloy electrode layer etching solution for use in the process of etching gate electrode, source electrode, or collecting electrode of the thin film transistor (TFT) in the liquid crystal display device or etching metallic wire.

Owner:SOULBRAIN CO LTD

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

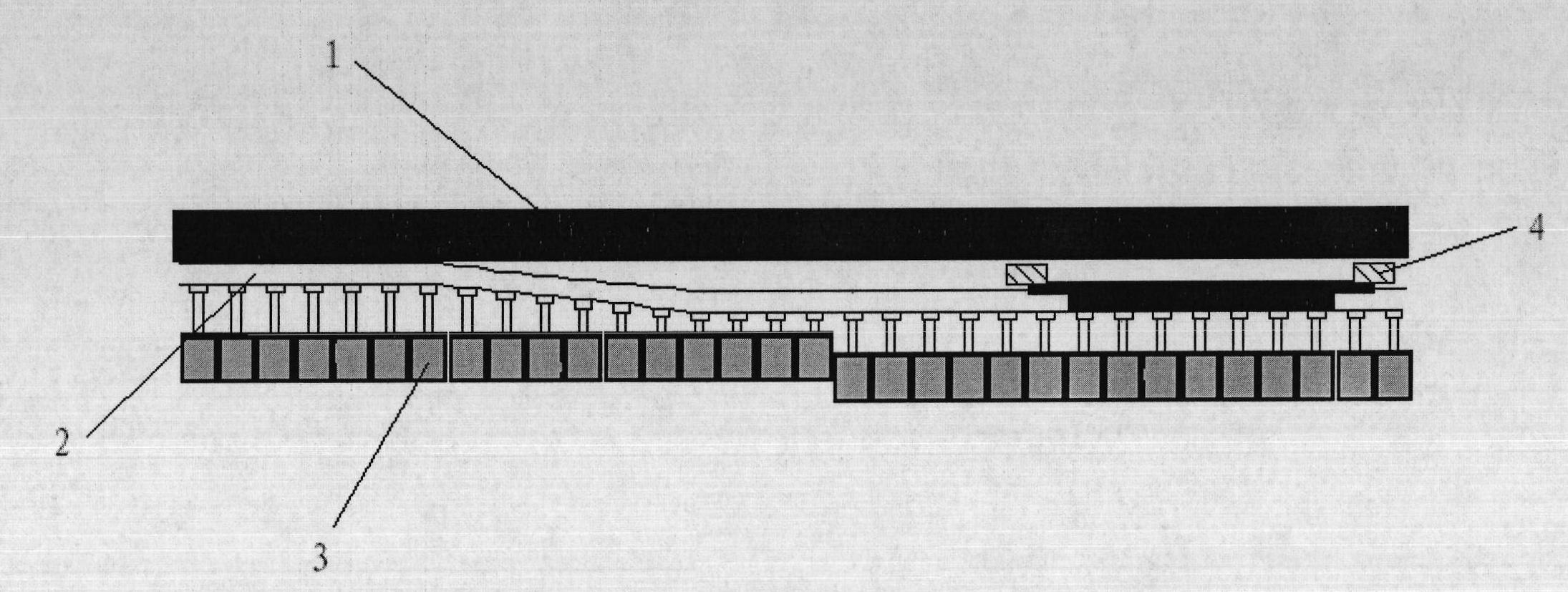

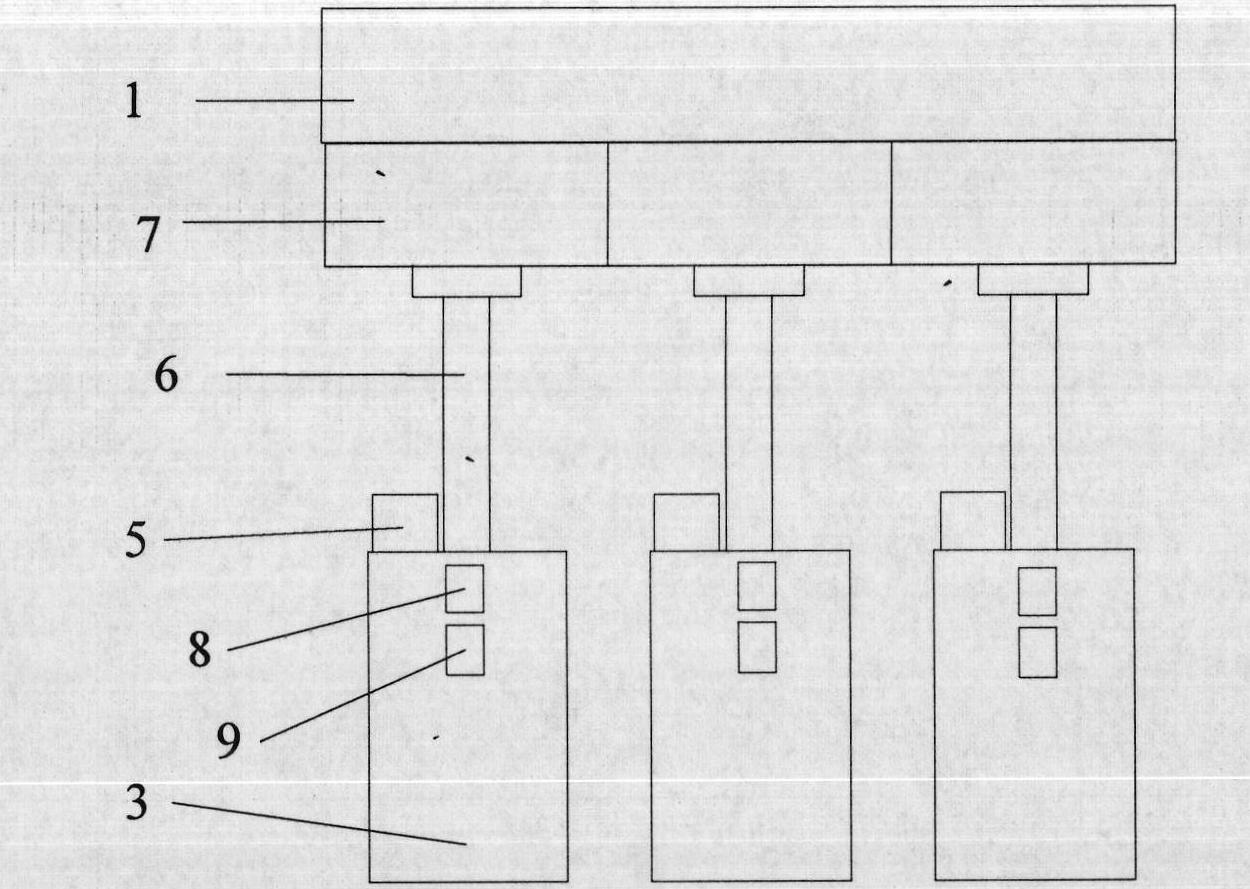

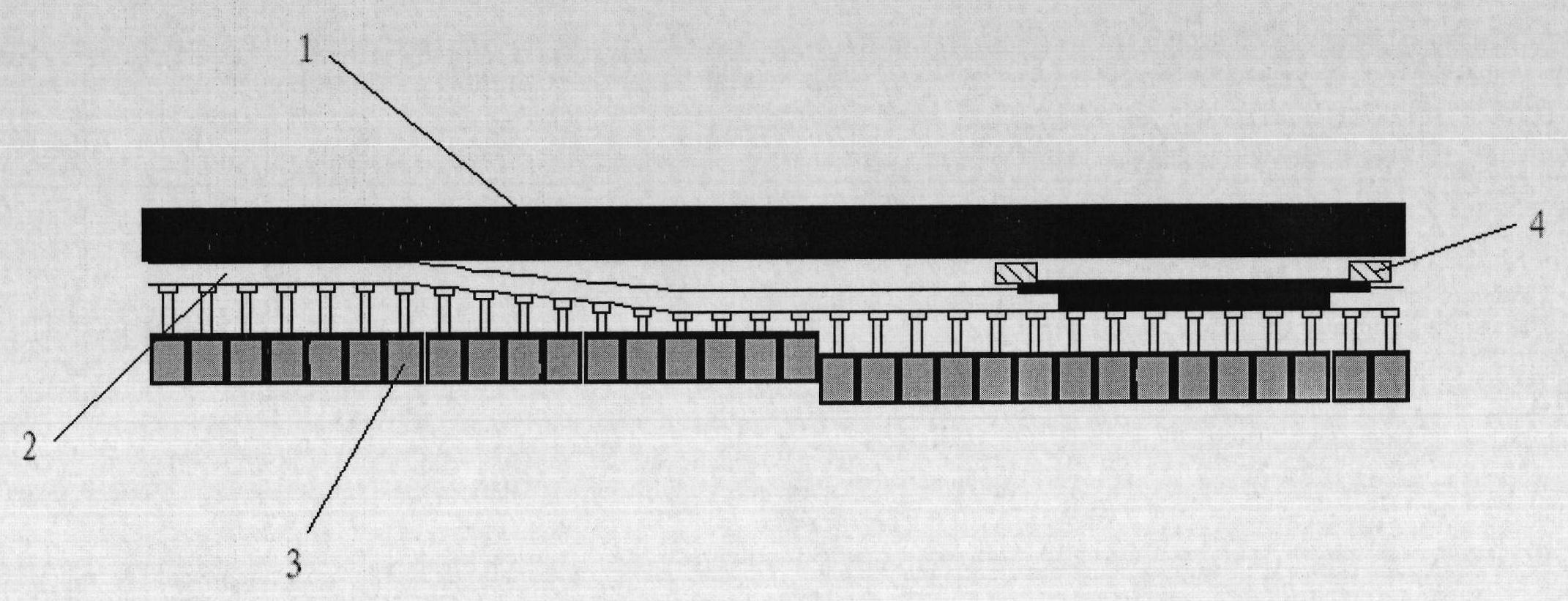

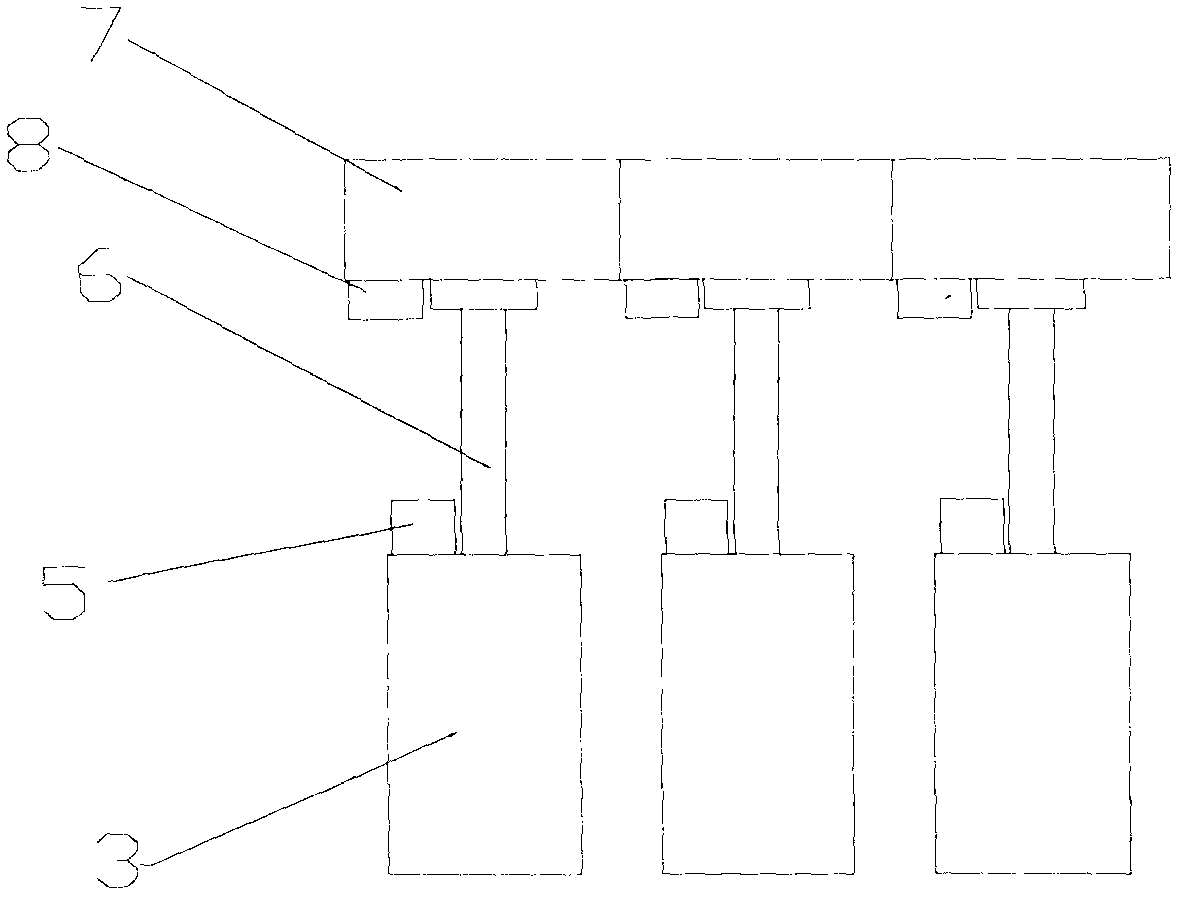

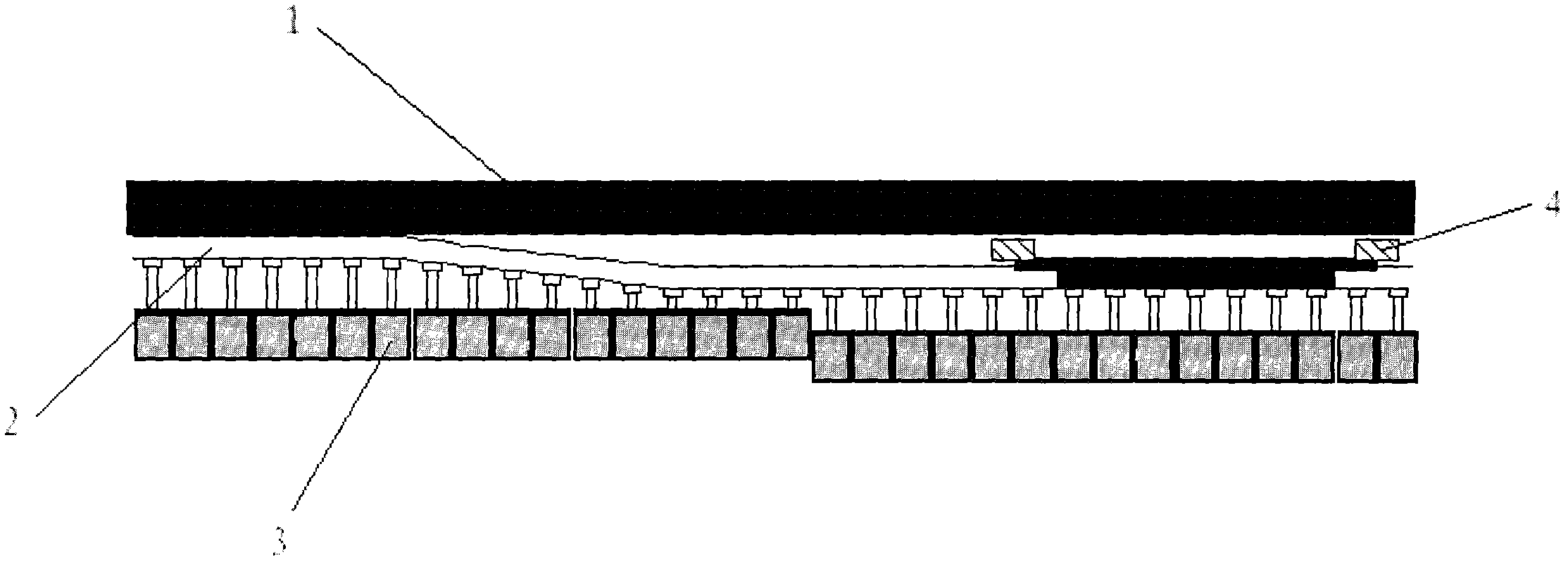

Coalface straightness control method

The invention discloses a coalface straightness control method. A range finder and an angle sensor are mounted on the top beam of a hydraulic support, the range finder is used for measuring the distance between the hydraulic support and a coal wall, and the angle sensor is used for detecting the posture of the top beam of the hydraulic support; a support controller is mounted on the hydraulic support and is used for detecting the states of the hydraulic support and controlling the actions of the hydraulic support. The hydraulic support and a scraper conveyer are connected by a pin lug, and the movement of the scraper conveyer is realized through the push-slip control of the hydraulic support. In the moving process of the hydraulic support, the distance between the hydraulic support and the coal wall is detected, and the moving travel of the hydraulic support is controlled at the same time, so the distance between the moved hydraulic support of the coalface and the coal wall remains the same, the control on the straightness of the coalface hydraulic support is realized, the control on the straightness of the scraper conveyer is realized through the push-slip action of the coalface hydraulic support, and the control on the straightness of the whole coalface is accordingly realized.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

