Patents

Literature

913 results about "Magnetic current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic current is, nominally, a current composed of fictitious moving magnetic monopoles. It has the dimensions of volts. The usual symbol for magnetic current is k which is analogous to i for electric current. Magnetic currents produce an electric field analogously to the production of a magnetic field by electric currents. Magnetic current density, which has the units of V/m² (volts per square meter), is usually represented by the symbols 𝔐ᵗ and 𝔐ⁱ.

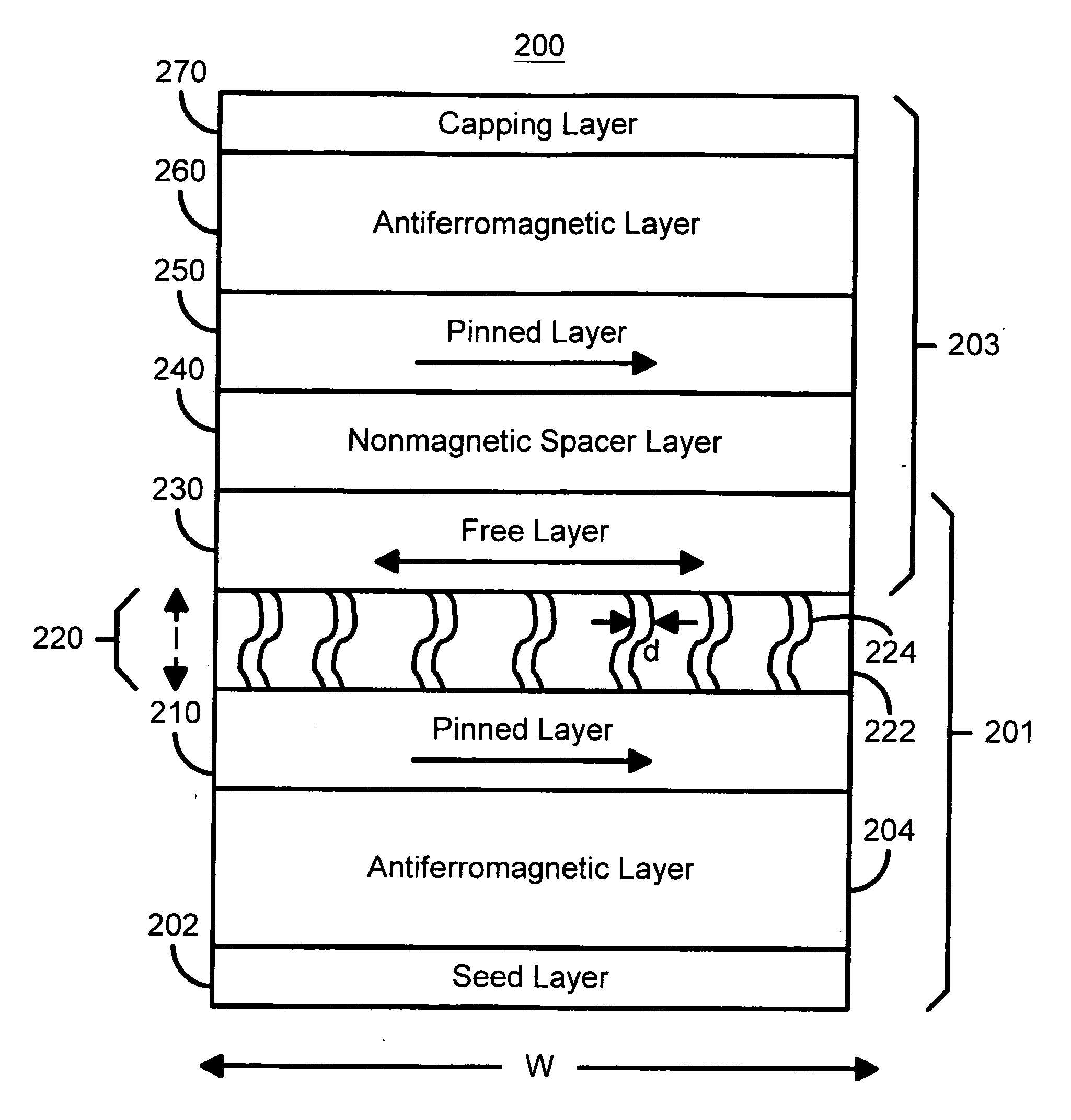

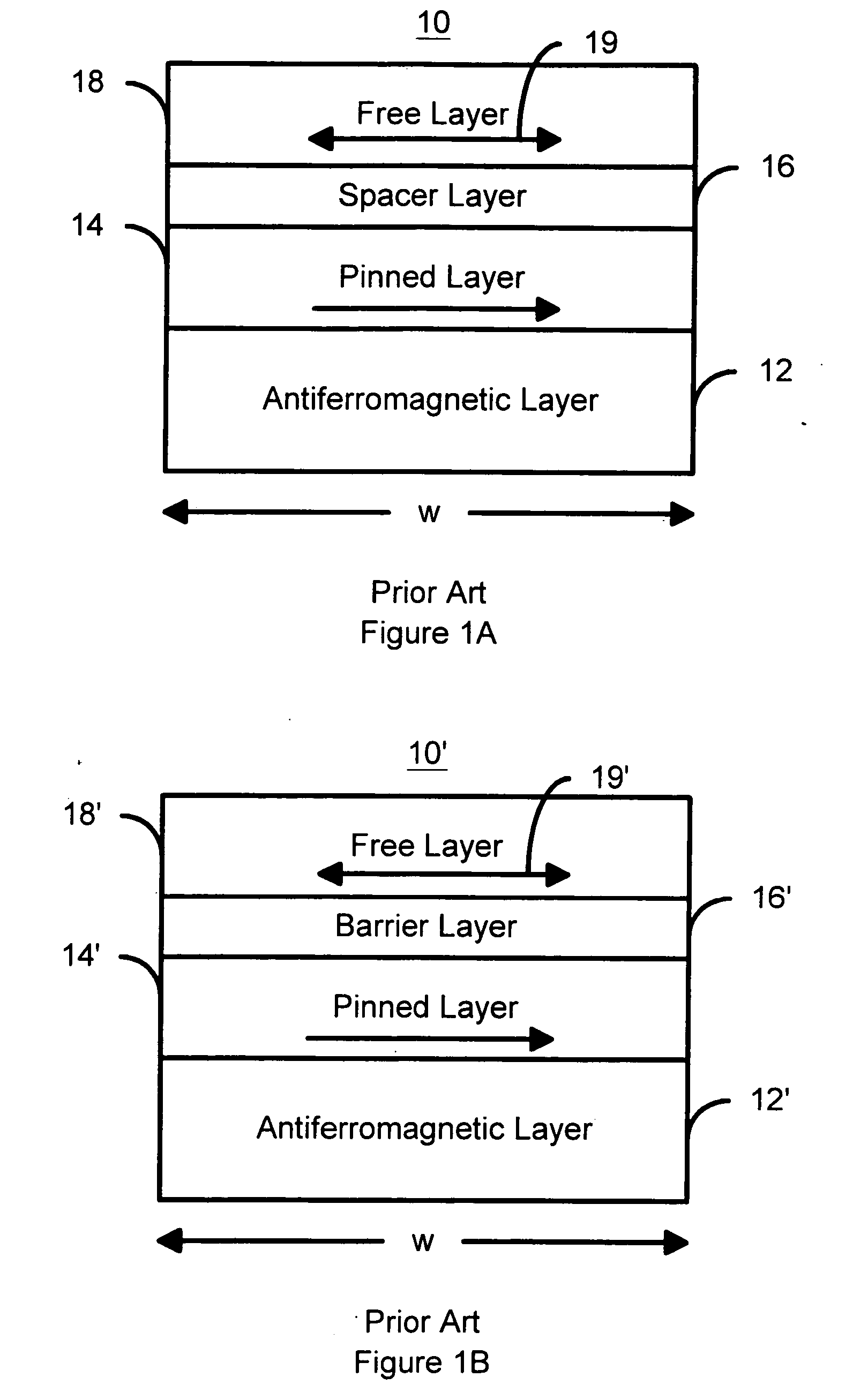

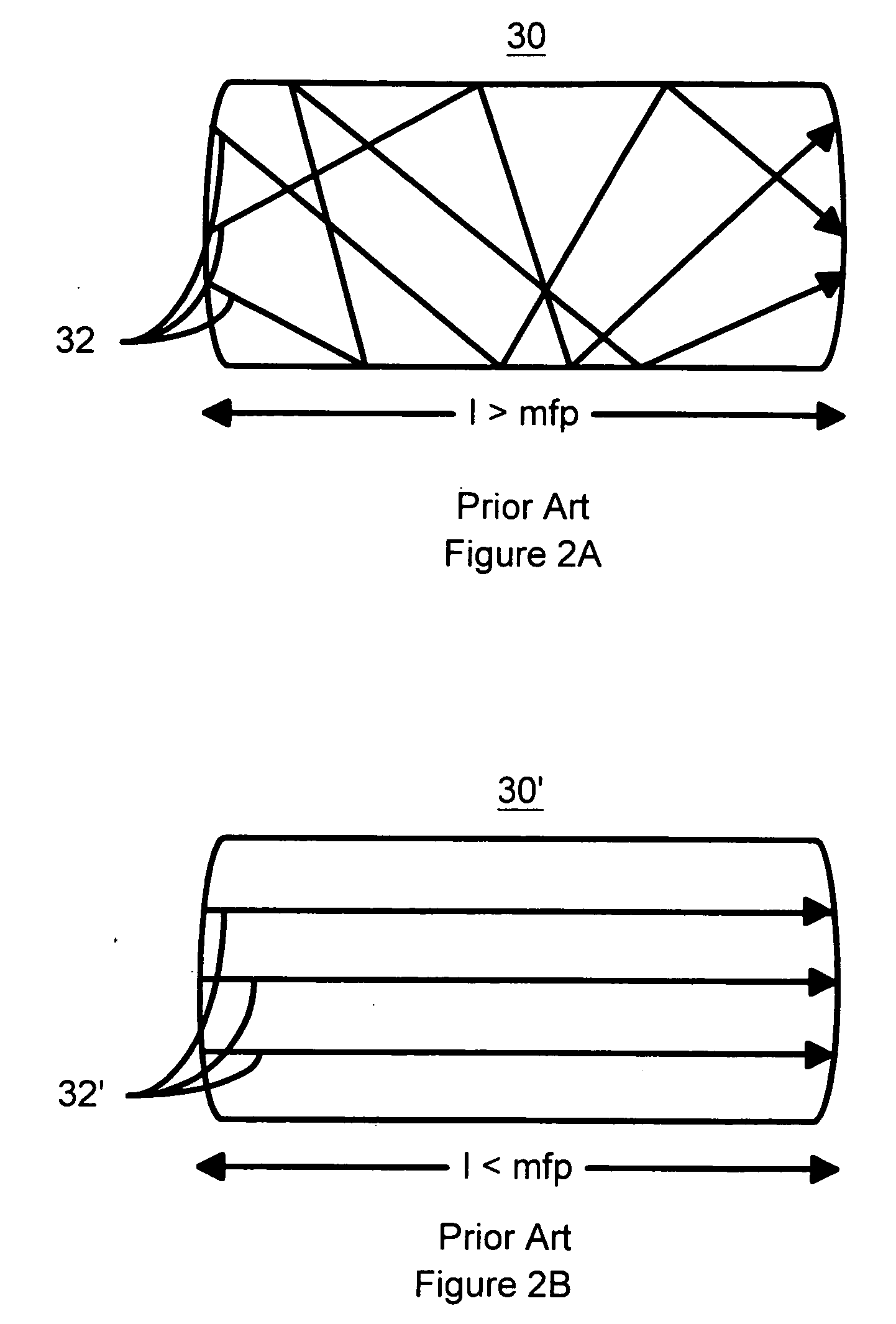

Magnetic elements with ballistic magnetoresistance utilizing spin-transfer and an MRAM device using such magnetic elements

InactiveUS20050136600A1Improve signal outputTransistorNanostructure applicationMagnetic currentCharge carrier

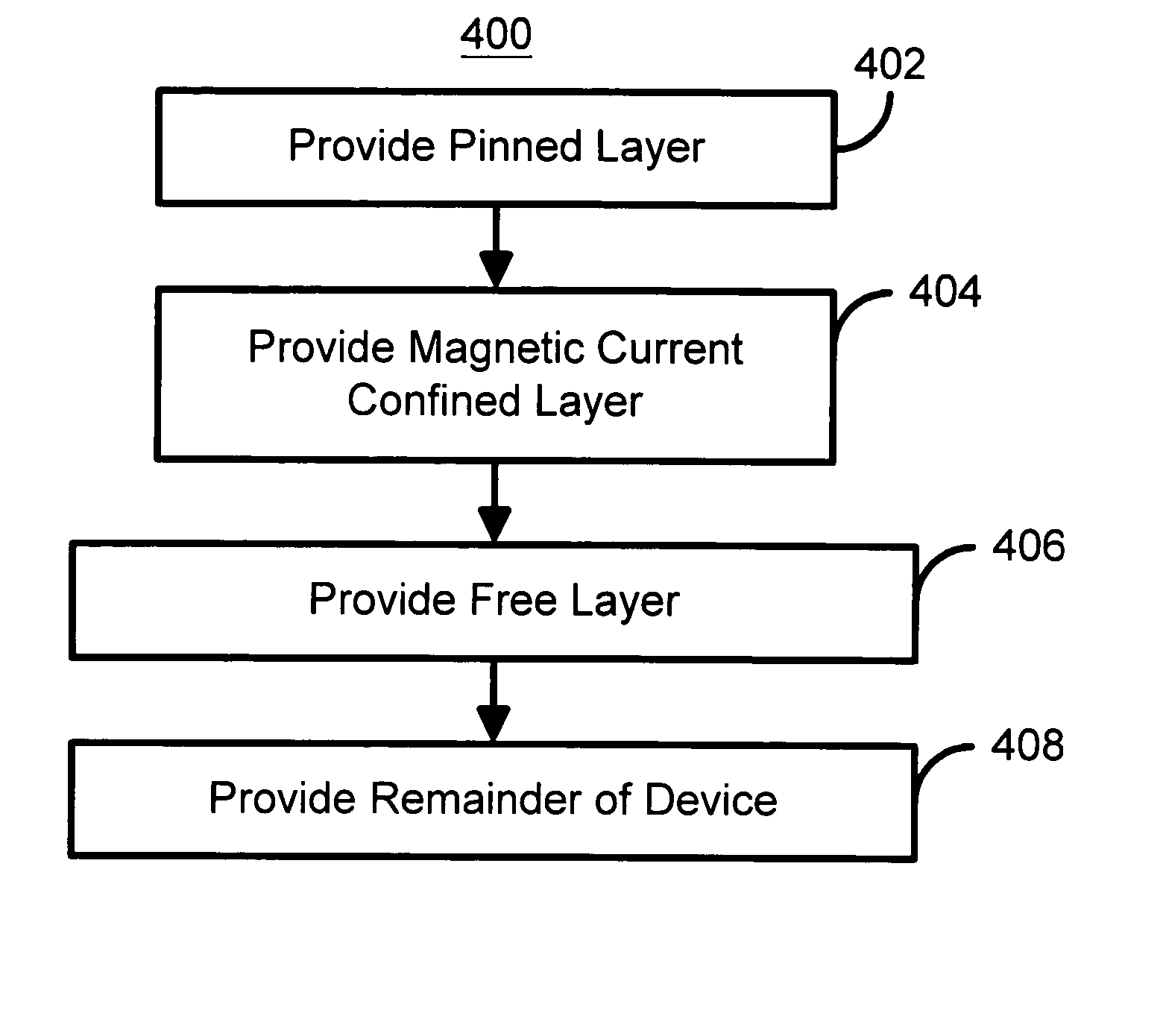

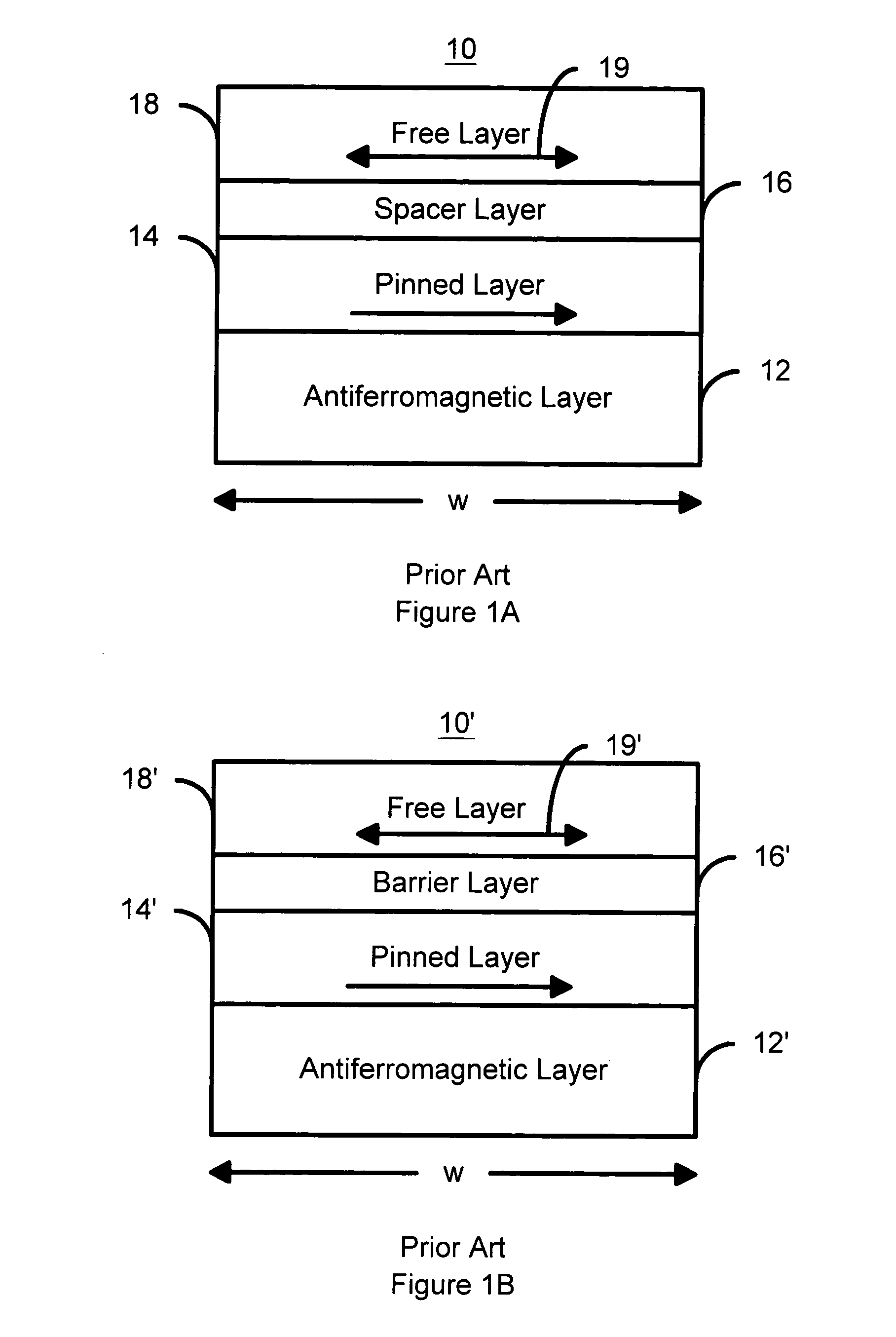

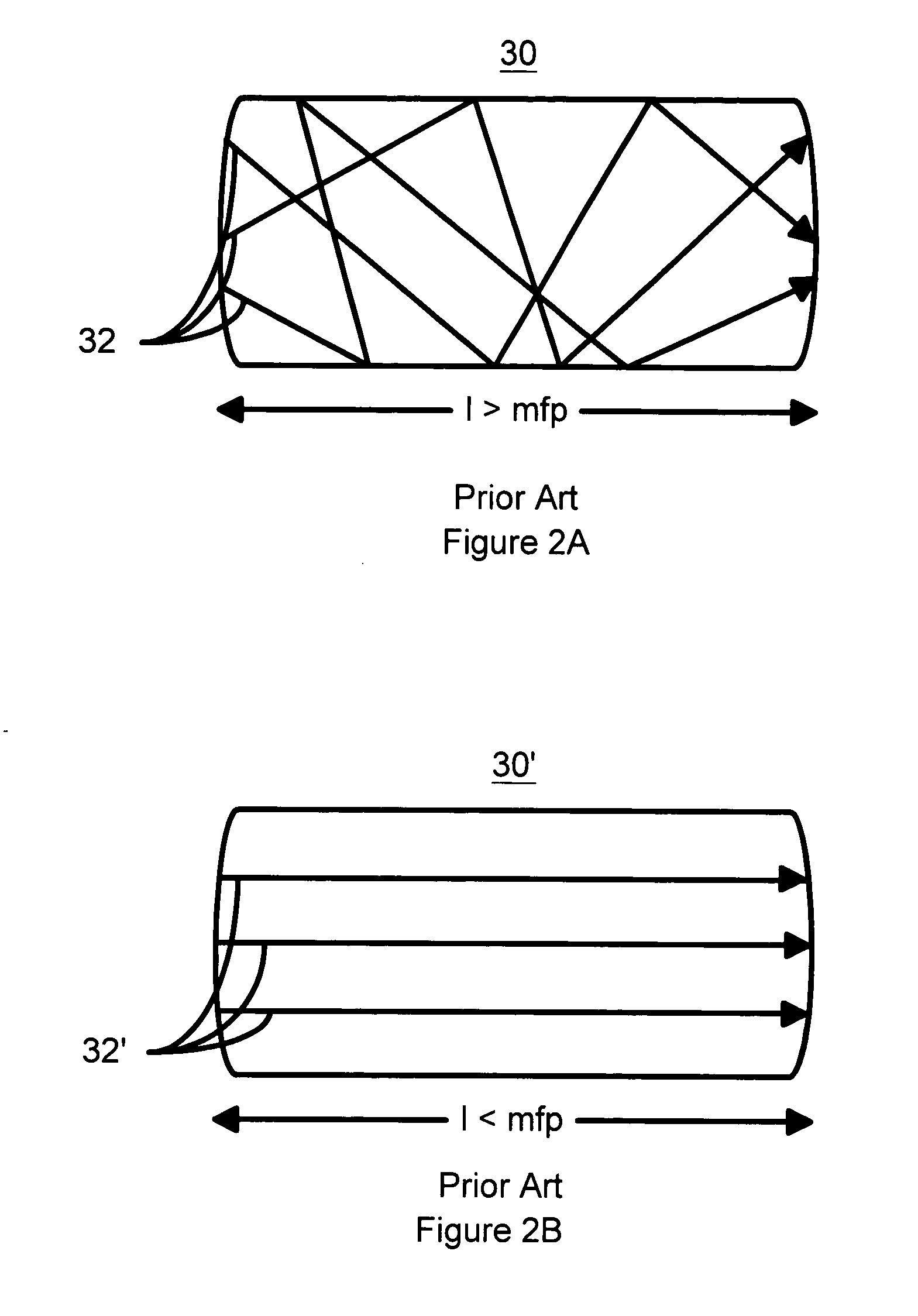

A method and system for providing a magnetic element is disclosed. The method and system include providing a pinned layer, a magnetic current confined layer, and a free layer. The pinned layer is ferromagnetic and has a first pinned layer magnetization. The magnetic current confined layer has at least one channel in an insulating matrix and resides between the pinned layer and the free layer. The channel(s) are ferromagnetic, conductive, and extend through the insulating matrix between the free layer and the pinned layer. The size(s) of the channel(s) are sufficiently small that charge carriers can give rise to ballistic magnetoresistance in the magnetic current confined layer. The free layer is ferromagnetic and has a free layer magnetization. Preferably, the method and system also include providing a second pinned layer and a nonmagnetic spacer layer between the second pinned layer and the free layer. In this aspect, the magnetic element is configured to allow the free layer magnetization to be switched using spin transfer.

Owner:GRANDIS

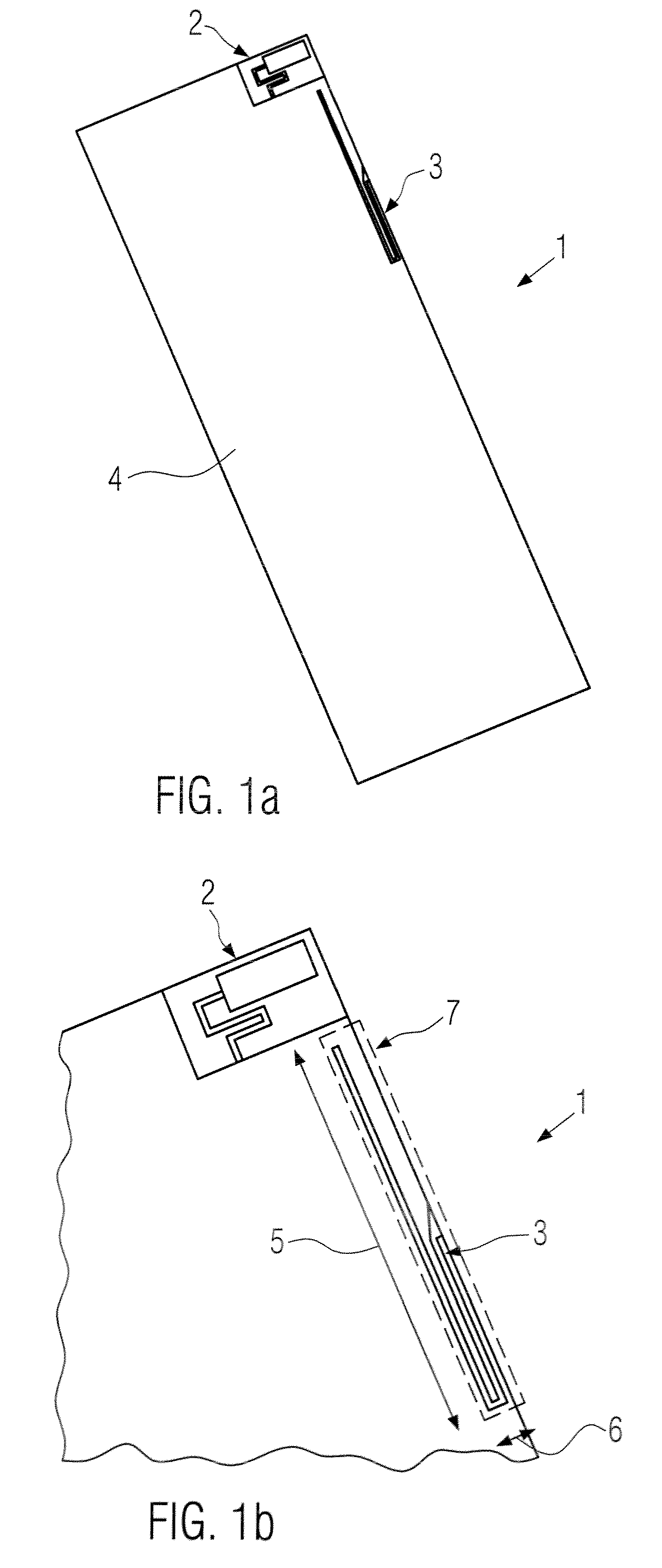

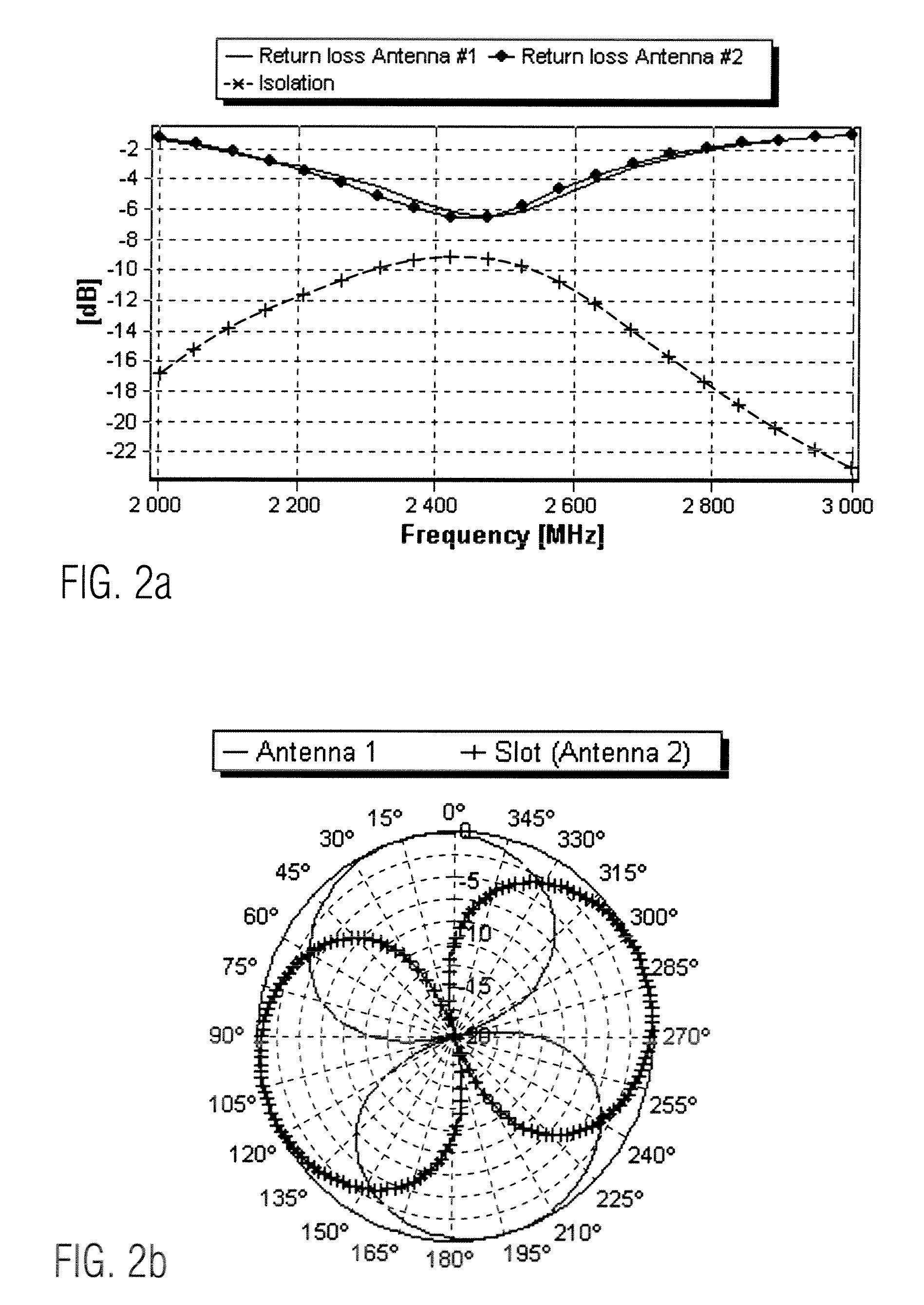

Antenna Diversity System and Slot Antenna Component

ActiveUS20080198082A1Increase diversityLittle PCB area overheadSimultaneous aerial operationsAntenna supports/mountingsMagnetic currentElectrical connection

The present invention refers to an antenna diversity system comprising at least a first antenna and a second antenna wherein the first antenna substantially behaves as an electric current source or as a magnetic current source, and the second antenna substantially behaves as an electric current source or as a magnetic current source and a corresponding wireless device. Further the invention relates to an SMT-type slot-antenna component comprising at least one conductive surface or sheet of metal in which the pattern of a slot is created, at least one contact terminal accessible from the exterior of said component to electrically connect the conductive surface included in the slot-antenna component with the ground plane of a circuit board such as a printed circuit board and a corresponding wireless device.

Owner:FRACTUS

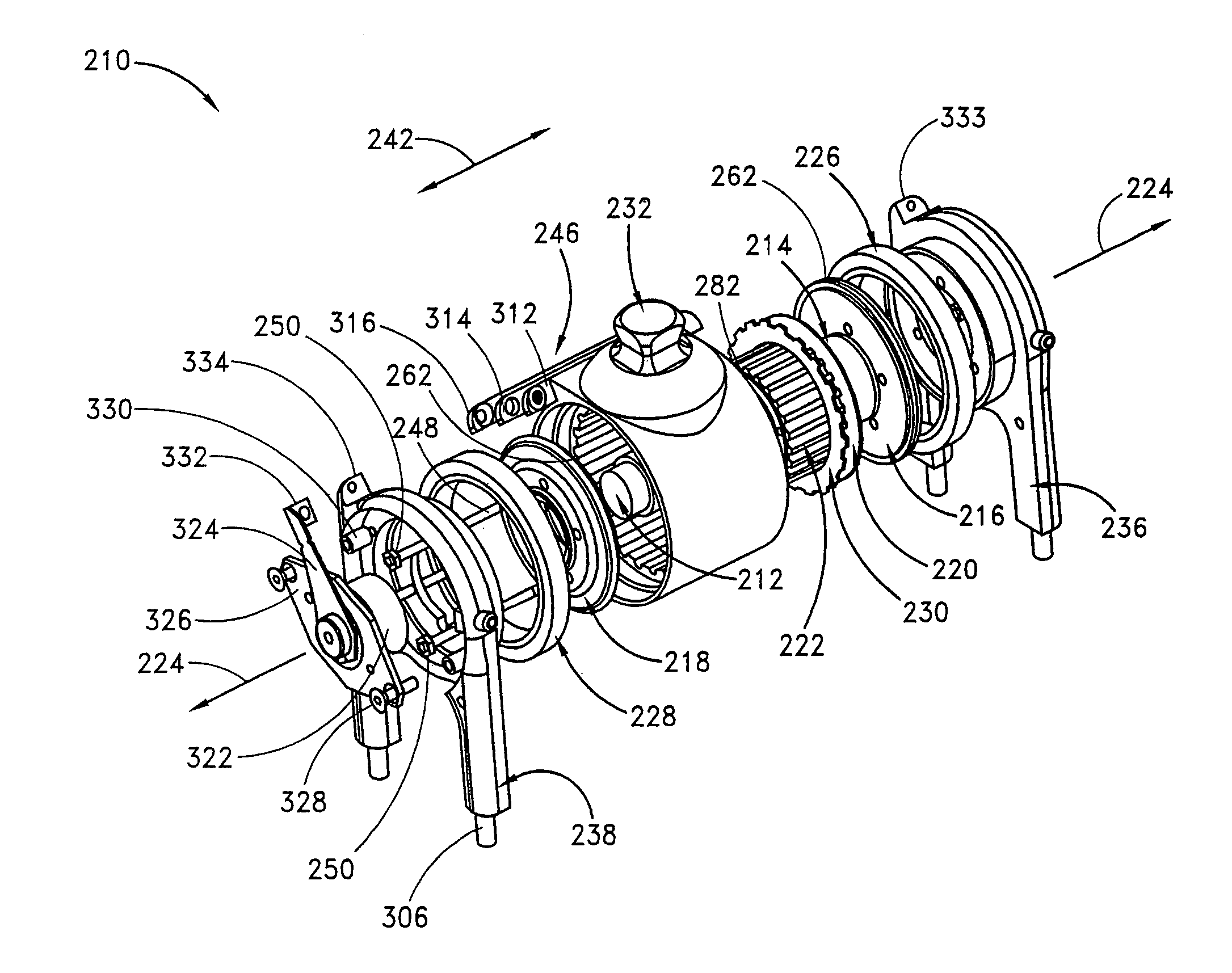

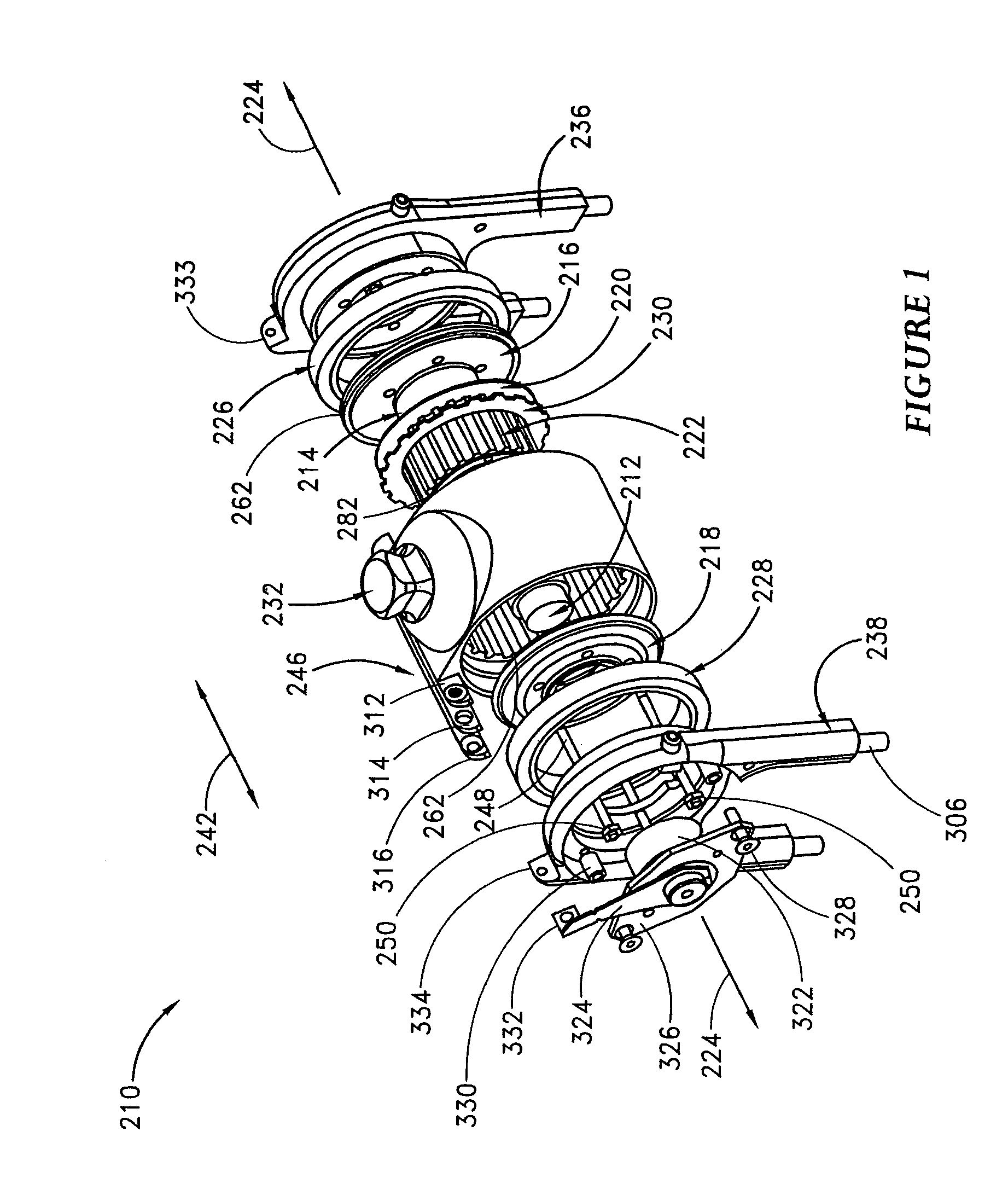

Magnetorheological fluid compositions and prosthetic knees utilizing same

The present invention relates in one embodiment to magnetorheological fluids utilized in prosthetic joints in general and, in particular, to magnetorheological fluids utilized in controllable braking systems for prosthetic knee joints. Preferred magnetorheological fluids of the present invention comprises polarizable iron particles, a carrier fluid, and optionally an additive. Preferred additives include, but are not limited to functionalized carrier fluids as well as derivatized fluoropolymers. Preferred carrier fluids include, but are not limited, to perfluorinated polyethers.

