Patents

Literature

87 results about "Single crystal sapphire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

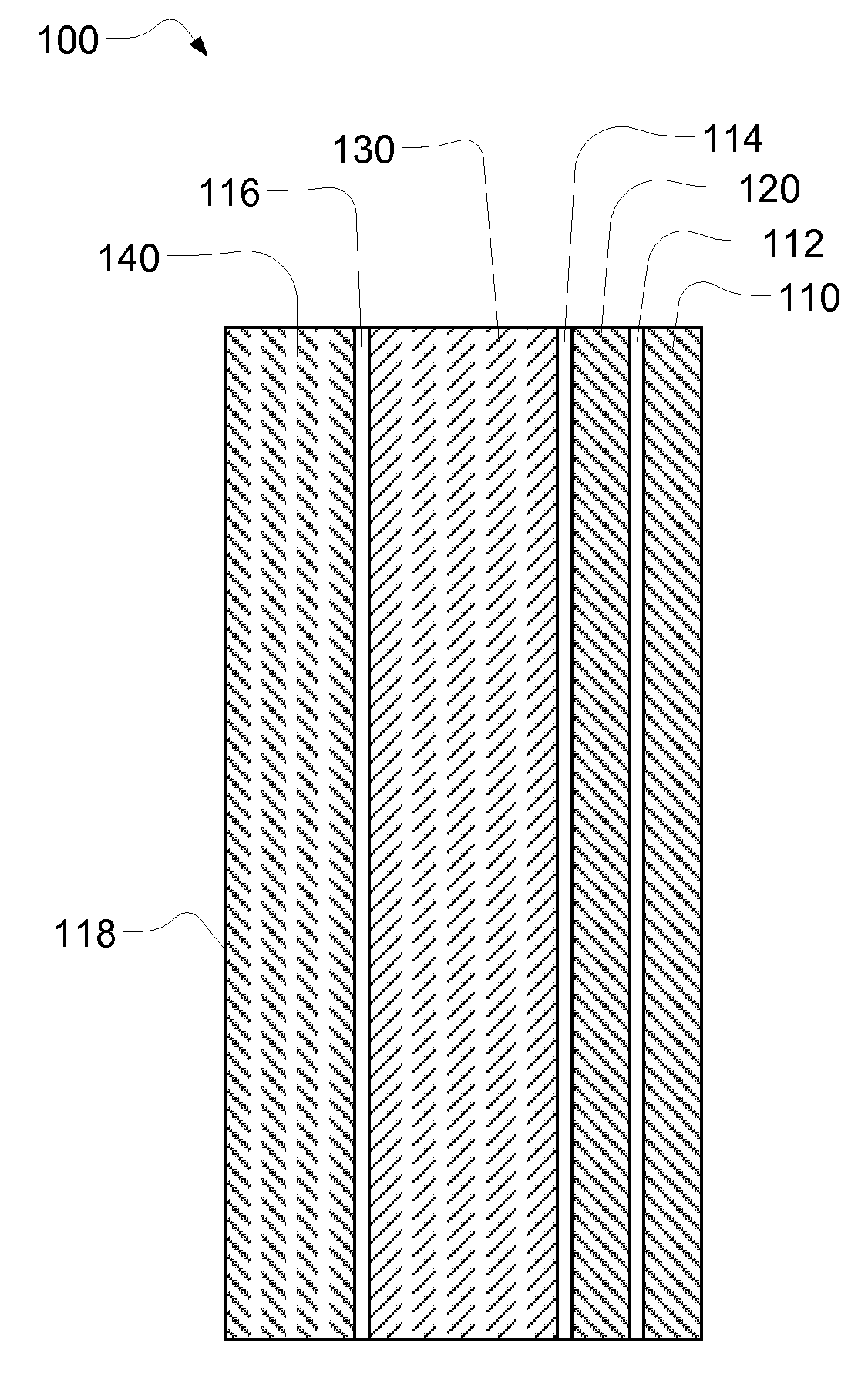

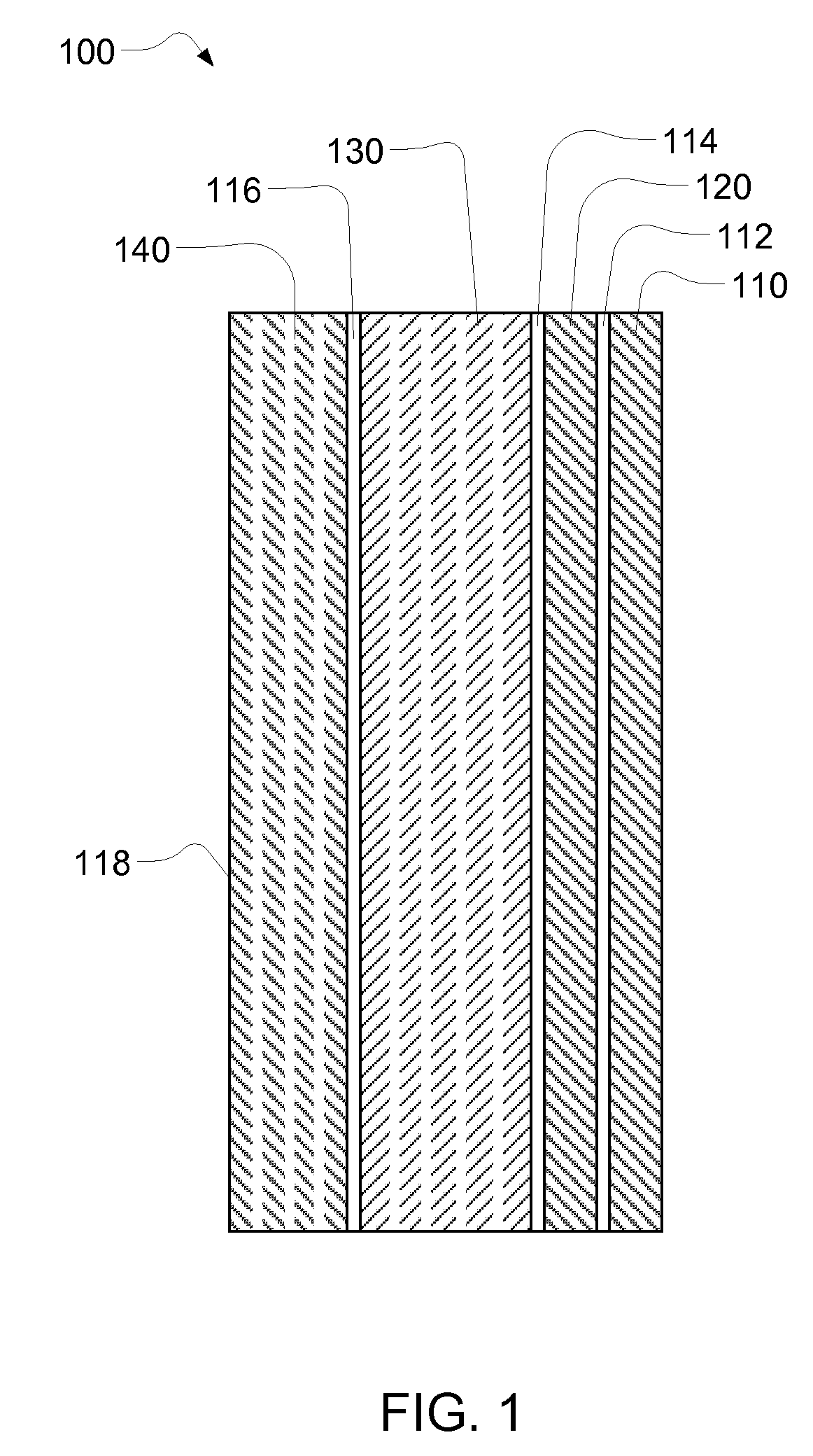

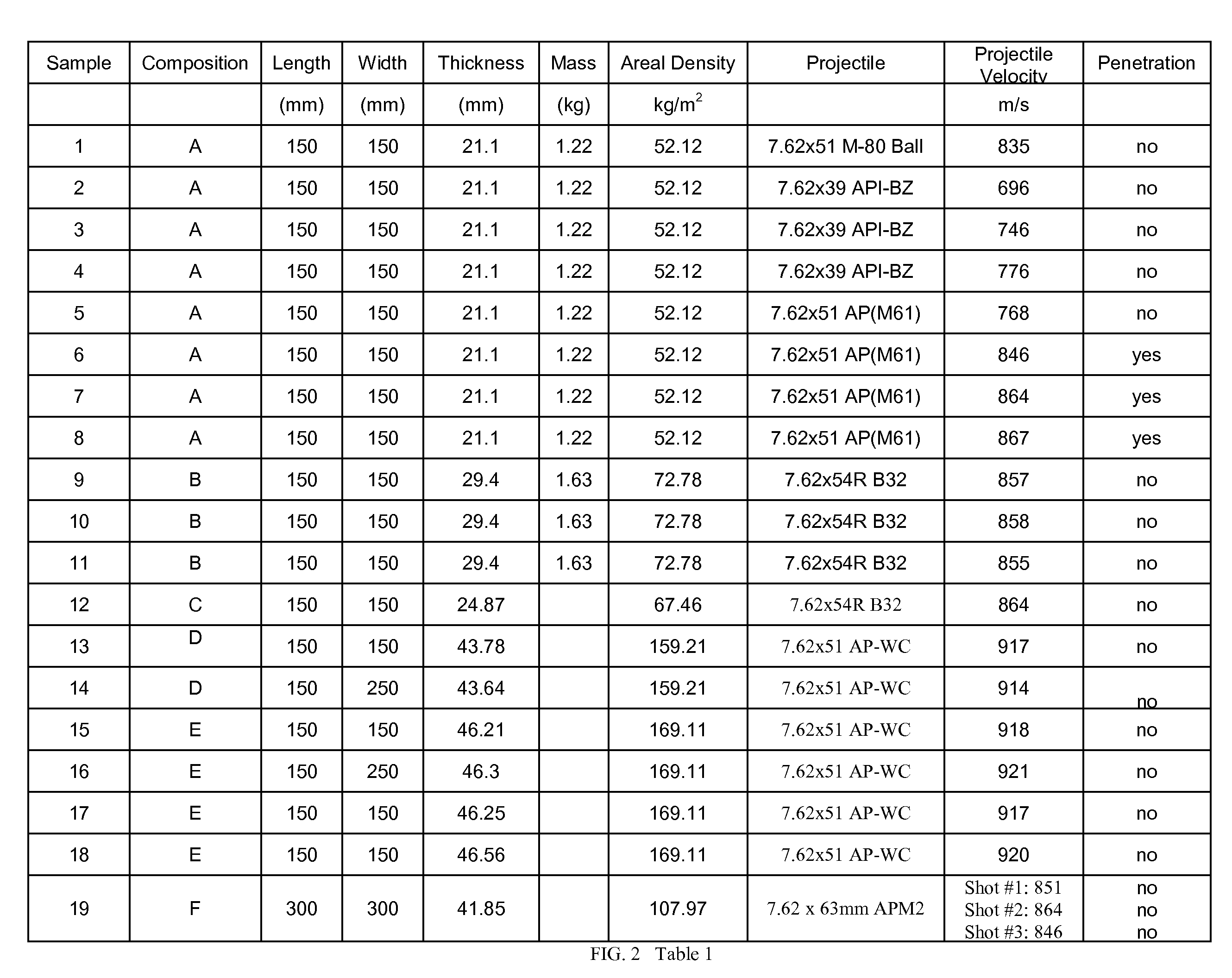

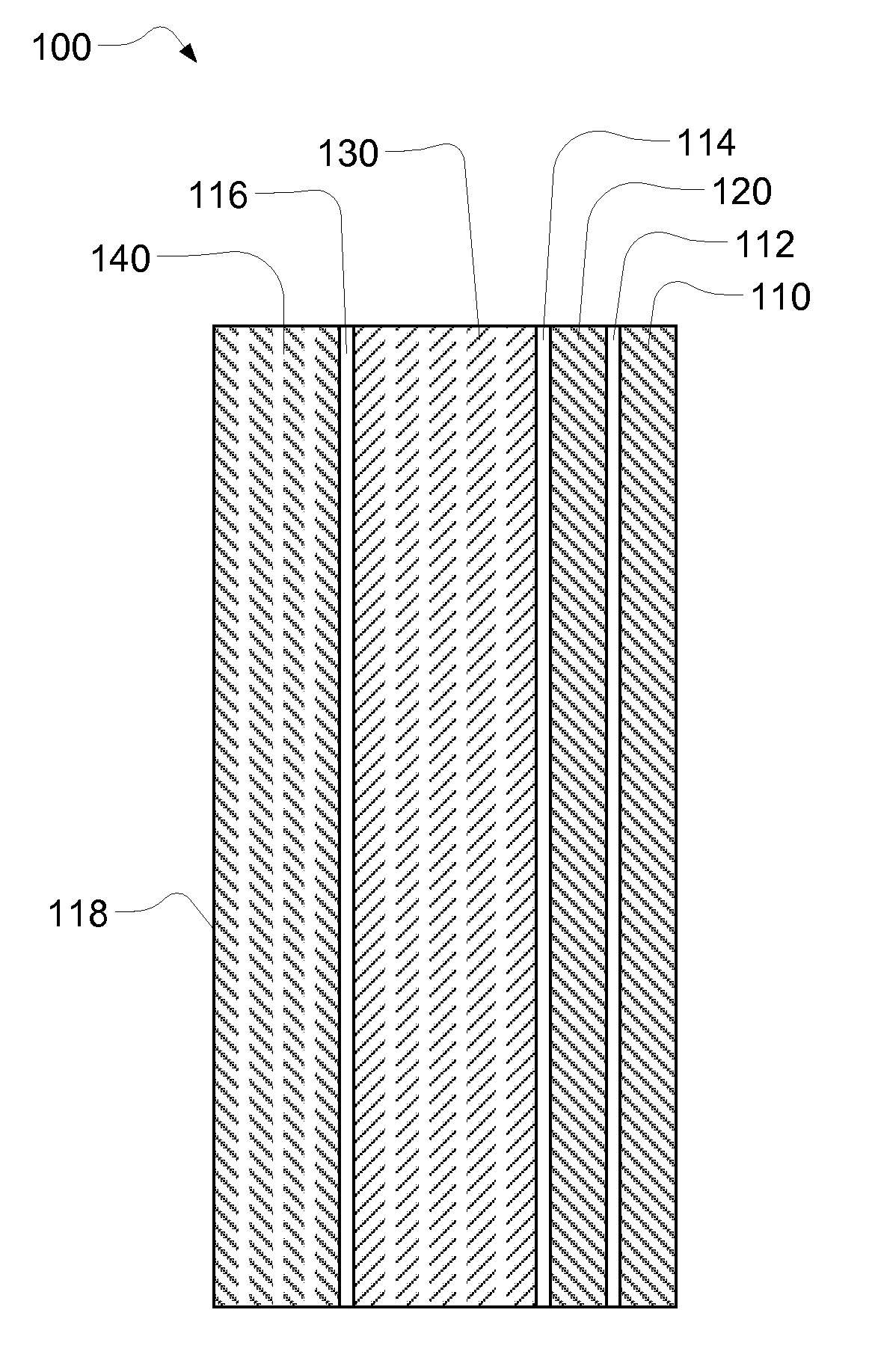

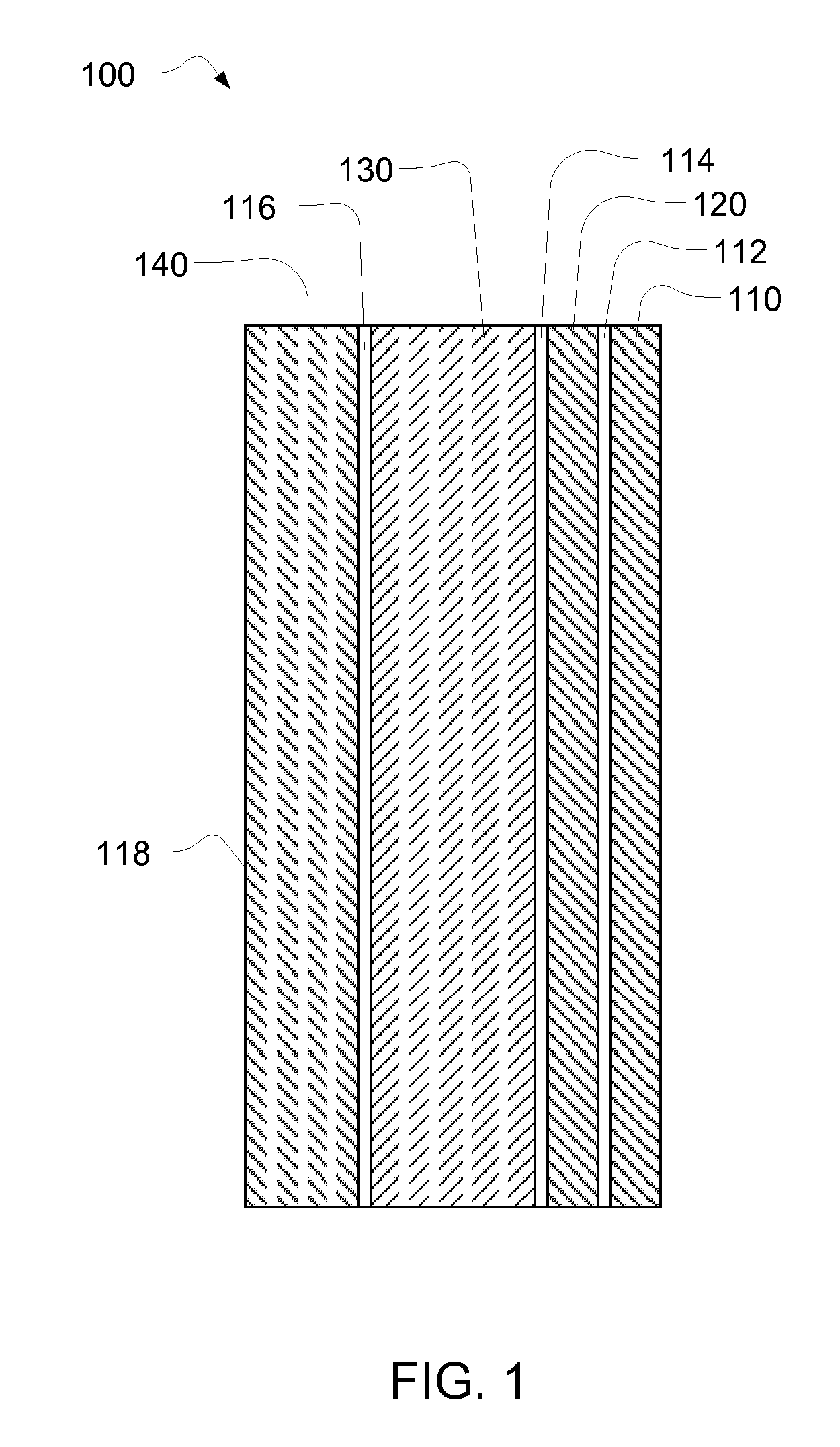

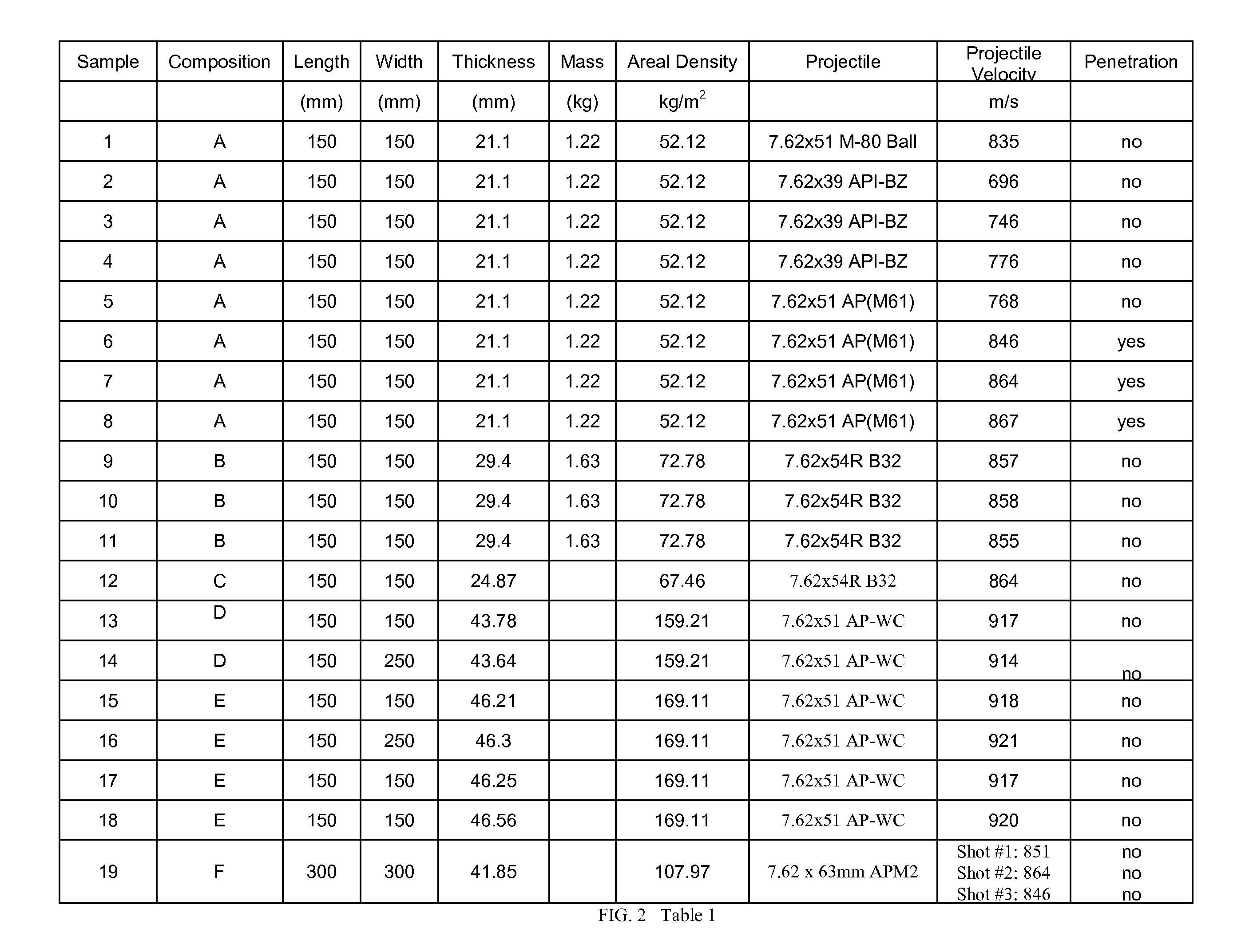

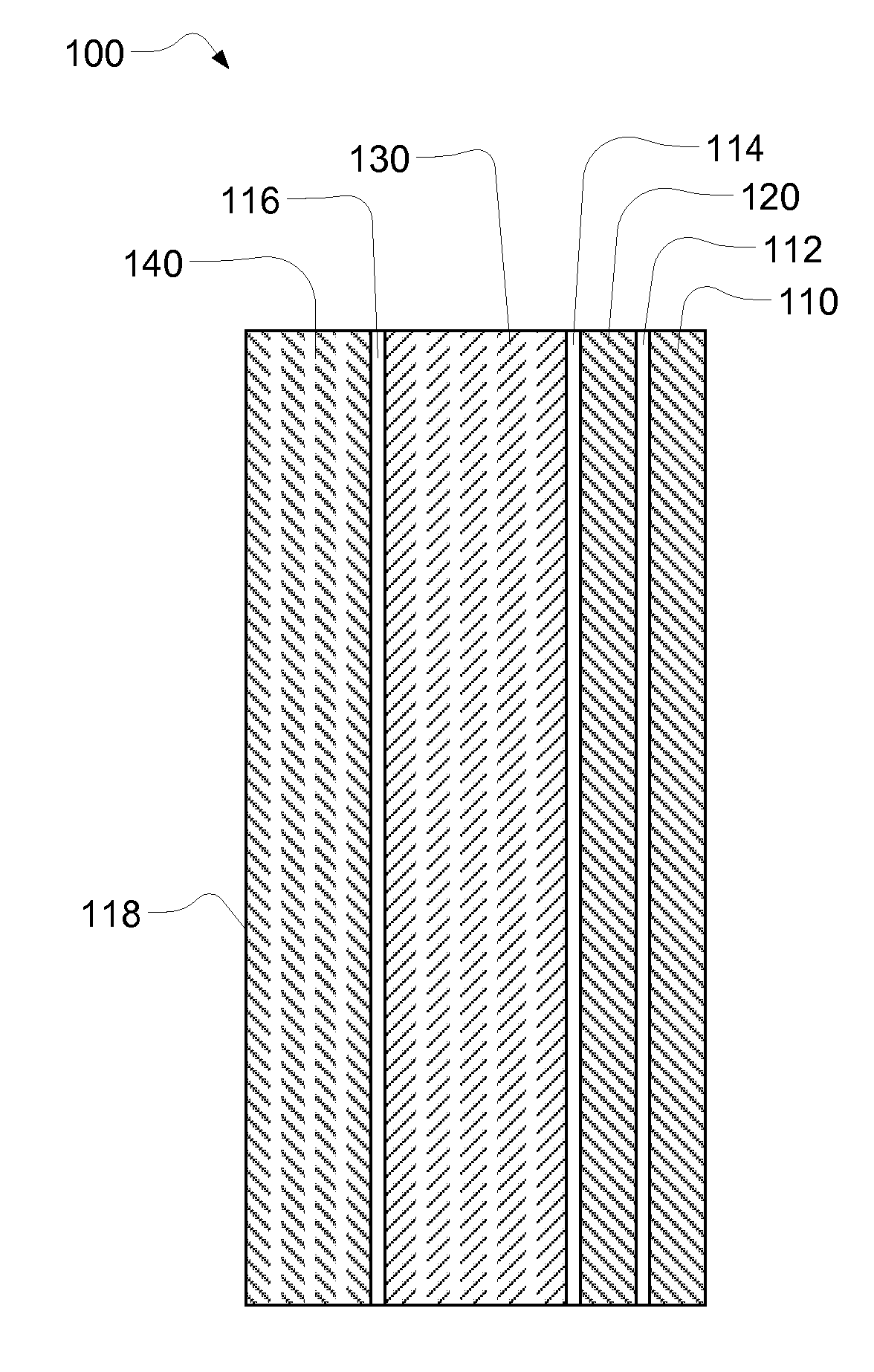

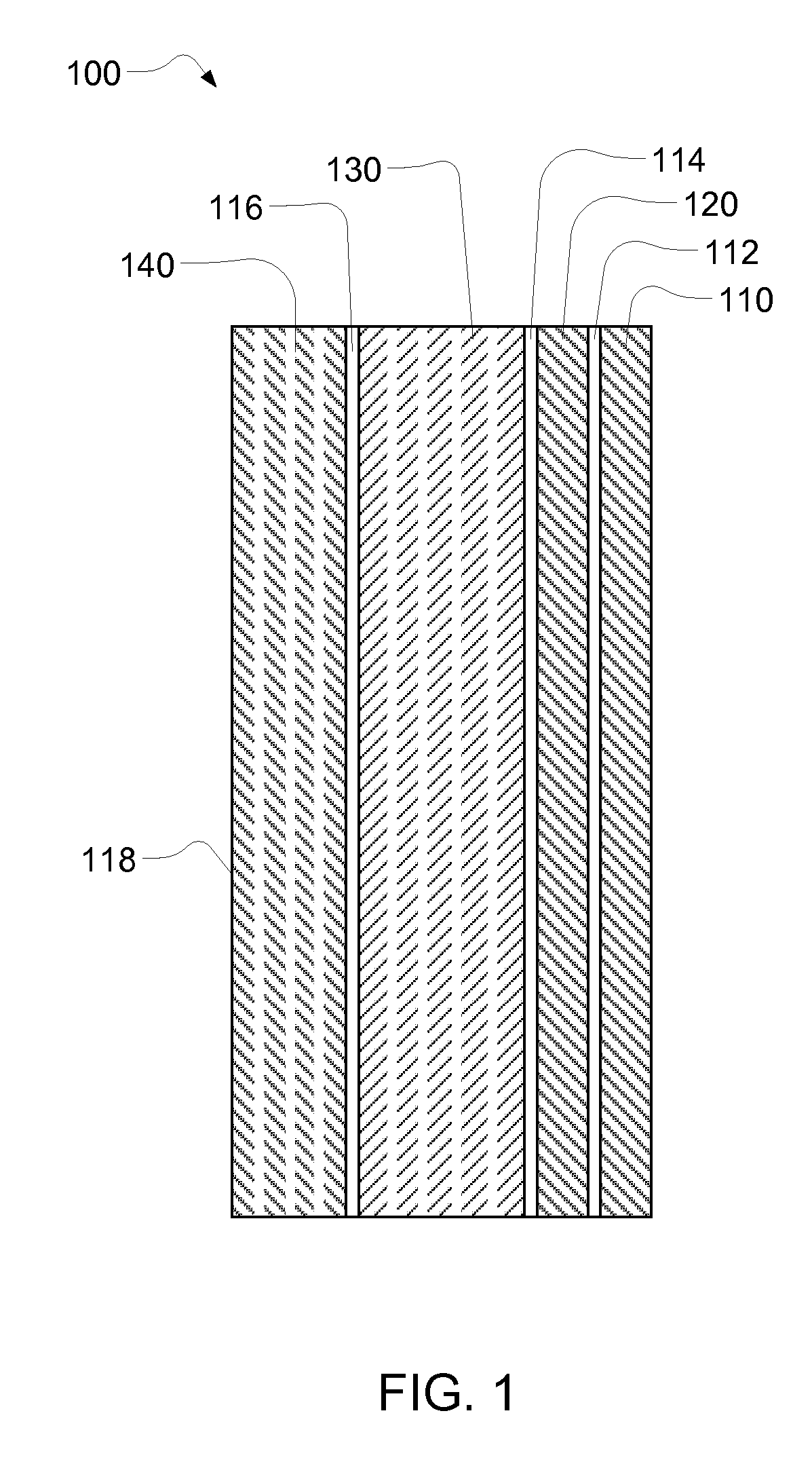

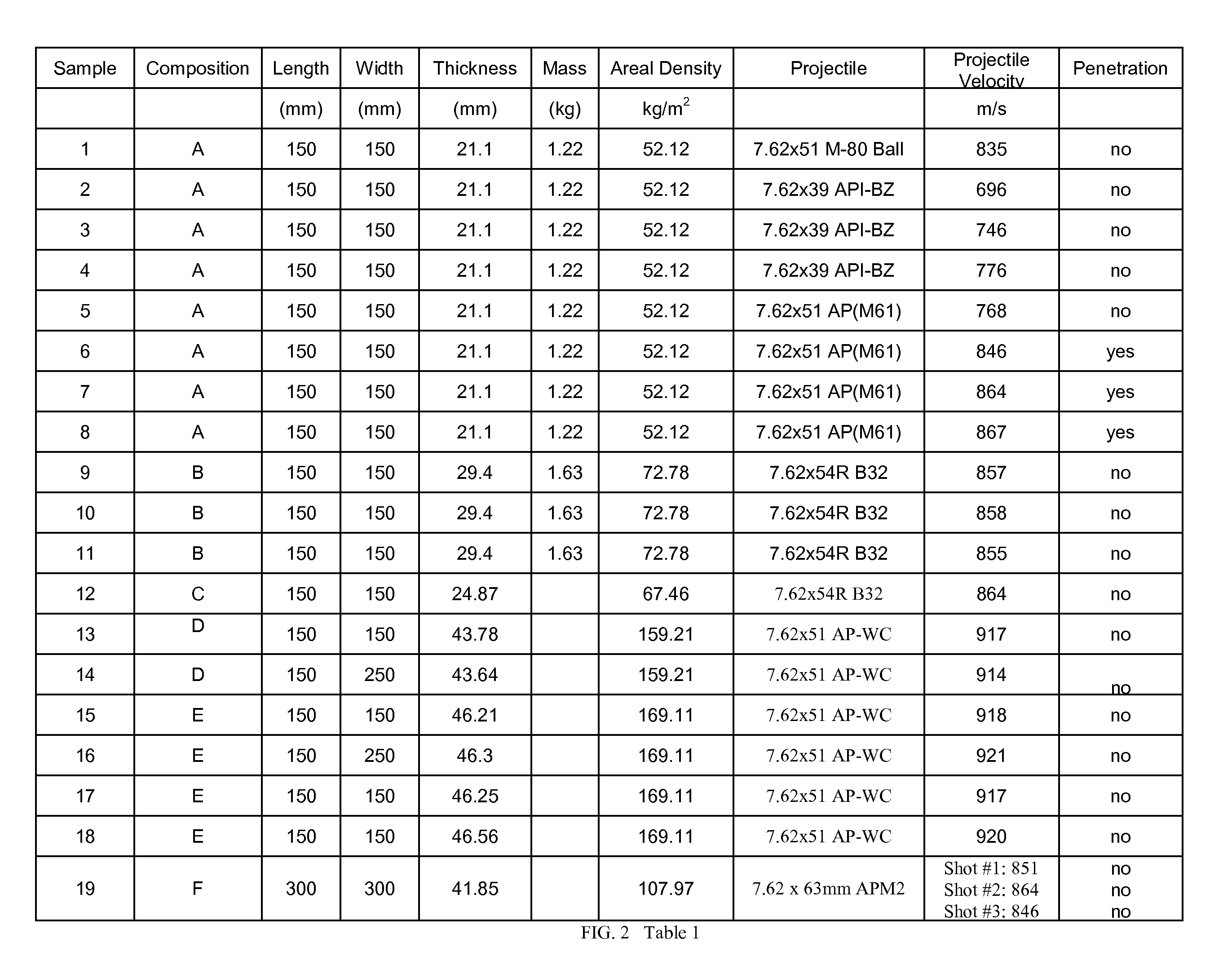