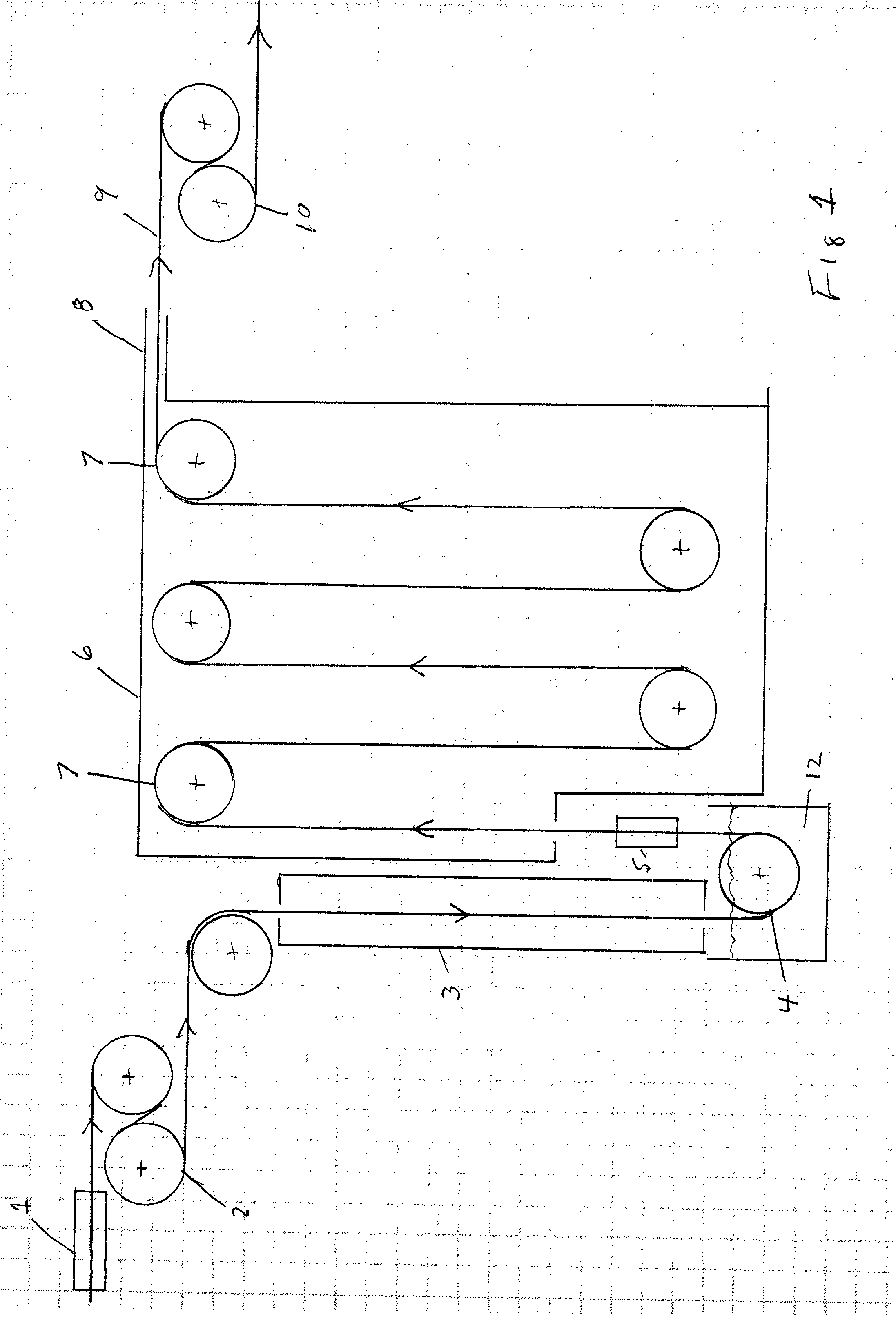

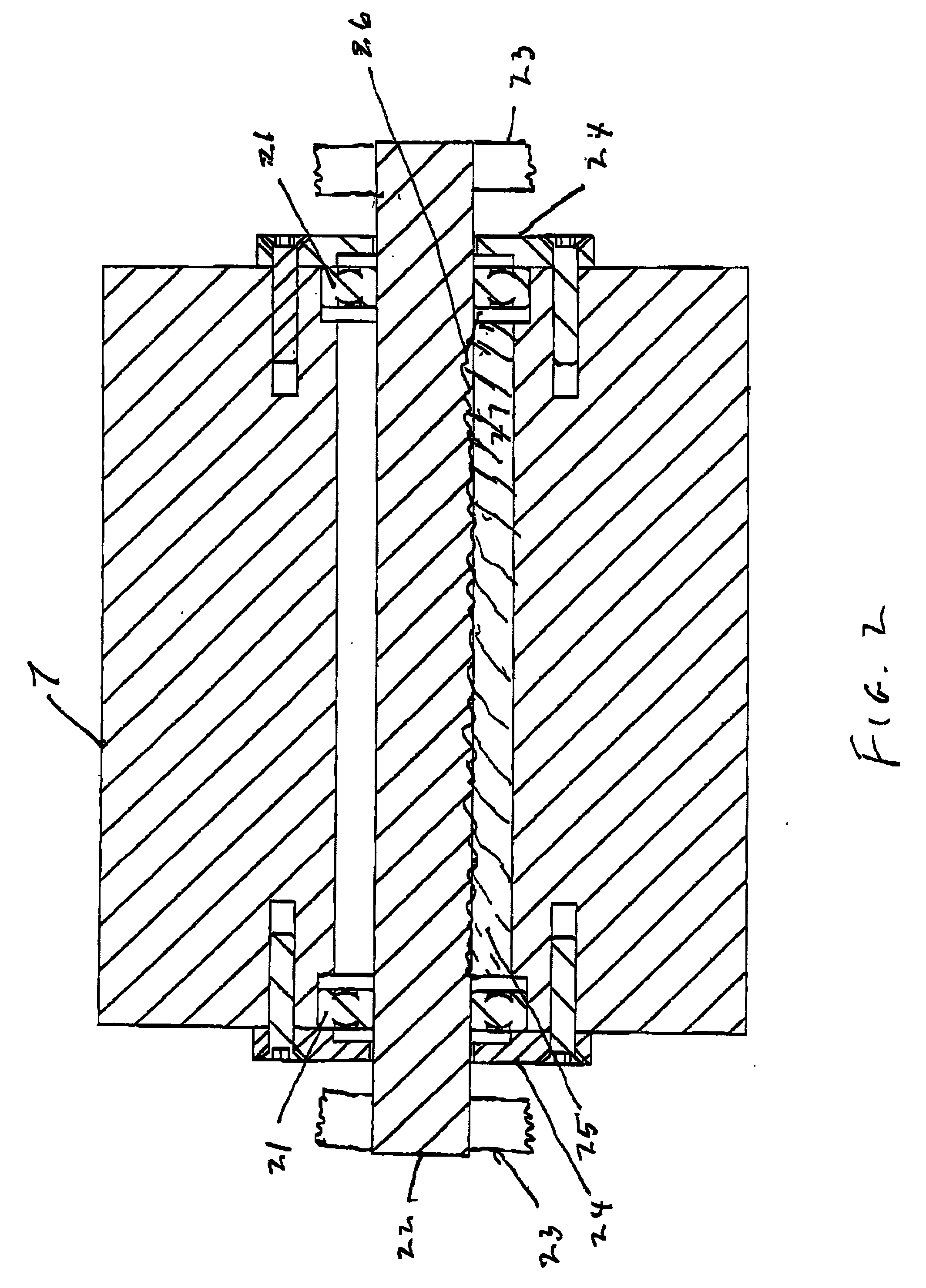

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

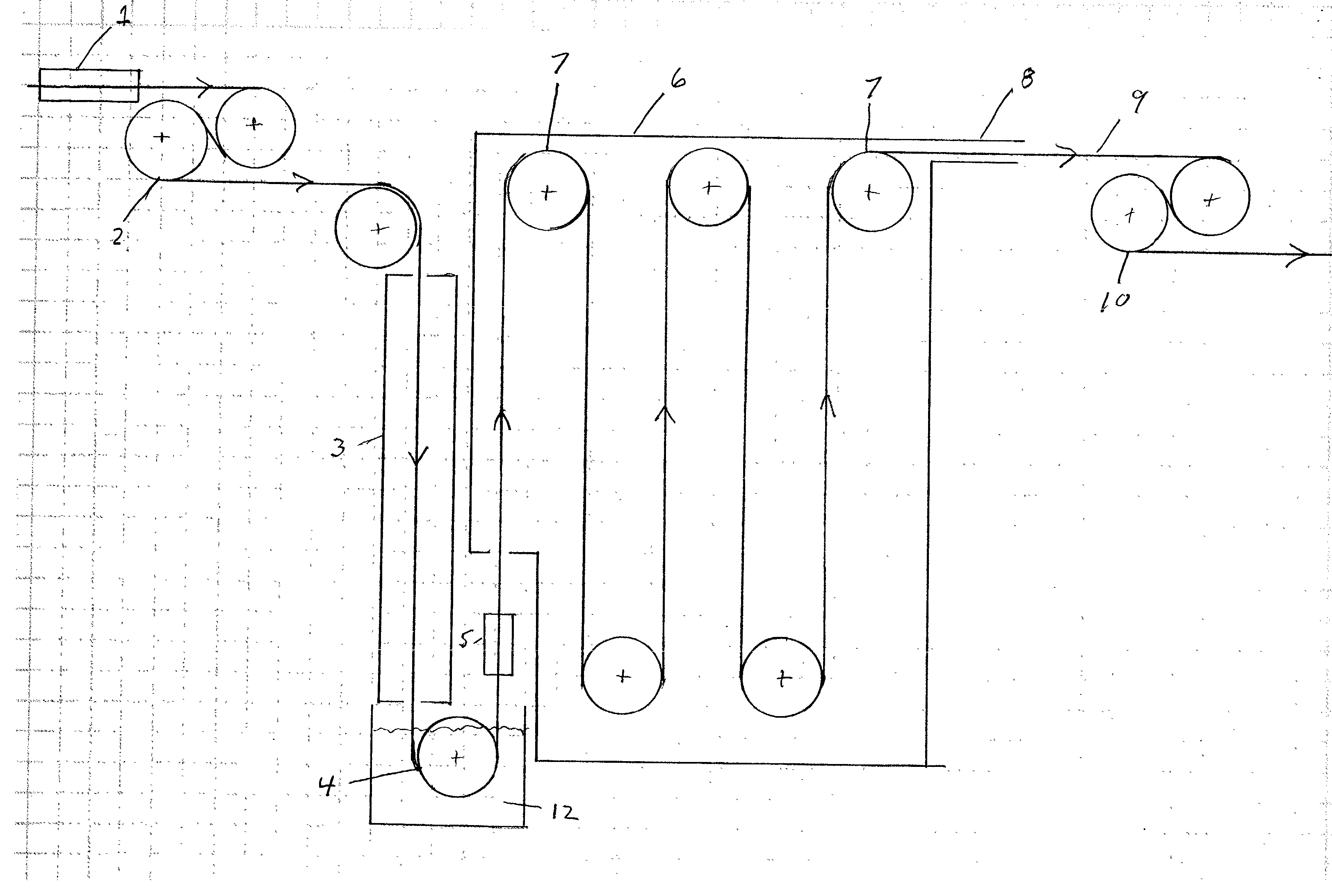

Method and apparatus for bainite blades

InactiveUS20020100522A1Maximize propertyMaximize straightnessRotary intaglio printing pressFurnace typesPad printingFerritic matrix

The present invention includes bainitic steel doctor blades, bainitic steel coating blades, bainitic steel creping blades and bainitic steel rule die knives used in gravure printing, flexographic printing, paper making, die cutting of materials including paper, plastic, foam, leather, etc. Other uses include printing processes such as pad printing and electrostatic printing. The invention also includes an improved method for producing bainitic steel strip. The present invention is accomplished by using bainitic steel components that exhibit superior straightness and wear properties and are bendable around small radii. The process of the present invention comprises the steps of annealing a carbon steel resulting in a microstructure of the steel having a dispersion of carbides in a ferritic matrix; cold rolling the annealed steel; cleaning the cold rolled steel to remove oil and dirt; bridle braking the cleaned steel to increase strip tension; austenitizing the steel; submersing the austenitized steel into a quenchant; removing excess quenchant; and isothermally transforming the austenitized steel into bainite. The present process of the invention also includes the use of turn rolls that are housed in an assembly containing salt and / or tin.

Owner:BENTON GRAPHICS

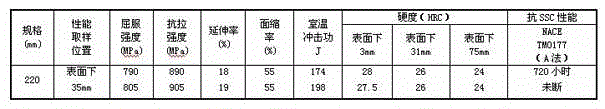

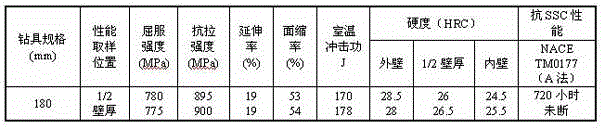

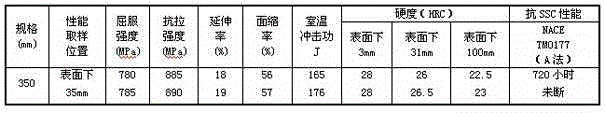

Round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for drilling tool and manufacturing method of round steel

The invention discloses a round steel with high strength and toughness and hydrogen sulfide stress corrosion resistance for a drilling tool and a manufacturing method of the round steel. The round steel comprises the following chemical components in percentage by mass: 0.20-0.30% of C, 0.15-0.40% of Si, 0.20-0.70% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.70-1.30% of Cr, 0.40-0.95% of Mo, less than or equal to 0.25% of Ni, 0.05-0.10% of Cu, 0.05-0.10% of Alt, less than or equal to 0.1% of V, less than or equal to 0.06% of Nb, less than or equal to 0.010% of Ti, less than or equal to 0.009% of N, 0.001-0.003% of B and the balance of Fe and inevitable impurities. By adopting the preparation method, the round steel with the maximum specification of 350mm can be manufactured, and the round steel is particularly suitable for being processed to be stress complex drilling tools with large specifications and high strength and toughness requirements such as hydrogen sulfide corrosion resistant drill rods, drill collars, and drill rod joints applied to acidic oil wells.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

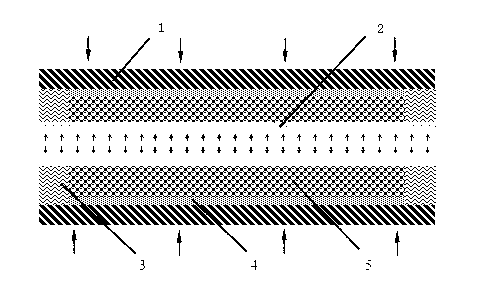

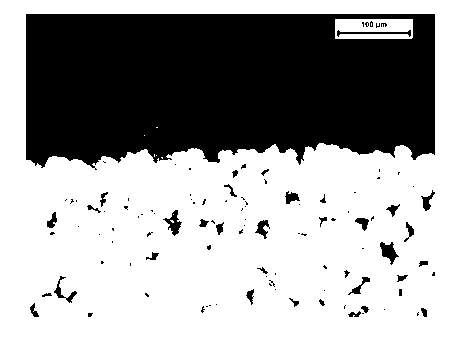

Preparation method of porous ceramic-metal composite film material

ActiveCN102836642AHigh specific surface areaIncrease contact areaSemi-permeable membranesCeramic coatingPorous metal

The invention provides a preparation method of a porous ceramic-metal composite film material. The method comprises steps of: using ceramic as a rigid outer mold; preparing a ceramic coating in the inner surface of the rigid outer mold; adding a metal powder into a hollow cavity between the rigid outer mold and an elastic inner mold; sealing; forming by cold isostatic pressure; sintering a formed porous ceramic-metal composite film blank together with the rigid outer mold; and separating a sintering body from the rigid outer mold. Through improvement on the preparation process, the ceramic coating and the metal powder subjected to isostatic pressure forming are sintered under high temperature condition, so that a porous metal substrate and the ceramic film layer expand synchronously under effect of compressive stress of the rigid outer mold during the sintering. The prepared porous ceramic composite film material has strong adhesion, high strength, smooth, flat and flawless film layer, and improved practicability.