Owner:OSSUR HF

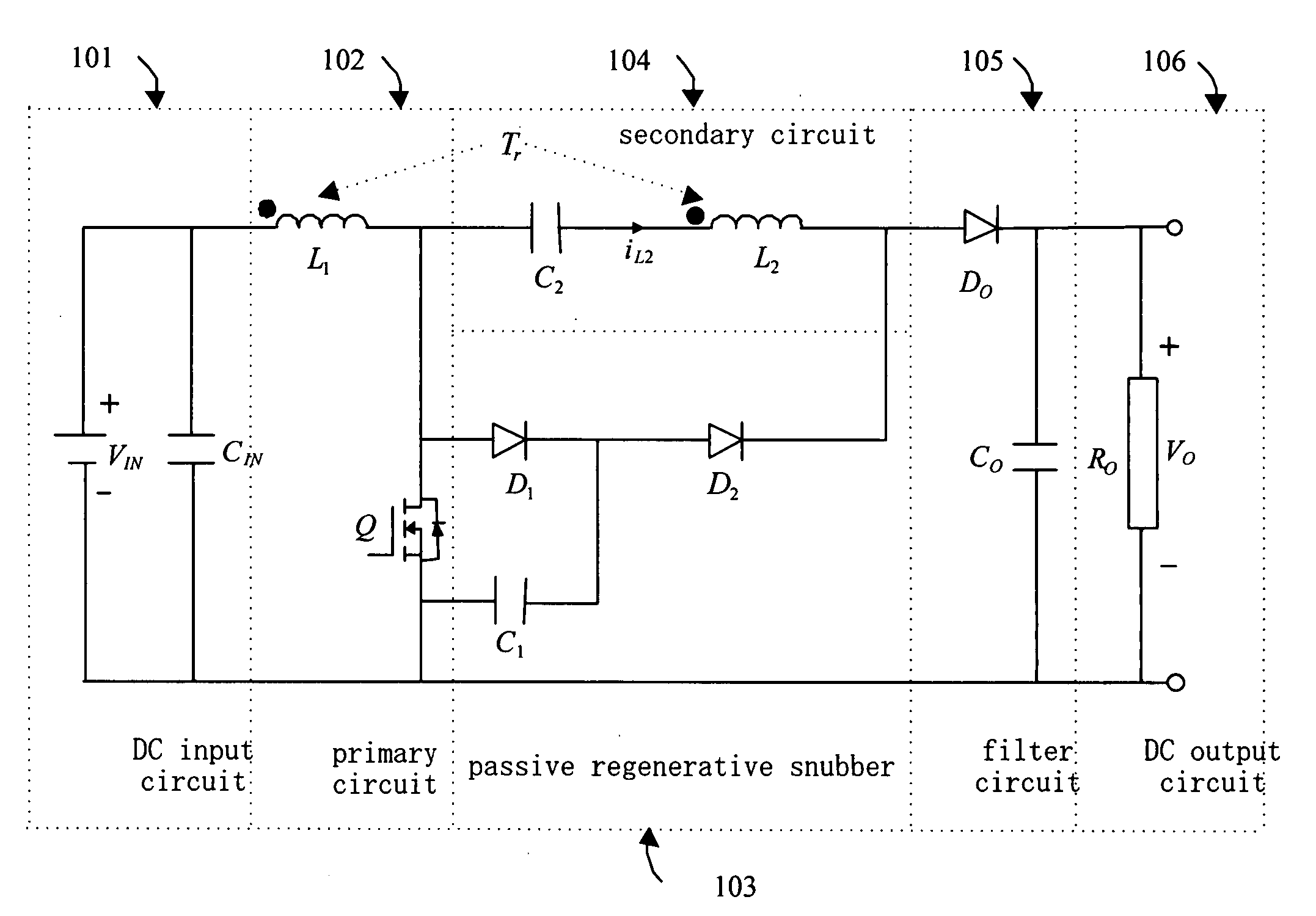

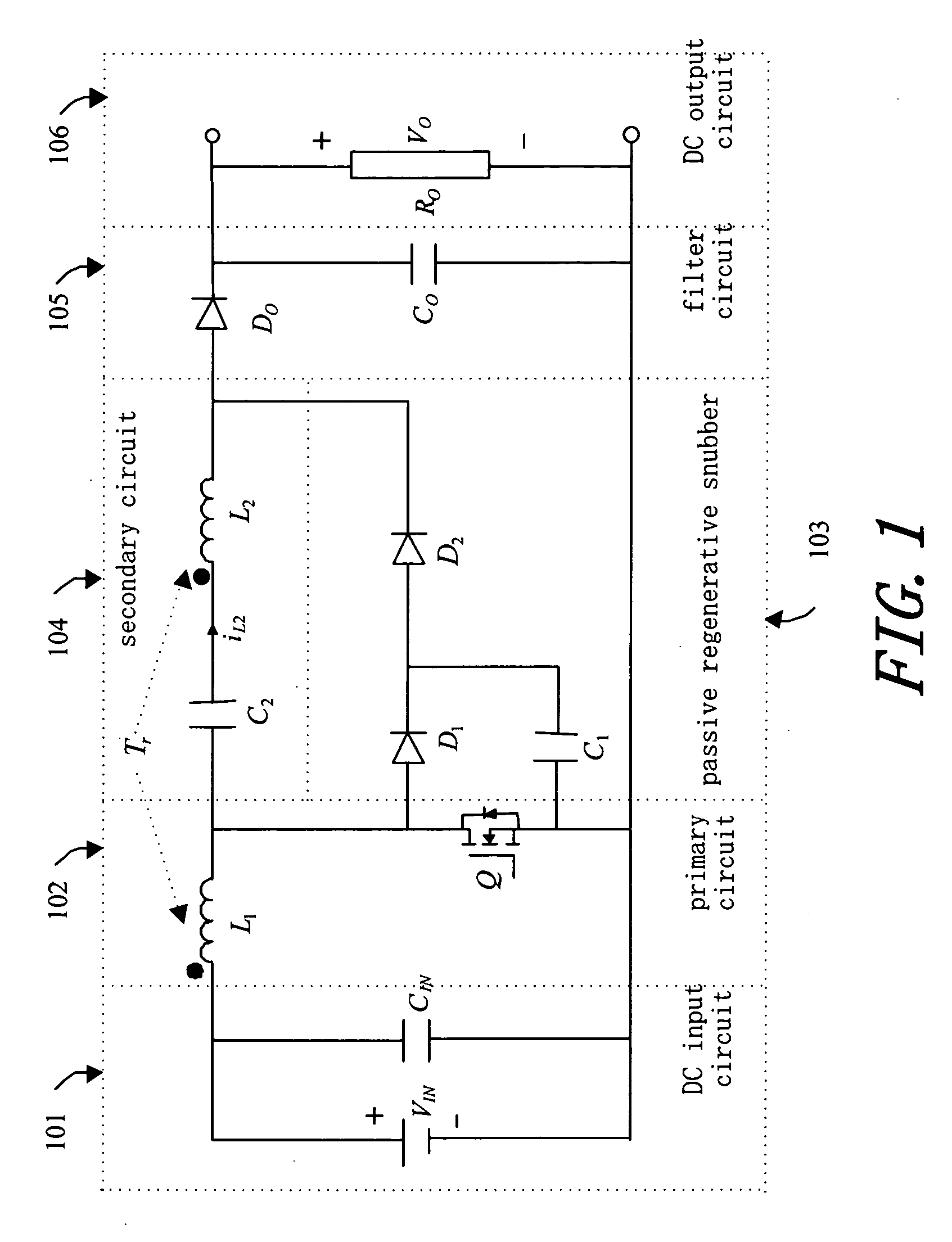

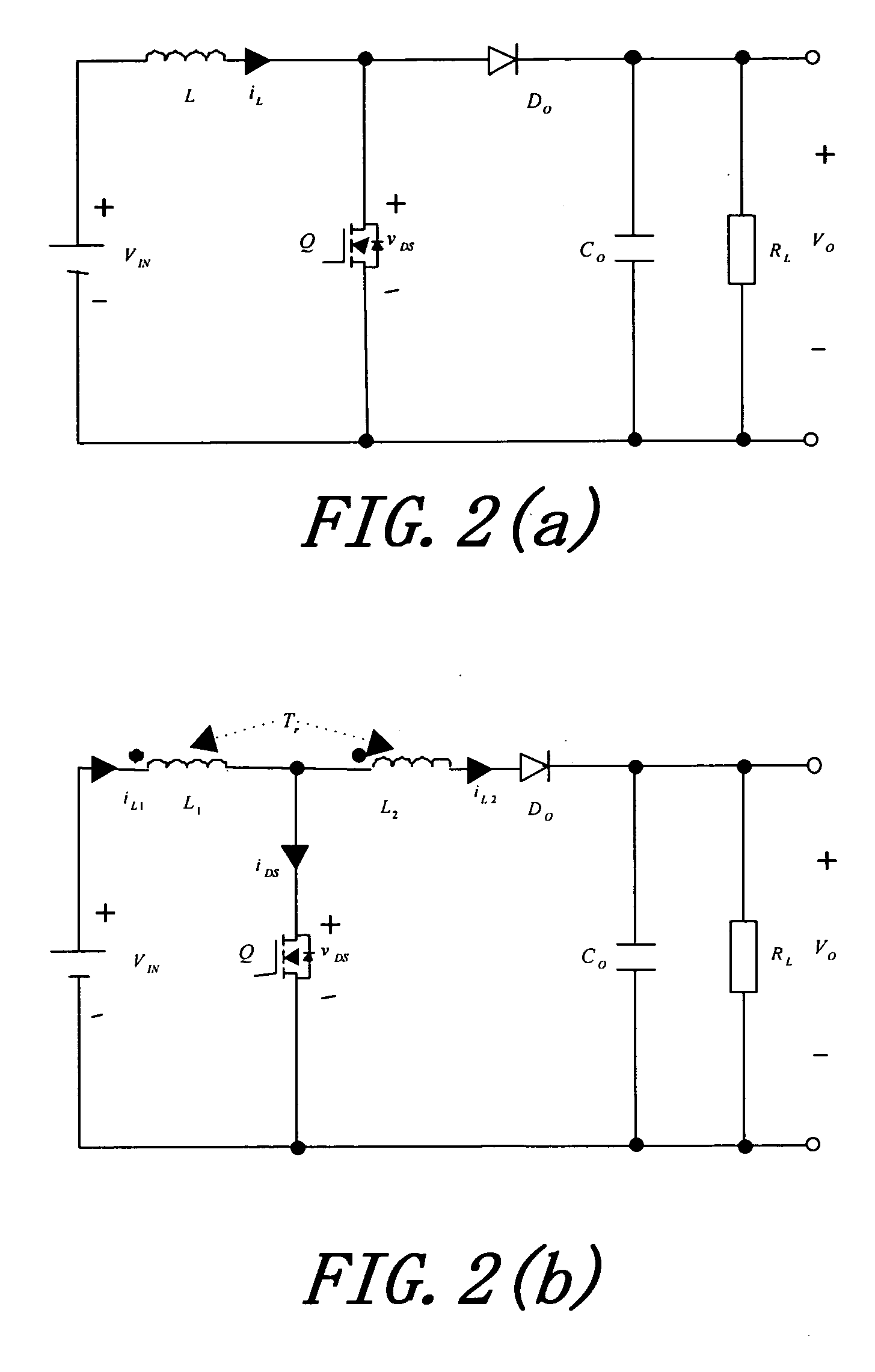

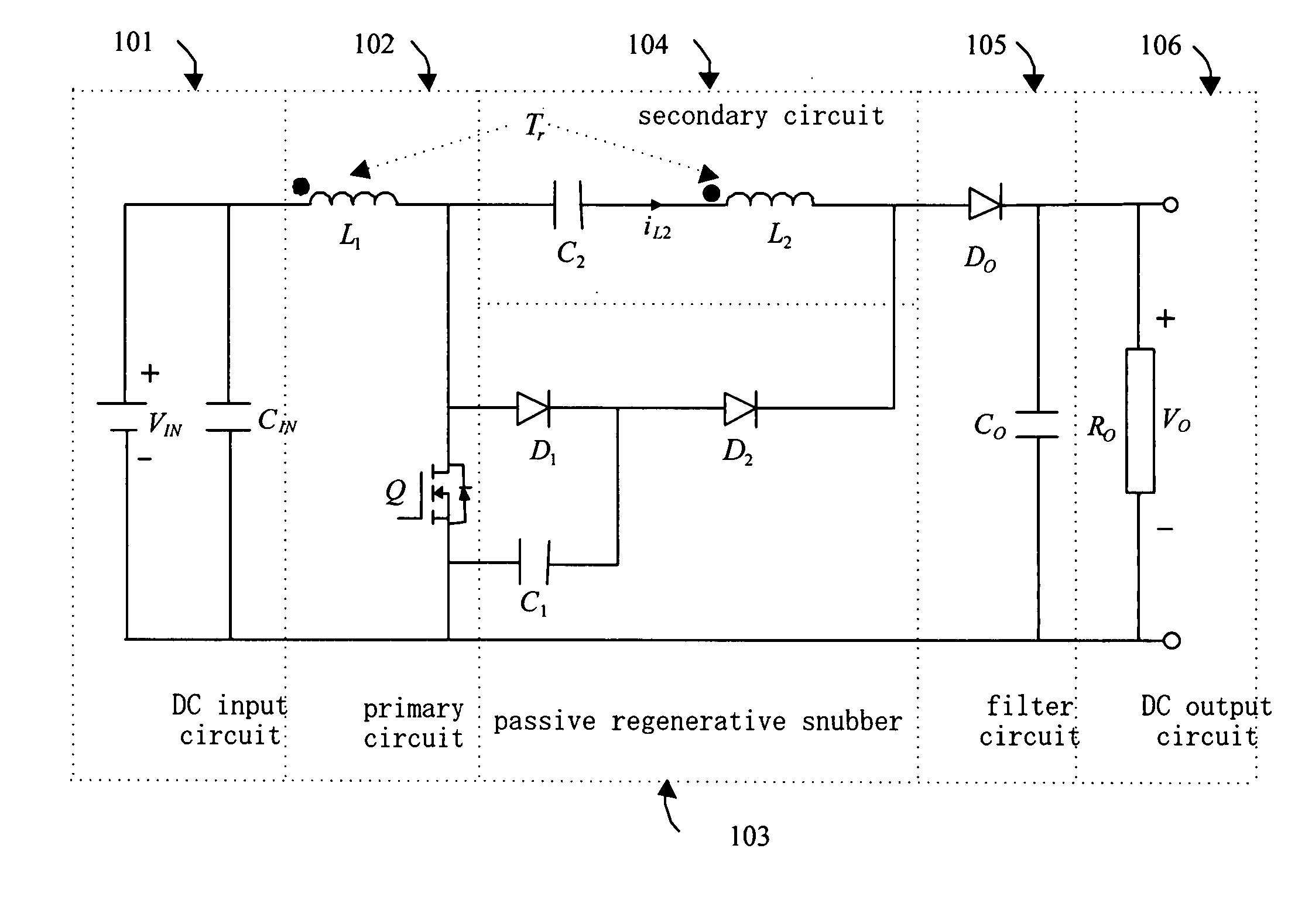

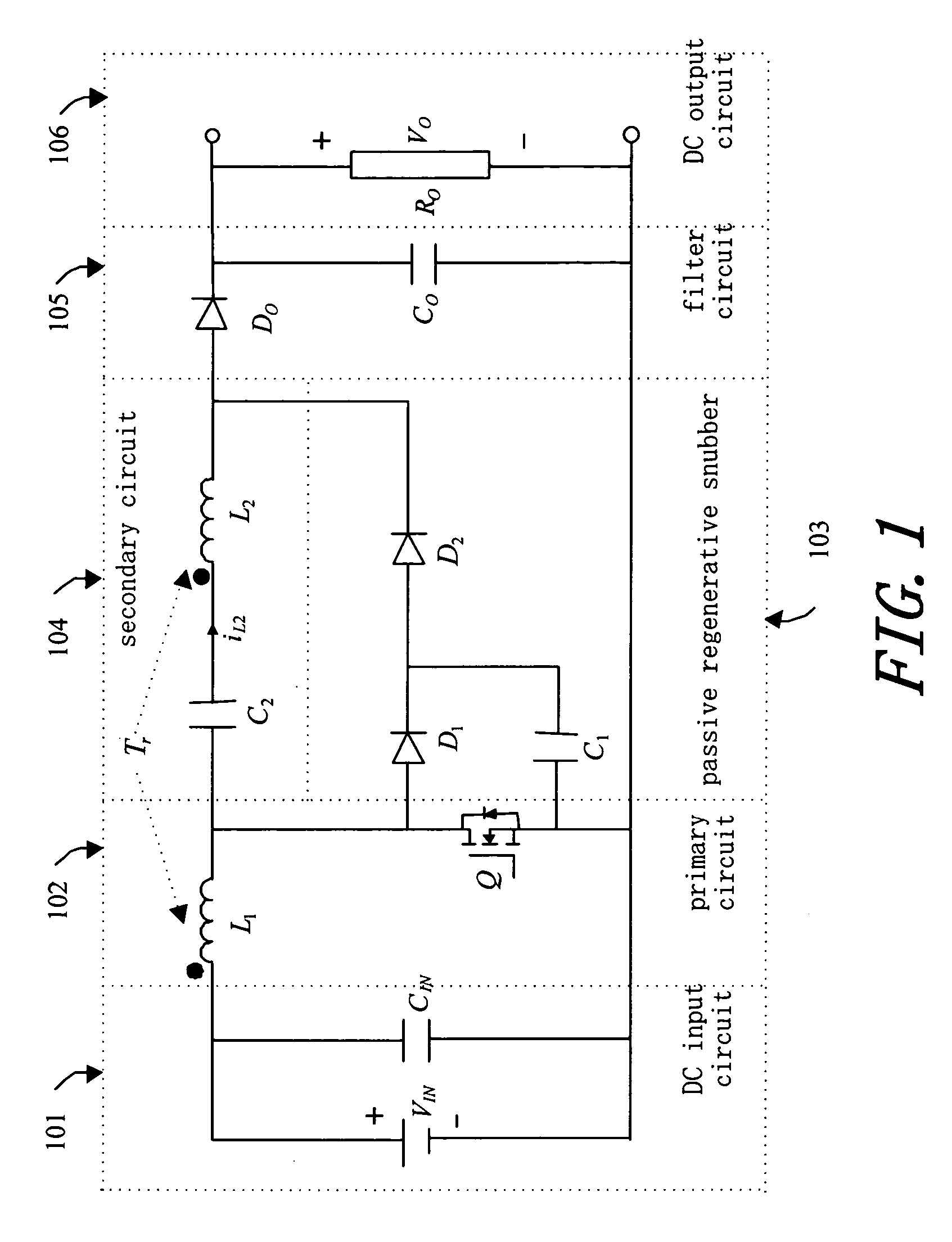

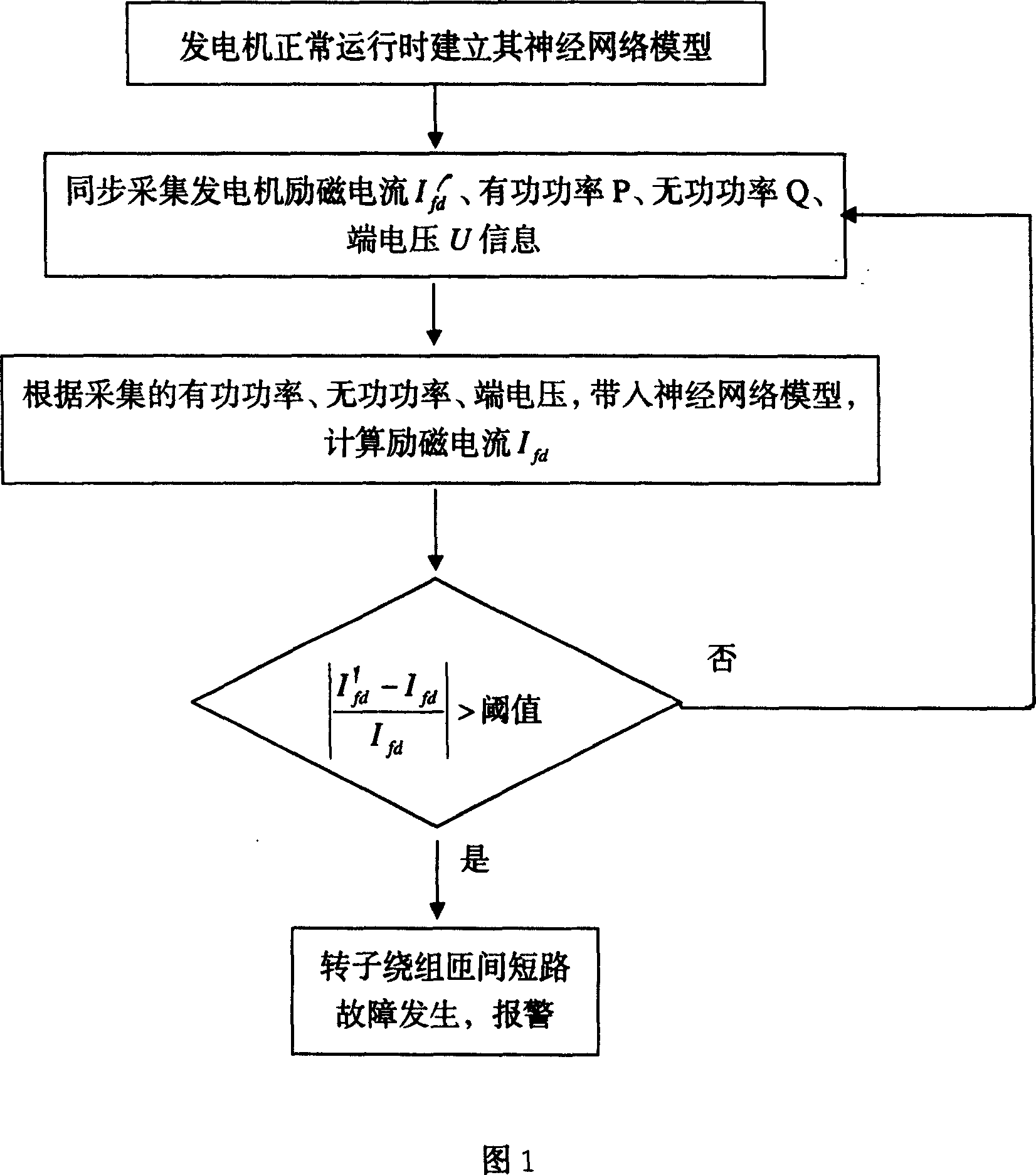

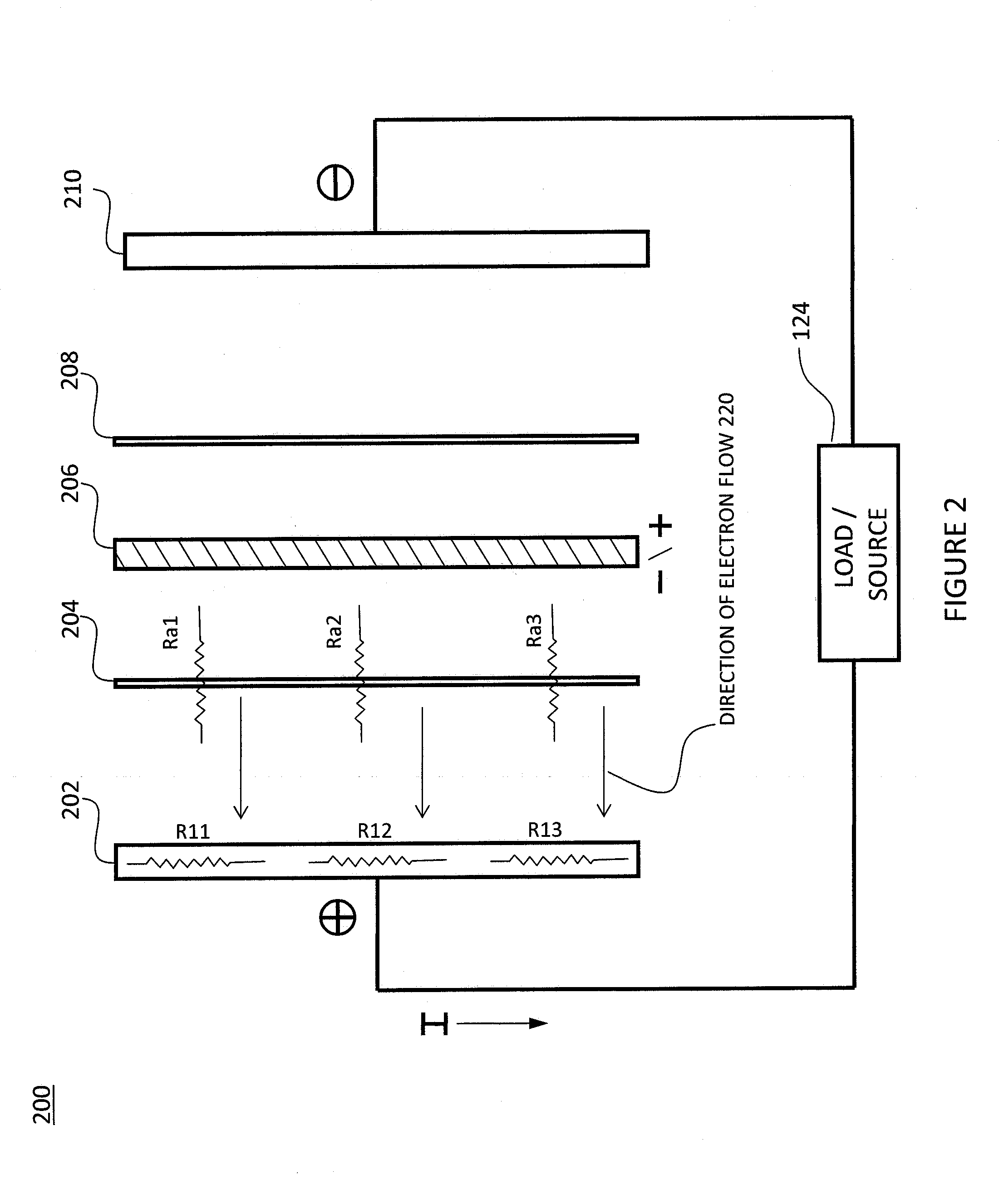

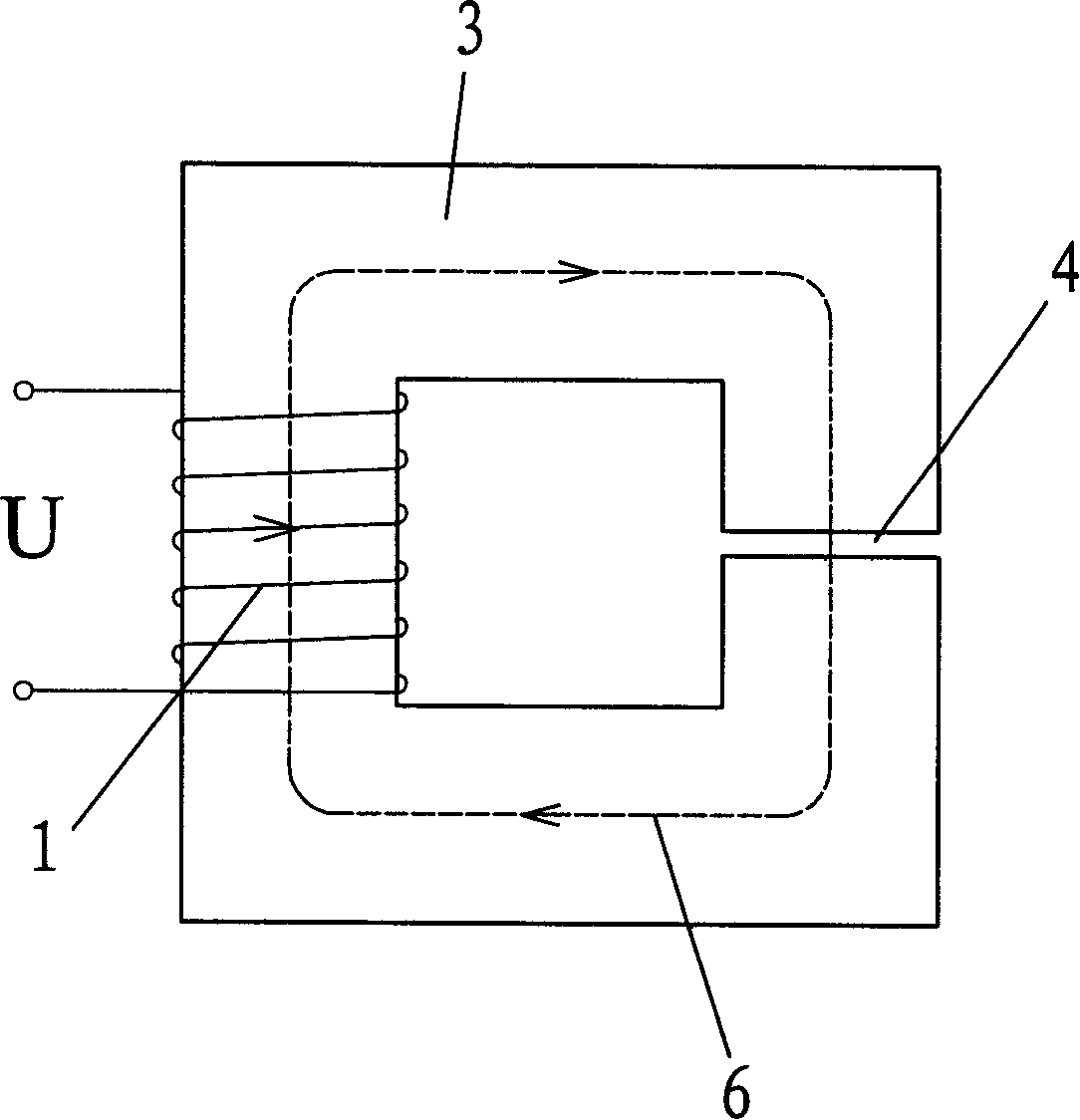

Boost converter utilizing bi-directional magnetic energy transfer of coupling inductor

ActiveUS20060226816A1Reduce loadTotal current dropDc-dc conversionElectric variable regulationMagnetic currentTransformer

A boost converter utilizing bi-directional magnetic energy transfer of coupling inductor provides a high efficiency boost DC-DC converting with above 30 times voltage boost rate, which uses a coupling inductor and low voltage switch to absorb circuit induction voltage of a passive regenerative snubber no matter if switch is turned on or off. Such that, a much higher voltage boost rate than the turn rate of transformer and wider range of switching duty cycle is obtained. A bi-directional magnetic energy path is utilized, that is, when switch is turned on the first winding of coupling inductor stores magnetic excited high current energy, and opposite magnetic flux is induced on the second winding at the same time. When switch is turned off the magnetic excited current continues and increases the voltage on the second winding. The second winding has bi-directional magnetic current induced and fully utilizes capacity of transformer's iron core.

Owner:YUAN ZE UNIV

Boost converter utilizing bi-directional magnetic energy transfer of coupling inductor

ActiveUS7161331B2Low efficiencyImprove efficiencyDc-dc conversionElectric variable regulationMagnetic currentLow voltage

A boost converter utilizing bi-directional magnetic energy transfer of coupling inductor provides a high efficiency boost DC-DC converting with above 30 times voltage boost rate, which uses a coupling inductor and low voltage switch to absorb circuit induction voltage of a passive regenerative snubber no matter if switch is turned on or off. Such that, a much higher voltage boost rate than the turn rate of transformer and wider range of switching duty cycle is obtained. A bi-directional magnetic energy path is utilized, that is, when switch is turned on the first winding of coupling inductor stores magnetic excited high current energy, and opposite magnetic flux is induced on the second winding at the same time. When switch is turned off the magnetic excited current continues and increases the voltage on the second winding. The second winding has bi-directional magnetic current induced and fully utilizes capacity of transformer's iron core.

