Dynamic magnetic field self-sharpening finishing device for flexible magnetorheological finishing pad and finishing method for dynamic magnetic field self-sharpening finishing device

A flexible polishing and dynamic magnetic field technology, which is applied in the direction of grinding drive device, grinding/polishing equipment, abrasive surface adjustment device, etc., can solve the problems of losing workpiece pressure, reducing processing effect, and difficult to guarantee the processing shape accuracy, etc. It is easy to achieve Cleaning and space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

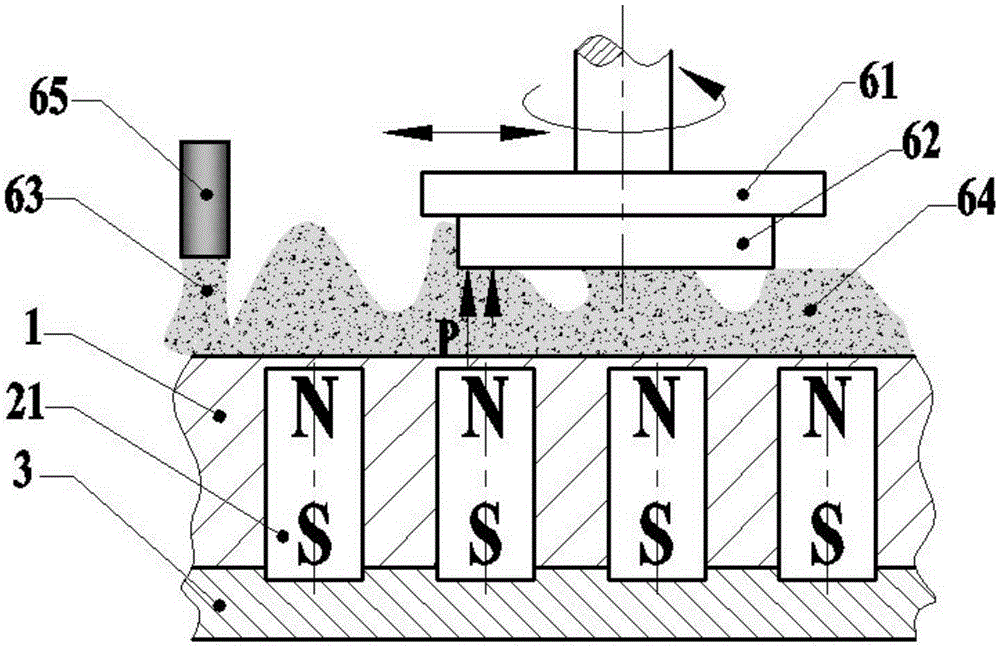

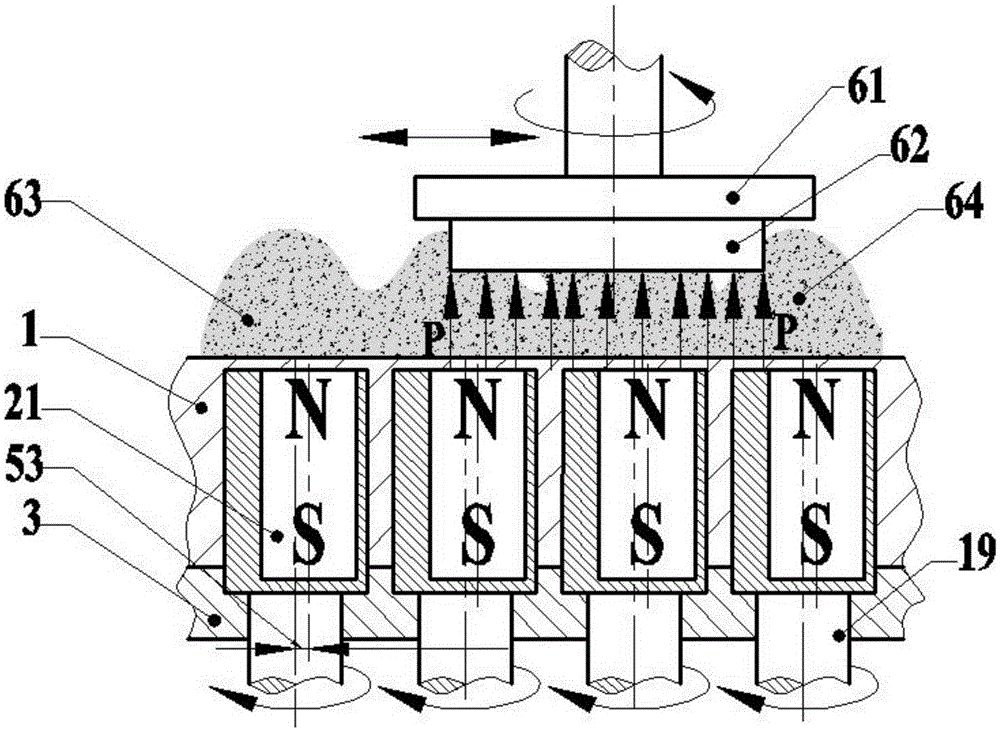

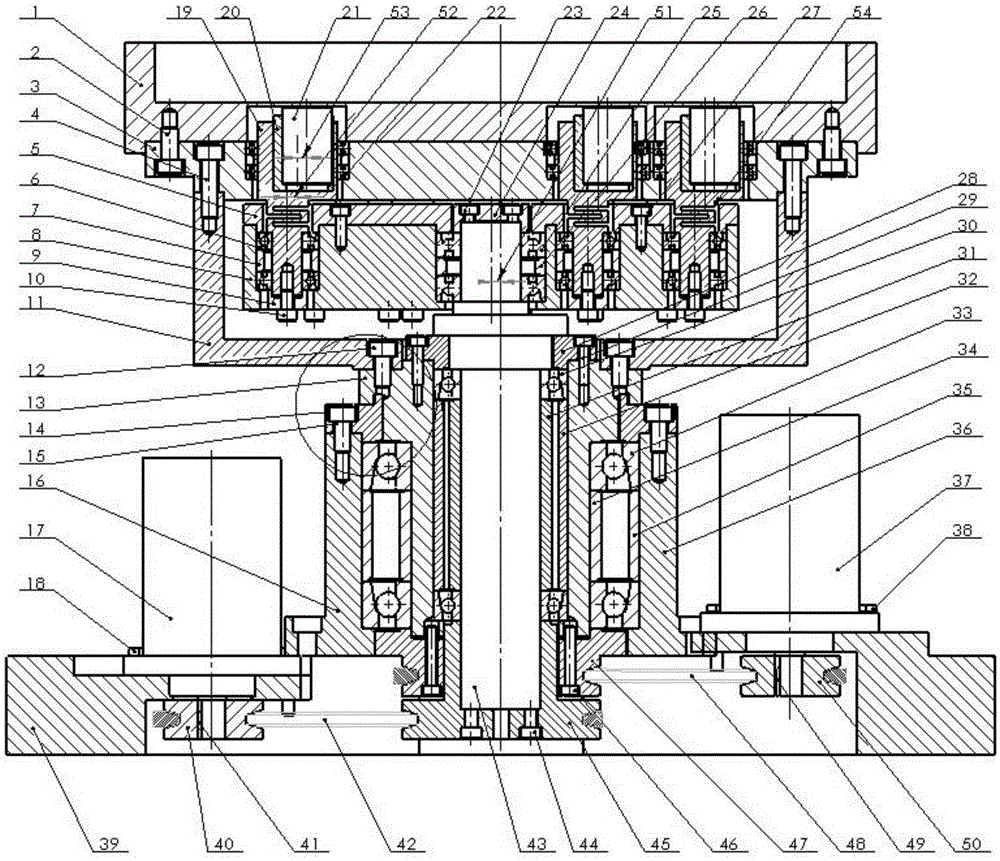

[0025] Such as image 3 As shown, a dynamic magnetic field self-sharpening polishing device for a magnetorheological flexible polishing pad of the present invention includes a polishing disc revolution mechanism and a multi-pole synchronous rotation drive mechanism. The polishing disc revolution mechanism includes a base 39, a transmission shaft motor 37, a transmission Shaft 13, adapter disc 11, eccentric shaft fixed disc 3, cup-shaped polishing disc 1, transmission shaft transmission mechanism, multi-pole synchronous rotation drive mechanism includes eccentric main shaft 43, synchronous rotation drive disc 8, flexible eccentric rotation shaft 19, eccentric Cover 20, magnetic pole 21, eccentric shaft fixed disk 3, main shaft motor 17, main shaft transmission mechanism, wherein the transmission shaft motor 37 is fixed on the base 39, and the active transmission part of the transmission shaft transmission mechanism is fixed on the output shaft of the transmission shaft motor 37,...

Embodiment 2