Owner:南京髙谦功能材料科技有限公司

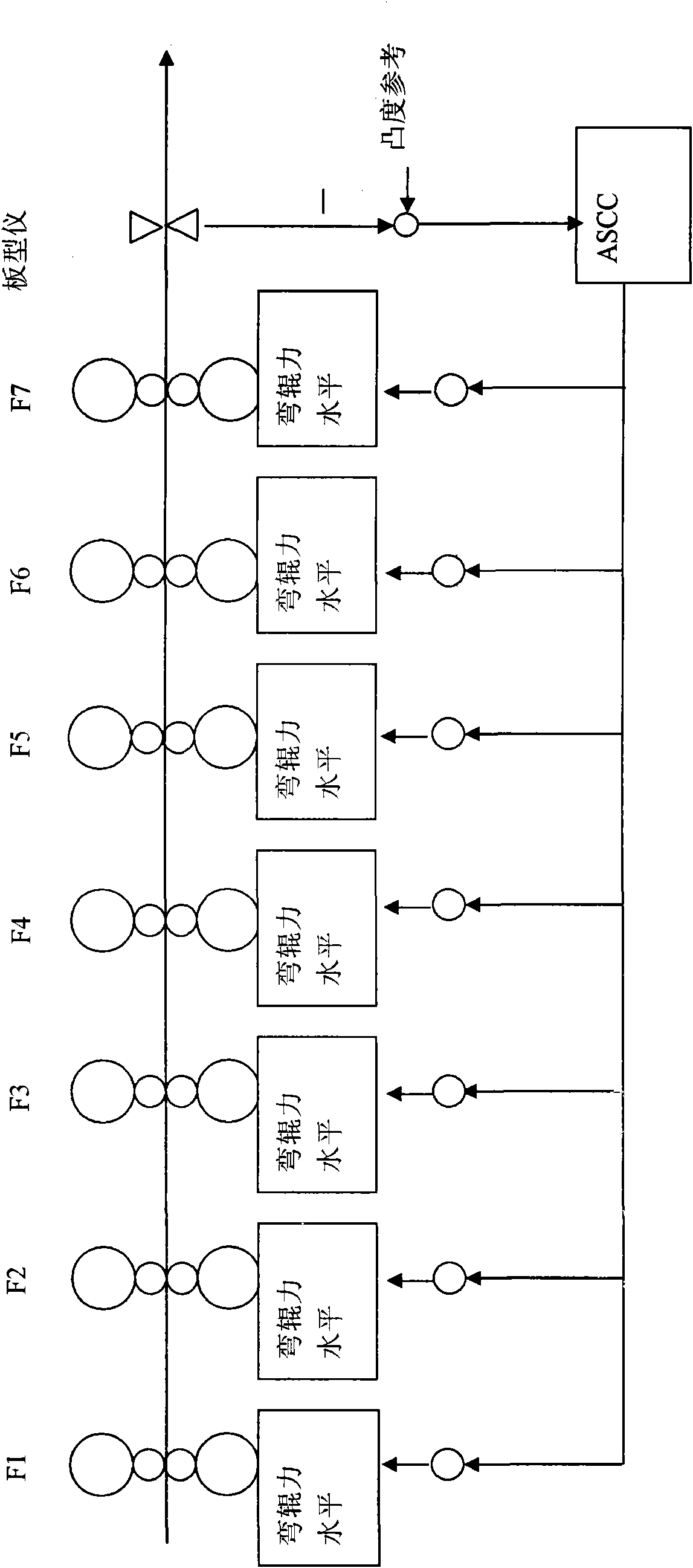

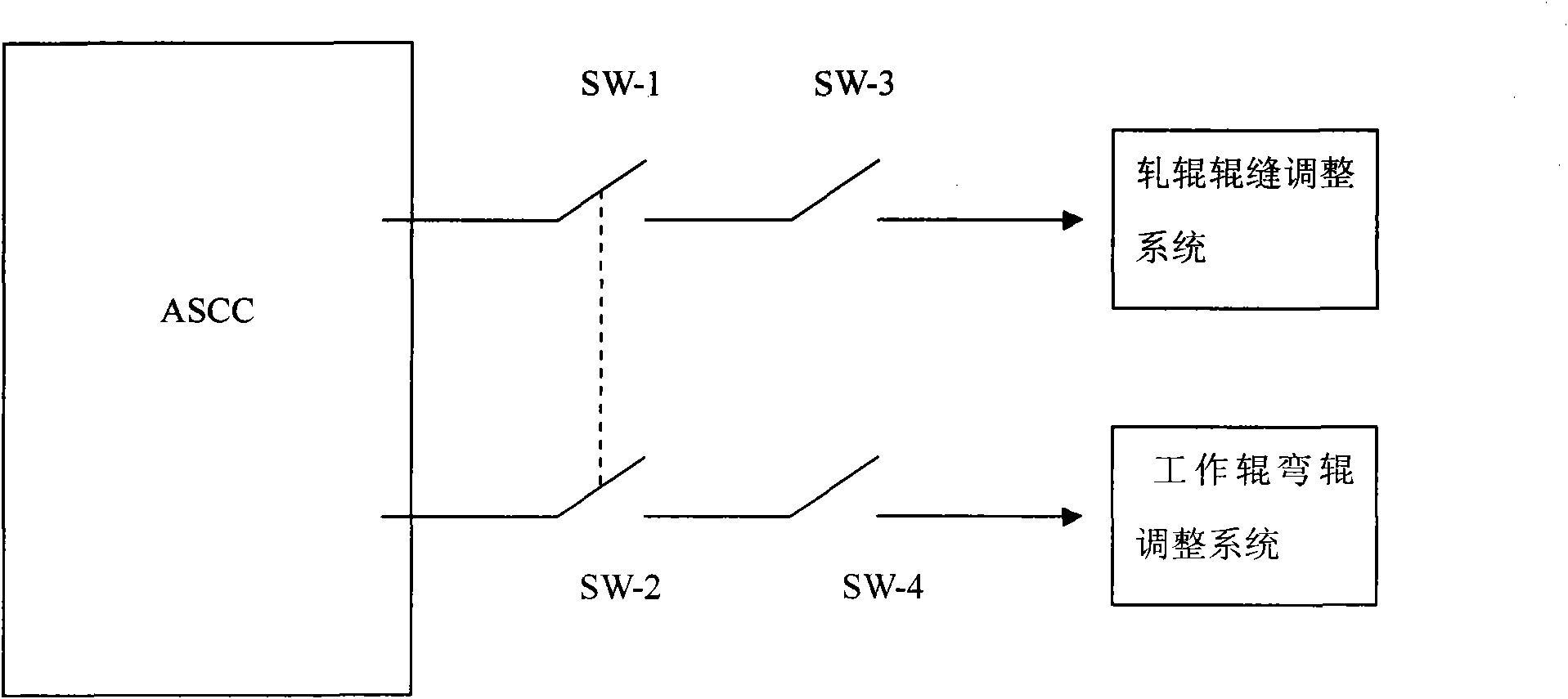

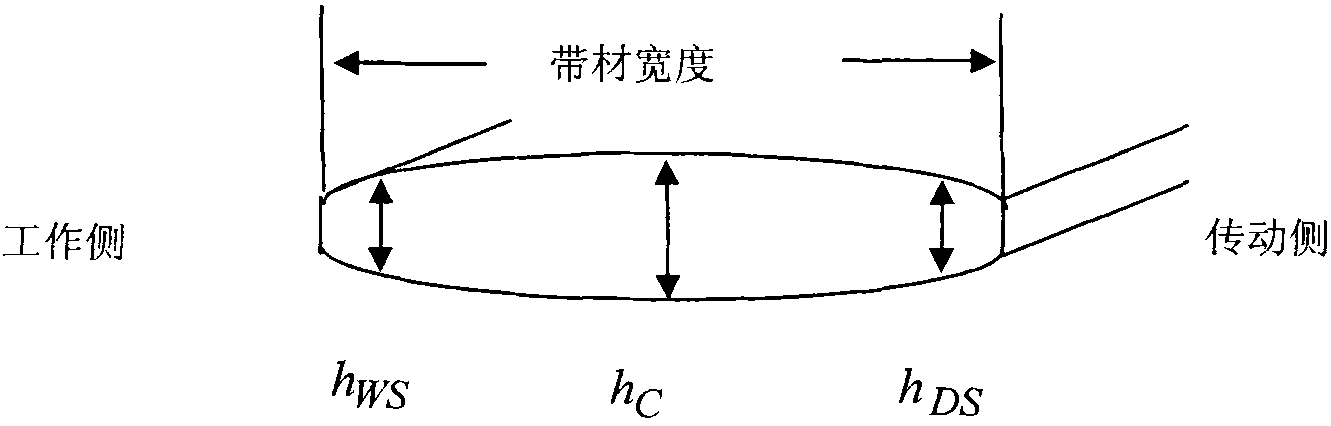

Method for automatically controlling convexity and/or wedge of hot rolled in series type rolling machine and system thereof

ActiveCN101890435AAvoid snaking motionEliminate single disadvantagesProfile control deviceAutomatic controlEconomic benefits

The invention relates to a method for automatically controlling the convexity and / or wedge of a hot rolled in series type rolling machine and a system (ASCC) thereof. The method comprises the following steps of: building feedback control for the bending of a working roll and the flattening of a roll gap from a first finishing mill stander to a final finishing mill stander in the hot rolled in series type rolling machine to automatically control the convexity (wedge) of strip steel, i.e. comparing the strip steel wedge which is detected by an ASCC model with the object wedge during rolling to obtain the difference; and correcting the difference through the comprehensive computation and the control method of the system to build a step type adjusting method. Therefore, the invention maximizes the response of the feedback control to correct the wedge and the convexity of the strip steel, guarantees the good flatness of products, prevents the strip steel to have snake-like motion in each stander, overcomes the defect that the existing convexity controlling method is single, and comprehensively balances the relationship between the convexity and the wedge. The invention can guarantee the convexity precision of the wedge along the long axis direction of the strip steel, improves the flatness, guarantees the product quality and the production safety, and can effectively improve the economic benefit of steel rolling factories.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

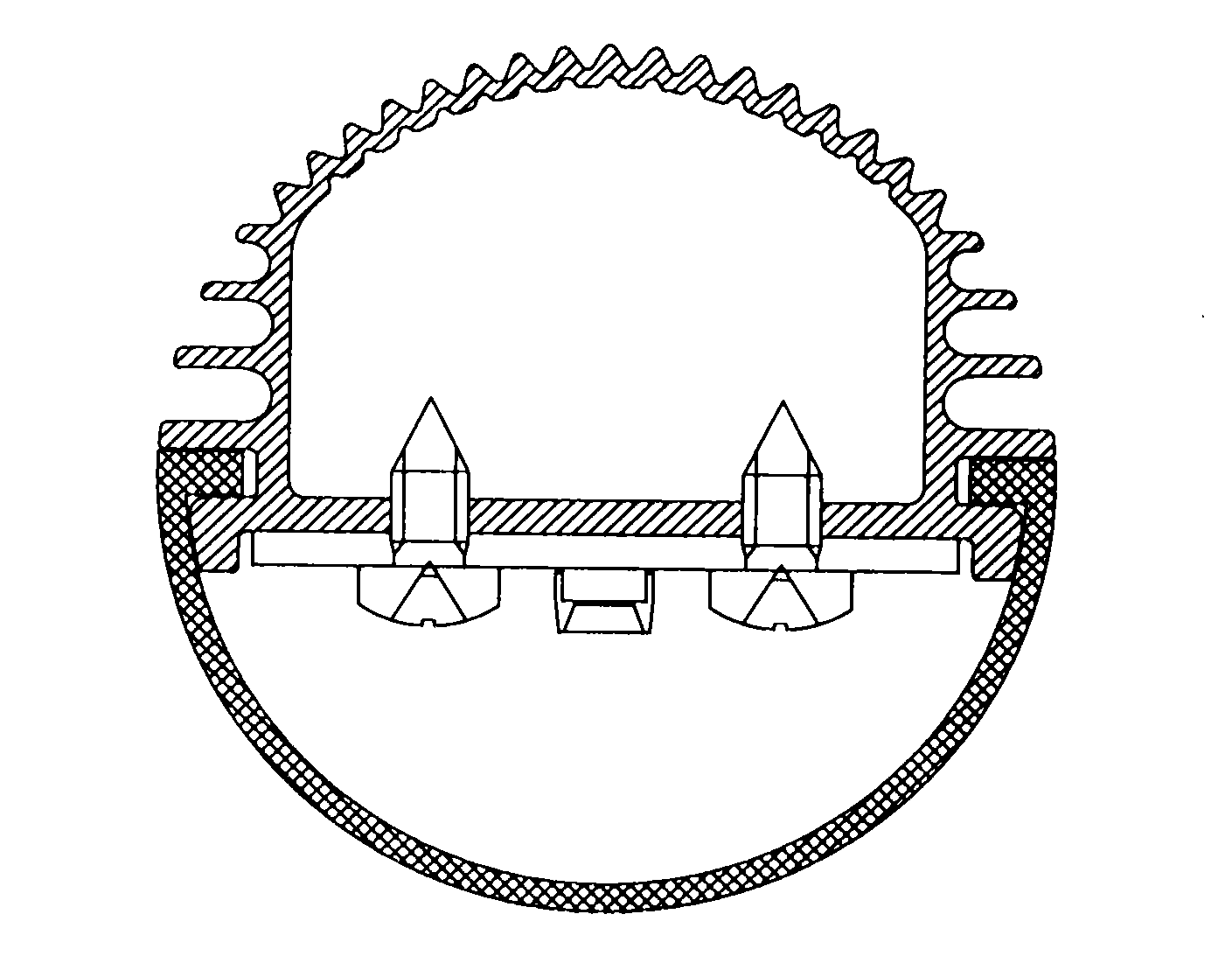

Manufacturing method of lamp-cover-supporting LED tubular lamp with self-clamping heat transmission substrate

InactiveCN103411140AAbsorb moreReduce absorptionPoint-like light sourceLighting heating/cooling arrangementsHeat transmissionEffect light

The invention discloses a manufacturing method of a lamp-cover-supporting LED tubular lamp with a self-clamping heat transmission substrate, and belongs to the technical field of supporting or hanging or connecting of lighting devices. The manufacturing method of the LED tubular lamp includes the steps that S1, the heat transmission substrate is inserted into strip-shaped clamping grooves from side ports of the strip-shaped clamping grooves; S2, after the heat transmission substrate is installed in the strip-shaped clamping grooves, a lamp cover covers a radiator; S3, the lamp cover exerts two acting forces on two T-shaped hooks, and the heat transmission substrate is installed in the strip-shaped clamping grooves in a clamped mode; S4, the radiator, the heat transmission substrate and the lamp cover form a lamp tube of the LED tubular lamp, and two end covers are installed at the two ends of the lamp tube of the LED tubular lamp. According to the lamp-cover-supporting LED tubular lamp with the self-clamping heat transmission substrate, the heat transmission substrate can be arranged in the strip-shaped clamping grooves in the clamped mode because the strip-shaped clamping grooves are formed in an installing part of the heat transmission substrate, heat dissipation efficiency can be improved, and the heat transmission substrate is prevented from thermal deformation.

Owner:辽宁三维传热技术有限公司 +1

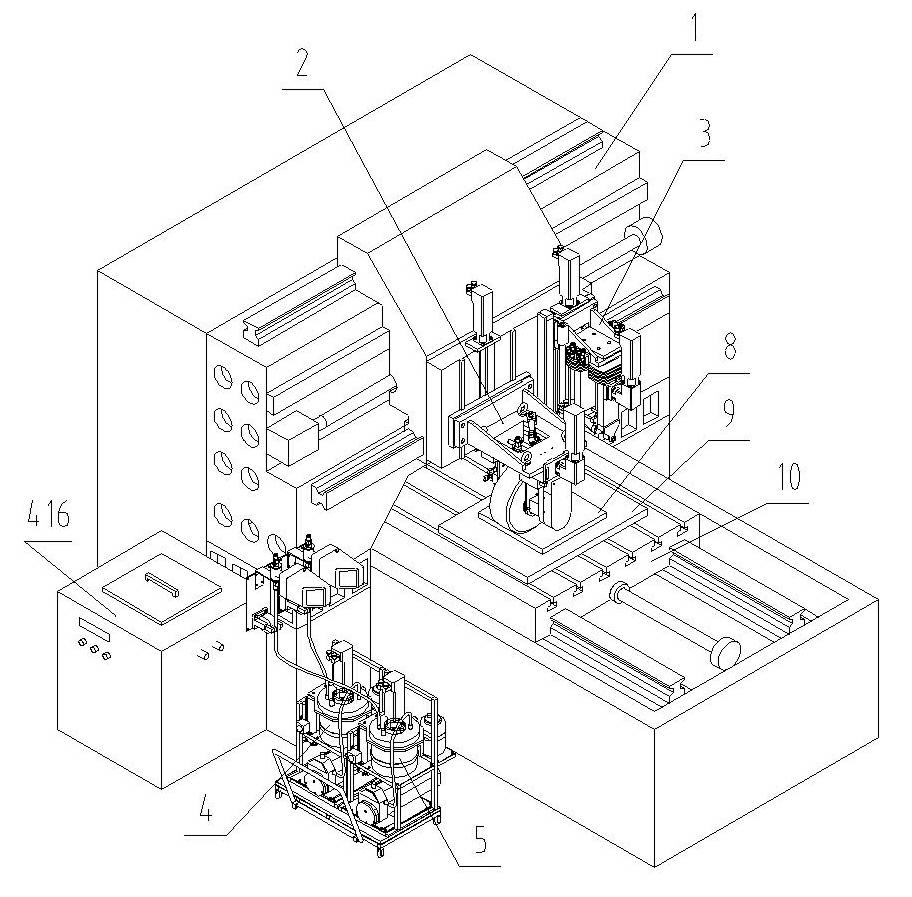

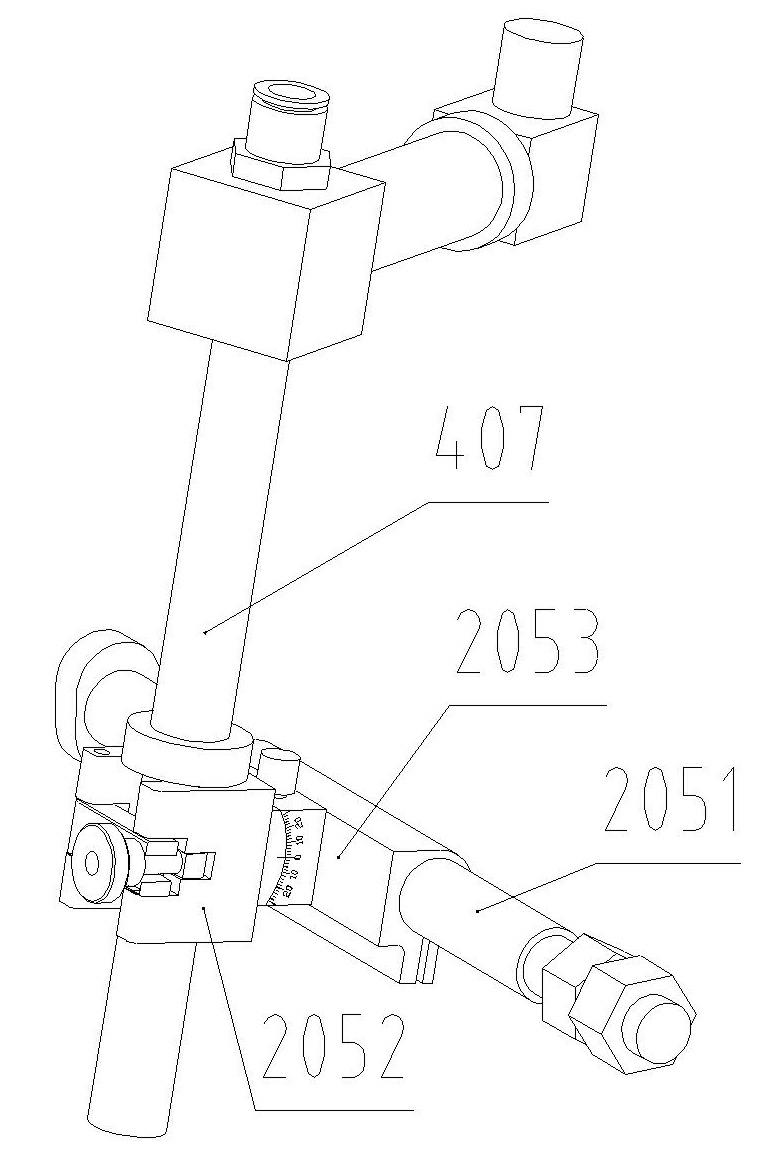

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Method for manufacturing aluminum alloy hollow section for sedan bumper

The invention discloses a method for manufacturing an aluminum alloy hollow section for a sedan bumper, relates to a method for manufacturing an aluminum alloy hollow section, and aims to solve the problem that domestic limousine bumpers are low in tensile strength and non-proportional extension strength and dependent on import. The method comprises the following steps of: 1, preparing alloy melt; 2, casting an alloy cast rod; 3, cutting the cast rod off; 4, turning the cast rod to remove oxide; 5, performing homogenizing annealing; 6, heating a cast ingot; 7, extruding; 8, pre-straightening;9, quenching; 10, straightening; 11, aging; and 12, cutting according to length to obtain the aluminum alloy hollow section for an automobile bumper. The straightness and size of the hollow section prepared by the method completely meet the standards of imported bumpers, and the hollow section has high comprehensive mechanical properties. The method can be used for processing and manufacturing sections for limousine bumpers.