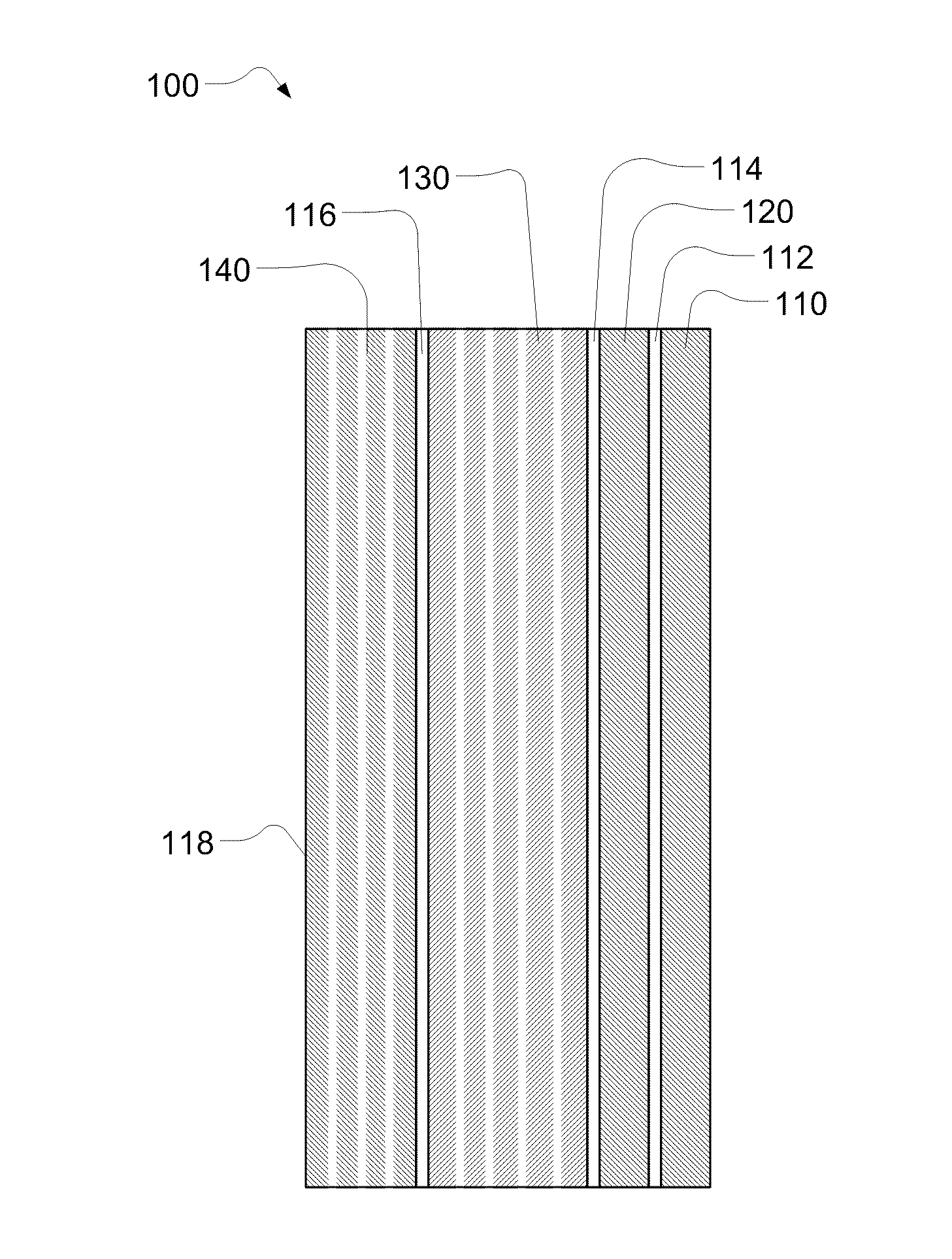

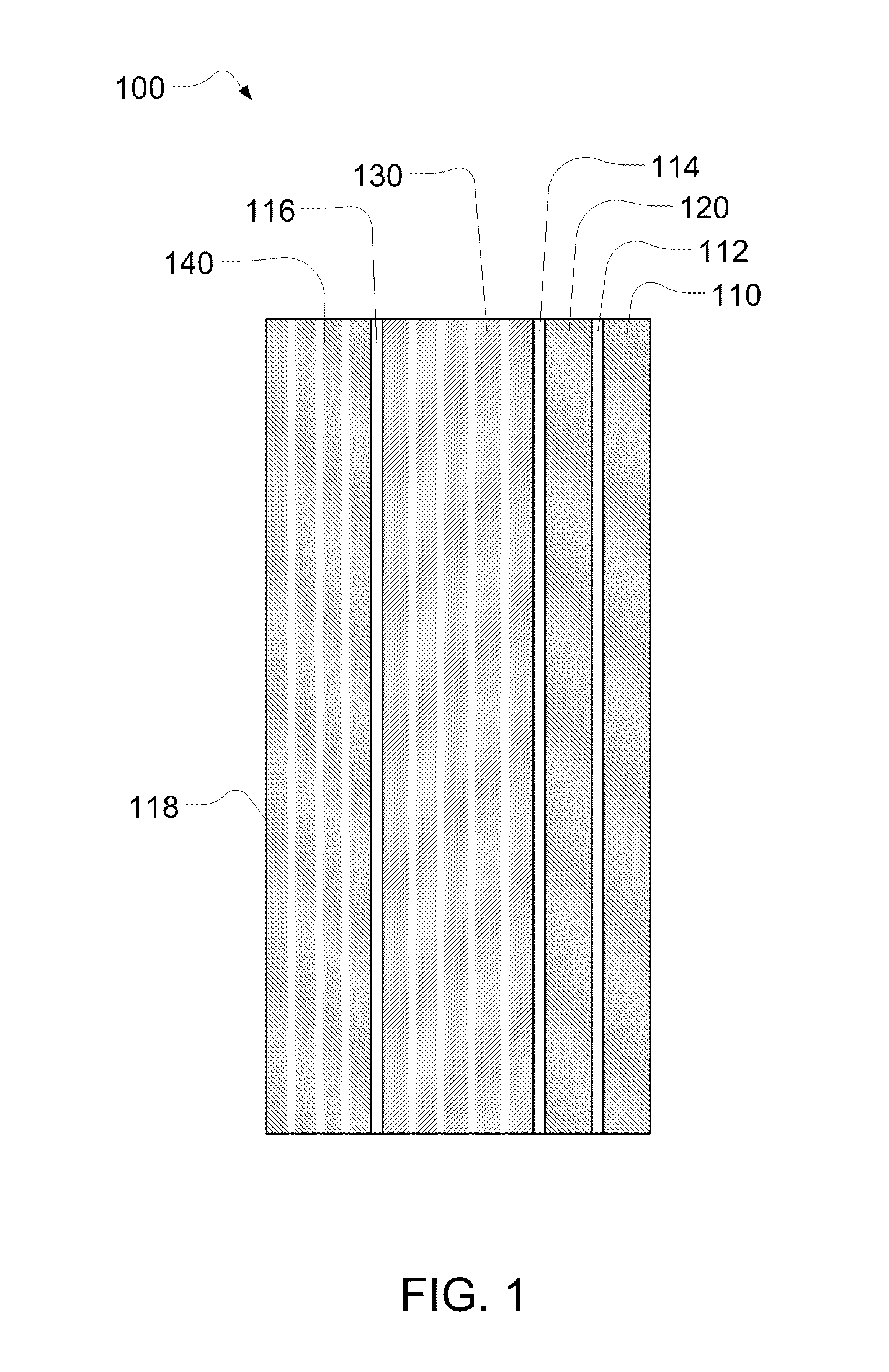

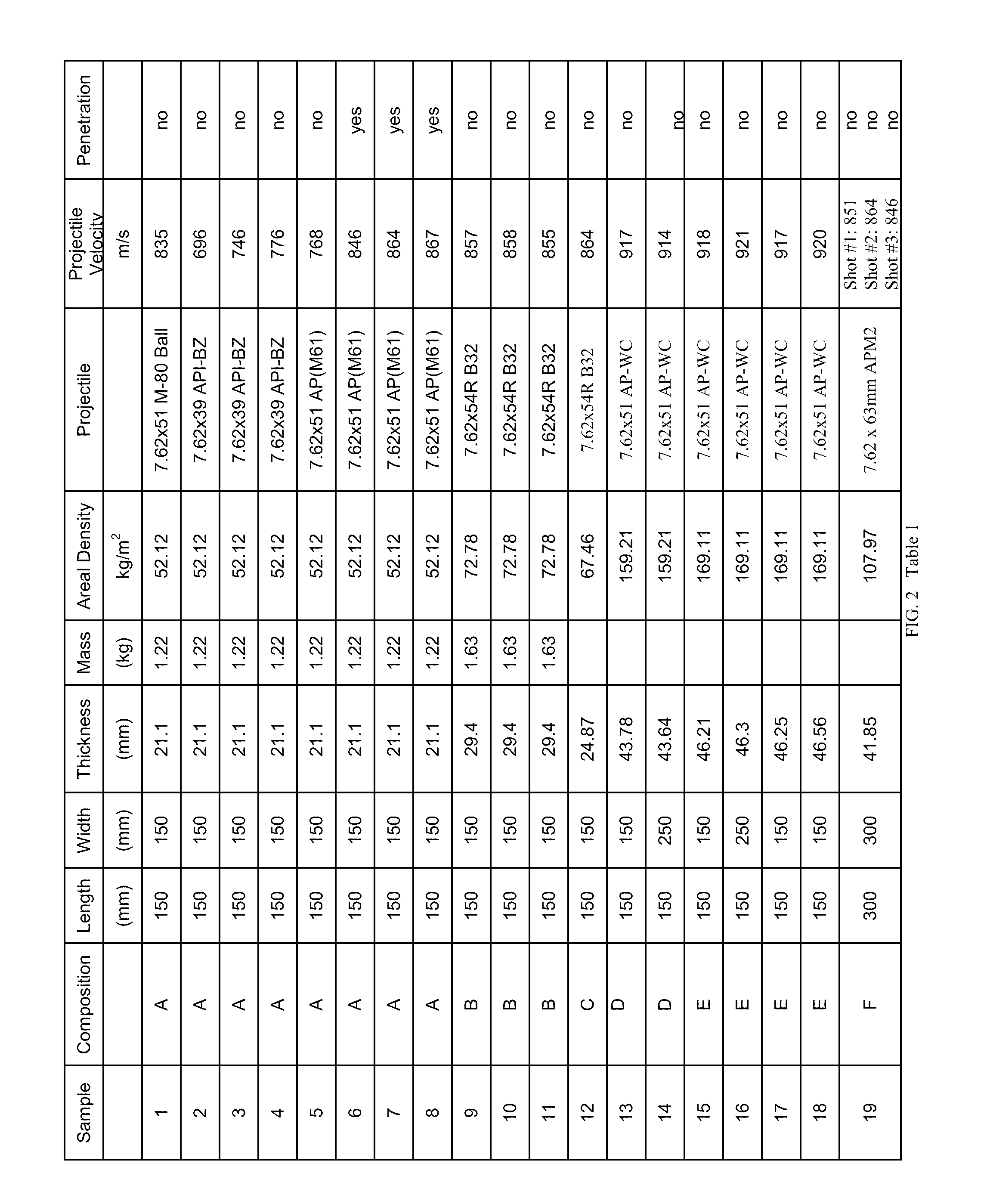

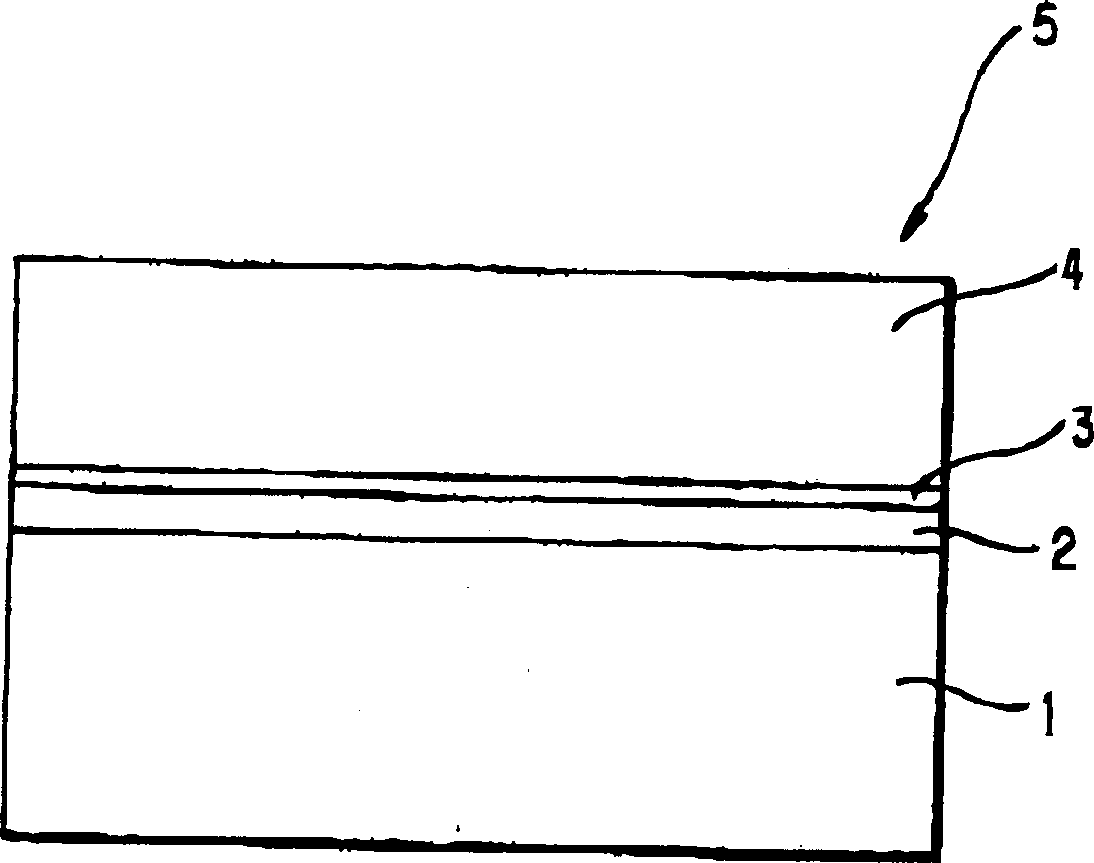

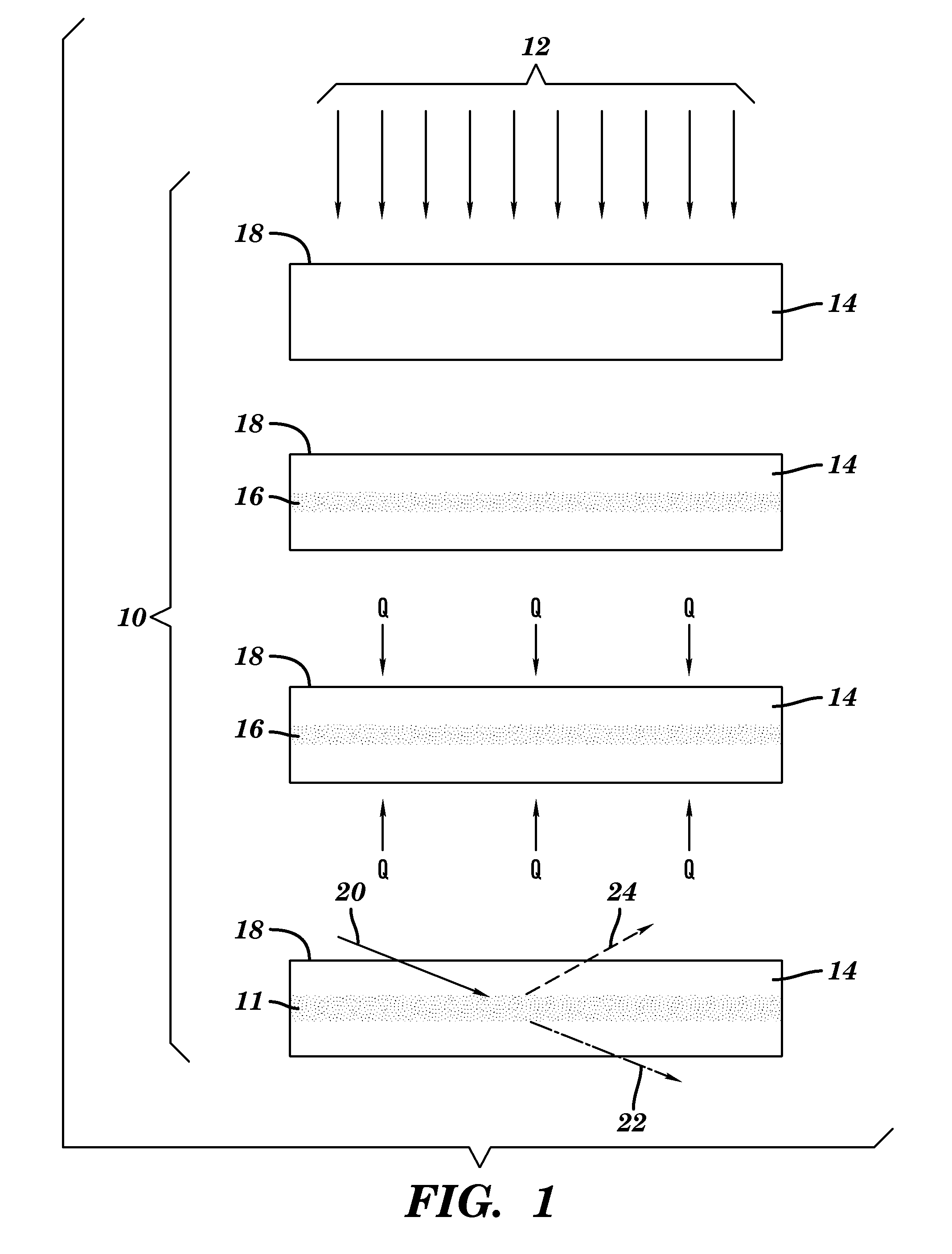

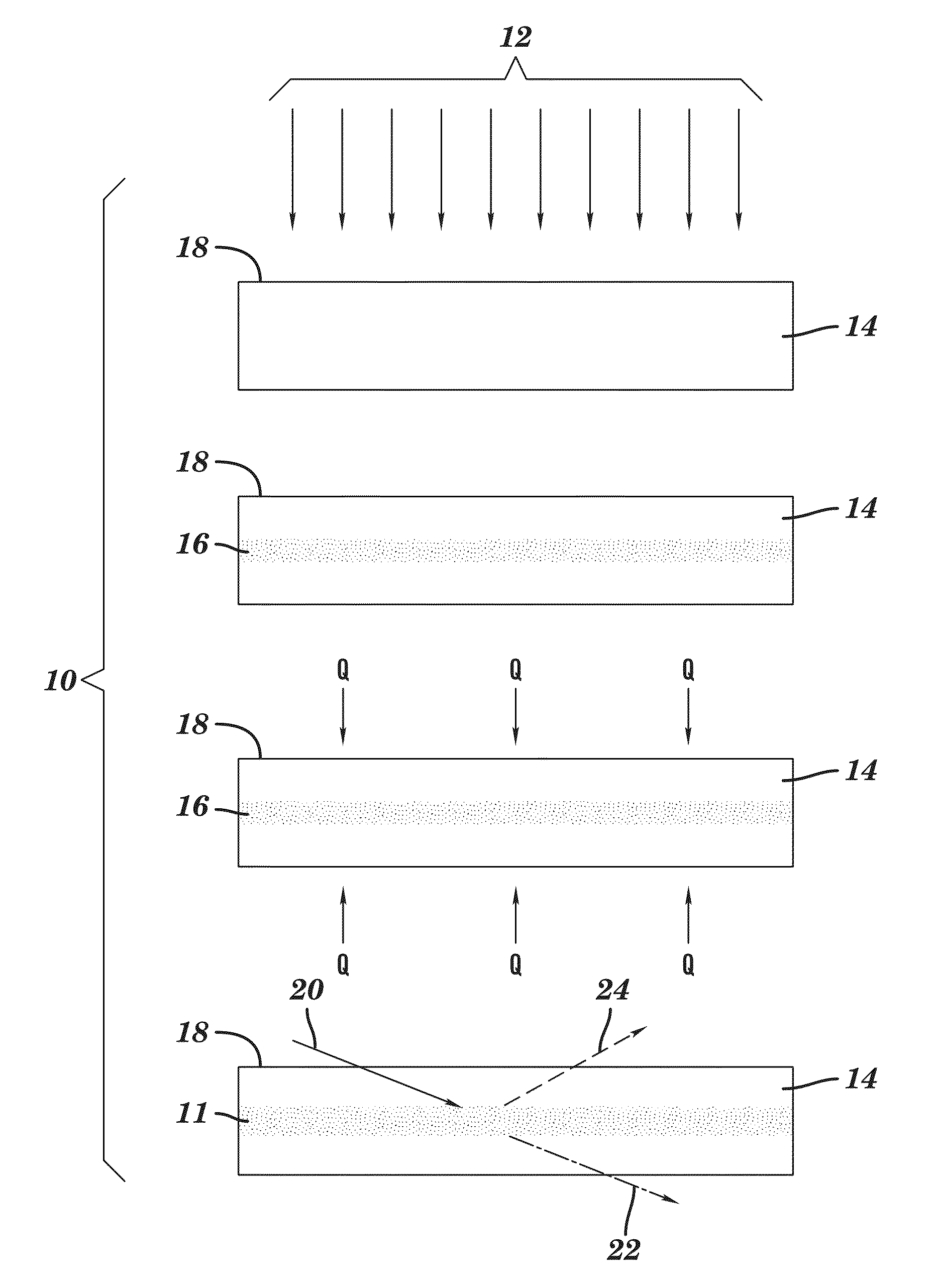

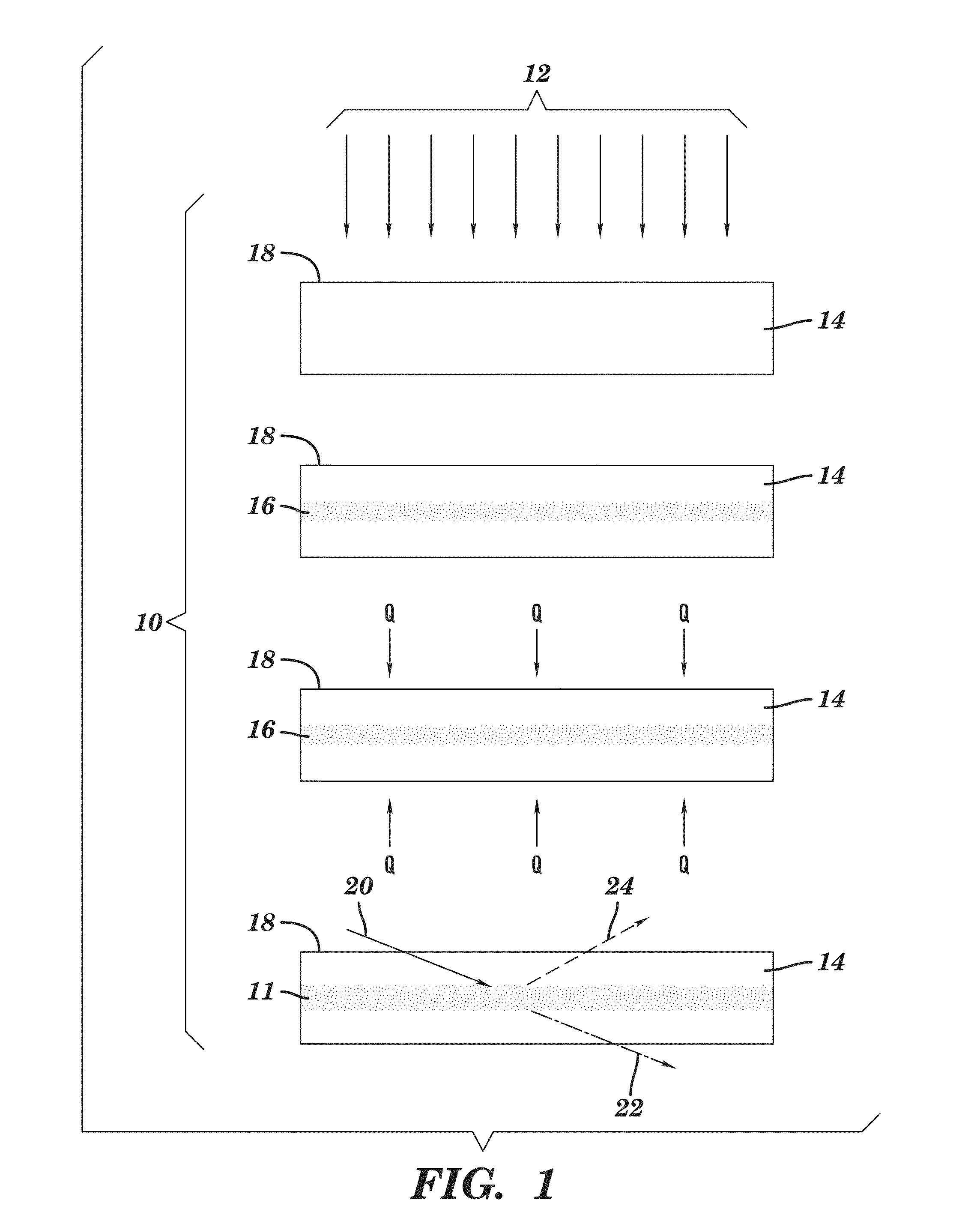

Transparent ceramic composite armor

InactiveUS7584689B2Prevent penetrationAdditive manufacturing apparatusGlass/slag layered productsCeramic compositeSingle crystal