Owner:YUAN ZE UNIV

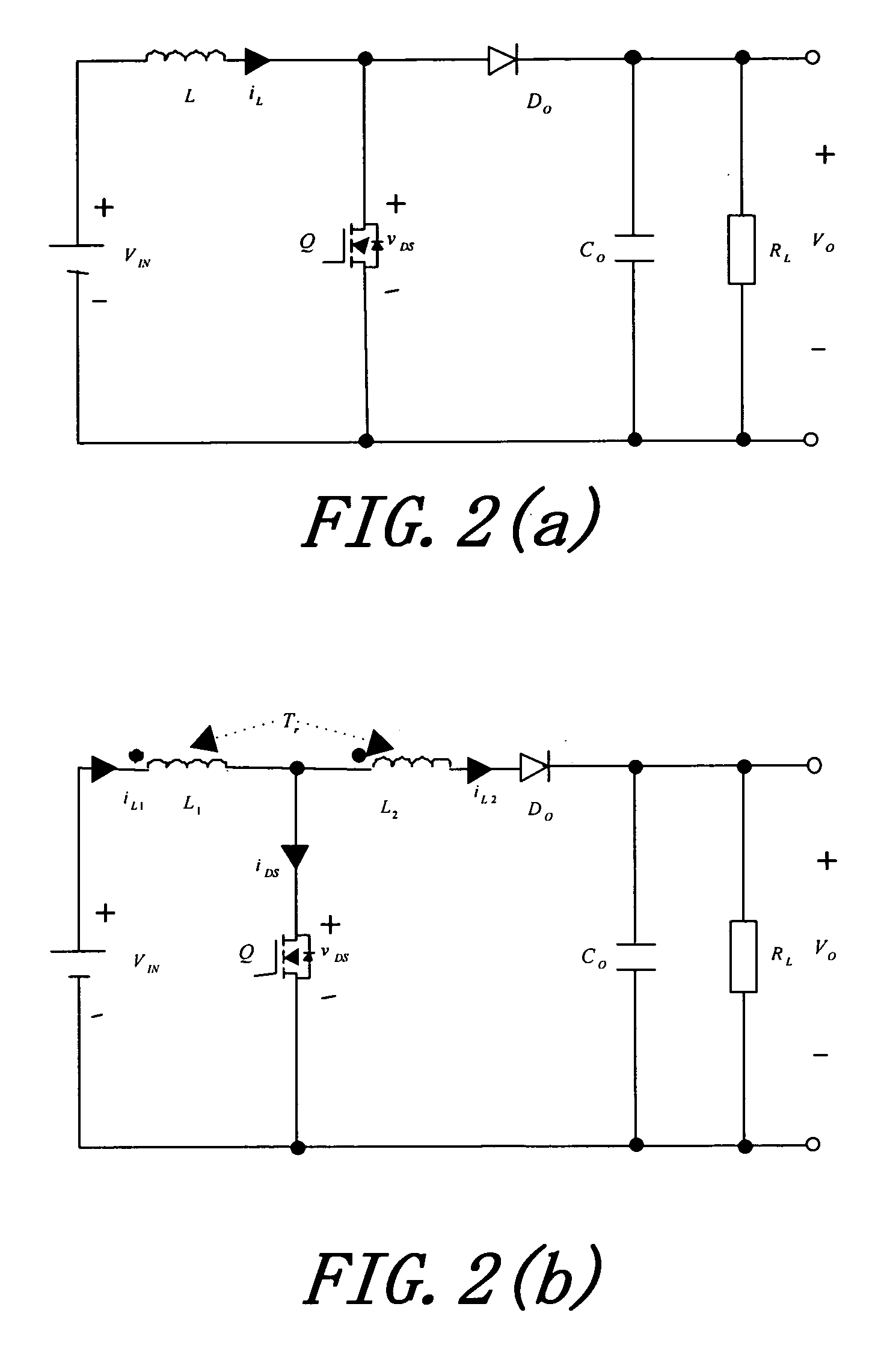

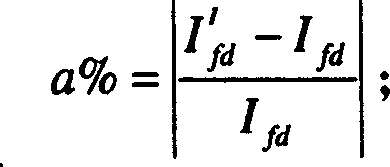

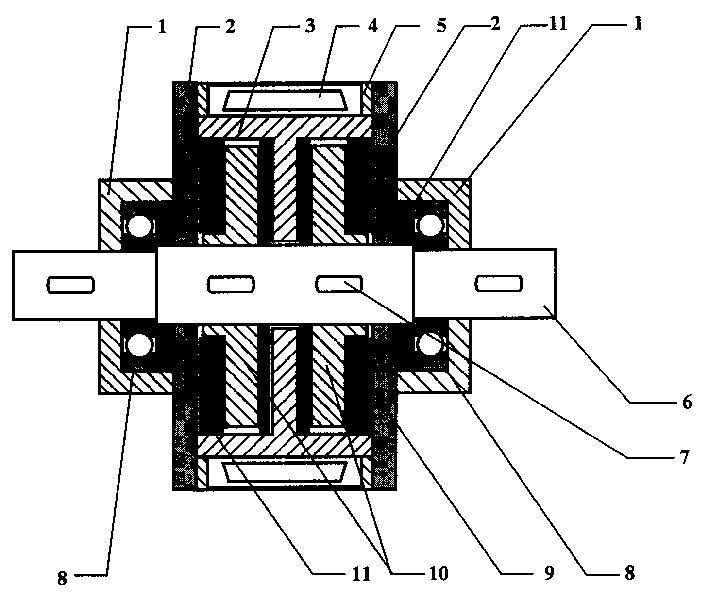

On-line fault diagnoses method on rotor winding inter turn short-circuit of turbine generator

InactiveCN101017191ASimple and fast operationHigh sensitivityDynamo-electric machine testingMagnetic currentExcitation current

This invention relates to one gas wheel motor rotor coil shortcut online test method in the test technique field, which comprises the following steps: through online real time collecting motor electrical parameter data and according to one certain work situation motor electrical parameter data to compute normal current theory values by reverse rotor normal current; then computing excitation magnetic current real value and theory value relative bias; the bias difference is as generation motor set to judge whether there is coil short cut fault as dialogue of the shortcut fault.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

