Medium/metal/medium nanostructure membrane and preparation method thereof

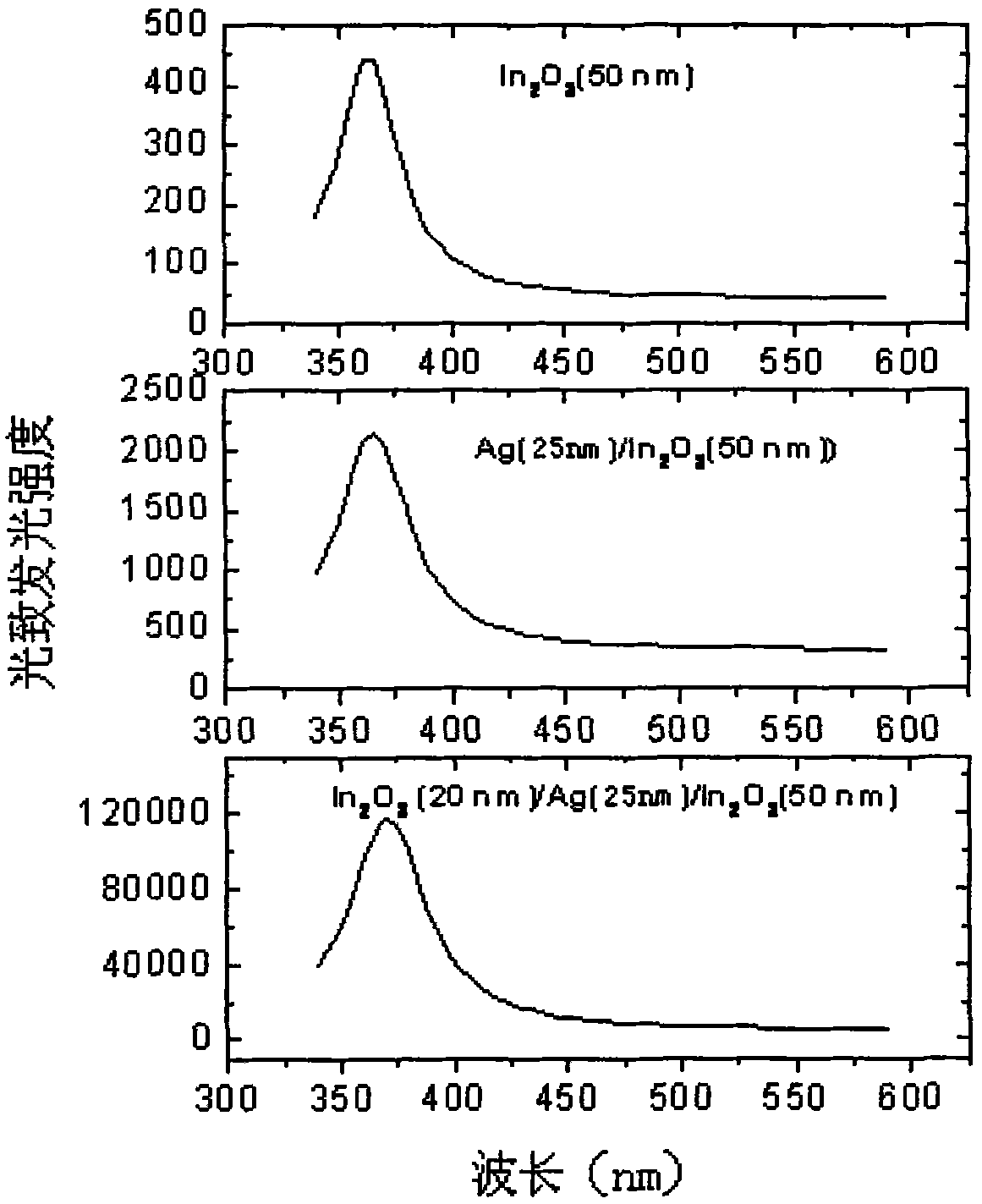

A nanostructure and dielectric technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of enhancement, metal/dielectric double-layer structure has not seen relevant reports, and achieve long service life and high luminescence enhancement factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