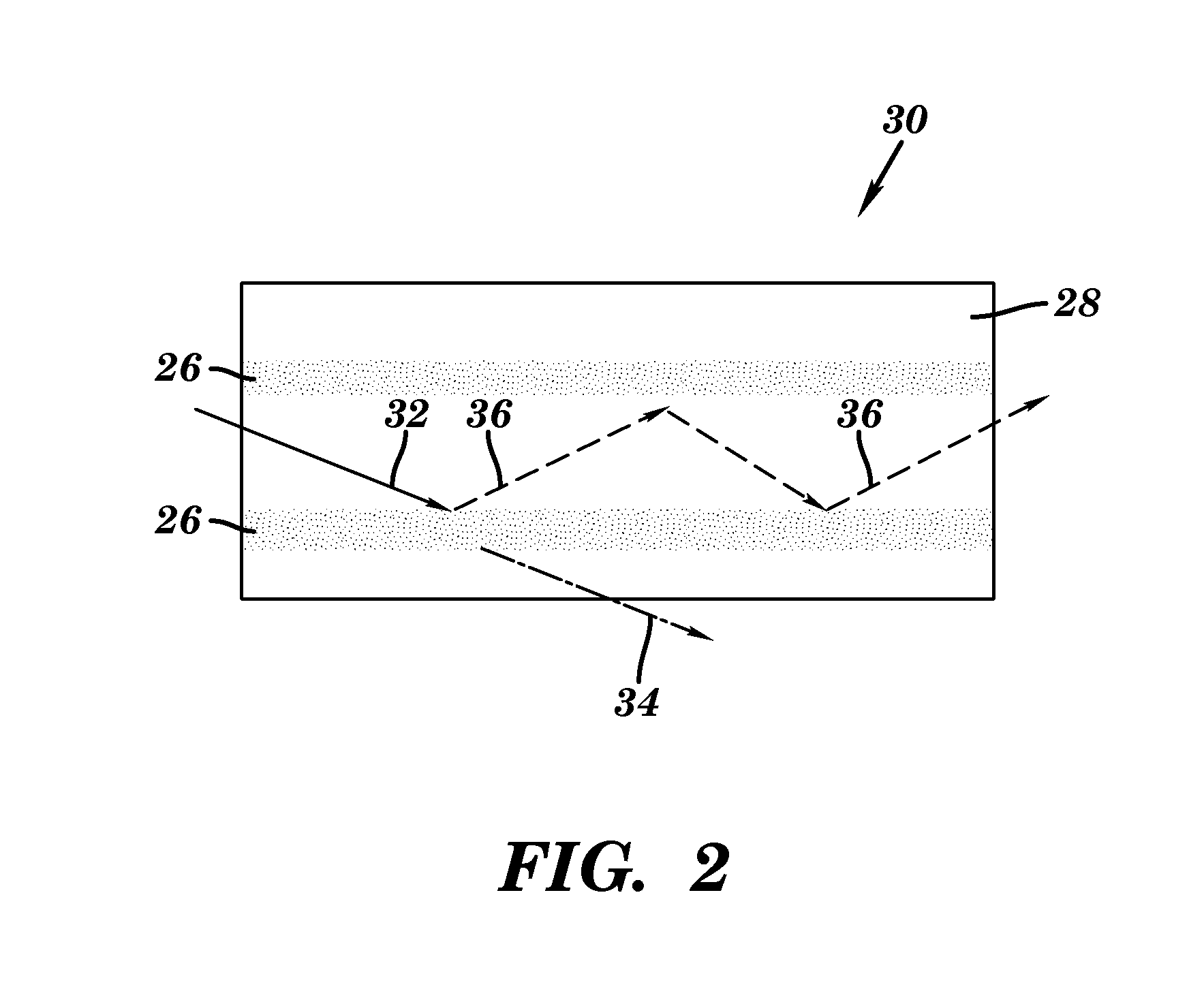

A ceramic composite and method of making are provided. The ceramic composite may be transparent and may serve as transparent armor. The ceramic portion of the composite may be single crystal sapphire. The composite may provide adequate protection from projectiles while exhibiting large surface areas and relatively low areal densities.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Transparent ceramic composite

InactiveUS20070068375A1Prevent penetrationAdditive manufacturing apparatusGlass/slag layered productsCeramic compositeSingle crystal

A ceramic composite and method of making are provided. The ceramic composite may be transparent and may serve as transparent armor. The ceramic portion of the composite may be single crystal sapphire. The composite may provide adequate protection from projectiles while exhibiting large surface areas and relatively low areal densities.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Transparent ceramic composite

InactiveUS20070068376A1Prevent penetrationAdditive manufacturing apparatusGlass/slag layered productsCeramic compositeSingle crystal

A ceramic composite and method of making are provided. The ceramic composite may be transparent and may serve as transparent armor. The ceramic portion of the composite may be single crystal sapphire. The composite may provide adequate protection from projectiles while exhibiting large surface areas and relatively low areal densities.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

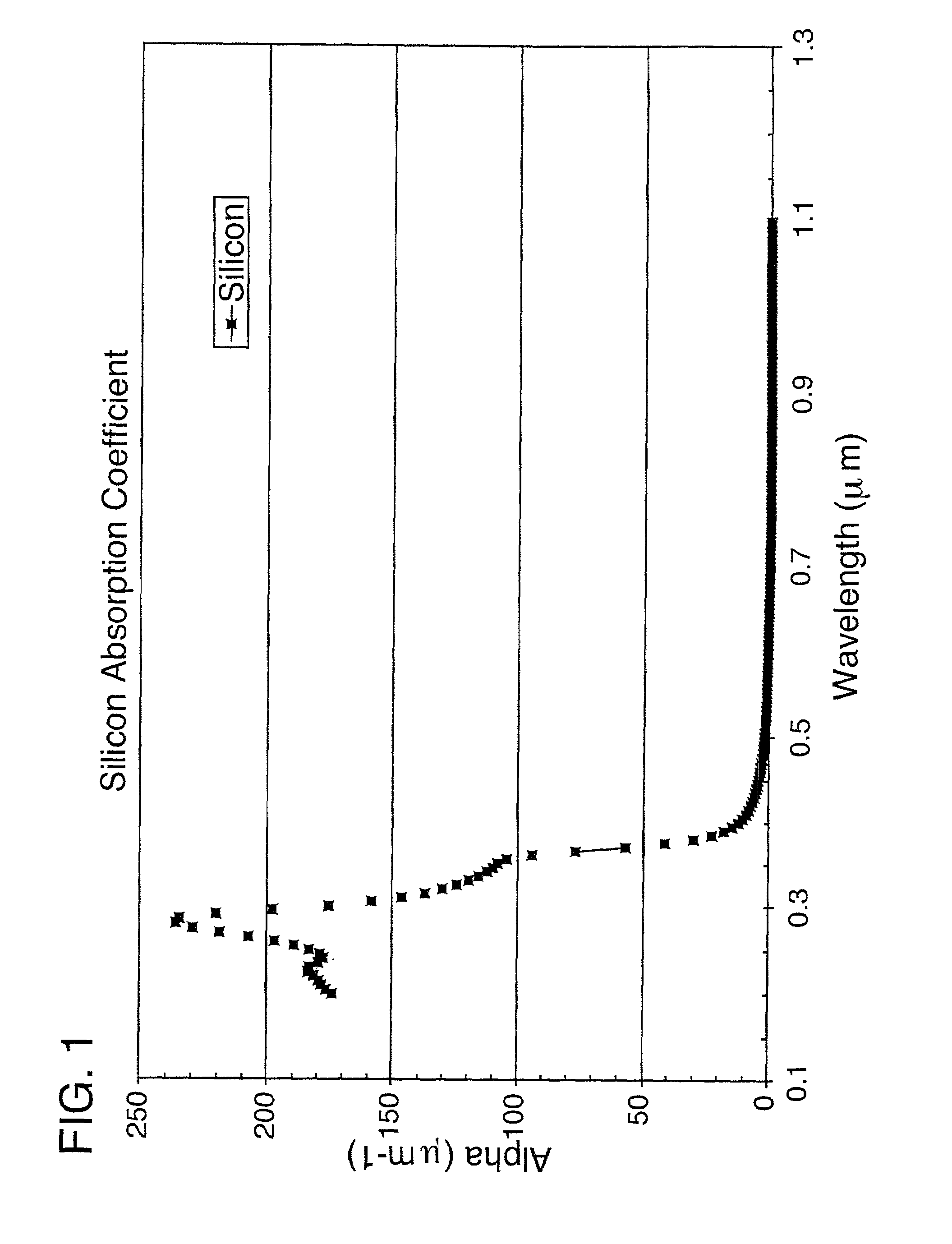

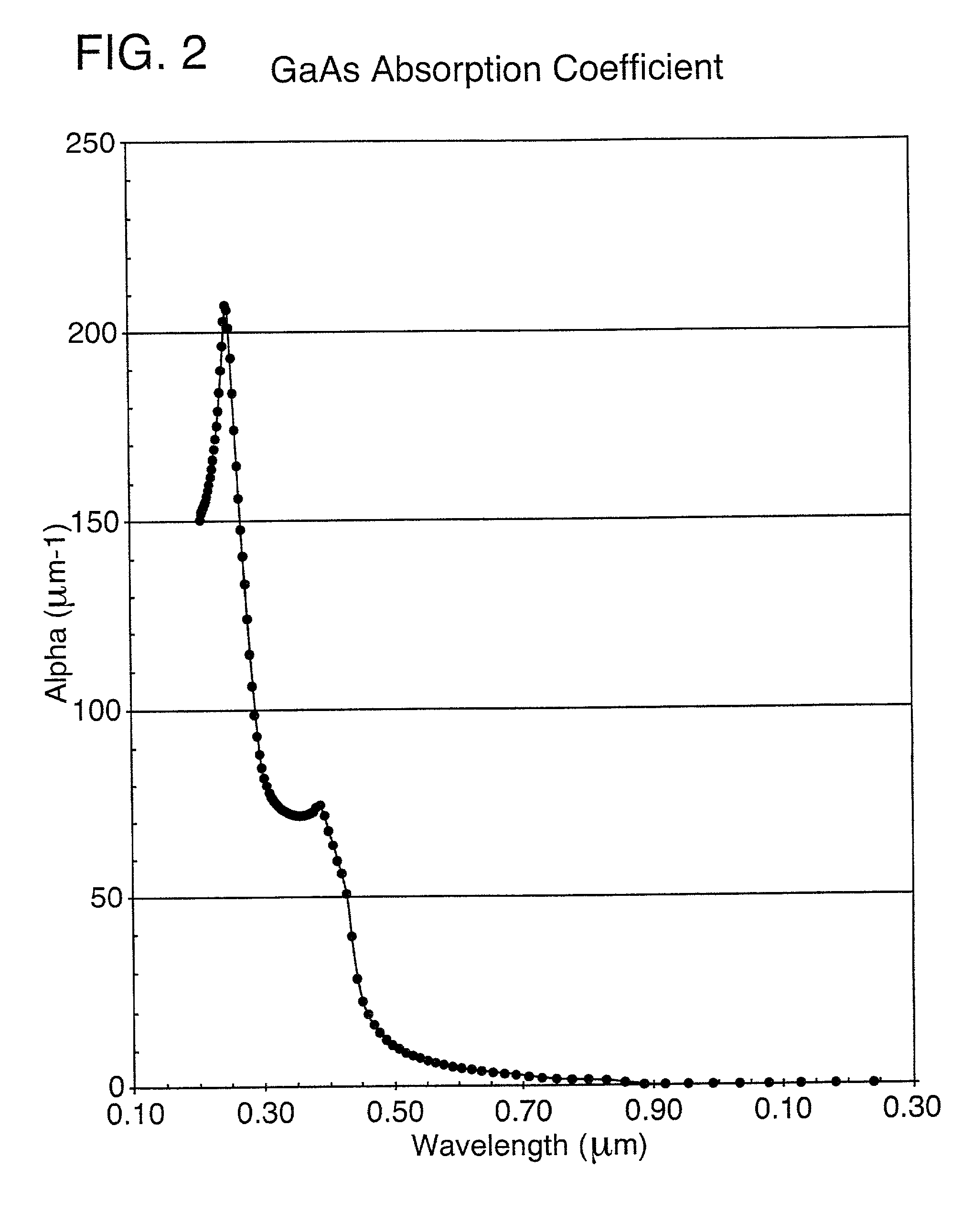

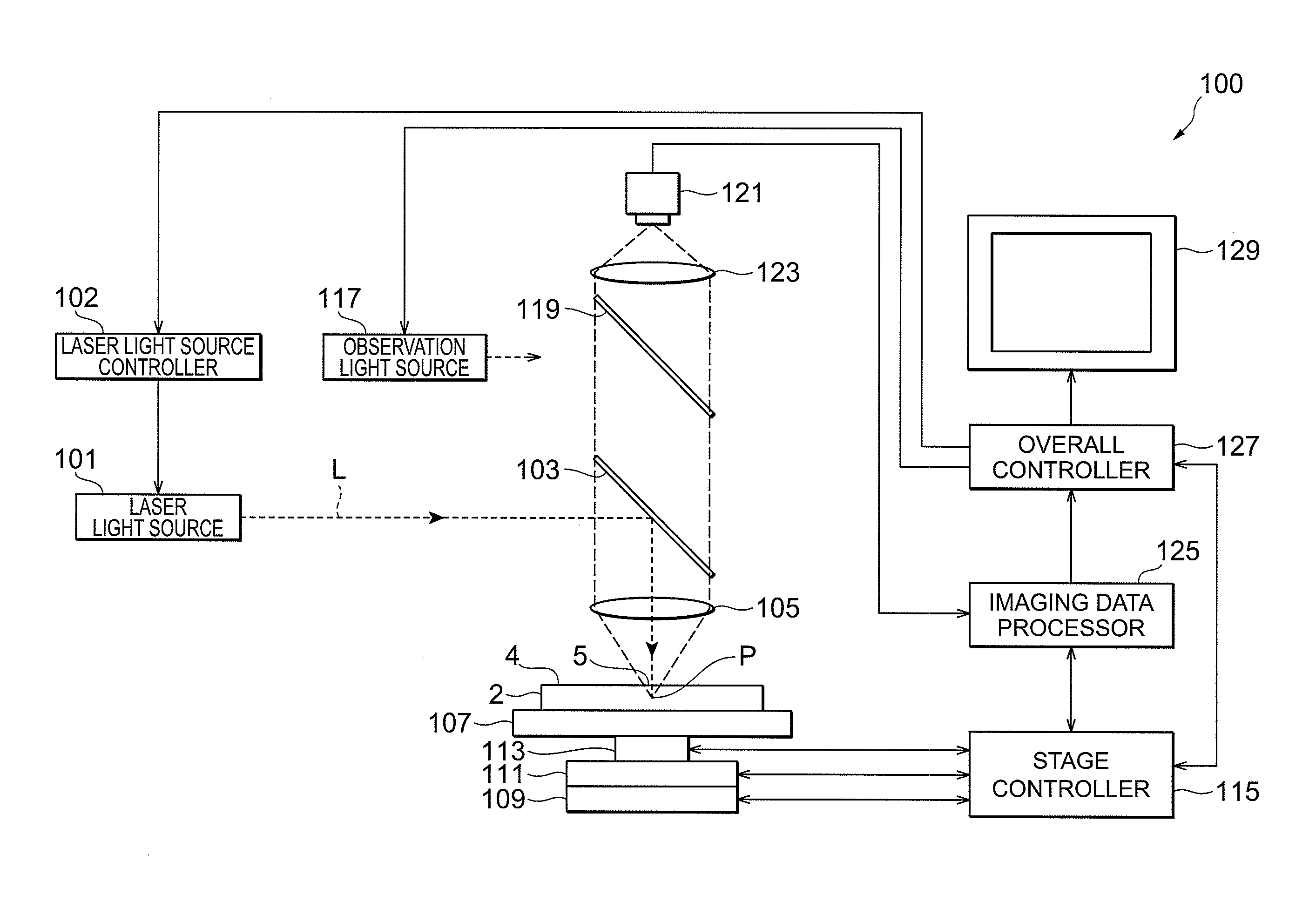

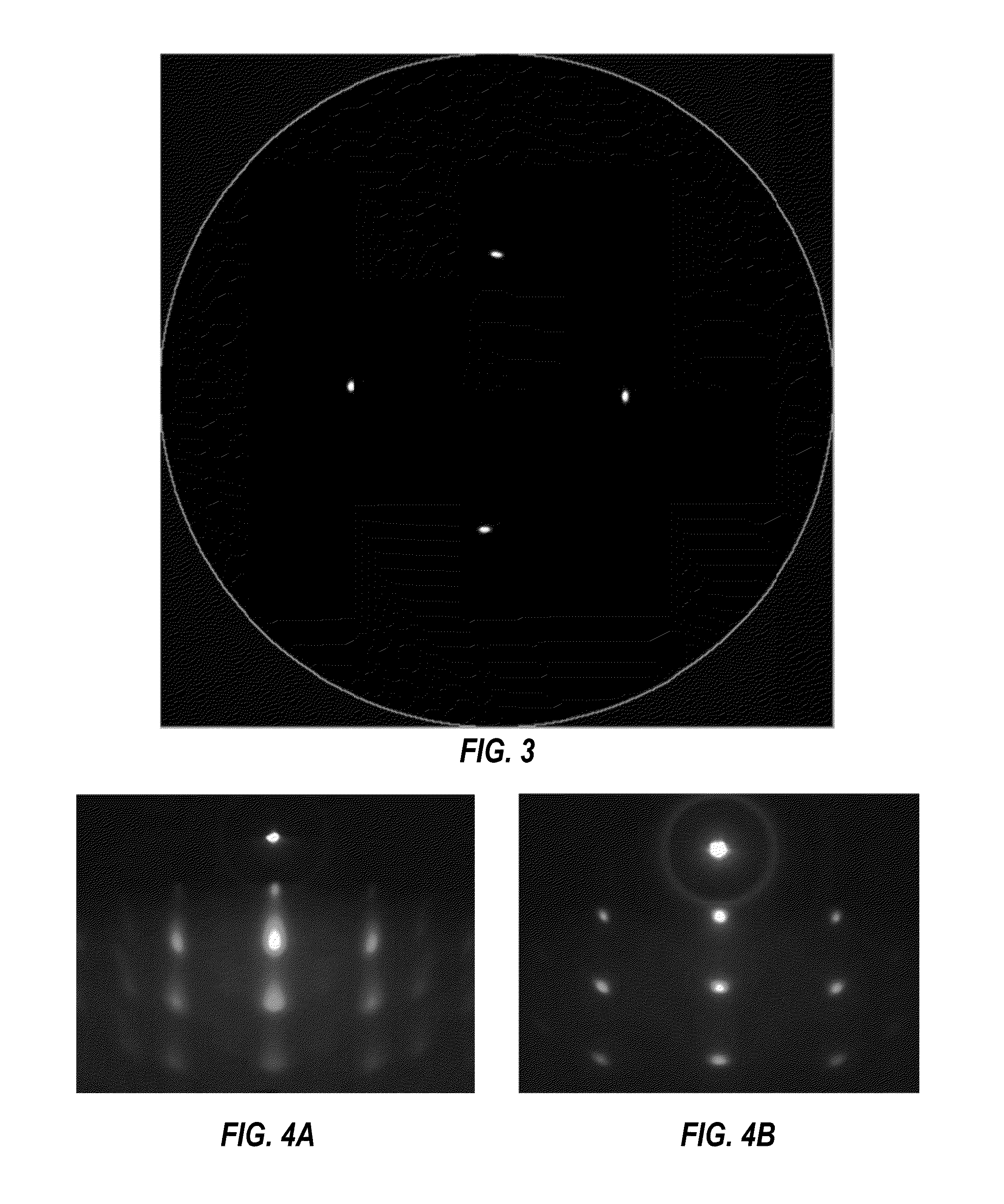

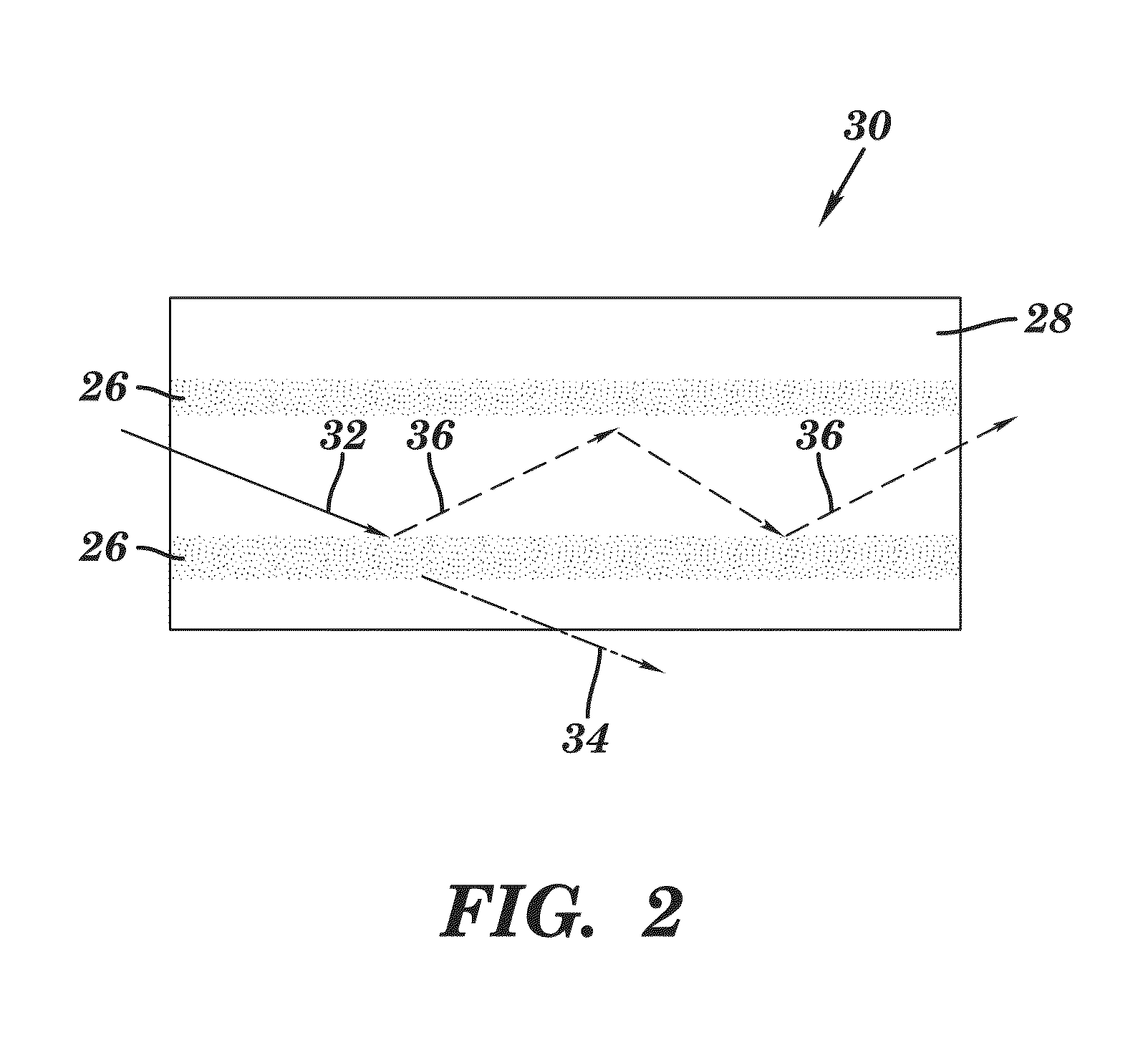

Ultraviolet laser ablative patterning of microstructures in semiconductors

InactiveUS7157038B2High aspect ratioGreat depth of focusSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesUltravioletSingle crystal

Patterns with feature sizes of less than 50 microns are rapidly formed directly in semiconductors, particularly silicon, GaAs, indium phosphide, or single crystalline sapphire, using ultraviolet laser ablation. These patterns include very high aspect ratio cylindrical through-hole openings for integrated circuit connections; singulation of processed die contained on semiconductor wafers; and microtab cutting to separate microcircuit workpieces from a parent semiconductor wafer. Laser output pulses (32) from a diode-pumped, Q-switched frequency-tripled Nd:YAG, Nd:YVO4, or Nd:YLF is directed to the workpiece (12) with high speed precision using a compound beam positioner. The optical system produces a Gaussian spot size, or top hat beam profile, of about 10 microns. The pulse energy used for high-speed ablative processing of semiconductors using this focused spot size is greater than 200 μJ per pulse at pulse repetition frequencies greater than 5 kHz and preferably above 15 kHz. The laser pulsewidth measured at the full width half-maximum points is preferably less than 80 ns.