Owner:NORTHEAST LIGHT ALLOY CO LTD

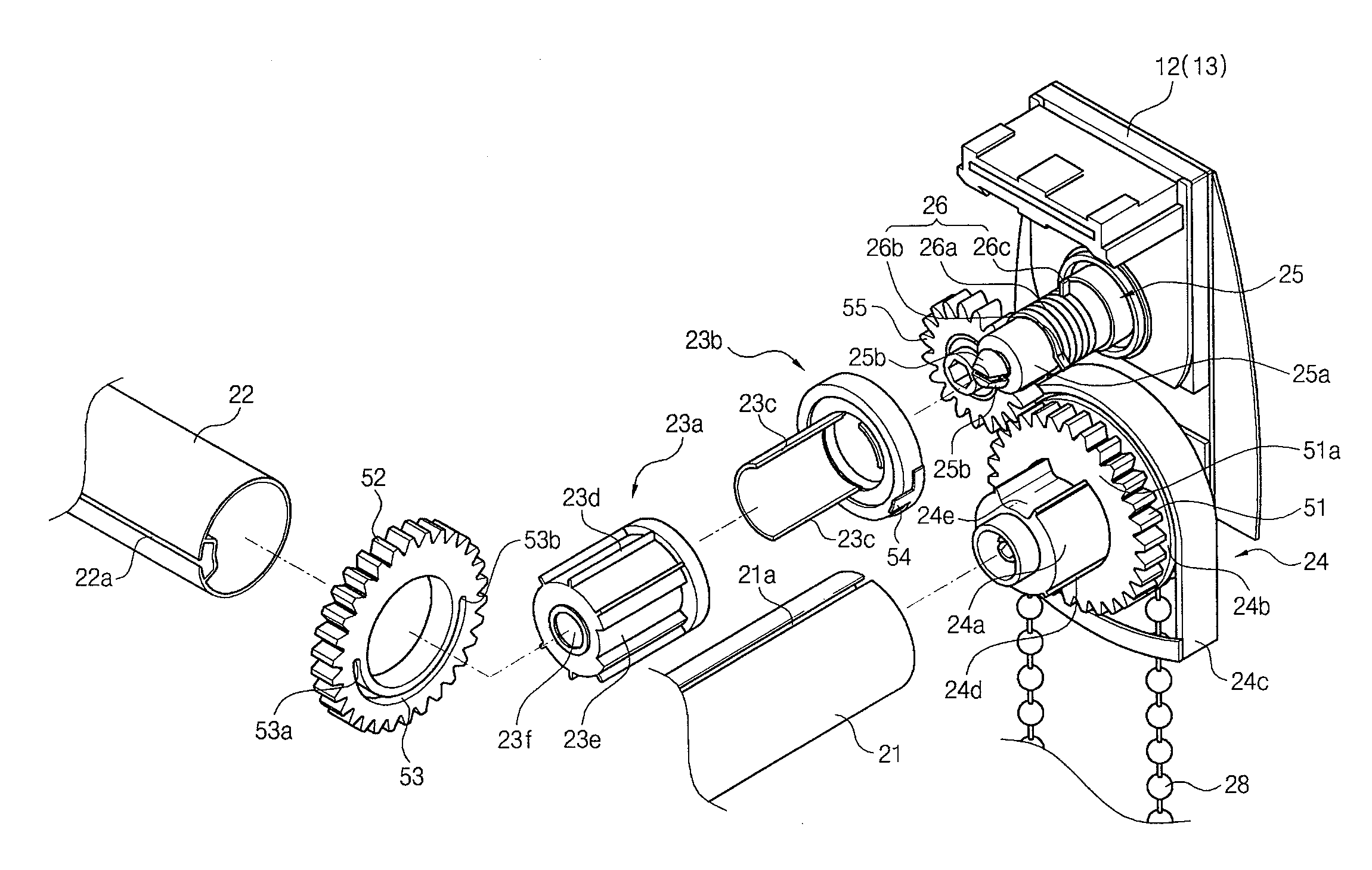

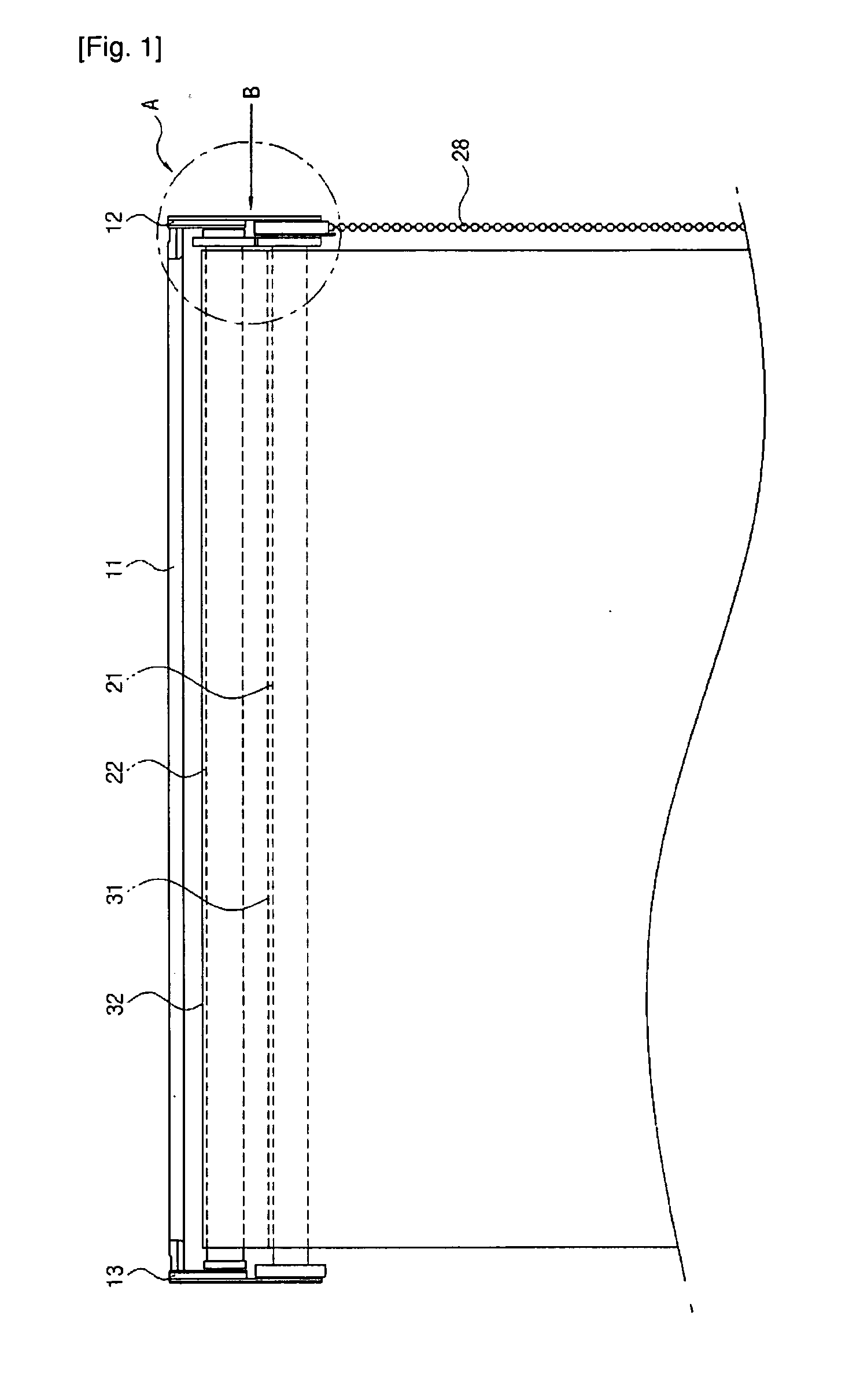

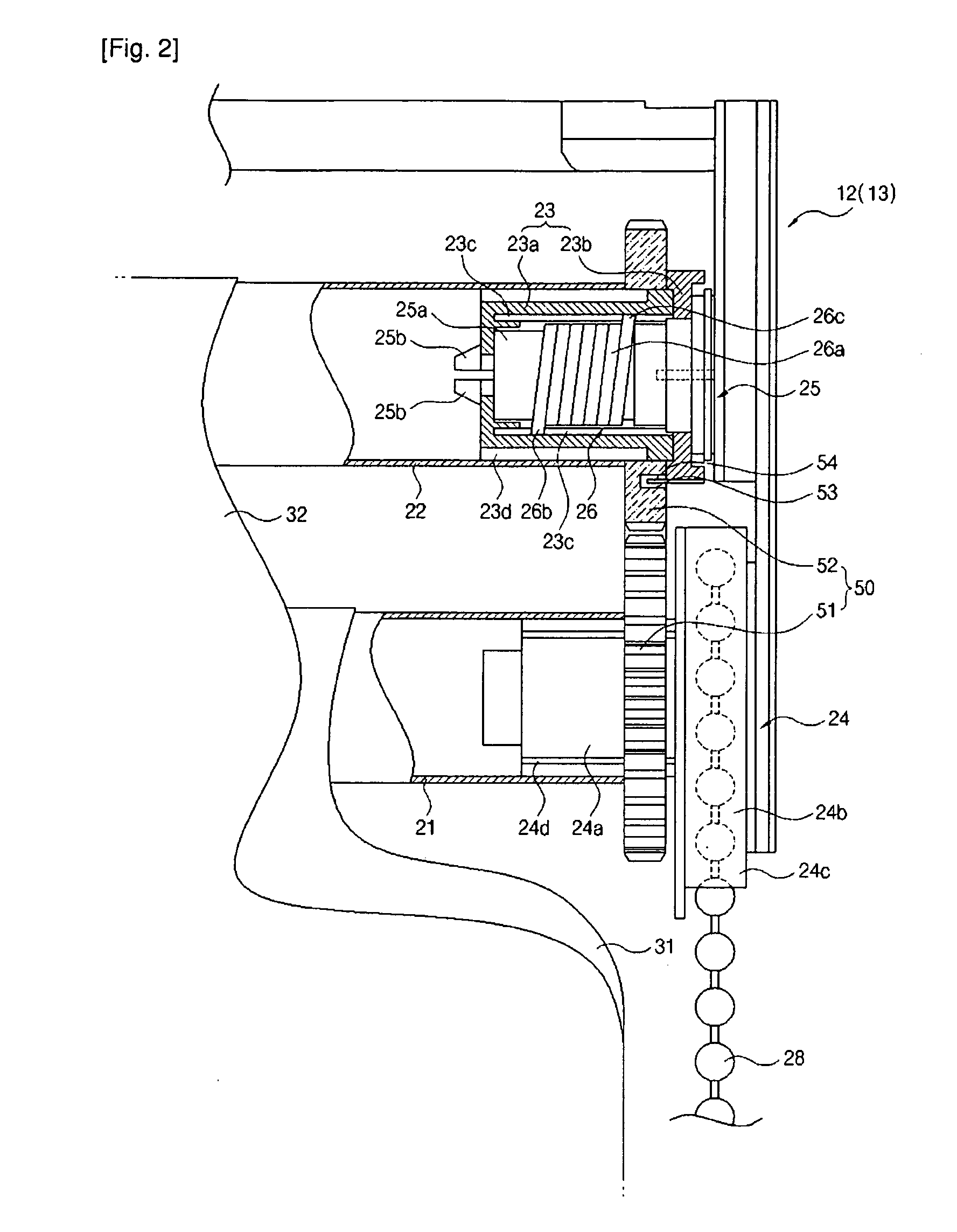

Roll blind

ActiveUS20110061821A1Improve convenienceSimple and rapid operationLight protection screensEngineeringTower

A roll blind is provided which can guarantee a simple operation. The roll blind includes: a supporting frame disposed in a window frame; first and second winding bars rotatably disposed in the supporting frame; a winding driver rotationally driving one of the first and second winding bars; first and second screens coupled to the first and second winding bars, respectively; a weight bar to which the tower ends of the first and second screens are fixed; and a clutch unit binding and unbinding the first and second winding bars with respect to each other.

Owner:BYEON TAE WOONG +1

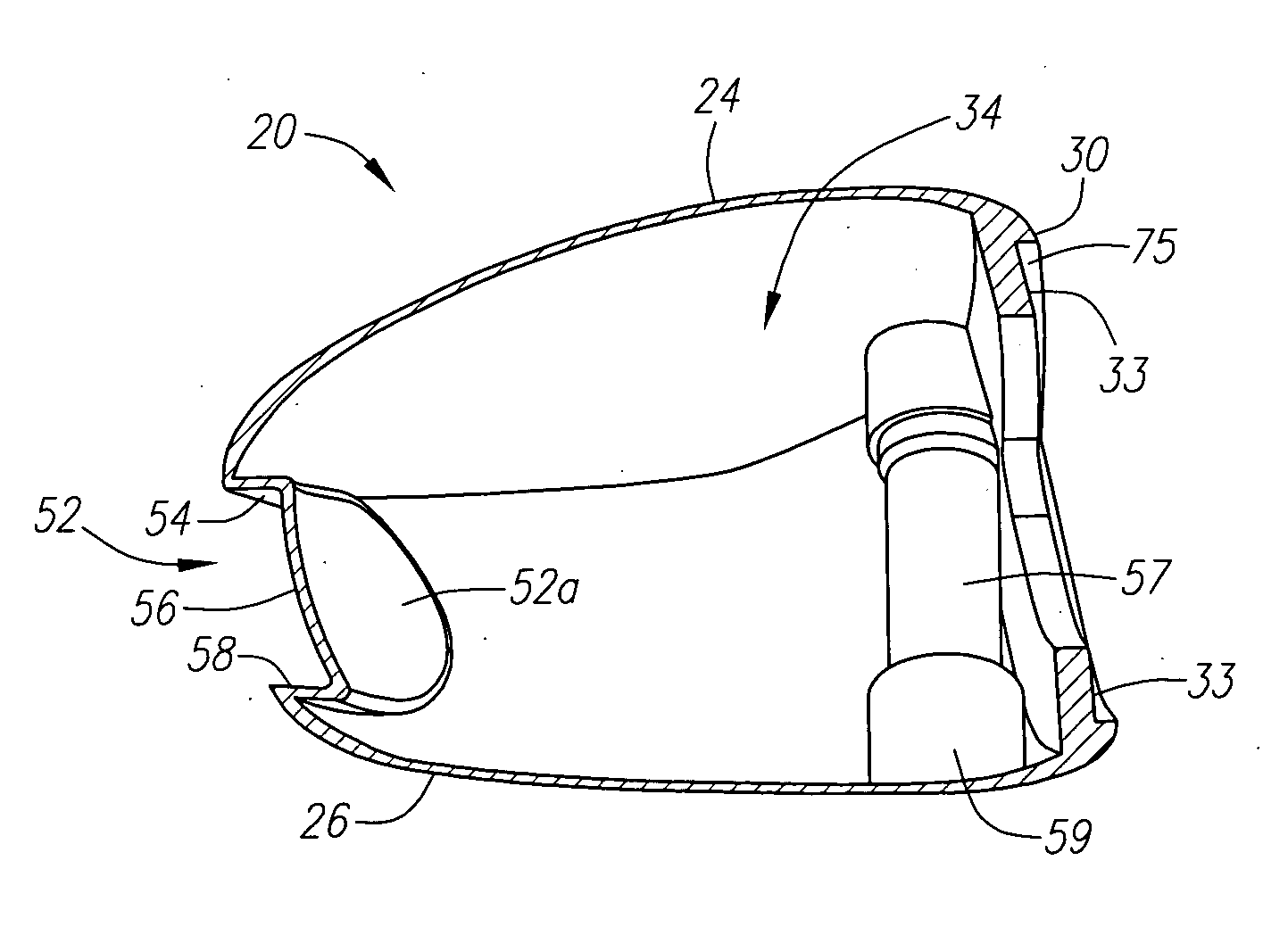

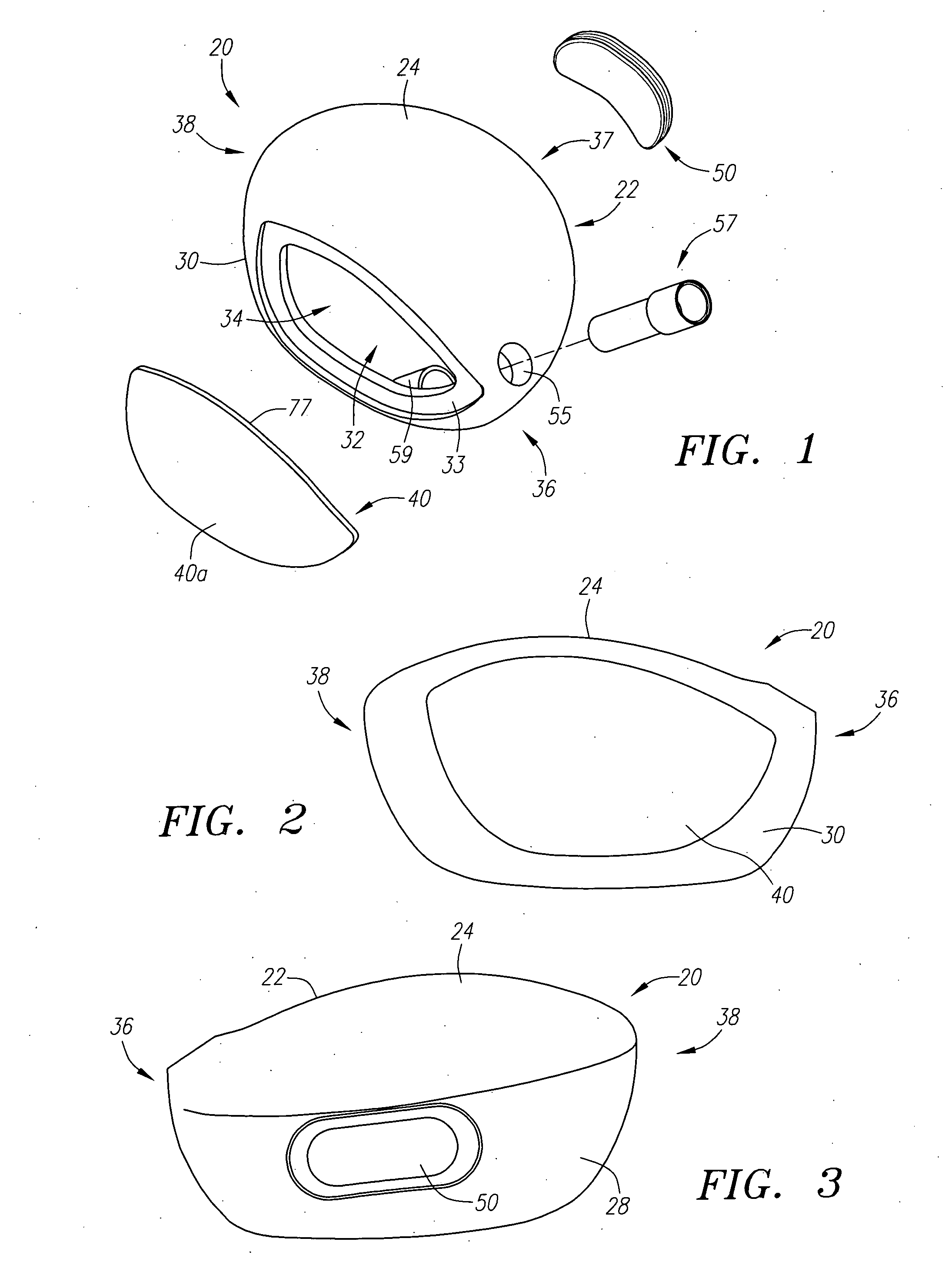

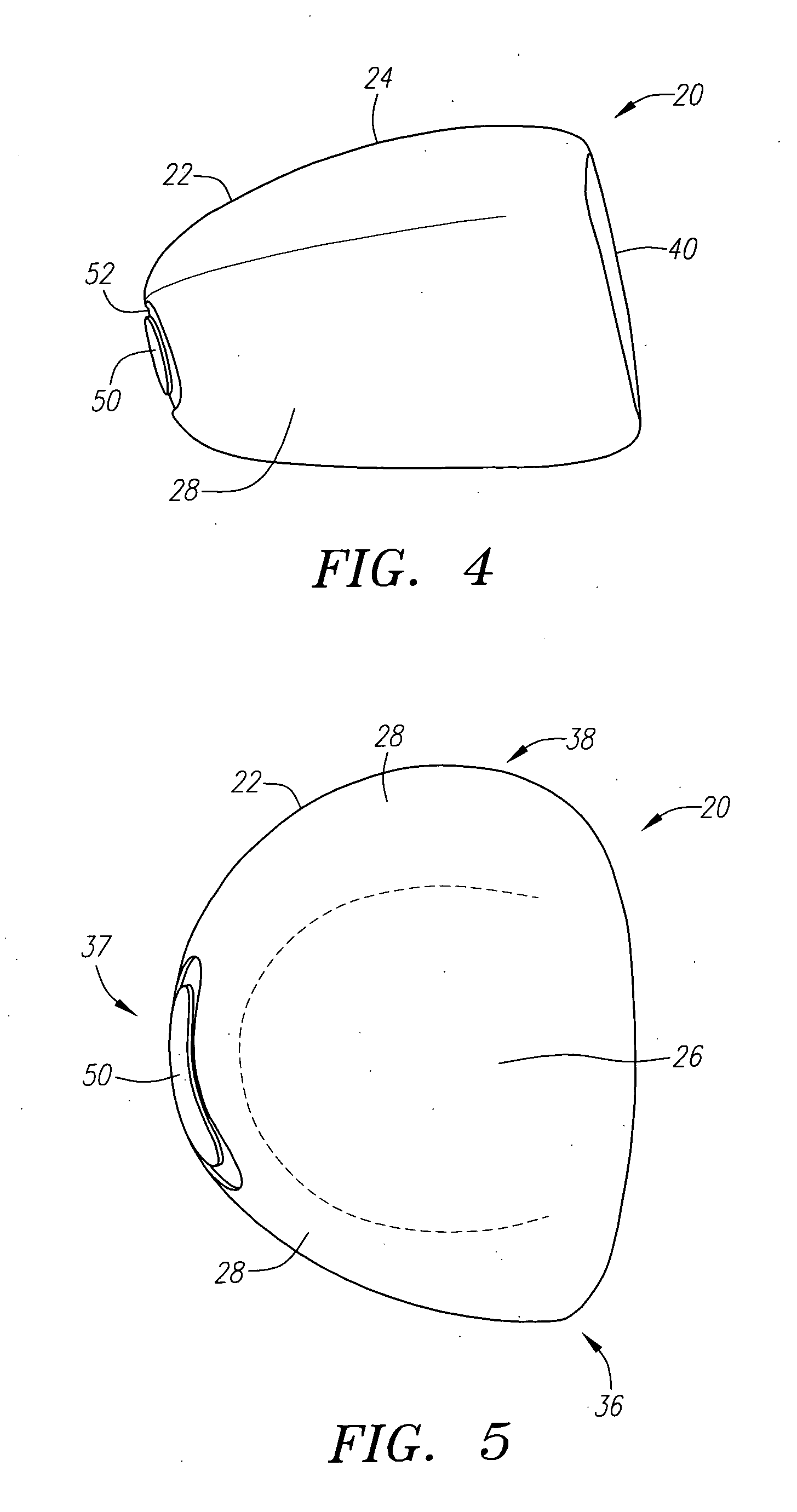

Golf club head

ActiveUS20050288124A1Improve mass distributionOptimized moments of inertiaGolf clubsRacket sportsEngineeringGravity center

A golf club head (20) having optimized inertial properties and center of gravity is disclosed. The golf club head (20) preferably has a volume between 300 cubic centimeters and 500 cubic centimeters. The golf club head (20) has a center of gravity located less than 1.7 inches from an exterior surface of a front wall (30). The positioning of the center of gravity of the golf club head (20) and the optimized inertial properties provide the golf club with greater ball spin robustness and better performance.