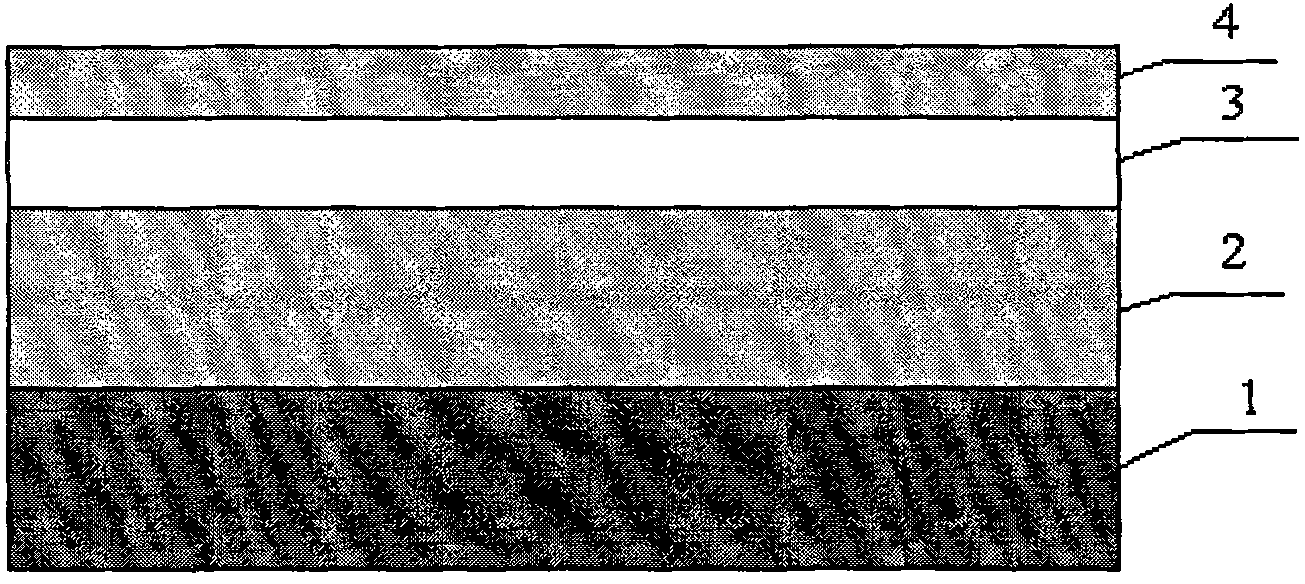

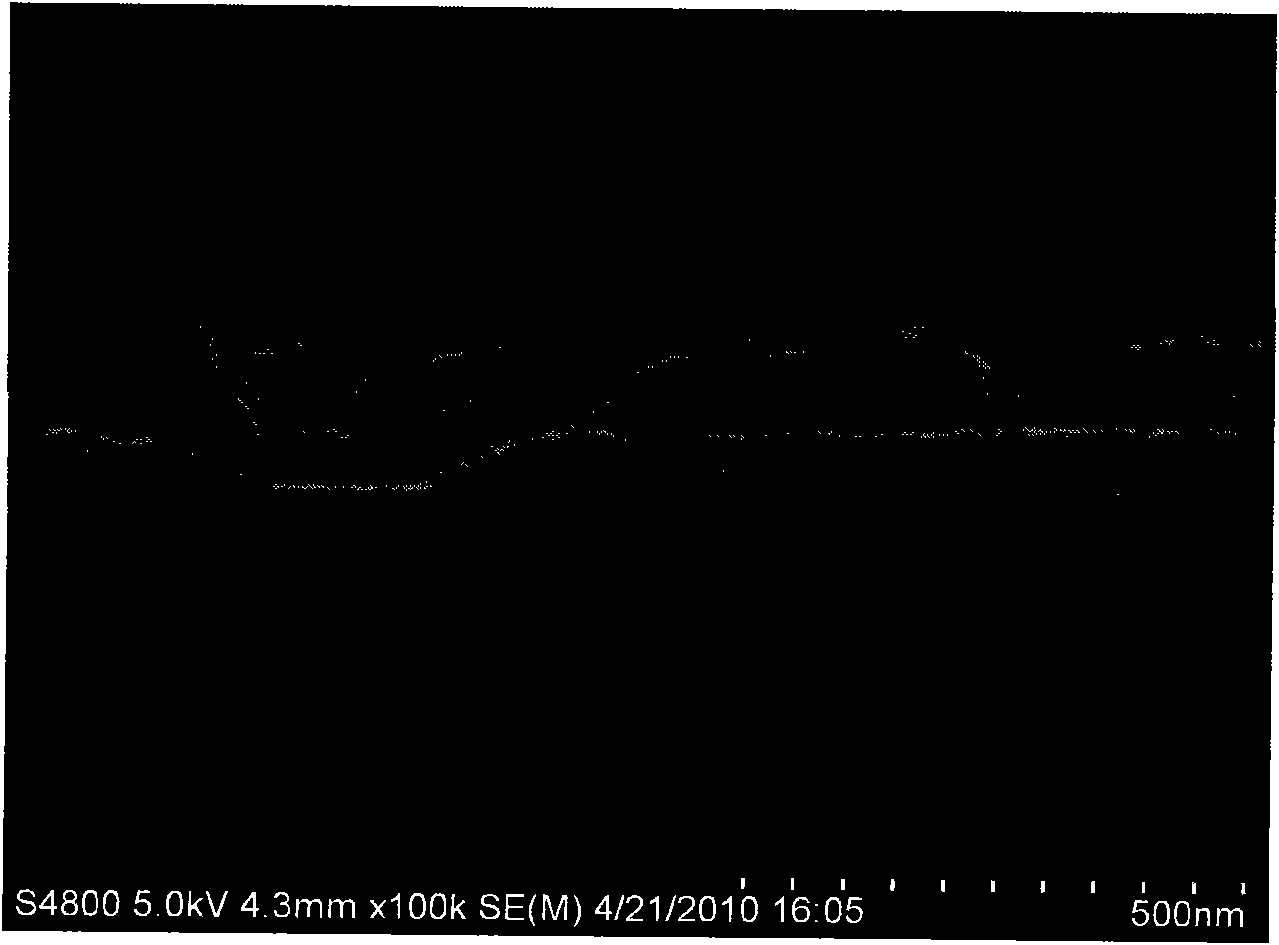

[0040] Preparation of In by electron beam evaporation 2 o 3 (20nm) / Ag(25nm) / In 2 o 3 (50nm) / Si type nanostructure film:

[0041] (1) Select a polished single-crystal silicon wafer as the substrate material, and grow it by the electron beam method: before the growth, fill the two crucibles with In 2 o 3 For the target and Ag target, put the substrate into the sample holder in the growth chamber; use the vacuum unit (oil diffusion pump + mechanical pump) to evacuate the vacuum to make the background vacuum of the growth chamber reach 1×10 -4 Pa; then the growth chamber is filled with Ar gas with a purity of 99.999%, and the air pressure is controlled at 1×10 -2 Pa; aim high-energy electron beam at In 2 o 3 The target begins to grow the first layer of In 2 o 3 Thin film; the substrate temperature is set to room temperature during growth; the growth rate is 3nm / min, and the thickness is controlled at 50nm;

[0042] (2) When the first layer In 2 o 3 After the thickness ...

Embodiment 2

[0050] Preparation of In by electron beam evaporation 2 o 3 (25nm) / Ag(30nm) / In 2 o 3 (70nm) / Si type nanostructure film:

[0051] (1) Select a polished single-crystal silicon wafer as the substrate material, and grow it by the electron beam method: before the growth, fill the two crucibles with In 2 o 3 Target material and Ag target material, put the substrate into the substrate rack; use the vacuum unit (oil diffusion pump + mechanical pump) to evacuate, so that the