Owner:ELECTRO SCI IND INC

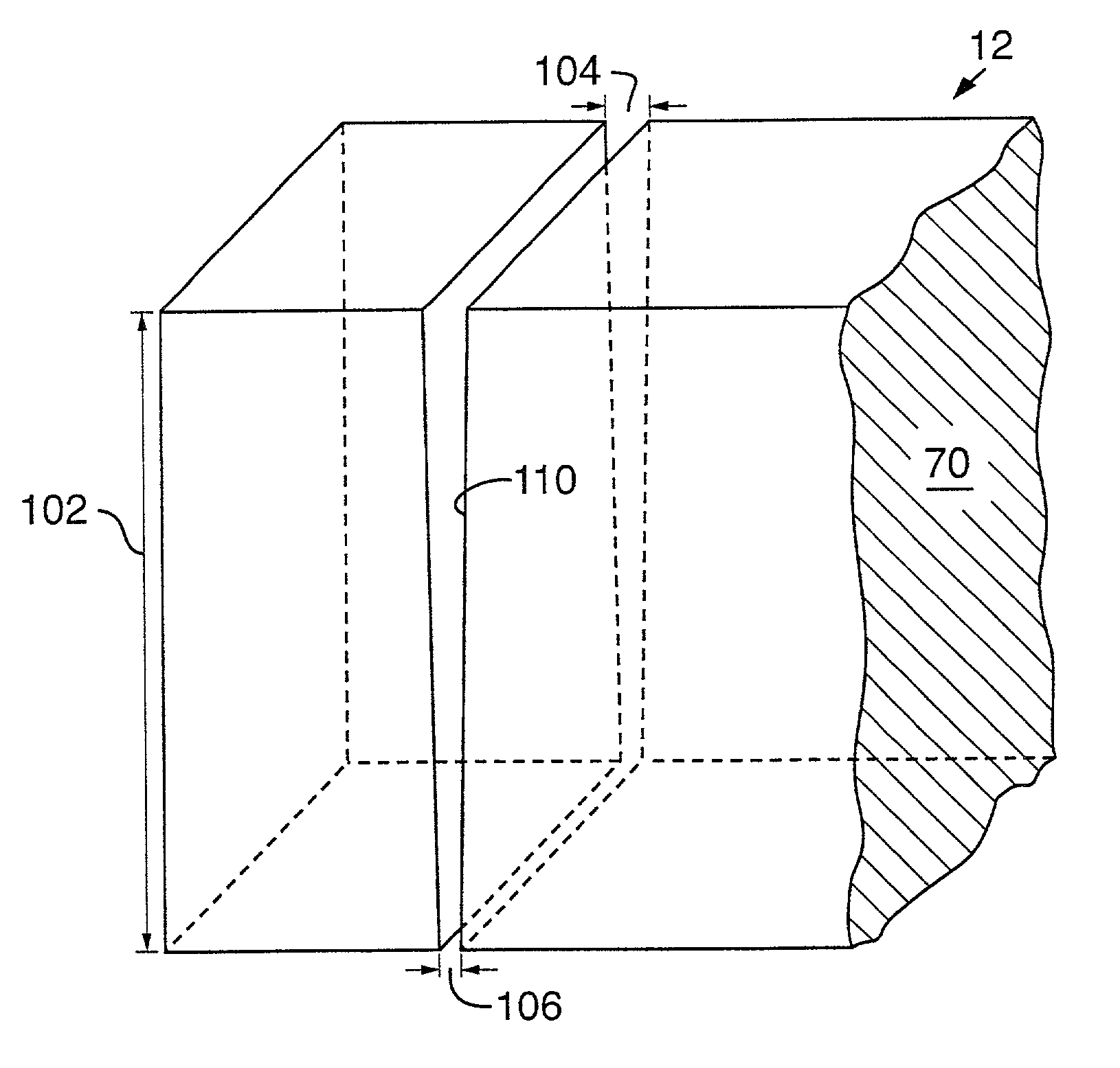

Transparent Ceramic Composite

InactiveUS20090308239A1Prevent penetrationAdditive manufacturing apparatusArmoured vehiclesCeramic compositeVolumetric Mass Density

A ceramic composite and method of making are provided. The ceramic composite may be transparent and may serve as transparent armor. The ceramic portion of the composite may be single crystal sapphire. The composite may provide adequate protection from projectiles while exhibiting large surface areas and relatively low areal densities.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

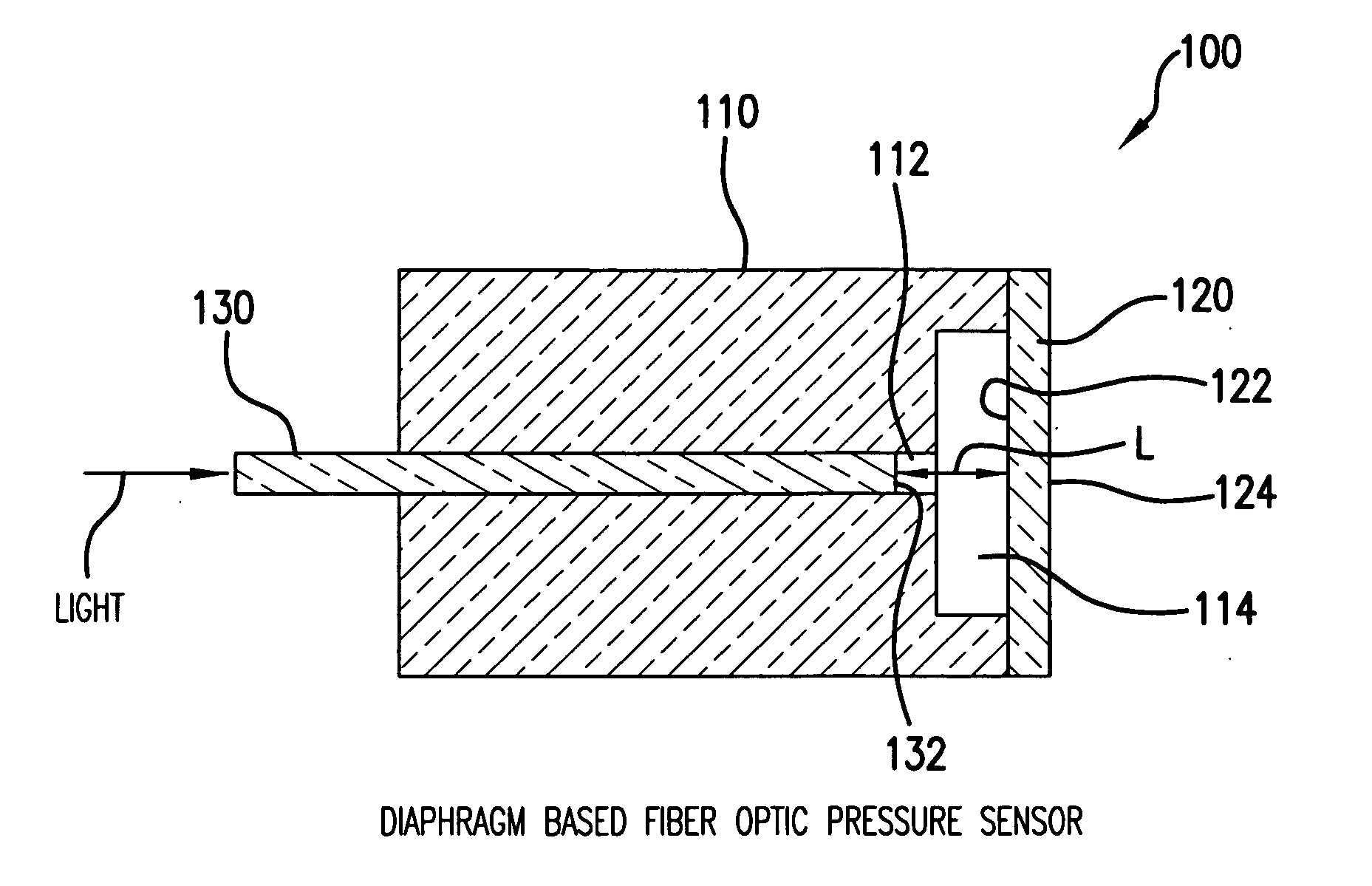

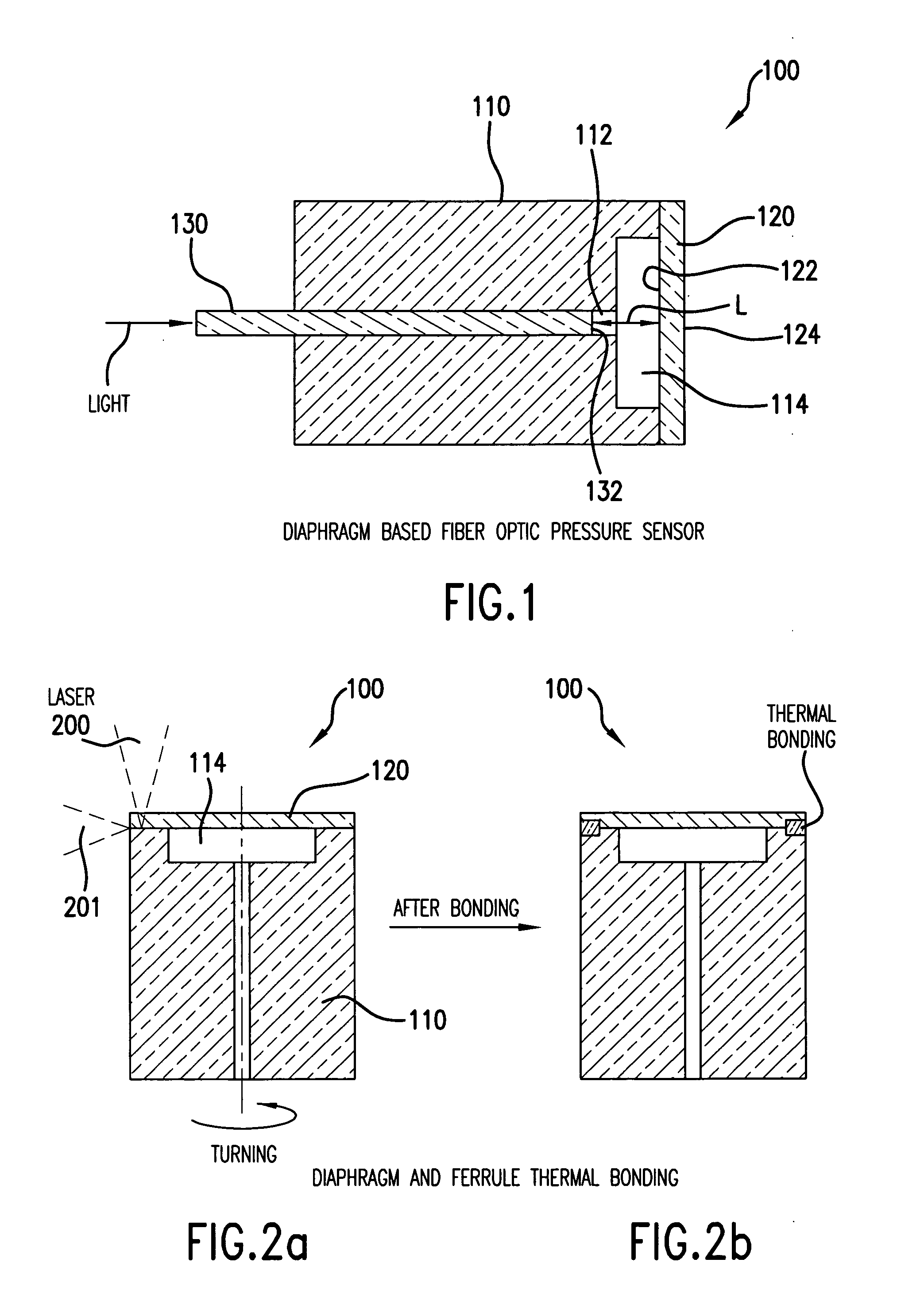

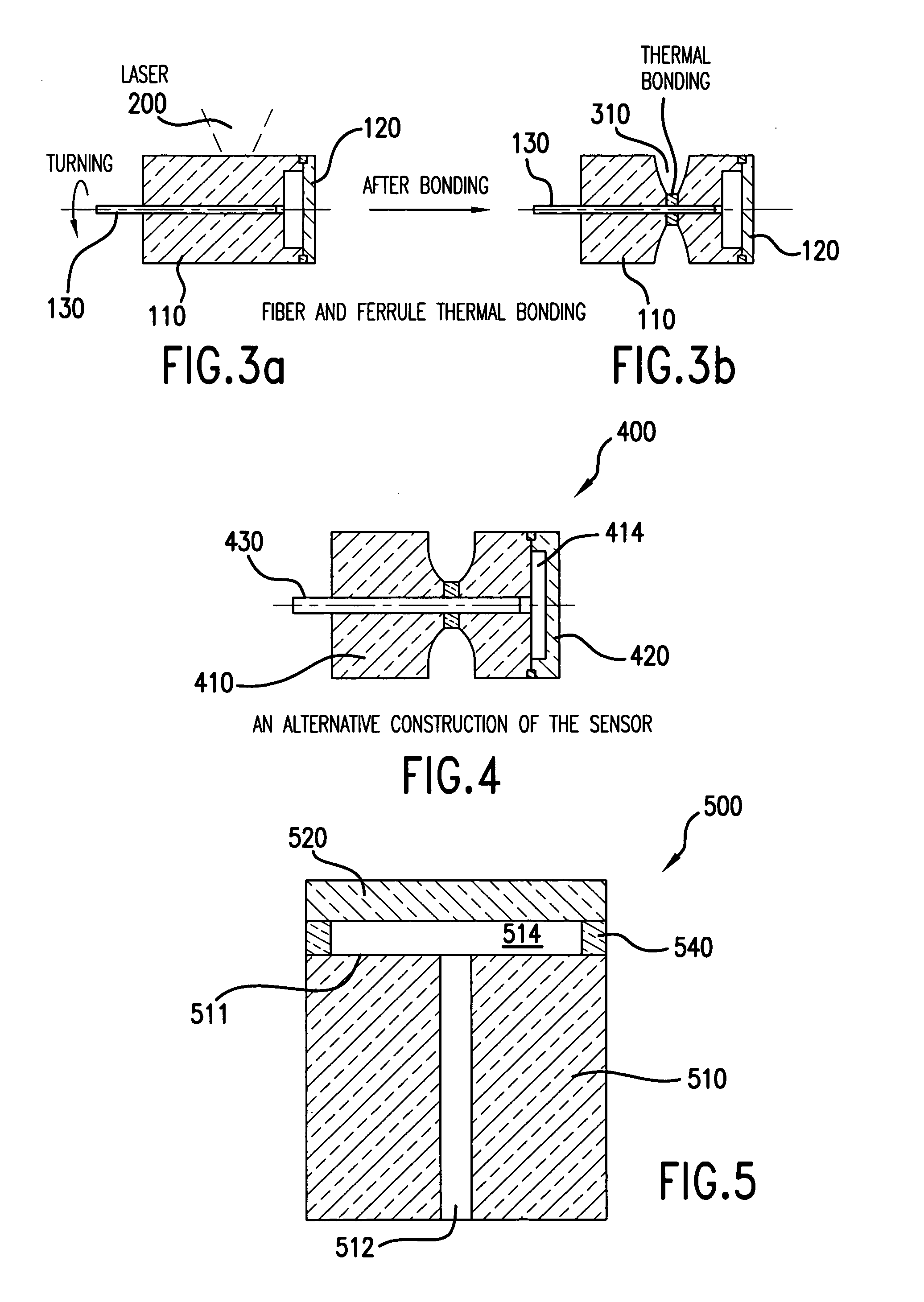

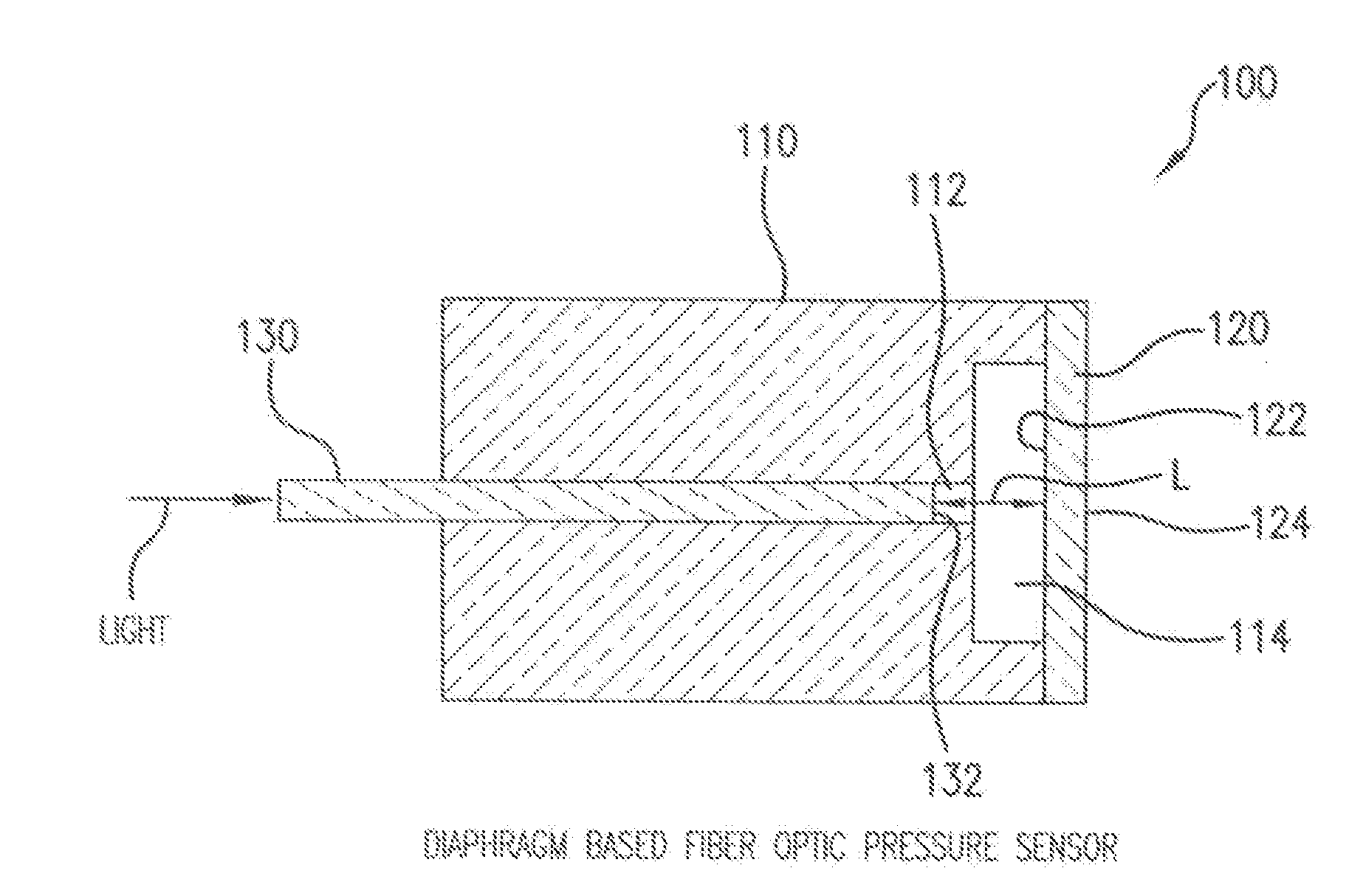

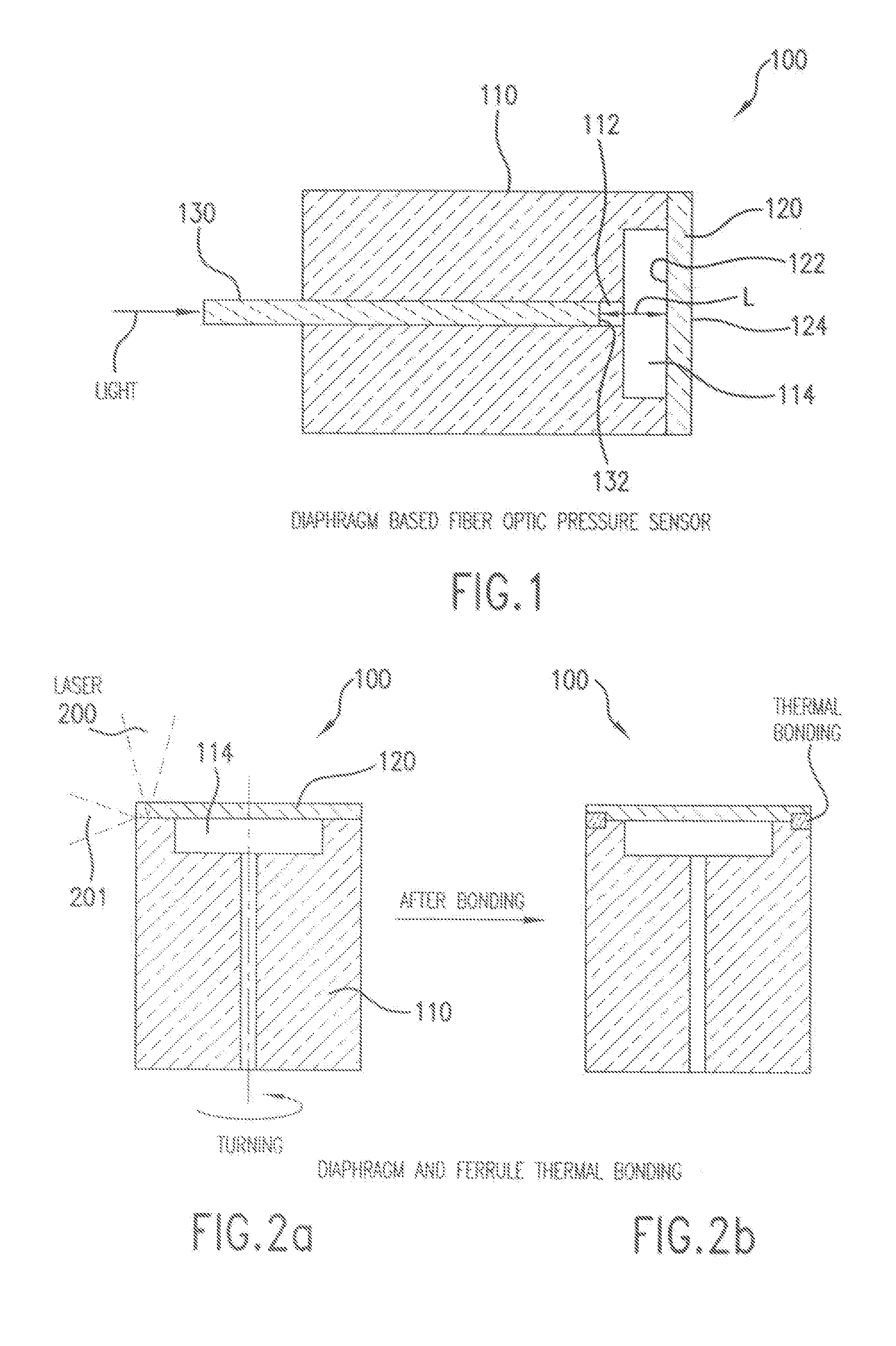

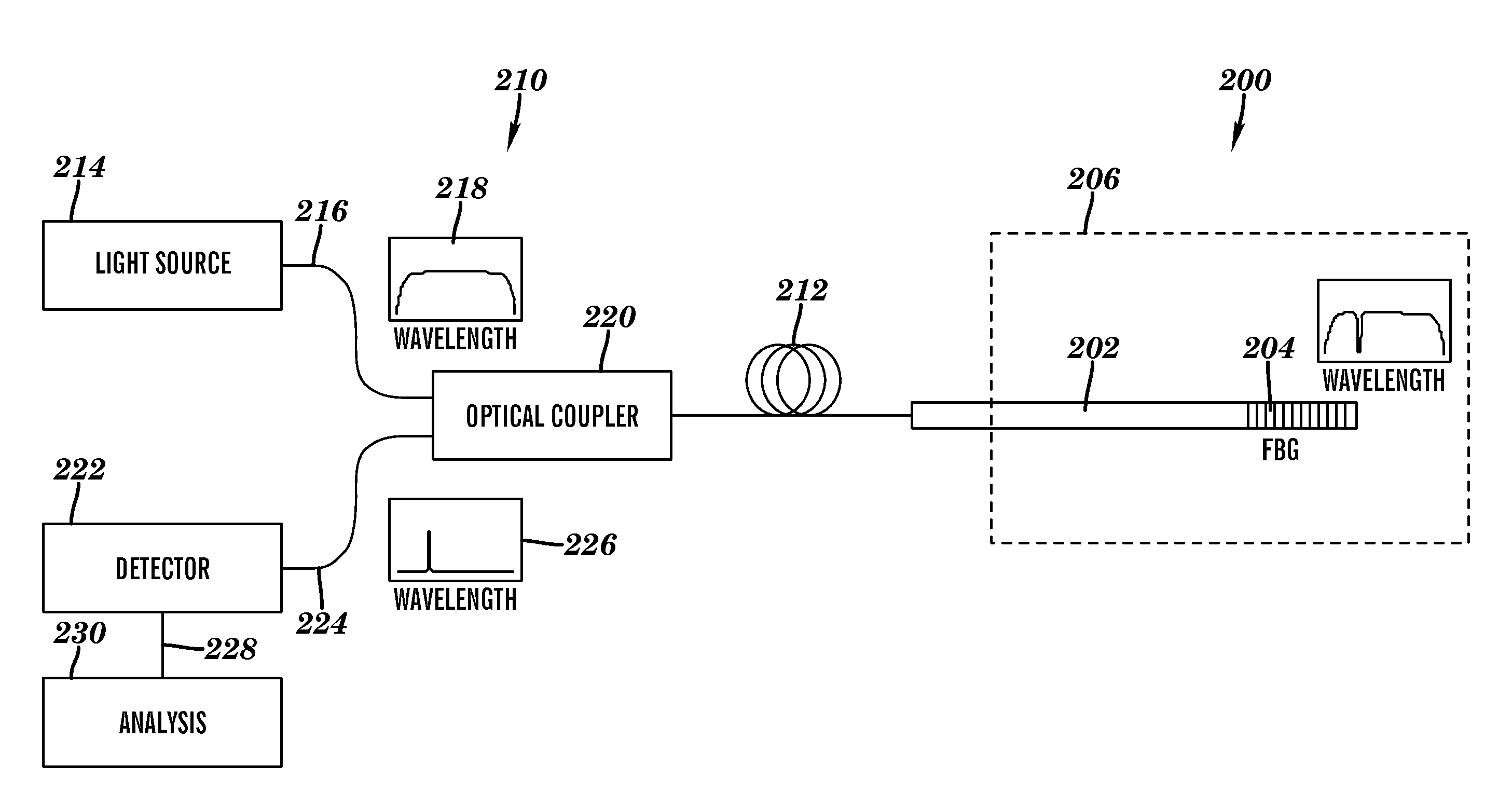

Crystalline optical fiber sensors for harsh environments

InactiveUS20050195402A1Reduce and eliminate temperature dependenceCompensation differenceFluid pressure measurement by electric/magnetic elementsUsing optical meansFiberEngineering

A diaphragm optic sensor comprises a single crystal ferrule, preferably single crystal sapphire, including a bore having an optical fiber disposed therein and a diaphragm attached to the ferrule, the diaphragm being spaced apart from the ferrule to form a Fabry-Perot cavity. The cavity is formed by creating a pit in the ferrule or in the diaphragm, or by interposing a spacer between the diaphragm and ferrule. The components of the sensor are preferably welded together, preferably by laser welding. In some embodiments, the entire ferrule is bonded to the fiber along the entire length of the fiber within the ferrule; in other embodiments, only a portion of the ferrule is welded to the fiber.

Owner:PRIME PHOTONICS LC

Formation of a graphene layer on a large substrate

ActiveUS20120112164A1Low costLow cost manufacturingSemiconductor/solid-state device manufacturingSemiconductor devicesSurface layerCarbide

A single crystalline silicon carbide layer can be grown on a single crystalline sapphire substrate. Subsequently, a graphene layer can be formed by conversion of a surface layer of the single crystalline silicon layer during an anneal at an elevated temperature in an ultrahigh vacuum environment. Alternately, a graphene layer can be deposited on an exposed surface of the single crystalline silicon carbide layer. A graphene layer can also be formed directly on a surface of a sapphire substrate or directly on a surface of a silicon carbide substrate. Still alternately, a graphene layer can be formed on a silicon carbide layer on a semiconductor substrate. The commercial availability of sapphire substrates and semiconductor substrates with a diameter of six inches or more allows formation of a graphene layer on a commercially scalable substrate for low cost manufacturing of devices employing a graphene layer.

Owner:GLOBALFOUNDRIES US INC

Crystalline optical fiber sensors for harsh environments

InactiveUS20070013914A1Low temperature dependenceReduce and eliminate temperature dependenceFluid pressure measurement by electric/magnetic elementsUsing optical meansFiberEngineering

A diaphragm optic sensor comprises a single crystal ferrule, preferably single crystal sapphire, including a bore having an optical fiber disposed therein and a diaphragm attached to the ferrule, the diaphragm being spaced apart from the ferrule to form a Fabry-Perot cavity. The cavity is formed by creating a pit in the ferrule or in the diaphragm, or by interposing a spacer between the diaphragm and ferrule. The components of the sensor are preferably welded together, preferably by laser welding. In some embodiments, the entire ferrule is bonded to the fiber along the entire length of the fiber within the ferrule; in other embodiments, only a portion of the ferrule is welded to the fiber.

