Patents

Literature

1003 results about "Flexural modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mechanics, the flexural modulus or bending modulus is an intensive property that is computed as the ratio of stress to strain in flexural deformation, or the tendency for a material to resist bending. It is determined from the slope of a stress-strain curve produced by a flexural test (such as the ASTM D790), and uses units of force per area. For a 3-point test of a rectangular beam behaving as an isotropic linear material, where w and h are the width and height of the beam, I is the second moment of area of the beam's cross-section, L is the distance between the two outer supports, and d is the deflection due to the load F applied at the middle of the beam, the flexural modulus: Ebₑₙd=L³F/4wh³d From elastic beam theory d=L³F/48IE and for rectangular beam I=1/12wh³ thus Ebₑₙd=E (Elastic modulus) Ideally, flexural or bending modulus of elasticity is equivalent to the tensile modulus (Young's modulus) or compressive modulus of elasticity.

Plasticized hetero-phase polyolefin blends

InactiveUS20080045638A1Increase stiffnessImprove impact toughnessPigment pastesPolyolefinHigh stiffness

This invention relates to hetero-phase polyolefin compositions comprising: a) 30 to 99.7 wt % of a polypropylene-based TPO comprising at least 50 wt % propylene and at least 10 wt % ethylene, and b) 0.1 to 20 wt % of one or more non-functionalized plasticizer, and c) 0.2 to 50 wt % of one or more filler; based upon the weight of the composition, and having: i) an MFR of 5 dg / min or more, and ii) a flexural modulus of 500 MPa or more, and iii) a notched Charpy impact strength at −30° C. of 1 kJ / m2 or more or a notched Izod impact strength at −18° C. of 50 J / m or more.These compositions are especially useful in applications such as automotive parts that demand both high stiffness and high impact toughness, as well as good processibility during fabrication.

Owner:EXXONMOBIL CHEM PAT INC

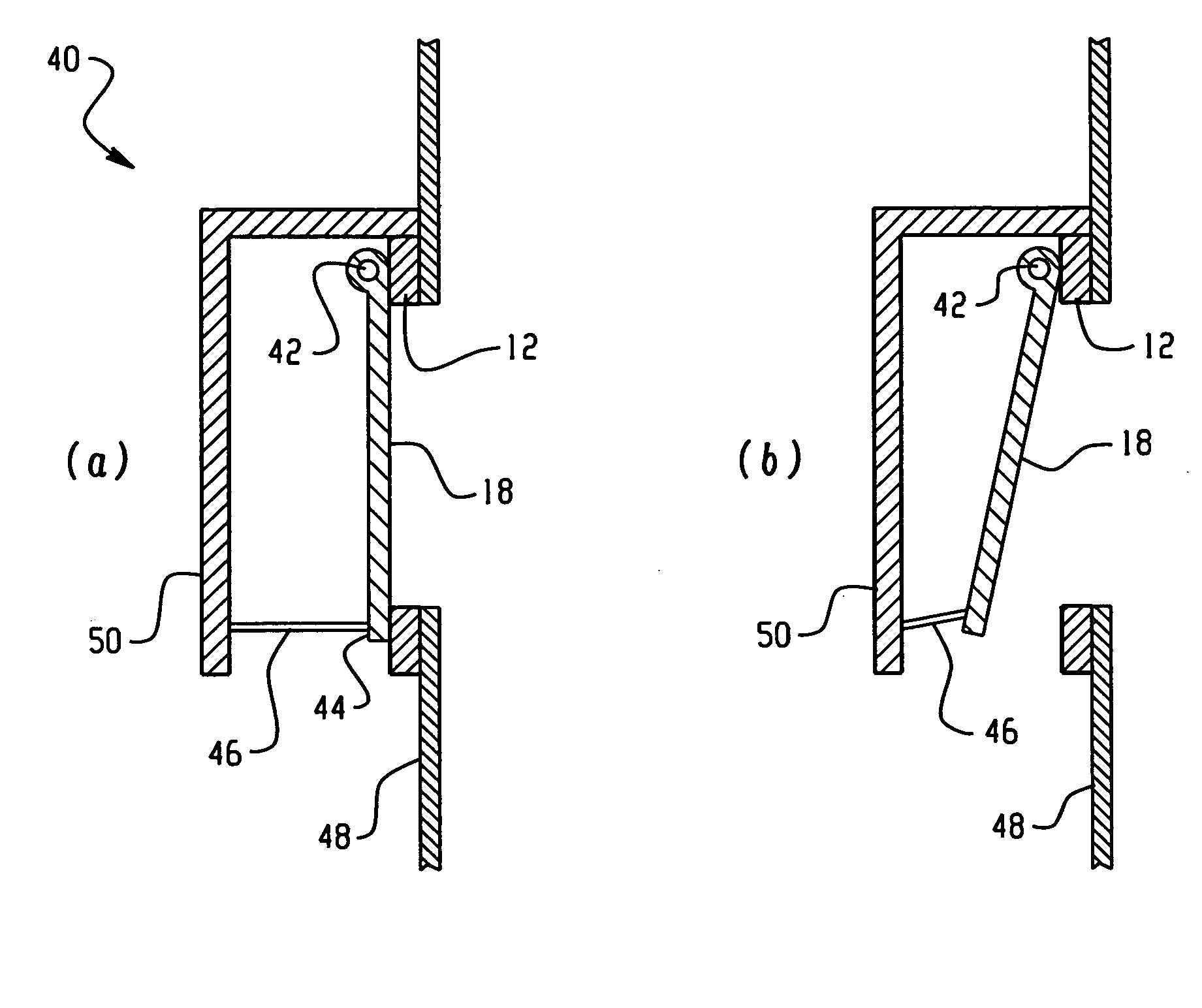

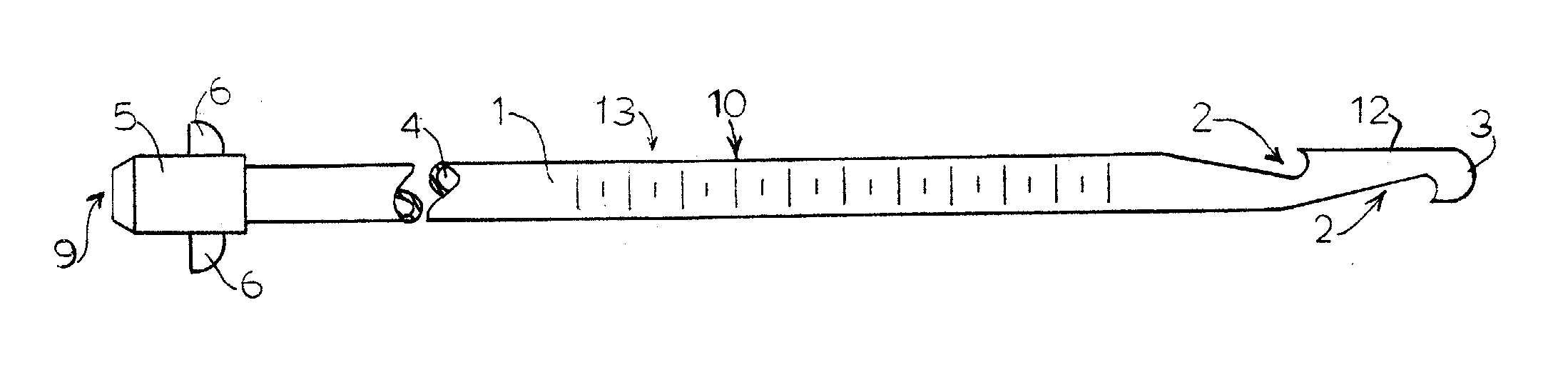

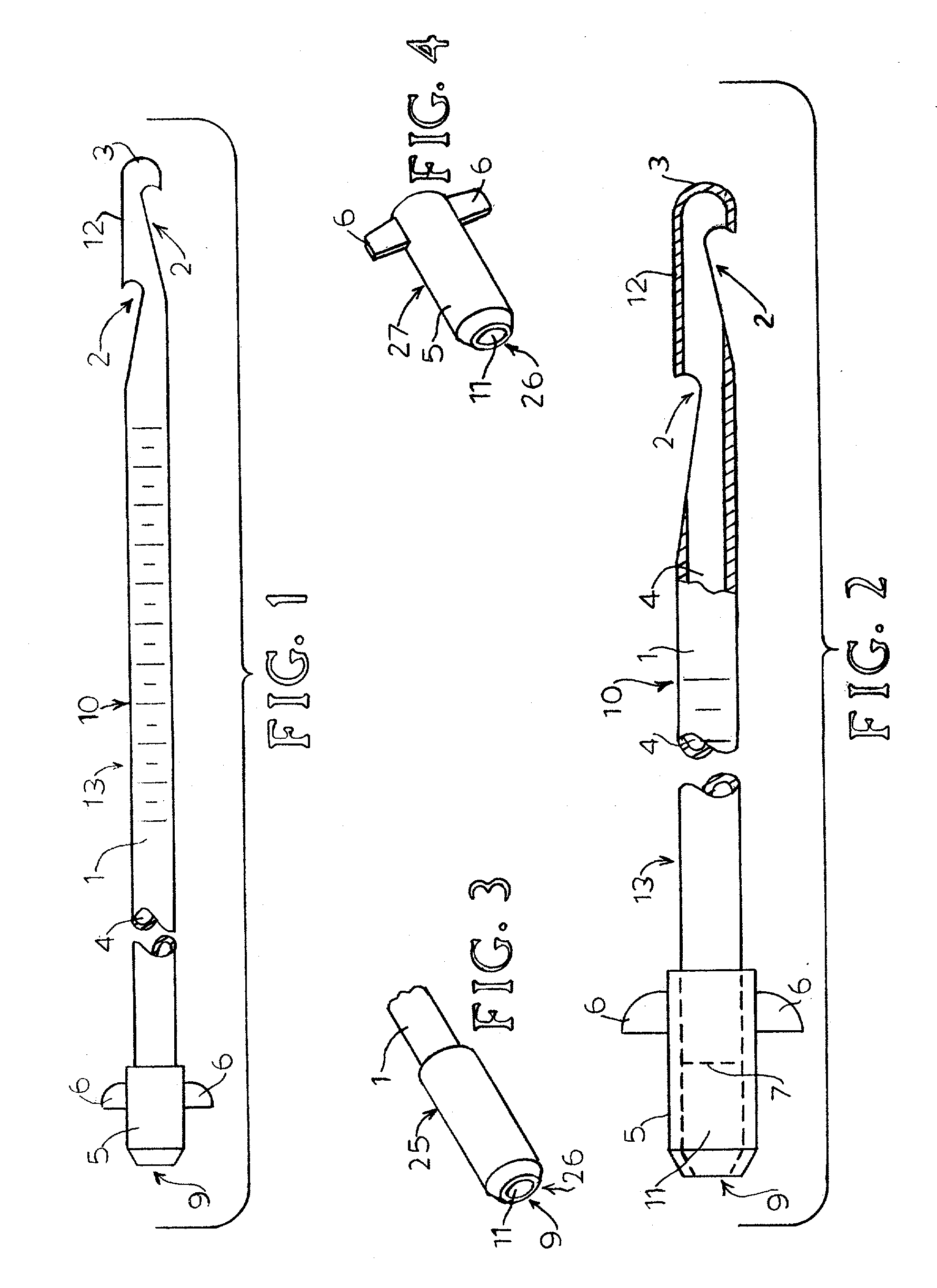

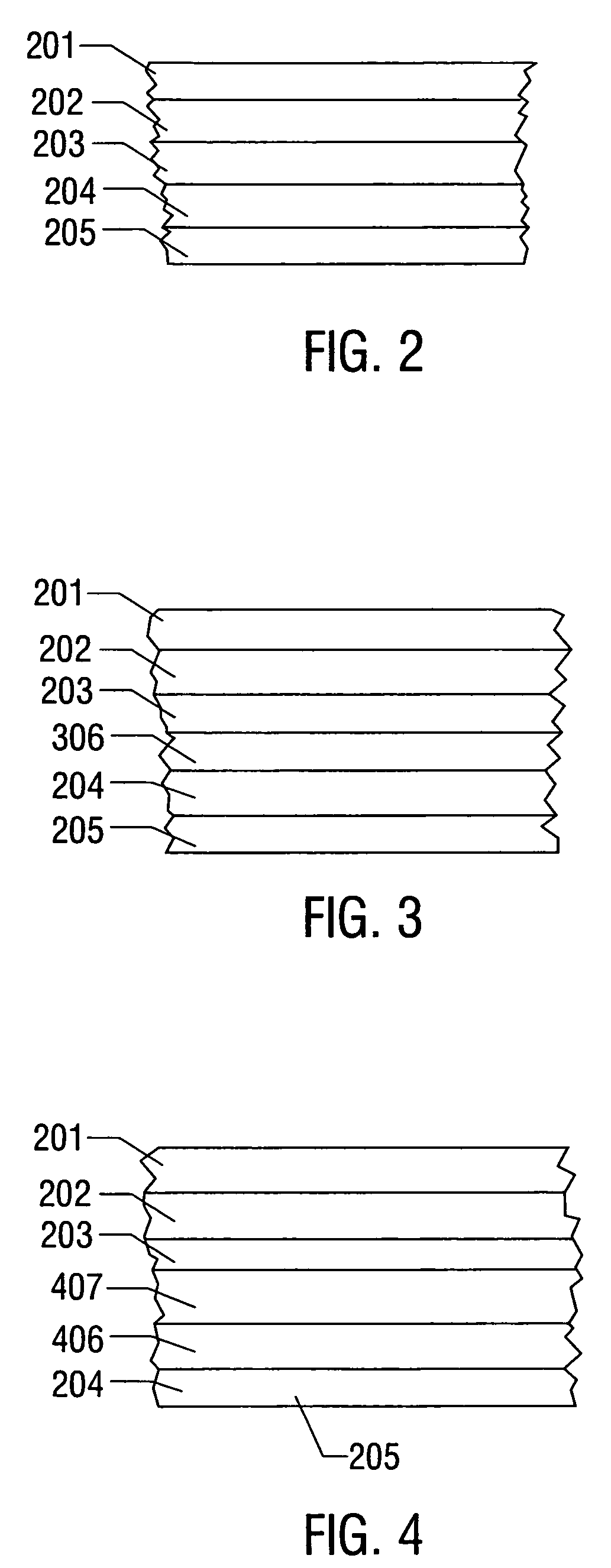

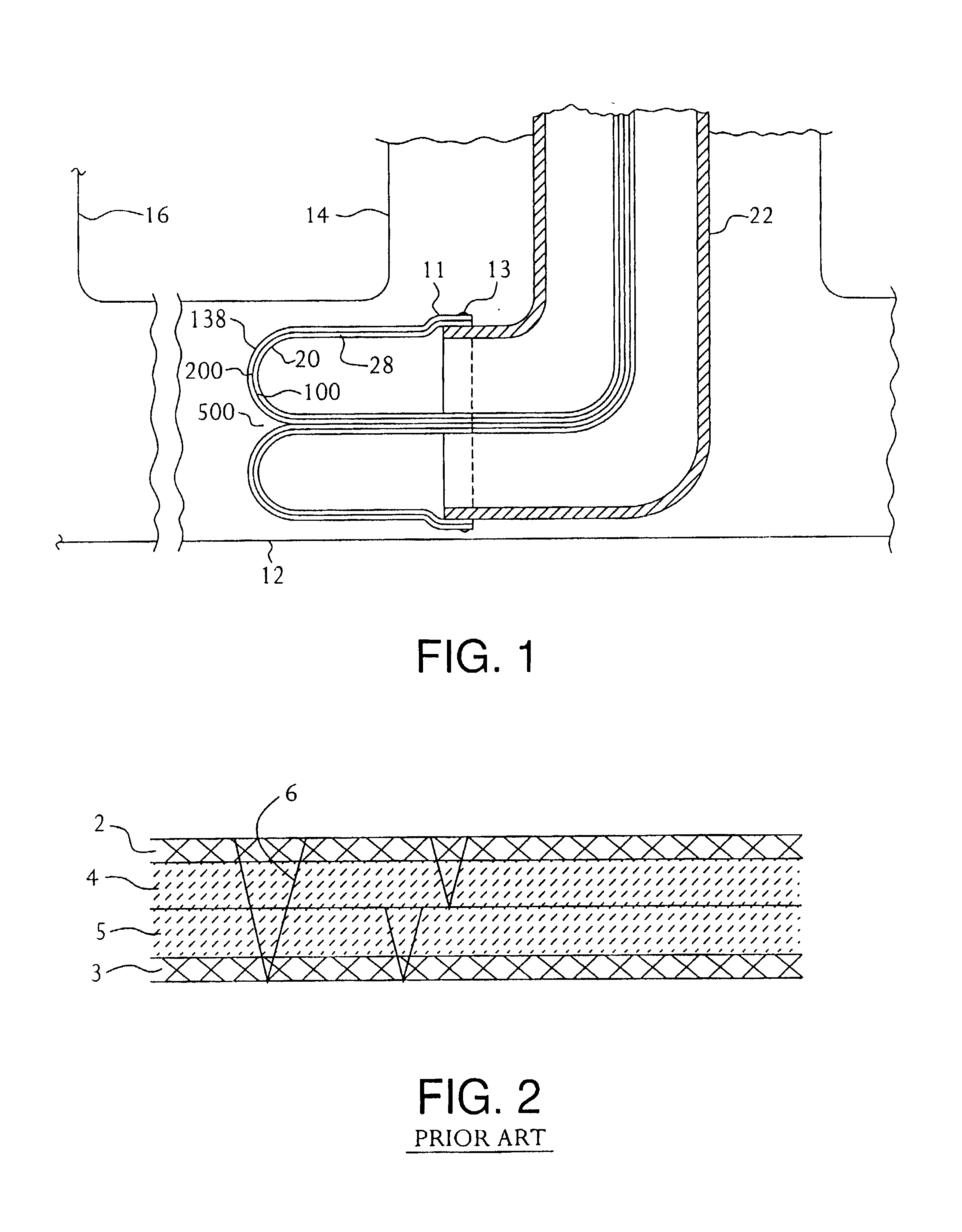

Guide catheter having selected flexural modulus segments

InactiveUS6858024B1Prevent guide catheter back-outIncreasing back-out resistanceGuide needlesFlexible pipesFlexural modulusAortic arch

A guiding catheter for use in coronary angioplasty and other cardiovascular interventions which incorporates a plurality of segment of selected flexural modulus in the shaft of the device. The segments which have a different flexibility than the sections immediately proximal and distal to them, creating zones in the catheter shaft which are either more or less flexible than other zones of the shaft. The flexibility and length of the shaft in a given zone is then matched to its clinical function and role. A mid-shaft zone is significantly softer than a proximal shaft or distal secondary curve to better traverse the aortic arch shape without storing too much energy. A secondary zone section is designed to have maximum stiffness to provide optimum backup support and stability.