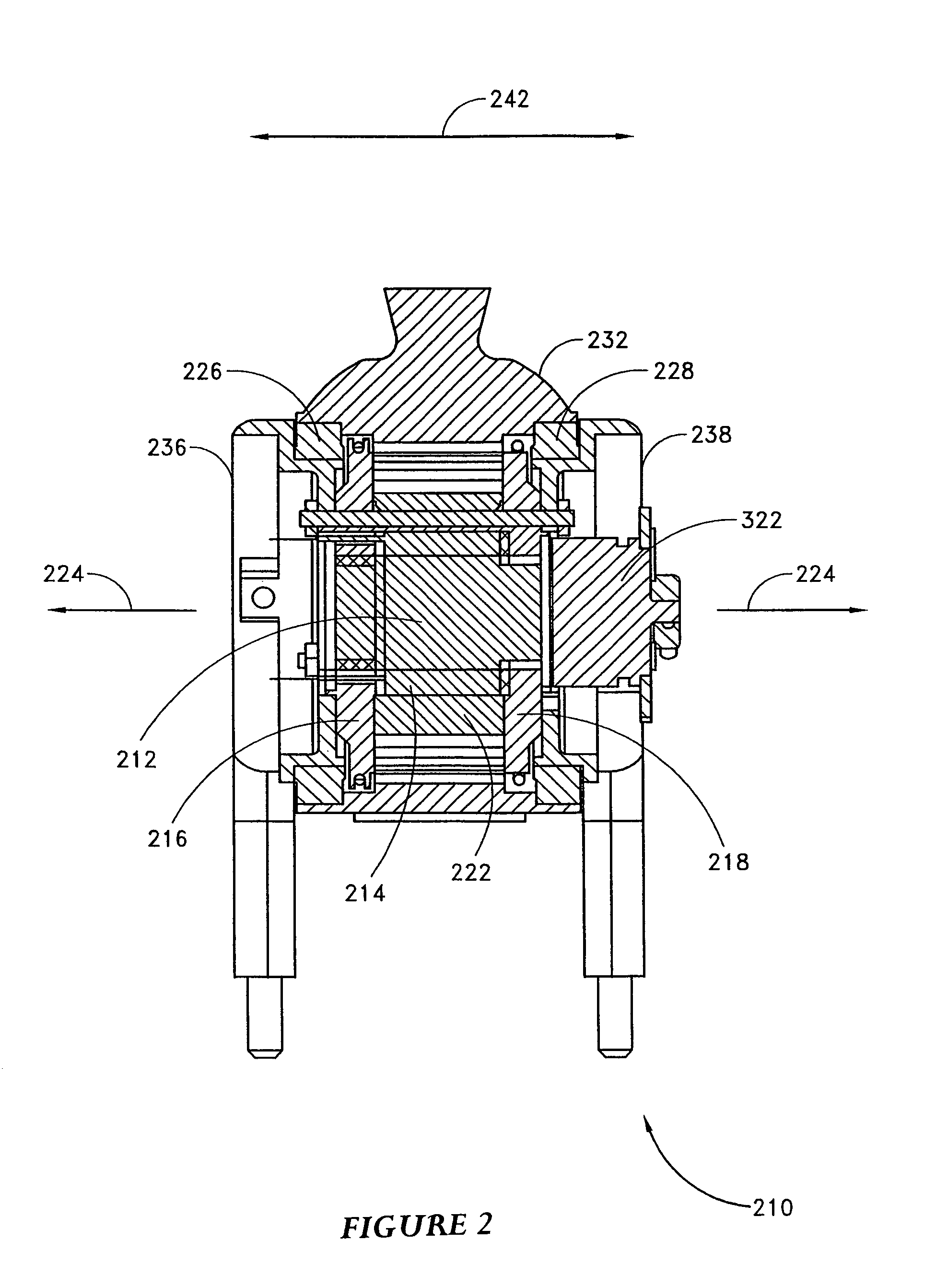

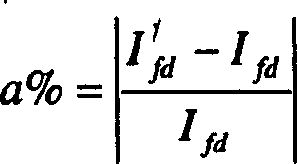

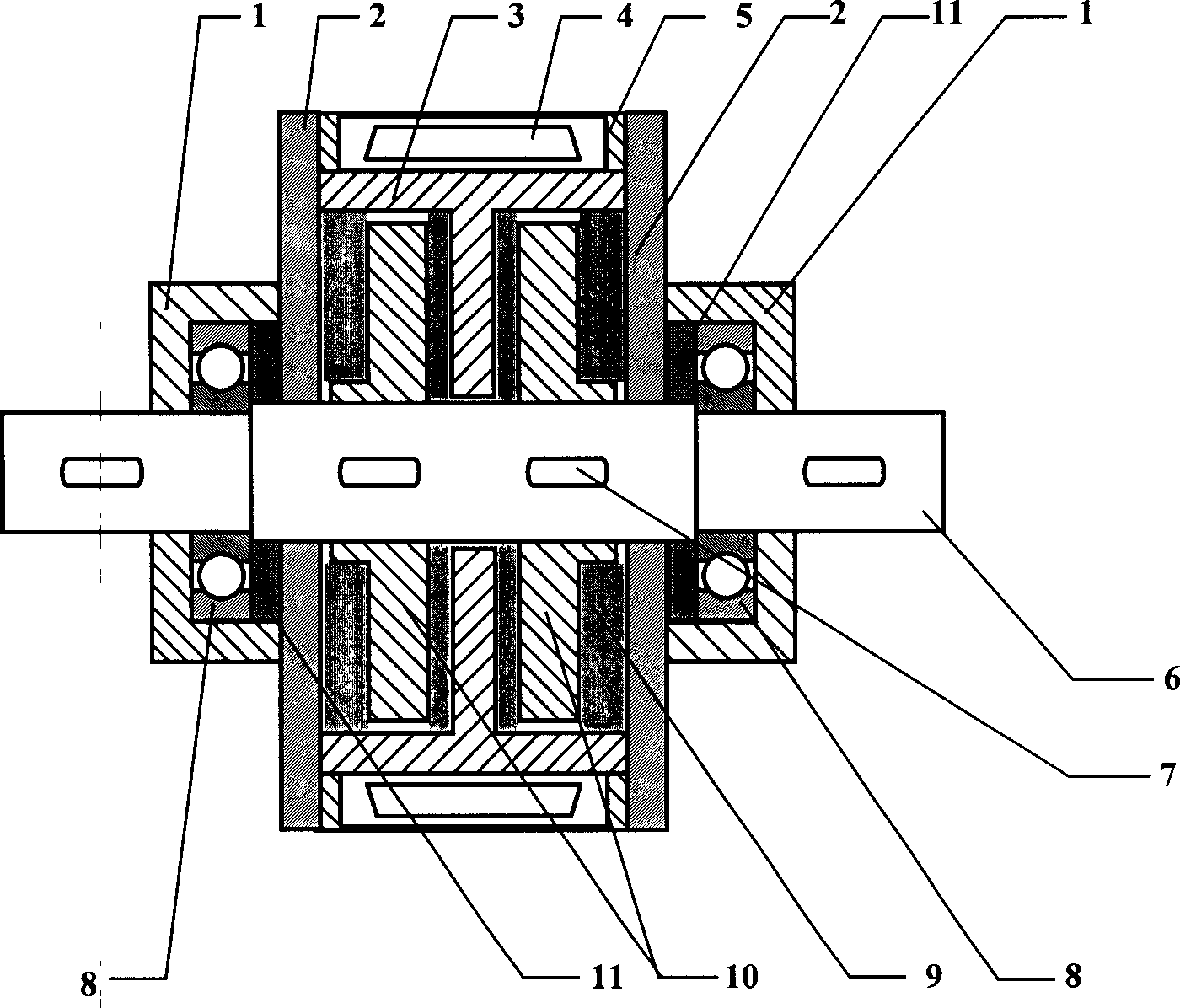

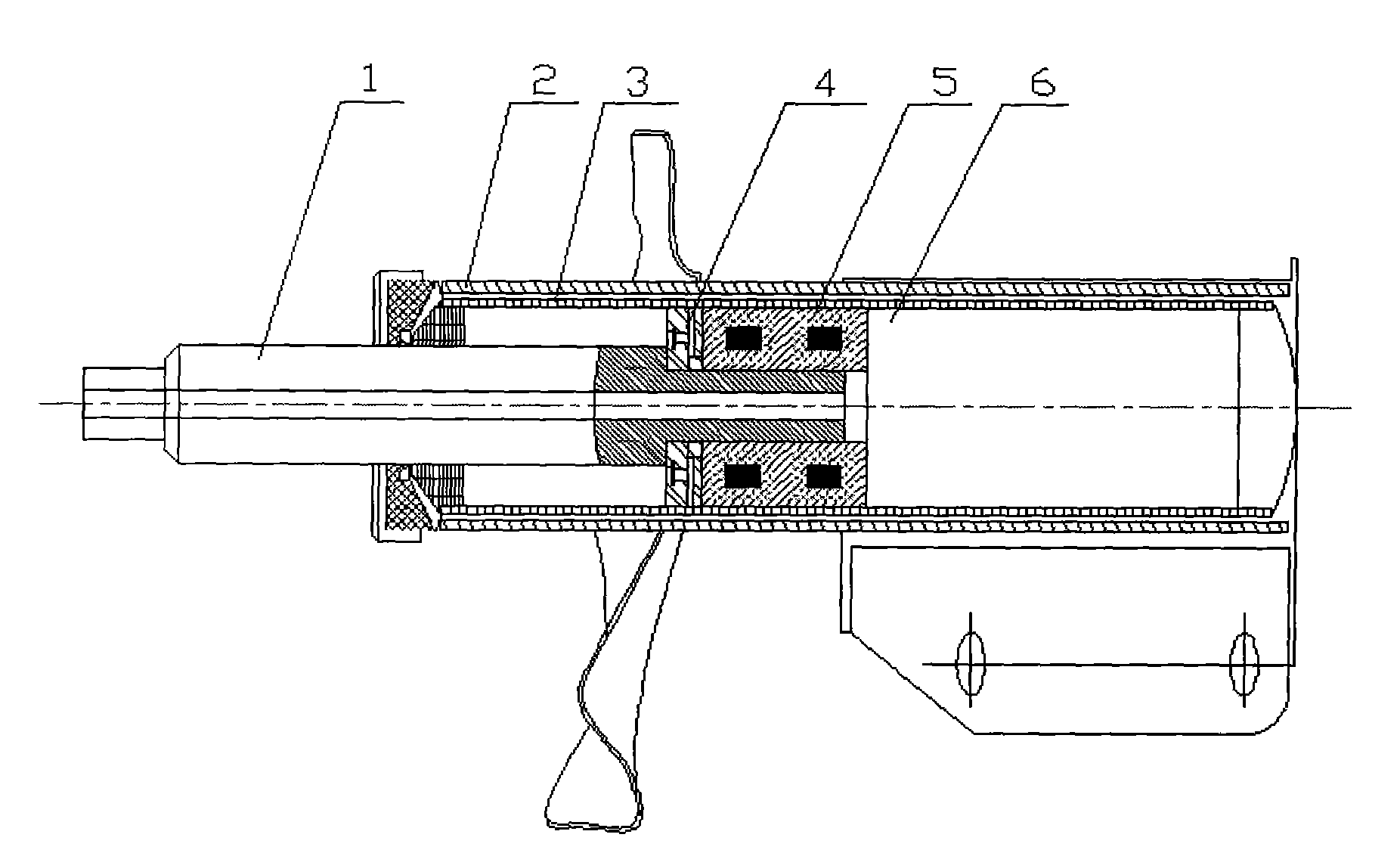

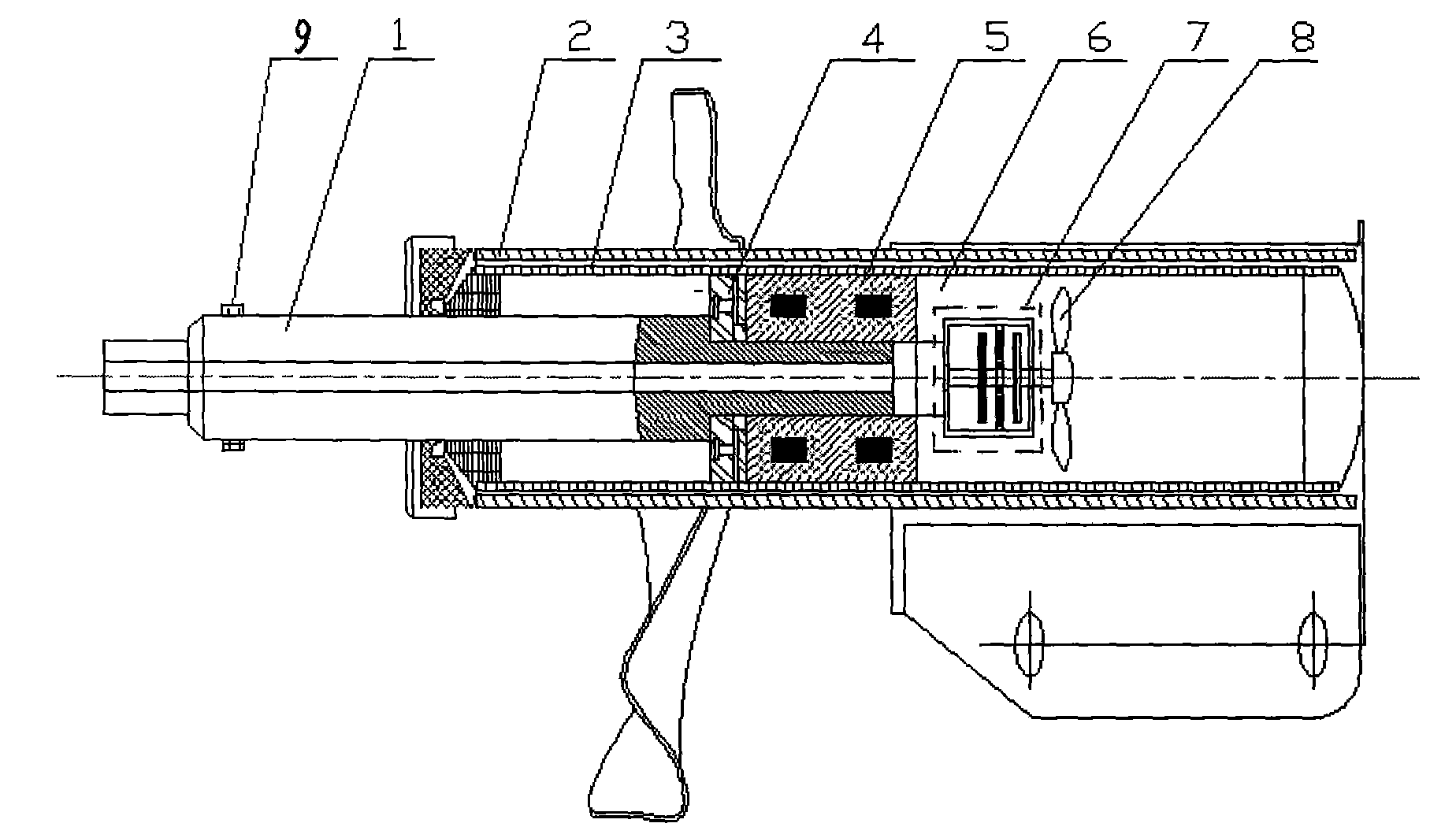

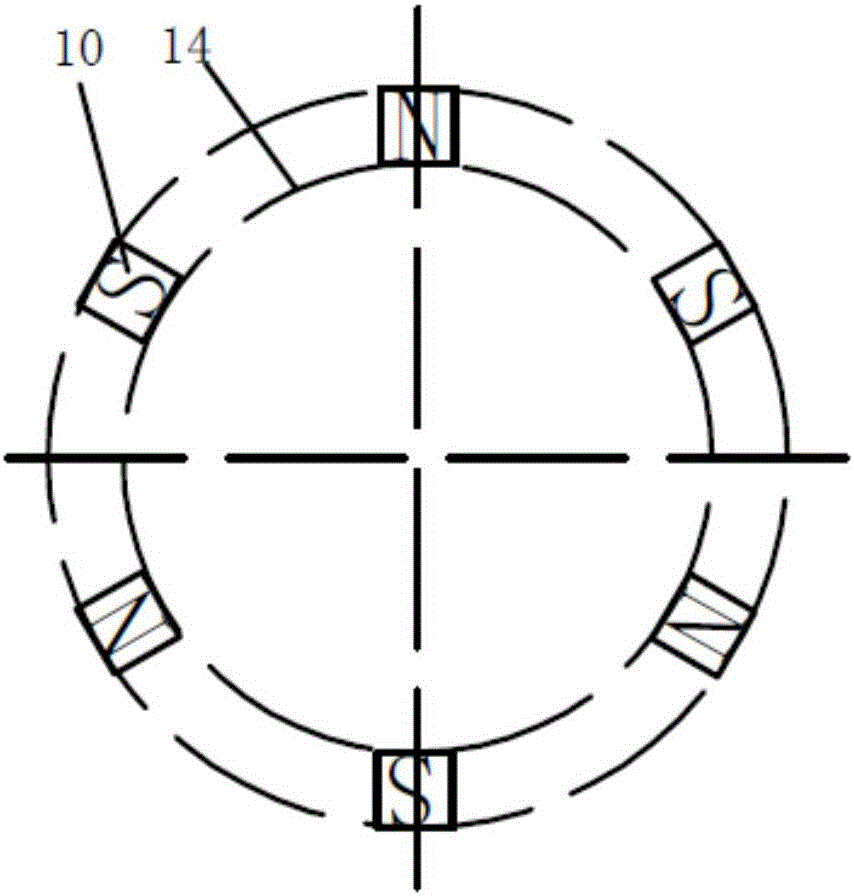

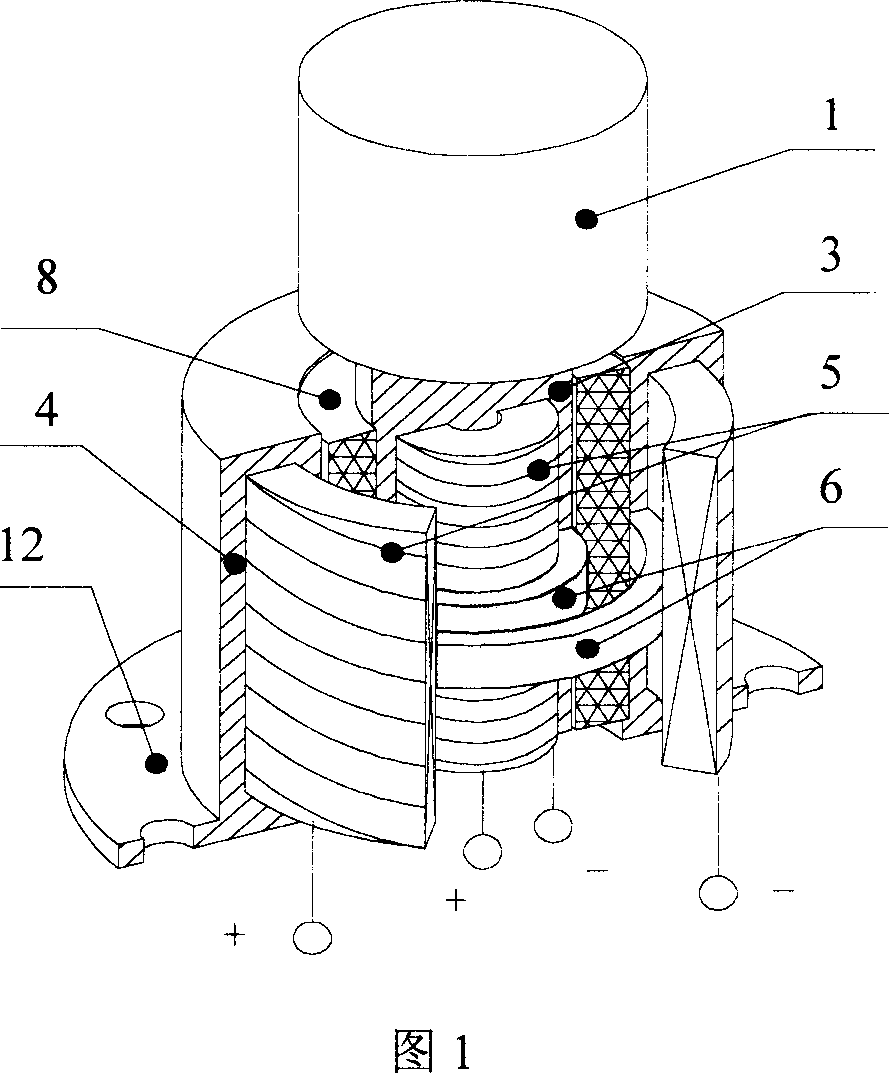

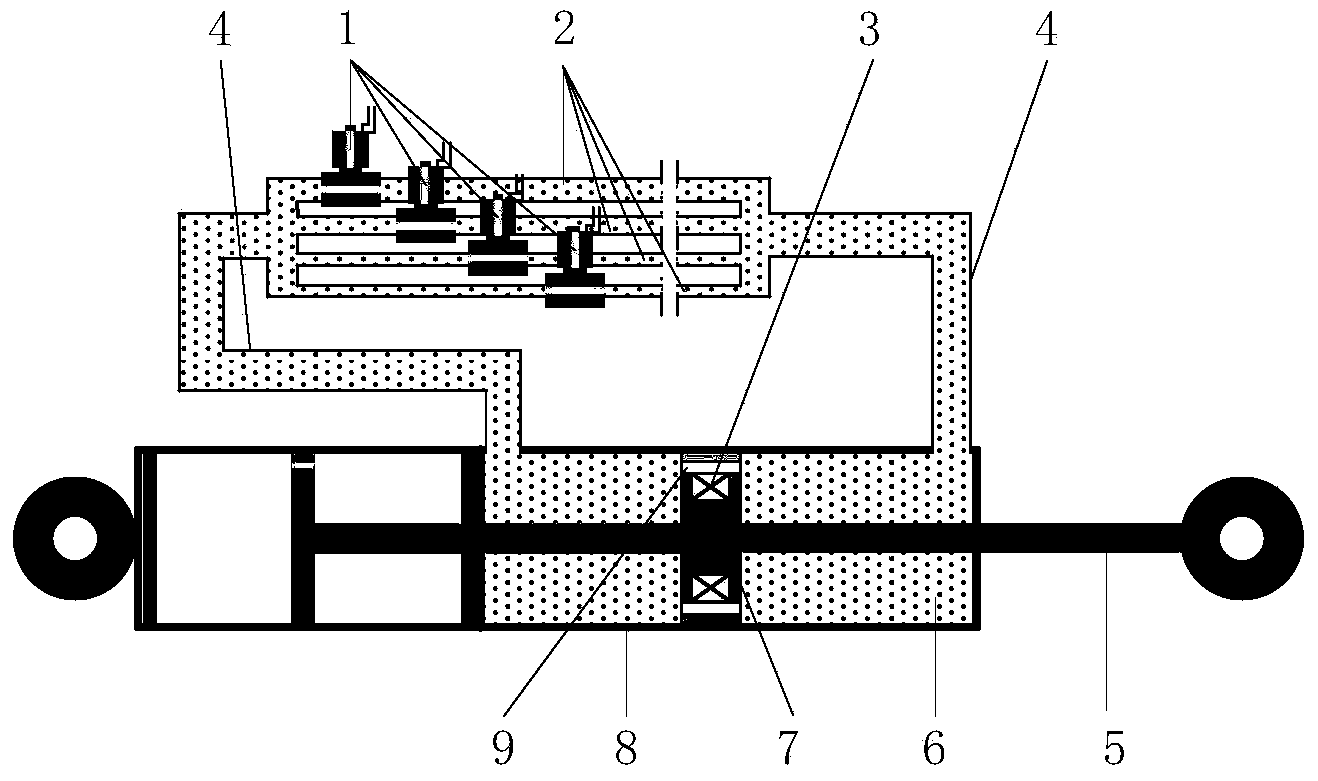

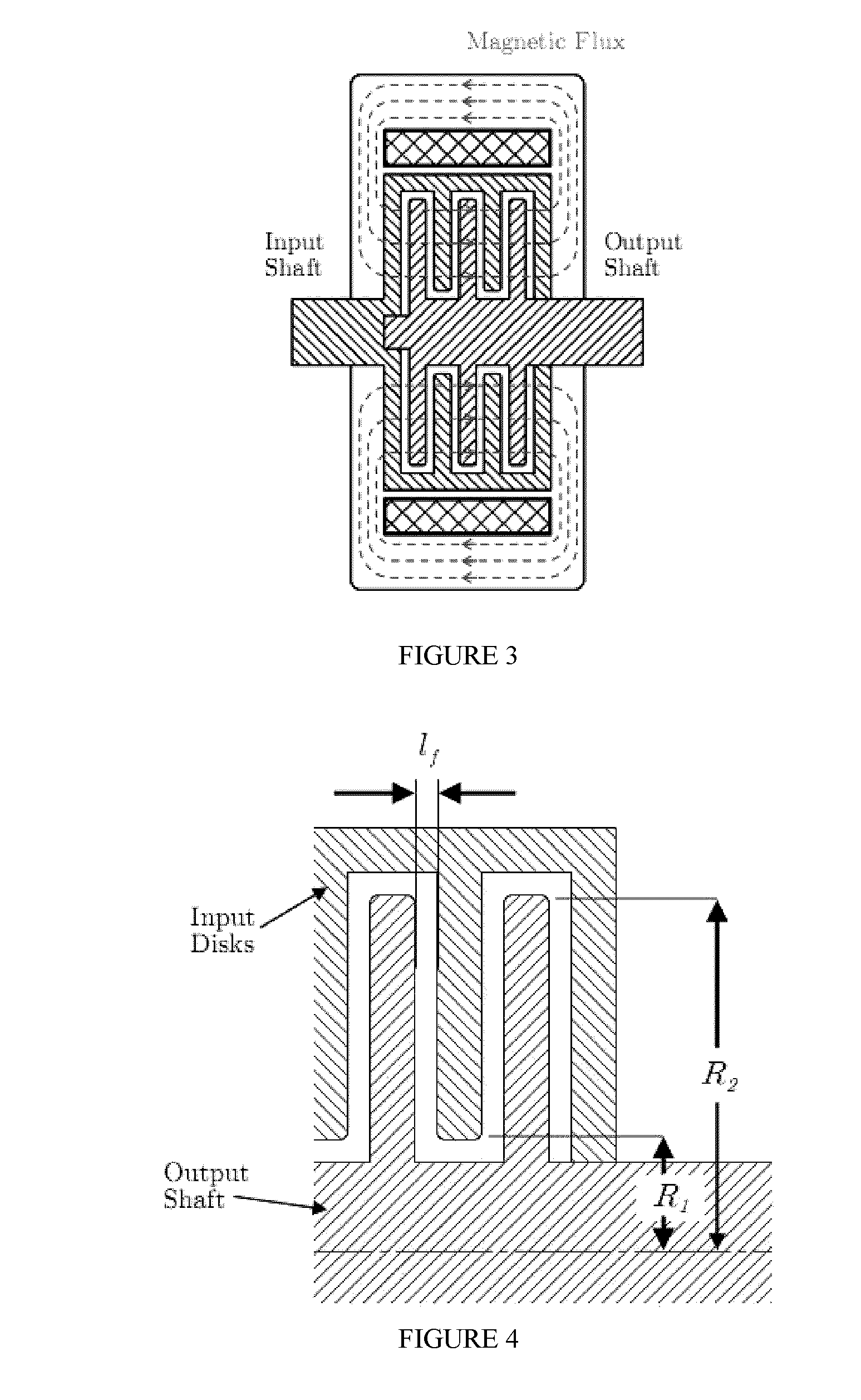

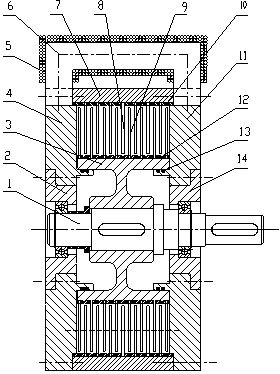

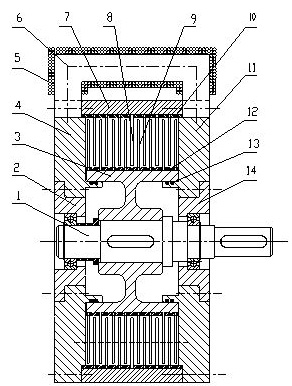

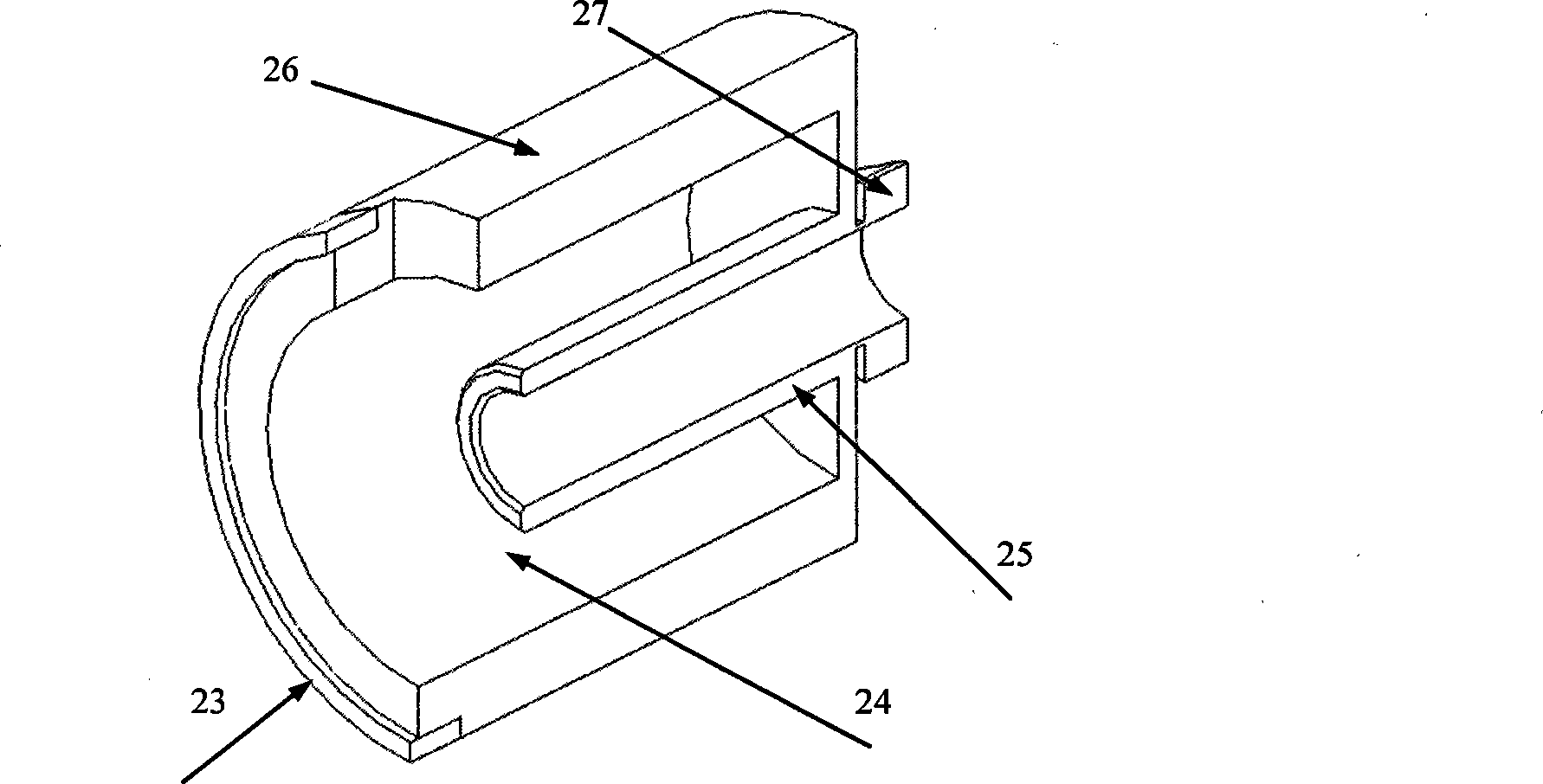

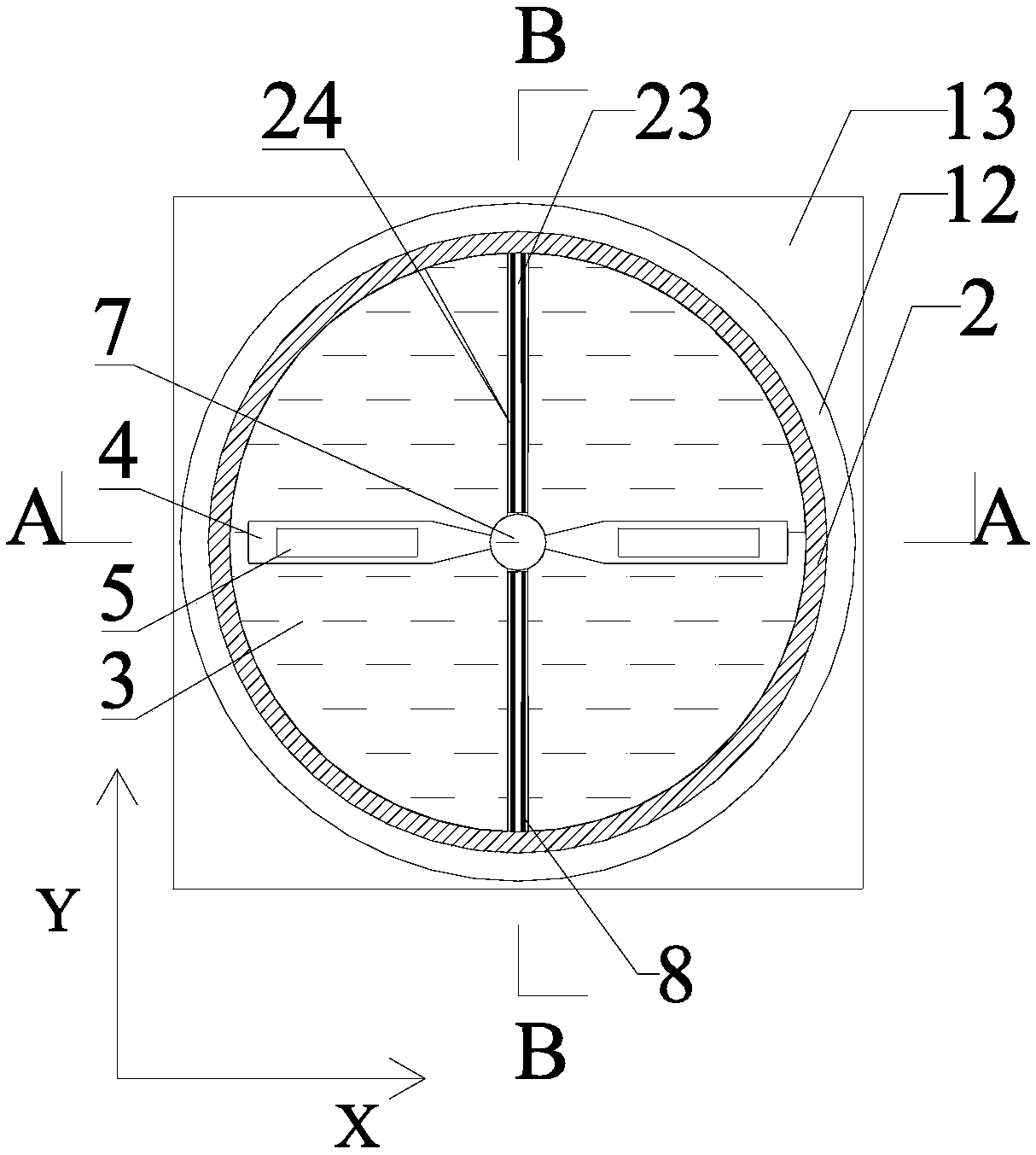

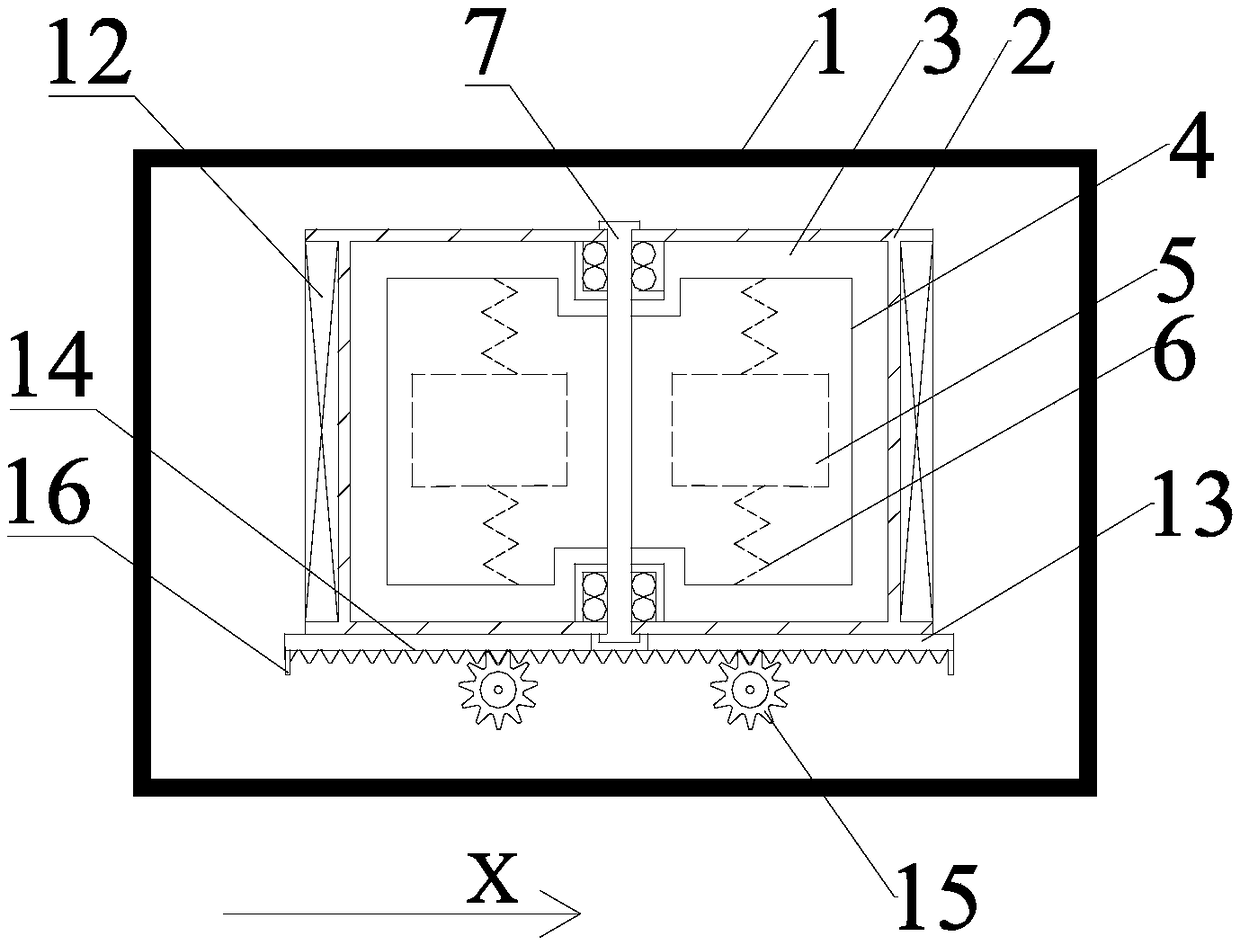

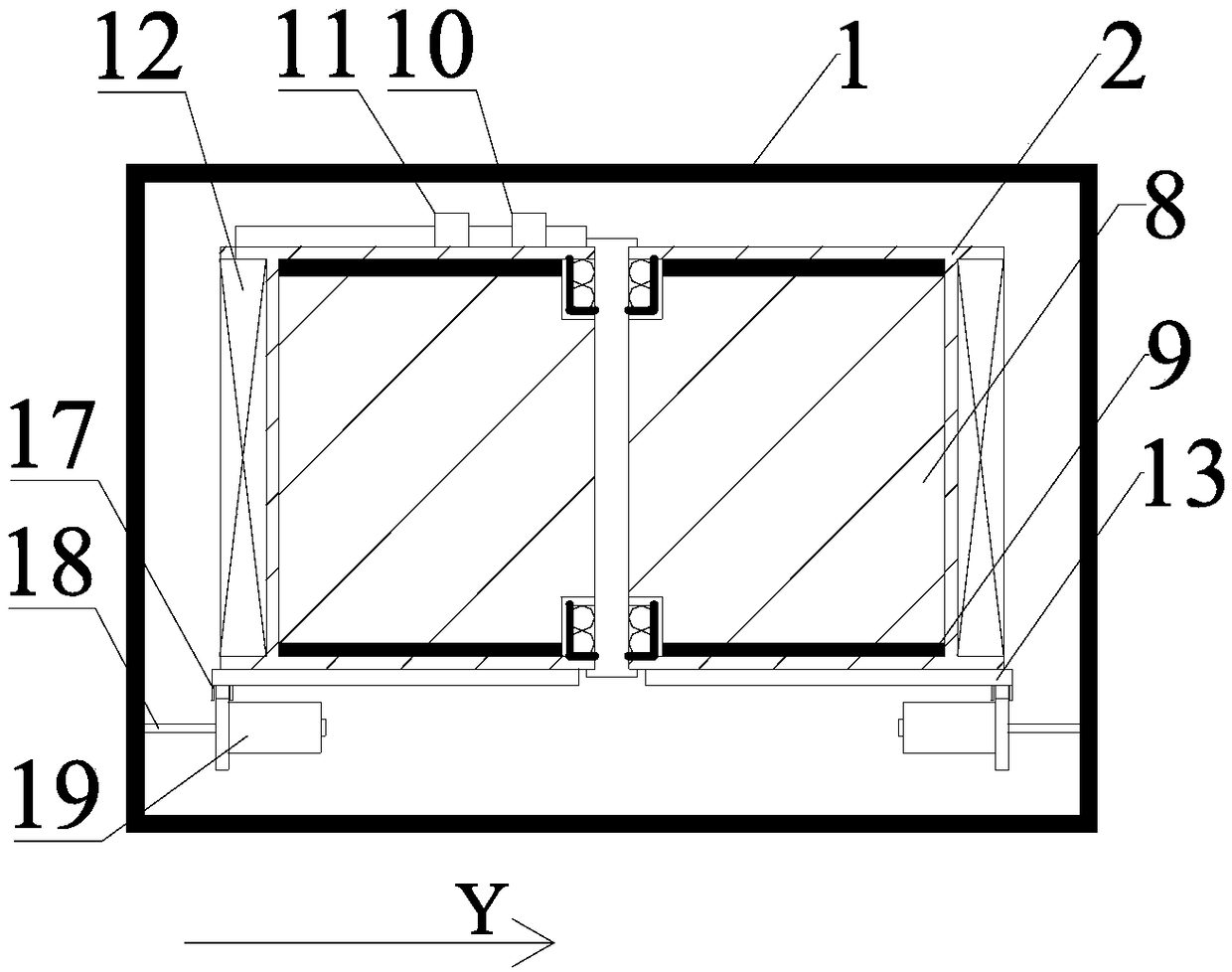

Construction variable rotary magnetic current flowing deforming brake

InactiveCN1482376ALarge damping torqueImproving magnetorheological efficiencyLiquid resistance brakesMagnetic currentRotating disc

Construction variable rotary magnetic current flowing deforming brake, mainly comprises a bearing end cap, sealing cap, magnetic conduction inside tube and outside tube, magnet coil, rotation shaft, positioning key, bearing, magnetic current variation liquid, rotating disc and sealing material, wherein the magnetic conduction inside tube and outside tube are both cylinders made of magnetic conduction material, and a separating arrangement is arranged on the magnetic conduction inner tube, the rotation shaft crosses the the magnetic conduction inner tube and connects with the rotating disc, the magnet coil is adhered into the magnetic conduction outer tube, and encloses the magnetic conduction inner tube, the magnetic current flowing deformation liquid is injected into the magnetic conduction inner tube, the separating arrangement is arranged on the magnetic conduction inner tube divides the brake into two chambers, which can determine to mount one or two rotating discs. The brake according to the invention can increase the magnetic current flowing deformation efficiency, and guarantees a large damping moment for the brake.

Owner:SHANGHAI JIAO TONG UNIV

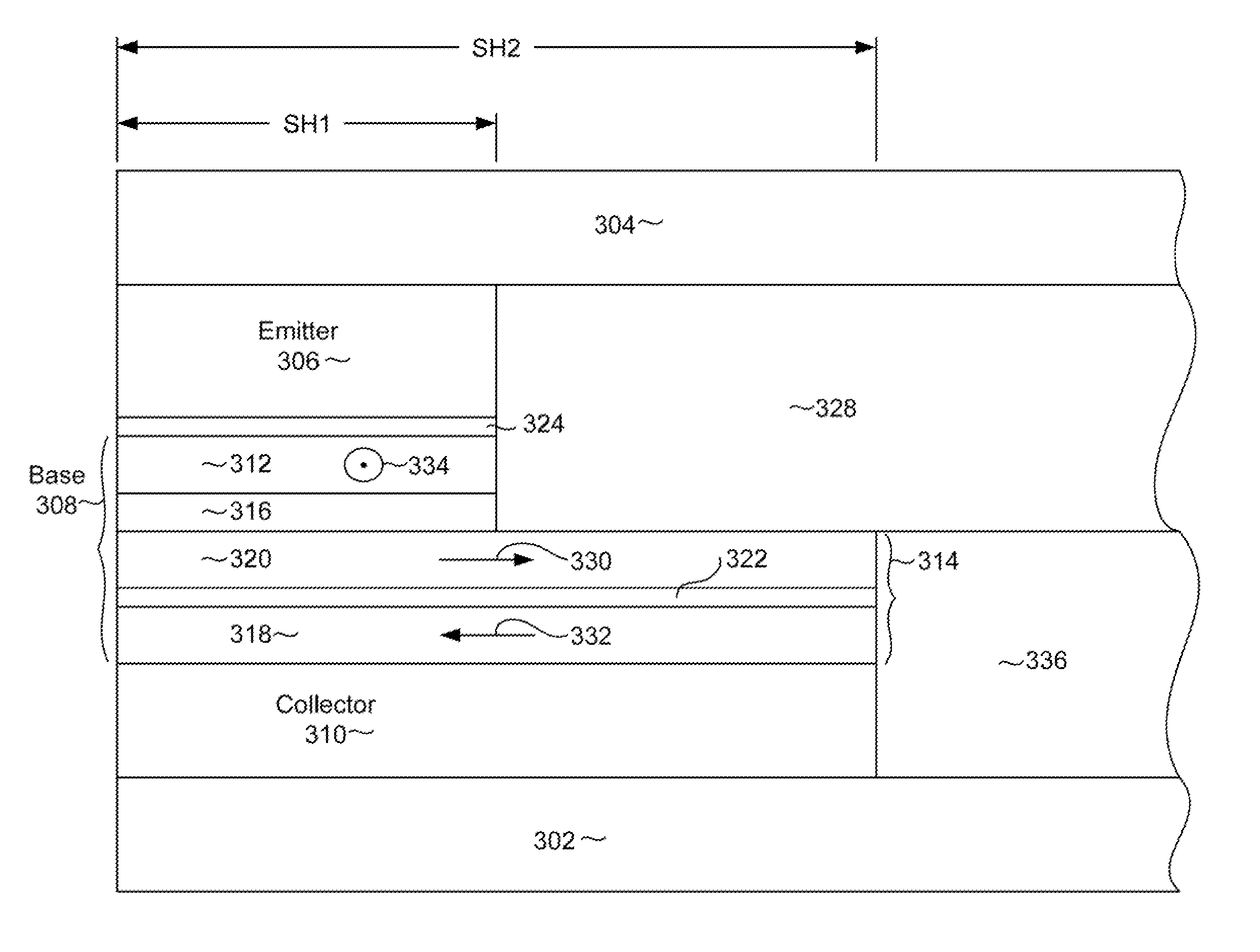

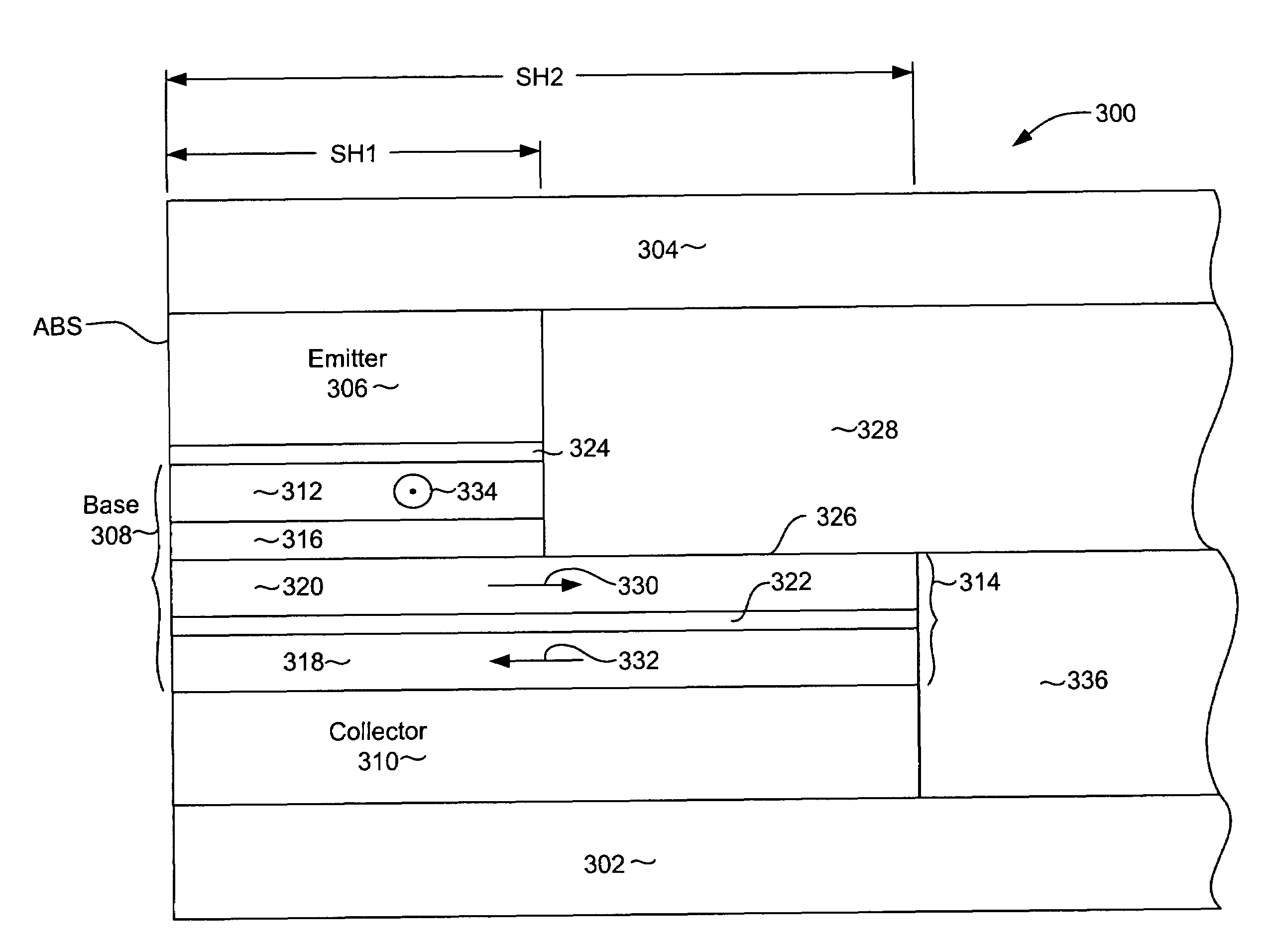

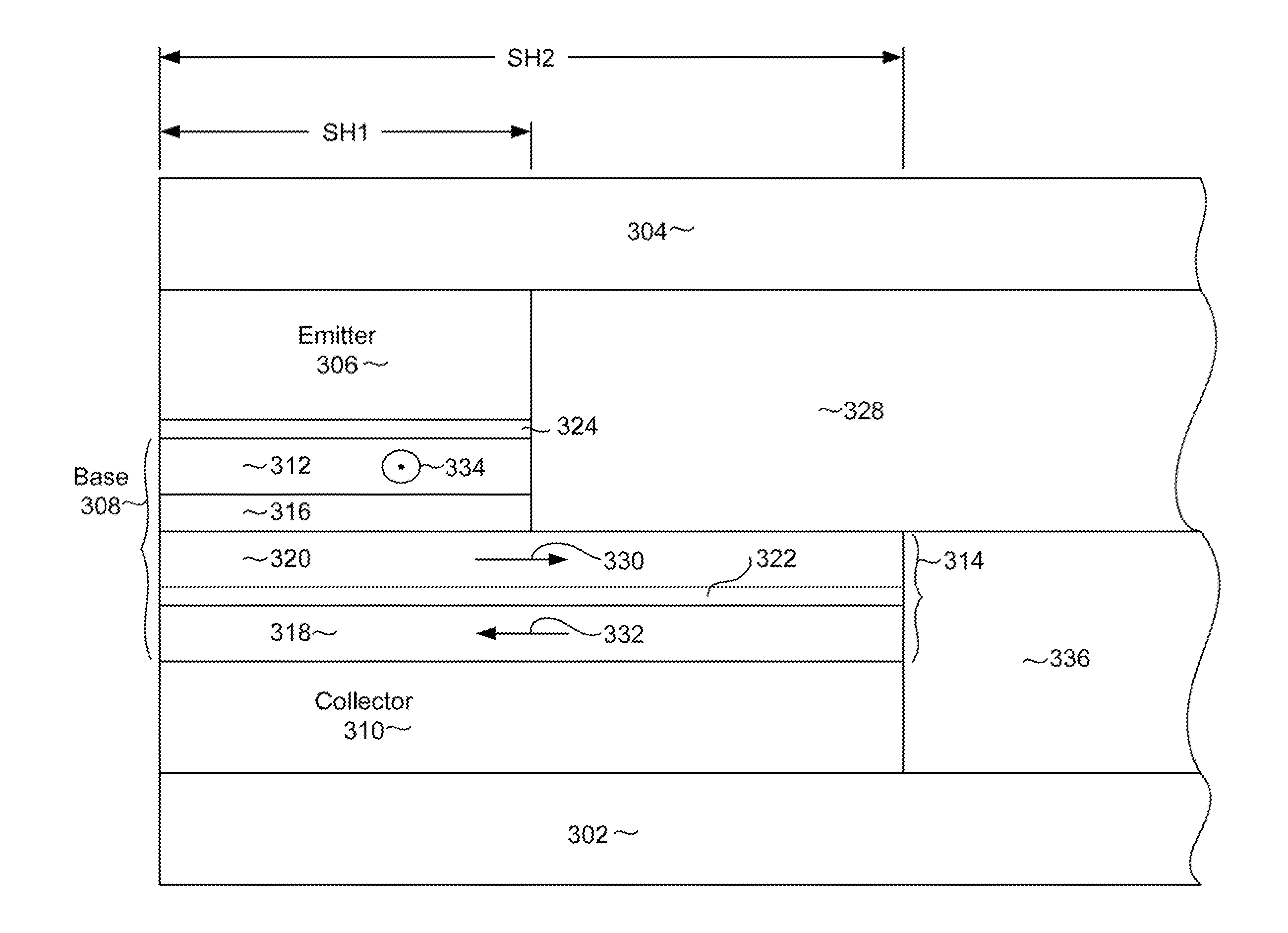

Magnetic tunnel transistor with high magnetocurrent

InactiveUS8068317B2Improve performanceReduce in quantityNanomagnetismNanoinformaticsMagnetic currentMagnetic anisotropy

A magnetic tunnel transistor (MTT) having a pinned layer that has no antiferromagnetic material in an active area of the sensor. The MTT can include a layer of antiferromagnetic material that is exchange coupled with the pinned layer in an area outside of the active area of me sensor, such as outside the track-width, beyond the stripe height, or both outside the track-width and beyond the stripe height. The pinned layer can also be pinned without any exchange coupling at all. In that case, pinning can be assisted by shape enhanced magnetic anisotropy, by extending the pinned layer beyond the stripe height.

Owner:WESTERN DIGITAL TECH INC

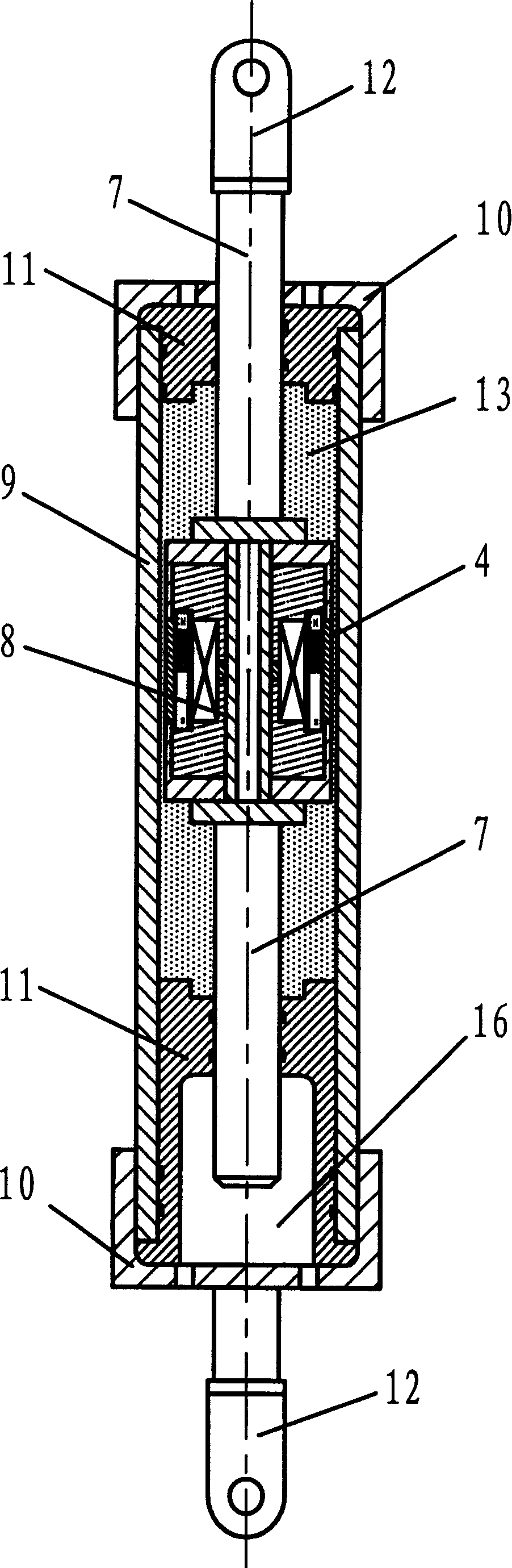

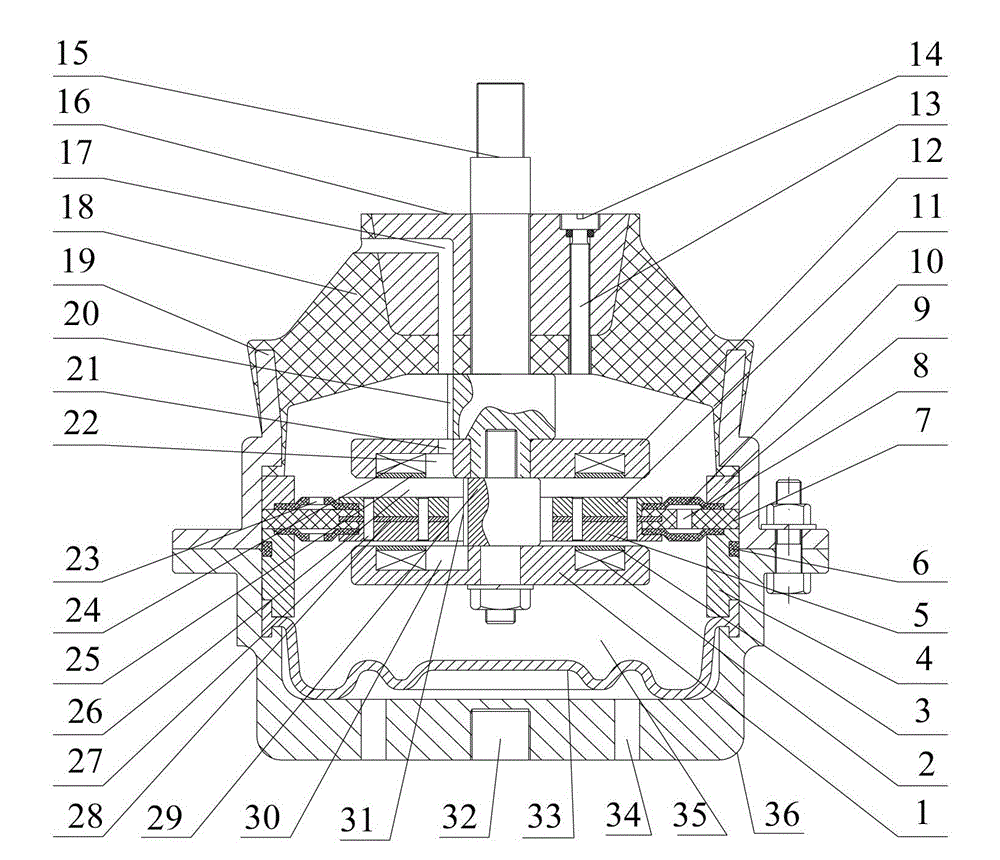

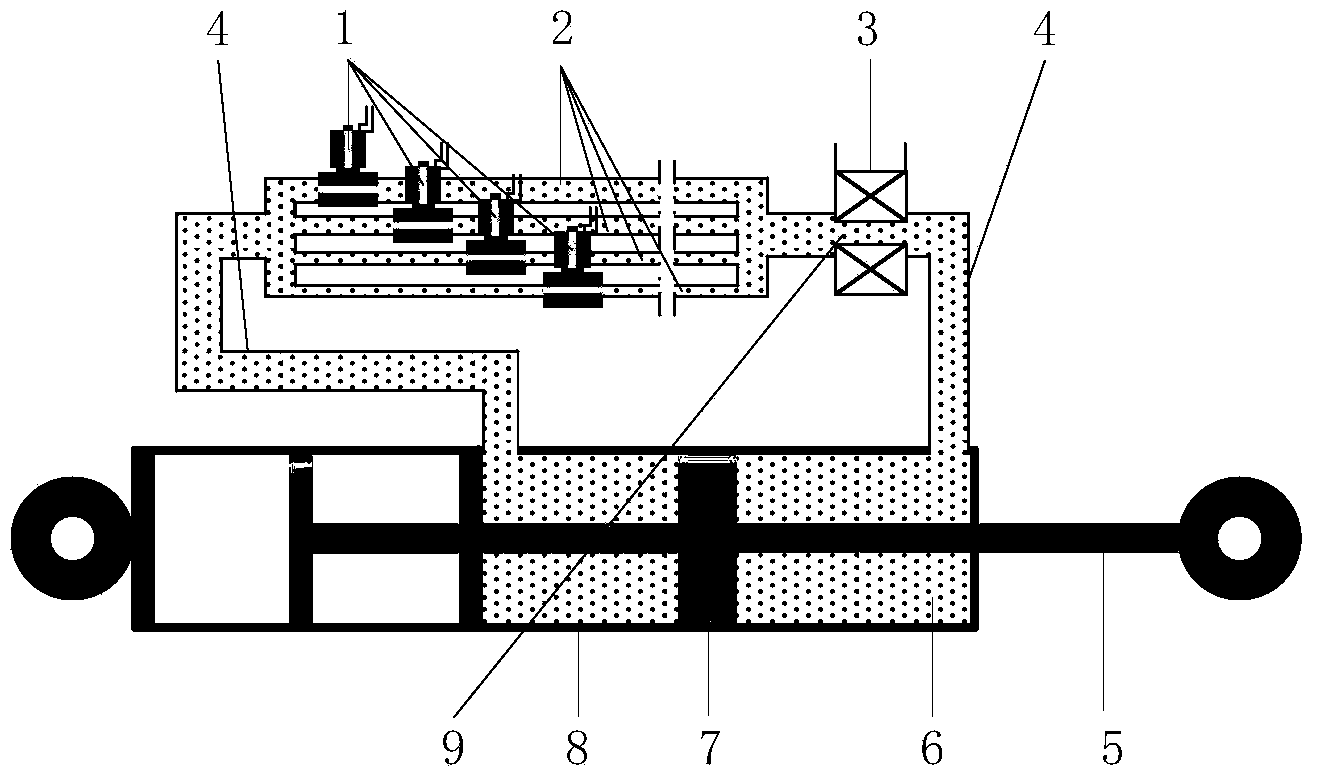

A self-supplied magnetic current damper

InactiveCN101550982AMeet the needs of workNon-rotating vibration suppressionMagnetic currentRare earth

The invention presents a self-supplied magnetic current damper, which includes a magnetic current damper, a vibration energy collector, and an energy storage management module. The energy collector is a multi-vane disc shaped electro-magnetism type mechanical energy collector installed on the piston bottom of the magnetic current damper, which is composed of multiple impellers and disc shaped magnetoelectric transducers, wherein, the disc shaped magnetoelectric transducers are mounted on the piston, the multiple impellers are mounted on the rotor of the disc shaped magnetoelectric transducers, and the energy produeced by the disc shaped magnetoelectric transducers is lead out by the coil on the stator. The output lines of the disc shaped magnetoelectric transducers are connected to the energy storage management module, and the output of the energy storage management module is connected to the magnetizing coil of the magnetic current damper. During work, the magnetic current liquid impacts the vanes, the impeller converts the fluid washing into the rotation of the disc shaped stator inlaid on the rare-earth permanent magnet, the magnetic flux of the coil on the disc shaped stator is changed, in order to achieve effective collection of mechanical energy, and greatly reduce the transducer volume.

Owner:CHONGQING UNIV

Magnetic tunnel transistor with high magnetocurrent and stronger pinning

InactiveUS7372674B2Improve performanceReduce in quantityNanoinformaticsMagnetic field measurement using galvano-magnetic devicesMagnetic currentPerformance enhancement

A magnetic tunnel transistor (MTT) having a pinned layer that is extended in a stripe height direction and is exchange coupled with an antiferromagnetic (AFM) layer in the extended portion outside of the active area of the sensor. Exchange coupling only the extended portion of the pinned layer with the AFM results in strong, robust pinning of the pinned layer while eliminating the AFM layer from the active portion of the sensor. The presence of an AFM layer within the active area of the sensor would result in an extreme loss of hot electrons resulting in a prohibitively large loss of performance. Therefore, eliminating the AFM layer from the active area provides a very large performance enhancement while maintaining robust pinning.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Magnetic elements with ballistic magnetoresistance utilizing spin-transfer and an MRAM device using such magnetic elements

InactiveUS20060192237A1Improve signal outputTransistorNanostructure applicationMagnetic currentCharge carrier

A method and system for providing a magnetic element is disclosed. The method and system include providing a pinned layer, a magnetic current confined layer, and a free layer. The pinned layer is ferromagnetic and has a first pinned layer magnetization. The magnetic current confined layer has at least one channel in an insulating matrix and resides between the pinned layer and the free layer. The channel(s) are ferromagnetic, conductive, and extend through the insulating matrix between the free layer and the pinned layer. The size(s) of the channel(s) are sufficiently small that charge carriers can give rise to ballistic magnetoresistance in the magnetic current confined layer. The free layer is ferromagnetic and has a free layer magnetization. Preferably, the method and system also include providing a second pinned layer and a nonmagnetic spacer layer between the second pinned layer and the free layer. In this aspect, the magnetic element is configured to allow the free layer magnetization to be switched using spin transfer.

Owner:SAMSUNG SEMICON

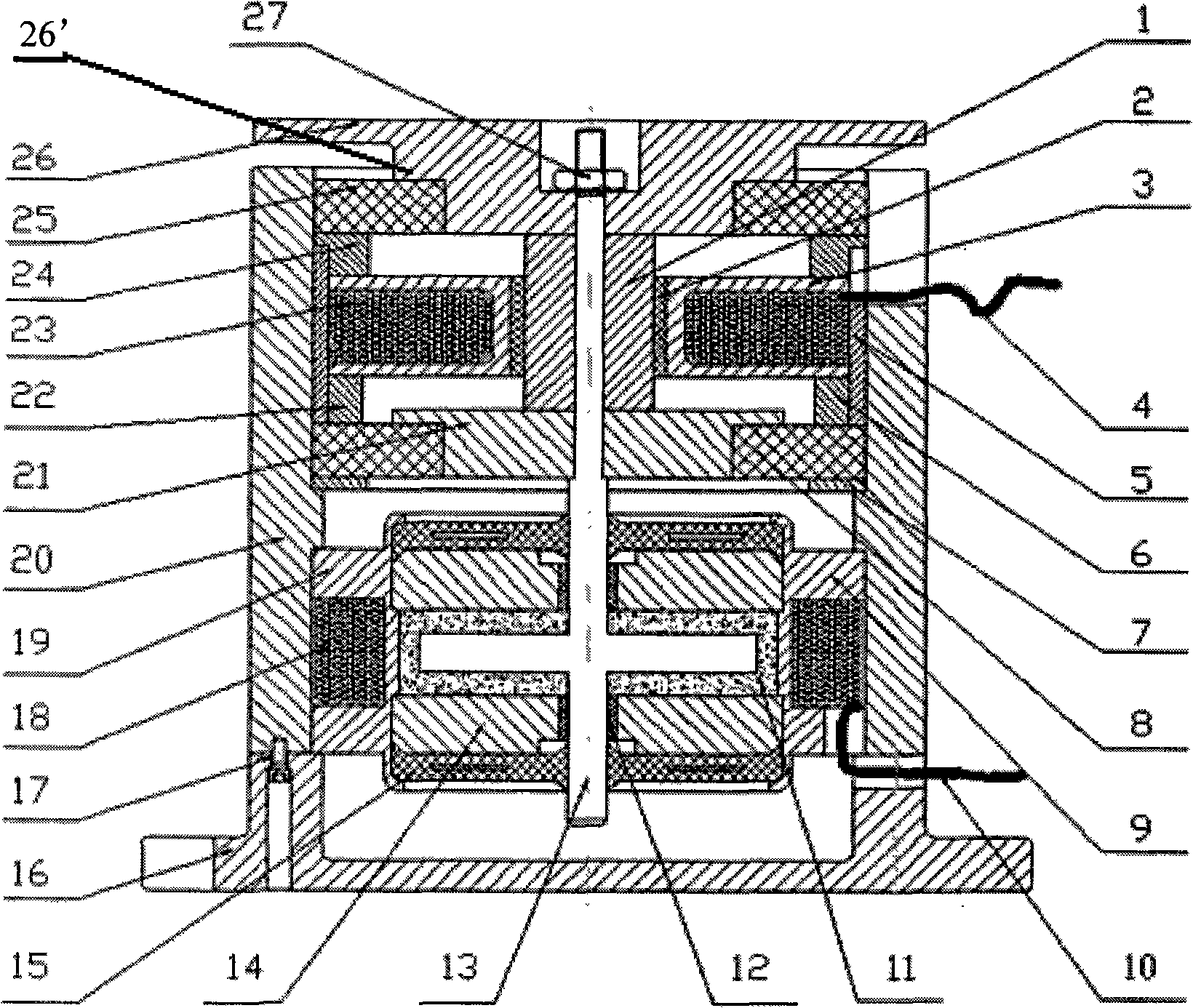

Inverse type magnetic flow damper

InactiveCN1587738AGuaranteed to workSpringsNon-rotating vibration suppressionMagnetic currentMaster cylinder

A kind of inversion magnetic current alter amortisseur,which has application in the absorption of vibration of the building structure and the locomotive cars. It includes the cylinder body,the piston, the piston rod which connected to it, the confinement gasoline device of the both sides of the cylinder body and the cylinder cap, there has magnetic current alternative liquid in the void of the cylinder body, and institutes the magnetizer that generates the magnetic field and the energizing coil and the electromagnet magnetic circuit component which is unitized of the running void, the cylinder body is composed of the master cylinder, or the master cylinder and the set jar, or the master cylinder and bypass jar, its character is:Institutes both the energizing coil and the permanent magnet magnetic circuit, composes the compounded magnetic circuit with the energizing coil and the permanent magnetic field, and also institutes the administer void in the electromagnet circuit, and when the power is cut, the most of the permanent magnetic field that generated by the permanent magnet will pass through the running void, so the amortisseur can work at the great amortization condition. The component of the electromagnet circuit may set at the pertinent position in terms of the different cylinder body. This kind of amortisseur can joint with the controlled structure, fulfills the semiactivly controlled with the absorption of vibration.