Owner:PRIME PHOTONICS LC

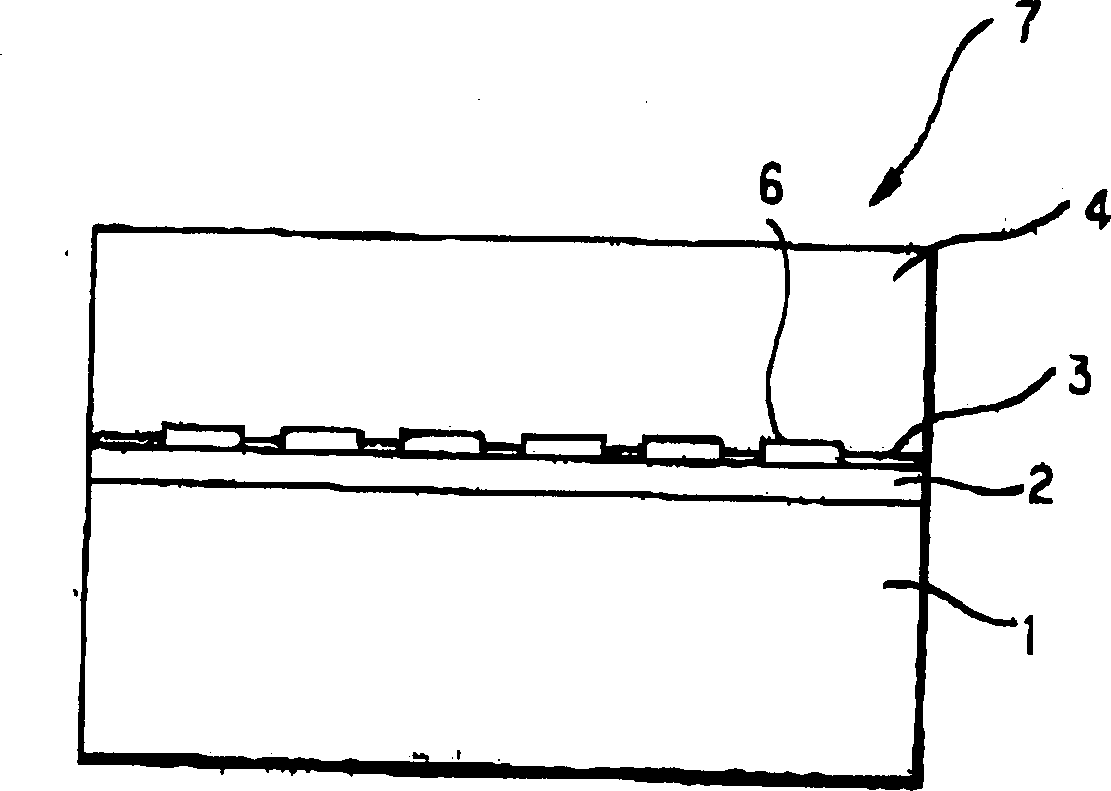

Method for growing GaN crystal chip and GaN crystal chip

InactiveCN1378238AReduce defectsEasy to separate and growPolycrystalline material growthLaser detailsSingle crystalSemiconductor

A layer of metal film is deposited on the initial substrate, which can be any one of single crystal sapphire substrate, substrate with single crystal GaN film grown on the sapphire substrate or single crystal semiconductor substrate. A GaN film is then deposited on the metal film to form a layered substrate. Due to the adoption of the above structure, after the GaN film is grown, the GaN film can be easily separated from the original substrate, and a GaN crystal substrate with low defect concentration and not seriously contaminated by impurities can be produced in a simple manner. .

Owner:SUMITOMO CHEM CO LTD

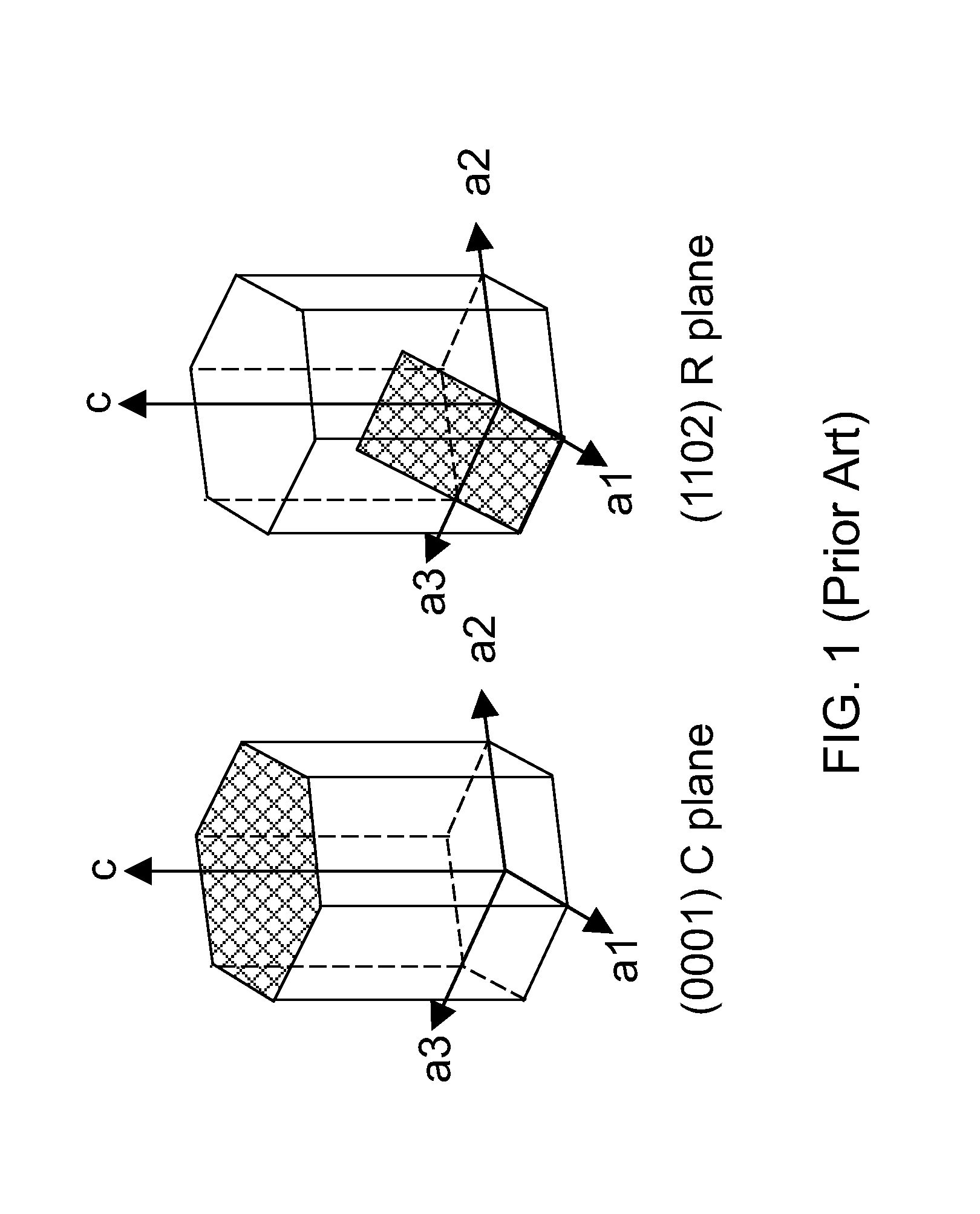

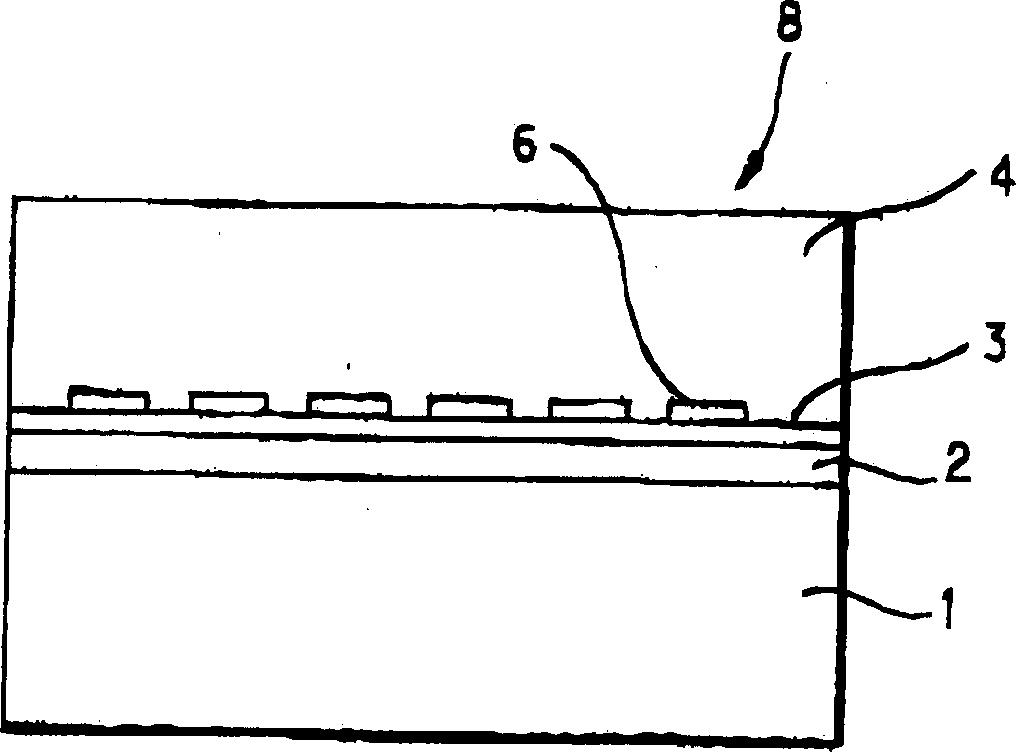

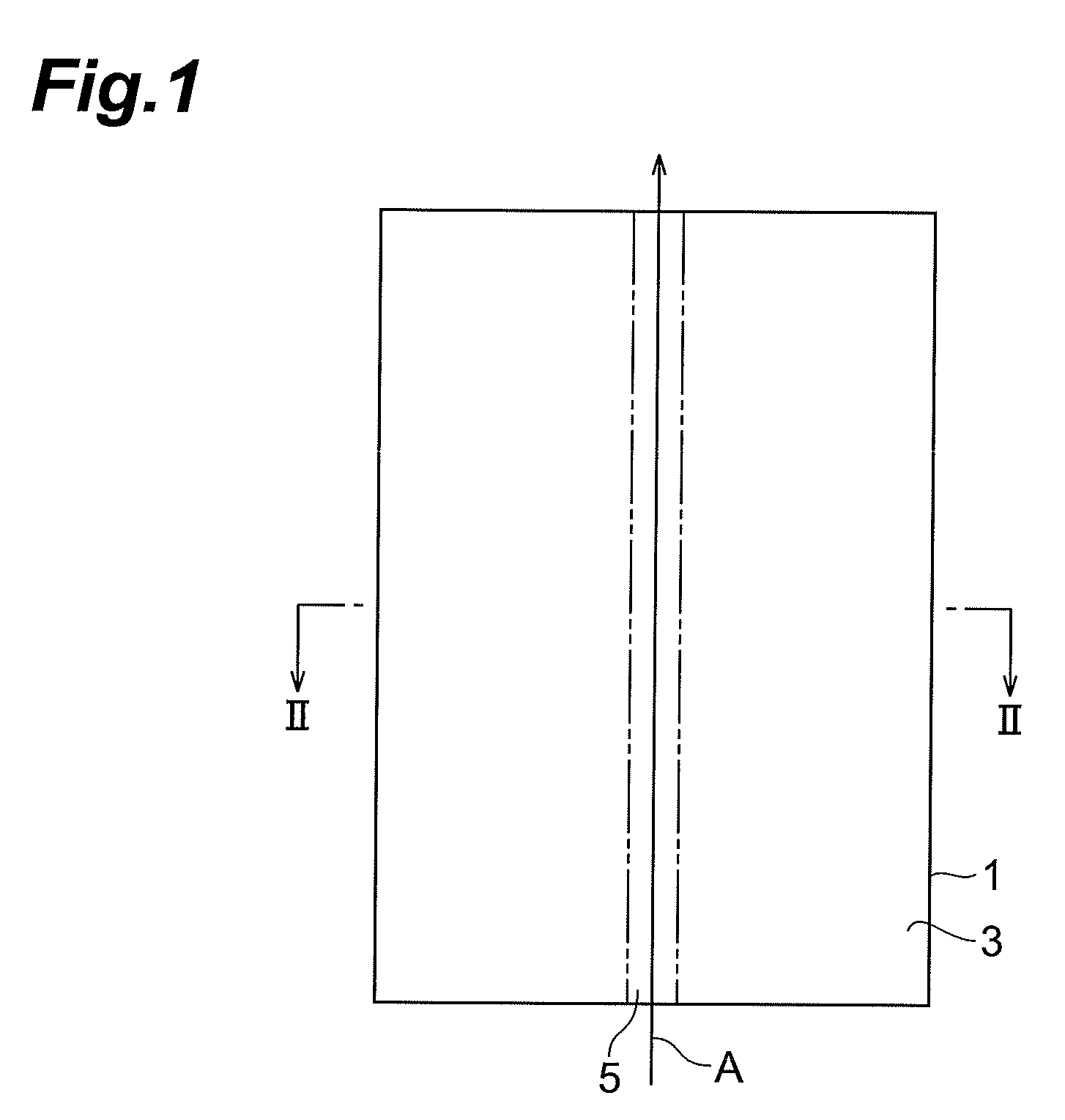

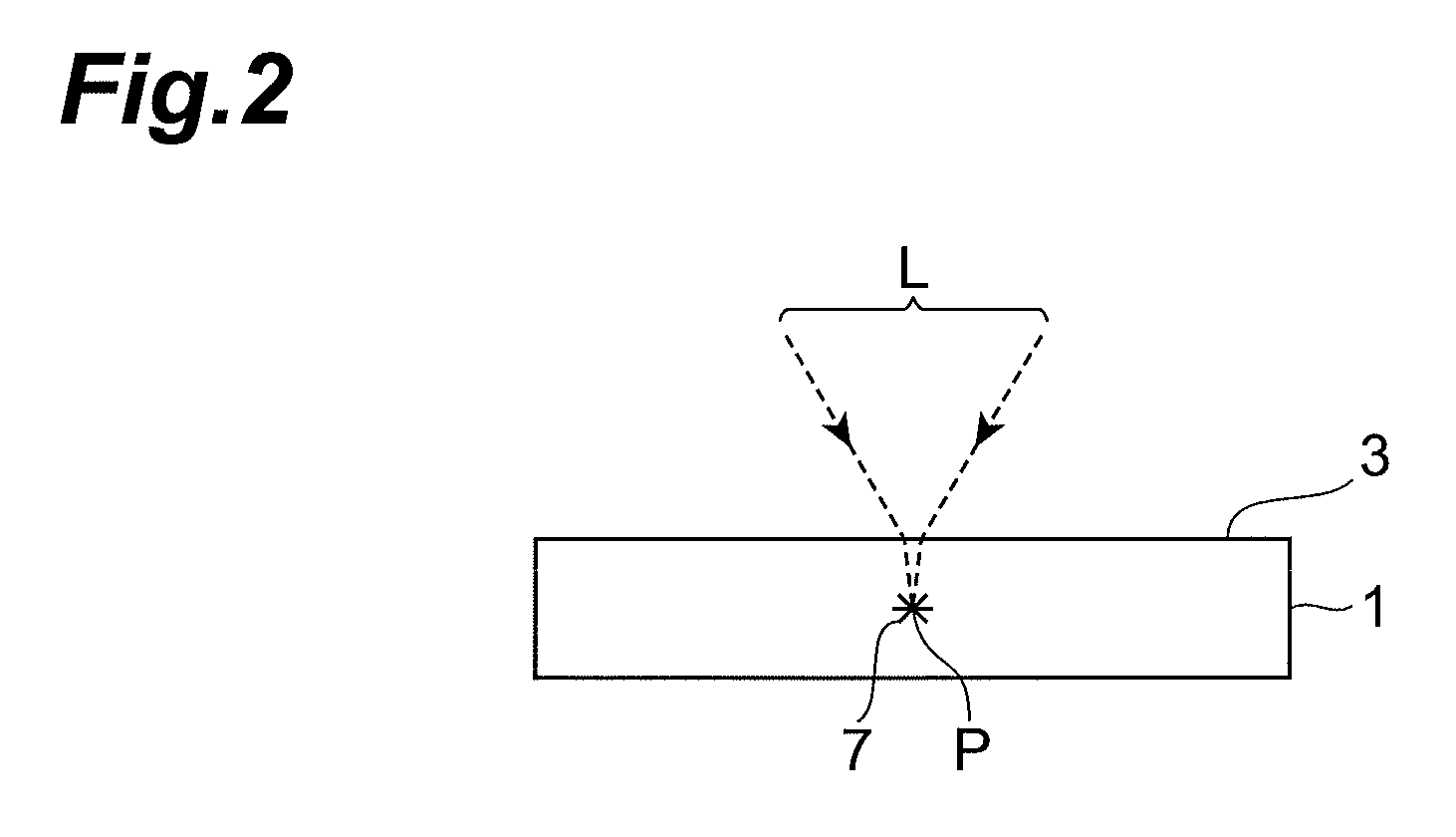

Laser processing method and method for manufacturing light-emitting device

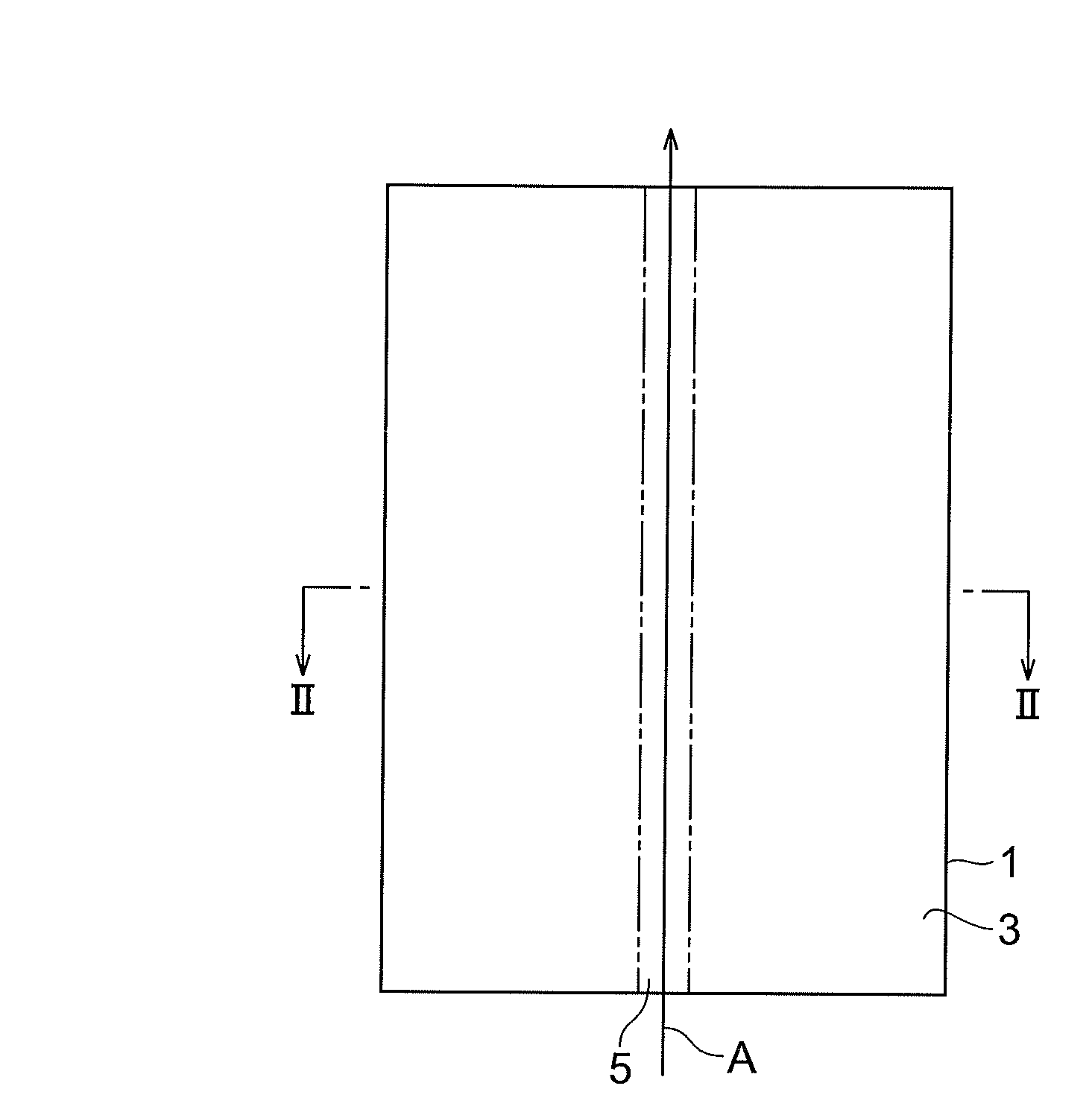

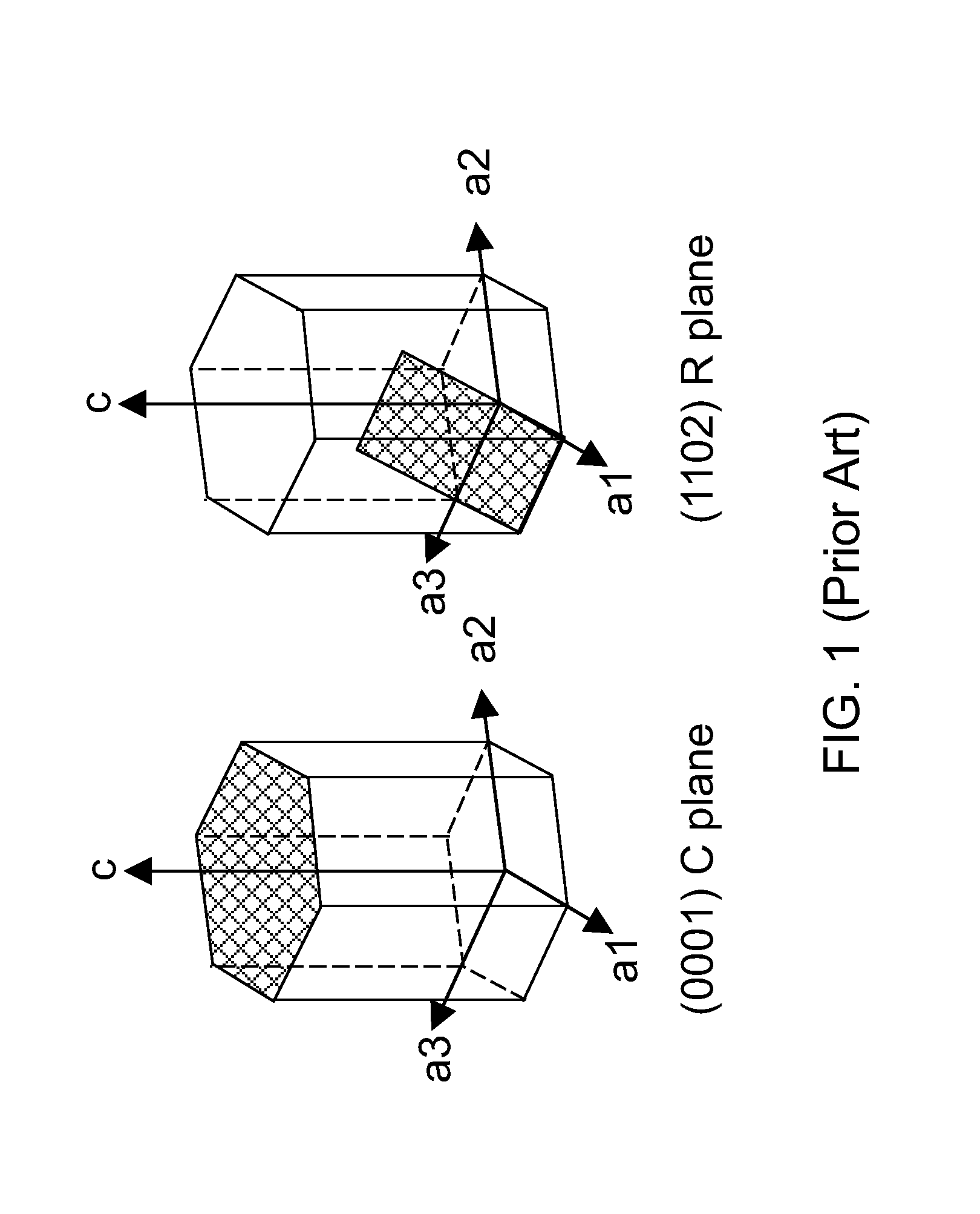

ActiveUS20120077296A1Little strengthHigh precisionSemiconductor/solid-state device manufacturingFine working devicesLaser processingSingle crystal

A plurality of modified parts are formed at a first formation pitch for a line arranged along the M-plane of a single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach a principal surface of the single-crystal sapphire substrate. A plurality of modified parts are formed at a second formation pitch narrower than the first formation pitch for a line arranged along the A-plane of the single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach the principal surface of the single-crystal sapphire substrate. Along the lines, a knife edge is pressed against a wafer from the side of the single-crystal sapphire substrate opposite from the principal surface of the single-crystal sapphire substrate where the fractures have reached, to cut the wafer along the lines.