Owner:BOSTON SCI SCIMED INC

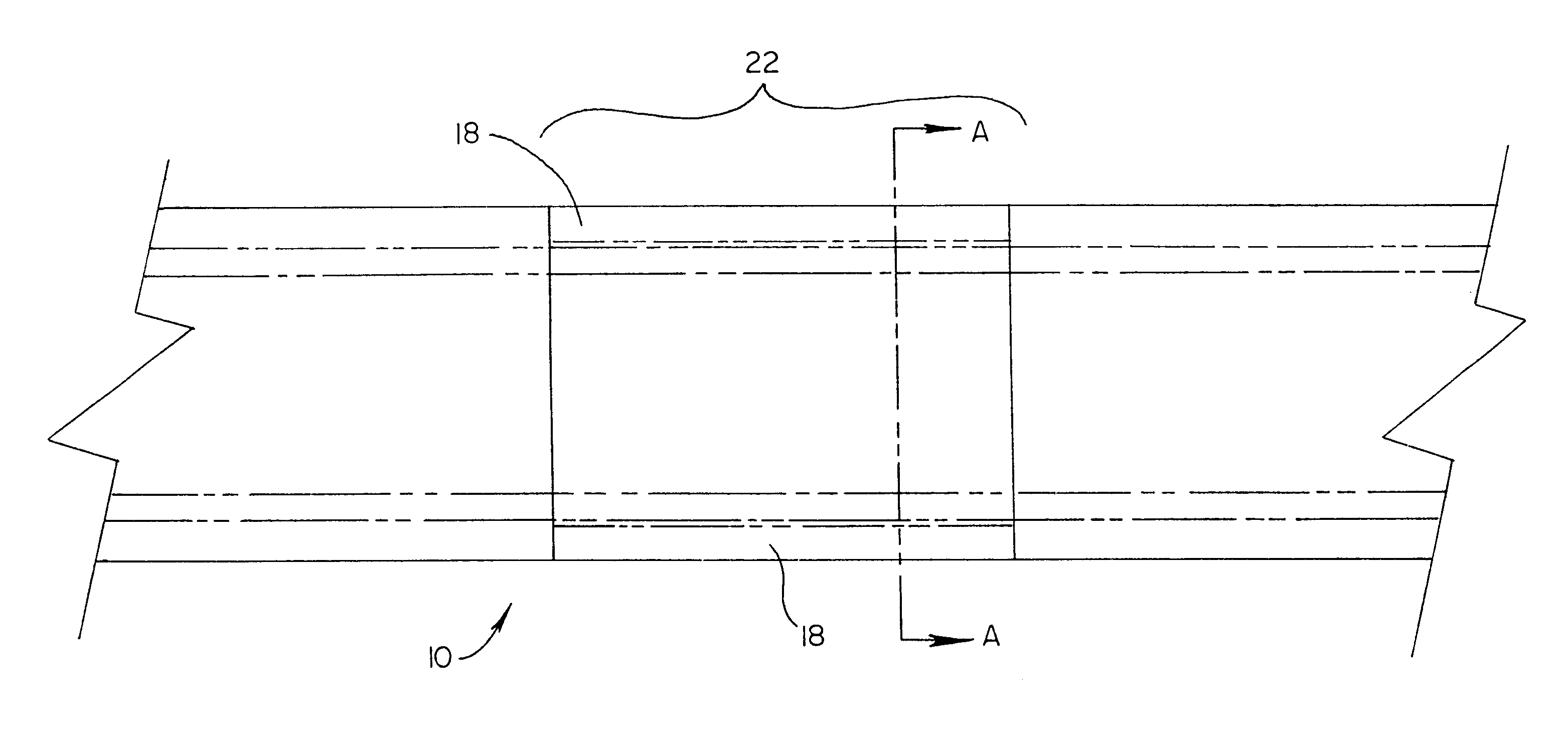

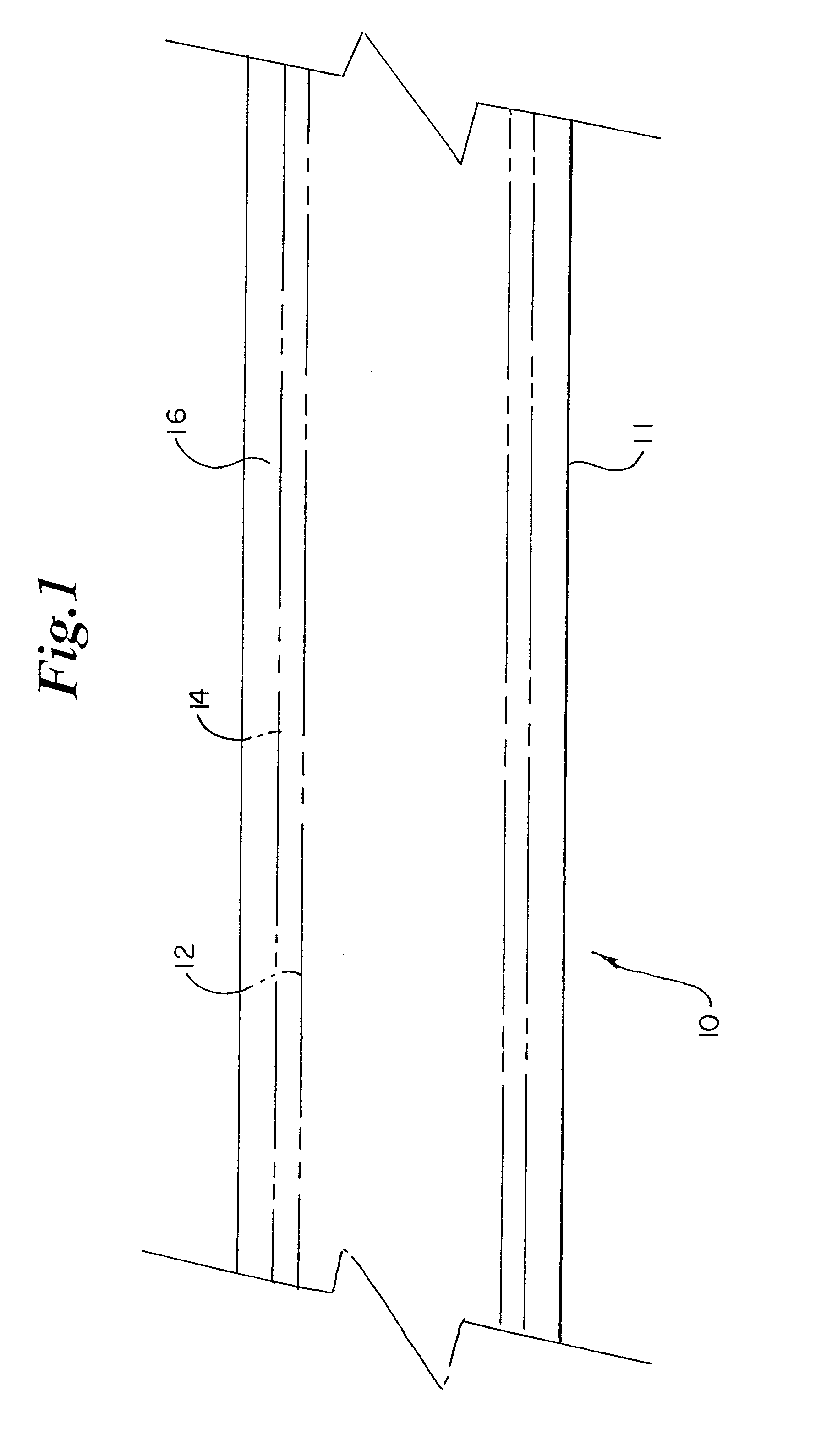

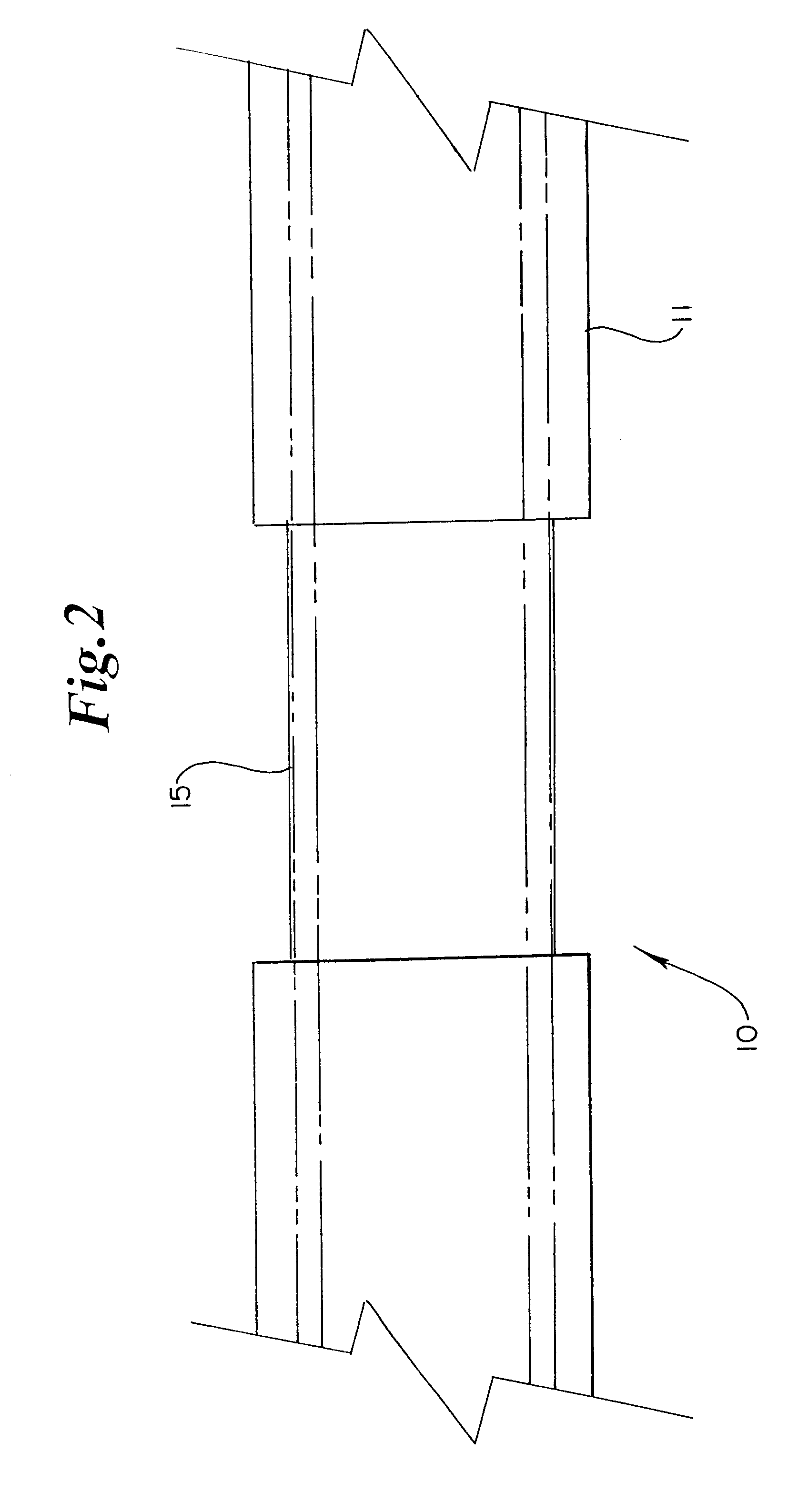

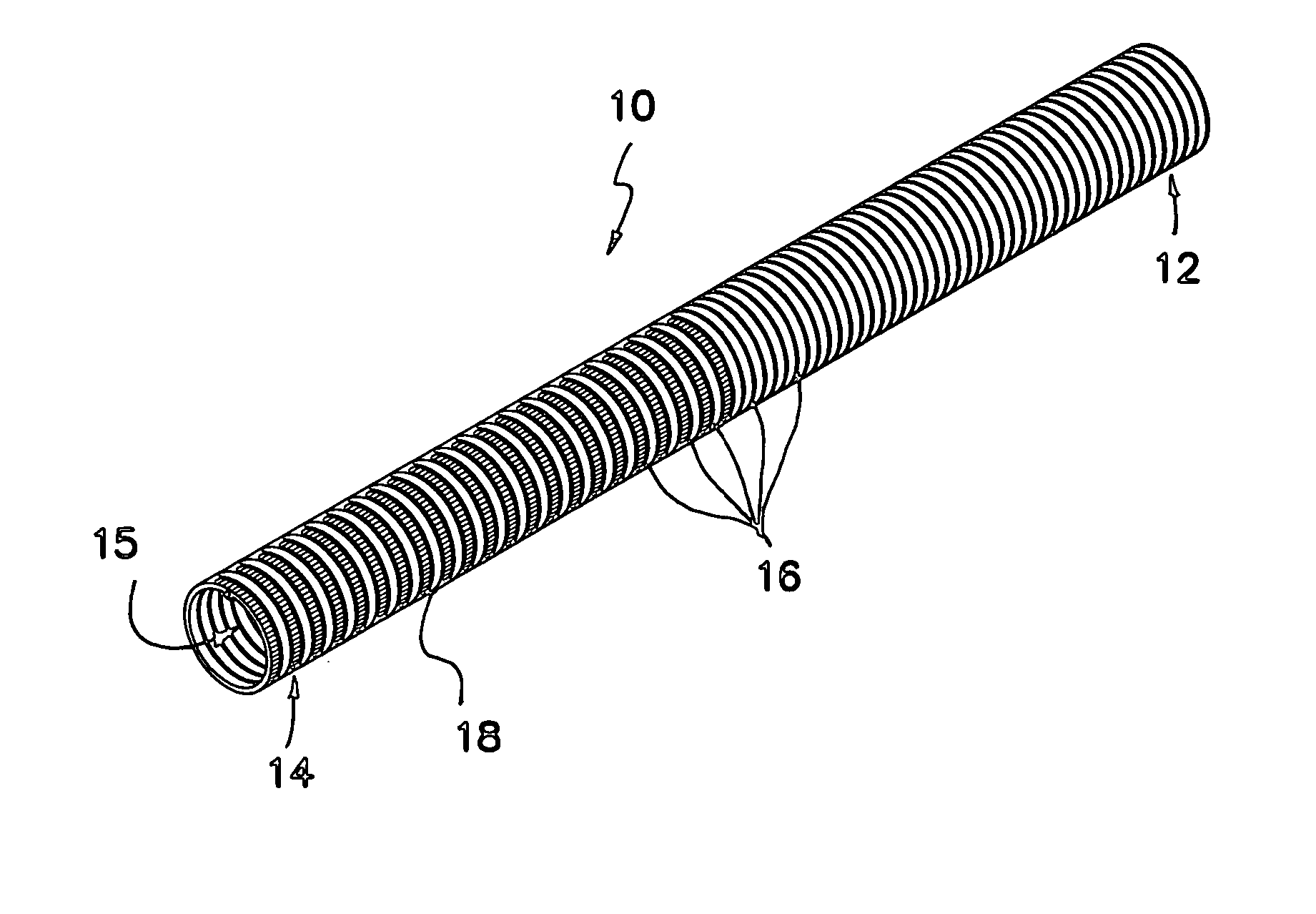

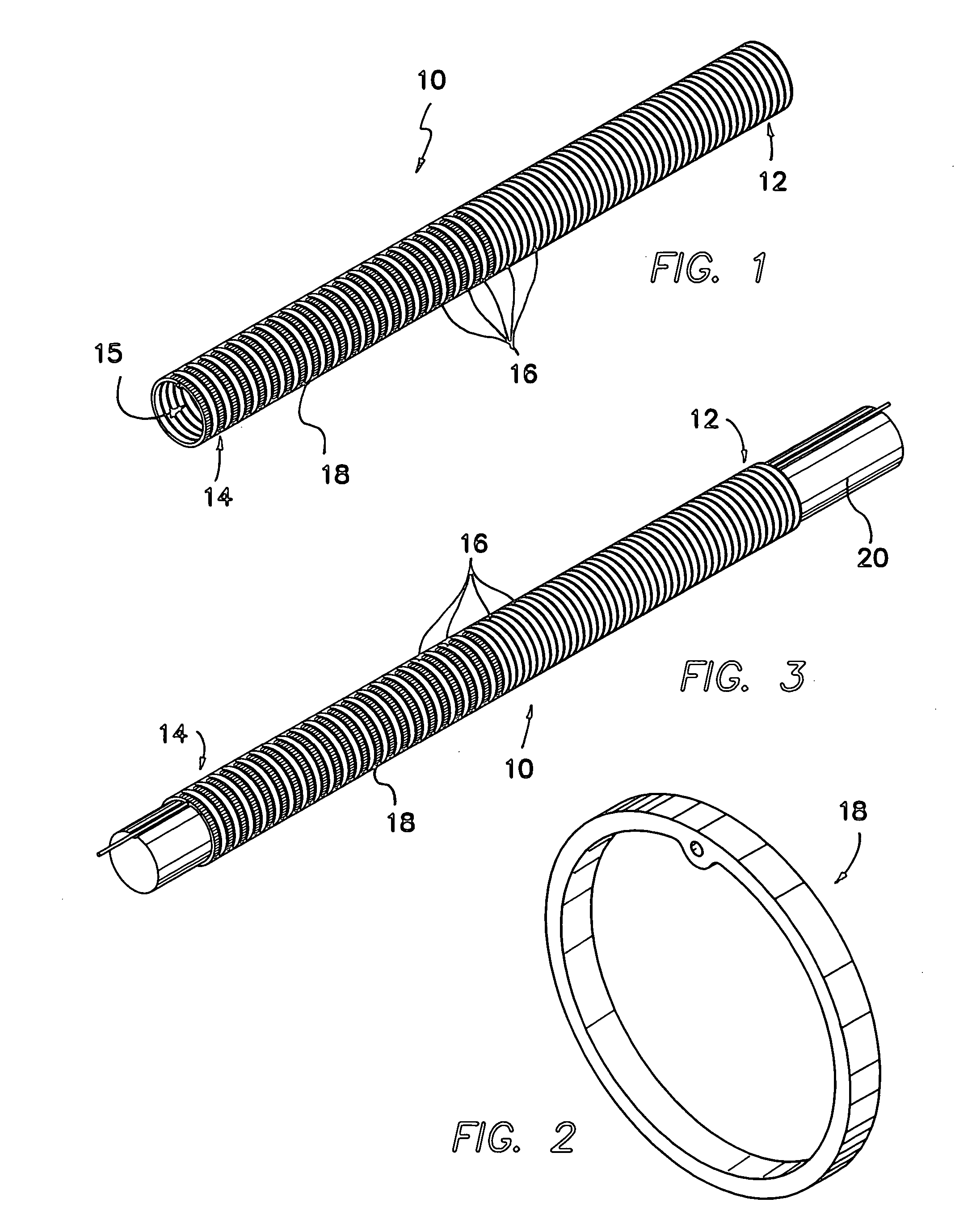

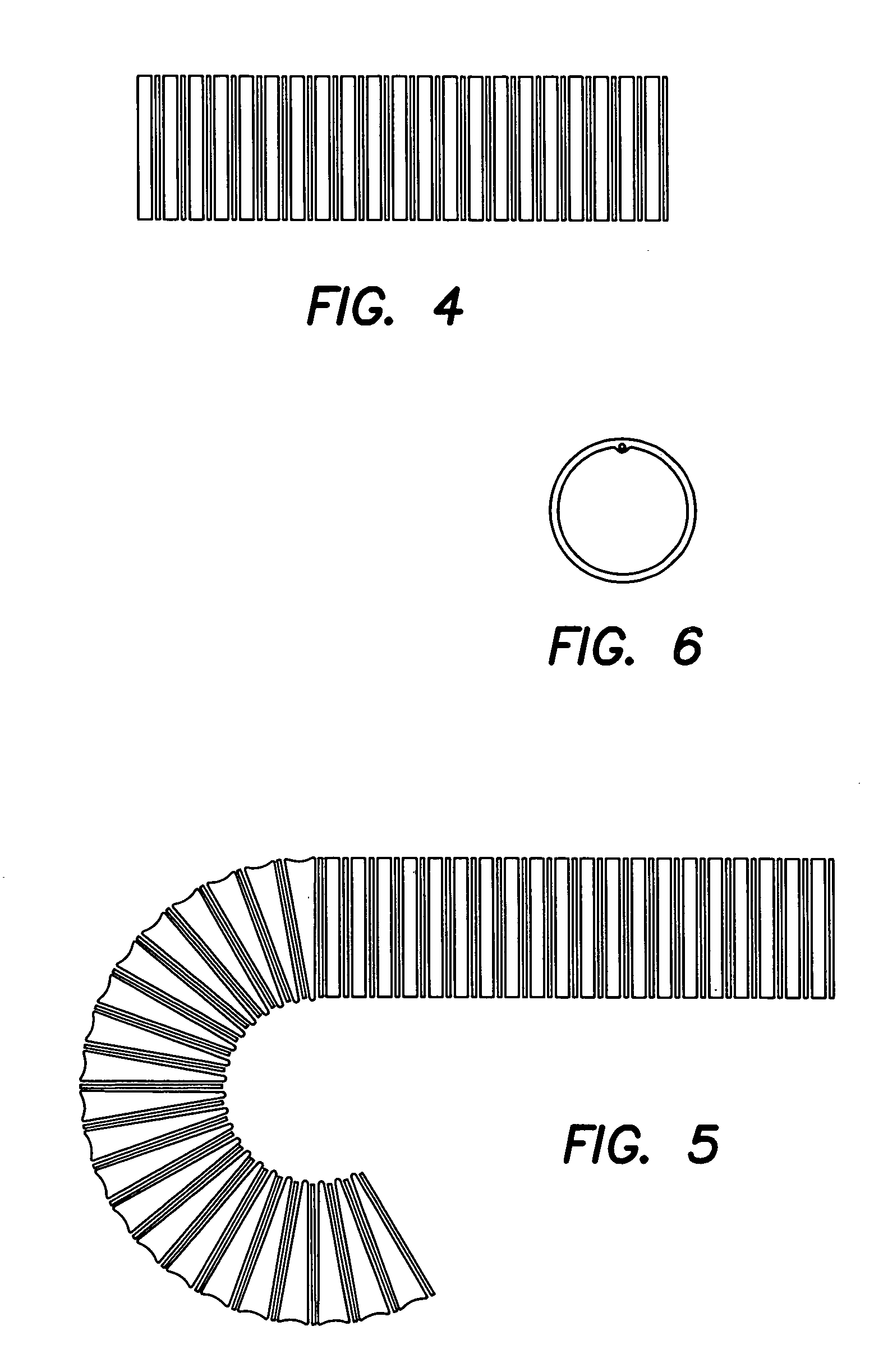

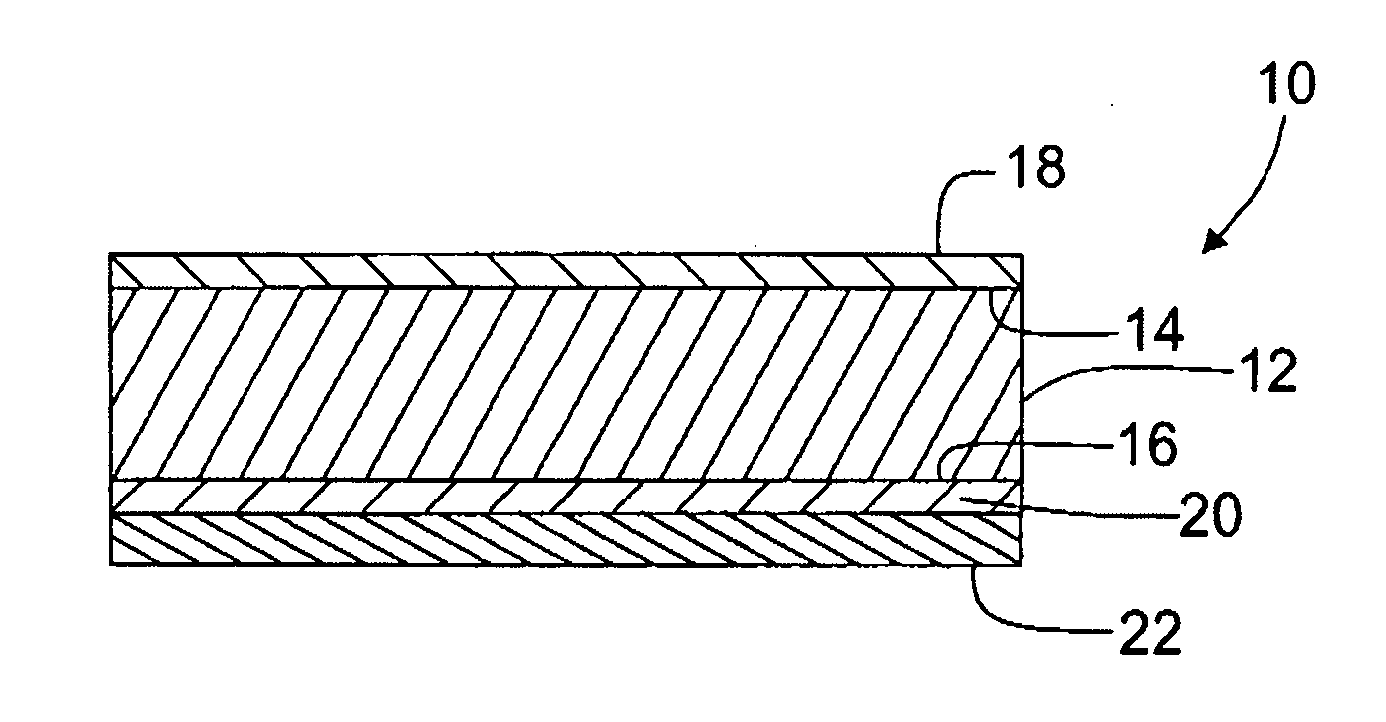

Medical tubing having variable characteristics and method of making same

The invention primarily is directed to a medical tubing adapted for insertion into a body tissue or cavity and method of manufacturing different variations of the tubing along a length of the tubing. The tubing comprises a plurality of individual, discrete, generally ring-shaped elements arranged in series and fused or bonded together forming a continuous tubular structure. The ring-shaped elements may be formed of a thermoplastic or a thermoset material. The ring-shaped elements may include plastic rings, metallic rings, un-reinforced plastic rings and / or metal reinforced plastic rings assembled along the length of the tubular structure to provide variable flexibility and kink-resistance. The tubular structure may have a cross-section of any geometric shape and it may be bent, twisted or curved without kinking. The ring-shaped elements may have different flexural modulus. The ring-shaped elements may include a combination of flexible and rigid ring-shaped elements assembled along different portions or sections of the tubular structure. The ring-shaped elements may be metallic and may be bonded with a resilient, flexible elastomeric adhesive, wherein the ring-shaped elements may have different lengths and may be fused closer or further apart to one another depending on the characteristics of a portion or section of the tubing. In another aspect of the invention, the medical tubing may further comprise a secondary lumen and a pull wire to control the tubular structure. The ring-shaped elements may be truncated to provide a bending bias. In another aspect of the invention, the ring-shaped elements may vary in diameter and / or composition in different portions or sections of the tubular structure. In yet another aspect of the invention, some of the ring-shaped elements may be radiopaque, or the ring-shaped elements may comprise of different colors to operate as indicators along the tubular structure.