Owner:BEIJING UNIV OF TECH

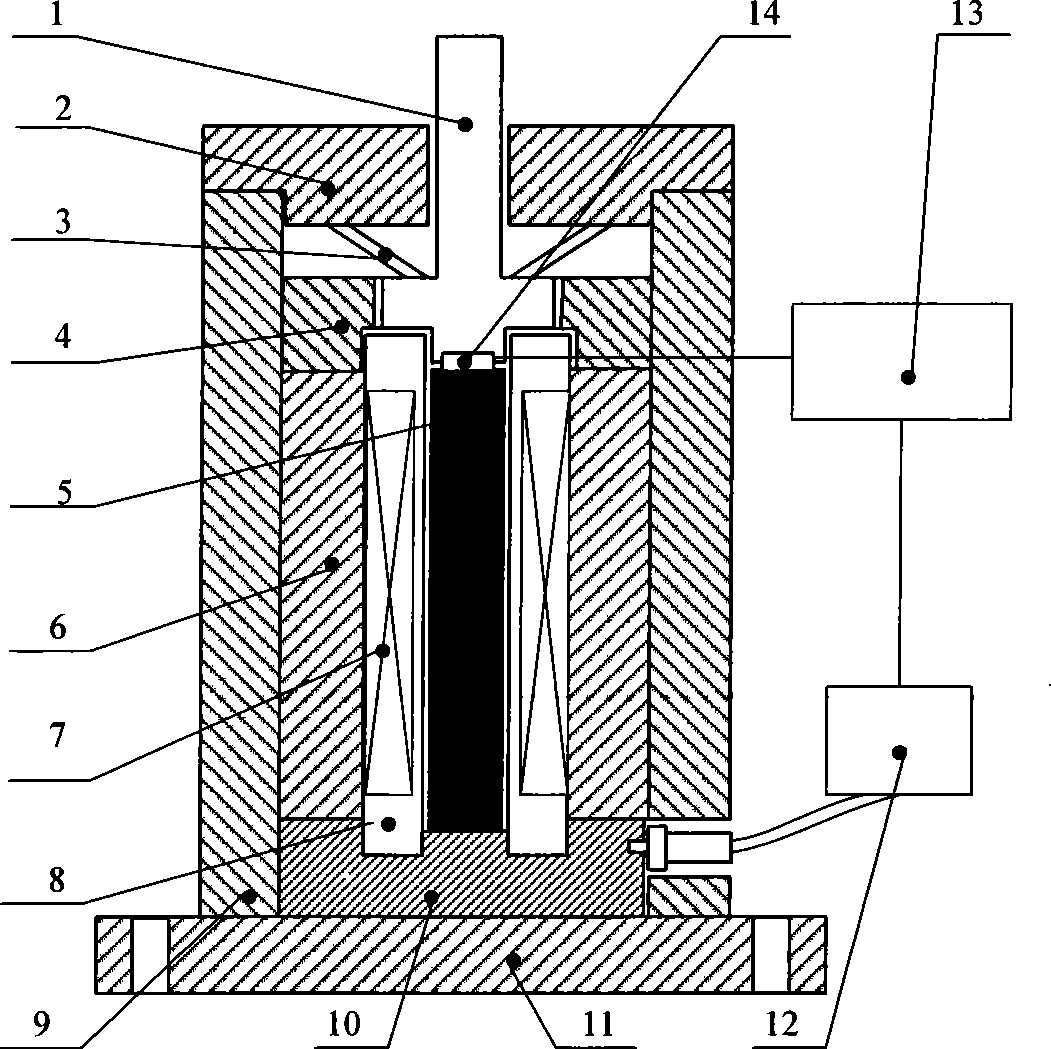

Magnetic rheology elastic body active-passive integrated damper based on extrusion type applied force

InactiveCN101251164AImprove control effectImprove carrying capacityNon-rotating vibration suppressionSolid based dampersMagnetic currentVibration control

The invention relates to a magnetorheological elastomer active and passive integrated damper based on an extrusion type stress, which belongs to the structure vibration isolation and control field, wherein a magnetorheological elastomer is arranged in a magnetic conductive sleeve; the upside of the magnetorheological elastomer is connected with a joint lever; the lower part of the magnetorheological elastomer is fixedly connected with a lower positioning plate; a groove is arranged on an outer circumferential surface of the magnetic conductive sleeve positioned in a permanent magnet, embedded with a coil winding and positioned and fixed by an upper positioning plate and the lower positioning plate; the permanent magnet, the upper positioning plate, the lower positioning plate and the lower part of the joint lever are arranged in an outer magnet isolating cylinder; the upside of the outer magnet isolating cylinder is provided with an upper end closure; the upper part of the joint lever extends out from a pylome of the upper end closure and is connected with a controlled object; a pretightening spring is sleeved on the joint lever; the bottom of the outer magnet isolating cylinder is provided with a lower end closure; a sensor is fixed on the joint lever and connected with a power amplifier through a control unit module; the power amplifier is connected with the coil winding through cables. The magnetorheological elastomer active and passive integrated damper has large bearing capacity, a simple structure and can be automatically suitable for active and passive vibration control and has wide application range.

Owner:SHANGHAI JIAO TONG UNIV

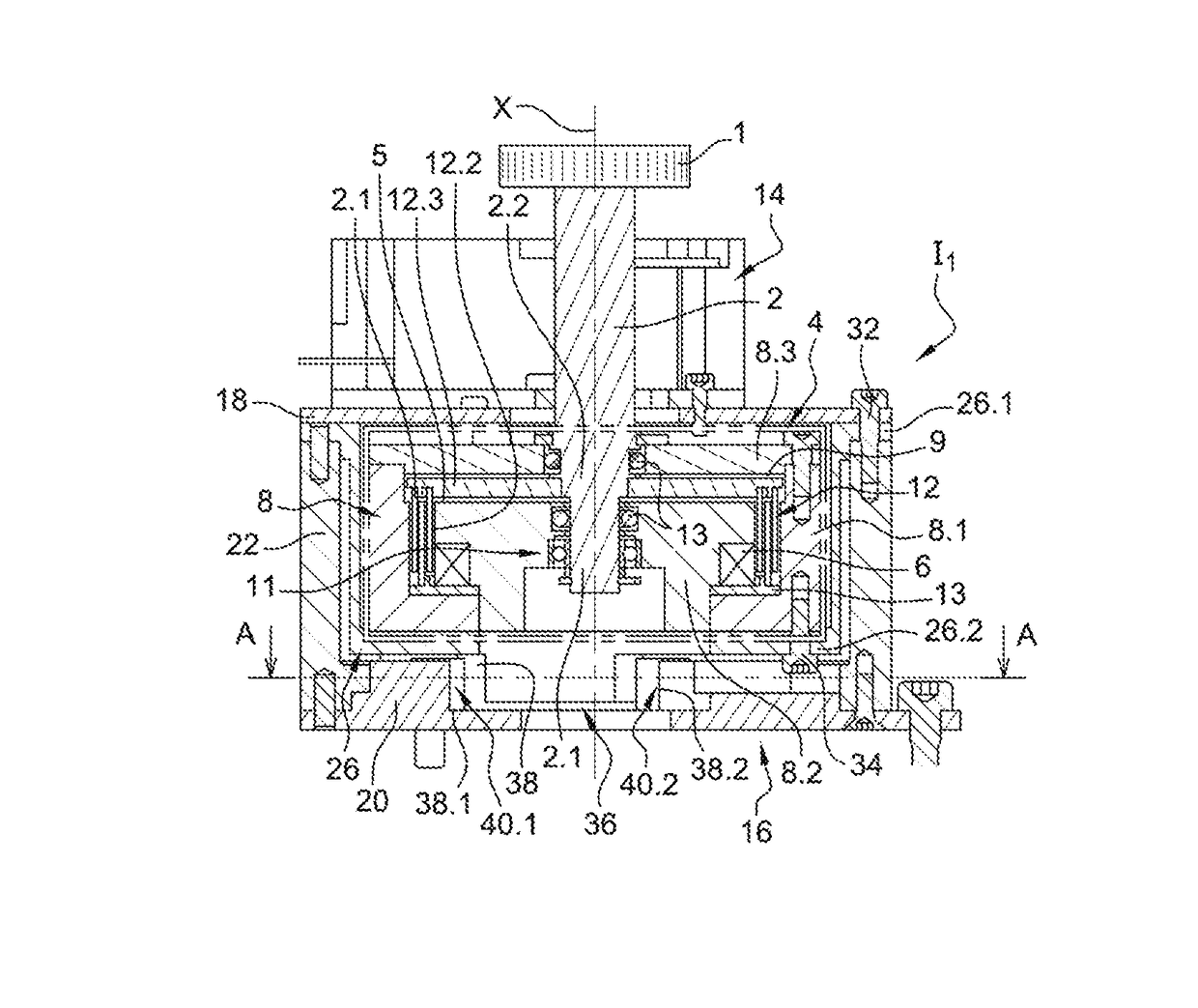

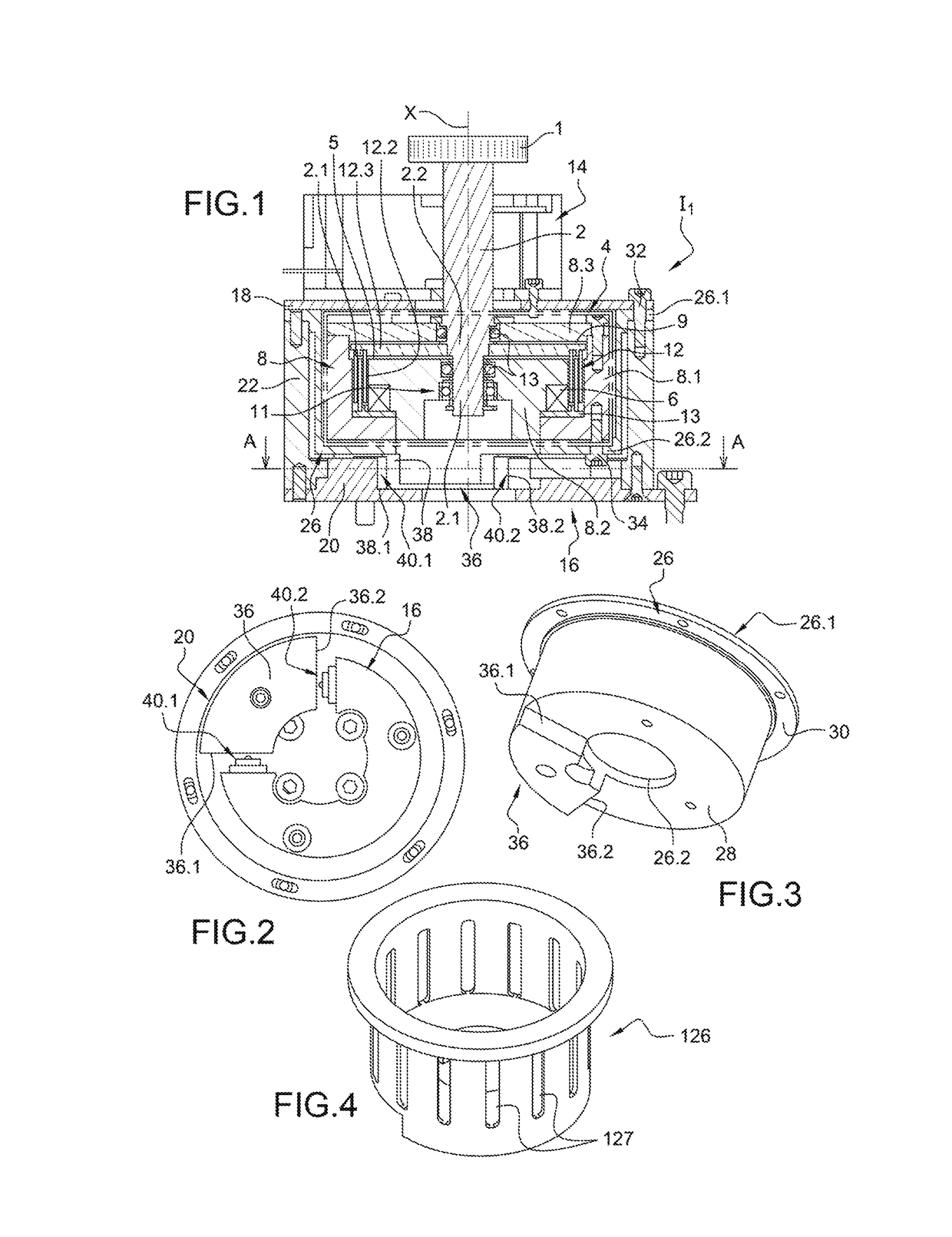

Fluid haptic interface with improved haptic rendering using a torque or load sensor

ActiveUS9898032B2Improved haptic renderingReduce, or even suppress, a spatial and time delay in the control of the interfaceControlling membersSpringsMagnetic currentLow speed

A haptic interface, including: a button which can be rotated by a user; an interaction element interacting with a magnetorheological fluid, secured to the button; a mechanism measuring a current position of the button; a brake including a magnetorheological fluid and a generation system to generate a magnetic field in the fluid; a controller configured to generate orders for the system to generate a magnetic fluid to modify a value of the magnetic field; and a mechanism to detect torque exerted by a user on the button to know direction of the torque and whether the torque is greater than a given value for a given direction, the controller controlling generation of a magnetic field based on obtained information about the torque at least when the button indicates zero or low speed.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

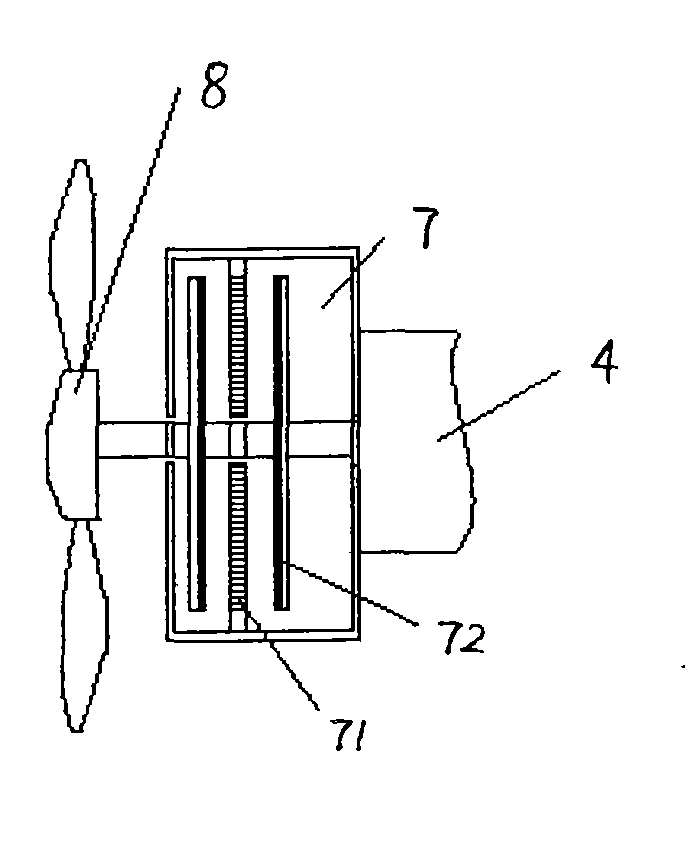

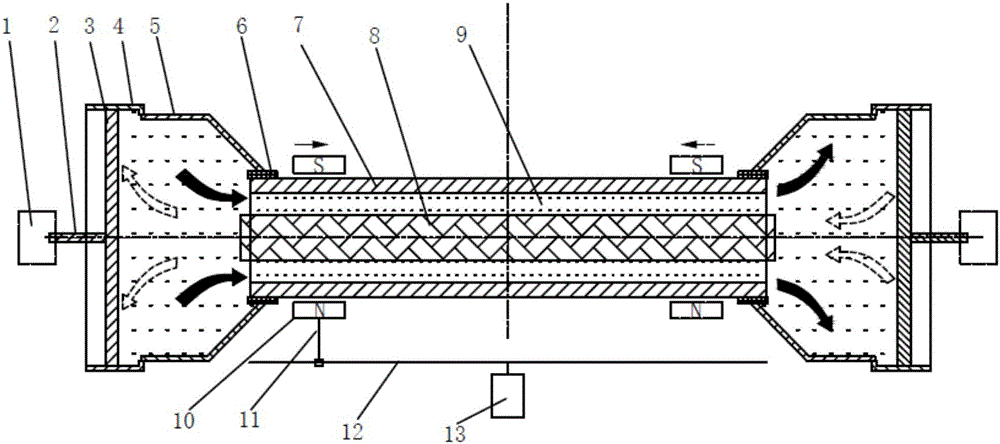

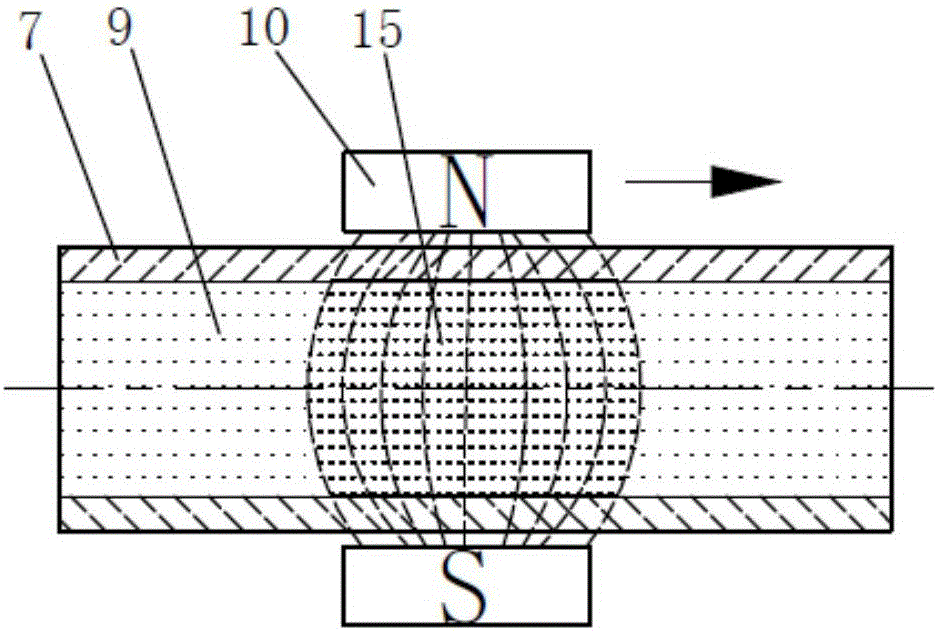

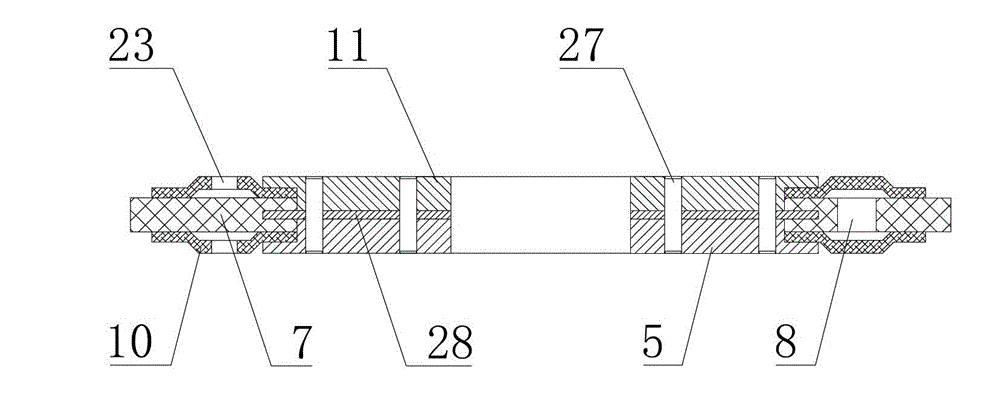

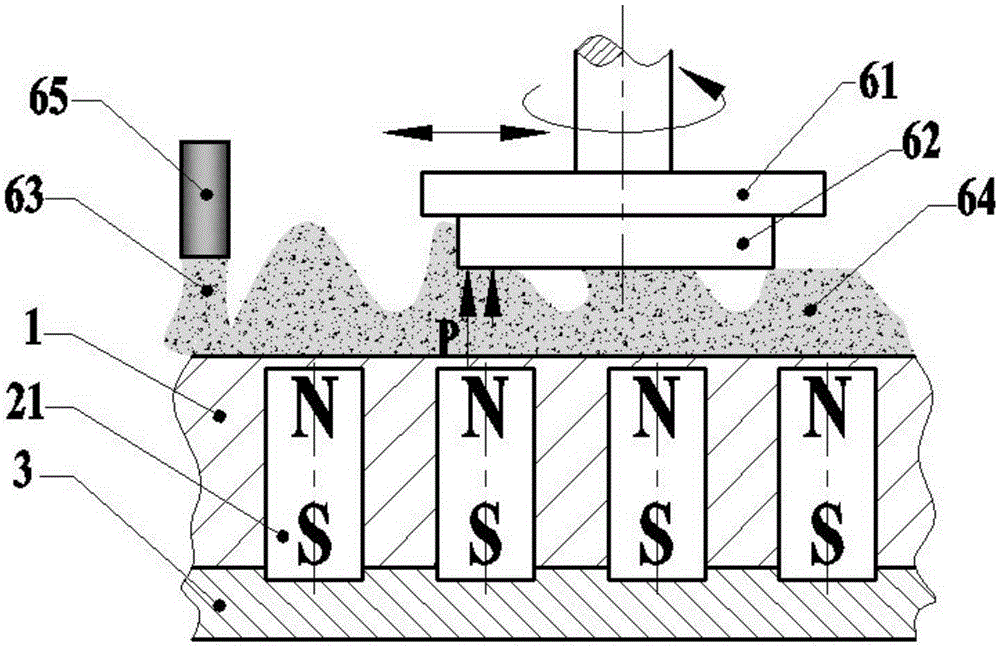

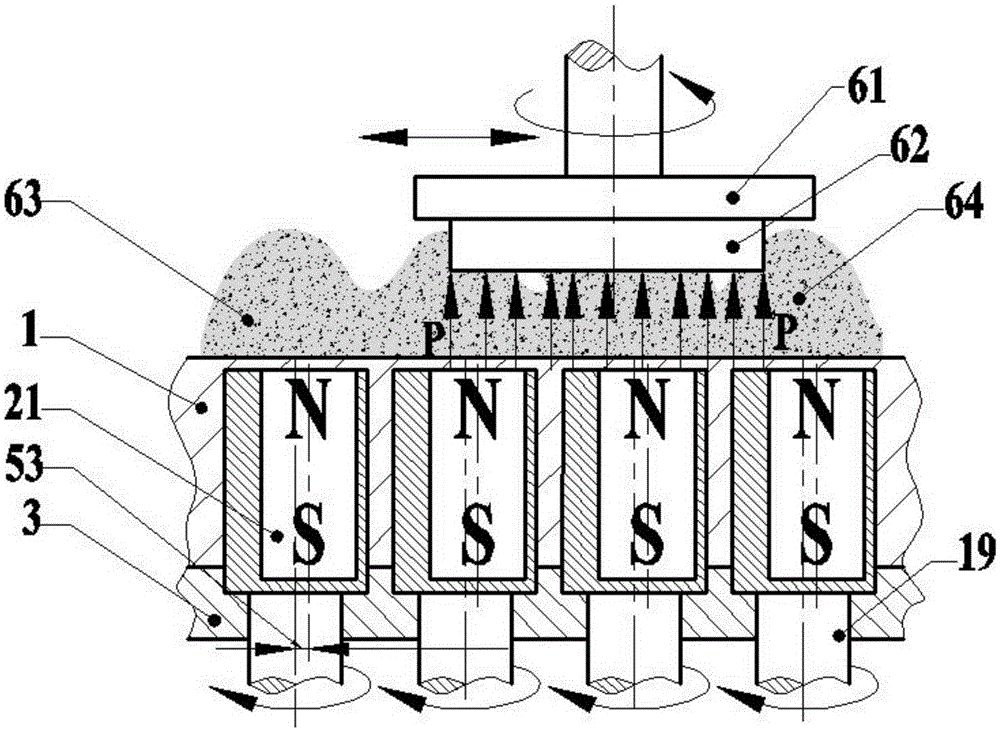

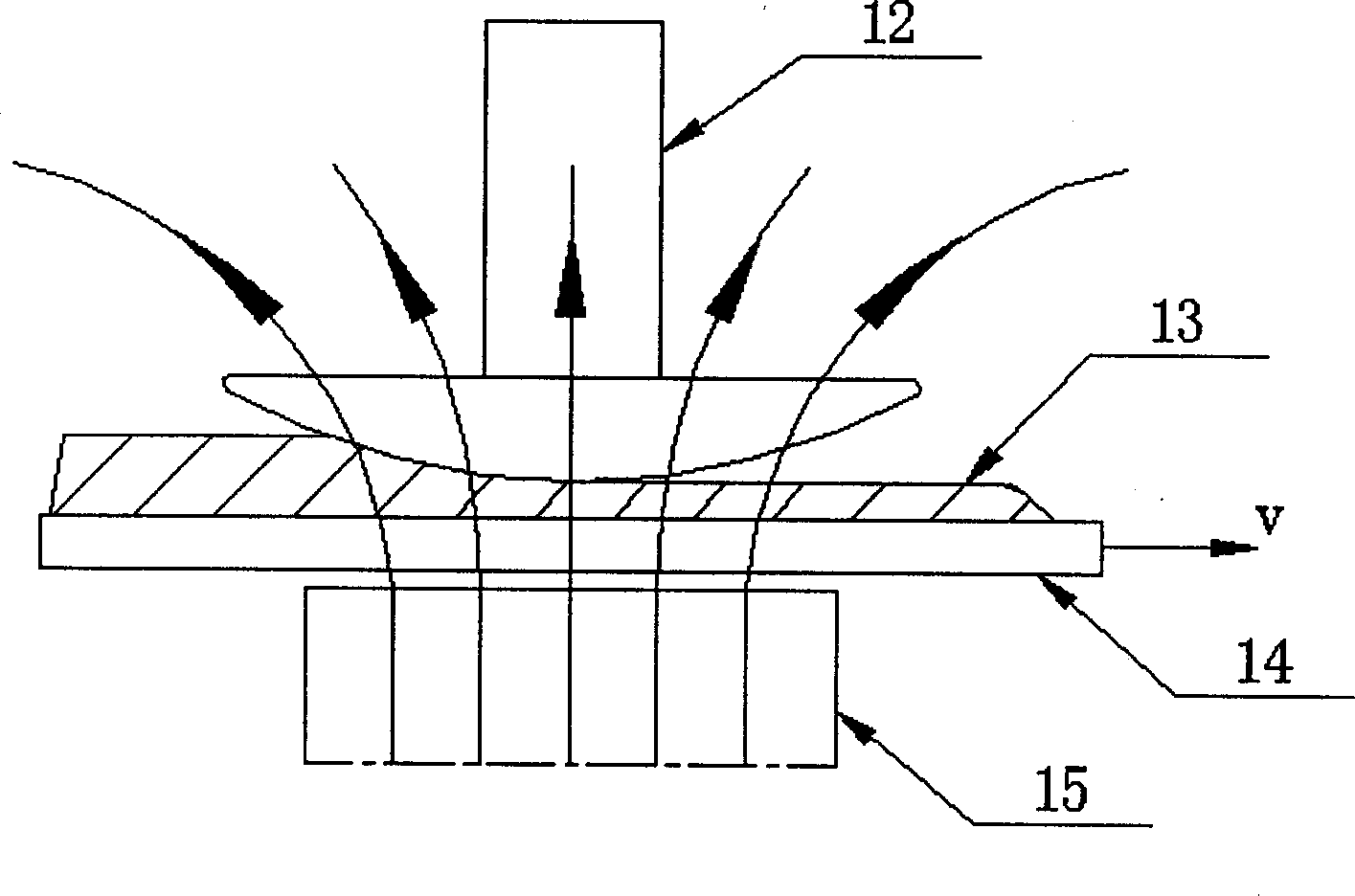

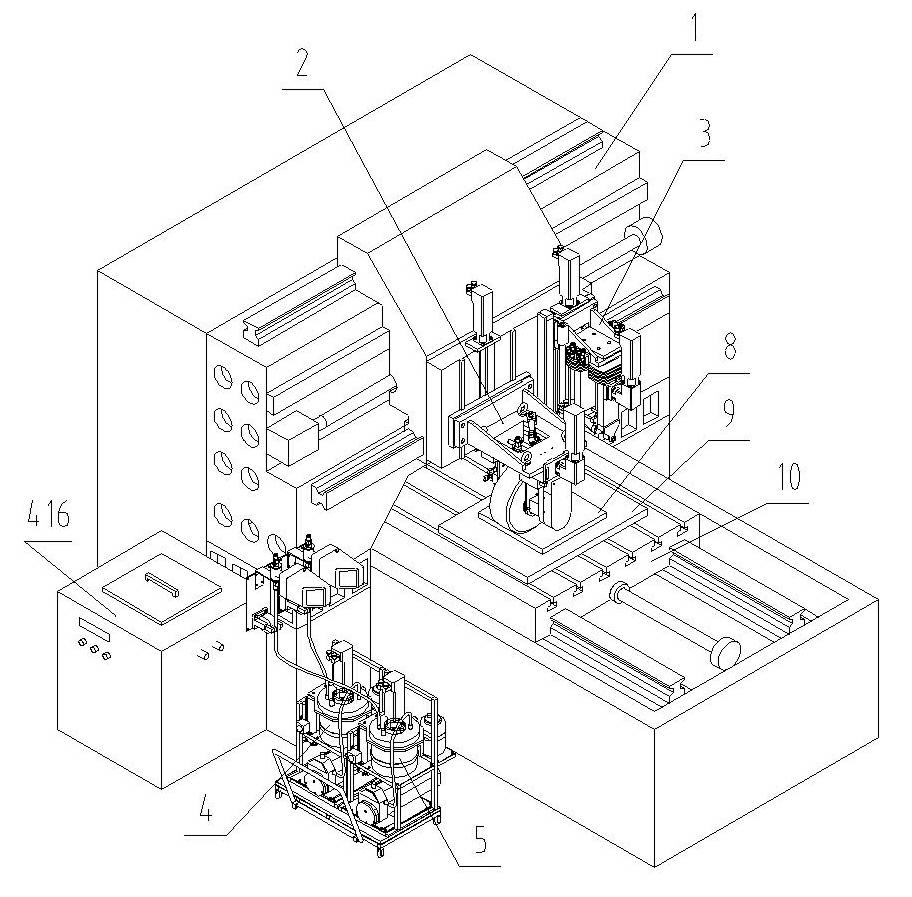

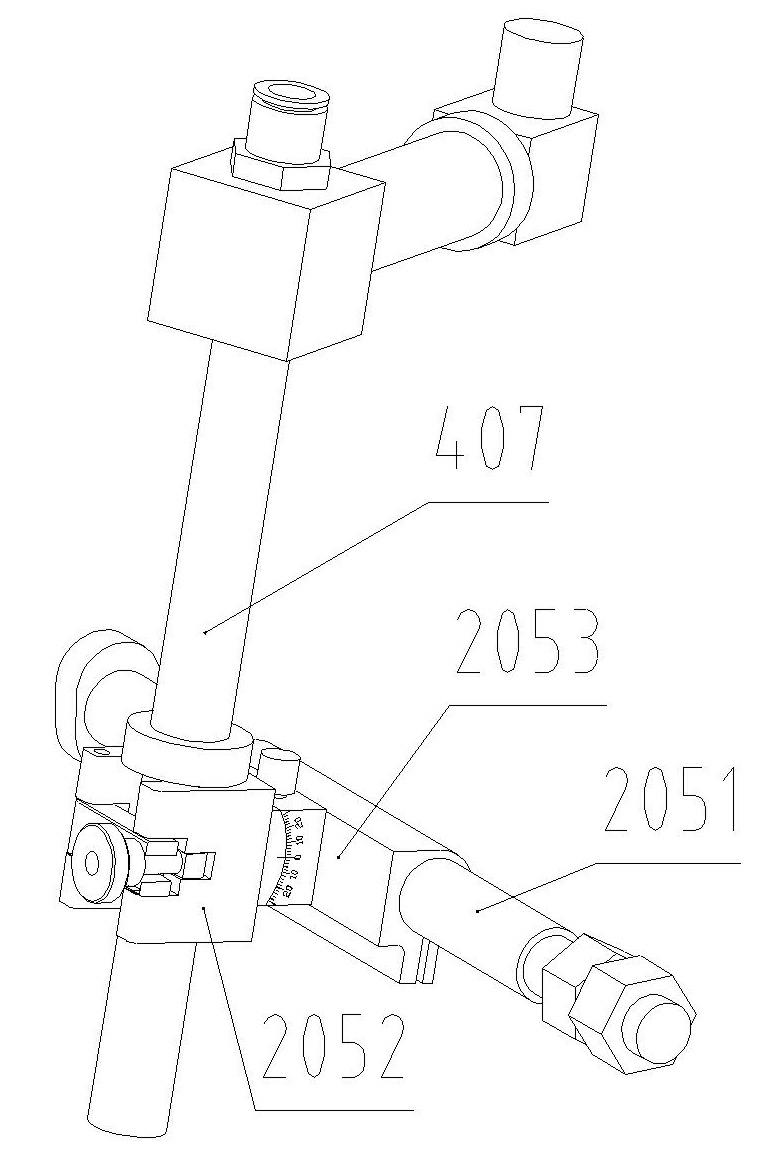

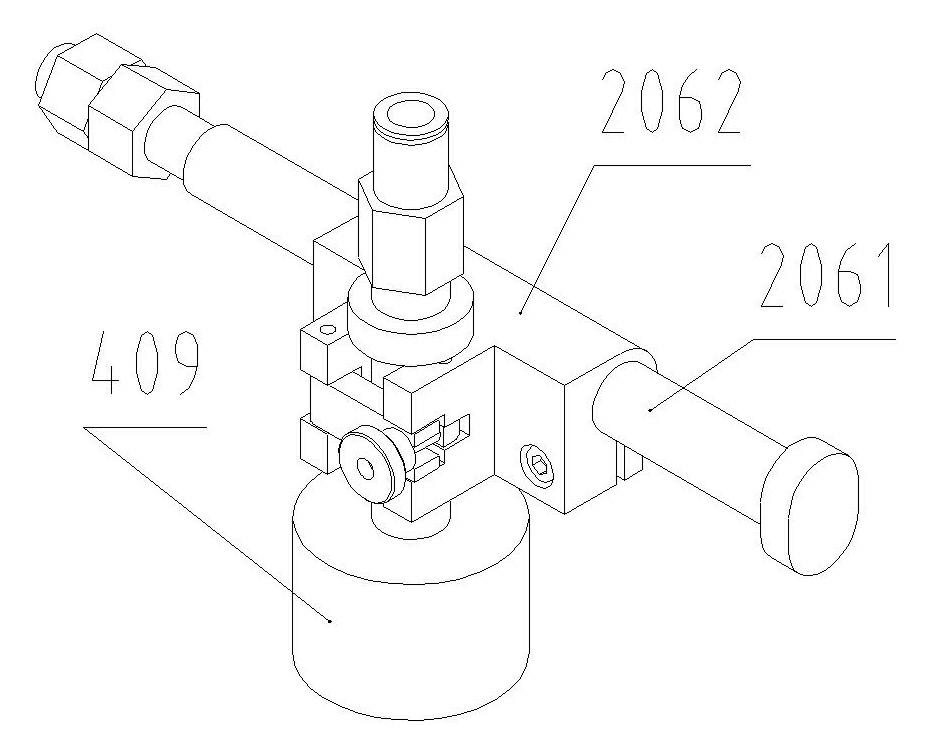

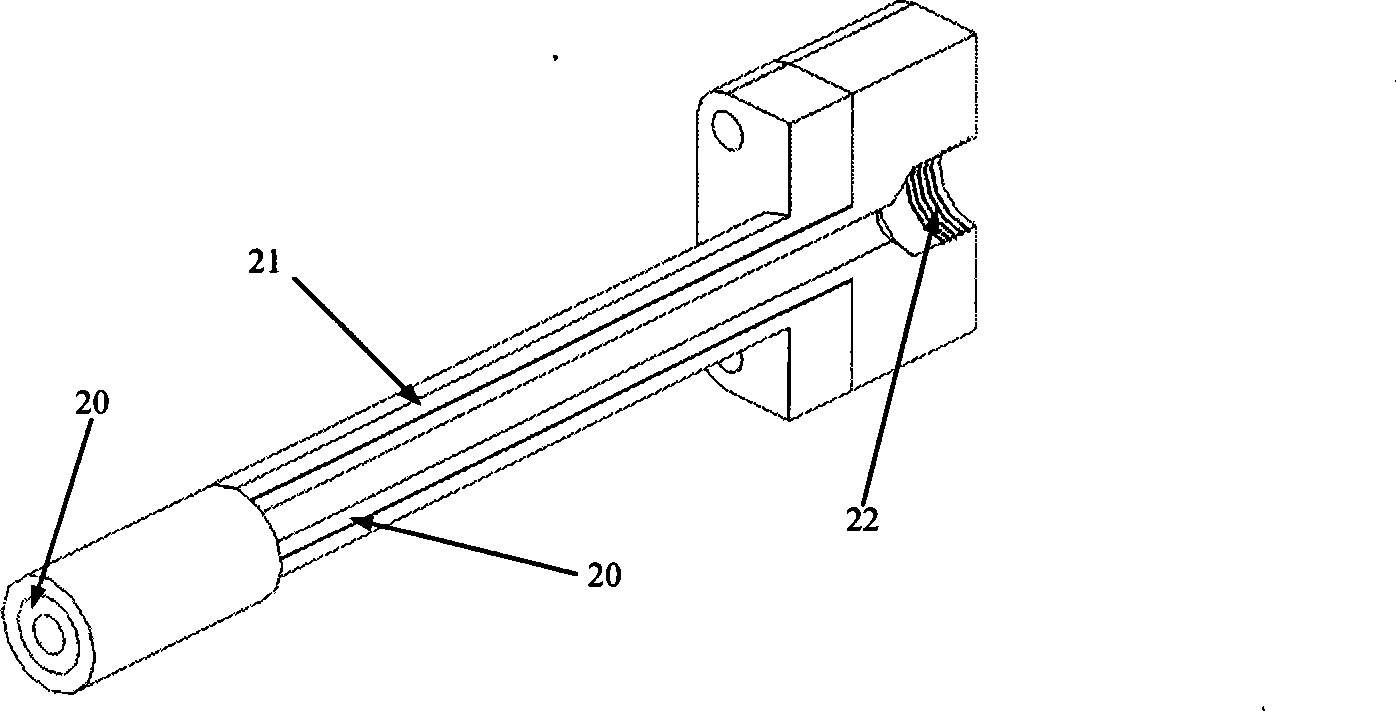

Self-pressurized high-speed polishing method and device for inner surface of hole by means of abrasive particles and magnetic flow

InactiveCN105881185AImprove machining accuracyImprove processing efficiencyEdge grinding machinesPolishing machinesMagnetic currentReciprocating motion

The invention provides a self-pressurized high-speed polishing method for the inner surface of a hole by means of abrasive particles and a magnetic flow. According to the method, the abrasive particles are coated with and restrained on the inner surface of the hole of a workpiece by the aid of ferromagnetic particles in a magnetorheological polishing fluid, which flows at a high speed, under the effect of a magnetic field produced by moving magnetic bodies, a flexible polishing abrasive brush flowing at a high speed is formed and reciprocates to rub against the inner surface of the hole of the machined workpiece to remove burrs and reduce the roughness of the inner surface of the hole, and burr removal and deterministic polishing are realized for various types of inner surfaces of holes. The invention further provides a self-pressurized high-speed polishing device for the inner surface of the hole by means of the abrasive particles and the magnetic flow. The device comprises a polishing mechanism, the magnetic bodies, a clamping mechanism, a sliding guide rail and a driving motor, wherein the driving motor drives the magnetic bodies to enable the polishing fluid to reciprocate in the hole at the high speed for polishing. The method and the device can solve problems that special holes are difficult to polish and the polishing efficiency is low, and have the advantages of high precision, high machining efficiency, low damage and low cost.