Owner:HAMAMATSU PHOTONICS KK

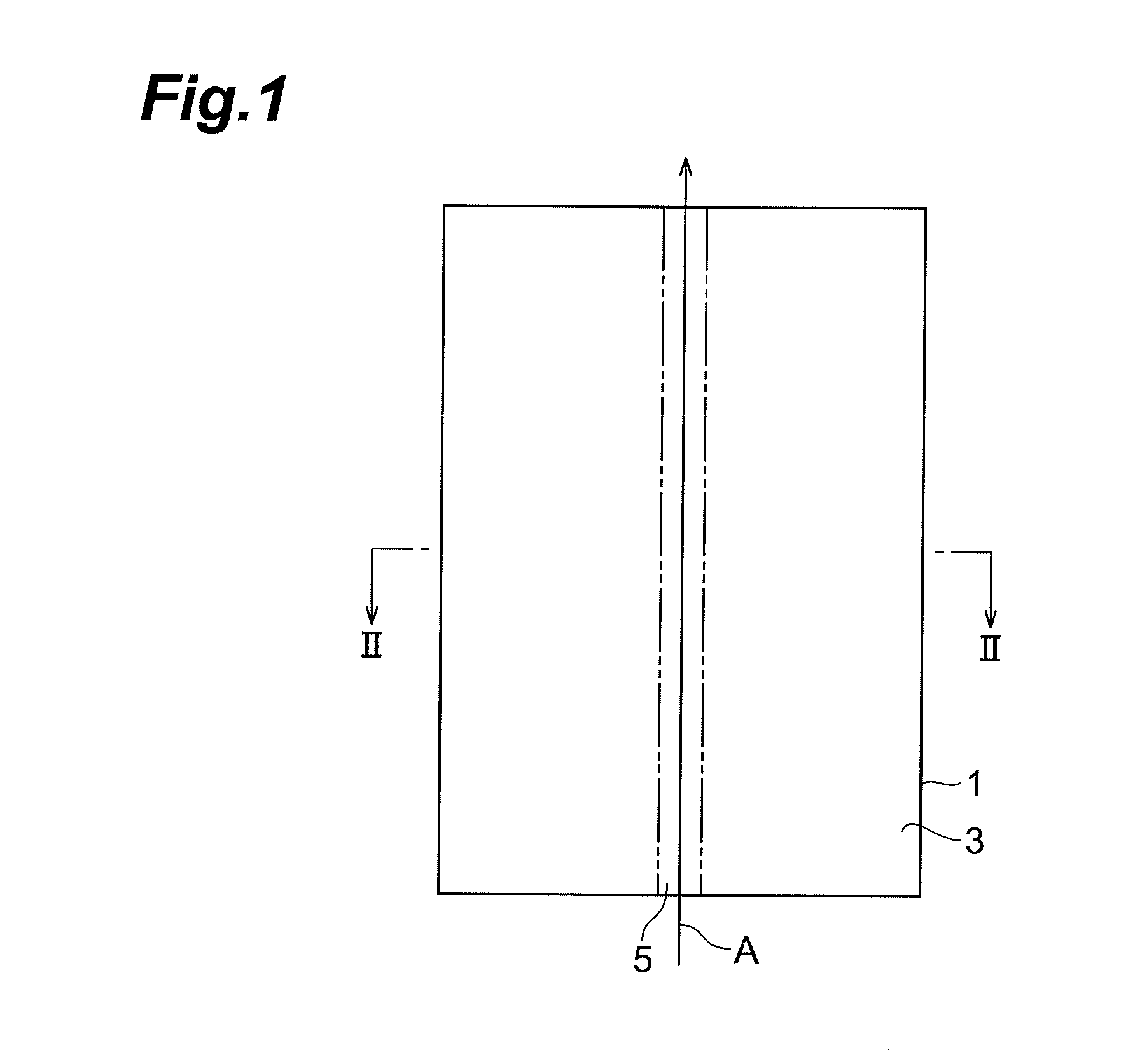

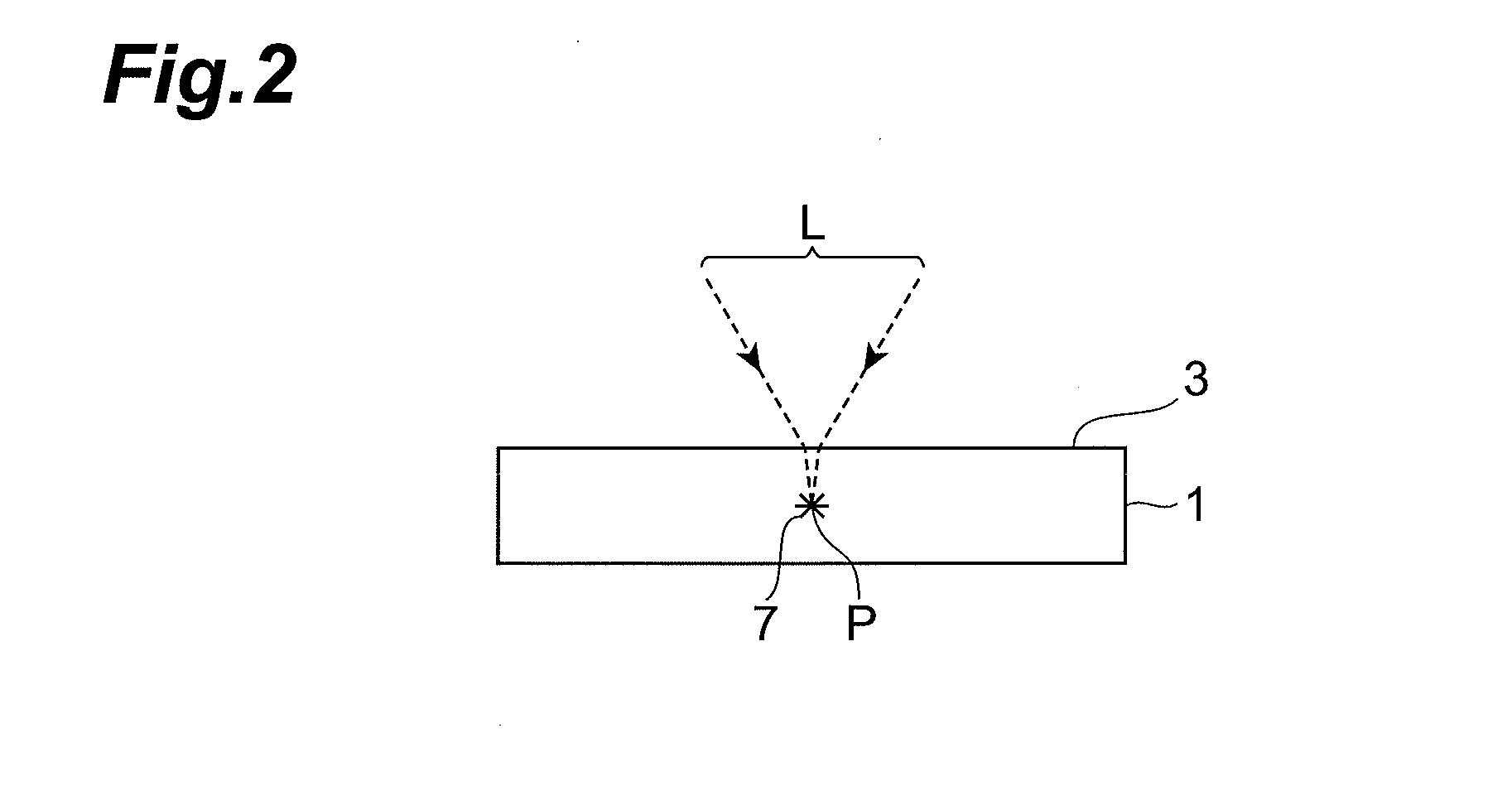

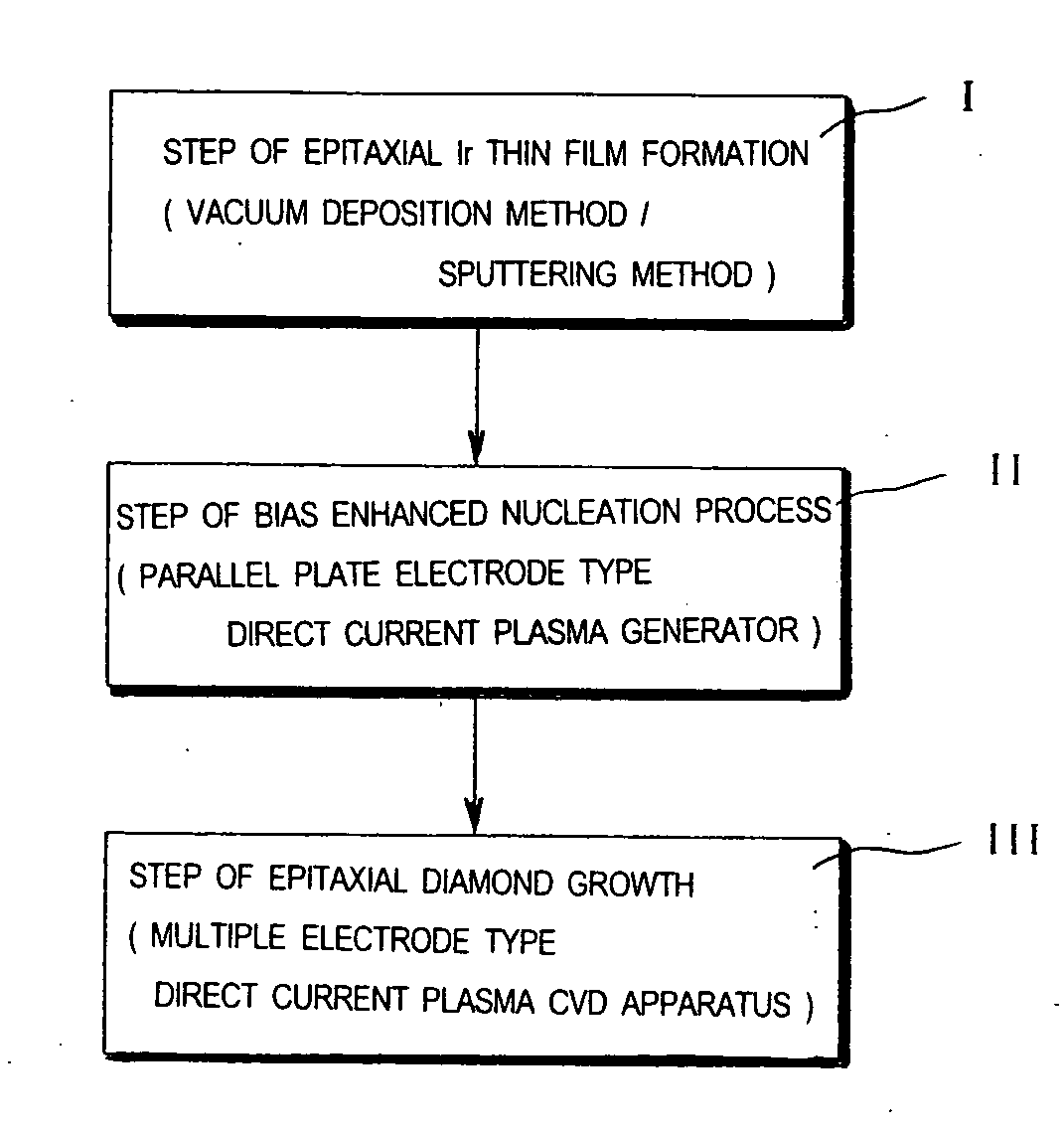

Base Substrate for Epitaxial Diamond Film, Method for Producing the Base Substrate for Epitaxial Diamond Film, Epitaxial Diamond Film produced With the Base Substrate for Epitaxial Diamond Film, and Method for Producing the Epitaxial Diamond Film

ActiveUS20090176114A1Easy to produceUniformly and highly densely generatingFrom gel stateFrom solid stateIridiumGeneration process

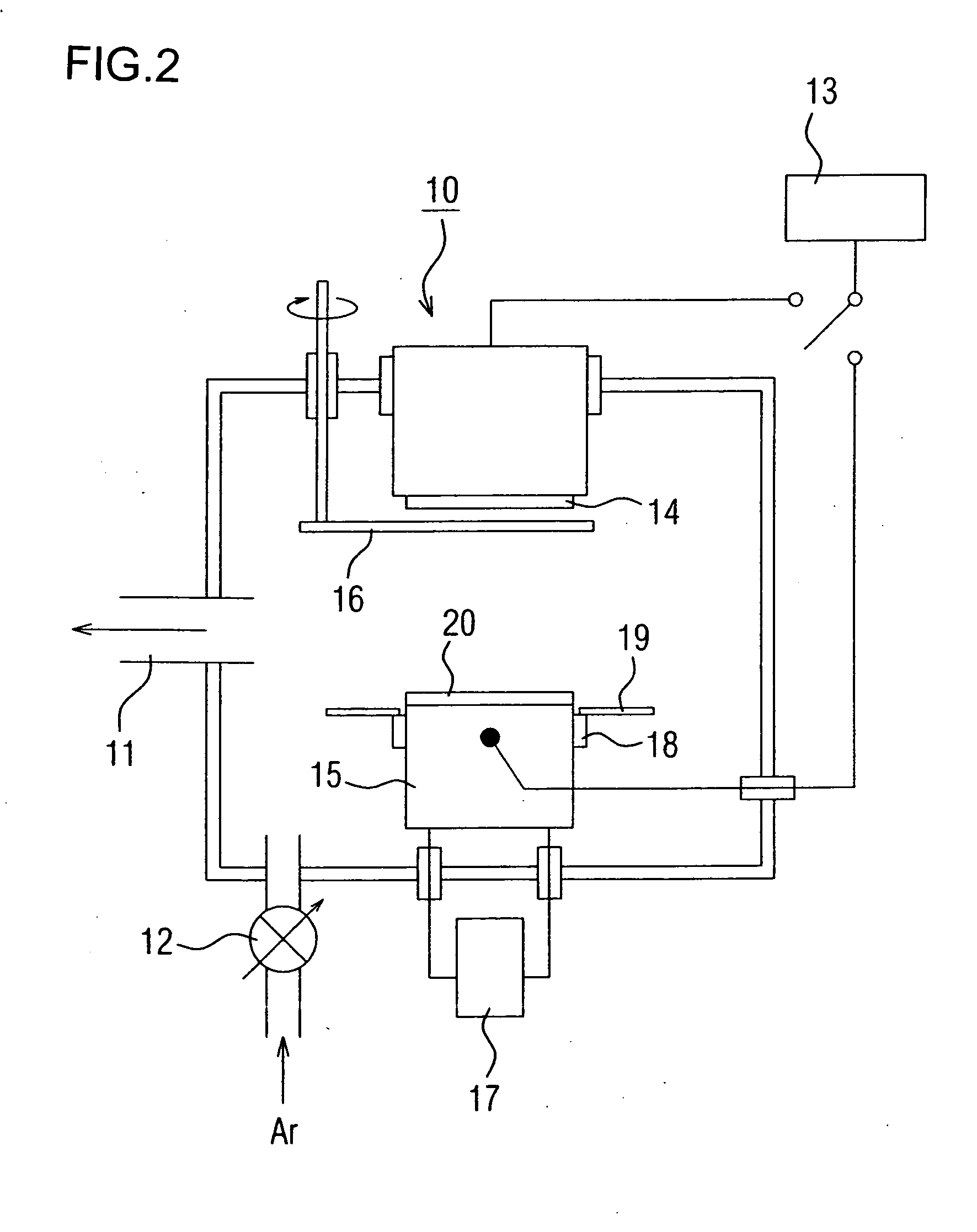

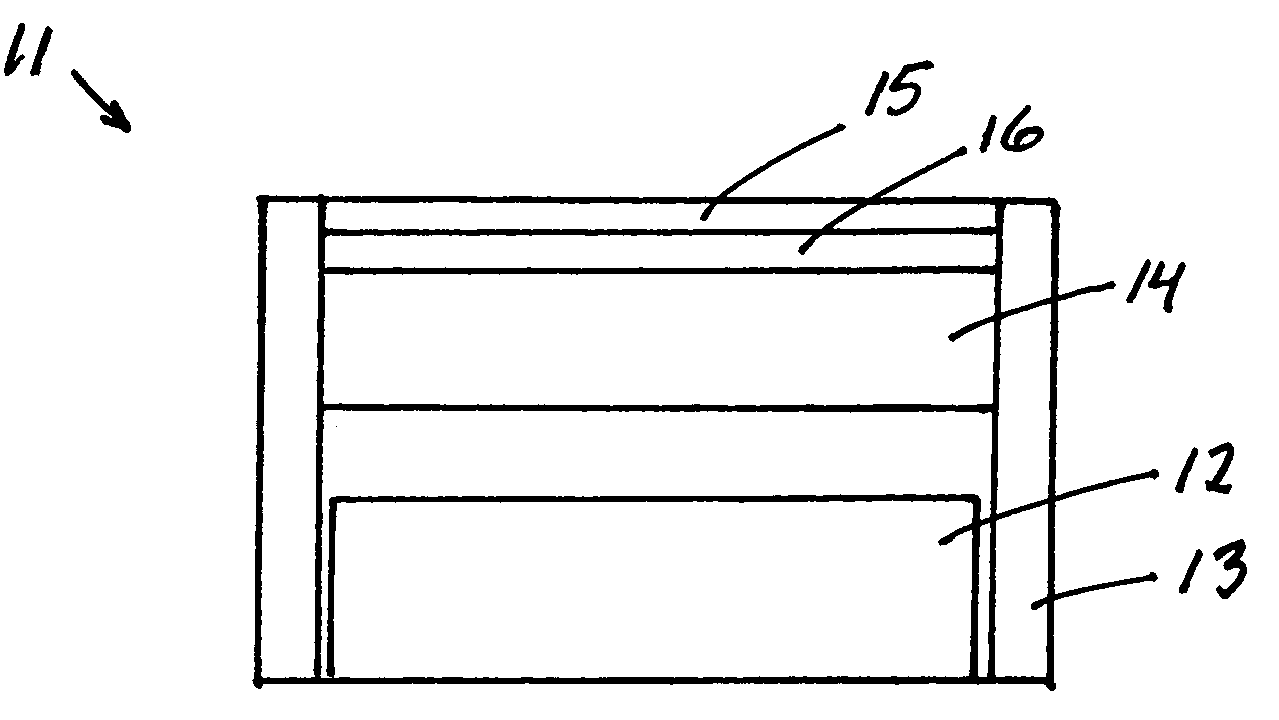

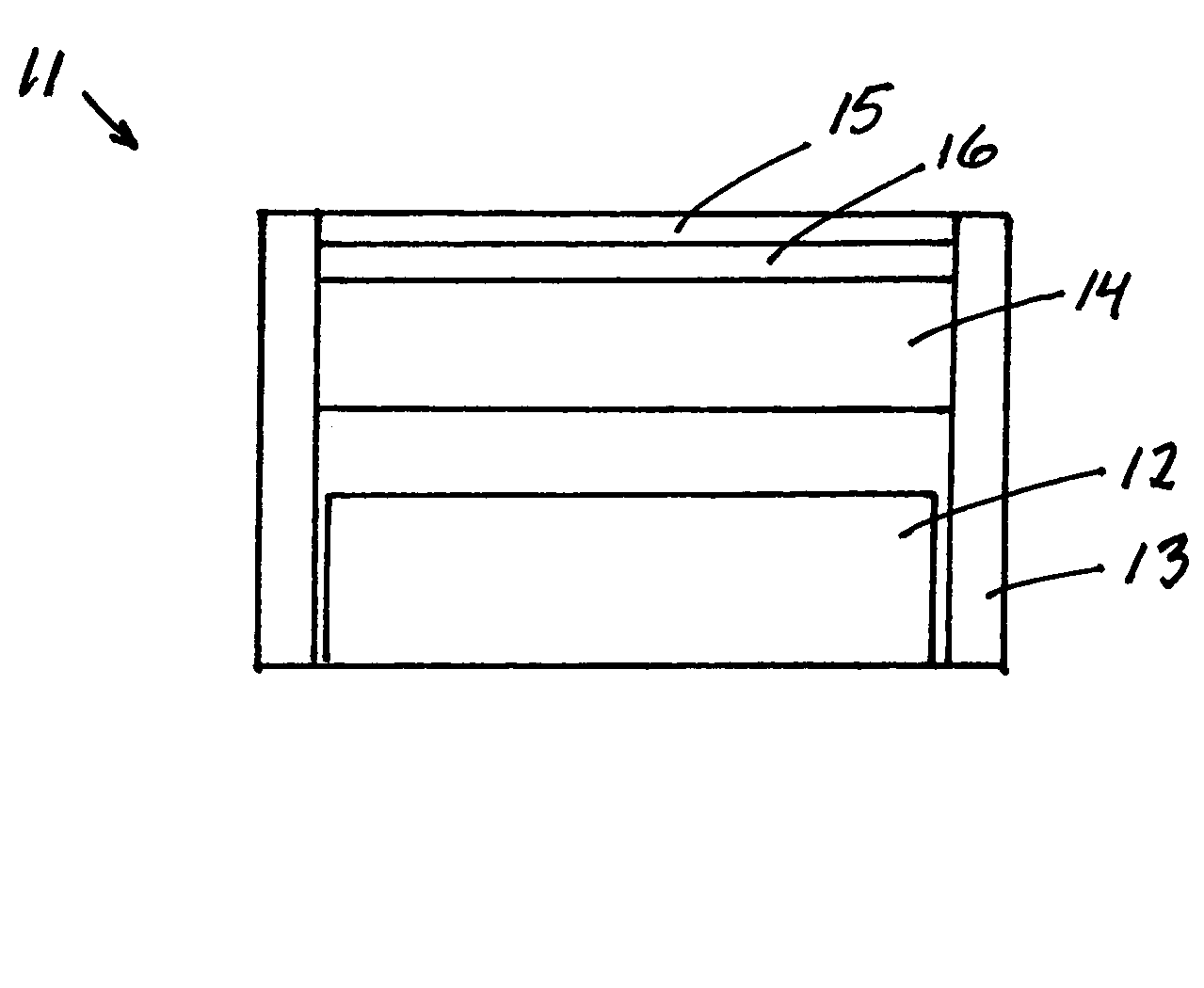

The present invention provides a base substrate for epitaxial diamond film capable of epitaxially growing a large area of high quality diamond, having a diameter of 1 inch (2.5 cm) or more, on an iridium base by using the CVD method, a method for producing the base substrate for epitaxial diamond film, an epitaxial diamond film produced with the base substrate for epitaxial diamond film and a method for producing the epitaxial diamond film. An iridium (Ir) film is formed by epitaxial growth on a single crystal magnesium oxide (MgO) substrate or a single crystal sapphire (α-Al2O3) substrate by means of a vacuum deposition method or a sputtering method, and a bias nucleus generation process of forming epitaxial diamond nuclei is applied to the surface of the iridium (Ir) base formed as a film by exposing an ion-containing direct current plasma to the surface of the iridium (Ir) base formed as a film.

Owner:SAWABE ATSUHITO

Polycrystalline optical window materials from nanoceramics

InactiveUS20060011839A1Exceptional propertyImprove transmittanceMaterial nanotechnologyRadiation pyrometryNanoceramicSingle crystal

Optical windows for protecting infrared sensing instruments are manufactured from nano-sized crystallites by compressing the crystallites into a continuous mass under high pressure in the presence of a pulsed electric current, preferably one produced by spark plasma sintering. The resulting materials have excellent optical and mechanical properties that make them favorable as replacements for the conventional single-crystal sapphire.

Owner:RGT UNIV OF CALIFORNIA

Polycrystalline optical window materials from nanoceramics

InactiveUS7148480B2Exceptional propertyImprove transmittanceMaterial nanotechnologyRadiation pyrometryNanoceramicSingle crystal

Optical windows for protecting infrared sensing instruments are manufactured from nano-sized crystallites by compressing the crystallites into a continuous mass under high pressure in the presence of a pulsed electric current, preferably one produced by spark plasma sintering. The resulting materials have excellent optical and mechanical properties that make them favorable as replacements for the conventional single-crystal sapphire.

Owner:RGT UNIV OF CALIFORNIA

Laser processing method and method for manufacturing light-emitting device

ActiveUS8722516B2Improve accuracyEfficient cuttingSemiconductor/solid-state device manufacturingFine working devicesLaser processingSingle crystal

A plurality of modified parts are formed at a first formation pitch for a line arranged along the M-plane of a single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach a principal surface of the single-crystal sapphire substrate. A plurality of modified parts are formed at a second formation pitch narrower than the first formation pitch for a line arranged along the A-plane of the single-crystal sapphire substrate to construct a modified region and cause a fracture occurring from the modified region to reach the principal surface of the single-crystal sapphire substrate. Along the lines, a knife edge is pressed against a wafer from the side of the single-crystal sapphire substrate opposite from the principal surface of the single-crystal sapphire substrate where the fractures have reached, to cut the wafer along the lines.

Owner:HAMAMATSU PHOTONICS KK

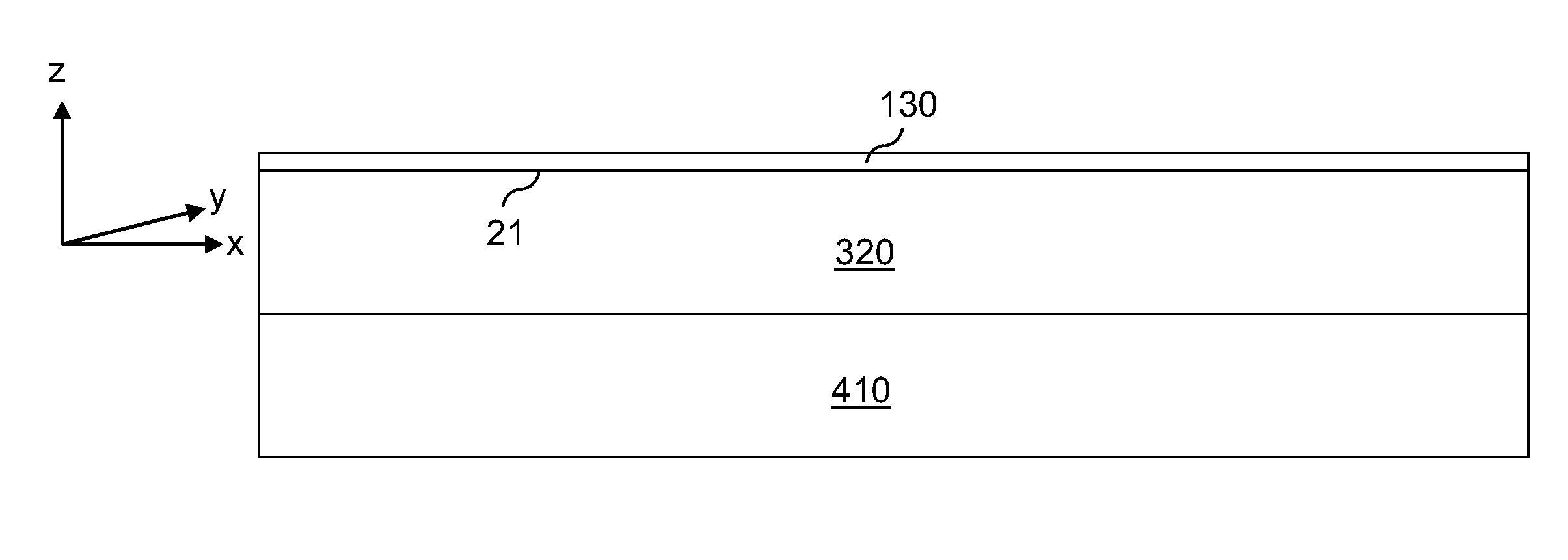

Optical barriers, waveguides, and methods for fabricating barriers and waveguides for use in harsh environments

ActiveUS20140070119A1Polycrystalline material growthAfter-treatment detailsCrystal structureRefractive index

Electromagnetic radiation barriers and waveguides, including barriers and waveguides for light, are disclosed. The barriers and waveguides are fabricated by directing charged particles, for example, ions, into crystalline substrates, for example, single-crystal sapphire substrates, to modify the crystal structure and produce a region of varying refractive index. These substrates are then heated to temperatures greater than 200 degrees C. to stabilize the modified crystal structure and provide the barrier to electromagnetic radiation. Since the treatment stabilizes the crystal structure at elevated temperature, for example, above 500 degrees C. or above 1000 degrees C., the barriers and waveguides disclosed are uniquely adapted for use in detecting conditions in harsh environments, for example, at greater than 200 degrees C. Sensors, systems for using sensors, and methods for fabricating barriers and waveguides are also disclosed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Metal matrix composite material used for 3D printing and preparation method thereof

ActiveCN106735174AHigh strengthImprove high temperature resistanceAdditive manufacturing apparatusTransportation and packagingCombustion chamberSingle crystal

The invention provides a metal matrix composite material used for 3D printing and a preparation method thereof. The metal matrix composite material used for 3D printing comprises, by weight, 30-80 parts of iron powder, 10-30 parts of auxiliary powder, 1-30 parts of monocrystal sapphire whiskers and 5-15 parts of lubricants. The auxiliary powder is a mixture of Cr, Ni, Cu, Mn, Si, Mo, Nb and C powder. The metal matrix composite material used for 3D printing has the various properties such as high strength, high-temperature resistance, oxidation resistance and corrosion resistance and is suitable for functional prototype parts and series parts (turbine engine combustion chambers, thin walls and complex parts) and widely applied to the fields of industry as well as aeronautics and astronautics.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN +1

Sapphire crystal growth method

InactiveCN101205628AAvoid melt flowControl cooling ratePolycrystalline material growthFrom solid stateLiquid stateSingle crystal

The invention discloses a growing method of sapphire crystal, which includes the steps that: alumina powder is crushed and grinded to ultra-micro powder particles; alumina particles are purified until the purity over 99.999 percent; the grinded and purified alumina with solvent is churned into pulpous state, pressed with a high pressure pump, delivered to a prilling nozzle, and sprayed into a high temperature drying tower, the pulpous state alumina which is sprayed from the prilling nozzle is dried into alumina particles and collected, and added with organic binder. The pure alumina powder particles are arranged in a mould, and added with the organic binder, and forms a body on a forcing press; the body is fired into an alumina block in half-done state in advance, arranged in a vacuum super-high-temperature furnace for preburning, thereby exhausting impure gas; the furnace is vacuumized and introduced with inert gas, and the alumina in half-done state is heated into liquid state, until the crystal growth is completed, and is solidified, cooled and contracted into monocrystal sapphire. The invention saves time for crystal growing, has low cost, is not limited in quality and size of the crystal, and fulfills the requirement of optic components, semiconductor components, communication components and other components.