Owner:APPL MEDICAL RESOURCES CORP

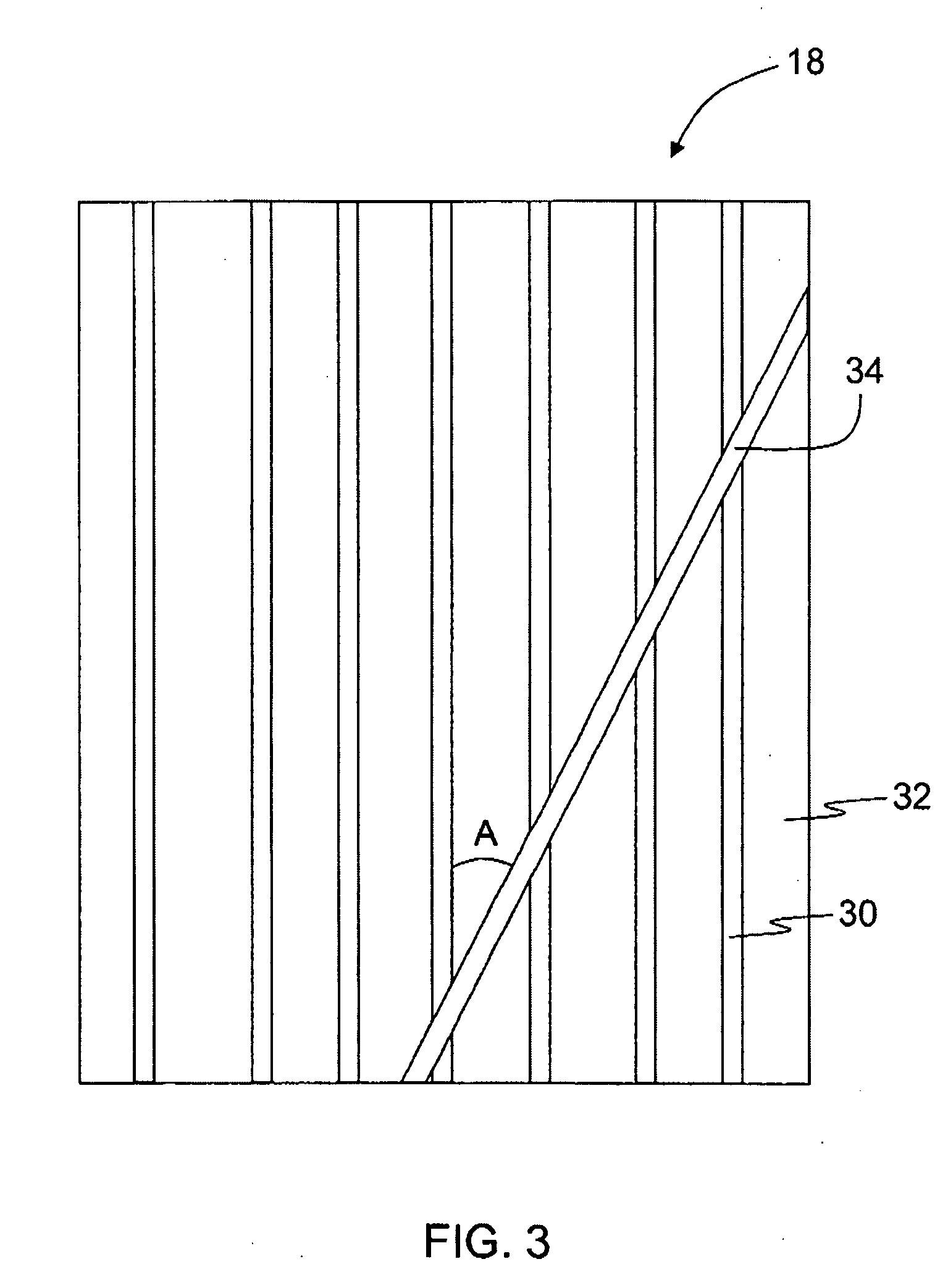

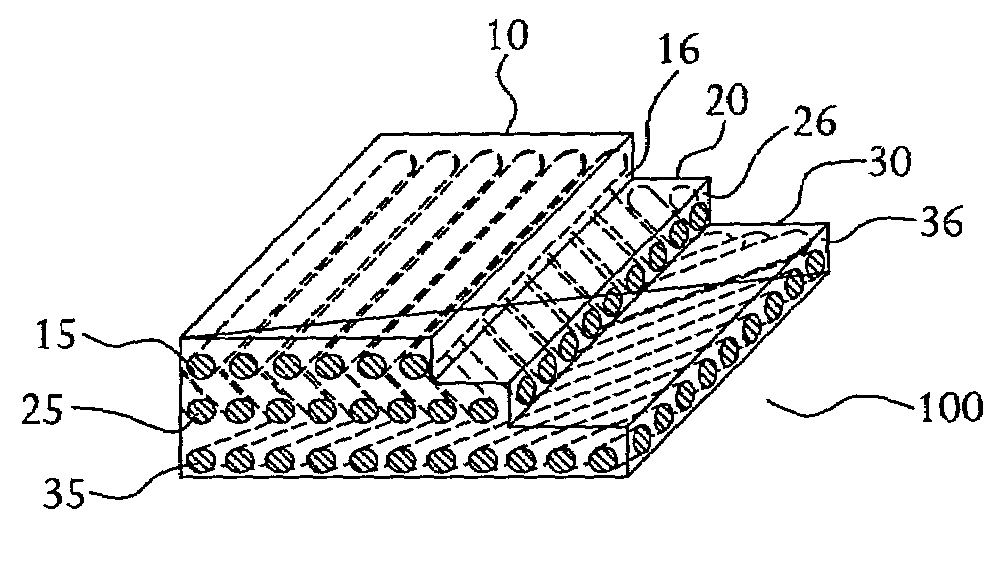

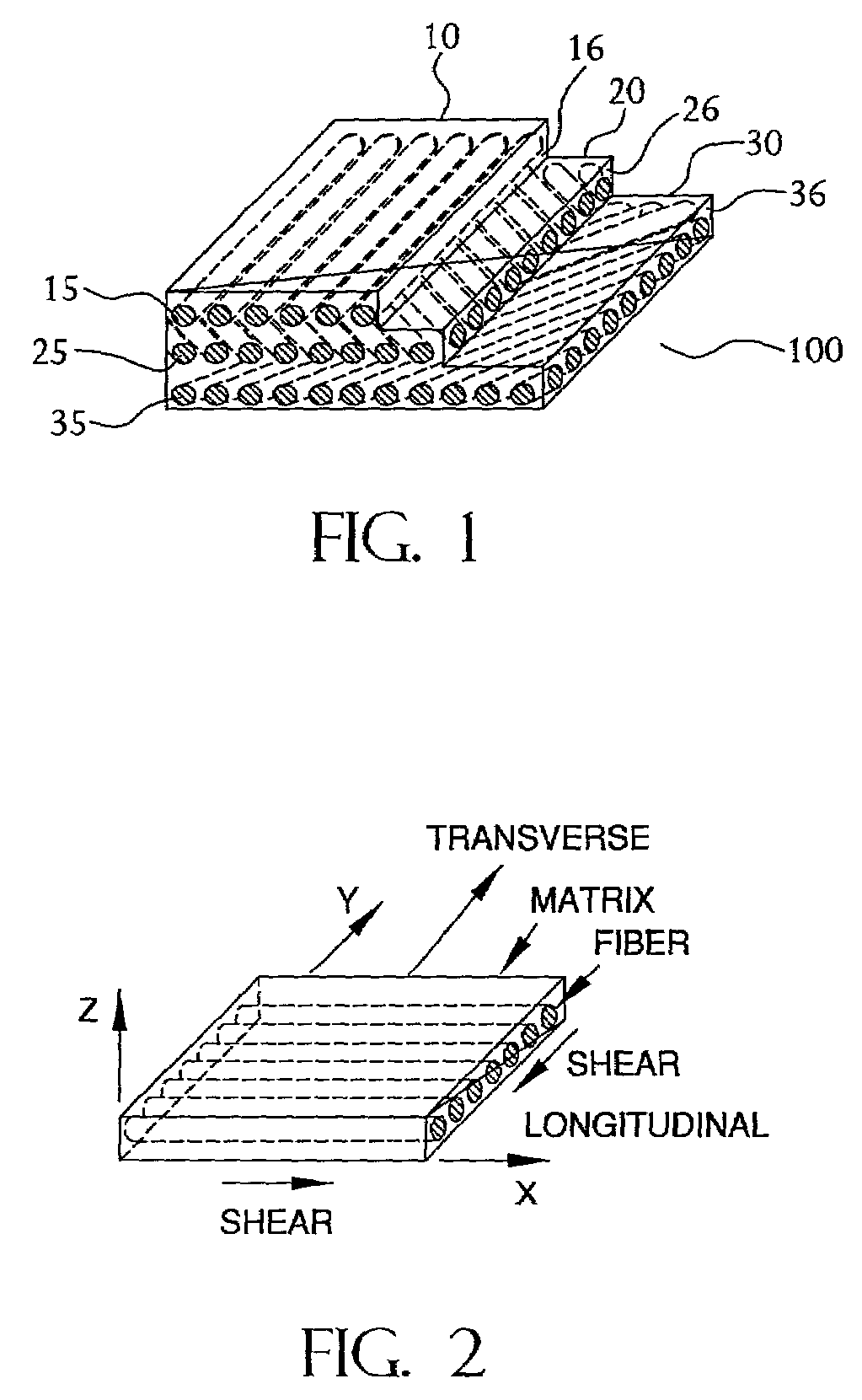

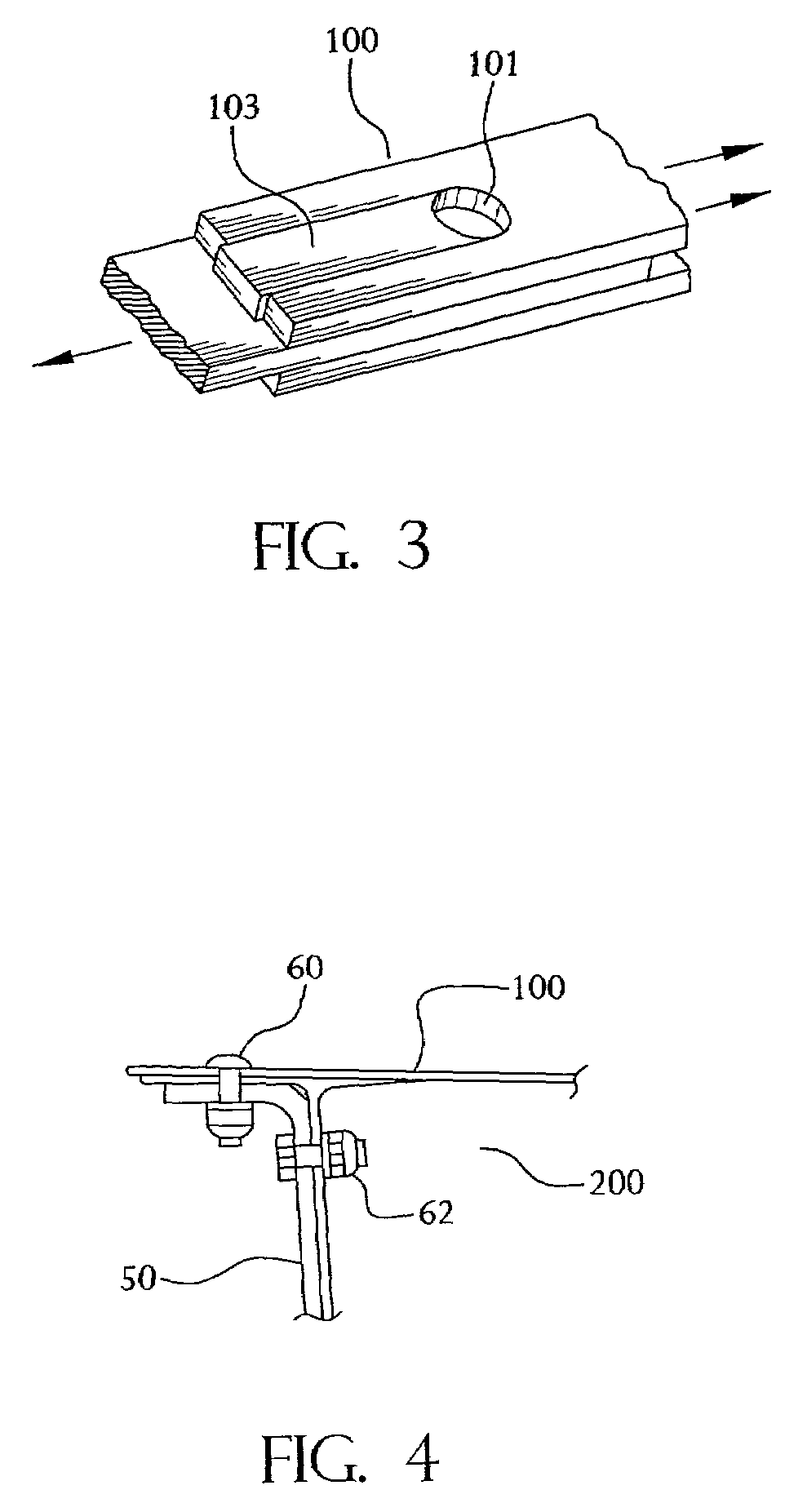

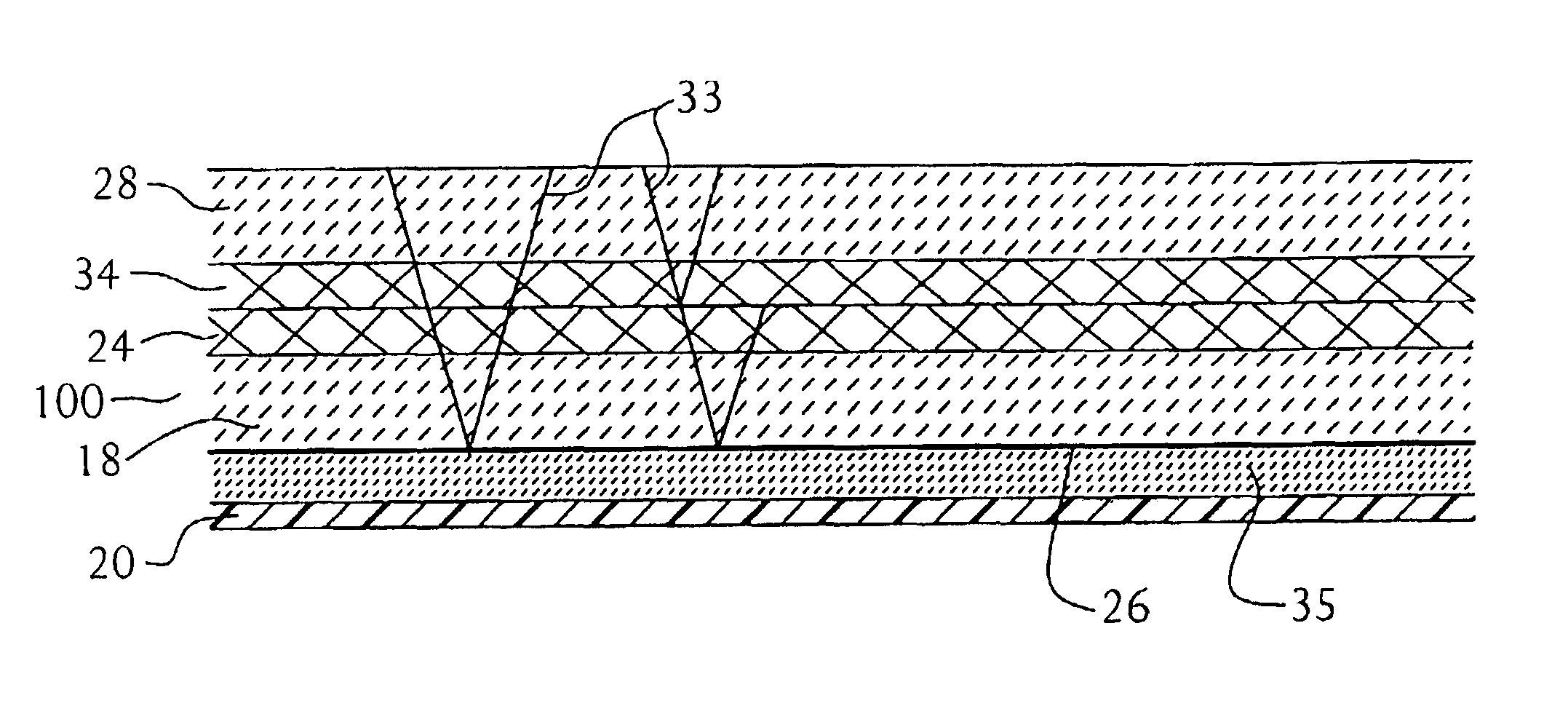

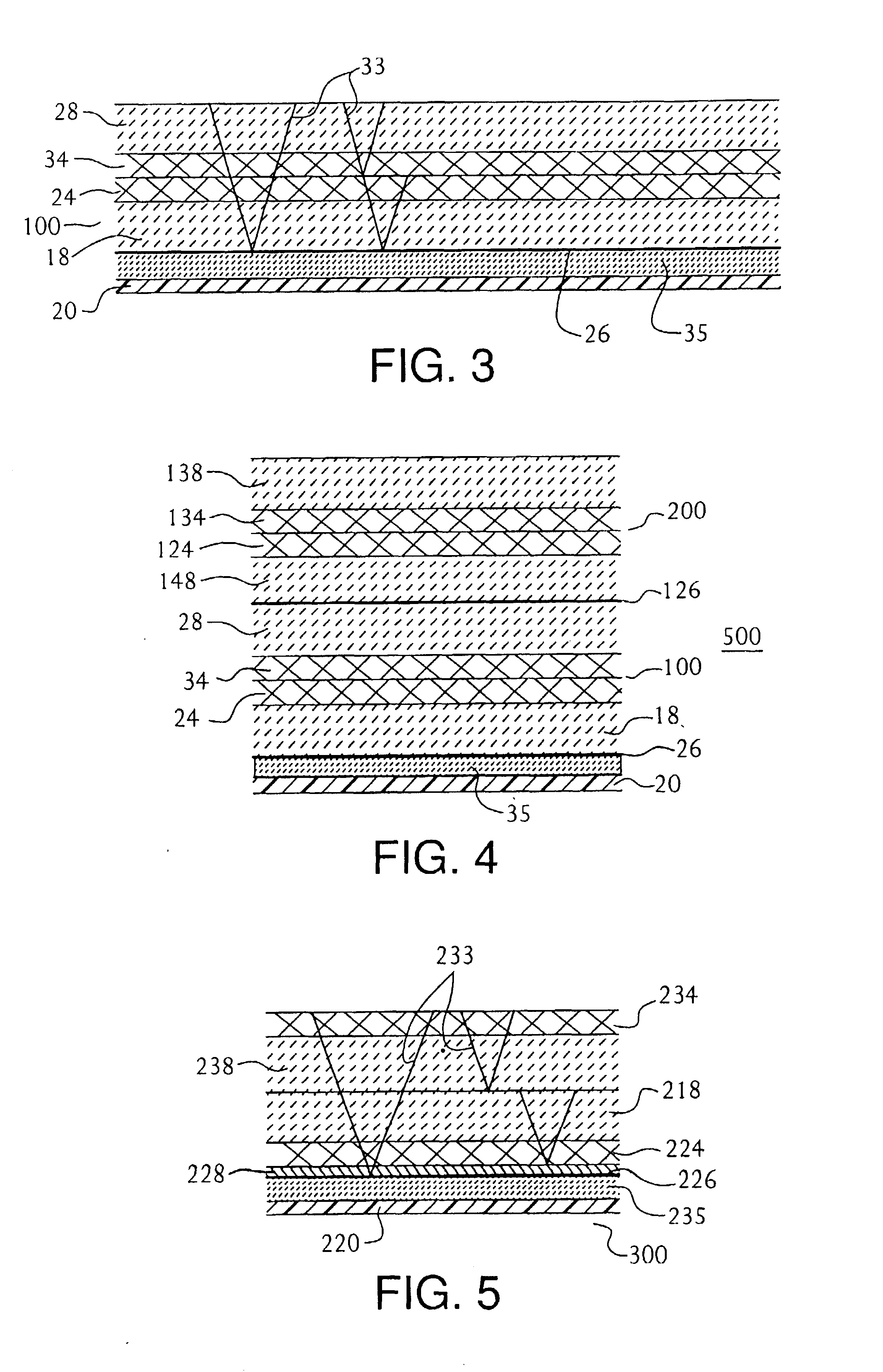

Lightweight thermoplastic composite including reinforcing skins

A lightweight fiber reinforced thermoplastic composite having an improved combination of surface roughness, flexural and shear characteristics. The composite generally comprises a fiber reinforced thermoplastic core containing reinforcing fibers bonded together with a first thermoplastic resin in which the core has a first surface and a second surface and at least one first skin applied to the first surface. The first skin comprises a plurality of fibers bonded together with a second thermoplastic resin, with the fibers in each first skin aligned in a unidirectional orientation within the first skin. The composite satisfies at least one of the conditions: an average surface roughness of the outer surface of the first skin is equal to or less than about 4.0 μm / 10 mm; the flexural modulus and strength are greater than about 10,000 MPa and greater than about 180 MPa, respectively; and the shear modulus and strength are greater than about 3,000 MPa and greater than about 100 MPa, respectively. In another embodiment, a fiber reinforced thermoplastic composite comprises a fiber reinforced thermoplastic core containing reinforcing fibers bonded together with a first thermoplastic resin, the core having a density of about 0.1 gm / cc to about 2.25 gm / cc and a porosity greater than about 0% by volume. The core has a first surface and a second surface and at least one first skin applied to the first surface, each of the first skins comprising fibers bonded together with a second thermoplastic resin. The first skin comprises a thermoplastic melt impregnated continuous fiber prepreg material, or commingled fiber rovings comprising reinforcing fibers and thermoplastic fibers, with the fibers in the first skin aligned in a unidirectional orientation within the first skin.

Owner:AZDEL INC

Active pressure relief valves and methods of use

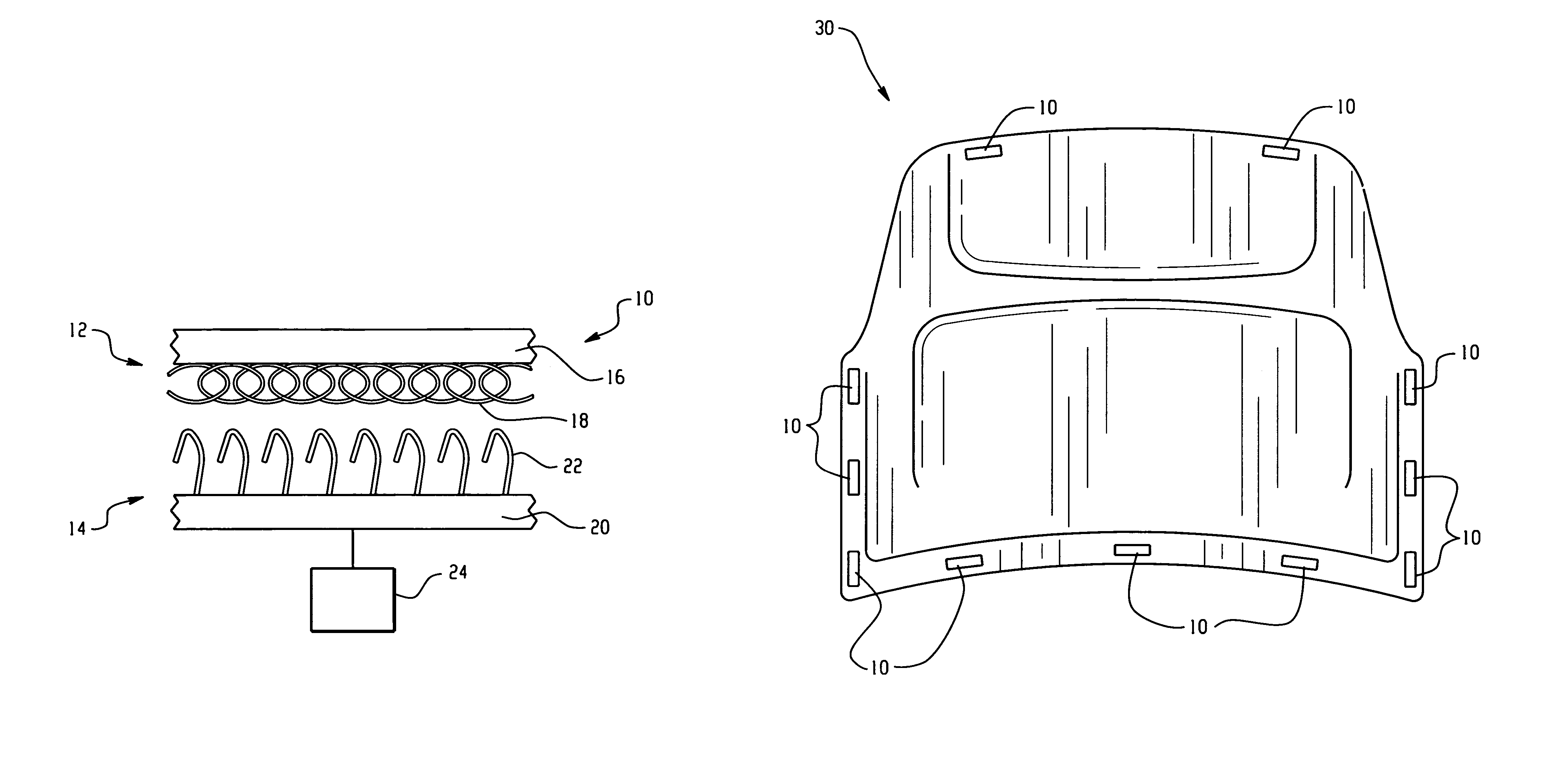

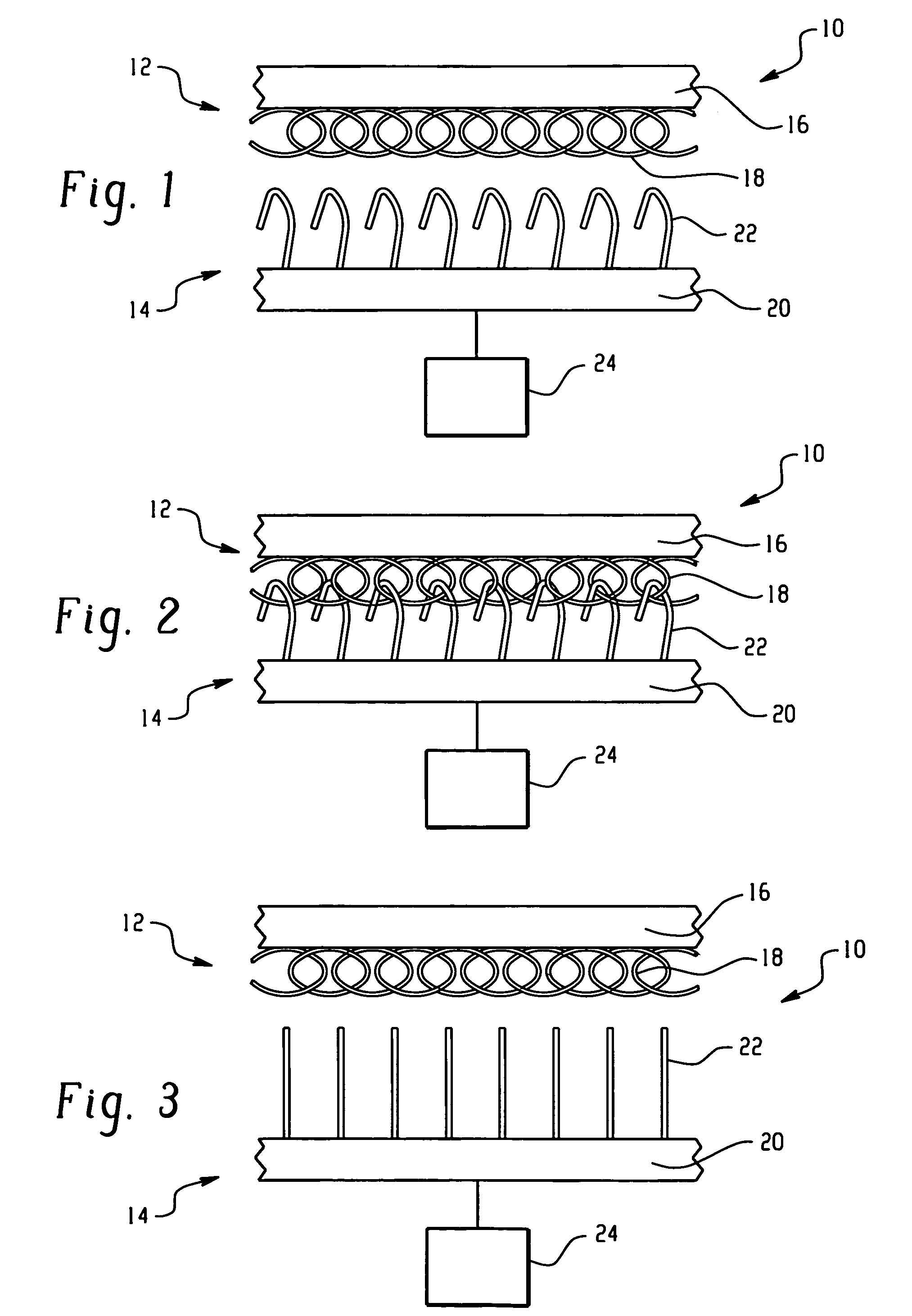

ActiveUS20050199845A1Efficient changeOperating means/releasing devices for valvesCheck valvesElastomerElectricity

Active pressure relief valves and methods of use for regulating atmospheric conditions within an interior compartment of a vehicle generally include an active material to effect movement of a flap relative to an opening. The active material has the ability to remember its original at least one attribute such as dimension, shape, and / or flexural modulus, which can subsequently be recalled by applying or removing an external stimulus, as will be discussed in detail herein. Suitable active materials include, without limitation, shape memory alloys, ferromagnetic shape memory alloys, shape memory polymers, piezoelectric materials, electroactive polymers, magnetorheological fluids and elastomers, electrorheological fluids, composites of one or more of the foregoing materials with non-active materials, combinations comprising at least one of the foregoing materials, and the like. Depending on the particular active material, the activation signal can take the form of, without limitation, an electric current, a temperature change, a magnetic field, a mechanical loading or stressing, or the like.

Owner:GM GLOBAL TECH OPERATIONS LLC

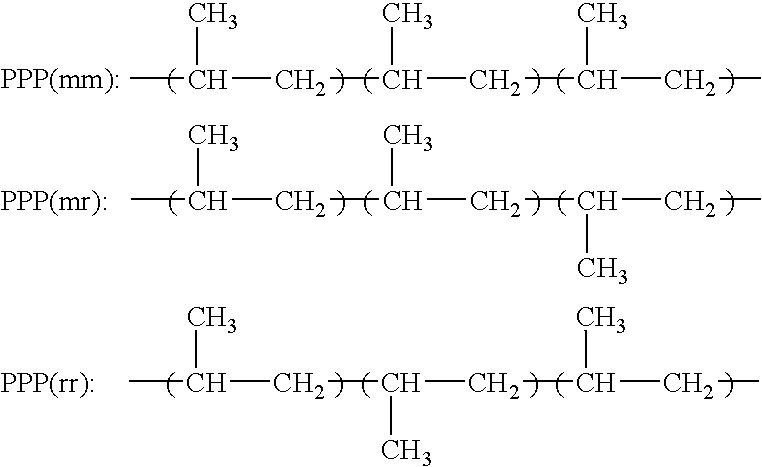

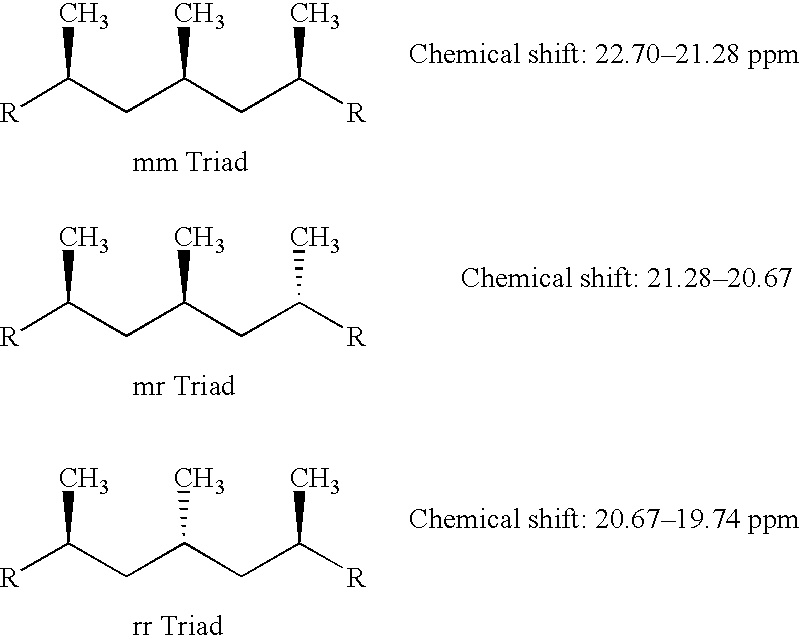

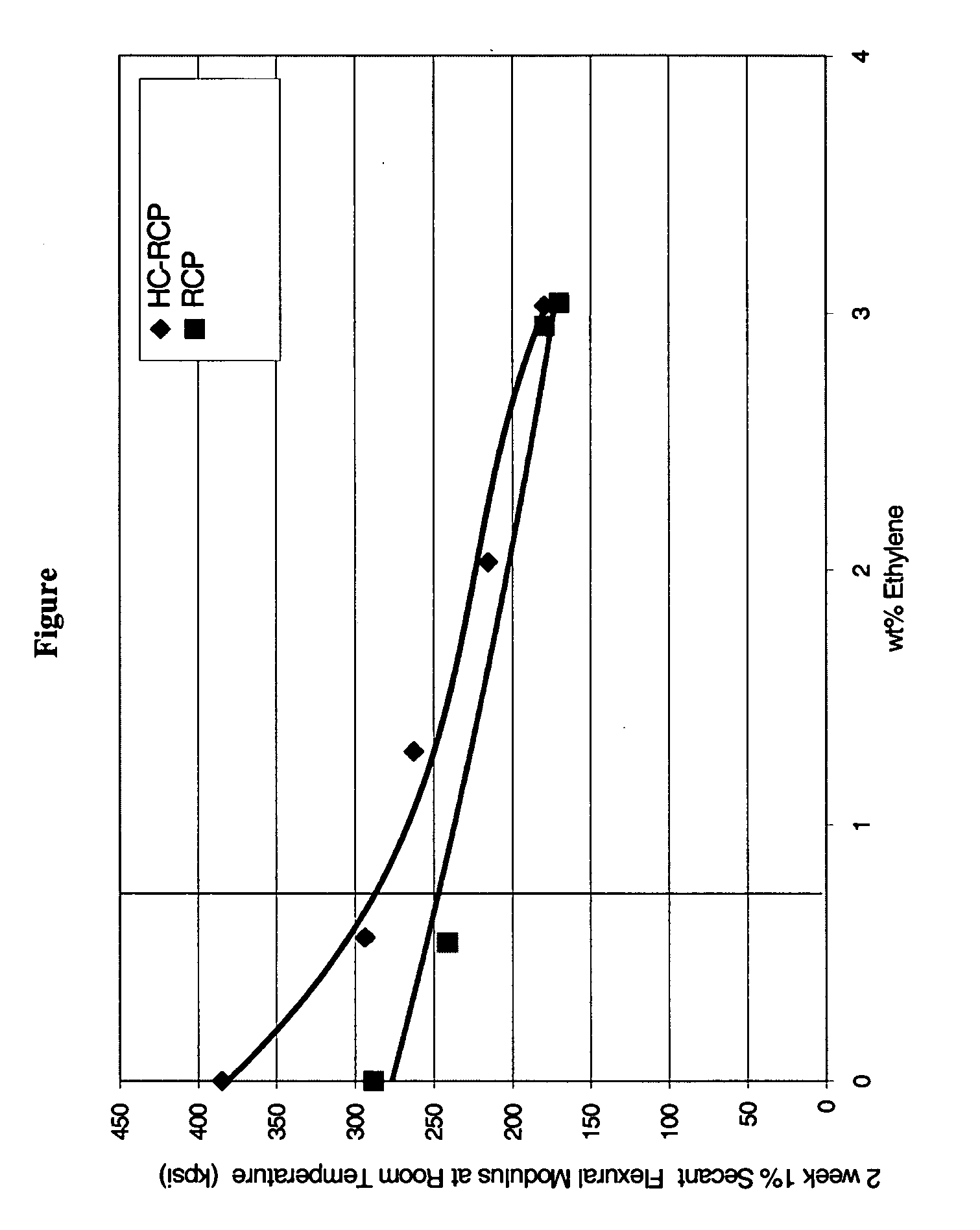

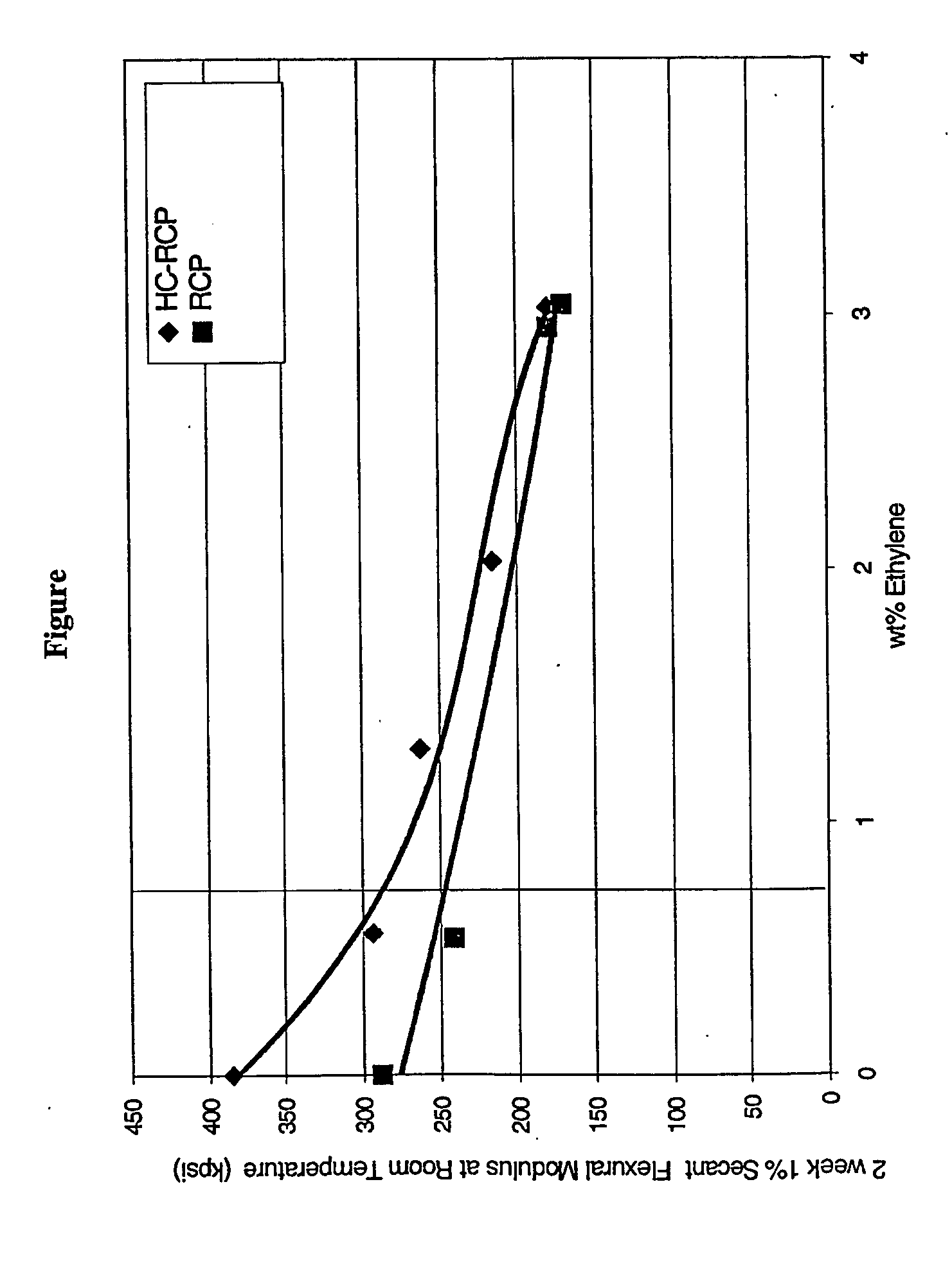

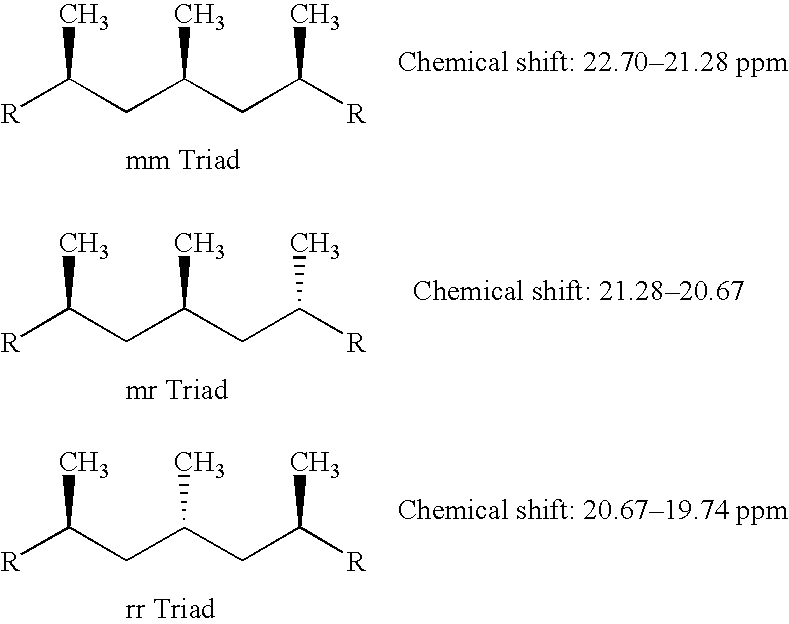

Highly crystalline polypropylene with low xylene solubles

ActiveUS20040122196A1Narrow molecular weight distributionLow melt flow rateFlexural modulusPolypropylene

The invention is directed to a polypropylene resin which has a Mw / Mn of less than 5, a melt flow rate of less than 7 g / 10 min., a 1% secant flexural modulus of greater than 300,000 psi and less than 2 wt. % xylene solubles.