Owner:GUANGDONG UNIV OF TECH

Magnetorheological hydraulic engine mount based on extrusion mode

InactiveCN103148158ALarge adjustment rangeImprove the vibration isolation effectNon-rotating vibration suppressionMagnetic currentMagnetorheological fluid

The invention discloses a magnetorheological hydraulic engine mount based on an extrusion mode, which comprises a housing, a rubber main spring, a connecting rod and a rubber bottom membrane, wherein a decoupler is arranged between the rubber main spring and the rubber bottom membrane; a field pole plate is fixedly arranged on the connecting rod, close to the decoupler; a field coil is wound in the field pole plate; an extrusion pole plate is arranged on the decoupler, corresponding to the field pole plate; and an extrusion damping channel is formed between the extrusion pole plate and the field pole plate and fully filled with magnetorheological fluid. The magnetorheological hydraulic engine mount adopts the extrusion mode, and the field pole plate arranged on the connecting rod forms the extrusion damping channel with the extrusion pole plate on the decoupler, so that the vibration isolation capability of the mount is improved. In addition, the extrusion mode can satisfy a maximum output damping force and expand an adjustable range of the damping force.

Owner:CHONGQING UNIV

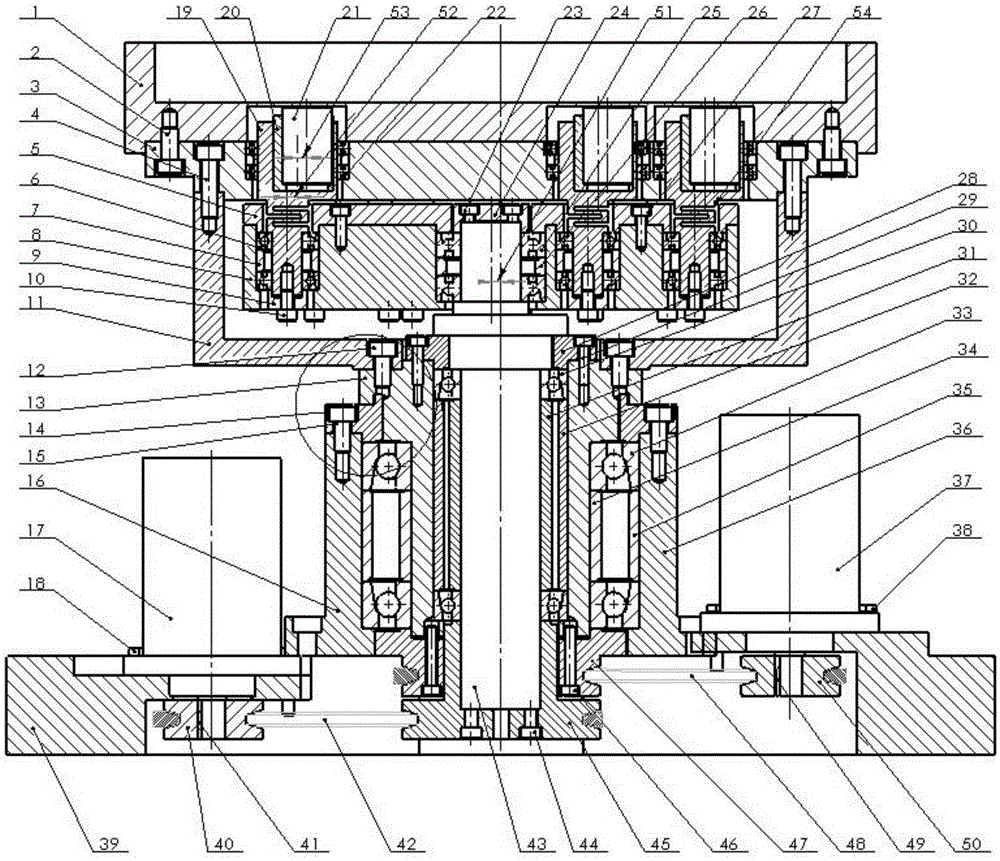

Dynamic magnetic field self-sharpening finishing device for flexible magnetorheological finishing pad and finishing method for dynamic magnetic field self-sharpening finishing device

ActiveCN105328516ASave spaceAchieve impactGrinding drivesAbrasive surface conditioning devicesExperimental researchMagnetic current

The invention relates to a dynamic magnetic field self-sharpening finishing device for a flexible magnetorheological finishing pad and a finishing method for the dynamic magnetic field self-sharpening finishing device. The dynamic magnetic field self-sharpening finishing device comprises a finishing disk revolution mechanism and a multi-magnetic-pole synchronous rotation driving mechanism, wherein the finishing disk revolution mechanism comprises a driving shaft motor, a drive shaft, an adapting disk, an eccentric shaft fixing disk, a cup-like finishing disk and a driving shaft transmission mechanism; the multi-magnetic-pole synchronous rotation driving mechanism comprises an eccentric spindle, synchronous rotation driving plates, flexible eccentric rotating shafts, eccentric sleeves, magnetic poles, the eccentric shaft fixing disk, a spindle motor and the like. According to the finishing device and the finishing method disclosed by the invention, the conditions that a circulating device is adopted for updating magnetorheological fluid and the magnetorheological fluid is changed in the processing process are avoided, so that the space is saved, and the whole process from rough finishing to fine finishing can be realized by one-time processing; obtained workpieces are good in surface consistency, high in processing efficiency, free from of surface and subsurface damage and low in cost, so the finishing device and the finishing method are suitable for high-efficiency ultra-smooth uniform finishing processing of planes of large-diameter optical elements; meanwhile, the finishing device and the finishing method disclosed by the invention are also suitable for experimental researches such as a material removing mechanism and subsurface damage detection of optical planar materials.

Owner:GUANGDONG UNIV OF TECH

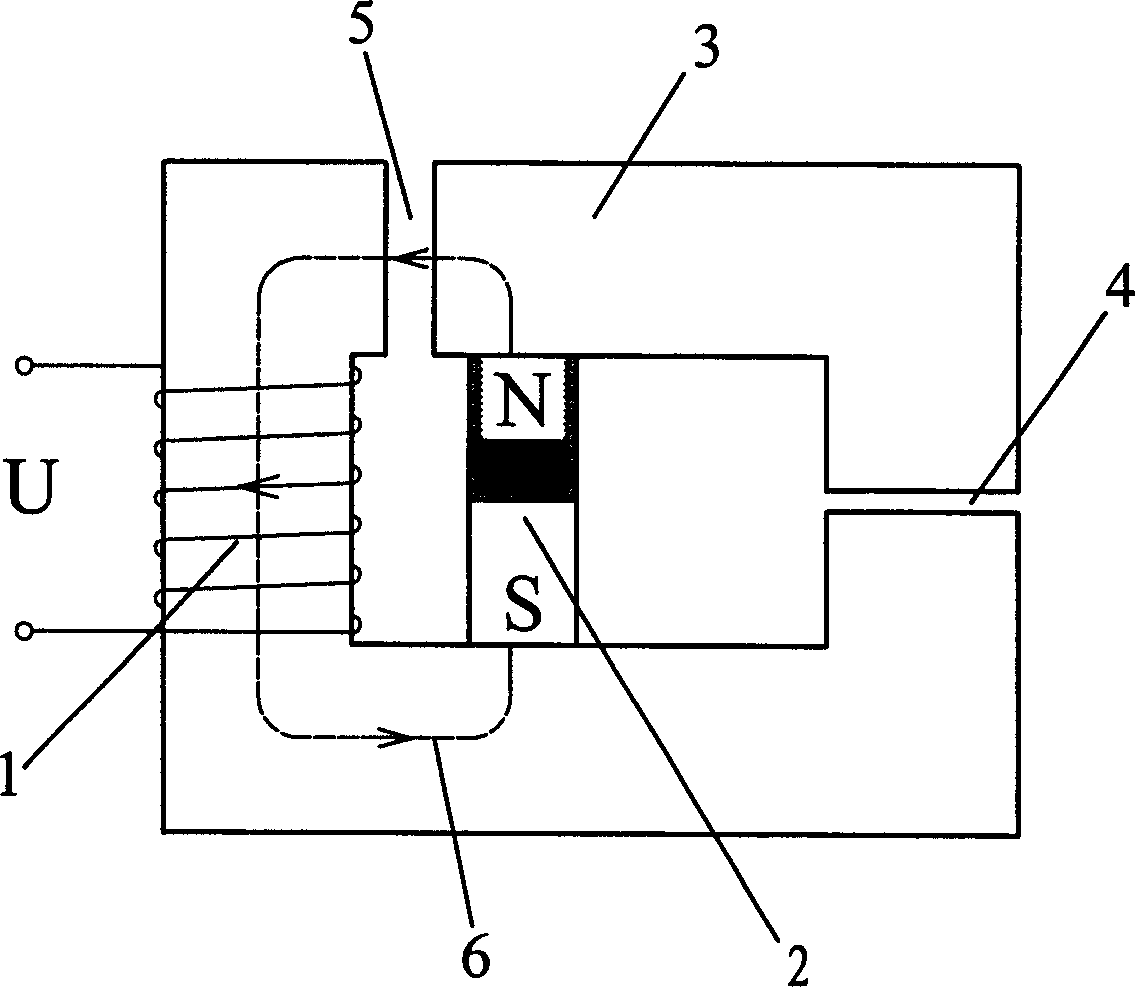

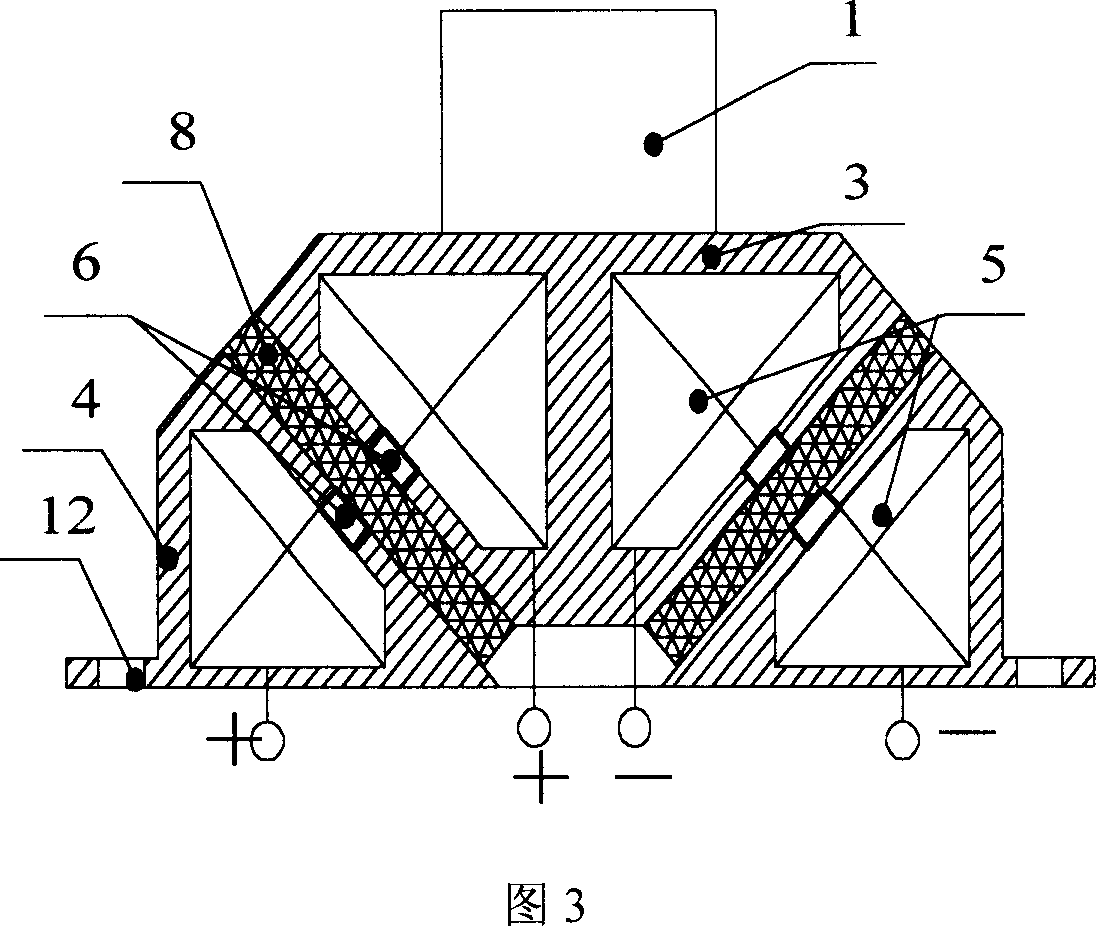

Magnetic flowing deformation elastomer frequency shift type attenuator and control method

InactiveCN1948781AAdjust the natural frequencyAdjust stiffnessNon-rotating vibration suppressionElastomerMagnetic current

The inventive vibration absorber comprises an execution unit, a control unit and a sensor. The execution unit consists of a magnetic inductor, a coil, a magnetic rheological elastic body, a vibration-absorbing mass block and a base. The above magnetic inductor consists of inner and outer sleeves, or a U-shaped iron-core and an armature or top and bottom plates and a column iron-core. Between inner and outer sleeves, the U-shaped iron-core and the armature or the top and bottom plates are filled the magnetic rheological elastic bodies. By regulating the voltage on the coil, the rigidity and the elasticity of the magnetic rheological elastic body are regulated to make its vibration frequency change, so as to make the vibration frequency of the vibration absorber execution unit is the same as that of the vibration-damping object.

Owner:UNIV OF SCI & TECH OF CHINA

Inerter and damping controllable magneto-rheological inerter device and control method thereof

ActiveCN103644248ASolve the problem that dynamic adjustment of inertia cannot be realizedTo overcome the shortcomings of only dynamically adjusting the dampingNon-rotating vibration suppressionSemi activeInertial effect

The invention relates to an inerter and damping controllable magneto-rheological inerter device and a control method thereof. The device comprises a cylinder, a piston, a piston rod, long and thin pipes, a thick pipe, a magneto-rheological fluid, switch valves, MR (magnetic resonance) conductors and a damping hole. According to the inerter and damping controllable magneto-rheological inerter device and the control method thereof, an apparent viscosity changing process of the magneto-rheological fluid is a continuous, stepless and reversible magneto-rheological effect under the action of an applied magnetic field, simultaneously, the low viscosity of the magneto-rheological fluid without the applied magnetic field and an inertial effect of the magneto-rheological fluid flowing in the long and thin pipes are utilized, the two effects are integrated in one device, further, the switch valves are adopted to control switching on and off of the long and thin pipes which have different pipe diameters and are filled with the magneto-rheological fluid, then the inerter is adjusted in a stepping manner,; and damping is adjusted steplessly by changing the magneto-rheological viscosity through the applied magnetic field simultaneously According to the invention, requirements for semi-active control when dynamical combination adjustment of inerter and damping is applied to a vibration isolation device for engineering are met, so that mounting and using are facilitated, the cost is reduced, and the production efficiency is improved.

Owner:JIANGSU UNIV

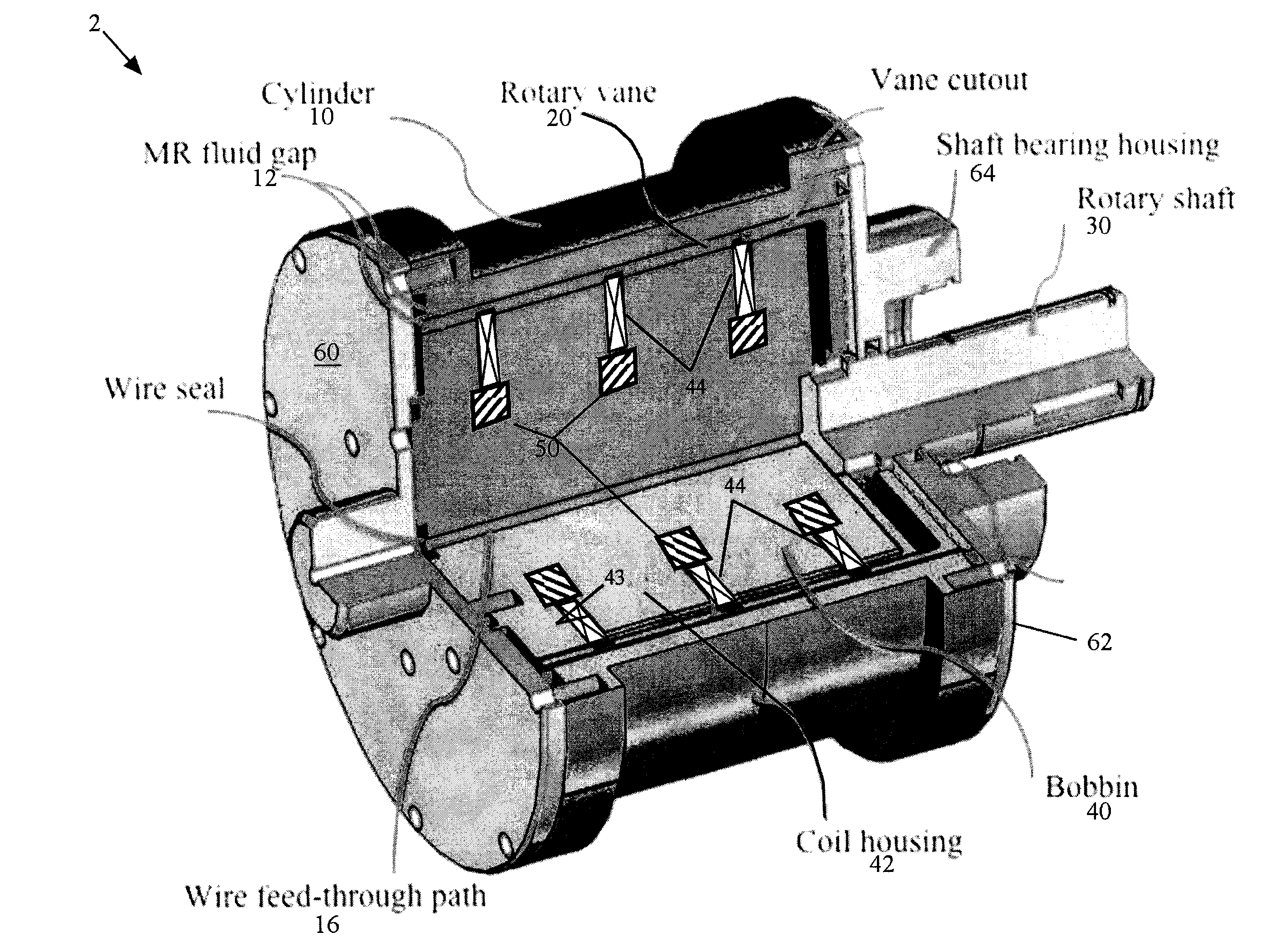

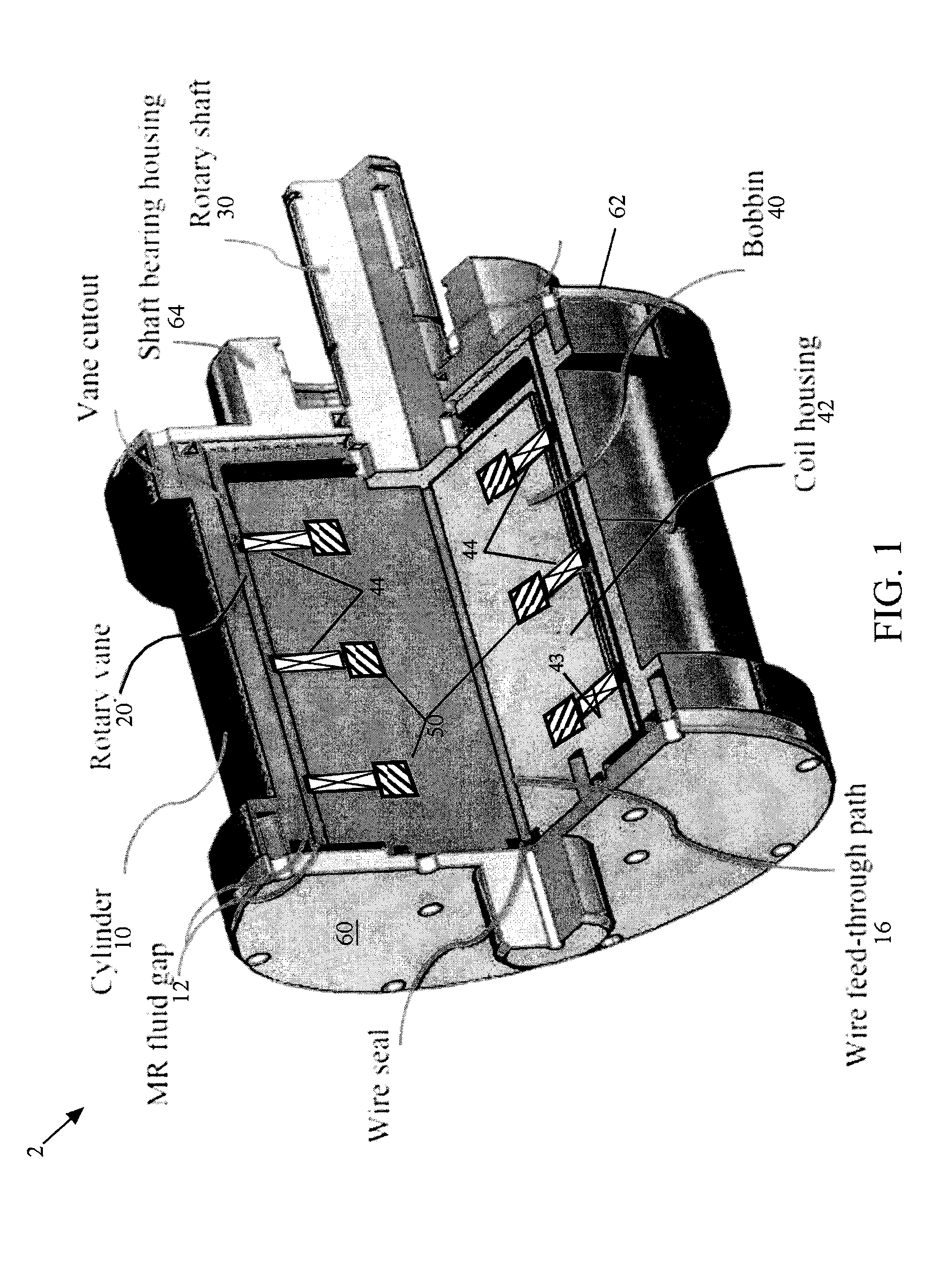

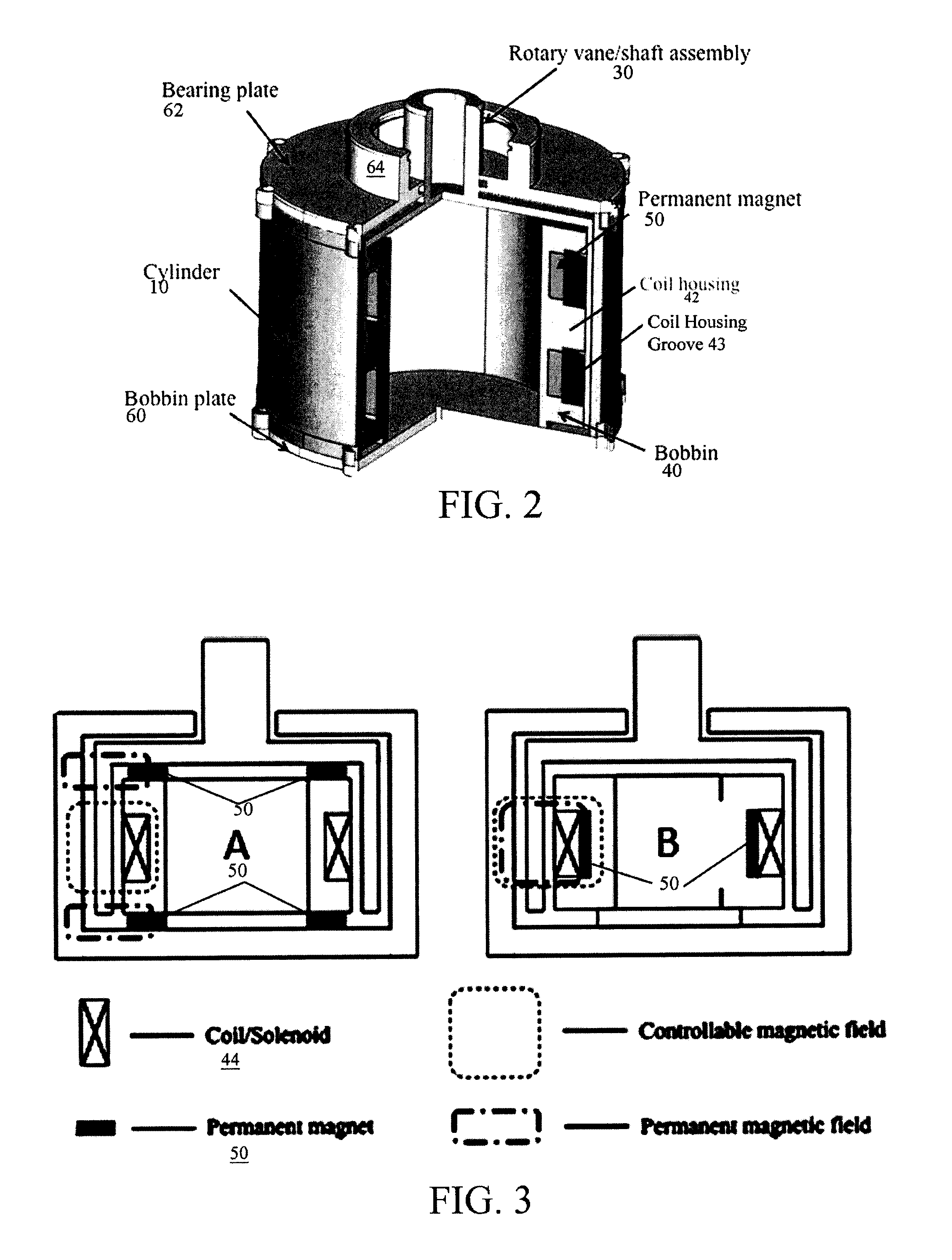

Failsafe magnetorheological (MR) energy absorber

ActiveUS20140152066A1Boost and reduces baseline magnetic fieldReduce energy impactSpringsNon-rotating vibration suppressionLinear motionMagnetic current

A compact and failsafe magnetorheological energy absorber design including both a light weight piston (LWP) embodiment in which linear motion is subjected to a linear damping force, and a light weight rotary vane (LWRV)embodiment in which linear motion is converted into rotary motion and is subjected to a rotary damping force. Both embodiments allow increased damper stroke within a compact mechanical profile. A new lightweight Magnetorheological energy attenuation system (LMEAS) for a vehicle seat is also disclosed using the new LMRW MREA.

Owner:INNOVITAL LLC +1

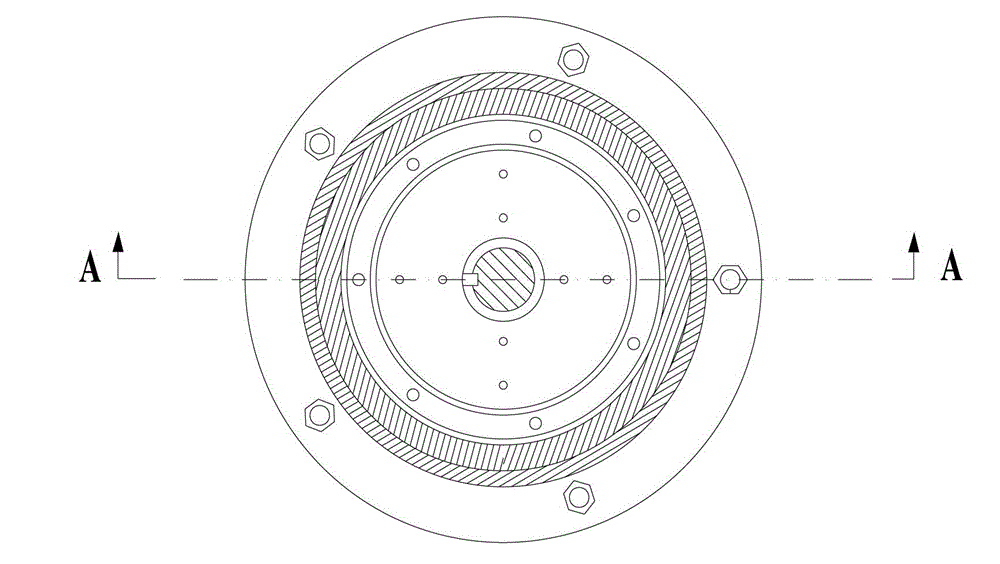

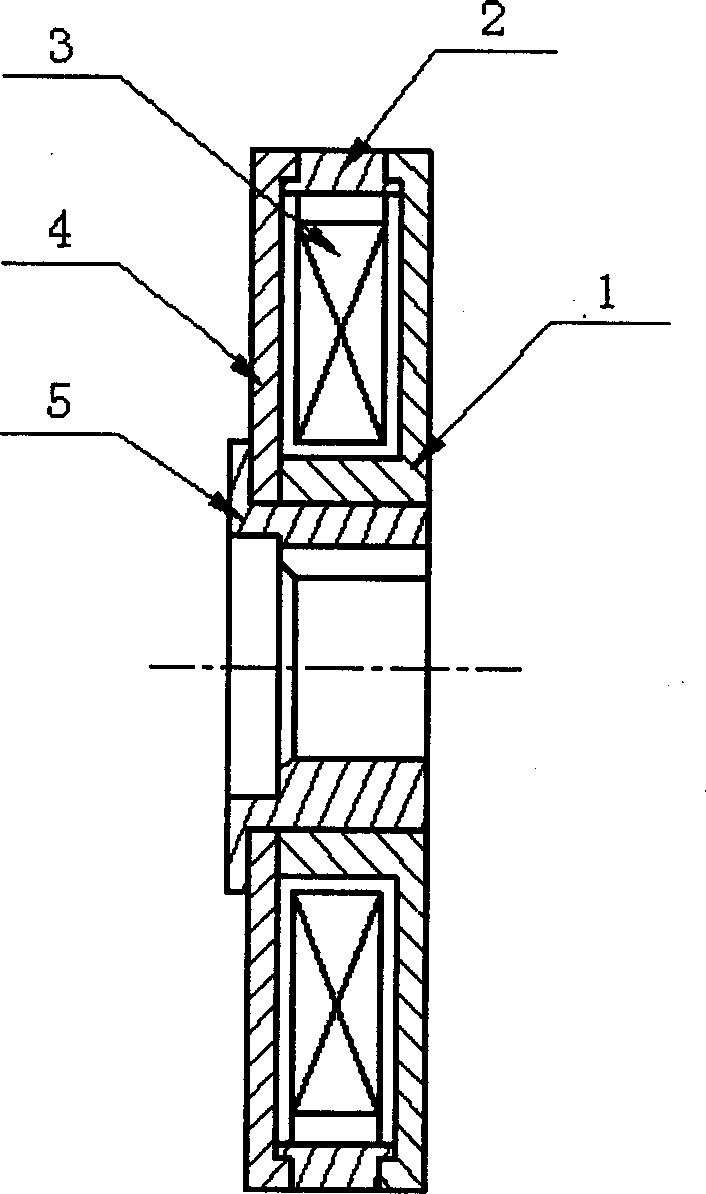

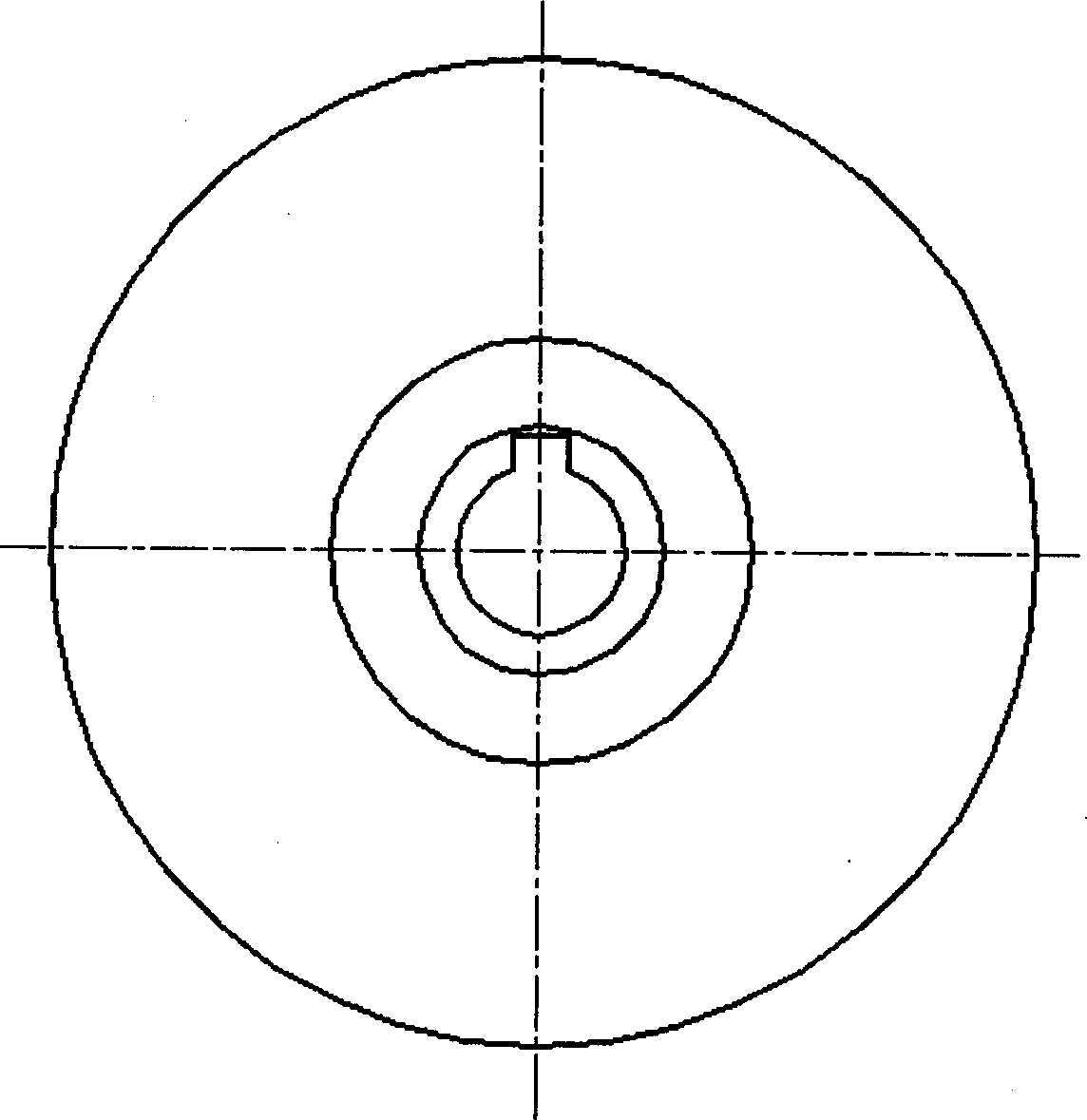

Magnetic rheologic polishing head in electromagnetic mode

The present invention relates to precise curved surface machining tool. The magnetic rheologic polishing head in electromagnetic mode includes electromagnetic wheel frame, magnetic isolating ring, electromagnetic winding, magnetically conducting disk and wheel core; and features the disc shaped polishing head, the magnetic isolating ring with steps on two side and installed via interference fit to outside of the electromagnetic wheel frame and the magnetically conducting disk, the electromagnetic wheel frame and the magnetically conducting disk installed via interference fit to the wheel core, the disk shaped electromagnetic winding inside the cavity formed by the electromagetic wheel frame and the magnetically conducting disk, and the wheel core connected via key to the outer rotating shaft. The present invention is superior to available technology and may be used in flexible and effectively controlled polishing.