Owner:庄育丰

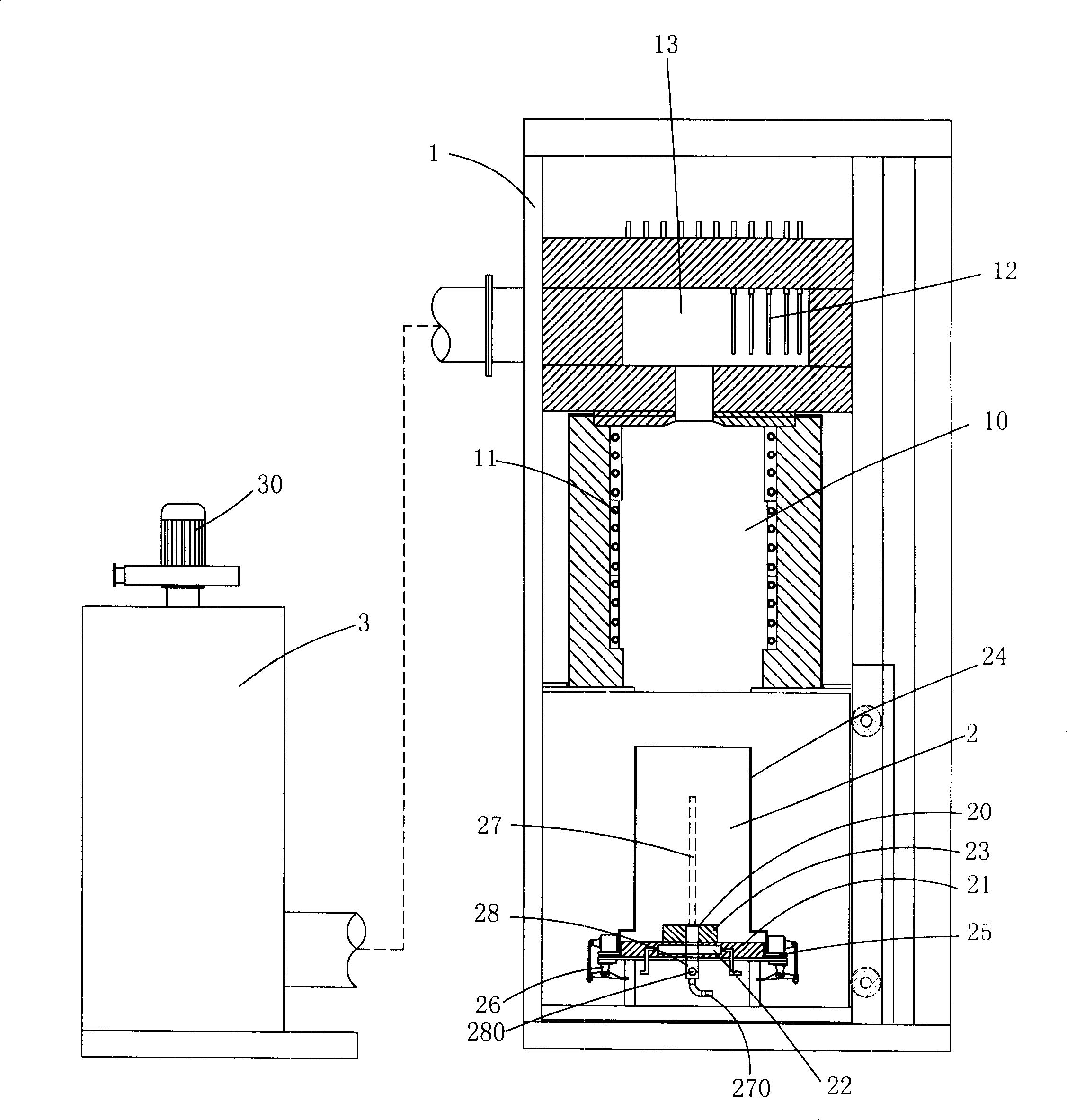

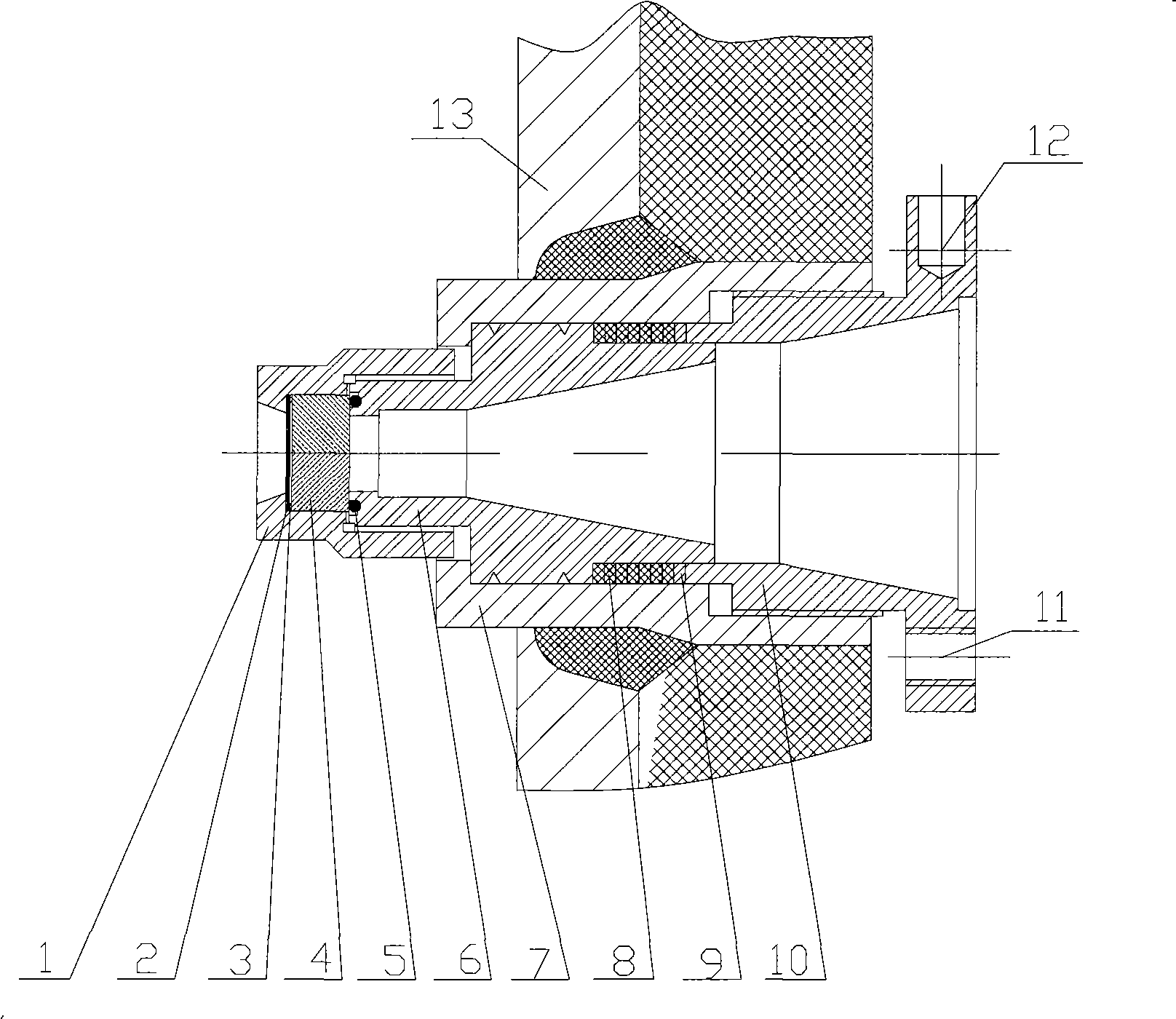

Viewing mirror for implementing in situ optical observation in high-temperature highly pressurised liquid entironment and applications

InactiveCN101363959AHigh light transmittanceStrong light transmittanceTelescopesMountingsOptoelectronicsLuminous flux

The invention relates to a lens structure, in particular to the lens structure which has safe and reliable sealing, realizes the in-situ optical observation under a high-temperature and high-pressure fluid environment (the maximum temperature and the maximum pressure can be 350 DEG C / 20MPa) as well as the application thereof, and solves the sealing and the visual (observation) problems under the high-temperature and high-pressure environment. The lens structure is assembled on an autoclave, and is composed of a pressure cap, a butterfly-shaped washer, a flat washer, a lens, an O-shaped ring, a lens barrel, a lens mount, a graphite washer, a clamping ring and a gland. When assembled, the components such as the pressure cap, the washers, the lens, and the like extend into the autoclave through the lens mount; then the gland is screwed on the lens mount until clamping the clamping ring and the washers tightly. In order to ensure that the lens barrel structure can stably work for a long time under the high-temperature fluid environment and can realize the high-quality in-situ optical observation, a single-crystal sapphire wafer with high high-temperature strength, good corrosion resistance and excellent optical performance is taken as the lens material. Besides, the invention increases the luminous flux through designing the lens barrel into a conical structure, thereby facilitating the realization of the in-situ optical observation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

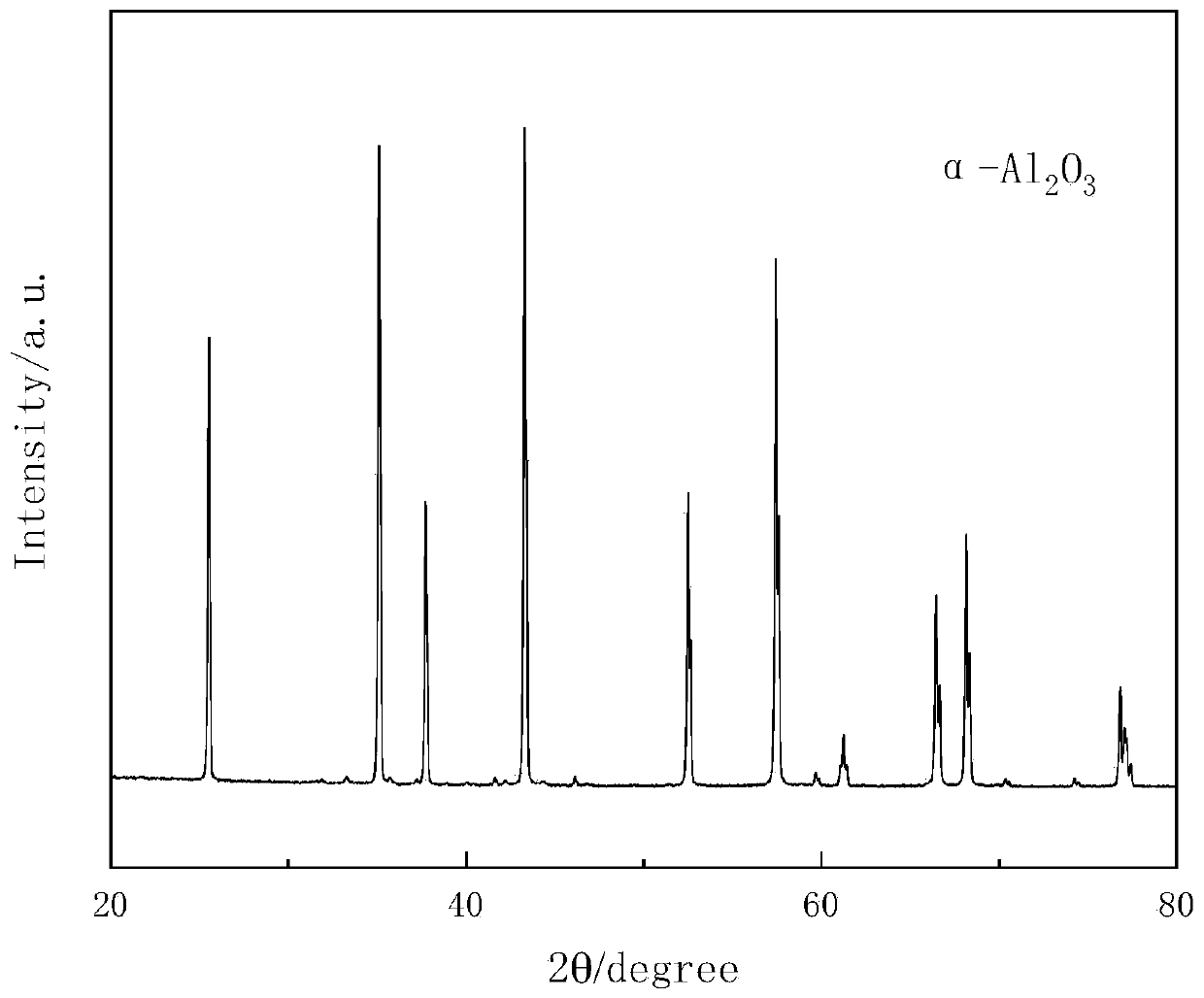

Preparation method of low-sodium orthohexagonal flaky alpha-alumina micropowder

The invention discloses a preparation method of a low-sodium orthohexagonal flaky alpha-alumina micropowder. The method which takes cheap industrial aluminum hydroxide as a raw material comprises thefollowing steps: mixing the industrial aluminum hydroxide, a dispersant and deionized water to prepare a slurry; carrying out grinding, sodium removal, solid-liquid separation, primary water washing,solid-liquid separation, drying, presintering and secondary water washing to obtain a low-sodium alumina precursor; and then adding a morphology inducer, and performing stirring, mixing and calciningto obtain the low-sodium orthohexagonal flaky alpha-alumina micropowder. The low-sodium regular orthohexagonal flaky alpha-alumina micropowder prepared by the method has a sodium oxide content of below 0.05%, an alpha-Al2O3 content of above 98%, has an orthohexagonal particle morphology, has a side length of below 1.5 [mu]m and a thickness of below 0.5 [mu]m, and can be applied to the fields of semiconductor materials, monocrystalline sapphire, reinforcing agents, protective layers and the like. The preparation method has the characteristics of wide sources of raw materials, simple device andproduction process, low production cost, realization of industrial production, environmental friendliness and the like.

Owner:CHINA JILIANG UNIV

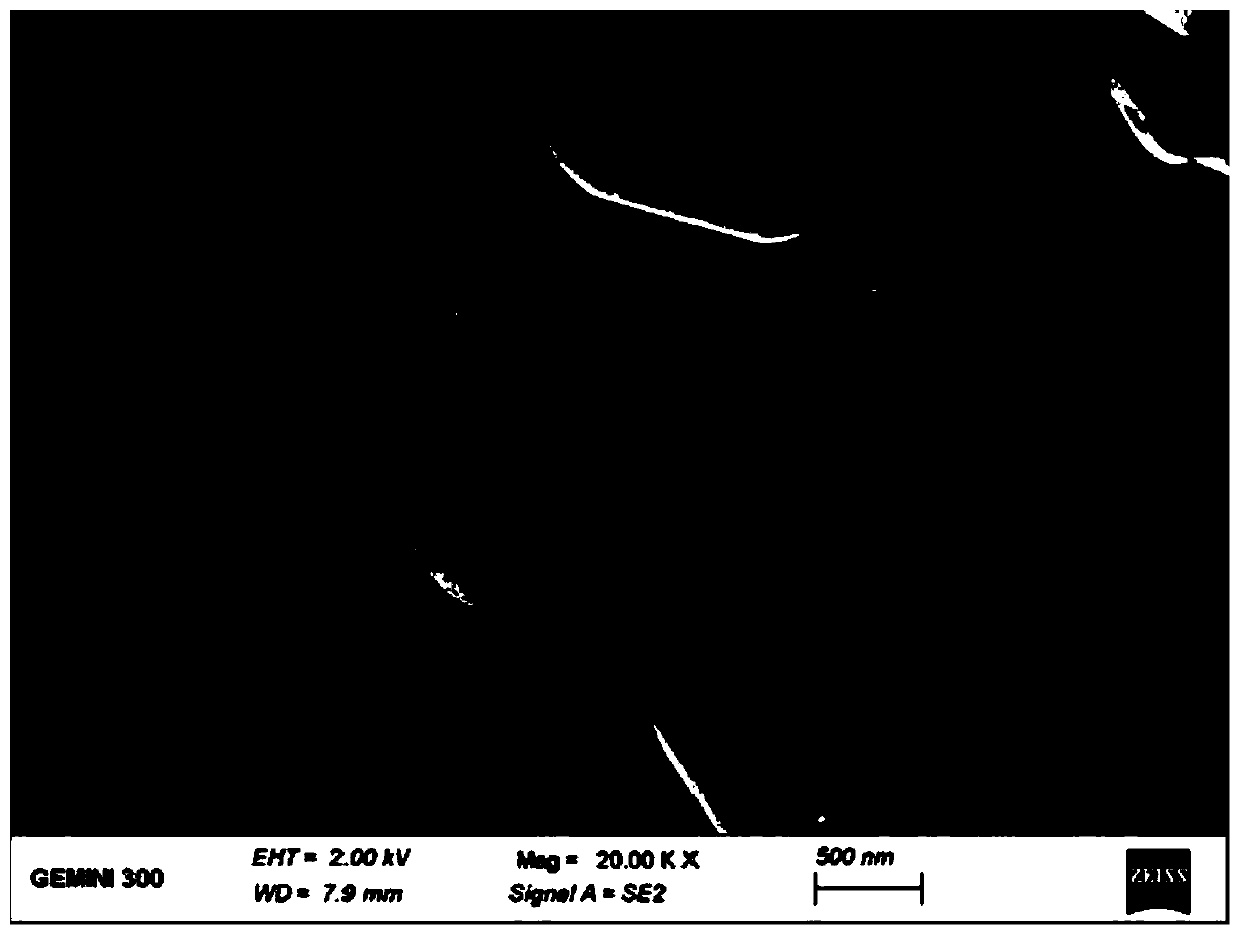

Dispersion method of single crystal sapphire fiber in aluminum oxide ceramic composite material and composite material

The invention provides a dispersion method of single crystal sapphire fiber in an aluminum oxide ceramic composite material. The dispersion method comprises the following steps: (a) preparing coating gel; (b) processing surface coating of the single crystal sapphire fiber; (c) uniformly mixing the single crystal sapphire fiber accompanied by coating and a dispersing agent, adding the mixture to zirconia ceramic powder after ultrasonic wave or boiling, and carrying out vacuum drying; and (d) sintering the ceramic composite material. By utilizing the dispersion method, the single crystal sapphire fiber is added to the zirconia ceramic powder to prepare the composite ceramic material, and the tolerance degree of the composite material in extreme environment is greatly increased. The dispersion method has great practical value and social meaning.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN

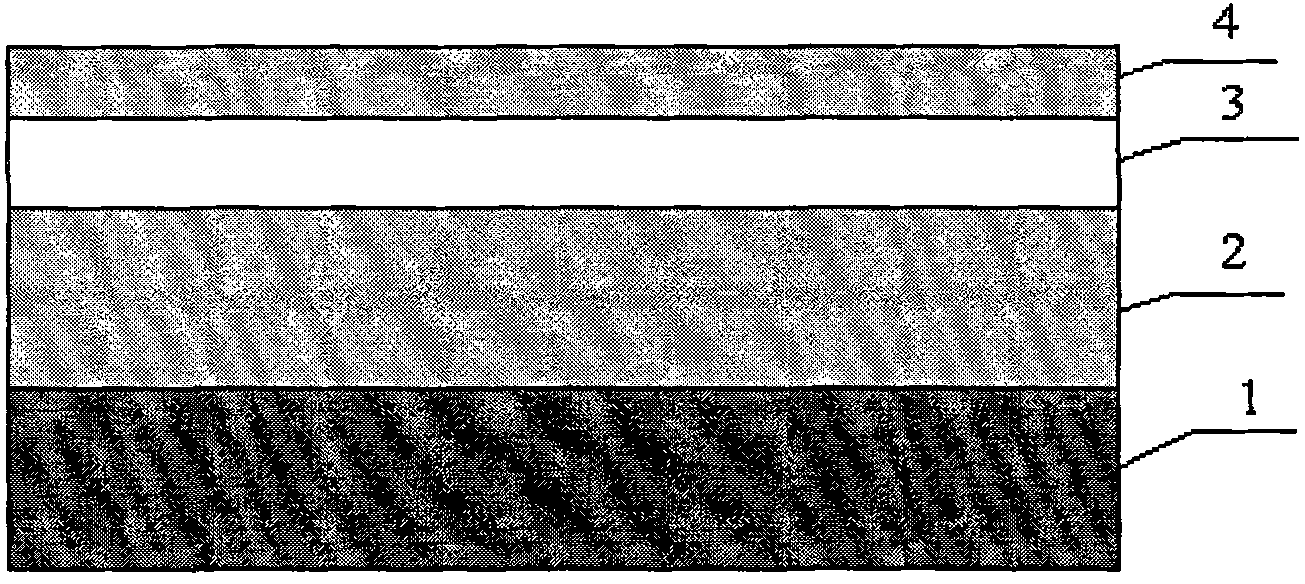

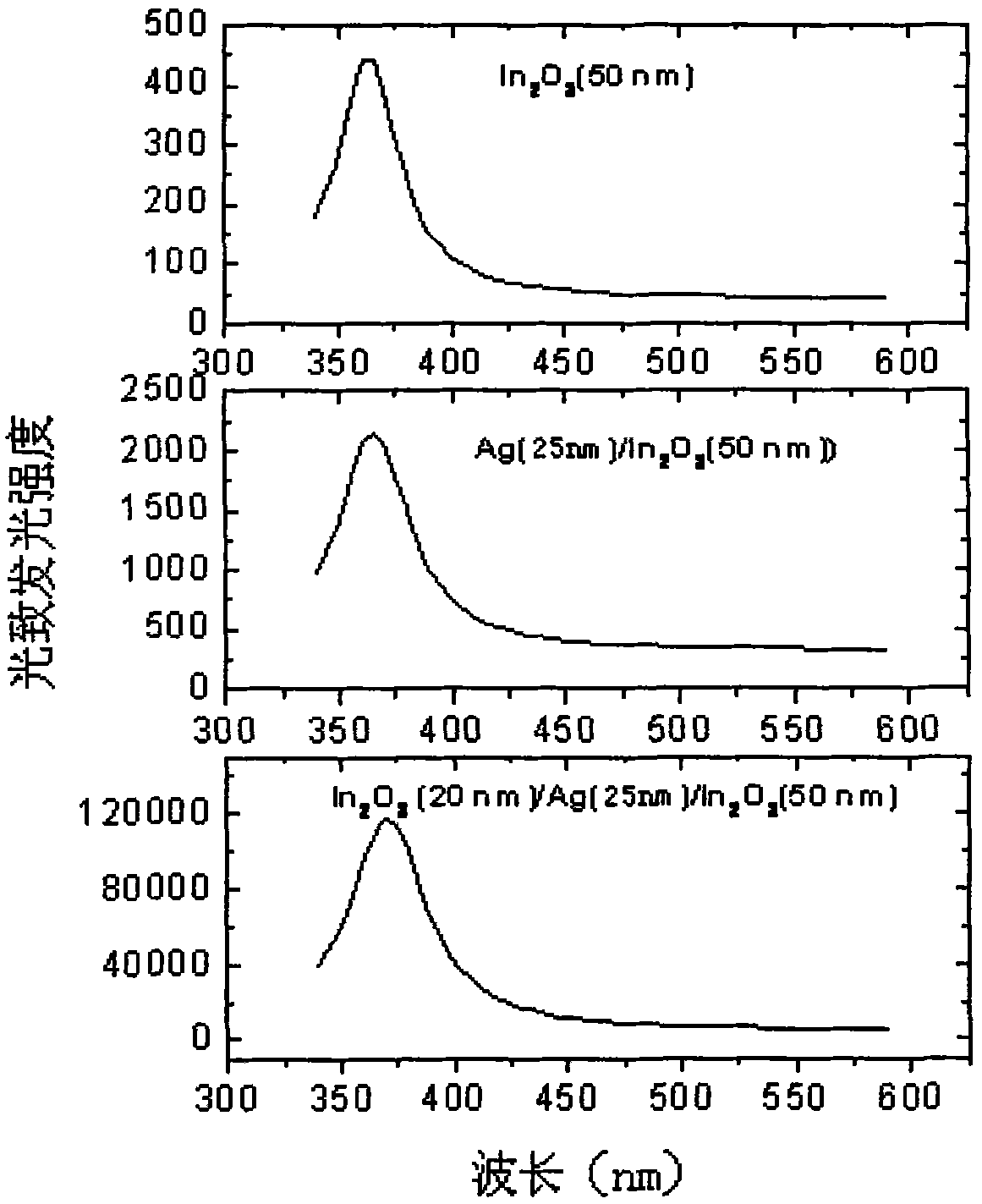

Medium/metal/medium nanostructure membrane and preparation method thereof

InactiveCN101885468AHigh Luminescence Enhancement FactorExtended service lifeIndividual molecule manipulationMetal layered productsEvaporationNanostructure

The invention discloses a medium / metal / medium nanostructure membrane. The membrane comprises a substrate, a first medium layer, a metal layer and a second medium layer, wherein the first medium layer, the metal layer and the second medium layer are arranged on the substrate in turn; the substrate is a mono-crystalline silicon slice, a mono-crystalline sapphire slice or a quartz glass sheet; the first medium layer and the second medium layer are simultaneously indium oxide layers or zinc oxide layers of which the thicknesses are between 20 and 100 nanometers; the metal layer is a silver layer,a gold layer or an aluminum layer of which the thickness is between 5 and 40 nanometers; and the nanostructure membrane can be prepared by an electron beam evaporation method or a method for combining magnetron sputtering with thermal evaporation. Compared with a metal / medium double-layer structure membrane, the medium / metal / medium nanostructure membrane of the invention has the advantages of high luminescence enhancement factor, long service life and wide development prospect.

Owner:ZHEJIANG UNIV

High purity alumina polycrystal block for growing sapphire crystals and preparation method thereof

InactiveCN102942201AQuality improvementImprove purityAluminates/aluminium-oxide/aluminium-hydroxide purificationChemical compositionMetallurgy

The invention discloses a preparation method of a high purity alumina polycrystal block for growing sapphire crystals, comprising the following steps: using commercial high-purity 5N(99.999%)a-Al2O3 powder as an initial raw material and filling the initial raw material into self-made tubby rubber molds with different diameters, sealing, keeping the pressure of 100-200 MPa in an isostatic pressing gauge for 1-5 min to conduct isostatic cool press forming; demolding to obtain a cylindrical biscuit; then sintering the cylindrical biscuit in air, vacuum or nitrogen environment with the sintering temperature of 1550-1750 DEG C and the sintering time of 2-5h to obtain an a-Al2O3 polycrystal block having the relative density of larger than 90% and the density of larger than 3.6g / cm. According to the invention, the a-Al2O3 polycrystal block prepared by the method is mainly used as a growing raw material for large-size single-crystal sapphire, has exactly the same crystal structure and chemical composition as single-crystal sapphire Al2O3; and the method can eliminate the secondary pollution problem in the preparation process of the a-Al2O3 polycrystal block.

Owner:SHANGHAI UNIV

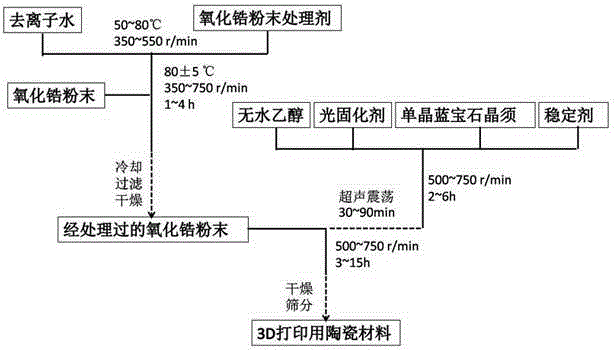

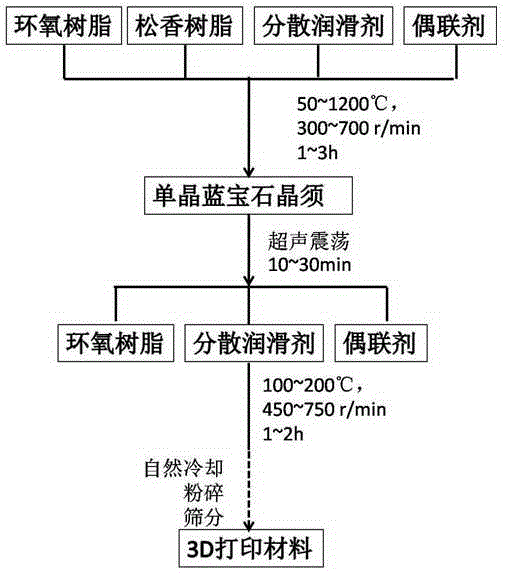

Ceramic material for 3D printing and preparation method thereof

The invention provides a ceramic material for 3D printing and a preparation method thereof. The ceramic material is prepared from, by weight, 50-150 parts of zirconia powder, 10-30 parts of zirconia powder treating agents, 100-500 parts of dispersion media, 1-10 parts of single-crystal sapphire whisker, 1-10 parts of stabilizing agents and 5-50 parts of light curing agents. The single-crystal sapphire whisker is added into the zirconia ceramics, so that the modulus of elasticity in static bending and the tensile strength of the product are significantly improved, and the preparation method is used for preparing high-strength and high-toughness fine engineering ceramics.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN +1

Polishing slurry and polishing method thereof

InactiveUS20140001153A1Increase speedHigh hardnessOther chemical processesDecorative surface effectsSolubilityHardness

The present invention provides a polishing technique capable of polishing, at a high speed, a substrate containing Al and having high hardness, such as single-crystal sapphire substrate, and capable of providing a polished surface of high accuracy. The present invention relates to a polishing slurry for polishing a substrate containing aluminum, comprising abrasive grains, an inorganic boron compound having a solubility in water at 20° C. of 0.1 g / 100 g—H2O or more, and water. In the present invention, it is preferable that the content of the inorganic boron compound is 0.1% by mass to 20% by mass in terms of boron atoms based on the polishing slurry.