Owner:BRASKEM AMERICA

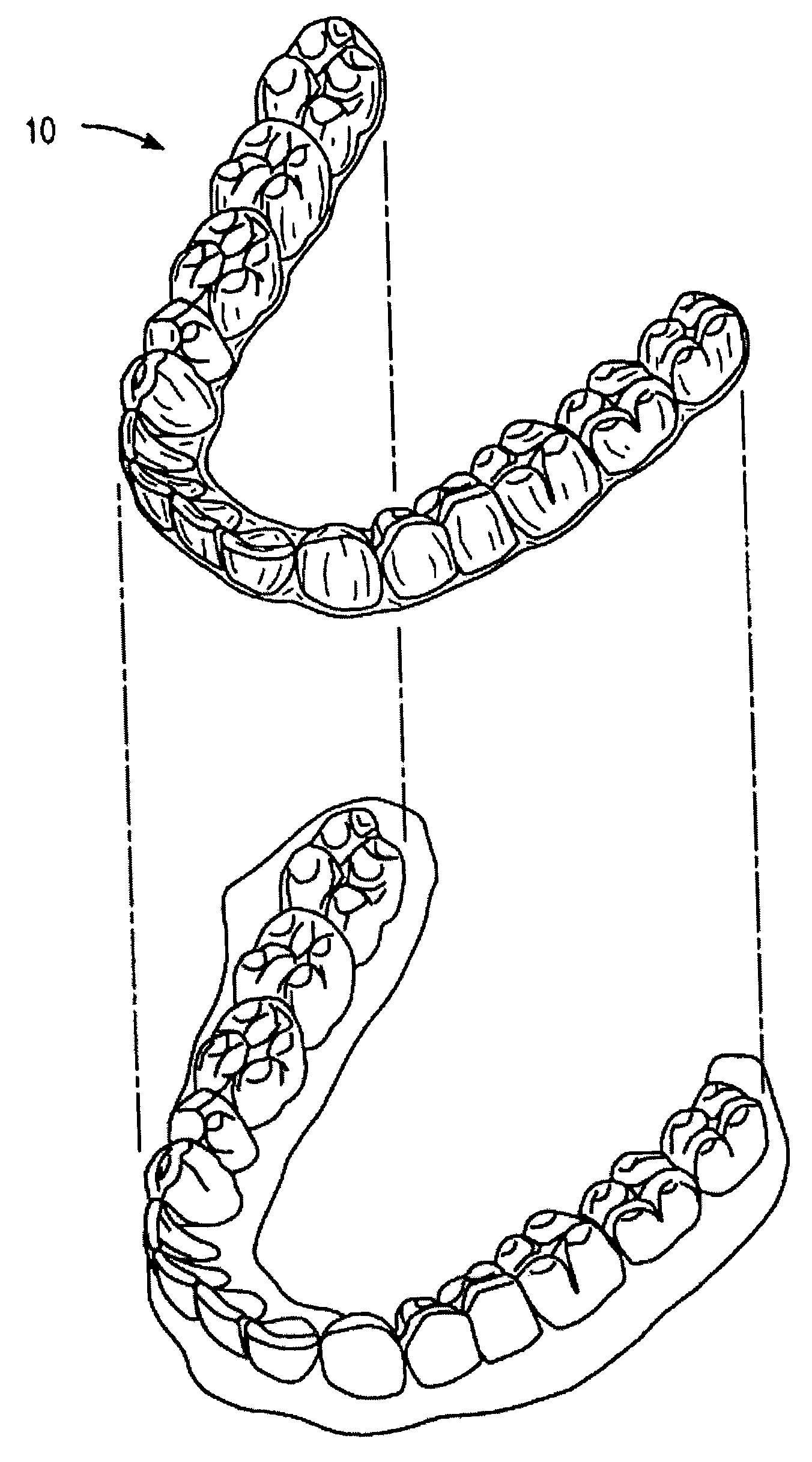

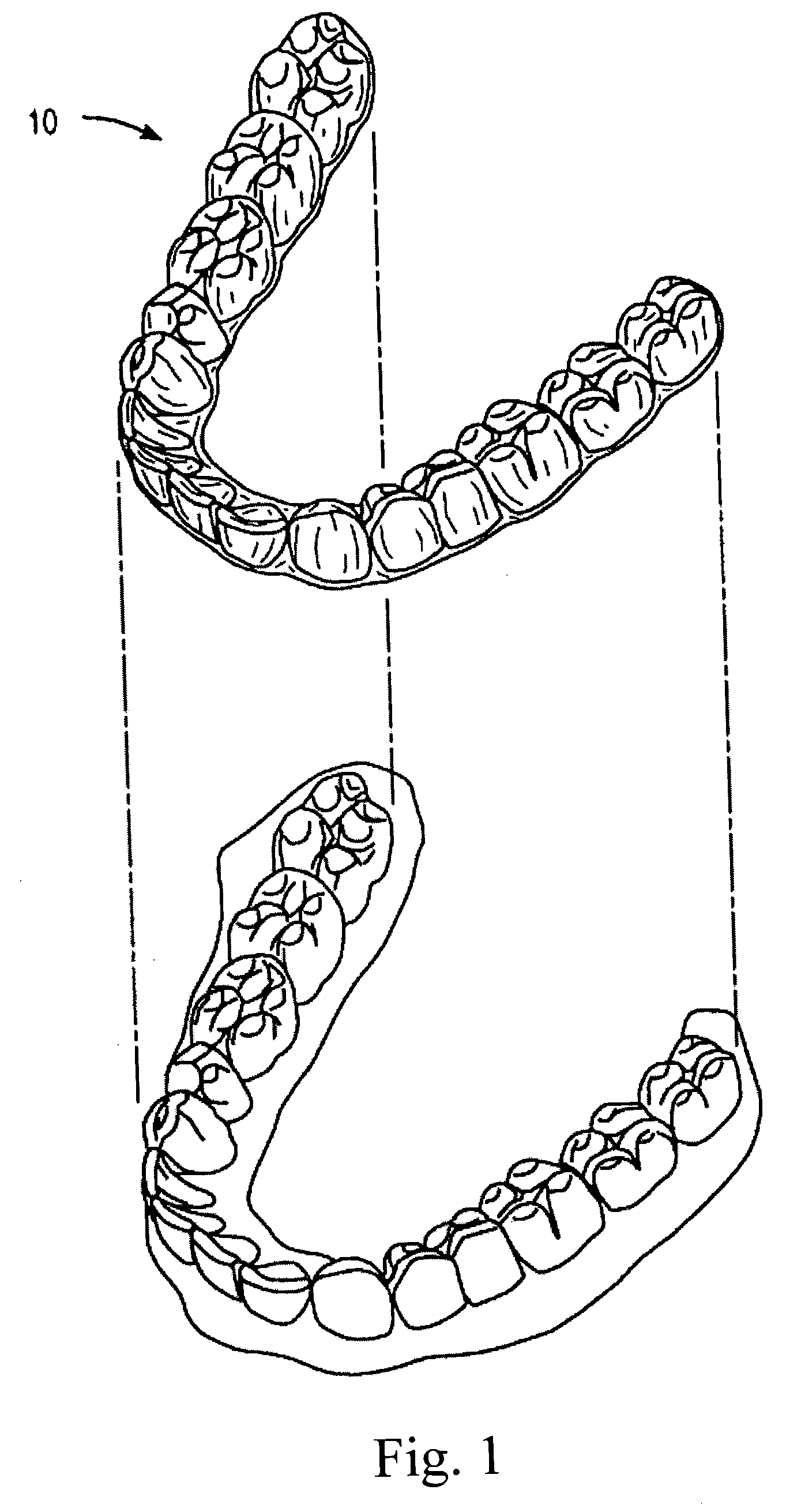

Orthodontic appliances and materials for making same

InactiveUS20060078841A1High glass transition temperatureOthrodonticsDental toolsFlexural modulusStress relaxation

The polymeric shell of a removable dental positioning appliance is formed from transparent polymeric materials having a tensile strength at yield of greater than 6,000 pounds per square inch (psi), an elongation at yield of greater than 4%, an elongation at break of greater than 80%, a tensile modulus greater than 200,000 psi, a flexural modulus greater than 200,000 psi, stress relaxation over time of not more than 50%, and a transmissivity of light between 400 nm and 800 nm greater than 75%.

Owner:ALIGN TECH

Non-halogen flame-retardant polypropylene composite material and preparation thereof

InactiveCN101412830AImprove flame retardant performanceImprove mechanical propertiesFlexural modulusAcrylonitrile

The invention provides a halogen-free flame-retardant polypropylene composite material, which is characterized by consisting of the following raw materials in weight portion: 82.5 to 12 portions of polypropylene, 0.3 to 2 portions of heat stabilizer, 0.2 to 1 portion of processing aid, 1 to 10 portions of toughening agent, 10 to 40 portions of flame retardant, 1 to 5 portions of glass fiber compatibilizer and 5 to 30 portions of glass fiber. The invention also provides a method for preparing the material. The material has the flame retardancy up to 1.6mm V0, the tensile strength higher than or equal to 50 MPa, the flexural modulus higher than or equal to 3,000 MPa, the notched impact strength more than or equal to 8KJ / m<2>, the shrinkage between 4 and 6 per thousand, the heat distortion temperature higher than or equal to 140 DEG C, as well as the other technical indexes up to or exceeding the standard of flame-retardant acrylonitrile-butadiene-styrene copolymer materials. As the material uses the phosphorus-nitrogen flame retardant containing no halogen, the flame-retardant effect of the material completely reaches UL94-V0 grade.

Owner:SHANGHAI KINGFA SCI & TECH +1

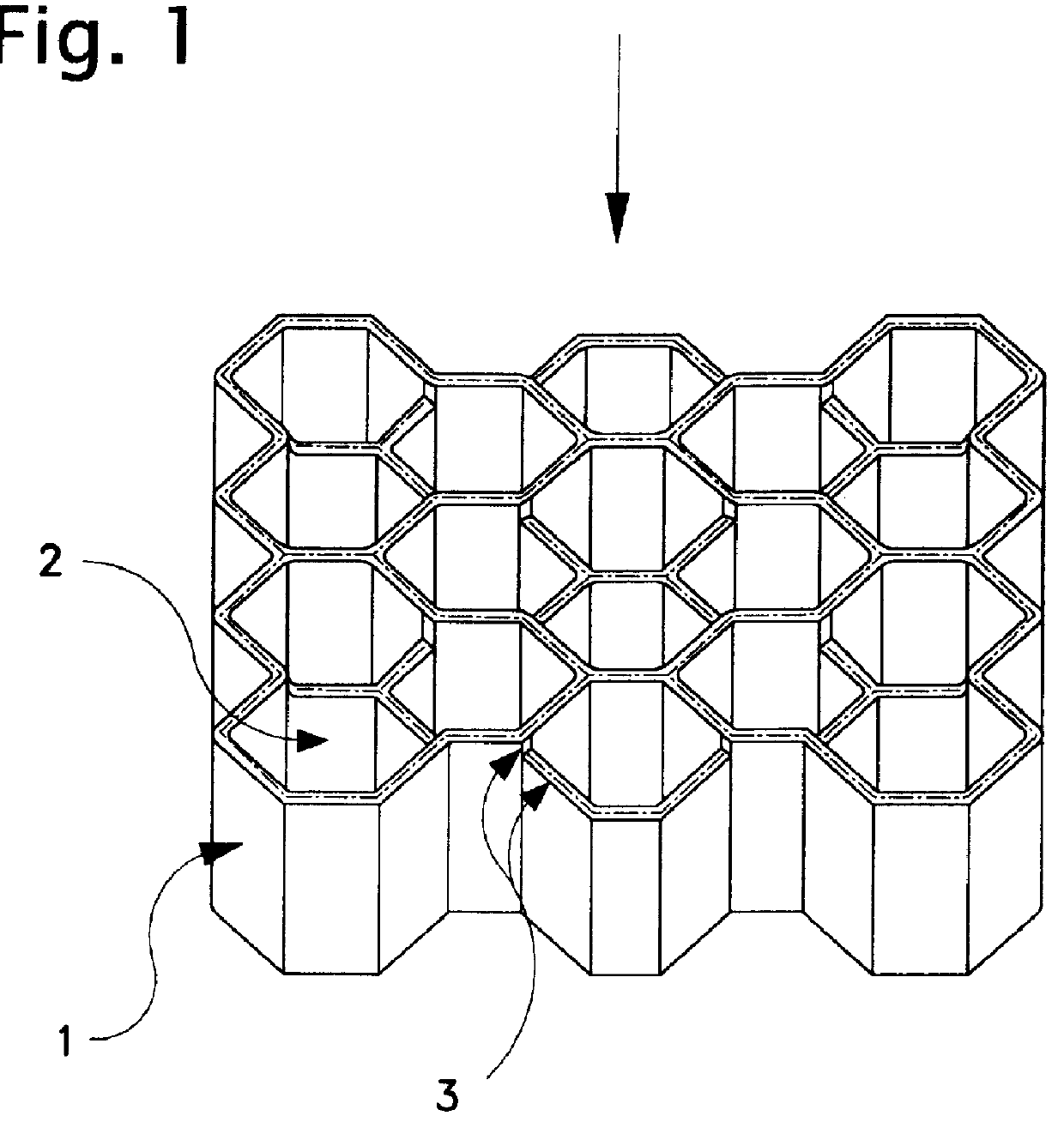

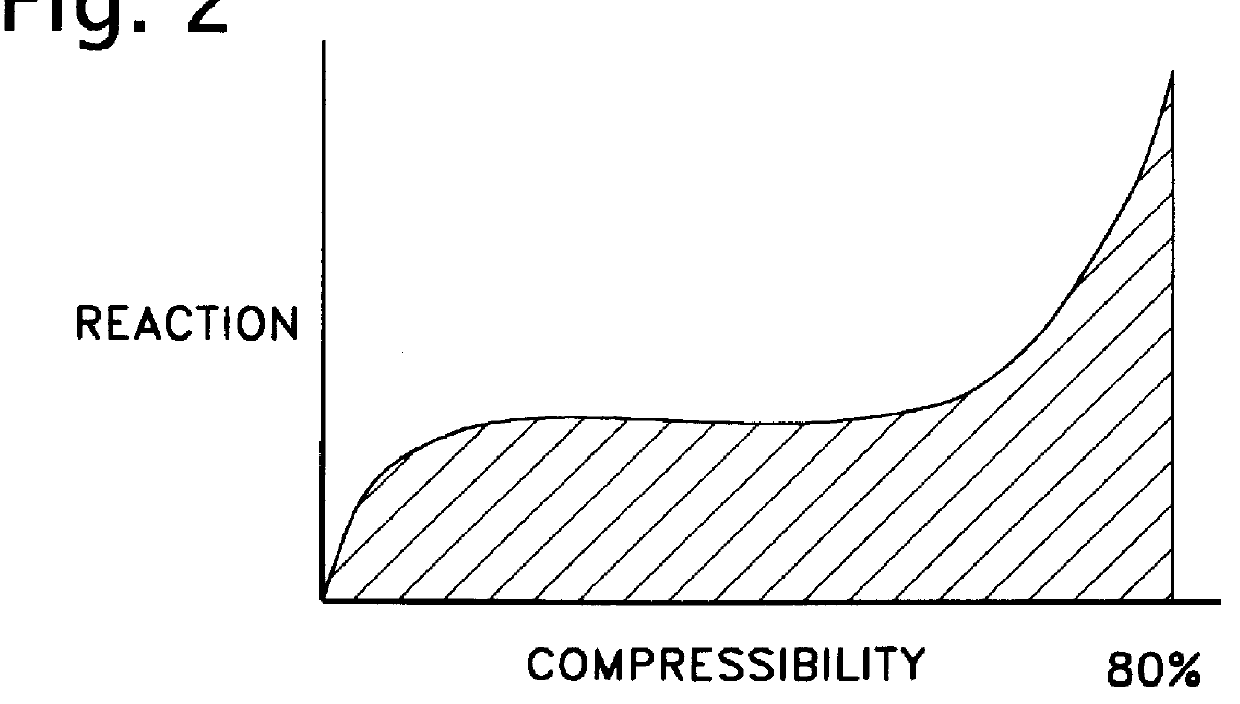

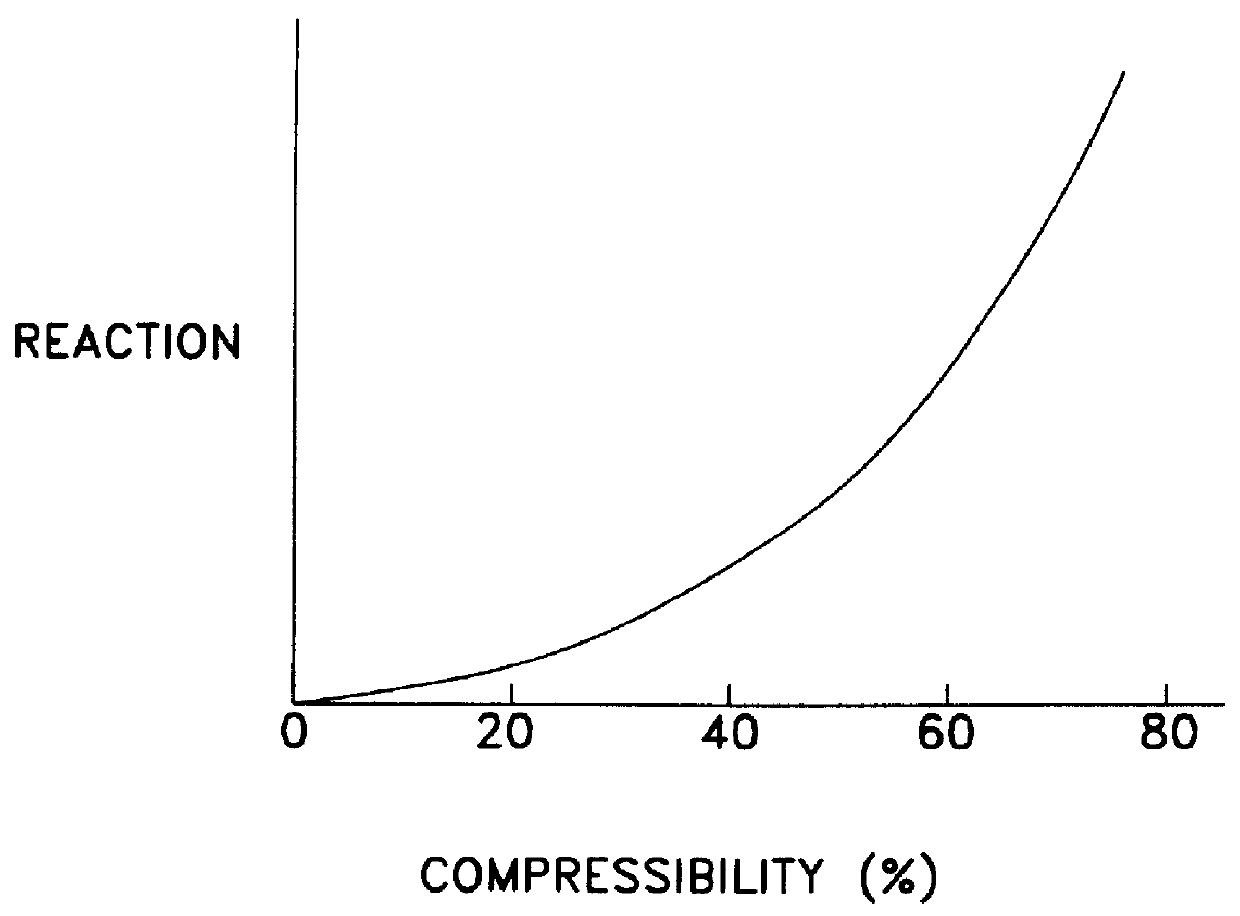

Impact absorber made of resin

InactiveUS6085878AImprove energy absorptionSmall sizeElastic dampersShock absorbersFlexural modulusHoneycomb

PCT No. PCT / JP97 / 04596 Sec. 371 Date Nov. 12, 1998 Sec. 102(e) Date Nov. 12, 1998 PCT Filed Dec. 12, 1997 PCT Pub. No. WO98 / 26195 PCT Pub. Date Jun. 18, 1998A resin impact absorber comprising a hollow columnar body having a honeycomb section or a hollow columnar body having a cylindrical shape, the hollow columnar body being made of a resin with a flexural modulus of 500 to 5000 kgf / cm2, wherein a reaction-compressibility curve at the time of compression in the lengthwise direction of the columnar body satisfies the following conditions: (a) yield strength> / =100 Tf / m2 and (b) compression energy absorption> / =50 Tf.m / m3. The resin impact absorber of the present invention is small in size and light in weight and exhibits a high impact energy absorption capacity. A site or structure with an impact absorber of the present invention disposed therein can be prevented from remarkable damage or breakage when it receives a high impact force.

Owner:TOYOBO CO LTD

TPE composition that exhibits excellent adhesion to textile fibers

InactiveUS6503984B2Increase stiffnessHigh modulusFibre typesOther rubber adhesivesTextile fiberPolyester

A combination of a low flexural modulus and low crystallinity polyolefin and a functionalized polyolefin were found to result in an olefin composition with excellent adhesion to metals and polar polymers (e.g. polyesters, polyamides, etc) especially fibers therefrom. When these two polyolefins were added to a thermoplastic vulcanizate (e.g. used to partially or fully replace the semicrystalline polyolefin of a thermoplastic vulcanizate), the thermoplastic vulcanizate was found to have the necessary adhesion to form fiber reinforced thermoplastic vulcanizate.

Owner:EXXONMOBIL CHEM PAT INC

Body tissue aspiration cannula

The invention relates to a body tissue aspiration cannula capable of being steam sterilizable comprising a tubular portion of a polymeric material with a flexural modulus of from about 100,000 psi to about 225,000 psi. It also relates to a novel cannula hub comprising a pair of opposing grip wings.