Owner:TSINGHUA UNIV

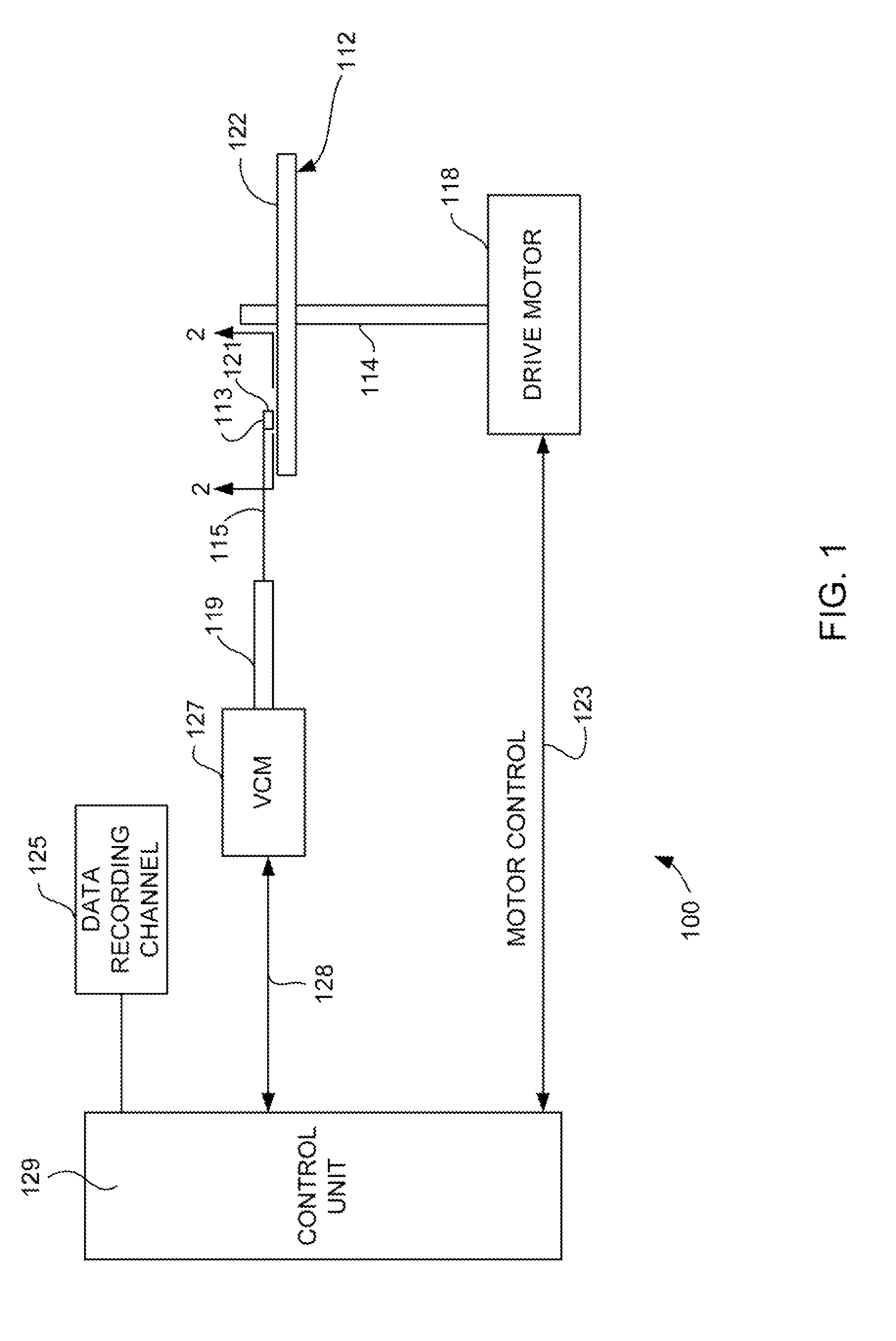

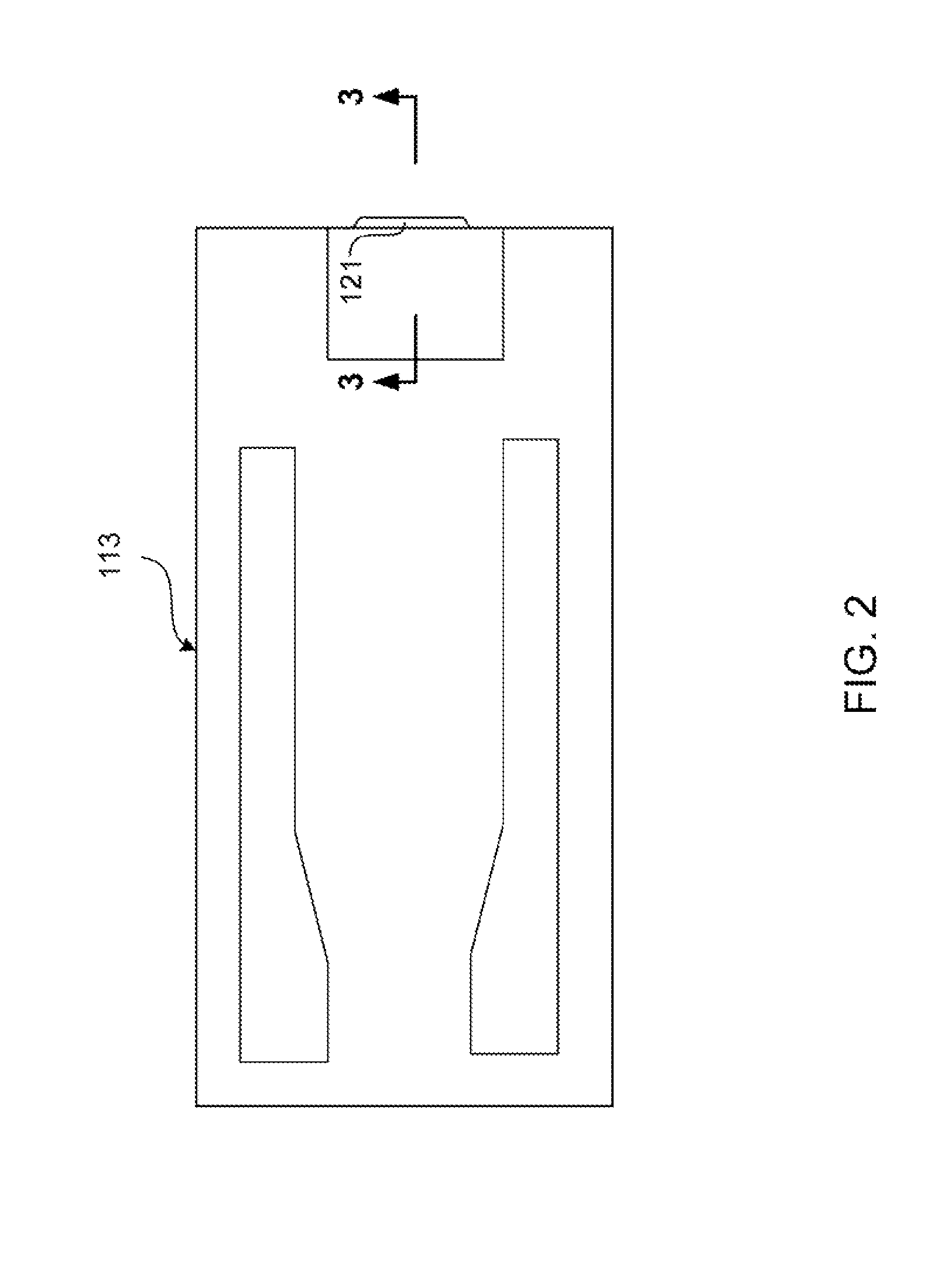

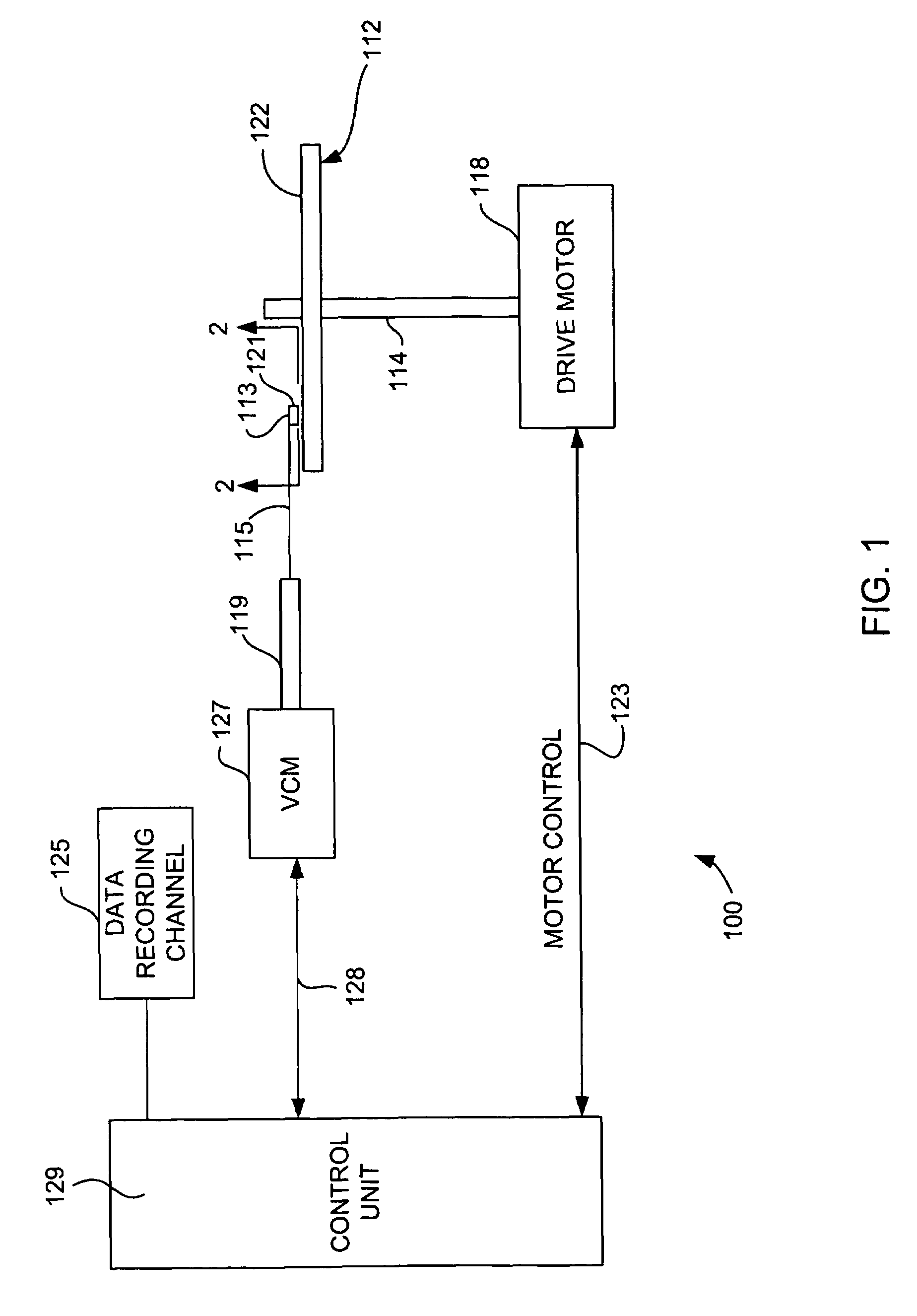

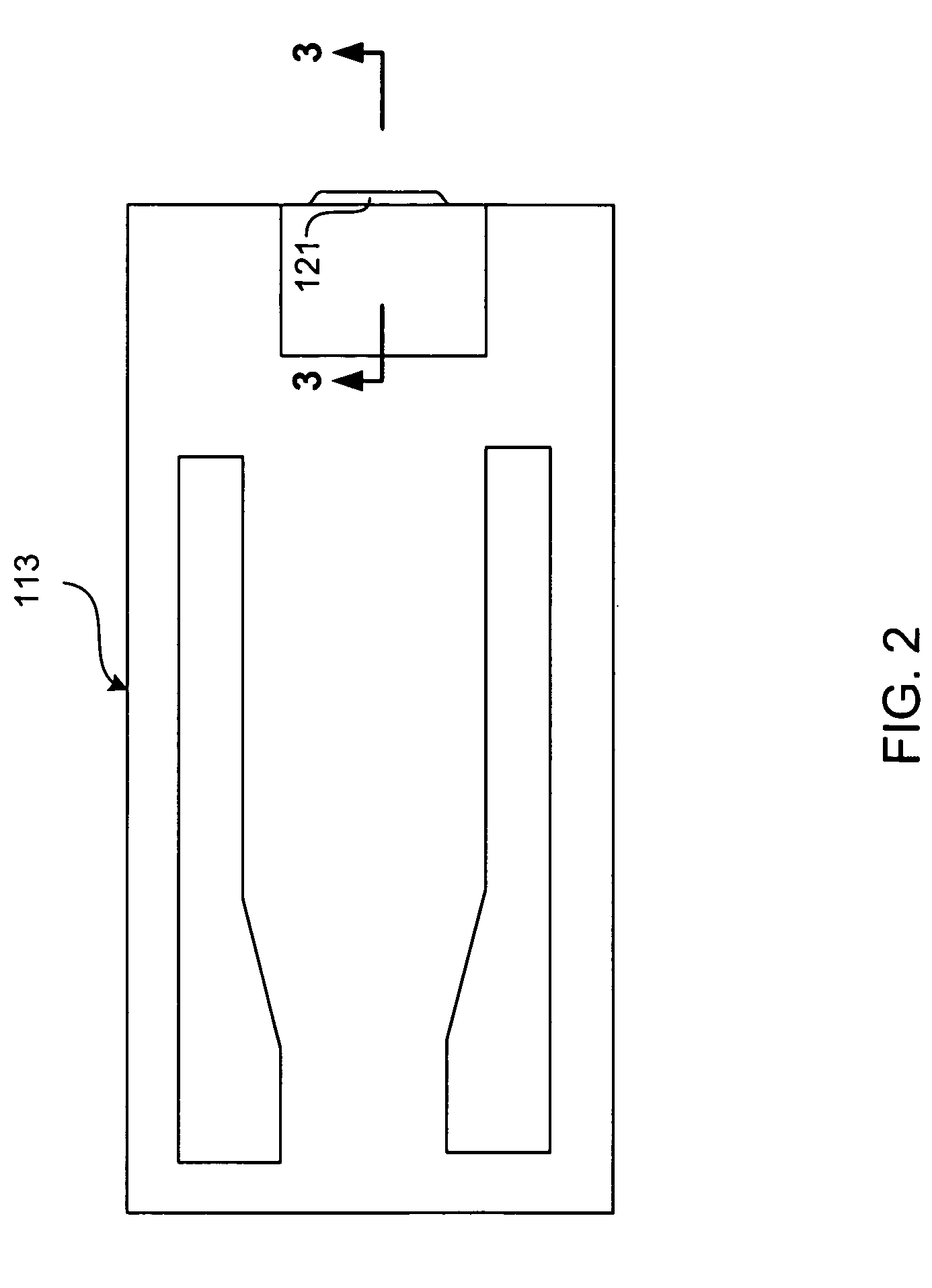

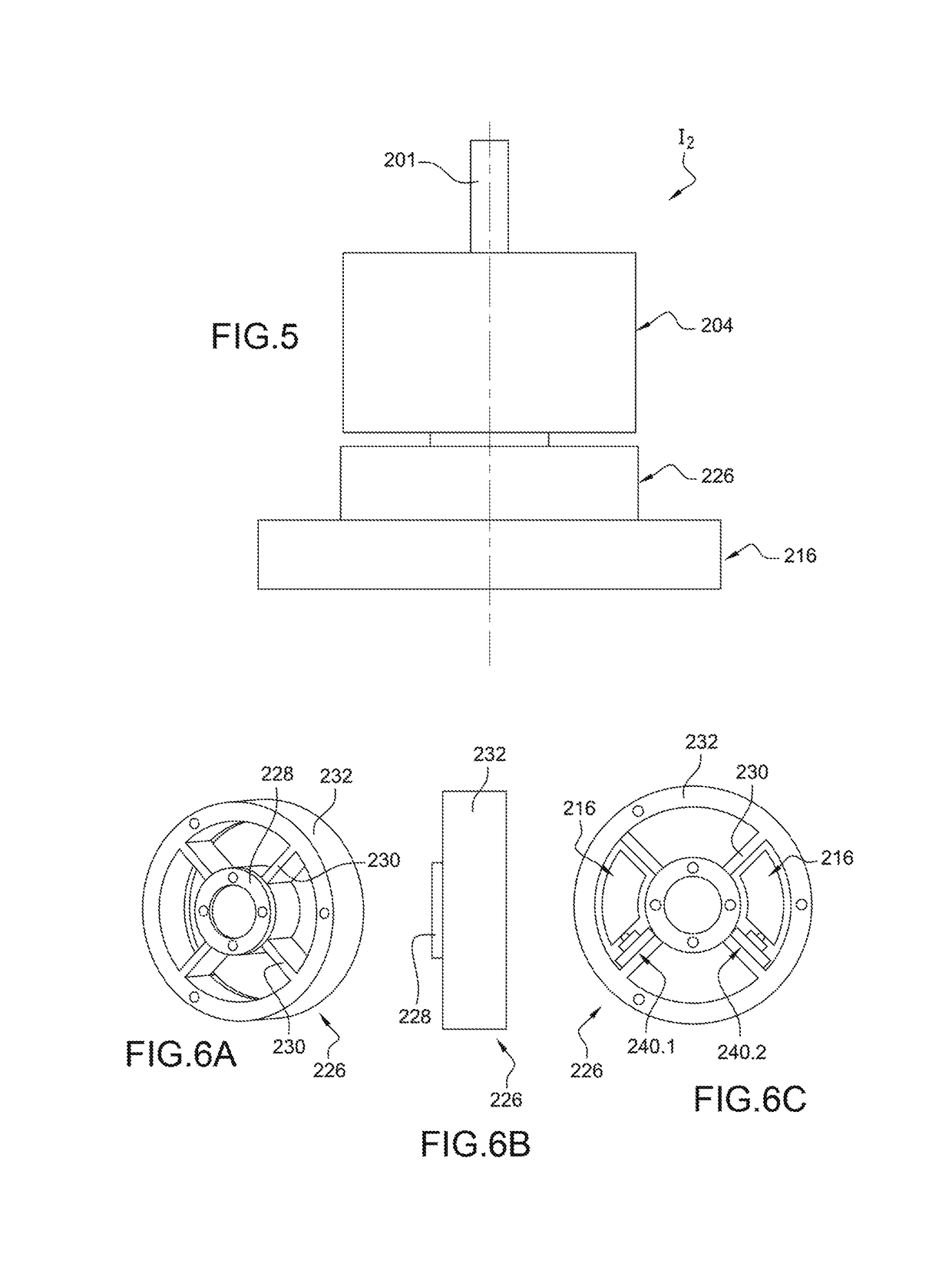

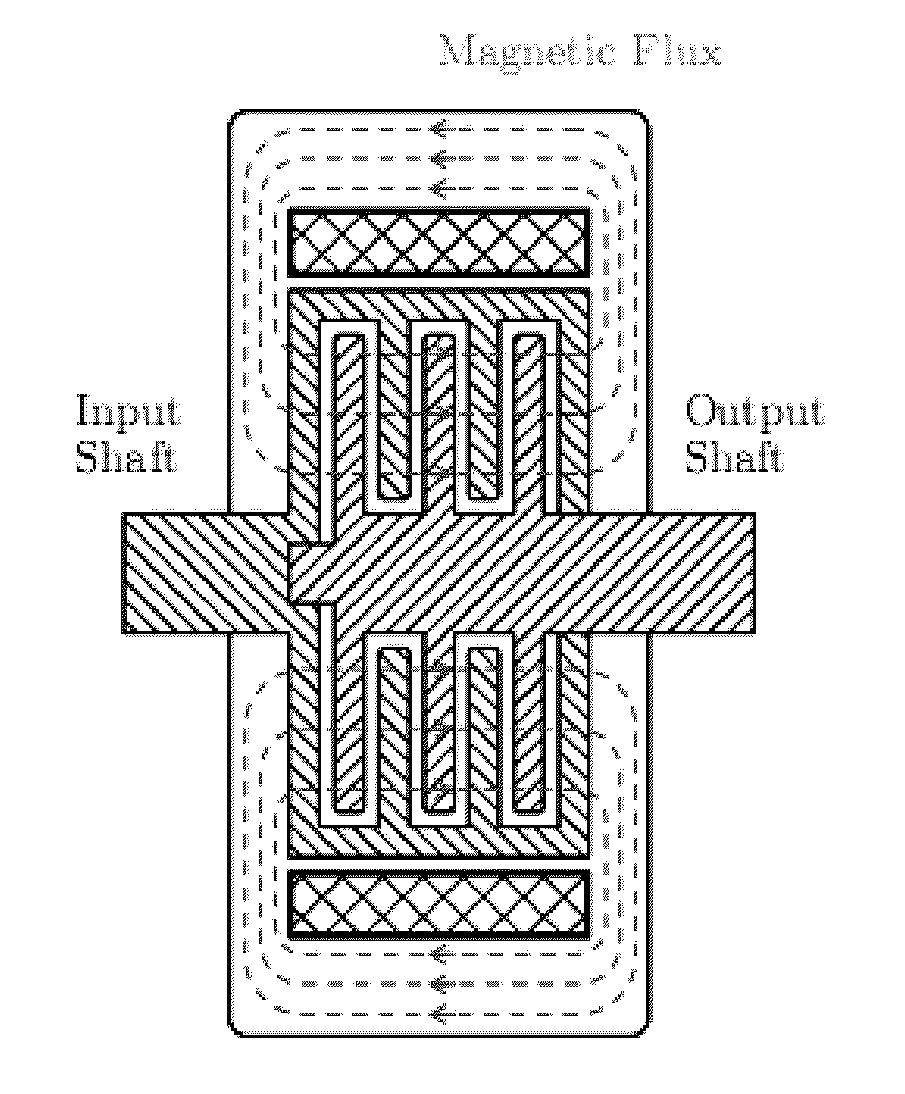

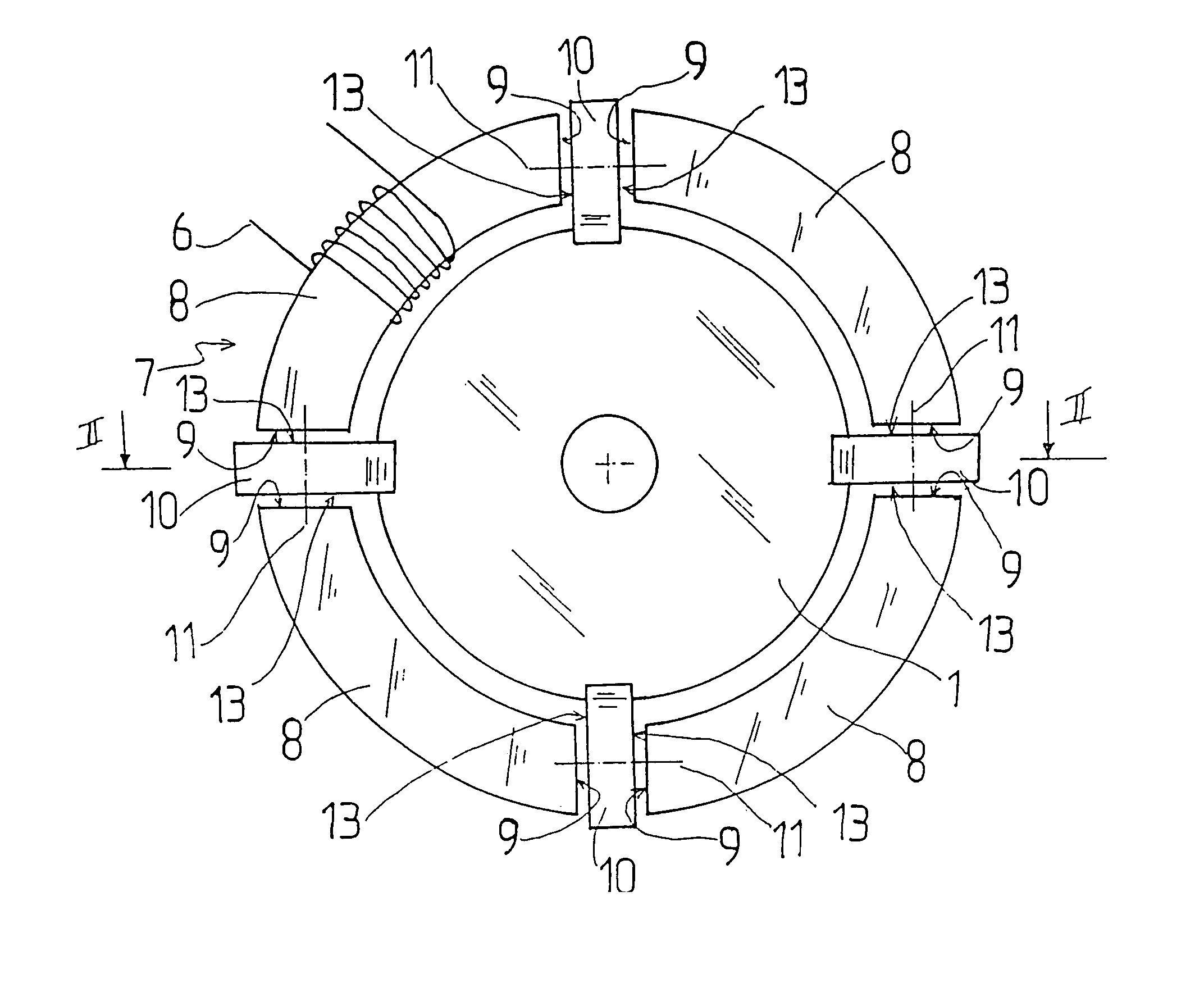

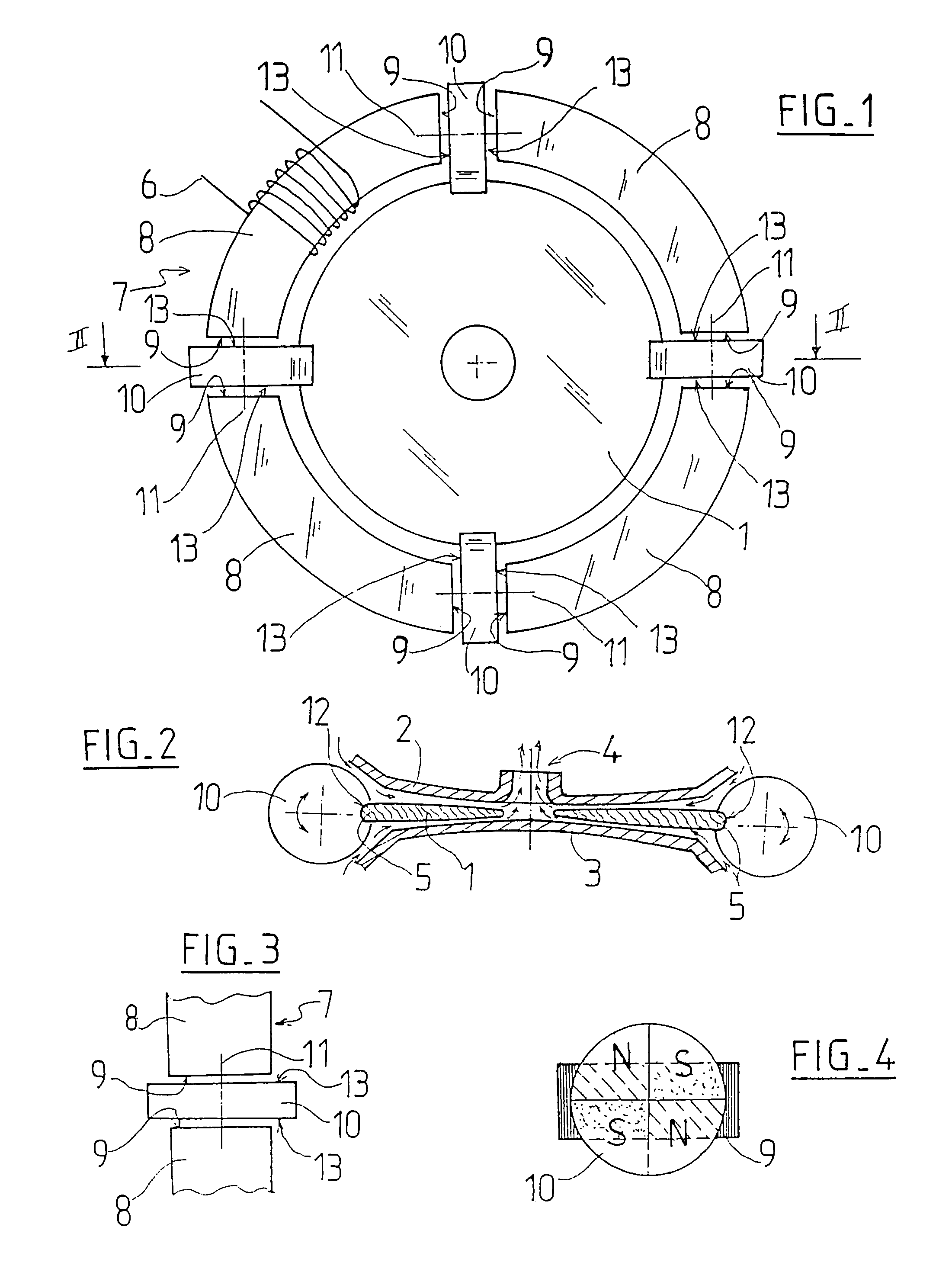

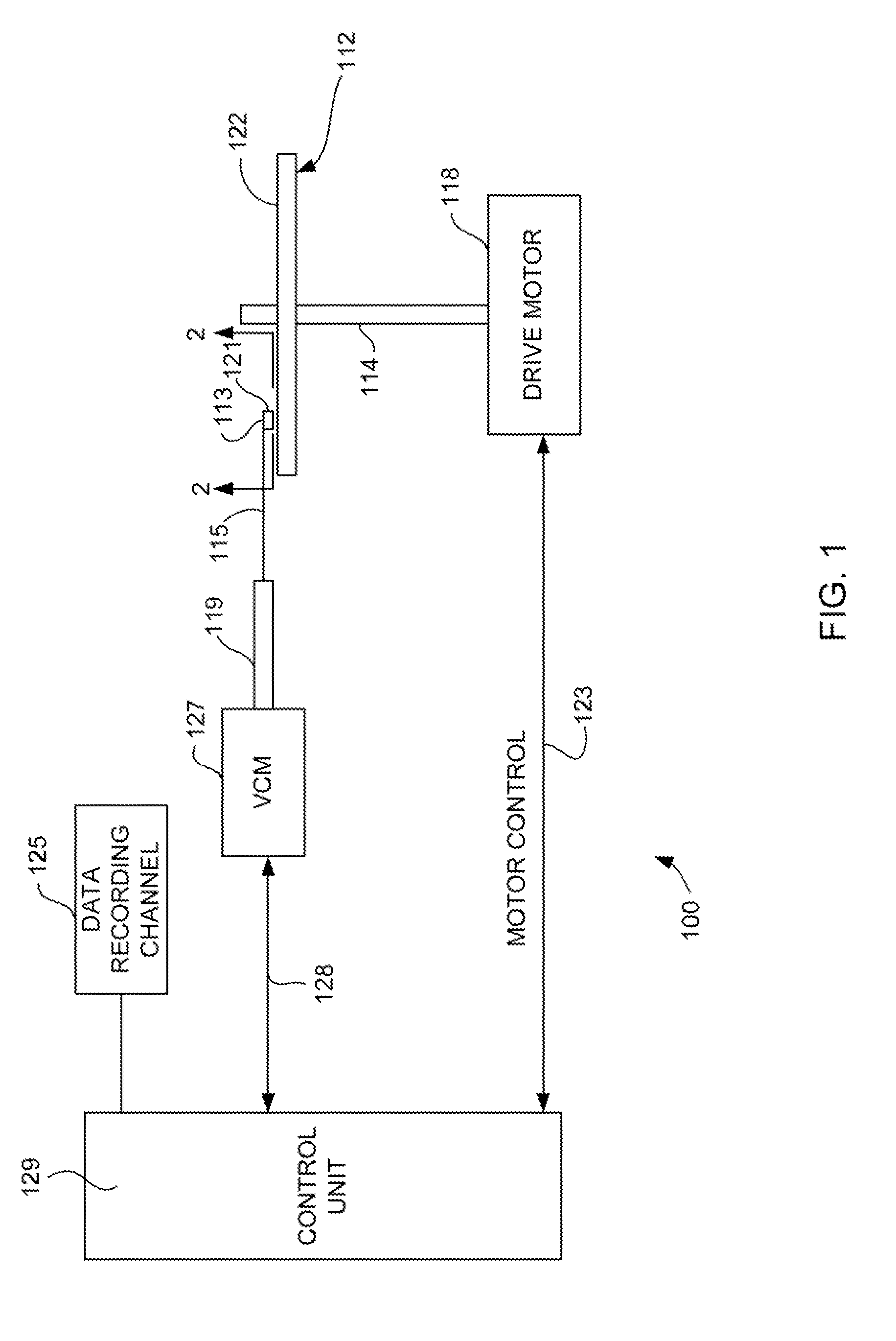

Magneto-rheological clutch with sensors measuring electromagnetic field strength

Systems and methods relating to a clutch system for use in controllably transmitting torque from an input shaft to an output shaft. The clutch system has a torque transmission fluid that has a viscosity that changes based on the strength of an electromagnetic field passing through the fluid. A number of sensors are placed at different radial locations on the torque transmission disks to detect the strength of the electromagnetic field. Based on the strength of the electromagnetic field, the amount of torque being transmitted from the input shaft to the output shaft can be adjusted. Also disclosed is a distributed actuation architecture that uses this clutch system. The distributed actuation architecture allows for the use of a single drive motor in conjunction with multiple instances of the clutch system to actuate a mechanical linkage, such as a robotic arm.