background vacuum degree of the growth chamber reaches 5×10 -4 Pa; then the growth chamber is filled with Ar gas with a purity of 99.999%, and the air pressure is controlled at 5×10 -2 Between Pa; align high-energy electron beams to In 2 o 3 The target begins to grow the first layer of In 2 o 3 Thin film; the substrate temperature is set to room temperature during growth; the growth rate is 5nm / min, and the thickness is controlled at 70nm;

[0052] (2) When the first layer In 2 o 3 After the thickness o...

Embodiment 3

[0055] Preparation of In by a combination of magnetron sputtering and thermal evaporation 2 o 3 (50nm) / Ag(21nm) / In 2 o 3 (50nm) / Si type nanostructure film:

[0056] (1) Select a polished single crystal silicon wafer as the substrate material, place it in the sample holder in the growth chamber, and use the vacuum unit (molecular pump + mechanical pump) to vacuum the growth chamber to 1×10 -4 The background vacuum of Pa, then fill the growth chamber with argon, and control the pressure of the growth chamber after filling the argon at 1Pa, and grow the first layer of In with a thickness of 50 nanometers on the substrate surface. 2 o 3For thin films, the substrate temperature is set to room temperature during growth; the growth rate is 6nm / min;

[0057] (2) The first layer of In with a thickness of 50 nanometers will be grown 2 o 3 The sample of the thin film is placed in the sample holder of the thermal evaporation growth chamber, and the second layer of Ag thin film is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com