Owner:IPAS

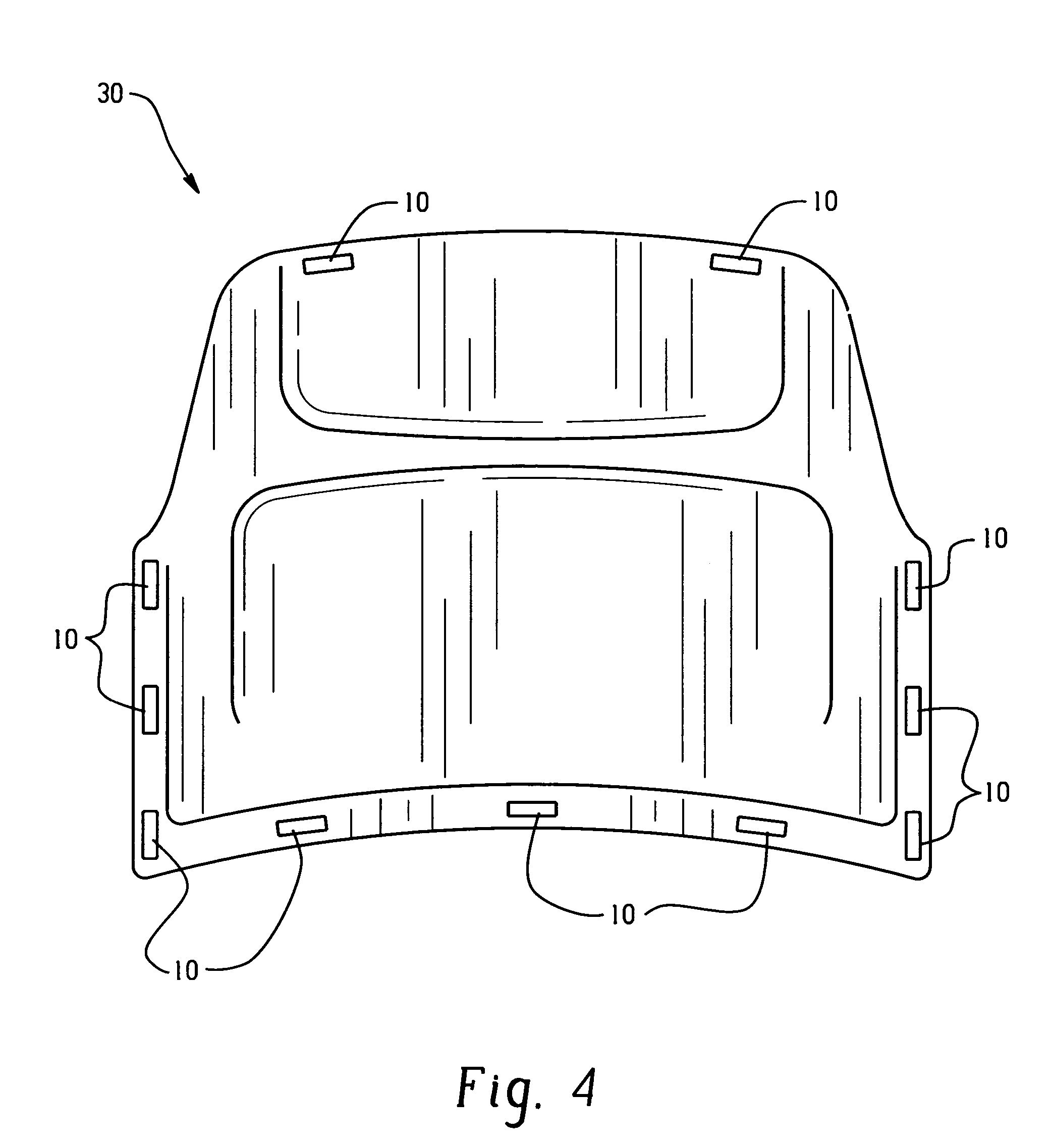

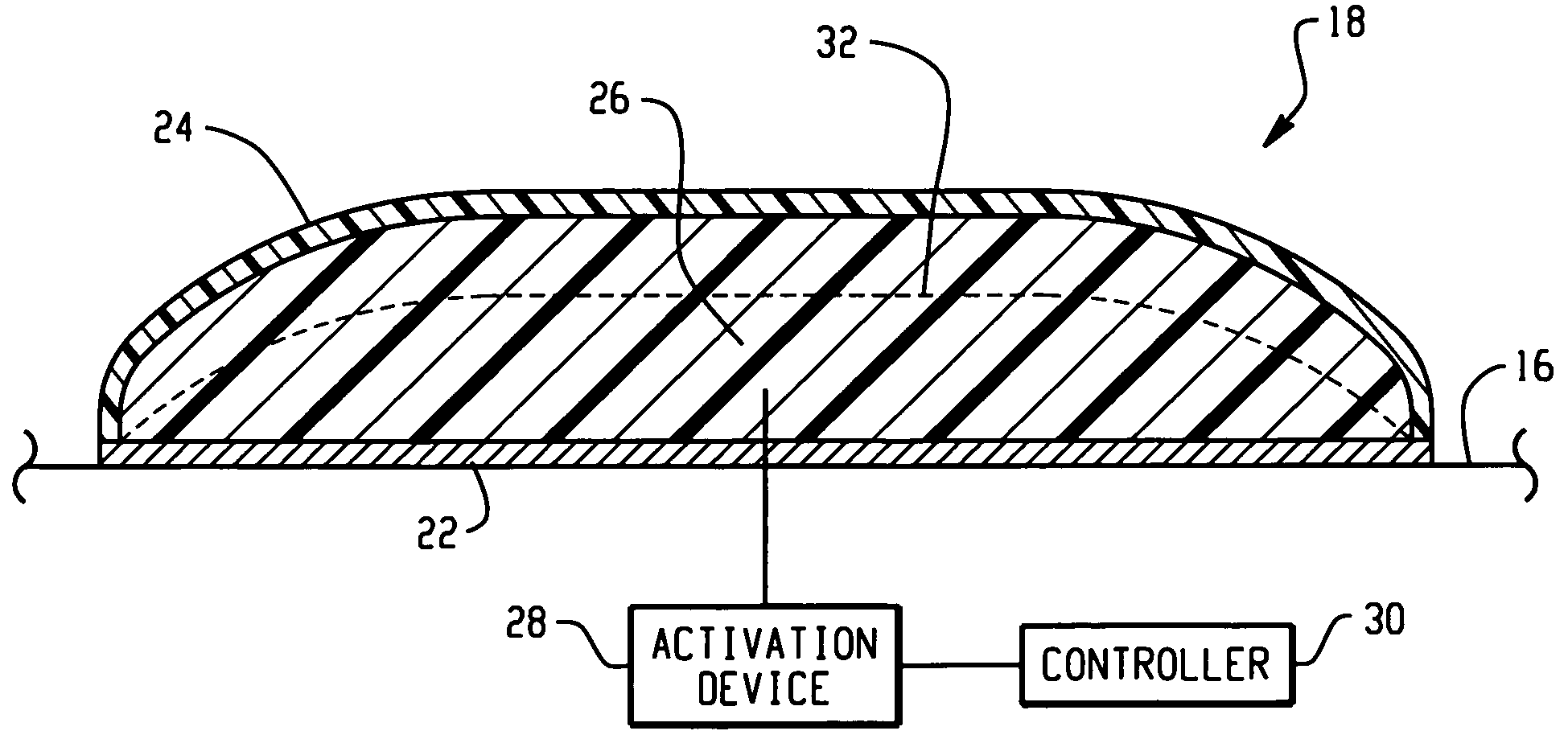

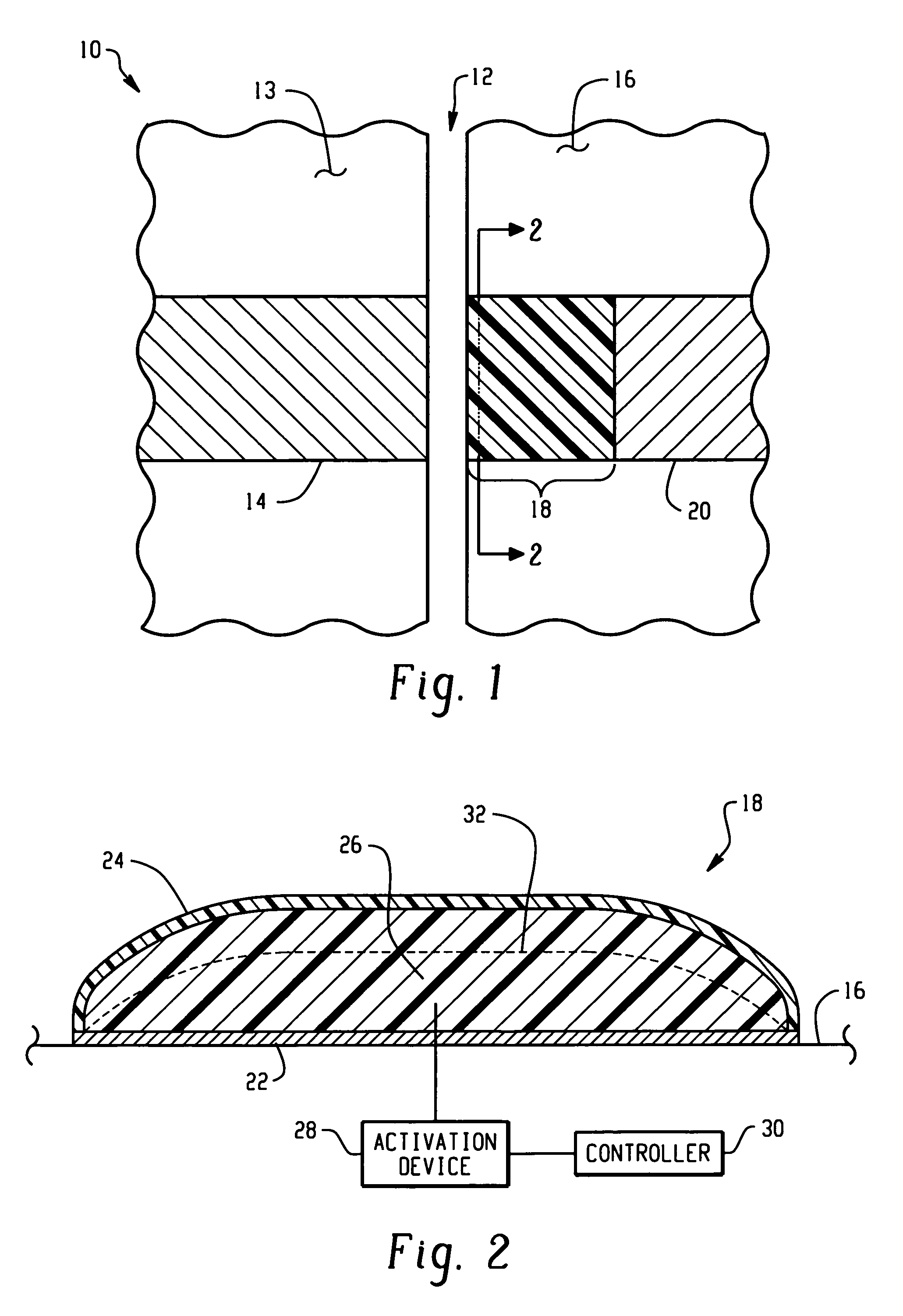

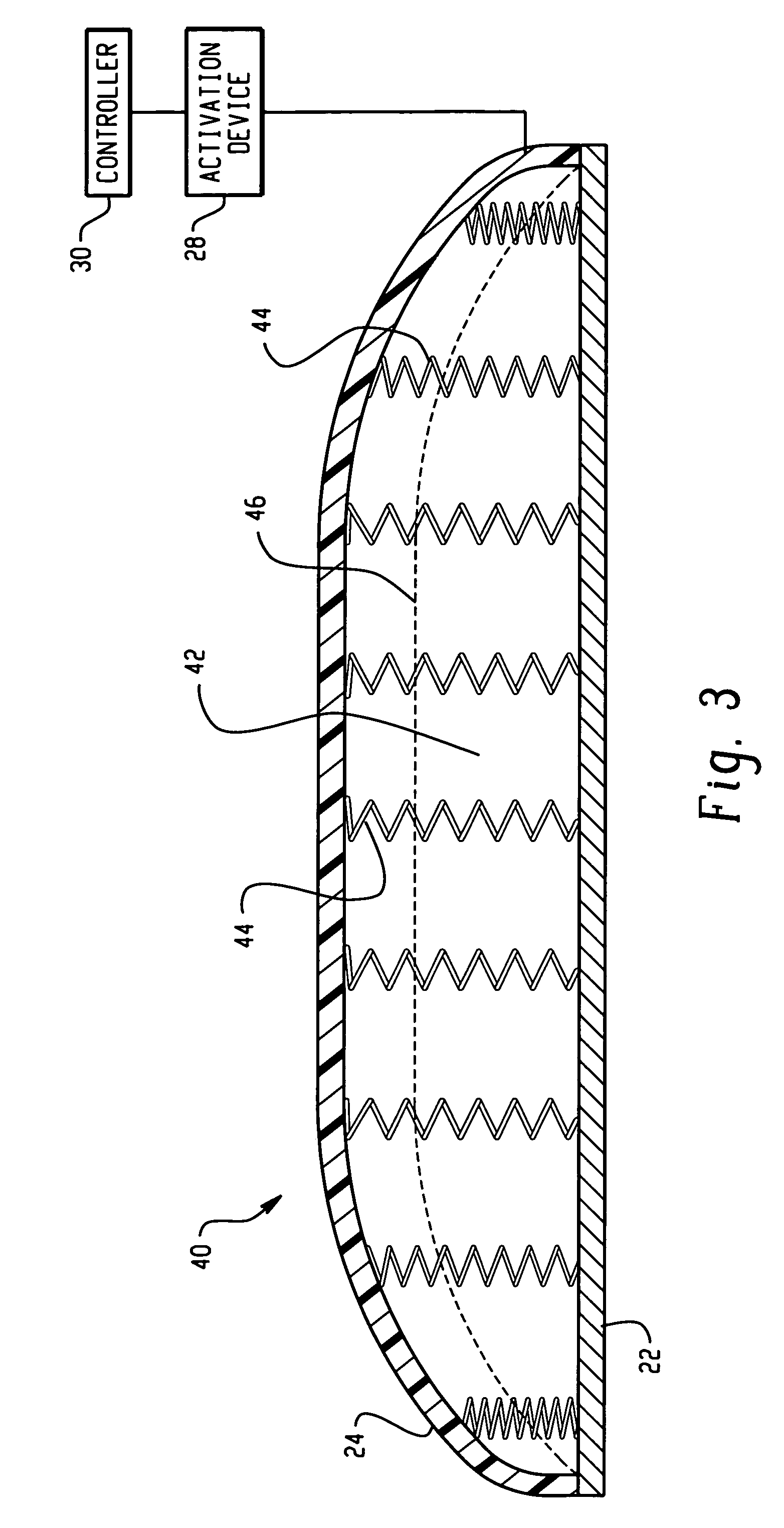

Active pressure relief valves and methods of use

Active pressure relief valves and methods of use for regulating atmospheric conditions within an interior compartment of a vehicle generally include an active material to effect movement of a flap relative to an opening. The active material has the ability to remember its original at least one attribute such as dimension, shape, and / or flexural modulus, which can subsequently be recalled by applying or removing an external stimulus, as will be discussed in detail herein. Suitable active materials include, without limitation, shape memory alloys, ferromagnetic shape memory alloys, shape memory polymers, piezoelectric materials, electroactive polymers, magnetorheological fluids and elastomers, electrorheological fluids, composites of one or more of the foregoing materials with non-active materials, combinations comprising at least one of the foregoing materials, and the like. Depending on the particular active material, the activation signal can take the form of, without limitation, an electric current, a temperature change, a magnetic field, a mechanical loading or stressing, or the like.

Owner:GM GLOBAL TECH OPERATIONS LLC

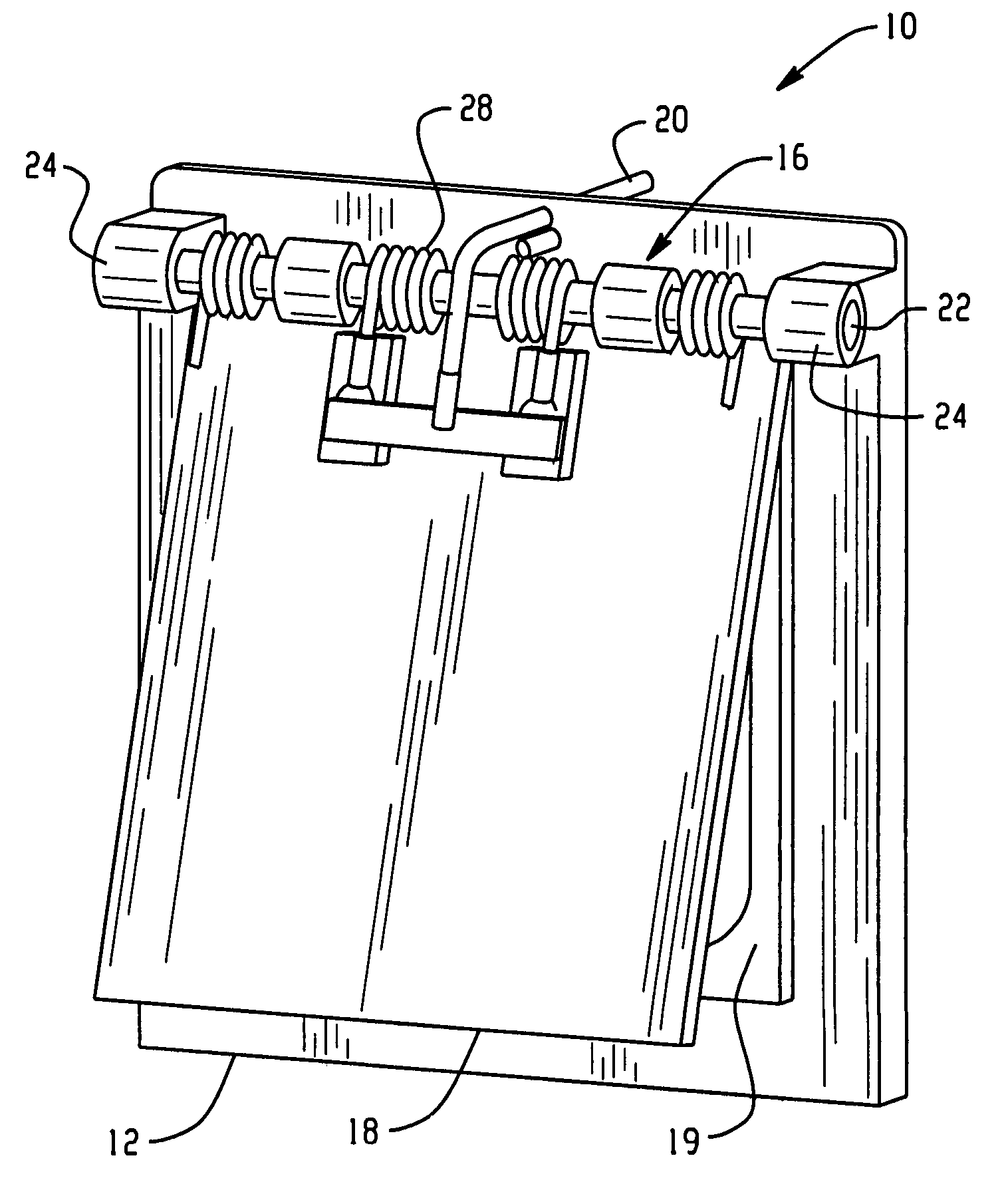

Closure lockdown assemblies and methods utilizing active materials

In combination with a vehicle and a closure, one or more lockdown regions disposed between the closure and the vehicle body, the one or more lockdown includes a device including an active material disposed in operative communication with the closure and the vehicle body, wherein the active material includes a shape memory alloy, a magnetic shape memory material, a shape memory polymer, a magnetorheological fluid, an electroactive polymer, a magnetorheological elastomer, an electrorheological fluid, a piezoelectric material, or combinations comprising at least one of the foregoing active materials; and an activation device coupled to the active material, the activation device being operable to selectively provide an activation signal to the active material and effectuate a change in a dimension, a shape, and / or a flexural modulus property of the active material, wherein the change in the dimension, a shape, and / or flexural modulus of the active material locks down or releases the closure from the vehicle. Such active materials include shape memory alloys, magnetic shape memory alloys, electroactive polymers, shape memory polymers, magnetorheological fluids, magnetorheological elastomers, electrorheological fluids, and piezoelectric materials. Also provided herein are methods for selectively stiffening a closure hingeably attached to a vehicle body.

Owner:GM GLOBAL TECH OPERATIONS LLC

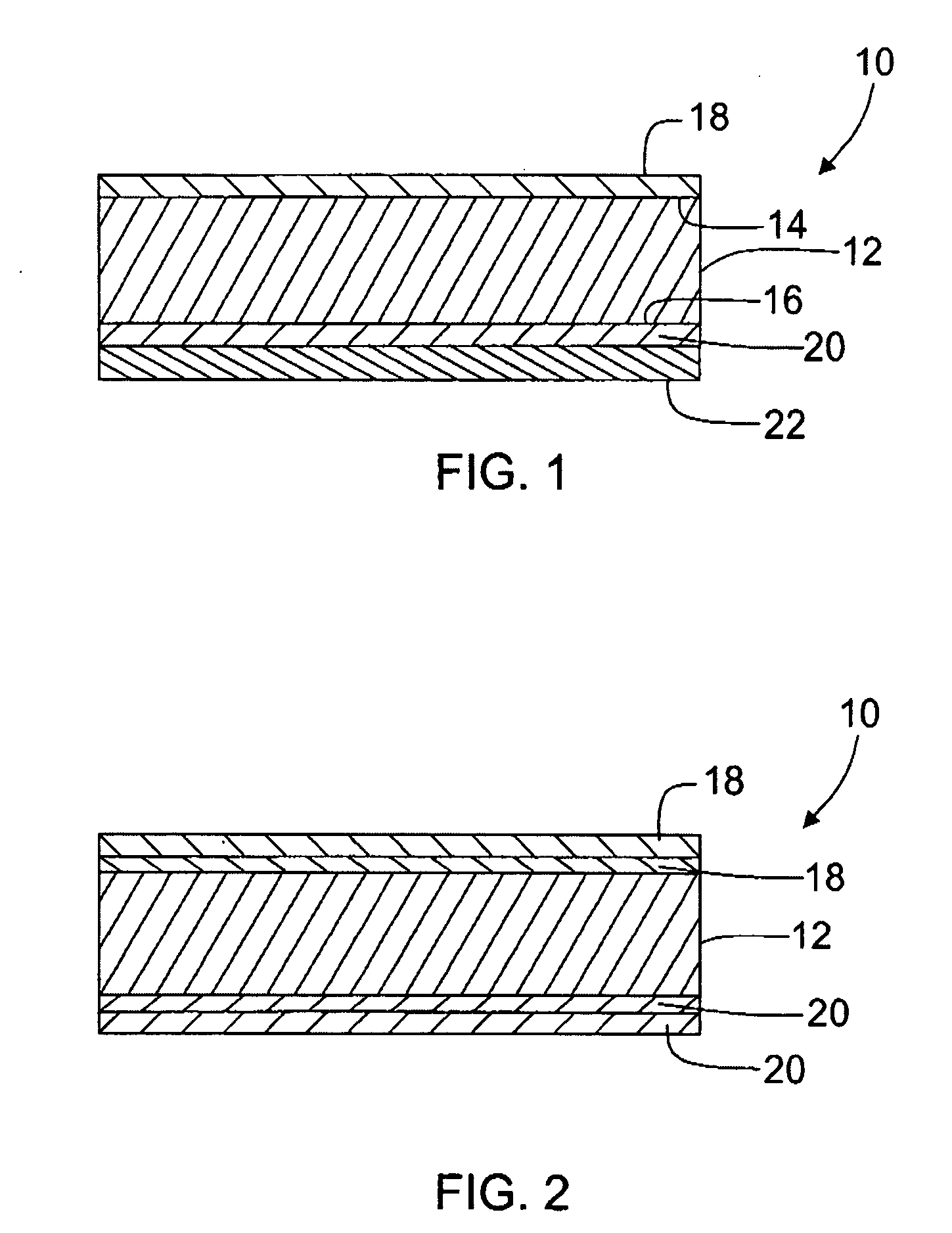

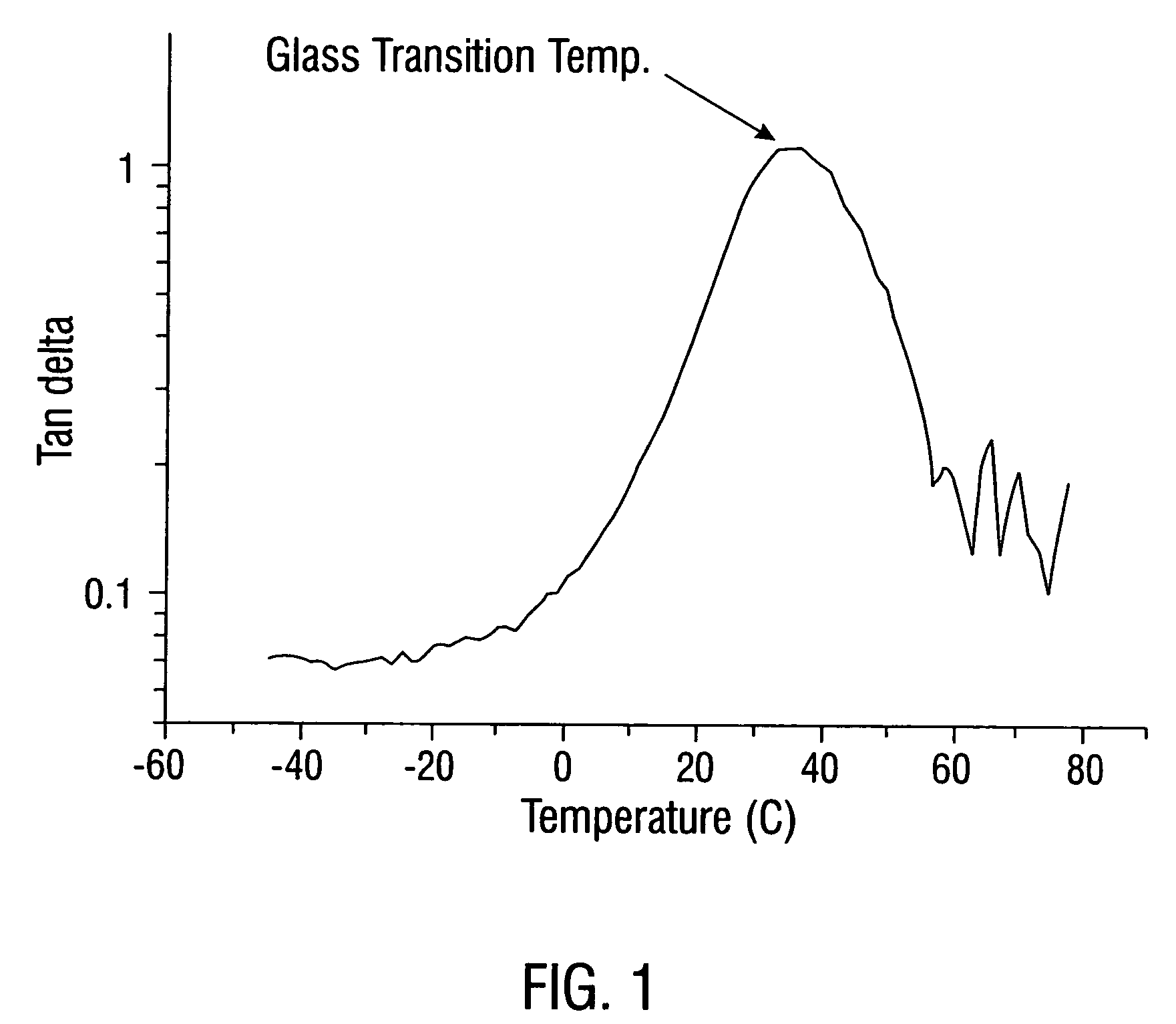

Intrusion resistant glass laminates

InactiveUS20050170160A1Increase stiffnessHigh stiffnessFilm/foil adhesivesSynthetic resin layered productsPolyvinyl butyralPolyethylene terephthalate

Composite laminate interlayers for adhering a glass laminate comprising a sheet of polyethylene terephthalate (PET) between layers of plasticized polyvinyl butyral (PVB) adhesive layers, wherein at least one of the PVB adhesive layers is stiffened, e.g. by reduction in the amount of plasticizer, and has a glass transition temperature greater than 35° C. The PET is preferably 0.075 to 0.25 mm (3-10 mils) thick and can have a functional coating for reducing radiation, e.g. UV or IR or visible light, transmission through the glass laminate. The laminate can also comprise at least one elastomeric layer adapted to reducing sound transmission through the glass laminate. The laminates exhibit enhanced maximum flexural modulus of greater than about 350 Newtons / centimeter.

Owner:SOLUTIA INC

Highly crystalline polypropylene with low xylene solubles

InactiveUS20050272858A1Narrow molecular weight distributionLow melt flow rateGranular deliveryFlexural modulusPolypropylene

The invention is directed to a polypropylene resin which has a Mw / Mn of less than 5, a melt flow rate of less than 7 g / 10 min., a 1% secant flexural modulus of greater 5 than 300,000 psi and less than 2 wt. % xylene solubles.

Owner:BRASKEM AMERICA

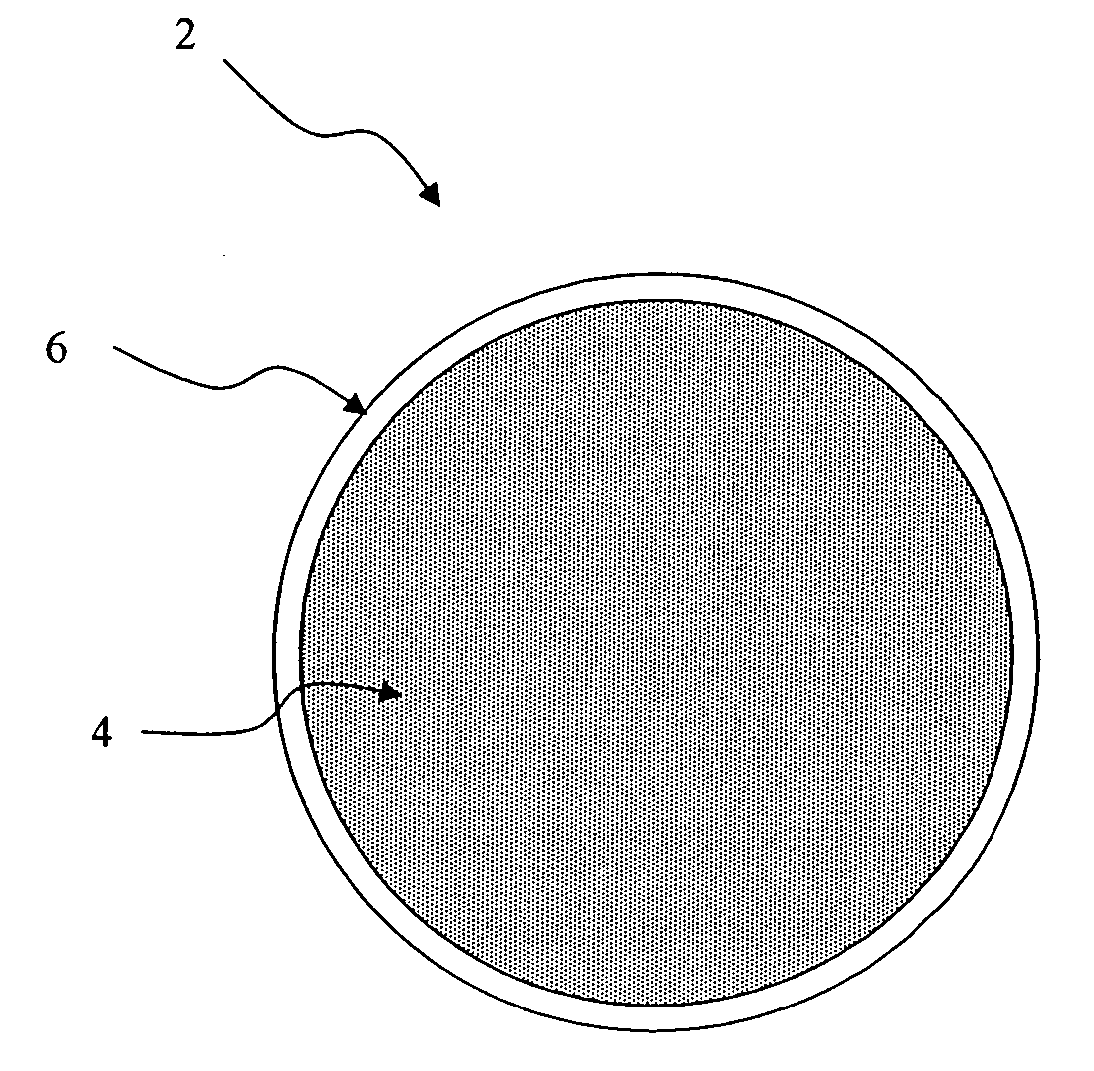

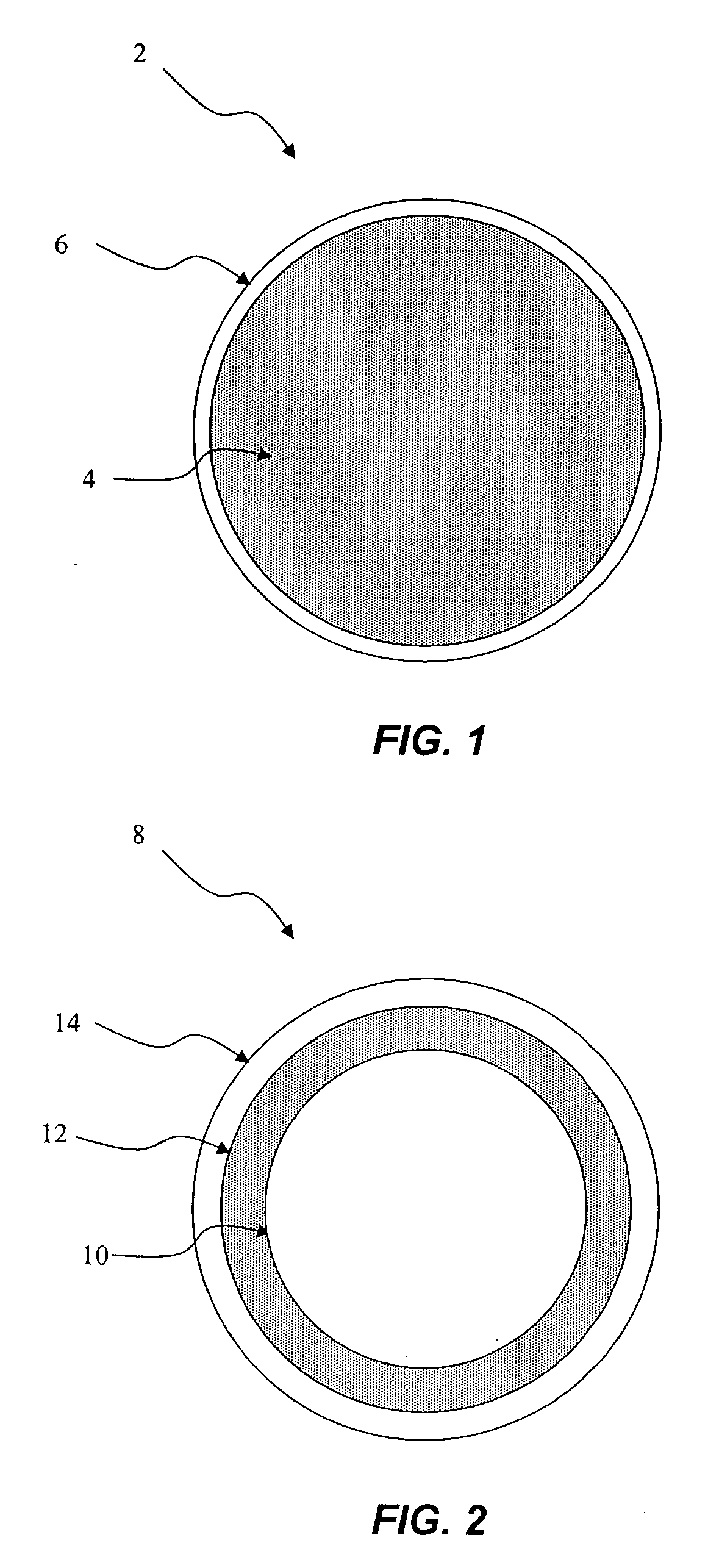

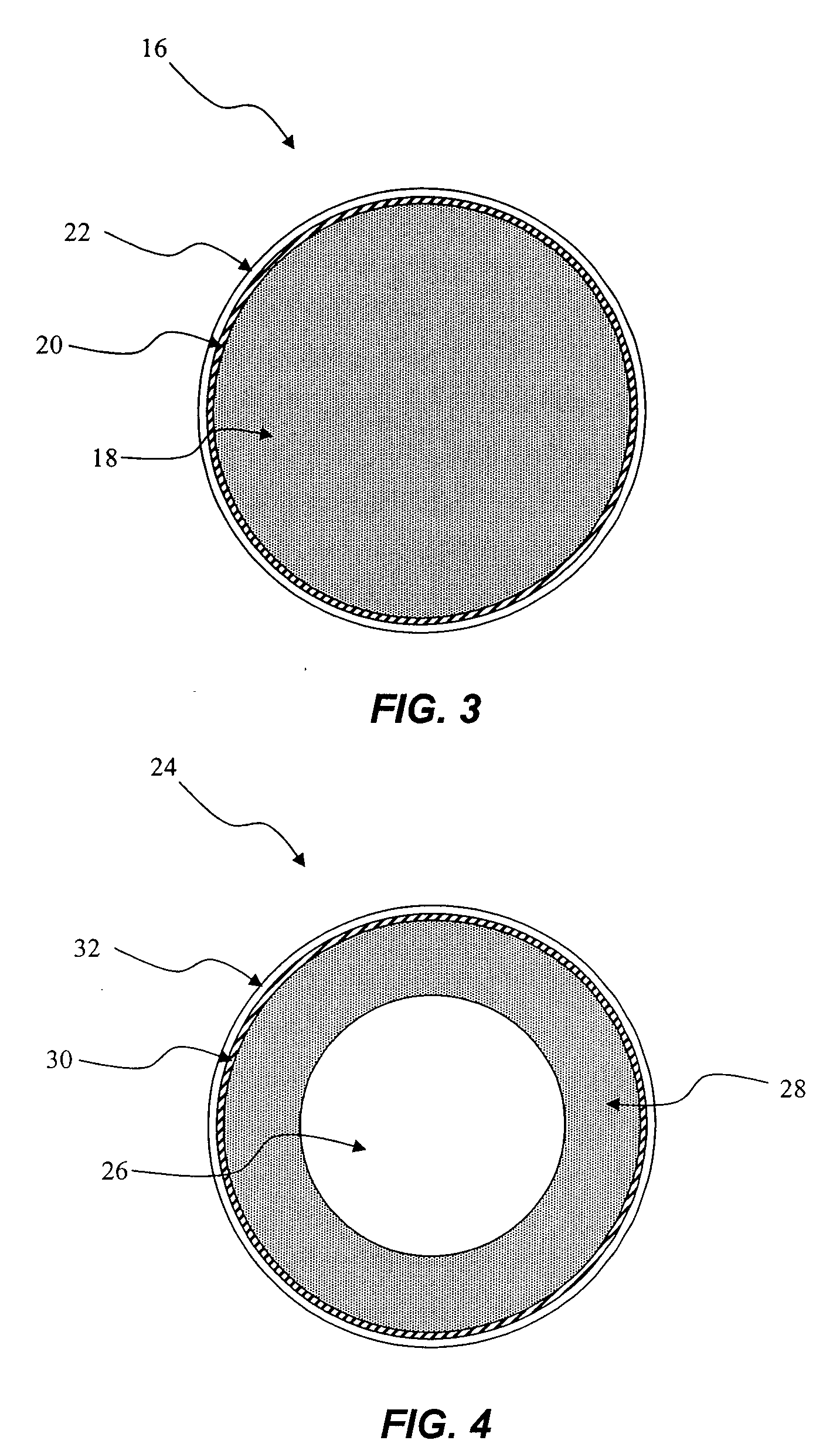

Golf ball with non-ionomeric layer

InactiveUS6872774B2Extrusion process is simpleImprove extrusion rateGolf ballsSolid ballsInter layerFlexural modulus

The present invention is directed to a multi-layer golf ball having a core, an intermediate layer and a cover. The intermediate layer has a non-ionomeric composition that includes an ethylene / acid polymer and a non-ionomeric stiffening polymer. The stiffening polymer provides the non-ionomeric composition with a flexural modulus and a hardness that are greater than those of the ethylene / acid polymer.