Owner:UNIV OF WESTERN ONTARIO

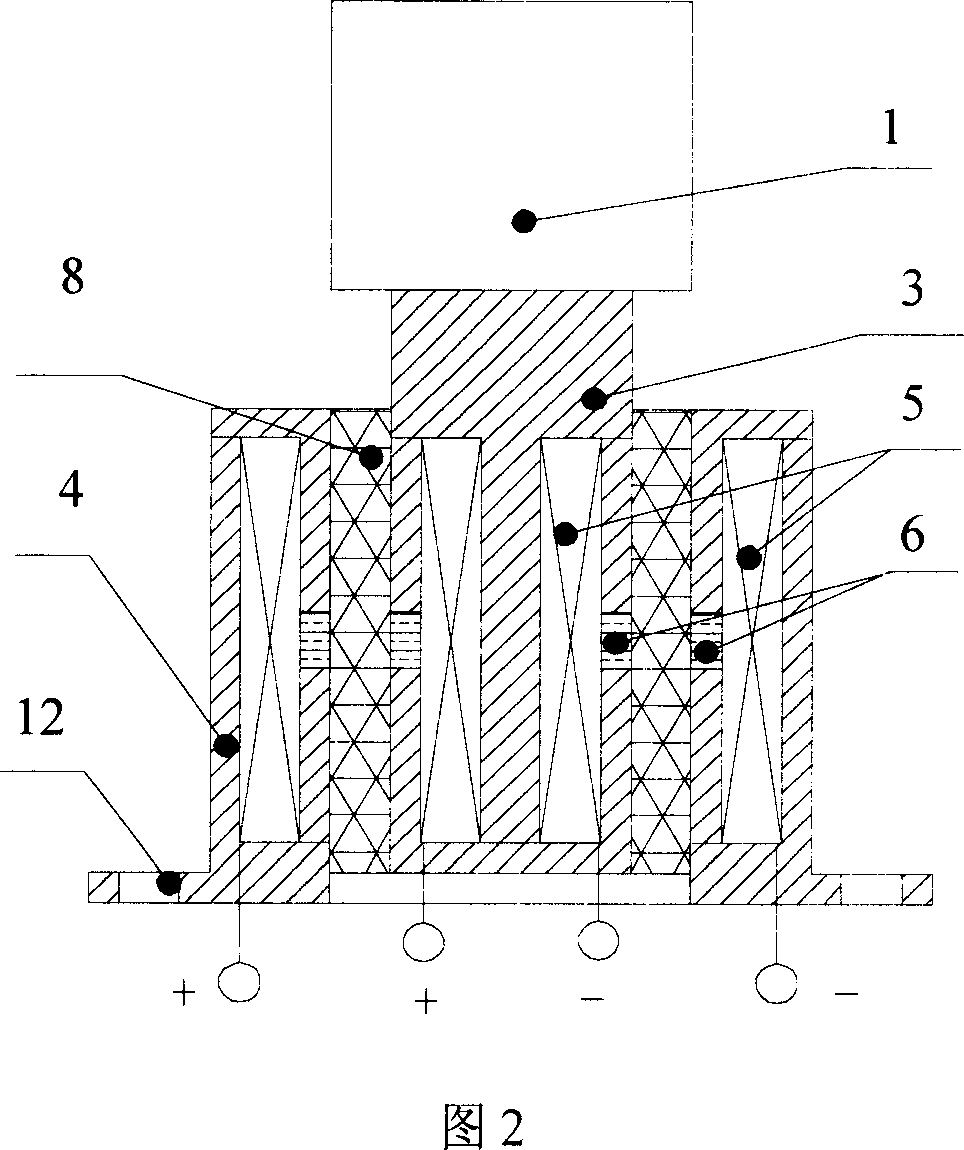

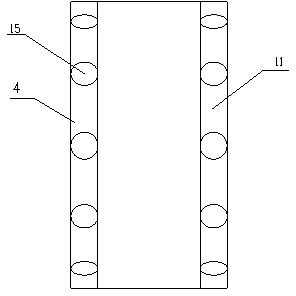

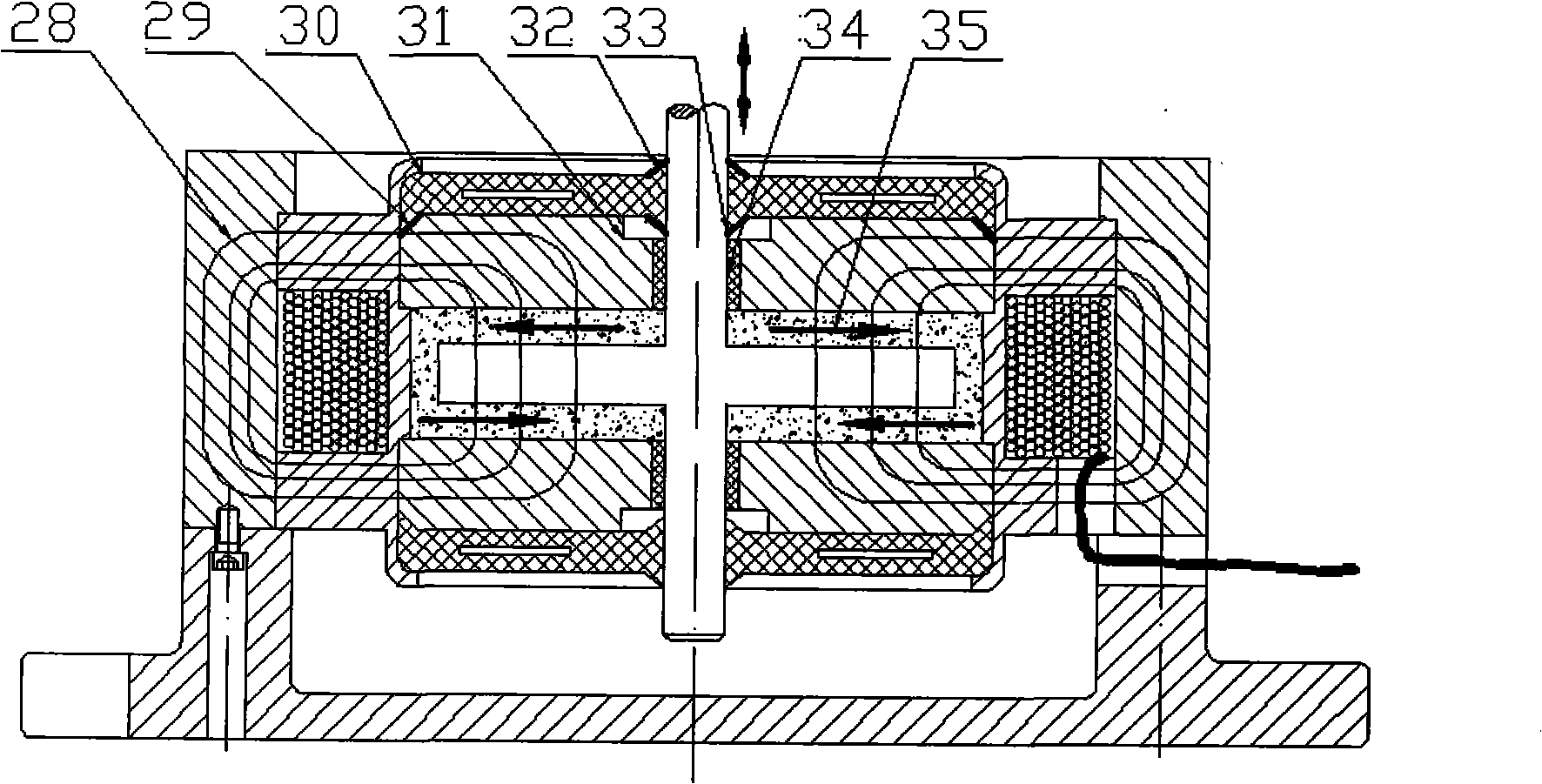

Multiple-disc type magnetorheological brake

InactiveCN102146968AGood heat dissipationImprove cooling effectLiquid resistance brakesMagnetic currentBrake torque

The invention relates to a multiple-disc type magnetorheological brake which mainly comprises a transmission shaft, a wheel hub, a drive friction plate group, a driven friction plate group, inner and outer magnetic isolation rings, an exciting coil with a U-shaped iron core, magnetic-conducting side plates and a magnetic isolation casing. A sealing ring is used for sealing magnetorheological fluid between the drive friction plate group and the driven friction plate group; the drive friction plate group and the driven friction plate group are respectively sleeved on the magnetic isolation rings and the wheel hub through splines; the drive friction plate group is separated from the driven friction plate group by the inner magnetic isolation ring and the outer magnetic isolation ring; the exciting coil with the U-shaped iron core is directly spliced in iron core jacks of the magnetic conducting side plates; and the braking torque can be changed through changing the current intensity of the coil. When the braking torque is not enough, the quantity of friction plates can be increased or the quantity of the exciting coil with the U-shaped iron core can be increased to adapt to the big torque braking. The multiple-disc type magnetorheological brake has the advantages that the structure is compact, the braking torque is big, the assembly and the disassembly are convenient, the coil is easily used for radiating the heat, and the number of turns wounded by the coil is more.

Owner:CHINA UNIV OF MINING & TECH

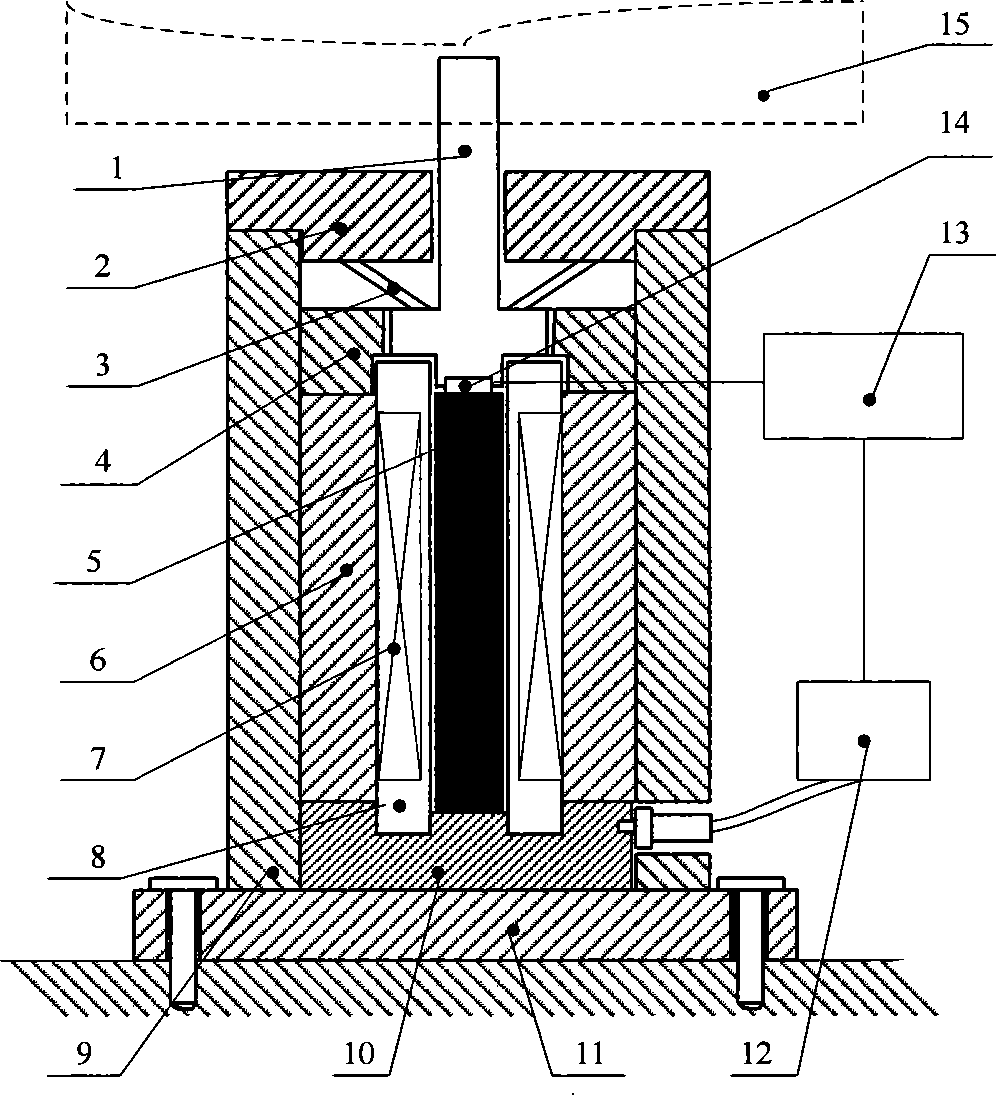

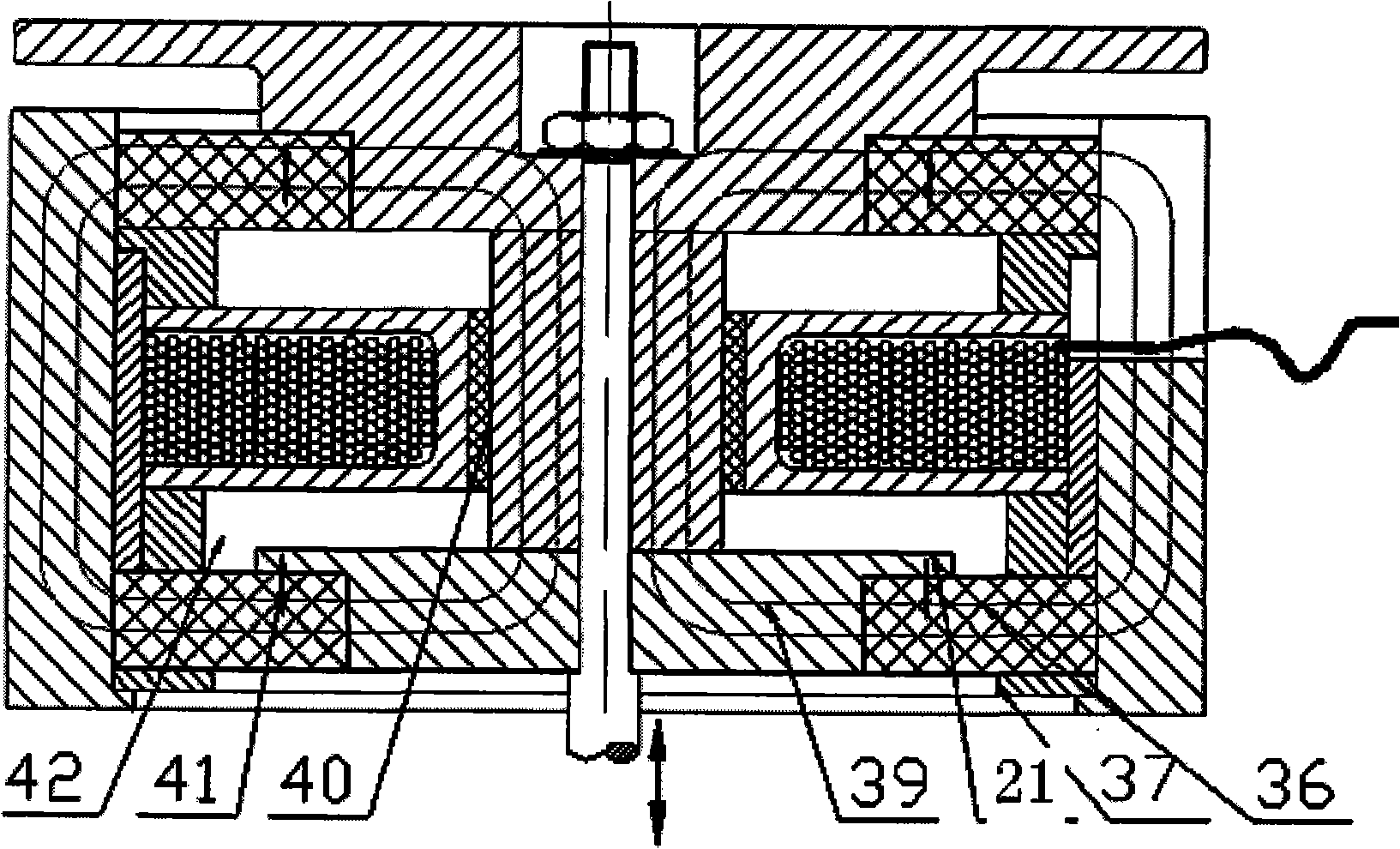

Controllable vibration isolator based on magnetic current change elastic element and damping element coupled action

InactiveCN101324257AMeet the requirements of the suspension parametersImproves sealing reliabilityNon-rotating vibration suppressionElastomerMagnetic current

The invention relates to an engine vibration isolation device of a magneto-rheological fluid damper in extrusion mode and a magneto-rheological elastomer in shearing mode for supporting static loads. The vibration isolation device comprises two pars of a damping adjusting unit and a rigidity adjusting unit; the damping adjusting unit is connected with the rigidity adjusting unit through a rigid connecting rod; the vibration of an engine causes the connecting rod to move upwards and downwards, so that the magneto-rheological fluid in the damping adjusting unit flows in radial direction and shearing occurs to the magneto-rheological elastomer in the rigid adjusting unit; a magnetic field generated by two exciting coils can be respectively adjust damping parameters and rigidity parameters of a vibration isolator. The magneto-rheological vibration isolator can meet the independent adjustment of the damping parameters and the elastic parameters of the vibration isolator under different vibrational excitation conditions, and achieve the coupling control of the transmission of engine vibration energy, and has great realistic significance in improving the technical level and market competence of special vehicles.

Owner:CHONGQING UNIV

Electromagnetic machine with a deformable membrane

ActiveUS7323961B2Little noiseLess noisyFlexible member pumpsMechanical energy handlingMagnetic currentEngineering

An electromagnetic machine with a deformable membrane (1) includes at least one fixed part which can direct a magnetic flow interacting with at least one moveable part (12) having regions which are magnetically polarized in order to ensure that alternative displacement of the moveable part (12) corresponds to an alternative variation of the magnetic flow in the fixed part, the moveable part (12) being kinetically linked to an edge (5) of the membrane (1) such that an undulation of the membrane (1) corresponds to an alternative displacement of the moveable part (12), wherein the fixed part and moveable part (12) are arranged in such a way that the moveable part (12) can be displaced in a rotating manner.

Owner:AMS R&D

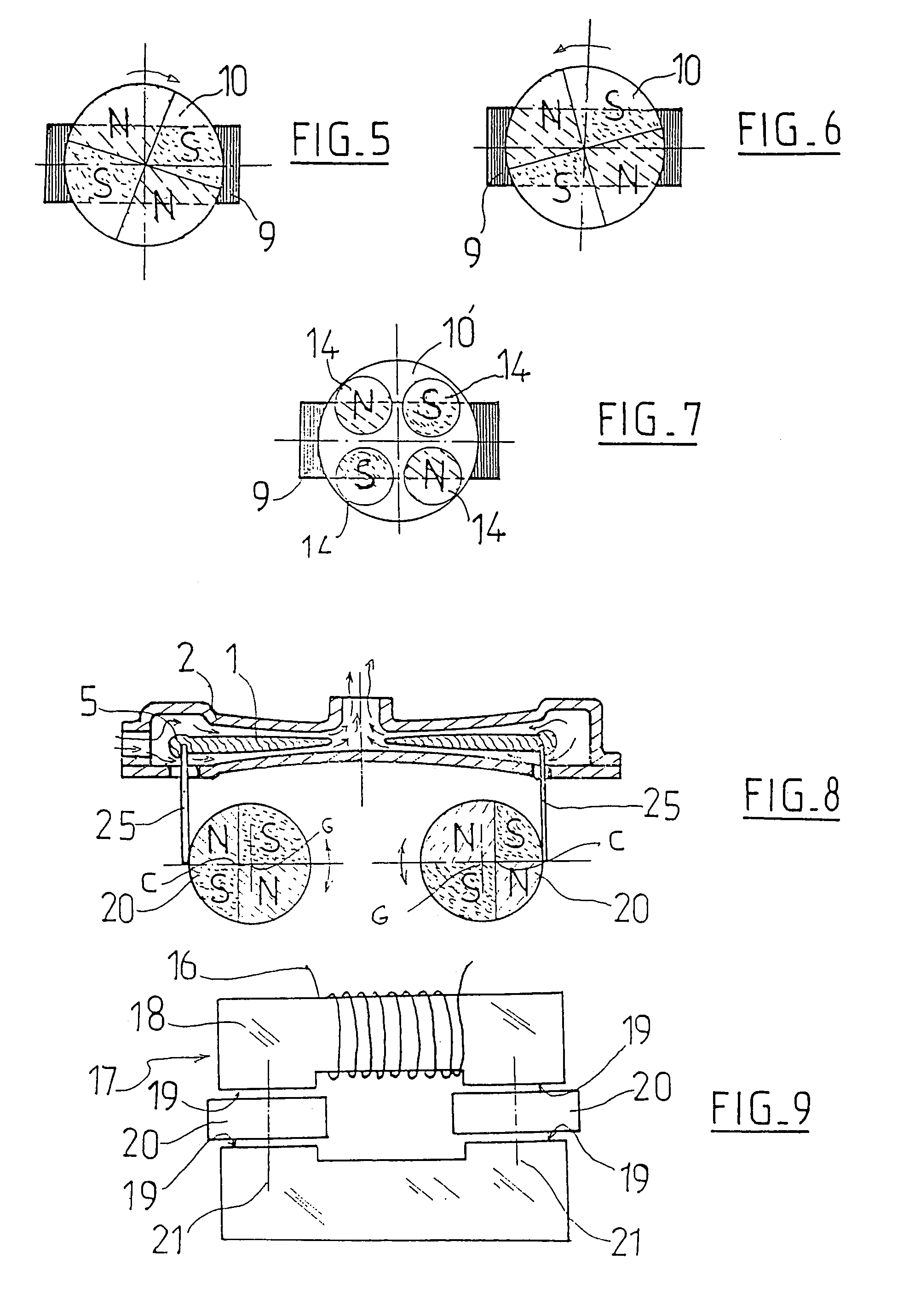

Double-flexible-grinding-head magnetorheological polishing device

ActiveCN102632435AEfficient removalEffectively match processing efficiencyGrinding drivesGrinding feed controlMagnetic currentEngineering

The invention discloses a double-flexible-grinding-head magnetorheological polishing device. In the device, a vertical gantry of a bed body and an X-axis are both fixed on a horizontal base; a worktable is fixed on a sliding block of the X-axis; a Y-axis is fixed on a horizontal beam of the vertical gantry; and a first Z-axis and a second Z-axis are arrangedon the Y-axis in parallel. A large flexible grinding head is installed on the first Z-axis; and a small flexible grinding head is arranged on the second Z-axis. A high-flow circulation system connected with the large flexible grinding head and a low-flow circulation system connected with the small flexible grinding head are arranged on a trolley. A control cabinet is arranged at the rear part of the vertical gantry; and a circulation system cabinet and a cleaning system are arranged at the side surface of the vertical gantry. The double-flexible-grinding-head magnetorheological polishing device provided by the invention has the advantages of high accuracy, high rigidness, high stability and high dynamic property. The double-flexible-grinding-head magnetorheological polishing device not only can be used for processing of large-caliber phase elements, but also can be used for high-accuracy processing of large-caliber planar optical elements within the range of full caliber. The optimal matching of the processing efficiency and the processing accuracy can be realized.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Magnetic tunnel transistor with high magnetocurrent

InactiveUS20080180863A1Improve performanceNanomagnetismNanoinformaticsMagnetic currentMagnetic anisotropy

Owner:WESTERN DIGITAL TECH INC

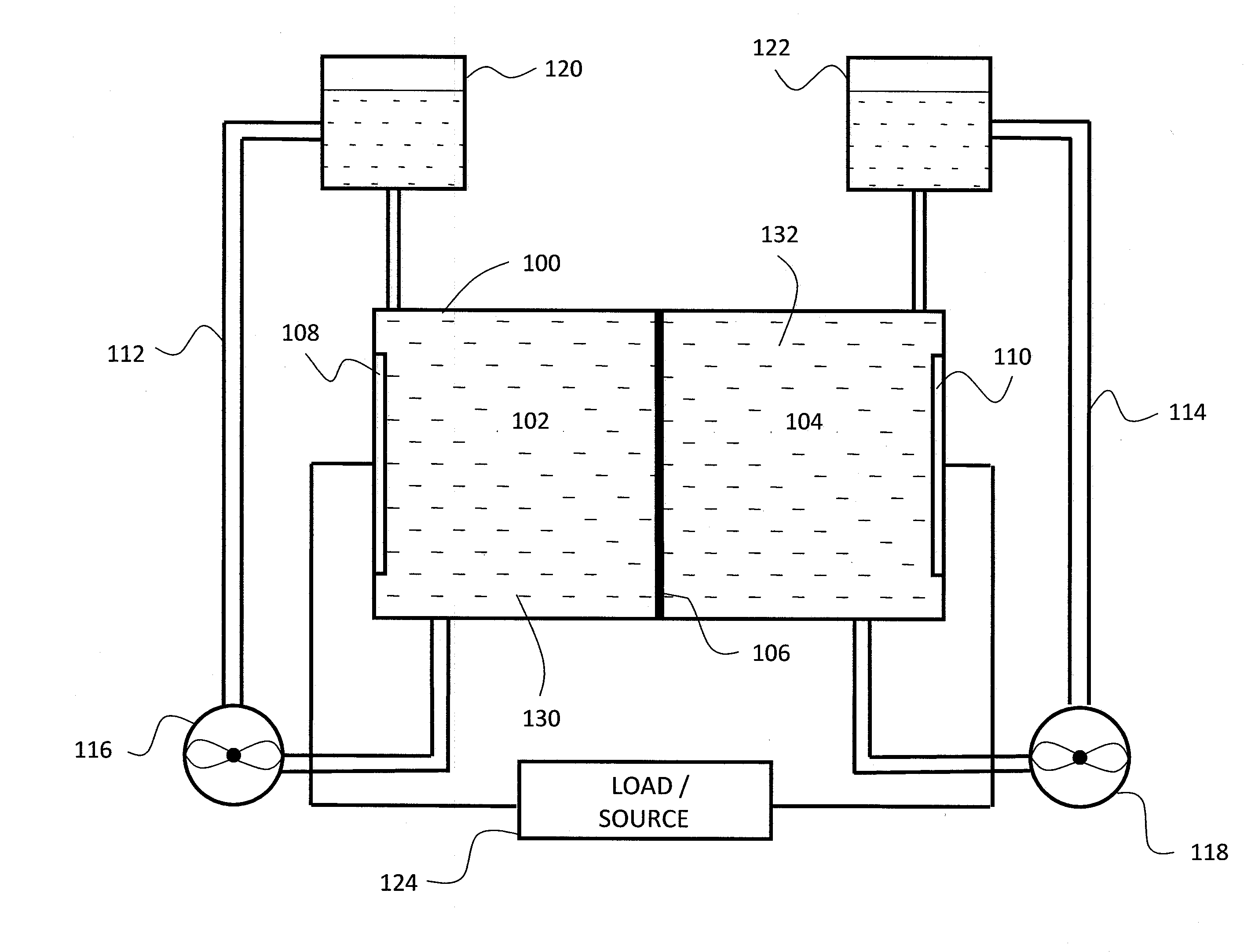

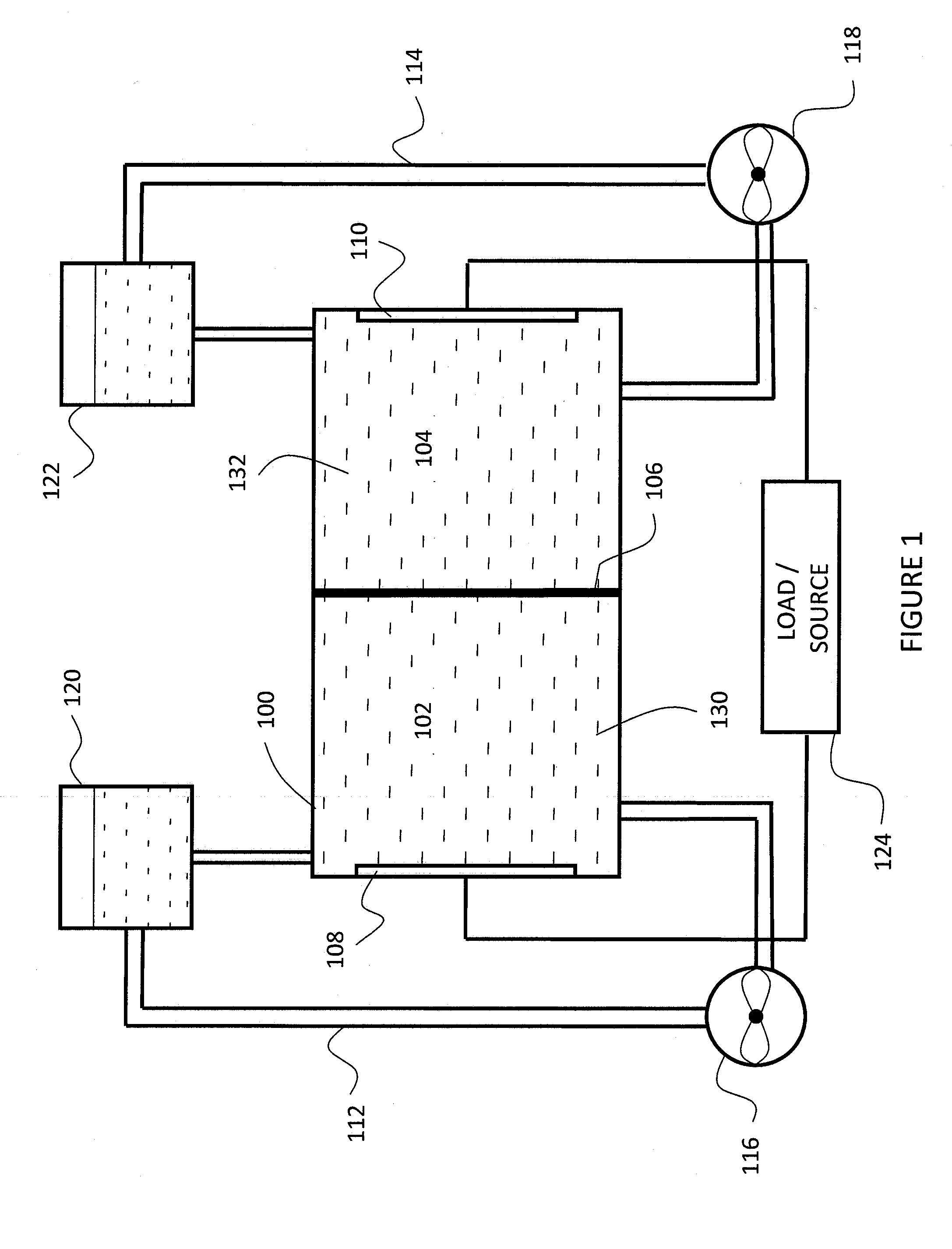

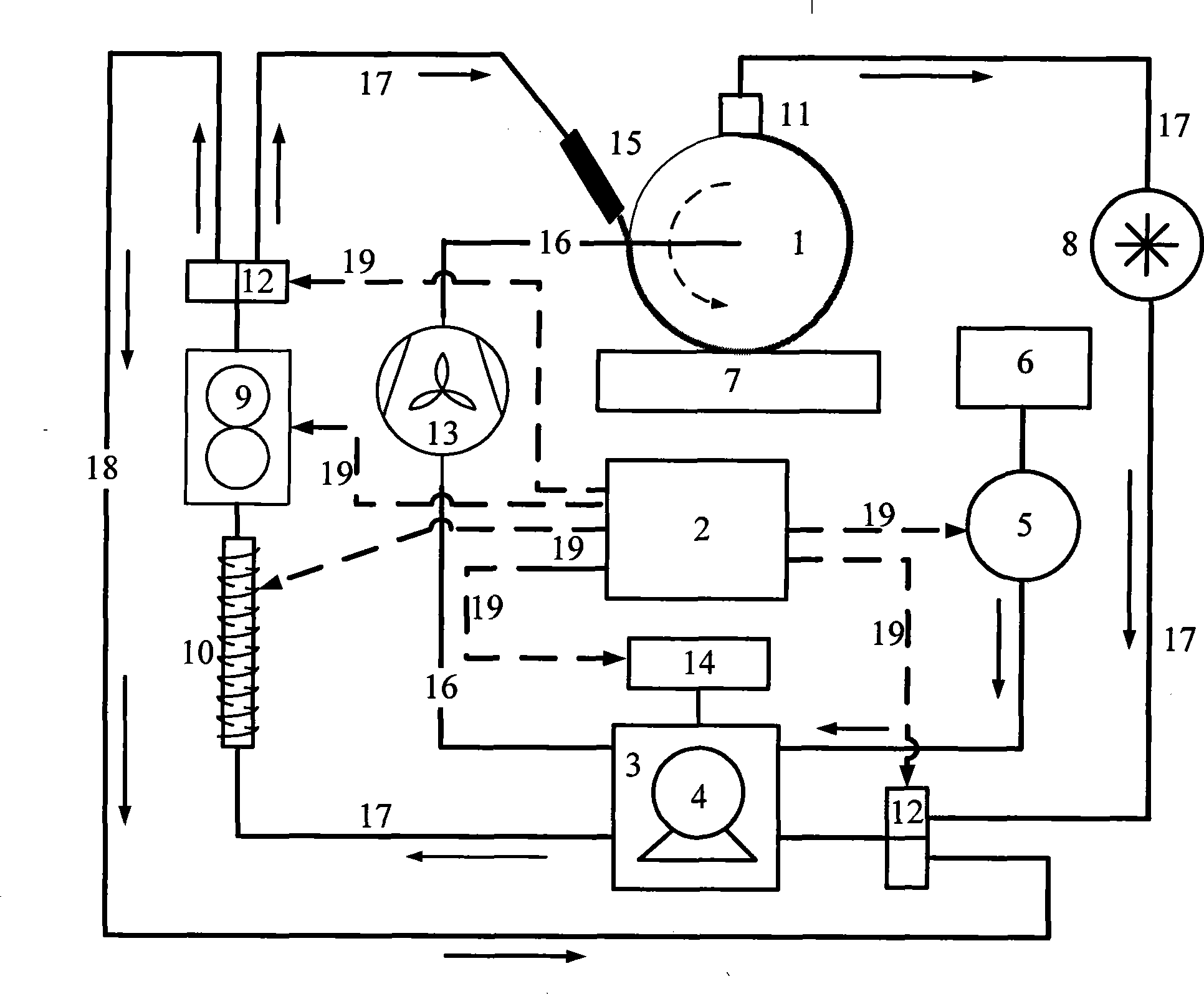

Magnetic current change polishing solution circulating device capable of long-time steadily polishing solution performance

InactiveCN101249637AStable flow rateComposition is stableOptical surface grinding machinesMagnetic currentSlurry

The invention discloses an MR polishing slurry cycle device which has longtime and stable polishing slurry performance. The liquid mixture tin is connected with the water tank through a metering pump and the cooling machine is connected with the liquid mixture tin through the cooling pipe; a polishing slurry circulation loop consists of the successively connected liquid mixture tin, electromagnetic flow meter, nozzle, recovery unit and recovery pump through a polishing circulation pipeline and a non-polishing slurry circulation loop consists of the successively connected liquid mixture tin and electromagnetic flow meter through a non-polishing circulation pipeline. The polishing slurry circulation loop and the non-polishing slurry circulation loop are connected in parallel and a switching control valve is arranged at the junction. The lateral pipe between the liquid mixture tin and the switching control valve is surrounded with spiral coil; the electromagnetic flow meter and the spiral coil are connected with the input terminal of the computer, of which the control output terminal is connected respectively with the switching control valve, the cooling machine, the power pump and the metering pump. The device has the advantages of high control precision, sound stability, etc., and can provide low cost, reliable and stable MR polishing slurry for MR polishing processing for a long time.

Owner:NAT UNIV OF DEFENSE TECH

Semi-active magnetic-current variable-piezoelectric feedback type damper

ActiveCN108729571AAdjust damping in real timeAdjust stiffness in real timeBridge structural detailsProtective buildings/sheltersMagnetic currentSemi active

The invention discloses a semi-active magnetic-current variable-piezoelectric feedback type damper, comprising an inner tube and an outer tube. A revolving shaft is arranged in the middle of the innertube, and is fixedly connected with two vanes which are arranged by the angle of 180 degrees in the inner tube. The vanes are hollow and provided with mass blocks inside respectively, the upper and lower ends of each mass block are connected with the inner wall of the corresponding vane through springs. Two thin plates are arranged in the inner tubes and perpendicular to the vanes respectively. The cavity of the inner tube is filled with magnetorheological fluid. Piezoelectric generator units are respectively arranged on the surfaces of the thin plates, and pressure sensors are respectively arranged at the tops of the piezoelectric generator units. The outer wall of the inner tube is wound with a field coil along the axis direction. The pressure sensors, the field coil, a controller and an electric power extracting and storing unit are in series connection to form a closed loop, wherein the controller and the electric power extracting and storing unit are arranged at the top of the inner tube.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com