Owner:MITSUI MINING & SMELTING CO LTD

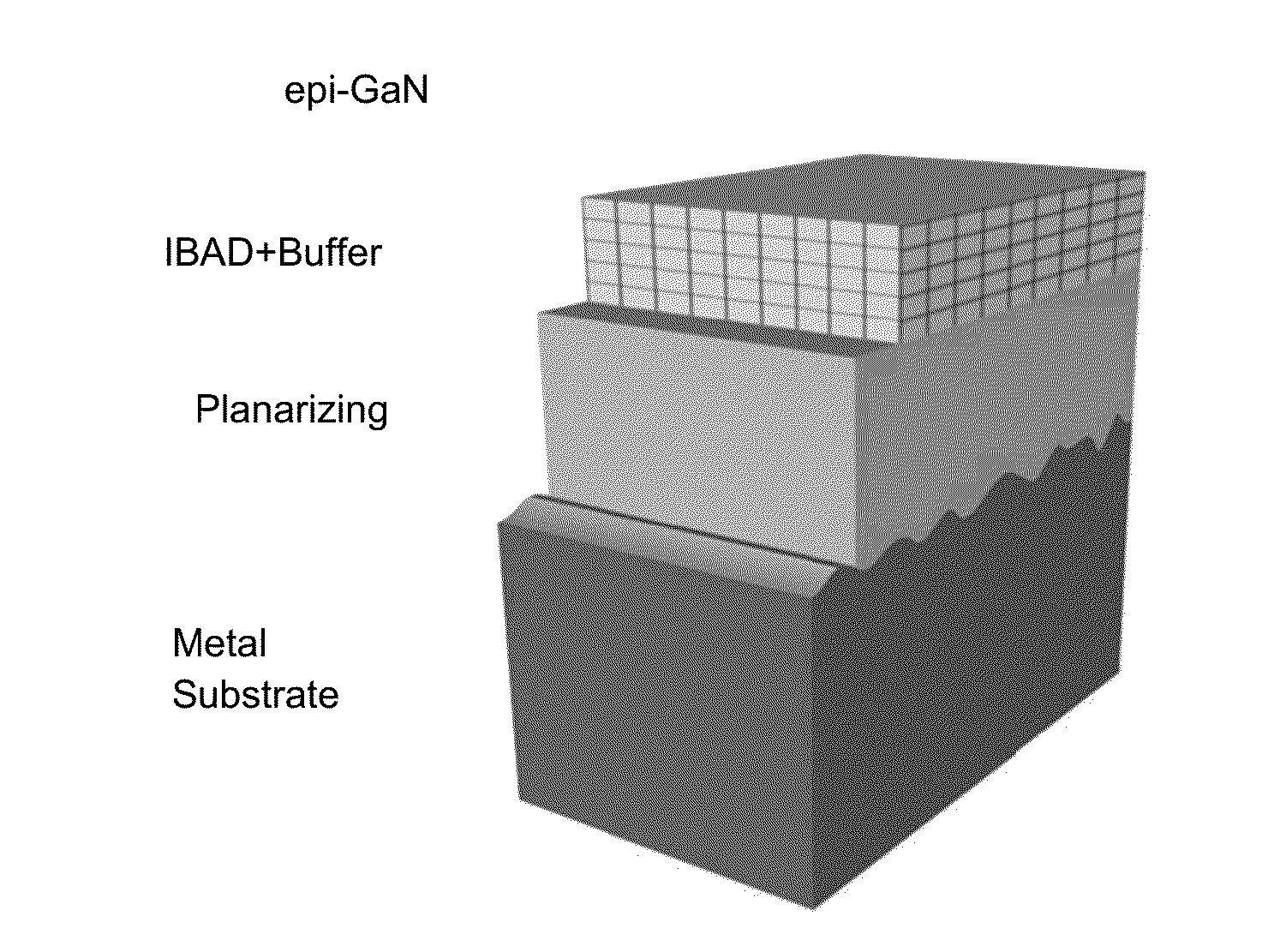

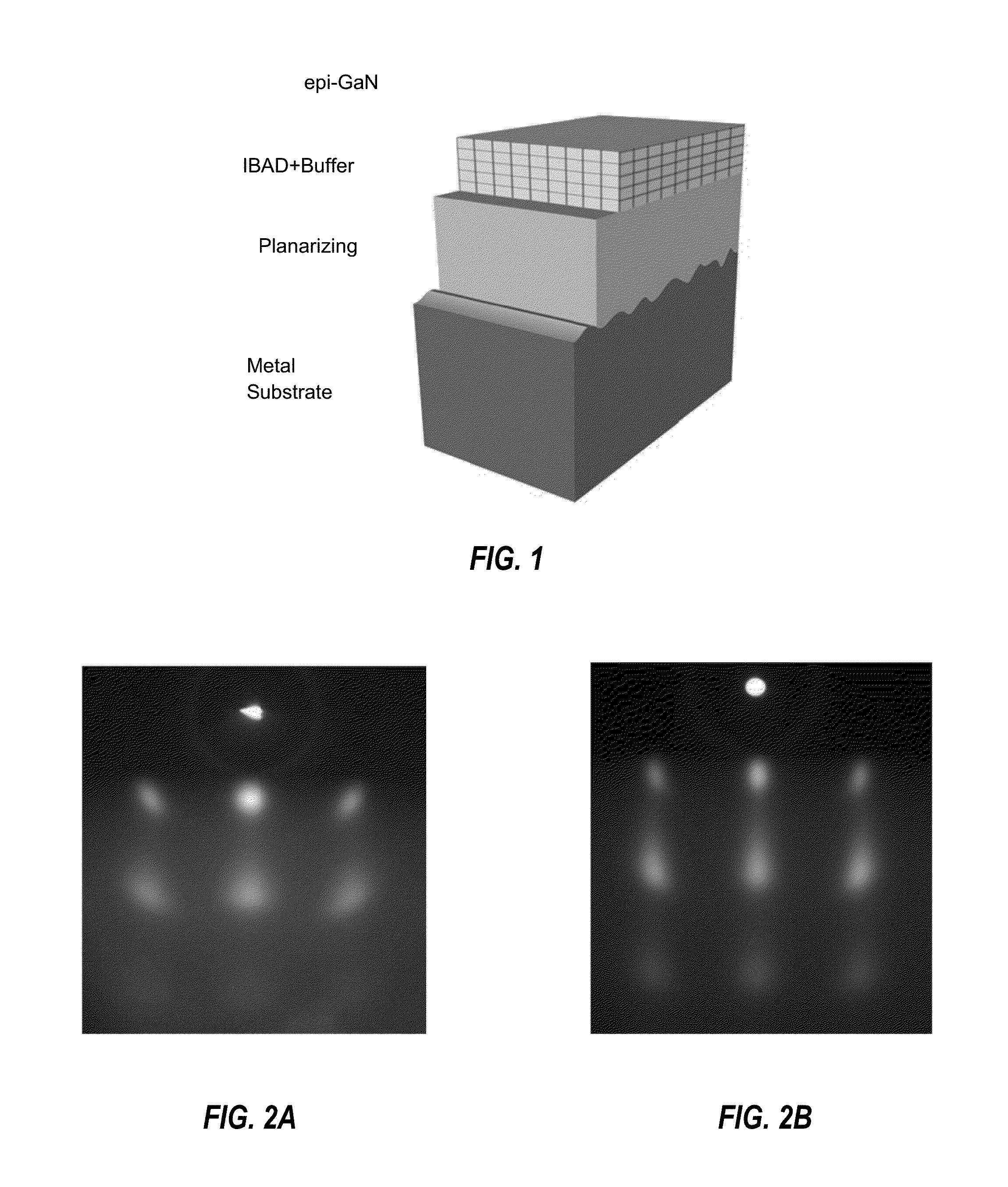

Epitaxial Hexagonal Materials on IBAD-Textured Substrates

ActiveUS20160233383A1Solid-state devicesSemiconductor/solid-state device manufacturingIn planeMetal foil

A multilayer structure including a hexagonal epitaxial layer, such as GaN or other group III-nitride (III-N) semiconductors, a <111> oriented textured layer, and a non-single crystal substrate, and methods for making the same. The textured layer has a crystalline alignment preferably formed by the ion-beam assisted deposition (IBAD) texturing process and can be biaxially aligned. The in-plane crystalline texture of the textured layer is sufficiently low to allow growth of high quality hexagonal material, but can still be significantly greater than the required in-plane crystalline texture of the hexagonal material. The IBAD process enables low-cost, large-area, flexible metal foil substrates to be used as potential alternatives to single-crystal sapphire and silicon for manufacture of electronic devices, enabling scaled-up roll-to-roll, sheet-to-sheet, or similar fabrication processes to be used. The user is able to choose a substrate for its mechanical and thermal properties, such as how well its coefficient of thermal expansion matches that of the hexagonal epitaxial layer, while choosing a textured layer that more closely lattice matches that layer.

Owner:IBEAM MATERIALS INC

Modified 3D printing material and preparation method thereof

InactiveCN105176070AHigh flexural modulusHigh tensile strengthAdditive manufacturing apparatusEpoxyFlexural modulus

The invention provides a modified 3D printing material and a preparation method thereof. The modified 3D printing material comprises the following components in parts by weight: 60-100 parts of polyamide, 30-80 parts of epoxy resin, 20-30 parts of rosin resin, 20-60 parts of monocrystal sapphire whiskers, 1-10 parts of a coupling agent, 0.1-5 parts of a flatting agent, 0.1-5 parts of a degassing agent and 1-10 parts of a dispersion lubricant. Compared with the traditional polyamide material, the modified 3D printing material provided by the invention is relatively high in flexural modulus, tensile strength, size stability and heat distortion temperature and can be used at high temperature.

Owner:TSINGHUA INNOVATION CENT IN DONGGUAN +1

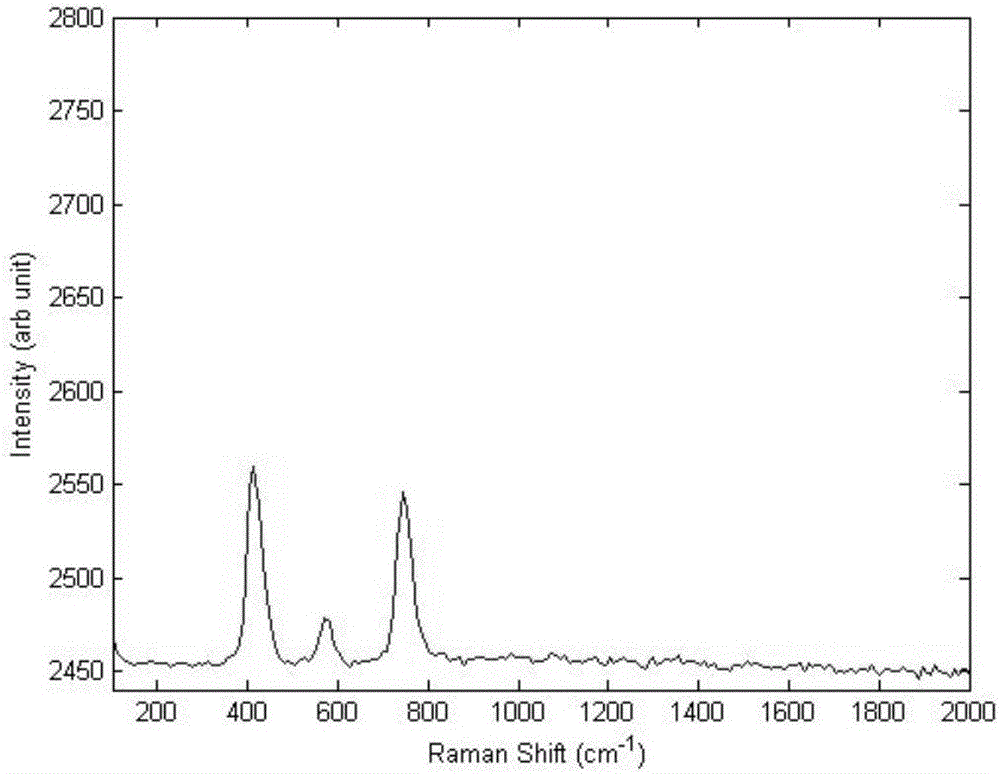

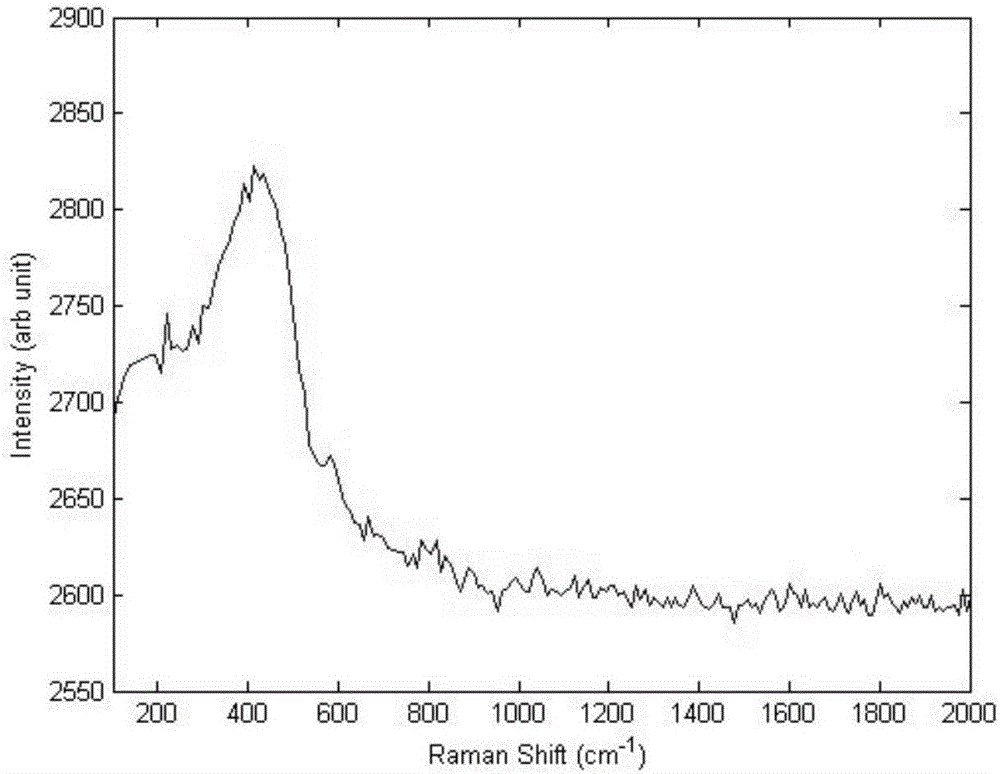

Raman spectrum detection system based on single crystal sapphire optical fibers and sapphire optical fiber probe manufacturing method

InactiveCN106556590AImprove coupling efficiencyImprove thermal stabilityRaman scatteringSignal lightSingle crystal

The invention discloses a Raman spectrum detection system based on single crystal sapphire optical fibers and a sapphire optical fiber probe manufacturing method. The system comprises a laser emitting module, a semi-transparent semi-reflecting first long pass light filter, a second coupler, a sapphire optical fiber probe and a spectrometer detection and analysis module. The laser emitting module is used for emitting single wavelength excitation light and introducing the single wavelength excitation light into the sapphire optical fiber probe. The sapphire optical fiber probe collects the Raman scattering signal light of the sample to be detected. The spectrometer detection and analysis module analyzes and detects the Raman spectrum. The manufacturing method comprises immersing the single crystal sapphire optical fibers in a mixed solution of a trisodium citrate solution and an AgNO3 solution under action of laser so that a silver nanoparticle film with Raman surface enhancement effects grows. The system and method simplify the optical fiber bundle filtering scheme for inhibiting the high background noise of the quartz optical fiber as the Raman probe material, and ensure the signal-to-noise ratio of the Raman spectrum detection.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Optical barriers, waveguides, and methods for fabricating barriers and waveguides for use in harsh environments

ActiveUS8852695B2Polycrystalline material growthAfter-treatment detailsCrystal structureRefractive index

Electromagnetic radiation barriers and waveguides, including barriers and waveguides for light, are disclosed. The barriers and waveguides are fabricated by directing charged particles, for example, ions, into crystalline substrates, for example, single-crystal sapphire substrates, to modify the crystal structure and produce a region of varying refractive index. These substrates are then heated to temperatures greater than 200 degrees C. to stabilize the modified crystal structure and provide the barrier to electromagnetic radiation. Since the treatment stabilizes the crystal structure at elevated temperature, for example, above 500 degrees C. or above 1000 degrees C., the barriers and waveguides disclosed are uniquely adapted for use in detecting conditions in harsh environments, for example, at greater than 200 degrees C. Sensors, systems for using sensors, and methods for fabricating barriers and waveguides are also disclosed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

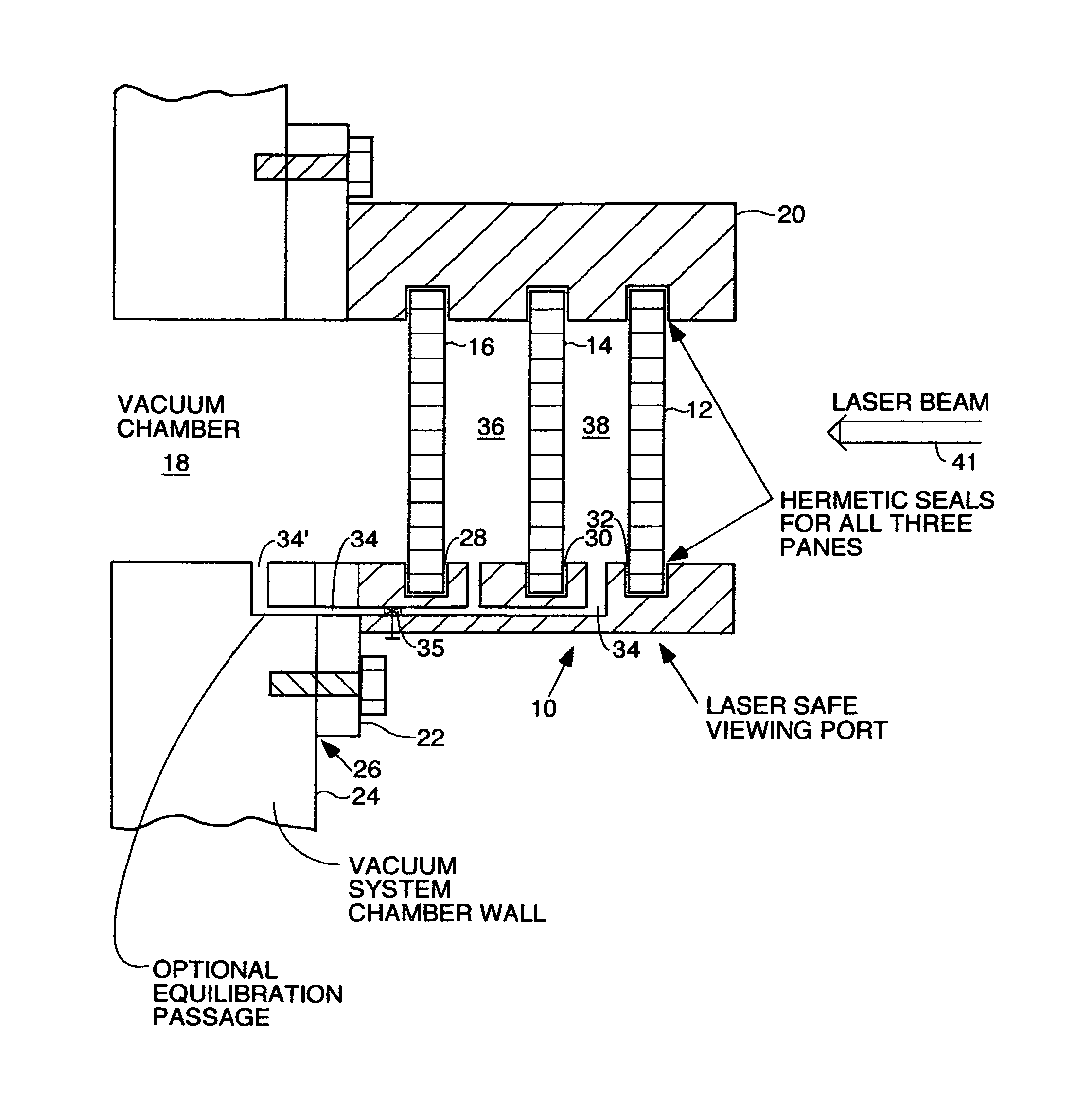

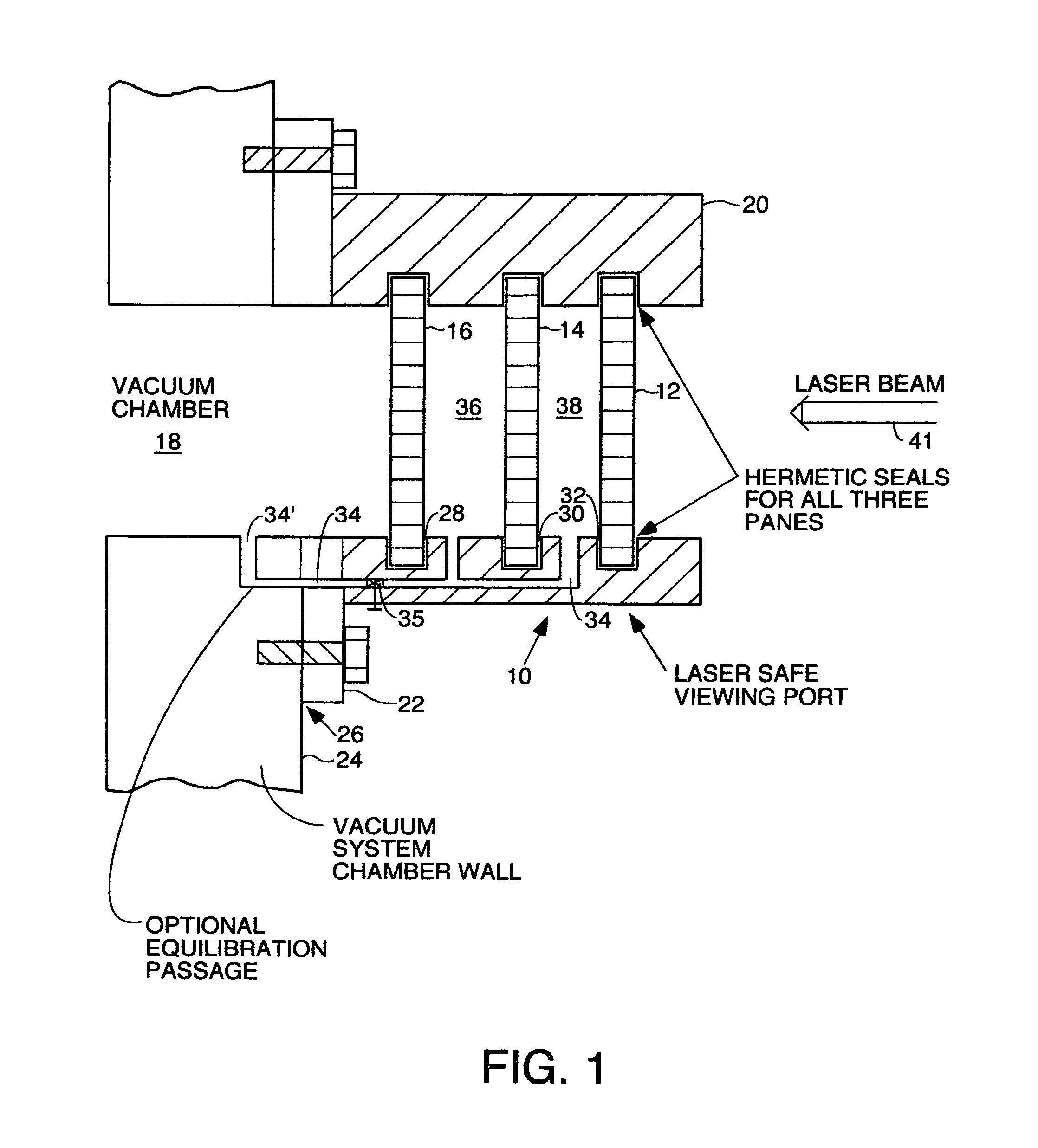

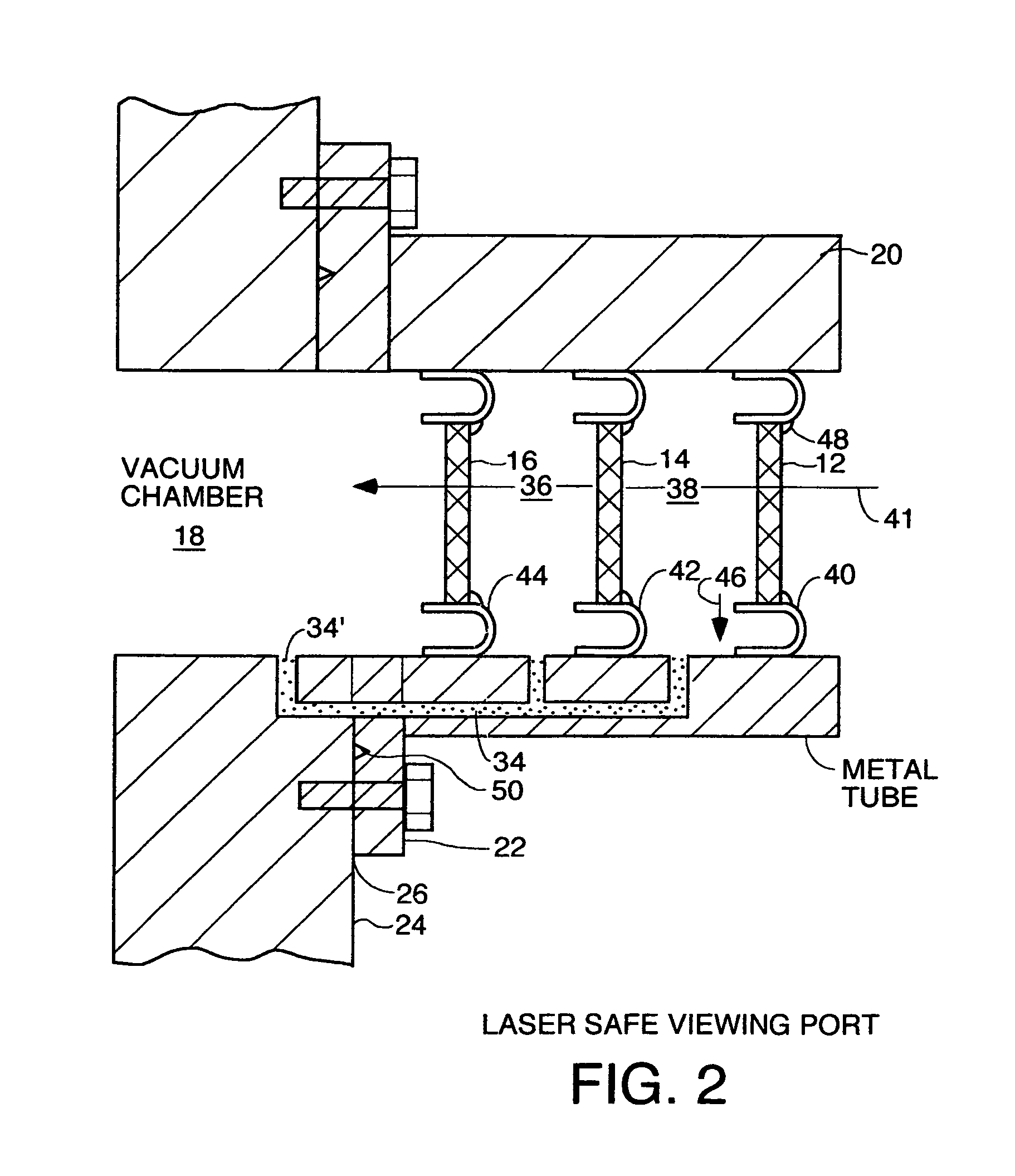

Safe pressure system viewing port

InactiveUS8916245B2Pressurized chemical processRadiation/particle handlingPressure systemEngineering

Owner:MANSOUR II JOSEPH ALEXANDER

Formation of a graphene layer on a large substrate

ActiveUS8541769B2Low costLow cost manufacturingSemiconductor/solid-state device manufacturingSemiconductor devicesSurface layerCarbide

A single crystalline silicon carbide layer can be grown on a single crystalline sapphire substrate. Subsequently, a graphene layer can be formed by conversion of a surface layer of the single crystalline silicon layer during an anneal at an elevated temperature in an ultrahigh vacuum environment. Alternately, a graphene layer can be deposited on an exposed surface of the single crystalline silicon carbide layer. A graphene layer can also be formed directly on a surface of a sapphire substrate or directly on a surface of a silicon carbide substrate. Still alternately, a graphene layer can be formed on a silicon carbide layer on a semiconductor substrate. The commercial availability of sapphire substrates and semiconductor substrates with a diameter of six inches or more allows formation of a graphene layer on a commercially scalable substrate for low cost manufacturing of devices employing a graphene layer.

Owner:GLOBALFOUNDRIES US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com