Owner:CALLAWAY GOLF CO

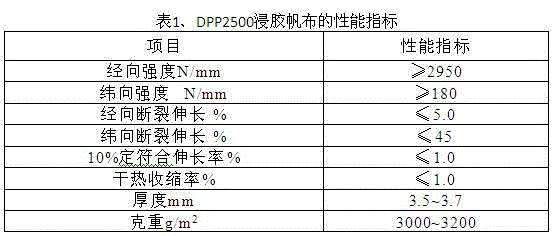

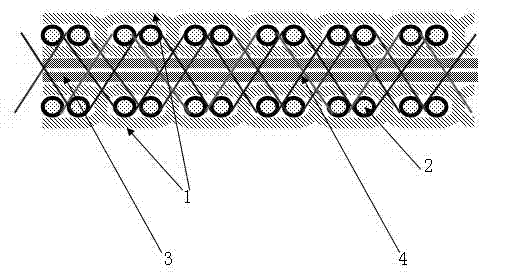

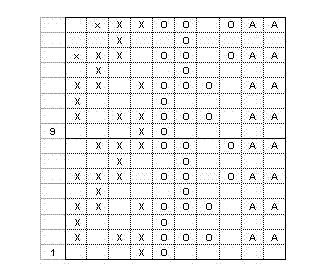

Aramid rubber canvas fabric structure for high-strength conveyor belts and production process of aramid rubber canvas fabric structure

InactiveCN104611819AEasy to weaveGood physical and mechanical propertiesConveyorsMulti-ply fabricsYarnEngineering

The invention discloses an aramid rubber canvas fabric structure for high-strength conveyor belts and a production process of the aramid rubber canvas fabric structure. The aramid rubber canvas fabric structure comprises warps and wefts, aramid materials are adopted in the warps, at least four warps are paved in the belt length direction, nylon industrial yarns are adopted in the wefts which are crisscrossly paved on upper end faces and lower end faces of the warps, the wefts on upper and lower layers are tightly crisscrossly bonded to the warps by adopting bundling yarns, and a canvas fabric structure is obtained after secondary bath gum dipping; the production process includes single-layer canvas knitting, secondary bath gum dipping and reeling. Single-layer structures of the warps adopting the aramid materials and the weft adopting the nylon materials are knitted through bundling yarns, the high-strength conveyor belts with the strength higher than 2500N / mm are produced after secondary bath gum dipping, mechanical physical properties of the conveyor belts are improved, layer reduction and weight reduction of the conveyor belts are realized during the production process, the conveyor belts are adaptively high strengthened, less layered and lightweight, energy consumption is reduced, the production process is further simplified, and production efficiency is higher.

Owner:浙江尤夫科技工业有限公司

Automatic plastering machine

The invention discloses an architectural working device especially a automatic plastering wall machine, which is characterized by the following: using a laser testing wall device and a squareness sensing device on the plastering wall machine; adjusting the plastering wall direction and the squareness of the machine; folding two vertical orbit of the machine; topping with ceiling; arranging plaster plate on the near wall end face of bin of main units; plastering lash on ascending and descending. This invention uses laser present, which possesses high line degree.

Owner:贺启宇

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

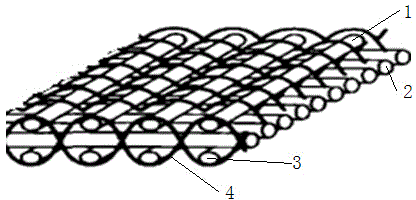

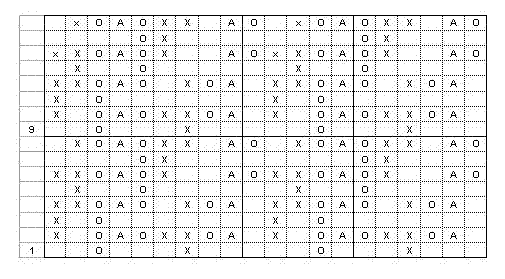

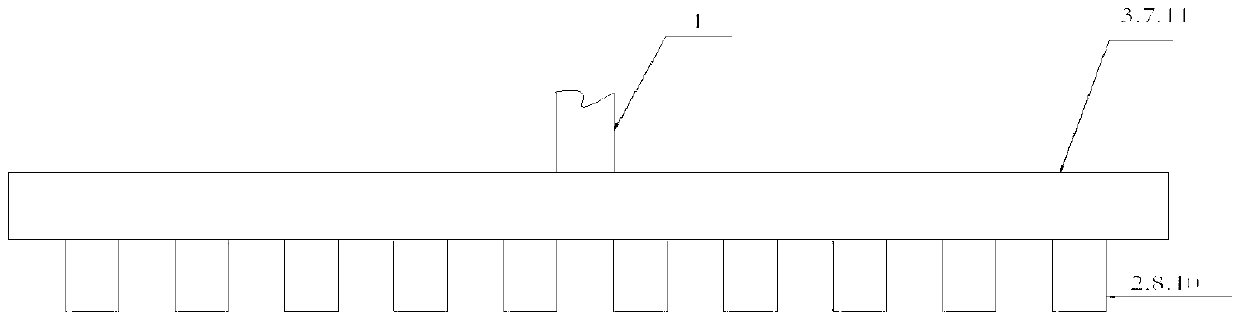

Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

ActiveCN102212917ASolve production technical problemsGood physical and mechanical propertiesFibre treatmentTwo or more solvent application treatmentPolyesterEngineering

The invention discloses a dipped canvas fabric structure in a three-dimensional structure for a heavy-duty conveyor belt and a production process thereof. The dipped fabric structure is characterized in that an upper layer and a bottom layer adopt ground-facing warps (1) in the plain weave structure and weft (2) interwoven with the ground-facing warp, a straight warp (3) in the straight warp structure is utilized as an intermediate layer, a bundling warp (4) is connected with the weft (2), and the upper layer, the intermediate layer, the bottom layer and the bundling warp form the three-dimensional structure. The production process comprises the following processes: the process of weaving a fabric on a machine: adopting double warp shafts to send a warp woven cloth; and the process of stipulating a dipping formula and preparing, wherein a dipping solution is a mixture of an RF (resorcinol-formaldehyde) resin water solution generated by virtue of condensation polymerization of hydroxyphenol and formaldehyde and VP (vinyl pyridine) latex (L), the total content of solids is 18-22%, the pH value is 9-11, and the ratio of the RF to the L is (1:5)-(1:7). Polyester dipped canvas in the three-dimensional structure is especially applicable to production of the heavy-duty rubber conveyor belts and has the characteristics of tear resistance, puncture resistance and impact resistance.

Owner:浙江尤夫科技工业有限公司

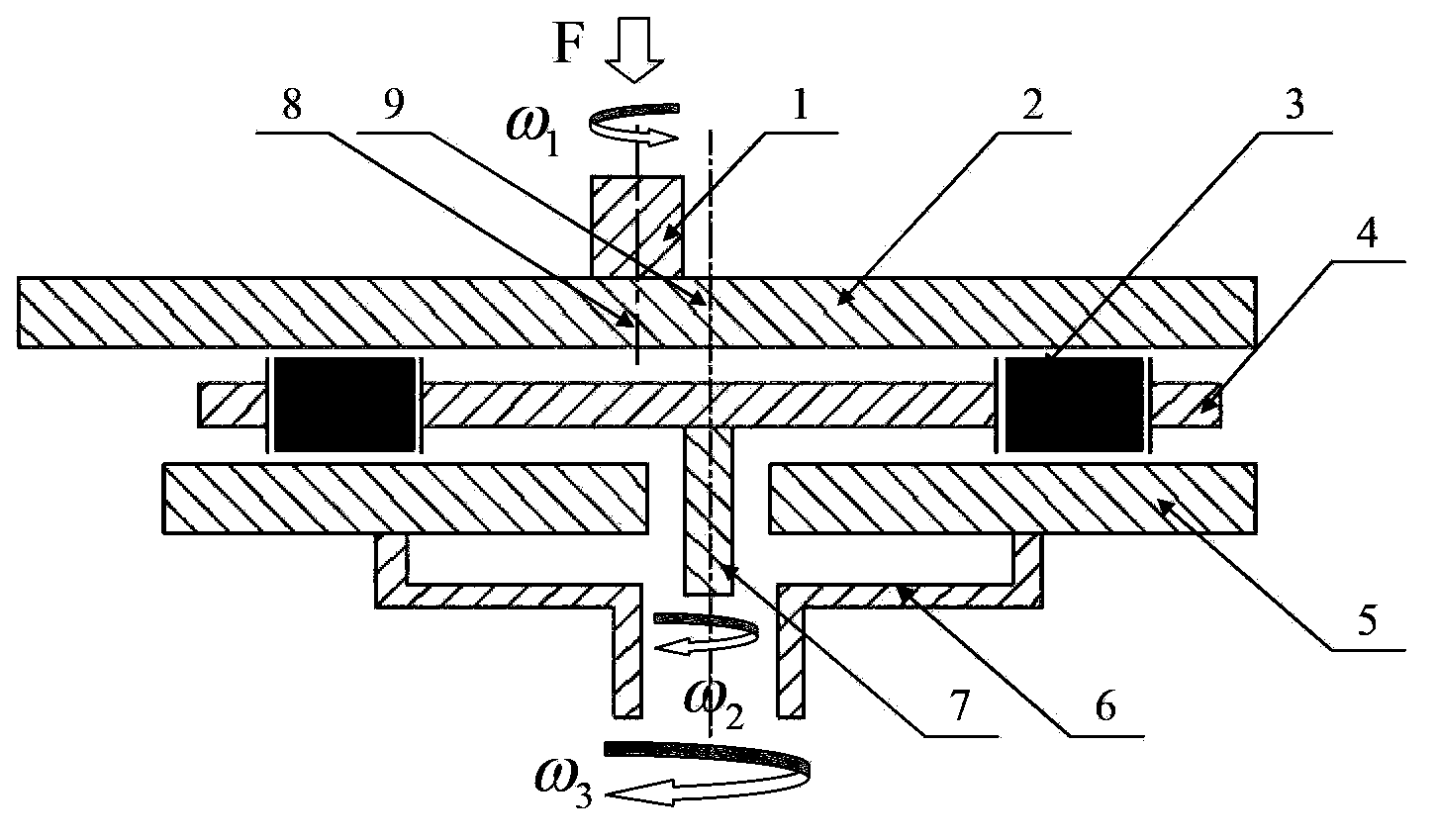

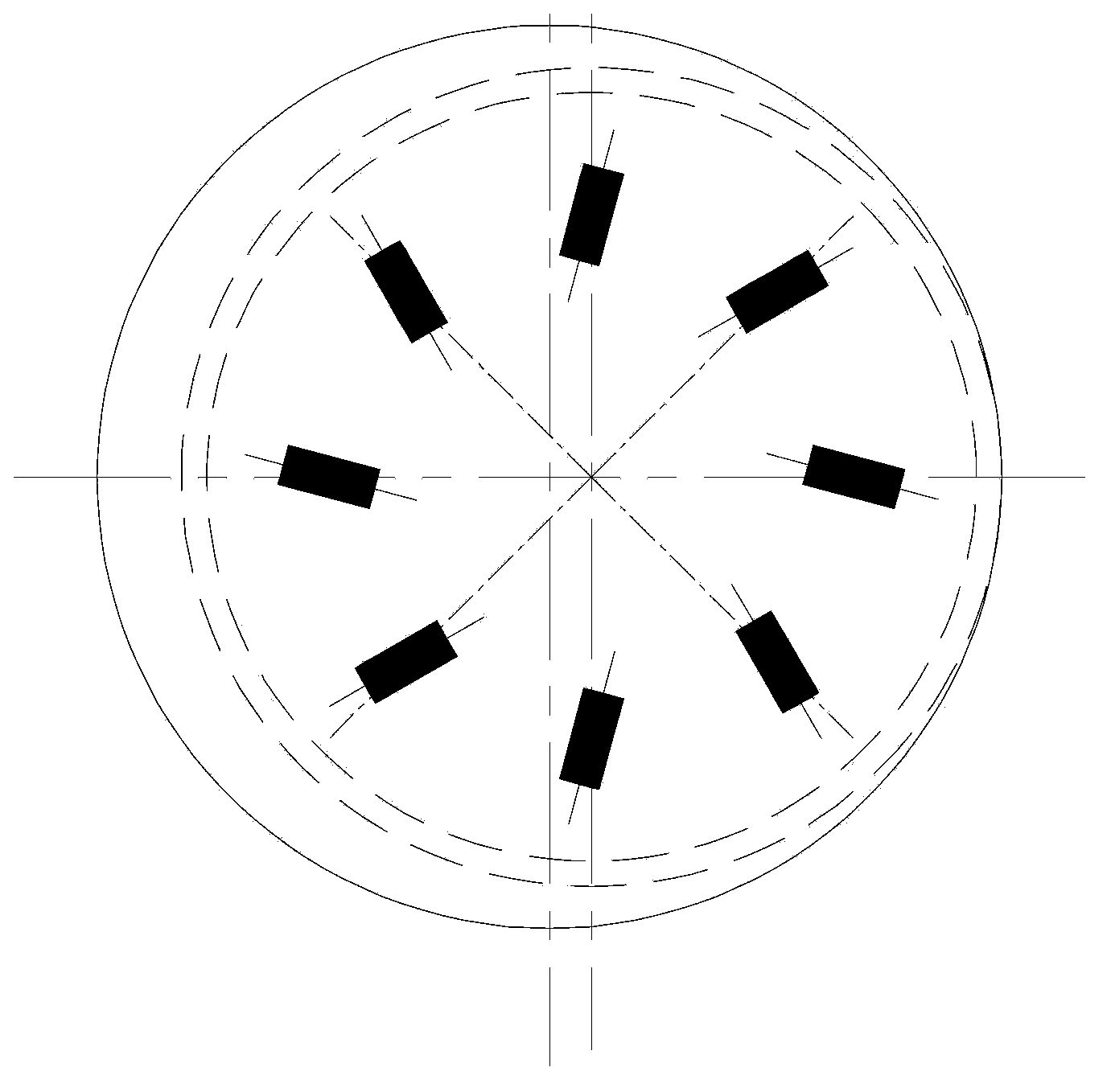

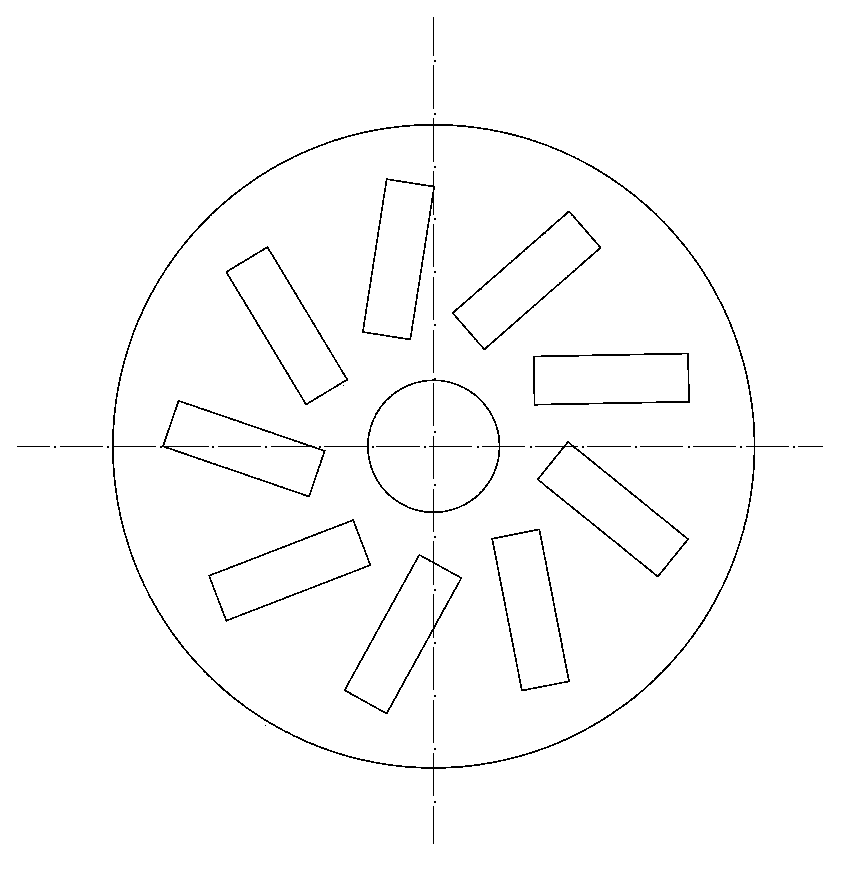

Method for processing outer circle of cylindrical part based on upper plate eccentric pressurizing

ActiveCN103522166AHigh precisionImprove consistencyLapping machinesWork carriersOffset distanceMechanical engineering

A method for processing an outer circle of a cylindrical part based on upper plate eccentric pressurizing. A processing device for achieving the processing method comprises an upper grinding plate, a holder and a lower grinding plate. The upper grinding plate is located above the lower grinding plate, the holder is located between the upper grinding plate and the lower grinding plate, a rotating shaft of the holder and a rotating shaft of the lower grinding plate are coaxial, and a definite offset distance exists between a rotating shaft of the upper grinding plate and the rotating shaft of the holder. In the process of processing, a loading device eccentrically acts on the cylindrical part through the upper grinding plate, and the outer circle of the cylindrical part is processed through the cooperation of a plane of the upper grinding plate, a plane of the lower grinding plate and matched abrasive materials. The method for processing the outer circle of the cylindrical part is high in precision and good in consistency.