Owner:ACUSHNET CO

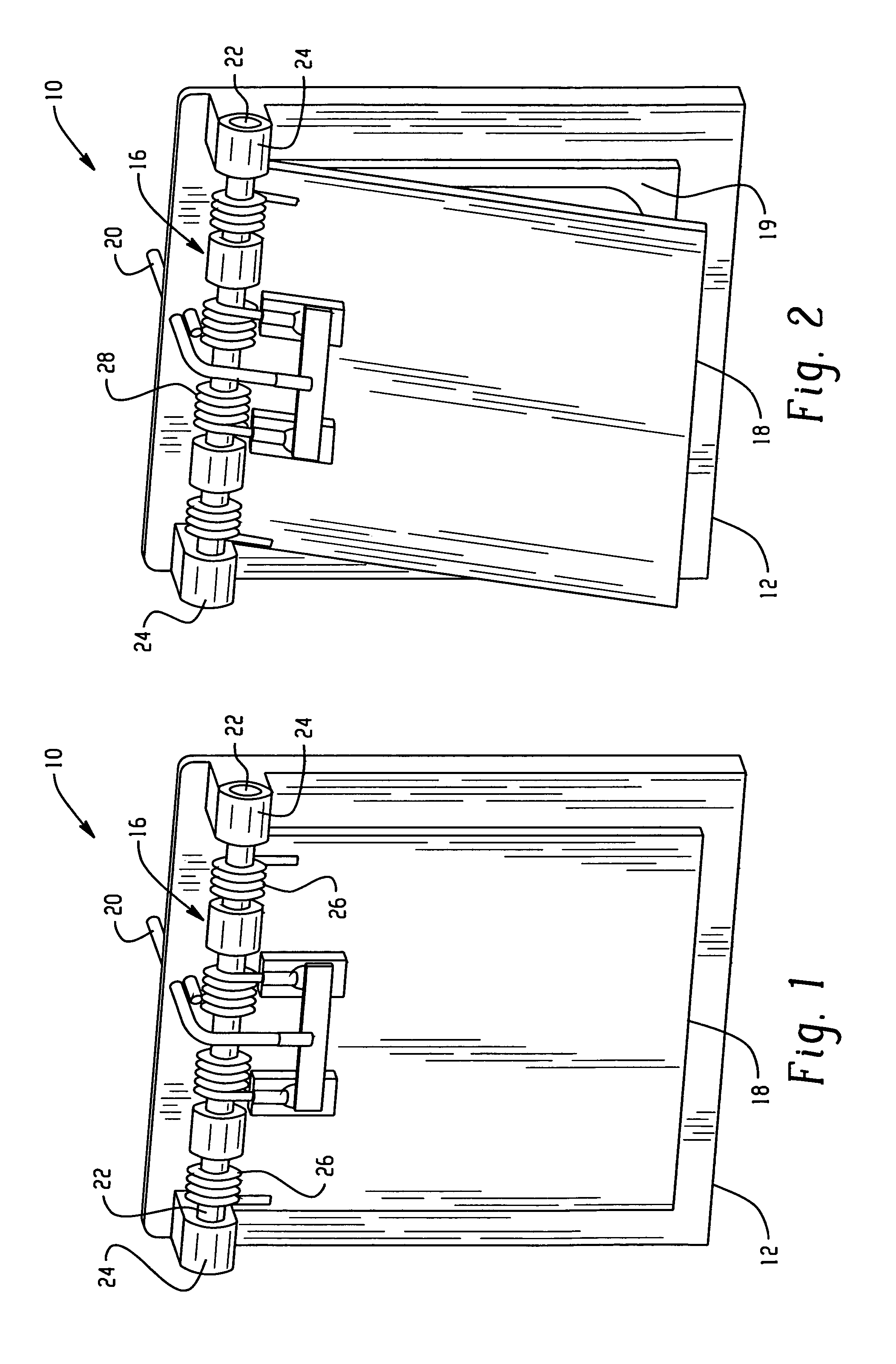

Active seal assemblies for movable windows

InactiveUS20050198904A1Lower sealing forceIncrease sealing forceSealingPower supplyFlexural modulusClassical mechanics

Active seal assemblies employing active materials that can be controlled and remotely changed to alter the seal effectiveness, wherein the active seal assemblies actively change modulus properties such as stiffness, shape orientation, and the like. In this manner, in seal applications such as a vehicle window application, the seal force can be selectively reduced during movement of the window and increased when the window is stationary, thereby selectively changing seal effectiveness. Active materials refers to several different classes of materials all of which exhibit a change in at least one attribute such as dimension, shape, and / or flexural modulus when subjected to at least one of many different types of applied activation signals, examples of such signals being thermal, electrical, magnetic, stress, and the like.

Owner:GM GLOBAL TECH OPERATIONS LLC

Elastomeric magnetic nanocomposite biomedical devices

InactiveUS20050267321A1Low flexural modulusIncrease stiffnessElectrotherapyMedical devicesMuscle tissueElastomer

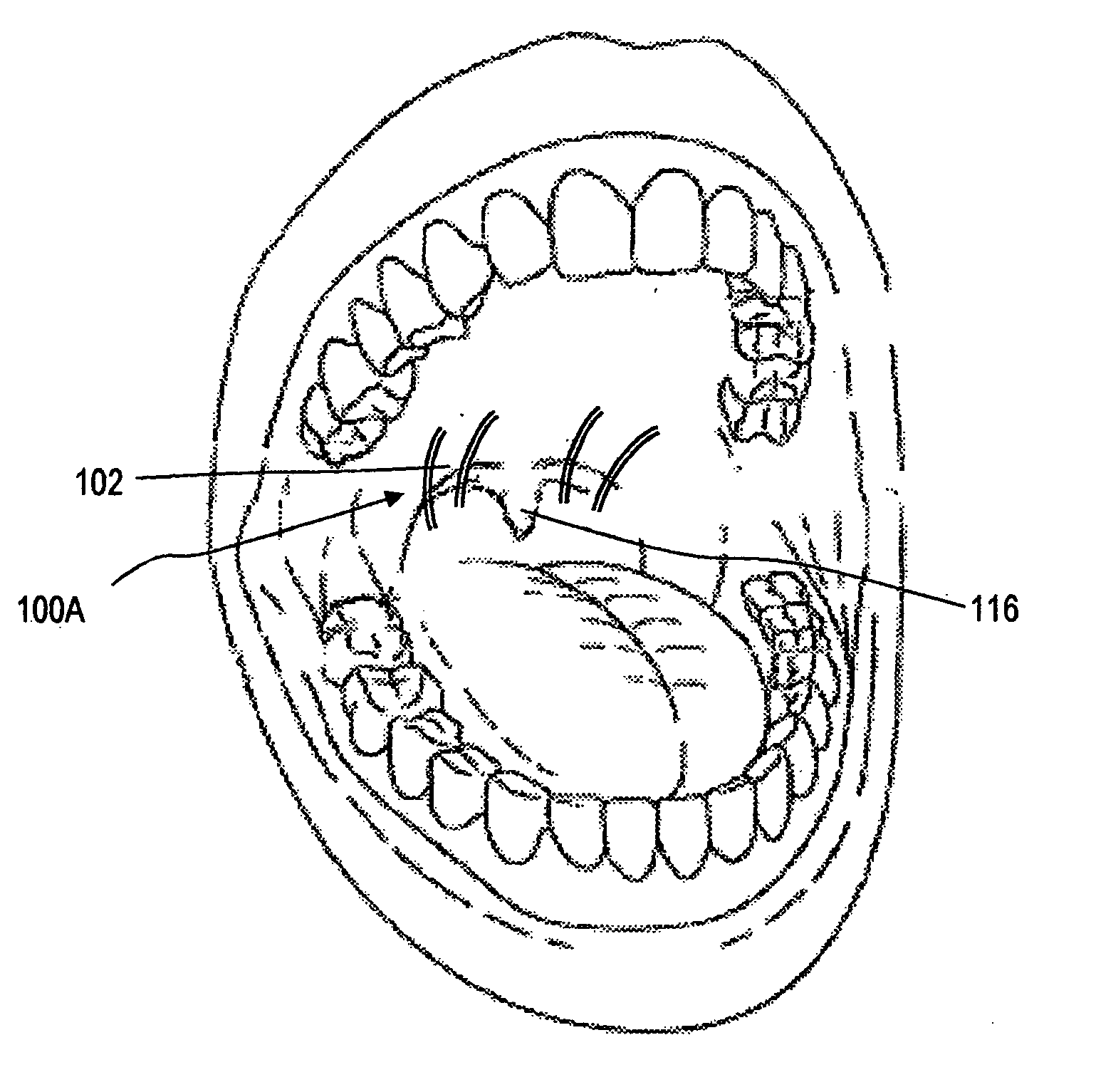

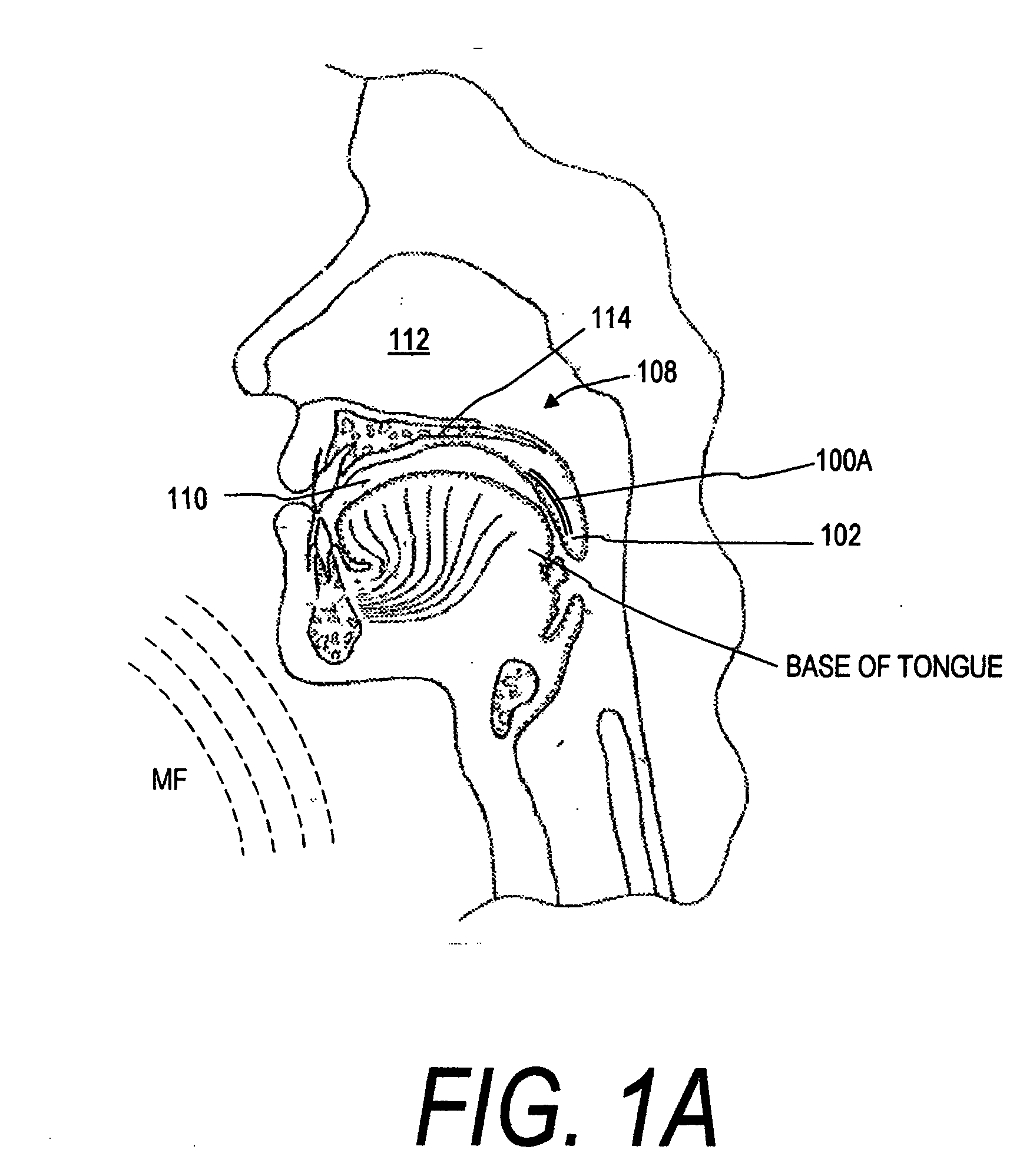

A biomedical device of a smart elastomer, more particularly relating to a class of low modulus elastomers with dispersed, aligned magnetic nanoparticles therein that allow for controlling the flexural modulus of the device and engaged tissue in response to an applied magnetic field. An exemplary embodiment is used for treating obstructive airway syndrome wherein one or more implants including an elastomer magnetic nanocomposite are placed in a patient's soft palate. During sleep, a source of magnetic flux is applied to stiffen the implants to dampen vibrations in tissue which occur in snoring and sleep apnea episodes. The magnetic flux is provided by a permanent magnet or by a magnetic field source coupled to a controller for modulating the stiffness of the implant(s). In similar embodiments, the controlled modulus implants can be used to treat various anatomic structures such as upper airway tissue, oral cavity tissue, gastrointestinal tract tissue, urinary tract tissue, cardiovascular tissue, muscle tissue, penile tissue, sphincters and skin.

Owner:SHADDUCK JOHN H

Stress blanching and stress crack resistant filling modified polypropylene, preparation method and application

Owner:SHANGHAI KINGFA SCI & TECH +1

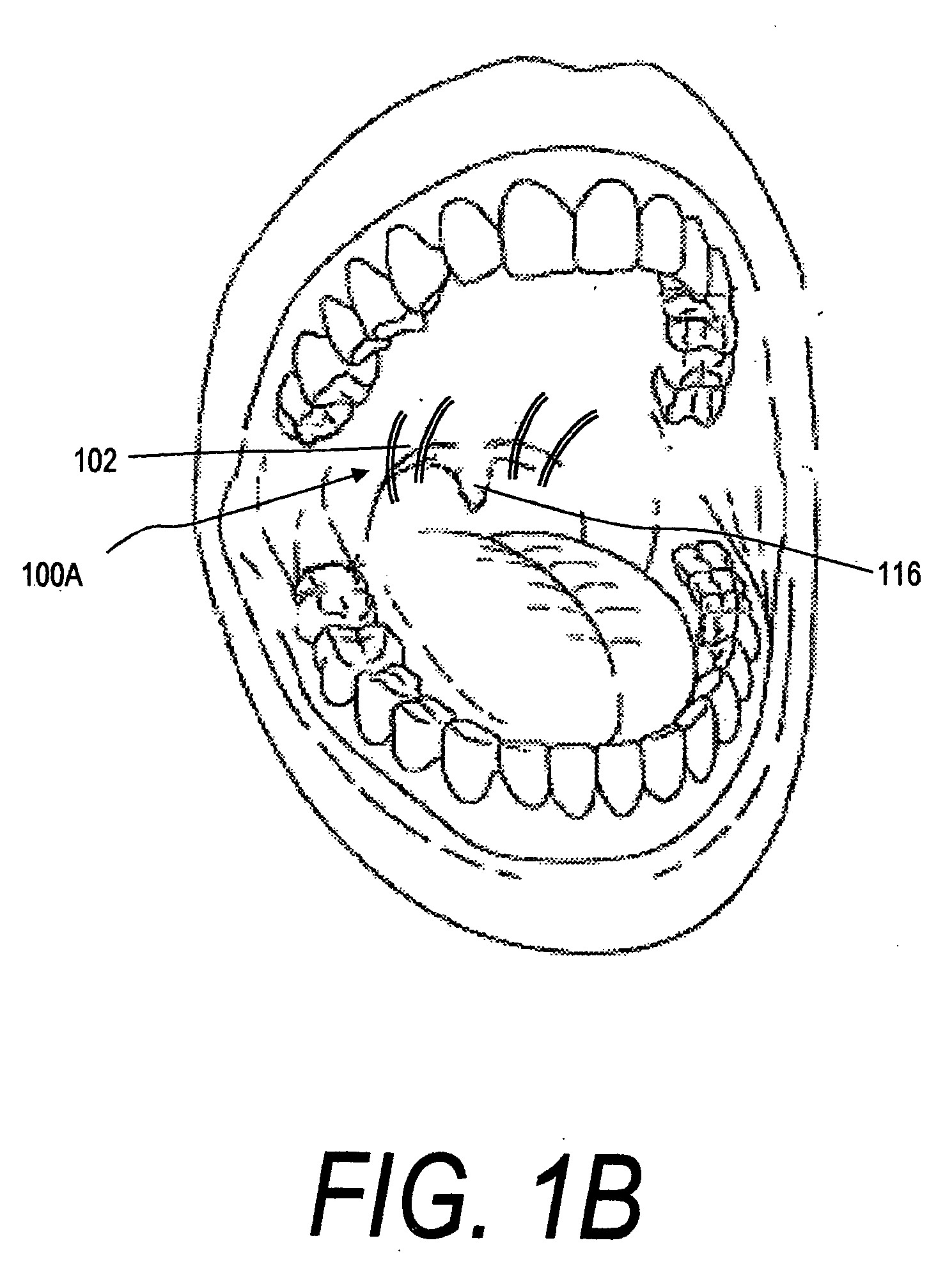

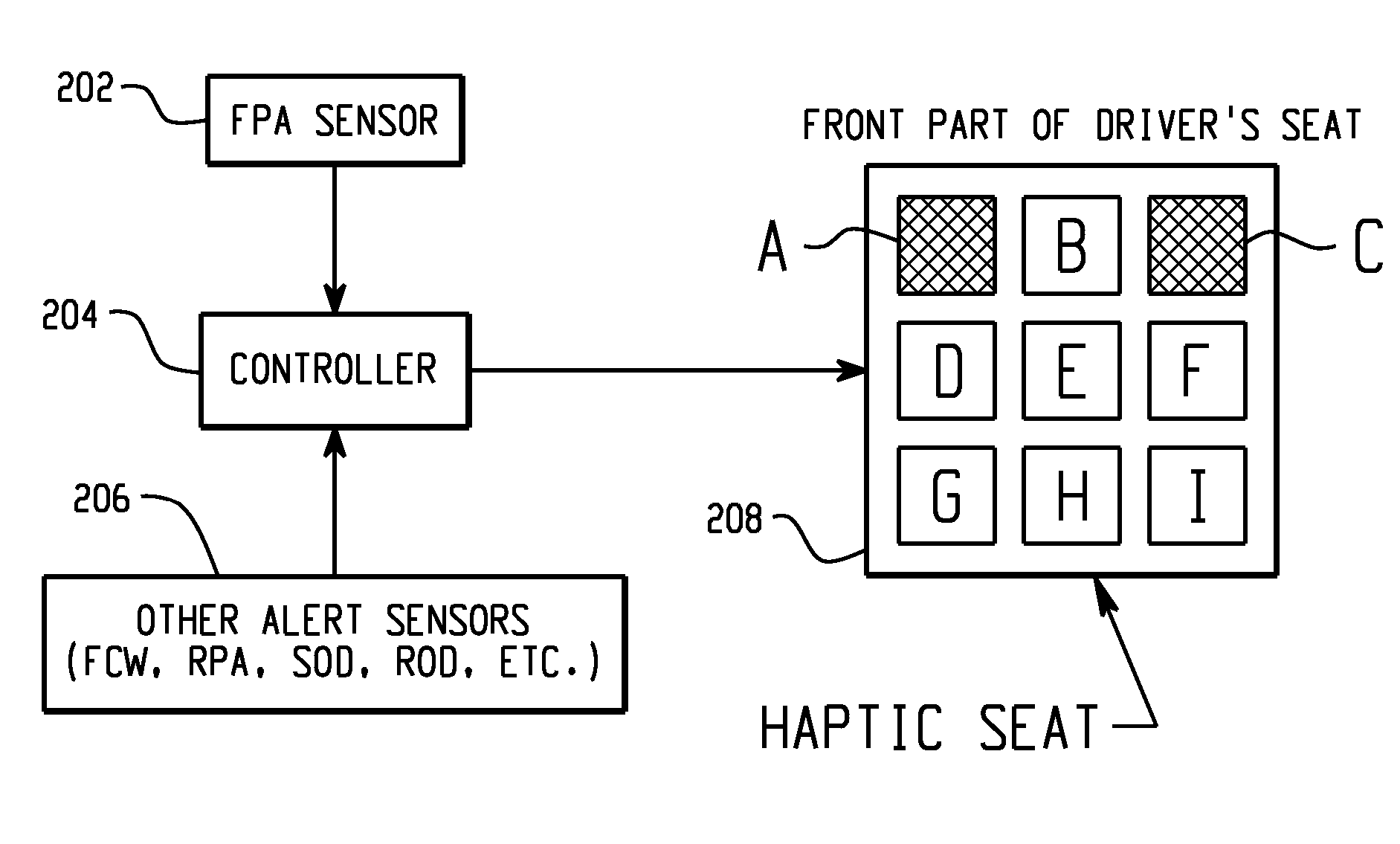

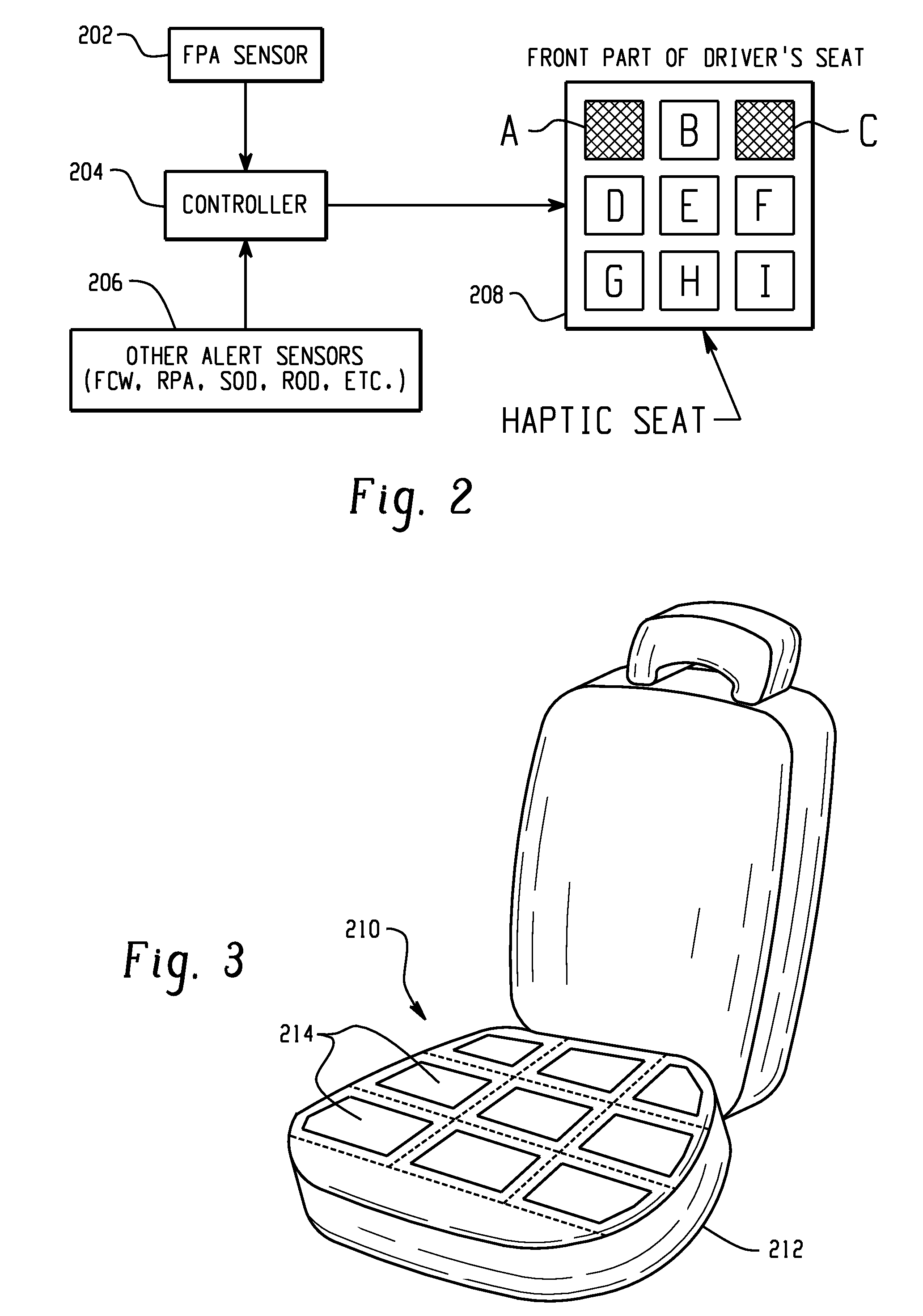

Active material based haptic alert system

ActiveUS20070109104A1Efficient changeRepeater circuitsOptical signallingFlexural modulusBiological activation

A haptic alert system generally includes an active material based actuator for providing the haptic alert. The active material based actuators refer to the use of several different classes of active materials all of which exhibit a change in at least one attribute such as dimension, shape, and / or flexural modulus when subjected to at least one of many different types of applied activation signals, examples of such signals being thermal, electrical, magnetic, stress, and the like.

Owner:GM GLOBAL TECH OPERATIONS LLC

PP composite material with low VOC and high performance specially used for automotive upholsteries and preparation method thereof

ActiveCN101691435AAvoid it happening againLow costSuperstructure subunitsPolypropylene compositesFlexural modulus

The invention belongs to a polypropylene (PP) composite material with a low volatile organic compound (VOC) and high performance specially used for automotive upholsteries and a preparation method thereof, relating to the automobile field. The special material is prepared from the following components by mass percent: 60-80% of polypropylene (PP), 10-25% of reinforcing filler, 10-15% of flexibilizer, 0.2-0.5% of antioxidant and 0.1-0.5% of light stabilizer. The total volatile organic compound (TVOC) of the polypropylene composite material obtained in the invention is less than 40 mu gC / g; the notch impact strength of a cantilever beam under 23 DEG C is 15-40kJ / m2; the flexural modulus is 1500-2300MPa; the melt index is more than 10g / 10min at a temperature of 230 DEG C and at a weight of 2.16kg; and the composite material has favorable light and heat stability, low VOC, few components, low cost, good performance, easy preparation and can be widely used in the production of automotive upholsteries.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