[0043] Such as image 3As shown, a dynamic magnetic field self-sharpening polishing device for a magnetorheological flexible polishing pad of the present invention includes a polishing disc revolution mechanism and a multi-magnetic pole synchronous rotation drive mechanism, and the polishing disc revolution mechanism is fixed by a base 39 and a tenth fixing screw 38 The transmission shaft motor 37 on the base 39, the transmission shaft driving pulley 50 fixed on the transmission shaft motor 37 by the second flat key 49, the bearing seat 16 that is vertically installed in the center of the base 39, and a bearing seat 16 that is installed in the bearing seat 16 The transmission shaft bearing 33, the bearing end cover 14 that is installed on the end face of the bearing seat 16 and compresses the outer ring of the transmission shaft bearing 33 through the fifth set screw 15, the inner fixed sleeve 34 and the outer fixed sleeve 35 that support the separation transmission bearing 33,...

Embodiment 3

[0058] The difference between the present invention and embodiment 1 is: the present invention is that the single crystal sapphire that diameter is 100mm is polished, the polishing method of the dynamic magnetic field self-sharpening polishing device of magnetorheological flexible polishing pad of the present invention, comprises the following steps:

[0059] 1) According to the characteristics of single crystal sapphire with a diameter of 100mm, select a magnetic pole 21 with a diameter of 15mm and a magnetic field strength of 3000Gs to be installed in the dynamic magnetic field self-sharpening device of the magnetorheological flexible polishing pad, and adjust the angle of the eccentric sleeve 20, Make each magnet rotation eccentric distance 53 be 1.5mm, as Figure 7 shown;

[0060] 2) A single crystal sapphire with a diameter of 100mm is installed on the tool head 62, the lower surface of the workpiece 61 is parallel to the upper end surface of the cup-shaped polishing disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com