Owner:ZHEJIANG UNIV OF TECH

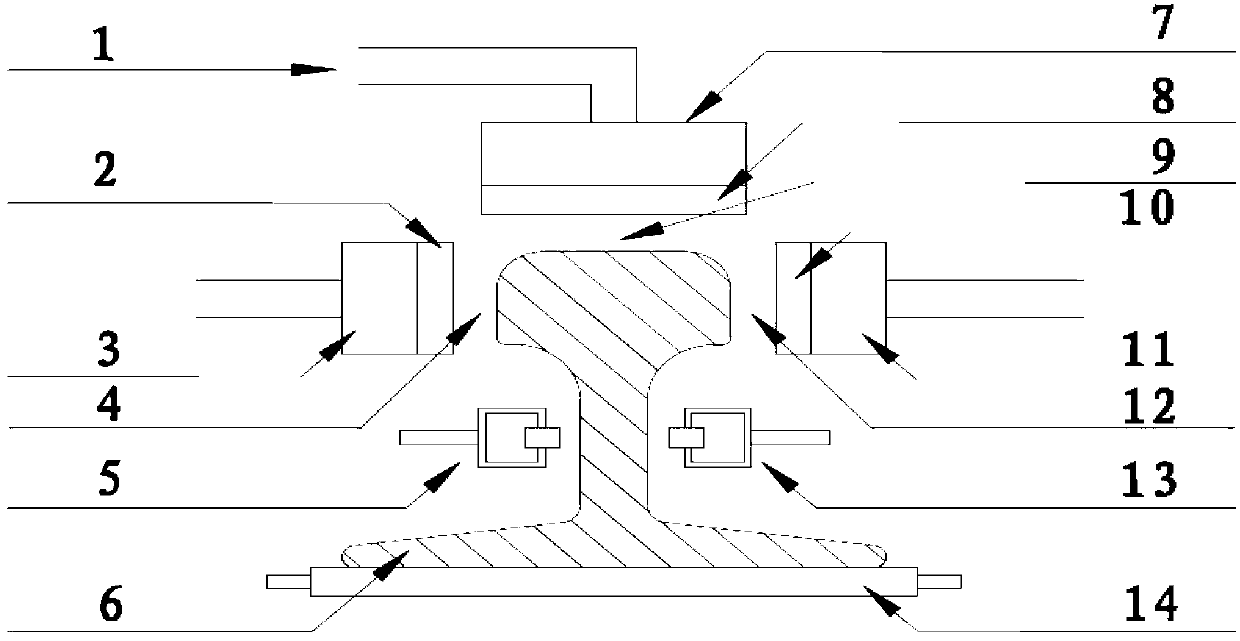

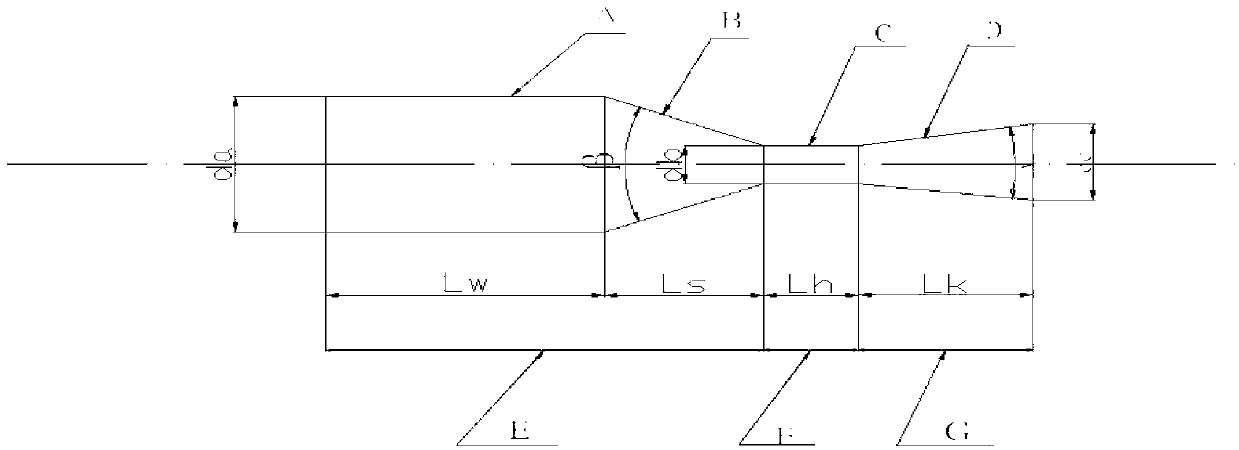

Steel rail on-line wind-jet quenching heat treatment simulation experiment device

InactiveCN103131826AEvenly distributedThe distribution is flat and stableFurnace typesQuenching agentsProduction lineExperimental research

The invention relates to a steel rail on-line wind-jet quenching heat treatment simulation experiment device, and belongs to the technical field of steel metallurgy. The experiment device is composed of the structures of: a Laval-type flat-slot nozzle system, a steel rail guiding system, a frame system, a valve system, a compressed air pipe system, a roller way system, a detection instrument system, a steel rail heating furnace system, and the like. With wind, water, heating furnace, and roller way conditions in an experimental innovation platform in metallurgical rolling, a steel rail on-line wind-jet quenching heat treatment simulation experiment device is designed and manufactured, and a steel rail on-line wind-jet quenching heat treatment simulation experiment method is developed. The method and the device are used for carrying out heavy rail full-length on-line quenching simulation experimental researches. The experiment method is simple and reliable. With the method, heavy rail full-length on-line quenching process research period can be greatly shortened, and process research cost can be reduced. The method is a feasible method of laboratory simulation research currently. With the device and he method, technical support can be provided for a heavy rail full-length on-line quenching production line.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

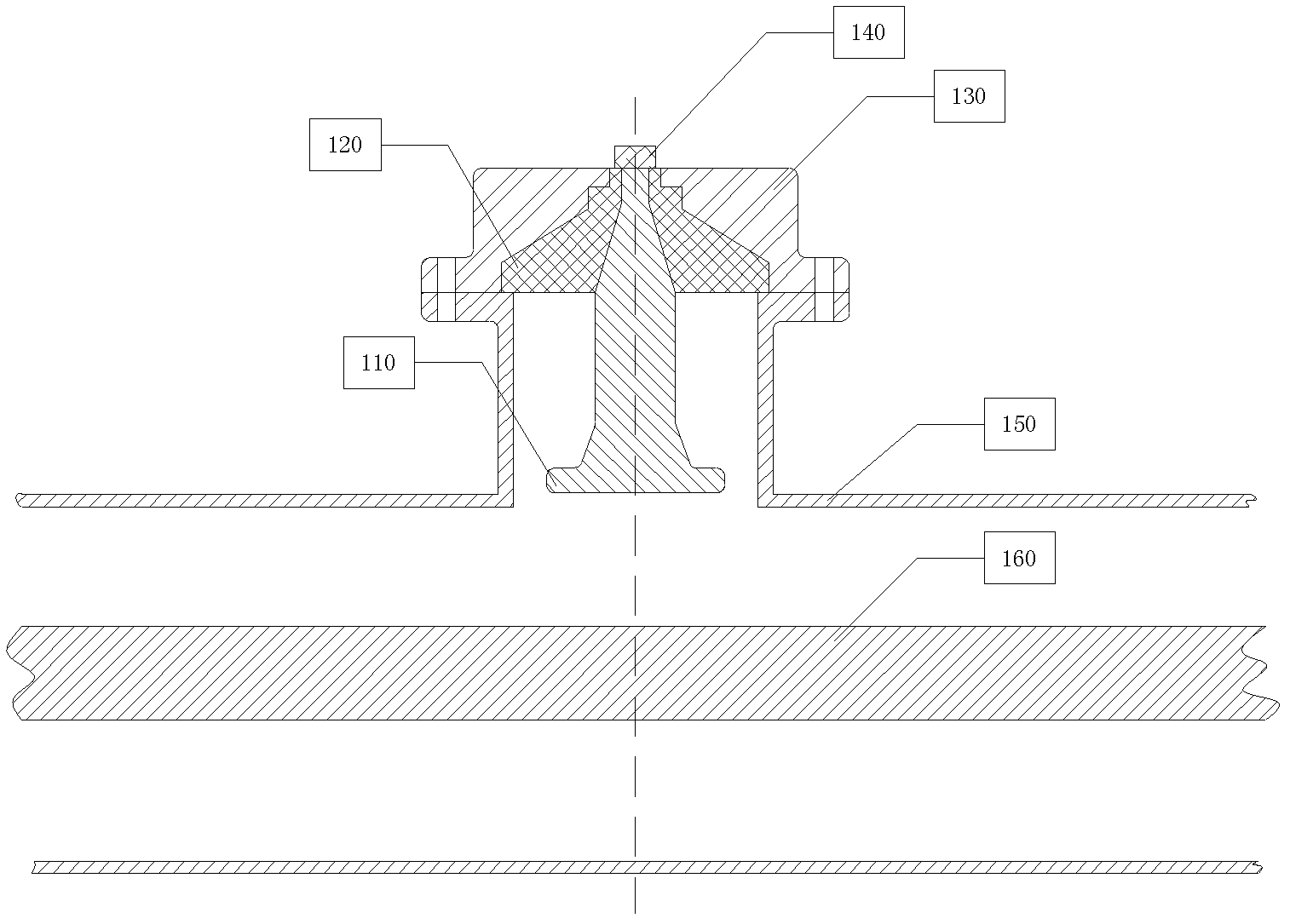

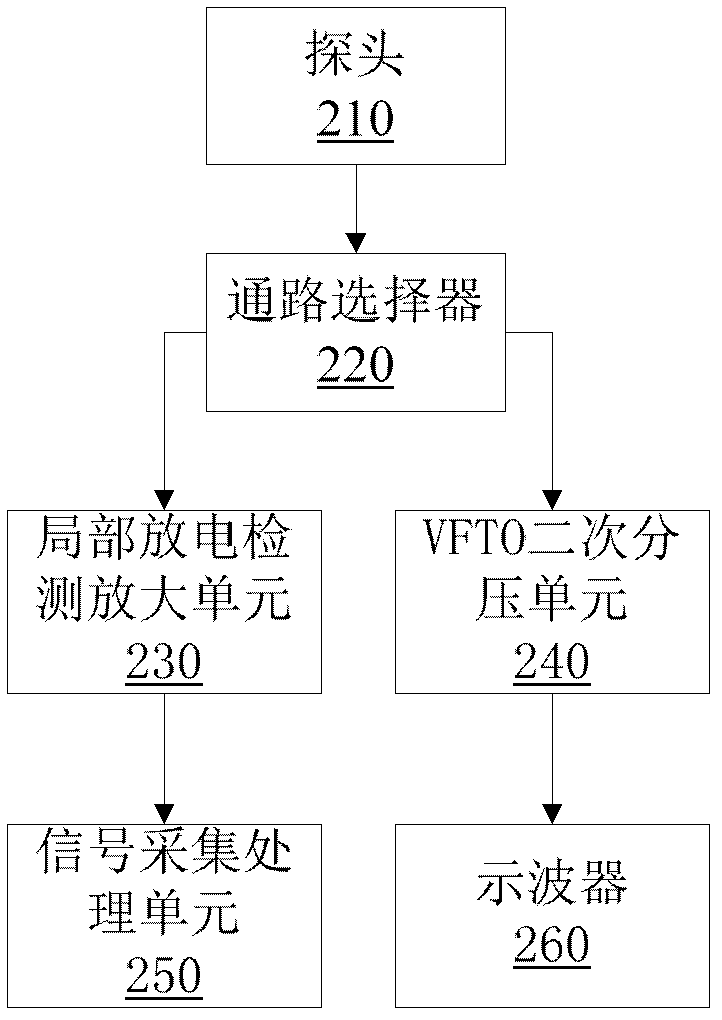

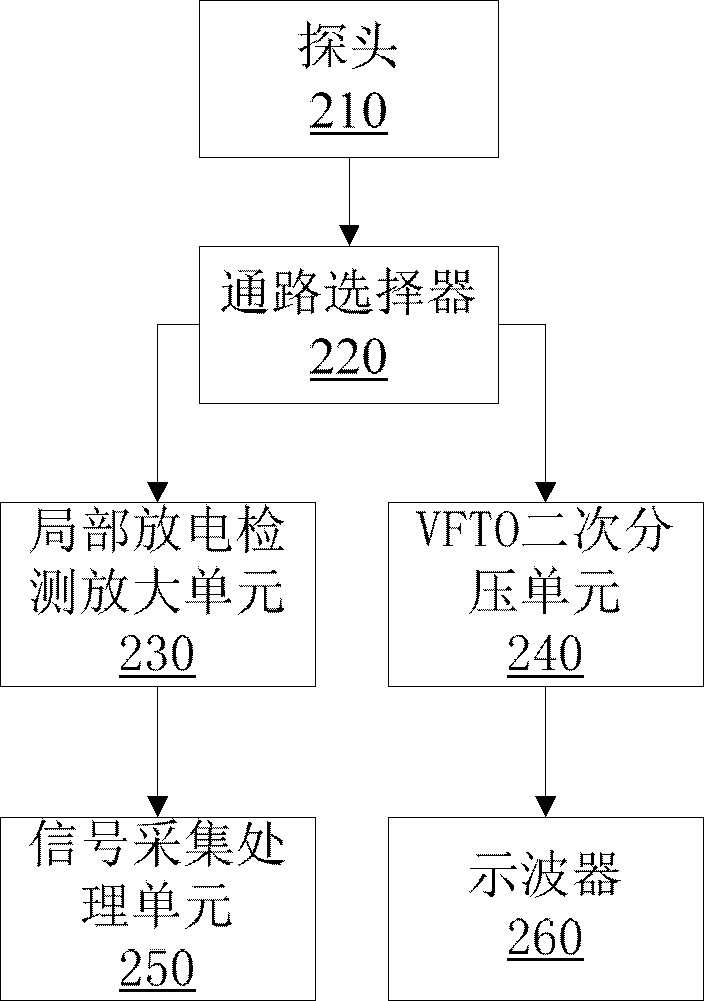

System for GIS (Global Information System) partial discharge measurement and VFTO (Very Fast Transient Overvoltage) measurement

ActiveCN102590718AReduce monitoring costsImprove straightnessTesting dielectric strengthCurrent/voltage measurementFrequency bandPhysics

The invention discloses a system for GIS (Global Information System) partial discharge measurement and VFTO (Very Fast Transient Overvoltage) measurement in the technical field of online monitoring systems of electric equipment. The system comprises a probe, a circuit selector, a partial discharge detection amplifying unit, a VFTO secondary partial pressure unit, a signal collecting and processing unit and an oscilloscope. The measurement system can use one probe to perform GIS partial discharge and VFTO measurement, and the two original systems are combined to the same system to reduce the GIS monitoring cost; the special probe design improves the measurement sensitivity of partial discharge; and the preferable VFTO secondary unit design improves the glancing flatness of wide frequency band measurement of a VFTO sensor.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

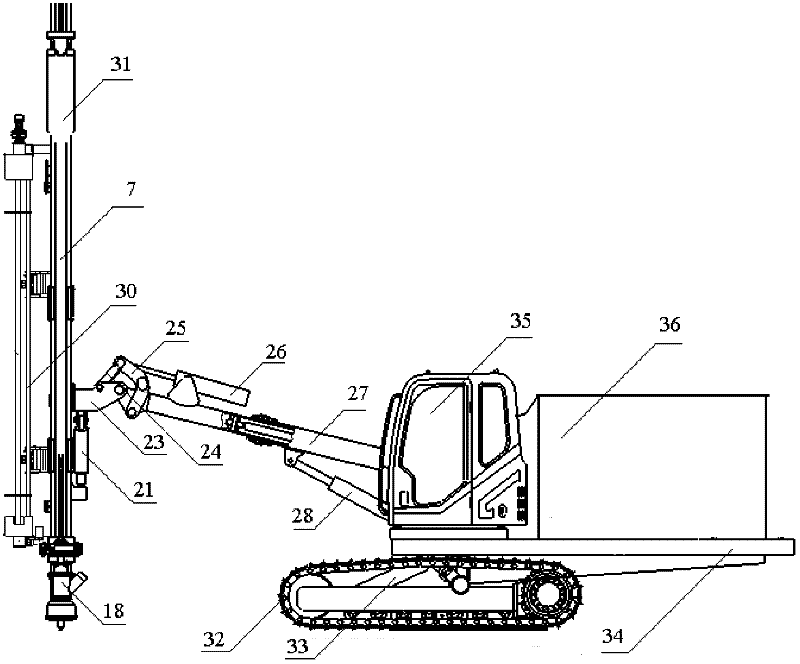

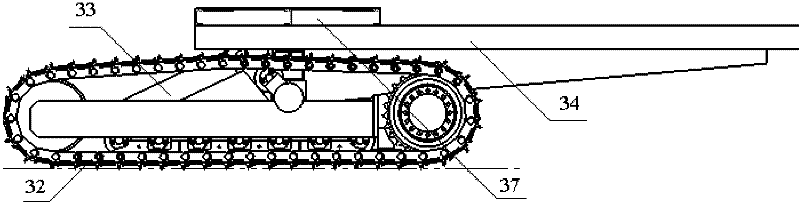

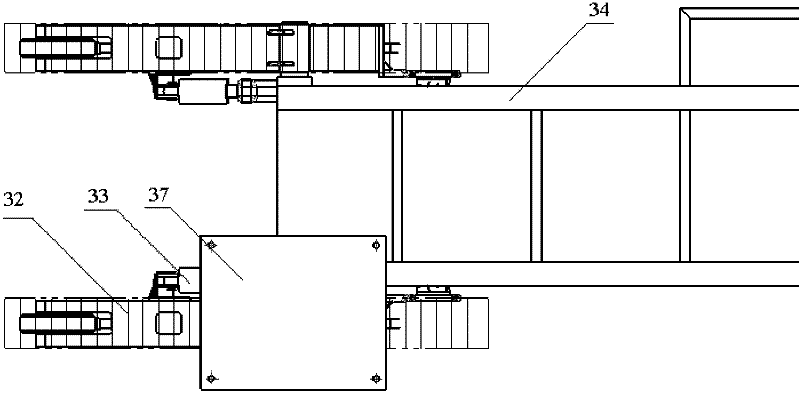

Telescopic arm open-cut rock drilling jumbo with drill rod replacing device

InactiveCN102418475AReduce design sizeReduce wearDrilling rodsDrilling casingsControl systemPropeller

The invention relates to a telescopic arm open-cut rock drilling jumbo with a drill rod replacing device. The telescopic arm open-cut rock drilling jumbo comprises a cab, a chassis assembly, a propeller assembly, a telescopic arm, the drill rod replacing device, a rock drill, a control system and a power and air control system 36; the cab is arranged on a cab bottom plate of the chassis assembly, the control system is arranged in the cab, and the control system is connected with the power and air control system; the telescopic length, the pitching angle and the deflection angle of the telescopic arm, the elongation of a propelling beam and the pitching angle of the cab are controlled by the control system; the arm seat of the telescopic arm is fixedly arranged at the front end of the cab, the propelling beam is in sliding fit with the telescopic arm through a bracket on a compensation cylinder, the telescopic end of the compensation cylinder is fixedly connected to the propelling beam, and extending compensation of the propelling beam can be realized by stretching of the compensation cylinder; and the drill rod replacing device is fixed on the propelling beam and positioned below a transmission rod, and the rock drill is fixed at the upper end of the propelling beam. The multi-azimuth drilling requirement of the jumbo can be met, and the gravity center of the whole jumbo is kept stable.