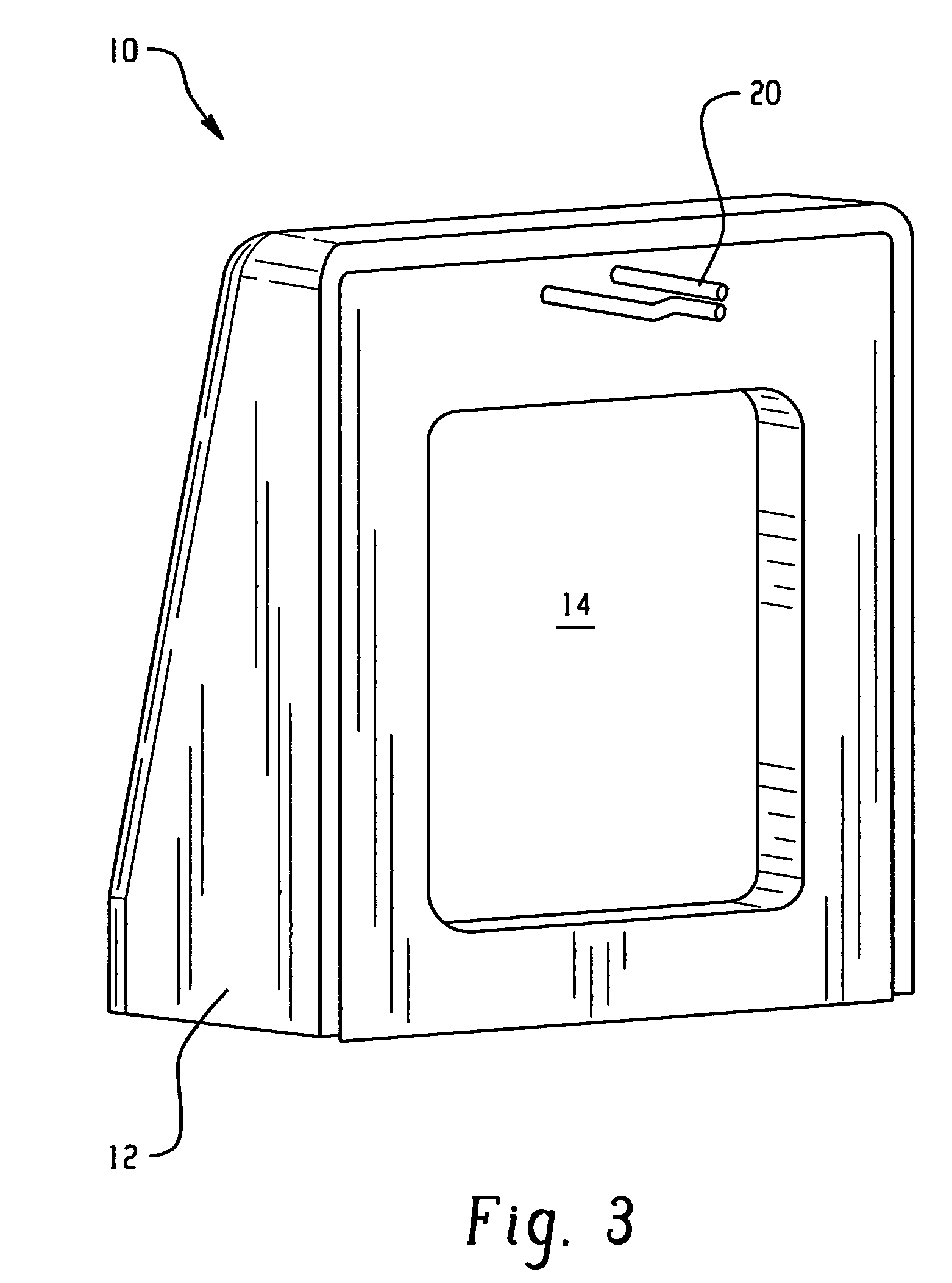

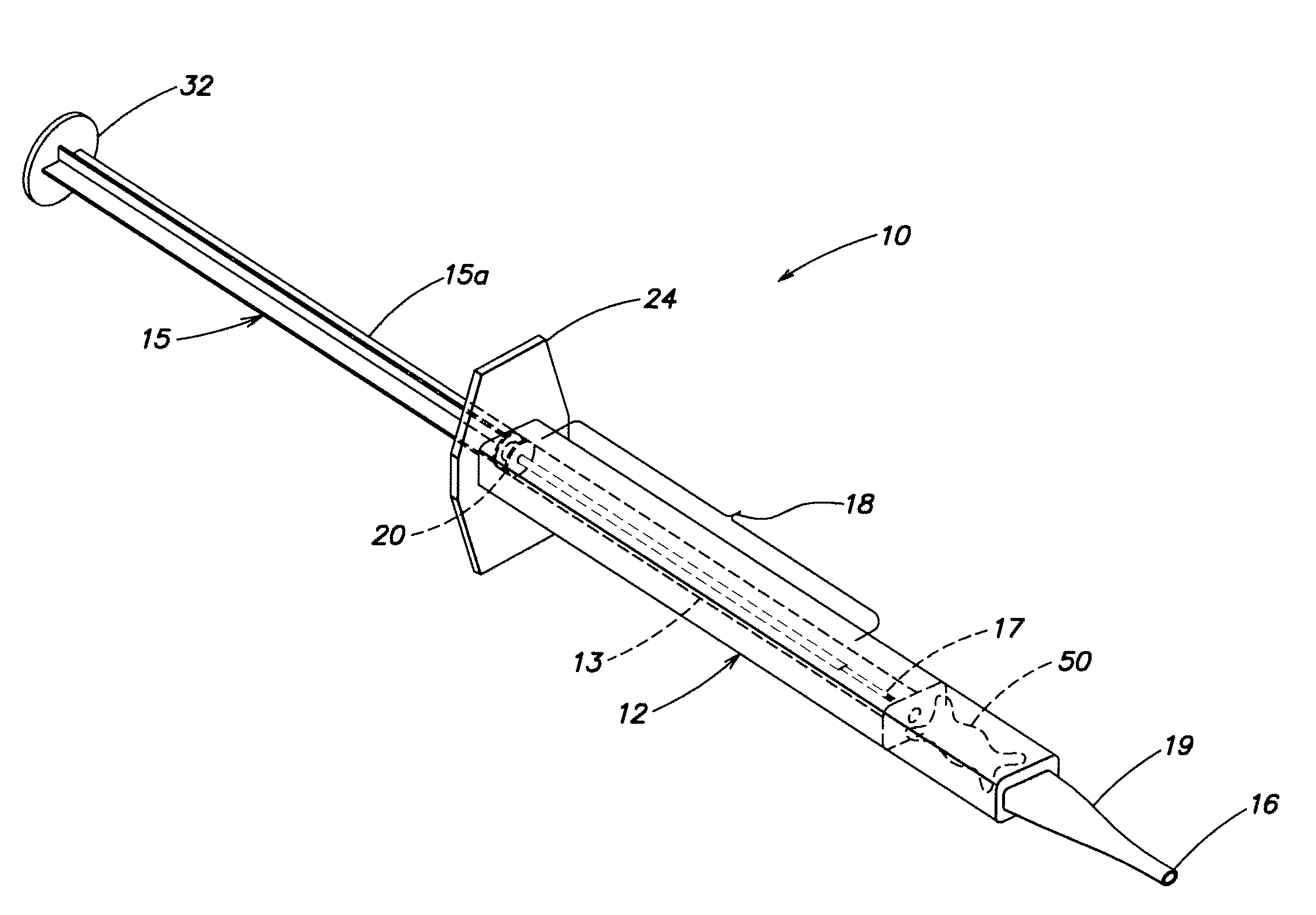

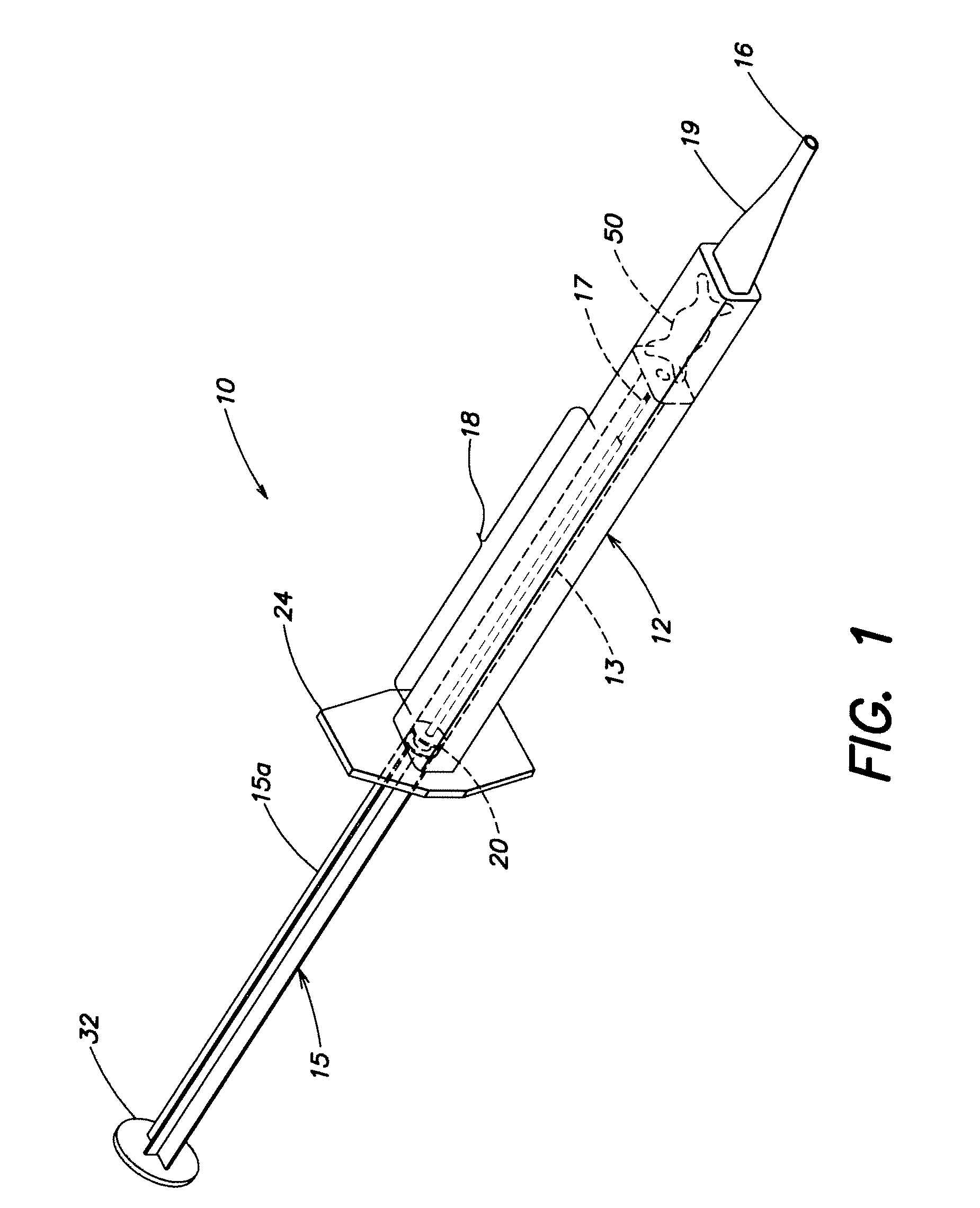

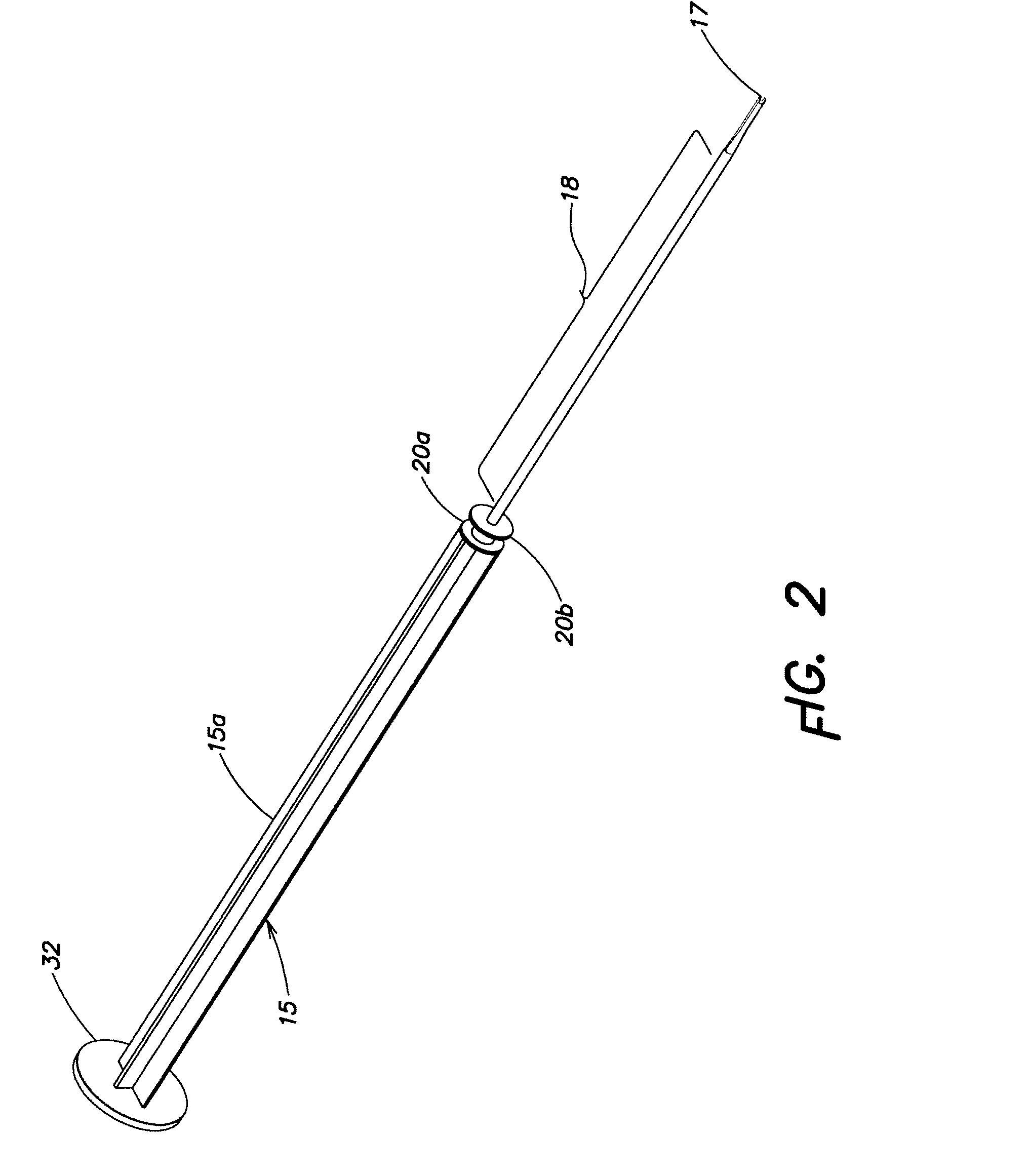

Intraocular Lens Inserter Plunger

InactiveUS20080027461A1Precise deliveryReduce deliveryEye surgeryIntraocular lensPolytetramethylene terephthalatePolyphthalamide

An IOL injector, comprising an injector body; and a plunger. The plunger comprises a shaft comprising a moldable material having a flexural modulus greater than 600 thousand psi, and a plunger tip. The moldable material may have a flexural modulus greater than 750 thousand psi or greater than 1 million psi. The plunger shaft may comprise, for example, Polybutylene Terephthalate (PBT), Polyphthalamide (PPA) or liquid crystal polymer (LCP).

Owner:BAUSCH & LOMB INC

Polypropylene composite material and preparation method thereof

The invention discloses a composite polypropylene material. The composite polypropylene material contains polypropylene resin, glass fiber and an antioxidant, wherein the fiber length of the glass fiber is between 0.4 and 1 millimeter. The invention also discloses a method for preparing the composite polypropylene material. The mechanical properties of the composite polypropylene material such as the tensile strength, the impact strength, the bending strength, the flexural modulus and so on are between the mechanical properties of short glass fiber reinforced polypropylene material and the mechanical properties of long glass fiber reinforced polypropylene material, and the cost of raw materials and the manufacturing cost are low.

Owner:BYD CO LTD

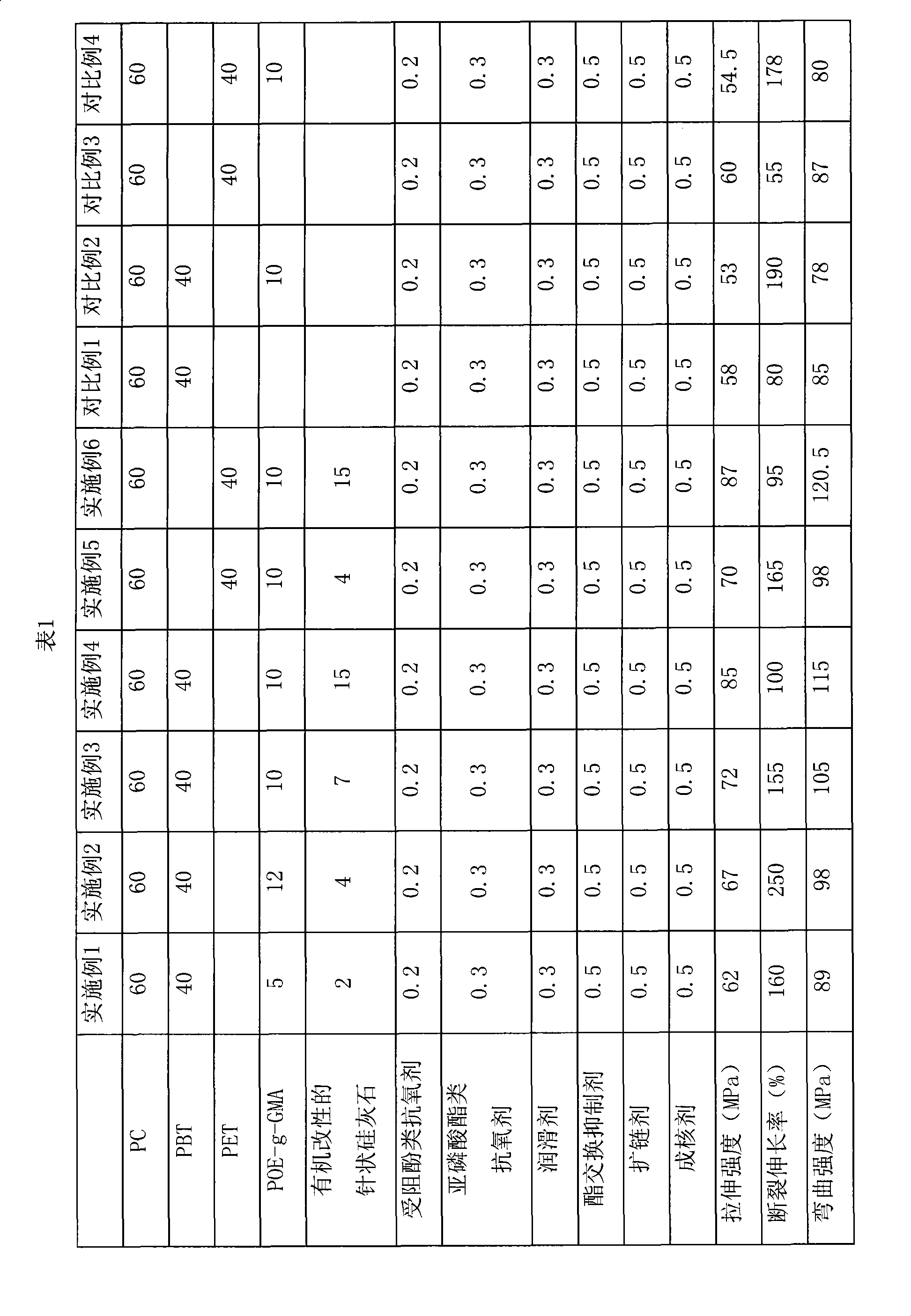

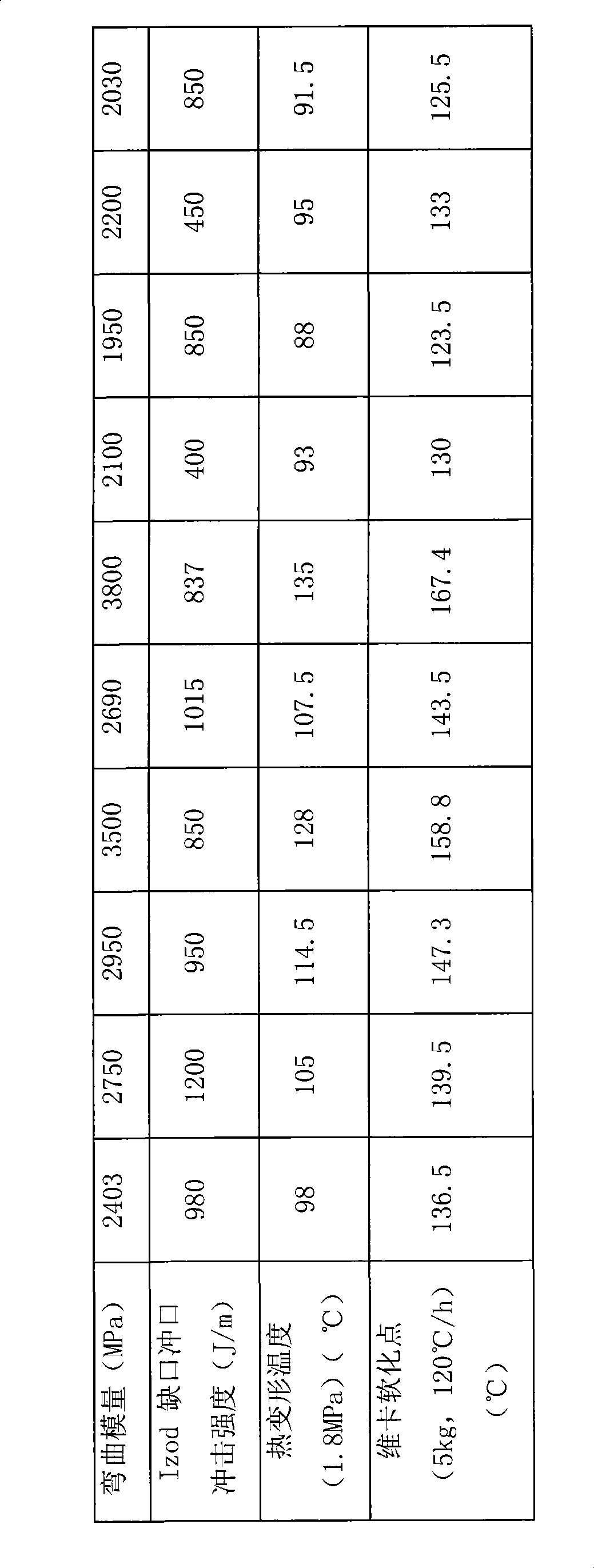

Method of manufacturing polycarbonate/polyester alloy

The invention discloses a preparation method of polycarbonate / polyester alloy. Glycidyl methacrylate grafted ethylene-octylene multipolymer / organic modified needle-shaped aedelforsite composite toughener, i.e. a technology of simultaneously using organic / inorganic rigid particle toughener is adopted; the glycidyl methacrylate grafted ethylene-octylene multipolymer, organic modified needle-shaped aedelforsite, polycarbonate and polyester are melted and mixed in a double-screw extruder, to obtain high-performance alloy material. The prepared polycarbonate / polyester alloy has excellent integrated mechanical properties and size stability, the notched impact strength reaches 1200J / m, the tensile strength reaches 67MPa, the elongation at break reaches 250 percent, the flexural strength is up to 98MPa, the flexural modulus reaches 2750MPa, and the thermal deformation temperature in high load (1.82MPa) is up to 105 DEG C. Therefore, the prepared polycarbonate / polyester alloy can be applied in cars, and to outer decorations, household electrical appliances, IT and the like industrial products.

Owner:SHANGHAI JIAO TONG UNIV +1

Energy absorbent laminate

InactiveUS7087296B2Tensile modulusImprove toughnessAutomatic/semiautomatic turning machinesSynthetic resin layered productsFiberFlexural modulus

Owner:SAINT GOBAIN TECHN FABRICS CANADA +1

On demand morphable automotive body moldings and surfaces

A morphable vehicle member utilizing at least one active material to change at least one attribute in response to an activation signal. The change in at least one attribute is a change in a shape dimension, a shape orientation, an expansion, a contraction, a morphing, a yield strength property, a flexural modulus or a combination. Preferably, the change in at least one attribute in the morphable vehicle member is reversible. Also disclosed herein are methods for the morphable vehicle member utilizing at least one active material to change at least one attribute on demand in response to an activation signal.

Owner:GM GLOBAL TECH OPERATIONS LLC

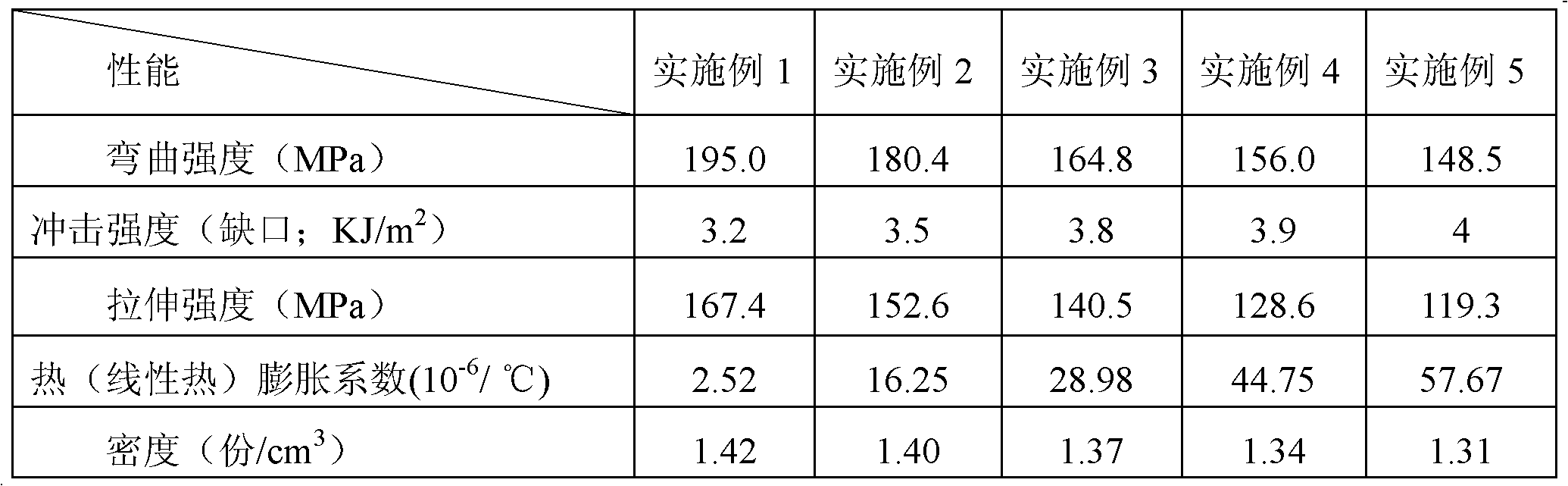

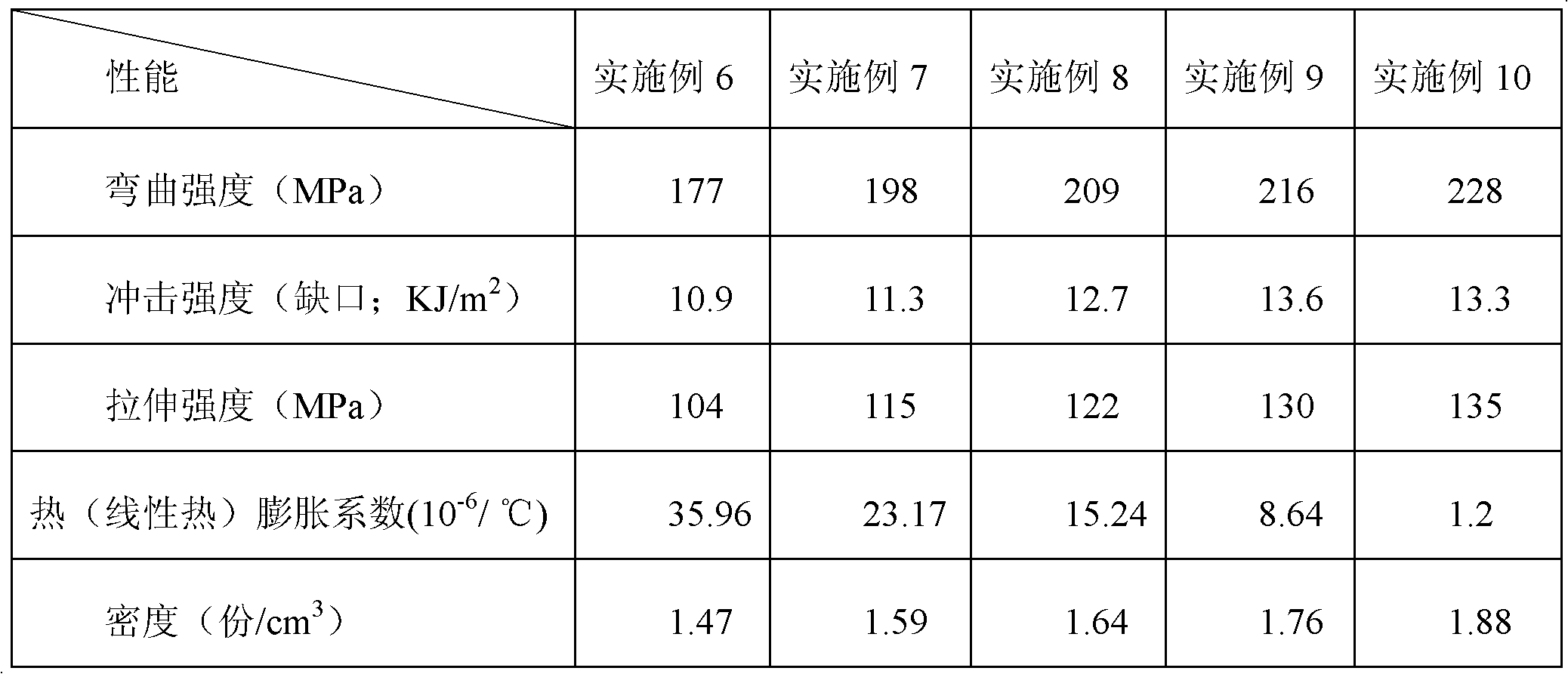

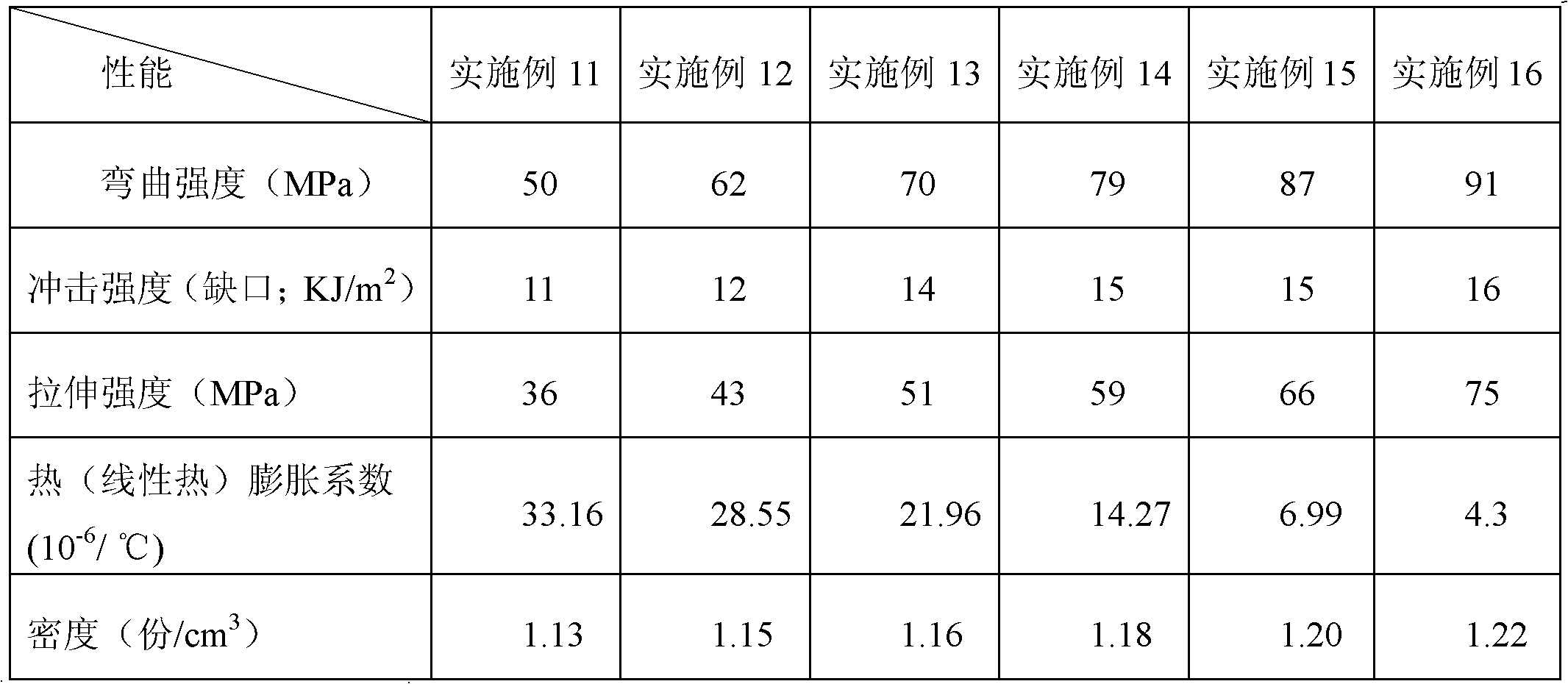

Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

The invention belongs to the technical field of high polymer materials, and discloses low coefficient of thermal expansion thermoplastic resin composition, a preparation method and application of the low coefficient of thermal expansion thermoplastic resin composition. The resin composition is composed of, by weight, 340 to 900 parts of thermoplastic resin, 100 to 500 parts of carbon fibers, 0 to 5 parts of antioxygen, 0 to 5 parts of lubricating agent and 0 to 150 parts of flexibilizer. The preparation method comprises adding the 340 to 900 parts of the thermoplastic resin, the 0 to 5 parts of the antioxygen, 0 to 5 parts of the lubricating agent and the 0 to 150 parts of the flexibilizer to a high mixing machine to mix for 1 to 30 min, adding the mixture to a double-screw extruder, adding the 100 to 500 parts of the carbon fibers from the glass fiber feeding port or the side feeding port of the double-screw extruder to mix evenly, and carrying out extruding, dragging and prilling on mixed materials in the double-screw extruder to obtain the low coefficient of thermal expansion thermoplastic resin composition. The use of the low coefficient of thermal expansion thermoplastic resin composition applied to the fittings of a metal piece is provided. The thermoplastic resin is high in flexural modulus, tensile strength and impact strength, and low in linear expansion coefficient.