Owner:CSIC ZHONGNAN EQUIP

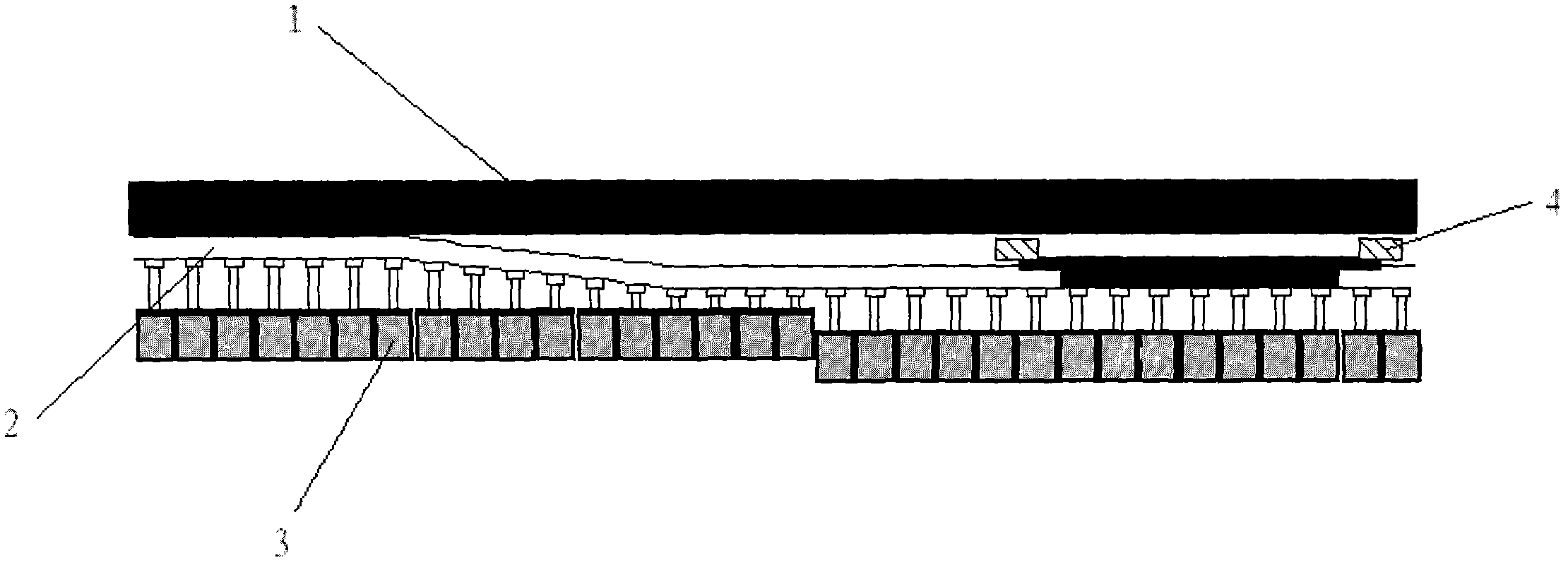

Attitude control system and method based on wireless three-dimensional gyroscope technology for scraper conveyer

ActiveCN102431784ARealize closed-loop controlIdeal curved segmentControl devices for conveyorsGyroscopeControl system

The invention discloses an attitude control system and a method based on a wireless three-dimensional gyroscope technology for a scraper conveyer. The system comprises a wireless three-dimensional gyroscope, hydraulic brackets, a bracket controller and a crossheading monitoring host, wherein the wireless three-dimensional gyroscope is arranged on a sliding chute of the scraper conveyer, and is used for detecting the running attitude of the scraper conveyer; a plurality of hydraulic brackets are connected to one side of the scraper conveyer in sequence; the movement of the scraper conveyer is realized under the pushing actions or pulling actions of the hydraulic brackets; the bracket controller is arranged on the hydraulic brackets, and is used for controlling the pushing or pulling actions of the hydraulic brackets; the crossheading monitoring host is arranged in a crossheading, and is used for concentrically monitoring and controlling the scraper conveyer, the bracket controller and hydraulic brackets; the wireless three-dimensional gyroscope is only communicated with the bracket controller in a wireless way; and the crossheading monitoring host and the bracket controller constitute a communication network system on a work surface through the bracket controller for performing data communication, so that attitude monitoring of the scraper conveyer is realized.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD

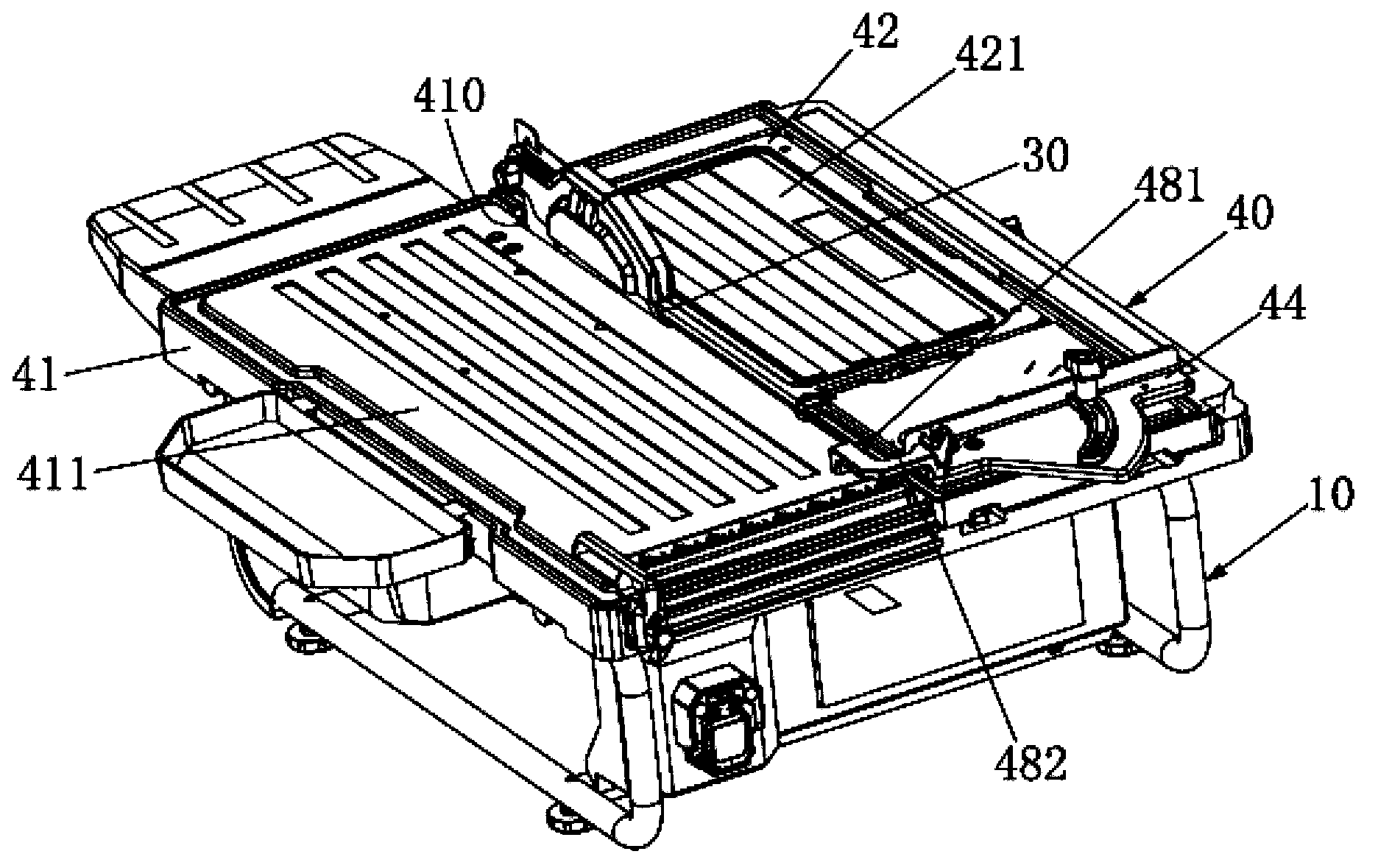

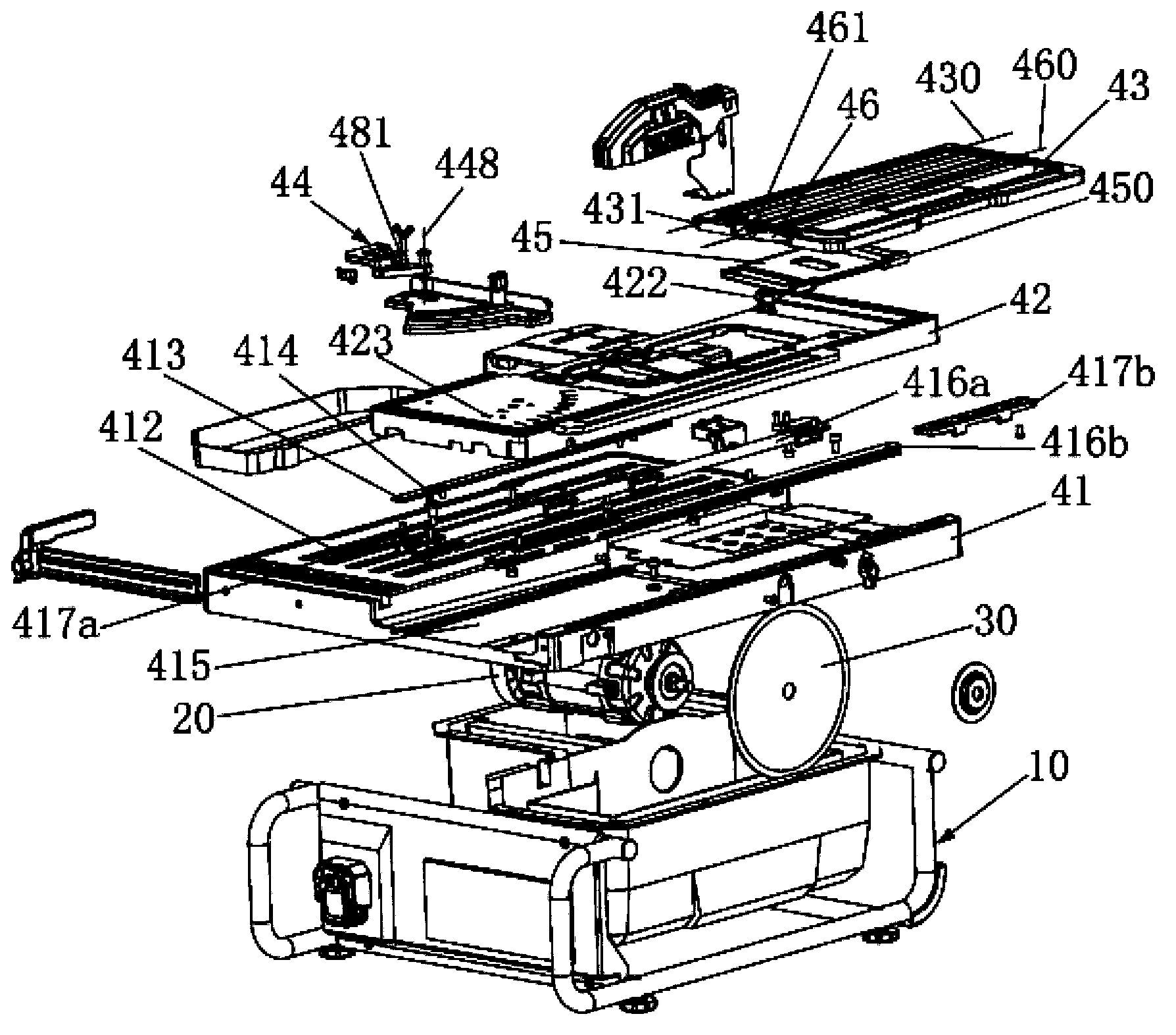

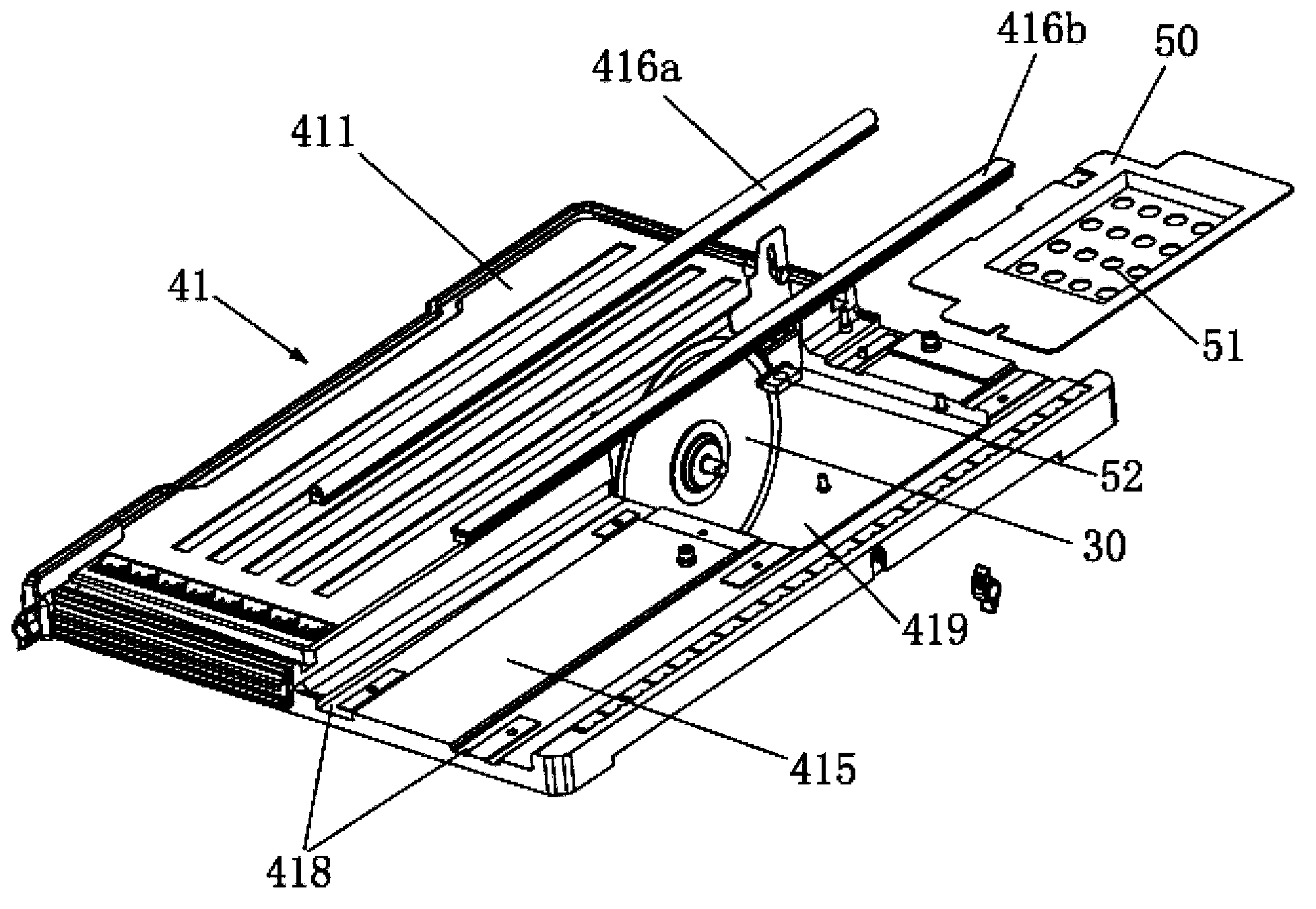

Stone cutter

ActiveCN104275749AReduce scratchesImprove straightnessWorking accessoriesStone-like material working toolsSTONE CUTTEREngineering

A tile cutting machine comprises a base, a motor accommodated in the base, a blade driven to rotate by the motor, and a working table supported on the base, wherein the working table comprises a fixed working table fixedly mounted to the base. A movable working table is slidably mounted to the fixed working table in a sliding direction parallel to a plane of the blade. The movable working table comprises a pivoting plate pivotally mounted to the movable working table about a pivoting axis parallel to the plane where the blade is located and a fence assembly mounted to the movable working table. The tile cutting machine can effectively enhance the ability to produce straight and / or square cuts.