Owner:HEFEI GENIUS NEW MATERIALS

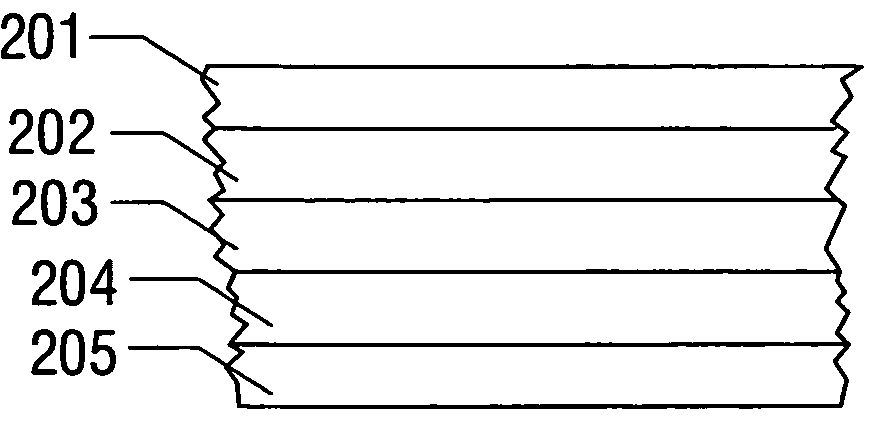

Inversion liner and liner components for conduits

Inversion liners are provided which in a first embodiment include first and second flexible fabric layers separated by one or more glass fiber containing layers and joined in tubular form. The second flexible fabric layer further is bonded to a third flexible fabric layer comprising a substantially fluid impermeable layer. An invertible glass-faced liner is also provided by this invention which includes a glass facing on one side and a substantially fluid impermeable layer on the other. The substantially fluid impermeable layer is joined to a flexible fabric layer which is preferably heat bonded to a thin veil joined to a second glass containing layer of this liner embodiment. The inversion liners of this invention can be built-up in multiple layers or blocks to meet end-use design demands while still providing flexural moduli in excess of 500 ksi, preferably about 700-800 ksi.

Owner:SAINT GOBAIN ADFORS CANADA LTD

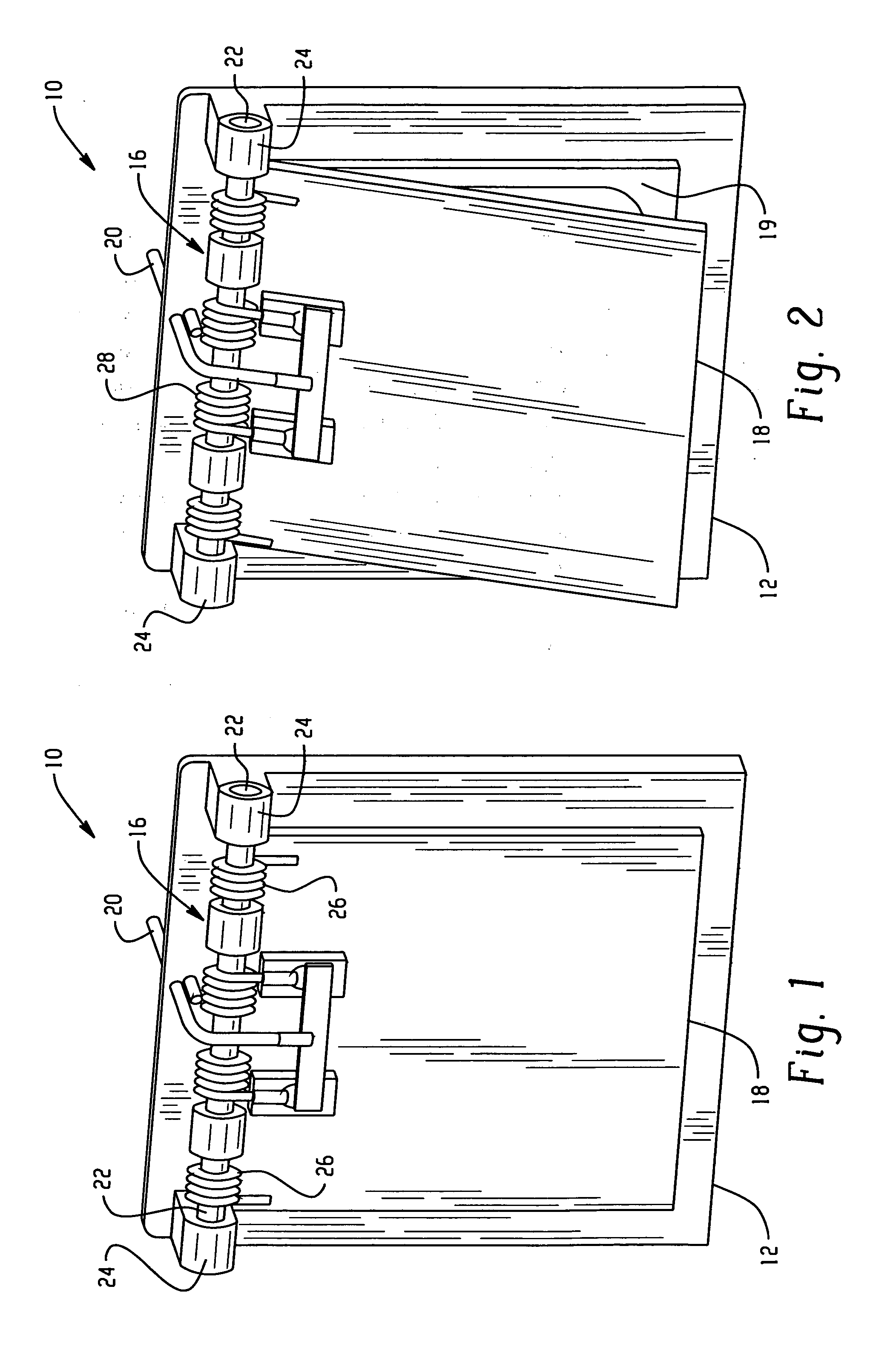

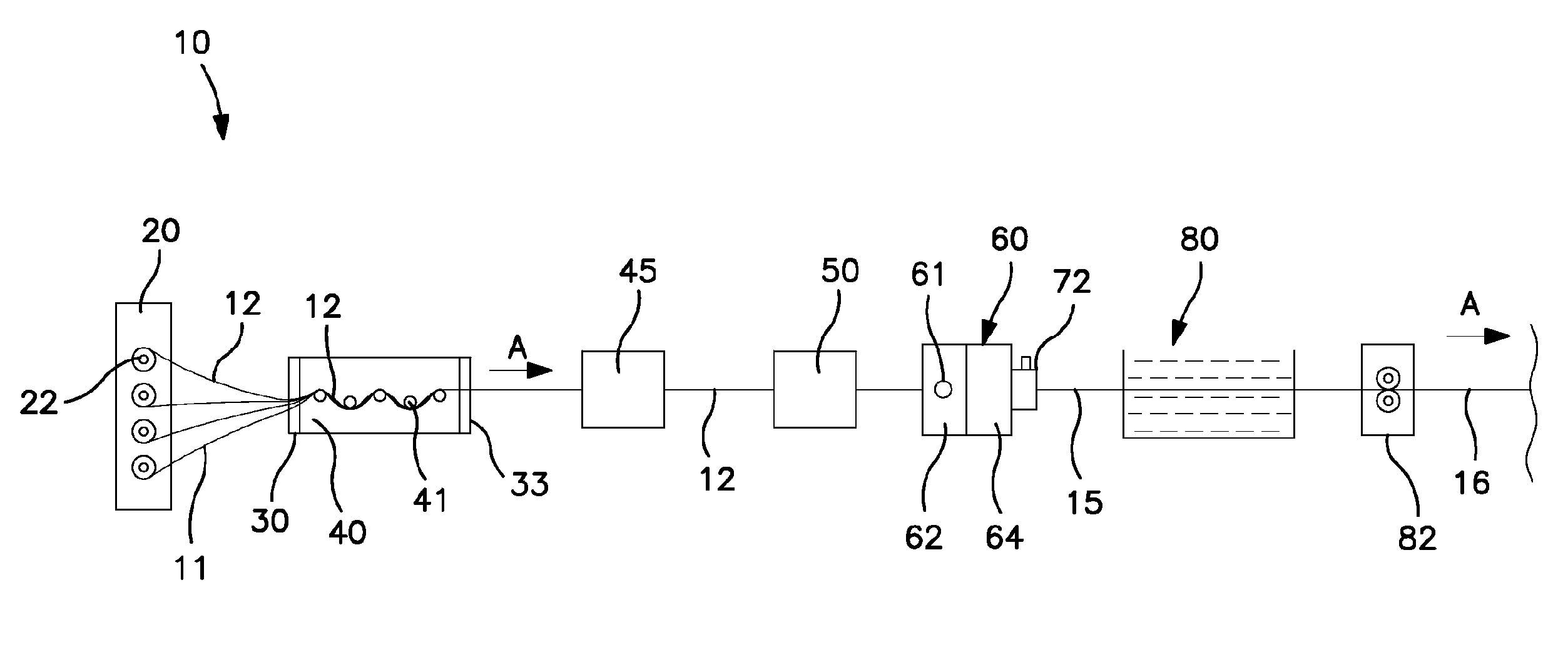

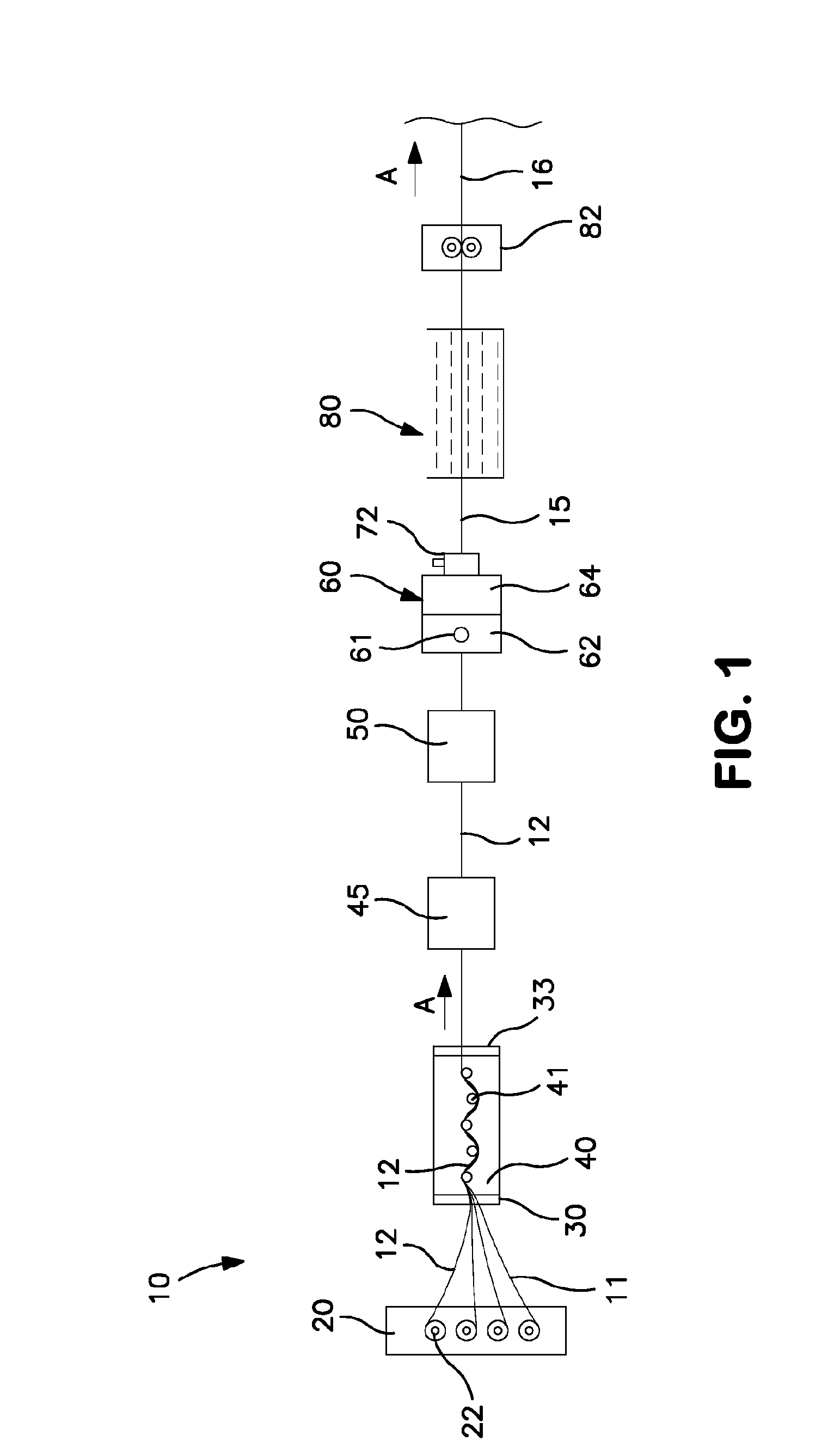

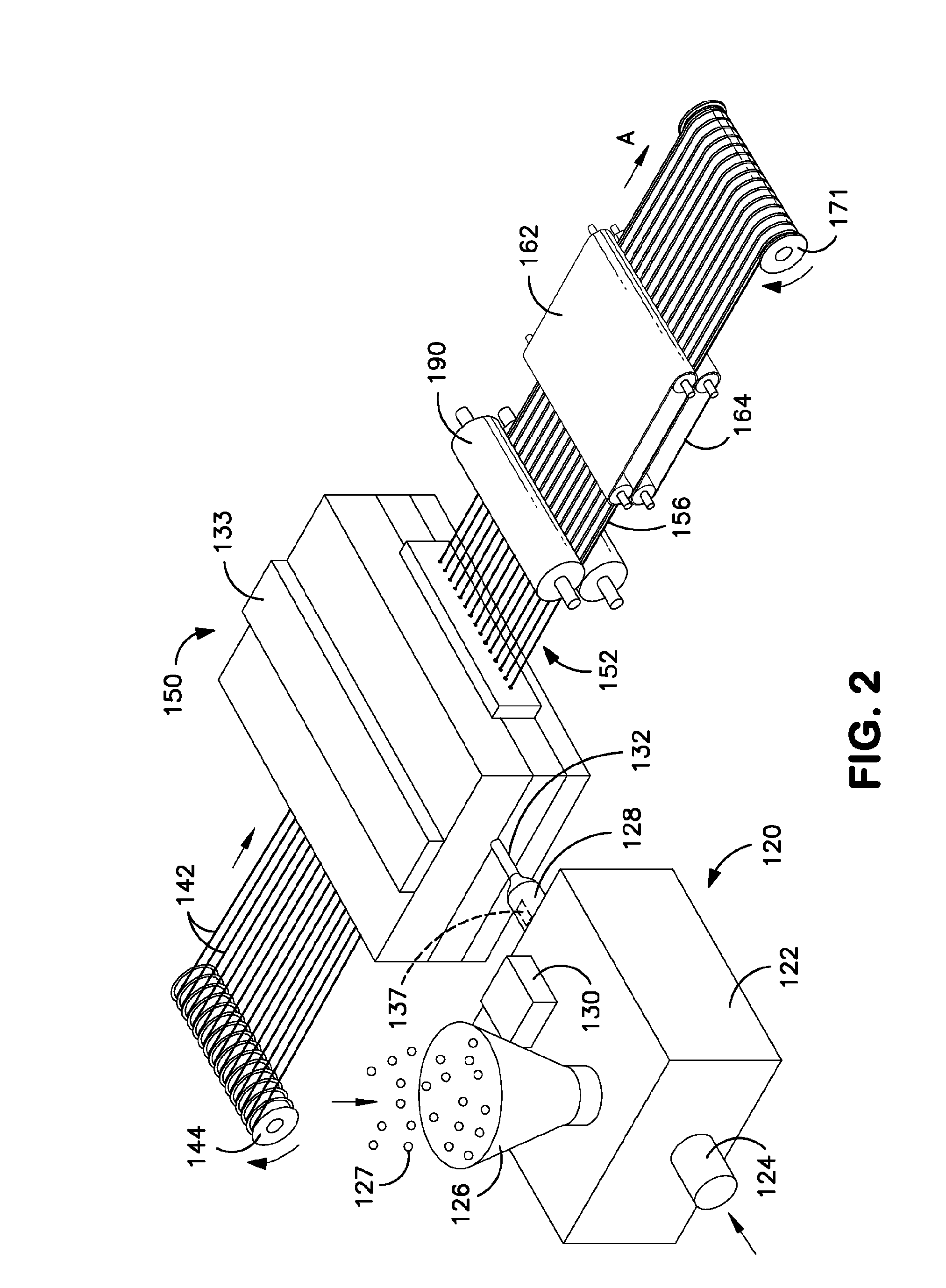

Method for Forming Reinfoced Pultruded Profiles

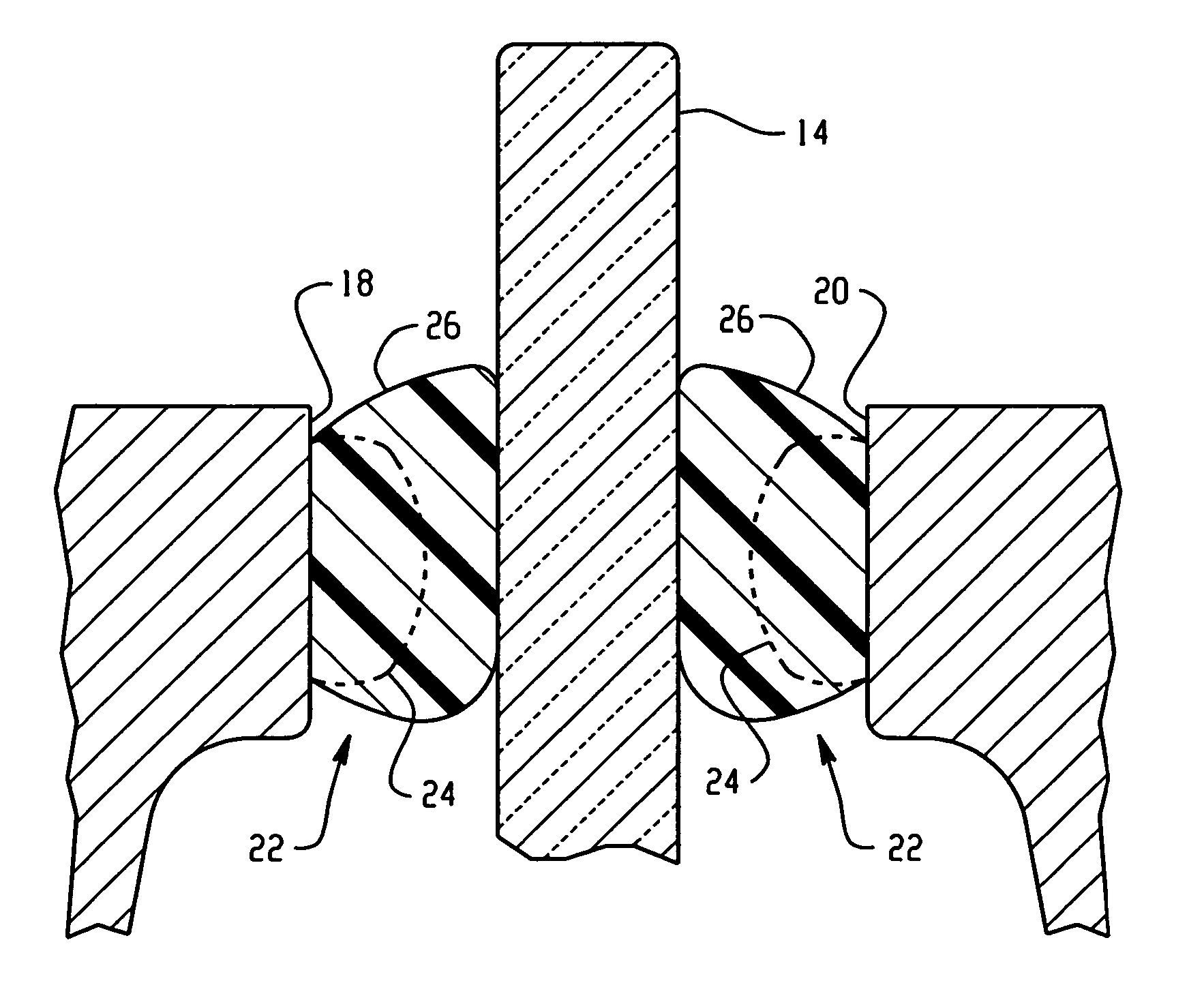

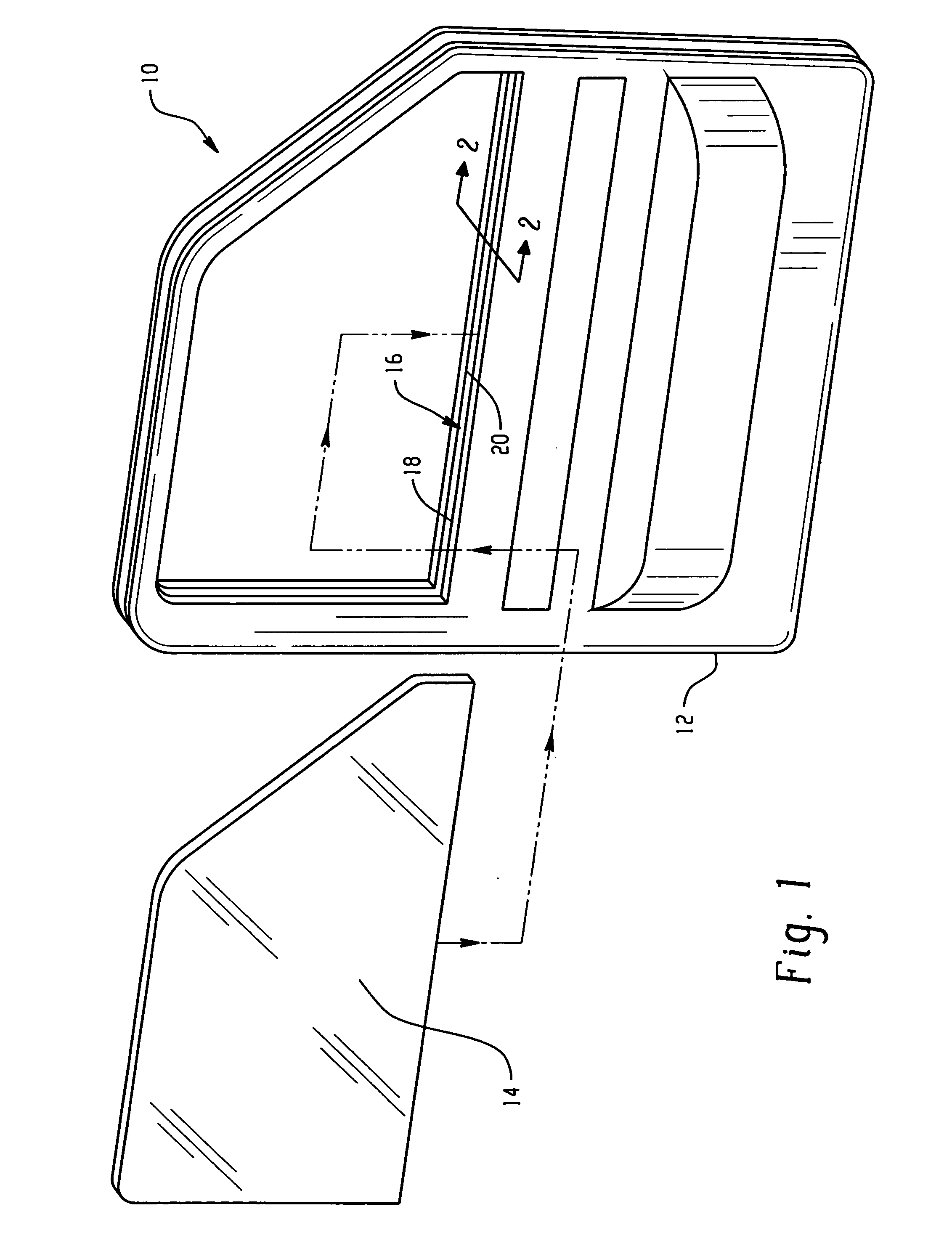

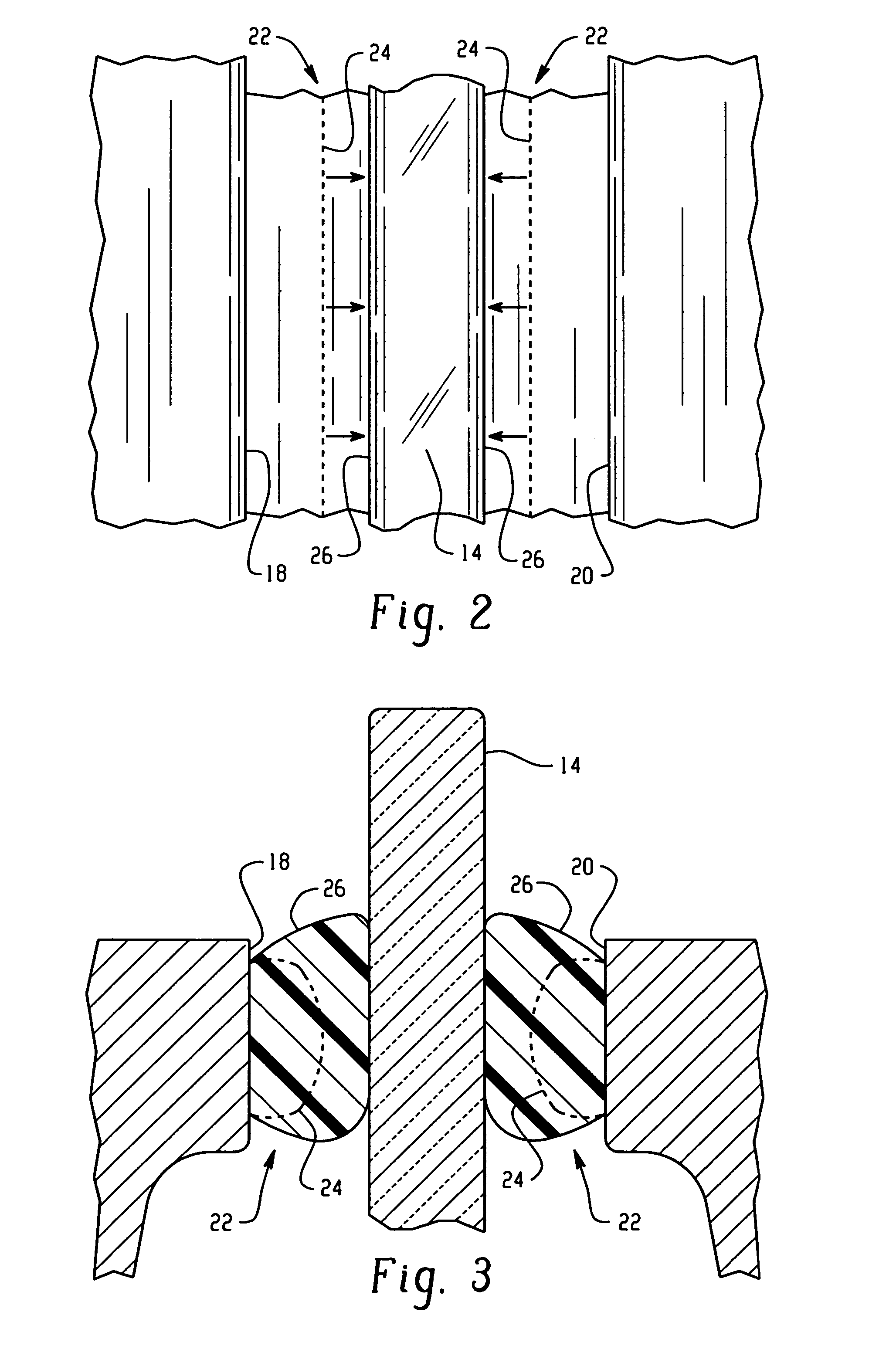

A method and apparatus for forming a profile that contains at least one layer of continuous fibers and at least one layer of discontinuous fibers. Said method allowing the selective control of features to achieve a profile that has increased transverse strength and flexural modulus. The layer of continuous fibers may be formed from one or more continuous fiber reinforced ribbons (“CFRT”) (12) that contain fibers embedded within a thermoplastic polymer matrix, whereby a void fraction and in turn is minimized and flexural modulus is optimized Further, the ribbon (s) are consolidated so that the continuous fibers remain fixed in alignment in a substantially longitudinal direction (e.g., the direction of pultrusion). In addition to enhancing the tensile properties of the profile, the use of such ribbons also allows an improved handability when placing them into the desired position within the pultrusion die. The discontinuous fibers are also embedded within a thermoplastic matrix, in such a way as to assist in bonding of the layers to achieve the desired strength. At least a portion of the fibers are oriented in the transverse direction to provide increased transverse strength.

Owner:TICONA LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com