Owner:NANJING CHERVON IND

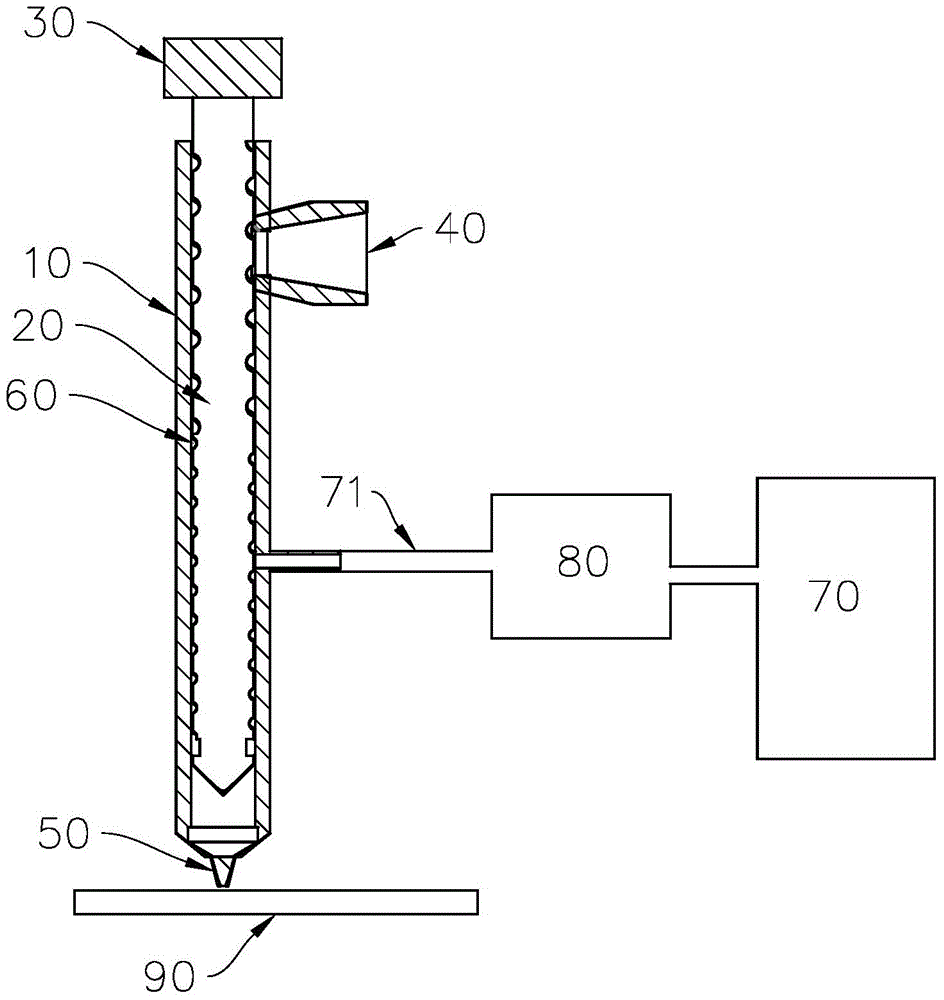

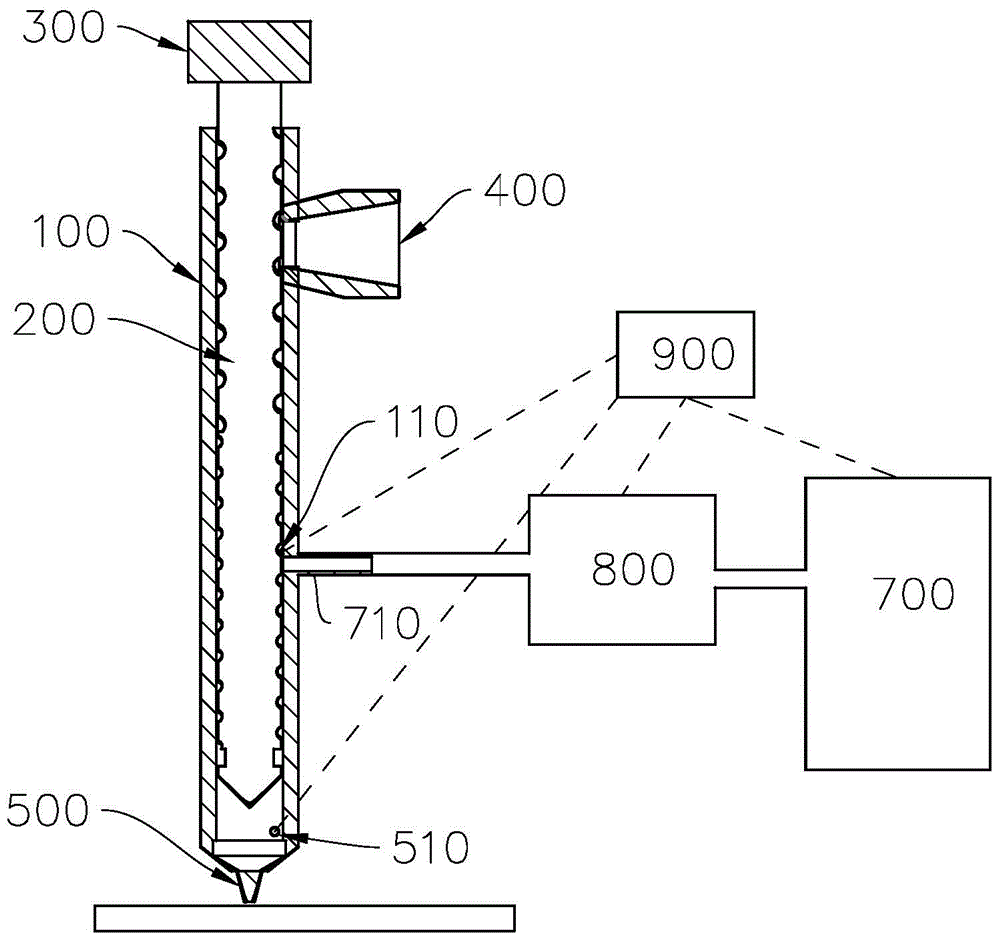

Three-dimensional printer and printing method and three-dimensional printing head

ActiveCN104875389ALow densityReduce the density valueAdditive manufacturing apparatusEngineeringVolumetric Mass Density

The invention relates to a three-dimensional printer, a three-dimensional printing head and a printing method. The three-dimensional printing head comprises a material volume cavity, wherein a screw rod is arranged in the material volume cavity, a motor is connected with the screw rod, a material supply device is communicated with the material volume cavity, a printing nozzle is arranged on the end part of the material volume cavity, a heater is arranged on the material volume cavity and positioned between the material supply device and the printing nozzle, and a supercritical fluid supply system is communicated with the material volume cavity. A molten printing material is mixed with supercritical fluid to generate a single-phase molten mixture under the mixing and stirring effect of the screw rod, and a uniform microporous bubble formation effect is formed, so that the density value of a printing object can be reduced, the size deviation of the three-dimensional printing object can be alleviated, the flatness and straightness of the three-dimensional printing object can be improved by more than 50 percent, the temperature for printing the molten printing material is effectively lowered, the energy is saved, and the operation personnel is prevented from being scalded.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

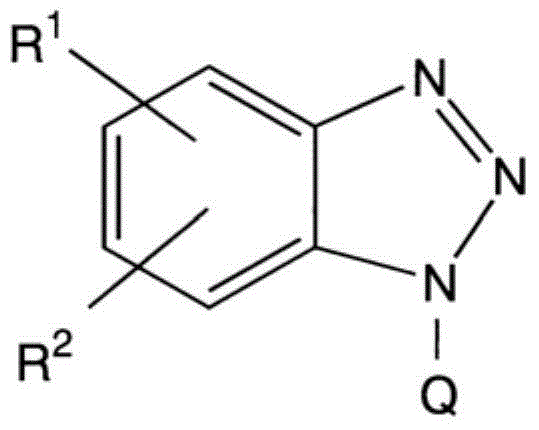

Etching composition for copper-based metal layer and method of preparing metal line

The invention relates to an etching composition for a copper-based metal layer and a method for preparing a metal line. The invention discloses an etching agent composition for the copper-based metal layer. The etching agent composition can represent an excellent cone angle profile. Furthermore the invention discloses a method of forming a wiring through the etching agent composition. The etching agent composition for the copper-based metal layer comprises the components of: 0.5-20% by weight of persulfate, 0.1-5% by weight of a triazole compound and the balance of water. Therefore the copper-based metal layer is selectively etched. An excellent straightness of the etched pattern is realized. Furthermore an improved cone angle profile is represented.

Owner:DONGWOO FINE CHEM CO LTD

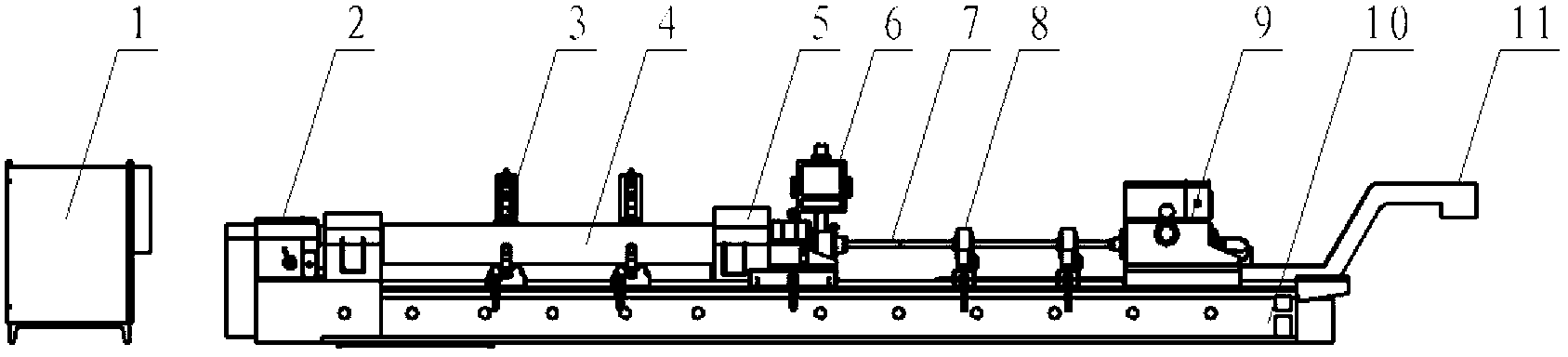

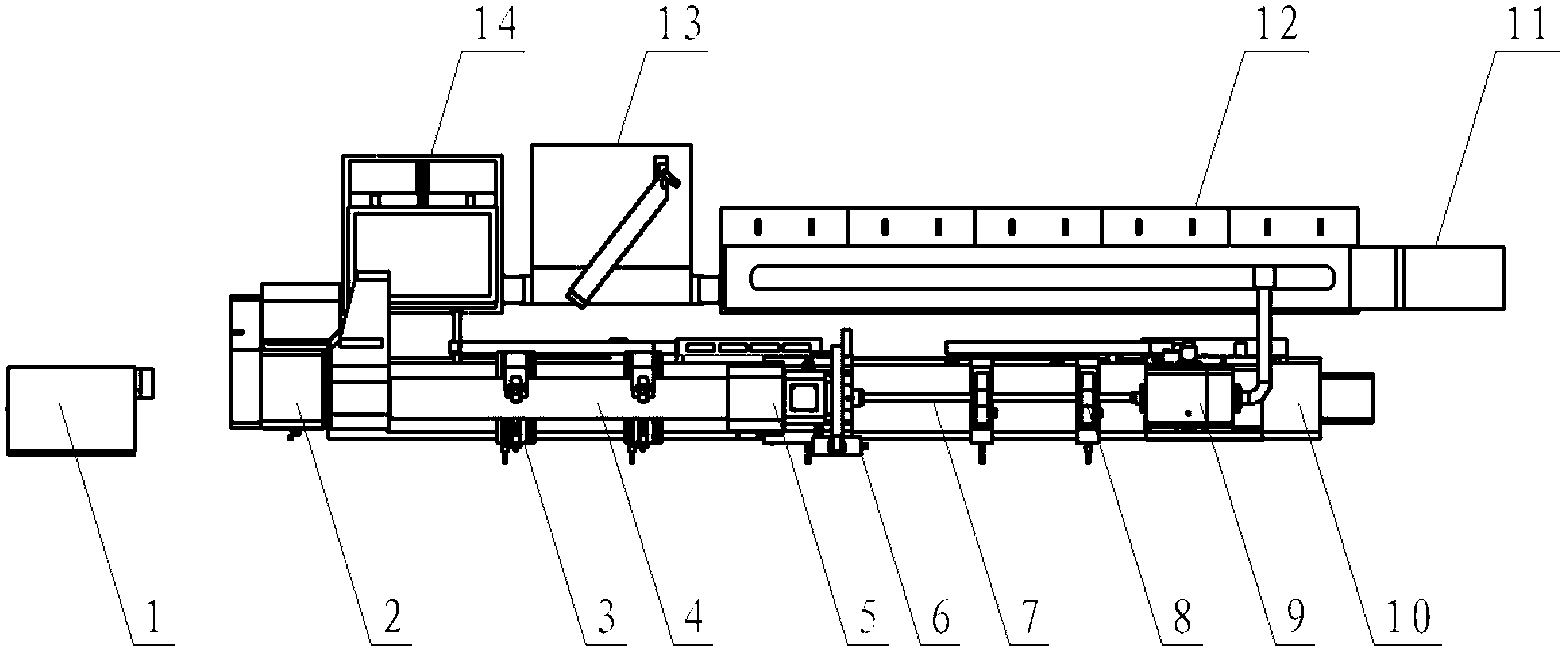

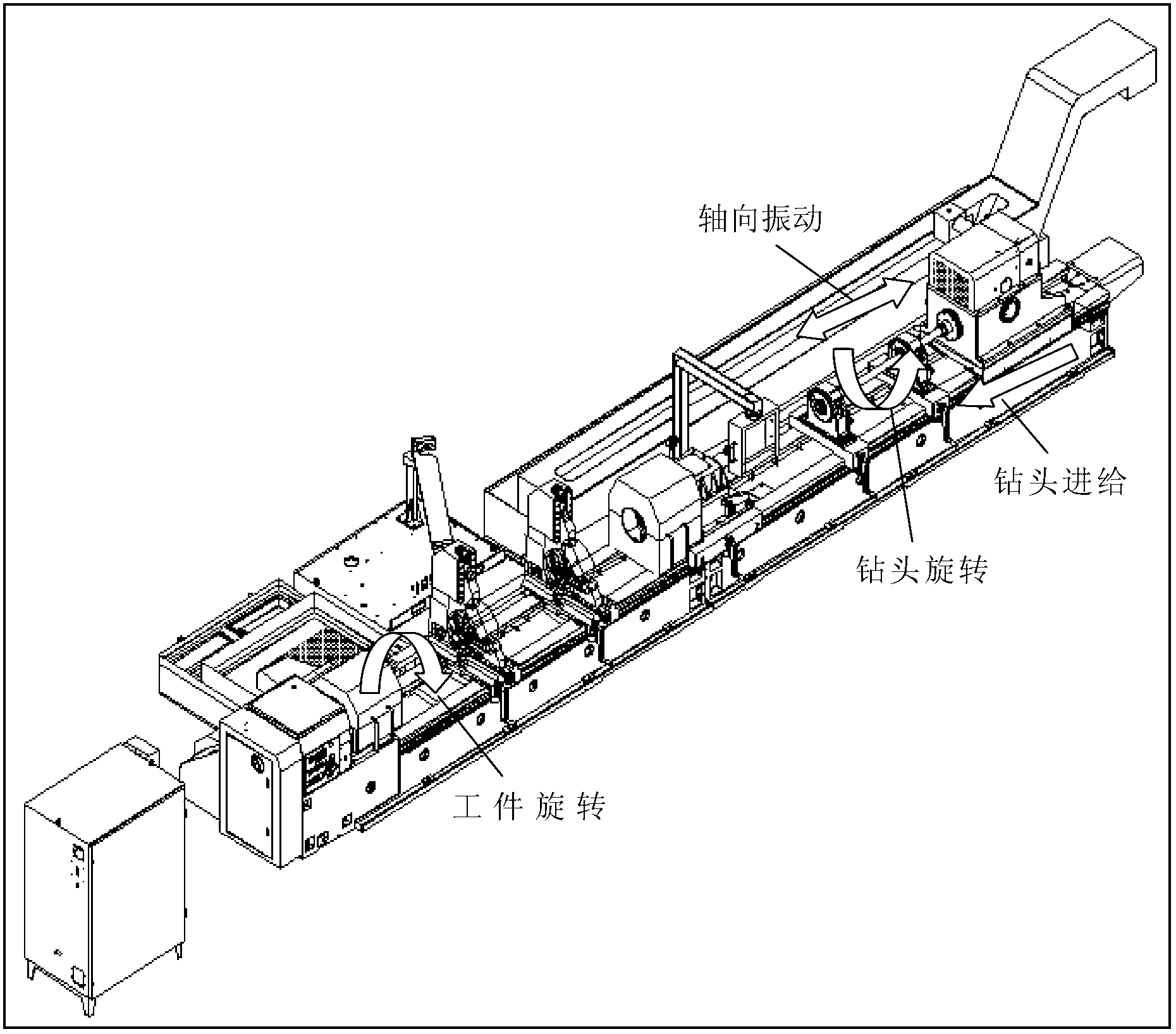

Numerical control vibration deep-hole drilling and boring machining equipment and method

InactiveCN102699375AImprove roundnessImprove straightnessBoring/drilling componentsMaintainance and safety accessoriesNumerical controlAxial vibration

The invention discloses numerical control vibration deep-hole drilling and boring machining equipment, which is characterized by comprising a workpiece arranged on a machine tool body, a drill bit and a drill stem, wherein the workpiece is driven by a main motor to rotate; and the drill bit is driven by the motor to rotate along with the drill stem and is simultaneously driven by a servo reducing motor and a vibration motor to make numerical control feed movement and axial reciprocating vibration. By the deep-hole drilling and boring equipment, the functions of rotating the workpiece and the drill bit in a bidirectional mode and axial vibration drilling can be realized, the severe working conditions and the lubricating effect of a cutting area of the drill bit are improved, the cuttings are automatically controlled, the process range of the equipment is greatly widened, the machining precision indexes of the holes such as roundness and straightness are improved, and the hole machining quality and efficiency are improved further; and moreover, the problem of chip breakage and removal in the prior art is solved, the cuttings can be automatically separated, collected and conveyed, automation of the drilling process is realized, and the equipment can be widely applied to the field of machining of rotary deep-hole parts.

Owner:XIAN UNIV OF TECH

Preparation method for high-purity high-compactness and large-dimension molybdenum-titanium alloy sputtering target material

ActiveCN105568236AEffective recoverySmall grain sizeVacuum evaporation coatingSputtering coatingSputteringCompression molding

The invention discloses a preparation method for a high-purity high-compactness and large-dimension molybdenum-titanium alloy sputtering target material. The preparation method comprises the following steps that (1) material mixing is conducted, molybdenum and titanium hydride are selected as powder raw materials, the two kinds of powder are mixed under the argon protection atmosphere, and alloy powder is obtained; (2) compression molding is conducted, and the mixed powder raw materials are put into a rubber jacket mold to be subjected to cold isostatic pressing treatment; (3) sintering is conducted, a compressed blank is subjected to first-stage dehydrogenation sintering and second-stage compacting sintering in a vacuum sintering furnace, and finally the sintered blank is obtained; (4) rolling is conducted; (5) annealing is conducted; and (6) machining is conducted, the target material blank after being subjected to annealing is subjected to machining, and a molybdenum-titanium alloy sputtering target material product is obtained. The molybdenum-titanium alloy sputtering target material produced through the preparation method is uniform in content, free of segregation, fine and small in grain size, high in purity, and good in compactness.

Owner:LUOYANG SIFON ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com